Patents

Literature

72results about How to "Facilitate the grafting reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

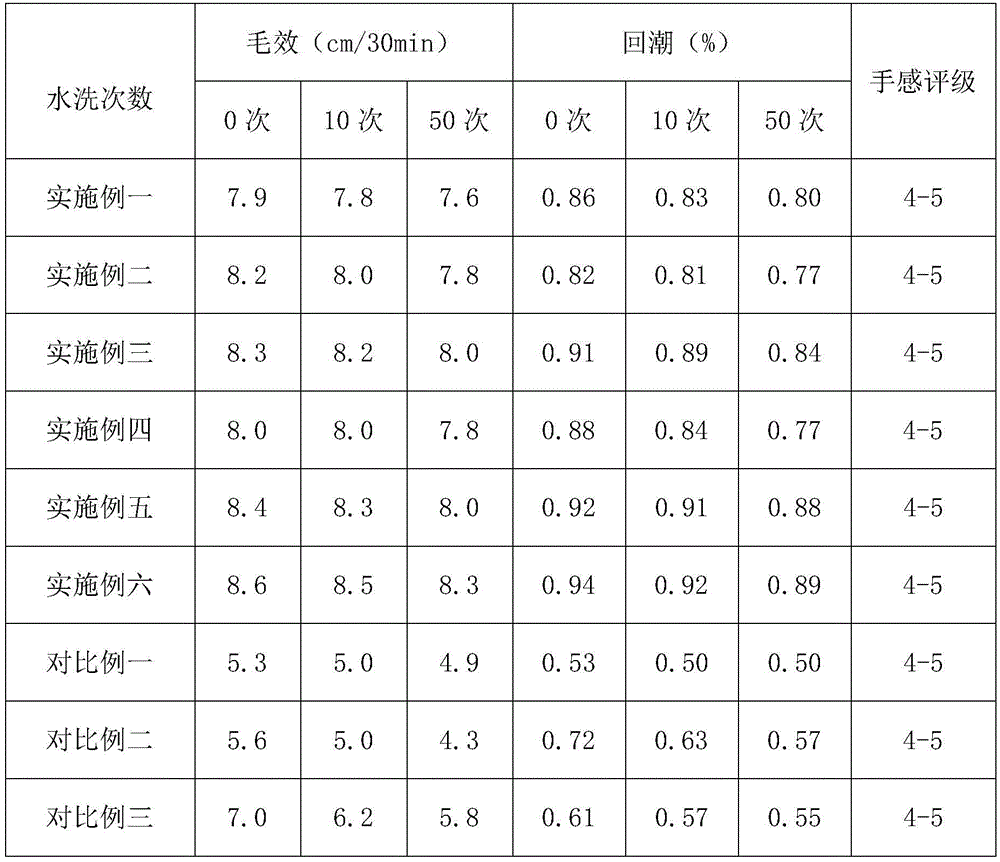

Preparation method of regenerated aramid composite paper

ActiveCN109457533AImprove hydrophilicityFacilitate the grafting reactionPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperHigh pressureAramid

The invention discloses a preparation method of regenerated aramid composite paper. The preparation method includes: pretreating para-aramid chopped fiber, para-aramid pulp fiber and meta-aramid pulpfiber, mixing, loosening to form a uniform fiber / aqueous suspension, adding a papermaking aid into the suspension, dewatering, and molding to obtain composite aramid raw paper; dissolving the meta-aramid fiber by using organic solvent / inorganic salt solution to obtain an aramid solution, dropwise adding the prepared aramid solution into the structure of the aramid composite raw paper, putting thearamid composite raw paper into the air for regeneration, after the regeneration is completed, hot pressing the paper a high temperature and high pressure, and cleaning residual organic solvent and inorganic salt by using water to obtain high-strength aramid composite paper. The quantity of the high-strength aramid composite paper is 20 to 200 g / m2, the thickness is 10 to 300 micrometers, the mechanical strength is greatly improved, and the tensile strength is improved by 20 times.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method of teflon composite substrate material

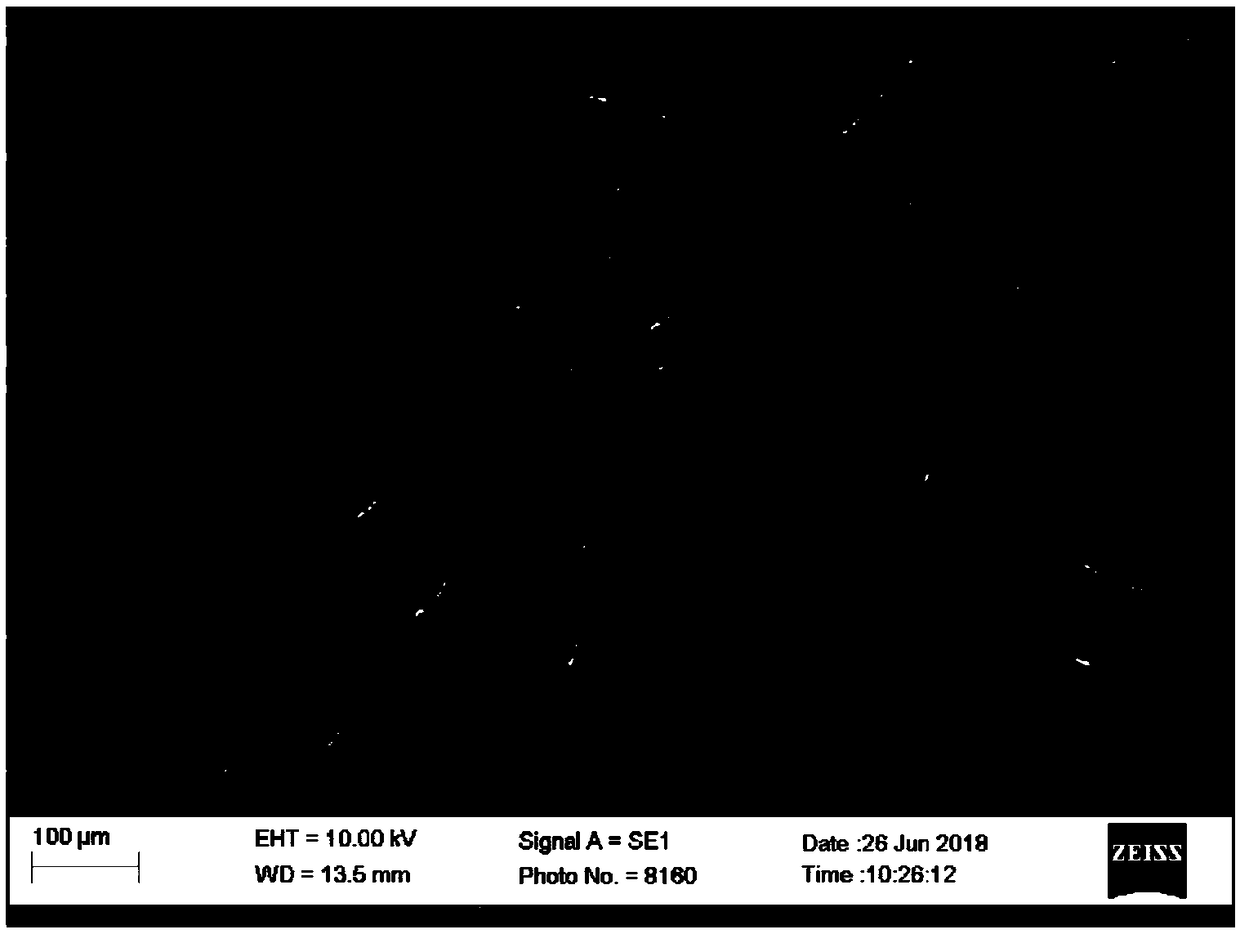

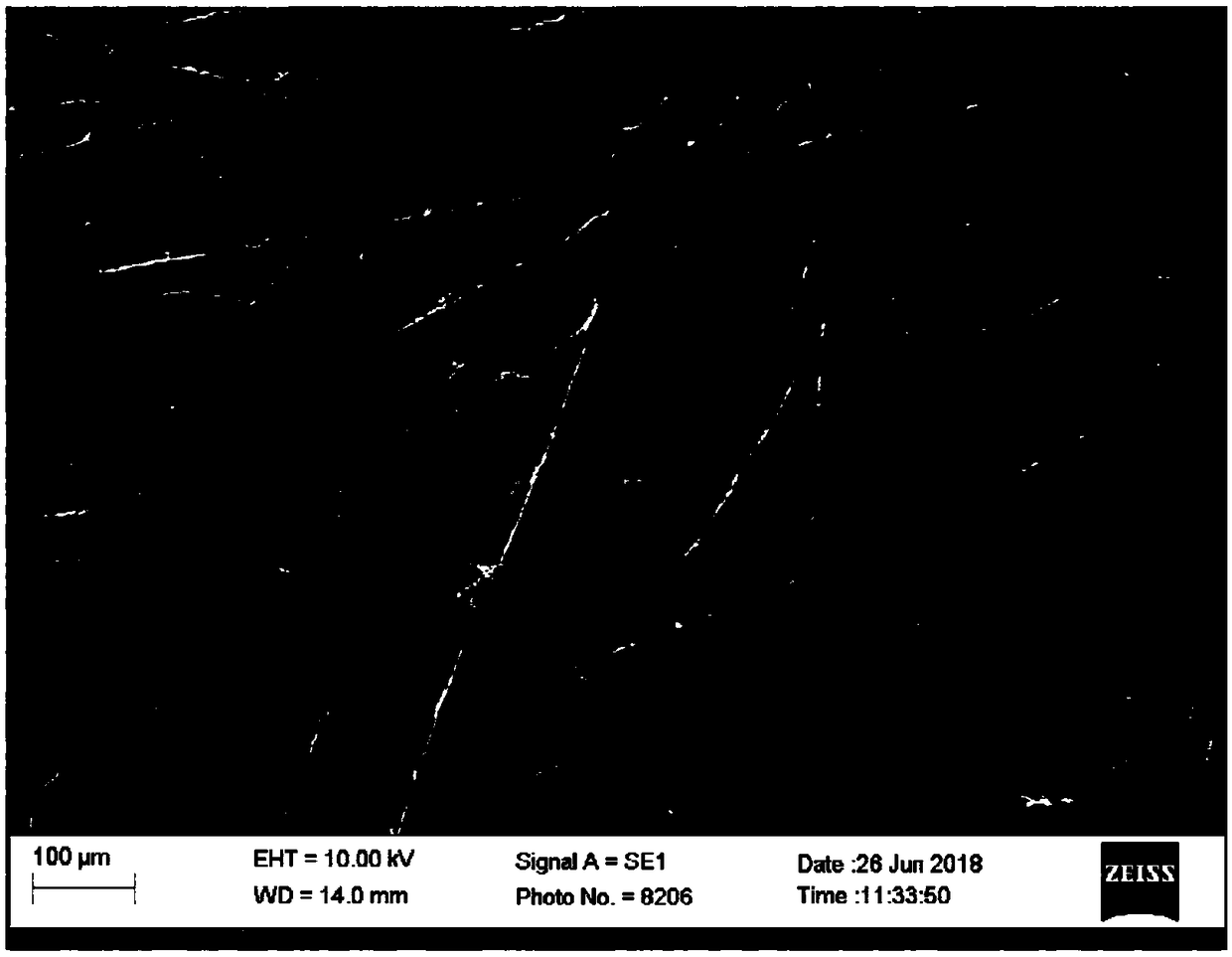

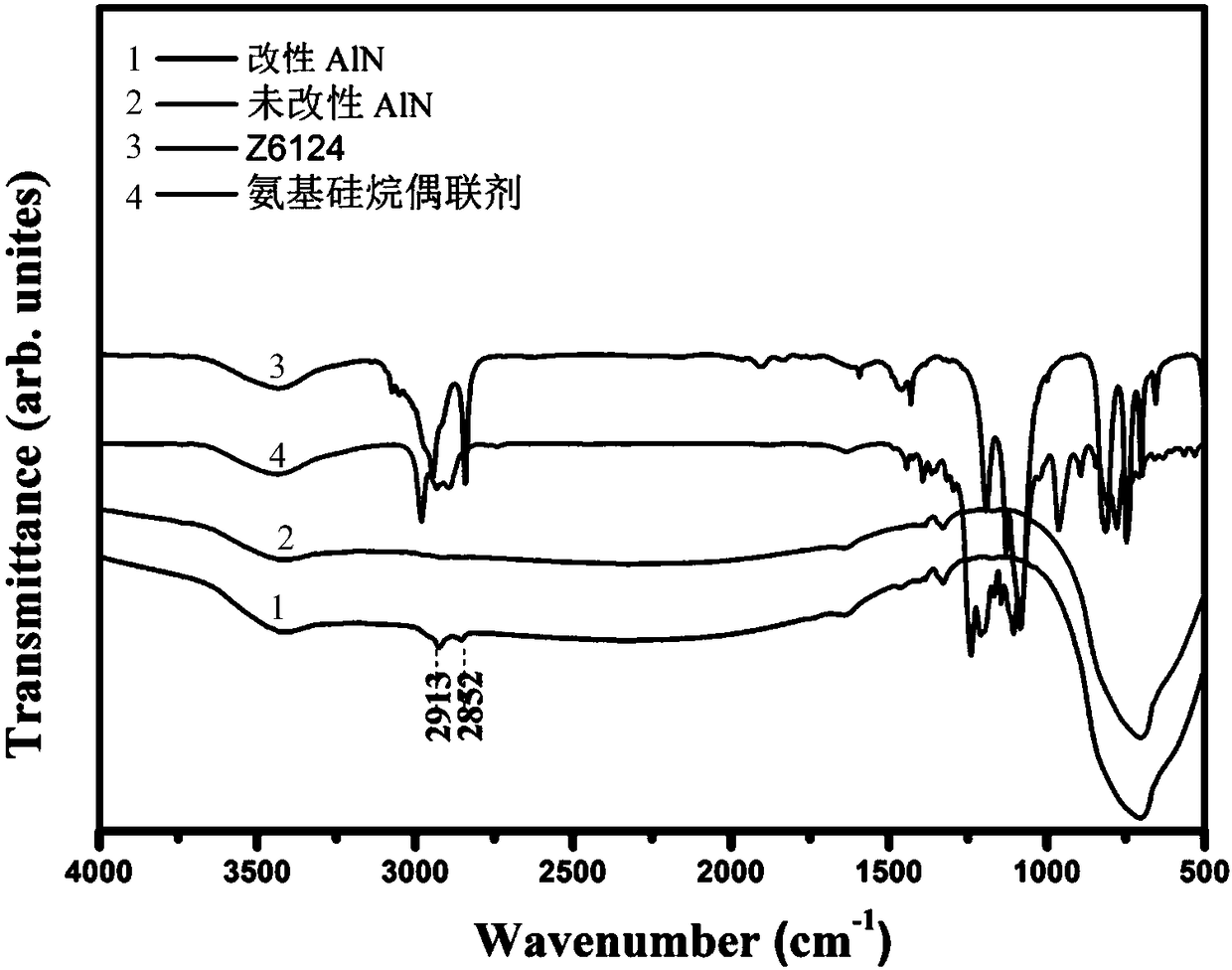

InactiveCN108570202AImprove water resistanceImprove dispersion uniformityComposite substrateMixed materials

The invention relates to a preparation method of a teflon composite substrate material and belongs to the field of organic / inorganic composite materials. The method includes the steps of firstly, oxidizing aluminum nitride ceramic powder at 800-1000 DEG C for 1-4 hours; secondly, adding the aluminum nitride ceramic powder into the mixed solution of deionized water and anhydrous ethanol, weighing acoupling agent, and evenly stirring and mixing in an ultrasonic manner to obtain a mixed material; thirdly, filtering the mixed material, and drying at 110-120 DEG C for 4-7 hours to obtain modifiedaluminum nitride ceramic powder; fourthly, placing the modified aluminum nitride ceramic powder into a powder processing cavity of 105-120 DEG C, and spraying a PTFE resin solution into the cavity ina high-pressure manner to obtain PTFE wrapped aluminum nitride powder; fifthly, adding a demulsifier to perform demulsification; sixthly, crushing; seventhly, performing cold press molding, and performing hot pressed sintering. The preparation method has the advantages that AIN powder is processed by a thermal oxidation process to oxidize the surface of the AIN powder to form a thin aluminum oxidelayer, and surface hydroxyl is beneficial to coupling agent grafting reaction.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

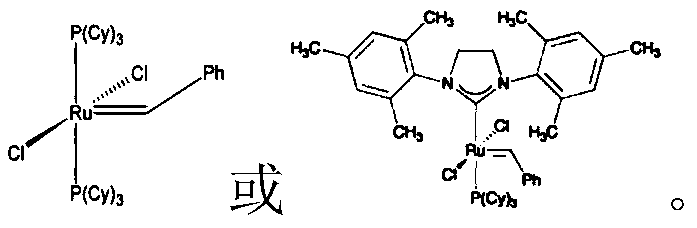

Rubber reinforcing agent, preparation method thereof, and preparation method of butadiene styrene rubber

InactiveCN105732690APlay a reinforcing roleFacilitate the grafting reactionGroup 4/14 element organic compoundsPolymer scienceReaction temperature

The invention provides a rubber reinforcing agent, a preparation method thereof, and a preparation method of butadiene styrene rubber. In the invention, firstly the rubber reinforcing agent having excellent reaction activity with butadiene styrene rubber latex is synthesized in a manner of mixing an aromatic compound containing an alkene unsaturated substituent and an organic siloxane monomer containing an alkene unsaturated substituent, adding an olefin metathesis catalyst and performing a normal-temperature reaction in a methylbenzene solvent with air and water isolated, and removing the methylbenzene solvent through a vacuum desolventizer to prepare the rubber reinforcing agent. The high-strength butadiene styrene rubber is prepared by feeding the rubber reinforcing agent and the butadiene styrene rubber latex into a polymerization kettle according to ratio with addition of an initiator, and performing a reaction for a certain time with reaction temperature controlled, and coagulating, washing and drying the product.

