Patents

Literature

1508results about How to "Good electrical conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

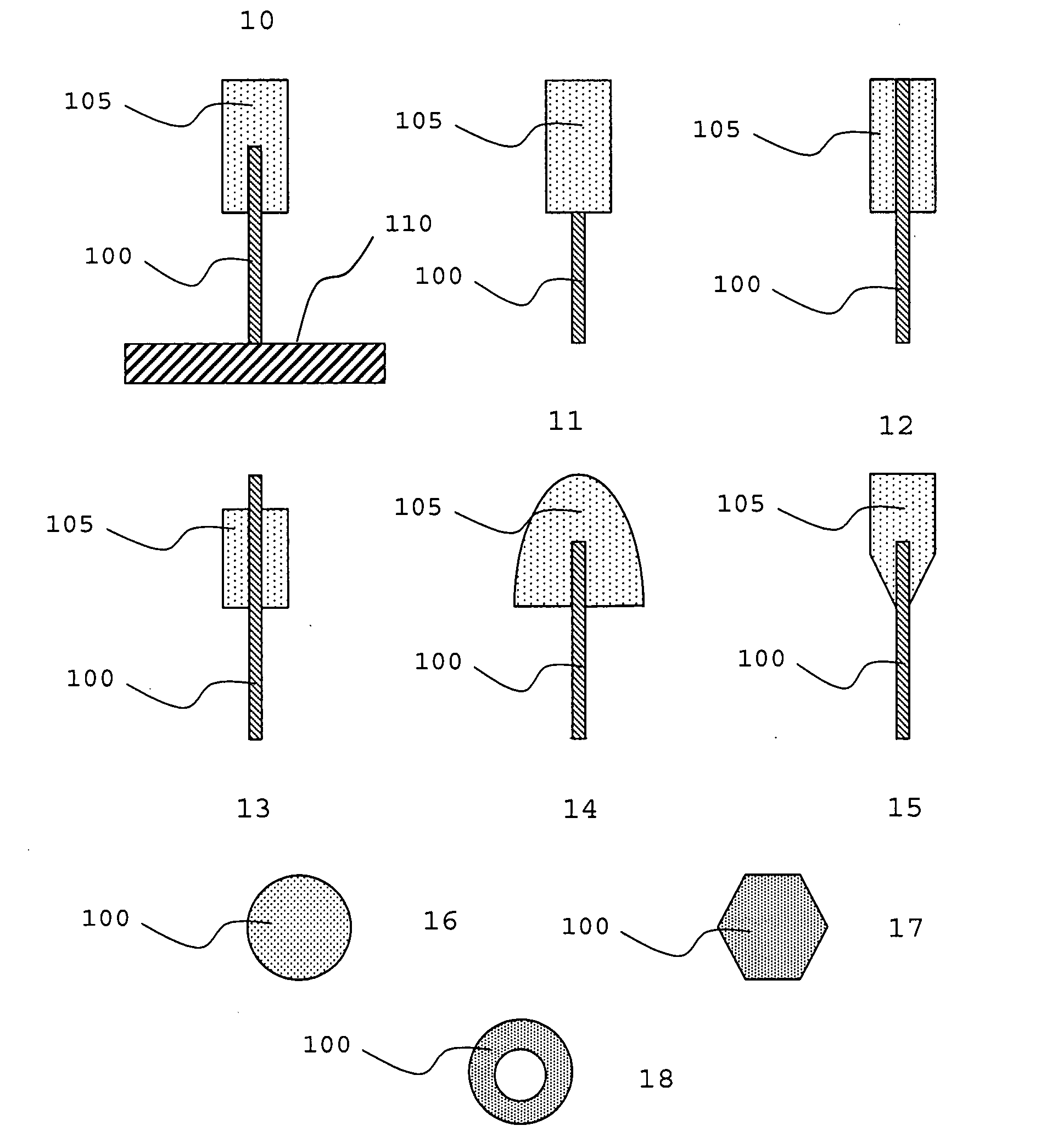

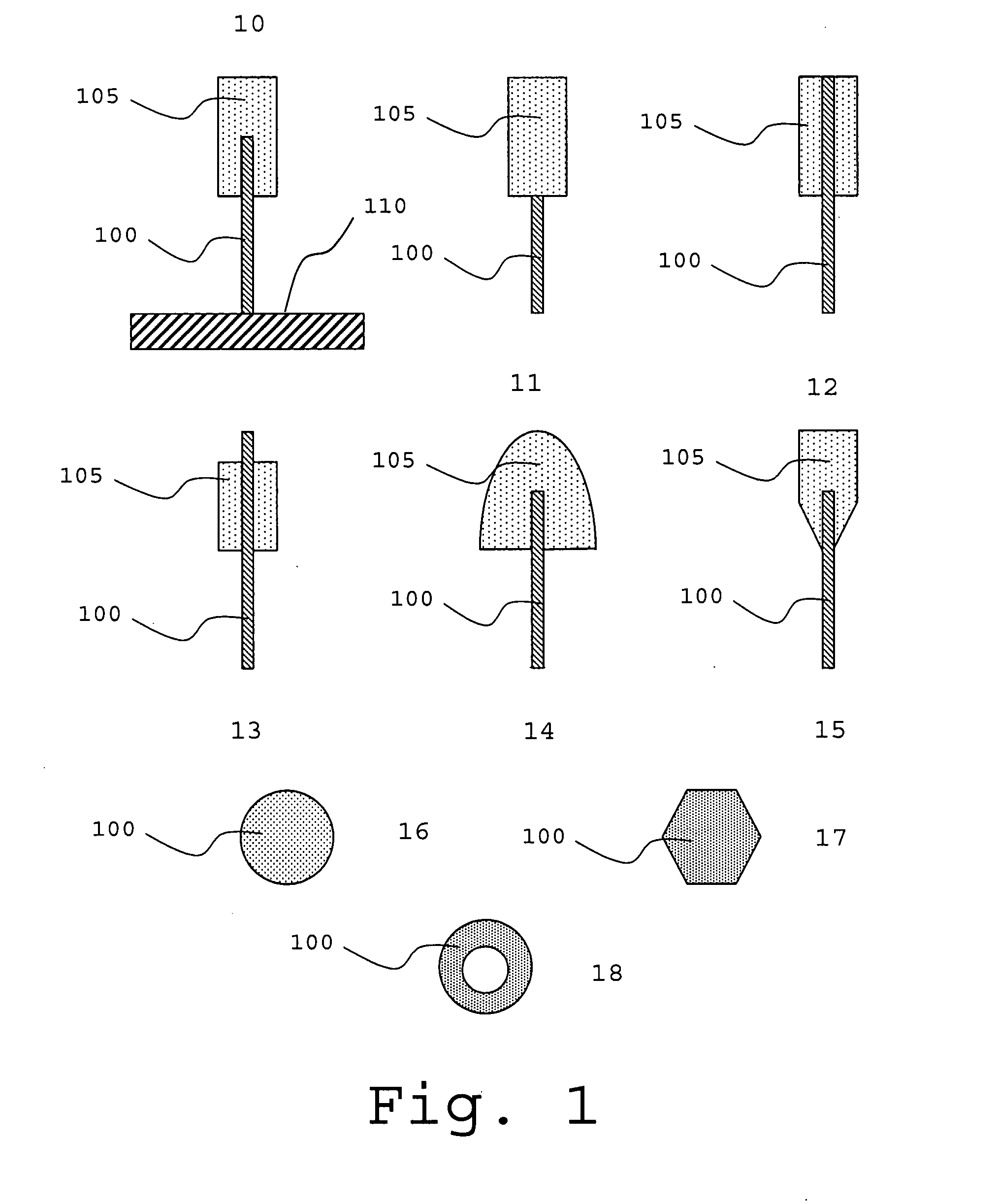

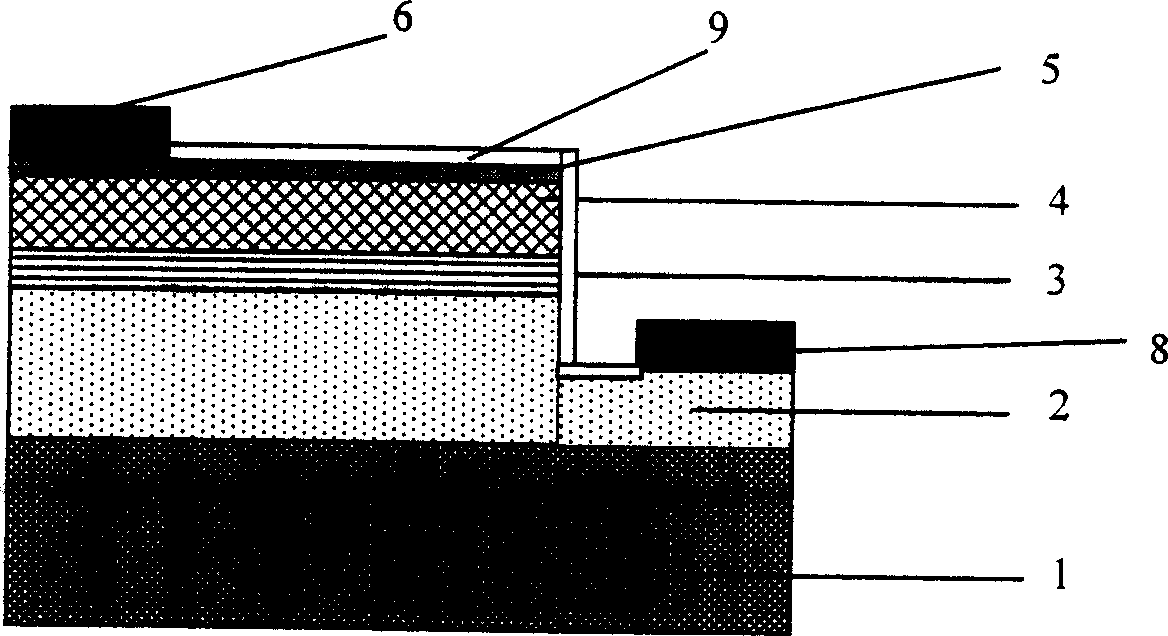

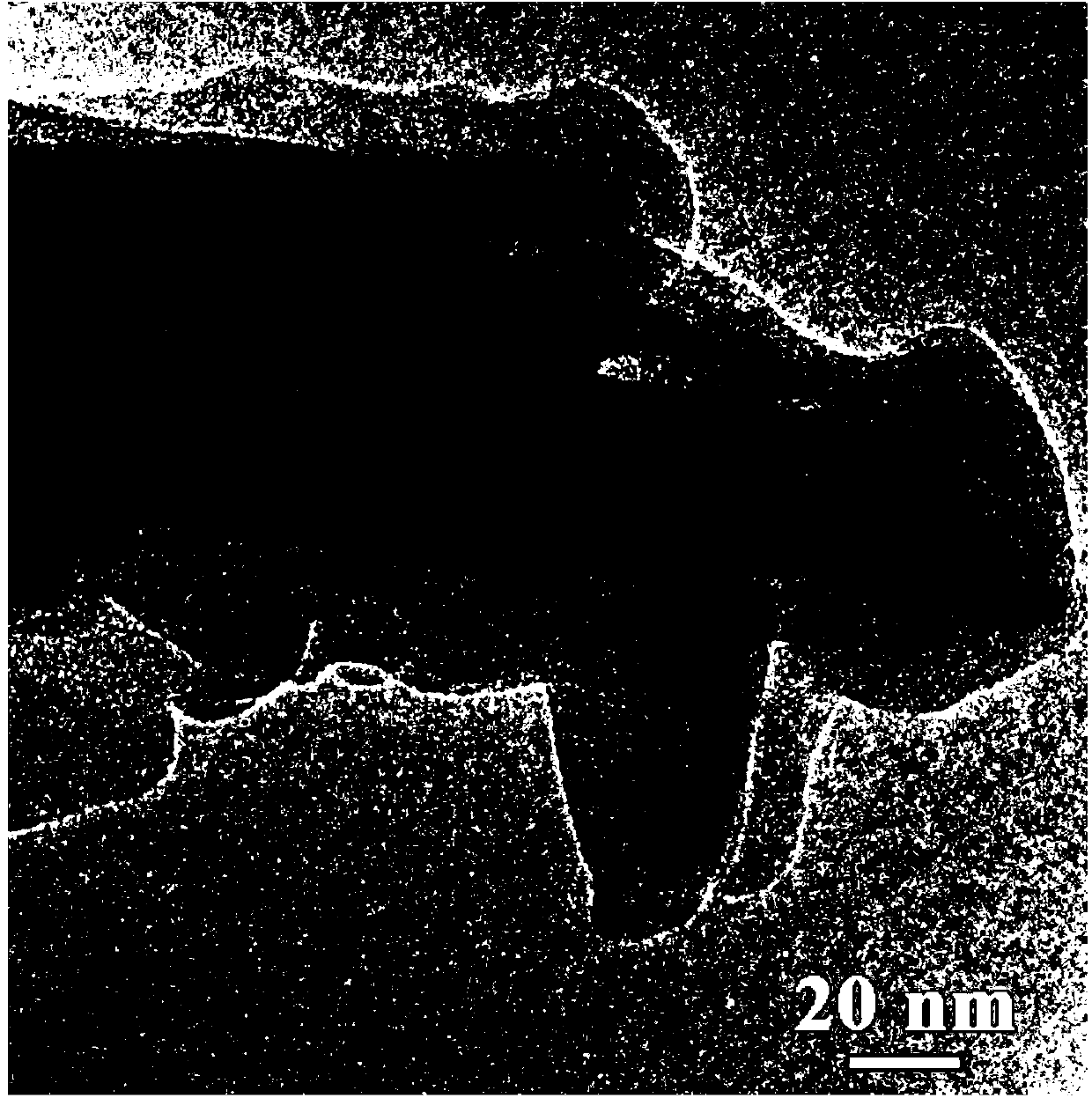

Nanoelectronic structure and method of producing such

InactiveUS20080149914A1Good electrical conductivityImproved/tailored pn-junctionsIndividual molecule manipulationNanoinformaticsAccess resistanceElectrical connection

The present invention relates to semiconductor devices comprising semiconductor nanoelements. In particular the invention relates to devices having a volume element having a larger diameter than the nanoelement arranged in epitaxial connection to the nanoelement. The volume element is being doped in order to provide a high charge carrier injection into the nanoelement and a low access resistance in an electrical connection. The nanoelement may be upstanding from a semiconductor substrate. A concentric layer of low resistivity material forms on the volume element forms a contact.

