Patents

Literature

258results about How to "High curing strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

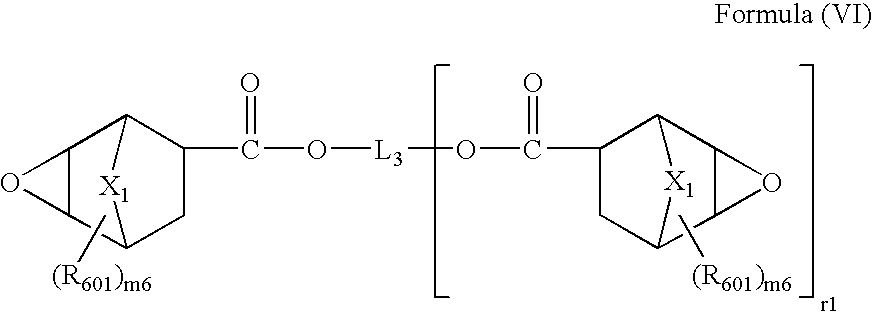

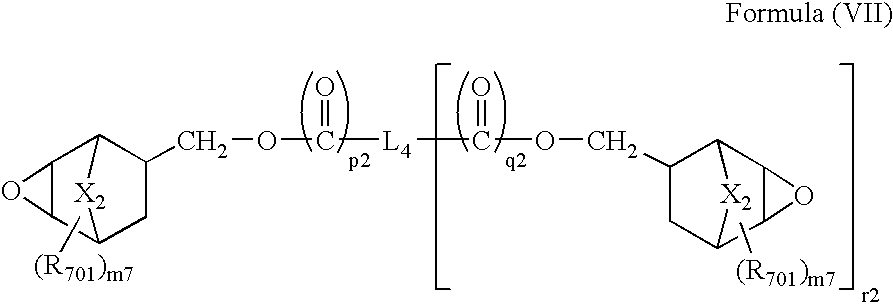

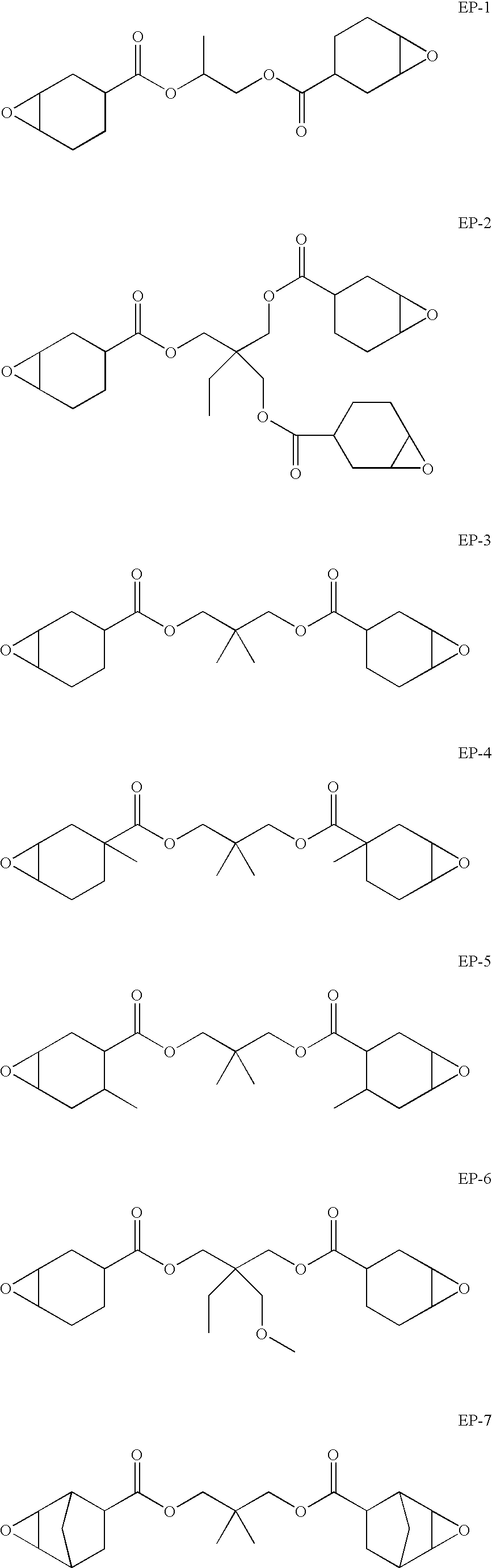

Radiation-curable composition and cured product thereof

To provide a radiation-curable composition which can provide a cured product capable of sufficiently satisfying all of light resistance, transparency and curability and therefore can be useful in much more applications in addition to optical members, lighting members, and automobile members. A radiation-curable composition used after cured by radiation energy, wherein a cured product produced by curing the curable composition by radiation energy of 2 J / cm2 satisfies: an initial light transmittance of 80% or more at a wavelength of 380 nm, and a light transmittance retention of 90% or more after 200 hours of accelerated light resistance test.

Owner:NIPPON SHOKUBAI CO LTD

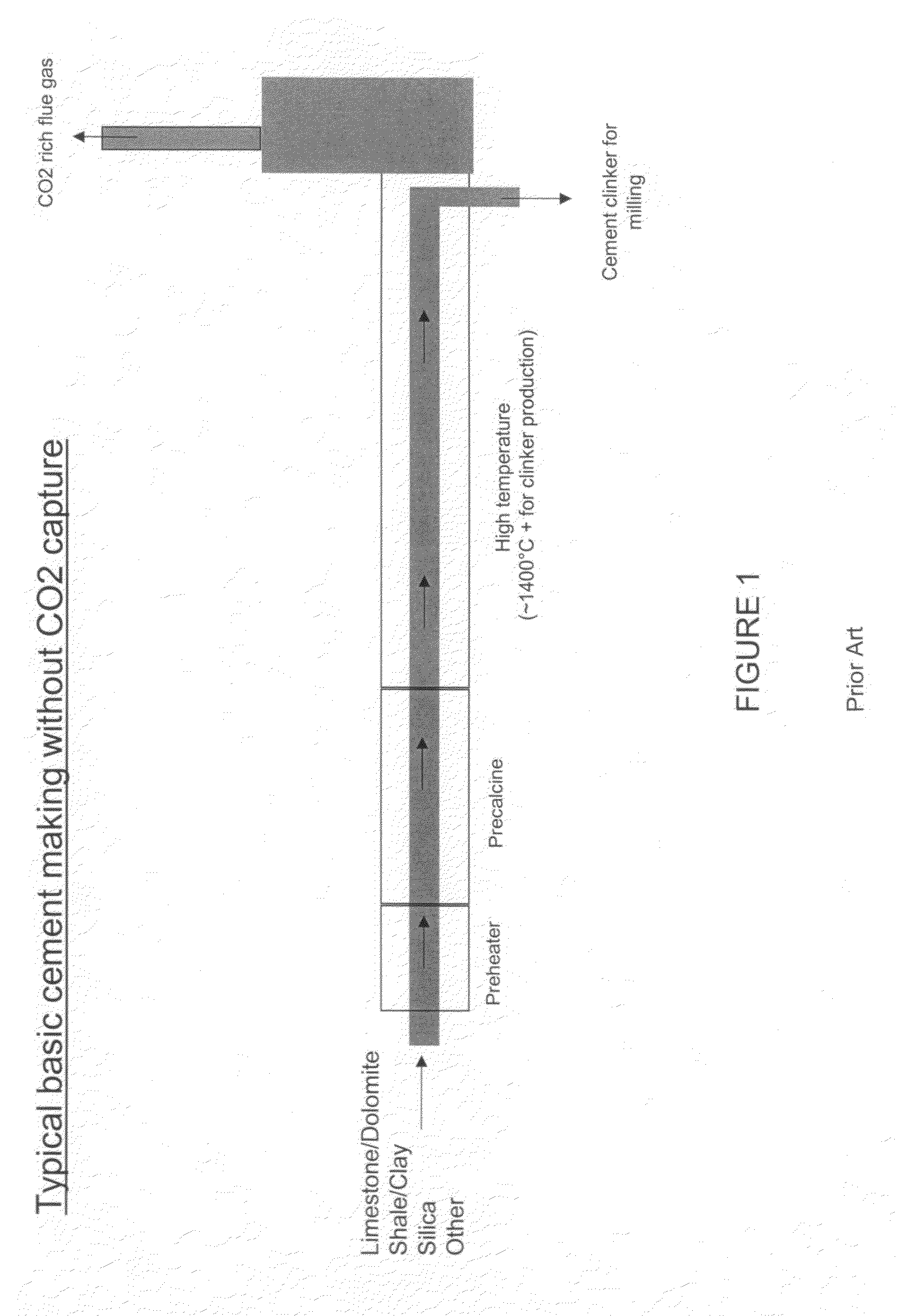

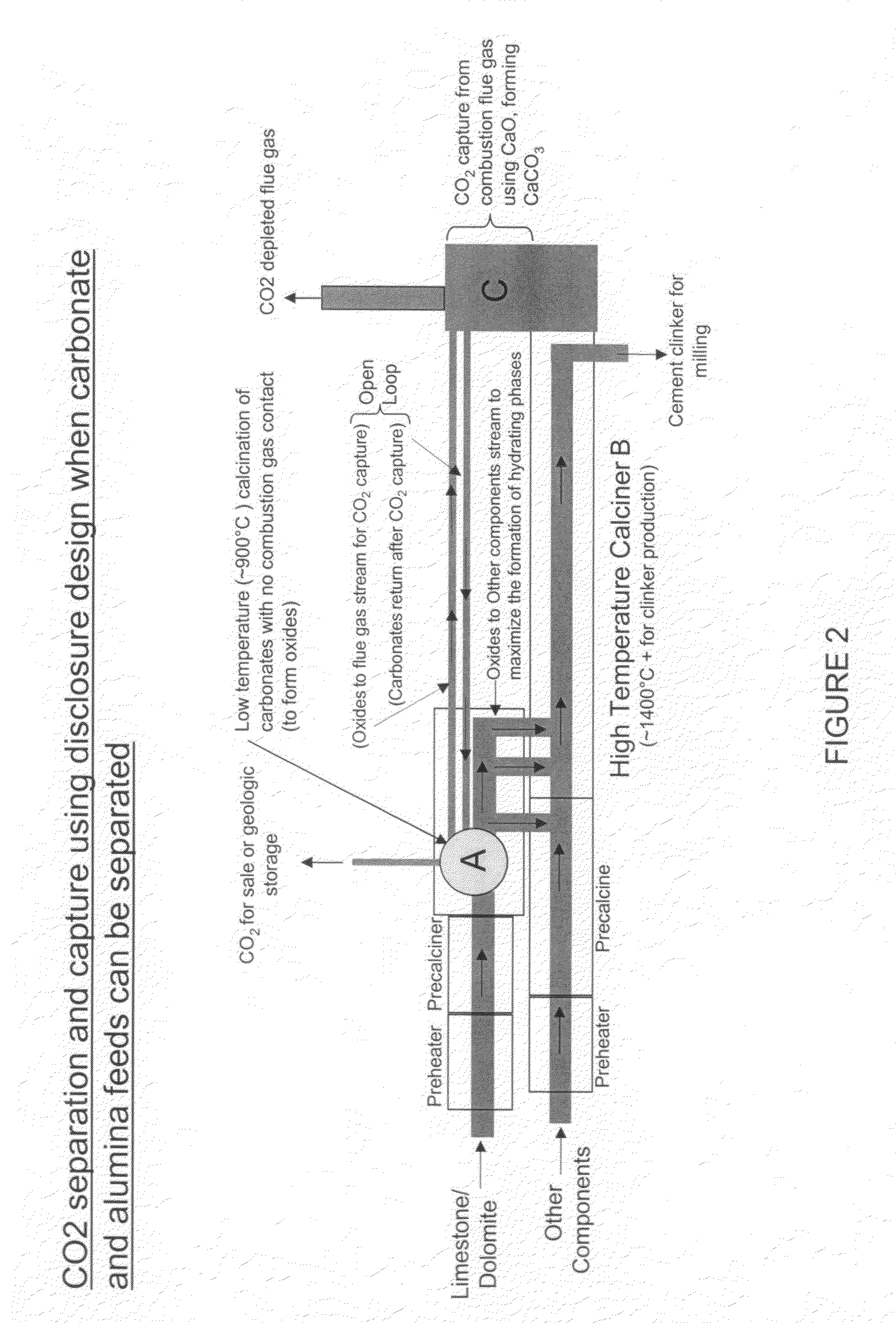

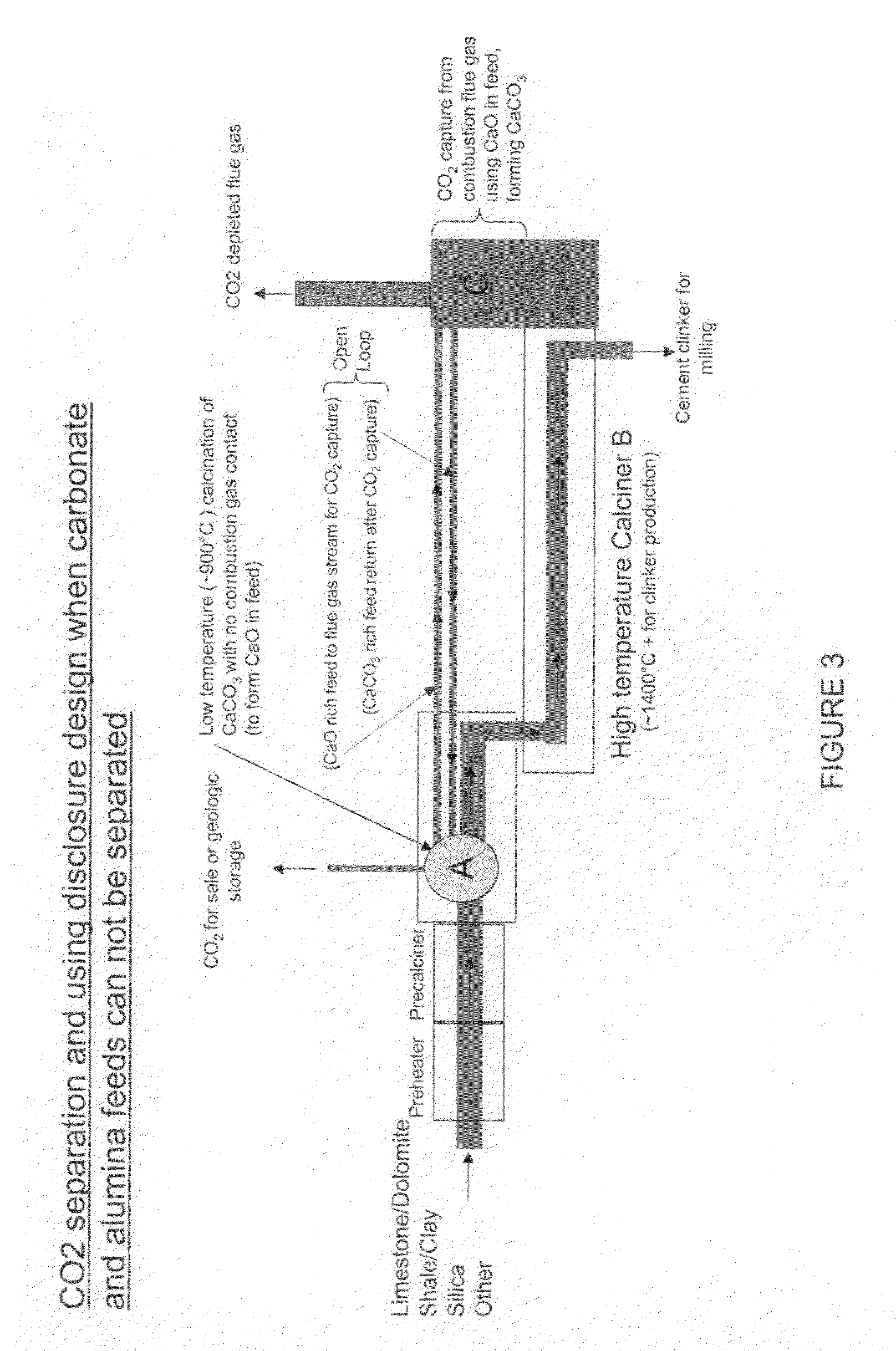

Carbon dioxide capture from a cement manufacturing process

ActiveUS20100319586A1Low formation temperatureIncreased yieldExhaust apparatusSilencing apparatusFlueCarbon dioxide

