Patents

Literature

37results about How to "Increase the low calorific value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

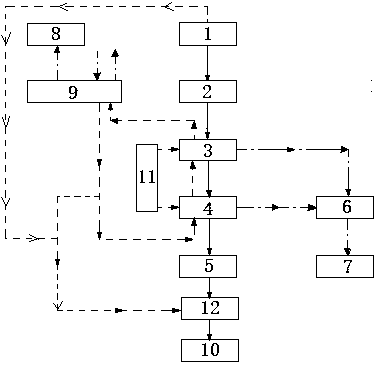

Method and apparatus for controlling secondary pollutants in biodrying of mixed domestic waste

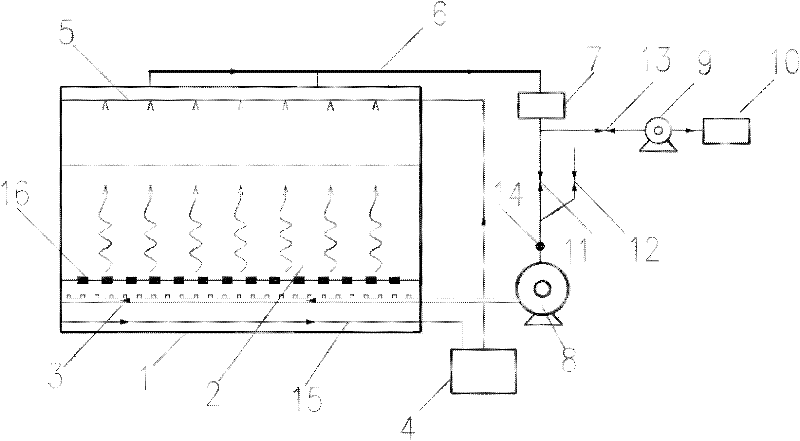

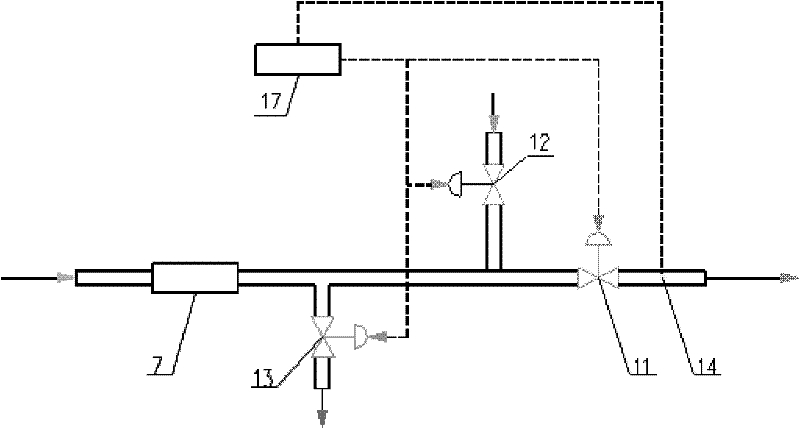

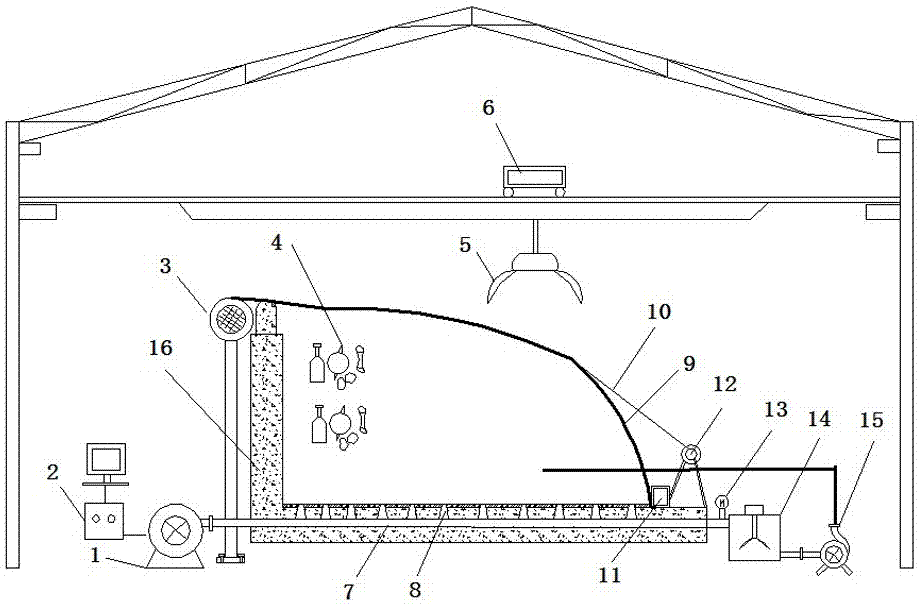

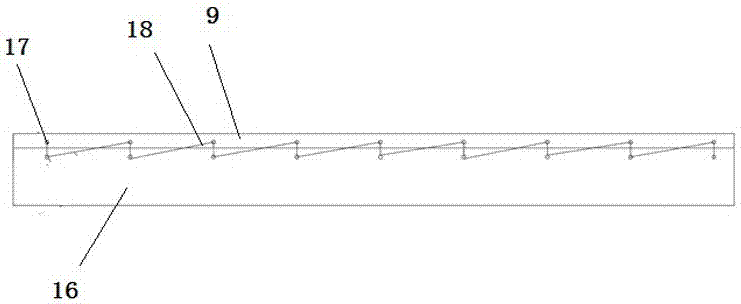

The invention relates to a method and apparatus for controlling secondary pollutants in biodrying of mixed domestic waste. The method comprises the following steps: (1) simple pretreatment; (2) stacking; (3) biodrying of waste; (4) back spraying of leachate; (5) drying, reflux and concentrated treatment of tail gas. The apparatus comprises a sealed reactor, a leachate collector, a ventilating system and a tail gas treating device, wherein, the leachate collector is respectively connected with a leachate collecting pipe and a spray pipe in the reactor through pipelines, the tail gas treating device comprises a tail gas recovering pipe, a drying box, a tail gas treating fan and a purifying means, the tail gas recovering pipe is connected with the drying box, the drying box is respectively connected with a ventilating fan and the tail gas treating fan, and the tail gas treating fan is connected with the purifying means through a pipeline. According to the invention, the leachate does not need to be treated individually; tail gas is collected in a totally enclosed environment, and the amount of tail gas to be treated is small; a low heating value of obtained dried waste is increased by 100%; the invention is widely applicable to mixed waste with high water content and enables resource values of burning and sorting of domestic waste to be improved.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

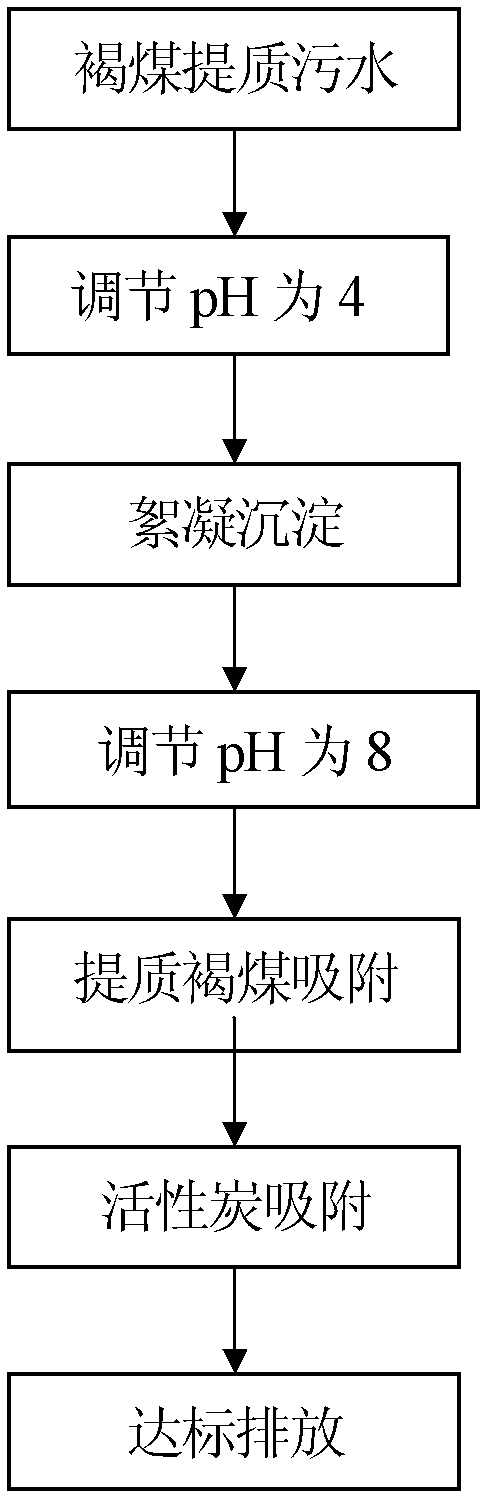

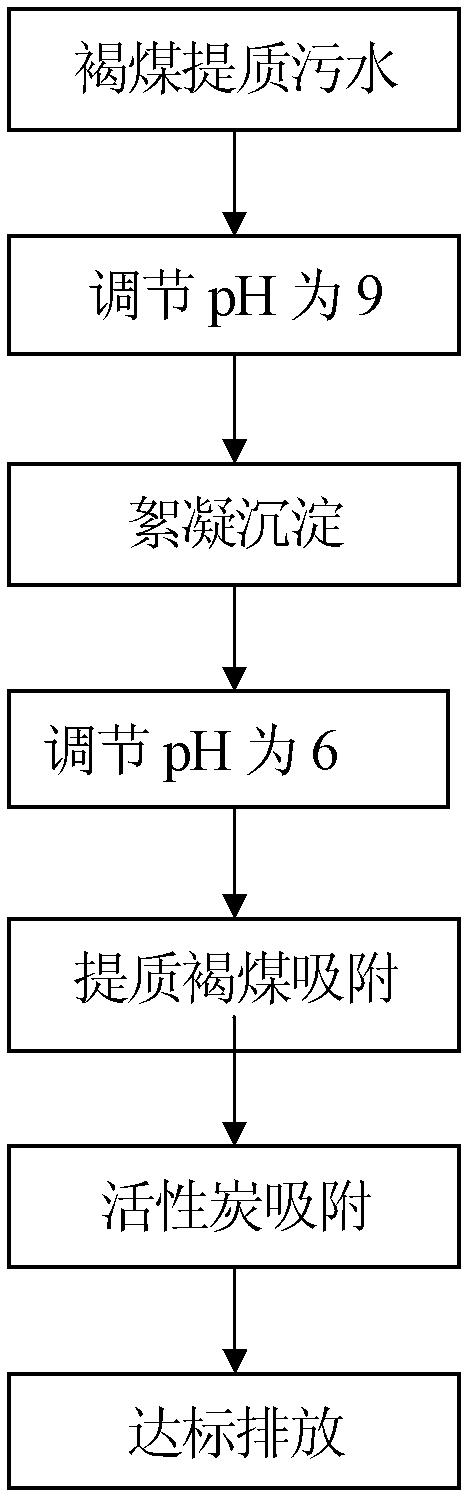

Treatment process of lignite upgrading wastewater

InactiveCN102358649AIncrease the low calorific valueReduce dosageMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationActivated carbonFlocculation

The invention discloses a treatment process of lignite upgrading wastewater. The treatment process comprises the following steps: 1) adjusting the pH value of the wastewater to be treated to 3-11; 2) adding a flocculant to precipitate; 3) then adjusting the pH value to 4-8; 4) using the upgraded lignite as an adsorbent to adsorb; and 5) then using activated carbon as an adsorbent to adsorb. In the treatment process, the pH value is adjusted firstly and flocculation and precipitation are performed secondly to precipitate suspended pollutants, thus the precipitation effect can be increased; then the product of the lignite upgrading process, namely upgraded lignite is used as the adsorbent to adsorb, the porous structure of the upgraded lignite is used for replacing a lot of activated carbon to perform the adsorption of pollutants and adsorbing most of harmful substances; and finally a little activated carbon is used for performing final adsorption. Therefore, the dosage of the activated carbon can be greatly reduced, the cost can be reduced, the treatment process can realize low cost and high self-sustainability, and the real standard discharge of the lignite upgrading wastewater can be realized on the premise of successfully reducing the treatment cost of the lignite wastewater.

Owner:李柏荣

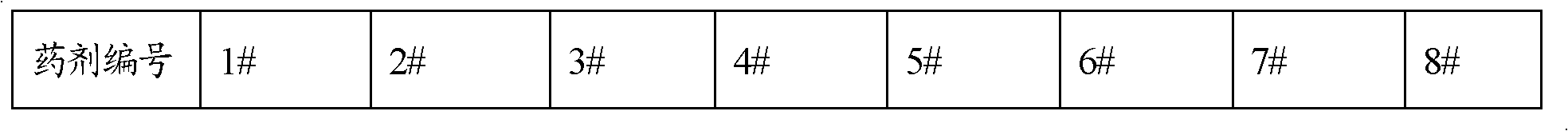

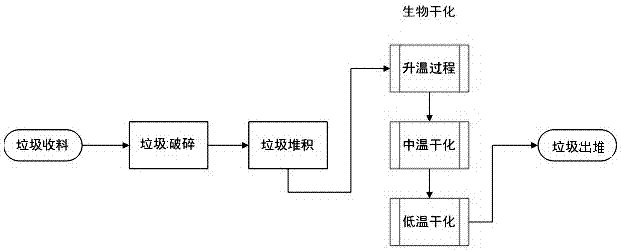

Bio-drying-based domestic refuse treatment method

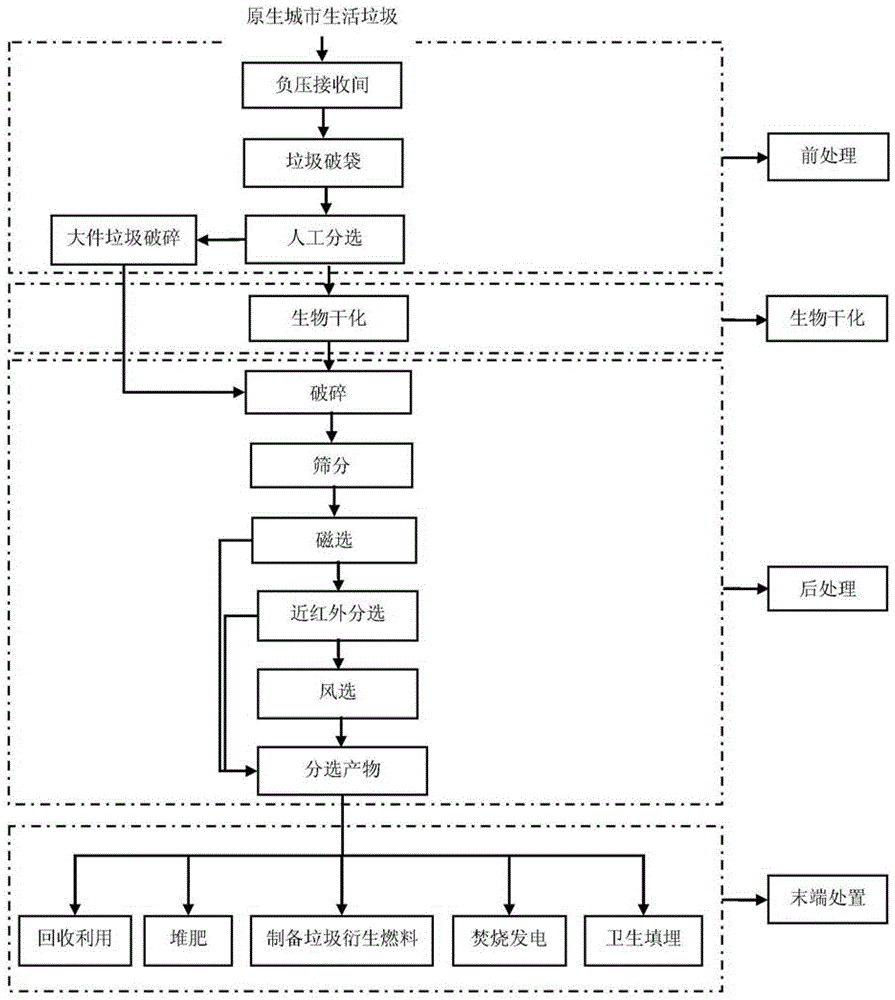

The invention provides a bio-drying-based domestic refuse treatment method. The method comprises the following steps: (1), pre-treatment: feeding domestic refuses into a negative-pressure receiving room to break bags and manually select; performing innocent treatment on selected harmful refuses which have potential pollution threats to the soil and the underground water, and crushing selected large-size refuses in a large-size refuse crusher, wherein the crushed large-size refuses are treated in a step (3), residual domestic refuses are treated in a step (2), and the air change rate of the negative-pressure receiving room is five to seven times per hour; (2), bio-drying: feeding the residual domestic refuses treated in the step (1) into a bio-drying storehouse, stacking to form a refuse dump body, and covering the refuse dump body with a selective semi-permeable membrane; (3), post-treatment: sequentially performing mechanical crushing, drum screen screening, magnetic separation, near-infrared separation and air separation on the dried products obtained in the step (2) and large-sized refuses crushed in the step (1); (4), tail end treatment: respectively recovering and utilizing according to property difference of products selected according to the step (3).

