Patents

Literature

43results about How to "Shorten the drying cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

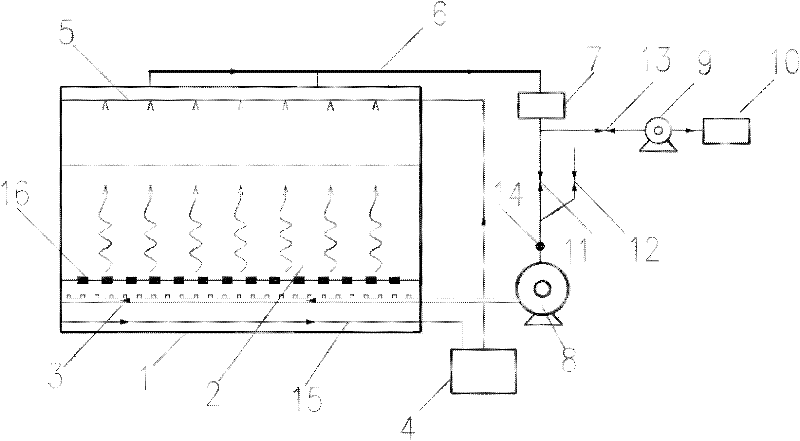

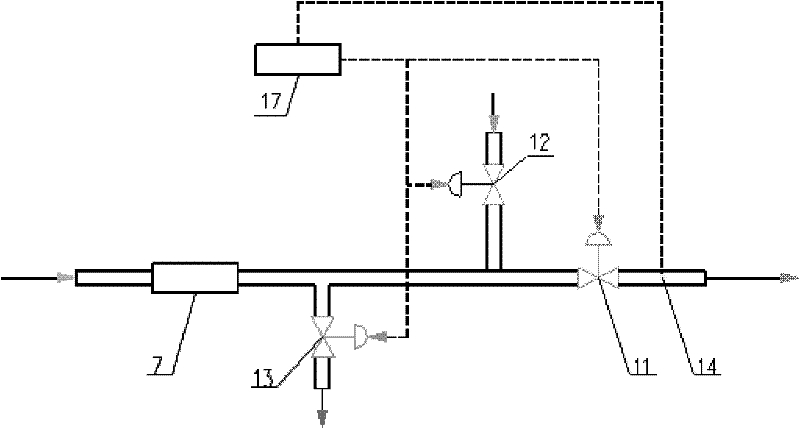

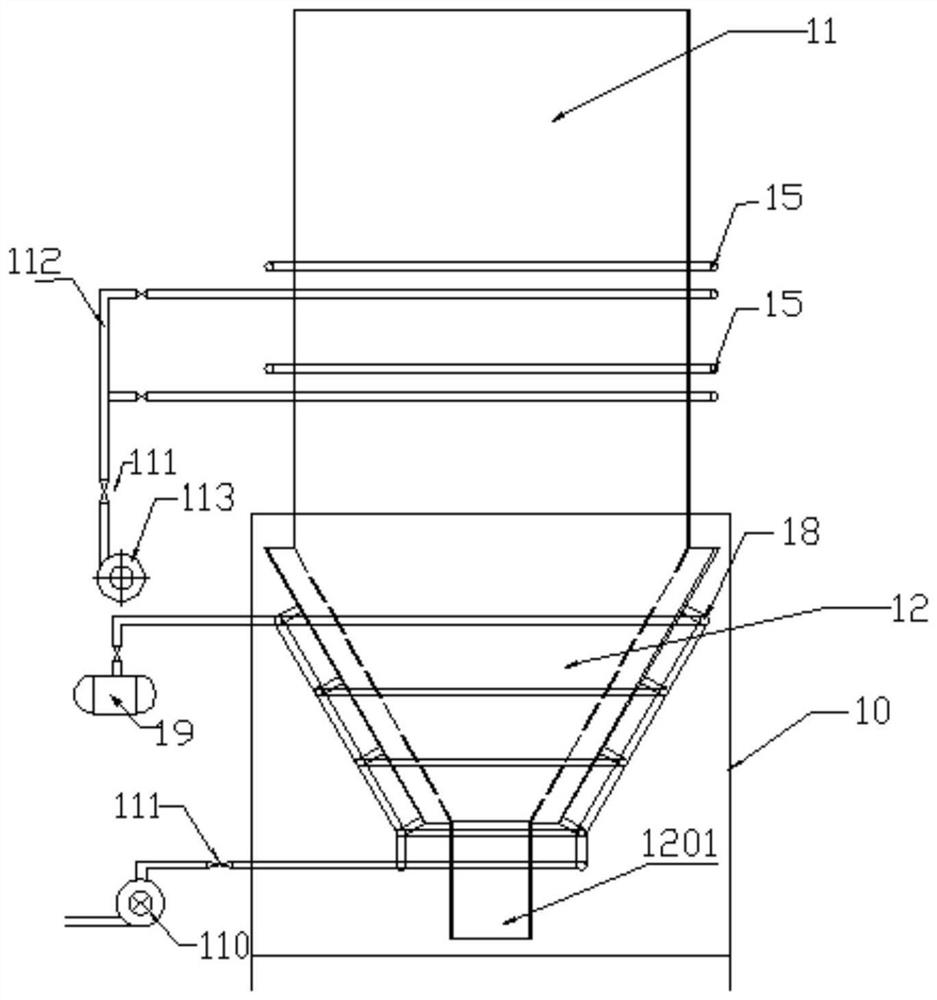

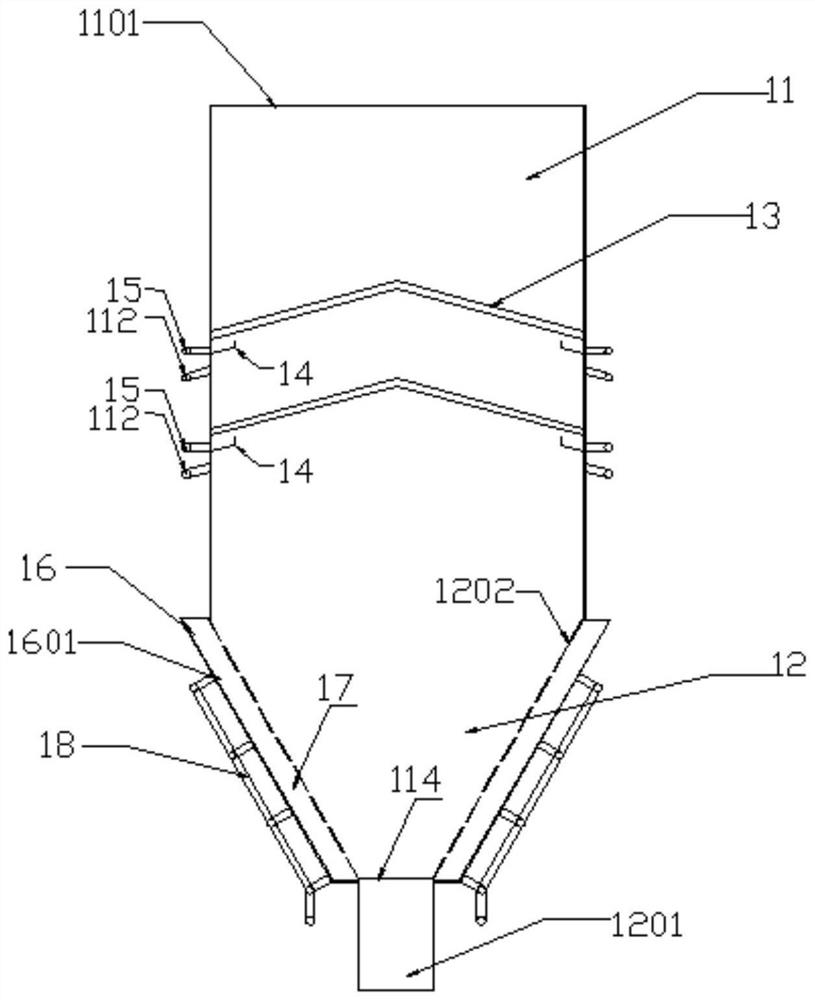

Method and apparatus for controlling secondary pollutants in biodrying of mixed domestic waste

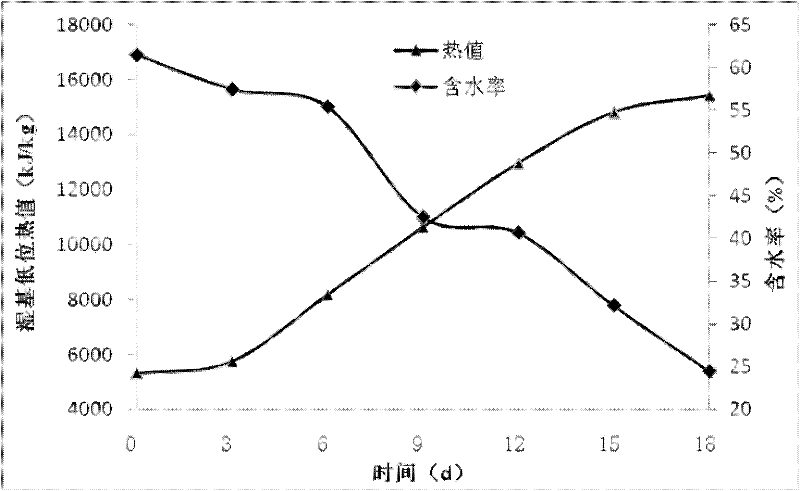

The invention relates to a method and apparatus for controlling secondary pollutants in biodrying of mixed domestic waste. The method comprises the following steps: (1) simple pretreatment; (2) stacking; (3) biodrying of waste; (4) back spraying of leachate; (5) drying, reflux and concentrated treatment of tail gas. The apparatus comprises a sealed reactor, a leachate collector, a ventilating system and a tail gas treating device, wherein, the leachate collector is respectively connected with a leachate collecting pipe and a spray pipe in the reactor through pipelines, the tail gas treating device comprises a tail gas recovering pipe, a drying box, a tail gas treating fan and a purifying means, the tail gas recovering pipe is connected with the drying box, the drying box is respectively connected with a ventilating fan and the tail gas treating fan, and the tail gas treating fan is connected with the purifying means through a pipeline. According to the invention, the leachate does not need to be treated individually; tail gas is collected in a totally enclosed environment, and the amount of tail gas to be treated is small; a low heating value of obtained dried waste is increased by 100%; the invention is widely applicable to mixed waste with high water content and enables resource values of burning and sorting of domestic waste to be improved.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

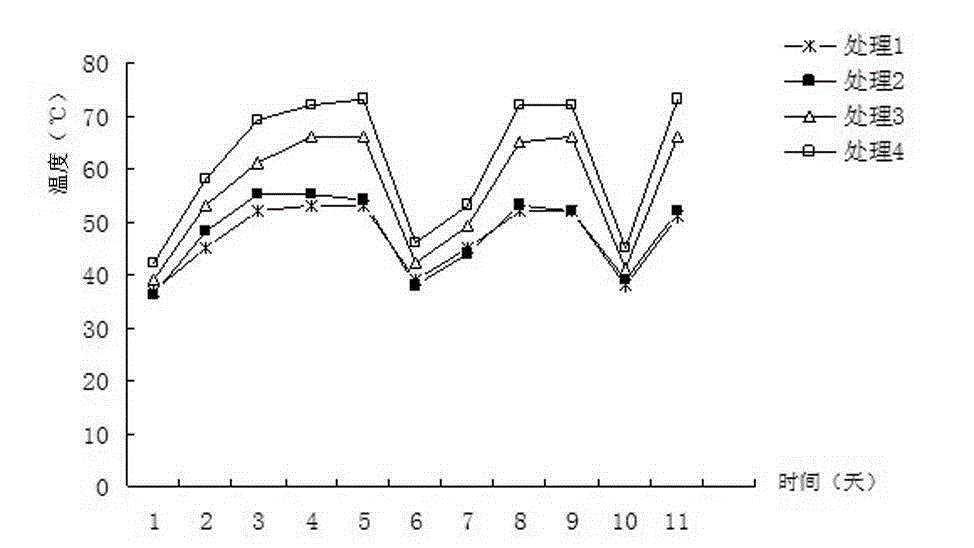

Sludge bio-drying treatment technology

InactiveCN104529112AImprove drying efficiencyShorten the drying cycleSludge treatment by de-watering/drying/thickeningBiological sludge treatmentMicroorganismSludge

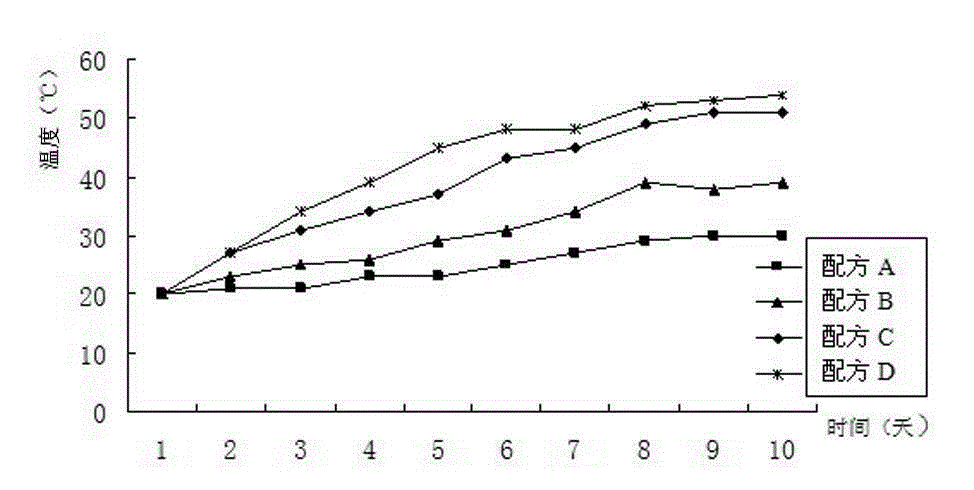

The invention relates to a sludge bio-drying treatment technology using microbial fermentation drying. Technical problems of high electricity consumption and sever environmental pollution of present sludge drying are solved in the invention. The technology is characterized in that concentrated fresh sludge with the water content of 76-84% is dried, and the technology comprises the following steps: blending the fresh sludge to adjust the water content, adding an inoculant, and fermenting and drying the sludge. Dried sludge obtained after the drying treatment can be used to replenish soil. The bio-drying technology using microbial aerobic fermentation produced heat to evaporate water fully utilizes the biological energy of the sludge, so the bio-drying technology has the advantages of economy, energy saving, environmental protection, increased drying efficiency and shortened drying cycle.

Owner:MINZU UNIVERSITY OF CHINA

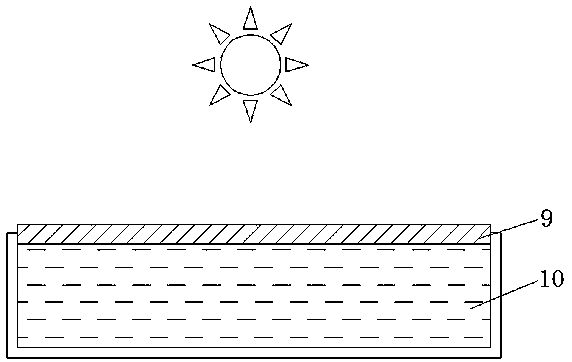

Novel photothermal salt sun-drying accelerating method and device

PendingCN108408742AReduce salt concentrationPrevent surface salt precipitation problemsEnergy inputAlkali metal chloridesExposure sunlightEngineering

The invention discloses a novel photothermal salt sun-drying accelerating method. The novel photothermal salt sun-drying accelerating method comprises the following steps of enabling a pumping deviceto inject the seawater into a salt tank; enabling one end of a hydrophilic material to extend into the seawater of the salt tank, and be in full contact with the seawater; enabling the other end of the hydrophilic material to be in full contact with an optical absorbing material, and exposing the optical absorbing material under the sun; injecting a heat insulation material between the optical absorbing material and the seawater; adjusting the contact area between the hydrophilic material and the seawater, and the hydrophility or width or thickness of a hydrophilic device, so as to control thewater absorbing rate of the hydrophilic material; drying the salt crystal at the bottom part of the salt tank under the sun. The invention also discloses a novel photothermal salt sun-drying accelerating device. The novel photothermal salt sun-drying accelerating method has the advantages that the salt-making seawater can be quickly evaporated, the salt sun-drying cycle is greatly shortened, andthe production efficiency of the salt sun-drying process is obviously improved.

