Patents

Literature

249results about How to "Improve friction and wear properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmental ceramic base friction material free of copper or metal and preparation method of material

InactiveCN103881657AGood mechanical skeleton performanceStable coefficient of frictionOther chemical processesFriction liningSulfurMetallic sulfide

The invention discloses an environmental ceramic base friction material free of copper or metal and a preparation method of the material. The environmental ceramic base friction material is characterized by comprising the following components by weight percent: 6-12% of phenolic resin, 2-10% of ceramic fiber, 2-8% of inorganic fiber, 2-10% of rubber, 4-12% of graphite, 10-25% of potassium titanate lamella, 3-15% of mineral fiber, 4-20% of metal sulfur compound, 6-20% of grinding aid and 5-20% of filler. The prepared friction material has excellent friction and wear properties, high heat-conducting property, excellent high-temperature decline property, stable friction coefficient, and excellent noise performance.

Owner:YANTAI SHENGRUI BRAKE SYST

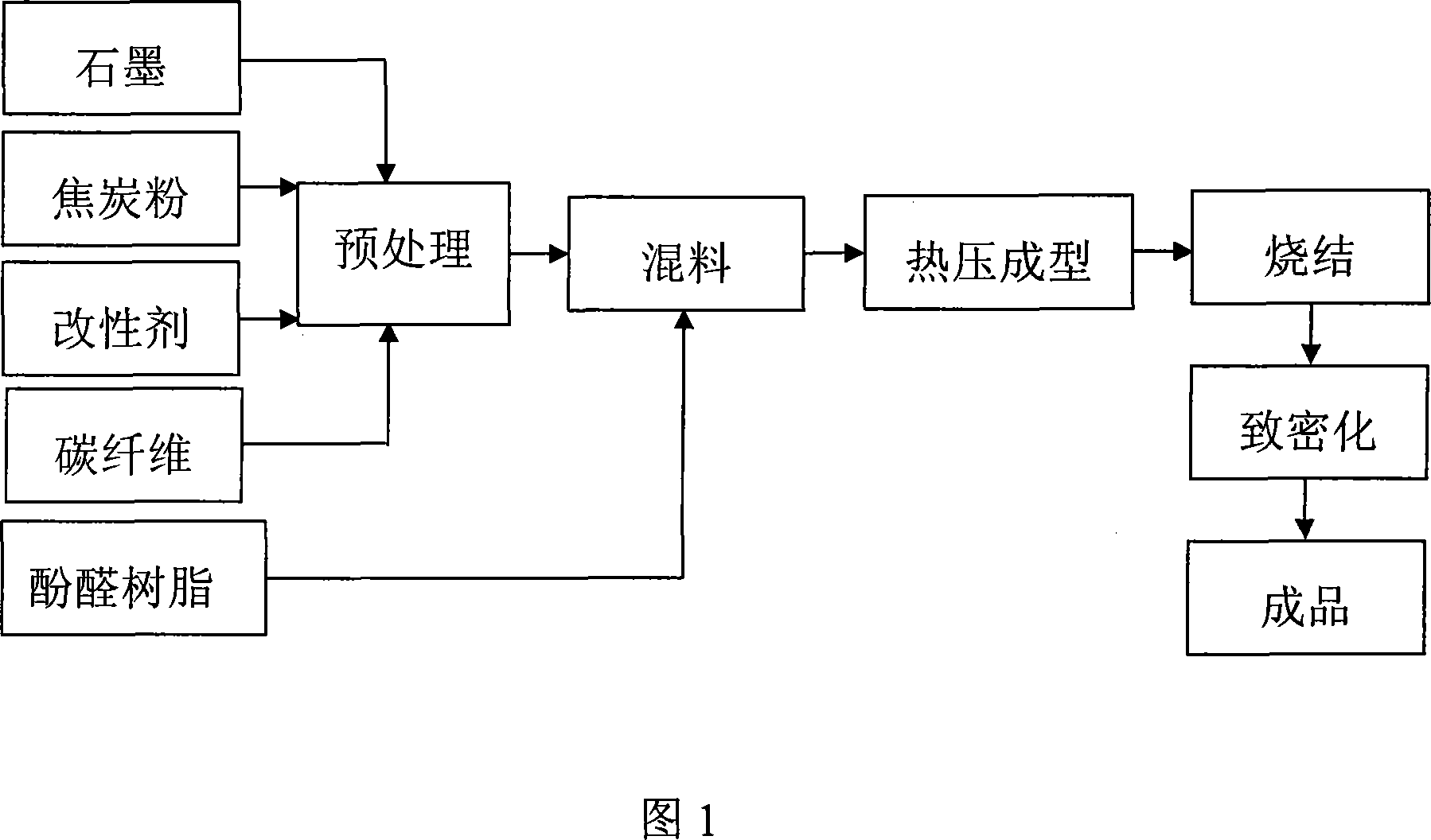

Preparation process of carbon base sliding block material for track vehicle

InactiveCN101165819AImprove conductivityImprove friction and wear propertiesNon-metal conductorsNon-conductive material with dispersed conductive materialFiberCarbon fibers

The preparation method comprises: 1) raw material processing: placing graphite, coke blacking, chopped carbon fiber and modifier at the drying cabinet to remove moisture from them; the drying temperature is 100 deg. C, and the drying time is 2-4 hours; 2) blending: evenly blending the graphite, coke blacking and chopped carbon fiber; adding the copper powder, copper fiber and modifier; in the last, adding phenolic resin to make mould material; 3) hot compacting and forming: placing the mould materials into die; heating and pressing it to make solidification forming; the press is 50-100MP, and the temperature is 160-170 deg. C; keeping 0.5-1 hours in room temperature; 4) sintering: making the sintering form the sample; the temperature is 800-900 deg. C, and the time length is 2-4 hours; 5) densification processing: after chemical vapor deposition or bituminizing, making the carbonizing treatment.

Owner:BEIHANG UNIV

Rotational molding wear-resistant polyolefin resin and preparation method thereof

InactiveCN101735505AImprove wear resistanceImprove friction and wear propertiesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a rotational molding wear-resistant polyolefin resin and a preparation method thereof. In the rotational molding wear-resistant polyolefin resin, raw materials commonly used in the rotational molding process, namely linear low-density polyethylene, high-density polyethylene or polypropylene is taken as a matrix material; and by adding components of an inorganic filler, ultrahigh molecular weight polyethylene and a lubricant, the wear resistance of the matrix resin is improved. The rotational molding wear-resistant polyolefin resin consists of the following components in percentage by mass: 70 to 80 percent of matrix resin, 10 to 15 percent of inorganic filler subjected to surface treatment, 4 to 13 percent of ultrahigh molecular weight polyethylene and 1.5 to 2 percent of lubricant, wherein the matrix resin is the linear low-density polyethylene, the high-density polyethylene or the polypropylene; and a range of a melt flow rate of the matrix resin is between 2g / 10min and 15g / 10min.

Owner:江苏吉星管业科技有限公司

TiSiN+ZrSiN composite nanometer coated cutting tool and preparation method thereof

InactiveCN103273687AImprove friction and wear propertiesReduce residual stressVacuum evaporation coatingSputtering coatingAlloyDry machining

The invention provides a TiSiN+ZrSiN composite nanometer coated cutting tool and a preparation method thereof and belongs to the field of mechanical machining. A base material of the coated cutting tool is a hard alloy or high-speed steel. The TiSiN+ZrSiN composite nanometer coated cutting tool is manufactured by adopting a multi-arc ion plating+intermediate frequency magnetron sputtering method. The TiSiN+ZrSiN composite nanometer coated cutting tool is of multilayered structure, a ZrSiN coating is formed on the surface of the cutting tool, a TiZrSiN transition coating is formed between the ZrSiN coating and a TiSiN coating, and a Ti transition coating is formed between the TiSiN coating and a substrate, wherein the atomic percentage of Si content in the TiSiN coating and the ZrSiN coating is 6%-10%. The TiSiN+ZrSiN composite nanometer coated cutting tool well combines the high hardness of the TiSiN coating and the low friction coefficient of the ZrSiN coating and has high hardness, good friction and wear property and excellent high-temperature oxidation resistance; and the bonding can be alleviated in the cutting process, and the wearing of the cutting tool is reduced, so that the service life of the cutting tool is prolonged. The coated cutting tool can be widely applied to drying machining and machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

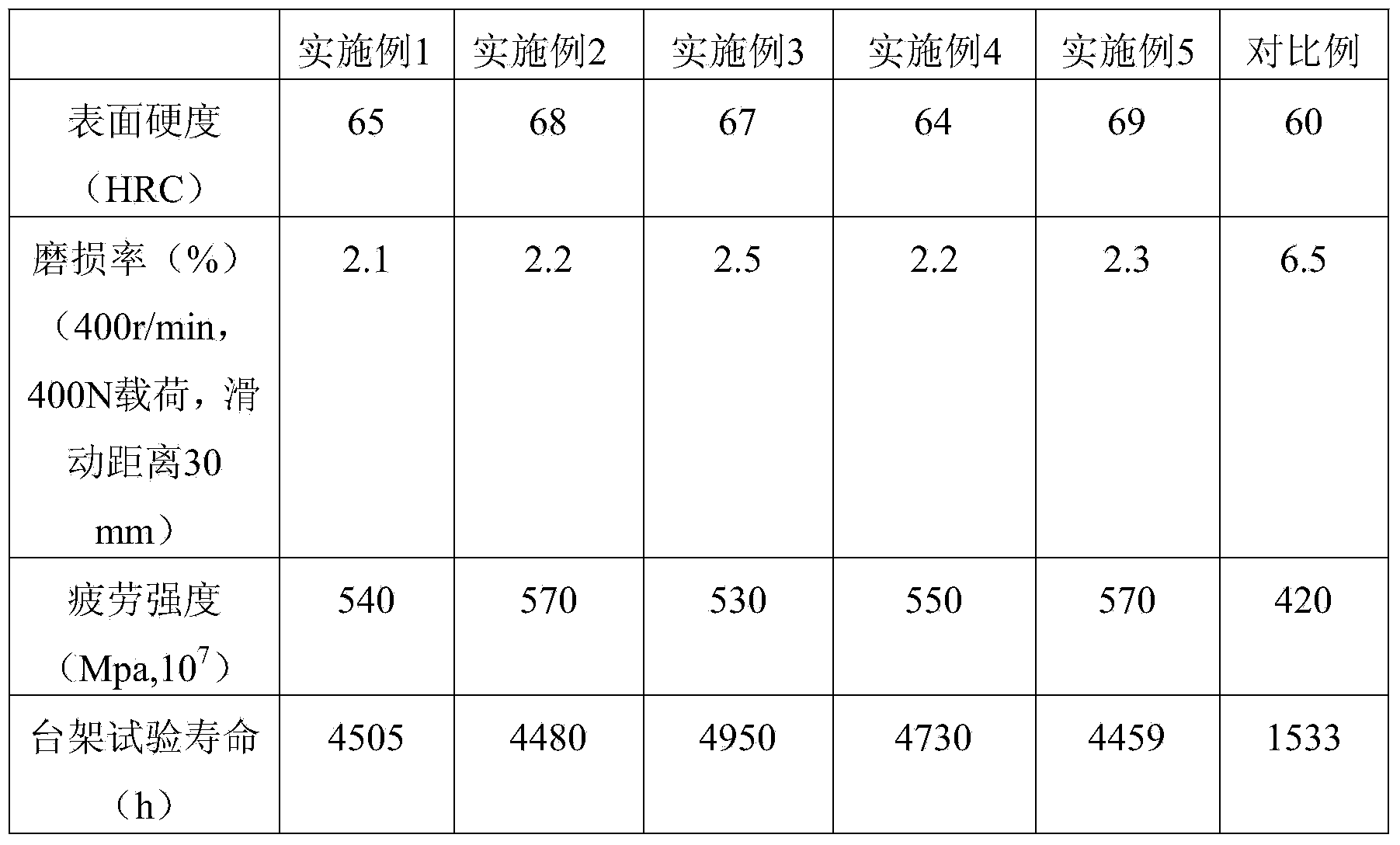

Air inlet valve and manufacturing method thereof

InactiveCN103627961AImprove heat resistanceImprove fatigueMachines/enginesLift valveHardnessHigh surface

The invention discloses an air inlet valve and a manufacturing method thereof. Alloy for manufacturing the air inlet valve comprises the following components in percentage by weight: 0.32-0.40% of C, 0.17-0.37% of Si, 2.5-3.5% of Mo, 0.50-0.80% of Mn, 0.80-1.10% of Cr, 0.50-1.0% of W, less than or equal to 0.030% of Ni, less than or equal to 0.015 of P, less than or equal to 0.015 of S, less than or equal to 0.010% of Cu and the balance of Fe. The air inlet valve is manufactured by the technologies such as surface nanocrystallization, low-temperature nitriding and surfacing of tungsten-zirconium alloy and the like. The air inlet valve has high surface strength, high hardness, good abrasion performance and long service life.

