Patents

Literature

2549 results about "Asphalt concrete" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Asphalt concrete (commonly called asphalt, blacktop, or pavement in North America, and tarmac, bitumen macadam, or rolled asphalt in the United Kingdom and the Republic of Ireland) is a composite material commonly used to surface roads, parking lots, airports, as well as the core of embankment dams. Asphalt mixtures have been used in pavement construction since the beginning of the twentieth century. It consists of mineral aggregate bound together with asphalt, laid in layers, and compacted. The process was refined and enhanced by Belgian inventor and U.S. immigrant Edward De Smedt.

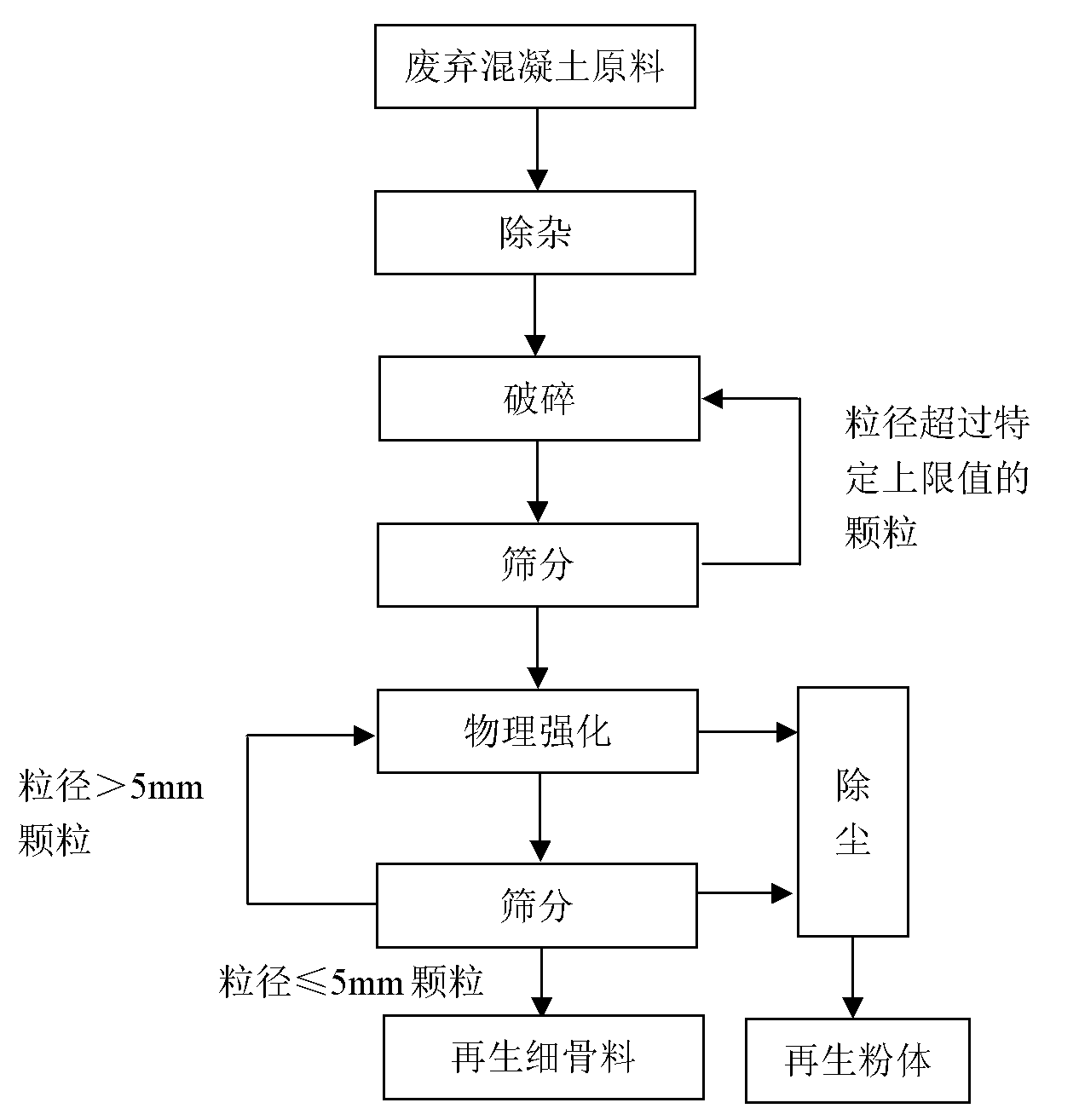

Method for treating and regenerating reuse building waste

ActiveCN101099974AAvoid excessive cement slurry contentAvoid Excessive Water DemandSolid waste managementSolid waste disposalPrillBrick

The present invention discloses building waste treating and reusing process, which includes the following steps: classifying building wastes into waste concrete, waste stone material, waste ceramic, waste sintered brick and waste lime-sand brick; crushing separately into coarse grains and eliminating metal, timber and other impurity; milling into 5 mm below regenerated fine aggregate; sorting 0.15 mm below high quality fine aggregate and milling into regenerated fine powder material of 250-600 sq m / kg specific surface area; and preparing mortar, concrete, asphalt concrete and other building material with the regenerated fine aggregate and the regenerated fine powder.

Owner:SOUTH CHINA UNIV OF TECH

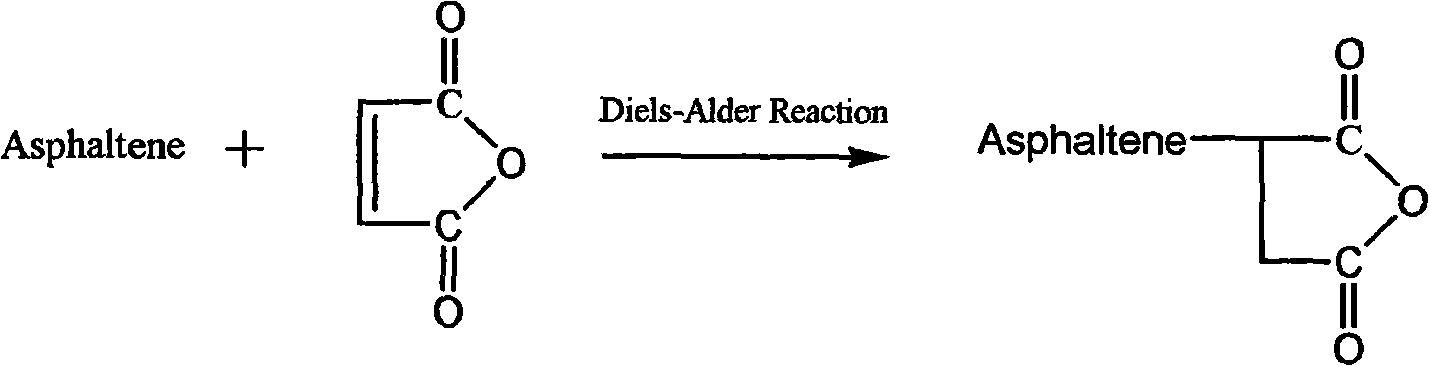

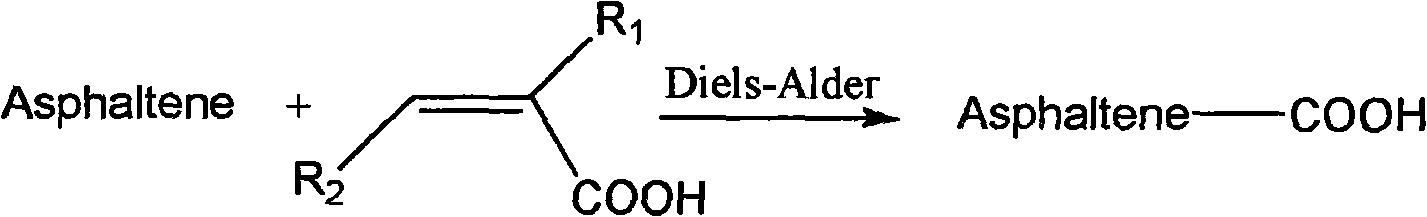

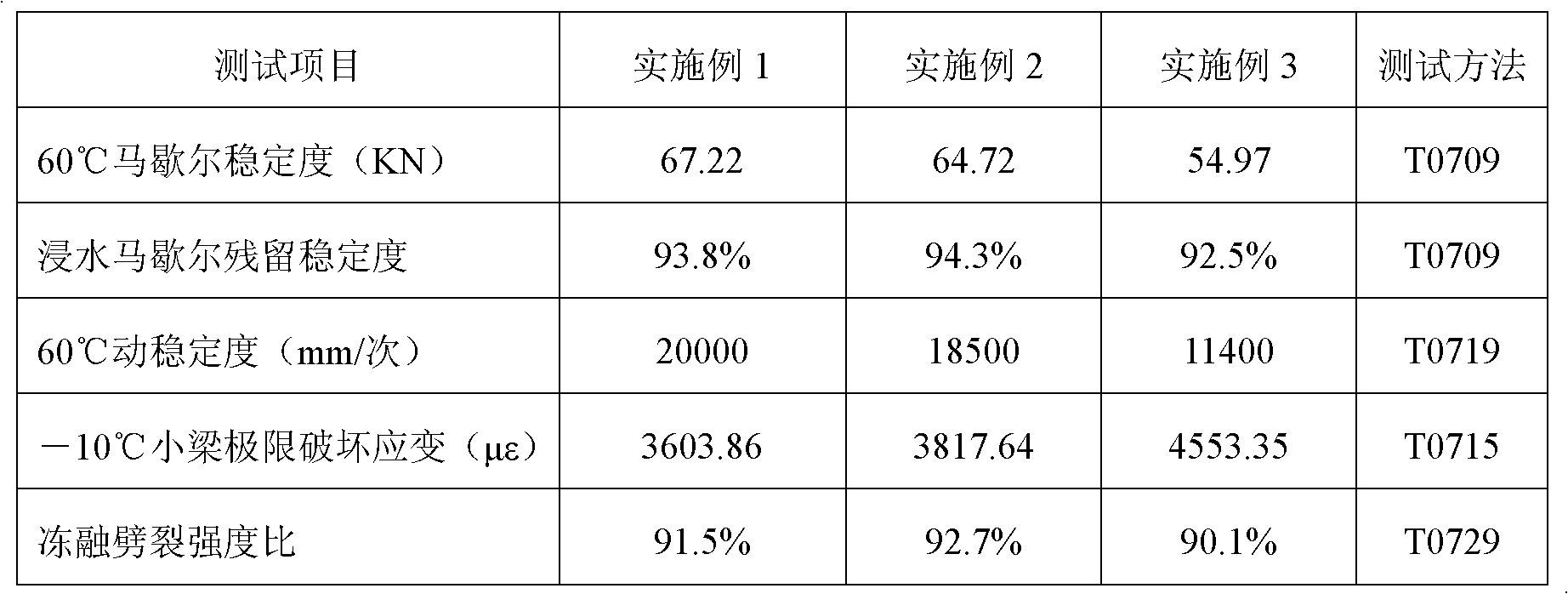

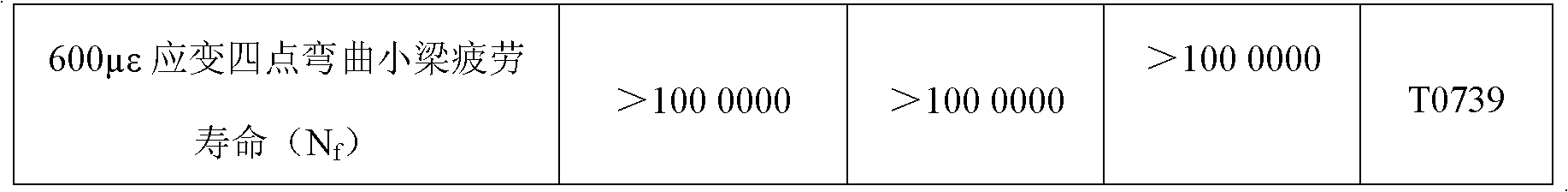

Epoxy asphalt material for road-bridge and environment-friendly preparation method thereof

The invention provides an epoxy asphalt material for bridge and green preparation method, comprising A part and B part, wherein the weight constitute of the A part is: modified asphaltum with carboxyl or anhydride group 60-76 parts, monohydric alcohol or polyhydric alcohol 2-20 parts, aliphatic diprotic acid, dimer acid or alkyd resin 11-25 parts, fatty acid anhydride 10-25 parts, solidified promoter 0.05-0.65 parts; and the constitute of the B part is epoxy resin. The mass ratio of A and B part is 2.2:1-10:1. The epoxy resin modified asphalt material has excellent property with high intensity and good flexibility; provides corresponding operation time according to different requirement and adjust the operation time to satisfy the different performance requirement at will with good storage stability. The corresponding epoxy asphalt concrete has excellent high, low temperature performance and fatigue endurance, and the environment is friendly, suitable for occasion with higher requirement such as autoroute and bridge, and arterial street, bus stop and airfield path. The invention also provides a preparation method thereof.

Owner:SOUTHEAST UNIV

Modified epoxy resin concrete material and preparation thereof

The invention discloses a modified epoxy resin concrete material and a method for preparing the same. The modified epoxy resin concrete material comprises a component A, a component B and stones, wherein the component A consists of the following components in portion by weight: 50 to 100 portions of epoxy resin, 2 to 20 portions of liquid toughening rubber, 5 to 50 portions of epoxy resin active thinner, 0.01 to 1 portion of antifoaming agent, 0.5 to 5 portions of carbon black, and 0.5 to 5 portions of ultraviolet ray absorbent; the component B comprises the following components in portion by weight: 50 to 100 portions of curing agent, 2 to 20 portions of epoxy resin inactive thinner, and 0.01 to 1 portion of the antifoaming agent; the weight percentage of the component A to the component B is 10:1-1:1; and the weight percentage of the total weight of the stones, the component A and the component B which are mixed together is 12.5:1-5:1. The modified epoxy resin concrete material has the advantages of high strength, strong deformability and good high and low temperature performance, and is unnecessary to be heated for stirring; besides, because a normal temperature curing agent is used, the latter curing speed is far higher than that of the prior epoxy asphalt concrete, and the time for traffic opening can be shortened greatly.

Owner:盐城市射阳荣港实业有限公司

Waterborne epoxy modified emulsified asphalt concrete for steel bridge surface and preparation method thereof

ActiveCN102173663AReduce energy consumptionSolve the problem of energy consumptionEnvironmental resistanceEpoxy

The invention provides a waterborne epoxy modified emulsified asphalt concrete for a steel bridge surface and a preparation method thereof. The waterborne epoxy modified emulsified asphalt concrete for the steel bridge surface is prepared by the following steps of: adding waterborne epoxy resin, a curing agent, and a stabilizing agent into modified emulsified asphalt, continuously stirring until the mixture is uniform, and shearing to obtain waterborne epoxy resin modified emulsified asphalt emulsion; and stirring coarse aggregate and fine aggregate in a container, adding the waterborne epoxyresin modified emulsified asphalt and then stirring, adding a filler and then mixing and stirring, and adding cement and stirring to obtain the waterborne epoxy modified emulsified asphalt concrete. A paving material prepared by the method has the characteristics of environment-friendliness, low volatile organic compound (VOC), low energy consumption, high bonding strength with a steel plate, high cryogenic stabilization, excellent water stability performance, high tenacity, and high fatigue resistance performance.

