Patents

Literature

3439results about How to "Improve surface roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

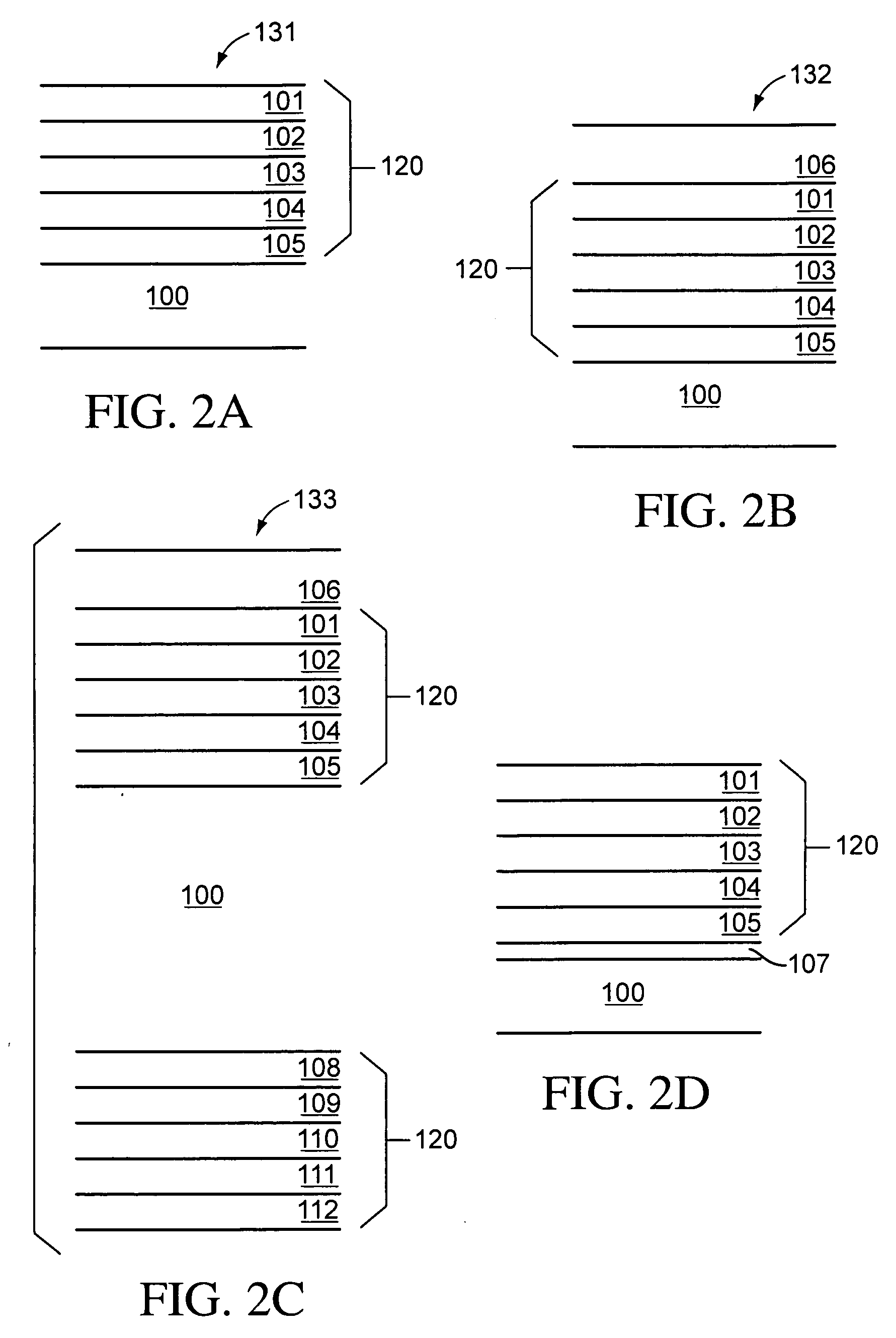

Gate oxides

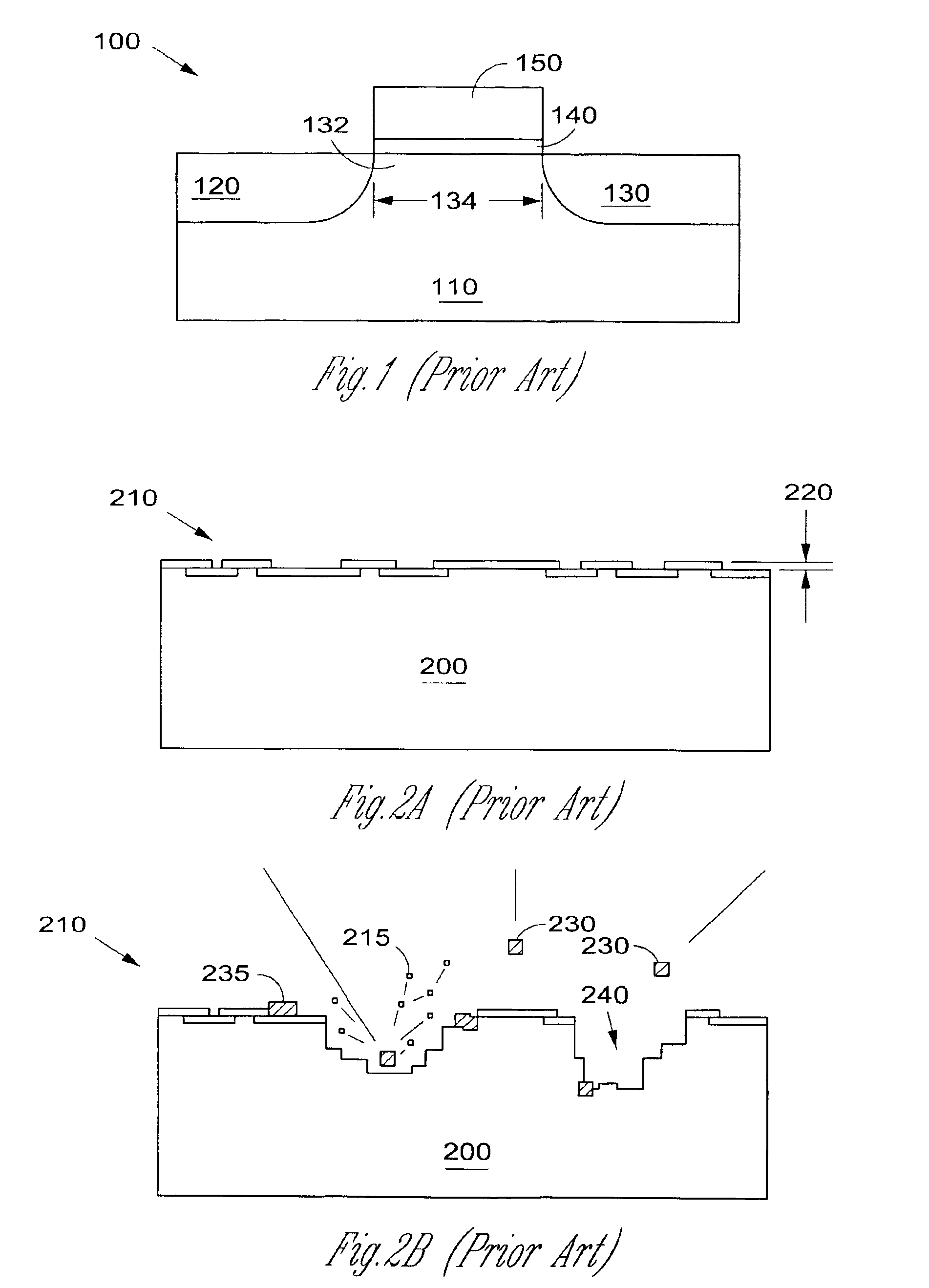

InactiveUS6844203B2Improve surface roughnessSmooth surface roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesEquivalent oxide thicknessGadolinium

A gate oxide and method of fabricating a gate oxide that produces a more reliable and thinner equivalent oxide thickness than conventional SiO2 gate oxides are provided. Also shown is a gate oxide with a conduction band offset of 2 eV or greater. Gate oxides formed from elements such as yttrium and gadolinium are thermodynamically stable such that the gate oxides formed will have minimal reactions with a silicon substrate or other structures during any later high temperature processing stages. The process shown is performed at lower temperatures than the prior art, which further inhibits reactions with the silicon substrate or other structures. Using a thermal evaporation technique to deposit the layer to be oxidized, the underlying substrate surface smoothness is preserved, thus providing improved and more consistent electrical properties in the resulting gate oxide.

Owner:HEWLETT PACKARD CO +1

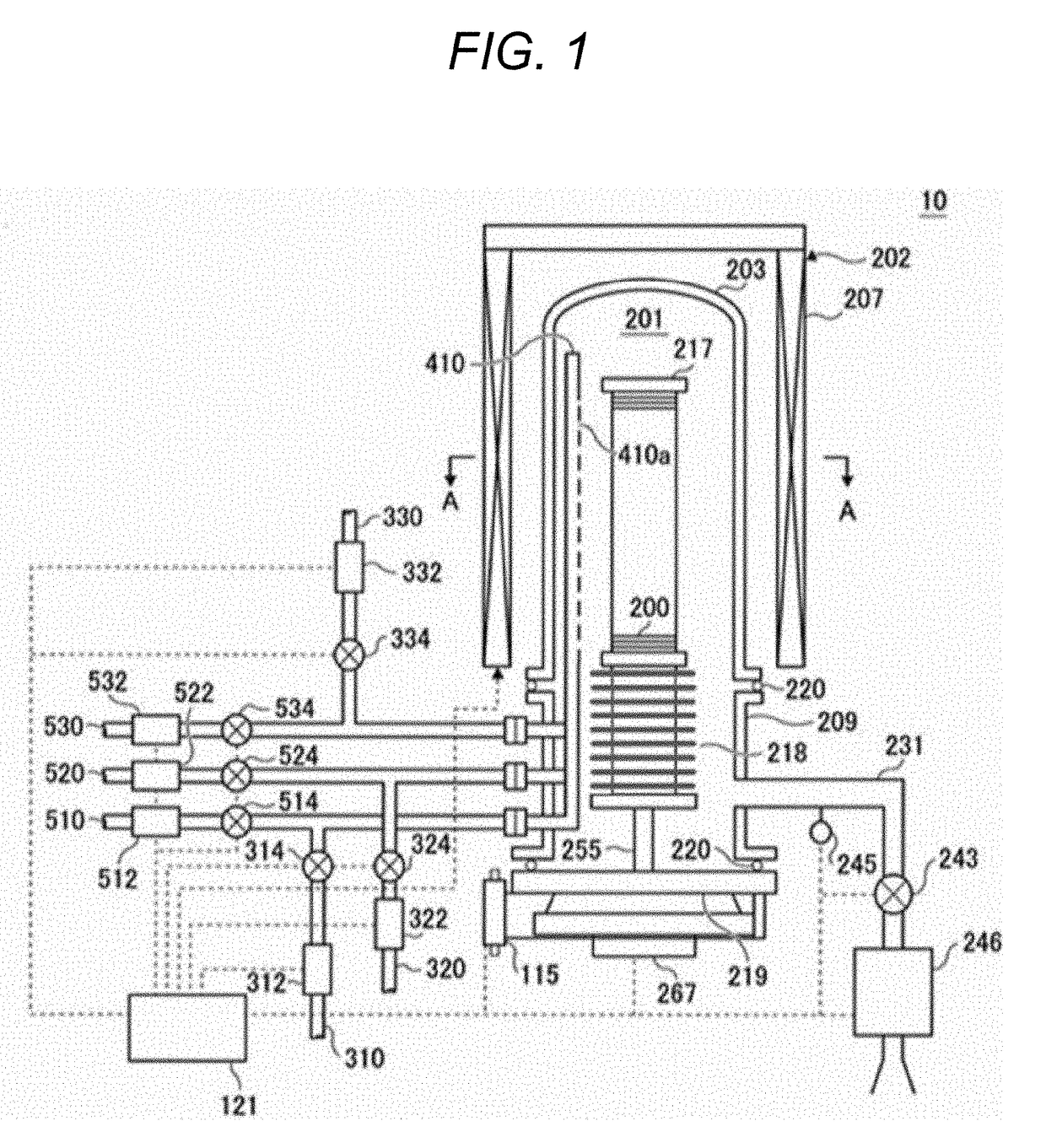

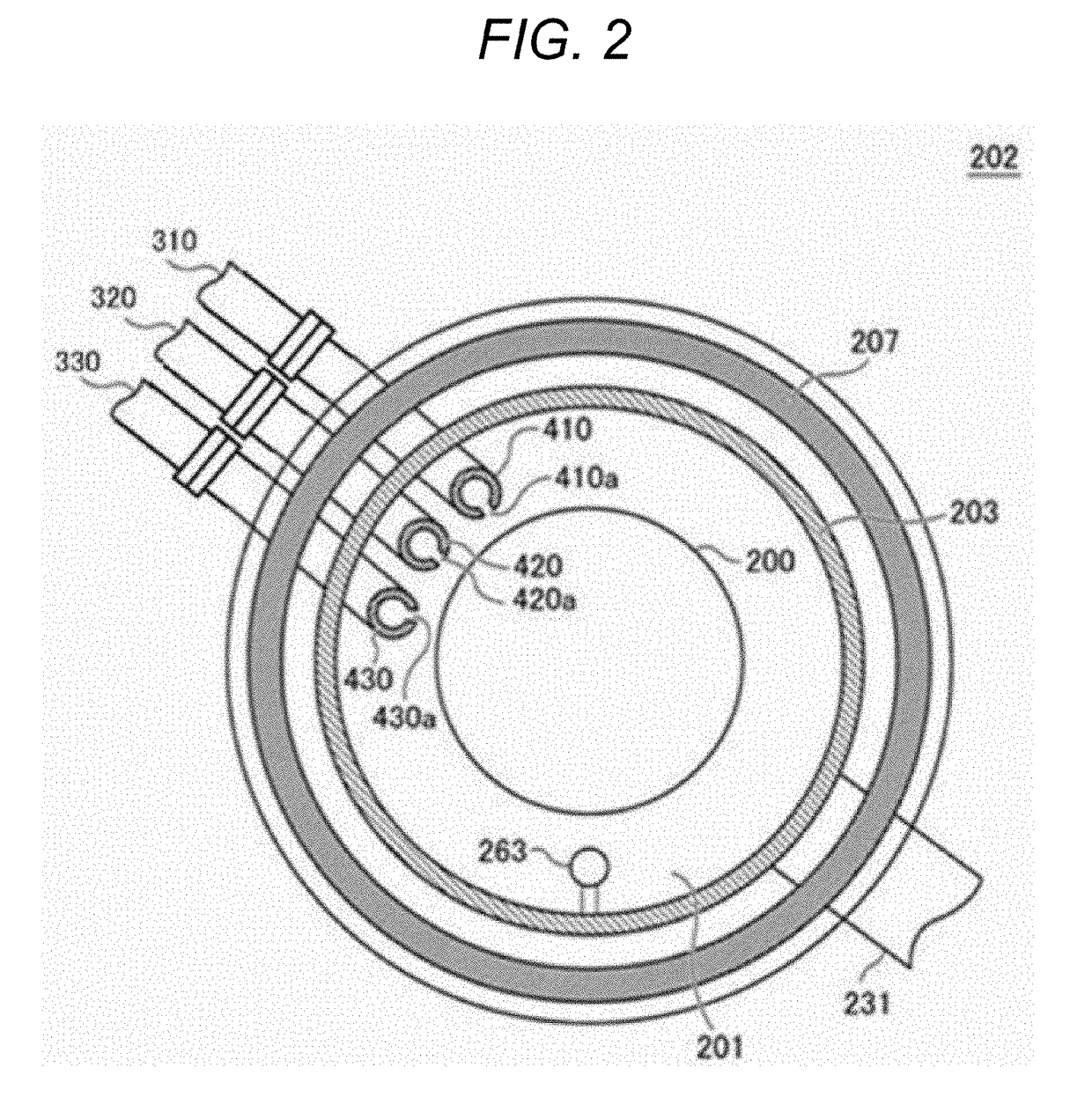

Method of manufacturing semiconductor device

PendingUS20170309490A1Reduce roughnessLow resistivitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingSemiconductorAmorphous metal

A method of manufacturing a semiconductor device includes: forming an amorphous metal film on a substrate by time-divisionally conducting a cycle a predetermined number of times, the cycle including: (a) simultaneously supplying a metal-containing gas and a first reducing gas to the substrate to form a first amorphous metal layer on the substrate, and (b) forming a second amorphous metal layer on the first amorphous metal layer by time-divisionally supplying, a predetermined number of times, the metal-containing gas and a second reducing gas to the substrate on which the first amorphous metal layer is formed; and forming a crystallized metal layer on the substrate by simultaneously supplying the metal-containing gas and the first reducing gas to the substrate on which the amorphous metal film is formed.

Owner:KOKUSA ELECTRIC CO LTD

Highly reliable amorphous high-k gate oxide ZrO2

InactiveUS20050029605A1Improve surface roughnessSmooth surface roughnessSolid-state devicesSemiconductor/solid-state device manufacturingPhysicsConduction band

A gate oxide and method of fabricating a gate oxide that produces a more reliable and thinner equivalent oxide thickness than conventional SiO2 gate oxides are provided. Also shown is a gate oxide with a conduction band offset in a range of approximately 5.16 eV to 7.8 eV. Gate oxides formed from elements such as zirconium are thermodynamically stable such that the gate oxides formed will have minimal reactions with a silicon substrate or other structures during any later high temperature processing stages. The process shown is performed at lower temperatures than the prior art, which further inhibits reactions with the silicon substrate or other structures. Using a thermal evaporation technique to deposit the layer to be oxidized, the underlying substrate surface smoothness is preserved, thus providing improved and more consistent electrical properties in the resulting gate oxide.

Owner:MICRON TECH INC

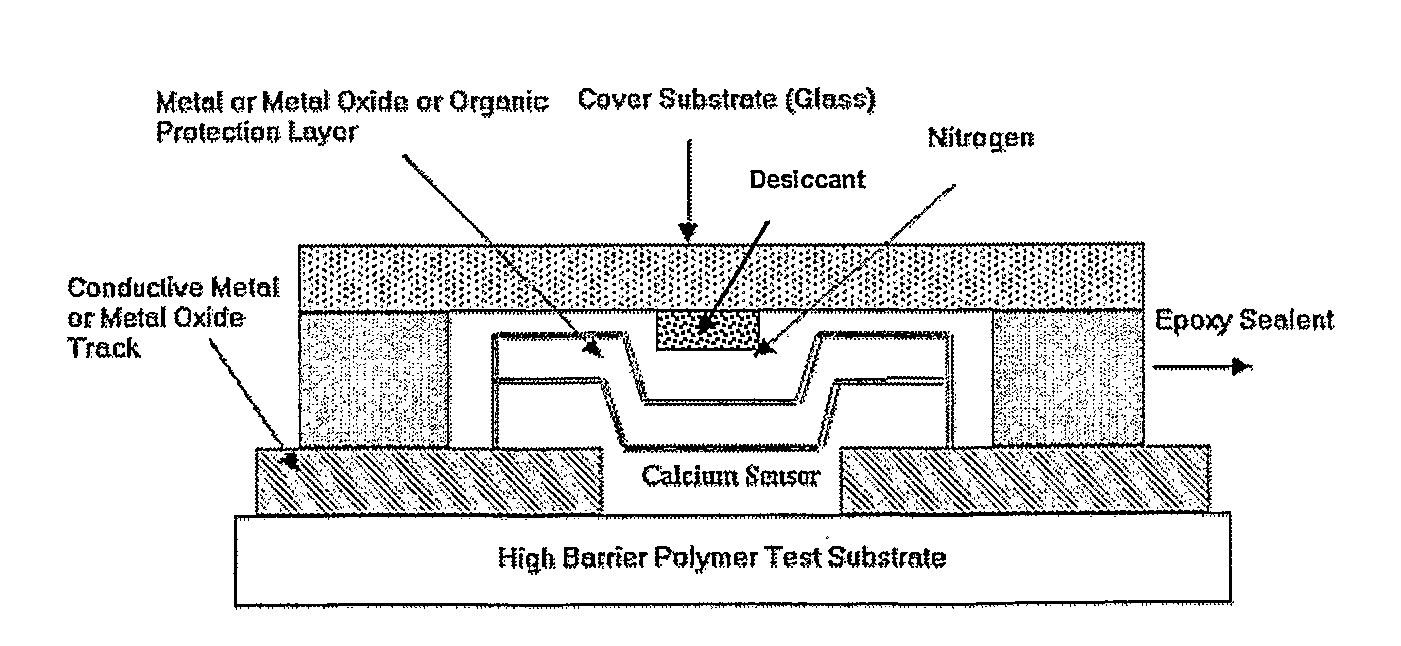

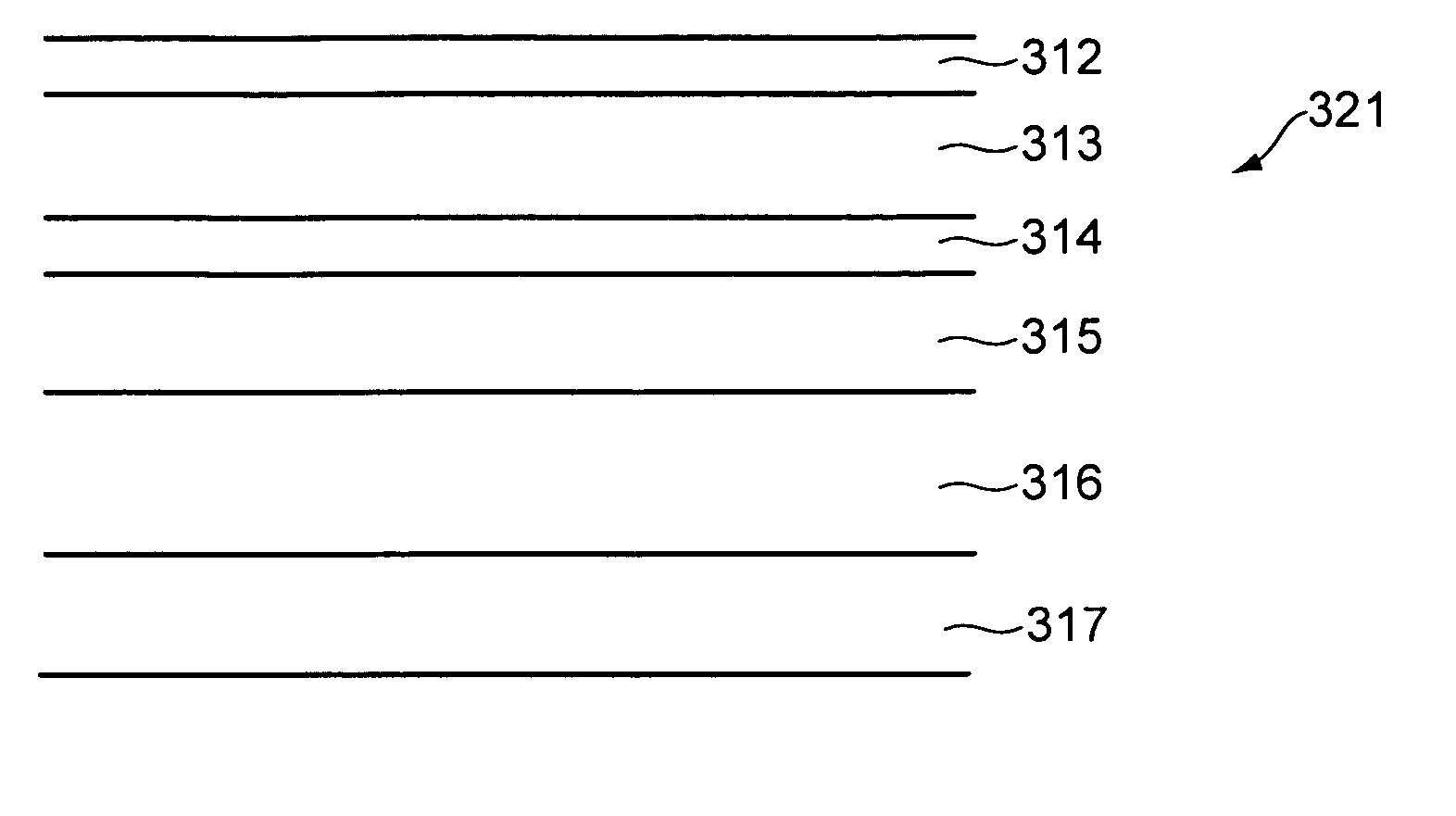

Nanoparticulate encapsulation barrier stack

ActiveUS20100089636A1Minimise lateral diffusionReduce probabilityMaterial nanotechnologyNanomagnetismChemistryNanometre

A barrier stack for encapsulating a moisture and / or oxygen sensitive electronic device is provided. The barrier stack comprises a multilayer film having at least one barrier layer having low moisture and / or oxygen permeability, and at least one sealing layer arranged to be in contact with a surface of the barrier layer, wherein the sealing material comprises reactive nanoparticles capable of interacting with moisture and / or oxygen, thereby retarding the permeation of moisture and / or oxygen through defects present in the barrier layer.

Owner:AGENCY FOR SCI TECH & RES

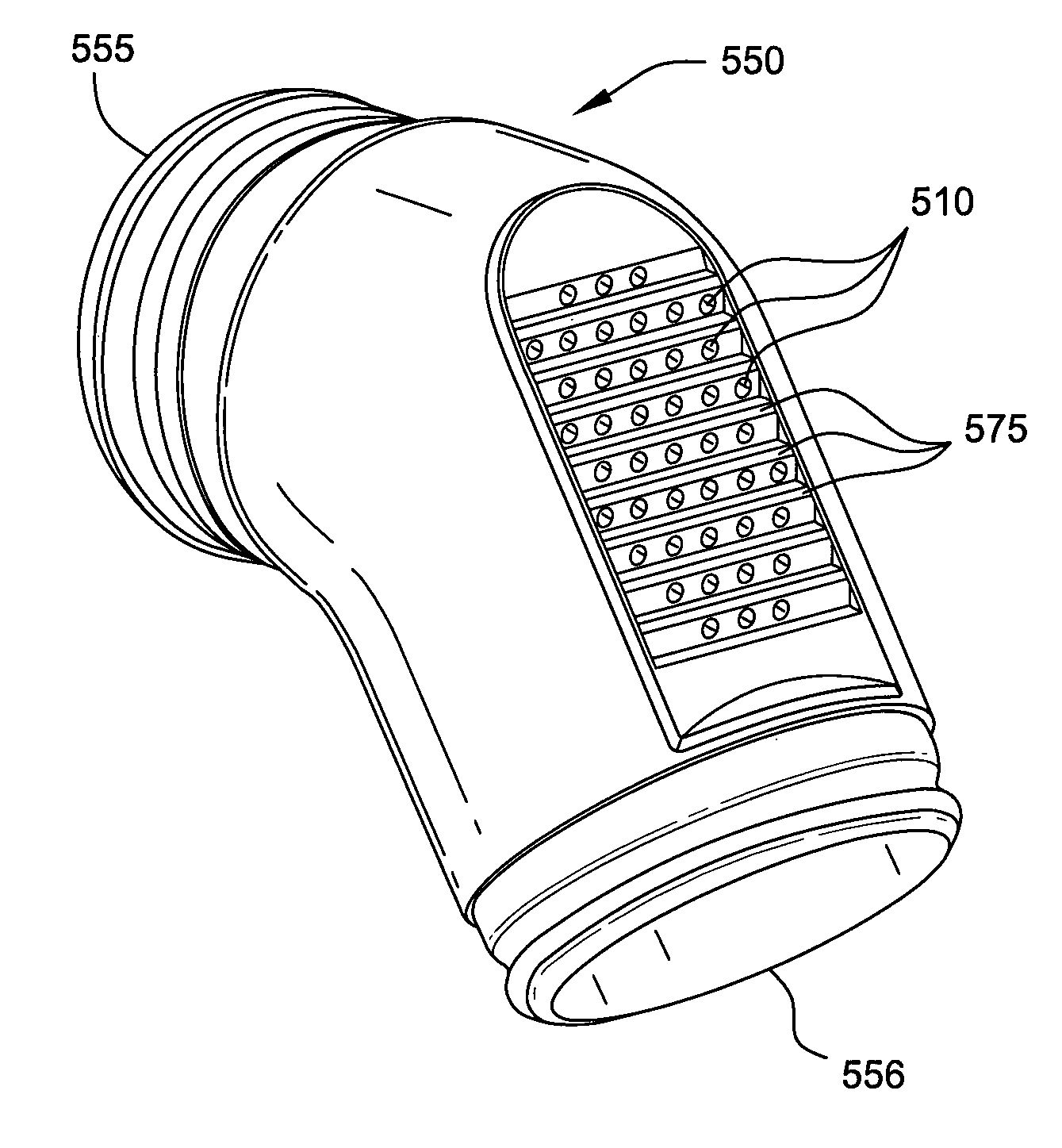

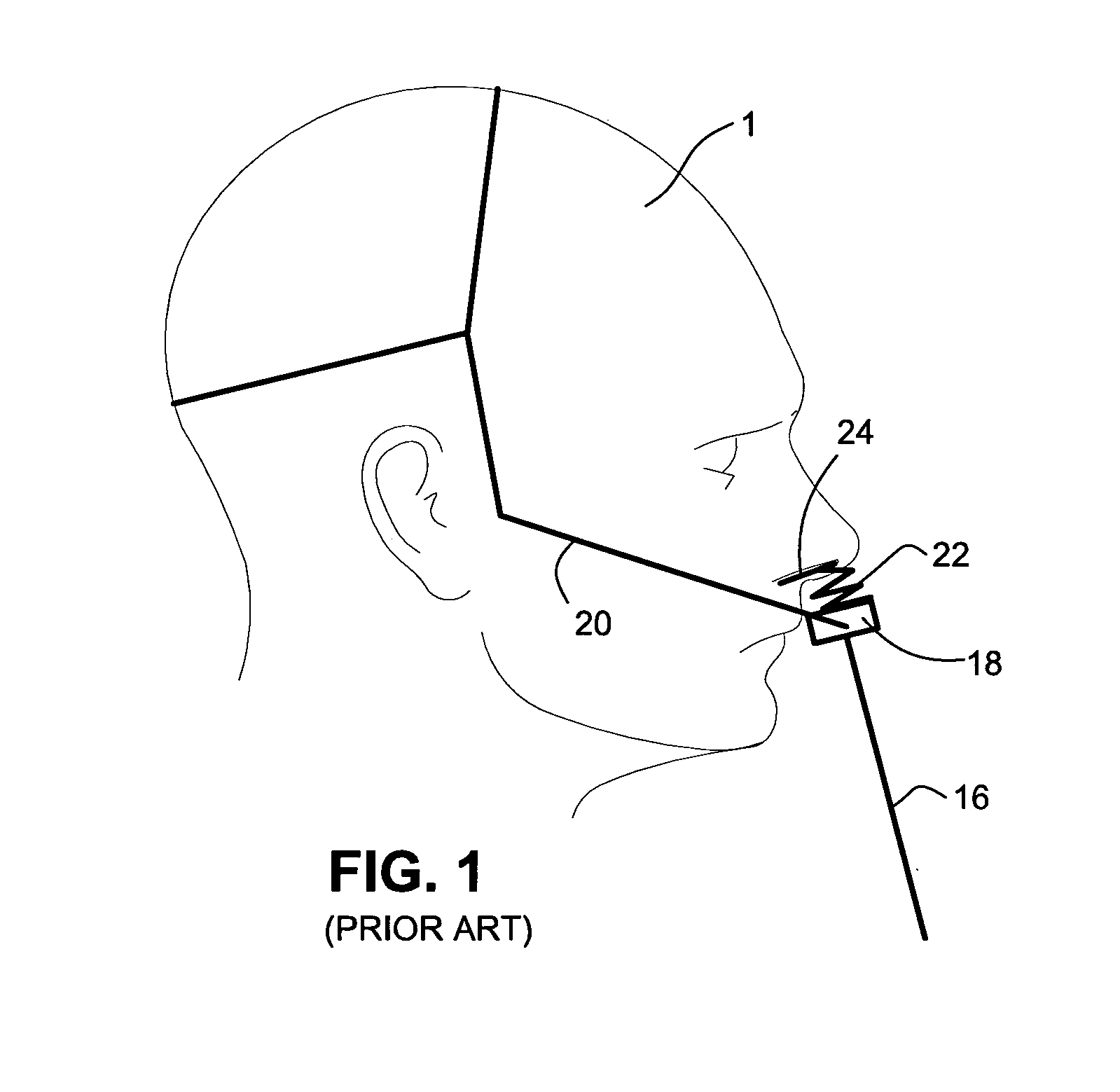

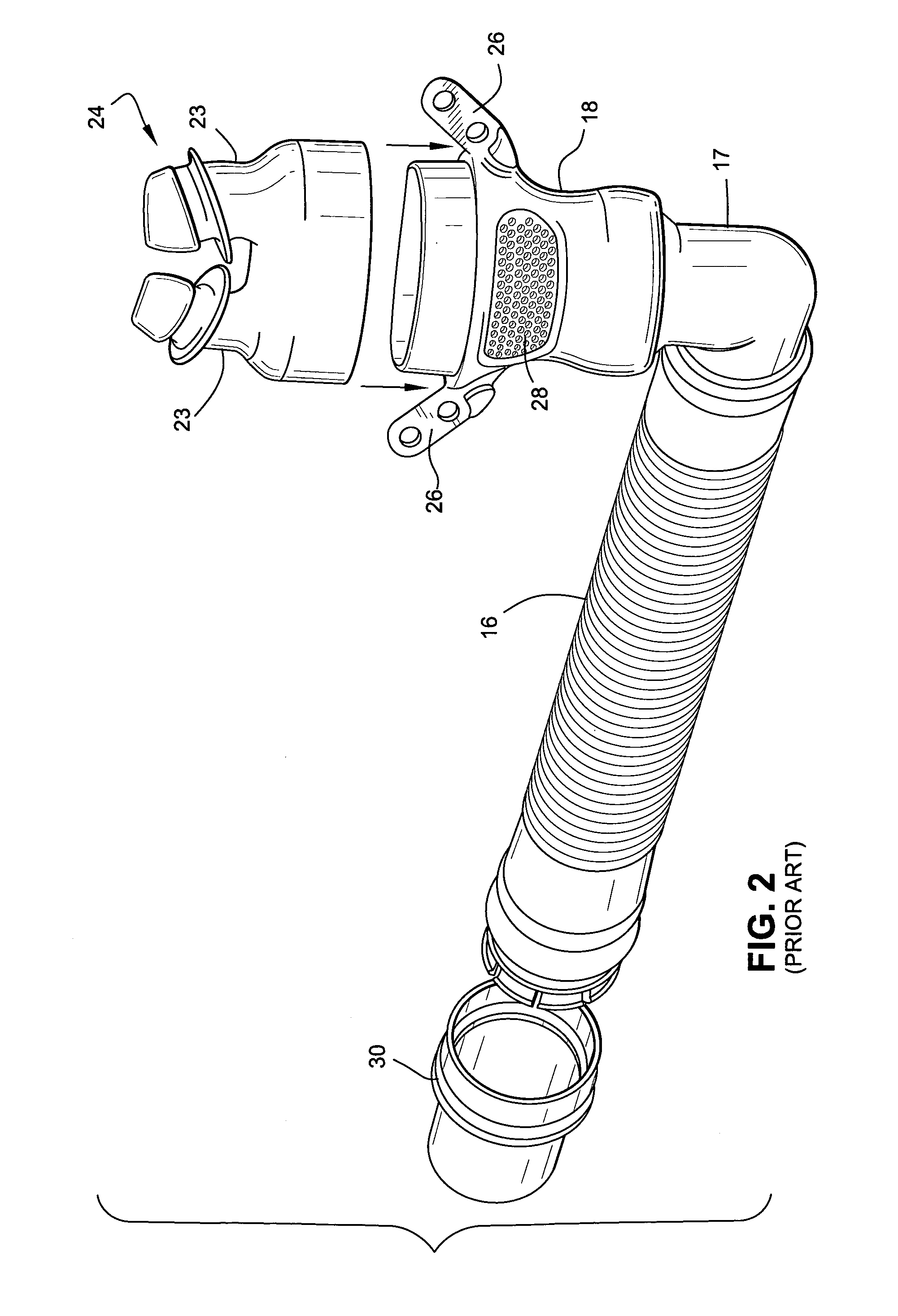

Patient interface systems

ActiveUS20120132209A1Easy to useEasy to appreciateControlling ratio of multiple fluid flowsBreathing masksElastomerEngineering

