Patents

Literature

481results about How to "Shorten the dissolution time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Erigeron breviscapus oral caving fast disintegration tablet and its preparation method

InactiveCN1429618AShorten the dissolution timeQuick effectOrganic active ingredientsUnknown materialsErigeron breviscapusActive component

A fast disintegrant tablet using the extract of Erigeron breviscapus as its active components for oral cavity contains the said active component (5-20 wt.%), disintegrant (2-10), lubricant (0.2-2), flowing aid (0.1-1.5), additive (0-0.5) and filter (the rest). The features fast disintegrating speed (60 seconds after it encounters saliva).

Owner:TSINGHUA UNIV

Method for preparing Al-Ti-B grain refiner

The Al-Ti-B crystal grain fining agent for metal material has the components including Ti 2-10 wt%, B 2 wt% and Al the rest. The preparation process includes the steps of: mixing industrial pure potassium fluorotitanate and potassium fluoroborate homogeneously, heating to melt industrial pure aluminum, adding the mixed salt into aluminum melt and covering the surface of the melt with KCl, introducing ultrasonic wave to over the melt, skimming slag, cooling the melt naturally while continuous ultrasonic treatment until the intermediate alloy solidifies completely to obtain the Al-Ti-B crystal grain fining agent. The present invention has short preparation period and less oxidation loss of aluminum melt, and the obtained casting structure has fine TiAl3 grains of homogeneous size below 20 microns and TiB2 grains with clear contour. The Al-Ti-B crystal grain fining agent is used in preparing industrial pure aluminum with crystal grains smaller than 120 microns.

Owner:SHANGHAI JIAO TONG UNIV

Method for measuring contents of aluminum, titanium, manganese, nickel, tungsten and iron in cobalt-base alloy

ActiveCN101718689AEasy to handlePromote precipitationPreparing sample for investigationColor/spectral properties measurementsManganeseMaterials science

The invention belongs to a technique for analyzing elements of an alloy, and relates to a method for measuring the contents of aluminum, titanium, manganese, nickel, tungsten and iron in a cobalt-base alloy. The method adopts an inductively coupled plasma atomic emission spectrometer and is different according to different measured elements and different tungsten contents; when high-content tungsten is dissolved, the volume of test solution needs to be maintained between 20 and 40 mL, or the tungsten is easy to be separated out; by performing interference experiments and spectrogram analyses, the method finds the optimal analytical line, overcomes the interferences caused by a plurality of elements such as major elements of cobalt, chromium, tungsten and the like in the cobalt-base alloy, and improves the measuring accuracy; the sample dissolving speed is accelerated, and the sample dissolving time is shortened to 2 hours from about two or three days; and the method has wide measuring ranges including: 0.05 to 0.30 percent of the aluminum, 0.05 to 0.30 percent of the titanium, 0.05 to 1.00 percent of the manganese, 0.05 to 24.00 percent of the nickel, 0.05 to 20.00 percent of the tungsten, and 0.05 to 3.00 percent of the iron.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

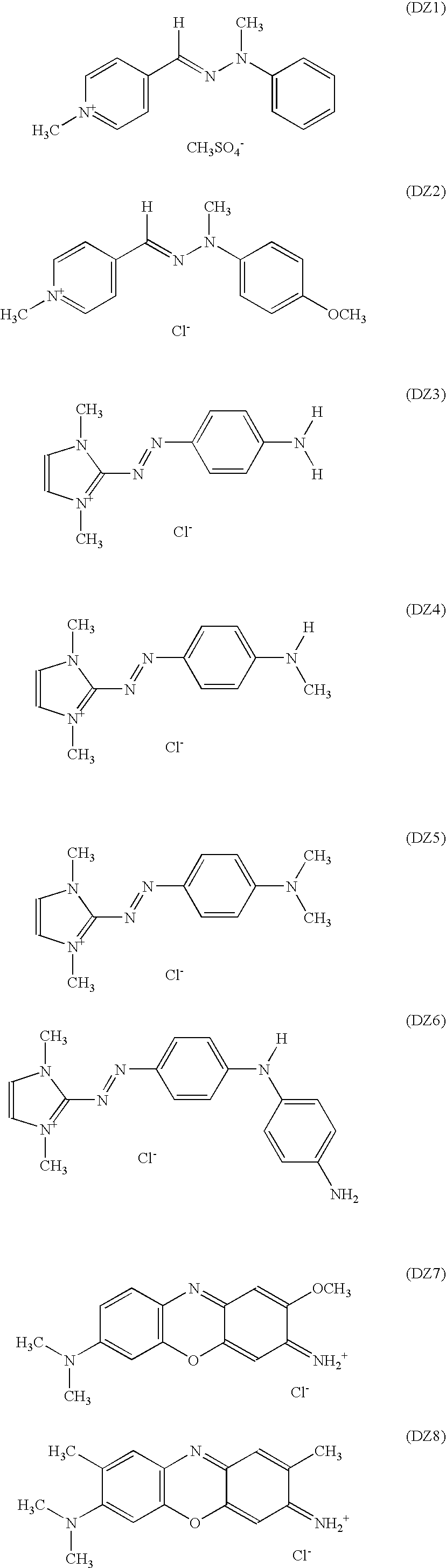

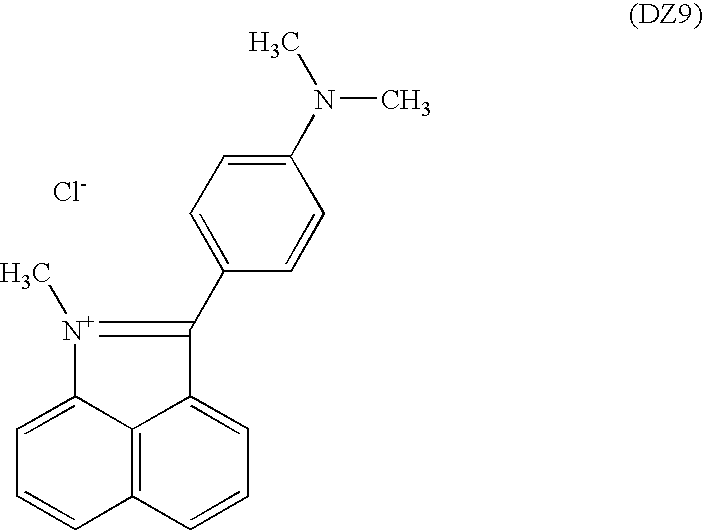

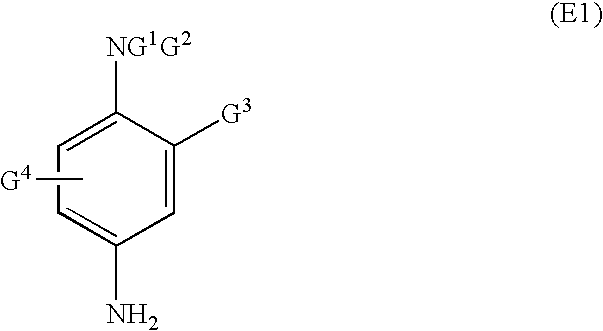

Colouring agents

InactiveUS20050039271A1Shorten the dissolution timeCutting can not be obtainedCosmetic preparationsHair cosmeticsFiberColoring agents

A shaped body for coloring keratinous fibers consisting of at least one dissolution accelerator and at least one oxidation dye precursor of the secondary intermediate type, contained within a cosmetically acceptable carrier. The shaped body is free from oxidation dye precursors of the primary intermediate type. Also disclosed are a method for coloring keratin fibers and a kit containing these ingredients.

Owner:HENKEL KGAA

Preparation method of fibroin blending regenerated cellulose fiber

ActiveCN102851777AImprove stabilityHigh chemical activityConjugated cellulose/protein artificial filamentsArtificial filaments from viscoseCross-linkAdhesive

The invention discloses a preparation method of fibroin blending regenerated cellulose fiber, comprising the steps of (1) degumming, swelling, drying and smashing the silk offcuts to obtain a fibroin powder with grain size of 0.1-0.5 micrometers; (2) dispersing the fibroin powder with sodium hydroxide solution, adding the dispersing agent and the cross-linking agent aliphatic acid alkylolamides to obtain the fibroin dispersion mother solution; and (3) blending the fibroin dispersion mother solution with the cellulose adhesive to obtain the blended adhesive, and carrying out spinning molding and post processing to obtain the fibroin blending regenerated cellulose fiber. According to the preparation method provided by the invention, the loss amount of the protein in the preparation process is low, the content of protein in the produced fibroin blending regenerated cellulose fiber is high, the production cost is low, the strength of the fibroin blending regenerated cellulose fiber is high; and the preparation method is easy for industrial production, improves the textile processing performance of the fibroin blending regenerated cellulose fiber and broadens the application range of the fibroin blending regenerated cellulose fiber.

Owner:湖州珠力纳米材料科技开发有限公司

Method for detecting contents of titanium, manganese, Ferrum, nickel and tungsten in tantalum contained cobalt-base alloy

InactiveCN102914532AFast sample dissolutionShorten the dissolution timePreparing sample for investigationAnalysis by electrical excitationManganeseMaterial resources

The invention provides a method for detecting contents of titanium, manganese, ferrum, nickel and tungsten in a tantalum contained cobalt-base alloy. The analyzing steps are as follows: weighing a specimen; preparing a specimen solution; preparing a correcting solution; drawing a working curve; measuring concentrations of titanium, manganese, ferrum, nickel and tungsten in the specimen solution; and calculating measuring results so as to obtain the contents of titanium, manganese, ferrum, nickel and tungsten. According to the invention, problems that a sample is hard to dissolve, serious interference on spectral line measurement is caused and so on are overcome; the sample dissolving speed is greatly increased; spectral interferences of a matrix on measuring elements are eliminated through matrix matching; and the measuring accuracy is enhanced. The method for detecting the contents of titanium, manganese, ferrum, nickel and tungsten in the tantalum contained cobalt-base alloy, provided by the invention, has the advantages of speediness in sample dissolution and and measurement as well as simplicity and convenience in operation; and a great deal of manpower and material resources are saved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Laundry liquid and preparation method thereof

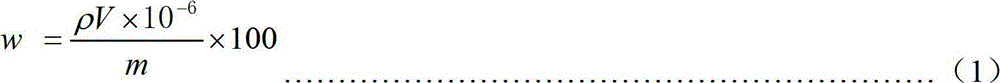

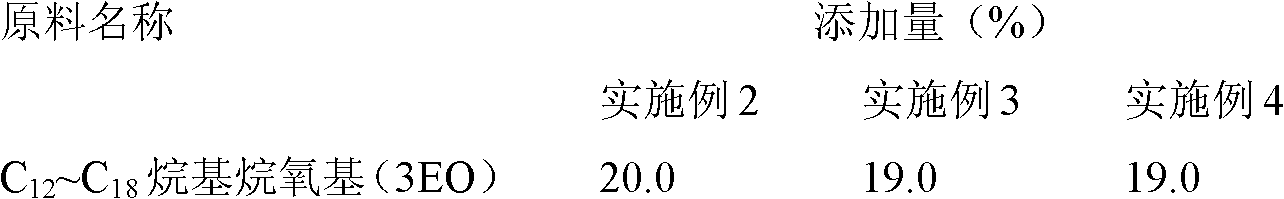

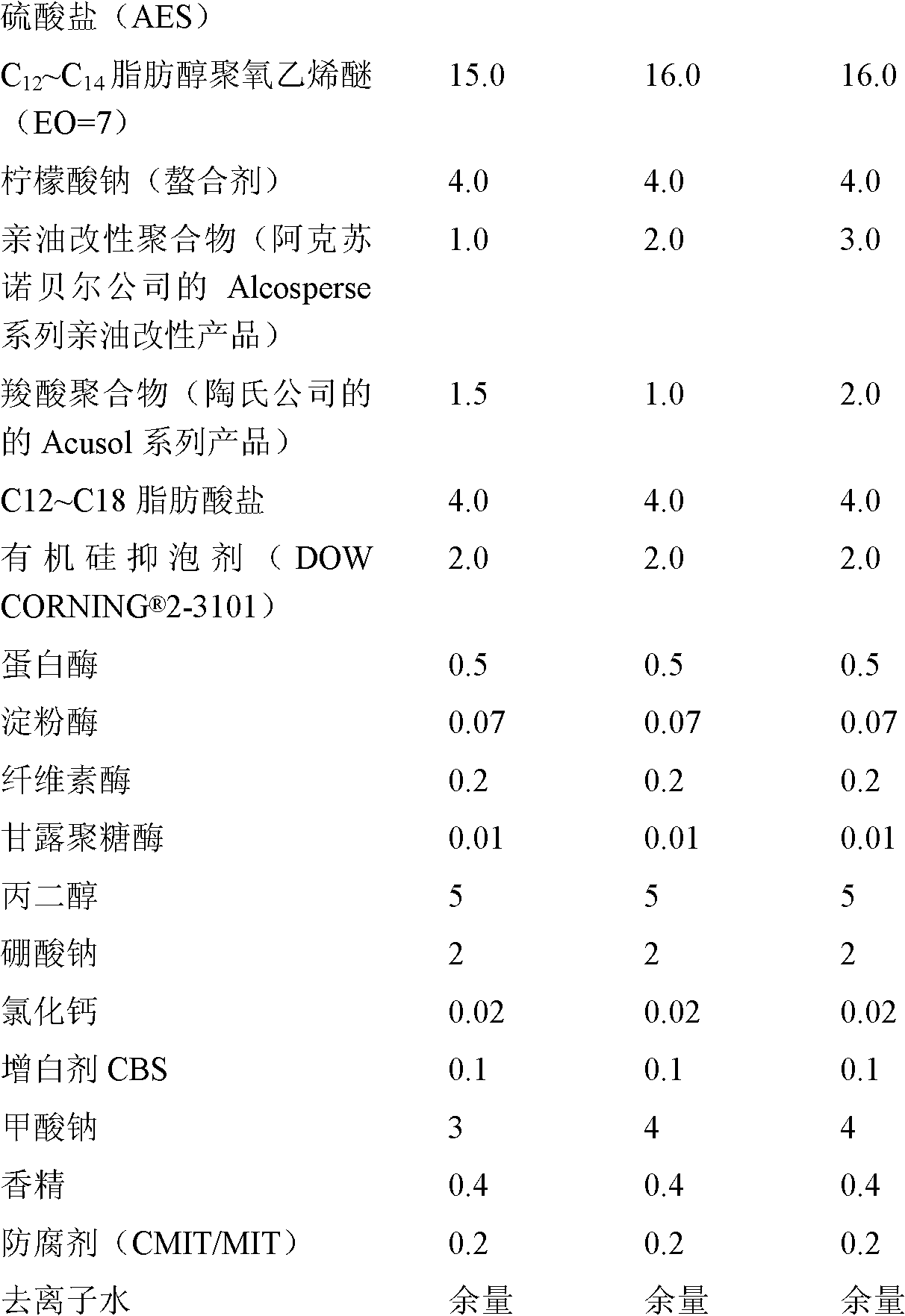

ActiveCN102071111AShorten the dissolution timeIncrease productivityNon-ionic surface-active compoundsOrganic detergent compounding agentsCarboxylic acidFOAM CONTROL

The invention discloses laundry liquid and a preparation method thereof. The laundry liquid is prepared by the following materials in percentage by mass: 0.1 to 5.0 percent of oleophylic modified polymer, 0.2 to 5.0 percent of carboxylic acid polymer, 1 to 25.0 percent of nonionic surfactant, 1 to 25.0 percent of anionic surfactant, 0.01 to 1.5 percent of enzyme, 0.1 to 15.0 percent of enzyme stabilizer, 0.5 to 8.0 percent of foam control agent, 0.5 to 10 percent of other auxiliary agents and the balance of water. By the preparation method of the laundry liquid, the production time can be reduced by about 30 percent, and the laundry liquid is efficiently produced; and the prepared laundry liquid has high detergency to mud and oil stains and high stain redeposition resistance.

