Patents

Literature

48results about How to "Increase system viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

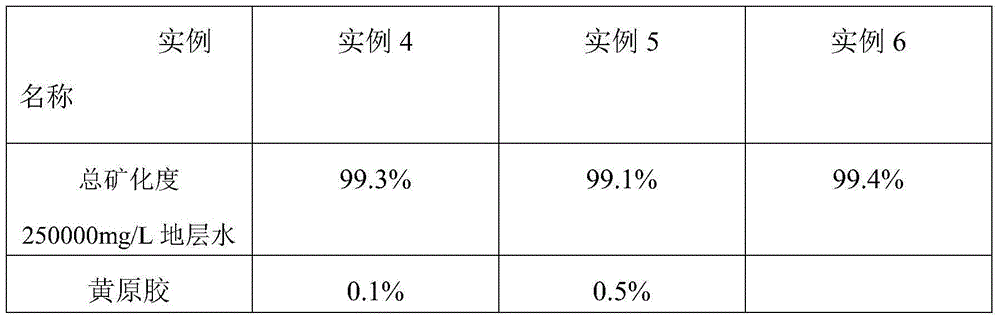

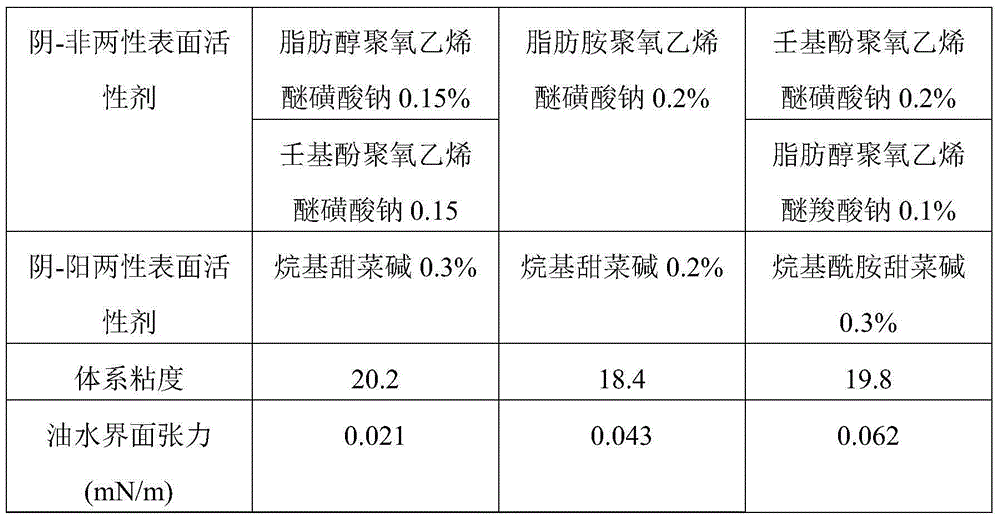

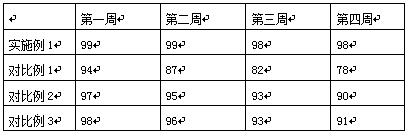

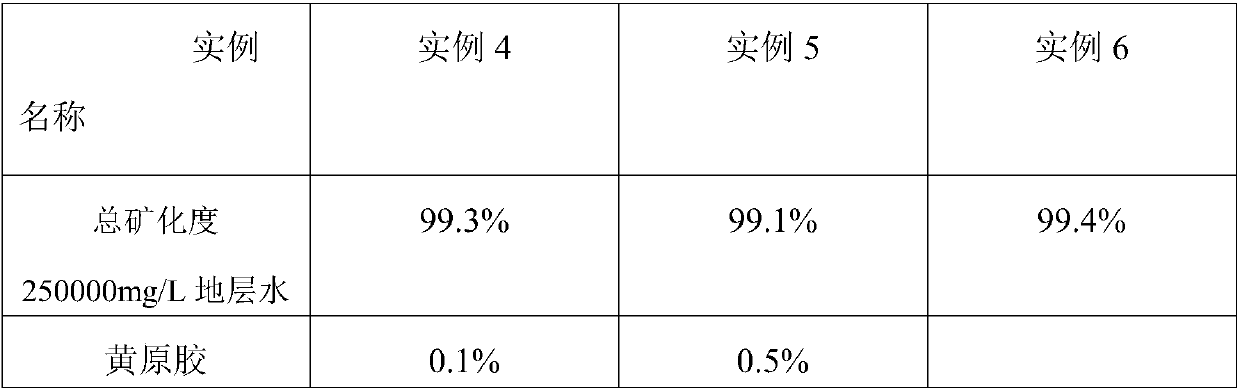

High mineralization oil reservoir composite oil displacement agent

ActiveCN104099077AHigh viscosityReduce interfacial tensionFluid removalDrilling compositionBiopolymerXanthan gum