Owner:BEIJING GEOENVIRON ENG & TECH

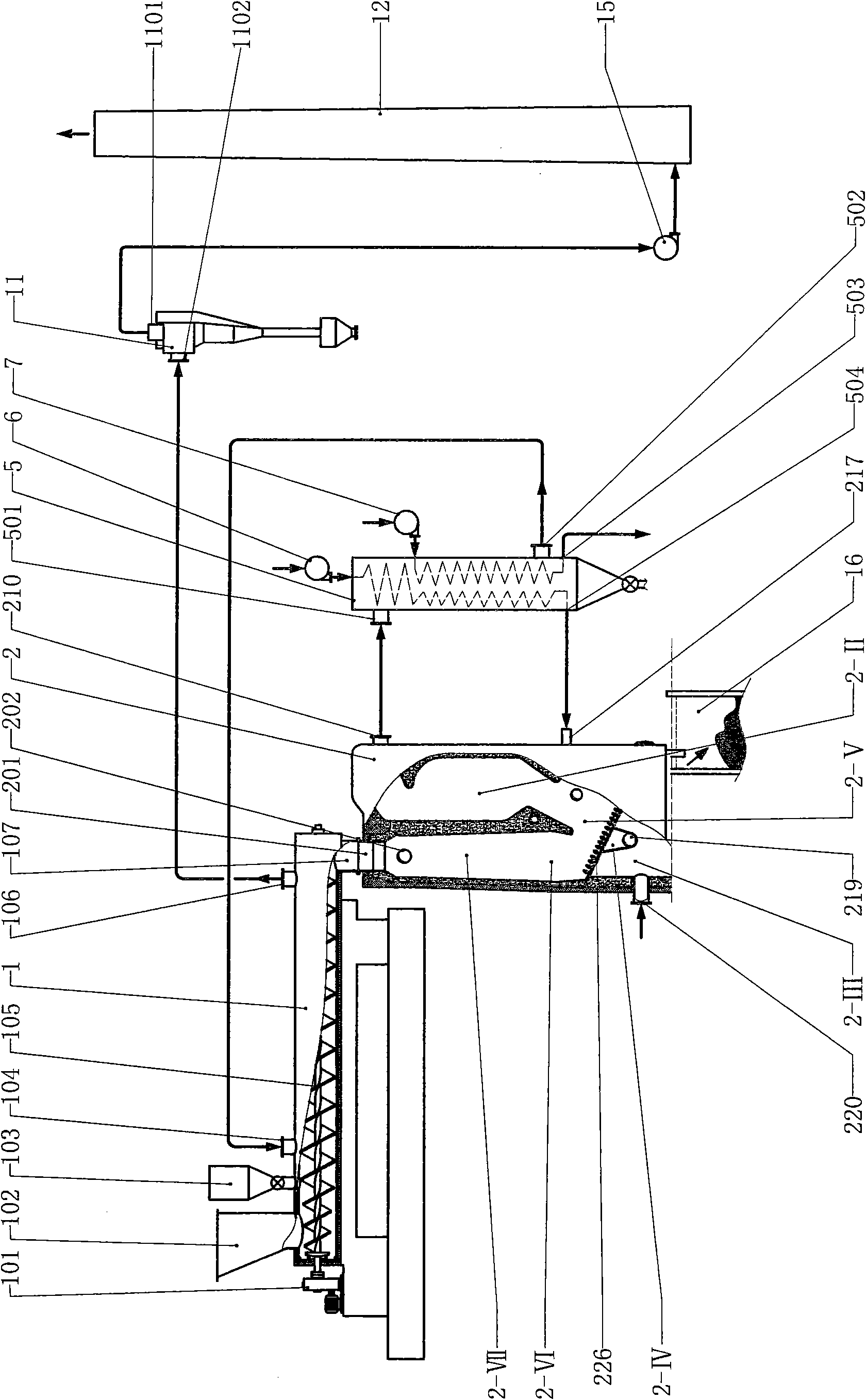

Clean incineration system of refuse and organic wastes and device thereof

InactiveCN101561144ARealize clean incineration treatmentFlexible sizeIndirect carbon-dioxide mitigationIncinerator apparatusPollutantDry distillation

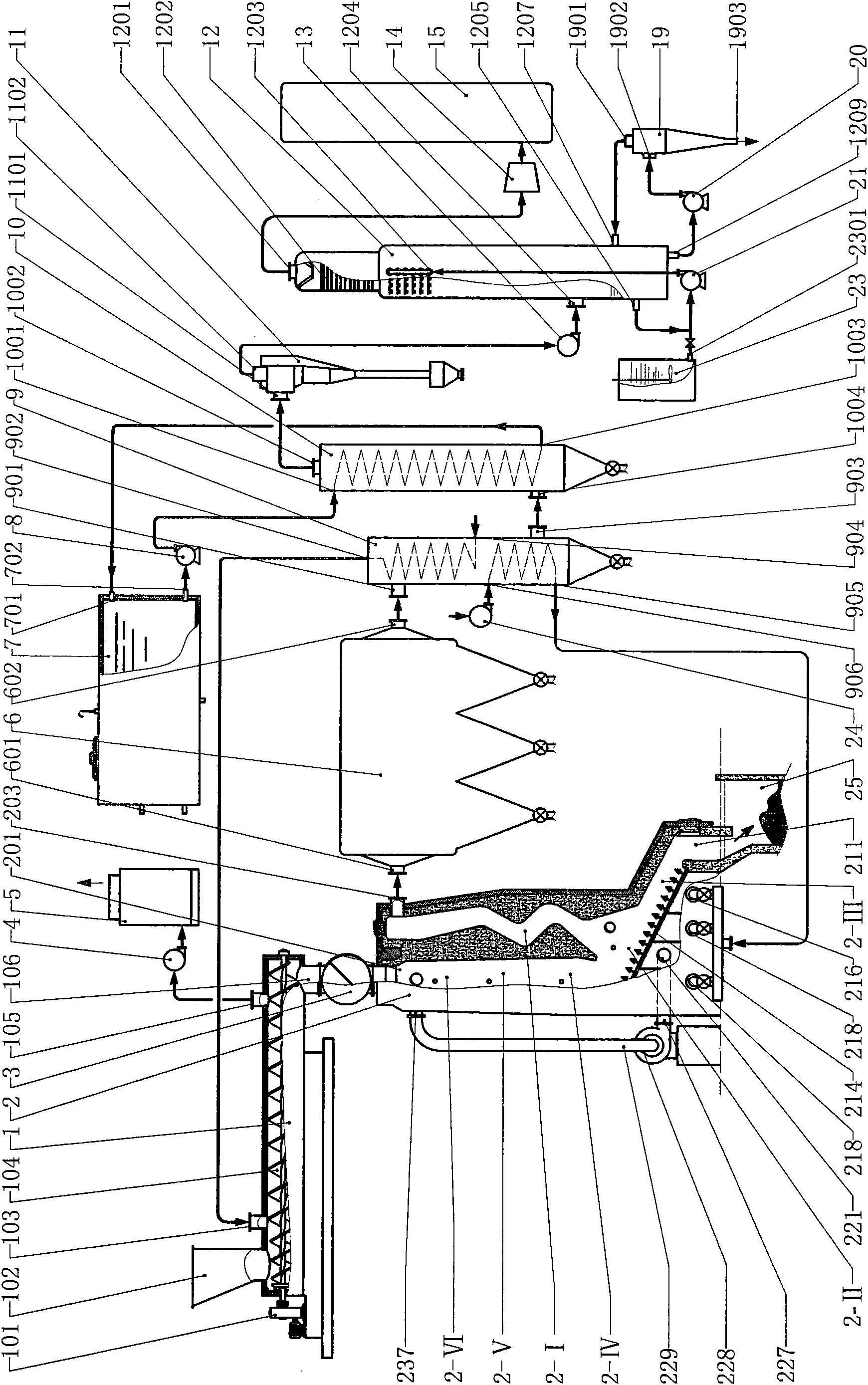

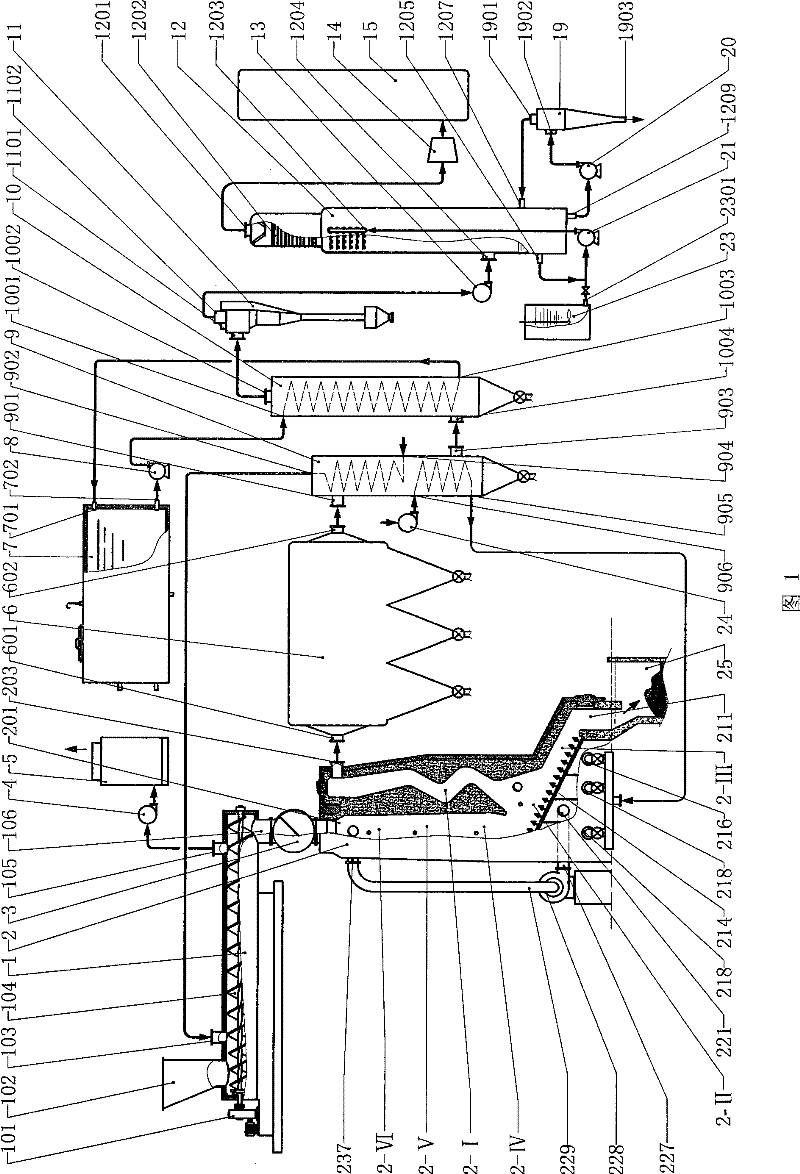

A clean incineration system of refuse and organic wastes and a device thereof relate to refuse incineration equipment. The incineration system mainly consists of an dry fan, a gas phase circulating incinerator, an air preheater, a dedusting / purification device, an induced draft fan and a chimney, a discharge outlet of the dry fan is connected to a feed inlet of the incinerator, a fume outlet of the incinerator is connected to the air preheater, the air preheater is connected to an air supply outlet of the dry fan, a suction opening of the dry fan is connected to a fume inlet of the dedusting / purification device, and a fume outlet of the dedusting / purification device is connected to the chimney by the induced draft fan. A dry distillation zone and a gasification zone form a gasification environment, and a first combustion zone and a second combustion zone form a combustion environment in the gas phase circulating incinerator, and a circulating air conduit and a circulating fan form a gas phase circulation loop outside the incinerator. Refuse fuel is gasified in the incinerator for combustion, and gaseous material generated in the gasification environment is allowed to have circulating gasification and combustion. The system and the device have the advantages of high burnout ratio, few pollutants generated from combustion and clean incineration of refuse.

Owner:周开根

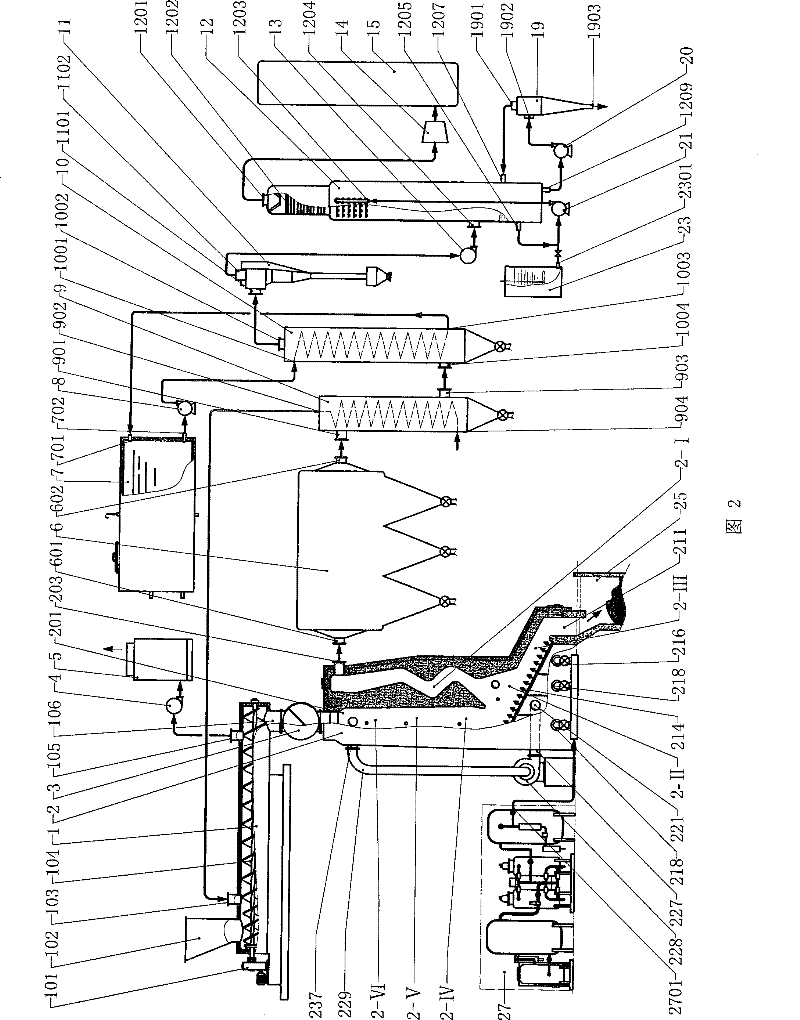

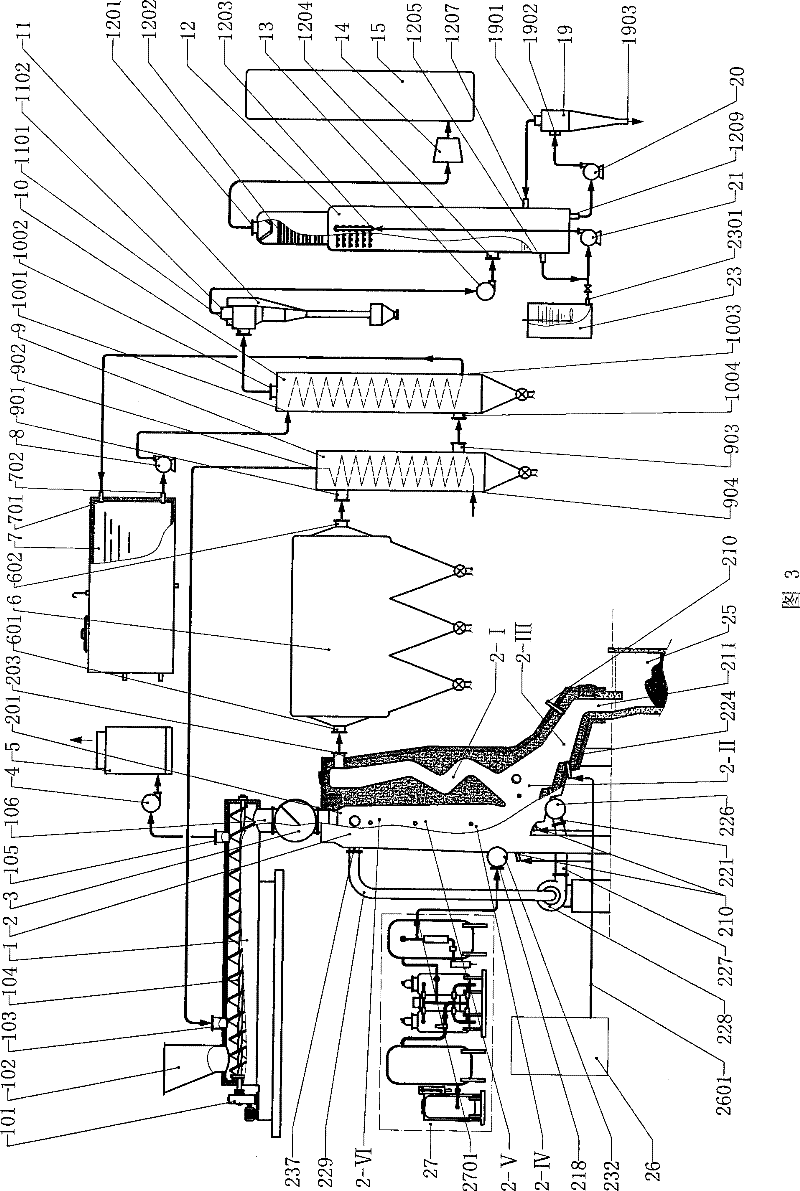

Gasification system of garbage and organic waste and device thereof

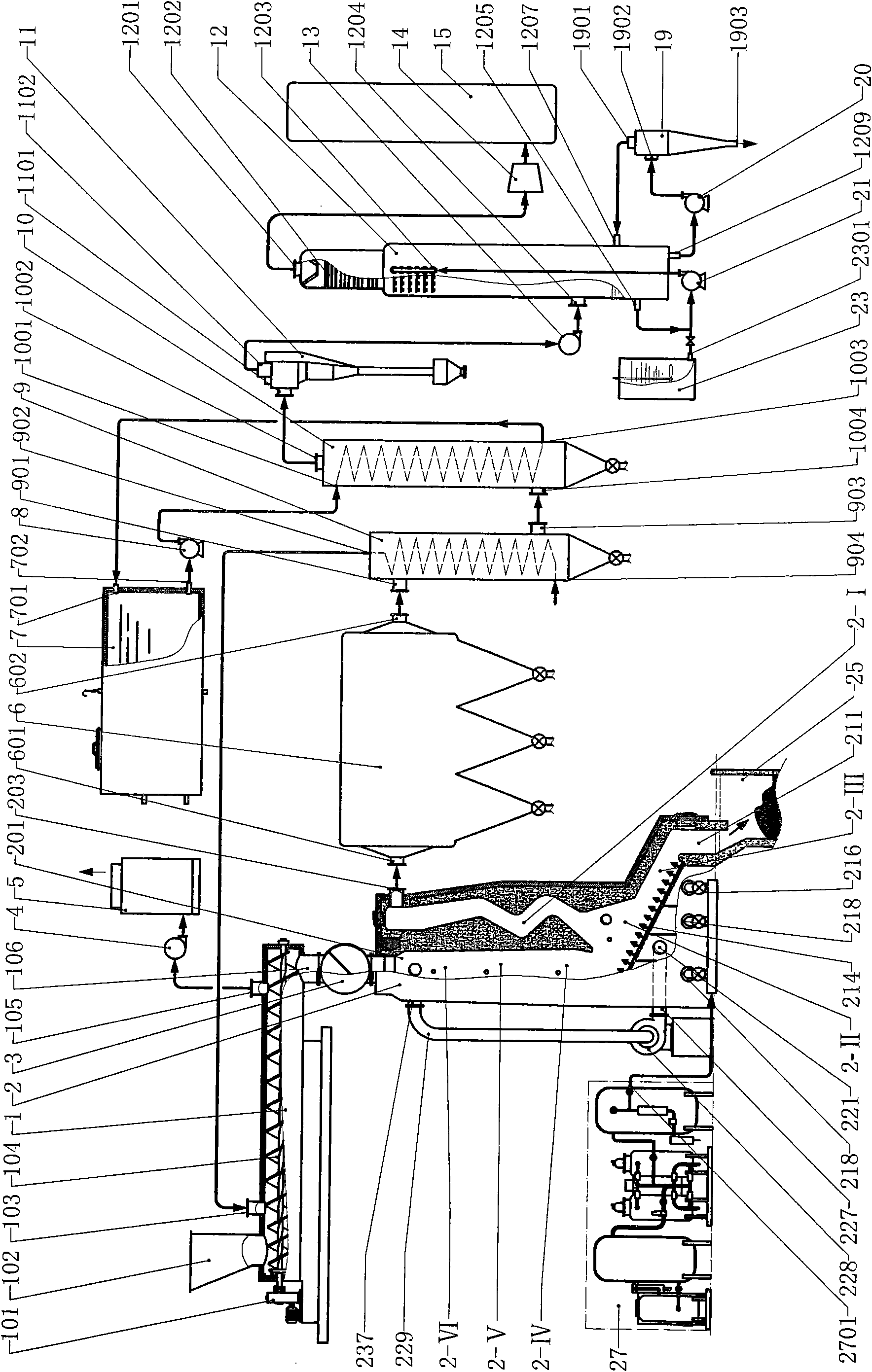

InactiveCN101560408AEliminate pollutionIncrease the low calorific valueWaste based fuelCombined combustion mitigationHydrogenGas phase

The invention discloses a gasification system of garbage and organic waste and a device thereof, and relates to a garbage treatment device. The gasification system mainly consists of a blast drier, a gas phase circulation gasification furnace, a dusting / purification device, a compressor, a gas receiver and connection pipelines, wherein, the gasification furnace is equipped with a baking zone, a pyrolysis zone, a first gasification zone, a second gasification zone, a burnout zone and a heat storage chamber, a recirculating blower and a recirculating wind pipeline form a gas phase circulation loop outside the furnace. In the system, a discharge port of the blast drier is connected to a feed inlet of the gasification furnace, a synthesis gas output interface of the gasification furnace is connected to the dusting / purification device by an induced draft fan, the dusting / purification device is connected to the compressor, and the compressor is connected to the gas receiver. The system utilizes a technical measure of arranging the heat storage chamber in a gas phase circulation gasification furnace to enhance gasification rate and quality of refuse fuel and decompose dioxin with severe toxicity and eliminate coke tar, convert garbage and organic waste into secondary clean energy which comprises producer city coal gas, hydrogen, methanol and dimethyl ether liquefied gas.