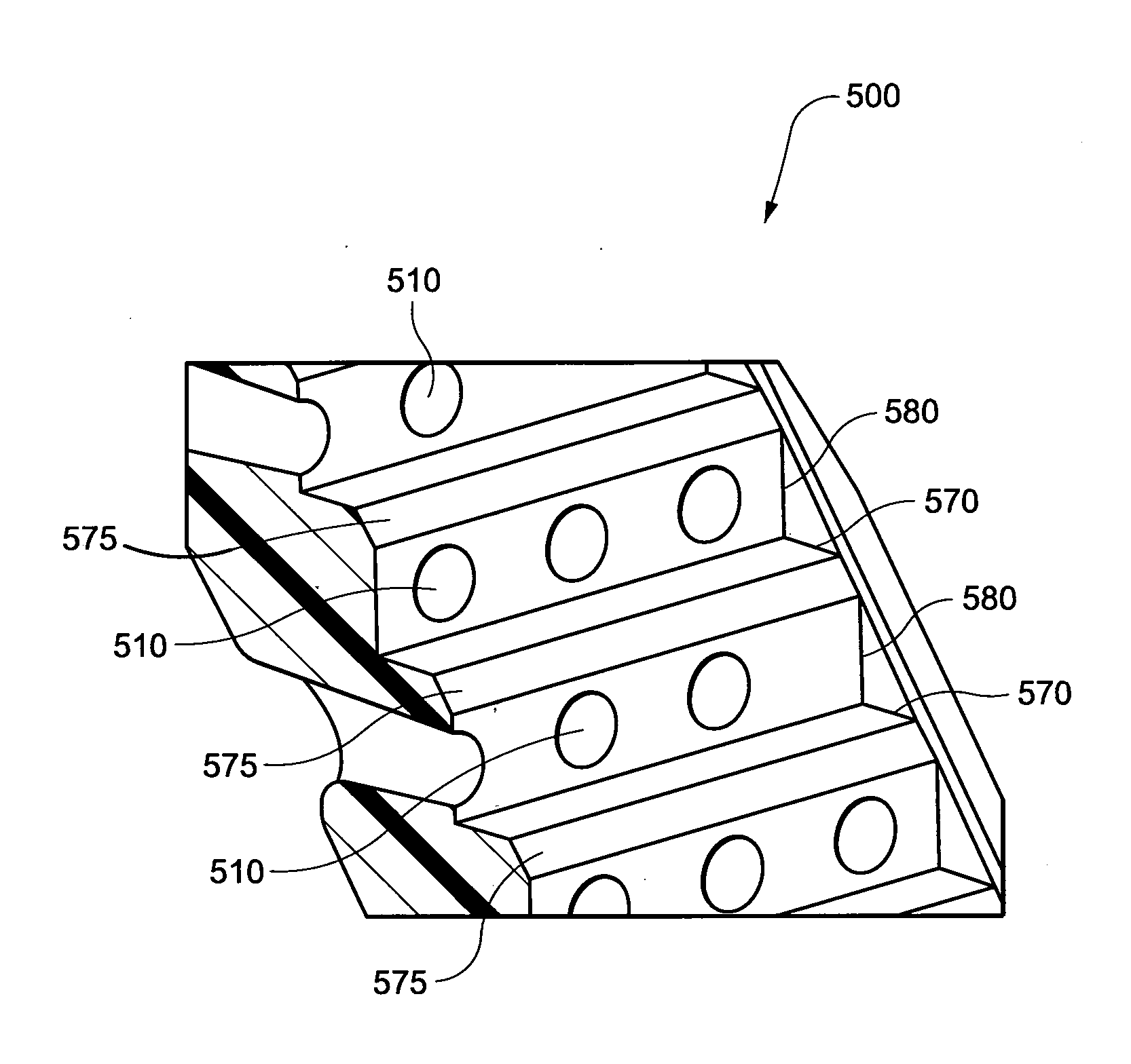

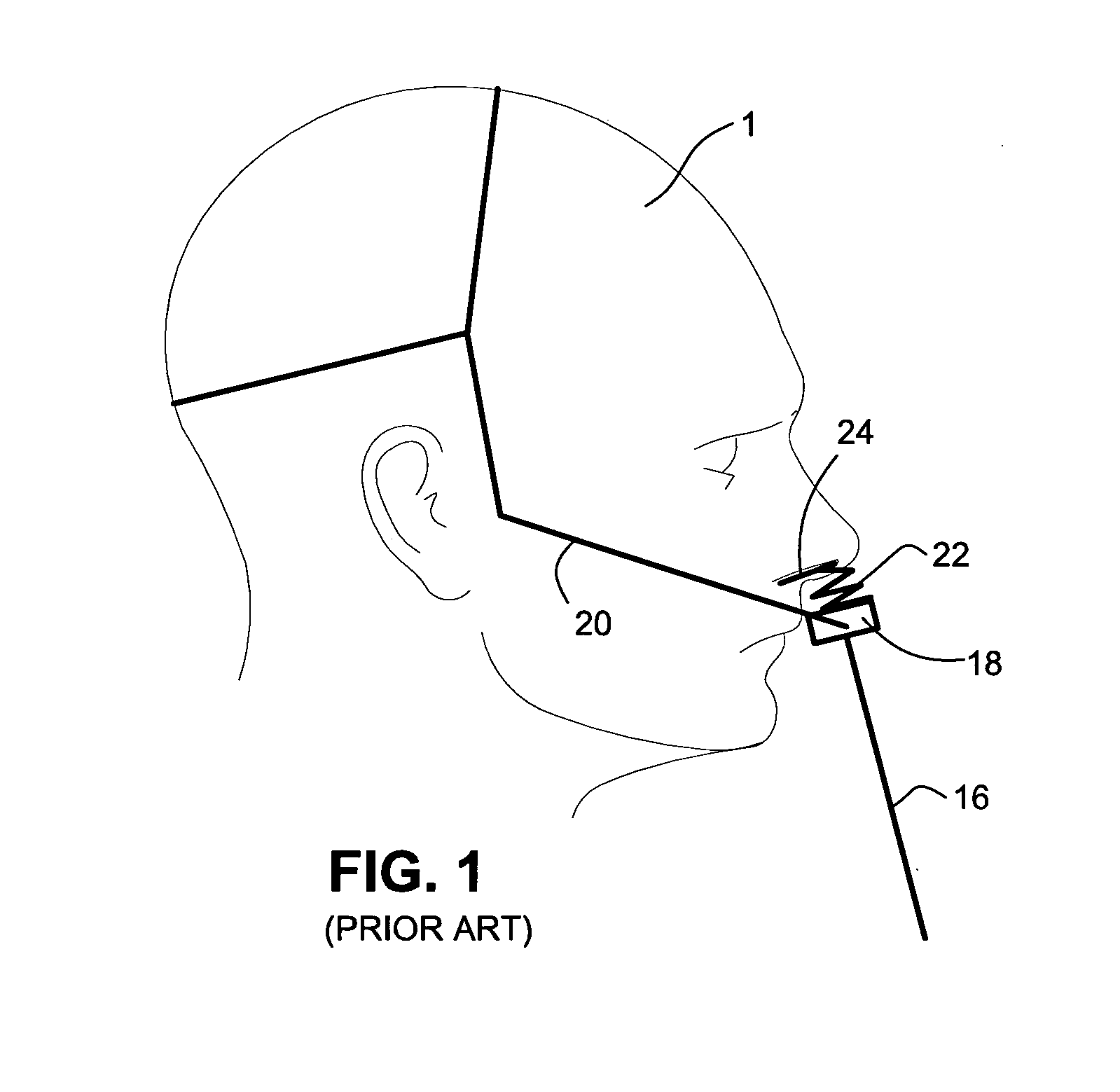

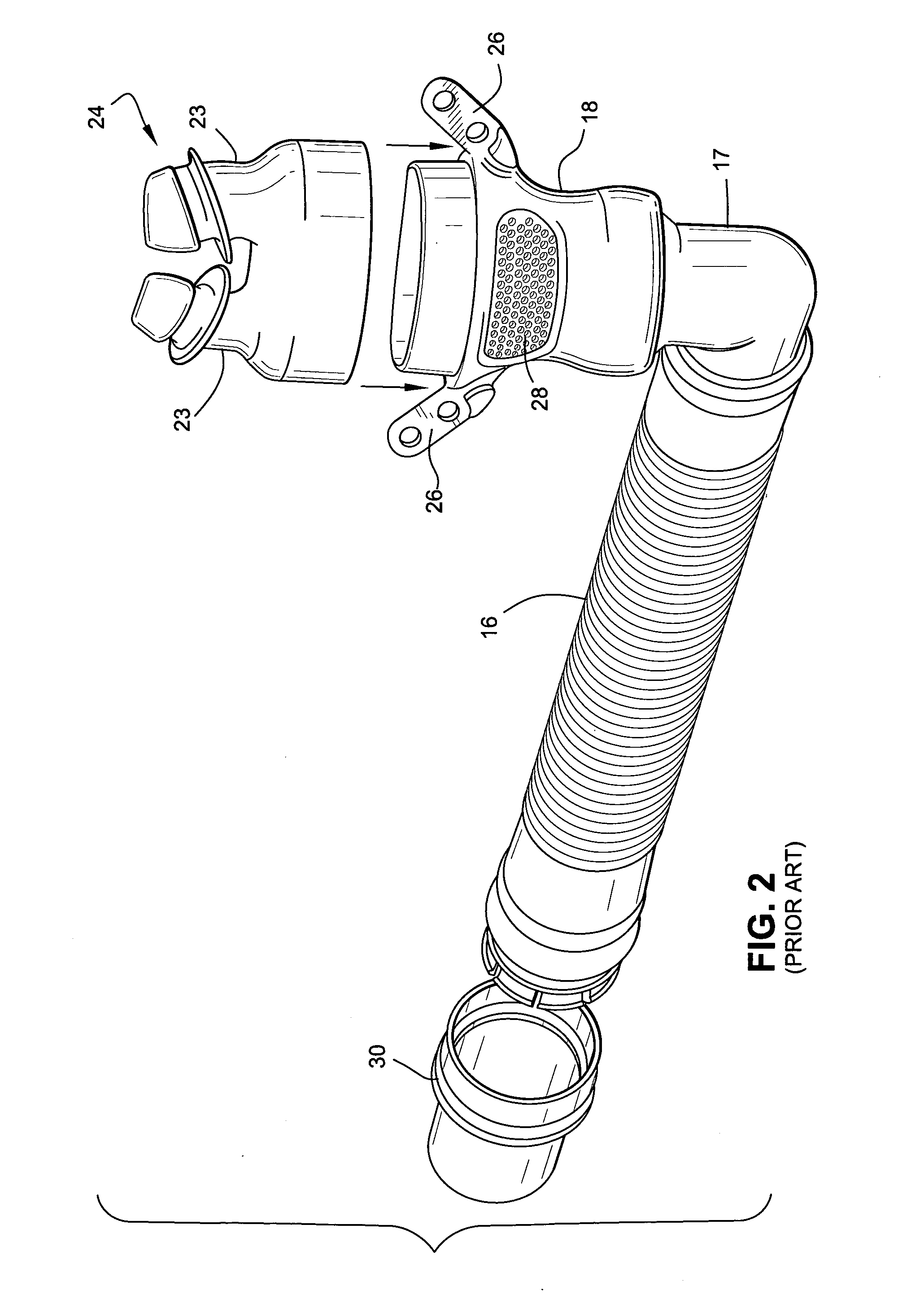

A headgear for use with a patient interface for delivering a flow of breathable gas to a patient includes at least a strap (741) adapted to position the patient interface in sealing engagement with the patient's airways. The strap is constructed from an elastomer and a first side of the strap includes a first region (215) on a portion of its surface that is textured to reduce friction with objects contacting the strap. A textured surface coating for a portion of an elastomer strap included in a headgear system is adapted to contact the skin of a patient, when in use, and the coating has a Ra value greater than zero. A vent (500) for use with a patient interface for delivering a flow of breathable gas to a patient includes a plurality of rises (580) and runs (570) in a stepped arrangement; and a plurality of holes (510) in the stepped arrangement for the venting of gas.

Owner:RESMED LTD

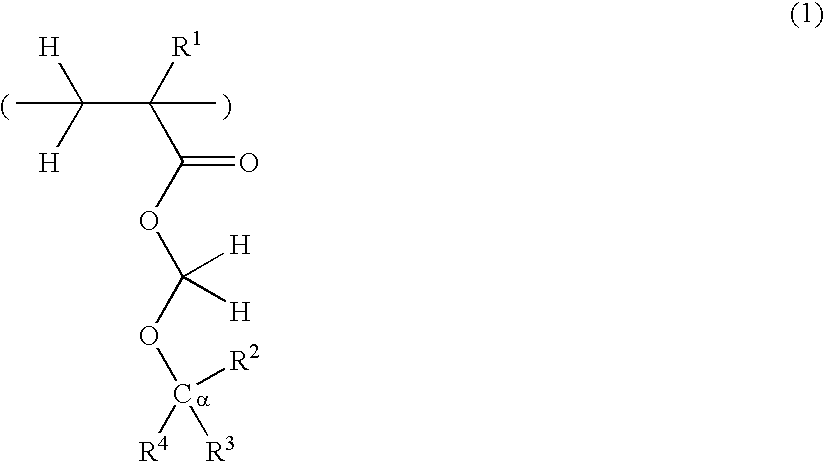

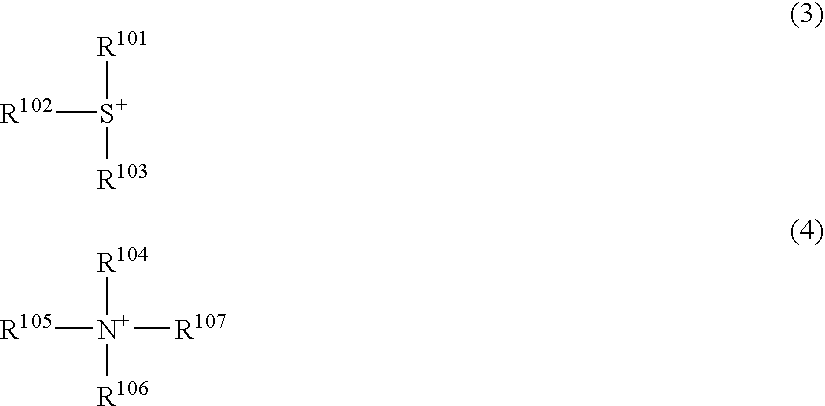

Positive resist composition and patterning process

ActiveUS20080153030A1Good storage stabilityHigh resolutionOrganic chemistryPhotosensitive materialsHigh energyPhotoacid generator

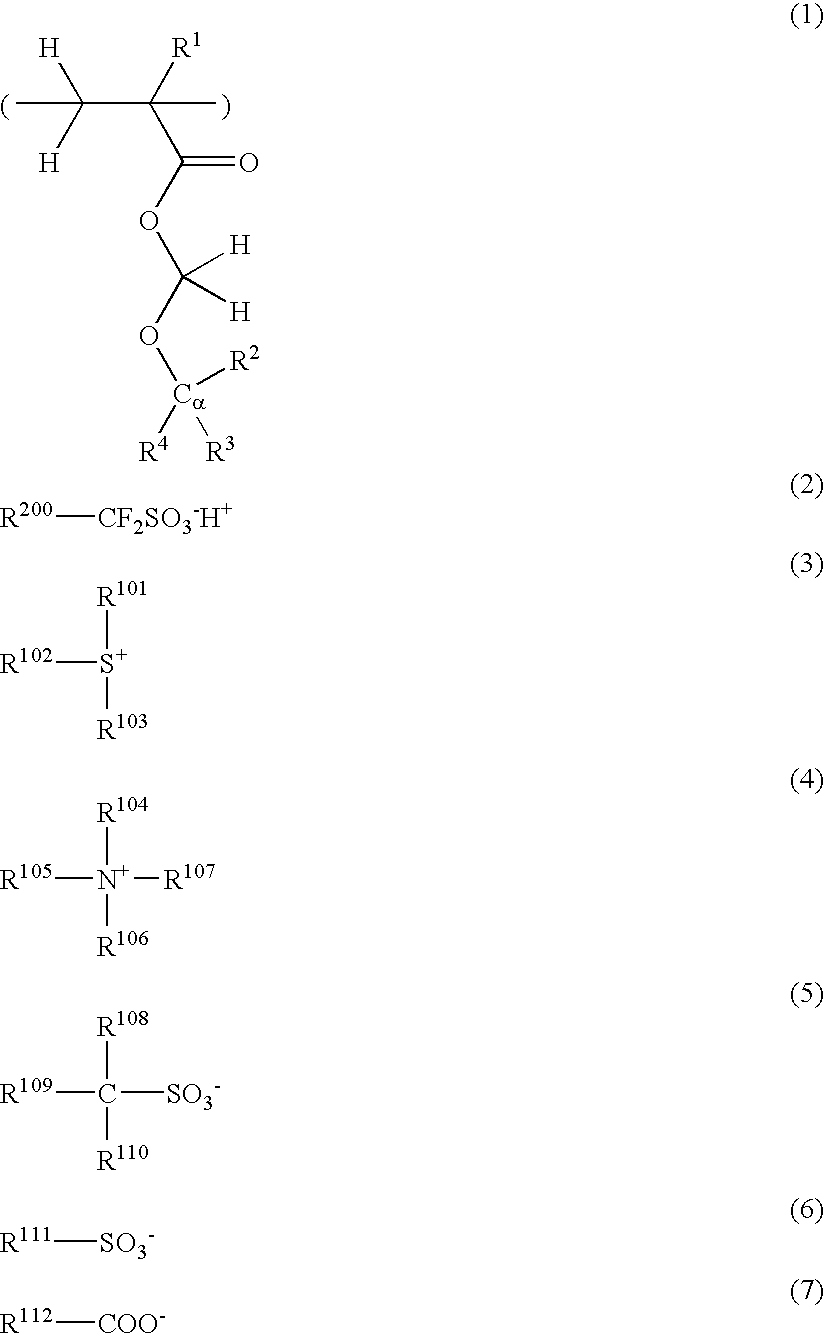

There is disclosed a resist composition that remarkably improves the resolution of photolithography using a high energy beam such as ArF excimer laser light as a light source, and exhibits excellent resistance to surface roughness and side lobe under use of a halftone phase shift mask; and a patterning process using the resist composition. The positive resist composition at least comprises (A) a resin component comprising a repeating unit represented by the following general formula (1); (B) a photoacid generator generating sulfonic acid represented by the following general formula (2) upon exposure to a high energy beam; and (C) an onium salt where a cation is sulfonium represented by the following general formula (3), or ammonium represented by the following general formula (4); and an anion is represented by any one of the following general formulae (5) to (7).

Owner:SHIN ETSU CHEM IND CO LTD

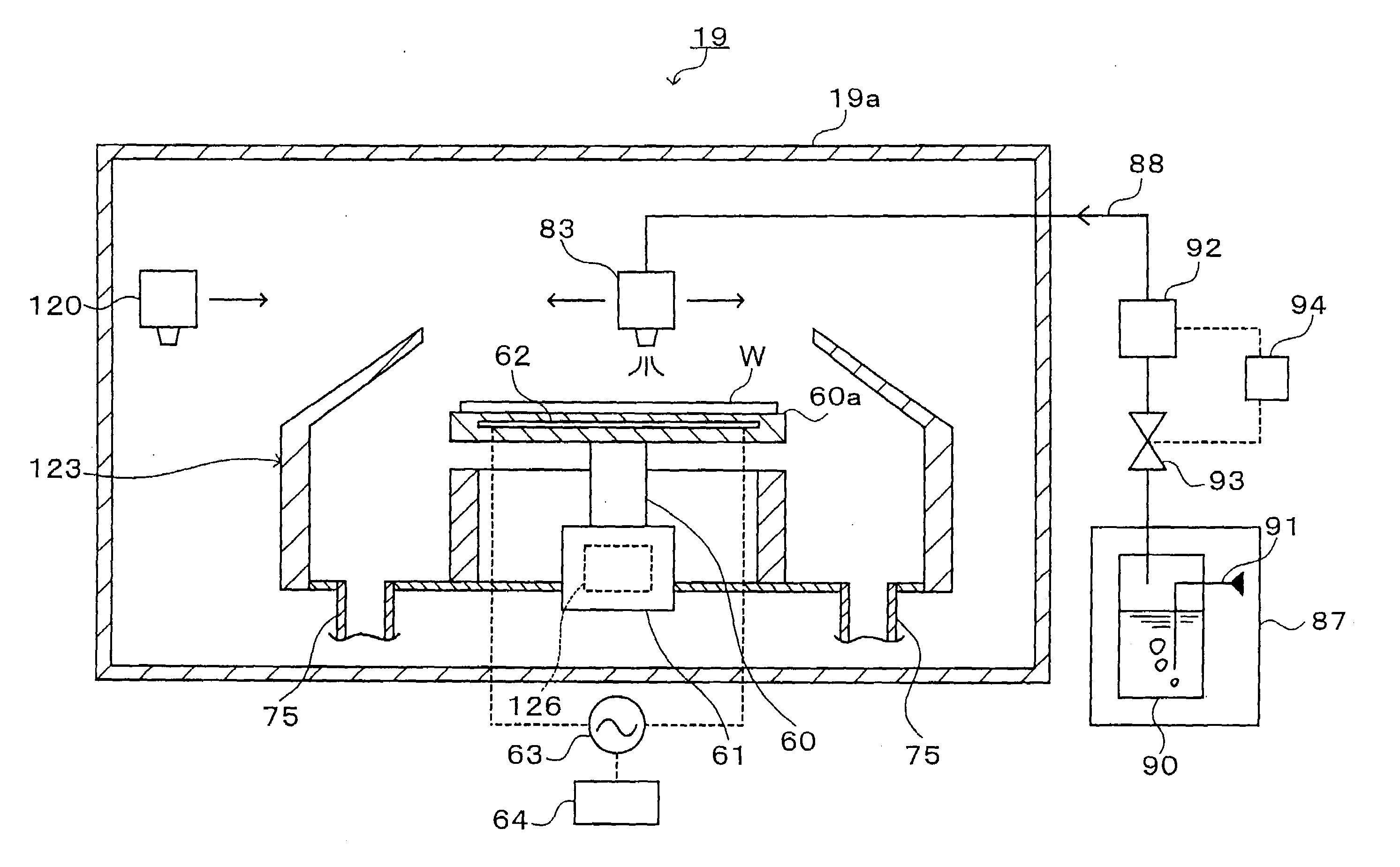

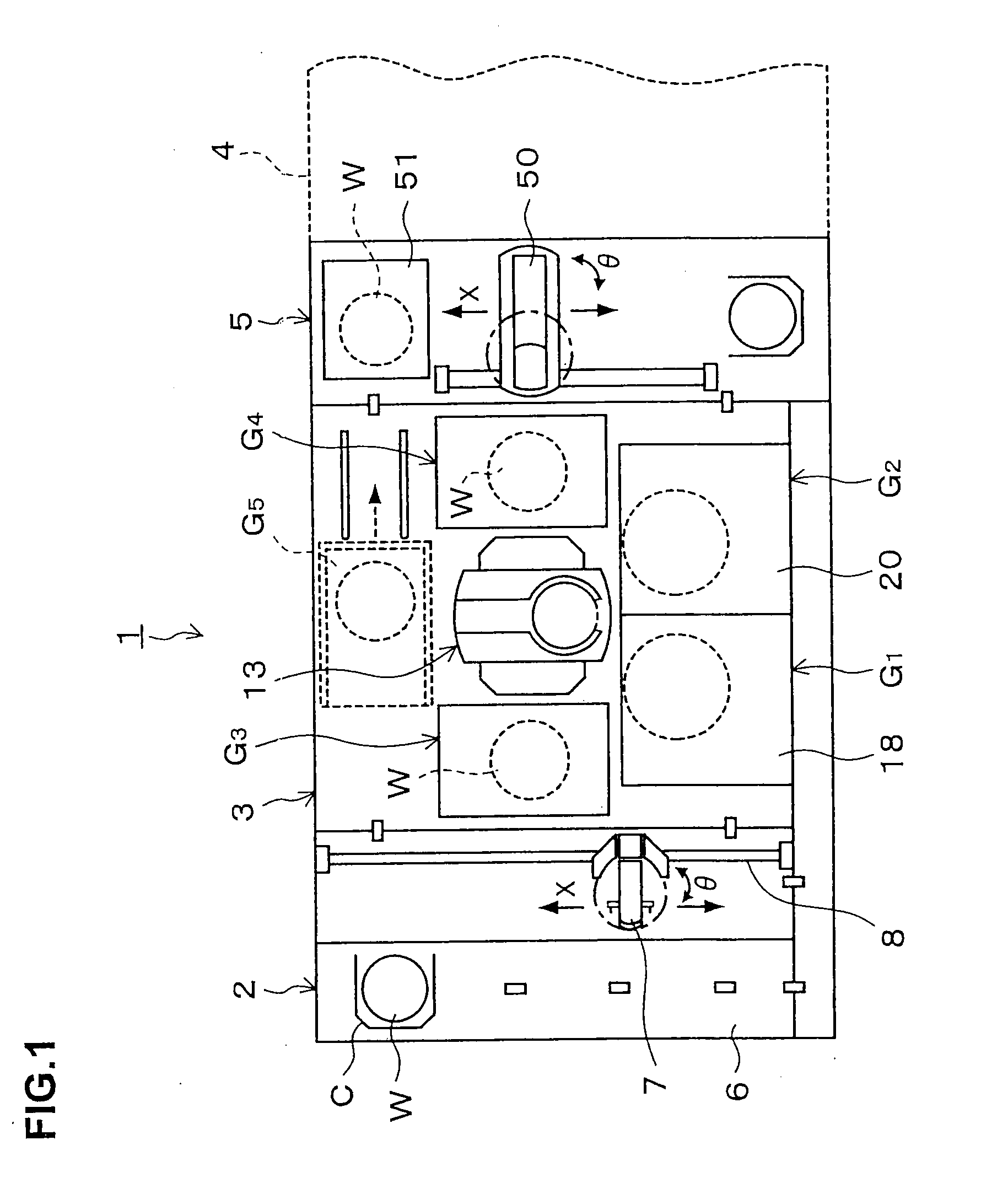

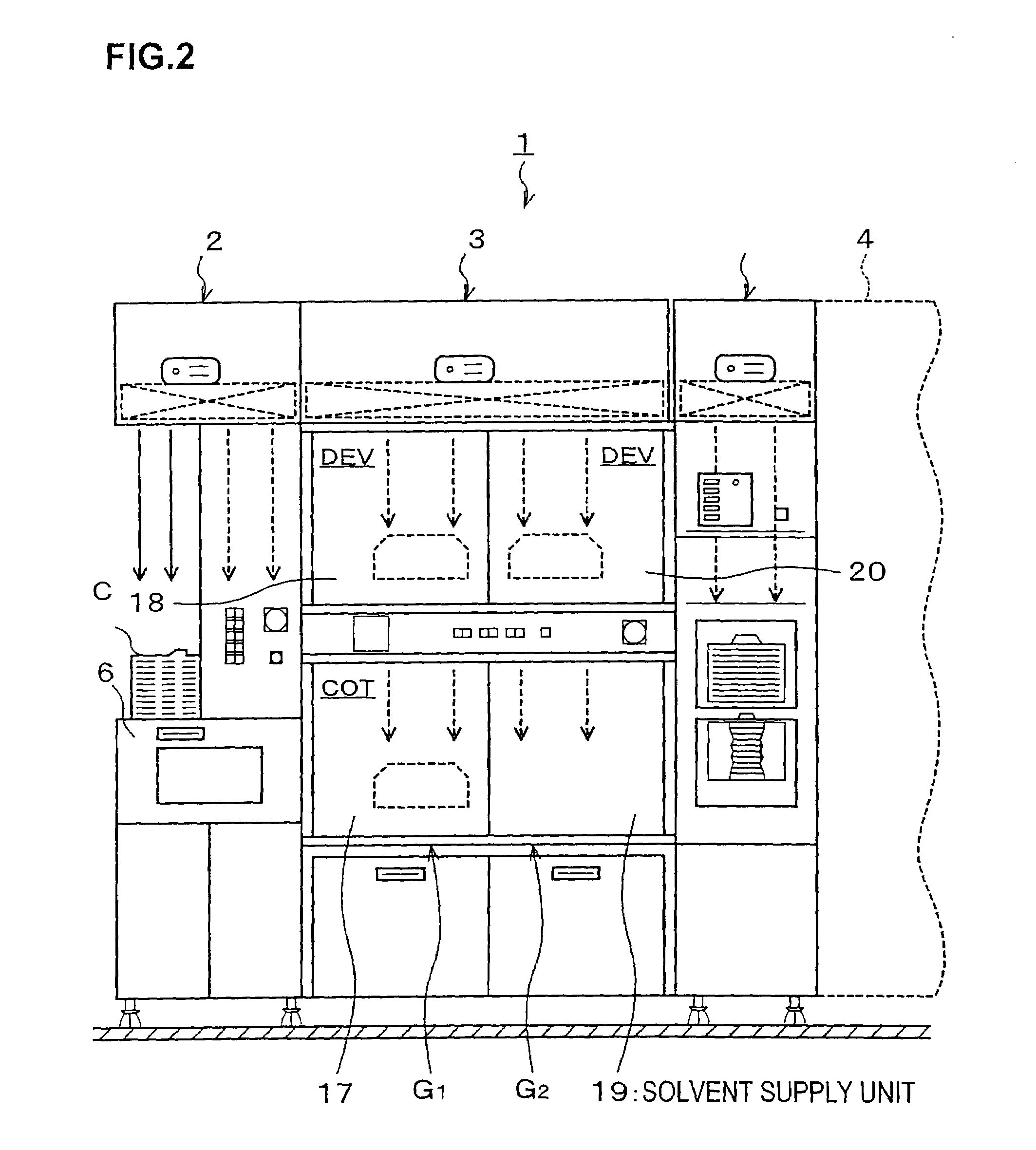

Method for improving surface roughness of processed film of substrate and apparatus for processing substrate

InactiveUS20100020297A1Improve surface roughnessIncrease productionSemiconductor/solid-state device manufacturingPhotosensitive material processingSpray nozzleSurface roughness

A treatment apparatus for treating a substrate on a surface of which a treatment film has been formed and subjected to exposure processing and developing treatment. The treatment apparatus includes a nozzle for supplying a solvent gas of the treatment film to the surface of the treatment film on the substrate, and a moving mechanism for moving the nozzle which is supplying the solvent gas, relative to the substrate. The nozzle has an elongated discharge portion at least longer than a diameter of the substrate and partition plates at a front and a rear in the moving direction of the nozzle.

