Patents

Literature

117 results about "Intercalation reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intercalation reaction. Also contains definition of: insertion reaction. https://doi.org/10.1351/goldbook.I03077. Reaction, generally reversible, that involves the penetration of a host material by @G02711@ species without causing a major structural modification of the host.

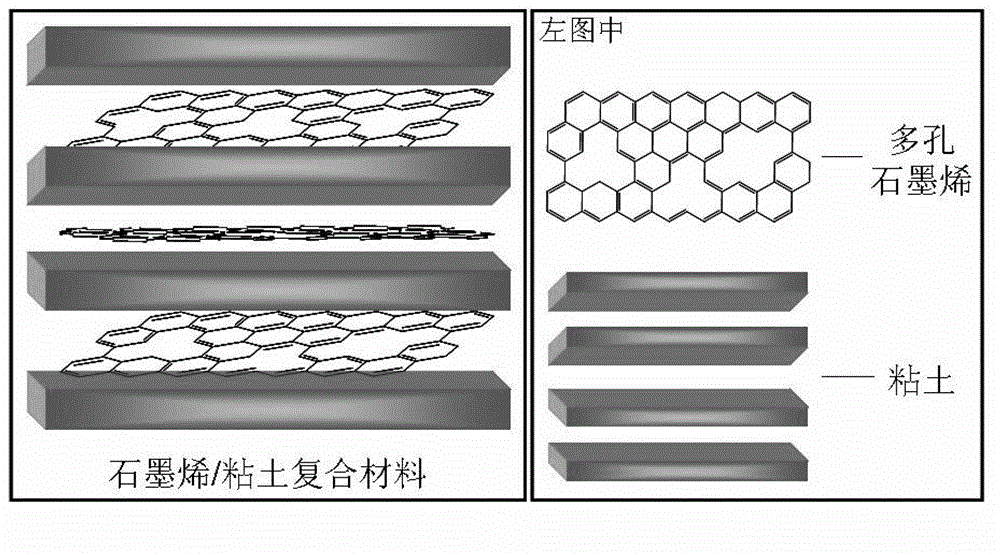

Graphene/clay composite material, and preparation method and application thereof

ActiveCN103143319AGood dispersionReduce reunionOther chemical processesWater/sewage treatment by sorptionIntercalation reactionDispersity

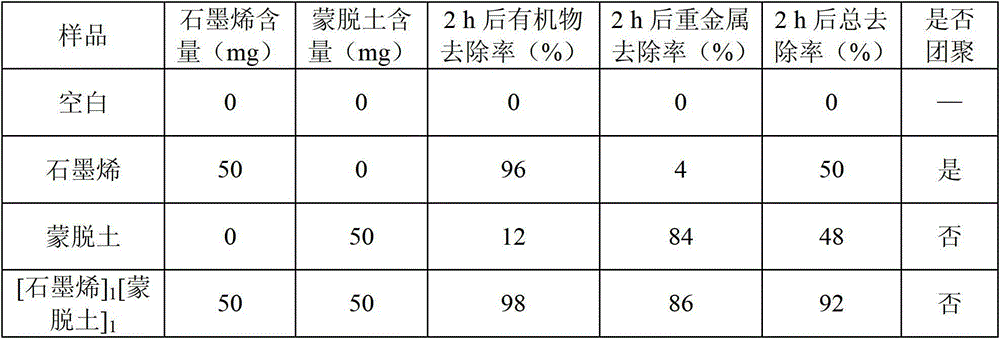

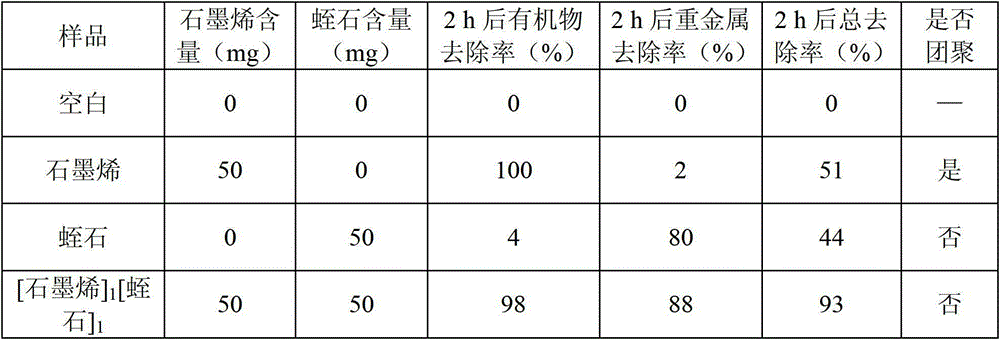

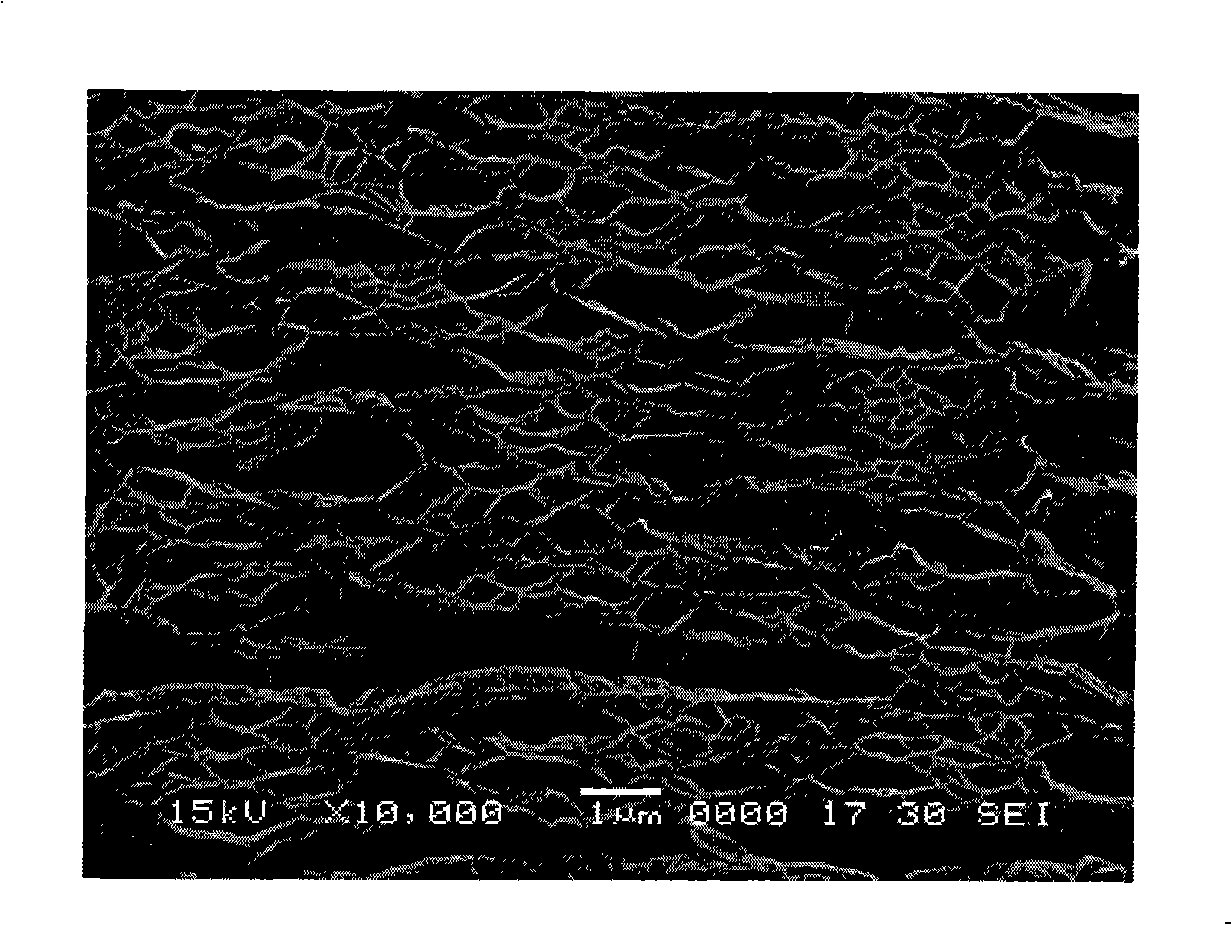

The invention belongs to the field of adsorbing materials, and relates to an inorganic-inorganic hybrid material, particularly a graphene / clay composite material. The composite material is powdery, is compounded from porous graphene and clay, and has a porous structure; the porous graphene is inserted among clay layers through intercalation reaction; the mass ratio of the porous graphene to the clay is 1:(0.1-10); the specific area of the graphene / clay composite material is 200-250 m<2> / g, and the weight loss within 900 DEG C is 3-6 wt%; and the clay is montmorillonite, vermiculite, illite, kaolin or rectorite. The graphene / clay composite material can be easily dispersed, can be used for comprehensively and efficiently adsorbing heavy metals and organic substances, and has the characteristics of high dispersity and efficient and selective adsorbability for heavy metals and organic substances; the maximum comprehensive removal rate can reach 99%; and thus, the invention has wide prospects in industrialized application.

Owner:JINAN UNIVERSITY

Preparation of low temperature expandable graphite

The invention relates to a preparation method of an expansible graphite (expansible graphite intercalation compound) which comprises the following steps: dipping a flake graphite in a solution mainly formed by oxidant and intercalation agent for intercalation reaction, replacing the intercalation compound between the graphite layers by water exchange method after filtration, drying the obtained solid formation to obtain target compounds. The invention has advantages of low energy consumption, environment friendly, and the prepared expansible graphite is capable of expansion at a low temperature.

Owner:EAST CHINA UNIV OF SCI & TECH

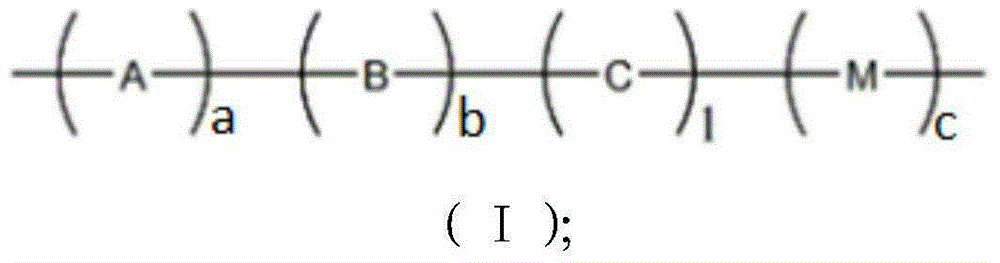

Super-early-strength PCE (polycarboxylate ether) superplasticizer and preparation method thereof

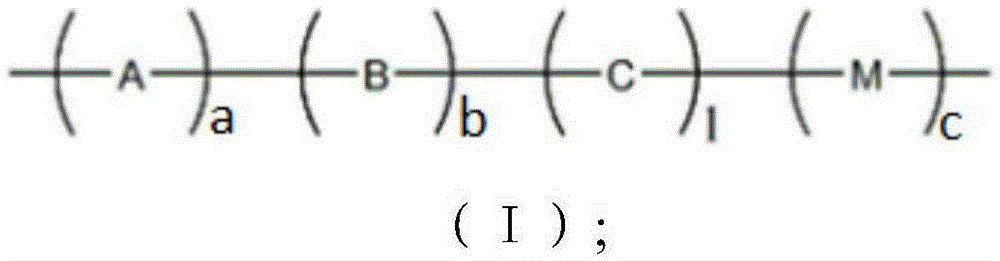

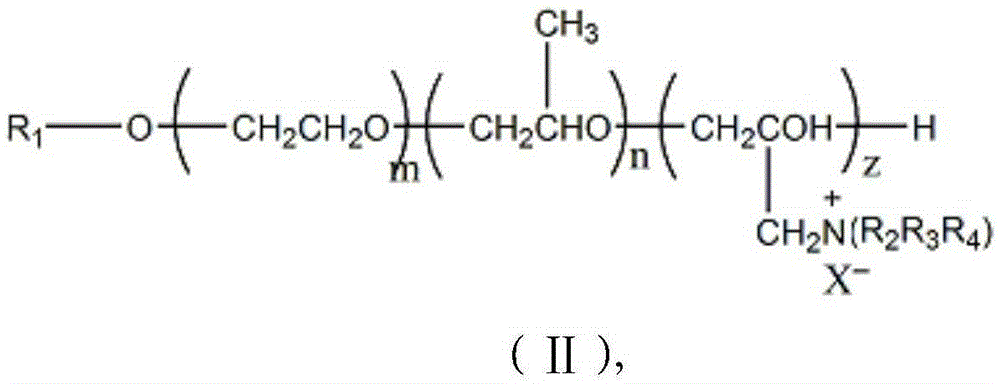

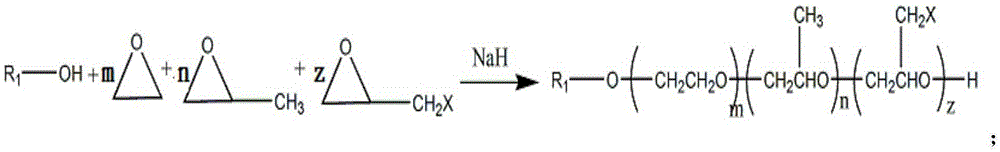

The invention provides a super-early-strength PCE (polycarboxylate ether) superplasticizer. The super-early-strength PCE superplasticizer is a compound shown in formula (I) and is synthesized with active macro-monomers used as raw materials, the space hindrance effect of the superplasticizer is further improved, and meanwhile, positive ions with good cement resistance are introduced in molecules, so that the superplasticizing rate, the cement resistance and the cement adaptability of the superplasticizer are increased. The superplasticizer has better tolerance and cannot have a continuous intercalation reaction with the cement. The positive ions of the super-early-strength PCE superplasticizer can inhibit expansion of the cement so as to reduce adsorption of the cement to an additive. The super-early-strength PCE superplasticizer can accelerate the hydration function of the cement and has the super-early-strength function. The super-early-strength PCE superplasticizer has super-early-strength and cement-resistant functions in common concrete.

Owner:GUANGDONG REDWALL NEW MATERIALS

Inorganic intercalation nano catalyst and preparation process thereof

InactiveCN1449866ALarge specific surface areaAtomic number increaseMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsIntercalation reactionNano catalyst

The present invention relates to an inorganic intercalation nano catalyst and its preparation method. It is an inorganic intercalation nano catalyst made up by using zinc binary carboxylate as insert and using montmorillonite, mica, vermiculite, moscow earth and kaolin as base body, and its preparation method includes the following steps: activating inorganic base body powder for 2-10 hr. at 600-1000 deg.C, cooling for stand-by; dissolving zinc binary carboxylate in strong polar solvent, then making it and inorganic base body implement intercalation reaction for 30-120 min, then adopting the weak polar solvent to make lattice modification so as to obtain the invented catalyst with good catalytic efficiency and good selectivity.

Owner:SUN YAT SEN UNIV

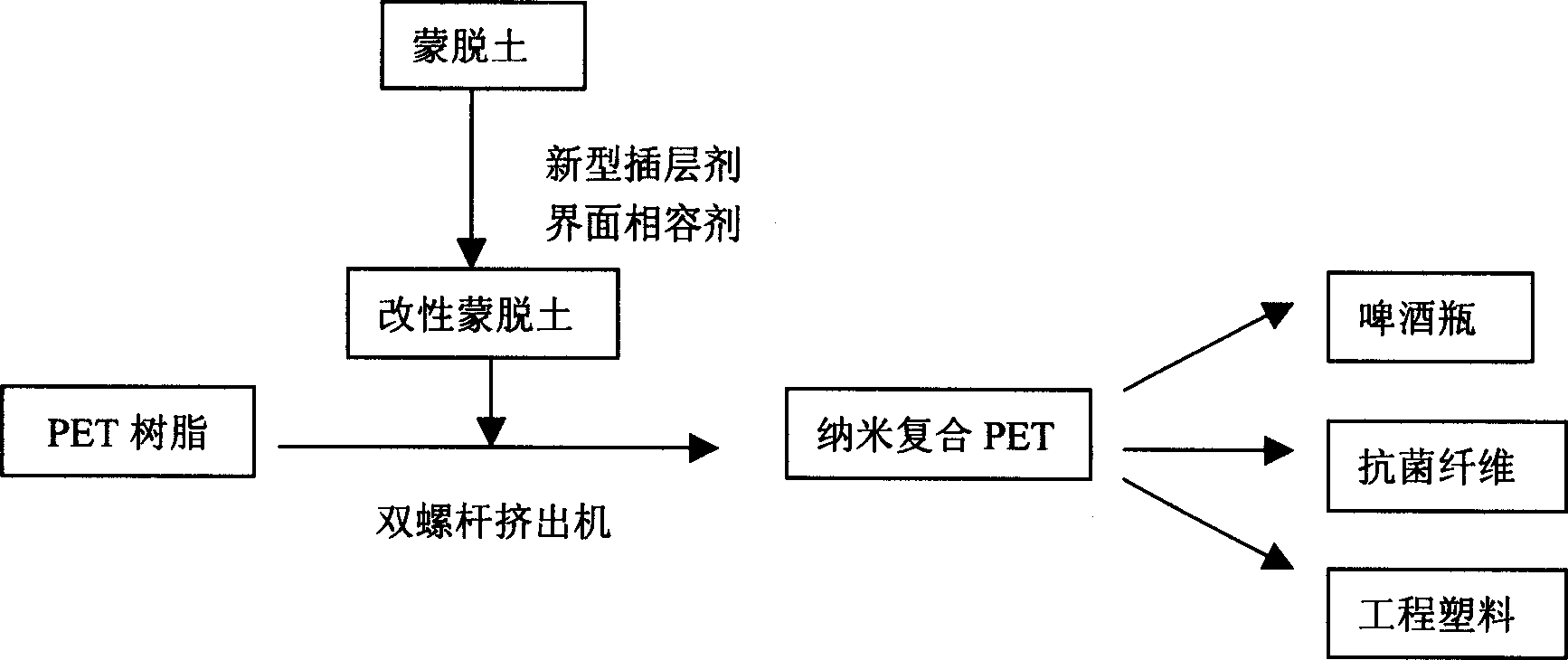

Polyester/lamellar silicate nano composite material and preparation method thereof

InactiveCN1465621AGood physical and mechanical propertiesLarge variable rangeFiberIntercalation reaction

The present invention relates to a kind of polyester / laminate silicate nano composite material and its preparation method. Said preparation method includes the following steps: making organic intercalation agent for silicate and auxiliary treatment agent to make intercalation reaction, then making the above-mentioned material and polyester undergo the process of mechanical melting and co-mixing or melt co-mixing in reactor and dispersing the laminate silicate in the polyester resin base body in nano size so as to obtain the invented nano composite material. Said invented composite material has good physical mechanical property, can be used for making high-choking packaging bottle and packaging bag, and functional fibre, etc.

Owner:CHANGZHOU CHAMGO NANO MATERIALS

Preparation method of polyacrylamide nano composite fracturing fluid

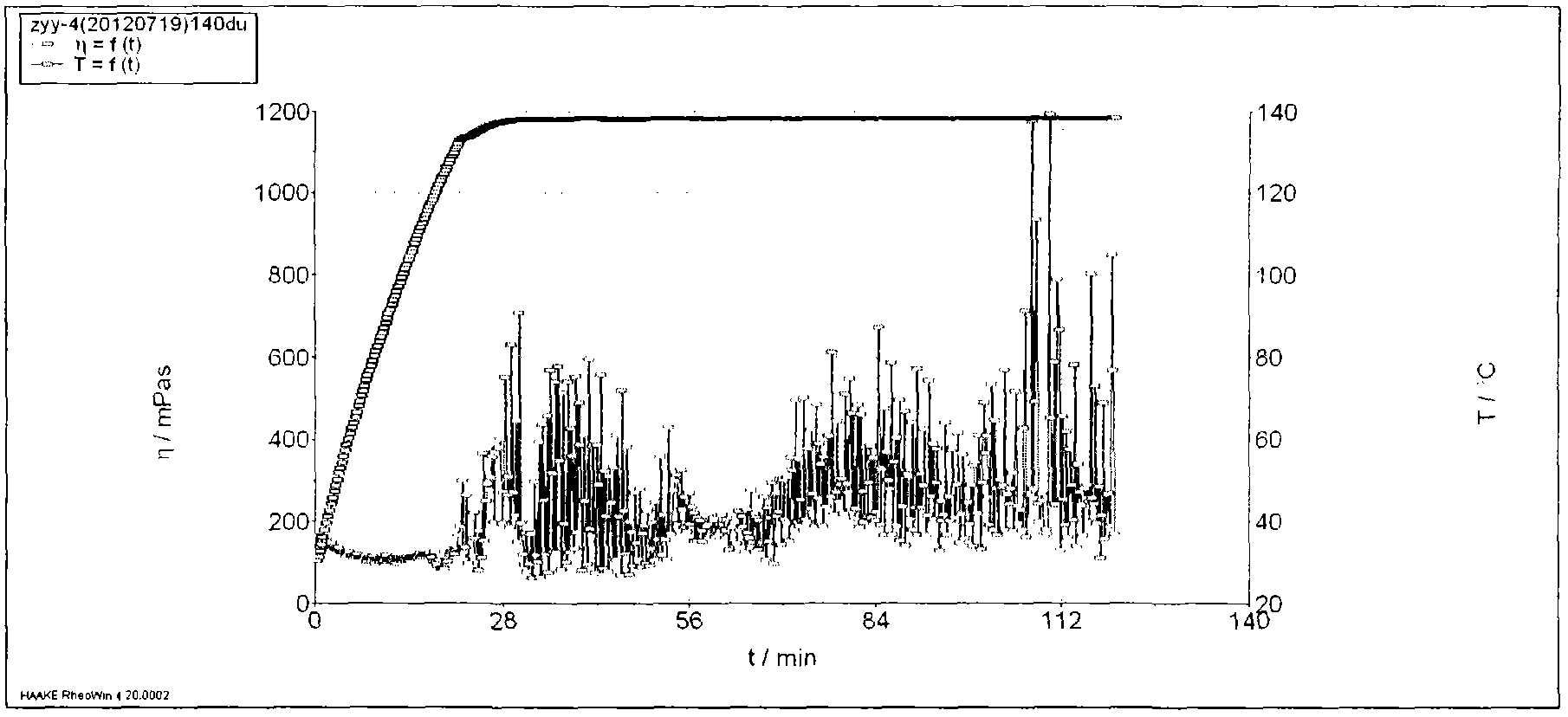

ActiveCN104109525AHigh temperature resistantSalt resistantDrilling compositionIn situ polymerizationFracturing fluid