Owner:JIANGSU UNIV OF SCI & TECH

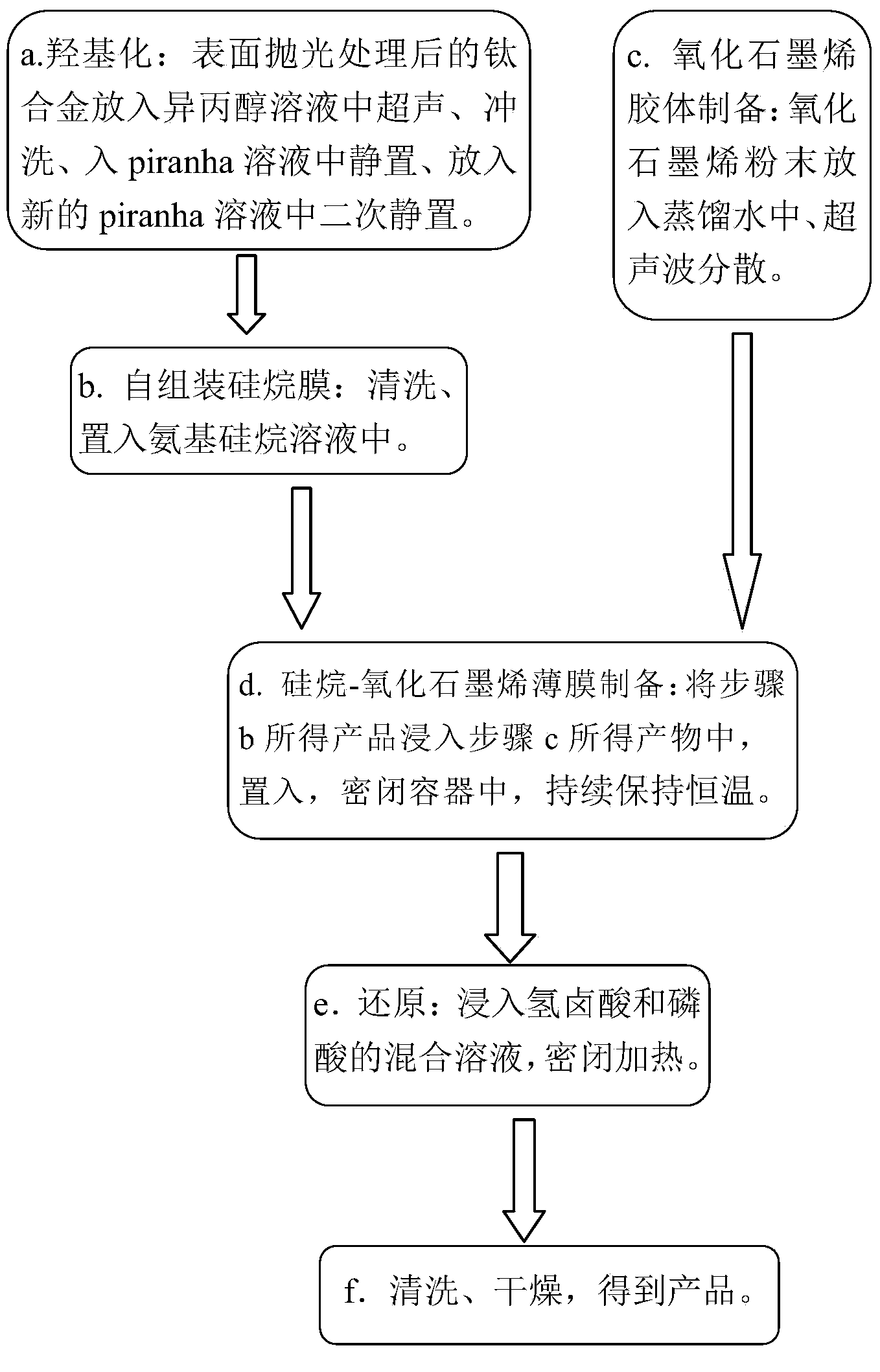

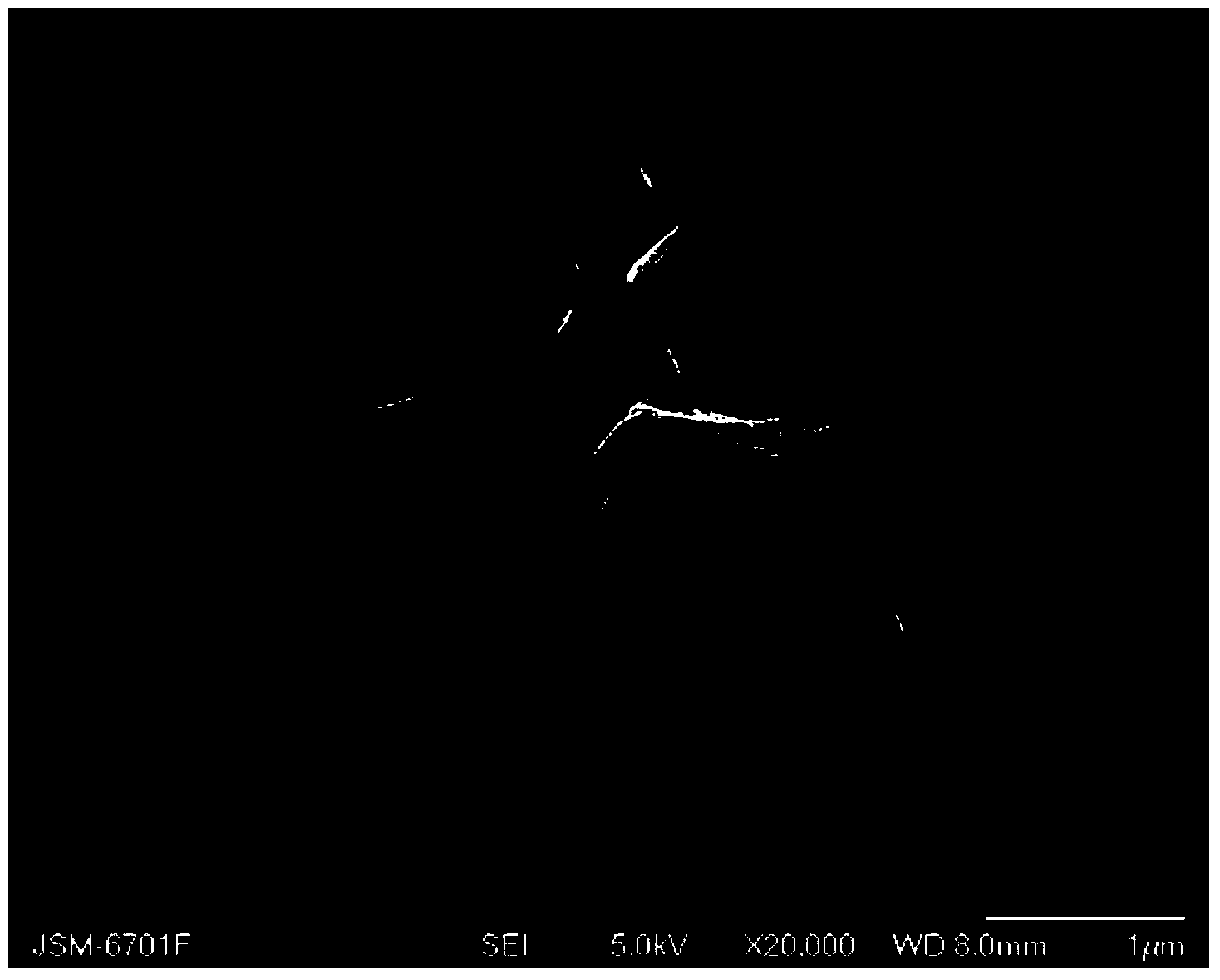

Method for preparing graphene film on surface of titanium alloy

InactiveCN104018145AReduce coefficient of frictionHigh strengthSolid/suspension decomposition chemical coatingHydrogen halideSilanes

The invention discloses a method for preparing a graphene film on the surface of titanium alloy. The method specifically comprises the following steps of putting a medical titanium alloy into a piranha solution and carrying out hydroxylation treatment, and then putting into an amino silane solution, and self-assembling a silane film; carrying out ultrasonic treatment on graphene oxide powder to obtain a stable graphene oxide colloid; immersing the titanium alloy of which the surface is attached with the silane film in the graphene oxide colloid to prepare a silane-graphene oxide film; and finally, reducing the graphene oxide film with hydrogen halide acid, and drying to obtain the reduced graphene oxide composite film. The method disclosed by the invention is simple and causes no harm to experiment operators, and the obtained film has the advantages of good integrity, high strength, low coefficient of friction and excellent wear resistance and is expected to become a medical joint material.

Owner:SHANGHAI JIAO TONG UNIV

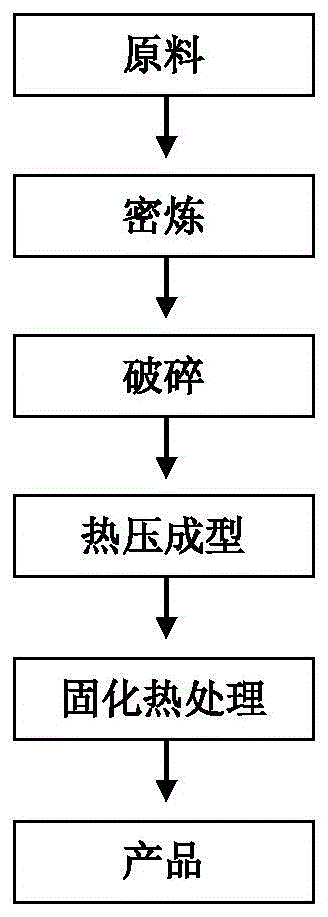

Highly ductile, abrasive-wearable self-lubricant polyformaldehyde material and its preparation method

ActiveCN1970621AImproves toughness and friction and wear propertiesReduce dosageSpheruliteCooling speed

The invention discloses a high-density, abrasion-proof self-lubricating polyformaldehyde material and making method, which comprises the following steps: drying 50-99% polyformaldehyde at 60-90 deg.c for 4-6h; adding 1-50% polyethylene oxide, 0.01-1% polyformaldehyde stabilizer, 0.01-1% formaldehyde and 0.01-1% formaldehyde adsorbent into high-speed stirrer to blend evenly; fusing at 170-200 deg.c to squeeze; cooling the squeezed material below crystallizing temperature of polyethylene oxide with cooling speed at 50-80deg.c / min; obtaining the product with high flexibility between the interior of polyformaldehyde spherulite and spherulite.

Owner:SICHUAN UNIV

Calcium carbonate whisker reinforced rubber base friction material and preparation method therefor

InactiveCN105111532AImprove brittlenessImprove heat resistanceOther chemical processesFriction liningButadiene-styrene rubberPetroleum coke

The present invention discloses a calcium carbonate whisker reinforced rubber base friction material, and a preparation method therefor. The material comprises: 8-15 parts of nitrile rubber, 10-15 parts of styrene-butadiene rubber, 5-10 parts of phenolic resin, 5-25 parts of calcium carbonate whisker, 10-20 parts of steel fiber, 2-8 parts of sepiolite fiber, 0-8 parts of mineral fiber, 0-3 parts of aramid fiber, 5-8 parts of barium sulfate, 5-10 parts of magnesium oxide, 2-3 parts of aluminum oxide, 5-10 parts of flake graphite, 1-5 parts of carbon black, 5-10 parts of petroleum coke, 3-6 parts of Cardolite cashew nut shell oil friction powder, 0.5-1 parts of sulfur, and 0.5-1 parts of accelerator. The preparation method comprises process steps of such as material collocation, mixing, pressing molding and the like. Brake pads synthesized by the method provided by the invention have the advantages including excellent friction and wear performance, stable braking performance, high heat-resistant property, safe, environmentally-friendly, and low in cost; and is suitable for braking devices for automobiles and motive power machines, thereby achieving a very wide application prospect and applying to industrial production.

Owner:GUANGXI UNIV +2

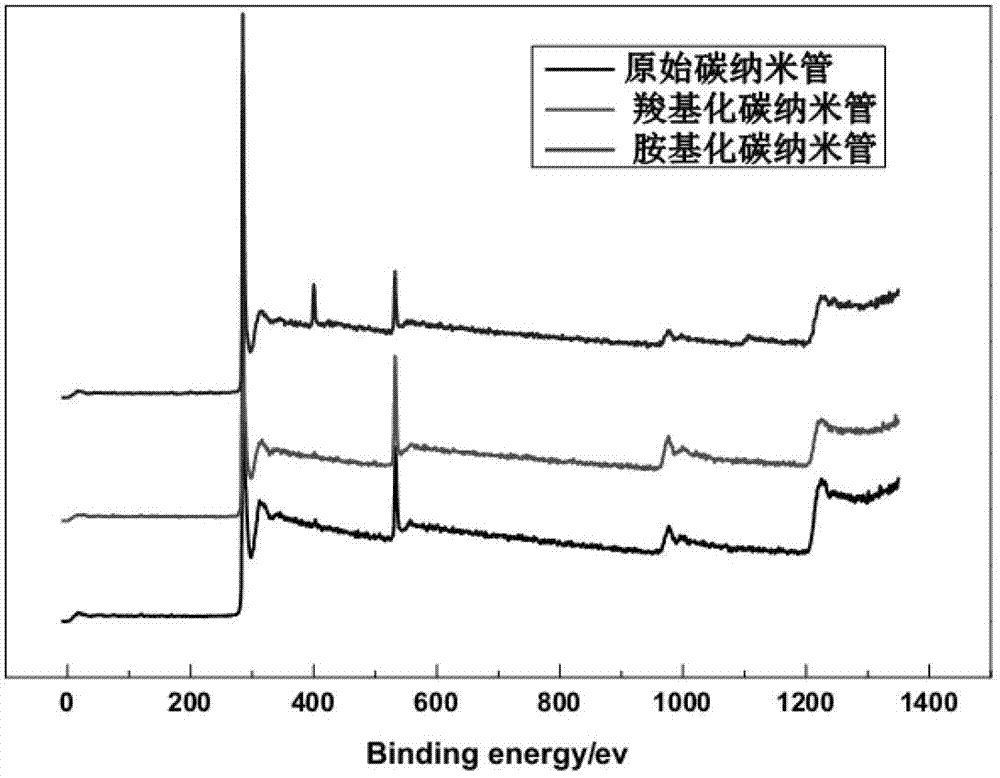

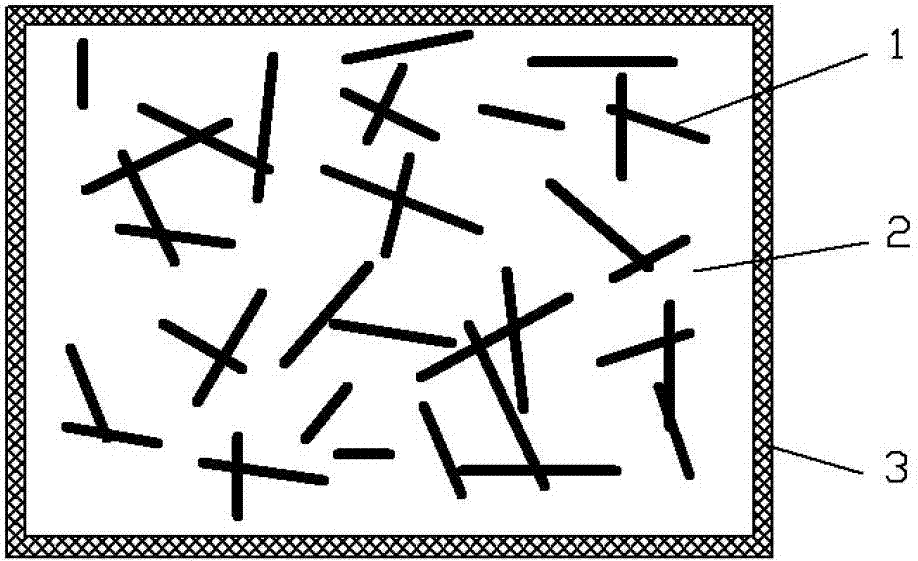

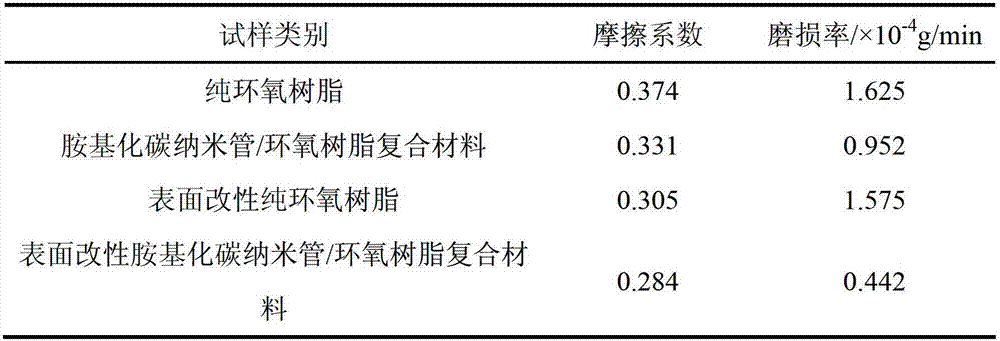

Modified inorganic nanoparticle/epoxy resin composite material with higher friction and wear properties and preparation method thereof

ActiveCN102924872AImprove wear resistanceImprove friction and wear propertiesLiquid/solution decomposition chemical coatingEpoxyFriction reduction

The invention provides a modified inorganic nanoparticle / epoxy resin composite material with higher friction and wear properties, comprising the following components by weight percentage: 95-99.9% of epoxy resin and 0.1-5.0% of modified inorganic nanoparticle, wherein the total quantity of the components is 100%. A preparation method of the material comprises the following steps of: firstly, respectively carrying out carboxylation modification and amino functionalization modification on an original carbon nano tube, mechanically mixing the obtained aminated carbon nano tube and epoxy resin, curing to obtain the carbon nano tube-enhanced epoxy resin composite material, and plating a layer of Ni-P-CNTs composite plating layer on the surface of the epoxy resin composite material by a surface chemistry composite plating technology. The effect of friction reduction and wear resistance can be achieved due to the organic synthesis between the filling of the nano-particles and the surface chemistry composite plating technology. Furthermore, the method is simple in technology and easy to implement, so that the abrasive resistance of the epoxy resin can be obviously improved.

