Patents

Literature

51results about How to "Restricted free movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extinguishing agent

InactiveCN102058951AReduce pollutionRestricted free movementFire extinguisherSesquioxideAluminium hydroxide

The invention discloses an extinguishing agent. The extinguishing agent is formed by mixing and stirring strong hydrophobic solid particles and aqueous solution at high speed, wherein the strong hydrophobic solid particles are one type or more of magnesium hydroxide particles, silicon dioxide particles, calcium carbonate particles, talcum particles, aluminium oxide particles, aluminium hydroxide particles, zinc borate particles, zinc oxide particles, iron sesquioxide particles, titanium dioxide particles, montmorillonite particles, hydrotalcite particles, coal ash particles, diatomite particles, mica particle, attapulgite particles and zeolite particles after hydrophobic modification. The extinguishing agent disclosed by the invention is nontoxic, environmental pollution is less, and secondary loss caused by strong flowability of water can be avoided while playing the advantages of the water as the extinguishing agent and reducing the using amount.

Owner:XIAN UNIV OF SCI & TECH

Polyamide composition with high dimensional stability and preparation method thereof

InactiveCN101857723AReduce the degree of orderLow water absorptionHeat deflection temperaturePolyamide

The invention relates to a polyamide composition with high dimensional stability and a preparation method thereof. The polyamide composition comprises the following components in parts by weight: 60 to 90 of fatty polyamide composition, 2 to 10 of compatilizer, 1 to 10 of inorganic metal compound, 0 to 5 of polysiloxane with low molecular weight and 0 to 2 of auxiliary agent. The preparation method comprises the following steps of: premixing the raw materials in a high-speed mixer for 10 to 30min, controlling the temperature to be 40 to 60 DEG C, then adding premix into a double-screw extruder, conveying, melting, shearing, extruding, cooling and granulating so as to prepare a polyamide composition product with high dimensional stability. Compared with the prior art, the invention shows excellent dimensional stability and heat distortion temperature with high retention rate, is suitable for occasions with higher requirement to the dimensional stability, such as the panel of the air conditioner of an automobile, an instrument panel, a camera bracket, a sports apparatus and the like, and can be directly processed by injection molding or other forming methods.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

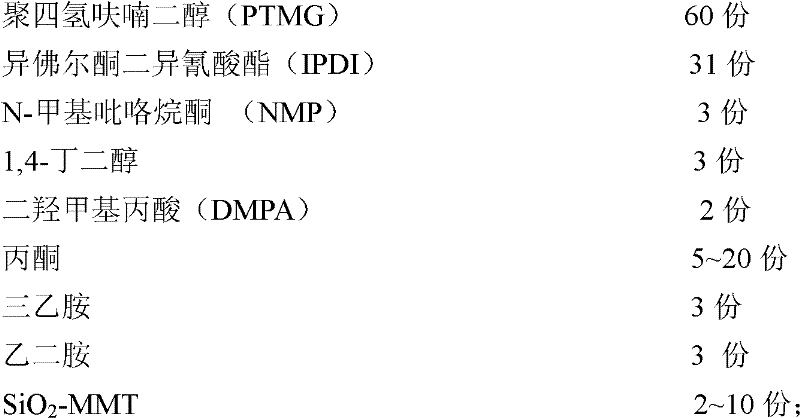

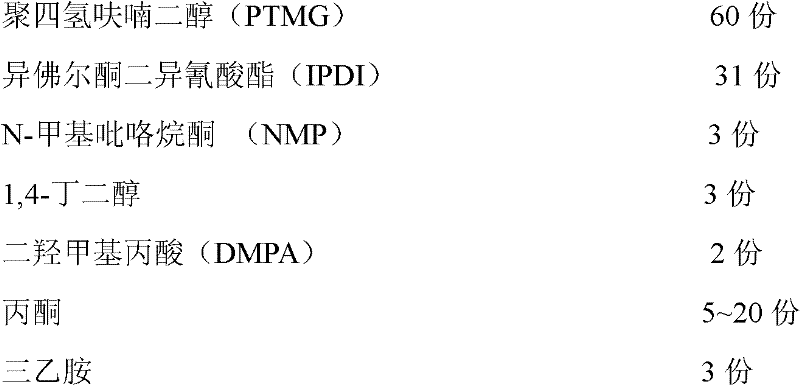

Nano-grade silica modified montmorillonite particle preparation method, and method for applying nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with in-situ method

ActiveCN102344699AGood compatibilityImprove stabilityPigment treatment with organosilicon compoundsSilicon dioxideMechanical property

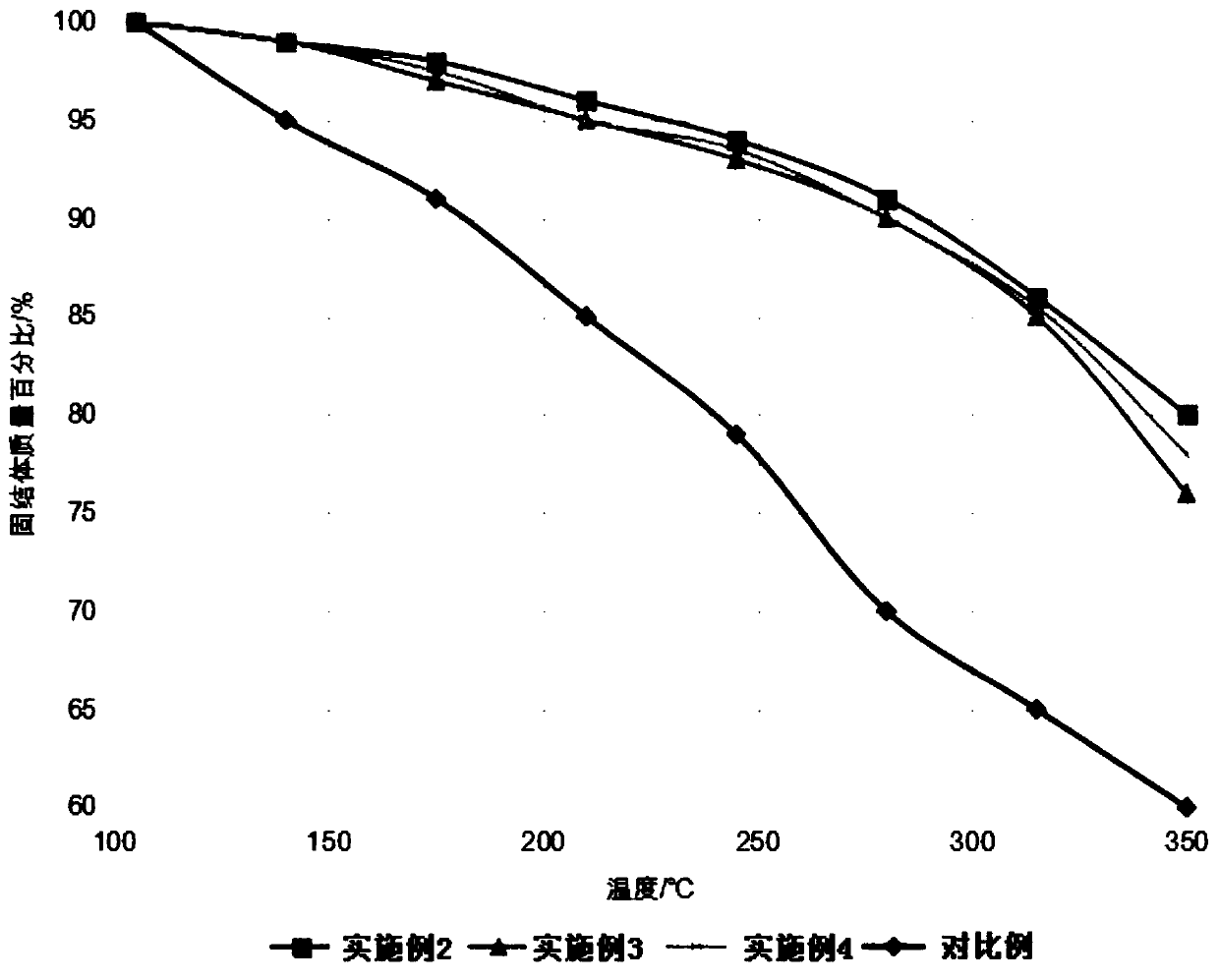

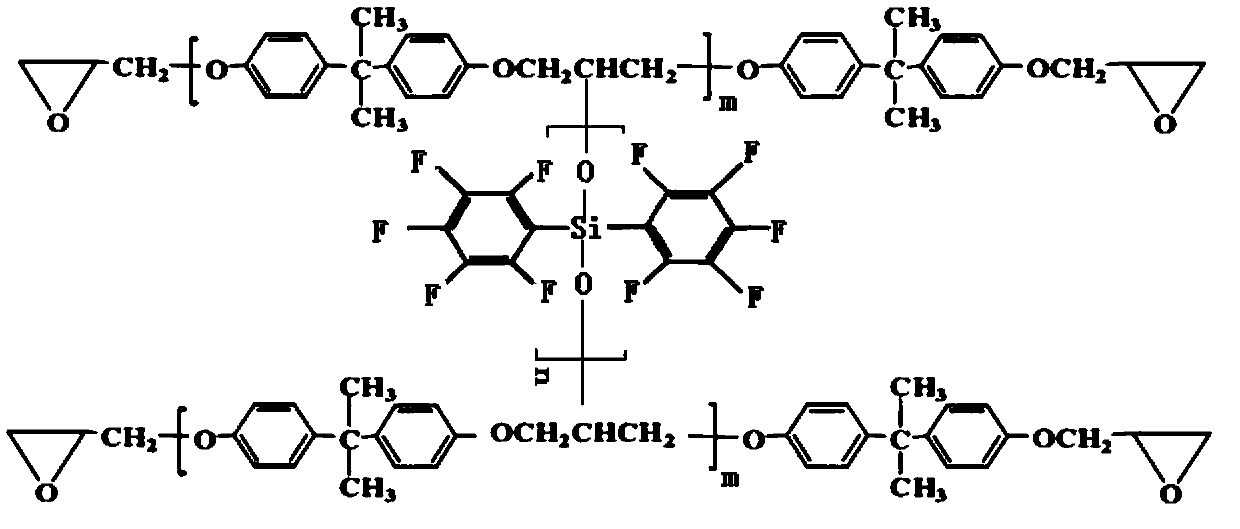

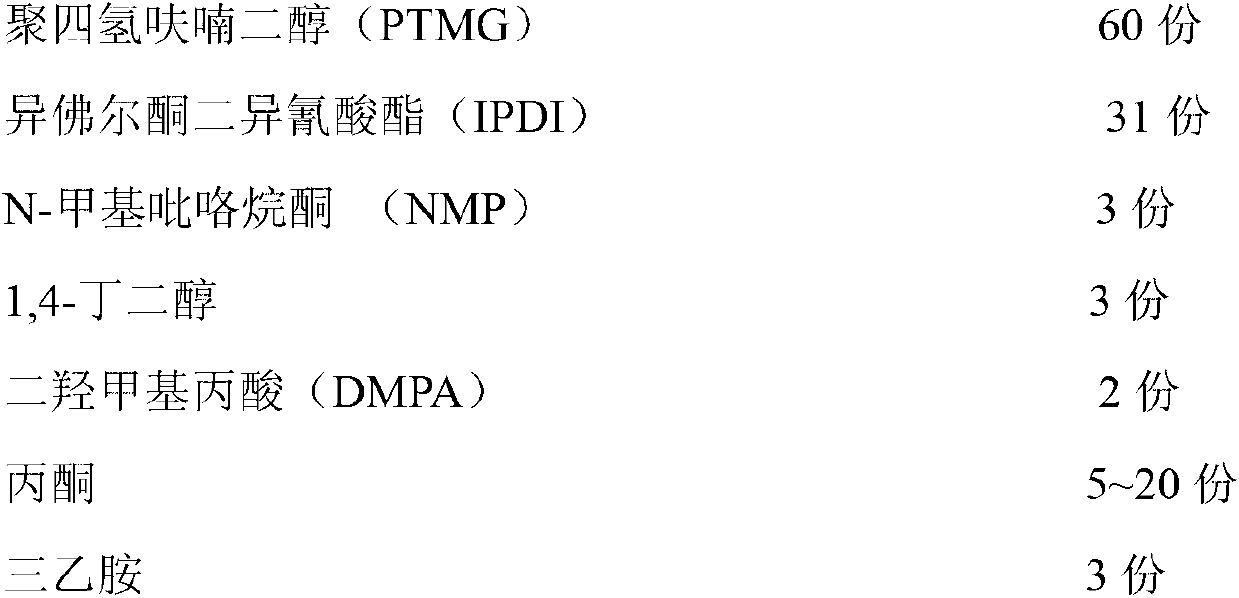

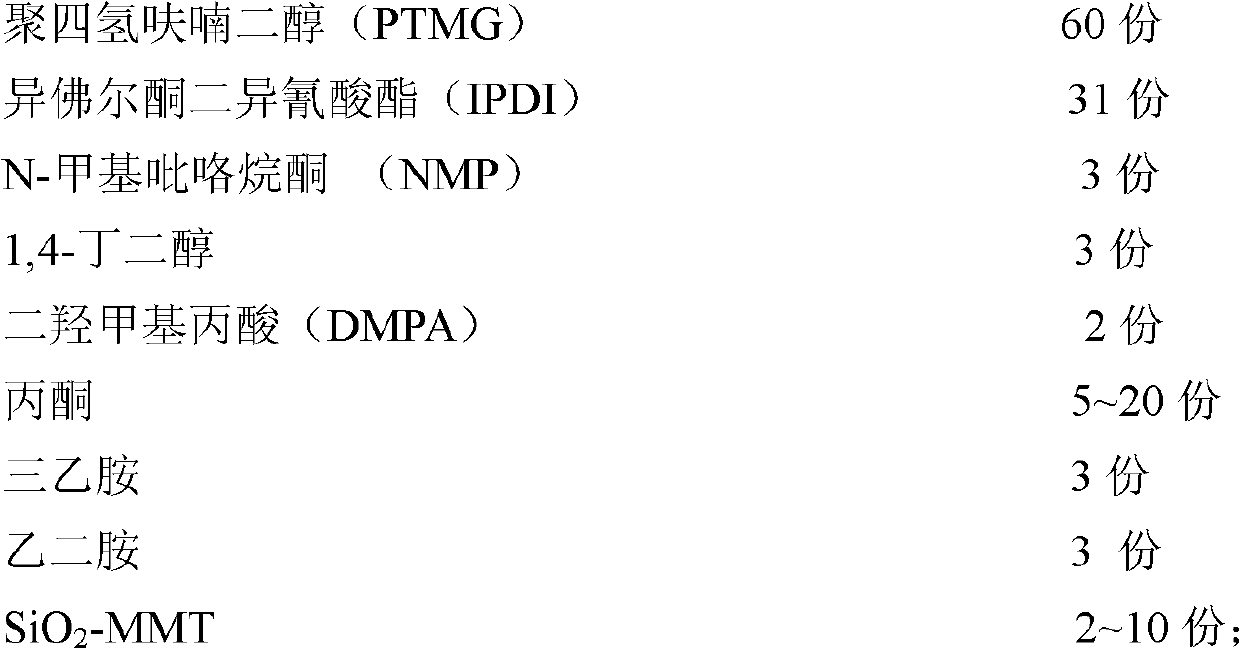

The invention relates to a nano-grade silica modified montmorillonite particle preparation method, and a method for applying the nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with an in-situ method. According to the invention, tetraethoxysilane, a silicane coupling agent and montmorillonite are subject to a modification reaction, such that anano-grade silica layer is modified on the surface of montmorillonite, and active amino-groups are modified. Therefore, the compatibility of montmorillonite in aqueous polyurethane resin is better, such that the emulsion can be more stable. According to the invention, silica modified montmorillonite is prepared through an in-situ method, a silica layer comprising a large amount of silanol is modified on the surface of montmorillonite, and lamella parts of montmorillonite are peeled. When the modified particles are positioned in an aqueous polyurethane system, high molecular chains of polyurethane are subject to an intercalation reaction with montmorillonite, such that free movements of polyurethane molecular chains are restricted, and mechanical properties and thermal stability of the material are improved. Compared to simple polyurethane, tensile strength of the material is improved by 1-2 times, and thermal decomposition temperature of the material is improved by 30 to 50 DEG C.