Owner:PETROCHINA CO LTD

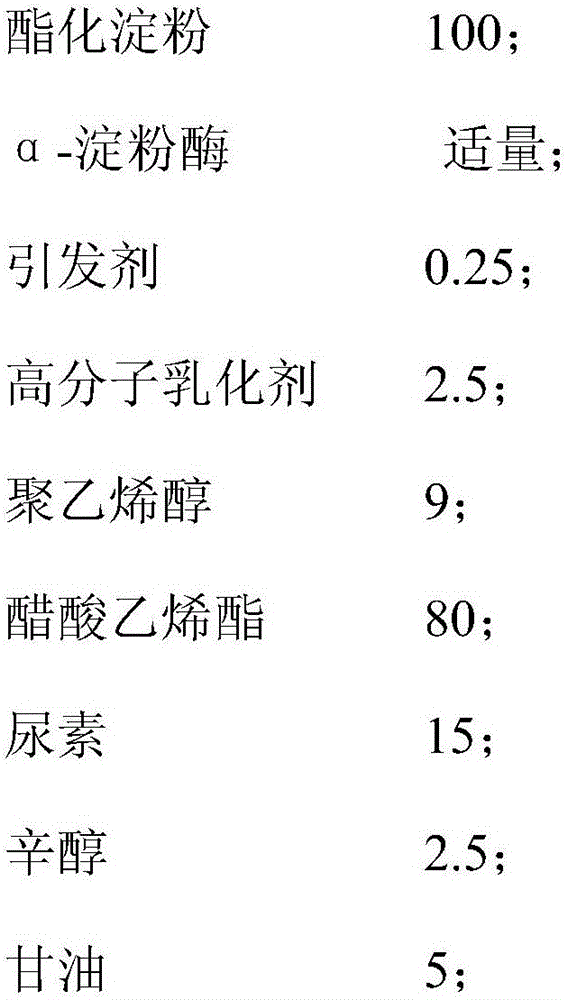

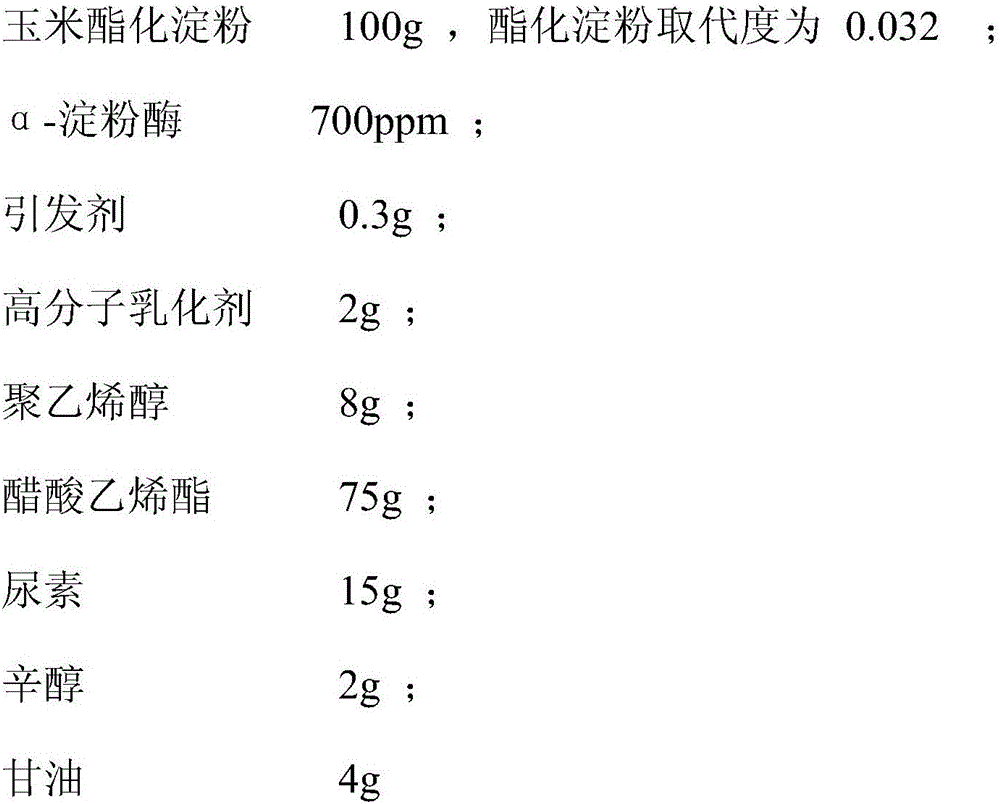

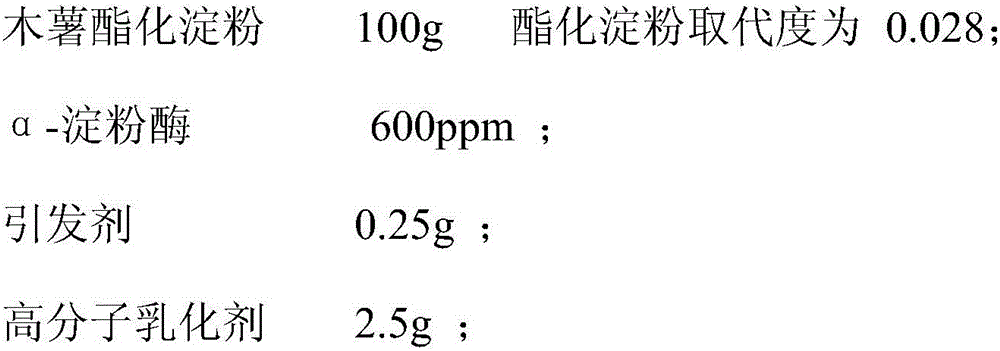

Modified starch adhesive and preparation method thereof

InactiveCN106220788AHigh bonding strengthImprove water resistanceGraft polymer adhesivesPolyvinyl alcoholAdhesive

The invention discloses a modified starch adhesive which comprises the following components in parts by mass: 100 parts of esterified starch, a right amount of alpha-amylase, 0.2-1 part of initiator, 1-4 parts of high-polymer emulsifier, 6-15 parts of polyvinyl alcohol, 70-80 parts of vinyl acetate, 10-20 parts of urea, 1-3 parts of octanol, 2-8 parts of glycerol and a right amount of water. By adding the right amount of water, the esterified starch can be made into starch milk with the starch concentration of 25-35% (m / m) on dry basis. The concentration of the alpha-amylase in the starch milk is 500-1000 ppm. The invention also discloses a preparation method of the modified starch adhesive. The bonding strength and water resistance of the modified starch adhesive are obviously enhanced. The bioenzyme is used for degradation, the material before grafting has uniform viscosity, and is beneficial to grafting reaction; and thus, the modified starch adhesive has the advantages of low cost, high safety and environment friendliness.

Owner:山东熙来淀粉有限公司

Garbage penetrating fluid efficient wastewater treating agent based on modified fly ash and preparation method

ActiveCN105251462ALarge average pore sizeIncrease the areaOther chemical processesWater/sewage treatment by sorptionChemistryDicarbonate

The invention discloses a garbage penetrating fluid efficient wastewater treating agent based on modified fly ash and a preparation method. The composition is prepared from, by weight, 50-60 parts of fly ash fine powder, 8-10 parts of dicarbonate, 11-17 parts of poly dimethyl diallyl ammonium chloride, 9-10 parts of cation polyacrylamide, 10-20 parts of carboxymethyl chitosan, 10-20 parts of quaternary ammonium salt of chitosan, 20-24 parts of smectite powder, 6-10 parts of biological bacterial sludges, 12-15 parts of magnetic tourmaline powder, 8-10 parts of basic aluminum chloride, 40-50 parts of loofahs and an adequate amount of ethyl alcohol, deionized water and water. According to the garbage penetrating fluid efficient wastewater treating agent based on the modified fly ash and the preparation method, pretreatment is conducted on coal ash powder through the dicarbonate, the porosity and the specific surface area of the coal ash power are increased, further compound modification is conducted on activation compound powder, the adsorption efficiency is increased, and the garbage penetrating fluid efficient wastewater treating agent based on the modified fly ash and the preparation method have the advantages that the adsorbent of the coal ash powder is high in capacity and easy to separate and recycle.

Owner:TIANJIN ZHONGKE CHEM

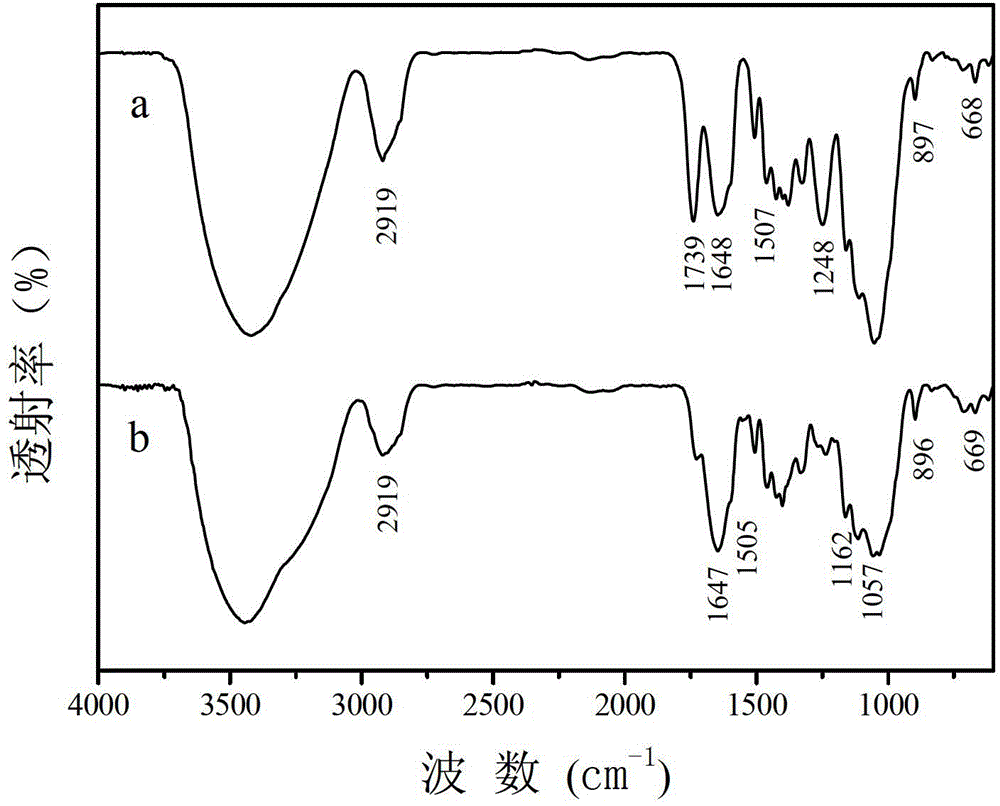

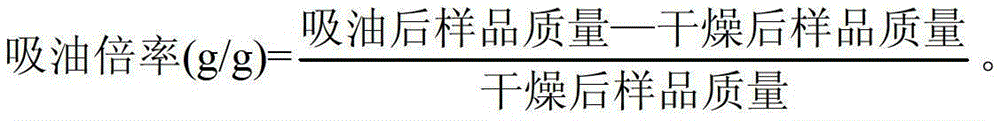

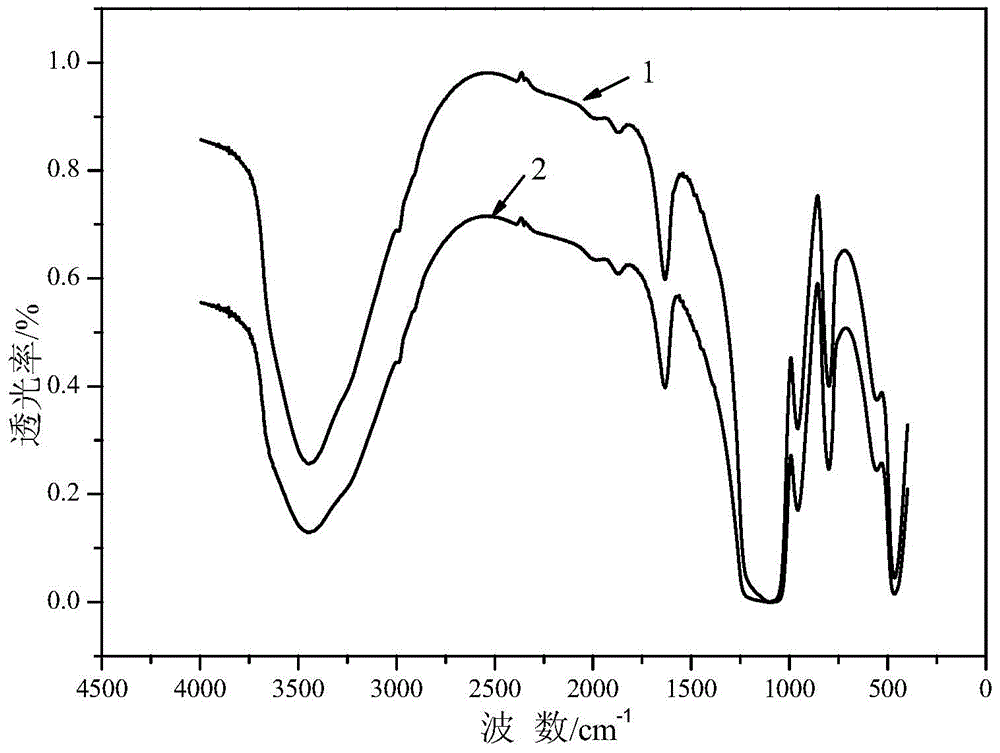

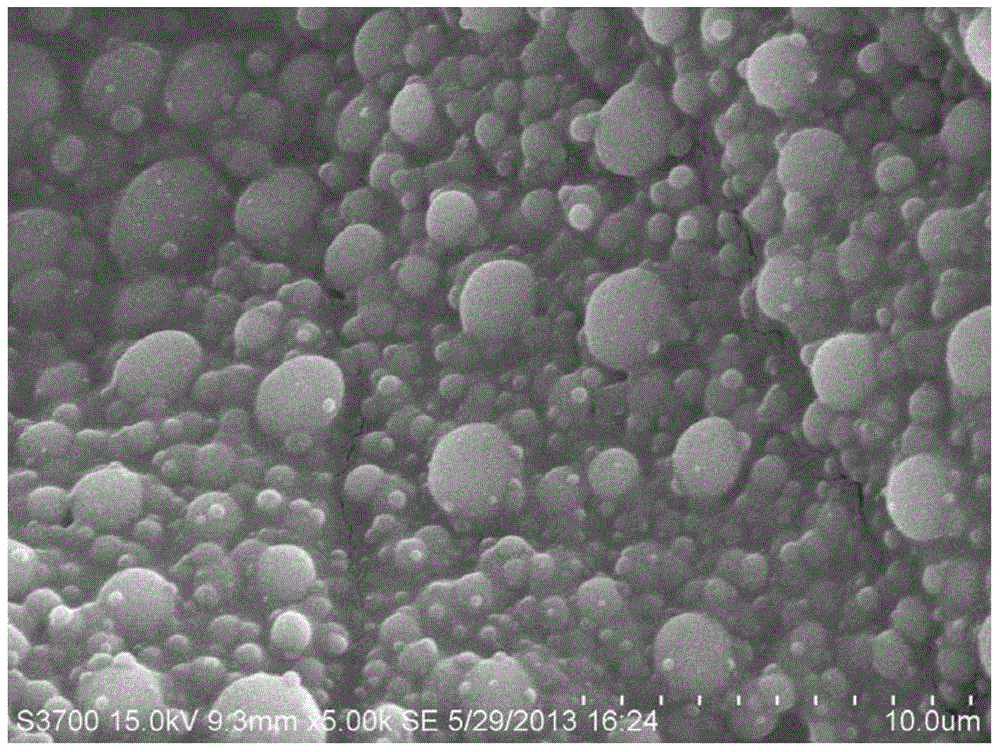

Preparation method of high oil-absorption material based on invasive plant

InactiveCN103145921AWide variety of sourcesImprove harmWater/sewage treatment by sorptionSolidago canadensisMonomer