Owner:WUHAN UNIV OF TECH

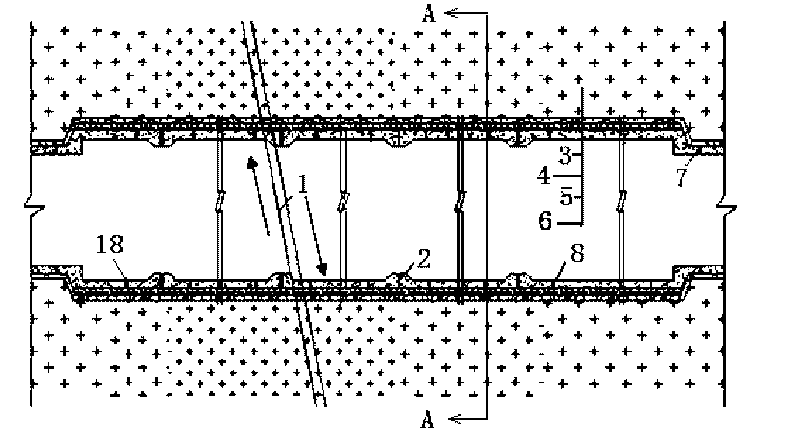

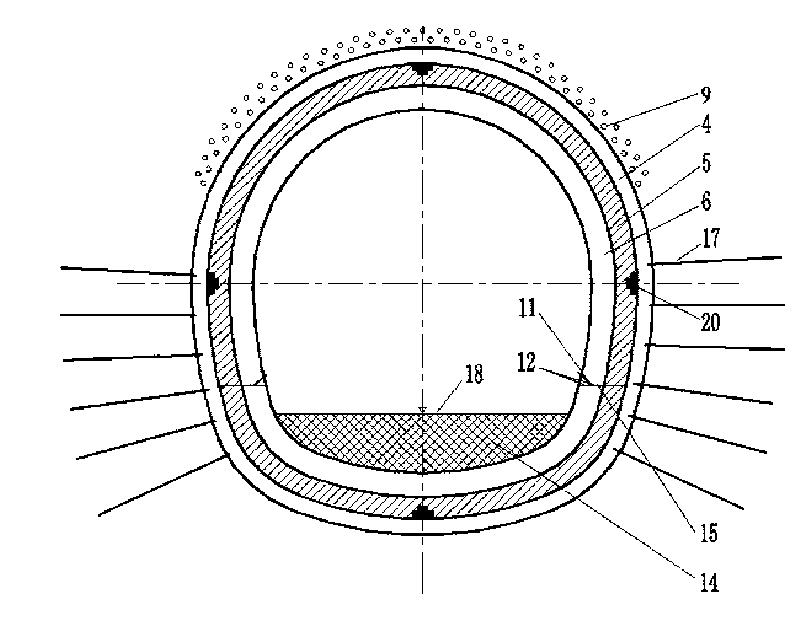

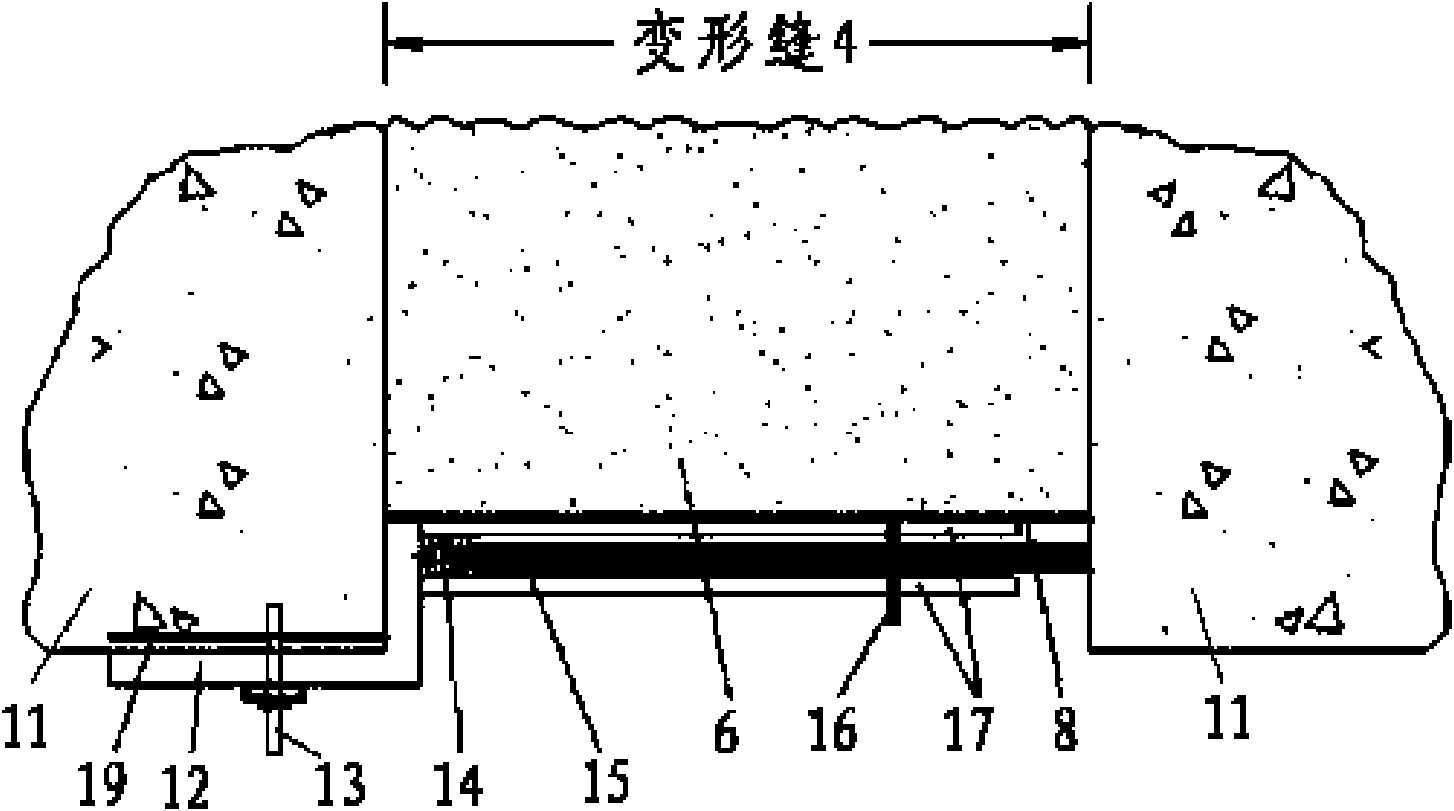

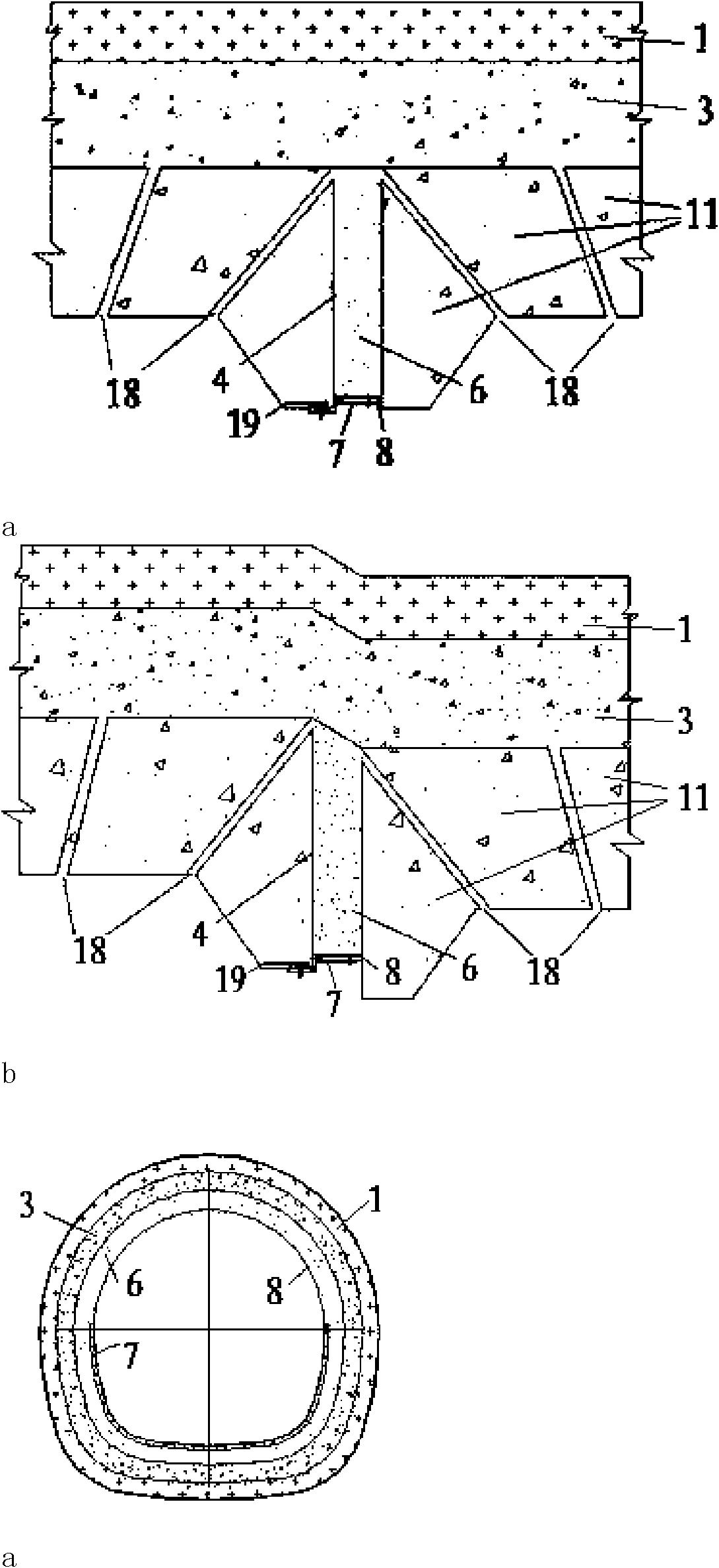

Ground fissure tunnel asphalt concrete composite lining and supporting method thereof

InactiveCN101737063AImprove stress environmentSimple structureUnderground chambersTunnel liningAsphalt masticHot melt

The invention discloses a ground fissure tunnel asphalt concrete composite lining, wherein an initial lining, an asphalt concrete composite lining and an inside lining are sequentially arranged in an influence interval of a ground fissure from a surrounding rock soil body to a tunnel axial center, deformation joints A are arranged on the inside lining at intervals along a tunnel axis, injected holes are reserved at the bottom of the inside lining at both sides of the deformation joints A, and a displacement monitor is installed at the outer side of the asphalt concrete composite lining. The invention also discloses a supporting method of the ground fissure tunnel asphalt concrete composite lining, and an asphalt concrete pouring material is prepared by mixing modified asphalt after hot melting with sand and stones by adopting a stepped excavation and mining construction method; an asphalt mastic material is filled in the deformation joints A to flexibly connect the two adjacent segments of inside linings and carry out waterproof processing and the like for construction joints at the section of the inside lining. The composite lining has simple structure, convenient construction, safety and reliability and is suitable for being used in ground fissure active regions or meizoseismal regions.

Owner:XIAN UNIV OF TECH

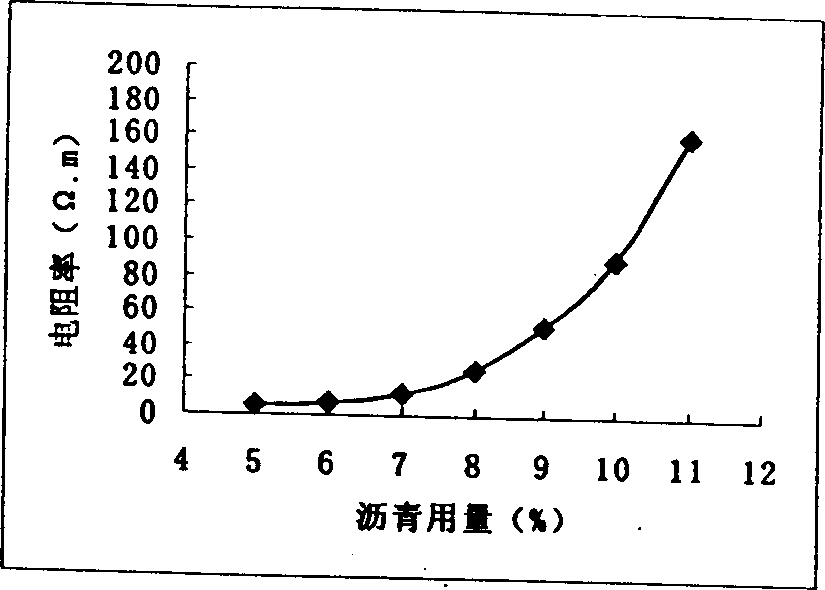

Microwave-absorbing asphalt concrete pavement material composition

InactiveCN101736671ASimple preparation processIncreased heating rate by microwave heatingIn situ pavingsMicrowaveSnow melting

The invention discloses a road asphalt concrete pavement material composition which is applicable to microwave absorption. Magnetic powder is added for replacing all or part of limestone mineral powder in the traditional asphalt concrete raw material; magnetic sand or silicon carbide sand is adopted for replacing all or part of natural aggregate in the traditional asphalt concrete raw material, wherein the weight of the magnetic powder accounts for 3-15% of the total weight of the composition; the weight of the magnetic sand or the silicon carbide sand accounts for 2-50% of the total weight of the composition; the weight of asphalt accounts for 5-10% of the total weight of the composition; the weight of the limestone mineral powder accounts for 0-5% of the total weight of the composition; and the weight of the natural aggregate accounts for 20-90% of the total weight of the composition, and the microwave-absorbing asphalt concrete pavement material composition is finally obtained. Compared with the traditional asphalt concrete, the microwave-absorbing asphalt concrete can improve the microwave heating rate by a plurality of times to dozens of times. The composition can greatly improve the microwave de-icing and snow-melting efficiency, and be extensively applied in a variety of asphalt concrete highway pavements, parking aprons of airports, factories, offices, schools, troops and other units for use.

