Patents

Literature

572results about How to "Reduce maintenance and repair costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

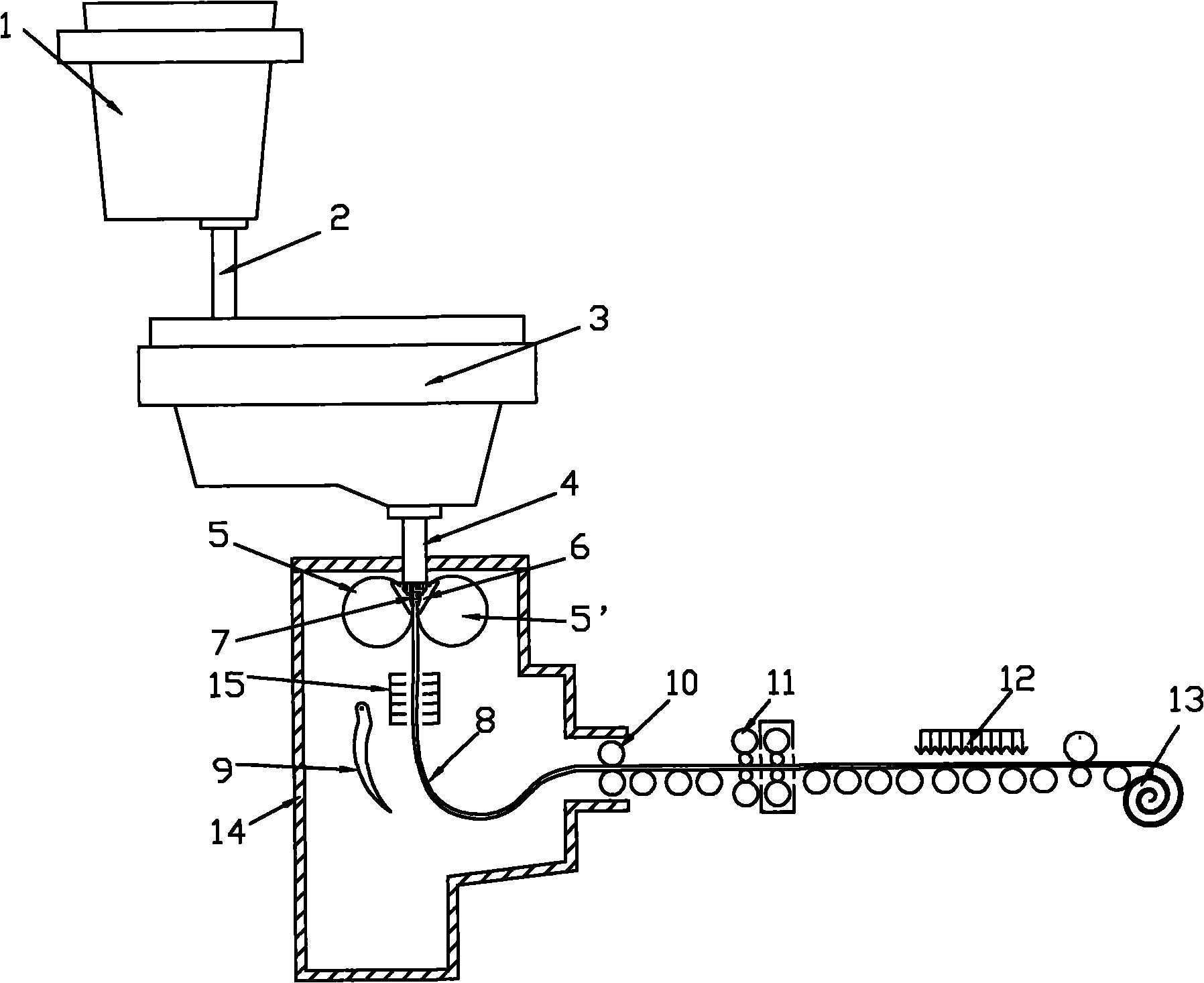

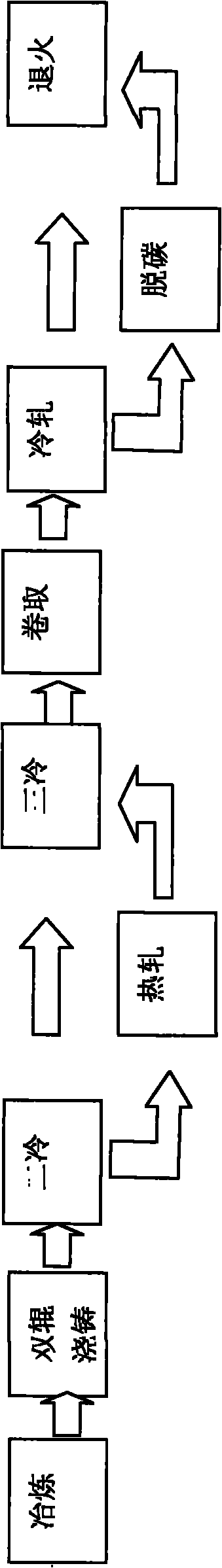

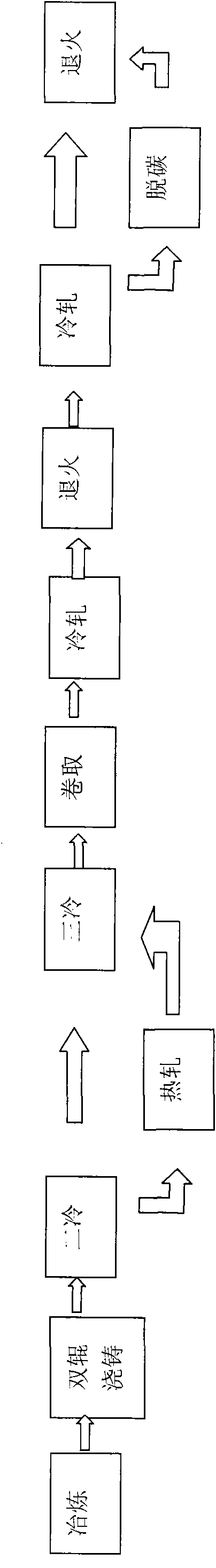

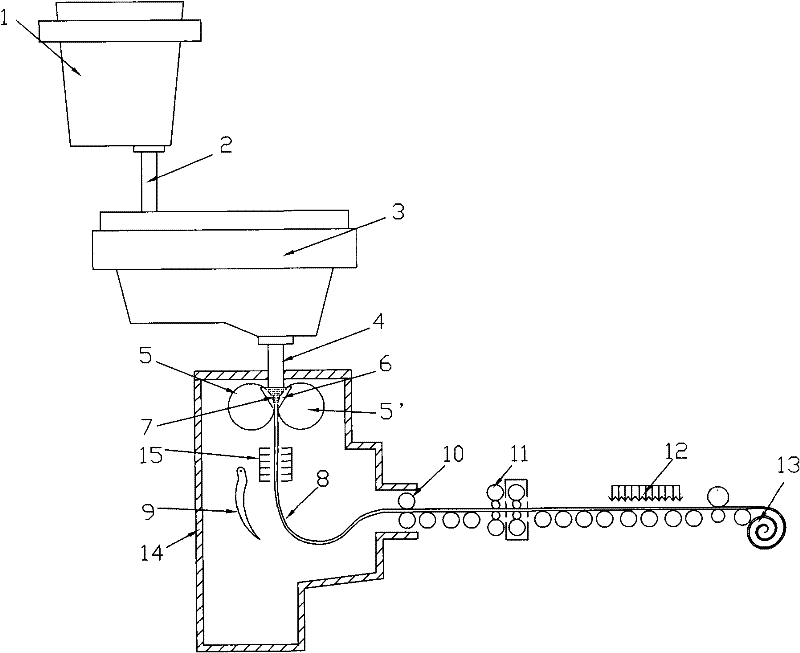

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

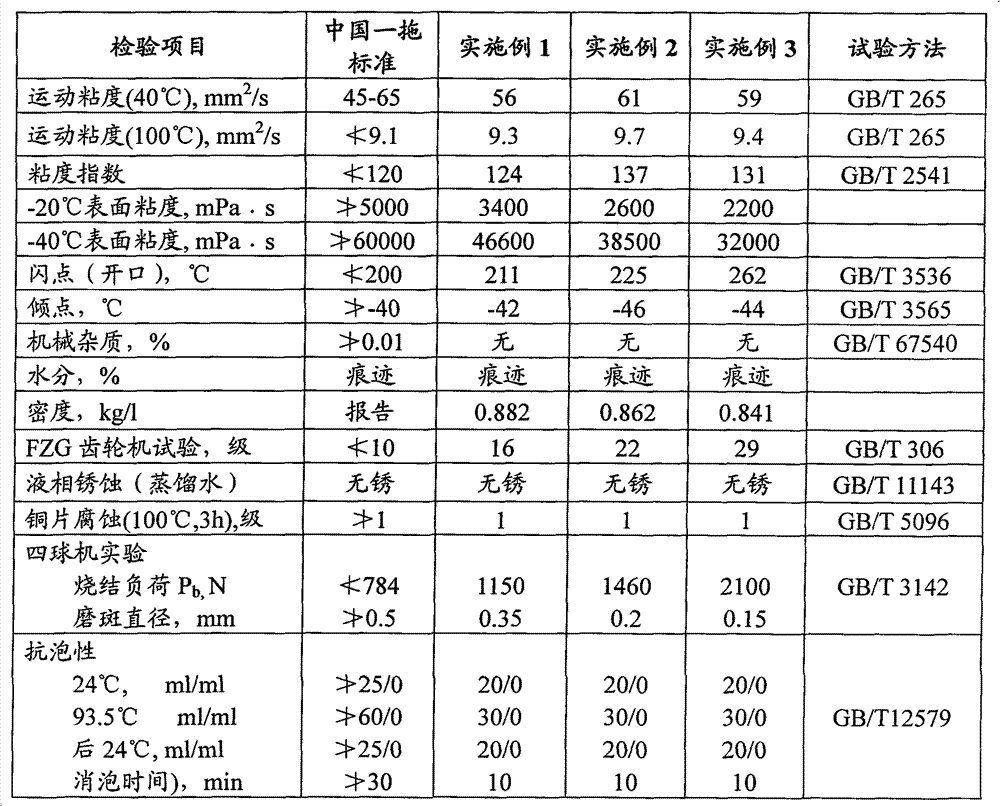