The invention relates to a preparation method of a high oil-absorption material based on an invasive plant. The method comprises the following steps: crushing stalk of an invasive plant-solidago Canadensis, pre-treating by an aqueous alkali and ethanol solution, adding in gelatin solution, orderly adding a hybrid reaction monomer, an initiator and a crosslinking agent, mixing under an ultrasonic cleaner to eliminate the bubble, flowing through a condensing reflow device, warming and reacting under the magnetic force stirring effect, washing by hot water after the reaction, and drying to obtain the invasive plant based oil-absorption material. The method provided by the invention is simple to operate, the ultrasonic cleaner can be used for promoting the reaction, the raw material is wide in resource, the utilized invasive plant is distributed in more than ten provinces and cities in China at present, the production cost of the product is reduced, the reclamation and environmental protection are realized, the oil-absorption multiplying power of the obtained product to the long-chain oil reaches a maximum of 25g / g.

Owner:DONGHUA UNIV

Hydrophilic aluminum foil with organic-inorganic hybrid coating, and preparation method and application thereof

ActiveCN104087086AFacilitate the grafting reactionImprove adhesionLayered productsPretreated surfacesMicro nanoCross-link

The invention discloses an organic-inorganic hybrid hydrophilic aluminum foil coating, and a preparation method and an application thereof. According to the method, a hydrophilic polymer film-forming agent is dissolved into water according to a mass ratio of 1-99%, such that a film-forming agent solution is prepared; inorganic nano-grade particles prepared with a raw material of tetraethoxysilane, tetramethoxysilane or tetraethoxytitanium are doped in; a cross-linking agent is added; water is added for dilution, and ultrasonic dispersing is carried out, such that the mixture is well dispersed, and the organic-inorganic hybrid hydrophilic aluminum foil coating is obtained. A silane coupling agent hydrolysate is adopted as a pretreatment agent for treating a well polished and cleaned aluminum foil surface; the hybrid hydrophilic aluminum foil coating is applied on the surface of the treated aluminum foil; and the coating is cured into a film with a heat curing method, such that a hydrophilic aluminum foil is obtained. The hydrophilic aluminum foil provided by the invention has a micro-nano binary rough structure on the surface. Water can spread quickly on the surface of the aluminum foil. A water contact angle of the aluminum foil is 0-5 DEG. Hydrophilic coating adhesion force reaches 0-1 level. The hydrophilic aluminum foil provided by the invention can be applied in various air conditioners, and has an excellent comprehensive performance.

Owner:SOUTH CHINA UNIV OF TECH

Gradient-structure nanometer aramid paper making method

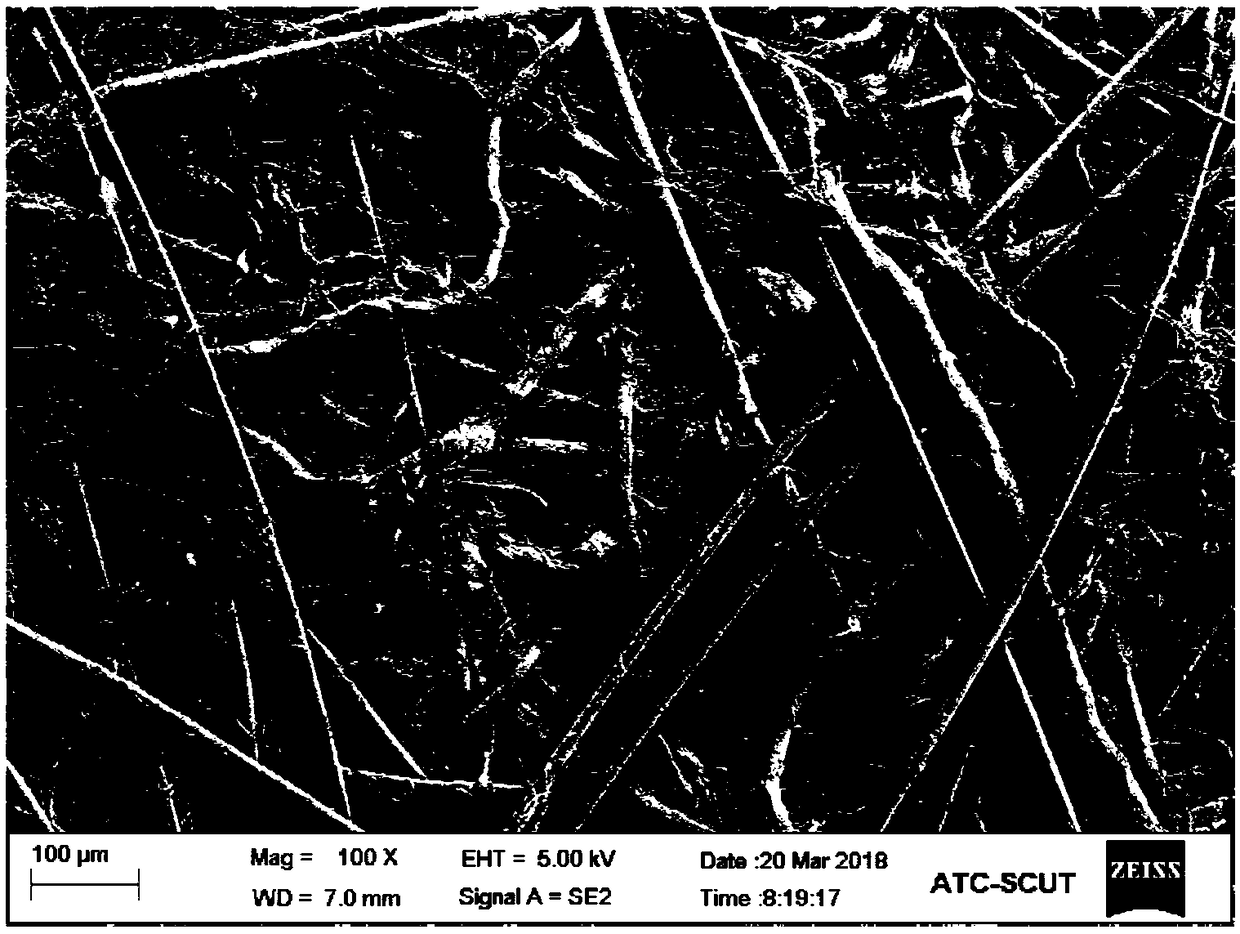

InactiveCN109468882AImprove hydrophilicityFacilitate the grafting reactionPulp properties modificationSpecial paperTemperature resistanceNanometre

The invention discloses a gradient-structure nanometer aramid paper making method. According to the making method, a pretreatment liquid is firstly prepared, the pretreatment liquid is used to pretreat a para-aramid chopped fiber, the pretreated aramid chopped fiber and a para-aramid pulp fiber are modified by a coupling agent or a coupling agent solution, paper is manufactured with pulp, a nanometer para-aramid fiber is used to strength the gradient structure of the paper, and the strength of the prepared nanometer aramid paper with the gradient structure is 10-25 times that of base paper. The method improves the defect of the aramid paper, and a product has the characteristics of high temperature resistance, flame retardance, excellent electrical insulation property, etc.

Owner:SOUTH CHINA UNIV OF TECH

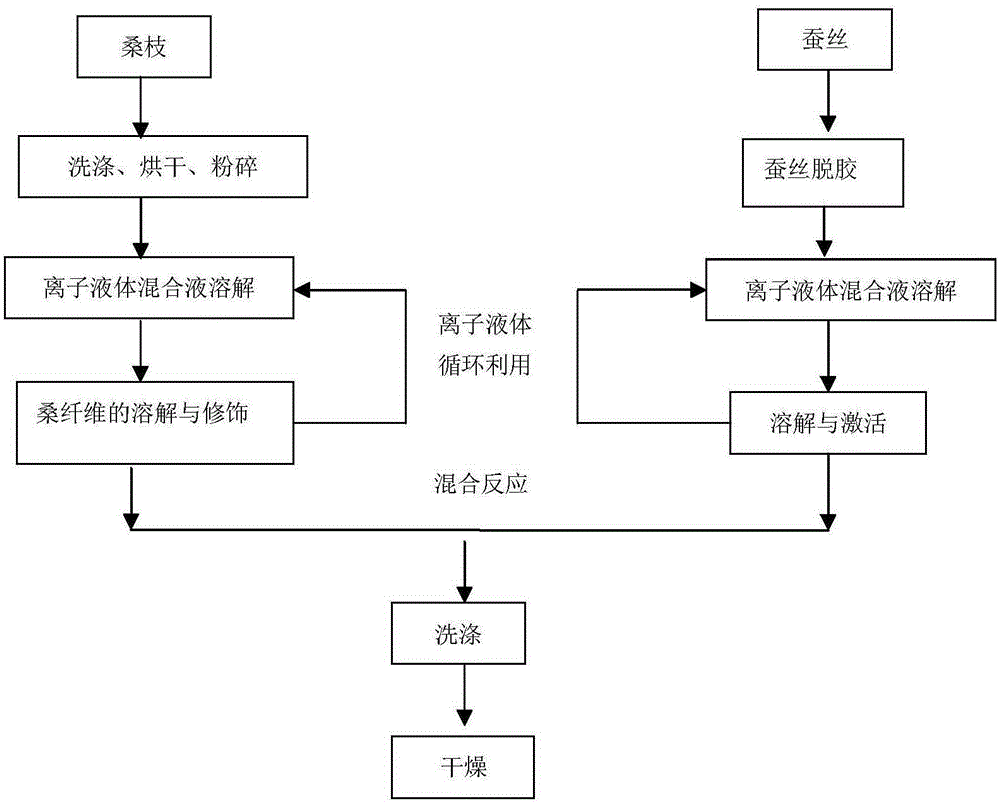

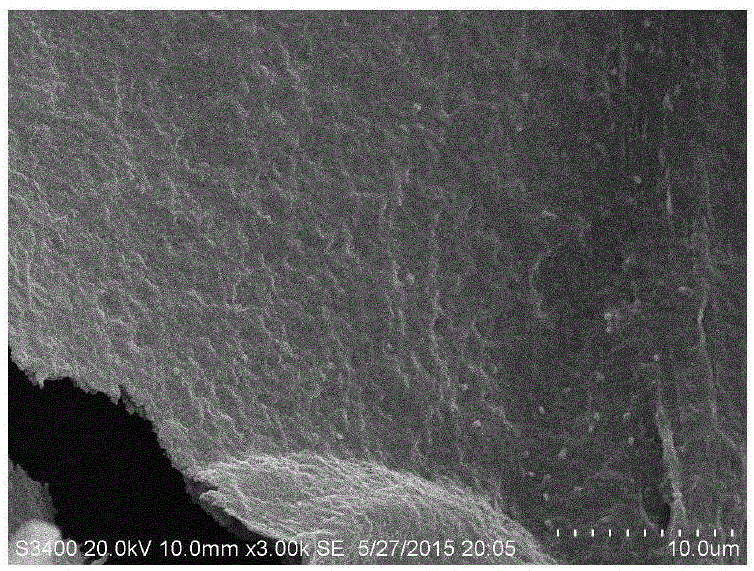

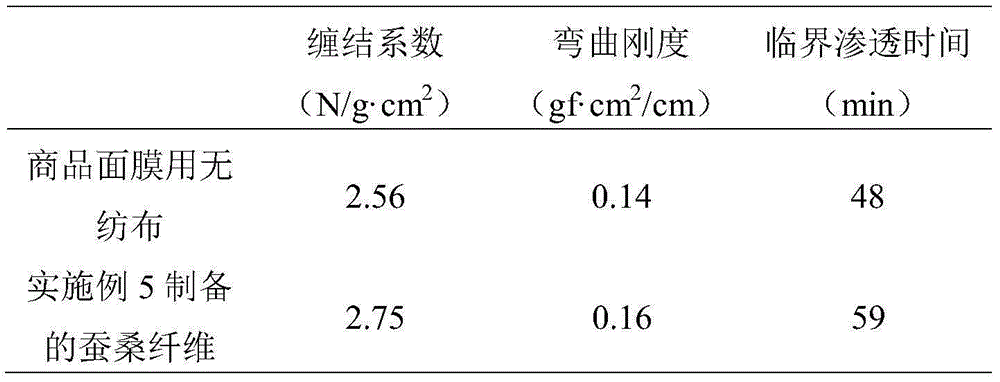

Preparation method of sericulture fiber material

ActiveCN105200558AAvoid partial breakageUniform sampleConjugated cellulose/protein artificial filamentsIonSilk fiber

The invention discloses a preparation method of a sericulture fiber material. The method comprises the following steps: (1) drying and crushing mulberry branches to obtain mulberry branch powder; mixing the mulberry branch powder and ion liquid to obtain a mixed solution, preserving the heat, adding additives, and stirring and heating; (2) uniformly mixing degummed silk fibers and ion liquid mixed solution, and heating; (3) mixing products of the step (1) and the step (2), heating and uniformly stirring, and facilitating the reaction; (4) washing an acquired sample by utilizing a renewable reagent, and drying solids to obtain the sericulture fiber. The sericulture fiber has characteristics of good water retention property, high heat stability, antibacterial property and environmental protection, has rigidness of the mulberry fiber and the flexibility of the silk fiber on the aspect of the physical performance; on the aspect of the biological performance, the sericulture fiber has characteristics such as smoothness, flexibility of the silk fiber and the permeability and moisturizing property of the mulberry fiber and has no allergen and immunity reaction, and the performance of the sericulture fiber is better than the mulberry fiber and the silk fiber.