Owner:徐州光头强木业有限公司

Organic montmorillonite-aqueous polyurethane compound leather finishing agent and method for preparing same

InactiveCN101544820ARestricted free movementImprove mechanical propertiesEthylene diaminePolymer science

The invention discloses an organic montmorillonite-aqueous polyurethane compound leather finishing agent and a method for preparing the same. The method comprises the following steps: firstly using quaternary ammonium salt such as cetyl trimethyl ammonium chloride, octadecyl dihydroxyethyl methyl ammonium bromide and the like, organic amine such as ethylene diamine, octadecylamine and the like, or a silane coupler, polyisocyanate and the like to organically modify montmorillonite to prepare organic montmorillonite; and secondly, performing intercalation reaction of emulsion of a polyurethane resin finishing agent and the organic montmorillonite to obtain the finished product of the organic montmorillonite-aqueous polyurethane compound leather finishing agent. In the method, the quaternary ammonium salt, the organic amine, the silane coupler or the polyisocyanate are used for organically modifying the montmorillonite, so that the interlamellar spacing of the montmorillonite is increased, the micro environment among the lamellas is improved, the compatibility of the montmorillonite and the organic phase is improved, and the intercalation reaction of the polyurethane molecules and the montmorillonite is easily performed; moreover, due to the interlamellar compound of the organic montmorillonite on the polyurethane resin finishing agent, the mechanical property, the thermal resistant stability, the water resistance and the water vapor permeability of the finishing material are improved. When the leather finishing material is applied to leather finishing, the leather finishing material has the advantages of greatly improving the mechanical strength and thermal resistant stability of the coating and having active effects on water resistance, sanitary property and the like of the coating.

Owner:SICHUAN UNIV

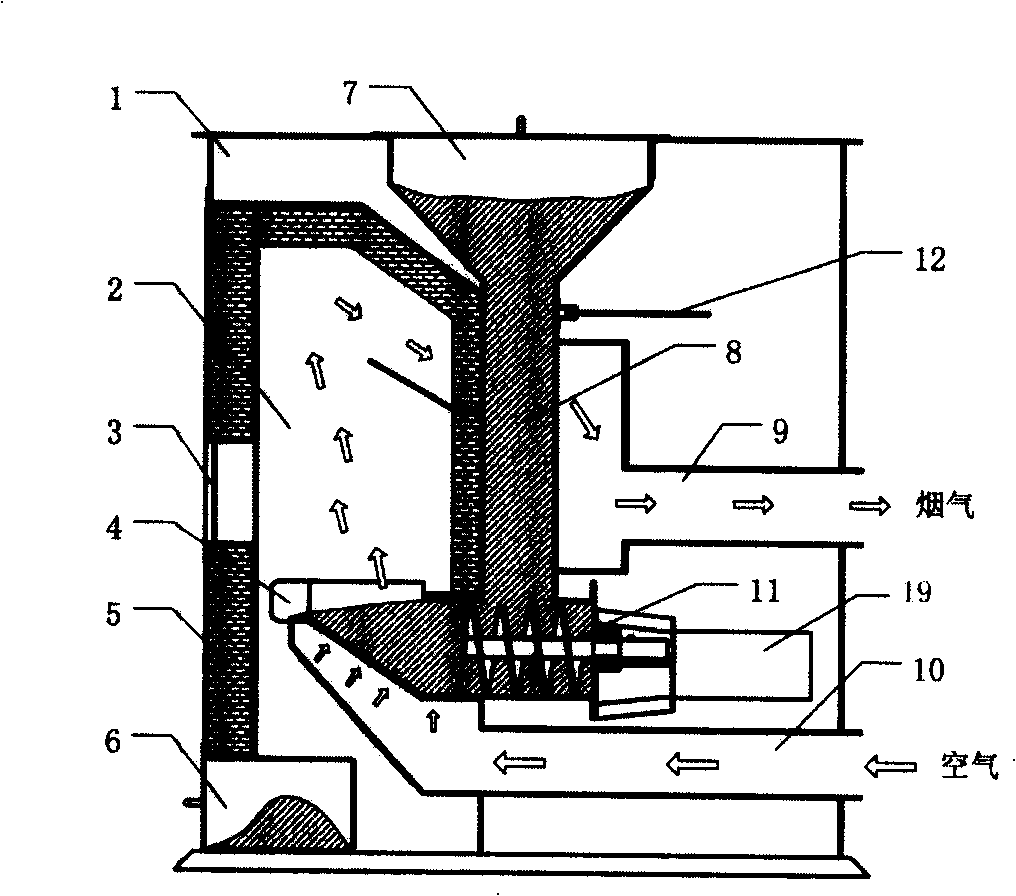

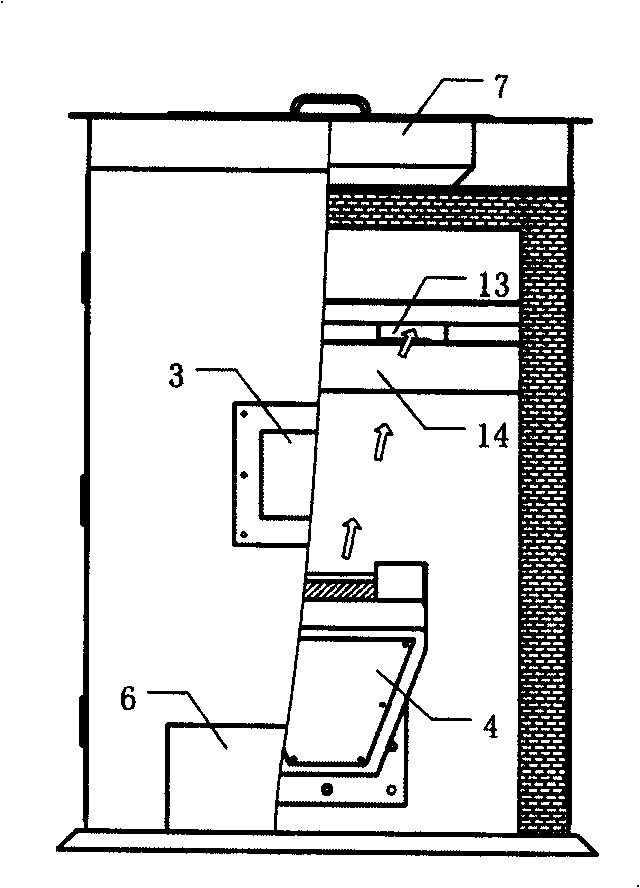

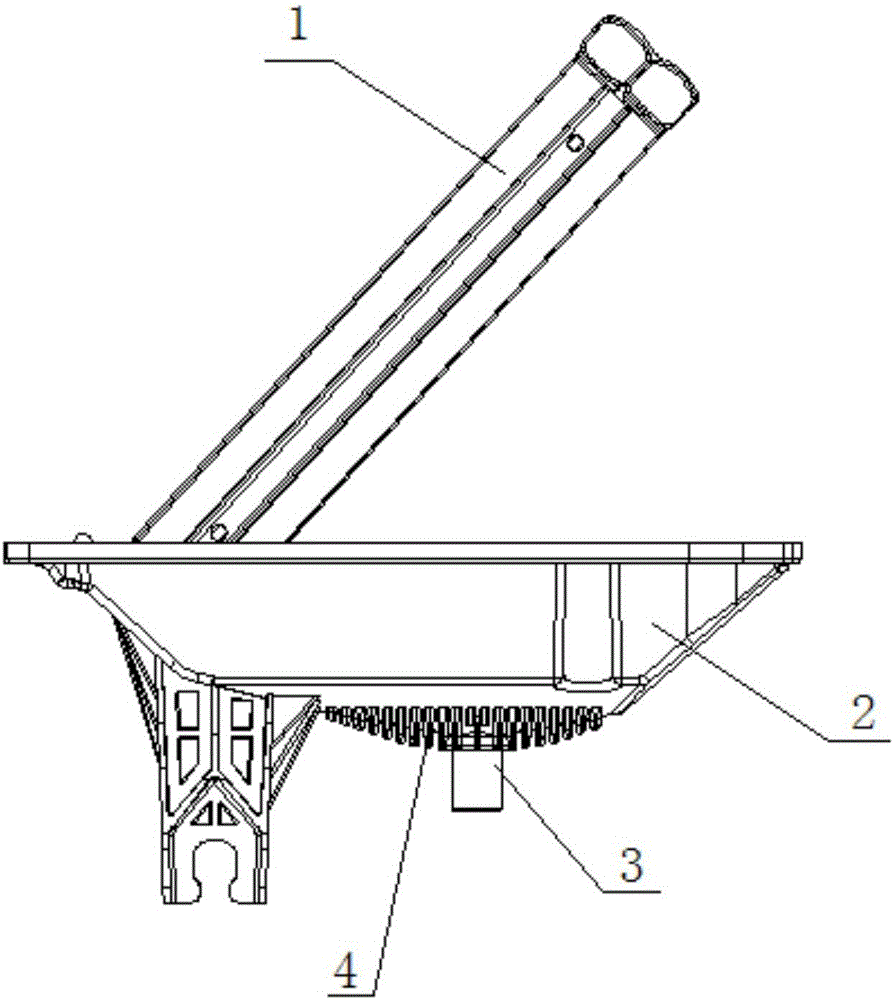

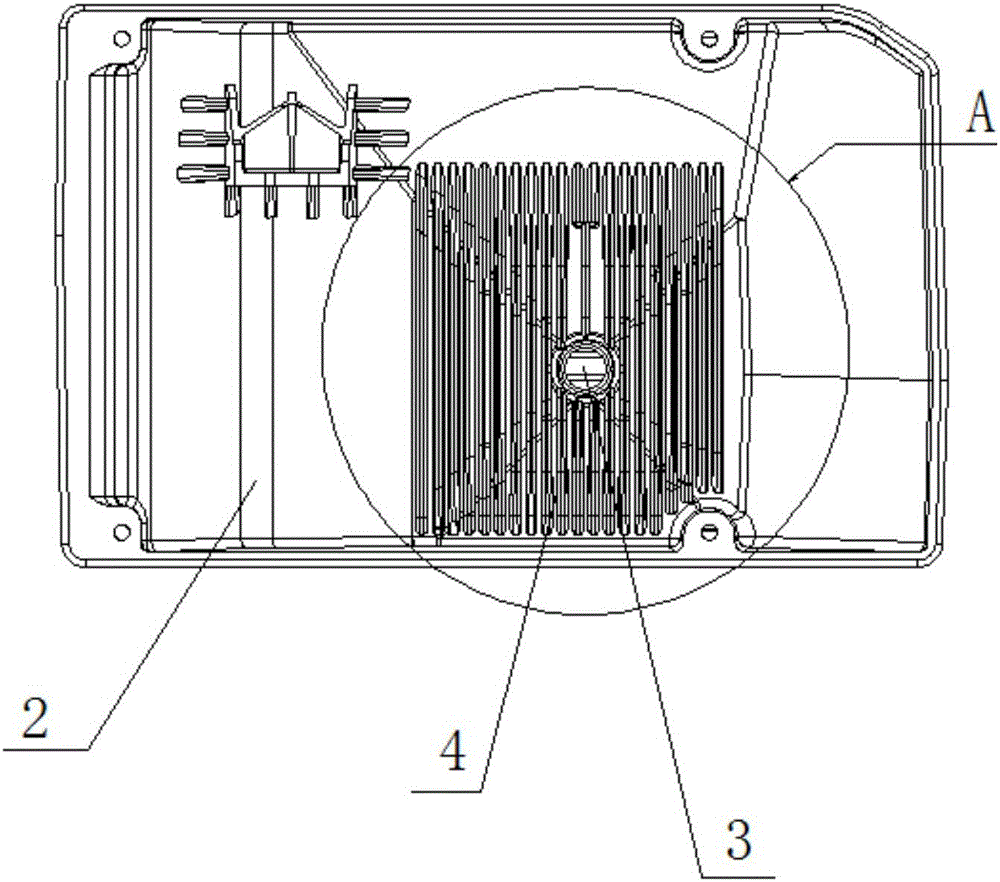

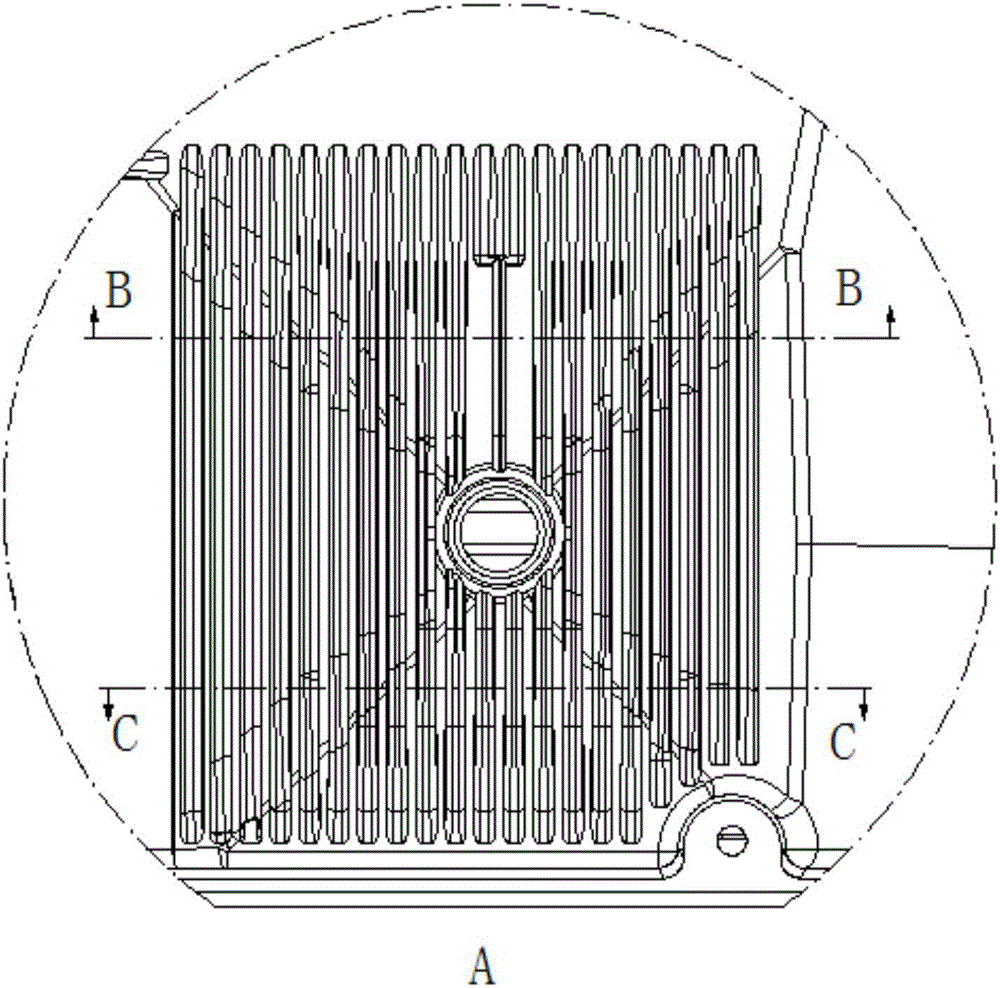

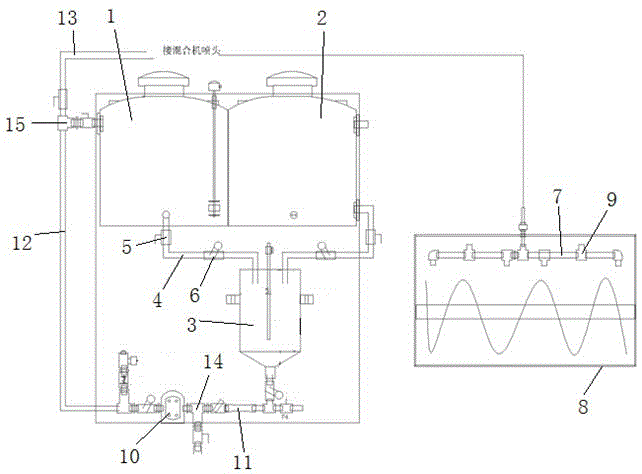

Biomass shaping fuel decoupling combustion device and combustion method thereof

InactiveCN101270875AMatching contradiction is smallReduce couplingIncinerator apparatusGeneration processCombustion chamber

The invention relates to a decoupling combustion device for the biomass briquetting fuel and the combustion method. The device comprises a vertical combustion furnace, a combustion chamber and a pyrolysis chamber; the bottom of the combustion chamber is communicated with the bottom of the pyrolysis chamber; a hopper is mounted on top of the pyrolysis chamber; a gate is mounted at the lower part of the combustion chamber. The invention is characterized in that a screw conveyor is mounted at the lower part of the pyrolysis chamber; a flue gas interlayer is mounted on the outside wall of the pyrolysis chamber, which is communicated with a flue gas channel at the lower part of the furnace body; an air duct is mounted at the lower part of the gate; a flue gas baffle is mounted in the combustion chamber; the upper part of the flue gas baffle is communicated with the flue gas interlayer. The method is combined with the combustion characteristic of the biomass briquetting fuel, which processes the pyrolysis and the combustion of the biomass briquetting fuel respectively in two areas with different temperature; the method alleviates the contradiction that the pyrolysis speed does not match with the combustion speed; the method eliminates the coupling of different pollutants in the generation process, reduces the loss of incomplete combustion and decreases the discharging amount of the pollutants such as CO and NOx through the re-organization of the combustion of the volatile and the char.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