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

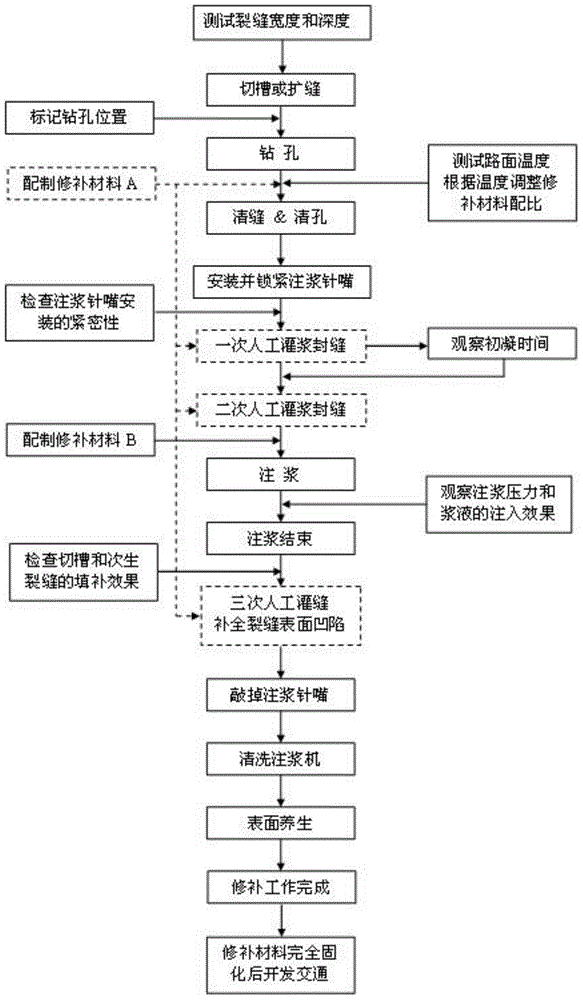

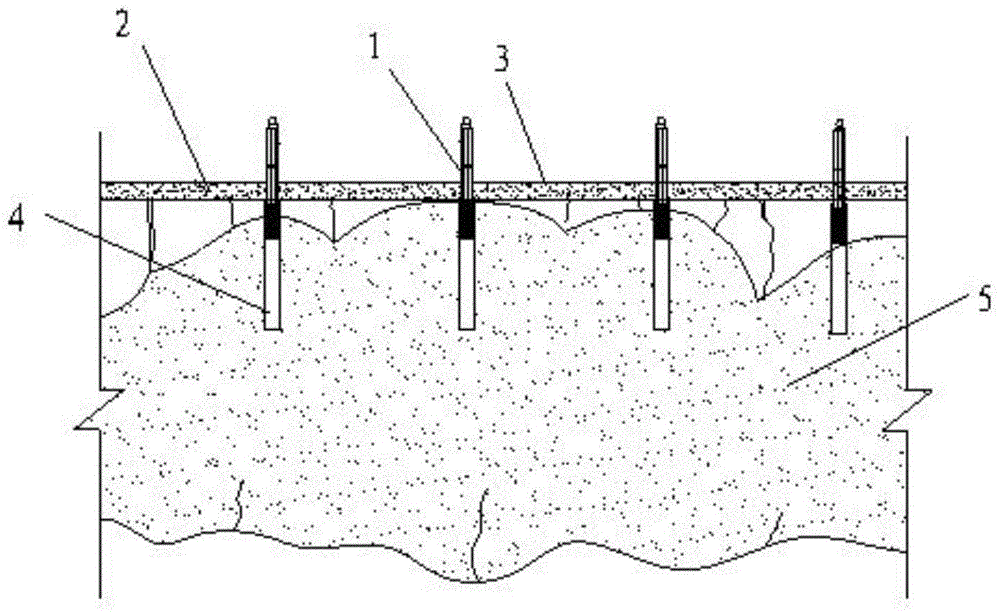

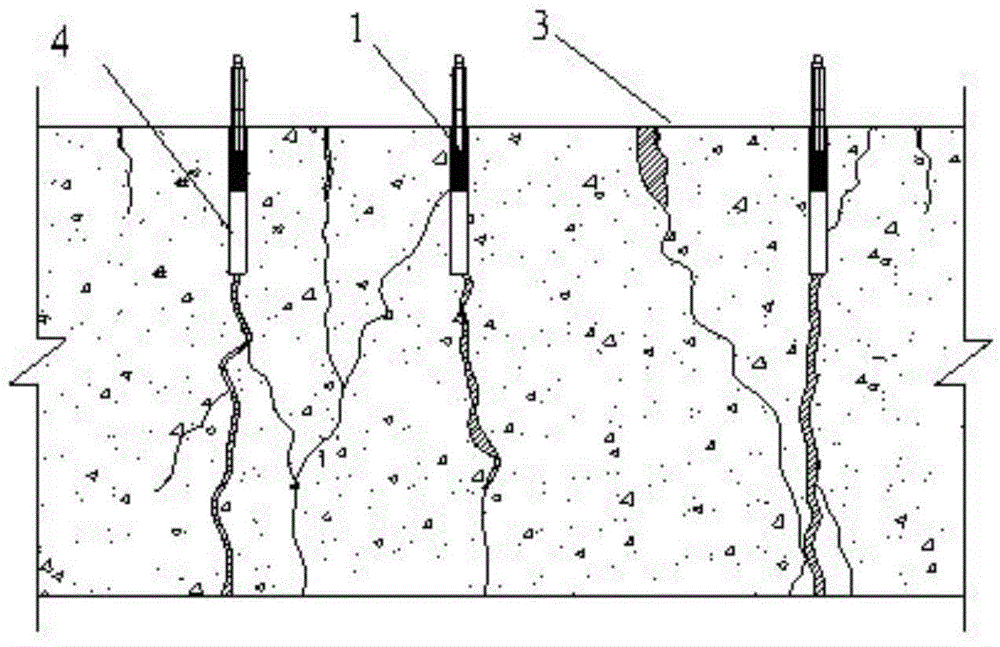

Method for repairing crack of asphalt concrete pavement

InactiveCN104480844AExtended service lifeEffective guidancePaving detailsRoads maintainenceSurface layerRepair material

The invention relates to the technical field of repair of a pavement crack, and provides a method for repairing a crack of an asphalt concrete pavement. According to the method, the pouring of the crack is saturated by effectively guiding a repair material through a mode of drilling along the crack of the pavement or along a slit obtained by slotting and crack expansion, so that the adhesive force between the repair material and the pavement is increased, and the structural strength of the repaired crack is enhanced; the adhesion area of an integral structure formed by a self hole and the crack is enlarged, and the connection between the repair material and the pavement is only limited to the upper part of a surface layer, so that the connected relation between the repair material and an original pavement is further consolidated. In conclusion, According to the method disclosed by the invention, the capability of resisting the influence of vehicle loads and environmental factors by the asphalt concrete pavement can be greatly improved, the service life of the asphalt concrete pavement can be prolonged, and the maintenance and repair cost of a highway can be outstandingly reduced.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