Owner:GUANGZHOU LIBY

Water soluble polyvinyl alcohol fiber and its prepn and use

InactiveCN1403641ADimensionally stableShorten the dissolution timeFibre treatmentMonocomponent synthetic polymer artificial filamentSolventChemistry

The present invention features that PVA of polymerization degree 500-2000 and alcoholysis degree 75-99 mol% in 100 portions is mixed with solvent mixture of dimethyl sulfoxide and water in 200-400 portions, the mixture is stirred and heated to 80-120 deg.c at -0.01--0.08 MPa pressure in a stainless steel reactor for 3-4 hr to compound the spinning solution, and the spinning solution is filtered and defoamed and used in spinning to obtain water soluble PVA fiber after post-treatment. The PVA fiber has a water solving temperature of 10-90 deg.c, strength greater than 3.5 cN / dtex, monofilament length of 1.5-10 dtex, fracture elongation of 15-30%. It may be processed into top, which may further blended with wool top, cotton, top, etc. to produce fine yarn or hollow yarn, or cut into staple fiber for producing non-woven fabric, etc.

Owner:CHINA PETROCHEMICAL CORP +2

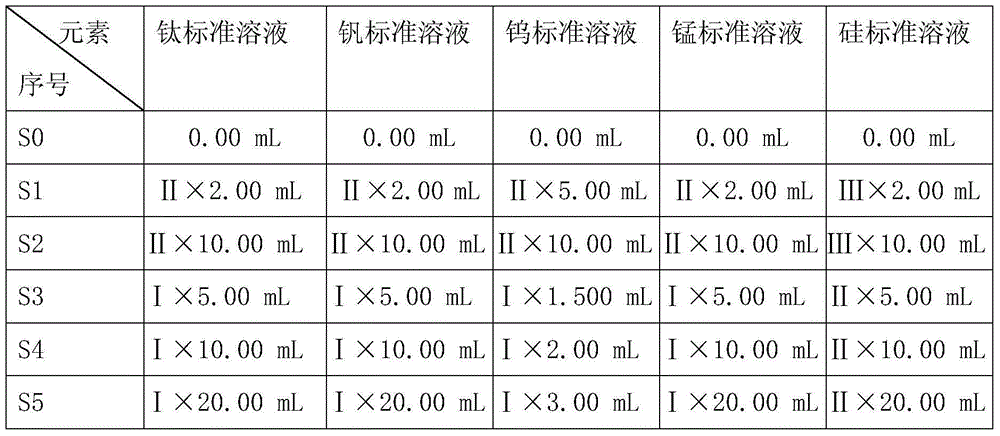

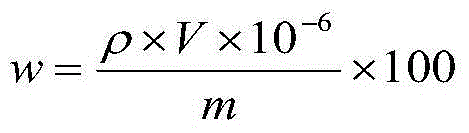

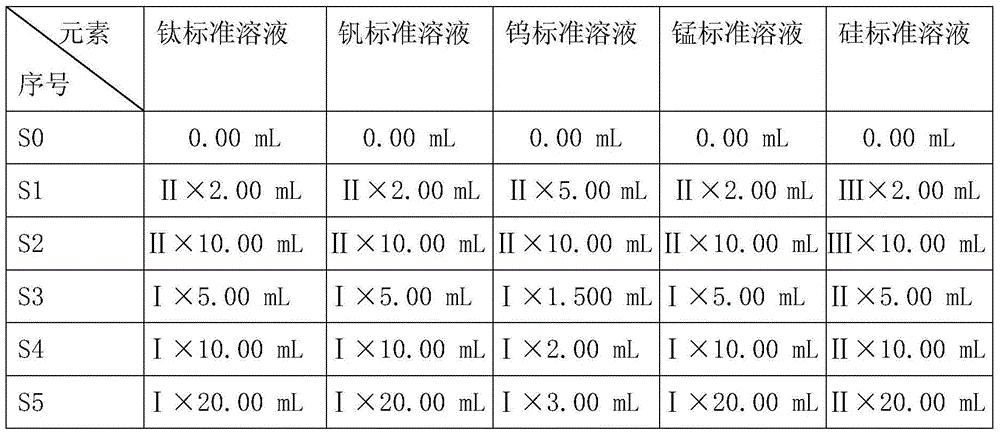

Analysis method for determining titanium, vanadium, tungsten, manganese and silicon in K25 chromium-base high temperature alloy

ActiveCN103604800ALarge amount of solutionReduce pollutionAnalysis by thermal excitationAlloy elementScrap

The invention belongs to the new material alloy element analysis technology, and relates to an analysis method for determining titanium, vanadium, tungsten, manganese and silicon in a K25 chromium-base high temperature alloy. The analysis steps comprise: weighing a sample; preparing a sample solution; preparing a calibration solution; measuring concentrations of titanium, vanadium, tungsten, manganese and silicon in the sample solution; and calculating the measurement result to obtain contents of titanium, vanadium, tungsten, manganese and silicon. According to the present invention, the ICP-AES method for determining contents of titanium, vanadium, tungsten, manganese and silicon in the K25 chromium-base high temperature alloy is provided, wherein the method has characteristics of high analysis sensitivity, simple operation, short analysis period, high efficiency and wide application prospect, can meet engineering application of the high temperature alloy, can meet requirements of scientific research and production on material quality control, and further has characteristics of product scrap rate reduction, development saving and production cost saving.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

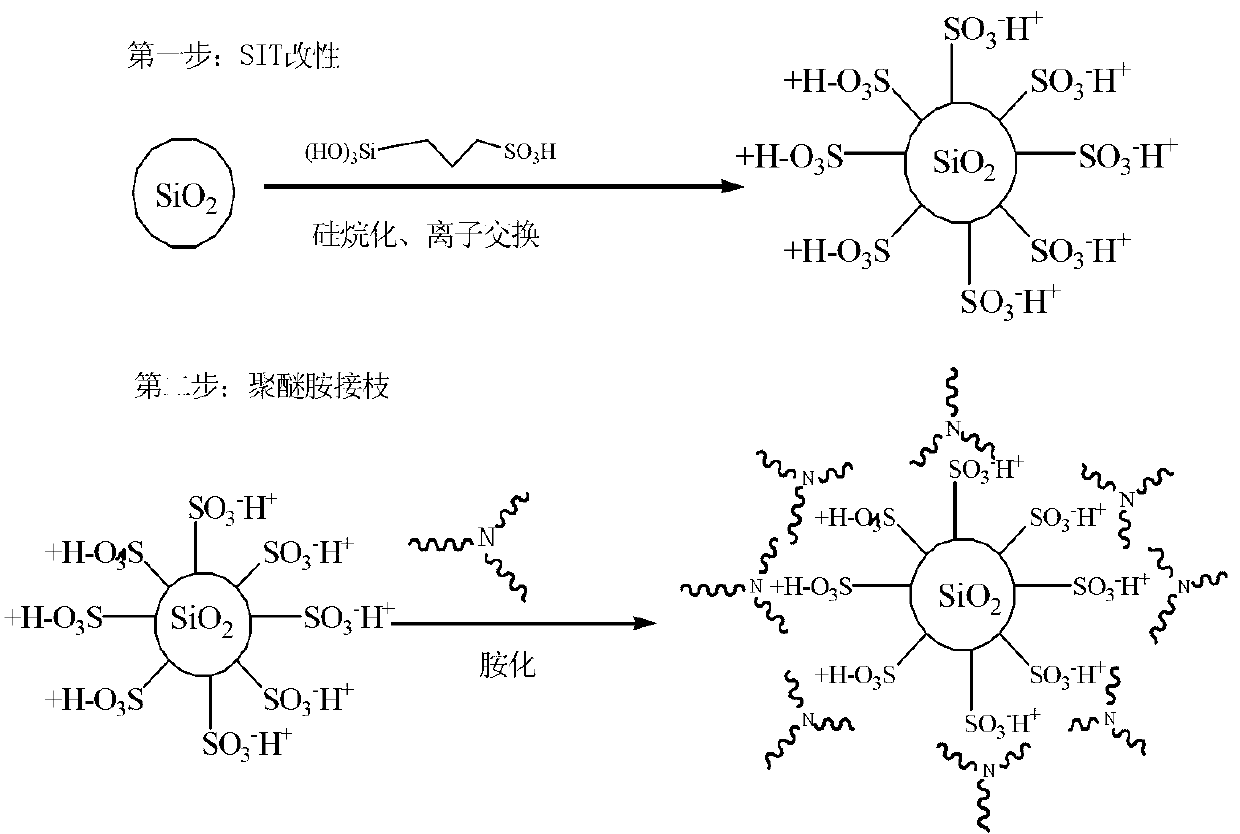

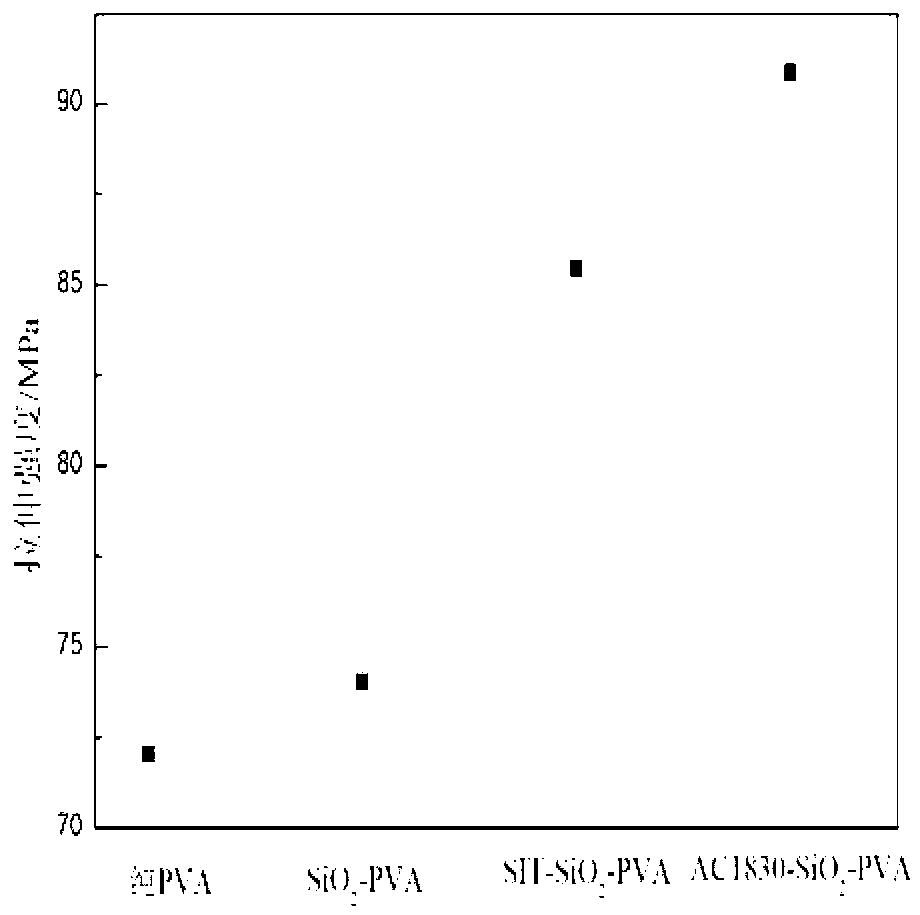

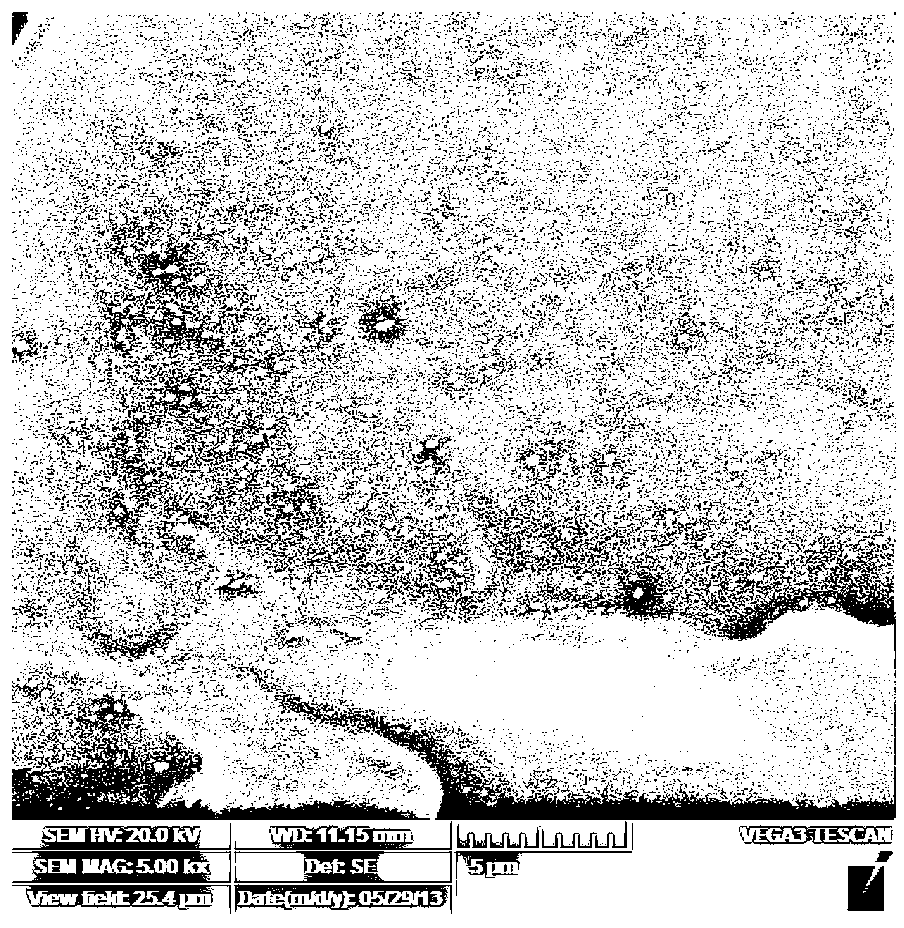

Modified SiO2/PVA (polyvinyl alcohol) film and preparation method thereof

The invention relates to a modified SiO2 / PVA (polyvinyl alcohol) film and a preparation method thereof. The preparation method comprises the following steps: dissolving m parts by mass of modified SiO2 particles and (m-100) parts by mass of PVA at dissolution temperature, cooling and carrying out cast molding, or carrying out integral molding at melting temperature, wherein 0<m<=20, and the PVA adopts PVA1750, PVA1778, PVA1788 or PVA1798. The film can be prepared by a running process, extrusion blow-molding process or calendering process. The modified SiO2 preparation method is simple, the modified SiO2 particles can be uniformly dispersed in the PVA, and the ether oxygen bond and amino group in the polyetheramine molecular chain and the hydroxy group in the PVA can form a hydrogen bond, so that the prepared SiO2 / PVA film has obviously higher stretching resistance, modulus and heat stability, and is especially suitable for preparing transparent PVA film products.

