Low-cost mass preparation method of high-quality graphene

A graphene, high-quality technology, applied in the directions of graphene, chemical instruments and methods, nano-carbon, etc., can solve the problems such as the decline of graphene's electrical conductivity, and achieve the effects of low preparation cost, easy to scale up production, and high electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

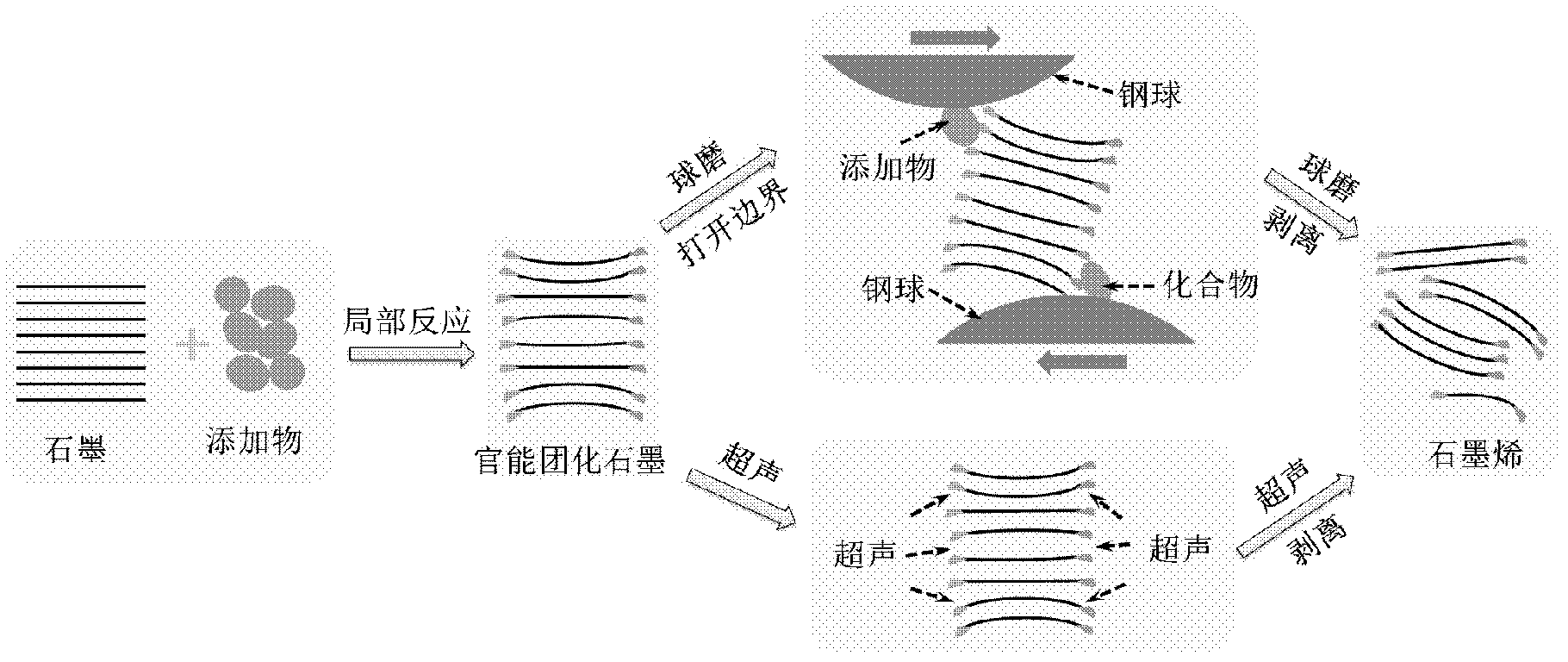

Method used

Image

Examples

preparation example Construction

[0048] D. Preparation of Graphene Films

[0049] Conductivity is an important indicator to prove the quality of graphene, and good conductivity is the prerequisite for the further utilization of graphene. To this end, graphene was prepared into thin films as follows.

[0050] (1) Gained graphene is dispersed in water, and configuration forms the graphene hydrosol that concentration is 0.05-0.5g / L, as figure 1 shown. The graphene concentration is determined according to the film thickness.

[0051] (2) Prepare a graphene film by vacuum filtration. Use a mixed fiber filter membrane with a pore size of 200 nm as the filter medium, and add 0.5-1 L of graphene hydrosol. Filtrate for 6-12 hours to obtain a graphene film attached to the mixed fiber filter membrane.

[0052] (3) drying the obtained film at 50-70° C. for 1-3 hours to obtain a flexible graphene film.

[0053] (4) In order to increase the contact between the graphene sheets, the obtained graphene film is pressed by...