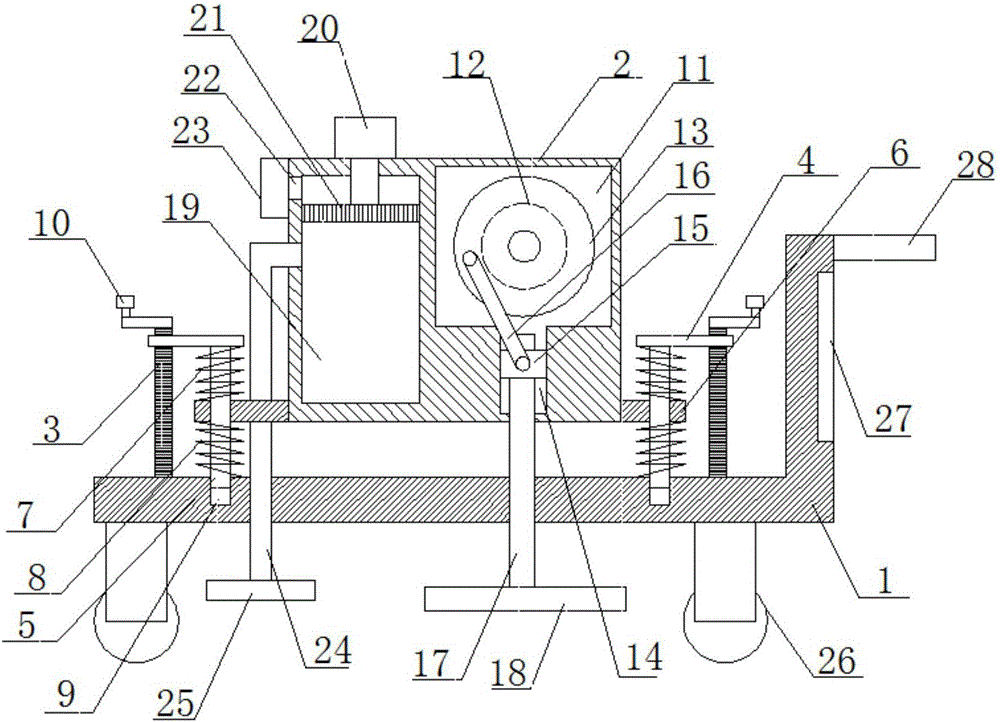

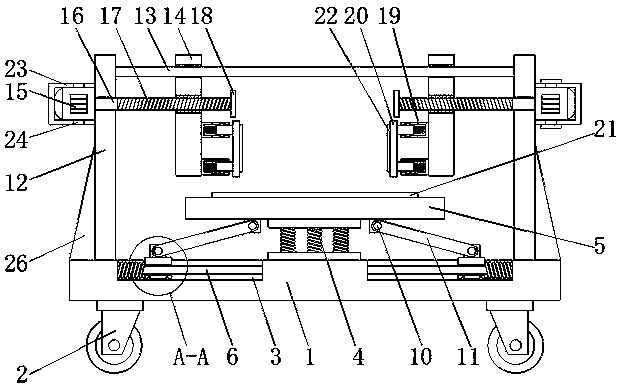

Rammer compactor used for building construction

InactiveCN106522070AAvoid frequent replacementGuaranteed flexibilityRoads maintainenceArchitectural engineeringEngineering

The invention discloses a rammer compactor used for building construction. The rammer compactor comprises a base frame and a box body. Threaded rods are arranged at the left end and the right end of the upper side of the base frame through connecting seats, the threaded rods are connected with adjusting plates in a thread mode, and a supporting rod is arranged at the lower ends of the adjusting plates; connecting plates are symmetrically arranged on the left and right sides of the box body, the connecting plates are connected with the supporting rod in a sliding mode, and upper damping springs and lower damping springs are arranged on the upper side and the lower side of the connecting plates of the connecting plates correspondingly; a motor cavity is formed in the right portion of the box body, an impurity absorption cavity is formed in the left portion of the box body, and an air inlet is formed in the upper portion of the left side of the impurity absorption cavity; a draught fan is arranged on the outer portion of the air inlet, an impurity absorption tube is connected to the draught fan, and the lower end of the impurity tube stretches out of the lower end of the base frame and is provided with an impurity absorption cover; a telescopic device is arranged at the upper end of the impurity absorption cavity, the lower end of the telescopic device stretches into the impurity absorption cavity, and a dust filter plate is arranged at the lower end of the telescopic device. According to the rammer compactor, the structure is simple, the using is convenient, the damping effect is good, maintenance cost is lowered, and the tamping quality is improved.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

