Patents

Literature

483results about How to "Improve surface hydrophobicity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super-amphiphobic polymer and super-amphiphobic surface prepared from super-amphiphobic polymer

InactiveCN102432742AGood scrub resistanceAccelerated corrosionWater-repelling agents additionPaper/cardboardPolymer scienceMicrosphere

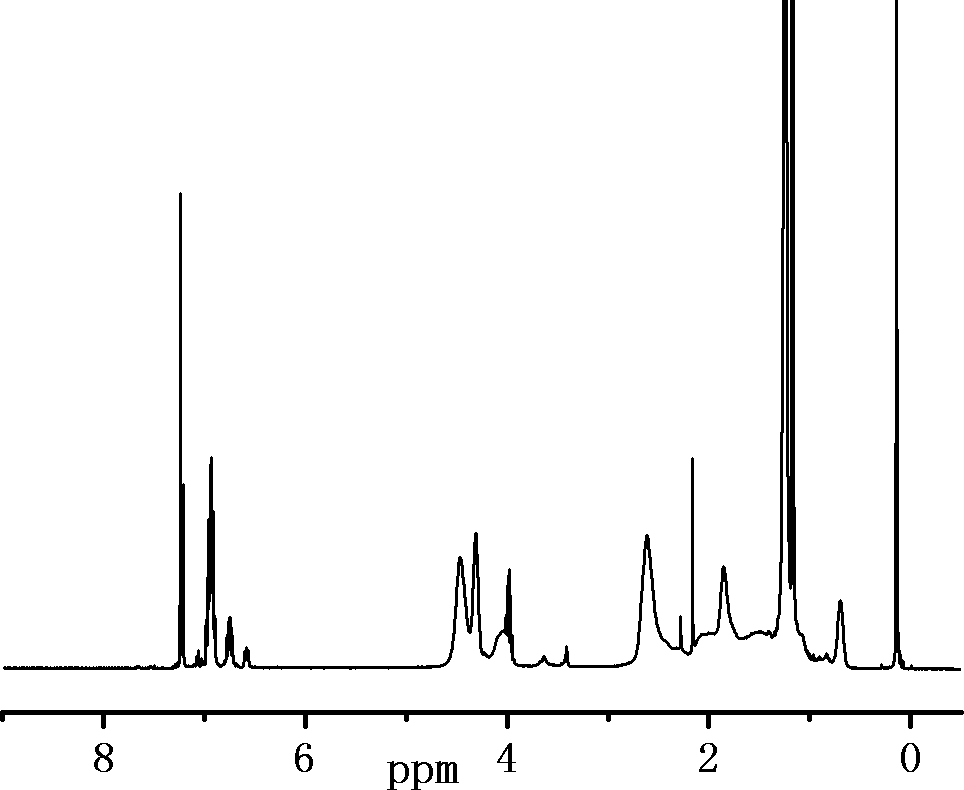

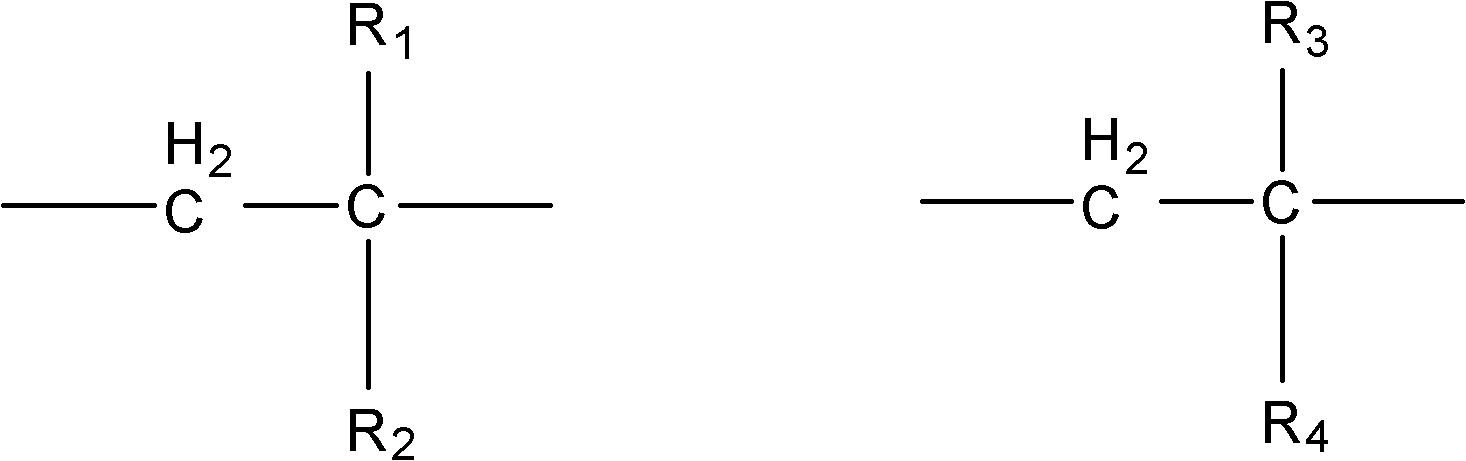

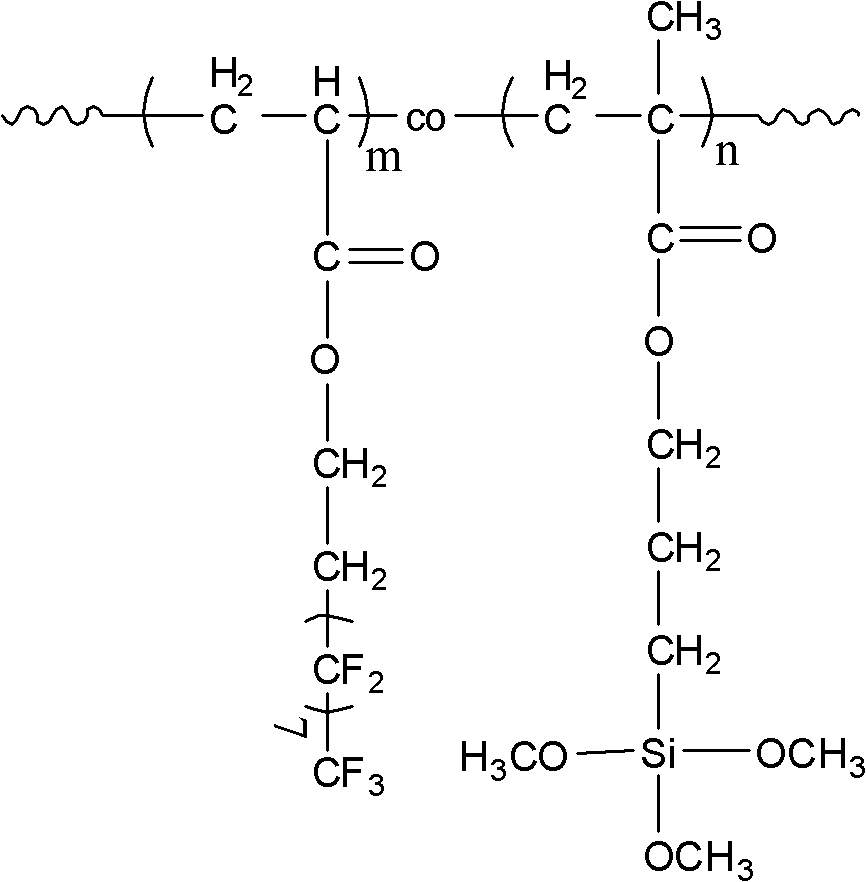

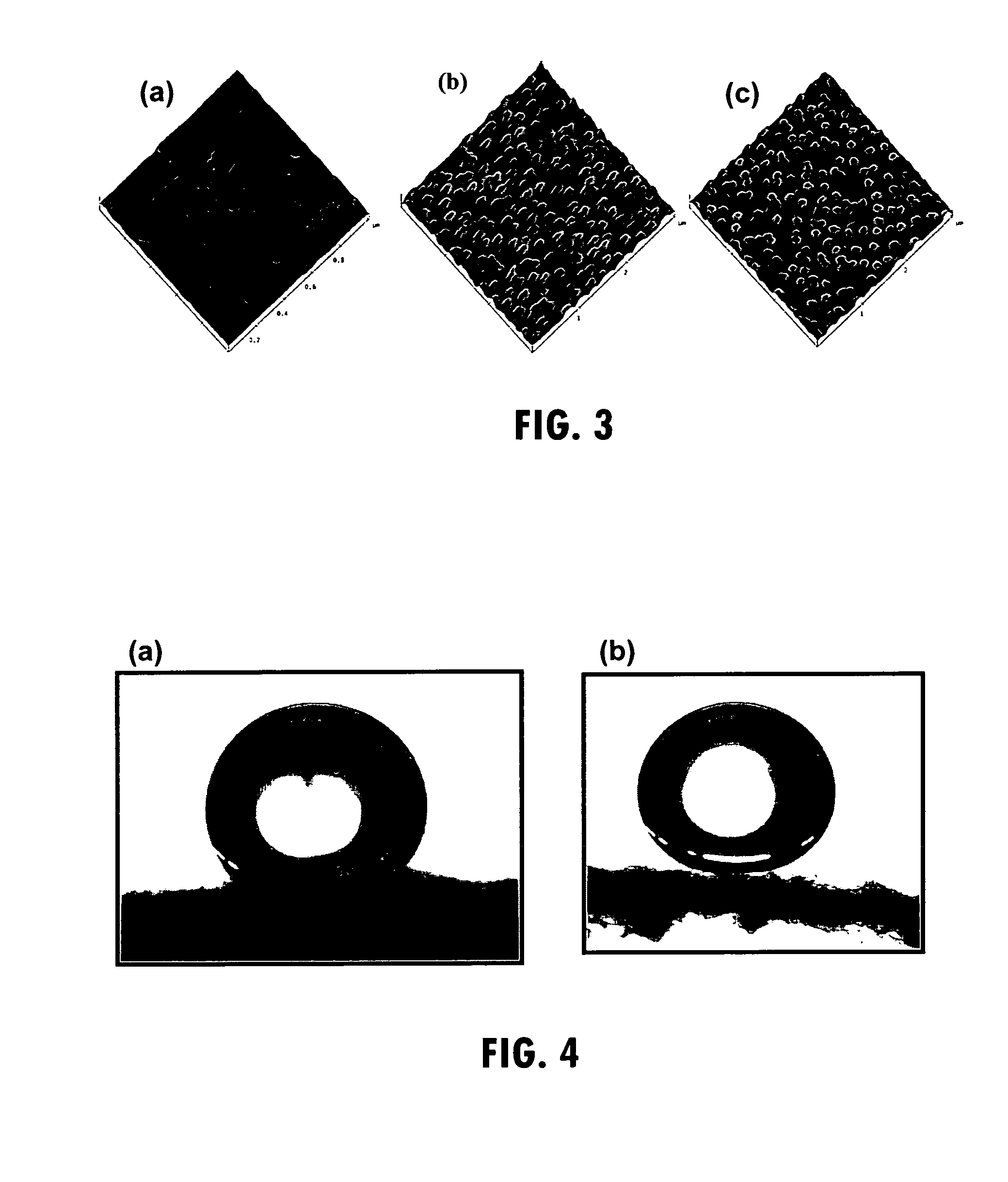

The invention belongs to the field of macromolecule super-amphiphobic materials and discloses a super-amphiphobic polymer and a super-amphiphobic surface. The super-amphiphobic polymer is a random copolymer composed of structural units shown as a formula I and a formula II. The super-amphiphobic surface is obtained by comprising the following steps of: pre-processing a substrate material; placinga micro-balloon in a fluorine-containing solvent, and ultrasonically dissolving to obtain a micro-balloon supernatant solution; adding the super-amphiphobic polymer, a hydrochloric acid tetrahydrofuran solution and water into the micro-balloon solution while stirring, placing the substrate material, and reacting for 5-24 h; and taking out the substrate material, washing by using the fluorine-containing solvent, methanol and water in turn, drying in vacuum, and obtaining the super-amphiphobic surface. The super-amphiphobic polymer disclosed by the invention can give good surface hydrophobic ability and oleophobic ability to the substrate. Because the polymer has the characteristics of the fluorine-containing polymer so that the polymer can be chemically bonded with the surface of the substrate, the obtained super-amphiphobic surface has good scrubbing resistant property and corrosion resistant property.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Ultrahydrophobic substrates