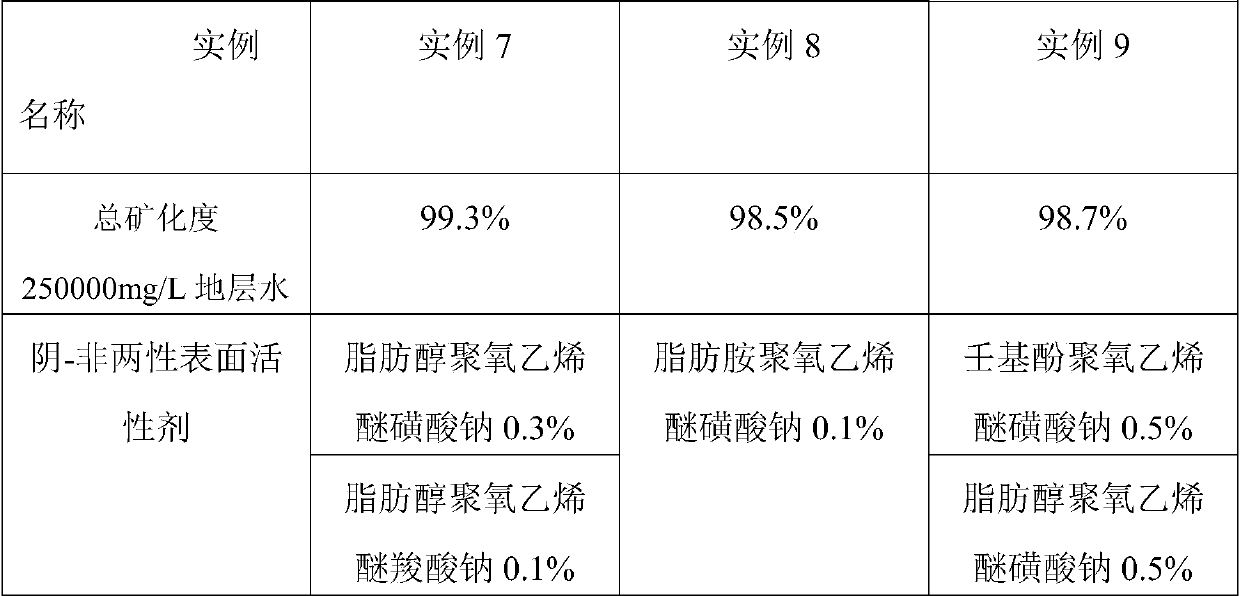

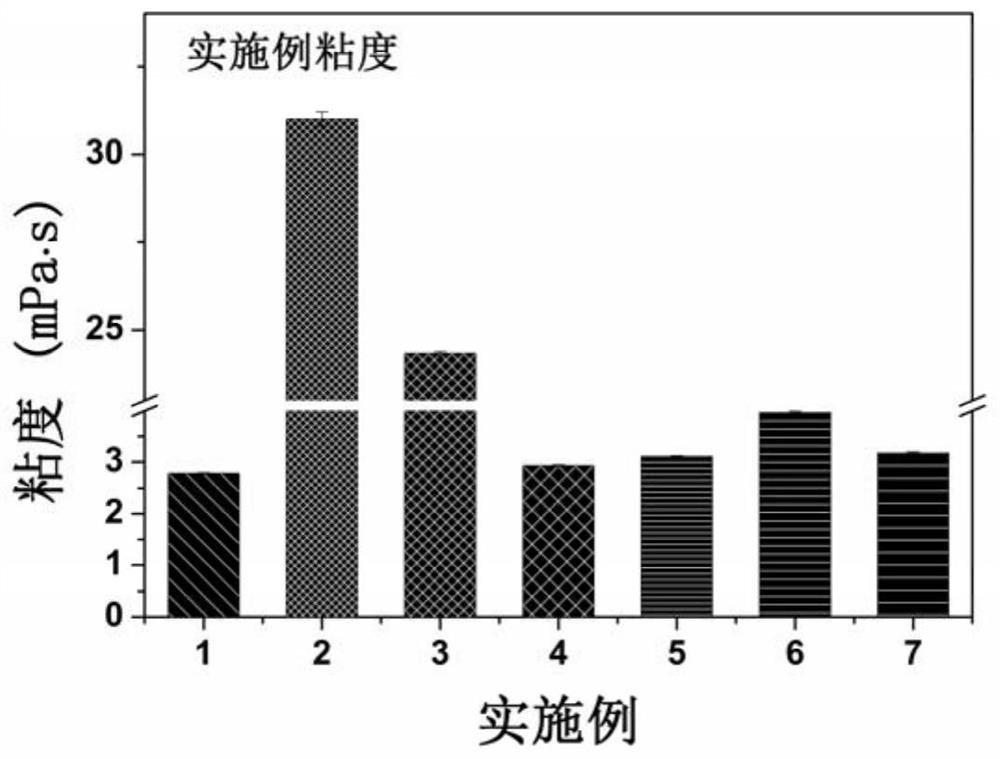

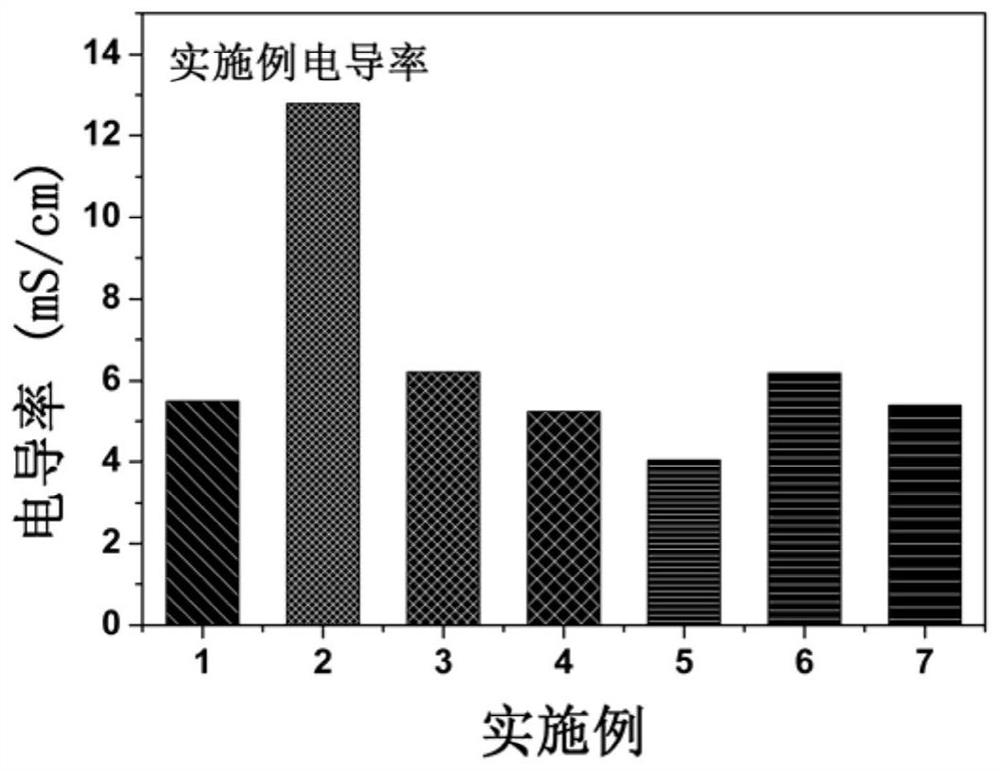

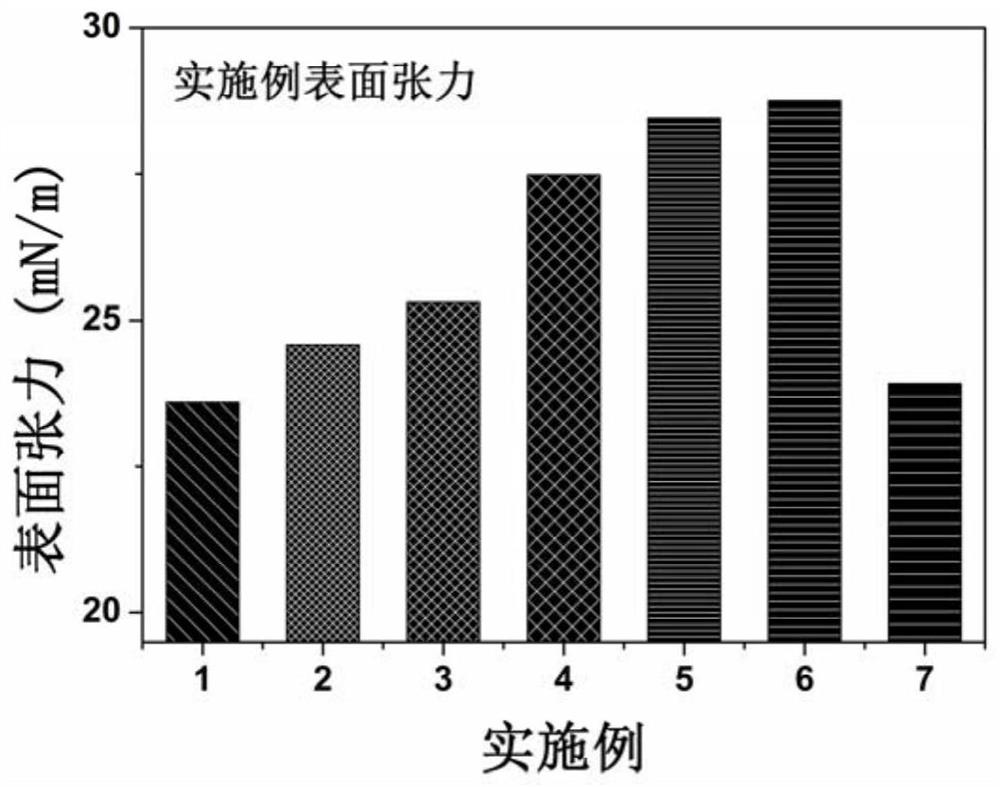

The invention relates to a kind of high mineralization oil reservoir composite oil displacement agent comprising the following components by mass: 97.5%-99.9% of highly mineralized formation brine with the salt content of 32000mg / L-360000mg / L and the Ca2 + and Mg2 + content of being greater than 1000mg / L, 0-0.5% of xanthan gum, 0.1%-1% of a negative-non ampholytic surfactant and 0%-1% of a negative-positive ampholytic surfactant, and by use of the synergistic effect among metal monovalent and divalent cations, biological polymers and amphoteric surfactant molecules, the oil displacement agent not only has higher viscosity, low interfacial tension, and long-term stability, and can meet the requirements of great improvement of recovery efficiency, technical oil displacement system wave and volume enlargement, and improvement of oil displacement efficiency of a high mineralization oil reservoir.

Owner:CHINA PETROLEUM & CHEM CORP +1

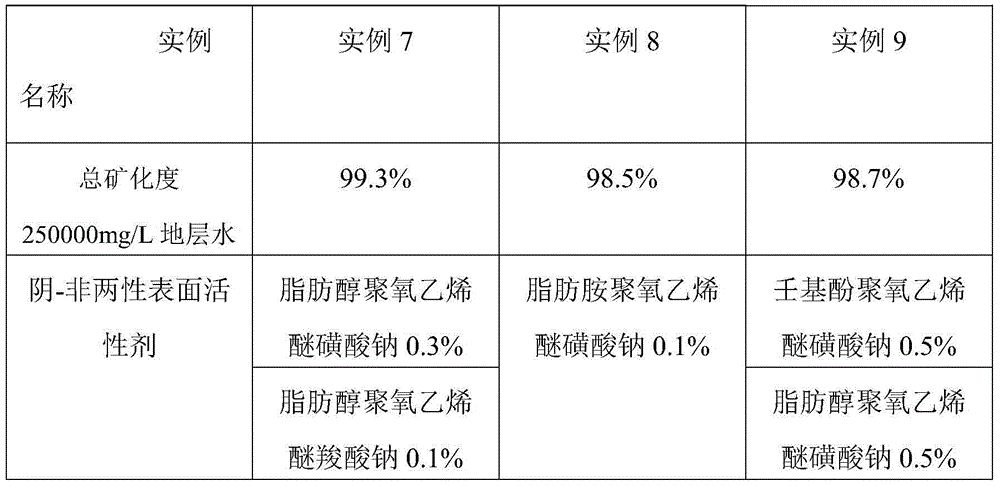

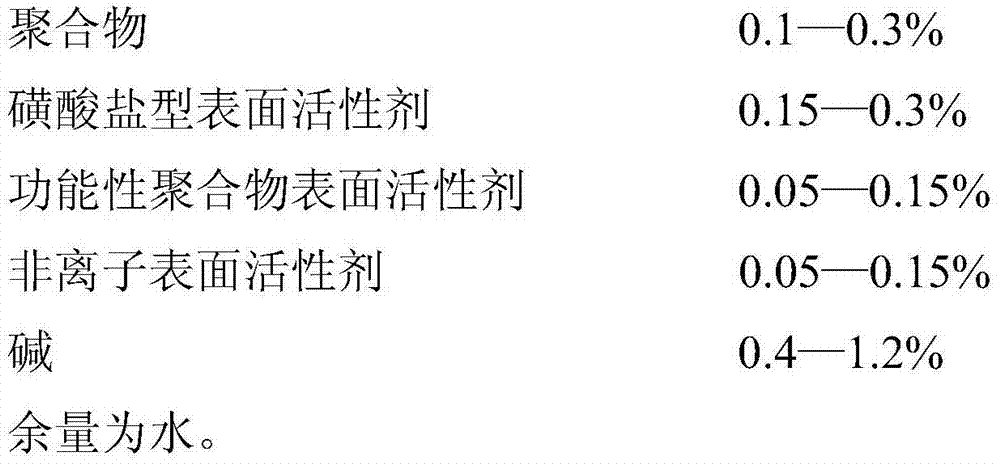

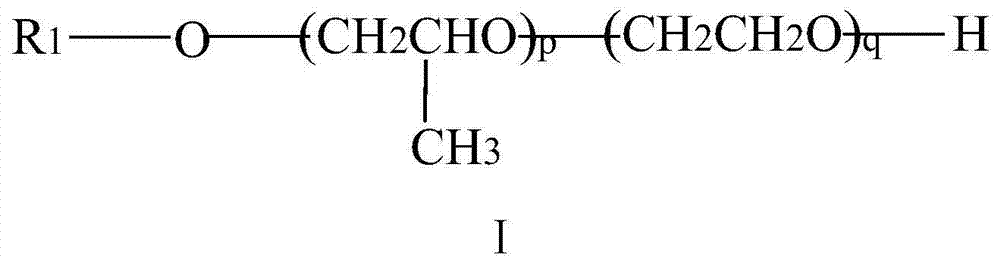

Functional polymeric surfactant reinforced combination flooding composition and application thereof

InactiveCN104327820AEnhanced overall recoveryGood emulsifying effectDrilling compositionHydrophilic monomerPolymeric surface

A functional polymeric surfactant reinforced combination flooding composition contains the following ingredients, by weight, 0.05-0.5% of polymer, 0.03-0.5% of a sulfonate surfactant, 0.01-0.3% of a functional polymeric surfactant, 0.0-0.3% of a nonionic surfactant, 0.2-1.5% of alkali and the balance water. The functional polymeric surfactant is a copolymer of an acrylamide monomer and / or a hydrophilic monomer and / or a functional monomer. According to the reinforced combination flooding composition, multiple oil-displacement mechanisms are combined. In a low-concentration system, the purpose that a three-compounds combination flooding has higher crude oil recovery can be achieved. After polymer flooding, oil reservoir also has a certain effect of raising crude oil recovery.

Owner:大连东方创新科技有限公司

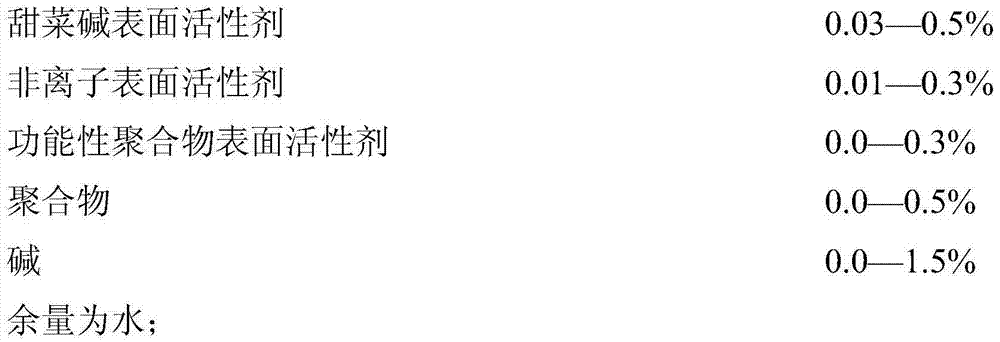

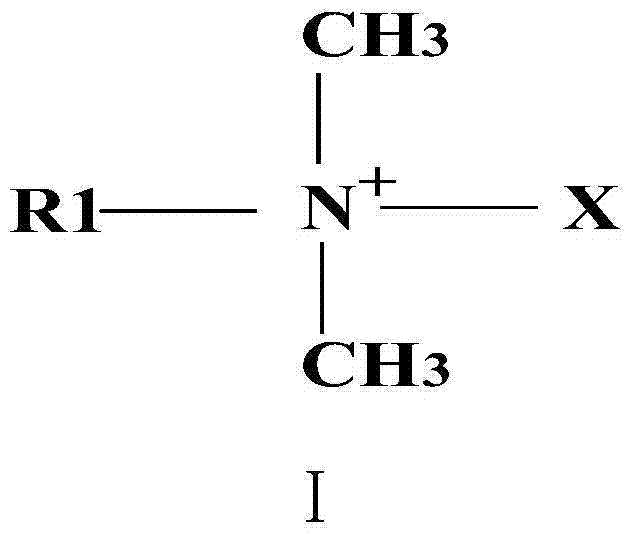

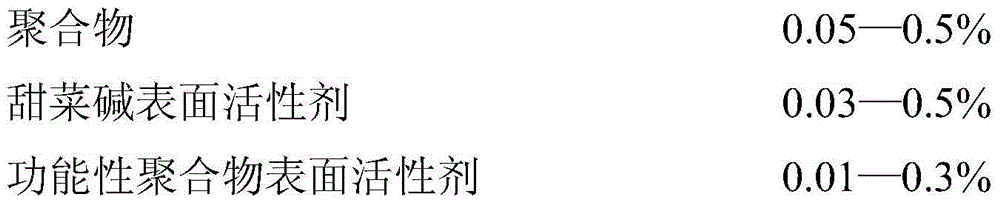

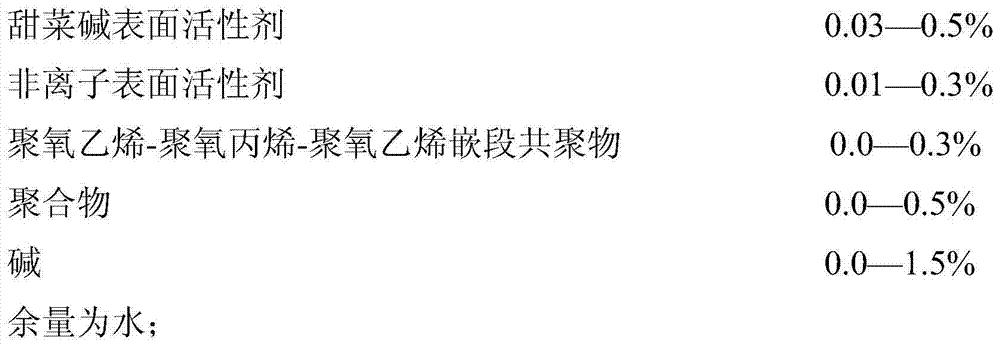

Betaine surfactant combination flooding composition and application thereof

InactiveCN104263344AReduce interfacial tensionFast mergeFluid removalDrilling compositionPolymeric surfaceBetaine

The invention relates to a betaine surfactant combination flooding composition and application thereof. The combination flooding composition comprises the following components in percentage by weight: 0.03-0.5% of betaine surfactant, 0.01-0.3% of nonionic surfactant, 0.0-0.3% of functional polymer surfactant, 0.0-0.5% of polymer, 0.0-1.5% of alkali and the balance of water. The functional polymer surfactant, polymer and alkali are not 0 at the same time. By using the cheaper betaine surfactant and integrating multiple mechanisms for enhancing the recovery rate, the surfactant combination flooding composition achieves good coordination between recovery rate enhancement effect and cost, can greatly enhance the oil recovery rate, and has economic effect of forced production in low-permeability reservoirs and reservoirs after polymer flooding.

