Patents

Literature

932results about "Fixation/solidifcation sludge treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for chemiophysical stabilization of waste

InactiveUS20050049449A1Solid waste managementSolid waste disposalEngineeringEnvironmental engineering

This invention provides a method for stabilization of combined heavy metal bearing materials and wastes subject to acid and water leaching tests or leach conditions by addition of stabilizing agents such that the leaching potential is inhibited to desired levels and the material or waste is free flowing. The resultant material or waste after stabilization is deemed suitable for on-site reuse, off-site reuse or disposal as RCRA non-hazardous waste.

Owner:FORRESTER KEITH EDWARD

In-container mineralization

InactiveUS20050096495A1High nitrate contentEliminating hazardous characteristicSolid waste managementTransportation and packagingMaterials scienceScrap

A method of waste stabilization by mineralization of waste material in situ in a treatment container suitable or treatment, transit, storage and disposal. The waste material may be mixed with mineralizing additives and, optionally, reducing additives, in the treatment container or in a separate mixing vessel. The mixture is then subjected to heat in the treatment container to heat-activate mineralization of the mixture and form a stable, mineralized, monolithic solid. This stabilized mass may then be transported in the same treatment container for storage and disposal.

Owner:STUDSVIK INC

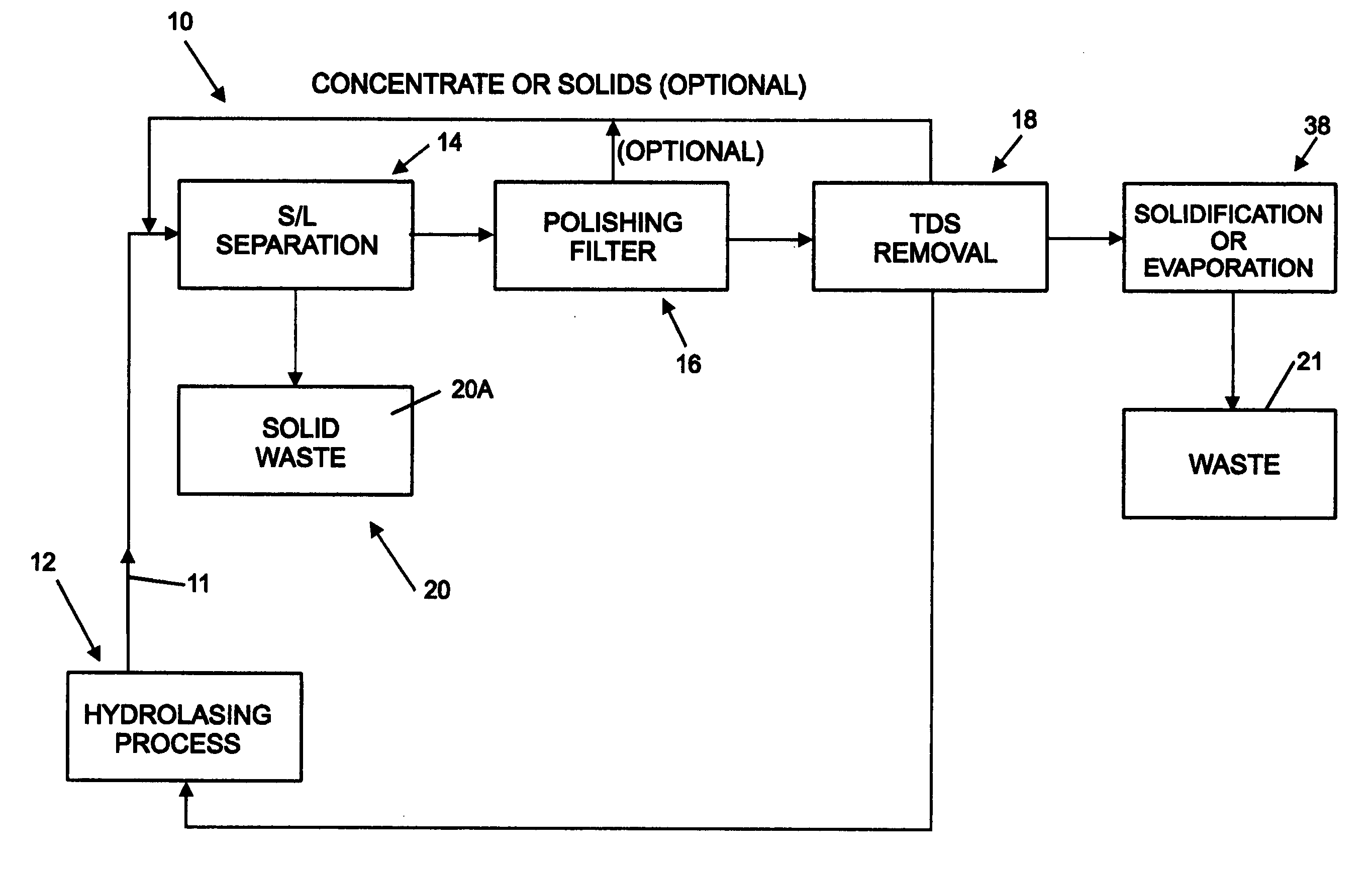

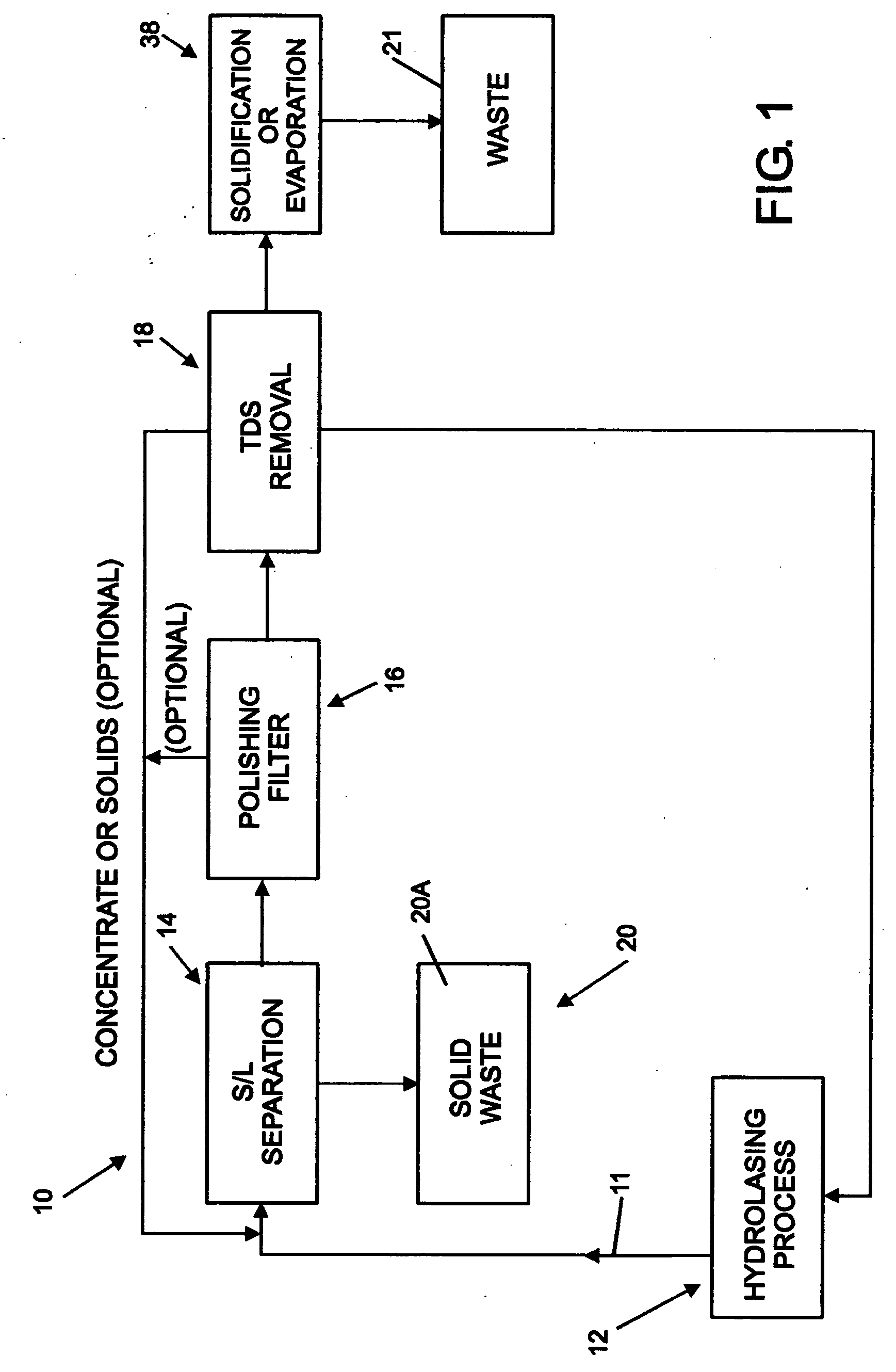

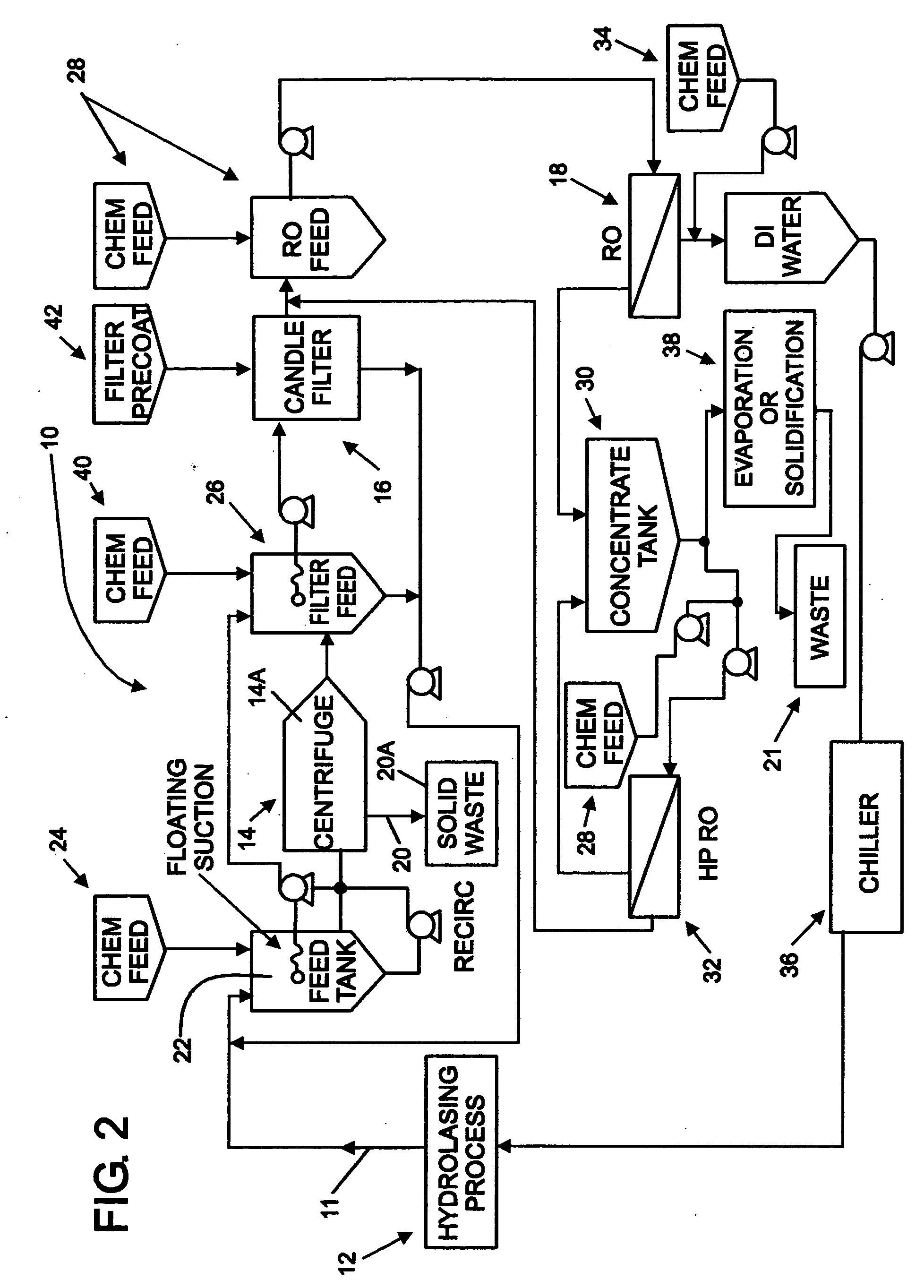

Method for processing hydrolasing wastewater and for recycling water

InactiveUS20050218077A1Liquid separation auxillary apparatusWater/sewage treatment by centrifugal separationParticulatesCandle

The invention relates to the process, method and system of treating, processing and recycling wastewater generated from a hydrolasing process, or similar operation, equipment utilization or cleaning project, utilizing amounts of water as a part of such a process. The invention is used for the purpose among others of greatly improving the cost and re-usability of water volumes. The method includes the subprocesses of wastewater conveyance or communication; separation of particulate matter; polishing filter or backwashable candle filter wastewater treatment; and removal of remaining dissolved solids / organics, producing a recyclable feed end product; and conveyance for recyclable use. Many different types of equipment can be utilized in the subprocesses of the invention.

Owner:DIVERSIFIED TECH SERIVES

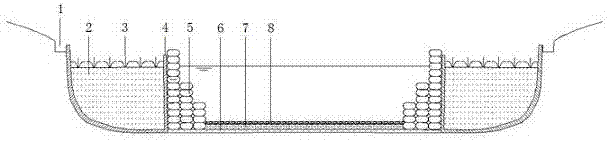

River pollution bottom sediment ecological remediation method

ActiveCN107445422AImprove landscape functionImprove water purification functionWater resource protectionSludge treatment by de-watering/drying/thickeningIn situ remediationWater flow

The invention relates to a river pollution bottom sediment ecological remediation method. A bottom sediment stacking region is arranged at a river bank side, anti-seepage treatment is carried out on the bottom and the periphery of the bottom sediment stacking region, bottom sediments dug from a river and polluted by heave metals are added with a curing agent and are stacked in the bottom sediment stacking region; a separation region is arranged between the bottom sediment stacking region and a river water flow passage, and at least one separation wall is arranged in the separation region; an in-situ covering region is arranged in the dredged river water flow passage, first covering layers are laid at both the bottom of the separation region and the bottom of the in-situ covering region, a second covering layer and a third covering layer are also arranged on the first covering layer of the in-situ covering region, a filler of the first covering layer is a mixture of clay and the curing agent, the second covering layer is formed by sand grains, and the third covering layer is formed by pebbles and natural zeolite. According to the river pollution bottom sediment ecological remediation method disclosed by the invention, not only can the heavy metals in the bottom sediments be adsorbed, but also water can be accumulated, and a landscape function of the river is promoted; an in-situ remediation technology not only can prevent release of bottom sediment pollutants, but also can improve a water quality purification function of the river.

Owner:SHANDONG JIANZHU UNIV

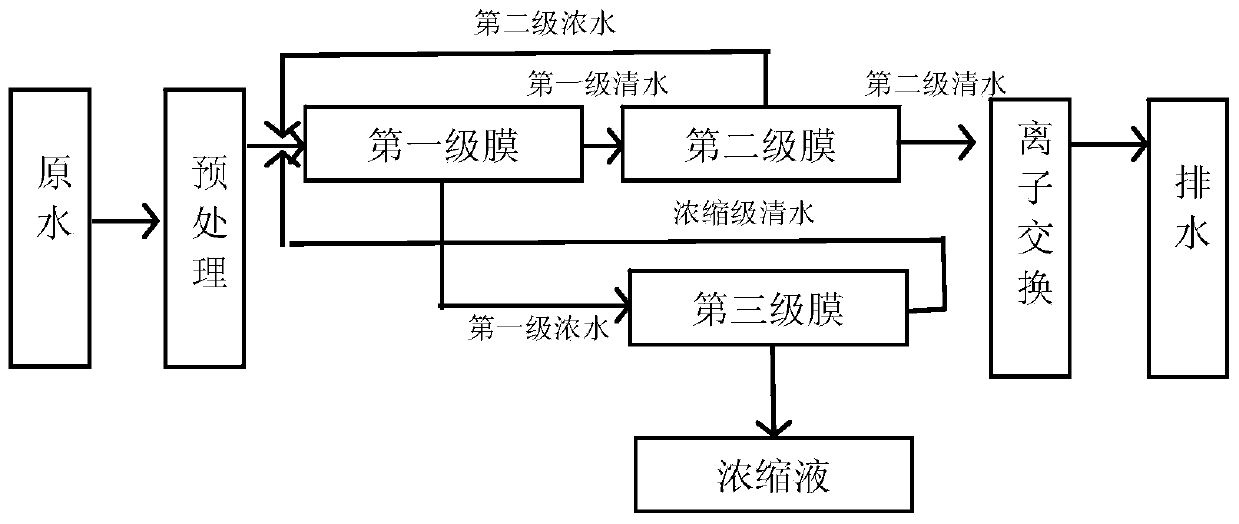

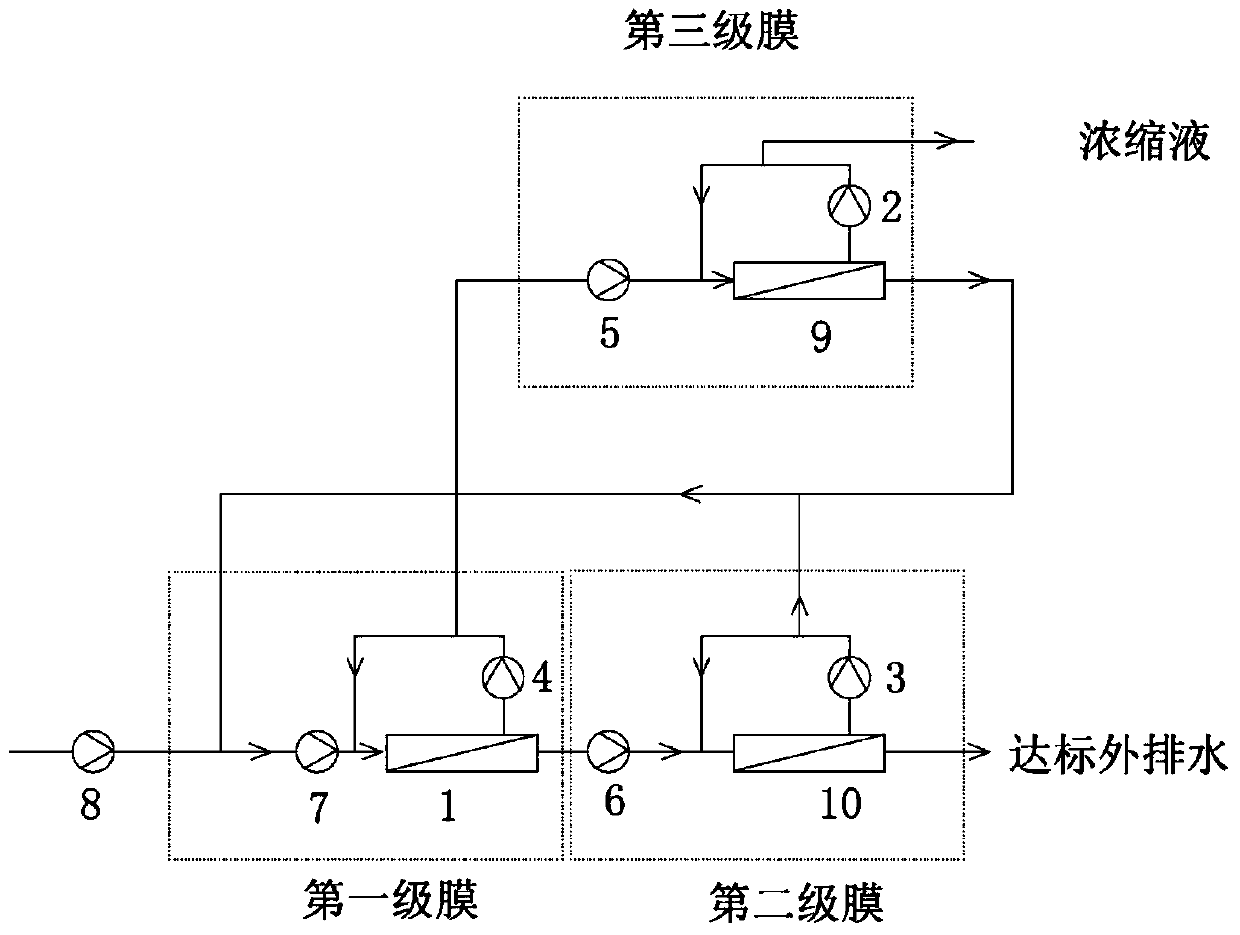

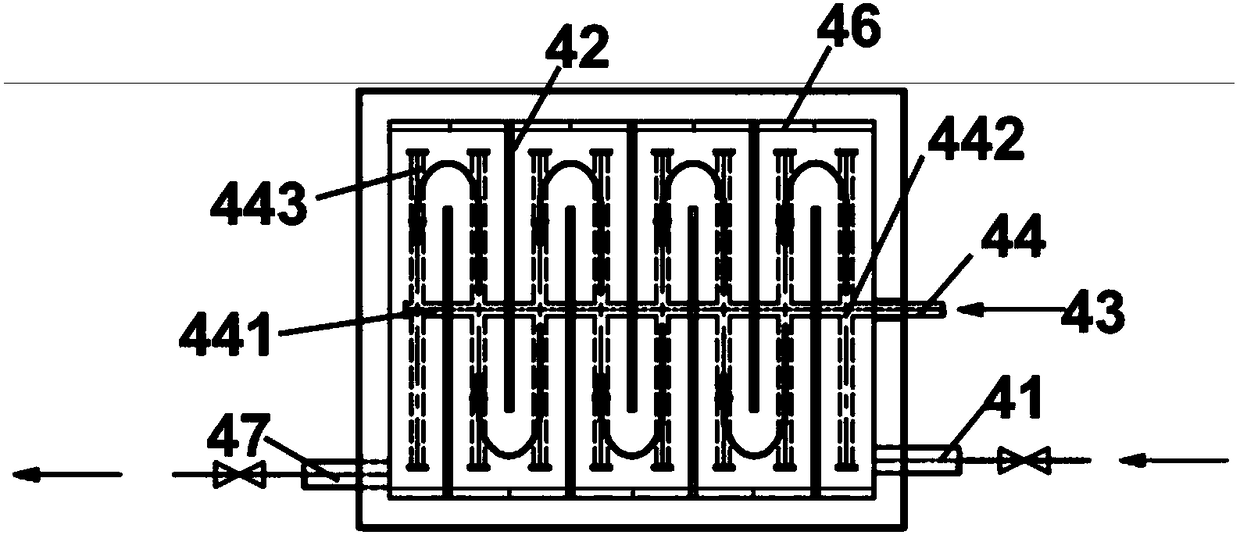

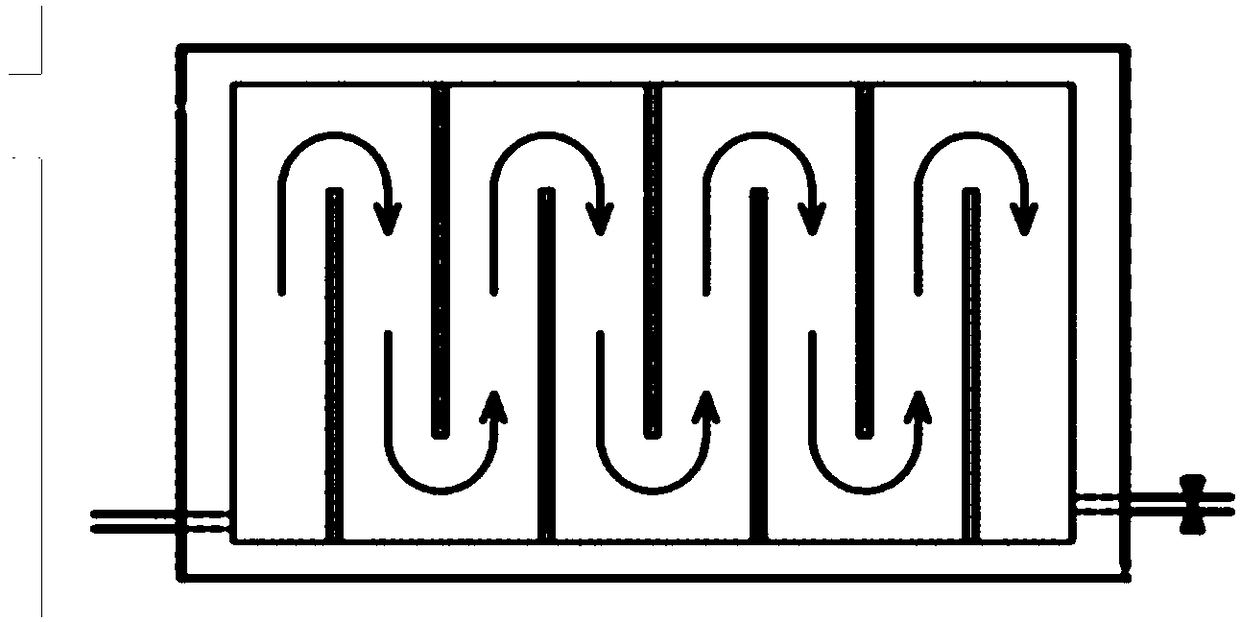

Method and device for processing radioactive wastewater

The invention provides a method and a device for processing radioactive wastewater. According to the method and the device, the radioactive wastewater is processed by a disk tubular reverse osmosis (DTRO) membrane component, so that effects of efficient decontamination factors and high cycles of concentration can be obtained at the same time. The method comprises the steps of enabling the radioactive wastewater to flow through a first-level membrane component and a second-level membrane component in sequence to obtain second-level water; and enabling first-level concentrated water out of the first-level membrane component to enter a third-level membrane component and obtain a concentrated solution.