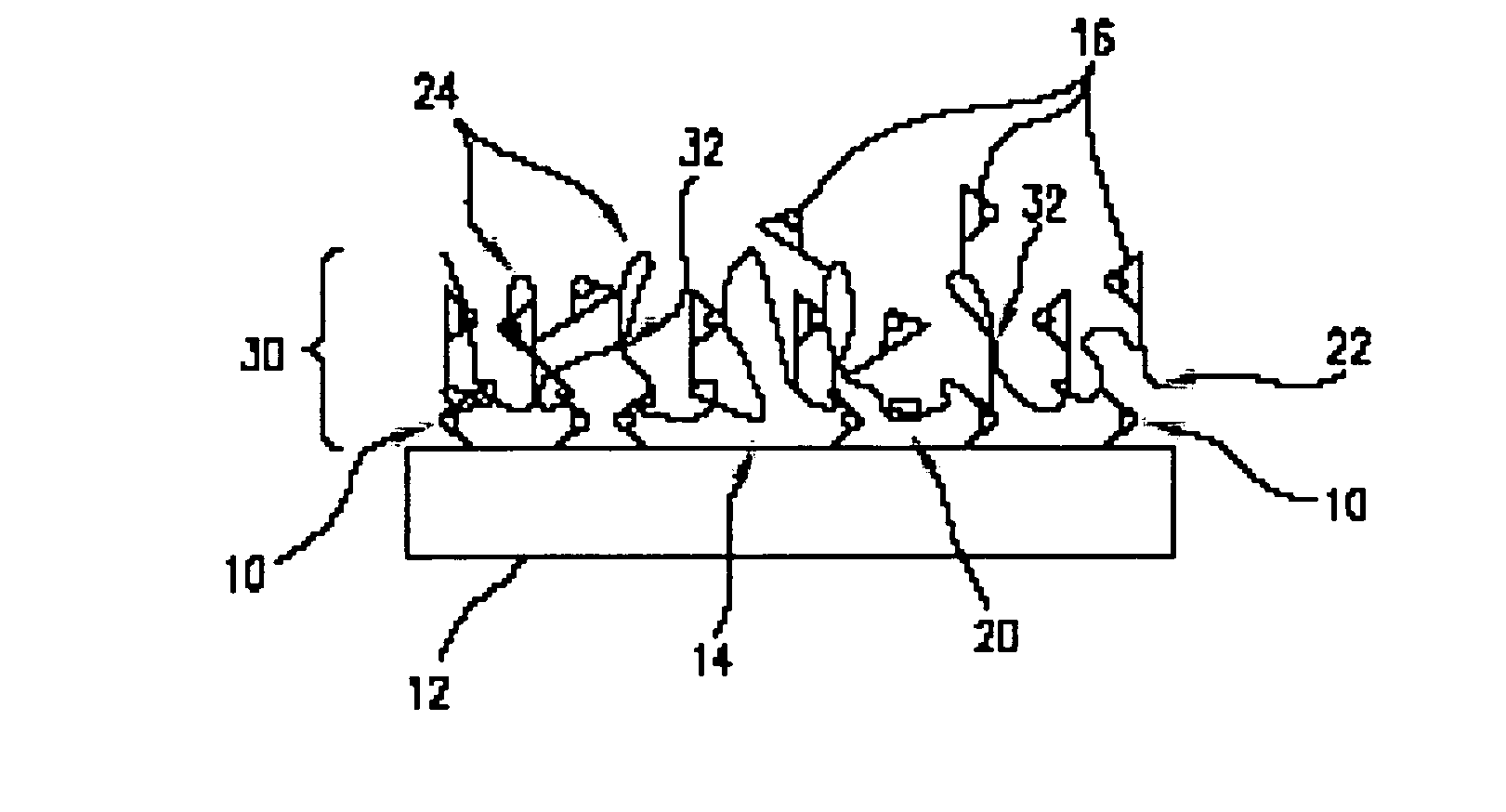

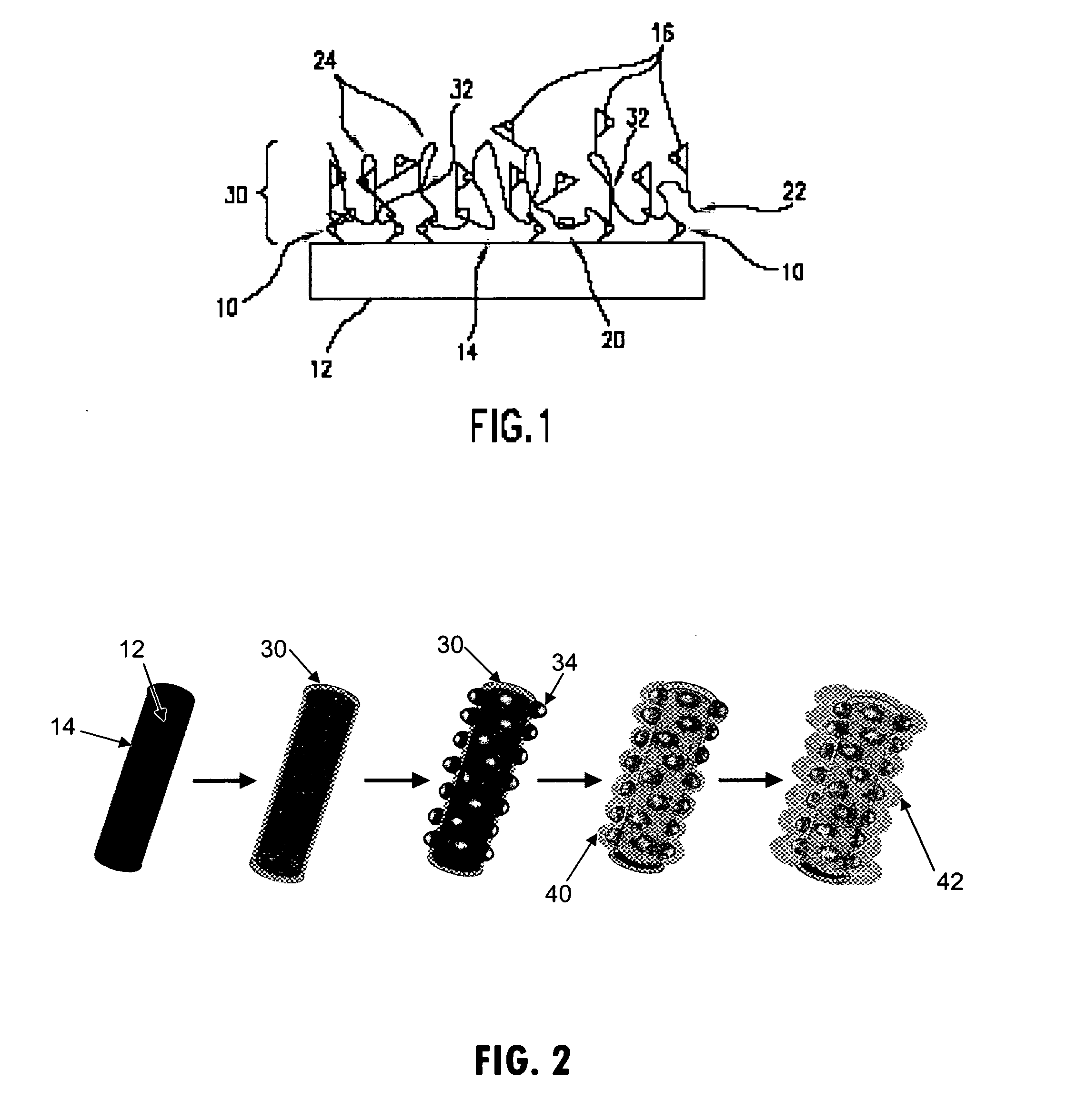

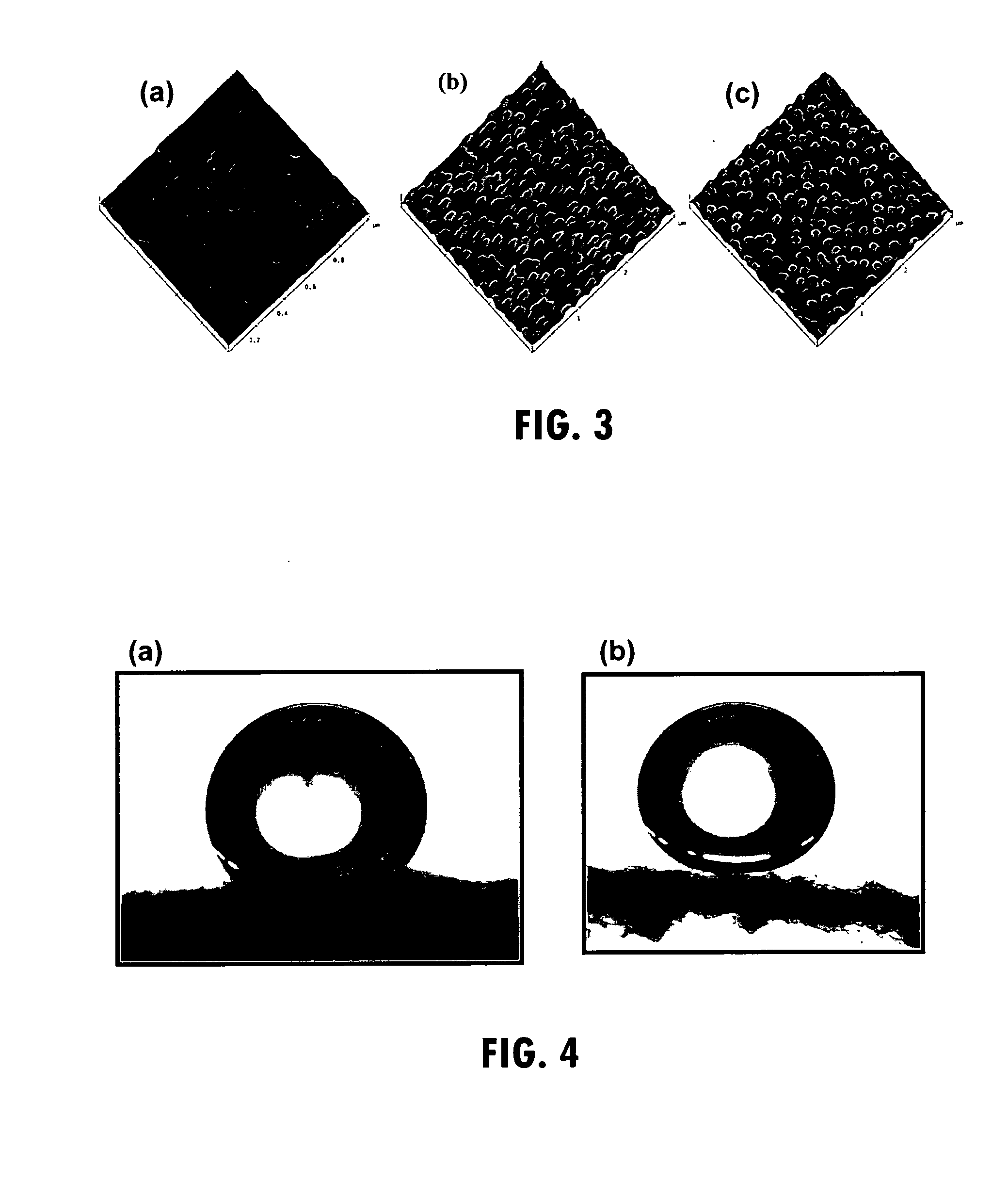

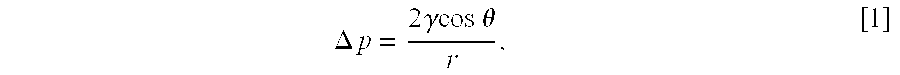

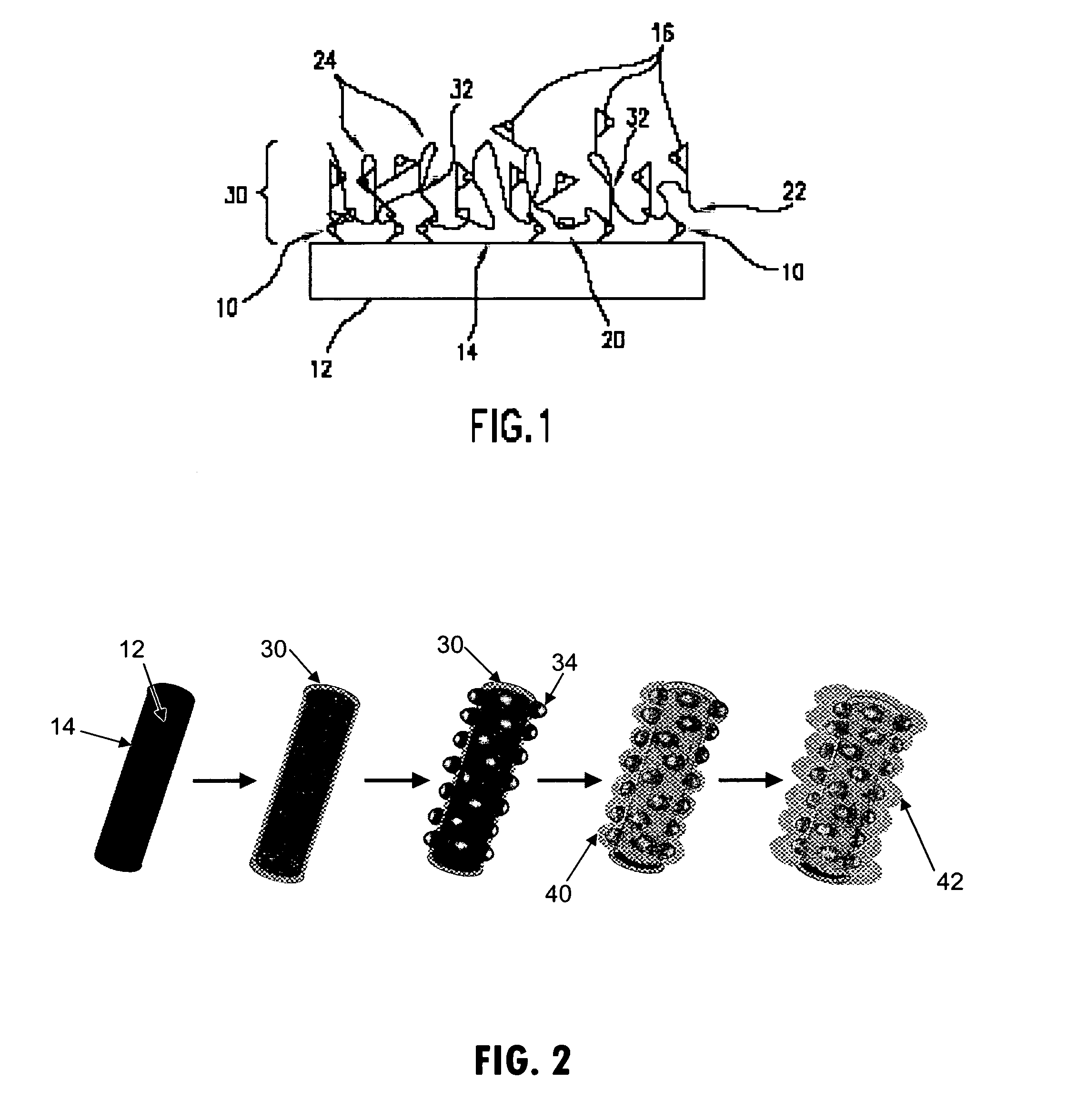

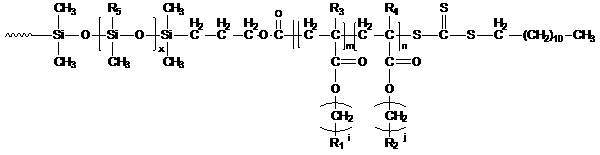

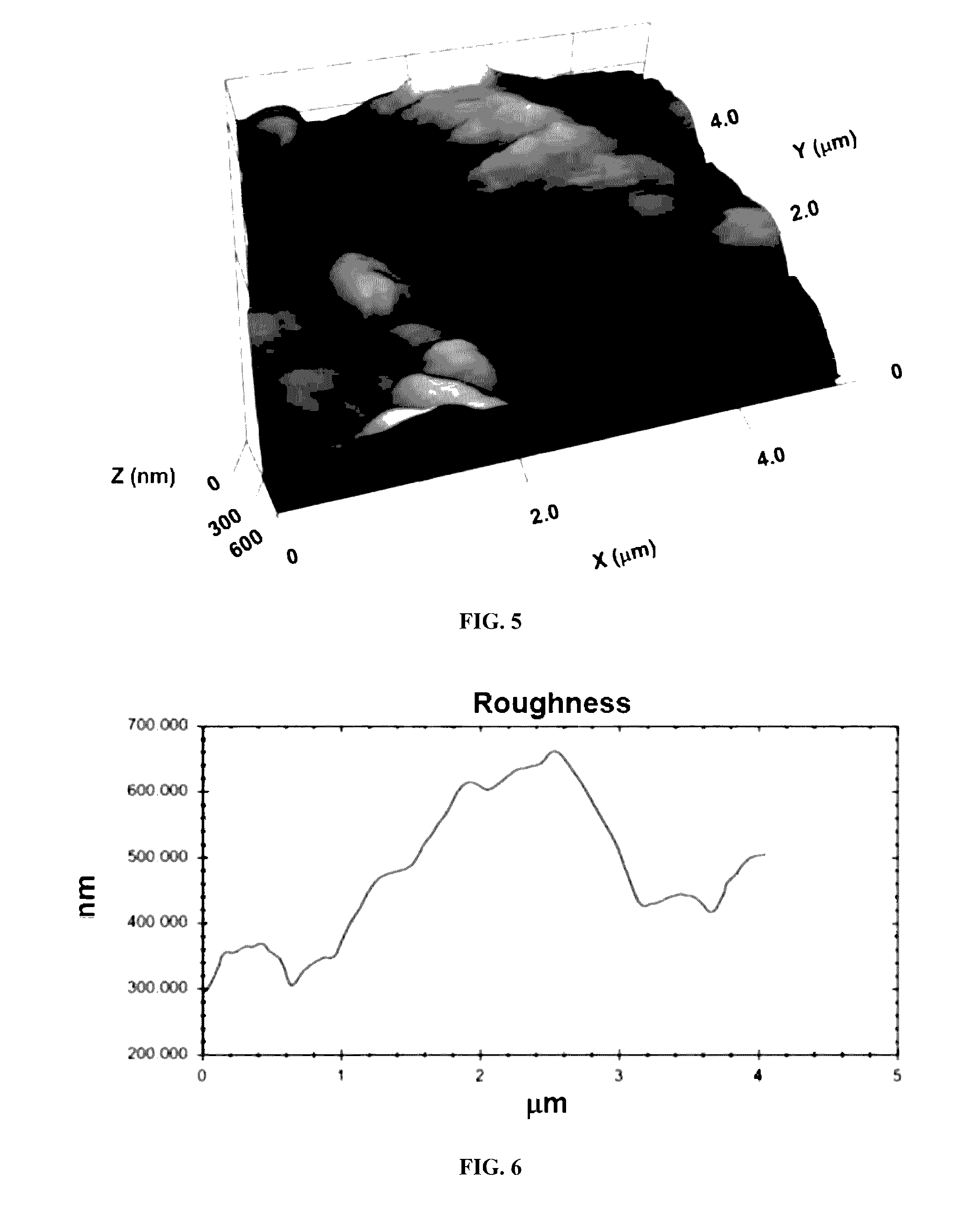

ActiveUS20070026193A1Improve surface roughnessImprove surface hydrophobicityFouling preventionLotus effect fibresSurface roughnessEngineering

Disclosed is a process for modification of a substrate so as to form an ultrahydrophobic surface on the substrate. Also disclosed are surface-modified substrates that can be formed according to the disclosed processes. The process includes attachment of a multitude of nano- and / or submicron-sized structures to a surface to provide increased surface roughness. In addition, the process includes grafting a hydrophobic material to the surface in order to decrease the surface energy and decrease wettability of the surface. The combination of increase surface roughness and decreased surface energy can provide an ultrahydrophobic surface on the treated substrate.

Owner:CLEMSON UNIVERSITY

Preparation method of silicon dioxide super-hydrophobic thin film and super-hydrophobic material

InactiveCN103359954AImprove surface hydrophobicityImprove stabilityOther chemical processesCoatingsAdhesion forcePtru catalyst

The invention provides a preparation method of a silicon dioxide super-hydrophobic thin film. The preparation method comprises the following steps of: step one. preparing alkaline colloidal sol, namely mixing orthosilicate ester, a basic catalyst, a solvent and water to prepare the SiO2 alkaline colloidal sol; step two. adding hexamethyl disilazane to the SiO2 alkaline colloidal sol for reaction to obtain modified SiO colloidal sol; and step three. coating the modified SiO colloidal sol on the surface of a substrate, and drying to obtain the silicon dioxide super-hydrophobic thin film. The invention also provides a super-hydrophobic material. The silicon dioxide super-hydrophobic thin film prepared by the method has strong adhesion force with a substrate and a good dewatering effect; complicated equipment is not needed; the process is simple; the preparation cycle is shortened; the cost is saved; and the application range is wide.

Owner:BYD CO LTD

Powder coating containing aerogel particles and preparing method thereof

InactiveCN101143981AImprove insulation performanceImprove sound insulationPolyurea/polyurethane coatingsPowdery paintsInsulation layerMixed materials

A powder coating containing aerogel particles and a method for preparing the same relates to a powder coating and a preparation method, which solves the problem that the existing heat insulating composite material containing aerogel is not suitable for making thinner heat insulation material and spraying insulation layer on the component surface, and the aqueous coating has high water content, long construction period and low heat insulation property. The coating of the invention is prepared by 5-80 percent of aerogel particles and 20-95 percent of powderedd resin by volume percentage, and the method includes the following steps: firstly, aerogel, resin and additive are mixed by volume percentage; secondly, the mixed materials are delivered into a melting-extruder melt and extrude; thirdly, the extrudate is pressed into thin sections; fourthly, the thin sections are ground into small pieces by roller machine; fifthly, the small pieces are conveyed into an air staged milling equipment to grind, so as to obtain the powder coating. The powder coating containing aerogel of the invention has advantages of environmental protection, clearness, economy, high efficiency, and good heat insulation property, sound insulation property and surface hydrophobicity.

Owner:HARBIN INST OF TECH

Methods of using natural products as dewatering aids for fine particles

InactiveUS6526675B1Reduce moistureImprove hydrophobicityPigmenting treatmentDrying using combination processesLipid formationSlurry

A method of dewatering fine particulate materials is disclosed. In this method, an aqueous slurry of fine particles is treated with appropriate hydrophobizing reagents so that the particulate material becomes moderately hydrophobic. A lipid of vegetable or animal origin is then added to the slurry in solutions of light hydrocarbon oils and short-chain alcohols, so that the hydrophobic lipid molecules adsorb on the moderately hydrophobic surface and, thereby, greatly enhance its hydrophobicity. By virtue of the enhanced hydrophobicty, the water molecules adhering to the surface are destabilized and more readily removed during the process of mechanical dewatering. The moisture reduction can be further improved using appropriate electrolytes in conjunction with the lipids, spraying surface tension lowering reagents onto the filter cake, subjecting the cake to a suitable vibratory means, and using combinations thereof.

Owner:YOON ROE HOAN

Method of manufacturing ultrahydrophobic substrates

ActiveUS7985451B2Improve surface roughnessImprove surface hydrophobicityFouling preventionLotus effect fibresSurface roughnessMaterials science

A process for modification of a substrate so as to form an ultrahydrophobic surface on the substrate is provided. Surface-modified substrates that can be formed according to the disclosed processes are also provided. The process includes attachment of a multitude of nano- and / or submicron-sized structures to a surface to provide increased surface roughness. In addition, the process includes grafting a hydrophobic material to the surface in order to decrease the surface energy and decrease wettability of the surface. The combination of increased surface roughness and decreased surface energy can provide an ultrahydrophobic surface on the treated substrate.

Owner:CLEMSON UNIVERSITY

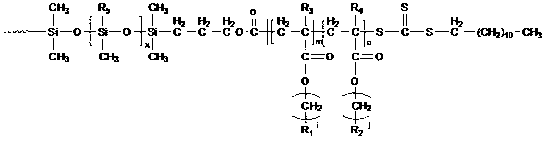

POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and preparation method thereof

InactiveCN102775567AMild surface energyLower surface energyAntifouling/underwater paintsPaints with biocidesPolymer scienceCopolymer

The invention discloses a POSS (polyhedral oligomeric silsesquioxane) contained polyacrylate-polysiloxane block copolymer and a preparation method thereof. The preparation method includes subjecting hydrogen-terminated polysiloxane and vinylcarbinol to reaction to obtain hydroxy-terminated polysiloxane; subjecting the hydroxy-terminated polysiloxane and carboxyl thiocarbonic acid ester to reaction to obtain polysiloxane macromolecular RAFT (reversible addition-fragmentation chain transfer polymerization) reagent; polymerizing the polysiloxane macromolecular RAFT reagent, acrylate monomer and POSS monomer with initiator to prepare the POSS contained polyacrylate-polysiloxane block copolymer. The method has the advantages of simple operation and mild reaction conditions, reaction products have better surface performance and bonding performance with substrates, and further, the reaction products can be used in low-surface-energy lyophobic coating materials and used for preparing ice and snow preventive and antifouling coatings.

Owner:TIANJIN UNIV

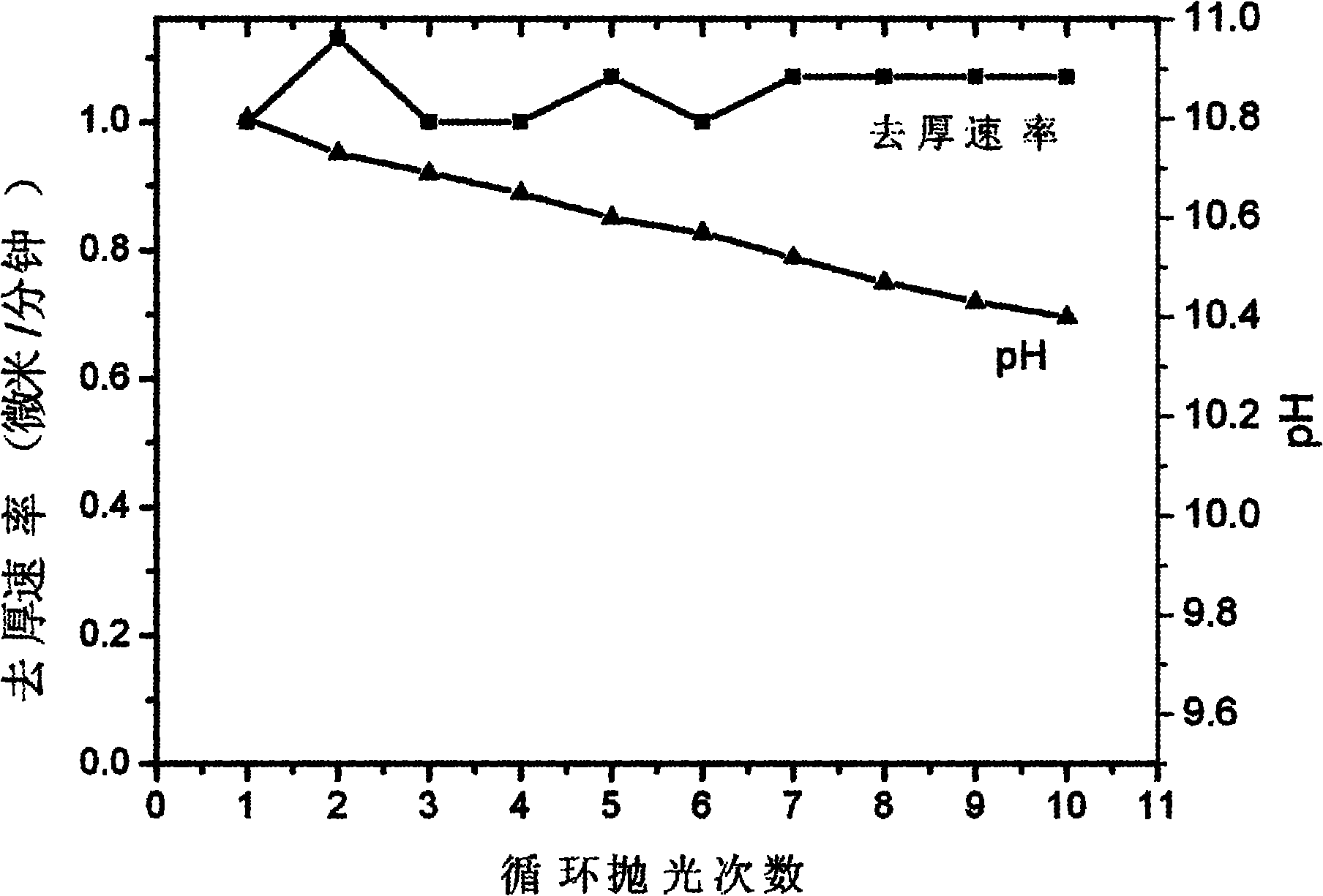

Silicon wafer chemical and mechanical polishing composition with high stability

InactiveCN102093820AWide applicabilityPracticalOther chemical processesPolishing compositions with abrasivesOrganic acidCompound (substance)