Owner:TIANJIN POLYTECHNIC UNIV

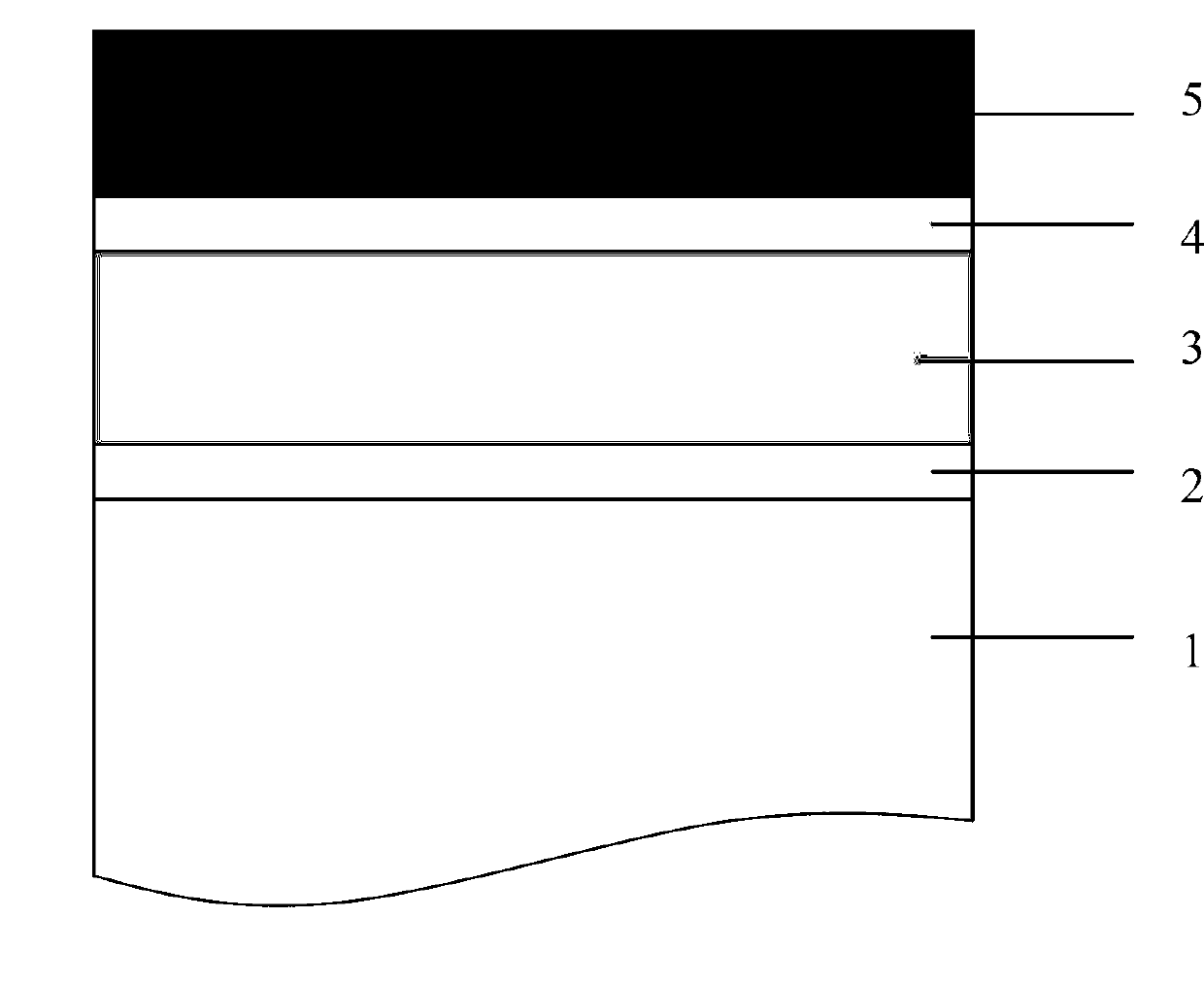

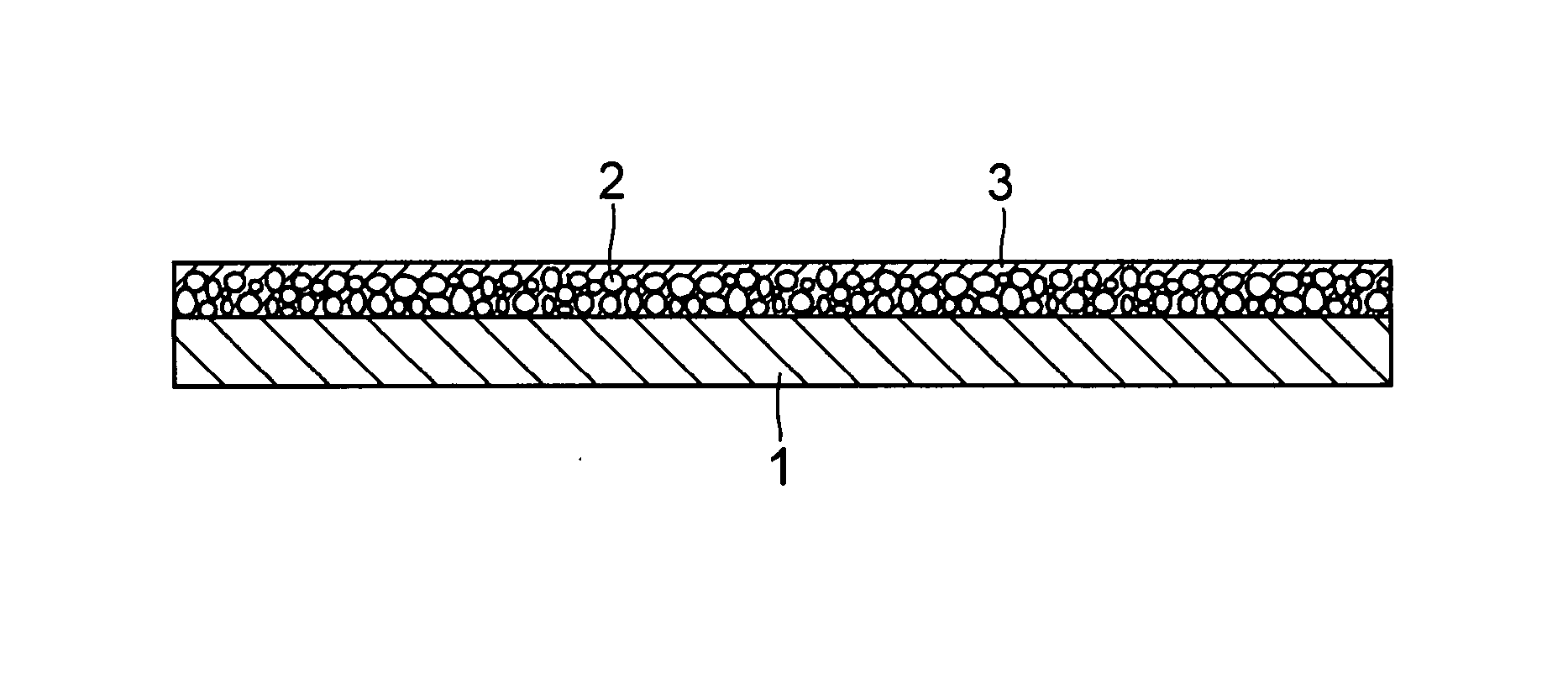

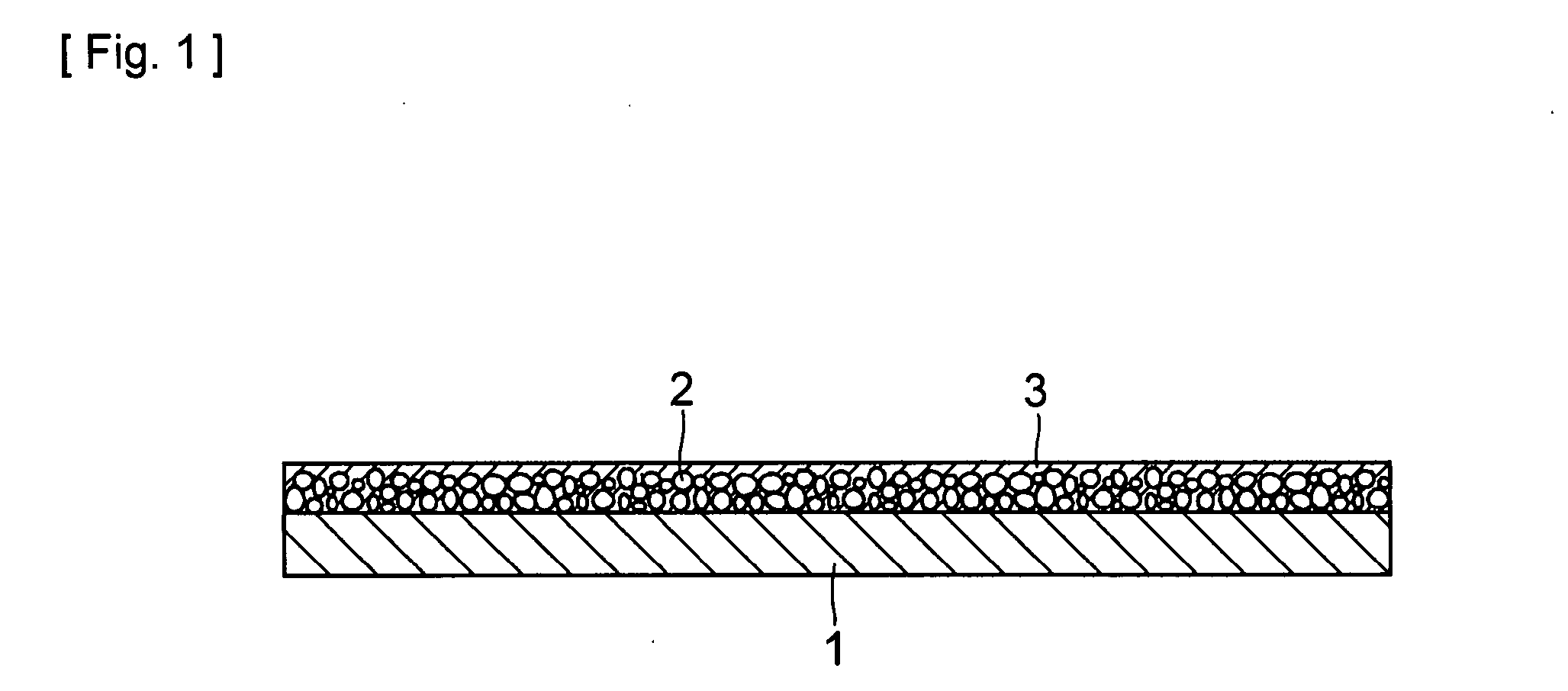

Multilayered Sliding Member

ActiveUS20070269674A1Improve friction and wear propertiesShaftsBearing componentsCompound aPhosphate

A multilayered sliding member has a resin composition filled in pores of, and coated on the surface of, a porous sintered metal layer 2 formed on the surface of a metallic backing plate 1. The resin composition is formed by compounding a phosphate, a carbon black, a melt moldable fluororesin, and a PTFE serving as a principal component, and is preferably formed by further containing graphite and / or a low molecular weight PTFE.

Owner:OILES CORP

MOF-5 nondestructive modified carbon fiber reinforced resin-based wet friction material and preparation method thereof

ActiveCN109608822ALarge specific surface areaHigh porosityOther chemical processesBulk chemical productionN dimethylformamideCarbon fibers

The invention discloses an MOF-5 nondestructive modified carbon fiber reinforced resin-based wet friction material and a preparation method thereof. The preparation method comprises the following steps: firstly, treating carbon fibers to remove a surface sizing agent other pollutants, then treating the carbon fibers by nitric acid at a certain temperature to obtain functionalized carbon fibers forproviding active sites for subsequent growth, dissolving the carbon fibers, zinc nitrate hexahydrate and terephthalic acid in an N,N-dimethylformamide solution, carrying out uniform magnetic stirring, then carrying out a hydrothermal reaction to modify the carbon fibers to obtain MOF-5 modified carbon fibers, finally, mixing the modified carbon fibers with aramid fibers, paper fibers and resin toprepare friction material body paper, and carrying out hot-pressing curing process to obtain the MOF-5 modified carbon fiber reinforced resin-based wet friction material. According to the invention,loss caused by a conventional treatment process on carbon fibers can be avoided, and strength of the fibers is not damaged while surface activity of the fibers is improved.

Owner:SHAANXI UNIV OF SCI & TECH

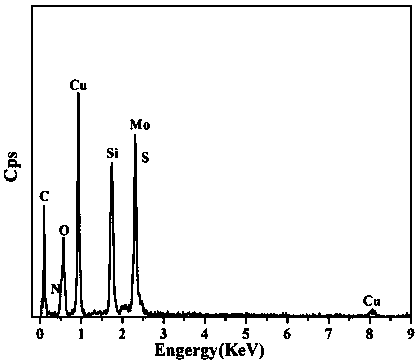

Preparation method of lubricating material with nano-copper particles loaded on molybdenum disulfide nanosheets

InactiveCN107557110AGood for lubrication synergyImprove friction and wear propertiesMaterial nanotechnologyAdditivesNano copperBase oil

The invention relates to a preparation method of a lubricating material with nano-copper particles loaded on molybdenum disulfide nanosheets. The preparation method comprises the following steps: dispersing molybdenum disulfide nanosheets into a Tris-HCl buffer solution, adding dopamine hydrochloride after uniform dispersion, and grafting polydopamine onto the surfaces of molybdenum disulfide nanosheets; then dispersing functional molybdenum disulfide nanosheets into ethanol, and adding soluble copper, adding a reducing agent after the soluble copper is completely dissolved and reacting, so that the copper salt is transformed into nano-copper to be in situ loaded on the surfaces of the molybdenum disulfide nanosheets. The preparation method provided by the invention has the advantages thatpolydopamine carries out biomimetic modification on the molybdenum disulfide nanosheets, the preparation technology is simple, polydopamine can organically combine the molybdenum disulfide nanosheetswith nano copper together, and abundant active groups are provided on the surfaces of the molybdenum disulfide nanosheets; after in situ reduction, the nano copper is uniformly adhered on the surfaces of the molybdenum disulfide nanosheets, so that the composite not only can be uniformly and stably dispersed into polar base oil but also has excellent antiwear and antifriction effects.

Owner:SHAANXI UNIV OF SCI & TECH

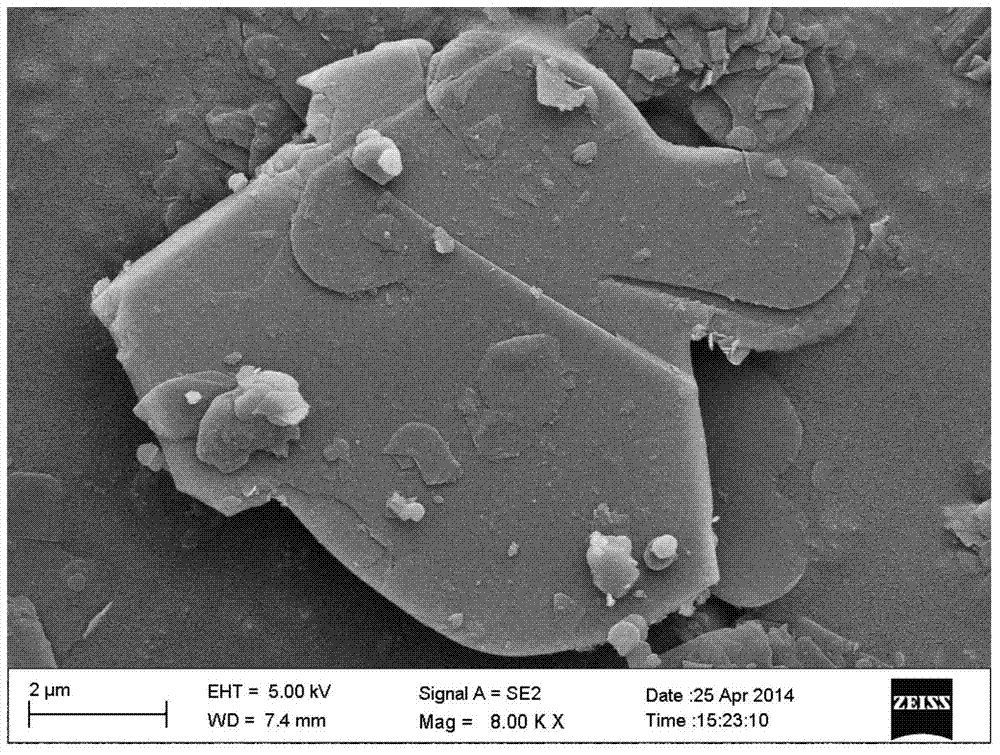

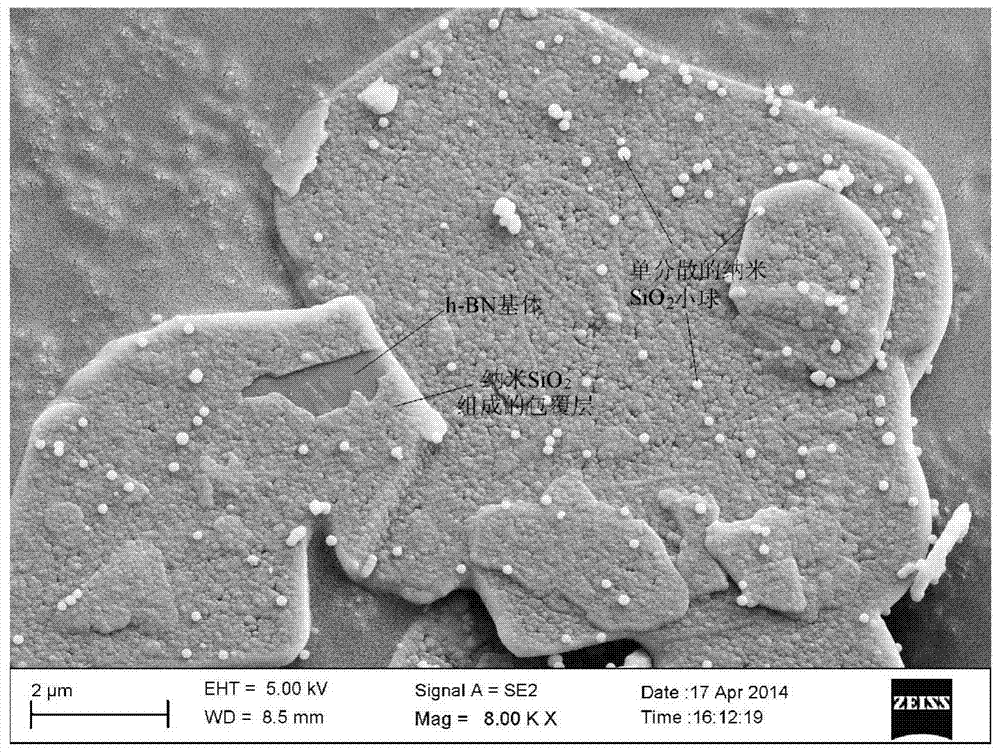

Preparation method of self-lubricating ceramic cutting tool material comprising spherical nanometer silicon dioxide coated hexagonal boron nitride composite powder

ActiveCN104844178AImprove mechanical propertiesTightly boundHexagonal boron nitrideCeramic cutting tool

The invention relates to a preparation method of self-lubricating ceramic cutting tool material comprising spherical nanometer silicon dioxide coated hexagonal boron nitride composite powder. The self-lubricating ceramic cutting tool material comprises the following raw material components in percentage by volume: 15-75% of TiC, 2-20% of h-BN@SiO2, 0.2-2.5% of MgO and the balance of Al2O3, wherein the h-BN@SiO2 is the spherical silicon dioxide coated hexagonal boron nitride composite powder which is obtained by dispersing h-BN powder in absolute ethyl alcohol and dropwise adding tetraethyl orthosilicate at the temperature of 30-70 DEG C. The invention also provides the preparation method of the self-lubricating ceramic cutting tool material. The added h-BN@SiO2 can improve the wettability of h-BN@SiO2 and a matrix and the mechanical property of the cutting tool material when the excellent lubricating property of the cutting tool material is remained, and reduce the agglomeration of air holes and the h-BN@SiO2 and the negative influence of the added h-BN on the mechanical property of the self-lubricating ceramic cutting tool material. The self-lubricating ceramic cutting tool material is suitable for application in manufacturing of self-lubricating ceramic cutting tools and can also be used for manufacturing ceramic molds, bearings and other wear-resisting anti-corrosion components and parts.

