Functional polymeric surfactant reinforced combination flooding composition and application thereof

A technology of surfactants and polymers, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult control of foam formation and stability, difficulty in industrial application, high risk of on-site implementation, etc., to achieve improved Oil recovery, low cost, and the effect of reducing interfacial tension between oil and water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

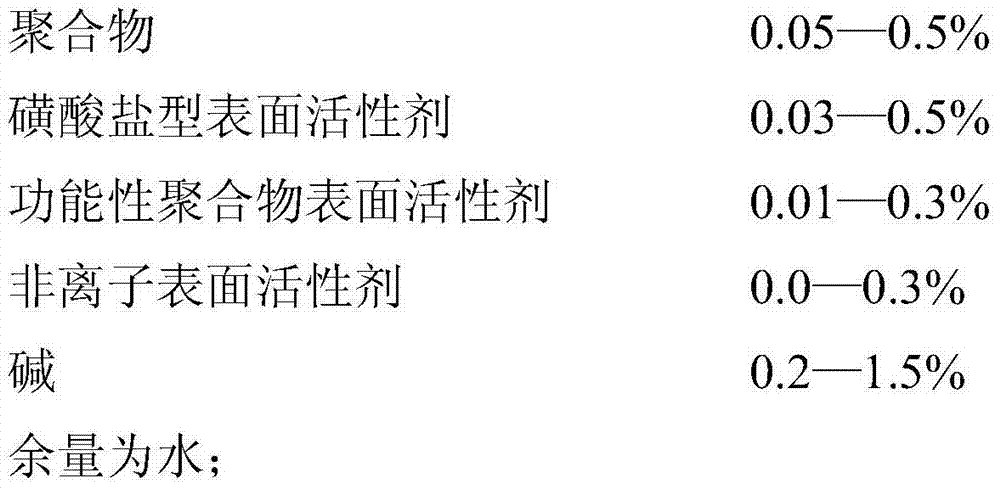

Method used

Image

Examples

Embodiment 1

[0038] (1) Polymer: The water-soluble polymer is partially hydrolyzed polyacrylamide HPAM, produced by Daqing Refining and Chemical Company, with a molecular weight of 25 million.

[0039] (2) Sulfonate-type surfactant: Heavy alkylbenzene sulfonate is produced by Daqing Donghao Investment Co., Ltd.

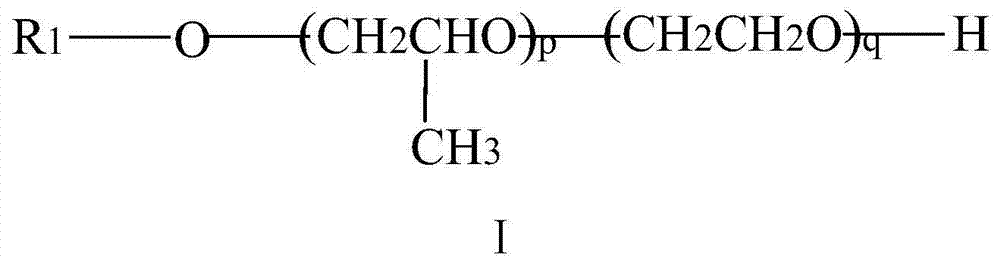

[0040] (3) Functional polymer surfactant: It is prepared from three monomers of acrylamide monomer, acrylic acid monomer and polyoxyethylene (9) alkyl acrylate through free radical initiated copolymerization:

[0041]Add acrylamide monomer, hydrophilic monomer acrylic acid, functional monomer acrylic acid polyoxyethylene (9) alkyl ester and sodium carbonate in a three-necked flask, dissolve in deionized water, add sodium formate and ammonia water, the total mass is three-necked flask 30% of the volume of the flask; under the protection of nitrogen, add azobisisobutyronitrile, sodium hydrogen sulfate and sodium persulfate, which is 0.05% of the total mass; seal the reaction for 3 h...

Embodiment 2

[0075] (1) polymer: with embodiment 1.

[0076] (2) Sulfonate-type surfactant: petroleum sulfonate is produced by Daqing Refining and Chemical Company.

[0077] (3) functional polymer surfactant: with embodiment 1.

[0078] (4) Nonionic surfactant: with embodiment 1.

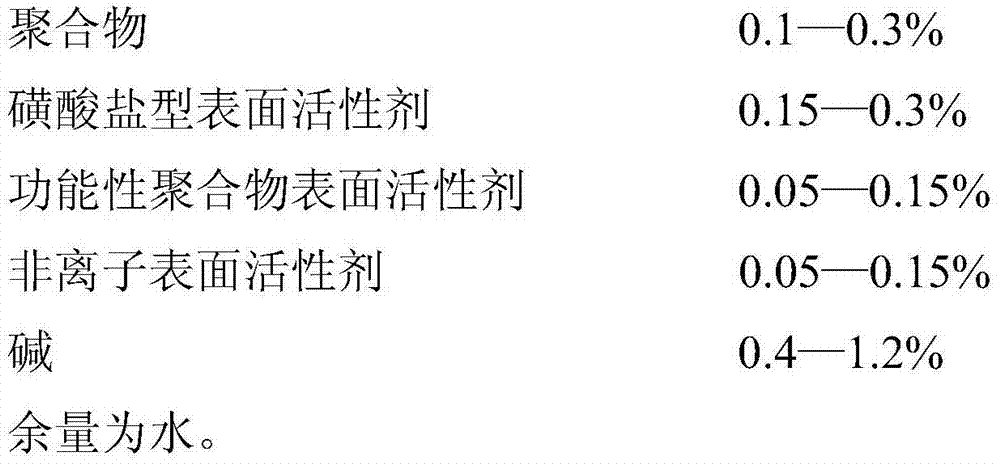

[0079] Composition of enhanced composite flooding composition:

[0080]

Embodiment 3

[0101] (1) Polymer: heat-resistant and salt-resistant polymer, produced by Beijing Hengju Chemical Group Co., Ltd., with an average molecular weight of 19 million.

[0102] (2) Sulfonate-type surfactant: C14-C20 mixed alkylbenzene sulfonate, self-synthesized, alkylation reaction of C14-C20 mixed α-olefin and benzene under the catalyst of aluminum trichloride, and then Those obtained by sulfonation and neutralization can be relatively easily completed by those skilled in the art by using methods in the prior art.

[0103] (3) Functional polymer surfactant: Example 1 at the same time.

[0104] (4) Non-ionic surfactant: m-xylyl octadecyl alcohol polyoxypropylene (5) polyoxyethylene (20) ether, self-synthesized, first mixed with polyoxypropylene (5PO) in m-xylyl octadecyl alcohol Carry out ring-opening reaction under basic catalyst, then carry out ethoxylation reaction with ethylene oxide (20EO) under basic catalyst to obtain, those of ordinary skill in the art can adopt the meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com