Owner:QUNANO

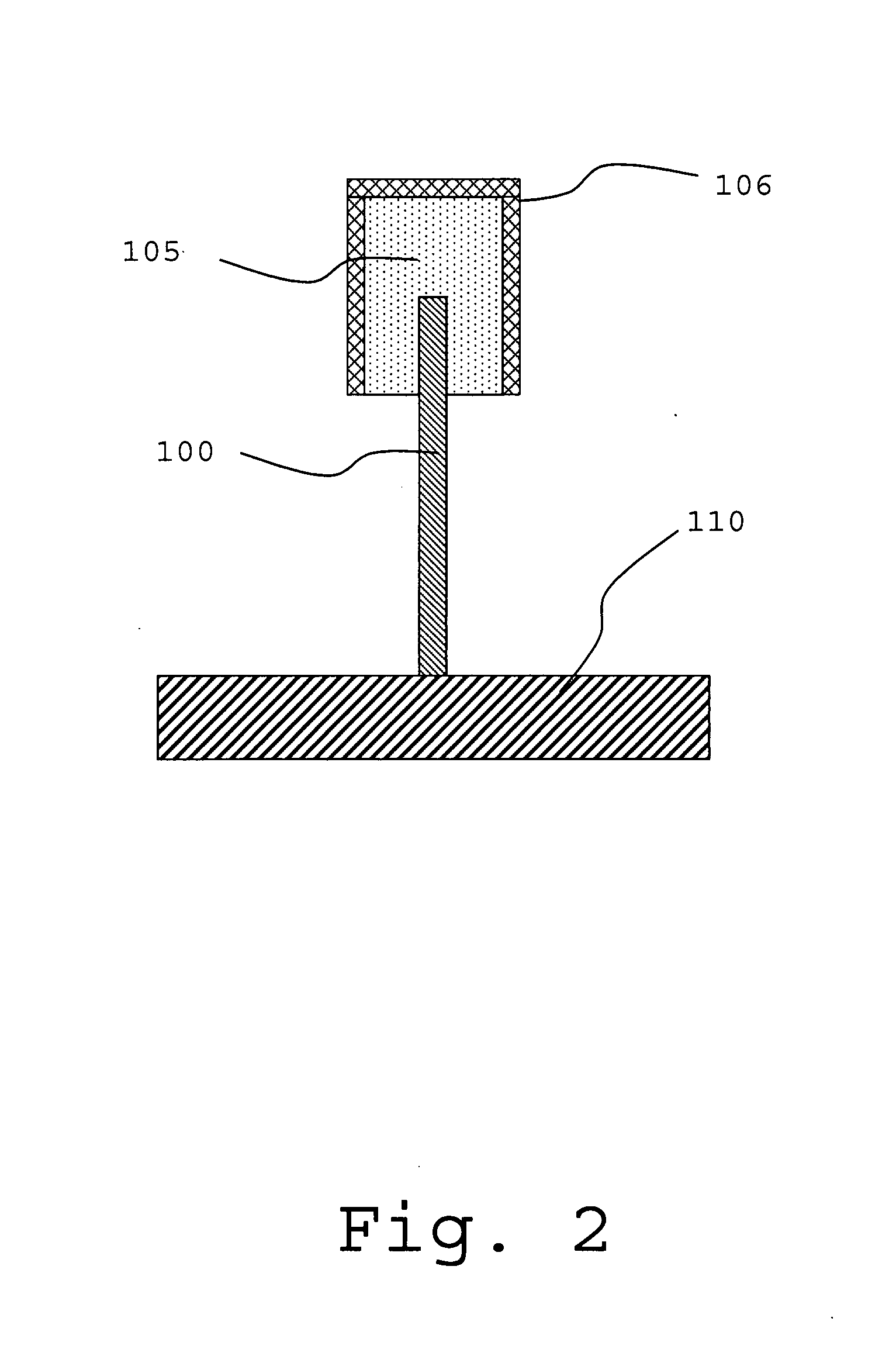

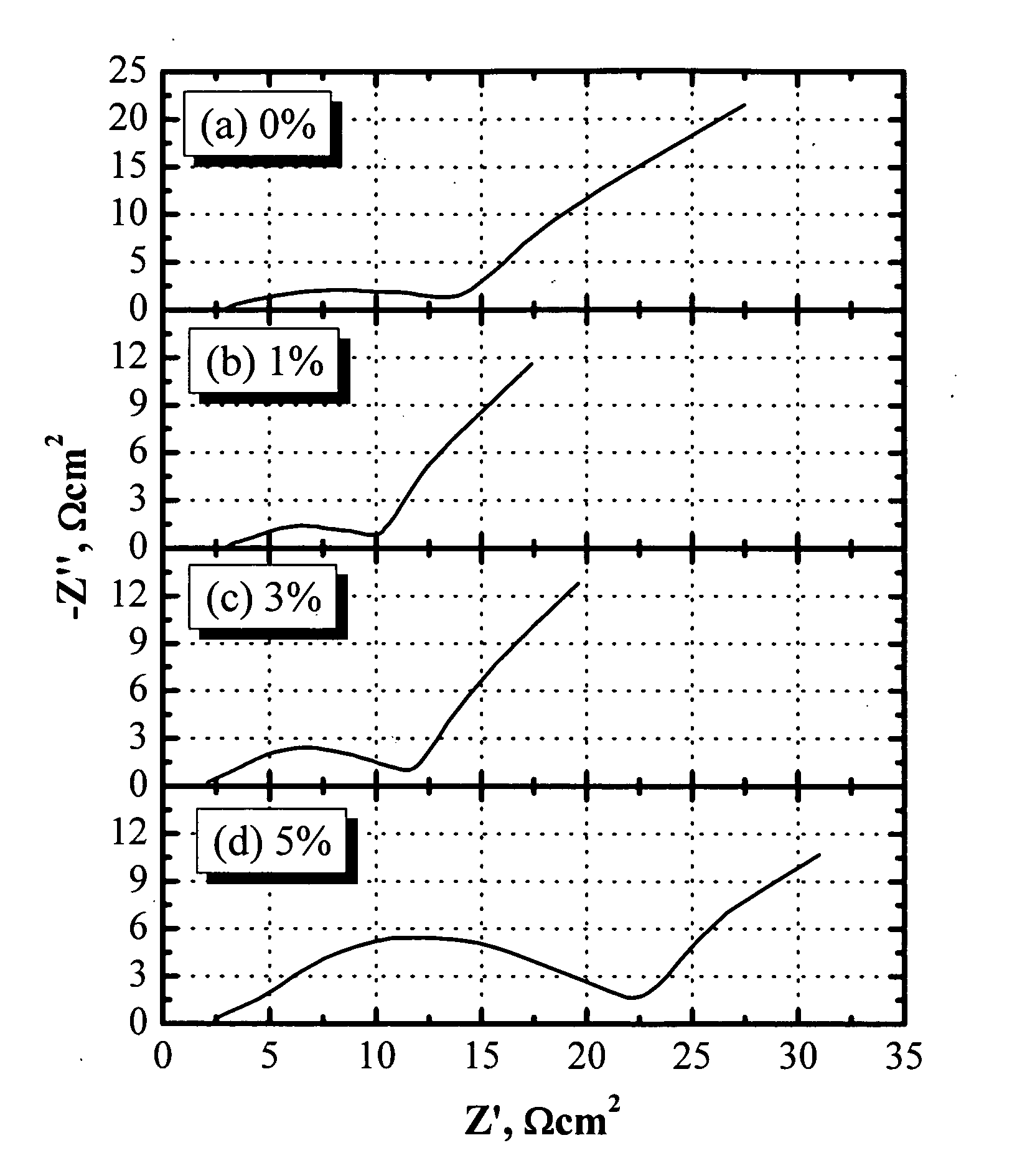

Non-aqueous electrolytes for lithium ion batteries

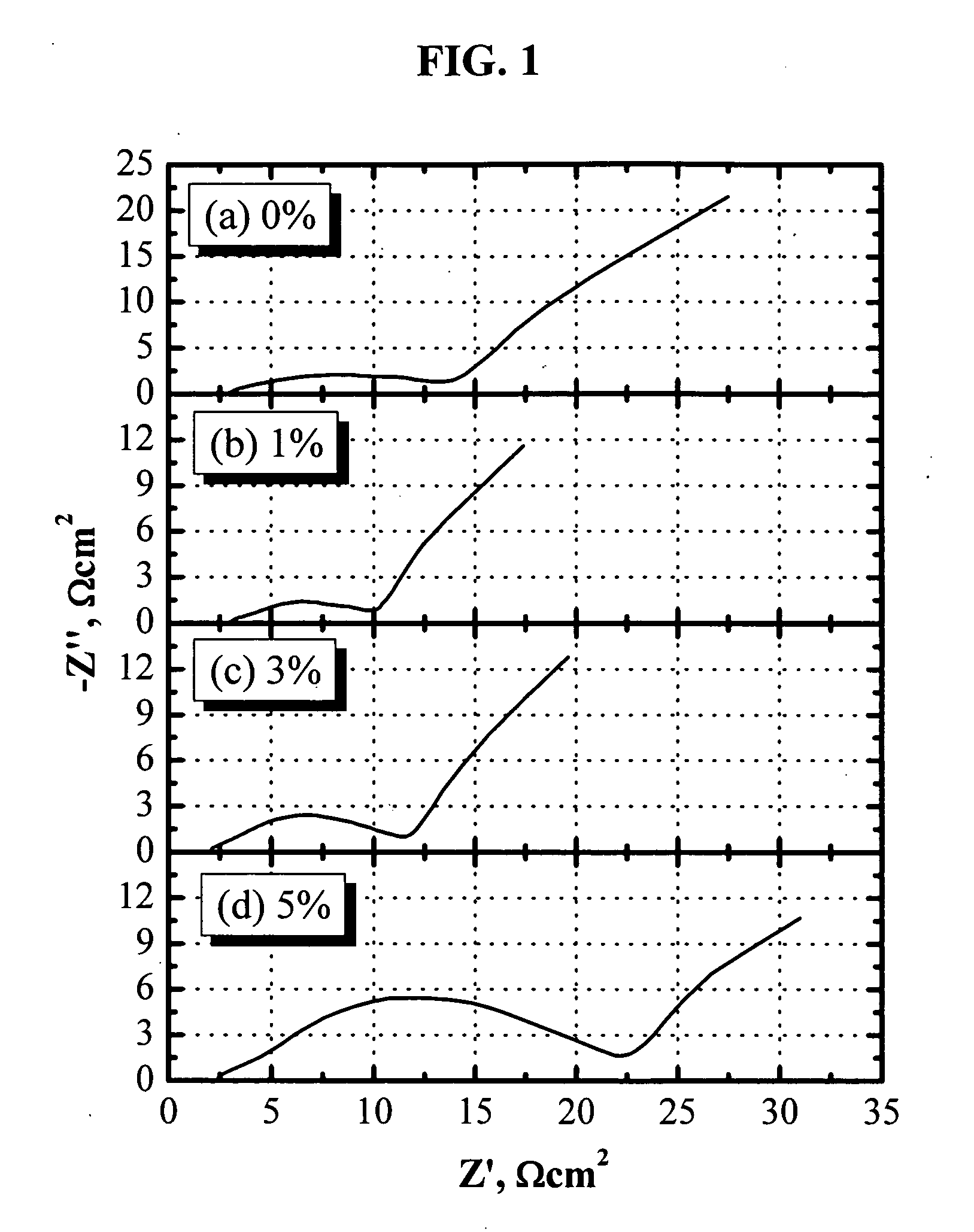

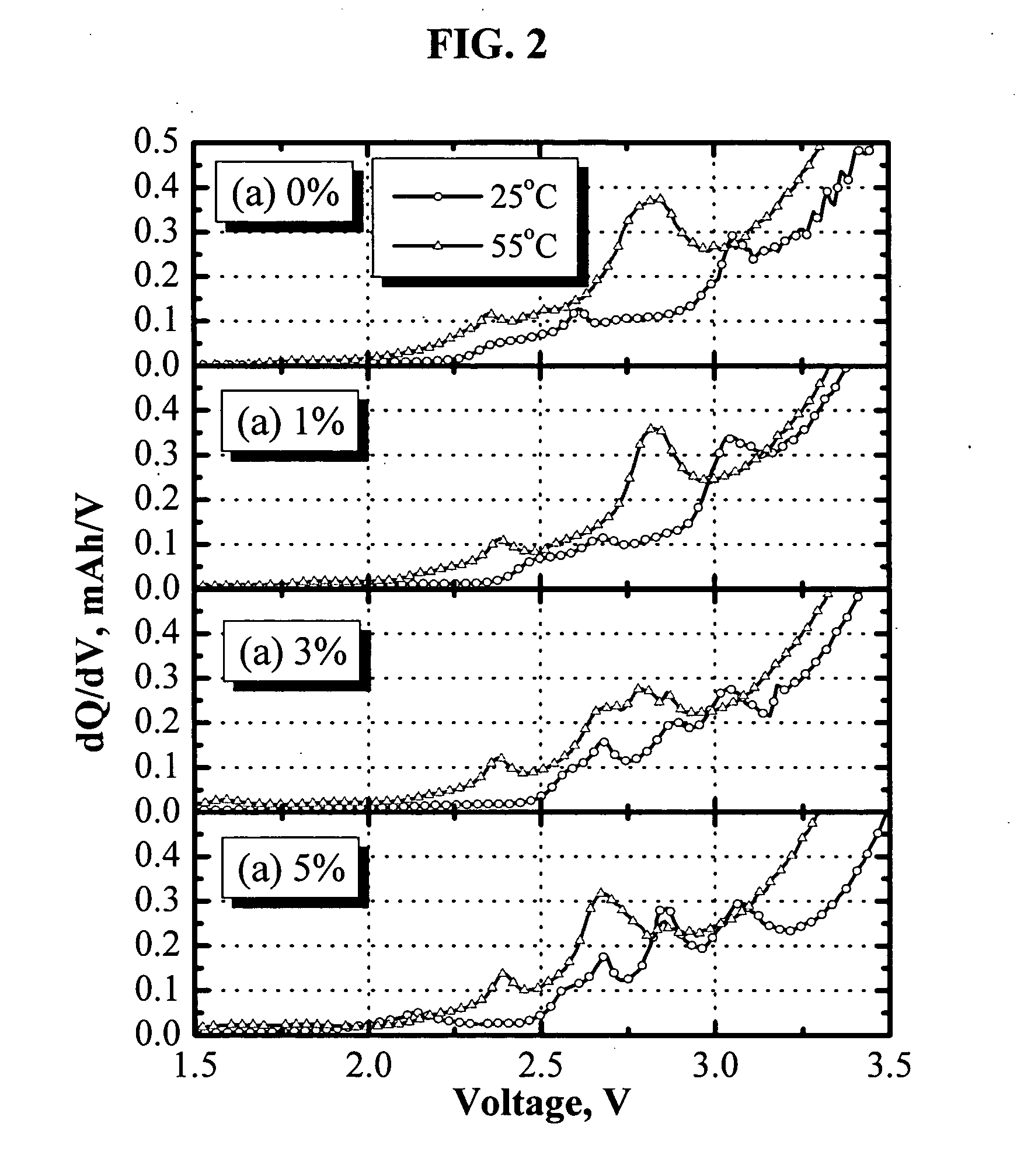

ActiveUS20060210883A1Good electrical conductivityLower impedanceCell electrodesOrganic electrolyte cellsSolventPower capability

The present invention is generally related to electrolytes containing anion receptor additives to enhance the power capability of lithium-ion batteries. The anion receptor of the present invention is a Lewis acid that can help to dissolve LiF in the passivation films of lithium-ion batteries. Accordingly, one aspect the invention provides electrolytes comprising a lithium salt; a polar aprotic solvent; and an anion receptor additive; and wherein the electrolyte solution is substantially non-aqueous. Further there are provided electrochemical devices employing the electrolyte and methods of making the electrolyte.

Owner:UCHICAGO ARGONNE LLC

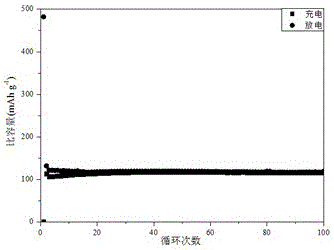

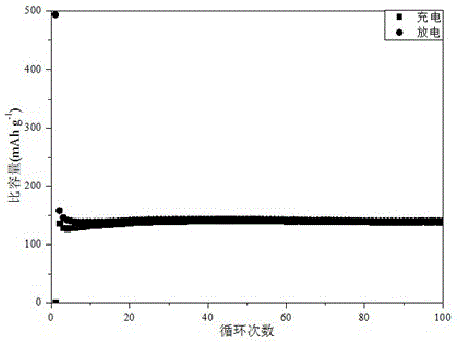

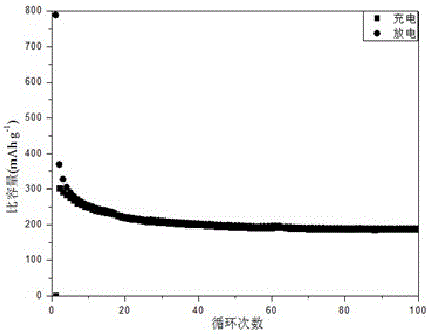

Preparation method and application of nitrogen-doped MXene battery anode material

ActiveCN106025200AGood electrical conductivityLow ion diffusion resistanceCell electrodesSecondary cellsChemistryPlasma treatment

The invention discloses a preparation method of a nitrogen-doped MXene battery anode material and application thereof in a lithium ion battery and a sodium ion battery. The preparation method of the nitrogen-doped MXene battery anode material comprises two steps of preparation of an MXene material and nitrogen doping on the MXene material, wherein the invention discloses a solvothermal method, a thermal treatment method, a plasma treatment method and a microwave irradiation gas phase method which are used for carrying out the nitrogen doping on the MXene material. According to the preparation method of the nitrogen-doped MXene battery anode material, disclosed by the invention, the nitrogen-doped MXene battery anode material prepared through multiple methods has good conductivity, good cyclic stability, good rate capability and higher specific surface area, and is suitable for large-scale development and application of the lithium ion battery or the sodium ion battery.

Owner:ZHEJIANG UNIV

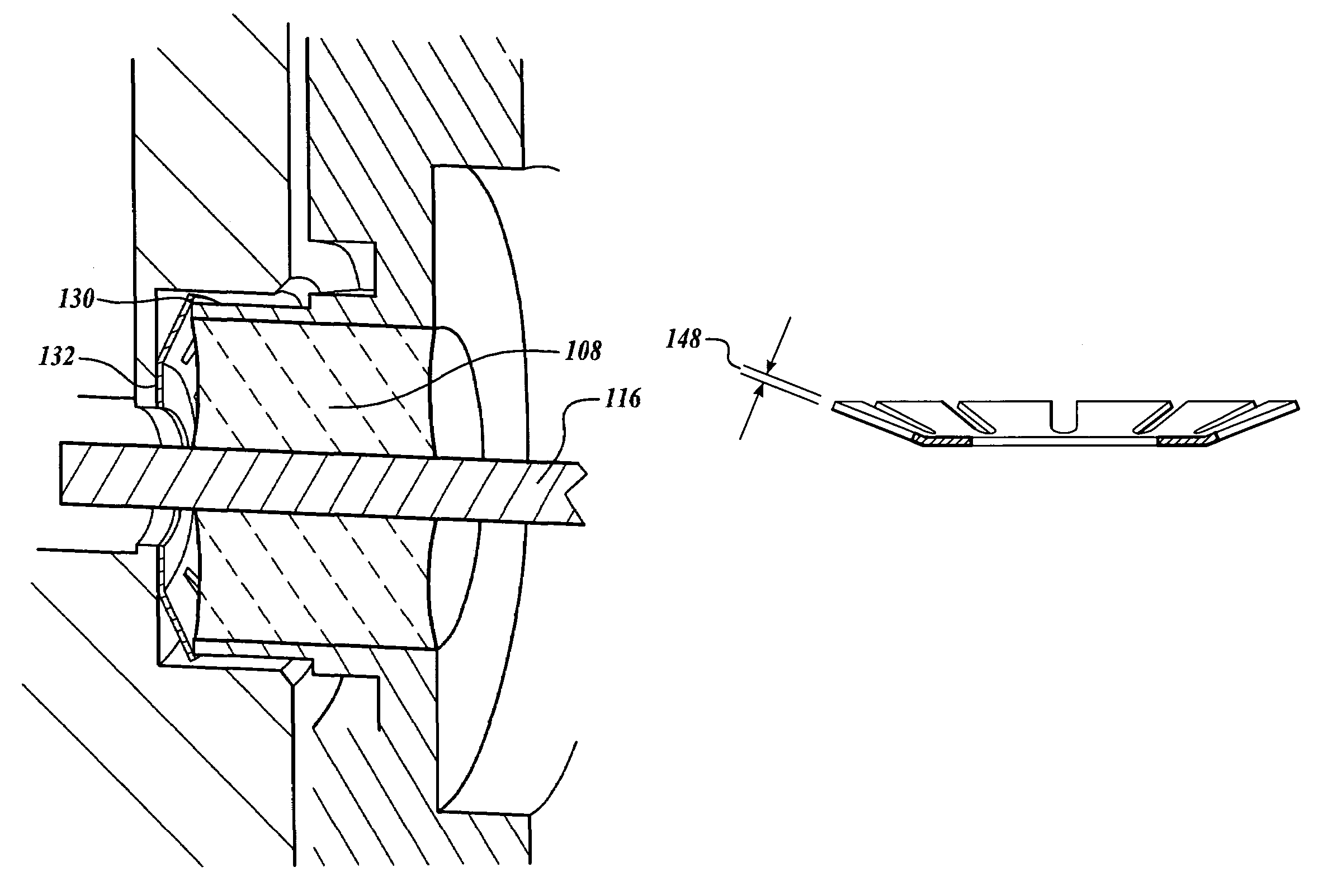

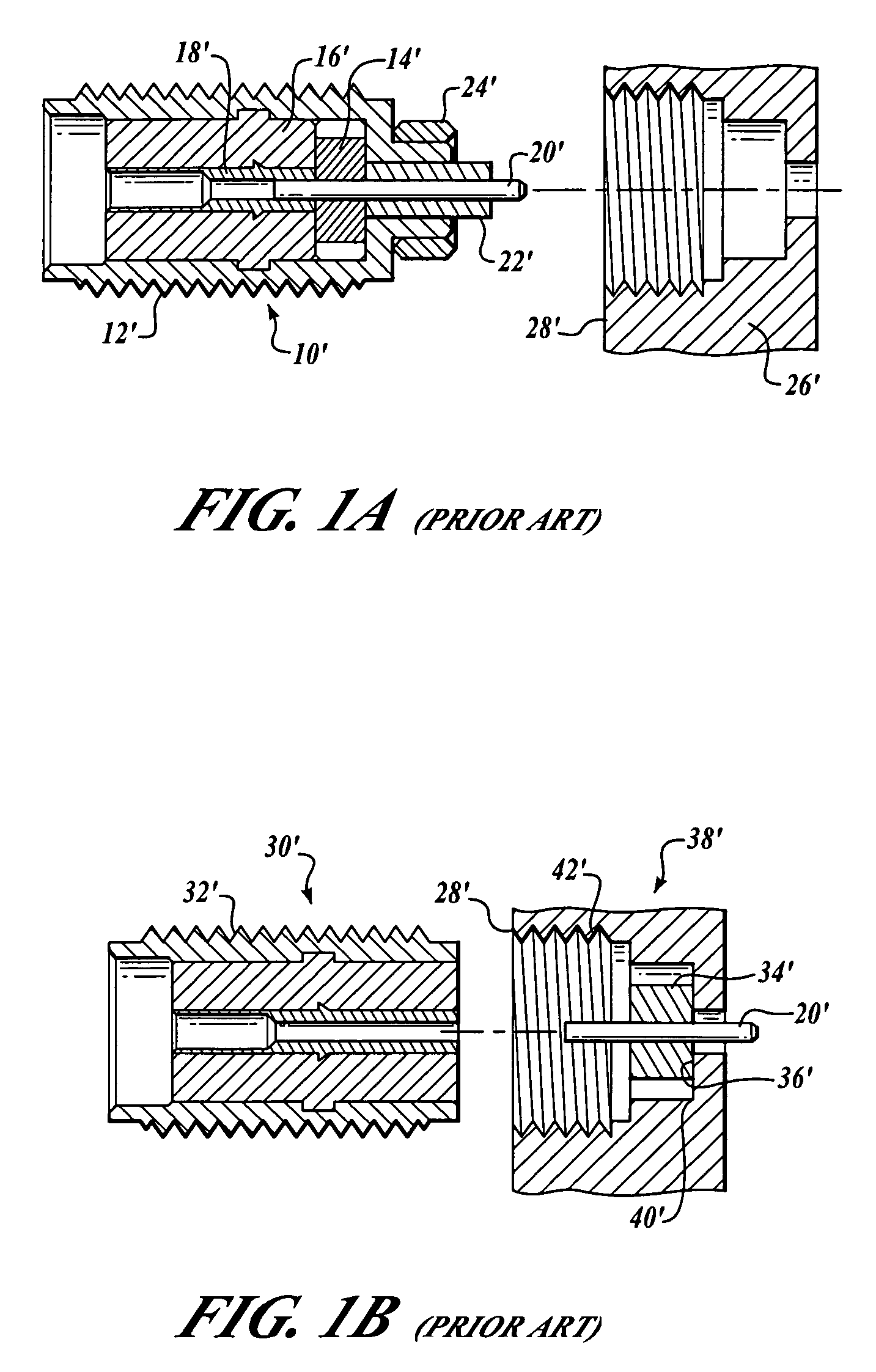

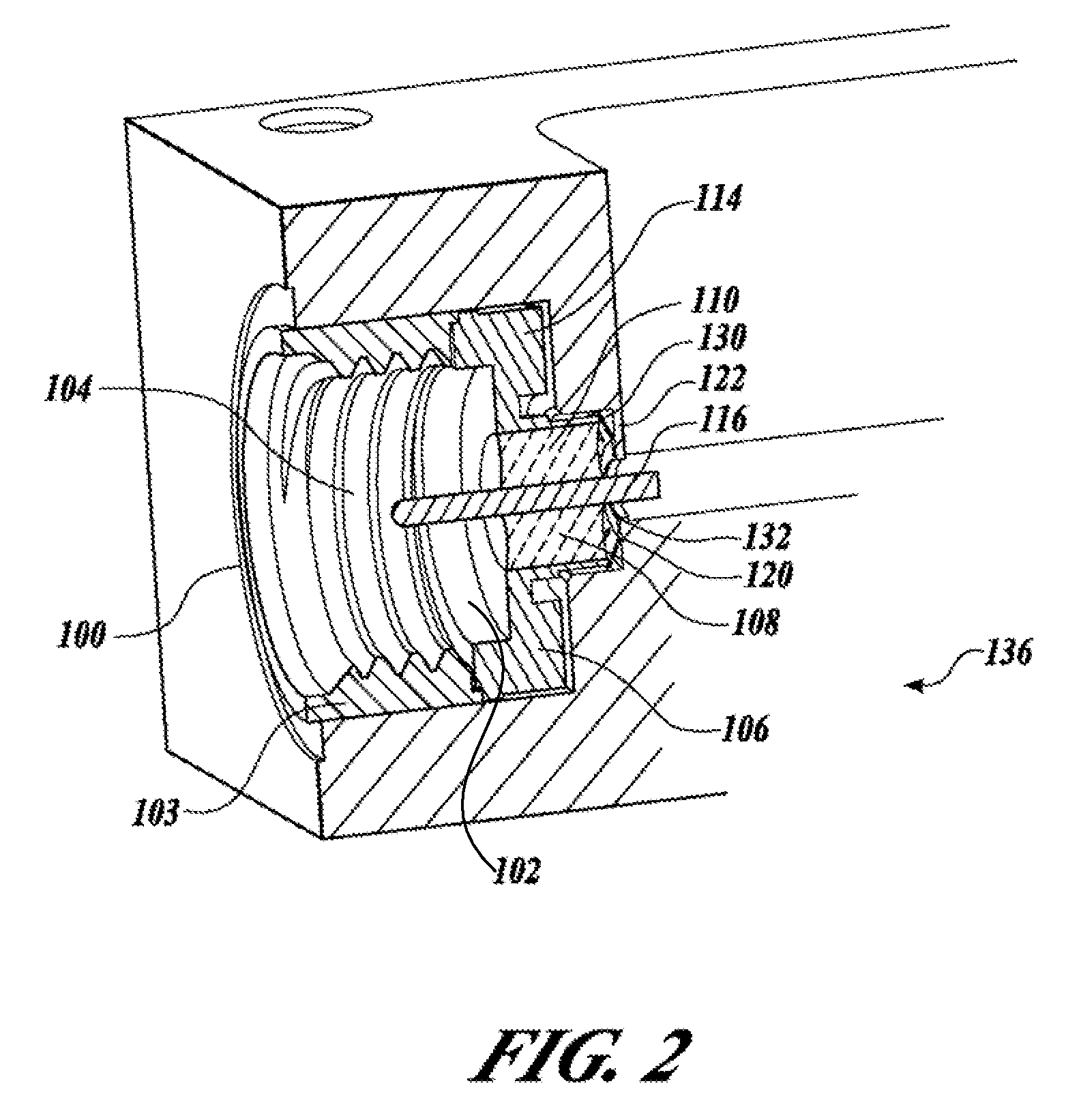

RF connectors having ground springs

ActiveUS7131867B1High conductanceGood electrical conductivityTwo pole connectionsTwo-part coupling devicesThermal fluctuationsAirplane

Radio frequency (RF) connectors and electronics housings and packages employing one or more inventive RF connector(s) provided herein utilize a ground spring to achieve improved conductivity of the ground signal by making a plurality of contacts with a ferrule member of the RF connector's hermetic feedthru and a plurality of contacts with the electronics housing or package at points adjacent to an air dielectric. Ground springs used in connection with the present RF connectors maintain predetermined spring properties under compression and / or extreme environmental conditions, including thermal fluctuations, and therefore may be suitably employed in aircraft and spacecraft.

Owner:PACIFIC AEROSPACE & ELECTRONICS

Graphene-coated porous silicon-carbon composite and method of manufacturing the same

ActiveUS20170047584A1Good electrical propertiesGood electrical conductivityElectrode thermal treatmentNegative electrodesSilicon particleCarbon composites

