Water-in-oil association type concentrated thickener for oil displacement and preparation method of water-in-oil association type concentrated thickener

A thickener and associative technology, which is applied in the field of concentrated thickener for water-in-oil associative type oil displacement and its preparation, can solve the problem of increasing the construction platform space, construction cost and construction difficulty, and the use frequency of the dispensing process. It can improve the performance of the system solution, shorten the dissolution time, reduce the difficulty of the process and reduce the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] The present invention also provides a preparation method of the above-mentioned water-in-oil association type oil displacement concentrated thickener, comprising the following steps:

[0075] A) mixing and stirring the dispersion medium, the dispersed phase and the composite emulsifier to obtain a water-in-oil emulsion;

[0076] B) adding a hydrophobic association polymer thickener for oil flooding to the water-in-oil emulsion, mixing and stirring to obtain a concentrated water-in-oil association thickener for oil flooding.

[0077] In the present invention, firstly, the dispersion medium, the dispersion phase and the composite emulsifier are mixed and stirred to obtain the water-in-oil emulsion;

[0078] Wherein, the mixing and stirring temperature is 35-70°C, preferably 40-65°C, more preferably 45-60°C; the mixing and stirring speed is 300-800rmp, preferably 400-700rmp; the mixing and stirring The time is 20 ~ 60min.

[0079] After the water-in-oil emulsion is obtai...

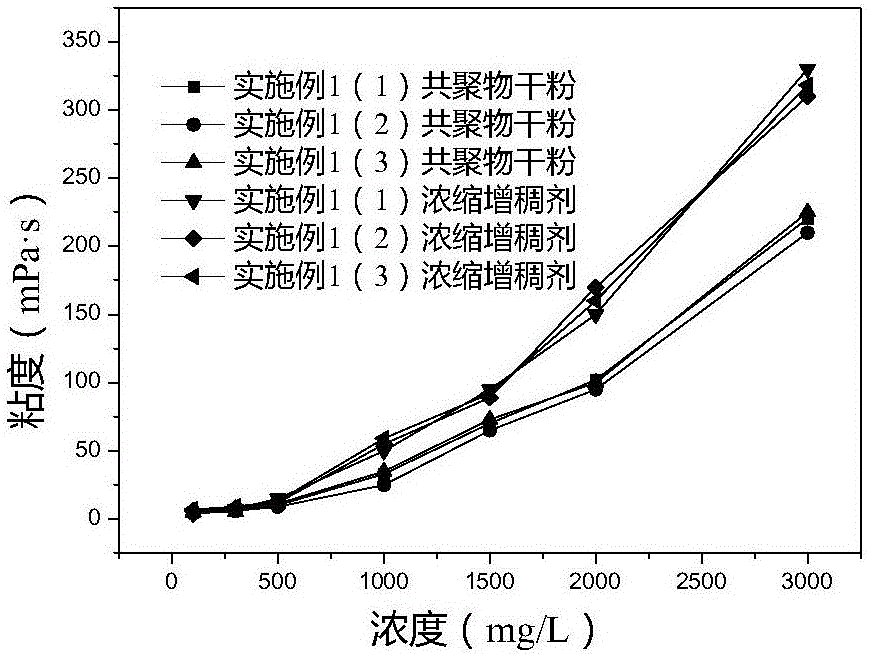

Embodiment 1

[0085] Preparation of concentrated thickener for water-in-oil (W / O) associative flooding (compound emulsifier: tripolyglycerol diisostearate + Pingpinga O O-5)

[0086] (1) A concentrated thickener for W / O association type oil displacement, comprising the following components in mass percentage:

[0087] 0# diesel oil 35.72%, water 35.72%, hydrophobic association polymer oil displacement thickener (hereinafter referred to as "oil displacement thickener") 25%, tripolyglycerol diisostearate 2.85%, Pingpingjia O O-5 0.71%;

[0088] Described oil displacement thickener is acrylamide / sodium acrylate / N-dodecyl substituted acrylamide copolymer, and described composite emulsifier is tripolyglycerol diisostearate and O-5 (ratio 4:1), the preparation steps are as follows:

[0089] At 40°C, control the mass ratio of oil to water to 5:5, mix and emulsify 357.2g diesel, 357.2g water, 28.5g triglyceryl diisostearate, 7.1g O-5, and stir at 600rmp After 30 minutes, a stable water-in-oil em...

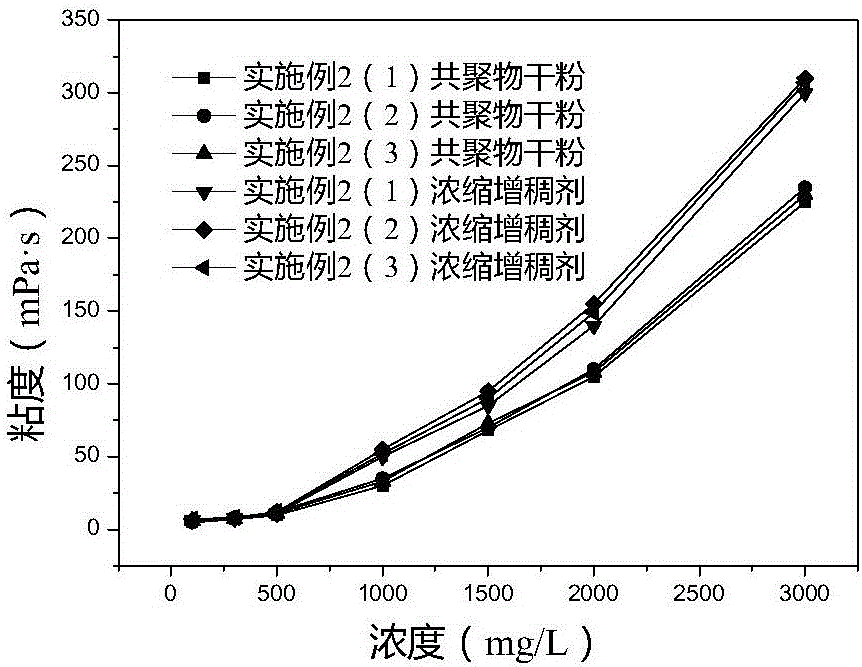

Embodiment 2

[0099] Preparation of concentrated thickener for water-in-oil (W / O) associative flooding (compound emulsifier is propylene glycol fatty acid ester PGMS+polyoxyethylene castor oil EL-20)

[0100] (1) A concentrated thickener for W / O association type oil displacement, comprising the following components in mass percentage:

[0101] 0# diesel oil 42.86%, water 28.57%, oil displacement thickener 25%, propylene glycol fatty acid ester PGMS 2.14%, polyoxyethylene castor oil EL-20 1.43%;

[0102] The thickener for oil displacement is acrylamide / sodium acrylate / N-vinylpyrrolidone / stearyl acrylate copolymer, and the composite emulsifier is PGMS and EL-20 (ratio 3:2), The preparation steps are as follows:

[0103] At 50°C, control the mass ratio of oil to water to 6:4, mix 428.6g diesel, 285.7g water, 21.4g PGMS, 14.3g EL-20 to emulsify evenly, stir at 600rmp for 30min to form a stable water-in-oil emulsion , and finally add 250g thickener for oil displacement, and form a uniform and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com