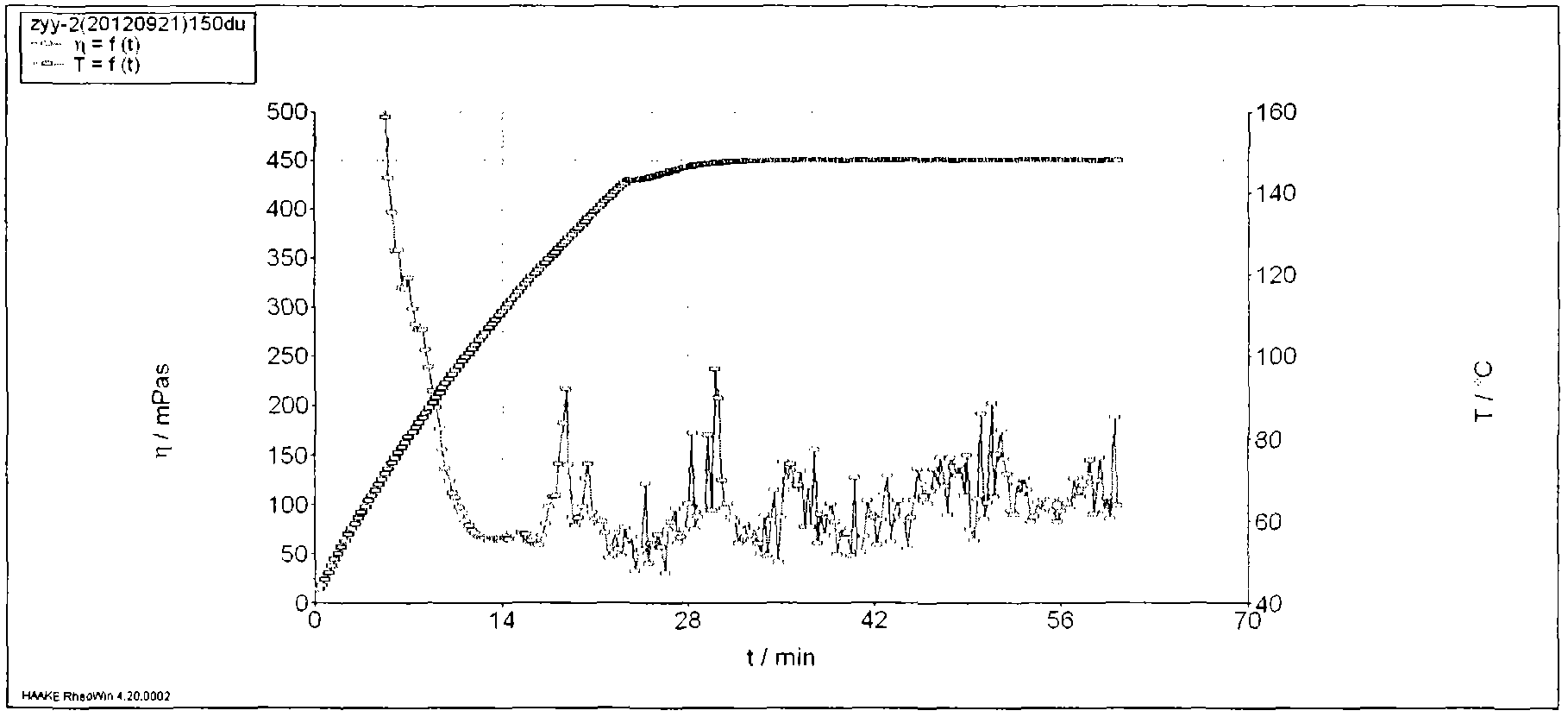

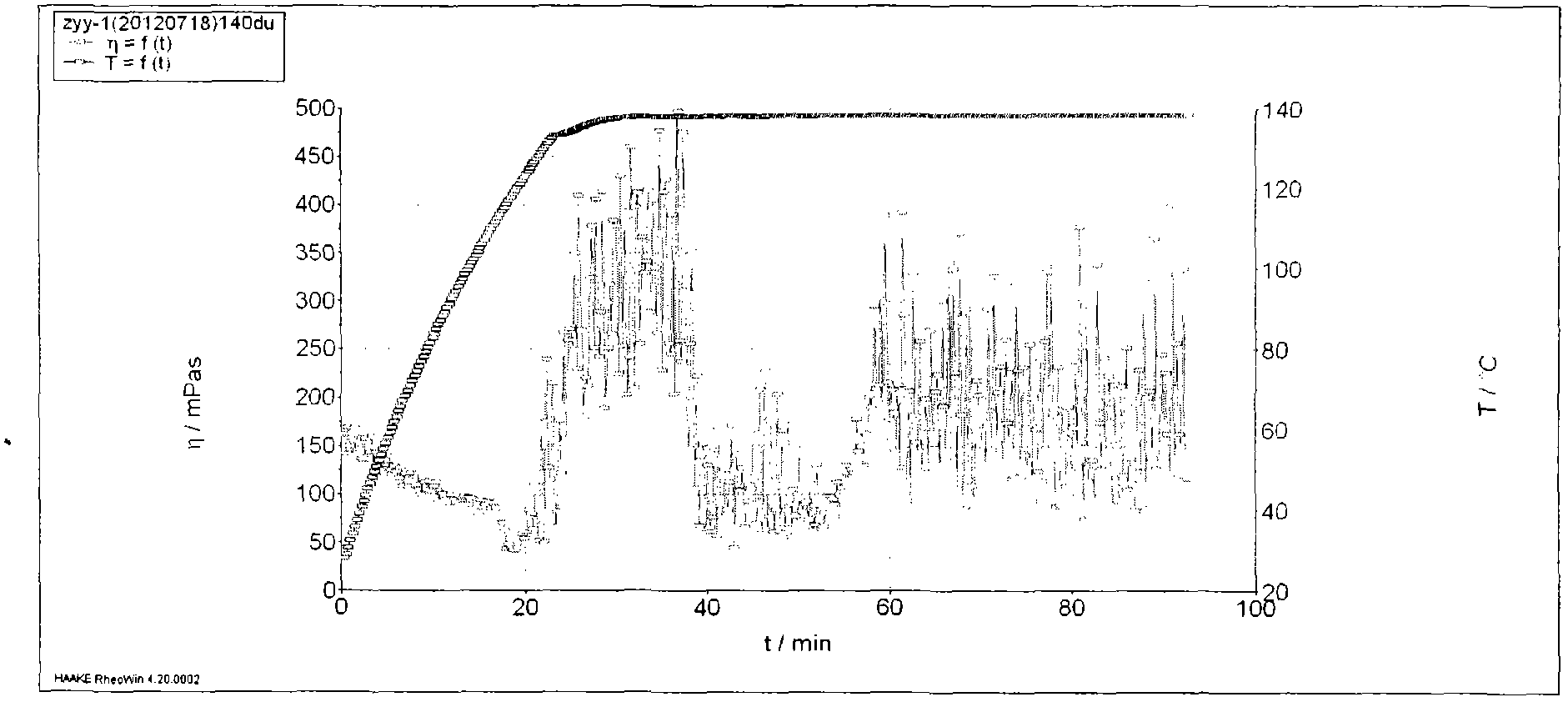

The invention adopts polyacrylamide and a nano inorganic phase to prepare a polyacrylamide nano composite material through an in-situ polymerization method and then forms a fracturing fluid thickening agent. The nano inorganic phase is prepared by mixing the products of intercalation reactions between an organic long-chain intercalator and layered silicate with magnesium nitrate and aluminum nitrate. The nano inorganic phase, acrylamide monomer, a coupling agent, a complexing agent, an initiator, an oxidant, a reductant, a cosolvent, an auxiliary agent, and deionized water form a suspension fluid reaction system, and the polyacrylamide nano composite material is formed after the polymerization-intercalation composite reactions. The polyacrylamide nano composite material with a mass percentage of 0.25% is taken as the thickening agent, and then is mixed with a crosslinking agent with a mass percentage of 0.20%, a gel breaker with a mass percentage of 0.20%, and other auxiliary agents to form a fracturing fluid system. The system is sheared for 70 minutes under a shearing speed of 170 s<-1> at a temperature of 150 DEG C so as to form a fracturing fluid with a viscosity larger than 50 mPa.s, and the fracturing fluid has the characteristics of high temperature resistance, shearing resistance, low frictional resistance, complete glue breaking effect, and good compatibility with the formation fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

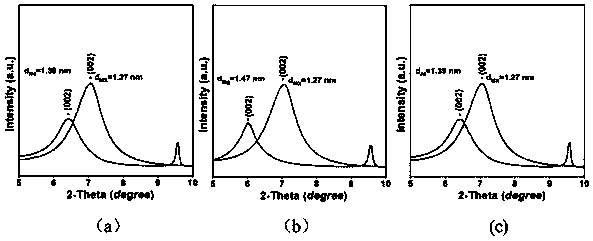

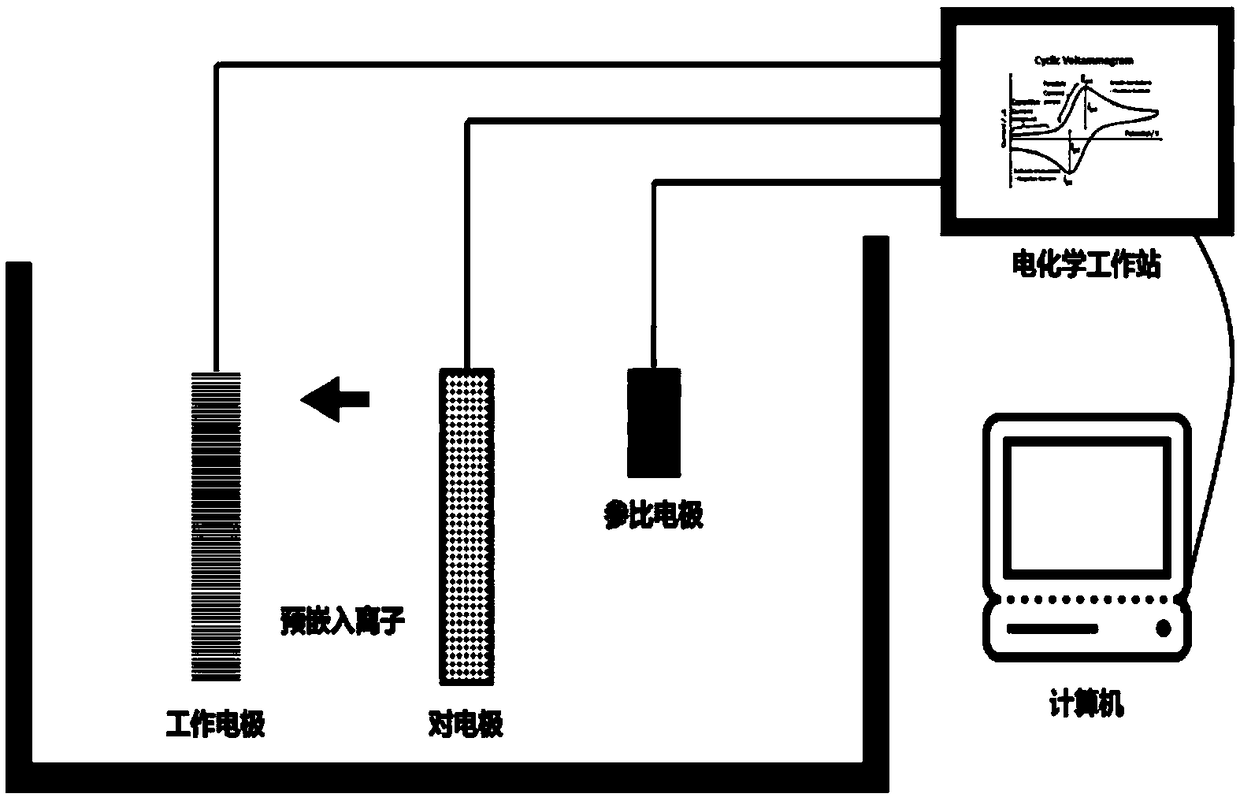

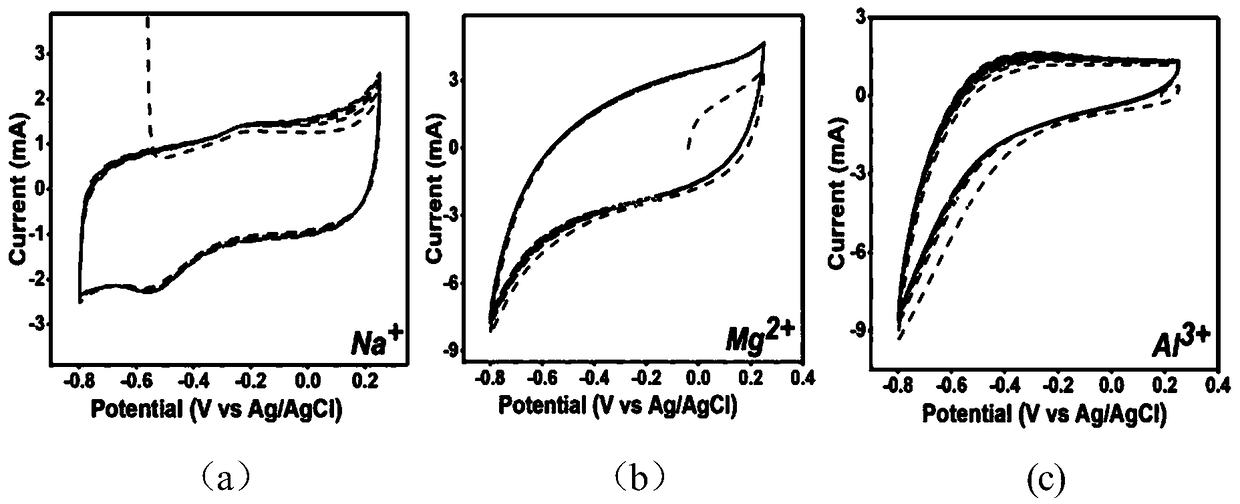

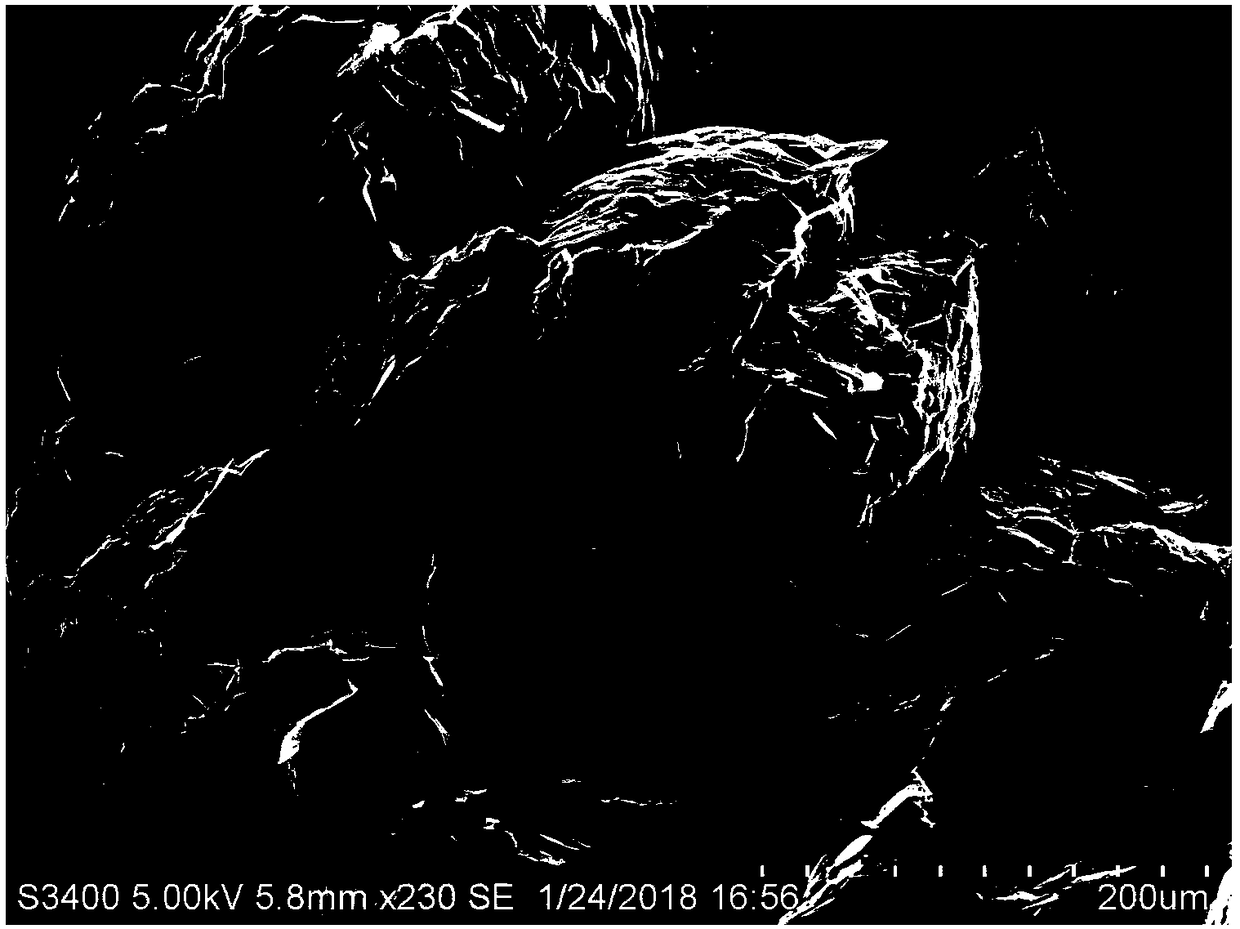

Ion pre-embedded two-dimensional layered material intercalation electrode and preparation method and application thereof

ActiveCN109216648AOptimize and improve structureOptimize and improve the interfaceElectrode manufacturing processesSecondary cellsConductive materialsWorkstation

The invention discloses an intercalation electrode constructed by pre-embedding ions into two-dimensional layered material and a preparation method and application thereof, belonging to the technicalfield of electrode material preparation for electrochemical energy storage devices. Firstly, the electrochemical ion pre-intercalation reaction system was constructed by using two-dimensional layeredmaterial as working electrode, solution containing pre-intercalated ions as electrolyte and high conductive material as counter electrode. The working electrode is applied with fluctuating potentials(cyclic voltammetry and galvanostatic charging and discharging techniques) in a specific voltage window by means of an electrochemical workstation, which forces ions to periodically intercalate between layers of two-dimensional layered materials in order to pre-open the ion transport channel. By controlling the final state potential, the pre-embedded ions are anchored between the inner layers of the two-dimensional material to achieve ion support, so as to construct a high-speed and stable ion transport channel, thereby enhancing the electrode function of the two-dimensional layered material and serving for the high-performance energy storage system.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