Owner:JIANGSU UNIV OF SCI & TECH

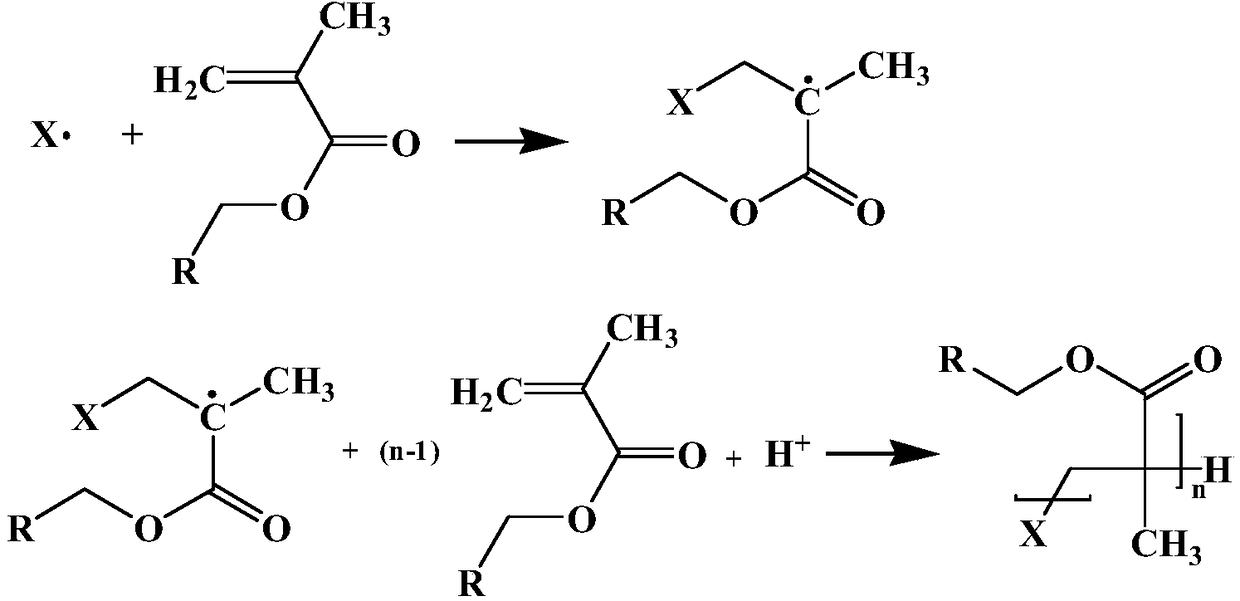

Method of surface grafting modification for nylon fabric

InactiveCN103074769AImprove anti-dripping performanceFacilitate the grafting reactionFibre treatmentNylon materialMicrowave method

The invention relates to a method of surface grafting modification for nylon fabric with a microwave irradiation method. The grafting reaction conducted with the microwave method has the advantages of short response time, uniform reaction and small influence on a property of the fabric. As hydroxyethyl methacrylate serves as a grafting monomer, the hygroscopicity of the grafted nylon fabric is improved obviously, and the dripping resistance is good; in addition, the reaction is combined with chemical bonds; an effect is stable and lasting; and the washing resistance is high.

Owner:BEIJING UNIV OF CHEM TECH

Heat-resisting chlorinated polyvinyl chloride material for power cable

InactiveCN106147092AImprove melt fluidityImprove flame retardant performanceAluminium hydroxidePolystyrene

The invention discloses a heat-resistant chlorinated polyvinyl chloride material for power cables. The raw material comprises the following components: chlorinated polyvinyl chloride, polyvinyl chloride, marble, calcium carbonate, calcined kaolin, calcium stearate, stearin Zinc acid, dibutyltin dilaurate, butyl stearate, oxidized polyethylene wax, aluminum hydroxide, magnesium hydroxide, tricresyl phosphate, bis(2‑ethylhexyl)phenyl phosphate, tris(2‑ethylhexyl) phosphate Ethylhexyl) ester, polystyrene, polyglutarimide, stearyl alcohol, silane coupling agent, antioxidant. The heat-resistant chlorinated polyvinyl chloride material for power cables proposed by the invention has high strength, good heat resistance and excellent impact resistance, and the cable material made of the material has good comprehensive performance and long service life.

Owner:安徽华润仪表线缆有限公司

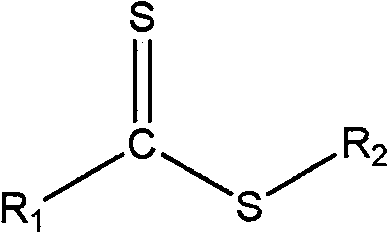

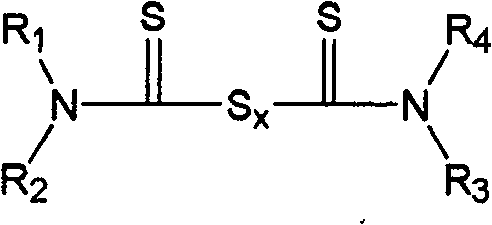

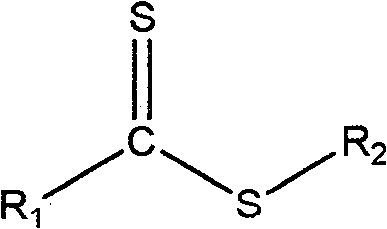

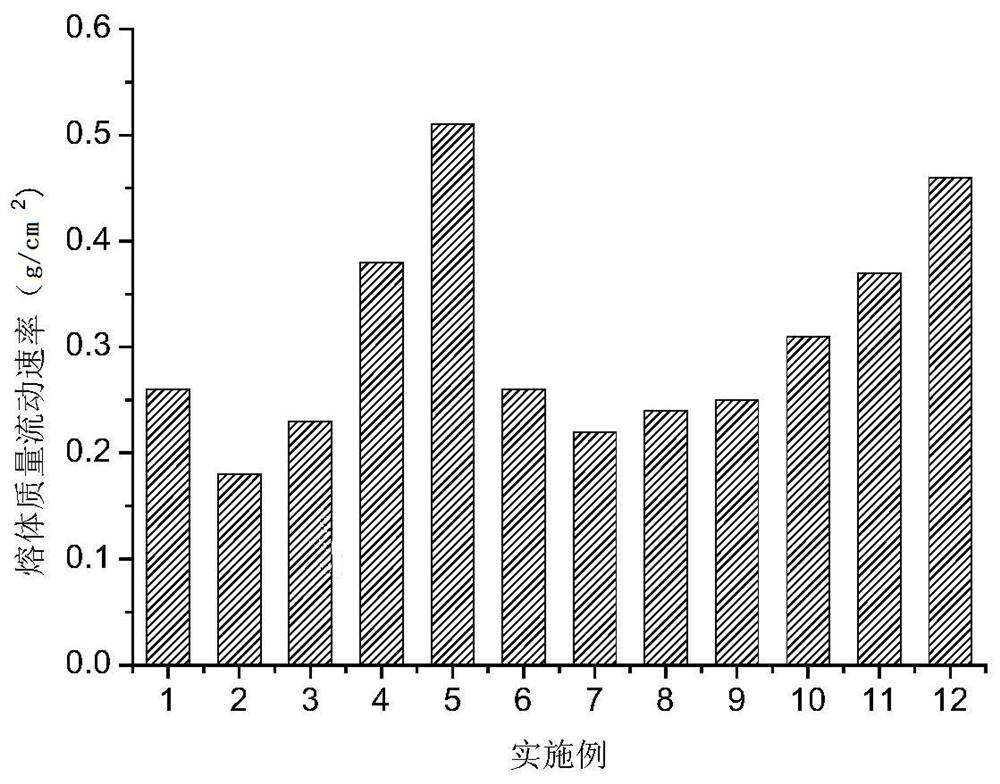

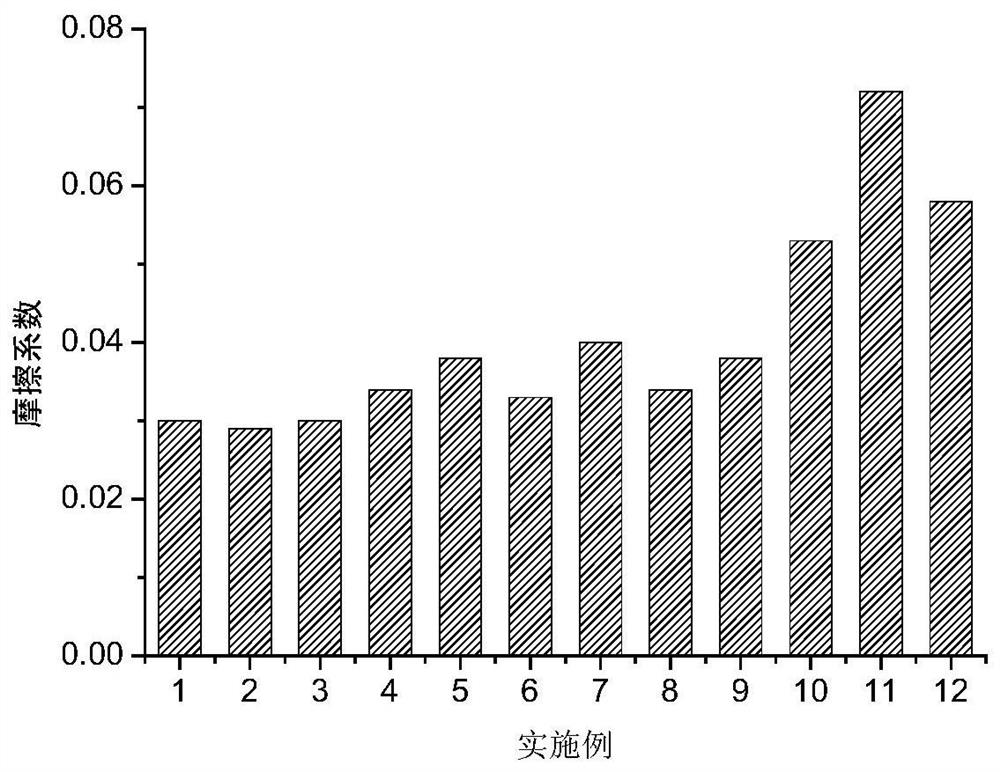

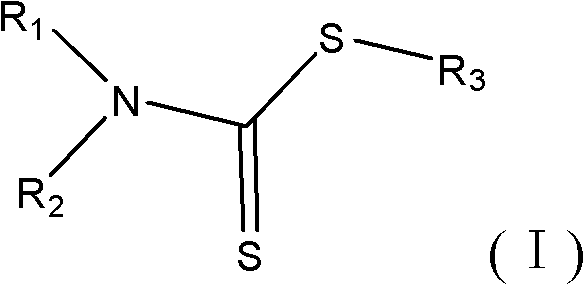

Method for increasing melt strength of polypropylene

The present invention uses 100 parts by weight of polypropylene and 0.1-10 parts by weight of comonomer, 0.001-5 parts by weight of free radical reversible stabilizer and 0.001-2 parts by weight of free radical initiator to melt and mix the reaction to improve the polypropylene the melt strength. Wherein the free radical reversible stabilizer is a dithioformate compound. Under the reaction conditions, the dithioformic acid group produced by the free radical reversible stabilizer can stabilize the polypropylene macromolecular free radical through a reversible process, and as a result, it can effectively inhibit the chain scission of the polymer and promote the occurrence of grafting reaction. Another cracking product is carbon free radicals, which can activate polymer macromolecules to obtain macromolecular free radicals, thereby reducing the amount of free radical initiators.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Fusion graft process for modified polypropylene/acrylic acid polyester ether

The improved polypropylene / acrylic polyether ester fusion grafting process includes the following steps: 1. mixing acrylic polyether ester monomer, peroxide initiator and antioxidant at normal temperature in a high speed dispersing machine to form grafting monomer / initiator mixture solution; 2. heating the double screw extruder to reaction temperature and feeding polypropylene resin; 3. adding the grafting monomer / initiator mixture solution to the extruder with one liquid pump, so as to mix peroxide initiator, acrylic polyether ester monomer and polypropylene melt well for reaction; and 4. pumping out low molecular matter with vacuum pump, cooling the extruded melt, and palletizing to obtain the grafted polypropylene / acrylic polyether ester product. The present invention has high grafting efficiency.

Owner:江苏创源科技新材料有限公司 +1

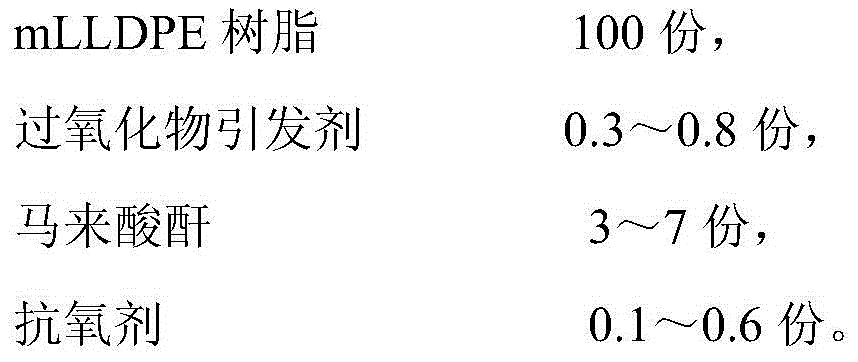

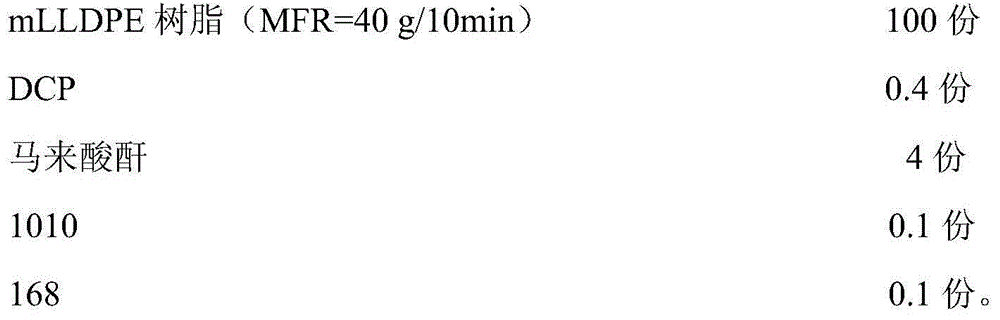

High-fluidity metallocene low-density polyethylene resin graft and preparation method thereof

ActiveCN105566573AImprove toughnessHigh transparencyLow-density polyethyleneLinear low-density polyethylene

The present invention belongs to the field of polymer material modification, and particularly relates to a high-fluidity metallocene low-density polyethylene resin graft, which comprises the following raw materials by weight: 100 parts of an mLLDPE resin, 0.3-0.8 part of a peroxide initiator, 3-7 parts of maleic anhydride, and 0.1-0.6 part of an antioxidant. The present invention further provides a preparation method of the graft. The preparation method comprises: feeding the materials into a co-rotating twin screw reaction extruder, and post-treating the reaction materials to obtain the grafted product, wherein the material drum of the extruder is divided into three sections, the first section is a melt mixing and dispersing section, the second reaction is a reaction section, and the third section is a metering molding section. According to the present invention, the maleic anhydride is successfully grafted onto the high-performance metallocene linear low-density polyethylene to prepare the high-fluidity metallocene low-density polyethylene resin graft, wherein the melt mass flow rate can achieve more than or equal to 15 g / 10 min, the tensile strength can achieve more than or equal to 17 MPa, and the high grafting rate is provided.

