Patents

Literature

1345 results about "Ultrahigh molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultra-High Molecular Weight Polyethylene (UHMW-PE) UHMW-PE is defined as polyethylene whose molecular weight is 3.1 million or higher. When making this determination, it was found that physical properties increased rapidly as lower MW values increased, and then leveled off at the 3,100,000 value.

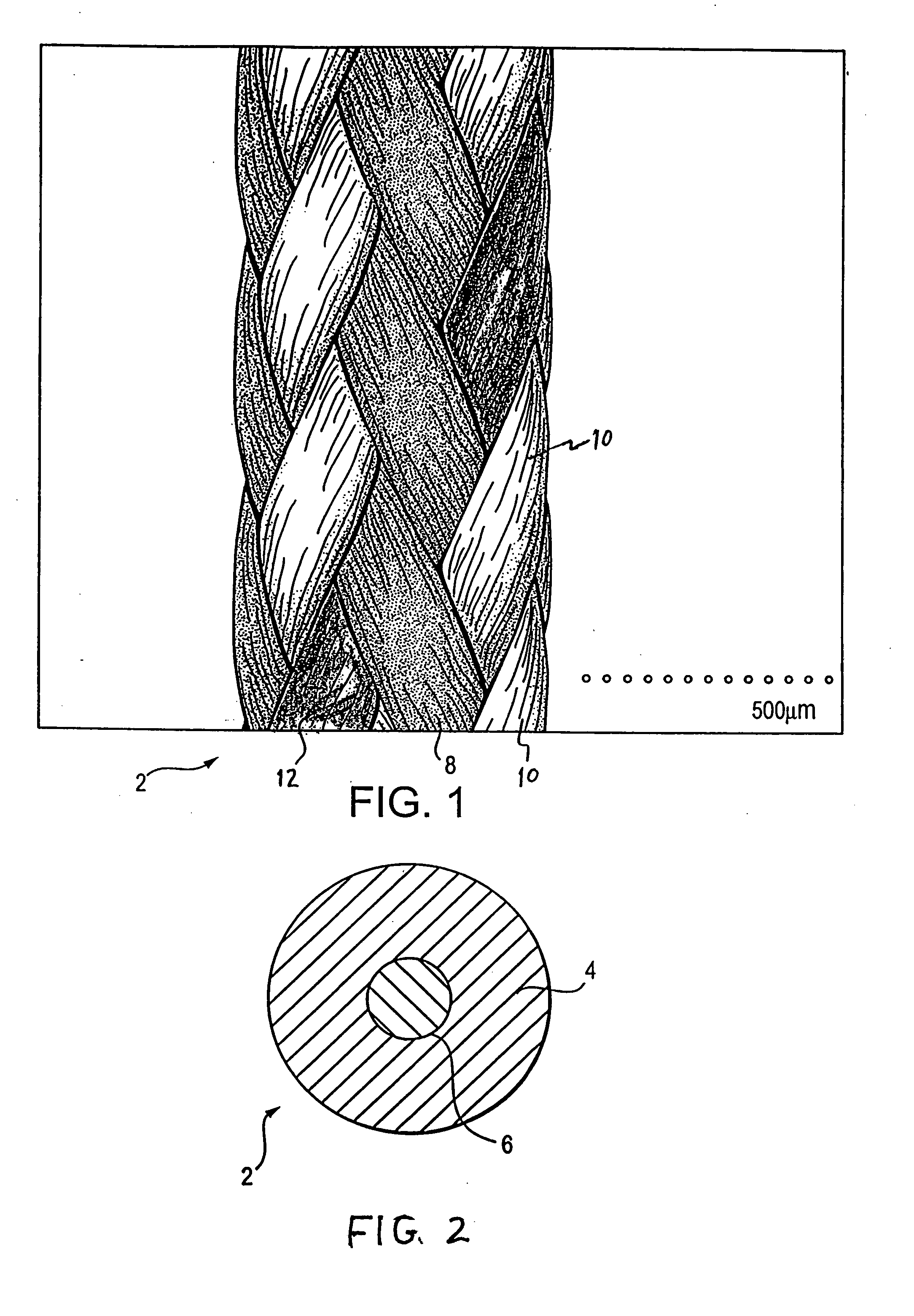

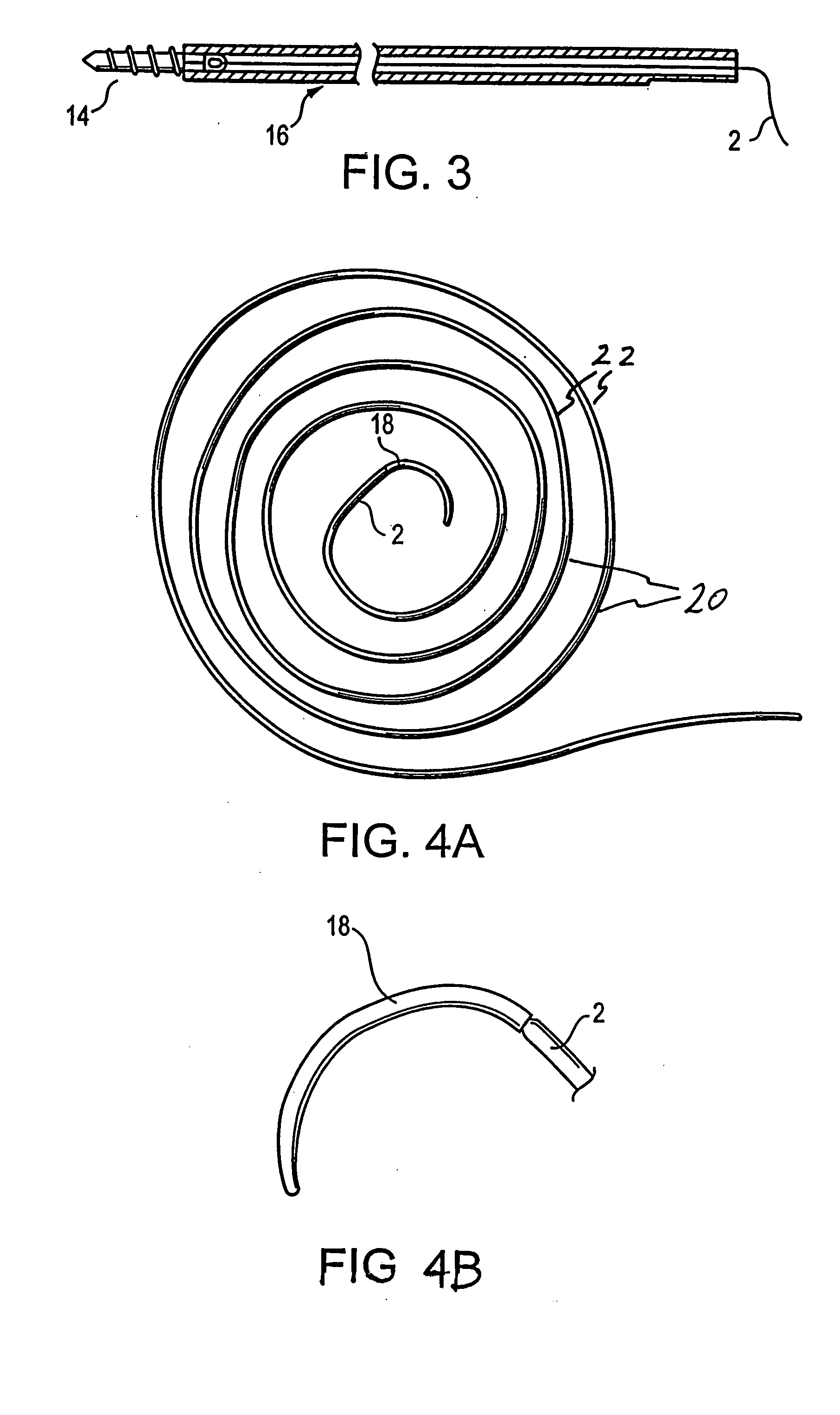

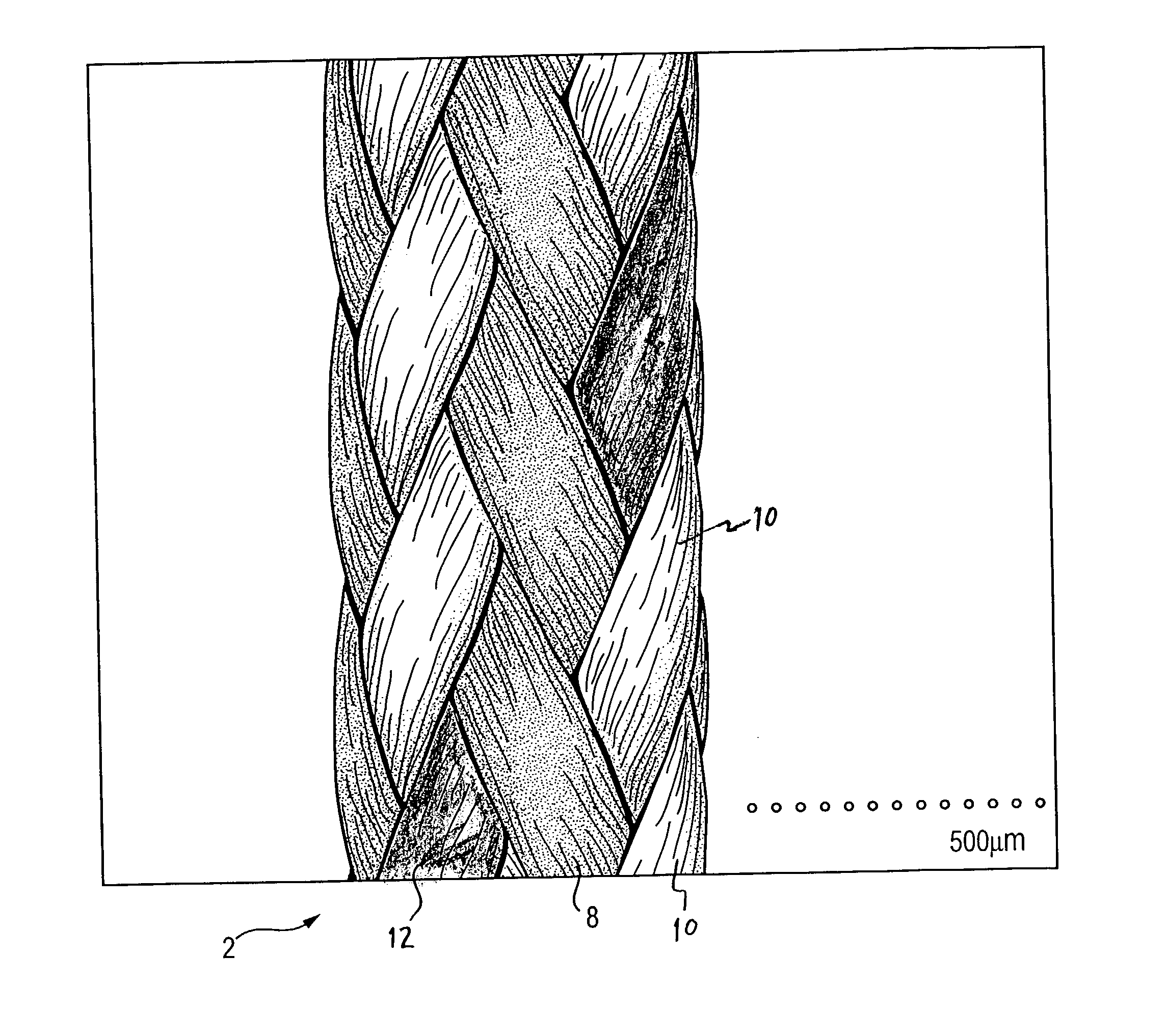