A process of manufacturing cement clinker is provided in which a clean supply of CO2 gas may be captured. The process also involves using an open loop conversion of CaO / MgO from a calciner to capture CO2 from combustion flue gases thereby forming CaCO3 / CaMg(CO3)2. The CaCO3 / CaMg(CO3)2 is then returned to the calciner where CO2 gas is evolved. The evolved CO2 gas, along with other evolved CO2 gases from the calciner are removed from the calciner. The reactants (CaO / MgO) are feed to a high temperature calciner for control of the clinker production composition.

Owner:SAVANNAH RIVER NUCLEAR SOLUTIONS +1

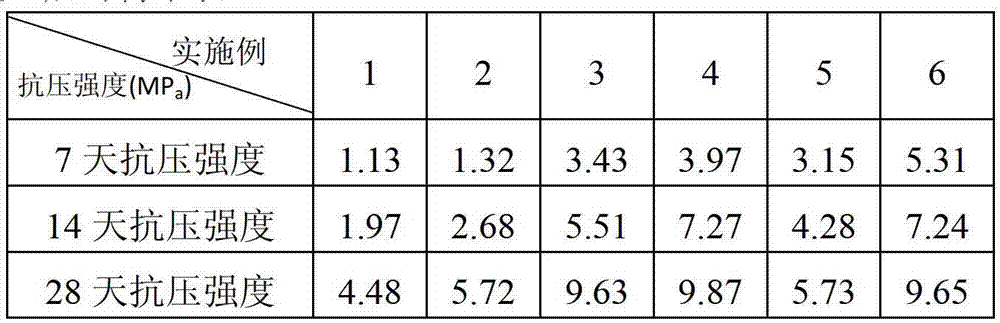

High-performance sand-soil consolidation material, as well as preparation method and using method thereof

The invention relates to a high-performance sand-soil consolidation material, as well as a preparation method and a using method thereof. The high-performance sand-soil consolidation material belongs to a mortar composition and is characterized by comprising the following raw materials in parts by weight: 5-40 parts of cement clinker, 3-6 parts of gypsum, 4-10 parts of alkali additive, 0.5-6 parts of compound activating agent, 1-4 parts of early strength agent, 2-10 parts of mineral activating agent, 3-8 parts of expansion agent and 22-77 parts of micro-powder formed by fine grinding of blast furnace water-quenched slag. The invention provides the high-performance sand-soil consolidation material which has the advantages of simple operation, convenient construction, good water resistance, fast consolidation, high early strength, stable improvement of post-strength, resistance to erosion of underground inorganic salt water, excellent anti-seepage performance and low production cost, as well as the preparation method and the using method thereof. The high-performance sand-soil consolidation material is suitable for consolidating mine tailings, natural weathered sand, fly ash, gravel, stone chips, stone powder, soil, sludge, construction waste, coal gangue and phosphorus slag into a solid material, and can be used for laying a subgrade, constructing a wall body and constructing a site foundation.

Owner:淄博乾耀固结材料有限公司

Curing resin composition cured film and antireflection film

InactiveUS20060052565A1High strengthSimple manufacturing processSynthetic resin layered productsCoatingsOligomerPolystyrene

A curing resin composition which enables formation of an antireflection layer having good antiscratchability and a cured film obtained from such a curing resin composition are disclosed. The curing resin composition contains (A) a siloxane oligomer having an average molecular weight of 500-10000 in terms of ethylene glycol and (B) a fluorine compound having a number-average molecular weight of 5000 or more in terms of polystyrene and having a fluoroalkyl structure and a polysiloxane structure.

Owner:NITTO DENKO CORP

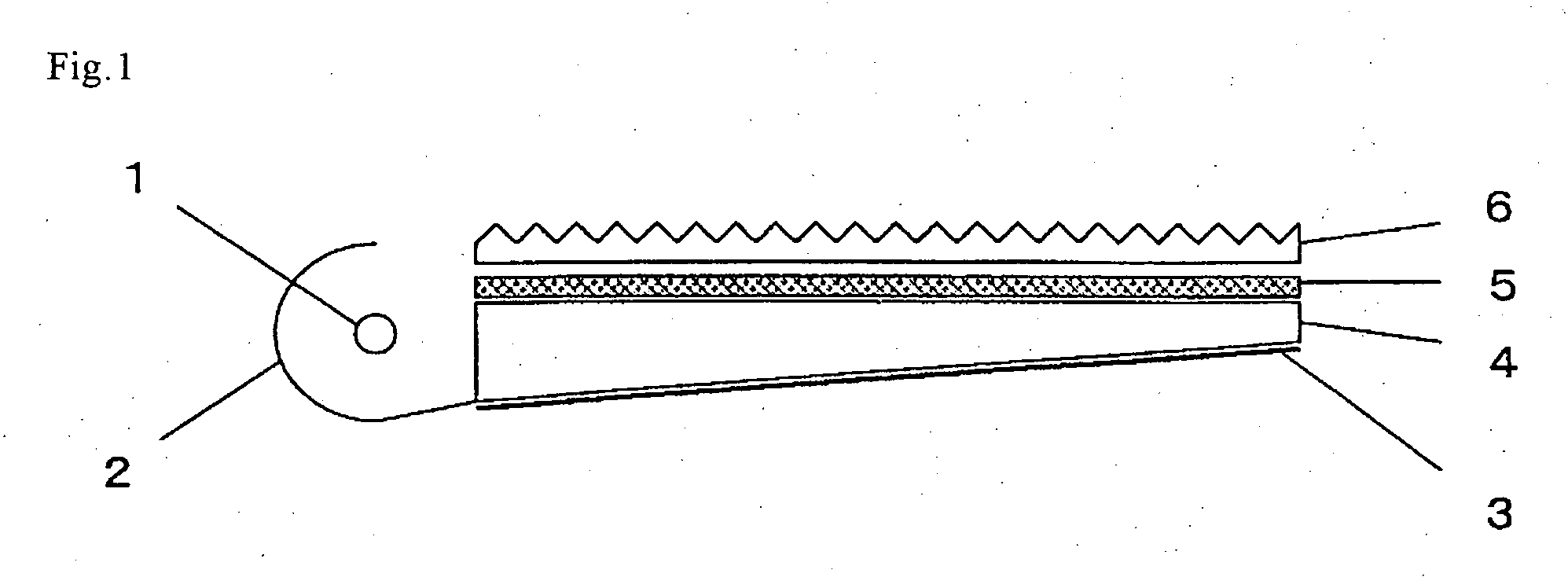

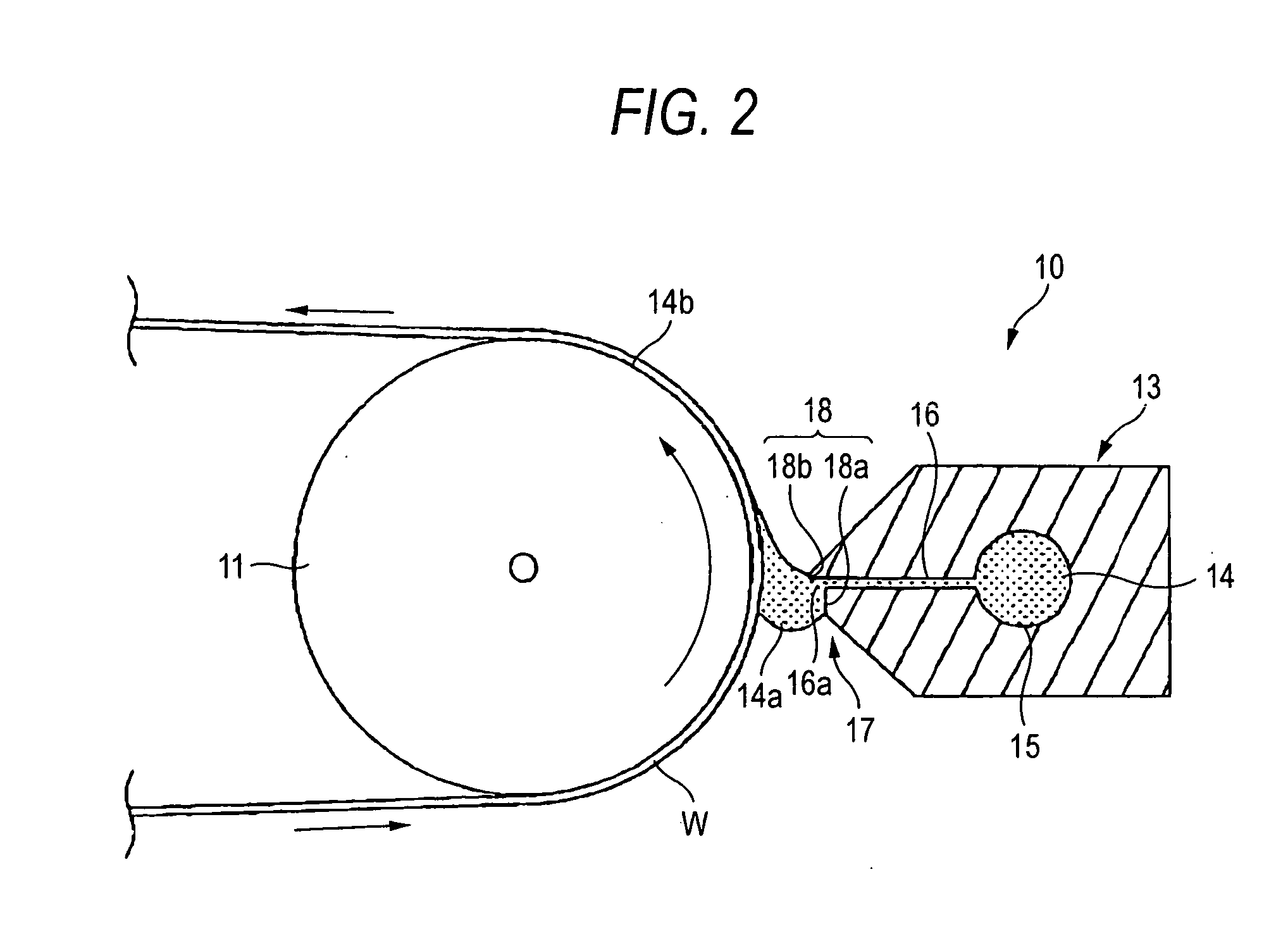

Epoxy resin binding agent for sand paper and its preparation method

InactiveCN1651542ALong shelf lifeExtended service lifeAbrasion apparatusEpoxy resin adhesivesEpoxyDiluent

An epoxy resin adhesive for abrasive paper is prepared from the component A composed of epoxy resin and diluent, the component B consisting of solidifying agent and toughening agent and the component C which is solvent through proportionally mixing component A with B, stirring, proportionally adding component C and stirring.

Owner:WUHAN UNIV OF TECH

Vinyl ester resin building steel-bar-planting glue and preparation method thereof

The invention discloses a vinyl ester resin building steel-bar-planting glue and preparation method thereof, wherein the glue comprises component A and component B by the weight ratio of 100 : 1-3, the component A comprises vinyl ester resin 30-45%, thickening agent 4-10%, filling material 40-55%, toughening agent 5-10%, defoaming agent 0.05-0.5%, coupling agent 0.05-0.5%, polymerization inhibitor 0.05-0.3%, accelerating agent 0.05-0.5%, and the component B comprises curing agent 50-70%, thinning agent 10-30%, filling material 10-30%, pigment 1-2%.