Owner:TSINGHUA UNIV

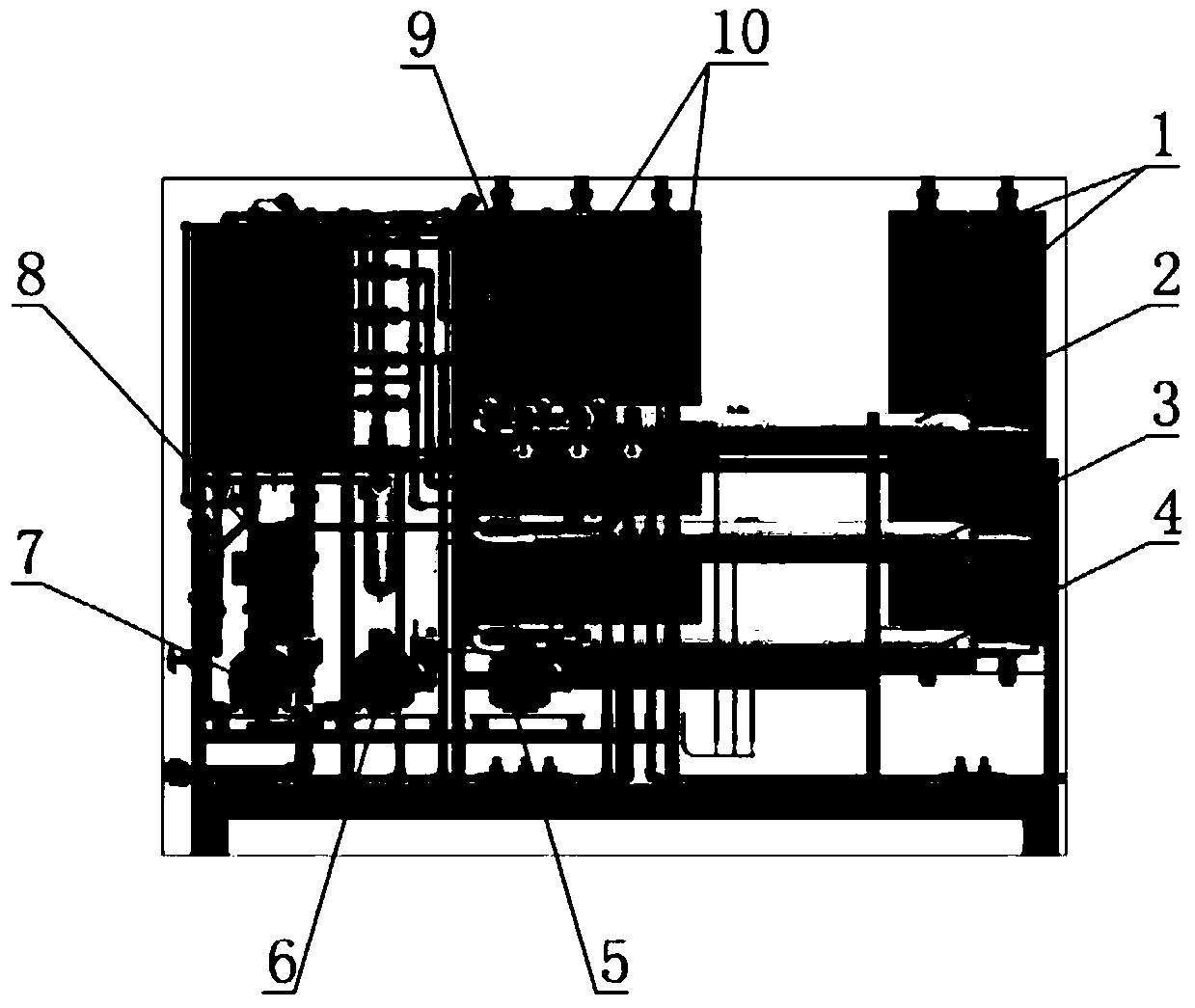

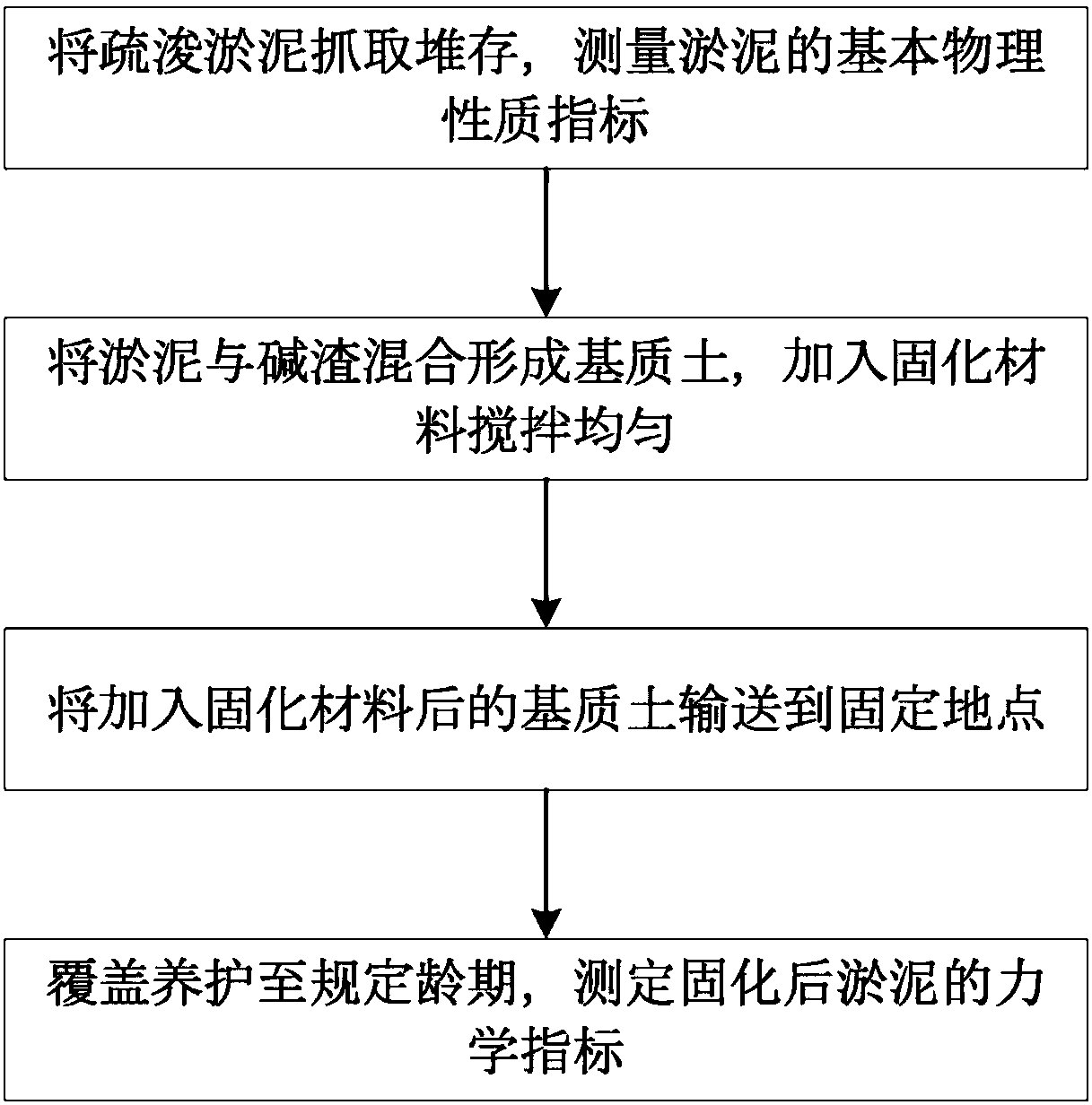

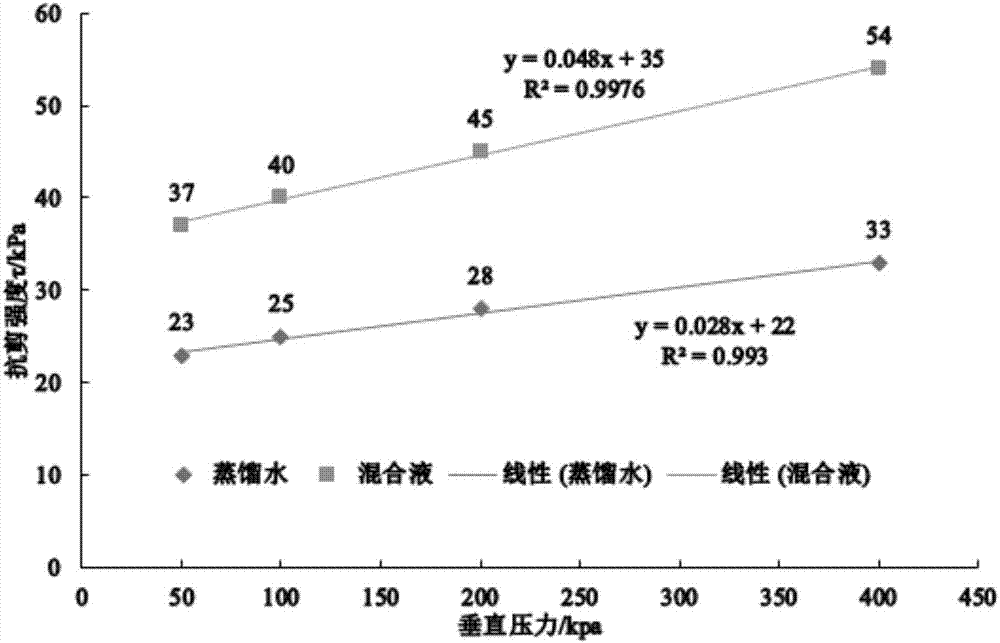

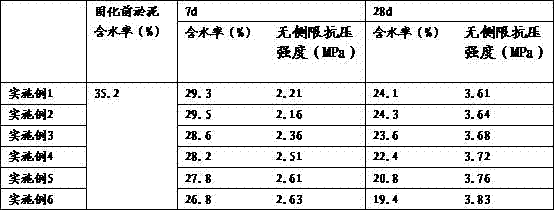

Method for solidifying sludge with high water content

InactiveCN108218317ARealize resource utilizationAchieve sustainable developmentFixation/solidifcation sludge treatmentSludgeMechanical index

The invention discloses a method for solidifying sludge with a high water content. At first, dredged sludge is collected and stored, basic physical indexes of sludge are measured, the sludge and alkali residues are mixed to form matrix soil; a curing material is added and then is evenly mixed and stirred; then the matrix soil containing the curing agent is transported to a fixed location; the matrix soil is covered and cured for a prescribed period; and finally the mechanical indexes of cured sludge are measured. The optimal ratio of alkali residues to dry sludge is 30-50:100. The curing material comprises following components in percentage by the weight of dry mixed soil: 10 to 25% of mineral powder, 0.1 to 0.5% of super absorbent resin, and 2 to 6% of sodium silicate. The cooperative effect between alkali residues and sludge with a high water content is utilized to form matrix soil; super absorbent resin is used to reduce the water content of sludge, the utilization rate of alkali residues is increased, the solidification cost is reduced, and the solidified soil has the advantages of high early strength and low compressibility and meets the engineering requirements of filling soil.

Owner:HUBEI UNIV OF TECH

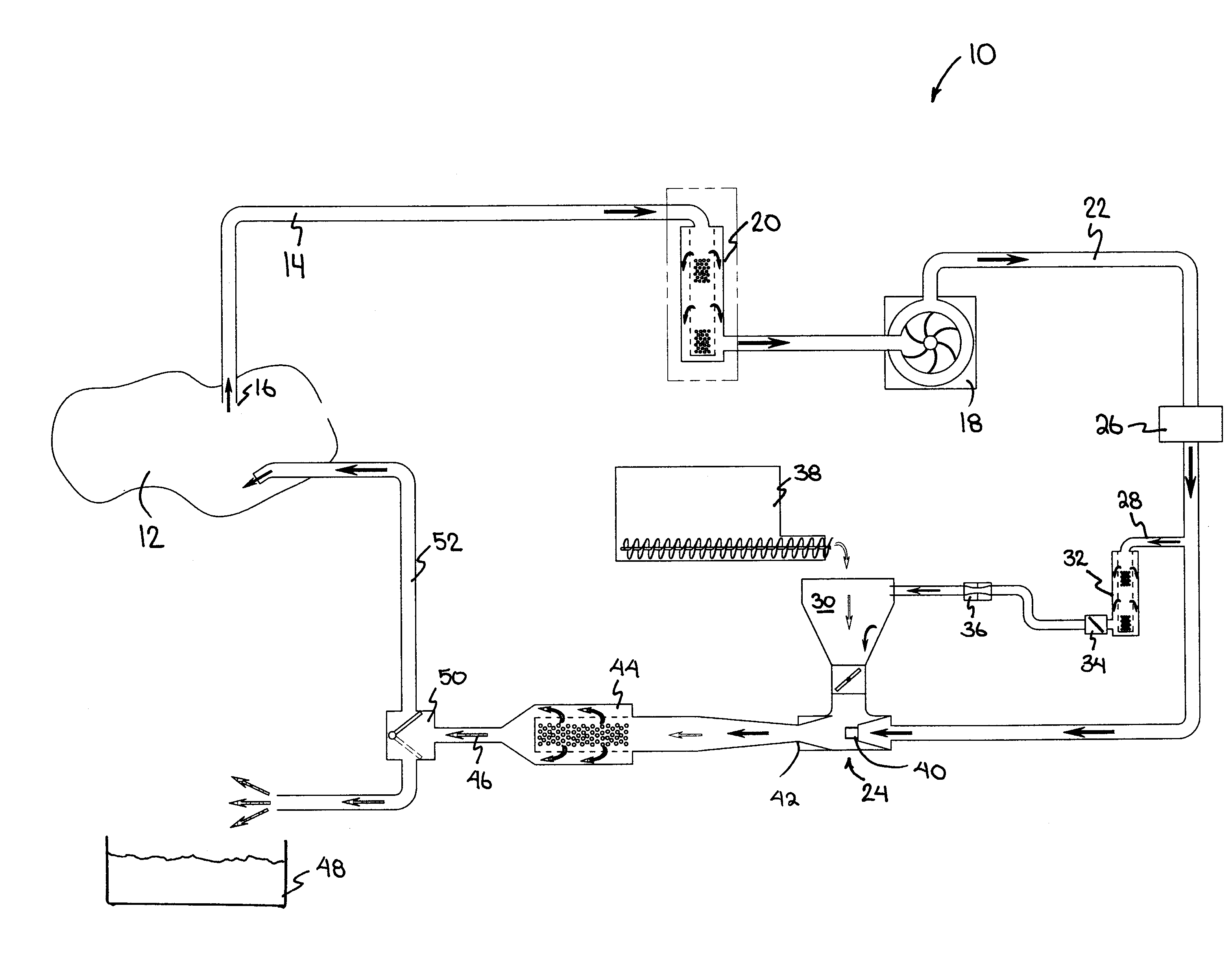

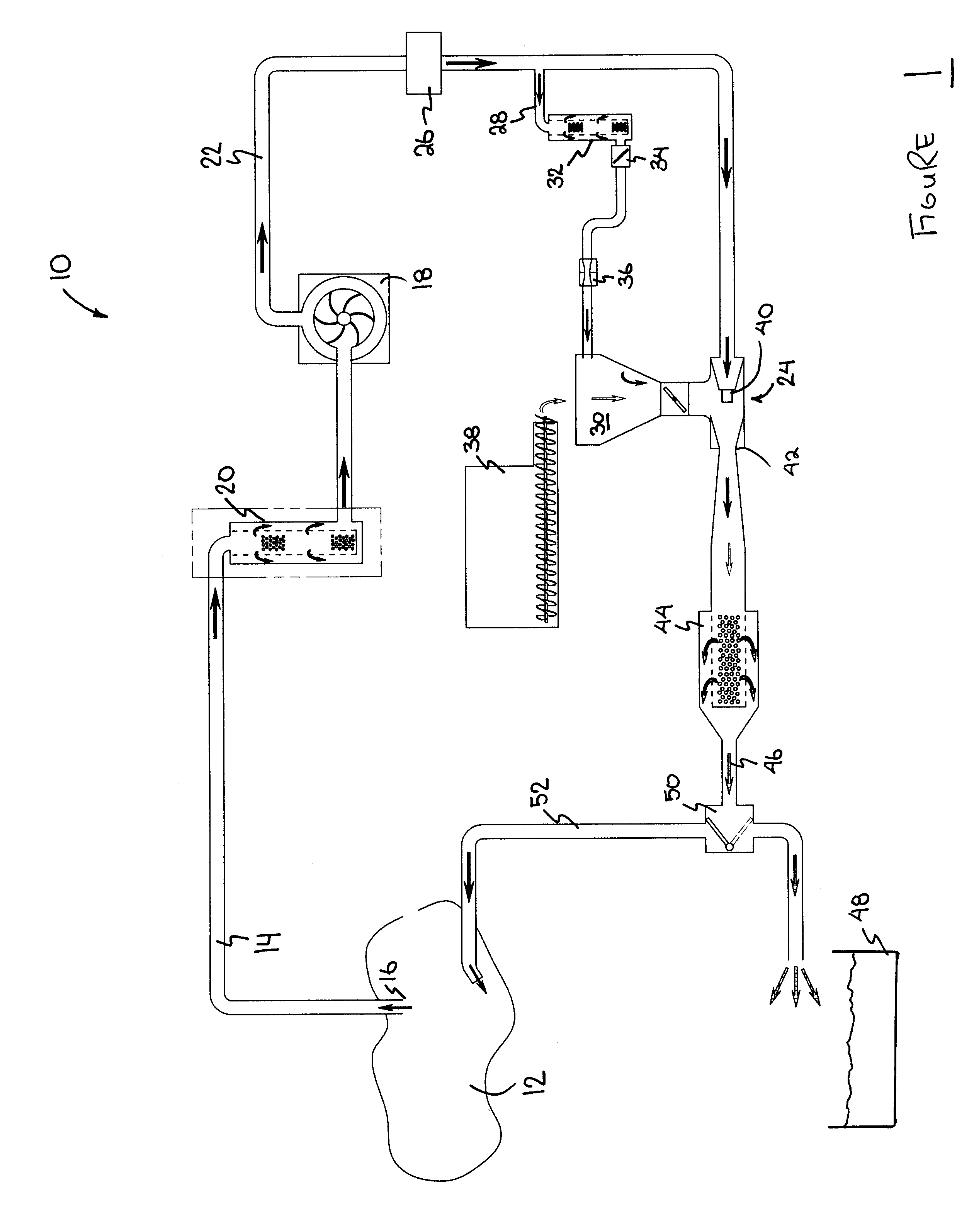

Apparatus for the incorporation of a dry treatment product into a liquid waste

ActiveUS7901571B2Reducing disposal costs and potential environmental issuesGood dispersionGeneral water supply conservationFlow mixersLiquid wasteWaste stream

A flow-through mixing apparatus for incorporating a dry treatment product into a waste stream. The apparatus comprises a pump for directing a liquid waste from a storage pit / tank, a mixer that receives the liquid waste from the pump, and a valve downstream of the mixer for either recirculating the liquid waste back to the storage pit / tank via a recirculation conduit, or directing the liquid waste to a discharge conduit. The mixer comprising a jet nozzle, a venturi tube and a high-shear assembly. The recirculation conduit establishes a calibration loop for determining the appropriate treatment regimen based on the characteristics of the waste liquid. The recirculation conduit also permits the homogenization of the pit / tank contents prior to addition of the dry treatment product. The dry treatment product introduced in the region of the mixer is subjected high shear forces, thereby incorporating the dry treatment product into the waste stream with increased dispersion and reduced agglomeration.

Owner:METAFLO TECH

Microbial solidification method for dredged sludge

InactiveCN107352768AHigh strengthImprove permeabilitySpecific water treatment objectivesFixation/solidifcation sludge treatmentSoil massSludge

The invention discloses a microbial solidification method for dredged sludge and belongs to the field of dredged sludge solidification. The method comprises the following steps that urea, calcium chloride and bacillus pasteurii liquid are added into the dredged sludge and then stirred to be uniform, and maintenance is conducted in a natural environment or the solidification is accelerated through pre-pressure drainage, wherein in the method, according to the relation between the addition amount of the urea, the calcium chloride and the bacillus pasteurii liquid and the amount of the dredged sludge, 40 g of urea, 70 g of calcium chloride and 40 mL of bacillus pasteurii liquid are added into every 1 kg of dredged sludge; or the concentration of the added urea is 0.1-1 mol / L, the concentration of the added calcium chloride is 0.1-1 mol / L, the addition amount of the bacillus pasteurii liquid is 1 / 50-1 / 5 of the water content of the dredged sludge. While making the soil mass cemented and enhancing the strength of the soil mass, the calcium carbonate generated through the induction of bacillus pasteurii can form drainage channels in the sludge so as to improve the permeability of the sludge; therefore, the water is quickly discharged under the action of external pressure, and the solidification time is shortened.