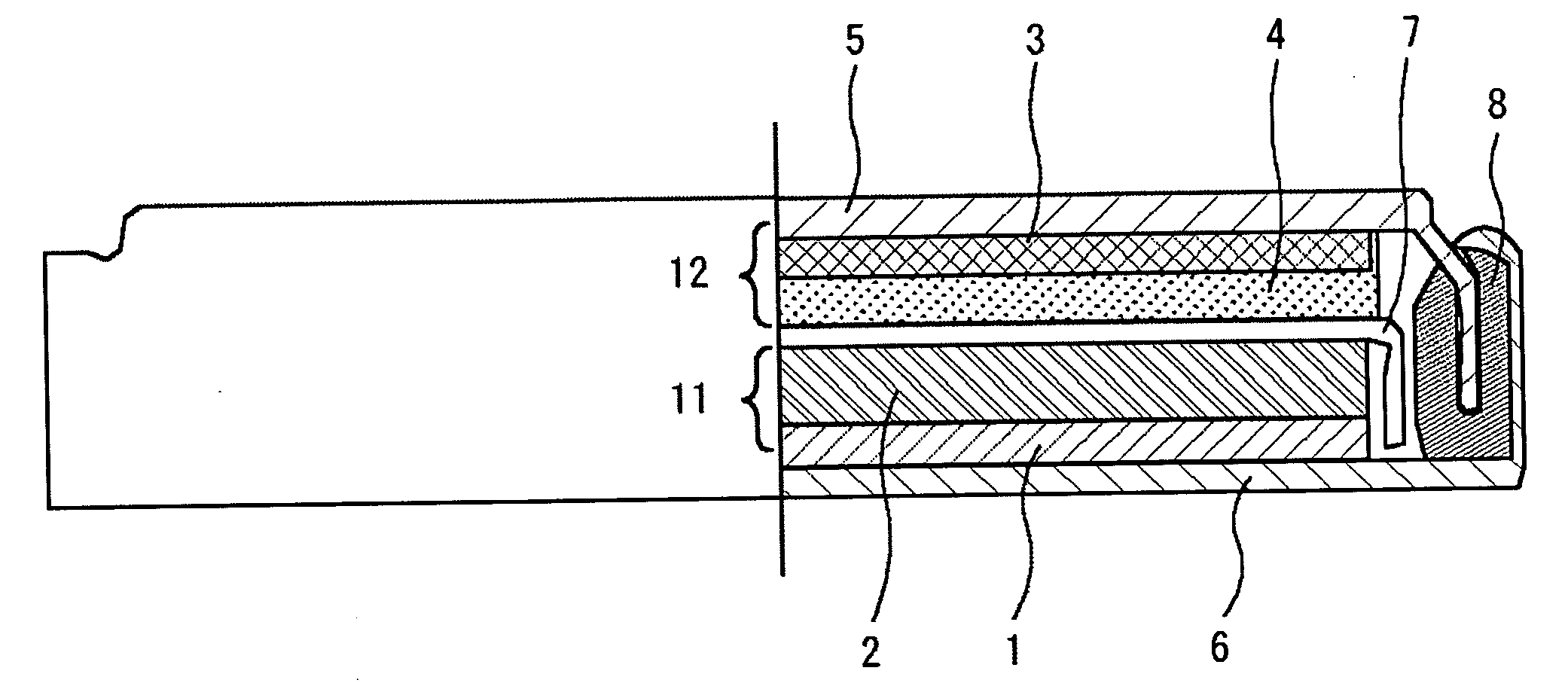

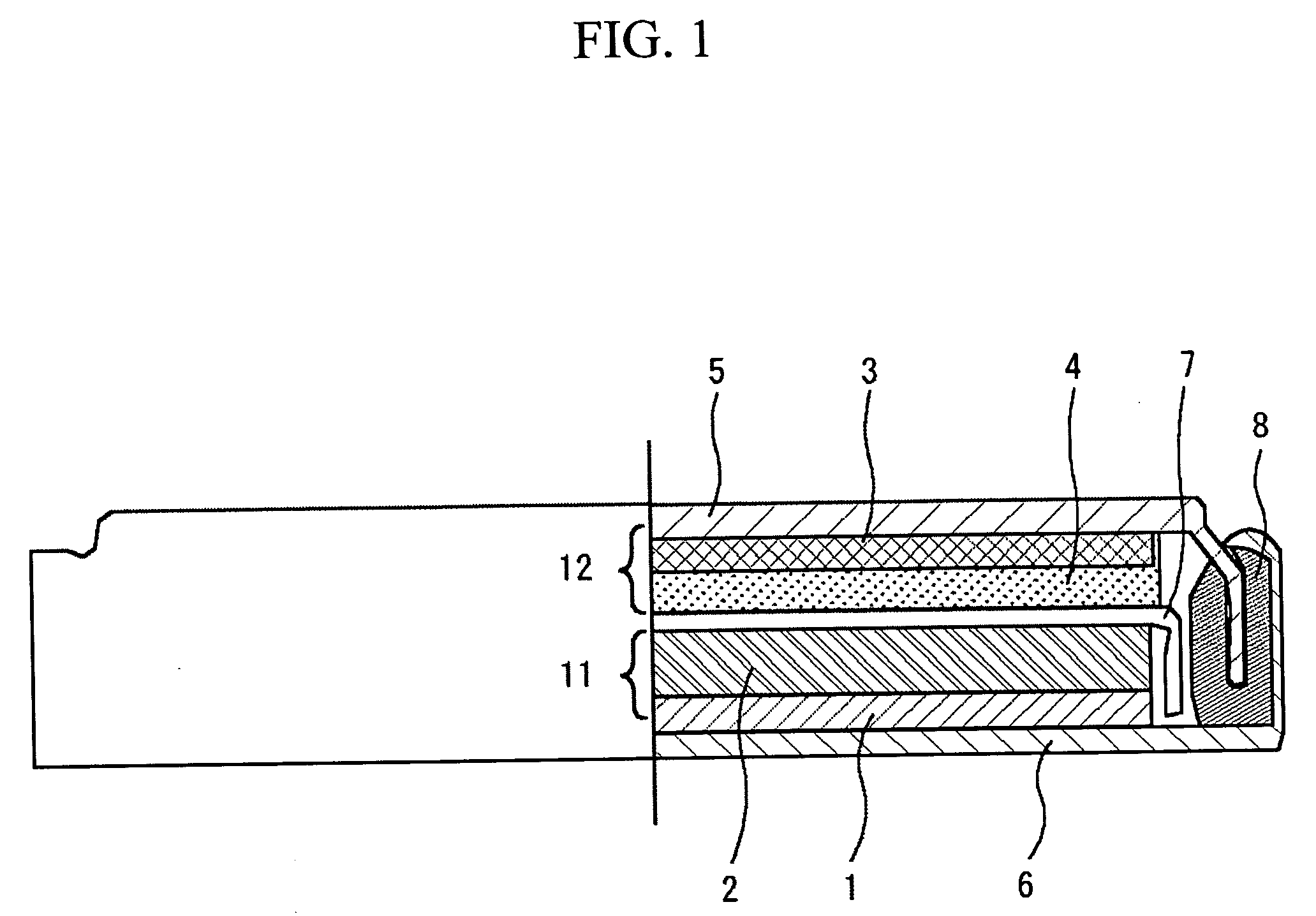

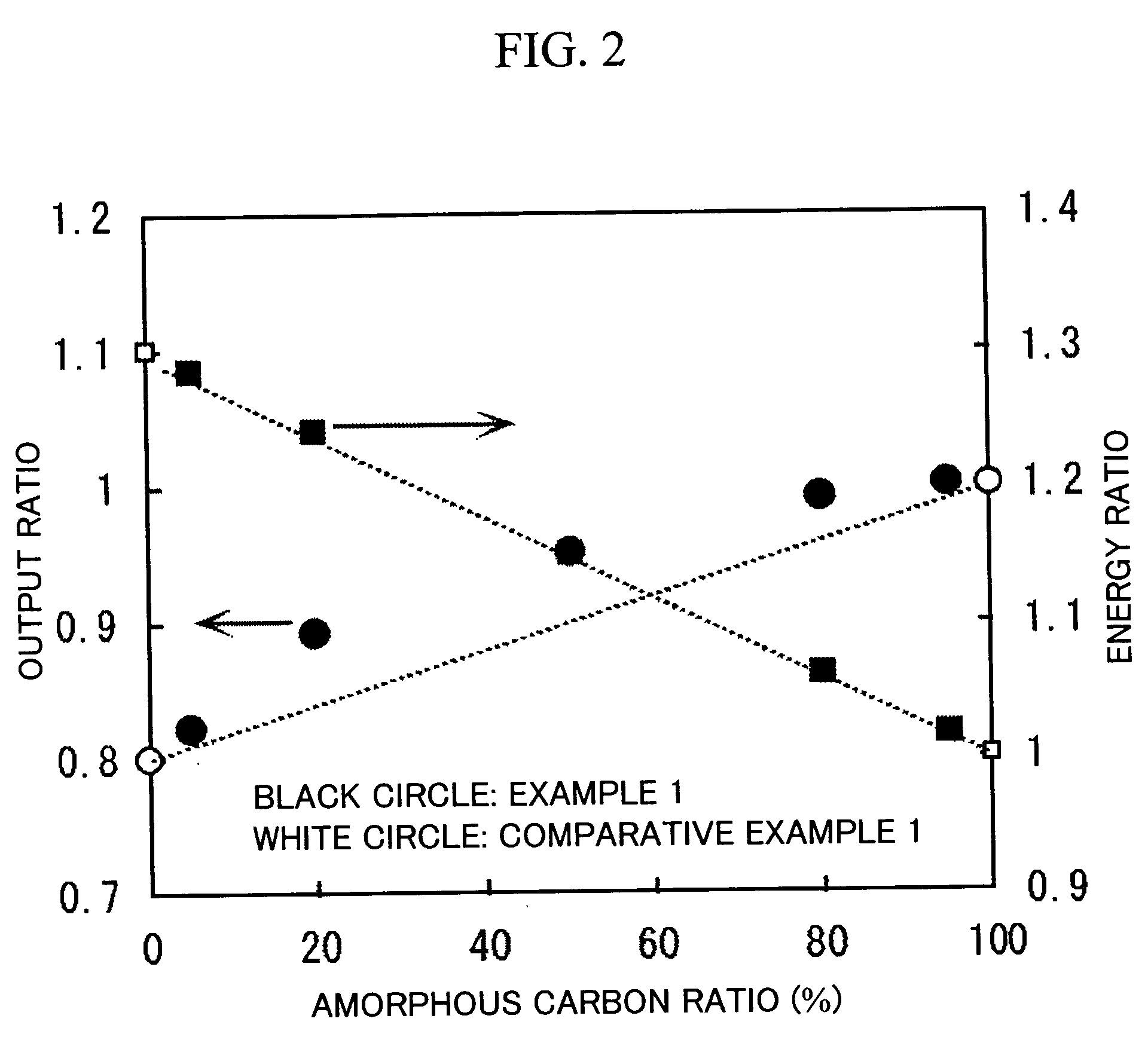

Energy storage device

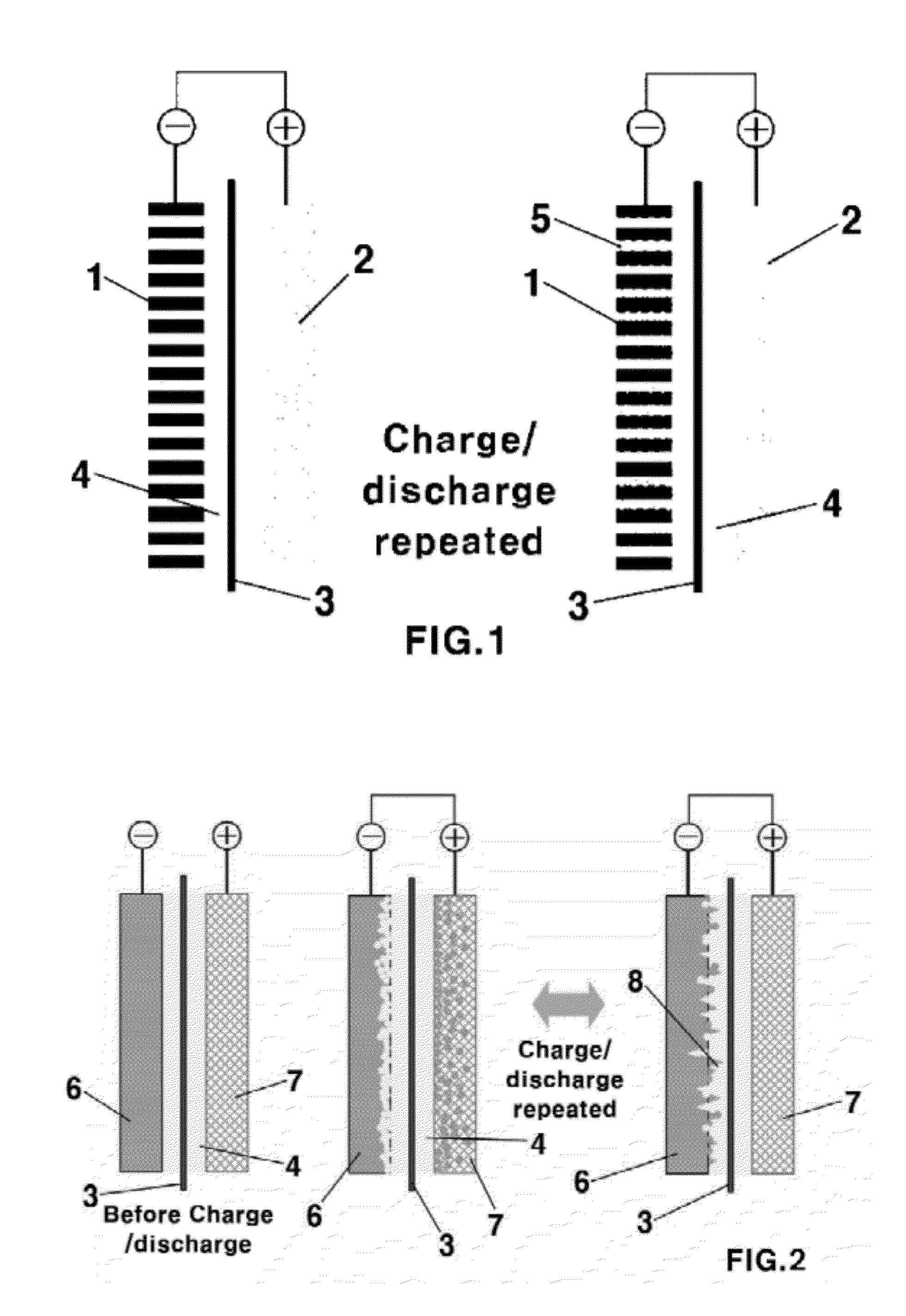

InactiveUS20060127771A1Excellent in input/output characteristicIncrease energy densityHybrid capacitor electrodesLiquid electrolytic capacitorsIntercalation reactionLithium

An energy storage device of excellent input / output characteristics and having high density of stored energy, the device having a cathode comprising a material conducting faradic reaction and a material conducting non-faradic reaction, and an anode comprising a material conducting faradic reaction, in which the faradic reaction is desorption / intercalation reaction of lithium ions, higher input / output characteristics being obtainable by providing a mix layer comprising a material conducting faradic reaction on a cathode collector and providing a material layer conducting non-faradic reaction further to the surface layer thereof.

Owner:HITACHI LTD

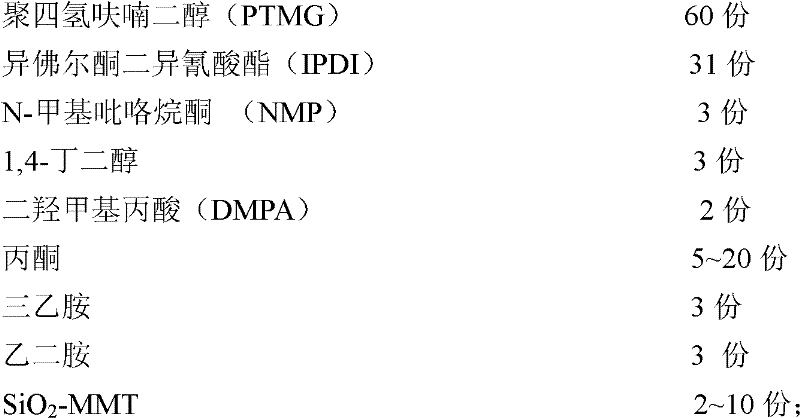

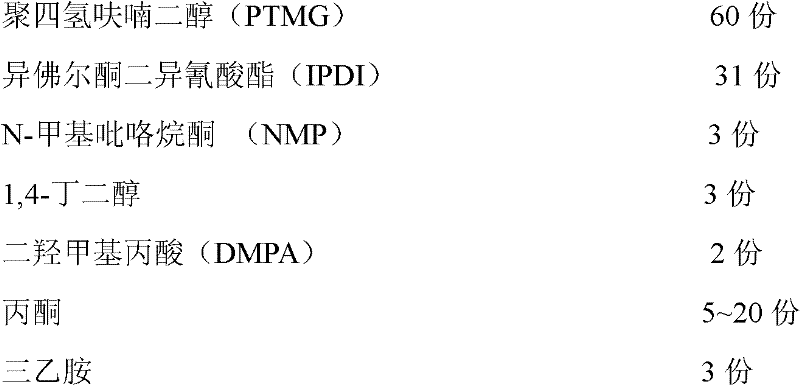

Nano-grade silica modified montmorillonite particle preparation method, and method for applying nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with in-situ method

ActiveCN102344699AGood compatibilityImprove stabilityPigment treatment with organosilicon compoundsSilicon dioxideMechanical property

The invention relates to a nano-grade silica modified montmorillonite particle preparation method, and a method for applying the nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with an in-situ method. According to the invention, tetraethoxysilane, a silicane coupling agent and montmorillonite are subject to a modification reaction, such that anano-grade silica layer is modified on the surface of montmorillonite, and active amino-groups are modified. Therefore, the compatibility of montmorillonite in aqueous polyurethane resin is better, such that the emulsion can be more stable. According to the invention, silica modified montmorillonite is prepared through an in-situ method, a silica layer comprising a large amount of silanol is modified on the surface of montmorillonite, and lamella parts of montmorillonite are peeled. When the modified particles are positioned in an aqueous polyurethane system, high molecular chains of polyurethane are subject to an intercalation reaction with montmorillonite, such that free movements of polyurethane molecular chains are restricted, and mechanical properties and thermal stability of the material are improved. Compared to simple polyurethane, tensile strength of the material is improved by 1-2 times, and thermal decomposition temperature of the material is improved by 30 to 50 DEG C.

Owner:徐州光头强木业有限公司

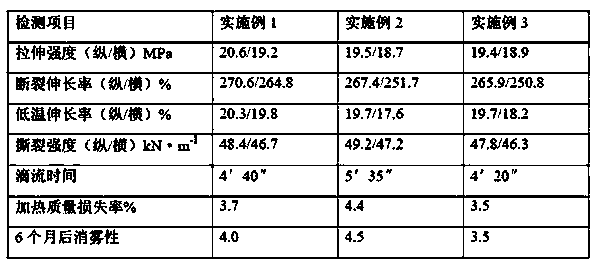

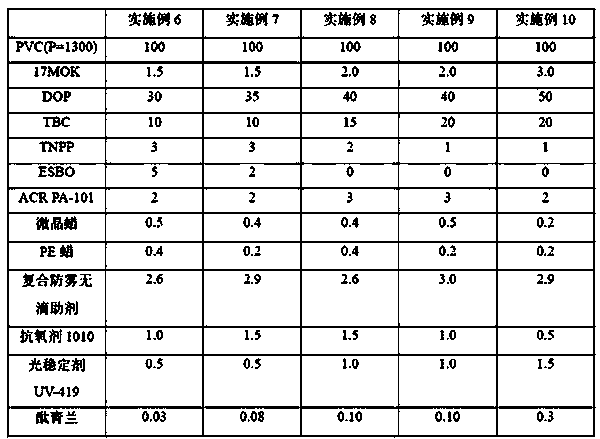

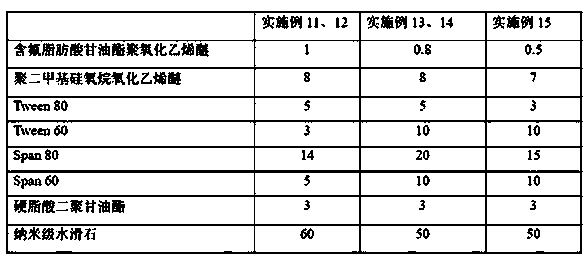

Fog-dissipation and anti-dropping polyvinyl chloride greenhouse film and preparation method thereof

ActiveCN104249522AExtended use timeReduce migration speedSynthetic resin layered productsLaminationIntercalation reactionSurface layer

The invention relates to a fog-dissipation and anti-dropping polyvinyl chloride greenhouse film and a preparation method thereof, and belongs to the technical field of polymer materials. The preparation method is characterized in that 100 parts by weight of a polyvinyl chloride resin is adopted as the main raw material, 2.5-5.0 parts by weight of a composite anti-fogging and anti-dropping additive is added, and a three-layer co-extruding composite calendering process is adopted to prepare the greenhouse film with a three-layer composite structure, wherein the concentration of the composite anti-fogging and anti-dropping additive in the middle layer is 1.5-2.5 times the concentration of the composite anti-fogging and anti-dropping additive in the surface layer, the thickness of the middle layer is 2-3 times the thickness of the surface layer, and the composite anti-fogging and anti-dropping additive is formed by carrying out an intercalation reaction on 10-15 parts by weight of a composite anti-fogging agent, 25-50 parts by weight of a composite anti-dropping agent, and 40-80 parts by weight of a slow-release agent. The durable fog-dissipation and anti-dropping polyvinyl chloride greenhouse film preparation method is the intercalation-material matching and mixing-calendering process of the anti-fogging agent, the anti-dropping agent and the slow-release agent. The fog-dissipation and anti-dropping polyvinyl chloride greenhouse film has effects of fog-dissipation and anti-dropping.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing graphene-containing phenolic foams

ActiveCN103788318AImprove efficiencyReduce manufacturing costP-Toluenesulfonic acidZinc Acetate Dihydrate

The invention discloses a method for preparing graphene-containing phenolic foams and relates to a method for preparing graphene-containing composite phenolic foams. The problem that an existing method for preparing a graphene high polymer composite material is high in cost, low in efficiency, complex in process and unsuitable for large-scale industrial production is solved. The method disclosed by the invention comprises the following steps: 1, preparing expansible graphite treated by a silane coupling agent; 2, mixing the expansible graphite treated by the silane coupling agent, phenol, a formaldehyde aqueous solution and zinc acetate to prepare a mixture A; 3, preparing a graphene-containing phenolic resin; and 4, mixing the graphene-containing phenolic resin, Tween-80, n-pentane, p-toluenesulfonic acid and polyethylene glycol 400 to obtain a mixture B, drying, and standing at room temperature to obtain the graphene-containing phenolic foams. The graphene is generated by utilizing intercalation reaction polymerization heat in situ, so that the graphene and the phenolic resin are synchronously generated, and the efficiency is improved. Meanwhile, the graphene is prevented from being directly taken as a raw material, the preparation cost is reduced, and the method is simple in process and suitable for large-scale industrial production.

Owner:HARBIN INST OF TECH

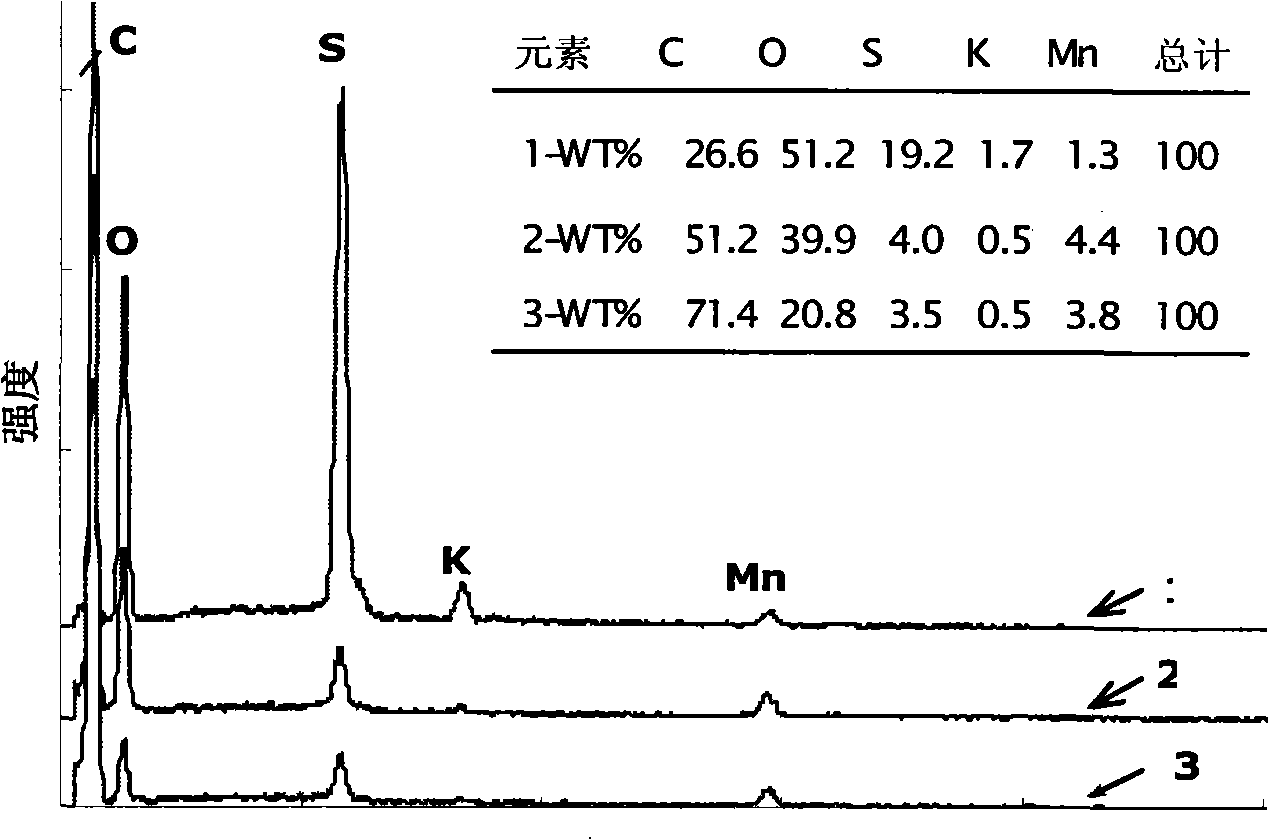

Preparation method of sulfur-free expansible graphite

ActiveCN105502360AEasy to realize industrial productionImprove corrosion resistanceChemical industryFiltrationDipotassium phosphate

The invention provides a low-temperature preparation method of sulfur-free expansible graphite. The sulfur-free expansible graphite is prepared from, by mass, natural flake graphite, potassium permanganate and perchloric acid according to the ratio of 1:(0.37-0.42):(8.5-9.0). The method includes the steps of mixing natural flake graphite with potassium permanganate, adding perchloric acid, conducting unceasing stirring, making the mixture react for 60-70 min at the temperature of 20-25 DEG C, soaking the mixed solution and a dipotassium phosphate solution for 60 min at the room temperature according to the volume ratio of 1:(2.0-2.5) after the reaction ends, conducting the secondary intercalation reaction, conducting water washing till the pH value is 5-7, conducting suction filtration and dehydration, conducting drying at the temperature of 60 DEG C to prepare the sulfur-free expansible graphite, and obtaining the expansible graphite capable of adsorbing oil type pollutant by conducting expansion in a muffle furnace at the temperature of 950 DEG C. The method is free of high-temperature operation, safety and energy conservation are achieved, no sulfur dioxide pollutant is generated, industrialized production can be easily achieved, the expansion volume of expansible graphite reaches 400-430 mL / g, and the oil adsorption effect is good.