Owner:江苏大力士云石护理材料有限公司

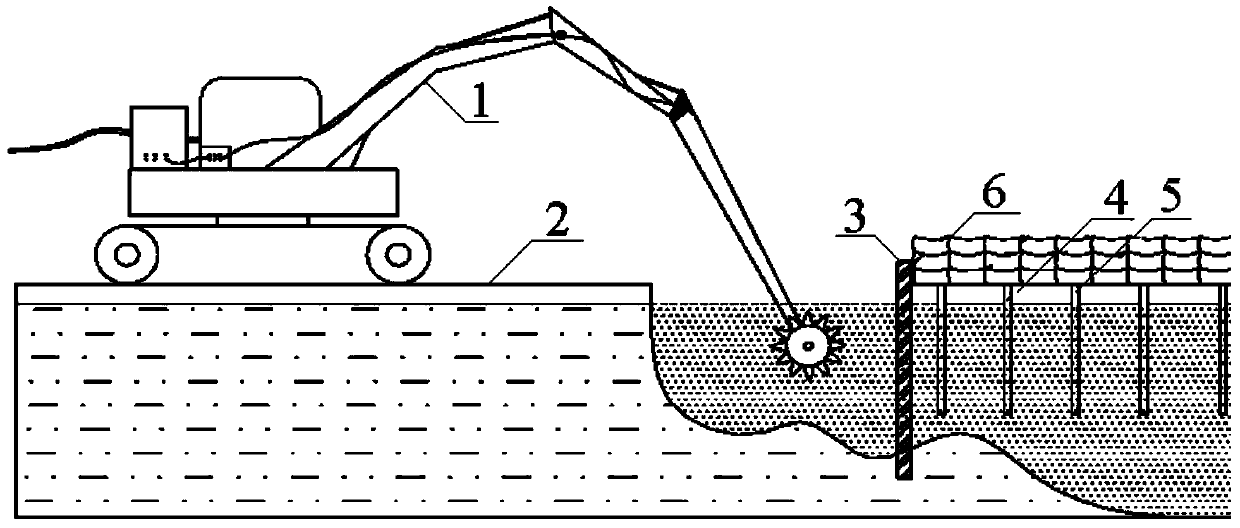

Biological solidification and stabilization method of bottom mud in riverways and lakes

InactiveCN102092916ASolve the way outReduce curing costsSludge treatment by de-watering/drying/thickeningBiological sludge treatmentAmylaseActive agent

The invention relates to improvement of a biological solidification and stabilization method of dredge bottom mud. The biological solidification and stabilization method is characterized by comprising the following steps: primarily dehydrating clay particles which have less possibility of being dehydrated, and mixing and stirring the dehydrated clay particles with dry soil to form mixed soil; and spraying a compound biological enzyme liquid at least consisting of reductase, amylase, cellulase, esterase, lipase, ligninase, prolease, urease, xylanase and a detergent surface active agent to be mixed with the mixed soil, then compacting and solidifying. The biological solidification and stabilization method has the advantages of short process flow and simplicity; by utilizing the method, the volume of the bottom mud to be solidified and stabilized is greatly reduced, the volume of the bottom mud to be solidified after classification and dehydration is 10%-15% of that of the bottom mud to be conventionally solidified, the processing flow is reduced compared with the existing biological enzyme solidification, the solidification cost is reduced, the solidification strength is high, the solidification filling shear strength can reach the Mpa grade, thus the method can be used for road construction, parking lots, slope solidification, reservoir surface solidification, refuse landfill bottom solidification and seepage prevention and public road building. By using the method, the outlet problem of the dredge bottom mud is effectively solved, and a novel decrement and solidification process for the bottom mud in the lakes is created.

Owner:GUANGZHOU ZHUSHUI ENVIRONMENT TECH

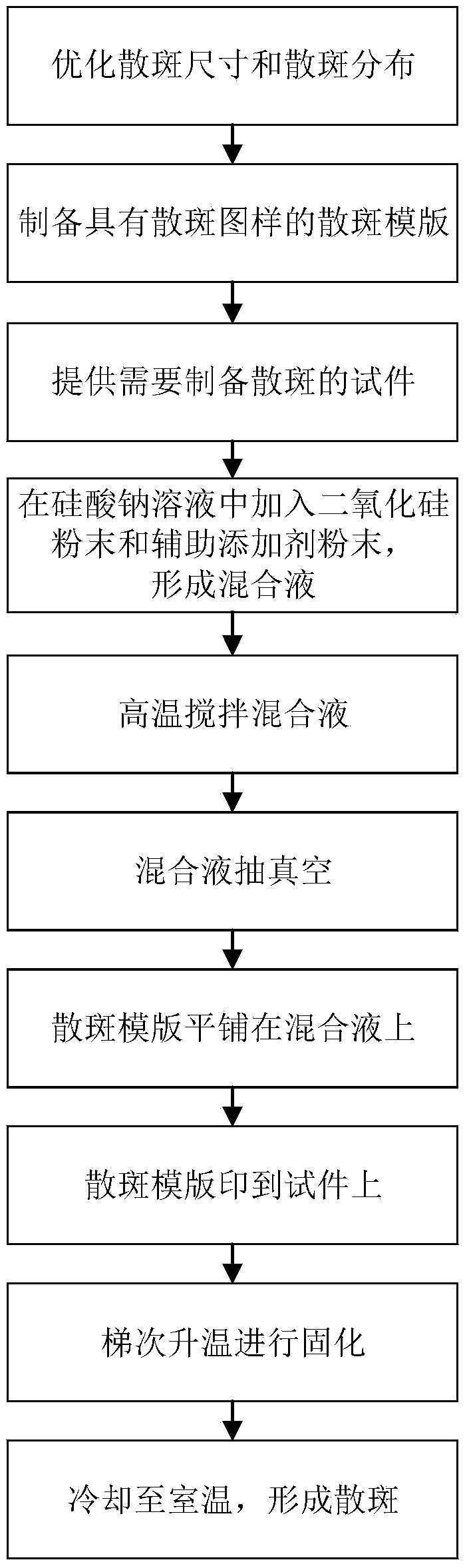

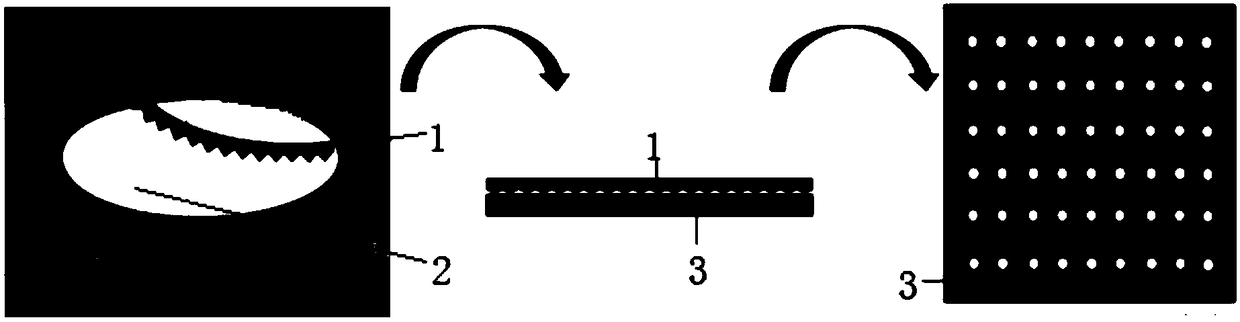

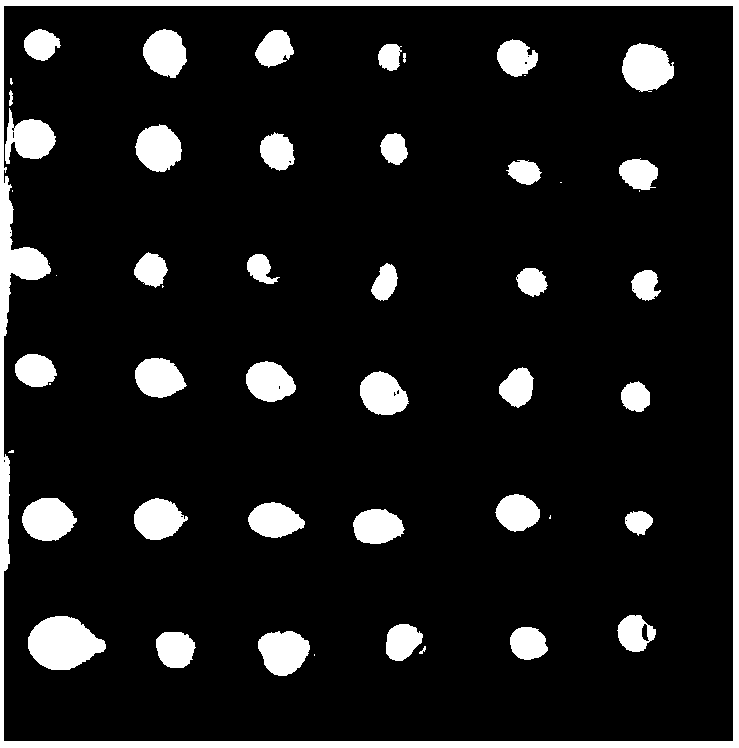

High-temperature speckle and controllable preparation method

ActiveCN108195298AGood high temperature resistance and high temperature adsorption performanceImproves curing strength and stabilityUsing optical meansToxicityEnvironmental resistance

The invention discloses a high-temperature speckle and controllable preparation method thereof. The high-temperature speckle uses a sodium silicate solution as a matrix, silicon dioxide powder and auxiliary additive powder are added to form a mixed liquid, the characteristics of short curing time, low curing temperature, good high-temperature-resistant performance, no toxicity and environmental protection are achieved, and sodium silicate itself has relatively high high-temperautre-resistant performance and high-temperature adsorption performance, and is suitable for being used for high-temperature speckle manufacture; a speckle template having a speckle pattern is prepared, thereby controlling the speckle size and speckle distribution; the speckle template can be repeatedly used, therebyfurther improving preparation efficiency; and after heating stirring, vacuumizing and gradient warming treatment, occurrence of a speckle bubbling phenomenon can be effectively reduced; materials of the high-temperature speckle are all conventional reagents, and are non-toxic under a normal using condition, thereby facilitating engineering practical application and large-scale manufacture; and thespeckle can meet a non-contact measurement requirement in high-temperature complex environments (thermal shock, and tension and compression deformation).

Owner:TSINGHUA UNIV

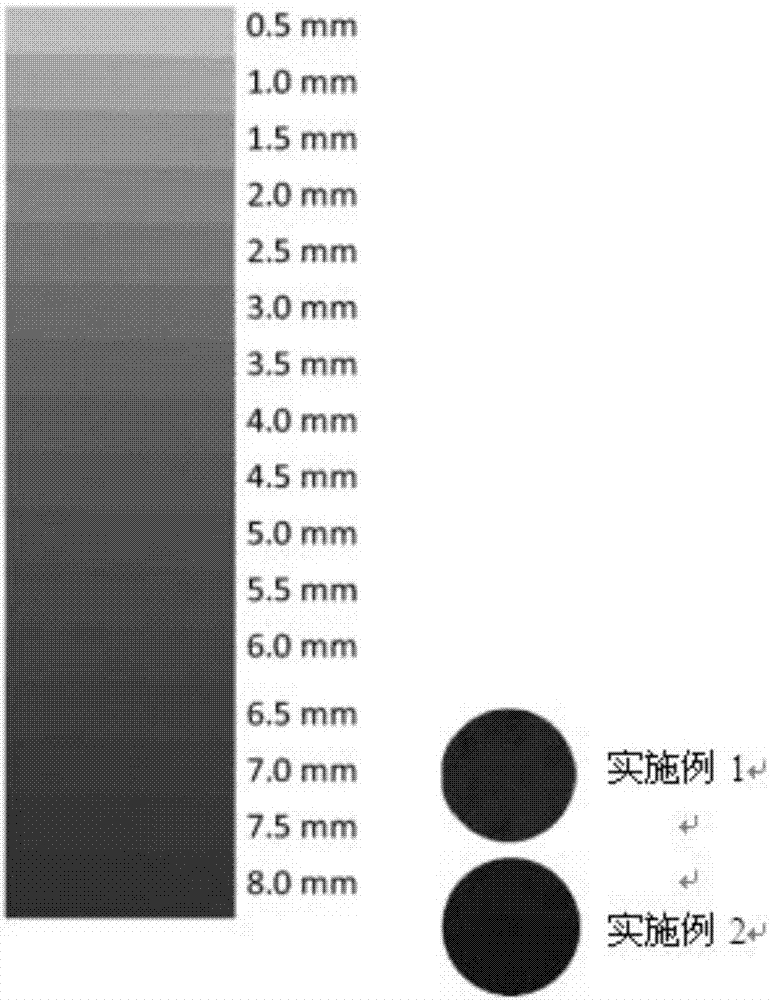

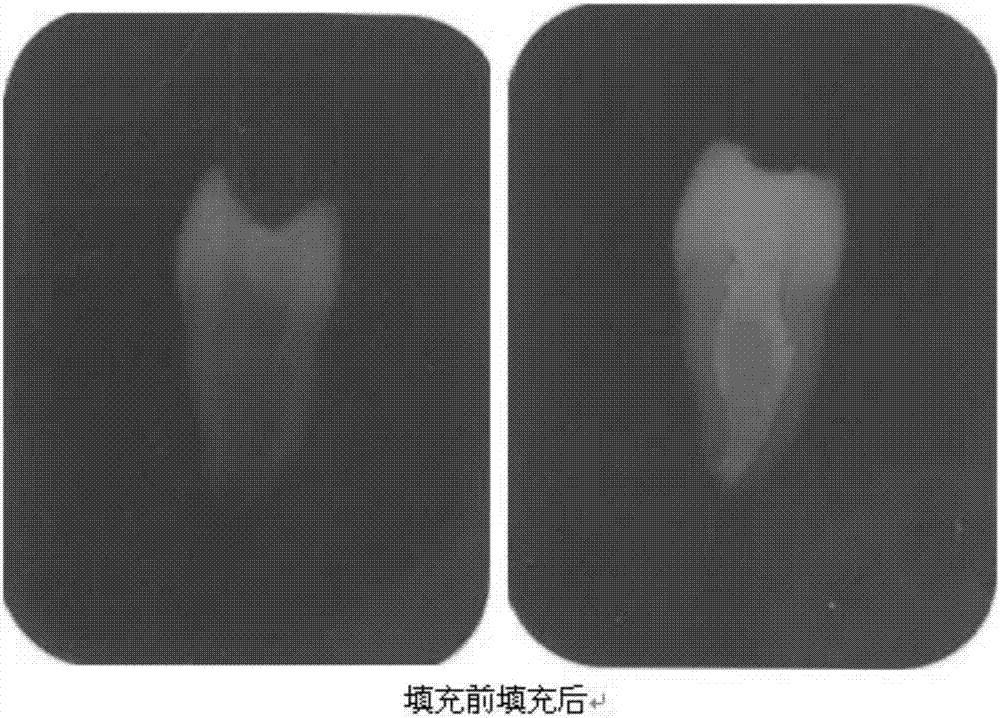

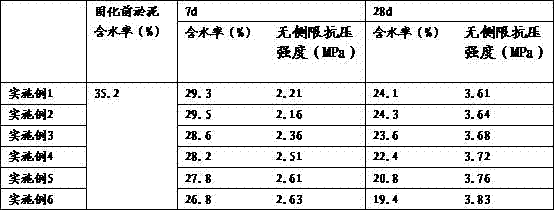

Premixed calcium silicate based root canal filling material with suspension stability as well as preparation method and application thereof

ActiveCN107080697APrevent precipitationPrevent flocculationImpression capsDentistry preparationsDispersion stabilityFlocculation

The invention provides a premixed calcium silicate based root canal filling material with suspension stability as well as a preparation method and an application thereof. At least one calcium silicate compound is used as a main phase, and at least a second phase for improving solidification performance, at least one nonaqueous phase solvent which can be mixed with water, at least one suspension stabilizing agent and at least one radiopaque material are added in order to prepare the root canal filling material with excellent injectable performance. An inorganic dispersant with suspension stabilizing effect is added into the premixed type calcium silicate based root canal filling material system, based on reservation of excellent biological compatibility, biological activity, marginal sealability, and the like of the calcium silicate material, layering, deposition or flocculation of the premixed system are effectively prevented, long-term dispersion stability of the premixed paste is improved, and the material can be used as a filling material for dental pulp capping, root canal therapy, and other dental restoration fields.