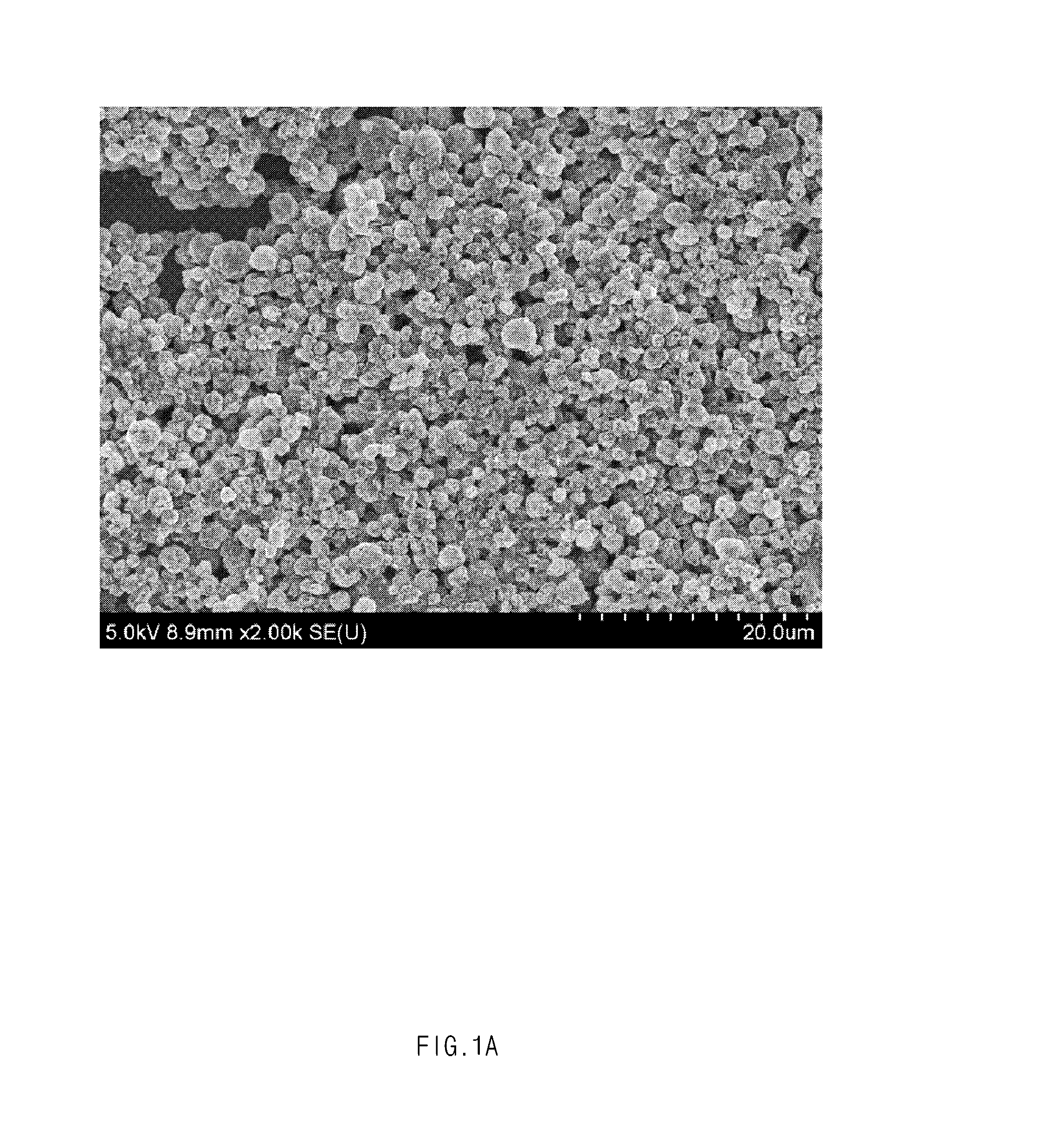

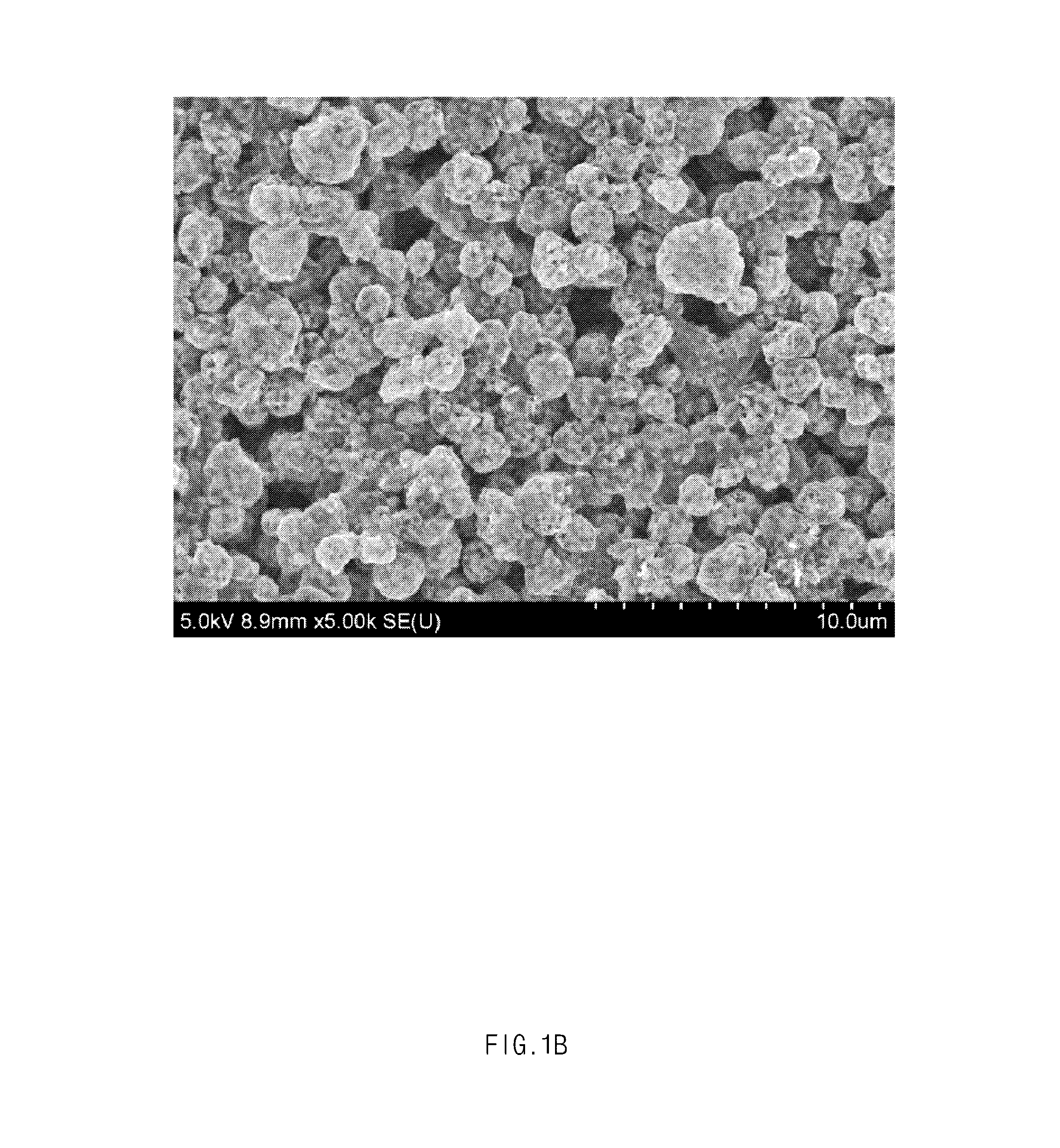

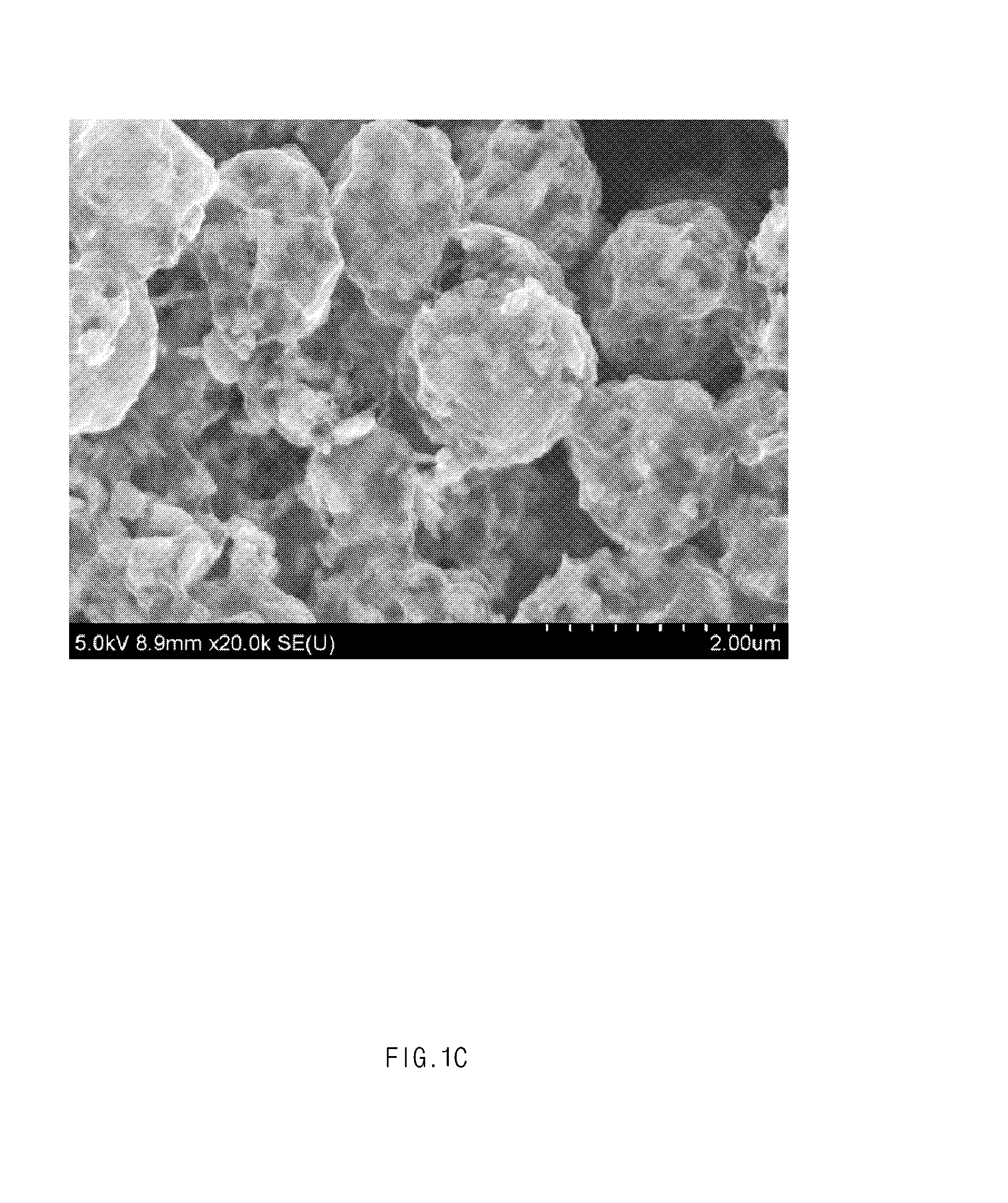

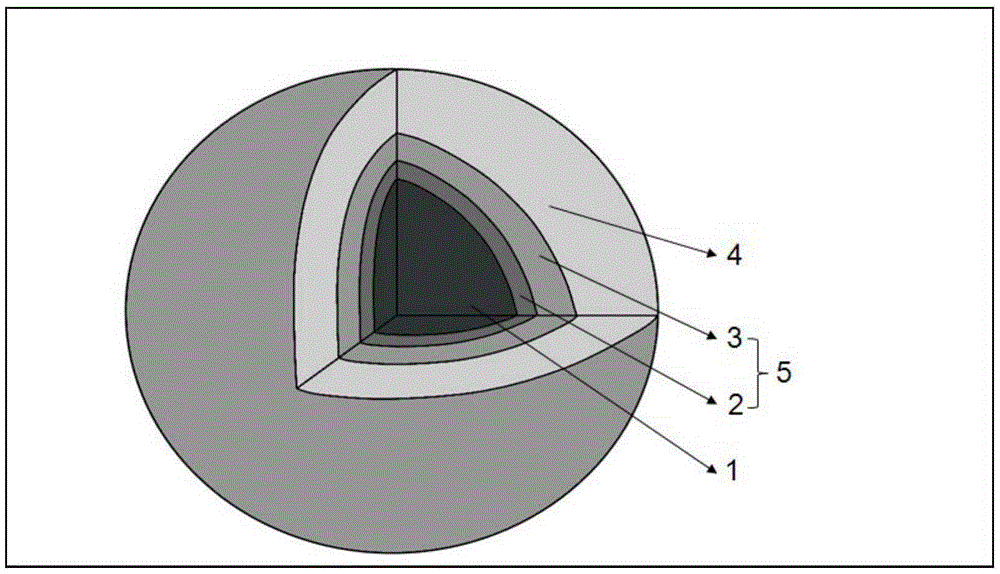

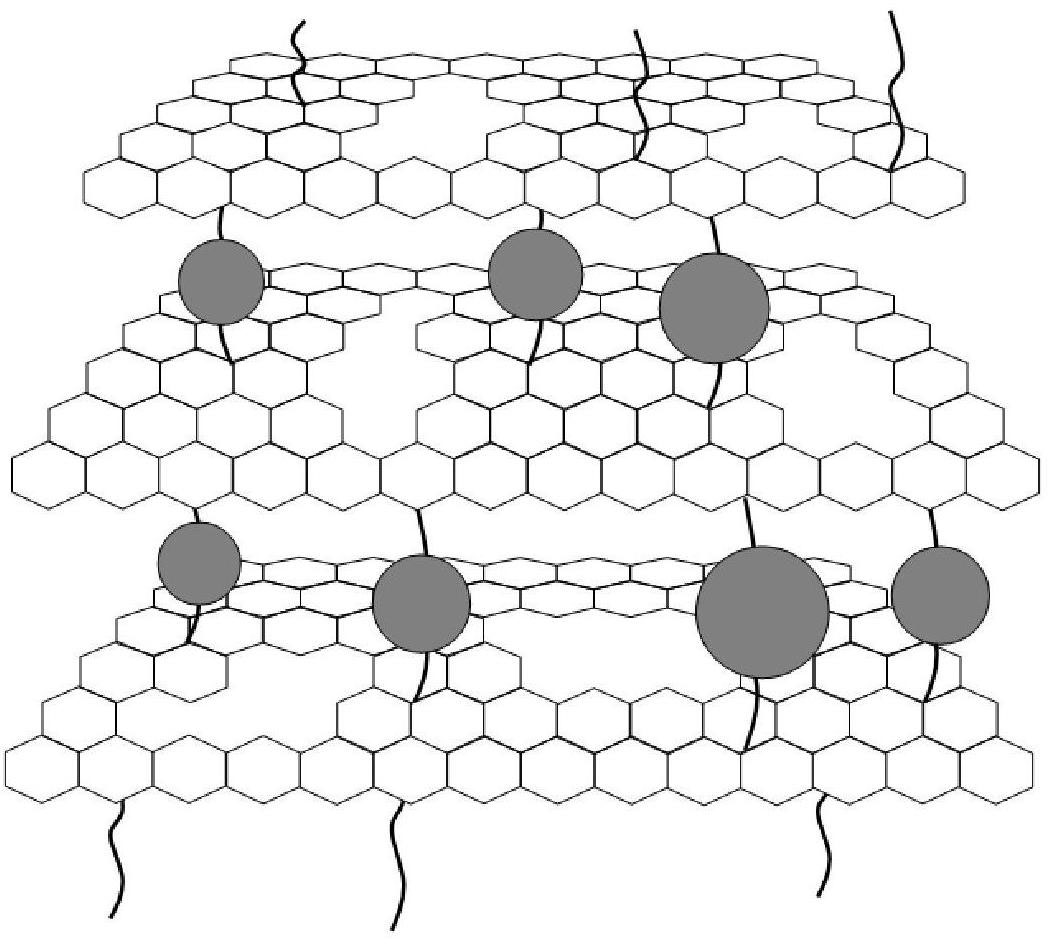

Provided are a porous silicon-carbon composite, which includes a core including a plurality of active particles, a conductive material formed on at least a portion of surfaces of the active particles, first pores, and second pores, and a first shell layer which is coated on the core and includes graphene, wherein the active particles include a plurality of silicon particles, silicon oxide particles, or a combination thereof, the first pores are present in the core and are formed by agglomeration of the plurality of active particles, and the second pores are irregularly dispersed and present in the core, has an average particle diameter smaller than an average particle diameter of the active particles, and are spherical, a method of manufacturing the same, and a negative electrode and a lithium secondary battery including the porous silicon-carbon composite.

Owner:LG ENERGY SOLUTION LTD

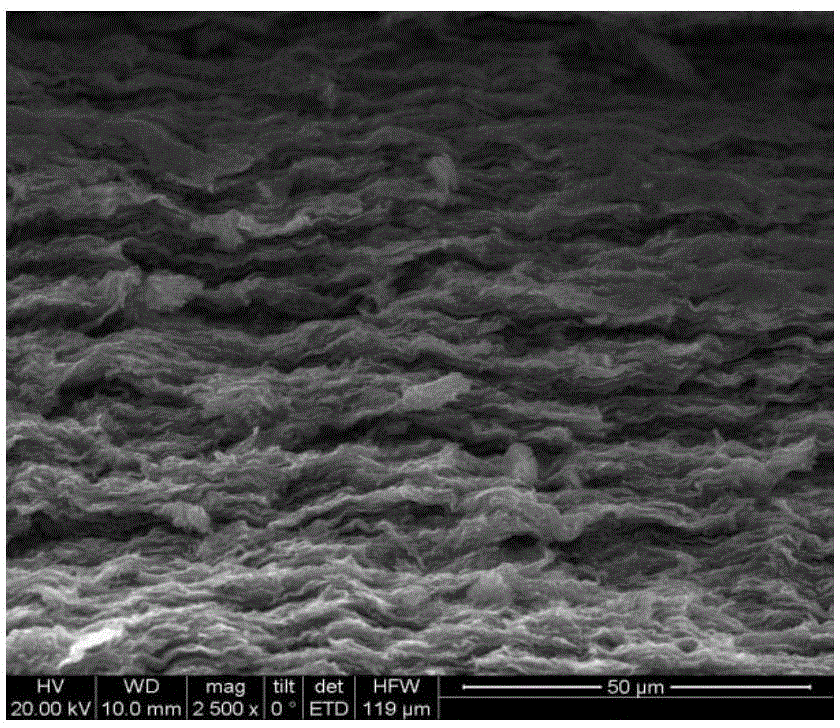

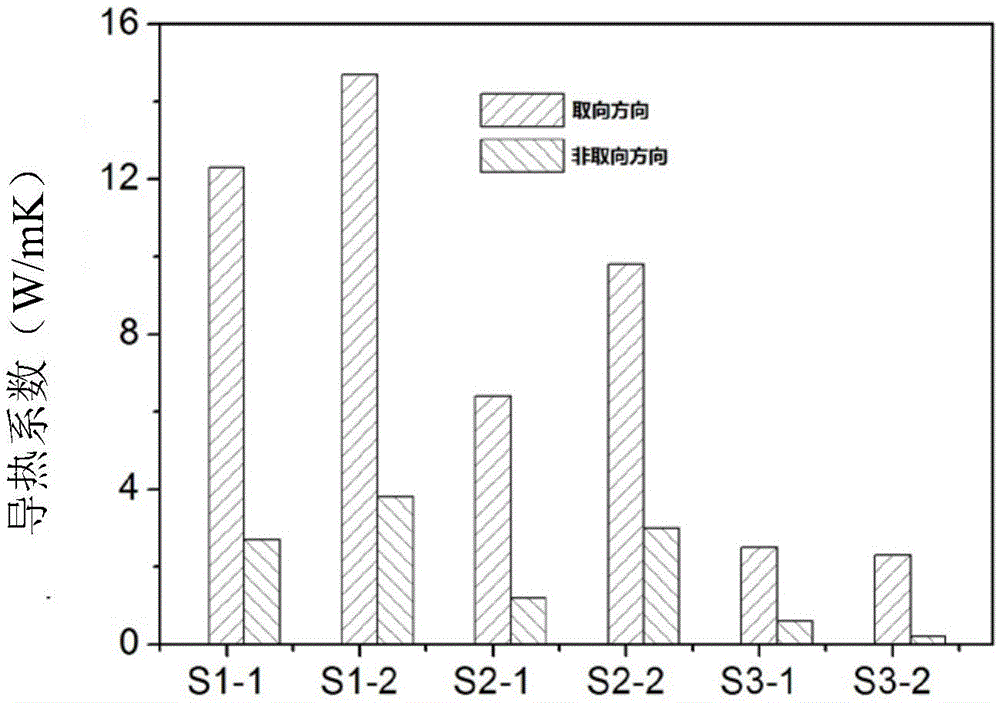

Oriented graphene/polymer composite system, and preparation method and application thereof

InactiveCN105176086AGood electrical conductivityEfficient deliveryNon-macromolecular adhesive additivesHeat-exchange elementsGraphitePolymer composites

An oriented graphene / polymer composite system, and a preparation method and an application thereof are provided. The composite system includes an oriented network component at least including graphene and a substrate component compounded with the oriented network component, wherein at least a part of graphene is arranged according to set orientation; the composite system at least has a heat conductivity coefficient in the set direction higher than heat conductivity coefficients in other directions. The preparation method includes the steps: the oriented network component is subjected to orientation treatment, at least a part of graphene is arranged according to the set orientation, and thus an oriented network is formed; and the substrate component at least containing a polymer is taken to be compounded with the oriented network component, and thus the composite system is formed. The composite system has high heat conductivity and high electrical conductive characteristic, can efficiently transfer heat in a needed direction when in use, has the characteristics of being simple, high in efficiency and the like, is suitable for scale production, and has broad application prospects in high-efficiency heat conductivity and heat dissipation.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Silicon dioxide composite anode material for lithium ion battery, as well as preparation method and application of silicon dioxide composite anode material

ActiveCN104022257AImprove electronic conductivityImprove efficiencyCell electrodesSecondary cellsLithium electrodeVolume effect

The invention discloses a silicon dioxide composite anode material for a lithium ion battery, as well as a preparation method and an application of the silicon dioxide composite anode material. The silicon dioxide composite anode material is prepared from the components of silicon dioxide powder and a conductive carbon layer with the surface of the silicon dioxide powder is uniformly and densely coated. With the adoption of the silicon dioxide composite anode material, the original component structure of an SiO material system is kept, so that the lower volume effect is ensured; the silicon dioxide dense carbon layer coating structure is successfully realized by adopting the technologies of mixing kneading, sheet rolling, press forming and the like, and thus the first coulombic efficiency of the silicon dioxide composite anode material is remarkably increased, and can reach a theoretical value being larger than 77 percent, and the cycle performance and the conductive characteristic are also remarkably improved, so that the silicon dioxide composite anode material is suitable for being charged and discharged with the large rate and can be applied to the power market.

Owner:BTR NEW MATERIAL GRP CO LTD +1

Antistatic, antibacterial and graphene-reinforced composite polyester fiber and preparation method thereof

InactiveCN103710790AGood spinnabilityGood electrical conductivityFilament/thread formingConjugated synthetic polymer artificial filamentsCvd grapheneChemistry

The invention provides an antistatic, antibacterial and graphene-reinforced composite polyester fiber, which is characterized in that the composite polyester fiber comprises a component A and a component B, wherein the component A is polyester excluding graphene, and the component B is polyester including 0.3-3.0wt% of graphene. The invention also provides a preparation method of the composite polyester fiber. The composite polyester fiber provided by the invention is low in cost, high in strength, and high in antistatic and antibacterial properties.

Owner:厦门翔鹭化纤股份有限公司

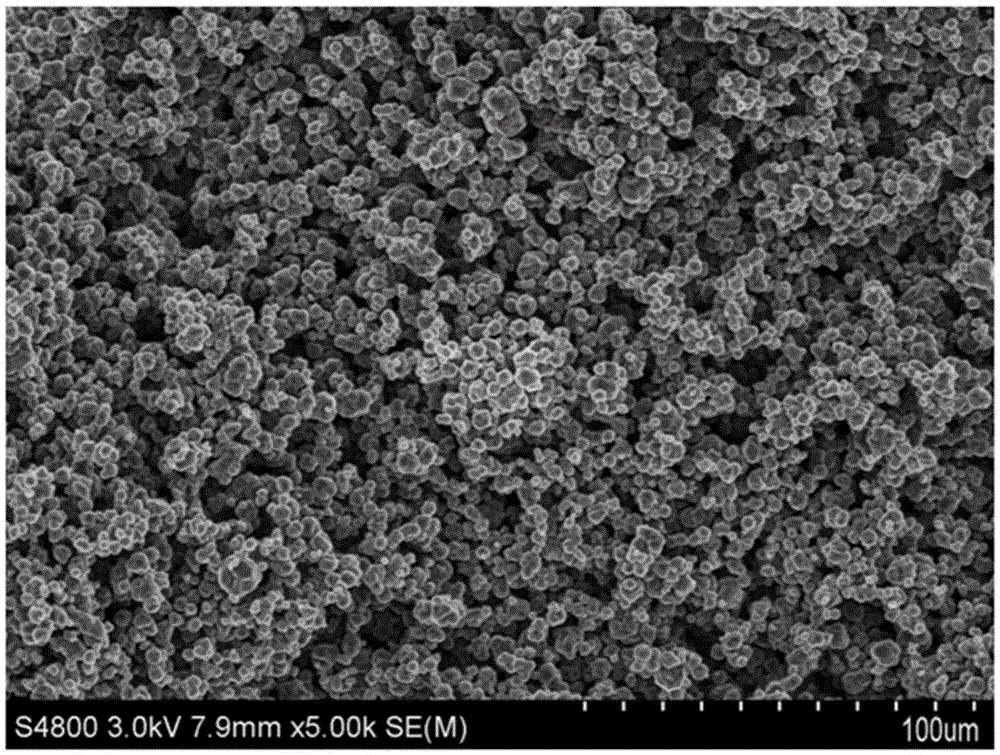

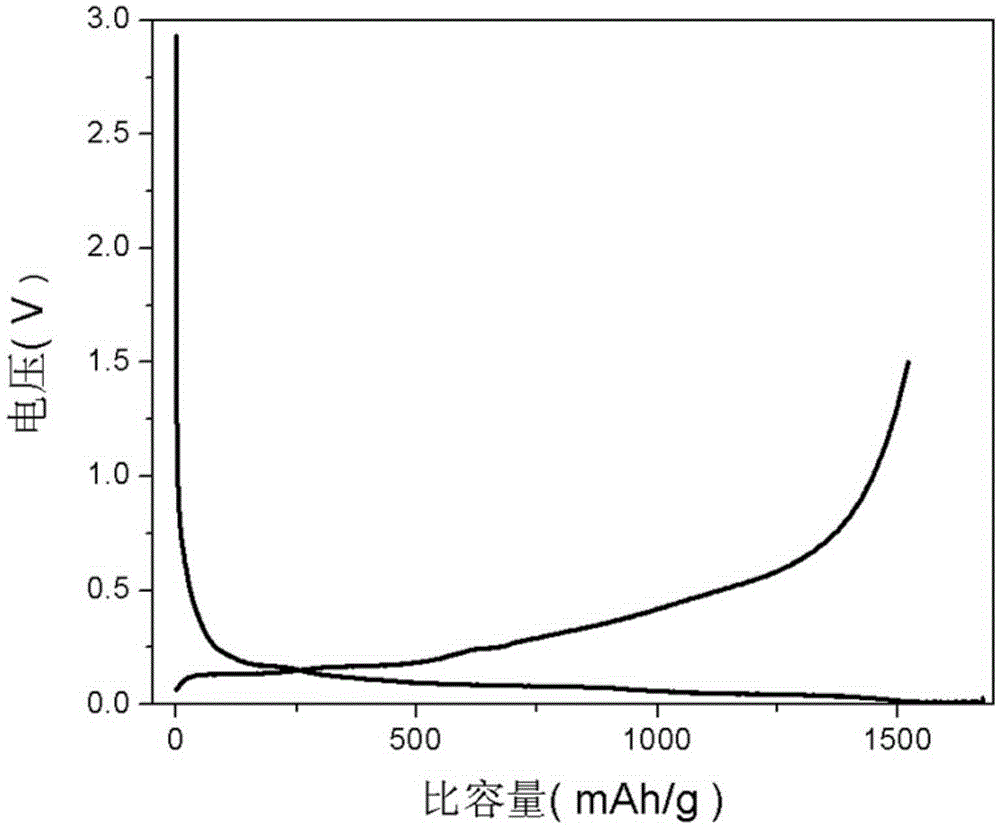

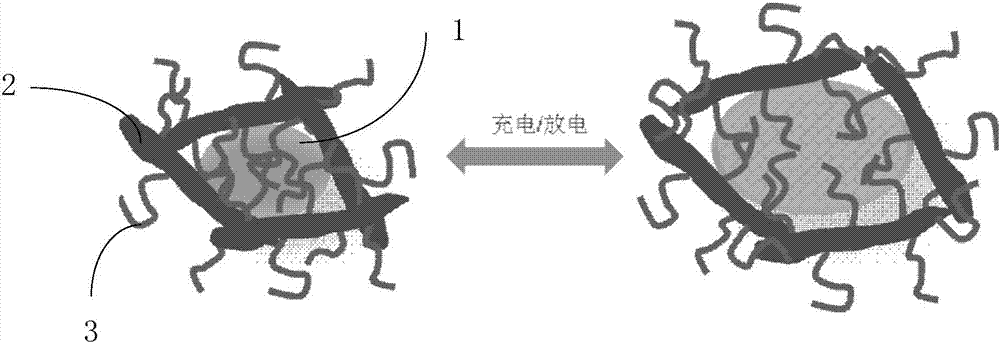

Composite silicon negative electrode material, and preparation method and application thereof

ActiveCN105406050AGood electrical conductivityIncrease capacitySiliconElectrode thermal treatmentCarbon layerLithium

The invention relates to a composite silicon negative electrode material. The composite silicon negative electrode material comprises nanometer silicon, a nanometer composite layer coating the surface of nanometer silicon and a conductive carbon layer uniformly coating the nanometer composite layer, wherein the nanometer composite layer is silicon oxide and metal alloy. According to the composite silicon negative electrode material with a three-layer structure, the nanometer composite layer composed of the silicon oxide and the metal alloy coating the surface of the silicon oxide effectively reduces volume expansion of the nanometer silicon, maintains the characteristic of high conductivity of the silicon material, improves mobility of lithium ions, prevents direct contact between a silicon negative electrode and an electrolyte, and can form a hard SEI film on the surface of the composite silicon negative electrode material, thereby allowing the cycle performance of the material to be substantially enhanced. The composite silicon negative electrode material has the characteristics of high capacity (greater than 1500 mAh / g), long cycle life (with a capacity retention ratio of more than 90% after 300 cycles) and high conductivity. The preparation method for the composite silicon negative electrode material is simple, easily controllable, and applicable to industrial production.

