Fabric material and production method thereof

A fabric material and fabric technology, applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems affecting the air permeability and comfort of fabrics, and achieve the effects of improving durability, improving bonding, and enhancing conductive stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

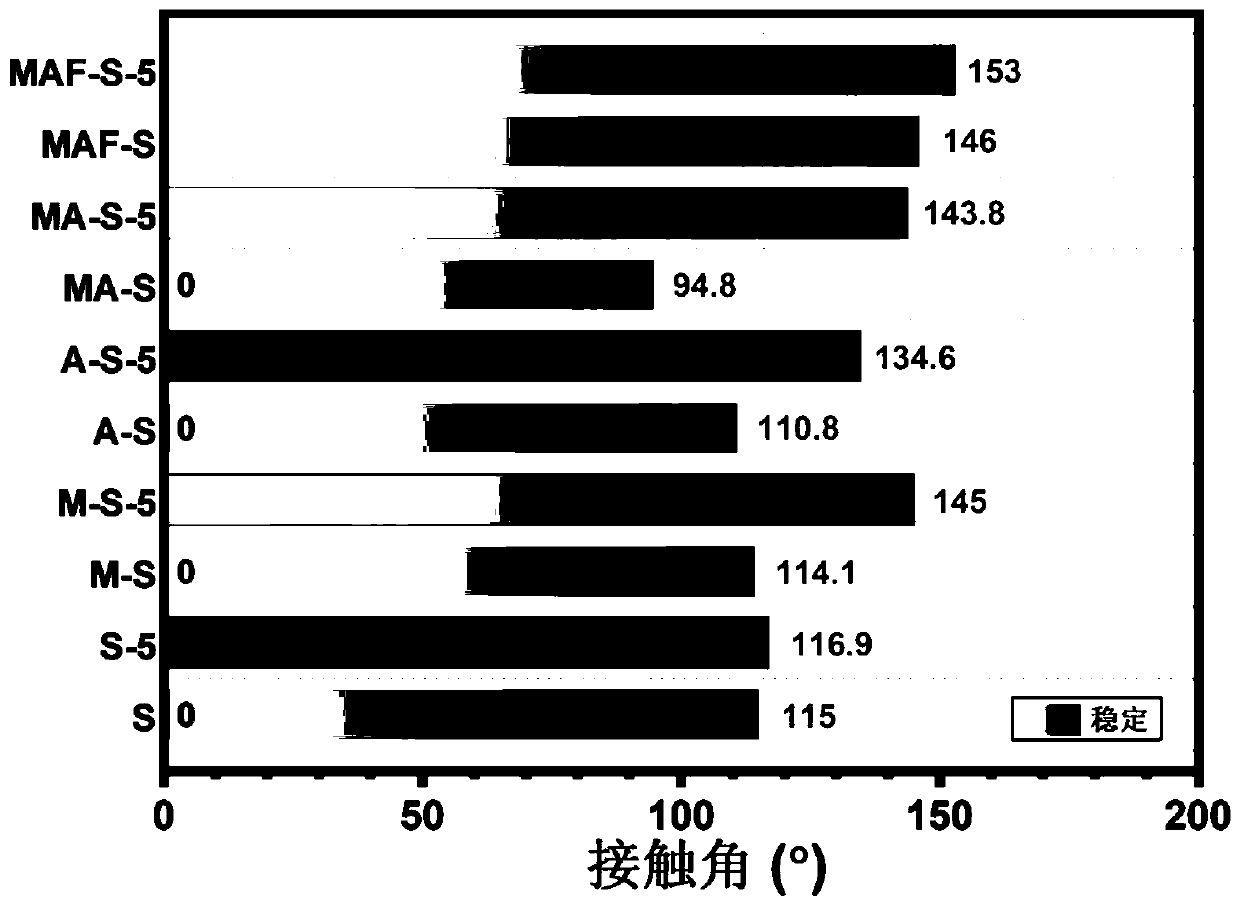

[0121] In the second aspect of the present invention, the preparation method of the fabric material with the modified layer described in the above is provided, and the term used in the has the same meaning as that of the meaning or definition. The method includes the step of forming a finishing layer on at least one side of the base layer by a layer-by-layer assembly method.

[0122] surface pretreatment

[0123] In some specific embodiments of the present invention, before forming the modification layer, the surface pretreatment of the fabric as the base layer may be performed first. The pretreatment can make the surface of the base fabric layer generate or have a positive charge, which can form a bond with the negatively charged one-dimensional and / or two-dimensional nano-conductive material in the subsequent treatment process, which helps the modification layer and The base layer is more reliable and firmly bonded.

