Nano-grade silica modified montmorillonite particle preparation method, and method for applying nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with in-situ method

A technology of nano-silica and nano-montmorillonite, which is applied in the treatment of dyed organosilicon compounds, fibrous fillers, etc., can solve the problems of nano-particle agglomeration and inability to disperse, and achieve good compatibility, high thermal decomposition temperature, Effect of Tensile Strength Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

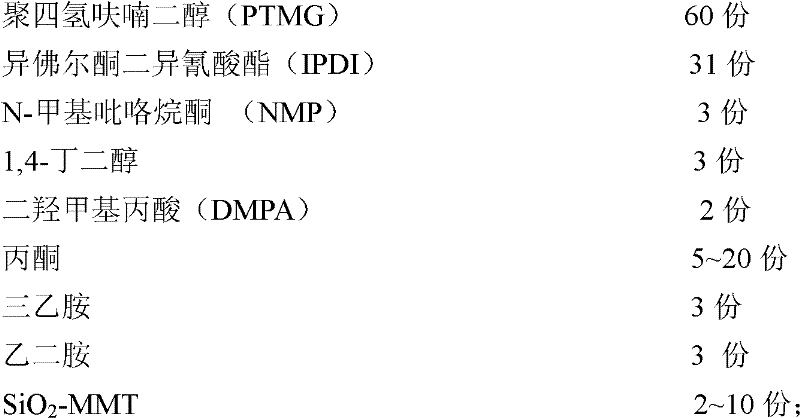

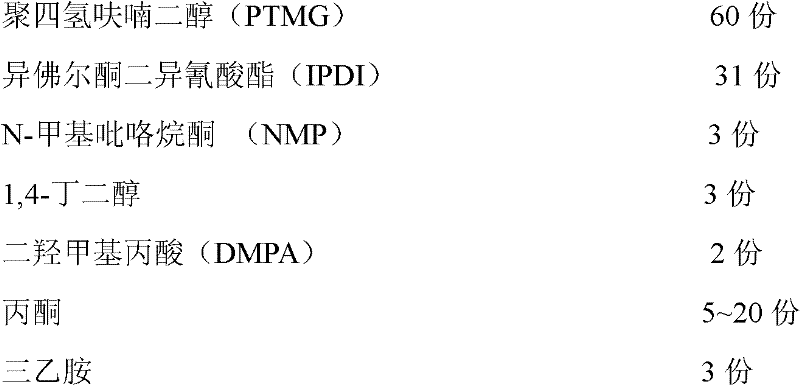

[0019] Example 1: Weigh 4.0 g of montmorillonite, swell it with distilled water and then disperse it with ultrasound until a uniform suspension is formed. Weigh 2.0 g of ethyl orthosilicate (TEOS), add absolute ethanol and stir for 30 minutes to prepare an alcohol solution of ethyl orthosilicate. The prepared solution is slowly added dropwise to the montmorillonite suspension, stirred vigorously until the solution is uniform, and dispersed by ultrasonic for about 1 hour. Add ammonia water dropwise to the suspension to control the pH value at 9.5, stir at room temperature for 24 hours, after the ethyl orthosilicate is hydrolyzed, the resulting reaction solution is dried in an oven at 60°C, and the resulting powder is ground into a powder, namely The nano-silica modified montmorillonite particles are obtained. Disperse the obtained product in 100mL ethanol / distilled water mixed solution (volume ratio 9:1), slowly add 0.8g γ-aminopropyltriethoxysilane (KH550) dropwise, stir at ro...

example 2

[0020] Example 2: Weigh 4.0 g of montmorillonite, swell it with distilled water and then disperse it with ultrasound until a uniform suspension is formed. Weigh 4.0 g of ethyl orthosilicate (TEOS), add absolute ethanol and stir for 30 min to prepare an alcohol solution of ethyl orthosilicate. The prepared solution is slowly added dropwise to the montmorillonite suspension, stirred vigorously until the solution is uniform, and dispersed by ultrasonic for about 1 hour. Add ammonia water dropwise to the suspension to control the pH value at 10, stir at room temperature for 24 hours, after the ethyl orthosilicate is hydrolyzed, the resulting reaction solution is dried in an oven at 60°C, and the resulting powder is ground into powder, namely The nano-silica modified montmorillonite particles are obtained. The obtained product was fully dispersed in a mixed solution of 100 mL ethanol / distilled water (volume ratio 9:1), 1.2 g of γ-aminopropyltrimethoxysilane was slowly added dropwis...

example 3

[0021] Example 3: Weigh 4.0 g of montmorillonite, swell it with distilled water and then disperse it with ultrasound until a uniform suspension is formed. Weigh 8.0 g of ethyl orthosilicate (TEOS), add absolute ethanol and stir for 30 minutes to prepare an alcohol solution of ethyl orthosilicate. The prepared solution is slowly added dropwise to the montmorillonite suspension, stirred vigorously until the solution is uniform, and dispersed by ultrasonic for about 1 hour. Add ammonia water dropwise to the suspension to control the pH at 10.5, stir at room temperature for 24 hours, after the ethyl orthosilicate is hydrolyzed, the resulting reaction solution is dried in an oven at 60°C, and the resulting powder is ground into powder, namely The nano-silica modified montmorillonite particles are obtained. Fully disperse the obtained product in a mixed solution of 100 mL ethanol / distilled water (volume ratio 9:1), and slowly add 1.6 g N-β (aminoethyl)-γ-aminopropylmethyldimethoxysi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com