Synchronous denitrification and phosphorus removal composite filler and preparation method and application thereof

A technology for simultaneous denitrification and phosphorus removal and composite fillers, which is applied in the field of simultaneous denitrification and phosphorus removal composite fillers and its preparation, can solve the problems of high energy consumption and limited effect of material denitrification and phosphorus removal, and achieve high curing strength and hardness , Improve the rate of autotrophic denitrification and promote the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

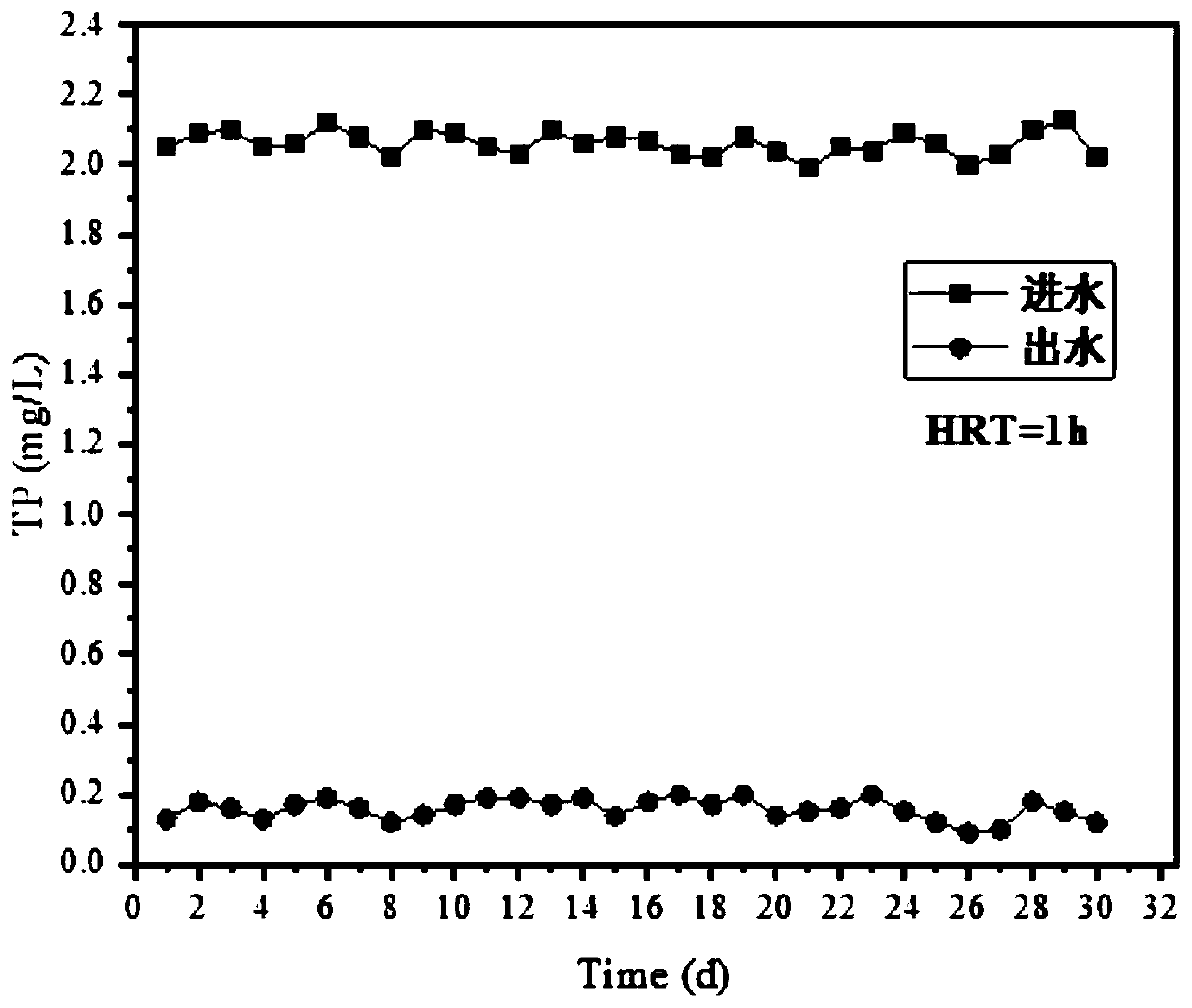

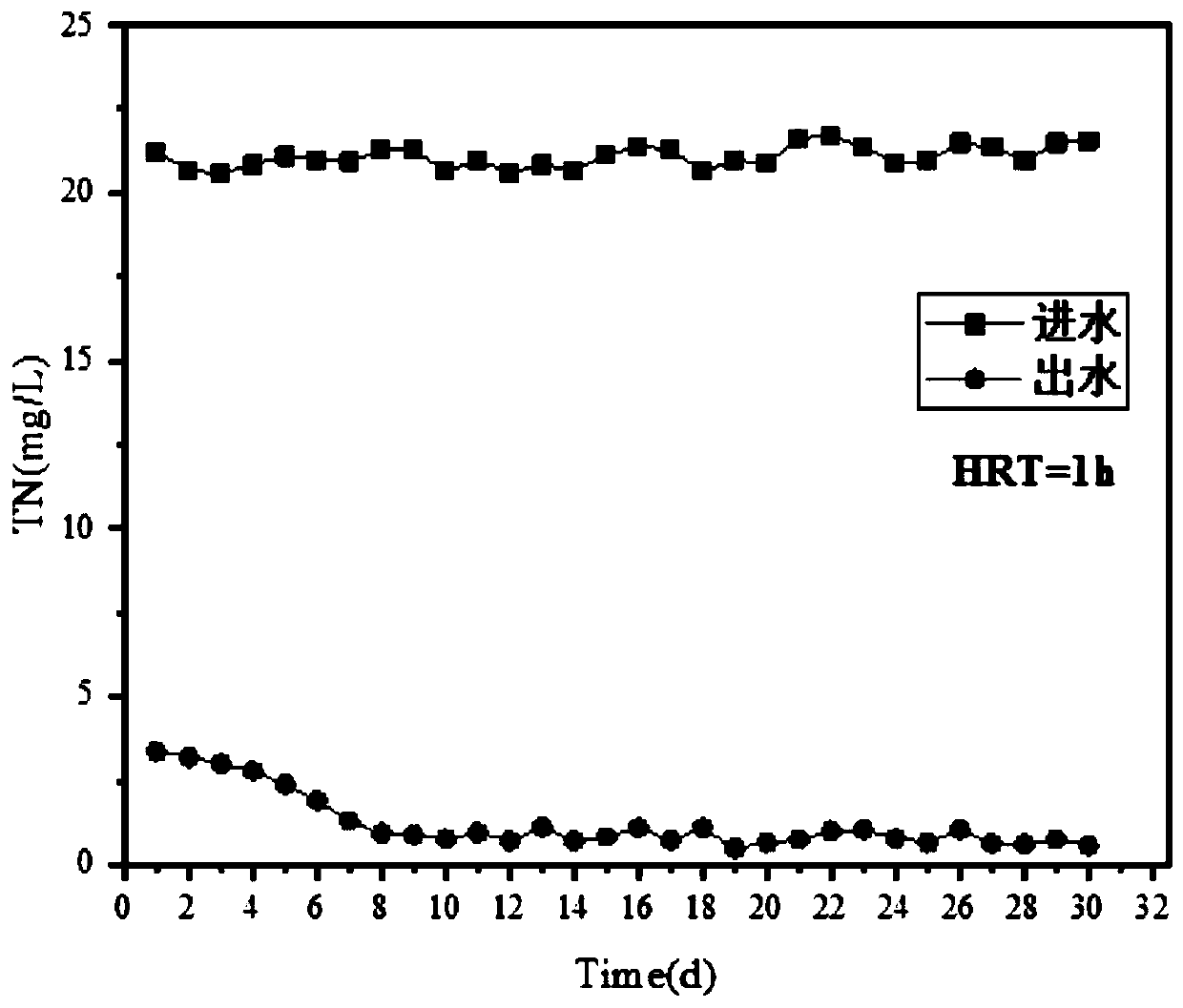

Image

Examples

Embodiment 1

[0032] This embodiment provides a composite filler for simultaneous denitrification and phosphorus removal, the raw materials of which are composed of the following components: pyrite powder (200 mesh) 350g, sulfur powder (100 mesh) 80g, limestone powder (100 mesh) 10g, silicon Salt cement (P·I 52.5) 96g, water 160g and 5% polyethylene glycol blowing agent aqueous solution 28g.

[0033] The preparation of the synchronous denitrification and dephosphorization composite filler by using the above raw materials includes the following steps:

[0034] (1) take by weighing pyrite powder, sulfur powder, limestone powder and portland cement of formula quantity respectively, mix evenly, must mix dry powder material;

[0035] (2) Add the clear water of formula quantity to above-mentioned mixed dry powder material, stir evenly, obtain mixed slurry;

[0036] (3) Add a formula amount of polyethylene glycol foaming agent to the above mixed slurry, stir and foam evenly for 10 minutes, pour...

Embodiment 2