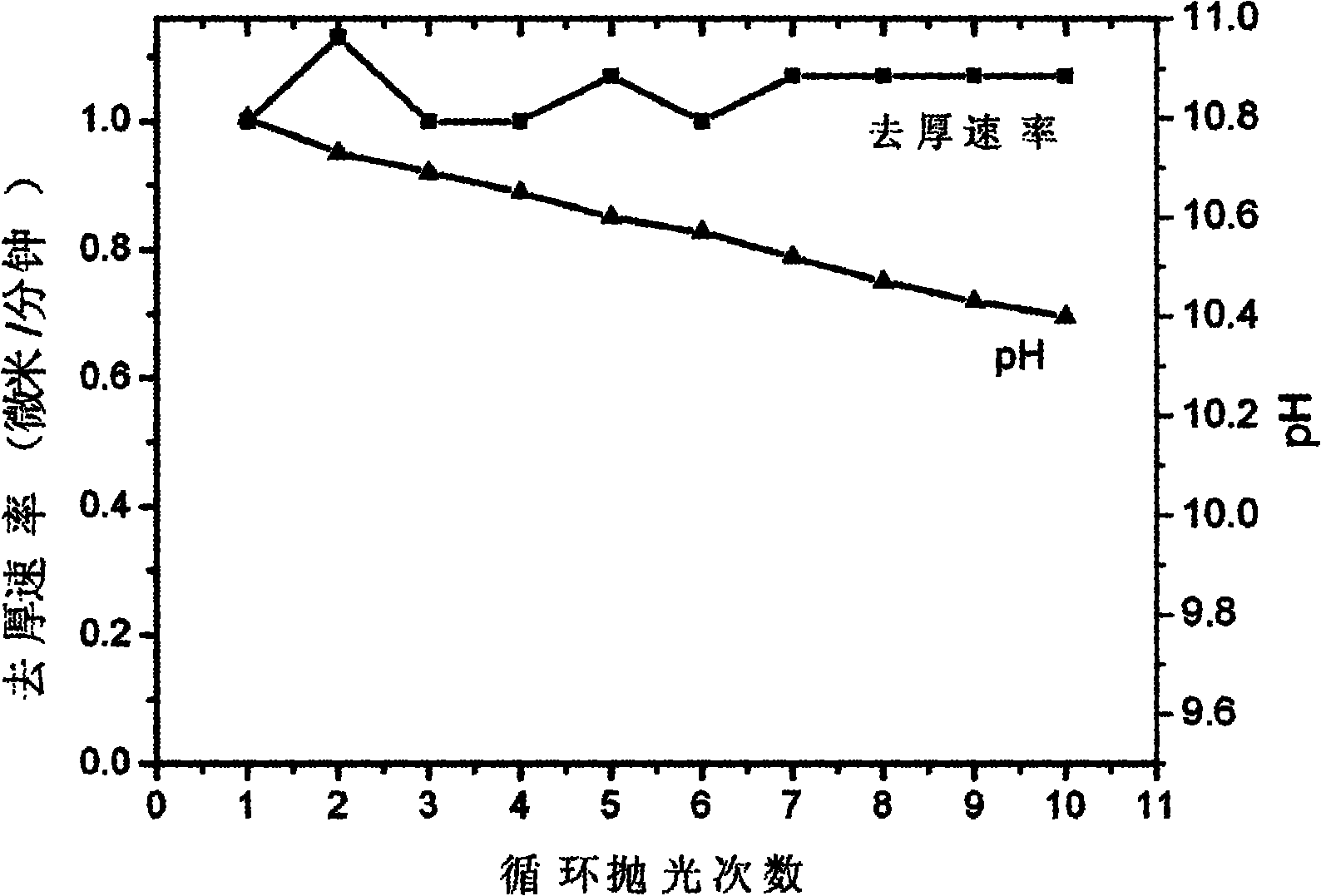

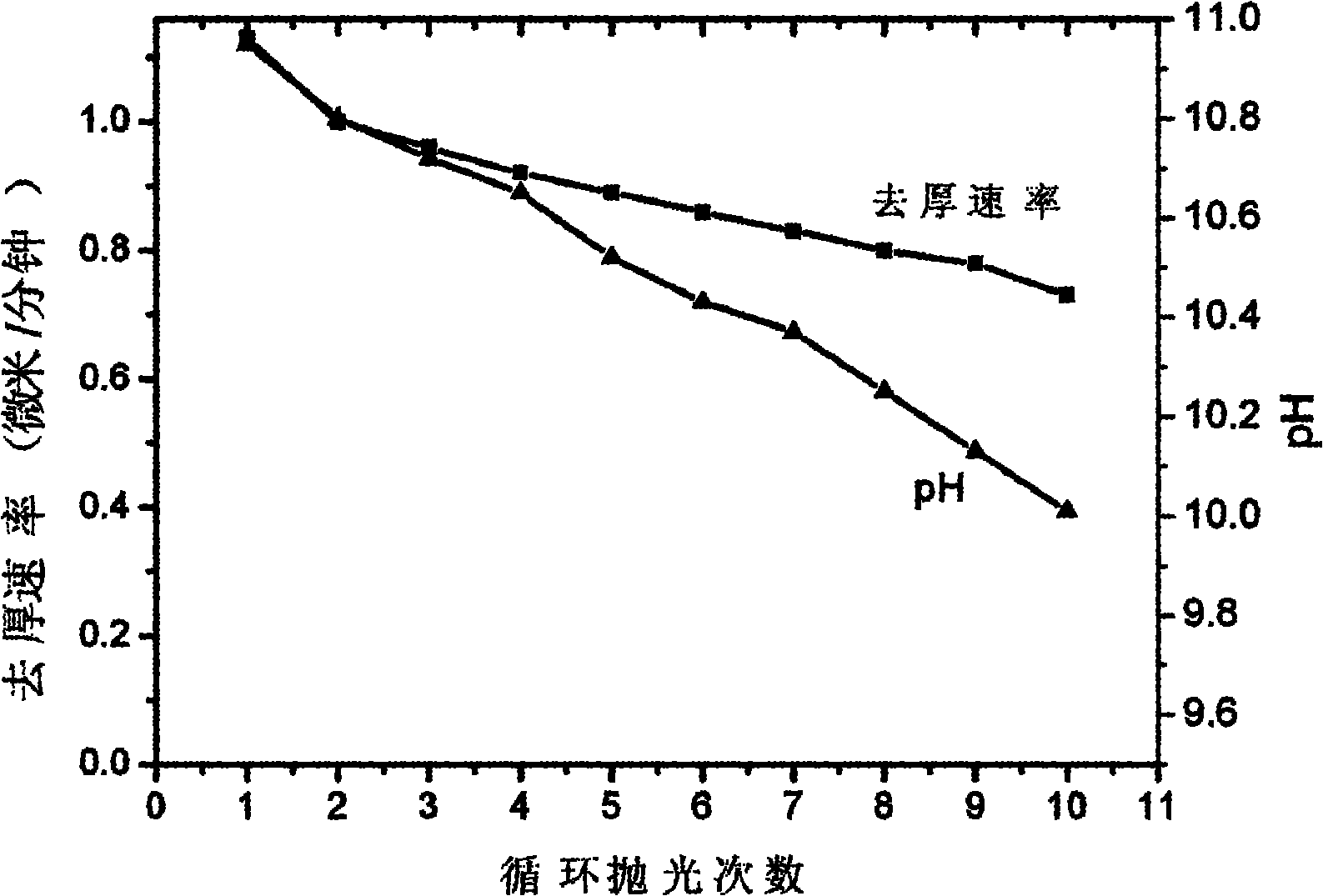

The invention discloses a silicon wafer chemical and mechanical polishing composition with high stability, belonging to the technical field of polishing compositions for roughlly polishing a semiconductor silicon substrate material. The polishing composition comprises the following components in percentage by weight: 0.5-50 percent of silicon dioxide abrasive particles, 0.01-10 percent of silicon-containing stabilizer, 0.01-20 percent of organic alkali corrosive, 0.01 -10 percent of organic acid chelating agent, 0.01-5.0 percent of other functional auxiliaries and the balance of deionized water. The polishing solution has a stabilization period of over 2 years, can perform repeated polishing or cyclic polishing, and has stable pH value and removal speed, wherein the number of cyclic polishing times can be up to 10. Meanwhile, the polishing composition has high silicon wafer removal rate up to over 1.0 mum / min, and the cyclic polishing removal rate in multiple times can be stable. The polishing solution is convenient to prepare and easy to use, has low cost, and is suitable for the rough polishing of silicon wafers of various types and sizes in the semiconductor industry.

Owner:TSINGHUA UNIV +2

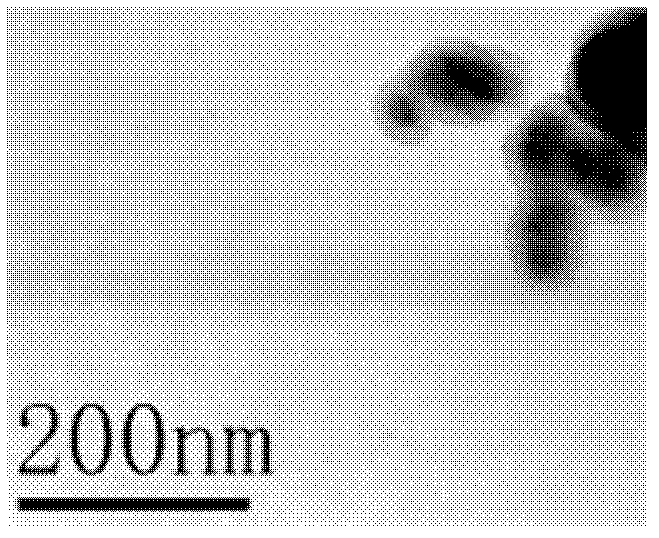

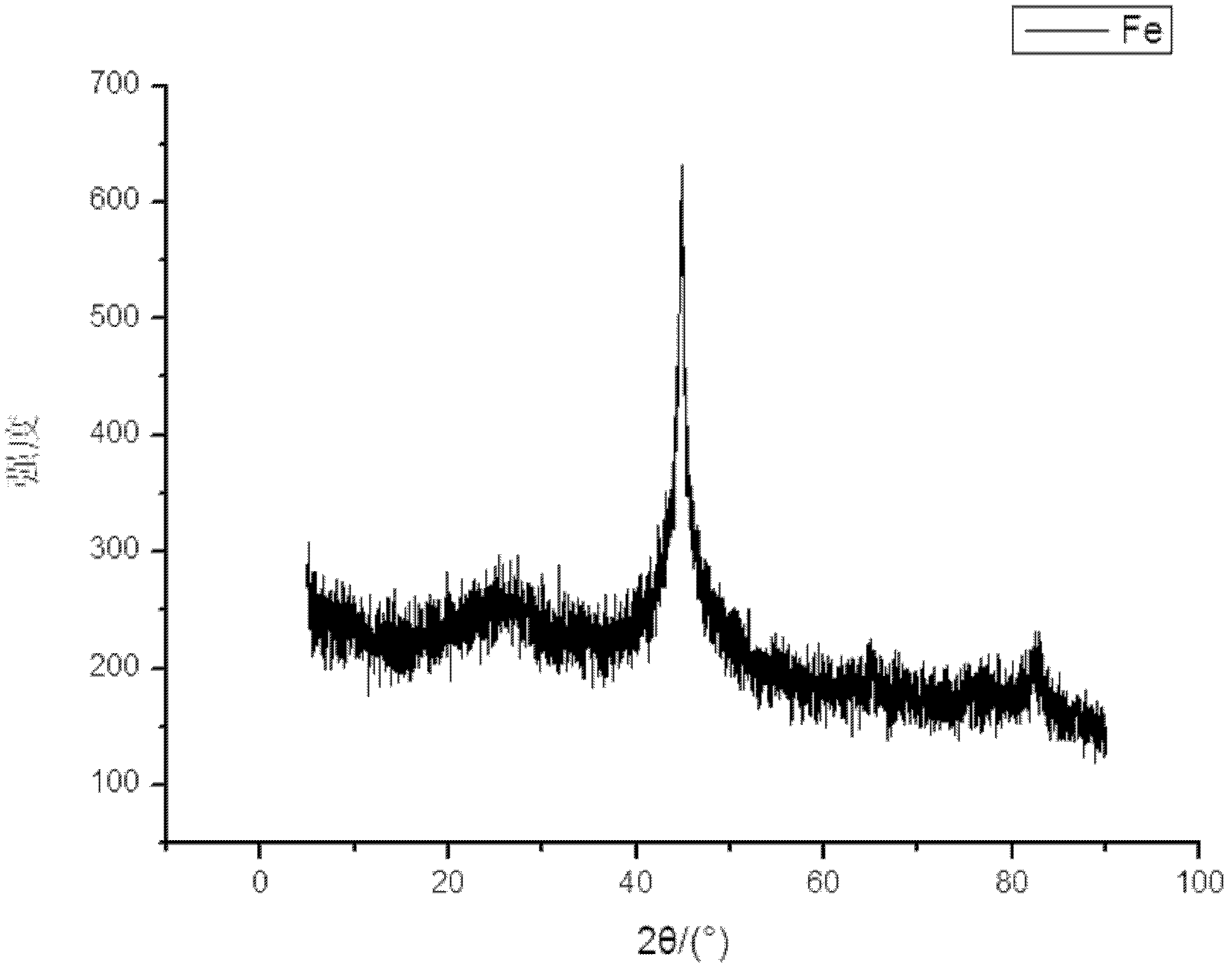

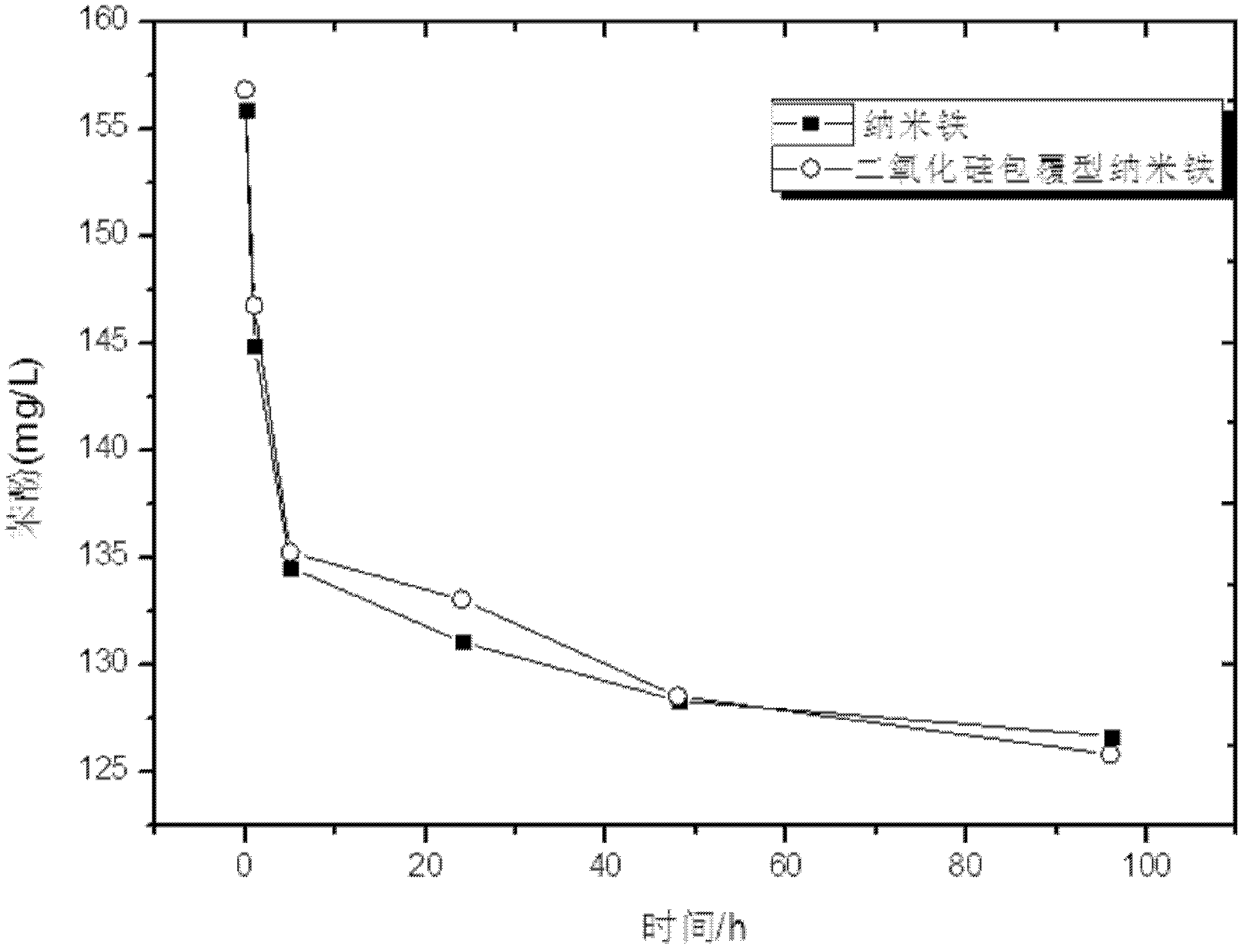

A kind of nano zero-valent iron stable in air and preparation method thereof

InactiveCN102284706AImprove surface hydrophobicityLow priceMaterial nanotechnologyPolyethylene glycolNitrogen gas

The invention discloses nanoscale zero-valent iron stable in air, wherein nanoscale zero-valent iron is taken as a core, and silicon dioxide is covered on the surface thereof. The preparation method comprises the following steps of: (1) adding isopropanol aqueous solution in ferrous sulphate, charging nitrogen, mechanically stirring for 15 to 30 minutes, dropping sodium borohydride solution containing sodium hydroxide while stirring, after that, adding polyethylene glycol, and continuing to react for 0.5 to 1 hours while stirring; (2) adding tetraethoxysilane in the solution, controlling the molar ratio of the sodium hydroxide to the sodium borohydride in the solution to be in a certain range, continuously stirring, and continuously charging nitrogen, after the reaction is finished, staying, vacuum-filtrating, then washing by absolute ethyl alcohol and deionized water respectively; and (3) vacuum-drying the obtained nano-iron to obtain the stable nanoscale zero-valent iron. The nanoscale zero-valent iron has a good inoxidizability in air; and the whole reaction process has the advantages of low material price, simple device, convenient operation, and easily-controlled and safe process condition.

Owner:SOUTH CHINA UNIV OF TECH

Carbon-based solid acid catalyst and preparation method thereof

InactiveCN102078823AGood dispersionHigh activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDistillationSolid acid

The invention provides a carbon-based solid acid catalyst and a preparation method thereof. The method comprises the following steps of: 1) putting a metal oxide into organic matter aqueous solution for soaking, drying by distillation and carbonizing so as to obtain a carbon / oxide compound; 2) performing a sulfonation reaction on the carbon / oxide compound so as to obtain a sulfonated carbon / oxidecompound; and 3) reacting the sulfonated carbon / oxide compound with acid or alkali so as to obtain the carbon-based solid acid catalyst. The carbon-based solid acid catalyst prepared by the method has high dispersibility and hydrophobicity in a liquid phase reaction system and high catalytic activity in an esterification reaction of oleic acid and methanol.

