Impact-resistant polyethylene plastic pipe and preparation method thereof

A polyethylene plastic pipe, impact-resistant technology, applied in the field of composite materials, can solve the problems of difficult processing and molding, poor stress resistance, easy cracking, etc., to improve toughness and environmental cracking resistance, improve wear resistance, and improve comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

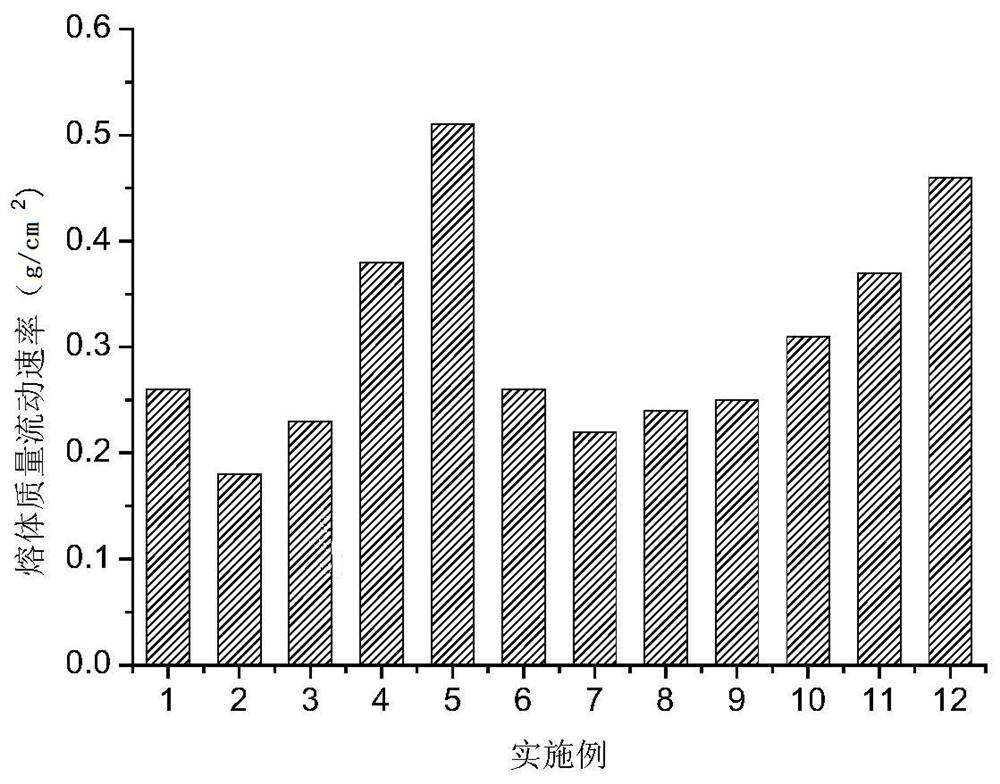

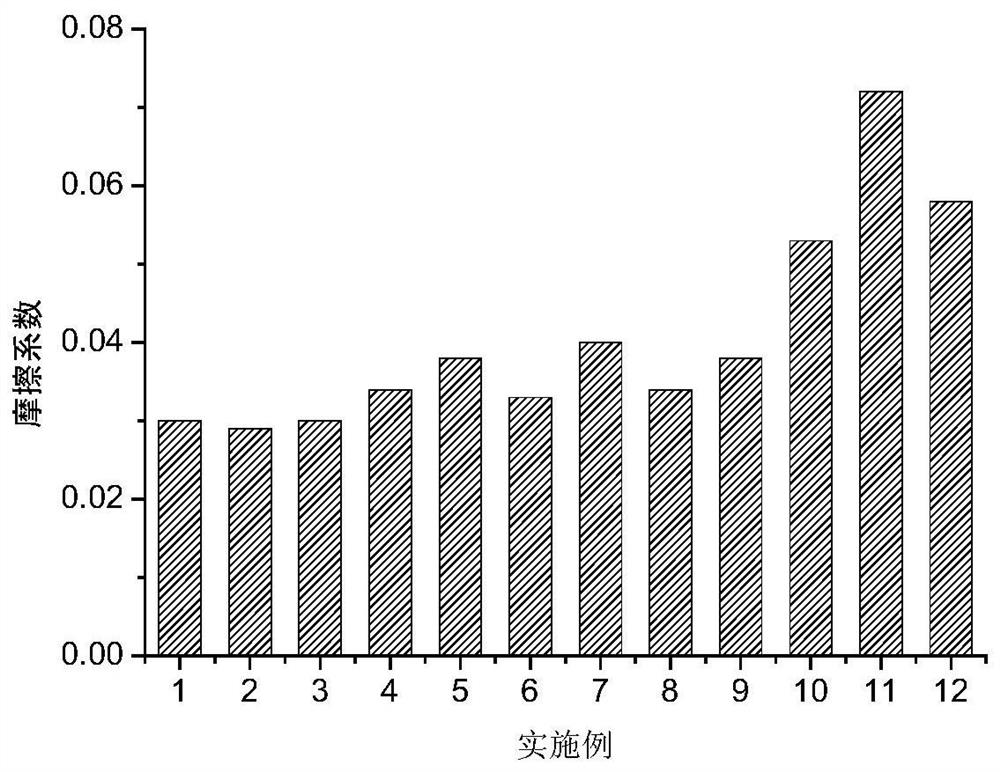

Examples

Embodiment 1

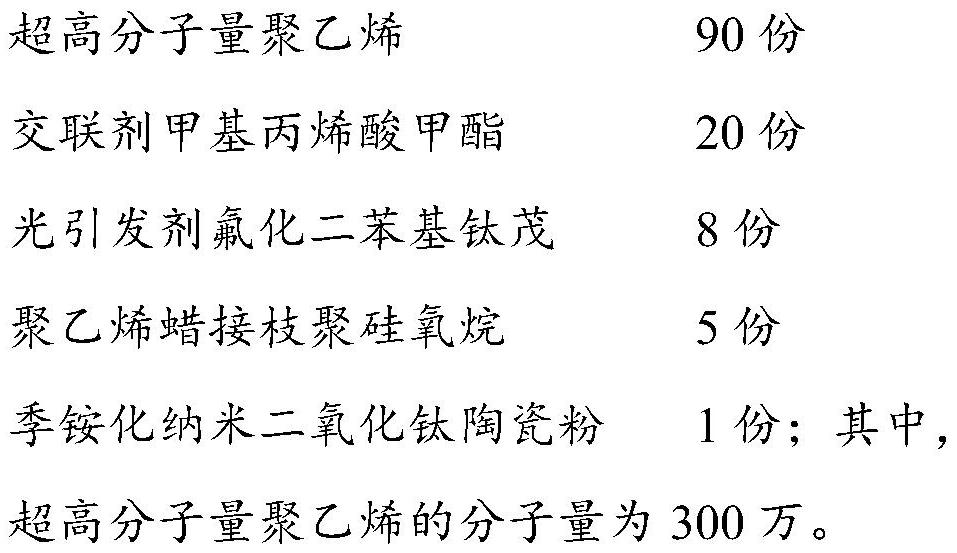

[0063] Embodiment 1: A kind of impact-resistant polyethylene plastic pipe:

[0064] This embodiment provides a kind of impact-resistant polyethylene plastic pipe, which is composed of the following raw materials by weight:

[0065]

[0066] Present embodiment also provides a kind of preparation method of impact-resistant polyethylene plastic pipe, specifically comprises the following steps:

[0067] 1) Preparation of polyethylene wax grafted polysiloxane:

[0068] 1.1) Add 10 parts by weight of polyethylene wax (molecular weight 4500) to 15 parts by weight of n-heptane / xylene mixed solution (mixing volume ratio is 1:0.6), under nitrogen protection, stir at 90°C for 20min to make it Uniform dispersion, the stirring speed is 400r / min;

[0069] 1.2) Mix 0.15 parts by weight of hydroxyethyl methacrylate with 0.05 parts by weight of benzoyl peroxide, and then add the mixed solution to the solution in step 1) at a rate of 0.1 mL / s at a rate of 300 r / min Under stirring reaction...

Embodiment 2

[0083] Example 2: Another impact-resistant polyethylene plastic pipe:

[0084] This embodiment provides another impact-resistant polyethylene plastic pipe. The components and formulation method are basically the same as in Example 1, except that in this example, step 1 of preparing polyethylene wax grafted polysiloxane ), the molecular weight of polyethylene wax is 1500.

Embodiment 3

[0085] Example 3: Another impact-resistant polyethylene plastic pipe:

[0086] This embodiment provides another impact-resistant polyethylene plastic pipe. The components and formulation method are basically the same as in Example 1, except that in this example, step 1 of preparing polyethylene wax grafted polysiloxane ), the molecular weight of polyethylene wax is 3000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com