The production method of graft modified starch size

A modified starch and production method technology, applied in textiles, papermaking, fiber treatment, etc., can solve the problems of restricting the development of grafted modified starch size, the large demand of the textile industry, and the high price, so as to shorten the sizing processing time and speed up the production process. The effect of rapid promotion and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

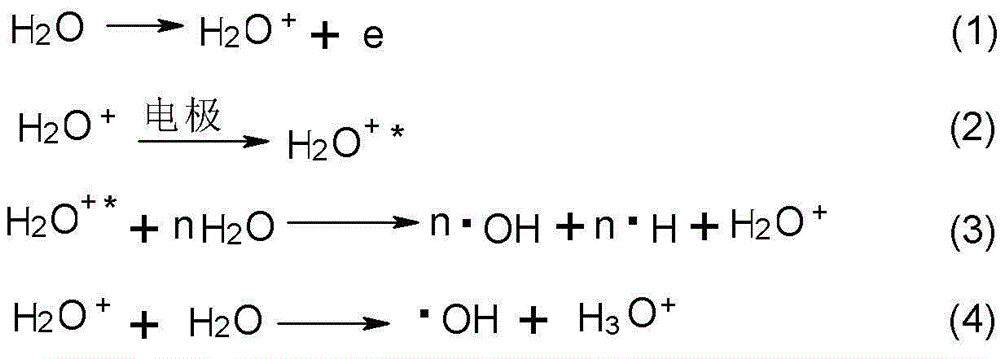

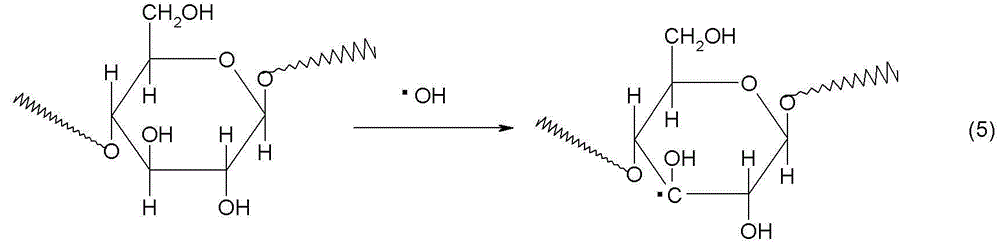

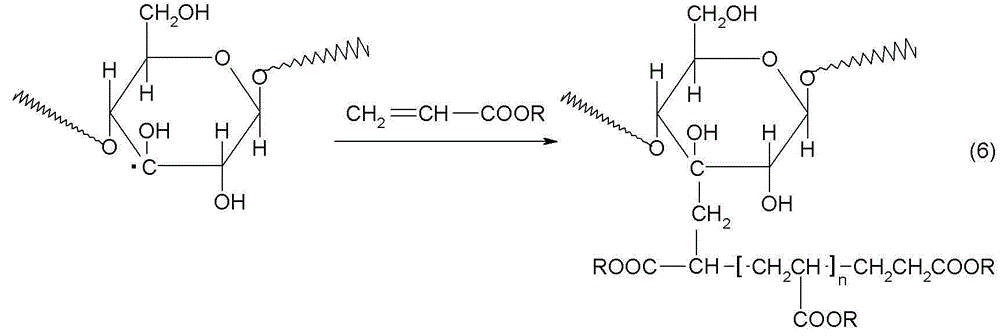

Method used

Image

Examples

Embodiment 1

[0031] Add NaOH solution to acrylic acid, control the pH of the solution to 5-7, and prepare sodium acrylate solution. The prepared sodium acrylate solution was mixed with a 35% solution containing acrylic acid as a grafted monomer mixture, wherein the molar ratio of sodium acrylate to acrylic acid was 1:6. Common potato starch was added to deionized water to prepare starch milk containing 30% starch, put it into an ultrasonic processor at room temperature, raise the temperature to 50°C, and turn on ultrasonic heat preservation for 25 minutes to obtain ultrasonically modified starch milk. The starch milk was transferred to the glow discharge reactor, and N was passed into the starch milk 2 10 min, while stirring slowly to lower the temperature of the reaction system to room temperature. Add the mixed monomer solution to the reaction system in proportion, wherein the mass ratio of starch milk to the mixed monomer solution is 70:10. Insert the electrode, continue to stir slowl...

Embodiment 2

[0034]Add NaOH solution to acrylic acid, control the pH of the solution to 5-7, and prepare sodium acrylate solution. Mix the prepared sodium acrylate solution with a 35% solution containing acrylic acid and butyl acrylate (acrylic acid and butyl acrylate molar ratio 10:1) as a grafted monomer mixture, wherein the molar ratio of sodium acrylate to acrylic acid is 1: 8. Ordinary cornstarch was added to deionized water to prepare starch milk containing 35% starch, put it into an ultrasonic processor at room temperature, raise the temperature to 45°C, and turn on ultrasonic heat preservation for 25 minutes to obtain ultrasonically modified starch milk. The starch milk was transferred to the glow discharge reactor, and N was passed into the starch milk 2 Oxygen in the system was replaced while stirring slowly to lower the temperature of the reaction system to 25°C. Add the mixed monomer solution to the reaction system in proportion, wherein the mass ratio of starch milk to the m...

Embodiment 3

[0037] Add NaOH solution to acrylic acid, control the pH of the solution to 5-7, and prepare sodium acrylate solution. The prepared sodium acrylate solution was mixed with a 30% solution containing acrylic acid and acrylonitrile (molar ratio 10:0.5) as a grafted monomer mixture, wherein the molar ratio of sodium acrylate to acrylic acid was 1:6. Common potato starch was added to deionized water to prepare starch milk containing 30% starch, put it into an ultrasonic processor at room temperature, raise the temperature to 50°C, and turn on ultrasonic heat preservation for 25 minutes to obtain ultrasonically modified starch milk. The starch milk was transferred to the glow discharge reactor, and N was passed into the starch milk 2 10 min while stirring slowly to lower the temperature of the reaction system to 25°C. Add the mixed monomer solution to the reaction system in proportion, wherein the mass ratio of starch milk to the mixed monomer solution is 80:20. Insert the electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com