Owner:周开根

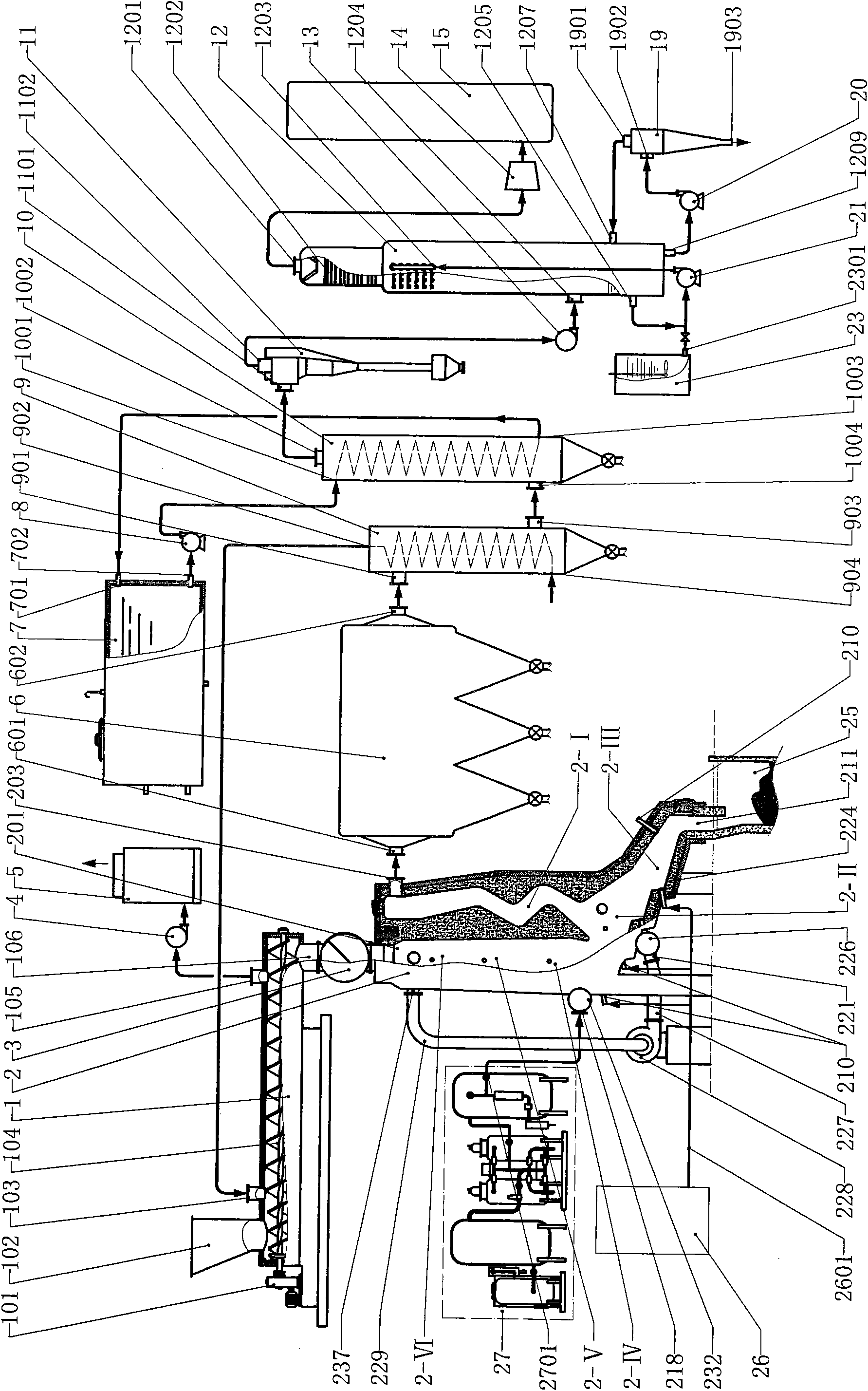

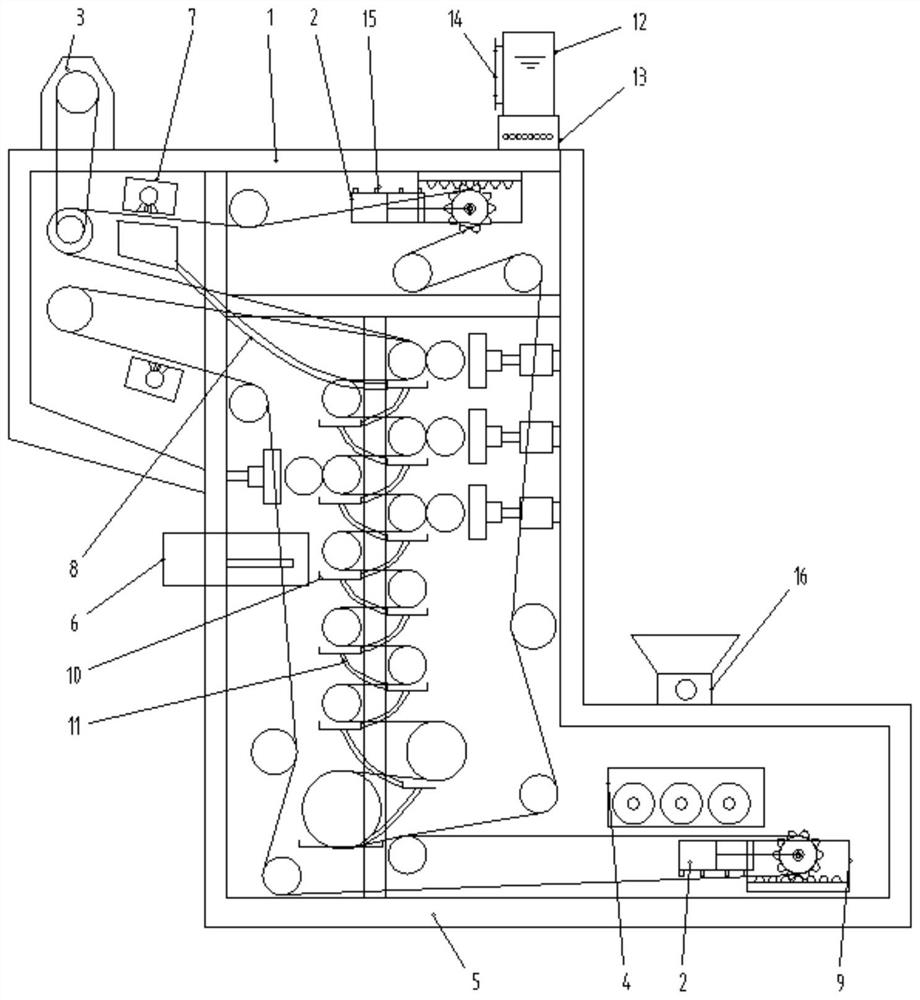

Drying pretreatment method and device for urban domestic garbage

InactiveCN101476729AIncrease the low calorific valueFully recycleIncinerator apparatusCombined combustion mitigationPretreatment methodEnvironmental engineering

The invention relates to a method and a device for drying pretreatment on municipal domestic refuse by municipal domestic refuse incineration technology. The invention adopts the technical proposal that the method comprises: incinerating the municipal domestic refuse, removing dust of the municipal domestic refuse, taking fume guided out of a fume extractor as a heat source for drying the domestic refuse, and utilizing the fume residual heat to dry the domestic refuse to be treated. The device and the method have the advantages that: 1) high-temperature fume generated from incineration is utilized to dry the domestic refuse, thereby fully recycling the heat energy, and having no influence on the steam generation amount and electricity generation amount synchronously; 2) the high-temperature fume generated from incineration is utilized to dry the domestic refuse, thereby reducing moisture in the refuse, improving 300 to 400 kacal / kg of lower heating value of the refuse, reducing auxiliary fuel addition amount, and reducing operation cost; and 3) after the refuse is dried, because partial moisture in the refuse is discharged, the total amount of the incinerated refuse is reduced, the scale of a incinerator can be reduced, and equipment investment is reduced.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP

Hydrolysis-aerobiosis two-section biological drying method for household garbage

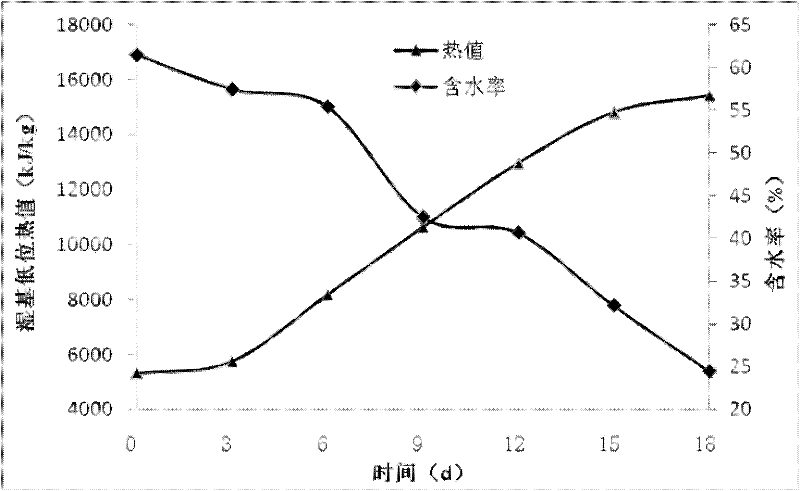

InactiveCN101947534AReduce the moisture content of garbageIncrease the low calorific valueWaste processingSolid waste disposalWater contentResource utilization

The invention discloses a hydrolysis-aerobiosis two-section biological drying method for household garbage and relates to a treatment technique for garbage water removal and partial biological stabilization. The method comprises the following steps of: stacking the household garbage in a groove type composting reactor and performing ventilation at long intervals; neutralizing all the generated percolate until the pH is 6.8 to 7.8; refluxing the percolate to the garbage stack in the groove type composting reactor to perform hydrolysis and drying on the garbage for four days; stopping refluxing the percolate; ventilating for two times every hour and turning for one time every two days to dry the garbage after repeating for twelve days; and removing the dried garbage from the groove type composting reactor for resource utilization or directly burning the dried garbage for energy recovery. After the biological drying process, the water content of the garbage is reduced from over 70 percent to below 45 percent; the lower heat value is increased by more than one time; the efficiency of separation is increased to 80 percent; and the recycling value of the household garbage is obviously increased. The method can be widely applied to drying treatment of the household garbage with the water content over 65 percent and solid waste which is mainly the biologically degradable waste.