Owner:YANTAI ZHENGHAI BIO TECH

Compound curing agent for dredged silt and preparation method thereof

ActiveCN107226661AFully and evenly absorbedNo localized underabsorptionFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentFiberGraphite

The invention relates to a compound curing agent for dredged silt and a preparation method thereof. The compound curing agent for dredged silt comprises the following components in parts by weight: 20-30 parts of aluminum sulfate cement clinker, 30-40 parts of expandable graphite, 5-10 parts of organobentonite, 3-8 parts of pozzolanic material, 1-3 parts of calcined diatomite, 3-5 parts of enhanced aggregate, 6-12 parts of quicklime, 10-15 parts of sodium hydroxide, 8-10 parts of expansible resin, 5-8 parts of sodium silicate and 5-8 parts of carbon fiber. The curing agent provided by the invention combines the respective advantages of multiple traditional soil stabilizers, and the various effective components are organically combined together according to a proper ratio, thereby giving full play to the characteristics and synergistic action of the components. The curing agent provided by the invention has the advantages of favorable early strength performance, excellent strength stability, favorable water stability and the like, can obviously improve the properties of silt such as high water content, low strength and the like, and converts the waste dredged silt into a reproducible geomaterial for utilization, thereby achieving excellent curing effects and economic effects.

Owner:余思哲

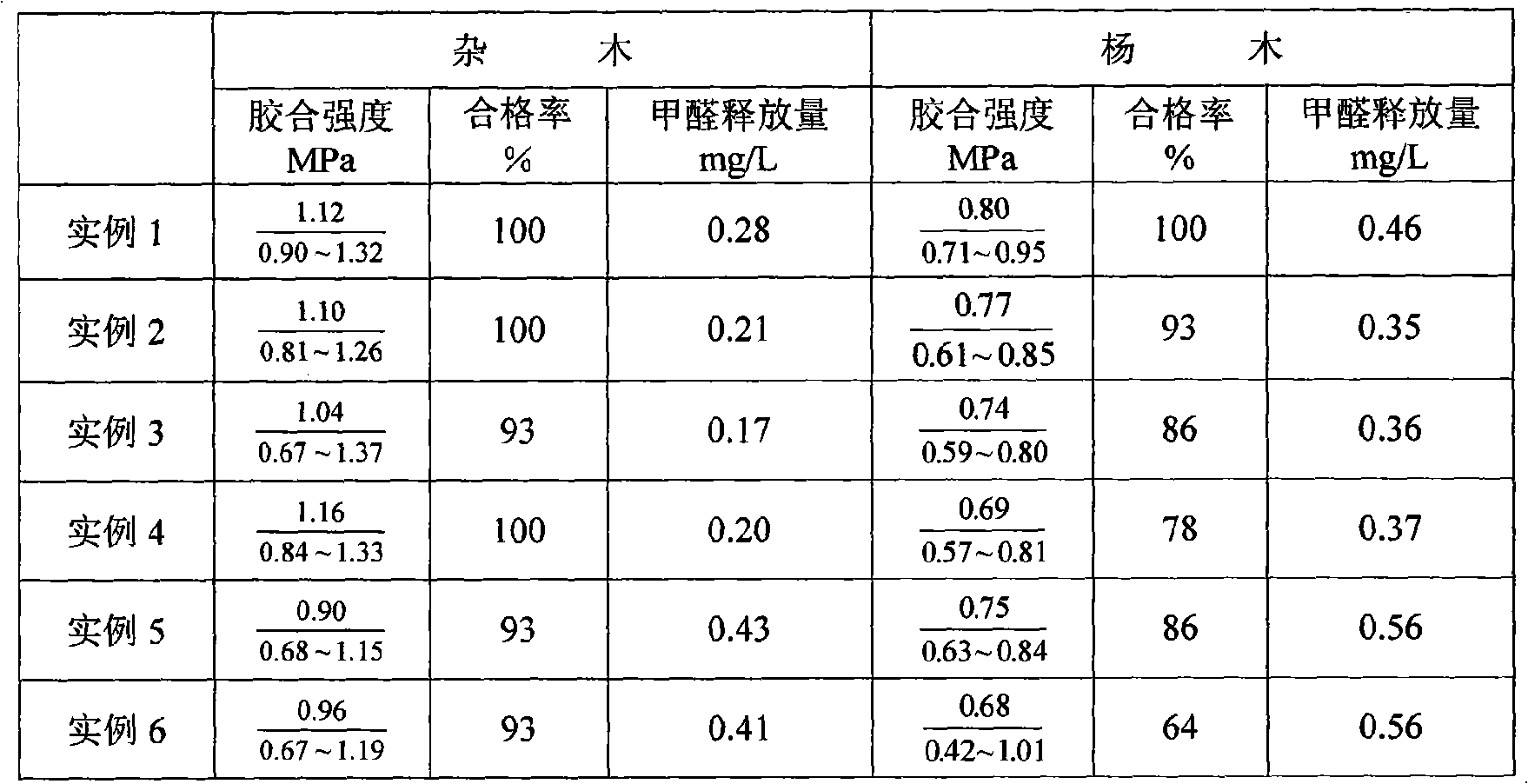

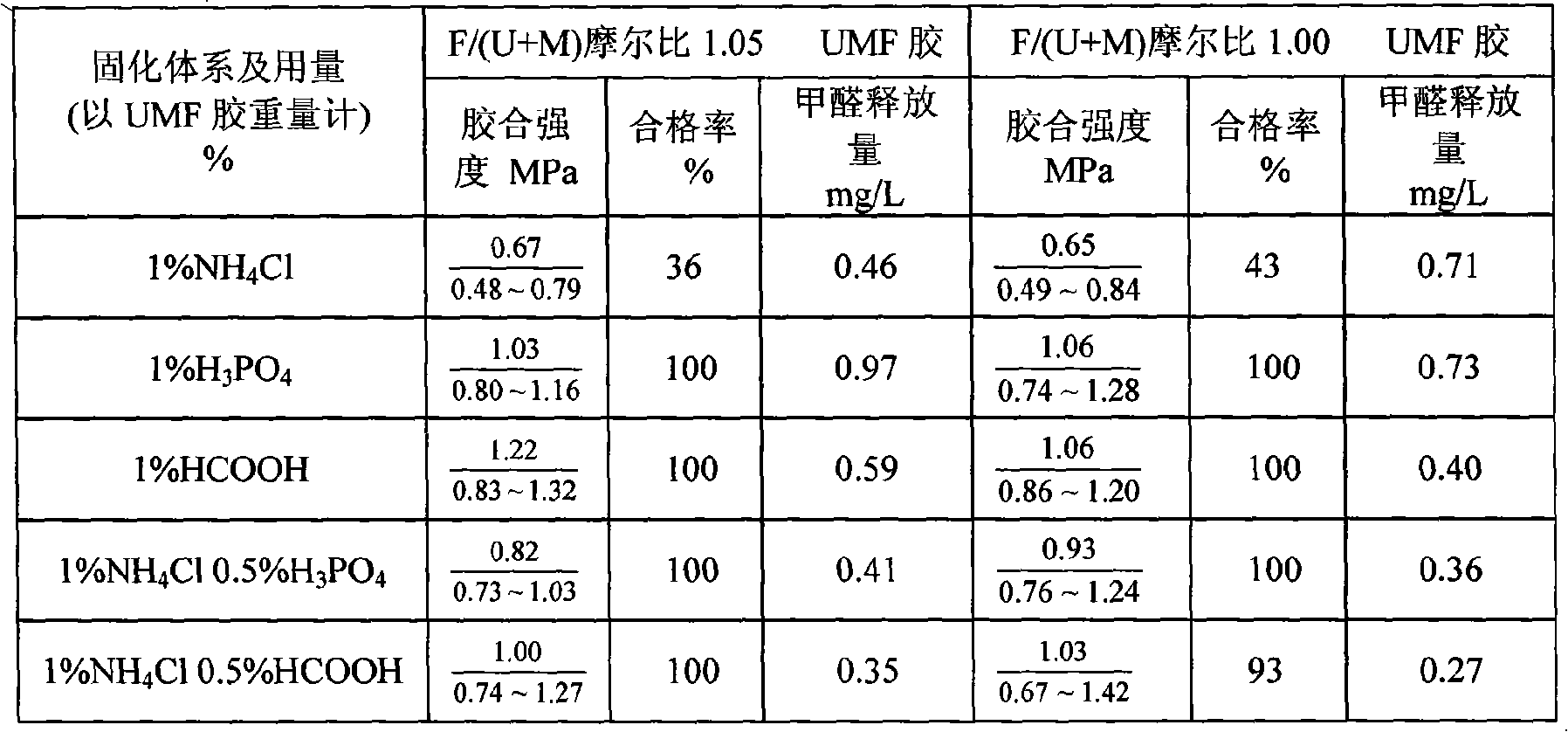

Preparation method of low-cost UMF resin adhesive used for E0-level plywood

InactiveCN101550323AReduce releaseIncrease the degree of cross-linkingAldehyde/ketone condensation polymer adhesivesEtherStrong acids

The invention discloses a preparation method of low-cost UMF resin adhesive used for an E0-level plywood. The preparation method of the adhesive is simple and has good reproducibility, lower cost and long storage period. For serayah plywood and poplar plywood pressed by the adhesive, the bonding strength and the formaldehyde emission thereof conform to the requirements of the E0-level plywood. The preparation method adopts the technique of a strong acid method, urea is selected for adding by four batches; melamine is added by three batches; the urea is added by batches, which can play the role of regulating the molecular weight of resin, especially the third adding of the urea not only can degrade macromolecule parts in rearranged molecules, but also can reduce the content of ether linkage therein, thus reducing the formaldehyde emission.

Owner:NANJING TECH UNIV

Single-composition room-temperature vulcanized silicone rubber sealant and preparation method thereof

ActiveCN104497959AWide temperature rangeGood weather resistanceNon-macromolecular adhesive additivesPolymer scienceVulcanization

A single-composition room-temperature vulcanized silicone rubber sealant and a preparation method thereof are disclosed. The sealant is composed of the following compositions in parts by weight: (A) 100 parts of alpha, omega-dihydroxy polydimethylsiloxane, (B) 10-30 parts of dimethicone, (C) 5-10 parts of a multi-functionality silane cross-linking agent mixture, (D) 1-5 parts of a silane coupling agent, (E) 50-150 parts of a reinforcing filling material, and (F) 0.1-0.3 parts of a catalyst; and the composition (C) is prepared by mixing the following components in percent by weight: C1, 0-30% of methyltris(methylethylketoxime)silane , C2, 0-30% of vinyltris(methylethylketoxime)silane, and C3, 50-80% of a ketoximinosilane partial hydrolysate. The novel multi-functionality silane mixture is employed as a cross-linking agent, so that the curing speed and the curing initial-stage strength are greatly improved, the dependence of the sealant to environment temperature and humidity is reduced, and the sealant still has relatively good curing speed under the conditions of low temperature and low humidity.

Owner:富乐(苏州)新材料有限公司

Beach sludge composite curing agent as well as preparation method, use method and application thereof

InactiveCN105924109AEnvironmental protection is goodObvious superioritySludge treatment by de-watering/drying/thickeningPortland cementSludge

The invention discloses a beach sludge composite curing agent as well as a preparation method, a use method and an application thereof. The beach sludge composite curing agent is obtained by mixing and grinding of an ordinary Portland cement clinker, a sulphoaluminate cement clinker, phosphogypsum, desulfurization gypsum, mineral waste residues, a naphthalene-based additive and sulfates, wherein the weight percentages of the raw materials are as follows: 40-60% of the ordinary Portland cement clinker, 5-10% of the sulphoaluminate cement clinker, 2-4% of the phosphogypsum, 3-6% of the desulfurization gypsum, 30-50% of the mineral waste residues, 1-3% of the naphthalene-based additive and 3-5% of the sulfates. The beach sludge composite curing agent disclosed by the invention can greatly shorten the curing time of sludge, and is small in doping amount, high in concretion strength, low in construction cost, and good in curing stability.

Owner:天津市三川恒泰科技有限公司

Actinic ray curable ink-jet ink and printed matter

ActiveUS7119130B2Improve securityImprove stabilityOrganic chemistryDuplicating/marking methodsActinic RaysEthylene oxide