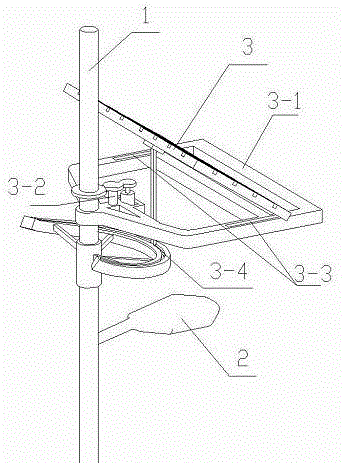

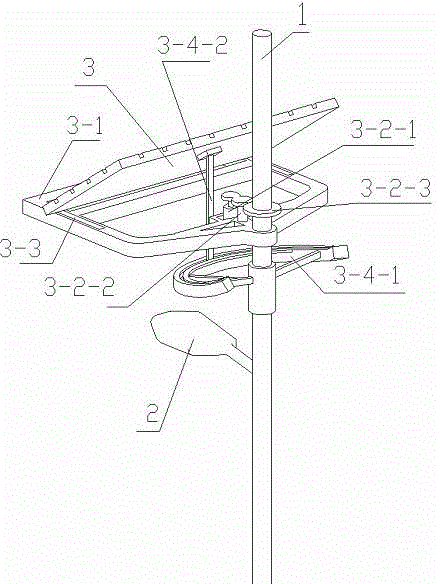

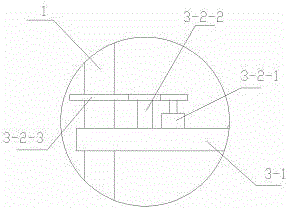

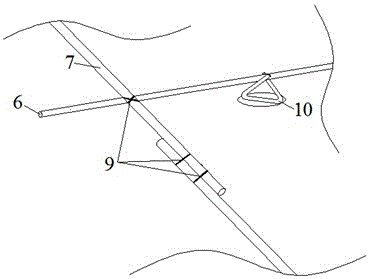

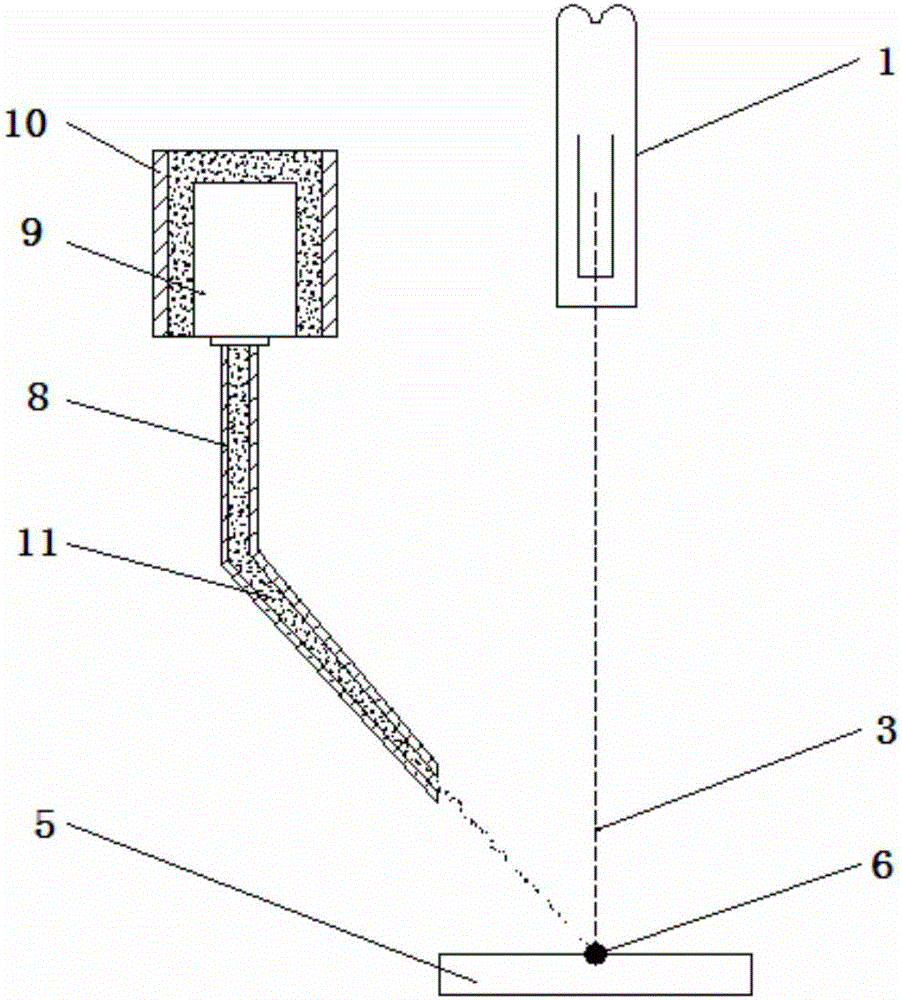

Sun-chasing device applied to solar street lamp

InactiveCN104613405AImprove photoelectric conversion efficiencySimple structurePhotovoltaic supportsSolar heating energySolar street lightEngineering

