Casing damage leakage well high-efficiency phenolic resin water plugging agent and application thereof

A technology of phenolic resin and water blocking agent, which is applied in wellbore/well components, drilling composition, earth-moving drilling, etc., can solve the problem of inability to achieve complete overall plugging, large differences in flow capacity and large distribution differences and other problems, to achieve the effect of reducing the amount of invalid injection and capital investment, increasing the filling rate, and having a long validity period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

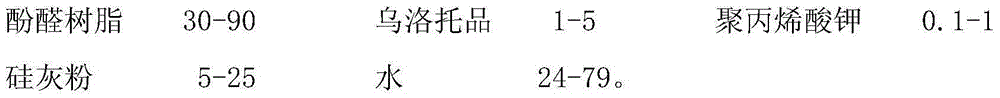

[0023] Take 79 kg of water and put it in the container, slowly add 0.1 kg of potassium polyacrylate into the container under stirring, according to the temperature conditions of the pre-sealing leakage formation and consider the safe construction time, then add 90 kg of phenolic resin, uroto 1 kilogram of product, 25 kilograms of silica fume powder, stir and mix, obtain casing loss leakage well high-efficiency phenolic resin water shutoff agent of the present invention.

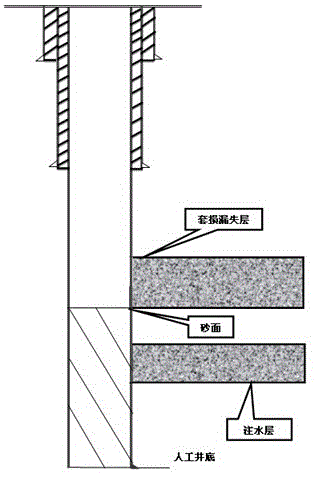

[0024] The water blocking agent is applied to water plugging of casing loss leakage water injection wells with a temperature of 60°C; firstly, 100-mesh quartz sand is put into the well, and the amount of sand is from the depth of the casing loss leakage layer to the inner volume of the artificial bottom casing, and the sand surface is reserved to the casing loss leakage. horizon, according to the formula Q=πr 2 hφ (where: r-water blocking agent treatment radius, h-casing loss loss layer thickness, φ-casing lo...

Embodiment 2

[0026] Take 24 kg of water and put it in the container, slowly add 1 kg of potassium polyacrylate into the container under stirring, according to the temperature conditions of the pre-sealing leakage formation, consider the safe construction time, and then add 30 kg of phenolic resin, uroto 5 kilograms of product, 5 kilograms of silica fume powder, stir and mix, obtain casing loss leakage well high-efficiency phenolic resin water shutoff agent of the present invention.

[0027] The water blocking agent is applied to the water plugging of casing loss water injection wells with a temperature of 130°C; firstly, 60 mesh quartz sand is put into the well, and the amount of sand is from the depth of the casing loss layer to the inner volume of the artificial bottom casing, and the sand surface is reserved to the casing loss. horizon, according to the formula Q=πr 2 hφ (where: r-water blocking agent treatment radius, h-casing loss loss layer thickness, φ-casing loss loss layer porosit...

Embodiment 3

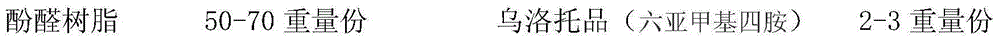

[0029] Take 45 kg of water and put it in the container, slowly add 0.5 kg of potassium polyacrylate into the container under stirring, according to the temperature conditions of the pre-sealing leakage formation, consider the safe construction time, and then add 50 kg of phenolic resin, uroto 3 kilograms of product, 12 kilograms of silica fume powder, stir and mix, obtain casing loss leakage well high-efficiency phenolic resin water shutoff agent of the present invention.

[0030] The water blocking agent is applied to water plugging of casing loss leakage water injection wells with a temperature of 60°C; firstly, 100-mesh quartz sand is put into the well, and the amount of sand is from the depth of the casing loss leakage layer to the inner volume of the artificial bottom casing, and the sand surface is reserved to the casing loss leakage. horizon, according to the formula Q=πr 2 hφ (where: r-water blocking agent treatment radius, h-casing loss loss layer thickness, φ-casing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com