Method for repairing crack of asphalt concrete pavement

A technology for asphalt concrete and pavement cracks, which is applied in the field of pavement crack repair. It can solve the problems of insufficient penetration of repair materials, easy aging, and non-environmental protection. It can improve the ability of vehicle load and environmental factors, improve structural strength, and extend The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

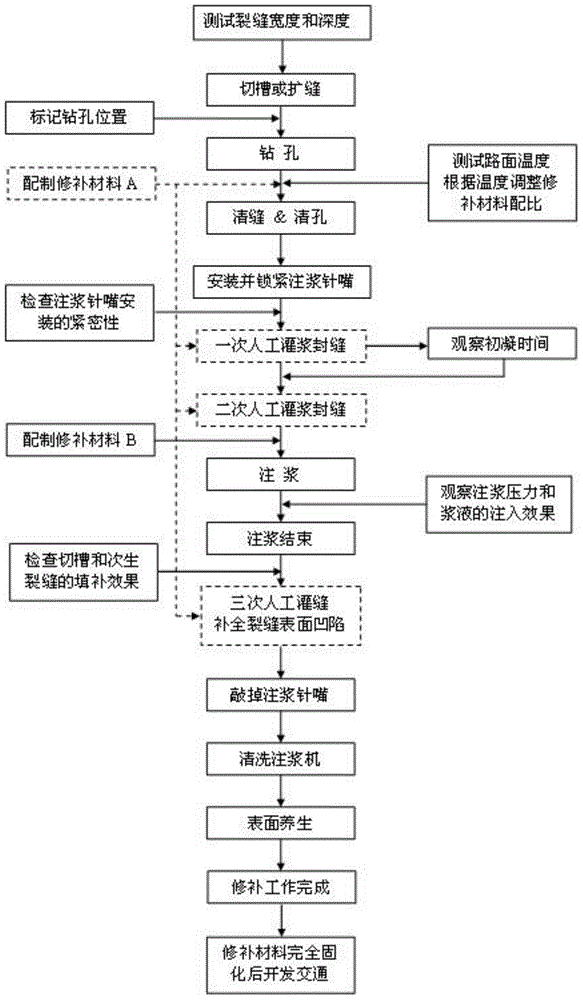

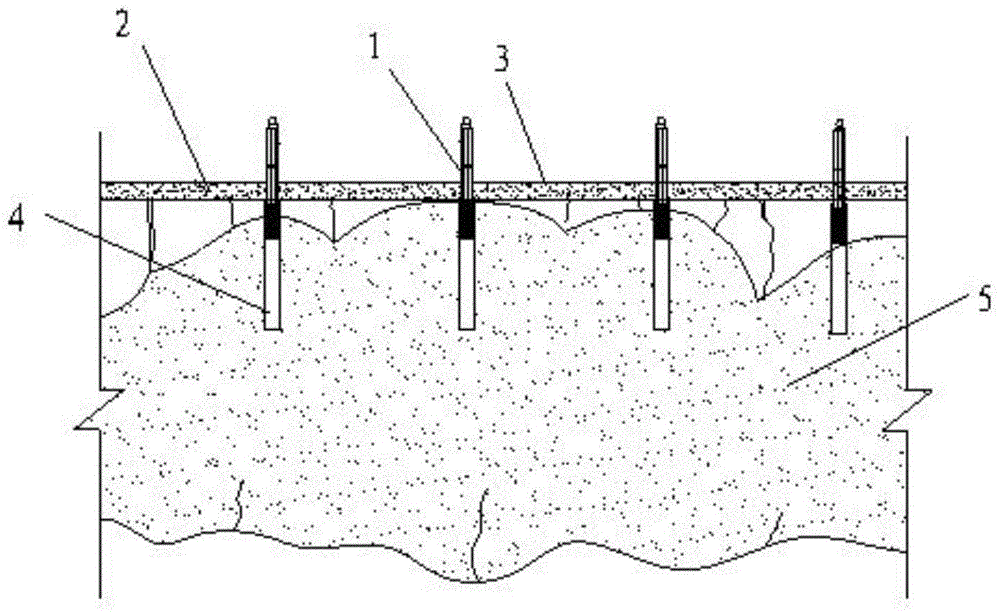

[0056] For serious structural damage cracks and through cracks such as reflection cracks formed by subgrade settlement and pavement hollowing out, the width is generally more than 5 mm, and drilling pressure grouting is suitable at this time. The repair method of drilling pressure grouting specifically includes the following steps:

[0057] S1: Groove or expand along the direction and shape of the crack to obtain slot 2;

[0058] S2: Remove impurities, debris and loose and broken concrete on the wall surface of slot 2 that affect the bonding effect, and expose a solid wall surface;

[0059] S3: According to the damage condition of the crack, select the drilling point along the slot 2, and drill the hole after the drilling point is determined, and clean the hole 4 and the slot 2 after the hole is drilled;

[0060] S4: install the lower end of the grouting nozzle 1 into the hole 4, the height of the grouting nozzle 1 is higher than the road surface 3;

[0061] S5: filling the ...