Owner:TOKYO ELECTRON LTD

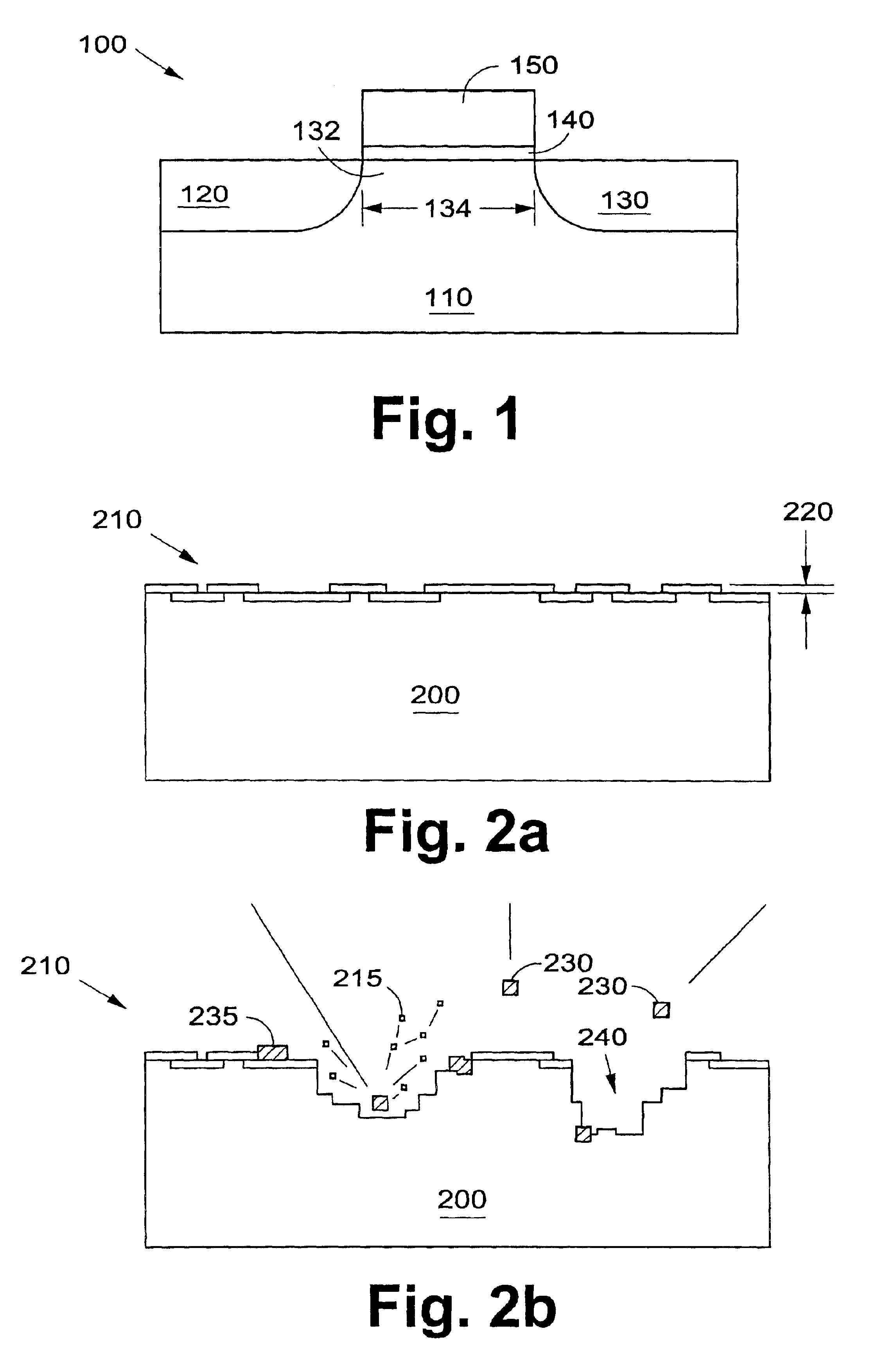

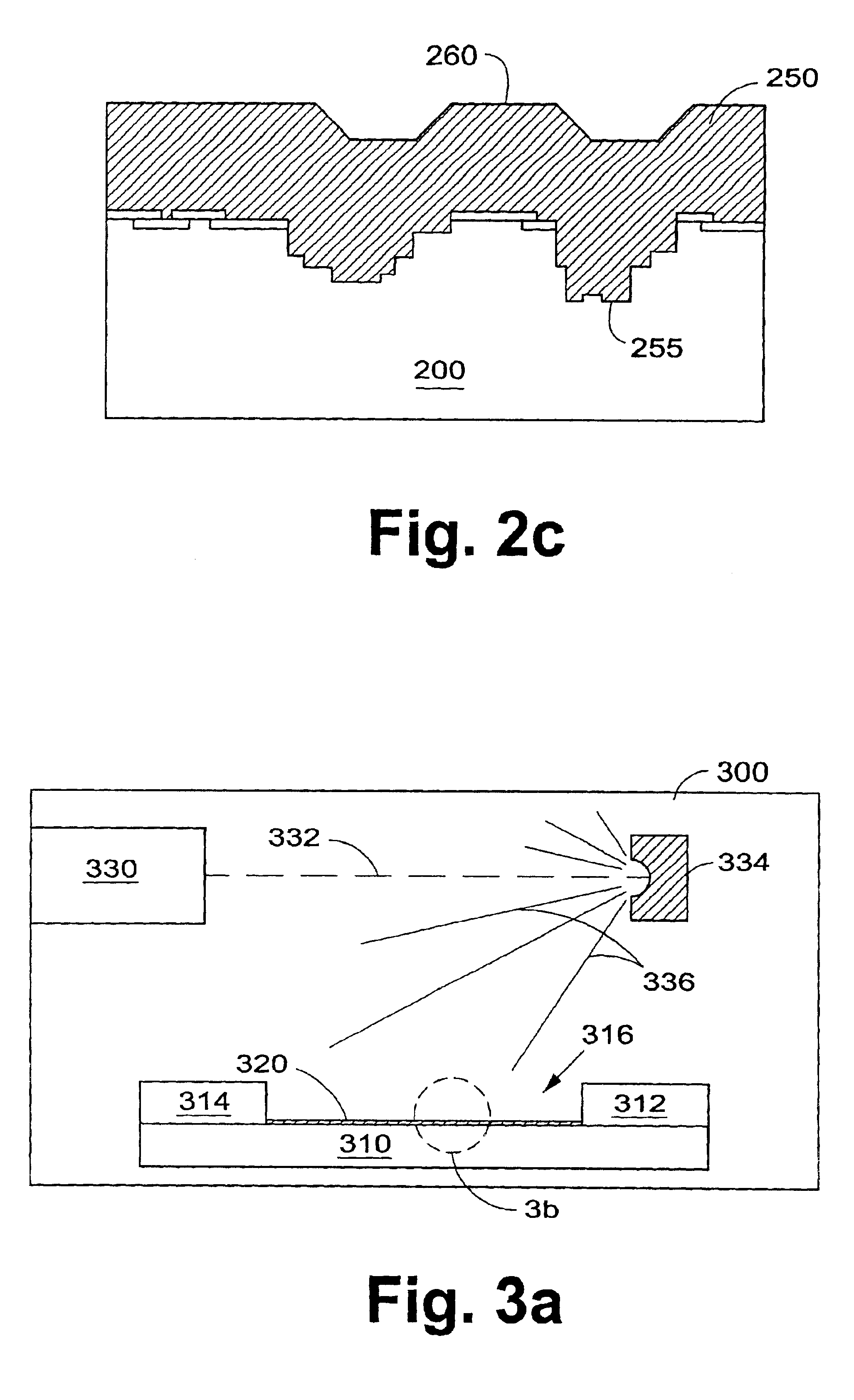

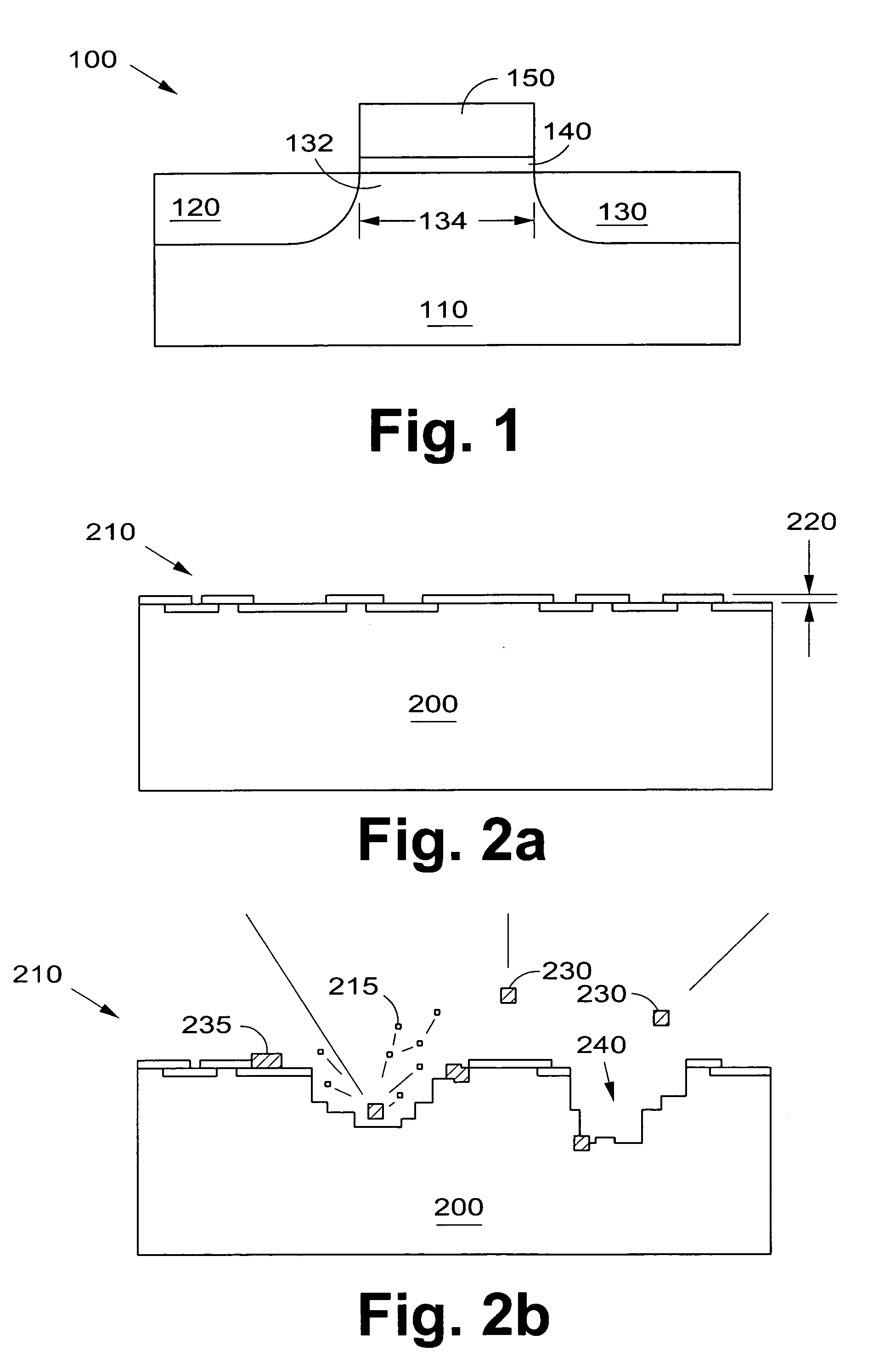

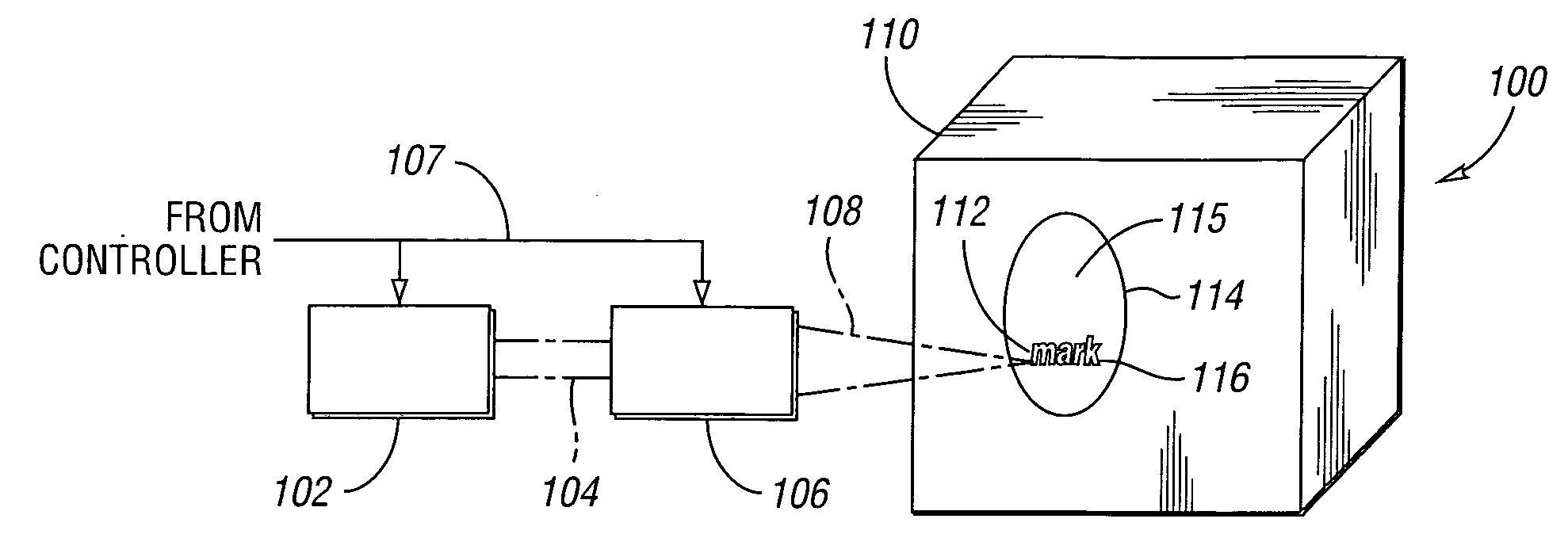

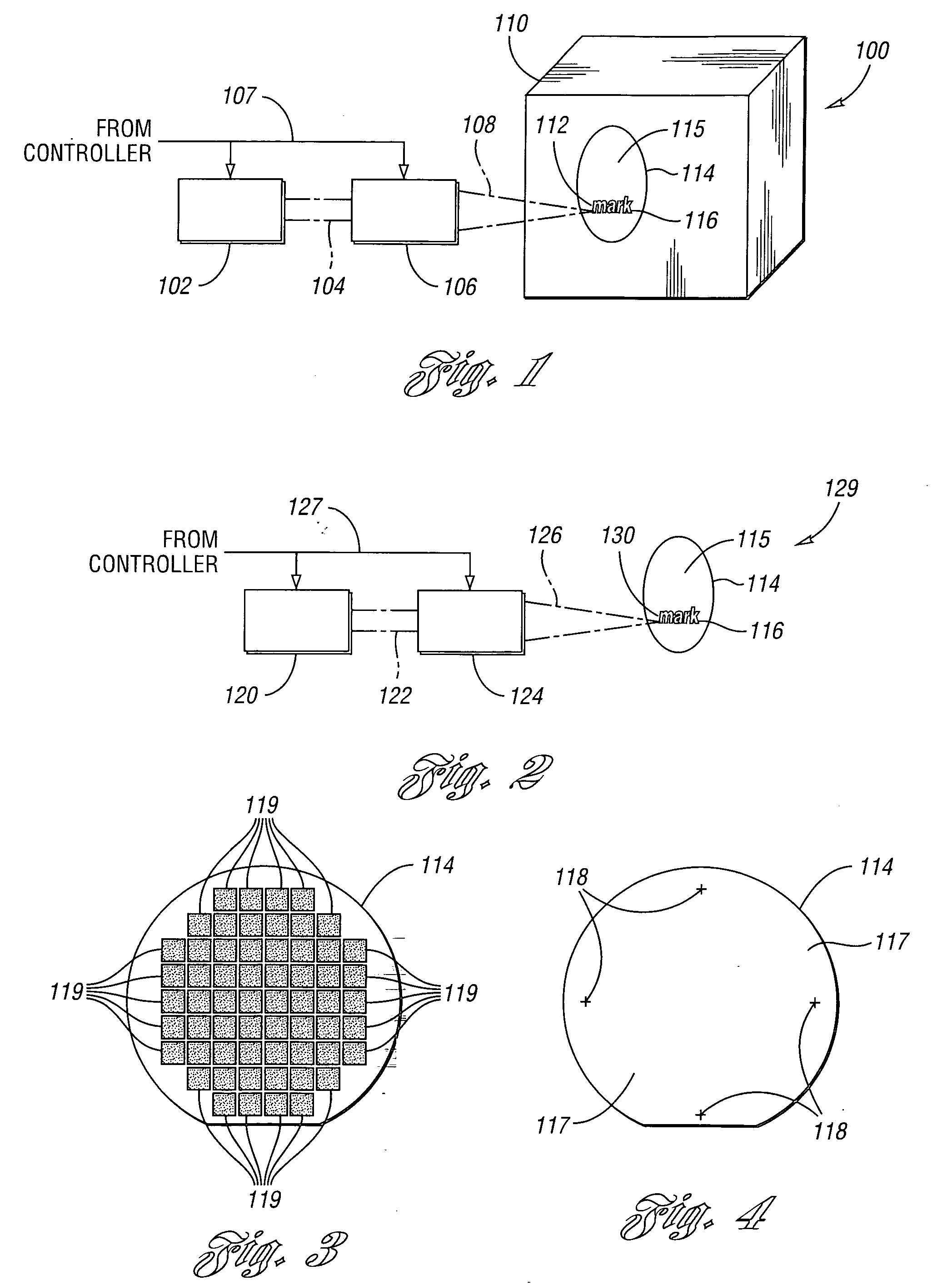

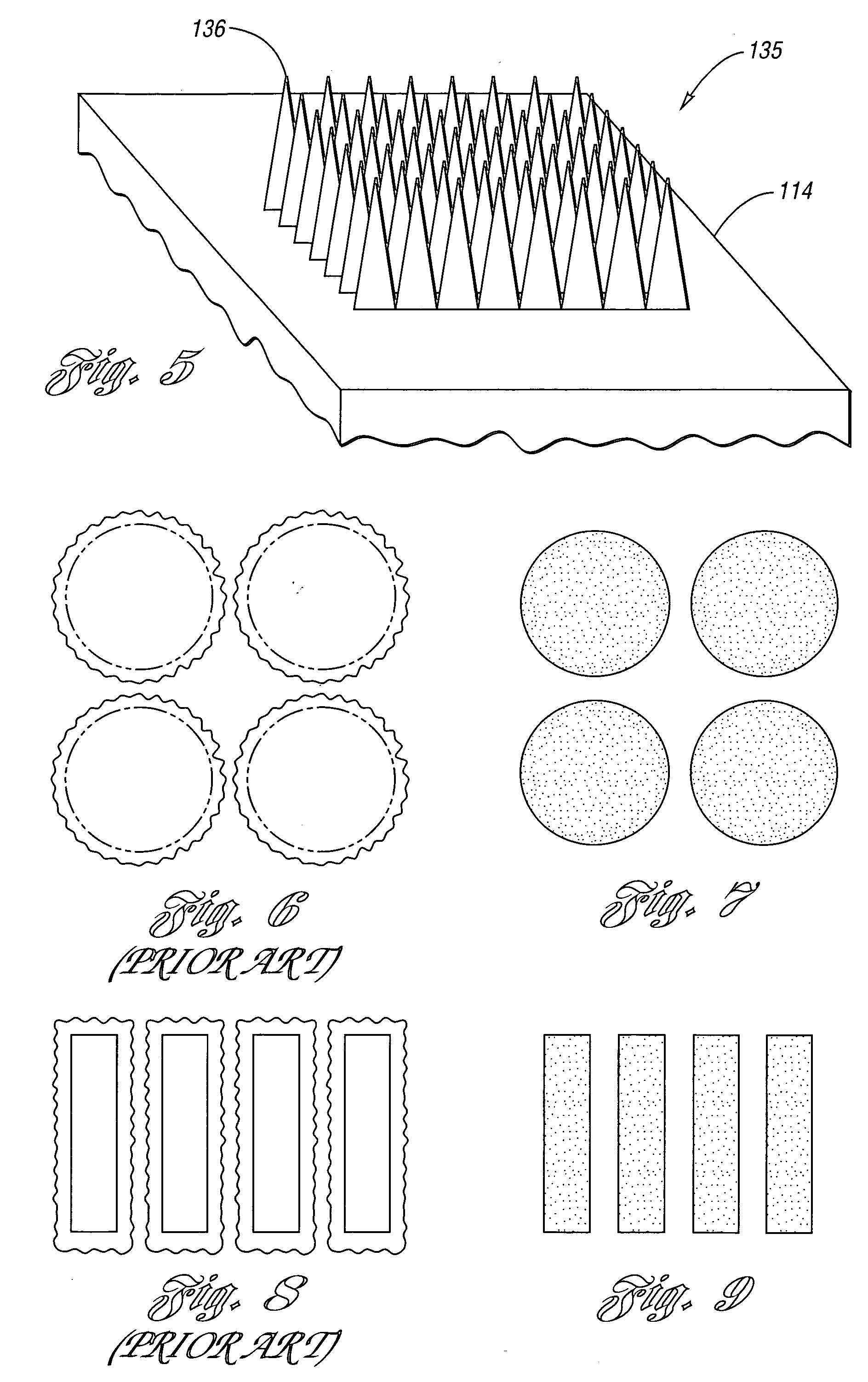

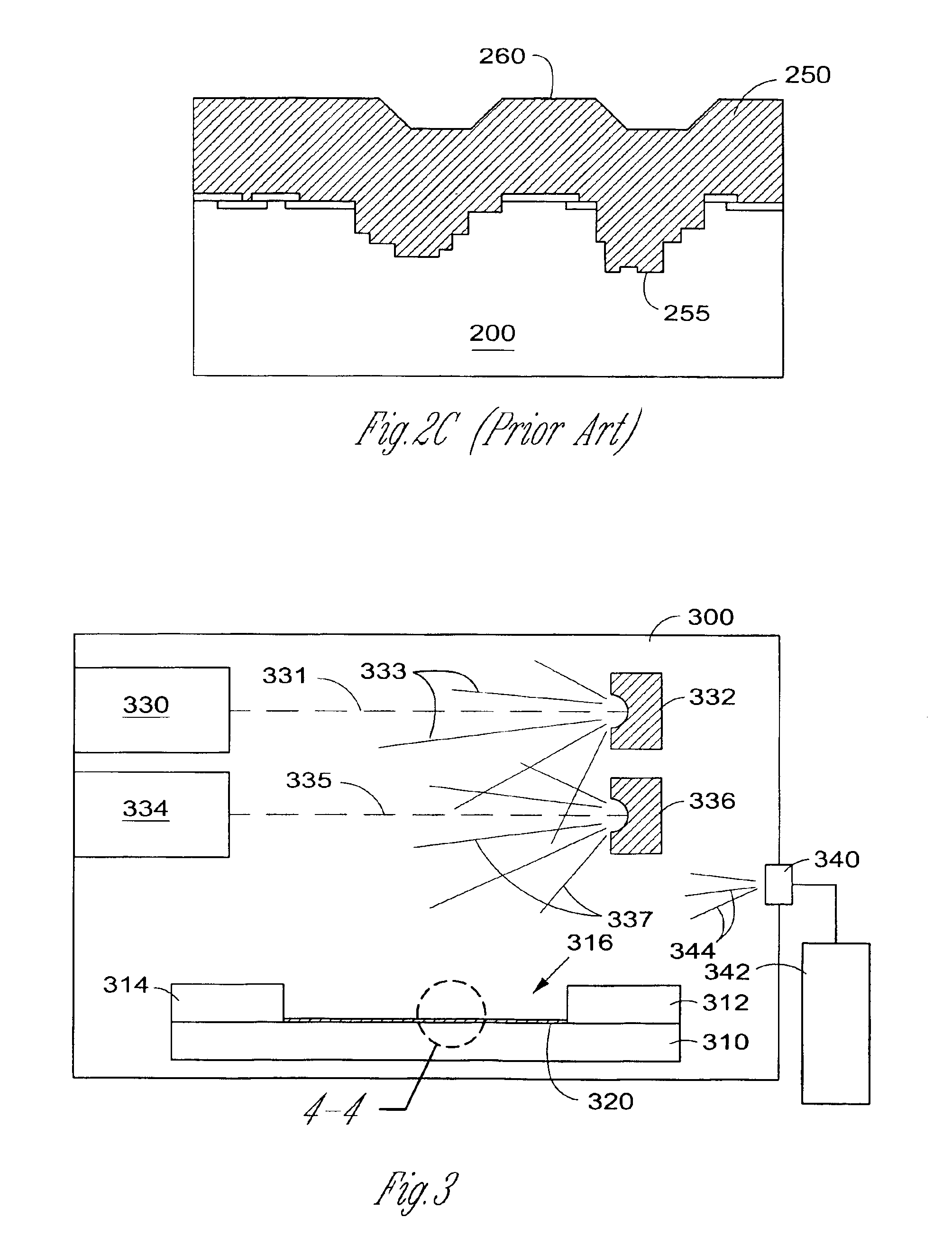

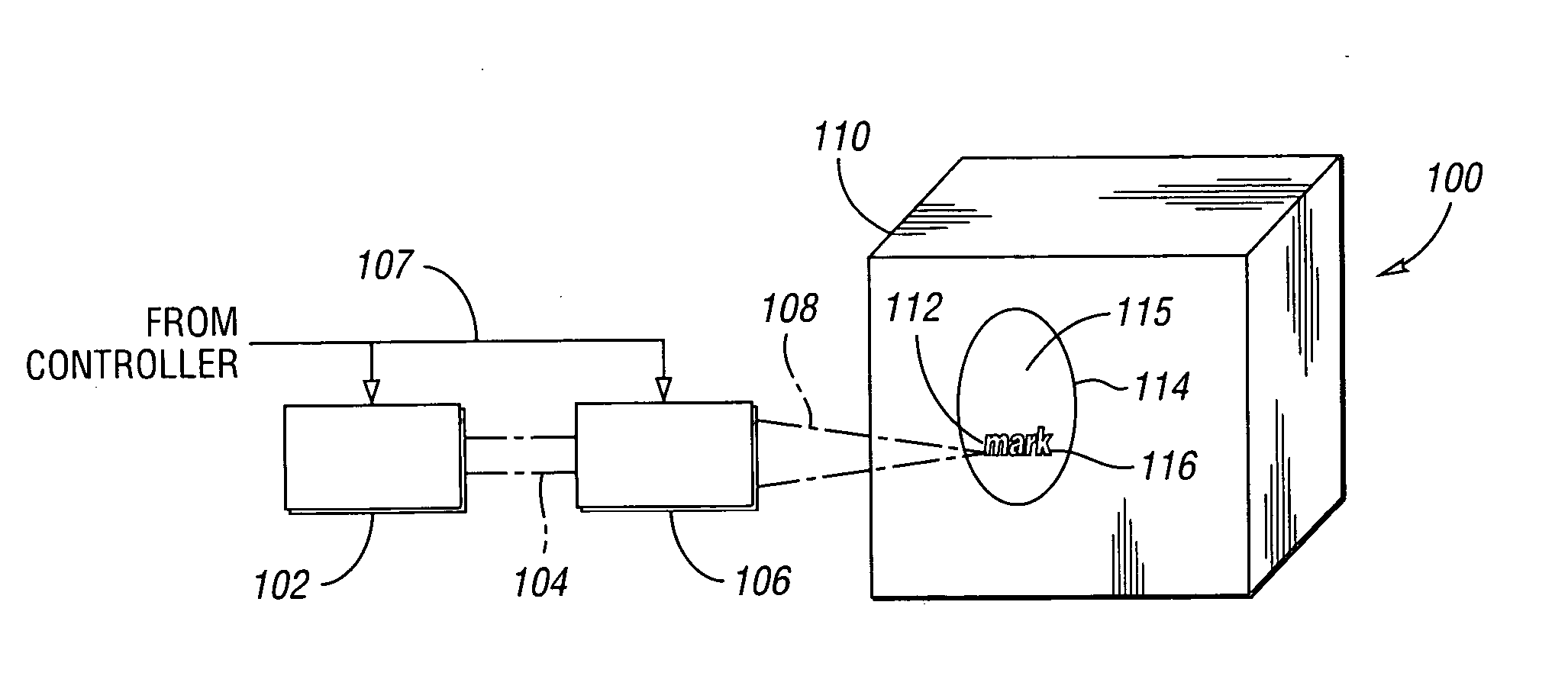

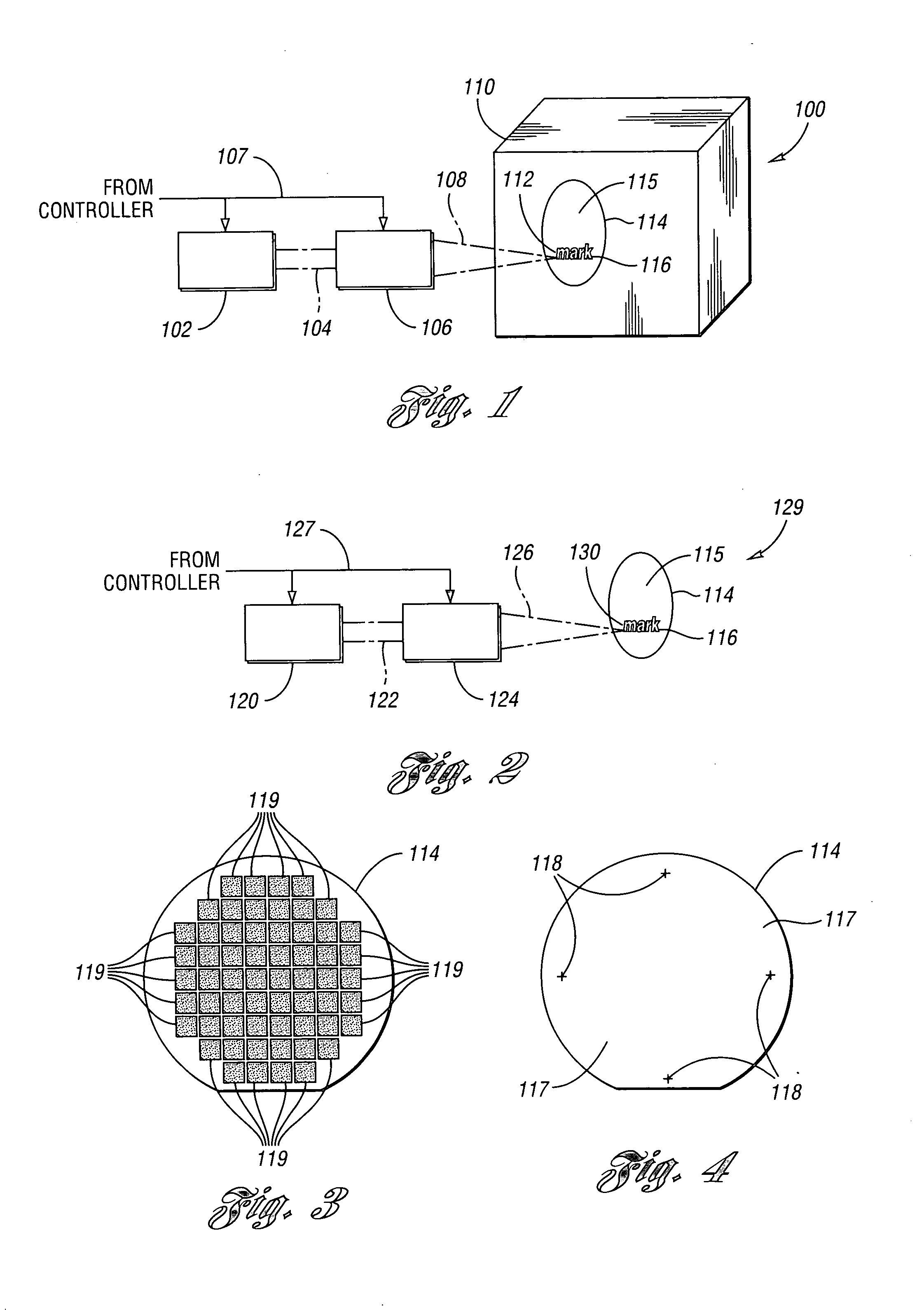

Laser-based method and system for processing targeted surface material and article produced thereby

InactiveUS20060000814A1Prevent unwanted changesSufficient total fluenceAdditive manufacturing apparatusSemiconductor/solid-state device detailsTarget surfaceSlag

A laser-based method and system for processing targeted surface material and article produced thereby are provided. The system processes the targeted surface material within a region of a workpiece while avoiding undesirable changes to adjacent non-targeted material. The system includes a primary laser subsystem including a primary laser source for generating a pulsed laser output including at least one pulse having a wavelength and a pulse width less than 1 ns. A delivery subsystem irradiates the targeted surface material of the workpiece with the pulsed laser output including the at least one pulse to texture the targeted surface material. The pulsed laser output has sufficient total fluence to initiate ablation within at least a portion of the targeted surface material and the pulse width is short enough such that the region and the non-targeted material surrounding the material are substantially free of slag.