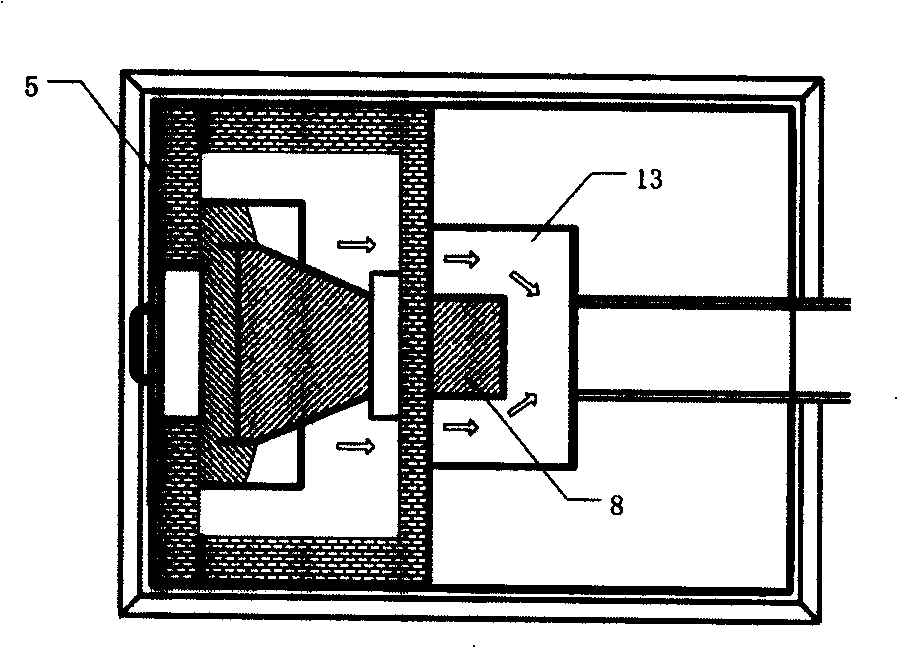

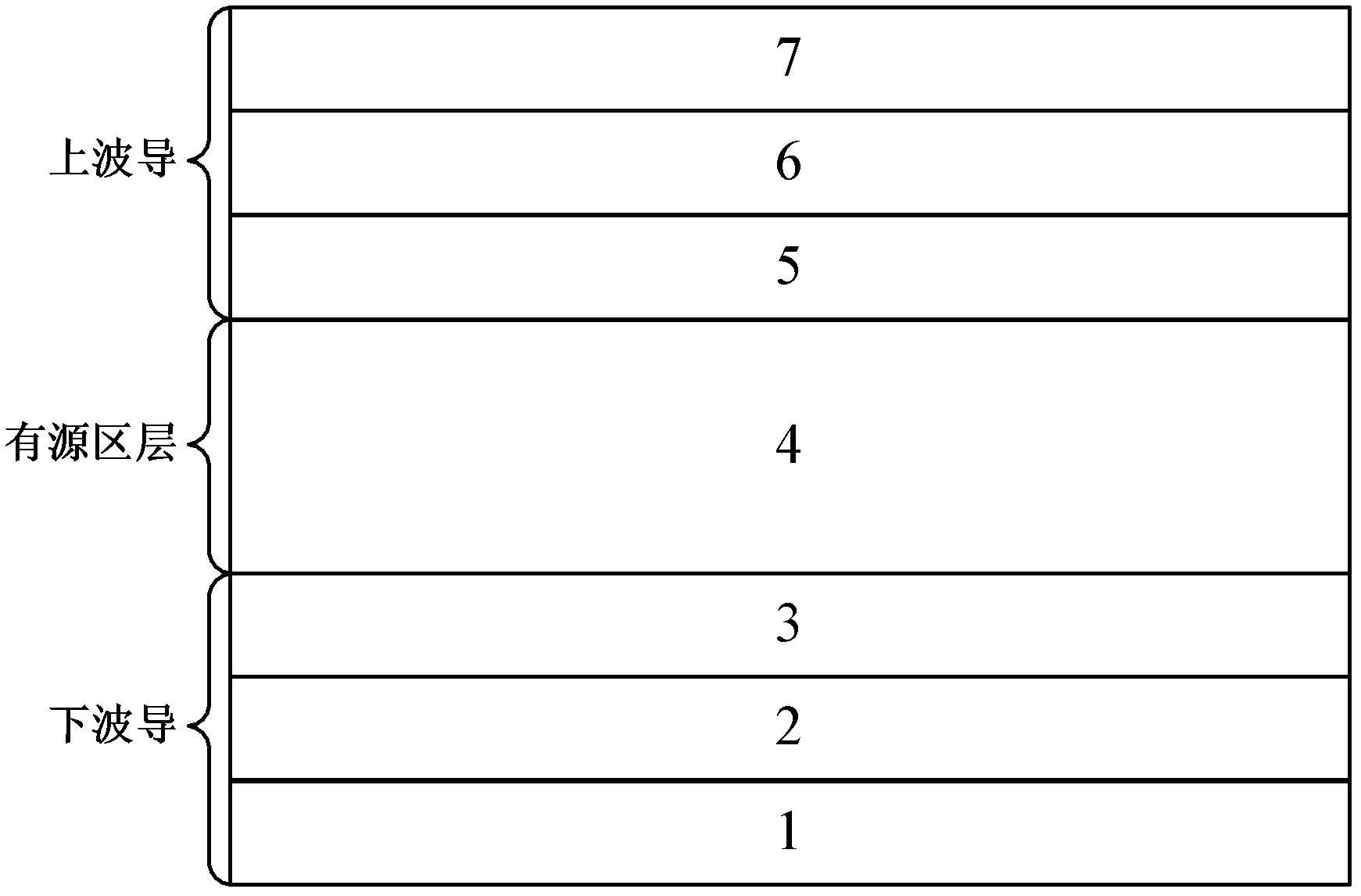

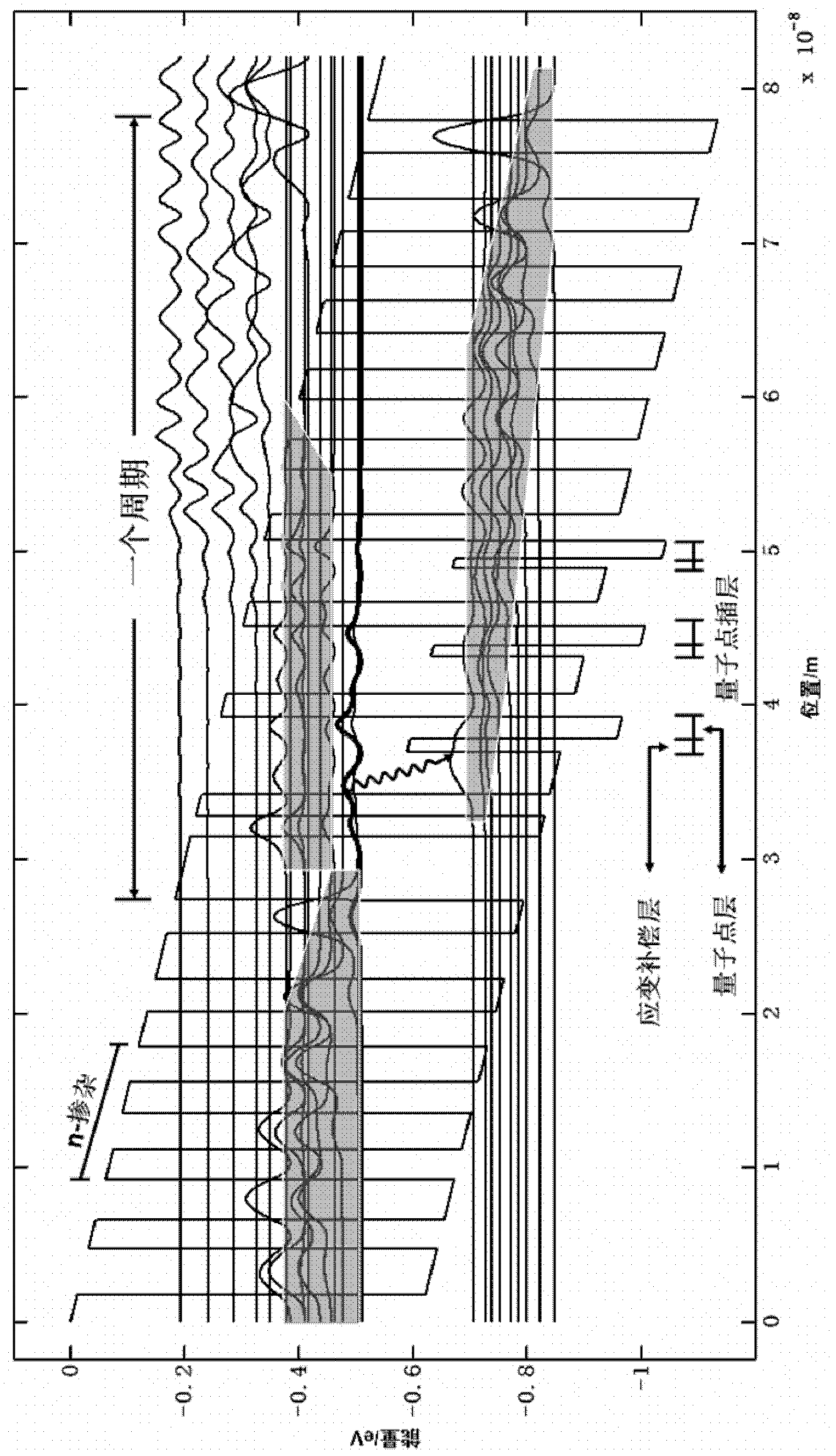

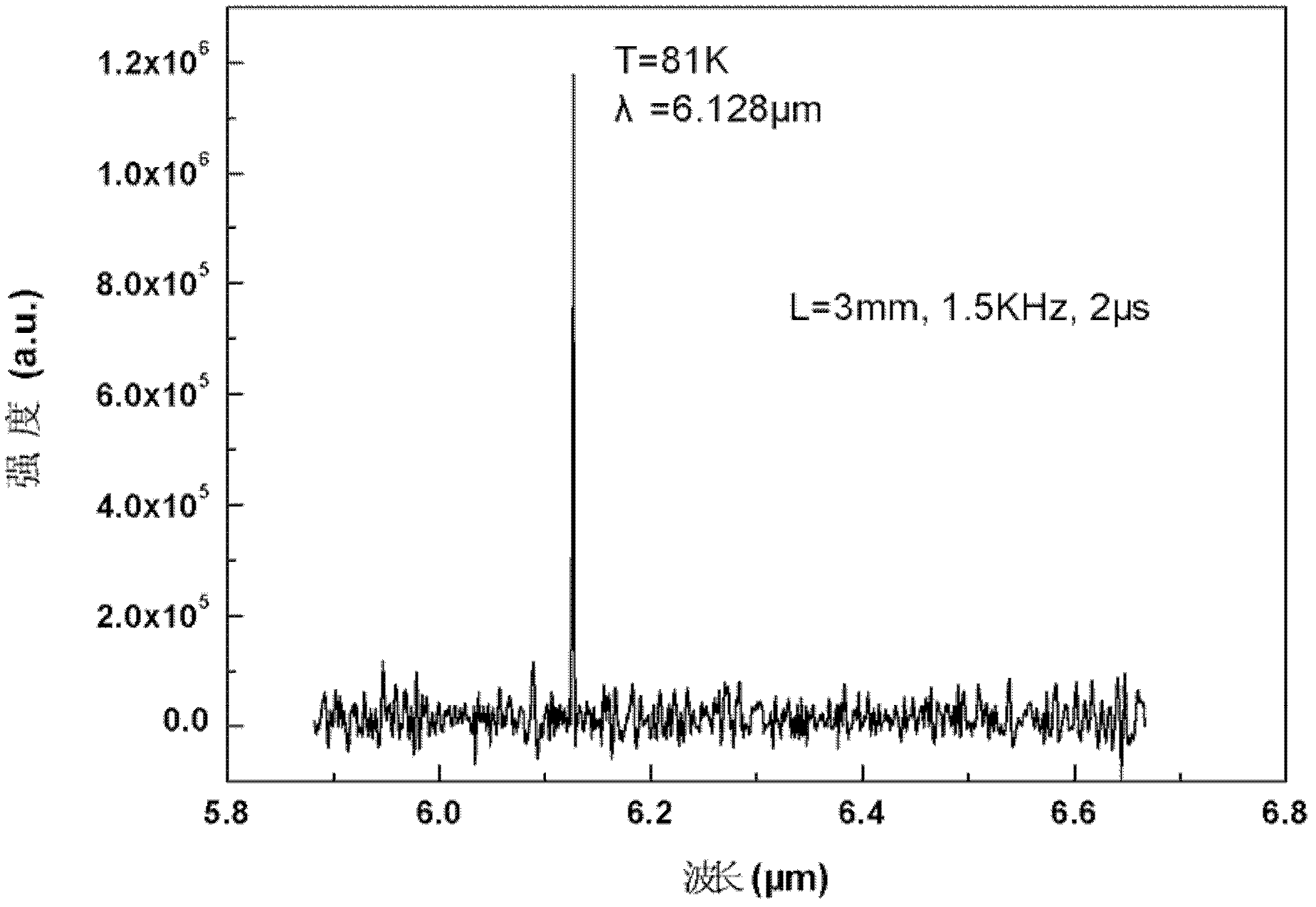

Quantum dot cascade laser

ActiveCN102611003ARestricted free movementImproved power conversion efficiencyLaser detailsLaser active region structureQuantum dotPerformance index

The invention discloses a quantum dot cascade laser, comprising a lower waveguide, a quantum dot active area layer and an upper waveguide. The quantum dot active area layer is of multi-period cascade, each period comprises multiple quantum wells / barriers and quantum dot intercalations, wherein the multiple quantum wells / barriers are used for regulating energy band structures so as to provide an electronic quantum conveying channel; and the quantum dot intercalations are used for realizing quantum dot participation sub-band lasing. In addition, a quantum well material of the quantum well / barrier is InxGa1-xAs, and x is larger than 0 and smaller than 1; and a quantum barrier material of the quantum well / barrier is InxAl1-yAs, and y is larger than 0 and smaller than 1. According to the quantum dot cascade laser disclosed by the invention, multiple quantum dot intercalations are guided to a suitable position in the quantum dot active area layer so that performance indexes of the quantum dot laser, such as power conversion efficiency, characteristic temperature and threshold density, are greatly improved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Silkworm pupa protein/lotus cellulose composite fibers and preparing method thereof

ActiveCN105821518ARich in proteinUniform performanceConjugated cellulose/protein artificial filamentsWet spinning methodsProtein solutionFiber

The invention provides silkworm pupa protein / lotus cellulose composite fibers and a preparing method thereof. The preparing method comprises the following steps that firstly, silkworm pupae are degreased, deodorized, dried and ground into silkworm pupa powder, the silkworm pupa powder is subjected to enzymolysis with cellulase, and a silkworm pupa protein solution is obtained; then, lotus stalks are dried, chopped, rubbed and then steeped into an alkaline solution to be boiled, precipitate is taken out, fully washed with water and naturally dried, and lotus cellulose is obtained; then, the lotus cellulose is dissolved in a strong acid solution, fiercely stirred, taken out and subjected to centrifugal washing 3-5 times until liquid supernatant is milk white, the liquid supernatant is regulated to be neutral and subjected to ultrasonic dispersion, and a lotus cellulose crystal whisker suspension is obtained; finally, the silkworm pupa protein solution and the lotus cellulose crystal whisker suspension are mixed and stirred evenly, concentrated and defoamed to form a spinning solution, and the silkworm pupa protein / lotus cellulose composite fibers are obtained with the wet spinning technology.