Owner:大连东方创新科技有限公司

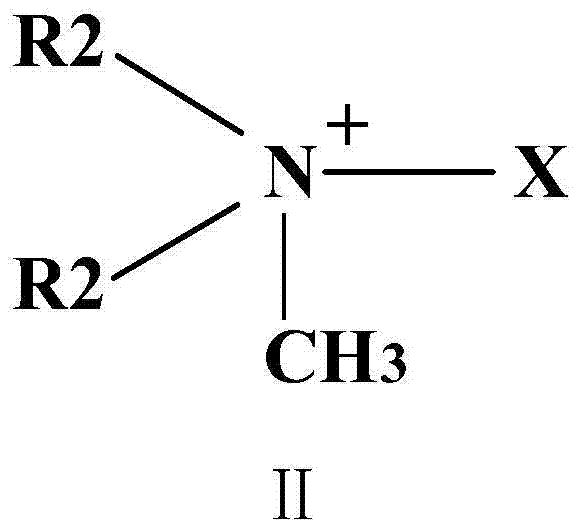

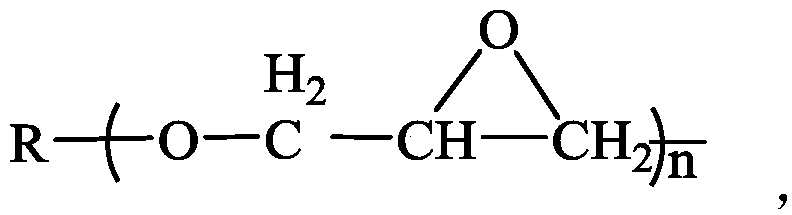

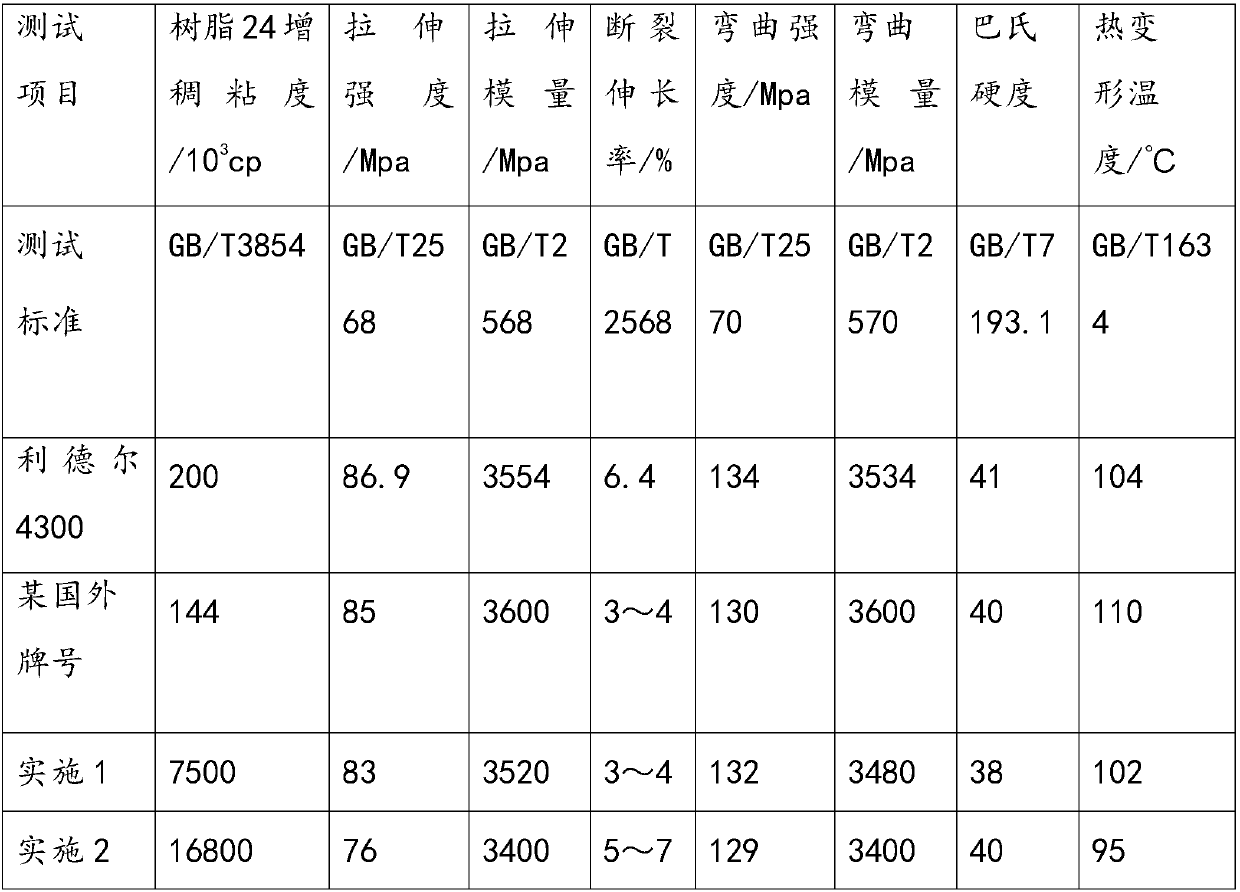

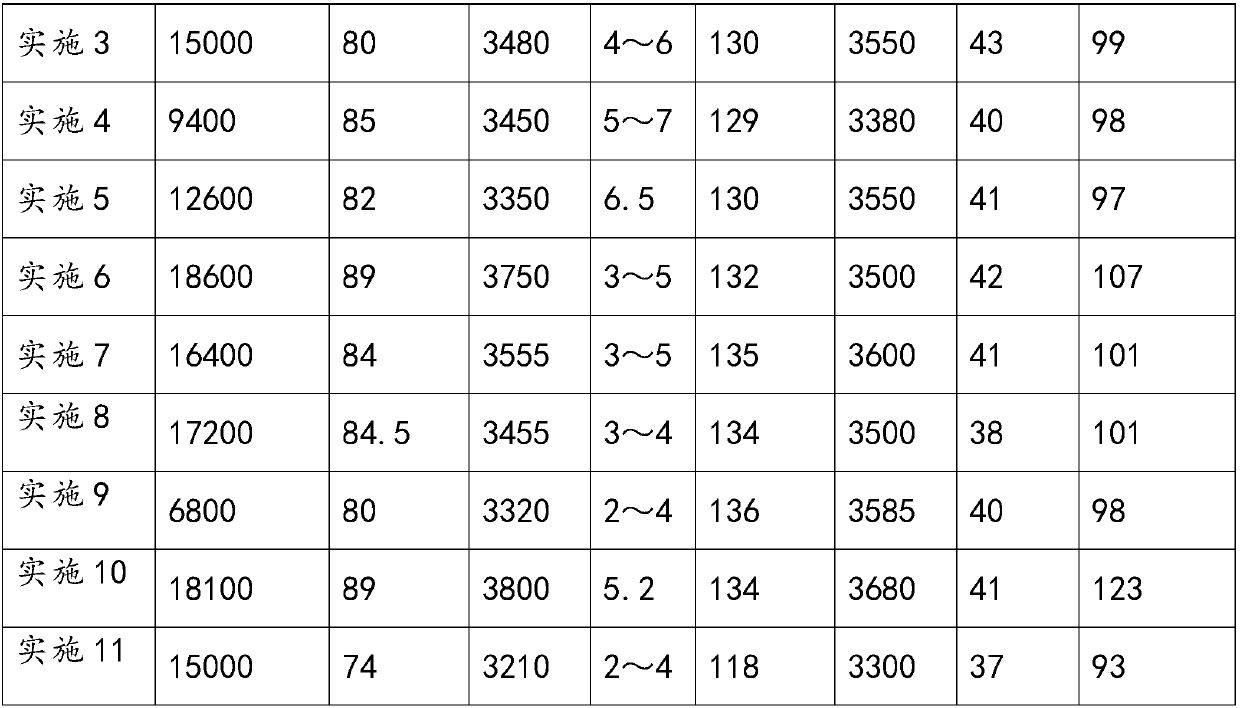

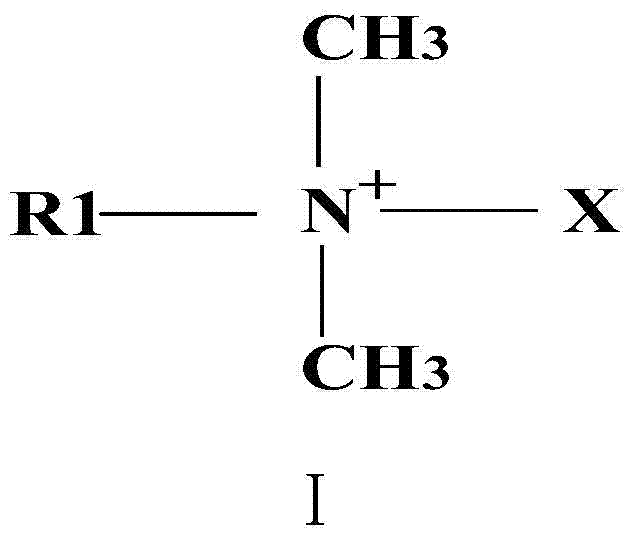

Polyhydroxy vinyl ester resin, preparation method thereof and thickening method

The invention discloses polyhydroxy vinyl ester resin, a preparation method thereof and a thickening method, which relate to the technical field of a composite material. The polyhydroxy vinyl ester resin comprises the following components in parts by weight: 10 to 30 parts of an epoxy compound, 20 to 50 parts of epoxy resin, 20 to 30 parts of unsaturated monoacid, 25 to 40 parts of a crosslinkingmonomer, 0.01 to 0.09 parts of a catalyst, and 0.1 to 0.3 parts of a polymerization inhibitor, A structure of the epoxy compound is shown as the specification, wherein the R contains -CmH2m+1, or thestructure shown as the specification, wherein the m=2-14, and n=2-6. The polyhydroxy vinyl ester resin takes the epoxy compound and epoxy resin as a base body, and unsaturated monoacid, the catalyst,the polymerization inhibitor, the crosslinking monomer and the base body are reacted to prepare the hydroxy-vinyl ester resin, the method is simple and convenient, and the polyhydroxy vinyl ester resin can realize rapid thickening.

Owner:镇江利德尔复合材料有限公司

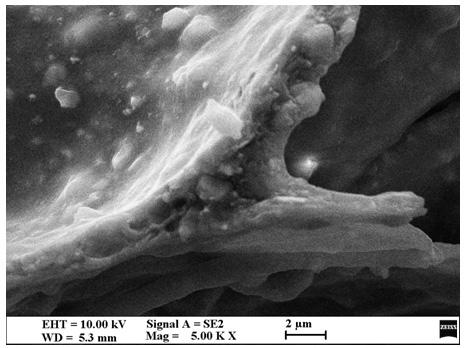

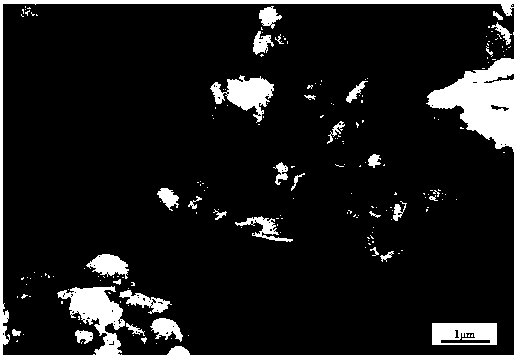

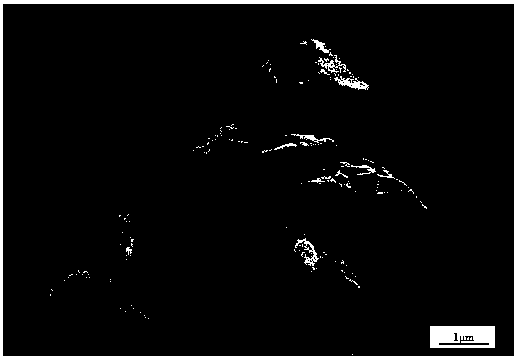

Preparation method of surface modified nano silicon dioxide colloid

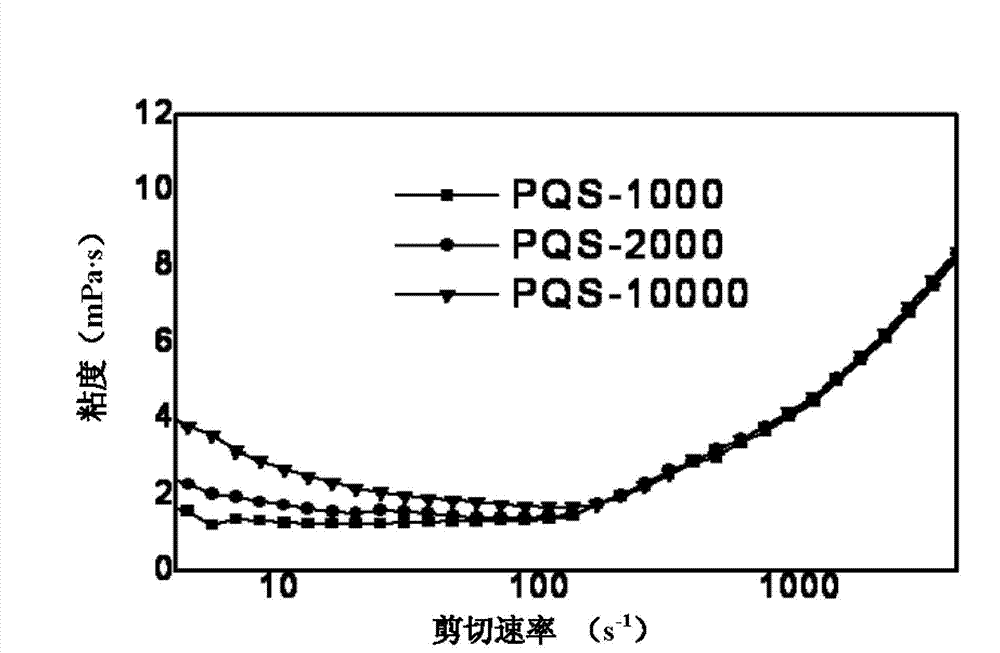

InactiveCN103160265AHas shear thickening propertiesAdjustable critical shear rateDrilling compositionColloidSilicon dioxide

The invention relates to a preparation method of surface modified nano silicon dioxide colloid, which comprises the following step: linking surface modifier to surfaces of nano silicon dioxide particles through a bridging agent, thus obtaining surface modified nano silicon dioxide colloid. The invention also relates to the surface modified nano silicon dioxide colloid which is prepared through the preparation method. The invention also relates to application of the surface modified nano silicon dioxide colloid in preparation of a shear thickening liquid. The surface modified nano silicon dioxide colloid provided by the invention has shear thickening property; and when being used for oil displacement, the shear thickening liquid prepared from the surface modified nano silicon dioxide colloid can achieve the effects of controlling the fluidity and increasing the swept volume so as to enhance the oil recovery ratio.