Owner:QILU UNIV OF TECH

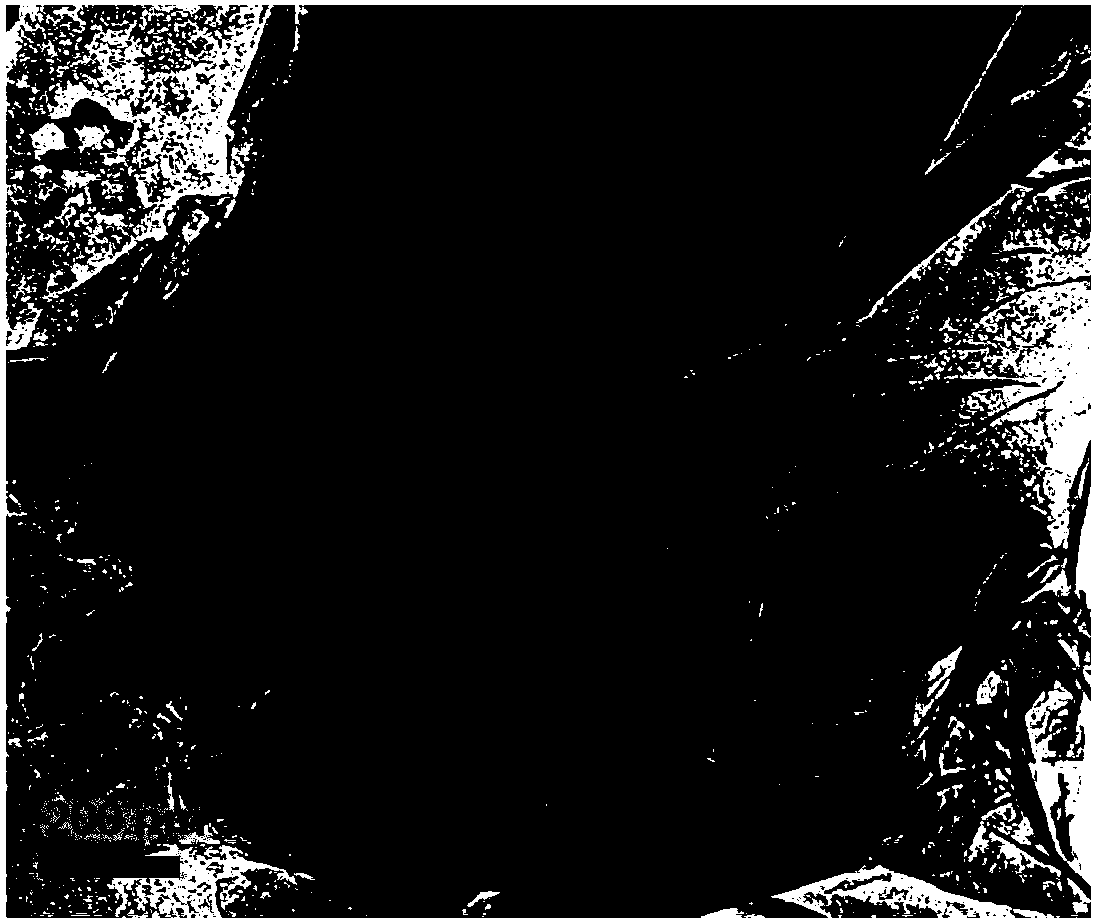

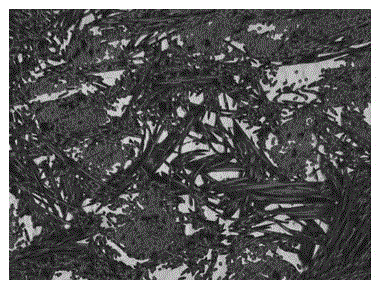

Carbon fabric integer fabric carbon-copper composite material and method of manufacturing thereof

The invention relates to a carbon fiber composite fabric or a carbon-copper compound material and the method thereof. The invention takes a porous carbon body prepared by the carbon fiber composite fabric densification as the prefabricated part, and the copper alloy is infiltrated in the pore of the prefabricated part. By adoption the method of no-pressure melt infiltration, the invention features the simple process, low cost, and easy realization of the industrialization, and is capable to prepare the carbon fiber composite fabric or the carbon-copper compound material with high electrical conductivity, outstanding self lubrication wear resistance performance, excellent hot-proof and anti-vibration and ablation resistance performance.

Owner:CENT SOUTH UNIV

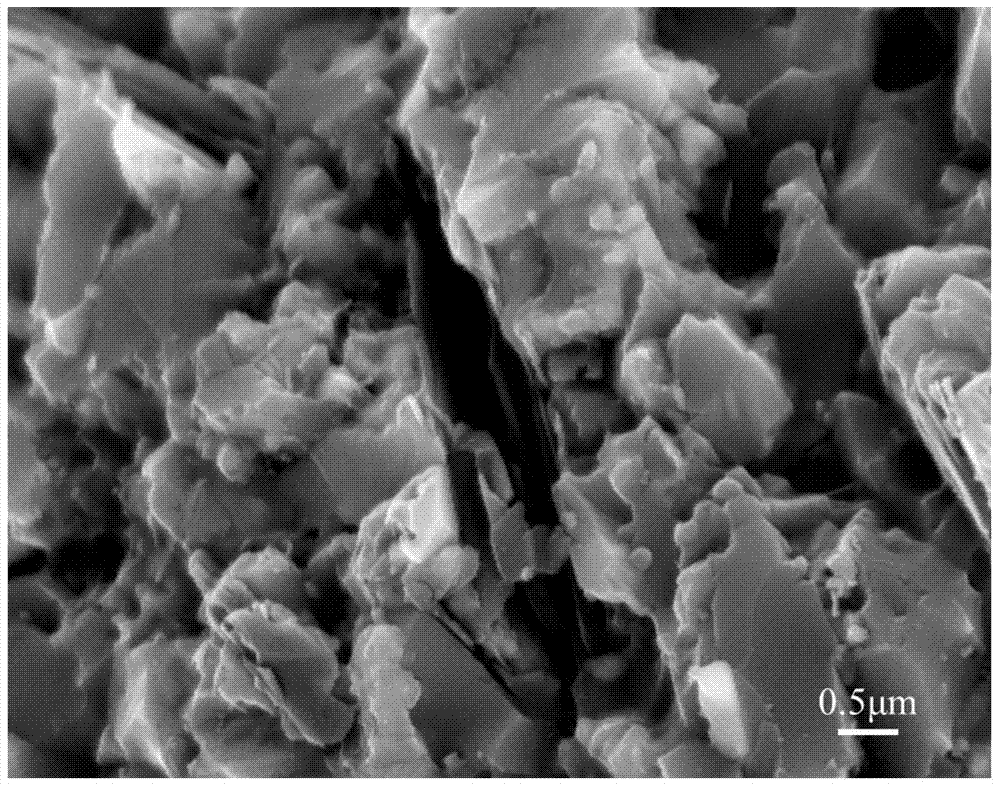

Preparation method of h-BN added titanium boride-based self-lubricating ceramic cutter material

The invention relates to a preparation method of an h-BN (hexagonal Boron Nitride) added titanium boride-based self-lubricating ceramic cutter material. According to the method, the material is formed in such a way that TiB2 as a base body, added micron WC (Wolfram Carbide) as a reinforced phase, the micron h-BN as a solid lubricant, and micron Mo and micron Ni as sintering additives are sintered. The preparation method comprises the following steps: respectively dispersing the micron TiB2 powder, the micron WC powder and the micron h-BN powder, and carrying out ball milling and drying so as to obtain powders, and finally, sintering the powders through a hot pressing method. The method has the advantages of simplicity, convenience in operation and the like. The self-lubricating ceramic cutter material has an excellent comprehensive mechanical property and an anti-friction wear-resisting property, and can be used for fabricating cutting tools, dies and other friction-resistant corrosion-resistant parts.

Owner:QILU UNIV OF TECH

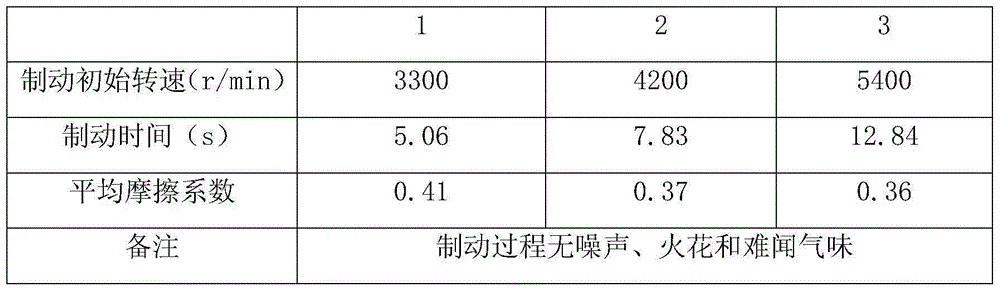

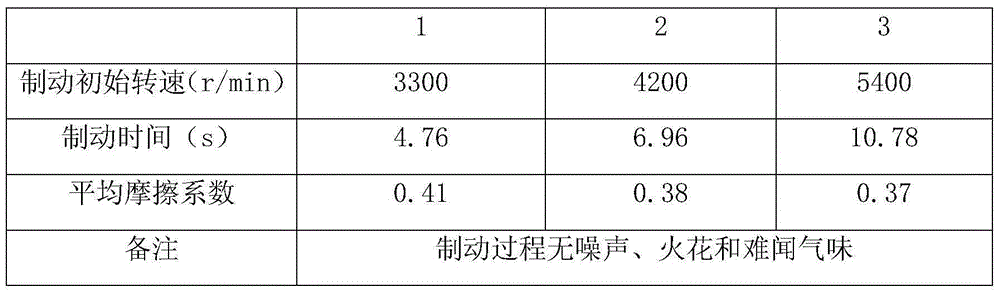

Synthetic brake shoe for urban railway vehicle and preparation method thereof

InactiveCN102134397AImprove basic performanceHigh temperature and high basic performanceFriction liningBrake arrangement with braking memberLow noiseWeather resistance

The invention discloses a synthetic brake shoe for an urban railway vehicle and a preparation method thereof. The synthetic brake shoe for an urban railway vehicle is prepared from acicular wollastonite used as a reinforcing material, polybismaleimide resin used as a base material, and a filling and frictional property regulator by a hot pressing technique. The synthetic brake shoe for an urban railway vehicle is prepared from 8-16% of polybismaleimide resin, 6-14% of nitrile-butadiene rubber, 12-24% of graphite, 4-16% of iron powder, 4-12% of wollastonite, 6-14% of friction powder, 21-39% ofbarite and 0-6% of coupling agent. The synthetic brake shoe for an urban railway vehicle has the advantages of stable friction factor, wear resistance, low abrasion, no cracking or metal inlay, favorable weather resistance and low noise, does not damage wheels, does not pollute the city, and can satisfy the operational requirements for urban railway trains.

Owner:DALIAN JIAOTONG UNIVERSITY

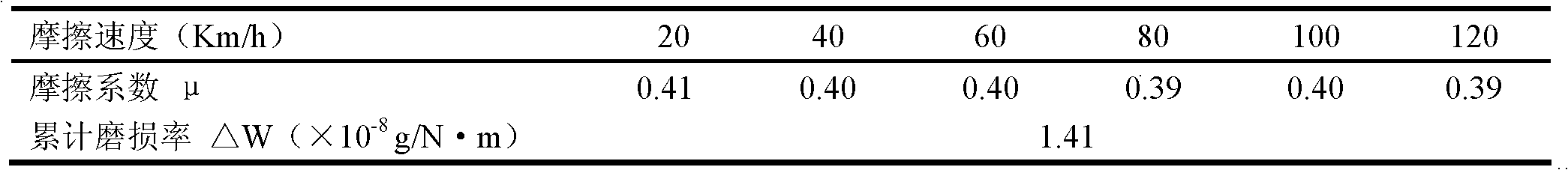

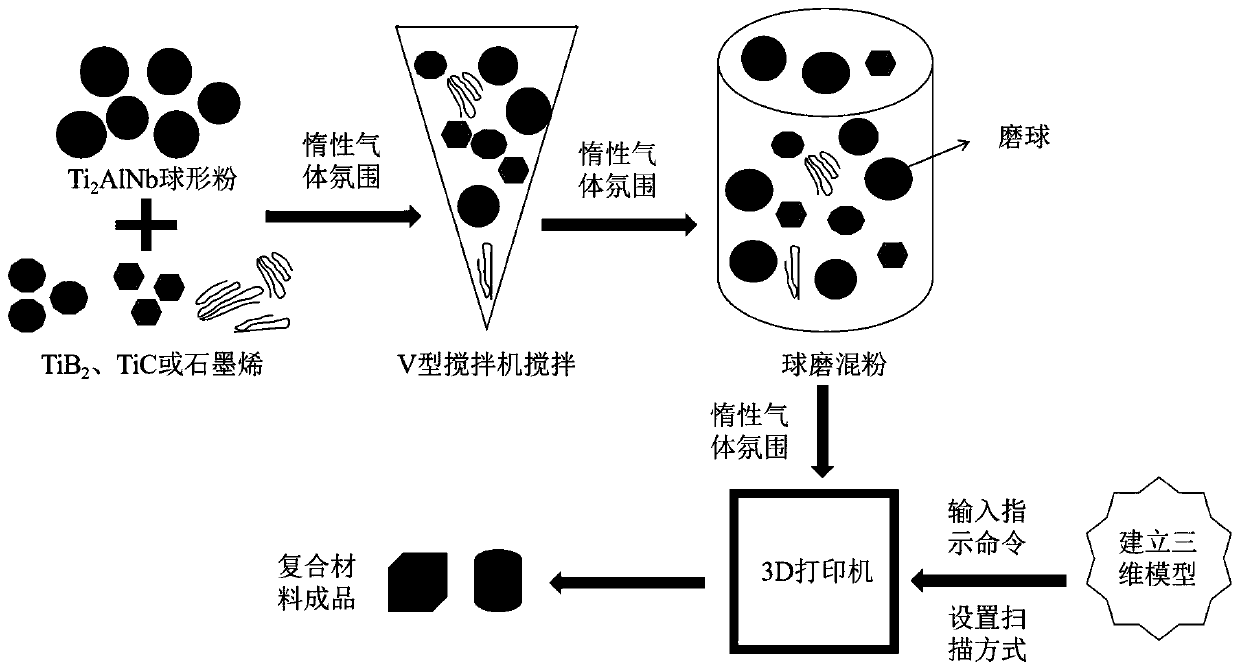

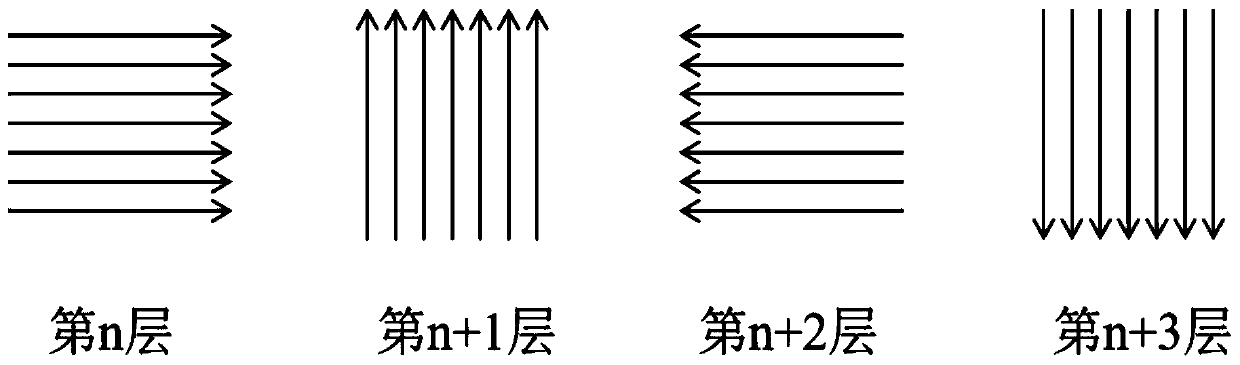

3D printing reinforcement/Ti2AlNb base composite material and preparation method thereof

ActiveCN109865836AEvenly dispersedScattered tightlyAdditive manufacturing apparatusIncreasing energy efficiencyHardnessGraphene

The invention discloses a 3D printing reinforcement / Ti2AlNb base composite material and a preparation method thereof, and belongs to the field of metal material manufacturing. The preparation method comprises the following steps: (1) Ti2AlNb spherical prealloy powder is used as a basal body; and TiB2, graphene or TiC powder is used as reinforced particles; (2) the selected powder is mixed for mechanical stirring; (3) the pre-stirred powder is mixed through dry ball milling; (4) a three-dimensional pattern of a needed sample is designed by using a computer; and drawing procedures are input intoa 3D printer; and (5) the ball-milled mixed powder is scanned layer by layer according to preset procedures to finally prepare the needed composite material. The process is simple; all the componentsare excellent in stability; a reinforcing phase is tightly combined with the basal body, and a second phase generated in the laser melting process achieves a pinning effect in metal; and the reinforcing phase and the second phase are coacted to achieve a refined crystalline strengthening effect, so that the defects of the material after 3D printing can be eliminated. The composite material is small in average grain size, and prominently optimizes the hardness and the friction and wear performances of the material.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