Owner:GUANGDONG YI SEN CARPET CONSULTANTS

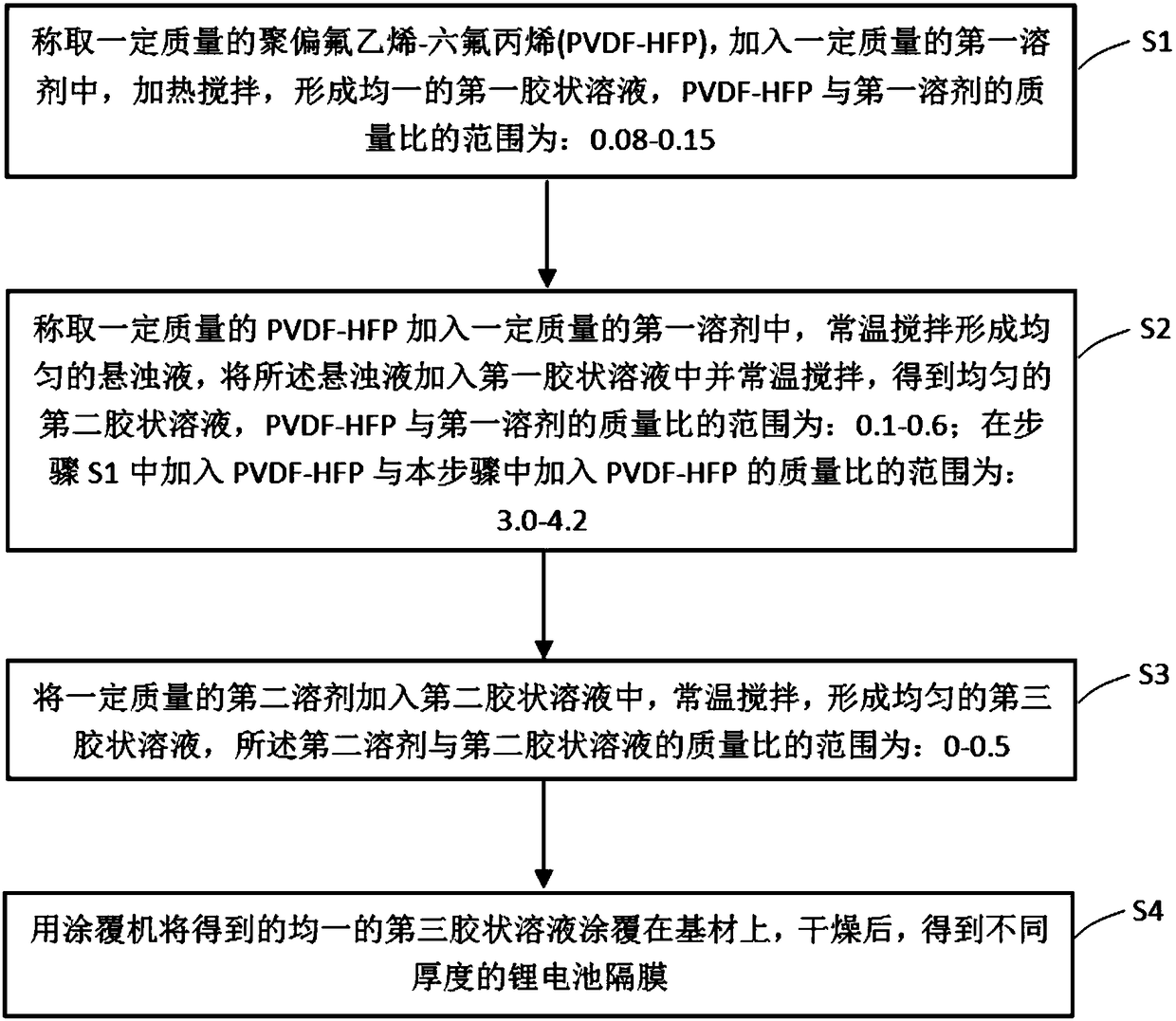

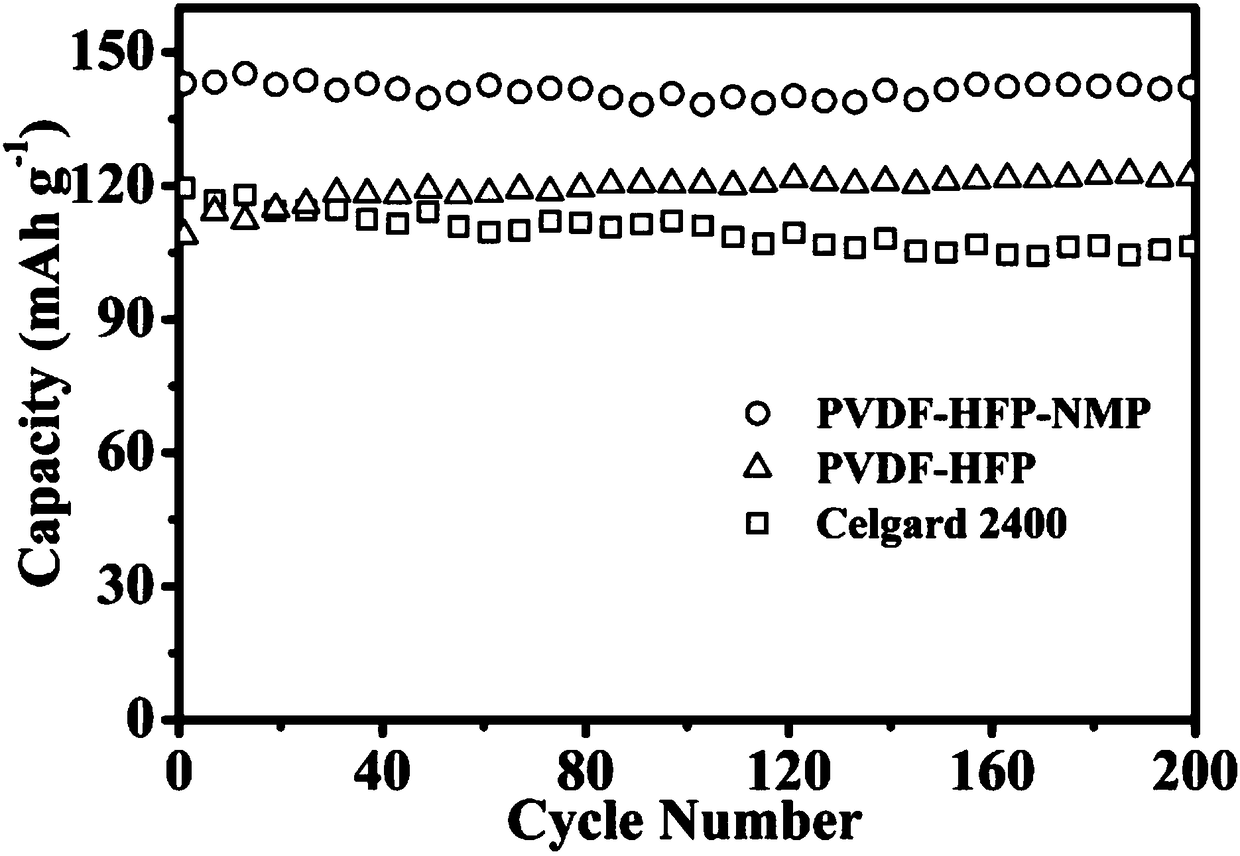

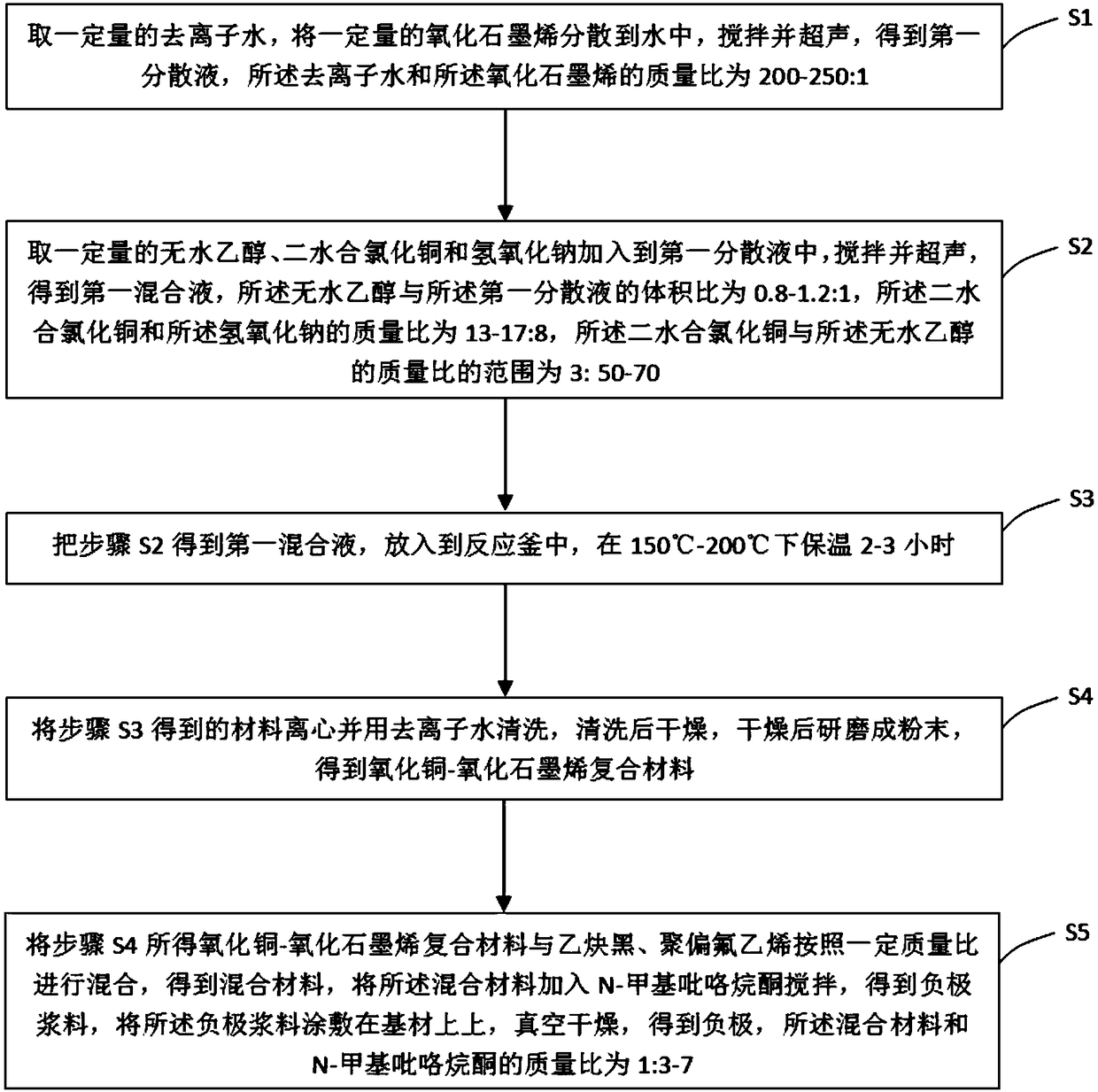

Lithium battery diaphragm preparation method based on mixed solvent multi-stage volatilization mechanism

ActiveCN108134034AImprove structural strengthImprove toughnessCell component detailsCoatingsCrystallographyCross-link

The invention discloses a lithium battery diaphragm preparation method based on a mixed solvent multi-stage volatilization mechanism. The preparation method comprises the steps of performing heating dissolution on a certain mass of PVDF-HFP in a certain mass of first solvent, performing normal temperature dissolution on a certain mass of PVDF-HFP in a certain mass of first solvent, enabling the above two parts to be mixed uniformly and then adding a certain mass of second solvent, performing uniform mixing and than coating a base material, and carrying out drying to obtain the lithium batterydiaphragm. According to the preparation method, the PVDF-HFP is added into the first solvent in two times to form a cross-linked network structure with link; then the second solvent is added to dissolve a part of the link, and the dissolved partial link forms the cross-linked network structure to wind around the linkage; after drying, the first solvent is volatilized to form main lithium ion transmission holes; and the second solvent is volatilized to form holes in the cross-linked network structure around the link, so that the surrounding strength of the link of the lithium battery thin filmis reinforced, and the strength of the lithium battery diaphragm is further reinforced.

Owner:SHENZHEN LI S TECH CO LTD

Silicon carbide/hafnium carbide nanowire modified silicon carbide coating reinforced graphene honeycomb-based nano aerogel heat-insulating and wave-absorbing composite material

PendingCN114466580AImprove mechanical propertiesLow densityThermal insulationMagnetic/electric field screeningSupercritical dryingNanowire

The invention discloses a silicon carbide / hafnium carbide nanowire modified silicon carbide coating enhanced graphene honeycomb-based nano aerogel heat-insulating and wave-absorbing composite material, which is composed of silicon carbide coating enhanced graphene honeycomb, silicon carbide / hafnium carbide nanowires and nano aerogel, firstly, a silicon carbide coating is prepared on the surface of a graphene honeycomb through a chemical vapor deposition process, and then internal pores of the graphene honeycomb are reinforced on the silicon carbide coating through a chemical liquid vapor deposition process to prepare the silicon carbide / hafnium carbide nanowire. And finally, nano aerogel is prepared on the surfaces of the silicon carbide / hafnium carbide nanowires through a sol-gel process, a supercritical drying technology and a carbonization reaction, a formed three-dimensional network structure can effectively block heat transmission and promote the absorption and dissipation effects on electromagnetic waves, and the heat insulation and wave absorption performance of the composite material is cooperatively provided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of industrial silicone sealant

InactiveCN112175575AStop burningPrevent intrusionNon-macromolecular adhesive additivesSilicone sealantFire retardant

The invention discloses a preparation method of an industrial silicone sealant. The silicone sealant is prepared from the following raw materials in parts by weight: 100-120 parts of alpha, omega-dihydroxypolydimethylsiloxane, 5-8 parts of a cross-linking agent, 3-5 parts of a catalyst, 3-5 parts of a coupling agent, 8-10 parts of a flame retardant and 10-15 parts of a high-temperature-resistant filler. The silicone sealant is used as a raw material, the flame retardant and the high-temperature-resistant filler are prepared, the flame retardant can generate a large amount of inorganic phosphoric acid during combustion, the silicone sealant is dehydrated and carbonized to form a carbon layer, the carbon layer can prevent invasion of oxygen and overflow of combustible gas, then matrix combustion is prevented, when the high-temperature-resistant filler and the flame retardant are mixed for use, the flame retardant effect of the silicone sealant is improved, meanwhile, the graphene oxide is of a quasi-two-dimensional limited structure, polymer molecules are bound between layers of the graphene oxide, free movement of molecular chains and segment chains is limited, and then the high temperature resistance of the silicone sealant is improved.

Owner:佛山巨马新材料有限公司

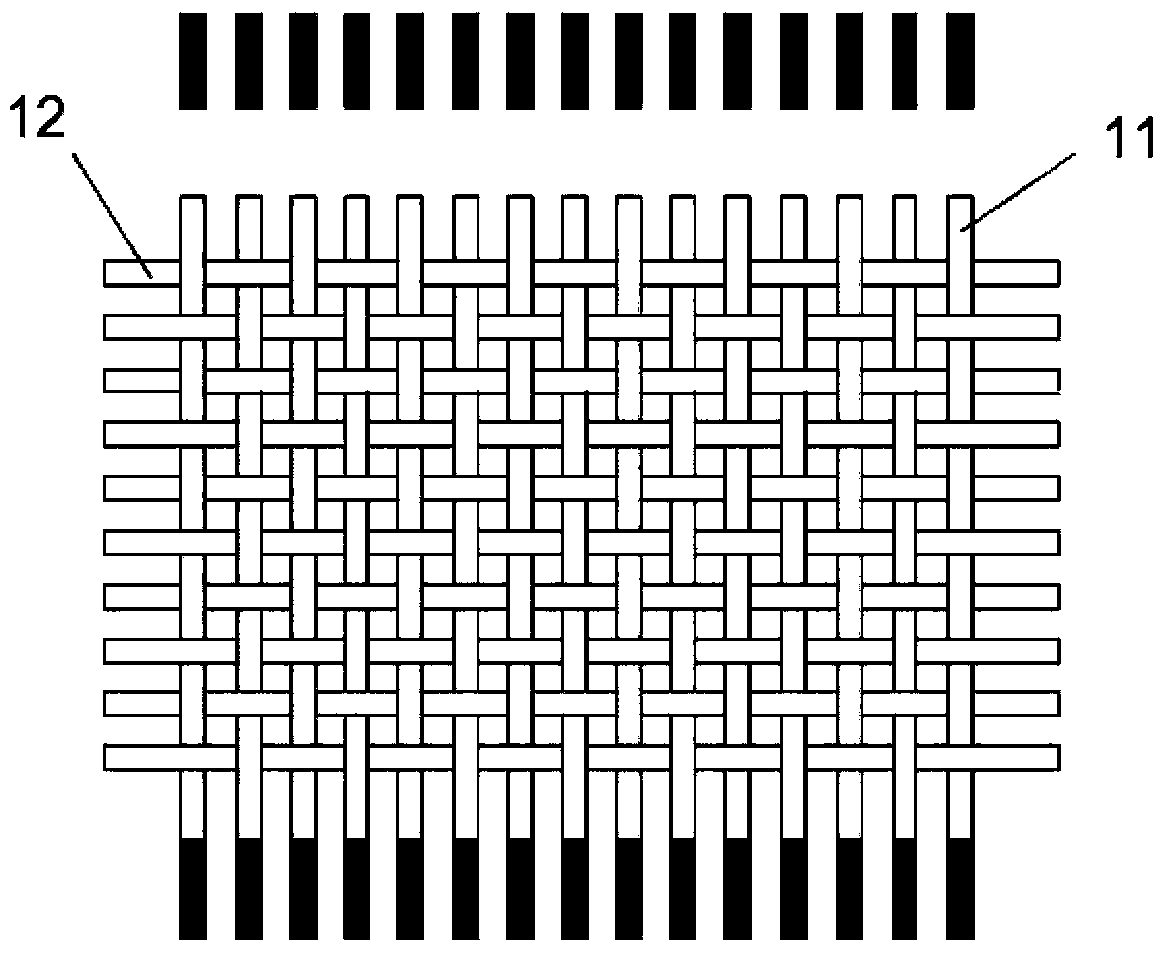

Down-drilling-preventive textile and production method thereof

InactiveCN104229711AReduce cloggingRestricted free movementUpholstery manufactureYarnEngineeringMechanical engineering

The invention discloses down-drilling-preventive textile and a production method thereof. The down-drilling-preventive textile comprises two or more layers of fabric. The production method includes adopting filaments as facial sutures; adopting another type of sewing threads, except for the filaments, as bottom sutures, sewing the fabric forming the textile to form a cavity, and filling a filler in the cavity. By improving the sewing facial sutures and the sewing bottom sutures, the sewing sutures are enabled to be less prone to causing down drilling in the process of sewing; the sewn position of the textile produced by the method is less prone to sliding during use, so that probability that the filler drills down through a needle hole channel is lowered effectively, and effect of down drilling prevention is realized.