Owner:CHANGAN UNIV

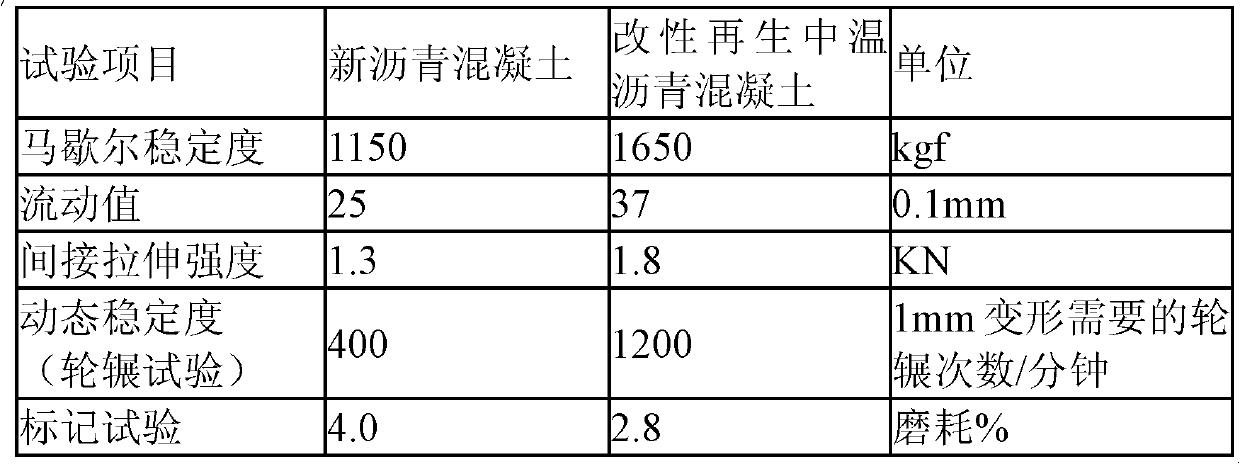

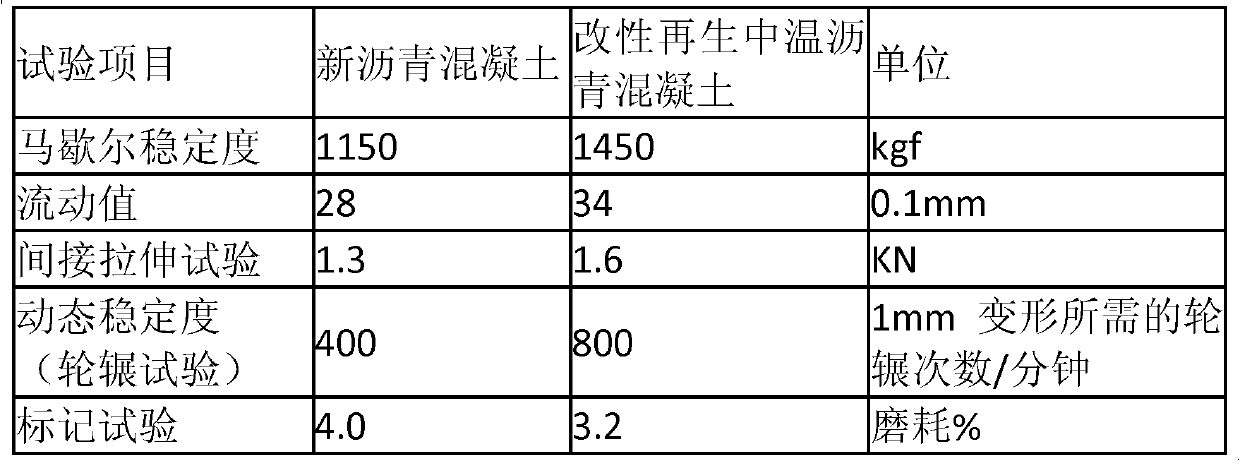

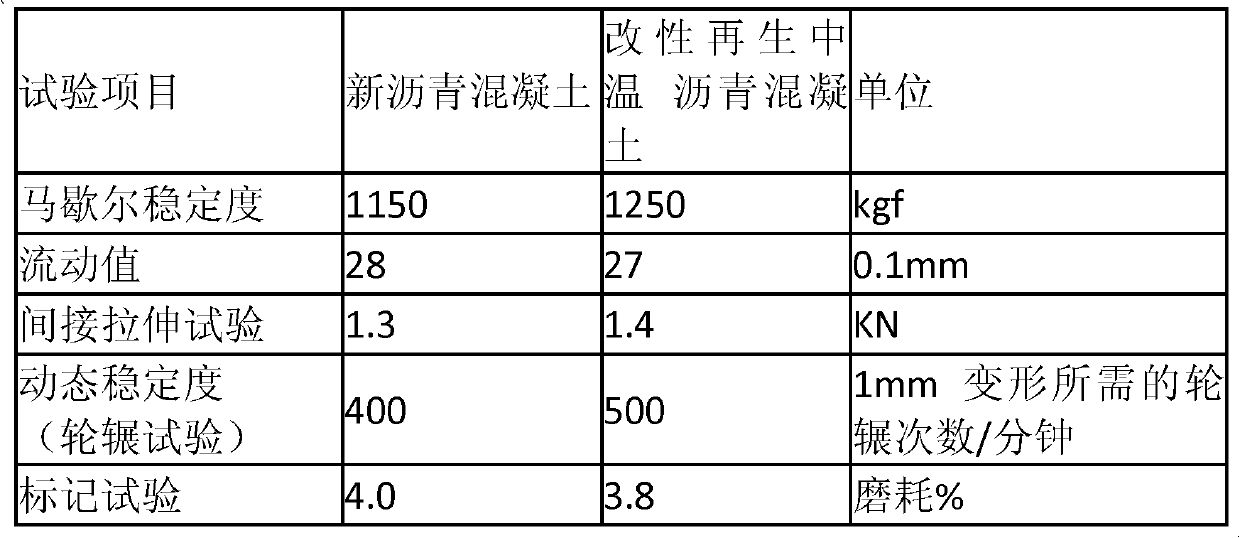

Temperature-adjusted and modified recycled ascon composition for reusing 100% of waste ascon for road pavement, and method for manufacturing same

InactiveCN102448907AImprove qualityLow production temperatureIn situ pavingsSolid waste managementCost savingsParticle-size distribution

Provided is a temperature-adjusted and modified recycled ASCON composition for reusing 100% of waste ASCON for road pavement, and a method for manufacturing same, wherein the composition is used in asphalt pavement as a material for the wearing course, surface course, binder course, and base course, and the method comprises: feeding 100 wt % of waste ASCON aggregate having up to a 53 mm particle size distribution into a mixer via a feeding inlet for new aggregate; adding 0.1 to 20 wt % of a recycling modifier and 0.1 to 20 wt % of a temperature-adjusting additive to the waste ASCON via the feeding via the inlet for new aggregate; and homogeneously mixing said materials at 5 to 180 DEG C for 0.5 to 3 minutes. The recycling modifier improves the physical properties of recycled ASCON, while the temperature-adjusting additive adjusts the temperatures for producing and constructing recycled ASCON. The present invention may provide economic, social and technological conveniences by improving the overall recycling technology of waste ASCON. The conveniences may be achieved by virtue of: cost-saving in production by using only waste ASCON without any new materials; saving waste disposal costs; preventing the destruction of nature to obtain aggregate; reducing the consumption of new asphalt; preventing environmental pollution through the reuse of waste products; preventing the early occurrence of plastic deformation and fatigue cracks due to improving the quality of the recycling modifier; economic benefits from the prolonged lifespan of road pavement; the possibility of being used as a material for the wearing course and surface course of major roadways; saving energy in the production and construction of recycled ASCON by adding the temperature-adjusting additive; and reducing greenhouse gas emissions.

Owner:许政道

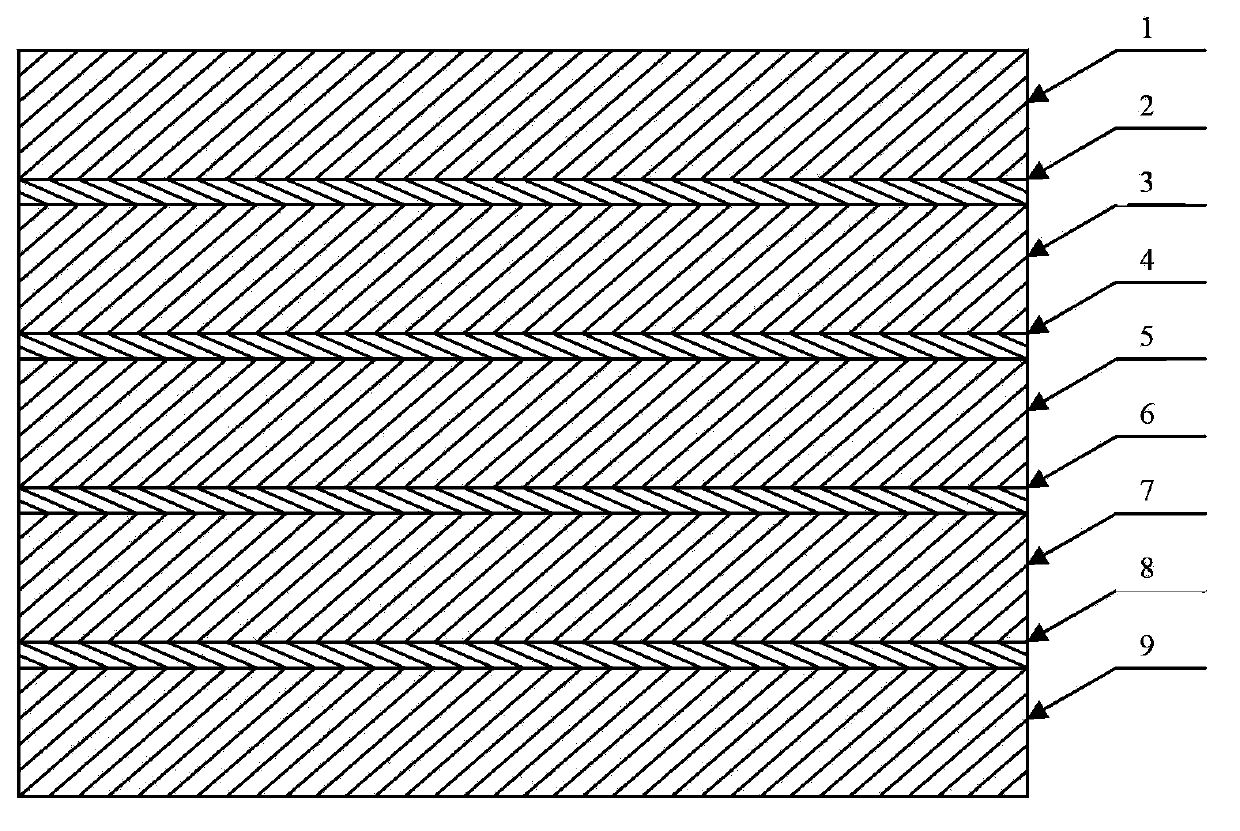

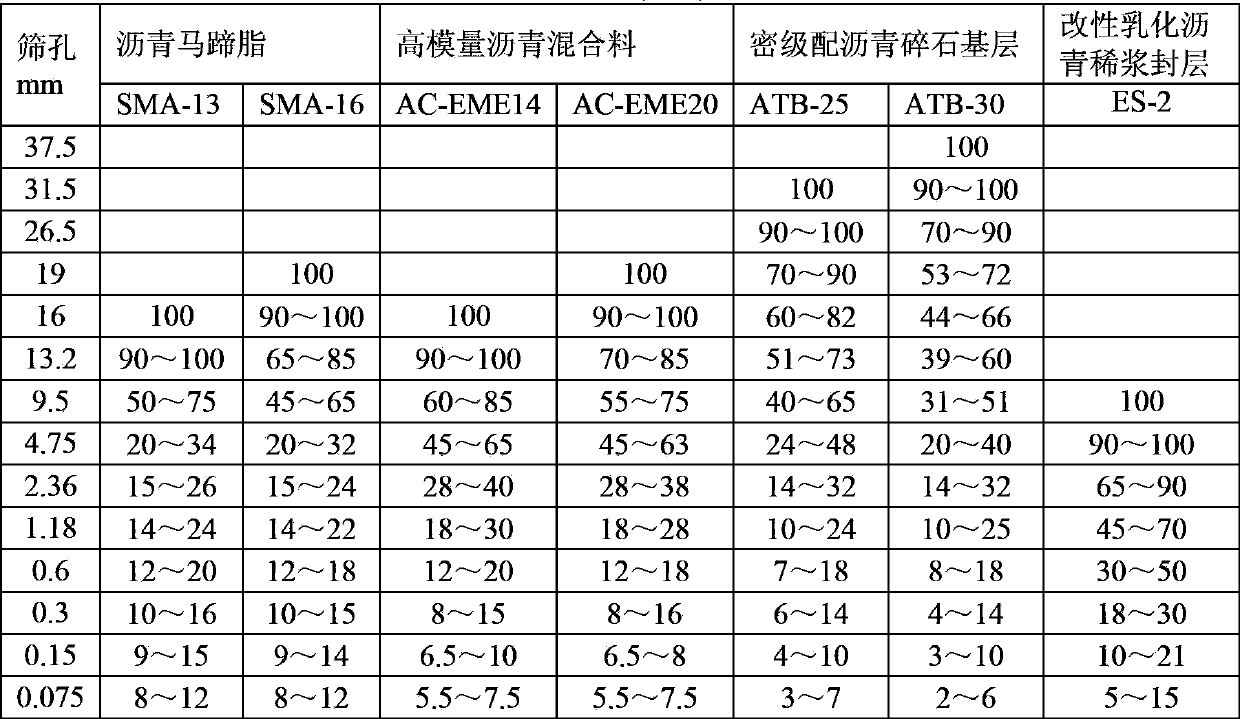

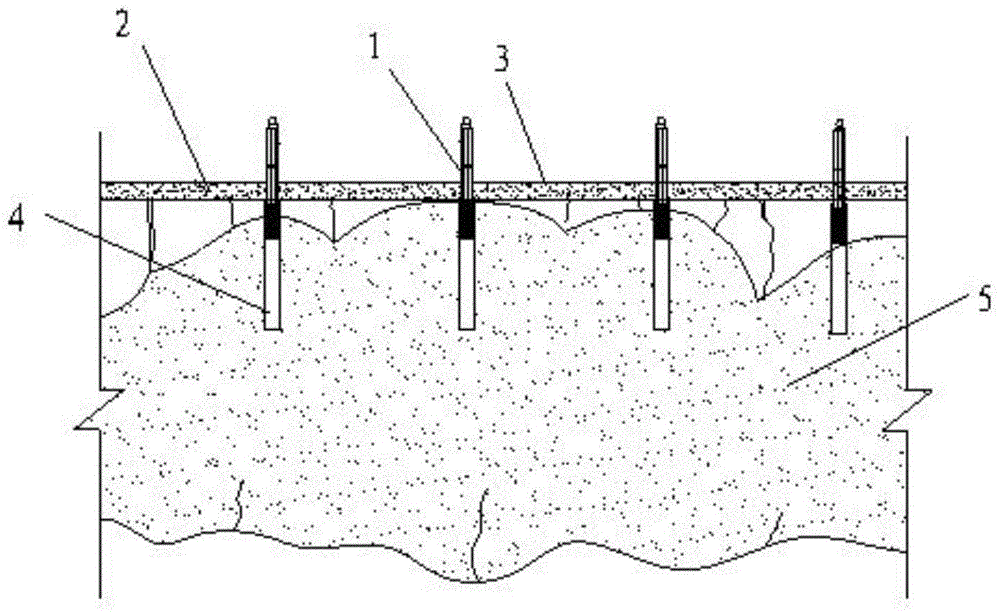

Semi-flexible heavy-duty pavement paving structure

ActiveCN103866667AImproves rutting resistanceImprove fatigue resistanceIn situ pavingsSurface layerLower grade

The invention relates to a semi-flexible heavy-duty pavement paving structure. The semi-flexible heavy-duty pavement paving structure comprises a surface layer having a thickness of 4-6cm and made of a high-viscosity modified asphalt mixture of SMA-13 or SMA-16, a middle surface layer having a thickness of 6-10cm and made of a high-modulus asphalt mixture of AC-EME14 or AC-EME20, a lower surface layer having a thickness of 10-12cm and made of a low-grade asphalt mixture of ATB-25 or ATB-30, and a semi-flexible base layer having a thickness of 6-12cm and made of skeleton solid cement-emulsified asphalt concrete; a high-viscosity modified asphalt bonding layer is arranged between the surface layer and the middle surface layer, between the middle surface layer and the lower surface layer and between the lower surface layer and the semi-flexible base layer, and the spreading quantity of the high-viscosity modified asphalt bonding layer per unit area is 0.6-0.8kg / m<2>; and an ES-2 modified emulsified asphalt slurry is arranged between the semi-flexible base layer and a bottom base layer, and has a suitable thickness of 6-10mm. The structure improves the rut resistance and the fatigue resistance of a pavement, and prolongs the service life of the pavement.

Owner:PETROCHINA CO LTD +1

High performance pavement material of epoxy asphalt, preparation method and application

InactiveCN101003688AGood weather resistanceImprove fatigue resistanceIn situ pavingsBuilding insulationsHigh resistanceEpoxy

This invention discloses a method for preparing high-performance epoxy asphalt road surface material and its application. The road surface material comprises components A and B. Component A is composed of: asphalt 50-100 parts, curing agent 20-50 parts, promoter 0.4-1 part, and antifoaming agent 0.5-1 part. Component B is epoxy resin. The weight ratio of A to B is (2.5-7):1. The method comprises: (1) heating asphalt to 100-130 deg.C, adding curing agent, mixing by high-speed shearing for 10-60 min, adding promoter and antifoamer, and mixing by high-speed shearing for 5-50 min to obtain component A; (2) heating component A to 100-160 deg.C, mixing components A and B according to the weight ratio of (2.5-7):1, stirring uniformly at 120-140 deg.C, and curing for 4-8 h. The product is a main material for producing epoxy asphalt concrete. The product has high resistance to corrosion, water, weathering, fatigue, creep at high temperatures, and cracking at low temperatures.

Owner:NANJING UNIV

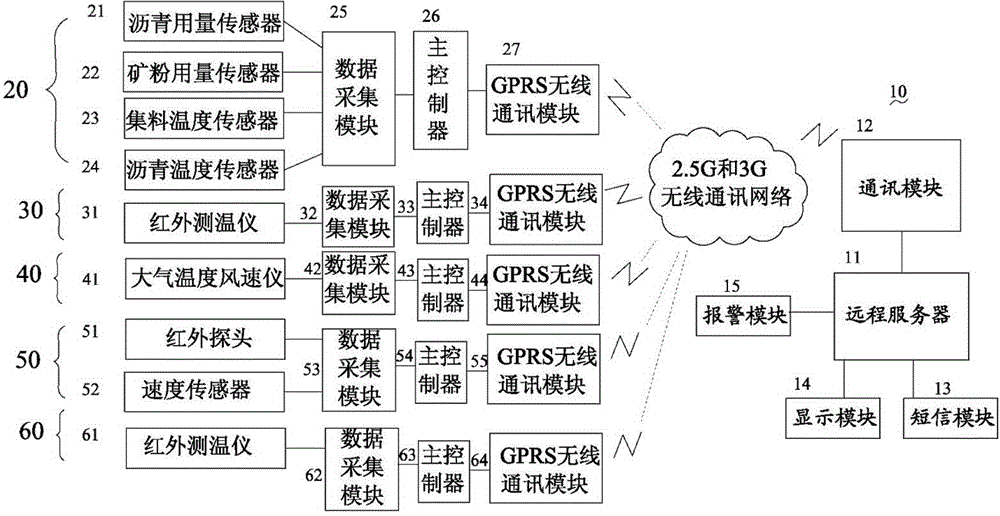

System and method of dynamic management for construction quality of asphalt concrete pavement

InactiveCN103336499ARealize dynamic controlPrevent fraudulent behaviorTotal factory controlProgramme total factory controlData informationTransmission technology

The invention discloses a system and a method of dynamic management for construction quality of an asphalt concrete pavement. The system gathers a plurality of subsystems of the dynamic management for the construction quality of the asphalt concrete pavement and a remote quality monitoring and controlling system, wherein the subsystems are composed of a production mix proportion monitoring subsystem, a discharging temperature monitoring subsystem, a construction environment monitoring subsystem, a pave data monitoring subsystem, and a rolling data monitoring subsystem. The technical scheme is that the sensing technology based on the architecture of the Internet of Things and the transmission technology base on 2.5 G and 3G are fully utilized to report data information of a manufacturing process, a construction process, and the like of asphalt mixture to a remote server through a communicating module, so as to dynamically and truthfully reflect the construction quality condition. The idea of the system and the method is to track and observe project processes, and compare the observation result with a planned value, and once a deviation is found, the rectification is performed for prevention.