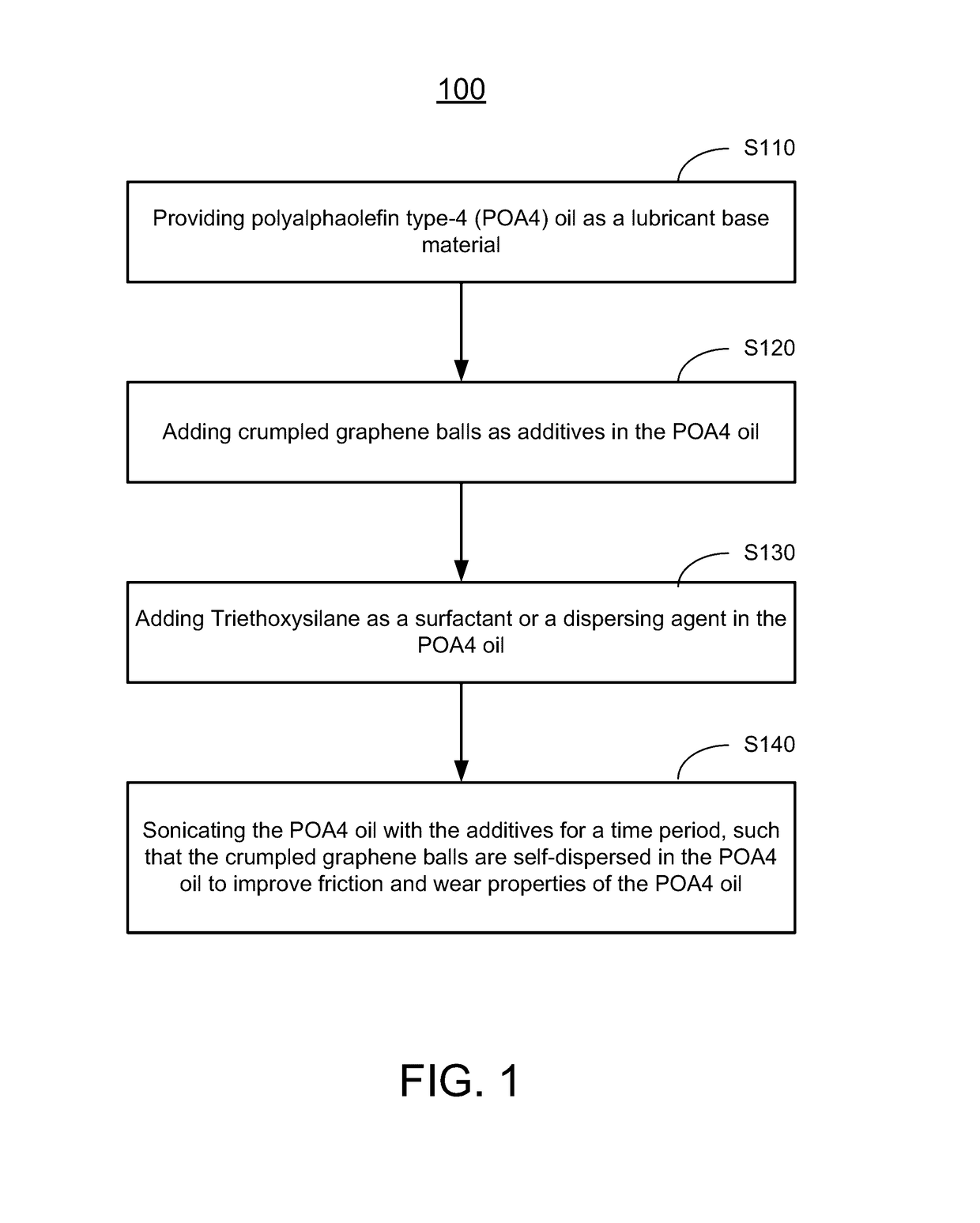

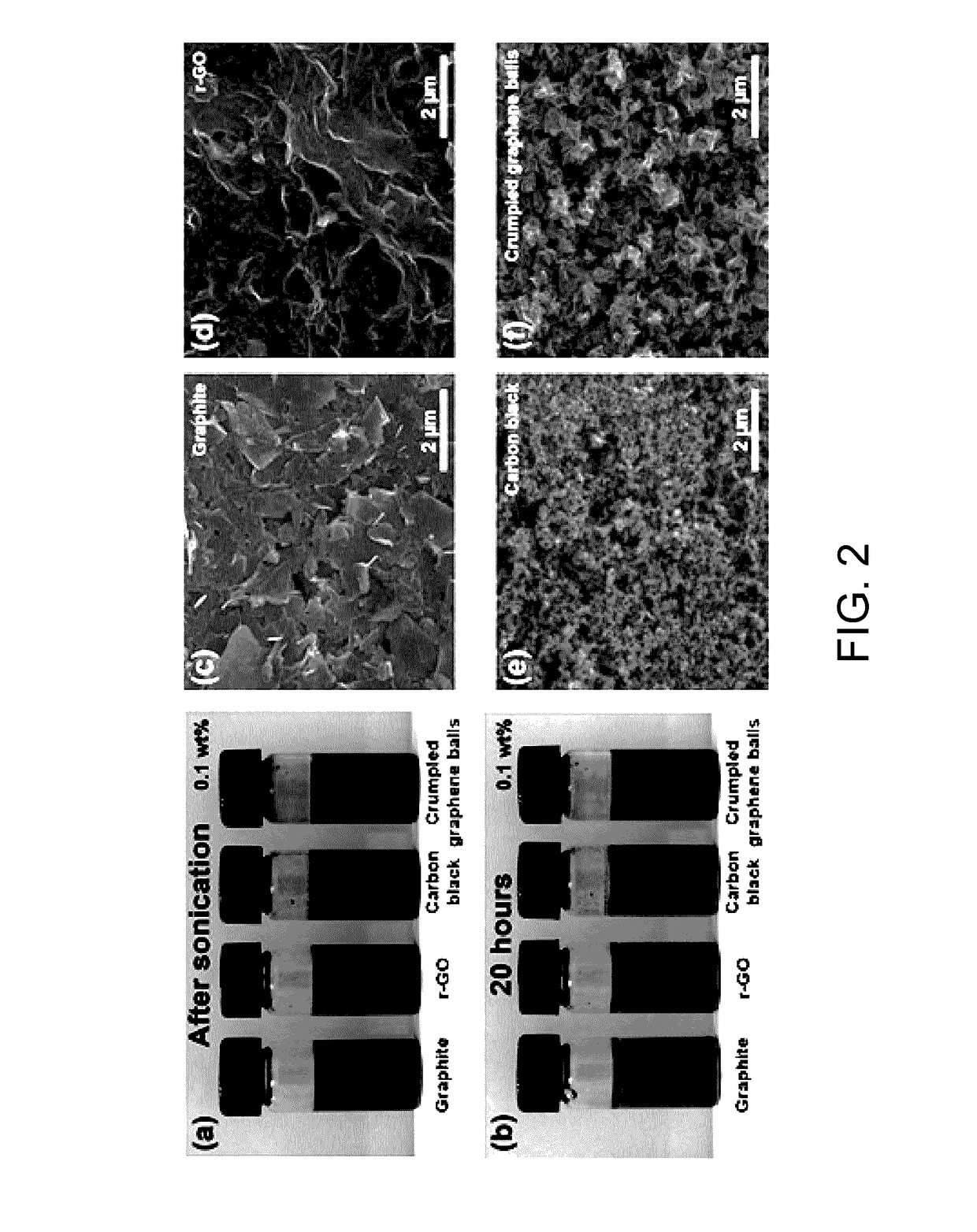

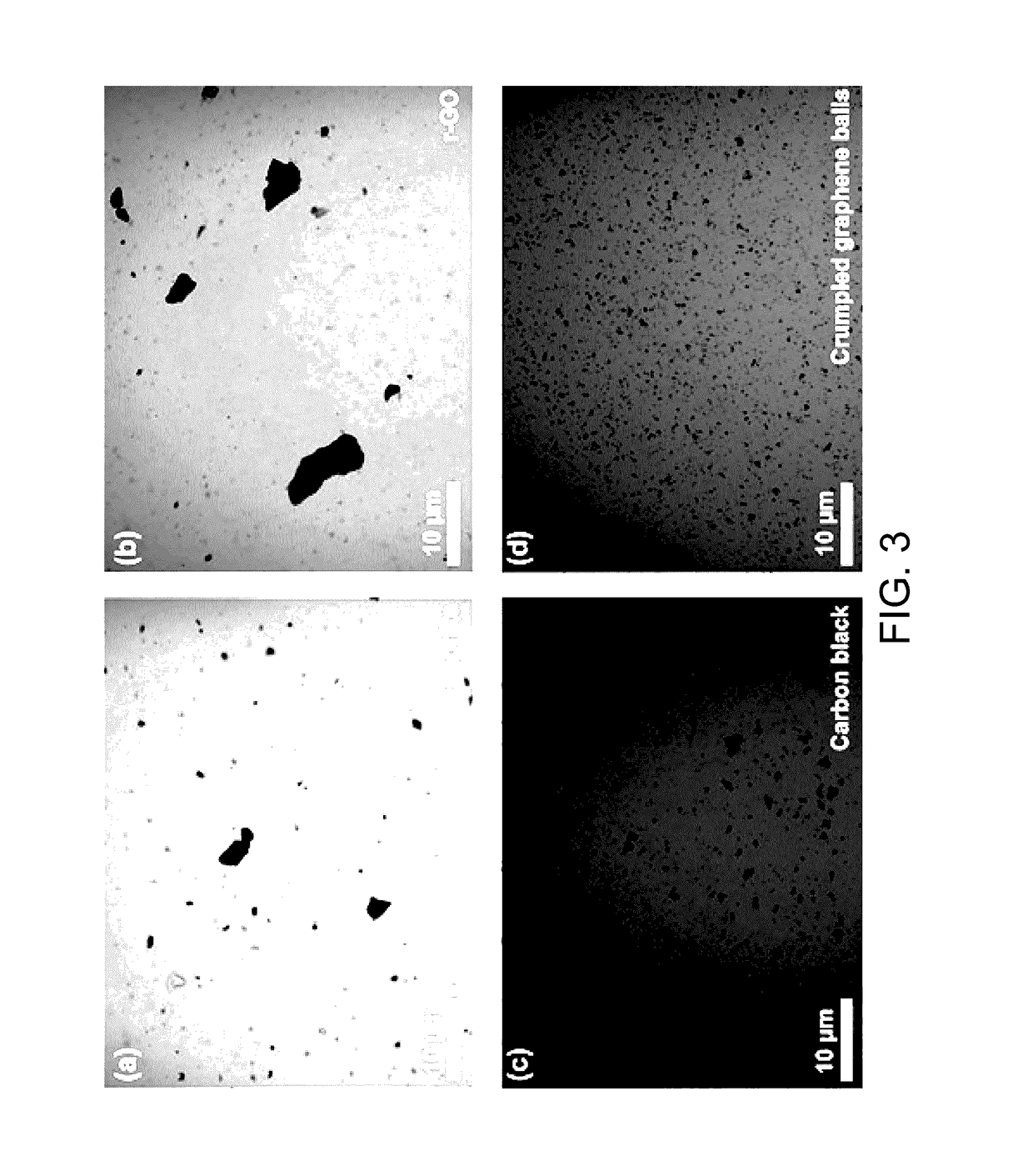

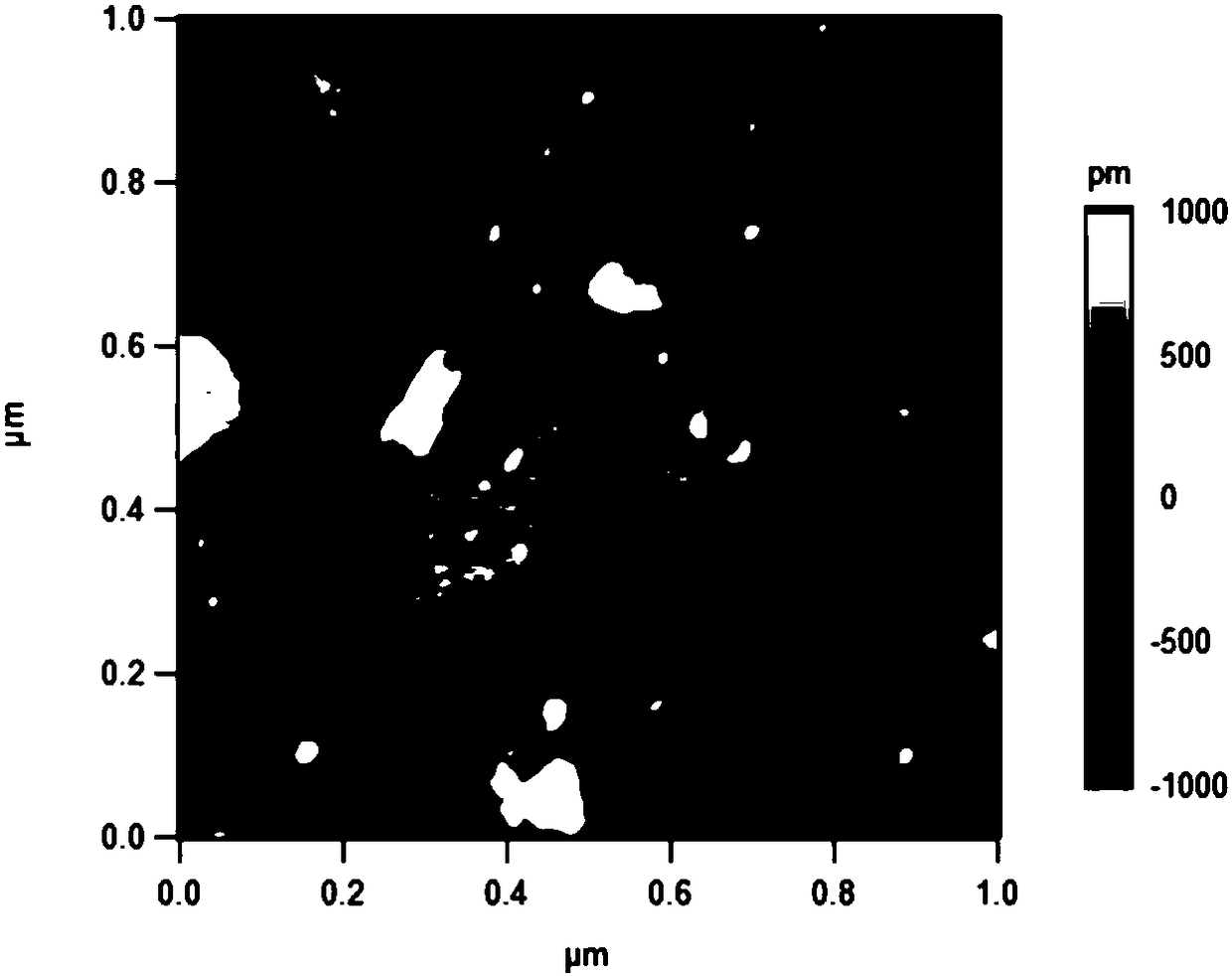

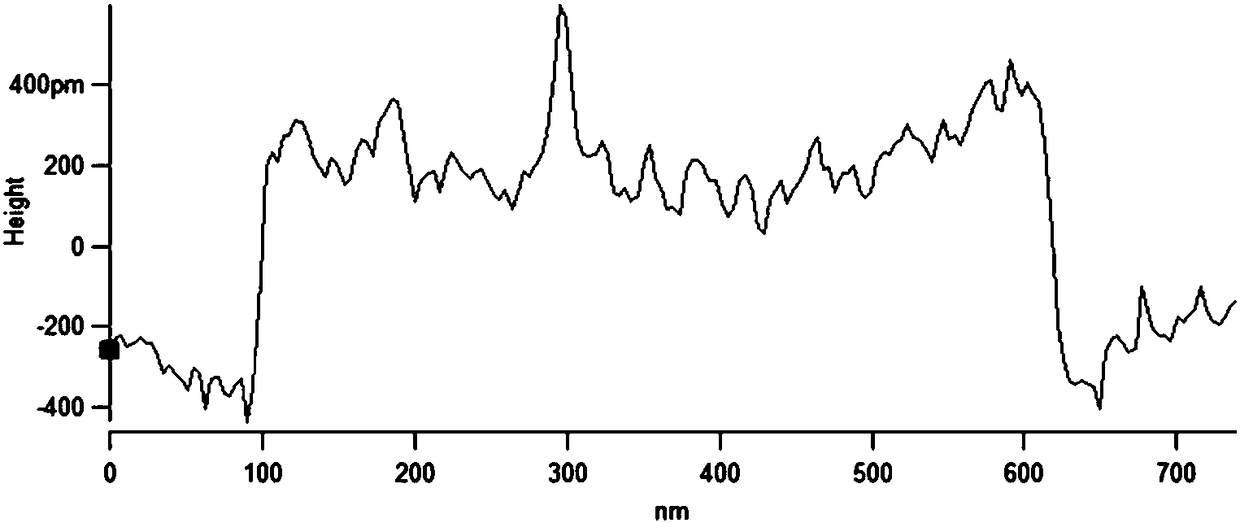

Lubrication material using self-dispersed crumpled graphene balls as additives in oil for friction and wear reduction

ActiveUS20170088788A1Increase frictionImprove wear propertyAdditivesFriction reductionTriethoxysilane

A method for forming a lubrication material using self-dispersed crumpled graphene balls as additives in a lubricant base fluid for friction and wear reduction. The lubricant base fluid may be, for example, a polyalphaolefin type-4 (PAO4) oil. After the crumpled graphene balls are added as additives in the lubricant base fluid, the lubricant base fluid with the additives are sonicated for a sonicating time period, so that the crumpled graphene balls are self-dispersed in the lubricant base fluid to improve friction and wear properties of the lubricant base fluid. In some cases, a dispersing agent, such as Triethoxysilane, may be added in the lubricant base fluid to enhance stability of dispersion of the crumpled graphene balls in the lubricant base fluid. The crumpled graphene balls may stay stably dispersed in the lubricant base fluid between a lower temperature (such as −15 ° C.) to a higher temperature (such as 90 ° C.).

