A method of external heating assisted sludge biological drying

A technology of biological drying and external heating, applied in chemical instruments and methods, sludge treatment, biological sludge treatment, etc., can solve the problems of high energy consumption in equipment operation, difficulty in large-scale promotion and application, high investment and operating costs, etc. Achieve the effect of saving processing cost, saving fermentation time, and rapid biological drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

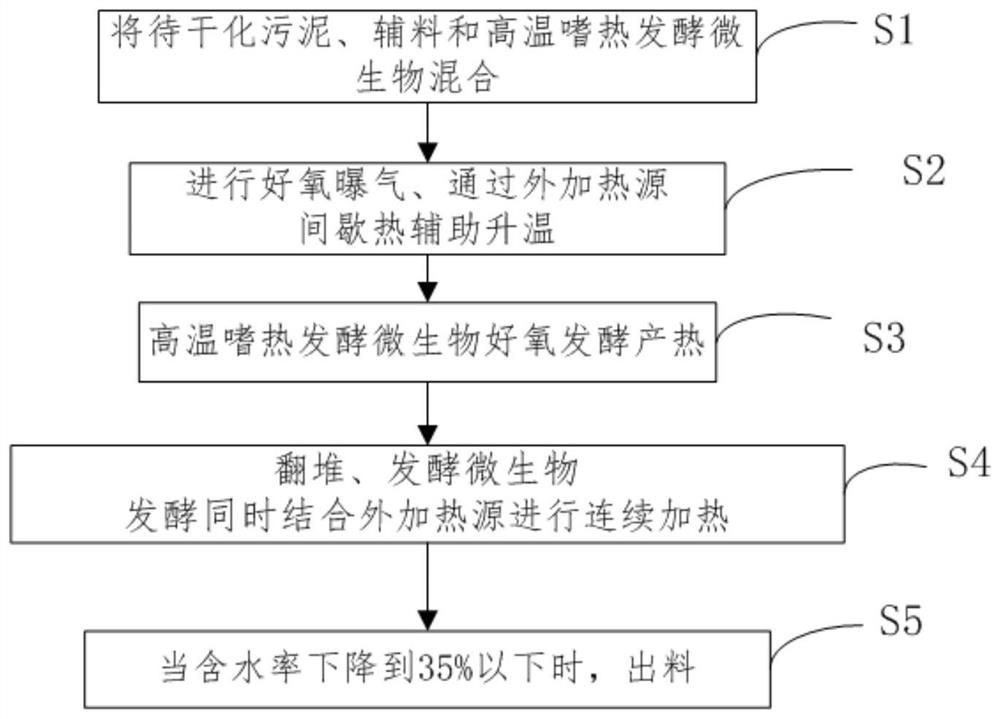

[0032] The present invention provides a method of external heating assisted sludge bio-drying, comprising the following steps;

[0033] S1, the sludge to be dried and the auxiliary materials are stirred and mixed in proportion to the high temperature thermophilic fermentation microorganisms are added to form a mixed material, because the moisture content of the mixed material is maintained at 50% to 56% after the auxiliary material is added, the height of the mixed material is 1 to 2m, and the fermentation microorganism in the sludge to be dried makes the mixed material ferment to form a fermentation heap;

[0034]Among them, the initial moisture content of the sludge to be dried in step S1 is 80% to 90%. The excipients are straw powder, rice husks, peanut husks, wheat bran or wood chips, and the quality of the excipients is 50% to 70% of the quality of the sludge to be dried. Since the initial moisture content of the sludge to be dried is relatively high, the auxiliary materials ...

Embodiment 2

[0045]S1, the moisture content of 88.7% to be dried sludge and straw powder according to the weight ratio of 2:1 evenly stirred and mixed, add high temperature thermophilic fermentation microorganisms to form a mixed material, adjust the moisture content of the mixed material so that the moisture content of the mixed material is maintained at 50%; of which, the height of the mixed material is 1m; the fermentation microorganism in the sludge to be dried makes the mixed material ferment to form a fermentation heap;

[0046] S2, aerobic aeration of the primary fermentation reactor, ventilation amount of 3m per cubic meter of reactor 3 / h, at the same time, the use of additional electric auxiliary heat to the primary fermentation reactor for the first thermal auxiliary heating, the ambient temperature of 24 ° C, the heating amount of 6750kJ / h per cubic meter of the reactor, electric auxiliary heating 20min, stop 40min, when the temperature of the primary fermentation reactor reaches...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com