Owner:PEKING UNIV

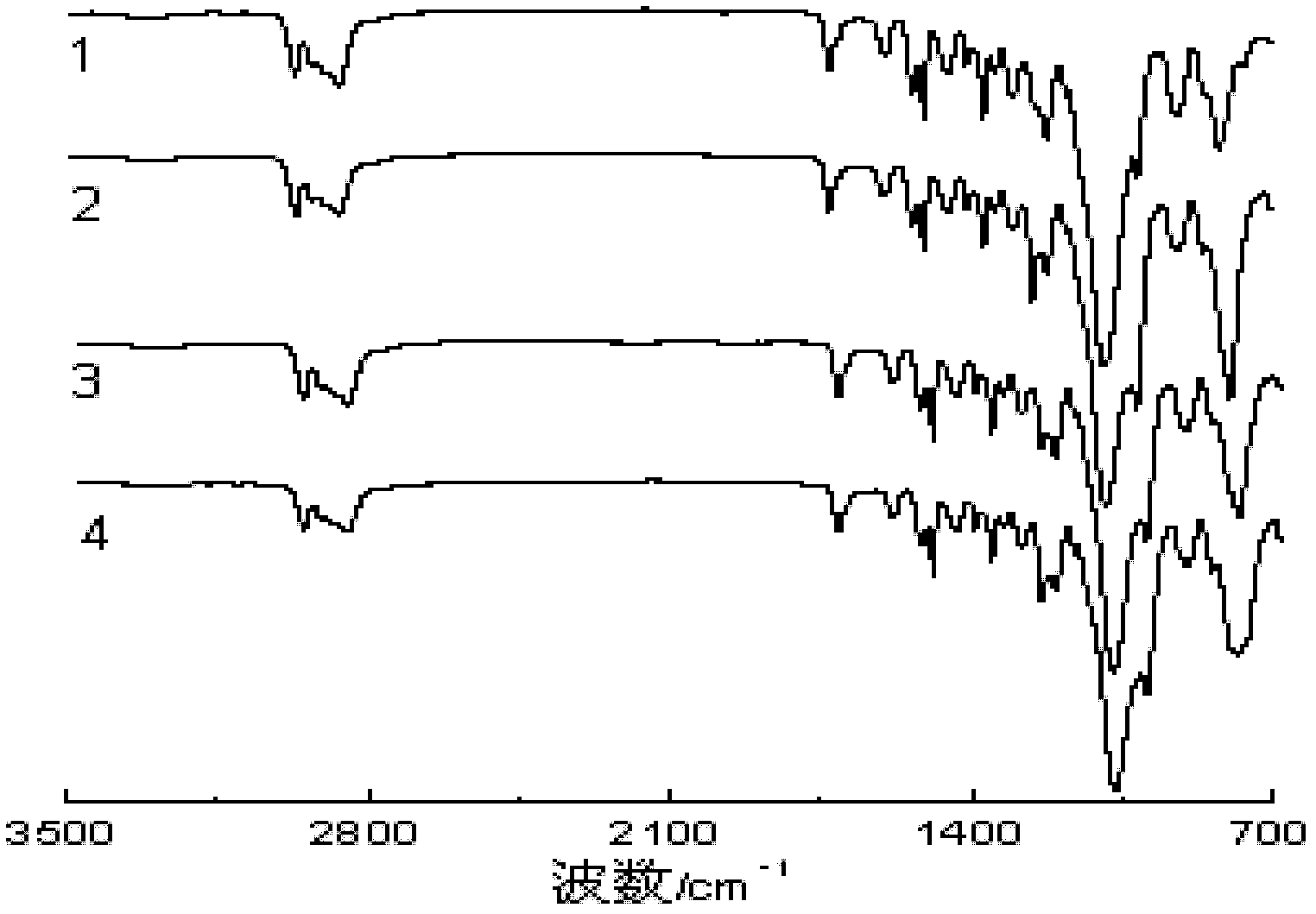

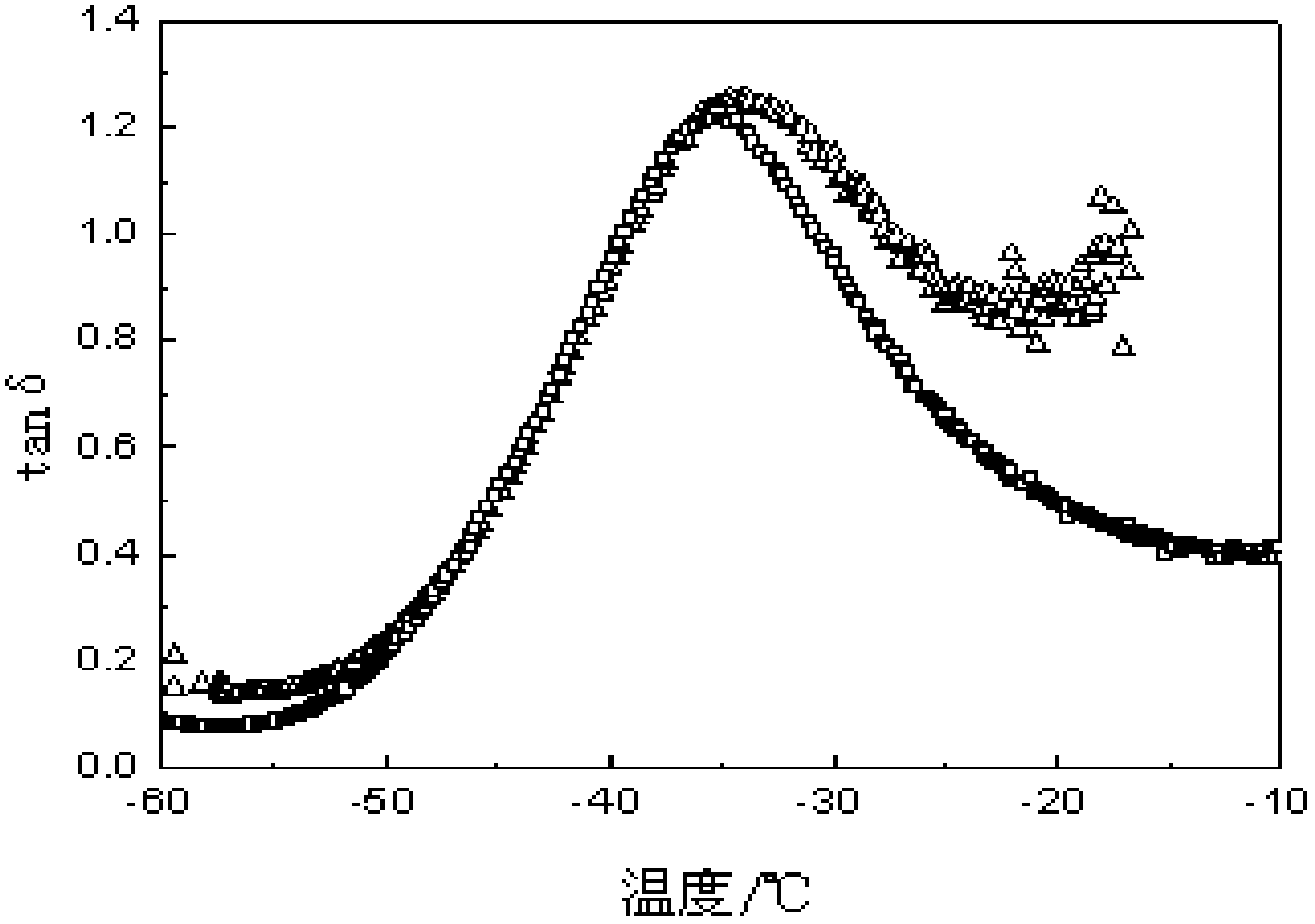

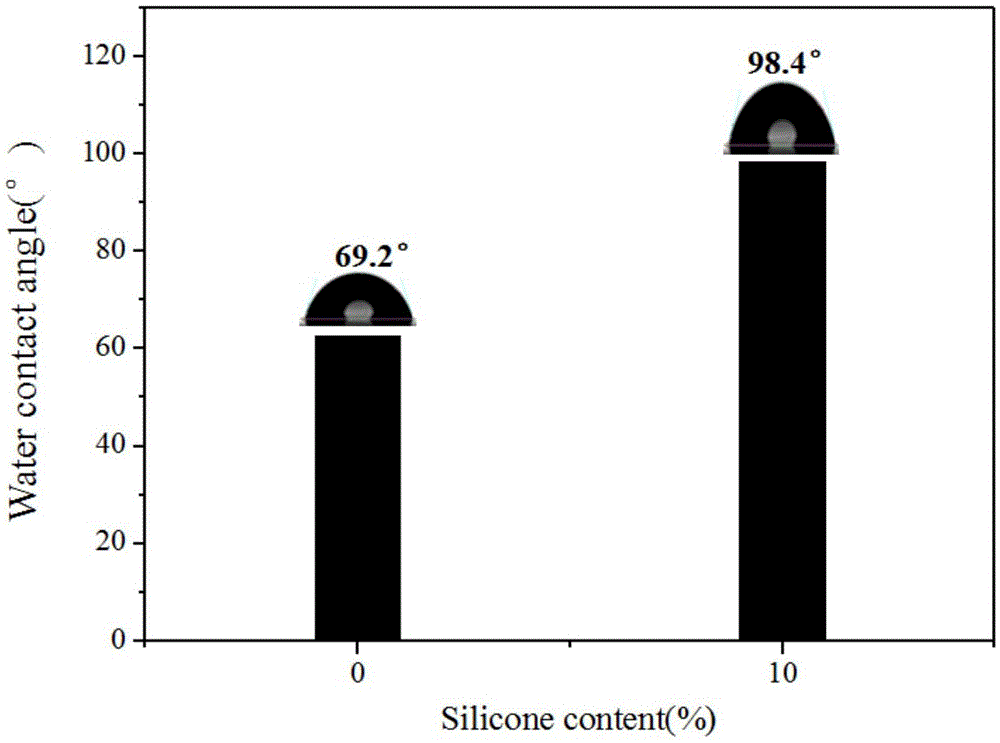

Polysiloxane modified polyurethane-epoxy resin polymer material, preparation method thereof and use thereof

The invention relates to a polysiloxane modified polyurethane-epoxy resin polymer material, a preparation method thereof and a use thereof. The preparation method comprises the following steps: 1, drying raw materials of a polyether, a bisphenol A type epoxy resin and a hydroxyl-terminated polysiloxane until water mass percentages of below 0.01%; 2, adding the polyester, the bisphenol A type epoxy resin and diisocyanate to a reaction vessel to generate a polyurethane-epoxy resin polymer system; 3, adding the hydroxyl-terminated polysiloxane to the polyurethane-epoxy resin polymer system, and reacting to generate a polysiloxane-polyurethane-epoxy resin prepolymer system; and 4, adding a curing agent and a catalyst before ending the reaction, uniformly stirring, dumping the obtained system to a die, and cure-molding. The polysiloxane modified polyurethane-epoxy resin polymer material has the advantage of the complementation of polyurethane-epoxy resin performances and also has the hydrophobic characteristic of the polysiloxane, so comprehensive properties of materials prepared from the polysiloxane modified polyurethane-epoxy resin polymer system are improved, thereby the polysiloxane modified polyurethane-epoxy resin polymer material is mainly applied to high damping materials, waterproof electronic packaging materials, medical materials, long-term storage materials and the like.

Owner:溧阳常大技术转移中心有限公司

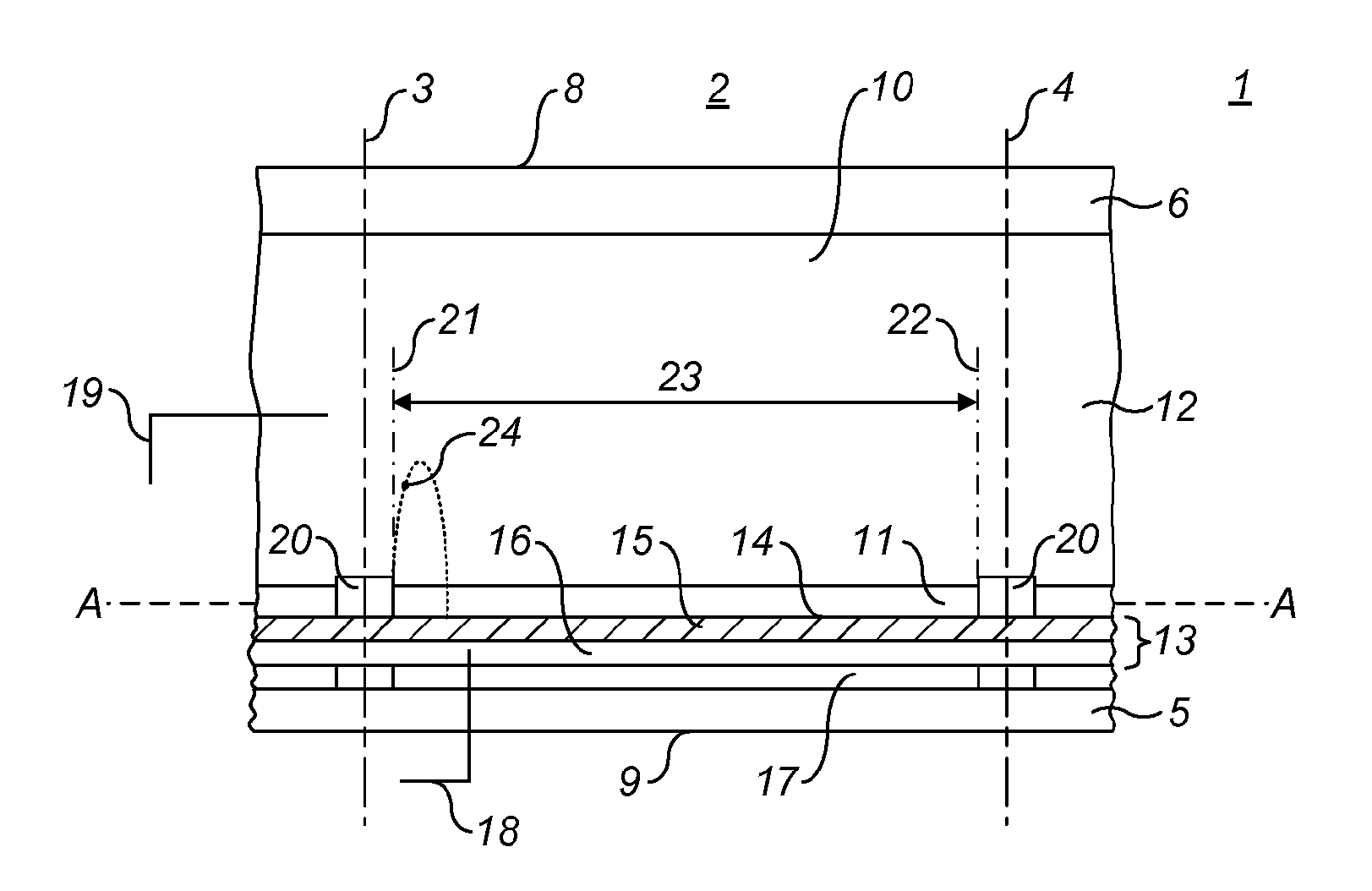

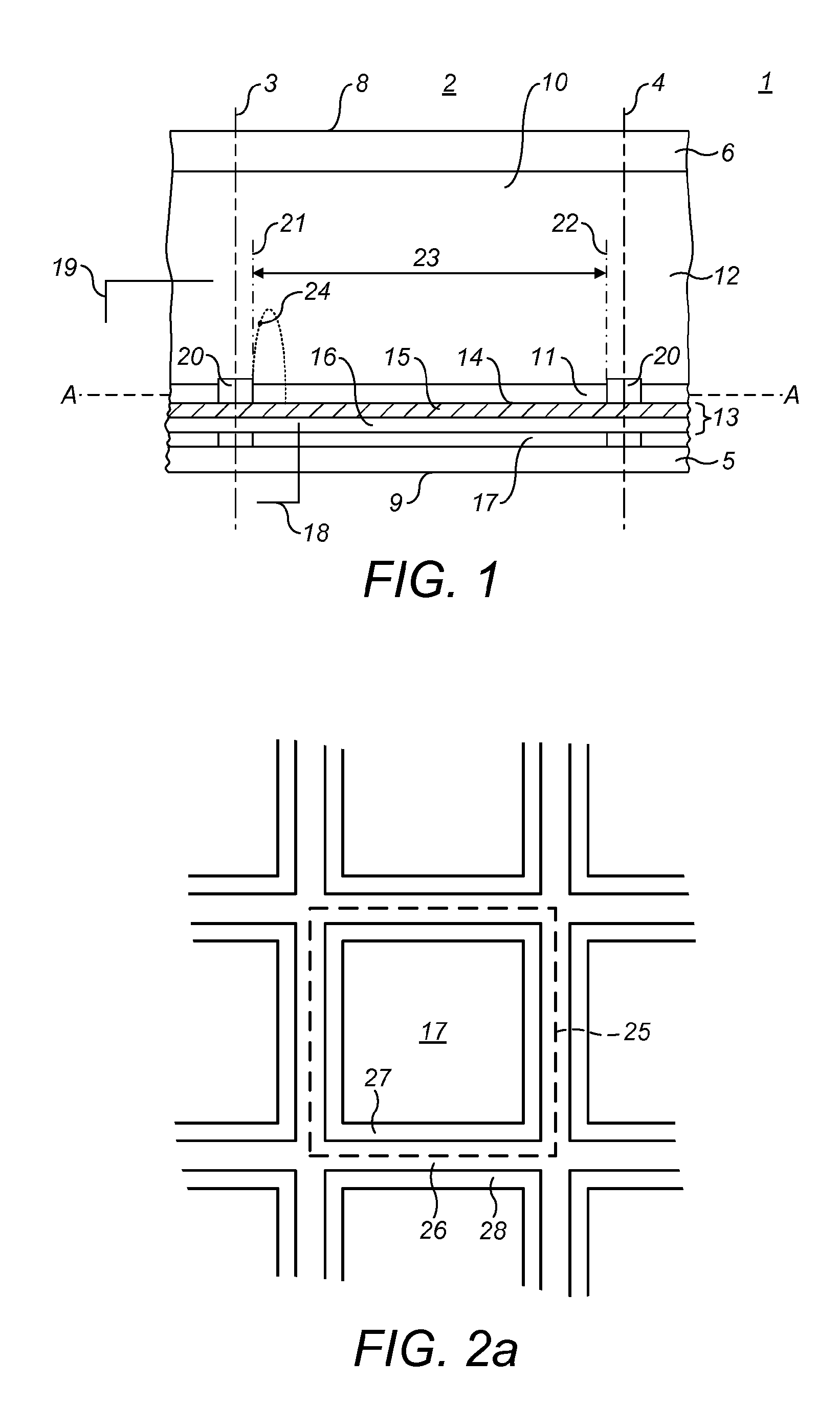

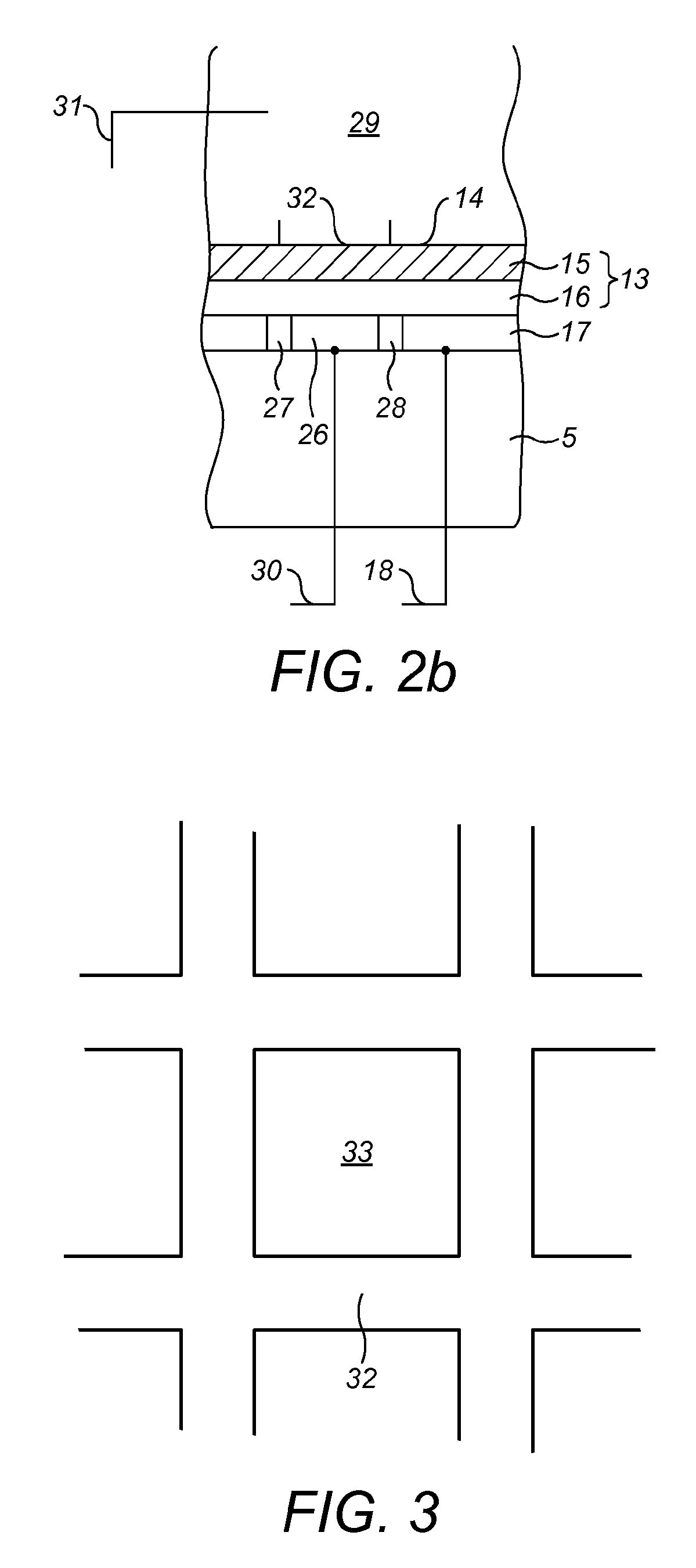

Electrowetting display device

InactiveUS20130010348A1Reduce hydrophobicityAffects longevityLine/current collector detailsOptical elementsDisplay deviceEngineering

The present invention relates to a method for making an electrowetting display device comprising a plurality of picture elements and a first support plate and a second support plate. Each picture element comprises a space between the first support plate and the second support plate. The method comprises the steps of: providing the first support plate with an electrode structure; arranging an insulating layer on the electrode structure, the insulating layer having a thickness and a hydropobic surface facing the space; temporarily applying an electric field across the thickness of the insulating layer to reduce permanently the hydrophobicity of a predetermined area of the surface. The invention further relates to an electrowetting display device and a use of an area of reduced hydrophobicity in an electrowetting device.

Owner:LIQUAVISTA BV

Light-weight foamed magnesia wall slab

InactiveCN1396140ASolve the technical problems applied to the wallImprove surface hydrophobicityCeramicwarePolymer scienceFoaming agent

A light-weight foamed wall slab is prepared from magnesium oxide (1070 wt. portions), magnesium chluride (60-70), water (20-50), stabilizer (5-26), short fibres (2-15), modifier (1.65-9), foaming agent (0.8-8), and water-resisting agent (0.15-1) through mixing while stirring, foaming and solidifying. Its advantages are high effect, low cost of modifier, light dead weight, high strength, and low cost.