Owner:江苏金羿射日新材料科技有限公司

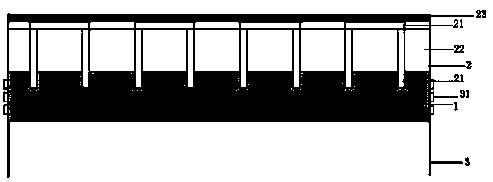

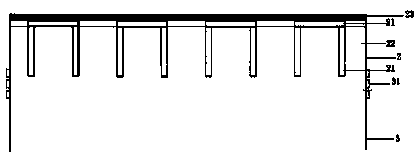

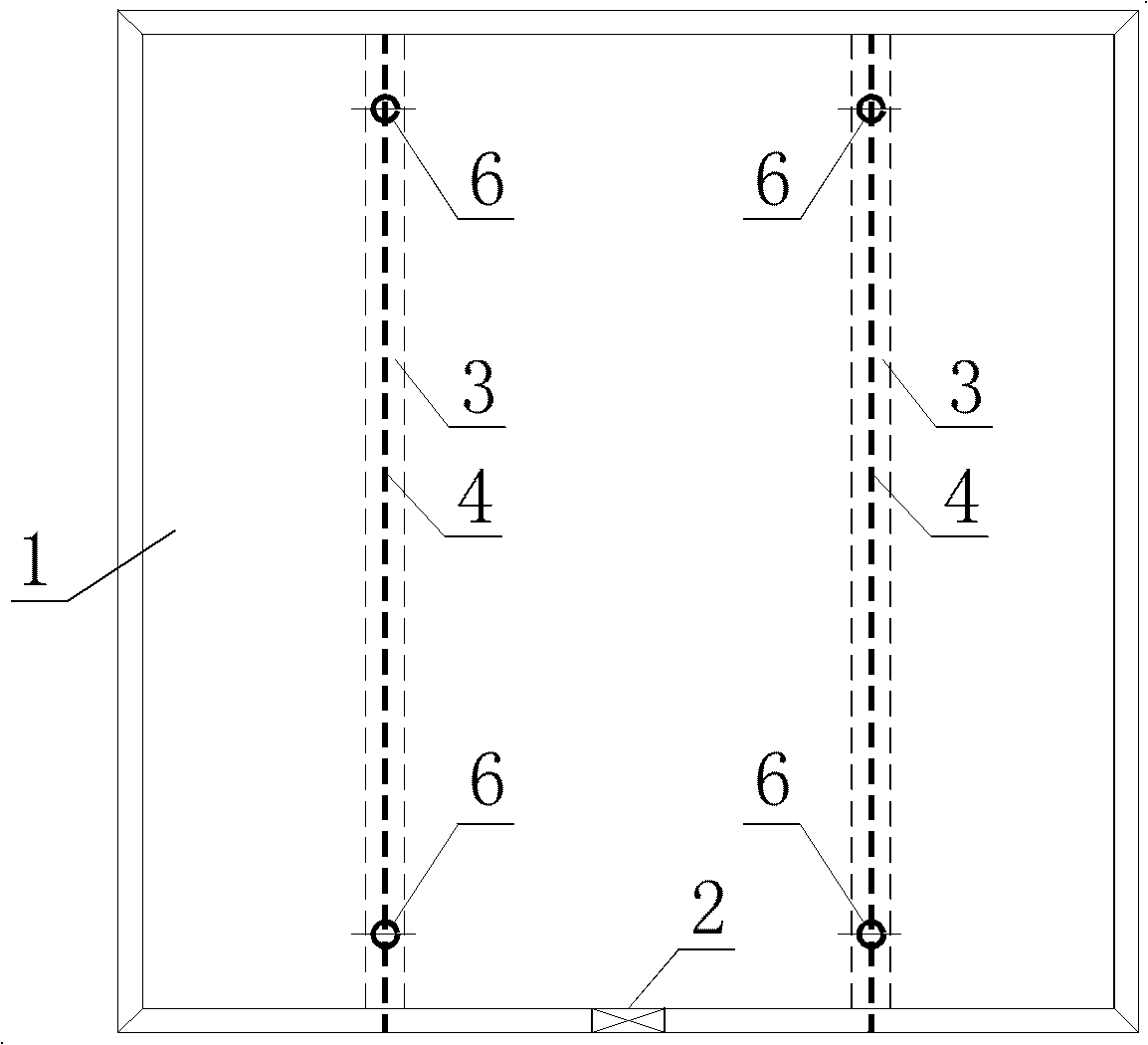

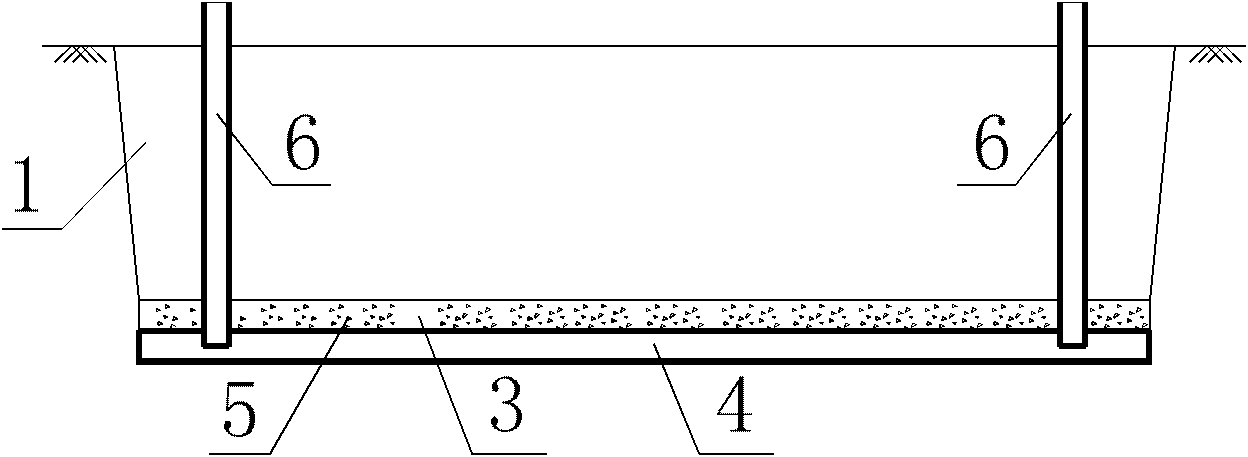

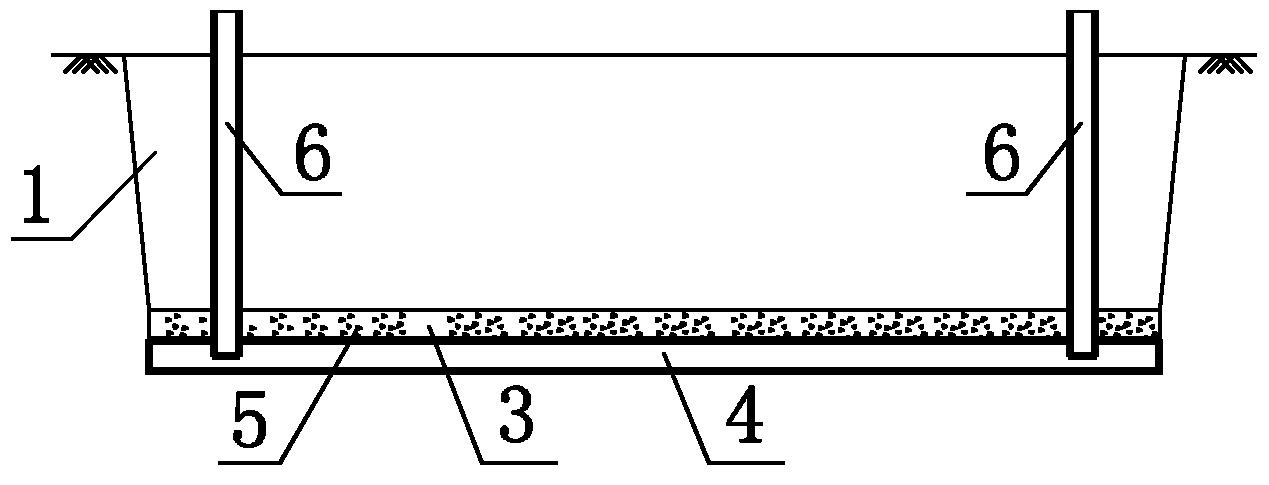

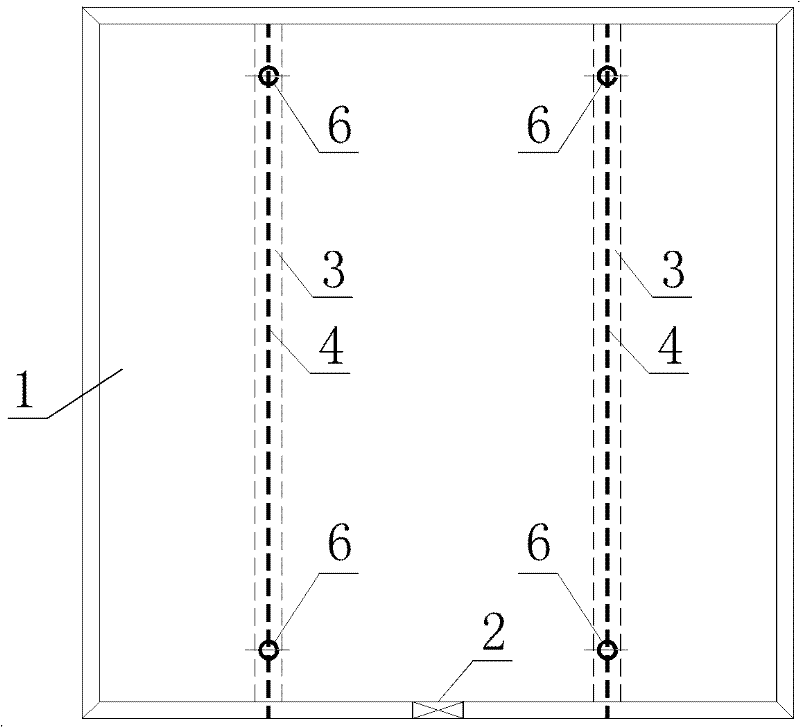

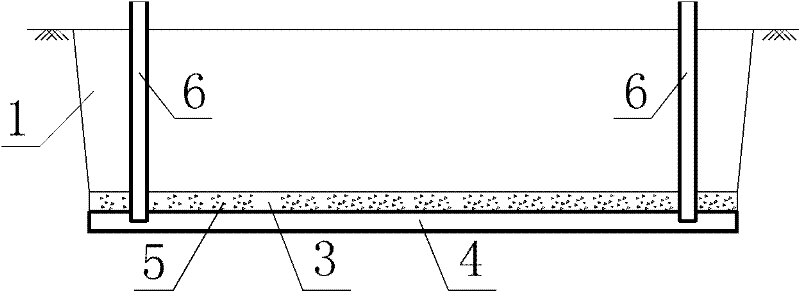

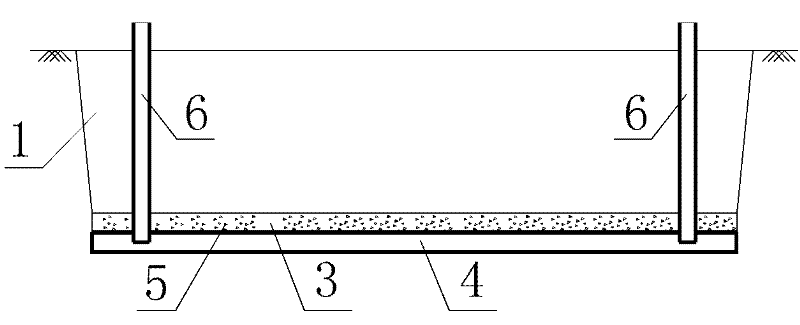

Dredged sediment dewatering and drying stockyard and establishment method thereof

ActiveCN101967821AImprove dehydration and drying speedQuick overflowSoil preservationCofferdamEngineering

The invention provides a dredged sediment dewatering and drying stockyard and an establishment method thereof, belonging to the environmental engineering technical field. The dredged sediment dewatering and drying stockyard comprises the stockyard encircled by a surrounding cofferdam, a drain outlet positioned at the upper part of the cofferdam of the stockyard, a plurality of drainage ditches which are parallel to each other and positioned at the lower part of the stockyard, drainage pipes, seepage gravel and a plurality of vertical guide tubes, wherein, the drainage pipes are laid in the drainage ditches; the seepage gravel is arranged between the drainage ditches and the drainage pipes; two ends of the drainage pipes are sequentially equipped with a plurality of the vertical guide tubes which are parallel to each other and connected with an external blower system; and the drainage pipes are arranged in the drainage ditches on the bottom of the stockyard and arranged towards the drain outlet slantwise, and the drain outlet is arranged on the cofferdam edge at one side of the stockyard. The invention can enhance the bearing capacity of the stockyard and shorten the occupied time of the temporary dredged sediment stockyard site.

Owner:戴勇鹏

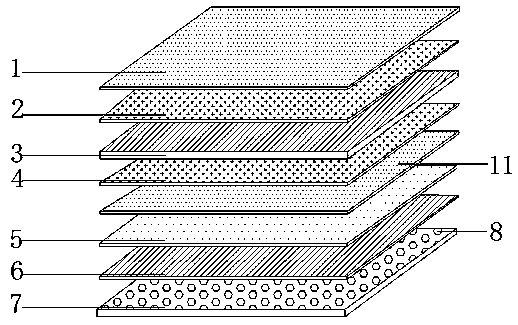

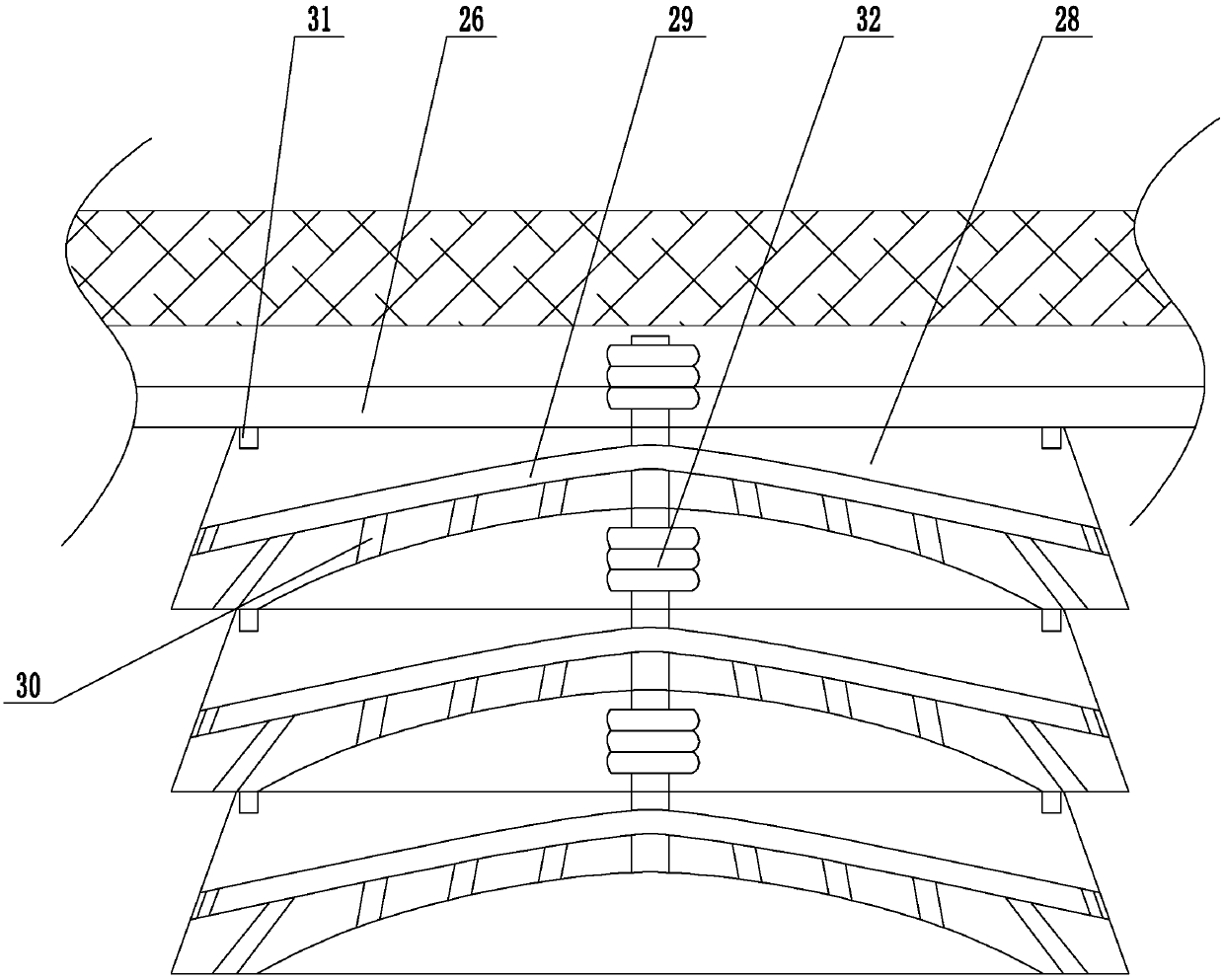

Photo-thermal plate for accelerating salt manufacture by means of brine evaporation and method for applying photo-thermal plate

PendingCN109354097APrevent infiltrationTo achieve the effect of salt resistanceGeneral water supply conservationSeawater treatmentInsulation layerBiochemical engineering

The invention discloses a photo-thermal plate for accelerating salt manufacture by means of brine evaporation and a method for applying the photo-thermal plate. The photo-thermal plate comprises a first hydrosol layer, a heat-insulation layer, a buoyancy material and a salt pond. A first hydrophobic layer is arranged on the upper side of the first hydrosol layer, and a black light absorption material is arranged on the lower side of the first hydrosol layer; a second hydrophobic layer is arranged on the upper side of the heat-insulation layer and is adhered with the black light absorption material via a second hydrosol layer, and a water absorption sheet is arranged on the lower side of the heat-insulation layer; a plurality of groups of through holes are uniformly formed in the surfaces of the buoyancy material, and a photo-thermal plate body floats on the salt pond. The photo-thermal plate for accelerating salt manufacture by means of brine evaporation and the method have the advantages that the second hydrophobic layer can prevent brine from being permeated into materials, salt which is dissolved out by means of brine evaporation is difficult to adhered to the surfaces of the materials, and accordingly salt-resistant effects of the materials can be realized; absorbers can be separated from water bodies by the aid of the hydrophobic properties of the materials, only the surface brine is heated, the brine can be quickly evaporated, the salt manufacture periods can be shortened to a great extent, and accordingly the salt manufacture quantities can be increased.