Owner:KONICA MINOLTA MEDICAL & GRAPHICS INC

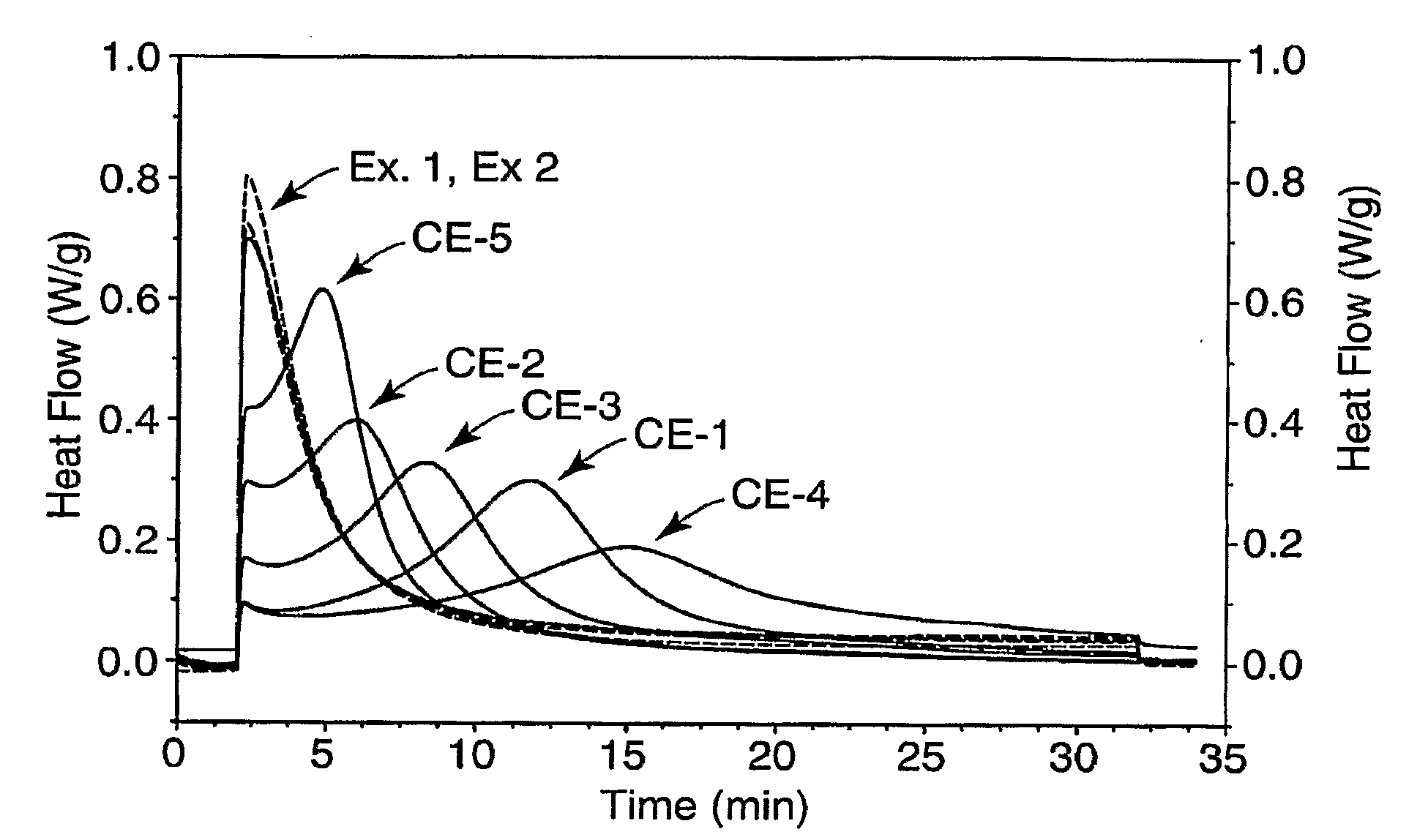

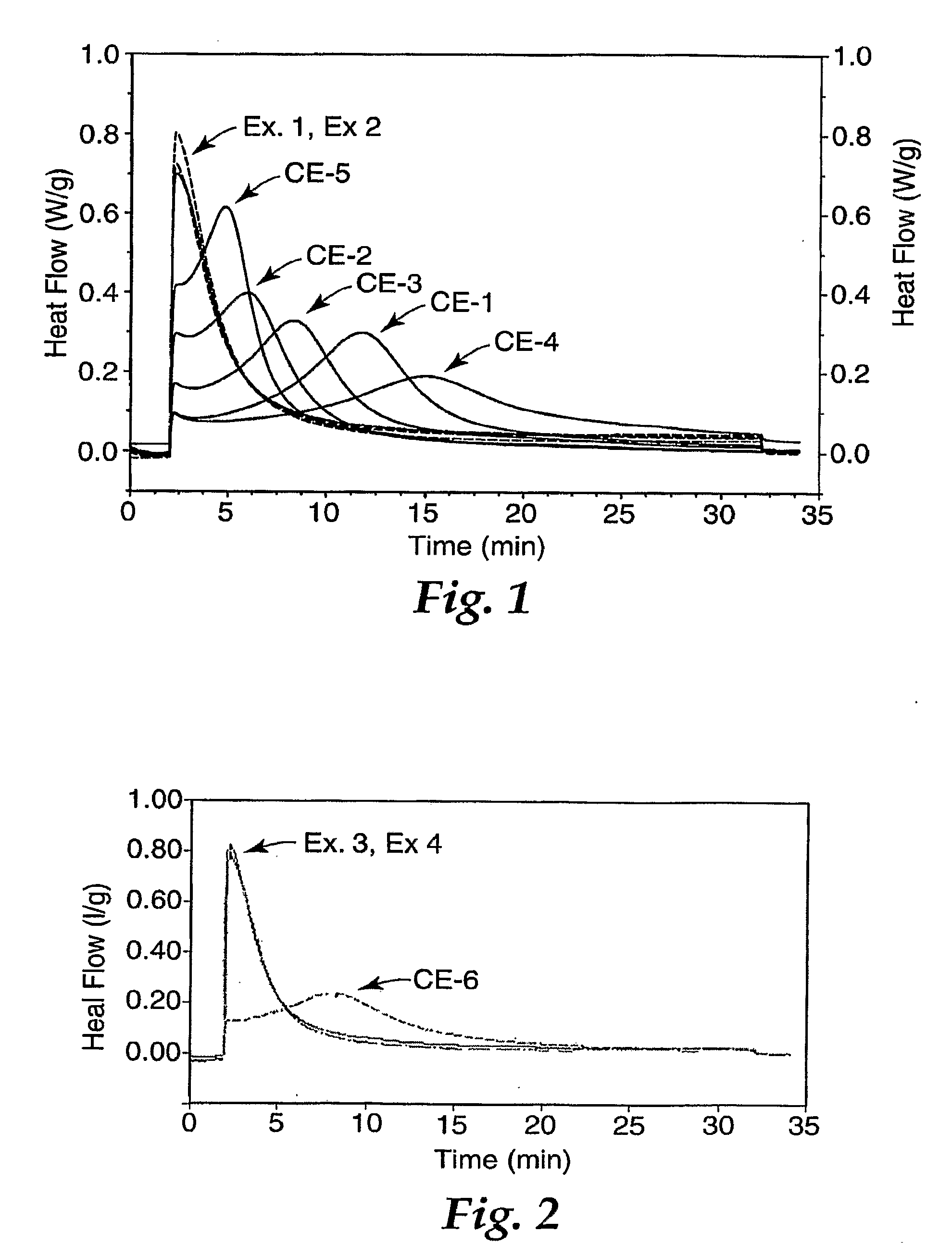

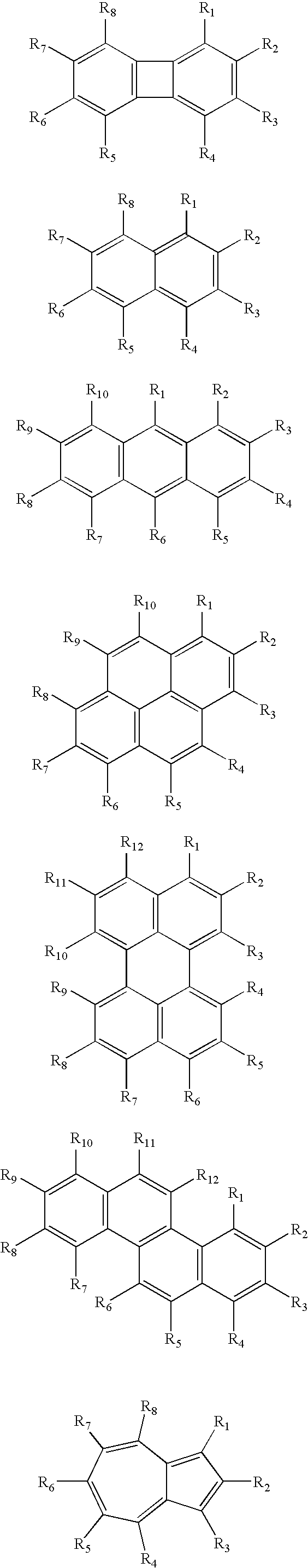

Dental Compositions and Initiator Systems with Polycyclic Aromatic Component

ActiveUS20090005469A1Desirable cureDesirable bond strength performanceImpression capsOther chemical processesPhotoinitiatorPhotochemistry

The invention features a polymerizable composition that comprises a free-radically polymerizable acidic resin, and a photoinitiator system comprising a polycyclic aromatic component. The photoinitiator system may also contain a visible light sensitizer, an iodonium salt, and a tertiary amine.