Owner:ELECTRO SCI IND INC

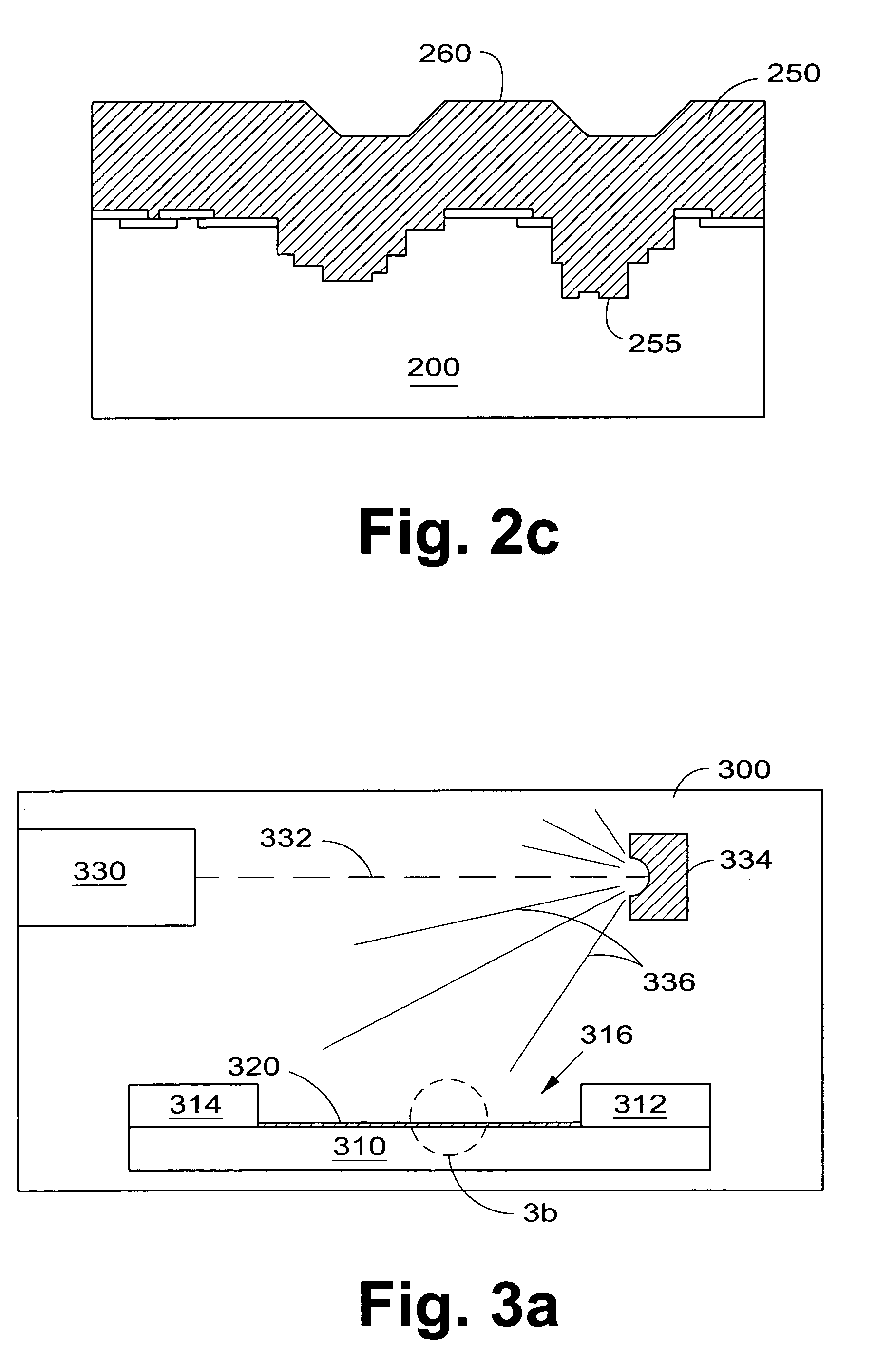

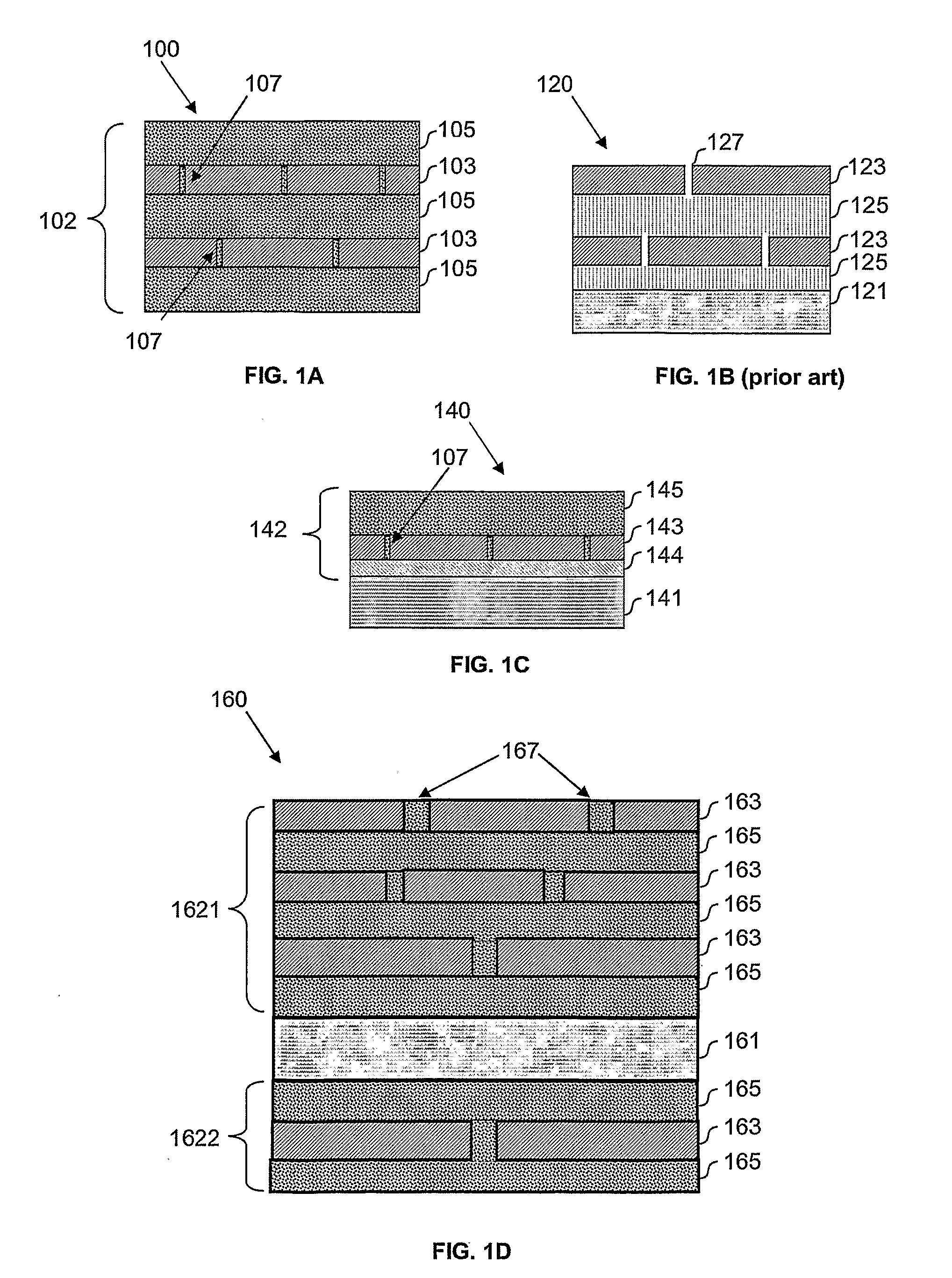

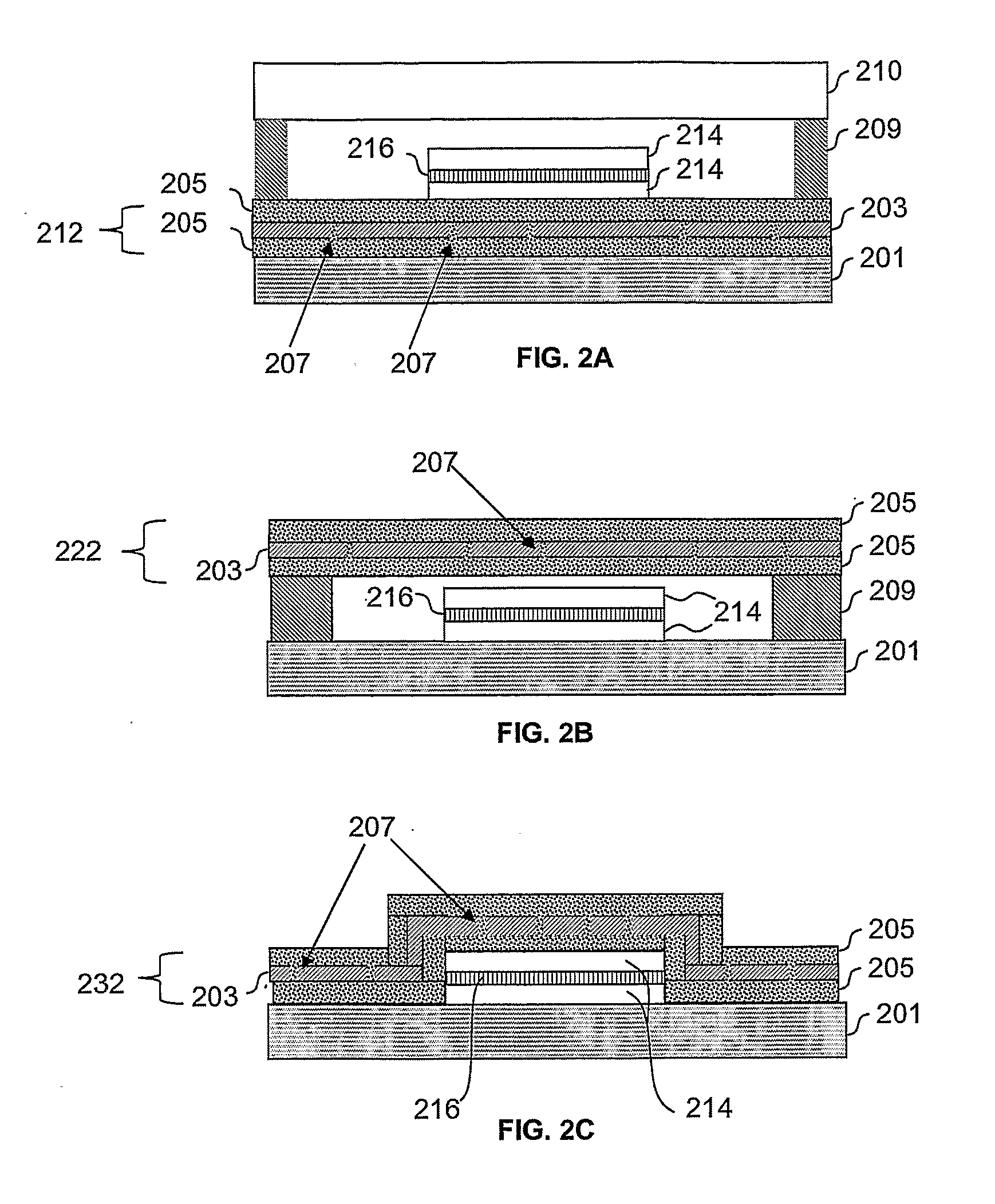

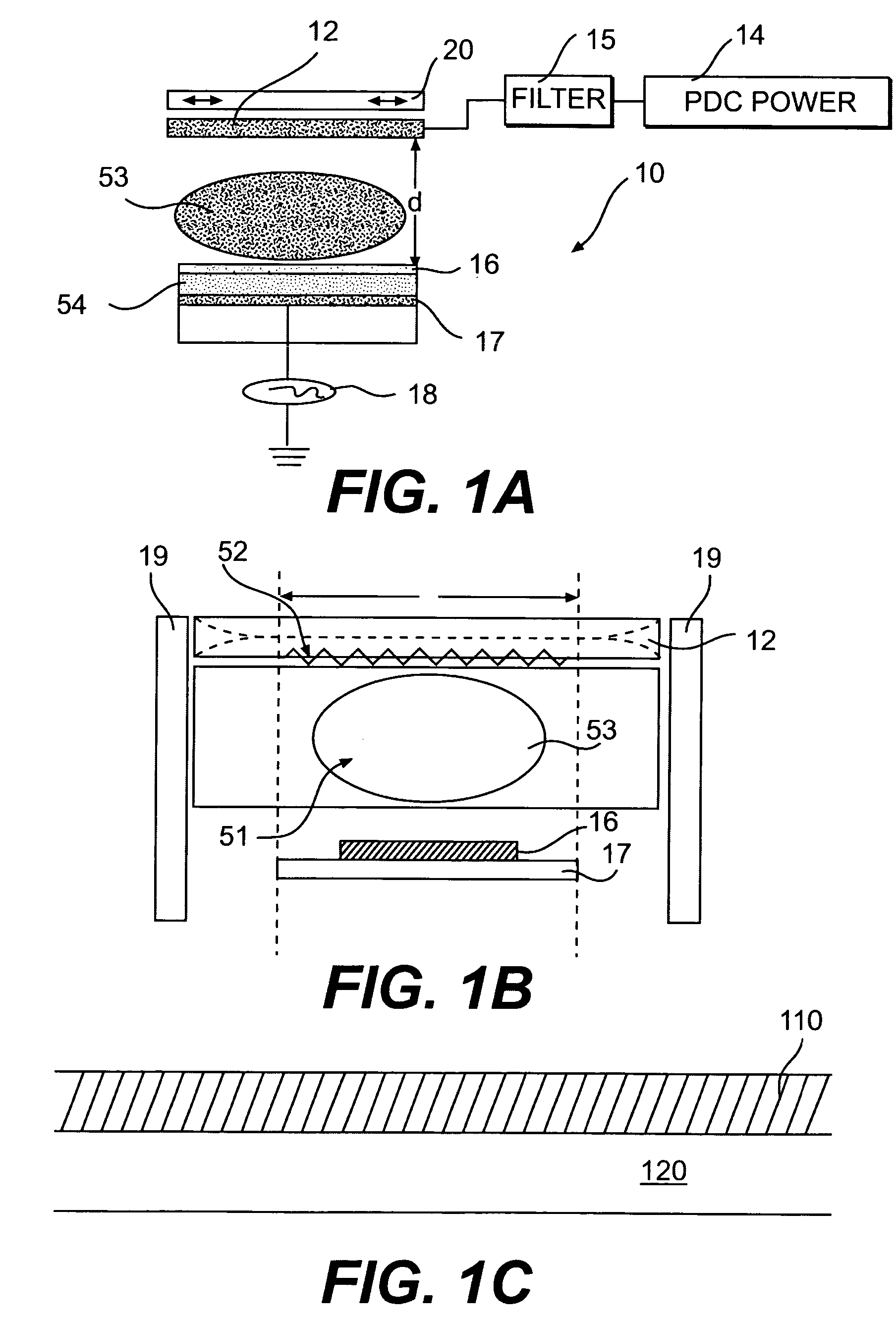

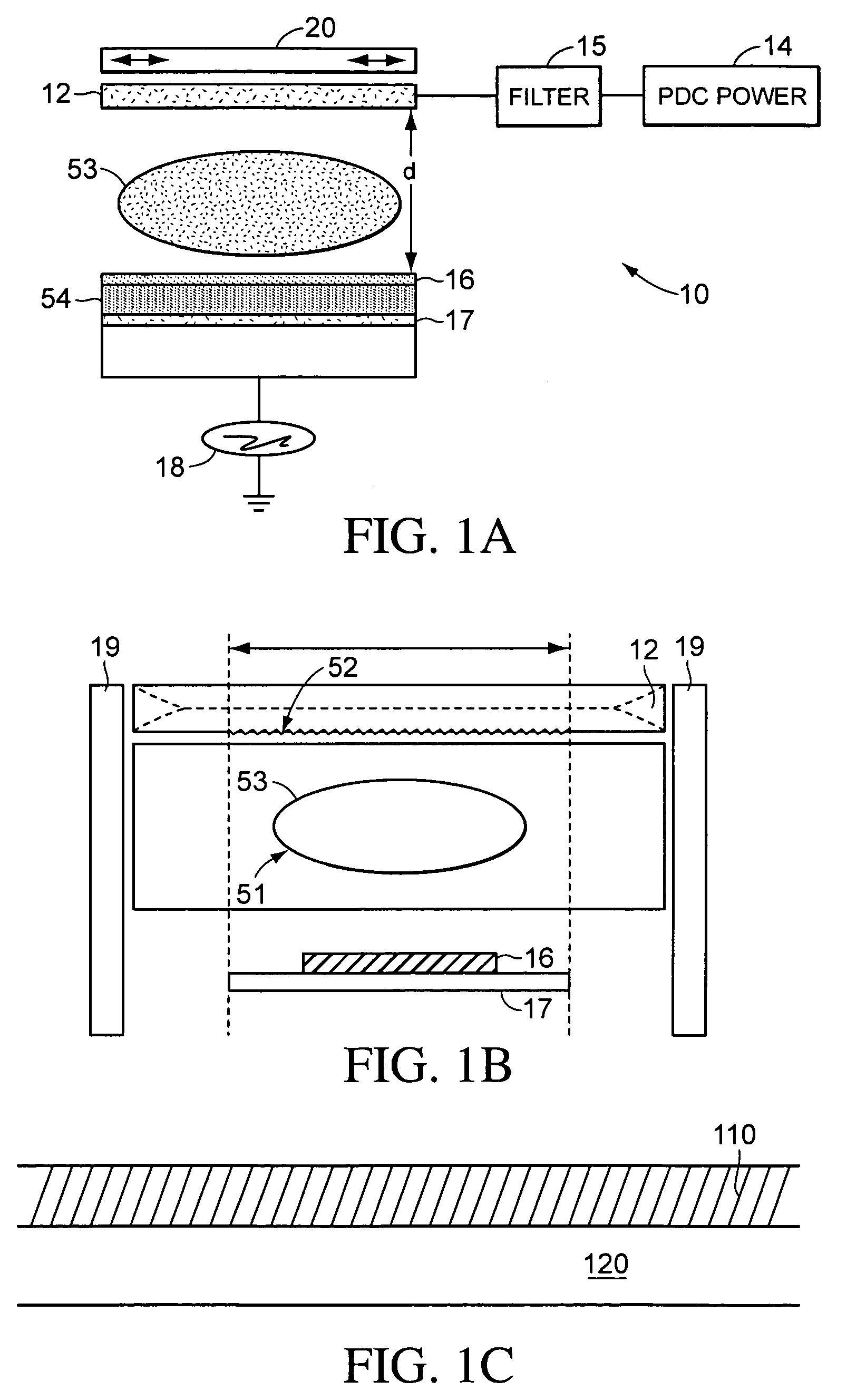

Dielectric barrier layer films

InactiveUS20050006768A1Improve performanceImprove uniformitySemiconductor/solid-state device detailsElectroluminescent light sourcesElectrical resistance and conductanceGas phase

In accordance with the present invention, a dielectric barrier layer is presented. A barrier layer according to the present invention includes a densified amorphous dielectric layer deposited on a substrate by pulsed-DC, substrate biased physical vapor deposition, wherein the densified amorphous dielectric layer is a barrier layer. A method of forming a barrier layer according to the present inventions includes providing a substrate and depositing a highly densified, amorphous, dielectric material over the substrate in a pulsed-dc, biased, wide target physical vapor deposition process. Further, the process can include performing a soft-metal breath treatment on the substrate. Such barrier layers can be utilized as electrical layers, optical layers, immunological layers, or tribological layers.

Owner:DEMARAY

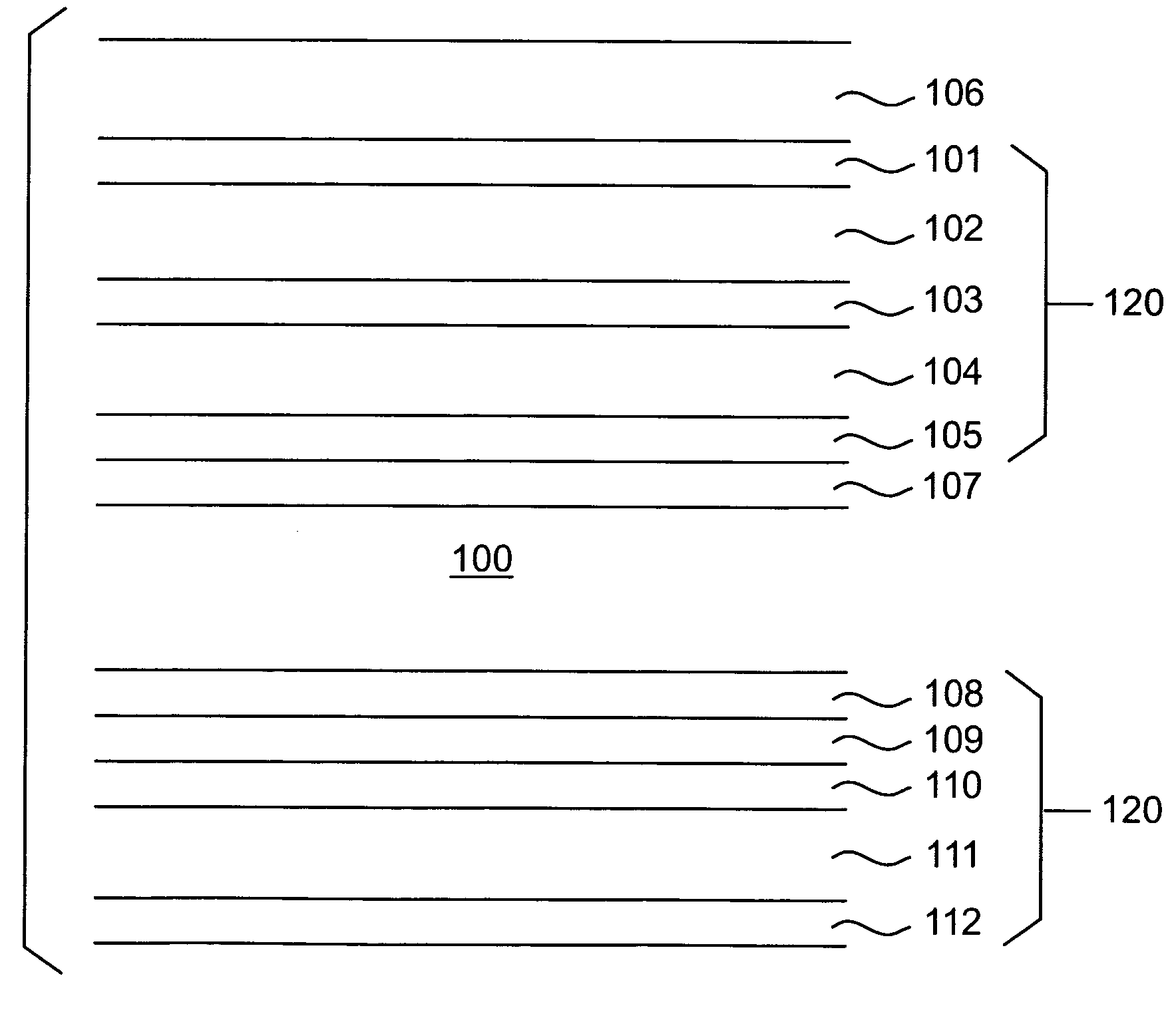

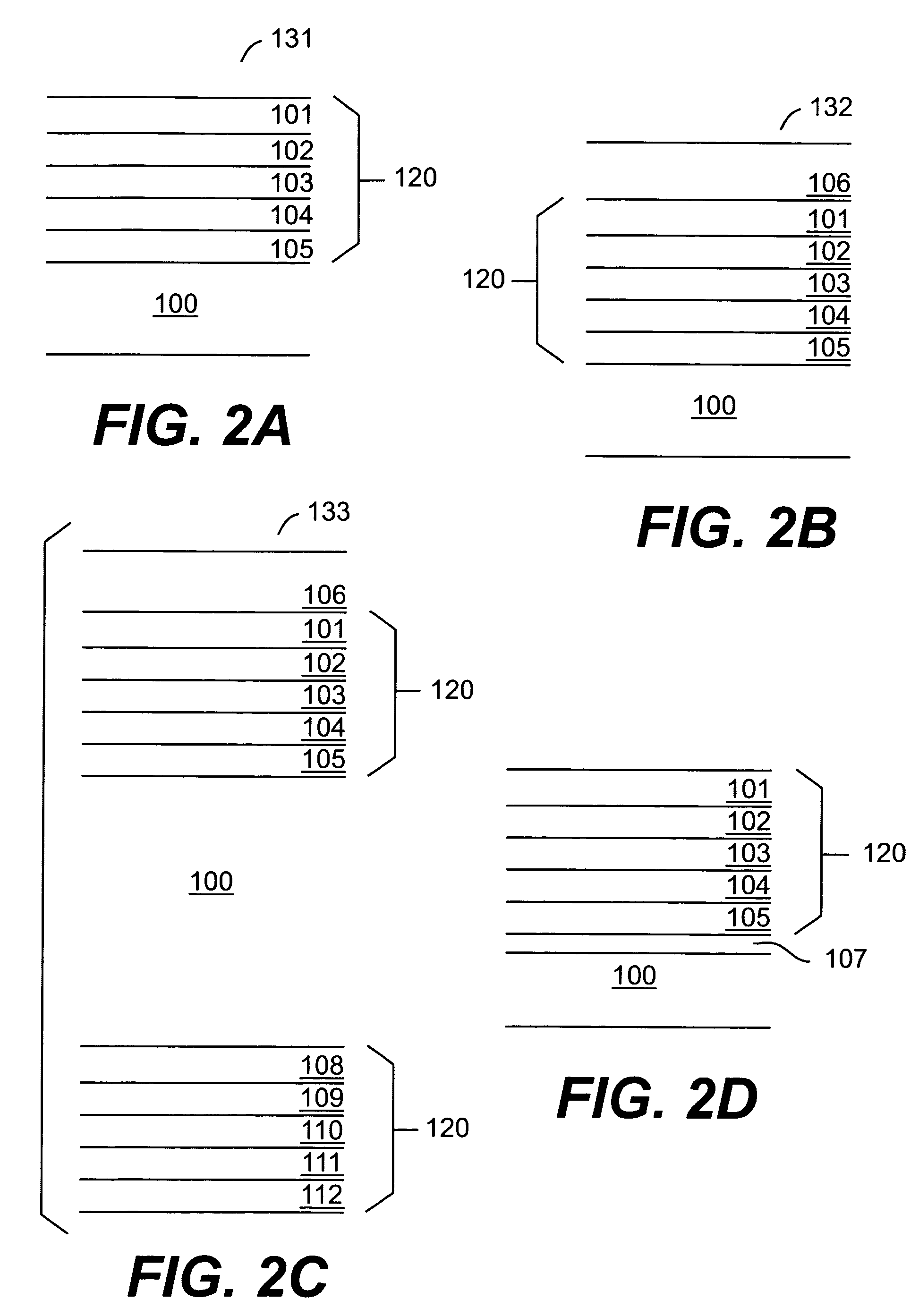

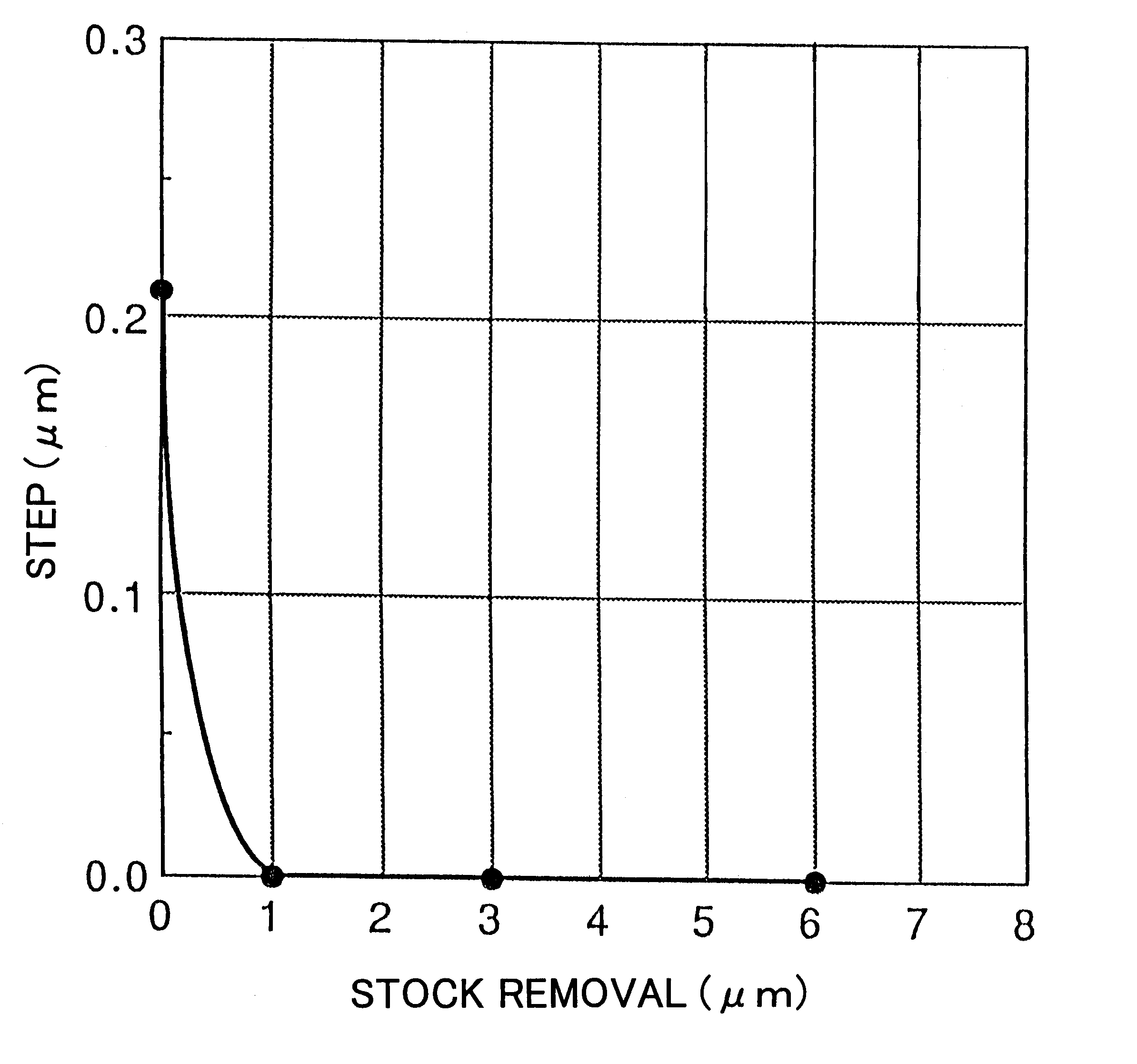

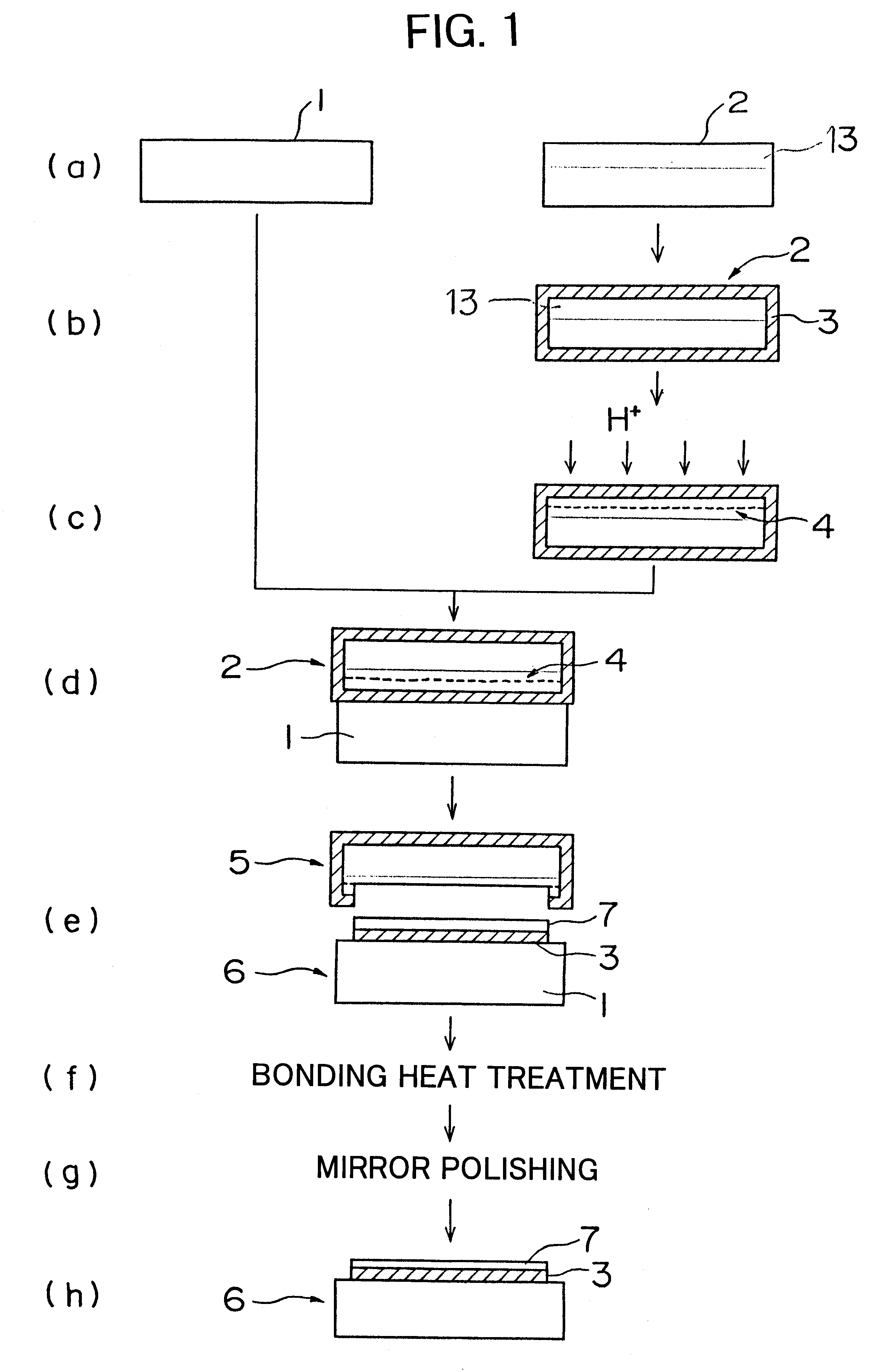

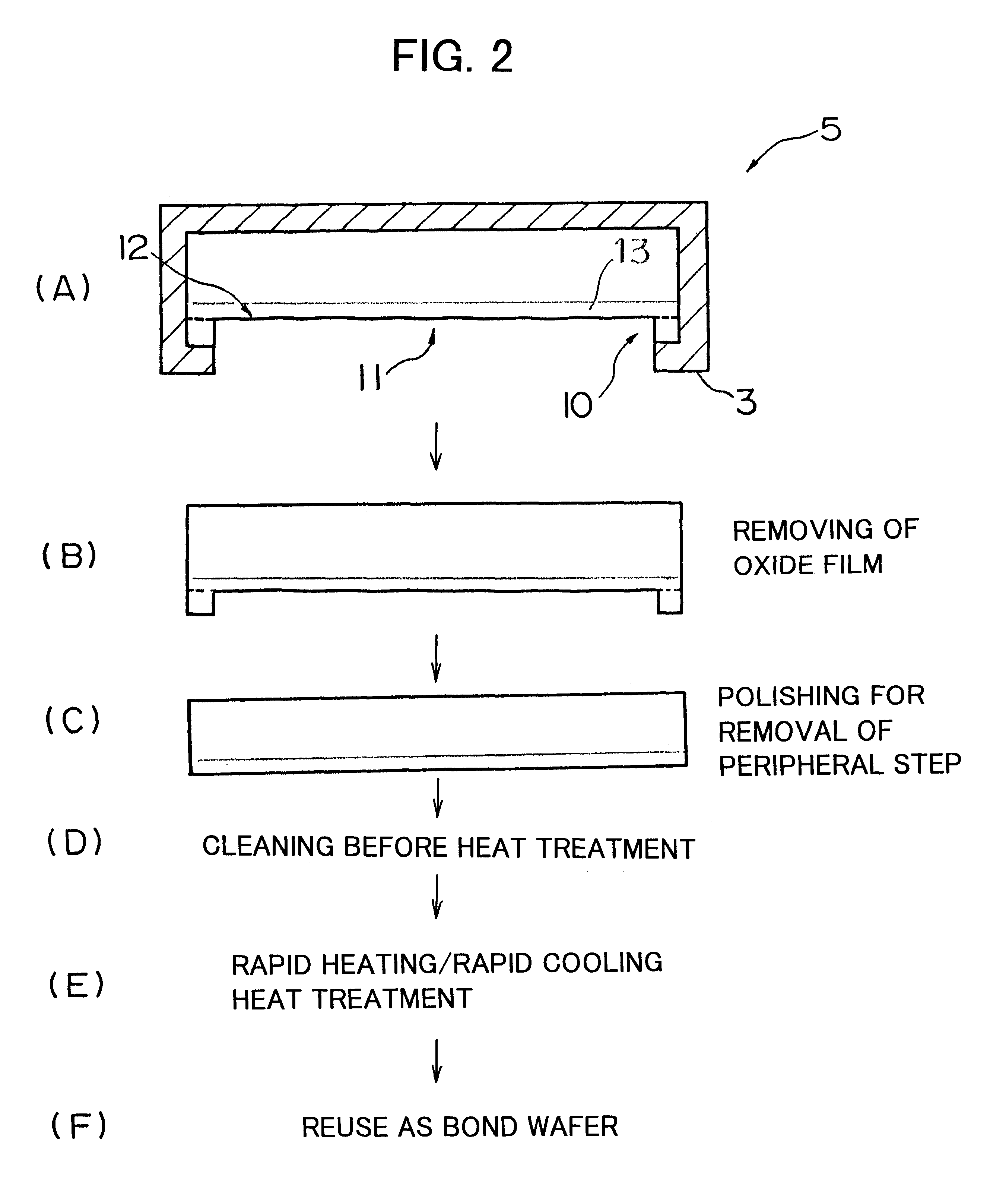

Method of recycling a delaminated wafer and a silicon wafer used for the recycling

InactiveUS6284628B1Easy to disassembleImprove surface roughnessSolid-state devicesSemiconductor/solid-state device manufacturingProduction rateWafering

There is disclosed a method of recycling a delaminated wafer produced as a by-product in producing an SOI wafer according to a hydrogen ion delaminating method by reprocessing it for reuse as a silicon wafer, wherein at least polishing of the delaminated wafer for removing of a step in the peripheral part of the delaminated wafer and heat treatment in a reducing atmosphere containing hydrogen are conducted as the reprocessing. There are provided a method of appropriately reprocessing a delaminated wafer produced as a by-product in a hydrogen ion delaminating method to reuse it as a silicon wafer actually, and particularly, a method of reprocessing an expensive wafer such as an epitaxial wafer many times for reuse, to improve productivity of SOI wafer having a high quality SOI layer, and to reduce producing cost.