Owner:江苏金羿射日新材料科技有限公司

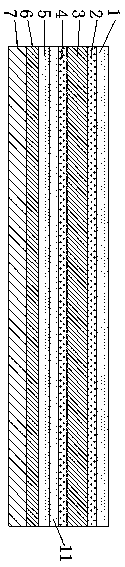

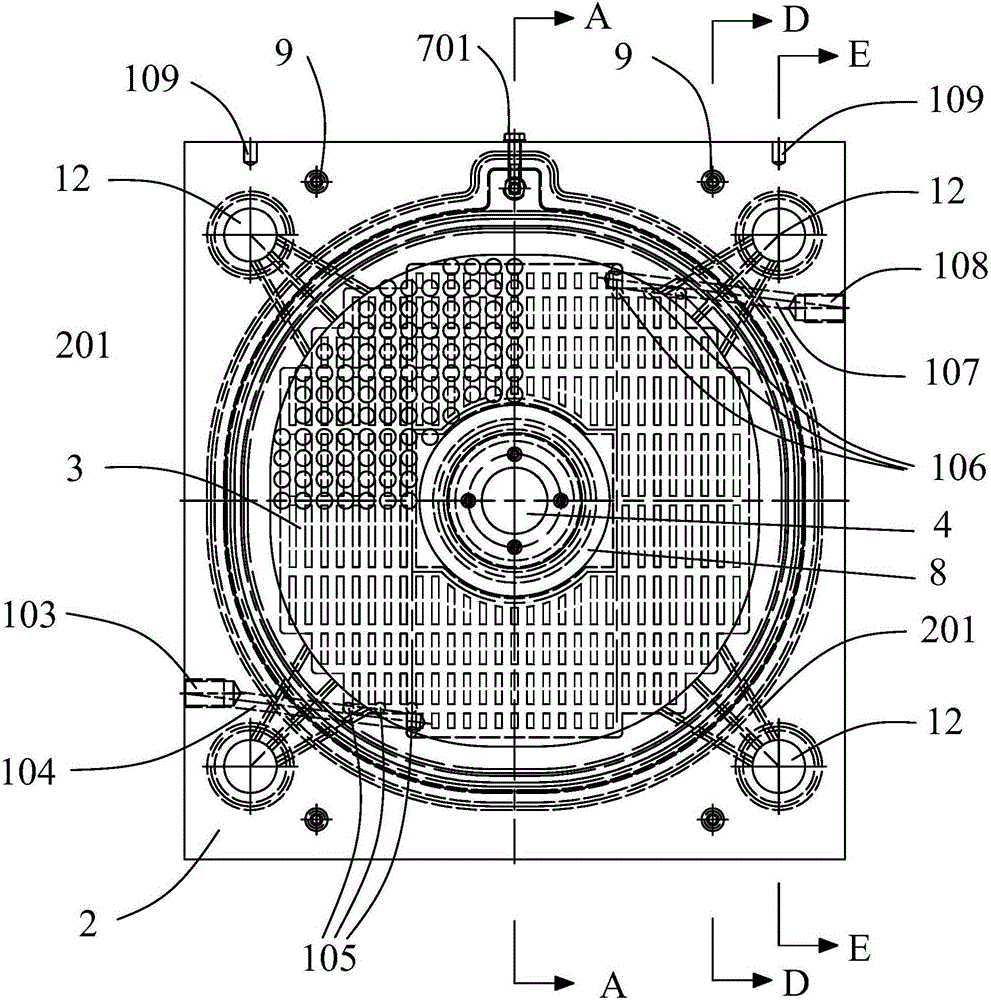

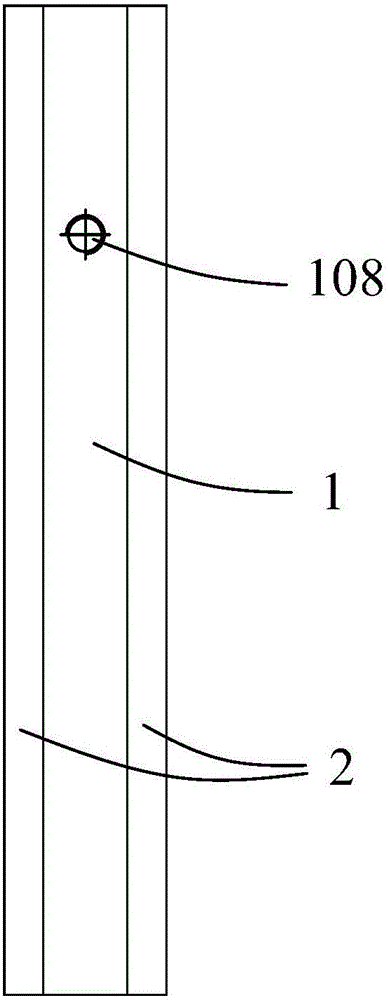

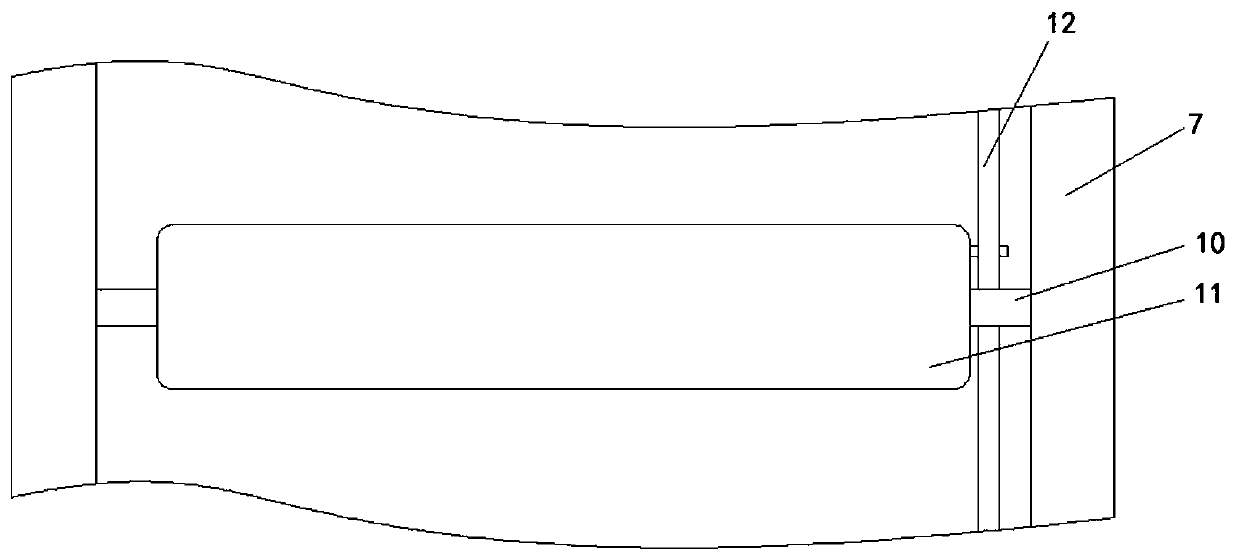

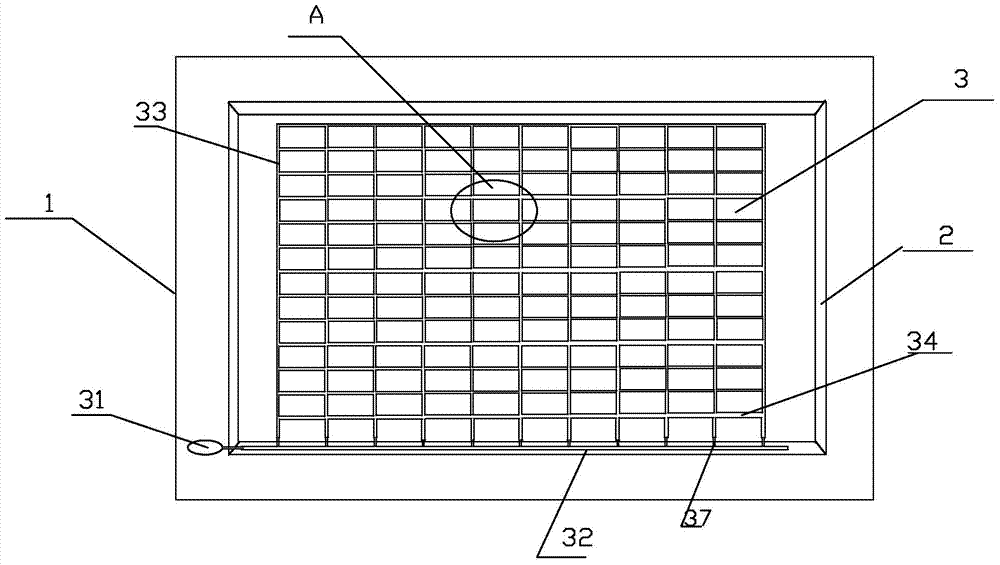

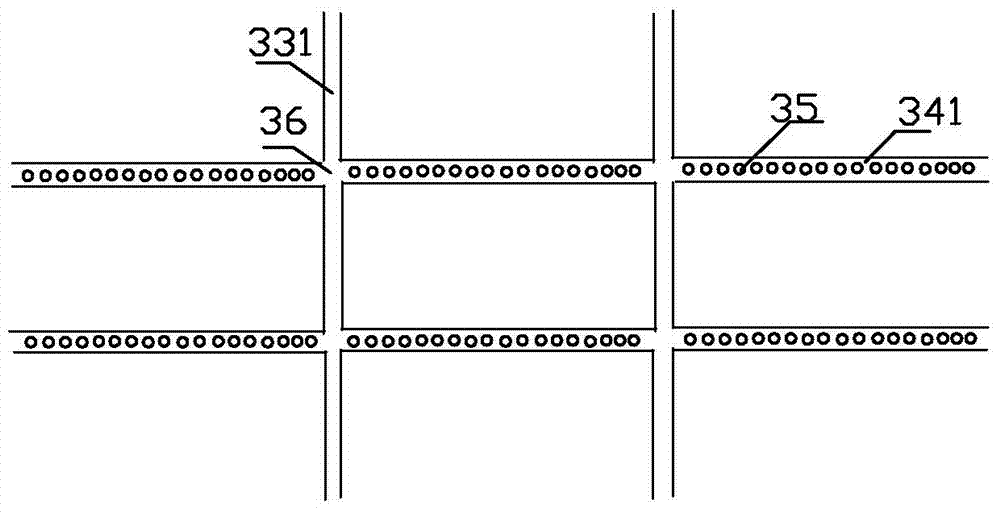

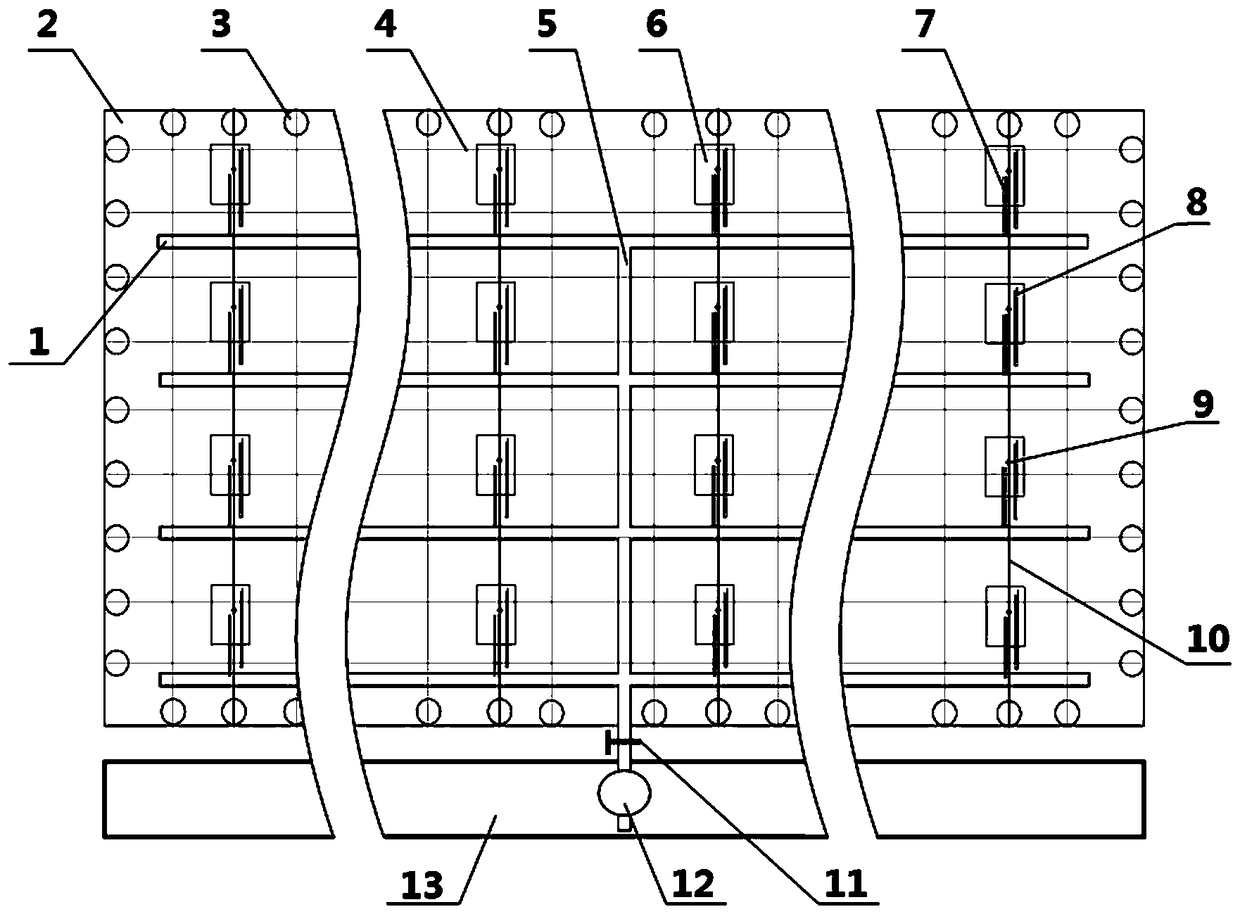

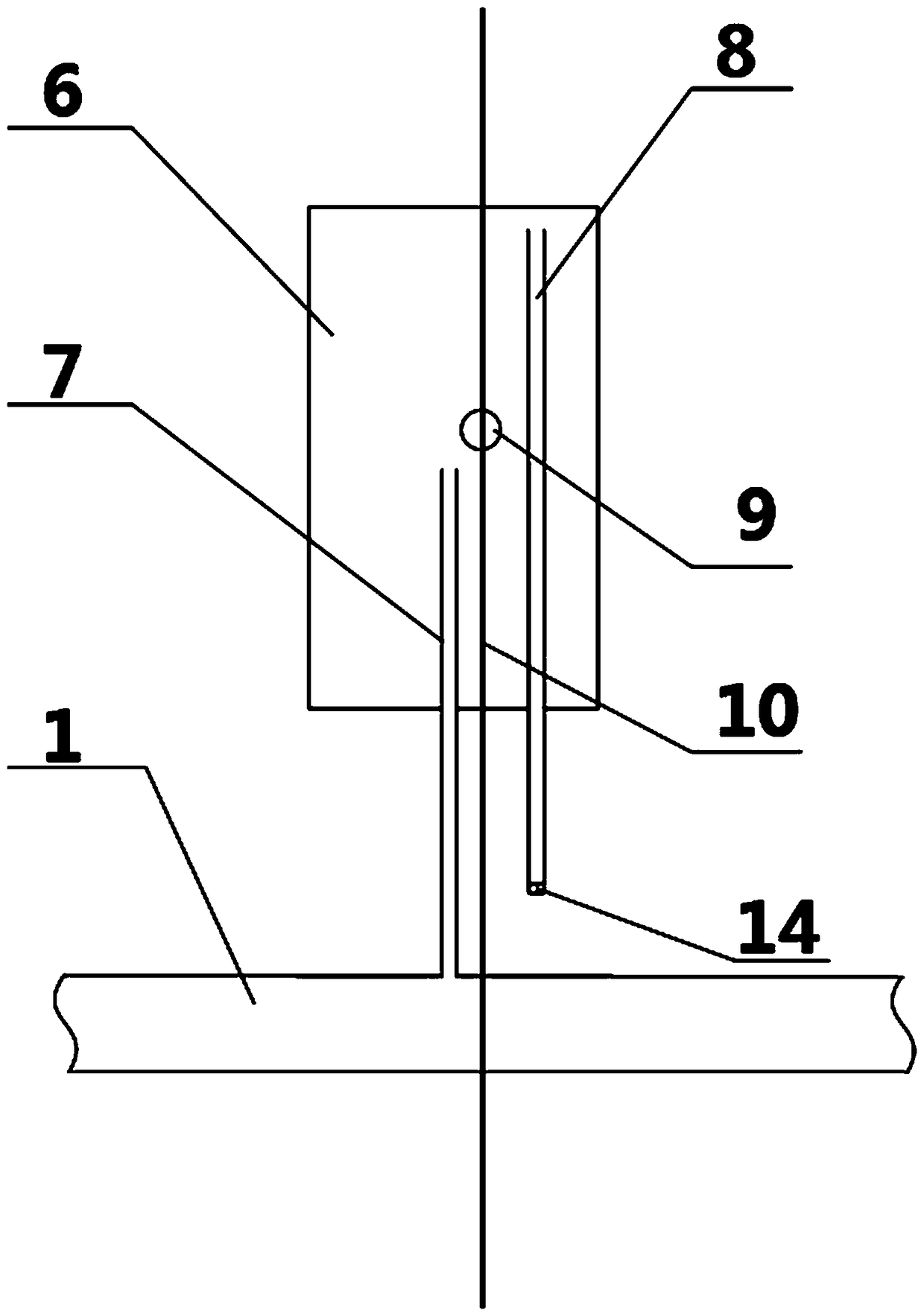

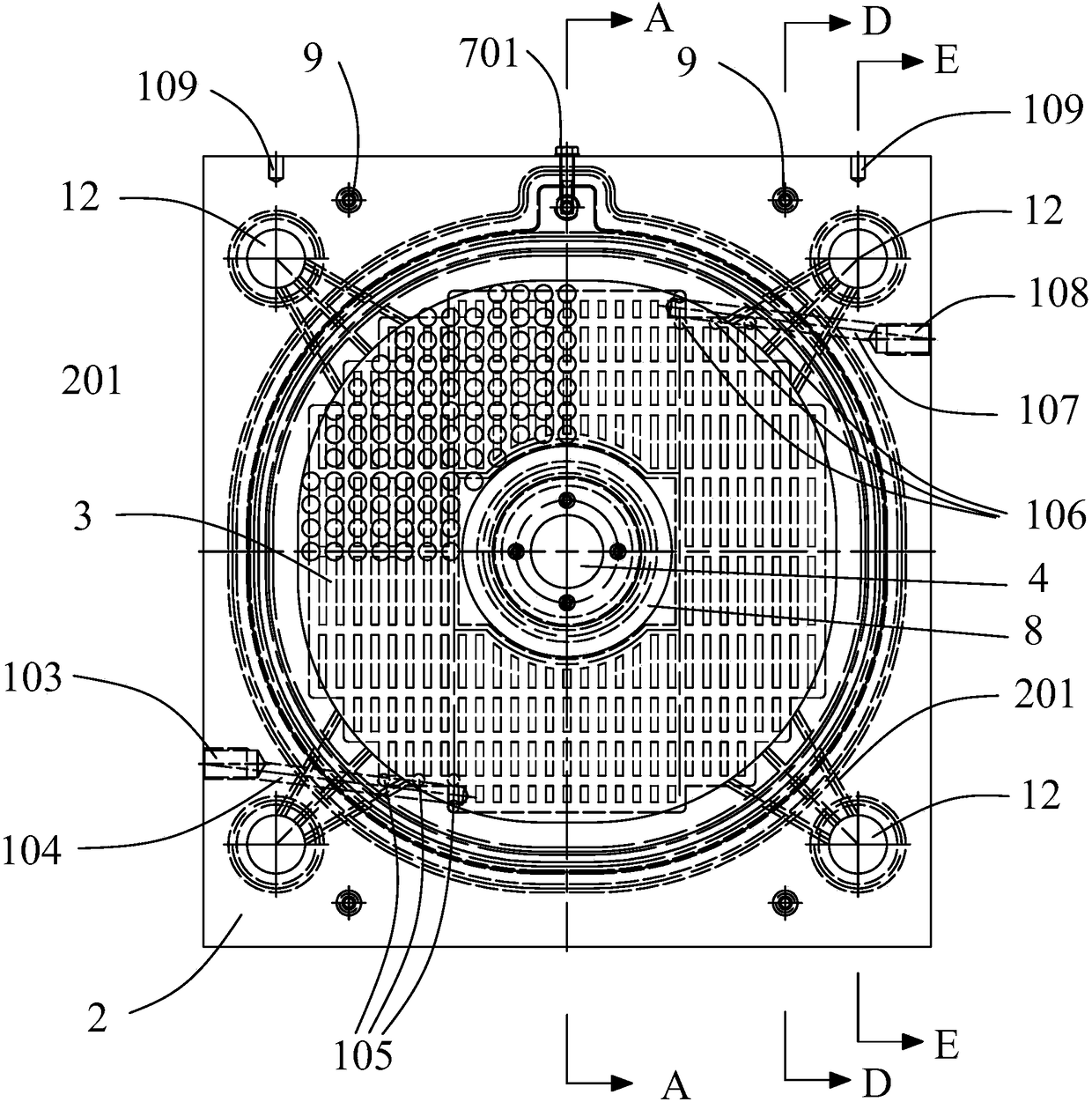

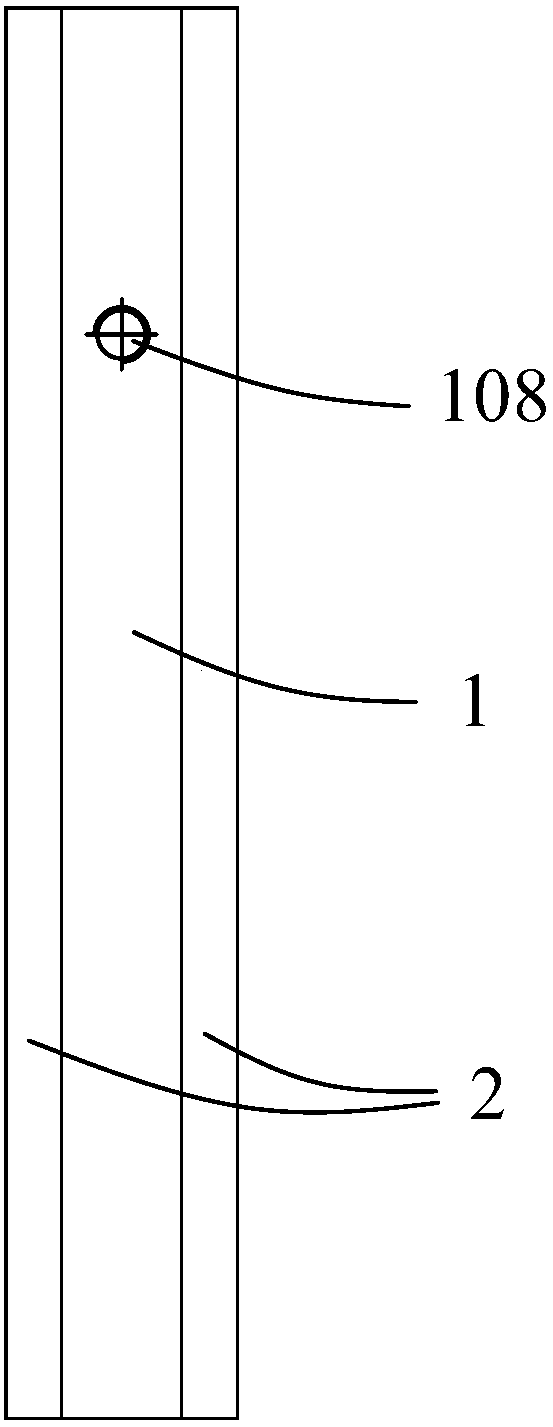

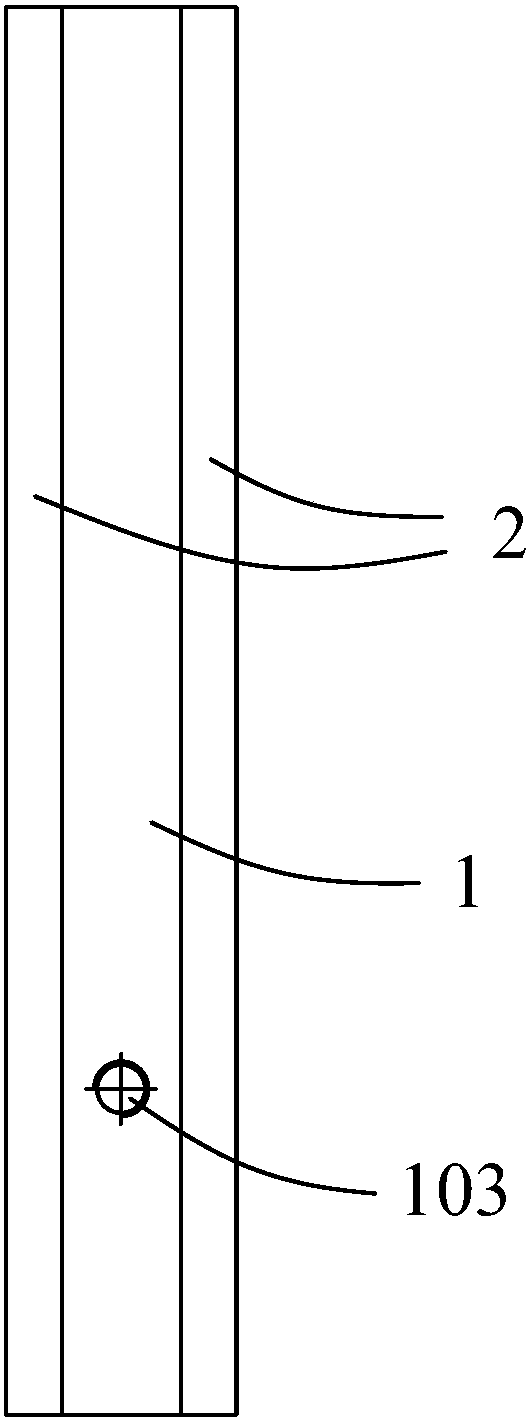

Multifunctional filter plate, filter press and making method of multifunctional filter plate

ActiveCN106422455AShorten the drying cycleAvoid deformationFiltration separationBiochemical engineeringWater flow

The invention provides a multifunctional filter plate, a filter press provided with the multifunctional filter plate and a making method of the multifunctional filter plate. The multifunctional filter plate comprises a core plate of a flat plate structure, filter plate frames fixedly arranged at the outer edges of the left side and the right side of the core plate, electrode heating plates fixedly arranged between the core plate and the filter plate frames and a feeding hole penetrating through the electrode heating plates and the core plate in the left-right direction; a material filling cavity communicated with the feeding hole is formed between the inner circumferential surface of each filter plate frame and the outer side face of the corresponding electrode heating plate, each electrode heating plate is provided with a plurality of protruding parts which protrude outwards and are arranged in the corresponding material filling cavity, an inner water flow groove is formed in the inner side of each protruding part, the left outer side face and the right outer side face of the core plate are provided with a plurality of outer water flow grooves, the inner water flow grooves and the outer water flow grooves are communicated to form a heating cavity, and the electrode heating plates are connected with a power source through wires. Filter cakes in the material filling cavities can be subjected to heating dehydration and electrodialytic deep dehydration through the electrode heating plates, so that the moisture content of the filter cakes is further lowered.