Owner:TONGJI UNIV

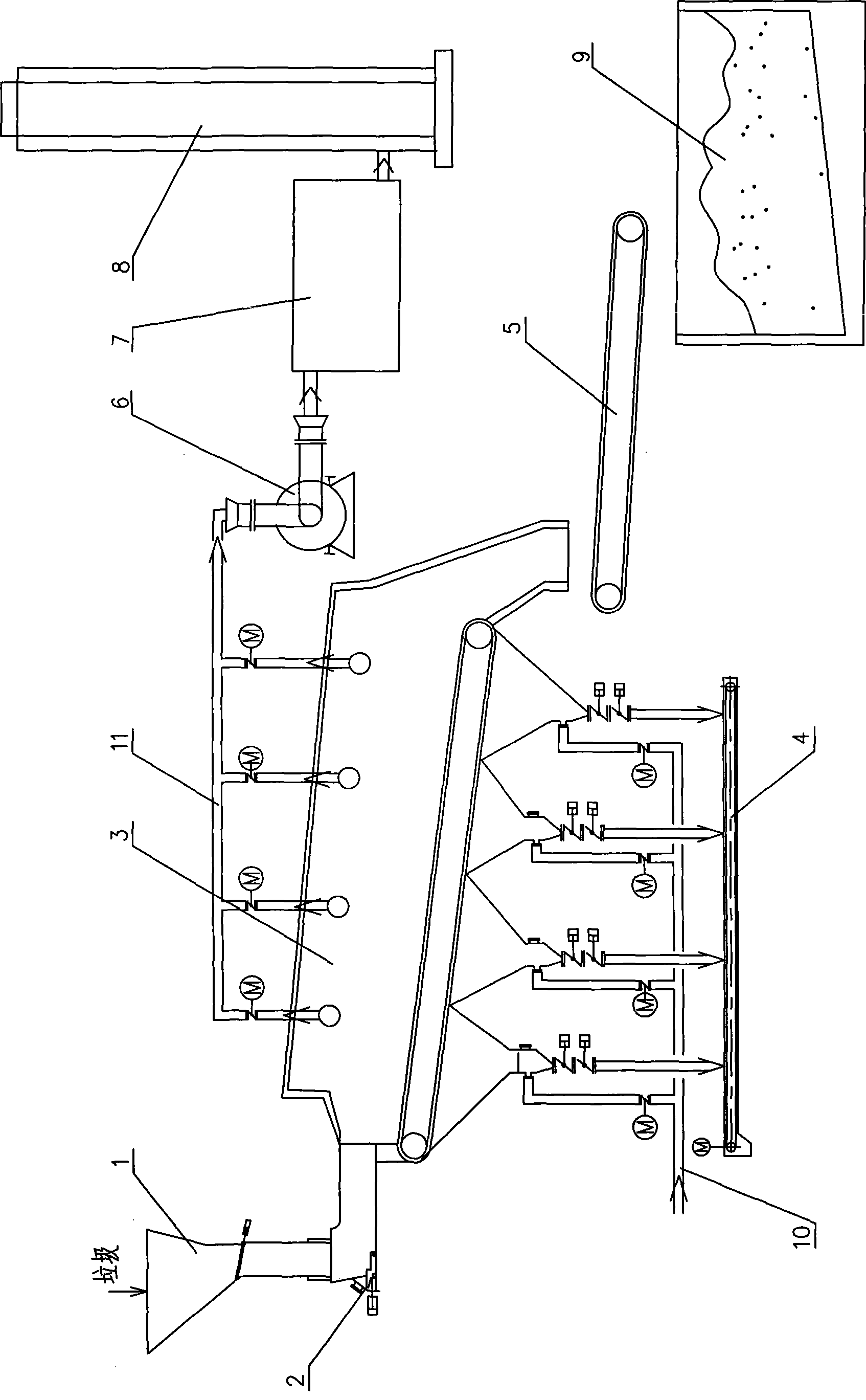

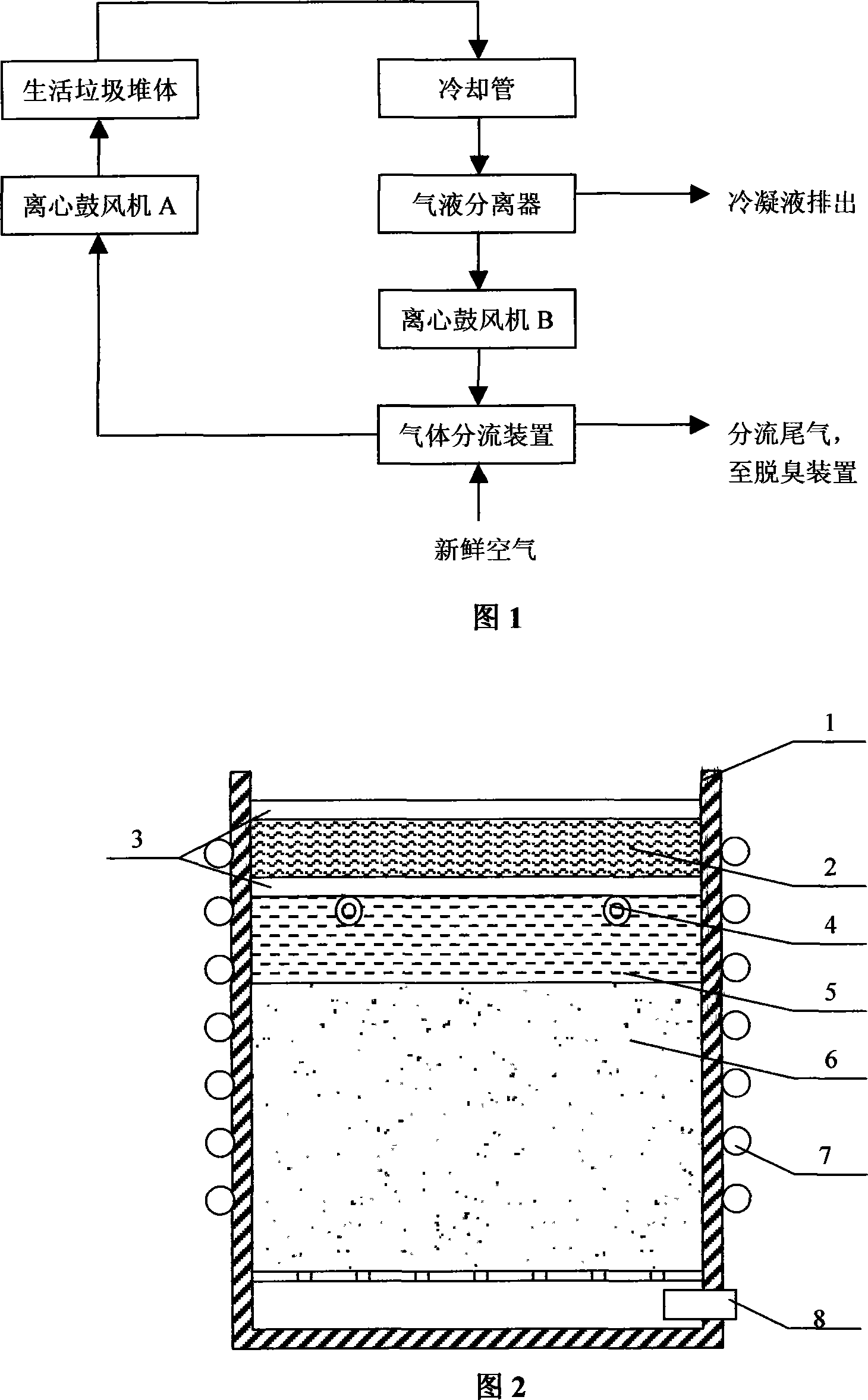

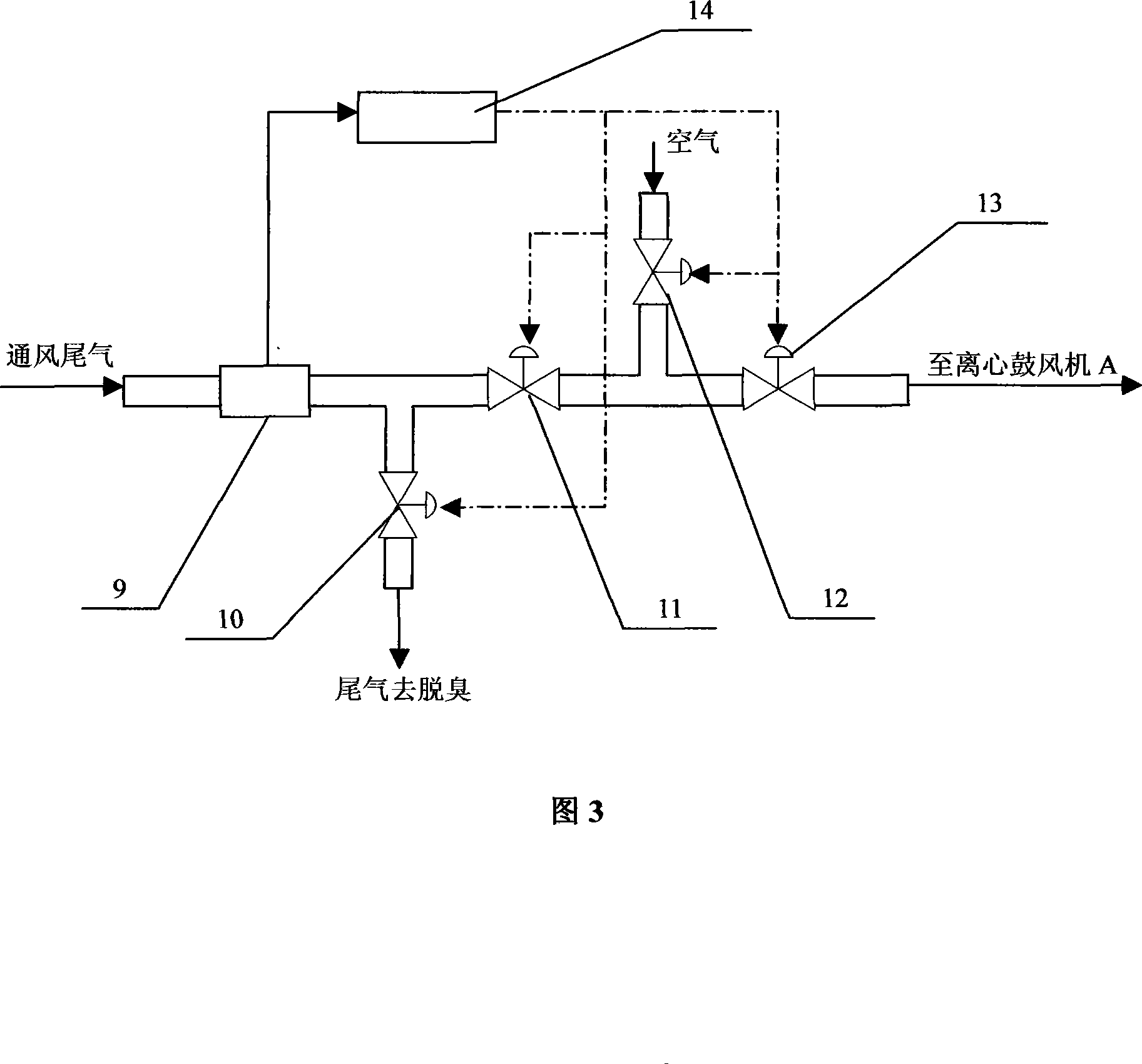

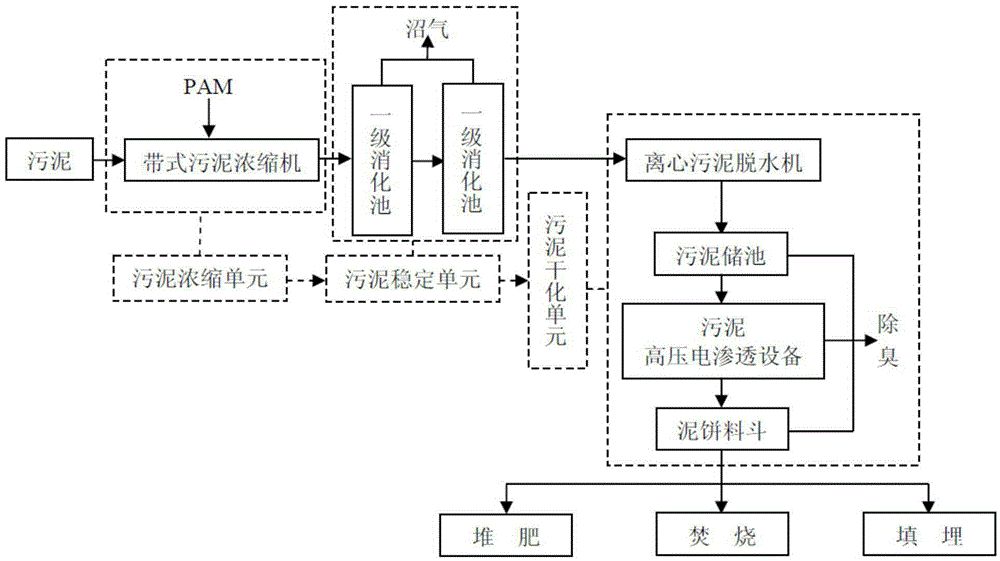

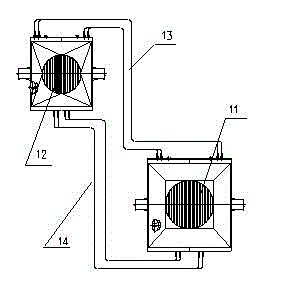

Biological drying method for life garbage

ActiveCN101025328AReduce latent heat lossReduce moisture contentDrying solid materials without heatVapor–liquid separatorLitter

A biologic method to drying life garbage, it is about a kind of technology to decrease the water of life garbage and biologic stable disposal. Firstly, after sieving out the big block from the life garbage, to stack it into groove-shape compost reactor, then to cover tying straw pad and compound heat insulating coiled material, to bonds the opening rubber tail gas gathering tube with the cooling tube under the coiled material. The cooling tube is connected with gas-liquid separator, centrifugal blast blower B, gas separation unit and centrifugal blast blower A sequentially, and the centrifugal A is connected with the bottom of the reactor. Secondly, to vent the air fitfully and circularly with firm discharge, to turn one time on the second day and the fourth day respectively, to complete drying in six days, offgas enters gas separation unit after liquor condensate is eliminated by the cooling tube and gas-liquid separator, after discharging part of offgas into off-odor unit, to supply equivalent clean air, then to put the offgas into the centrifugal A for garbage venting. The quantity of offgas off odor and running cost of this invention is low, the water-content coefficient of the garbage is smaller than 40% after disposal, and it can be used for drying the life garbage with water-content coefficient 60%.

Owner:TONGJI UNIV

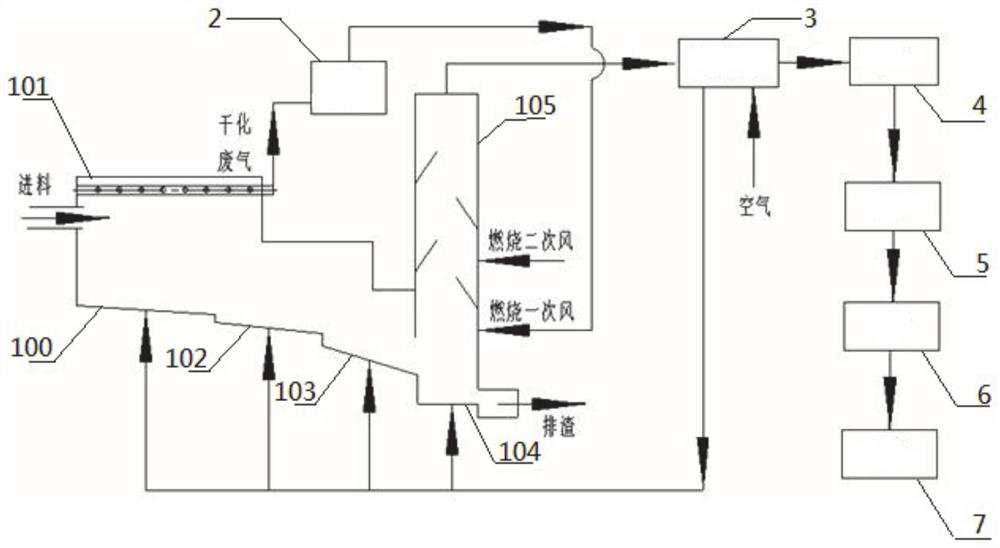

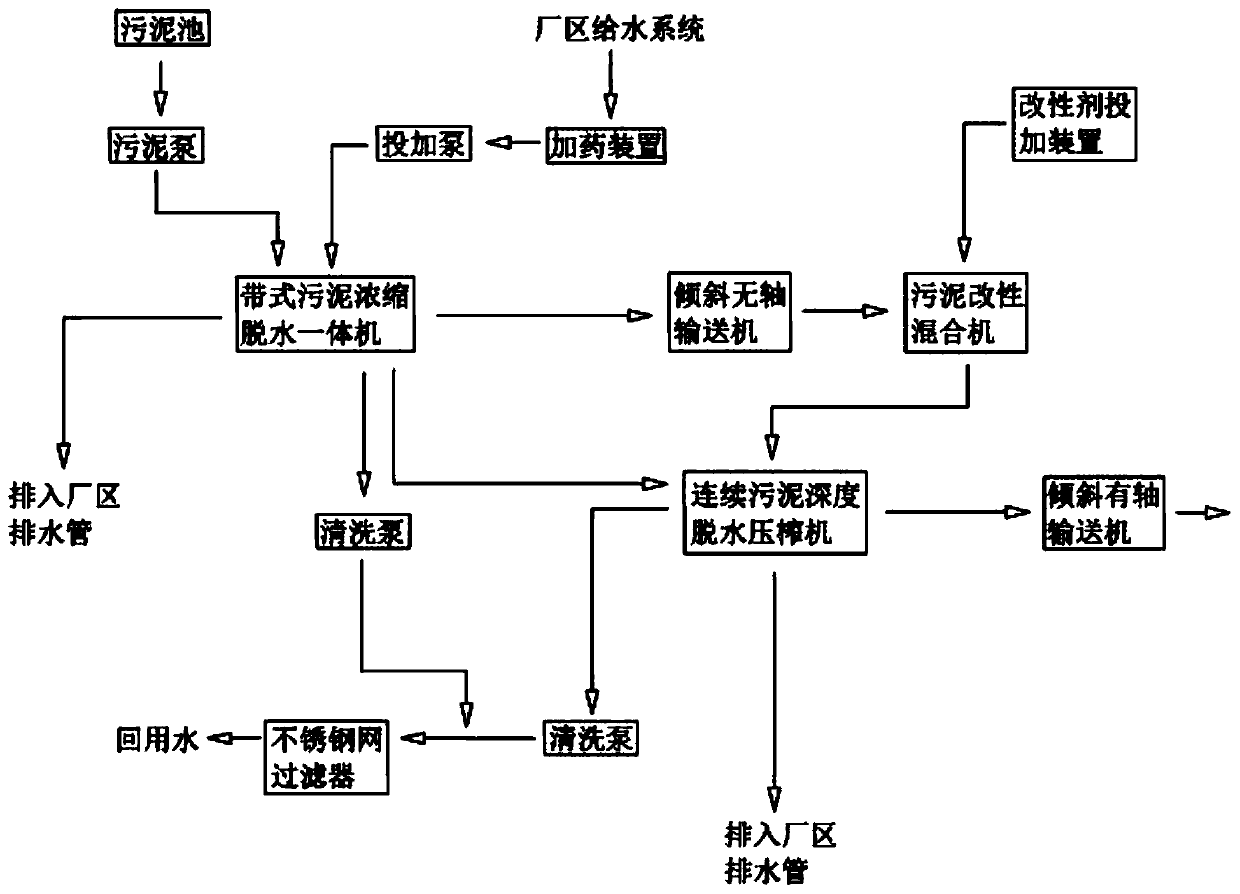

Sludge drying system

ActiveCN105399293AReduce moisture contentIncrease moisture contentSludge treatment by de-watering/drying/thickeningWater contaminantsSludge cakeReagent

The invention discloses a sludge drying system, comprising a sludge concentrating unit, a sludge stabilizing unit and a sludge drying unit which are connected in sequence, wherein the sludge concentrating unit comprises a belt sludge concentrator which is provided with a PAM adding device, the sludge stabilizing unit is provided with a medium-temperature sludge anaerobic digestion tank which is provided with a biogas outlet, the sludge drying unit comprises a sludge centrifugal dehydrator, a sludge storage tank, a sludge high-voltage electro-osmosis unit and a sludge cake hopper which are connected in sequence, the sludge high-voltage electro-osmosis unit is provided with a deodorizing device, and the sludge cake hopper is connected with a composting device, a burning device and / or a dumping device. The sludge drying system realizes quantitative reduction, harmlessness and recycling of sludge without addition of a reagent.

Owner:BEIJING SOUND ENVIRONMENTAL ENG +1

Garbage pyrolysis and gasification incineration system and process

InactiveCN111853801AImprove utilization efficiencyIncrease the low calorific valueCombustion technology mitigationIncinerator apparatusWater vaporDust collector

The invention particularly relates to a garbage pyrolysis and gasification incineration system and process. According to the garbage pyrolysis and gasification incineration system, a pyrolysis and gasification furnace, a high-temperature heat exchanger, a quench tower, a demister, a dust collector and an exhausting device are connected successively, and the pyrolysis and gasification furnace is provided with a drying area, a pyrolysis area, a gasification area, an ash after-combustion area and a gas combustion area which are integrally formed. The drying area is further provided with an exhaust gas recovery pipeline to extract water vapor generated in a garbage drying process on the one hand to improve the stability of garbage pyrolysis and gasification and combustion reaction processes, and on the other hand, the dried exhaust gas can be further taken as primary combustion air of gas combustion. Heat generated by garbage incineration is distributed again to enter an incineration furnace to assist garbage combustion. The system can operate stably by controlling an air distribution proportion without extra energy for supporting combustion. A low generation rate of pollutants such asdioxin, heavy metals, oxynitride and oxysulfide can be further guaranteed. The garbage pyrolysis and gasification incineration system and process have good popularization and application value.

Owner:山东百川同创能源有限公司

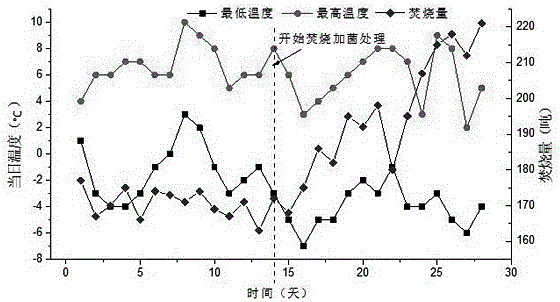

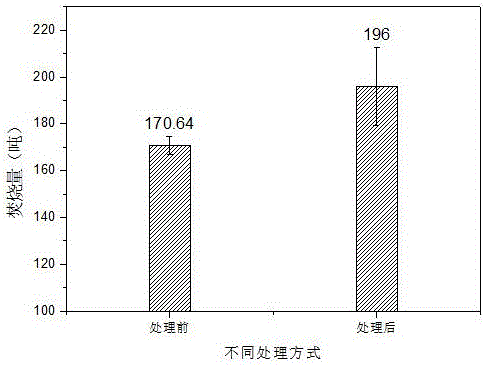

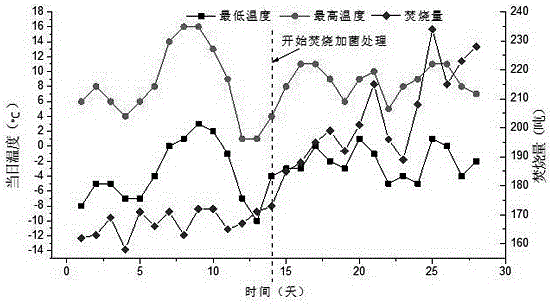

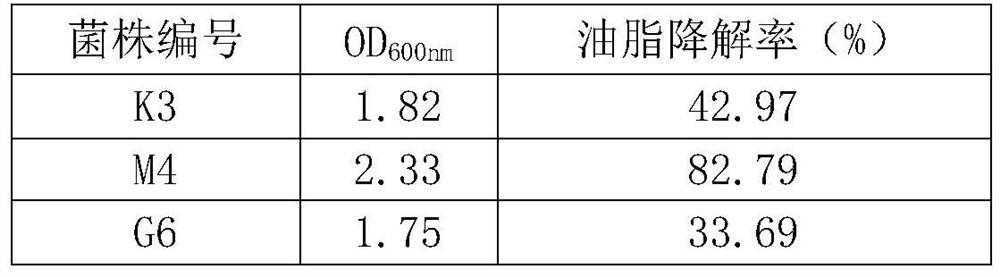

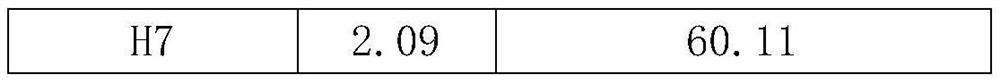

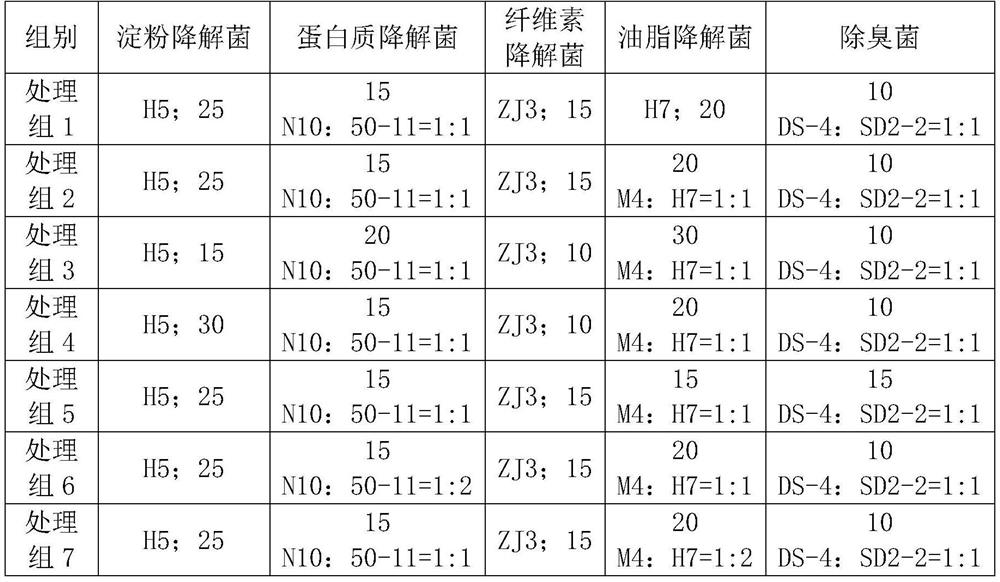

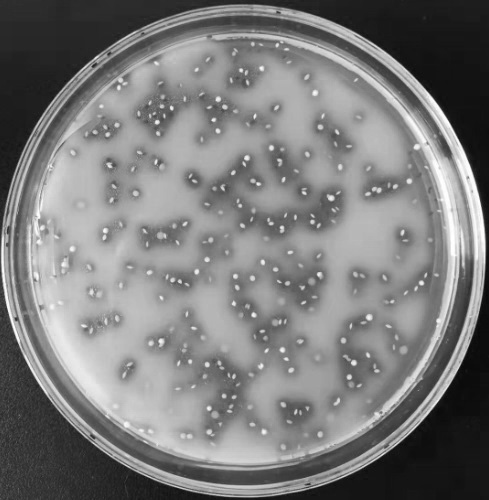

Microbial agent for garbage composting as well as preparation method and application thereof

ActiveCN105861369AEasy to produceImprove product qualityFungiBacteriaMicrobial agentLactobacillus acidophilus

The invention discloses a microbial agent for garbage composting as well as a preparation method and application thereof. The microbial agent comprises bacillus amyloliquefaciens, candida utilis, lactobacillus acidophilus and rhodopseudomonas palustris and is a liquid bacterial agent or solid bacterial agent. The microbial agent for garbage composting, disclosed by the invention, has the advantages of easiness in production, stable product quality, low cost and strong controllability in a garbage composting process; after the microbial agent is added into the garbage, the content of beneficial efficient microorganisms in the garbage can be increased, the microbial activity is improved, the garbage fermentation process is accelerated, the leaching of water and the increase of the lower calorific value of garbage are promoted, and the incineration efficiency of the garbage is improved; in a region with relatively low winter temperature, the microbial agent can reduce the influence caused by the low-temperature environment change so as to guarantee smooth operation of the garbage incineration according to the technology design; and by adopting the microbial agent, the generation of garbage smell can be reduced, and the working environment is improved.