Owner:SHIN-ETSU HANDOTAI CO LTD

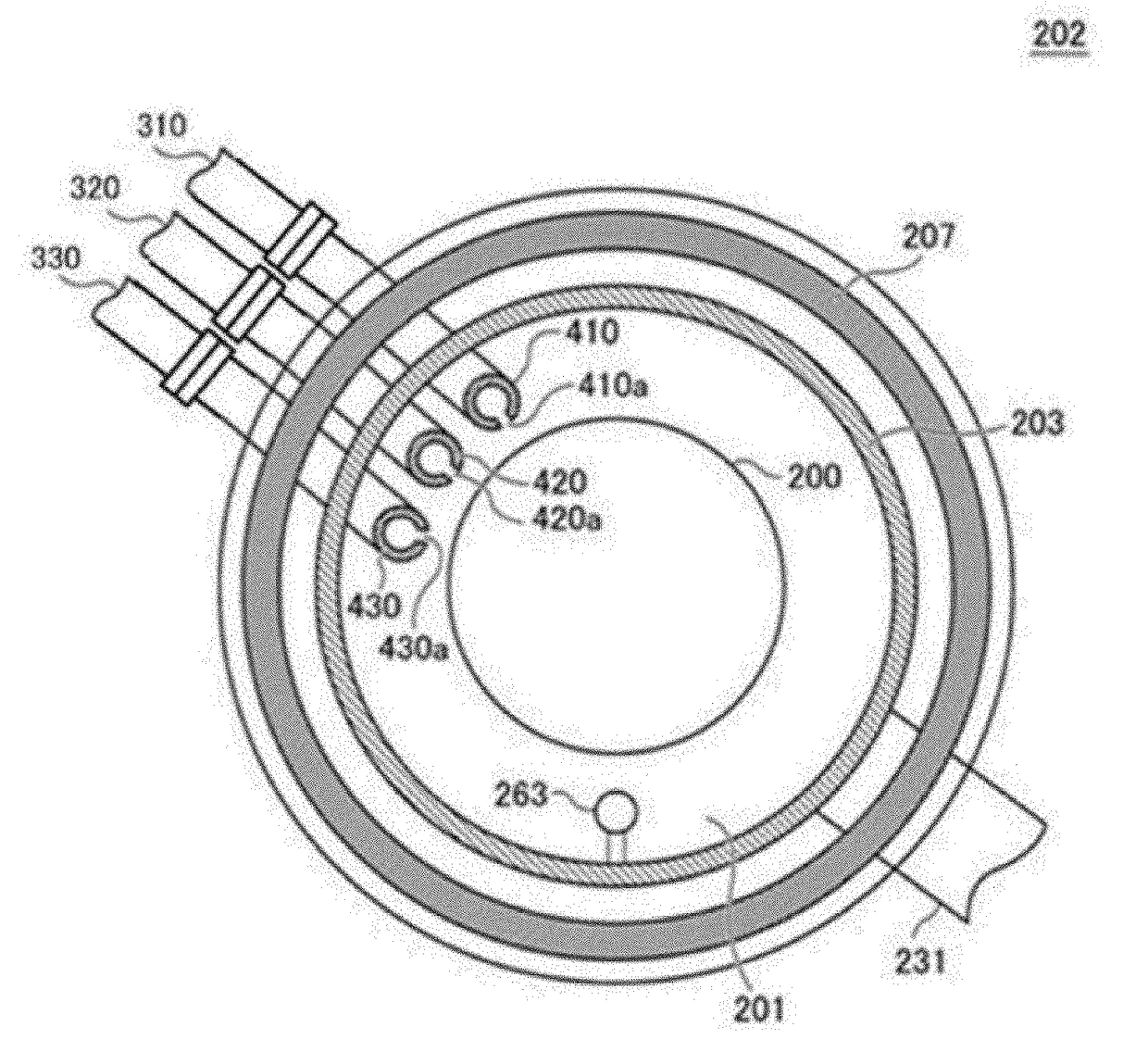

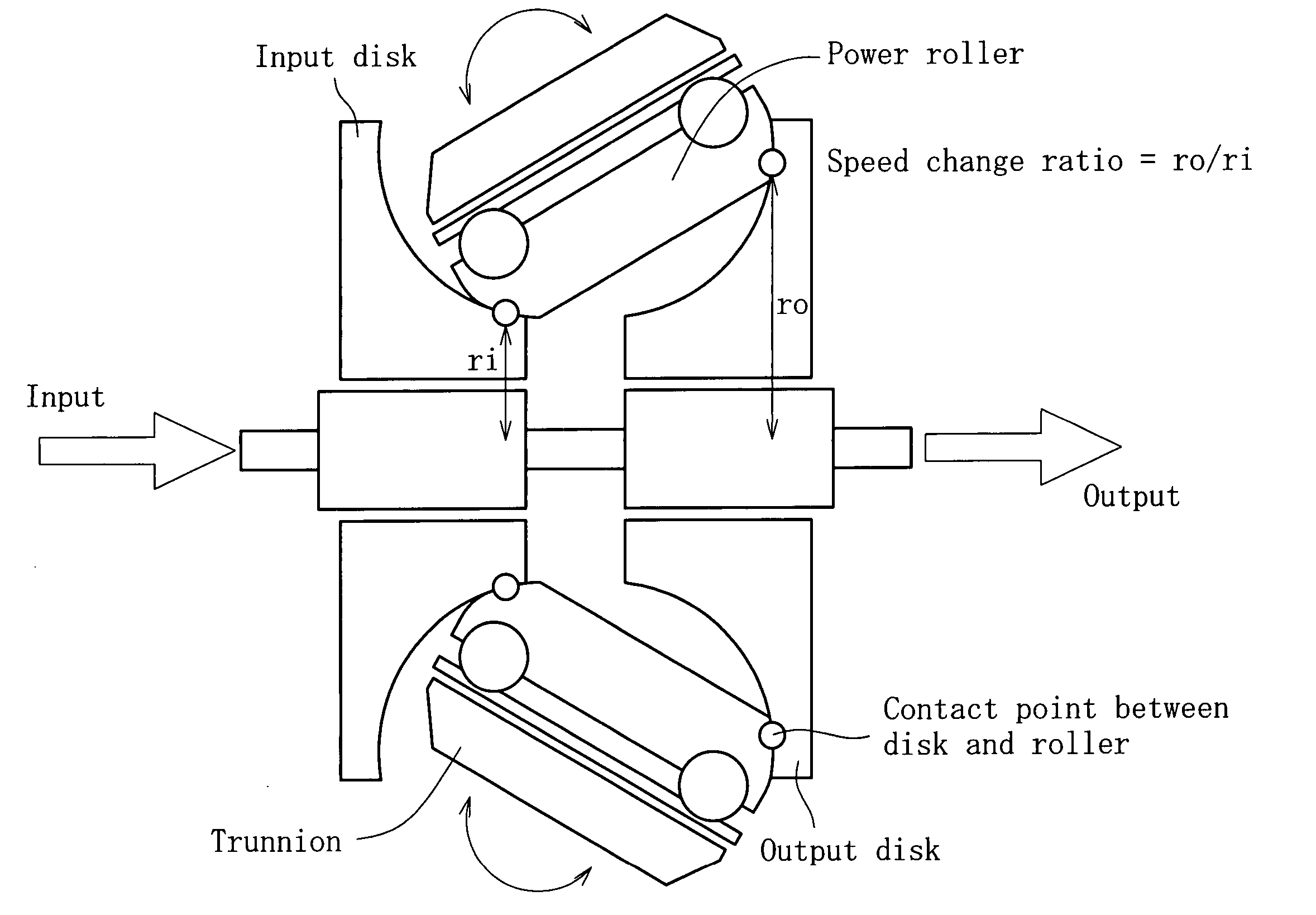

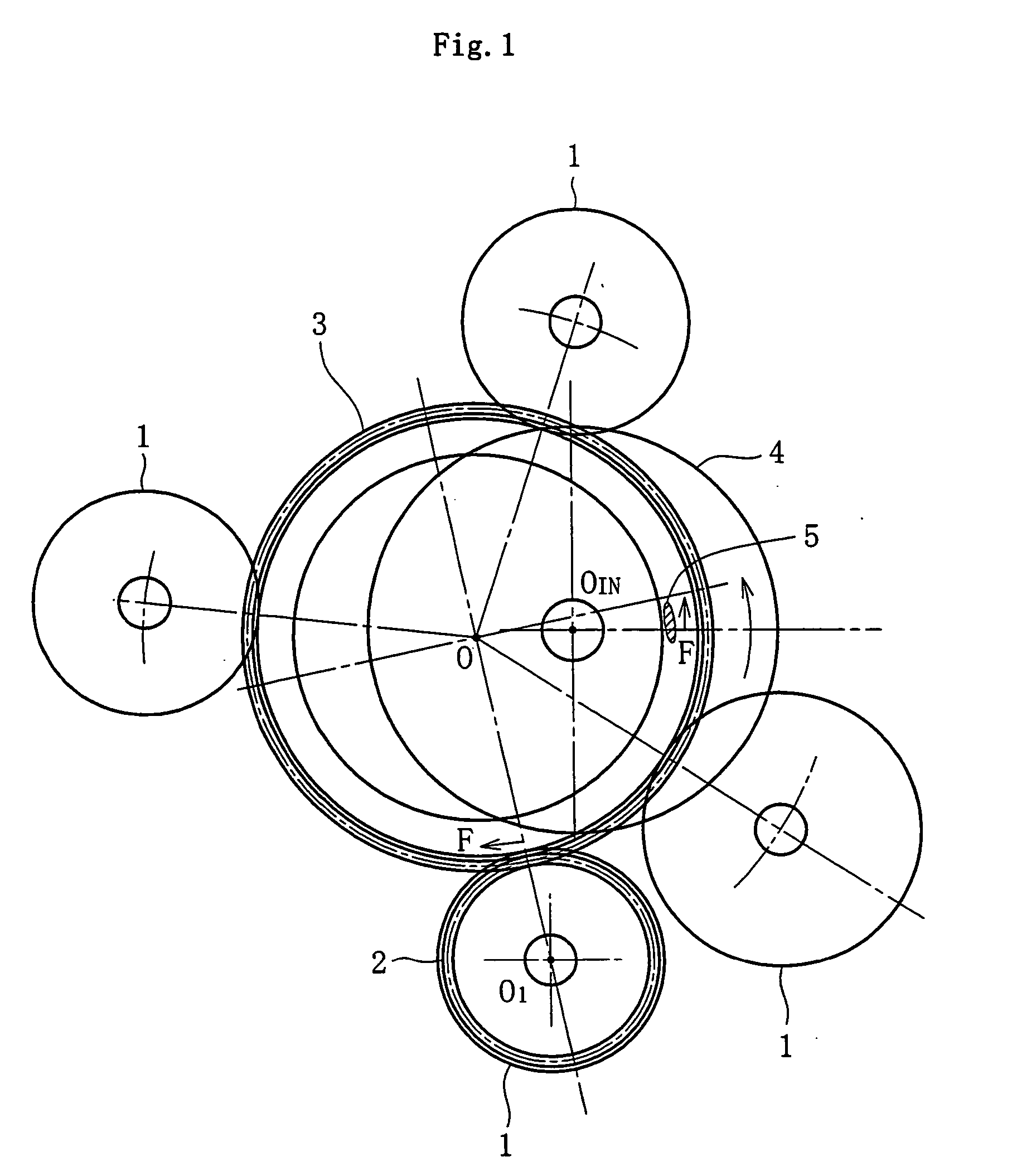

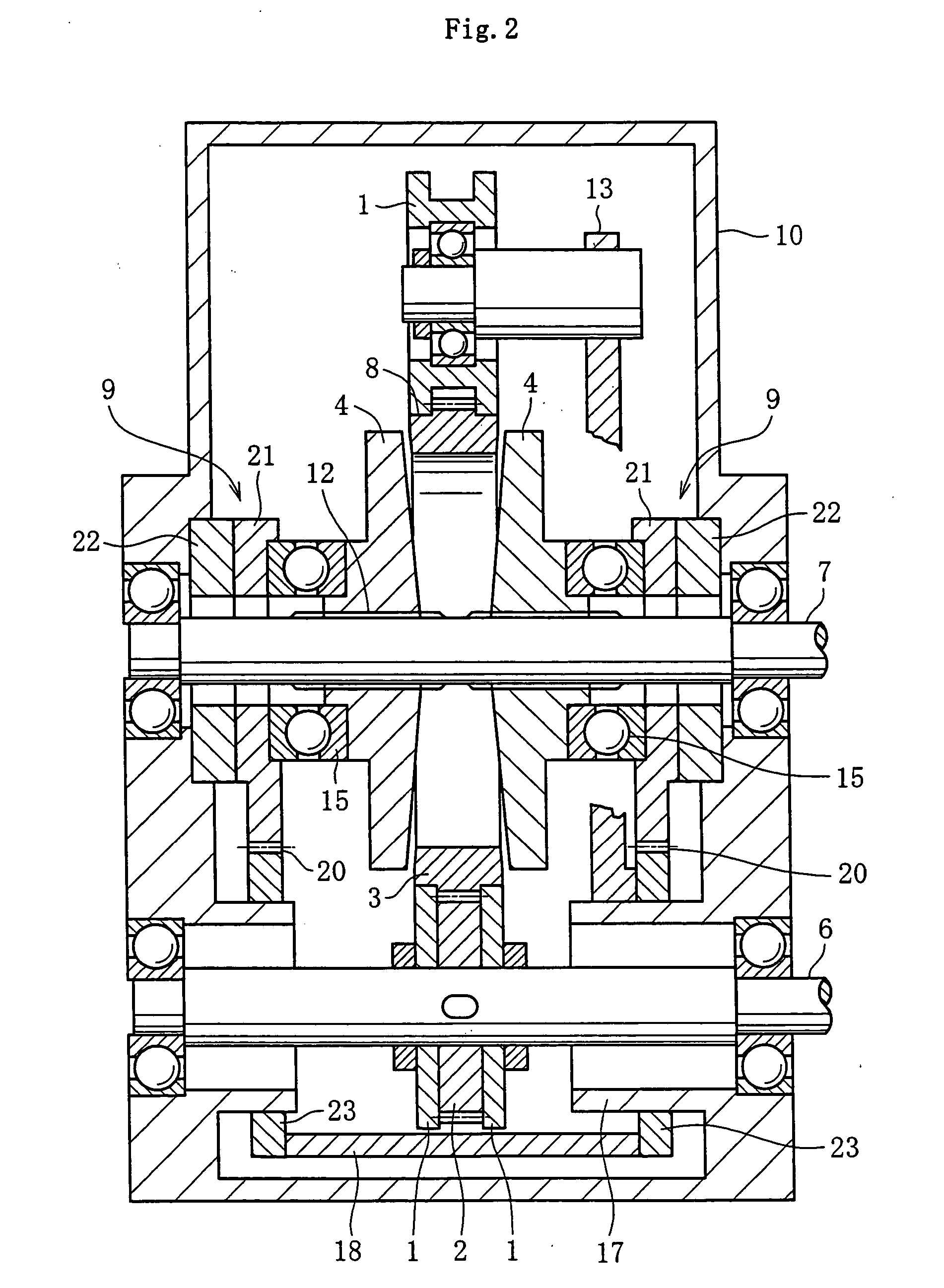

Traction drive type continuously varible transmission

InactiveUS20060223667A1Guaranteed normal transmissionSolution to short lifePortable liftingGearing elementsVariatorInput/output

A traction drive type continuously variable transmission, comprising a first input / output shaft (6) rotatably supported on a casing (10), a second input / output shaft (7) rotatably supported on the casing (10), a V-pulley (4) supported on the first input / output shaft (6) and having a pair of pulley members forming a V-groove with variable grove width, a ring (3) engaged with the V-pulley (4) and supported at the outer periphery thereof, and a mechanism for moving the ring (3) to the periphery of the second input / output shaft (7).

Owner:NTN CORP

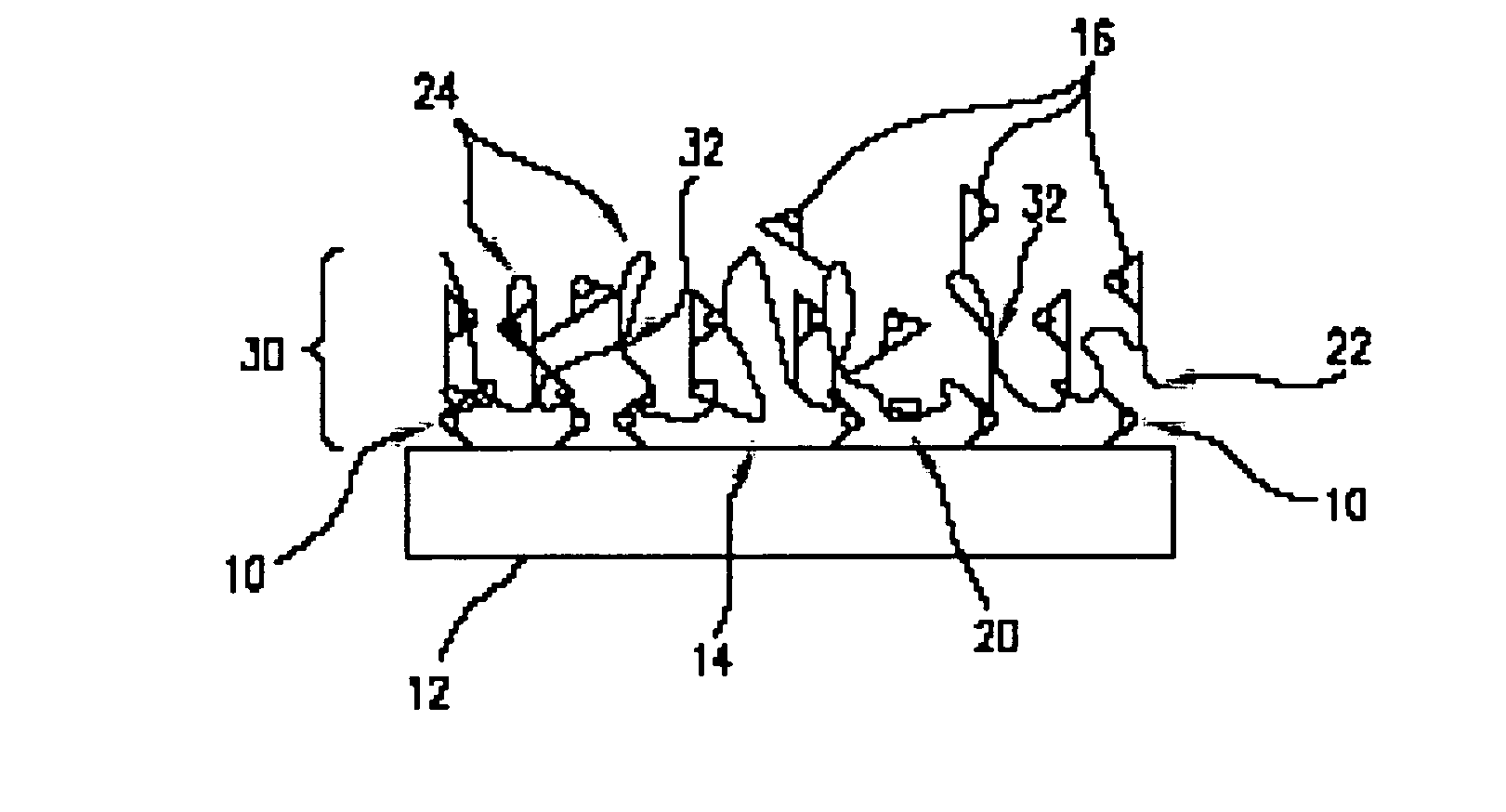

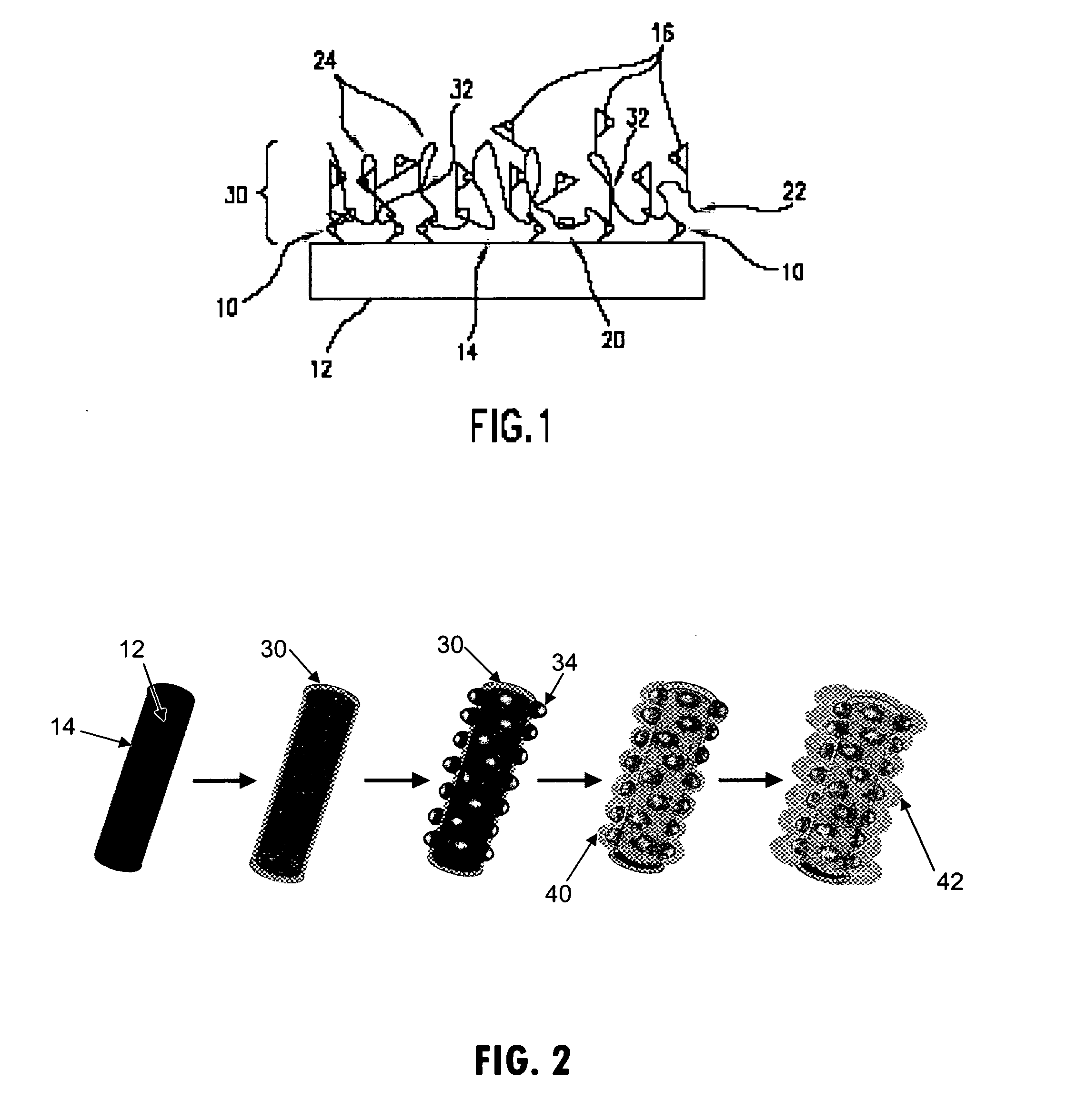

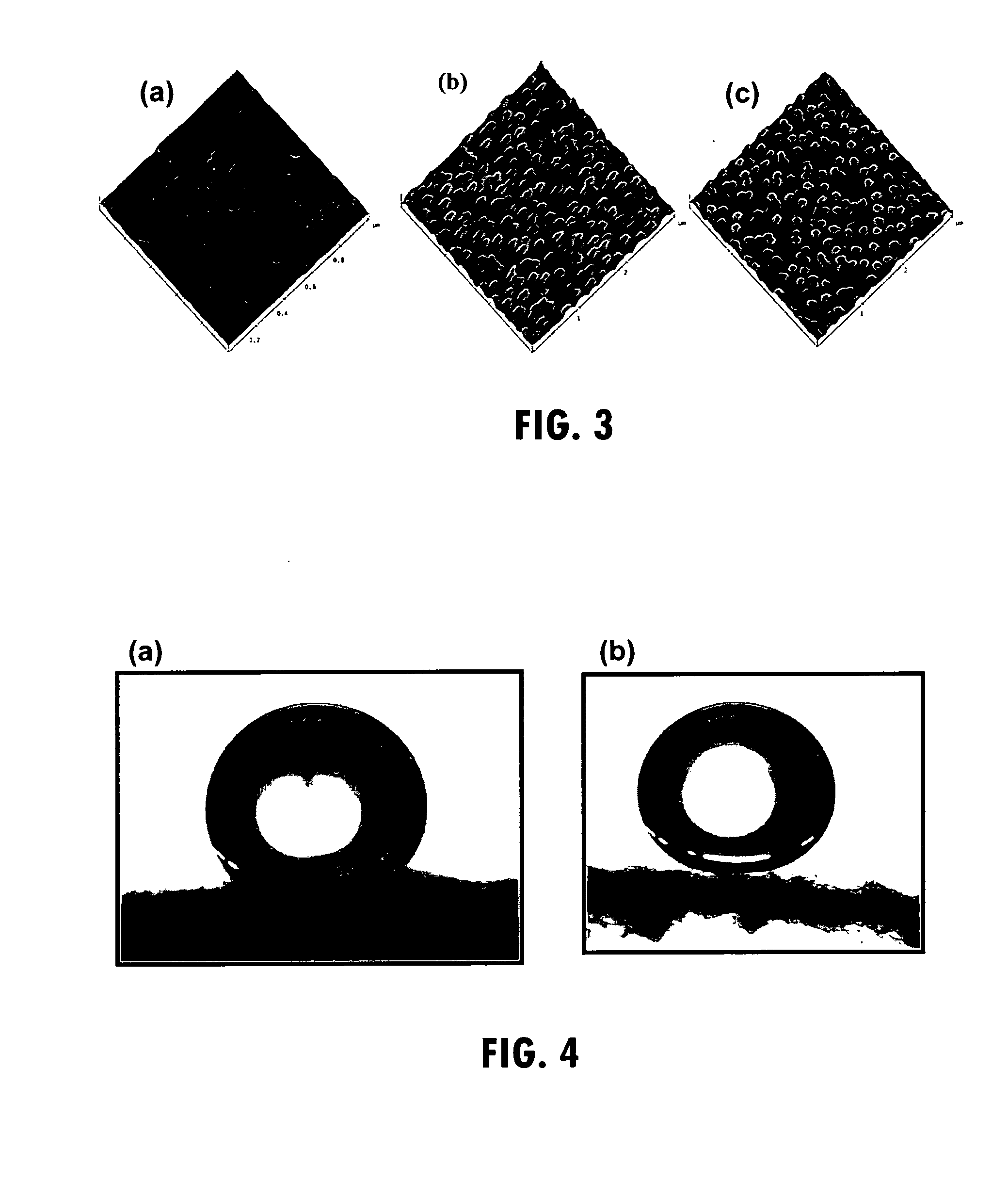

Ultrahydrophobic substrates

ActiveUS20070026193A1Improve surface roughnessImprove surface hydrophobicityFouling preventionLotus effect fibresSurface roughnessEngineering

Disclosed is a process for modification of a substrate so as to form an ultrahydrophobic surface on the substrate. Also disclosed are surface-modified substrates that can be formed according to the disclosed processes. The process includes attachment of a multitude of nano- and / or submicron-sized structures to a surface to provide increased surface roughness. In addition, the process includes grafting a hydrophobic material to the surface in order to decrease the surface energy and decrease wettability of the surface. The combination of increase surface roughness and decreased surface energy can provide an ultrahydrophobic surface on the treated substrate.

