Silt/sludge solidifying agent and application thereof

A sludge solidifying agent and sludge technology, which are used in fixed/solidified sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc., to achieve high solidification strength and reduce moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in conjunction with examples.

[0013] Active SiO 2 30%, active Al 2 o 3 10%, active CaO50%, active Fe 2 o 3 5%, active MgO5% mixed in the furnace and calcined for 20 minutes to obtain a sintered product;

[0014] The obtained sinter was mixed with CaSO 4 Mix evenly with nano-silicon dioxide at a ratio of 1:0.05:0.02, grind until D95≤15μm, and obtain nano-micron modified gelling material.

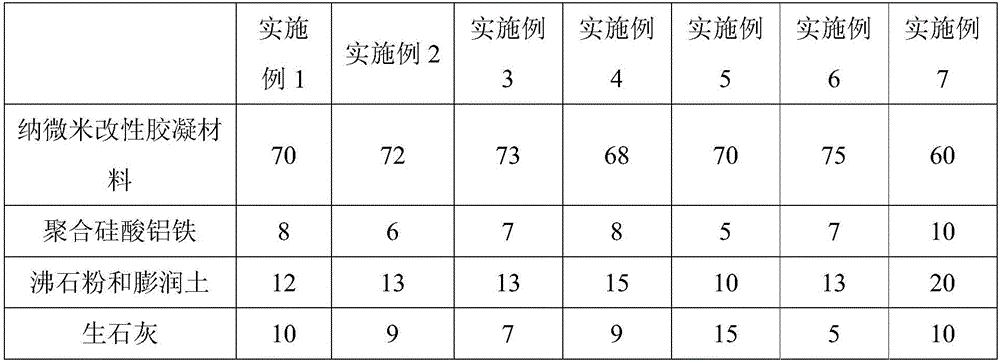

[0015] Raw materials used in each embodiment of table 1 and proportioning unit %

[0016]

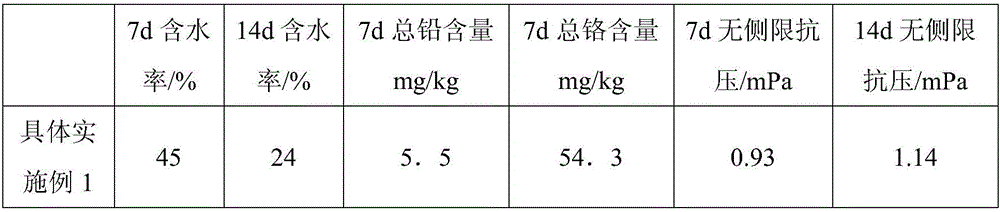

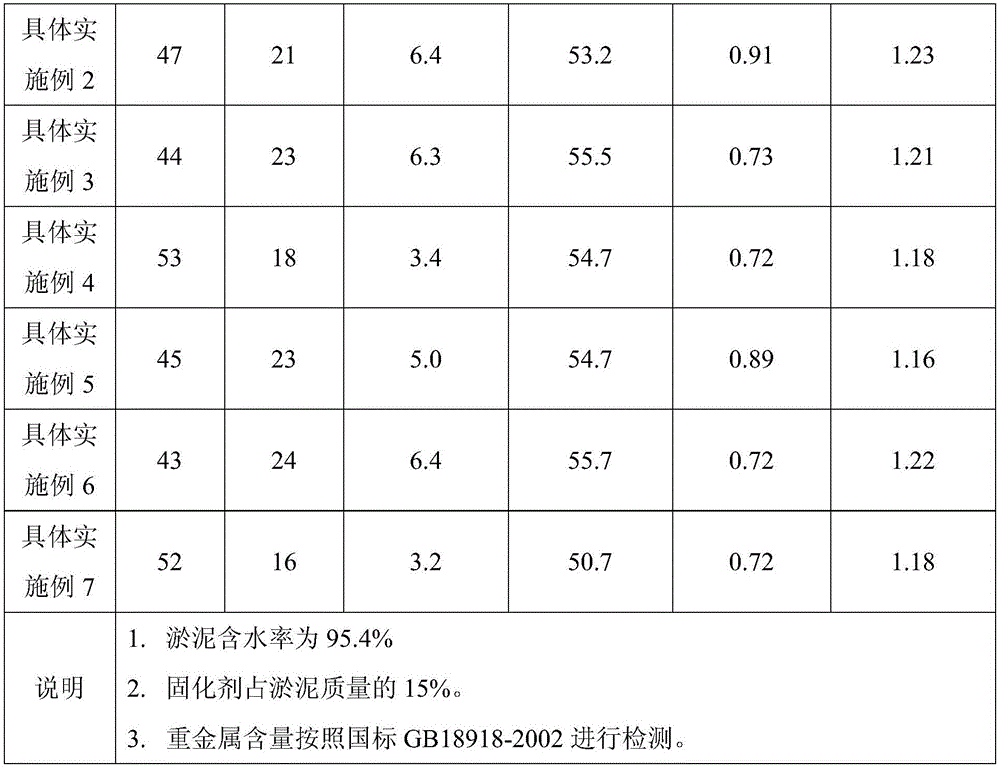

[0017] Table 2. is the result of the dehydration and solidification treatment of lake bottom silt by the raw materials and proportioning used in Examples 1 to 7 shown in Table 1.

[0018] Table 2 Effects of dehydration and solidification of sludge

[0019]

[0020]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com