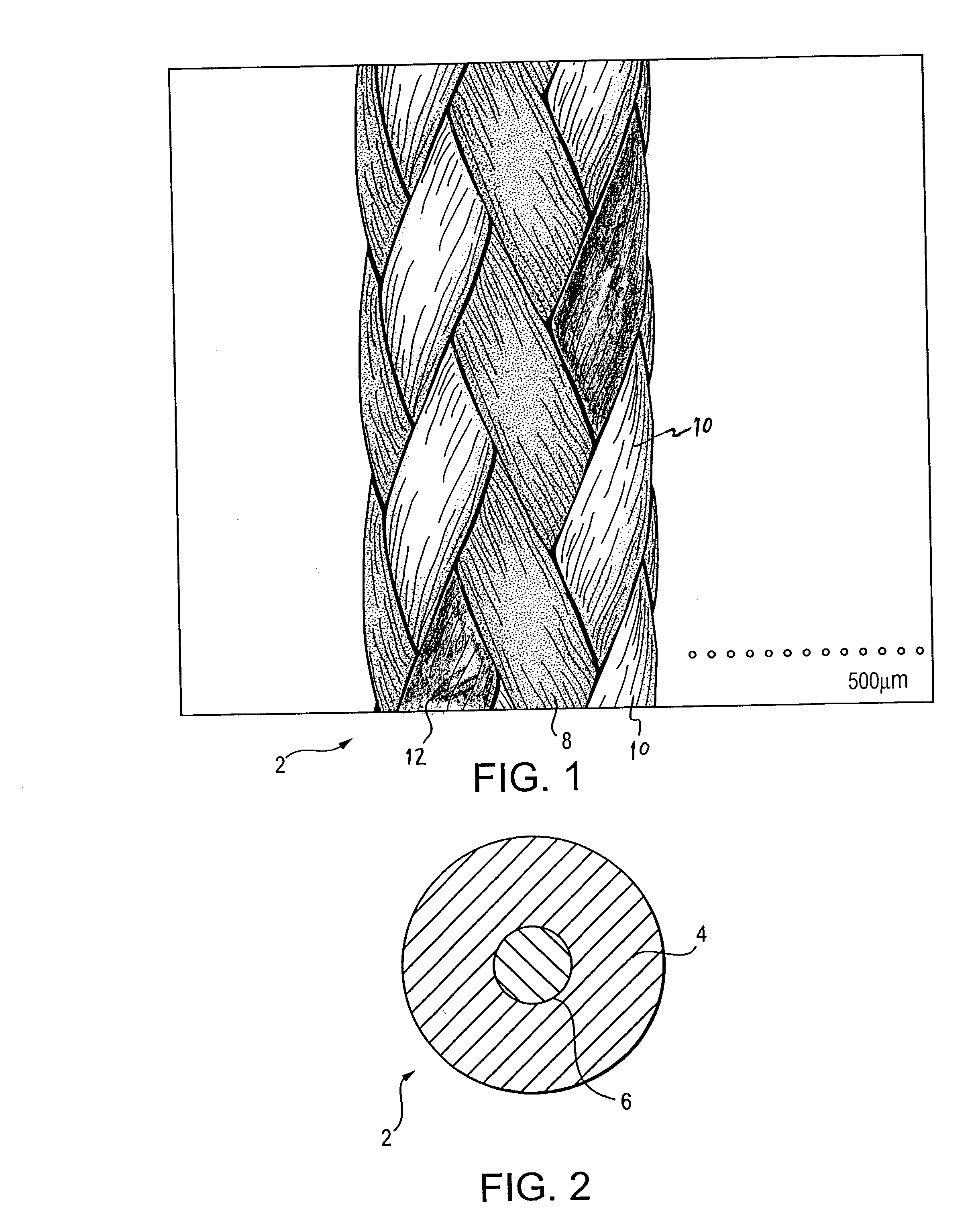

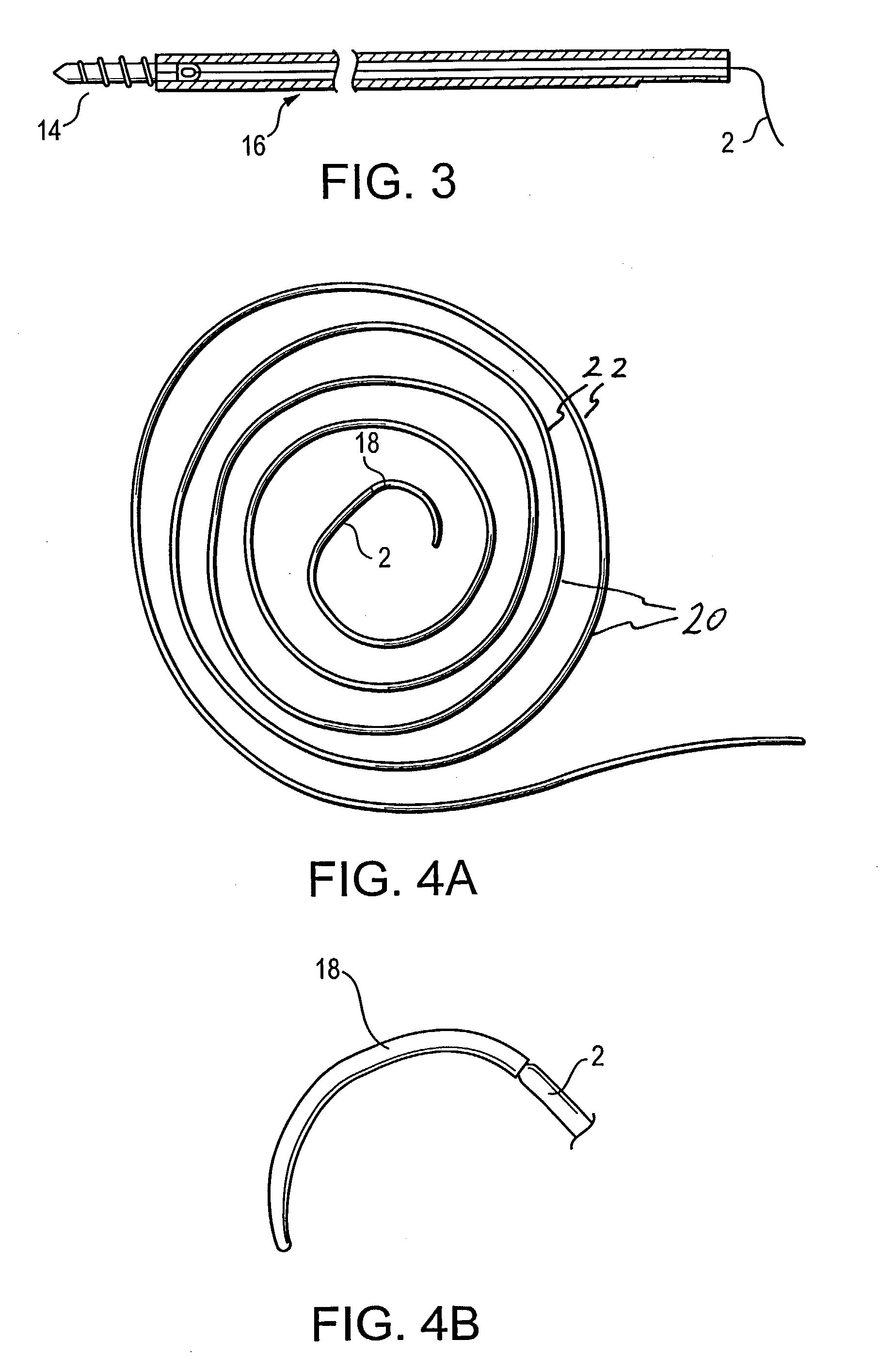

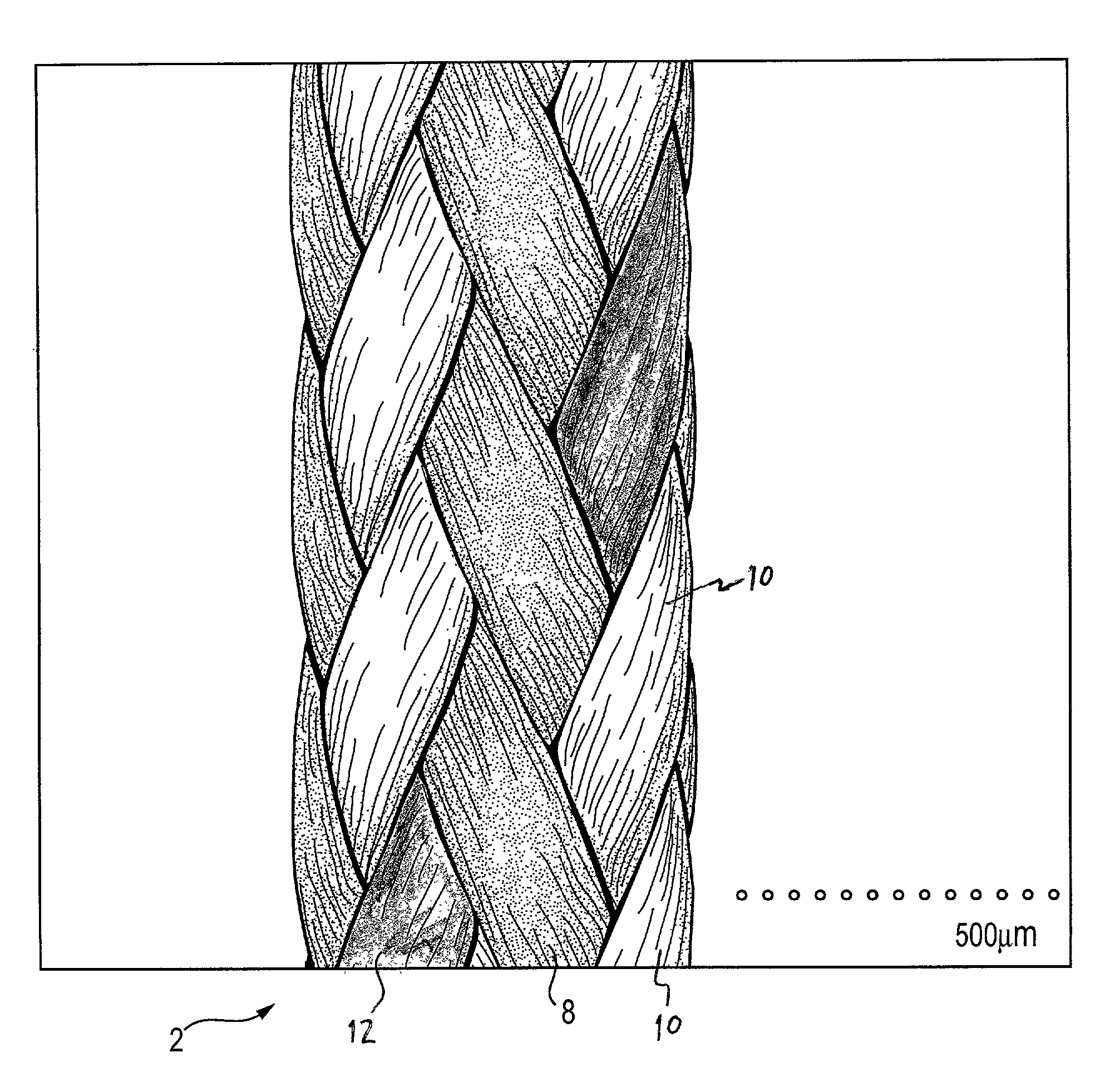

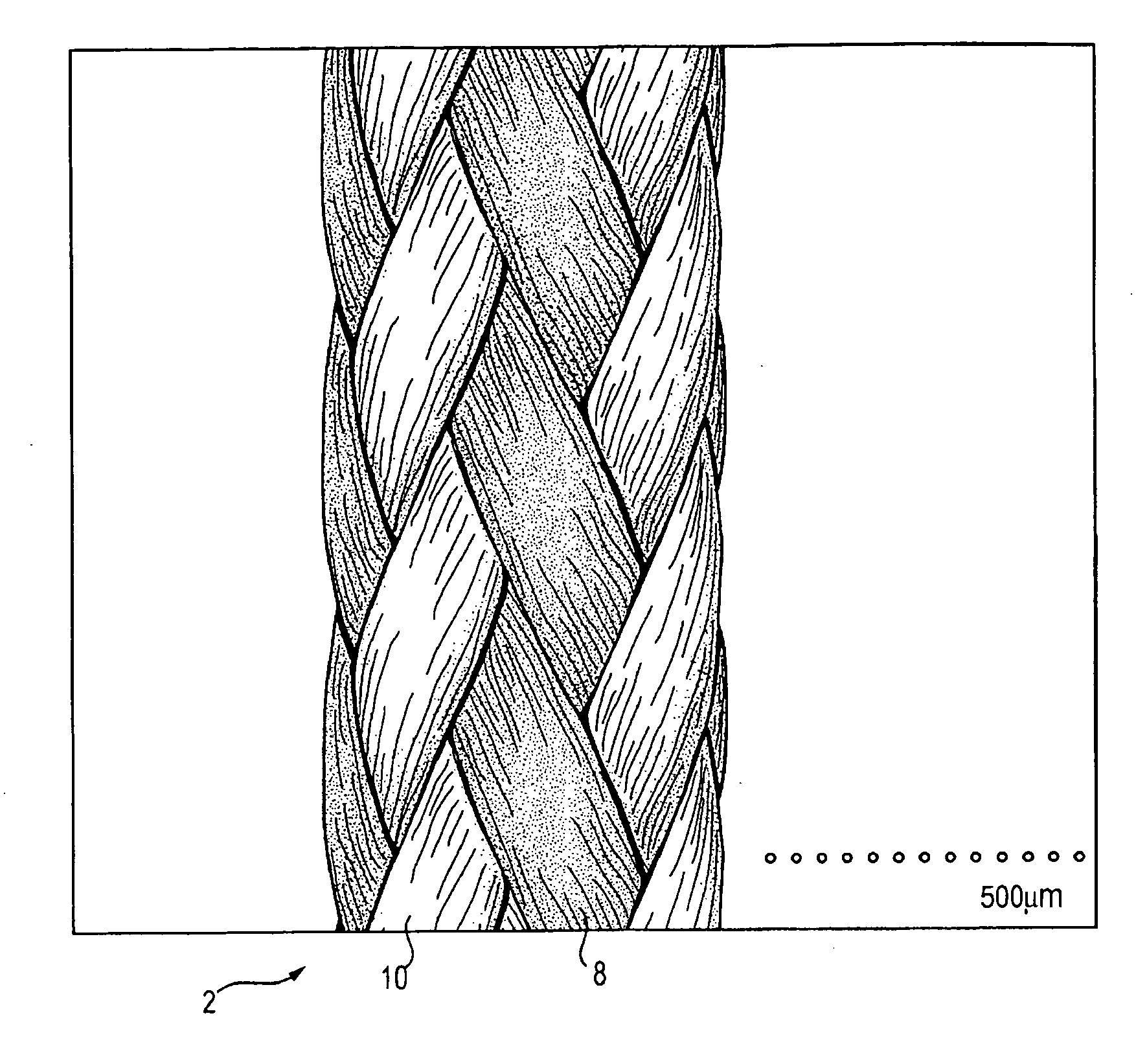

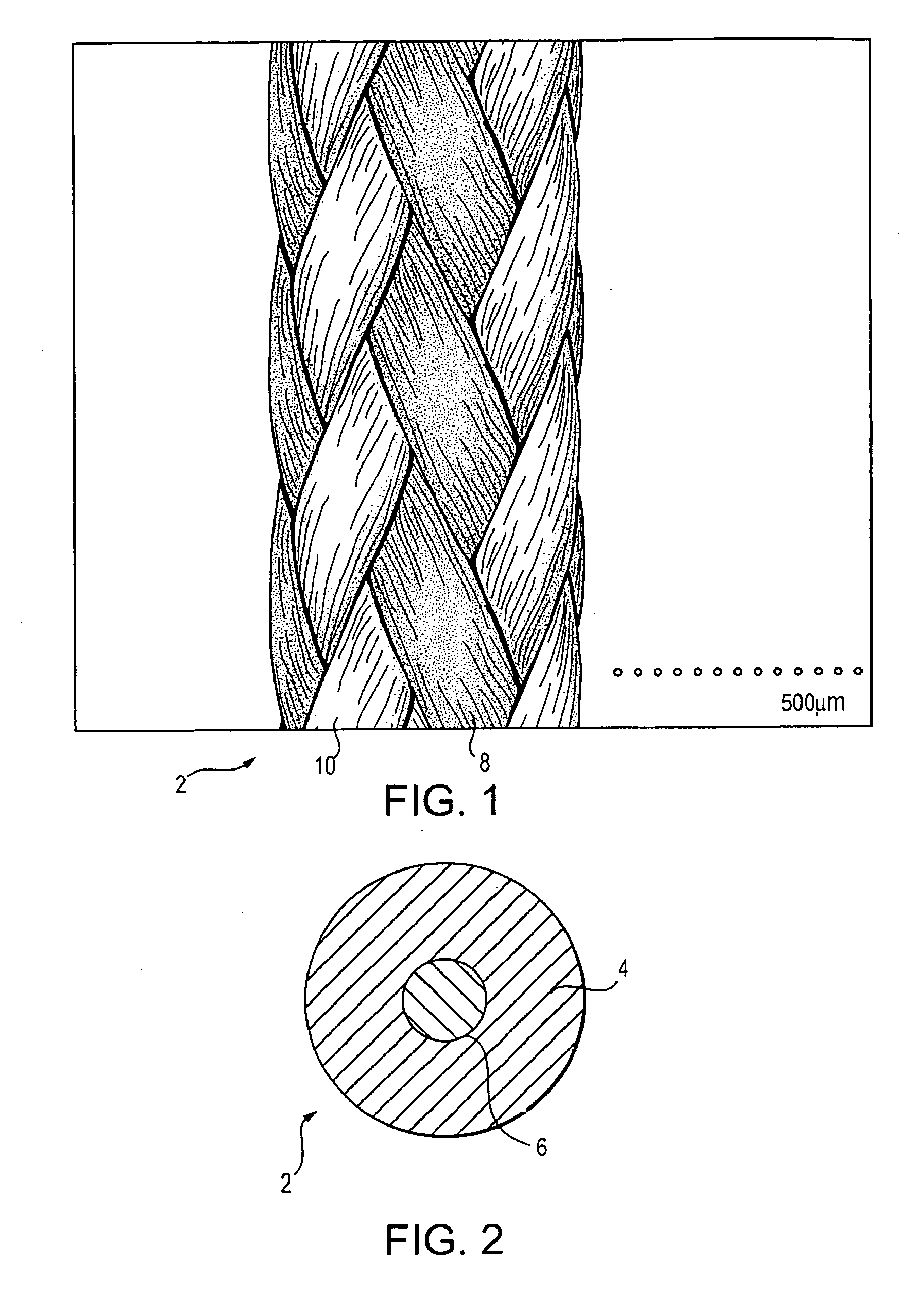

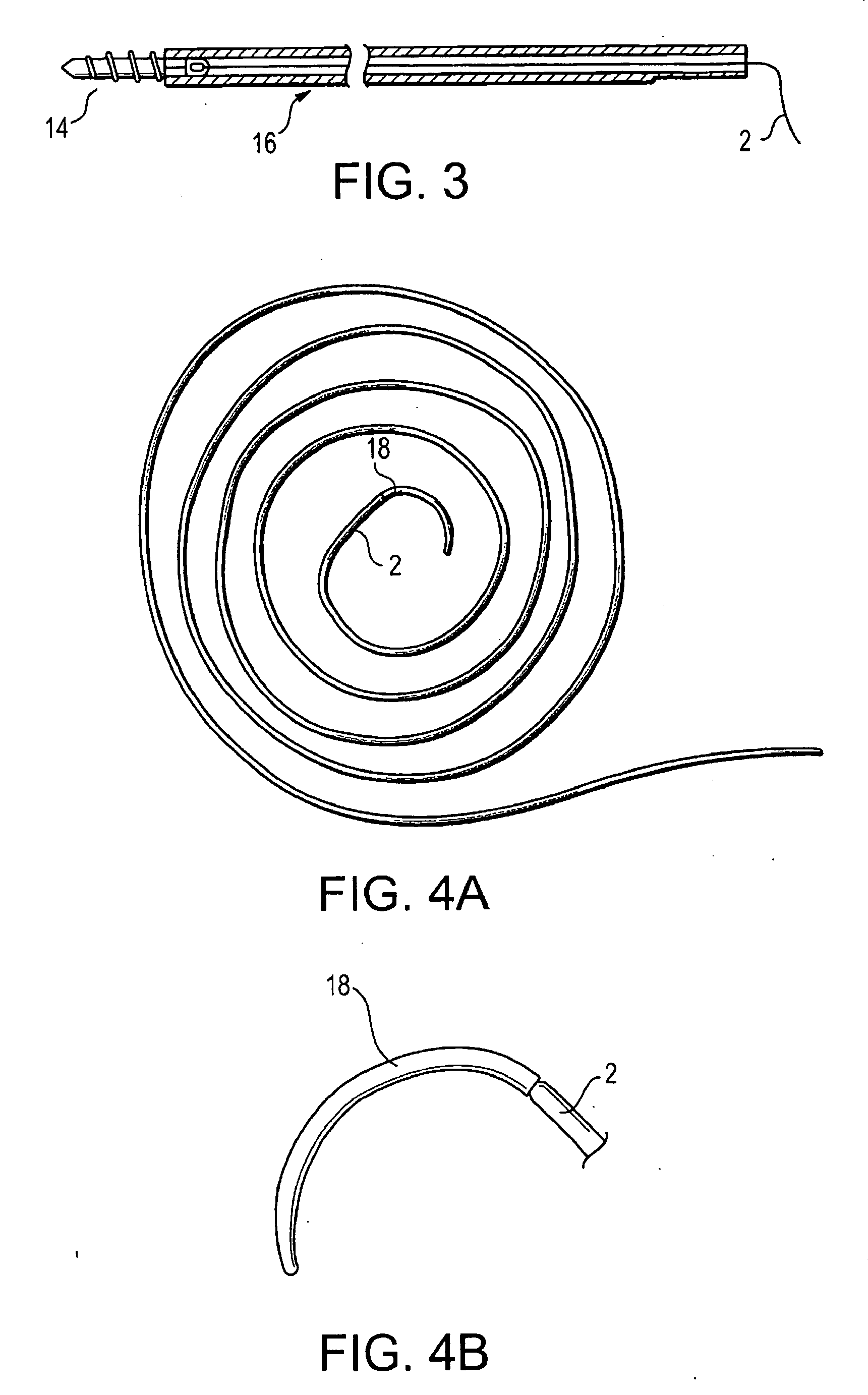

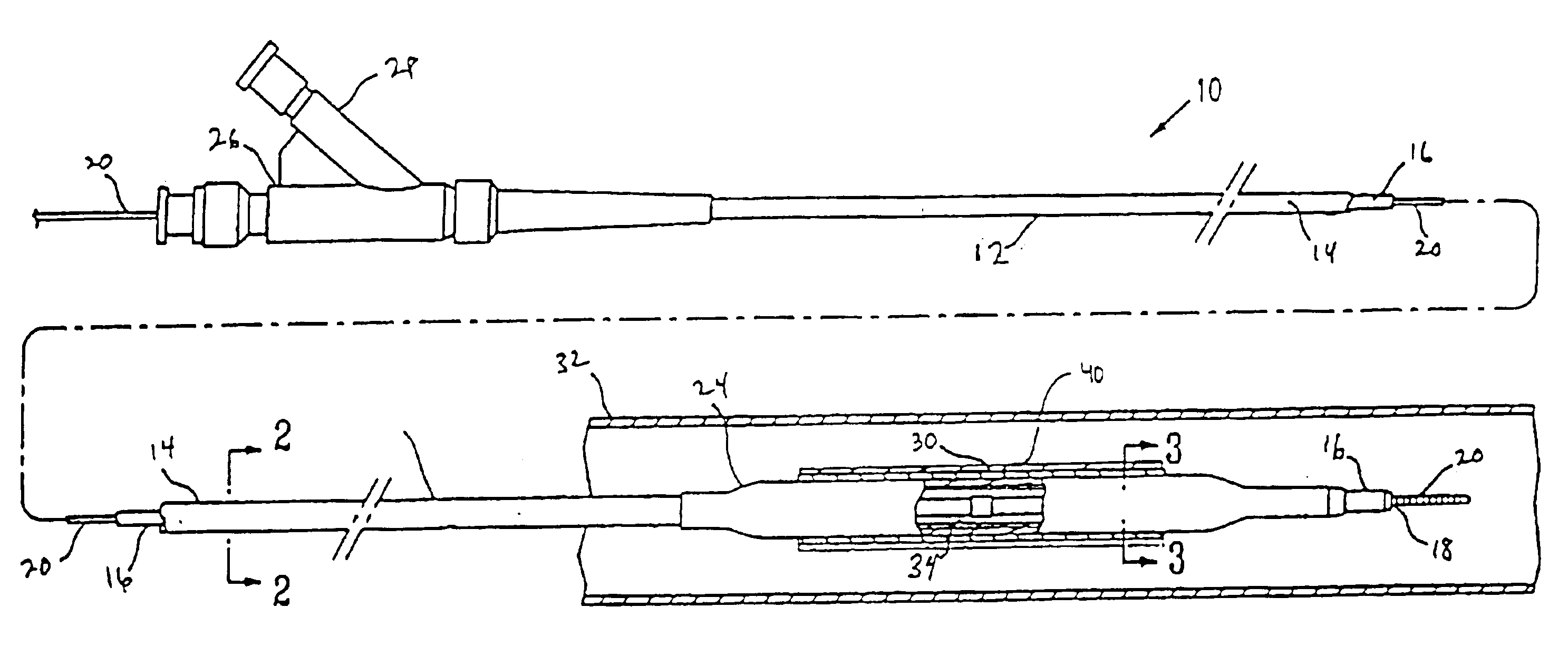

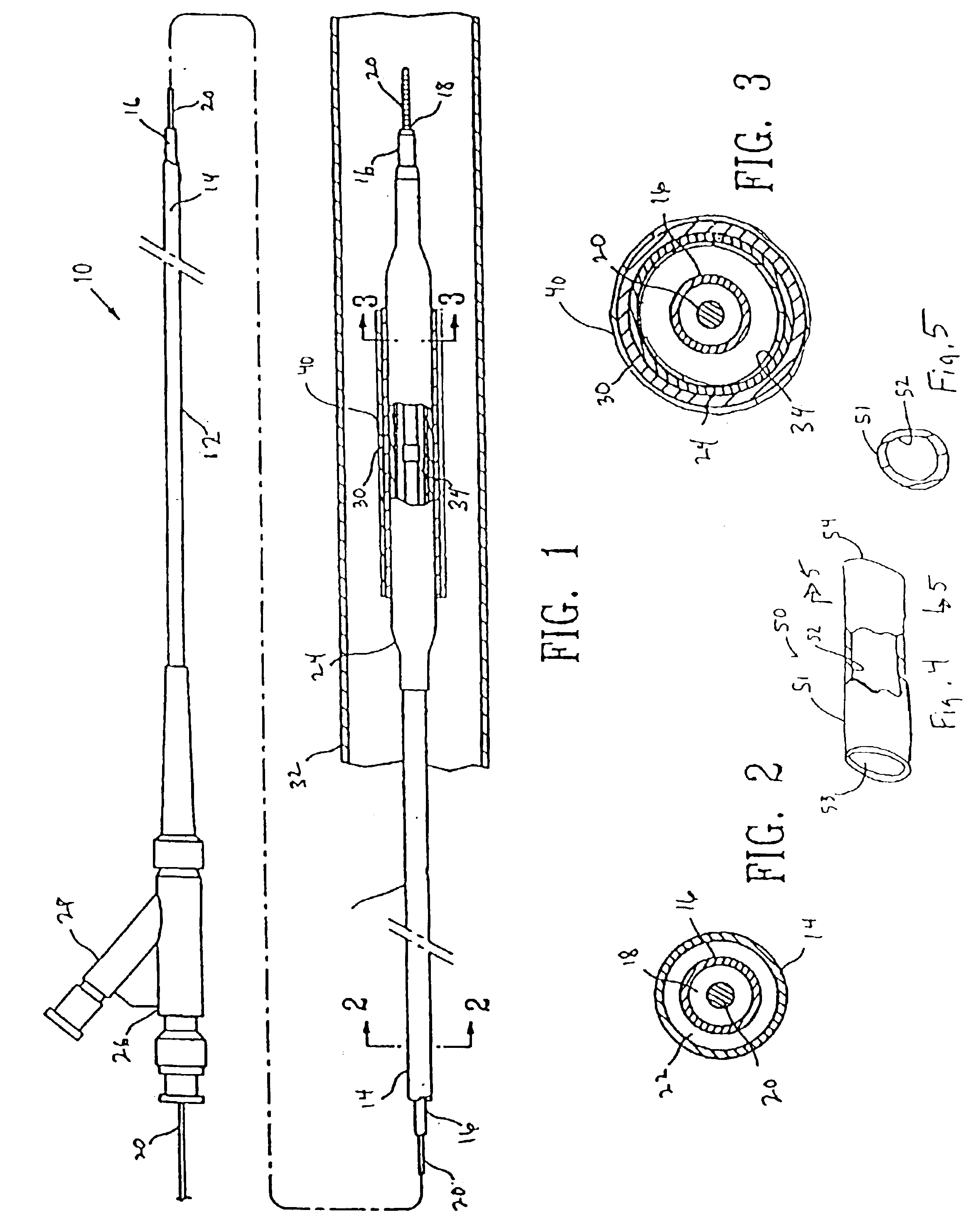

High strength suture with colored trace at one end

InactiveUS6994719B2High strengthImproved tie down characteristicSuture equipmentsDiagnosticsPolyesterEngineering