Owner:WUHAN UNIV OF TECH

Hair Relaxer

InactiveUS20080131389A1Good water solubilityShorten the dissolution timeCosmetic preparationsHair cosmeticsAlkalinityNeutral ph

A hair relaxer includes at least one specific mercapto compound such as 2-methoxyethyl 3-mercaptopropionate, 2-mercapto-4-butanolide and 2-mercapto-4-butyrolactam. The hair relaxer can achieve an excellent effect of shaping and relaxing hair over a wide range of pH values from weak acidity to weak alkalinity. In particular, the hair relaxer displays a more superior hair shaping and relaxing performance in a weakly acidic to neutral pH range. Consequently, the hair relaxer can drastically reduce the damage to the hair and skin and can reliably perform straightening, uncurling, curling and other hair processing.

Owner:SHOWA DENKO KK

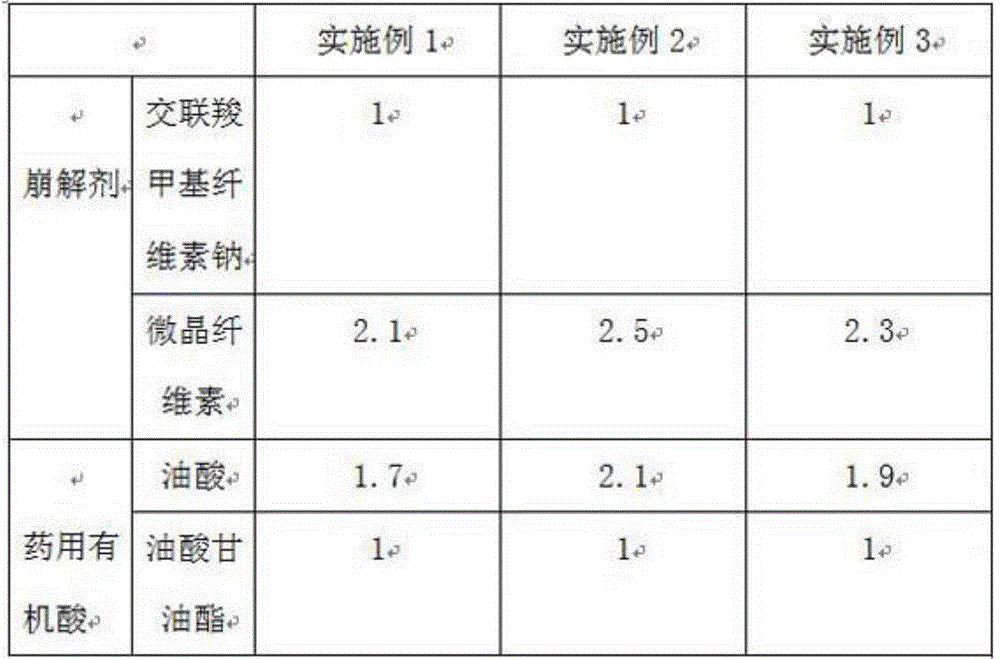

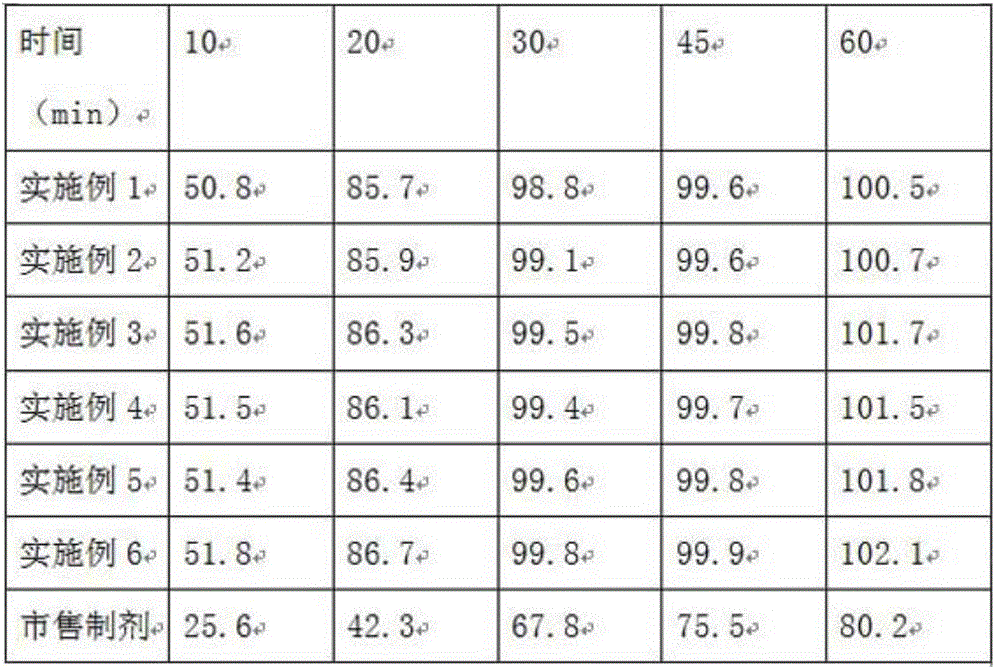

Pharmaceutical composition containing ibrutinib

InactiveCN106619643AGood solubilityGood compatibilityOrganic active ingredientsPharmaceutical non-active ingredientsDrugOrganic acid

The invention relates to a pharmaceutical composition containing ibrutinib. The pharmaceutical composition is prepared from, by weight, 13-15 parts of ibrutinib, 30-50 parts of solvent, 20-30 parts of solubilizer, 8-12 parts of filler, 6-10 parts of disintegrant and 21-26 parts of officinal organic acid, wherein the solvent is glycerolformal, and the officinal organic acid is a mixture of oleic acid and glyceryl monooleate based on the mass ratio of (1.7-2.1):1. The pharmaceutical composition containing ibrutinib has the advantages that compared with traditional pharmaceutical compositions, the variety of the solvent in the formula is changed, glycerolformal which is high in safety performance serves as the solvent with dosage unlimited, and multiple medicines are soluble in glycerolformal; meanwhile, due to the fact that the officinal organic acid is a mixture of oleic acid and glyceryl monooleate, the pharmaceutical composition containing ibrutinib is more stable and simpler than traditional pharmaceutical compositions adopting single officinal organic acid.

Owner:ABA CHEM SHANGHAI

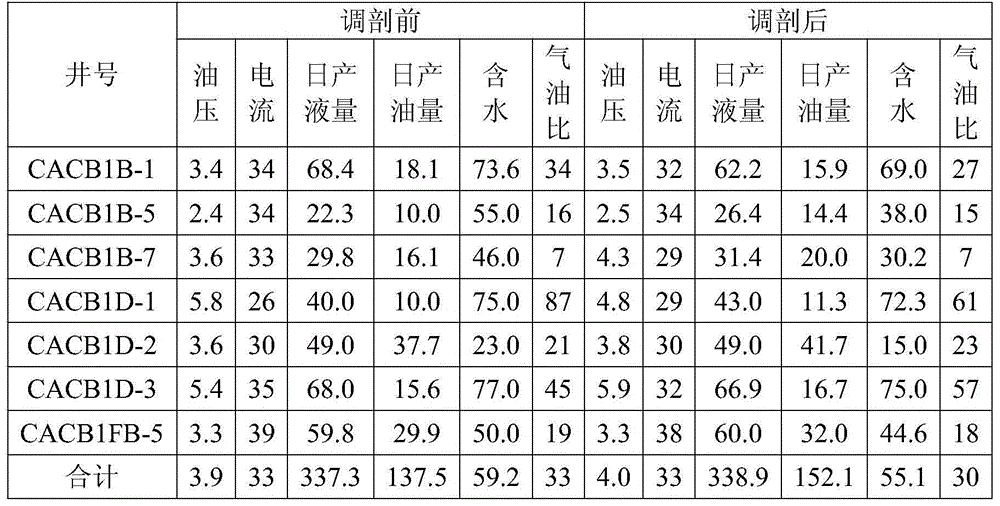

Anionic polyacrylamide water-in-water emulsion water shutoff profile control agent, and preparation method and using method thereof

The invention discloses an anionic polyacrylamide water-in-water emulsion water shutoff profile control agent, and a preparation method and a using method thereof. The anionic polyacrylamide water-in-water emulsion water shutoff profile control agent consists of an anionic polyacrylamide water-in-water emulsion and a cross-linking agent. The preparation method comprises the following steps: adding deionized water, a stabilizing agent, part inorganic salts, nonionic monomers, anionic monomers, a chelating agent and (a chain transfer agent) into a reaction container, stirring uniformly, adjusting the pH value to a suitable range, introducing nitrogen to remove oxygen, adding an initiator to initiate a reaction, adding the remaining part inorganic salts in a reaction process, preserving heat, and discharging materials to obtain the anionic polyacrylamide water-in-water emulsion. The using method of the anionic polyacrylamide water-in-water emulsion serving as a water shutoff profile control agent comprises the following steps: diluting the water-in-water emulsion on situ or on line to prepare a uniform aqueous solution with a certain concentration, adding a certain amount of the cross-linking agent under the condition of stirring, stirring uniformly and injecting the aqueous solution into a stratum to realize the purpose of improving crude oil recovery rate.

Owner:SHENGLI OILFIELD SHENGLI CHEM

Method for manufacturing cellulose/ion liquid spinning liquid with double-screw extrusion machine

InactiveCN101220522AShorten the dissolution timeEasy to industrializeArtificial filaments from cellulose solutionsSpinning solutions preparationIonPre filtering

The invention relates to a method for using a double screw extruder to prepare celluloses / ionic liquids spinning solution and the preparation comprises that the celluloses are uniformly mixed with the ionic liquids according to the weight ratio of 5:95 to 25:75, and then the mixture is put into the double screw extruder which has two vacuum orifices and the screw length diameter ratio of which is 36:1 to 60:1, the control range of temperature is 40 to 120 DEG C, and the light brown and transparent celluloses / ionic liquids spinning solution is formed after strongly mixing and dissolving for 8 to 40 minutes and vacuum dehydration; the obtained celluloses / ionic liquids spinning solution is supercharged by a booster pump and sprayed from a spinneret after coming into a metering pump by a pre-filter, and then cellulose fibers are formed by a plurality of steps such as solidification, washing, cutting and drying, etc. The invention not only shortens the dissolution time of the celluloses but also leads to the more fully mixing and dissolving of materials, and achieves the purposes of energy-saving, high efficiency, decreasing degradation and improving the quality of spinning original solution, so the industrialization becomes easier.

Owner:DONGHUA UNIV +1

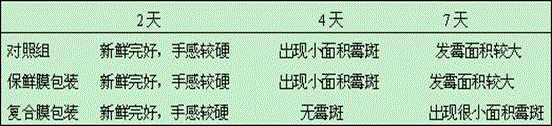

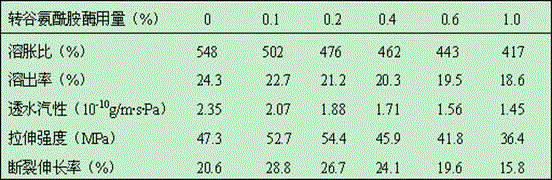

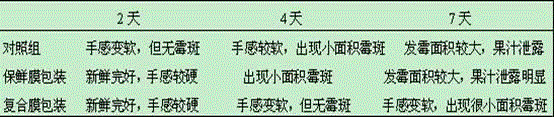

Preparation method and application of gelatin-chitosan composite membrane

InactiveCN105001463AShorten the time required for dissolutionImprove efficiencyFlexible coversWrappersChemistryGlutaminase

The invention discloses a preparation method of a gelatin-chitosan composite membrane. The method includes the steps that chitosan is added into a three-opening flask at an indoor temperature, then deionized water is added, stirring is conducted for 3-5 minutes, an acid solution is added while stirring is conducted after the chitosan is evenly dispersed, the pH value is adjusted to be 3.5-6, sufficient stirring is conducted continuously, and accordingly a chitosan solution is obtained; a gelatin solution and the chitosan solution are mixed, and PEG 200 is added into the gelatin / chitosan mixed solution; afterwards, the solution is neutralized by a weak NaOH solution till the pH value is 6; transglutaminase (TGase) is added, stirring is conducted to enable gelatin and chitosan to undergo crosslinking, then the solution is heated to be boiled, enzyme denaturalixation is carried out for 8-12 minutes, defoaming is conducted when the temperature of the solution is lowered to the indoor temperature, and membrane casting is achieved. The time needed for dissolving the chitosan can be shortened obviously, efficiency is improved, and after the TGase undergoes catalytic crosslinking, the water solubility, swelling ratio and moisture permeability of the gelatin-chitosan composite membrane are lowered. The gelatin-chitosan composite membrane can play obvious antibacterial and fresh-keeping effects when being used for packaging fruits.