[0124] For surface pretreatment methods, plasma s...

Embodiment

[0147] Examples of the present invention will be described below, but the present invention is not limited to the following examples.

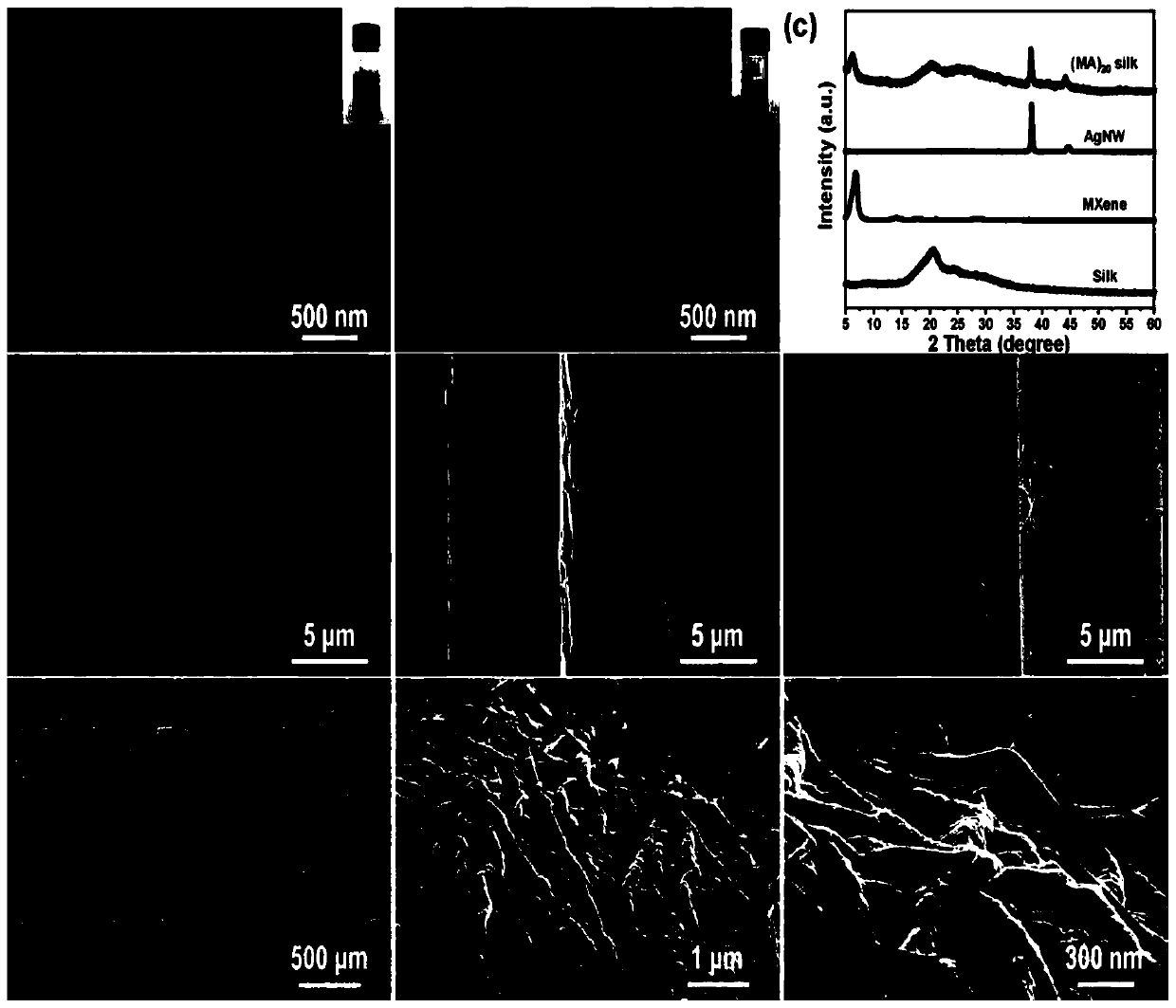

[0148] One-dimensional nanoconductive materials

[0149] Silver nanowires (AgNWs, with an average diameter of 50 nm and an average length of about 150 μm);

[0150] Two-dimensional nanoconductive materials

[0151] MXene nanosheets (which remove Ti by LiF / HCl solution 3 AlC 2 The aluminum layer is then prepared by ultrasonic delamination, and its thickness does not exceed 3.6nm);

