MOF-5 nondestructive modified carbon fiber reinforced resin-based wet friction material and preparation method thereof

A fiber-reinforced resin, wet friction material technology, applied in chemical instruments and methods, other chemical processes, bulk chemical production, etc. Surface energy, solving the effect of low interface strength and increasing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing MOF-5 nondestructively modified carbon fiber reinforced resin-based wet friction material, comprising the following steps:

[0029] Step 1: Firstly, acetone is used in a Soxhlet extractor under oil bath conditions, and a mixture of acetone and water is used to treat carbon fibers in a supercritical state to remove surface sizing agents and other pollutants. It was washed and dried repeatedly with deionized water. Wherein, the temperature and time of the oil bath used were 110° C. and 2 h, respectively, and a mixed solution of acetone and water with a volume ratio of 5:1 was used to treat the carbon fibers in a Soxhlet extractor.

[0030]Step 2: The above-mentioned carbon fibers were treated with nitric acid at 130° C. for 2 hours, filtered and recovered, washed with deionized water, and placed in an oven at 70° C. for drying to obtain functionalized carbon fibers.

[0031] Step 3: Dissolve a certain amount of zinc nitrate hexahydrate and terephth...

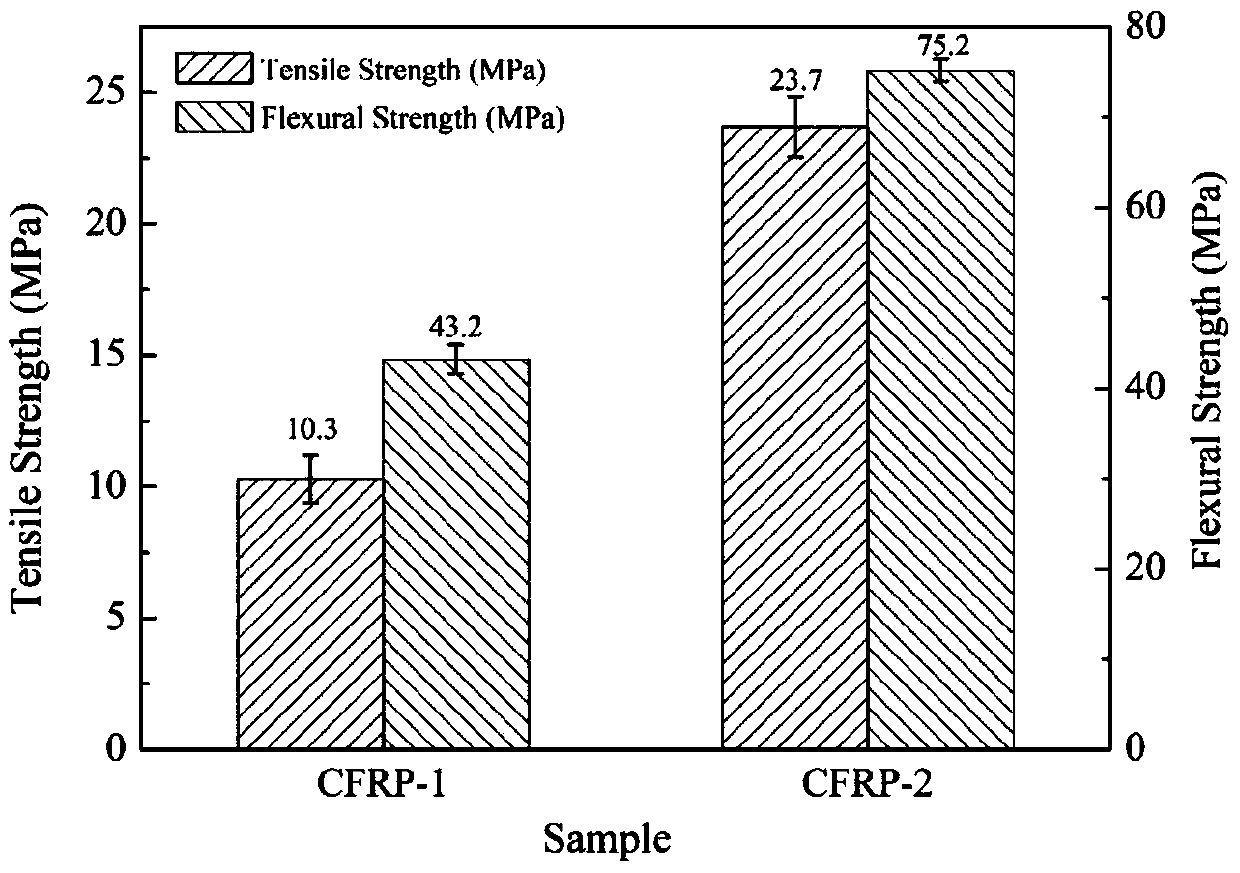

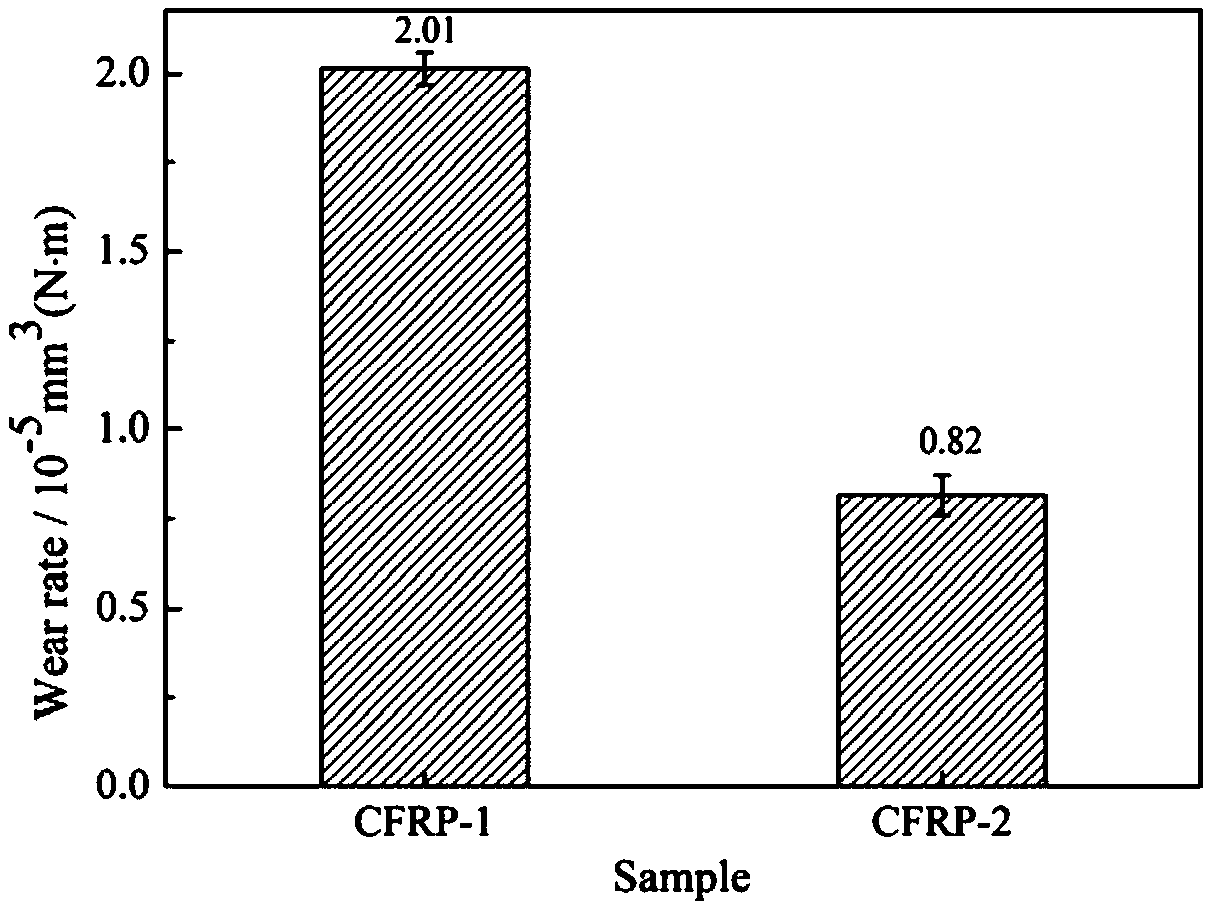

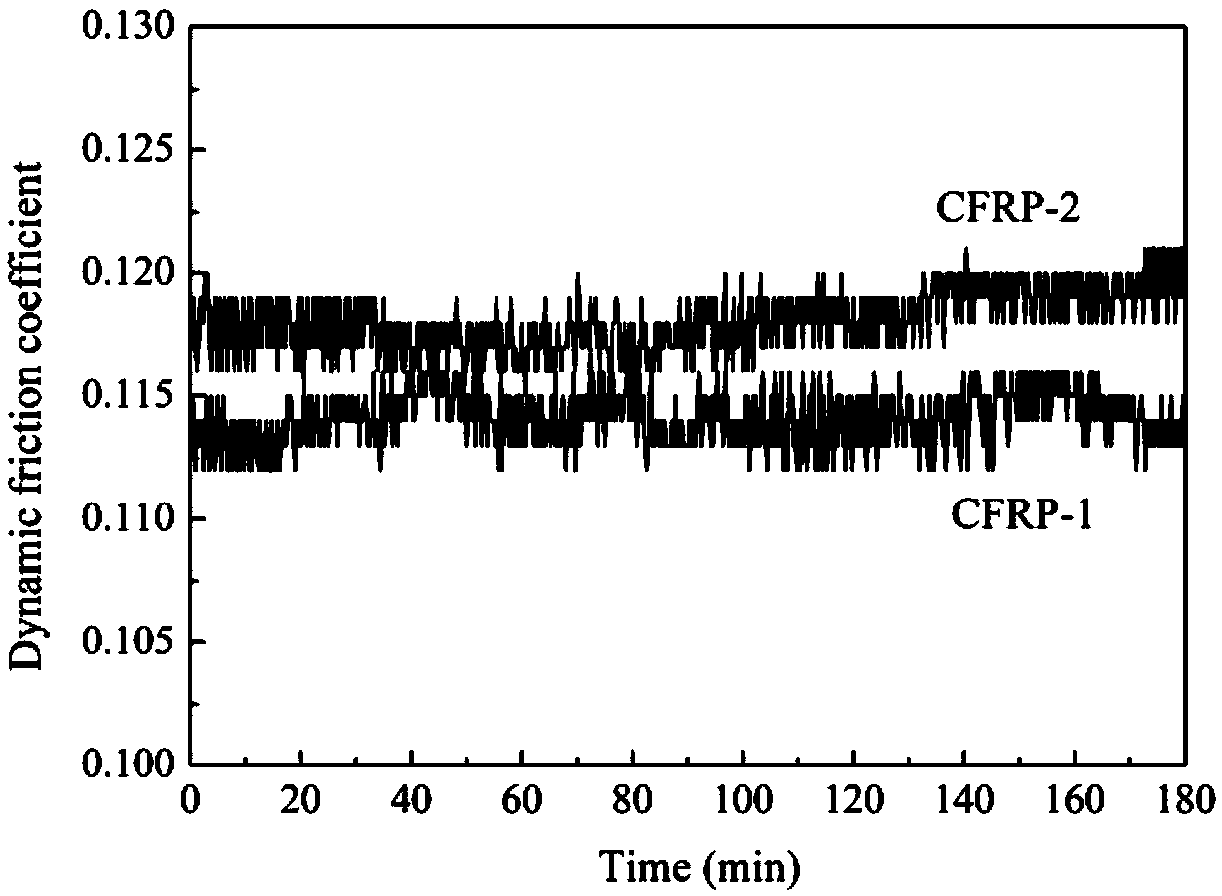

Embodiment 1

[0037] Step 1: Firstly, acetone and a mixture of acetone and water are used to treat the carbon fiber at a supercritical state of 110°C in a Soxhlet extractor under oil bath conditions, so as to remove surface sizing agents and other pollutants. It was washed and dried repeatedly with deionized water. The above-mentioned carbon fibers were treated with nitric acid at 130°C for 2 hours, recovered by filtration, washed with deionized water, and placed in an oven at 70°C to dry for later use to obtain functionalized carbon fibers.

[0038] Step 2: Dissolve 0.1g polyacrylonitrile-based carbon fiber, 0.714g zinc nitrate hexahydrate and 0.133g terephthalic acid in 50mL N,N-dimethylformamide, magnetically stir for 1 hour, and perform a homogeneous reaction at 130°C React in the container for 24 hours, cool with the furnace, take out the carbon fiber after the reaction is completed, wash the carbon fiber with DMF and chloroform repeatedly for 3 times, age for 12 hours, and then dry it...

Embodiment 2

[0042] Step 1: Firstly, acetone and a mixture of acetone and water are used to treat the carbon fiber at a supercritical state of 110°C in a Soxhlet extractor under oil bath conditions, so as to remove surface sizing agents and other pollutants. It was washed and dried repeatedly with deionized water. The above-mentioned carbon fibers were treated with nitric acid at 130°C for 2 hours, recovered by filtration, washed with deionized water, and placed in an oven at 70°C to dry for later use to obtain functionalized carbon fibers.

[0043] Step 2: Dissolve 0.01g polyacrylonitrile-based carbon fiber, 0.714g zinc nitrate hexahydrate and 0.133g terephthalic acid in 50mL N,N-dimethylformamide, magnetically stir for 1 hour, and perform a homogeneous reaction at 130°C React in the container for 24 hours, cool with the furnace, take out the carbon fiber after the reaction is completed, wash the carbon fiber with DMF and chloroform repeatedly for 3 times, age for 12 hours, and then dry i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com