Owner:DINGYUAN NEW ENERGY TECH CO LTD

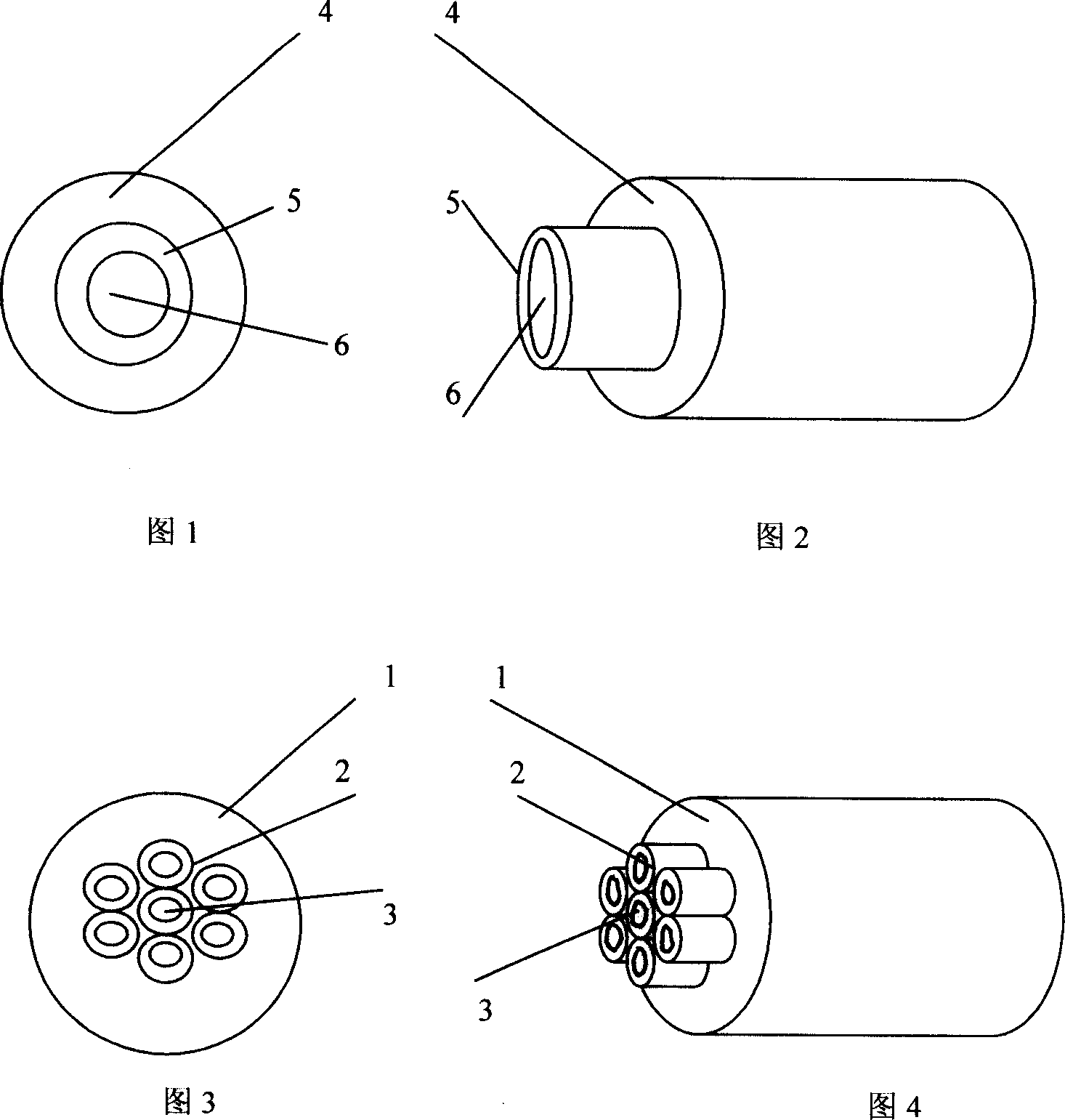

Aluminum core cable and line covered by copper

InactiveCN101086906AGood electrical conductivityHigh strengthRubber insulatorsPlastic/resin/waxes insulatorsCross-linked polyethyleneCopper-clad aluminium wire

The invention uses copper-clad aluminium conductor as conductive wire core whose inner core is aluminium wire and outer is cylinder copper roofing, the conductive wire also can be at least two conductive wire cores of copper-clad aluminium conductor which are parallel or winding with each other, the outer of conductive wire core is covered with insulated layer of PVC or polyethylene or cross-link polyethylene or rubber. The insulated material such as PVC, polyethylene, cross-link polyethylene or rubber is covered around the conductive wire core to produce copper-clad aluminium wire cable. The copper-clad aluminium wire cable possesses the same conductivity as copper core cable with the same specification, weight is light, easy to process, usage is convenient, and copper can be saved for 80% or above, cost of product can be decreased effectively, defects that the surface of aluminium cable is easy to be oxidized, resistance is big, corrosion resistance and machine performance are poor can be avoided.

Owner:大连极速金属复合材料有限公司

Conducting fiber containing nano car bon tube and its prepn. method

ActiveCN1563526AGood electrical conductivityReduce volume resistanceElectroconductive/antistatic filament manufactureMonocomponent polyesters artificial filamentElectrically conductivePolyester

A conducting fiber containing carbon nm tubes includes the following three components polyester, carbon nm tube and coupler with the weight ration of polyester 80-94.9, carbon nm tube 0.05-10, the coupler 0.05-10. The three components are prepared to conducting fibers via mix, extrusion and fiber spinning having the composite shapes of interlayer, sheath-core and island, characterizing in utilizing the fine conductivity of the carbon nm tubes and extremely length-diameter ratio to prepare conducting fibers, Special coupler is selected to strongthen the interaction of carbon nm tube and the polyerter to open the coacervates of the tube in the blend process by cutting.

Owner:TSINGHUA UNIV

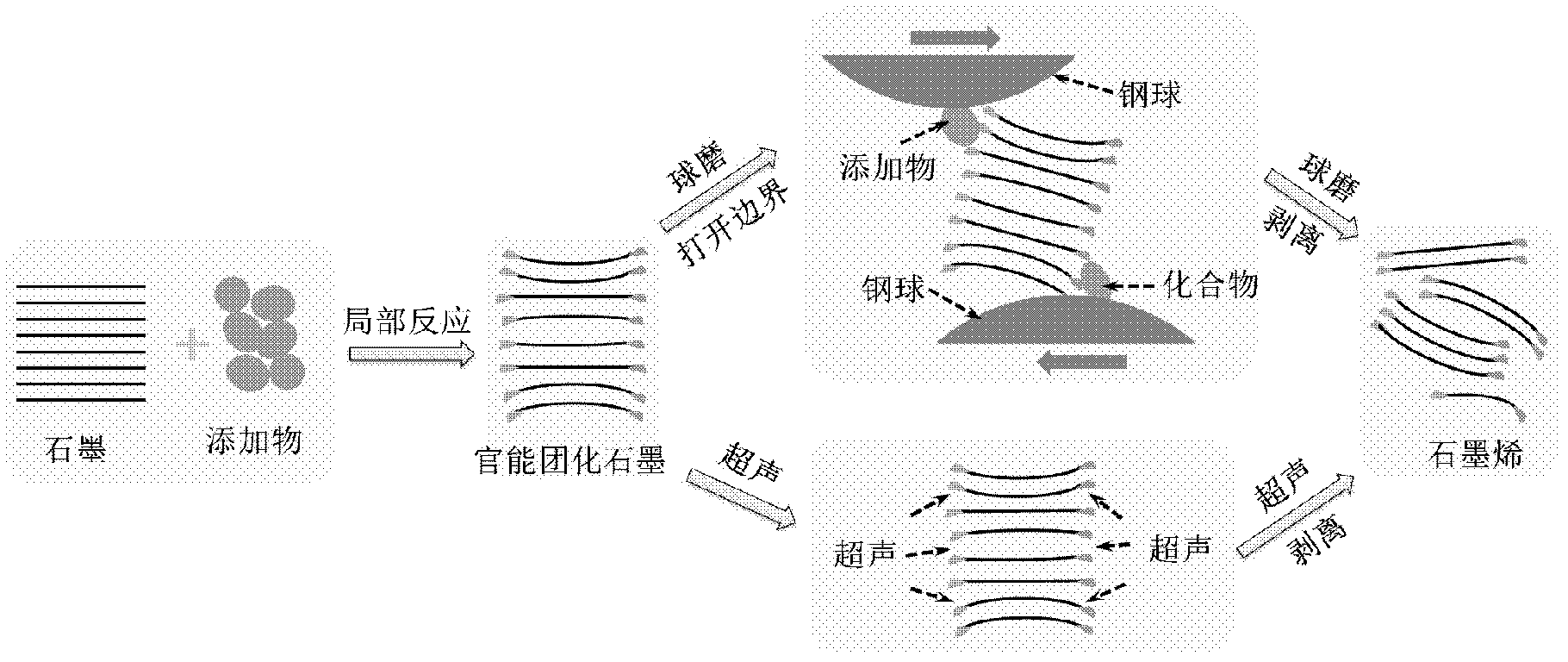

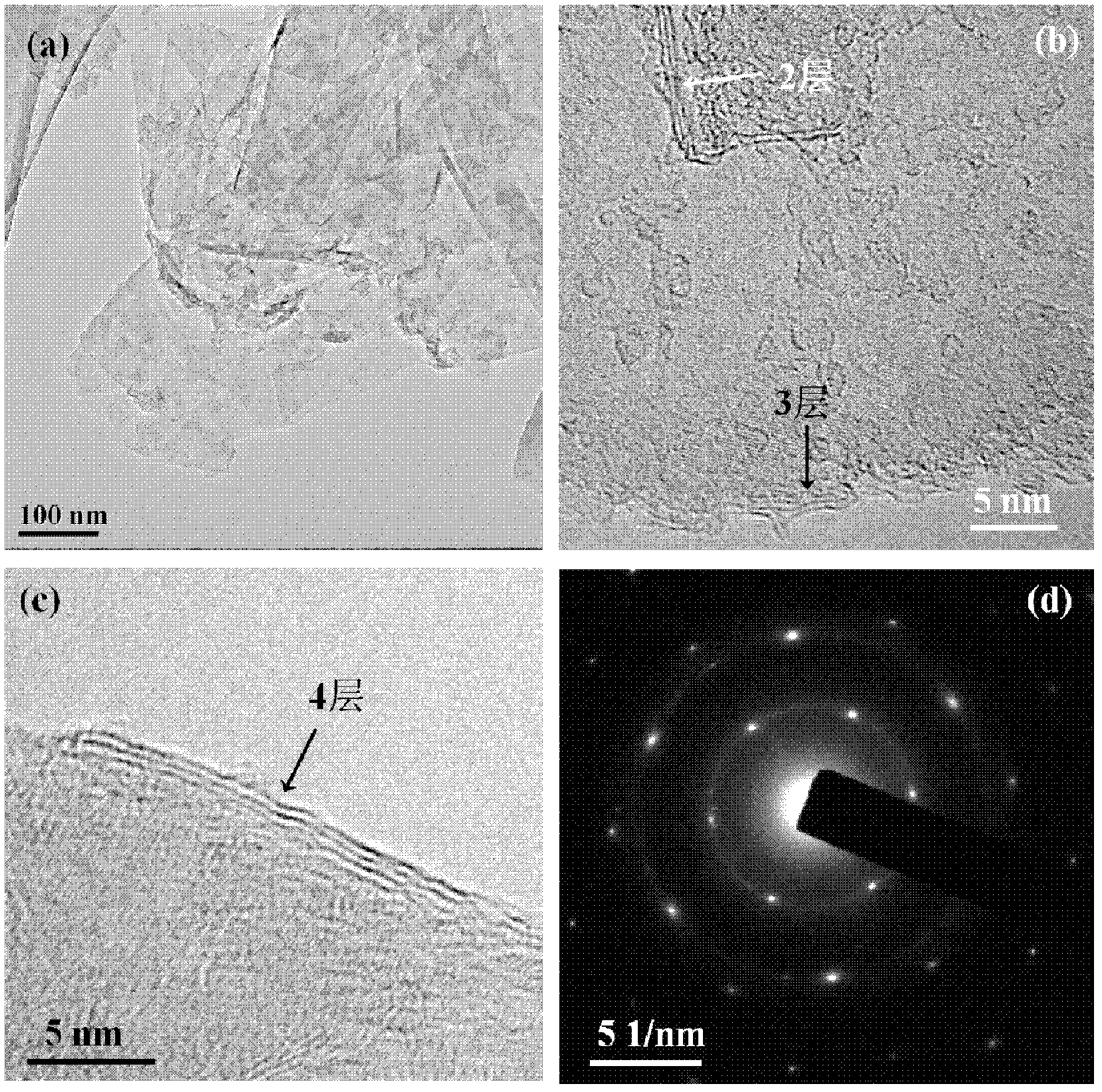

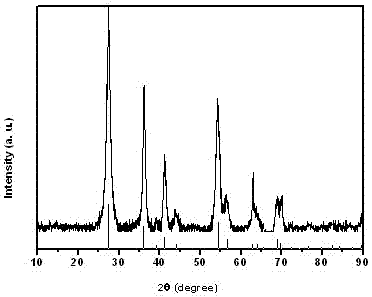

Low-cost mass preparation method of high-quality graphene

The invention discloses a low-cost mass preparation method of high-quality graphene. The low-cost mass preparation method comprises the following steps that graphite and an additive undergo a local or intercalation reaction so that boundary functionalization or intercalated graphite formation is realized; and graphite is peeled by ball milling or an ultrasonic method so that graphene is obtained. The high-quality graphene has water solubility and can forms good graphene hydrosol. Compared with graphene obtained by the traditional chemical peeling method, the high-quality graphene provided by the invention can be prepared simply, has a low cost, less defects, good conductivity and high quality and is suitable for mass production. The high-quality graphene provided by the invention has wide application prospects in photoelectric devices such as copper indium gallium diselenide, cadmium telluride and dye sensitization solar cells and in fields of panel display, supercapacitors, field emitter materials, and lithium ion batteries.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ultraviolet curing coating for preventing static on plastic surface and method for preparing the same

InactiveCN101423675ALight weightGood electrical conductivityElectrically-conductive paintsSolventPhotoinitiator

The invention relates to an ultraviolet photo-cured coating for the electrostatic prevention of the surface of plastic and a preparation method thereof, in particular to a photo-cured coating containing conductive powder of a metal oxide system or composite conductive powder. The coating comprises the following compositions in weight percent: 30 to 70 percent of oligomer, 25 to 65 percent of active thinner, 0.5 to 10 percent of light evocating agent, 5 to 40 percent of conductive powder, 0.2 to 8 percent of additive and 0 to 50 percent of solvent. As the added conductive powder of the metal oxide system and the composite conductive powder is white or light color, the prepared photo-cured has the characteristic of easy color modulation, has lasting antistatic property, high rigidity and wearing resistance, can be used for electrostatic prevention of the surface of electronic equipment, plastic vessel, shell of an electric appliance, office supplies, sports equipment and other plastic products.

Owner:SICHUAN UNIV

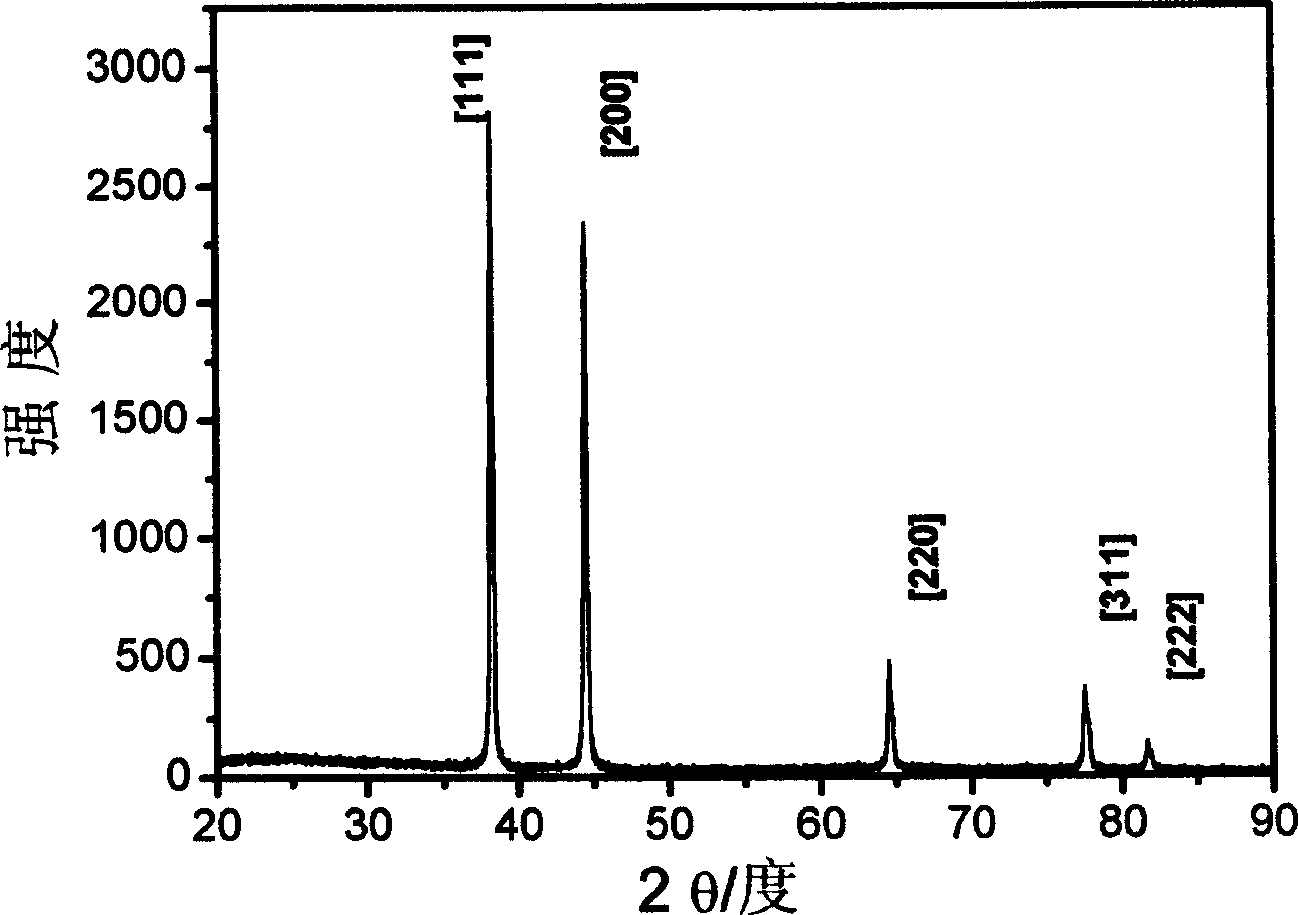

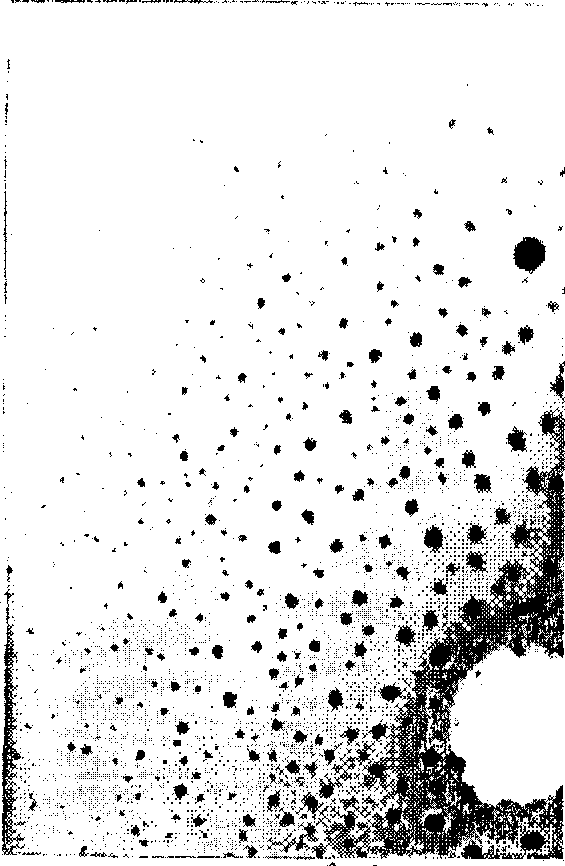

Preparing method for cubic silver nanometer grain

InactiveCN1552547AGood electrical conductivityGood self-assembly performanceAg nanoparticlesNanometre

A process for preparing the cubic silver nanocrystals includes such steps as proportionally dissolving surfactant and silver nitrate in organic solvent while stirring, slowly adding to an organic solvent at 150-180 deg.C to obtain the saturated solution of Ag nanoparticles, continuous reacting, and slow cooling while stirring to obtain the sol of cubic silver nanocrystals. Its advantage is high purity and dispersity.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

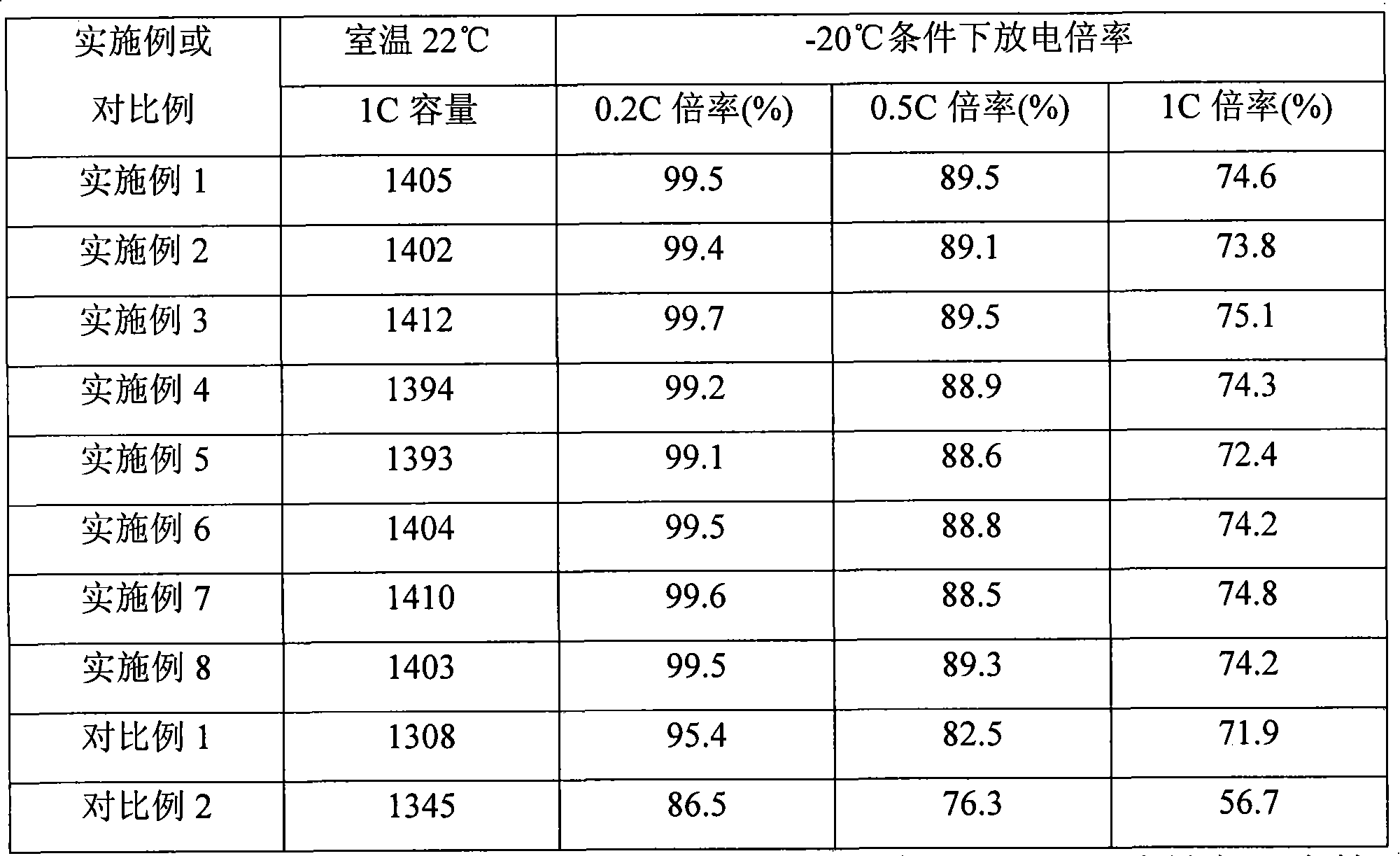

Formation method of lithium ion secondary battery

InactiveCN101640285AImprove electrochemical performanceGood electrical conductivitySecondary cells charging/dischargingMethyl formateMethyl acetate

The invention relates to a formation method of a lithium ion secondary battery. The method comprises the following steps: performing a first formation on a battery containing a first electrolytic solution; and then injecting a second electrolytic solution into a battery container after the first formation to perform a second formation, wherein the first electrolytic solution contains an electrolyte and a first solvent which is mixture of a solvent A and a solvent B; the solvent A is ethylene carbonate, and the solvent B is one or more selected from dimethyl carbonate, diethyl carbonate, methylethyl carbonate, dimethyl sulfite and diethyl sulfite; and the second electrolytic solution contains electrolyte and a second solvent, and the second solvent is one or more selected from propylene carbonate, butylene carbonate, dimethoxyethane, gamma-butyrolactone, methyl formate, ethyl formate, methyl acetate, ethyl acetate, ethyl propionate, ethyl butyrate and propyl butyrate. The lithium ion secondary battery obtained by the method has excellent cycle performance and low-temperature multiplying factor discharge performance.