Owner:WUHAN UNIV OF SCI & TECH

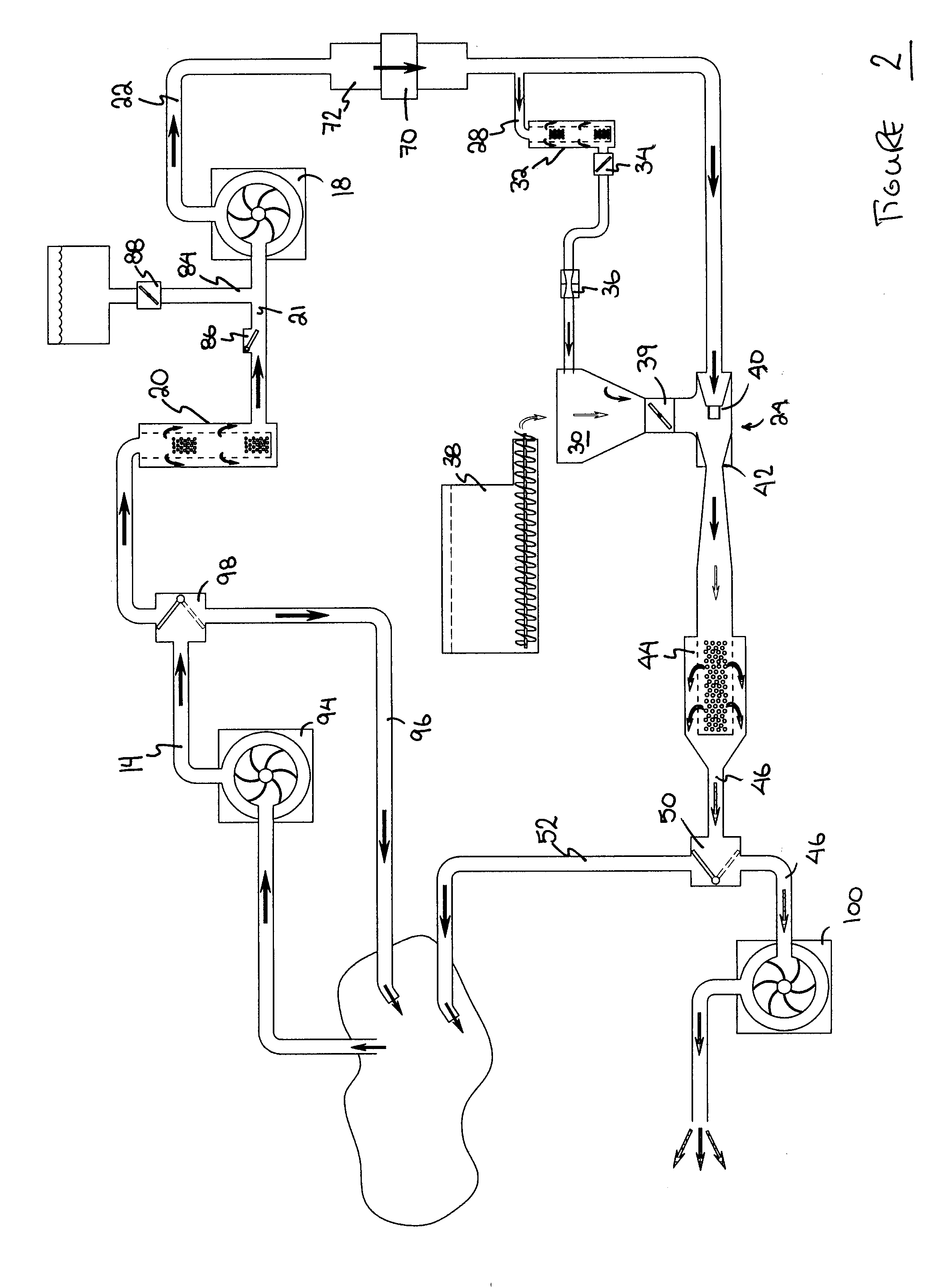

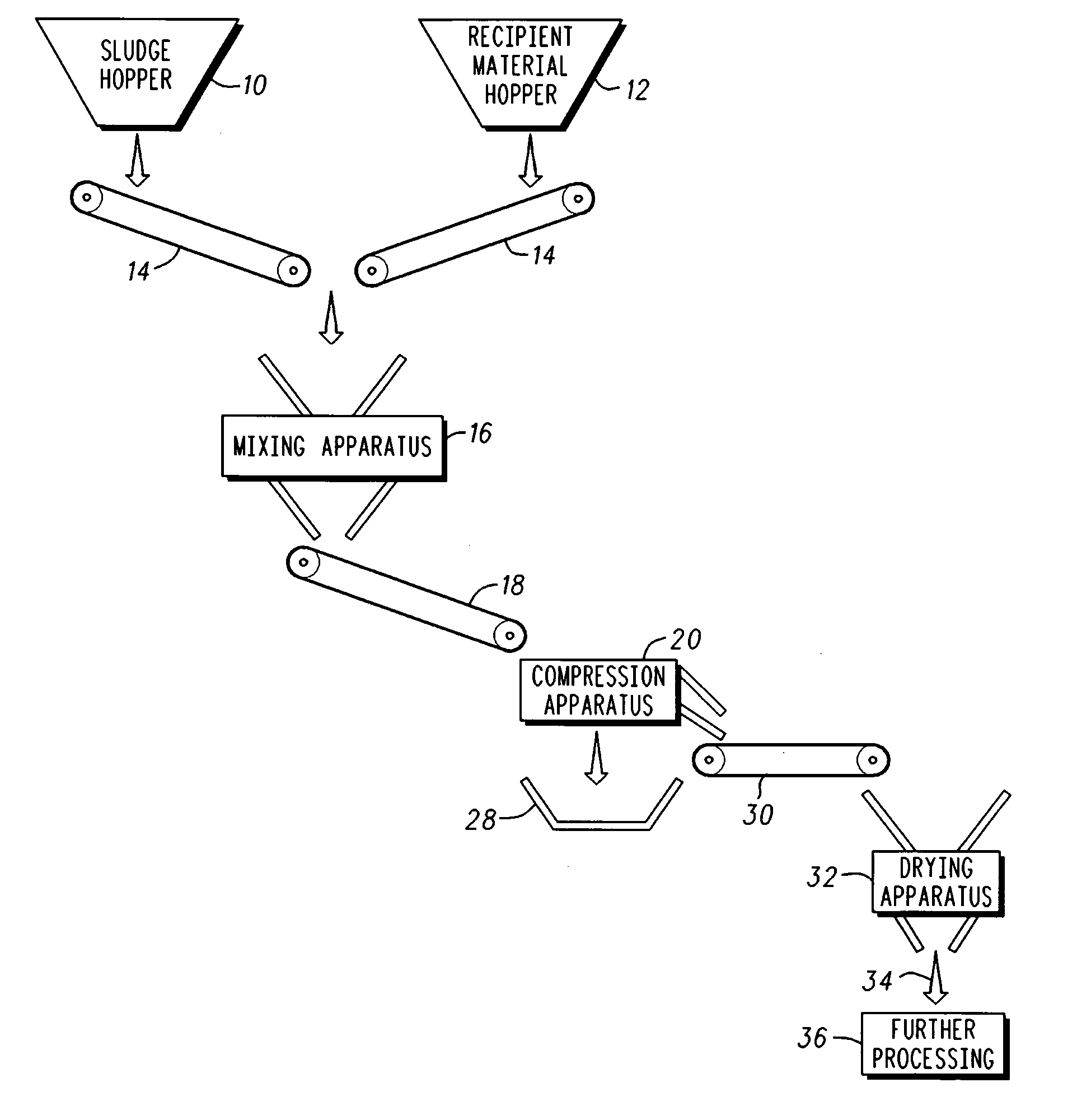

Waste treatment system

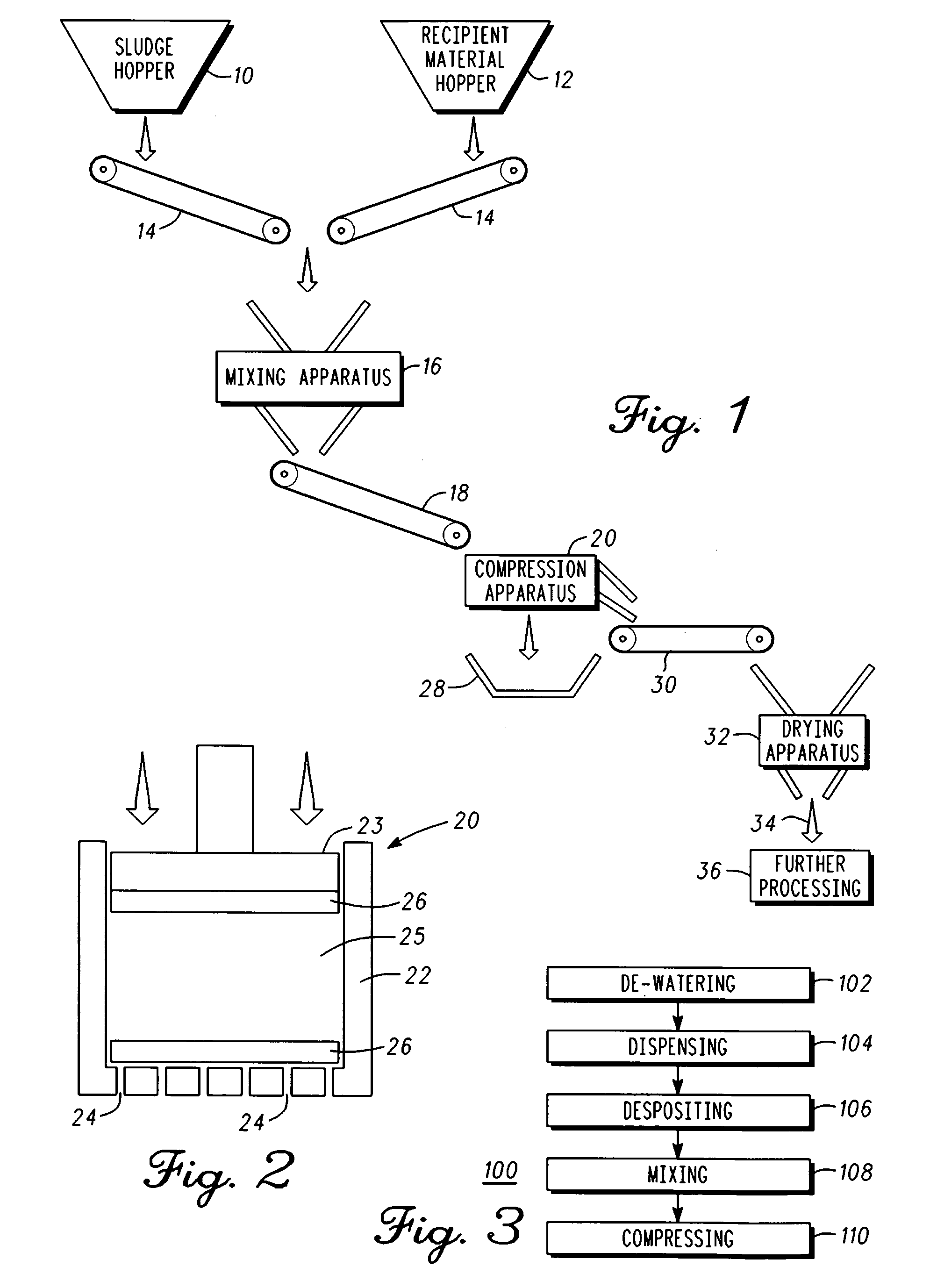

InactiveUS20100096336A1Drying using combination processesDrying solid materials without heatSludge cakeWater treatment system

A system for removing water from sludge is disclosed. The system (100) includes: de-watering (102) sludge comprising an output from a wastewater treatment system to form a semi-solid sludge cake; dispensing (104) the sludge in a sludge hopper and dispensing a blending material in a recipient blending material hopper; depositing (106) the sludge and the blending material in a mixing device; mixing (108) the sludge and the blending material having a porous structure in a weight ratio of the sludge to the blending material of about from 2:1 to about 10:1; and compressing (110) the sludge and the blending material to release moisture. The system (100) provides an improved method of de-watering sludge, for more efficient processing, transporting and recycling, depending on the application.

Owner:HYDROPRESS HLDG

Remediation agent and remediation method for in-situ remediation of water body and sediment

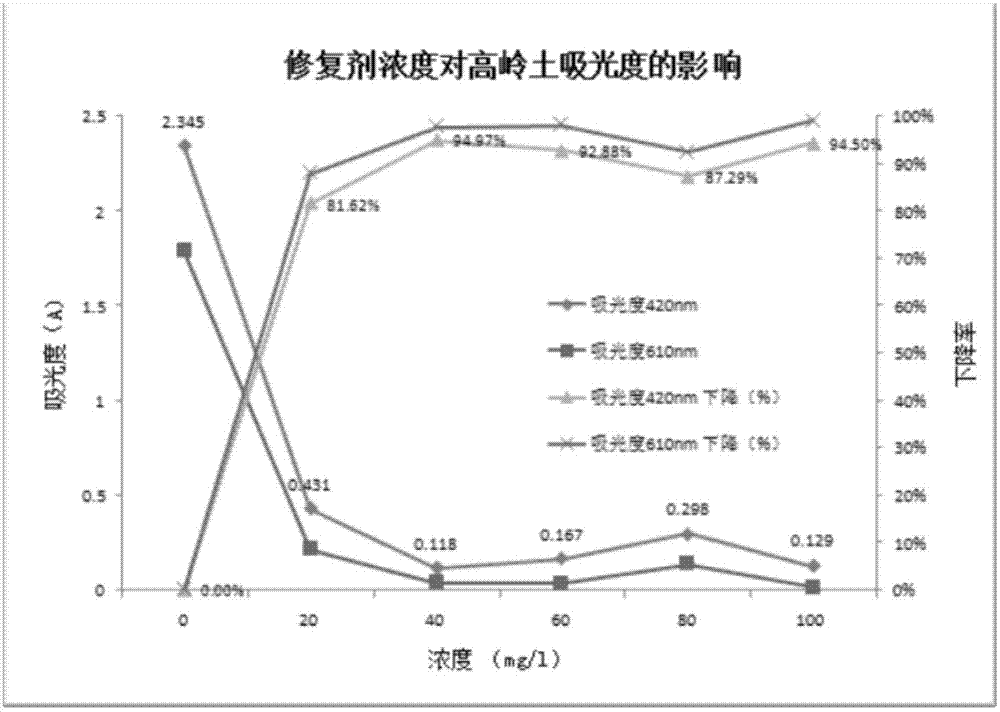

InactiveCN106865639AIn situ repairHelp nature buildWater contaminantsWater/sewage treatment by flocculation/precipitationFlocculationEutrophication

The invention provides a remediation agent and a remediation method for in-situ remediation of a water body and sediment. The remediation agent is prepared by mixing a metal ion complexing agent, an adsorbent, a high efficient flocculant, a specific gravity regulator, a curing agent, auxiliary agents and other components according to a certain proportion, and then compounding the mixture; the remediation agent is added into the water body or the sediment to be treated, and is mixed with the water body or the sediment by stirring; heavy metals in the water body or muddy water are subjected to in-situ complexing of the remediation agent, and pollutants and flocculations in the water body are absorbed by the remediation agent, so as to float to the surface of the water body or transfer into the sediment, so that the aims of realizing in-situ collection and enrichment of the pollutants in the water body and enabling the pollutants to be solidified and sealed in the sediment are achieved; after the remediation agent is used, the water quality of the water body and the environment of the sediment are rapidly improved, and the natural construction of a water ecosystem is facilitated, so that the in-situ remediation of the water body and the sediment are realized. The remediation agent and the remediation method can be used for comprehensive remediation of eutrophic or organic and heavy metal seriously polluted lakes, rivers, reservoirs, wetlands and ponds.

Owner:HANGZHOU ENJOY ENVIRONMENTAL PROTECTION TECH

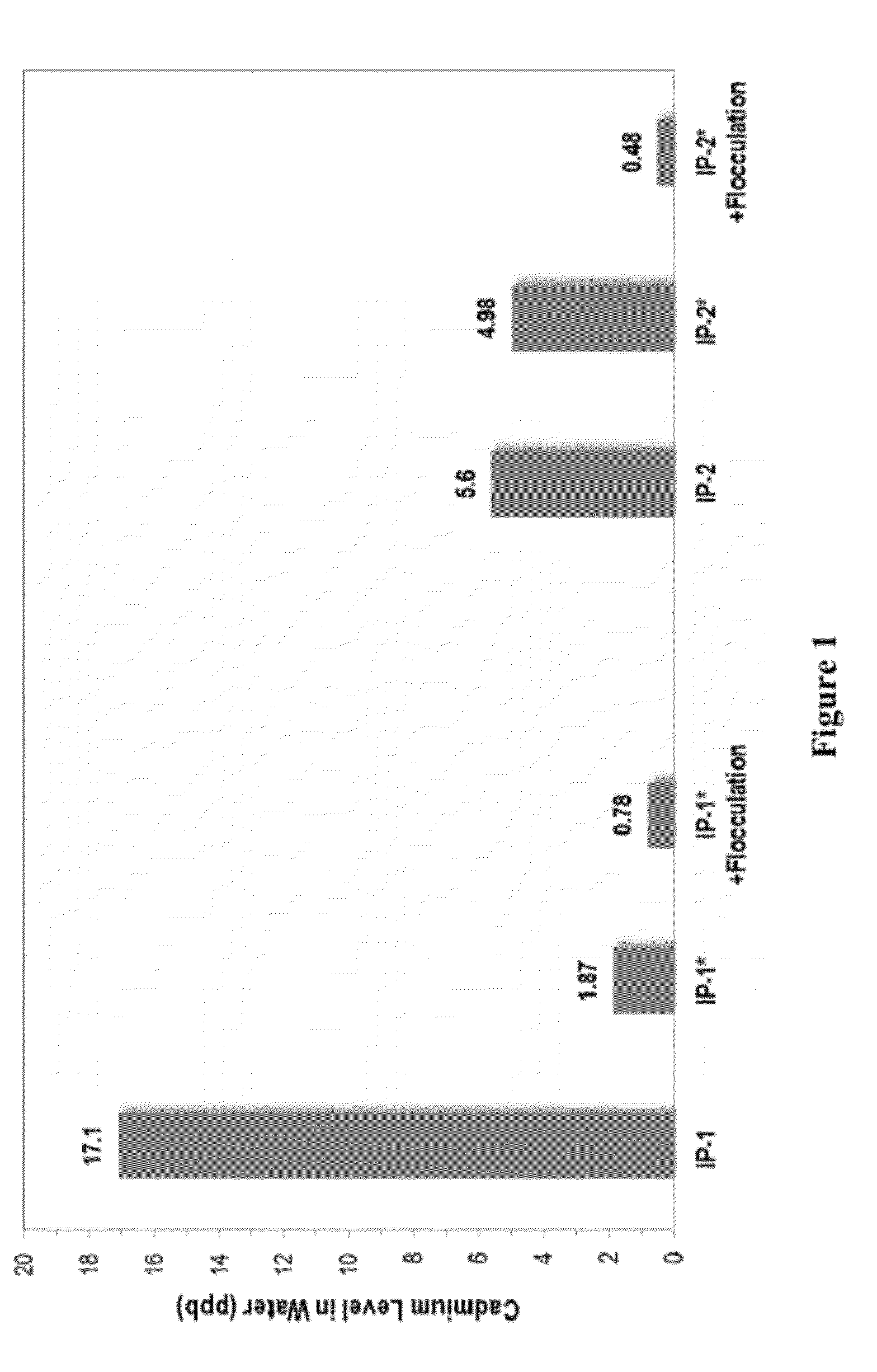

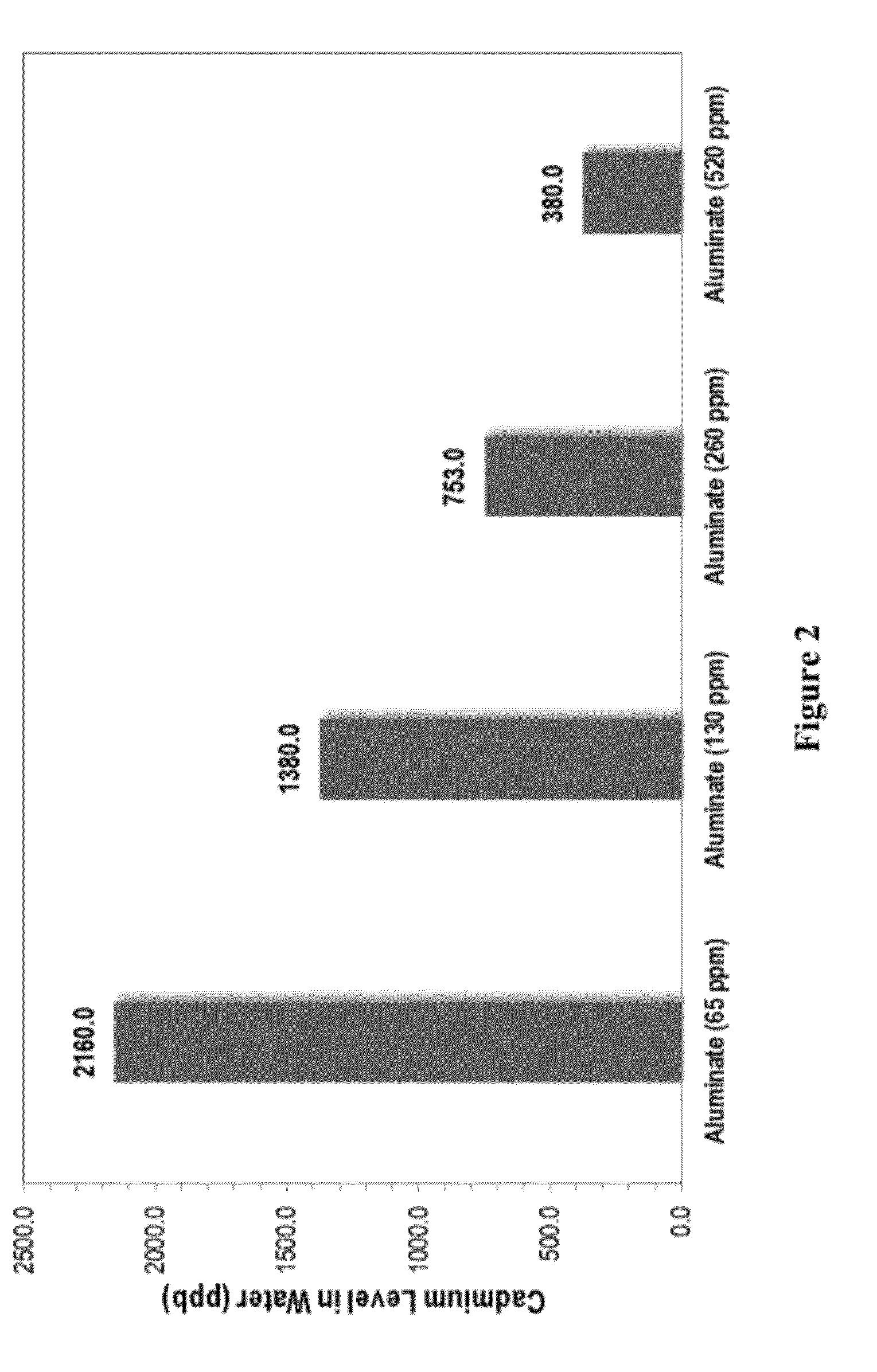

Methods for removing contaminants from aqueous systems

Methods for removing one or more contaminants from an aqueous stream comprising: adding one or more hydraulic binders and one or more promoters to the aqueous stream, and separating the contaminants from the aqueous stream are provided. The methods may be used for removing contaminants that are arsenic-based, selenium-based, cadmium-based, zinc-based, mercury-based, iron-based, chromium-based and / or phosphate-based.