Owner:NORTHWESTERN UNIV

Boron and linseed oil double-modification phenolic resin-based friction resistance composite material and preparation method thereof

The invention provides a boron and linseed oil double-modification phenolic resin-based friction resistance composite material and a preparation method thereof, and relates to the field of friction resistance composite materials. According to the preparation method, the phenolic resin is toughened and modified by using the linseed oil which has a rich source. The method for preparing the phenolic resin-based friction resistance composite material comprises the following steps: mixing boron modified phenolic resin prepolymer with relatively mature production process technology and self-made linseed oil modified phenolic resin prepolymer; adding a reinforcement material such as glass fiber and other components into the mixture; forming the boron and linseed oil double-modification phenolic resin by heating; and performing binary modification of toughness and heat resistance on the boron and linseed oil double-modification phenolic resin to obtain a phenolic resin-based friction resistance composite material. Compared with a tung oil and cashew nut shell oil toughened and modified phenolic resin-based friction resistance composite material, the boron and linseed oil double-modification phenolic resin-based friction resistance composite material has the advantages of rich material resource, comparatively simple purification process, and stable performance of the obtained products. Compared with a rubber and thermoplastic resin toughened and modified phenolic resin-based friction resistance composite material, the boron and linseed oil double-modification phenolic resin-based friction resistance composite material has the advantages of high heat resistance and friction-wear performance of the products, and no off-odor generated during the use of the friction resistance material.

Owner:JIANGSU UNIV

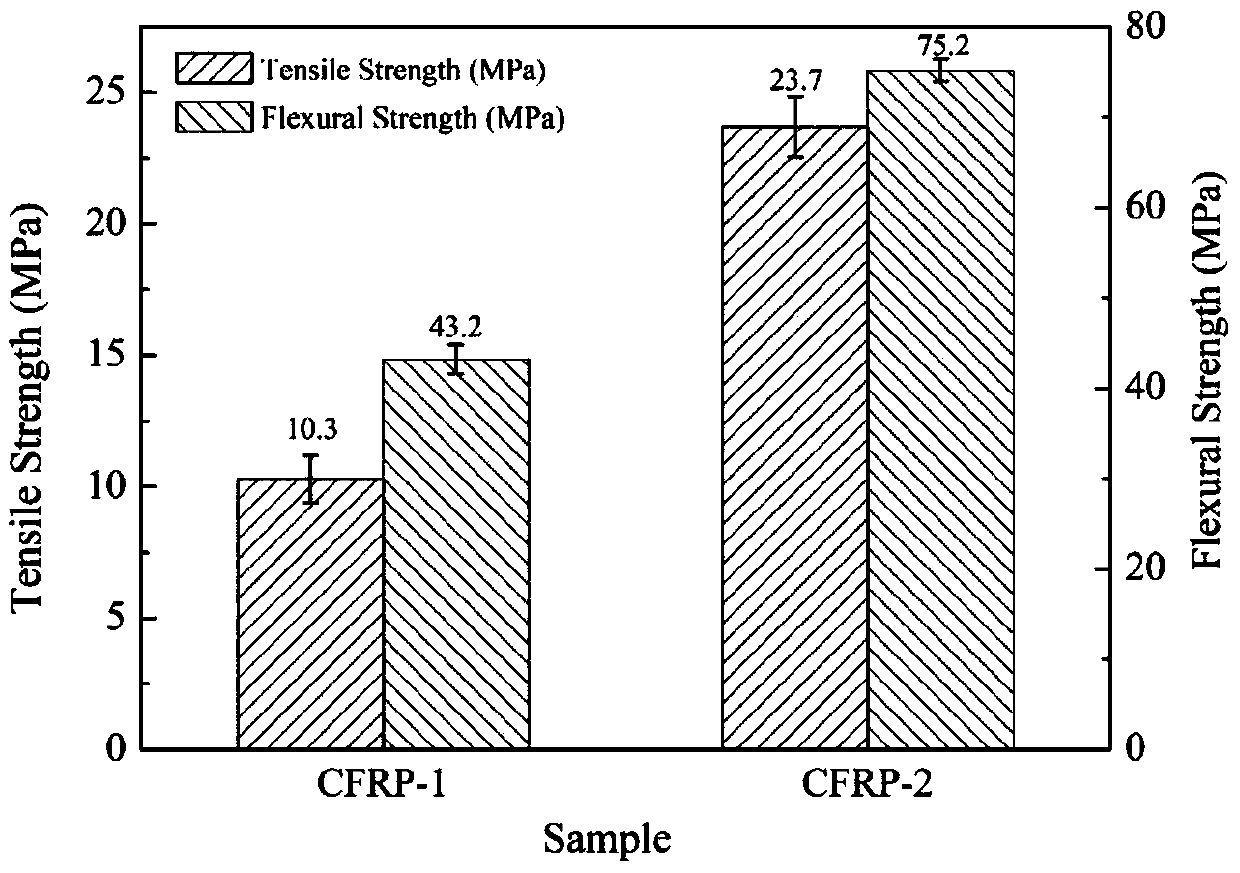

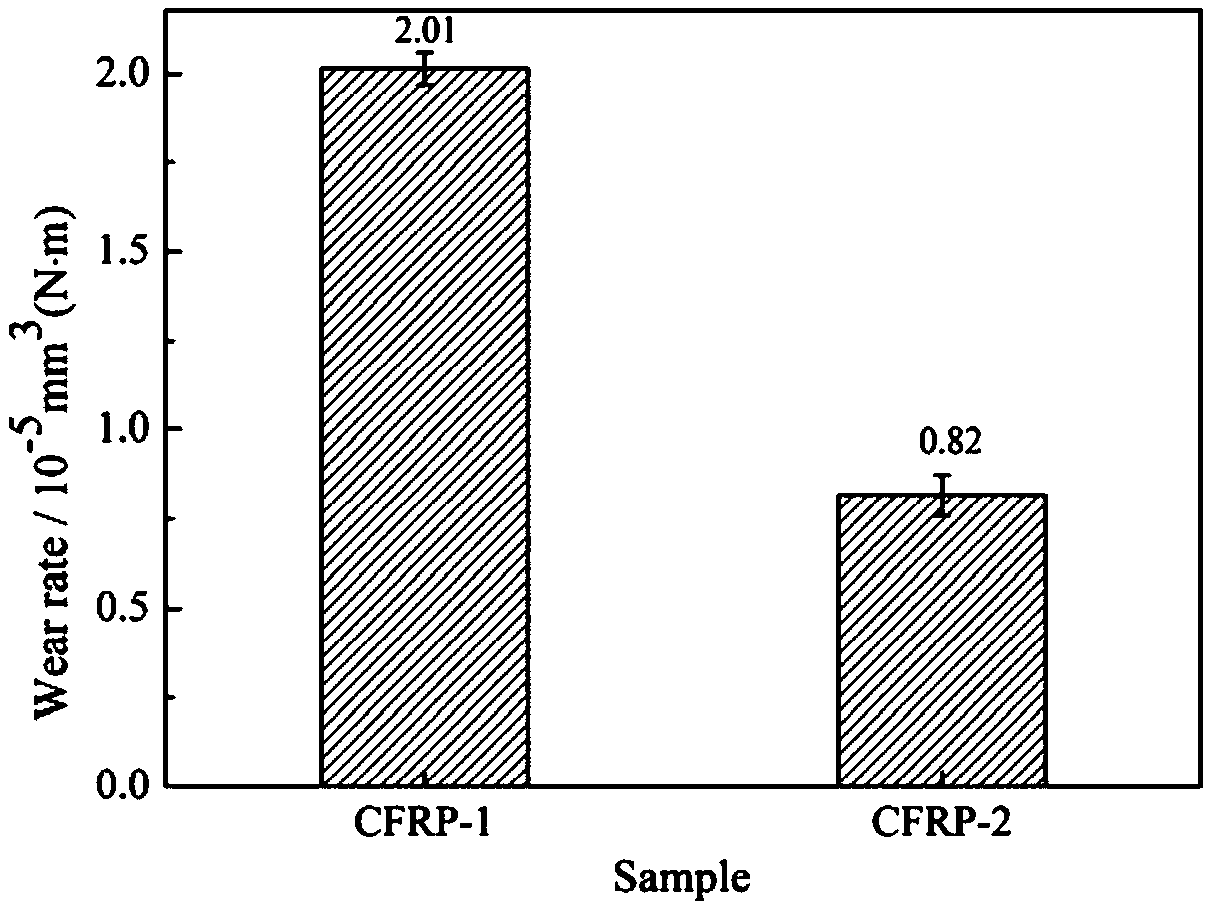

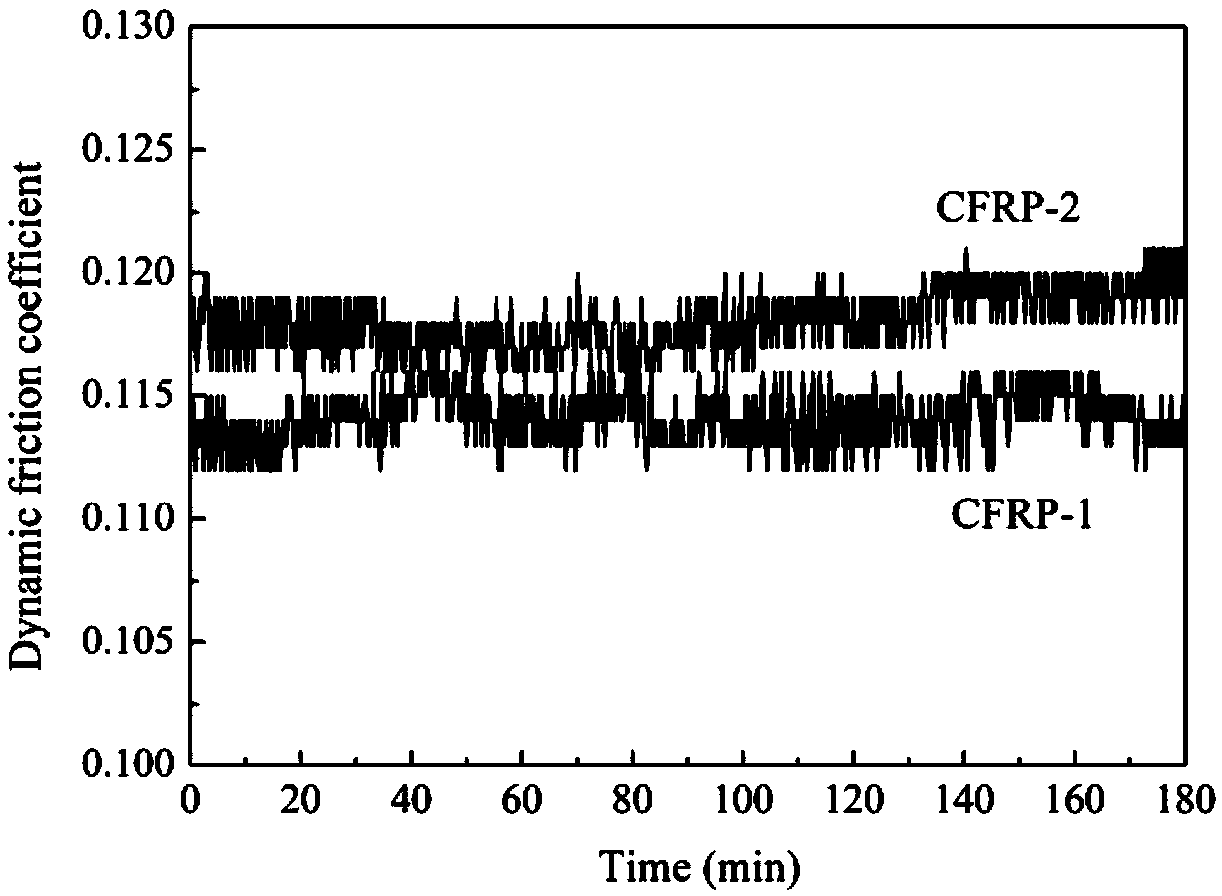

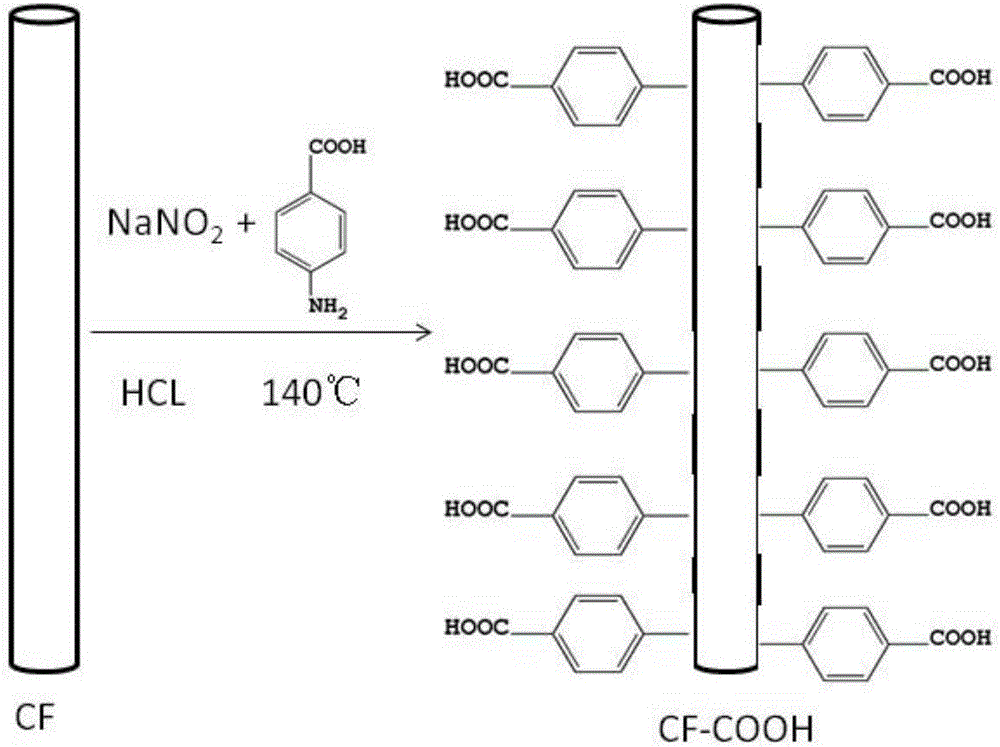

Preparation method for para aminobenzoic acid lossless modified carbon fiber enhanced paper base wet-type friction material

The invention discloses a preparation method for a para aminobenzoic acid lossless modified carbon fiber enhanced paper base wet-type friction material. Carbon fibers, para aminobenzoic acid and excessive hydrochloric acid are added to a three-neck flask, a certain quantity of sodium nitrite is slowly added after a reaction reaches certain temperature, a short-time diazo-reaction is conducted under the condition of a magnetic stirring oil bath, and carbon fibers with the surfaces grafted by benzoic acid are obtained. Then, the modified carbon fibers, aramid fibers, paper fibers, padding and resin are mixed to prepare friction material base paper, the friction material base paper is then hot-pressed and solidified, and the para aminobenzoic acid modified paper base wet-type friction material is obtained. A friction material sample is subjected to a frictional wear performance test, the dynamic friction coefficient of the sample reaches 0.12 to 0.15, the wear rate is 0.9*10<8>cm<3> / J to 1.2*10<8>cm<3> / J, the excellent frictional wear performance is shown, the technological process is simple, cost is low, and the preparation method is an efficient and environment-friendly graft modification treatment method and has the wide application prospect.

Owner:SHAANXI UNIV OF SCI & TECH

Water-based 2D/0D nanometer composite material lubricant

ActiveCN108441312AImprove material performanceStable physicochemical propertiesLubricant compositionWater basedNanoparticle

The invention discloses a water-based 2D / 0D nanometer composite material lubricant, which is formed by mixing and stirring 0.02-2 wt% of 2D nanometer thin sheets, 0.02-2 wt% of 0D nanoparticles and 96-99.6 wt% of deionized water, wherein the 2D nanometer thin sheets are selected from one or a variety of 2D nanometer thin sheets containing C and O functional groups, the 0D nanoparticles are selected from one or a variety of metal oxide particles containing Al, Fe, Cu, Zr, Zn or Ti and O functional group, and the 2D nanometer thin sheets and the 0D nanoparticles form a 2D / 0D nanometer compositematerial. According to the present invention, the synergistic effect is provided by combining the excellent characteristics of the 2D nanometer material and the 0D nanometer material, and the obtainedproduct has advantages of good stability, easy re-dispersion, low friction coefficient, good wear resistance and environmental friendliness, and can replace the traditional oil-based lubricant systemso as to achieve low energy consumption and prolonged service life of equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

Carbon fiber/copper composite material and preparation method thereof

The invention discloses a preparation method of a carbon fiber / copper composite material, belongs to the field of metal-based composite materials, and particularly relates to a technical scheme of a carbon fiber / copper composite material and a preparation method of the carbon fiber / copper composite material. The preparation method is characterized in that a porous carbon blank which is obtained by pressing short carbon fibers is taken as a prefabricated body; and a copper alloy is permeated to pores of the prefabricated body so as to make the copper alloy fully fill in the pores of the carbon blank, and finally the copper alloy-based carbon fiber / copper composite material which is in network continuous distribution is formed. The carbon fiber / copper composite material can be used as a friction material, a carbon body material, an ablative material, various sliding bearing bushes, a sliding block and even a biological material. Compared with other preparation methods of the carbon fiber / copper composite material, the preparation method uses a non-pressure infiltration method, is simple in process, low in cost and easy to industrialize, and can prepare the carbon fiber / copper composite material with high conductivity, excellent self-lubrication abrasion resistance, excellent thermal shock resistance and ablation resistance.