Owner:SHANGHAI BYD

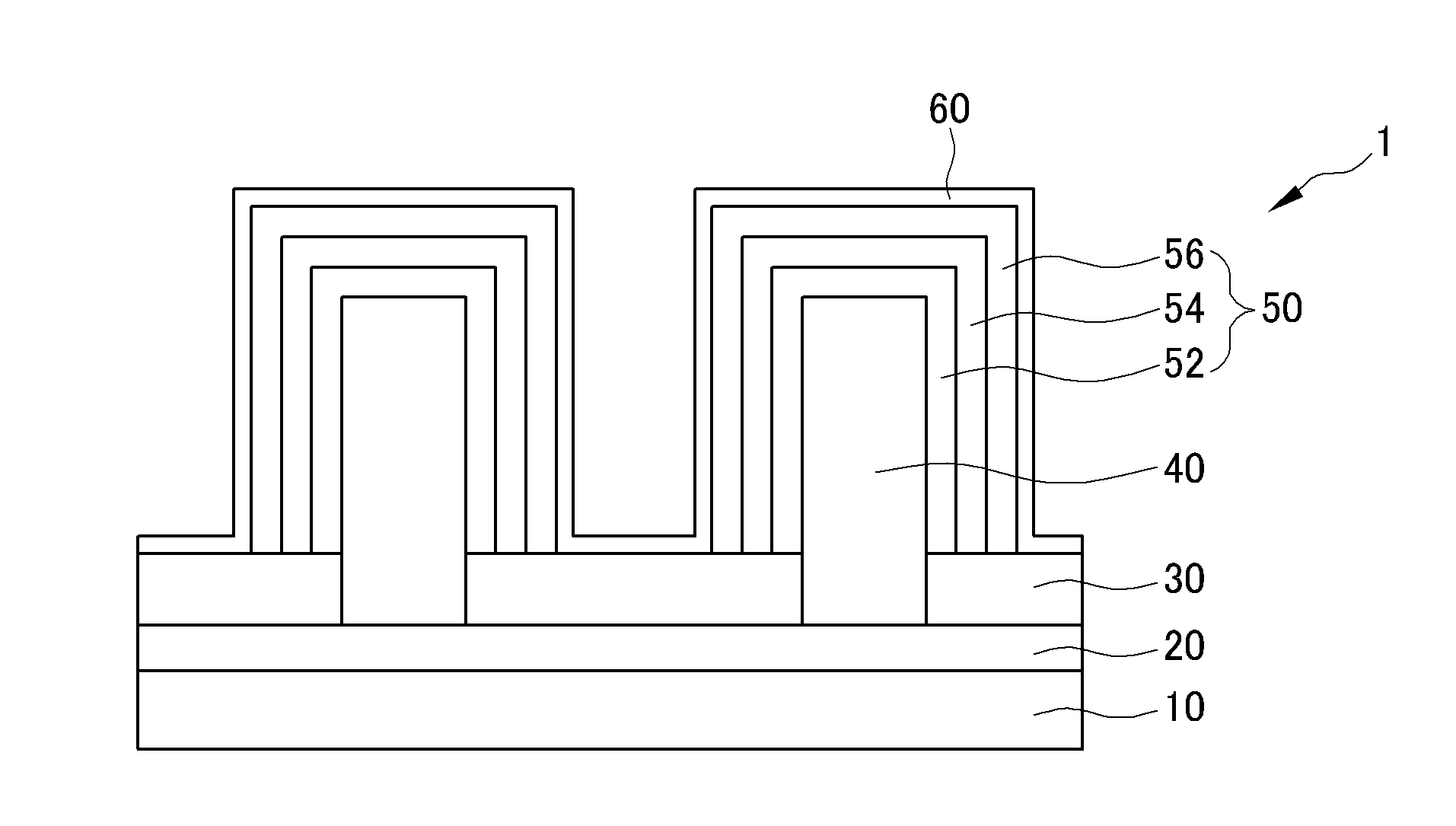

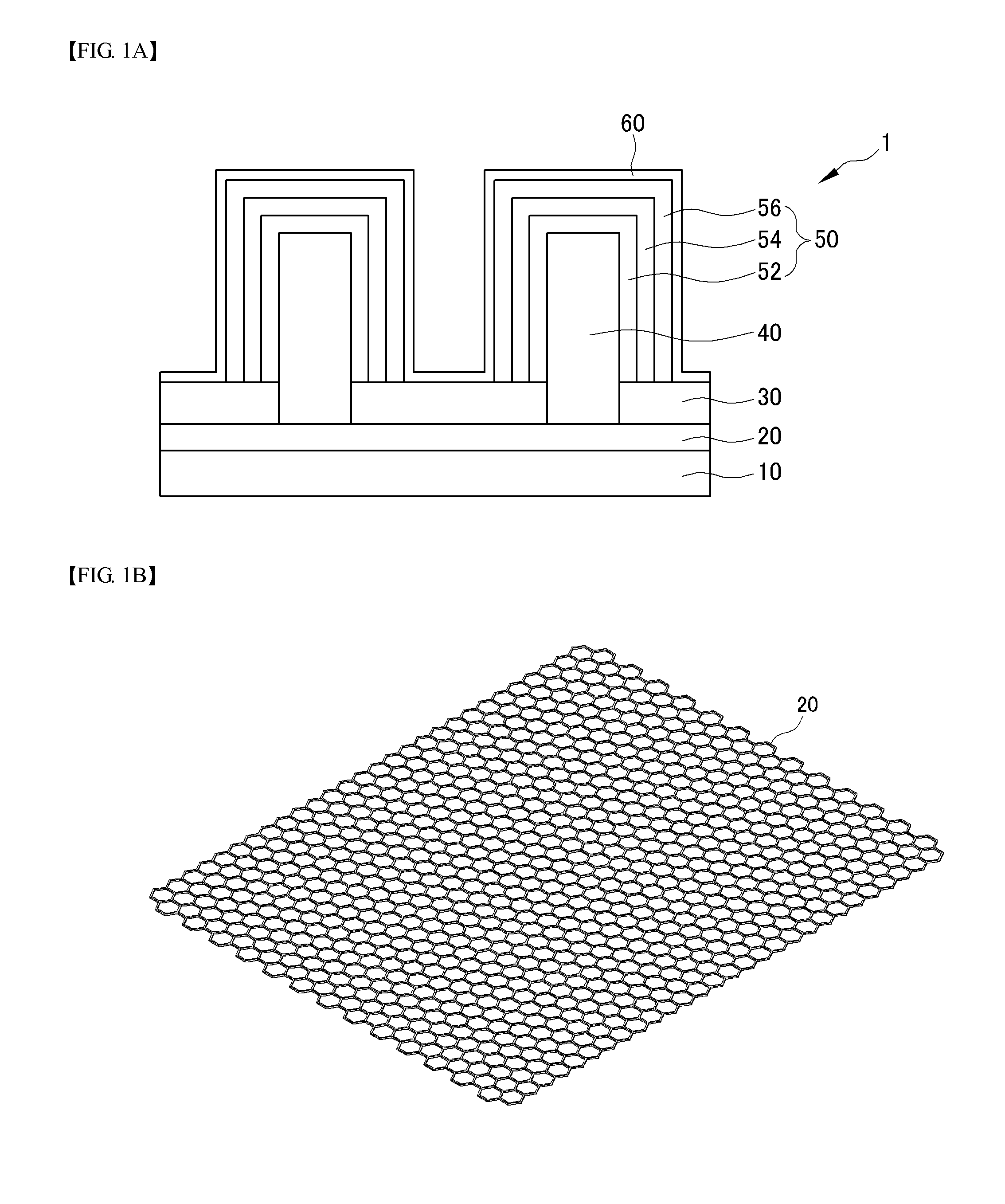

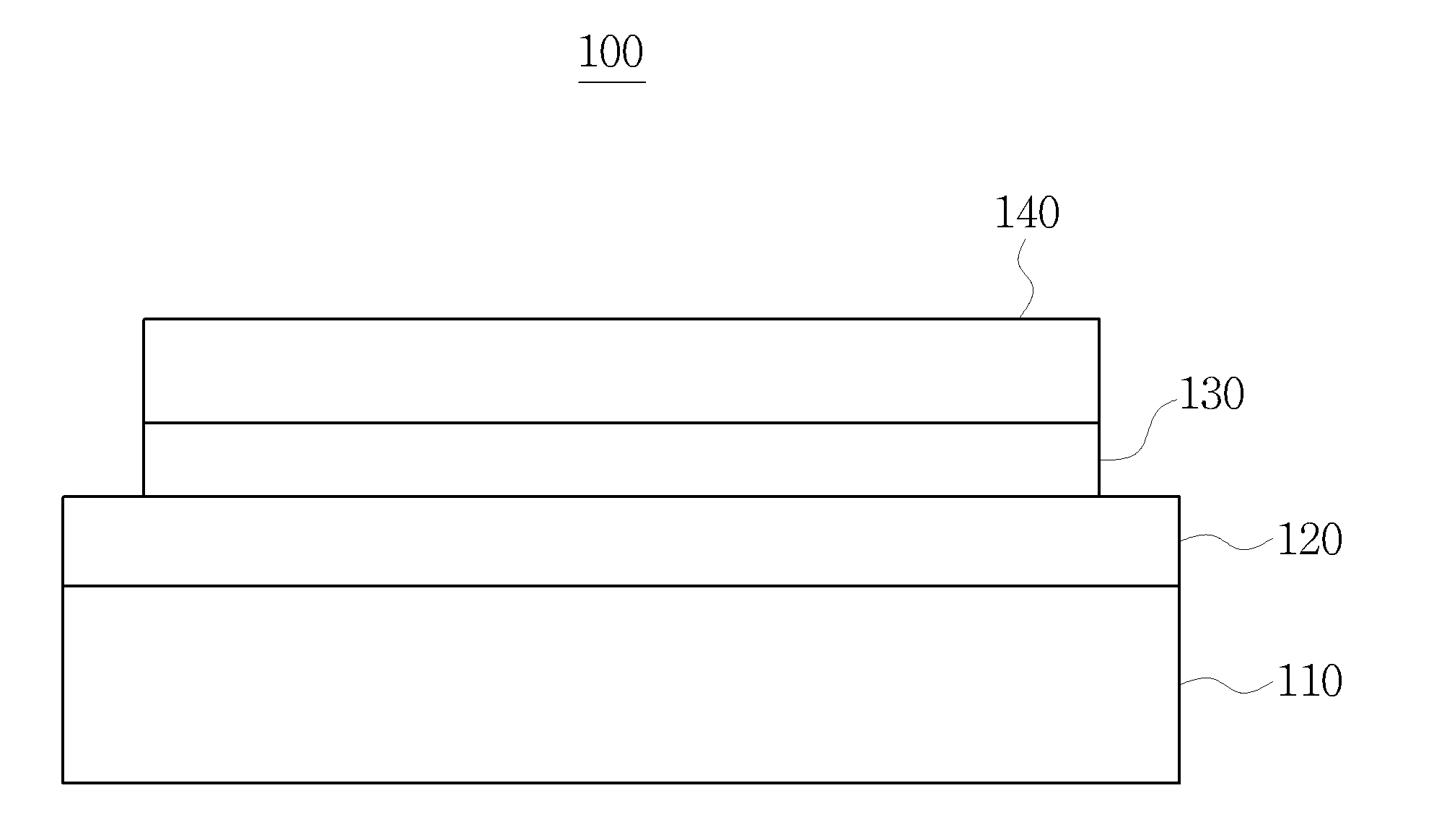

Light-emitting element and method for manufacturing same

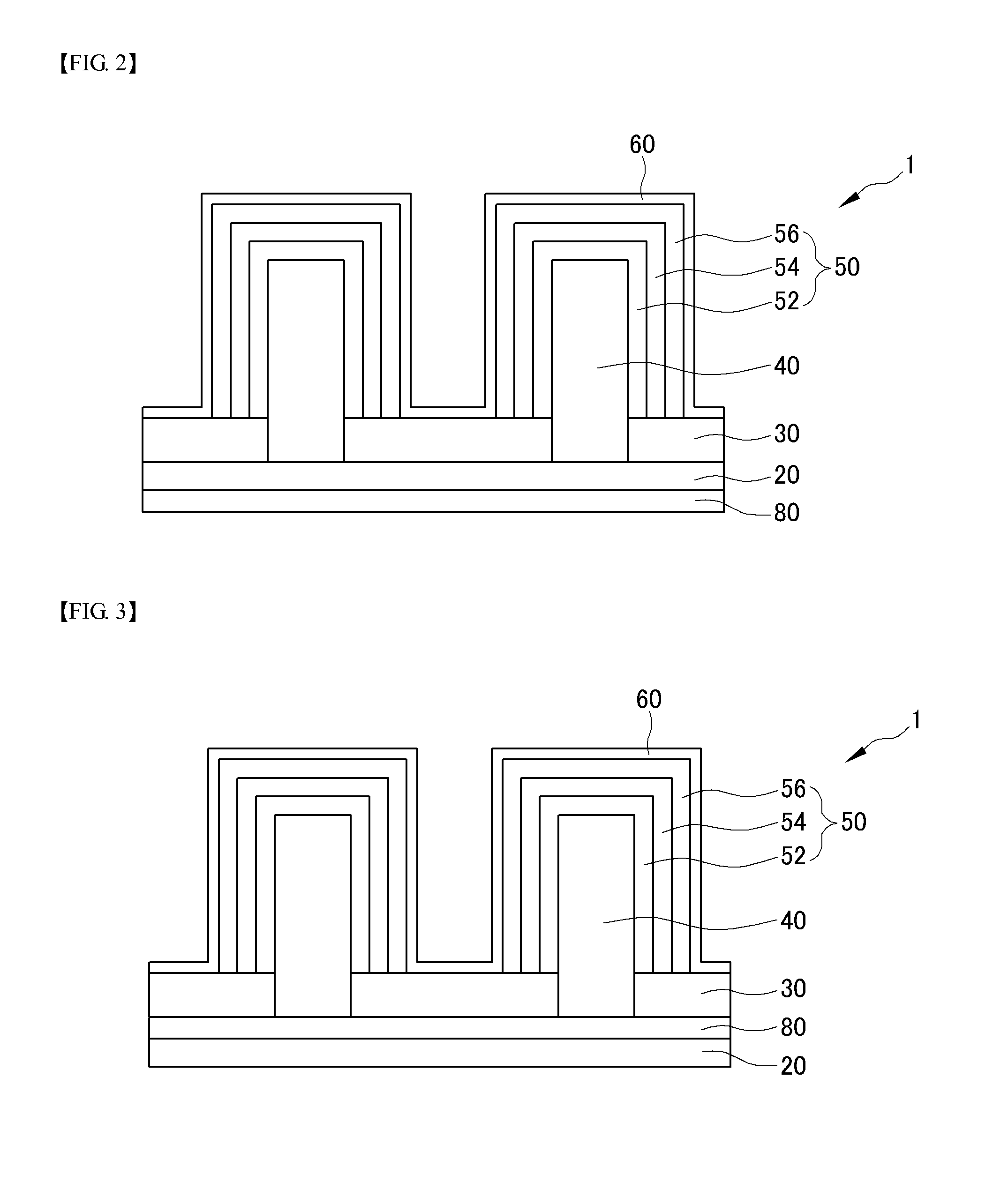

ActiveUS20130187128A1Improve efficiencyGood electrical conductivitySemiconductor/solid-state device manufacturingNanoopticsOptoelectronicsFine structure

The present invention provides a light-emitting element comprising: a carbon layer comprising a graphene; a plurality of fine structures having grown toward the upper side of the carbon layer; and a light-emitting structure layer formed on the surface of the fine structures