Owner:KEMIRA OY

Method for Waste Stabilisation and Products Obtained Therefrom

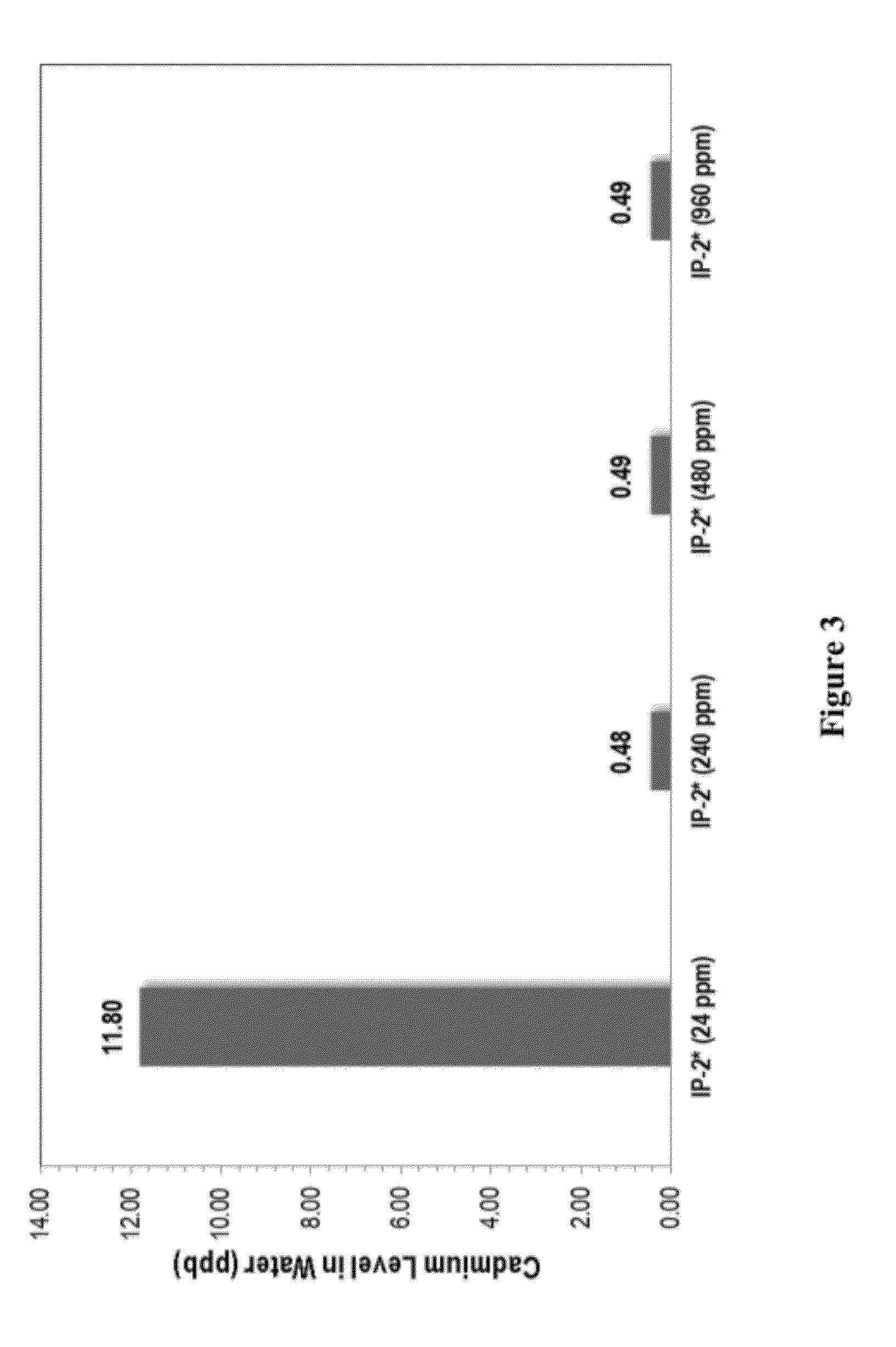

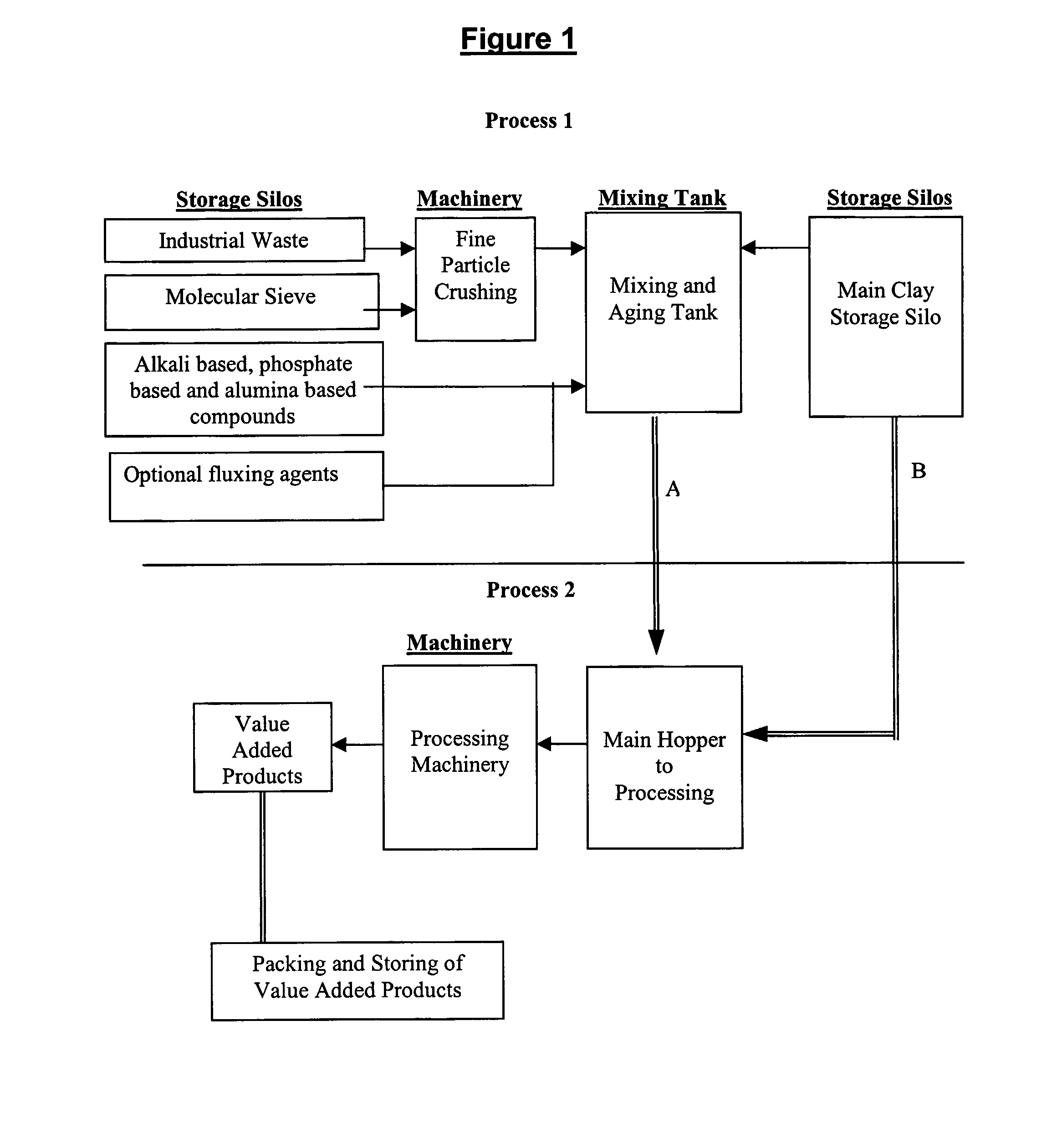

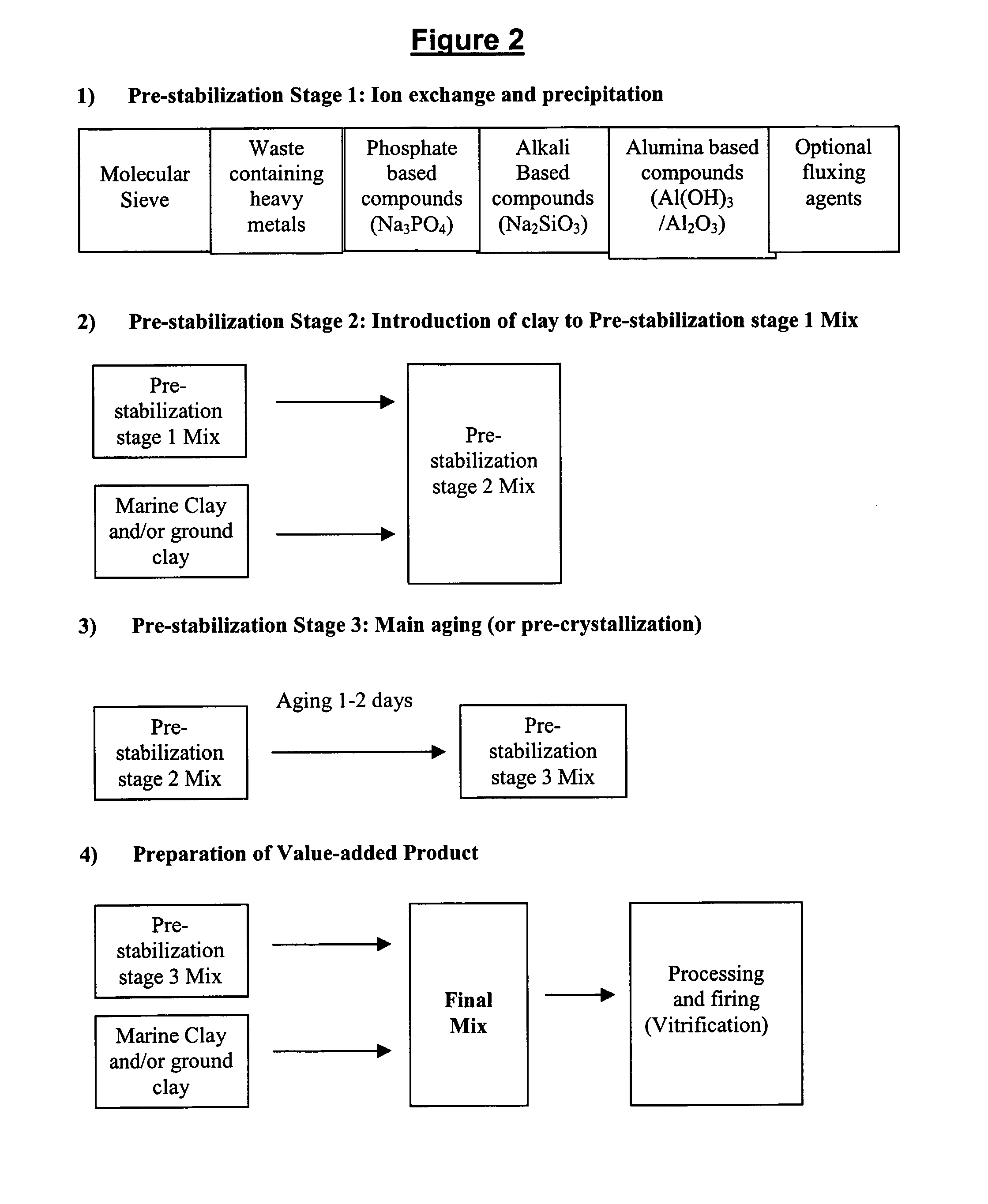

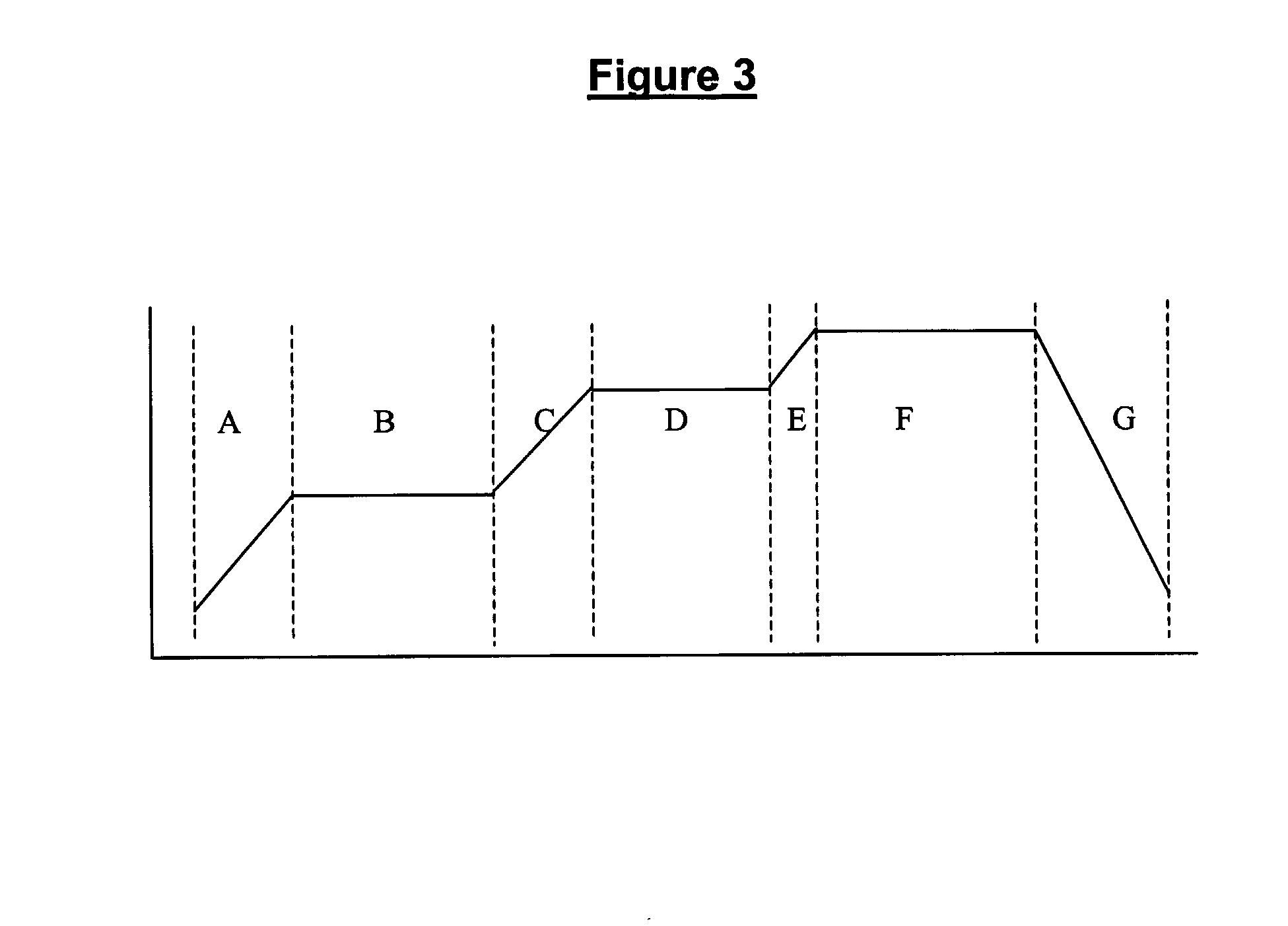

InactiveUS20080108495A1Stabilise the heavy metalsCapacity of heavySolid waste disposalTransportation and packagingVitrificationMolecular sieve

A method is provided for heavy metal stabilisation comprising: mixing waste, comprising heavy metals, with molecular sieve with the proviso that carbon-based molecular sieve is excluded, and clay; and vitrifying the mixture. In particular, a method comprising the steps of: preparing a pre-stabilised mixture by mixing waste, comprising heavy metals, with the molecular sieve, and optionally other chemicals; mixing the pre-stabilised mixture with clay; and vitrifying the obtained mixture is provided. It also provides a product comprising heavy metals that have been stabilised into the structure of the clay-based ceramic matrix, wherein the product is a vitrified product of a mixture of at least waste, comprising heavy metals, molecular sieve (with the proviso that carbon-based molecular sieve is excluded) and clay.

Owner:NEWEARTH PTE

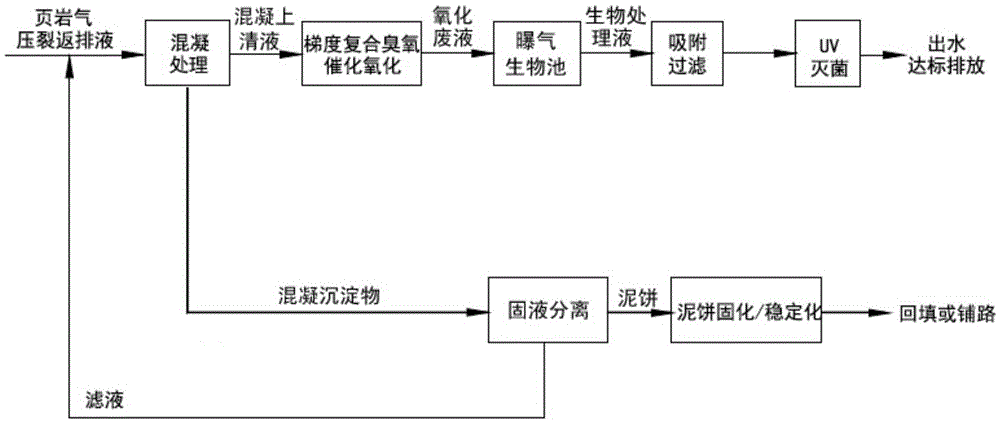

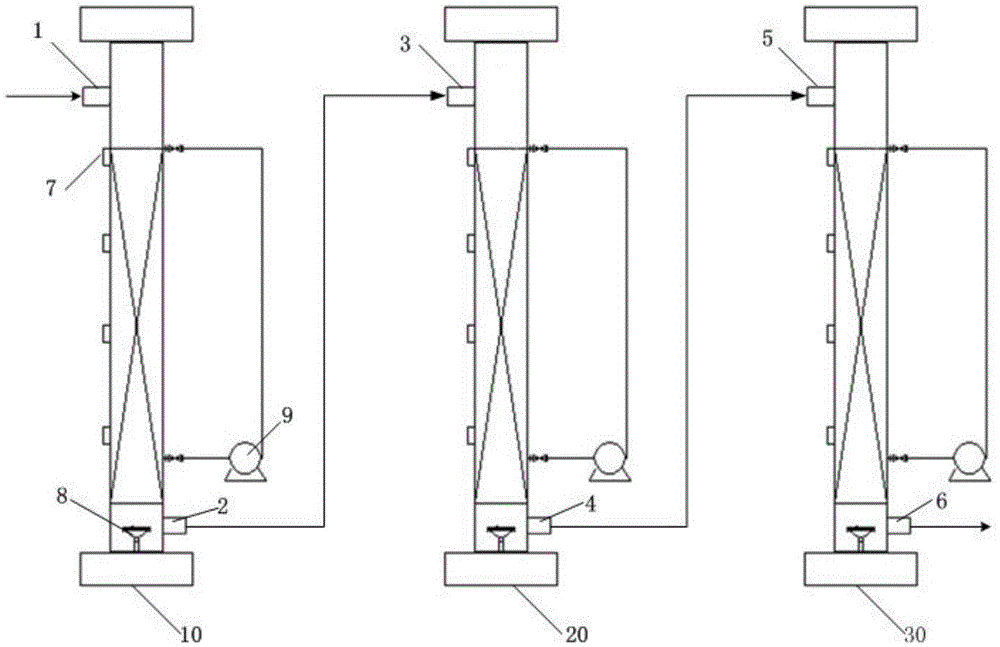

Treatment method of shale gas fracturing flowback liquid

ActiveCN105621809ARealize resource utilizationMeet emission standardsWaste water treatment from quariesTreatment using aerobic processesResource utilizationEmission standard

The embodiment of the invention discloses a treatment method of shale gas fracturing flowback liquid.The method comprises the steps that when the pH value of the shale gas fracturing flowback liquid is 5-10, an inorganic coagulant is added to the shale gas fracturing flowback liquid, stirring is conducted, a first organic coagulant and a second organic coagulant are added, stirring is continuously conducted, standing settling is conducted, filtering is conducted, and coagulation supernatant and a coagulation sediment are obtained; the pH value of the coagulation supernatant is adjusted to be 7-9 and then introduced into a gradient ozone catalytic oxidation device for gradient ozone catalytic oxidation treatment; oxidized waste liquid is treated through a biological aerated filter treatment technology; biological treatment liquid is subjected to adsorption and filtration treatment and UV sterilization treatment and then discharged; the coagulation sediment is subjected to solid-liquid separation treatment, filtrate returns back to the step for circulation treatment, and a filter cake is subjected to solidification and stabilization treatment.By means of the treatment method of the shale gas fracturing flowback liquid, pollution of the shale gas fracturing flowback liquid is removed, the treated shale gas fracturing flowback liquid meets the emission standard, the filter cake can be backfilled or be used for paving after being treated, and resource utilization of waste materials is achieved.

