Preparation method and application of gelatin-chitosan composite membrane

A technology of chitosan and composite film, which is applied in the direction of flexible coverings, packaging, wrapping paper, etc., can solve the problems of chitosan easy to form agglomerates, low production efficiency, and long time, and achieve antibacterial and fresh-keeping effects and improve efficiency , the effect of significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of gelatin-chitosan composite film, the steps are as follows:

[0025] (1) At room temperature, add 2.0g of chitosan into a three-neck flask, add 98mL of deionized water and stir for 3 minutes to disperse the chitosan evenly, then add 2mL of phosphoric acid solution dropwise while stirring, adjust the pH to 3.5, and continue to stir fully , to obtain a 2% (w / v) chitosan solution;

[0026] (2) Mix 10 mL of gelatin solution with a concentration of 20% (w / v) with the chitosan solution prepared in step (1), the mass ratio of gelatin to chitosan is 1:1, and stir at 40°C Make the mixture evenly to obtain the gelatin / chitosan mixed solution, add 0.4g PEG 200 into the gelatin / chitosan mixed solution, stir under the condition of 40°C to make the mixed evenly, and then neutralize it with a NaOH solution with a concentration of 1mol / L to pH is 6;

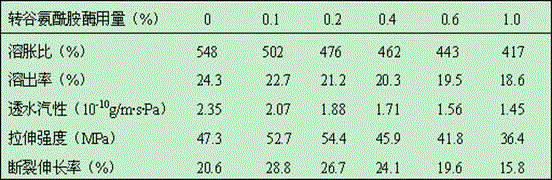

[0027] (3) Add 0.004g of transglutaminase (TGase) to the reaction product of step (2), continue to stir at 40°C...

Embodiment 2

[0029] A preparation method of gelatin-chitosan composite film, the steps are as follows:

[0030] (1) At room temperature, add 4g of chitosan into a three-necked flask, add 99mL of deionized water and stir for 5 minutes to disperse the chitosan evenly, then add 1mL of formic acid solution dropwise while stirring, adjust the pH to 6, and continue to stir fully. A chitosan solution with a concentration of 4% (w / v) was obtained;

[0031] (2) Mix 80 mL of gelatin solution with a concentration of 5% (w / v) with the chitosan solution prepared in step (1), the mass ratio of gelatin to chitosan is 1:1, stir at 60°C Mix well to get a gelatin / chitosan mixed solution, add 2.4g PEG 200 to the gelatin / chitosan mixed solution, stir at 60°C to make the mixture evenly, at this time, the pH is above 6, close to 6.5, no need to adjust again pH;

[0032] (3) Add 0.04g of transglutaminase (TGase) to the reaction product of step (2), continue to stir at 60°C for 35 minutes, heat up to boiling to...

Embodiment 3

[0034] A preparation method of gelatin-chitosan composite film, the steps are as follows:

[0035] (1) At room temperature, add 3.5g of chitosan into a three-neck flask, add 98mL of deionized water and stir for 4 minutes to disperse the chitosan evenly, then add 2mL of nitric acid solution dropwise while stirring, adjust the pH to 4, and continue to stir fully , to obtain a chitosan solution with a concentration of 3.5% (w / v);

[0036] (2) Mix 50 mL of 7% (w / v) gelatin solution with the chitosan solution prepared in step (1), the mass ratio of gelatin to chitosan is 1:1, and stir at 50°C Make the mixture uniform to obtain a gelatin / chitosan mixed solution, add 1.75g PEG 200 into the gelatin / chitosan mixed solution, stir at 50°C to make the mixture uniform, and then neutralize it with a NaOH solution with a concentration of 0.5 mol / L to pH 6;

[0037](3) Add 0.07g of transglutaminase (TGase) to the reaction product of step (2), continue to stir at 50°C for 40 minutes, raise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com