Owner:PETROCHINA CO LTD

Preparation method for high-toughness material of polypropylene/shear thickening fluid microcapsule

InactiveCN103506057AReserved natureImprove toughnessMicroballoon preparationMicrocapsule preparationOrganic solventThickened fluids

The invention relates to a preparation method for a high-toughness material of a polypropylene / shear thickening fluid microcapsule. The method comprises the following steps: firstly, dispersing nano silicon dioxide in polypropylene glycol under a high-speed mixing effect of a high-speed shearing and emulsifying machine to obtain a shear thickening fluid; secondly, uniformly mixing the prepared shear thickening fluid with water according to a certain ratio to obtain a uniform solution; thirdly, adding an emulsifier and an organic solvent into the uniform solution and mixing through a mixer to obtain a uniform water-in-oil emulsion; fourthly, transferring the water-in-oil emulsion into a three-mouth flask and adding isocyanate for reaction to obtain a shear thickening fluid microcapsule; fifthly, carrying out melt blending on polypropylene and the shear thickening fluid microcapsule in one or a combination of more of an open mixer, an internal mixer and an extruder to obtain the high-toughness material of the polypropylene / shear thickening fluid microcapsule. Compared with a general toughening polypropylene material, the rigidity of polypropylene cannot be reduced while the toughness of polypropylene is enhanced, the heat resistance and the processing flowability of polypropylene are improved, and the shear thickening fluid microcapsule is changed into solid powder which is more convenient to form in comparison with liquid.

Owner:EAST CHINA UNIV OF SCI & TECH

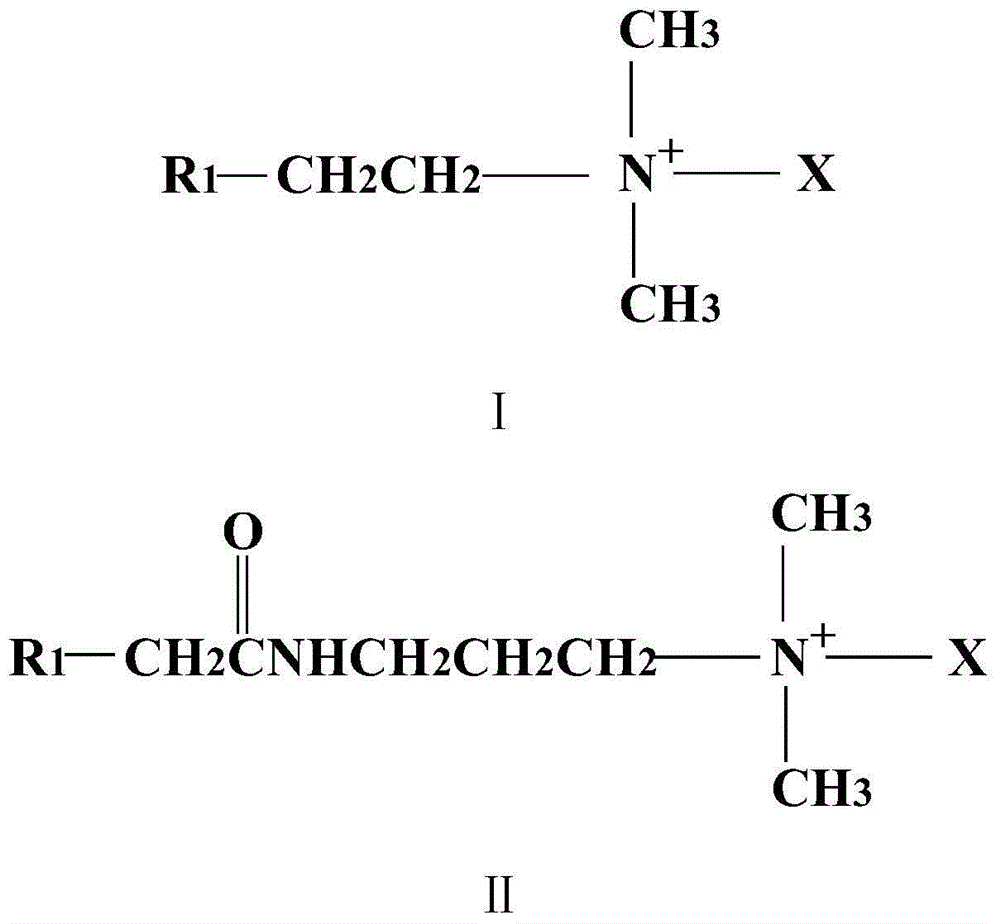

Functional polymeric surfactant-reinforced betaine composite flooding system and use thereof

InactiveCN104312566AExpand the affected volumeImprove oil washing efficiencyFluid removalDrilling compositionPolymeric surfaceBetaine

The invention discloses a functional polymeric surfactant-reinforced betaine composite flooding system and a use thereof. The functional polymeric surfactant-reinforced betaine composite flooding system comprises, by weight, 0.05-0.5% of a polymer, 0.03-0.5% of a betaine surfactant, 0.01-0.3% of a functional polymeric surfactant, 0.01-0.3% of a nonionic surfactant, 0.0-1.5% of an alkali and the balance water. The functional polymeric surfactant-reinforced betaine composite flooding system utilizes combination of a plurality of oil flooding mechanisms, can greatly improve crude oil extraction ratio, can realize further oil extraction of oil reservoir subjected to polymer flooding, can greatly improve final oil extraction ratio of the oil reservoir and has effects better than those of the existing oil flooding system.

Owner:大连东方创新科技有限公司

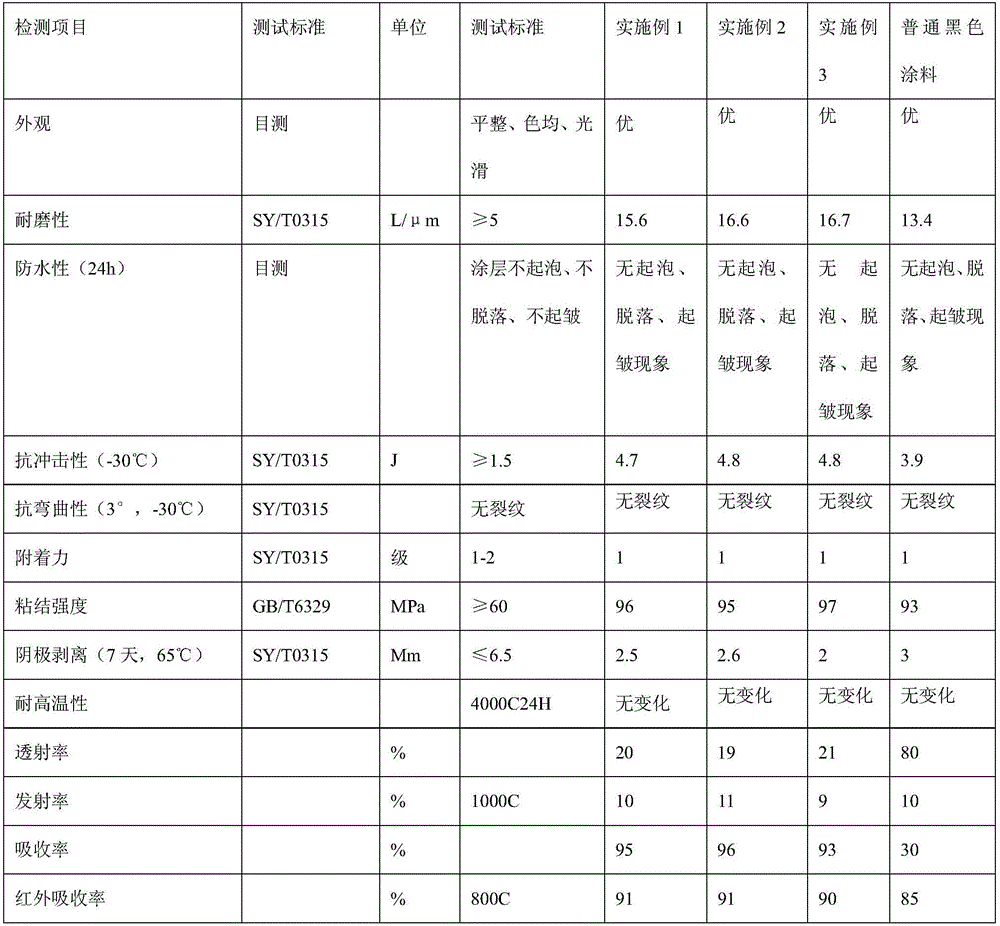

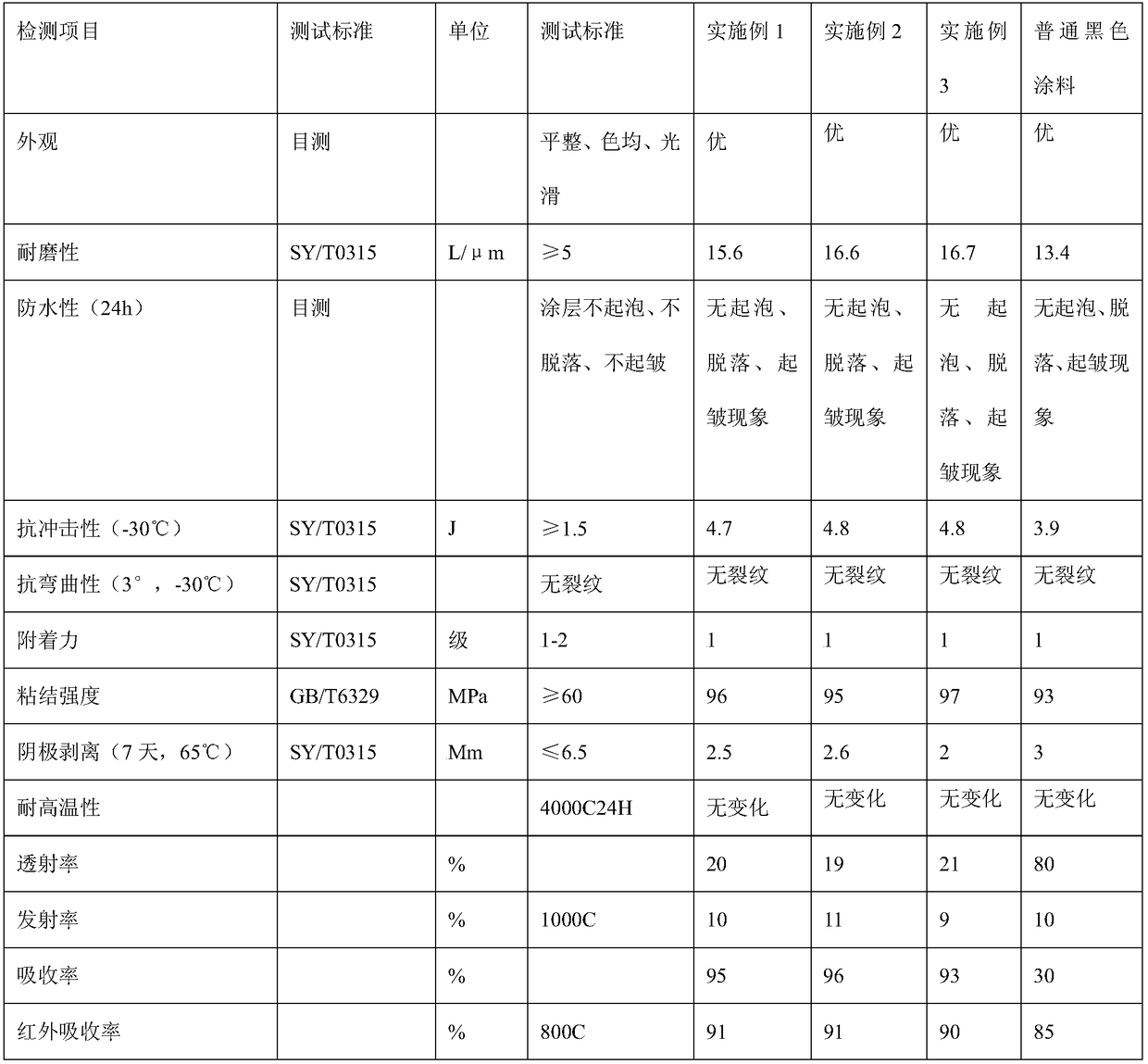

High-light-absorptivity solar heat-absorbing paint

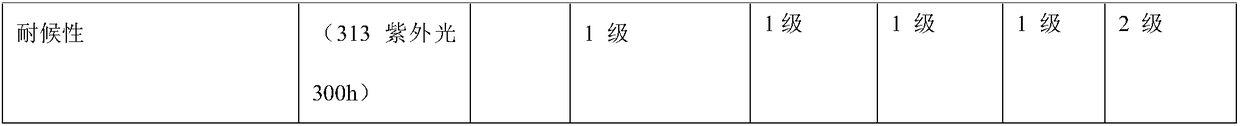

ActiveCN105713502AReduce volumeIncrease surface areaPolyurea/polyurethane coatingsRadiation-absorbing paintsWeather resistanceSimple mode

The invention discloses a high-light-absorptivity solar heat-absorbing paint which can be used for any heat collection device capable of converting solar energy into heat energy. The paint is formed by dispersing and uniformly mixing a resin, a light absorber, a solvent and aids according to certain parts by weight by a sand mill. By using the light absorber treated by a novel simple mode as the critical raw material for preparing the paint, the sunlight absorptivity of the paint is greatly enhanced, so that the light-heat conversion efficiency of the heat collection device is enhanced. Besides, the paint has the advantages of excellent weather resistance and longer service life.