Owner:3M INNOVATIVE PROPERTIES CO

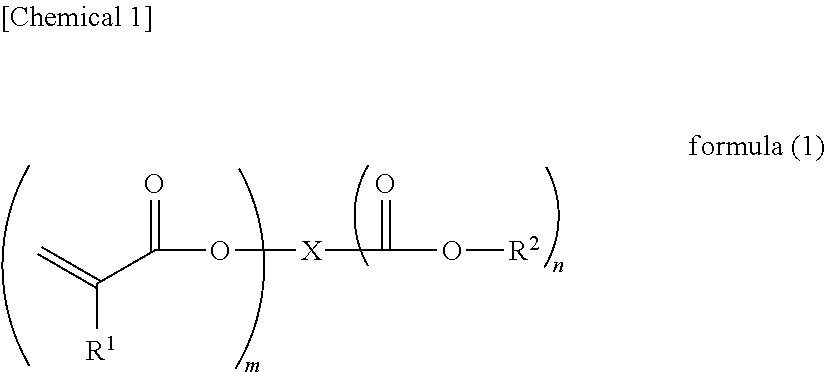

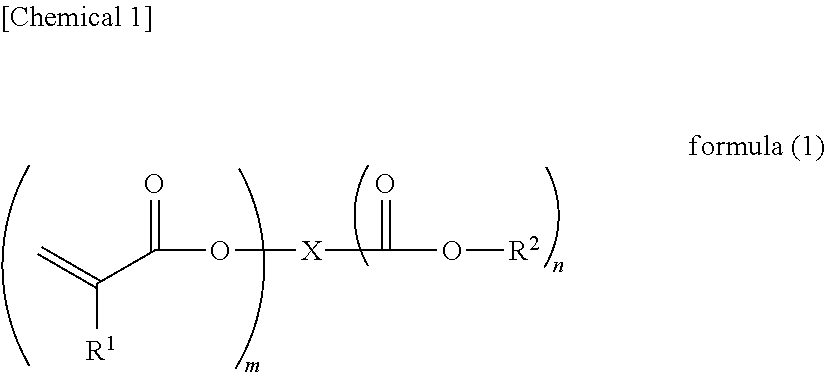

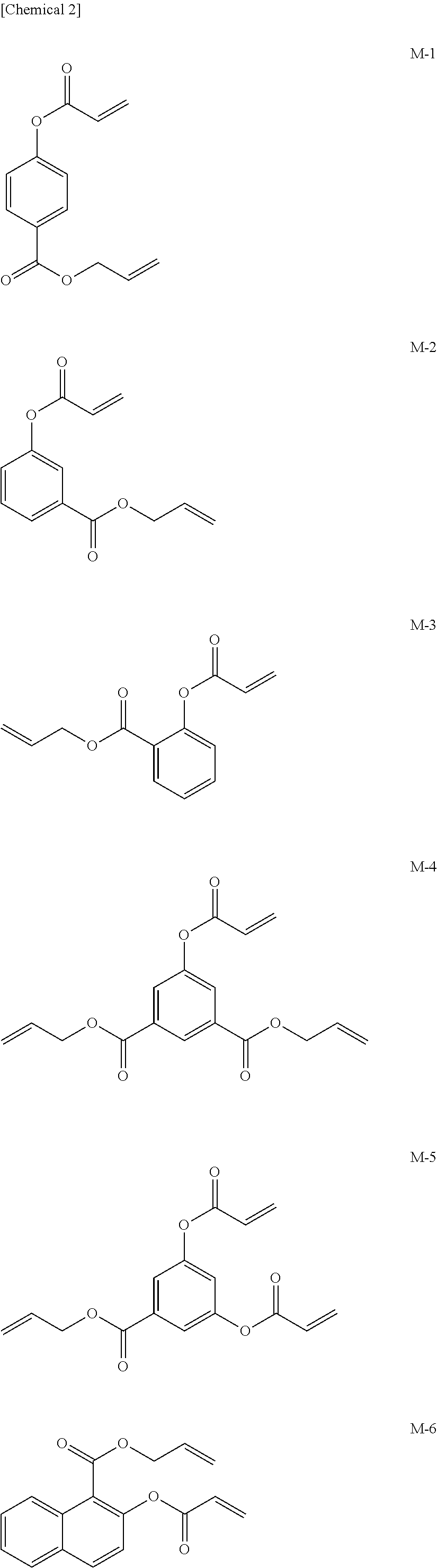

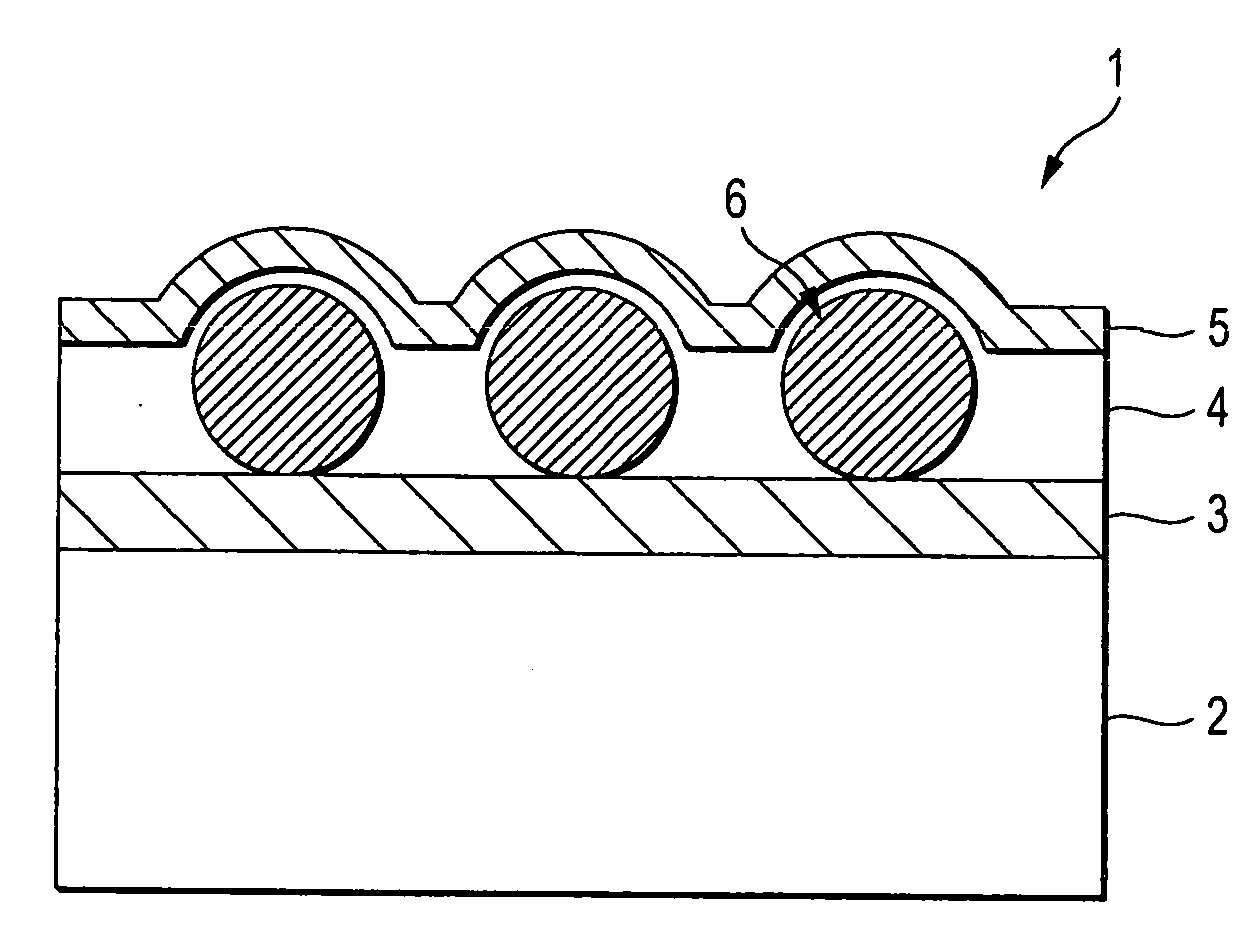

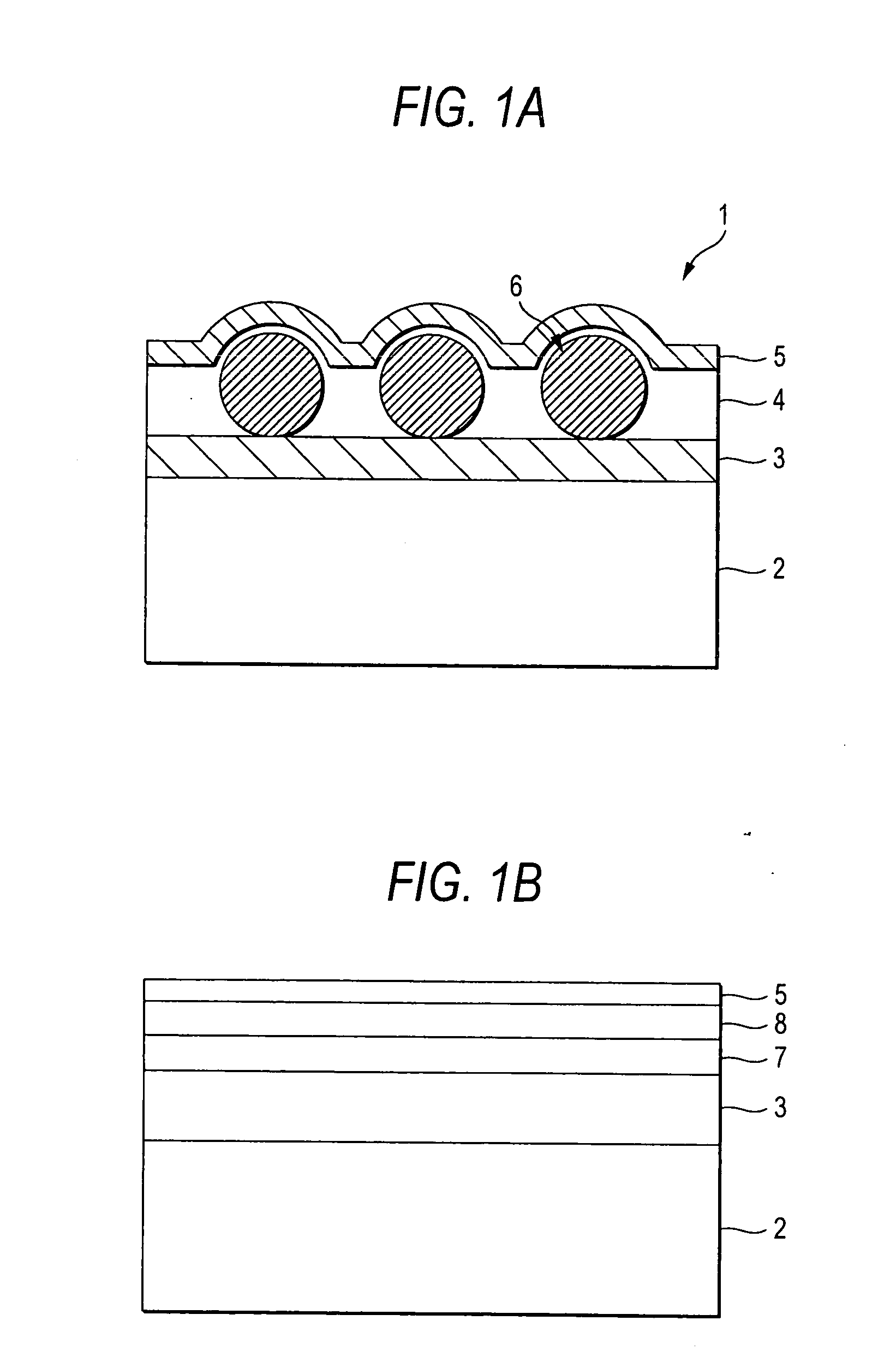

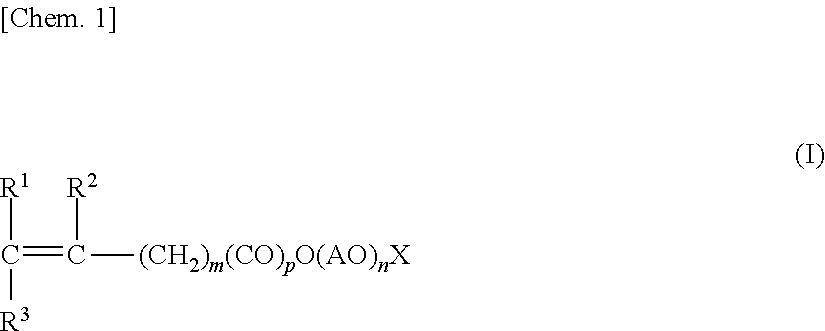

(METH)acrylate compound, curable composition using the same, curable composition for photo-nanoimprints, cured product of curable composition and method for manufacturing cured product

InactiveUS20110003909A1Satisfactory physical propertyHigh hardnessOrganic chemistryOrganic compound preparationMethacrylateHydrogen atom

It's object is to provide a (meth)acrylate compound excellent in photocurability, a curable composition comprising the compound and excellent in all of pattern accuracy, peelability, surface hardness, elasticity recovery and solvent resistance, an optical nanoimprint composition and a cured product of the curable composition and a method for producing it, especially to provide a composition favorable for a permanent film for flat panel displays, etc.A (meth)acrylate compound represented by the following formula (1):wherein R1 represents a hydrogen atom or a methyl group, R2 represents a substituent having carbon atoms of 2 to 6 and having a carbon-carbon double bond, X represents an organic group having carbon atoms of 1 to 10, m and n each are an integer of 1 to 3.

Owner:FUJIFILM CORP

Preparation method and application of phosphate inorganic casting binder suspension curing agent

InactiveCN101941045AHigh solid contentHigh solid content (>60%)Foundry mouldsFoundry coresOrganic acidPhosphate

The invention discloses a phosphate inorganic casting binder suspension curing agent and a preparation method thereof. The preparation method comprises the following steps of: adding organic resin to an alcoholic solvent; stirring to be fully dissolved and adding organic acid; stirring to be fully dissolved and then adding powder magnesia; and evenly stirring and dispersing to prepare the suspension curing agent. The invention also discloses the application of the curing agent to the foundry industry. The preparation method of the phosphate inorganic casting binder suspension curing agent is simple and adopts easily obtained raw materials with lower cost. The curing agent has the excellent performances of high efficiency, suspension rate and solid content, free toxicity, moderate reaction speed with the binder, and the like; a casting sand mould bonded by utilizing the curing of the curing agent and the organic binder has high sintering strength and stable sintering performance without a dust flying phenomenon in a sand-mixing process or generating dust pollution and is easy to popularize and apply in the foundry industry.

Owner:HUBEI UNIV OF TECH

Antireflection film, polarizing plate, and image display device

InactiveUS20090080073A1Sufficient anti-reflection propertyImprove scratch resistanceFibre treatmentSynthetic resin layered productsRefractive indexDisplay device

An antireflection film comprising a transparent support and a low-refractivity layer as an outermost layer, the low-refractivity layer being formed by a specific fluoropolymer-containing composition, and a polarizing plate and an image display device comprising the antireflection film.

Owner:FUJIFILM CORP

River sludge composite curing material with high organic matter content and application thereof

The invention discloses a river sludge composite curing material with high organic matter content. Cement, coal ash, quick lime and yellow ground are adopted as main materials; and the additive is one or more of an activator, a reinforcer and an early strength agent; and the river sludge composite curing material comprises the following components in percentage by weight: 40%-60% of river sludge with high organic matter content, 10%-20% of cement, 10%-20% of coal ash, 2%-10% of quick lime, 2%-10% of yellow ground, 0-10% of activator, 0-1% of reinforce and 0-1% of early strength agent, wherein the contents of the activator, the reinforce and the early strength agent cannot be simultaneously zero. The composite curing material disclosed by the invention is applied to the river sludge with high organic matter content, so that the sludge can be cured into a building material. The original method of improving the strength by purely adding cement is improved; the additive disclosed by the invention has the advantages of being small in adding amount, low in price, easily available and high in strength increase proportion. Besides, the river sludge composite curing material disclosed by the invention can be used for effectively increasing the curing strength of the sludge with high organic matter content.

Owner:HOHAI UNIV

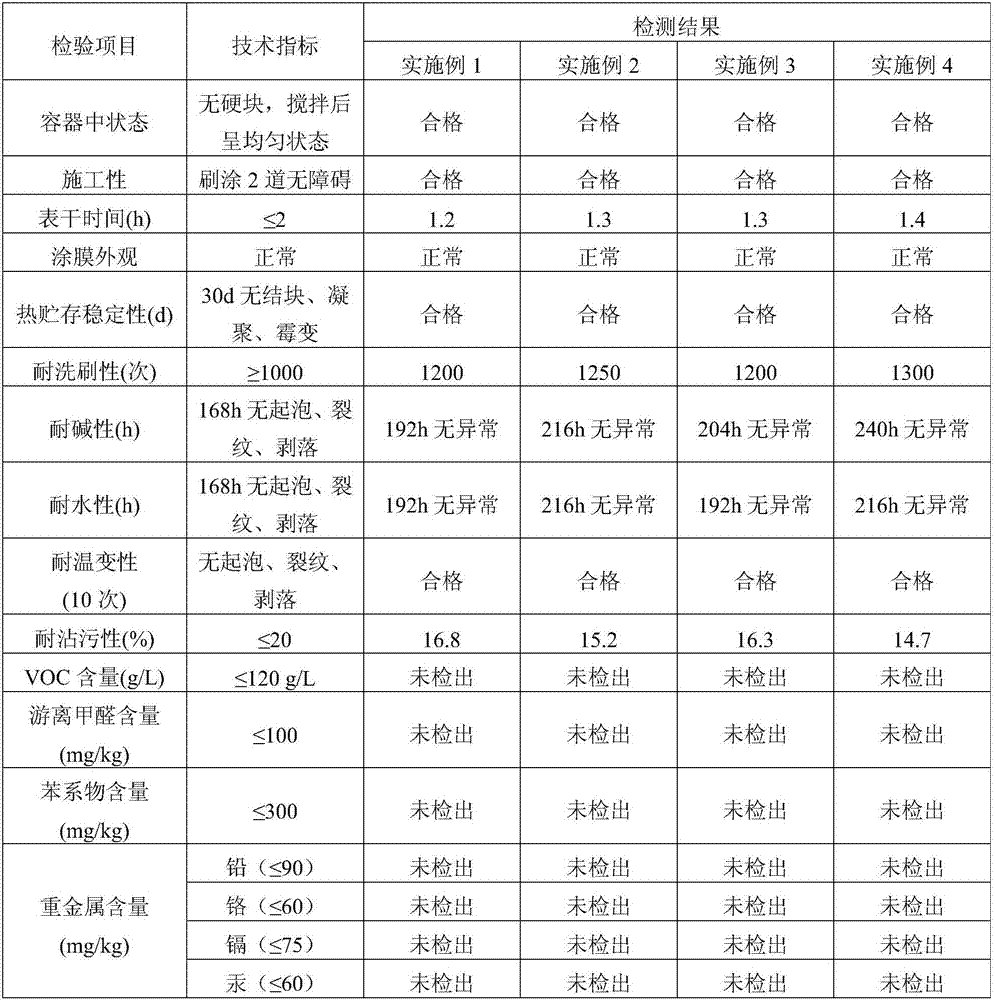

Novel environment-friendly waterborne inorganic paint and preparation method thereof

InactiveCN107266944AFire retardantAntibacterial and antifungalFireproof paintsAntifouling/underwater paintsPolyvinyl alcoholFire resistance

The invention discloses novel environment-friendly waterborne inorganic paint and a preparation method thereof. The novel environment-friendly waterborne inorganic paint is prepared from, by weight, 55-65 parts of kaolin, 12-20 parts of sodium silicate, 20-30 parts of titanium dioxide, 1-5 parts of nano zinc oxide, 5-10 parts of ultrafine wollastonite powder, 1-10 parts of nano calcium carbonate, 1-5 parts of ultrafine white mica powder, 7-15 parts of polyvinyl alcohol, 1-4 parts of ultrafine molybdenum disulfide powder, 2-10 parts of nano silicon dioxide, 2-12 parts of nano magnesium oxide, 2-12 parts of nano aluminum oxide, 1-3 parts of magnesium chloride, 1-3 parts of a sodium silicate hardening accelerator, 2-5 parts of a pH value regulating agent, 1-8 parts of a waterproof agent, 6-10 parts of an antifoaming leveling agent, 1-3 parts of a thickening anti-settling agent and 280-310 parts of water. The novel environment-friendly waterborne inorganic paint which is environment-friendly waterborne inorganic paint for buildings is high in storage stability, excellent in water resistance and alkali resistance, strong in adhesion, high in fire resistance, high in strength and hardness, resistant to scratching and contamination, excellent in corrosion resistance and antibacterial property, free of formaldehyde, benzene compounds, VOC (volatile organic compounds) and heavy metal elements, completely environmental friendly and nontoxic, suitable for industrial production, easy for painting and convenient and quick in construction.