Owner:HENAN INST OF ENG

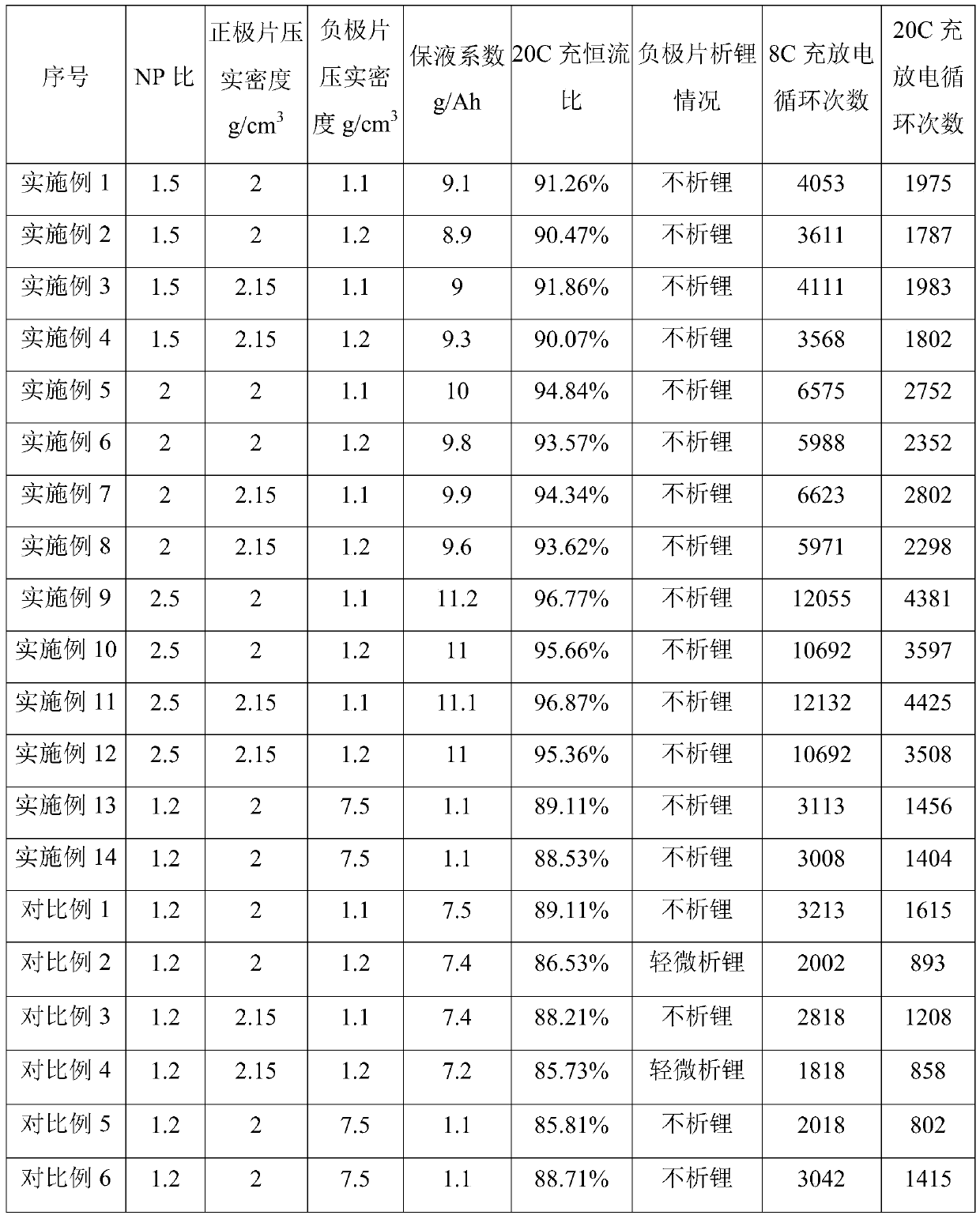

Lithium ion battery and preparation method thereof

PendingCN111403801AImprove cycle performanceImprove securityFinal product manufactureElectrode carriers/collectorsPhysical chemistryPositive current

The invention relates to the technical field of batteries, in particular to a lithium ion battery and a preparation method thereof. The lithium ion battery is characterized in that the lithium ion battery comprises a positive plate, a negative plate, a diaphragm, an electrolyte and a battery housing. The positive plate comprises a positive current collector and positive slurry, and the negative plate comprises a negative current collector and negative slurry, wherein the ratio of the capacity of the negative plate to the capacity of the positive plate is 1.41-9.41. According to the lithium ionbattery, the ratio of the capacity of the negative plate to the capacity of the positive plate in the battery is optimized, the surplus capacity is supplemented through a lithium supplementing technology, and the parameters of the positive plate and the negative plate are optimized, so that the cycle performance, the safety performance and the rate charging performance of the lithium ion batteryare improved, and the lithium ion battery has the characteristics of high rate and long service life.

Owner:FARASIS TECH (GANZHOU) CO LTD

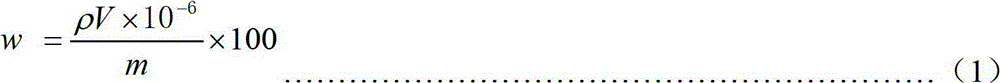

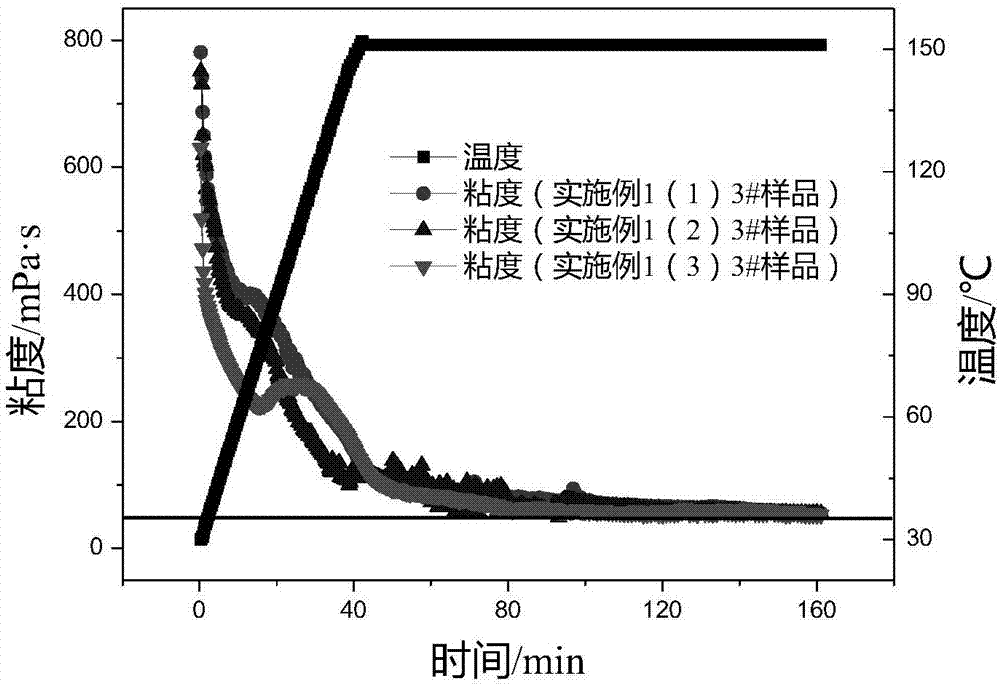

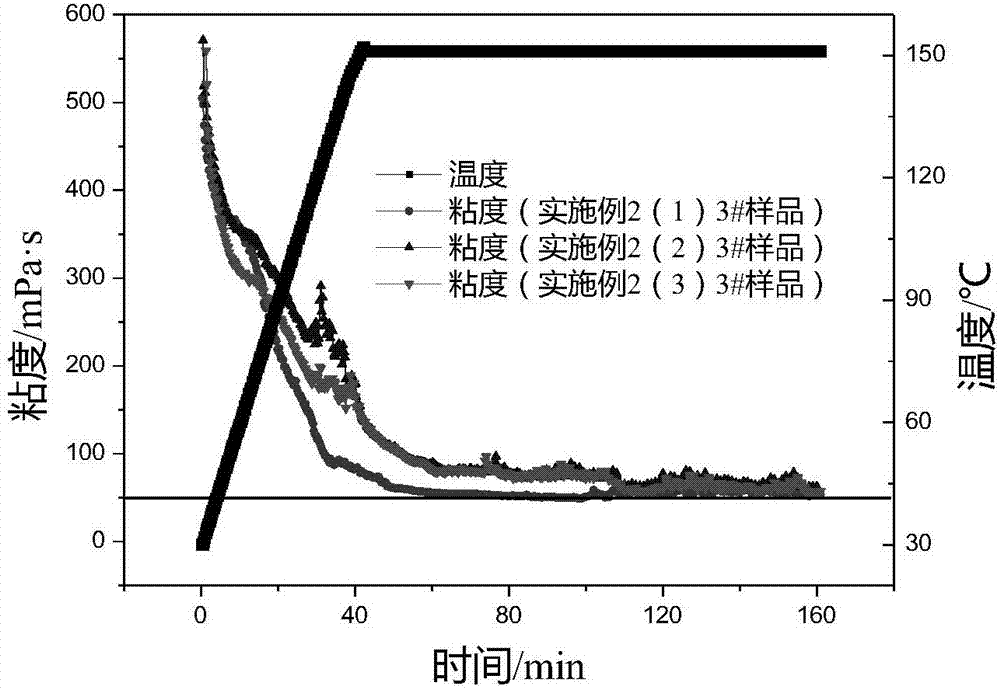

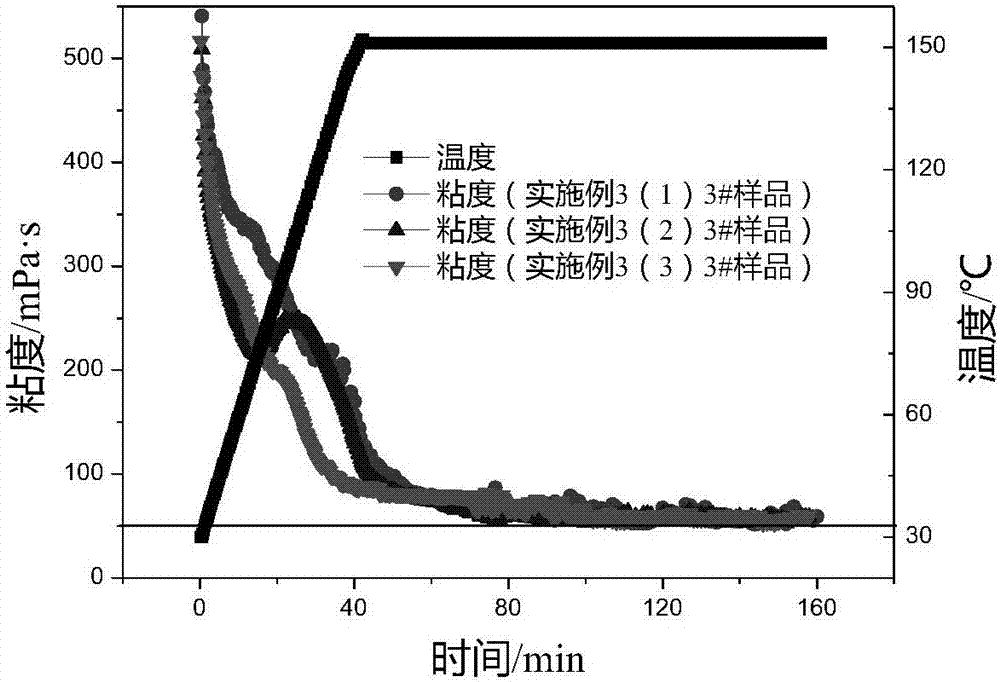

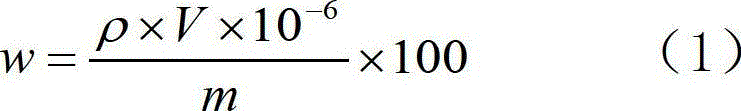

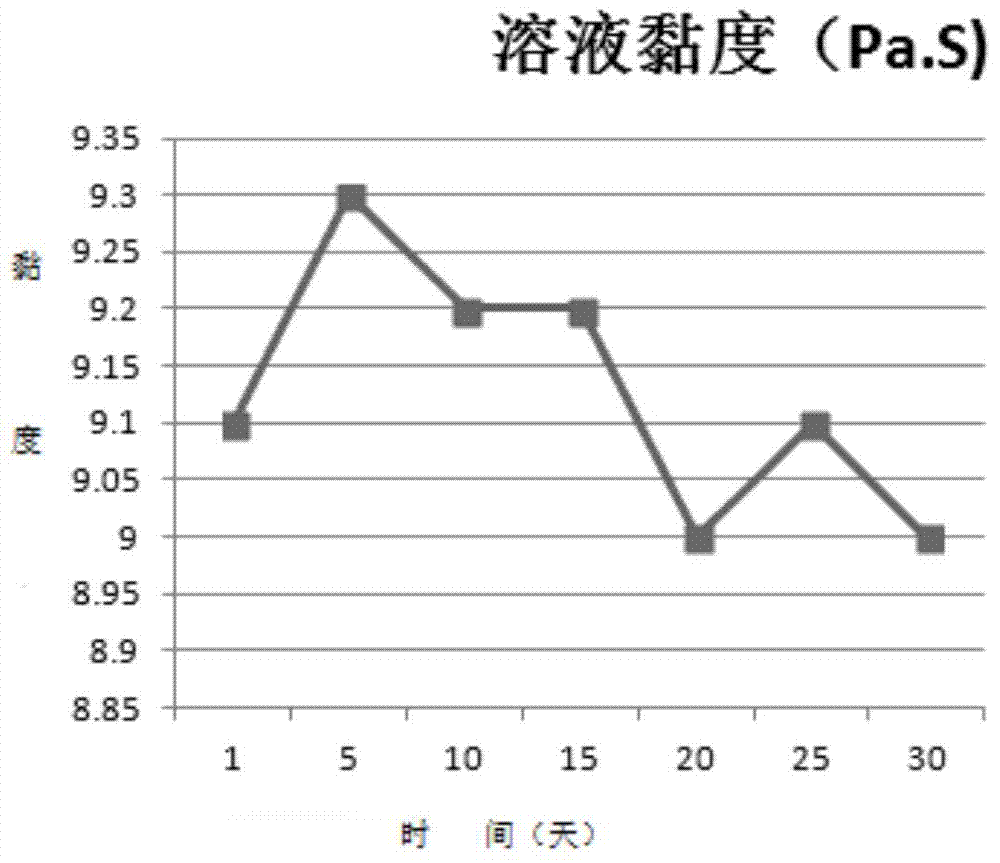

Water-in-oil associated non-crosslinked fracturing fluid concentrating and thickening agent and preparation method thereof and fracturing fluid

InactiveCN106928960AHigh strengthImprove sand carrying capacityDrilling compositionPolymer scienceOrganic solvent

The invention provides a water-in-oil associated non-crosslinked fracturing fluid concentrating and thickening agent, which is prepared from the following components in percentage by mass: 25-50wt% of a dispersion medium, 18-40wt% of a disperse phase, 20-40wt% of a hydrophobic associated polymer fracturing fluid thickening agent and 2.5-6wt% of a compound emulsifier, wherein the dispersion medium is an organic solvent incompatible with water; the disperse phase is water; the compound emulsifier is the compound emulsifier compounded by an emulsifier of which the HLB value is 3-7 and an emulsifier of which the HLB value is 8-10; and the sum of the content of various components is 100wt%. The stabilization time of the prepared concentrating and thickening agent is greater than 120d and the dissolution time is smaller than 1min. The solution property of the fracturing fluid prepared from the concentrating and thickening agent is superior to that of the fracturing fluid which is directly prepared from corresponding fracturing fluid thickening agent dry powder.