Owner:CHINA PETROLEUM & CHEM CORP

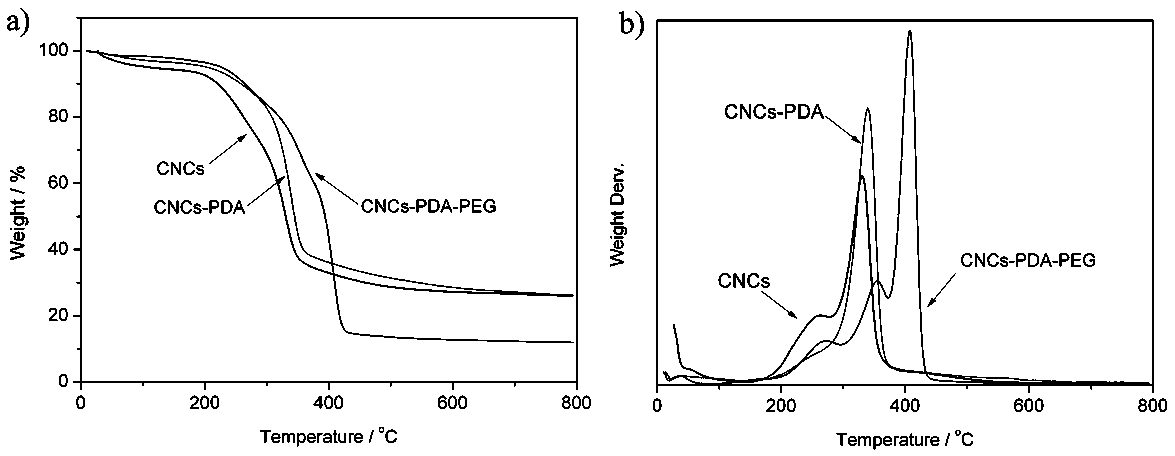

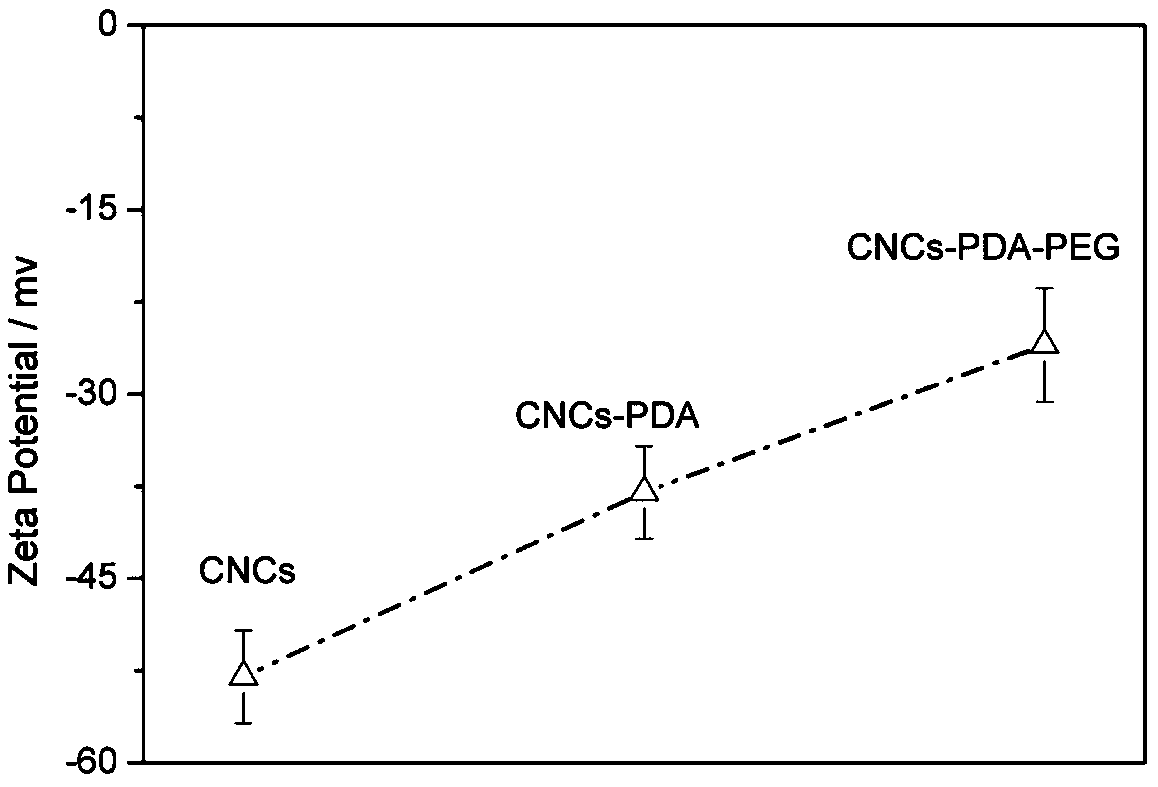

Nano-cellulose/polydopamine/polyethylene glycol composite material and preparation method thereof

The invention discloses a nano-cellulose / polydopamine / polyethylene glycol composite material. The nano-cellulose / polydopamine / polyethylene glycol composite material is prepared by modifying the surface of nano-cellulose through polydopamine and is grafted with polyethylene glycol; the polyethylene glycol is the polyethylene glycol which is subjected to amination or sulfhydrylation modification orterminated by methoxyl. Meanwhile, the invention provides a corresponding preparation method. The nano-cellulose / polydopamine / polyethylene glycol composite material disclosed by the invention can be dispersed in polar solvents, such as water, N',N-dimethylformamide, dimethyl sulfoxide or ethyl alcohol, again; the dispersibility is high; a settlement phenomenon is avoided; the thermal stability ishigh; moreover, the composite material is only limited to modify the surface of the nano-cellulose (CNCs); the structures of nano-crystals of the CNCs are not influenced.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

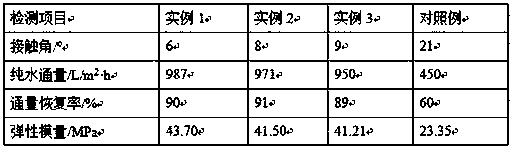

Hydrophilic modification method for polyester fibers with bromoethane and PVA

The invention discloses a hydrophilic modification method for polyester fibers with bromoethane and PVA and belongs to the technical field of macromolecules. According to the method, a sodium hydroxide solution is added to the polyester fibers, the mixture is stirred, heated and preprocessed, the surfaces of the polyester fibers are damaged, and subsequent modification processing is facilitated; a bromoethane solution is added to the polyester fibers, the mixture is stirred and heated and subjected to modification treatment, then a PVA solution with the mass ratio being 4-5.5% is added to the polyester fibers, the mixture is stirred and heated, and the polyester fibers obtained after hydrophilic modification is obtained. According to the method, after the sodium hydroxide solution is added for preprocessing the polyester fibers, the bromoethane solution and the PVA are utilized to conduct modification processing on the polyester fibers, and the polyester fibers good in hydrophilia and antistatic performance are obtained. The method is easy and convenient to operate, the reaction speed and the reaction temperature are easy to control, the amount of organic solvent added in the reaction process is small, low toxin, low pollution and low emission are achieved, subsequent operation is easy and convenient to conduct, industrialized popularization are facilitated, and high economic benefits are achieved.

Owner:苏州东奕盛材料科技有限公司

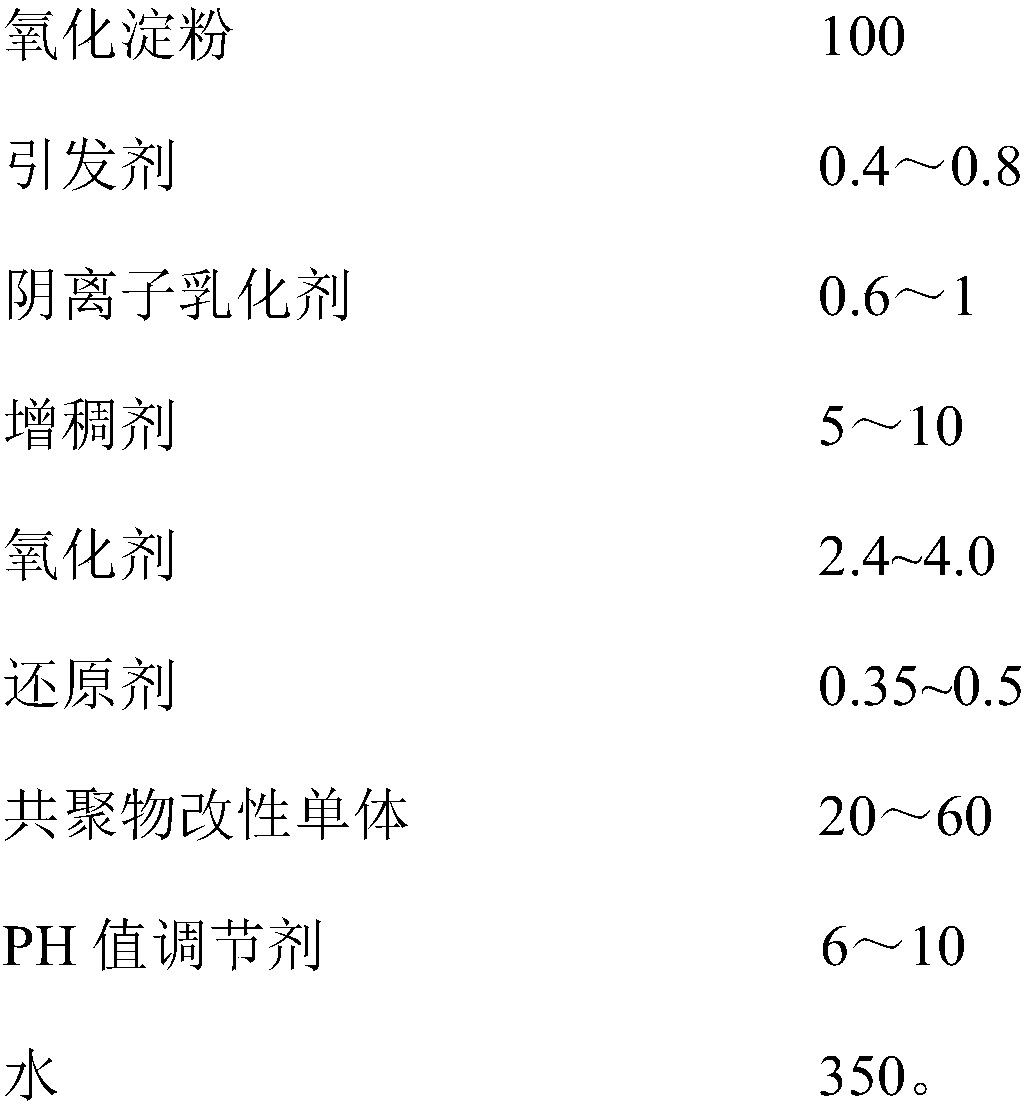

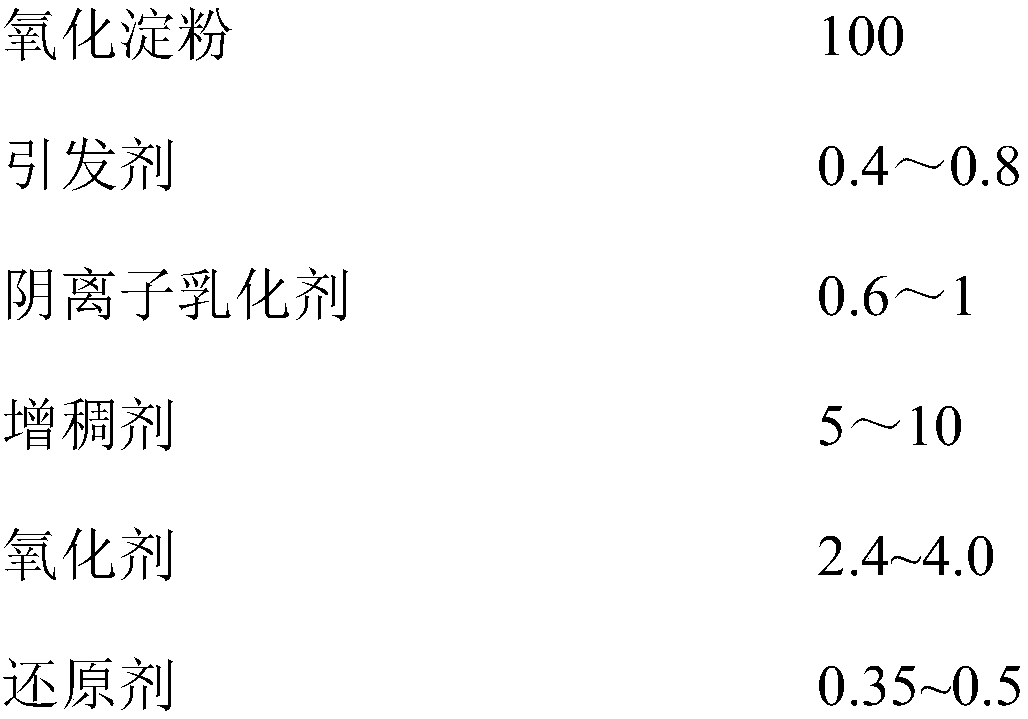

Grafted modified oxidized starch adhesive and preparation method thereof

ActiveCN107286883AHigh bonding strengthLow moisture absorptionGraft polymer adhesivesEnvironmental resistanceAdhesive

The invention discloses grafted modified oxidized starch adhesive and a preparation method thereof. The grafted modified oxidized starch adhesive is prepared from the following components in parts by weight: 100 parts of oxidized starch, 0.4-0.8 part of initiator, 0.5-0.8 part of anionic emulsifier, 0.5-1.2 parts of nonionic emulsifier, 1-3 parts of a thickening agent, 30-50 parts of reactive grafted modified monomer, 8-12 parts of pH value regulator and 385 parts of water. The grafted modified oxidized starch adhesive has the characteristics of high adhesion strength, low moisture absorption rate, excellent moisture resistance, uniform starch pasting liquid viscosity, benefit for grafting reaction, simple process, zero VOC emission, safety, environment friendliness and the like.