Owner:博慧检测技术(北京)有限公司

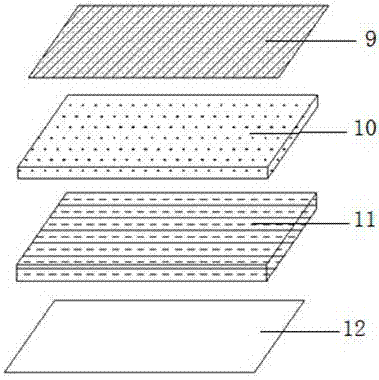

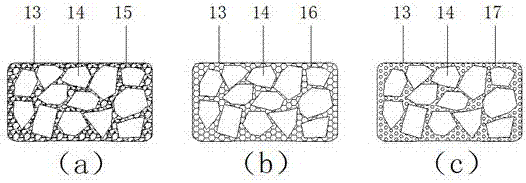

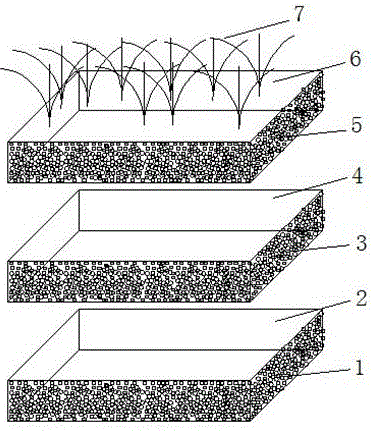

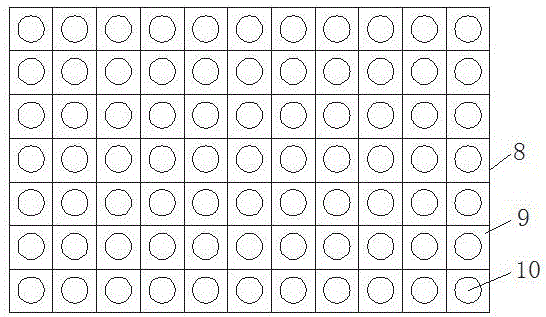

Water body heavy metal polluted sediment in-situ covering and repairing method

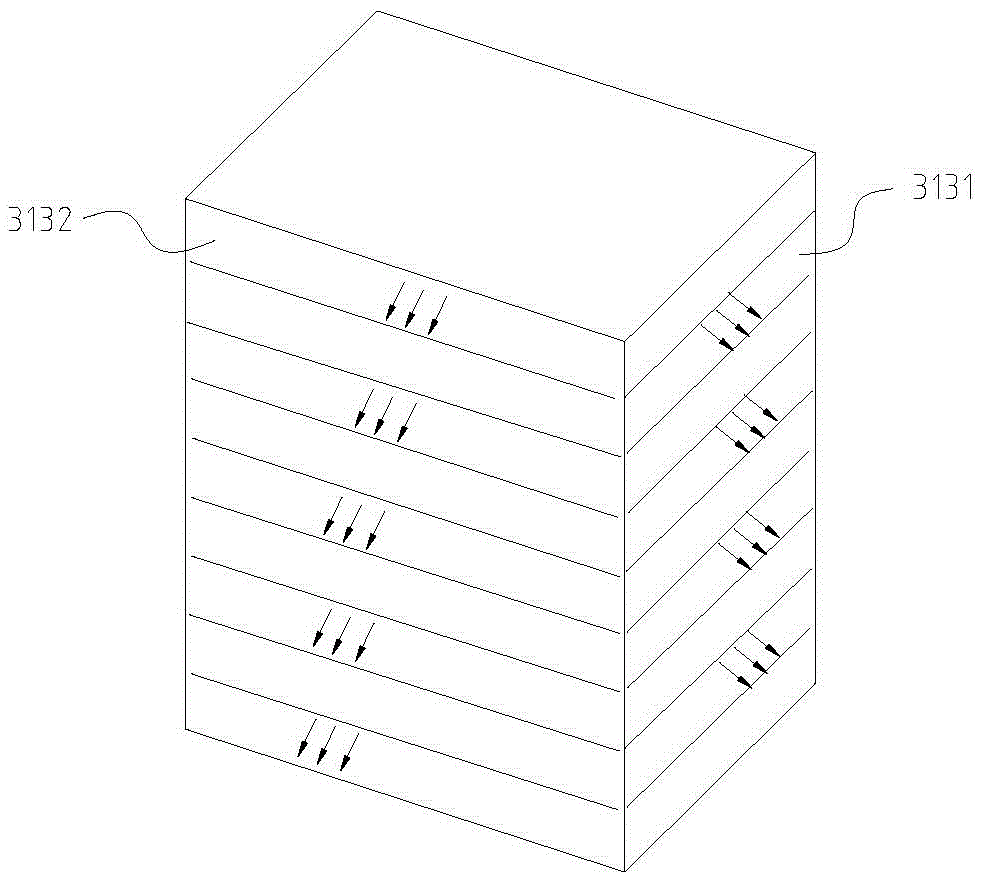

ActiveCN106673384APollution Elimination or ReductionEasy to recycleWater contaminantsFixation/solidifcation sludge treatmentActivated carbonStructure of the Earth

The invention discloses a water body heavy metal polluted sediment in-situ covering and repairing method. The water body heavy metal polluted sediment in-situ covering and repairing method is characterized in that at least one layer of a first covering layer, a second covering layer and a third covering layer is sequentially arranged on polluted river sediment or a river slope from bottom to top; filler in the first covering layer is a mixture of cerium modified zeolite and zero-valent iron; filler in the second covering layer is selective heavy metal curing filler; filler in the third covering layer is mixed filler of activated carbon and sand; a water body can be divided into a shallow water slow flowing water body, a deep water body and a torrent water body according to the depth and the flowing speed of the water body by the three covering layers, and the shallow water slow flowing water body, the deep water body and the torrent water body can be selectively combined. The water body heavy metal polluted sediment in-situ covering and repairing method disclosed by the invention aims at different sediment pollution situations; a covering body combines physical, chemical and biological repairing measures together through a way of stacking different structure layers up and down, so that sediment pollution is efficiently removed or reduced, and the covering layers and heavy metals adsorbed thereby can be well recycled.

Owner:SHANDONG JIANZHU UNIV

Method of removing phosphorus from wastewater

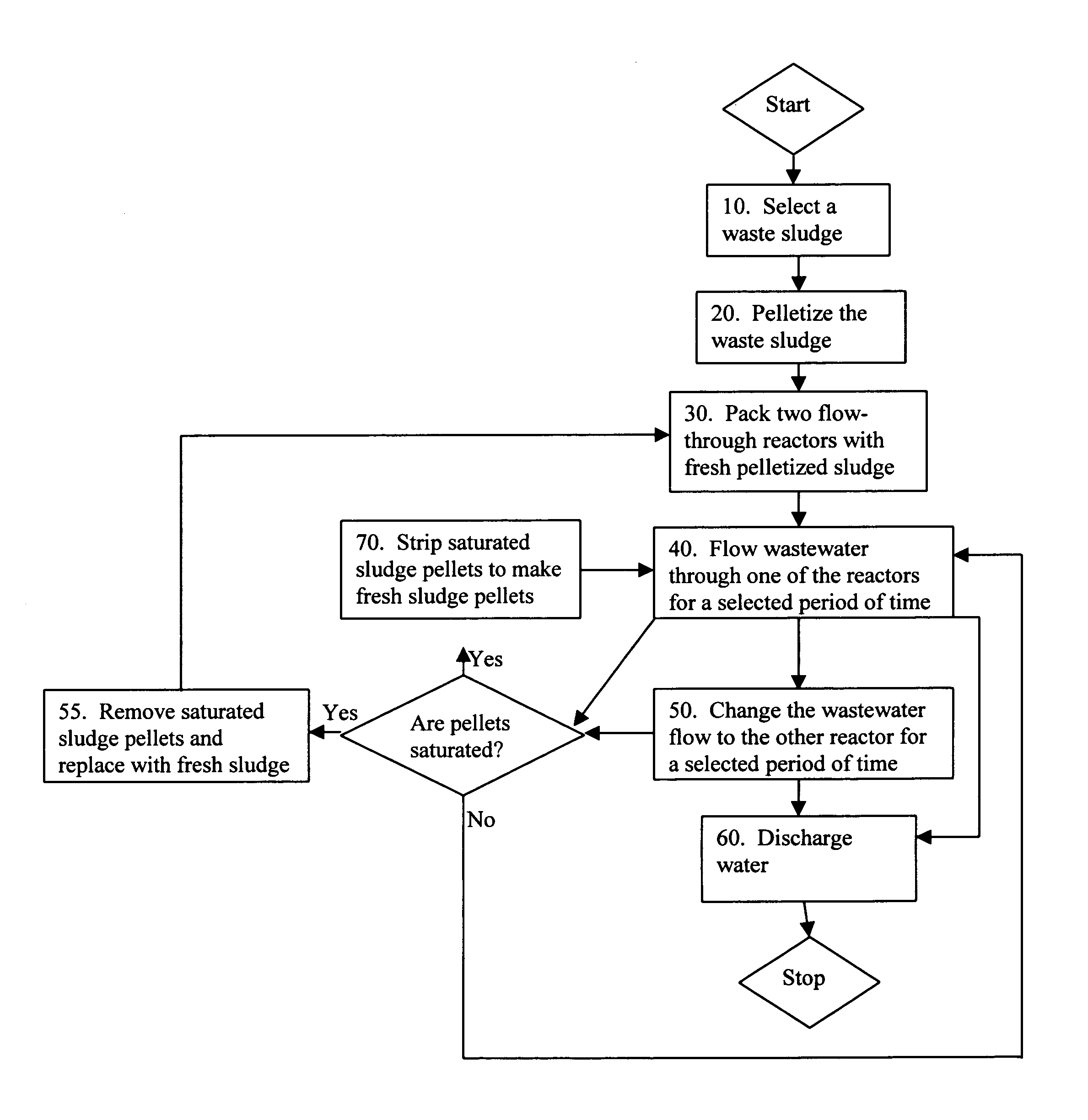

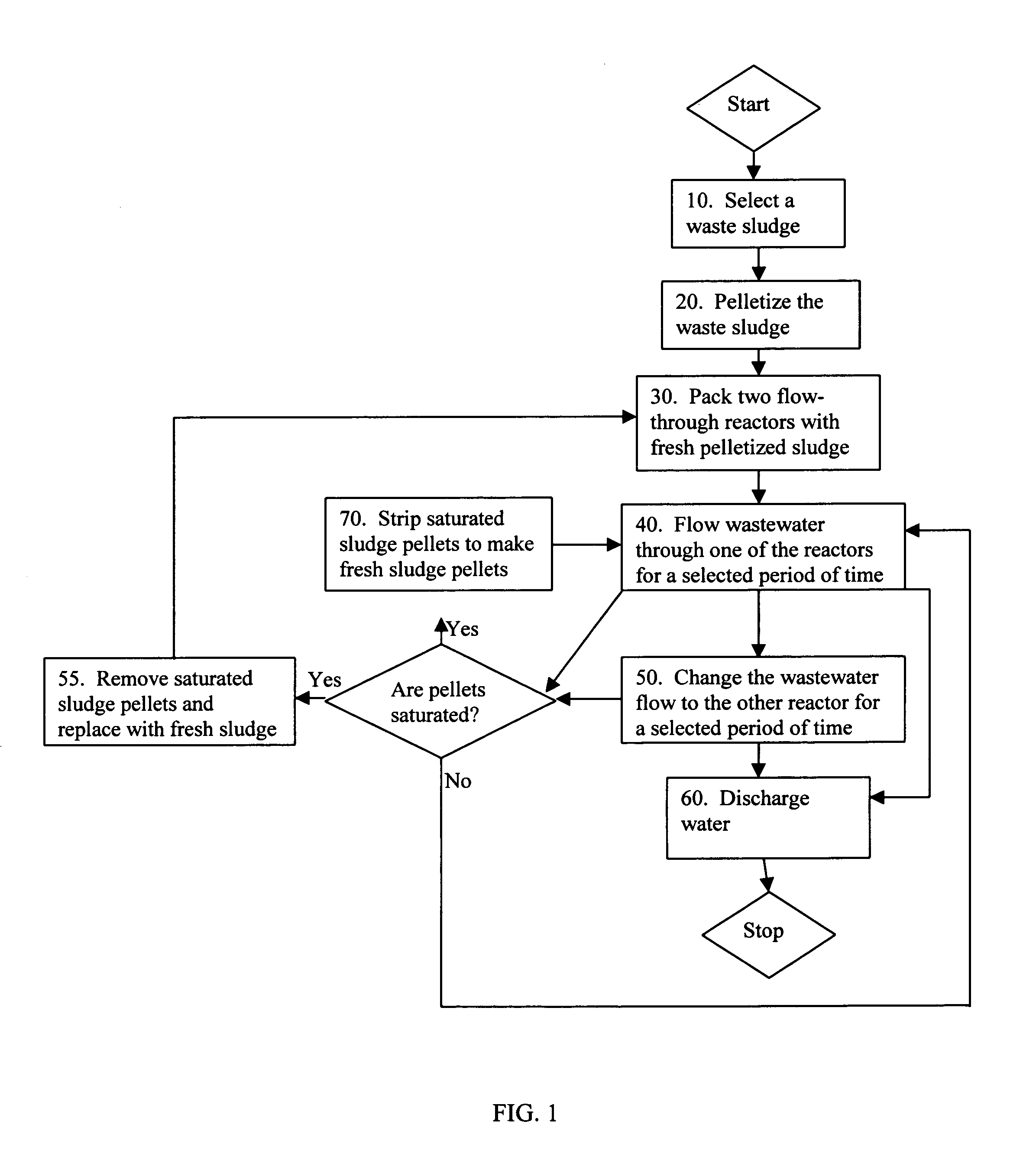

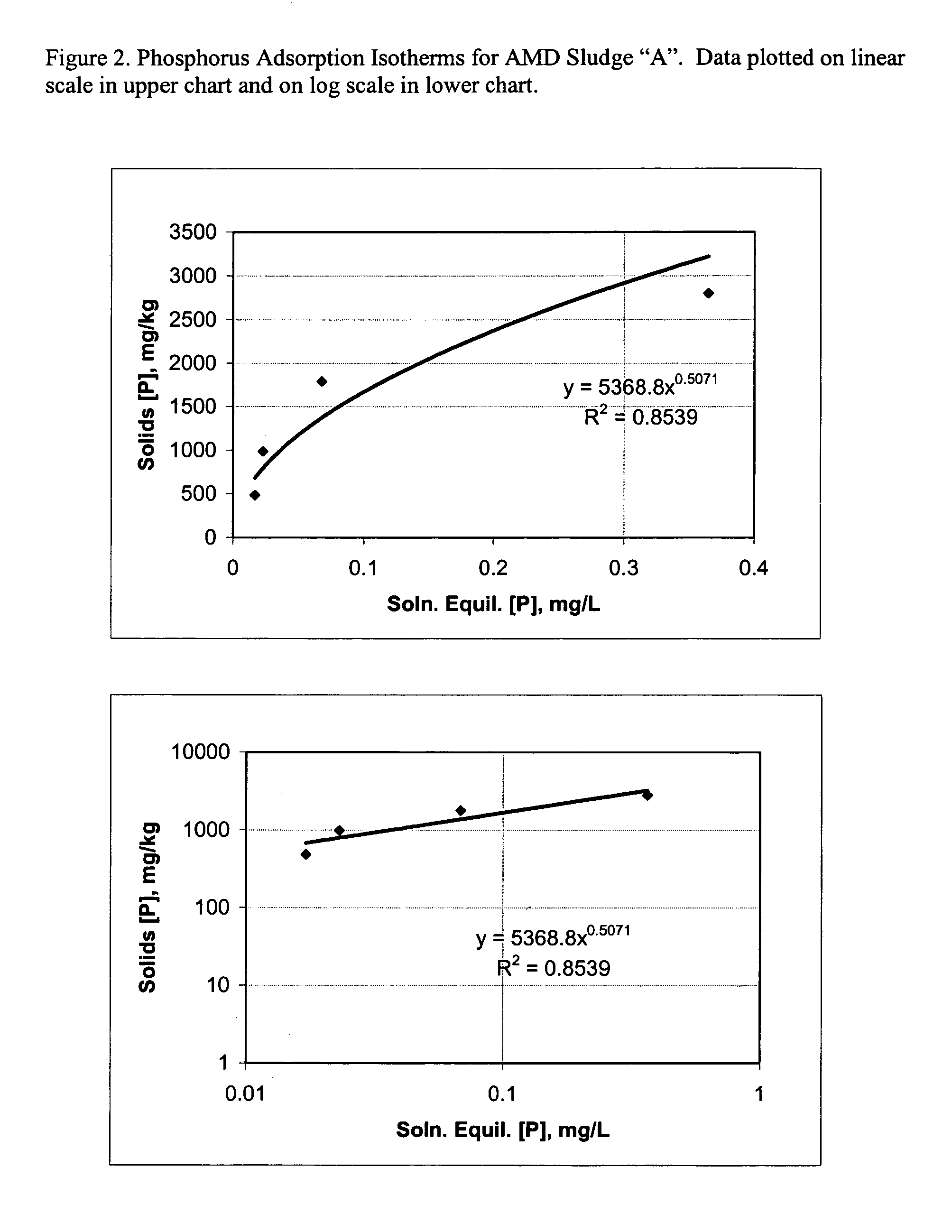

ActiveUS7294275B1Reduce phosphorus loadReduce loadWaste water treatment from quariesWater treatment parameter controlAbsorption capacitySludge

A method of and system for removing phosphorus from wastewater using a waste sludge that has a high affinity for phosphorus. So the waste sludge can be used in a flow-through contact reactor to remove the phosphorus from a wastewater stream, the waste sludge is pelletized. The waste sludge pellets are packed into one or more flow-through contact reactors. In the configuration described herein, phosphorus removal is maximized by flowing the wastewater through the reactor(s) in a “pulsed” manner, rather than continuously. Thus, wastewater is flowed through the reactor(s) for a period of time and stopped for a period of time. By giving the sludge absorbent a rest period, the absorption capacity of the sludge is increased significantly, thus decreasing the frequency of regeneration or replacement of the sludge. Sludge regeneration can be accomplished with a stripping step using an alkaline solution of pH 13, followed by rinsing with water.

Owner:U S A AS REPRESENTED BY THE SEC OF THE DEPT OF THE INTERIOR

Compound curing agent for dredged silt and preparation method thereof

ActiveCN107226661AFully and evenly absorbedNo localized underabsorptionFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentFiberGraphite

The invention relates to a compound curing agent for dredged silt and a preparation method thereof. The compound curing agent for dredged silt comprises the following components in parts by weight: 20-30 parts of aluminum sulfate cement clinker, 30-40 parts of expandable graphite, 5-10 parts of organobentonite, 3-8 parts of pozzolanic material, 1-3 parts of calcined diatomite, 3-5 parts of enhanced aggregate, 6-12 parts of quicklime, 10-15 parts of sodium hydroxide, 8-10 parts of expansible resin, 5-8 parts of sodium silicate and 5-8 parts of carbon fiber. The curing agent provided by the invention combines the respective advantages of multiple traditional soil stabilizers, and the various effective components are organically combined together according to a proper ratio, thereby giving full play to the characteristics and synergistic action of the components. The curing agent provided by the invention has the advantages of favorable early strength performance, excellent strength stability, favorable water stability and the like, can obviously improve the properties of silt such as high water content, low strength and the like, and converts the waste dredged silt into a reproducible geomaterial for utilization, thereby achieving excellent curing effects and economic effects.

Owner:余思哲

Composition and method for the solidification of toxic or hazardous drilling and agricultural waste

InactiveUS20090093665A1Improve adsorption capacityFast reaction timeSolid waste managementTransportation and packagingLiquid wasteSufficient time

A method of solidifying toxic or hazardous liquid waste, including the steps of pumping an aqueous waste, e.g., from a drilling fluid holding area; through a shearing device; adding the layered phyllosilicate to said aqueous waste in an amount sufficient to solidify the aqueous waste sufficiently such that the solidified aqueous waste has no free liquid; shearing the pumped aqueous waste, containing said layered phyllosilicate, sufficiently to partially exfoliate the layered phyllosilicate into phyllosilicate platelets and tactoids while in contact with the aqueous waste; pumping the sheared aqueous waste and layered phyllosilicate to a solidification area; and allowing the sheared aqueous waste and partially exfoliated layered phyllosilicate sufficient time to solidify such that there are no free liquids remaining in the solidified waste.