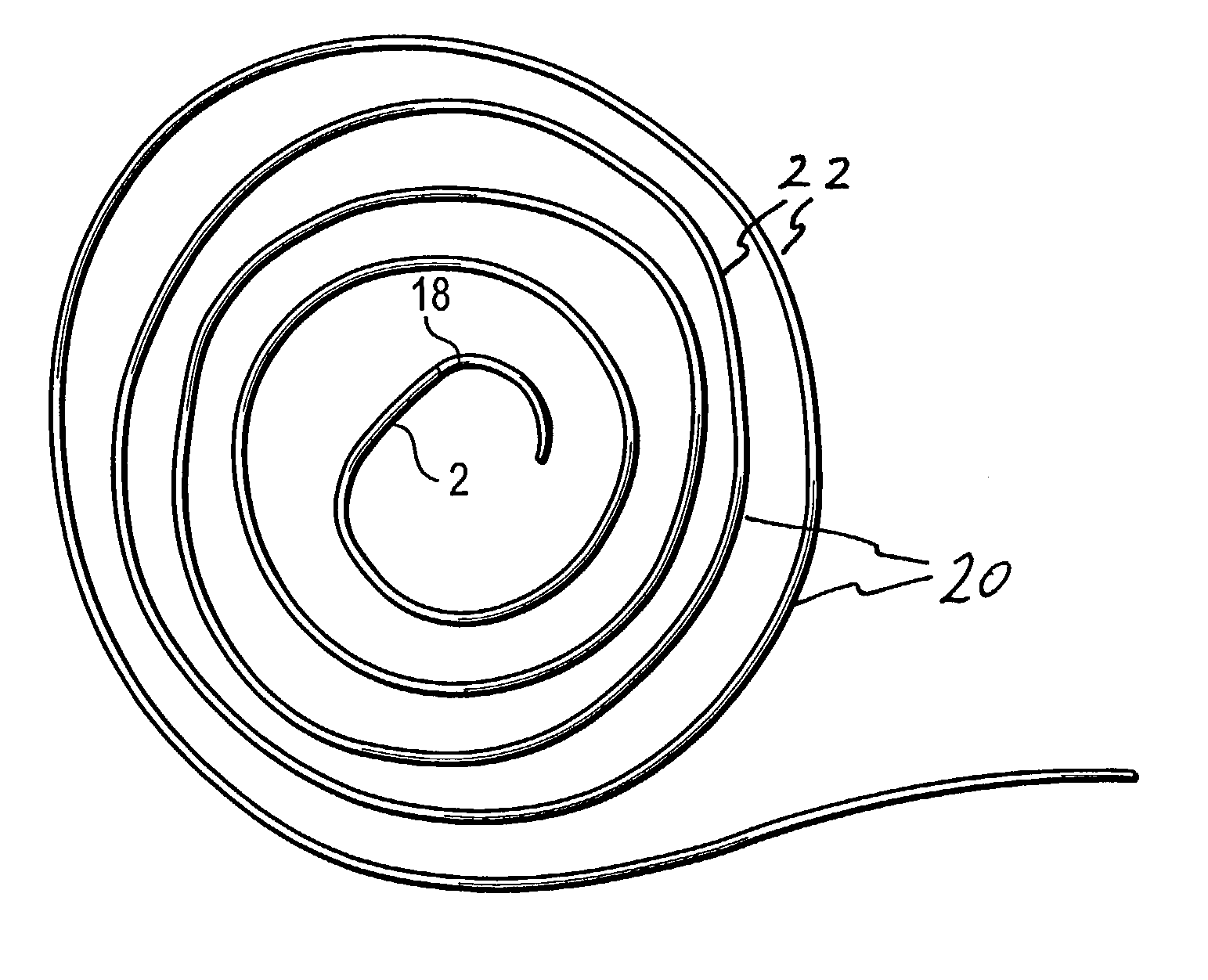

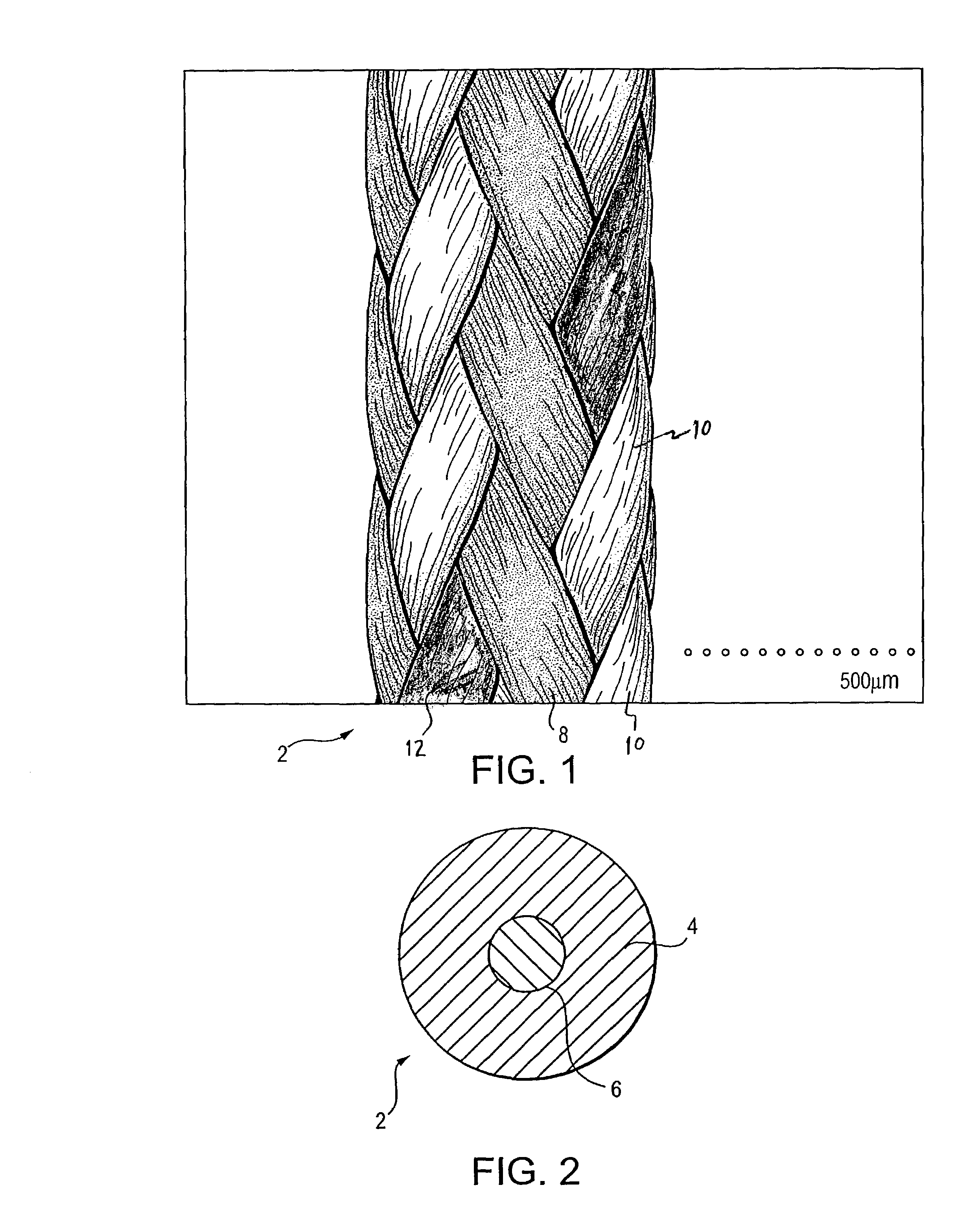

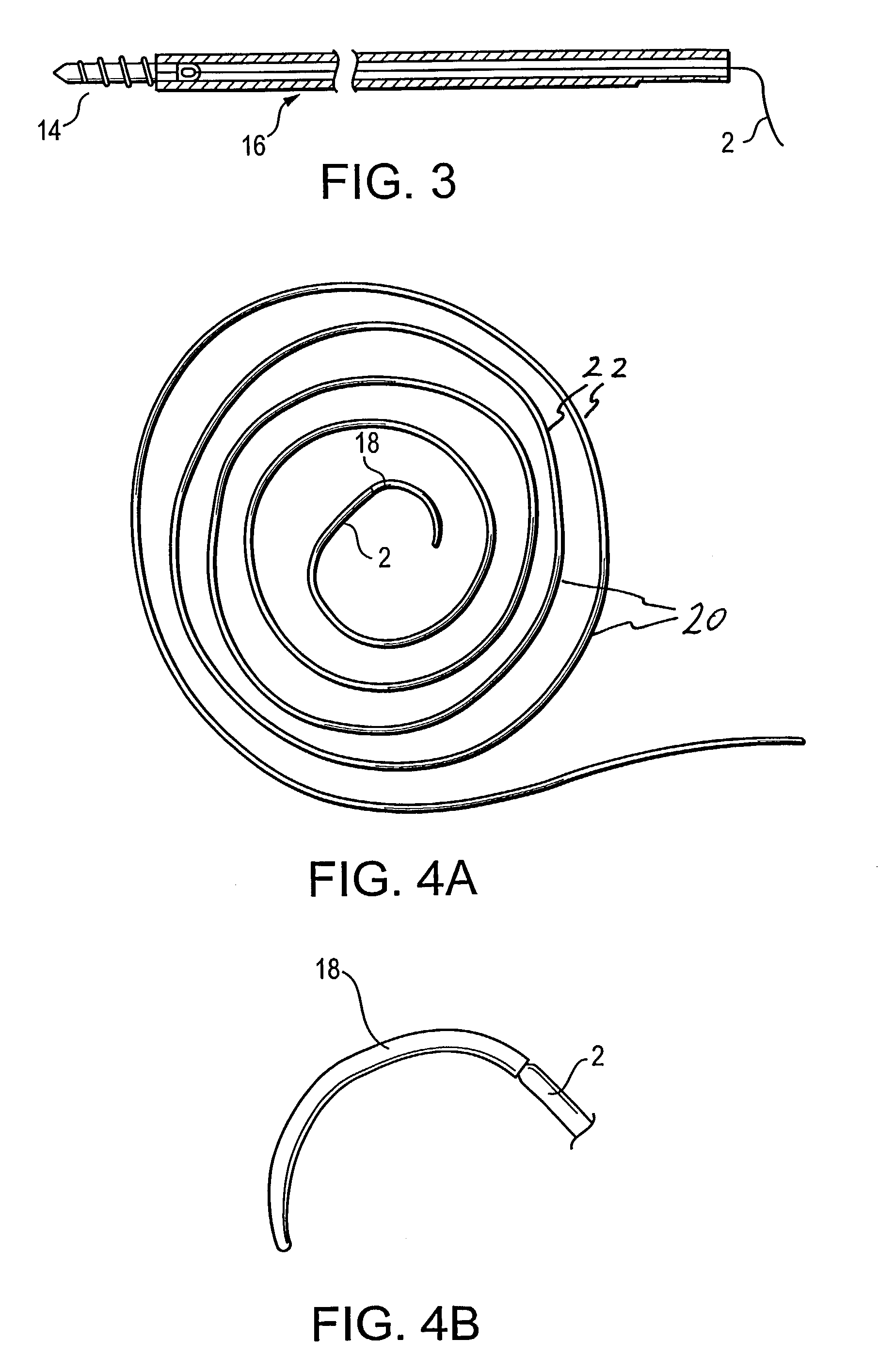

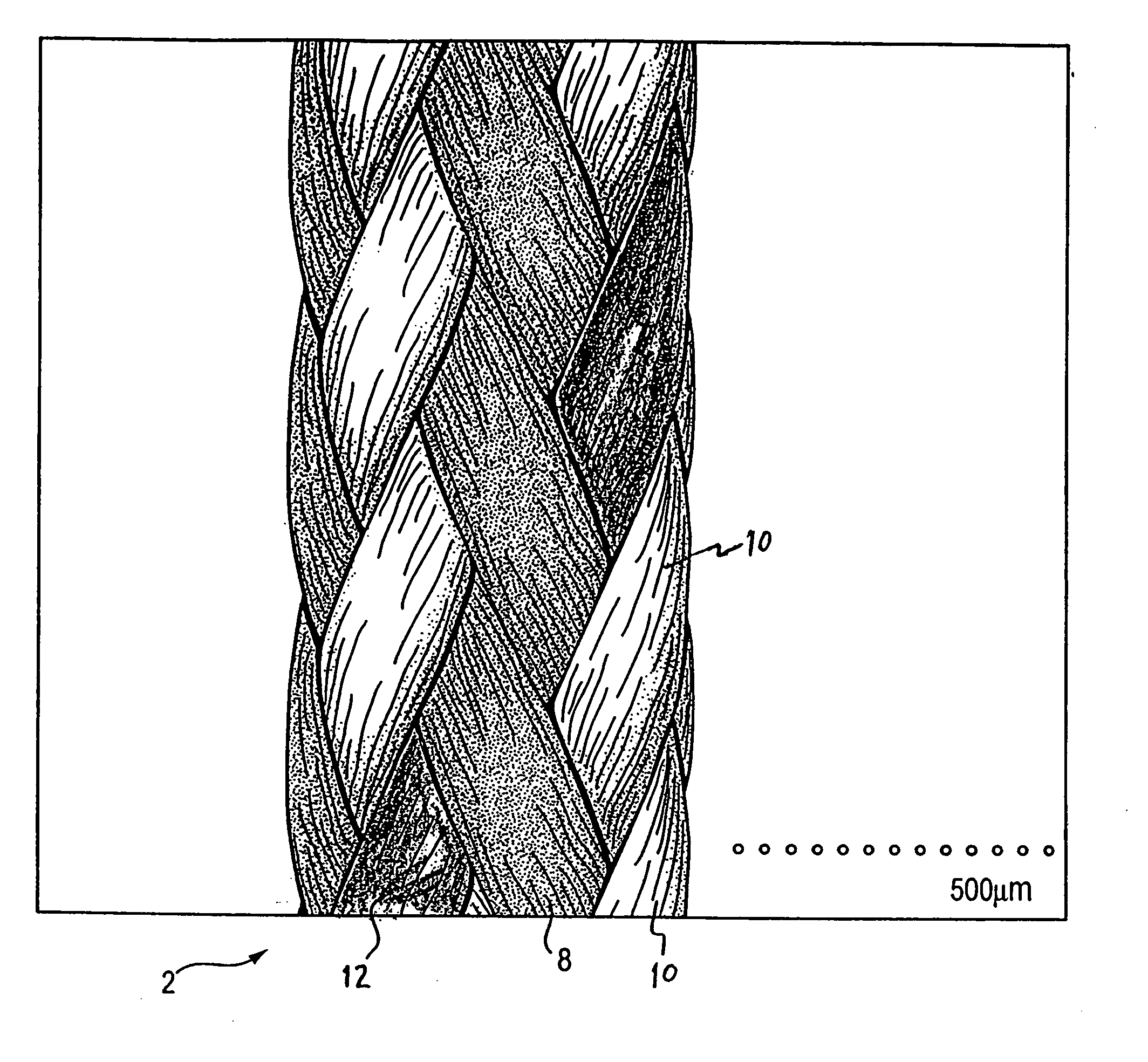

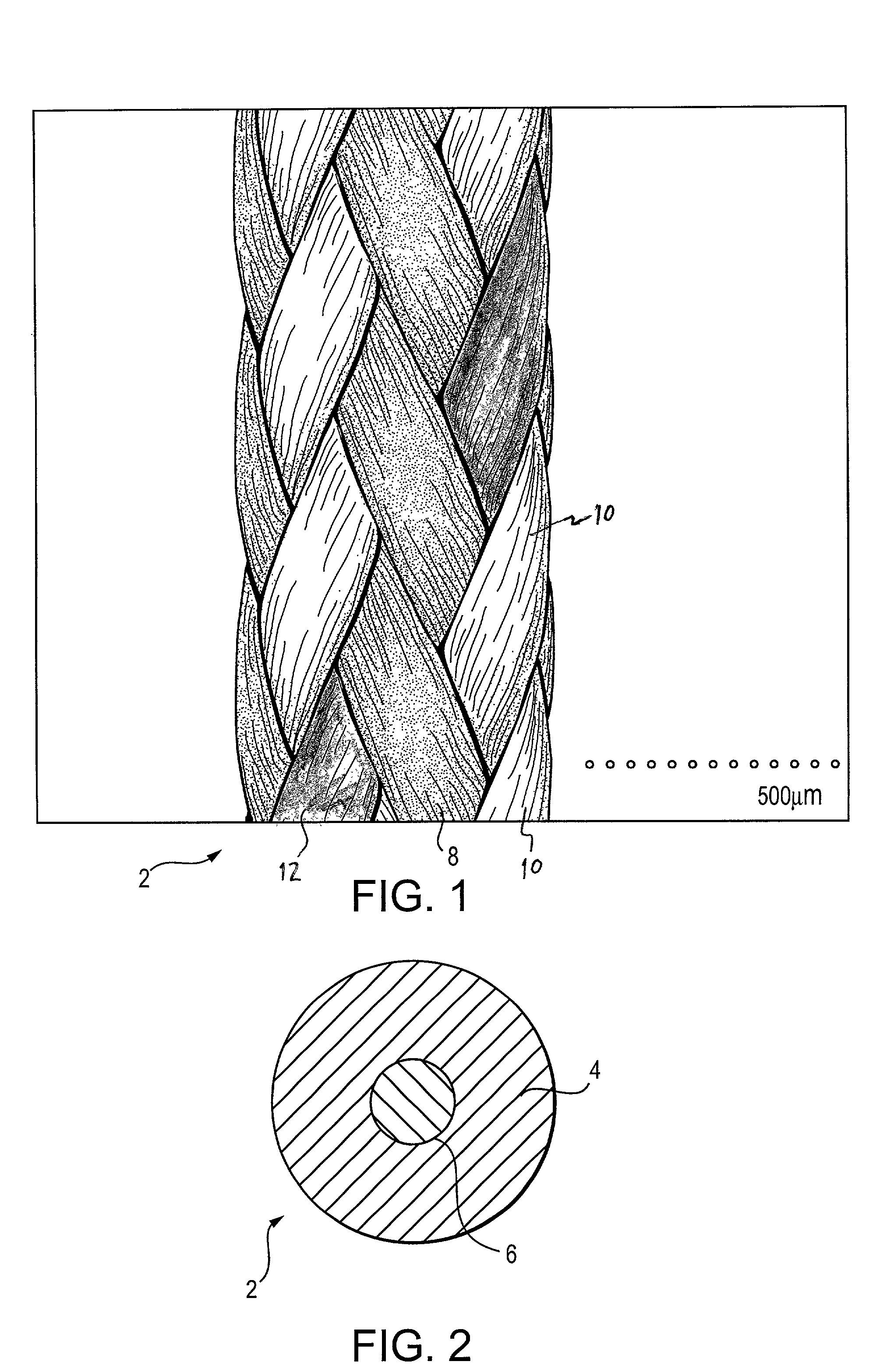

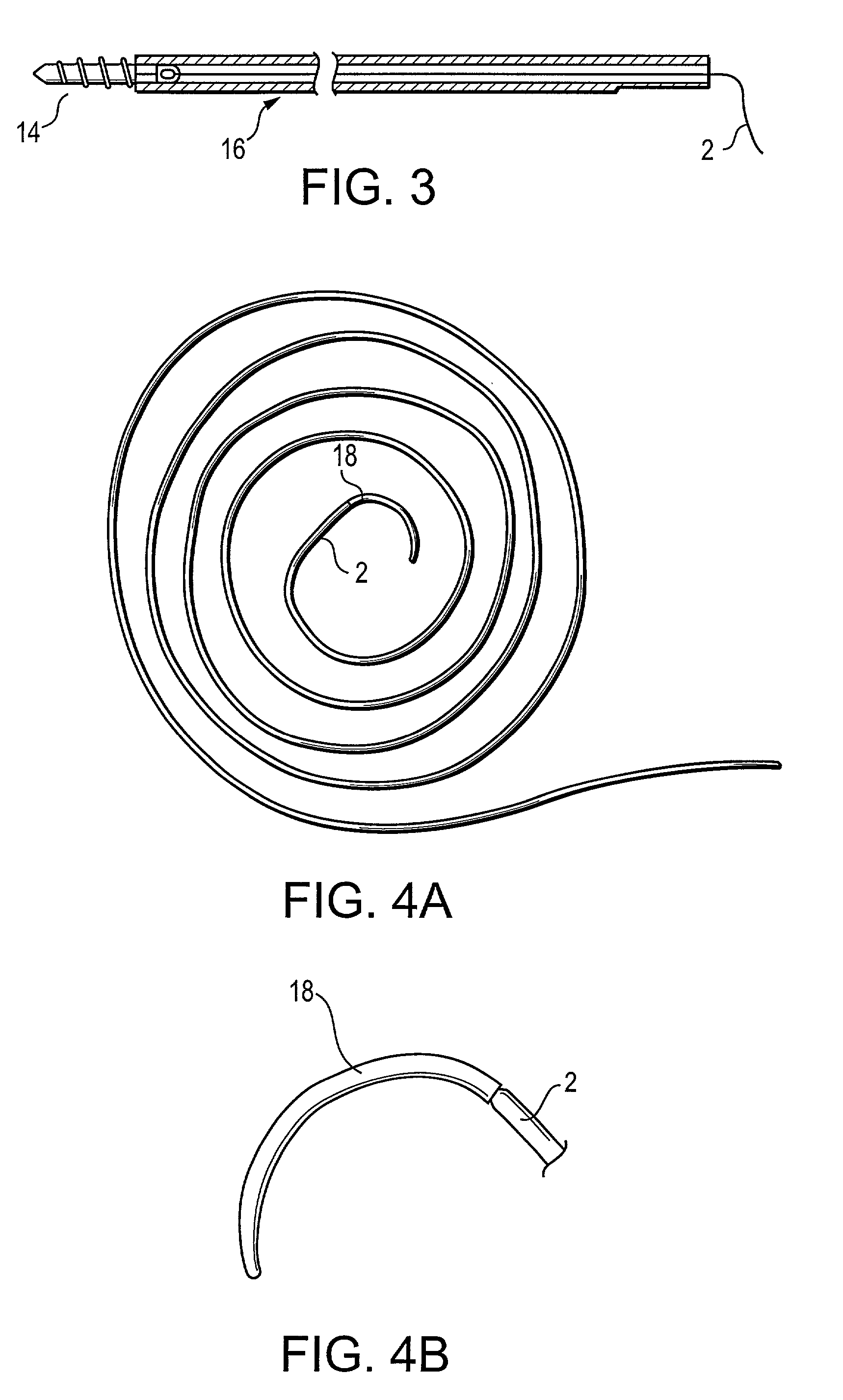

A high strength abrasion resistant surgical suture material with improved tie down characteristics is color coded for visualization and identification purposes. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polyester, nylon or a bioabsorbable material. Selected nylon fibers in the cover are provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle. The identifiable trace preferably is provided along one half of the length of the suture, so that when the suture is loaded onto a suture anchor, for example, the two legs of the length of suture on either side of the suture anchor can be readily identified.

Owner:ARTHREX INC

High strength suture with collagen fibers

InactiveUS20050033362A1High strengthGood tissue compatibilitySuture equipmentsSurgical needlesPolyesterTissue remodeling

Owner:ARTHREX

High strength suture with colored trace at one end

Owner:ARTHREX

High strength suture with coating and colored trace

A high strength abrasion resistant surgical suture material with improved tie down characteristics is color coded for visualization and identification purposes. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polyester, nylon or a bioabsorbable material. Selected nylon fibers in the cover are provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle.

Owner:ARTHREX

Manufacture of polyolefin fishing line

InactiveUS6148597AReduce resistanceReduce wearAgriculture tools and machinesFilament/thread formingYarnPolyolefin

Yarns and fishing lines are made by a process that includes the step of exposing an opaque yarn made from ultrahigh molecular weight, gel spun polyolefin filaments to a temperature within the melting point range of the filaments for a time sufficient to at least partially fuse the contact surfaces of adjacent filaments. For ultrahigh molecular weight, gel spun polyethylene, this temperature is preferably within the range from about 150 DEG -157 DEG C. The surface fusion between and among filaments imparts desirable handling characteristics to the ultrahigh molecular weight, gel spun polyolefin yarns and fishing lines that are similar to those of a conventional monofilaments. Preferably, the temperature, residence time, and stretching ratio at the selected temperature are chosen to provide a fishing line exhibiting a tensile modulus within the range from about 230 g / d to about 780 g / d with a tenacity of at least 15 g / d.

Owner:PURE FISHING

Special plastic/acrylonitrile butadiene styrene (PC/ABS) alloy for notebook computer shell

ActiveCN101974218AExcellent surface hardnessImprove scratch resistanceGlass fiberPolymethyl methacrylate

The invention discloses a special plastic / acrylonitrile butadiene styrene (PC / ABS) alloy for a notebook computer shell. The formula comprises the following materials in parts by weight: 30-80 parts of polycarbonate, 5-65 parts of acrylonitrile-butadiene-styrene copolymer, 5-15 parts of compatilizer, 1-15 parts of flame retardant agent, 3-20 parts of filler, 1-10 parts of hardness modifier, 0.5-5 parts of anti-falling agent and 0-1 part of auxiliary agent. By adopting specific high-molecular polymers of polymethyl methacrylate (PMMA), ultrahigh-molecular polysiloxane and the like, the special PC / ABS alloy selects mineral fillers of specific-size mica, glass fiber and the like to carry out rematching therewith and generates synergistic effect, thus obviously improving the surface hardness and scraping resistance of the material and simultaneously having no influence on the other performances of the material. The PC / ABS alloy material has excellent impact resistance, surface scraping resistance and flame retardance, can meet the requirements of plastic for the notebook computer shell and has considerable promotion and application values.

Owner:大河宝利材料科技(苏州)有限公司

High strength suture formed of UHMWPE and PBT

InactiveUS20070135840A1High strengthImproved tie down characteristicSuture equipmentsBraidFiberPolytetramethylene terephthalate

A high strength abrasion resistant surgical suture material with improved tie down characteristics is color coded for visualization and identification purposes. The suture features a multifilament cover formed of strands of ultra high molecular weight long chain polyethylene braided with polybutylene terephthalate. Selected fibers in the cover may be provided in a color contrasting with the other cover fibers to provide an identifiable trace. The cover surrounds a core formed of twisted strands of ultrahigh molecular weight polyethylene. The suture, provided in a #2 size, has the strength of #5 Ethibond, is ideally suited for most orthopedic procedures, and can be attached to a suture anchor or a curved needle.

Owner:ARTHREX

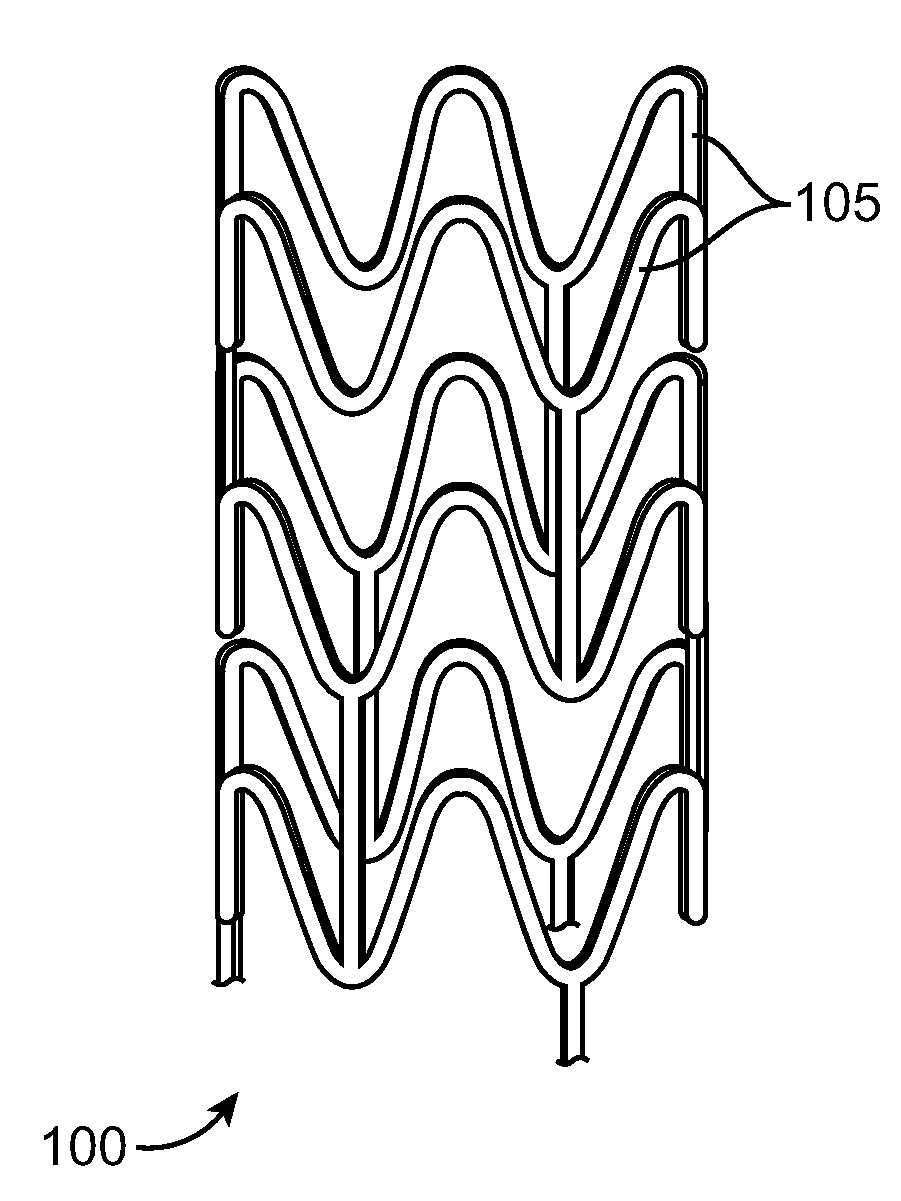

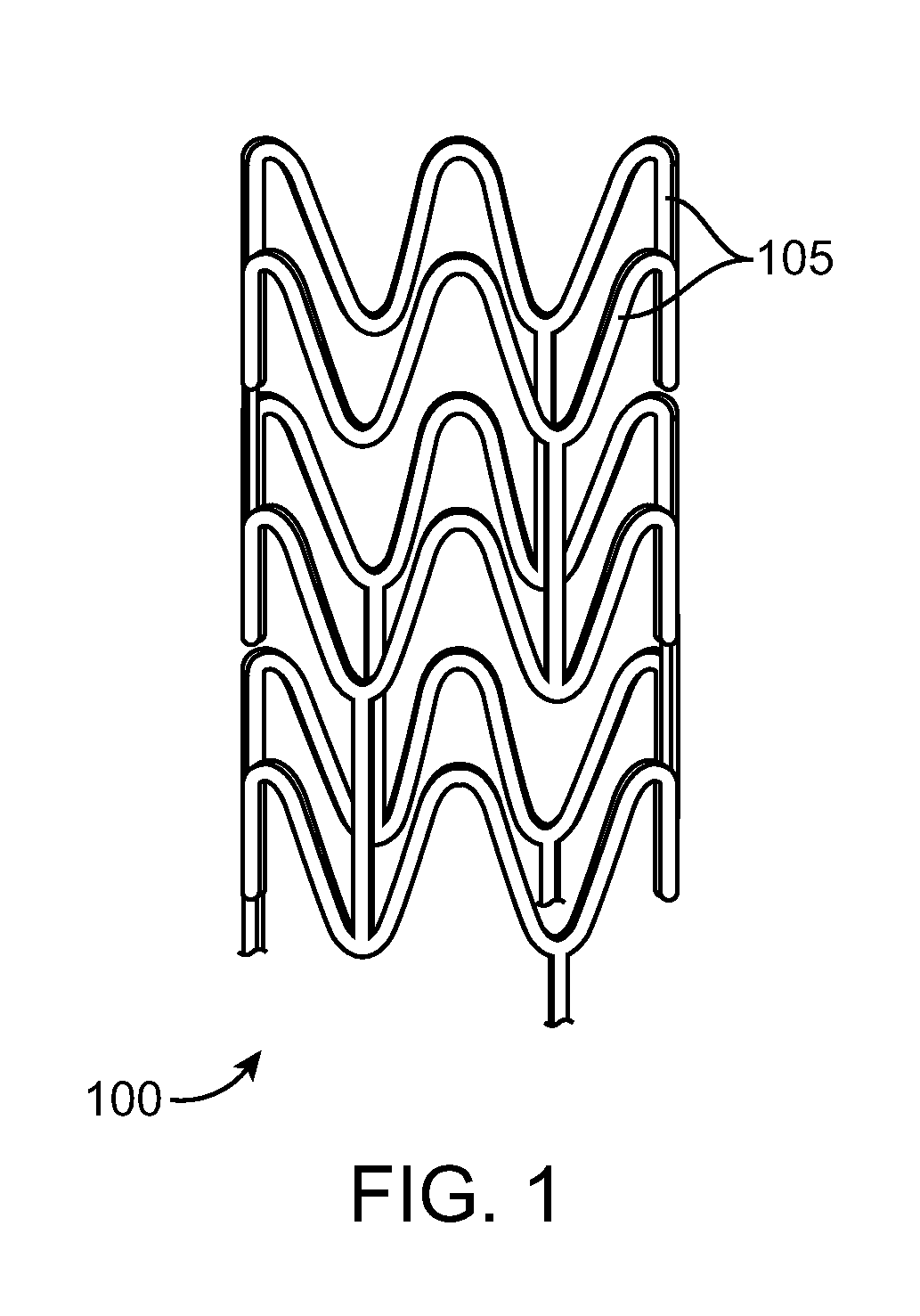

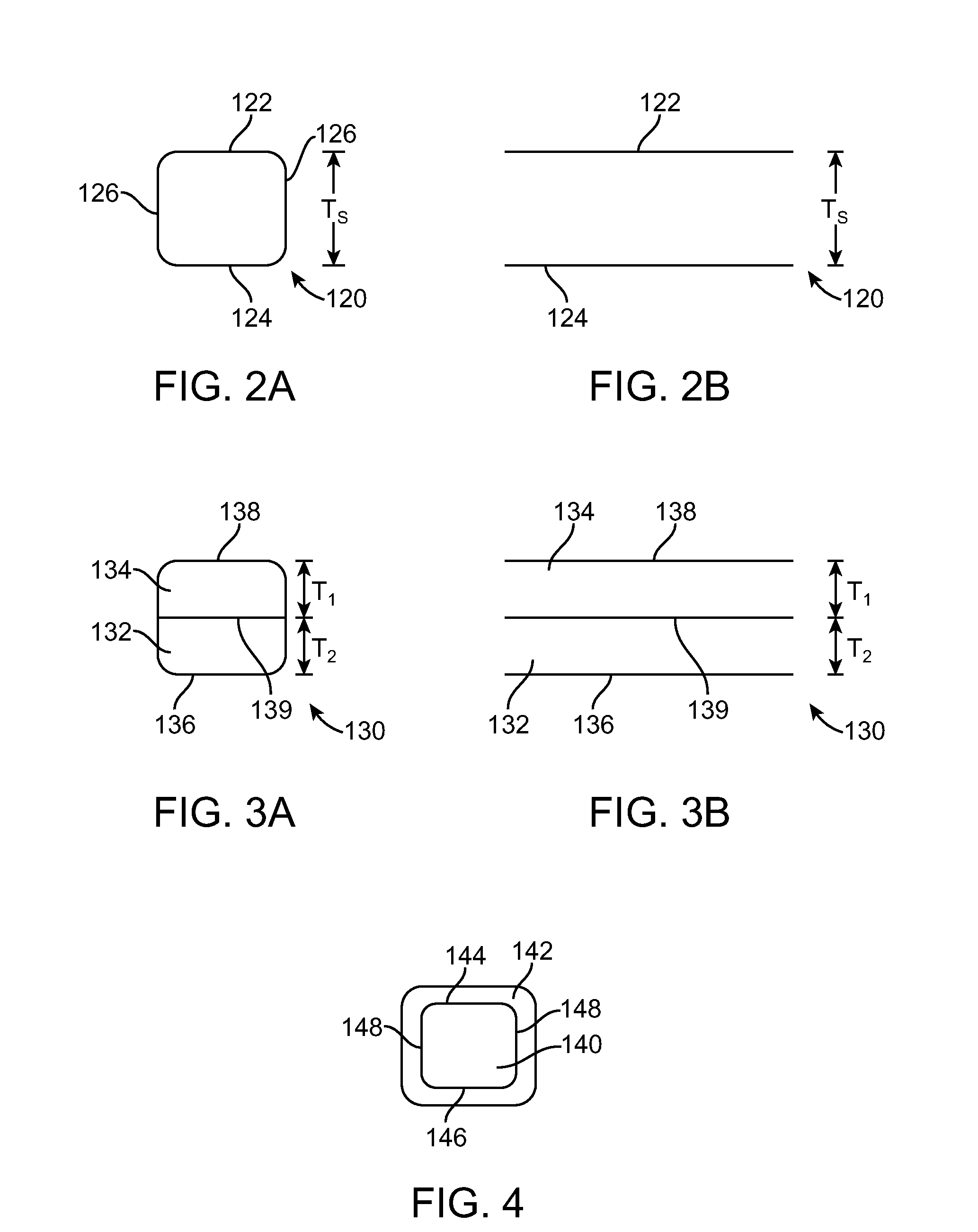

Medical device formed of ultrahigh molecular weight polyolefin

Medical devices having at least a component, such as a catheter balloon, stent cover and vascular graft, formed of ultrahigh molecular weight polyolefin, such as ultrahigh molecular weight polyethylene. The device component is formed from ultrahigh molecular weight polyethylene that has been processed so that it is microporous and has an oriented node and fibril structure. The device component expands compliantly at low strains and are substantially less compliant at higher strains. The invention also comprises methods for making such medical devices, including the steps of compacting a polyethylene powder and deforming it to impart the oriented structure.