Owner:WUXI HAITE NEW MATERIAL RES INST +1

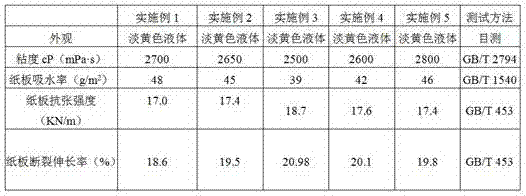

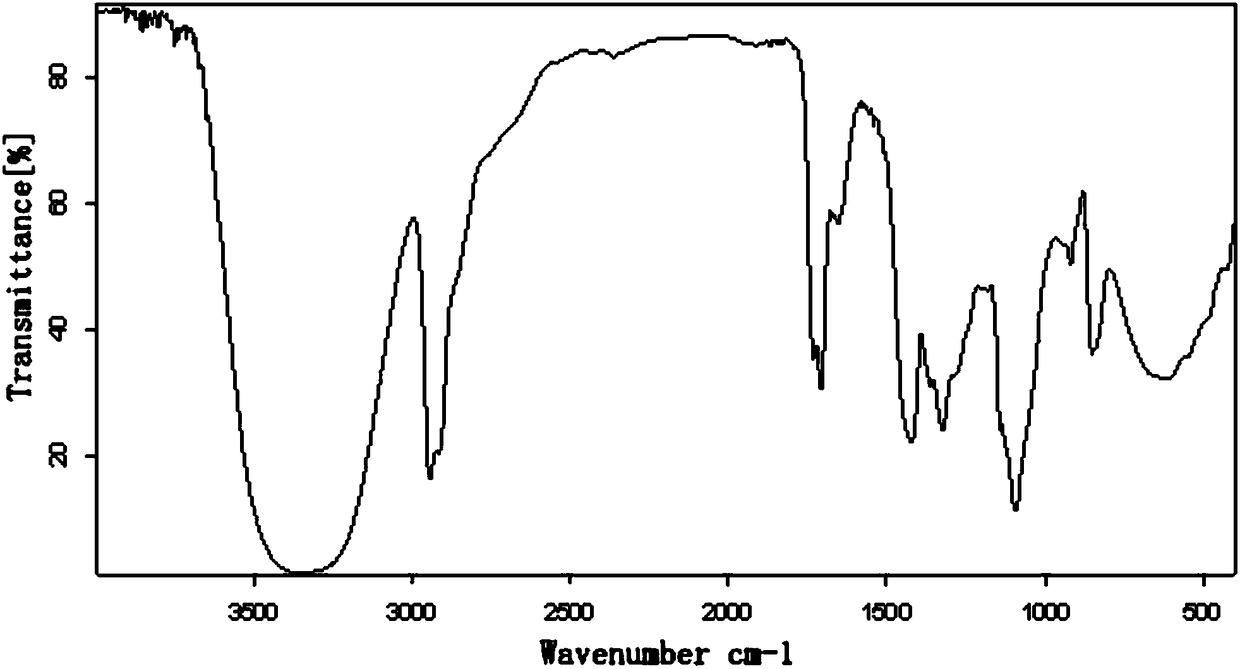

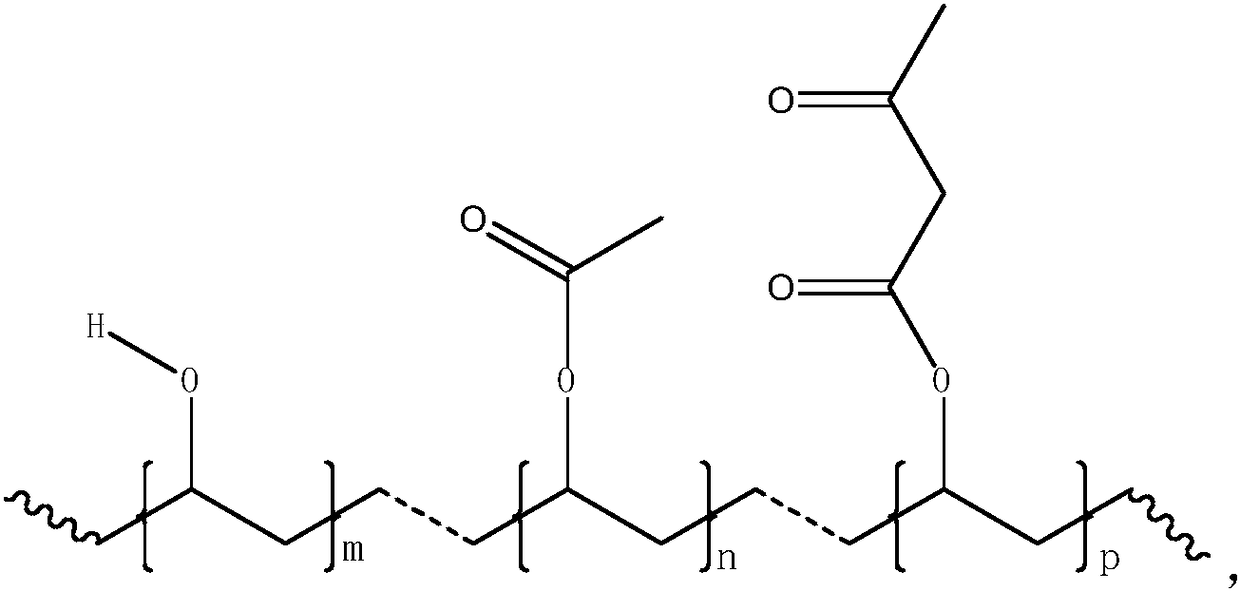

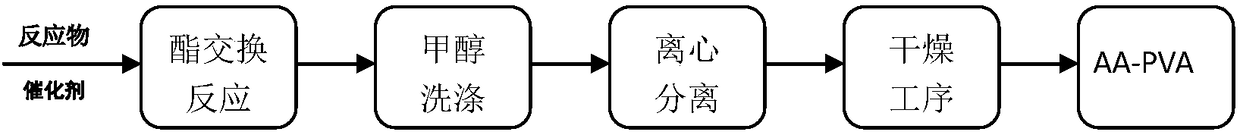

Acetoacetyl modified polyvinyl alcohol as well as preparation method and application thereof

InactiveCN108219035AHigh grafting rateImprove performanceMonocarboxylic acid ester polymer adhesivesUnsaturated alcohol polymer adhesivesAcetoacetatesHydroxylamine

The invention discloses acetoacetyl modified polyvinyl alcohol (AA-PVA) which is prepared from acetylacetic ester and PVA (Polyvinyl Alcohol) through ester exchange. Compared with polyvinyl alcohol (PVA), the acetoacetyl modified polyvinyl alcohol has relatively high reaction activity, and is used as protection colloid of emulsion polymerization of polyvinyl acetate (PVAc), the acetoacetyl modified polyvinyl alcohol is liable to cause grafting reactions, is capable of increasing the grafting rate of PVA and is capable of improving properties of PVAc emulsions. The acetoacetyl modified polyvinyl alcohol or a PVAc emulsion with the acetoacetyl modified polyvinyl alcohol as the protection colloid are liable to cause cross-linking reactions with substances such as hydrazine, hexamethylendiamine, semicarbazide, hydroxylamine or amides at a room temperature, the bonding strength of an adhesive can be remarkably improved, particularly the primary viscosity and the water resistance can be improved. By adopting the acetoacetyl modified polyvinyl alcohol, an extremely toxic substance, namely diketene, is avoided, and thus the working environment and the body health of operators are effectively ensured.

Owner:SINOPEC SICHUAN VINYLON FACTORY +1

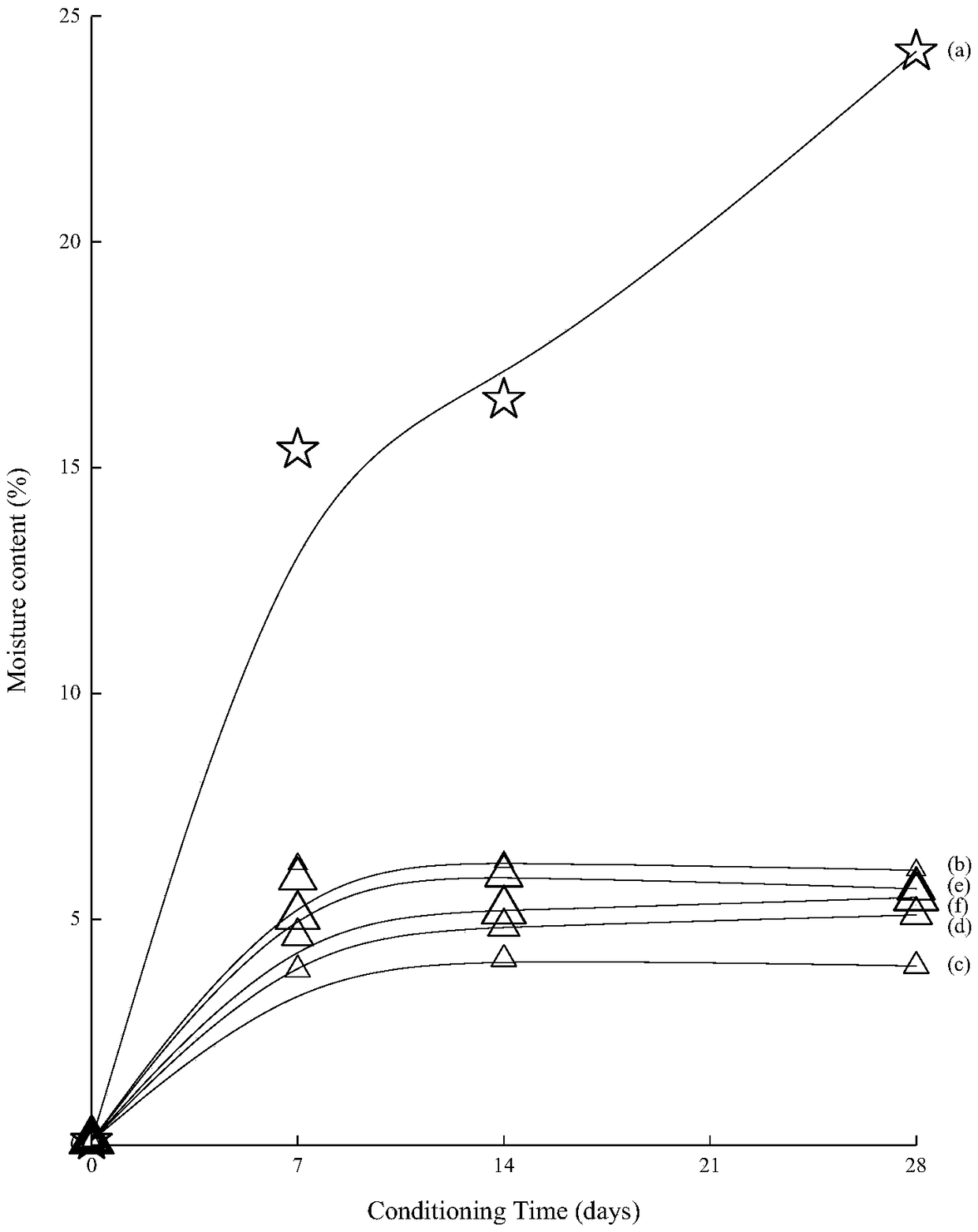

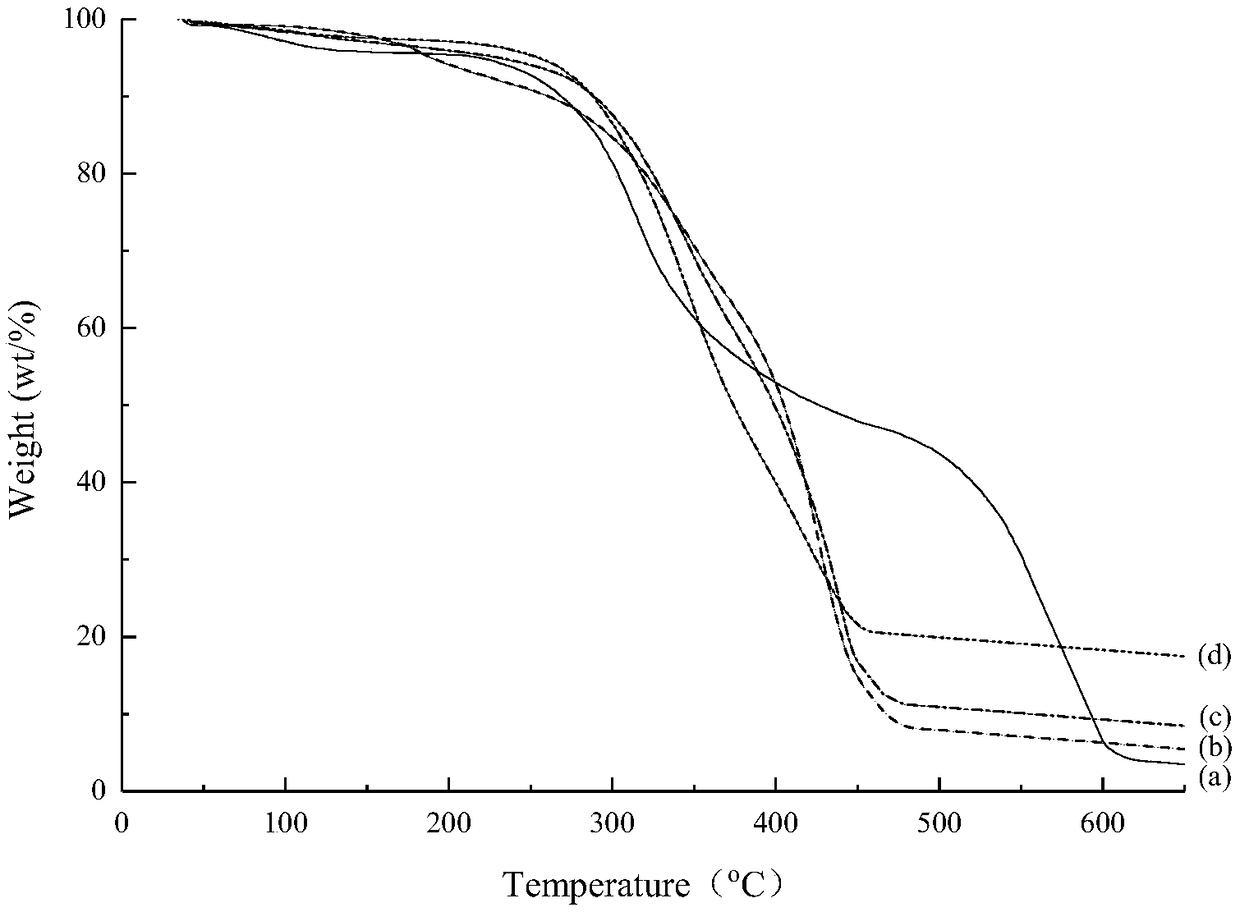

Method for preparing functional polyvinylidene fluoride membrane

InactiveCN110743391AFully stretchImprove antibacterial propertiesMembranesSemi-permeable membranesPhotocatalytic reactionCellulose acetate

The invention relates to a method for preparing a functional polyvinylidene fluoride membrane and belongs to the technical field of separation membranes. The functional polyvinylidene fluoride membrane provided by the invention has good antibacterial properties and hydrophilicity; when titanium dioxide is subjected to photon excitation of certain energy, a photocatalytic reaction can be resulted and a large number of substances with strong oxidization can be generated, the substances with strong oxidization have a series of redox reactions with organic matter to degrade the organic matter, andas microorganisms, including viruses, bacteria and fungi, are composed of organic matter, the titanium dioxide can degrade organic components of the microorganisms under excitation of light to damageor even kill the viruses, bacteria and fungi; and according to the method, modified cellulose acetate is blended with modified polyvinylidene fluoride powder, N, N-dimethyl acetamide is adopted as asolvent, polyvinyl pyrrolidone is adopted as a modification additive, and thus the functional polyvinylidene fluoride membrane with good hydrophilicity and transmissibility is prepared.

Owner:周丹丹

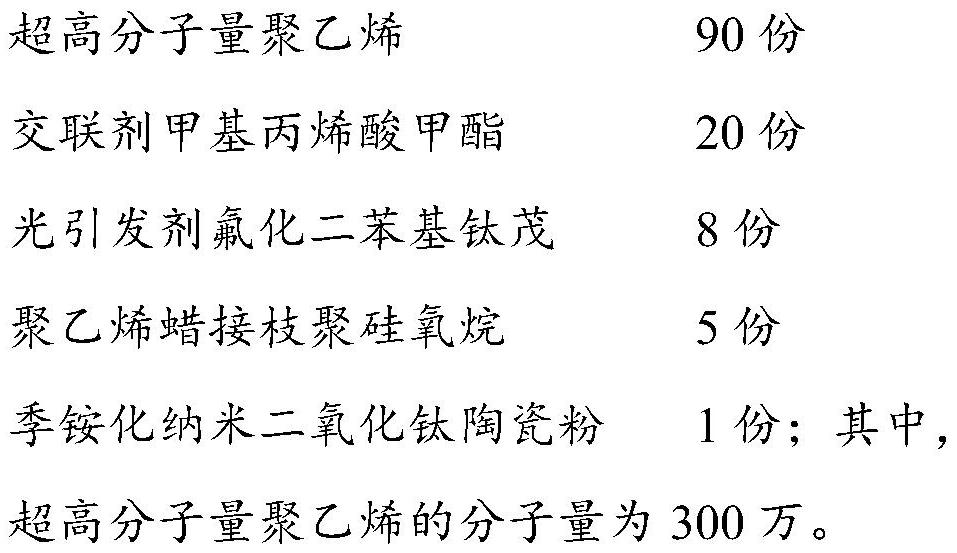

Impact-resistant polyethylene plastic pipe and preparation method thereof

The invention relates to the technical field of composite materials, and in particular, relates to an impact-resistant polyethylene plastic pipe and a preparation method thereof; ultrahigh molecular weight polyethylene is used as a main raw material, the surface of the ultrahigh molecular weight polyethylene is modified by an ultraviolet radiation cross-linking technology, and the polyethylene plastic pipe is prepared by adding polyethylene wax grafted polysiloxane and a quaternized nano ceramic powder processing aid, so that the defects that the ultra-high molecular weight polyethylene pipe is difficult to process and form, poorer in stress resistance and easy to crack are overcome, and the excellent impact strength of a traditional ultra-high molecular weight polyethylene pipe is reserved; the wear resistance and creep resistance are also improved, and the impact-resistant polyethylene plastic pipe is endowed with antibacterial properties; and the preparation method is sanitary, non-toxic and pollution-free, and is suitable for large-scale popularization and production.

Owner:河北鸿翔电讯器材有限公司

Cellulose-based goat milk protein fibers and preparation method thereof

PendingCN112609461AGood neutralization of acid and alkaliQuick clearStain/soil resistant fibresVegetal fibresBiotechnologyIRRITATION SKIN

The invention discloses cellulose-based goat milk protein fibers and a preparation method thereof. Goat milk protein is grafted to cellulose fibers by utilizing cyanuric chloride; the obtained goat milk protein fibers are milky white and warm and moist as jade; the goat milk protein fibers are rich in polar groups such as amino and carboxyl, have a good effect of neutralizing acid and alkali, can be used for rapidly removing sweat odor, have the characteristics of moisture absorption, moisture retention, damp-heat adjustment, static resistance and dust prevention, and do not irritate the skin to cause allergy; and meanwhile, a textile prepared from the goat milk protein fibers is good in rebound resilience, is smooth, glutinous and refreshing, silk-like and velvet-like in touch feeling and obviously superior to regenerated cellulose fibers in size stability, has no oppression feeling on the skin when being worn, and is skin-friendly and non-sticky to the skin.