Owner:CLEMSON UNIVERSITY

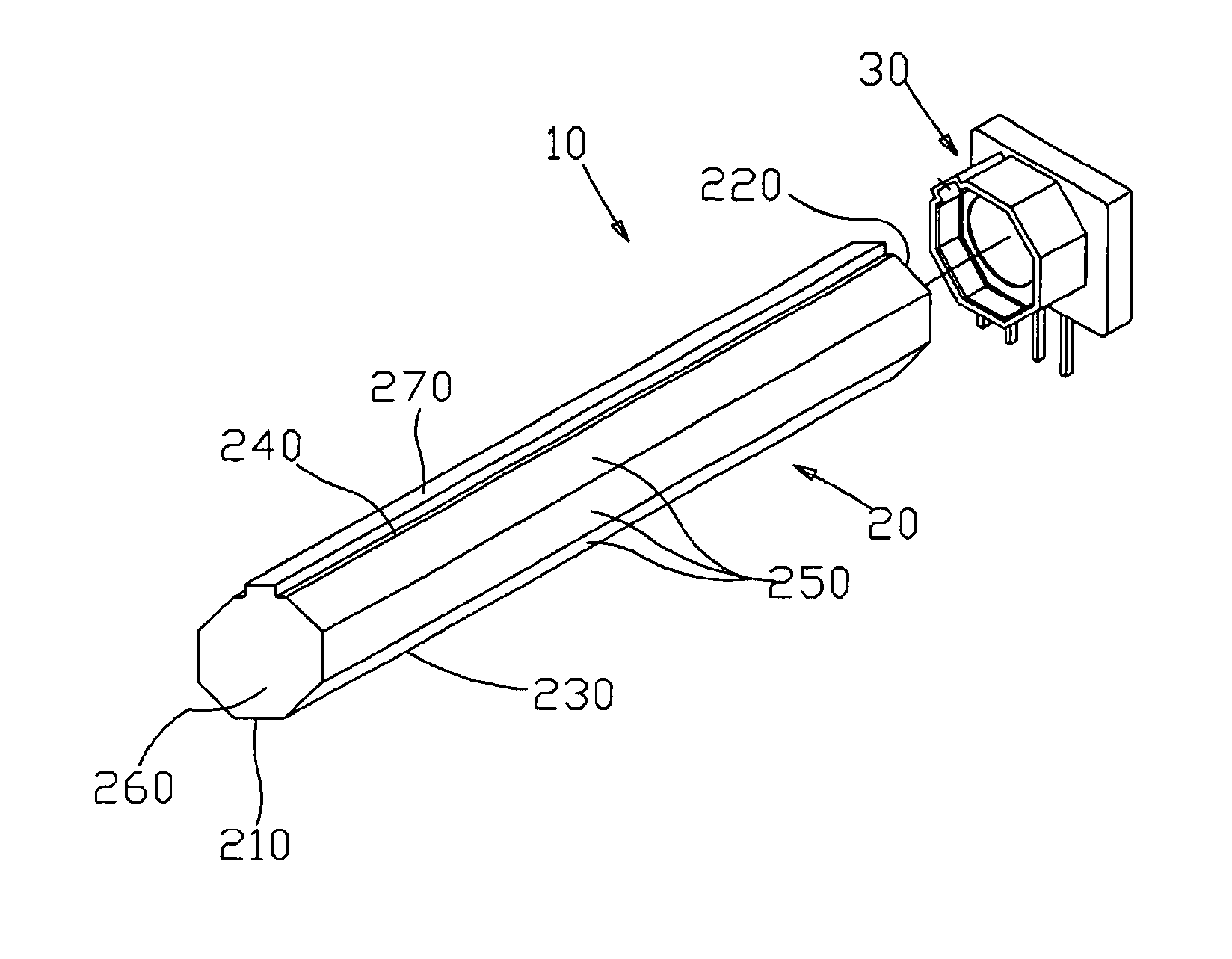

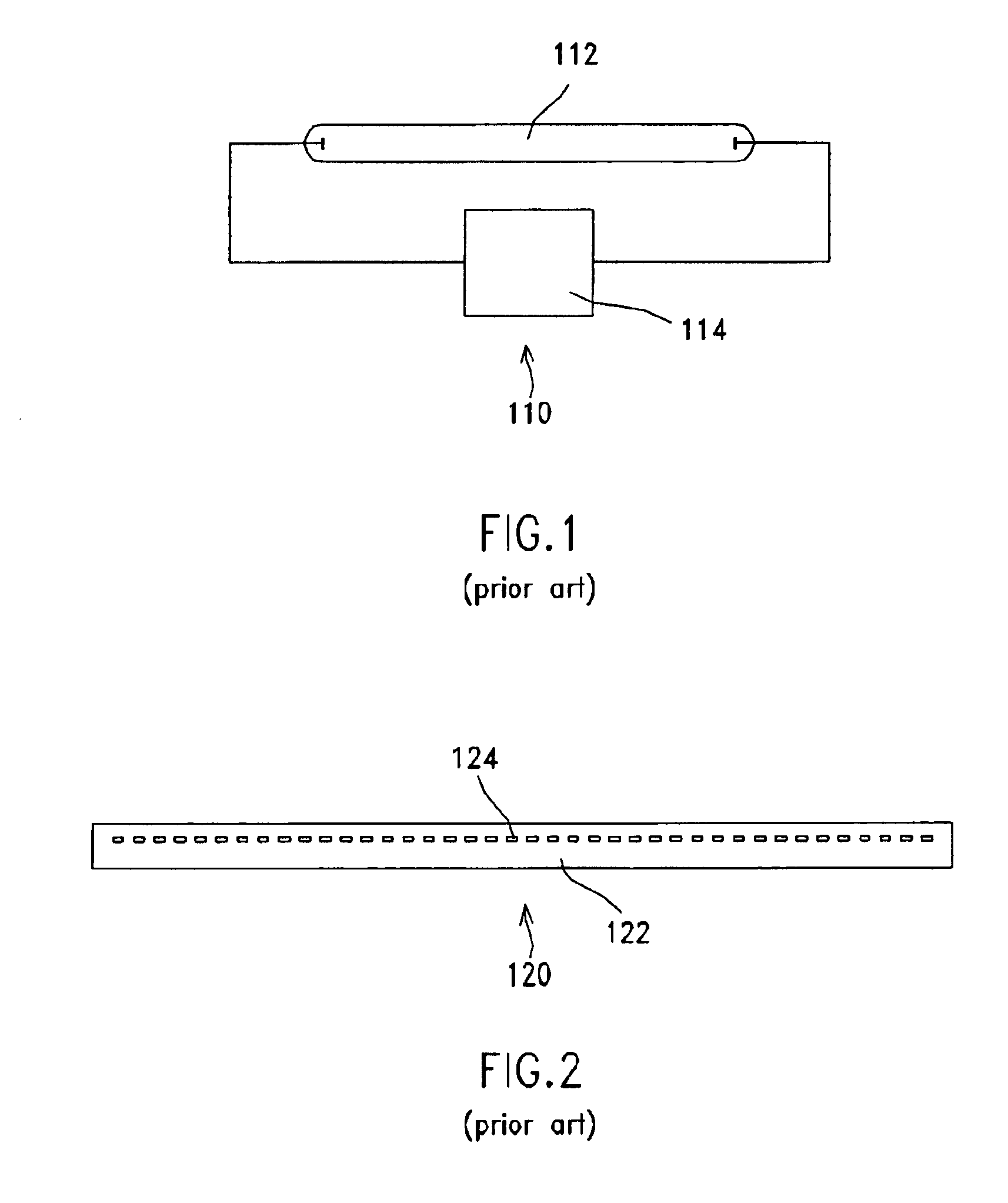

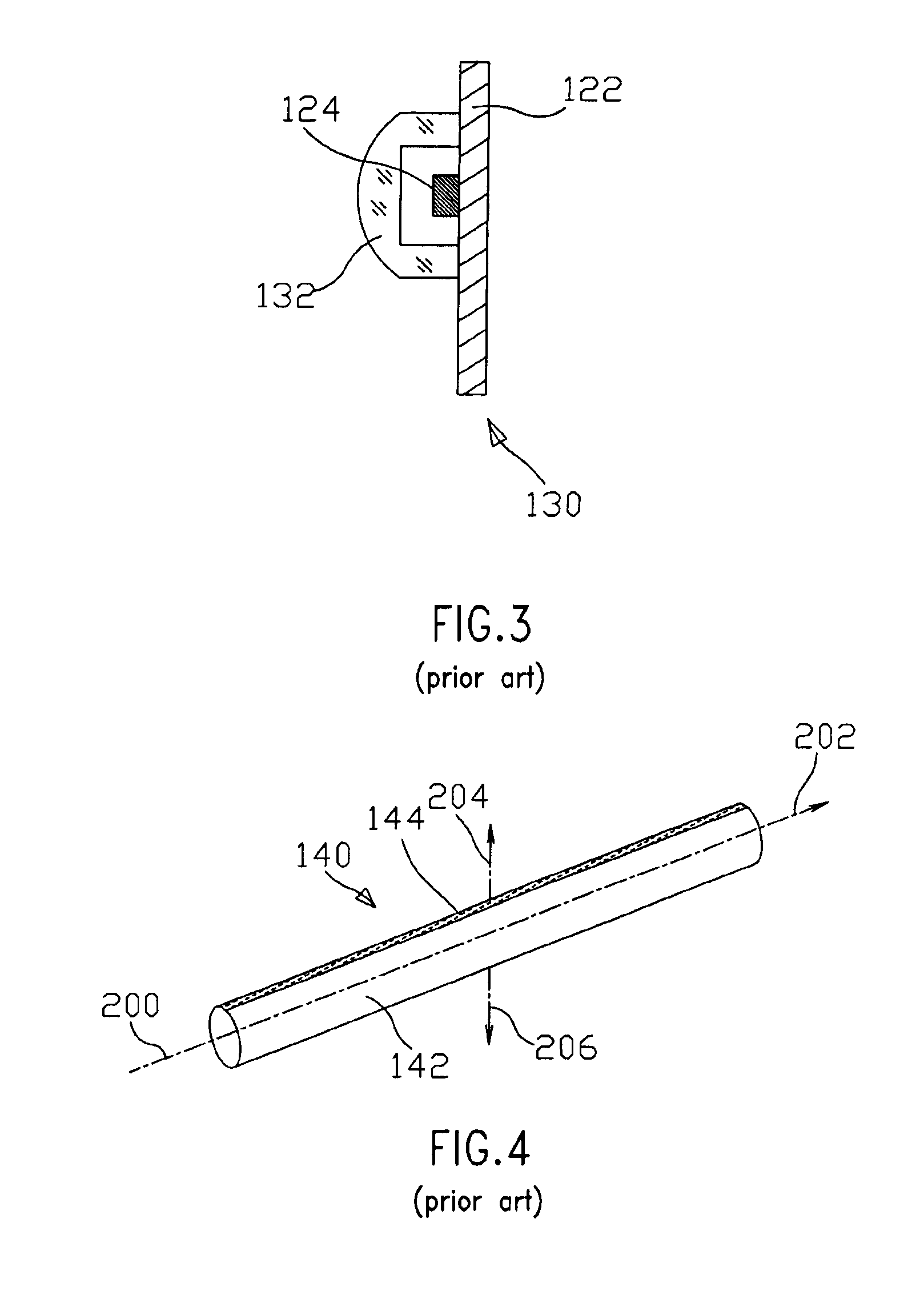

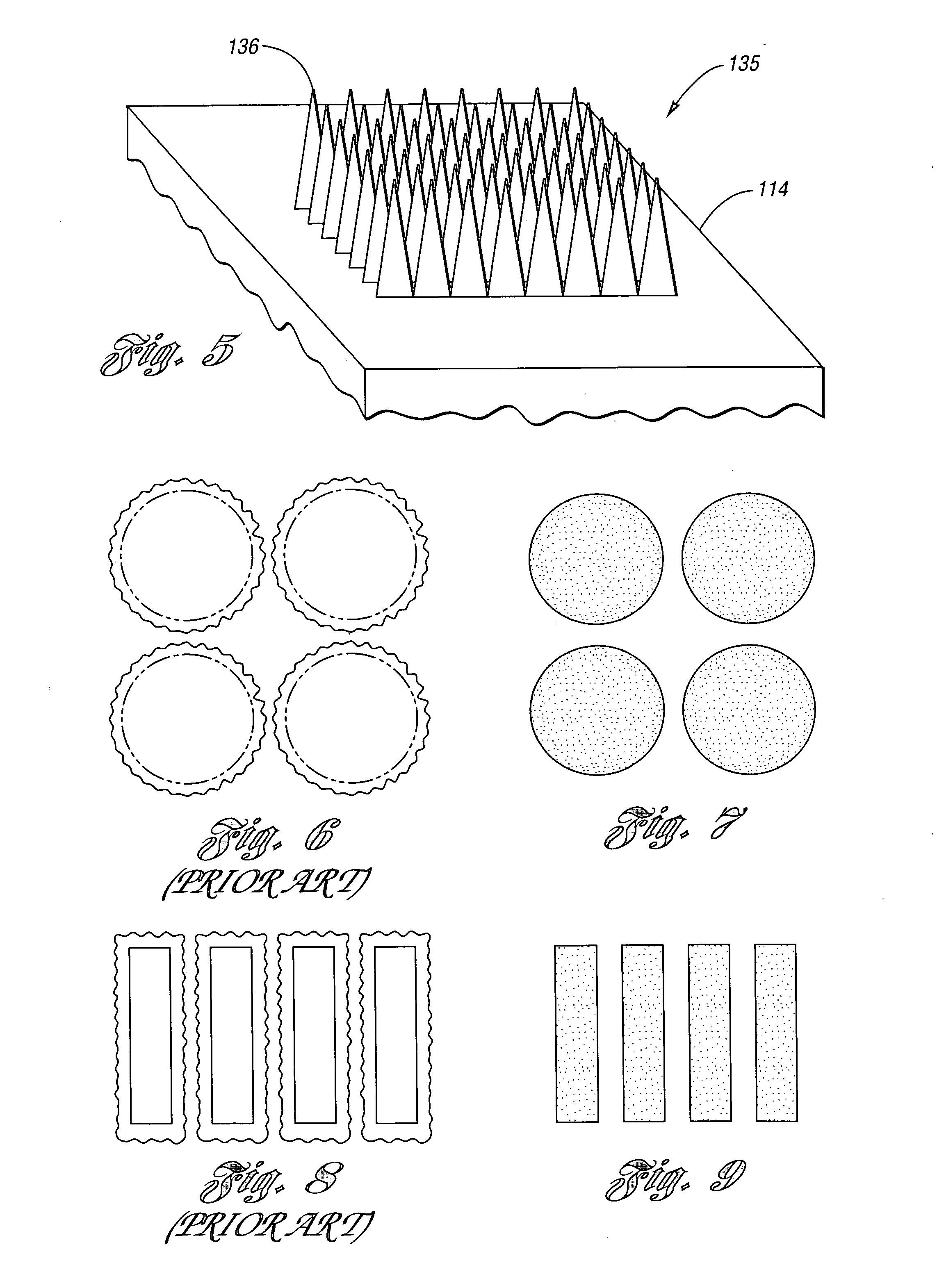

Linear light source device for image reading

InactiveUS6851816B2Simple configurationSimple structureLighting support devicesDiffusing elementsExit planeHigh rate

A linear light source device for image reading. The main body of the linear light source device includes at least a light-guide bar and a light source assembly. The light-guide bar is a polygonal column with one surface having stripes thereon, acting as a reflective plane with a reflective function. The opposite plane to the reflective plane is a light-exiting plane, and all the remaining planes are reflective layers. At least one of the ends of the polygonal column is an incident plane for a light beam to enter. Light is transmitted through both of the two ends of the polygonal column (or one end with the other end acting as a reflective plane) and uniformly transmits through the light-exiting plane. The light-guided bar has a simple structure and configuration, a compact volume, a high rate of utilization in light energy, is flexibly changed in length, and is easy to manufacture with high product yield and low manufacturing cost. In addition, it can provide uniform monochromatic and colored light, with high luminance, and at a low cost.

Owner:PIXON TECH CORP

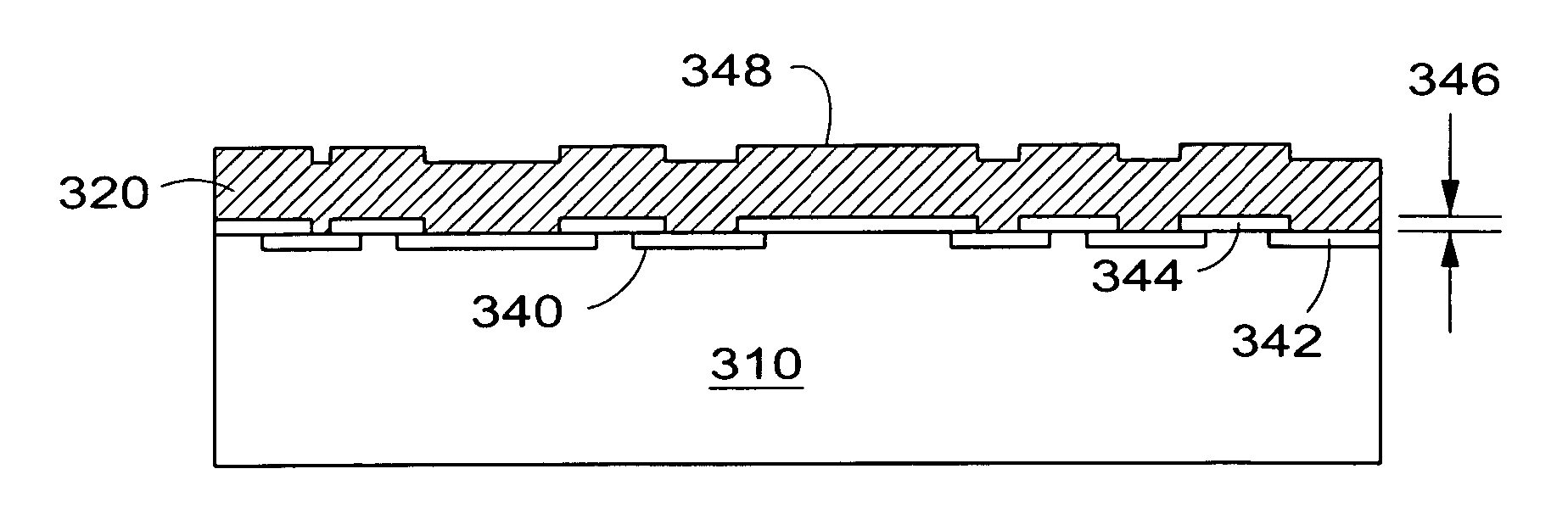

Evaporation of Y-Si-O films for medium-K dielectrics

InactiveUS6930346B2Improve surface roughnessSmooth surface roughnessTransistorSolid-state devicesDielectricEquivalent oxide thickness

A gate oxide and method of fabricating a gate oxide that produces a more reliable and thinner equivalent oxide thickness than conventional SiO2 gate oxides are provided. Gate oxides formed from yttrium, silicon, and oxygen are thermodynamically stable such that the gate oxides formed will have minimal reactions with a silicon substrate or other structures during any later high temperature processing stages. The process shown is performed at lower temperatures than the prior art, which inhibits unwanted species migration and unwanted reactions with the silicon substrate or other structures. Using a thermal evaporation technique to deposit the layer to be oxidized, the underlying substrate surface smoothness is preserved, thus providing improved and more consistent electrical properties in the resulting gate oxide.

Owner:MICRON TECH INC

Patient interface systems

ActiveUS8573201B2Easy to useEasy to appreciateControlling ratio of multiple fluid flowsBreathing masksElastomerEngineering

A headgear for use with a patient interface for delivering a flow of breathable gas to a patient includes at least a strap (741) adapted to position the patient interface in sealing engagement with the patient's airways. The strap is constructed from an elastomer and a first side of the strap includes a first region (215) on a portion of its surface that is textured to reduce friction with objects contacting the strap. A textured surface coating for a portion of an elastomer strap included in a headgear system is adapted to contact the skin of a patient, when in use, and the coating has a Ra value greater than zero. A vent (500) for use with a patient interface for delivering a flow of breathable gas to a patient includes a plurality of rises (580) and runs (570) in a stepped arrangement; and a plurality of holes (510) in the stepped arrangement for the venting of gas.

Owner:RESMED LTD

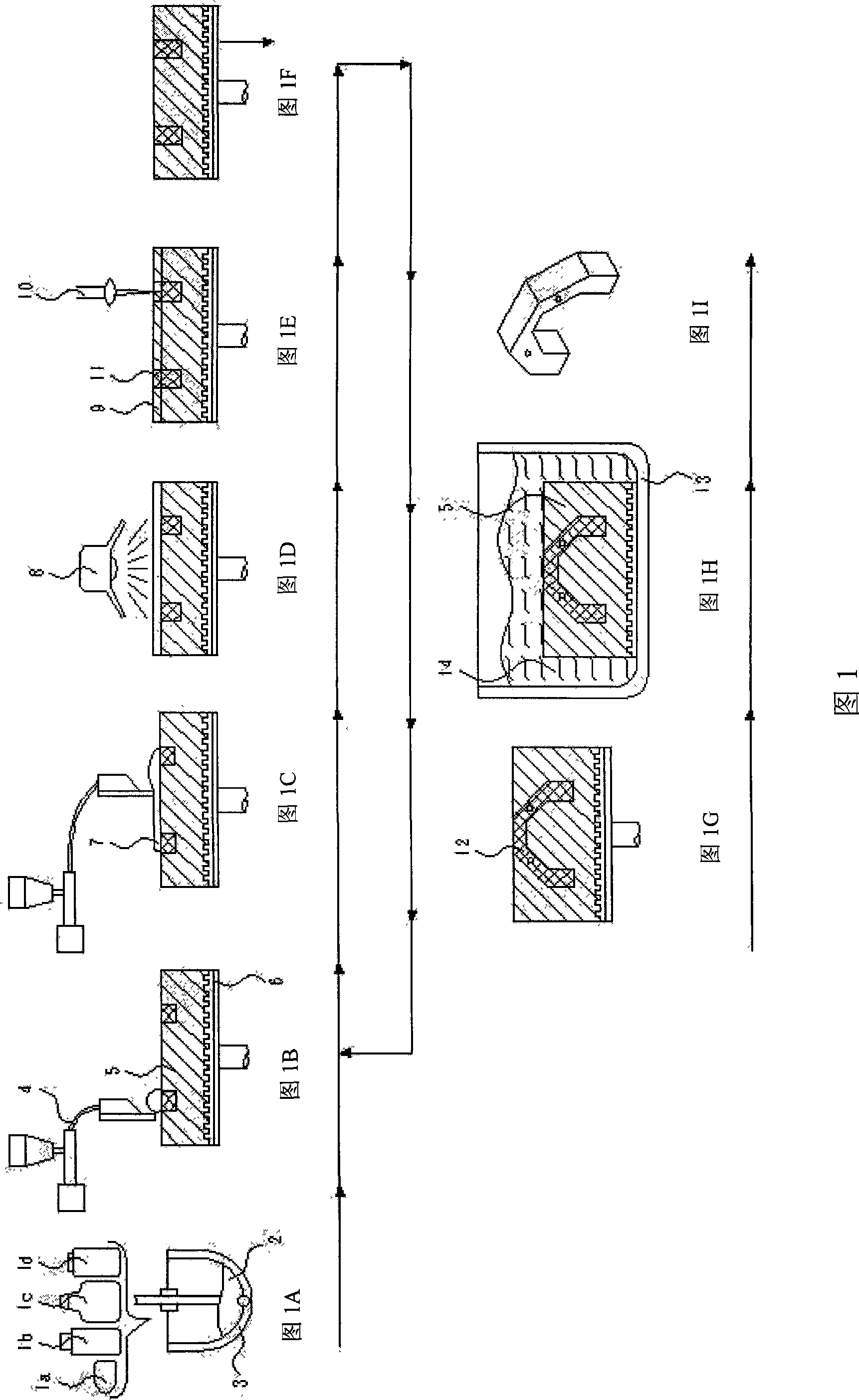

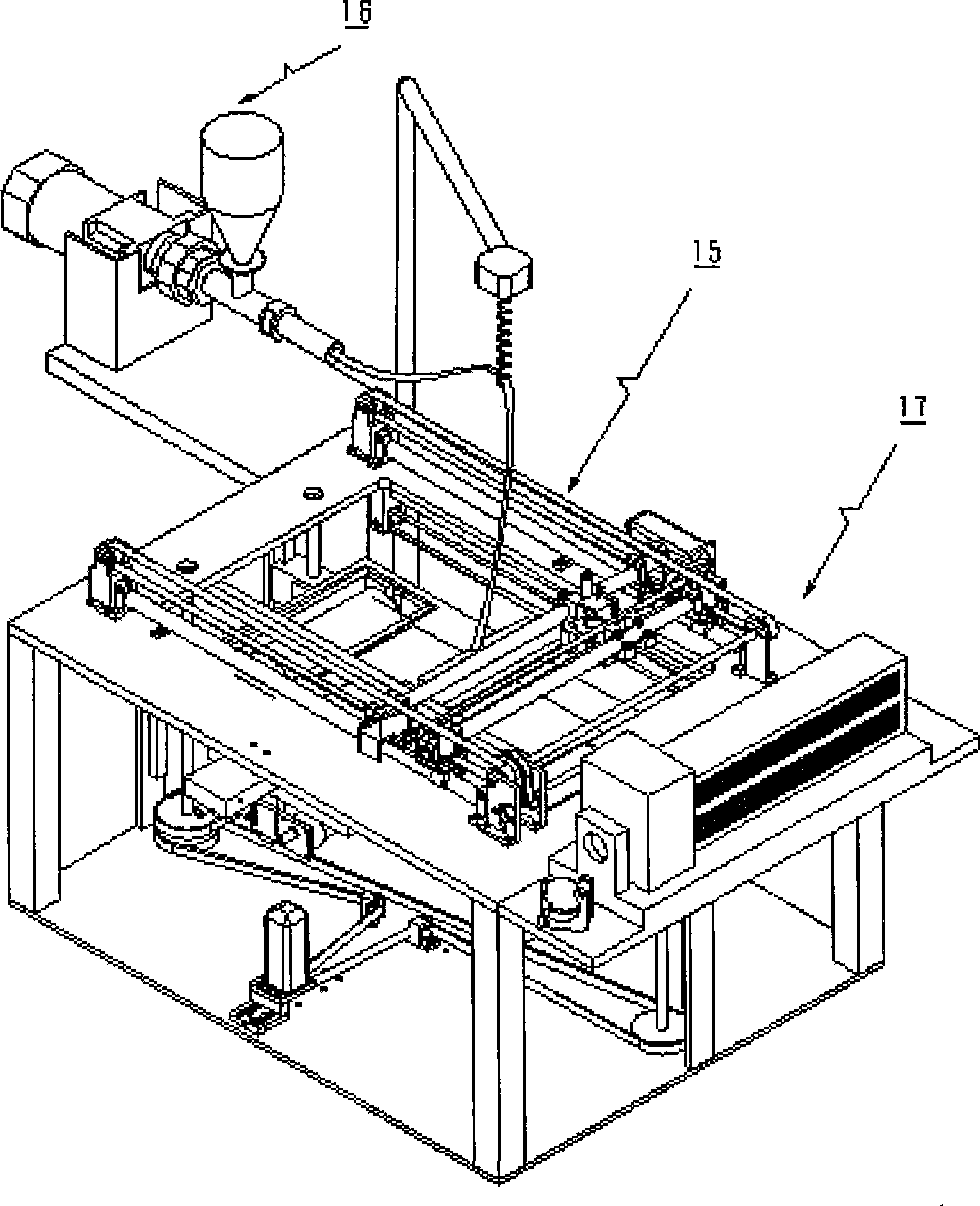

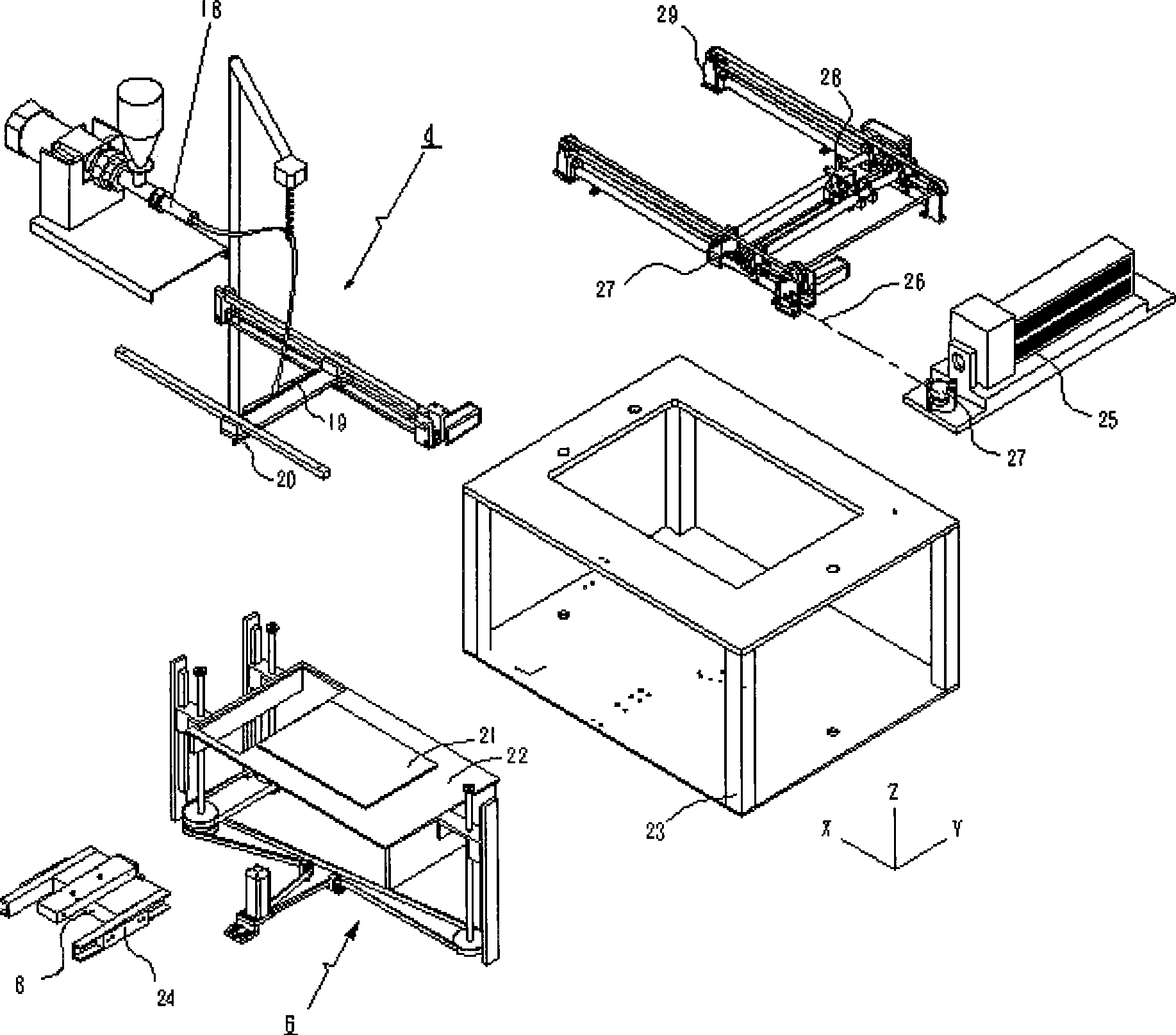

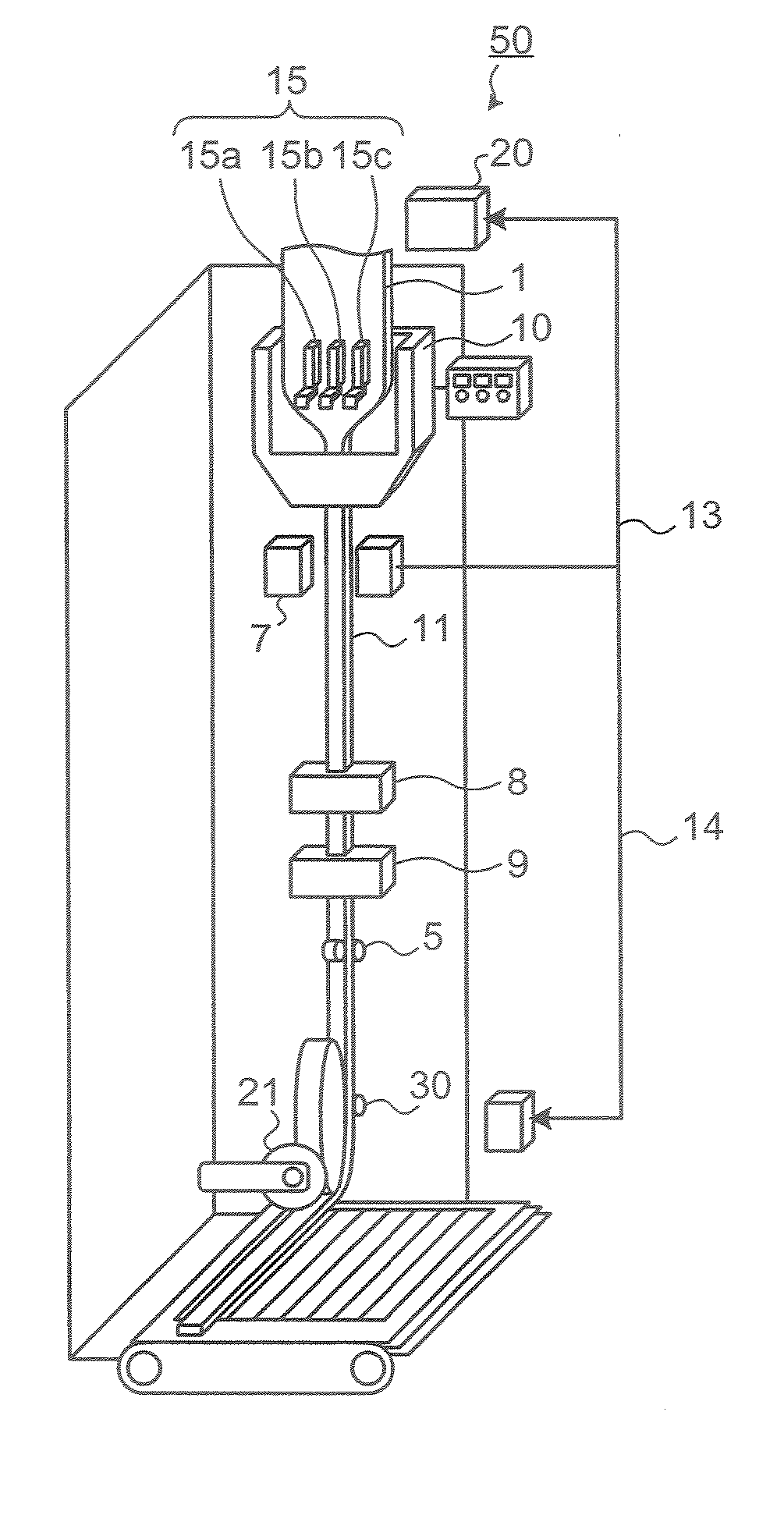

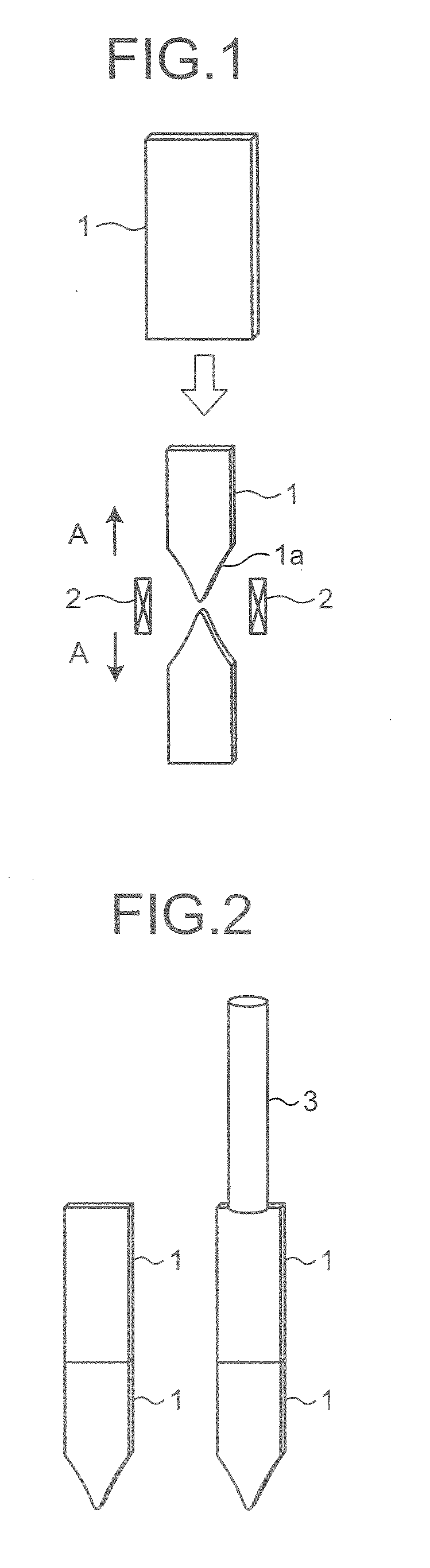

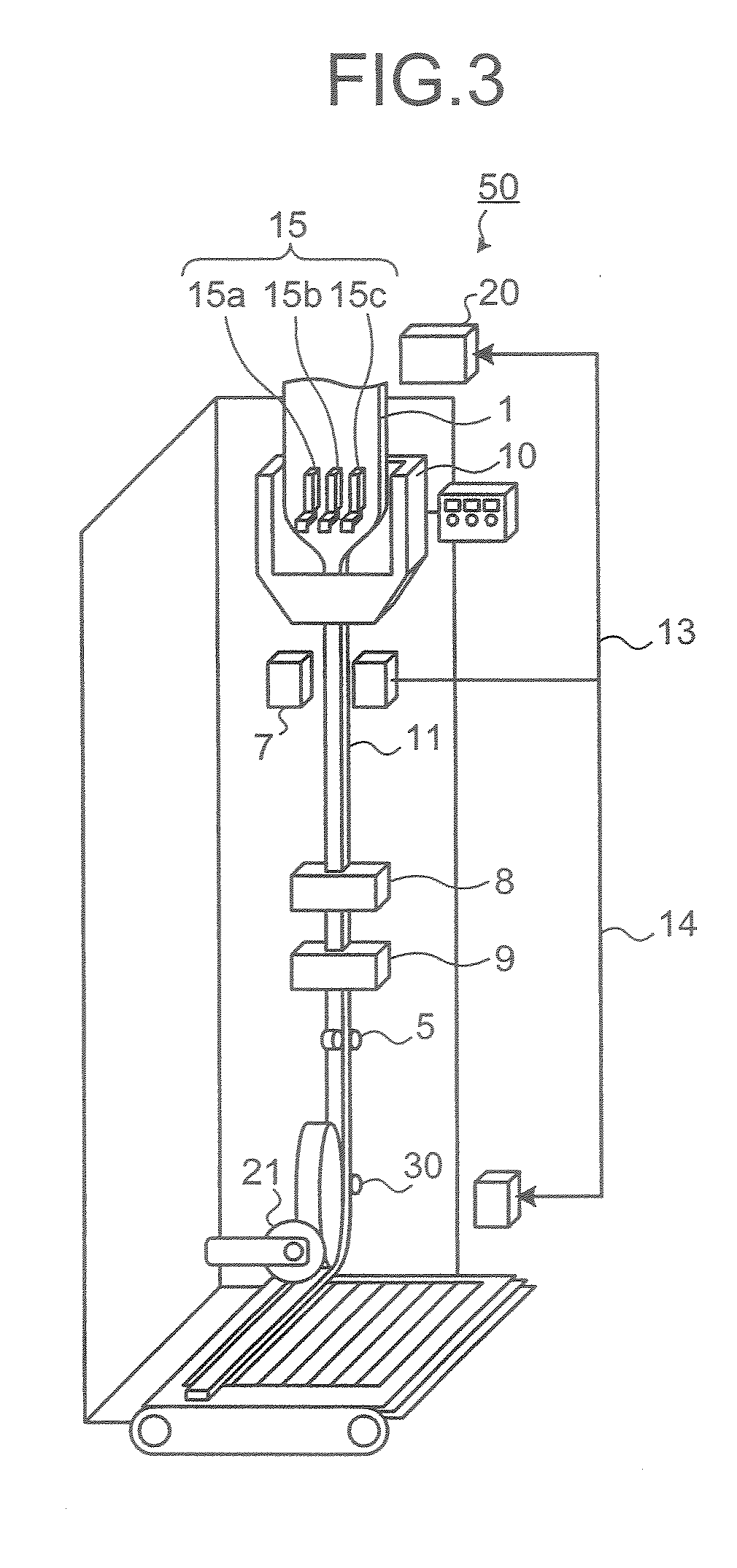

Manufacture method and device of three-dimensional workpiece

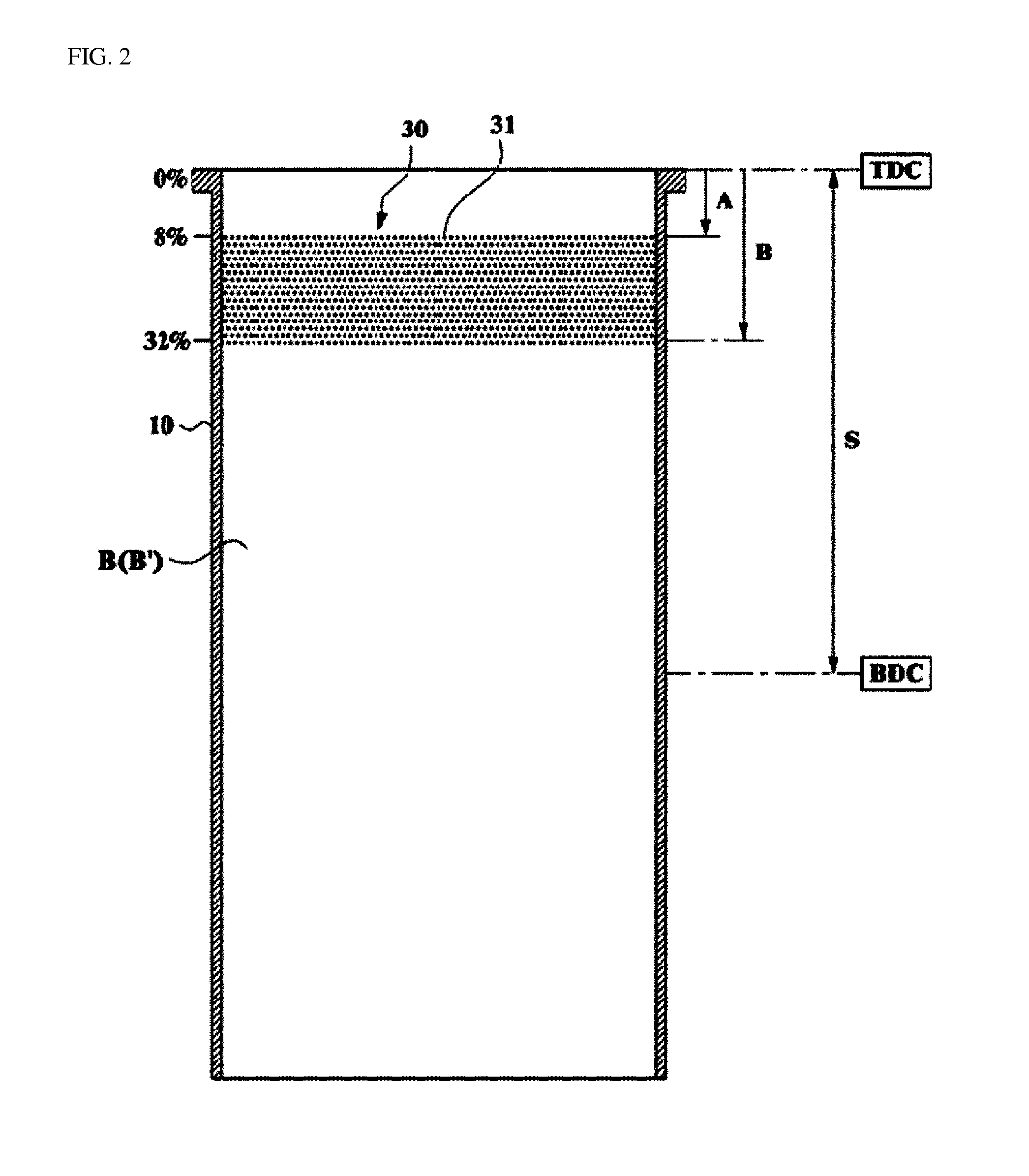

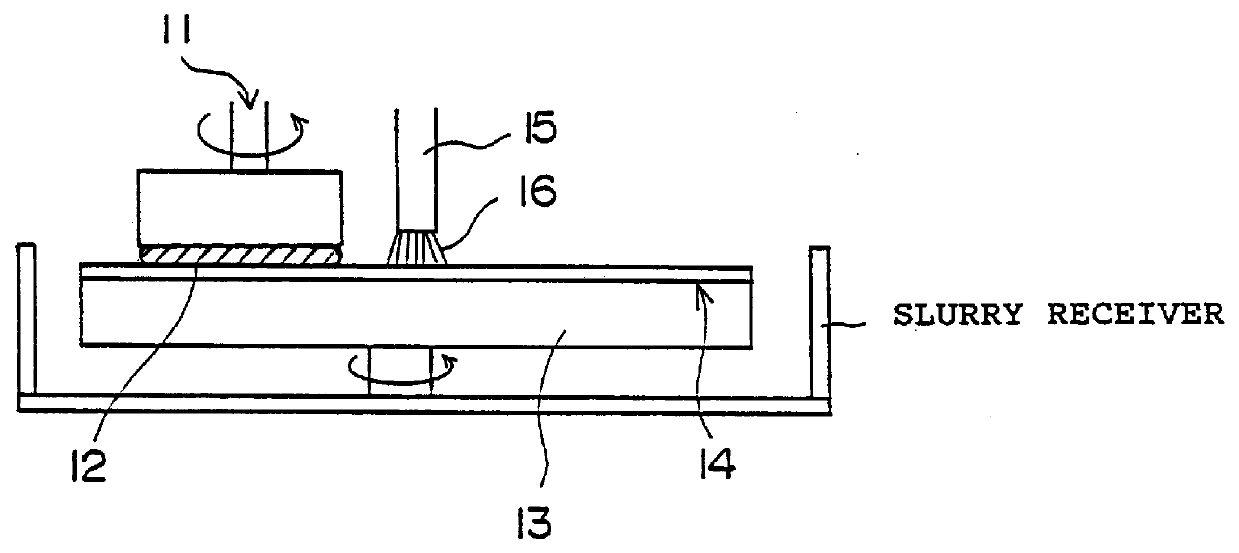

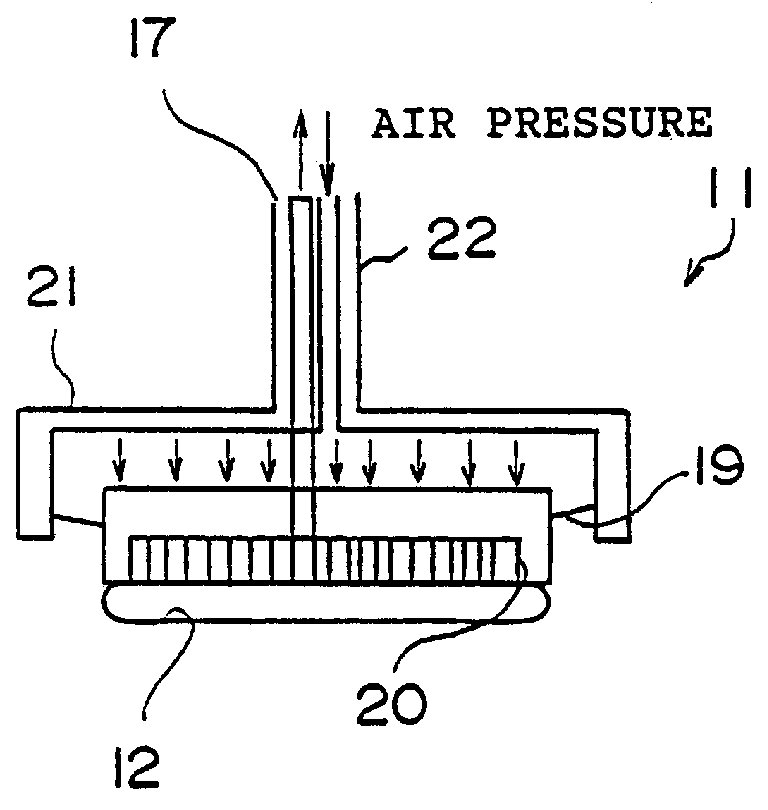

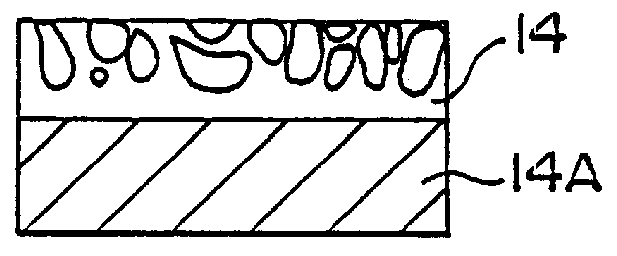

InactiveCN101422963AReduce the staircase effectHigh resolutionLiquid surface applicatorsIncreasing energy efficiencySelective laser sinteringAdhesive