Owner:SICHUAN GUANGYA POLYMER CHEM

Method for detecting zirconium content in tantalum-cobalt-base alloy in microwave solution sample dissolving manner

InactiveCN102879384AFast sample dissolutionShorten the dissolution timePreparing sample for investigationAnalysis by thermal excitationMaterials scienceTantalum

The invention provides a method for detecting the zirconium content in tantalum-cobalt-base alloy in a microwave solution sample dissolving manner. The method comprises the analyzing steps of: weighing a sample; preparing a sample solution; preparing a calibration solution; drawing a working curve; measuring the concentration of zirconium in the sample solution; and calculating a measurement result, so as to obtain the zirconium content. The problems that the sample is difficult to dissolve, a measurement spectral line is interfered seriously and the like can be overcome, so that the sample dissolving speed is greatly accelerated; the spectral interference of a base body on measurement elements can be avoided by base body matching; and the accuracy of the measurement is improved. The method has the advantages of rapid sample solution and measurement, simplicity and convenience in operation, and good labor and material saving performance.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

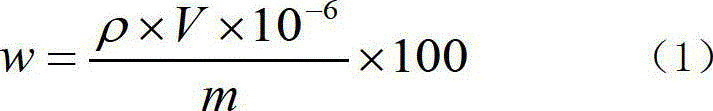

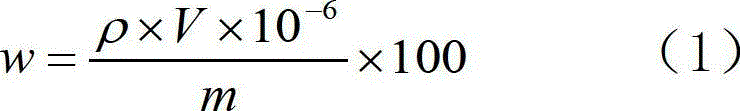

Oral disintegration tablets contg. p-acetaminophenol, and prepn. method therefor

InactiveCN1559390ADisintegrates quicklyPromote dissolutionOrganic active ingredientsAntipyreticWater solubleLubricant

Owner:CSPC ZHONGQI PHARM TECH (SHIJIAZHUANG) CO LTD +1

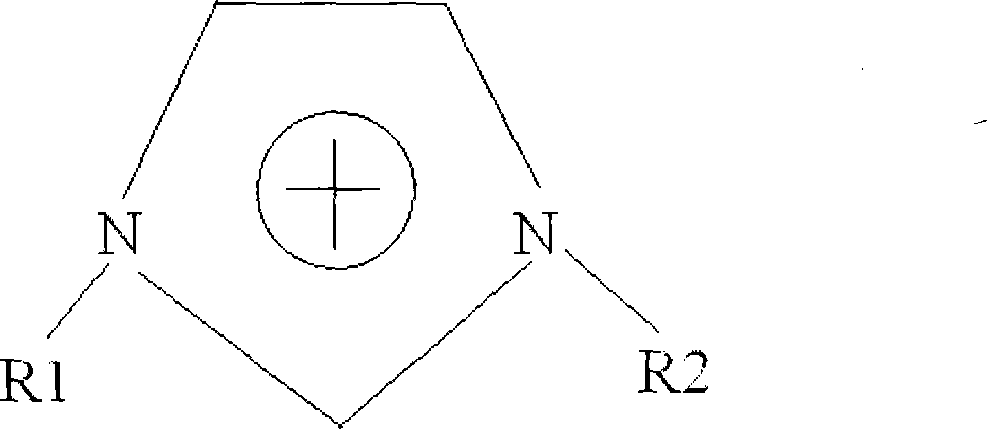

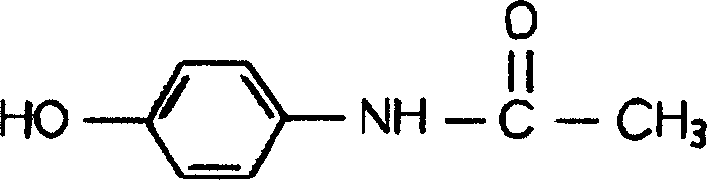

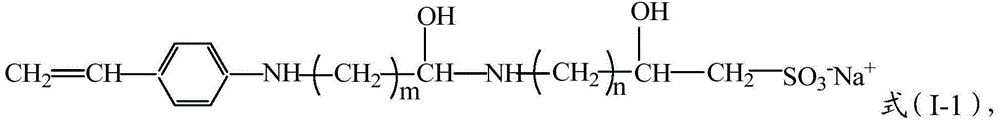

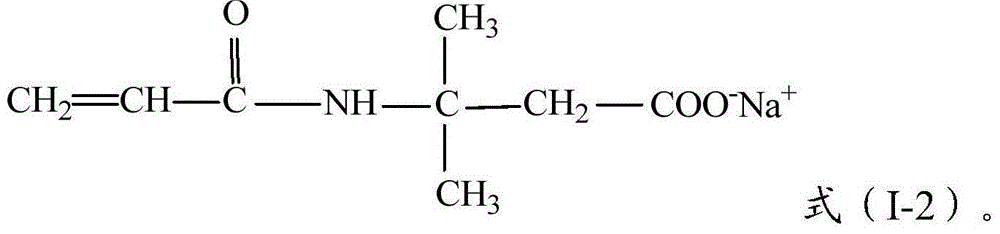

Heat-resistant and salt-tolerant polymer oil-displacing agent and preparation method thereof

ActiveCN105085800AImprove high temperature resistancePromote hydrationDrilling compositionPolymer scienceTemperature resistance

The invention provides a heat-resistant and salt-tolerant polymer oil-displacing agent and a preparation method thereof. The heat-resistant and salt-tolerant polymer oil-displacing agent has the structure shown in the formula (I) (in the description); both a structural unit, namely a structural unit of sulfonic acid containing a phenyl group and hydroxyl groups, shown in the formula (I-1) (in the description) and a structural unit of sodium-3-acrylamido-3-methylbutanoate are introduced onto a polyacrylamide molecular main chain, so that the heat-resistant and salt-tolerant polymer oil-displacing agent has good high temperature resistance and salt tolerance when being applied to polymer flooding in an oil field; when acting on a high-temperature or high-salinity oil reservoir of which the temperature is higher than 80 DEG C and the formation water salinity is greater than 30000 mg.L<-1> (Ca<2+> and Mg<2+> are greater than 1665 mg.L<-1>), the polymer oil-displacing agent has the advantage that the oil recovery ratio is greatly increased in comparison with other polymer oil-displacing agents under the same conditions, so that an effective solution is provided for further improvement of the polymer flooding effect.

Owner:华鼎鸿基采油技术服务(北京)有限公司

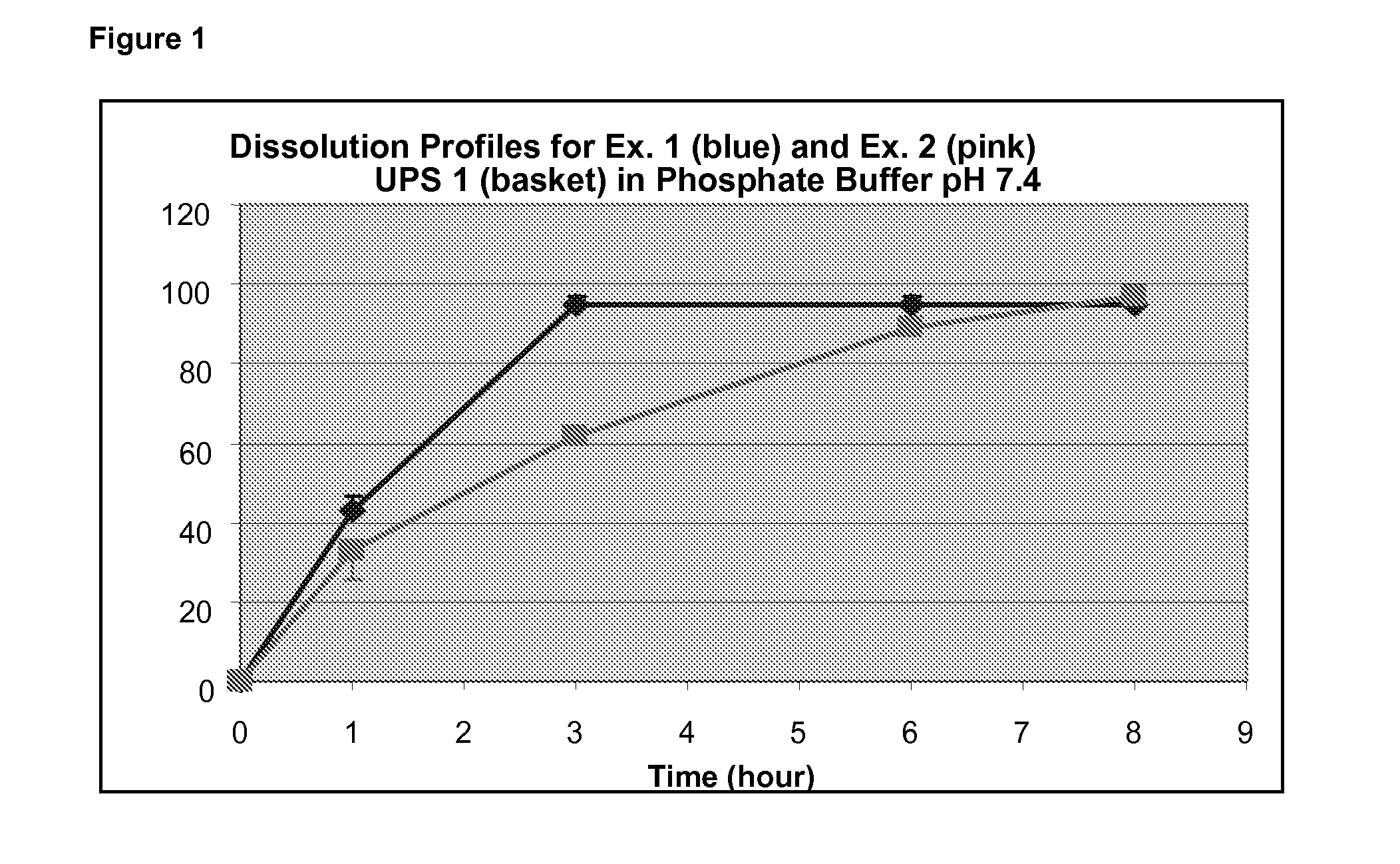

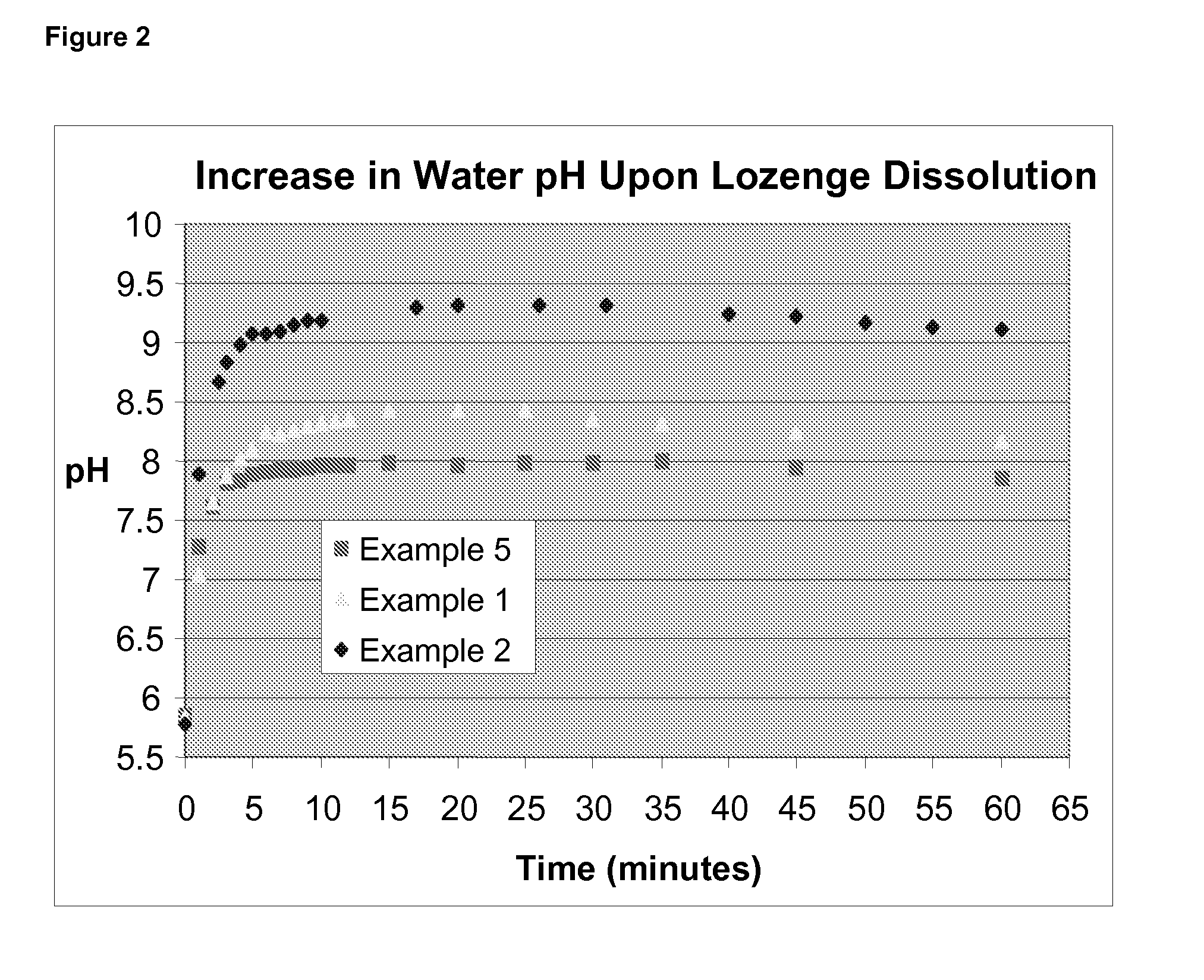

Nicotine lozenge compositions

ActiveUS20110110880A1Low levelOptimal and palatable oral pHOrganic active ingredientsNervous disorderBuffering agentNicotine

The present invention relates to nicotine lozenge compositions comprising reduced levels of buffering agents from traditional nicotine lozenges and which provide optimal oral pH and prompt nicotine absorption in a smaller, more convenient dosage form.