Owner:QINGDAO GENYUAN BIOLOGICAL TECH GRP

Intermediate-temperature drying method and device for biological film of garbage

ActiveCN107088572AIncrease the low calorific valueReduce difficultySolid waste disposalTransportation and packagingWater contentStop time

The invention relates to an intermediate-temperature drying method and device for a biological film of garbage, and aims at solving the problems of low drying efficiency of an existing garbage treatment biological film drying method and negative effects caused by the treatment process on the environment. The method comprises the following steps: a, crushing the garbage; b, stowing the garbage, and covering with the film; c, bio-drying, namely, intermittently blowing air, and maintaining for 14-16 day, wherein the air blowing-in / air stopping time ratio of an air blower is 1: 5-1: 4; slowly increasing ventilating until the final air blowing-in / air stopping time ratio of the air blower is 1: 1.2-1: 0.8, wherein the temperature of a garbage pile is kept between 20-72 DEG C, and the oxygen content is kept between 2-8mg / L; and d, removing the garbage, namely, removing the garbage from a bio-drying bin. The invention also discloses the drying device for the abovementioned method. With the adoption of the method and the device, the temperature in the biological film drying process is increased; the calorific value of the dried garbage is increased by about 60-80%; and the water content can be decreased by about 18-23%.

Owner:杭州科晟能源技术有限公司

Chromium-based boiler slag-removing ash-removal coal-saving composition and preparation method thereof

ActiveCN104910996AHigh active specific surface areaHigh hydrogen contentSolid fuelsFuel additivesPetroleumElectric power

The present invention relates to an additive product suitable for coal-fired boilers of electric power, thermal power, petroleum, chemical and metallurgical industries, and particularly relates to a chromium-based boiler slag-removing ash-removal coal-saving composition, and the chromium-based boiler slag-removing ash-removal coal-saving composition consists of the following components in parts by weight: 50 to 65 parts of chromium oxide, 8 to 15 parts of copper oxide, 5 to 9 parts of cerium oxide, 5 to 9 parts of barium molybdate, 7 to 14 parts of cobaltous oxide, 12 to 17 parts of potassium permanganate, 10 to 16 parts of manganese carbonate, 12 to 17 parts of barium carbonate, 8 to 15 parts of titanium dioxide, zinc oxide, 15 to 20 parts of zinc oxide, 6 to 10 parts of potassium chlorate, 6 to 10 parts of potassium perchlorate, 20 to 28 parts of sodium carbonate, 25 to 35 parts of active attapulgite carclazyte and 0.1 to 0.3 part of alkyl glycerol ether sulfonate. The chromium-based boiler slag-removing ash-removal coal-saving composition is an environmentally-friendly product which is efficient in combustion helping, and high in coal saving ratio, can reduce pollution, improve combustion efficiency, and extend the boiler service life, and is convenient to use and stable in performance, and when in use, only the chromium-based boiler slag-removing ash-removal coal-saving composition is added into a fuel to participate in the combustion without equipment transformation.