Owner:YANSHAN UNIV

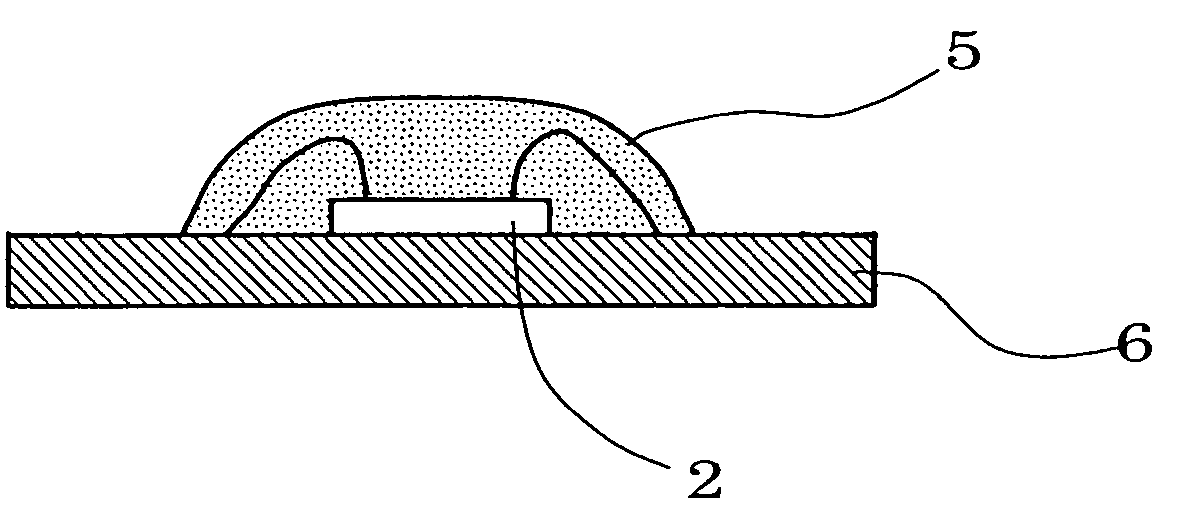

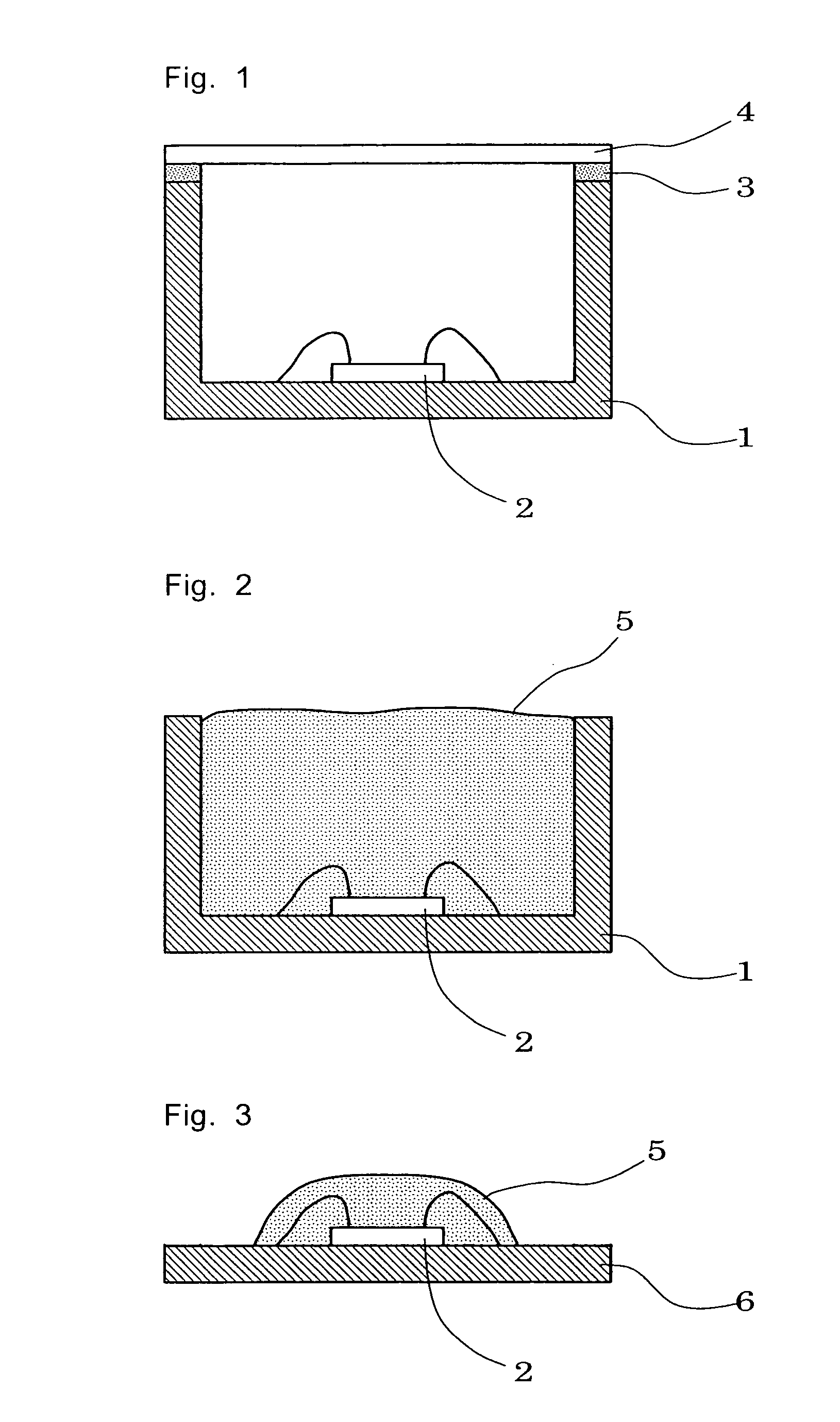

Optical semiconductor package sealing resin material

InactiveUS20100270581A1High transparencyImprove thixotropyPigmenting treatmentGroup 4/14 element organic compoundsIntercalation reactionHectorite

An optical semiconductor package sealing resin material used to seal an optical semiconductor chip in a semiconductor package includes a thermosetting epoxy composition and a hydrophobic smectite clay mineral. The hydrophobic smectite clay mineral is hydrophobized by subjecting a hydrophilic smectite clay mineral to an intercalation reaction with an alkylammonium halide. The smectite clay mineral is bentonite, saponite, hectorite, vermiculite, stevensite, tainiolite, montmorillonite, or nontronite.

Owner:DEXERIALS CORP

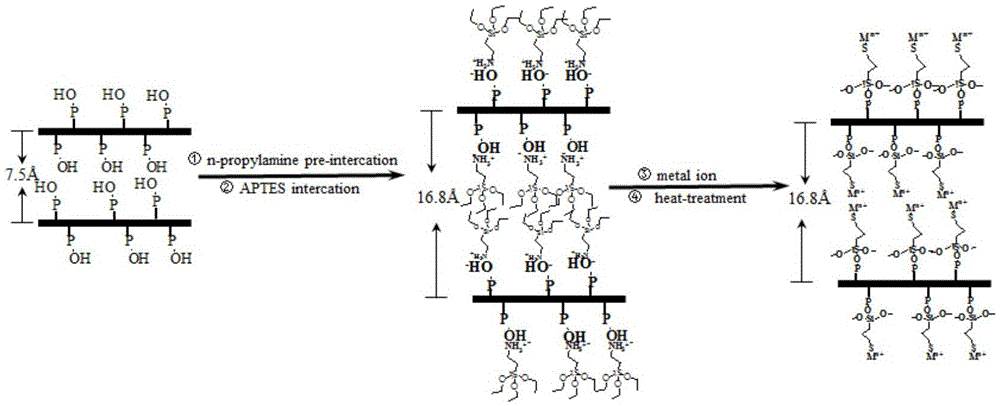

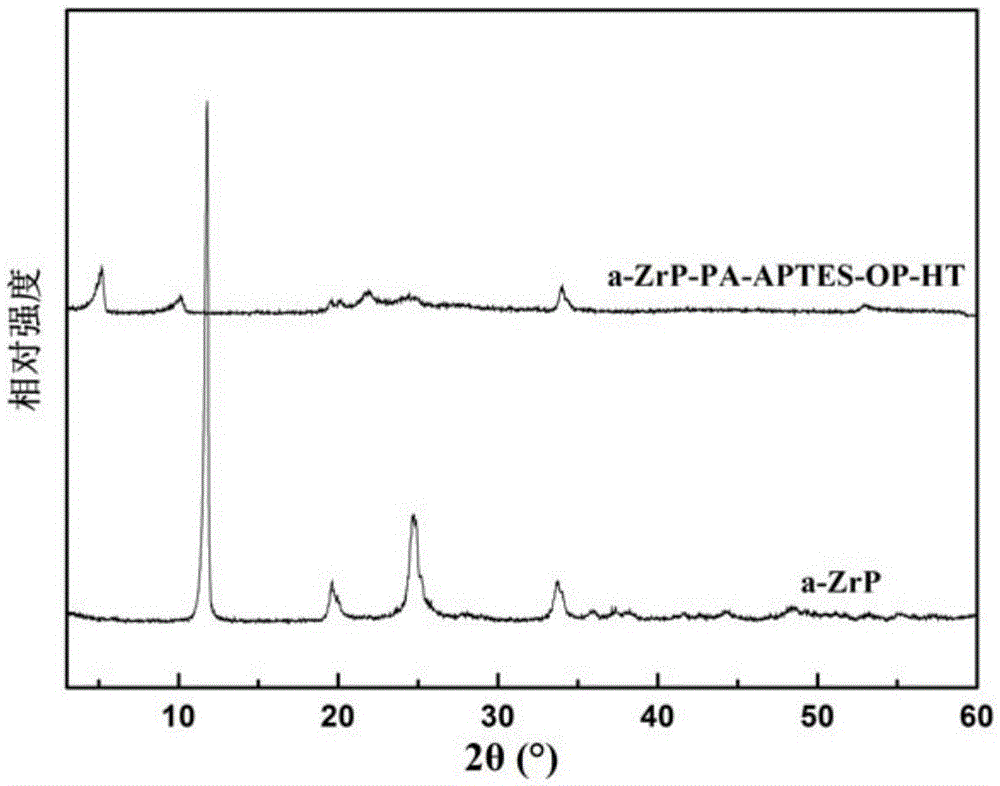

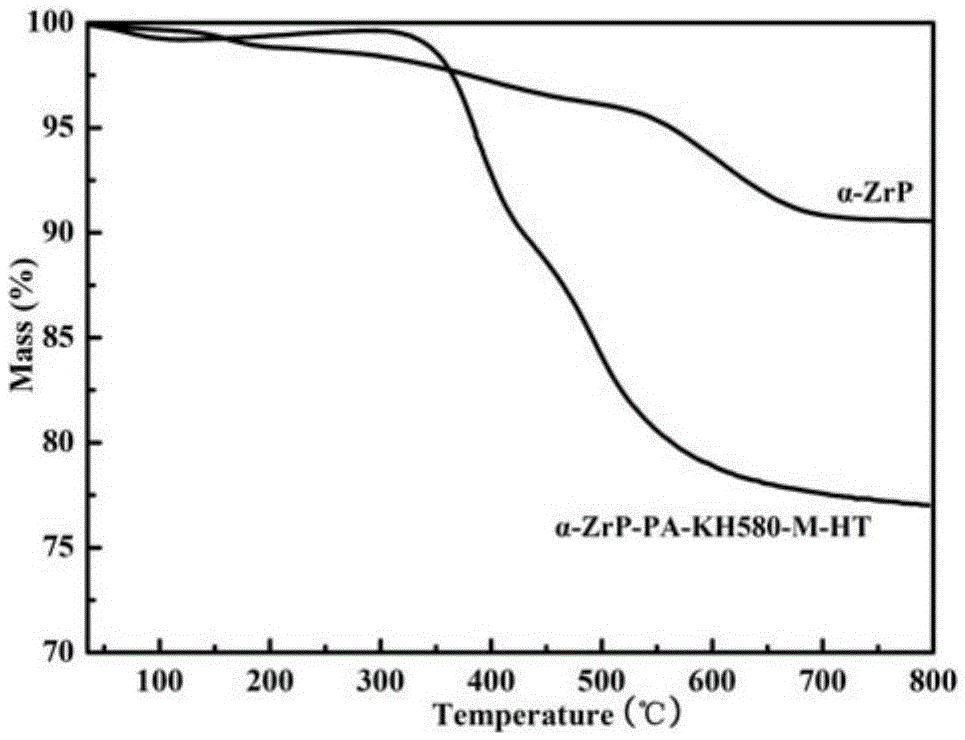

Preparation method of polymer-organically-modified and metal-ion-loaded alpha-ZrP composite fiber material

ActiveCN105483852AGood dispersionGood compatibilityElectroconductive/antistatic filament manufactureFlame-proof filament manufactureIntercalation reactionMixed materials

The present invention discloses a preparation method of a polymer-organically-modified and metal-ion-loaded alpha-ZrP composite fiber material, and the method comprises the following steps: 1) organized alpha-ZrP can be obtained by intercalation reaction of a silane coupling agent and alpha-ZrP, organically-modified and metal-ion-loaded alpha-ZrP can be obtained by mercapto group reaction of a metal ion and the silane coupling agent, the organically-modified and metal-ion-loaded alpha-ZrP is mixed with a sufficiently-dried polymer in the weight ratio of 0.1: 99 to 20: 80 to obtain a mixed material, the mixed material is melted and mixed by a twin-screw extruder at 250-290 DEG C to obtain a polymer-organically-modified and metal-ion-loaded alpha-ZrP composite resin chip; and 2) the polymer-organically-modified and metal-ion-loaded alpha-ZrP composite resin chip obtained by the step 1) is sufficiently dried, and a conventional melt spinning method is used for spinning of the polymer-organically-modified and metal-ion-loaded alpha-ZrP composite resin chip to obtain the polymer-organically-modified and metal-ion-loaded alpha-ZrP composite fiber material. The polymer-organically-modified and metal-ion-loaded alpha-ZrP composite fiber material produced by the method has good spinning property, high fiber-forming strength, flame retardance, bacterium resistance, fatigue resistance, dimensional stability and gas barrier properties.

Owner:浙江慧博新材料科技有限公司

Gelatin-chitosan/montmorillonite drug carried microspheres and preparation method thereof

InactiveCN101703480AGood tissue compatibilityImprove performancePeptide/protein ingredientsInorganic non-active ingredientsMicrosphereTissue Compatibility

The invention discloses a gelatin-chitosan / montmorillonite drug carried microsphere and a preparation method thereof. The drug carried microsphere is prepared by the following steps: dissolving the hydrophilic drug in the gelatin water solution, adding montmorillonite suspended water solution, carrying out intercalation reaction to obtain solution A; dissolving the chitosan in the acetic acid water solution, stirring and dissolving to obtain solution B; stirring and emulsifying liquid paraffin wax and span-80 to obtain C; adding solution B into solution A, carrying out intercalation reaction, adding C, stirring, standing, dropwise adding glutaric dialdehyde water solution, crosslinking and curing, adding isopropyl alcohol and stirring, removing supernate after standing and delaminating, vacuum filtrating to remove liquid; and washing with anhydrous ether and isopropyl alcohol in sequence, and drying to obtain the microsphere. The drug carried microsphere in the invention has good tissue compatibility, low toxicity or no toxicity, and is a drug carried material with excellent performance. The method in the invention can reduce the dosage of chemical crosslinking agent, lower the toxity of the microsphere, dramatically lower the rate of drug release, and further improve slowly controlled release ability of the drugs.

Owner:TIANJIN UNIV

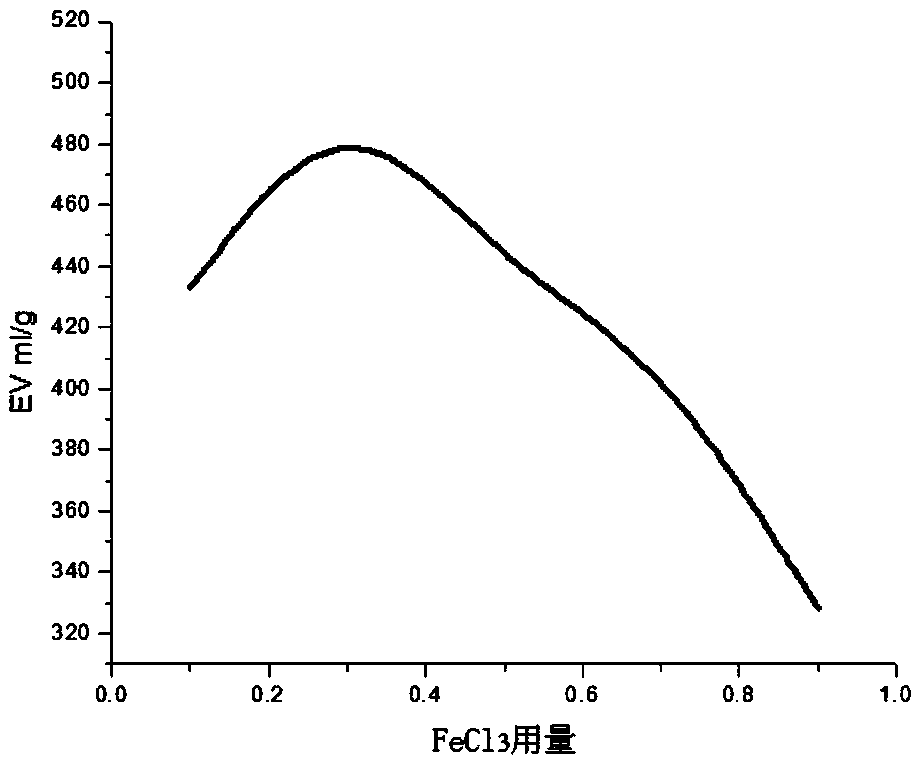

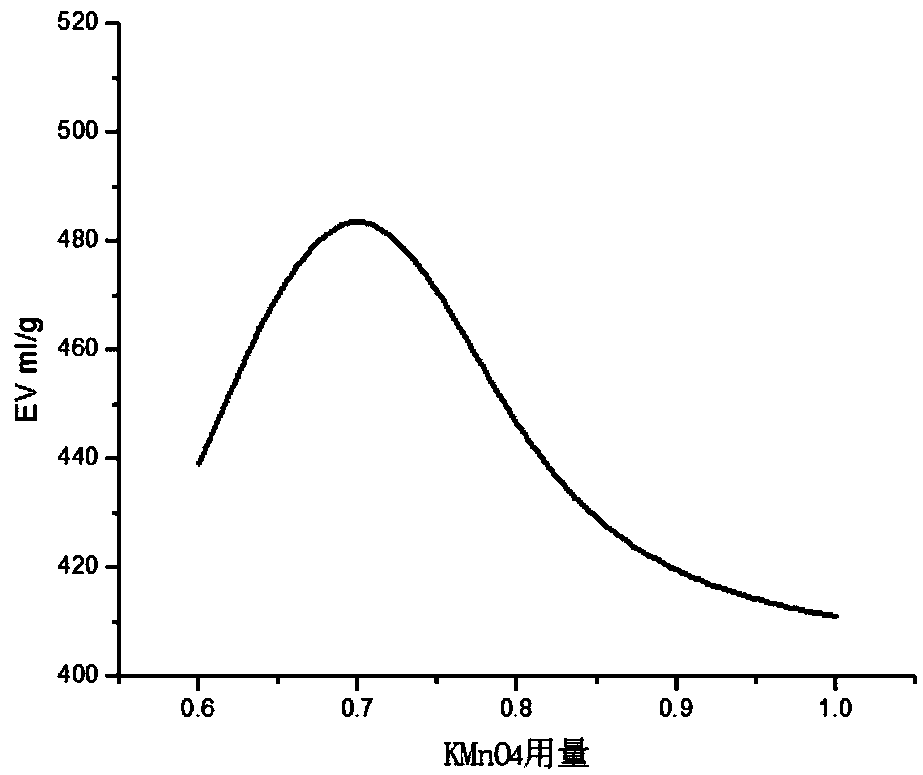

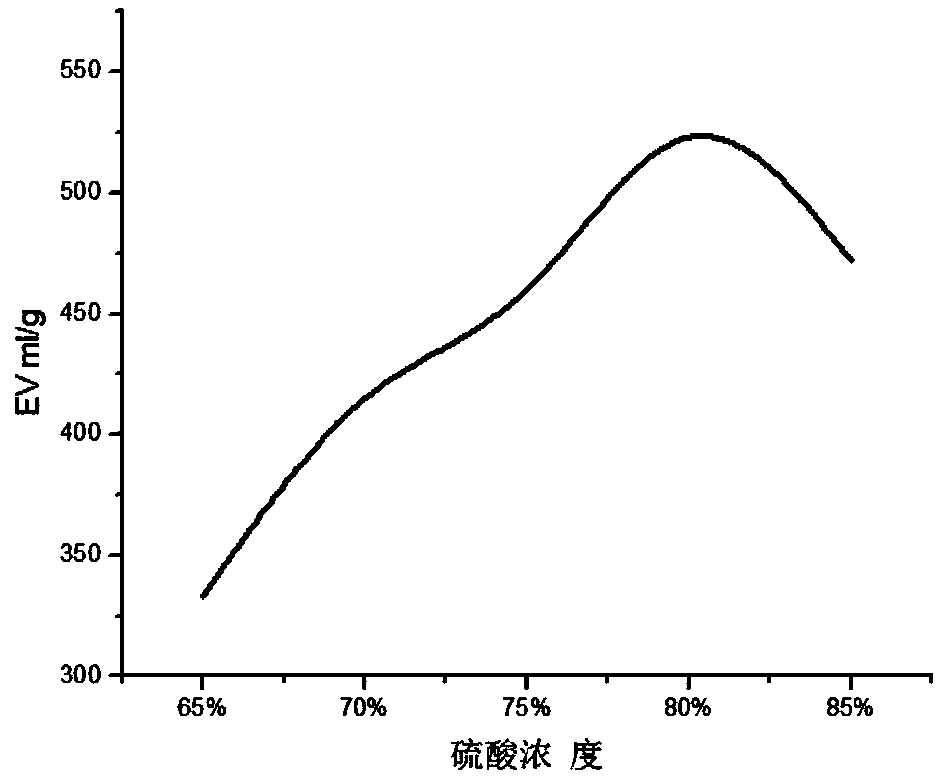

Preparation method of expandable graphite by optimizing proportional ratio of intercalation agent

InactiveCN108862271AImprove conductivityImprove magnetic propertiesGraphiteIntercalation reactionSulfur

The invention discloses a preparation method of expandable graphite by optimizing proportional ratio of an intercalation agent, and belongs to the field of preparation of expandable graphite. A trivalent iron salt with flame-resistant characteristic is used as an auxiliary intercalation agent, and is coupled with graphite through intercalation reaction, so as to prepare the composite expandable graphite. The proportional ratios of graphite material to oxidant and intercalation agent to auxiliary intercalation agent are optimized on the basis of multiple times of experiment; finally, the expandable graphite with initial expanding temperature of 160 DEG C and expanding volume of 578mL / g is prepared. Proofed by experiment, the preparation method has the advantages that by intercalating ferrictrichloride, one part of sulfuric acid is replaced, so that the content of sulfur is reduced; the expanding property of the product is improved, the initial expanding temperature is improved, the flame-retardant property and ductility of the expandable graphite are good, and the expandable graphite can be used as a flame-retardant material to be added into inflammable materials.

