Heavy load resistant anti-rut agent and preparation method thereof

An anti-rutting agent and load-bearing technology, which is applied in the field of road maintenance, can solve the problems of unsatisfactory anti-rutting performance, and achieve the effects of improving anti-rutting performance, good heavy load resistance, and increasing internal friction angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

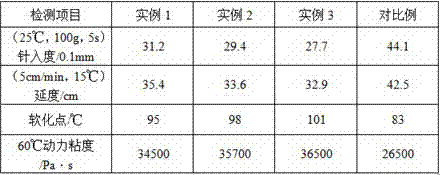

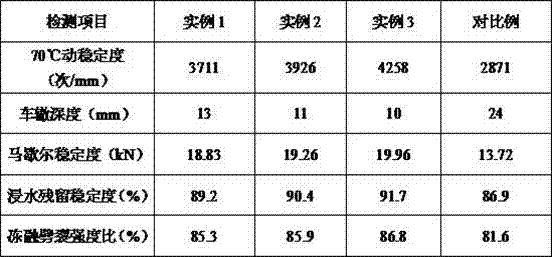

Examples

example 1

[0022] Take the rice husk and wash it, mix the washed rice husk with 10% sodium hydroxide solution in a mass fraction of 1:10, heat in a water bath at 90°C and filter to obtain a filter cake, rinse it with deionized water for 3 times Dry in a tube atmosphere furnace at 125°C for 25 minutes, then pass nitrogen to remove the air, control the nitrogen flow rate to 100mL / min, raise the temperature to 450°C at 5°C / min under nitrogen protection, keep it warm for 1 hour, and then let it cool down to room temperature , to obtain carbonized rice husks, weigh 45 parts of carbonized rice husks, 10 parts of sodium fluoride and 15 parts of nano-iron powder, stir and mix them in a graphite crucible, and place the graphite crucible at 1250 ° C under argon Sintering treatment under air atmosphere for 3 hours, after the sintering is completed, stop feeding argon and naturally cool to 650°C, after oxidation treatment for 5 hours, naturally cool to room temperature, collect the calcined particles...

example 2

[0024]Take the rice husk and wash it, mix the washed rice husk with 10% sodium hydroxide solution in a mass fraction of 1:10, heat in a water bath at 93°C and filter to obtain a filter cake, rinse it with deionized water for 4 times Dry in a tube atmosphere furnace at 128°C for 28 minutes, then pass nitrogen to remove the air, control the nitrogen flow rate to 125mL / min, raise the temperature to 475°C at 5°C / min under the protection of nitrogen, keep it warm for 1 hour, and then let it cool down to room temperature , to obtain carbonized rice husks, weigh 48 parts of carbonized rice husks, 13 parts of sodium fluoride and 18 parts of nano-iron powder, stir and mix them in a graphite crucible, and place the graphite crucible at 1375 ° C under argon Sintering treatment under air atmosphere for 4 hours, after the sintering is completed, stop feeding argon and naturally cool to 725°C, after oxidation treatment for 6 hours, naturally cool to room temperature, collect the calcined par...

example 3

[0026] Take the rice husk and wash it, mix the washed rice husk with 10% sodium hydroxide solution at a mass fraction of 1:10, heat in a water bath at 95°C and filter to obtain a filter cake, rinse with deionized water for 5 times Dry in a tube atmosphere furnace at 130°C for 30 minutes, then pass nitrogen to remove the air, control the nitrogen flow rate to 150mL / min, raise the temperature to 500°C at 5°C / min under nitrogen protection, keep warm and carbonize for 2 hours, then let it stand and cool to room temperature , to obtain carbonized rice husks, weigh 50 parts of carbonized rice husks, 15 parts of sodium fluoride and 20 parts of nano-iron powder, stir and mix them in a graphite crucible, and place the graphite crucible at 1500 ° C under argon Sintering treatment under air atmosphere for 5 hours, after the sintering is completed, stop feeding argon and naturally cool to 800 ° C, after oxidation treatment for 7 hours, naturally cool to room temperature, collect the calcin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com