Owner:ZHEJIANG FUJIE ENVIRONMENTAL PROTECTION EQUIP CO LTD +1

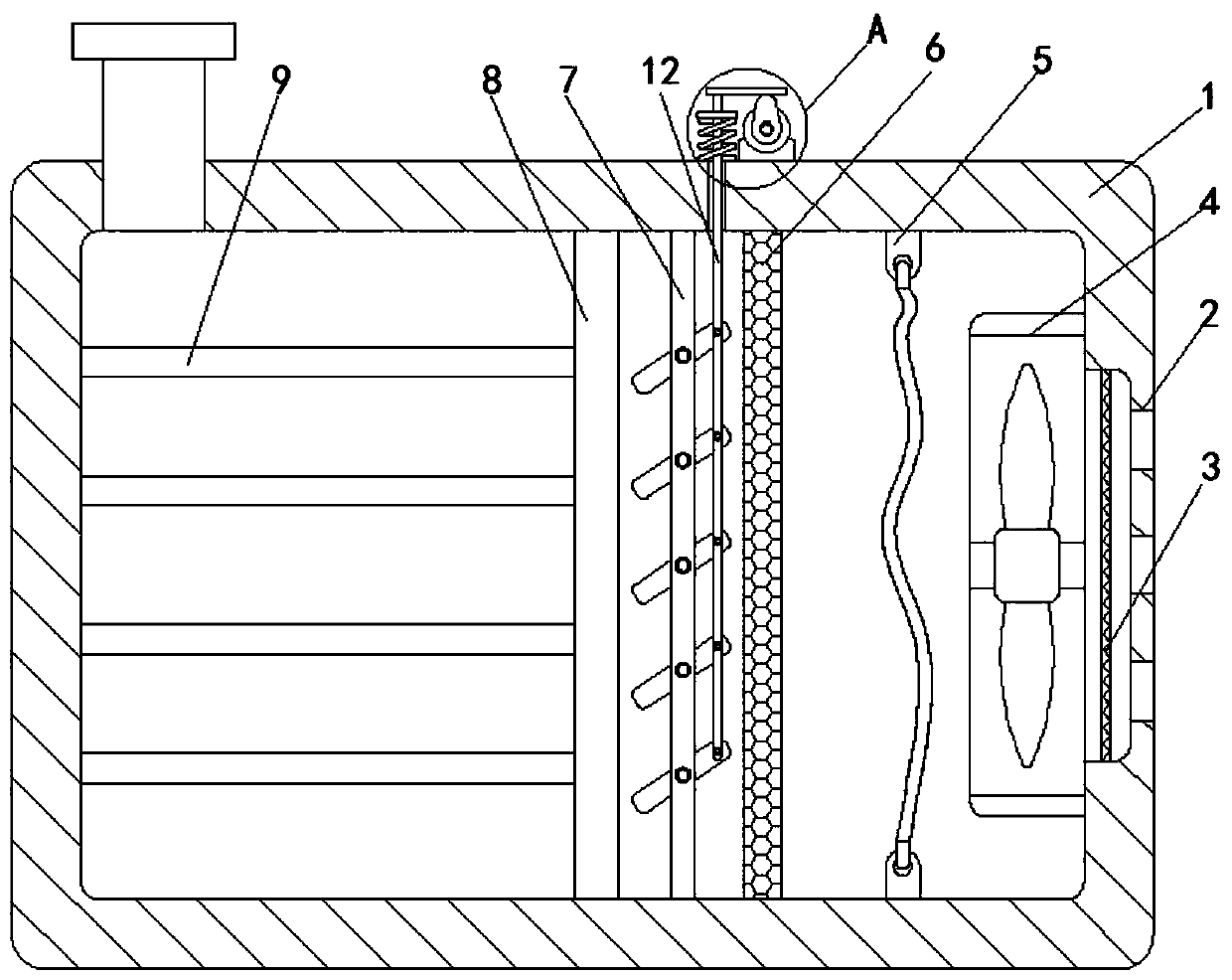

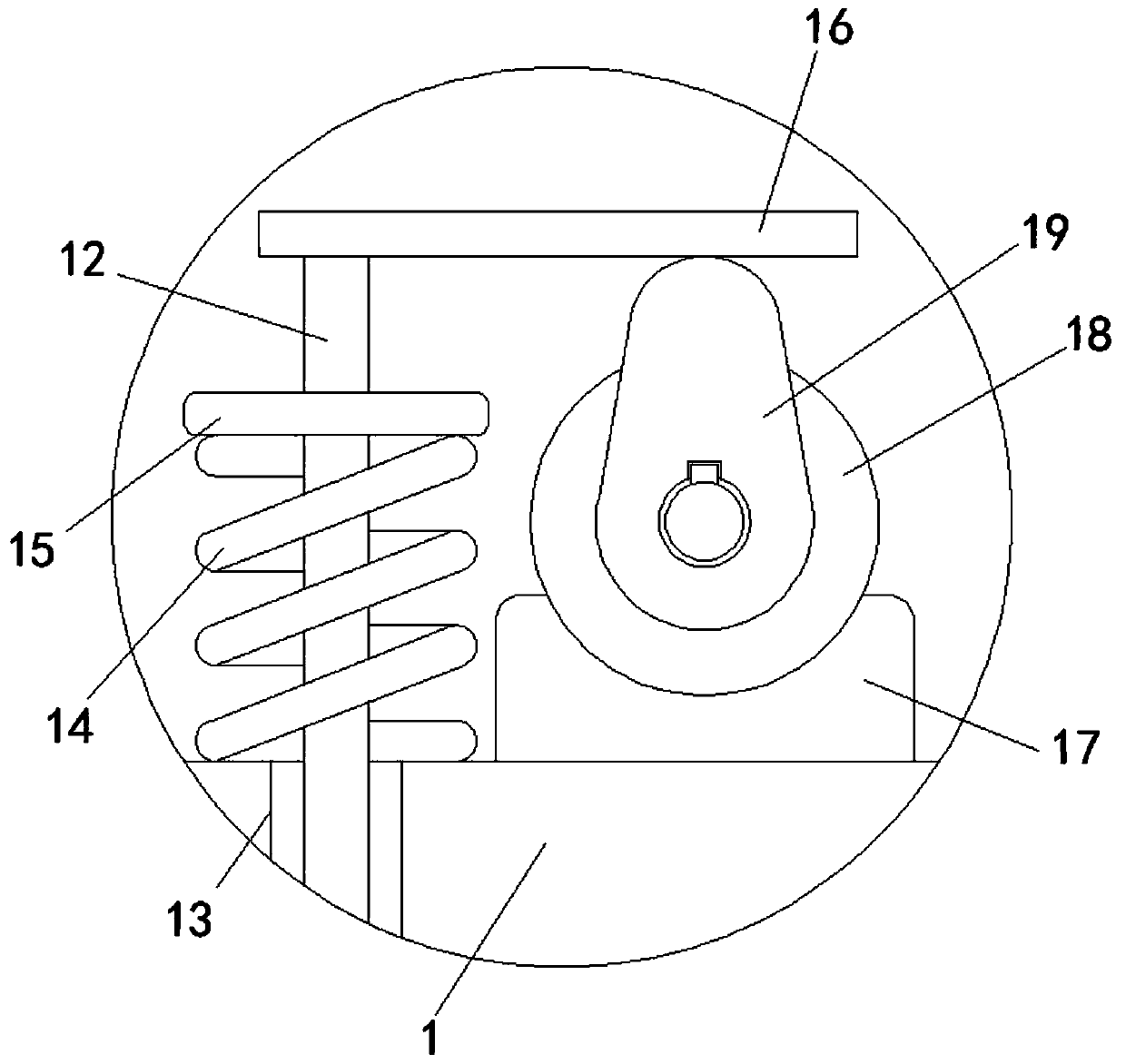

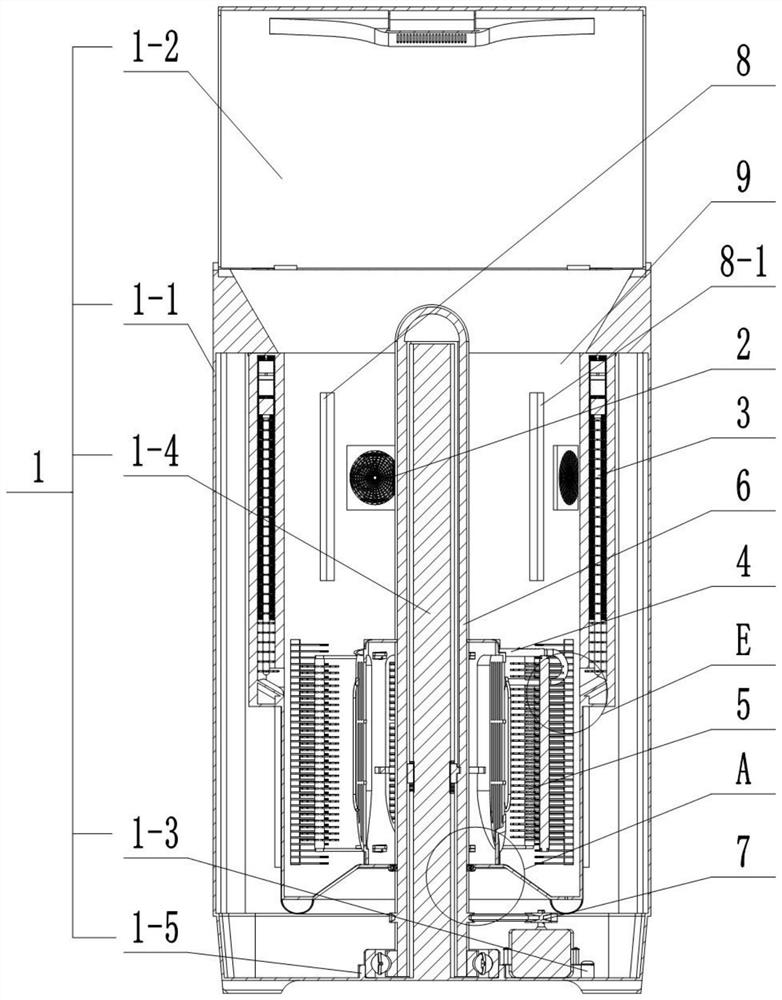

Electric heating air blowing drying box with good dehumidifying effect

InactiveCN110319661AImprove dehumidification effectGuaranteed drynessDrying gas arrangementsDrying chambers/containersDrive motorEngineering

The invention relates to the technical field of drying boxes, and discloses an electric heating air blowing drying box with a good dehumidifying effect. The electric heating air blowing drying box comprises a drying box body, a through hole is formed inside the drying box body, and a dust screen is fixedly installed inside the through hole. According to the electric heating air blowing drying boxwith the good dehumidifying effect, a driving motor is arranged at the top of the drying box body, and a cam is driven by the rotation of the driving motor to push a transverse plate to move, so thata connecting rod is driven to move up and down; and when the connecting rod moves upwards, an auxiliary spring can be stretched, when the cam does not push the transverse plate, the elasticity of theauxiliary spring is restored so that the connecting rod can move downwards, a rotating plate can rotate on a rotating shaft, the angle of air generated from a fan can be changed, the interior of the drying box body can be uniformly blown by hot air, the moisture removal efficiency of the drying box body is improved, the drying degree of objects on an object carrying plate can be guaranteed, and the drying period of the objects can be shortened.

Owner:湖北祺美中检联检测有限公司

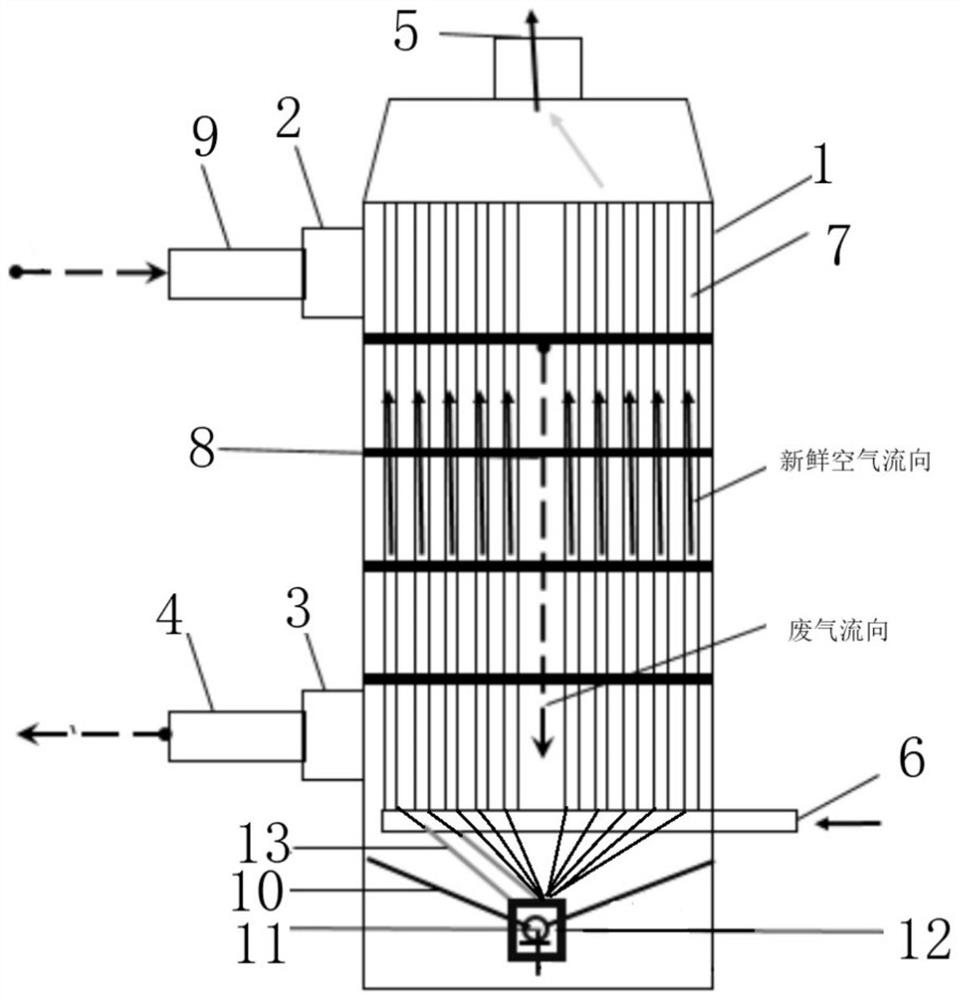

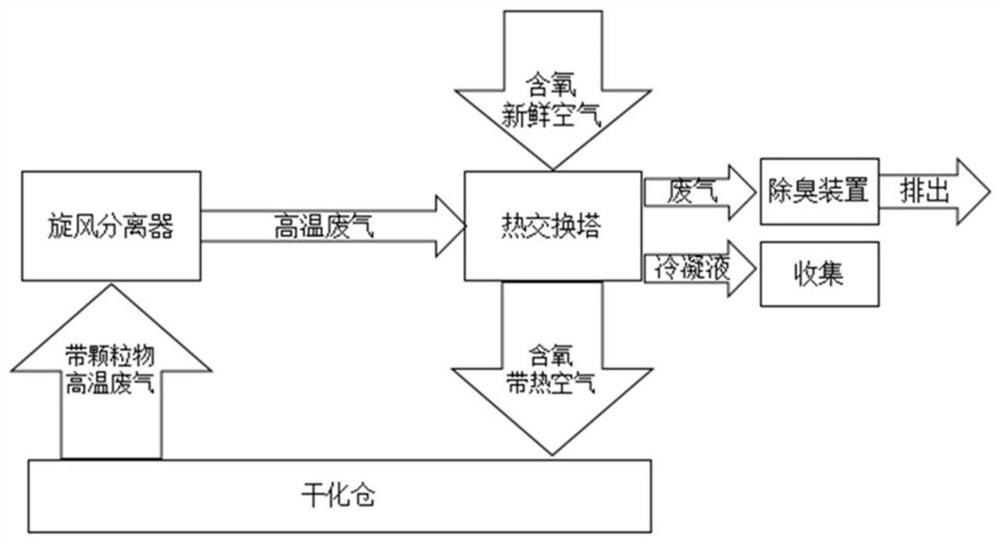

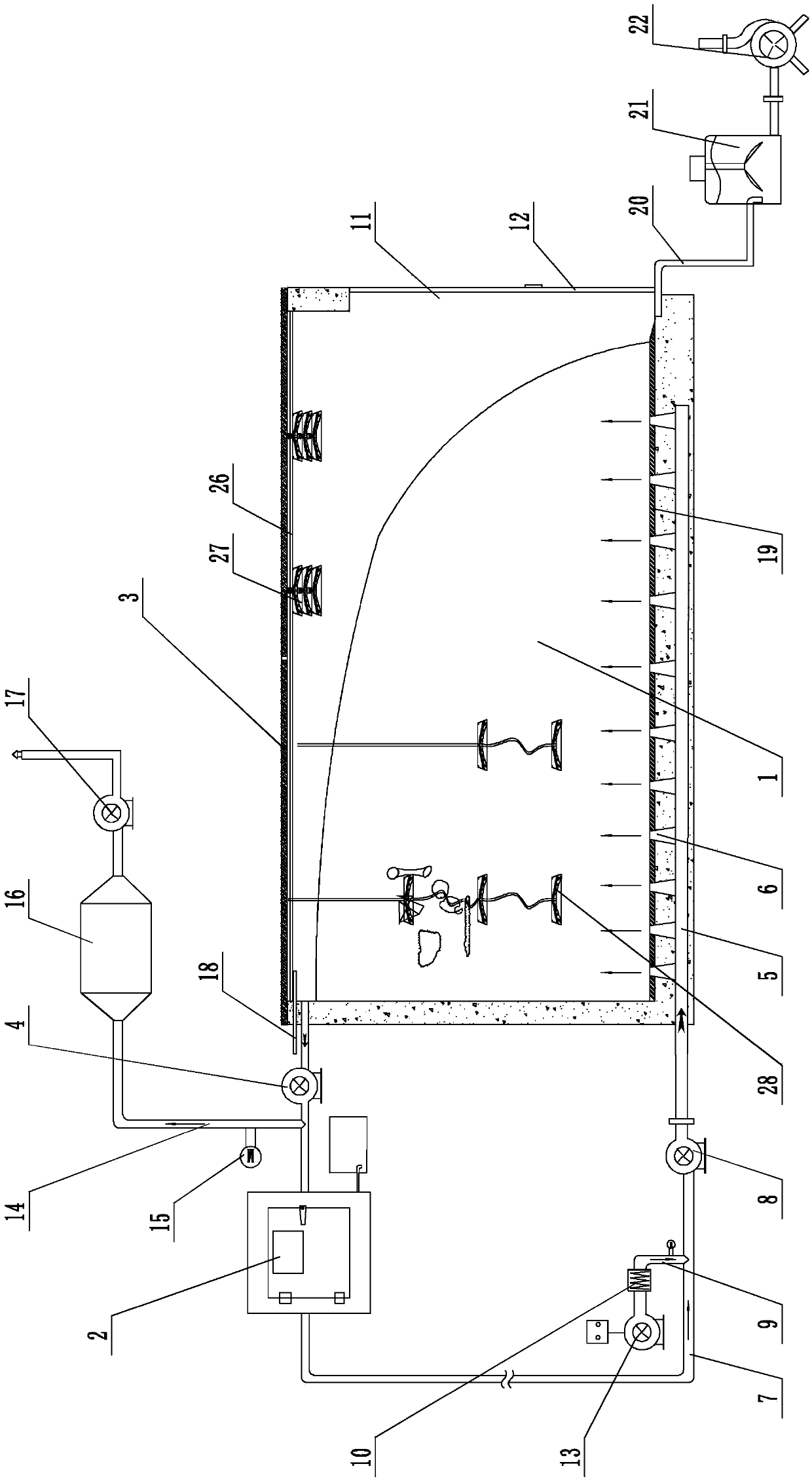

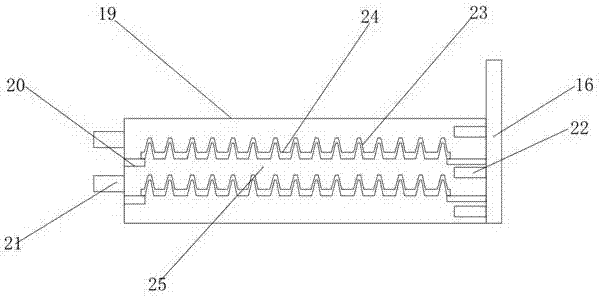

Waste gas recycling system for organic waste biological drying process

InactiveCN111790212AReduce loss costAccelerates the drying processRecuperative heat exchangersDispersed particle separationExhaust fumesFresh air