The invention provides a method and equipment using organic adhesive mixed solvent and powder to manufacture three-dimensional workpieces. The work principle is as follows: the raw materials are stirred into slurry, which is laid as a green compact thin layer that can disintegrate in disintegrant; the green compact thin layer can form a workpiece thin layer that does not disintegrate in the disintegrant after scanned by an energy beam; in such a cycle, the steps of laying the thin layer and energy beam scanning are repeated, and then the three-dimensional workpiece can be formed; and the disintegant is used for separating the green compact not scanned by the energy beam from the workpiece, thus remaining the needed three-dimensional workpiece. The invention is widely applicable to manufacturing plastic, metallic, ceramic and compound workpieces, can avoid the defects of a selective laser sintering method, can use fine and very thin powder and therefore, can manufacture a finished product which is better than that made in the traditional selective laser sintering method in surface roughness and texture fineness, in addition, through subsequent densified sintering, the metallic and ceramic workpieces can have the strength superior to that in the traditional selective laser sintering method.

Owner:OUKESI INT

Dielectric barrier layer films

InactiveUS20060071592A1Improve performanceImprove uniformityDischarge tube luminescnet screensElectroluminescent light sourcesElectrical resistance and conductancePulsed DC

In accordance with the present invention, a dielectric barrier layer is presented. A barrier layer according to the present invention includes a densified amorphous dielectric layer deposited on a substrate by pulsed-DC, substrate biased physical vapor deposition, wherein the densified amorphous dielectric layer is a barrier layer. A method of forming a barrier layer according to the present inventions includes providing a substrate and depositing a highly densified, amorphous, dielectric material over the substrate in a pulsed-dc, biased, wide target physical vapor deposition process. Further, the process can include performing a soft-metal breath treatment on the substrate. Such barrier layers can be utilized as electrical layers, optical layers, immunological layers, or tribological layers.

Owner:DEMARAY

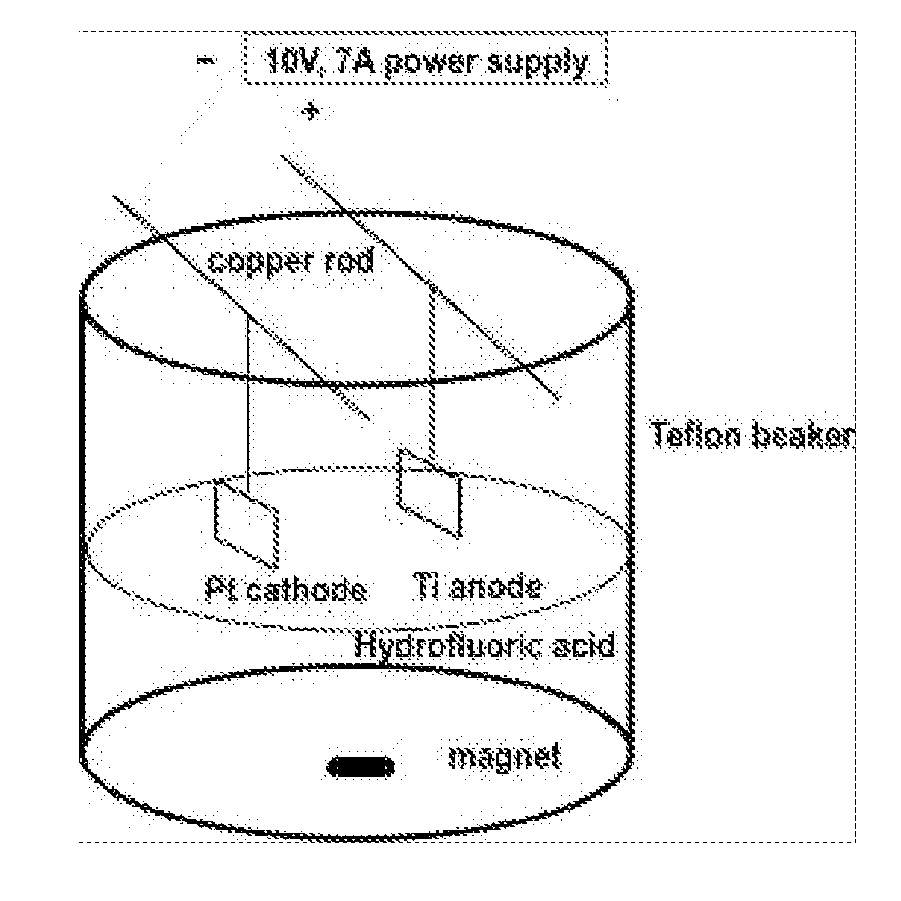

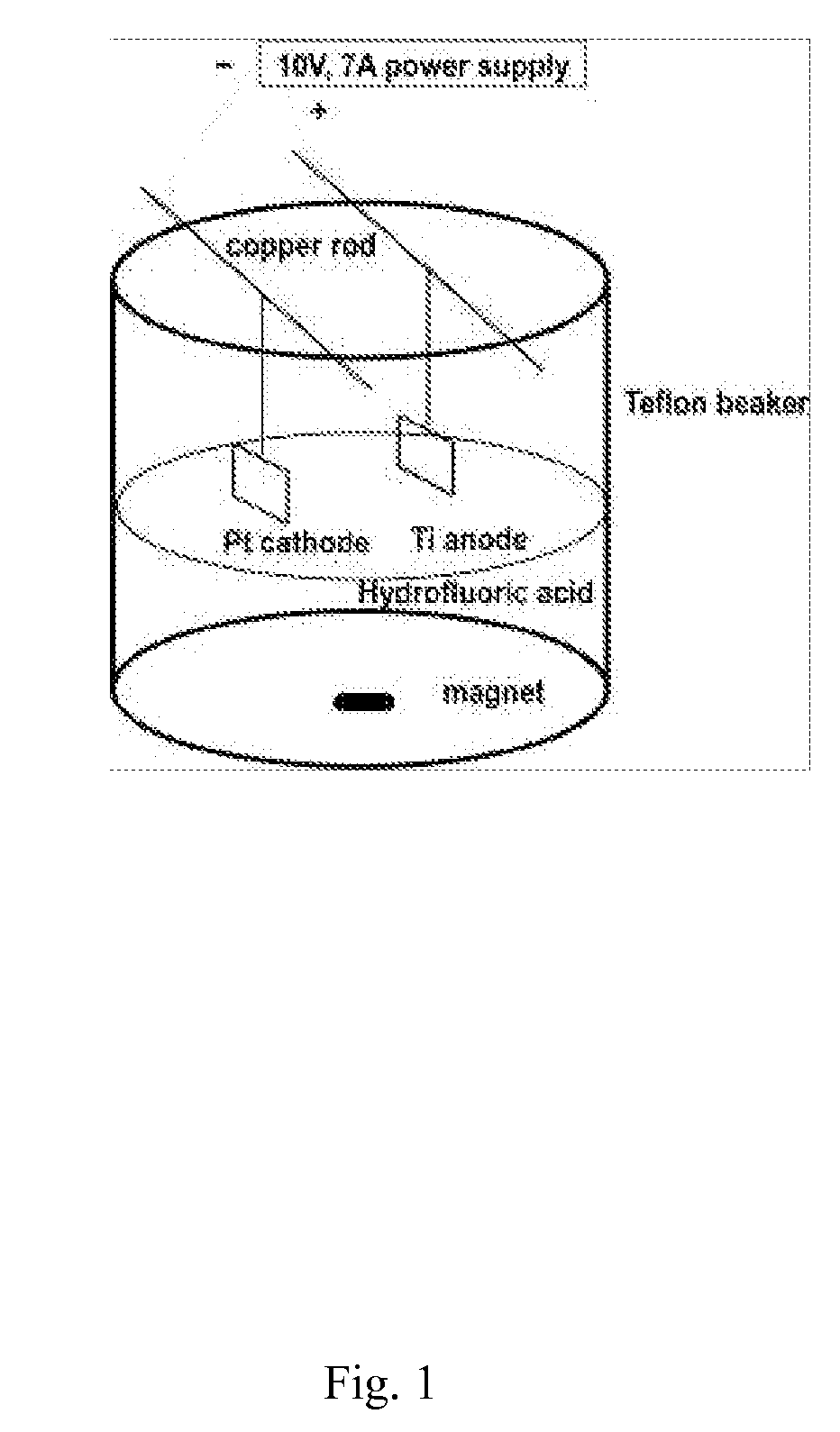

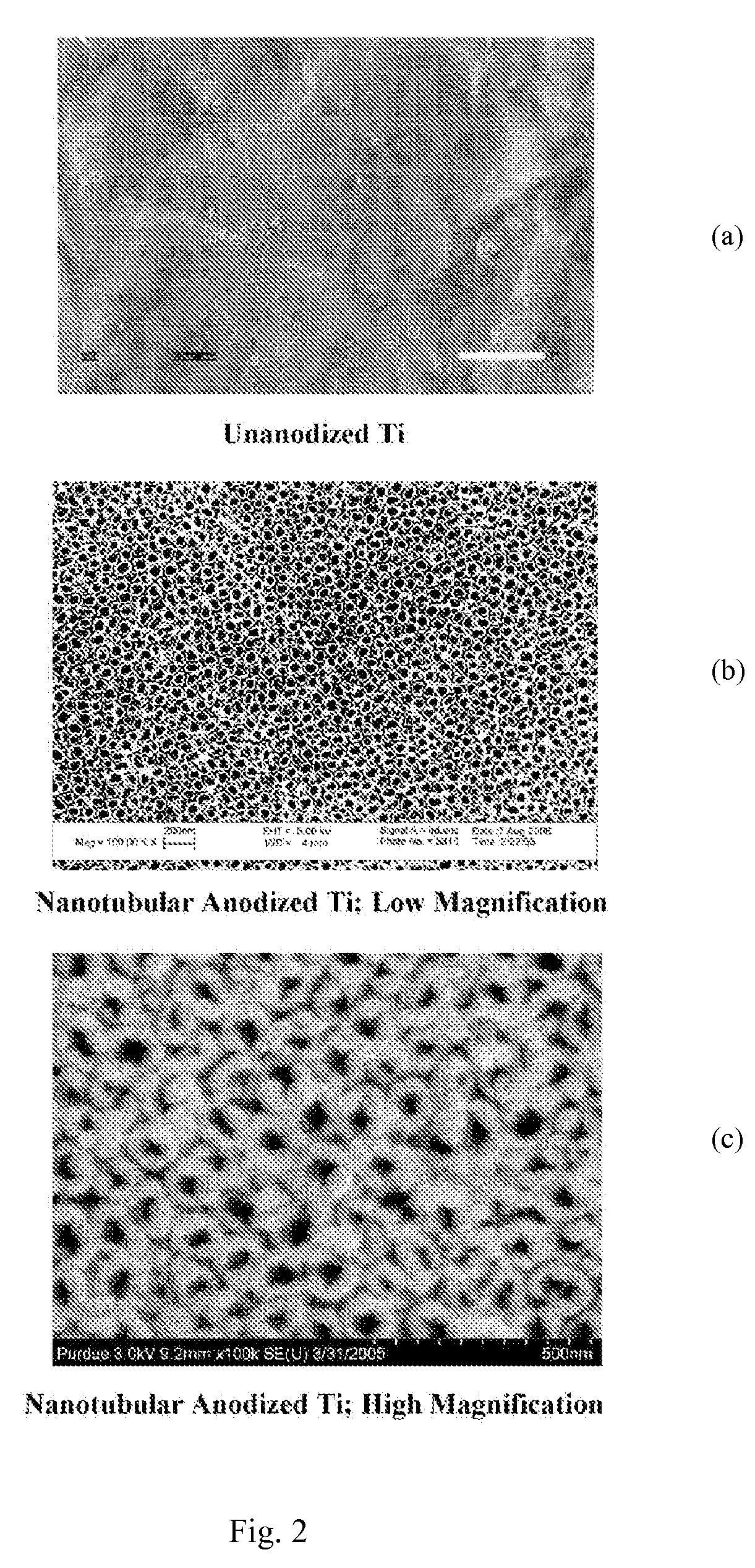

Method for producing nanostructures on a surface of a medical implant

InactiveUS20110125263A1Enhanced and increased in vivo chondrocyte functionalityImprove adhesionSurface reaction electrolytic coatingPharmaceutical delivery mechanismPorosityIn vivo

A method for treating a surface of a medical implant to create nanostructures on the surface that results in increased in-vivo chondrocyte adhesion to the surface. Further, disclosed is a method to fabricate a drug delivery system. The drug delivery system includes a medical implant that has undergone a surface treatment process that results in the modification of the surface configuration and topography. The modified surface acts as a depot or reservoir for loaded biological material, biologic agents or pharmaceutical products. Additionally, a device for delivering pharmaceutical products or other biological materials is disclosed. The device includes integrally attached nanostructures that retain or adsorb the loaded pharmaceutical products and / or biological materials. Further disclosed is a medical implant that includes a surface configured to allow for and regulate protein adsorption. The surface of the medical implant has a layer of nanostructures rigidly attached with varying porosity and orientation that allow for surface protein adsorption to be controlled.

Owner:BROWN UNIVERSITY

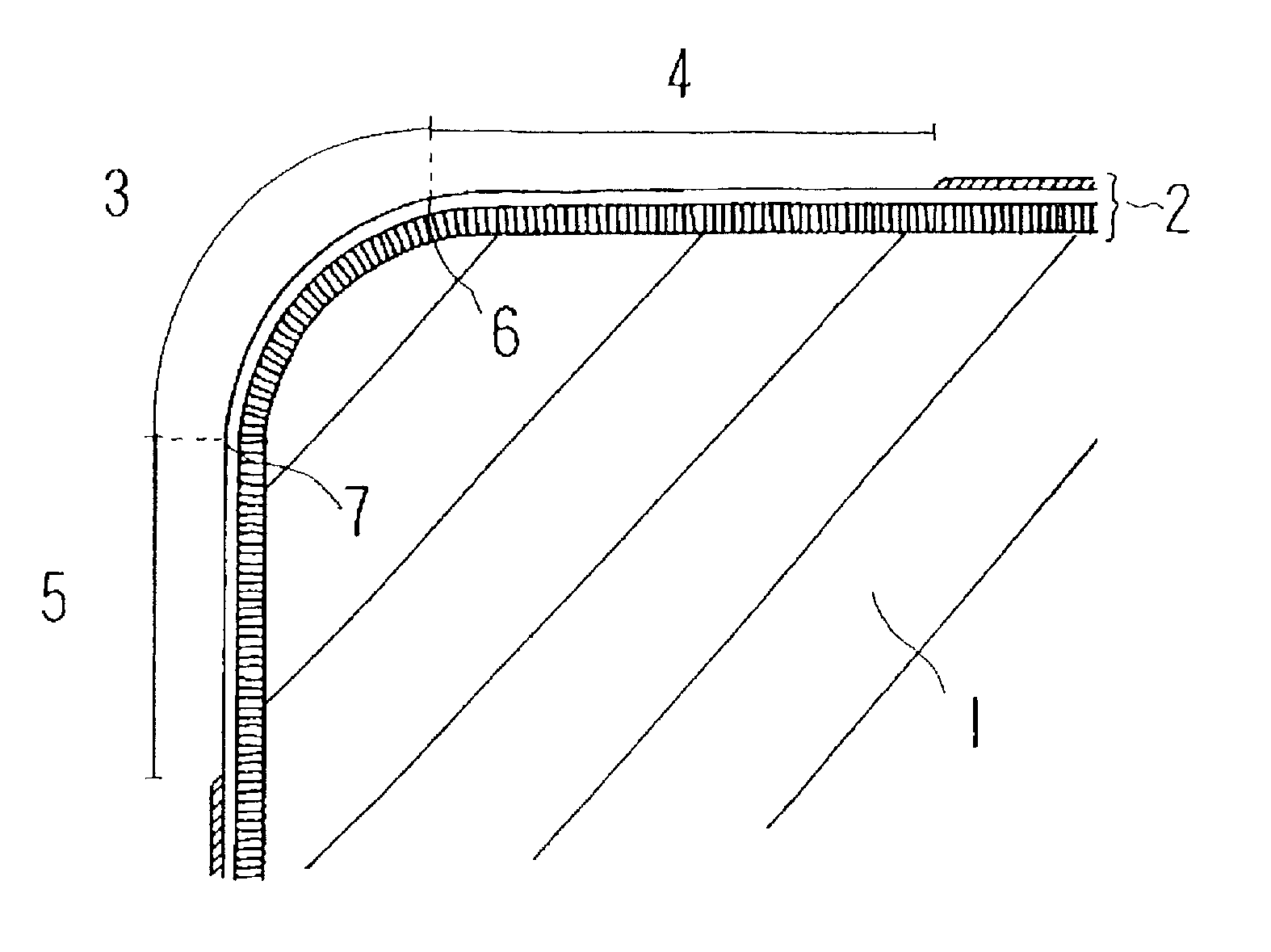

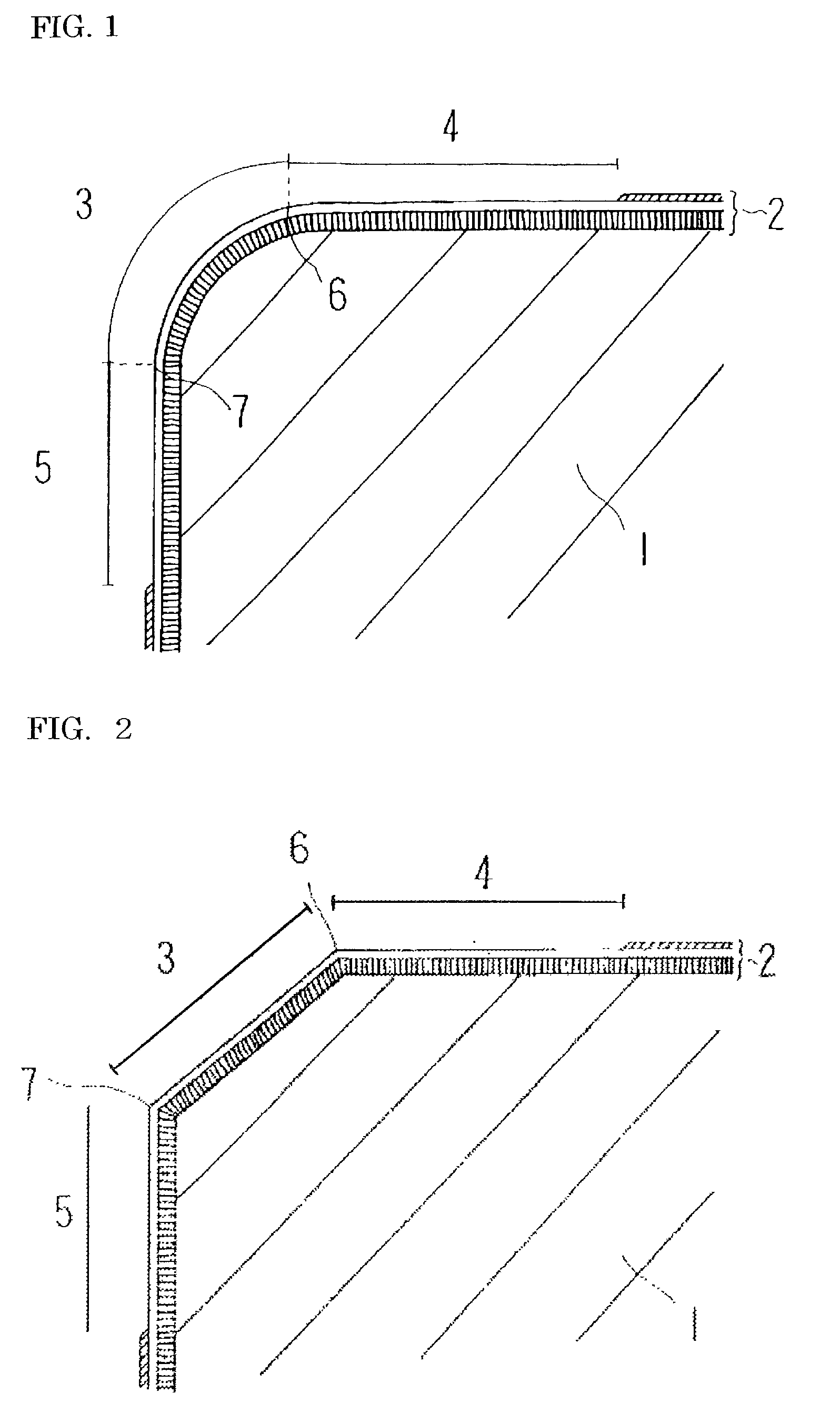

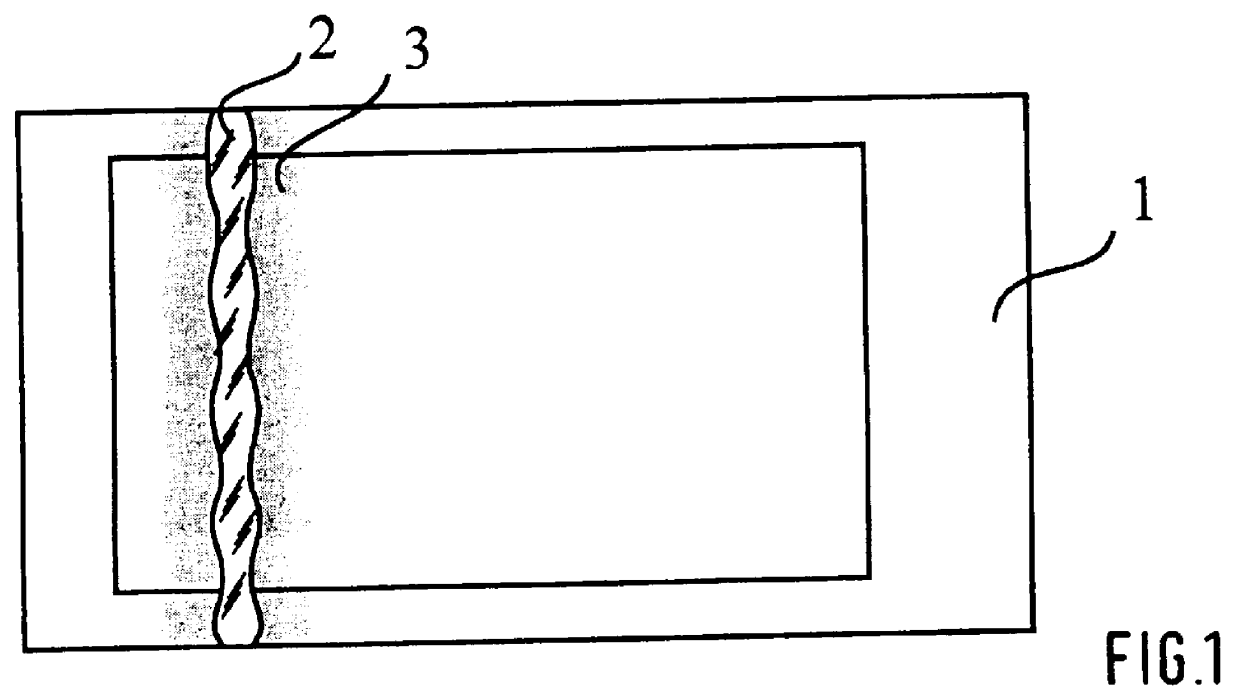

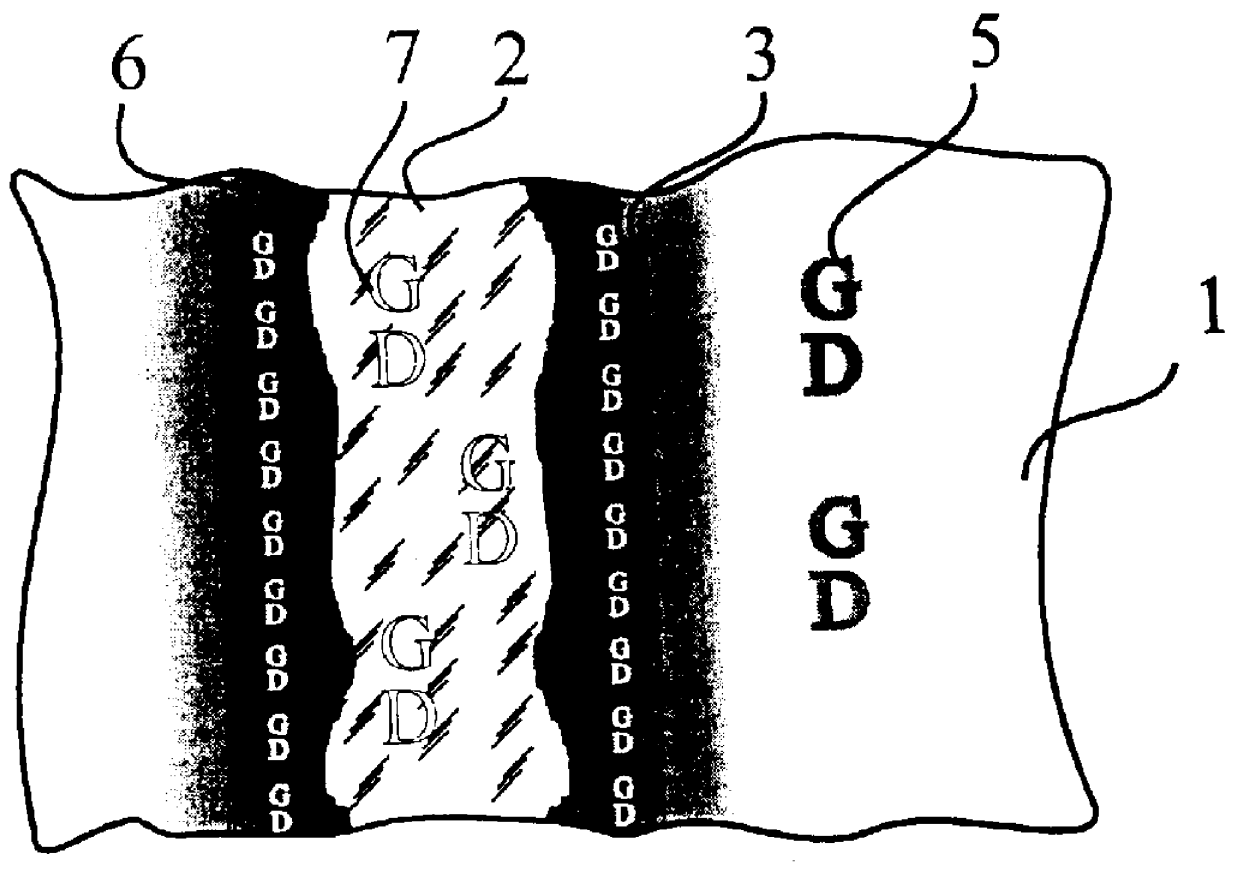

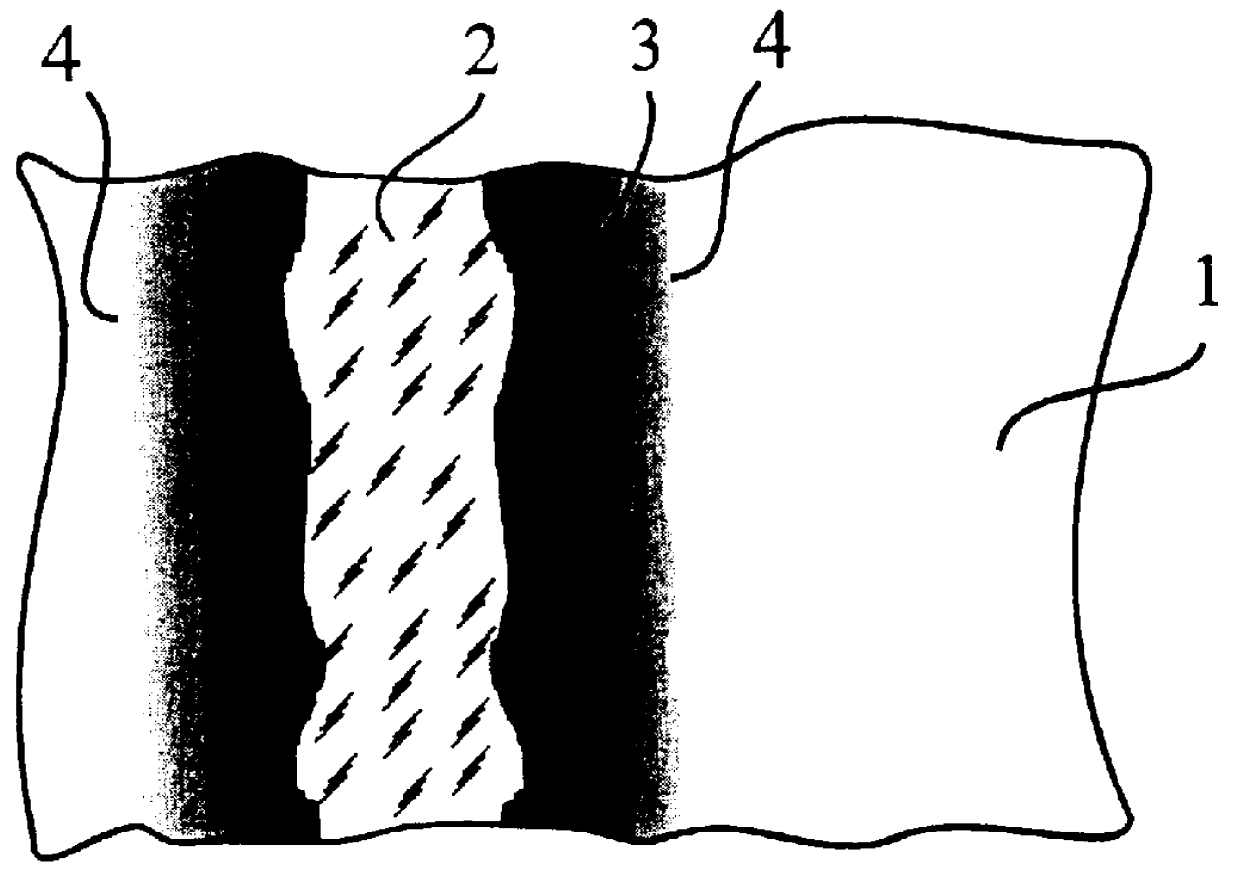

Coated cutting tool

InactiveUS20020187370A1Improve tool lifeIncrease resistanceTurning toolsCeramic layered productsIron groupSurface roughness

The present invention provides a coated cutting tool in which fracture resistance and wear resistance are simultaneously realized, tool life is improved, and surface roughness of machined workpiece is improved The coated cutting tool is provided with hard coating layer 2 on substrate 1. The substrate 1 is formed of a binder phase comprising one or more kinds of iron-group metals and a hard phase comprising one or more kinds of substances selected from the group consisting of carbides, nitrides, and oxides of the periodic table IVa-, Va-, and VIa-group elements, and solid solutions thereof. In the coating layer 2, blade-edge ridge 3, a range of at least 200 mum from the rake face side boundary 6 of the same ridge toward the rake face side, and a range of at least 50 mum from the flank side boundary 7 of the same ridge toward the flank side are formed to be smooth surfaces which substantially have surface roughness (Rmax) of 0.2 mum or less (reference length: 5 mum).