Owner:GANSU HEIMA PETROCHEM ENG

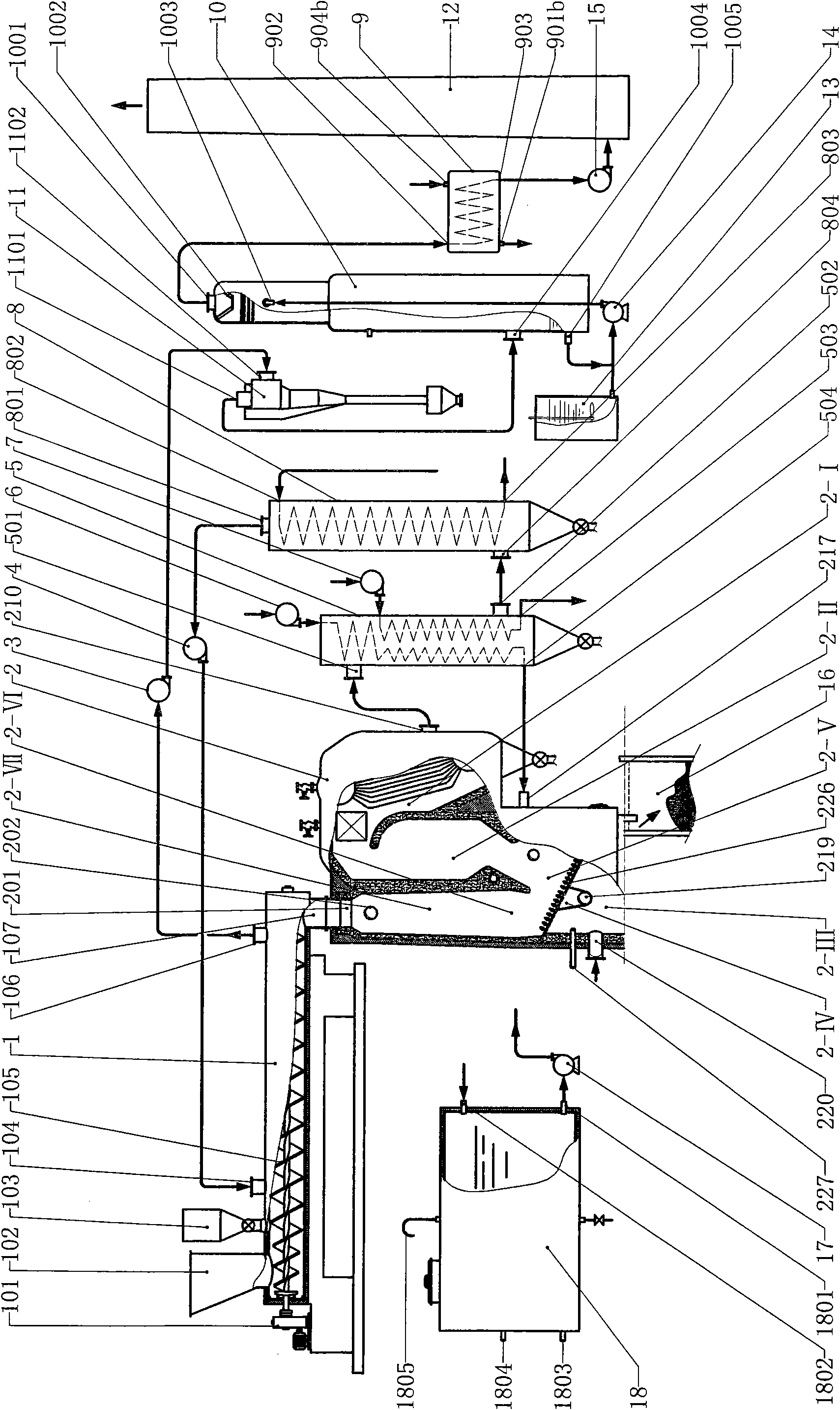

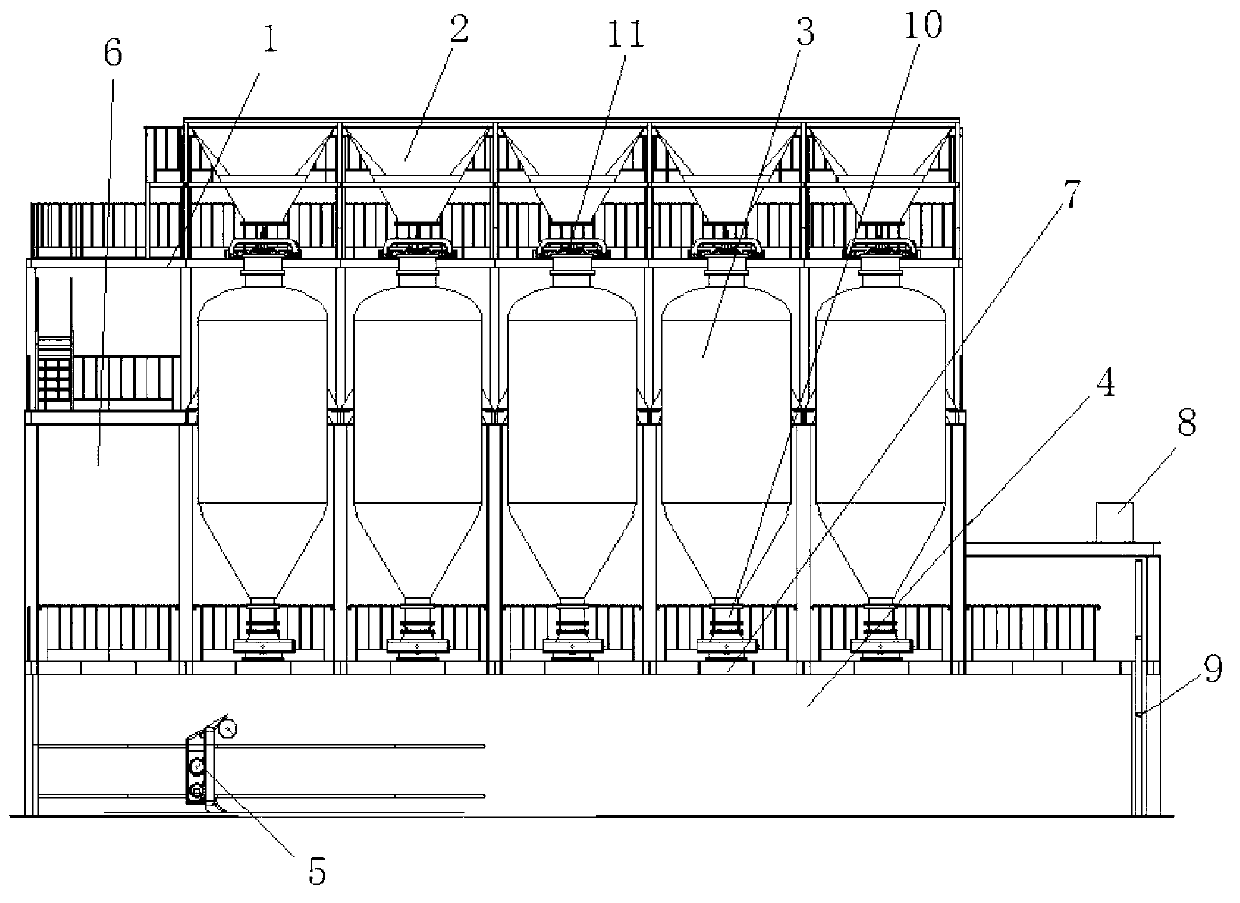

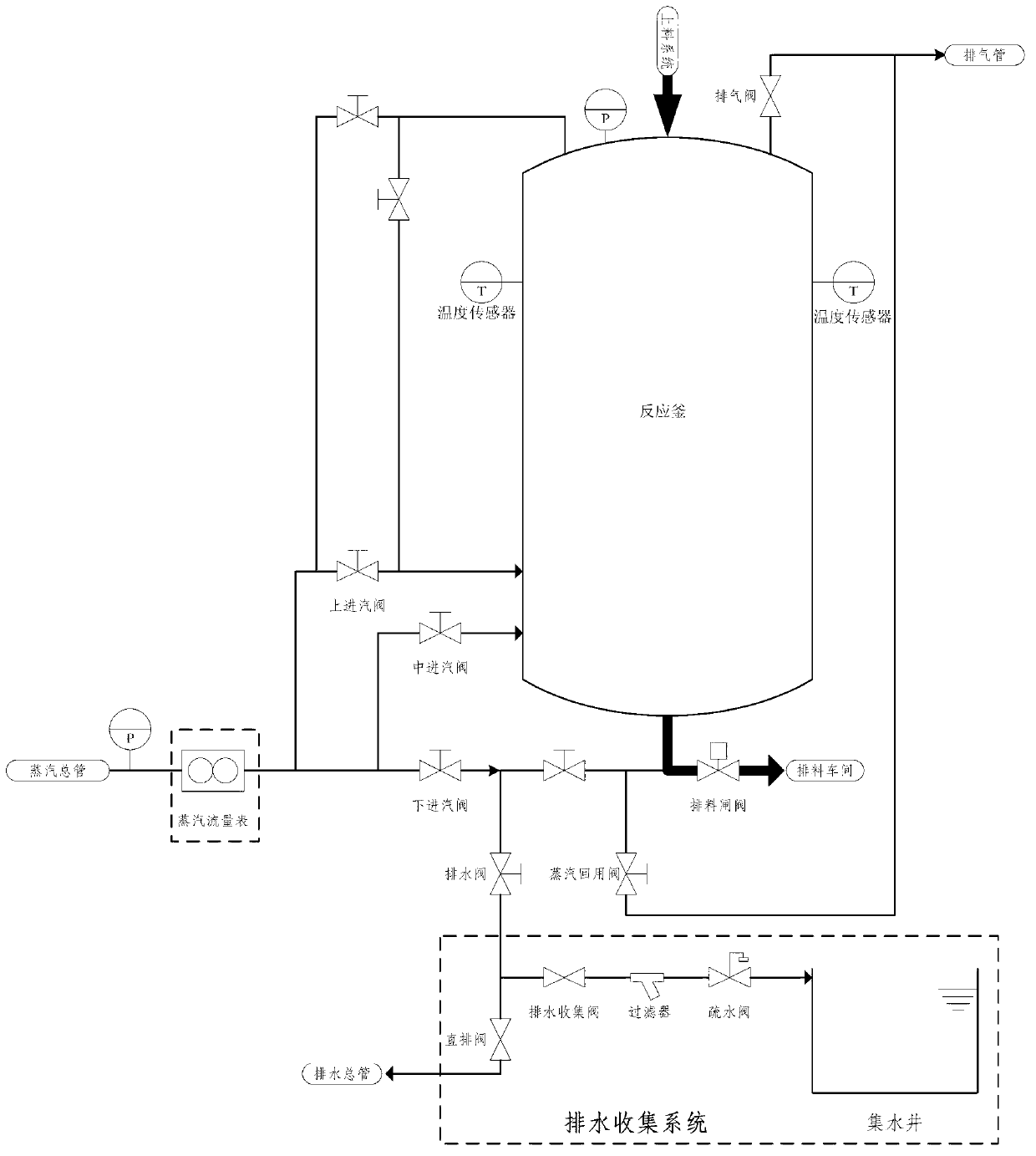

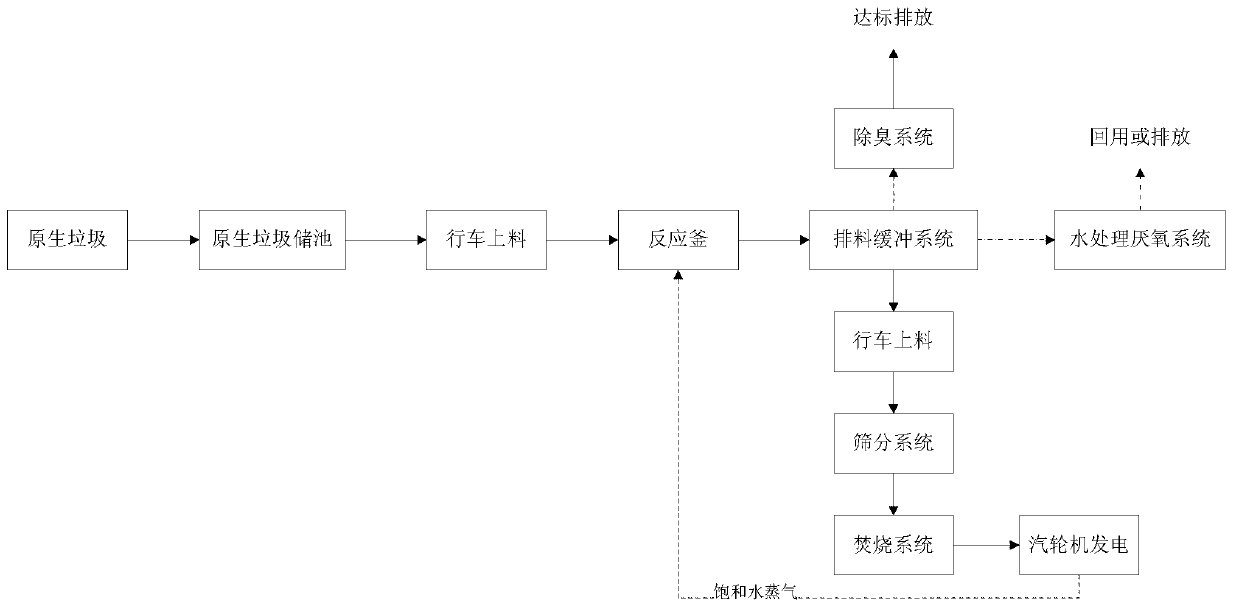

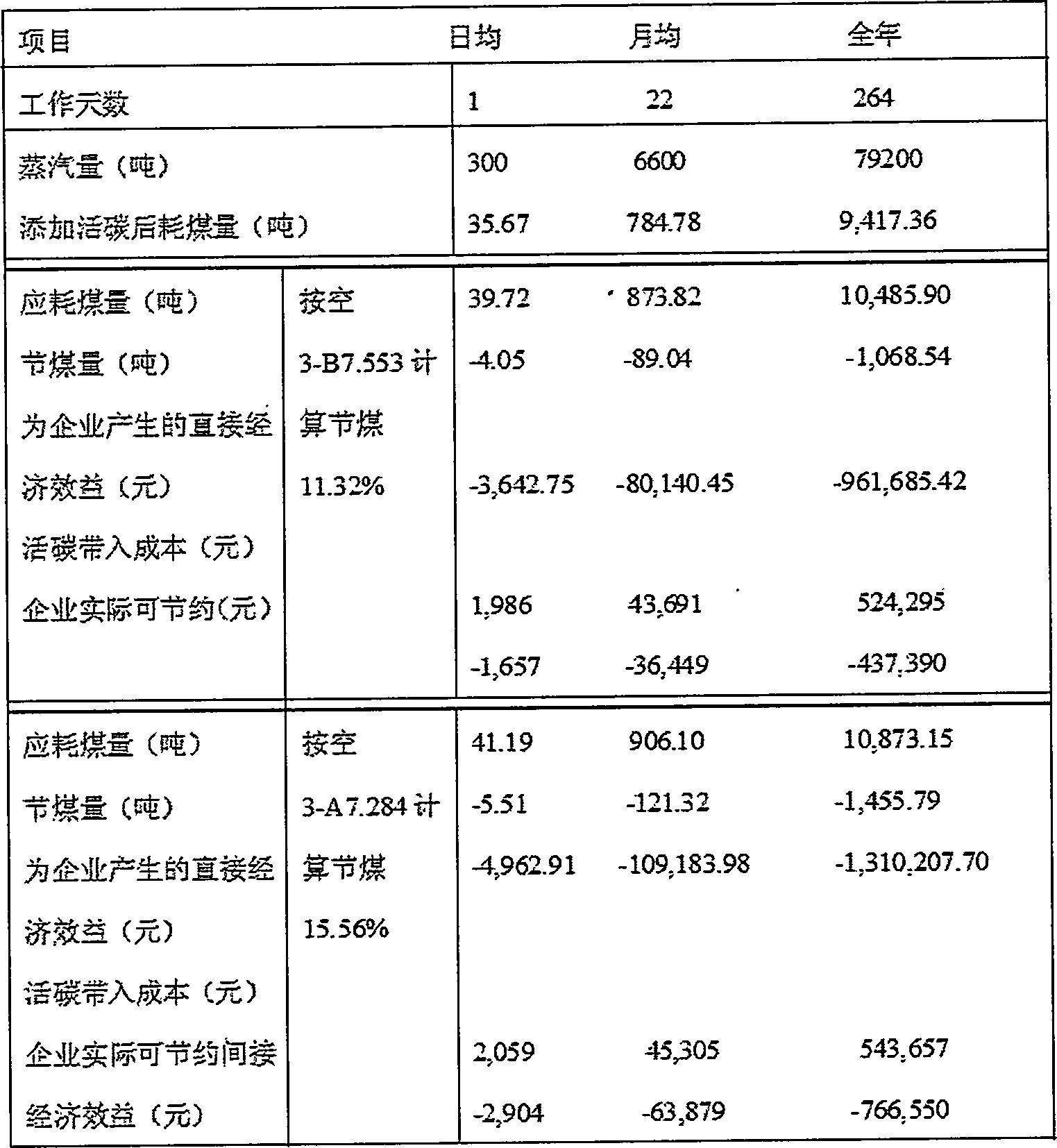

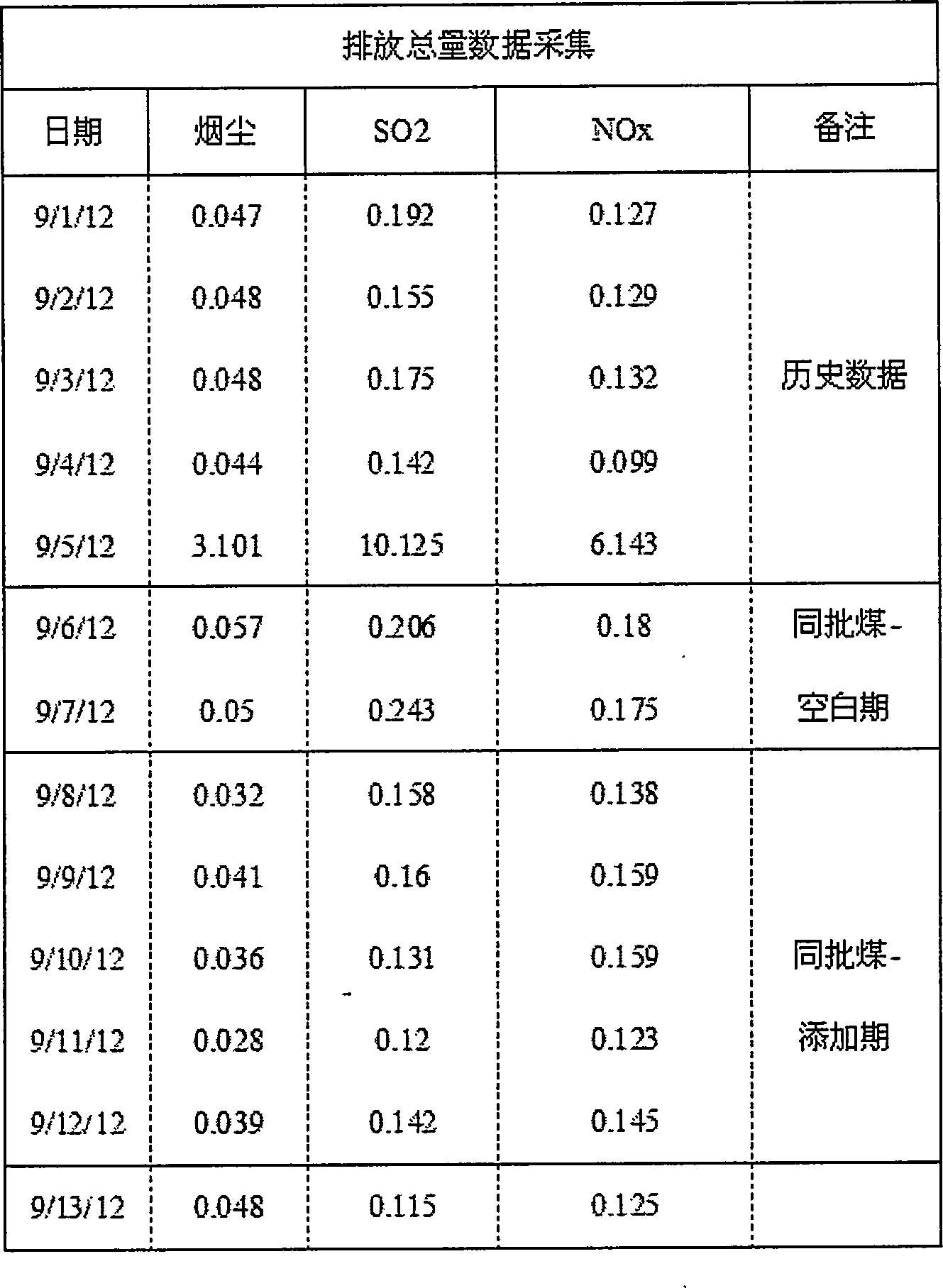

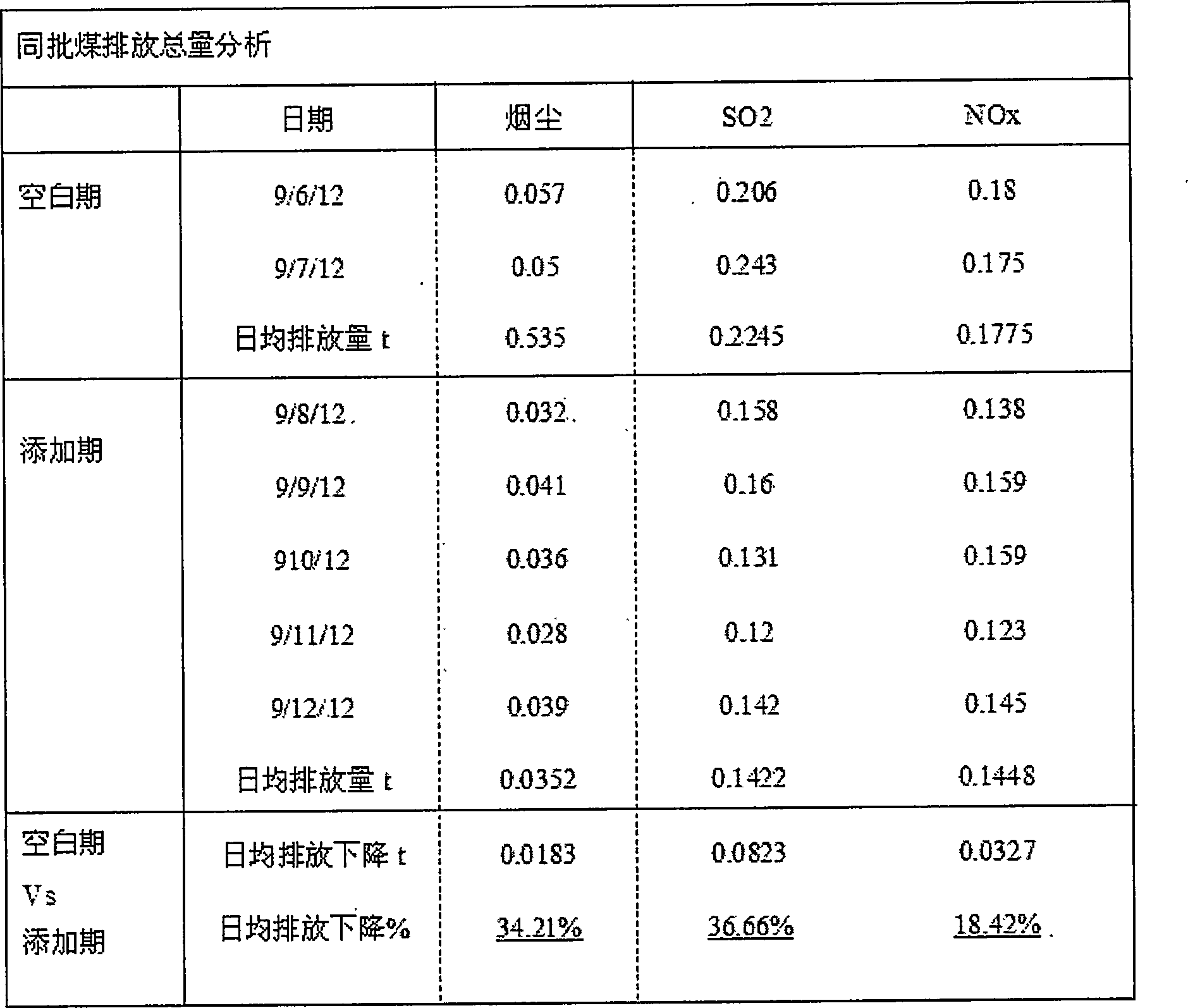

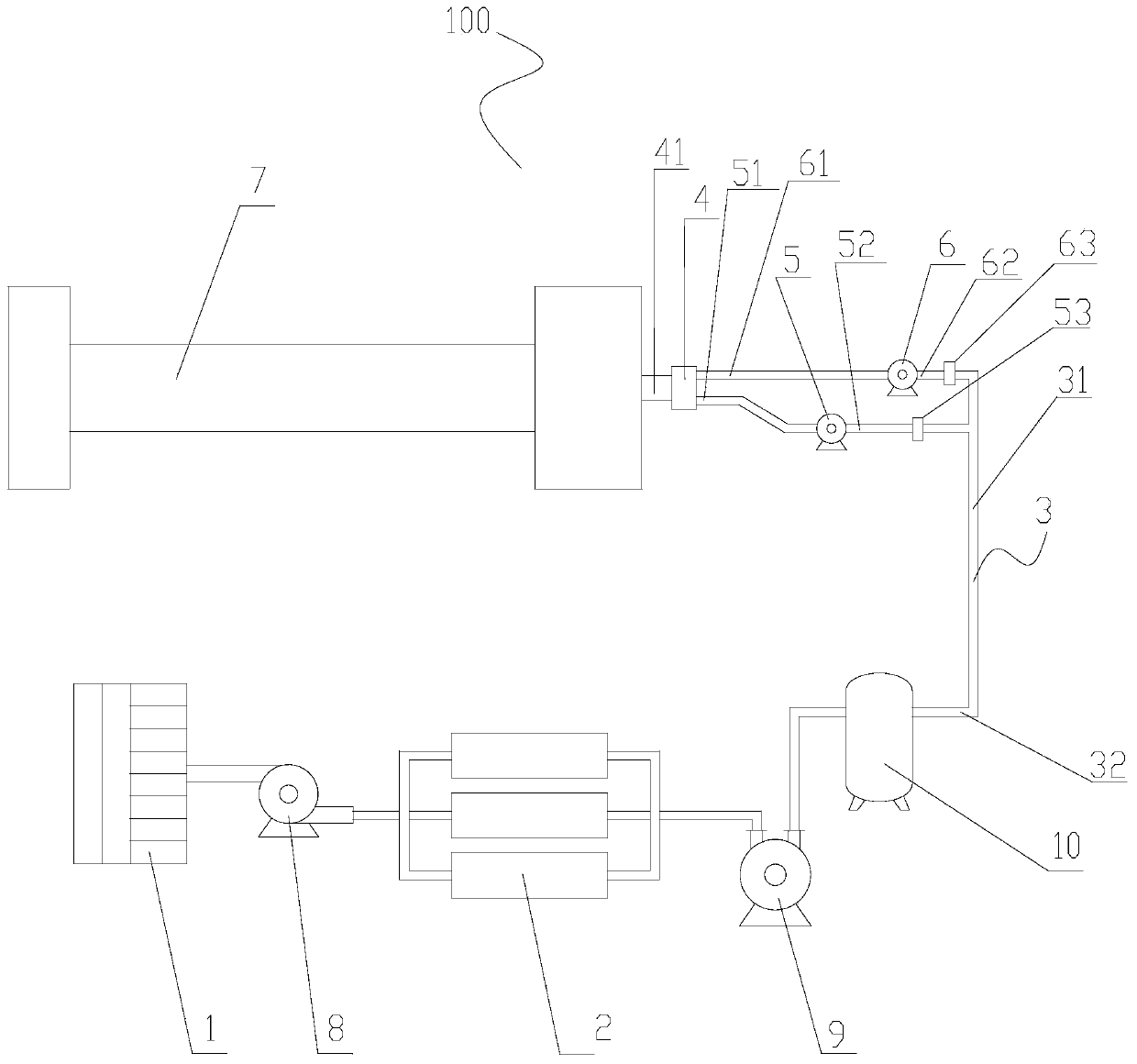

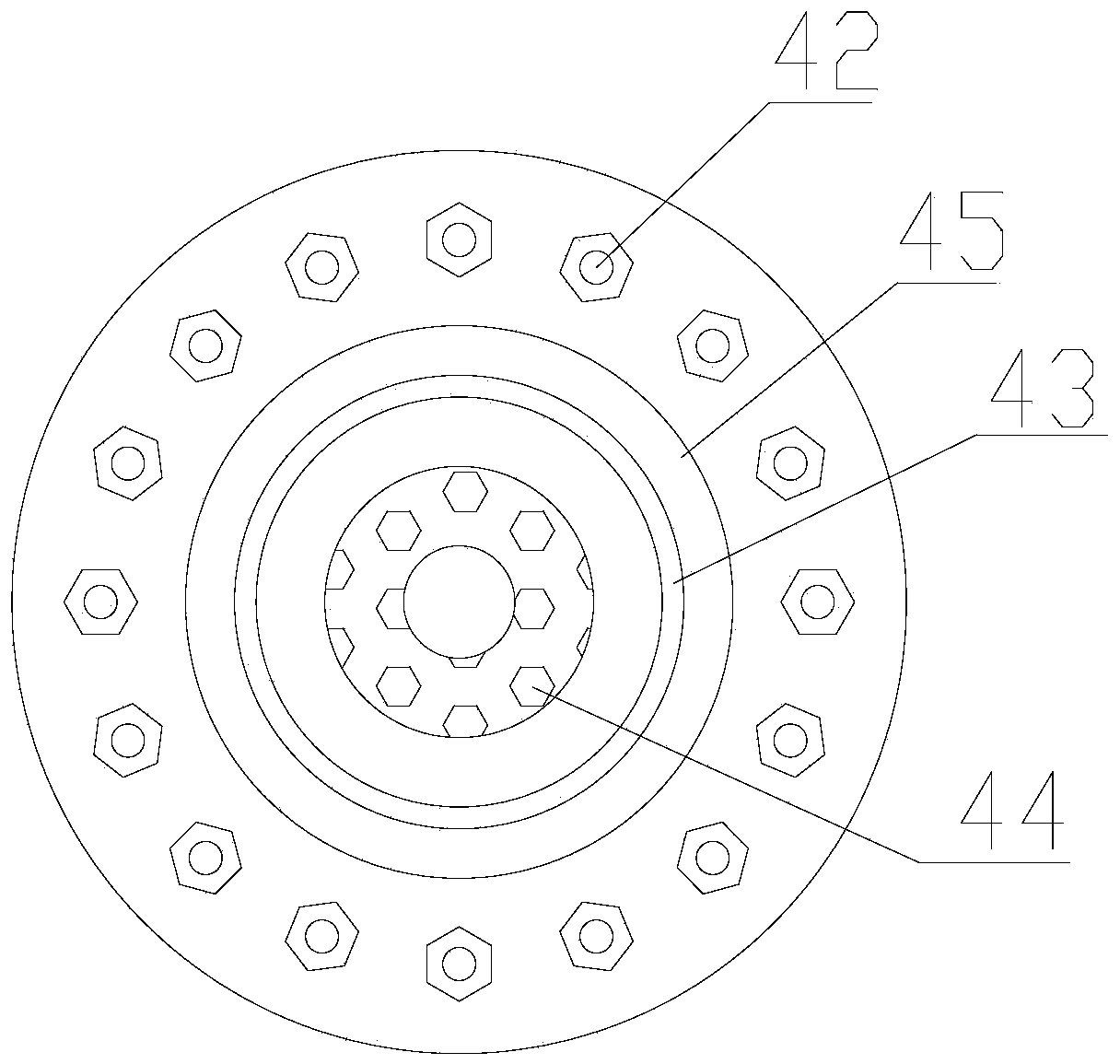

High temperature and high pressure steam dehydration system and method for household garbage

The invention relates to a high temperature and high pressure steam dehydration system and method for household garbage, and belongs to the technical field of household garbage burning pretreatment. The method is characterized in that household garbage is subjected to a reaction at a certain time under the saturated vapor pressure action of a certain pressure, free water in garbage components is separated, the household garbage is discharged in an instant discharge mode under pressure after the reaction is finished, the household garbage in the discharging process is subjected to flashing, puffing and crushing, the free water in individual tissues is separated, the garbage is further dehydrated, the dehydrated garbage is subjected to incineration treatment, and liquid waste which is generated after dehydrating is subjected to anaerobic methane treatment. The household garbage household garbage steam dehydration system and method provided by the invention have the advantages that bound water of the household garbage is changed into the free water among particles, the moisture contained in the garbage are separated through gravity settling, the garbage heat value is greatly increased, the methane generated by anaerobic digestion can provide heat energy supplies such as steam, and the resources recycling is guaranteed.

Owner:北京市城市管理研究院 +1

Coal additive

ActiveCN103320195APlay a catalytic roleLower the ignition temperatureSolid fuelsRare-earth elementCombustion

The invention provides a coal additive. The coal additive comprises an emulsifier, a dispersant, a corrosion inhibitor and a penetrant. The coal additive contains O, Mg, Al, Si, S, Ca, Ba and Mn. The coal additive has the advantages that the emulsifier, the dispersant, the corrosion inhibitor and the penetrant are used and the rare earth elements improve catalyst activity so that a traditional exterior-to-interior combustion mode is changed into an interior-exterior synchronous combustion mode and thus a coal complete-combustion degree is improved and a heat loss caused by chemical incomplete combustion and mechanical incomplete combustion of coal in a furnace is reduced; and through composite carriers having mesoporous structures, catalyst activity is improved, a hydrodesulfurization process is finished and discharge amounts of flue dust and harmful gas in exhaust gas are reduced so that coal saving and sulfur fixation are realized.