Owner:金泰线业(上海)有限公司

Feed water adjusting agent and method for restoring normal water of feed

ActiveCN104115998AReduce the risk of mildewLower water activityAnimal feeding stuffAccessory food factorsPropionateSucrose

The invention discloses a feed water adjusting agent and a method for restoring normal water of a feed. The feed water adjusting agent consists of the following components in percentage by weight: 5.0-20.0% of a plurality of nonionic surfactants, 50.0-80.0% of propionic acid and propionate and 0.0-45.0% of water, wherein the nonionic surfactants are prepared from sucrose fatty acid ester with an HLB (Hydrophile-Lipophile Balance) value being 11-14. The method for restoring normal water of a feed comprises the following steps: firstly mixing the feed water adjusting agent with water uniformly to form a 3-6% feed water adjusting agent aqueous liquid, subsequently adding the feed water adjusting agent aqueous liquid into a feed mixer in a fog mode according to the size of feed water replenishing amount, fully and evenly mixing the feed water adjusting agent aqueous liquid with other raw materials for producing the feed in the feed mixer. The feed water adjusting agent is capable of converting most of free water to hydrate water, increasing the feed water-retention rate and preventing the feed from mildewing.

Owner:重庆新威士生物科技有限公司

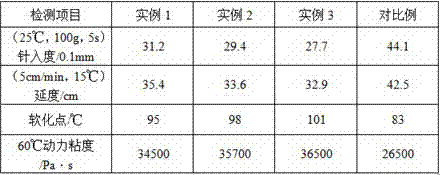

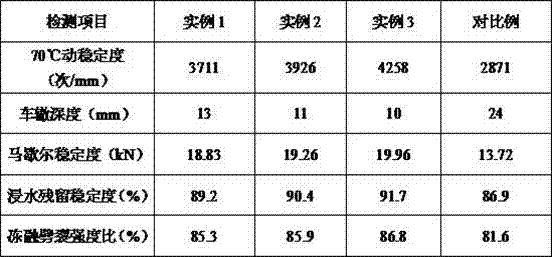

Heavy load resistant anti-rut agent and preparation method thereof

The invention belongs to the technical field of road maintenance and particularly relates to a heavy load resistant anti-rut agent and a preparation method thereof. The preparation method disclosed by the invention comprises the following steps: washing rice husks, and heating and filtering with a sodium hydroxide solution so as to obtain a filter cake; washing, drying, maintaining the temperature and carbonizing so as to obtain the carbonized rice husk; sintering with sodium fluoride and nano iron powder and performing oxidation treatment; collecting calcined particles, mixing and standing with a hydrofluoric acid solution; filtering, and drying to obtain modified particles; mixing sodium hydroxide with a magnesium sulfate solution, and dispersing with the modified particles so as to obtain precursor slurry, carrying out a high-pressure reaction, and filtering to obtain filter residues; washing, drying, performing mixed extrusion granulation with natural rock asphalt, polyvinyl butyral, polycarbonate and the like; finally, cooling, so as to obtain the heavy load resistant anti-rut agent. According to the heavy load resistant anti-rut agent disclosed by the invention, the rut resistance of a concrete pavement under heavy load and high temperature conditions can be effectively improved, and the rut resistance is improved, therefore, the pavement rut diseases are effectively reduced.

Owner:谢新昇

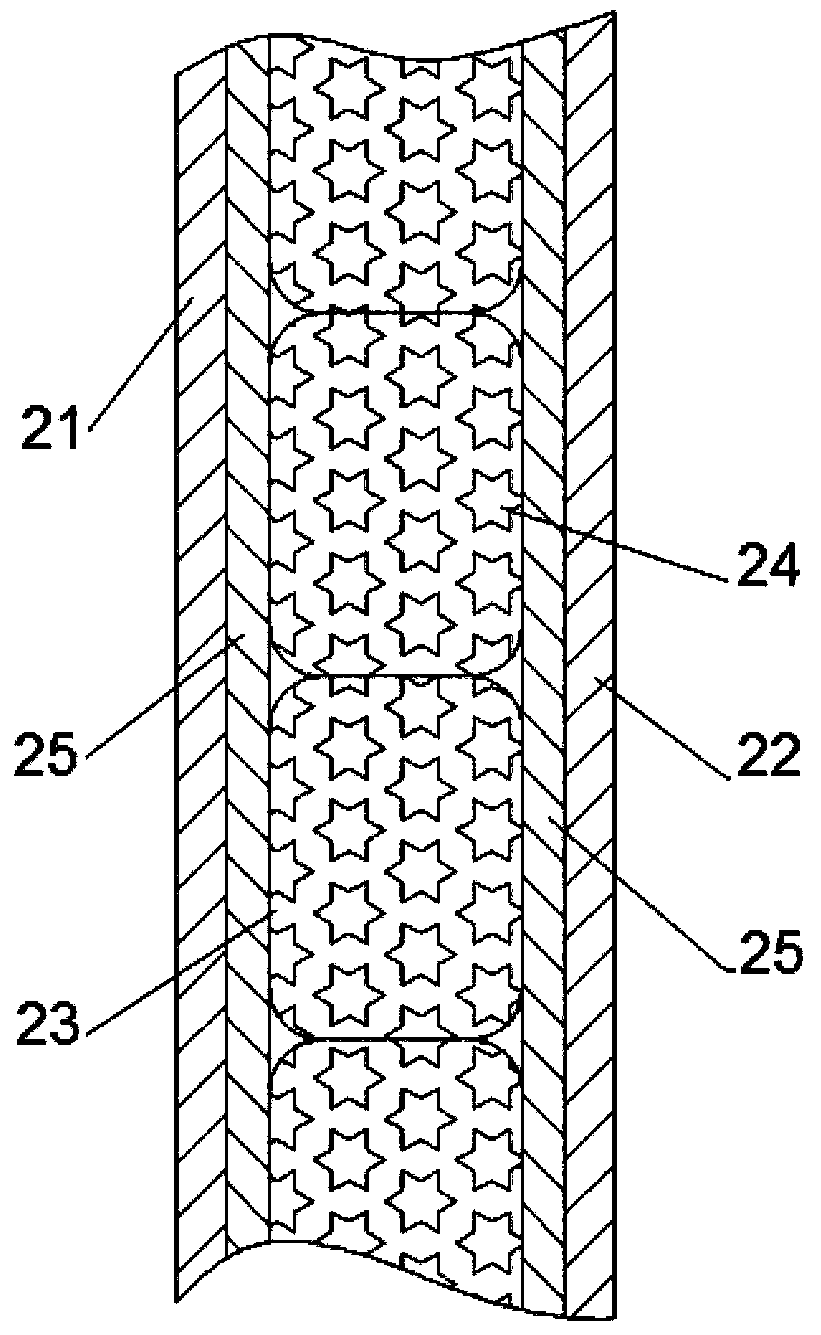

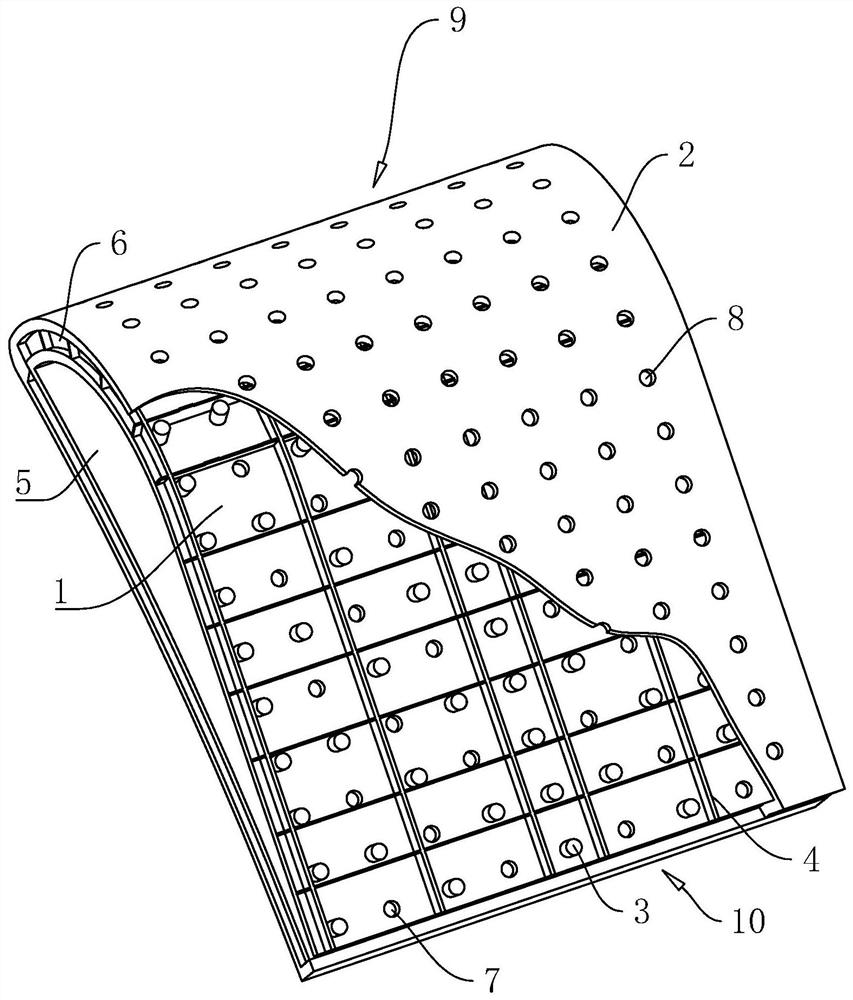

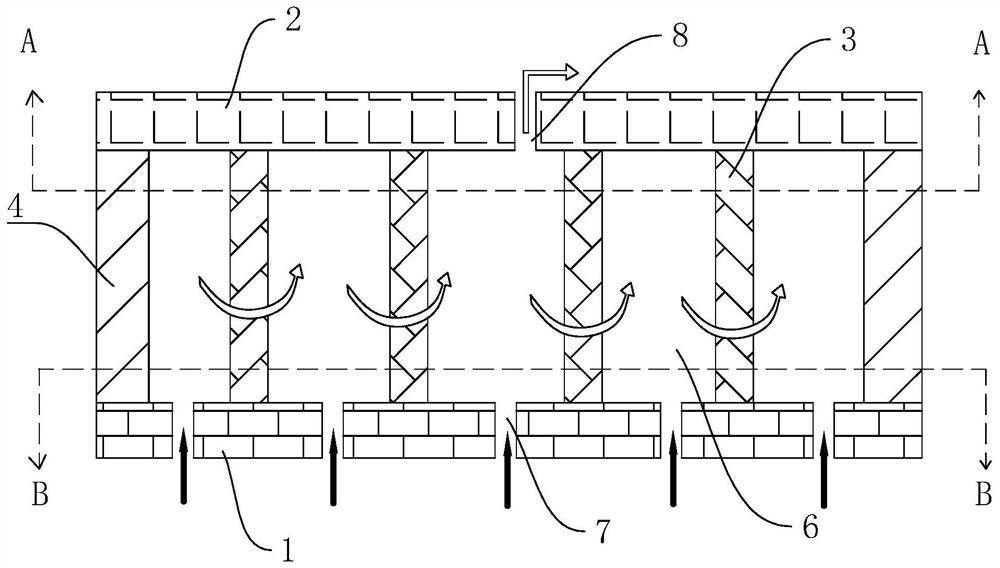

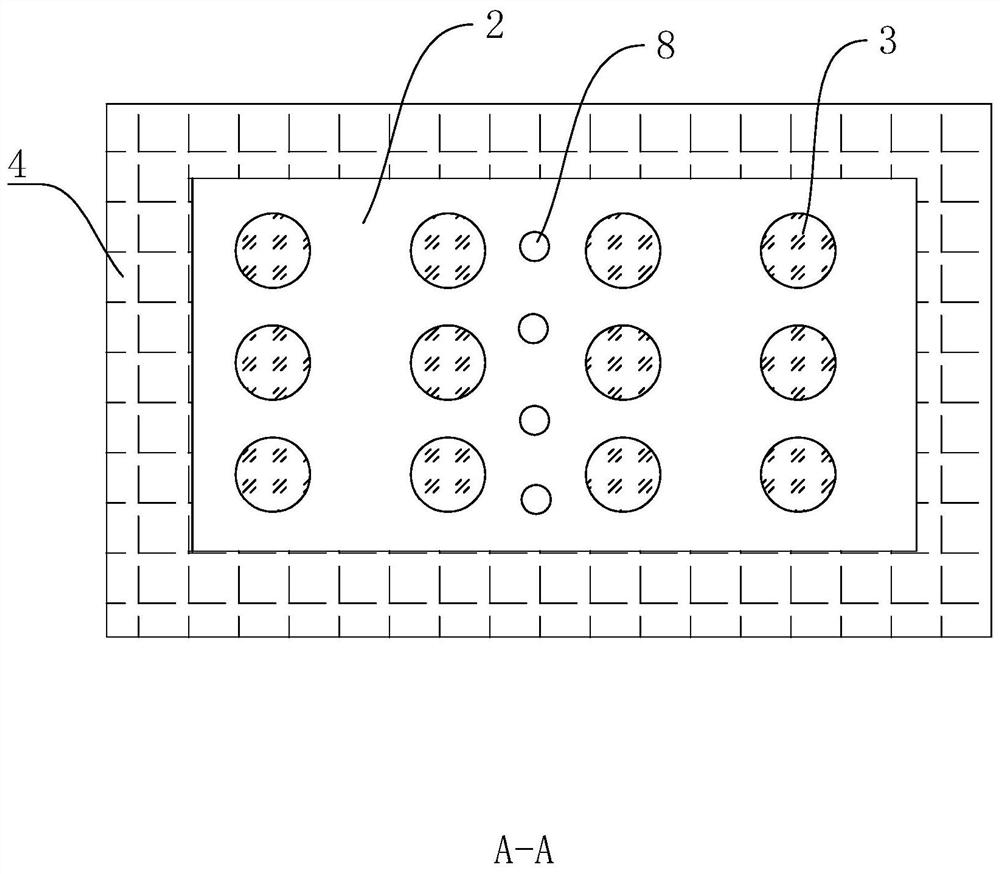

Double-wall cooling blade, turbine blade applying cooling blade and gas turbine

InactiveCN113513371ARestricted free movementImprove cooling efficiencyBlade accessoriesMachines/enginesTurbine bladeGas turbines

The invention relates to a double-wall cooling blade, a turbine blade applying the cooling blade and a gas turbine. The double-wall cooling blade comprises a blade inner wall, a blade outer wall, a partition plate and heat exchange structures, wherein the blade inner wall is surrounded to form a high-pressure chamber; the blade outer wall is positioned on the outer side of the blade inner wall, and is detachably connected with the blade inner wall; the blade outer wall and the blade inner wall are surrounded to form an annular chamber; the partition plate is arranged in the annular chamber, and is used for dividing the annular chamber into a plurality of independent areas; the heat exchange structures are arranged in the independent areas; a plurality of impact holes for communicating the high-pressure chamber with the annular chamber are formed in the blade inner wall; and at least one row of cold air holes for communicating the annular chamber with the outside are formed in the blade outer wall. The double-wall cooling blade can solve the engineering application problem of a double-wall cooling structure.