Owner:AMCOL INTERNATIONAL CORPORATION

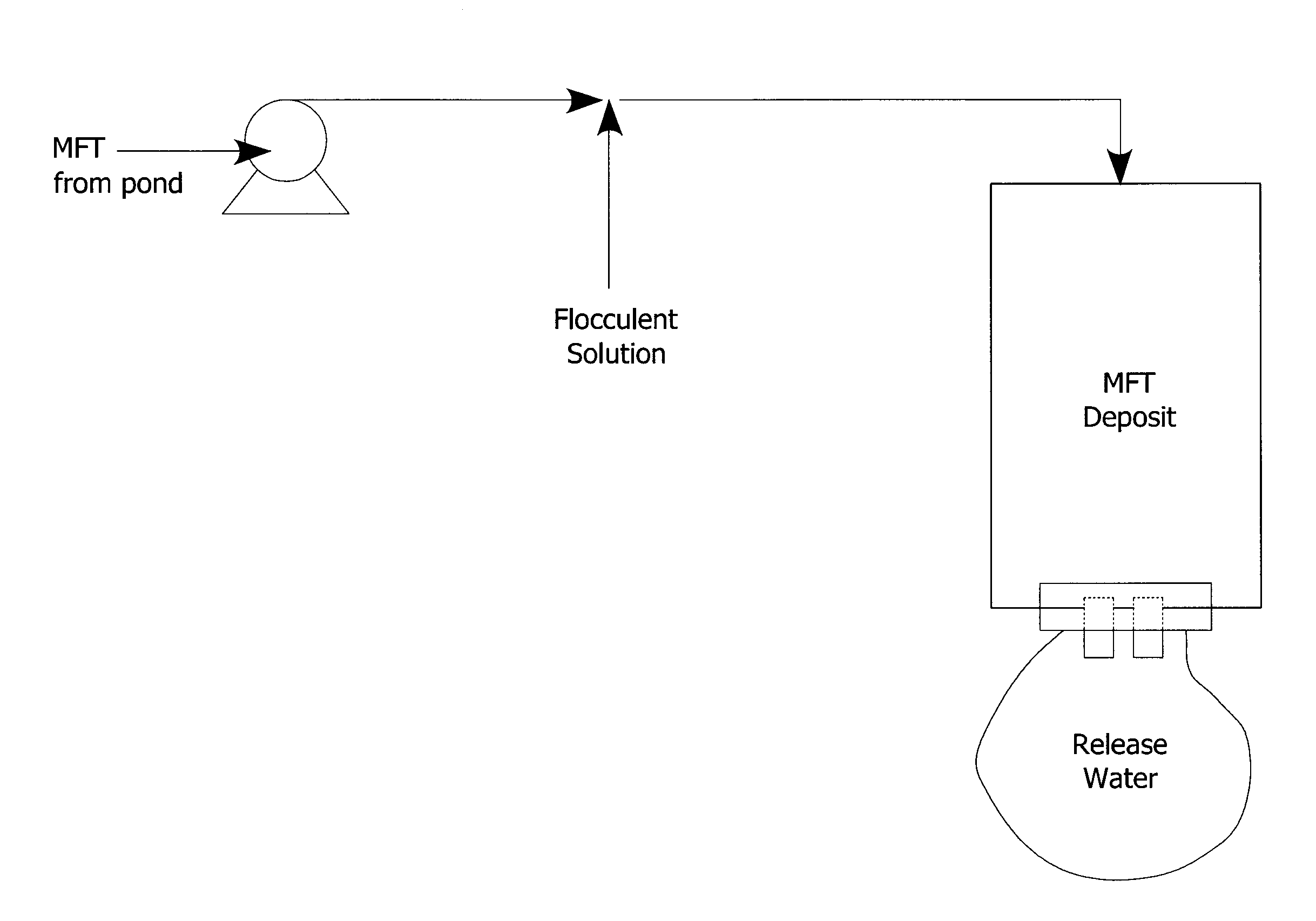

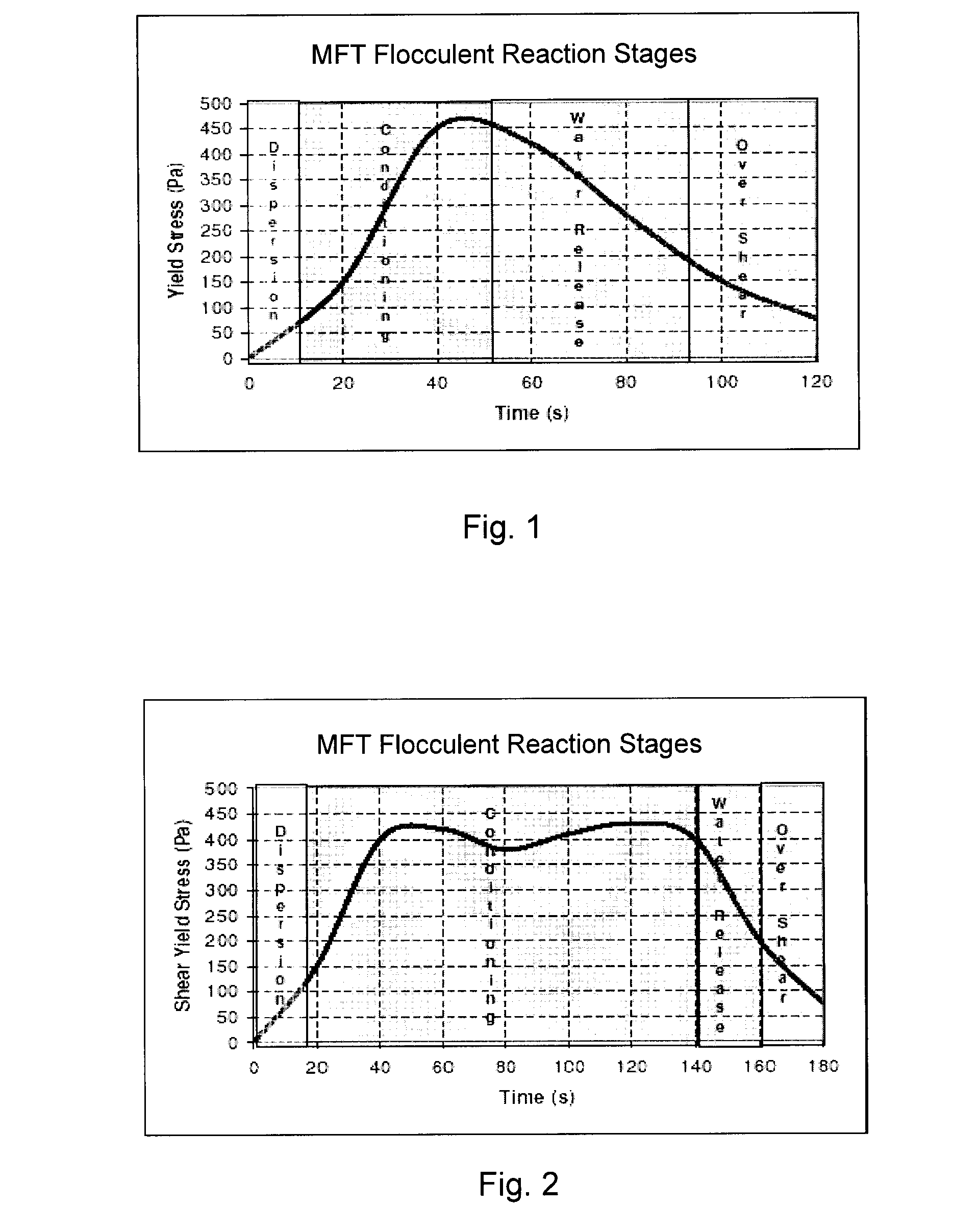

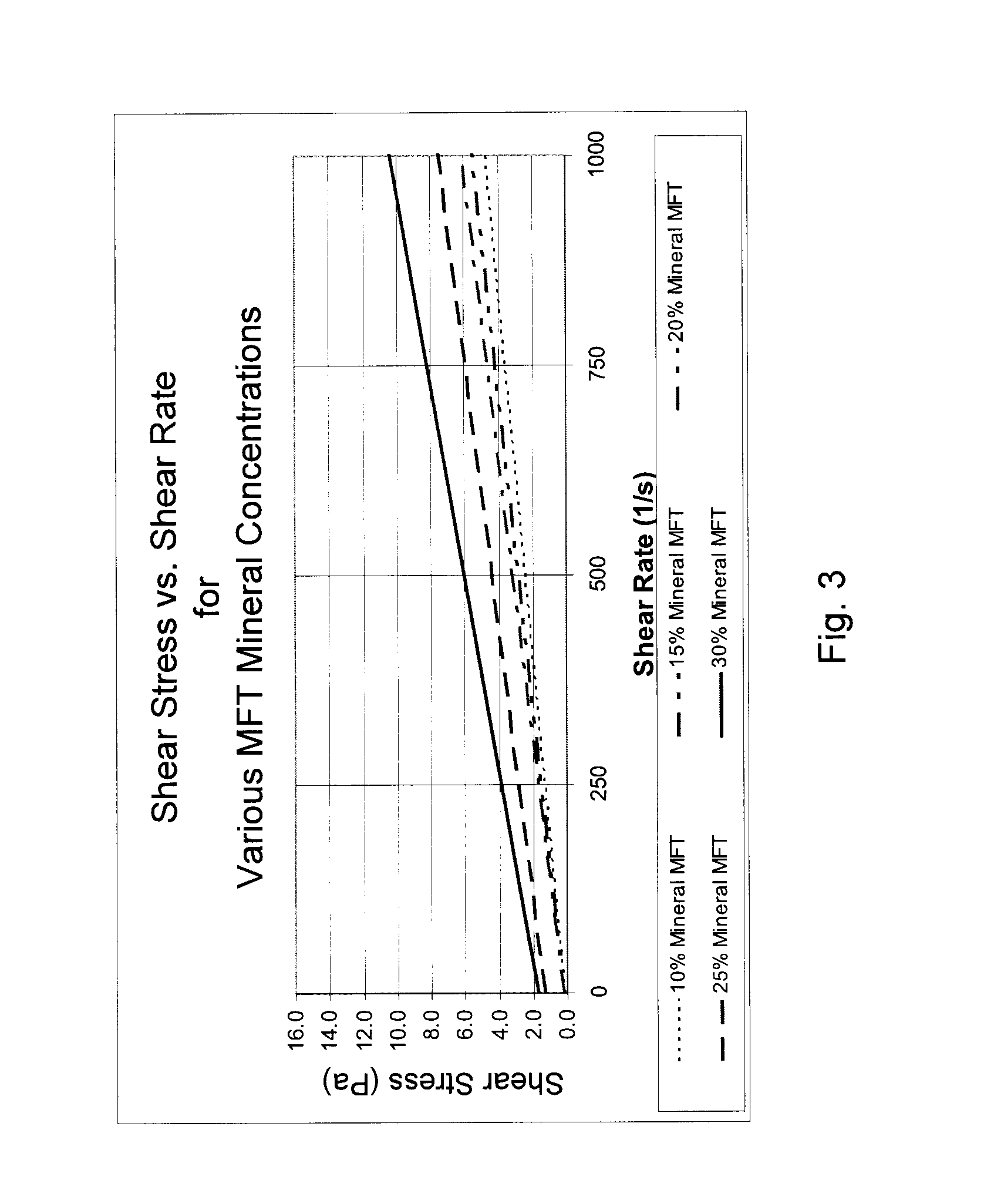

Process for Drying Oil Sand Mature Fine Tailings

ActiveUS20130043165A1Efficient actionSufficient energyDewatering/demulsification with chemical meansSludge treatment by de-watering/drying/thickeningFlocculationReactor system

A process for drying fine tailings is provided. The process, which may use a pipeline reactor system, comprises providing an in-line flow of the fine tailings; continuously introducing a flocculent solution to cause dispersion and commence flocculation of the fine tailings and may comprise rapid turbulent mixing; subjecting the fine tailings to flocculation and water release conditioning in-line to cause formation and rearrangement of floes and increasing the yield shear stress to form flocculated fine tailings while avoiding over-shearing of the flocs; and depositing the fine tailings to allow the release of water, formation of a non-flowing fine tailings deposit and drying of the non-flowing fine tailings deposit. The process enables effective in-line dispersion, flocculation and water release, resulting in reliable deposition and drying of the fine tailings deposit.

Owner:SUNCOR ENERGY INC

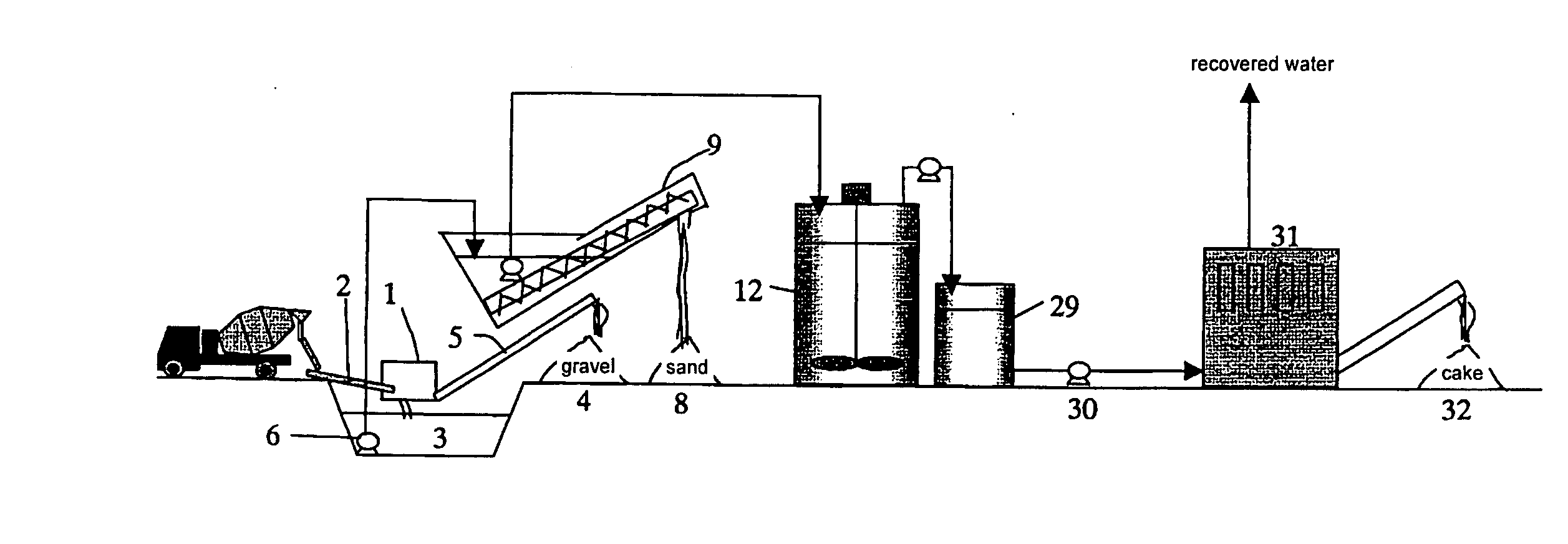

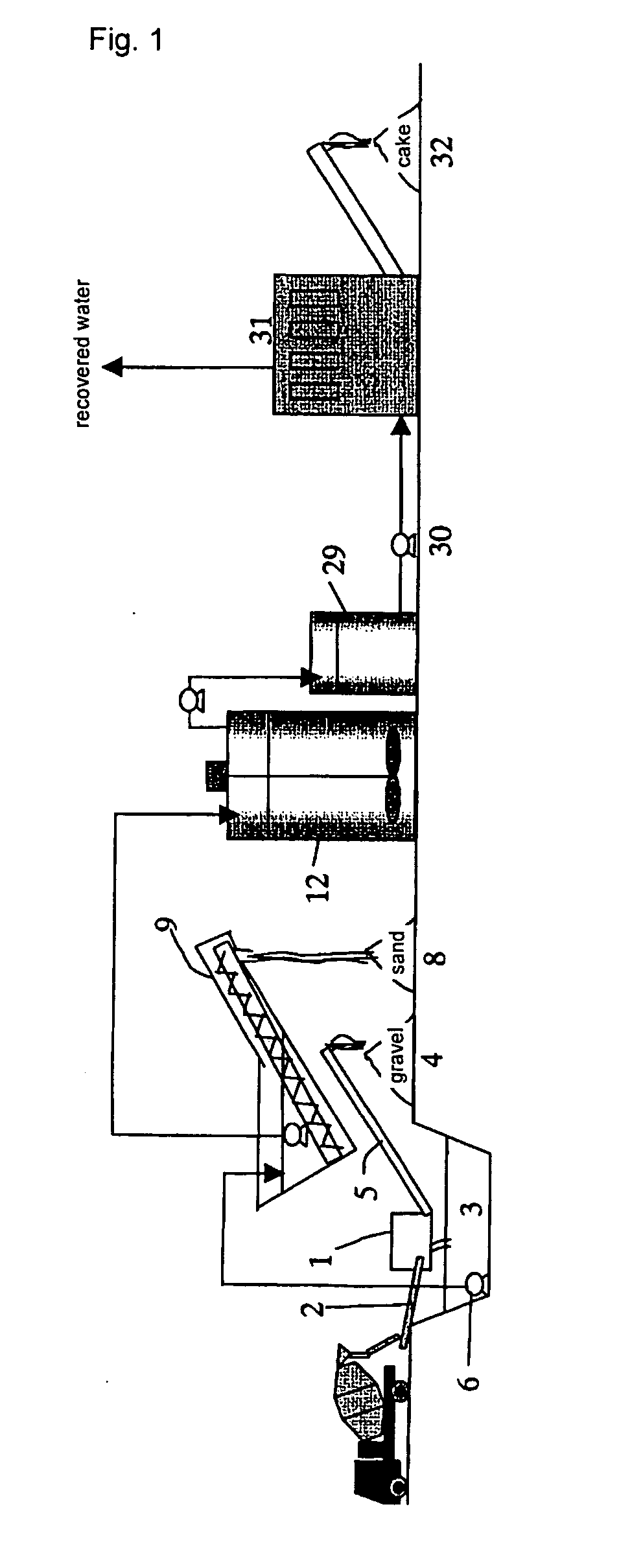

Process For Producing Concrete Material And Apparatus Therefor

InactiveUS20070199482A1Inhibition is effectiveAvoid bleedingSludge treatment by de-watering/drying/thickeningConstruction waste recoverySludgeSlurry

An object of the present invention is to manufacture a material for concrete by using a fresh concrete sludge as a starting material. The invention relates to a method of manufacturing a material for concrete in which a material for concrete is manufactured from a slurry composed of a fresh concrete sludge obtained by treating a fresh concrete waste to separate a coarse aggregate and a fine aggregate. The manufacturing method comprises a grinding step of obtaining a product containing fine particles with a mean particle size of 10 μm or less by wet grinding the slurry under a condition of water content of 60 wt. % or more.

Owner:SUMITOMO OSAKA CEMENT CO LTD

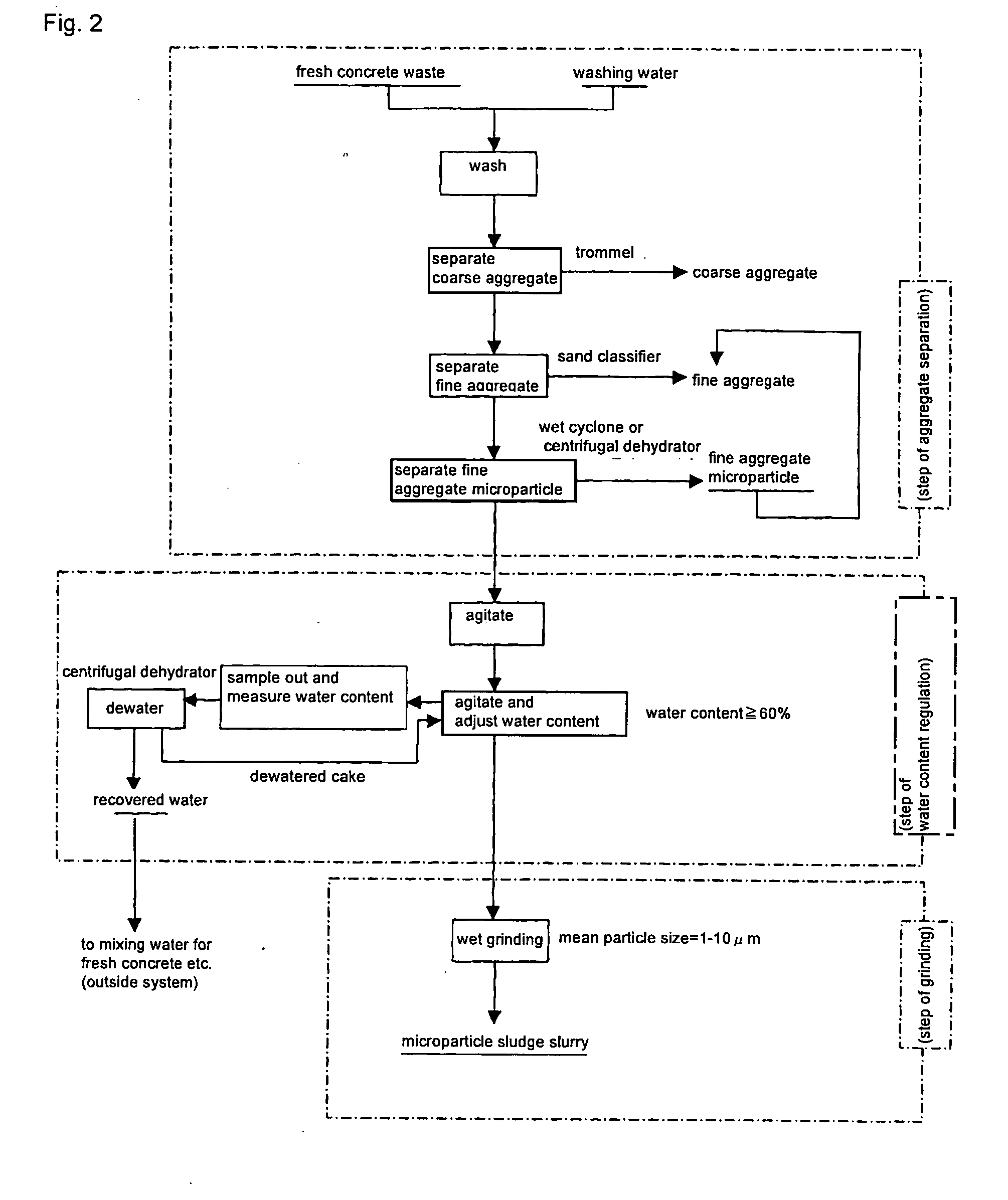

Drying treatment method of oil-containing sludge

ActiveCN106630545ANothing producedNo secondary pollutionSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCombustionOil sludge

The invention relates to a drying treatment method of oil-containing sludge. The drying treatment method is characterized in that, in an oil-containing sludge drying treatment device, modifying treatment is carried out on the oil-containing sludge by utilizing an added improver, and the oil-containing sludge is made into fuel powder with a high combustion heat value through agitating and disintegrating the oil-containing sludge. The drying treatment method comprises the following specific steps of measuring the water content of to-be-treated sludge of the oil-containing sludge, and preparing the improver; conveying to-be-treated oil-containing sludge into the oil-containing sludge drying treatment device, starting agitation, and adding the improver into the oil-containing sludge drying treatment device according to a proportion of 10 to 40; ceaselessly agitating to-be-treated greasy filth in the oil-containing sludge drying treatment device, after the agitation is sufficient, starting a disintegration mechanism, carrying out disintegration on the modified greasy filth, and making the greasy filth into the fuel powder. The drying treatment method of the oil-containing sludge has the following beneficial effects that the extra use of water and an extracting agent is not needed in a production process; no waste gas is generated; the secondary pollution does not exist; only are the agitation and the disintegration needed in a treatment process, so that an overall technical process can be completed.

Owner:TIANJIN ENVIRONMENTAL PROTECTION TECHNICAL DEV CENT DESIGNING INST

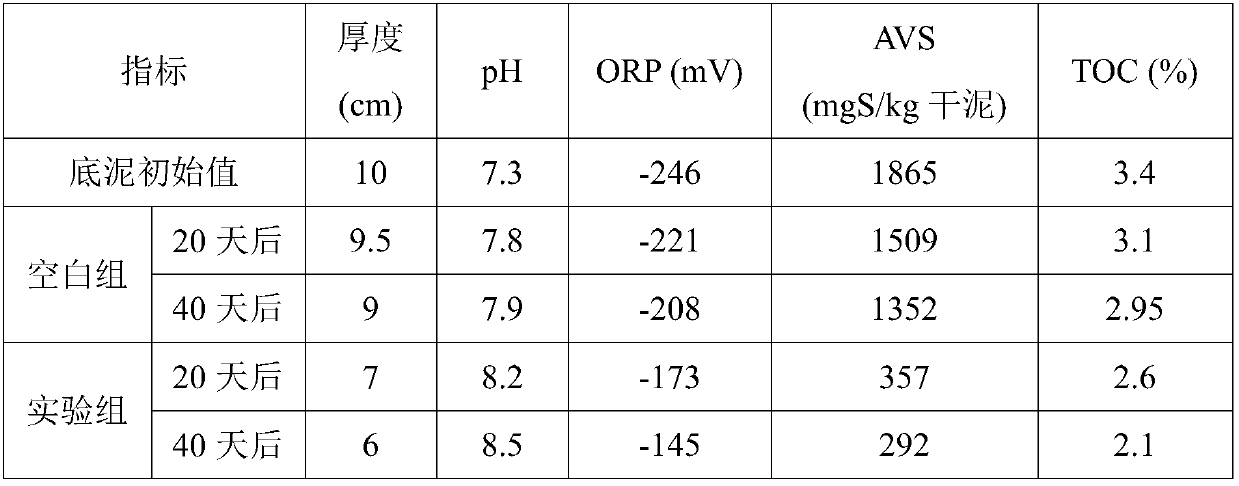

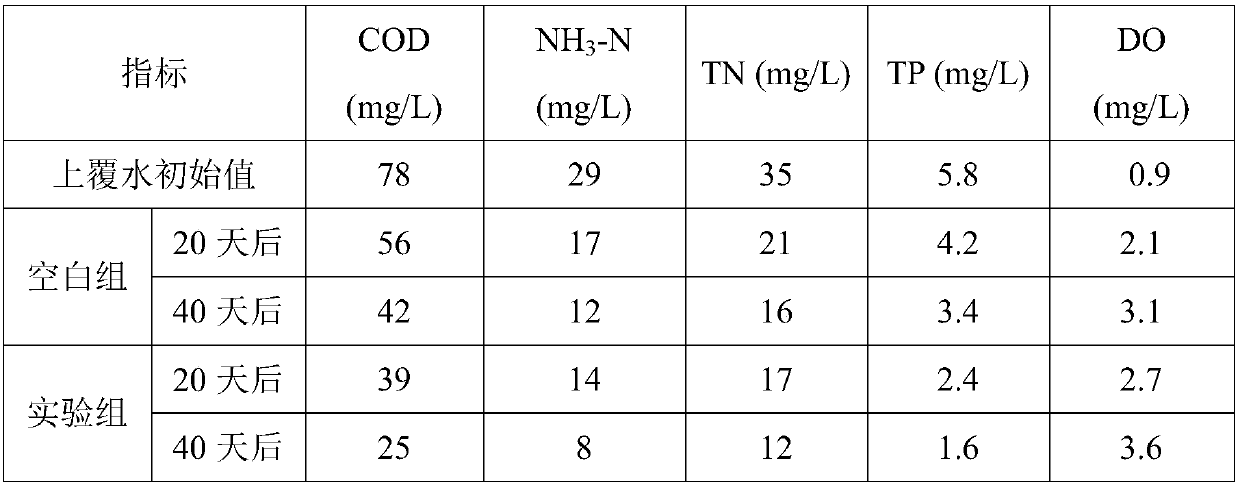

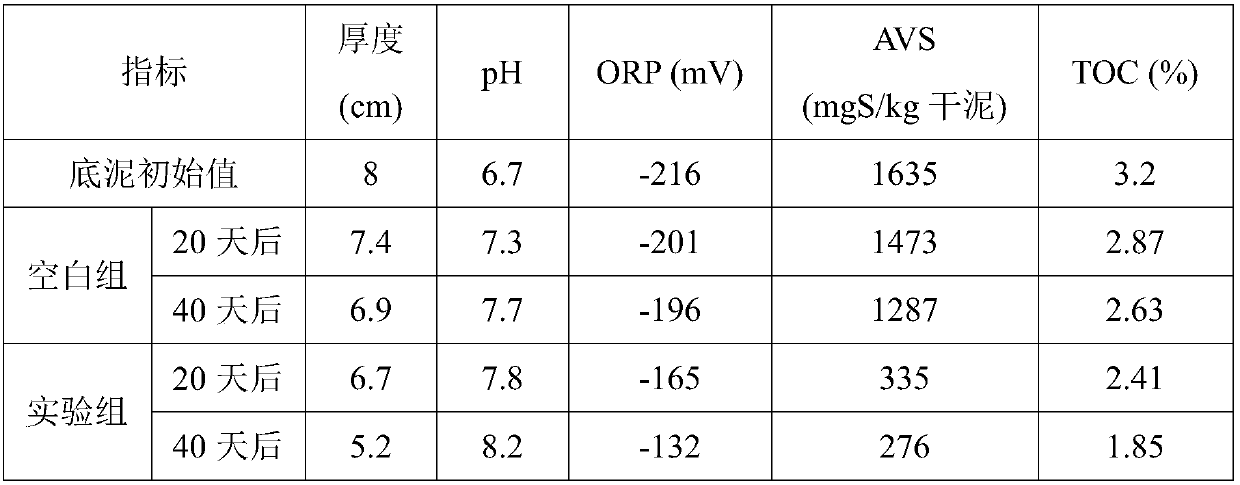

Black and odorous water bottom mud in-situ remediation material and preparation method thereof