Owner:ZHONGSHAN TOPWARE ELECTRONICS TECH

Construction method for reconstructing old concrete pavement by paving asphalt-concrete surface layer

InactiveCN101691736ALow costShorten the construction periodRoads maintainenceSurface layerRoad surface

The invention relates to pavement reconstruction, in particular to a construction method for reconstructing an old concrete pavement by paving an asphalt-concrete surface layer, which is characterized by comprising the following: 1) a step of old concrete pavement processing, which comprises breaking and removing damages blocks and pouring again, mudjacking the old concrete pavement, impacting and rolling old concrete pavement, crack pouring and replacing hardened verges; and 2) a step of paving a asphalt-concrete pavement, which comprises spraying a prime coat and viscous oil and spreading the asphalt-concrete pavement. The breaking and removing damages blocks and pouring again comprise: breaking and removing seriously damaged blocks of the old pavement; shoveling loose parts of an old cement stabilized base away, and pouring concrete in a 15-centimeter thickness which is the same as that of the old base for leveling; filling up the pits on the base with cement mortar and tamping the filled cement mortar; and pouring a 24-centimeter C35 concrete pavement board. In the method, the requirements on cost, quality, construction period, environmental protection and the like are met when the old concrete pavement is reconstruction by paving the asphalt-concrete pavement.

Owner:中交二公局第六工程有限公司

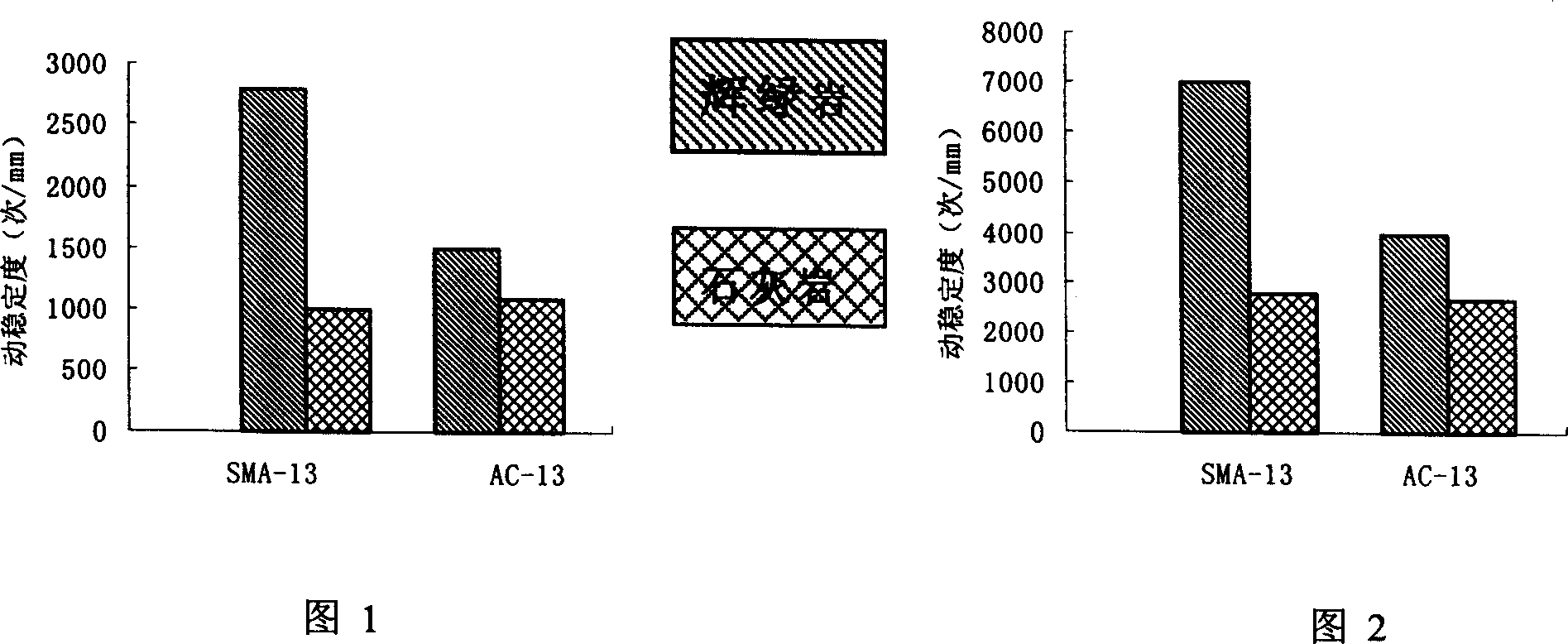

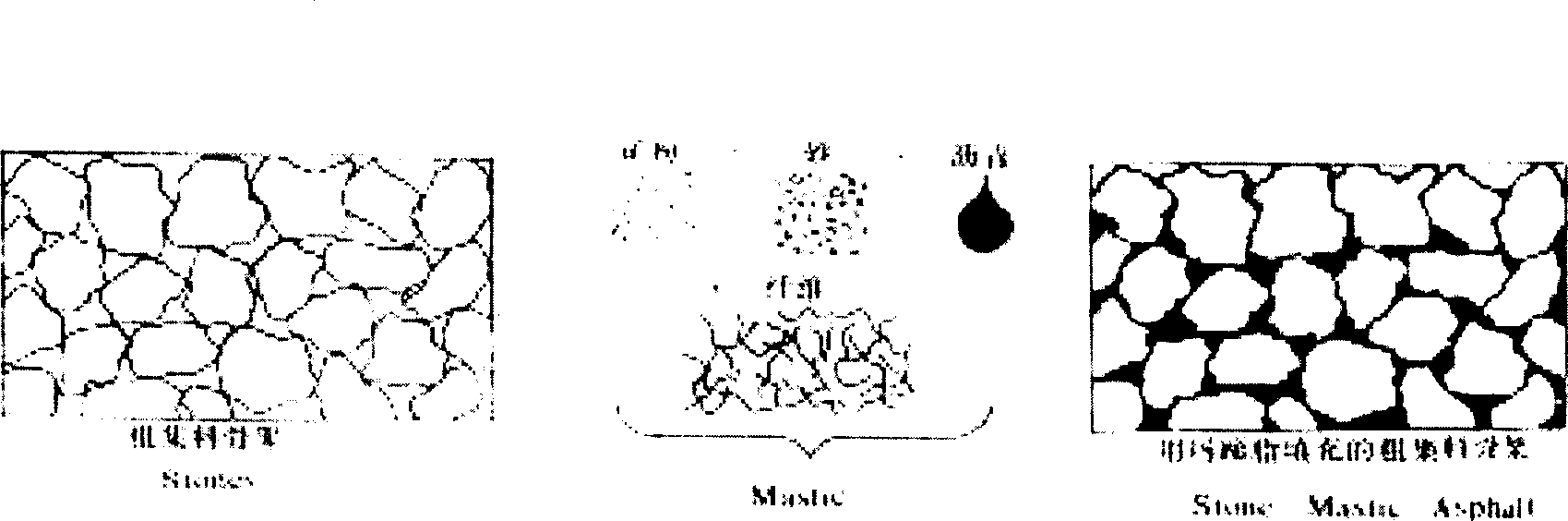

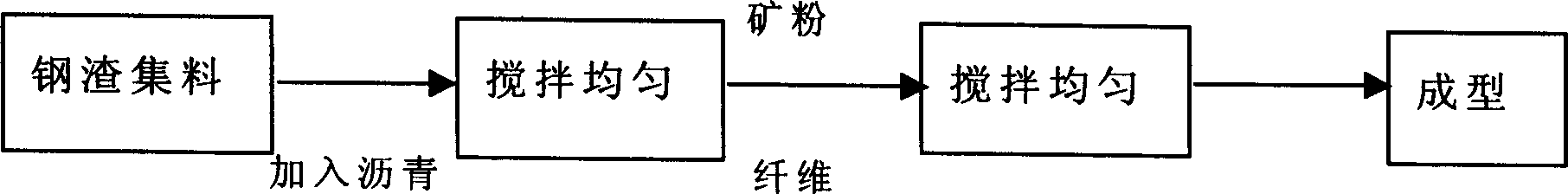

Steel scoria mastic detritus asphaltum concrete and method for preparing the same

InactiveCN1482091AImprove long-term road performanceLow costSolid waste managementCeramic shaping apparatusFiberAdhesive

Steel slag as aggregate for road engineering has not only excellent pressure resisting and wear resisting performance but also high adhesion. The asphalt concrete consists of steel slag as aggregate, mineral powder stuffing, fiber as stabilizer and asphalt as adhesive. The production process includes heating the aggregate to 170 deg.c and mixing with hot molten liquid asphalt, mixing with mineral powder, adding fiber as stabilizer, and beating the steel slag SIA asphalt mixture on two sides for 50 times each or rolling for 18 times to form. The steel slag SIA asphalt concrete has its performance indexes reaching national standard, dynamic stability up to 5846 times / mm and may be used in expressway. In addition, the use of steel slag can lower engineering cost and reduce environmental pollution.

Owner:武汉钢铁集团冶金渣有限责任公司 +1

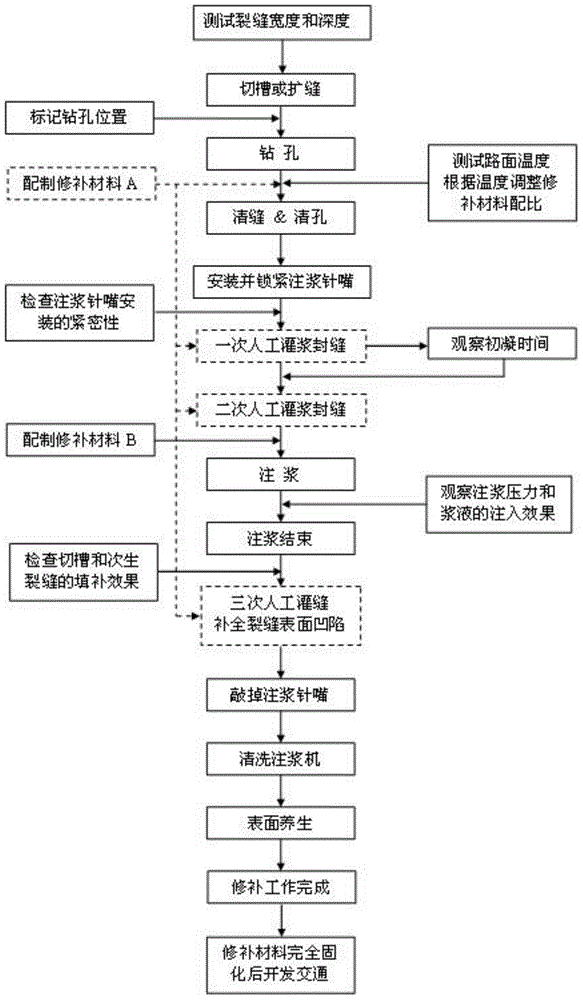

Method for repairing crack of asphalt concrete pavement

InactiveCN104480844AExtended service lifeEffective guidancePaving detailsRoads maintainenceSurface layerRepair material

The invention relates to the technical field of repair of a pavement crack, and provides a method for repairing a crack of an asphalt concrete pavement. According to the method, the pouring of the crack is saturated by effectively guiding a repair material through a mode of drilling along the crack of the pavement or along a slit obtained by slotting and crack expansion, so that the adhesive force between the repair material and the pavement is increased, and the structural strength of the repaired crack is enhanced; the adhesion area of an integral structure formed by a self hole and the crack is enlarged, and the connection between the repair material and the pavement is only limited to the upper part of a surface layer, so that the connected relation between the repair material and an original pavement is further consolidated. In conclusion, According to the method disclosed by the invention, the capability of resisting the influence of vehicle loads and environmental factors by the asphalt concrete pavement can be greatly improved, the service life of the asphalt concrete pavement can be prolonged, and the maintenance and repair cost of a highway can be outstandingly reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Poured epoxytar concrete material and its prepn process

InactiveCN101020601AImprove low temperature performanceReduce construction temperatureRoadwaysEpoxyEther

The present invention relates to poured road surface laying material, and is especially one kind of poured epoxy asphalt concrete material with low construction temperature, high flowability and construction convenience and its preparation process. The poured epoxy asphalt concrete material consists of component A and component B in the weight ratio of 8-50 as well as stone material in the amount of 3-9 times the component A. The component A consists of asphalt 45-90 weight portions, epoxy resin 4.5-36 weight portions, modified alkylphenol 9-27 weight portions and glycidol ether 0-3 weight portions, and the component B is curing agent. The poured epoxy asphalt concrete material is prepared through mixing the materials of the component A, stirring at 120-160 deg.c, adding stone material, and final adding the heated curing agent and maintaining the temperature for 0-120 min.

Owner:重庆市智翔铺道技术工程有限公司

Method for paving resin filling type asphalt concrete steel box-beam bridge deck combined structure

ActiveCN101200873AHigh strengthChemically stableBridge structural detailsBuilding insulationsSheet steelSurface layer

The present invention relates to a paving method of the paving layer of the bridge deck of a steel box girder bridge. A resin infusion type paving method of the composite structure of the asphalt concrete steel box girder bridge deck includes three steps: (1) the sand blasting and the derusting of the steel plates of the steel box girder bridge deck; (2) the preparation of materials: (a) the preparation of high-viscosity modified asphalt; (b) mineral aggregate gradation; (c) the preparation of large pored asphalt concrete; (d) the preparation of thermoset resin grouting material; (3) The pavement of the paving layer of the bridge deck: (a) The large pored asphalt concrete is paved on the steel plates of the steel box girder bridge deck, the pavement thickness is 2cm to 4cm, and after final pressure, a large pored asphalt concrete skeleton layer is formed; (b) While the large pored asphalt concrete skeleton layer is still in a hot state, the thermoset resin grouting material is grouted into the large pored asphalt concrete skeleton layer; (c) After the maintenance of three days, a layer of bonding oil is sprinkled, and an asphalt abrasion surface layer with the thickness of 4cm is paved. The paving method is characterized in good interface cohesive property and simple and convenient construction process.

Owner:WUHAN MUNICIPAL CONSTR GROUP

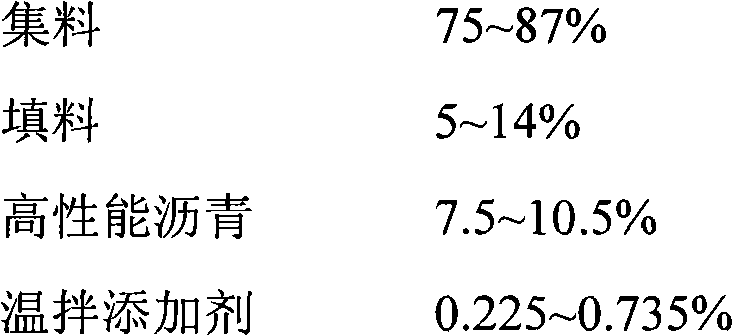

Ultra-thin wearing layer of pavement

The invention belongs to the technical field of a building material used in road engineering, and specifically relates to drainage asphalt mixture for an ultra-thin wearing layer. The mixture comprises aggregated material, stuffing, high-performance asphalt and warm mixing additive; the maximal nominal size of the mixture is 6.7mm; the thickness of a pavement layer is 10-20mm; the aggregated material is basalt or dolerite; the used stuffing is mixture of limestone powder and common silicate cement, and the used high-performance asphalt is prepared from general modified asphalt by adding waste tire rubber powder which is 20-28% of weight of the asphalt and modifying. An ultra-thin finishing coat and low-temperature construction are realized by the asphalt mixture by adding the warm mixing additive; the ultra-thin wearing layer has the advantages of low construction cost, convenience in construction and the like, and is suitable for building of an asphalt concrete pavement and function-improving works of the pavement.