Owner:海丰县美达化工涂料有限公司

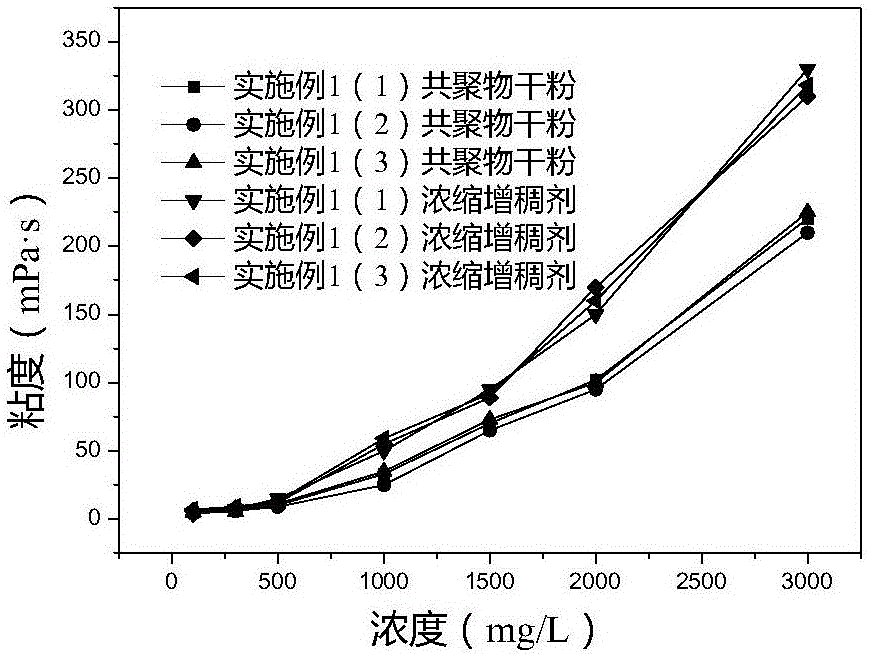

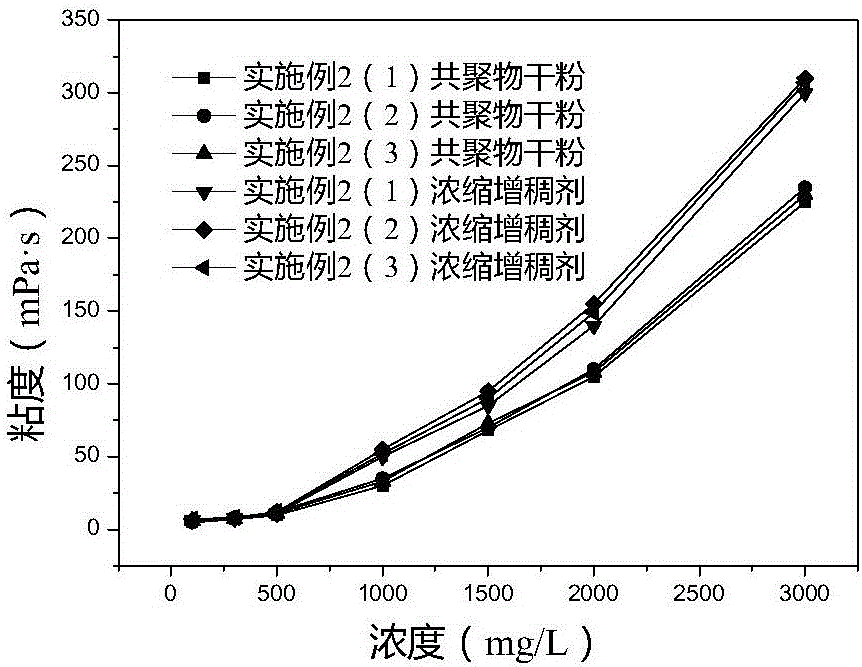

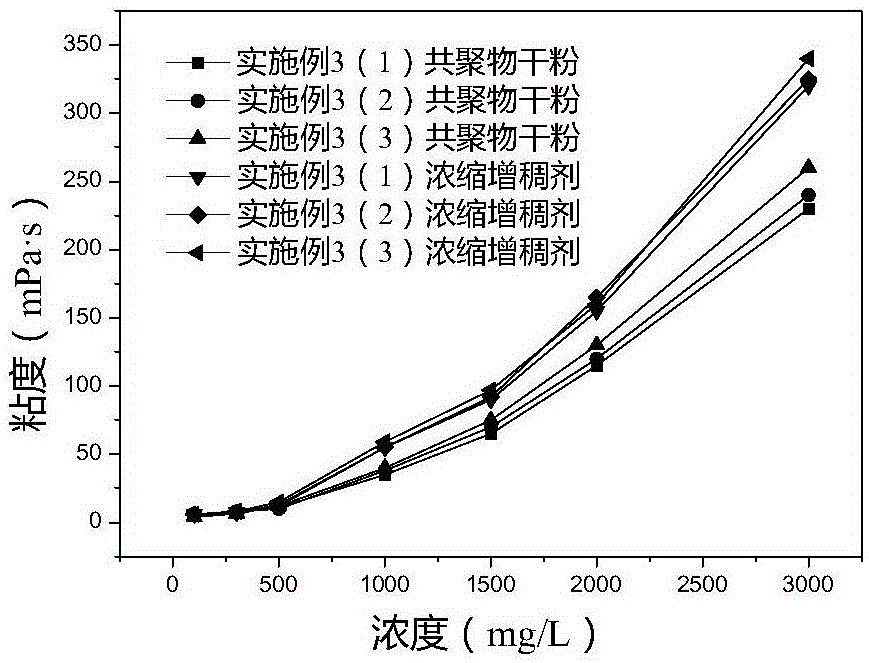

Water-in-oil association type concentrated thickener for oil displacement and preparation method of water-in-oil association type concentrated thickener

InactiveCN106833590AShorten the dissolution timeImprove dissolution efficiencyDrilling compositionOrganic solventAssociation type

The invention provides a water-in-oil association type concentrated thickener for oil displacement. The water-in-oil association type concentration thickener is prepared from the following components in percentage by mass: 25 weight percent to 50 weight percent of a dispersion medium, 18 weight percent to 45 weight percent of a dispersion phase, 20 weight percent to 40 weight percent of a hydrophobic association polymer thickener for the oil displacement and 2.5 weight percent to 6 weight percent of a compound emulsifier, wherein the dispersion medium is an organic solvent which is not compatible with water; the dispersion phase is water; the compound emulsifier is a compound emulsifier formed by compounding an emulsifier with the HLB (Hydrophile-Lipophile Balance) value of 3 to 7 and an emulsifier with the HLB value of 8 to 10. According to the concentrated thickener provided by the invention, the stabilization time is more than 120d and the dissolution time is less than 5min; performances of a polymer solution prepared from the concentrated thickener provided by the invention are better than performances of a polymer solution which is directly prepared from corresponding thickener powder for the oil displacement.

Owner:SICHUAN GUANGYA POLYMER CHEM

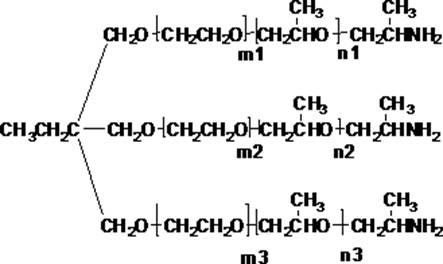

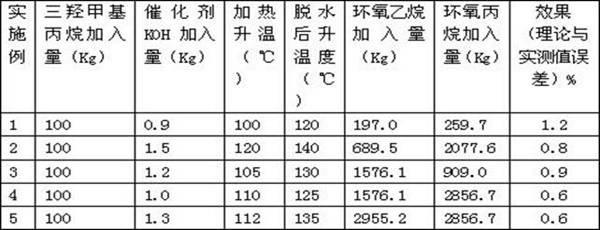

Polyether amine for textile printing and dyeing auxiliary and preparation method for polyether amine

InactiveCN102634006AOvercome drifting oilOvercome stabilityOrganic compound preparationFibre treatmentEmulsionWoven fabric

The invention discloses polyether amine for a textile printing and dyeing auxiliary and a preparation method. The preparation method includes: adding trimethylolpropane serving as initiator and catalyst KOH (potassium hydroxide) into a reaction kettle, and sequentially feeding epoxyethane and epoxypropane into the reaction kettle so that a polyether crude product is prepared by means of reaction; neutralizing and adsorbing the reactant prior to filtering dehydration, and then refining through reduced pressure distillation and dehydration so that polyether is prepared; and adding the prepared polyether, supported catalyst, liquid ammonia and hydrogen so that the polyether amine for the textile printing and dyeing auxiliary is prepared. The polyether amine serves as a textile printing and dyeing softener, demulsification temperature of emulsion is high, polyether consumption is less, and total production cost can be reduced. The polyether amine prepared by the preparation method is high in amino terminating ratio, equimolar consumption of a main system is reduced, system viscosity is increased, and produced textiles are integrally softer in hand feeling. Besides, the preparation method is less in reaction by-products, loose in reaction condition, low in equipment requirements and small in equipment investment.

Owner:ZHEJIANG HUANGMA TECH

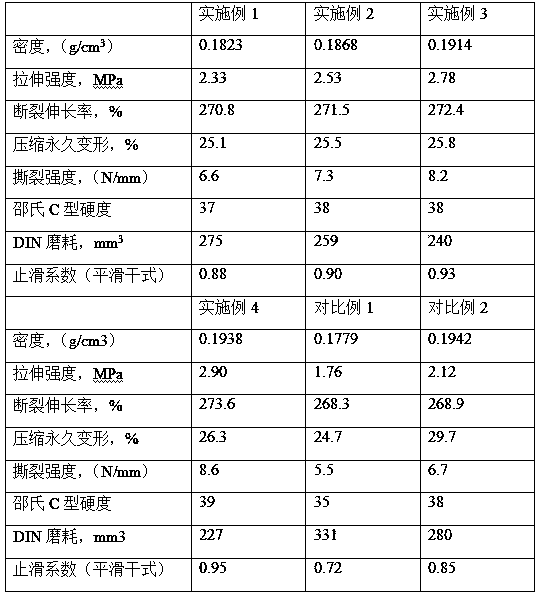

High-mechanical-strength wear-resistant EVA composite foam material and preparation method thereof

The invention discloses a high-mechanical-strength wear-resistant EVA composite foam material and a preparation method thereof. The foam material comprises the following components: ethylene-vinyl acetate copolymer, maleic anhydride grafted EVA, ethylene-octene copolymer, a composite wear-resistant agent, rosin resin, naphthenic oil, a foaming agent, an accelerant, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide and an antioxidant. The composite wear-resistant agent is a modified white corundum / graphene oxide composite material. Compared with the traditional EVA foam material, the high-mechanical-strength wear-resistant EVA composite foam material prepared by the invention has the advantages that good mechanical properties and wear resistance are obtained under the condition thatthe addition amount of the filler is small; better processability is achieved; the manufacturing process is easy to operate, energy is saved, the environment is protected, and wide application prospects and market requirements are achieved in actual application.