Owner:GLAXO SMITHKLINE LLC

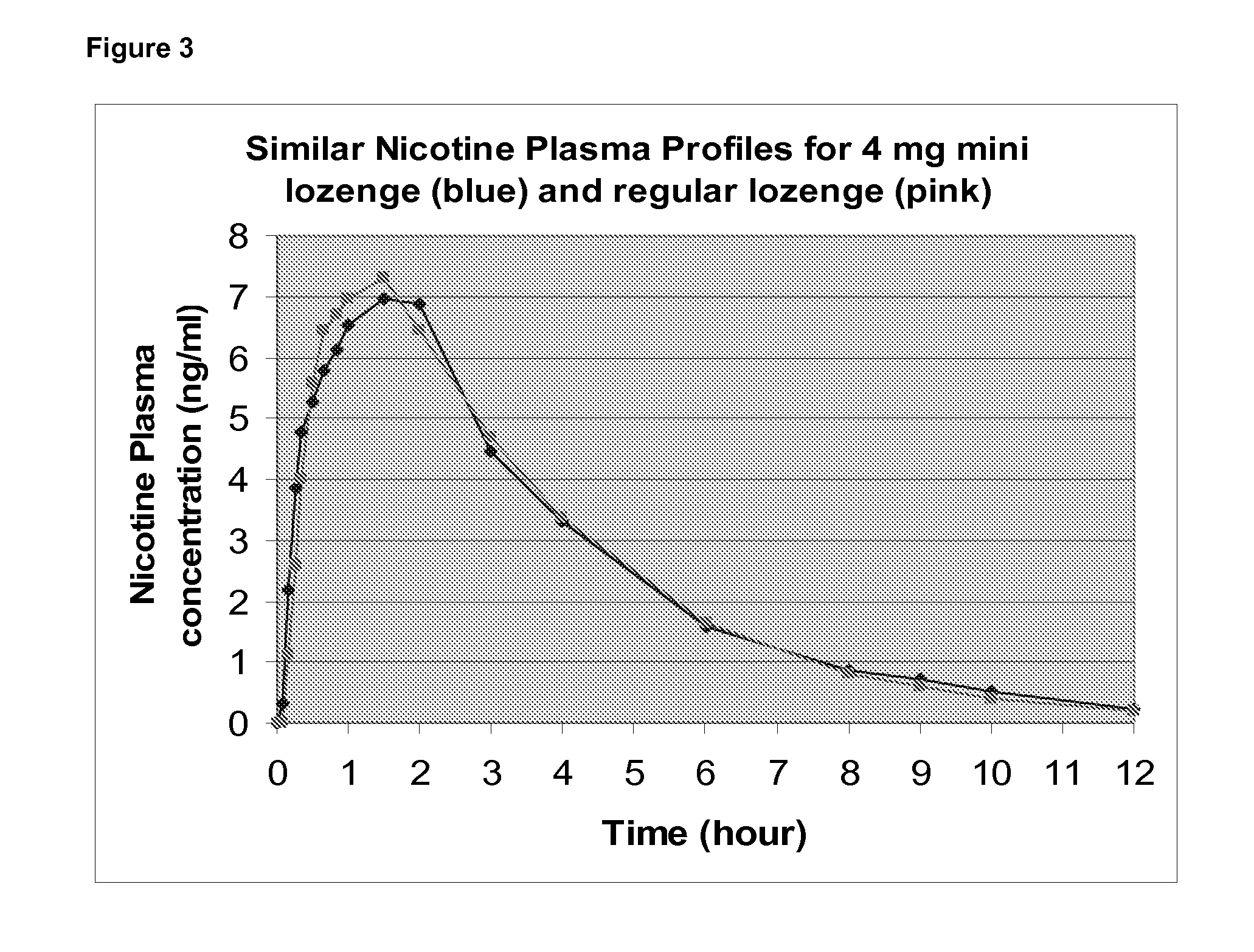

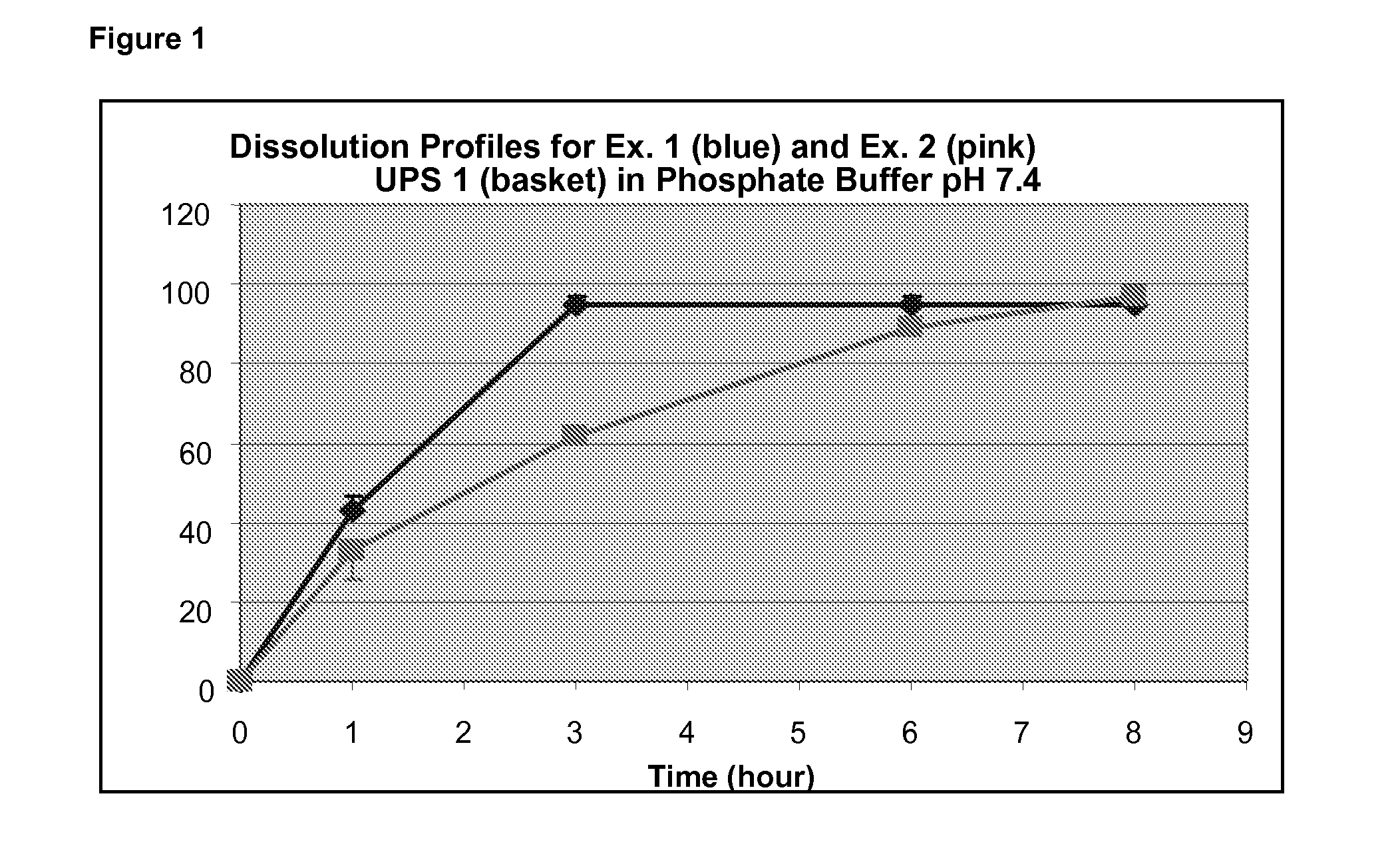

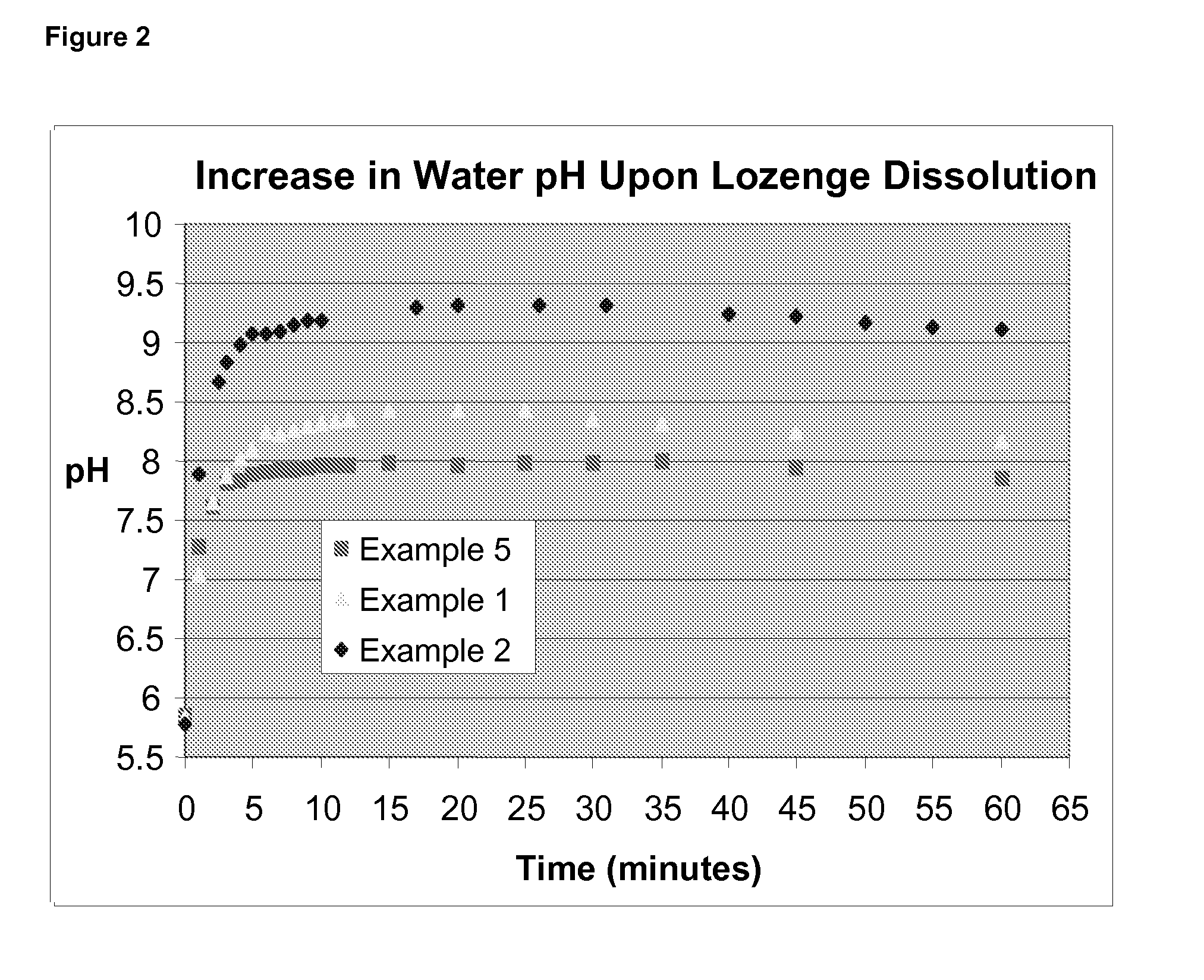

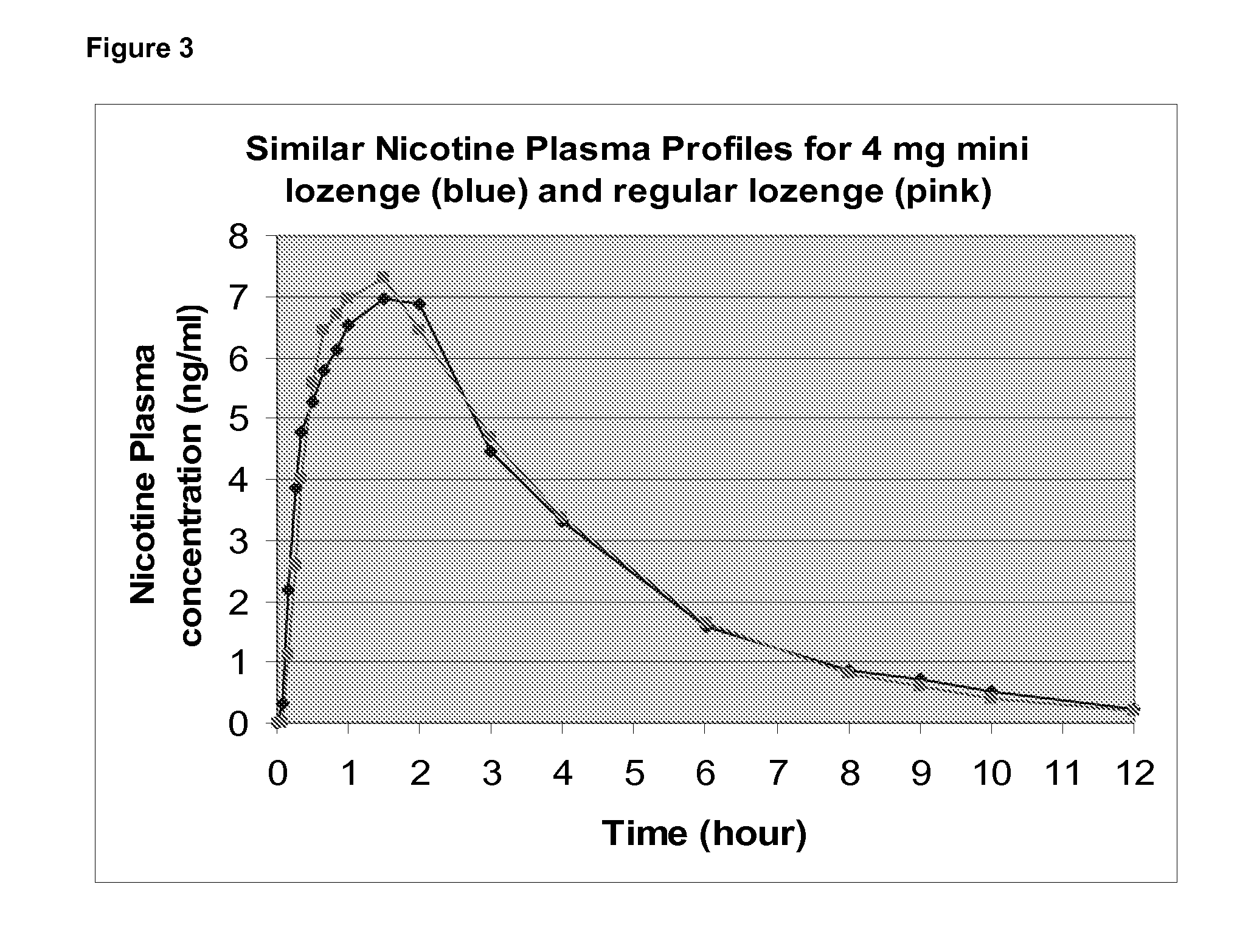

Nicotine lozenge compositions

ActiveUS8501164B2Low levelIncrease speedOrganic active ingredientsNervous disorderBuffering agentNicotine

The present invention relates to nicotine lozenge compositions comprising reduced levels of buffering agents from traditional nicotine lozenges and which provide optimal oral pH and prompt nicotine absorption in a smaller, more convenient dosage form.

Owner:GLAXO SMITHKLINE LLC

Imatinib mesylate orally disintegrating tablets and preparation method thereof

InactiveCN101401795APromote dissolutionQuickly exert the therapeutic effect of the whole bodyOrganic active ingredientsPill deliveryOrally disintegrating tabletPharmaceutical formulation

The invention relates to the technical field of pharmaceutical preparation, in particular to an orally disintegrating tablet containing imatinib mesylate and a method for preparing the same, wherein the orally disintegrating tablet comprises effective amount of the imatinib mesylate and a pharmaceutic adjuvant which is acceptable in pharmacy and can rapidly collapse and release drugs in an oral cavity. The orally disintegrating tablet containing the imatinib mesylate has the advantages of faster action speed compared with the prior tablets and capsulated drugs, has convenient use and good taste in taking, and is more suitable for children, the elderly, and patients who can not swallow solid medicines.