Owner:TAIYUAN UNIV OF TECH

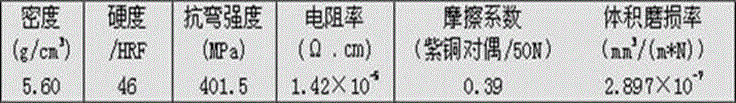

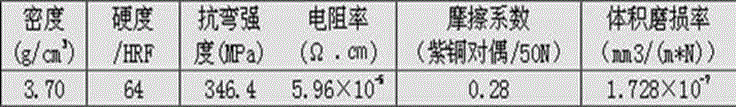

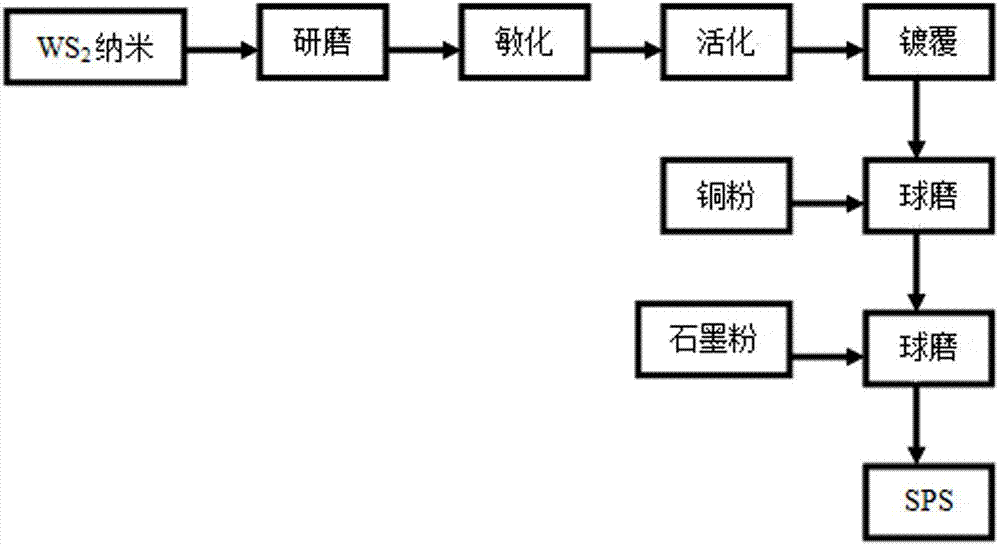

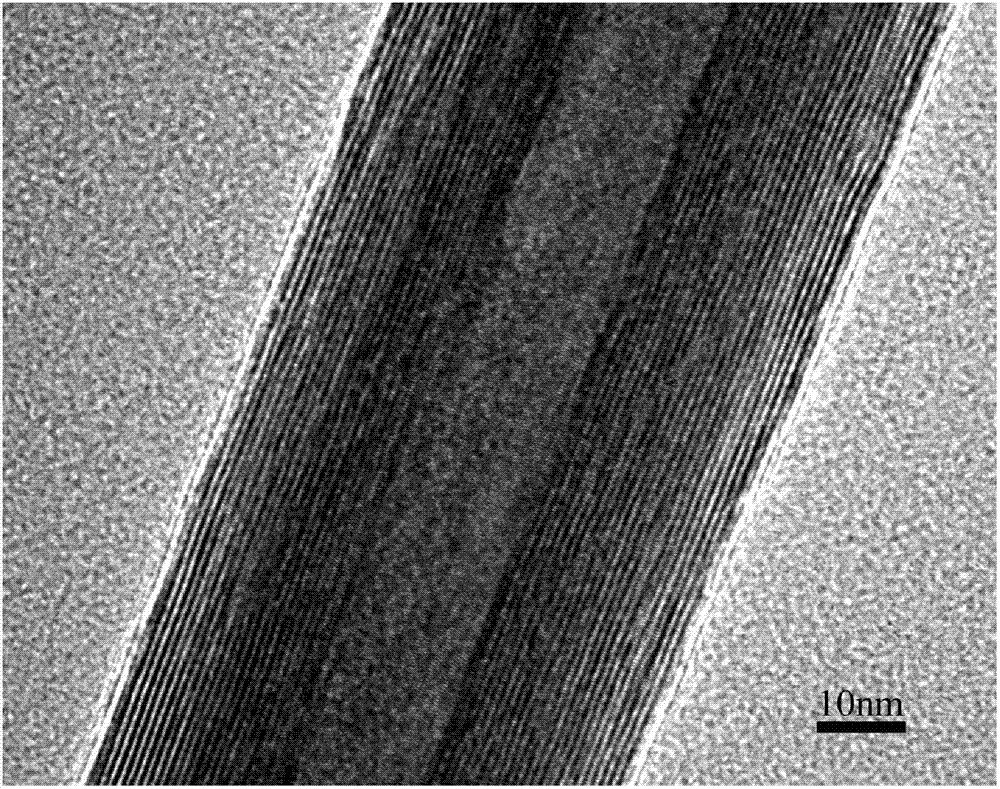

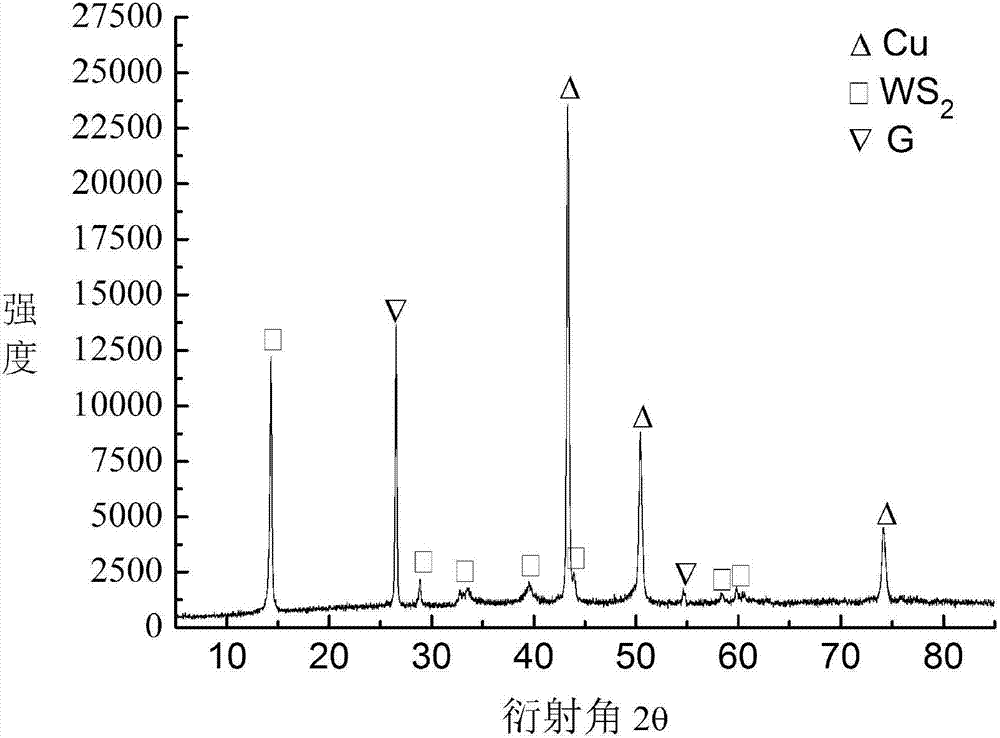

Copper-graphite-tungsten disulfide nanotube self-lubricating composite material and preparation method thereof

ActiveCN103045971AImprove friction and wear propertiesImprove environmental adaptabilityCopper platingElectrolysis

The invention discloses a copper-graphite-tungsten disulfide nanotube self-lubricating composite material and a preparation method thereof, wherein the self-lubricating composite material is prepared by taking copper as a substrate and graphite as well as tungsten disulfide nanotube as solid lubricating additives through a spark plasma sintering process, and consists of the following components in percentage by weight: 80-90% of copper, 7-10% of graphite and 3-10% of tungsten disulfide nanotube. The preparation method comprises the following steps of: grinding, sensitizing, activating and chemically copper-plating the tungsten disulfide nanotube, uniformly mixing with electrolytic copper powder and graphite powder in proportion through a mechanical ball-milling process; and implementing a spark plasma sintering process to the mixing powder, to prepare the tungsten disulfide nanotube and graphite reinforced copper-base self-lubricating composite material. The copper-base self-lubricating composite material prepared by the preparation method disclosed by the invention is high in mechanical intensity, excellent in friction and abrasion resistance and good in environmental suitability.