Owner:LIAONING UNIVERSITY

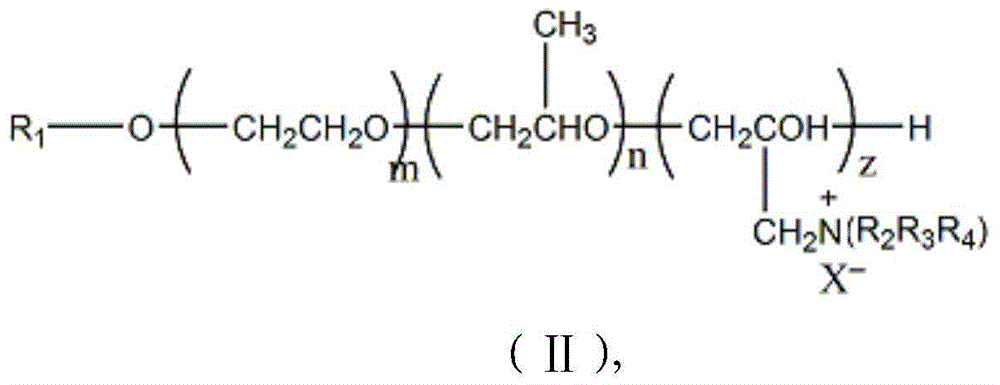

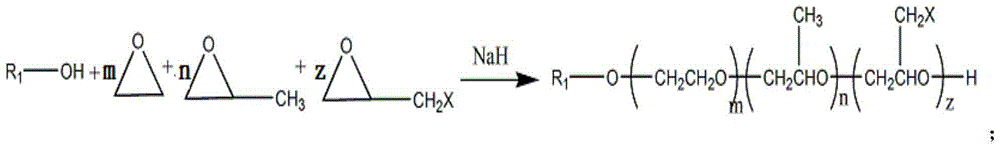

Polycarboxylate superplasticizer with super high early strength and preparation method of polycarboxylate superplasticizer

ActiveCN105271900AIncreased steric hindranceHigh water reduction rateIntercalation reactionSuperplasticizer

The invention provides a polycarboxylate superplasticizer with super high early strength. The polycarboxylate superplasticizer with super high early strength is a compound shown in the formula (I) and is synthesized with an active macromonomer as the raw material, cations are introduced into molecules while the steric hindrance effect of the superplasticizer is further improved, the cations have good soil resistance, so that the water-reducing rate of the superplasticizer is increased, and the soil resistance and the cement adaptability of the superplasticizer are improved. The polycarboxylate superplasticizer has better tolerance for soil and does not have an intercalation reaction with the soil. The cations of the polycarboxylate superplasticizer with super high early strength can inhibit soil expansion, so that admixture adsorption by the soil is reduced. The polycarboxylate superplasticizer with super high early strength can accelerate hydration of cement and has the super high early strength function. The polycarboxylate superplasticizer with super high early strength has super high early strength and soil resistance functions when applied to common concrete.

Owner:GUANGDONG REDWALL NEW MATERIALS

Environment-friendly synthesis method of two-dimensional transition metal carbide or nitride nanosheets

InactiveCN106744732AThe synthesis process is green and environmentally friendlyRich synthesis methodsNitrogen-metal/silicon/boron binary compoundsTitanium carbideTransition metal carbidesIntercalation reaction

The invention discloses an environment-friendly synthesis method of two-dimensional transition metal carbide or nitride nanosheets. The environment-friendly synthesis method comprises the following steps: mixing a corrosion intercalation agent and a ternary layered ceramic material, performing a corrosion intercalation reaction, and then performing shearing dispersion treatment to obtain the two-dimensional transition metal carbide nanosheets or the two-dimensional transition metal nitride nanosheets. The synthesis method of the two-dimensional transition metal carbide or nitride nanosheets, provided by the invention, is environment-friendly, simple in process, easy to operate, safe and controllable in process and low in time consumption and energy consumption; and by the synthesis method, the synthesizing way of the two-dimensional transition metal carbide or nitride nanosheets is enriched and popularization and application of the two-dimensional transition metal carbide or nitride nanosheets can be effectively promoted.

Owner:SUZHOU UNIV

Mud-resisting agent composition applied to concrete

The invention discloses a mud-resisting agent composition applied to concrete. The mud-resisting agent composition comprises the following components: 10-70% of glycine betaine and derivative thereof, 10-70% of quaternary ammonium salt derivative and 0-80% of water. When the mud-resisting agent composition is applied to high-mud concrete, the intercalation reaction of polycarboxylic acid water reducer in the clay can be effectively reduced; high workability and working retainability of the concrete can be maintained; compared with the existing mud-resisting agent, the concrete mud-resisting agent composition is high in cost performance.

Owner:SHANGHAI SUNRISE POLYMER MATERIAL CO LTD

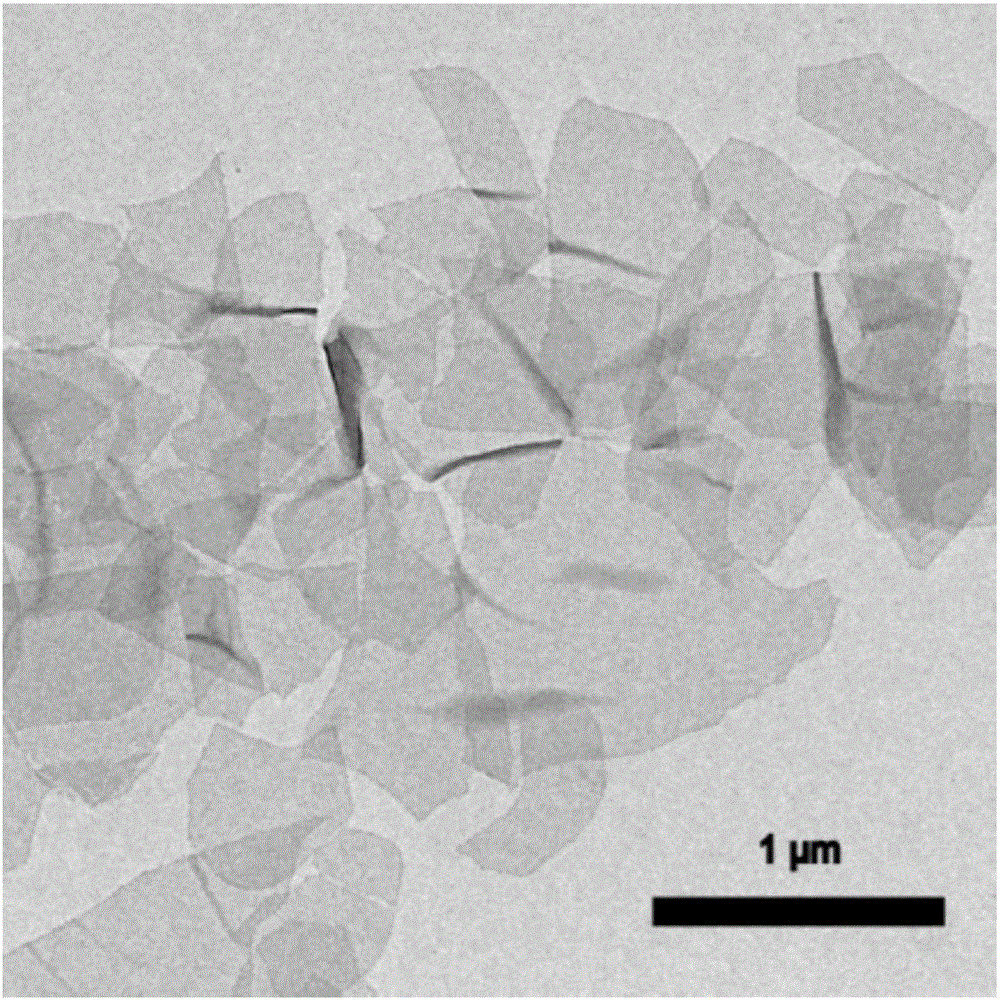

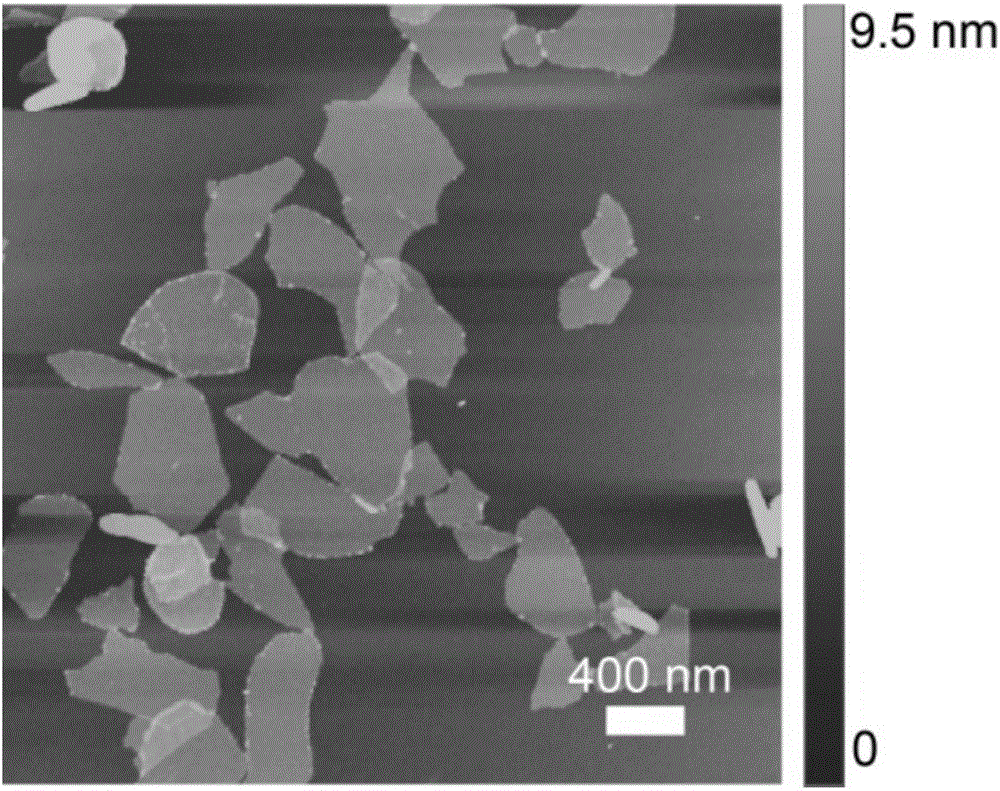

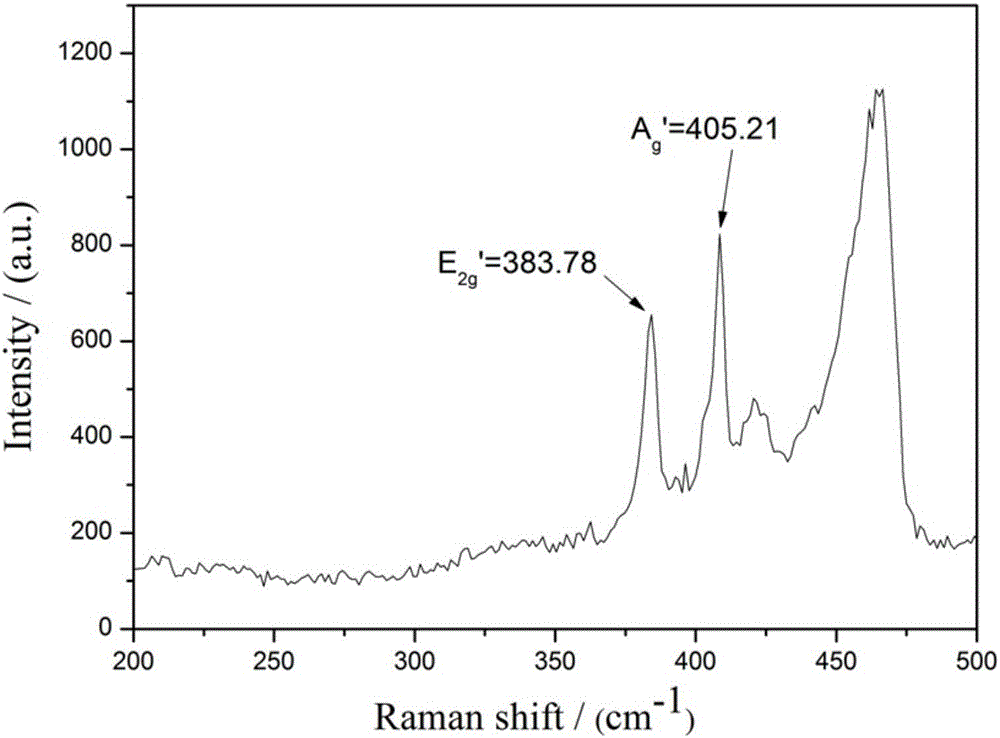

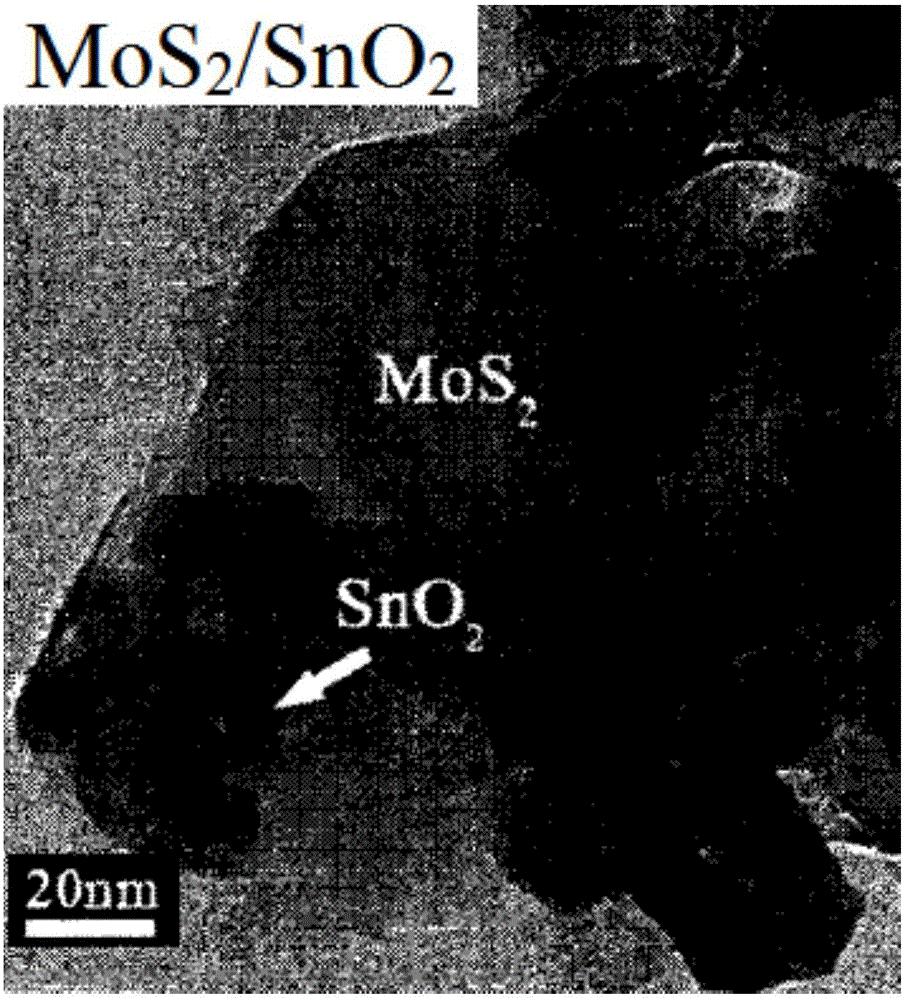

Method for preparing layered MoS2-SnO2 nano composite material

ActiveCN105688944AReduce van der Waals forces between layersEasy to operateCatalyst activation/preparationNanotechnologyCharge carrier mobilityThioether

The invention provides a method for preparing a layered MoS2-SnO2 nano composite material. Molybdenum disulfide powder is added into a layering solution for layering reaction to form a mixed solution; oxidant is added into the mixed solution for oxidation-intercalation reaction, then SnO2 nano powder is added under the stirring condition and continues to be stirred evenly, and intercalation MoS2-SnO2 mixed powder is obtained; the intercalation MoS2-SnO2 mixed powder and an explosion agent are mixed for explosion reaction, an explosion reaction product is taken out after being cooled to room temperature, and the layered MoS2-SnO2 nano composite material is obtained. The sulphophile characteristic of aromatic thioether is used, interlayer van der Waals' force of molybdenum disulfide raw material powder is reduced, and intercalation exfoliation is conducted on the molybdenum disulfide raw material powder in cooperation with explosion impact. The product prepared through the method is the layered molybdenum disulfide and SnO2 nano-particle composite nano material with high carrier mobility, SnO2 nano-particles are evenly attached to a single-layer molybdenum sulfide lamella, catalytic hydrogenation and lubricating performance of the single-layer molybdenum sulfide lamella are improved, and the application range of molybdenum sulfide is greatly enlarged.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

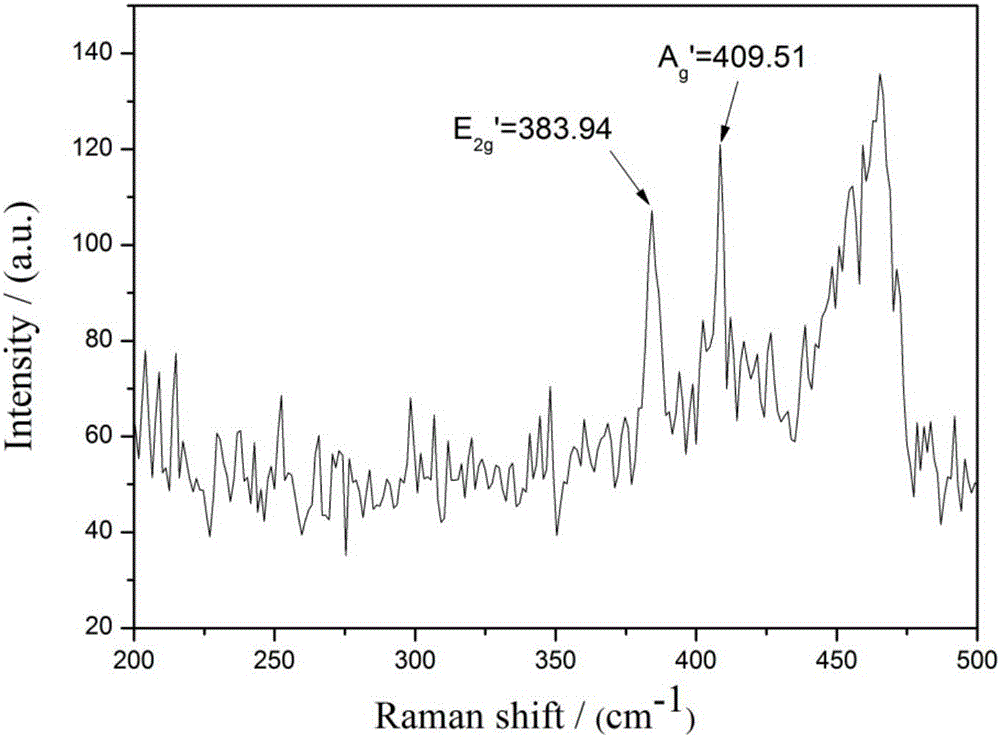

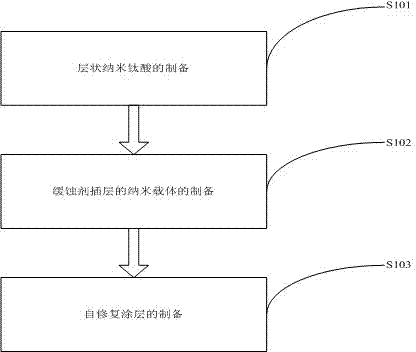

Preparation method of self-repair coating based on corrosion inhibitor intercalated nano-titanate carrier

InactiveCN103483897APlay self-healing functionIntrinsic structure restorationAnti-corrosive paintsThioureaDysprosium titanate

The invention relates to a preparation method of a self-repair coating based on a corrosion inhibitor intercalated nano-titanate carrier. The preparation method comprises the following steps: preparation of layered nano-titanate, preparation of the corrosion inhibitor intercalated nano-carrier and preparation of the self-repair coating, wherein the preparation of the layered nano-titanate comprises the step of grinding K2CO3 and TiO2 solids according to a certain molar ratio; the preparation of the corrosion inhibitor intercalated nano-carrier comprises the steps of taking organic amines, imidazoles, allyl thiourea and other nitrogen-containing organic matters as objects, taking the layered nano-titanate as a subject, and preparing the collision inhibitor intercalated nano-carrier through intercalation reaction in an ethanol solvent under microwave conditions; the preparation of the self-repair coating comprises the step of finally mixing prepared functional particles with sol-gel to prepare a functional sol-gel film to coat on the surface of a metal to be protected. The preparation method disclosed by the invention has the advantages of simplicity in preparation, large loading capacity and corrosion inhibition release-response function, expands the types of loaded corrosion inhibitors, enables an inherent structure of the titanate to tend to be restored, and plays a self-repair role.