Owner:龚德馨 +2

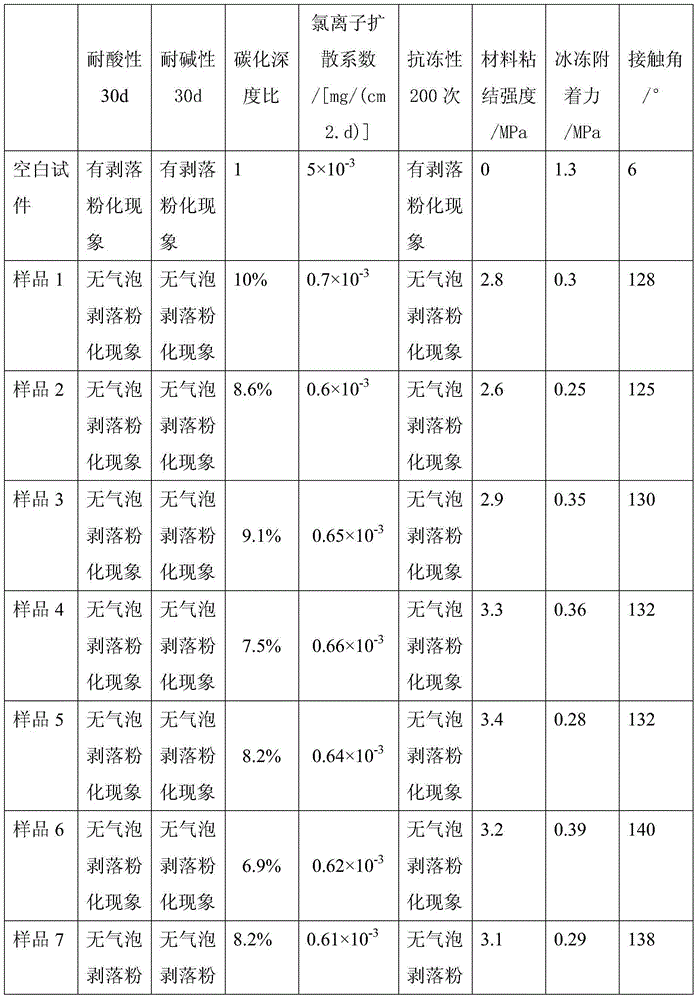

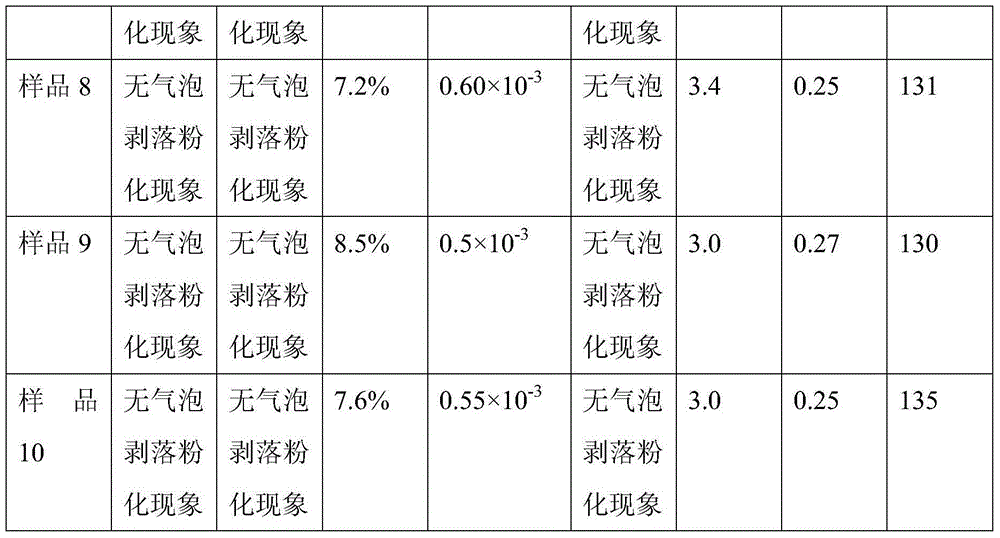

High-weather-proof and anti-icing polysiloxane material for concrete and preparation method of high-weather-proof and anti-icing polysiloxane material

ActiveCN104559770ALower surface energyImprove surface hydrophobicityOther chemical processesCoatingsEpoxySilsesquioxane

The invention provides a high-weather-proof and anti-icing polysiloxane material for concrete. The high-weather-proof and anti-icing polysiloxane material comprises the following components in parts by weight: 20-70 parts of amino-modified polyether polysiloxane, 10-30 parts of epoxy-modified polysiloxane, 10-20 parts of poly(methylphenylsilsesquioxane), 5-10 parts of poly(propylmethylsilsesquioxane) and 5-10 parts of alkoxy silane. The polysiloxane material can be used for effectively reducing the surface energy of the concrete and improving the surface hydrophobicity as well as anti-corrosion and anti-icing performances of the concrete, has excellent anti-corrosion and anti-icing capacities and can be applied to the protection of the concrete under the water work, maritime work and low-temperature climates.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

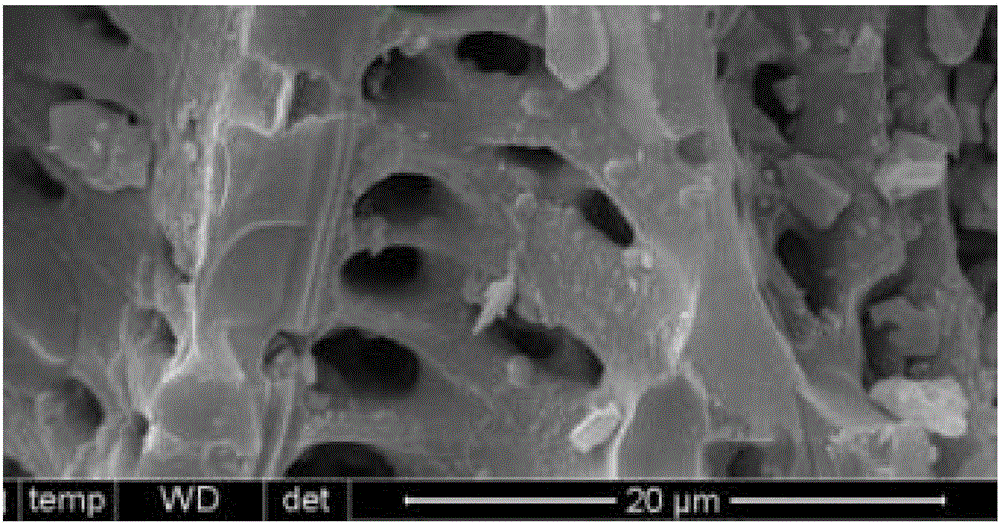

Preparation method and application of biochar-based carrier modified through high-temperature alkalization

InactiveCN107523561AOptimized for controlled etchAchieve controlled etchOn/in inorganic carrierEtchingMicrobial agent

The invention belongs to the technical field of environmental remediation and the field of microbial immobilization and particularly relates to a preparation method and an application of a biochar-based carrier modified through high-temperature alkalization. The preparation method is characterized in that by means of the steps of drying and smashing of biomass materials, pyrolysis, cooling, acidification and alkalization as well as controlled etching processing for pore channels in biochar, the pore channel structure in the biochar is beneficial to microbial growth and metabolism, and the biochar whose surface is modified with a high-temperature alkaline solution is used for preparing a carbon-based immobilized microbial agent. According to the preparation method, the biochar is prepared from the biomass materials such as straw and corncob, the pore diameter and length of gaps in the prepared biochar-based carrier are controlled precisely through controlled etching of the pore channels in the biochar, so that the pore channel structure in the biochar is beneficial to microbial growth and metabolism, finally, the biochar subjected to surface modification can be used for preparing the carbon-based immobilized microbial agent, and the biochar-based carrier is used for remediating petroleum hydrocarbon contaminated soil and treating agricultural waste.

Owner:CHINA NAT PETROLEUM CORP SAFETY & ENVIRONMENTAL TECH RES INST CO LTD

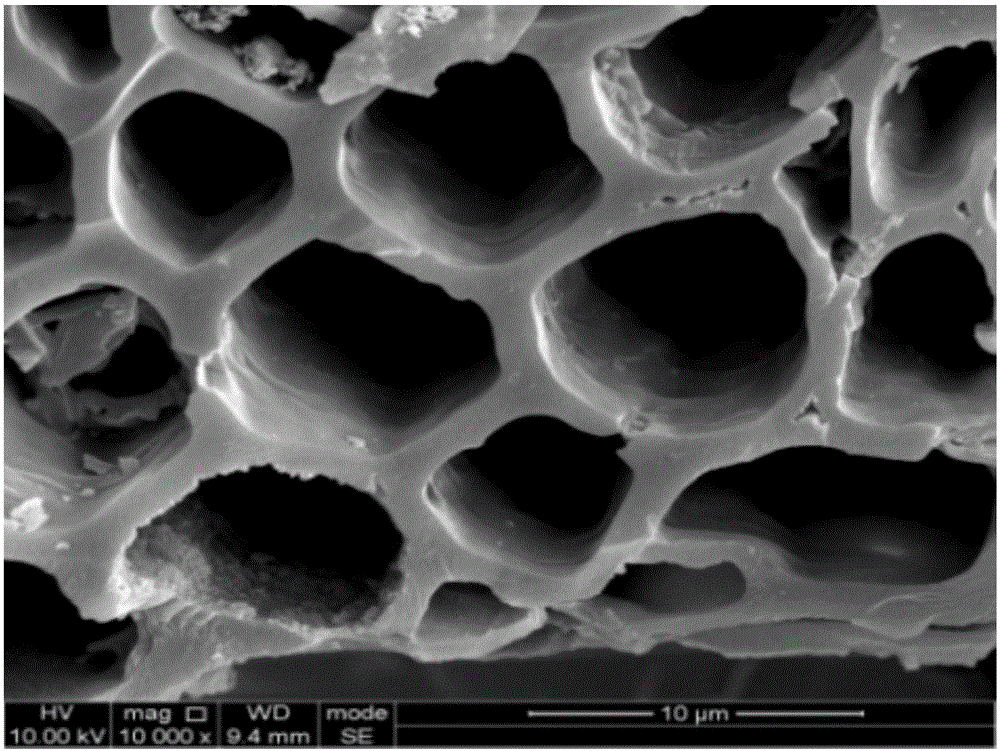

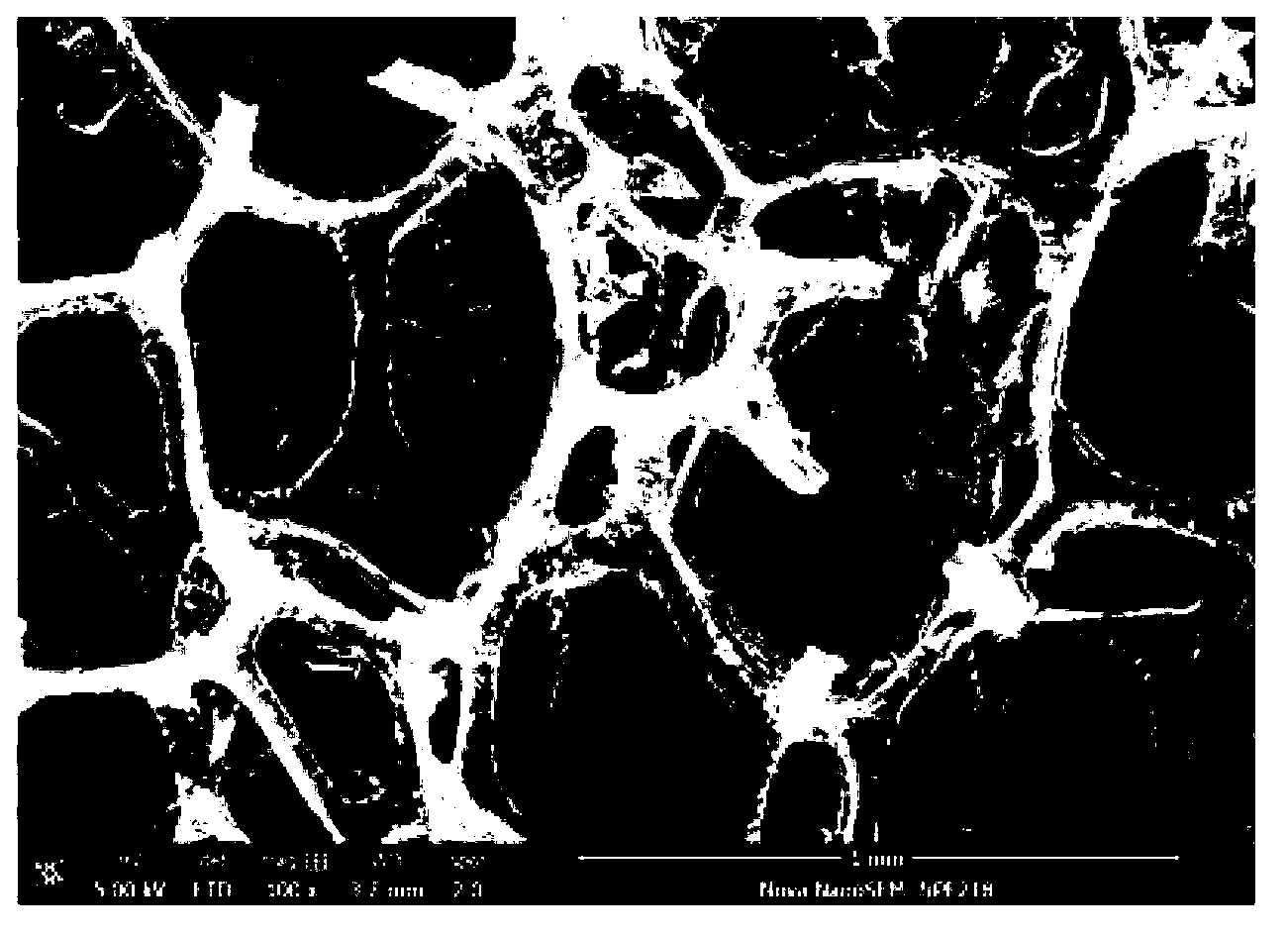

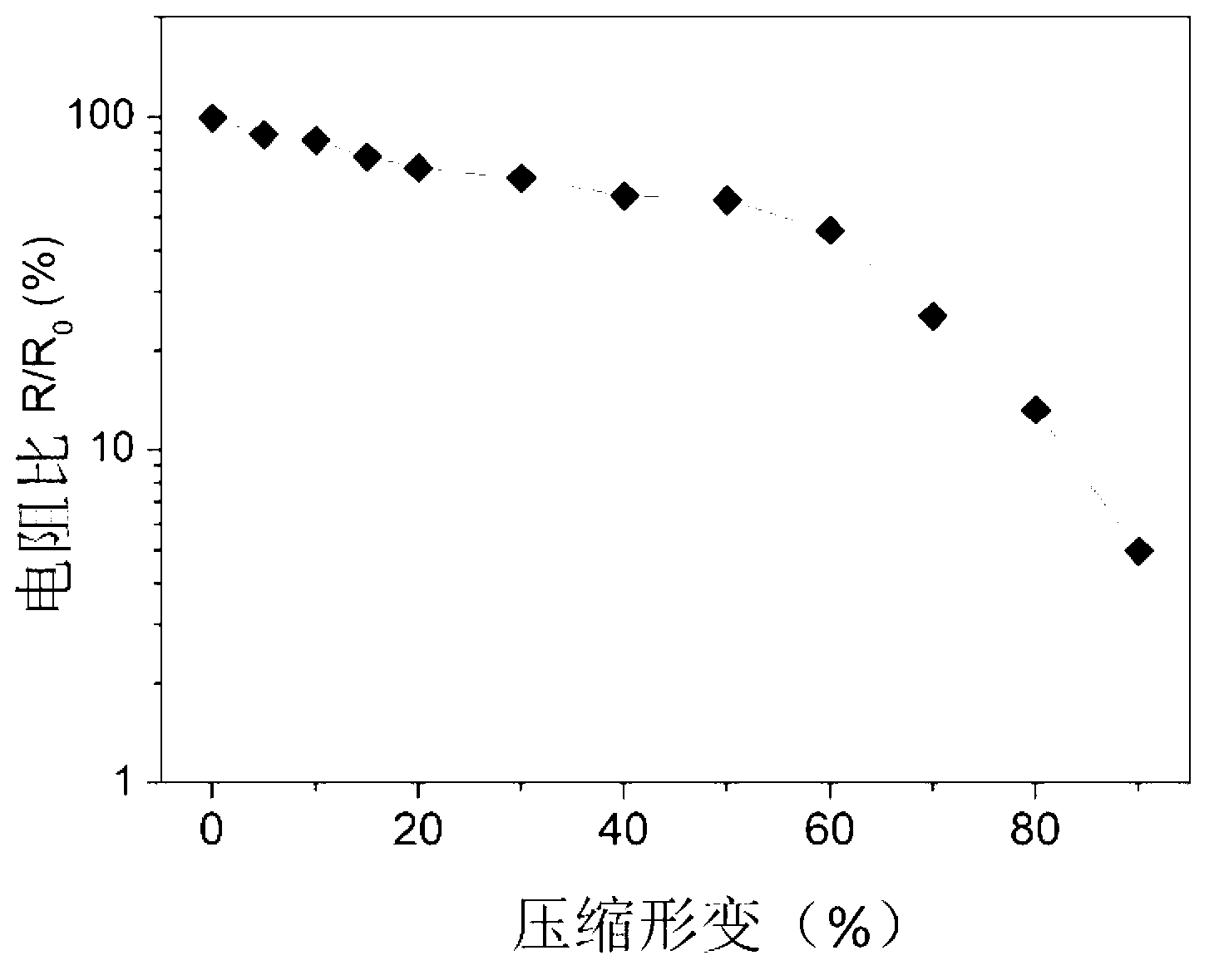

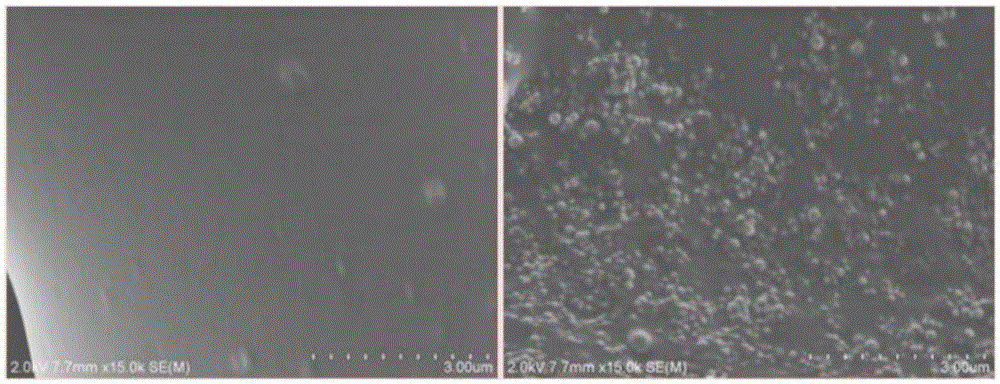

Flexible polymer-based graphene foam material and preparation method thereof

The invention relates to the field of graphene foam composite materials, and in particular relates to a porous flexible polymer-based graphene foam material and a preparation method thereof. According to the flexible polymer-based graphene foam material provided by the invention, in the foam material, polymer foam accounts for 90-99.9wt%, and graphene accounts for 0.1-10wt%. Compared with the prior art, the volume of the flexible polymer-based graphene foam material provided by the invention can be prepared as required; and the flexible polymer-based graphene foam material has excellent compression and resilience mechanical properties, electrical conductivity and surface hydrophobicity.