The invention discloses a waste gas recycling system for an organic waste biological drying process, which comprises a heat exchange tower body, the upper part of the heat exchange tower body is provided with a waste gas inlet, the lower part of the heat exchange tower body is provided with a waste gas outlet, and the waste gas outlet is provided with a deodorizer; a fresh air outlet is formed inthe upper portion of the heat exchange tower body, a fresh air inlet is formed in the lower portion of the heat exchange tower body, multiple heat exchange pipes are arranged in the heat exchange tower body, the bottom end is connected with the fresh air inlet, and the top end is connected with the fresh air outlet, the waste gas inlet is communicated with a gas outlet of the drying reactor, the fresh air outlet is communicated with a gas inlet, waste gas in the drying reactor flows from the tower top to the tower bottom for deodorization and then is discharged, fresh air flows from the towerbottom to the tower top through the heat exchange pipe for heat exchange, and gas in the drying reactor can be updated at any time and heat can be recycled. According to the system, automatic heat energy recycling is achieved, meanwhile, air pollution generated in the waste gas emission process is effectively avoided, and possibility is provided for energy-saving and resourceful treatment of high-temperature waste gas.

Owner:ZHONGNONGXINKE SUZHOU ORGANIC RECYCLING RES INST CO LTD

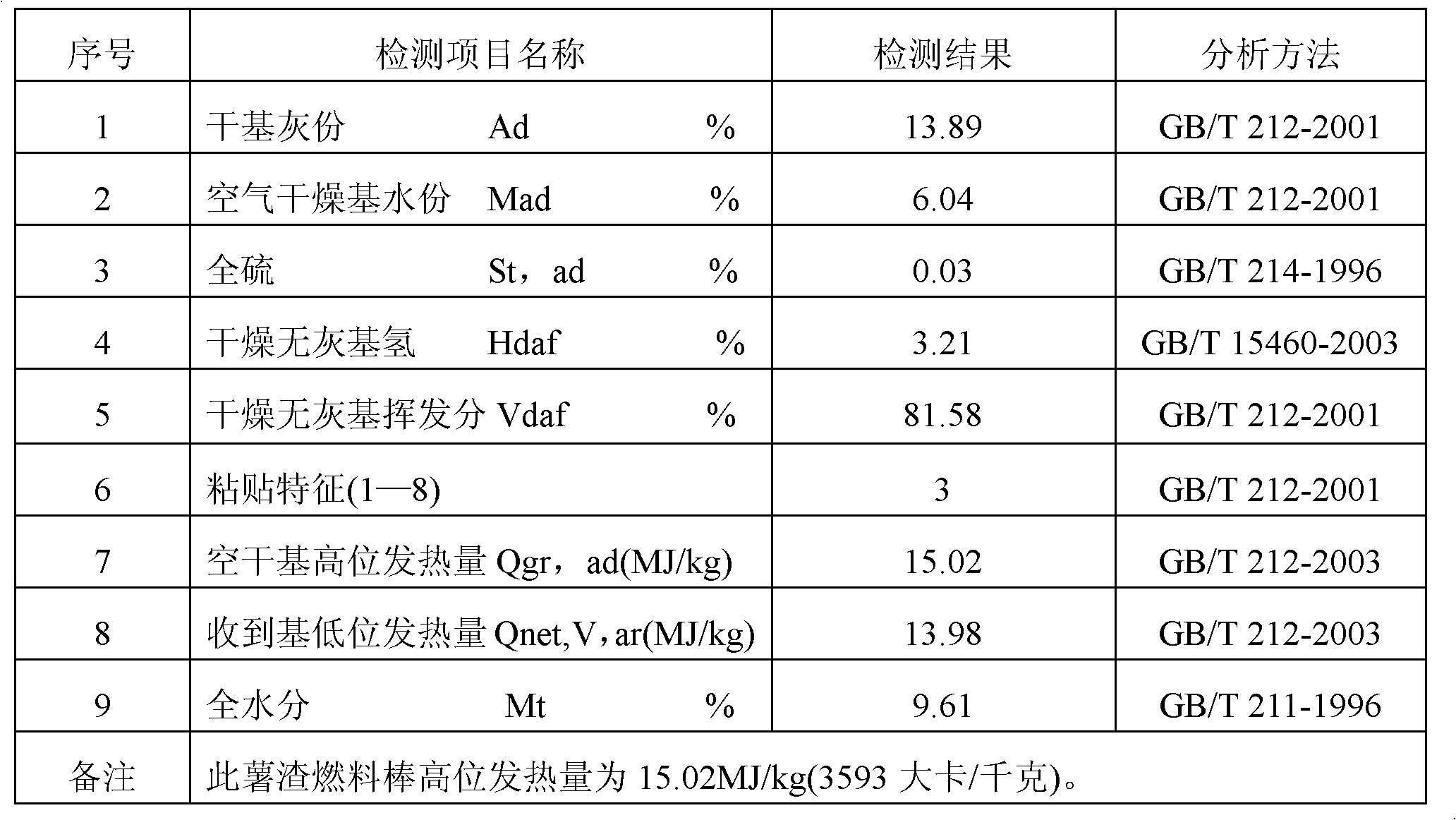

Production technology of cassava-potato residue-made fuel rod

InactiveCN102492510AReduce production and processing costsReduce pollutionBiofuelsSolid fuelsEngineeringSolanum tuberosum

The invention relates to a production technology of a cassava-potato residue-made fuel rod. The production technology of the cassava-potato residue-made fuel rod mainly solves the problems that the existing fuel rod production technology has a high cost and cassava-potato residues obtained by starch production adopting raw materials of cassava and potato are discharged and then can cause environmental pollution. The production technology of the cassava-potato residue-made fuel rod comprises the following steps of 1, adding polyacrylamide into cassava-potato residues, and carrying out extrusion dehydration to obtain cassava-potato residue filter cakes, 2, carrying out airing drying of the cassava-potato residue filter cakes to obtain cassava-potato residues A having water content of 50 to 60%, mixing the cassava-potato residues A and the cassava-potato residue filter cakes, and carrying out airing drying to obtain the cassava-potato residues A having water content of 50 to 60%, 3, drying the cassava-potato residues A obtained by the step 2, and mixing the dried cassava-potato residues A and the aired cassava-potato residues A obtained by the step 2 to obtain mixed cassava-potato residues, and 4, crushing the mixed cassava-potato residues, and carrying out extrusion molding to obtain the cassava-potato residue-made fuel rod. The production technology provided by the invention realizes waste utilization, reduces environmental pollution caused by cassava-potato residue discharge, reduces a production cost, and is suitable for fuel rod production.

Owner:李伟光 +2

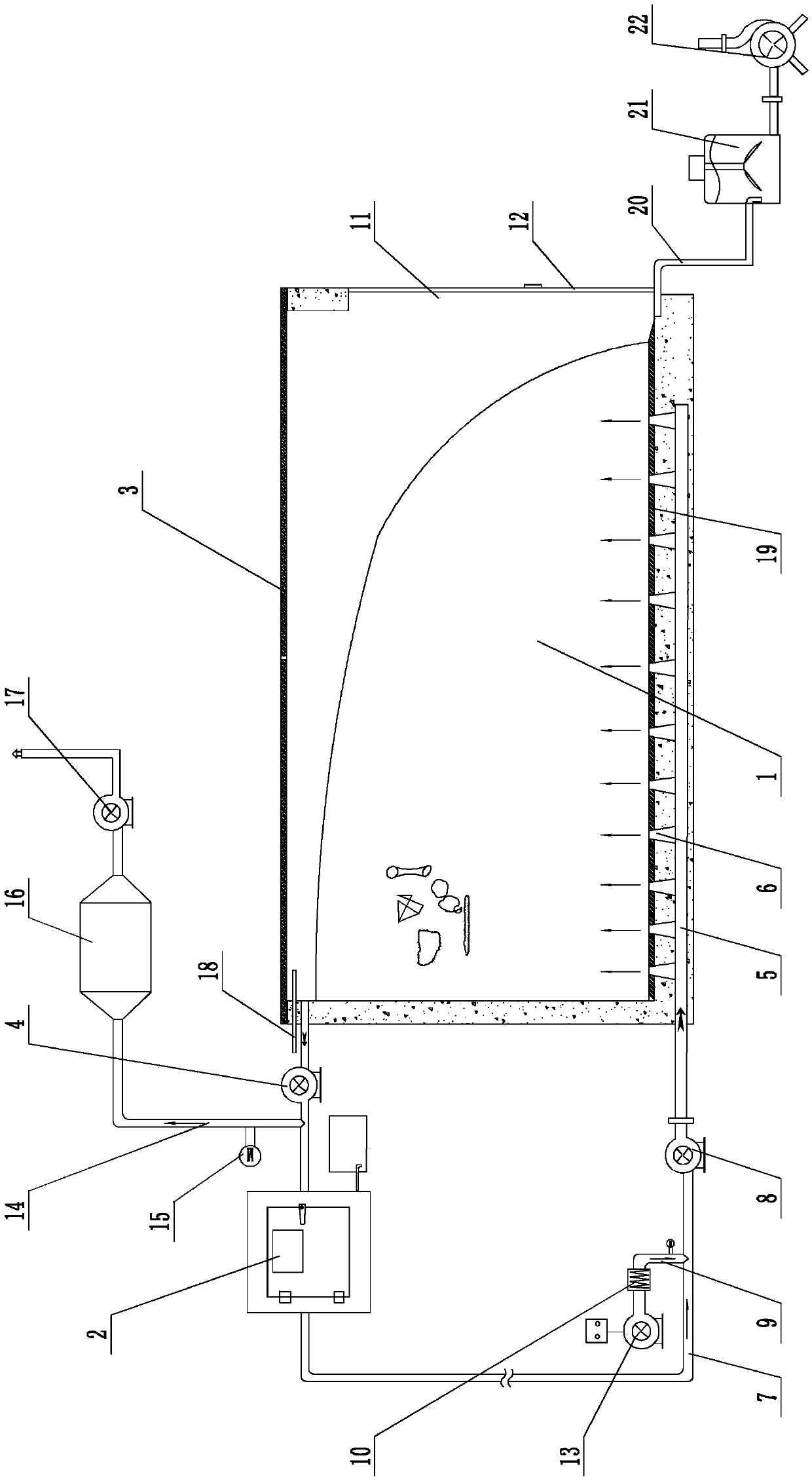

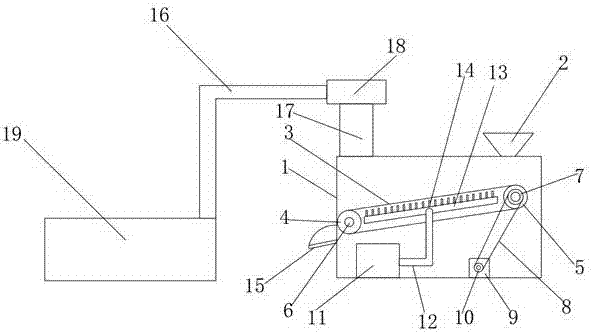

Garbage drying treatment system and method

ActiveCN109539271AImprove drying effectShorten the drying cycleBatteries circuit arrangementsDrying gas arrangementsSolar powerTreatment system

The invention discloses a garbage drying treatment system and method. The garbage drying treatment system and method aims to overcome the shortage of a long dry cycle, large area, and high cost. The garbage drying treatment system comprises a drying chamber and a dehumidifying heat pump, a solar panel for supplying power to the entire waste drying system is installed on top of the drying chamber,the position, near the top end, of the drying chamber communicates with a suction fan, the dehumidifying heat pump communicates with the suction fan, a ventilation duct is mounted at the bottom of thedrying chamber, a plurality of ventilation nozzles for injecting air into the drying chamber are mounted on the ventilation duct, a hot air pipe communicates between the ventilation duct and the dehumidifying heat pump, the hot air pipe is provided with a blower, a bypass pipe communicates between the blower on the hot air pipe and the dehumidifying heat pump, an electric heating wire is mountedin the bypass pipe, a door hole is formed in one side wall of the drying chamber, and a chamber door is sealed and mounted on the position of the door hole on the drying chamber.

Owner:杭州正晖建设工程有限公司

Bubbling baysalt device applied to seawater shoal

InactiveCN103754895ALarge mass transfer areaIncrease evaporation rateAlkali metal chloridesEngineeringSeawater

The invention provides a bubbling baysalt device applied to a seawater shoal. The device comprises a bubbling unit arranged in a salt pan, so that bubbles are continuously generated on the surface of seawater in the salt pan. By adopting the device provided by the invention, the baysalt period can be shortened, the yield of the salt pan is improved, the adaptive capacity of the salt pan to severe climates is enhanced, and the speed of conventional seawater baysalt is improved by 2-4 times. In addition, the device can be distributed in an existing salt pan and the original salt pan is slightly modified. The device is easily automatically operated and controlled, and has strong feasibility.

Owner:ZHEJIANG OCEAN UNIV

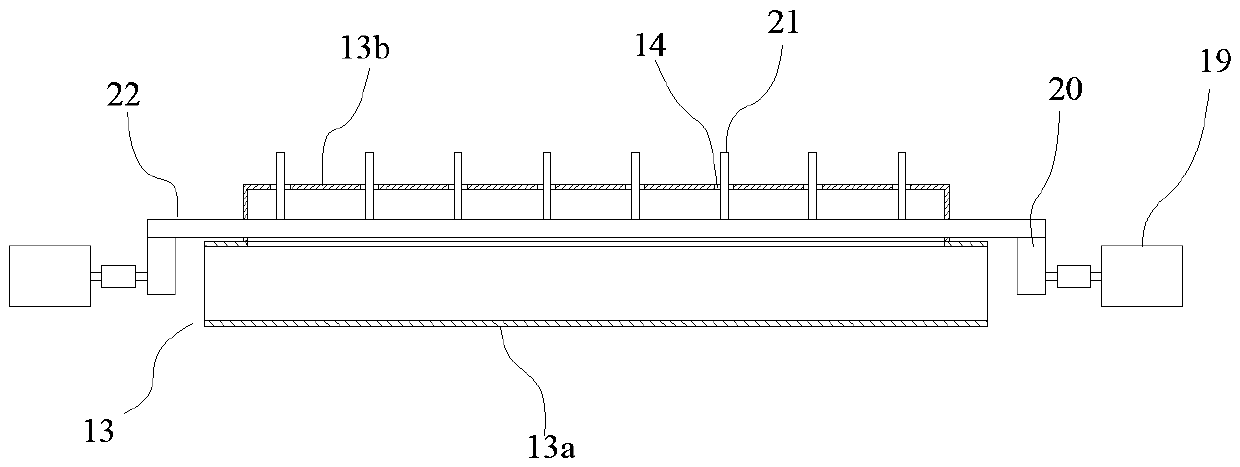

Fodder drying device

InactiveCN107478045AShorten the drying cycleSmall footprint for installationDrying gas arrangementsHeating arrangementForward backwardEngineering

The invention discloses a fodder drying device comprising a case. The case is hollow, a feeding inlet is formed in the upper surface of the case, and a blanking hopper is welded to the outer side of the feeding inlet in an abutting mode; a fodder conveying device is arranged on the inner side of the case and comprises a driving roller and a driven roller; the driving roller is located in the upper right position of the driven roller, and the driving roller and the driven roller are both horizontally arranged in the forward-backward direction; and the driving roller and the driven roller are movably mounted in the case through roller shafts of the driving roller and the driven roller. Preheating treatment is adopted, waste gas is conveyed into a preheating box to preheat and pre-dry fodder, thus, the whole fodder is dried through hot air quite rapidly, the drying stroke of the fodder is shortened, in this way, the mounting occupied area of the fodder drying device can be decreased, and the overall cost is lower.

Owner:黄贤飞

Method for breeding microalgae in salt airing pond and microalgae breeding system

PendingCN109355195AAvoid pollutionBreeding species are no longer restrictedBioreactor/fermenter combinationsBiological substance pretreatmentsDisinfectantEconomic benefits

The invention discloses a method for breeding microalgae in a salt airing pond and a microalgae breeding system. The method is characterized in that a porous mesh is arranged under the liquid surfaceof the interior of the salt airing pond, and a plurality of transparent microalgae culture plastic bags connected to an air supply pipeline are arranged below the porous mesh; an exhaust pipe is arranged on the upper side face of each microalgae culture plastic bag and fixedly opened upward; the microalgae culture plastic bags are also provided with material pipes for introducing or discharging algae seeds, algae liquid, sea water, nutrient solutions and a disinfectant. According to the provided method for breeding the microalgae in the salt airing pond and the microalgae breeding system, thearea of microalgae culture water is greatly expanded, breeding of the microalgae in a marine environment is achieved, the impact of algae pollution on the environment is relieved, and the economic benefits are increased.