Owner:YIBIN SPARK NEW FIBER CO LTD

Acrylic and polyester fiber blended yarn and preparation method thereof

The invention relates to the technical field of household textiles, in particular to a preparation method of an acrylic and polyester fiber blended yarn. The method comprises the following steps of (1) performing polyester modification treatment: adding persulfate, N,N-dimethylformamide and acrylamide into water, uniformly stirring to prepare a solution, then putting polyester fibers into the solution, carrying out a grafting reaction under the ultrasonic action in a nitrogen atmosphere, and then carrying out washing and drying to obtain modified polyester; and (2) mixing the modified polyester obtained in the step (1) with acrylic fibers, and spinning a mixture into the blended yarn through open-end spinning. Hydrophilic groups are grafted to the polyester fibers through the grafting reaction, so that the hygroscopicity of polyester is improved; and the modified polyester and the acrylic fibers are blended to prepare the yarn, so that the hygroscopicity and softness of the acrylic and polyester blended yarn can be further improved. A textile prepared from the blended yarn is good in hygroscopicity and softness.

Owner:LUOLAI LIFESTYLE TECH CO LTD +1

Modified oxidized starch adhesive as well as preparation method and application thereof

ActiveCN107236497AHigh bonding strengthLow moisture absorptionGraft polymer adhesivesAdhesiveMoisture absorption

The invention discloses a modified oxidized starch adhesive as well as a preparation method and an application thereof. The modified oxidized starch adhesive is characterized by being prepared from the following components in parts by weight: 100 parts of oxidized starch, 0.2-0.8 parts of an initiator, 0.5-0.8 parts of an anionic emulsifier, 0.5-1.2 parts of a non-ionic emulsifier, 1-2 parts of a thickener, 30-50 parts of a modified monomer, 6-9 parts of a stabilizer and 340 parts of water. The modified oxidized starch adhesive has high adhesion strength, low moisture absorption rate and excellent water resistance.

Owner:WUXI HAITE NEW MATERIAL RES INST +1

Thermoplastic soybean protein composite material and preparation method thereof

The invention relates to a thermoplastic soybean protein composite material and a preparation method thereof. The thermoplastic soybean protein composite material is characterized by comprising the following components by mass: 65-90 parts of thermoplastic soybean protein, 5-30 parts of polyacrylate resin, 1-5 parts of a plasticizer and 0.5 to 1 part of an antioxidant. The preparation method comprises the following steps: thoroughly mixing the above components by using a high-speed mixer; performing extrusion granulation on a blend by using a twin-screw extruder, wherein the temperature of each heating stage is set to be 160-200 DEG C in the first stage, 180-220 DEG C in the second stage, 200-240 DEG C in the third stage, 200-240 DEG C in the fourth stage and 180-230 DEG C in the fifth stage; and subjecting the granulated thermoplastic soybean protein composite material to vacuum drying at 50-80 DEG C for 12-24 h to allow water content to be no more than 0.1 wt% so as to obtain the finished thermoplastic soybean protein composite material. The thermoplastic soybean protein composite material prepared by using the method of the invention has good thermoplasticity and processing properties, excellent degradation performance, low cost, environment friendliness and great application potential.

Owner:河南滨湖印务科技有限公司

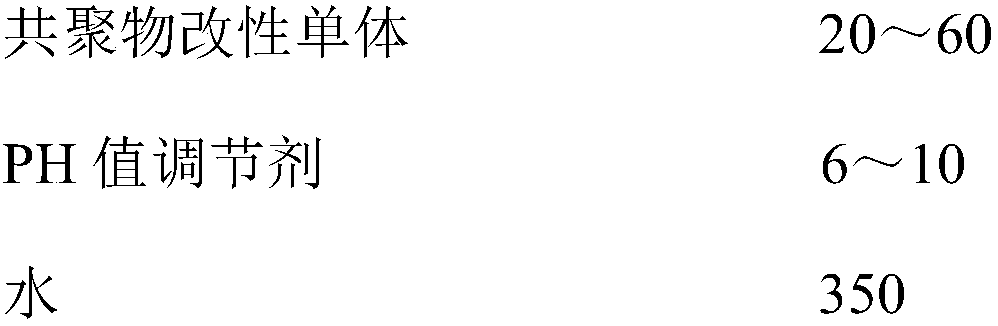

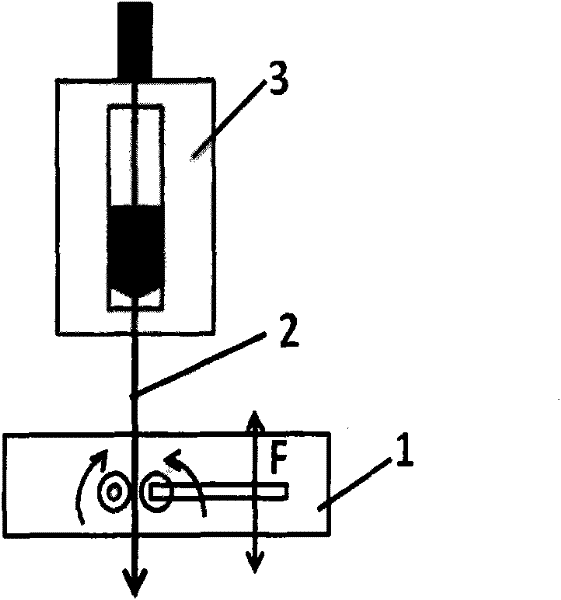

St/BA Copolymerization-modified oxidized starch adhesive and preparation method thereof

InactiveCN107619648AHigh bonding strengthLow moisture absorptionGraft polymer adhesivesBreaking strengthStarch gelatinization

The invention discloses St / BA copolymerization-modified oxidized starch adhesive and a preparation method thereof. The St / BA copolymerization-modified oxidized starch adhesive is made from, by weight,100 parts of oxidized starch, 0.4-0.8 part of an initiator, 2.4-4.0 parts of an oxidant, 0.35-0.5 part of a reducing agent, 0.6-1 part of an anionic emulsifier, 5-10 parts of a thickener, 20-60 partsof a copolymer modifying monomer, 6-10 parts of a PH regulator, and 350 parts of water. The St / BA Copolymerization-modified oxidized starch adhesive of the invention has the advantages that, for instance, the adhesive has high adhesive strength, low moisture absorption rate, excellent waterproofness and excellent breaking strength, has good viscosity uniformity in gelatinized state and is good for grafting reaction, and the process is simple, free of VOC (volatile organic compound) emission and is good in safety and environmental friendliness.

Owner:WUXI HAITE NEW MATERIAL RES INST +1

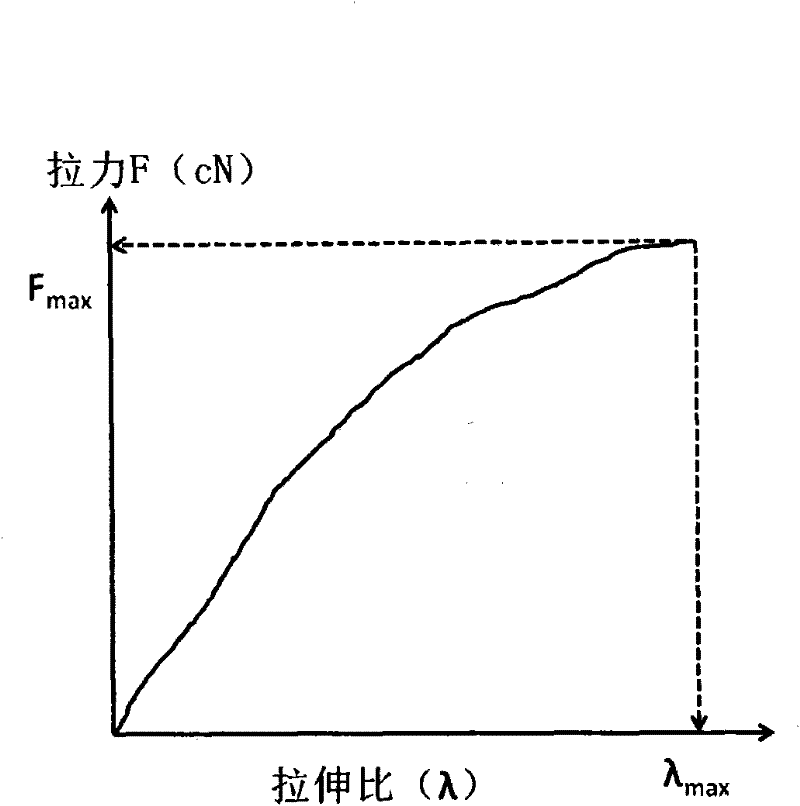

Method for preparing polypropylene melt with high melt strength

The embodiment of the invention discloses a method for preparing polypropylene melt with high melt strength, which uses alkadiene as a modified monomer, thus improving the tensile property of the polypropylene melt with high melt strength due to good compatibility of the alkadiene and polypropylene resin. In addition, the alkadiene monomers can perform grafting reaction with the polypropylene melt, and the alkadiene monomer has lower activity, thus inhibiting cross-linkage reaction so as to expedite the grafting reaction in a certain degree and ensure polypropylene to have higher melt strength. Therefore, the polypropylene melt with high melt strength prepared by the method provided by the invention not only has higher melt strength, but also has larger draw ratio and excellent melt ductility.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