Owner:HEFEI UNIV OF TECH

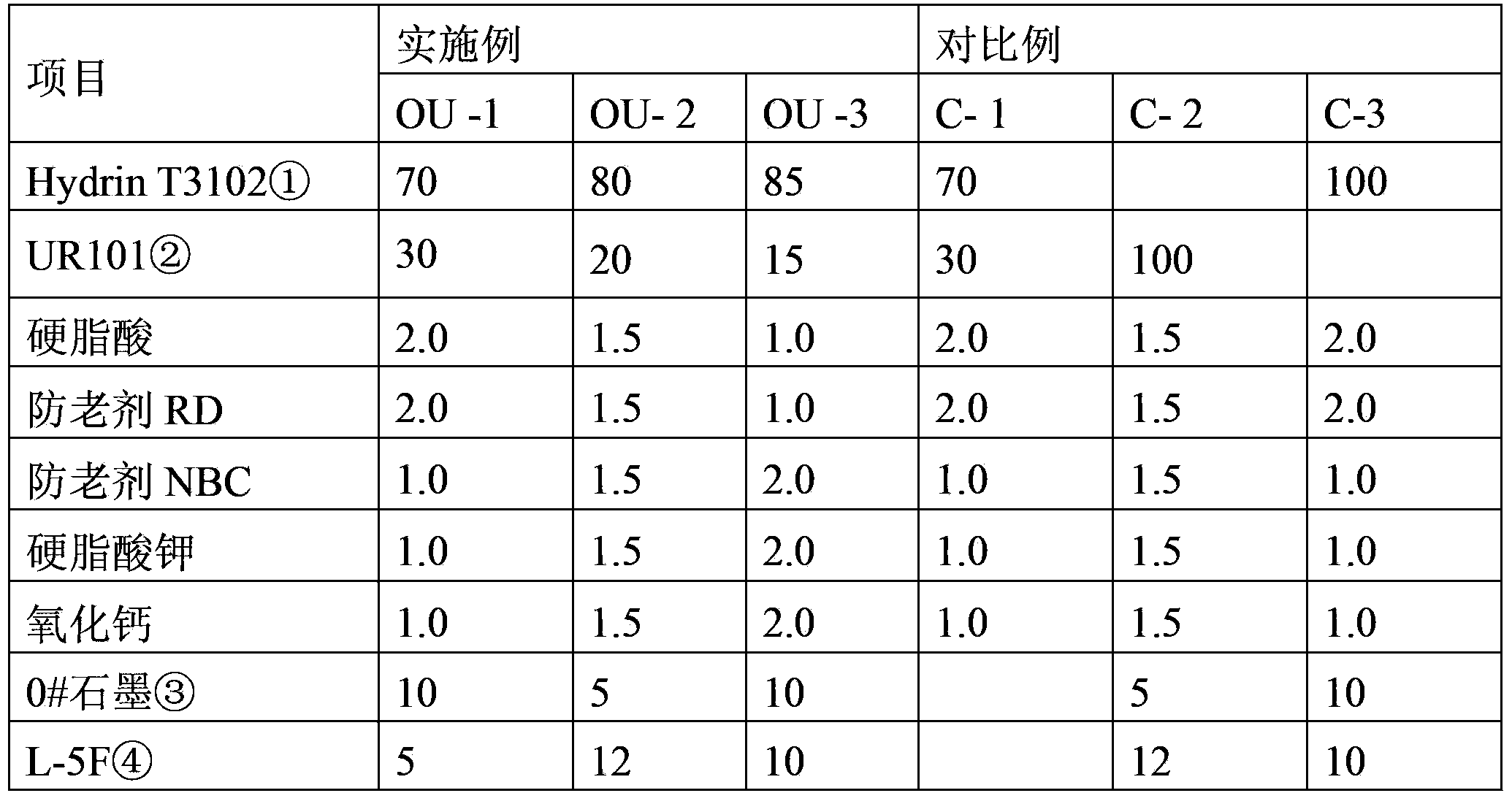

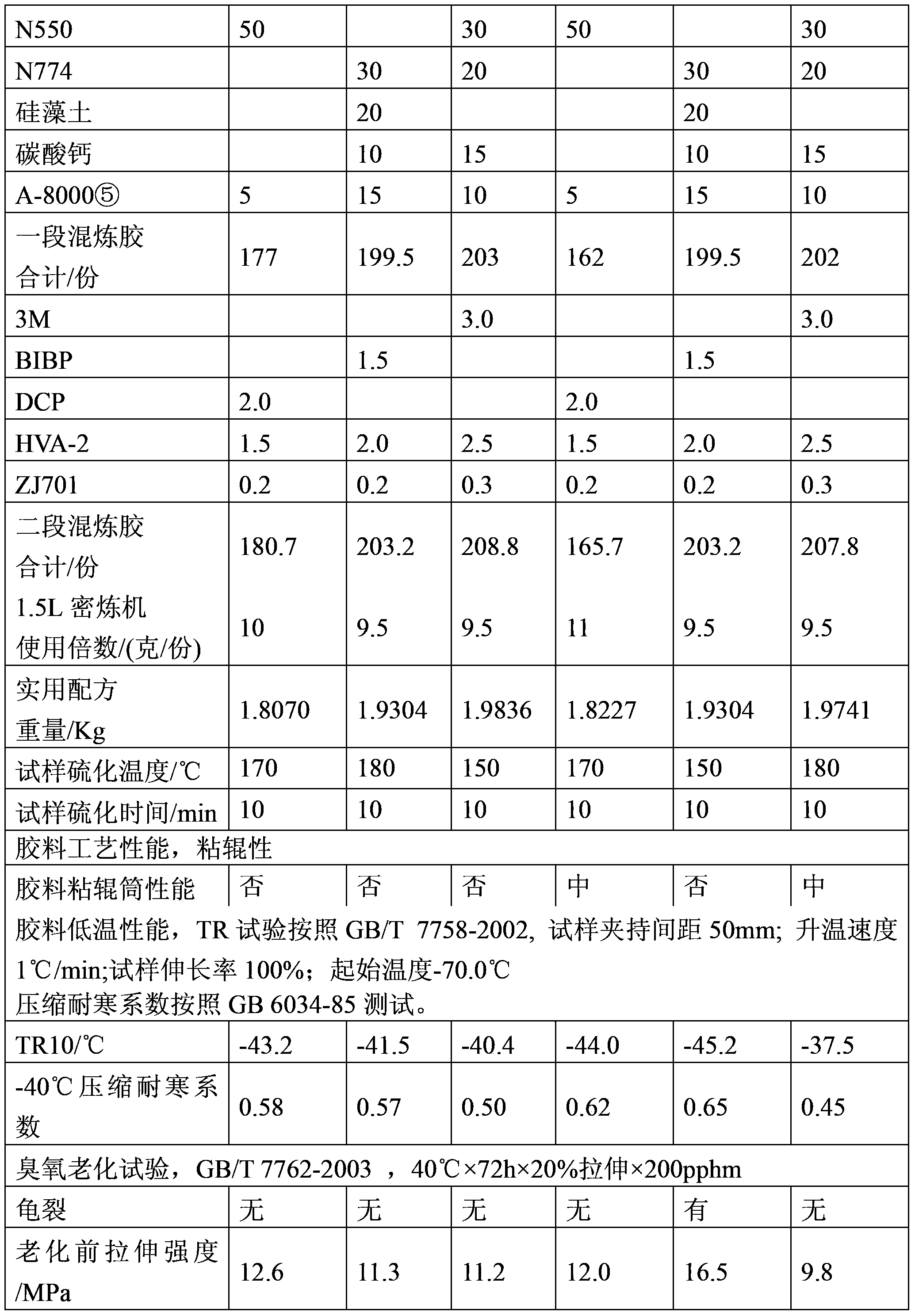

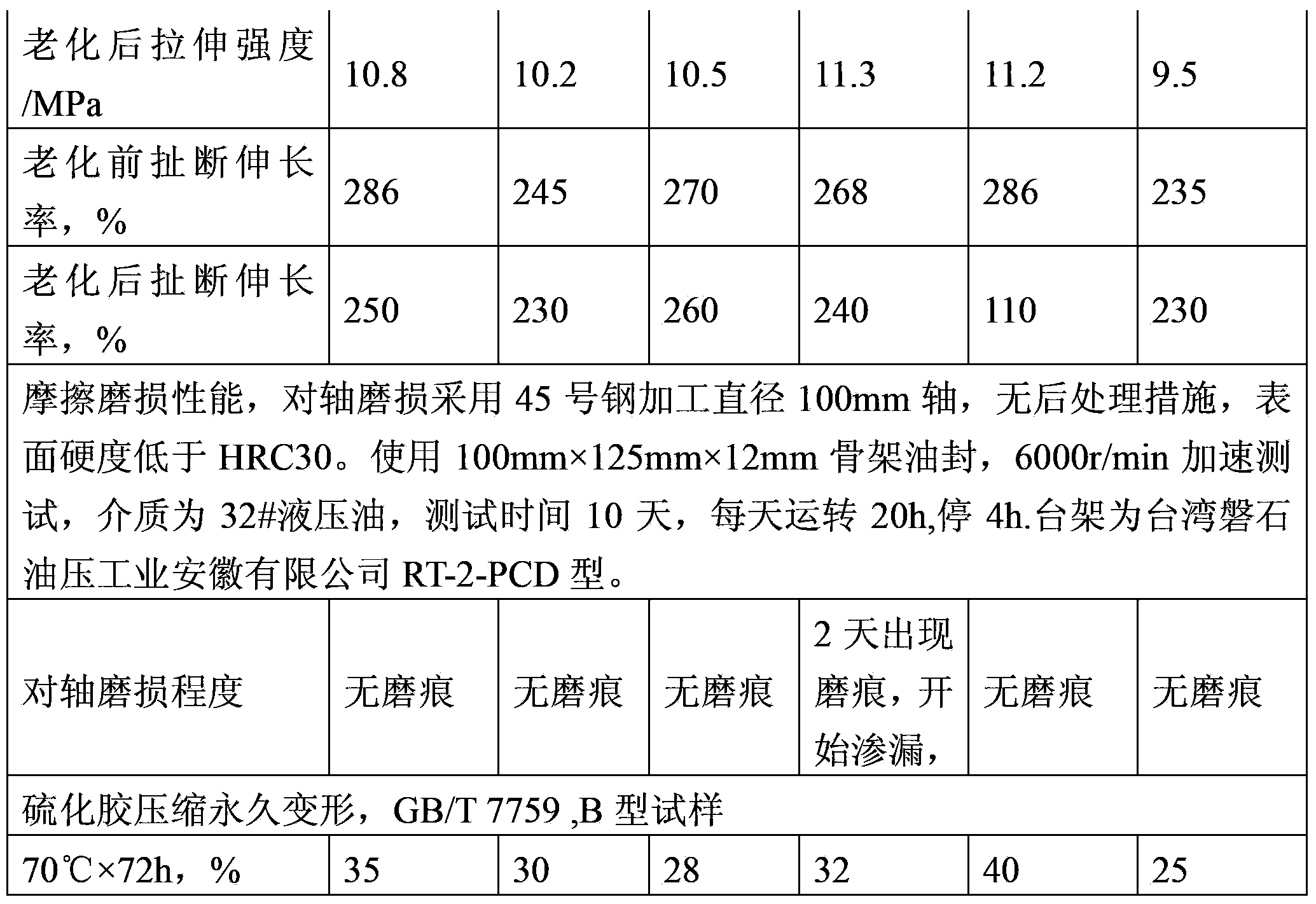

Sizing material for sealing rotating shaft of fan

ActiveCN103450655AGood anti-adhesionGood weather resistanceOther chemical processesPolyether polyurethaneHardness

The invention discloses a sizing material for rotary sealing of megawatt-level fans, and belongs to the technical field of rubber seal. The prepared sizing material disclosed by the invention is prepared from ternary polymerization epichloro-hydrin rubber, millable polyether polyurethane rubber, a solid self-lubricant material and a hyperoxide curing system. The sizing material has the characteristics of good low temperature resistance, abrasive resistance, long-term weather aging resistance and self-lubricating property, is free of abrasion with a shaft, and is especially suitable for manufacturing of a rotary seal element of the fan capable of resisting a low temperature of -40 DEG C, or manufacturing of a fan sealing element of which the surface hardness of the rotating shaft is smaller than rockwell hardness (HRC)55, or manufacturing of an end face sealing element of the fan assembled in a drawing manner.

Owner:广州国机密封科技有限公司

Melamine resin microcapsule lubricating oil and lubricating oil coating material, and preparation methods thereof

InactiveCN104130844AImprove stabilityImprove friction and wear propertiesCoatingsLubricant compositionChemical industryPolyvinyl alcohol

The invention discloses a melamine resin microcapsule lubricating oil and a lubricating oil coating material, and preparation methods thereof. The melamine resin microcapsule lubricating oil is prepared through the following steps: adding polyvinyl alcohol, sodium dodecyl benzene sulfonate and deionized water into a beaker, dissolving, then adding a lubricating oil, and stirring for emulsification; slowly pouring the emulsified lubricating oil into a melamine resin prepolymer in three times, controlling a stirring revolving speed, and emulsifying for 30 min, to obtain an emulsified lubricating oil; adjusting the pH value to 2-3 with hydrochloric acid, and carrying out a heating reaction for 3 hours in a 65 DEG C water bath; and carrying out suction filtration on the product, washing with water, drying for 24 h, and thus obtaining the melamine resin microcapsule lubricating oil. The invention also discloses the lubricating oil coating material prepared from the melamine resin microcapsule lubricating oil and the preparation method thereof. The coating material has the stability of solid lubricant materials, also has excellent lubricating performance of liquid oils, and can be widely applied in heavy-load and high-temperature mechanical friction parts required for aeronautics and astronautics, machinery, electronics, chemical industries, shipping and the like.

Owner:TAIZHOU JIADI NEW MATERIAL

Long basalt fiber reinforced PA6 composite material and melt impregnation preparation method thereof

ActiveCN105694444AOvercoming performance deficienciesImprove mechanical propertiesTemperature controlPolymer science

The invention belongs to the field of composite materials, and in particular relates to a long basalt fiber reinforced PA6 composite material and a melt impregnation preparation method thereof. The composite material is prepared from the following raw materials by weight percent: 15 to 50 percent of long basalt fibers, 48 to 80 percent of PA6 master batch and 2 to 5 percent of processing additive; and the processing additive is a silane coupling agent. Compared with the prior art, the melt impregnation preparation method of the long basalt fiber reinforced PA6 composite material realizes sufficient impregnation of the resin to the fibers by virtue of a concave-convex wheel structure of an impregnation roll and can realize the precise control to the melt temperature by combining a temperature control device of an impregnation mold. According to the long basalt fiber reinforced PA6 composite material prepared by the method, the fibers and a resin matrix are closely combined, and the mechanical performance and the friction abrasion performance are excellent, so that the performance deficiency of the PA6 matrix can be solved, the reinforcing effect and the cost performance advantages of the basalt fibers can be sufficiently realized, the processing method is simple, and the industrialized application prospect is wide.

Owner:ZHONGBEI UNIV

Carbon fiber containing ceramic particles

InactiveUS20090148699A1Increase frictionImprove wear propertyCarbon fibresCeramic layered productsCarbon compositesCarbon fibers

Small ceramic particles (e.g., of TiC) are incorporated into fibers. The ceramic particles enhance the friction and / or wear properties of a carbon-carbon composite article made with the impregnated or coated fibers. The impregnated fibers can be, e.g., polyacrylonitrile (PAN) fibers, pitch fibers, and other such fibers as are commonly employed in the manufacture of C—C friction materials. The impregnated fibers can be used to make woven, nonwoven, or random fiber preforms or in other known preform types. Preferred products are brake discs and other components of braking systems. The particles may be included in the fibers by mixing them with the resin employed to make the fibers and / or by applying them to the surfaces of the fibers in a binder.

Owner:HONEYWELL INT INC

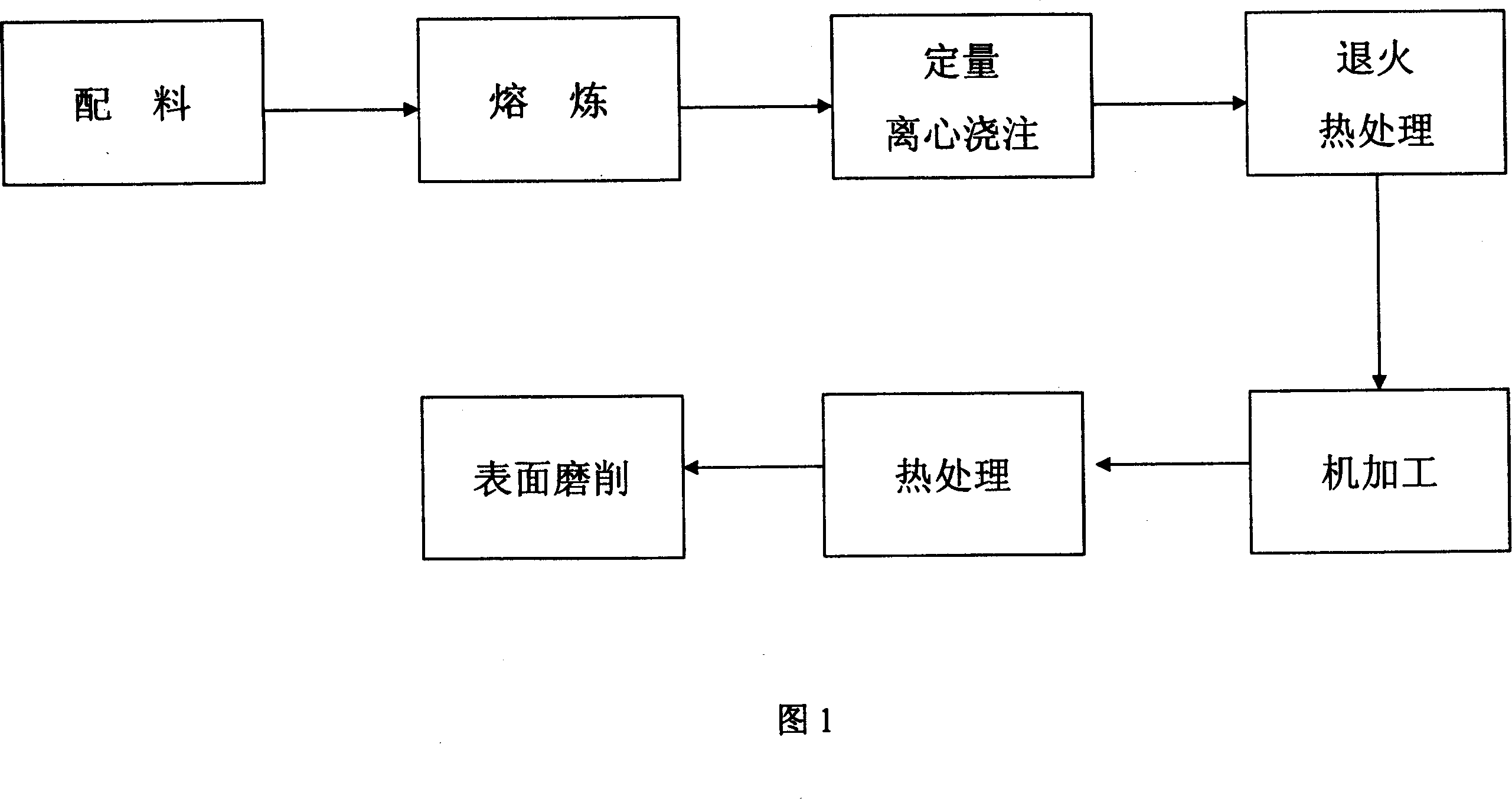

Method for manufacturing brake disk mounted on axis

InactiveCN101063471AIncrease braking powerGood high temperature mechanical properties and thermal fatigue resistanceBraking discsFriction liningAfter treatmentEngineering

The invention relates to a manufacturing method of brake disk arranged on the shaft, comprising batching, smelting, pouring, annealing treatment, after treatment or the like, the brake disk manufactured can meet the need of motor cars, locomotives and automobiles of 50km / h-160km / h, which has the advantages that the invention has great brake power and is applicable to the high-velocity or high-duty locomotives with better high-temperature mechanic property and heat fatigue durability, good frictional dissipation property, stable frictional factor and smooth braking with greatly improved processing performance of the structure.

Owner:湘潭高耐合金制造股份有限公司

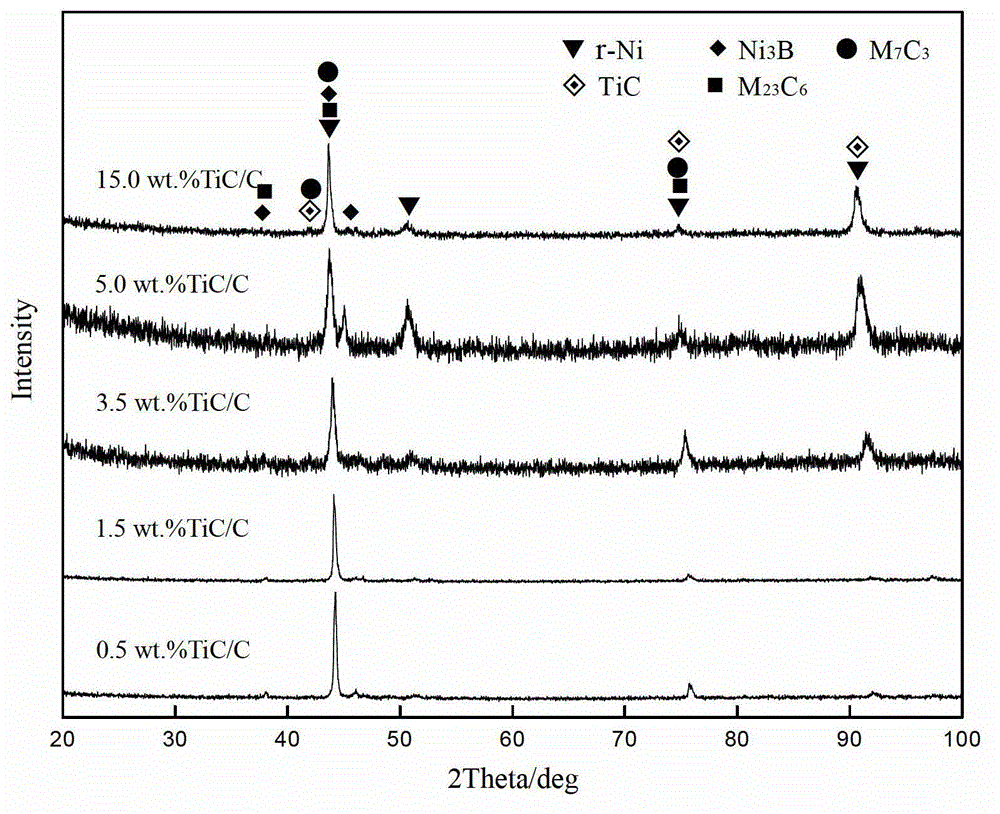

Nanocarbon clad titanium carbide enhanced nickel-based composite coating material and laser cladding process thereof

InactiveCN102978444AUniform and dense tissueImprove corrosion resistanceMetallic material coating processesProcess scaleTitanium carbide

The invention discloses a nanocarbon clad titanium carbide enhanced nickel-based composite coating material and a laser cladding process thereof, belonging to the technical field of material surface modification. The nanocarbon clad titanium carbide enhanced nickel-based composite coating material is prepared from Ni65.83 Cr15B3.0Si3.5C0.7Fe12 nickel-based self-fluxing alloy powder as a matrix material and nanocarbon clad titanium carbide of 0.5-20vol.% as a wild phase on a steel and alloy matrix by using a laser cladding technology. The nanocarbon clad titanium carbide enhanced nickel-based composite coating material has the advantages of uniform and compact coating structure, good flexibility and excellent corrosion resistance and wear resistance, has better metallurgical bonding with the matrix, can meet the requirements of carbon steel and alloy steel members for friction wear resistance under different working conditions, is large in scale and high in automation degree in a coating preparation process, and can be widely applied to fields such as aerospace, machinery, automobiles, war industry and the like.

Owner:DALIAN UNIV OF TECH

Microencapsulated lubricating oil, lubricating oil coating material and preparation method of microencapsulated lubricating oil

ActiveCN104140868AImprove stabilityImprove friction and wear propertiesMicroballoon preparationLubricant compositionChemical industryEmulsion

The invention discloses microencapsulated lubricating oil. The microencapsulated lubricating oil is obtained through the following steps that lubricating oil and mixed emulsifiers are mixed evenly according to the mass ratio of 16:3; a part of a PVA water solution is poured into the mixture at the temperature ranging from 80 DEG C to 85 DEG C; the remaining PVA water solution is added into the mixture after the mixture is stirred for 10 minutes; the mixture is subjected to emulsification; NaCl is added into the mixture in the stirring process, the mixture is stirred for 30 minutes, and then an emulsion is obtained; an tetraethyl orthosilicate and acetic acid solution is slowly added into the emulsion and stirred for 3 hours at the temperature of 55 DEG C; initiating agents are added into the emulsion, the emulsion is heated for 5 hours at the temperature of 75 DEG C, subjected to centrifugal separation, washed and dried, and finally the microencapsulated lubricating oil is obtained. A lubricating oil coating material is excellent in performance and capable of being widely applied to high-load and high-temperature mechanical friction parts and components needing to be properly protected in aerospace, machinery, electronics, chemical industry, ships and other industrial sectors.

Owner:TAIZHOU JIADI NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com