Owner:FULL DIMENSION POWER TECH

Low-cost rubber material and preparation method thereof

InactiveCN106397875AImprove thermal stabilityImprove mechanical propertiesRubber materialPeroxydisulfate

The invention discloses a low-cost rubber material. The low-cost rubber material consists of the following raw materials in parts by weight: polytetrahydrofuran glycol 5-7 parts, dry carbide slag 3-4 parts, an antioxidant D 4-6 parts, graphene oxide 10-14 parts, sodium borohydride 1-2 parts, p-aminobenzene sulfonic acid 3-4 parts, 0.8-1 mol / l of hydrochloric acid 14-20 parts, sodium nitrite 1-2 parts, styrene 43-50 parts, potassium peroxydisulfate 0.3-0.5 part, hydrazine hydrate 0.5-1 part, butadiene rubber 210-300 parts, tricresyl phosphate 24-30 parts, ditetradecylene 3-4 parts, benzotriazole 2-3 parts, zirconium ammonium carbonate 4-5 parts, N, N-diethylaniline 2-3 parts, tetramethyl thiourea 1-2 parts, maleic anhydride 3-4 parts, flyash 10-12 parts and a vulcanizing agent PM 1.7-2 parts. The raw materials such as the flyash and the carbide slag are added as packing, waste resources are utilized effectively, and production cost is reduced.

Owner:曾庆华

Condensate water dripping preventing structure at water dripping pipe position of evaporator

InactiveCN106196553ARestricted free movementSave on Waterproof SpongeCondensate preventionLighting and heating apparatusEnvironmental engineeringEvaporator

The invention provides a condensate water dripping preventing structure at the water dripping pipe position of an evaporator. The condensate water dripping preventing structure comprises an evaporator core, an evaporator lower shell arranged at the outer portion of the evaporator core, a water dripping pipe communicating with the bottom of the evaporator lower shell, and a plurality of rib plates arranged on the bottom face of the evaporator lower shell. The multiple rib plates are parallel. The height of the multiple rib plates is 5 mm, the width of the multiple rib plates is 3 mm, and the distance between every two adjacent rib plates is 4.5 mm. The above structure is additionally arranged at the water dripping pipe position, so that when condensate water is separated out on the surface of the evaporator lower shell, free flowing of the condensate water on the evaporator lower shell is limited through the arrangement of the close rib plates; and the condensate water can freely evaporate, and the situation that little condensate water is accumulated and drips into a cab cannot happen. Meanwhile, an inner surface waterproof sponge can be omitted through the design, the technology that the sponge is bonded to the inner surface of the evaporator lower shell is omitted, cost is saved, and efficiency is improved.

Owner:ANHUI JIANGHUAI SONGZ AIR CONDITIONING

Self-polymerized consolidated pressure-resistant high-permeability temperature-resistant sand control agent

ActiveCN111303851AImprove hydrophobicityEnhanced hydrophobic barrier effectGroup 4/14 element organic compoundsDrilling compositionPolymer scienceDibutyl tin dilaurate

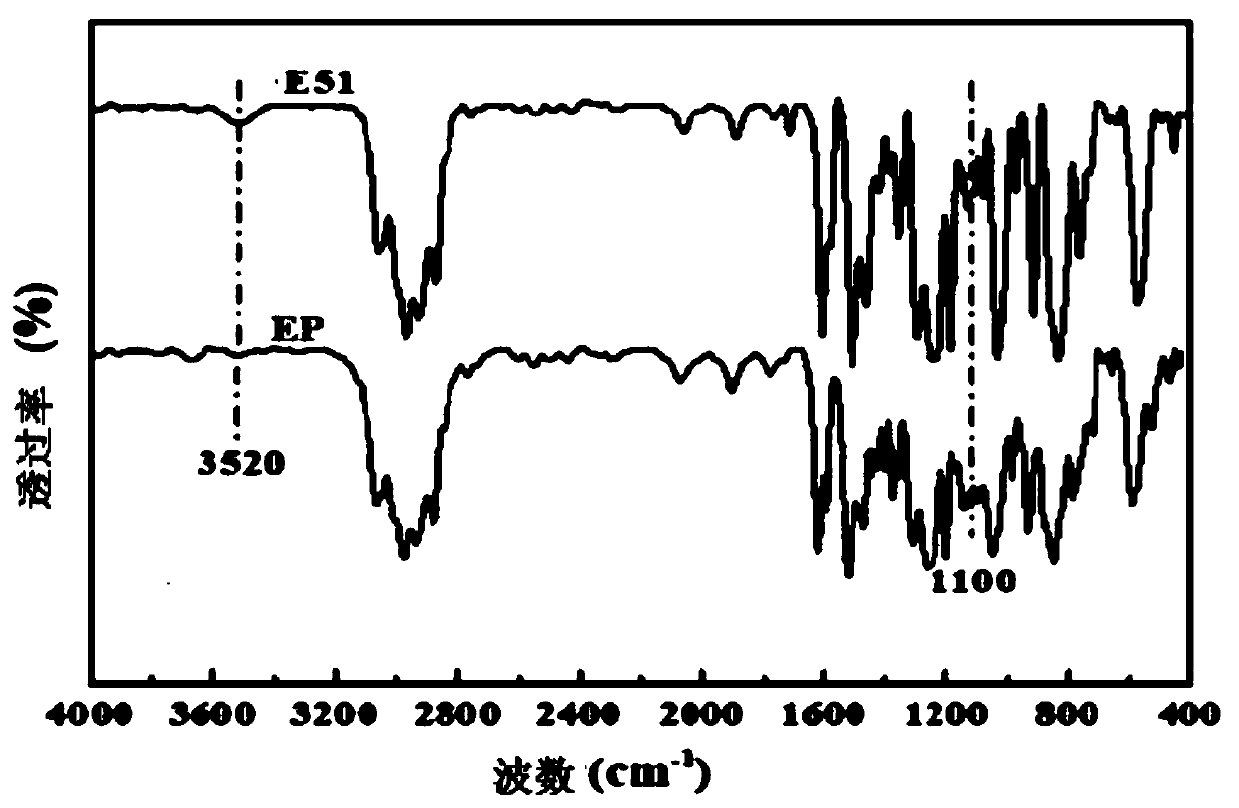

The invention discloses a self-polymerized consolidated pressure-resistant high-permeability temperature-resistant sand control agent. The sand control agent comprises the following components in percentage by mass: 35-40% of modified epoxy resin, 40-45% of an organic solvent, 5-7% of a coupling agent, 5-8% of an emulsifier and 5-6% of a curing agent. A preparation method of the modified epoxy resin comprises the following steps: reacting dimethoxybis(pentafluorophenyl)silane with epoxy resin in a solvent toluene, carrying out a stirring reaction for 8 hours at a reaction temperature of 85-90DEG C with dibutyltin dilaurate as a catalyst, and after the reaction is finished, carrying out cooling and removing toluene and unreacted dimethoxybis(pentafluorophenyl)silane to obtain the modifiedepoxy resin. The sand control agent is suitable for sand control and sand consolidation of high-temperature and high-pressure wells, is good in waterproofness, excellent in high-temperature resistanceand scouring resistance, high in compressive strength and excellent in permeability, can be injected into a stratum through an original production tubular column or in a fracturing later-period tailing mode, and plays a role in sand control or sand consolidation.

Owner:BEIJING GEPETTO OIL TECH

Nano-grade silica modified montmorillonite particle preparation method, and method for applying nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with in-situ method

ActiveCN102344699BGood compatibilityImprove stabilityPigment treatment with organosilicon compoundsSilicon dioxideMechanical property

The invention relates to a nano-grade silica modified montmorillonite particle preparation method, and a method for applying the nano-grade silica modified montmorillonite particles in producing modified aqueous polyurethane resin with an in-situ method. According to the invention, tetraethoxysilane, a silicane coupling agent and montmorillonite are subject to a modification reaction, such that anano-grade silica layer is modified on the surface of montmorillonite, and active amino-groups are modified. Therefore, the compatibility of montmorillonite in aqueous polyurethane resin is better, such that the emulsion can be more stable. According to the invention, silica modified montmorillonite is prepared through an in-situ method, a silica layer comprising a large amount of silanol is modified on the surface of montmorillonite, and lamella parts of montmorillonite are peeled. When the modified particles are positioned in an aqueous polyurethane system, high molecular chains of polyurethane are subject to an intercalation reaction with montmorillonite, such that free movements of polyurethane molecular chains are restricted, and mechanical properties and thermal stability of the material are improved. Compared to simple polyurethane, tensile strength of the material is improved by 1-2 times, and thermal decomposition temperature of the material is improved by 30 to 50 DEG C.

Owner:徐州光头强木业有限公司

Polyamide composition with high dimensional stability and preparation method thereof

InactiveCN101857723BReduce the degree of orderLow water absorptionHeat deflection temperaturePolyamide

The invention relates to a polyamide composition with high dimensional stability and a preparation method thereof. The polyamide composition comprises the following components in parts by weight: 60 to 90 of fatty polyamide composition, 2 to 10 of compatilizer, 1 to 10 of inorganic metal compound, 0 to 5 of polysiloxane with low molecular weight and 0 to 2 of auxiliary agent. The preparation method comprises the following steps of: premixing the raw materials in a high-speed mixer for 10 to 30min, controlling the temperature to be 40 to 60 DEG C, then adding premix into a double-screw extruder, conveying, melting, shearing, extruding, cooling and granulating so as to prepare a polyamide composition product with high dimensional stability. Compared with the prior art, the invention shows excellent dimensional stability and heat distortion temperature with high retention rate, is suitable for occasions with higher requirement to the dimensional stability, such as the panel of the air conditioner of an automobile, an instrument panel, a camera bracket, a sports apparatus and the like, and can be directly processed by injection molding or other forming methods.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Spinning milk protein fiber and preparation method thereof

InactiveCN110130091ARestricted free movementImprove mechanical propertiesMonocomponent protein artificial filamentBiochemical treatment with enzymes/microorganismsFiberYarn

The invention discloses spinning milk protein fiber and a preparation method thereof and belongs to the technical field of textile. A prepared toughening additive better fixes active components in milk fiber, so that the milk fiber has better energy storage performance, besides, the mechanical performance of the milk fiber is improved, the tensile property is improved, the milk fiber cannot breakeasily during spinning, and the spinning effect is improved while original characteristics of the milk fiber are kept; by the aid of a prepared fixation film forming agent, dopamine is oxidized to form a film by self-polymerization in an oxygen environment, and a formed film structure facilitates fixation of dye; by the aid of a prepared anti-adhesion coating, during spinning of the spun yarn prepared from the milk fiber, adhesion to parts due to viscosity of the milk fiber is reduced by use of low surface performance of the milk fiber, and the phenomenon of flying during spinning can be avoided. The problems that fiber adheres to parts easily and the phenomenon of flying is serious during spinning of the milk fiber at present is solved.

