Modified SiO2/PVA (polyvinyl alcohol) film and preparation method thereof

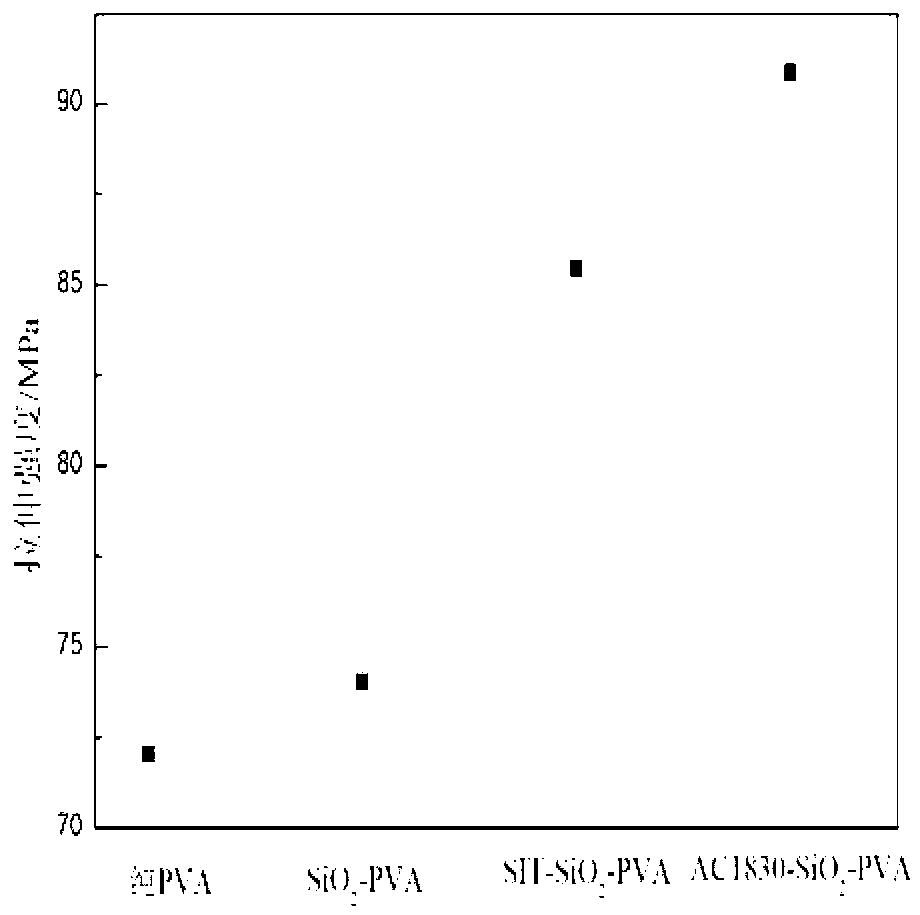

A technology of PVA1798 and PVA1788, which is applied in the field of modified SiO2/PVA film and its preparation, can solve the problems that transparent PVA film cannot be prepared, the combination effect of particles and organic matter is not well improved, and the effect of particle surface modification is not obvious, etc. , to achieve the effect of improving the performance enhancement effect, improving the tensile strength and improving the thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Modified SiO 2 / PVA film

[0028] The film is modified by m parts of SiO by mass ratio 2 Particles and m to 100 parts of PVA are dissolved at the dissolution temperature, cooled and molded, or formed at a melting temperature, wherein 0<m≤20, and the PVA is one of PVA1750, PVA1778, PVA1788, and PVA1798.

[0029] The polyether amine can be fatty amine polyoxyethylene ether, polyoxyethylene-polyoxypropylene monoamine or polyoxyethylene-polyoxypropylene diamine.