[0152] fabric as base

[0153] silk, cotton, nylon, wool;

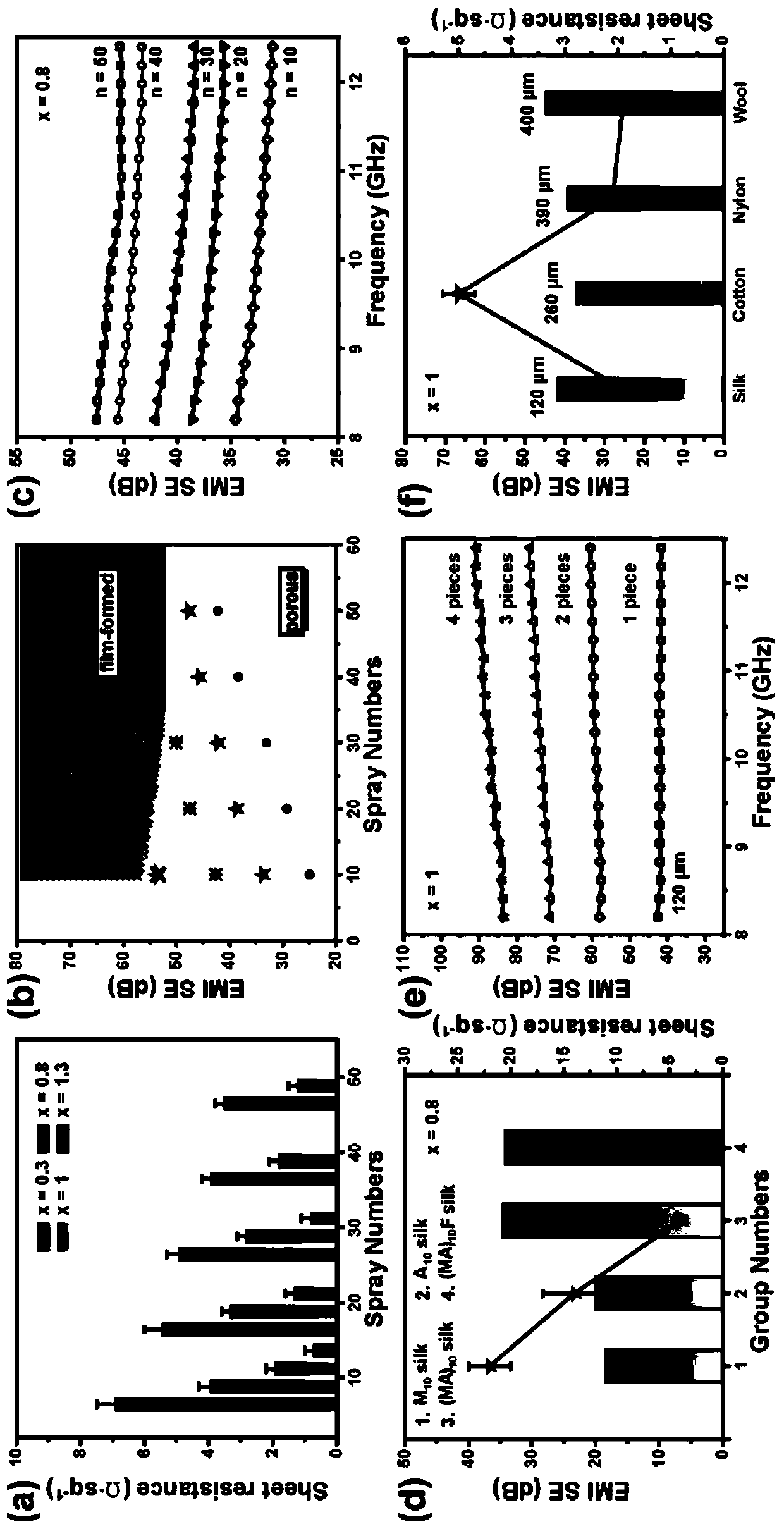

[0154] process

[0155] The silk substrate was sequentially treated with oxygen plasma and polyethyleneimine (PEI) solution to introduce sufficient polar (positively charged) groups to facilitate the loading of conductive nanomaterials. Then, by using the vacuum-assisted layer-by-layer assembly method, the treated silk was alternately sprayed with MXene nanosheets and AgNWs (nano silver wires...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Antenna | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com