Owner:ABBOTT CARDIOVASCULAR

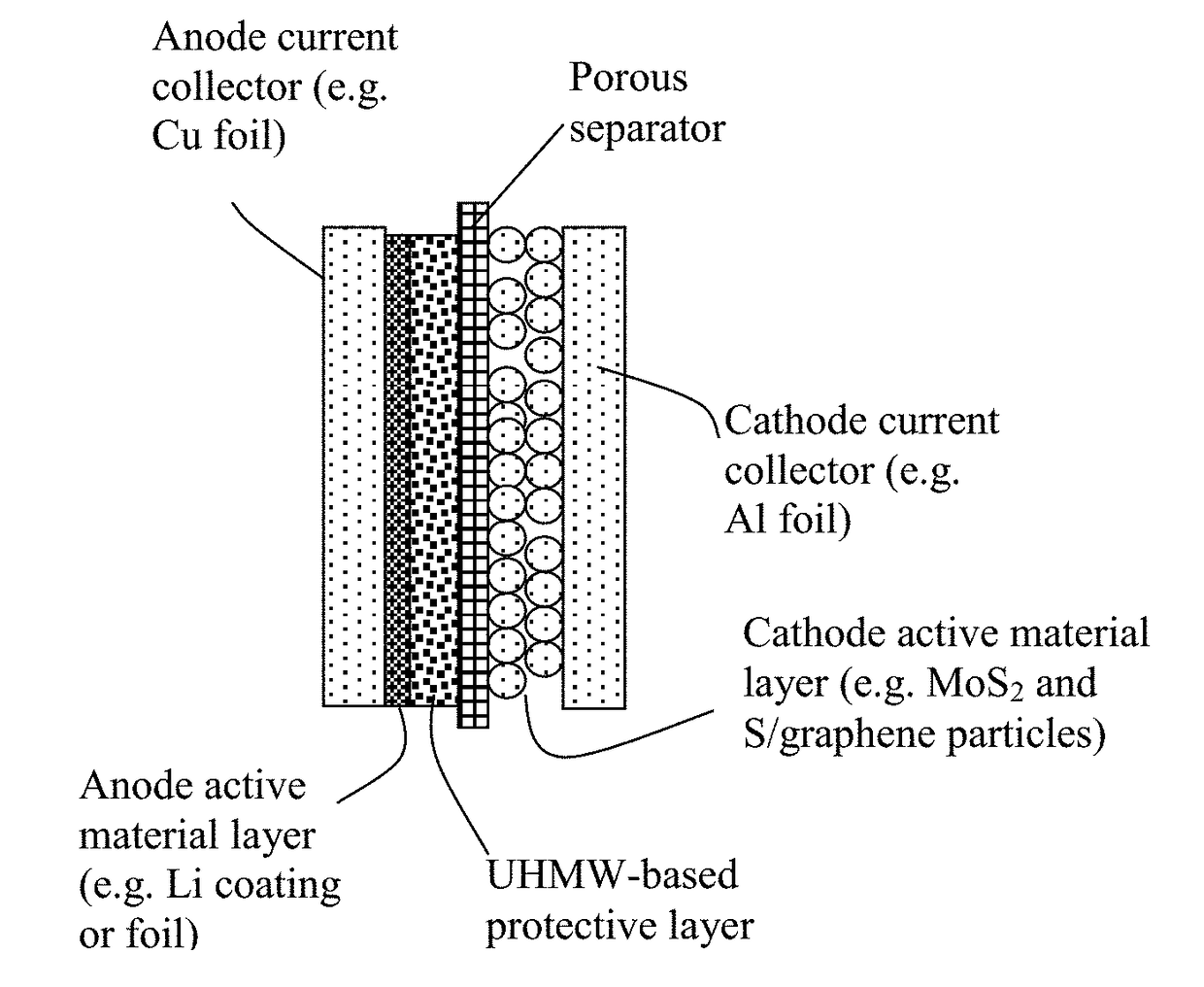

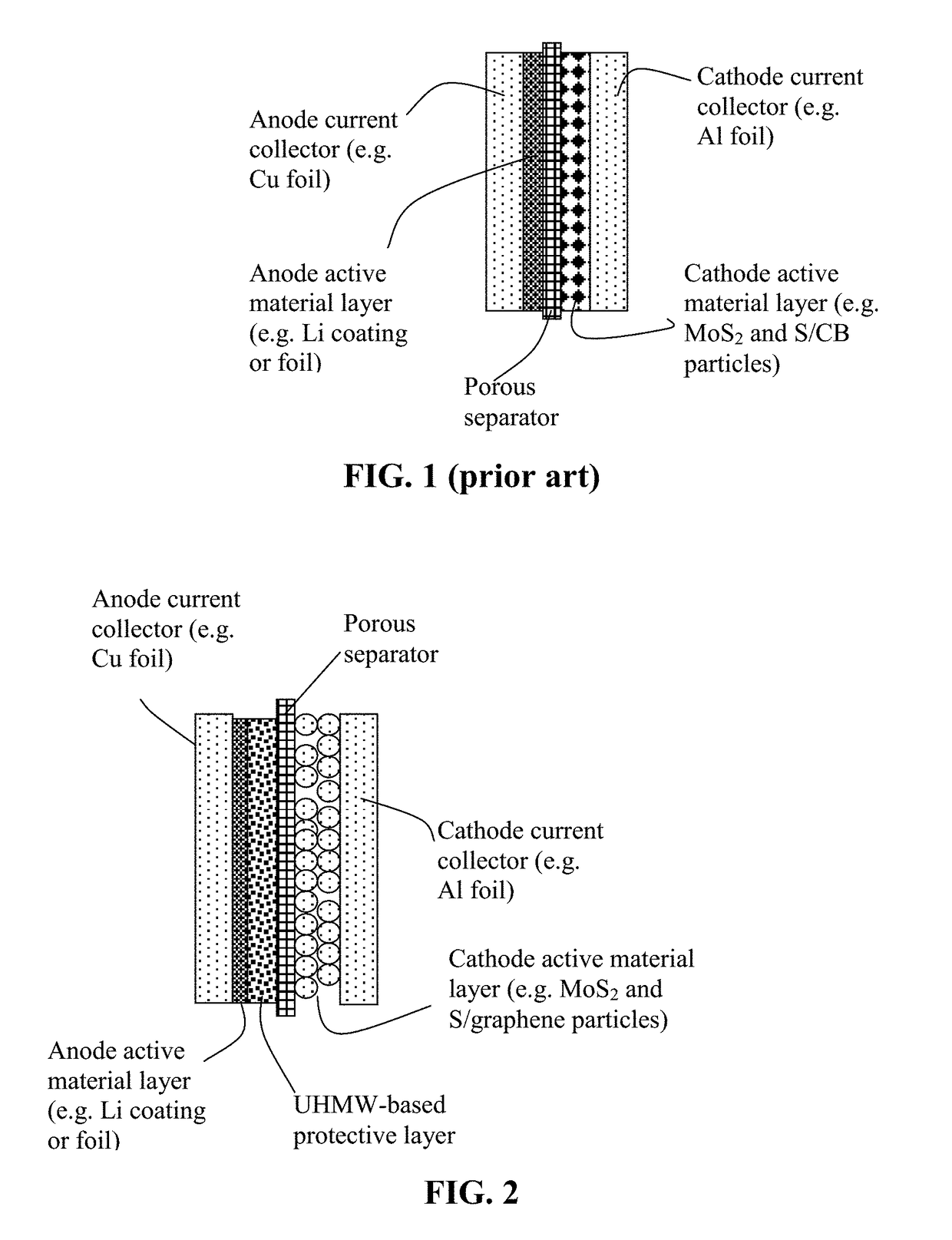

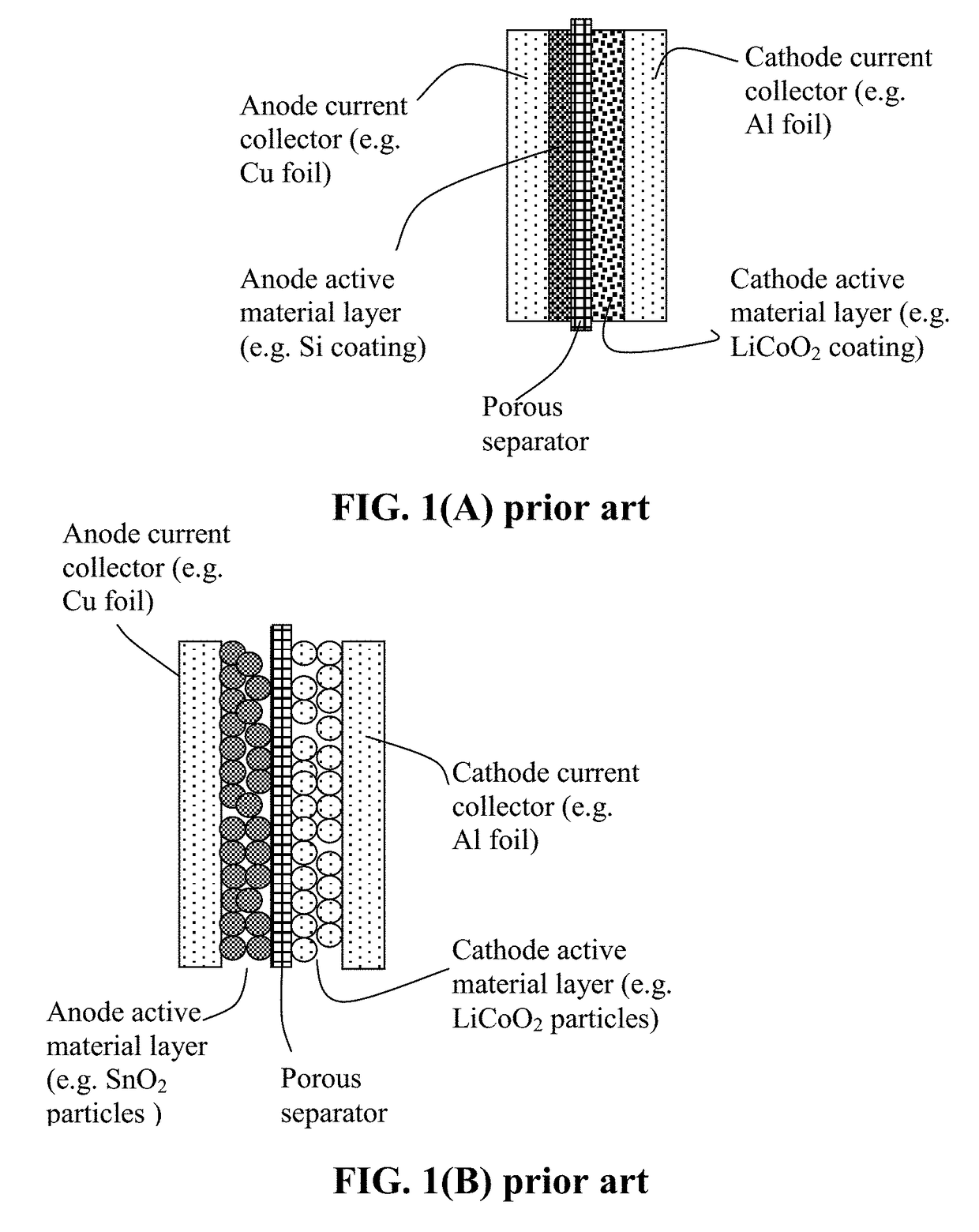

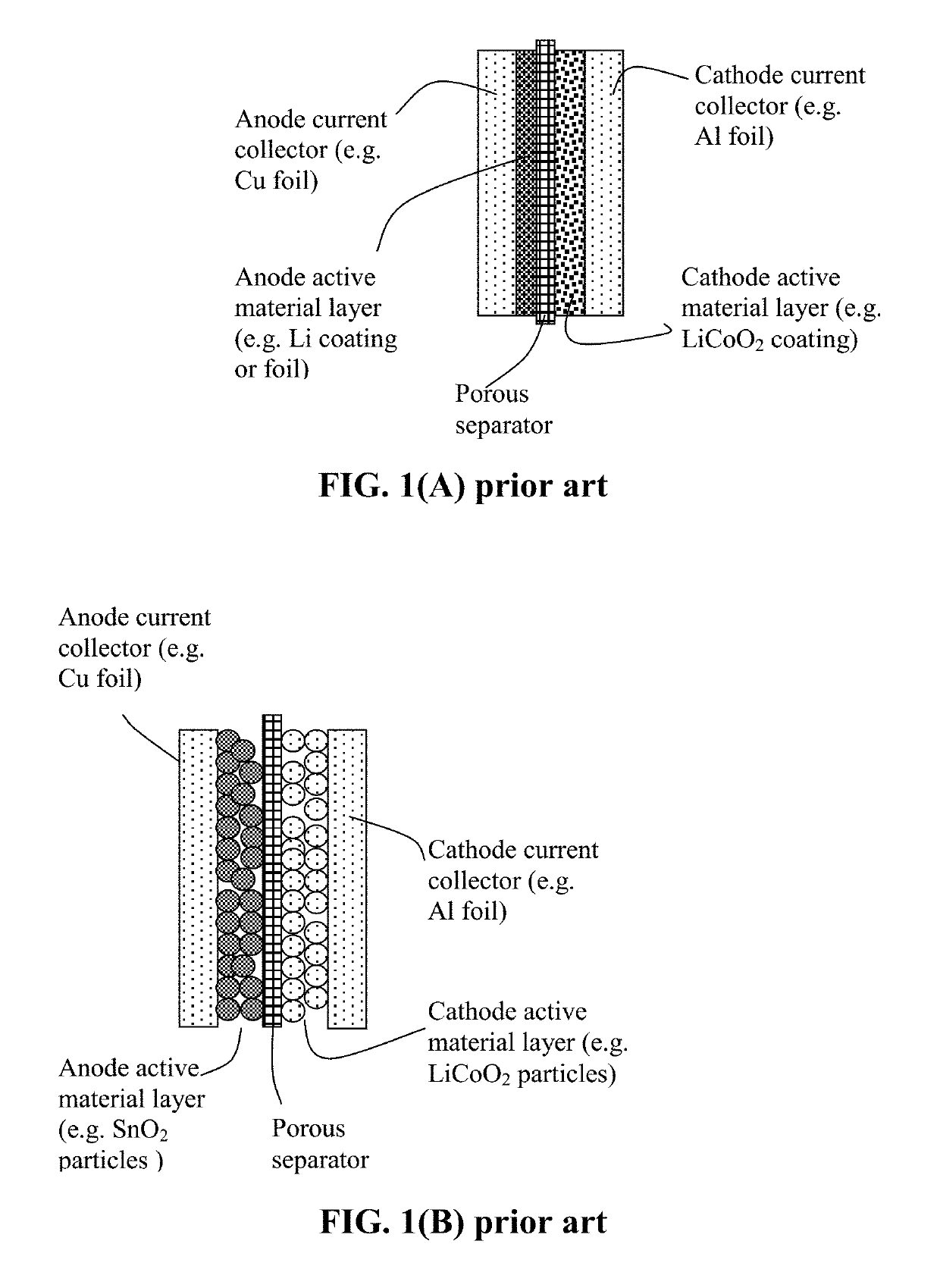

Lithium Metal Secondary Battery Containing an Anode-Protecting Polymer Layer and Manufacturing Method

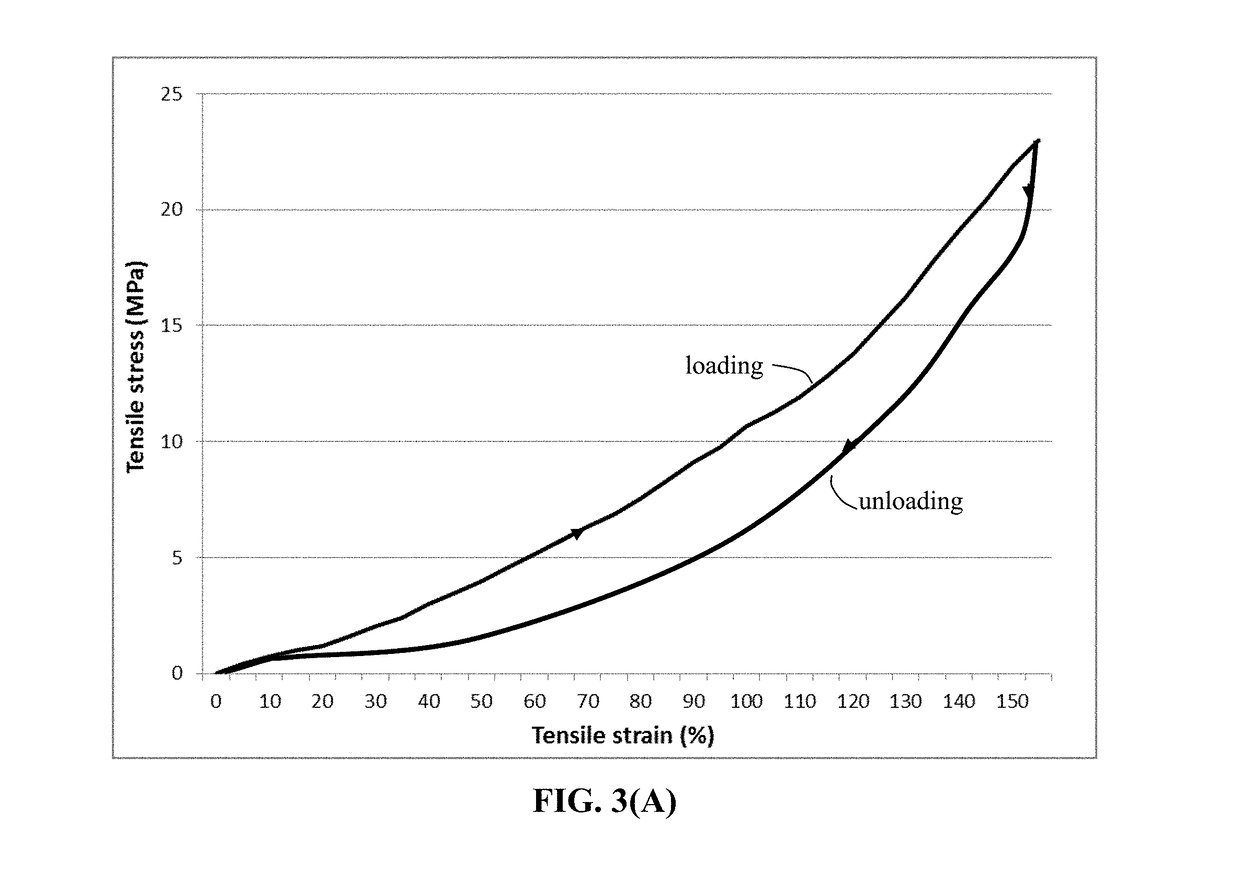

ActiveUS20180294476A1Improve lithium ion conductivityReduce thicknessSolid electrolytesFuel and secondary cellsTensile strainLithium metal

Provided is lithium secondary battery comprising a cathode, an anode, and an electrolyte or separator-electrolyte assembly disposed between the cathode and the anode, wherein the anode comprises: (a) a foil or coating of lithium or lithium alloy as an anode active material; and (b) a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 1 nm to 10 μm, wherein the high-elasticity polymer contains an ultrahigh molecular weight polymer having a molecular weight from 0.5×106 to 9×106 g / mole and is disposed between the lithium or lithium alloy and the electrolyte or separator-electrolyte assembly.

Owner:GLOBAL GRAPHENE GRP INC

Stent Made From An Ultra High Molecular Weight Bioabsorbable Polymer With High Fatigue And Fracture Resistance

A stent made from an ultra high molecular weight bioabsorbable polymer is disclosed herein. The bioabsorbable polymer can have a Mw greater than 1 million g / mole or greater than 2 million g / mole. Methods of making the ultra high molecular weight polymer stent without degrading the molecular weight are further disclosed.