Owner:YANCHENG INST OF TECH

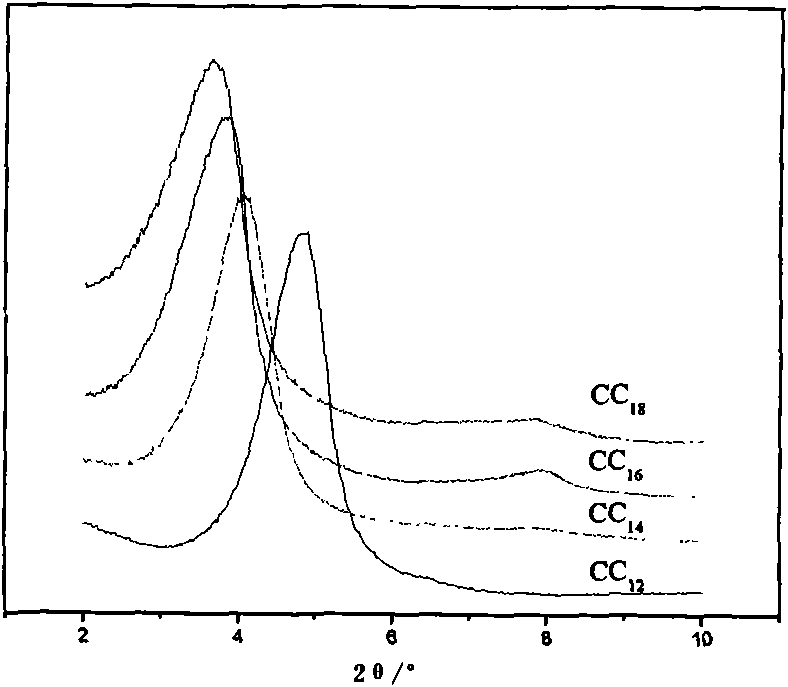

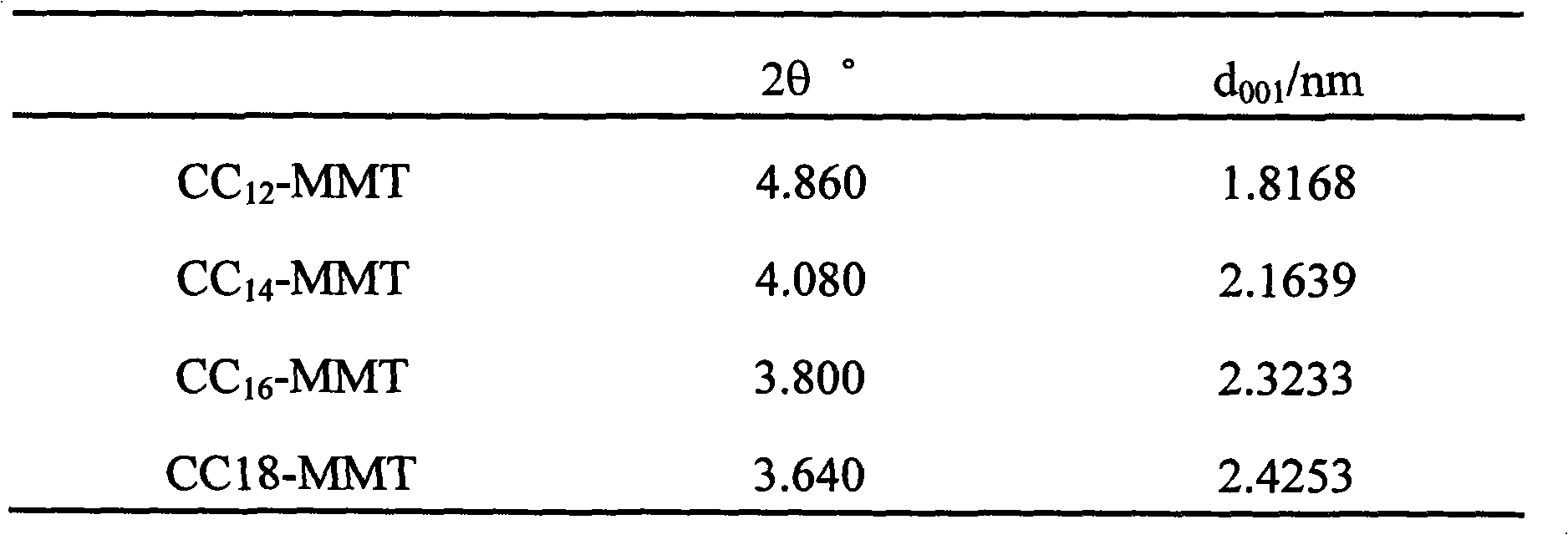

Preparation method of diallyl containing quaternary ammonium salt modified montmorillonoid

InactiveCN101597067AHigh positive charge densitySilicon compoundsIntercalation reactionQuaternary ammonium cation

The invention relates to a preparation method of diallyl containing quaternary ammonium salt modified montmorillonoid, in particular to a method of diallyl methyl alkyl quaternary ammonium salt monomer modified montmorillonoid capable of cyclopolymerization. Currently, systemic study on diallyl methyl alkyl quaternary ammonium salt monomer modified montmorillonoid is rarely reported. The invention adopts diallyl containing quaternary ammonium salt as intercalation agent of montmorillonoid, the monomer is efficient and non-toxic and has high positive charge density, intercalation reaction can occur owning to cation performance thereof, cyclopolymerization can occur between montmorillonoid layers to generate polymer containing five-membered ring as the monomer contains non-conjugated diene bond. The monomer modified montmorillonoid provides a new method for preparing polymer base montmorillonoid nano composite material by intercalation cyclopolymerization between montmorillonoid layers.

Owner:SHAANXI UNIV OF SCI & TECH

Laminated MoS2-Fe3O4 nano composite material and preparation method thereof

ActiveCN105800697AGood magnetic guiding performanceEasy to operateMaterial nanotechnologyFerroso-ferric oxidesExplosive AgentsNano composites

The invention provides a laminated MoS2-Fe3O4 nano composite material and a preparation method thereof.Molybdenum disulfide powder is added to a layered solution, and layered reaction is performed to form a mixed solution; an antioxidant is added to the mixed solution for oxidation intercalation reaction, and intercalated molybdenum disulfide powder is obtained after filtration and drying; Fe3O4 nano powder and an explosive agent are added to the intercalated molybdenum disulfide powder for explosive reaction, an explosive reaction product is taken out after cooling is performed to reach room temperature, namely the MoS2-Fe3O4 nano composite material is obtained.The sulphophile characteristics of aromatic thioether are utilized to reduce the interlayer van der Waals' force of the raw material molybdenum disulfide powder, and the molybdenum disulfide powder successively undergoes layered stripping in combination with explosive impact.By the adoption of the combination of a sol-gel method and the high-temperature explosive impact, rapid Fe3O4 reduction and MoS2 stripping is completed only through one-step explosion after the intercalated molybdenum disulfide powder is fused with sol, and the laminated MoS2-Fe3O4 nano composite material is successively prepared.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

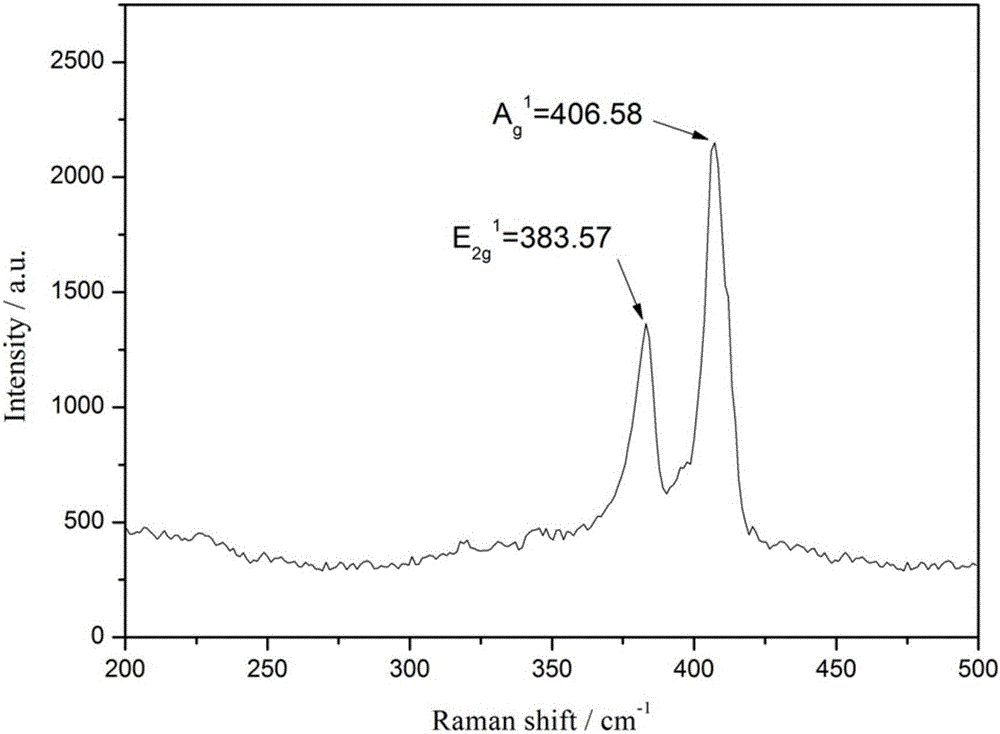

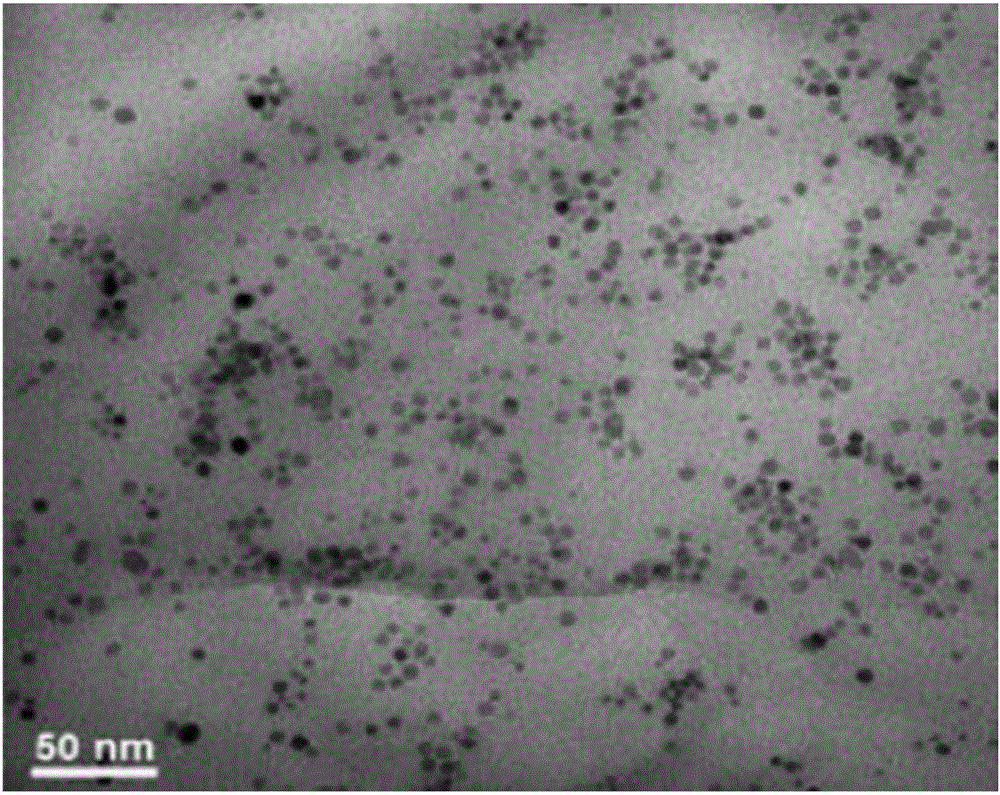

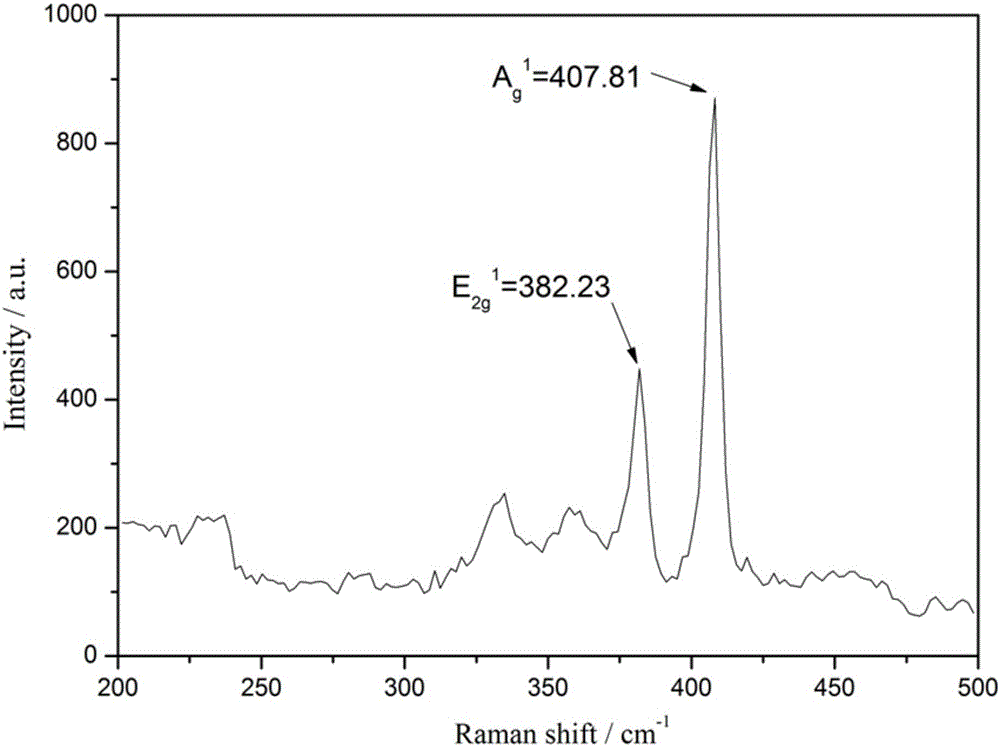

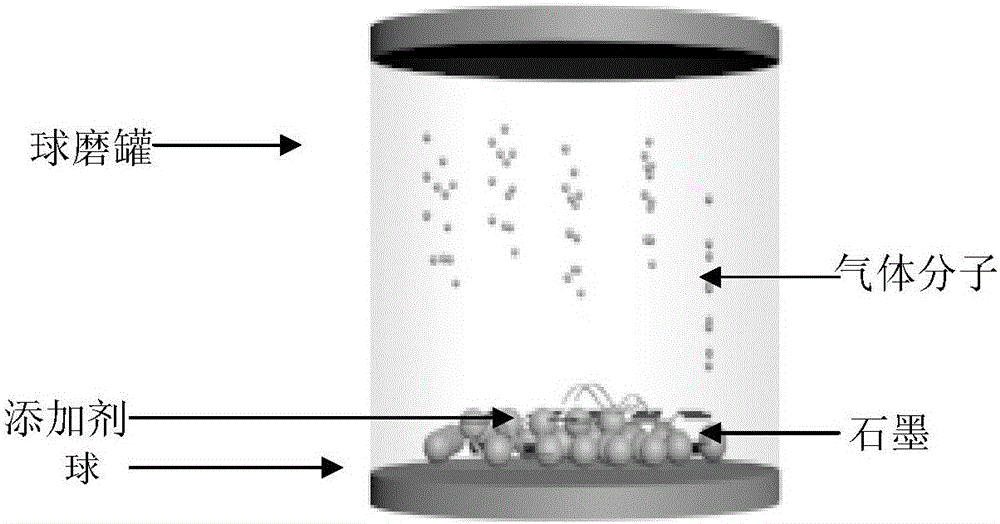

Lipophilic graphene and preparation method thereof

The invention provides lipophilic graphene and a preparation method thereof. The method comprises the following steps that 1, after graphite powder, an additive and a liquid intercalation medium are added into a ball-milling tank, the ball-milling tank is sealed; 2, a gaseous intercalation medium is introduced into the ball-milling tank, the pressure is controlled at 4-12 MPa by regulating the gas intake of the gaseous intercalation medium, a ball-milling in-situ aided molecule intercalation reaction is conducted by increasing the temperature of the system to 35 DEG C-150 DEG C under the pressure, and after the reaction is finished, the lipophilic graphene is obtained.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