Owner:FUZHOU UNIV

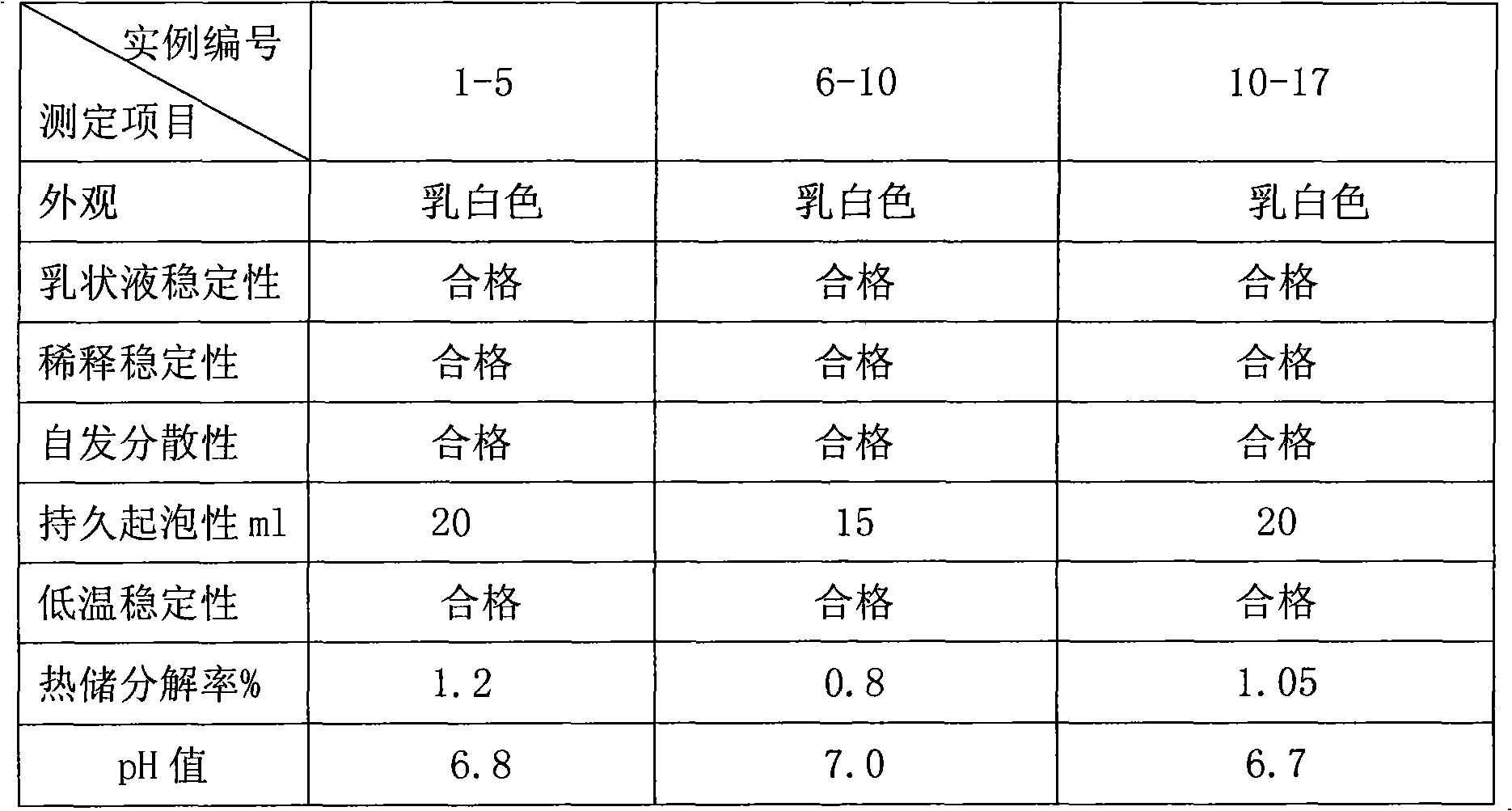

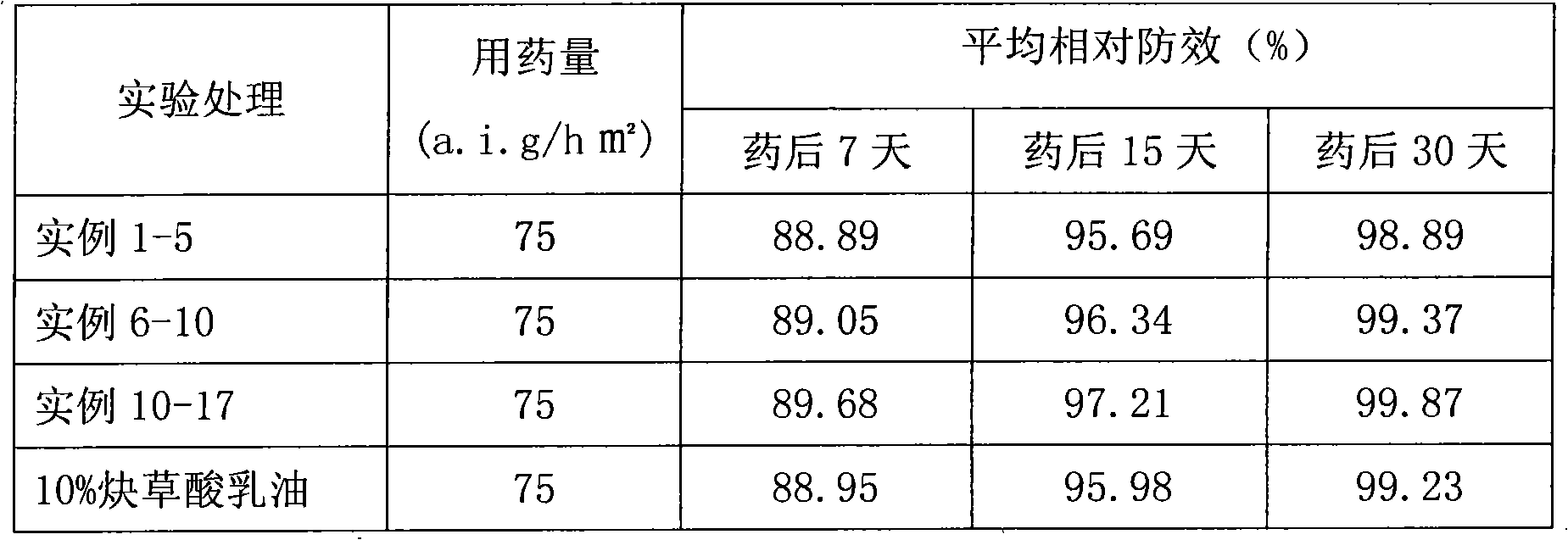

Clodinafop-propargyl aqueous emulsion and preparation method thereof

ActiveCN101843240AIncrease system viscosityImprove stabilityBiocideAnimal repellantsChemistryToxicity

The invention relates to selective stem leave herbicide for wheat and a preparation method thereof, in particular to clodinafop-propargyl aqueous emulsion and a preparation method thereof. The clodinafop-propargyl aqueous emulsion comprises the following components in percentage by mass: 10 to 30 percent of clodinafop-propargyl, 5 to 17 percent of surfactant, 0.5 to 1 percent of PH regulator, 1 to 5 percent of antifreeze agent, 20 to 35 percent of organic solvent and the balance of water. The preparation method comprises the following steps of: dissolving the clodinafop-propargyl into the organic solvent, stirring the mixture mechanically until the solution is transparent, adding the surfactant, and stirring the mixture uniformly to prepare an oil phase; dissolving the PH regulator, a thickening agent, a defoaming agent and the antifreeze agent in the balance of water to prepare a water phase; and adding the water phase into the oil phase slowly, and simultaneously, performing shearing by using a high-shear emulsion machine for 10 to 30 minutes to prepare the clodinafop-propargyl aqueous emulsion. Compared with missible oil products, in products of the clodinafop-propargyl aqueousemulsion, the use level of the organic solvent is reduced by 60 percent at most, the environmental pollution and the toxicity of pesticide are reduced, flash points of the products are improved, and the safety of production, transportation and users is improved; and compared with wettable powder products, the products of the clodinafop-propargyl aqueous emulsion completely avoid dust pollution.

Owner:SHANGHAI XIANGLIN AGRI TECH CO LTD

High-wear-resistance anti-slip EVA composite foam material and preparation method thereof

ActiveCN111004434AImprove surface structureUniform particle sizeChemical industryOxide compositeOctene

The invention discloses a high-wear-resistant anti-slip EVA composite foam material and a preparation method thereof, wherein the foam material is prepared from the following components: an ethylene-vinyl acetate copolymer, maleic anhydride grafted EVA, an ethylene-octene copolymer, a terpene resin, a wear-resistant anti-slip agent, naphthenic oil, polyisobutene, a foaming agent, an accelerant, stearic acid, zinc stearate, zinc oxide, dicumyl peroxide and an antioxidant, wherein the wear-resistant anti-slip agent is a modified steel slag / graphene oxide composite material. Compared with the traditional EVA foam material, the high-wear-resistant anti-slip EVA foam composite material prepared by the invention has good wear resistance and good anti-slip performance under the condition of a lowfiller addition amount, has good processability and good mechanical properties, is simple in the operation of the manufacturing process, energy saving and environmentally friendly, and has wide application prospects and market requirements in actual application.

Owner:FUZHOU UNIV

Water-based inorganic mineral composite terrace coating and preparation method thereof

InactiveCN111019415ACommon inertWon't fall offFireproof paintsCovering/liningsCoating systemSilicic acid

The invention relates to a water-based inorganic mineral composite terrace coating. The coating comprises primer, finish paint and varnish from bottom to top, potassium silicate liquid is used as a base material; silicon dioxide is used as a main raw material, the water-based inorganic mineral composite coating is natural and environment-friendly, has fireproof and flame-retardant characteristics,is combined with mineral matrixes such as cement to generate a petrochemical effect, is modified by adding the hydrophobic agent into a thickening agent, improves the construction performance and thewater resistance of the coating, resists acid, alkali and salt mist, does not fall off, and is suitable for wide weather conditions. The preparation method of the coating is simple and efficient, andthe obtained coating system is complete.

Owner:广州市维思涂料科技有限公司

Betaine surfactant combination flooding system and application thereof

The invention relates to a betaine surfactant combination flooding system and application thereof. The combination flooding system comprises the following components in percentage by weight: 0.03-0.5% of betaine surfactant, 0.01-0.3% of nonionic surfactant, 0.0-0.3% of polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer, 0.0-0.5% of polymer, 0.0-1.5% of alkali and the balance of water. The polyoxyethylene-polyoxypropylene-polyoxyethylene block copolymer, polymer and alkali are not 0 at the same time. By using the cheaper betaine surfactant and integrating multiple mechanisms for enhancing the recovery rate, the surfactant combination flooding system achieves good coordination between recovery rate enhancement effect and cost, can greatly enhance the oil recovery rate, and has economic effect of forced production in low-permeability reservoirs and high-temperature high-salt reservoirs.

Owner:大连东方创新科技有限公司

Composite foaming agent for cast-in-place foam concrete

ActiveCN109574543AStrong hydrophilic abilityIncreased water carrying capacityFoam concreteFatty alcohol

The invention discloses a composite foaming agent for cast-in-place foam concrete. The foaming agent is prepared from, by mass, 2.0%-8.0% of fatty alcohol polyoxyethylene lauryl ether sodium sulfate,1.5%-8.0% of alkyl glycoside, 0.5%-3.0% of a foam stabilizer, 0%-1.5% of a tackifier and the balance water, wherein the total mass percentage is 100%, a mass ratio of fatty alcohol polyoxyethylene lauryl ether sodium sulfate to alkyl glycoside is 1:4-4:1, the foam stabilizer refers to modified silicon resin polyether emulsion and / or polyvinylpyrrolidone, and the tackifier refers to hydroxypropyl methyl cellulose and / or polyacrylamide. The foaming agent is fast in foaming, high in foaming quantity, great in foam stability, excellent in performance, great utilization effects can be achieved without adding of other auxiliary agents, and the foaming agent can be diluted by 30-60 times to be used for preparation of cast-in-place foam concrete. Raw materials of the foaming agent are excellent inbiodegradability, safe and environmentally friendly, and the prepared foaming agent is green and environmentally friendly. In addition, a preparation process of the foaming agent is simple, mild in condition and applicable to industrial production.

Owner:SHAANXI NORMAL UNIV

High-rupture-strength baking-free brick and production method thereof

The invention discloses a high-rupture-strength baking-free brick. The high-rupture-strength baking-free brick is prepared from the raw materials including ordinary Portland cement 42.5, gravels, medium sand, nano calcium carbonate, mineral powder, nano silicon dioxide, nano aluminum oxide, coal cash, talcum powder, ferric chloride, magnesium chloride, magnesium oxide, modified carbon fiber, asbestos fiber, plant straw, sepiolite, polystyrene emulsion, polyvinyl acetate emulsion, polyphenyl emulsion, bentyl benzene emulsion, water reducer, accelerator, thickener, polyvinyl alcohol, dispersant, diffusant, water, silane coupling agent KH-570 and modified additives. The invention also discloses a preparation method of the high-rupture-strength baking-free brick. The prepared high-rupture-strength baking-free brick is excellent in rupture strength.

Owner:无为县严桥双龙建材厂(普通合伙)

Water-based organic paste and aluminum solder paste comprising paste

ActiveCN107755921AImprove anti-settling performanceHigh affinityWelding/cutting media/materialsPigment treatment with macromolecular organic compoundsWater basedOrganic solvent

The invention discloses water-based organic paste. The water-based organic paste comprises a matrix and an additive, wherein the matrix comprises a water-based organic solvent and water-based high polymer. The matrix of the water-based organic paste has a polar hydrophilic group, also has a non-polar lipophilic group, integrates the advantages of water and oil organic substances, abandons the defects of the water and oil organic substances, has mutual solubility with water, and can be blended with water; and in the presence of water-based high polymer, viscosity of the matrix is relatively high, so that anti-settling performances of the solder paste prepared from the matrix can be effectively improved. Meanwhile, the invention further discloses solder paste comprising the water-based organic paste. The aluminum solder paste can realize automatic charging, and also has the characteristics of being easy to clean, environmentally friendly, high in welding quality and the like.

Owner:广州有研焊接材料科技有限公司

Rubber composite material for cable sheathes

InactiveCN104194073AImprove hydrophobicityDecreased water-swelling capacityRubber insulatorsInsulated cablesFiberAluminium hydroxide

The invention discloses a rubber composite material for cable sheathes. The rubber composite material comprises the following raw materials in parts by weight: 100 parts of natural rubber, 25-32 parts of modified cotton fiber, 2-4 parts of zinc oxide, 1.8-2.3 parts of sulphur, 1-2 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 40-45 parts of heavy calcium carbonate powder, 20-25 parts of white carbon black, 15-25 parts of superfine active clay, 1.5-2 parts of stearic acid, 0.5-1.2 parts of gamma-aminopropyl triethoxysilane, 2-3 parts of hydroxyl silicone oil, 1.5-2 parts of polysiloxane, 0.00005-0.00012 part of platinum catalyst and 20-25 parts of aluminium hydroxide. The rubber composite material for cable sheathes has excellent mechanical property, high tensile strength, high elongation at break, low cost and simple preparation process.