Owner:上海砼仁环保技术发展有限公司

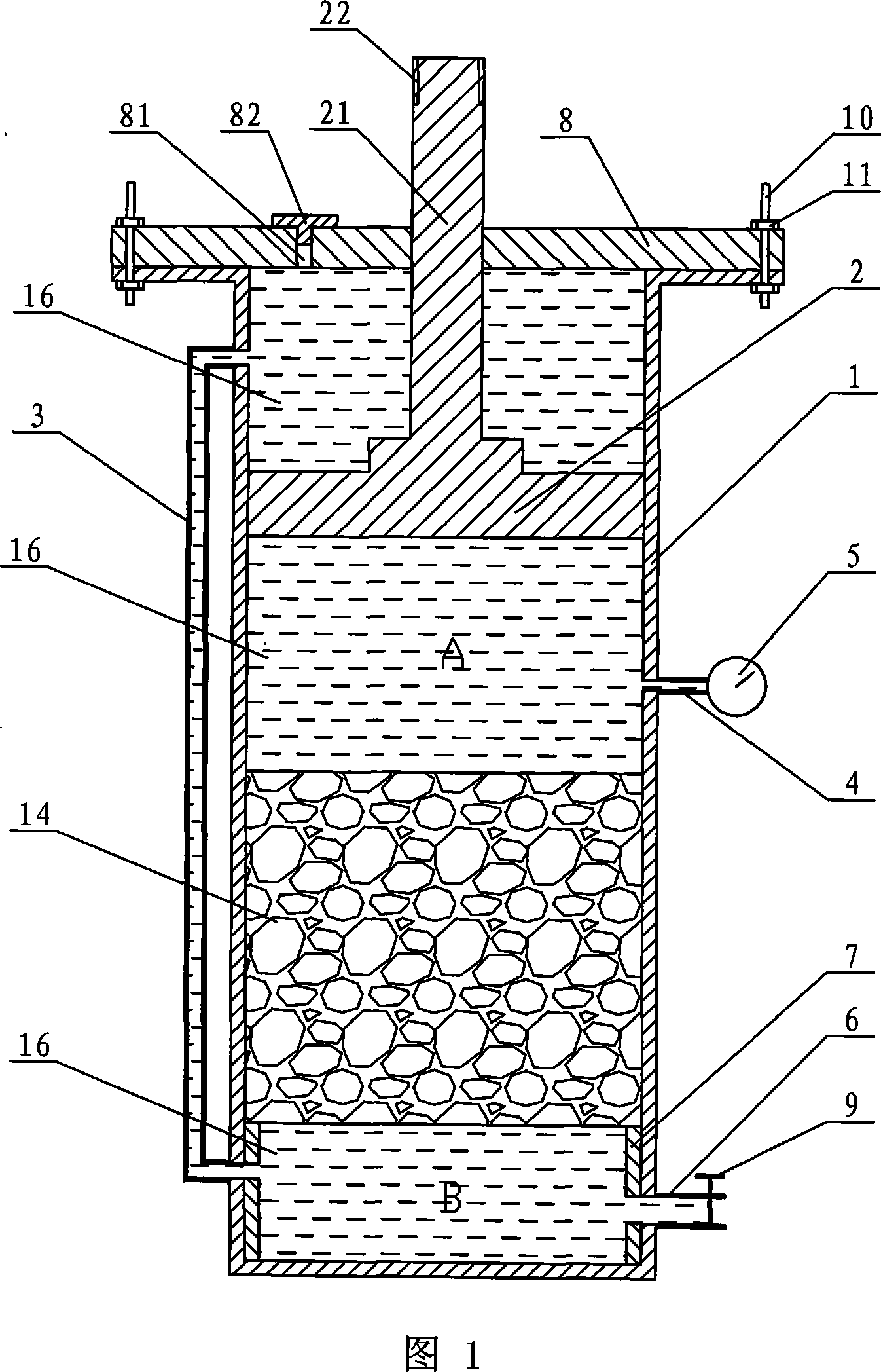

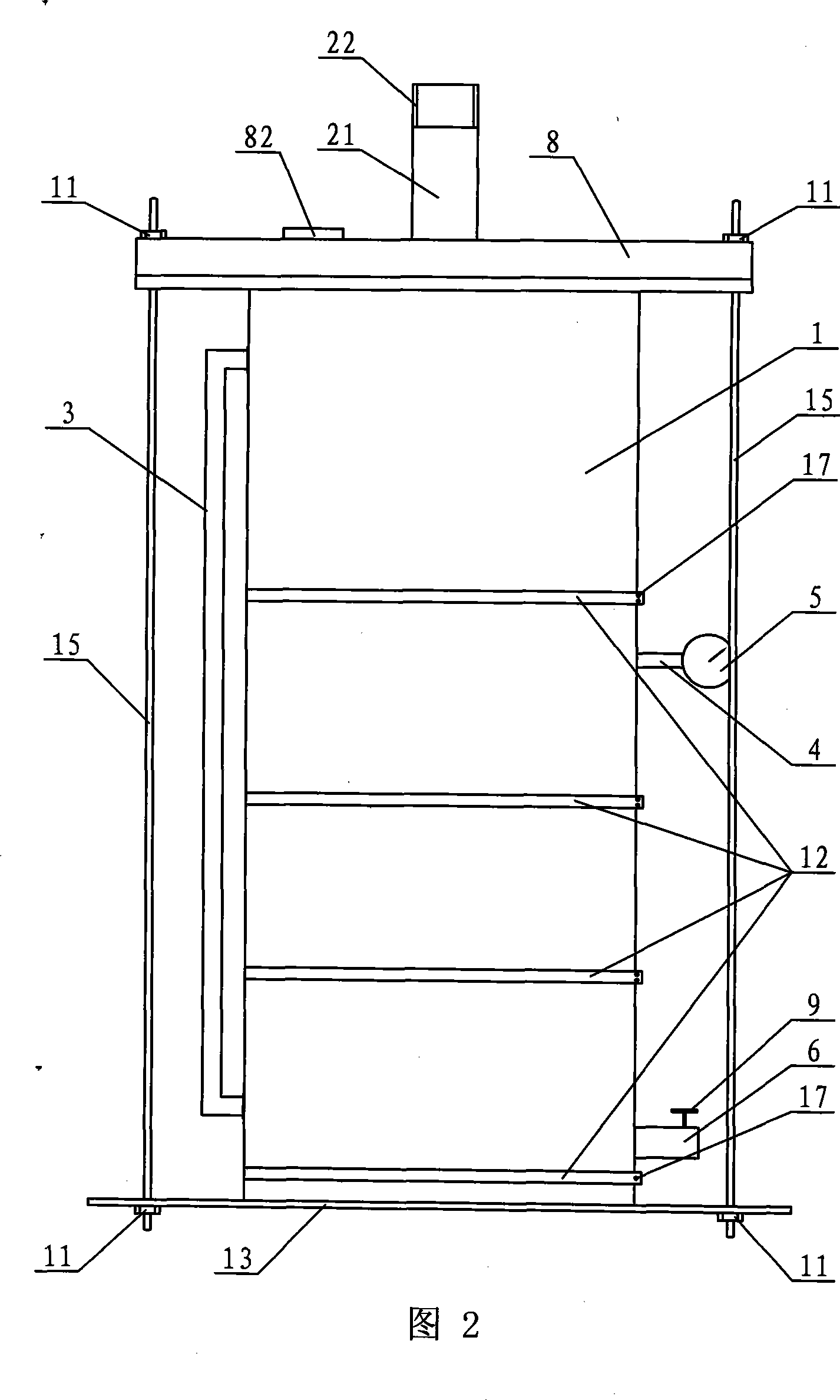

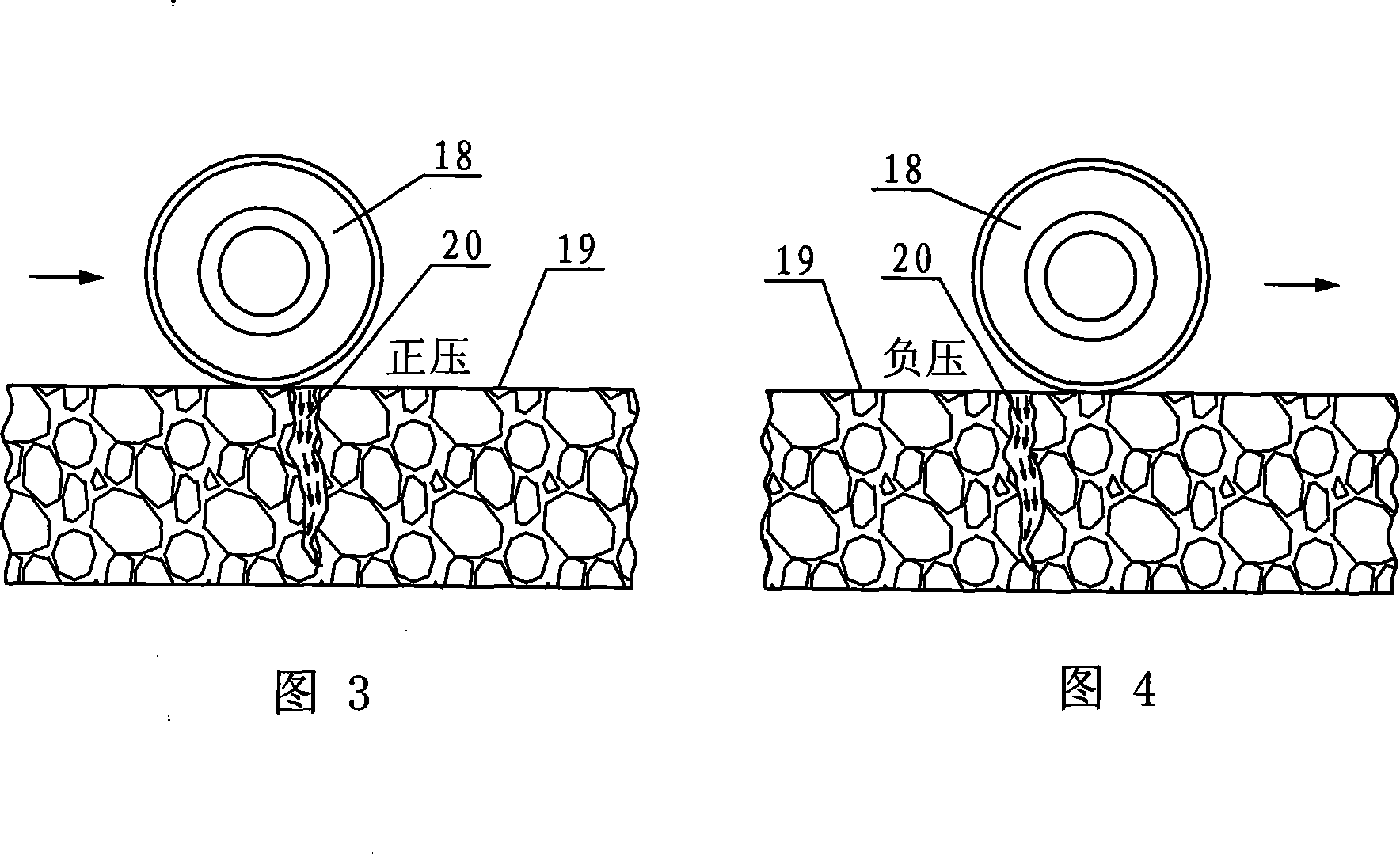

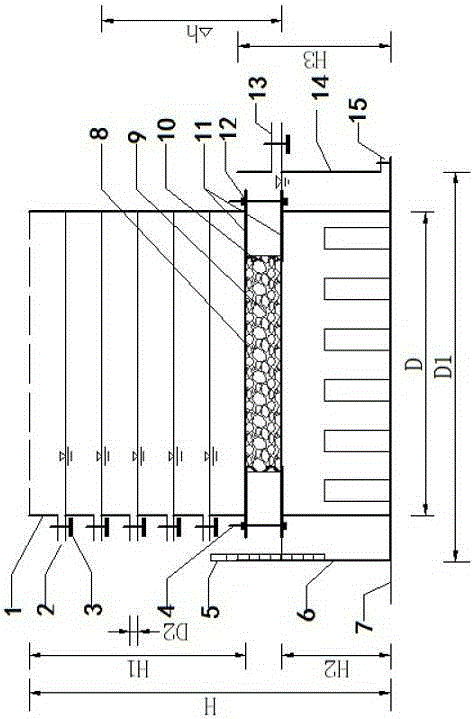

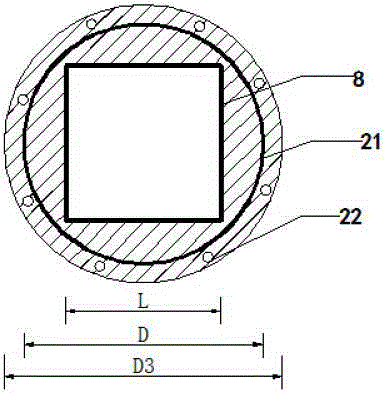

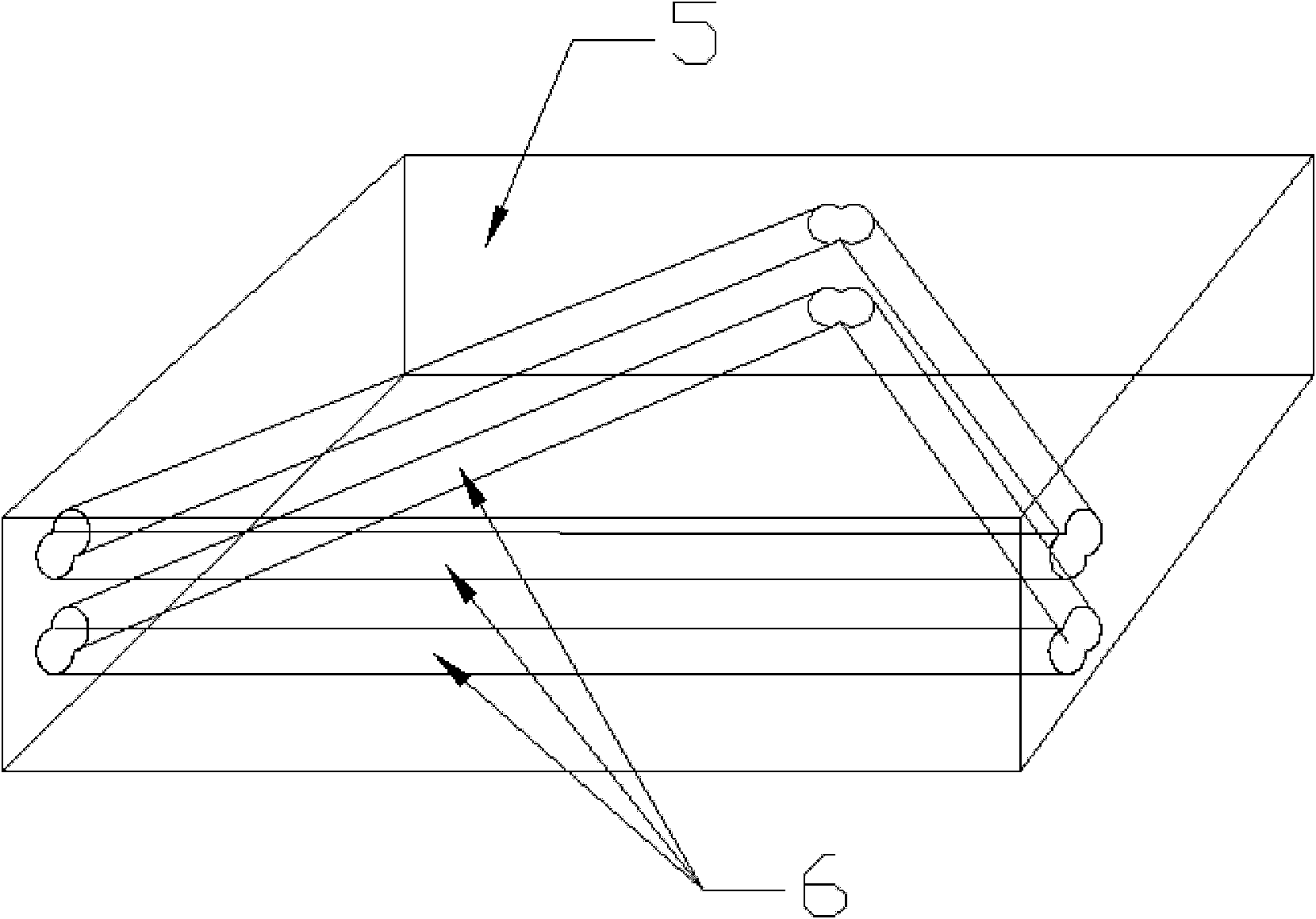

Test device for asphalt mixture resisting moving water scouring

InactiveCN101210870AWeather/light/corrosion resistanceMaterial testing goodsPore water pressureWashout

The invention relates to a test device, specifically to a flowing water washout prevention test device for asphalt mixture. The invention aims to solve the problem that no test device is available for evaluating the washout effect of flowing water on asphalt mixture. In the inventive device, a pedestal is disposed at the bottom of the inner cavity of a washout barrel (1), a piston (2) is disposed on the inner cavity of the washout barrel (1), an upper cover is disposed at the top end of the washout barrel (1), a conduit (3) and an upper water pipe (4) are disposed at the side wall of the washout barrel (1), a pressure meter (5) is disposed on the upper water pipe (4), and a lower water pipe (6) is disposed in the lower part of the side wall of the washout barrel (1) and provided with a valve (9). The invention can simulate the effect of flowing water pressure arising from vehicle traveling on the asphalt concrete pavement on the asphalt pavement under different temperature conditions.