Owner:CHENGDU POLYTECHNIC

Oil and water well sealing and plugging agent and preparation method thereof

ActiveCN102504781ASatisfy the requirements of sealing blow-byEasy to prepareDrilling compositionCuring (chemistry)Oil field

The invention relates to the technical field of oilfield chemistry, in particular to an oil and water well sealing and plugging agent and a preparation method of the oil and water well sealing and plugging agent. The oil and water well sealing and plugging agent is suitable for sealing and plugging an oil and water well. The oil and water well sealing and plugging agent consists of the following raw materials: XP lost circulation additive, G-class oil-well cement, blast furnace KZ micro powder, borax and water. The oil and water well sealing and plugging agent has the beneficial effects that the oil and water well sealing and plugging agent is simple to prepare, is convenient to construct, is safe and reliable and has high plugging strength; the oil and water well sealing and plugging agent has the characteristics of excellent suspension stability, low initial viscosity, easiness for pumping, high temperature resistance, high curing strength and the like and is mainly applied to non-corresponding production layers caused by poor cementing quality or damage to a sleeve above and below a perforated section of the oil and water well; the requirements on sealing and plugging of the oil and water well can be met; and currently, the oil and water well sealing and plugging agent is accumulatively implemented for over 90 well times, good sealing and plugging effects are obtained and the water injection efficiency is also improved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

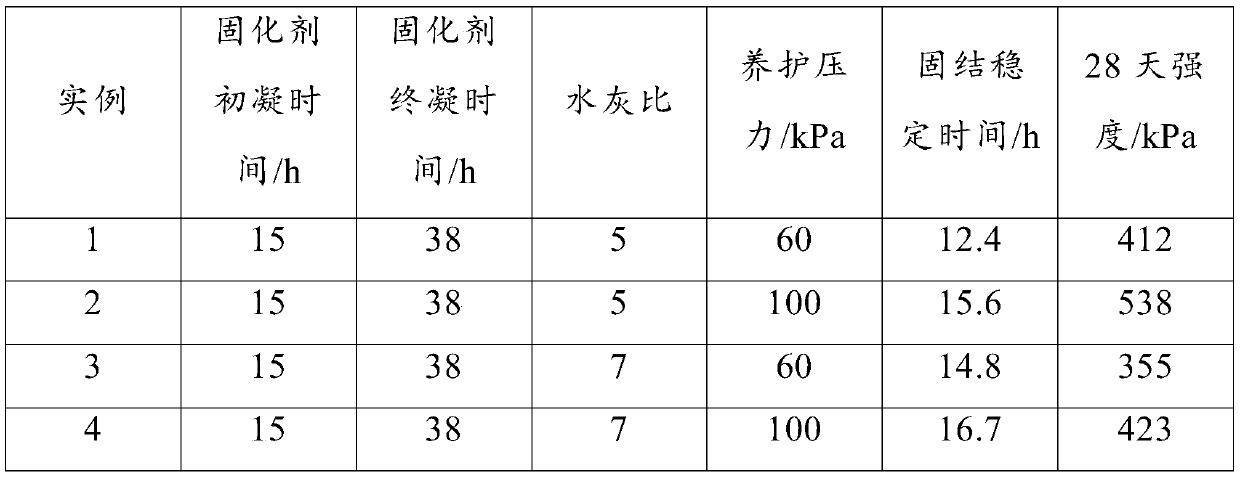

High-efficiency curing method for soft soil site with high moisture content

The invention belongs to the technical field of environment rock-soil engineering and discloses a high-efficiency curing method for a soft soil site with high moisture content. The high-efficiency curing method comprises an in situ chemical curing step and a preloading drainage step; the in situ chemical curing step comprises investigating sites, determining physical and chemical indexes such as depth, area, moisture content, organic matter content, liquid plastic limit and salt content of the soft soil site; blending a curing agent, determining the types, adding ratio, and initial and final setting time of the curing agent based on the physical and chemical indexes; blocking the site, and building partition walls for site blocking in the soft soil site; carrying out chemical curing construction, and uniformly mixing the blended curing agent with to-be-cured soft soil; carrying out preloading drainage construction according to three construction modes of vacuum preloading or surchargepreloading or vacuum surcharge preloading; unloading and repairing the site; after preloading time reaches 28 days, swabbing off drained water from the upper surface layer of curing blocks, unloadingand injecting cement slurry into a drain board for secondary repair and reinforcement by adopting a high-pressure grouting pump.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

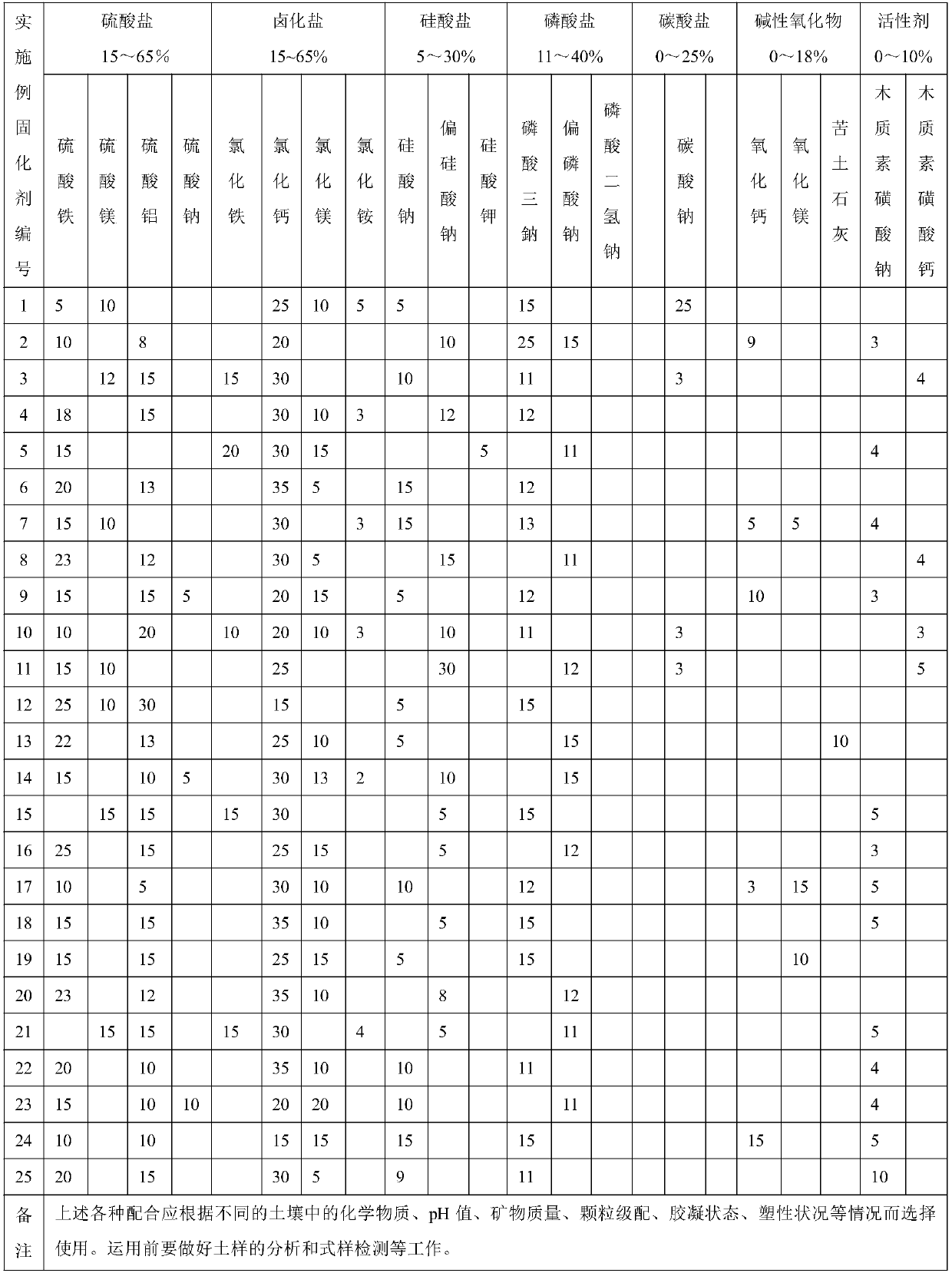

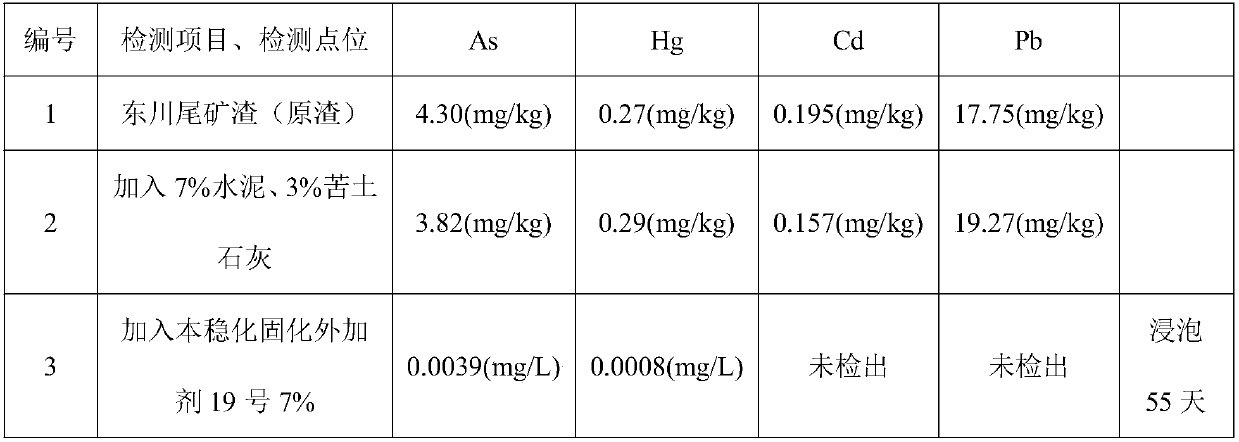

Environment-friendly inorganic soil solidification additive

InactiveCN105950157AImprove compatibilityFull effectOther chemical processesBuilding constructionsSoil propertiesHazardous substance

The invention provides an environment-friendly inorganic soil solidification additive which comprises, by mass, 15-65% of sulfate, 15-65% of halide salt, 11-40% of phosphate, 5-30% of silicate, 0-25% of carbonate, 0-18% of basic oxide and 0-10% of lignosulfonate. The environment-friendly inorganic soil solidification additive is characterized in that all components in soil directly or indirectly undergo soil particle surface chemical modification and modification of substances among soil particles, and generation of colloidal gel materials and generation of various materials of crystal structures are promoted. As time goes, hardened skeletons such as ettringite needle-shaped crystals and apatite crystals appear gradually in solidified soil, soil solidification compressive strength, hydrophobicity, water permeability, stability of heavy metal and other harmful materials and other physical and chemical solidification effects are good, and the environment-friendly inorganic soil solidification additive can adapt to various climates, geographies and soil properties and is high in compatibility and obvious in stabilization and solidification effect on heavy metal and other harmful materials.

Owner:松田勤

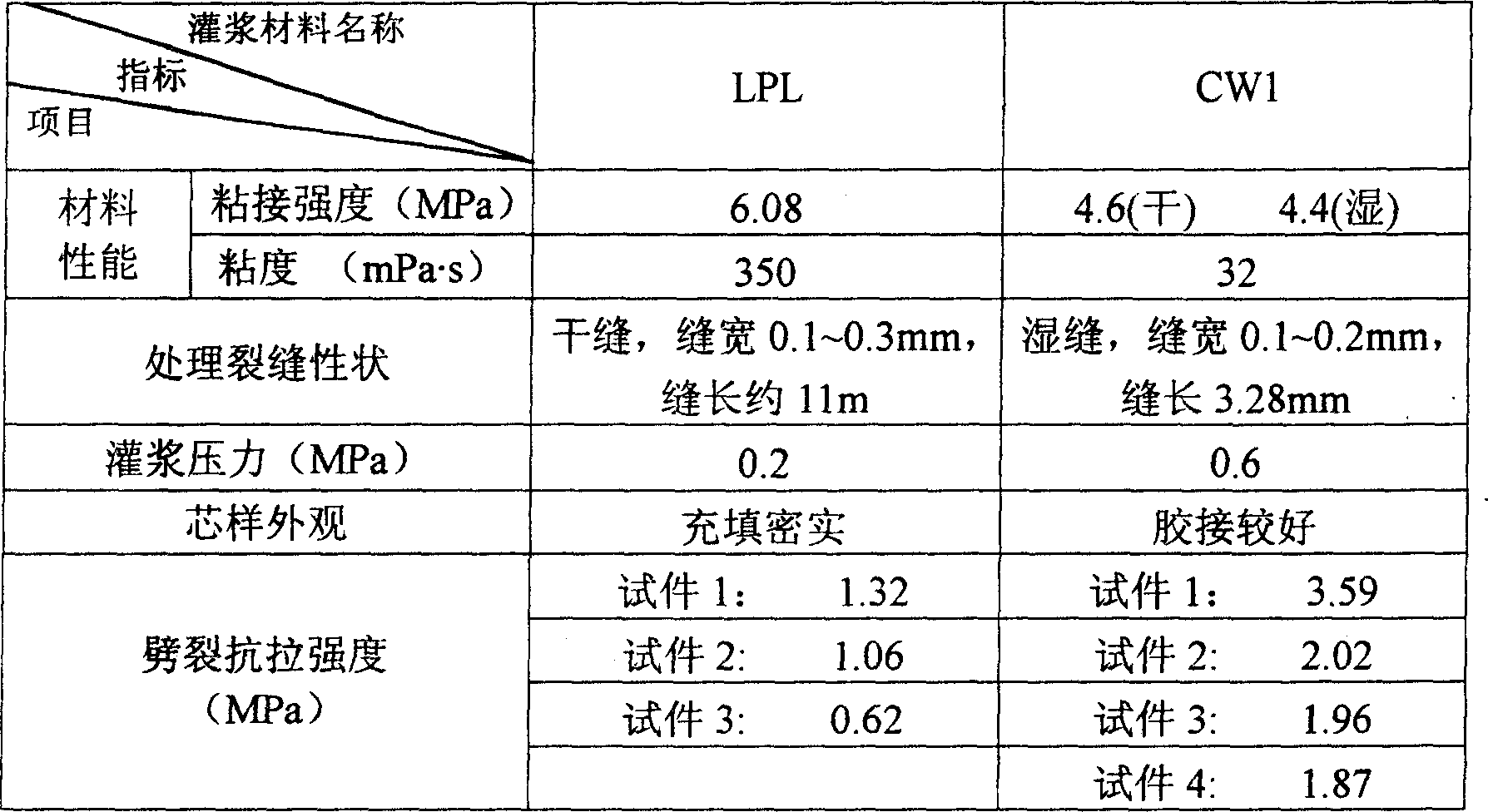

Underwater epoxy resin grouting material

InactiveCN1524916AGood cure shrinkageGood adhesionOther chemical processesSoil preservationEpoxyBenzaldehyde

A submerged epoxy resin grouting material which uses by weight of 100 parts of liquid epoxy resin with epoxide value of 0.51-0.54 as the host, and uses 5-50 parts of propanone, 10-60 parts of furfuraldehyde as the viscosity-reducing agent in grouting construction process and reactants in curing procedure, by admission of 10-60 parts of benzaldehyde hexamethylene diamine condensate or benzaldehyde m-phenylenediamine condensate and 0.5-5 parts of silanes through moistening, penetration and intensifier bonding to prepare the material, which can be suitable not only for dry and humid environment, but also for water containing condition.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Method for repairing concrete pavement

The present invention relates to a method for repairing concrete pavement. Said method includes removing powdered impurity and grease stain from surface of pavement let to be repaired; drying sand and broken stone; coating or spraying unsaturated polyester resin; using (by weight portion ratio) 1 portion of unsaturated polyester resin, 0.02-0.06 portion of solidifying agent, 3-5 portions of said and 4-6 portion of broken stone, firstly, uniformly mixing unsaturated polyster resin and solidifying agent, then mixing them with said and broken stone to obtain component A; uniformly mixing 1-2 portions of cement and 0.02-0.04 portion of accelerator to obtain component B; uniformly mixing A and B to obtain repairing material; spreading the repairing material to the lot to be repaired, compacting, striking off and spreading small quantity of dried cement powder on said lot so as to implement said repairing operation.