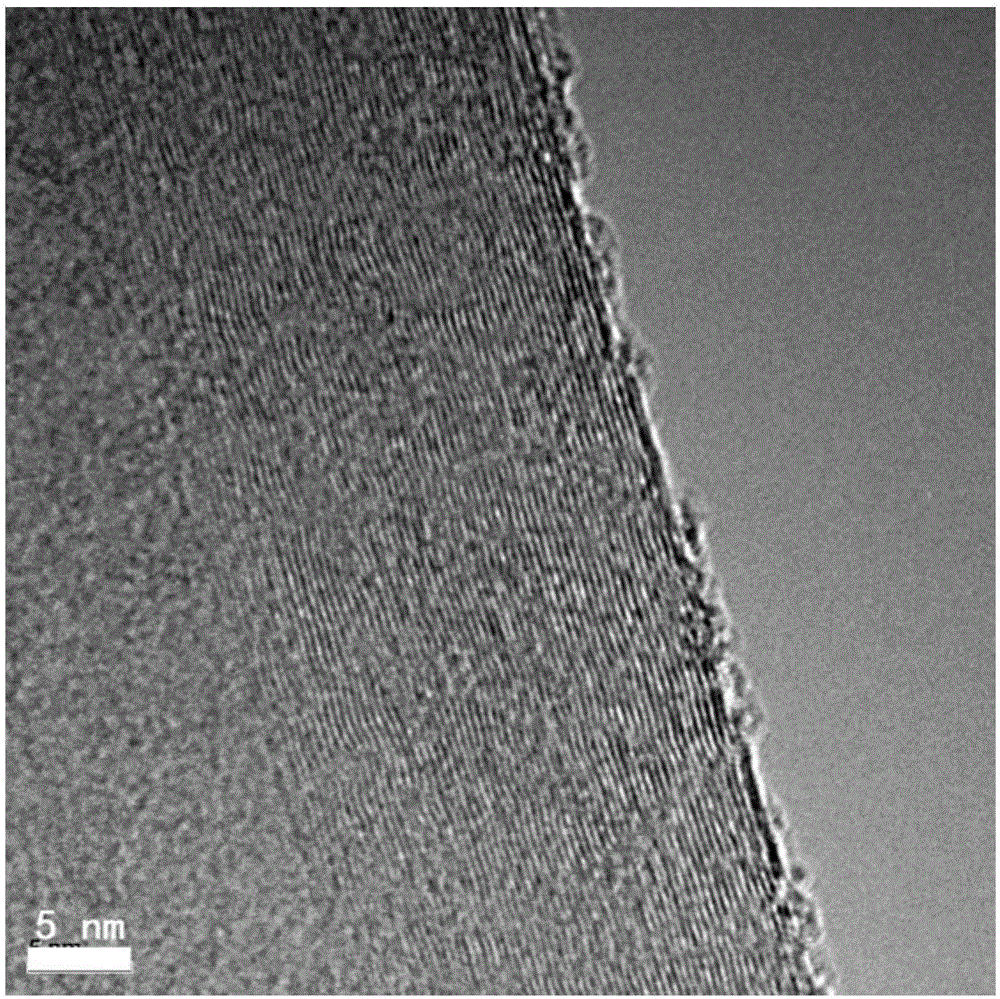

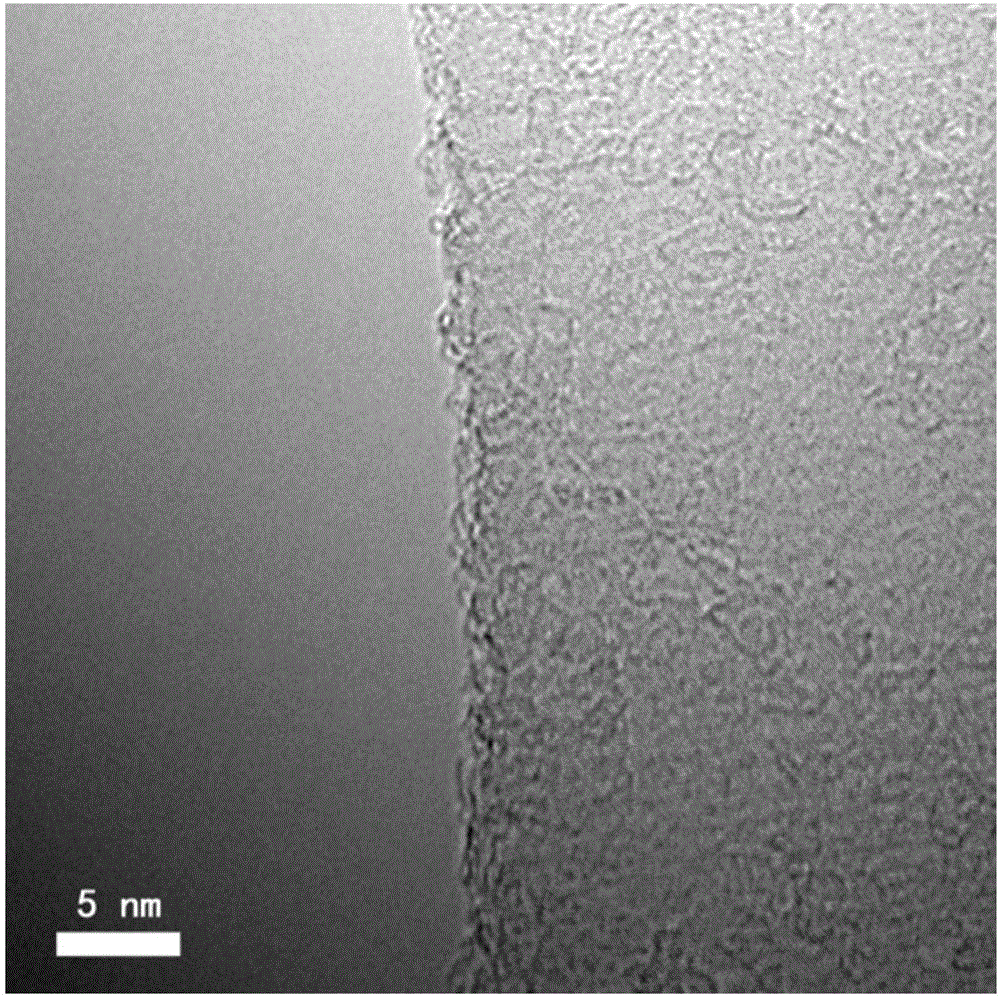

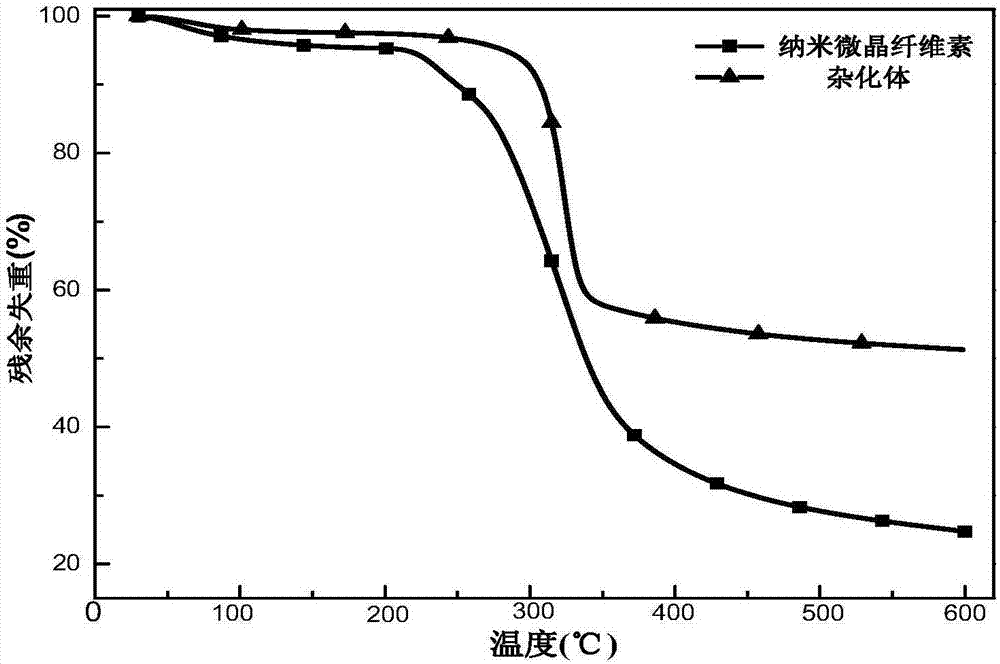

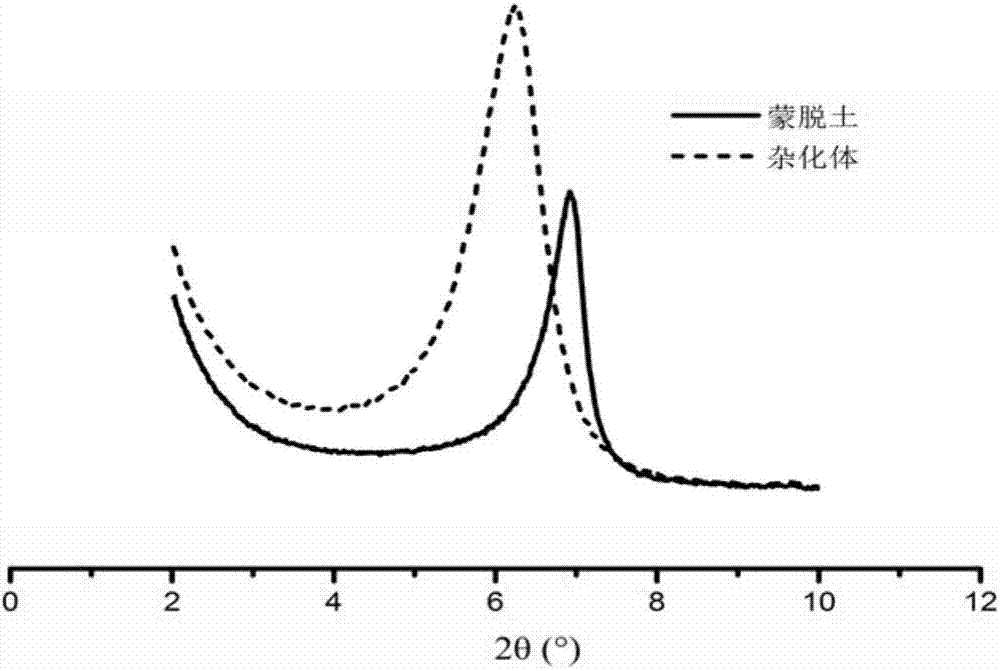

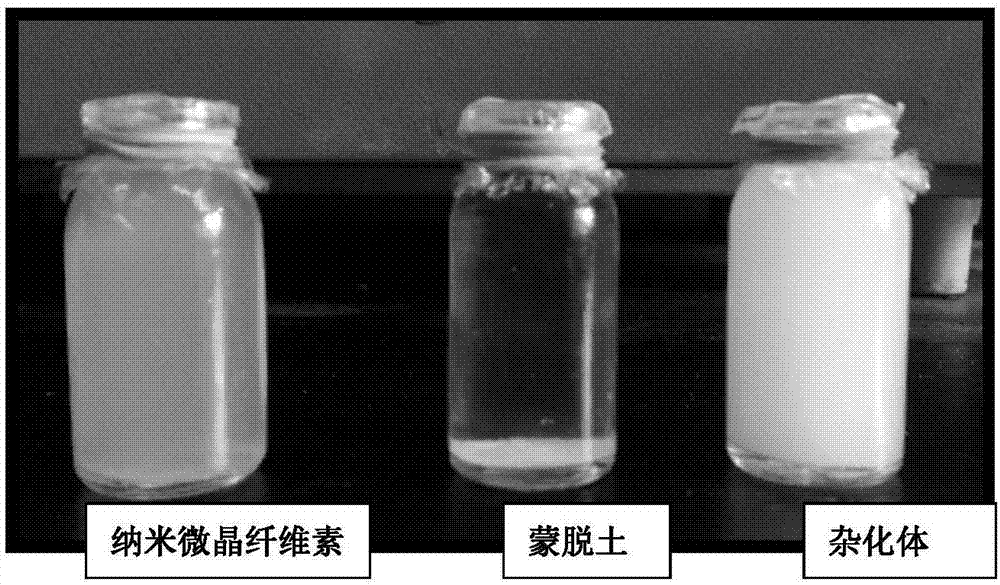

Nano microcrystalline cellulose/layered silicate hybrid and preparation method thereof

The invention discloses a nano microcrystalline cellulose / layered silicate hybrid and a preparation method thereof. According to the preparation method, sulfuric acid is utilized to carry out hydrolysis to prepare nano microcrystalline cellulose at first; then nano microcrystalline cellulose is dispersed in a diluent and a catalyst to carry out an alkalization treatment; a cationic etherifying agent is added then, fibers and the etherifying agent are evenly mixed and carry out reactions in the presence of an alkaline catalyst to prepare a cationic cellulose dispersion liquid; and different kinds of layered silicate and the cationic microcrystalline cellulose dispersion liquid are mixed to carry out intercalation reactions to obtain the nano microcrystalline cellulose / layered silicate hybrid. The used layer silicate is cheap and easily available and is suitable for the preparation of nano microcrystalline cellulose organic-inorganic hybrids prepared from various natural plant fibers; through hybridization, the thermal stability of nano cellulose is effectively improved, the intercalation of layered silicate is realized, and the one-dimensional and two-dimensional nano filling materials are hybridized into hybrids with multiple dimensions.

Owner:SOUTH CHINA UNIV OF TECH

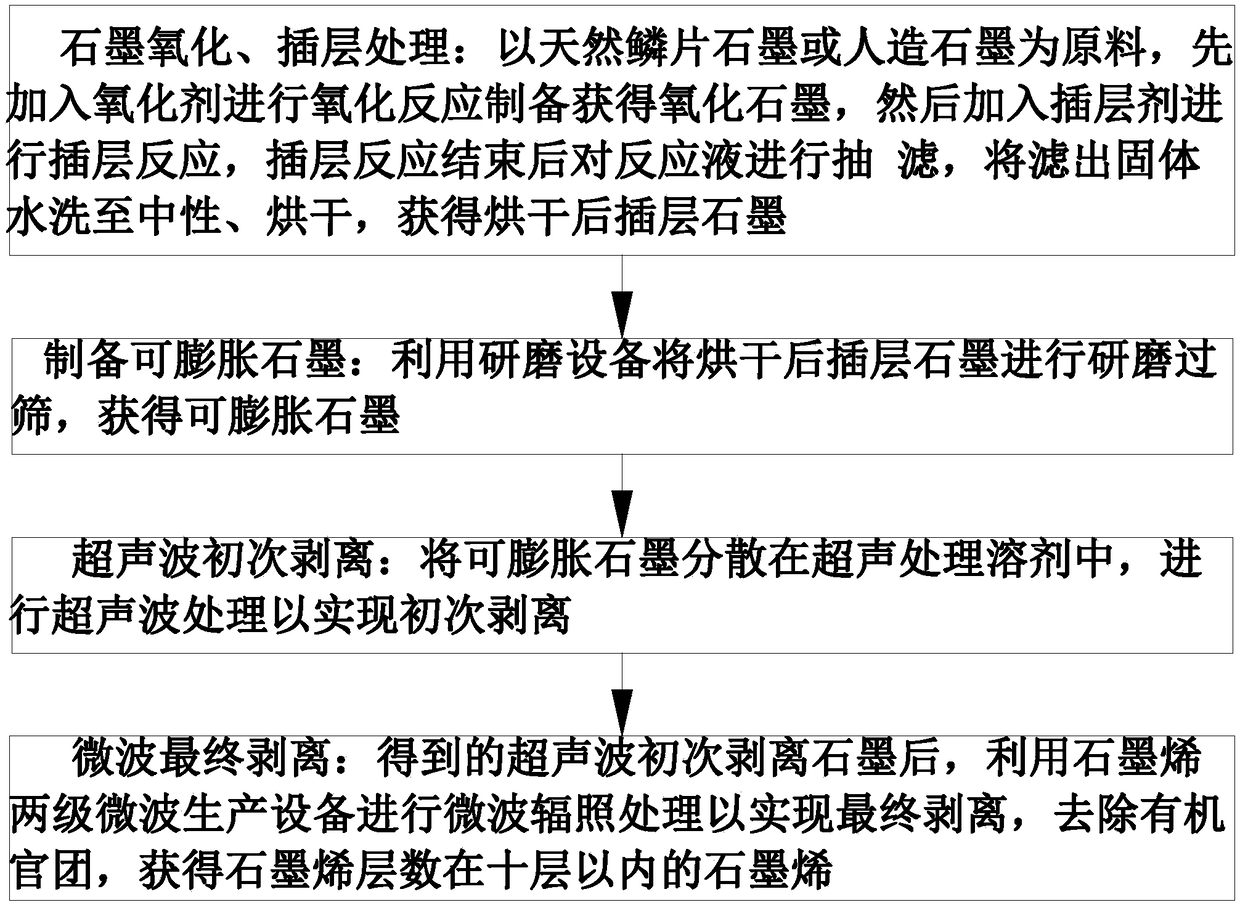

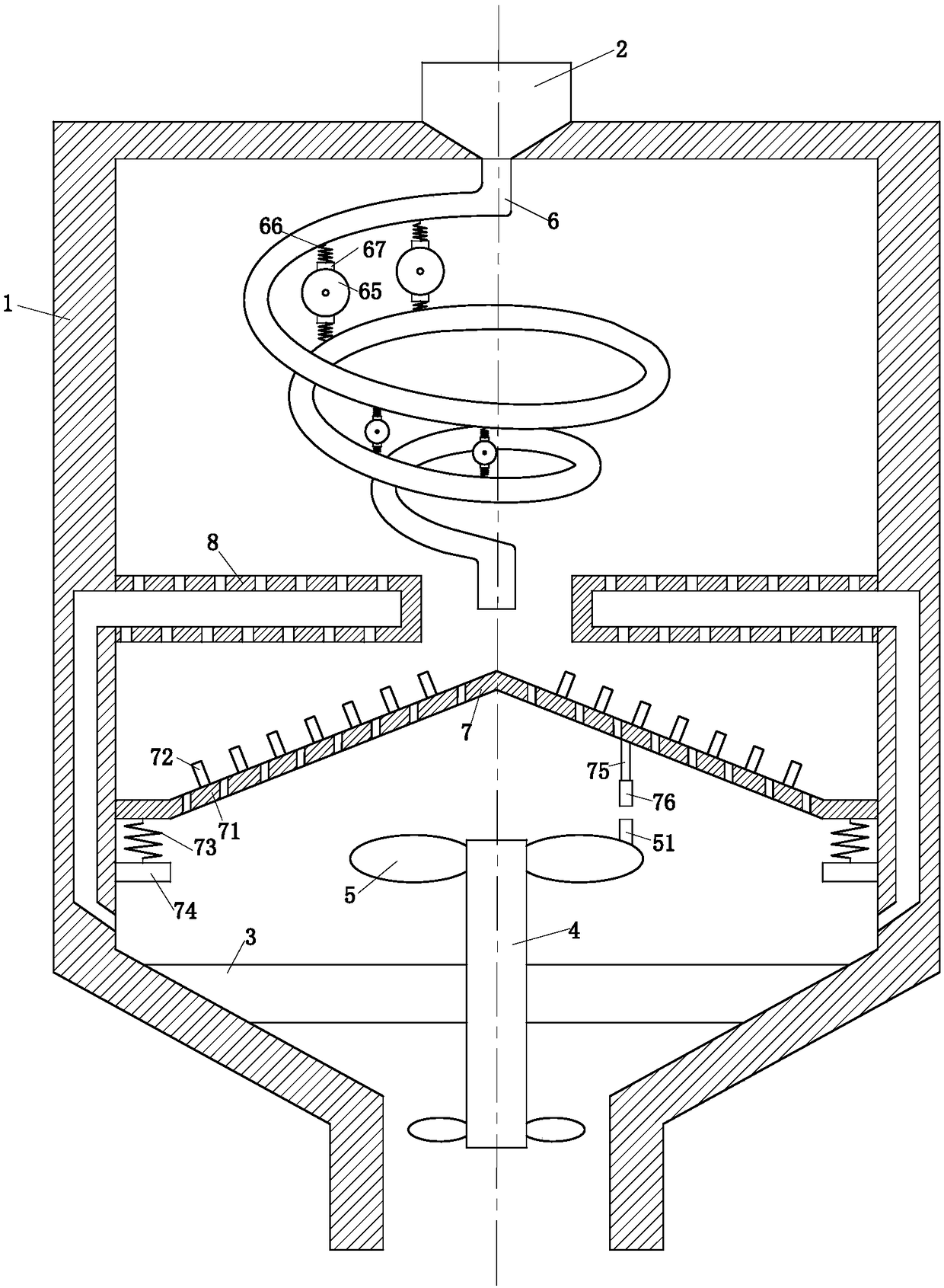

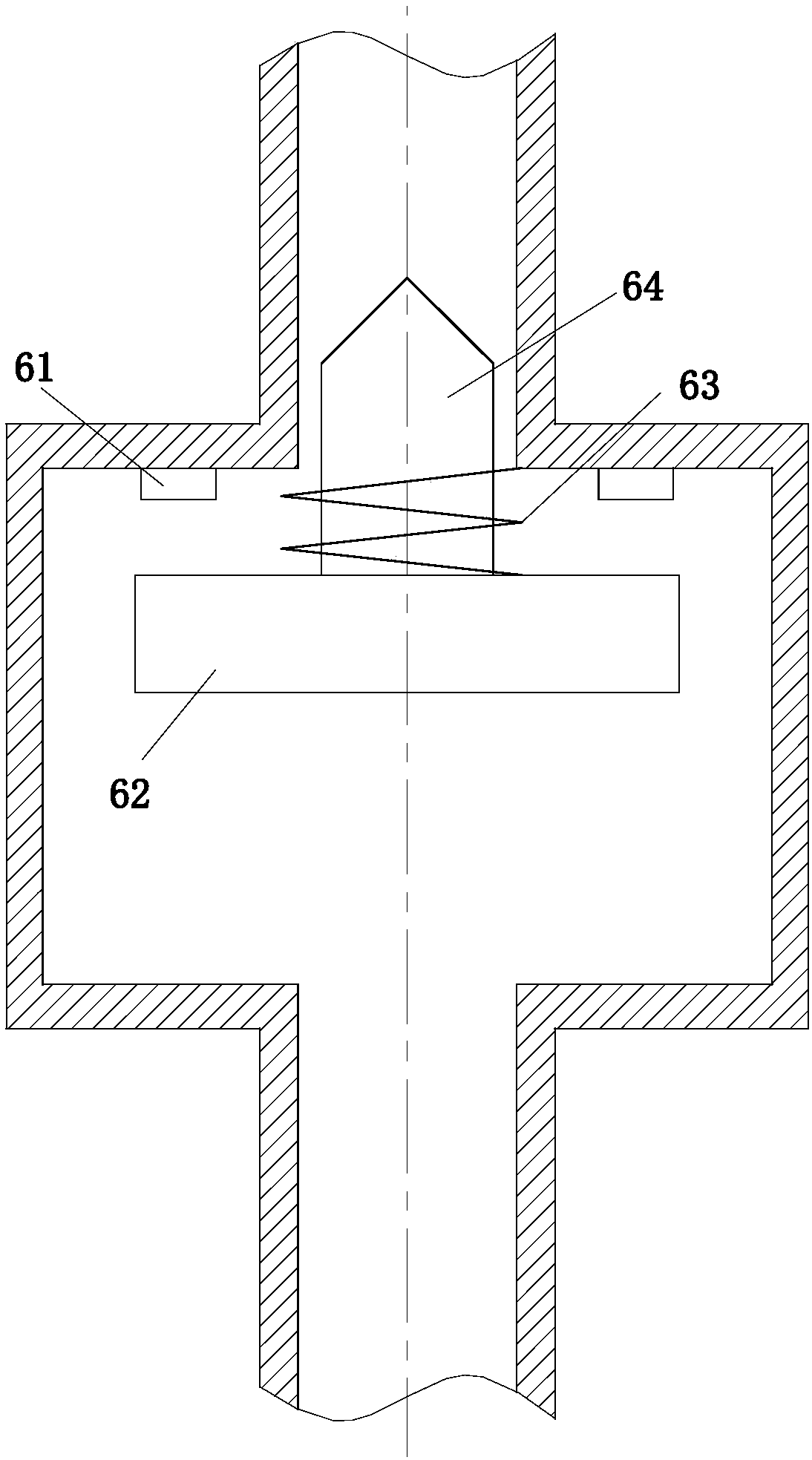

Graphene production process

The invention belongs to the technical field of graphene preparation, in particular to a graphene production process. The graphene production process includes the following steps of: using natural flake graphite or artificial graphite as raw materials, adding oxidant for oxidation reaction to obtain graphite oxide, then adding intercalation agent for intercalation reaction, and conducting suctionfiltration to reaction solution after the intercalation reaction is finished to obtain intercalated graphite after drying; grinding and sieving the prepared dried intercalated graphite by using a grinding device to obtain expandable graphite; dispersing the obtained expandable graphite in sonication solvent to conduct ultrasonic treatment and realize primary stripping; conducting microwave irradiation treatment of the obtained graphite of ultrasonic primary stripping through graphene two-stage microwave production equipment to realize final stripping. The graphene production process has the advantages that with the ultrasonic and microwave radiation to strip the graphite twice, the graphene obtained by stripping is highly fluffy; with graphene finished products not containing organic functional groups, quality of graphene products is improved.

Owner:李训祺

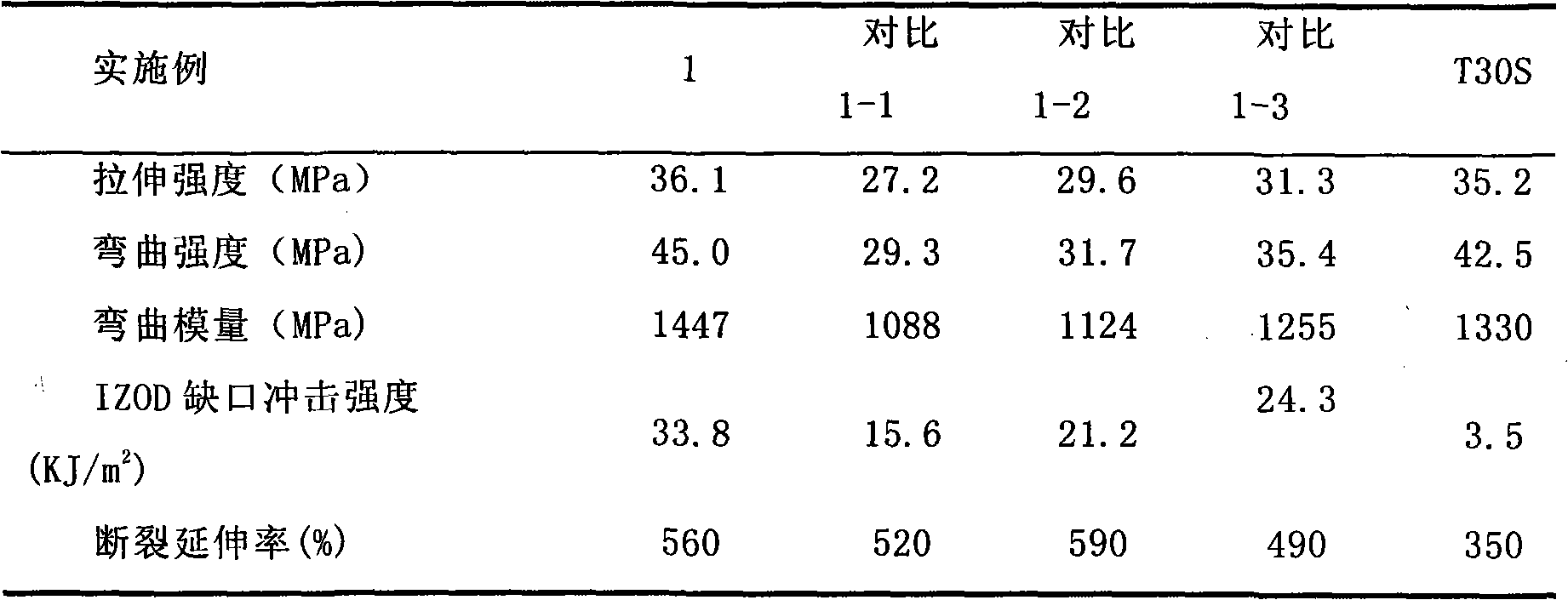

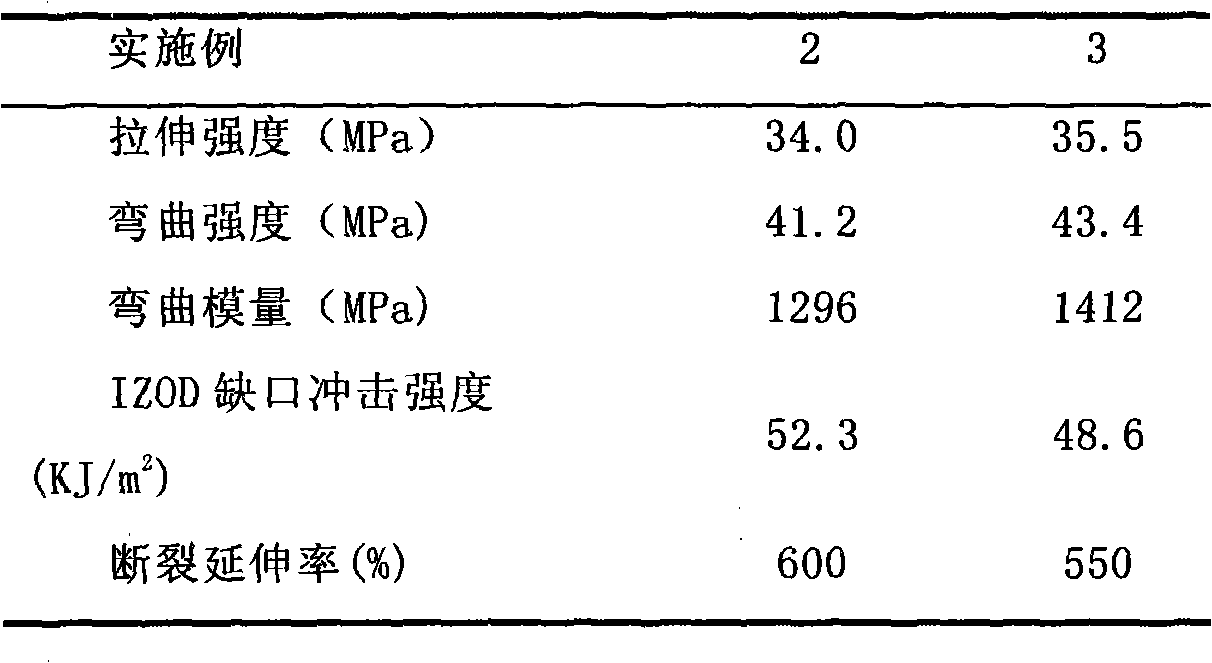

High toughness and high rigidity polypropylene nano-composite material, and preparation method thereof

InactiveCN102372889AImprove toughnessImprove rigidityPigment treatment with macromolecular organic compoundsPigment treatment with non-polymer organic compoundsFunctional monomerIntercalation reaction

The present invention relates to a high toughness and high rigidity polypropylene nano-composite material prepared by a reactive extrusion and blending method. According to the present invention, with a coupling effect of polypropylene and elastomer macromolecular radical in a reaction by a multi-functional monomer, a interface interaction between the polypropylene and the elastomer macromolecular radical is enhanced so as to improve compatibility and toughness; meanwhile, the multi-functional monomer is inserted into the middle of a layered silicate to generate an in situ grafting intercalation reaction, such that the dispersion separation of the multi-functional monomer in the polypropylene is prompted, the layers of the silicate affect the interface reaction, and provide a stabilizing effect and a refining effect for the elastomer dispersion phase. With the present invention, the co-intercalated organic layered silicate is adopted, and provides a significant rigidity increasing effect and a significant toughness increasing effect; the polypropylene nano-composite material of the present invention has high toughness and rigidity.