Owner:SEOUL NAT UNIV R&DB FOUND

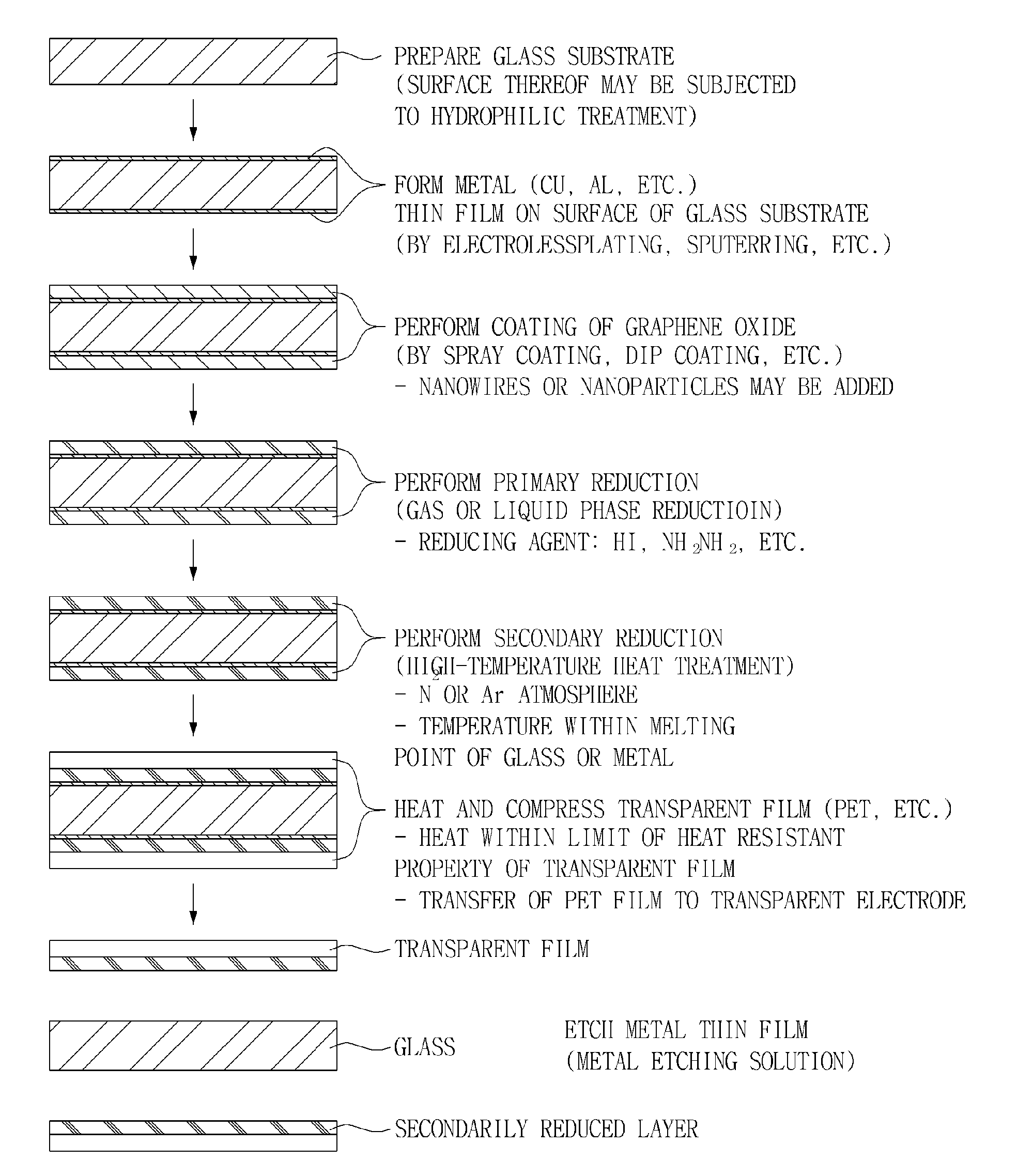

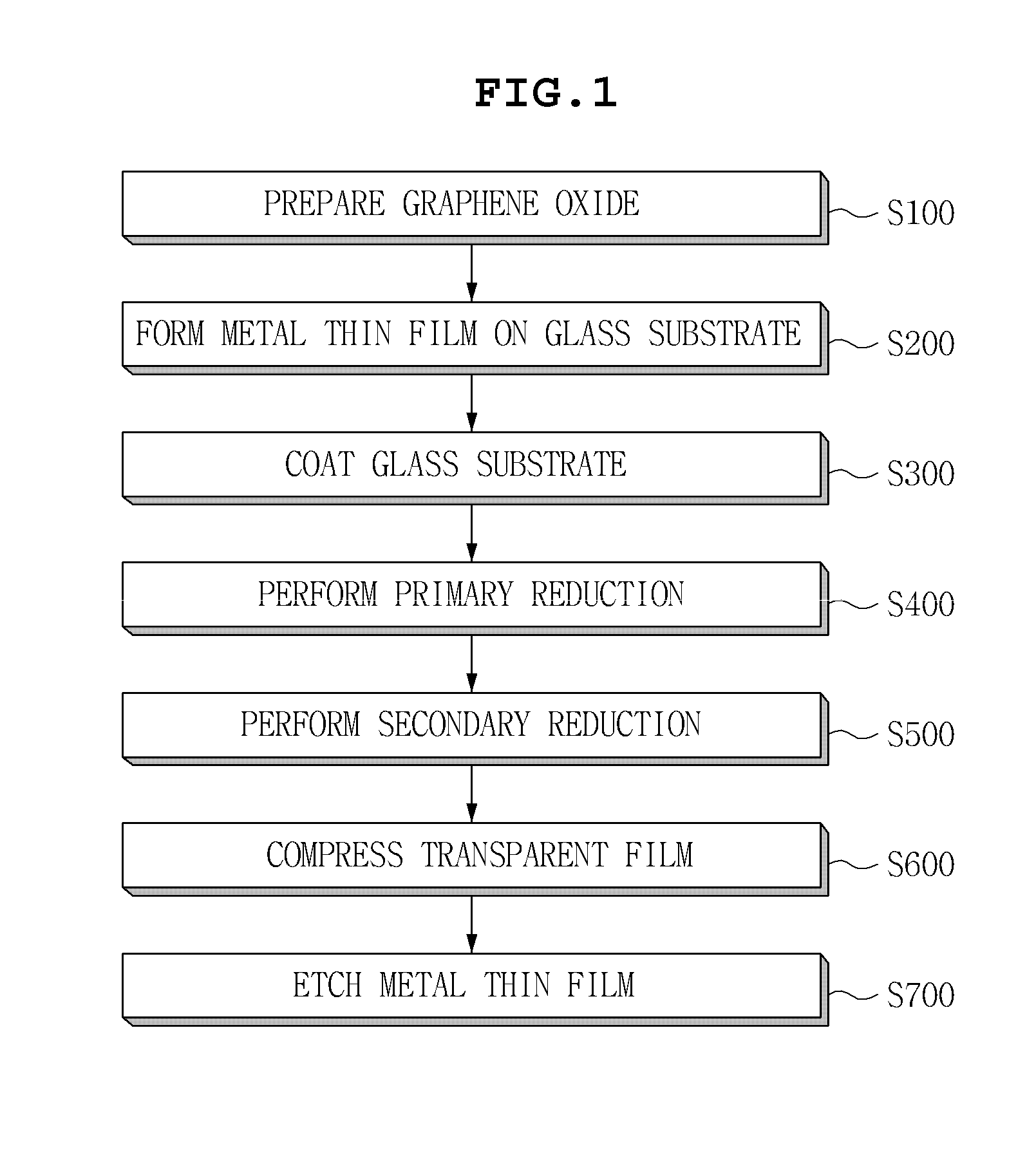

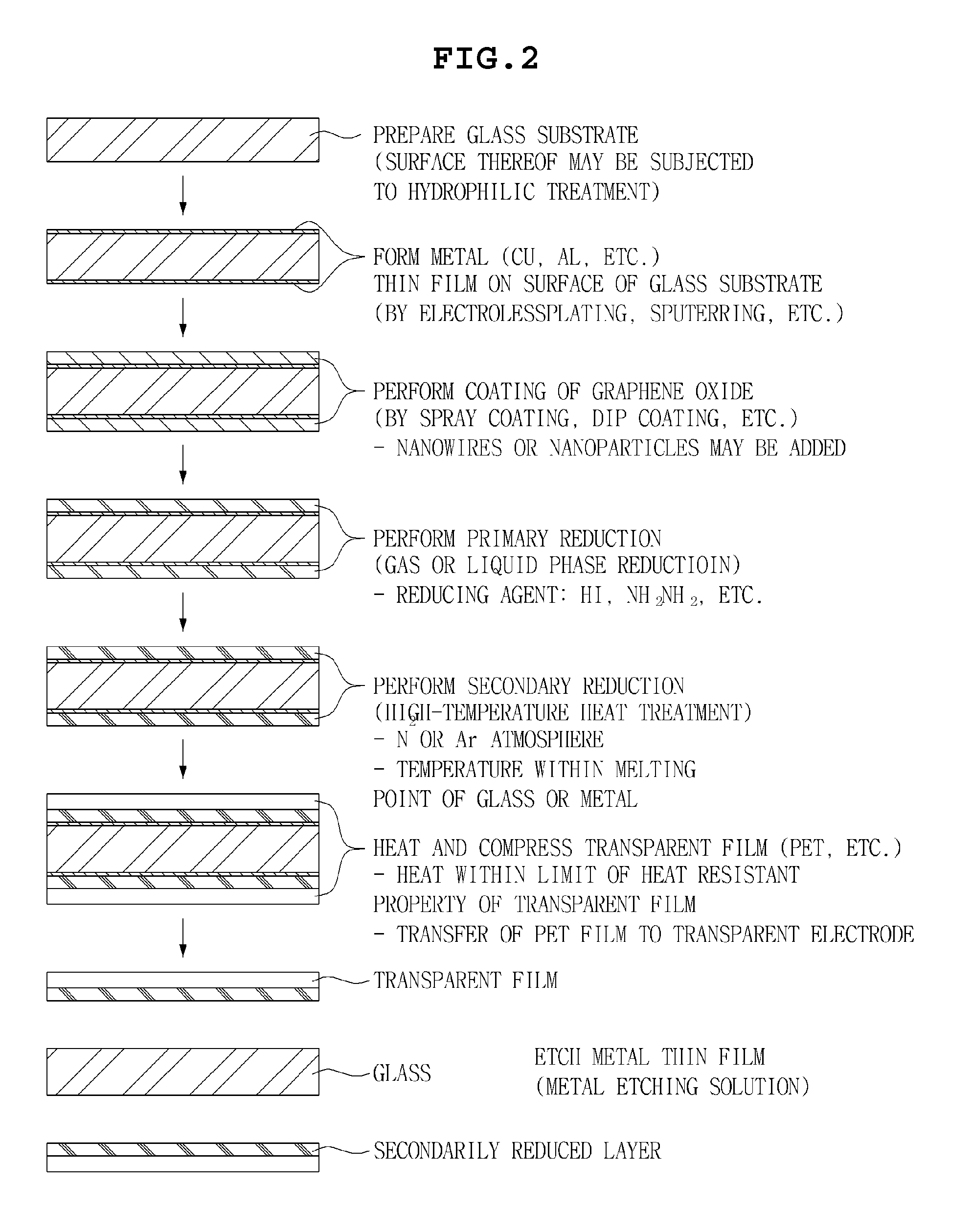

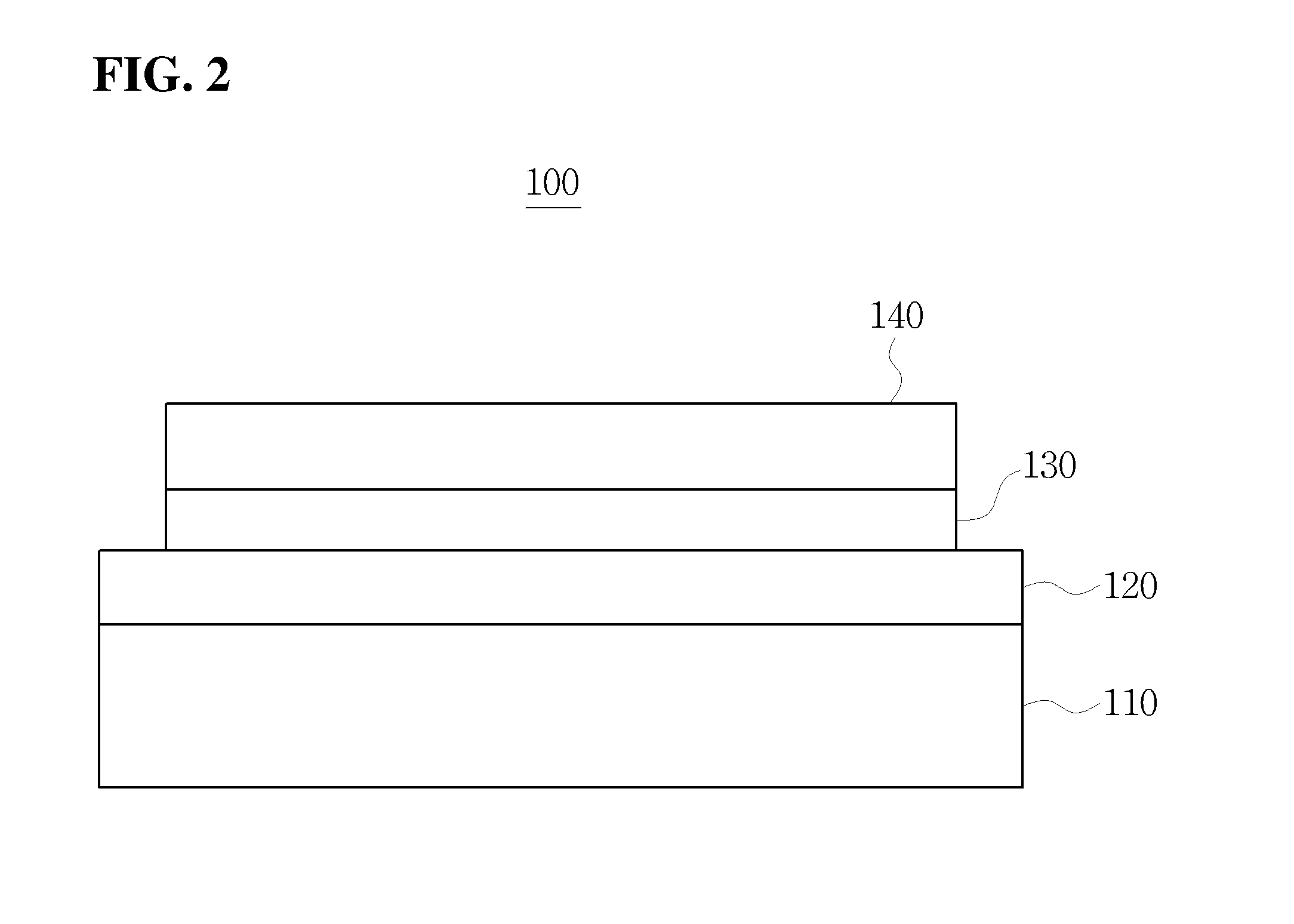

Graphene transparent electrode and method for manufacturing the same

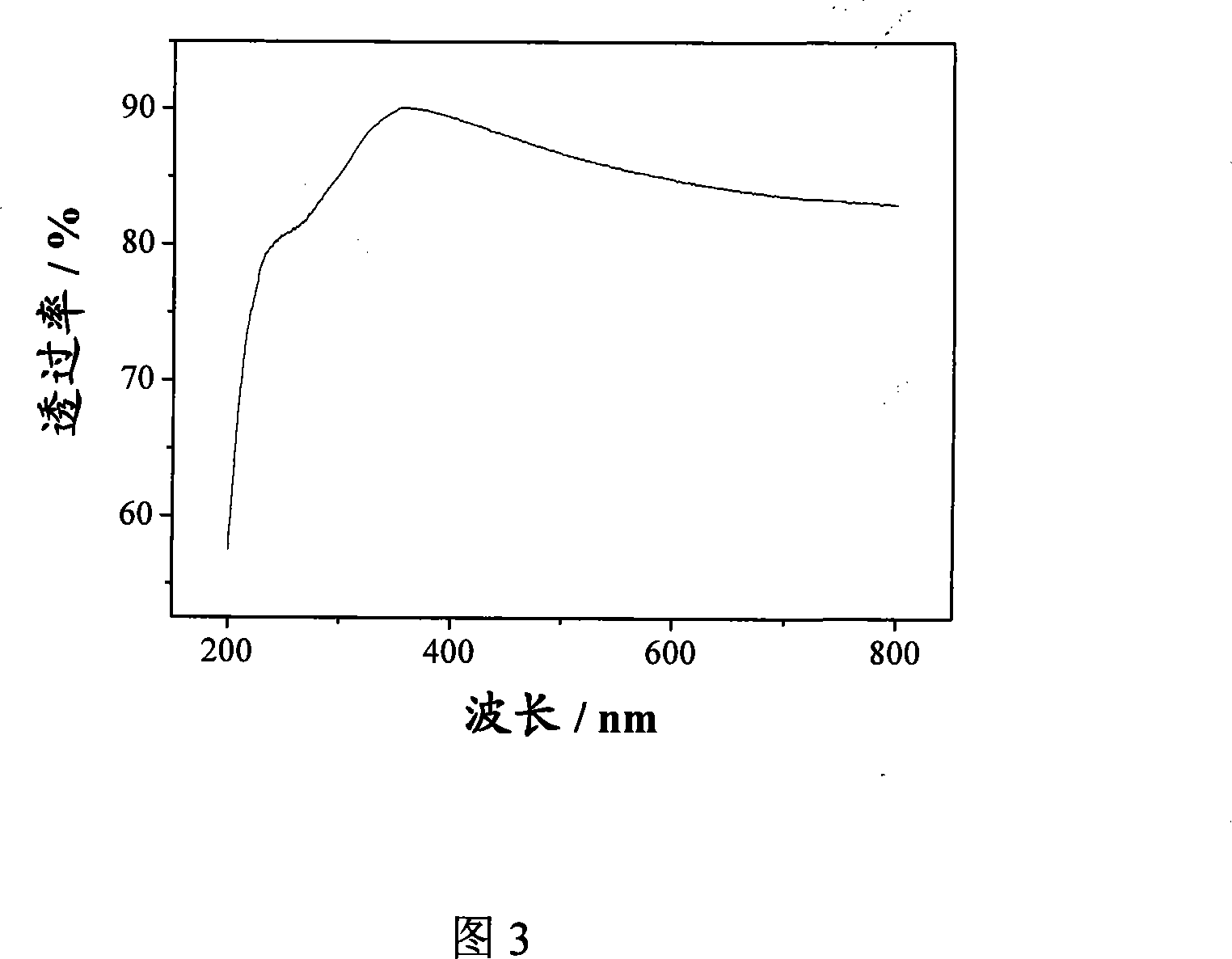

InactiveUS20130133925A1Excellent dispersibilityGood electrical conductivityMaterial nanotechnologyConductive layers on insulating-supportsCvd grapheneGraphite oxide

Disclosed herein are a method for manufacturing a graphene transparent electrode and a graphene transparent electrode manufactured by the method. The method includes: providing a graphene oxide solution: forming a metal thin film on a glass substrate; coating the graphene oxide solution on the metal thin film, followed by drying; primarily reducing the thus obtained graphene oxide by using a reducing agent, to obtain reduced graphene oxide; secondarily reducing the reduced graphene oxide by heat treatment under the inert atmosphere, to form a reduced layer; compressing a transparent film on the reduced layer; and etching the metal film by an etching solution. The method enables a graphene transparent electrode having economical feasibility and excellent electric conductivity to be manufactured.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

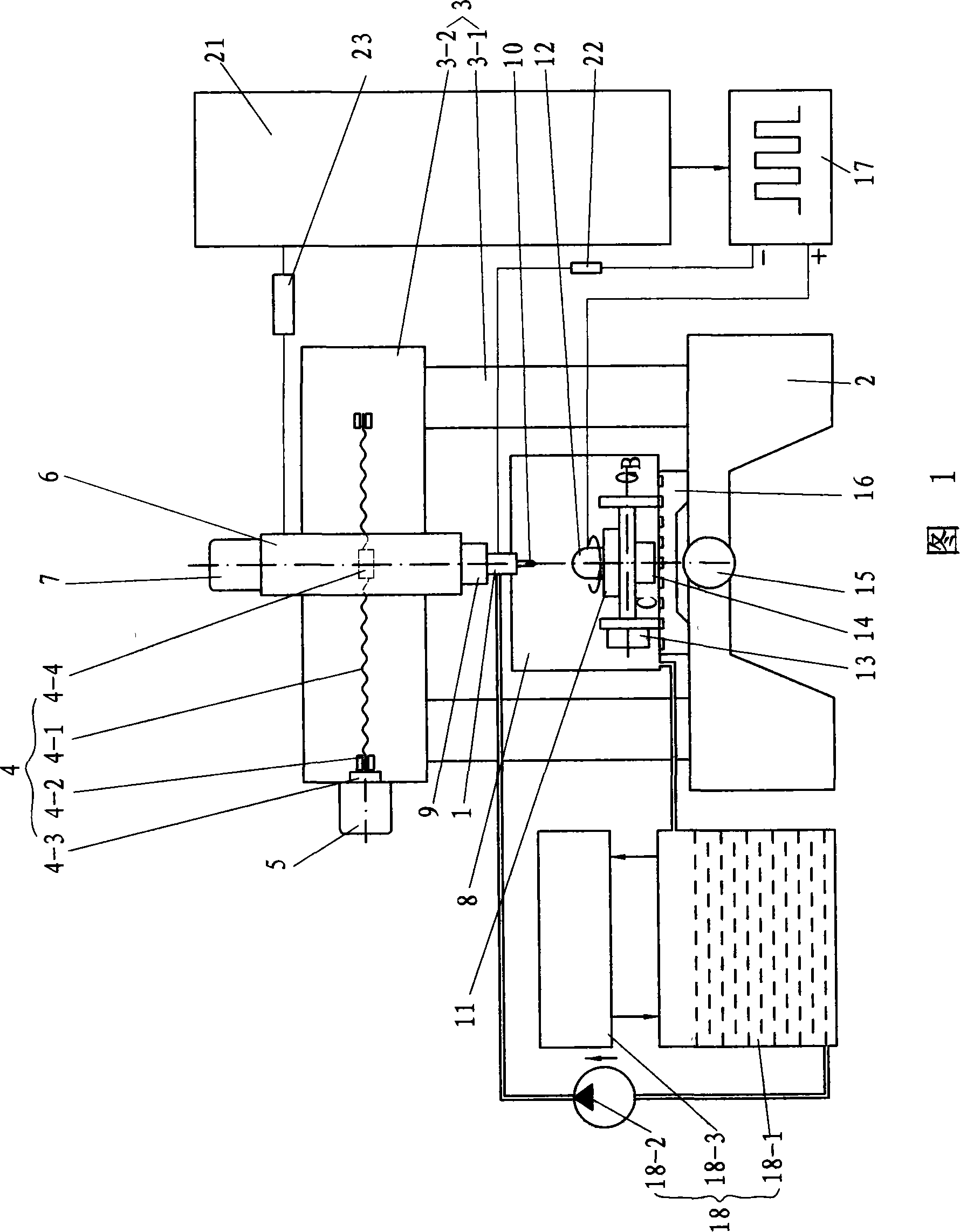

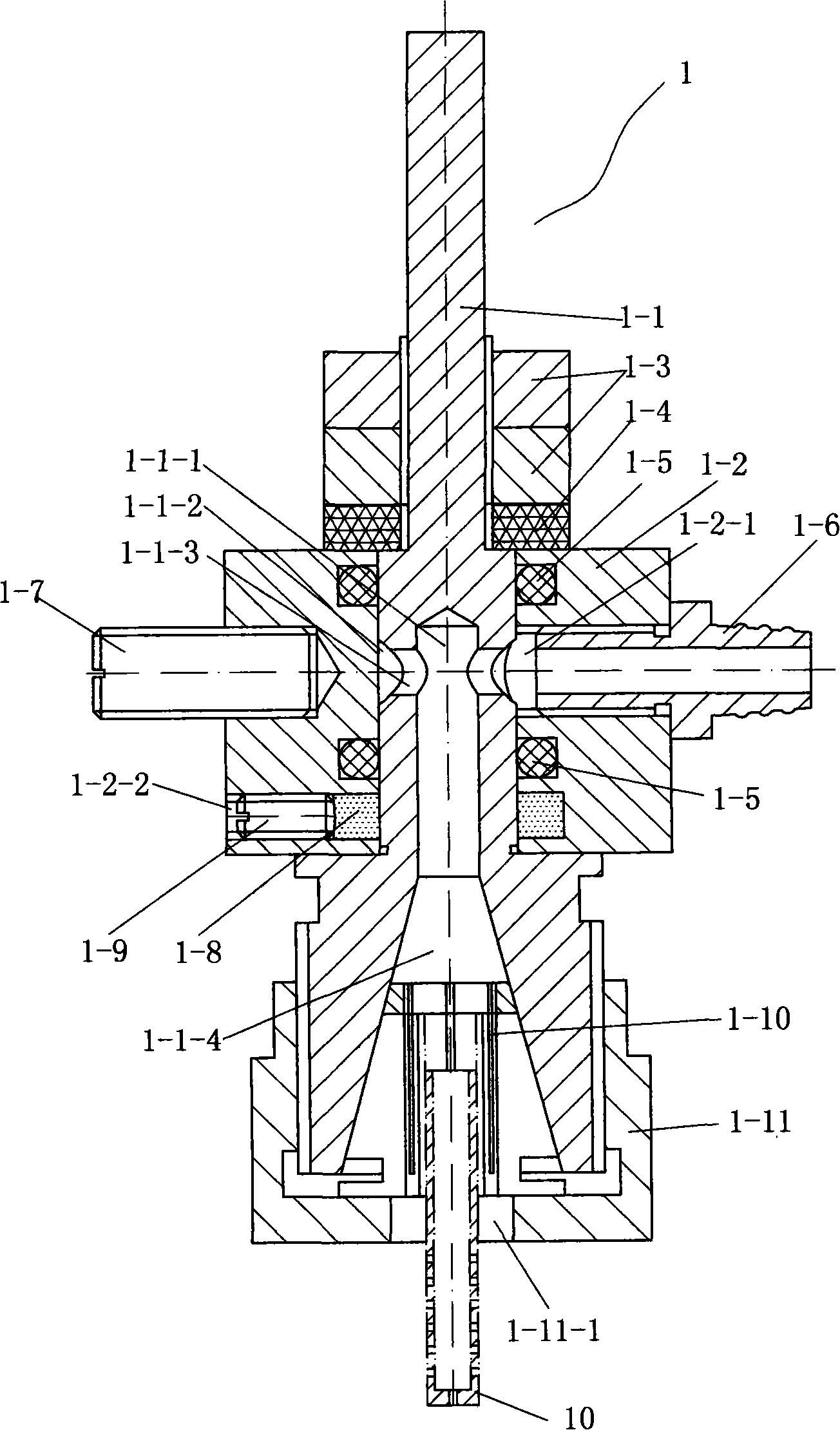

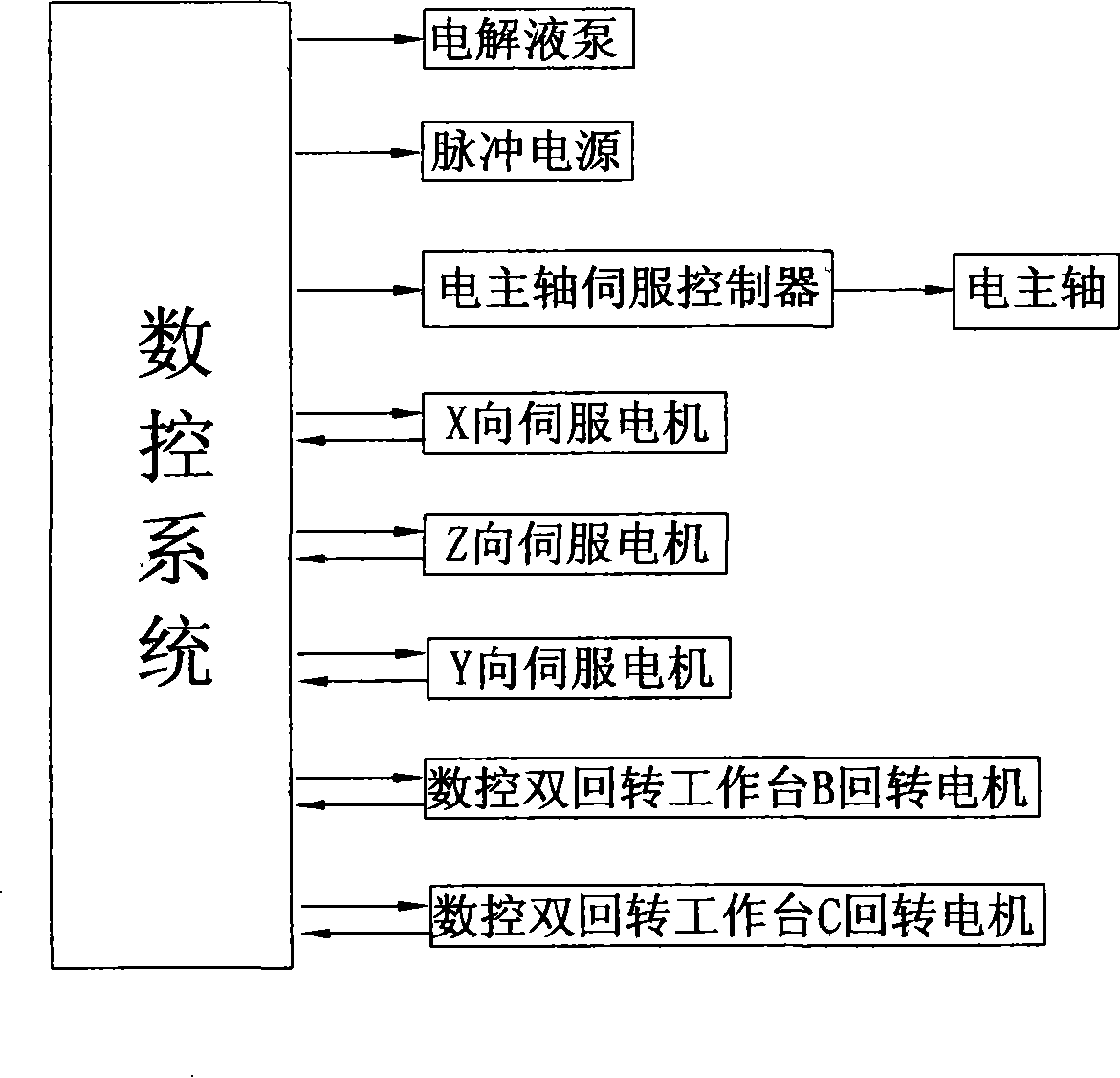

Numerical control electrolyze mechanical compound processing machine tool

InactiveCN101249578AEliminate installation errorsImprove machining accuracyFeeding apparatusElectric circuitsElectric machineryComposite cathode

A numerical control electrolytic-mechanical composite machine tool comprises a machine body, a frame, a horizontal work bench, a numerical control double-revolving work bench, a protection box, a spindle head, an electrical spindle, a numerical control system, a pulse power supply, an electrolyte circulating device, and an X-direction transmission mechanism, a Z-direction transmission mechanism as well as a Y-direction transmission mechanism, wherein the electrical spindle, the pulse power supply, an electrolyte pump of the electrolyte circulating device, an X-direction servo motor, a Z-direction servo motor, a Y-direction servo motor, and a B revolving motor and a C revolving motor of the numerical control double-revolving motor are all controlled by the numerical control system. By controlling the relative movement of a composite cathode and an anode workpiece, the machine tool can process mold cavities and mold surfaces for complex workpieces, thus processing workpieces of different shapes. By changing different composite cathodes and adjusting different processing parameters, rough processing, finish processing and surface smoothing of one part can be achieved by one machine tool in different processing manners such as drilling, milling, cutting, grinding and polishing, thus eliminating installation error caused by repeated installation of workpieces.

Owner:CHANGZHOU INST OF TECH

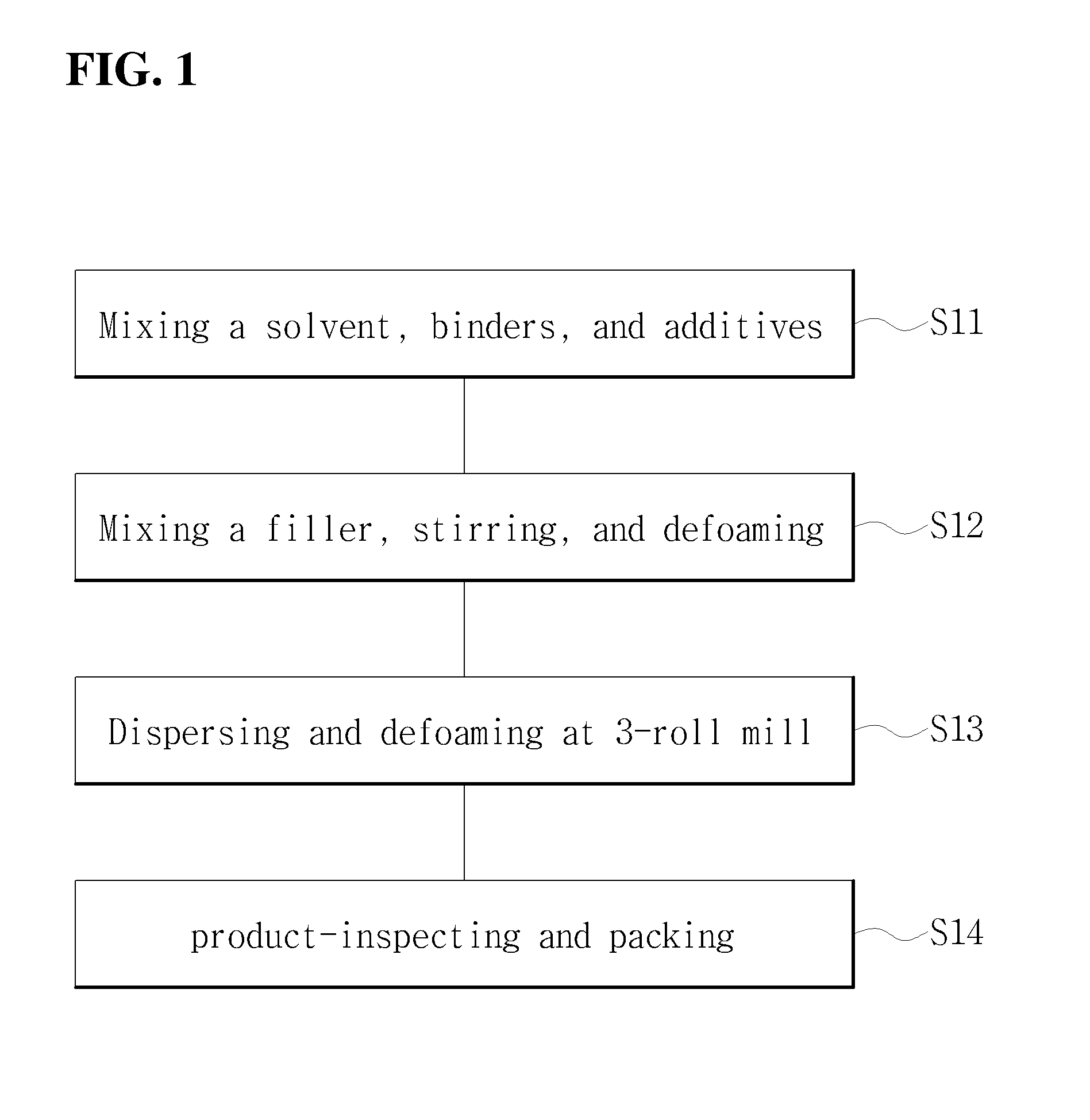

Conductive adhesive, method for manufacturing the same, and electronic device including the same

InactiveUS20120228560A1Good electrical conductivityEnhanced large adhesive forceMaterial nanotechnologyNon-macromolecular adhesive additivesAdhesiveAlloy

The present invention relates to a conductive adhesive, a method for manufacturing the same, and an electronic device including the same. The conductive adhesive includes: a conductive particle; a low-melting alloy powder including an alloy including Sn and at least one material selected from the group consisting of Ag, Cu, Bi, Zn, In, and Pb; a nano powder; a first binder including a thermosetting resin; and a second binder including a rosin compound.