Owner:ABBOTT CARDIOVASCULAR

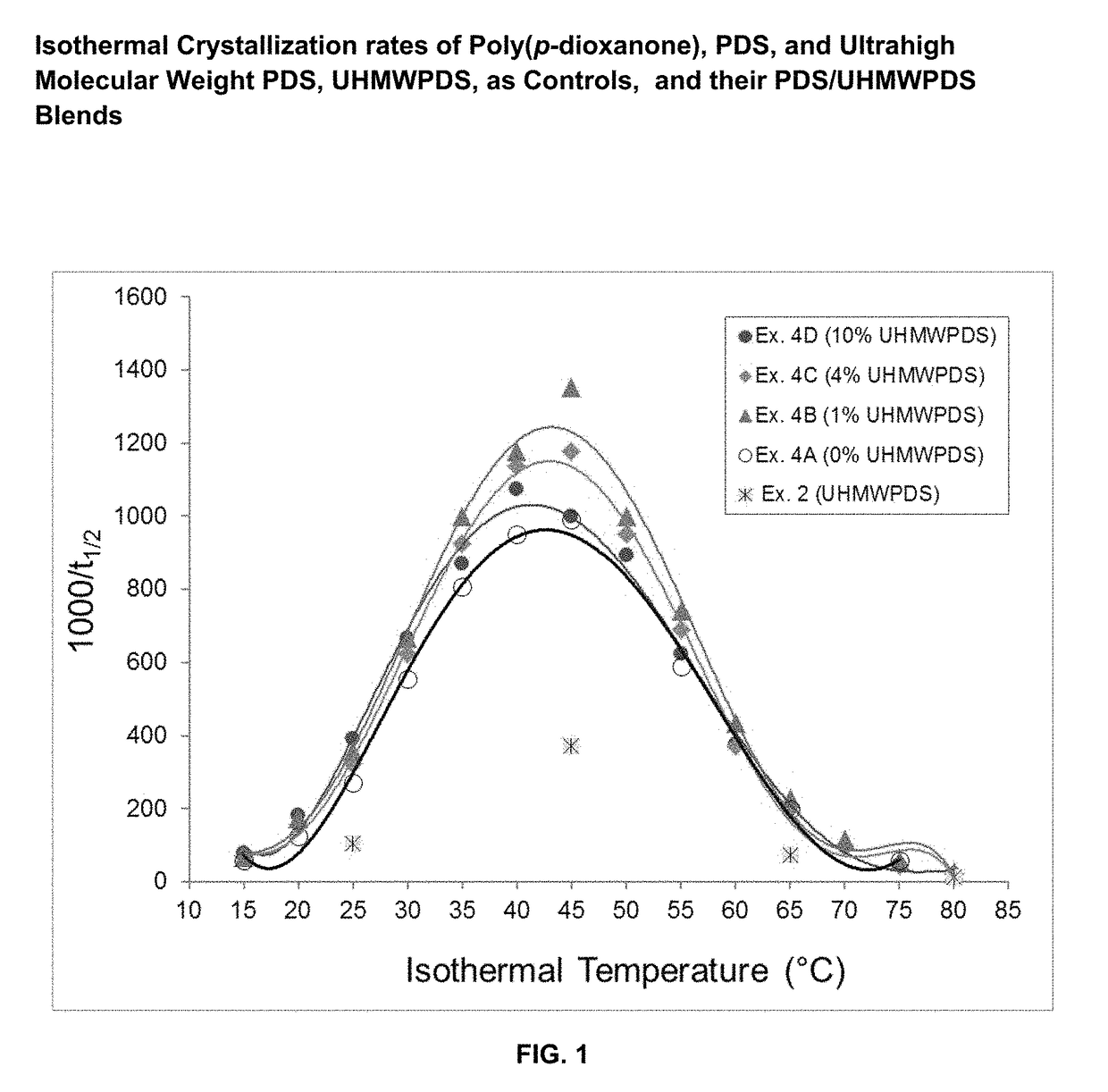

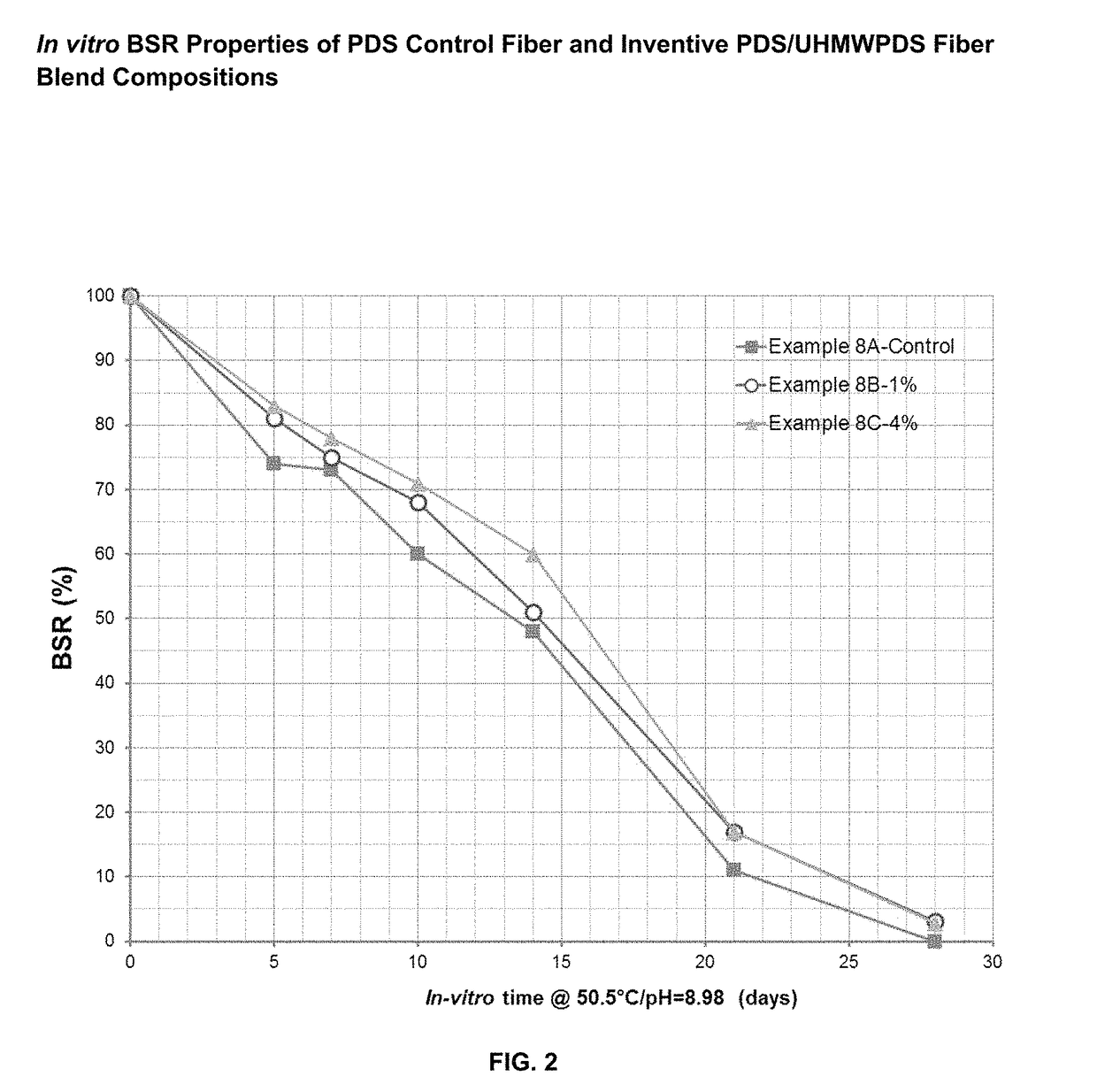

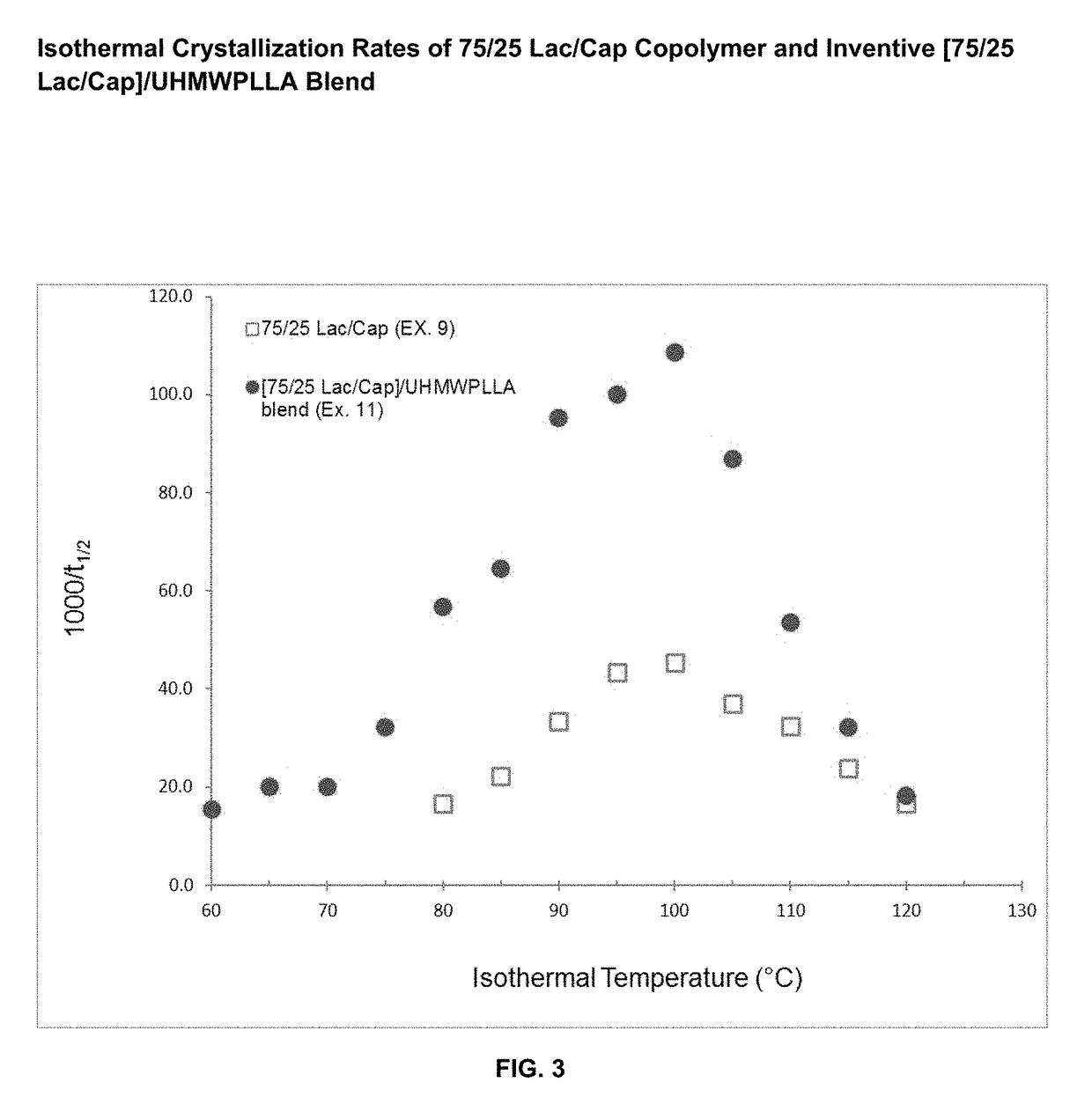

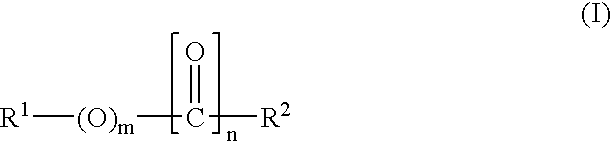

Absorbable polymer blend compositions having enhanced nucleation rates

ActiveUS9873790B1Increase the rate of crystallizationHigh crystallization kineticsSuture equipmentsPharmaceutical non-active ingredientsAbsorbable polymersFiber

Novel absorbable, semi-crystalline, polymer blend compositions are disclosed exhibiting enhanced crystallization and nucleation rates. Also disclosed are medical device constructs, such as fibers made from such blends. The blends have a first absorbable polymeric component having a first molecular weight distribution and a second absorbable polymeric component which has an ultrahigh molecular weight distribution. The first and second polymeric components may be the same polymer.

Owner:ETHICON INC

Preparation of a double metal cyanide catalyst

InactiveUS6977236B2High activityIncrease the molar ratioOrganic chemistryOrganic compound preparationSaline waterPolyol

The present invention relates to a process for the preparation of a double metal cyanide (DMC) catalyst, which process involves:(a) combining an aqueous solution of metal salt with an aqueous solution of a metal cyanide salt and reacting these solutions; and(b) recovering the DMC catalyst from the reaction mixture,in which process the DMC catalyst is prepared in the presence of from 0.03 to 0.4 mole of alkaline metal compound, based on amount of metal salt. Further, the present invention relates to DMC catalyst obtainable by such process, to DMC catalyst prepared from a metal salt and a metal cyanide salt in which the molar ratio of metal derived from the metal salt to metal derived from the metal cyanide salt is at least 2.25 and to a process for polymerization of alkylene oxides which process involves reacting initiator with alkylene oxide in the presence of at most 15 ppm of DMC catalyst. It also relates to a process for the polymerization of alkylene oxides in which the resulting polyol contains less than 60 ppm of ultra-high molecular weight compounds.

Owner:SHELL USA INC

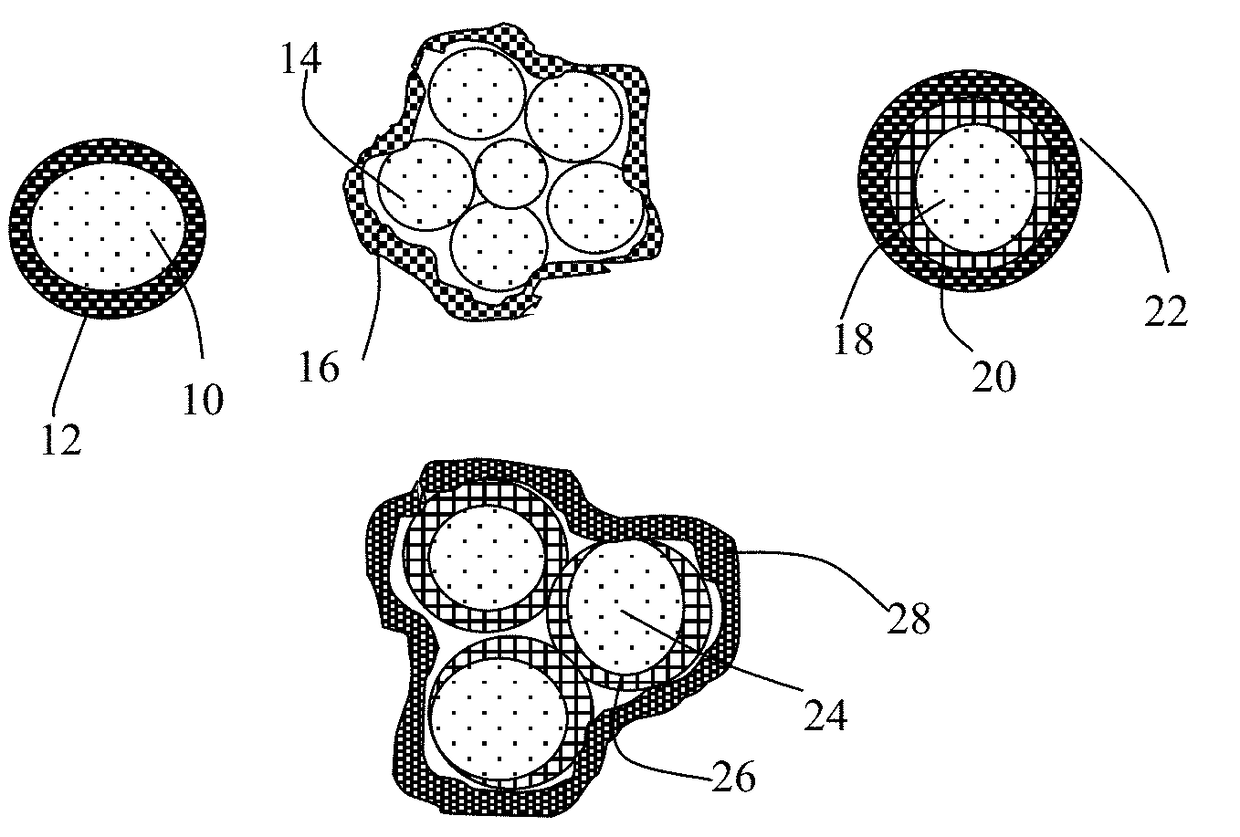

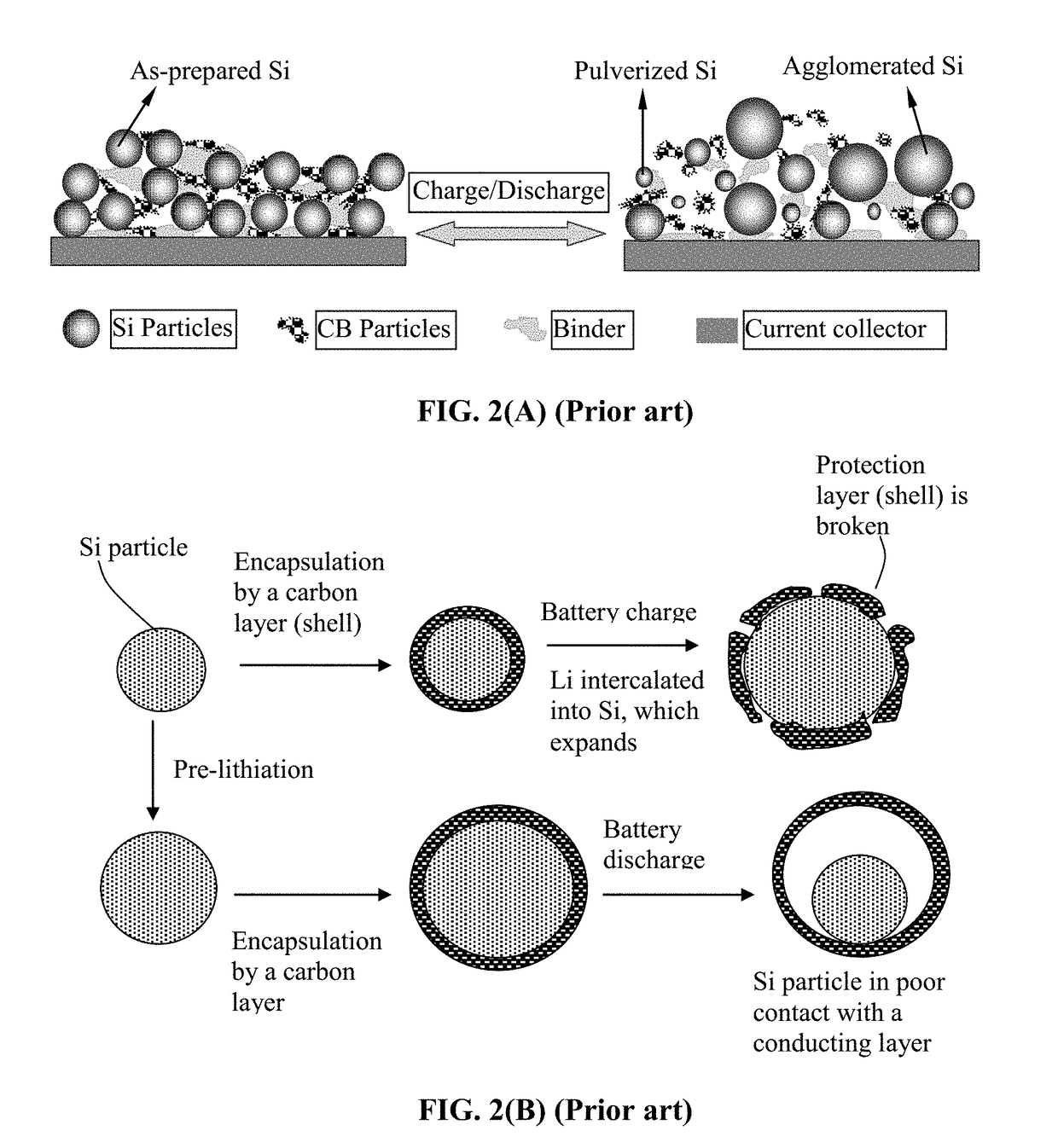

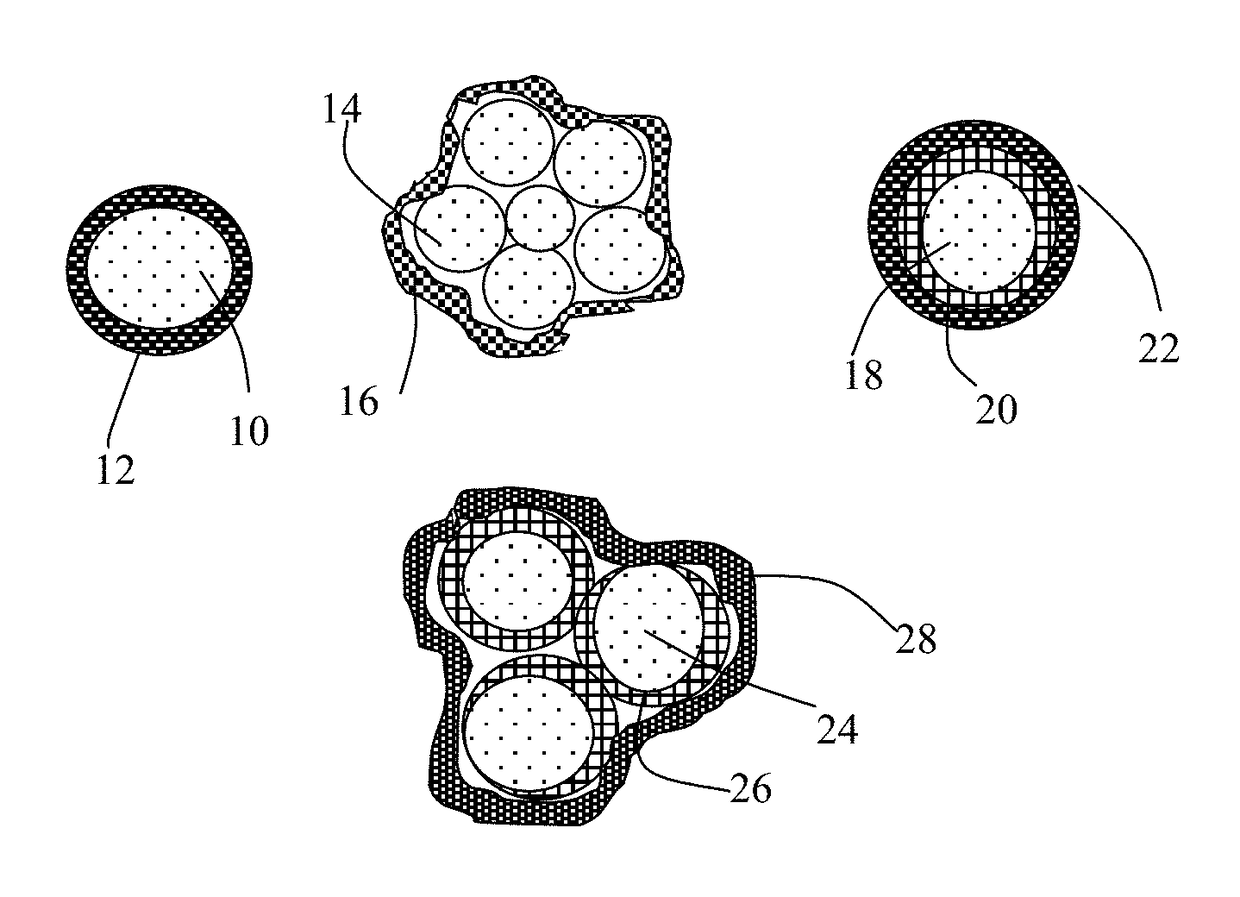

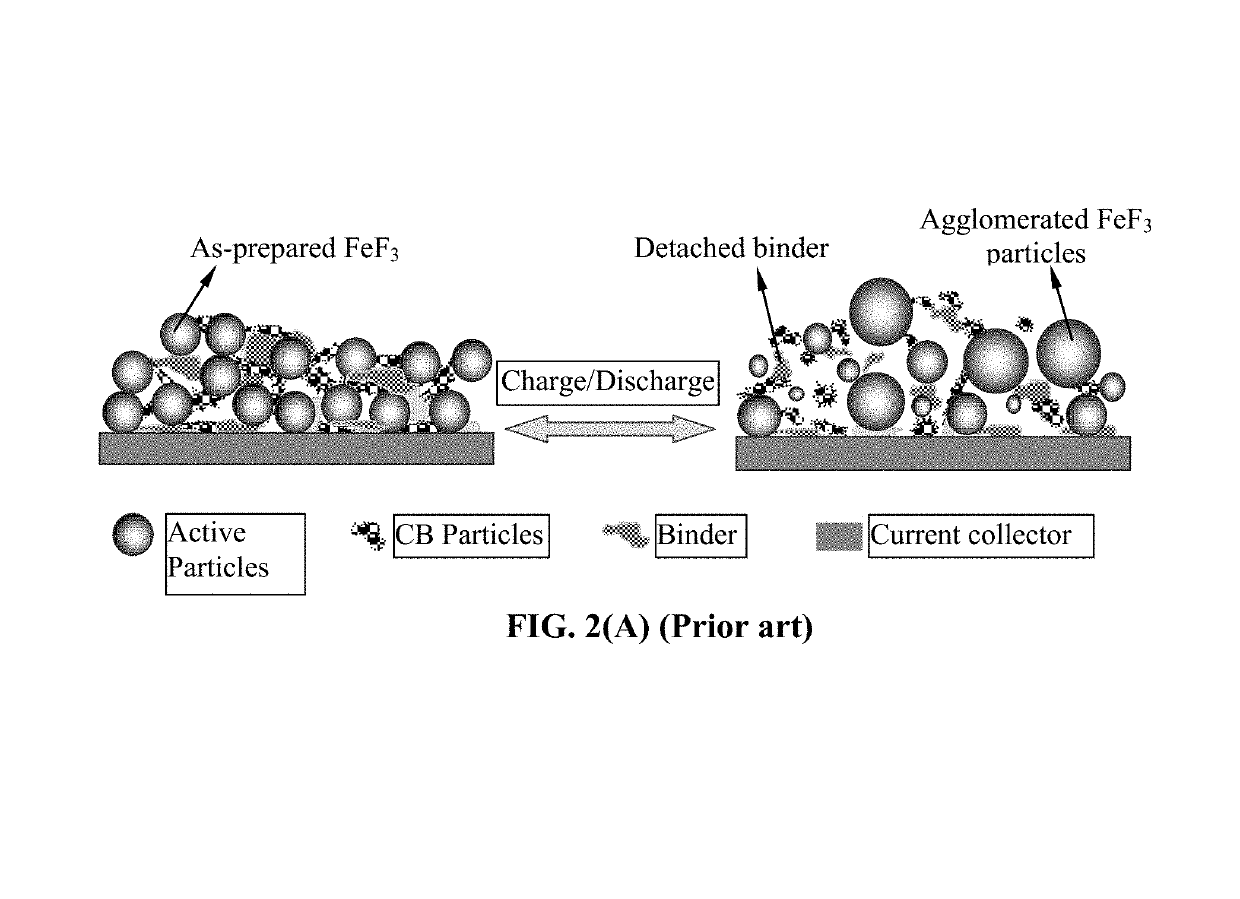

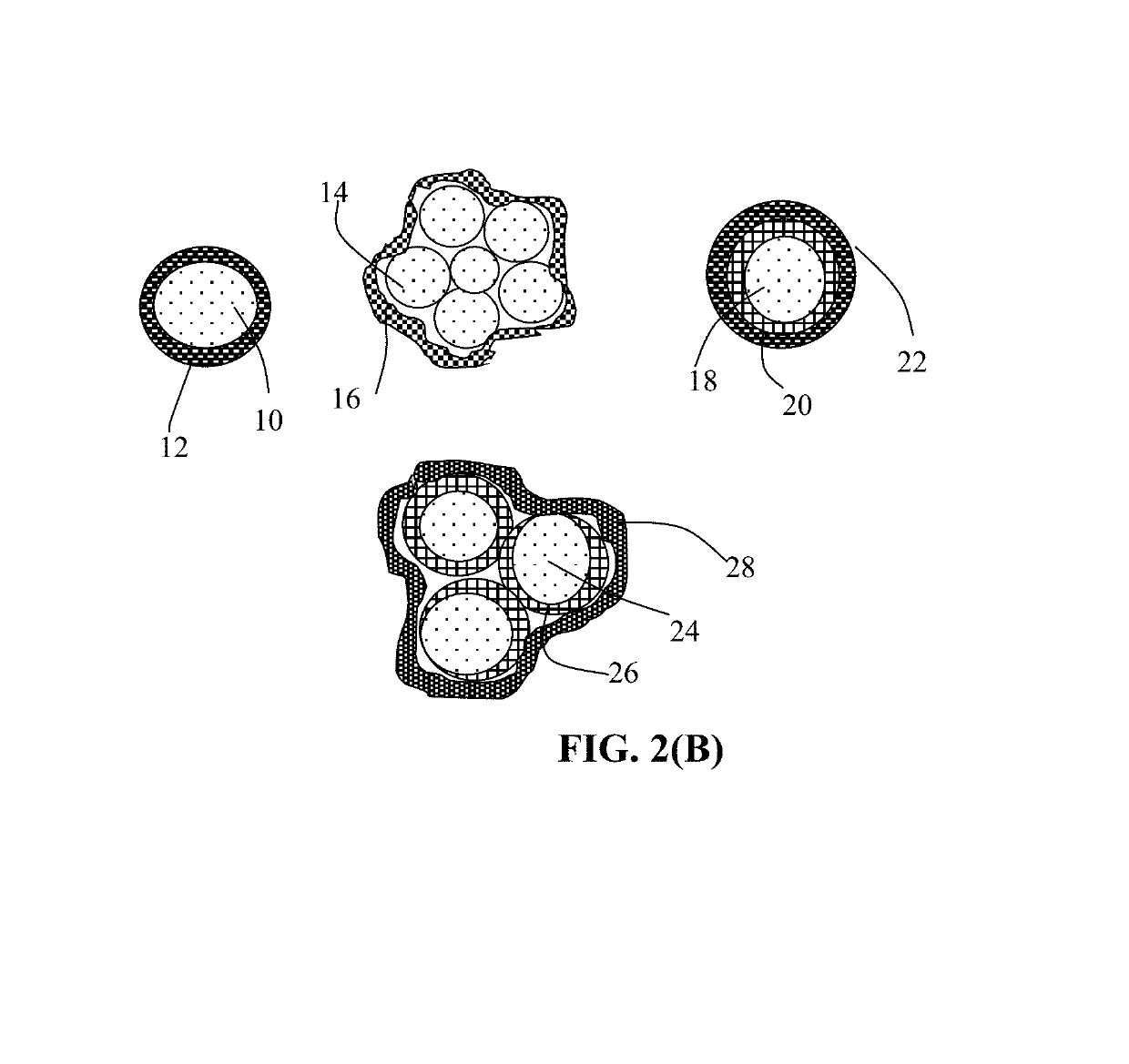

Encapsulated Anode Active Material Particles, Lithium Secondary Batteries Containing Same, and Method of Manufacturing