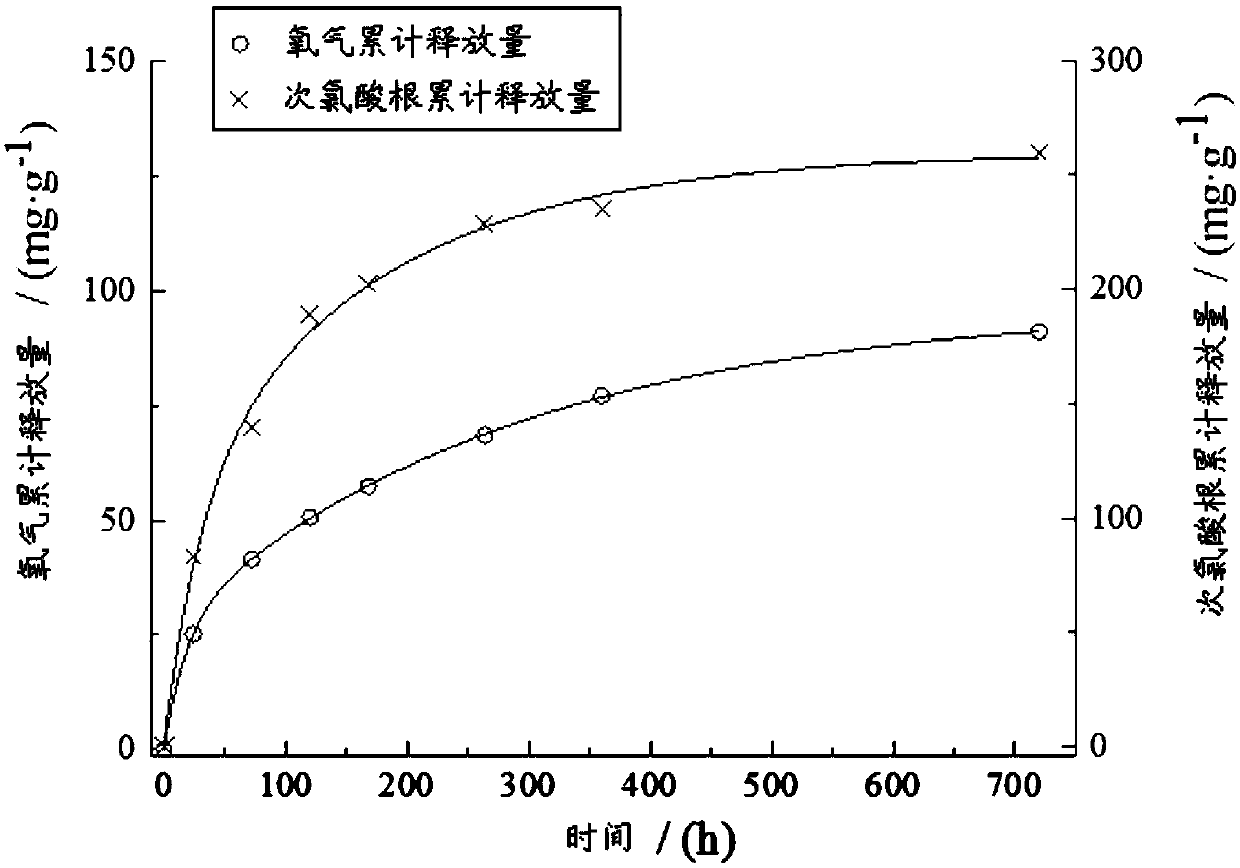

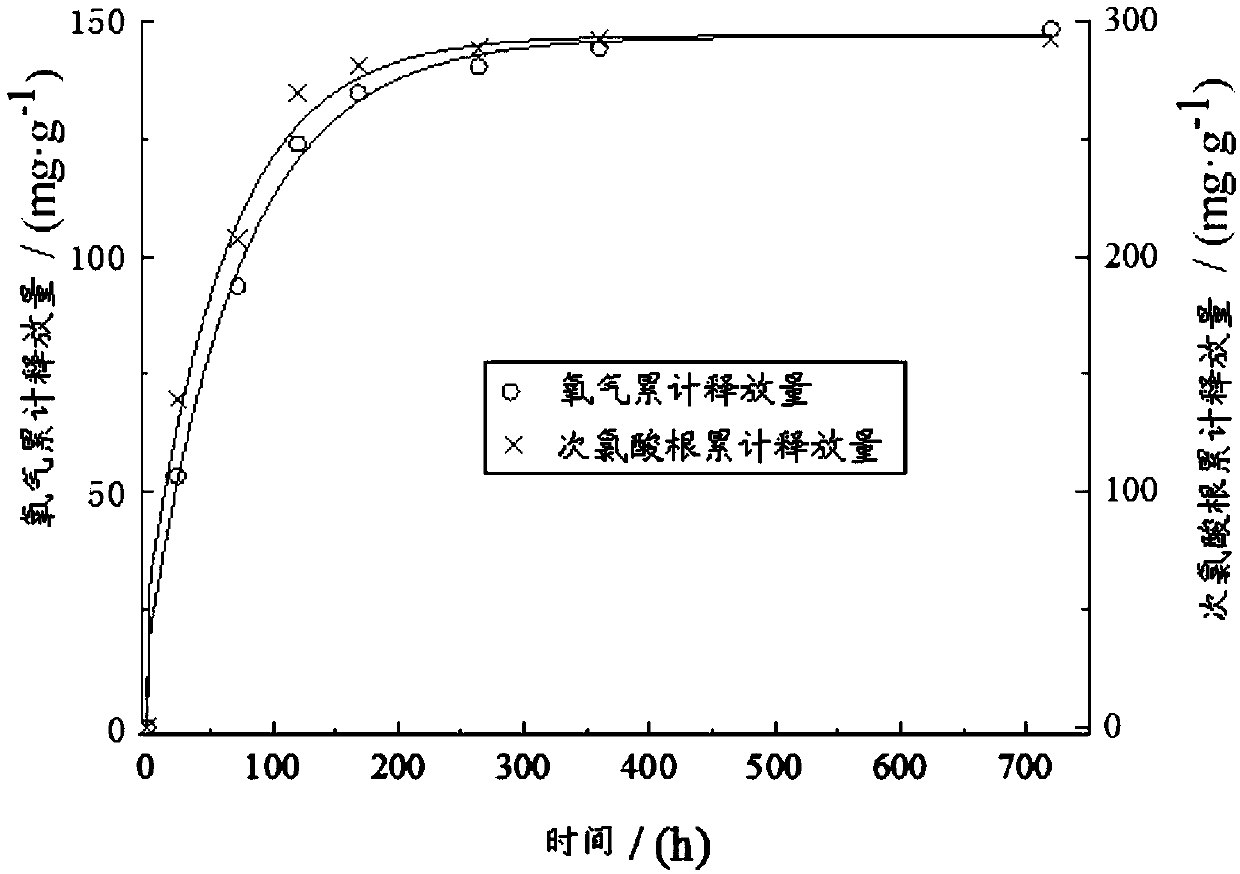

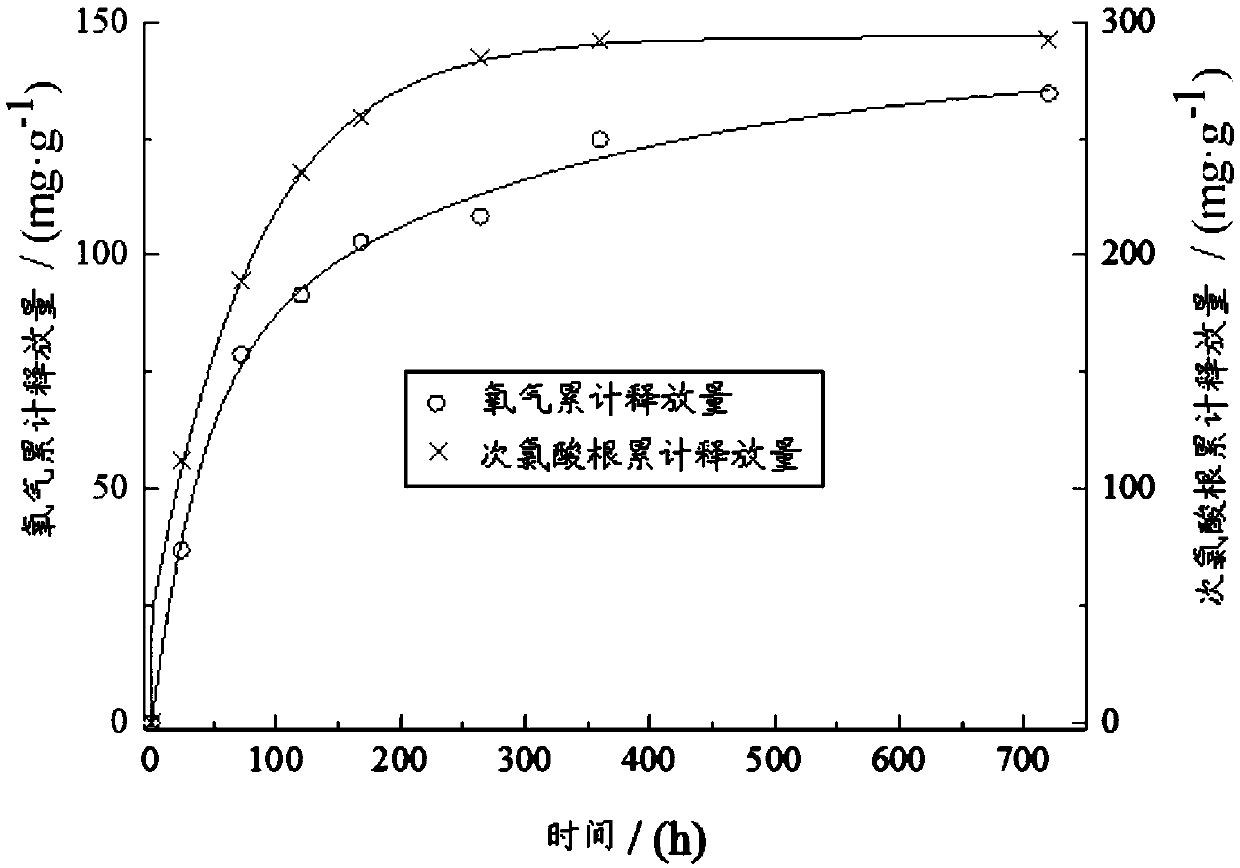

PendingCN109607993AIncrease dissolved oxygenEliminate black odorWater treatment parameter controlSpecific water treatment objectivesAmmoniacal nitrogenIn situ remediation

The invention discloses a black and odorous water bottom mud in-situ remediation material and a preparation method thereof. The material is prepared from an oxygen release agent, an ammonia-nitrogen oxidant, aggregates, a binder, a pH regulator and a solidification regulator. The black and odorous water bottom mud in-situ reduction and solidification function material is prepared from the following steps that all raw materials are mixed to be uniform, granulation is conducted, or a mold is filled with chemicals, maintenance is conducted, and after the maintenance period is finished, the material can be obtained. Accordingly, the applied materials are easy to obtain and friendly to environment, preparation is easy, and the cost is low; meanwhile, oxygen slowly released from the chemicals and hypochlorite ions can improve the redox potential of black and odorous water, ammonia and nitrogen can be oxidized, sulfur release is inhibited, and remediation can be provided for the black and odorous water efficiently and enduringly.

Owner:TSINGHUA UNIV

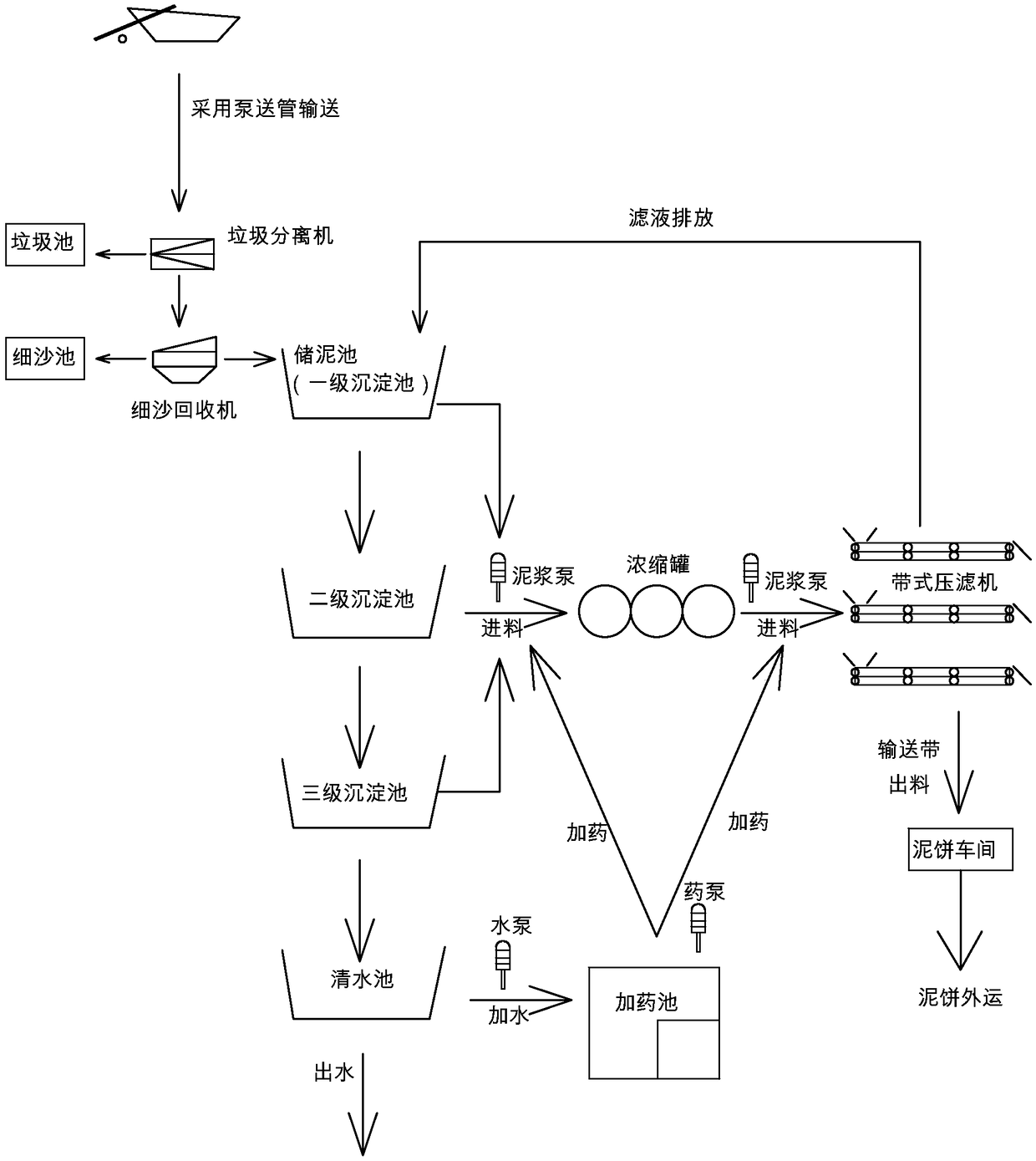

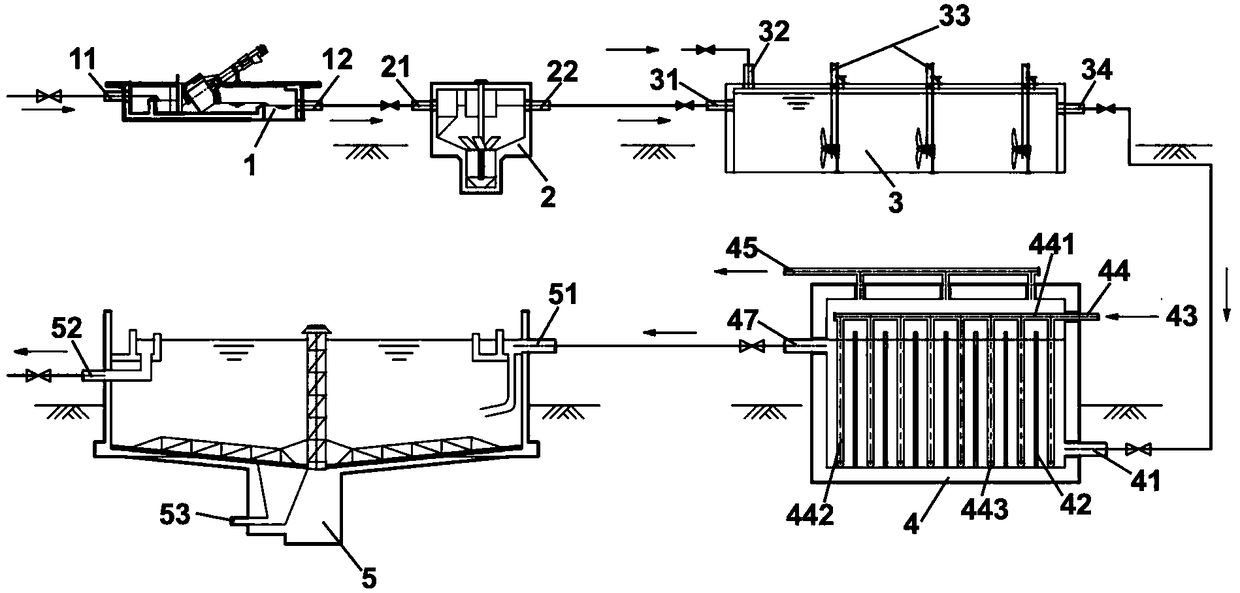

Sludge treatment process

InactiveCN109467296AQuickly Eliminate Black OdorIncrease concentrationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeWater circulation

The invention relates to a sludge treatment process. The process comprises the steps as follows: a river is dredged by a dredging device and sludge is conveyed by a sludge pipeline; the sludge is sentto a garbage sorting machine for garbage sorting; the sludge is sent to a sand scraping separation system to remove sand in the sludge; the sludge is sent to a first-stage sedimentation tank of a sludge storage tank, a second-stage sedimentation tank and a third-stage sedimentation tank are arranged behind the sludge storage tank, and overflow water in the third-stage sedimentation tank is conveyed to a clear water tank; a dosing platform blends required chemicals and adds agents to sludge output by the sludge storage tank, output sludge is mixed, conditioned and then conveyed into a concentration tank to increase sludge concentration, then, secondary dosing is performed before dewatering, the sludge is sent to a dewatering platform for dewatering, and filter pressing water produced by the dewatering platform flows back to the second-stage sedimentation tank; overflow water in the third-stage sedimentation tank is discharged to the clear water tank, water in the clear water tank is recycled or directly discharged to the river. A relatively efficient water recycling system is adopted and dependence on clean water is reduced.

Owner:GUANGDONG JINSONG CONSTR ENG CO LTD

In-situ biochemical repairing agent for bottom mud of black and odorous water body, preparation method and repairing method

InactiveCN107651821AReduce pollutionPollution reduction effect The reduction effect is obviousWater treatment parameter controlSludge treatment by oxidationChemical treatmentBiology

The invention relates to an in-situ biochemical repairing agent for bottom mud of a black and odorous water body. The in-situ biochemical repairing agent is prepared from the following raw-material constituents in parts by weight: 30 to 40 parts of modified biological charcoal powder, 20 to 60 parts of aggregate, 15 to 20 parts of microbial bacterial agent and 10 to 15 parts of co-substrate. The biochemical repairing agent provided by the invention is combined with physical absorption, chemical treatment and biological treatment; all components have mutual synergistic effects; the effect of reducing the pollution by the bottom mud is obvious, wherein modified biological charcoal can be used for effectively adsorbing a heavy metal and part of organic matters, which are released by the bottom mud; diatomite and montmorillonite, which serve as the aggregate, on one hand, can be used for effectively adsorbing part of pollutants, and on the other hand, can be used for providing an attachment carrier for the growth of a microbe together with the modified biological charcoal at the same time; the co-substrate can be used for promoting the growth of the microbe and activating the activityof the microbial bacterial agent; the repairing agent for the bottom mud is spherical, is difficult to flow away along with water, and can sufficiently exert an effect, and in addition, the in-situ biochemical repairing agent for bottom mud, which is provided by the invention, is wide in material source and low in cost and has practical popularization and application conditions.