Owner:SHANGHAI JIAO TONG UNIV

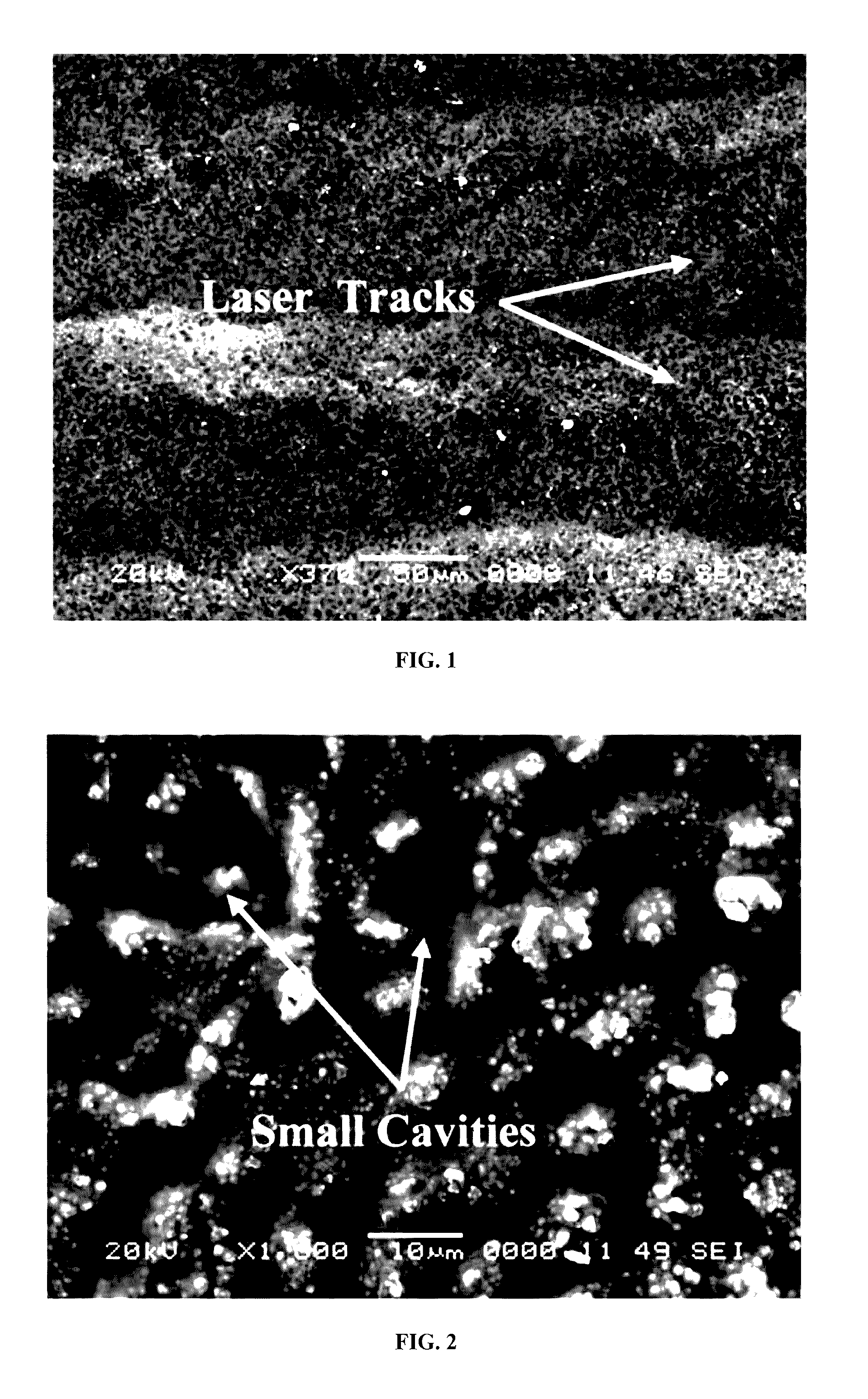

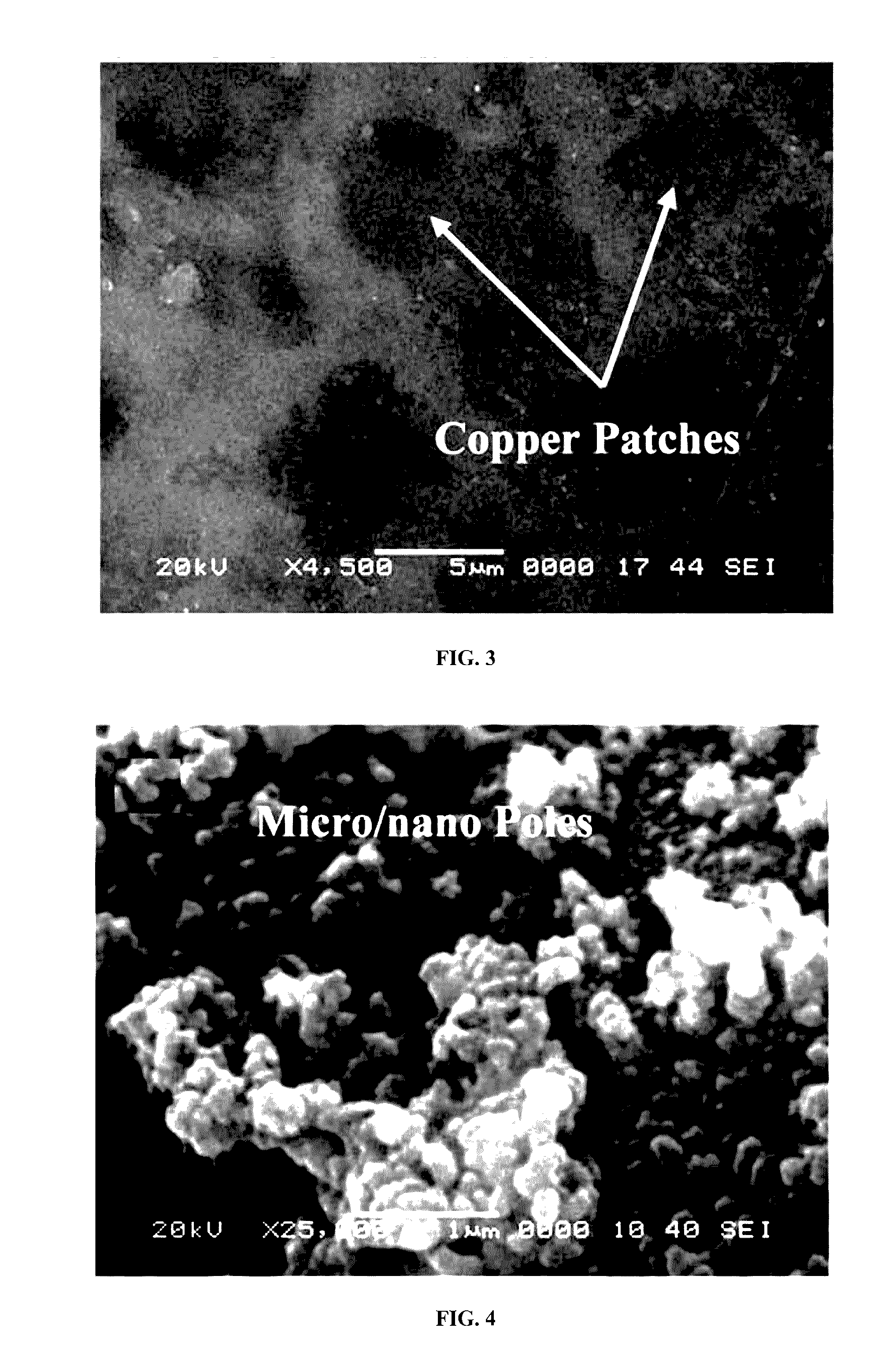

Laser ablation method for treating a copper alloy containing metallic surface and increasing hydrophobicity

InactiveUS20170014946A1Improve fracture toughnessImprove surface hydrophobicityWelding/soldering/cutting articlesLaser beam welding apparatusPhosphor bronzeHigh surface

A method of treating a metallic surface comprising a copper alloy, such as phosphor bronze, whereby the metallic surface is ablated by directing a laser beam with a diameter of 200-400 μm produced by a CO2 laser with a pulse frequency of 1200-1800 HZ onto the metallic surface, and a N2 assist gas is concurrently applied with a pressure of 550-650 KPa co-axially with the laser beam to form an ablated metallic surface comprising microgrooves with Cu3N present on a surface of the microgrooves, wherein the ablated metallic surface has a higher surface hydrophobicity than the metallic surface prior to the ablating.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Method for separating quartz from low-grade potassium and sodium feldspar ore

ActiveCN105618271ALower surface oxidation potentialIncrease the surface contact angleFlotationPhysical chemistryPotassium

The invention provides a method for separating quartz from low-grade potassium and sodium feldspar ore. The method comprises the steps of providing low-grade potassium and sodium feldspar ore powder; mixing the low-grade potassium and sodium feldspar ore powder and water for obtaining low-grade potassium and sodium feldspar ore slurry; adjusting the pH value of the low-grade potassium and sodium feldspar ore slurry to 8-10 through conditioning agents, and then carrying out roughing, scavenging, concentrating and drying on the low-grade potassium and sodium feldspar ore slurry for obtaining fine potassium and sodium feldspar powder and floating the quartz; adding activating agents, inhibitors and amine collecting agents in the roughing process and the scavenging process each time. The method has the advantages that the production cost is low, the requirement for corrosion prevention of equipment is low, pollution to the environment is small, and the quality of the obtained fine potassium and sodium feldspar powder meets the use standard GB / T9195-1999 of the ceramic industry.

Owner:ZHENGZHOU SHANCHUAN HEAVY IND CO LTD

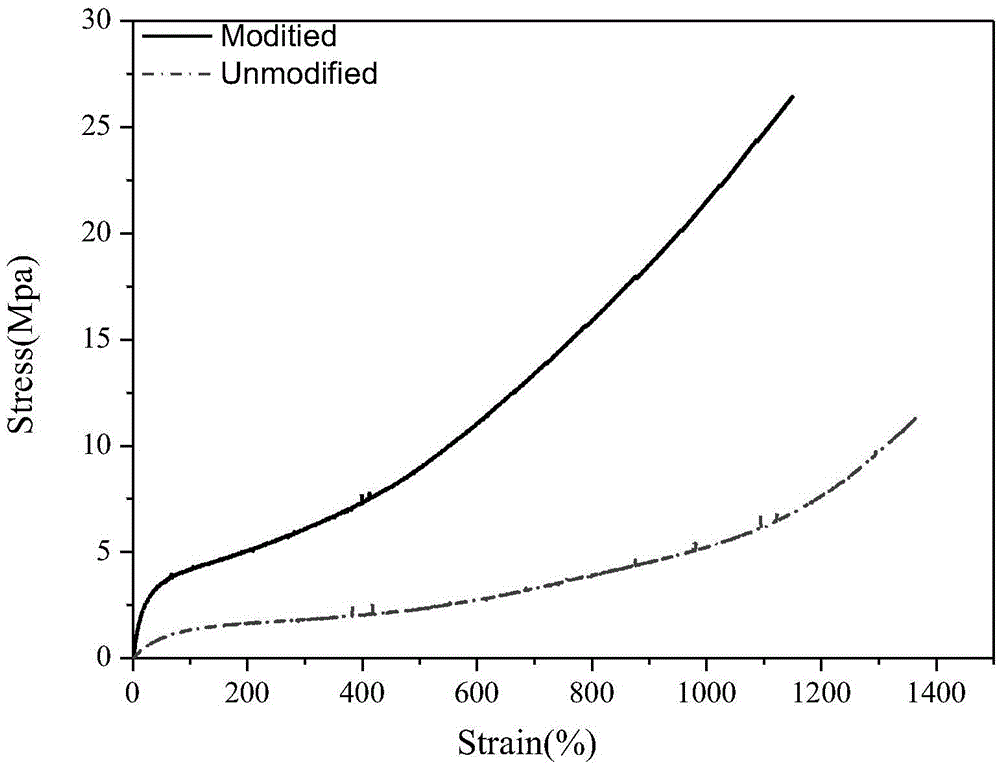

Preparation method for polysiloxane emulsion modified waterborne polyurethane emulsion

The invention particularly relates to a preparation method for polysiloxane emulsion modified waterborne polyurethane emulsion. The preparation method comprises the steps of taking oligomer dihydric alcohol as a soft section and an isocyanate compound as a hard section, and introducing polysiloxane emulsion in an emulsifying process to prepare the polysiloxane emulsion modified waterborne polyurethane emulsion. The introduction of polysiloxane effectively improves the tensile strength and modulus of a waterborne polyurethane emulsion film; the surface hydrophobicity of the film is enhanced; the water absorption rate is reduced; and the film has relatively high transparency. The waterborne polyurethane hybrid emulsion prepared with the method can be widely applied to the fields of high-performance coating materials, printing ink, adhesives, sealing materials and the like.

Owner:RUNTAI CHEM TAIXING CO LTD

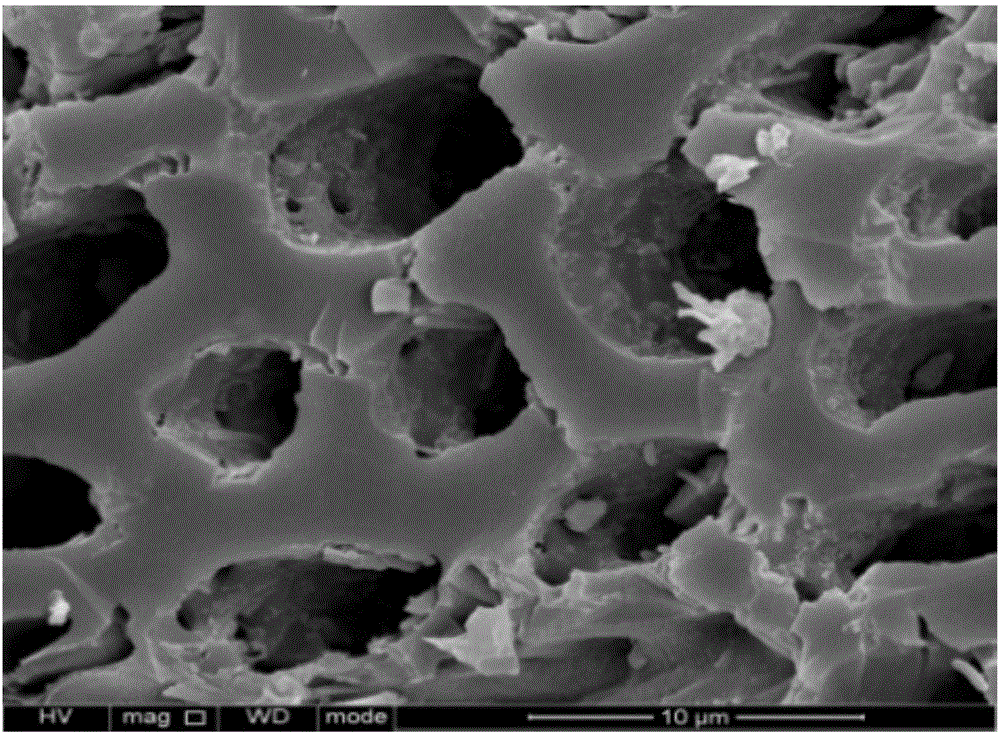

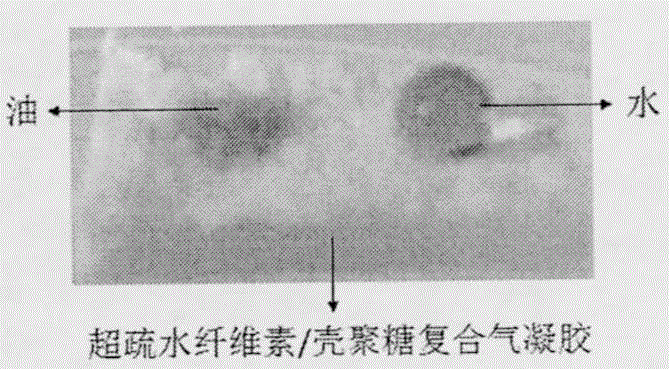

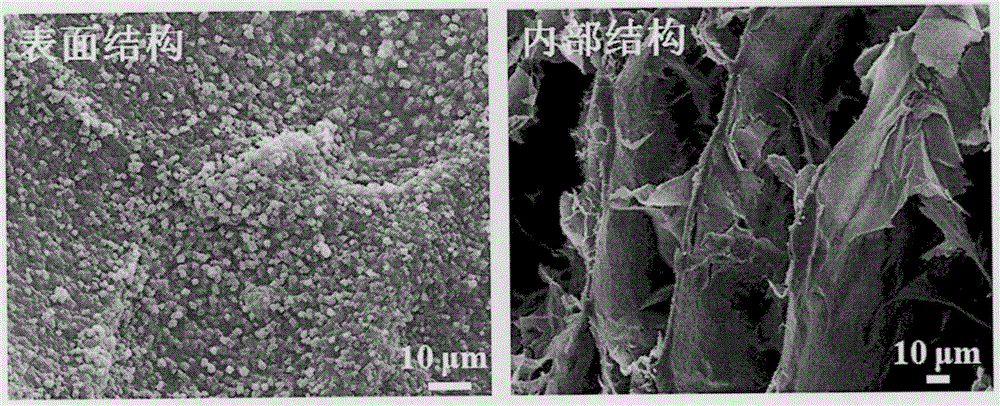

Preparation method of super-hydrophobic cellulose/chitosan compound aerogel oil-water separation material

ActiveCN105709695AControl apertureControl porosity sizeOther chemical processesAlkali metal oxides/hydroxidesPorosityCellulose

The invention relates to a preparation method of a super-hydrophobic cellulose / chitosan compound aerogel oil-water separation material. The method includes the first step of cellulose / chitosan compound solution preparation, the second step of cellulose / chitosan compound aerogel preparation, and the third step of super-hydrophobic cellulose / chitosan compound aerogel preparation. Prepared cellulose / chitosan compound aerogel has a high pore rate, the surface of the cellulose / chitosan compound aerogel has high roughness, the preparation process is simple, and raw materials are wide in source, low in cost, green and environmentally friendly. By means of the related hydrophobic modification method, super-hydrophobic fruit can be rapidly and effectively obtained in an energy-saving mode, and greasy dirt collection, oil-water separation and the like can be economically and rapidly achieved.

Owner:刘 志勇 +3

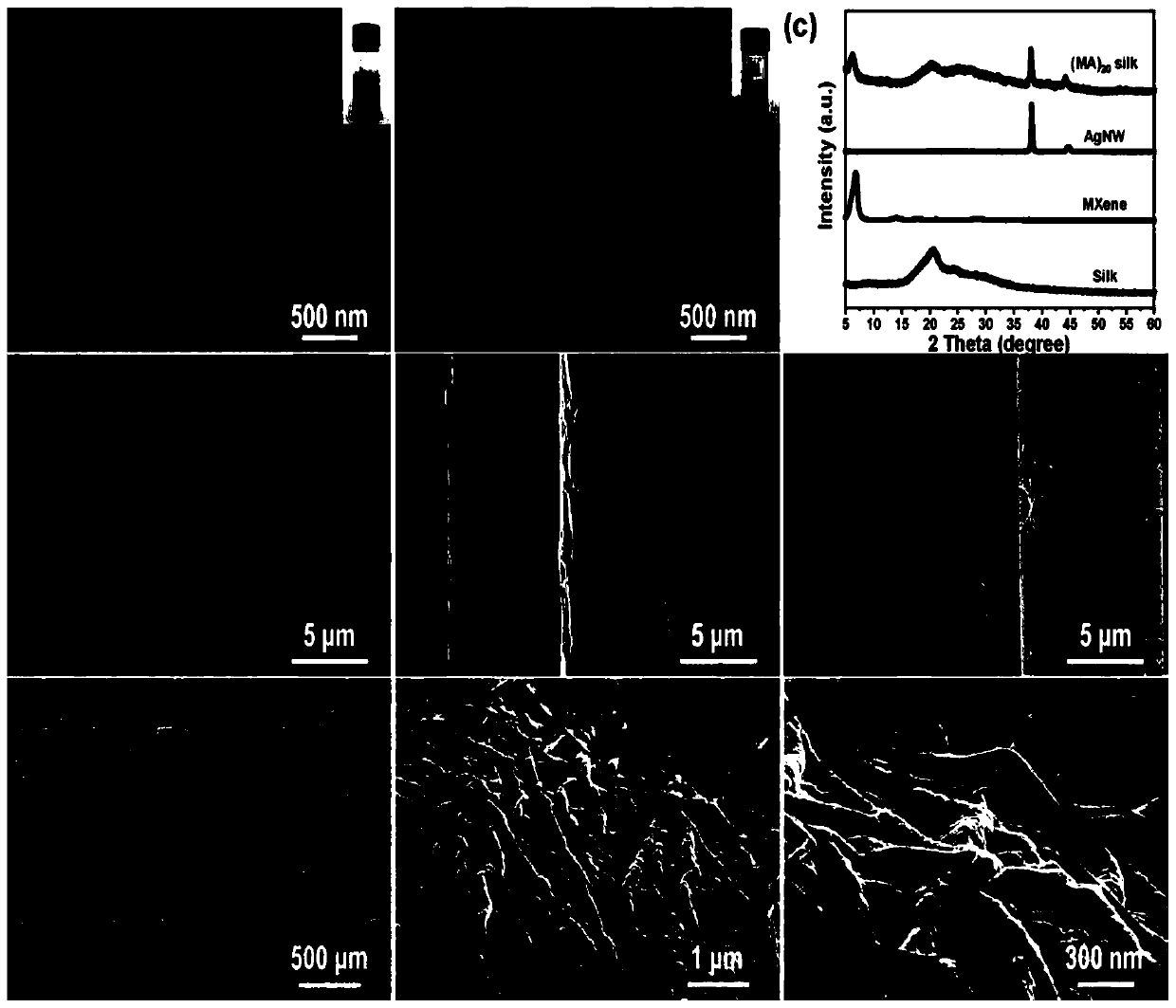

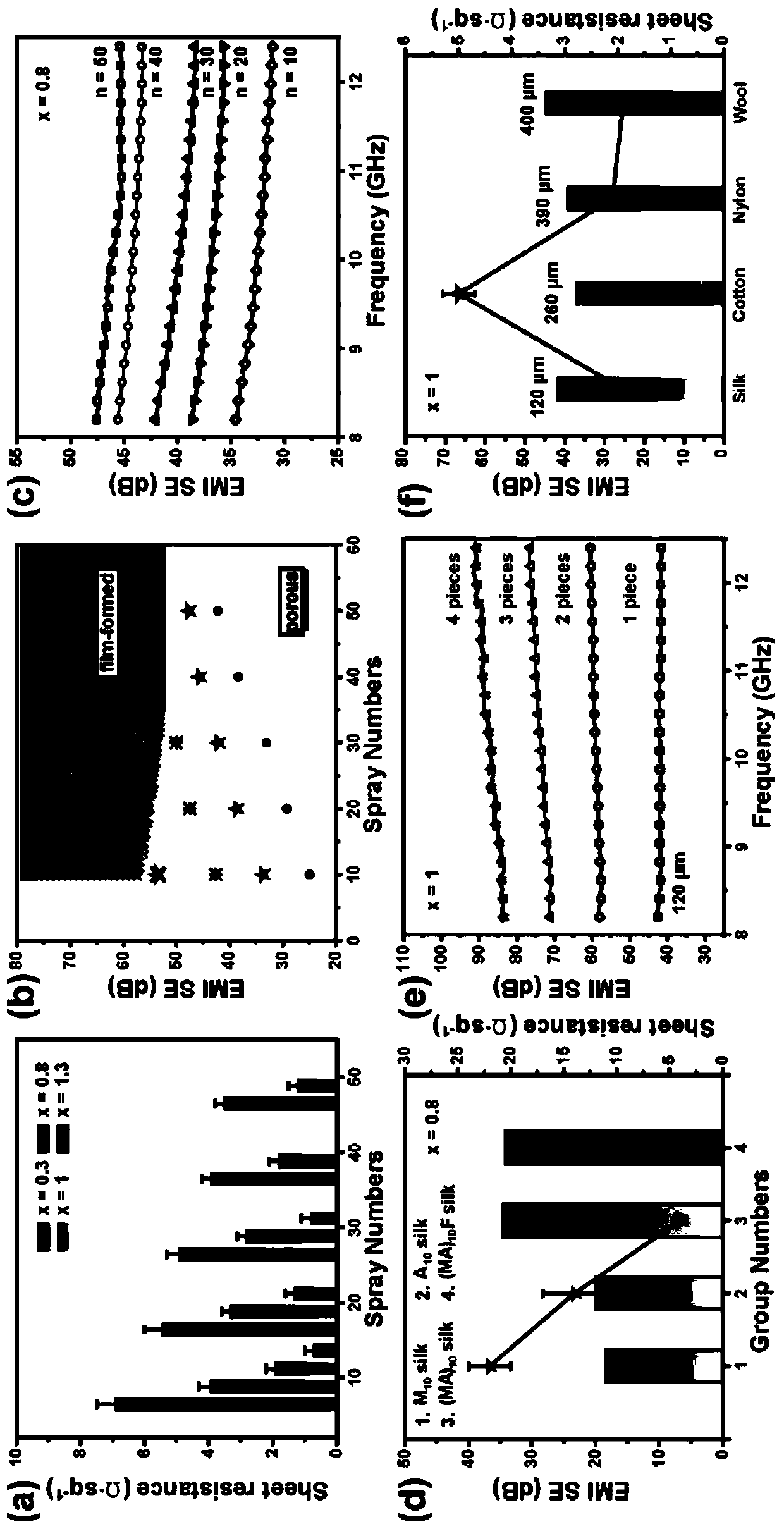

Fabric material and production method thereof

The invention relates to a fabric material and a production method thereof. The fabric material comprises a substrate layer and modification layers formed on at least one side of the substrate layer,wherein the substrate layer comprises a fabric layer, each modification layer comprises a one-dimensional nano conductive material and a two-dimensional nano conductive material, the surface of each modification layer is a layer formed by the two-dimensional nano conductive material, and the two-dimensional nano conductive material is selected from two-dimensional transition metal carbon / nitrogencompound. The two-dimensional nano conductive material and the one-dimensional nano conductive material are assembled on the substrate layer, nanowire contact resistance is lowered, excellent electromagnetic shielding performance is achieved, the aging spontaneous hydrophobicity and humidity responsiveness of the two-dimensional conductive material on porous fabric allow the electronic fabric to have hydrophobicity and a humidity monitoring function. The multifunctional fabric is widely applicable to fields such as intelligent garments, humidity sensors and electromagnetic shielding.

