Self-cleaning cotton fiber and preparation method thereof

A cotton fiber, self-cleaning technology, applied in the direction of plant fiber, fiber treatment, anti-color pollution/anti-fouling fiber, etc., can solve the problem of self-cleaning performance decline, easy precipitation of nano-titanium dioxide particles and AgI nanoparticles, nano-particles and cotton The problem of low fiber bonding fastness, etc., can improve the affinity, improve the stability of water washing, and improve the rate of graft polymerization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

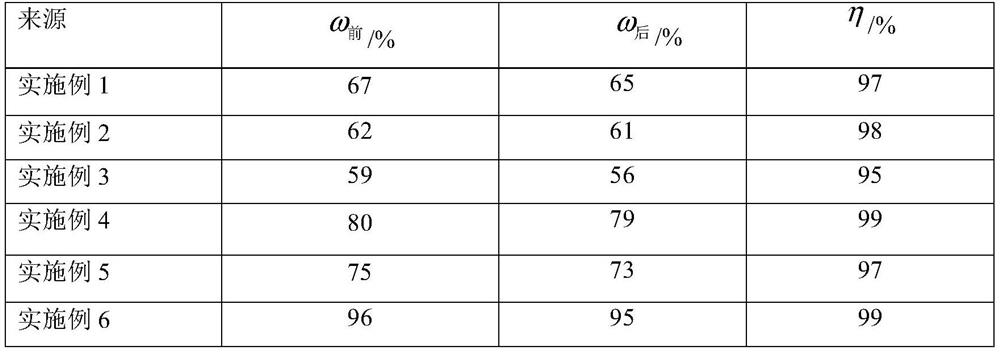

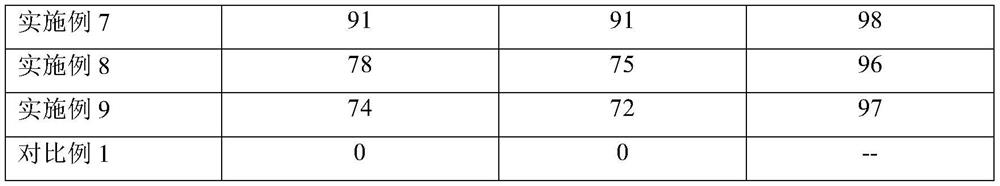

Examples

preparation example Construction

[0045] The invention provides a kind of preparation method of self-cleaning cotton fiber, comprises the following steps:

[0046]A. adding particle diameter to ethanol is nano-titanium dioxide, methacrylic acid and cerium ammonium nitrate, and the concentration of methacrylic acid is 1wt%-4wt%, and the concentration of cerium ammonium nitrate is 1wt%-1.5wt% The mixed solution, the mass ratio of nano-titanium dioxide and methacrylic acid is 3-6:100; and in an inert gas atmosphere at a temperature of 50-60 ° C for 2-4h grafting reaction, followed by filtration, washing and filtering the obtained solid; then in Dry at 50-60°C for 20-30 minutes to obtain methacrylic acid-modified nano-titanium dioxide;

[0047] B. Add methacrylic acid modified nano titanium dioxide and ceric ammonium nitrate in ethanol, the concentration that is mixed with ceric ammonium nitrate is the reaction solution of 1wt%-1.5wt%, the mass ratio of methacrylic acid modified nano titanium dioxide and ceric amm...

Embodiment 1

[0054] A kind of preparation method of self-cleaning cotton fiber, concrete steps are as follows:

[0055] A. Add methacrylic acid in ethanol, after stirring, add nano-titanium dioxide and ammonium cerium nitrate with a particle diameter of 10nm, stir, and prepare a mixed solution that the concentration of methacrylic acid is 4wt%, and the concentration of ammonium cerium nitrate is 1.5wt%. , the mass ratio of nano-titanium dioxide to methacrylic acid is 6:100; and the grafting reaction is carried out in a nitrogen atmosphere at a temperature of 60°C for 4h, filtered, and the solid obtained by filtering is washed with ethanol for 3 times, each time for 1.5min, in ethanol, ethanol The volume ratio to water is 2:1; then dry at 60°C for 20 minutes to obtain methacrylic acid-modified nano-titanium dioxide;

[0056] B. add methacrylic acid in ethanol, add methacrylic acid modified nano-titanium dioxide and ceric ammonium nitrate after stirring, stir, the concentration that is mixed...

Embodiment 2

[0059] A kind of preparation method of self-cleaning cotton fiber, concrete steps are as follows:

[0060] A. Add methacrylic acid in ethanol, add the nano-titanium dioxide and cerium ammonium nitrate that particle diameter is 50nm after stirring, stir, the concentration that is mixed with methacrylic acid is 2.5wt%, the concentration of cerium ammonium nitrate is the mixing of 1.2wt% Solution, the mass ratio of nano-titanium dioxide to methacrylic acid is 5:100; and carry out grafting reaction at 55°C for 3h in a nitrogen atmosphere, filter, wash and filter the solid obtained with ethanol twice, each time for 2min; then at 55°C Dry at high temperature for 25 minutes to obtain methacrylic acid-modified nano-titanium dioxide;

[0061] B. add methacrylic acid modified nano titanium dioxide and ceric ammonium nitrate in ethanol, stir, the concentration that is mixed with ceric ammonium nitrate is the reaction solution of 1.2wt%, the mass ratio of methacrylic acid modified nano ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com