Owner:BEIJING TRADE STAR MEDICAL TECH

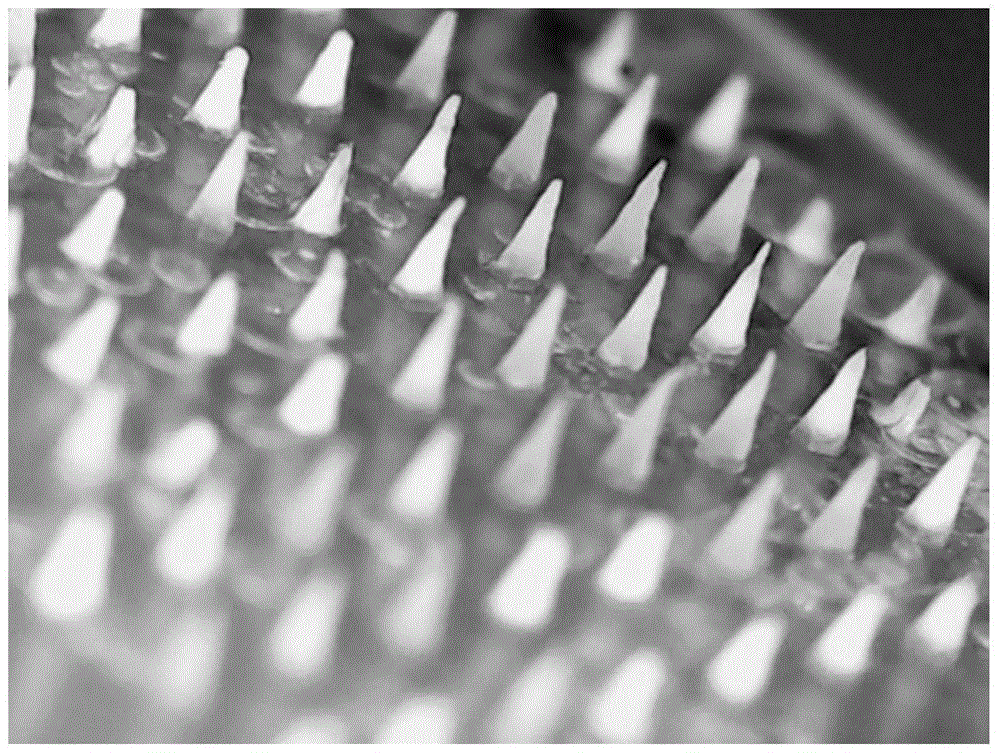

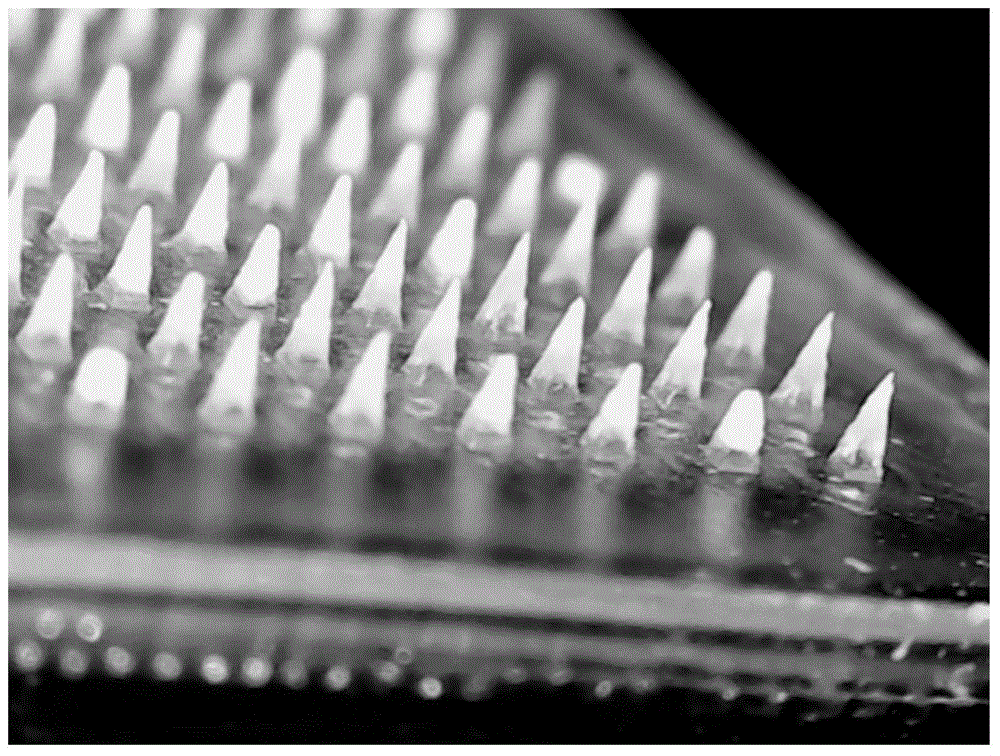

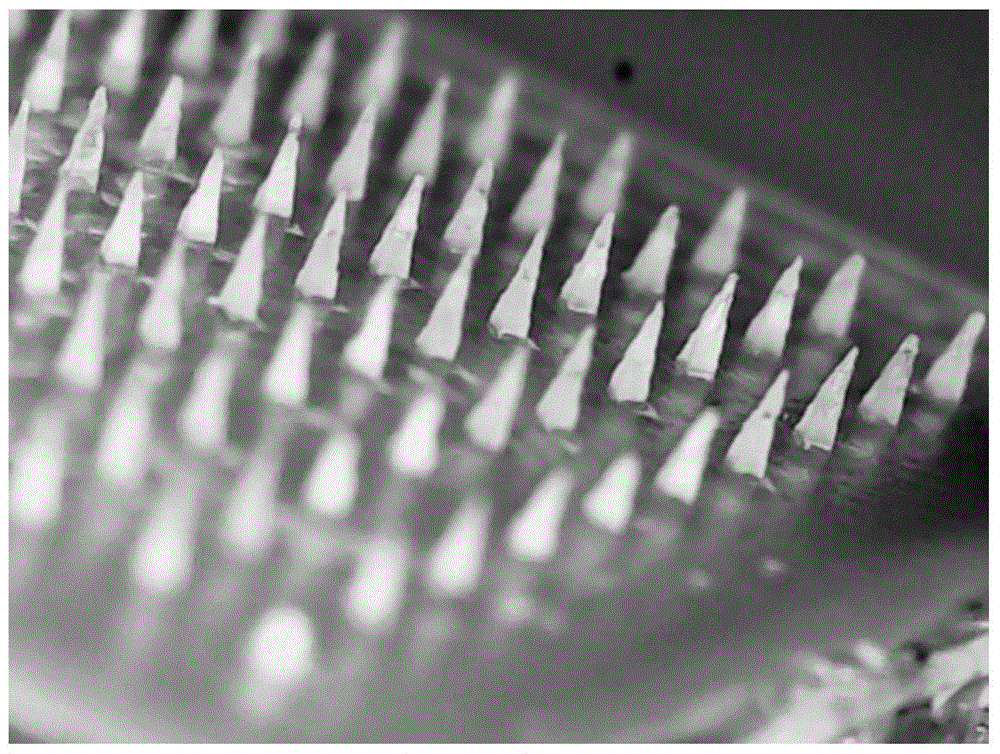

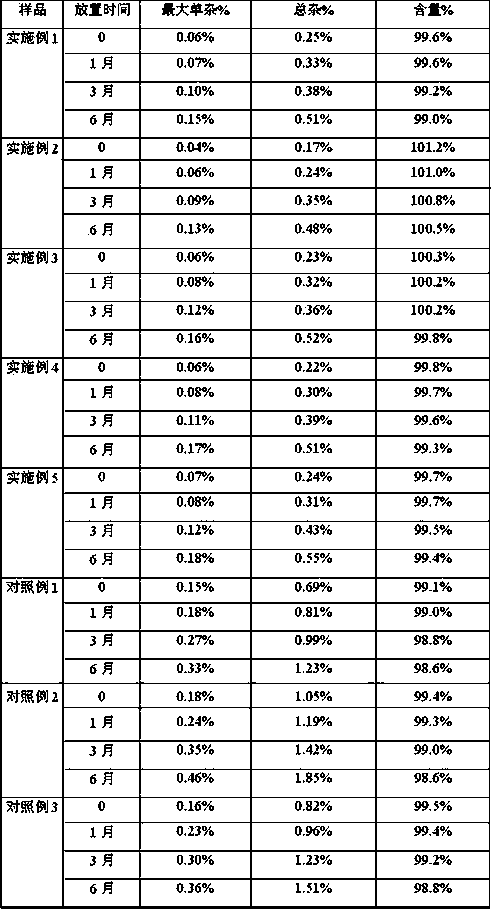

Temperature-sensitive soluble microneedle and preparation method thereof

ActiveCN105726458AFast dissolutionGood formabilityPharmaceutical delivery mechanismPharmaceutical non-active ingredientsIrritationPolyvinyl alcohol

The invention relates to a temperature-sensitive soluble microneedle and a preparation method thereof.The microneedle comprises a needle tip and a base layer, the needle tip is prepared from a temperature-sensitive material and a macromolecular shaping material, and the base layer is prepared from a macromolecular material; the temperature-sensitive material is composed of a material A and a material B, wherein the material A is selected from one or more of chitosan, polyvinyl alcohol and methylcellulose or hydroxypropyl methyl cellulose, the material B is selected from one or more of beta-sodium glycerophosphate, elastic protein polypeptides, poloxamer 184, poloxamer 188 and poloxamer 407, and the mass ratio of the material A to the material B is 1:(1-20); the mass ratio of the temperature-sensitive material to the macromolecular shaping material is 1:(1-10).The microneedle can be quickly dissolved in the skin, therefore, irritation of the microneedle to the skin is reduced, and medicine can be more safely and effectively released.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD +1

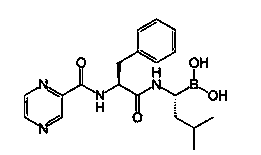

Bortezomib freeze-dried composition and preparation method thereof

InactiveCN103446068AShorten the dissolution timeReduce moisture contentPowder deliveryDipeptide ingredientsFreeze-dryingMannitol

The invention belongs to the field of medicine and provides a bortezomib freeze-dried composition and a preparation method thereof. The bortezomib freeze-dried composition is a freeze-dried composition which is obtained through the steps of spraying the mixed solution of bortezomib, mannitol and tertiary butanol into liquid nitrogen to form frozen microparticles, dissolving the microparticles in water for injection, and finally, performing freeze-drying. The bortezomib freeze-dried composition provided by the invention is better in quality and higher in stability.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