Owner:BEIJING UNIV OF CHEM TECH

Repairing method for silicon rubber casing pipe ageing

InactiveCN103219111AWith coupon recoveryStrong anti-pollution flashover abilityInsulatorsInsulation layerSilica gel

The invention relates to a repairing method for silicon rubber casing pipe ageing. The repairing method for silicon rubber casing pipe ageing comprises the following steps of: (1) cleaning an operated and aged synthetic silicon rubber casing pipe, removing dust, salt crust, greasy dirt and other attachments on the surface, and wiping off a pulverized ageing layer; (2) coating with organosilicone glue to close up fissures, and activating the surface of the aged synthetic silicon rubber casing pipe; (3) filling and leveling up with a silicon rubber putty, and rebuilding cracked and damaged positions; (4) rebuilding a damaged sheath and umbrella skirt by a prefabricated silicon rubber strip; and (5) painting PRTV anti-pollution flashover composite coating to form a new completely-covering outer insulation layer. The outer insulation layer has the advantages of simple method, low construction cost, strong durability against pollution and long service life.

Owner:HEBEI SILICON VALLEY CHEM CO LTD

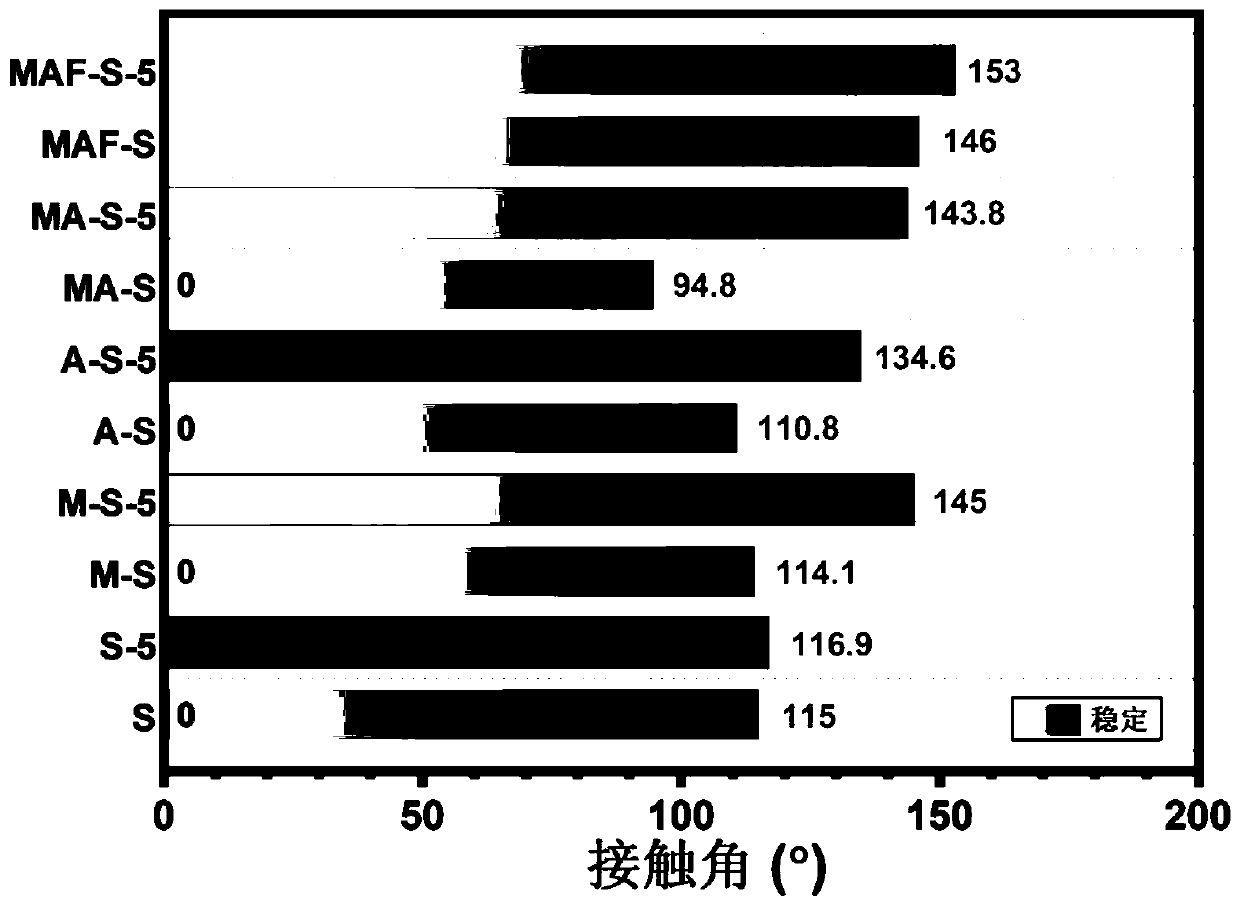

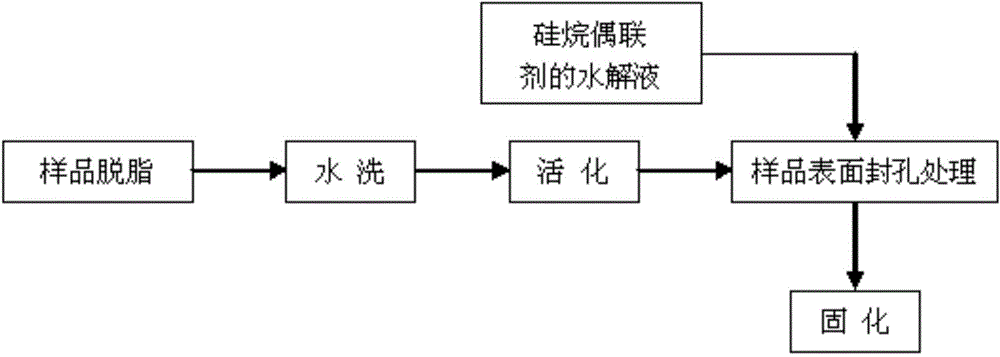

Method for carrying out hole sealing treatment on anodic alumina, component of overhead contact system of electric railway, by using silane coupling agent

InactiveCN104451821AFacilitated DiffusionReduce surface tensionSurface reaction electrolytic coatingMass ratioBiological activation

The invention provides a method for carrying out hole sealing treatment on anodic alumina, a component of an overhead contact system of an electric railway, by using a silane coupling agent, belonging to the field of metal surface retreatment and metal corrosion resistance improvement. The method comprises the following steps: firstly carrying out ultrasonic treatment on an anodic alumina sample in an acetone solution for 10-15 minutes, then washing the anodic alumina sample with distilled water for 3-5 times and then soaking the anodic alumina sample in hydrogen peroxide activation liquor at 65 DEG C for 5-10 minutes; mixing the silane coupling agent, alcohol and water in a mass ratio of 1 to (6-8) to 1, then adding an organic acid as a hydrolysis catalyst, and regulating the pH value of a silane coupling agent, alcohol and water solution to 4-6, wherein the hydrolysis time is controlled to be 0.5-8 hours; and soaking the sample subjected to activation treatment in the silane coupling agent, alcohol and water solution for 10-80 minutes and then taking out and curing the sample. The method has the beneficial effects that the method is used for performing sealing treatment on porous anodic alumina film layers, is low in raw material prices and simple in operation procedures and is convenient to maintain; the corrosion resistance and pollution resistance of the product are substantially improved after hole sealing; the product is nontoxic and environmentally friendly; safe operation of the electric railway is ensured.

Owner:BEIJING UNIV OF CHEM TECH +1

High hydrophobic anti pasting poster paint

ActiveCN101550303AImprove surface hydrophobicityStrong surface anti-adhesionCoatingsEmulsionPreservative

A high hydrophobic anti pasting poster paint, which is characterized in that the coating includes following components, weight parts of each is: water 20-40, thickening agents 0.1-3, AMP 95 0.1-0.5, dispersant 0.2-2, defoamer 0.1-0.5, color filling agent 20-50, hydrophobic surface anti pasting agent 0.1-0.5, emulsion 10-40, film-forming additive 0-2, preservative agent 0.1-1. the color filling agent is composed of diatomite or calcium carbonate matching with quartz powder and titanium dioxide and mixing, wherein the weight ratio of diatomite or calcium carbonate: quartz powder: titanium dioxide is 1: 0.5-5.5: 1-5. The present invention is provided with characteristics of high surface hydrophobic nature and surface anti pasting ability after film-forming, not easy to doodle or covered by sewerage or other coatings, and not easy to be pasted by common advertisement sticker with gum in the back, stable property, simple production process and convenient for construction.

Owner:GUANGDONG HUARUN PAINT CO LTD

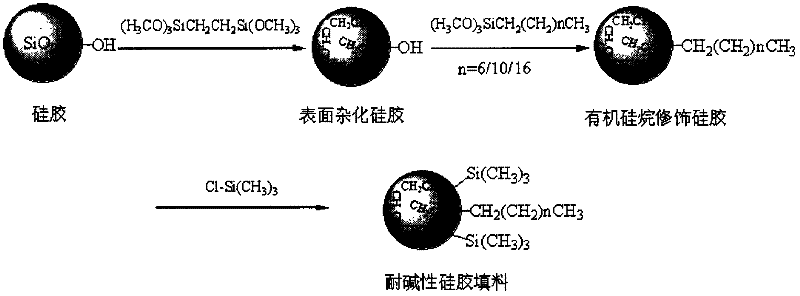

Preparation method of alkali-resistant silica gel chromatographic column filling material

InactiveCN102489271AIncrease coverageReduce the impactOther chemical processesStationary phaseMetal impurities

The invention discloses a preparation method of an alkali-resistant silica gel chromatographic column filling material. The preparation method provided by the invention comprises the following steps of preparing a silica gel matrix of which the surface has alkali resistance by a short-carbon chain silane coupling agent-based silica gel surface organic hybridization method, and carrying out stationary phase bonding. The preparation method is characterized in that a part of silanol groups on a totally porous spherical silica gel surface undergo bonding reactions in the presence of a short-carbon chain silane coupling agent so that the totally porous spherical silica gel surface is covered partly with short carbon chains, and thus organic hybridization of the totally porous spherical silica gel surface is realized and alkali-resistant silica gel having a thin and uniform organic covering layer is obtained; and through surface stationary phase bonding and last end-capping, the alkali-resistant silica gel chromatographic column filling material is obtained. The alkali-resistant silica gel chromatographic column filling material obtained by the preparation method has good alkali resistance, reduces a residual silanol effect, covers metal impurities on a silica gel surface, and has good application potentials.

Owner:UNIV OF JINAN

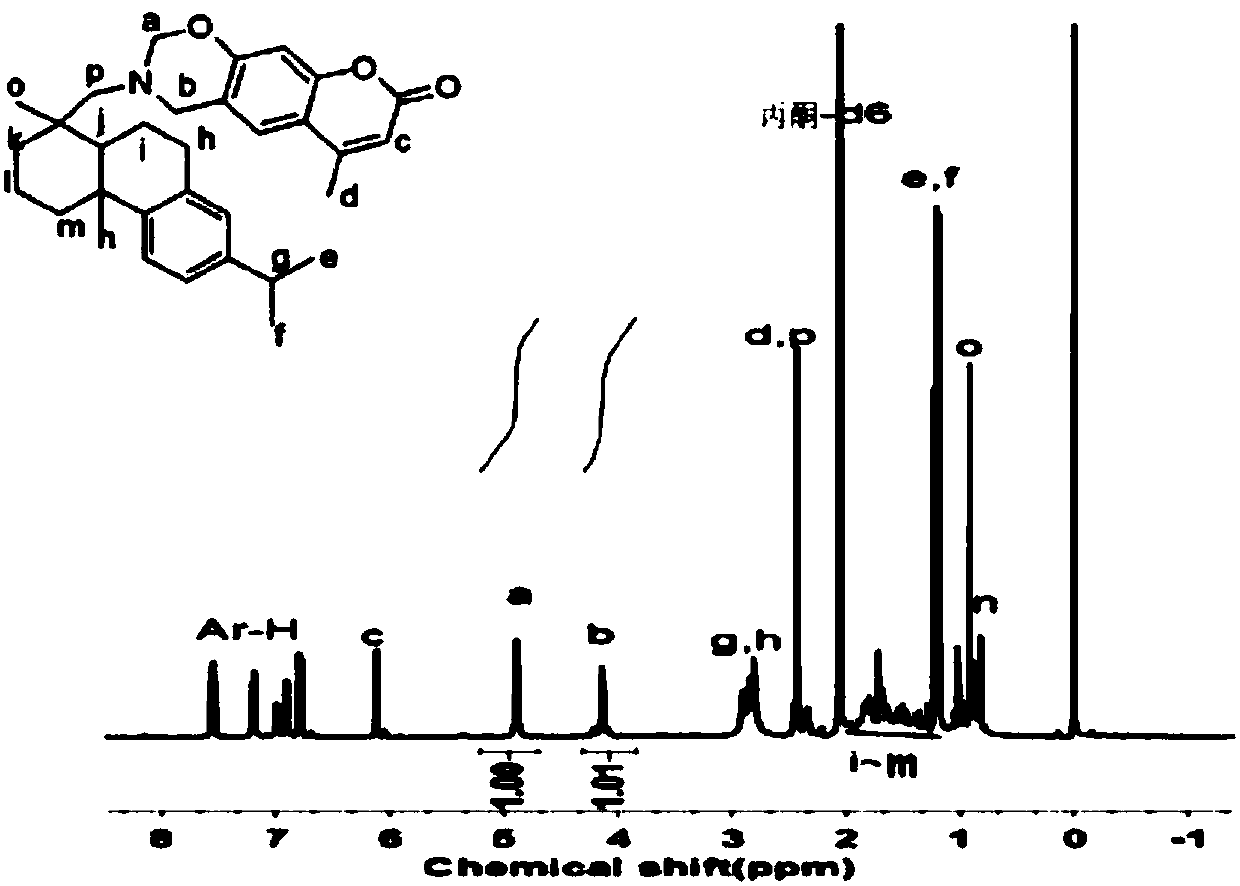

Total-biology-base benzoxazine resin and preparation method thereof

InactiveCN107759615AThe synthesis process is simpleThe synthesis process is reasonableOrganic chemistryAnti-corrosive paintsRosinPetroleum

The invention provides total-biology-base benzoxazine resin and a preparation method thereof. A monomer of the resin is prepared by reacting dehydroabietylamine as a rosin derivative, biological phenol and paraformaldehyde at the temperature of 85 DEG C with a solution method for 20 hours. The preparation method comprises the following steps: cooling reactants to room temperature, washing with a sodium bicarbonate solution, washing with deionized water, and crystallizing with ethanol to obtain a purified monomer; performing ring-opening crosslinking on the monomer in a heating state or in thepresence of an added catalyst to generate the total-biology-base benzoxazine resin. The total-biology-base benzoxazine resin has the advantages of reasonable synthesis process, no need of inertial gasprotection, high product purity and environmental friendliness; compared with other biology-base benzoxazine and a part of petroleum-base benzoxazine, the obtained novel total-biology-base benzoxazine resin has great competitiveness on the aspects of ring-opening temperature and thermal stability, and shows high corrosion resistance.