Embodiment 1

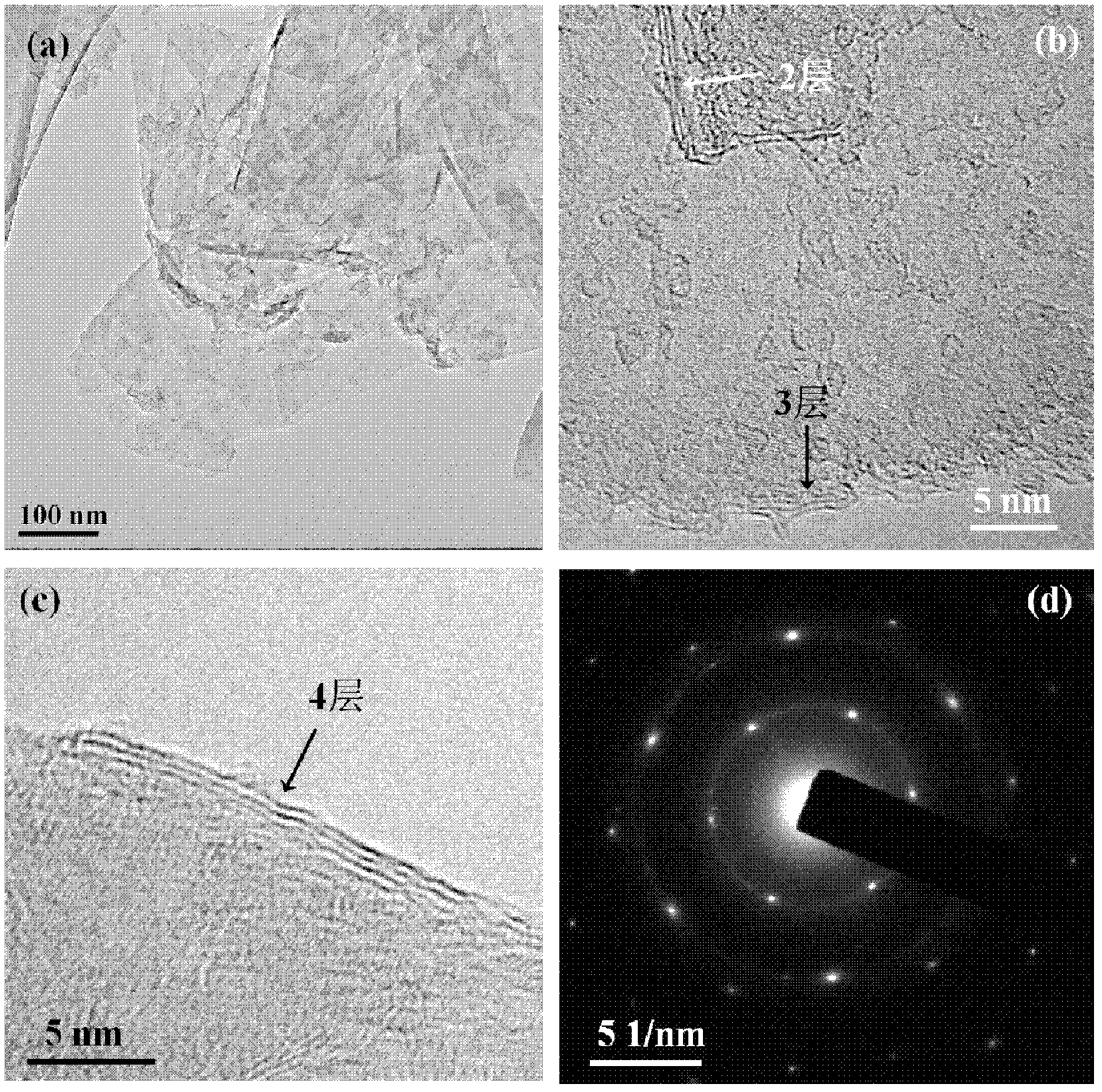

[0058] Synthesis of Graphene of the present invention

[0059] Get 5 grams of 100-mesh flake graphite (particle size less than 150 μm) and 15 grams of oxalic acid and put it into a ball mill jar with an inner diameter of 10 cm, and add stainless steel balls with a particle size of 5 mm that account for about 1 / 3 of the ball mill jar volume. After tightening the ball mill jar, put it into the high energy ball mill. After ball milling at a rotational speed of 500 rpm for 24 hours, 1 L of deionized water was added to wash out the graphene. Stir well for 1 hour to ensure that the oxalic acid is all dissolved in the water. Filter, wash with 1L of deionized water, and obtain graphene powder after vacuum drying.

[0060] Weigh, obtain the graphene of 4.45g. The yield is calculated to be 0.89 grams of graphene per gram of graphite.

[0061] Graphene prepared by chemical exfoliation method in the prior art

[0062] In order to highlight the excellent electrical conductivity of the...

Embodiment 2

[0078] Get 5 grams of 100-mesh flake graphite (particle size less than 150 μm) and 500 grams of dry ice and put it into a ball mill jar with an inner diameter of 10 cm, and add stainless steel balls with a particle size of 5 mm that account for about 1 / 3 of the ball mill jar volume. After tightening the ball mill jar, put it into the high energy ball mill. After ball milling for 48 hours at a rotating speed of 500 rpm, the ball mill jar was opened to allow the dry ice to fully volatilize to obtain graphene powder. Weigh, obtain the graphene of 4.01g. The yield is calculated to be 0.8 grams of graphene per gram of graphite.

[0079] The ball milling agent used in the invention is non-toxic, harmless and cheap dry ice, which saves the process of washing, filtering and drying. Let the process of the invention be simpler.

[0080] The preparation of the graphene film and the test of its conductivity are as in Example 1, and the measured conductivity is 1085 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com