Owner:甘肃泰聚环保科技有限公司

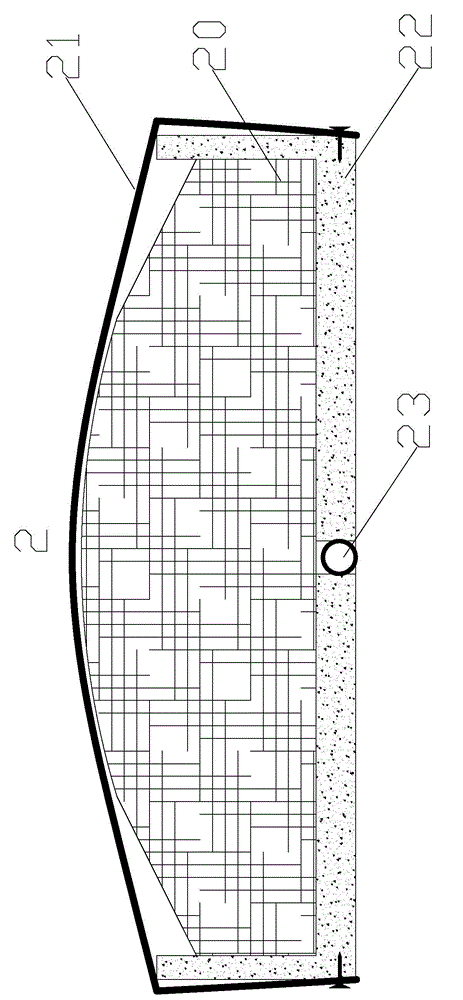

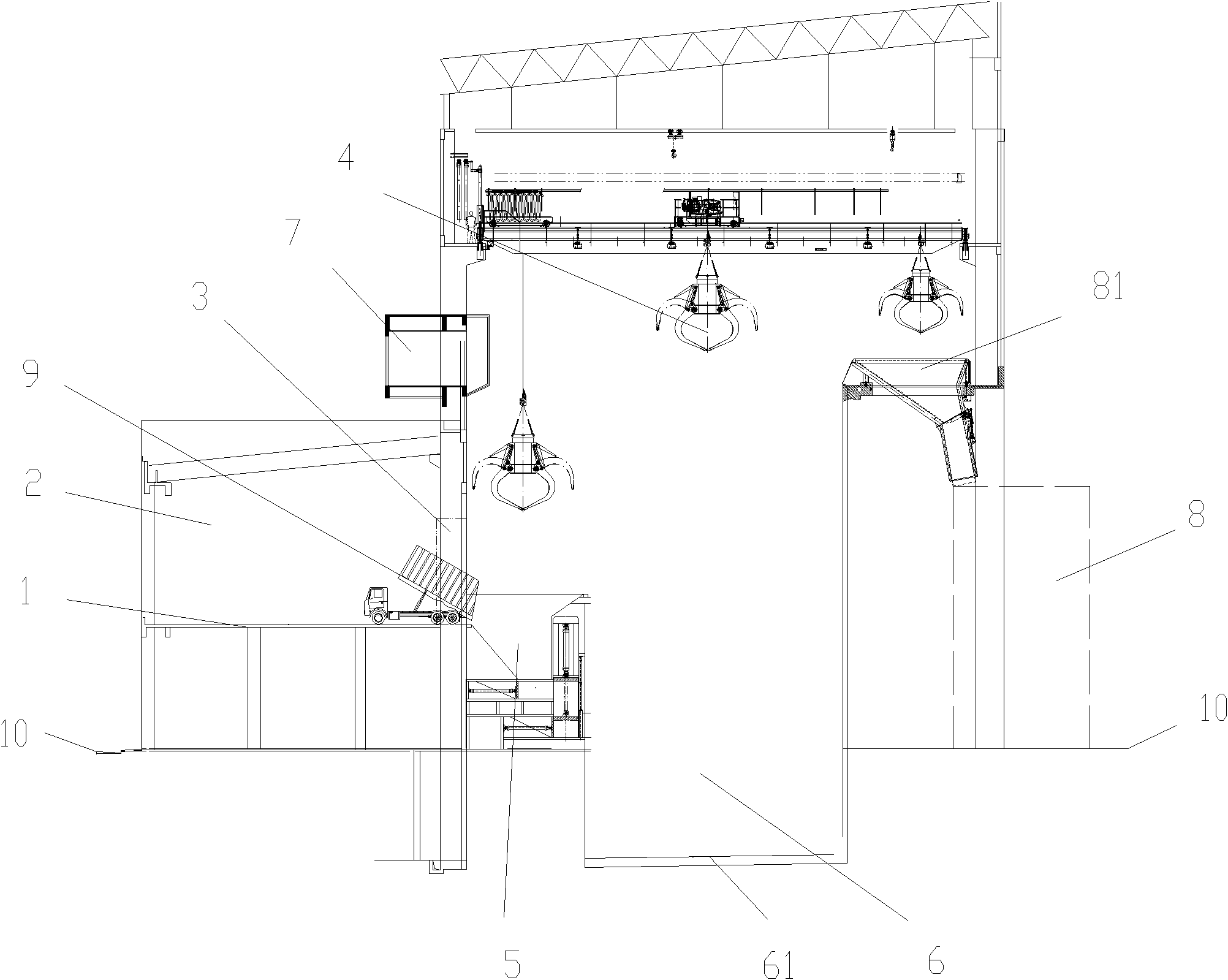

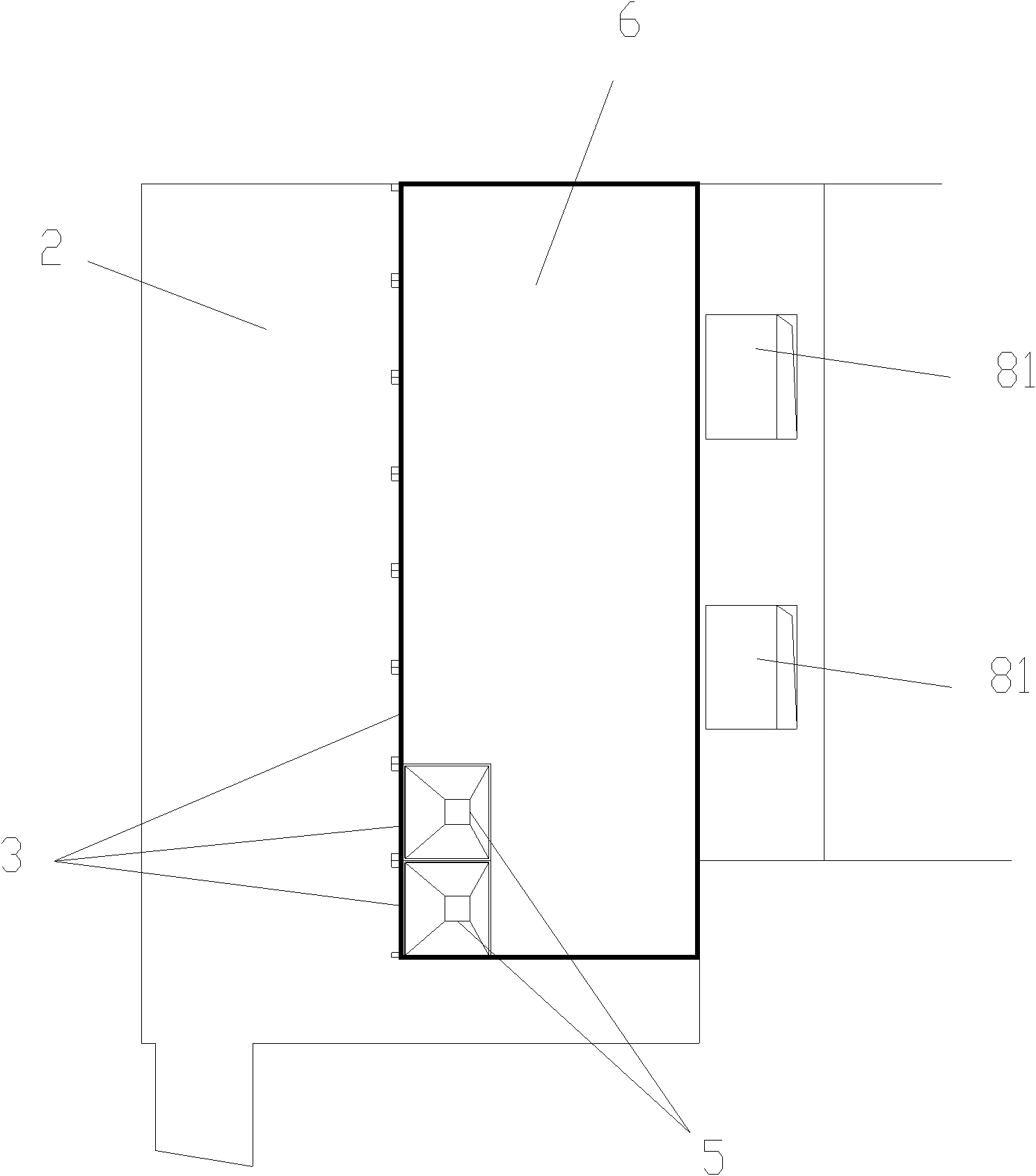

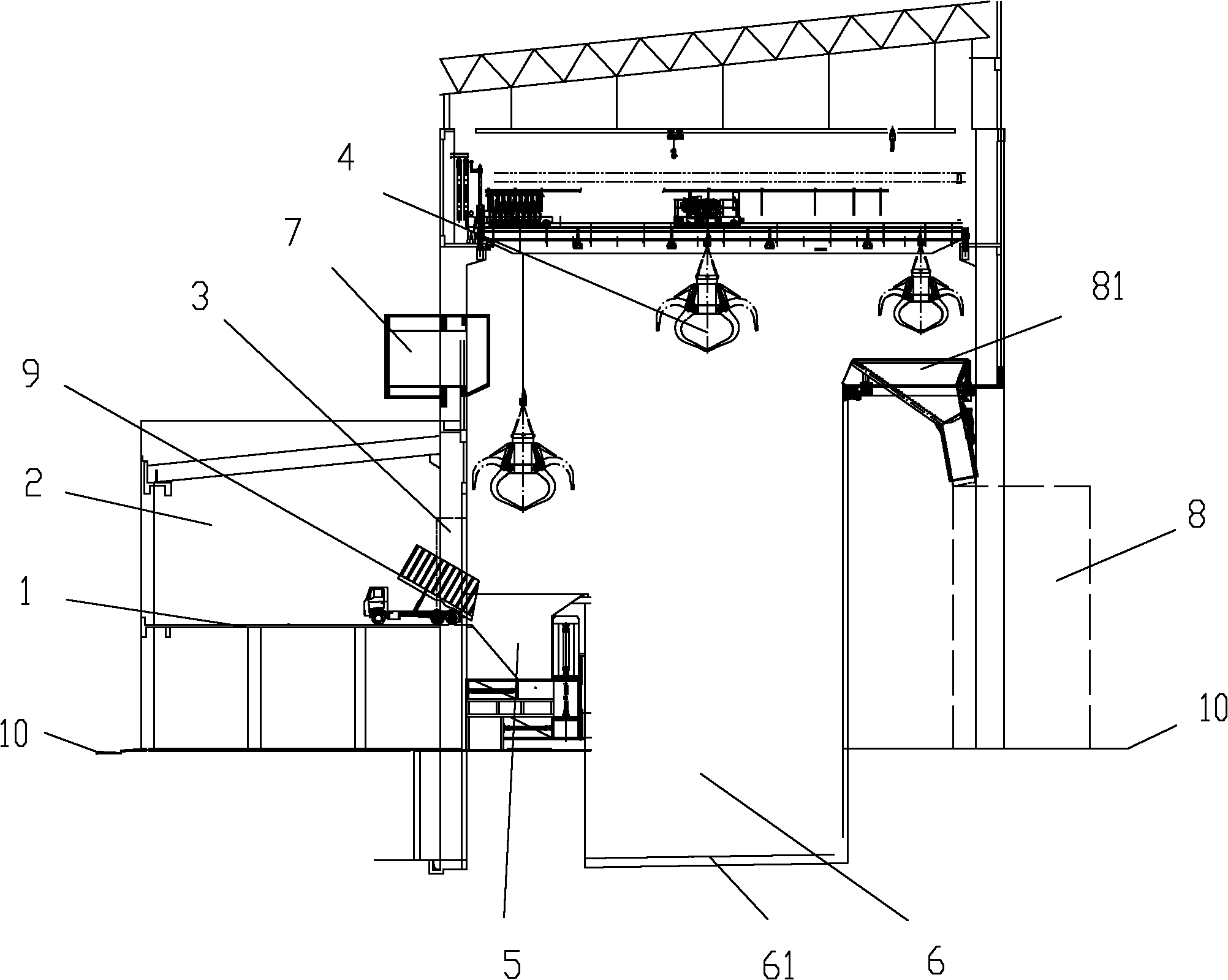

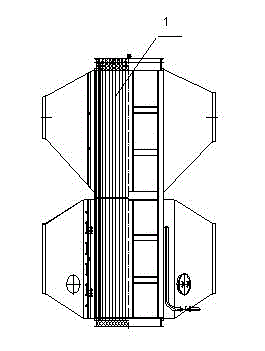

Waste storage tank for dehydrating waste

InactiveCN102091707AImprove dehydration treatment efficiencyStable combustionSolid waste disposalLitterOverhead crane

The invention discloses a waste storage tank for dehydrating waste, which comprises a waste storage tank body, a discharging door arranged at one side of the waste storage tank body, a bridge crane and a waste grab bucket arranged below the top roof of the waste storage tank body, and a compressed waste dehydrator arranged below the discharging door, wherein the compressed waste dehydrator is provided with a collecting hopper with an upward opening, the collecting hopper is positioned below the discharging door, and a discharging platform is arranged outside the discharging door. By the compressed waste dehydrator, the waste storage tank can dehydrate and store crude waste generated by factories in sequence, and also can deeply dehydrate the fermented waste stored in the tank body, remarkably improves the dehydration efficiency of waste, saves the dehydration time of waste, improved the lower heat value of waste, and reduces cost; and the volume of the whole waste storage tank can be reduced.

Owner:SHENZHEN DINGZHU ENVIRONMENTAL PROTECTION TECH

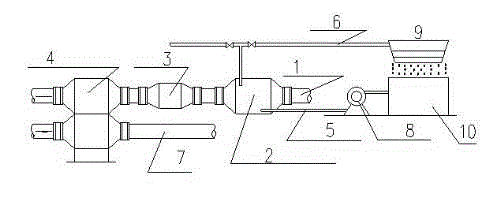

Blast furnace gas preprocessing method and device

InactiveCN102942967AImprove dehydration rateIncrease the calorific value of combustionEnergy inputBlast furnace detailsPretreatment methodCombustion

The invention provides a preprocessing method and device which can effectively perform condensation and dehydration on high-moisture blast furnace gas from iron and steel plants, and can utilize waste heat of flue gas for heating. The method comprises the following steps of: performing heat exchange on water and the wet furnace gas entering a condensing dryer; removing part of saturated water in the furnace gas which is cooled after the heat exchange, and meanwhile, heating the cold water in the condensing dryer through the heat transfer; and removing mechanical water of the furnace gas from the condensing dryer in a demister; and warming the furnace gas through absorbing the waste heat of the flue gas in a flue gas waste heat recovery device after the furnace gas is subjected to cooling, condensation and dehydration as well as mechanical dewatering. The method and the device provided by the invention effectively solve the problems of erosion and blockage of the flue gas waste heat recovery and heat exchange device caused by high moisture of the blast furnace gas; and meanwhile, the combustion heat of the dried gas preprocessed by the method and the device is greatly improved, and thus the whole heat recovery efficiency is improved.

Owner:NANJING SHENGNUO HEAT PIPE

Sulfur-fixation, denitration and coke-cleaning additive for coal-fired boiler

InactiveCN107739642AImprove breathabilityAccelerated destructionSolid fuelsEmission standardRare earth

The invention discloses a coal-fired boiler sulfur-fixing, denitrification and coke-clearing additive, which is composed of the following raw materials in parts by weight: 8-20 parts of nano-titanium dioxide; 20-50 parts of natural marble; 1-6 parts of rare earth components; 20-20 parts of nitrate 30 parts; 3-10 parts of plant ash; 5-10 parts of activated carbon; each raw material in said parts by weight is stirred evenly and added to coal powder for further mixing. The invention can effectively reduce coal consumption, reduce sulfur dioxide emission rate and nitrogen oxide emission, and has coke cleaning effect, realize effective sulfur fixation, denitrification and coke cleaning, stable performance, high coal saving rate, high emission reduction rate, simple use and convenient application Advantages, what is more characteristic is that it overcomes the defects of traditional pulverized coal boilers relying on external exhaust pipes to implement flue gas desulfurization and denitrification equipment with large investment and poor results. The invention is combined with the traditional flue gas wet desulfurization and denitrification process, can effectively reduce the desulfurization and denitrification cost of enterprises, and fully complies with the national air pollution emission standards.

Owner:李旺

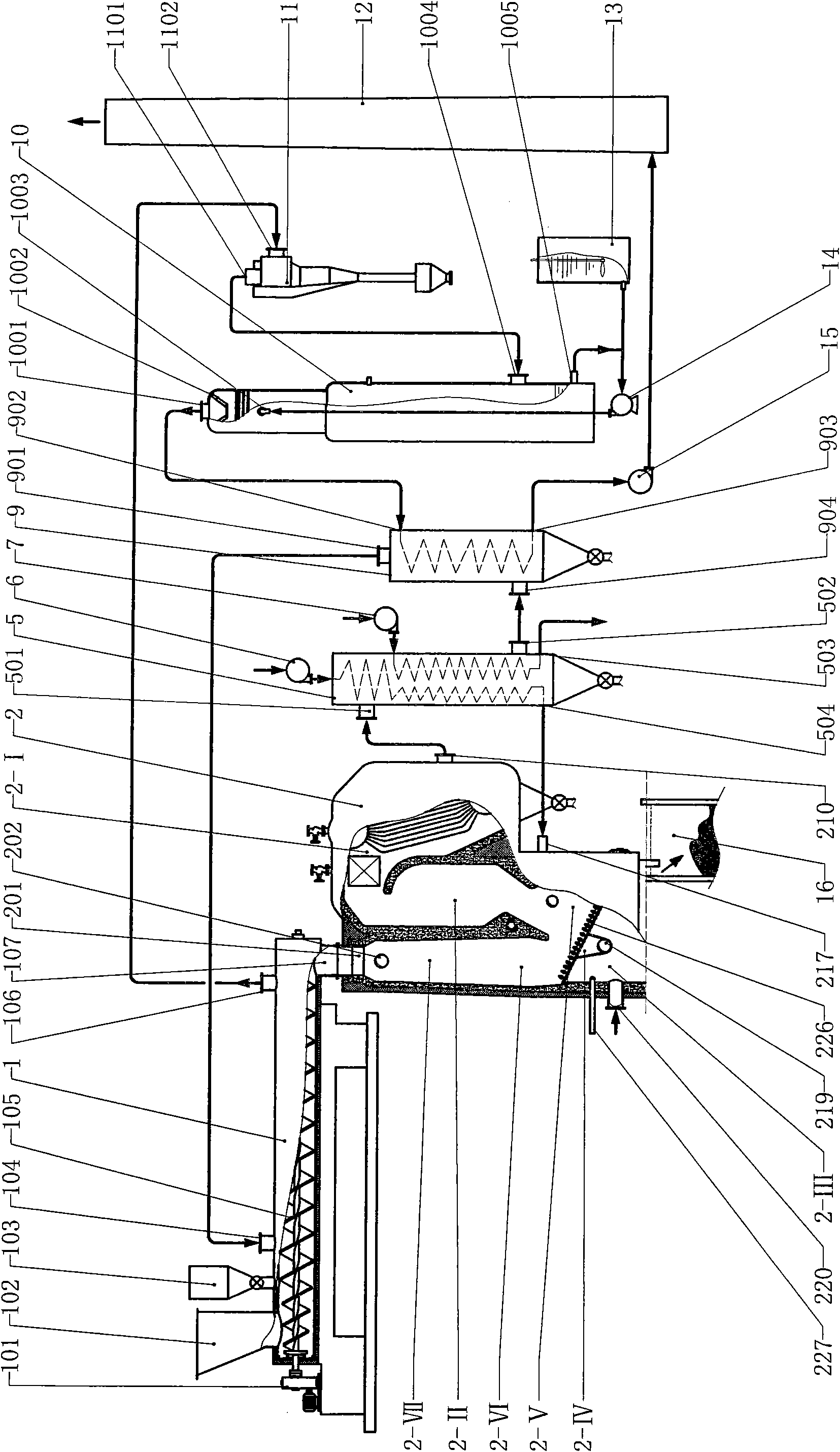

Household waste incineration power generation and sludge drying treatment synergetic method and system

PendingCN108413411APromote harmlessnessPromote reductionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesLitterWastewater

The invention discloses a household waste incineration power generation and sludge drying treatment synergetic method and system. According to the household waste incineration power generation and sludge drying treatment synergetic method, a low-pressure extracted steam of a steam turbine generator set of a household waste incineration power generation system is used as a heat source for sludge drying treatment, and the dried sludge and household waste are mixed and incinerated for power generation; and odor and waste water in the sludge drying process and smoke and ash generated in the sludgeincineration process are jointly treated through waste water, waste gas and waste residue pollution preventing facilities in the household waste incineration power generation system. By the adoptionof the household waste incineration power generation and sludge drying synergetic treatment method and system, by means of synergy between the household waste incineration power generation and sludgetreatment, the effects of reduction, disinfection, sterilization and odor removal are achieved in the drying process, the harmless requirement of sludge treatment is met, reduction and recycling of the sludge are achieved in a real sense on this premise, and good economic, social and environment benefits are achieved.