Owner:EAST CHINA UNIV OF SCI & TECH

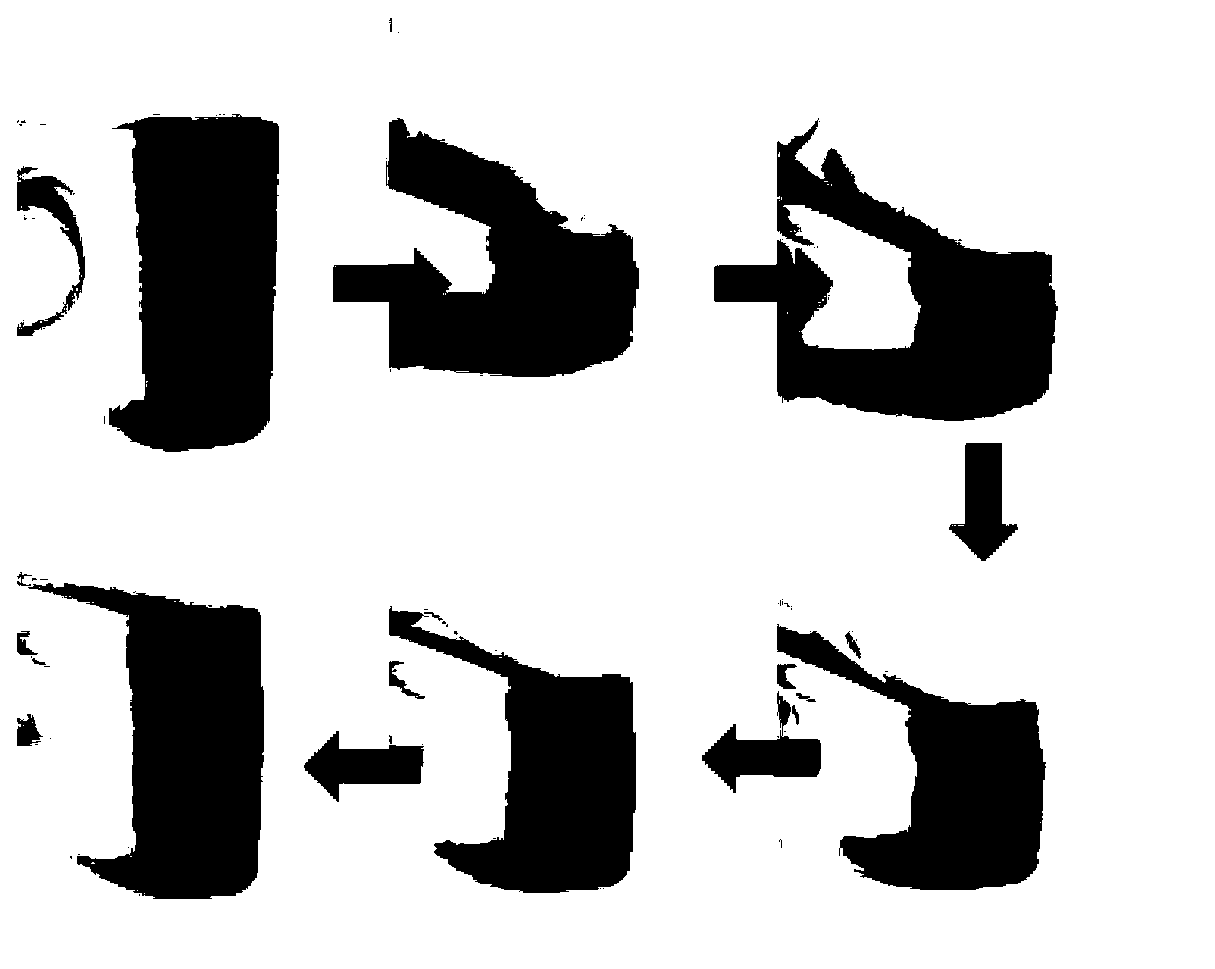

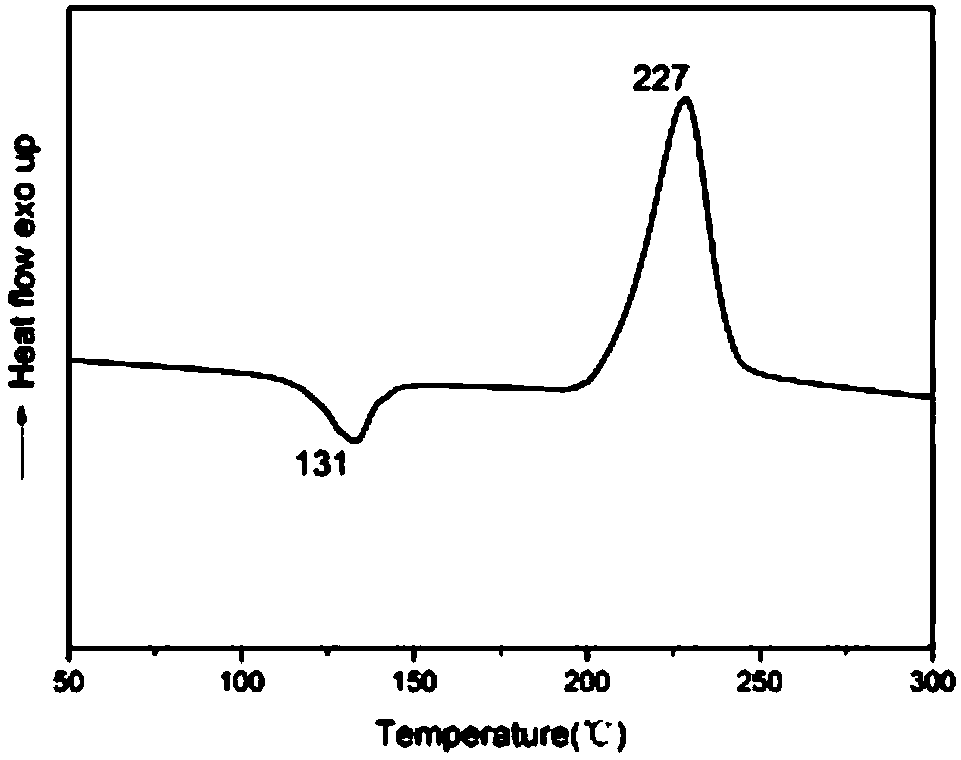

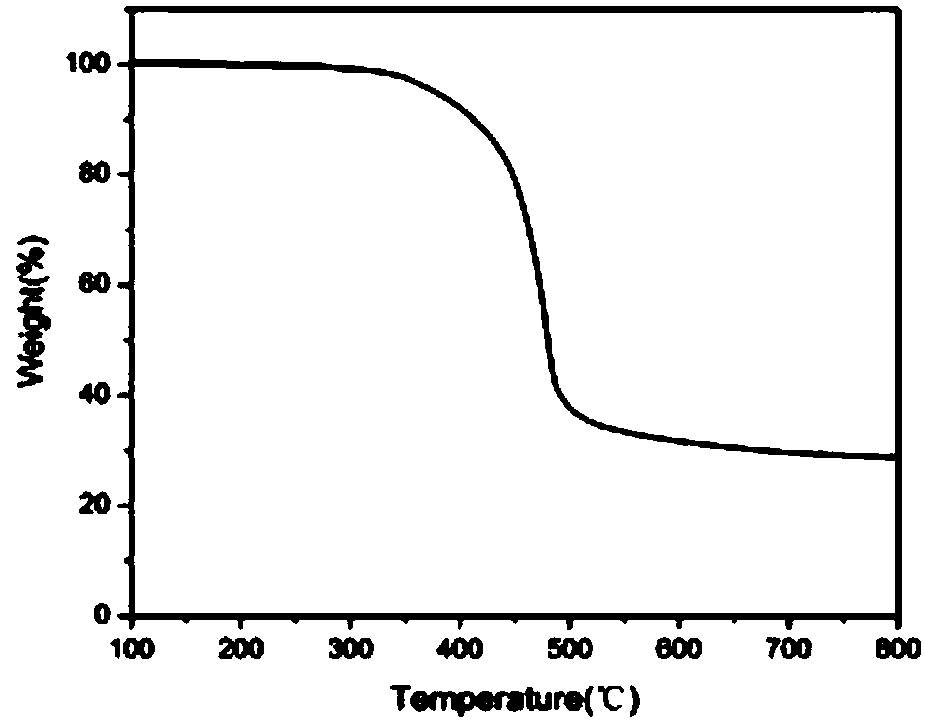

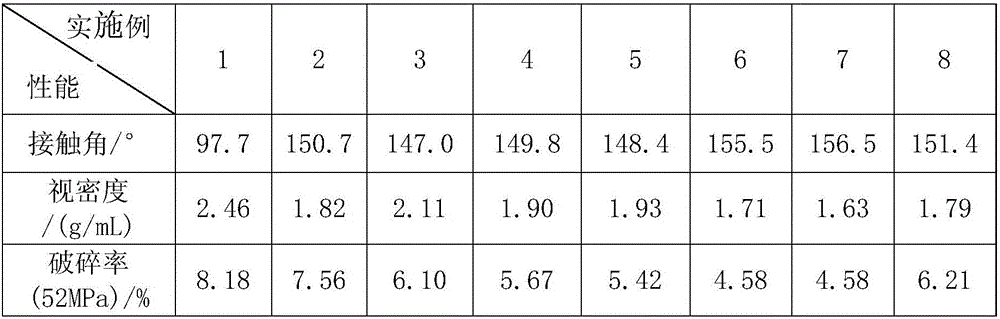

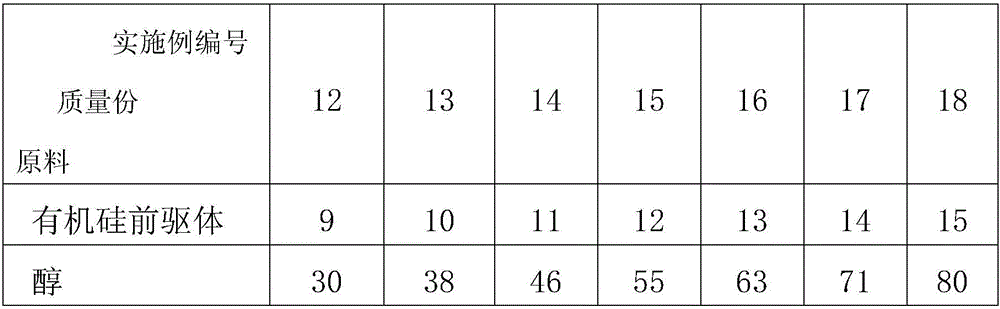

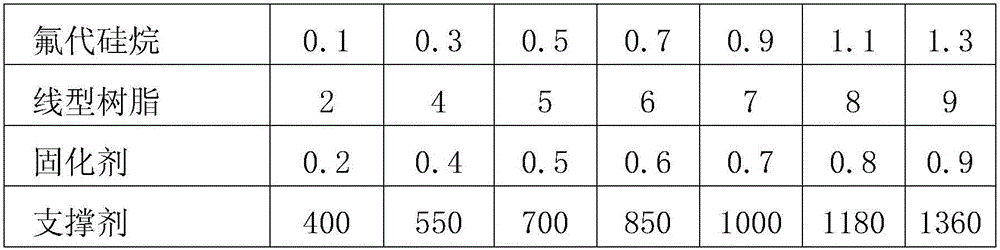

Preparation method of propping agent coated with superhydrophobic polymeric membrane

ActiveCN106147744AReduce contact areaAdhesionFluid removalDrilling compositionAlcoholShale oil and gas

The invention discloses a preparation method of a propping agent coated with a superhydrophobic polymeric membrane. The preparation method is characterized by comprising the steps that an organosilicone precursor and alcohol are mixed, the pH value is regulated to be 12-13 through alkali liquor, reacting is conducted for 0.5-5 h at the temperature of 30 DEG C to 70 DEG C, and then fluorosilane is added for reacting; liquor obtained after reacting and linear resin are mixed, and the temperature of the mixed liquor is increased to 70 DEG C to 100 DEG C; a curing agent is added, after the mixed liquor and a propping agent are mixed to be cured for 1-3 h at the temperature of 90 DEG C to 120 DEG C, curing is conducted for 1-3 h by increasing the temperature to 150 DEG C to 200 DEG C, and then the propping agent coated with the superhydrophobic polymeric membrane is prepared. According to the preparation method, the contact angle between the surface of the prepared polymeric membrane and water is larger than 150 degrees, the hydrophobicity of the surface of the propping agent can be greatly improved, the propping agent modified with the polymeric membrane serves as a key material of a hydrofracture technique, the exploitation quality of shale oil and gas can be improved, the exploitation yield of the shale oil and gas can be increased, and the practicability is high.

Owner:SOUTHWEAT UNIV OF SCI & TECH

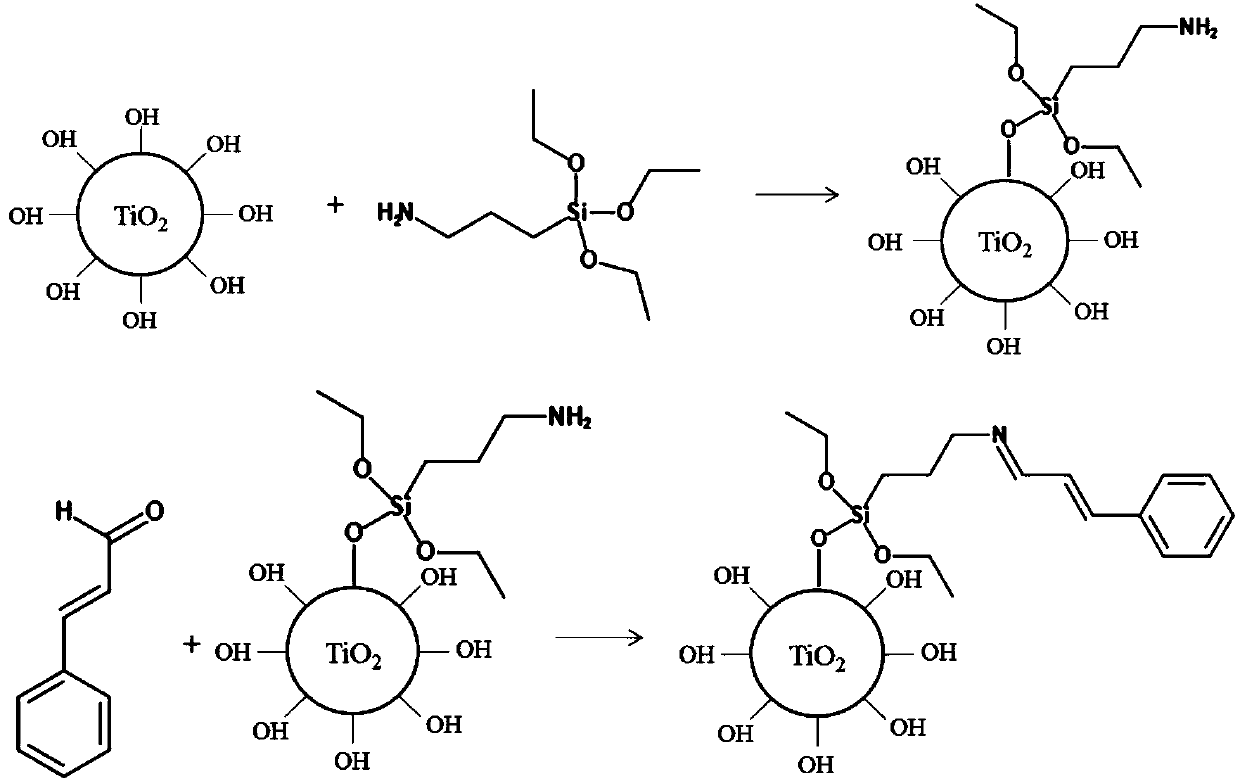

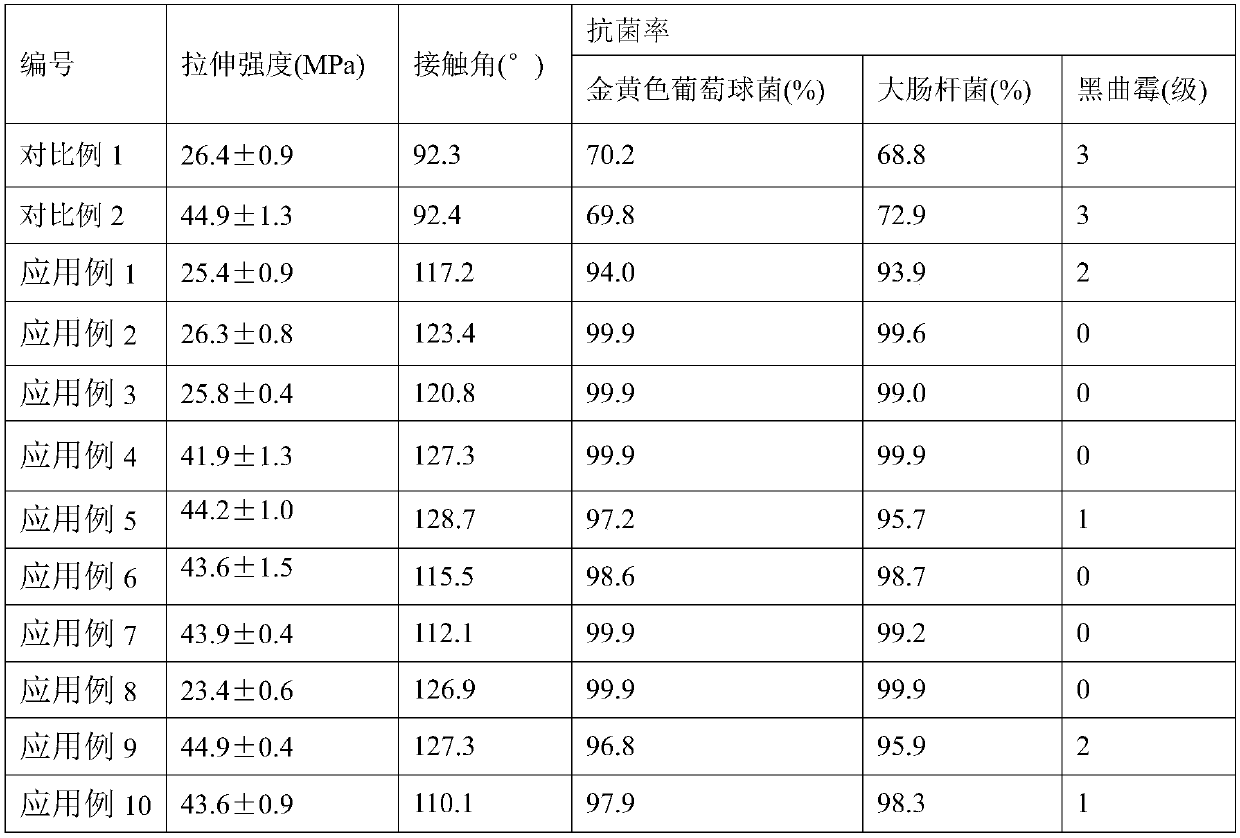

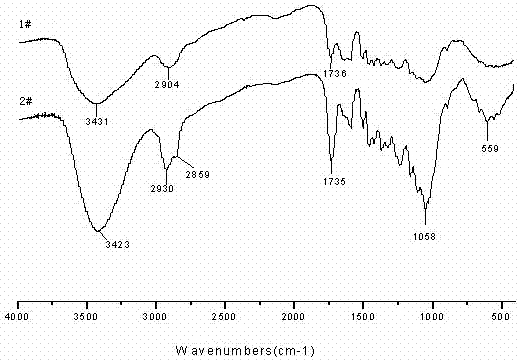

Preparation method of inorganic-organic hybrid antibacterial agent with antibacterial and hydrophobic functions and application of antibacterial agent

ActiveCN109627492ANo pollution in the processPolarity adjustableEscherichia coliStaphylococcus aureus

The invention relates a preparation method of an inorganic-organic hybrid antibacterial agent with antibacterial and hydrophobic functions and application of the antibacterial agent in a polymer material matrix. The antibacterial agent overcomes the problem in the prior art that the antibacterial performance of a natural antibacterial agent cannot completely meet the demands of users when being used alone. Specifically, the antibacterial agent adopts an amino-containing coupling agent as a bridge, and antibacterial inorganic nanoparticles such as titanium dioxide and zinc oxide are coated withantibacterial aldehydes such as organic citral and cinnamaldehyde to form the inorganic-organic hybrid antibacterial agent. The inorganic-organic hybrid antibacterial agent can be widely applied to polymer materials such as PP and ABS and achieve an antibacterial and hydrophobic effect; the antibacterial rate of the antibacterial agent for gram-negative bacteria such as escherichia coli can reach99.9%, the antibacterial rate of the antibacterial agent for gram-positive bacteria such as staphylococcus aureus can reach 99.9%, the antibacterial rate of the antibacterial agent for aspergillus niger and other molds can reach 0 grade, and the contact angle between the material surface and water can reach 120 degrees. Meanwhile, the antibacterial polymer material maintains the great mechanicalproperty.

Owner:ZHEJIANG UNIV OF TECH

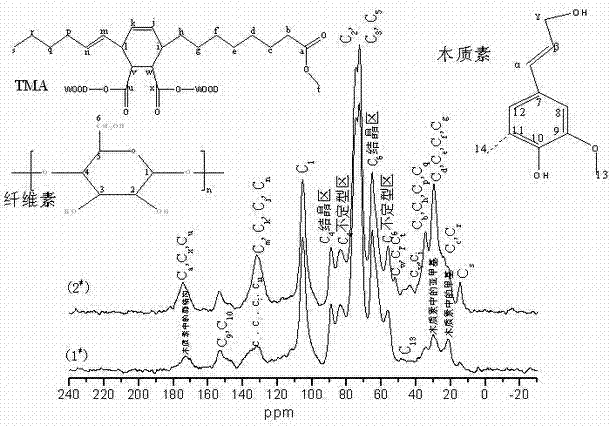

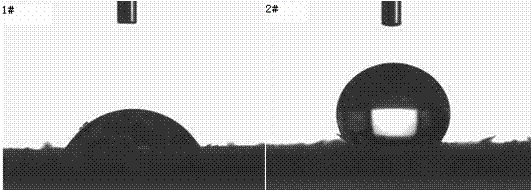

Method for manufacturing methyl malei-eleostearate anhydride modified wood fiber

InactiveCN102206917AAbundant and cheap resourcesReduce surface polarityVegetal fibresFiberCooking & baking

The invention discloses a method for manufacturing methyl malei-eleostearate anhydride modified wood fiber by virtue of reaction of wood fiber and methyl malei-eleostearate anhydride. The method comprises the following steps of: firstly, with dimethyl formamide as solvent, carrying out reaction on the wood fiber and methyl malei-eleostearate anhydride at the temperature of 25-130 DEG C for 2-12 hours, wherein the dosage of dimethyl formamide is 20ml per g of the wood fiber, and the dosage of methyl malei-eleostearate anhydride is 2.5-15 times that of the wood fiber; and secondly, extracting reaction products with mixed solvent for 16 hours, removing unreacted small molecular compound, and baking, thus the methyl malei-eleostearate anhydride modified wood fiber is obtained. Catalyst pyridine is added in the first step preferably. The method disclosed by the invention has the advantages of being rich in resources, being low in cost and being environmentally-friendly. The surface polarity of the modified wood fiber manufactured by adopting the method disclosed by the invention is reduced, and the surface hydrophobicity is improved, thus the interface compatibility with synthetic resin is enhanced.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

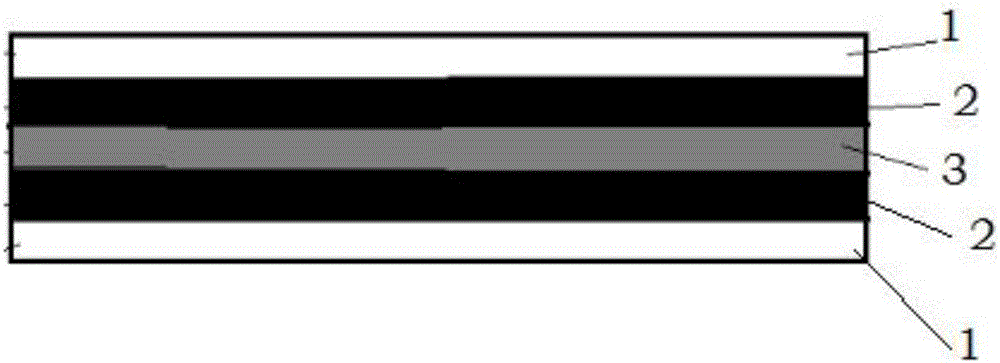

High-toughness high-water-steam-baffled completely-biodegraded composite multilayer film and preparation method thereof

InactiveCN106393919AHigh water vapor barrierImprove toughnessSynthetic resin layered productsFlat articlesWater vaporUltimate tensile strength

The invention relates to the technical field of polymer materials, and specifically relates to a high-toughness high-water-steam-baffled completely-biodegraded composite multilayer film and a manufacturing method thereof. The film comprises a structure from the second layer to the seventh layer and is composed of a PBAT based high-toughness high-barrier biodegradable material (A), a high-weatherability high-barrier biodegradable material (B), and a high-toughness functional biodegradable material layer (C). A multi-layer co-extrusion film blowing technology is adopted. Multiple material layers are compounded to prepare the film. The film is highly tough, the tensile strength can reach 18 MPa, the horizontal / vertical breaking elongation rate can reach more than 500%, no prominent difference exists in the vertical direction and the horizontal direction, the water steam baffling performance is strong, the water steam penetration rate of the film with a thickness of 10 [mu]m is 240 g / m2.24h; the processing performance is good, the minimal thickness of the film can reach 5 [mu]m; the processing equipment does not need frequent adjustment, and the film is used as a package film, an agricultural cover film, and the like.

Owner:SHANGHAI HONGRUI CHEM PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com