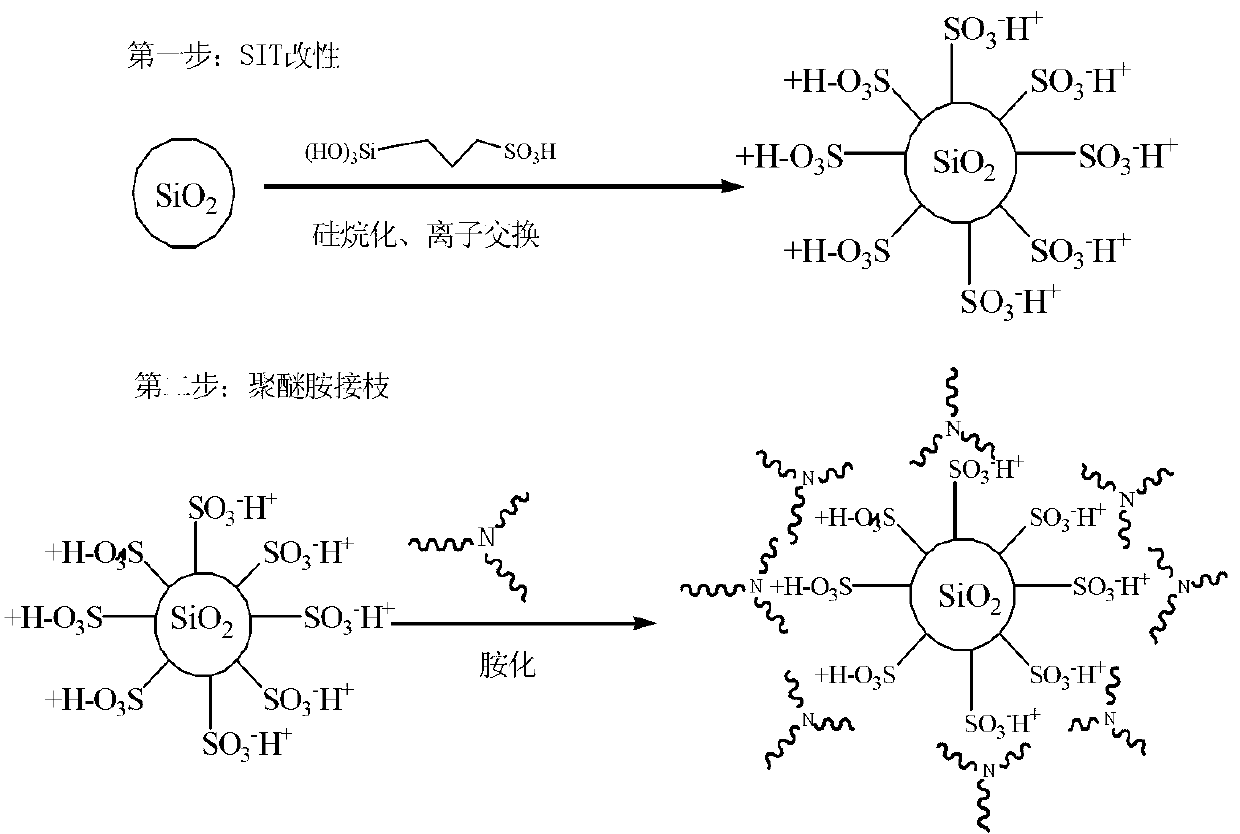

[0030] The modified SiO 2 Particles are a class of organic acids containing hydrolyzable silanol and SiO2 surface-SiOH reaction to make SiO 2 The surface contains acidic groups, and then grafts polyetheramine on the surface through the principle of acid-base reaction. It has both hydrophilic and lipophilic properties and can be evenly dispersed in the polymer. A type of SiO 2 Particles, the diameter of which is 12-100nm. According to modified SiO 2 Filling amount of particles in PVA, SiO 2 The ma...

