Method and device for oxidizing and treating sewage or sludge containing organic substances by supercritical water

A technology of supercritical water oxidation and organic matter, which is applied in the direction of oxidation treatment of sludge, oxidized water/sewage treatment, by-product vaporization, etc. It can solve the problems of high operating costs, complicated connections, toxic and harmful gases escaping into the atmosphere, etc., and achieve construction With the effect of reduced operating costs, reasonable and practical process structure, and fast and smooth system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

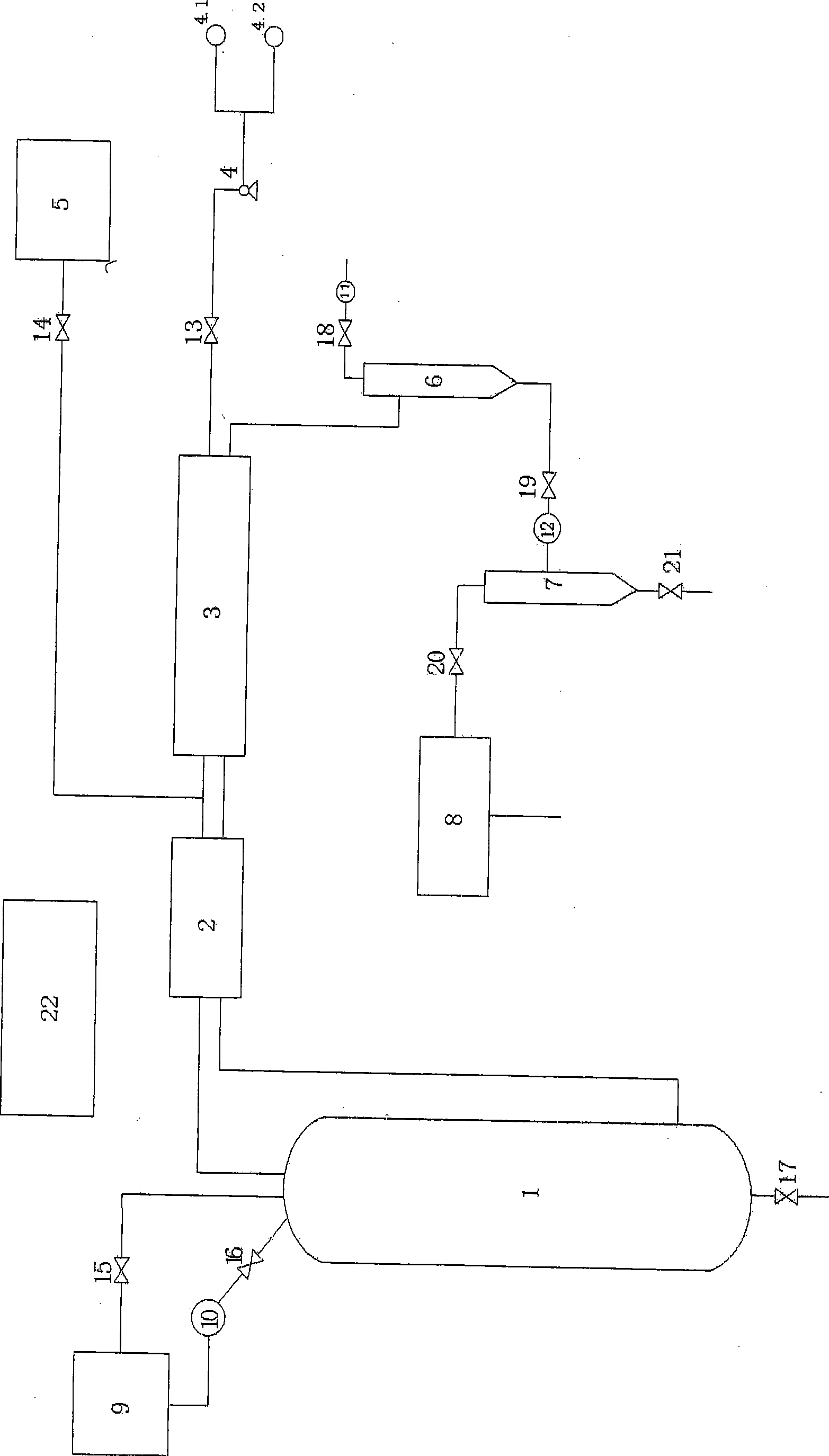

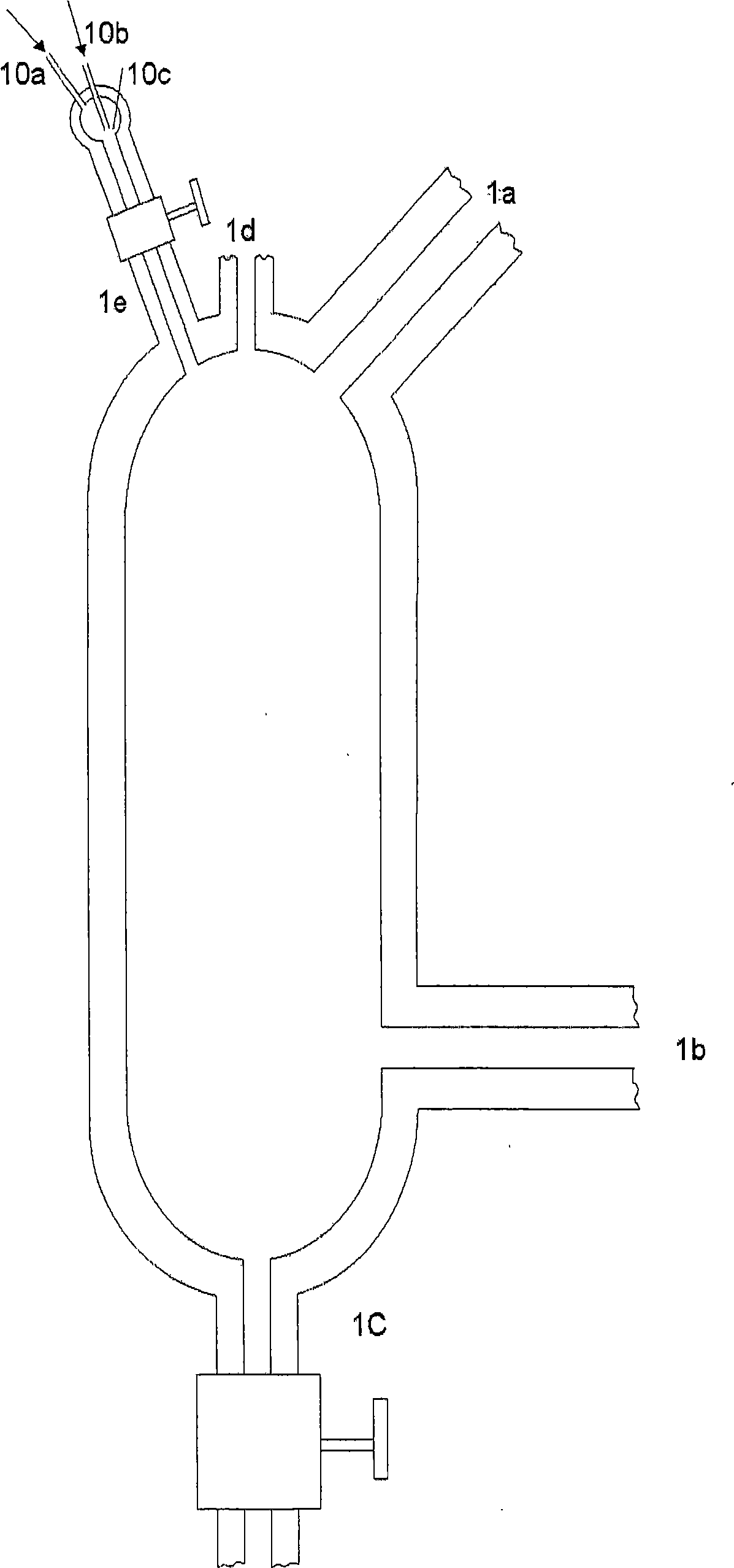

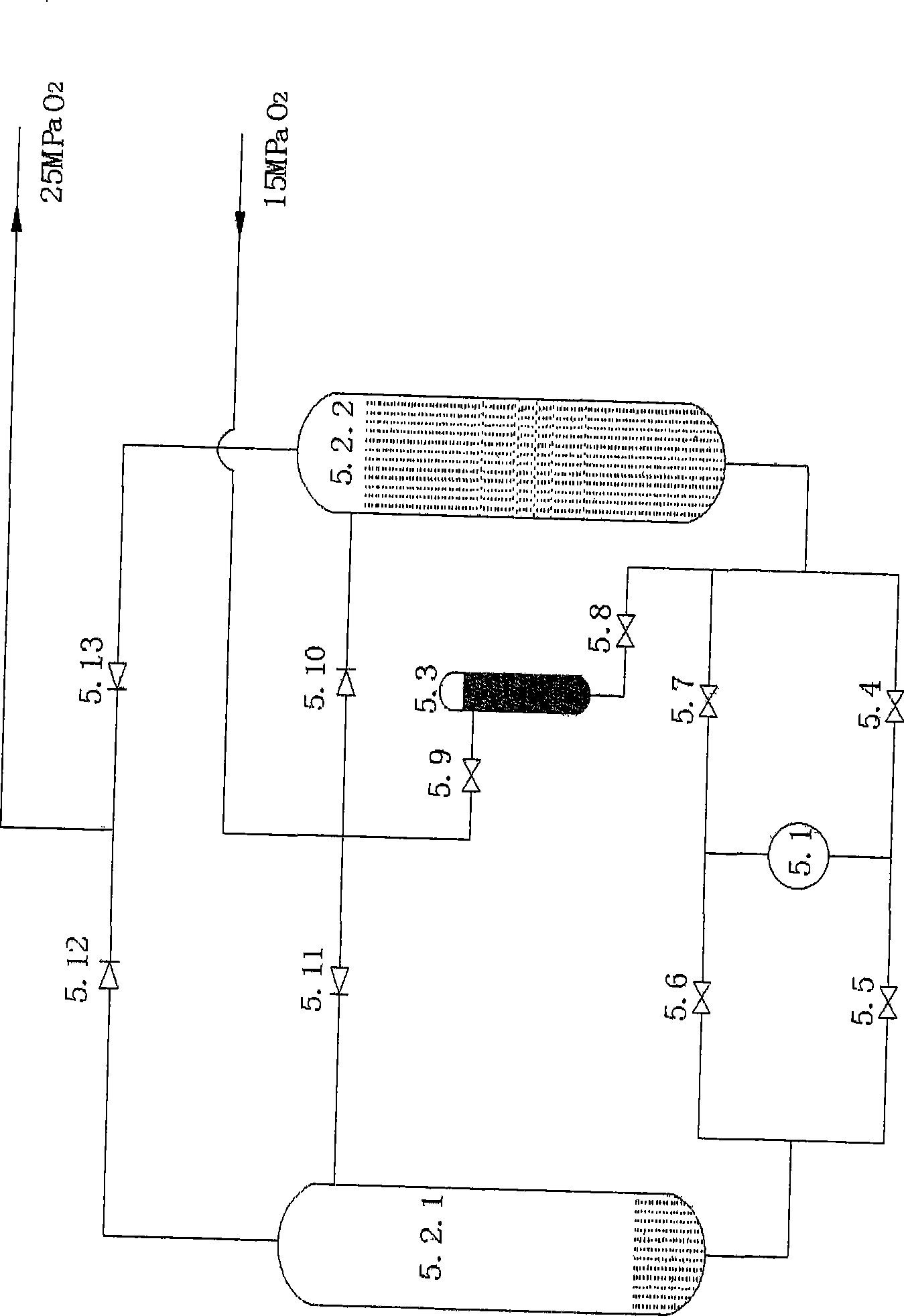

[0034] like Figure 1-3 , a device for supercritical water oxidation treatment of sewage or sludge containing organic matter, which includes a combustion reaction furnace 1, wherein the inlet of the high-pressure pump 4 for feeding materials can be switched to connect with sewage pools and tap water pipes through pipes and valves, and the feeding of materials The outlet of the high-pressure pump 4 is connected to an inlet of the heat exchanger 3 through the outlet valve 13, and 5, the oxidant (oxygen) supply system 5 is connected between the heat exchange reactor 2 and the heat exchanger 3 through its outlet valve 14, and the heat exchange The outlet of the reactor 2 is connected to the material inlet 1a at the top of the combustion reactor 1, and the material outlet 1b at the bottom of the reactor 1 is returned to be connected to another inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com