ActiveUS20180287142A1Improve lithium ion conductivitySolid electrolytesNegative electrodesParticulatesPolyethylene oxide

Provided is particulate of an anode active material for a lithium battery, comprising one or a plurality of anode active material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm, wherein the polymer contains an ultrahigh molecular weight (UHMW) polymer having a molecular weight from 0.5×106 to 9×106 grams / mole. The UHMW polymer is preferably selected from polyacrylonitrile, polyethylene oxide, polypropylene oxide, polyethylene glycol, polyvinyl alcohol, polyacrylamide, poly(methyl methacrylate), poly(methyl ether acrylate), a copolymer thereof, a sulfonated derivative thereof, a chemical derivative thereof, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

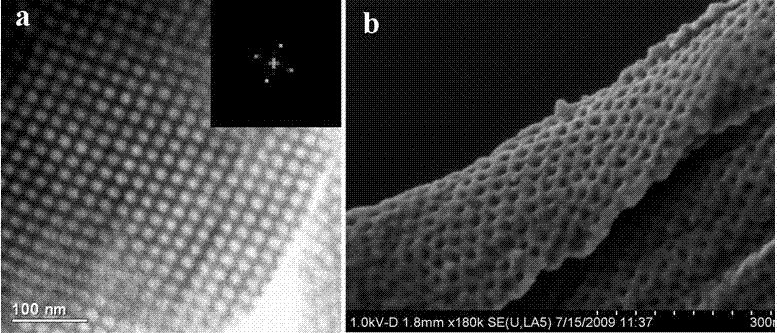

Preparation method and application of ultrahigh molecular weight polyethylene/graphene composite fiber

ActiveCN102618955AHigh strengthImprove mechanical propertiesFilament/thread formingPersonal protection gearFiberPolymer science

The invention discloses an ultrahigh molecular weight polyethylene / graphene composite fiber and a preparation method as well as application thereof. The composite fiber consists of ultrahigh molecular weight polyethylene (UHMWPE) and graphene; the weight-average molecular weight of the ultrahigh molecular weight polyethylene is 1*10<6>-4*10<6>, particularly 1*10<6>-3*10<6>; the diameter of the graphene is 0.6-1.8 mum; and the thickness of the graphene is 0.5-5 nm. The graphene is a material which has the maximum strength in the world up to now. According to the invention, the graphene powder is introduced into the ultrahigh molecular weight polyethylene fiber, so that the ultrahigh molecular weight polyethylene / graphene composite fiber has excellent mechanical property. Preliminary research shows that the tensile strength of the ultrahigh molecular weight polyethylene / graphene composite fiber prepared by the method can reach 2.5 GPa, the tensile modulus is 130 GPa, and the thermal decomposition temperature in nitrogen gas can reach up to over 390 DEG C.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

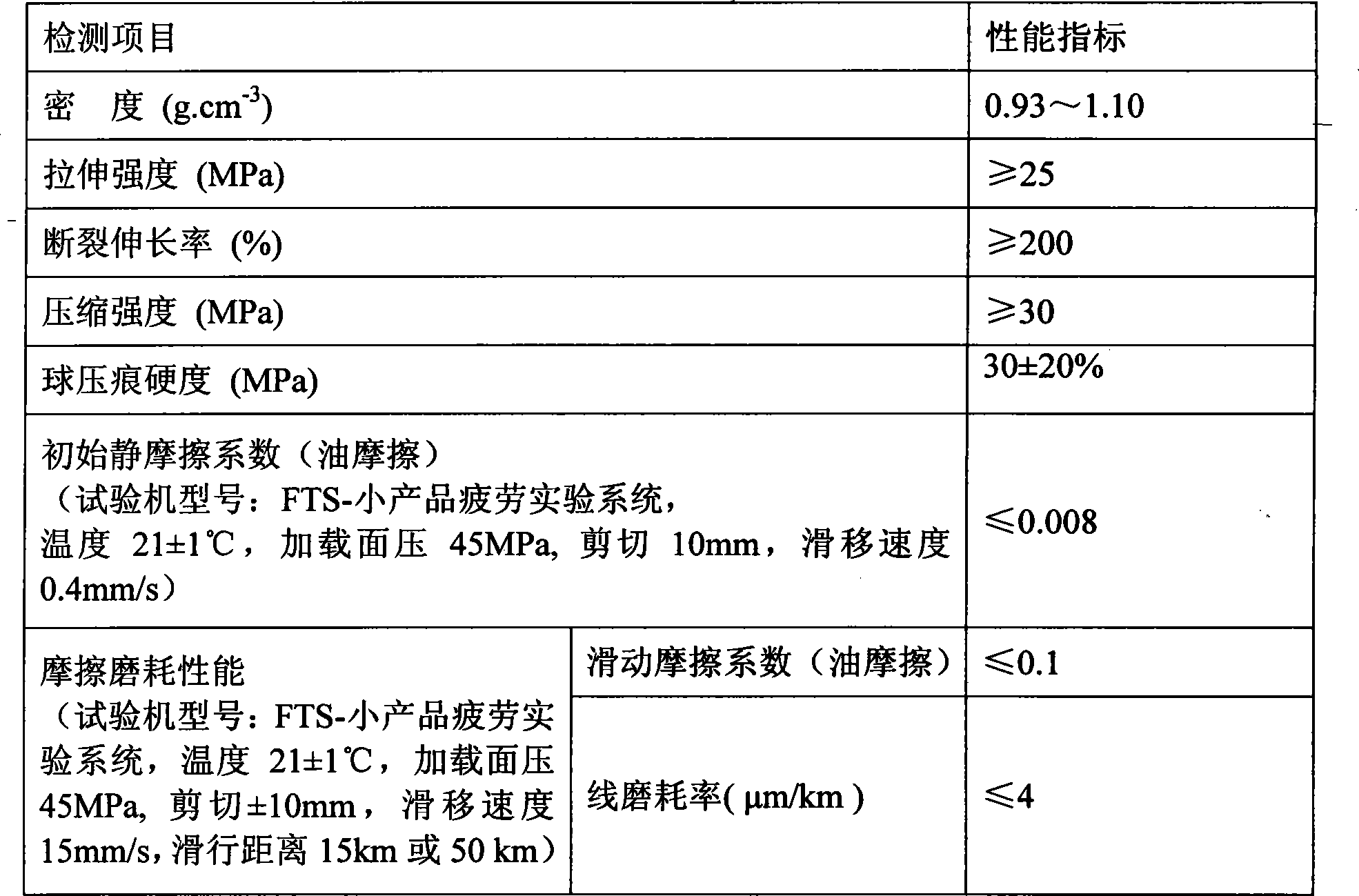

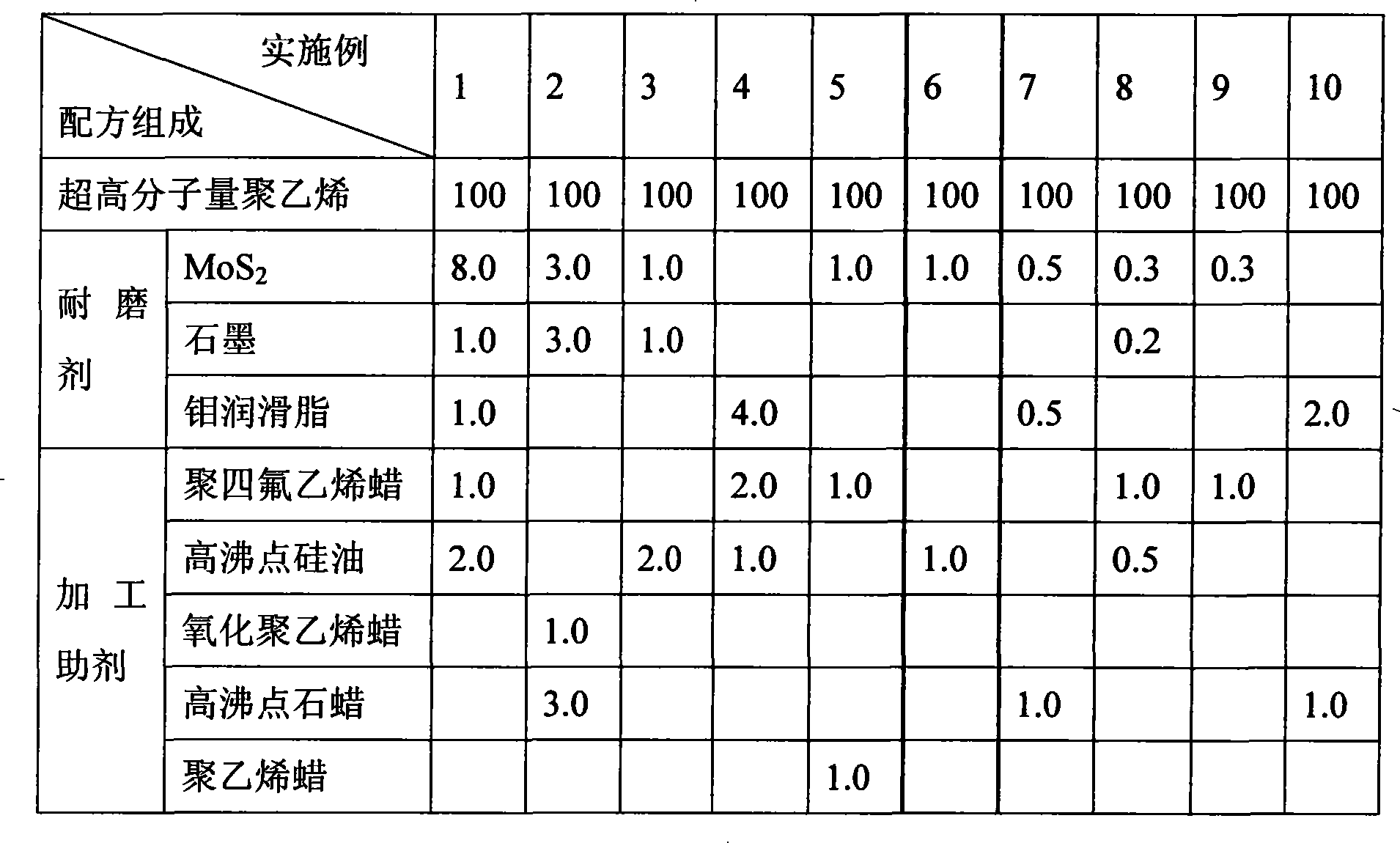

Super-high molecular weight polyethylene low frictional coefficient wearable composite material and its preparation and use

InactiveCN101240092AImprove performanceExcellent formulaBridge structural detailsParaffin waxProcedure Agents

Ultra high molecular weight polyethylene composite with low molar mass and high friction resistance, preparation and application thereof. Raw materials of 100 parts by weight of ultra high molecular weight polyethylene, 0.1-10 parts by weight of wear-resisting agent, 0.1-5.0 parts by weight of processing aid is prepared into highly friction resistant composite by mixing, chill-pressing, heating to melt, compression molding, cooling for shaping and cutting. The mentioned utra high molecular weight polyethylene has a matrix molecular weight of greater than 6 millionl. The mentioned wear-resisting agent is MoS2 surface treated by coupling agent, black lead, lubricating grease of molybdenum, copper powder, or mixture of more than two of them. The mentioned processing agent is organic silicon oil with high boiling point, polytetrafluroethylene, oxidized polyethylene wax, olefin or polyethylene wax with high boiling point, or mixture of more than two of them.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

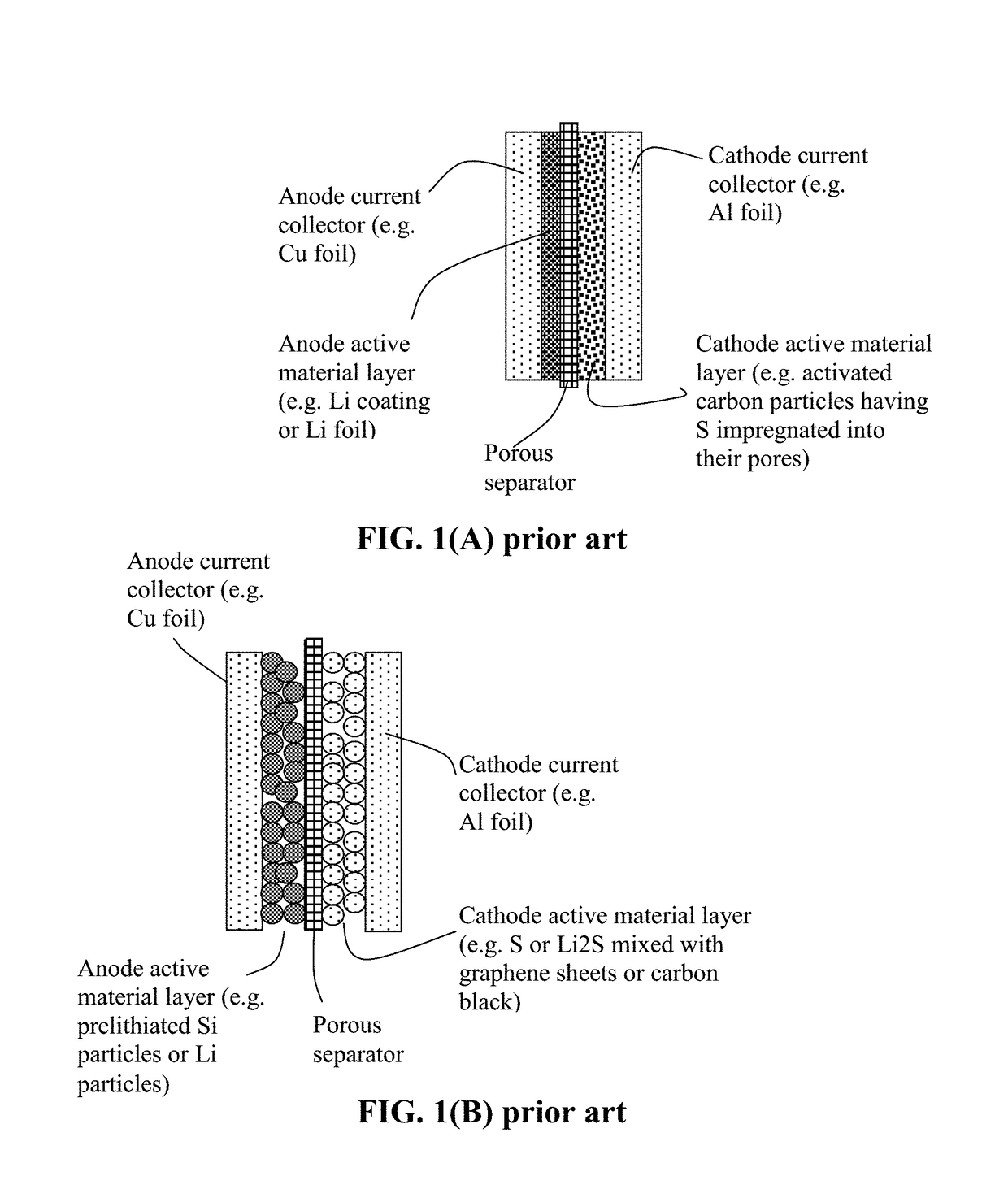

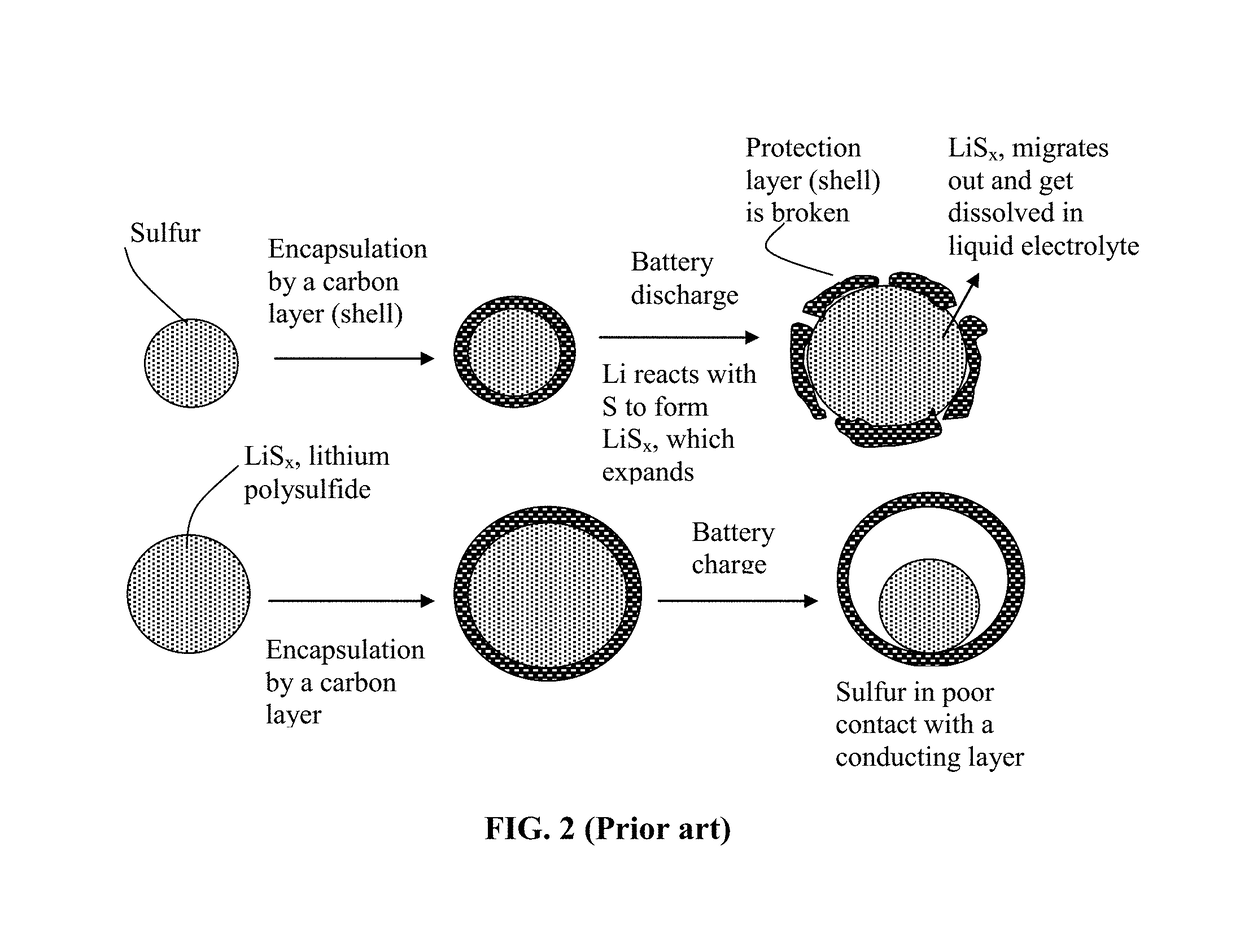

Alkali Metal-Sulfur Secondary Battery Containing a Polymer-Encapsulated Sulfur Cathode and Manufacturing Method

ActiveUS20180294475A1Inhibited DiffusionReduce and eliminate effectFinal product manufacturePositive electrodesConductive polymerElectrical battery

Provided is a rechargeable alkali metal-sulfur cell comprising an anode active material layer, an electrolyte, and a cathode active material layer containing multiple particulates of a sulfur-containing material selected from a sulfur-carbon hybrid, sulfur-graphite hybrid, sulfur-graphene hybrid, conducting polymer-sulfur hybrid, metal sulfide, sulfur compound, or a combination thereof and wherein at least one of the particulates is composed of one or a plurality of sulfur-containing material particles being embraced or encapsulated by a thin layer of a high-elasticity ultra-high molecular weight polymer having a recoverable tensile strain no less than 2%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm This battery exhibits an excellent combination of high sulfur content, high sulfur utilization efficiency, high energy density, and long cycle life.