Owner:AEROSPACE KAITIAN ENVIRONMENTAL TECH CO LTD

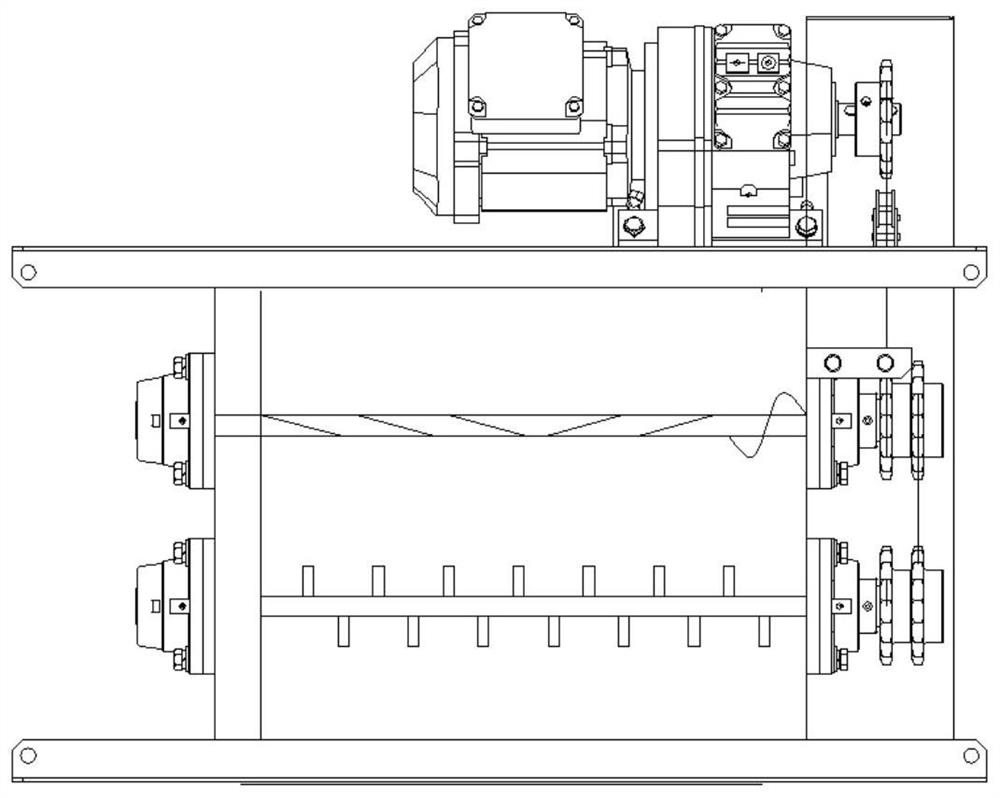

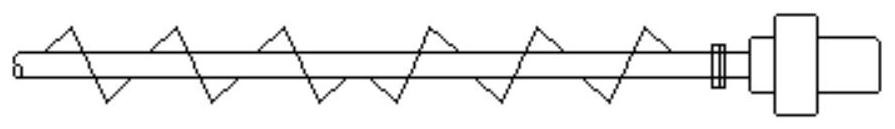

Sludge high-pressure belt type deep dehydrator and application method thereof

PendingCN113896398AReduce moisture contentLow running costSludge treatmentSpecific water treatment objectivesProcess engineeringFilter press

The invention provides a sludge high-pressure belt type deep dehydrator, which comprises a main body frame, an upper filter belt and a lower filter belt, wherein a feeding module, a filter pressing module and a discharging module are arranged in the main body frame, the filter pressing module is arranged between the feeding module and the discharging module, the feeding module comprises a uniform distribution mechanism, the uniform distribution mechanism is arranged above the lower filter belt, a feeding opening is formed above the uniform distribution mechanism, the filter pressing module comprises pressing rollers and a squeezing mechanism, the squeezing mechanism comprises a low-pressure area and a high-pressure area, a plurality of pressing rollers are distributed in the low-pressure area and the high-pressure area, a large-roller-diameter pressing roller and a small-roller-diameter pressing roller are arranged in the filter pressing module through bearings, the upper filter belt and the lower filter belt are wound on the pressing rollers, the large-roller-diameter pressing roller and the small-roller-diameter pressing roller respectively, the discharging module comprises a discharging device and a flushing mechanism, and the working surface of the flushing mechanism covers the working surfaces of the upper and lower filter belts. According to the invention, the problems of complex process flow, poor dehydration effect, low sludge treatment capacity, high investment cost, high labor cost and high operation cost of the existing sludge dehydration equipment are solved.

Owner:上海凌逍环保科技有限公司

Processing method of biomass fuel

InactiveCN108085087AImprove molding rateImprove physical and chemical propertiesBiofuelsSolid fuelsSODIUM COCOYL SARCOSINATEWater vapor

The invention discloses a processing method a biomass fuel and relates to the technical field of biomass fuels. The processing method comprises the following steps: (1) crushing; (2) adding of a binder; (3) heating and heat insulation; and (4) shaping. The biomass fuel prepared by the processing method is high in shaping rate. Crushed materials are subject to fumigated by water vapor, and then a sodium cocoyl sarcosinate solution is adopted to soak the fumigated materials, so that the physicochemical property of the crushed materials can be greatly improved, the crushed materials are easier toshape, and the shaping rate is effectively increased. Meanwhile, cationic etherified starch is adopted to prepare a starch slurry to serve as the binder, the biomass raw materials can be shaped undera simper condition. Besides, the shaping rate, the product density and durability, and the lower calorific value of the granular fuel can be effectively improved.

Owner:ANHUI DADI ENERGY SAVING SCI & TECH

Rotary cement kiln local full-oxygen-enriched calcining device and process

PendingCN111288792AIncrease the low calorific valueHigh flame temperatureRotary drum furnacesMaintainance of heating chambersThermodynamicsAir cleaning

The invention discloses a rotary cement kiln local full-oxygen-enriched calcining device and process. The rotary cement kiln local full-oxygen-enriched calcining device comprises an air purification device, an oxygen-enriched generation device, an oxygen-enriched conveying pipe and a pulverized coal burner which are connected in sequence; the pulverized coal burner is connected with an outlet of aprimary air Roots blower and an outlet of a pulverized coal air Roots blower; an inlet of the primary air Roots blower and an inlet of the pulverized coal air Roots blower are connected with the output end of the oxygen-enriched conveying pipe; and a fire outlet of the pulverized coal burner is connected with a rotary cement kiln. By the adoption of the technical scheme, air used for calcining ofthe rotary cement kiln, namely air used by the pulverized coal burner, is completely replaced with oxygen-enriched gas, the low-level fever value of fire coal is increased, thus the flame temperaturecan be increased to be 180-200 DEG C, the optimal fire coal saving effect is achieved, and the coal saving rate can reach 10% or above.

Owner:山东钧辰清洁能源科技有限公司

Chromium-based boiler slag-removing coal-saving composition and preparation method thereof

The present invention relates to an additive product suitable for coal-fired boilers of electric power, thermal power, petroleum, chemical and metallurgical and other industries, and particularly relates to a chromium-based boiler slag-removing coal-saving composition used for a coal fired boiler, and the chromium-based boiler slag-removing coal-saving composition consists of the following components in parts by weight: 50 to 65 parts of chromium oxide, 8 to 15 parts of copper sulfate, 5 to 9 parts of cerium oxide, 5 to 9 parts of barium molybdate, 7 to 14 parts of cobalt carbonate, 12 to 17 parts of potassium permanganate, 10 to 16 parts of manganese oxide, 12 to 17 parts of potassium carbonate, 8 to 15 parts of titanium dioxide, zinc oxide, 15 to 20 parts of zinc oxide, 6 to 10 parts of potassium chlorate, 6 to 10 parts of potassium perchlorate, 20 to 28 parts of sodium carbonate, 25 to 35 parts of active attapulgite carclazyte and 0.1 to 0.3 part of lignonaphthalenesulfonate. The chromium-based boiler slag-removing coal-saving composition is a high-tech energy-saving environmentally-friendly product which is efficient, combustion-helping, and high in coal saving ratio, and can reduce pollution, improve combustion efficiency, and extend the boiler service life; fuel gas spray old coke body on and around furnace water cooling wall tube can be cleanly removed in 3 to 5 days; and new generated coke residue body can be automatically and periodically shed off.

Owner:刘音希

Microorganism-enhanced microbial agent capable of remarkably promoting composting effect before household garbage incineration, and application thereof

ActiveCN111004748AEasy growth metabolismGrow fastBacteriaSolid waste disposalBiotechnologyMicroorganism

The invention discloses a microorganism-enhanced microbial agent capable of remarkably promoting the composting effect before household garbage incineration, and an application thereof. The enhanced microbial agent is prepared by mixing a plurality of composite microbial agents or mixing the composite microbial agents with a carrier, and the composite microbial agents comprise Lactobacillus pasteurii with the preservation number of CGMCC No.18391, Clostridium butyricum with the preservation number of CGMCC No.14499, Bacillus lentus with the preservation number of CGMCC No.18392, and Bacillus psychrophilus with the preservation number of CGMCC No. 18393. The microorganism-enhanced microbial agent can obviously promote the composting effect before household garbage incineration, increase thelow calorific value during garbage incineration and promote garbage dehydration, also can increase the abundance and content of functional microorganisms in garbage composting and accelerate the garbage fermentation process, and can rapidly start the composting process in cold regions to remarkably reduce the use of a combustion improver.

Owner:QINGDAO SHANGDE BIOTECH

A biological drying and stabilizing bacteria agent for kitchen waste, its preparation method and application

ActiveCN111662853BReduce moisture contentIncrease the low calorific valueBacteriaClimate change adaptationBiotechnologyCellulose

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

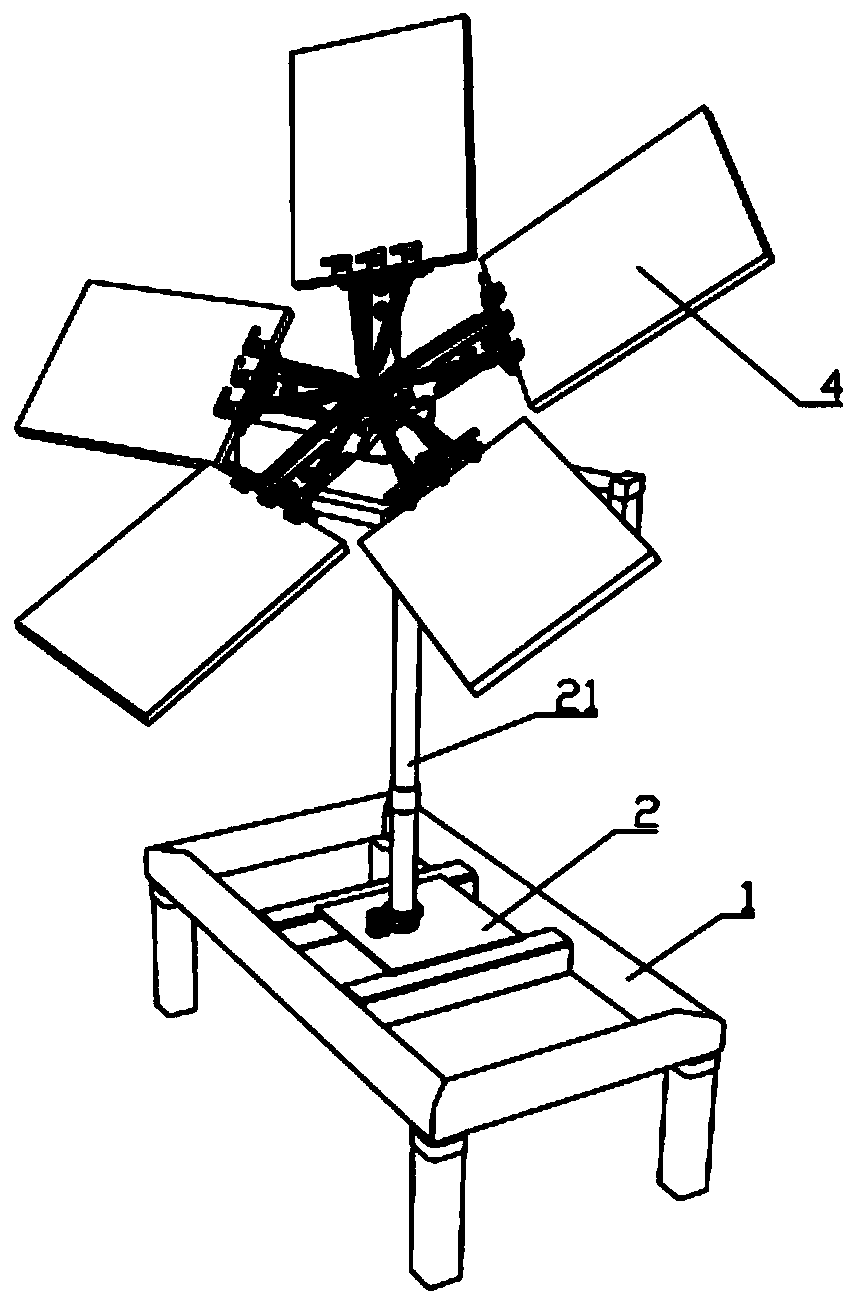

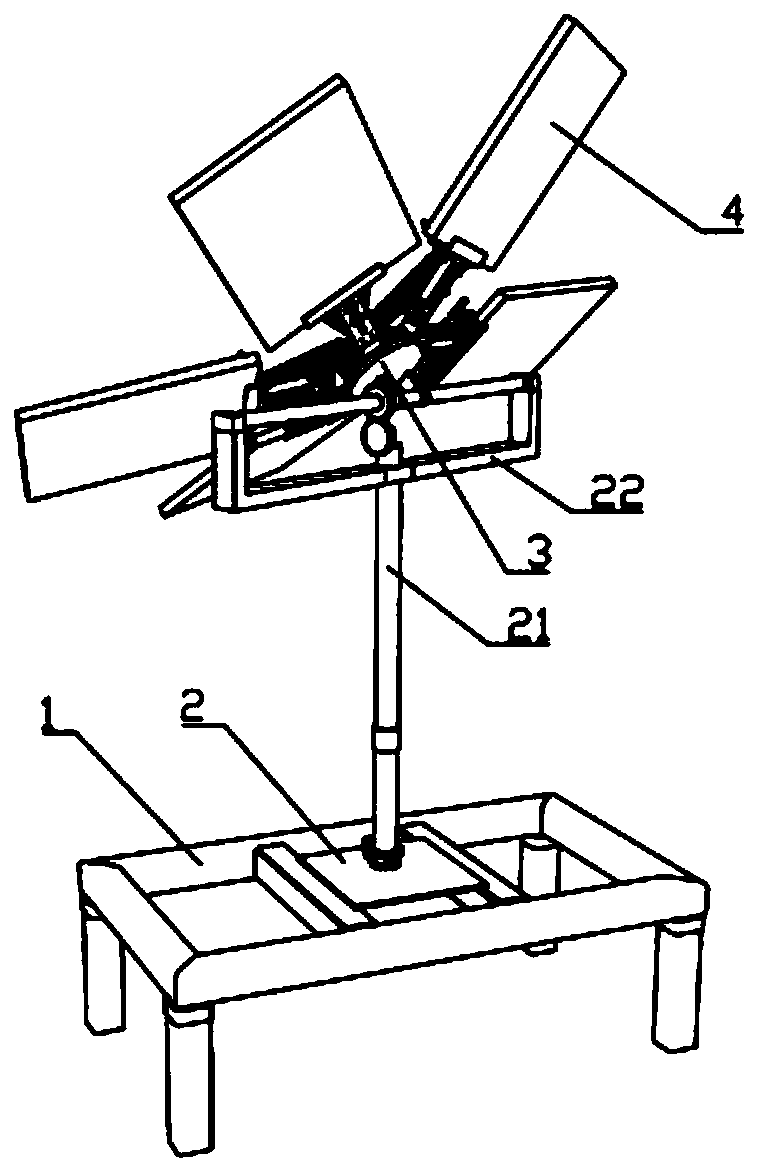

Advanced sludge treatment equipment and using method thereof

InactiveCN110590106AHigh porosityImprove dehydration effectSludge treatmentSpecific water treatment objectivesWater supplySolar power

The invention belongs to the technical field of sludge treatment, and particularly relates to advanced sludge treatment equipment. The equipment comprises a solar power supply mechanism, a sludge tank, a sludge pump, a belt type sludge concentration and dehydration integrated machine, a dosing device, a dosing pump, an inclined shaftless conveyor, a sludge modification mixer, a modifier dosing device, a continuous sludge deep dehydration squeezer, an inclined shaft conveyor, a cleaning pump and a stainless steel mesh filter; the output end of the solar power supply mechanism is electrically connected to the sludge pump, the belt type sludge concentration and dehydration integrated machine, the dosing pump, the inclined shaftless conveyor, the sludge modification mixer, the continuous sludge deep dehydration squeezer, the inclined shaft conveyor and the cleaning pump separately; and the input end of the belt type sludge concentration and dehydration integrated machine respectively communicates with the sludge pump and the dosing pump through two branches, an inlet of the sludge pump communicates with the sludge tank, an inlet of the dosing pump communicates with the dosing device, and an inlet of the dosing device communicates with a plant area water supply system. The invention further relates to a using method of the advanced sludge treatment equipment.

Owner:青海天普伟业环保科技有限公司

A kind of microbe-enhanced bacterial agent and its application that can significantly promote the composting effect before domestic waste incineration

ActiveCN111004748BEasy growth metabolismGrow fastBacteriaSolid waste disposalBiotechnologyBacillus lentus

The invention discloses a microorganism-enhanced bacterial agent for significantly promoting the composting effect before incineration of domestic garbage and an application thereof. The enhanced bacterial agent is made by mixing a variety of composite bacterial agents or composite bacterial agents with a carrier, and the composite bacterial agent includes Lactobacillus parreni with a preservation number of CGMCC No.18391, and a preservation number of CGMCC No.14499. Clostridium butyricum, Bacillus lentus with preservation number CGMCC No.18392 and Psyrophilic Bacillus with preservation number CGMCC No.18393. The microbial enhanced bacterial agent of the present invention can significantly promote the effect of composting fermentation before domestic waste incineration, increase the low calorific value during waste incineration, promote the dehydration of garbage, and can also increase the abundance and content of functional microorganisms in garbage composting fermentation, and accelerate the efficiency of garbage fermentation process, and in cold regions, the bacterial agent can also quickly start the composting process, significantly reducing the use of combustion aids.

Owner:QINGDAO SHANGDE BIOTECH

Boiler chromium-based slag-removing coal-saving agent composition and preparation method thereof

Owner:刘音希

A biological drying-based domestic waste treatment method

The invention provides a bio-drying-based domestic refuse treatment method. The method comprises the following steps: (1), pre-treatment: feeding domestic refuses into a negative-pressure receiving room to break bags and manually select; performing innocent treatment on selected harmful refuses which have potential pollution threats to the soil and the underground water, and crushing selected large-size refuses in a large-size refuse crusher, wherein the crushed large-size refuses are treated in a step (3), residual domestic refuses are treated in a step (2), and the air change rate of the negative-pressure receiving room is five to seven times per hour; (2), bio-drying: feeding the residual domestic refuses treated in the step (1) into a bio-drying storehouse, stacking to form a refuse dump body, and covering the refuse dump body with a selective semi-permeable membrane; (3), post-treatment: sequentially performing mechanical crushing, drum screen screening, magnetic separation, near-infrared separation and air separation on the dried products obtained in the step (2) and large-sized refuses crushed in the step (1); (4), tail end treatment: respectively recovering and utilizing according to property difference of products selected according to the step (3).

Owner:BEIJING GEOENVIRON ENG & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com