Owner:HARBIN INST OF TECH

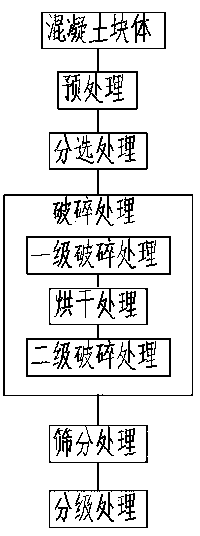

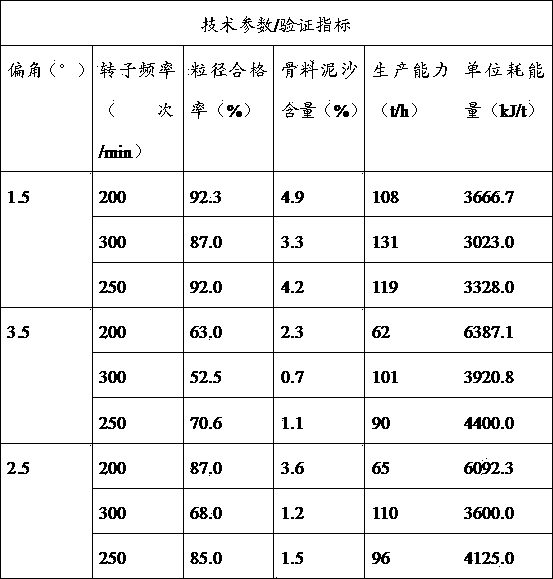

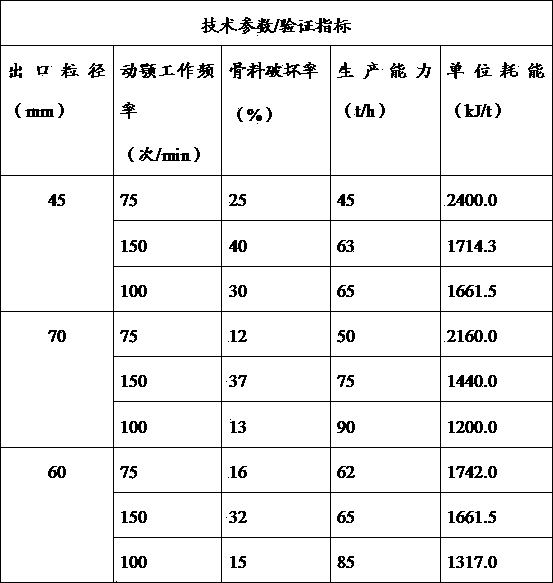

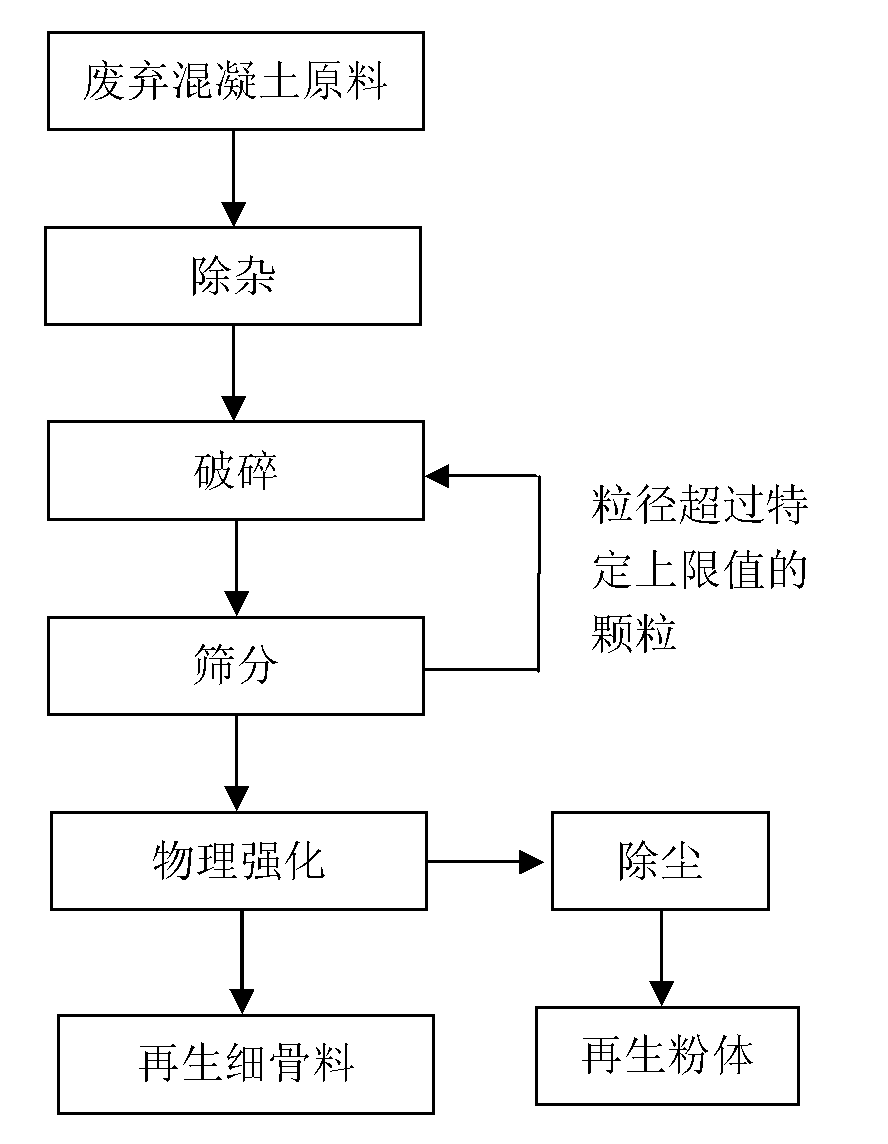

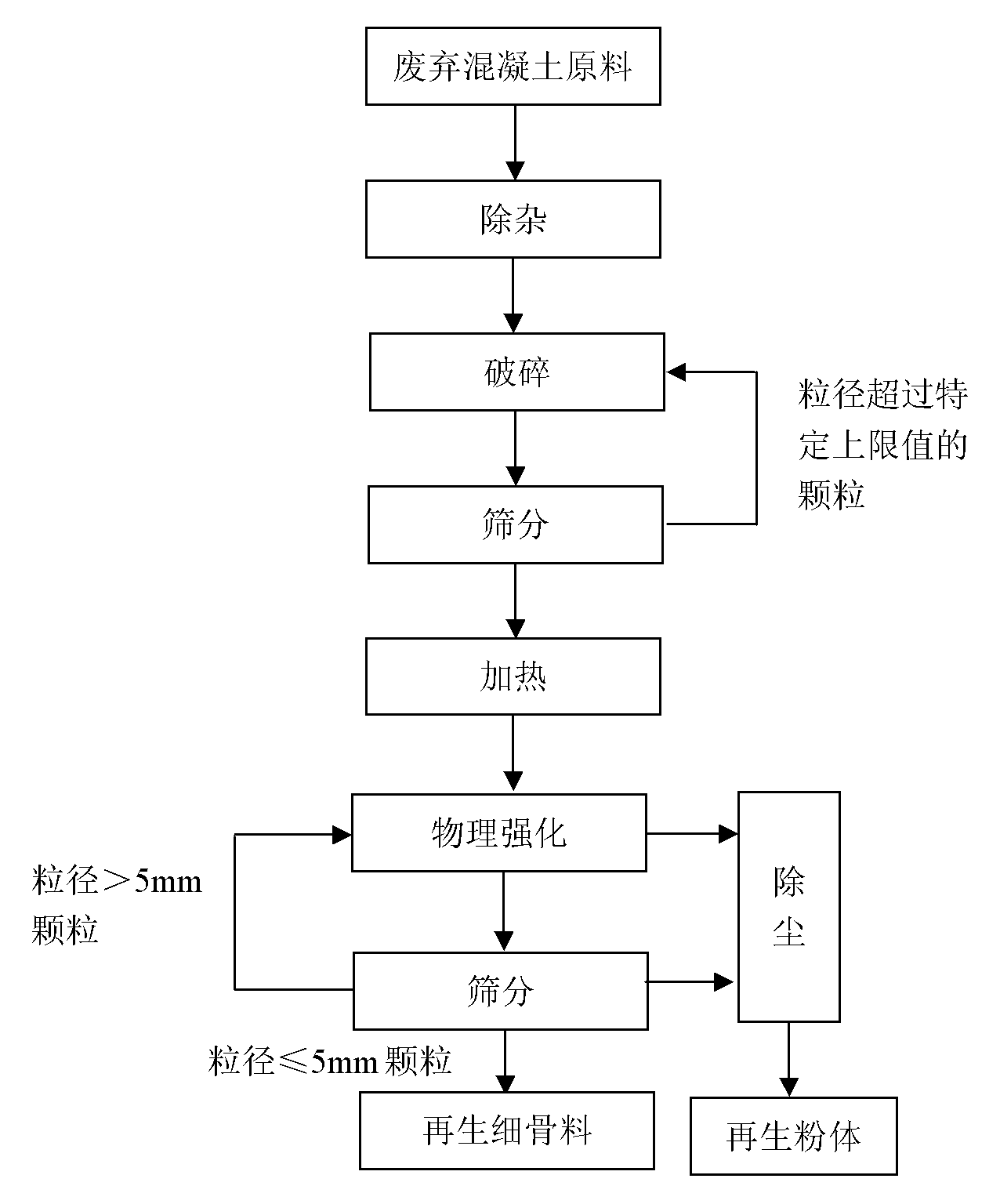

Preparation process of recycled concrete aggregate

The invention discloses a preparation process of a recycled concrete aggregate. The preparation process comprises the following treatment steps: hammering concrete blocks with the grain size being greater than 300mm, cutting reinforcing steel bars in the concrete blocks and picking impurities in the concrete blocks; separating; removing iron impurities and non-iron impurities in sequence; performing primary crushing treatment, then performing drying thermal treatment, and performing secondary crushing treatment; screening to obtain recycled concrete aggregate particles with the grain sizes being 20-40mm, 5-20mm and less than 5mm respectively; performing wind power grading treatment on the recycled concrete aggregate with the particle size being less than 5mm, and removing fine powder with the grain size being less than 0.15mm to obtain the recycled concrete aggregate particles being 0.15-0.5mm. By adopting a mode, the preparation process of the recycled concrete aggregate has the advantages that the quality of the recycled concrete aggregate is improved, the recovery rate of waste concrete is increased, no secondary pollution is caused, and the preparation process is economic, feasible and convenient to operate.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +2

Porous cement concrete using regenerative concrete aggregate

InactiveCN101407390AReduce the amount of miningEasy to useSolid waste managementPerformance indexWater circulation

The invention relates to water permeable cement concrete using recycled concrete as the aggregate, which has the raw material compositions with the weight parts of 250-400 parts of cement, 1500-2000 parts of recycled concrete aggregate, 25-40 parts of inorganic plastering agent and 2.5-5 parts of synthetic fiber, wherein, the recycled concrete aggregate has 5-12mm of unitary size fraction and 25 percent or smaller of crushing value. The ecological water permeable concrete has the advantages of increasing the service means of the high added value of waste concrete, reducing the mining quantityof natural aggregates, lowering the cost for confecting water permeable materials, improving the traffic safety factors of the road, improving the water circulation function of the environment and having the performance indexes meeting the requirements of the set mechanical performance and other technical indexes.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

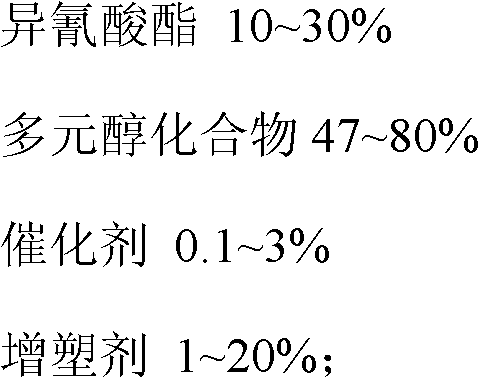

Polyurethane asphalt concrete as well as preparation method and application thereof

The invention discloses polyurethane asphalt concrete prepared from aggregate, diluted asphalt and polyurethane prepolymer which serve as raw materials, wherein the aggregate is basalt, diabase or limestone; the diluted asphalt is a mixture formed by diluting road petroleum asphalt and gasoline or diesel at a weight ratio of 100:(18-100); and the polyurethane prepolymer is prepared by reacting isocyanate with a polyalcohol compound, a catalyst and a plasticizer. The polyurethane asphalt concrete serving as cool-mixed and cool-spread type asphalt concrete is applied to pavement or repair of an asphalt road surface; compared with the conventional hot state technology for a hot-mixed and hot-repaired asphalt mixture, the polyurethane asphalt concrete has the advantages that the energy is saved, emission of a large amount of greenhouse gas and emission of toxic and harmful gas during asphalt heating are reduced, the surrounding environment is protected, and the environment pollution is reduced; and furthermore, the polyurethane asphalt concrete is operated easily and high in efficiency and cannot be limited by a transparent condition, a repair dispersion condition and the like during production and construction.