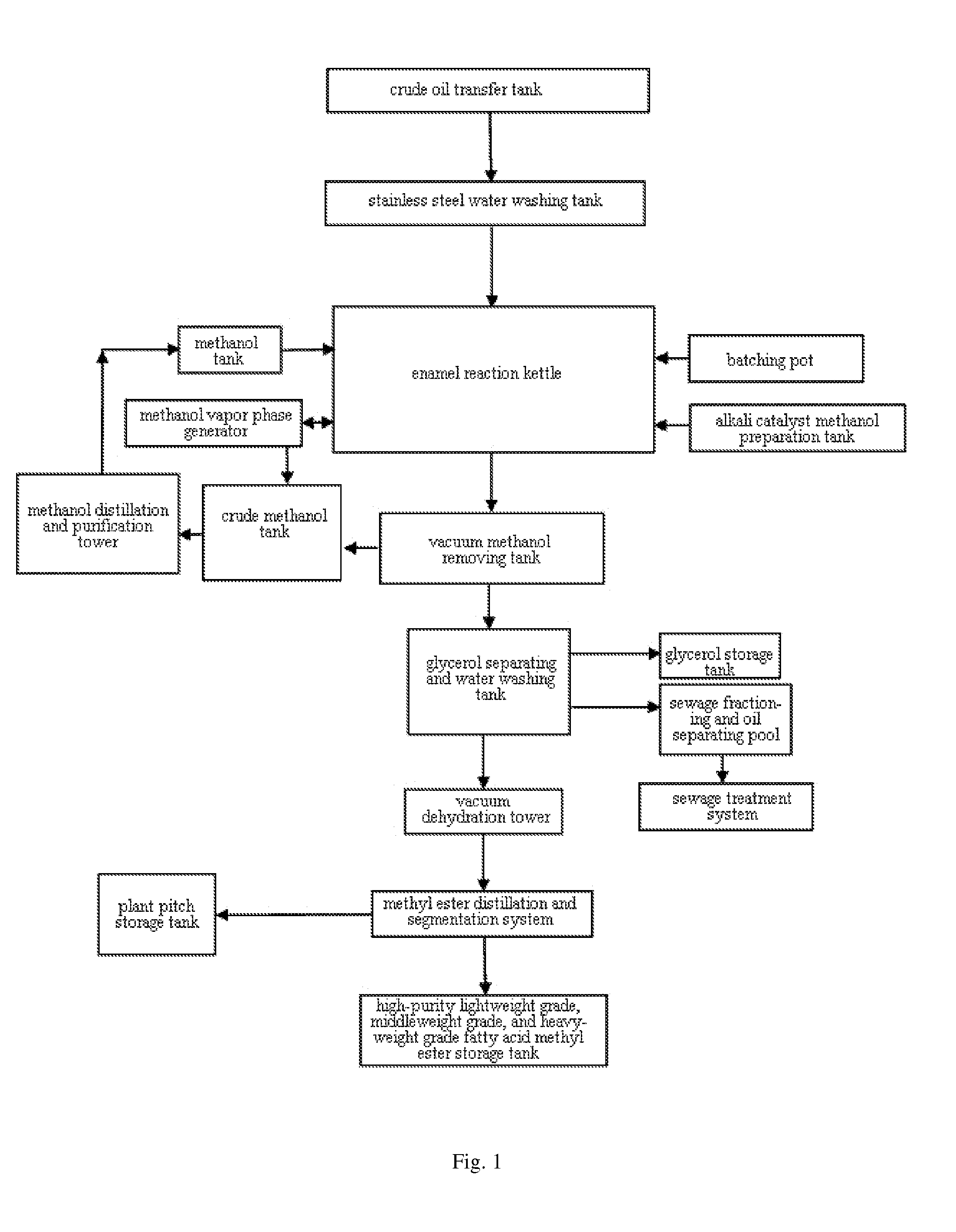

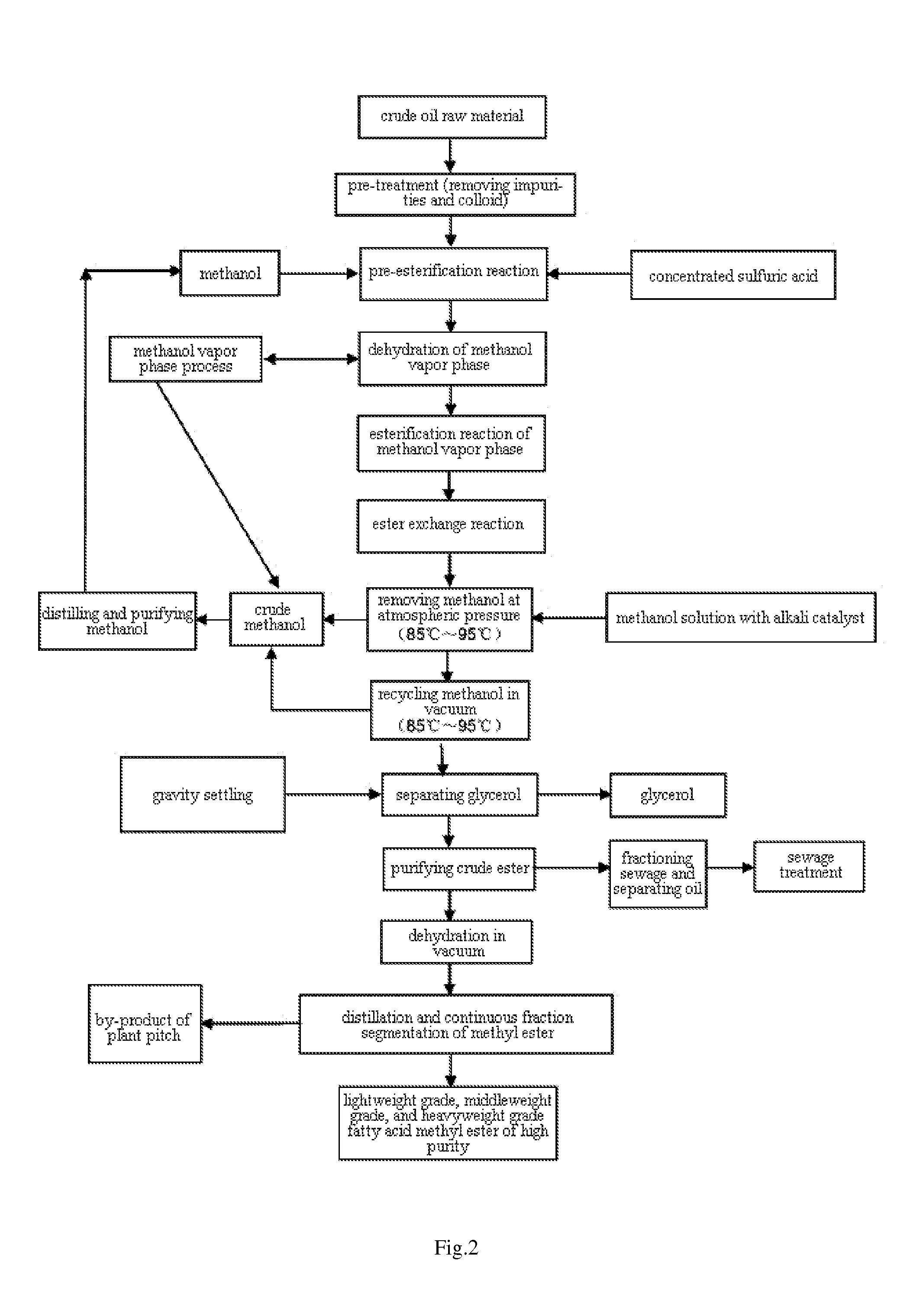

Method for preparing high purity biodiesel

ActiveUS20140194634A1Wide raw material sourceReduce energy consumptionFatty oils/acids recovery from wasteFatty acid esterificationTrans esterificationPtru catalyst

Disclosed is a method for preparing high purity biodiesel from crude oils. The method comprises the steps of: pre-treating the crude oil raw material to remove impurities; pre-esterifying the pre-treated crude oil raw material under the effect of a catalyst of concentrated sulfuric acid; and then carrying out an ester exchange reaction in the presence of an alkali catalyst; recycling methanol, and separating glycerol, so as to obtain a crude fatty acid methyl ester; and subjecting the obtained fatty acid methyl ester to purification, distillation and segmentation to obtain a high-purity fatty acid methyl ester.

Owner:BEIJING QINGYANLIHUA GASOLINEEUM CHEM

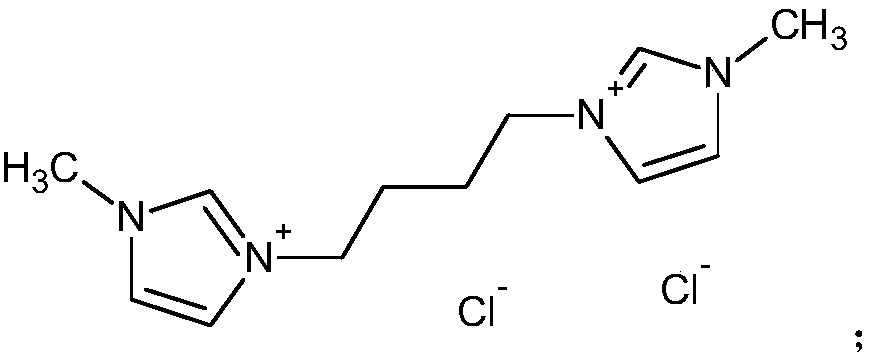

Preparation method of antibacterial cellulose fibers

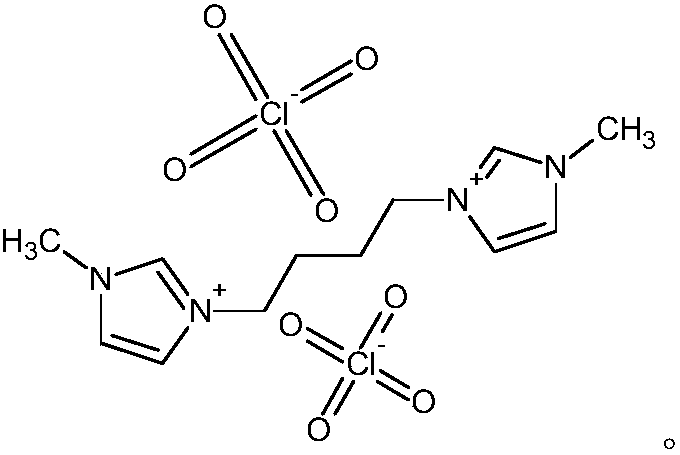

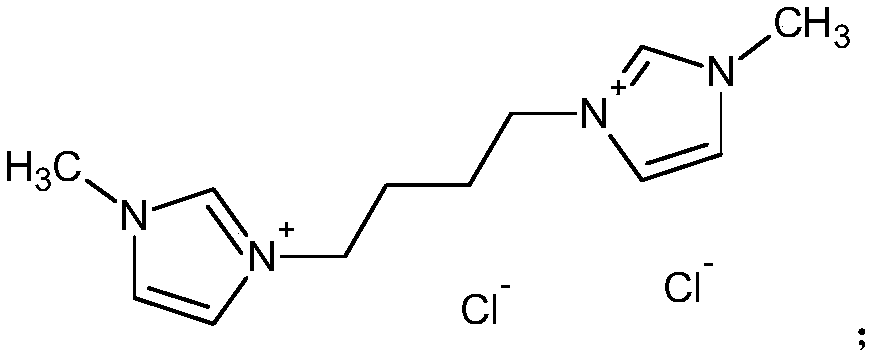

ActiveCN109183169ALow viscosityImprove mechanical propertiesMonocomponent cellulose artificial filamentSpinning solutions preparationPerchlorateCellulose fiber

The invention discloses a preparation method of antibacterial cellulose fibers. The preparation method comprises the following steps: a) after mixing a dispersant, an antibacterial agent and cellulose, dissolving a mixture in an ionic liquid water solution to prepare a mixed spinning raw solution, wherein the adding amount of the antibacterial agent is 0.1 to 1 weight percent of the cellulose; andb) filtering the mixed spinning raw solution, spinning, condensing, stretching, washing with water, bleaching, applying oil and drying to obtain the antibacterial cellulose fibers. The ionic liquid is obtained by mixing 1-butyl-3-methylimidazolium chloride, bi1,4-di[1-(3-methylimidazolium)]butyl dichloride and bi1,4-di[1-(3-methylimidazolium)]butyl diperchlorate. An experiment shows that the antibacterial cellulose fibers prepared by the invention have excellent mechanical property, antibacterial property and stability property; and a preparation process is simple, is low in cost, is environmentally friendly and has no pollution.

Owner:龙丝(上海)新材料科技有限公司

Extraction method of amygdalin

InactiveCN101362782AReduce distractionsHigh yieldSugar derivativesSugar derivatives preparationAlcoholAmygdalin

The invention relates to an extraction method for laetrile. Hypercritical carbon dioxide is adopted to be added with an absolute ethyl alcohol entraining agent; in hypercritical carbon dioxide equipment, extraction is carried out to bitter almond meal after degreasing in an extraction kettle; then primary separation, secondary separation and low-temperature crystallization are carried out, and a crude product of the laetrile is obtained. After the crude product of the laetrile is dissolved by using absolute ethyl alcohol secondarily, the temperature is reduced to minus 3 DEG C to 4 DEG C, thus obtaining a fine product of the laetrile. The extraction method for the laetrile has simple and convenient extraction procedure, short extraction time, target products with high yield and low overall cost; the products do not have harmful residual solvents.

Owner:SHANXI BLISS BIOLOGY TECH

Method for dissolving natural cellulose

InactiveCN103788383AReduce crystallinityShorten the dissolution timeArtificial filaments from cellulose solutionsSpinning solutions preparationCelluloseAlcohol

The invention belongs to natural macromolecules and particularly relates to a method for dissolving natural cellulose. The method comprises the steps of cutting the natural cellulose into pieces, adding the natural cellulose into a NaOH solution, performing ultrasonic activation for 40-90 minutes, cleaning the natural cellulose with deionized water until the natural cellulose is neutral, respectively immersing the natural cellulose into a dimethylacetamide solution and an anhydrous alcohol solution for 30-60 minutes, and drying; under the protection of nitrogen, dissolving LiCl into dimethylacetamide, heating to 90-110 DEG C, adding the dried natural cellulose at 90-110 DEG C and stirring for 100-140min till the dried natural cellulose is dissolved; cooling to 20-25 DEG C, stirring for 3-5 hours, and performing ultrasonic oscillation. The method for dissolving the natural cellulose, which is provided by the invention, is used for performing activation pretreatment on the natural cellulose, so that the crystallinity of the cellulose is reduced, and the dissolving time of the cellulose is shortened; furthermore, the solution is uniform and stable. The method is friendly to the environment, pollution-free, high in operability, low in production cost and high in safety.

Owner:SHANGHAI UNIV OF ENG SCI

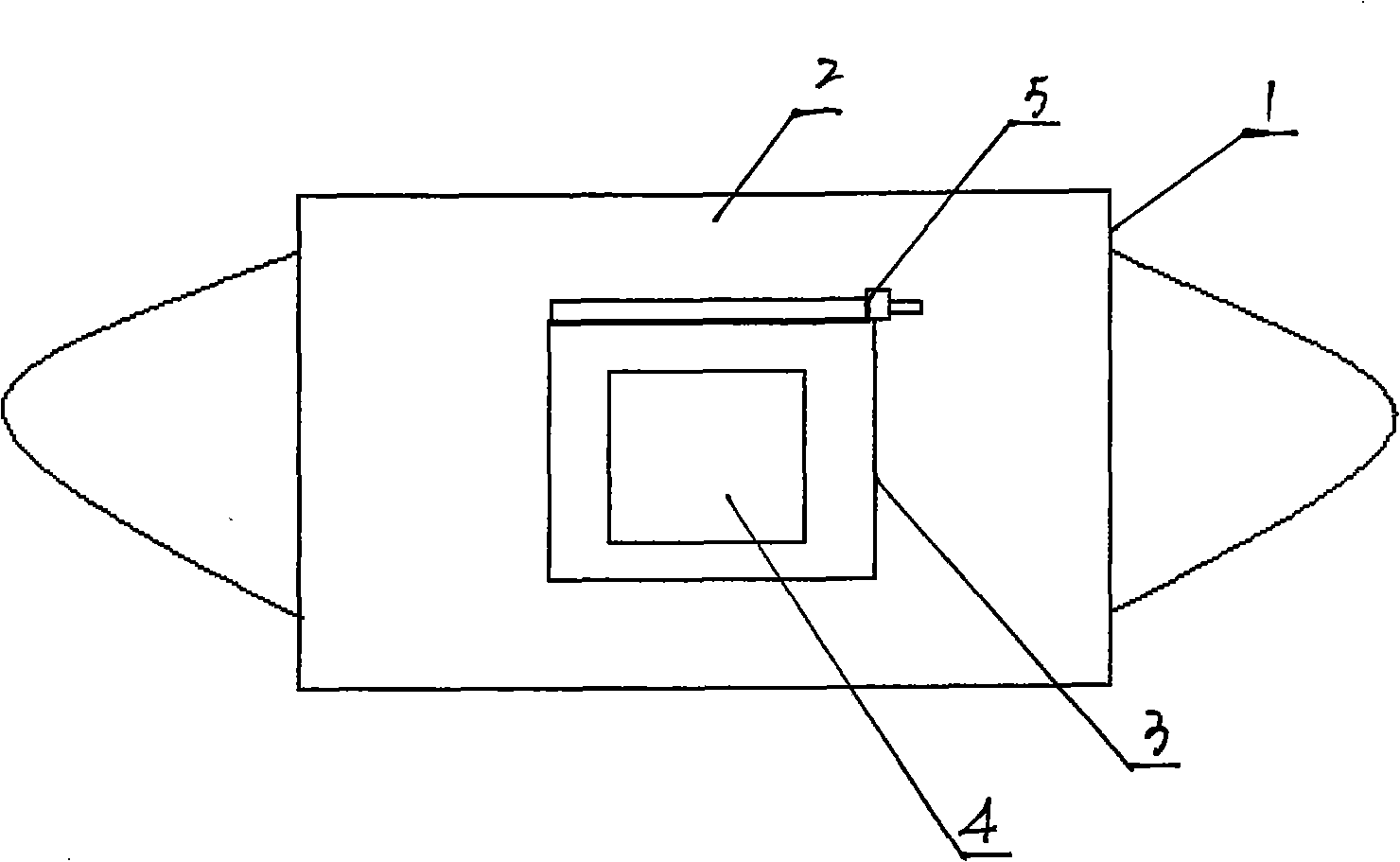

Disease preventing and curing medicinal mouth-muffle and medicinal composite

InactiveCN101524190AEasy to wearShort course of treatmentAntibacterial agentsHeavy metal active ingredientsCinnabarMyrrh

The invention relates to a disease preventing and curing medicinal mouth-muffle and a medicinal composite. The disease preventing and curing medicinal mouth-muffle (1) comprises a mouth-muffle body (2), one surface of the mouth-muffle body (2) is provided with an insert pocket (3), and a powder bag (4) which packages the medicinal composite is placed in the insert pocket (3). The medicinal composite comprises the following Chinese herbs by weight: 2.2 percent of chrysanthemum and muskiness, 4.2 percent of cinnamon, good ginger, long pepper, radix aconite, frankincense, myrrh and clove, 5.0 percent of vermilion, 6.4 percent of asarum, eaglewood, croton, resina draconis, early plum flowers and rhizoma ligustici wallichii and 7.6 percent of tooth soap, arsenic sulphide and brain sand. The disease preventing and curing medicinal mouth-muffle internally carries the medicinal composite which plays a role during the mouth-muffle wearing process, thereby having disease prevention and cure and being simple and direct and also effective in treatment.

Owner:孙永春

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com