Owner:谭运桂

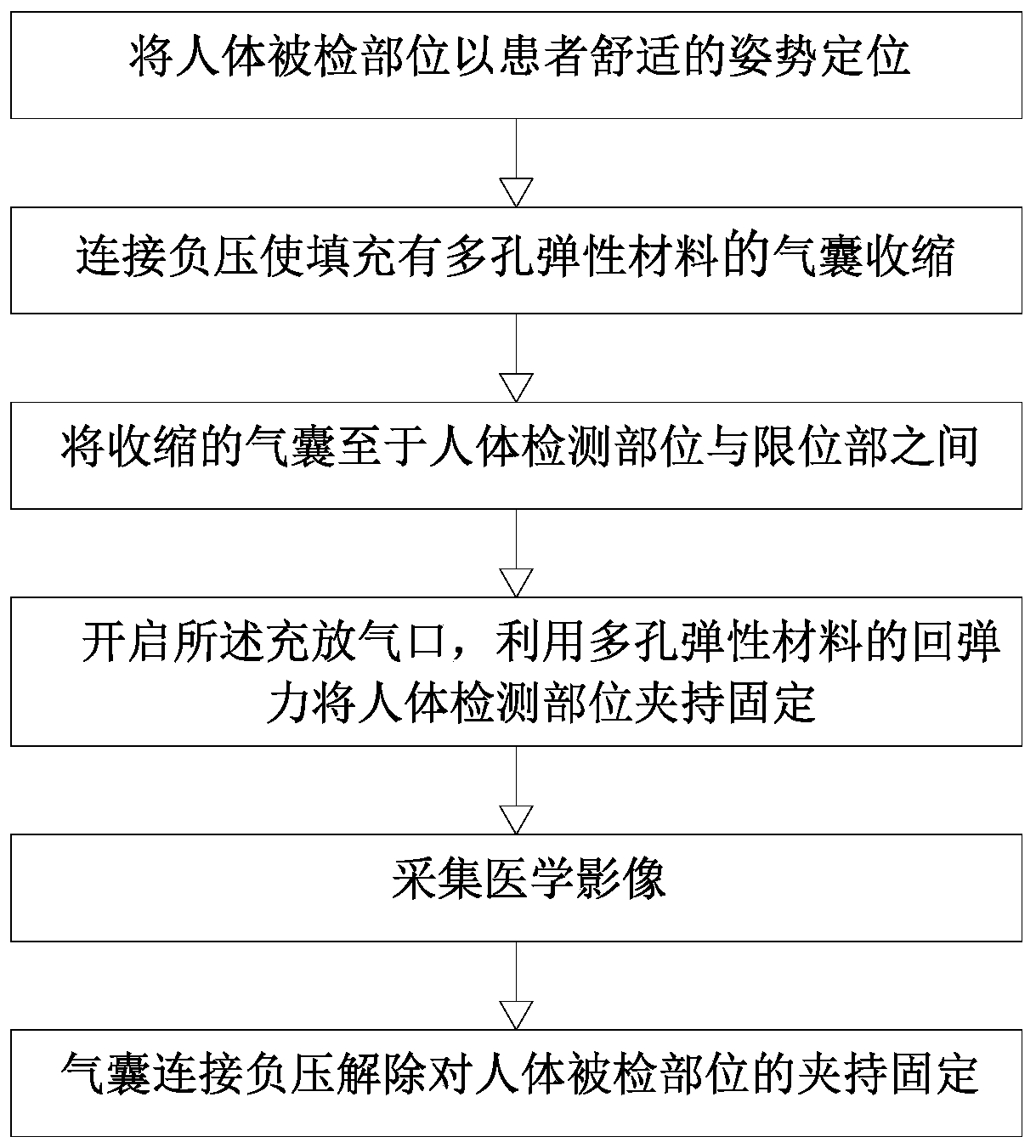

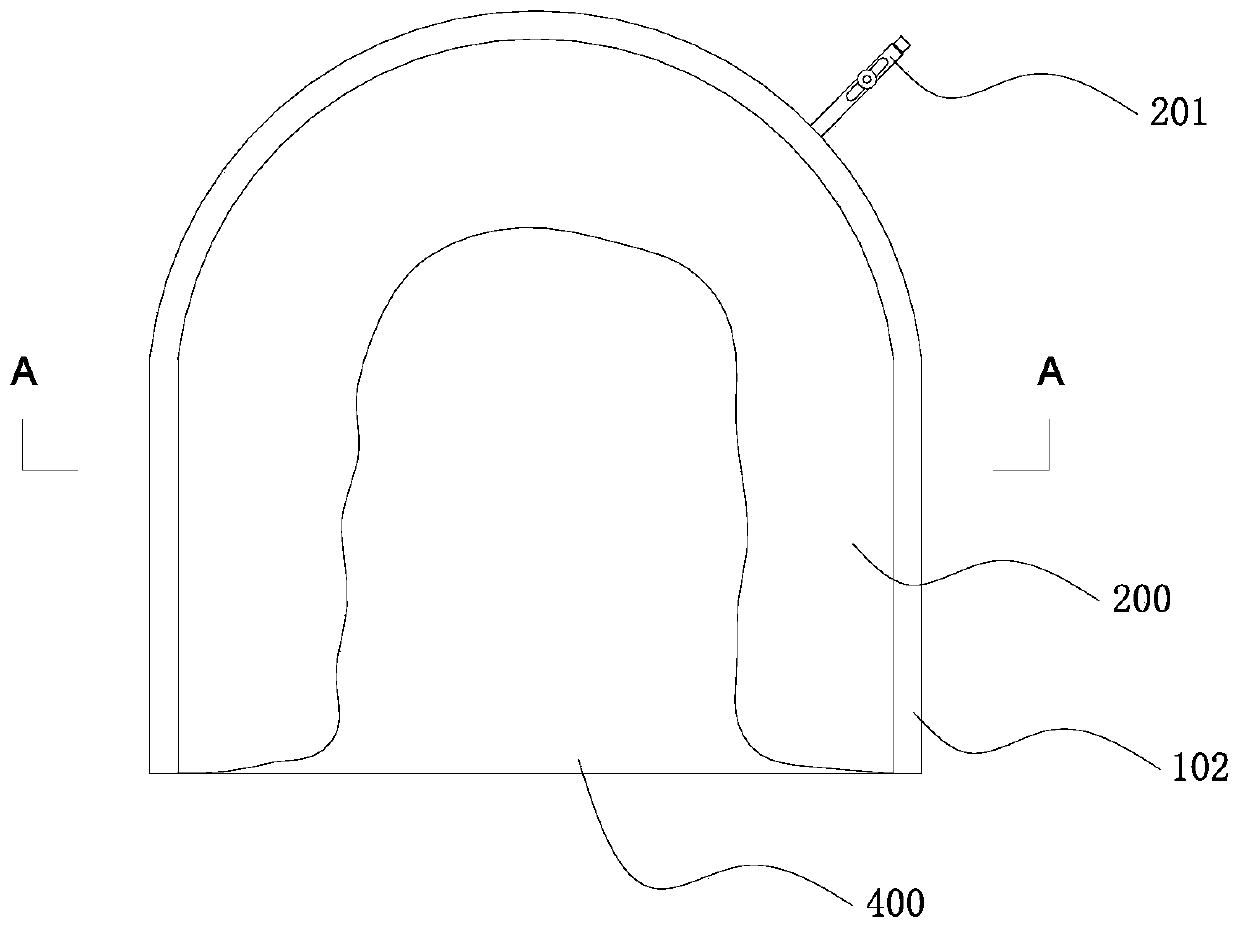

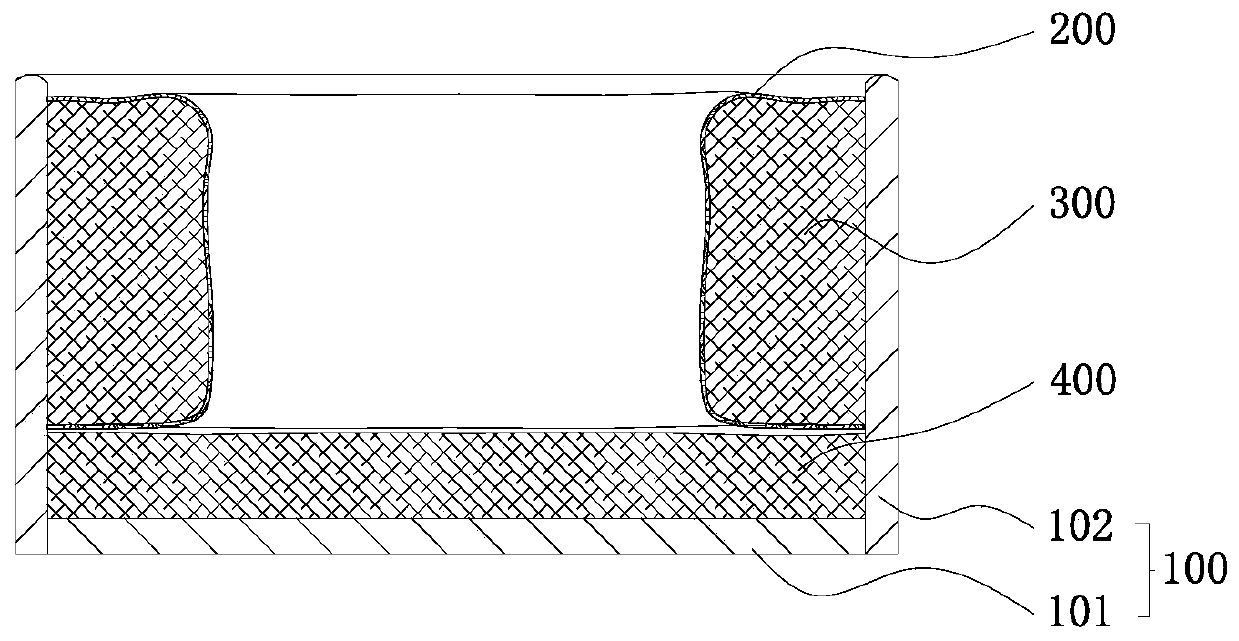

Method and device for improving stability of examined part in medical image examination process

ActiveCN110916709AImprove stabilityImprove comfortPatient positioning for diagnosticsDiagnostic recording/measuringImage InspectionHuman body

The invention discloses a method and device for improving the stability of an examined part in the medical imaging examination process, and belongs to the technical field of medical imaging equipment.According to the method, after the body position of a patient is placed, the examined part of the human body is fixed in an adaptive fixing mode; the medical image is acquired, so as to be suitable for patients with different figures and body types and equipment with different models, and the device is simple to operate, firmer to fix and higher in comfort level. Due to the fact that the air bagwraps the porous elastic material, free circulation of air in the porous elastic material and the atmosphere is limited, after the air bag is connected with negative pressure, the air bag can flattenthe porous elastic material under the pressure of the atmospheric pressure, and the elastic potential energy of the porous elastic material is increased. After the air bag is communicated with the atmosphere, the elastic potential energy of the porous elastic material is gradually released to support the air bag, so that a high-pressure air source is not needed; high-pressure inflation is not needed after the air bag is placed in place, and operation is convenient; no air leakage or explosion risk exists in the image inspection process, and the safety coefficient is very high.

Owner:WEST CHINA HOSPITAL SICHUAN UNIV

Extinguishing agent

InactiveCN102058951BReduce pollutionRestricted free movementFire extinguisherSesquioxideAluminium hydroxide

Owner:XIAN UNIV OF SCI & TECH

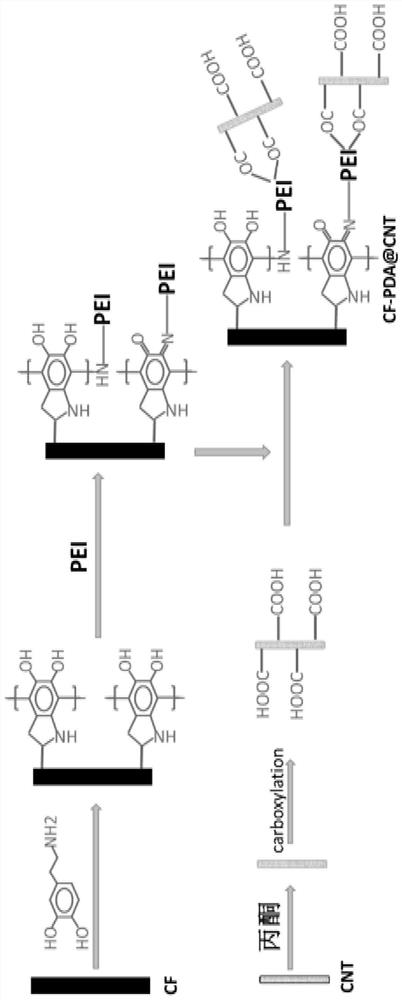

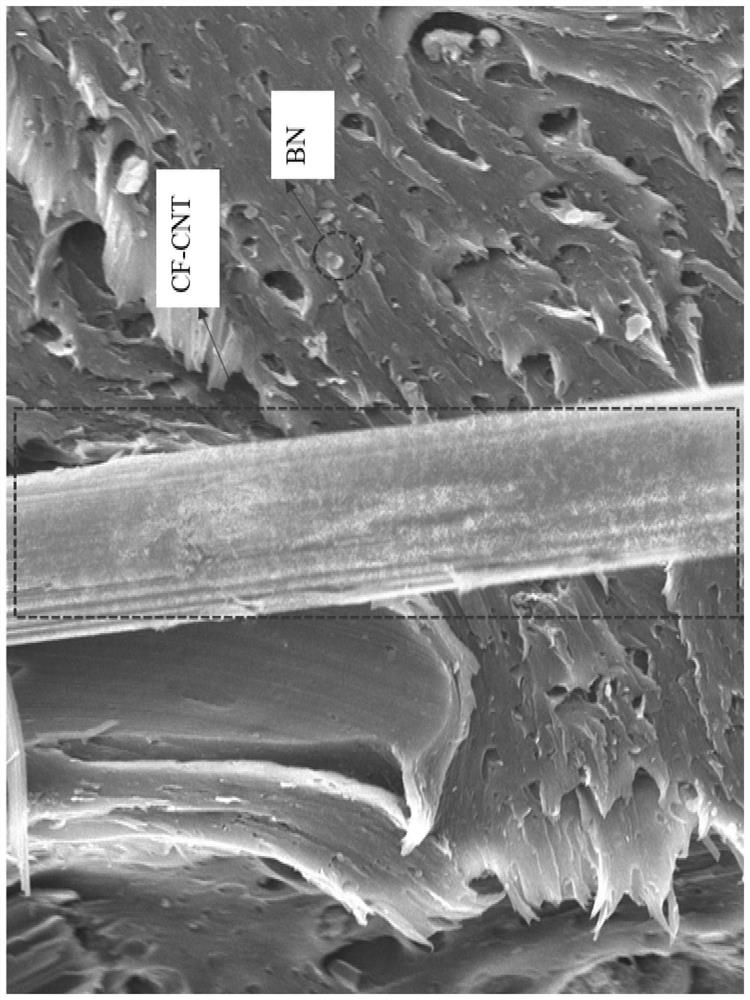

Nano-regulation-based multi-scale insulating and heat-conducting PC composite material and preparation method thereof

ActiveCN114196186AImprove interface interfaceIncrease the areaChemical industryHexagonal boron nitrideBoron nitride

The invention relates to the technical field of high polymer materials, and discloses a nano-regulation-based multi-scale insulating and heat-conducting PC composite material and a preparation method thereof.The nano-regulation-based multi-scale insulating and heat-conducting PC composite material comprises 5-10 parts of PC, 1-4 parts of modified hexagonal boron nitride and 0.5-2 parts of multi-scale heat-conducting filler; the multi-scale heat-conducting filler is obtained by grafting aminated CF and PEI to obtain an intermediate and grafting the intermediate with carboxylated CNT, and the mass ratio of the aminated CF to the PEI to the carboxylated CNT is (1-4): 2: 1. According to the PC composite material, the carbon-series material and the BN material are combined, and BN is combined through the carbon-series material to form a heat-conducting bridge, so that heat transfer is accelerated, and continuity of a heat-conducting network and discontinuity of a conductive network are guaranteed.

Owner:XIHUA UNIV

Impact resistant rubber material and preparation method thereof

InactiveCN106554524AImprove thermal stabilityImprove mechanical propertiesPotassium persulfateRubber material

The invention discloses an impact resistant rubber material. The impact resistant rubber material comprises the following raw materials in parts by weight: 4 to 6 parts of an anti-aging agent RD, 18 to 20 parts of talcum powder, 1 to 2 parts of aluminium triphosphate, 18 to 20 parts of dioctyl azelate, 2 to 3 parts of an accelerant DM, 10 to 14 parts of graphene oxide, 1 to 2 parts of sodium borohydride, 3 to 4 parts of sulfanilic acid, 14 to 20 parts of hydrochloric acid of which the concentration is 0.8 mol / l to 1 mol / l, 1 to 2 parts of sodium nitrite, 43 to 50 parts of styrene, 0.3 to 0.5 part of potassium persulfate, 0.5 to 1 part of hydrazine hydrate, 210 to 300 parts of butadiene rubber, 1.7 to 2 parts of a vulcanizing agent MOCA, 2 to 3 parts of tributyl tin chloride, 4 to 7 parts of magnesium stearate, 3 to 4 parts of ammonium metaborate, 1 to 2 parts of beta-hydroxyalkylamide, 2 to 3 parts of polytetrafluoroethylene, 1 to 2 parts of inositol and 1.7 to 2 parts of gamma-aminopropyltriethoxysilane. The rubber material is high in surface strength and good in toughness, and has quite good impact resistance.

Owner:曾庆明

Anti-cracking seal rubber material and preparation method thereof

InactiveCN106519340AImprove thermal stabilityImprove mechanical propertiesOther chemical processesPotassium persulfateTin

The invention discloses an anti-cracking seal rubber material which is prepared from the following raw materials in parts by weight: 2-4 parts of magnesium sulfate, 1-3 parts of barium metaborate, 0.3-1 part of bisphenol a diglycidyl ether, 2-4 parts of alkyl ketene dimer, 3-4 parts of anti-aging agent TNP, 26-30 parts of butyl methacrylate, 10-14 parts of graphene oxide, 1-2 parts of sodium borohydride, 3-4 parts of sulfanilic acid, 14-20 parts of 0.8-1 mol / L hydrochloric acid, 0.3-0.5 part of potassium persulfate, 0.5-1 part of hydrazine hydrate, 210-300 parts of cis-1,4-polybutadiene rubber, 1.7-2 parts of vulcanizing agent PM, 1-2 parts of tin monosulfide, 3-4 parts of glyceryl carboxylate, 2-3 parts of polyamide wax micropowder, 0.7-1 part of 4-dimethylaminopyridine, 10-14 parts of wollastonite powder and 0.7-1 part of silane coupling agent kh560. The rubber material has the advantages of favorable sealing property, high surface strength, favorable addition property, high cracking resistance and high impact resistance.