Owner:BOHAI UNIV

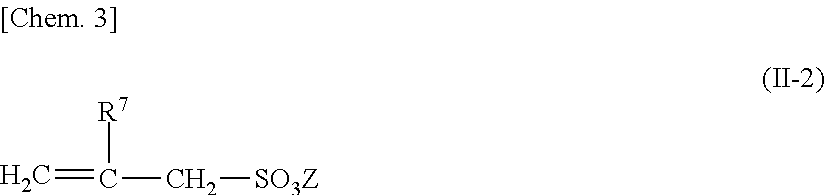

Shrinkage-reducing agent for hydraulic material and shrinkage-reducing agent composition for hydraulic material

ActiveUS20110291053A1High curing strengthQuality improvementOrganic chemistryOther chemical processesPolyolAlcohol

Provided are a shrinkage-reducing agent for a hydraulic material and a shrinkage-reducing agent composition for a hydraulic material including a compound represented by the general formula (1): R1—[O-(A1O)m—R2]n (1), where: R1 represents R1 derived from a polyhydric alcohol represented by R1—[OH]n; A1O represents an oxyalkylene group having 2 to 18 carbon atoms; R2 represents a hydrogen atom or a hydrocarbon group having 1 to 30 carbon atoms; m represents an average added mole number of oxyalkylene groups A1O's; n represents 3 or 4; and when n equals 3, m represents 30 to 150, and when n equals 4, m represents 5 to 150.

Owner:NIPPON SHOKUBAI CO LTD

Heavy crude thermal recovery steamed well slag plugging agent

ActiveCN101353570AImprove suspension stabilityShorten the setting timeDrilling compositionSlagBlock effect

The invention relates to a thick oil thermal steam injection well slag blocking agent, which is prepared by the following components: 5-10 percent of suspension dispersant, 10-40 percent of slag, 0.3-2.0 percent of hydration activator, 0.5-3.0 percent of retarder, 0.5-2.0 percent of intensifier and the rest of water. The blocking agent is characterized by good suspension stability, low initial viscosity, easy pumping, high temperature resistance and high solidified strength, etc., and can meet the requirements for blocking off a steam escape channel in exploring oil reservoirs by thick oil steam. The blocking agent has simple preparation, convenient construction, low cost and high blocking strength, is safe and reliable, and achieves excellent blocking effect after the application in exploring oil reservoirs by thick oil steam for more than 20 times.

Owner:中国石油新疆油田分公司采油工艺研究院

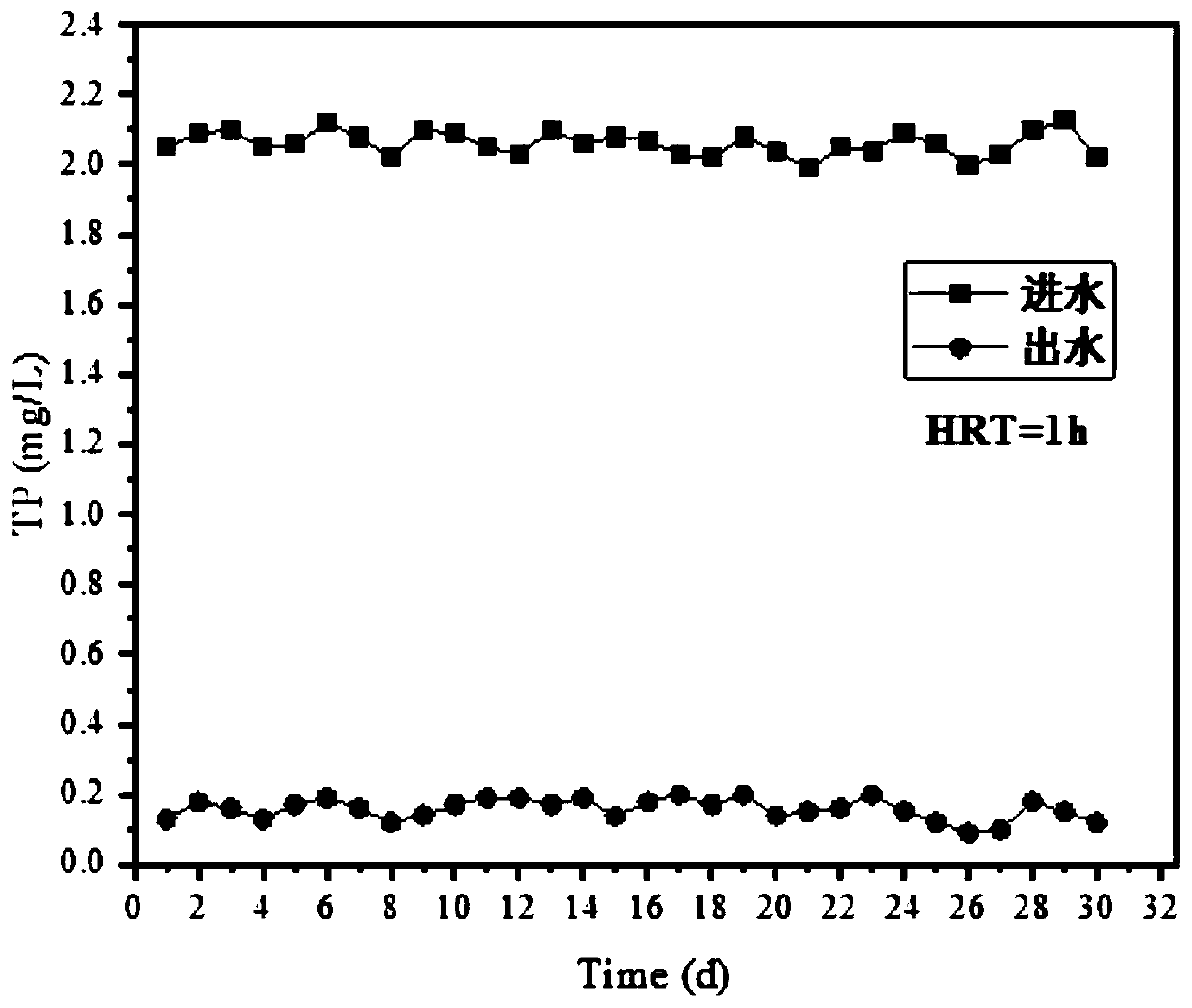

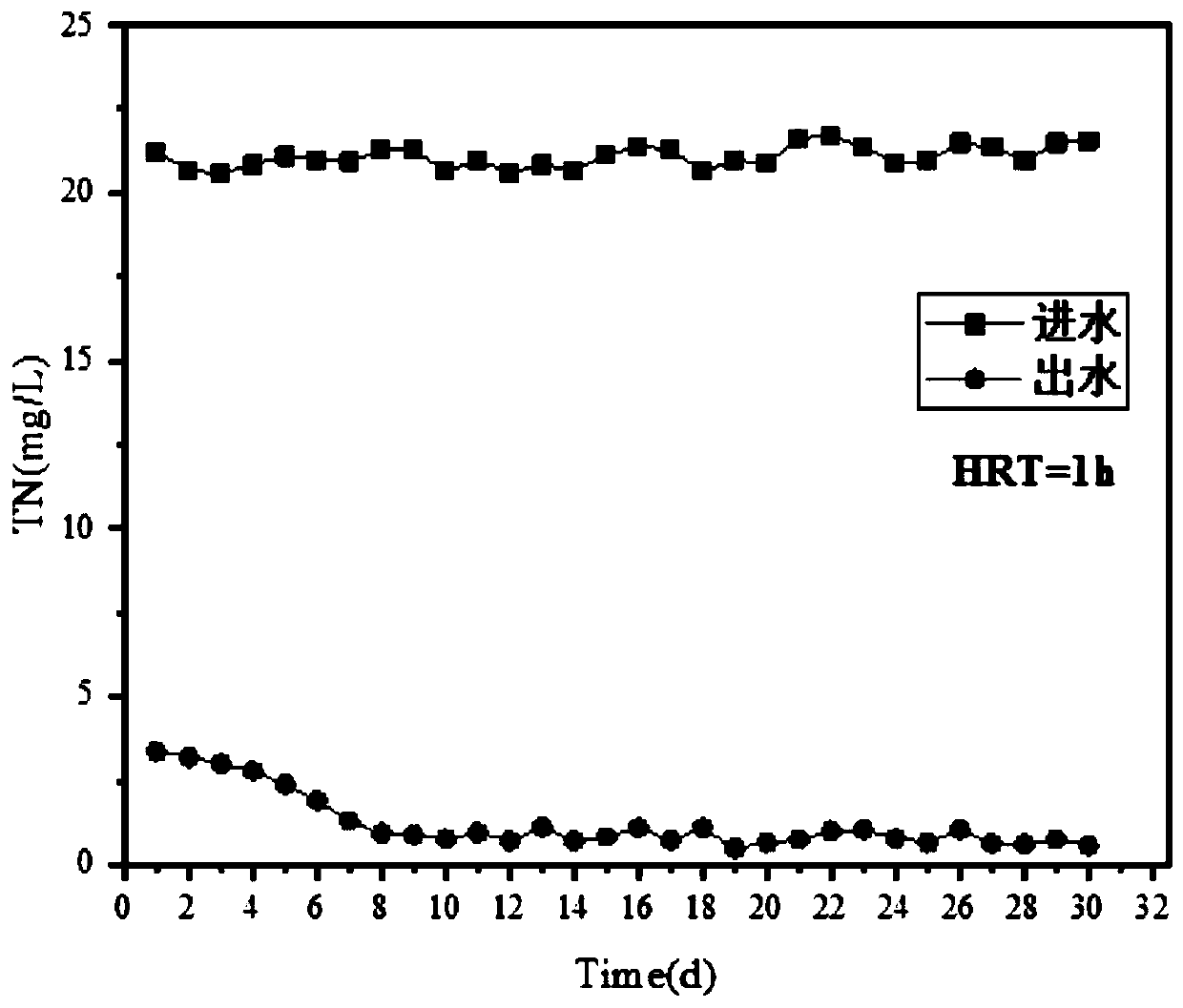

Synchronous denitrification and phosphorus removal composite filler and preparation method and application thereof

InactiveCN110683631AAchieve removalImprove stabilityTreatment with microorganism supports/carriersCarbonate mineralsSilicate Cement

The invention relates to the technical field of sewage treatment, and discloses a synchronous denitrification and phosphorus removal composite filler and a preparation method and application thereof.The composite filler comprises the following components in parts by weight: 15-20 parts of pyrite; 2-8 parts of sulfur; 0.5-1 part of carbonate minerals of calcium; 4.5-10 parts of Portland cement; 7.5-19.5 parts of water; and 0.5-3.0 parts of a foaming agent aqueous solution. Compared with a traditional sulfur autotrophic denitrification pyrite filler, the composite filler has a large specific surface area, high reactivity, light weight, and high hardness and strength, has efficient adsorption and precipitation effects on phosphorus, and has the characteristic that a large number of microorganisms can be loaded for biological denitrification, so that the composite filler is a multifunctional composite filler, and has good application prospects.

Owner:南京华创环境技术研究院有限公司

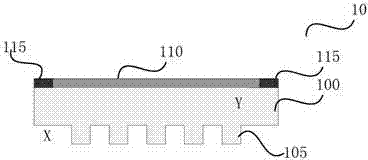

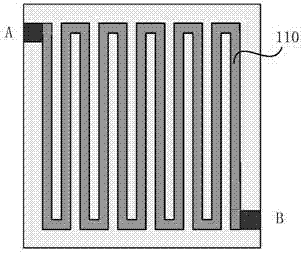

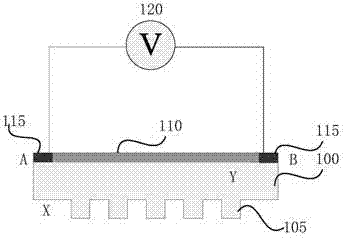

Nano-imprinting template, system thereof and imprinting method

ActiveCN103926789AReduce volumeLow costNanoinformaticsPhotomechanical apparatusUltraviolet lightsEngineering

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

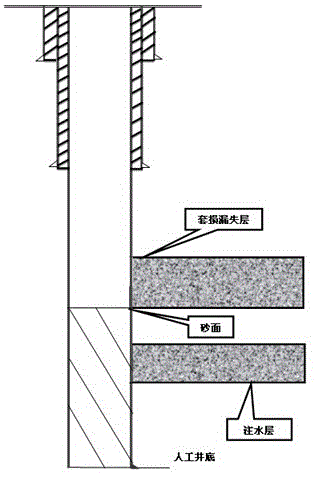

Casing damage leakage well high-efficiency phenolic resin water plugging agent and application thereof

InactiveCN106433590AExpand the affected volumeImprove fill rateDrilling compositionSealing/packingInjection pressurePorosity

The invention provides a casing damage leakage well high-efficiency phenolic resin water plugging agent and an application thereof; the water plugging agent is composed of the following raw materials in parts by weight: 30-90 parts of phenolic resin, 1-5 parts of urotropine, 0.1-1 part of potassium polyacrylate, 5-25 parts of silica fume, and 24-79 parts of water. The water plugging agent is applied for water plugging of a casing damage leakage water injection well with the temperature of 60 DEG C-130 DEG C; firstly, 60 mesh-100 mesh quartz sand is added into the well, the sand amount is equal to the volume from the depth of a casing damage leakage layer to the interior of an artificial well bottom casing pipe, the position from the sand surface to the casing damage leakage layer is reserved, and the amount of the water plugging agent is calculated according to the formula Q=[Pi]r<2>h[Phi], wherein r represents the water plugging agent treatment radius, h represents the casing damage leakage layer thickness, and [Phi] represents the casing damage leakage layer porosity; then the water plugging agent is pumped and injected into a leakage stratum, pumping injection is stopped until the injection pressure is increased to 3-5 MPa, the responding time to close a wellhead gate is not less than 48 hours, and the water plugging agent is overall cured at the casing damage leakage part and the stratum.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com