A kind of natural carboxylate-polymer microsphere binary compound flood control system and its preparation and application

A binary compound and polymer technology, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of low saturation and low degree of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1: Determination of oil-water interfacial tension between natural mixed carboxylate and Gudao East heavy oil

[0067] Raw material: natural mixed carboxylate 3.0g.

[0068] Natural mixed carboxylate is composed of the following ingredients: animal oil soap 2%, peanut oil soap 4%, soybean oil soap 2%, cottonseed oil soap 90%, tea saponin 2%. For the preparation method, refer to CN1069913A (CN96109015.4).

[0069] Sewage 997g, sewage after oil-water separation in the east area of Gudao Oil Production Plant.

[0070] Add the above raw materials into a mixer with stirring, and stir at room temperature for 3-4 hours.

[0071] Experimental process: when the temperature is 70°C and the speed is 5000 rpm, the lowest interfacial tension measured is 3.2×10 -4 mN / m.

Embodiment 2

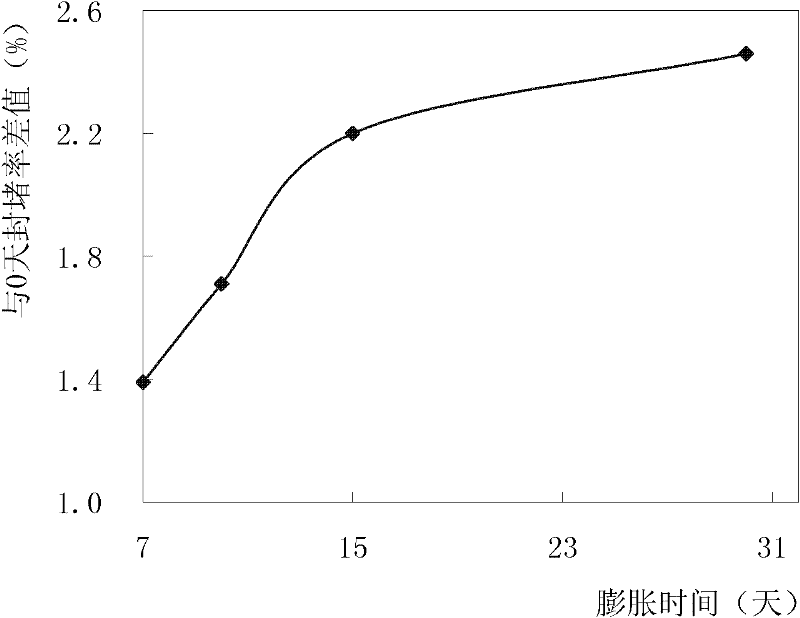

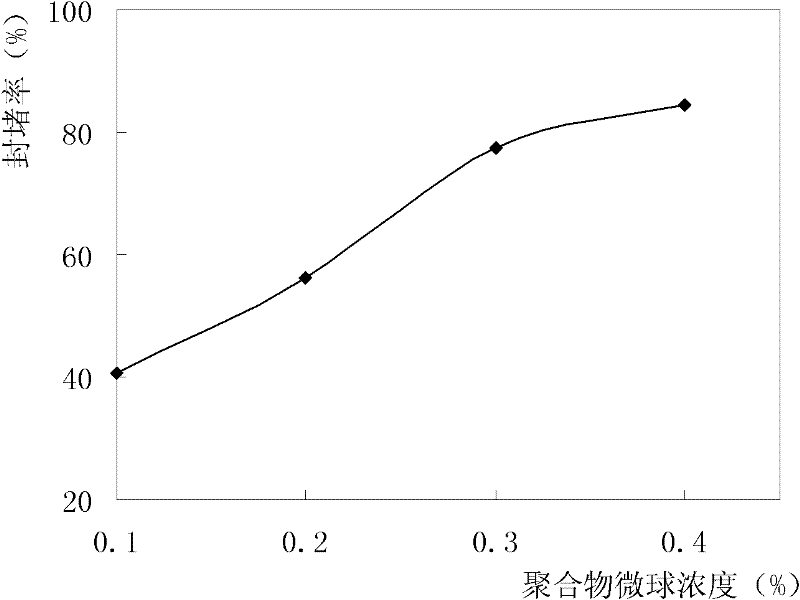

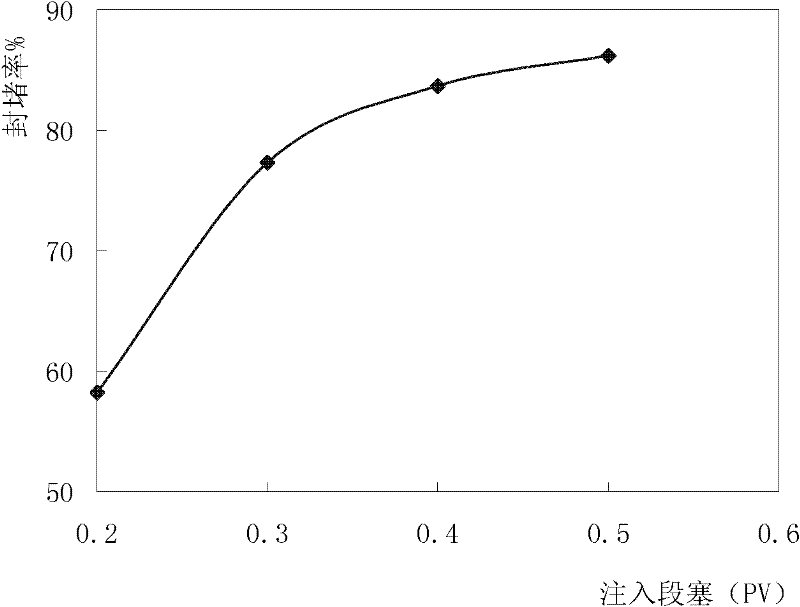

[0072] Example 2: Evaluation of plugging performance of polymer microspheres

[0073] 1. Preparation of polymer microspheres:

[0074] (1) Preparation of water-soluble monomer solution: Dissolve 10g of water-soluble anionic monomer 2-acrylamido-2-methylpropanesulfonic acid in 12g of deionized water, add 2.5g of dispersant polyvinylpyrrolidone, stir, and then add 31g of acrylamide monomer is fully stirred until the solution is clear and free of solid insolubles, then the solution is adjusted to pH = 7 with NaOH solution, 0.25g of cross-linking agent polyethylene glycol diacrylate is added, and stirred for 1 to 2 hours;

[0075] (2) Emulsion system preparation: Take 10g of Span-80 and dissolve it in 22g of toluene. After fully dissolving, gradually add the water-soluble monomer solution in step (1) and fully stir to obtain a transparent emulsion polymerization reaction system;

[0076] (3) photopolymerization reaction: 1g photoinitiator benzoin methyl ether is dissolved with 1....

Embodiment 3

[0085] Example 3: Preparation of Binary Composite Regulating and Flooding System

[0086]Raw materials: the polymer microspheres of Example 2 and the natural mixed carboxylate of Example 1.

[0087] Suspending agent: partially hydrolyzed polyacrylamide (HPAM), molecular weight 18 million, degree of hydrolysis 28%, product of Shengli Oilfield Polymer Co., Ltd.

[0088] Water: Sewage from the east area of Gudao Oil Production Plant of Shengli Oilfield.

[0089] Preparation: Take 300.0g concentration of 1.0% polymer microsphere mother liquor, swell at constant temperature for 15 days at 70°C, add 3.0g natural mixed carboxylate, 0.5g suspending agent HPAM, and 696.5g sewage into a mixer with stirring, Stir at room temperature for about 4 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com