Owner:HUNAN YONKER ENVIRONMENTAL PROTECTION RES INST +1

Arsenic-containing waste water treatment method and apparatus

PendingCN108249544AHigh reactivityLow toxicitySludge treatment by oxidationWater/sewage treatment by irradiationDielectricSludge

The invention belongs to the technical field of water pollution treatment, and particularly relates to an arsenic-containing waste water treatment method and apparatus. The method comprises the following steps: performing the microwave catalytic oxidation precipitation treatment on arsenic-containing waste water with a pH value less than or equal to 10 under the catalytic effect of a microwave catalyst in an oxygen-containing atmosphere, and converting trivalent arsenic to pentavalent arsenic, co-precipitating the pentavalent arsenic and trivalent iron, thus obtaining the arsenic-containing waste water after the microwave treatment and iron arsenate-containing sludge, wherein the microwave catalyst is a wave absorption substance loading zero-valent iron, and a relative dielectric constantof the wave absorption substance is not less than 4. The arsenic-containing waste water after the microwave treatment can be discharged up to standard, a sludge stabilizer is added into the sludge, and the pH of the sludge is adjusted, so that the sludge is stabilized and reaches a bury standard. The method is an arsenic-containing waste water treatment method with low cost and high efficiency, and solves the technical problems in the arsenic-containing waste water treatment method in the prior art that the efficiency is low, the cost is high, secondary pollution is caused and heavy metal is difficult to mineralize and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

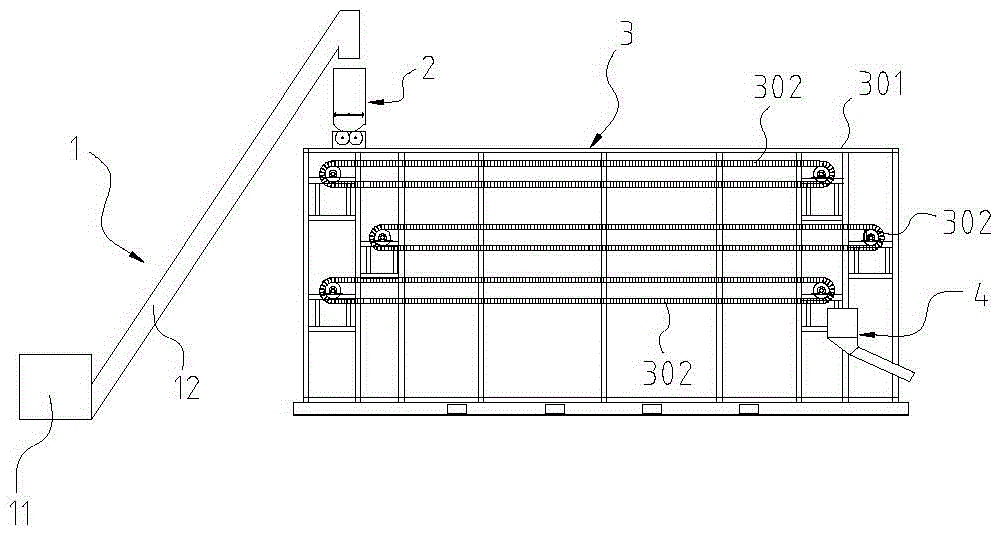

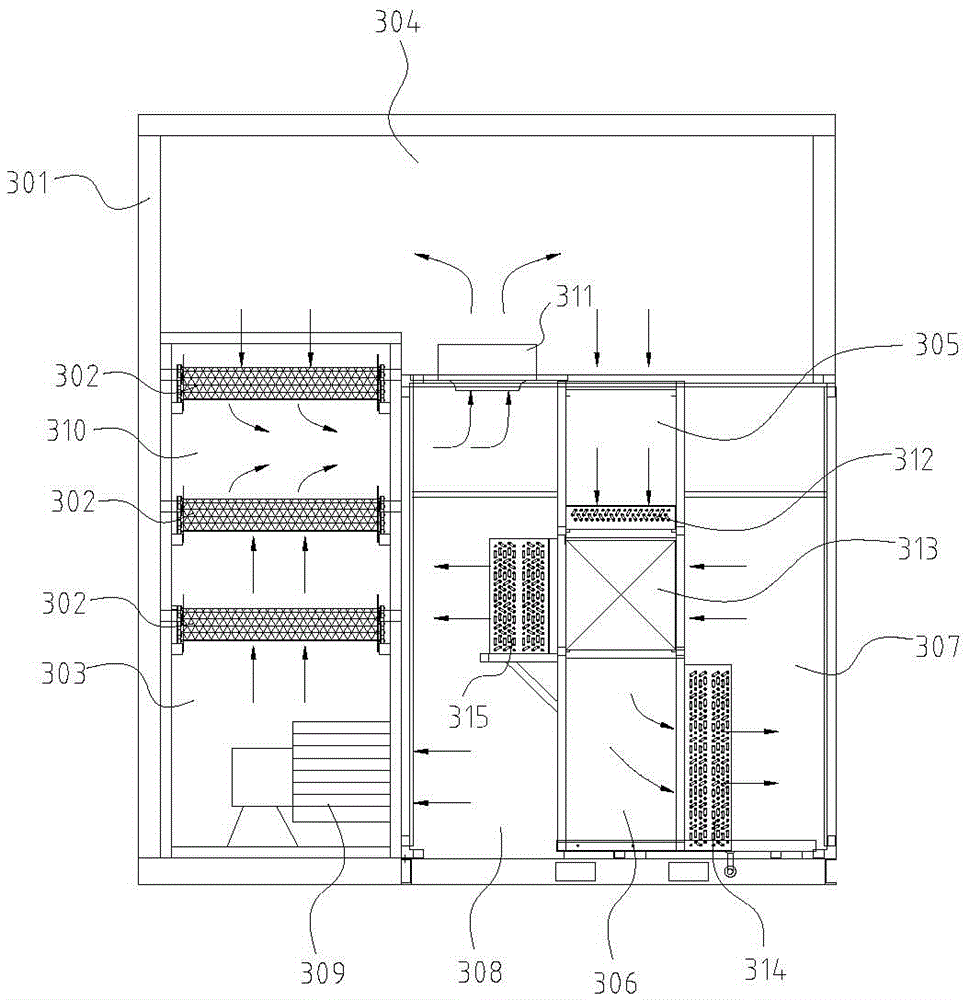

Sludge drying full-automatic production line

ActiveCN105948431AImprove continuityGuaranteed continuitySludge treatment by de-watering/drying/thickeningFixation/solidifcation sludge treatmentProduction lineSludge

The invention relates to a sludge drying full-automatic production line. Along the material conveying direction, the sludge drying full-automatic production line sequentially comprises a feeder, a sludge forming machine, a drying dehumidifier and a discharger, wherein the sludge forming machine comprises a sludge tank, a forming roller and a stirring pressurization cutter; the top of the sludge tank is provided with a feed port, the bottom of the sludge tank is provided with a discharge port, and the forming roller is arranged at the discharge port of the sludge tank; the stirring pressurization cutter comprises a rotating shaft, a driving mechanism for driving the rotating shaft to rotate, and more than two blades which are circumferentially uniformly distributed on the periphery of the rotating shaft; the blades are connected with the rotating shaft through connecting rods; one surface of each blade facing towards the rotating shaft is a joint surface, and the other surface away from the rotating shaft is a pressurization surface which is cambered; and when the blades rotate to the bottommost end, the cambered pressurization surface of each blade can apply a certain pressure to the sludge at the forming roller, so that the accumulated sludge becomes compact, and the compacted sludge is extruded into the forming roller to be formed, so that the formed sludge has favorable continuity and is compact without easily becoming loose.

Owner:GUANGZHOU KAINENG ELECTRIC EQUIP

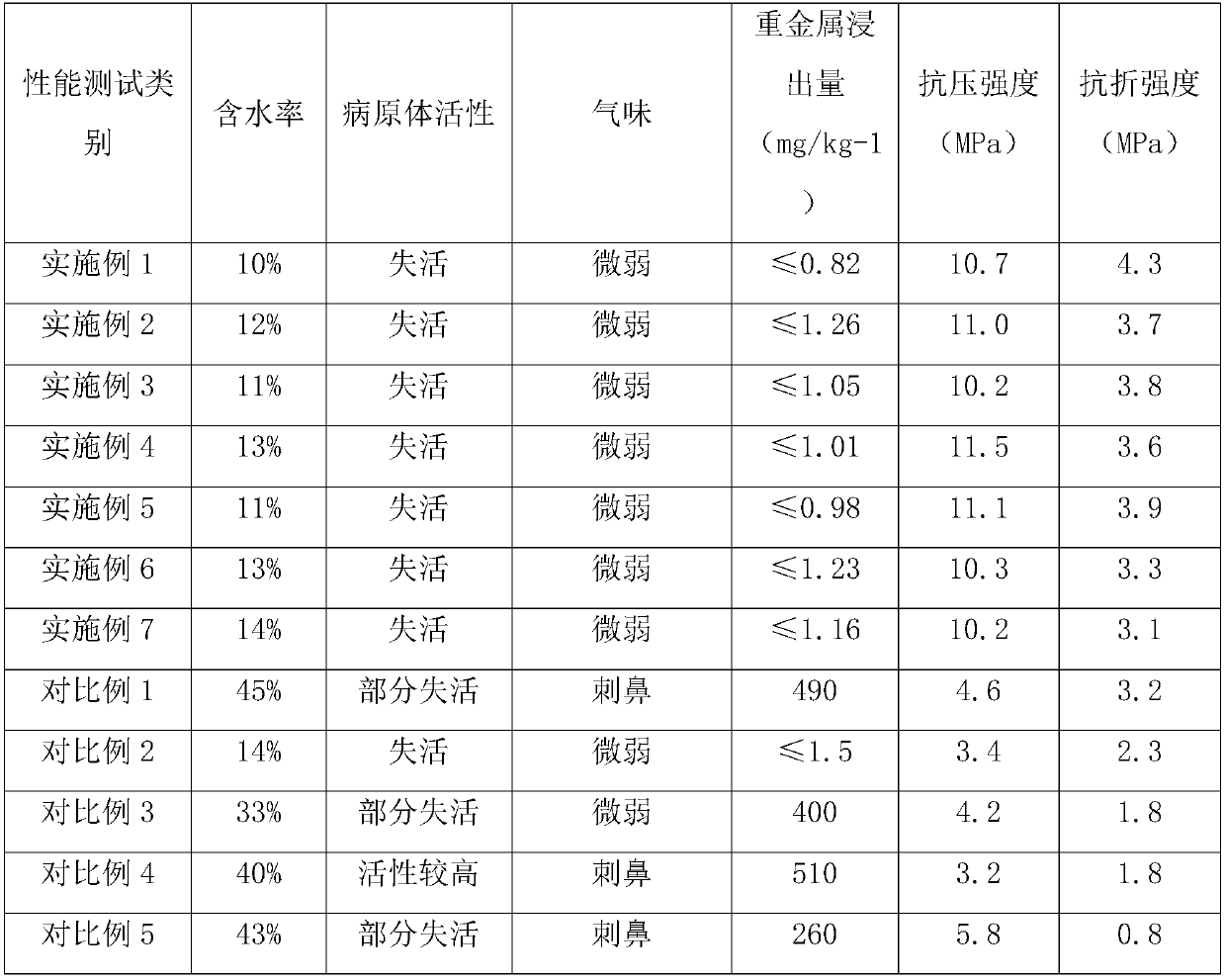

Sludge curing agent and application thereof

ActiveCN107673572AAchieve reuseAchieve solidificationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeFlexural strength

The invention discloses a sludge curing agent and application thereof. The sludge curing agent is suitable for curing treatment on high-water-content sludge in town sewage treatment plants, rivers andlakes. The sludge curing agent comprises the following raw materials in percentage by weight: 26 to 44 percent of silicon aluminum iron calcium oxide, 19 to 37 percent of calcium oxide, 13 to 30 percent of special cement, 5 to 25 percent of polyacrylamide and 0.2 to 3 percent of chitosan. The sludge curing agent realizes sludge curing and stabilization through the chemical property of the industrial waste and the mutual activity excitation; the water content of the sludge is effectively reduced, the early-stage compressive strength and the flexural strength of the sludge are improved, and mechanical operation during backfilling is facilitated; heavy metal in the sludge is adsorbed by the chitosan, organic matters are degraded, the pathogene is deactivated, pollution is reduced and stink can be eliminated; and the sludge curing agent is low in price and simple in curing process, and the cured sludge does not cause secondary pollution.

Owner:武汉鹏森环境科技有限公司

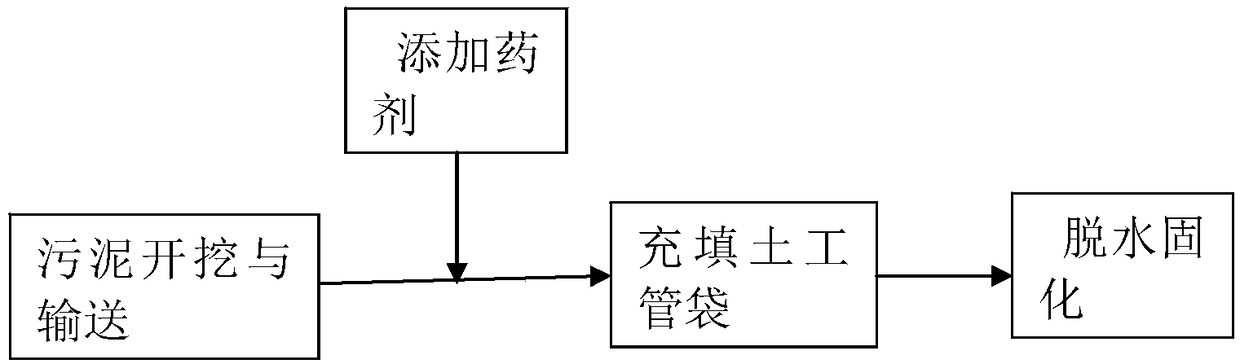

Construction method for dredging ditch sediment based on hydraulic punching and filling geotechnical pipe bag

InactiveCN108978577AContinuityClosedSludge treatment by de-watering/drying/thickeningClimate change adaptationSurface cleaningCut and fill

The invention relates to a construction method for dredging ditch sediments based on a hydraulic punching and filling geotechnical pipe bag and belongs to the technical field of dredging constructionof sediments in stinky water body ditches. The construction method for dredging the ditch sediments based on the hydraulic punching and filling geotechnical pipe bag includes the following steps of temporary storage yard construction, surface cleaning, sectional construction of cofferdam, construction drainage, assembly of a mud conveying pipeline, hydraulic punching and dredging of the sediments,adding medicament, geotechnical pipe bag filling, sludge dewatering and solidification and transportation or reuse of solidified soil. For the construction method, earth excavation is completed withthe help of hydraulic cutting; soil is then filled by a mud pump through the mud conveying pipeline to a large geotechnical pipe bag; in the dredging pipes, dredging mud and the medicament are fully stirred to produce a flocculation group to be precipitated in a geotechnical pipe belt, and then dehydration and solidification treatment of the sediments is achieved. The construction method for dredging the ditch sediments based on the hydraulic punching and filling geotechnical pipe bag has the advantages of continuity, integrated operation of dredging, conveying and filling, low cost, high construction efficiency, sealing property, no secondary pollution during transportation, good environmental protection performance, high construction precision, good effect, convenient operation and savedworking space.

Owner:CCCC TIANJIN DREDGING HARBOR CONSTR ENG

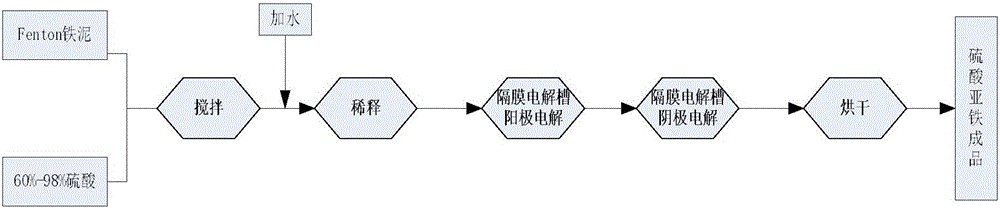

Method for resource utilization of Fenton iron mud

ActiveCN105836987AReduce pollutionReduce energy consumptionWater contaminantsIron sulfatesFerrous sulfate ironSulfate

The invention discloses a method for resource utilization of Fenton iron mud. The method comprises the following steps: adding sulfuric acid to the Fenton iron mud, converting Fe(OH)3 into Fe2(SO4)3 wholly, adding water to dilute after dissolving until the concentrations of iron ions are 70 to 98g / L to obtain a treatment solution I; adding the obtained treatment solution I to an anode chamber of a diaphragm electrolyzer, carrying out oxidation treatment on organic matters in the Fenton iron mud firstly, and then pumping into a cathode chamber of the diaphragm electrolyzer to carry out electroreduction treatment to obtain an Fe<2+> reducing solution; carrying out concentrated crystallization on the Fe<2+> reducing solution under the protection of an inert gas to prepare an industrial product, namely the ferrous sulfate product. According to the invention, the industrial ferrous sulfate is produced through electroreduction, so that the iron mud is fully subjected to resource utilization.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

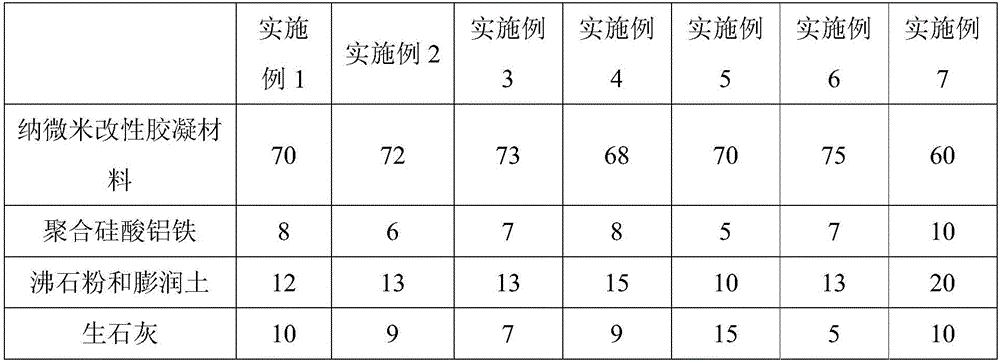

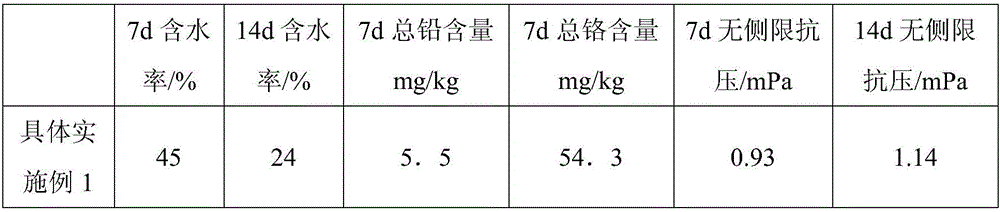

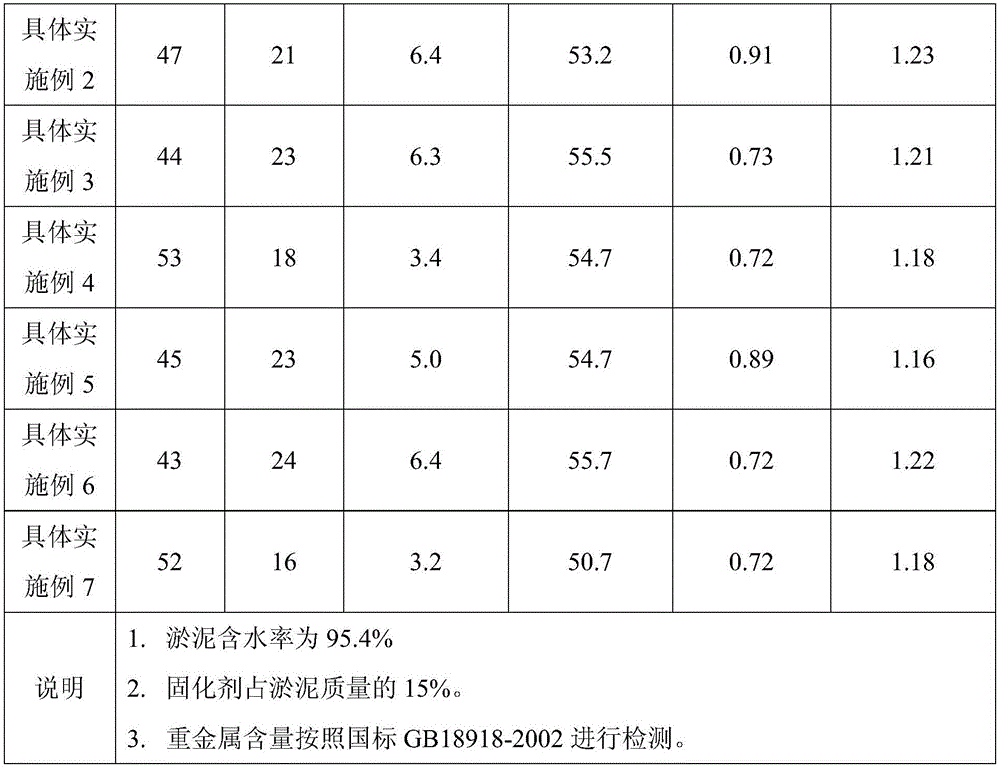

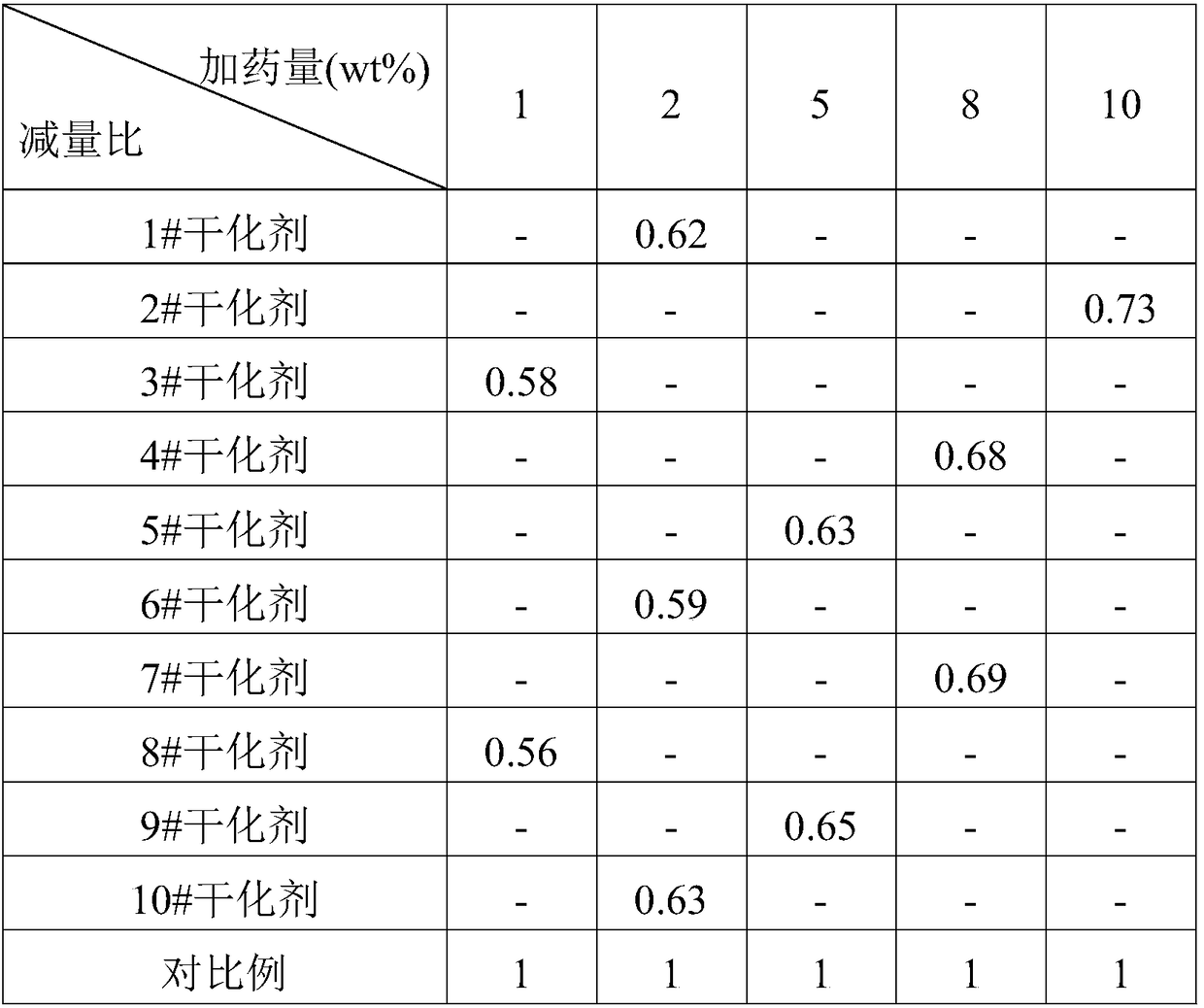

Silt/sludge solidifying agent and application thereof

ActiveCN105753279AIncrease moisture contentHigh curing strengthSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSodium BentoniteSludge

The invention particularly relates to a silt / sludge solidifying agent and application thereof.The silt / sludge solidifying agent is characterized by being mainly prepared by mixing, by mass, 60-75% of nano-micron modified binding material, 5-10% of poly-aluminum-ferric silicate, 10-20% of zeolite powder or bentonite and 5-15% of quicklime.Paving construction of road filling can be performed by adding the silt / sludge solidifying agent accounting for 10-20% of total amount of silt / sludge into the silt / sludge, mixing and stirring in a stirrer for 10-30 min and placing under sunlight for sufficient irradiation and solidification after stirring is finished.The silt / sludge solidifying agent can lower water content of high-water-content silt / sludge, is high in solidifying strength and capable of effectively solidifying heavy metals in the silt / sludge and reaches requirements of filling and building earth filling.

Owner:BEAUTIFUL ORIENTAL ENVIRONMENTAL PROTECTION CO LTD

Oily sludge drying agent, and preparation and application methods thereof

ActiveCN108689560AReduce processing difficultyReduce moisture contentSludge treatment by de-watering/drying/thickeningWater contaminantsSludgeLignosulfonates

The invention specifically relates to an oily sludge drying agent, and preparation and application methods thereof, belonging to the technical field of solid waste treatment. According to the oily sludge drying agent and the preparation and application methods thereof in the invention, oily sludge drying efficiency is greatly improved and the addition amount of the drying agent is effectively reduced by comprehensively utilizing industrial solid waste such as fly ash and compounding effective components such as limestone, gypsum and lignosulfonate; raw materials are easily available, and preparation cost is low; and when applied to drying of oily sludge, the oily sludge drying agent can greatly reduce the outward transportation volume and treatment cost of the oily sludge and has good economic, environmental and application value.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com