Owner:重庆市智翔铺道技术工程有限公司

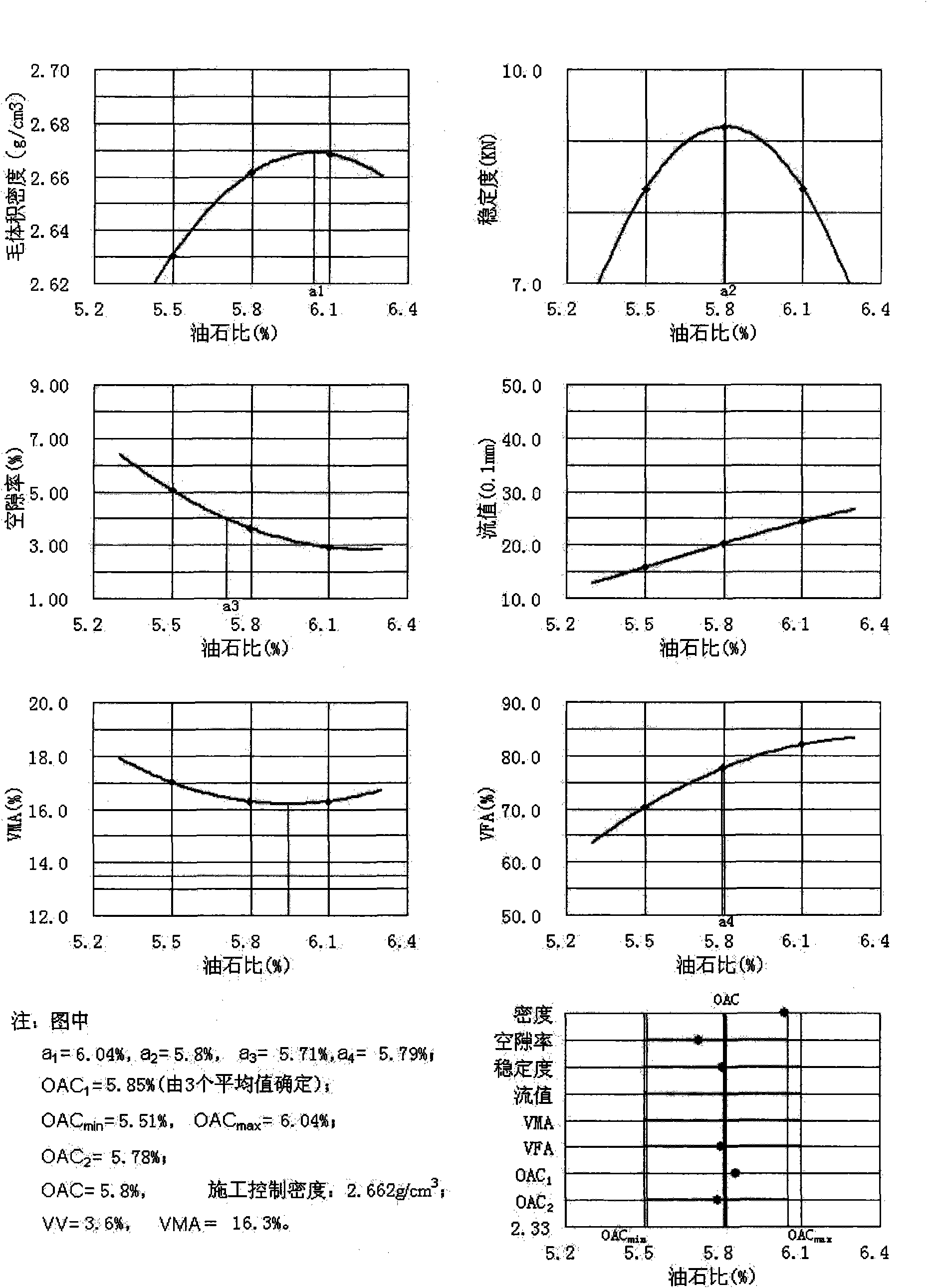

Steel slag and rubber asphalt concrete and preparation method thereof

The invention provides a steel slag and rubber asphalt concrete and a preparation method thereof. In the concrete, the steel slag is selected as a coarse aggregate and rubber asphalt is selected as a binder, and the concrete further comprises a fine aggregate and a filler; the mineral aggregate of the asphalt mixture is graded to form a coarse aggregate gap gradation framework solid type; the ratio of the rubber asphalt to the mineral aggregate is comprehensively determined through a Marshall compacting experiment to determine the range via the volume parameter of a Marshall test piece and verification on the road properties such as high-temperature rutting resistance and water damage resistance; when the rubber asphalt and the mineral aggregate are mixed and stirred, the heating temperature of the rubber asphalt is 175-180 DEG C and the heating temperature of the mineral aggregate is 10-30 DEG C higher than that of the rubber asphalt; moreover, the dry mixing time of the mineral aggregate is 15-20 s and the wet mixing time of the mineral aggregate is 35-40 s; and the ex-factory temperature of the steel slag and rubber asphalt concrete formed after the mixing and the stirring is 175-185 DEG C. The invention replaces the mineral aggregate by the steel slag, and can recycle the waste materials, save the stone resources, and reduce the destruction from the stone mining to the environment.

Owner:RES INST OF HIGHWAY MIN OF COMM

Mix proportion design method of emulsified asphalt cold-patch mixture

InactiveCN102773923APracticalWell consideredIn situ pavingsMixing operation control apparatusEngineeringRoad surface

The invention belongs to the technical field of roads and urban roads, and specifically relates to a mix proportion design method of an emulsified asphalt cold-patch mixture. The method is characterized by compaction and maintenance technologies of test pieces and determination of optimal total water content and optimal emulsified asphalt consumption. aiming at the special strength forming process of emulsified asphalt materials, different and special compaction methods and maintenance conditions are adopted for different stages of the mix proportion design, so that the optimal total water content and the optimal emulsified asphalt content can be determined, wherein the field actual conditions are simulated and the early damages of asphalt road surfaces are considered in the compaction methods and the maintenance conditions. After the optimal total water content and the optimal emulsified asphalt content are determined, the water stability and anti-stripping capability of the emulsified asphalt cold-patch mixture in the early stage of use are evaluated. The mix proportion design method of the emulsified asphalt cold-patch mixture is comprehensive in consideration and strong in practicability; and the emulsified asphalt cold-patch mixture obtained according to the method can obtain favorable pavement performance.

Owner:SHANGHAI SHENQIAO SCI & TECH DEV

Special concrete using waste and old rubber particle and steel slag particle as aggregate

InactiveCN101921087AImprove volume stabilityImprove the natural environmentSolid waste managementSlagRoad surface

The invention provides a special concrete using waste and old rubber particles and steel slag particles as aggregate, which comprises the following components in parts by mass: 100 parts of cement, 0.1-3 parts of water reducing agent, 0-50 parts of mineral admixture, 0-600 parts of sand, 200-400 parts of steel slag particle, 15-50 parts of rubber particle and 20-80 parts of water. The invention has the advantages that the two wastes of the waste and old rubber particles and steel slag are simultaneously added into concrete, the wastes can be greatly utilized, and the natural environment is improved; the expansion stress of free calcium oxide in steel slag is adsorbed by utilizing the elastic characteristic of the waste and old rubber particles, the steel slag can be utilized without special processing, and the integral volume stability of materials is high; by adding the waste and old rubber particles, the elasticity of the special concrete is higher than that of common concrete; and the special concrete can be widely applied to places in which common concrete, such as road surfaces, parking lots, buildings, and the like can be applied.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Penetration coefficient determination apparatus for permeable asphalt concrete track board test piece, and test method thereof

ActiveCN105203443AReasonable structureSimple and fast operationPermeability/surface area analysisWater storageGraduated cylinder

The invention provides a penetration coefficient determination apparatus for a permeable asphalt concrete track board test piece, and a test method thereof. The determination apparatus comprises a test device and a water supply device, and the test device comprises a workbench, an overflow water tank, an upper sleeve, a lower sleeve, two flanges, an electronic thermometer and a measuring cylinder; the outer sidewall of the upper sleeve is provided with water overflow ports connected with the inside of the upper sleeve, the two same flanges are provided with a ring of a slot, and the two flanges and the sleeve are cemented to form an integral body; the lower sleeve is connected through the overflow water tank, and the overflow water tank is provided with an overflow port and a water drainage port; the test piece is placed between the two flanges, a rubber sealing pad is arranged between each of the flanges and the test piece, the flanges are provided with screw holes, and the test piece is fixed through allowing long bolts to traverse through the screw holes and through using nuts; and the water supply device comprises a water storage barrel, a water pump and a power switch. The apparatus has the advantages of reasonable structure, simple operation, satisfactory solving of the seepage problem of the side wall, realization of flexible control of hydraulic gradient, and reasonable and reliable determination result.

Owner:YANGZHOU UNIV

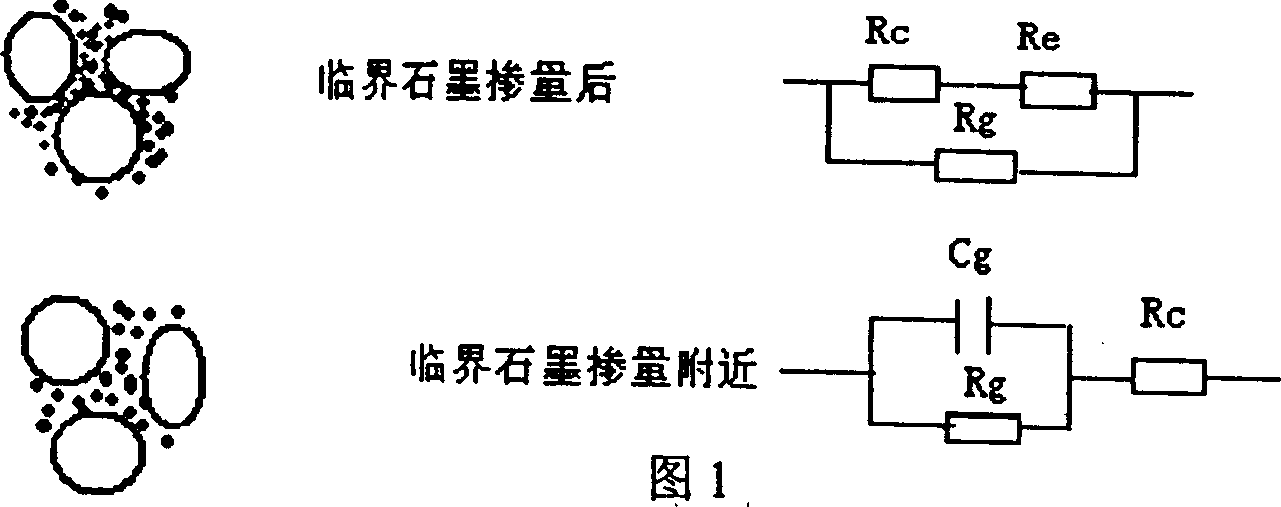

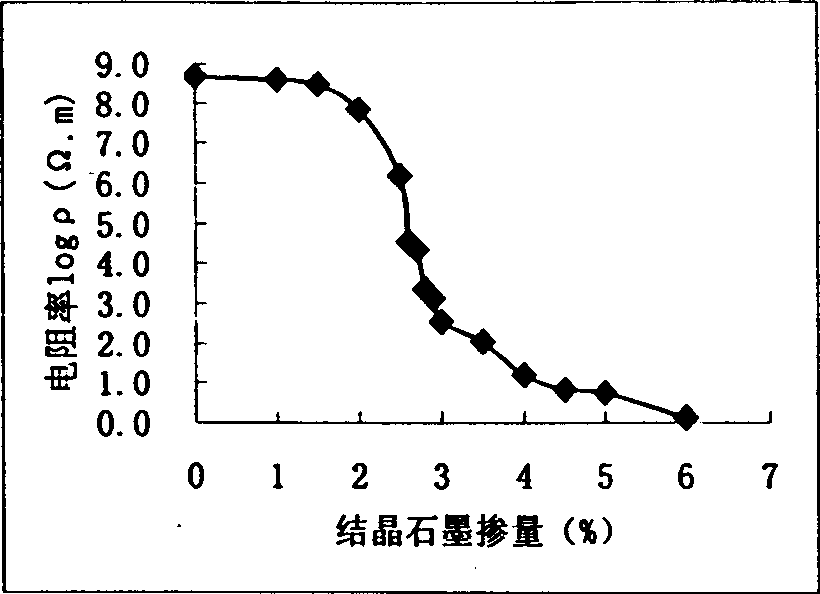

Conducting asphalt concrete and its prepn process

InactiveCN1403401AImprove electrical performanceImprove road performanceNon-conductive material with dispersed conductive materialFiberCarbon fibers

The conducting asphalt concrete consists of coarse aggregate, fine aggregate, slag powder filler, asphalt, and graphite powder, carbon fiber or steel fiber as conducting material. The preparation process includes heating aggregate and asphalt to 170 deg.c and mixing, mixing with other material, compacting via Marshall process or rolling to form. The present invention improves the electrical performance and other performance of asphalt road.

Owner:葛洲坝武汉道路材料有限公司

Method for preparing high-quality recycled fine aggregates by utilizing waste concrete

InactiveCN102010144ALow water absorptionReduce the water demand ratio of mortarSolid waste managementResource protectionSingle stage

The invention belongs to the field of building materials and relates to a method for preparing recycled fine aggregates with waste concrete as a raw material. The method comprises the following steps: collecting waste concrete and utilizing crushing equipment to crush the concrete to aggregate particles with maximum size being not beyond 5-10mm through single-stage crushing or multi-stage crushing; utilizing strengthening equipment to remove the mortar and cement paste adhering to the surfaces of the aggregate particles, eliminate the protruding edges of the aggregate particles and ensure the appearances of the aggregate particles to be smooth to realize strengthening treatment of the aggregate particles and removing dust in the strengthening treatment process; and screening the strengthened aggregate particles and removing dust in the screening process, thus obtaining the particles with size being not beyond 5mm, namely the finished products. The method has strong applicability and high waste utilization rate, provides a feasible new way for recycling various waste concrete and has great significance in environment protection and resource protection and even sustainable social development.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