Owner:GENOMINE

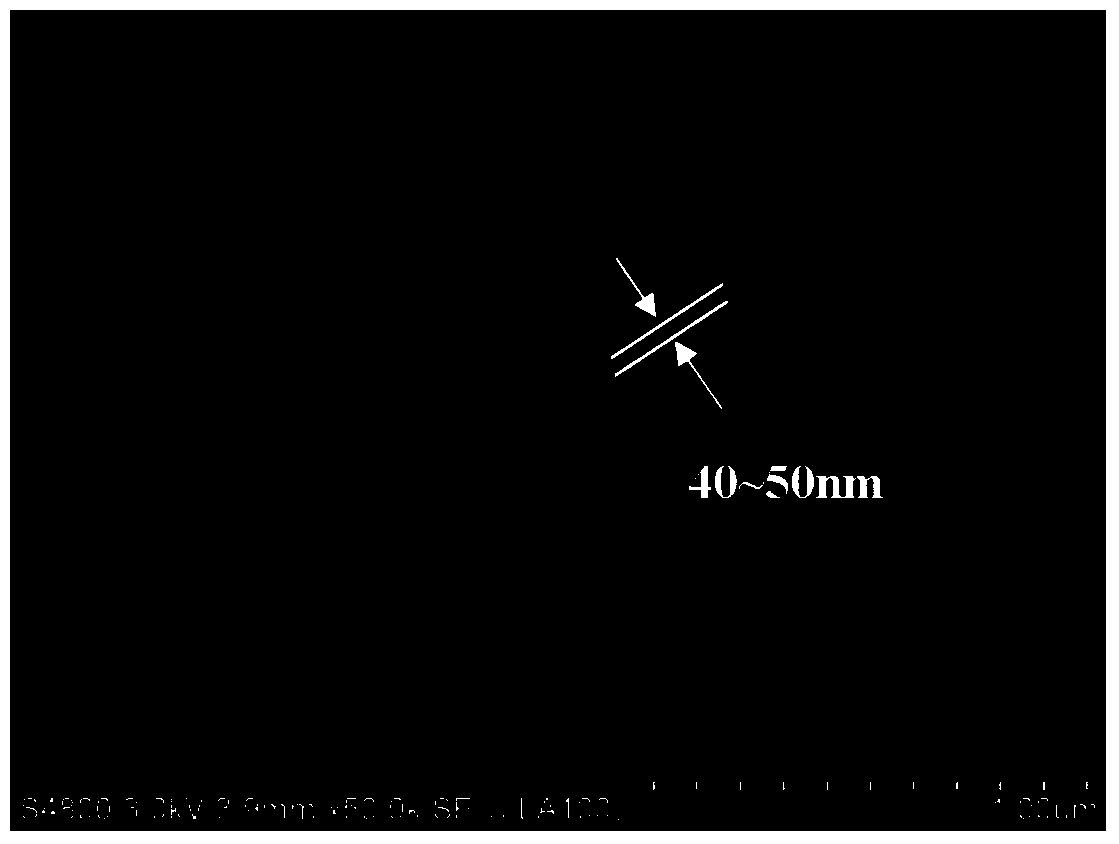

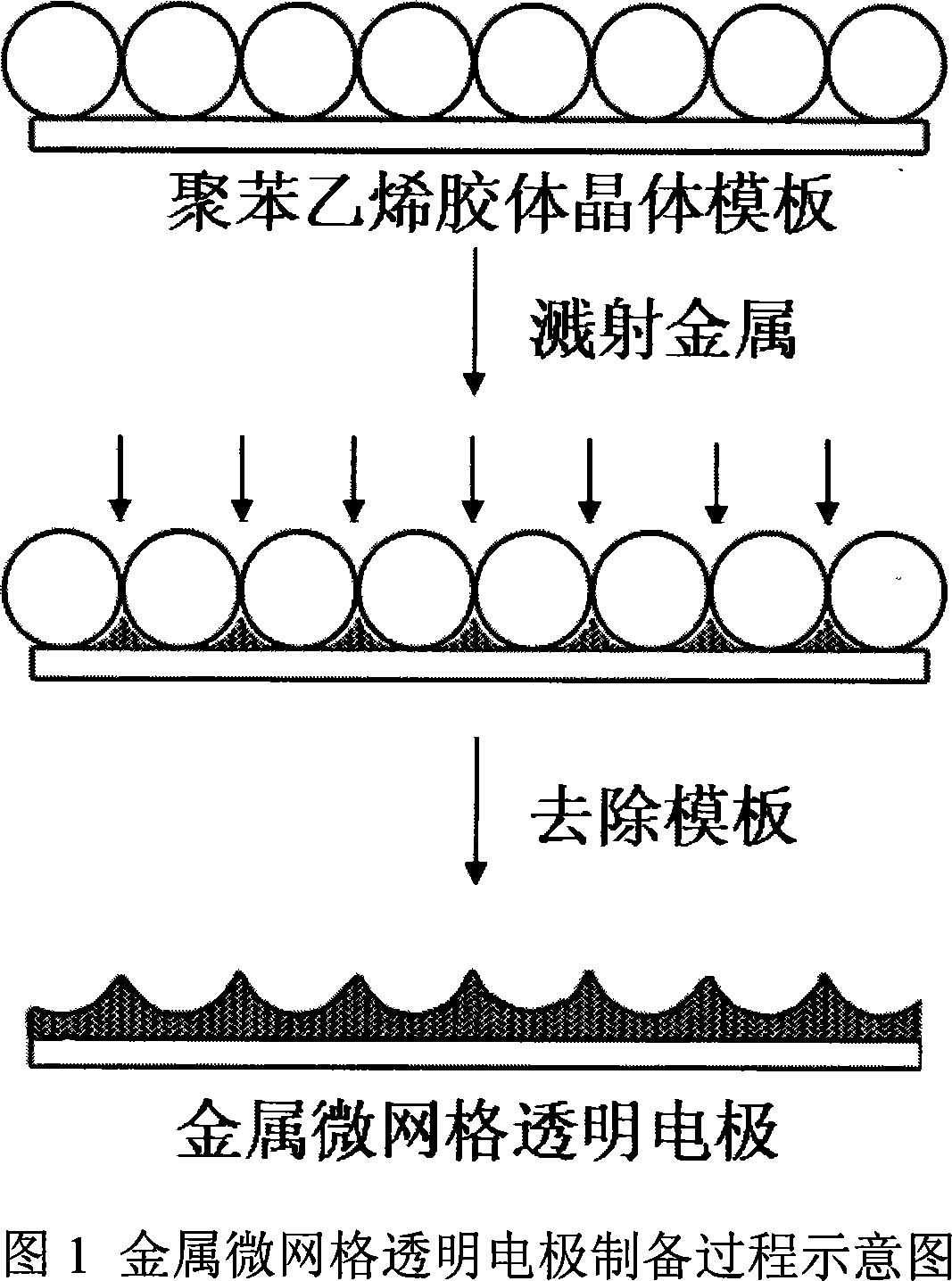

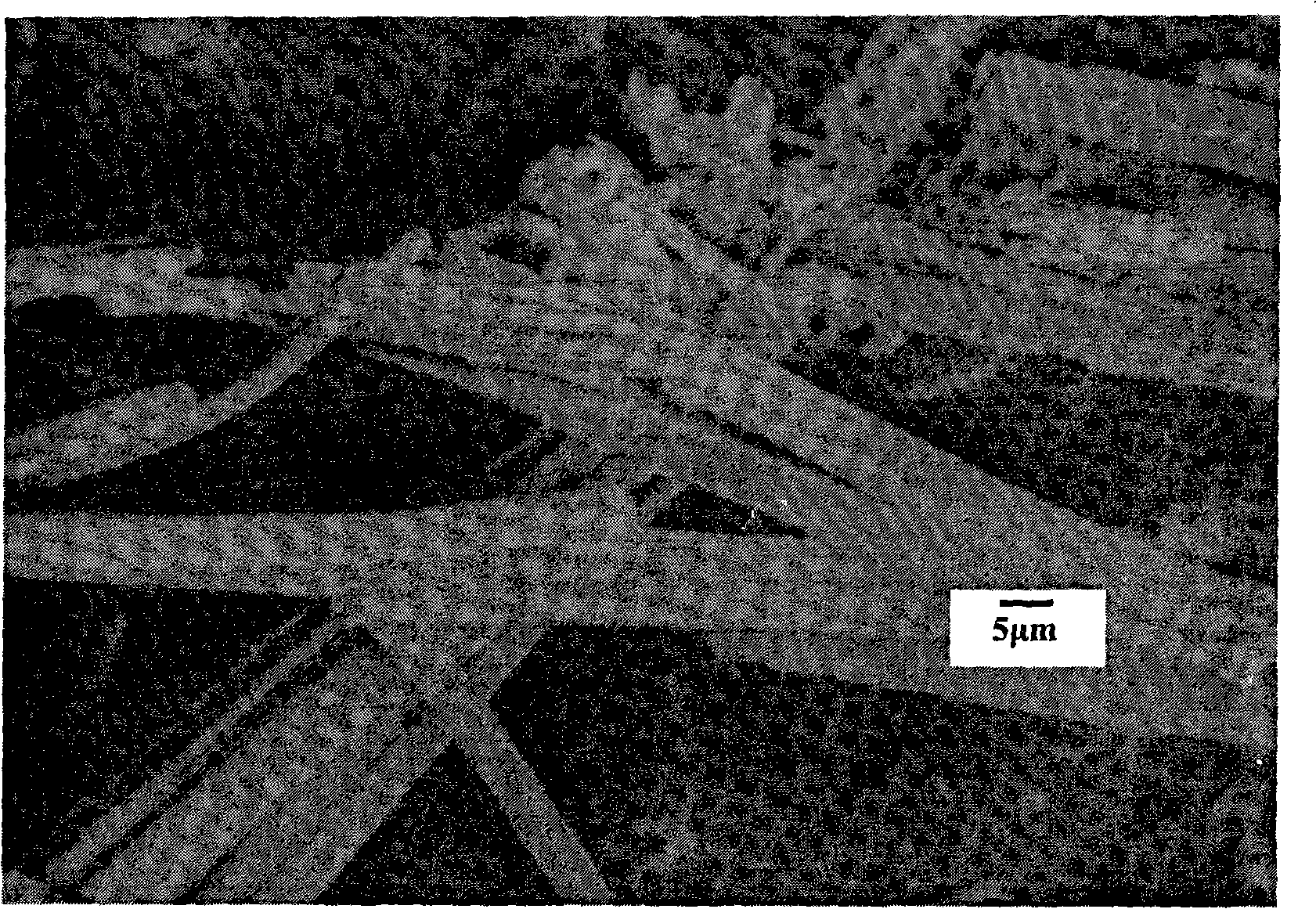

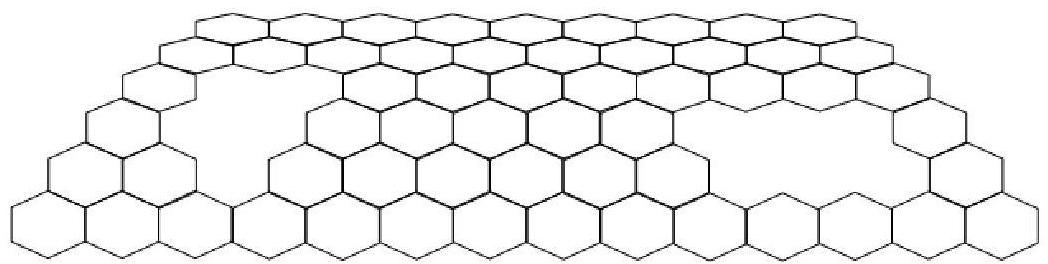

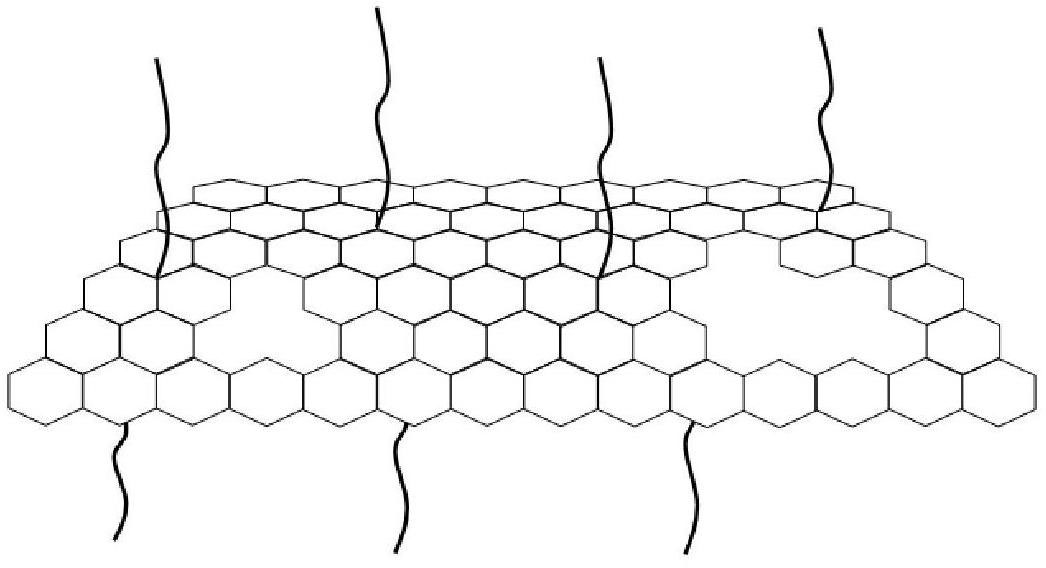

Metal microgrid transparent electrode and method for producing the same

InactiveCN101246911AImprove transmittanceGood electrical conductivitySemiconductor/solid-state device detailsVacuum evaporation coatingPolystyrene microsphereOptical transmittance

The present invention relates to a metal microgrid transparent electrode and fabricating method thereof. The transparent electrode has orderly metal microgrid structure whose thickness is 10-50nm, width is 140-800 nm and aperture is 1-6 mum. The fabricating method is that: assembling single-layer colloid crystal template by monodisperse polystyrene microspheres, depositing metal in template sews by magnetron sputtering technique, and the sputtering time is 5-10 minutes; at last, eliminating single-layer colloid crystal template by ultrasonic washing of organic solvent for 20-30 minutes and the said transparent electrode is gained. The metal microgrid structure of transparent electrode has high light transmittance, low resistance and low cost, has widely usage in optoelectronic device, photodetector and semiconductor irradiance. The fabricating method of present invention has simply technics and easy operation.

Owner:BEIHANG UNIV

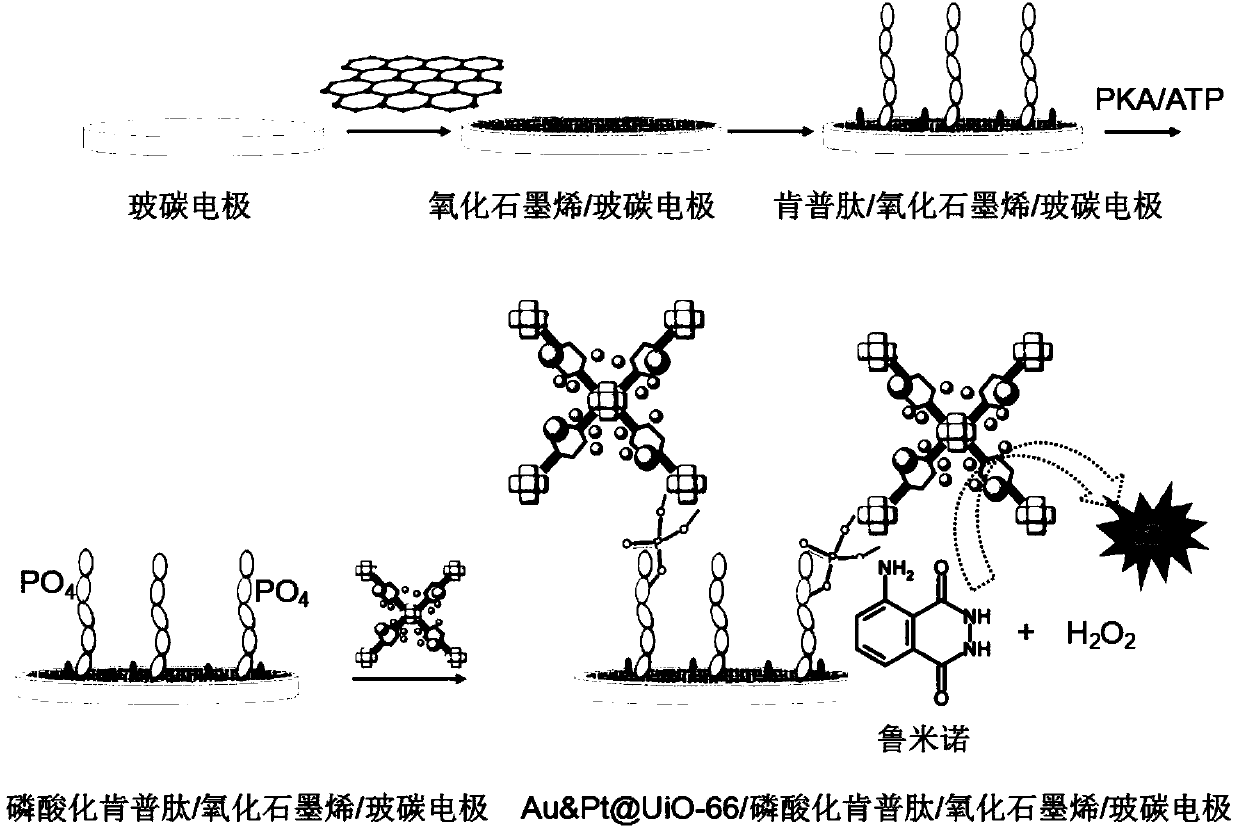

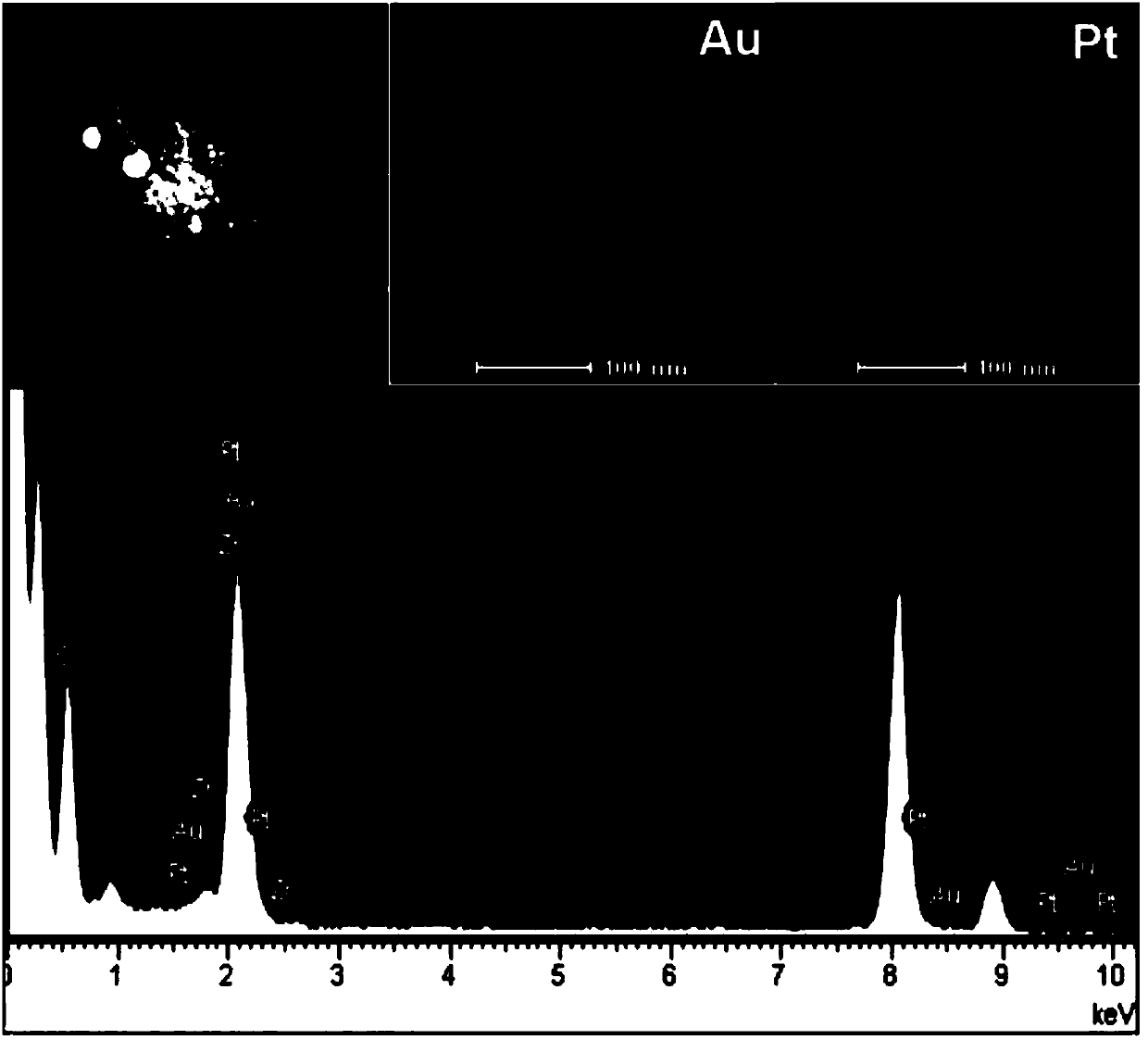

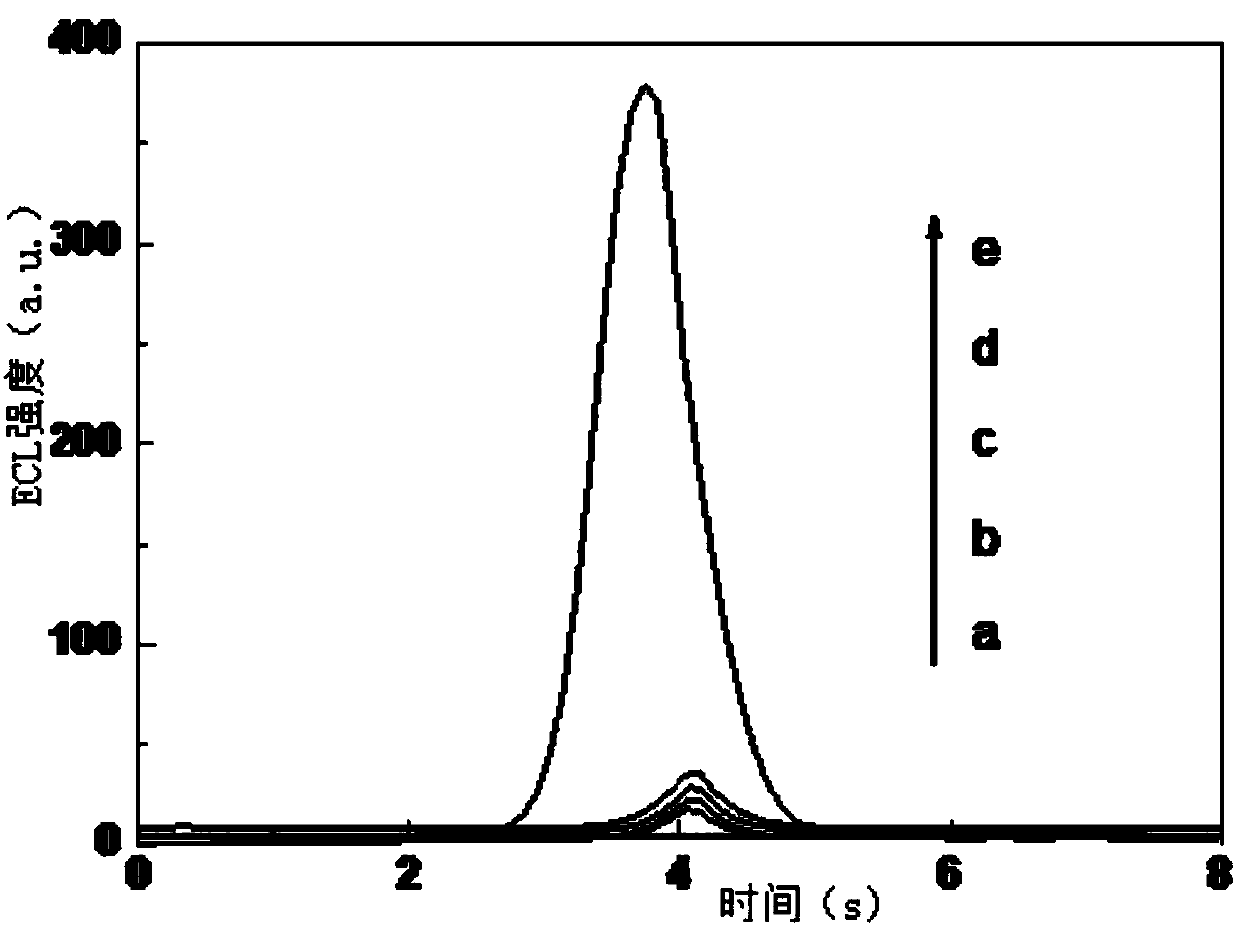

Noble-metal nanoparticle-loading metal-organic framework, preparation method and application

InactiveCN107607525AGood electrical conductivityPromote catalysisChemiluminescene/bioluminescenceMaterial analysis by electric/magnetic meansIonMetal-organic framework

The invention relates to the field of materials and analytical chemistry, and particularly relates to a noble-metal nanoparticle-loading metal-organic framework composite material, a preparation method and application. The preparation method of the metal-organic framework composite material loading two or more than two noble-metal nanoparticles, provided by the invention, comprises the following steps: mixing raw materials containing organic metal ligands, metal ions and one, two or more than two kinds of first noble-metal nanoparticles, then, putting the mixture in a reaction still or microwave oven, and carrying out a reaction, so as to obtain a metal-organic framework loading one, two or more than two kinds of first noble-metal nanoparticles; mixing the metal-organic framework loading the first noble-metal nanoparticles, a precursor solution of second noble-metal nanoparticles and a reducer, thereby obtaining the metal-organic framework composite material. The composite material hasthe characteristics of high specific surface area, high porosity and easiness in surface functionalization, meanwhile, has the electric conductivity and catalytic effect of the noble-metal nanoparticles, and can be applied to an electrochemiluminescence system.