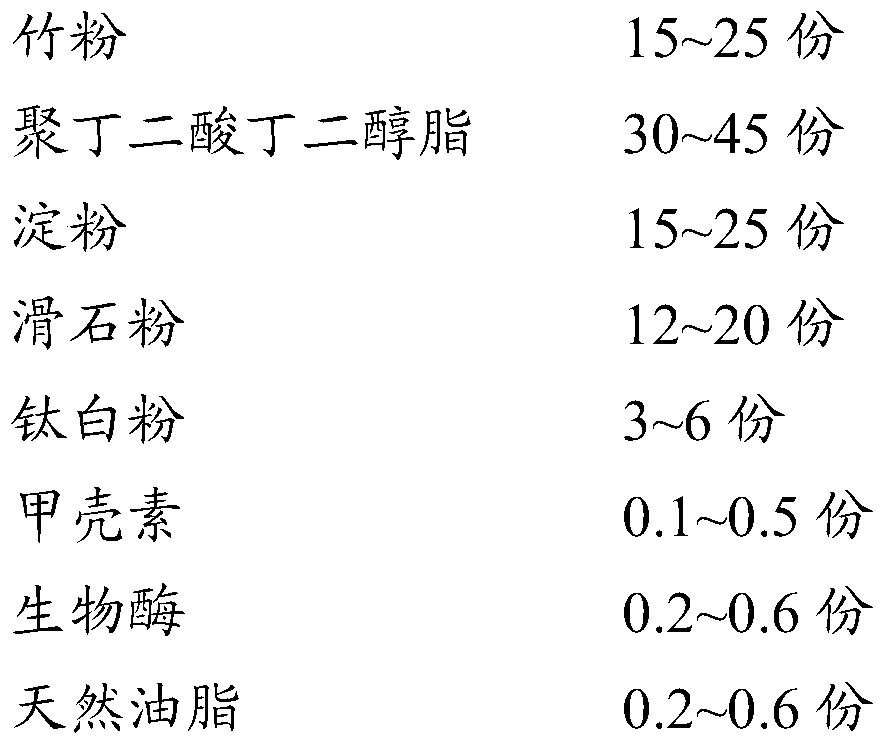

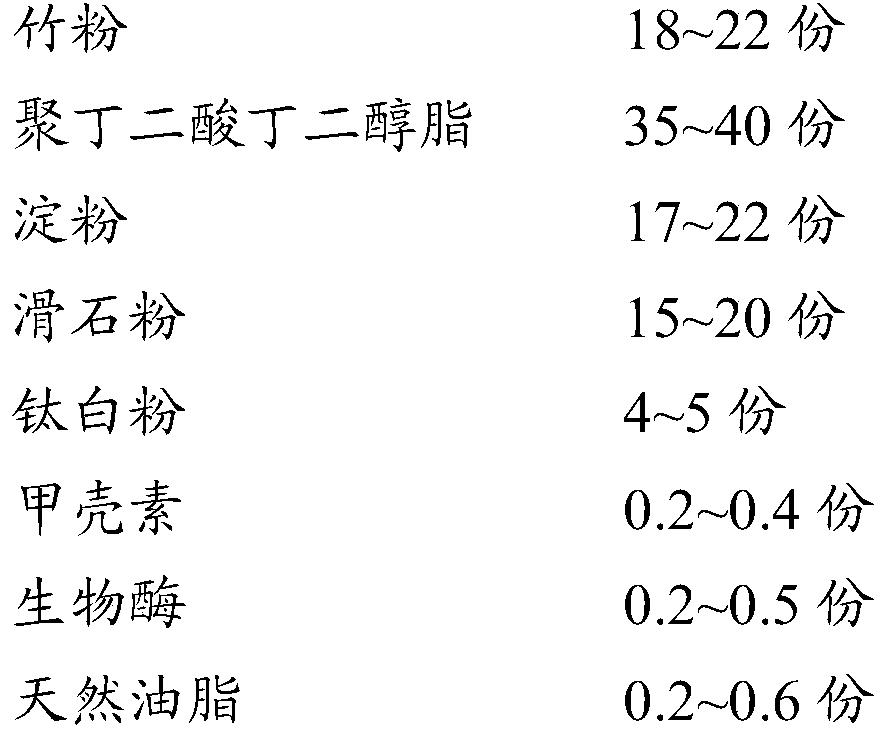

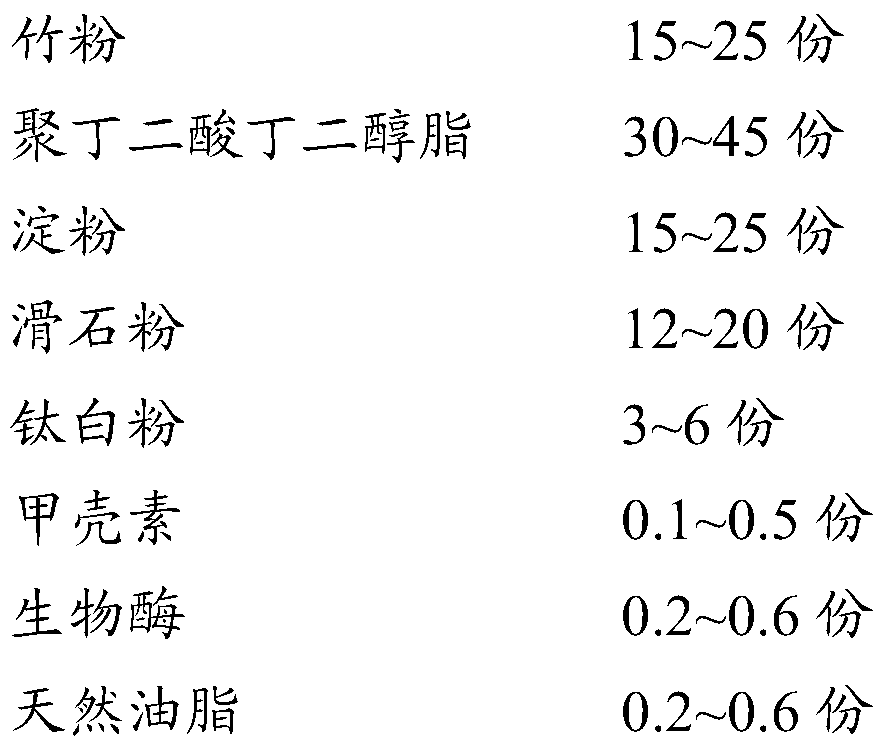

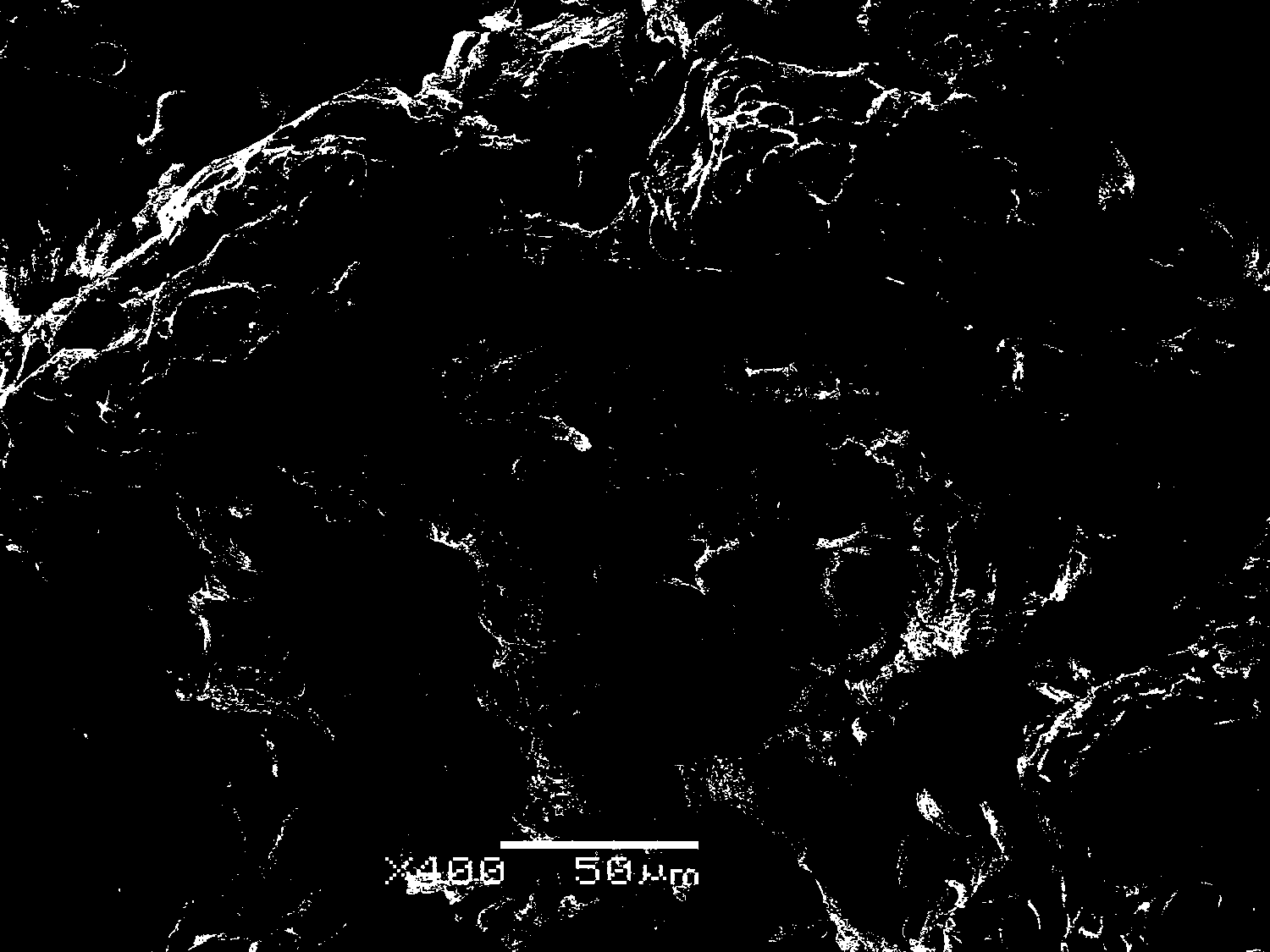

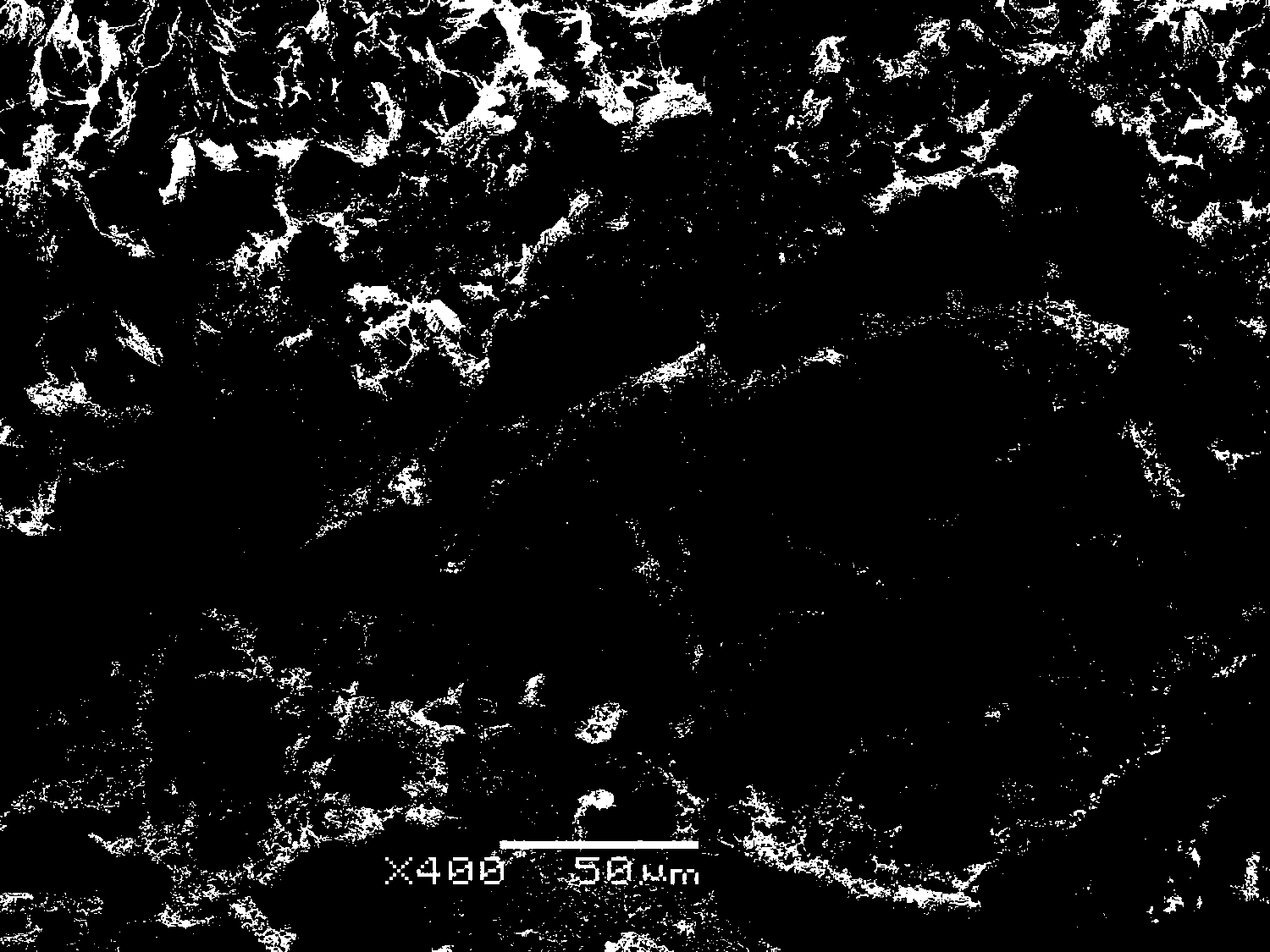

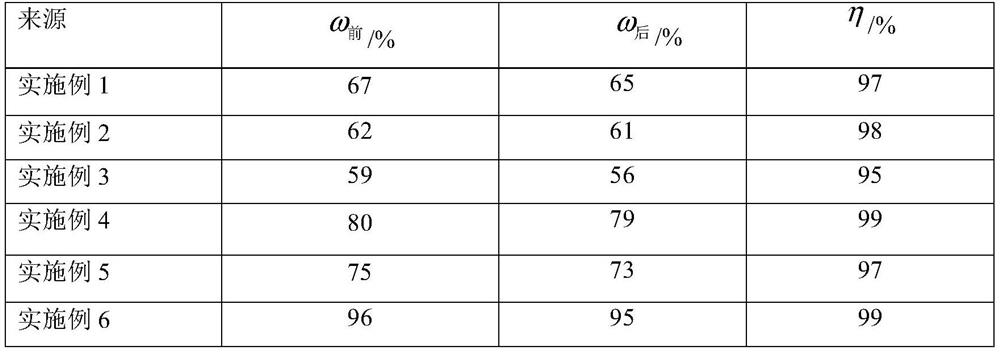

Bamboo powder/poly(butylene succinate)/starch biodegradable plastic and preparation method thereof

InactiveCN111560159ASources are extensive and secureExcellent physical and chemical propertiesPolymer sciencePolymer chemistry

The invention provides bamboo powder / poly(butylene succinate) / starch biodegradable plastic and a preparation method thereof. The bamboo powder / poly(butylene succinate) / starch biodegradable plastic provided by the invention comprises the following components in parts by weight: 15-25 parts of bamboo powder, 30-45 parts of poly(butylene succinate), 15-25 parts of starch, 12-20 parts of talcum powderand the like. The bamboo powder / poly(butylene succinate) / starch biodegradable plastic prepared by the invention is wide in raw material source and safe, does not contain any chemical additive with toxic and side effects, can be used for producing disposable tableware products such as knives, forks, spoons, cup covers, straws, bowls and lunch boxes, can be completely degraded after being used, andis short in degradation period.

Owner:汕头市雷氏塑化科技有限公司

Polyolefin/polystyrene blend-based wood plastic composite material and preparation method thereof

The invention belongs to the field of wood-plastic composite materials, and relates to a polyolefin / polystyrene blend-based wood plastic composite material and a preparation method thereof. The preparation method of the polyolefin / polystyrene blend-based wood plastic composite material comprises the following steps: dissolving an initiator and maleic anhydride in acetone for preparing a solution, uniformly mixing the solution with the polyolefin / polystyrene blend, storing in an open manner for completely volatilizing the solvent; adding wood fiber, the stearic acid and the styrene into a high-speed mixer, uniformly mixing, adding the mixed plastic mixture, and uniformly mixing; and adding the mixed materials into a double-screw extruder, and extruding to obtain the polyolefin / polystyrene blend-based wood plastic composite material. The interface adhesion between a plastic base body and the wood fiber in the wood-plastic composite material, and the compatibility between the plastic components polyolefin and the polystyrenes are improved, so that the tensile strength and impact strength of the composite material are improved. Moreover, the preparation method of the polyolefin / polystyrene blend-based wood plastic composite material has the advantages of being simple in process, high in generating efficiency and low in cost.

Owner:罗卫华

Self-cleaning cotton fiber and preparation method thereof

PendingCN114438774AHigh bonding strengthImprove self-cleaning performance, wash resistance and stabilityStain/soil resistant fibresVegetal fibresGraft reactionCotton fibre

The invention relates to a self-cleaning cotton fiber and a preparation method thereof. The preparation method comprises the following steps: adding nano titanium dioxide, methacrylic acid and ceric ammonium nitrate into ethanol, carrying out grafting reaction in an inert gas atmosphere, filtering, washing and filtering to obtain a solid, and drying; adding the obtained methacrylic acid modified nano titanium dioxide and ceric ammonium nitrate into ethanol; soaking the cotton fiber in water, drying, placing the cotton fiber in the mixed solution in an inert gas atmosphere, carrying out grafting reaction, washing, and carrying out secondary drying. According to the invention, methacrylic acid is grafted to nano titanium dioxide through a grafting reaction to obtain methacrylic acid modified nano titanium dioxide, and then the methacrylic acid modified nano titanium dioxide is grafted to cotton fibers through the grafting reaction, that is, the nano titanium dioxide is introduced into the cotton fibers through chemical bonds; the bonding strength of the nano titanium dioxide and the cotton fibers is improved, so that the self-cleaning performance and the washable stability of the fabric are improved.

Owner:LUOLAI LIFESTYLE TECH CO LTD +1

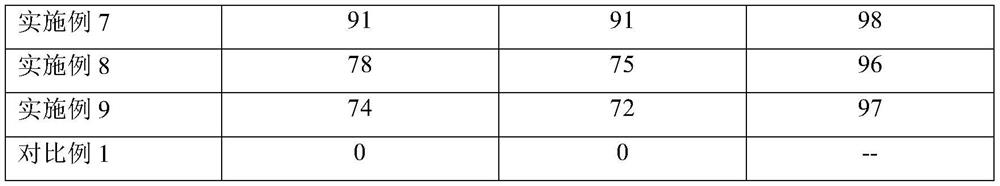

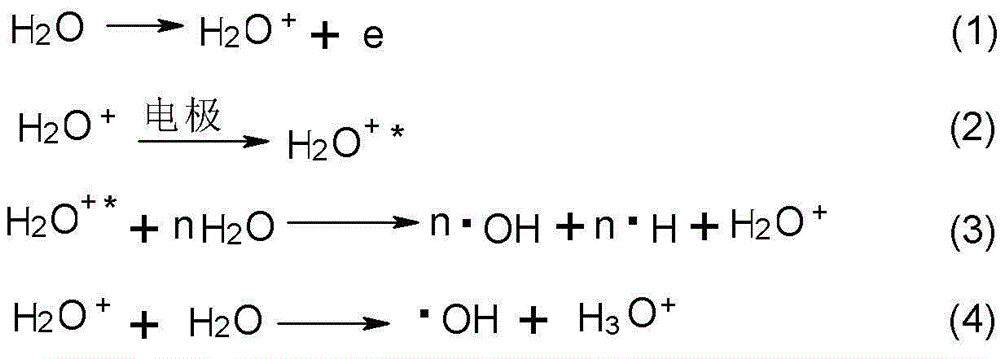

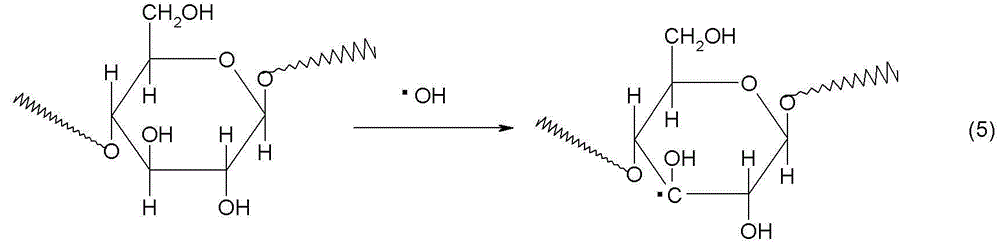

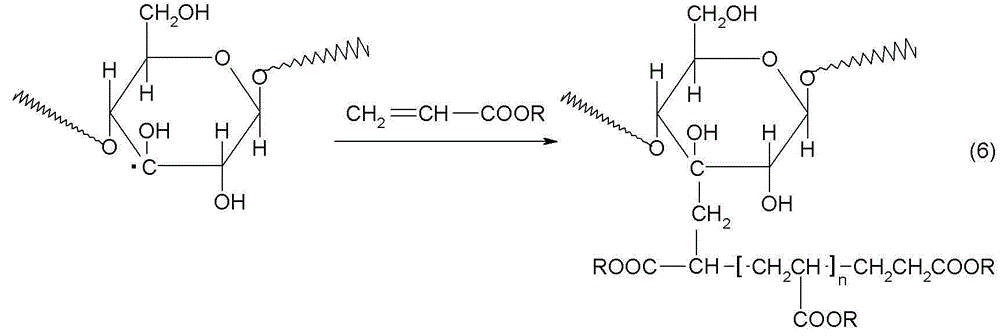

The production method of graft modified starch size

InactiveCN103059225BShort processing timeReduce energy consumptionFibre treatmentEnvironmental resistanceSlurry

The invention discloses a production method of graft modified starch size, comprising the following steps: firstly using an ultrasonic processor to carry out ultrasonic preprocessing on original starch milk; then adding acrylic mixed graft monomers in the system; inserting a glow discharge electrode to carry out glow discharge; trigger graft copolyreaction in the system; turning off a power supply; keeping the temperature of reaction system to be 35-50 DEG C; and carrying out a polymerization reaction for 2-3h so as to obtain loose graft starch. The graft reaction can be triggered efficiently through the glow discharge technology, the temperature is smooth to control in the triggering process, and the product graft rate is relatively high. The technology of ultrasonic preprocessing and glow discharge has the characteristics of being low in energy consumption, few in pollution, short in processing time and obvious in effect, so that the production process of the graft starch becomes a clean and efficient environmentally-friendly process.

Owner:LANYAN GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com