Owner:SHIYAN FEINAKE TECH

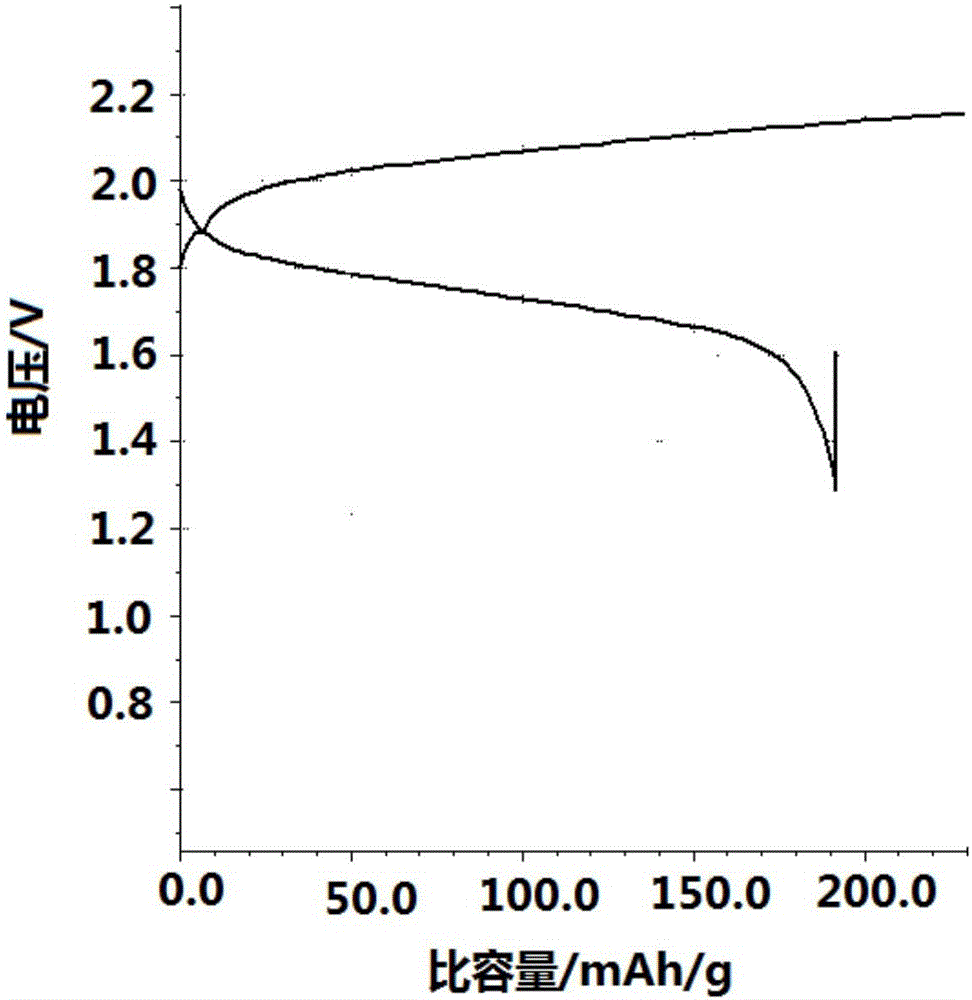

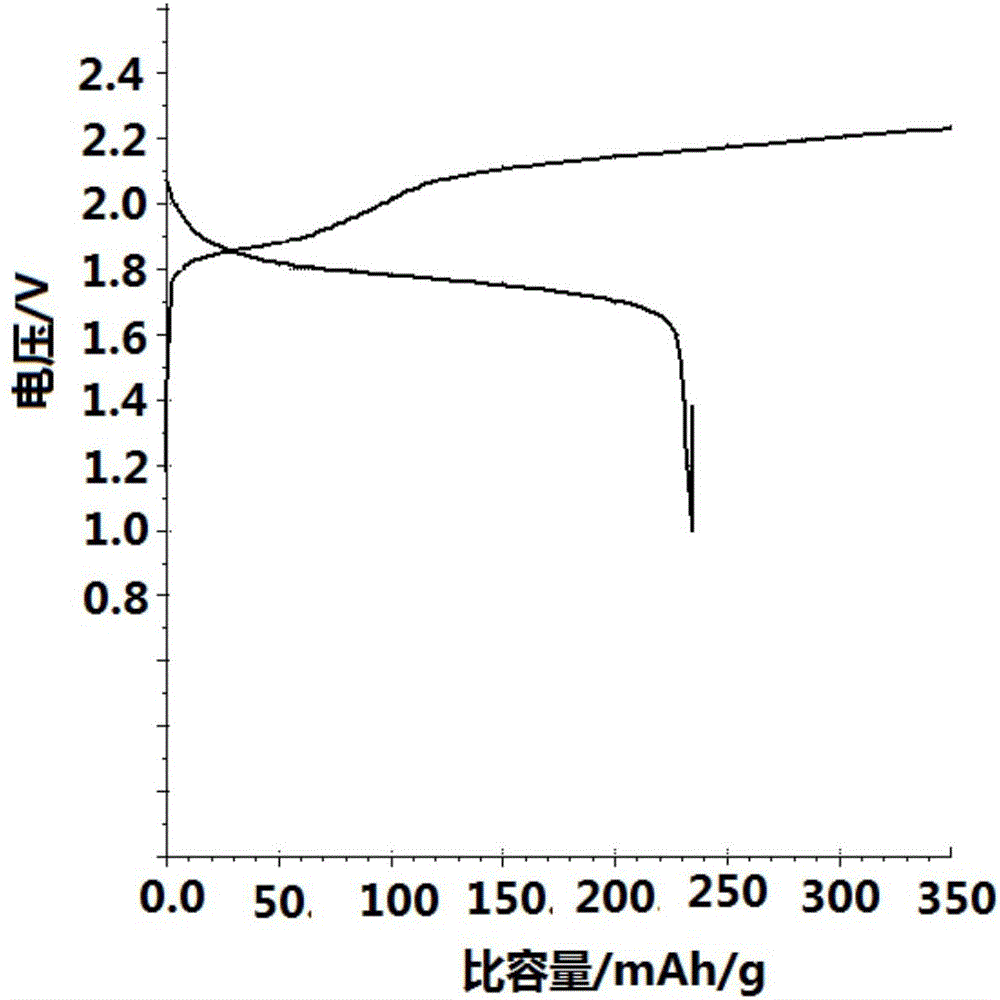

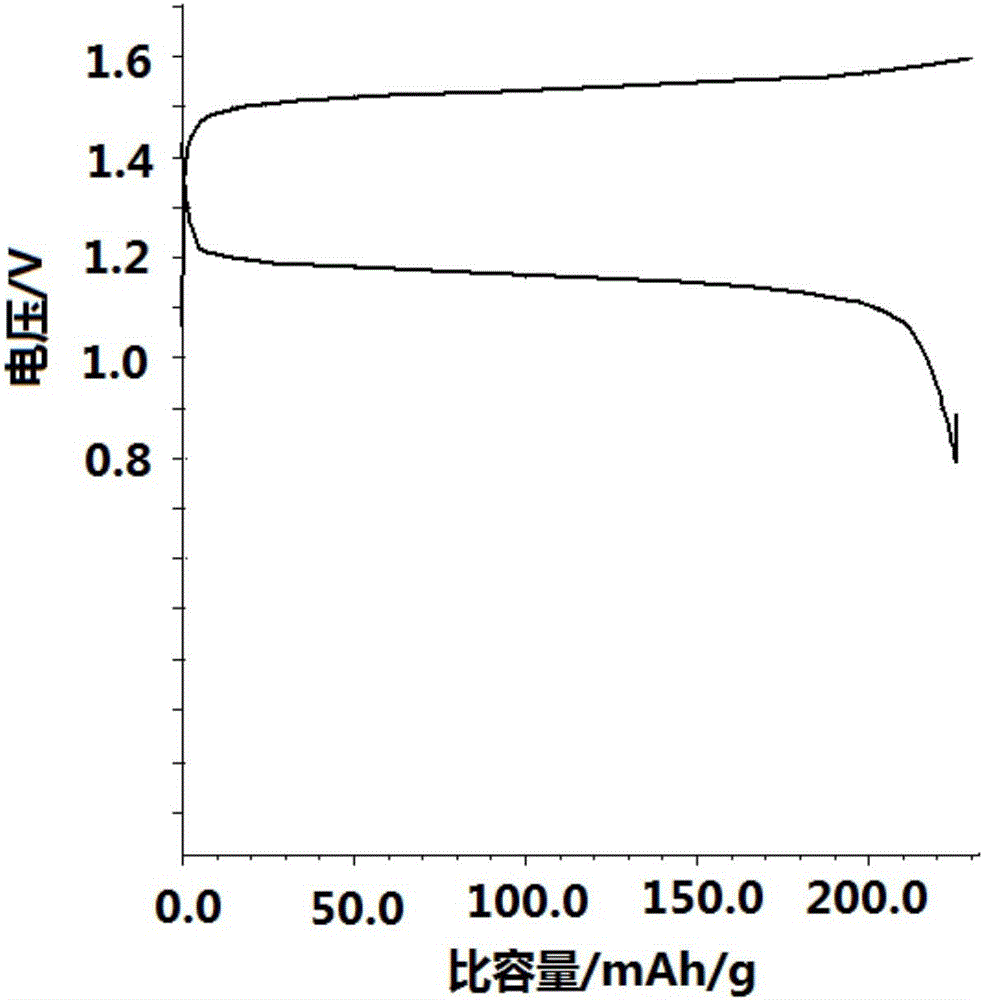

Cathode and electrolyte of aqueous solution lithium ion secondary battery, and battery

ActiveCN106207253APolycrystalline material growthFrom normal temperature solutionsSolubilityLithium hydroxide

The invention provides a cathode and electrolyte of an aqueous solution lithium ion secondary battery, and the battery. Active substances of the cathode are zinc tartrate and / or one or more of crystalline hydrates of the zinc tartrate. The electrolyte of the battery is lithium tartrate aqueous solution or mixed aqueous solution of lithium tartrate and lithium hydroxide. A battery system integrates the advantages of high specific energy, environmental protection and low price of the conventional zinc electrode, and stable structure and good cycling performance of a lithium intercalation material for an anode of the lithium ion battery, and the defects of low energy density, poor cycling performance and the like of a lithium intercalation anode material of a rocking chair type lithium ion secondary battery in an aqueous application, and a problem of short service life caused by thermodynamics instability, easiness in solubility and dendritic crystal of a zinc electrode in alkaline electrolyte are avoided. A precipitation-intercalation and de-intercalation reaction mixing mechanism of double ion is cleverly utilized to achieve a breakthrough of application of the aqueous lithium ion battery.

Owner:胡晓光

Heat-conducting graphite paper and preparation method thereof

The invention relates to a preparation method of heat-conducting graphite paper. The preparation method comprises the following steps: mixing flake graphite with a concentrated sulfuric acid solutionto obtain a first mixture; adding an oxidizing agent into the first mixture for carrying out an oxidative intercalation reaction so as to obtain a second mixture; washing the second mixture to obtaina prefabricate product; putting the prefabricate product into a chamber, first vacuumizing the chamber and then introducing inert gas into the chamber, and carrying out high temperature expansion treatment to obtain an expanded graphite material; rolling the expanded graphite material for at least once to obtain the heat-conducting graphite paper. The invention also provides the heat-conducting graphite paper.

Owner:乌兰察布市大盛石墨新材料股份有限公司

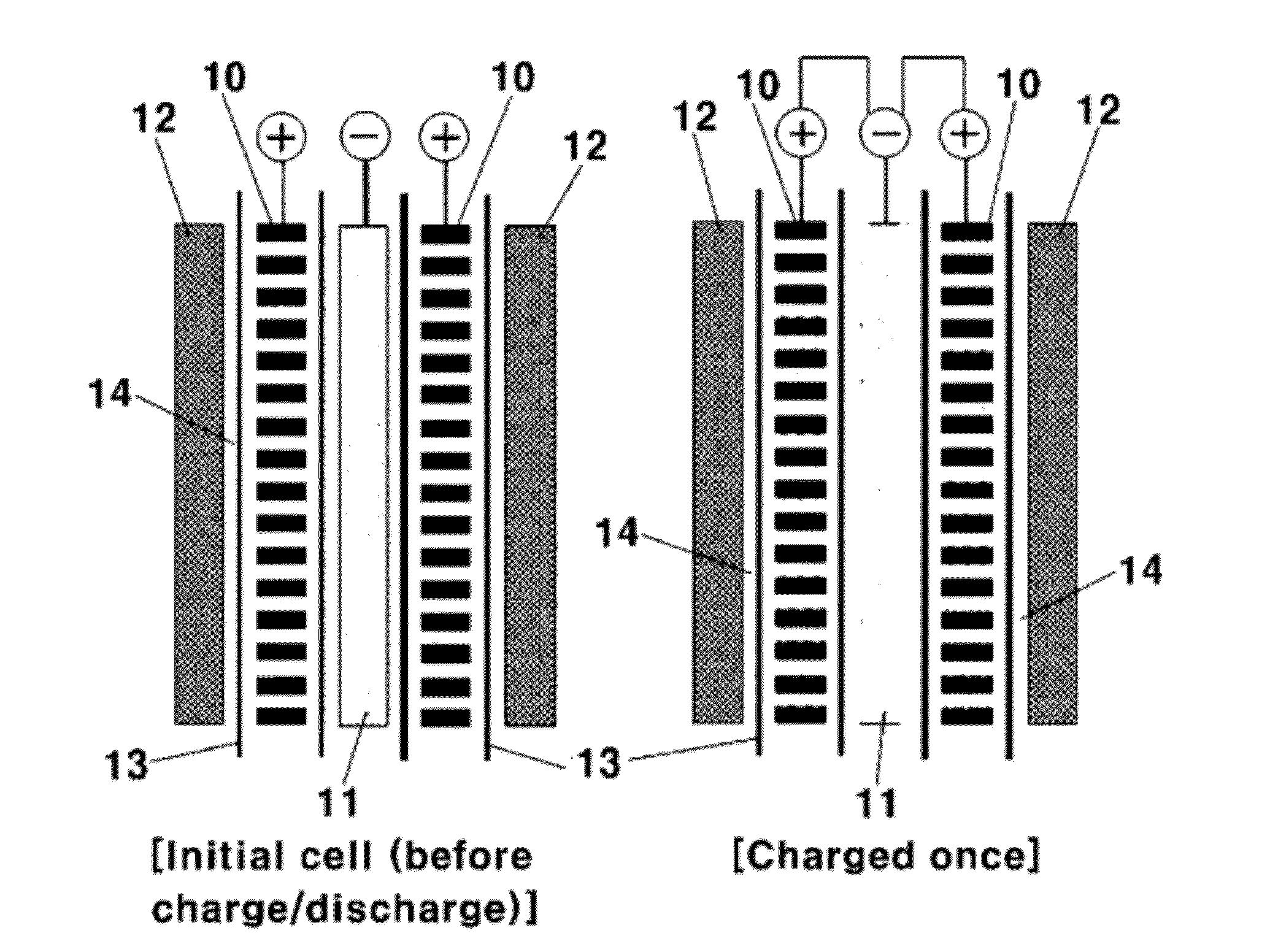

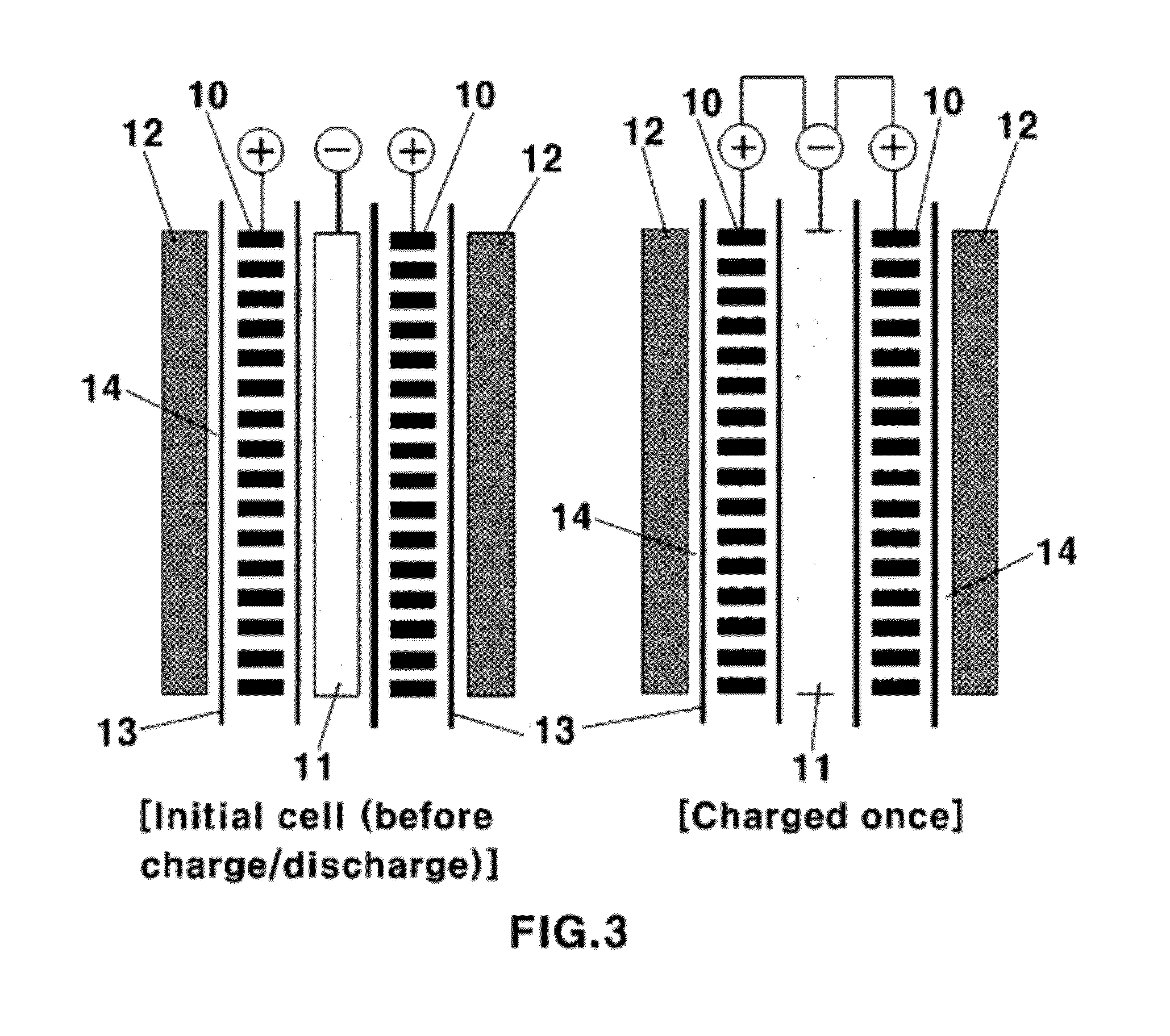

Lithium ion-sulfur battery

ActiveUS20120141876A1Increase energy densityImproving charge/discharge durabilityFinal product manufactureElectrode collector coatingIntercalation reactionLithium metal

The present invention provides a lithium ion-sulfur battery including a lithium metal used as a supply source of lithium ions, a sulfur electrode used as a positive electrode and an intercalation electrode. The intercalation electrode is (i) interposed between the lithium metal and the sulfur electrode, (ii) has a structure capable of causing an intercalation reaction, and (iii) is used as a negative electrode after the lithium ions are intercalated from the lithium metal to be charged and discharged together with the sulfur electrode. The lithium metal is used only to intercalate the lithium ions into the intercalation electrode during initial use, and the intercalation electrode, into which the lithium ions are intercalated, is used as a negative electrode during actual use. Therefore, it is possible to prevent the formation of dendrite caused when the lithium ions are used as the negative electrode, and thus the charge / discharge durability is improved.

Owner:HYUNDAI MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com