Owner:SUMITOMO ELECTRIC IND LTD

Data carrier with an optically variable element

InactiveUS6036232AIncrease product assuranceProvide authenticityOther printing matterLight effect designsEngineering

PCT No. PCT / EP97 / 01411 Sec. 371 Date Mar. 3, 1998 Sec. 102(e) Date Mar. 3, 1998 PCT Filed Mar. 20, 1997 PCT Pub. No. WO97 / 35732 PCT Pub. Date Oct. 2, 1997The invention relates to a data carrier, in particular bank note, paper of value, identity card or the like, having a security element disposed on the surface thereof. The data carrier is provided in at least one partial area with a background layer containing at least one authenticity feature. The optically variable element is applied to this background layer such that it overlaps the latter at least partly but does not completely cover it.

Owner:GIESECKE & DEVRIENT CURRENCY TECHNOLOGY GMBH

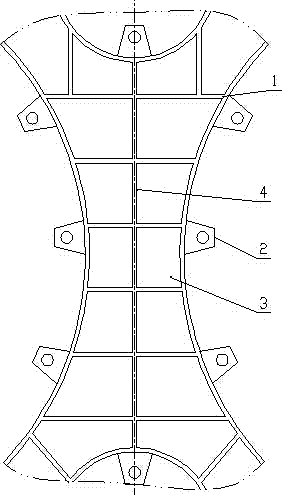

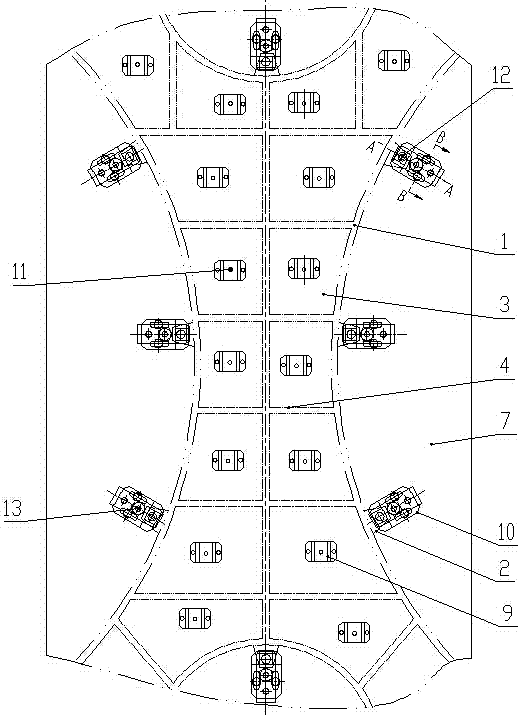

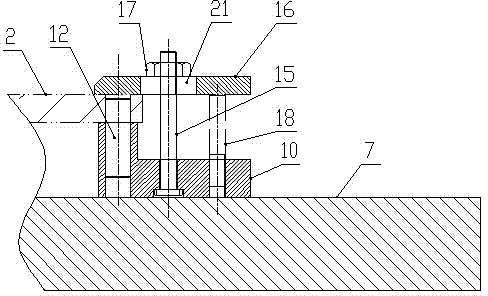

Plane wing titanium alloy thin-wall web efficient numerical control machining technology

A plane wing titanium alloy thin-wall web efficient numerical control machining technology comprises the following steps that (1) blanking is carried out; (2) web outer contour machining is carried out, and an ear piece for locating is machined; (3) a web is clamped, and a cavity on the front face of the web is machined; (4) a web side wall is machined; (5) web quick converting is carried out, and a cavity on the back face of the web is machined; (6) the locating ear piece is removed by milling; and (7) quality testing is carried out. The rigidity of a machining technology system is improved, unstressed machining is achieved, by optimized design of a feed track, the stability of a machining process is improved, machining speed is increased, titanium alloy shallow cutting large feeding milling technology parameters are used, heat deforming during machining is lowered, rectifying processes are omitted, the metal removing rate is improved by 30%-50%, finally, machining efficiency is obviously improved, the clamping time of workpieces is obviously shortened through a quick-reloading technology, the repeated locating accuracy of clamping is guaranteed, and accordingly numerically-controlled machine tool machining efficiency is greatly improved.

Owner:HUANGHE S & T COLLEGE

Laser-based method and system for processing targeted surface material and article produced thereby

ActiveUS20080011852A1Prevent unwanted changesSufficient total fluenceAdditive manufacturing apparatusSemiconductor/solid-state device detailsTarget surfaceSlag

Owner:ELECTRO SCI IND INC

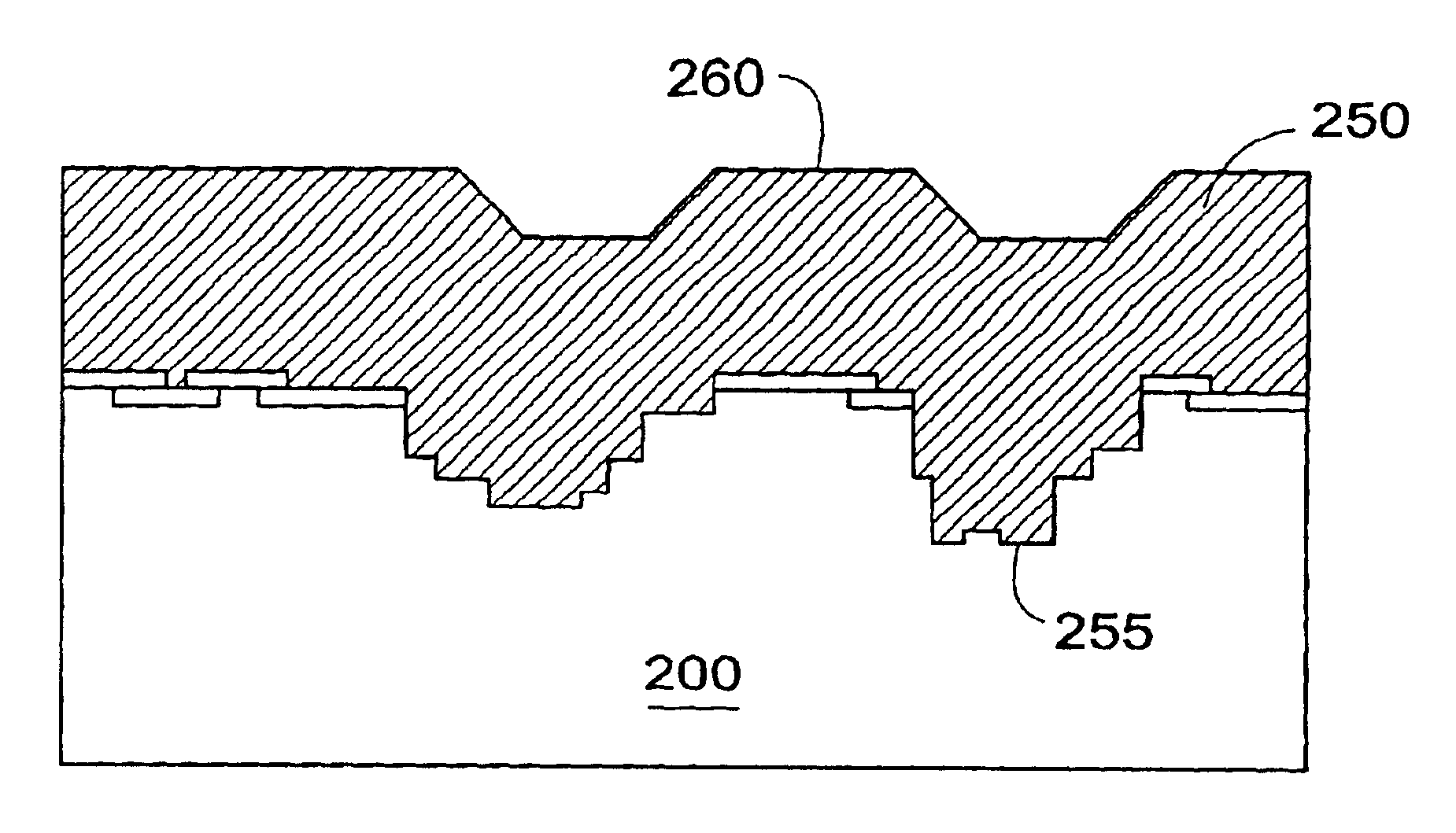

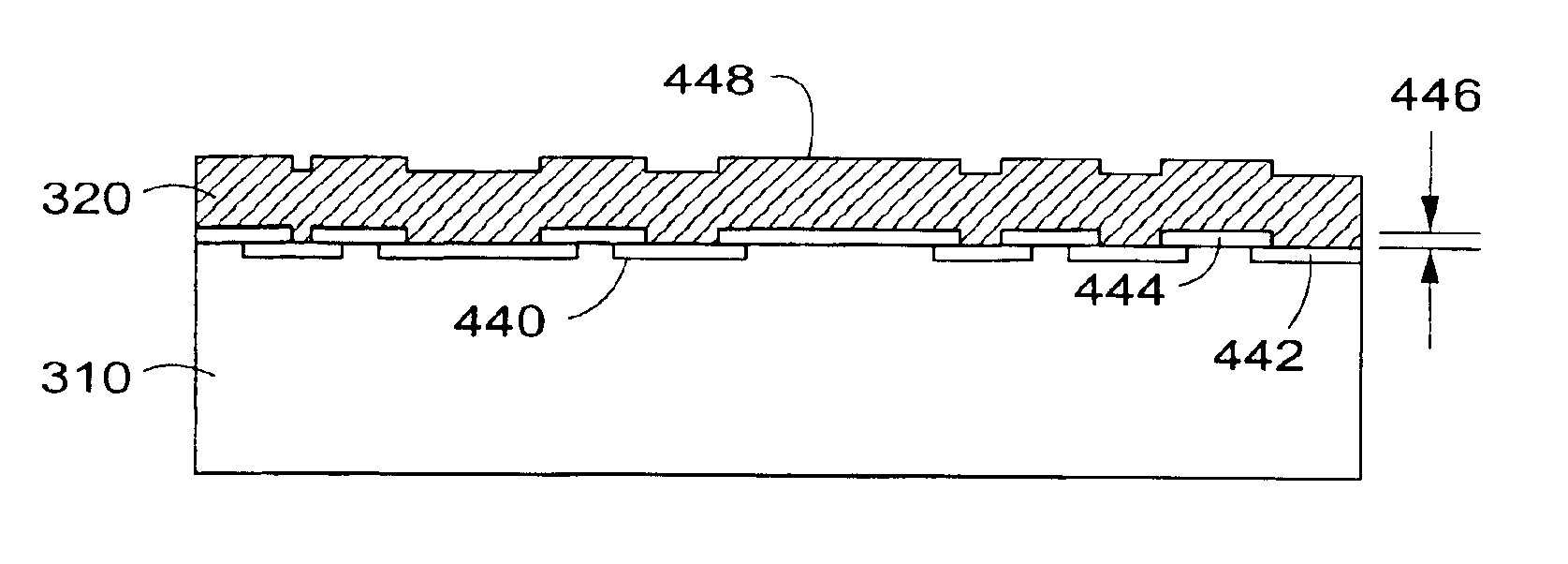

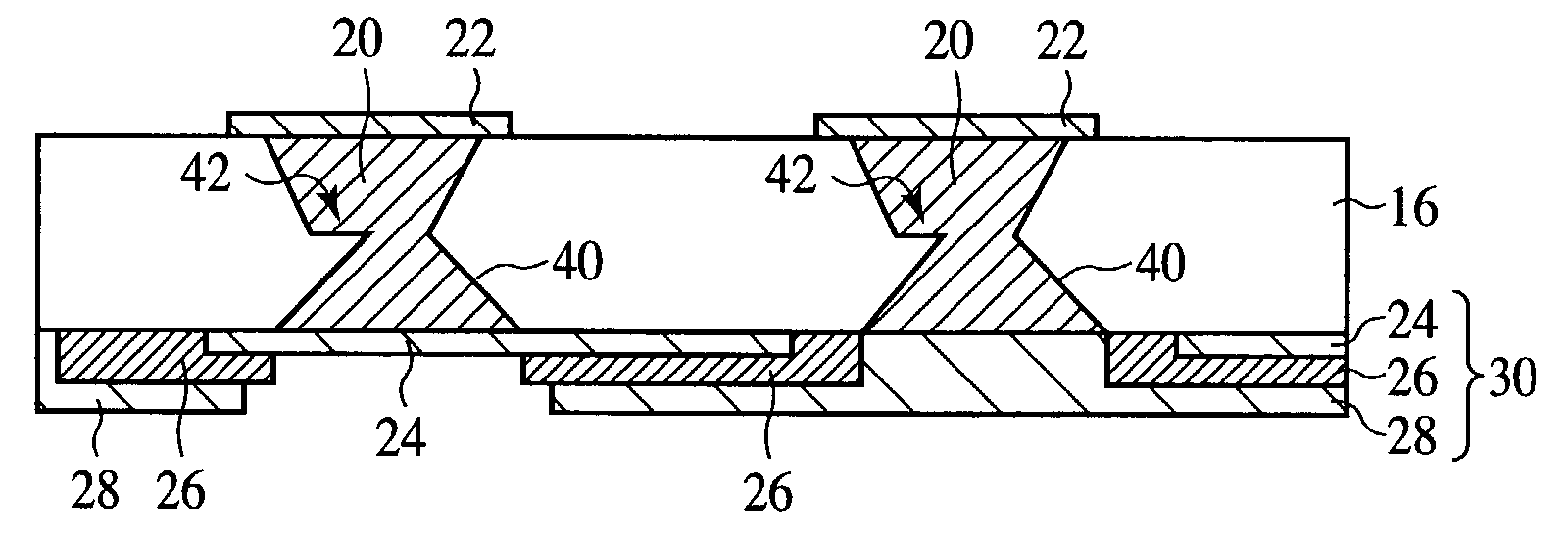

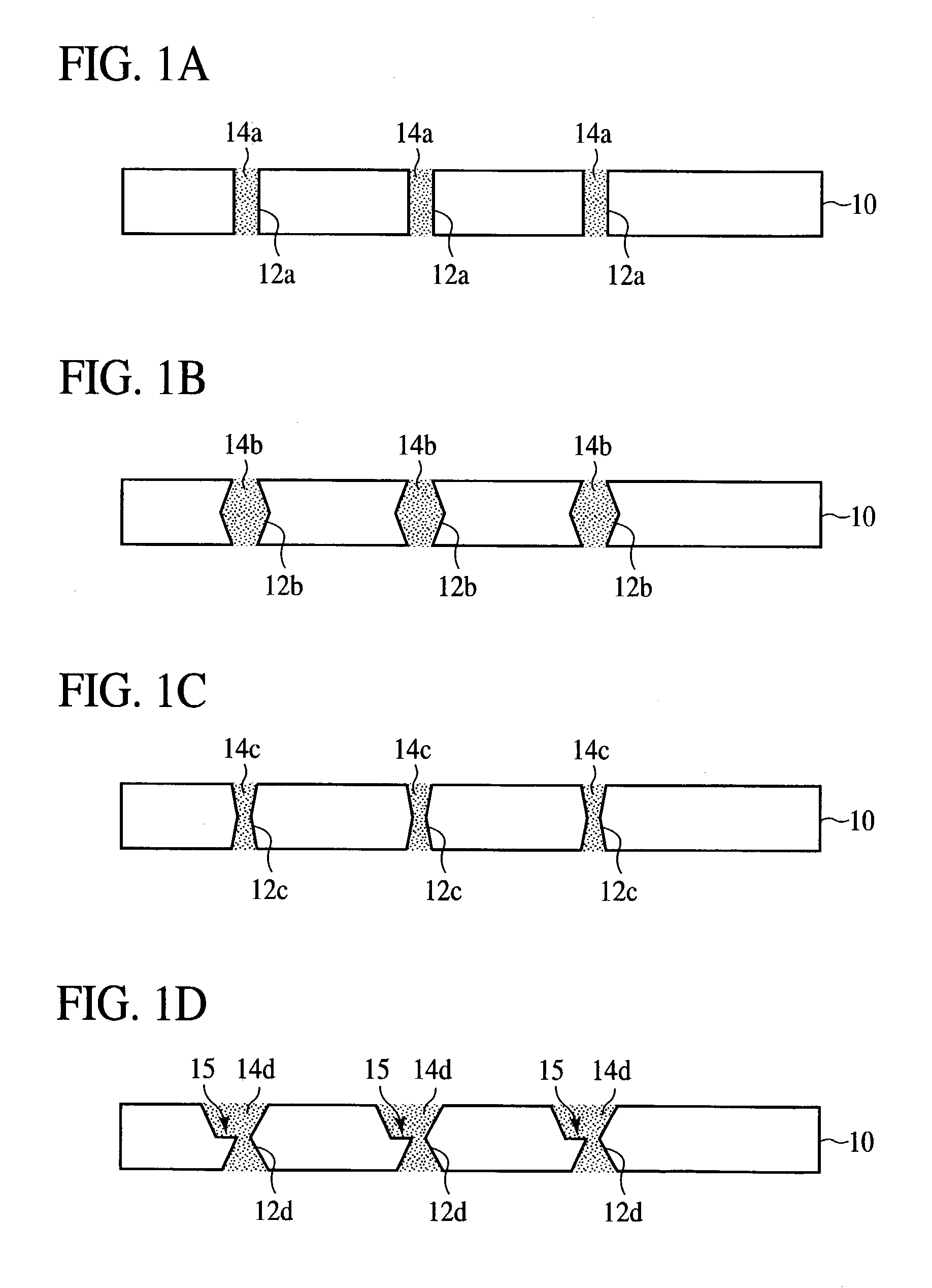

Circuit substrate and method for fabricating the same

InactiveUS7211899B2Improve surface roughnessRelieve stressSemiconductor/solid-state device detailsPrinted circuit aspectsSurface roughnessOptoelectronics

A circuit substrate comprises a glass substrate 16, through-holes 18 formed through the glass substrate 16 and via electrodes 20 buried in the through-holes 18. An opening width of the through-holes 18 is minimum inside the glass substrate and is increased toward both surfaces of the glass substrate 16. Accordingly, the detachment of the via electrodes 20 can be prevented without increasing the surface roughness of the inside walls of the through holes, and stresses generated in the core substrate can be mitigated.

Owner:FUJITSU LTD

Process for Producing Glass Strip, Glass Strip and Glass Substrate

InactiveUS20070271957A1Improve flatnessReduce adhesionSynthetic resin layered productsGlass reforming apparatusInternal pressureSurface roughness

A manufacturing method of a glass strip, the method including a heating and drawing process of heating and softening a glass plate preform (1), drawing the glass plate preform to have a desired thickness and forming a glass strip (11), wherein at the heating and drawing process the glass plate preform (1) is drawn so that an internal pressure of a heating furnace (3) is kept positive relative to an atmospheric pressure and so that gas flows introduced to both surfaces of the glass plate preform (1) respectively are equal to each other within the heating furnace (3). It is possible to improve a surface roughness and obtain a desired surface roughness.

Owner:FURUKAWA ELECTRIC CO LTD

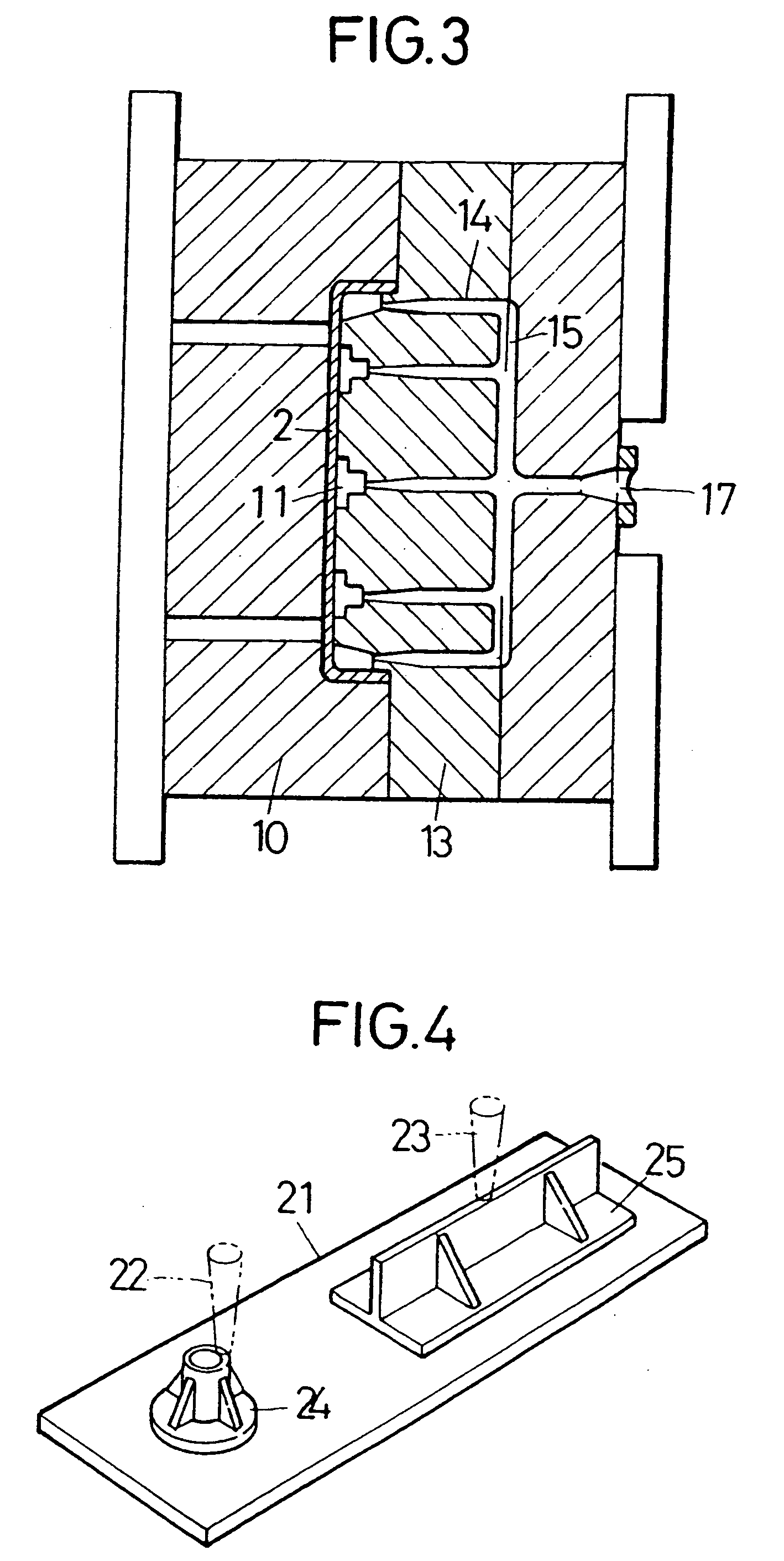

Composite of aluminum alloy and resin and production method therefor

InactiveUS20080127479A1Excellent mechanical propertiesGood physical propertiesMetal rolling stand detailsMetallic material coating processesMetal frameworkWater soluble

The present invention is useful for achieving a reduction in weight and for attaining increased strength in not only electronic devices and domestic electric devices but also various parts and structures. As a pretreatment, a rib (3) is dipped in an aqueous solution of ammonia, hydrazine, a hydrazine derivative, or a water-soluble amine compound. A metal frame (2) is inserted into an injection mold for forming ribs (3) by injection molding. A thermoplastic resin composition is injected to the surface of the metal frame (2) by injection molding to form ribs (3). In the housing of a casing cover (1) thus formed, the metal frame (2) and the ribs (3) made of the thermoplastic resin composition are integrally bonded together. Thus, the housing improves strength and external appearance. Moreover, a complicated configuration and structure can be formed in the housing.

Owner:TAISEI PLAS CO LTD

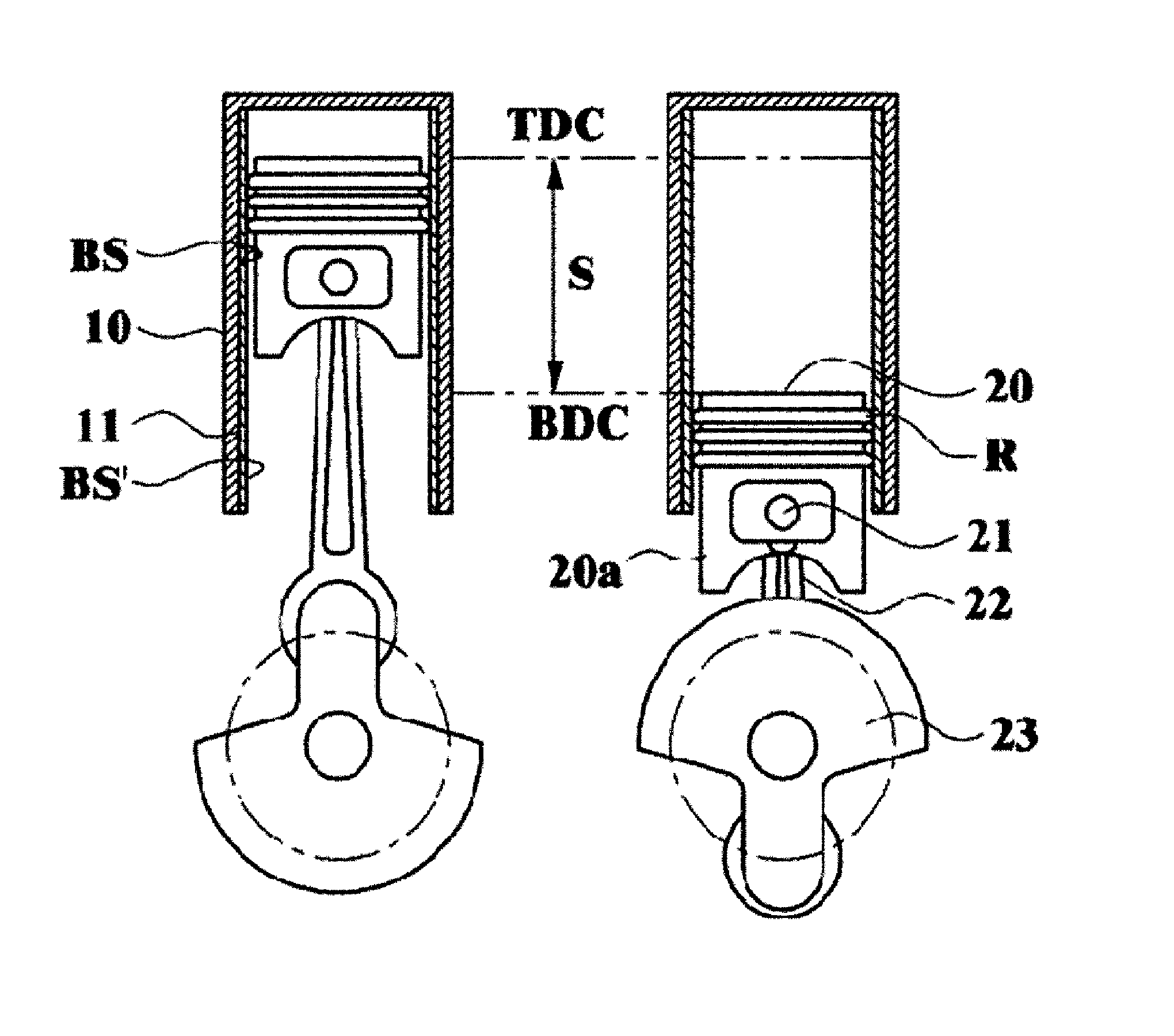

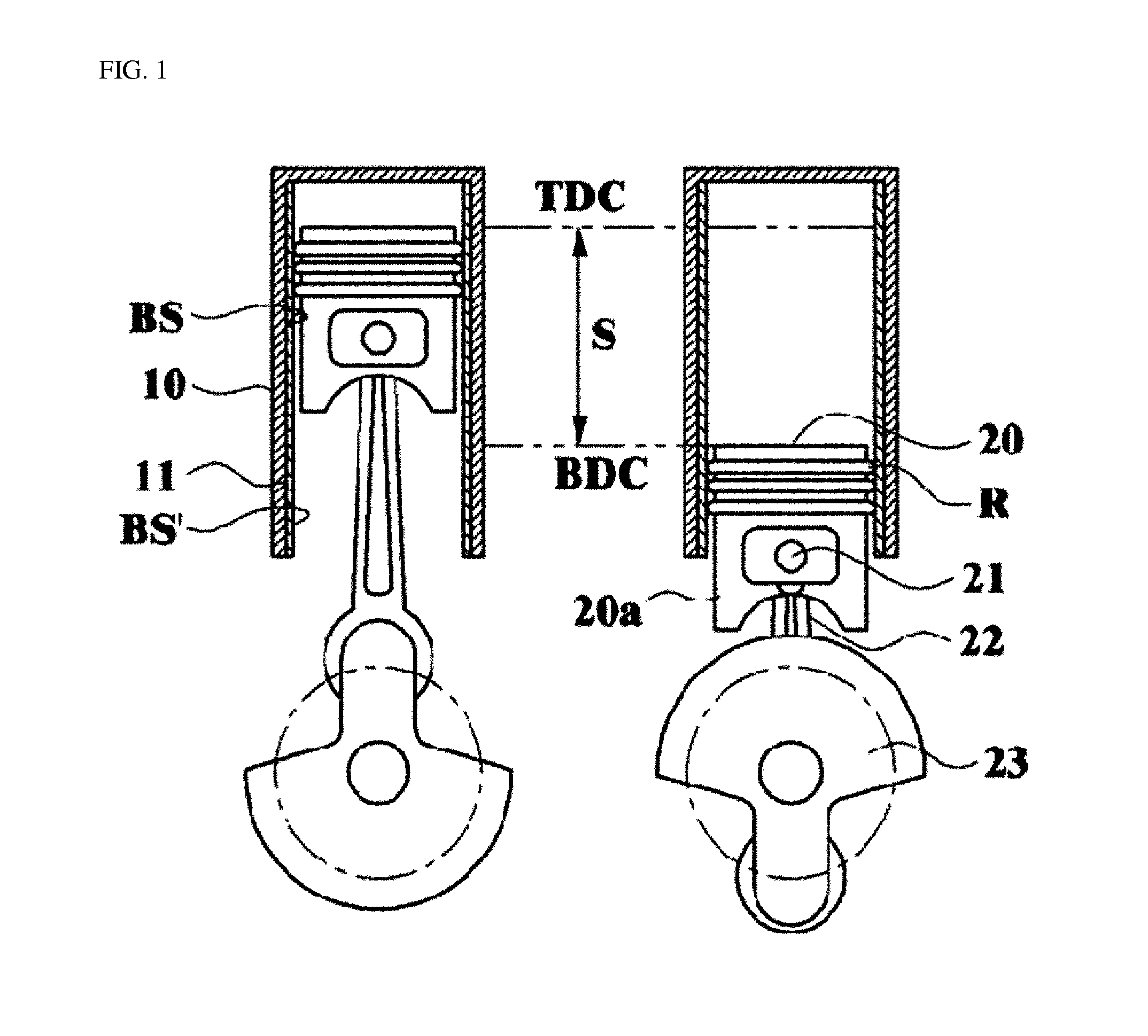

Cylinder device having improved wear resistance through optimal arrangement of fine textures

ActiveUS20140345453A1Reduce oil consumptionAvoid performance degradationCylinder headsCylindersPiston ringSurface roughness

There is provided a cylinder device having optimal arrangement of fine textures and optimal surface roughness capable of reducing wear of a cylinder bore side and a piston ring by processing fine textures in an optimal selection region of the cylinder bore side to improve lubrication characteristics between the piston ring and the cylinder bore side while reducing engine oil consumption by processing surface roughness of the cylinder bore side to an optimal status.

Owner:DOOSAN INFRACORE CO LTD

Polishing method for semiconductor wafer and polishing pad used therein

InactiveUS6120353AGood haze levelIncrease roughnessLapping machinesFlexible-parts wheelsEngineeringSemiconductor

In a polishing method for a semiconductor wafer in which polishing slurry is interposed between the semiconductor wafer and a polishing pad and the semiconductor wafer is mirror-polished by a polishing step for planarization, when polishing is conducted using a suede-like foam urethane resin polishing pad having physical properties of low compressibility lower than 9 % and high pore density equal to or higher than about 150 pores / cm.sup.2 as the polishing pad used in the polishing step, a mirror silicon wafer with good surface roughness of 50 bits in haze can be manufactured.

Owner:SHIN-ETSU HANDOTAI CO LTD

Fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof

ActiveCN102021819AExcellent water repellencyBasic physical and mechanical propertiesSilicon compoundsVegetal fibresOrganic solventHYDROSOL

The invention relates to a fluorine-free superhydrophobic finishing agent containing modified nano silicon dioxide hydrosol and application thereof. The finishing agent is prepared by the following steps of: (1) mixing a precursor, an anionic surfactant and water and stirring violently at the temperature of between 20 and 50 DEG C; and (2) slowly adding ammonia water serving as a catalyst dropwise, stirring, adding long-chain alkylsiloxane serving as a modifier and stirring continually so as to obtain modified SiO2 hydrosol. The finishing agent has a stable property, avoids the pollution of an organic solvent and has high water repellency when used for performing superhydrophobic finishing on textiles.

Owner:DONGHUA UNIV +1

Metal piece and method for processing surface of metal piece

ActiveCN101591798AImprove electrochemical uniformityImprove surface roughnessSurface roughnessHigh pressure

The invention relates to a metal piece, the roughness concentration of the surface of the metal piece is 0.02 micron to 0.1 micron, and the reflectivity of the surface is 65 percent to 90 percent. A method for processing the surface of the metal piece is used for obtaining the metal piece by polishing a metal substrate, and the polishing comprises the following steps: polishing pretreatment is carried out to the metal substrate; the metal substrate after the polishing pretreatment is dipped in polishing liquid containing ammonium salt and an addition agent, the metal substrate is put on a positive pole, and a pulse electric field with high frequency and high voltage is applied for plasma body polishing; and the metal piece is obtained after the polished metal substrate is washed and parched. Compared with the traditional polishing method, the method for processing the surface of the metal piece has the advantages that the electrochemistry leveling of the surface of the metal substrate is greatly increased, and the roughness concentration is reduced.

Owner:BYD CO LTD

Method for processing monocrystal silicon carbide wafer

InactiveCN102107391AQuality improvementImprove surface roughnessLapping machinesFine working devicesOptoelectronicsSingle crystal

The invention provides a method for obtaining the high-quality surface of monocrystal silicon carbide through mechanical grinding and chemical polishing. By adopting the method, point defects, linear defects and planar defects of the monocrystal silicon carbide surface can be removed through double-side grinding, single-side swinging arm type rough grinding, single-side swinging arm type fine grinding and single-side swinging arm type CMP (chemically mechanical polishing), and surface blemishes and damaged layers of a wafer can be eliminated to the utmost extent, so that the high-quality surface of a monocrystal silicon carbide wafer can be obtained.

Owner:BEIJING TIANKE HEDA SEMICON CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com