Owner:无棣鲁东大学海洋研究院 +1

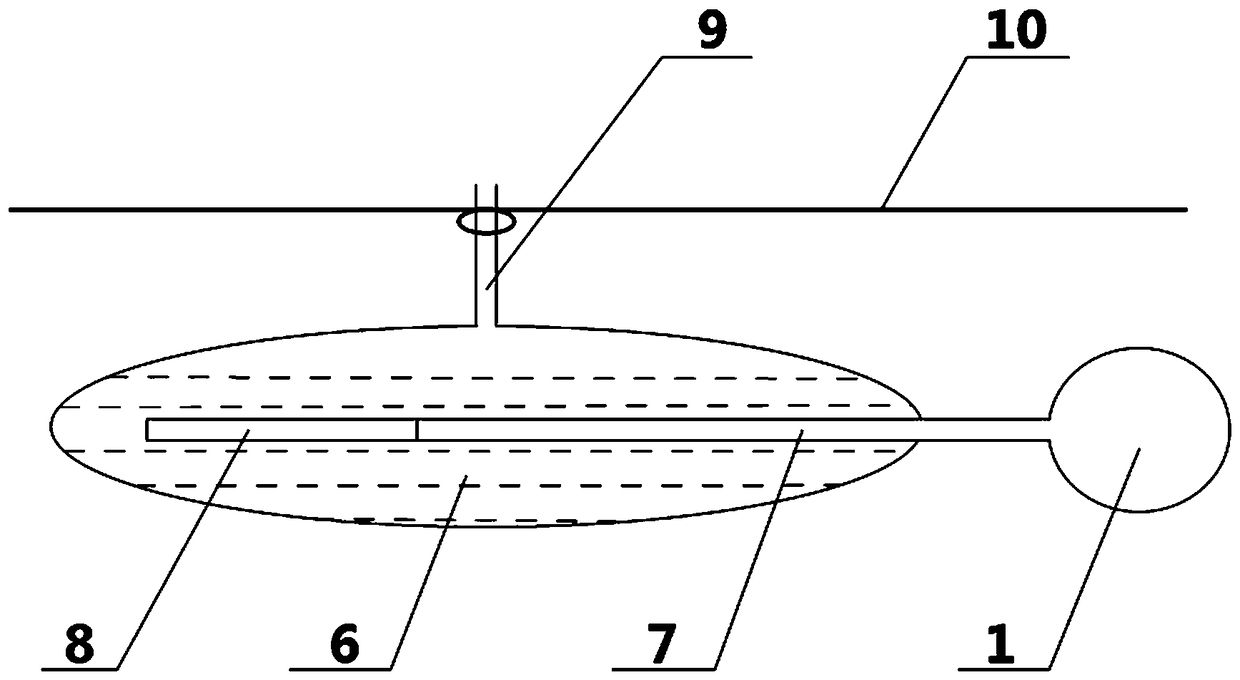

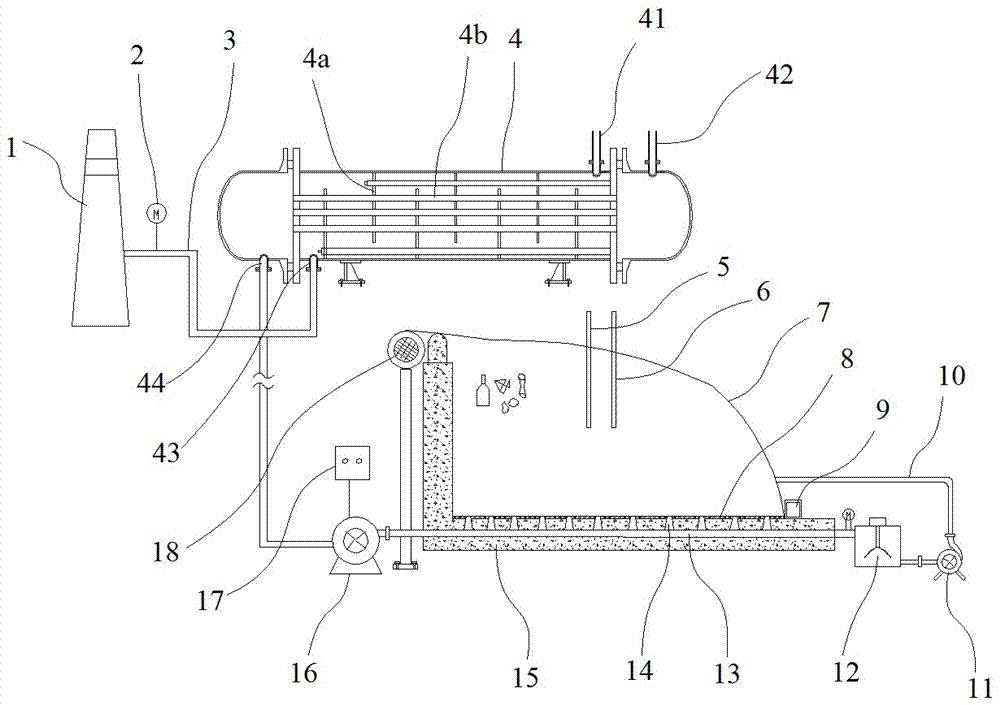

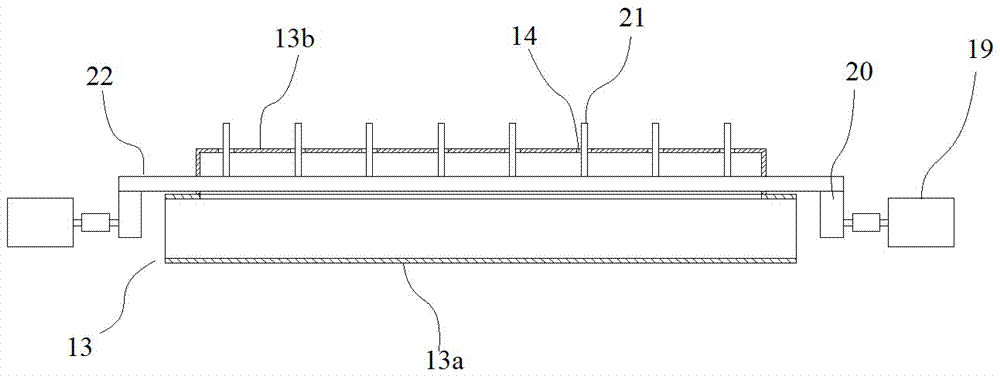

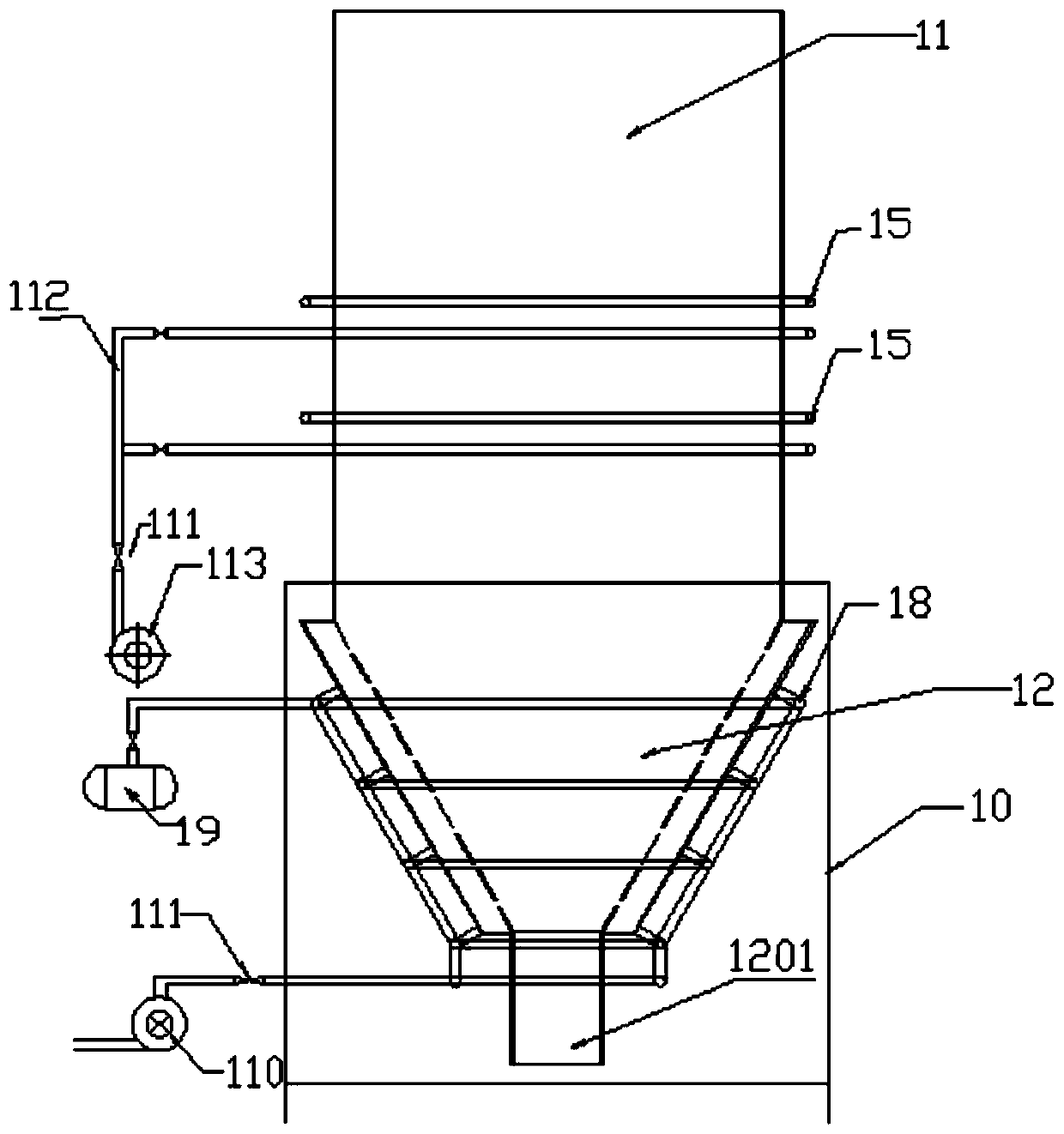

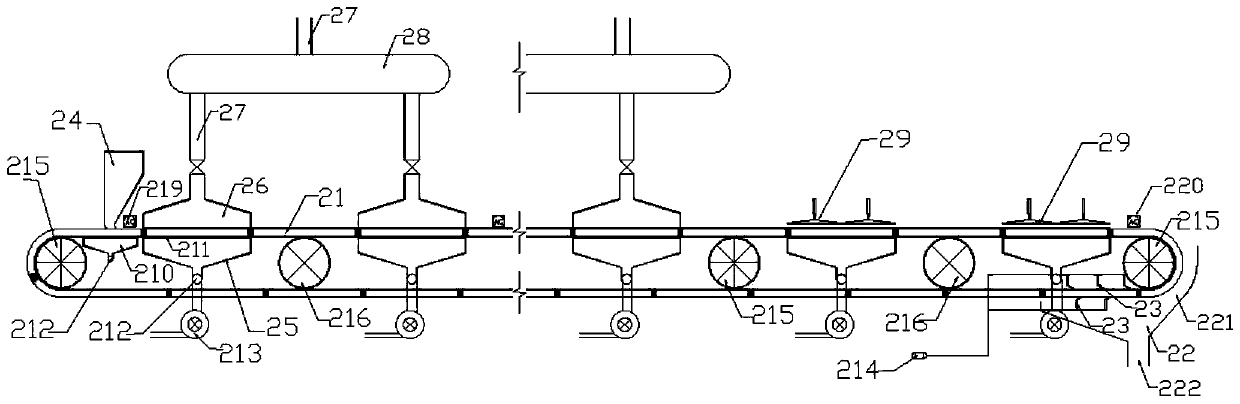

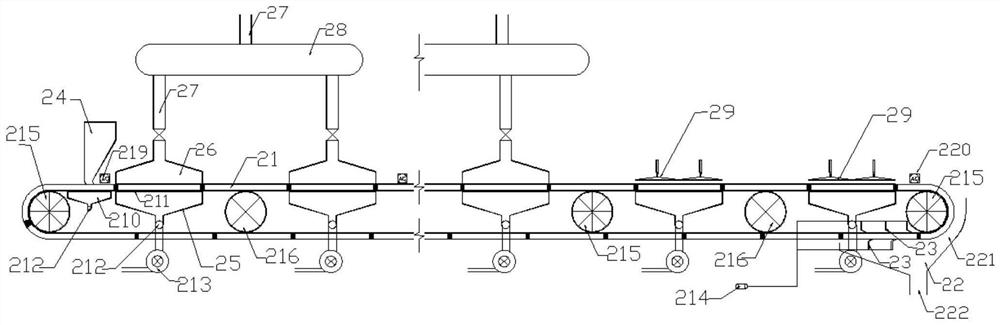

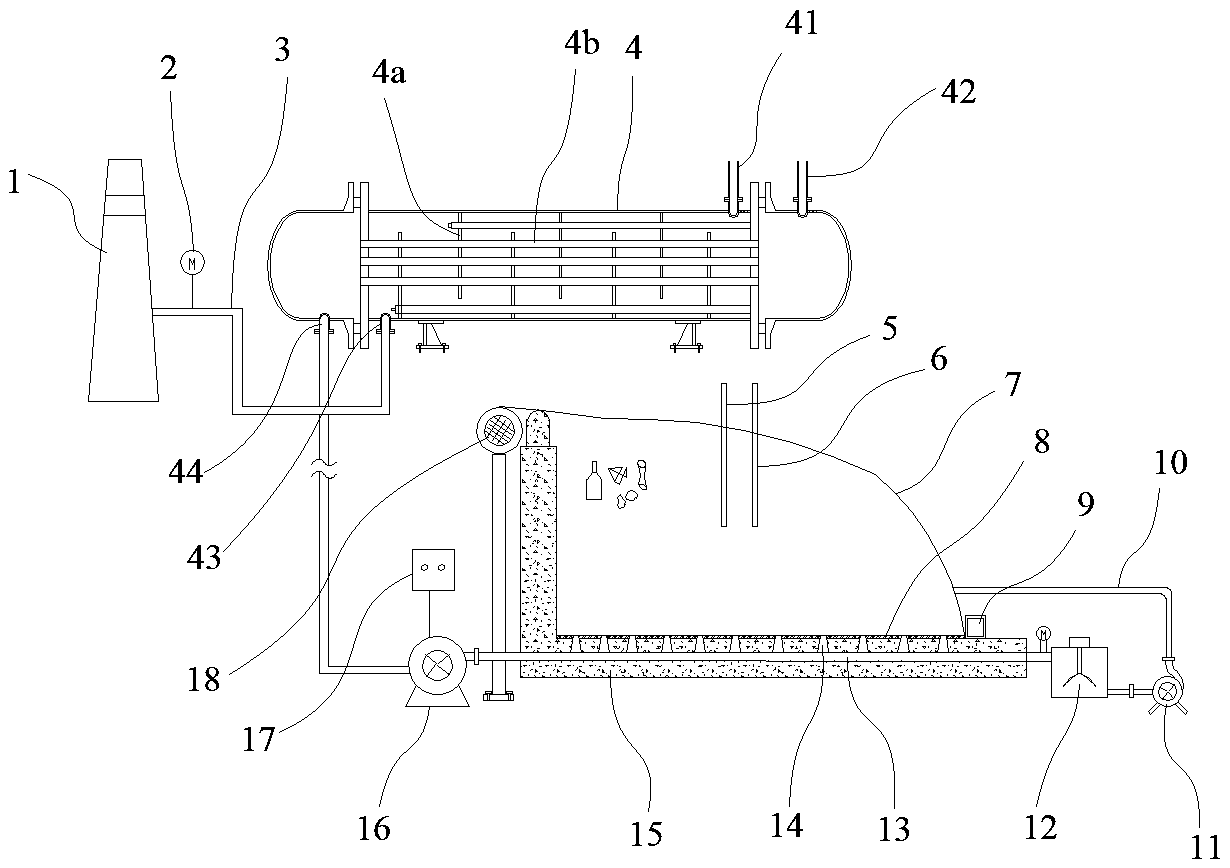

Film drying system and method for exhausting flue gas waste heat through garbage incineration to dry garbage

ActiveCN107388252AImprove energy efficiencyImprove waste drying efficiencyCoatingsIncinerator apparatusProcess engineeringFlue gas

The invention discloses a film drying system and method for exhausting flue gas waste heat through garbage incineration to dry garbage. The film drying system comprises a heat exchanger and a stacking bin. The heat exchanger is provided with a flue gas exhaust inlet and a flue gas exhaust outlet communicating with the flue gas exhaust inlet. The flue gas exhaust inlet is provided with a flue gas exhaust pipe communicating with a flue gas exhaust chimney. The heat exchanger is provided with an air inlet and an air outlet communicating with the air inlet. Multiple parallel ventilating pipelines are arranged at the bottom of the stacking bin and communicate with the air outlet, and the top of the stacking bin is covered with a biological drying film in sealing fit. Nozzles for spraying air into the stacking bin are arranged on the ventilating pipelines, and the stacking bin is provided with a leachate recovery device capable of enabling the outlet ends of the ventilating pipelines to communicate with the stacking bin. The film drying system and method exhaust the flue gas waste heat through garbage incineration to dry the garbage, so that it is avoided that stinks are exhausted in the drying process, and the drying period of the garbage is shortened.

Owner:HANGZHOU JINHUAN INVESTMENT CO LTD

Processing method for dehydrating toadstool

InactiveCN107660616AReduce churnShorten the drying cycleFruits/vegetable preservation by dehydrationVitamin CAdditive ingredient

The invention discloses a processing method for dehydrating toadstool. The method comprises the following steps: A, selecting materials; B, washing; C, blanching; D, cooling; and E, protecting color,namely soaking toadstool at normal temperature, with a color fixative which is mixed by phytic acid, citric acid, vitamin C, edible salt, edible glucose and water; F, draining; G, freezing, namely freezing the drained toadstool at negative 20-negative 30 DEG C; H, lyophilizing with microwave, namely starting a microwave source at a vacuum degree of 65-125pa, and dehydrating with microwave; and I,packaging. According to the method, a microwave lyophilizing drying process is adopted, the dehydrating and drying time can be shortened, and the problem of slightly high content of moisture inside toadstool in a traditional drying process can be solved; and the moisture content of toadstool is less than 5 percent when the drying method is adopted, so that long-time preservation can be facilitated, and nutritional ingredients are slightly lost. The color fixative adopted in the processing method has low content of sulfur dioxide, and is harmless to body health.

Owner:巫溪县汇域农产品有限公司

Method and device for low-temperature drying of residual activated sludge from sewage treatment

ActiveCN110255846AReduce drug costsFast dehydrationSludge treatment by de-watering/drying/thickeningChemical agentsResource utilization

The invention discloses a method and device for low-temperature drying of residual activated sludge from sewage treatment. The device comprises sludge freezing equipment, a sludge maintenance chamber, a sludge unfreezing and primary dehydrating device, sludge dehydrating equipment and a sludge airing device; and the residual activated sludge, which is obtained after primary dehydrating treatment is conducted, of a sewage treatment plant is treated by the sludge freezing equipment, the sludge maintenance chamber, the sludge unfreezing and primary dehydrating device, the sludge dehydrating equipment and the sludge airing device sequentially to obtain sludge subjected to low-temperature drying. According to the method and device for low-temperature drying of the residual activated sludge from sewage treatment, through cooperation of the sludge unfreezing and primary dehydrating device, the sludge dehydrating equipment and the sludge airing device, the sludge is continuously dehydrated and aired, a sludge drying cycle is shortened, and a drying effect is obvious. All drying processes are conducted under conditions of normal temperature and temperature lower than the normal temperature, and volatile gas which is generated due to secondary fermentation of microorganisms in the sludge is reduced, so that pollution is reduced. According to the method and device for low-temperature drying of the residual activated sludge from sewage treatment, the sludge is directly frozen, no other chemical agents need to be added, the drying cost is reduced, and meanwhile, the biology characteristics of the sludge remain unchanged, so that a foundation is laid for resource utilization of the sludge.

Owner:杨红兵

Method for evaporating brine to obtain salt by utilizing porous ceramic plate

ActiveCN110372010ASuperior solar radiation absorption rateEasy to absorb heatEnergy inputAlkali metal chloridesEvaporationAbsorption rate

The invention relates to a method for evaporating brine to obtain a salt by utilizing a porous ceramic plate. The method specially comprises the following steps: water in pores of the porous ceramic plate after absorbing seawater is evaporated by utilizing action of sunlight and wind power for precipitating the salt; and a certain amount of seawater is added to repeatedly wash the porous ceramic plate until the salt content of the seawater after washing reaches 15-26%, and concentration is performed to prepare the salt. The porous endothermic ceramic plate provided by the invention has a superior solar radiation absorption rate, can absorb solar radiation energy well, has good thermal conductivity and a two-dimensional or three-dimensional communication structure, can reduce air flow resistance, facilitates uniform distribution and stabilization of an air flow, has a high specific surface area, and ensures a large heat exchange area of a material; and the porous endothermic ceramic plate is utilized as an evaporation medium, so that the method solves the problem that a traditional method for evaporating brine to obtain a salt has a large evaporation tank volume and slow seawater evaporation, and shortens the cycle of evaporating the brine to obtain the salt.