Owner:曾庆明

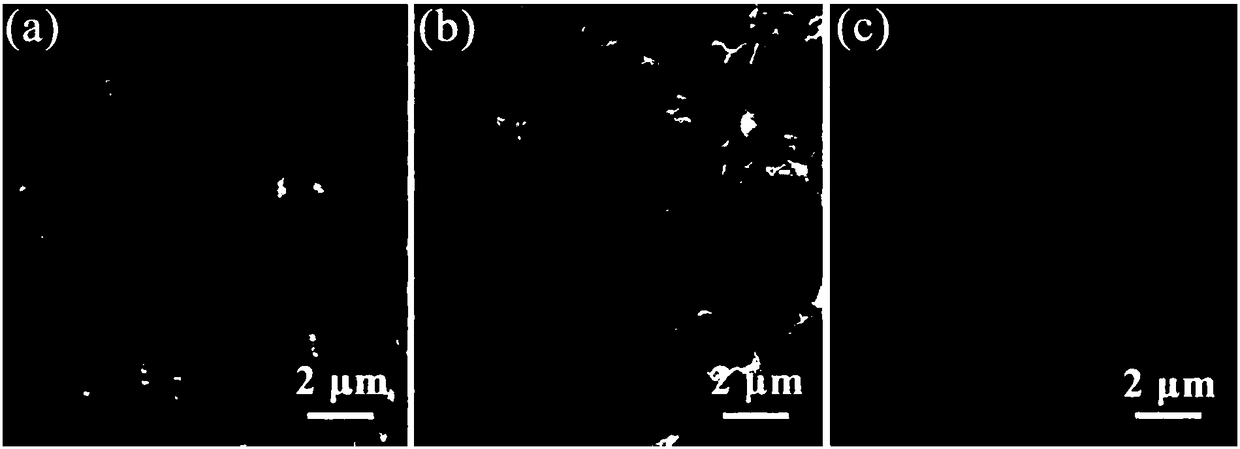

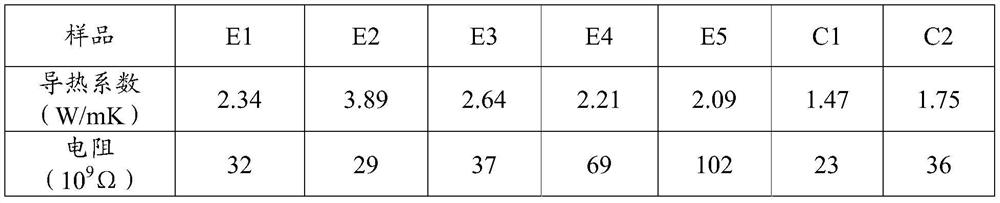

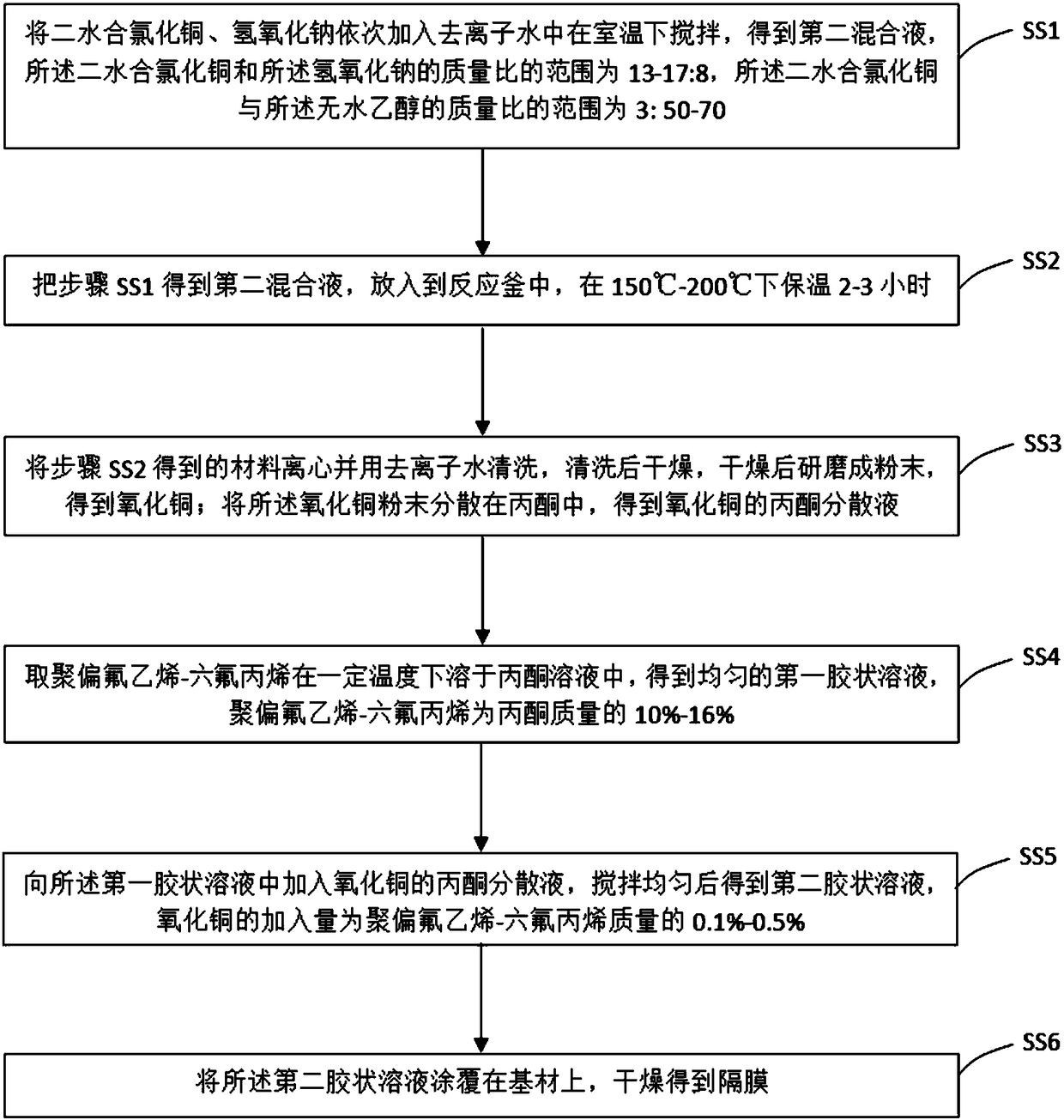

Lithium-ion battery

ActiveCN108199078AImprove structural strengthClose contactNegative electrodesSecondary cellsHexafluoropropyleneOxide composite

The invention discloses a lithium-ion battery, which comprises a positive electrode, a negative electrode and a membrane arranged between the positive electrode and the negative electrode, wherein thenegative electrode is a copper oxide-graphene oxide composite material / aetylene black / polyvinylidene fluoride; copper oxide directly grows in graphene oxide through the copper oxide-graphene oxide composite material by adopting a hydrothermal method; and the membrane is copper oxide / polyvinylidene fluoride-hexafluoropropylene. According to the lithium-ion battery, the copper oxide directly growsin the graphene oxide by adopting the hydrothermal method, so that the condition that the electron conductivity is relatively low due to the fact that the copper oxide is directly mixed with a carbonmaterial and is not closely combined is avoided; and the copper oxide is doped into the membrane, so that the structural strength of the membrane is improved. The ratio of an amorphous phase of the polyvinylidene fluoride-hexafluoropropylene membrane is improved, so that formation of holes of the membrane of the lithium-ion battery is facilitated; and the negative electrode and the membrane of thelithium battery generate synergistic effects through the copper oxide in the negative electrode and the copper oxide in the membrane.

Owner:SHENZHEN LI S TECH CO LTD

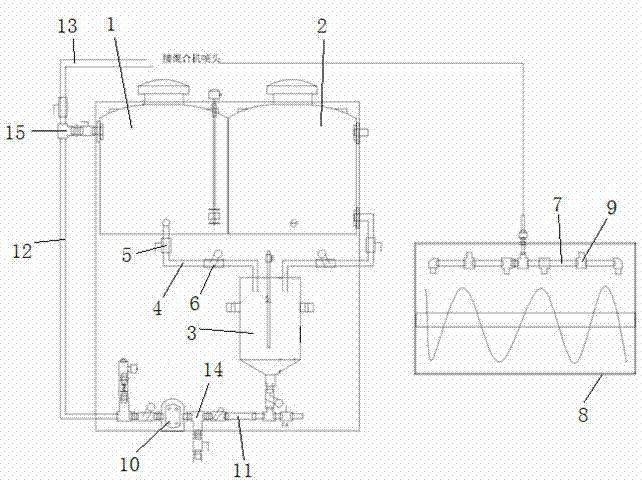

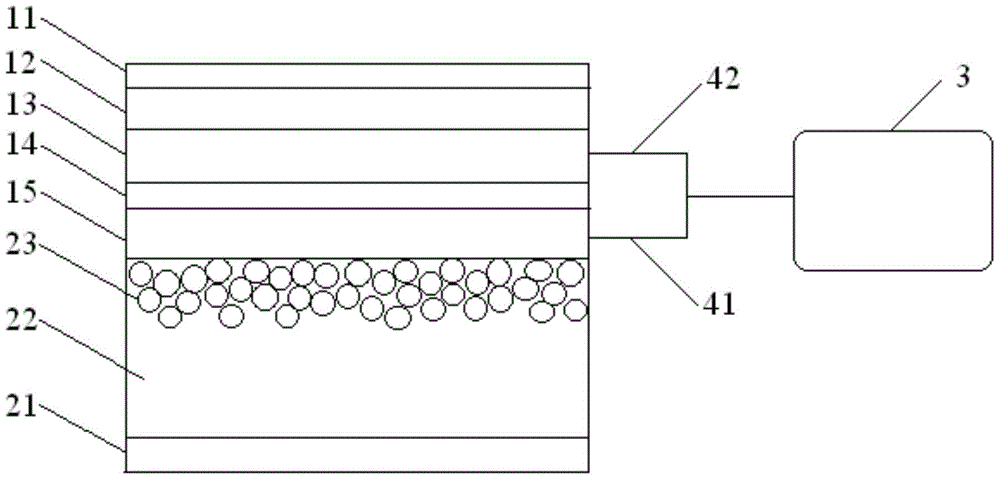

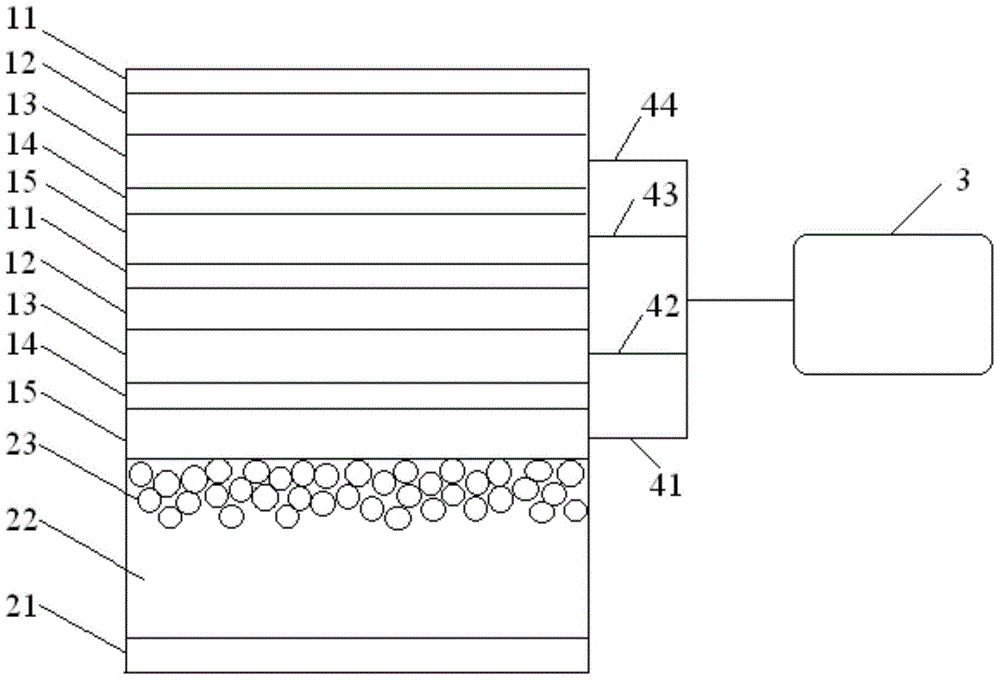

A solar continuous power generation system

ActiveCN104539222BIncrease profitAchieve continuous power generationPV power plantsPhotovoltaic energy generationSemiconductor electrodeHydrogen fuel cell

The invention provides a continuous solar power generation system which comprises a composite photovoltaic power generation device and a hydrogen cell, wherein the composite photovoltaic power generation device comprises an upper electrode layer, a window layer, a light absorbing layer, a lower electrode layer, a semiconductor electrode layer and a counter electrode layer which are arranged from top to bottom in sequence; the upper electrode layer, the window layer, the light absorbing layer, the lower electrode layer and the semiconductor electrode layer are all arranged in a light permeation manner; water or electrolyte is filled between the semiconductor electrode layer and the counter electrode layer; the hydrogen cell is arranged outside the composite photovoltaic power generation device; a first hydrogen conveying pipeline is arranged between the hydrogen cell and the semiconductor electrode layer. By adopting the continuous solar power generation system, the utilization rate of solar energy is increased, and continuous power generation is achieved.

Owner:HONGDA TECH BEIJING CO LTD

A feed moisture regulator and method for restoring normal moisture content of feed

ActiveCN104115998BReduce the risk of mildewLower water activityAccessory food factorsPropionateSucrose

Owner:重庆新威士生物科技有限公司

Organic montmorillonite-aqueous polyurethane compound leather finishing agent and method for preparing same

The invention discloses an organic montmorillonite-aqueous polyurethane compound leather finishing agent and a method for preparing the same. The method comprises the following steps: firstly using quaternary ammonium salt such as cetyl trimethyl ammonium chloride, octadecyl dihydroxyethyl methyl ammonium bromide and the like, organic amine such as ethylene diamine, octadecylamine and the like, or a silane coupler, polyisocyanate and the like to organically modify montmorillonite to prepare organic montmorillonite; and secondly, performing intercalation reaction of emulsion of a polyurethane resin finishing agent and the organic montmorillonite to obtain the finished product of the organic montmorillonite-aqueous polyurethane compound leather finishing agent. In the method, the quaternary ammonium salt, the organic amine, the silane coupler or the polyisocyanate are used for organically modifying the montmorillonite, so that the interlamellar spacing of the montmorillonite is increased, the micro environment among the lamellas is improved, the compatibility of the montmorillonite and the organic phase is improved, and the intercalation reaction of the polyurethane molecules and the montmorillonite is easily performed; moreover, due to the interlamellar compound of the organic montmorillonite on the polyurethane resin finishing agent, the mechanical property, the thermal resistant stability, the water resistance and the water vapor permeability of the finishing material are improved. When the leather finishing material is applied to leather finishing, the leather finishingmaterial has the advantages of greatly improving the mechanical strength and thermal resistant stability of the coating and having active effects on water resistance, sanitary property and the like of the coating.

Owner:SICHUAN UNIV

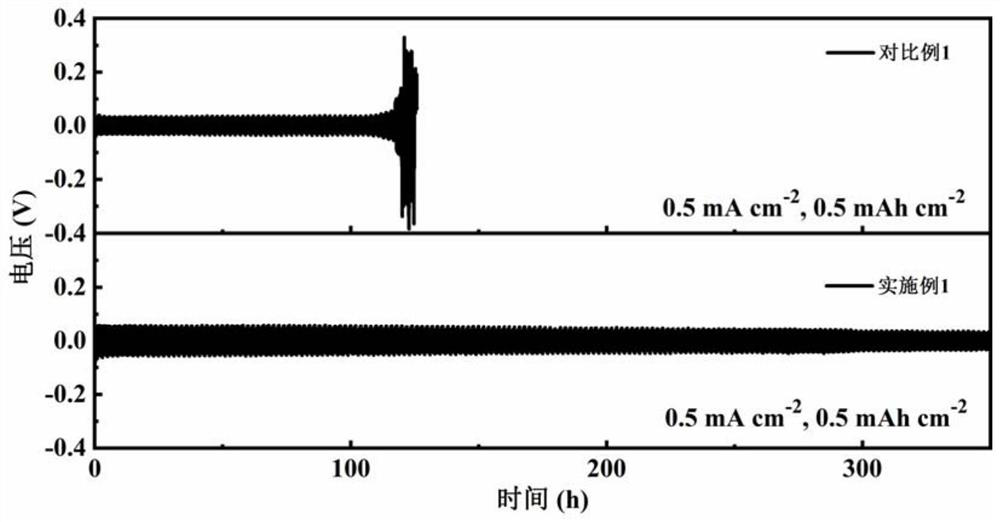

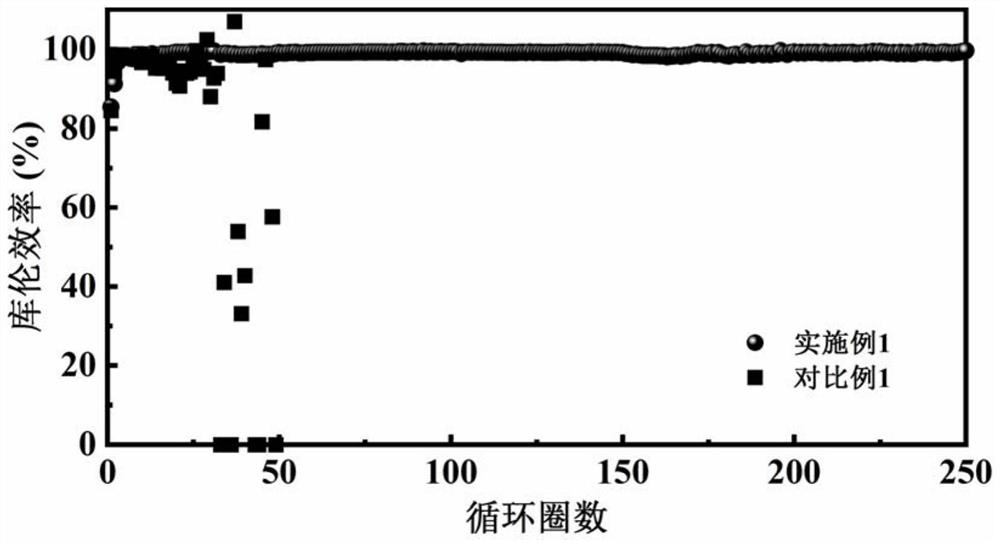

Polyanion zinc salt hydrogel electrolyte and zinc battery system

PendingCN114195935AInhibits the growth of zinc dendritesLong cycle lifeSecondary cellsElectrolyte immobilisation/gelificationOrganic acidBoronic acid

The invention discloses a polyanion zinc salt hydrogel electrolyte and a zinc battery system, the electrolyte is an organic acid zinc salt polymer, and is prepared from an organic matter monomer, a zinc salt, a cross-linking agent and an initiator through a polymerization reaction; wherein the concentration of the organic matter monomer is 0.1-10 mol / L, and the amount-of-substance concentration ratio of the organic matter monomer to the zinc salt is 0.1: 1-10: 1; the organic matter monomer contains a carbon-carbon double bond and contains at least one group of a sulfonic acid group, an imide group, a sulfonyl imide group, a carboxylic acid group and a boric acid group; the zinc salt is soluble zinc salt. According to the zinc battery system, polyanion zinc salt hydrogel electrolyte is adopted, negative ions in the electrolyte are fixed, side reactions are reduced, growth of zinc dendrites is inhibited, and the electrochemical performance and cycling stability of the zinc battery system are improved.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com