Owner:ANHUI LAND GRP

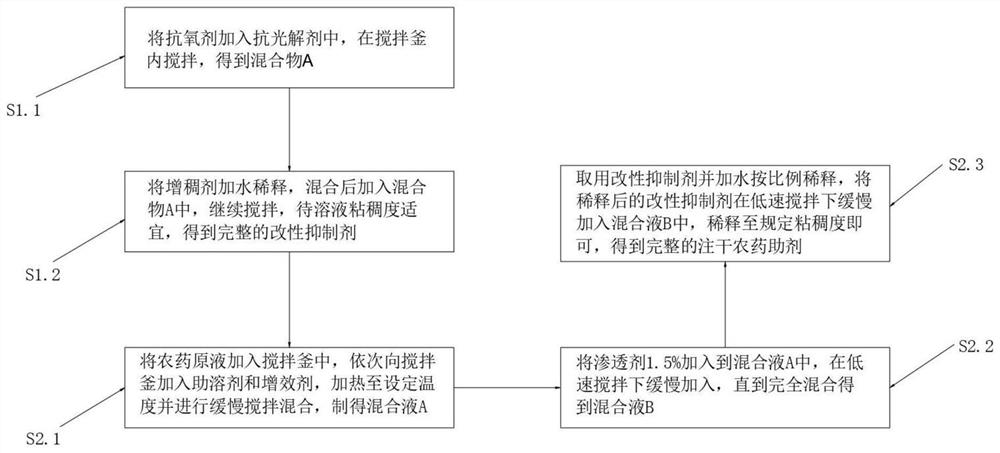

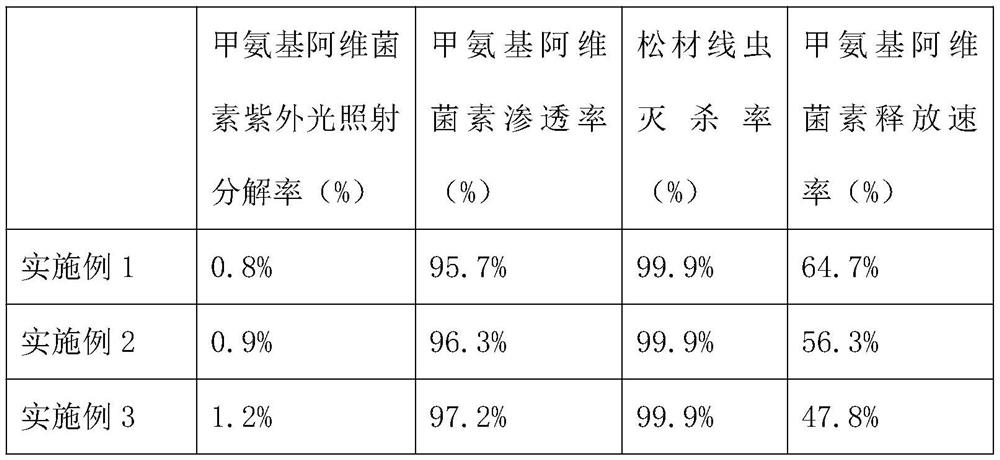

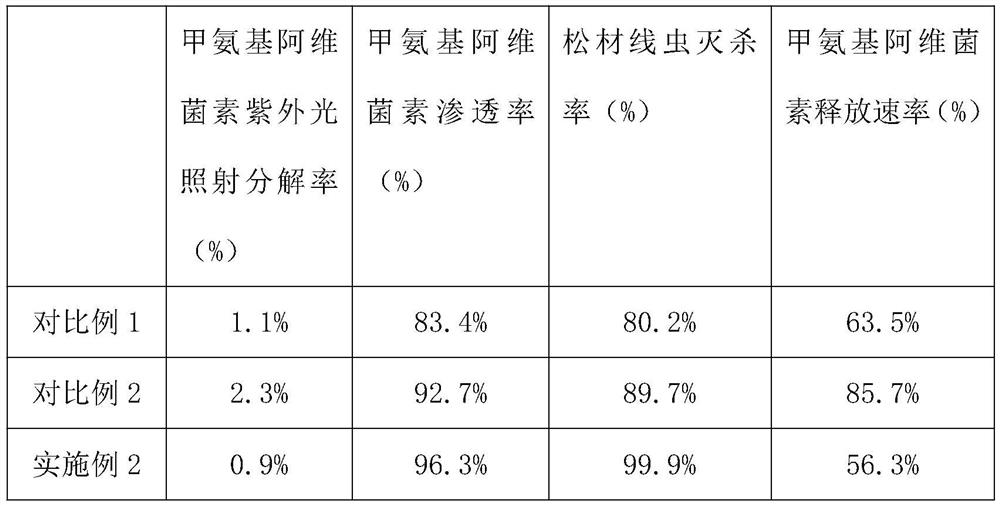

Research, development and preparation method of trunk injection pesticide adjuvant

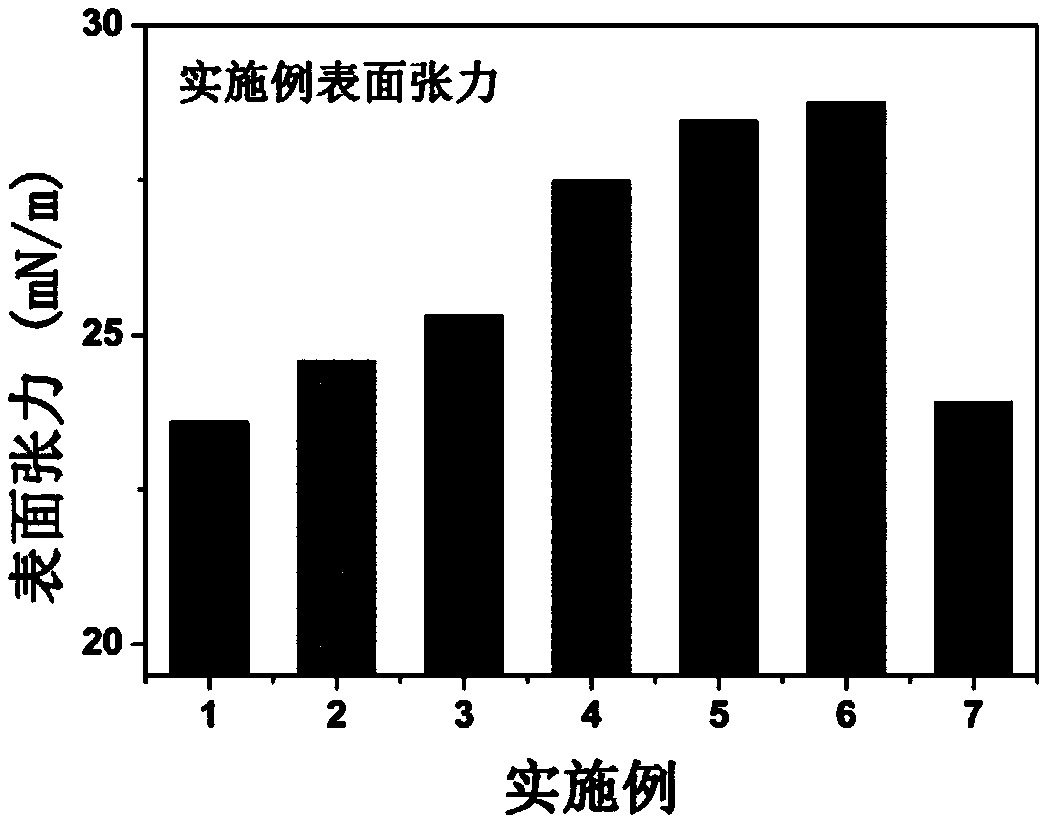

InactiveCN113749110AIncrease system viscosityReduce the release rate of decompositionBiocideNematocidesAlkaneAdjuvant

The invention relates to the technical field of trunk injection agents, in particular to a research, development and preparation method of a trunk injection pesticide adjuvant. The adjuvant comprises the following raw materials in percentage by mass: an active compound, a synergist, a penetrant, a modification inhibitor and a cosolvent. The synergist is a perfluoroalkane organic fluorine compound. The penetrant is formed by mixing a polyoxyethylene ether compound with one or more of secondary alkyl sodium sulfonate, sodium dioctyl sulfosuccinate and sodium alkyl naphthalene sulfonate. The modified inhibitor comprises the following raw materials in percentage: an anti-photolysis agent, an antioxidant, a thickening agent and water. The modified inhibitor can increase the system viscosity of the trunk injection pesticide auxiliary agent, reduce the decomposition and release rate of the emamectin benzoate under ultraviolet light. The modified inhibitor can reduce the decomposition rate of the emamectin benzoate, so that the emamectin benzoate flows for a longer time in the trunk, the pesticide activity of the emamectin benzoate is improved, and the emamectin benzoate still has an efficient killing effect on pine wood nematodes after penetrating through rosin.

Owner:湖南正林益森生物科技有限公司

Method for preparing polishing solution by utilizing tailings recovered from crystal silicon cutting waste mortar

InactiveCN102492366BSolve the cladding problemGood synergyPolishing compositions with abrasivesMicrometerTwo step

The invention discloses a method for preparing a polishing solution by utilizing tailings in the process of recycling crystal silicon cutting waste mortar. The method comprises the following steps of: deironing by two steps, grinding, converting, stabilizing and the like. According to the method, the problems that silicon powder is passivated, silicon carbide is wrapped by silica sol and the like are solved effectively by a crushing and grinding process of a wet-method superfine stirring mill, wherein the solation conversion rate of a silicon component is over 98.5 percent. According to the method, silicon carbide of less than 5 micrometers and the silicon component resources are utilized comprehensively, the prepared novel silicon carbide and silica sol composite polishing solution has the high-efficiency grinding capacity of the silicon carbide, and silicon dioxide sol can be embedded into gaps of a textured surface in a polishing surface, so that the polishing surface is smooth.

Owner:JIANGSU JIAYU RESOURCE UTILIZATION

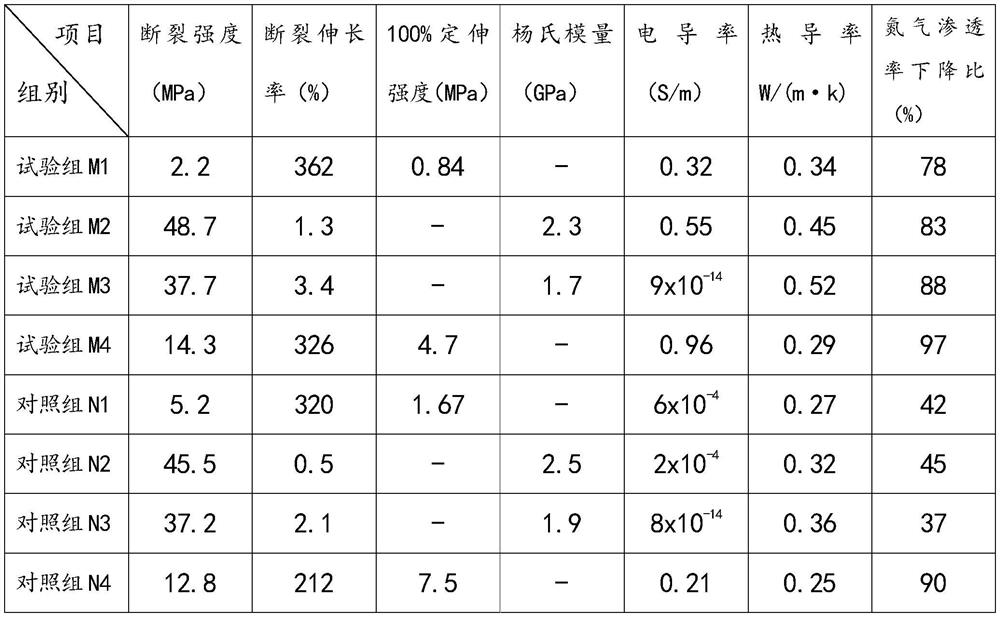

Cross-linked polymer composite material with isolation filler network structure and preparation method of cross-linked polymer composite material

ActiveCN112745544AImprove conductivityImprove barrier propertiesCompression moldingCrosslinked polymers

The invention belongs to the field of high polymer materials, and discloses a cross-linked polymer composite material with an isolation network structure and a preparation method of the cross-linked polymer composite material. The cross-linked polymer composite material with the isolation network structure is obtained by introducing an exchange bond into a cross-linked polymer, mixing the cross-linked polymer with a filler and carrying out compression molding. The obtained cross-linked polymer composite material has high mechanical properties and conductivity. The preparation method is suitable for preparing the cross-linked polymer composite material, and is particularly suitable for preparing the cross-linked polymer composite material with the isolation network structure.