Owner:GLOBAL GRAPHENE GRP INC

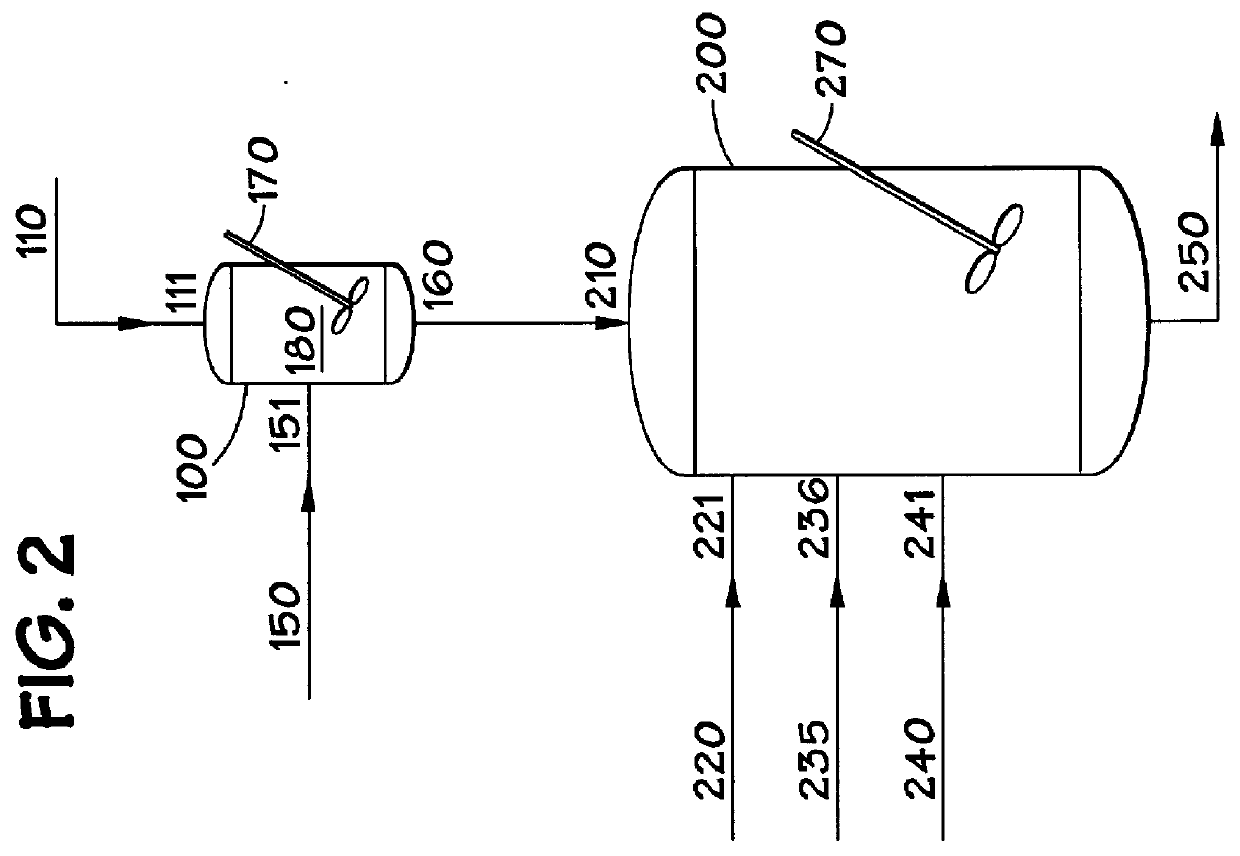

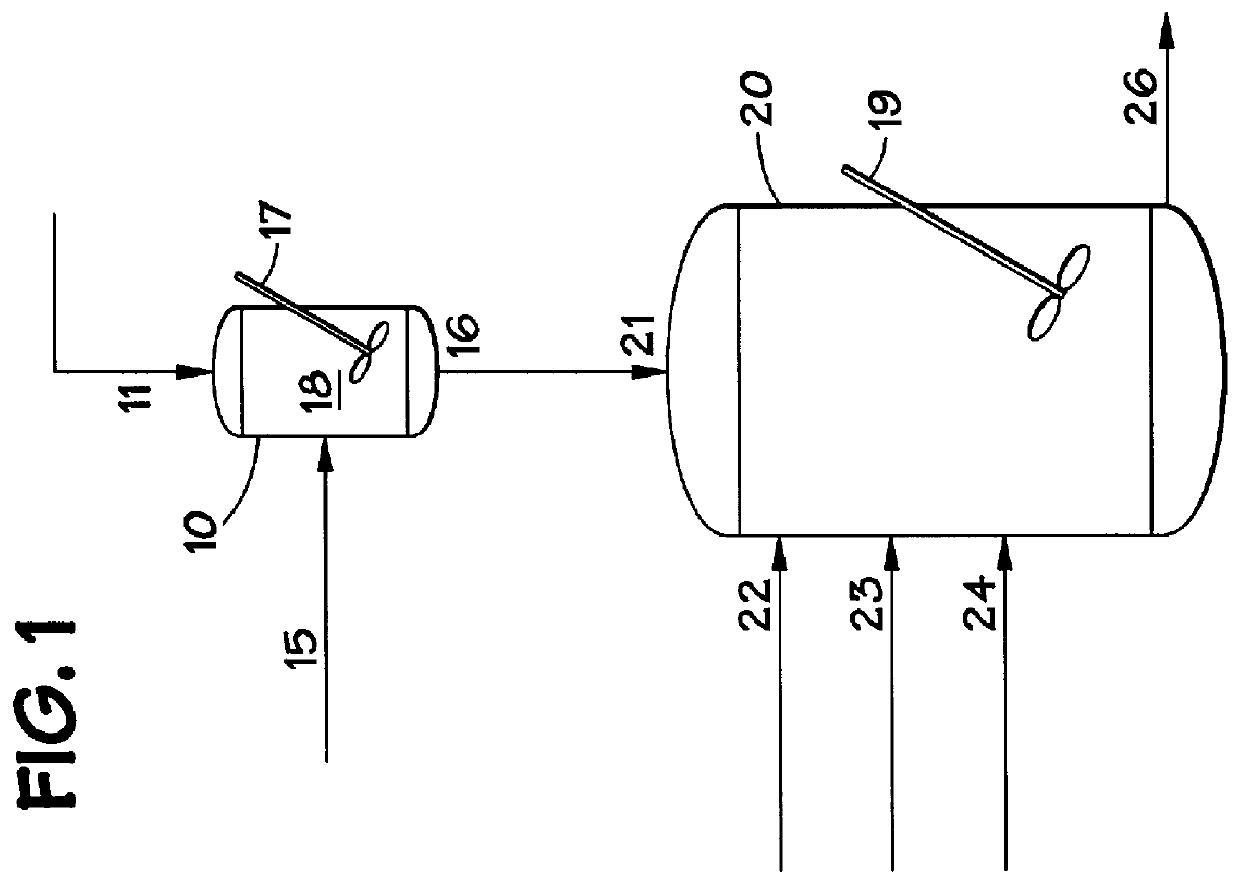

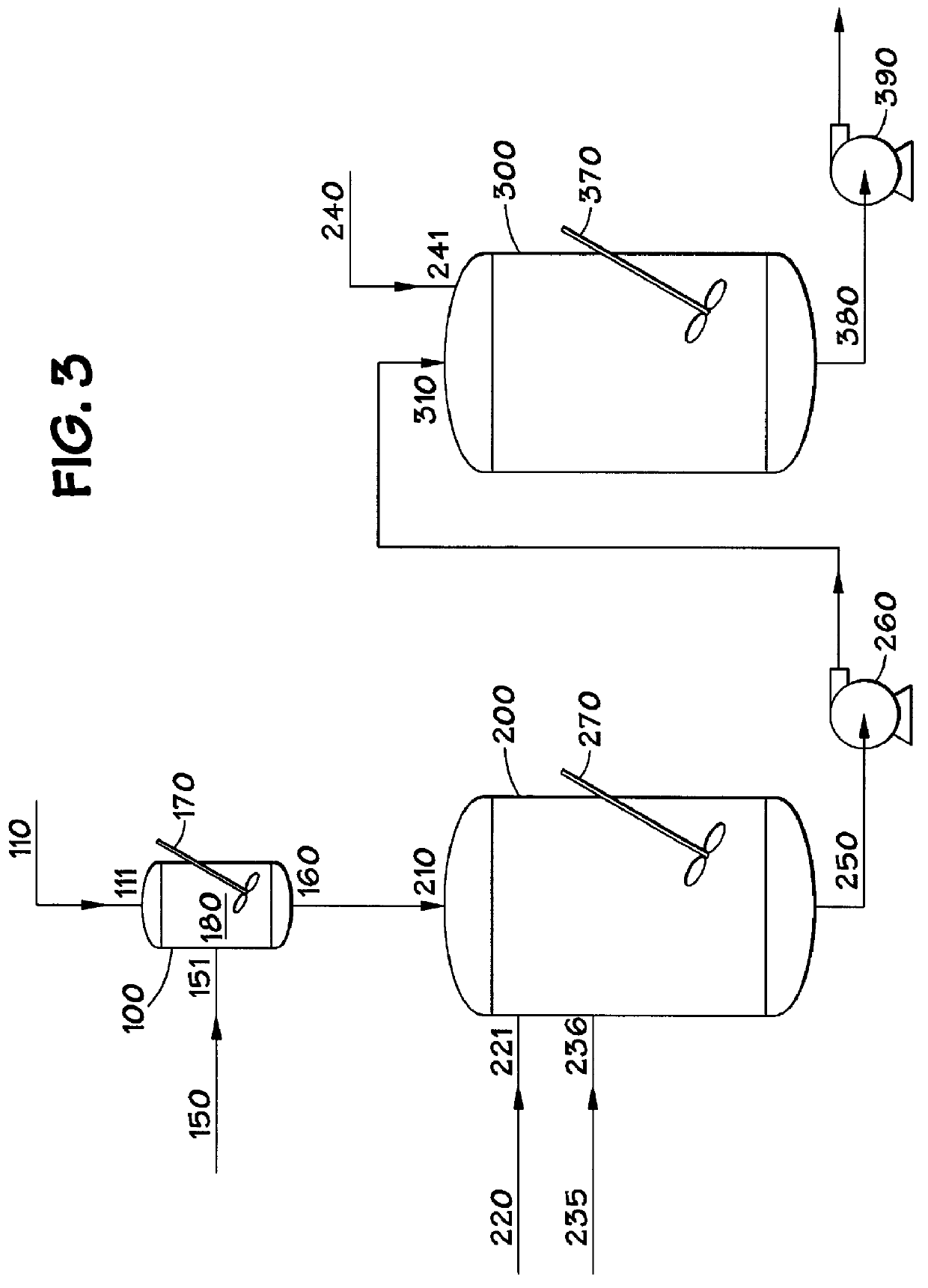

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents

InactiveUS6015779AReduce frictional energy lossHigh molecular weightOther chemical processesLiquid organic insulatorsHalohydrocarbonAlpha-olefin

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

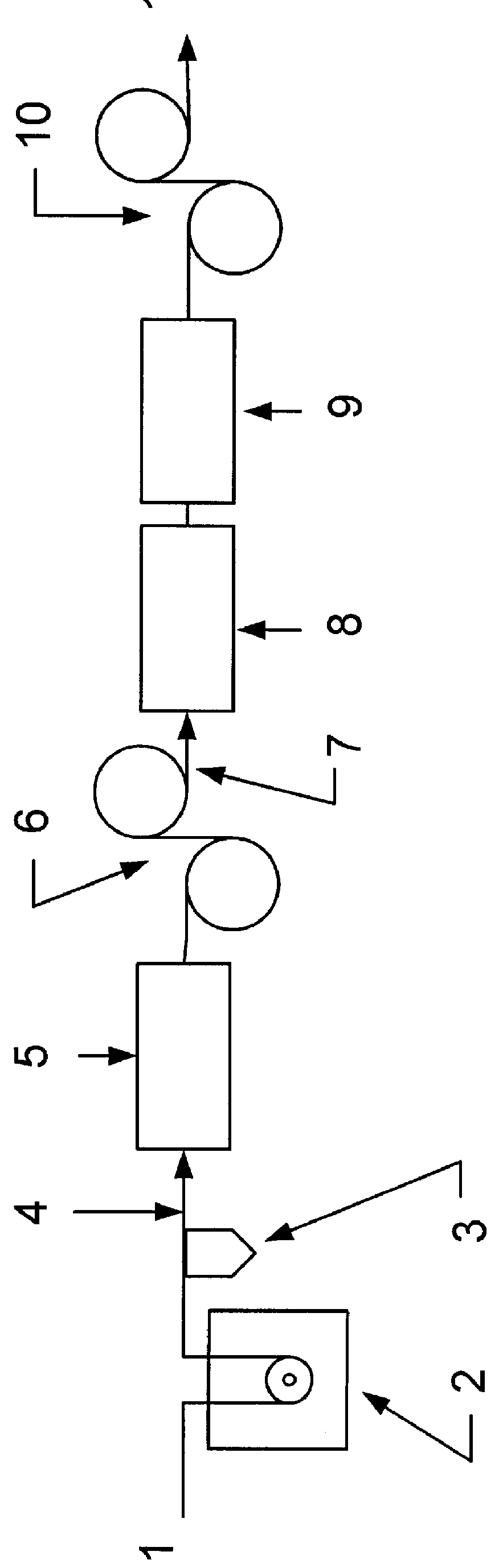

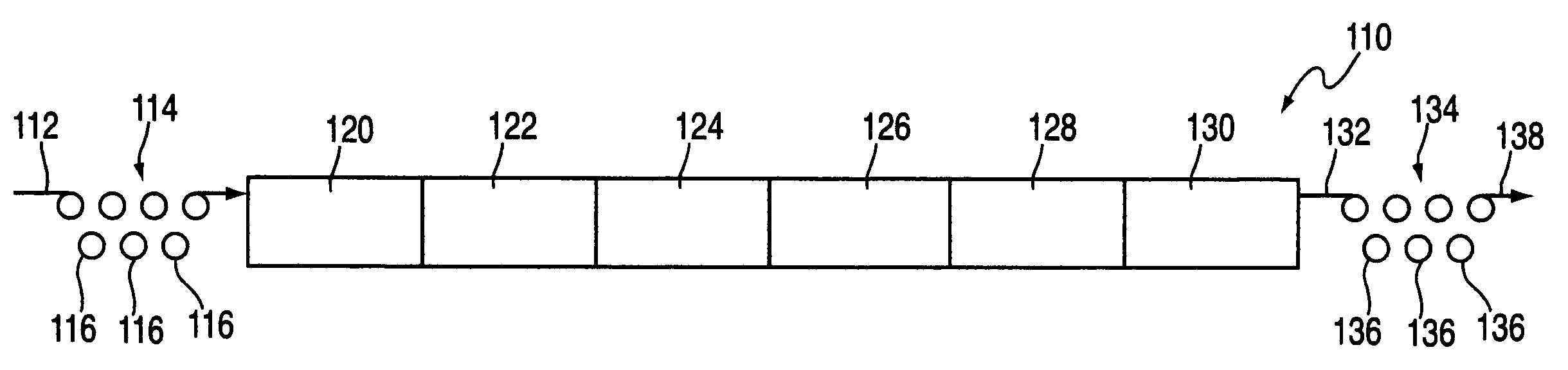

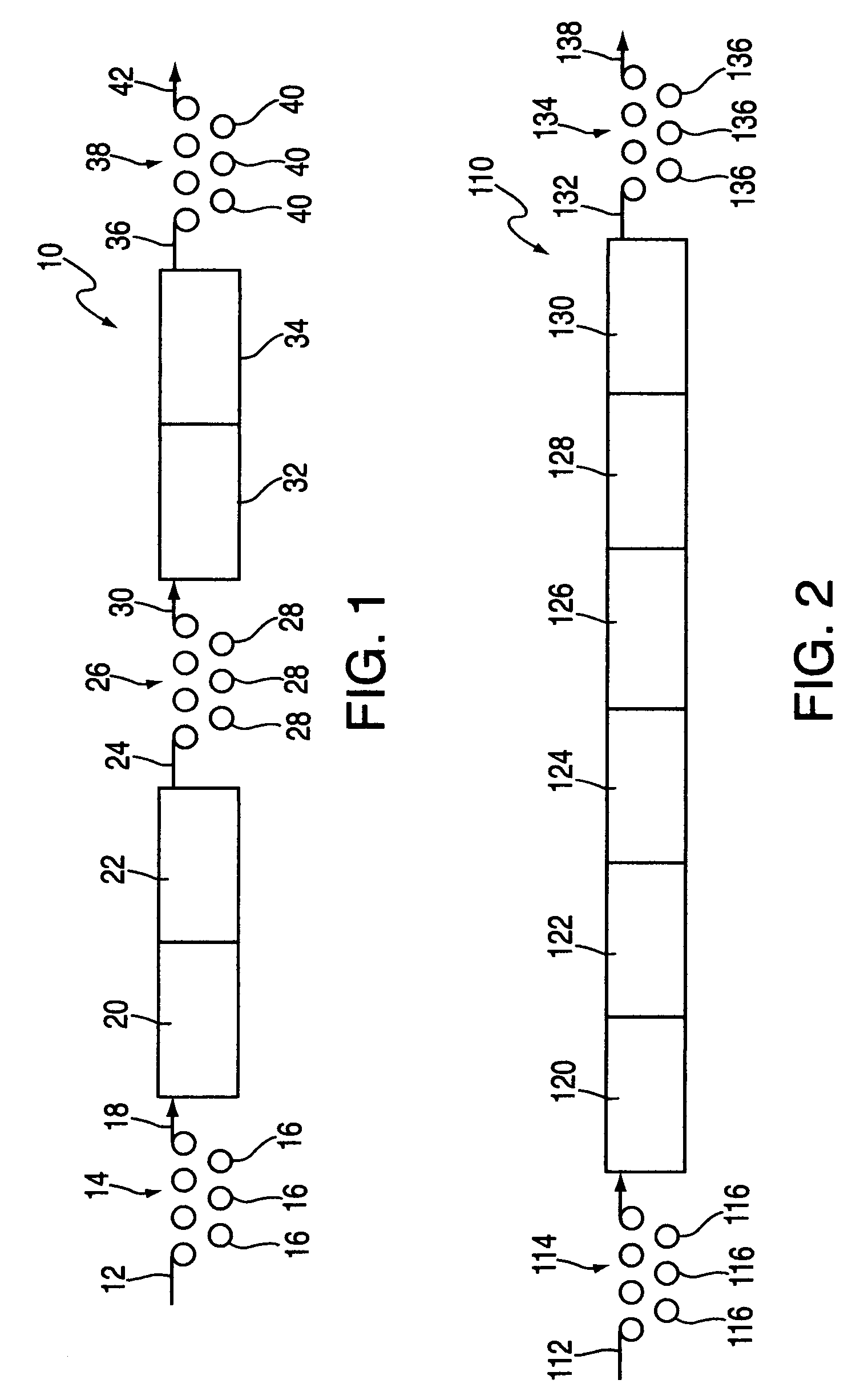

Heating apparatus and process for drawing polyolefin fibers

ActiveUS7370395B2Lower capital expenditureLower expensesDrying gas arrangementsDrying machines with progressive movementsFiberPolyolefin

Owner:HONEYWELL INT INC

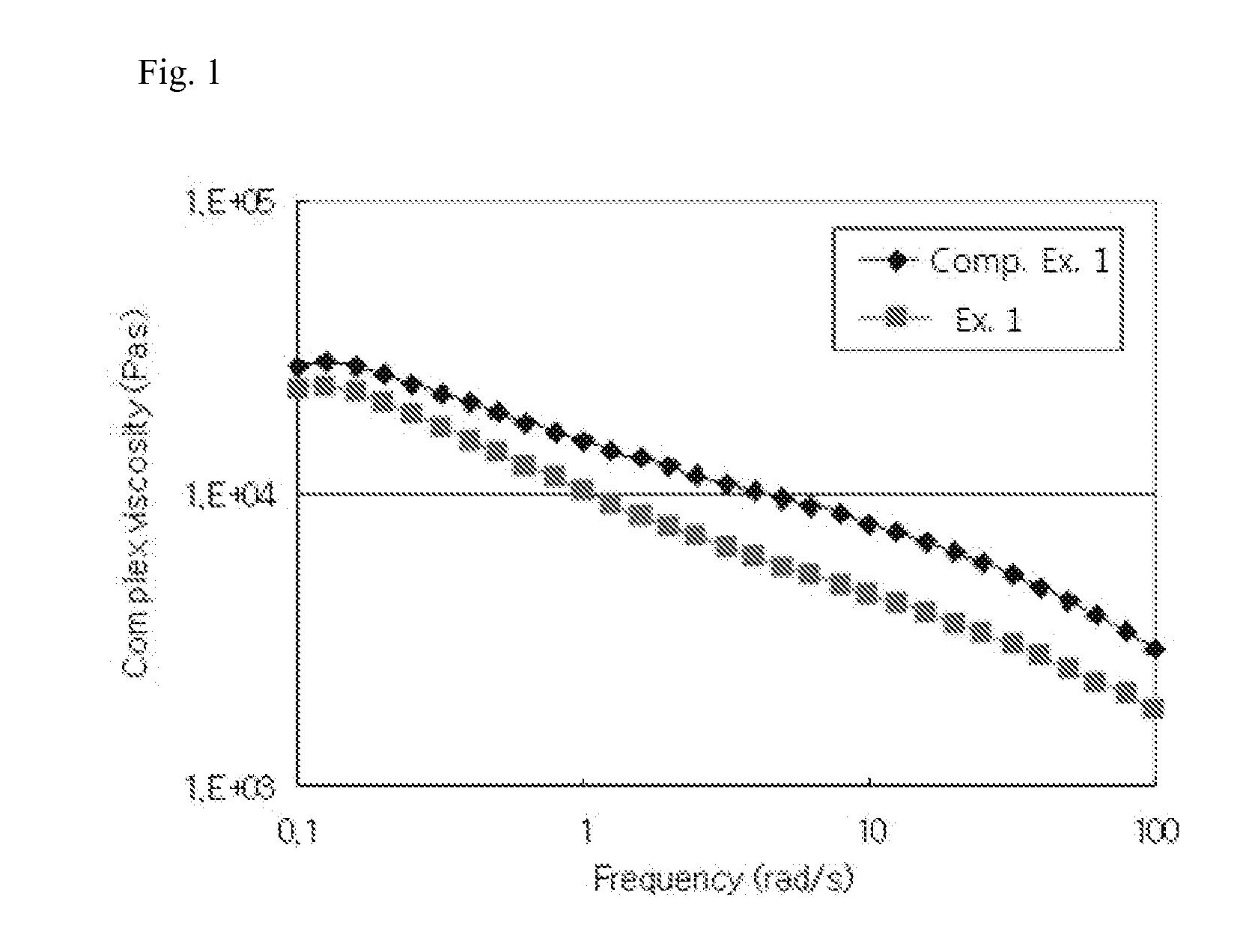

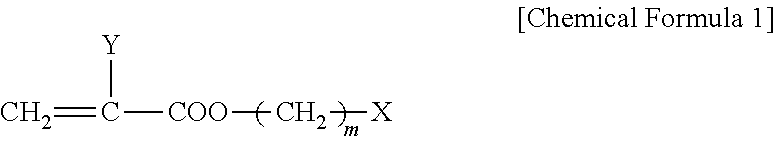

Transparent Thermoplastic Resin Composition with Improved Impact Strength and Melt Flow Index

The present invention provides a transparent thermoplastic resin composition which may comprise (A) about 1 to about 100 parts by weight of an ultra-high molecular weight branched acrylic copolymer resin; (B) about 0 to about 99 parts by weight of an acrylic resin; and (C) about 0 to about 40 parts by weight of an acrylic impact modifier, based on 100 parts by weight of (A) and (B). The ultra-high molecular branched acrylic copolymer resin (A) may be prepared by polymerizing a monomer mixture comprising (a1) about 50 to about 99.899% by weight of a mono-functional monomer, (a2) about 0.1 to about 40% by weight of a (meth)acrylic monomer having a flexible segment represented following Chemical Formula 1, and (a3) about 0.001 to about 10% by weight of a branch-inducing monomer. The thermoplastic resin composition of the present invention can have improved transparency, scratch resistance, flowability, and impact strength.wherein m is an integer from 3 to 18, Y is methyl or hydrogen, and X is methyl or hydrocarbon.

Owner:LOTTE ADVANCED MATERIALS CO LTD

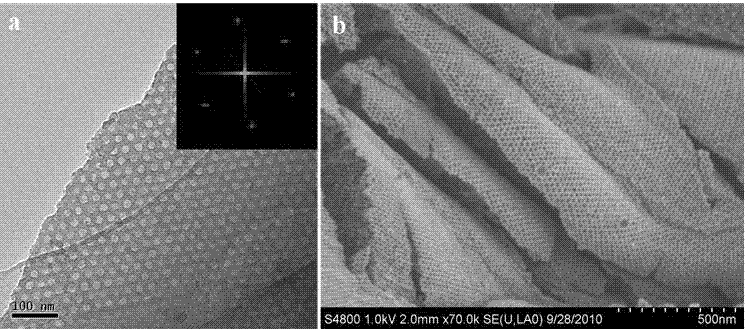

Super high molecular mass polythylene/carbon nano tube composite fiber used in jelly glue spinning and its preparation

InactiveCN1431342AImprove performanceAvoid damageMonocomponent polyolefin artificial filamentFiberRefractory

A gel-spinning ultrahigh-molecular-weight composite polyethene (UHMWPE) / carbon nanotube fibre is composed of UHMWPE and carbon nanotubes (0.01-5 wt.%) as modifier. It is prepared through purifying and organizing carbon nanotubes, preparing gel, and spinning. Its advantages are simple preparing process and high refractory and anticreep performance.

Owner:DONGHUA UNIV

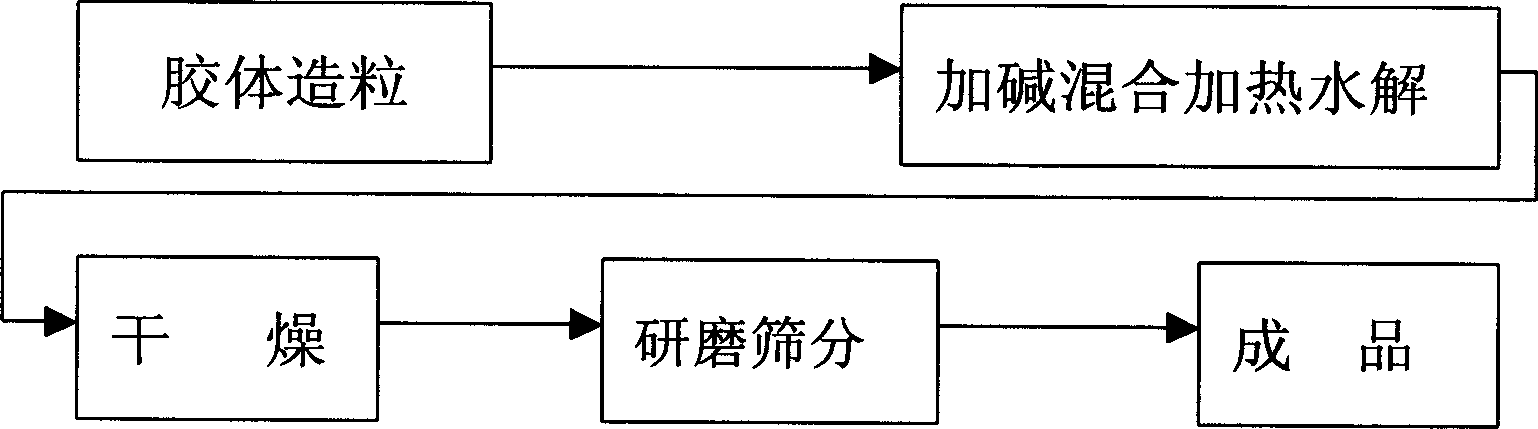

Hydrolysis method in technique for synthesizing polyacrylamide with super molecular weight

A hydraulic process for synthesizing the ultrahigh-molecular polyacrylamide used to treat the sewage in oil field includes polymerizing reaction of the acquous solution of acrylamide to become colloid, granulating, proportionally mixing it with solid alkali, and stirring in stirrer while heatinb by the hot water jacket of stirrer. Its molecular weight can reach 28,000,000.

Owner:PETROCHINA CO LTD

Rotational molding wear-resistant polyolefin resin and preparation method thereof

InactiveCN101735505AImprove wear resistanceImprove friction and wear propertiesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a rotational molding wear-resistant polyolefin resin and a preparation method thereof. In the rotational molding wear-resistant polyolefin resin, raw materials commonly used in the rotational molding process, namely linear low-density polyethylene, high-density polyethylene or polypropylene is taken as a matrix material; and by adding components of an inorganic filler, ultrahigh molecular weight polyethylene and a lubricant, the wear resistance of the matrix resin is improved. The rotational molding wear-resistant polyolefin resin consists of the following components in percentage by mass: 70 to 80 percent of matrix resin, 10 to 15 percent of inorganic filler subjected to surface treatment, 4 to 13 percent of ultrahigh molecular weight polyethylene and 1.5 to 2 percent of lubricant, wherein the matrix resin is the linear low-density polyethylene, the high-density polyethylene or the polypropylene; and a range of a melt flow rate of the matrix resin is between 2g / 10min and 15g / 10min.