[0039] This embodiment provides a composite filler for simultaneous denitrification and phosphorus removal, the raw materials of which are composed of the following components: pyrite powder (150 mesh) 330g, sulfur powder (80 mesh) 60g, limestone powder (80 mesh) 15g, silicon Salt cement (P·I 52.5) 95g, water 190g and 5% alkylbenzenesulfonic acid foaming agent aqueous solution 15g.

[0040] The preparation of the synchronous denitrification and dephosphorization composite filler by using the above raw materials includes the following steps:

[0041] (1) take by weighing pyrite powder, sulfur powder, limestone powder and portland cement of formula quantity respectively, mix evenly, must mix dry powder material;

[0042] (2) Add the clear water of formula quantity to above-mentioned mixed dry powder material, stir evenly, obtain mixed slurry;

[0043] (3) Add the alkylbenzene sulfonic acid foaming agent of formulation amount to above-mentioned mixed slurry, stir and foam evenly...

Embodiment 3

[0046] This embodiment provides a composite filler for simultaneous denitrification and phosphorus removal, the raw materials of which are composed of the following components: pyrite powder (150 mesh) 390g, sulfur powder (100 mesh) 60g, limestone powder (80 mesh) 10g, silicon Salt cement (P·I 52.5) 100g, water 205g and 4% foam concrete foaming agent aqueous solution 20g.

[0047] The preparation of the synchronous denitrification and dephosphorization composite filler by using the above raw materials includes the following steps:

[0048] (1) take by weighing pyrite powder, sulfur powder, limestone powder and portland cement of formula quantity respectively, mix evenly, must mix dry powder material;

[0049] (2) Add the clear water of formula quantity to above-mentioned mixed dry powder material, stir evenly, obtain mixed slurry;

[0050] (3) Add the animal protein foaming agent of formula quantity to above-mentioned mixed slurry, stir and foam evenly for 30 minutes, pour ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com