Owner:SOUTH CHINA UNIV OF TECH

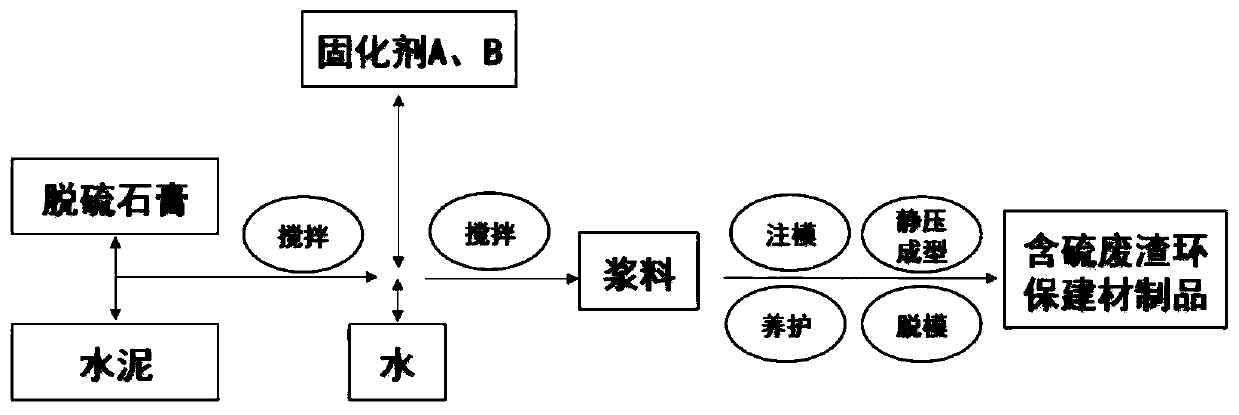

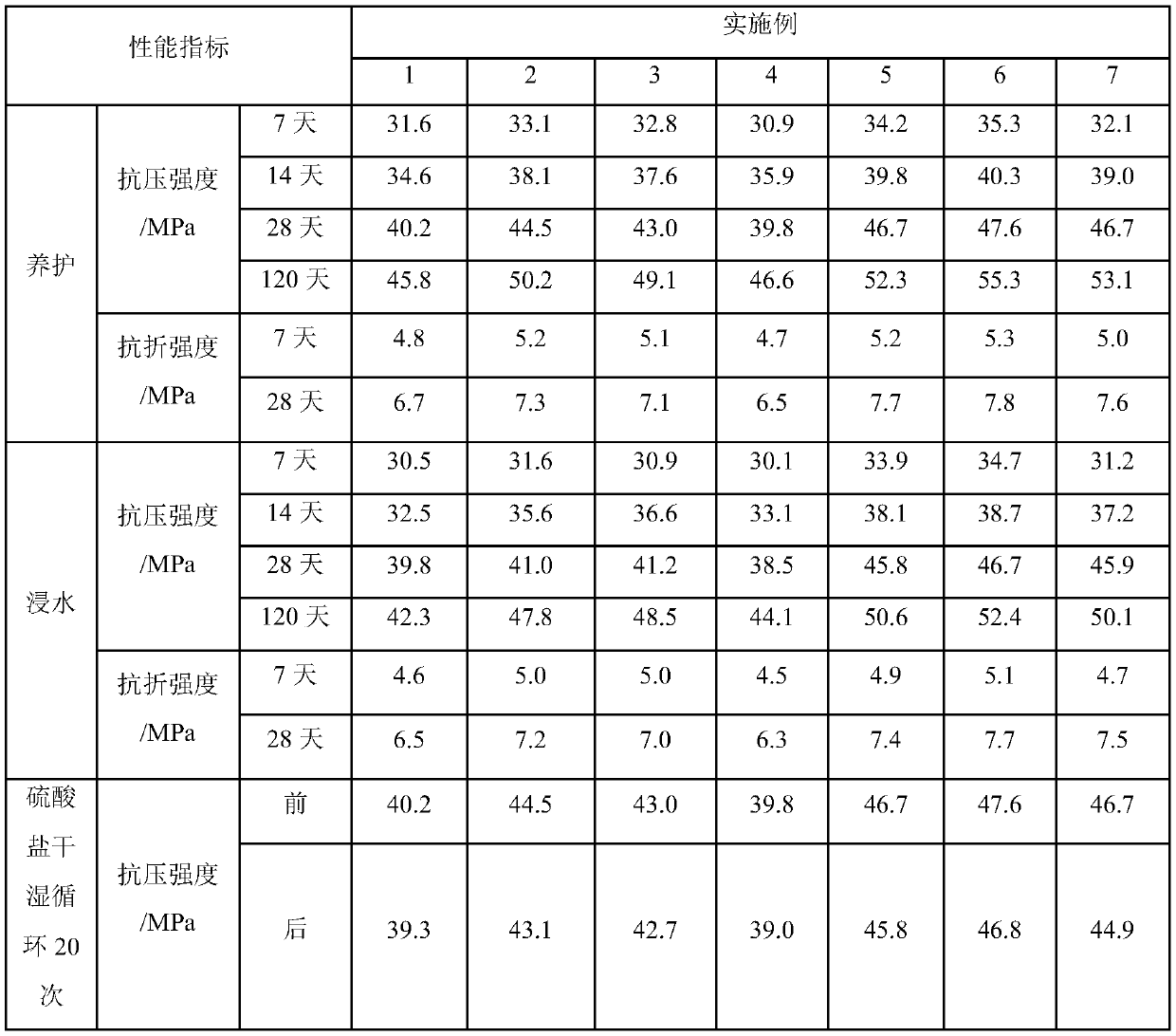

Sulfur-containing waste residue environment-friendly building material product and preparation method thereof

InactiveCN111393126ASmall particle sizeLarge specific surface areaCeramic shaping apparatusSocial benefitsEconomic benefits

The invention discloses a sulfur-containing waste residue environment-friendly building material product and a preparation method thereof. The formula comprises the following components by weight: 75-95 parts of desulfuration gypsum, 5-25 parts of cement, 0.1-0.6 part of a curing agent A, 0.1-0.6 part of a curing agent B and 6-15 parts of water. The preparation method specifically include: makingthe raw materials into a slurry, mixing the prepared slurry evenly, then performing injection molding, conducting static pressure forming under a pressure of 10-60MPa to obtain a green body, and maintaining the pressure for 10s-3min; and conducting curing and demolding to obtain the sulfur-containing waste residue environment-friendly building material product. According to the invention, the burden of industrial solid waste emission on the environment is greatly reduced, the cost is reduced, resource consumption is reduced, functionalization, greenization and value increment of the product are achieved while a large amount of desulfuration gypsum is consumed, and the sulfur-containing waste residue environment-friendly building material product has good economic benefits and social benefits.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN) +1

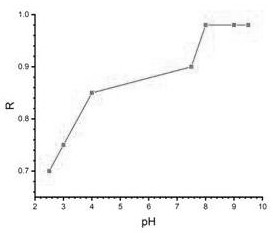

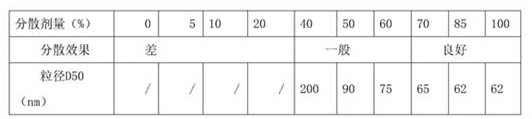

Preparation method of carbon black dispersion liquid for black polyimide film

The invention relates to a preparation method of a carbon black dispersion liquid for a black polyimide film, which is characterized by comprising the following steps of: dissolving a diamine monomer into a strong-polarity aprotic organic solvent, adding a dianhydride monomer in batches, controlling the molar ratio of the dianhydride monomer to the diamine monomer to be 0.7-0.98, controlling the reaction temperature to be 40-50 DEG C, and reacting for 40-60 minutes to obtain a carbon black dispersing agent of a polyamide acid system; the preparation method comprises the following steps: adding carbon black into a carbon black dispersant of a polyamide acid system, stirring, and grinding for 9-11 hours by using a grinding machine to obtain a carbon black dispersion liquid; the carbon black can realize high-stability dispersion in the aspect of preparing modified polyimide, and stable preparation of the high-performance carbon black-polyimide composite material is realized.

Owner:山东万达微电子材料有限公司

A solar heat-absorbing coating with high light absorption rate

ActiveCN105713502BReduce volumeIncrease surface areaPolyurea/polyurethane coatingsRadiation-absorbing paintsWeather resistanceSimple mode

The invention discloses a high-light-absorptivity solar heat-absorbing paint which can be used for any heat collection device capable of converting solar energy into heat energy. The paint is formed by dispersing and uniformly mixing a resin, a light absorber, a solvent and aids according to certain parts by weight by a sand mill. By using the light absorber treated by a novel simple mode as the critical raw material for preparing the paint, the sunlight absorptivity of the paint is greatly enhanced, so that the light-heat conversion efficiency of the heat collection device is enhanced. Besides, the paint has the advantages of excellent weather resistance and longer service life.

Owner:海丰县美达化工涂料有限公司

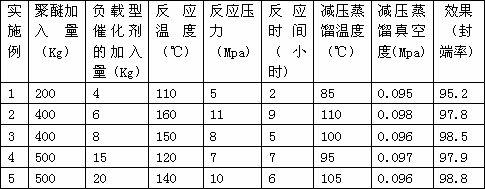

A kind of modified nano-microcrystalline cellulose composite chitosan fiber and its preparation method

ActiveCN109811427BSimple methodLow costConjugated cellulose/protein artificial filamentsCelluloseFiber

The invention provides a modified nano-microcrystalline cellulose composite chitosan fiber, the composite chitosan fiber is composed of a chitosan fiber matrix and modified nano-microcrystalline cellulose distributed in the fiber matrix; the modified The mass fraction of nano-microcrystalline cellulose in the composite fiber is 3-10%. The present invention also provides a preparation method of the above-mentioned composite chitosan fiber. The preparation method of the chitosan composite fiber provided by the present invention can be produced by relying on a conventional chitosan fiber production line, and the method is simple and low in cost. The chitosan composite fiber prepared by the present invention is entirely composed of chitosan and cellulose, both of which belong to polysaccharides and have good compatibility; there is an ionic interaction between the modified nano-microcrystalline cellulose and the chitosan molecular chain, The mixed solution has a certain gelation phenomenon, the viscosity of the system increases, and it can withstand multiple drafts of the coagulation bath and plasticizing bath, effectively improving the mechanical properties of the composite fiber.

Owner:JIAXING UNIV +1

Slow-release type organic granular fertilizer and preparation method thereof

InactiveCN108689762AReduce lossesIncrease profitExcrement fertilisersOrganic fertiliser preparationTrace elementMontmorillonite

The invention discloses slow-release type organic granular fertilizer and a preparation method thereof. The slow-release type organic granular fertilizer is prepared from the following raw materials:straw, earthworm cast, animal manure, vermiculite, plant ash, trace element solution, kaolin, montmorillonite and a slow-release additive. The preparation method comprises the following steps of: 1) mixing the straw, the earthworm cast, the animal manure, the vermiculite and the plant ash and fermenting; 2) after fermentation is ended, sieving out completely-composted powder and granules, pouringinto a container, adding the trace element solution and carrying out high-pressure electrostatic treatment; 3) after mixing and crushing the kaolin and the montmorillonite and mixing with treated powder and granules, carrying out oscillatory rotation in a vacuum container, and using a high-pressure jet pump to spray the slow-release additive into the container; 4) placing the materials in the step3) into a granulating machine, and drying to prepare the fertilizer. The slow-release type organic granular fertilizer disclosed by the invention has the beneficial effects that the preparation process is simple, the operation is easy, the fertilizer can be effectively bonded and combined with soil together after being applied, so that the fertilizer loss caused by rain wash is reduced and the utilization rate of the fertilizer is increased.

Owner:界首市沃土生物科技有限公司

A kind of compound oil displacement agent for high salinity reservoir

ActiveCN104099077BReduce dosageImprove long-term thermal stabilityFluid removalDrilling compositionSalt contentBiopolymer

Owner:CHINA PETROLEUM & CHEM CORP +1

High specific surface area graphene aggregate and preparation method thereof, graphene electrostatic conductive coating and preparation method thereof

ActiveCN109971233BIncrease contentEasy to useElectrically-conductive paintsConductive coatingElectrostatic coating

The invention provides a graphene aggregate with a high specific surface area and a preparation method thereof, a graphene conductive electrostatic coating and a preparation method thereof. The graphene content in the high specific surface area graphene aggregate is 10wt%-30wt%. The preparation method of the graphene aggregate with high specific surface area comprises: first dispersing graphene in a highly volatile solvent, then mixing the high volatile solvent dispersed with graphene with a low volatile solvent, and then separating the high volatile solvent by distillation. Volatile solvents can obtain high specific surface area graphene aggregates, and the high specific surface area aggregates are in a semi-solid state. The high specific surface area graphene aggregate provided by the invention has high graphene content, uniform dispersion, more convenient use and better stability, and can be uniformly dispersed by simple stirring.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

A composite foaming agent for cast-in-place foam concrete

ActiveCN109574543BImprove hydrophilic abilityIncreased water carrying capacityCelluloseFoam concrete

The invention discloses a composite foaming agent for cast-in-place foam concrete. The foaming agent is composed of: 2.0% to 8.0% of fatty alcohol polyoxyethylene ether sodium sulfate, 1.5% to 8.0% of alkyl glycoside, stable Foaming agent 0.5%~3.0%, thickening agent 0%~1.5%, water added to 100%, wherein the mass ratio of fatty alcohol polyoxyethylene ether sodium sulfate to alkyl glycoside is 1:4~4:1, to stabilize foam The agent is modified silicone resin polyether emulsion and / or polyvinylpyrrolidone, and the tackifier is hydroxypropyl methylcellulose and / or polyacrylamide. The foaming agent of the invention has fast foaming, large foaming volume, good foam stability and excellent performance without adding other additives to achieve a good use effect, and can be diluted 30-60 times for the preparation of cast-in-place foam concrete. The raw materials used in the foaming agent of the present invention have excellent biodegradability, safety and environmental protection, and the prepared foaming agent product is green and environment-friendly. In addition, the foaming agent of the present invention has a simple preparation process and mild conditions, and is suitable for industrial production.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com