Owner:江苏吉星管业科技有限公司

Microporous material

ActiveUS20110256364A1Synthetic resin layered productsTobacco devicesPolyolefinVolumetric Mass Density

Microporous materials that include thermoplastic organic polyolefin polymer (e.g., ultrahigh molecular weight polyolefin, such as polyethylene), particulate filler (e.g., precipitated silica), and a network of interconnecting pores, are described. The microporous materials of the present invention possess controlled volatile material transfer properties. The microporous materials can have a density of at least 0.8 g / cm3; and a volatile material transfer rate, from the volatile material contact surface to the vapor release surface of the microporous material, of from 0.04 to 0.6 mg / (hour*cm2). In addition, when volatile material is transferred from the volatile material contact surface to the vapor release surface, the vapor release surface is substantially free of volatile material in liquid form.

Owner:PPG IND OHIO INC

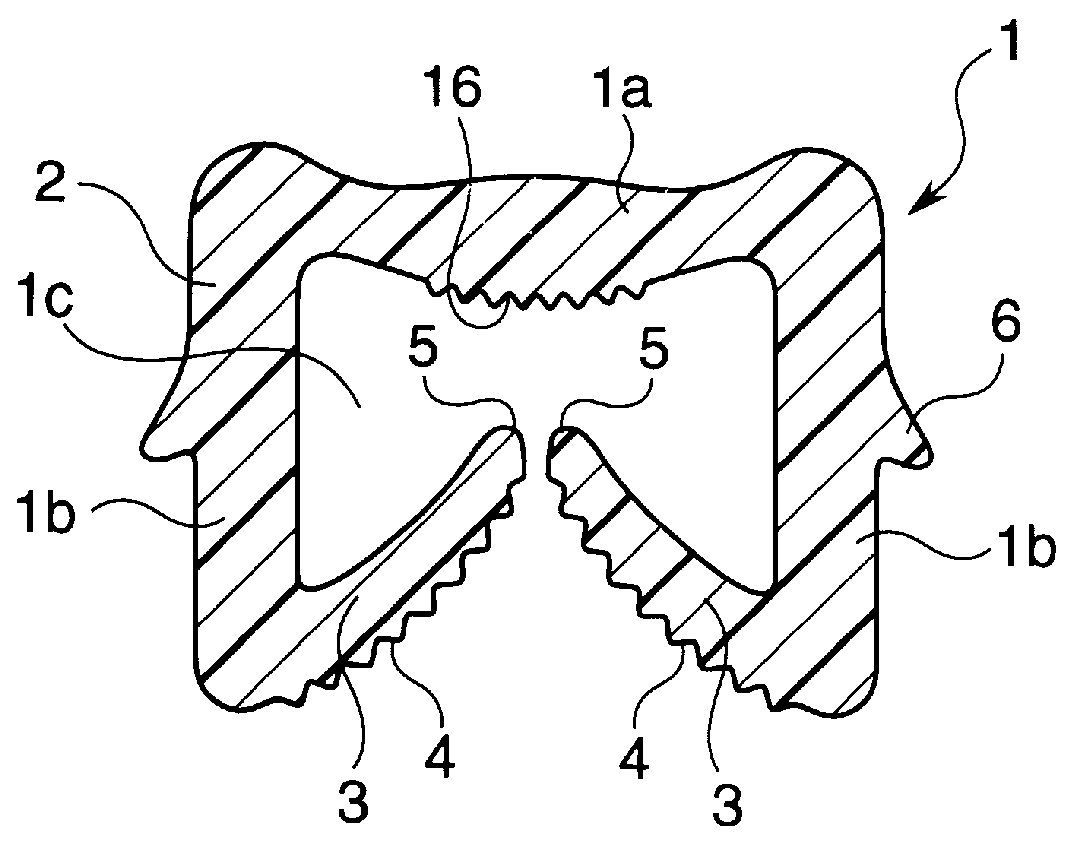

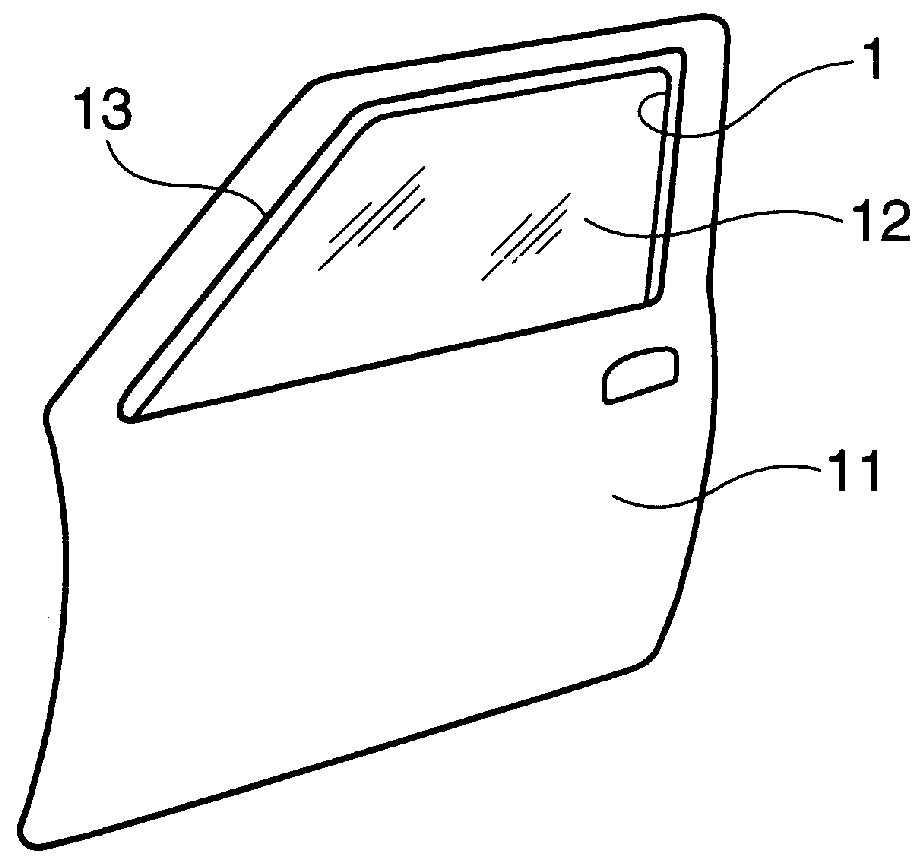

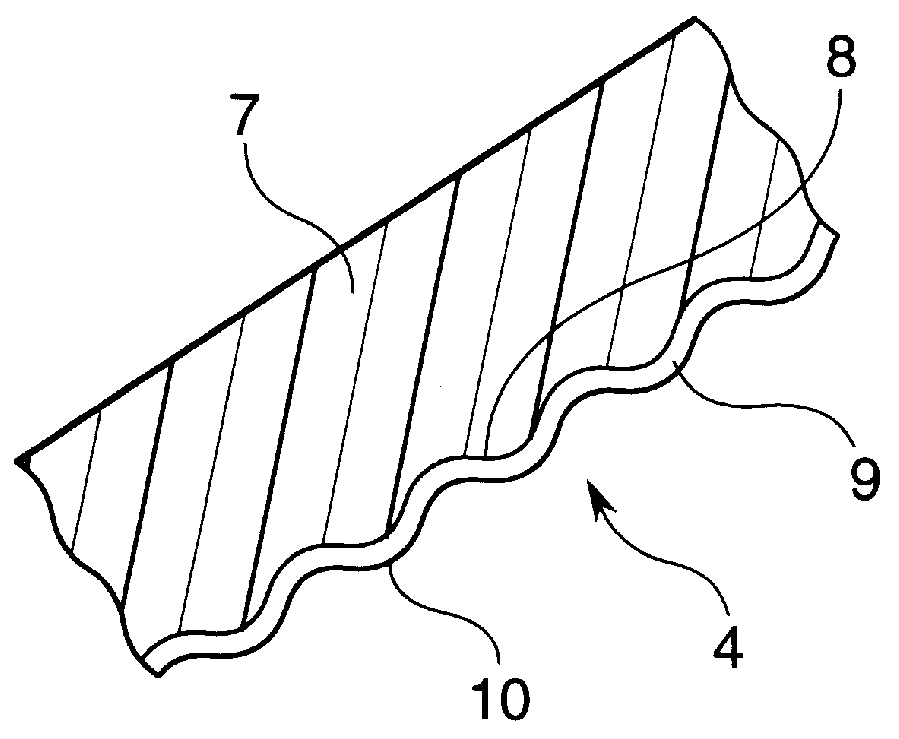

Glass run channel

InactiveUS6146739AReduce the number of stepsIncreased durabilityWindowsEngine sealsElastomerPolymer science

A glass run channel comprising a glass run channel body composed of a bottom wall and side walls extending from two opposite edges of the bottom wall, the glass run channel body having a substantially U-shaped section and provided with a groove, and tonguelike draining parts protruding from vicinities of distal edges of the side walls toward the bottom wall of the glass run channel body so as to become proximate to each other. Each of the tonguelike draining parts has a window glass contact part composed of a surface to be brought into contact with a window glass, which comprises a layer of a thermoplastic elastomer and a layer of an ultrahigh molecular weight polyolefin composition. The layer of ultrahigh molecular weight polyolefin composition is arranged so as to contact a window glass. The ultrahigh molecular weight polyolefin composition comprises at least a polyolefin (composition) having a specified intrinsic viscosity and an olefinic thermoplastic elastomer. The glass run channel is excellent in the durability, tight contactability with a window glass exhibited when the window glass is held closed and supple slide exhibited when a window glass is closed or opened and, even when twisted or bent, is free from a creasing of the ultrahigh molecular weight polyolefin composition layer.

Owner:MITSUI CHEM INC

Microporous material

Microporous materials that include thermoplastic organic polyolefin polymer (e.g., ultrahigh molecular weight polyolefin, such as polyethylene), particulate filler (e.g., precipitated silica), and a network of interconnecting pores, are described. The microporous materials of the present invention possess controlled volatile material transfer properties. The microporous materials can have a density of at least 0.8 g / cm3; and a volatile material transfer rate, from the volatile material contact surface to the vapor release surface of the microporous material, of from 0.04 to 0.6 mg / (hour*cm2). In addition, when volatile material is transferred from the volatile material contact surface to the vapor release surface, the vapor release surface is substantially free of volatile material in liquid form.

Owner:PPG IND OHIO INC

Ordered mesoporous metal oxide material with ultra-large aperture and preparation method thereof

InactiveCN102173390AIncrease freedomReduce the rate of hydrolysisMaterial nanotechnologyOxide/hydroxide preparationSynthesis methodsMesoporous material

The invention belongs to the field of advanced nano-sized porous materials and techniques, in particular relates to an ordered mesoporous metal oxide material with ultra-large aperture and a preparation method thereof. According to the invention, a block copolymer with ultrahigh-molecular-weight hydrophobic segments is used as a template agent for the mesoporous material, and based on the principle of ligand-assisted self-assembly, the microphase separation of the ultrahigh-molecular-weight hydrophobic segments from hydrophilic phases occurs during the solvent evaporation process, to form an ordered mesoscopic structure. A variety of materials are used for synthesizing the mesoporous material, such as titanium dioxide, aluminum oxide and zinc oxide. The synthesized mesoporous material retains the order of mesopores and has an extremely large aperture not less than 20 nm. The invention provides an effective and convenient method for synthesizing ultra-large aperture mesoporous materials. The material and the synthesis method of the material have wide application prospect in various fields. The method is simple, has easily-available raw materials, and is suitable for large-scale production.

Owner:FUDAN UNIV

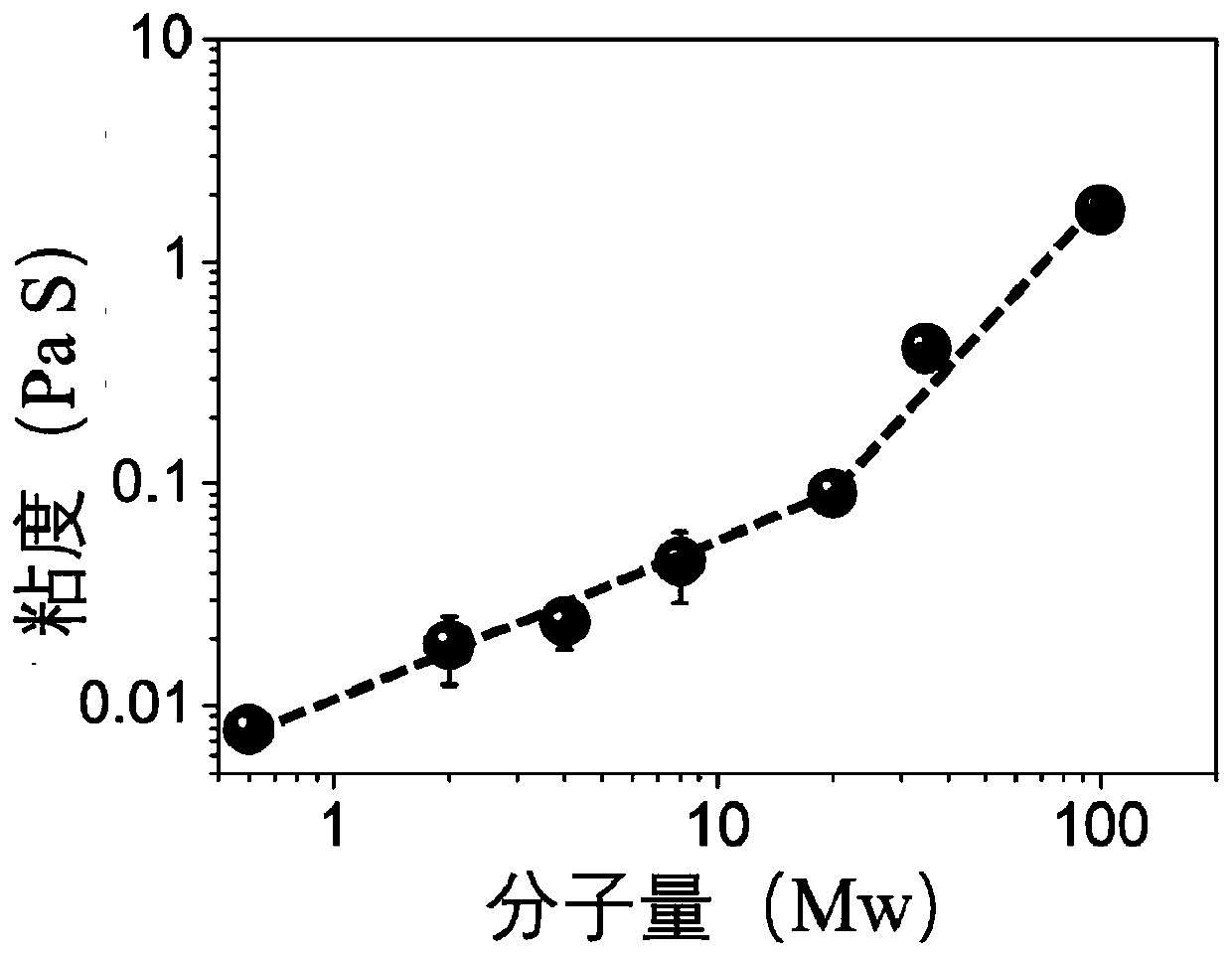

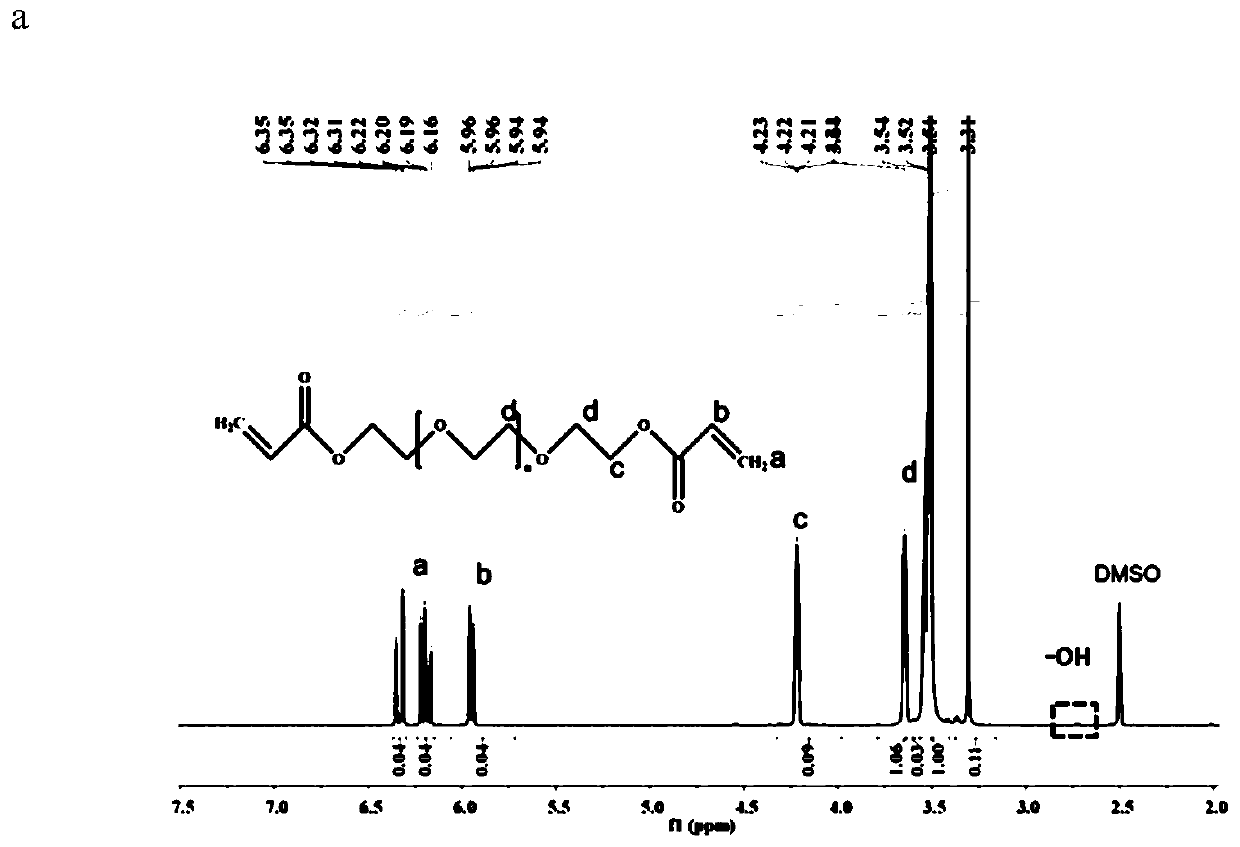

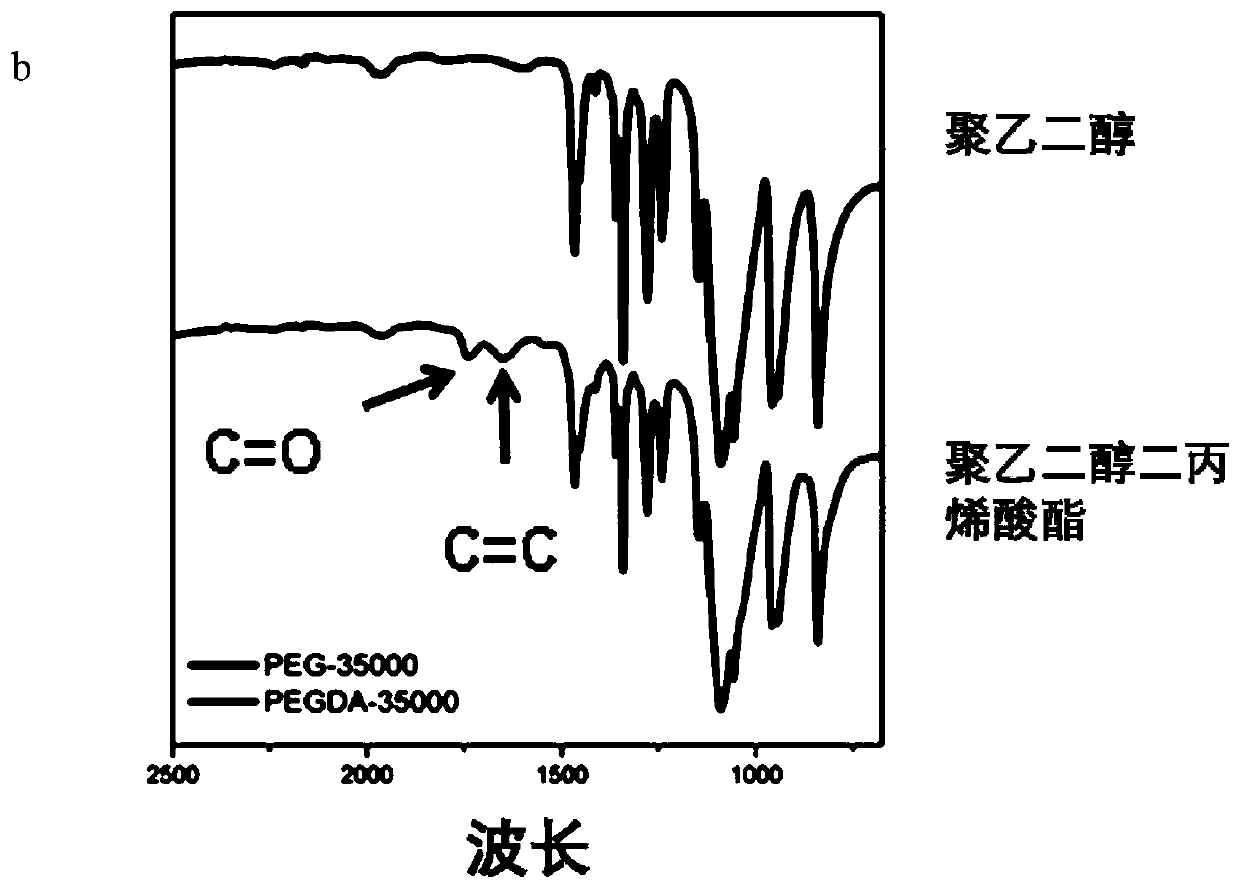

High-extension, high-adhesion and high-self-healing double network hydrogel and preparation method and application thereof

ActiveCN110240712AImprove tensile propertiesIncrease stickinessSurgical adhesivesAerosol deliverySelf-healingDouble network

The invention provides a a design strategy of a novel adhesive hydrogel material and obtains a high-extension, self-healing, and high-adhesion biocompatible hydrogel material. Based on a double network structure design principle, polymerizable polyethylene glycol-based high polymer constitutes a first covalent crosslinked network, and hydrophilic high polymer with ultra-high molecular weight forms a second noncovalent crosslinked network through entanglement. A mesh size of a first network is larger than a molecular effective size of second network high polymer, and molecular weigh of high polymer forming a second network should be larger than a critical entanglement molecular weight thereof, so that effective molecular entanglement is formed, high-extension, self-healing, and high-adhesion characteristics are given to double network hydrogel. The novel hydrogel can rapidly and repeatedly form stable adhesion with surfaces of various materials. Damaged by an external force, the hydrogel can rapidly and repeatedly perform self healing. The material can be used as a cell cultivating carrier, a sewing-free novel dressing, and can be applied to wearble sensors.

Owner:DALIAN UNIV OF TECH

Ultra high molecular weight polyethylene low-resistance wear-resistance support friction pair material and preparation thereof

An ultra high molecular weight polyethylene low-resistance wear-resistance support friction pair material comprises the following components by weight percentage: 40 to 97.8 percent of ultra high molecular weight polyethylene, 1 to 30 percent of inorganic reinforcing filler treated by a coupling agent; 1 to 15 percent of oil pad treated by a coupling agent; 0.1 to 2 percent of antioxidant, and 0.1 to 5 percent of light screener. The preparation of the support friction pair material comprises three steps of filler pretreatment, material mixing and compression molding forming. The ultra high molecular weight polyethylene UHMWPE has extremely low friction coefficient, excellent self-lubrication and wear resistance topped plastics but low surface hardness, low mechanical strength and low high temperature-resistance performance, so modification by a filling or coupling method of the ultra high molecular weight polyethylene is required. The material is advantages over pure poly(tetrafluoroethylene) in terms of bearing strength and wear resistance, is characterized by low friction coefficient and small creep deformation, improves compatibility, further ensures the wear resistance of the material and meets use requirements.

Owner:LUOYANG SUNRUI SPECIAL EQUIP

Encapsulated cathode active material particles, lithium secondary batteries containing same, and method of manufacturing

ActiveUS10483533B2High molecular weightInhibition of dissolutionSolid electrolytesCell electrodesPolyethylene oxideMeth-

Provided is particulate of a cathode active material for a lithium battery, comprising one or a plurality of cathode active material particles being embraced or encapsulated by a thin layer of a high-elasticity polymer having a recoverable tensile strain no less than 5%, a lithium ion conductivity no less than 10−6 S / cm at room temperature, and a thickness from 0.5 nm to 10 μm, wherein the polymer contains an ultrahigh molecular weight (UHMW) polymer having a molecular weight from 0.5×106 to 9×106 grams / mole. The UHMW polymer is preferably selected from polyacrylonitrile, polyethylene oxide, polypropylene oxide, polyethylene glycol, polyvinyl alcohol, polyacrylamide, poly(methyl methacrylate), poly(methyl ether acrylate), a copolymer thereof, a sulfonated derivative thereof, a chemical derivative thereof, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Polycarbonate Resin Composition with Excellent Scratch Resistance and Impact Strength

A polycarbonate resin composition according to the present invention comprises a polycarbonate resin and an ultra-high molecular weight branched acrylic copolymer resin and can have excellent transparency, appearance, and flowability, as well as scratch resistance and impact strength.

Owner:LOTTE ADVANCED MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com