Owner:QINGDAO UNIV

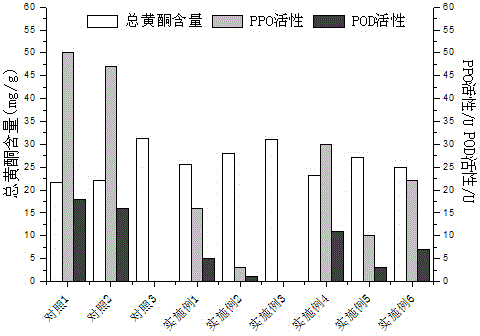

Chrysanthemum drying method with shape keeping and brown stain preventing functions

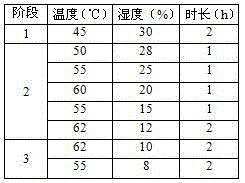

InactiveCN104964518AEasy to operateEasy to controlDrying solid materials with heatTea substituesStainChrysanthemum morifolium

A chrysanthemum drying method with shape keeping and brown stain preventing functions comprises the following steps that (1) picked chrysanthemums are classified and selected and then are manually placed in a disc; (2) heat pump drying is carried out, a heat pump is used for drying the chrysanthemums for 9-13 hours in a phased mode, and the water content of the chrysanthemums is made to be 9.5% to 11.5%; (3) steam inactivation is carried out, the chrysanthemums dried in the step (2) are placed in a sealed glass container, and then the sealed glass container is placed in a steam pressure cooker and is processed for 3-10 minutes under the steam temperature of 70-95 DEG C; (4) the chrysanthemums processed in the step (3) are classified and selected again according to quality, and nitrogen-filled packing is carried out on the chrysanthemums one by one. According to the chrysanthemum drying method with the shape keeping and brown stain preventing functions, operation is simple, monitoring is convenient, continuous work is achieved without manual watching, and industrial production efficiency is high; the phenomena of petal scattering and falling in the drying process of chrysanthemums are effectively avoided; brown stain of chrysanthemums and dissolution of the effective constituent, namely total flavonoid compounds, in the brewing process are prevented, and storage time is prolonged.

Owner:YICHUN UNIVERSITY

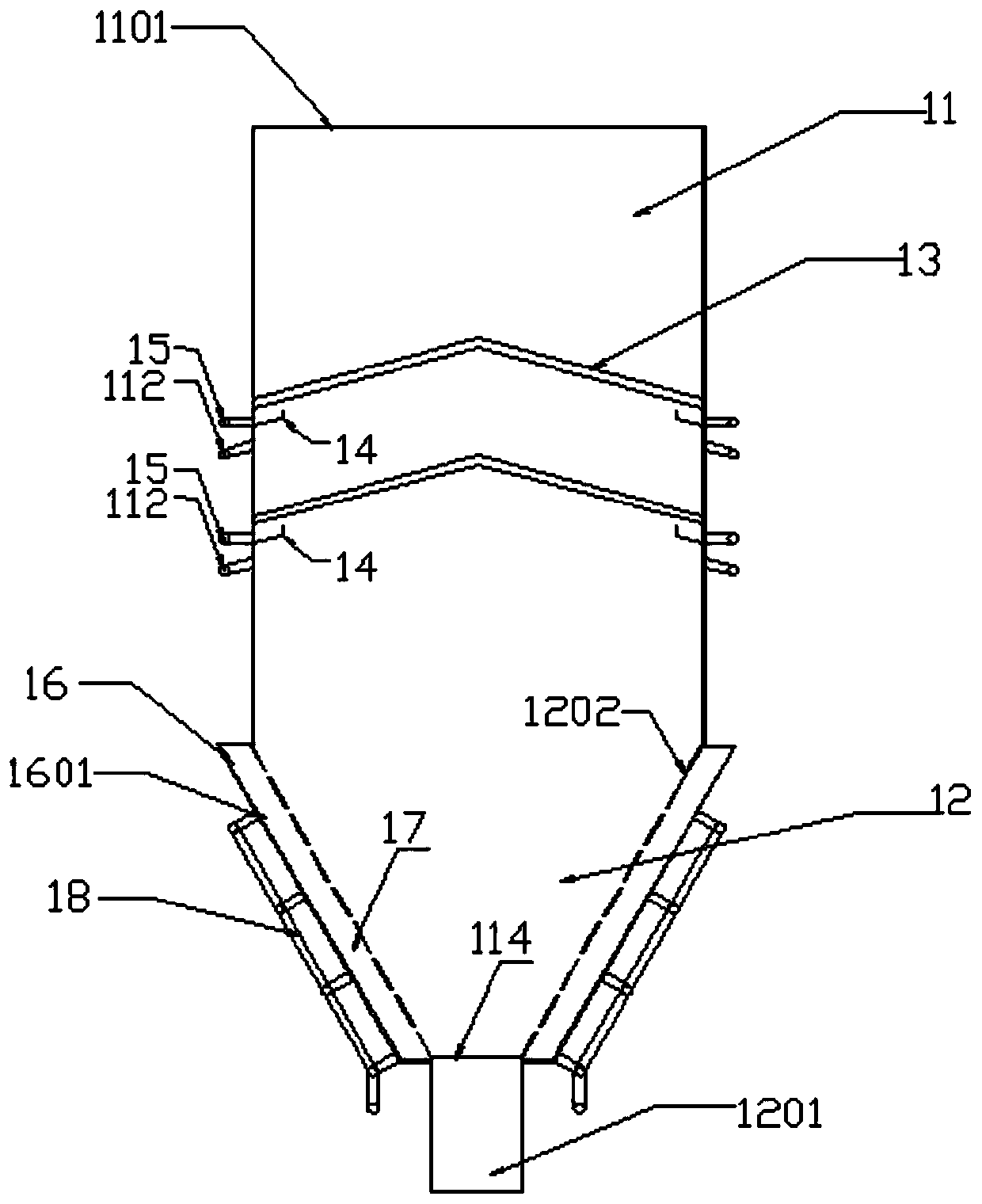

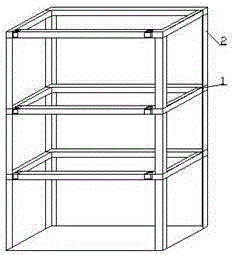

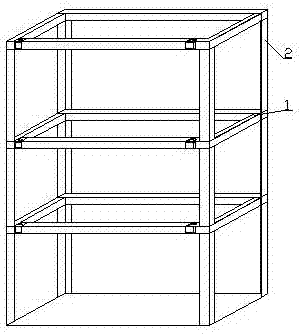

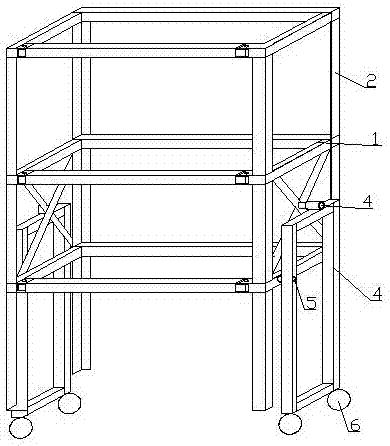

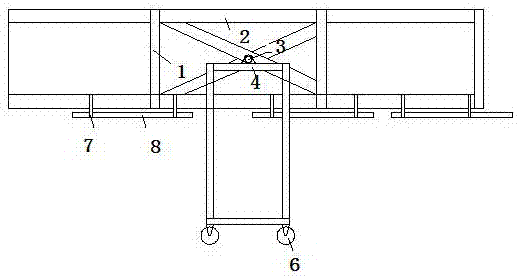

Tobacco hanging frame for baking flue-cured tobacco and using method thereof

InactiveCN105286064AThe smoking process is fastShorten the drying cycleTobacco preparationFlueTobacco processor

The invention discloses a tobacco hanging frame for baking flue-cured tobacco and a using method thereof. The tobacco hanging frame comprises two or more layers of rectangular tobacco hanging frame bodies (1), vertical supports (2) are arranged between the two layers of rectangular tobacco hanging frame bodies (1) which are arranged with one higher than the other and between the rectangular tobacco hanging frame bodies (1) and the ground, tobacco leaves with downward petioles are clamped in the rectangular tobacco hanging frame bodies (1), and insertion rods are inserted in the tobacco leaves located above the clamping faces of the rectangular tobacco hanging frame bodies (1). The tobacco hanging frame integrates the advantages of braided-tobacco baking and loose leave baking. The new tobacco containing device and an operating mode thereof are put forward, the device can finish baking tobacco leaves with the number equal to or even larger than that of loosely-baked tobacco leaves within braided tobacco baking time, the degree that labor used during braided tobacco baking is basically the same as labor used during loose leaf baking and the tobacco leaf baking quality is close to the braided tobacco baking quality can be achieved, the defects of braided tobacco baking and loose leaf baking can be well overcome if the device can be popularized in a wide range, and according to the statistics of an applicant, the per-mu income of tobacco growers can be increased by 260 RBM yuan, and cost of 300 RBM yuan can be saved.

Owner:BIJIE COMPANY OF GUIZHOU TOBACCO

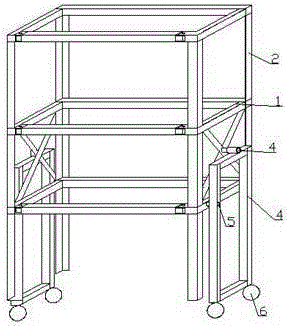

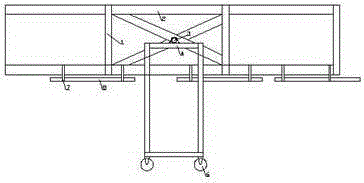

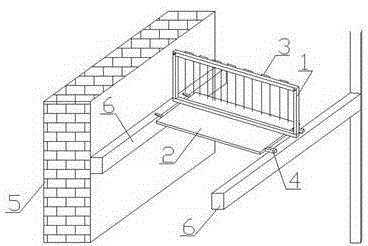

Frame-type hanging curing device for flue-cured tobaccos and hanging curing using method thereof

InactiveCN105077551AIncrease incomeSolve the smoke bakingTobacco preparationManual conveyance devicesEngineeringFlue

The invention discloses a frame-type hanging curing device for flue-cured tobaccos and a hanging curing using method thereof. The frame-type hanging curing device for flue-cured tobaccos comprises a rectangular tobacco hanging frame (1), a tobacco holding operating turning plate (2) and insertion rods (3), wherein the rectangular tobacco hanging frame (1) is a rectangular metal frame; one long edge of the rectangular metal frame is movably connected; the tobacco holding operating turning plate (2) is a rectangular flat plate; two movable supporting legs (4) are respectively connected to the short edges of the rectangular flat plate; and at least one supporting leg (4) on the two edges of the rectangular flat plate is connected with one short edge of the rectangular flat plate through a hinge. Within the tobacco-weaving curing time, the charging amount of loose cured tobacco leaves is completed, even exceeded, the tobacco-weaving curing is almost the same as the loose curing in labor consumption, the tobacco leaf curing quality of tobacco leaves cured loosely is proximal to the tobacco leaf curing quality of tobacco leaves cured through tobacco-weaving.

Owner:BIJIE COMPANY OF GUIZHOU TOBACCO

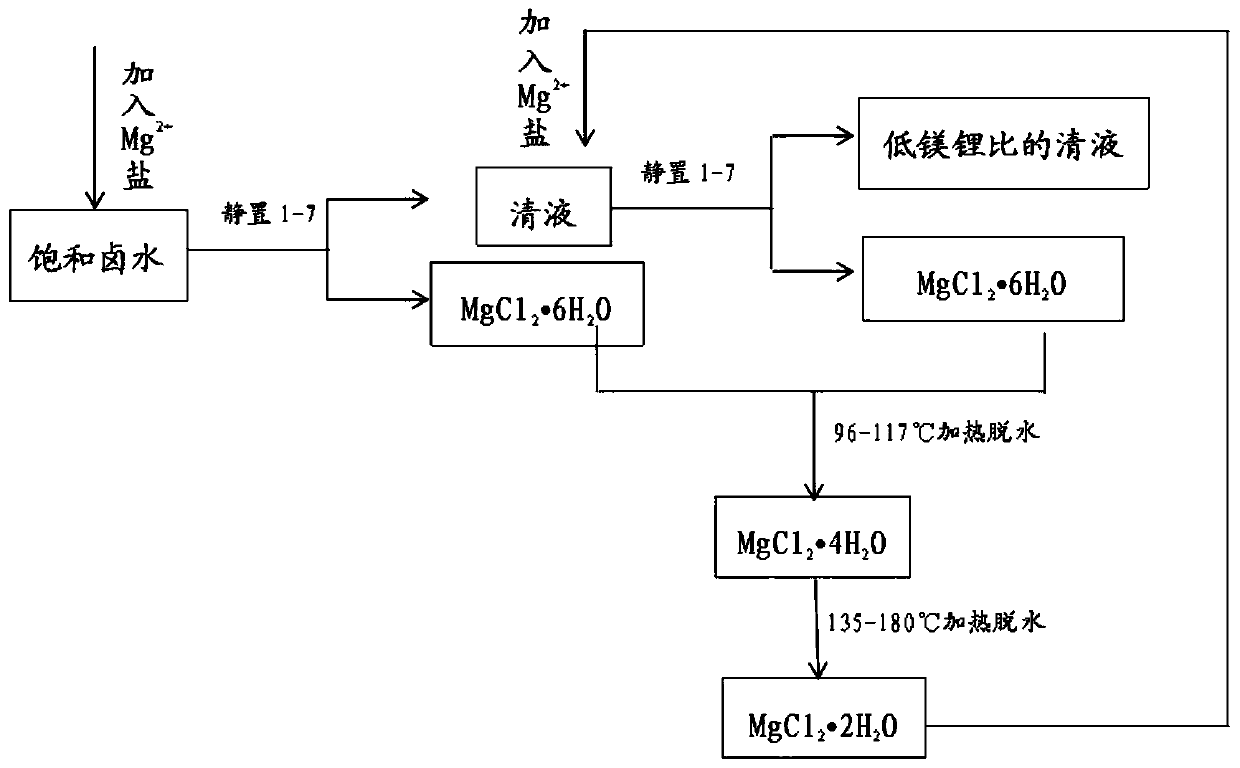

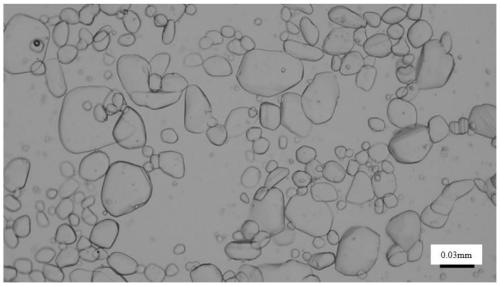

Method for reducing ratio of magnesium to lithium in salt lake through solar-assisted salt crystallization

ActiveCN110342553AAchieve dehydrationAchieve magnesium removalMagnesium chloridesAlkali metal chloridesLithiumSalt lake

The invention relates to a method for reducing the ratio of magnesium to lithium in a salt lake through solar-assisted salt crystallization. The method comprises the following steps: (1) adding a Mg<2+> salt at a molar ratio of the added Mg<2+> salt to Mg<2+> in saturated brine at (1:5)-(1:10) to the saturated brine which has a molar ratio of magnesium to lithium at (200:1)-(10:1), and drying thesaturated brine in the sun for 1-7 days so as to obtain a clear liquid and a granular precipitated crystal MgCl2.6H2O; (2) heating the precipitated crystal MgCl2.6H2O so as to obtain MgCl2.4H2O, MgCl2.2H2O or MgCl2; (3) adding a Mg<2+> salt to the clear liquid at a molar ratio of the added Mg<2+> salt to Mg<2+> in the clear liquid in the step (1) at (1:5)-(1:10), wherein the added Mg<2+> salt comprises MgCl2.4H2O, MgCl2.2H2O or MgCl2 obtained in the step (2); and drying the clear liquid in the sun for 1-7 days so as to obtain a clear solution and a granular precipitated crystal MgCl2.6H2O again; and (4), repeating the steps of (2) and (3), and repeating the cycle 2-8 times. According to the method, the products are generated through cyclic induction of the products, the entire salt dryingcycle is shortened, the production process is simple, less equipment investment is required, and no contaminants is introduced in the production process.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

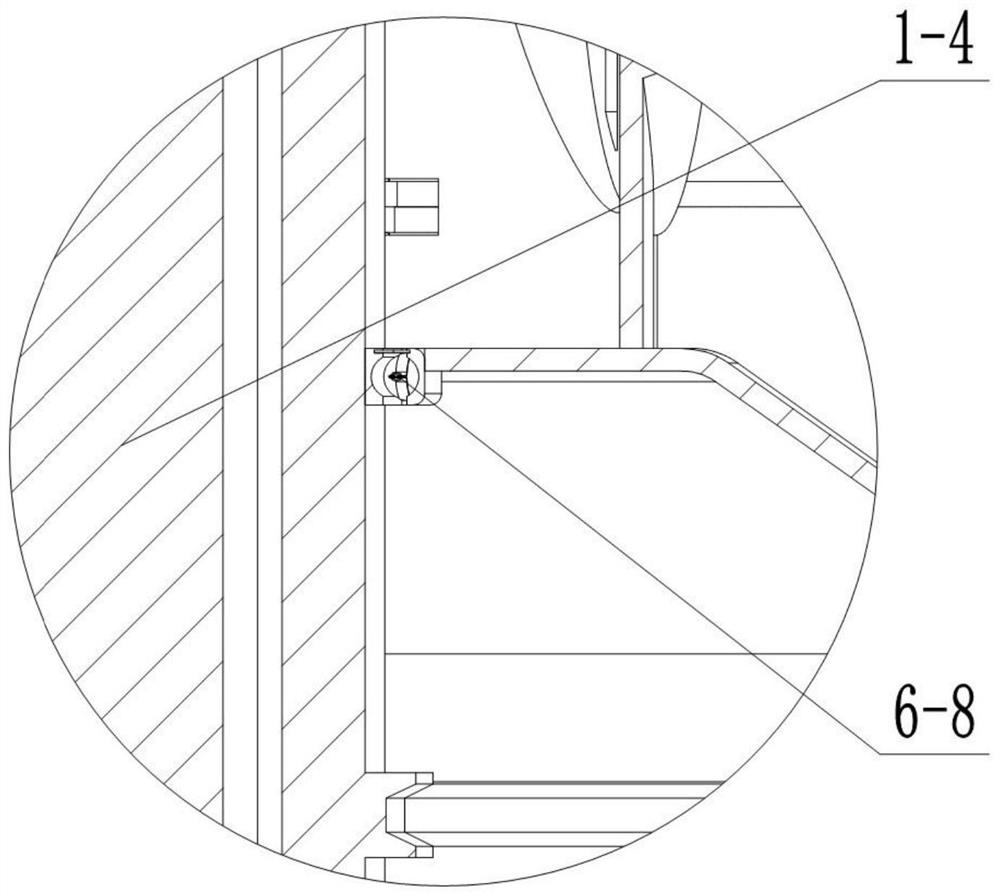

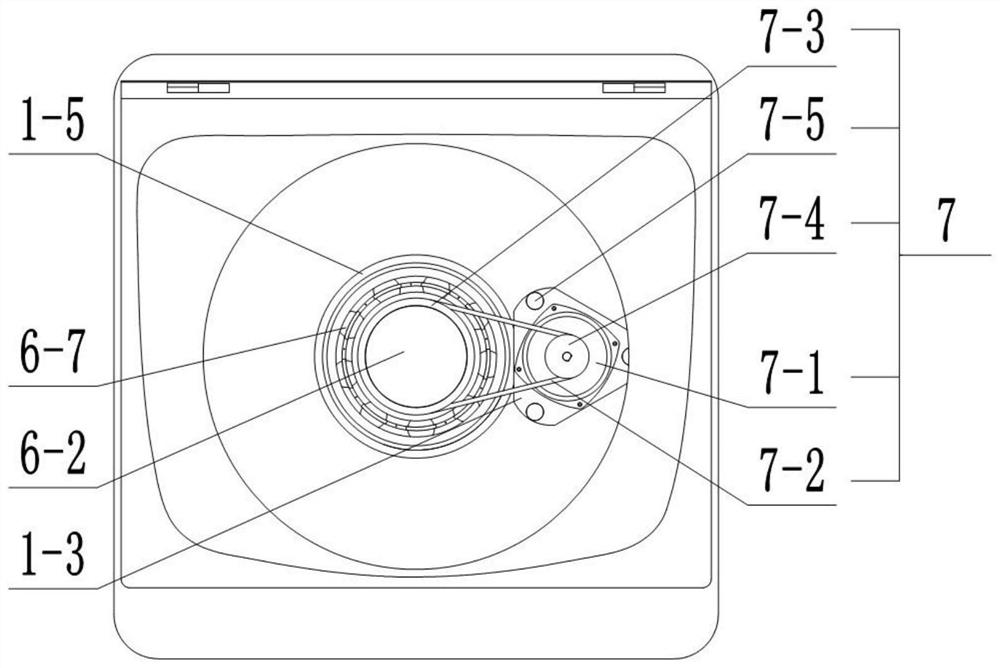

Multifunctional shoe washing machine

InactiveCN113576367AGuaranteed cleanlinessImprove cleaning efficiencyFootwear cleanersRadiationEngineeringMechanical engineering

The invention discloses a multifunctional shoe washing machine which comprises a machine body shell, and the machine body shell comprises a shell body; an inner cylinder is fixedly connected in the shell, a plurality of water outlet holes are formed in the bottom end of the inner cylinder, and an air-drying sterilization device, a scrubbing device and a lifting mechanism are arranged in the inner cylinder; an ascending stud is fixedly connected to the middle part of the bottom end of the shell, and the top end of the ascending stud penetrates through the bottom end of the inner cylinder and extends into the inner cylinder; the lifting mechanism comprises a power transmission column arranged on the outer side of the ascending stud in a sleeving mode and a connecting part, the bottom end of the power transmission column penetrates through the inner cylinder and is rotationally connected with the bottom end of the shell, and the power transmission column is rotationally connected with the inner cylinder; the connecting part slidably sleeves the power transmission column, the inner side of the connecting part is in threaded connection with the ascending stud, and a shoe rack mechanism and an outer brush mechanism are both mounted on the outer side of the connecting part; a power mechanism is arranged between the bottom end of the inner cylinder and the bottom end of the shell, is in transmission connection with the power transmission column and is fixedly connected to the inner wall of the bottom end of the shell. The shoe washing machine can brush the interior and exterior of a shoe, and the cleaning effect on the shoe is guaranteed.