Owner:BEIJING CENT FOR PHYSICAL & CHEM ANALYSIS

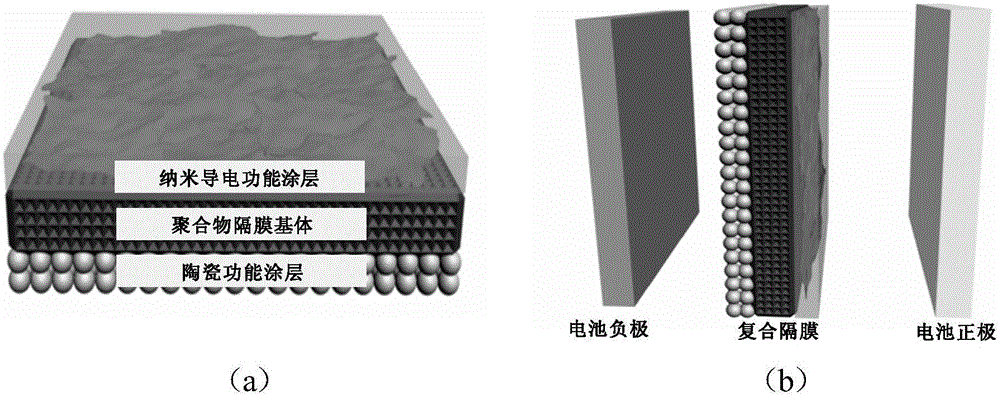

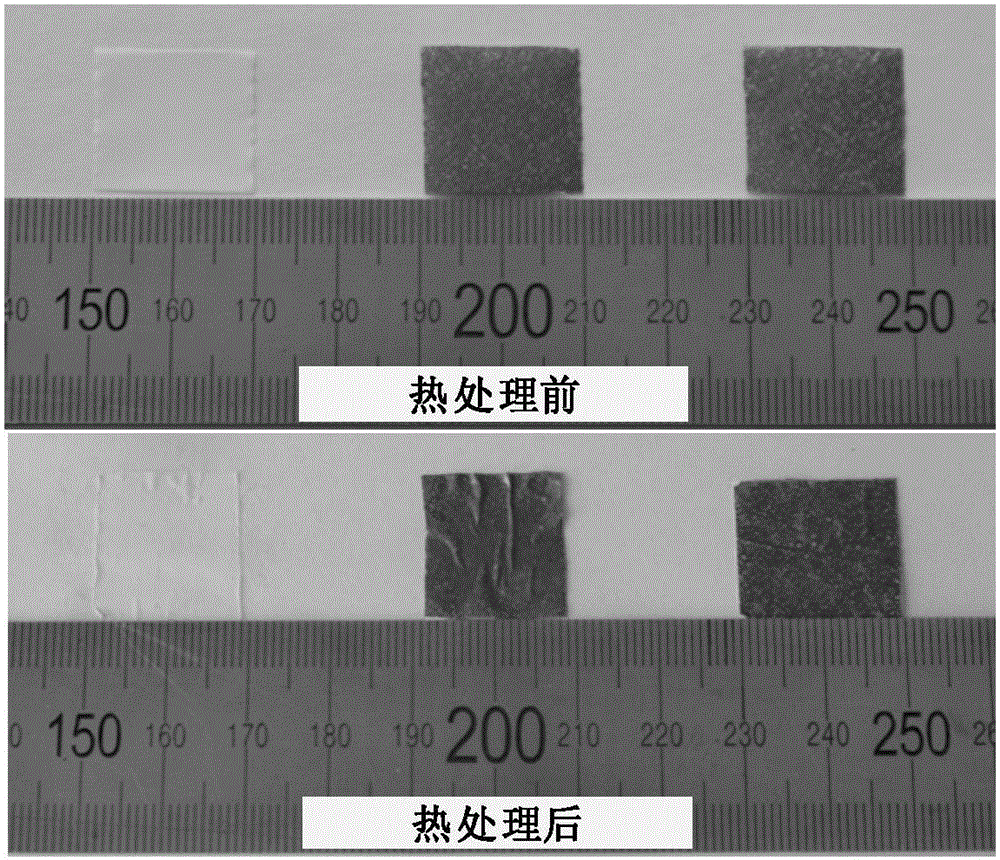

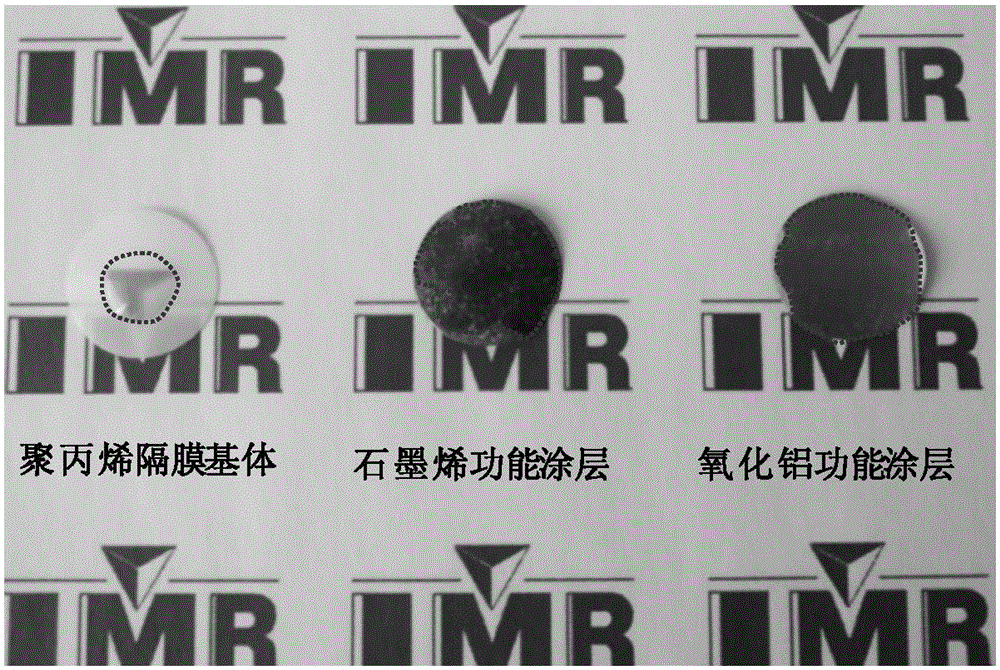

Composite diaphragm for lithium ion battery for lithium-sulfur battery and preparation method and application of composite diaphragm for lithium ion battery

InactiveCN106356488AFacilitates fast transfersImproved thermal stability and safety performanceCell component detailsElectrochemical energy storageLithium electrode

The invention discloses a composite diaphragm for lithium ion battery for a lithium-sulfur battery and a preparation method and application of the composite diaphragm for lithium ion battery, and belongs to the technical field of electrochemical energy storage. The composite diaphragm of the battery is a three-layer composite diaphragm prepared by respectively coating two sides of a polymer base body with a nano conductive functional coating layer and a ceramic functional coating layer. The nano conductive functional coating layer can accelerate quick transmission of electrons and ions in the battery, and the ceramic functional coating layer can improve the heat stability and the safety of the battery at high temperature, so that the battery prepared based on the composite diaphragm is excellent in electrochemical performance and heat stability. The method is simple in process and liable for industrialization; the prepared composite diaphragm can be widely applied to various lithium ion batteries and lithium-sulfur batteries.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Conductive adhesive for lithium ion batteries, preparation method thereof, electrode plate of lithium ion battery, preparation method thereof and lithium ion battery

ActiveCN107369835AGood electrical conductivityGood bonding performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesPolyvinylidene fluorideSodium carboxymethylcellulose

The invention provides a conductive adhesive for lithium ion batteries. The conductive adhesive comprises graphene and a first adhesive grafted to the surface of the graphene, and the first adhesive comprises at least one of polyvinyl alcohol, sodium carboxymethylcellulose, polyethylene glycol, polylactic acid, polymethyl methacrylate, polystyrene, polyvinylidene fluoride, hexafluoropropylene polymer, styrene-butadiene rubber, sodium alga acid, starch, cyclodextrin and polysaccharide. The conductive adhesive for lithium ion batteries has good conductivity and adhesive property, and is of certain strength, so that the integral mechanical strength of the electrode plate can be strengthened; the conductive adhesive realizes that the adhesive is combined with a conductive agent, so that the content of active substances in the electrode plate can be increased, and the energy density of cells is further increased. The invention also provides a preparation method of the conductive adhesive, an electrode plate containing the conductive adhesive and the lithium ion battery.

Owner:HUAWEI TECH CO LTD

Carbon nano-tube fiber cement-based material and preparation thereof

The invention relates to a cement-based material of carbon nano tube fiber and a preparation method thereof, in particular to a toughened cement-based material and a preparation method thereof. The invention solves the problems of relatively low anti-bending and anti-breaking intensity and toughness of the existing fiber toughened cement-based material. The material is produced by a fiber dispersant, an organic solvent, carbon fibers, carbon nano tubes, deionized water, a superplasticizer, a polymer emulsion, mineral admixture and cement. The preparation method of the invention is as follows: the fiber dispersant is added into mixed slurry of the cement and stirred; the primarily mixed slurry is fed into a high shearing colloid mill for shearing at high speed for 5 to 30min; the evenly stirred slurry is poured into a test mould which is moved to a vacuum drying case for pressure reducing and bubble-removing and heated for evaporation of the solvent for 0.5 to 3 hours; after 24 hours, and the material is obtained after tearing the mould and maintained in water at room temperature. The fracture energy GF and the fracture toughness of the material obtained by using the method of the invention respectively are 106.3N question mark m and 0.998Mpa / m<-1 / 2>, which are respectively 112.6 percent and 33.1 percent higher than the fracture energy and the fracture toughness of the existing fiber toughened cement-based material.

Owner:HARBIN INST OF TECH

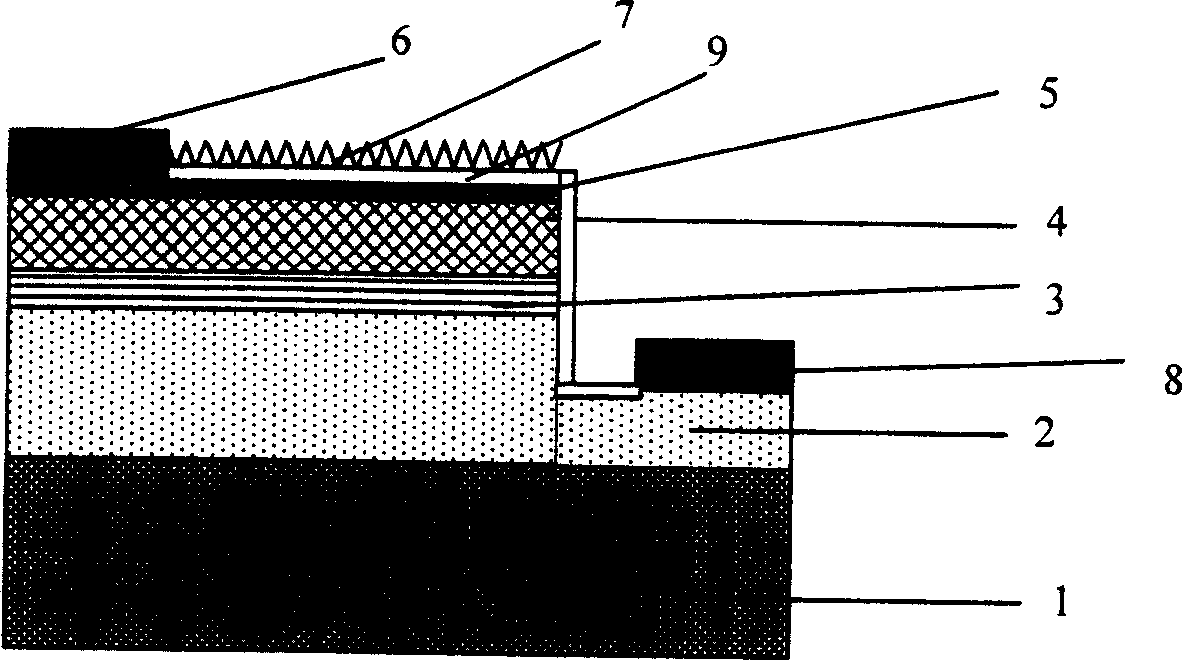

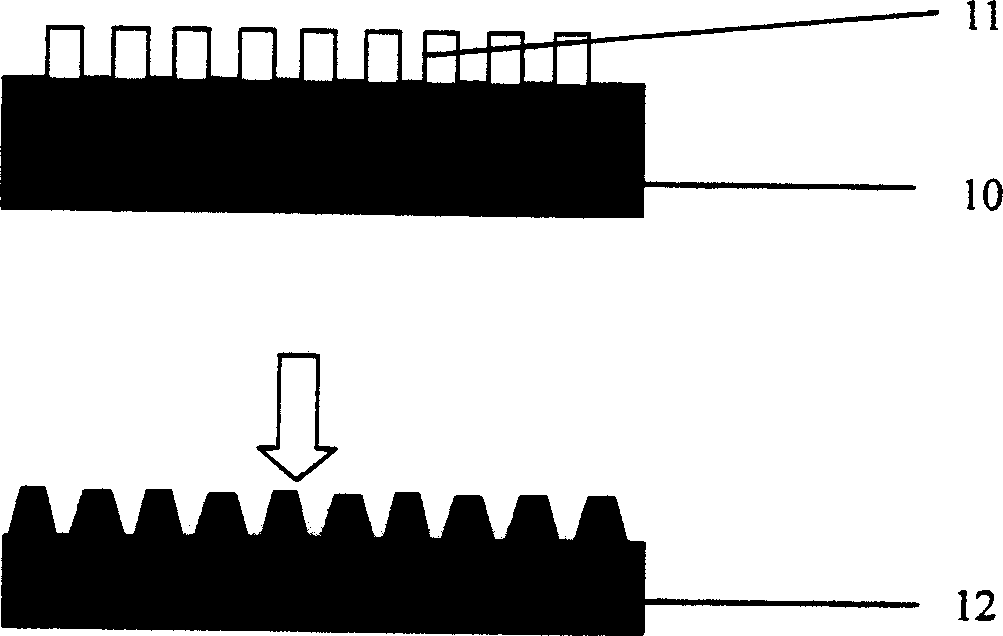

High-luminance chip of luminescent tube in GaN base, and preparation method

InactiveCN1874012AImprove thermal characteristicsImprovement and conductivityLaser detailsSolid-state devicesPhotonic crystal structureLead structure

The technical scheme discloses high brightness LED structure with graphic surface and microstructure. Using Nano pressing technique prepares each graphic film from organic material on luminous surface of LED so as to form microstructure on LED surface in favor of transgression of emitting light from active region, for example micrographics with structure or coarsening, and photon crystal structure. Introducing the said micrographics on surface makes interfacial area of light emergence medium increase. The increased surface presents great lot small areas unordered arranged. Emergence of light from active region and interface of medium is at random in a certain extent. The invention improves directions of emergence light, increases probability of emergence so as to raise light extraction efficiency and external quantum efficiency of LED.

Owner:PEKING UNIV

High-dispersity acidic copper plating additive as well as preparation method and application thereof

InactiveCN105734623AImprove ductilityImprove current efficiencyPrinted element electric connection formationDispersityCopper plating

The invention relates to the field of highly dispersive all-bright acidic copper plating of printed circuit boards, in particular to a highly dispersive acidic copper plating additive and its preparation method and application. A highly dispersed acidic copper plating additive: at least one divalent sulfide main brightener, at least one polyethylene glycol or polypropylene glycol or both block copolymer polymer inhibitors, at least one alkyl quaternary ammonium salt Type cationic surfactant, 5‑50ml / L sulfuric acid, 0.1‑4ml / L formaldehyde. Its preparation method is to slowly add a specified amount of concentrated sulfuric acid into water, stir evenly and cool to room temperature, then sequentially add the inhibitor, surfactant, main brightener and formaldehyde into the sulfuric acid aqueous solution, stir until completely dissolved Concentrate to the final volume to obtain the highly dispersed acidic copper plating additive of the present invention. The high-dispersion acidic copper plating additive of the invention is especially suitable for electroplating through-holes with high thickness-to-diameter ratio of printed circuit boards, and can obviously improve the dispersion ability of the plating solution.

Owner:GUANGDONG LEAR ELECTROCHEM LTD

Graphene composite material for cathode of lithium ion battery and preparation method of graphene composite material

ActiveCN102683657AGood electrical conductivityLow priceCell electrodesSecondary cellsCvd grapheneStructural stability

The invention relates to a graphene composite material for a cathode of a lithium ion battery and a preparation method of the graphene composite material, belonging to the technical field of preparation of the electrodes of the lithium ion batteries. The preparation method of the graphene composite material for the cathode of the lithium ion battery comprises the steps of: oxidizing and ultrasonically dispersing a graphene material in a concentrated acid environment, then mixing the obtained graphene material with a titanium source, and drying and calcining an obtained mixture to obtain the graphene composite material. The graphene composite material for the cathode of the lithium ion battery, provided by the invention, is high in electric conductivity; an obtained electrode slice is low in resistance and has structural stability in a charge / discharge process; and the prepared lithium ion secondary battery is high in capacity, good in safety, favorable in cyclic performance and long in service life.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

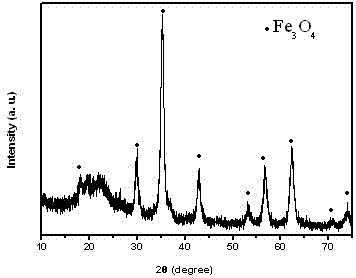

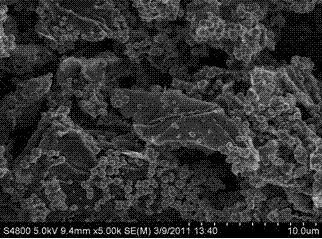

Graphene composite titanium dioxide photocatalyst capable of magnetic separation and recovery, and preparation method thereof

ActiveCN102489284AHigh specific surface areaGood electrical conductivityWater/sewage treatment by irradiationCatalyst activation/preparationTitanium dioxide nanoparticlesGraphene

The present invention relates to a graphene composite titanium dioxide photocatalyst capable of magnetic separation and recovery, and a preparation method thereof. The photocatalyst is synthesized by a two-step hydrothermal method, wherein graphene and magnetic particles are compounded to prepare magnetic graphene, the magnetic graphene is compounded with titanium dioxide nanoparticles synthesized by a hydrothermal method to prepare the three-element composite photocatalyst. The photocatalyst comprises three parts of the graphene, the titanium dioxide, and the magnetic nanoparticles, wherein the magnetic nanoparticles are loaded on the graphene lamellas to form the magnetic graphene having large specific surface area and magnetism, the rutile type titanium dioxide has a three-dimensional ordered nanostructure, and is loaded on the magnetic graphene lamellas to form the graphene composite rutile type titanium dioxide photocatalyst with the characteristic of magnetic separation, whereinthe photocatalyst has the large specific surface area, the nanoparticles have the magnetism, the photocatalyst can be separated and recovered, and has the efficient catalytic performance.

Owner:ZHEJIANG UNIV

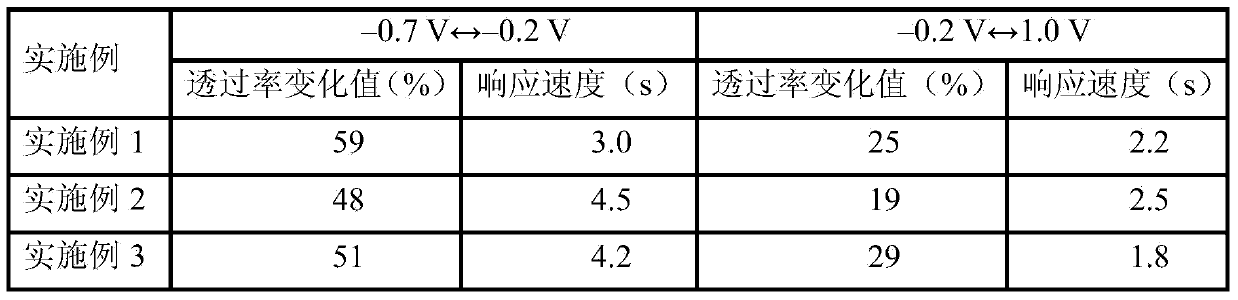

Tungsten trioxide/polyaniline core-shell nanowire array radiochromic film and preparation method thereof

ActiveCN103469272AGood electrical conductivityLarge spectrum adjustment rangeMaterial nanotechnologyNanoopticsChemistryHydrogen peroxide

The invention provides a tungsten trioxide / polyaniline core-shell nanowire array radiochromic film and a preparation method thereof. The preparation method comprises the following steps: dissolving white tungstic acid in aqueous hydrogen peroxide liquor to prepare peroxide tungstate liquor; coating the peroxide tungstate liquor on an electric conductive face of a clean electric conductive substrate; dissolving tungstate in alcohol to form precursor liquor, fixing the electric conductive substrate in a reaction kettle, adding the precursor liquor into the reaction kettle, carrying out a reaction at 150-250 DEG C for 8-16 hours, and taking out and carrying out thermal treatment at 300-450 DEG C for 1-3 hours to obtain a tungsten trioxide nanowire array; and mixing aniline and dilute sulphuric acid to form electrolyte for preparing polyaniline and carrying out electro-polymerization on polyaniline to obtain the tungsten trioxide / polyaniline core-shell nanowire array radiochromic film. The preparation process is convenient to control, lower in preparation cost and easy to realize industrialization. The film has the advantages of large spectrum adjustment range, abundant radiochromic types, high coloring efficiency, fast response speed, long cycle life and the like.

Owner:ZHEJIANG UNIV

Low-content nanometer conducting silver paste and its prepn

InactiveCN1437200AEasy size distributionGood electrical conductivityNon-conductive material with dispersed conductive materialElectrically-conductive paintsSilver particlesHigh conductivity

The present invention relates to one kind of nano conducting silver paste and its preparation, and aims at solving the problems of conducting paste with higher conducting stuffing content, high colloid viscosity and unsuitability in connecting through holes in multi-layer circuit board. According to the self-assembling and low temperature welding features of the nano silver particles, the presentinvention prepares nano silver powder via microemulsion process and low-content conducting nano silver particle paste with epoxy resin stuffing component. The paste has high conductivity, low colloidviscosity and thus wide application foreground in fixing electronic elements onto circuit board, connecting electrodes and especially connecting through holes in multi-layer circuit board.

Owner:SUN YAT SEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com