Embodiment 2

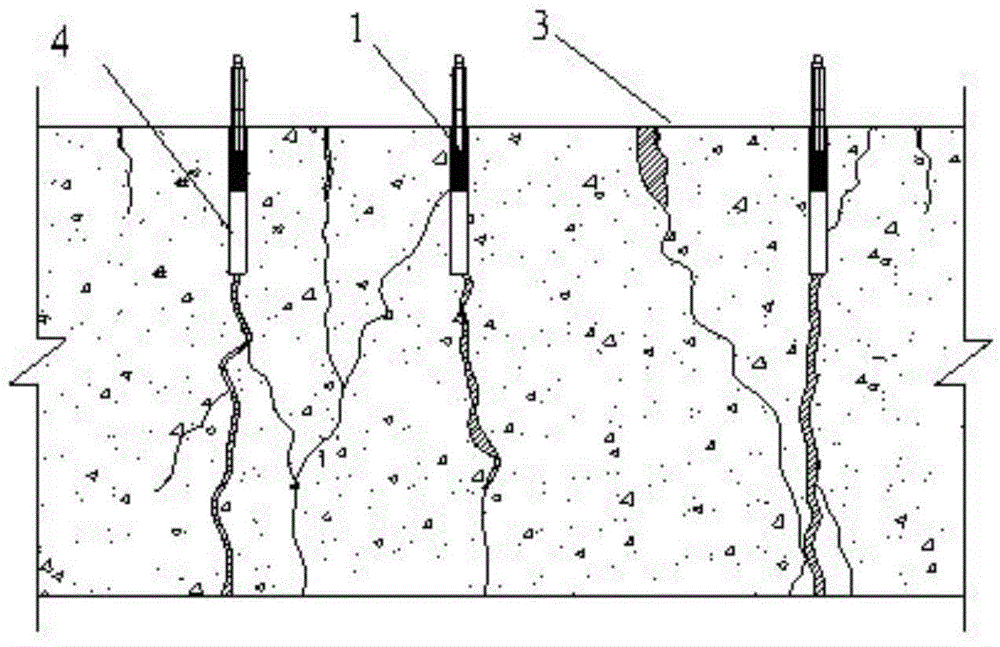

[0085] For road surface fatigue cracks, temperature cracks and secondary cracks with large width and depth, etc., the width is generally 3-5 mm. At this time, the repair method of slotting and filling is suitable. The method for slotting and filling joints comprises the following steps:

[0086] Step S1: slotting or expanding along the direction and shape of the crack to obtain slot 2;

[0087] Step S2: removing impurities, debris and loose and broken concrete on the wall surface of the slot 2 that affect the bonding effect, exposing a solid wall surface;

[0088] Step S3: According to the damage of the crack, select a drilling point along the slot 2, and perform drilling after the drilling point is determined, and clean the hole 4 and the slot 2 after the hole is drilled;

[0089] Step S4: pouring repair material along the slot 2 until the sealing is completed.

[0090] During the specific repairing process, the pouring of the repairing material can be carried out by using ...

Embodiment 3

[0093] For the initial cracks such as micro cracks at the corners or secondary cracks derived from the main cracks, the width is generally within 3mm and the cracks are relatively shallow. At this time, it is suitable to use the non-destructive filling method. Non-destructive perfusion repair does not need to go through slits and expansions, and specifically includes the following steps:

[0094] Step S1: According to the damage condition of the cracks on the road surface 3, select drilling points along the cracks on the road surface 3, and perform drilling after the drilling points are determined;

[0095] Step S2: cleaning the drilled holes 4 and cracks;

[0096] Step S3: pouring repair material into the crack until the sealing is completed.

[0097] In the specific implementation process, compressed air can be used to blow away the sundries and dust in the cracks when cleaning the cracks, and then the spray gun of the grouting machine can be used to pour repair materials int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com