Embodiment 2

[0040] Example 2: Modified SiO 2 / Preparation of PVA film

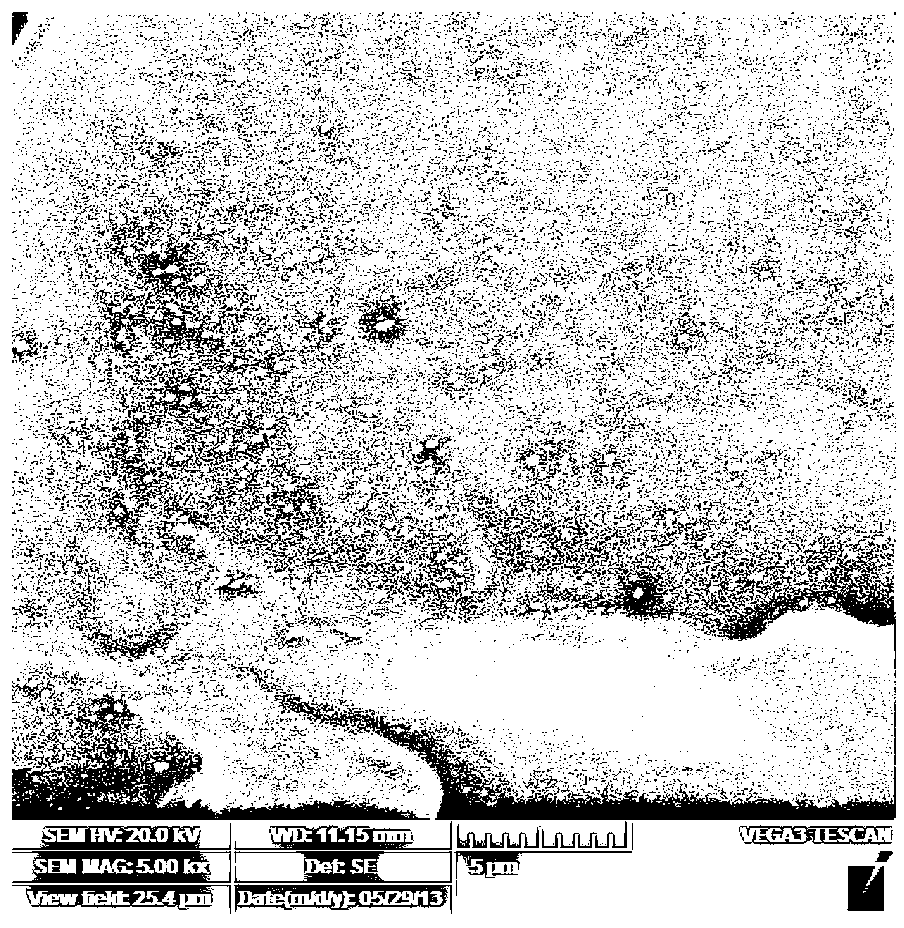

[0041] In parts by weight, weigh 0.5 parts of SiO with organic acid surface treatment 2 and 99.5 parts of PVA1750±50, placed in a 150ml Erlenmeyer flask, added distilled water to make an aqueous solution with a PVA concentration of 5%-10%, stirred magnetically for 30min, and ultrasonicated for 30min. Gradiently raise the temperature from room temperature to 90°C, keep stirring for 90 minutes, stop stirring, and cool to room temperature. Cast on a pre-made glass plate mold to form a film with a film thickness of 0.06-1mm; dry at room temperature for 3 days and demould, and dry at 60°C for 2 hours to obtain a film.

Embodiment 3

[0042] Example 3: Modified SiO 2 / Preparation of PVA film

[0043] Weigh 10 parts of AC1810 modified SiO by mass fraction 2 and 90 parts of PVA1750±50, placed in a 150ml Erlenmeyer flask, added distilled water to make an aqueous solution with a PVA concentration of 5%-10%, stirred magnetically for 30min, and ultrasonicated for 30min; repeat this process 3 times. Starting from room temperature, the temperature was gradually increased to 90 °C at a rate of 10 °C / min, stirred and kept for 90 min, stopped stirring, and cooled to room temperature. Cast on a pre-made glass plate mold to form a film with a film thickness of 0.06-1mm; dry at room temperature for 3 days and demould, and dry at 60°C for 2 hours to obtain a film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com