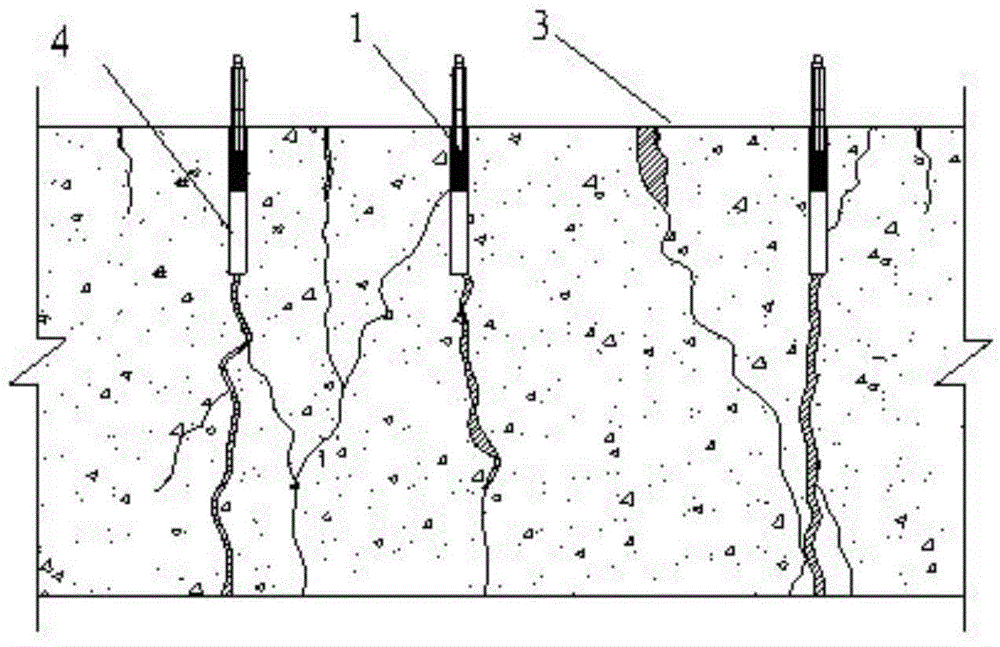

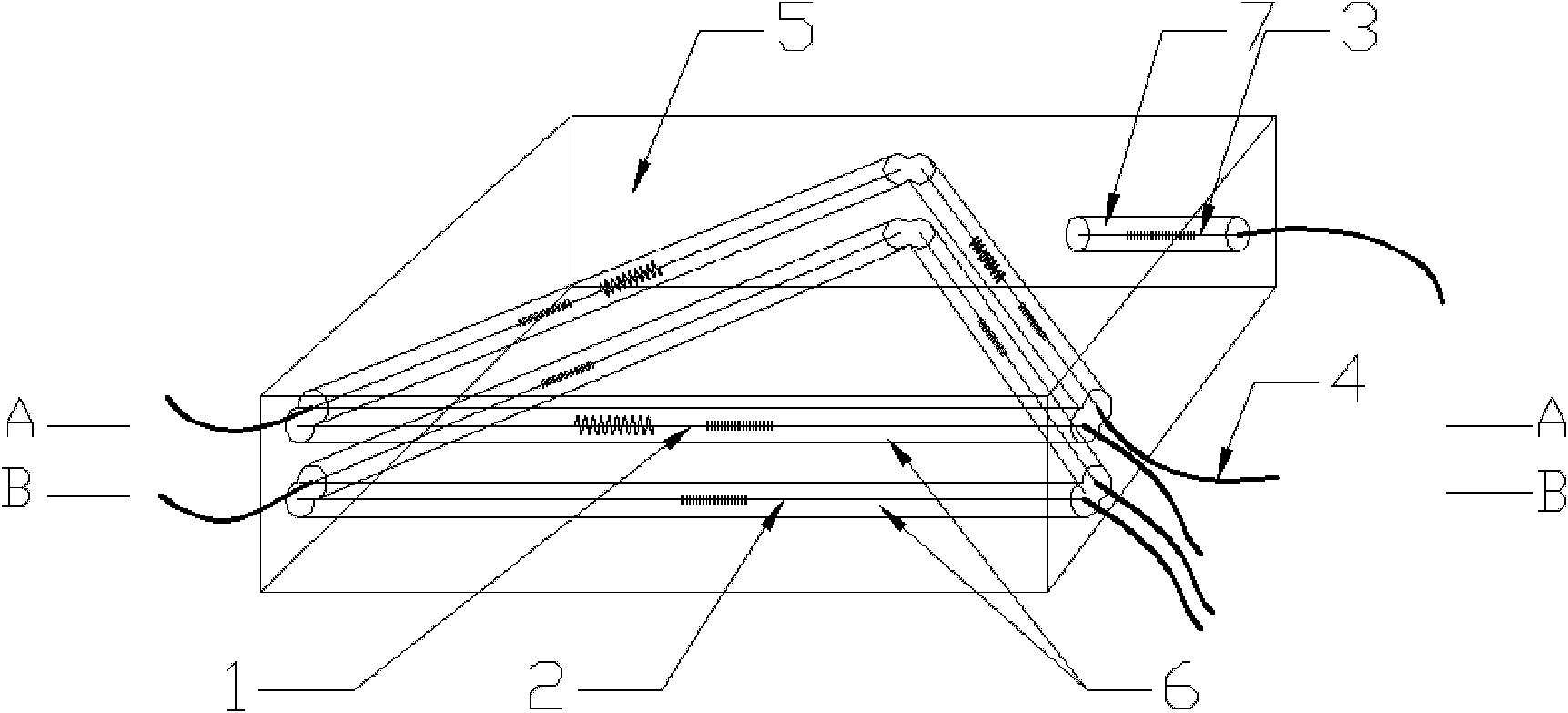

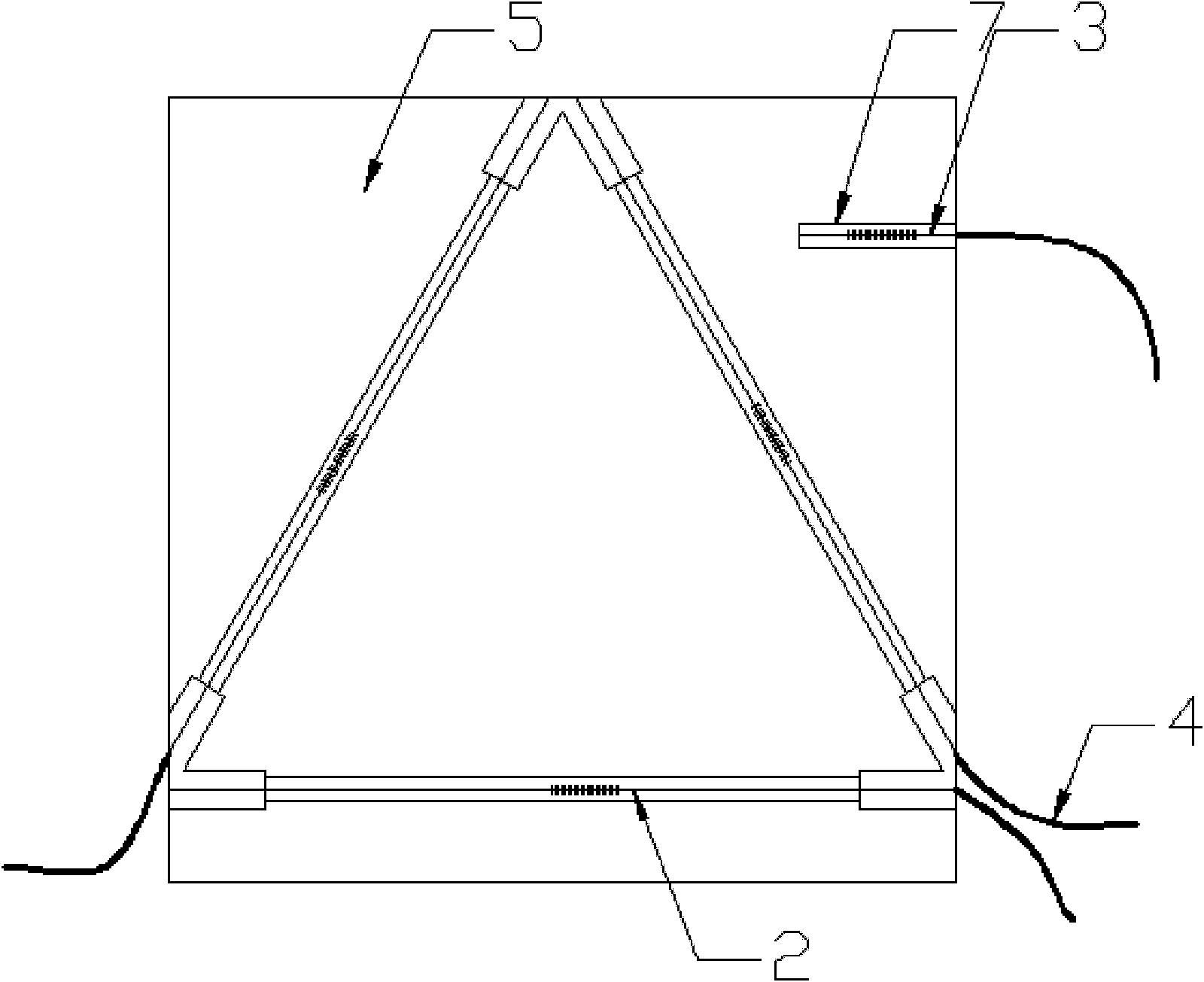

Packaged FBG Sensors for Strain and Crack Tests on Asphalt Concrete Pavements

InactiveCN102278947ASimple processSuitable for industrial productionForce measurement by measuring optical property variationMaterial analysis by optical meansGratingCrazing

The invention discloses a packaged FBG (Fiber Bragg Grating) sensor for strain and crack test of bituminous concrete road surface. The sensor comprises three spring FBGs, three pure FBGs, a prefabricated bituminous concrete packaging structure, six through grooves, a temperature sensing groove, a temperature sensor and an armored cable, wherein the three spring FBGs and the three pure FBGs are respectively embedded into the upper and lower layers of through grooves; then, one ends of the spring FBGs and one ends of the pure FBGs are fixedly connected with the bituminous concrete packaging structure by glue; the spring FBGs and the pure FBGs are applied with prestress, and then the other ends of the six groups of FBGs are fixedly connected; the temperature sensor is embedded into the temperature sensing region; and finally, the armored cable is connected with the six groups of educed FBGs and the temperature sensor. The sensor disclosed by the invention has the advantages of simple process, convenience for laying, high precision and large measuring range, can realize the monitoring of main stress direction and size of the bituminous concrete road surface, is suitable for inside change of the bituminous concrete rod surface in health monitoring of civil engineering structures and is also suitable for industrialization.

Owner:DALIAN UNIV OF TECH

Preparation method for asphalt concrete with conduction function

InactiveCN101215124ALow costAlleviate problems such as insufficient aggregateSolid waste managementForeign matterMaterials preparation

The invention relates to a process for preparing asphaltic concrete with conducting function, which is characterized in that the process includes the procedures of 1), preliminary treatment of aggregates, which means washing away the foreign matters of the steel slag with water. 2), raw materials preparation, which means that the percentage by weight of each component is that rough aggregates is 55%-80%, fine aggregates is 13%-30%, mineral filler is 7%-15%, the rough aggregates, fine aggregates and mineral filler are selected to reserve as aggregates, consumption of asphalt cement is 6%-8% of the weight of the aggregates, consumption of fabric stabilizer is 0.1%-0.5% of the gross weight of the aggregates and the asphalt cement, consumption of conducting material is 10-30% of the weight of the asphalt cement, and gradation design of SMA mixture is employed. 3), mixture blending, which means charging fractionally and blending multitime, the temperature is kept not lower 150 DEG C when molding. The preparing process has simple technique and low cost. The prepared asphaltic concrete has good conducting function and pavement using property.

Owner:WUHAN UNIV OF TECH

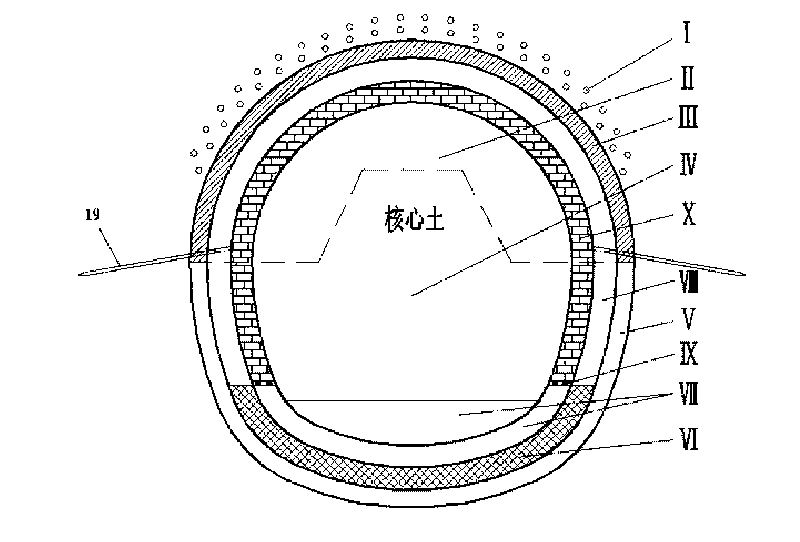

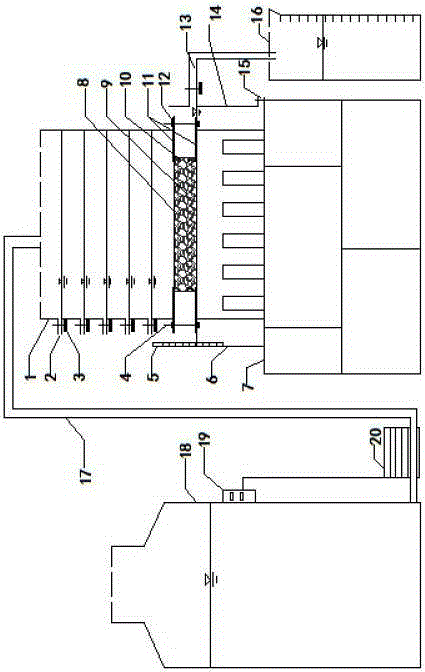

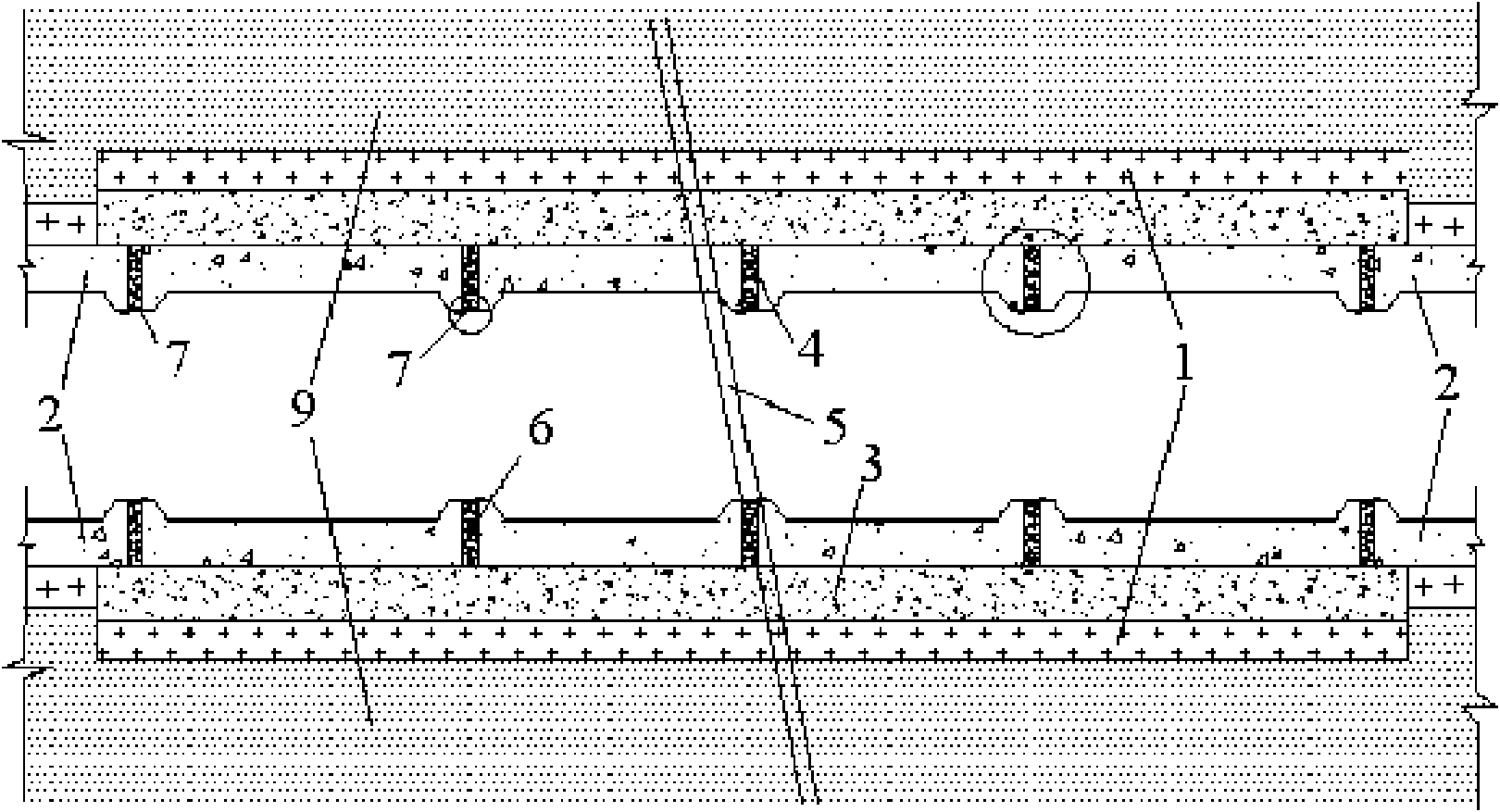

Anti-seepage structure of composite lining deformation joints of ground fissure stratum tunnel and construction method thereof

InactiveCN101603429APrevent rheological deformationUnderground chambersTunnel liningGlass fiberReinforced concrete

The invention discloses an anti-seepage structure of composite lining deformation joints of a ground fissure stratum tunnel. A primary supporting lining, an asphalt concrete lining and a reinforced concrete lining are sequentially paved from the wall rock to the interior of the tunnel; a plurality of deformation joints are pre-preserved in the reinforced concrete lining; end part linings embedded with bases and injected holes are arranged on two sides of the deformation joints; the bases are connected with a retractable baffle device; glass fiber cloth is paved between the retractable baffle device and the deformation joints; a plurality of cavities consist of the asphalt concrete lining, the asphalt concrete lining at two ends of each deformation joint and the glass fiber cloth; and matrix asphalt anti-seepage bodies are poured into the cavities. The invention also discloses a construction method of the structure, which comprises the following steps: firstly, casting a composite lining structure and preserving deformation joints; secondly, casting end part linings on two sides of the deformation joints, and arranging the deformation joints and glass fiber cloth; and finally poring the matrix asphalt anti-seepage bodies. The anti-seepage structure has good rheological characteristic and anti-seepage performance, and is convenient to repair.

Owner:XIAN UNIV OF TECH

High-performance low-noise asphalt pavement conserving material and preparation method thereof

The present invention relates to a high-performance low-noise asphalt pavement maintaining material and the preparing method thereof, the maintaining material is mainly composed of conventional micro-surfacing asphalt concrete and waste rubber powder and polymer fiber, and the content of the waste rubber powder and polymer fiber respectively accounts for the gross weight of the micro-surfacing asphalt concrete 1-5% and 0.1-0.3%. The maintaining material preparing method is mixing the waste rubber power and the polymer fiber and the dry mixture of the prescribed grading aggregate to uniform, then adding filling agent, water and modified emulsified asphalt in sequence, and mixing to uniform. The material of the invention is improved with the bonding capacity to the original asphalt pavement because of the adding of the waste rubber powder and the polymer fiber, the capacity of the micro-surfacing asphalt concrete is increased, the excellent high-temperature-resisting track and low-temperature cracking capacity is facilitated to be possessed, has the advantages of excellent water-proofing and water-resisting property, excellent noise reducing, skid resistance, abrasion-proofing, impact resistance, cracking resistance and freeze-thaw resistance; and the material of the invention has the advantages of simple preparing method, low construction cost and less environmental pollution and the like.

Owner:WUHAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com