Owner:BINZHOU UNIV

Tobacco hanging rack for baking flue-cured tobacco and using method thereof

InactiveCN105286064BIncrease incomeSolve the shortcomingsTobacco preparationEngineeringTobacco processor

The invention discloses a tobacco hanging rack for curing flue-cured tobacco and a method for using the same. There is a vertical support (2) between the cigarette rack (1) and the ground, and the tobacco leaf with the leaf handle facing down is clamped in the rectangular tobacco rack (1), and the tobacco leaf on the clamping surface of the rectangular tobacco rack (1) The top tobacco leaves are inserted with cuttings. The present invention combines the advantages of knitting tobacco curing and loose leaf curing, and proposes a new tobacco loading device and its operation mode, which can be completed or even exceed the drying time of loose leaf curing tobacco leaves The amount of labor is almost the same as that of loose leaf curing, and the quality of tobacco leaf curing is similar to that of braided tobacco. If it can be extended, it can solve the problem of braided tobacco and loose leaf curing. Disadvantages, with the applicant's statistics, the income of tobacco farmers can be increased by 260 yuan per mu, and the cost can be saved by 300 yuan.

Owner:BIJIE COMPANY OF GUIZHOU TOBACCO

A kind of multifunctional filter plate and filter press, and the preparation method of multifunctional filter plate

ActiveCN106422455BShorten the drying cycleAvoid deformationFiltration separationBiochemical engineeringWater flow

The invention provides a multifunctional filter plate, a filter press provided with the multifunctional filter plate and a making method of the multifunctional filter plate. The multifunctional filter plate comprises a core plate of a flat plate structure, filter plate frames fixedly arranged at the outer edges of the left side and the right side of the core plate, electrode heating plates fixedly arranged between the core plate and the filter plate frames and a feeding hole penetrating through the electrode heating plates and the core plate in the left-right direction; a material filling cavity communicated with the feeding hole is formed between the inner circumferential surface of each filter plate frame and the outer side face of the corresponding electrode heating plate, each electrode heating plate is provided with a plurality of protruding parts which protrude outwards and are arranged in the corresponding material filling cavity, an inner water flow groove is formed in the inner side of each protruding part, the left outer side face and the right outer side face of the core plate are provided with a plurality of outer water flow grooves, the inner water flow grooves and the outer water flow grooves are communicated to form a heating cavity, and the electrode heating plates are connected with a power source through wires. Filter cakes in the material filling cavities can be subjected to heating dehydration and electrodialytic deep dehydration through the electrode heating plates, so that the moisture content of the filter cakes is further lowered.

Owner:ZHEJIANG FUJIE ENVIRONMENTAL PROTECTION EQUIP CO LTD +1

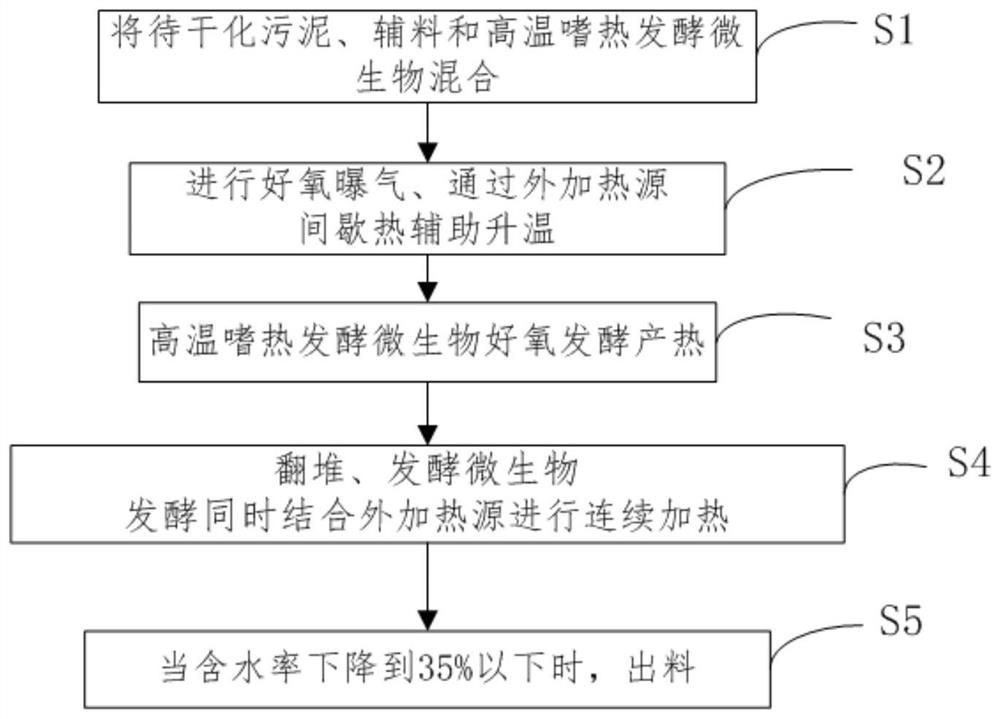

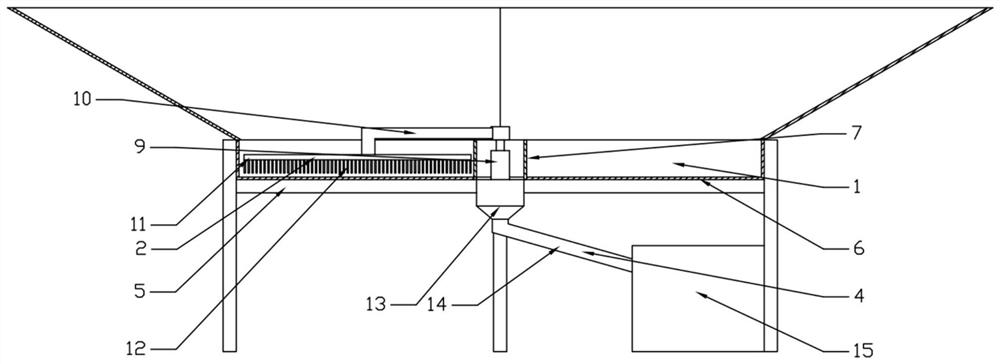

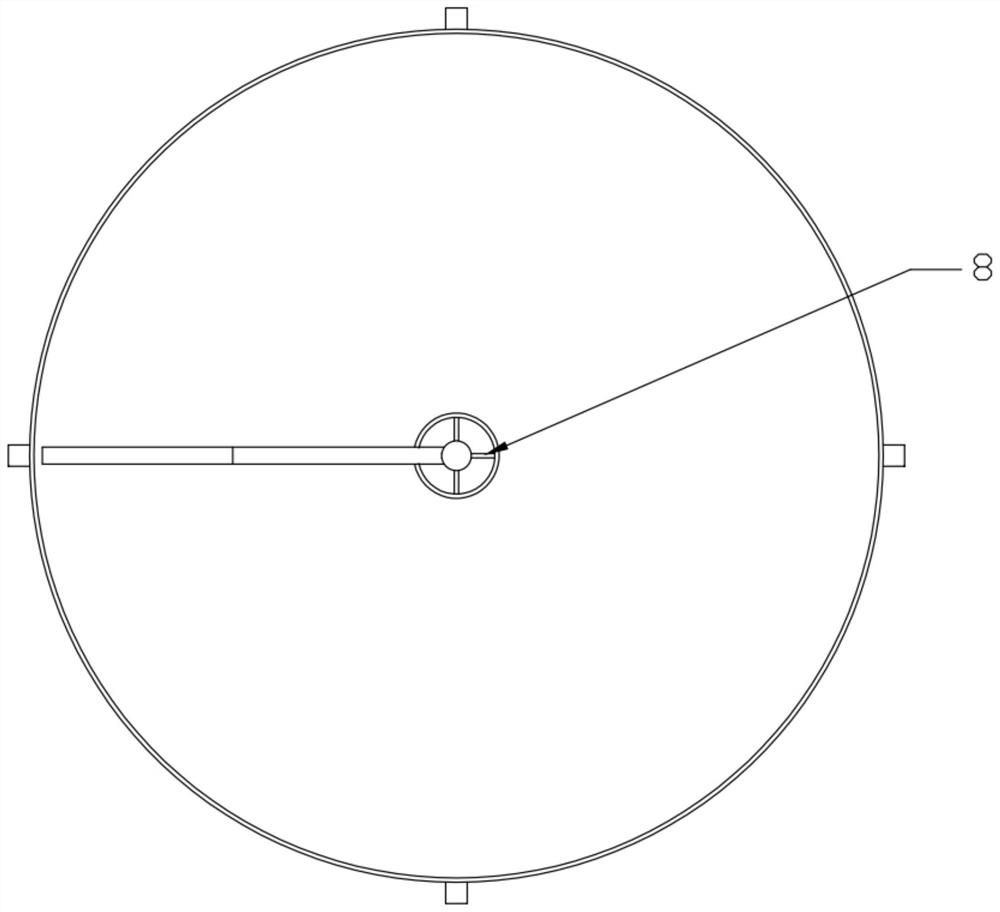

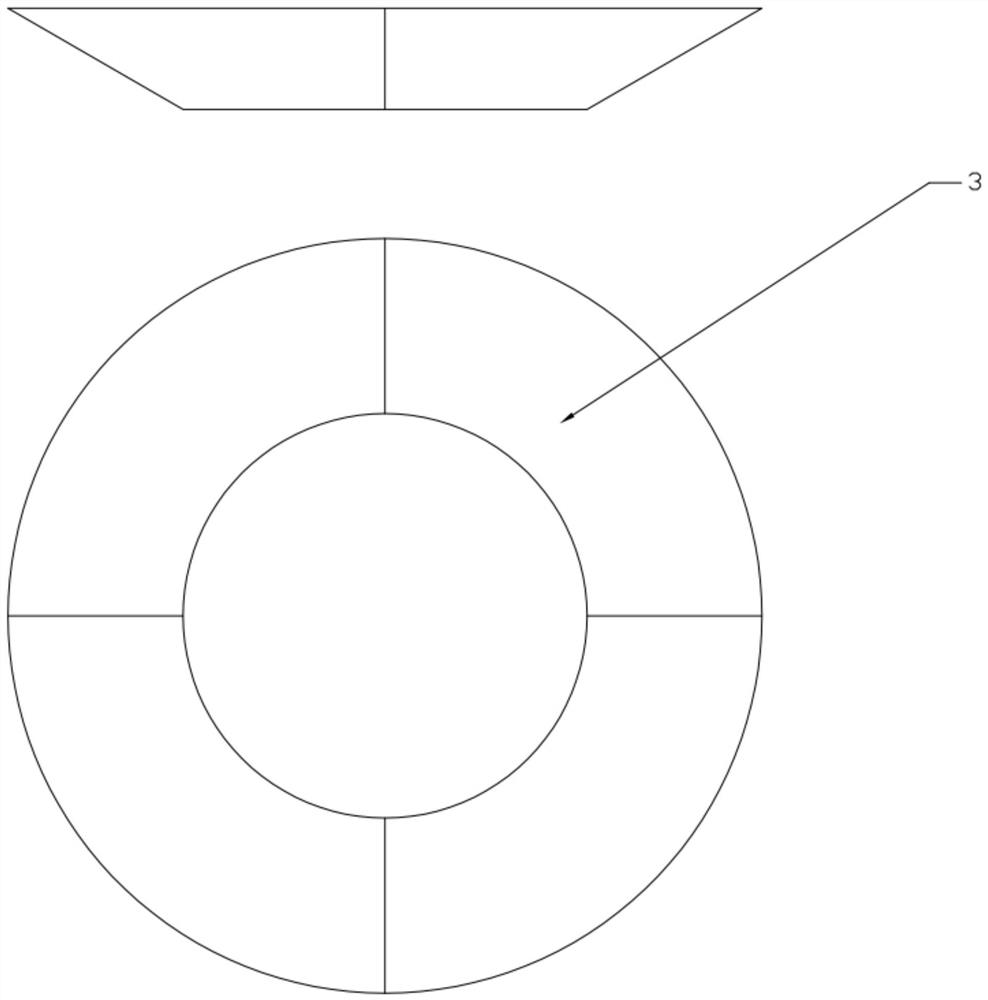

A method of external heating assisted sludge biological drying

ActiveCN112897827BPromote reproductionShorten breeding timeEnergy based wastewater treatmentFixation/solidifcation sludge treatmentMicroorganismBiochemical engineering

The invention belongs to the technical field of sludge treatment, and in particular relates to a method for assisting biological drying of sludge by external heating. In this method, the sludge to be dried and auxiliary materials are stirred and mixed in proportion, and then high-temperature thermophilic fermentation microorganisms are added to form a mixture material, and the fermentation microorganisms in the sludge to be dried ferment the mixture material to form a primary fermentation pile; Aerobic aeration is carried out on the body, and at the same time, the temperature of the primary fermentation pile is assisted by intermittent heating through an external heat source; the heat generated by the aerobic fermentation of high-temperature thermophilic fermentation microorganisms makes the second fermentation pile body reheated for 12 to 18 hours; When the temperature of the fermentation pile drops below 50°C, the fermenting microorganisms ferment and continuously heat the three fermentation piles through an external heating source at the same time. When the temperature rises to 65-70°C, the external heating is stopped, and the moisture content is reduced by repeated repetitions. to below 35%. Therefore, the method greatly saves sludge drying time and treatment cost, has low energy consumption, shortens the drying cycle, and realizes rapid biological drying of sludge.

Owner:NORTHEASTERN UNIV LIAONING

Grain particle airing rack

PendingCN112378243AShorten drying timeSave human effortDrying solid materialsDrying machines with local agitationPhysicsEngineering

The invention discloses a grain particle airing rack which comprises an airing assembly, a tedding assembly, an energy gathering cover and a collecting assembly. The airing assembly is arranged on theground, the tedding assembly is arranged above the airing assembly, the energy gathering cover is arranged above the tedding assembly, and the collecting assembly is arranged below the airing assembly. The airing assembly comprises a support, an airing disc and a check ring, the support is arranged on the ground, the airing disc is arranged on the support, and the check ring is arranged in the center of the airing disc. The tedding assembly comprises a motor frame, a rotating motor, a cantilever, a tedding plate and tedding teeth. The collecting assembly comprises a funnel, a grain conveyinggroove and a grain storage box. The invention relates to the technical field of grain airing, in particular to the grain particle airing rack which is provides a fixed place for grain airing, grain can be turned over and aired through a machine, the airing time is shortened, and the airing efficiency is improved.

Owner:南县粮食行业协会

Poultry manure high-temperature drying bacterial agent and application method thereof

InactiveCN110156498AAvoid lostAdaptableBio-organic fraction processingExcrement fertilisersMicroorganismNitrogen

The invention is applicable to the technical field of fermentation preparations, and provides a poultry manure high-temperature drying bacterial agent and an application method thereof. A multiple-microorganism optimization combination is adopted, so that the drying bacterial agent has the characteristics that adaptability is high and organic matter is completely decomposed; the drying treatment effect is better than the drying treatment effect of a single strain, and loss of nitrogen in a biological drying process is effectively avoided; no external heating source is needed in the drying process, and heat required by drying is derived from aerobic fermentation of microorganisms in the system and belongs to the biological energy of the materials, so that economic performance, energy conservation and environment friendliness are achieved, and manual control can be achieved; and forced air blowing can be carried out to promote the drying process and shorten the drying period.

Owner:江苏思威博生物科技有限公司

A method and device for low-temperature drying of residual activated sludge in sewage treatment

ActiveCN110255846BAccelerated settlementLow costSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningActivated sludgeMicroorganism

The invention discloses a low-temperature drying method and device for residual activated sludge in sewage treatment. The device includes sludge freezing equipment, a sludge curing room, a sludge thawing and preliminary dehydration device, sludge dehydration equipment and sludge Air-drying device: The residual activated sludge after preliminary dehydration treatment in the sewage treatment plant is sequentially processed by the above-mentioned device to obtain low-temperature dried sludge. The present invention cooperates with the sludge thawing device, the sludge dehydration device and the sludge air-drying device to continuously dehydrate and air-dry the sludge, shorten the sludge drying period, and have an obvious drying effect. All drying processes are carried out at normal temperature and below, which reduces the volatile gas produced by the secondary fermentation of microorganisms in the sludge, thereby reducing pollution. The invention directly freezes the sludge without adding other chemical agents, reduces the drying cost, keeps the biological characteristics of the sludge unchanged, and lays a foundation for the resource utilization of the sludge.

Owner:杨红兵

Membrane drying system and method for drying waste by using waste heat from waste incineration exhaust flue gas

ActiveCN107388252BRealize biological aerobic reactionImprove drying efficiencyCoatingsIncinerator apparatusFlue gasProcess engineering

Owner:HANGZHOU JINHUAN INVESTMENT CO LTD

Dredged sediment dewatering and drying stockyard and establishment method thereof

ActiveCN101967821BImprove dehydration and drying speedQuick overflowSoil preservationCofferdamEngineering

The invention provides a dredged sediment dewatering and drying stockyard and an establishment method thereof, belonging to the environmental engineering technical field. The dredged sediment dewatering and drying stockyard comprises the stockyard encircled by a surrounding cofferdam, a drain outlet positioned at the upper part of the cofferdam of the stockyard, a plurality of drainage ditches which are parallel to each other and positioned at the lower part of the stockyard, drainage pipes, seepage gravel and a plurality of vertical guide tubes, wherein, the drainage pipes are laid in the drainage ditches; the seepage gravel is arranged between the drainage ditches and the drainage pipes; two ends of the drainage pipes are sequentially equipped with a plurality of the vertical guide tubes which are parallel to each other and connected with an external blower system; and the drainage pipes are arranged in the drainage ditches on the bottom of the stockyard and arranged towards the drain outlet slantwise, and the drain outlet is arranged on the cofferdam edge at one side of the stockyard. The invention can enhance the bearing capacity of the stockyard and shorten the occupied time of the temporary dredged sediment stockyard site.

Owner:戴勇鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com