The invention discloses a sun-chasing device applied to a solar street lamp, and belongs to the field of solar power generation devices. The sun-chasing device structurally comprises a rotating support and a solar cell panel, wherein the rotating support is hinged to a lamp pole, and the solar cell panel is arranged on the rotating support. The sun-chasing device is characterized in that with the help of a rotating driving mechanism, the rotating support forms a horizontal rotation driving structure, and with the help of combined limiting of a horizontal movement mechanism and an angle adjusting and limiting mechanism, the solar cell panel forms a linkage type perpendicular rotation adjusting structure. Through a combined limiting device composed of the horizontal rotation driving structure and the linkage type perpendicular rotation adjusting structure, the alignment angle and light-receiving angle of the solar cell panel can be adjusted in real time according to the sun motion, it is ensured that the solar cell panel works at the maximum photoelectric conversion efficiency, and the sun-chasing device is simple in structure and high in reliability.

Owner:JULU SHENTONG LAMPS

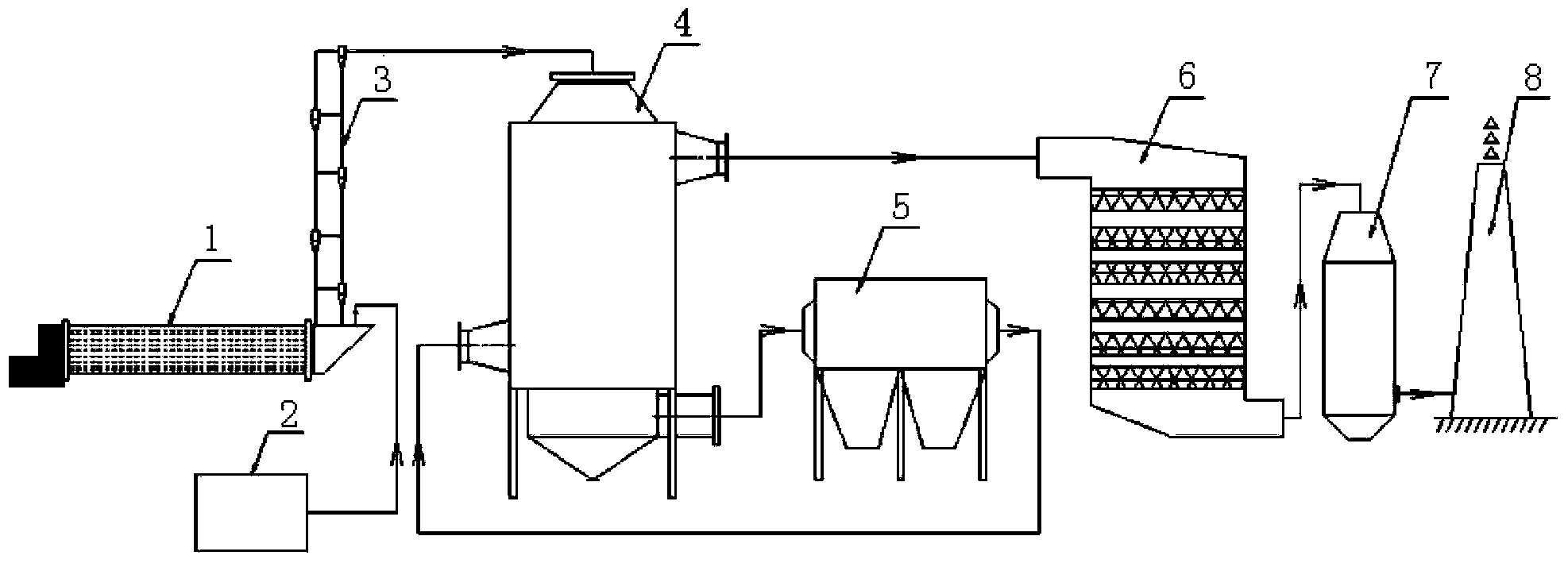

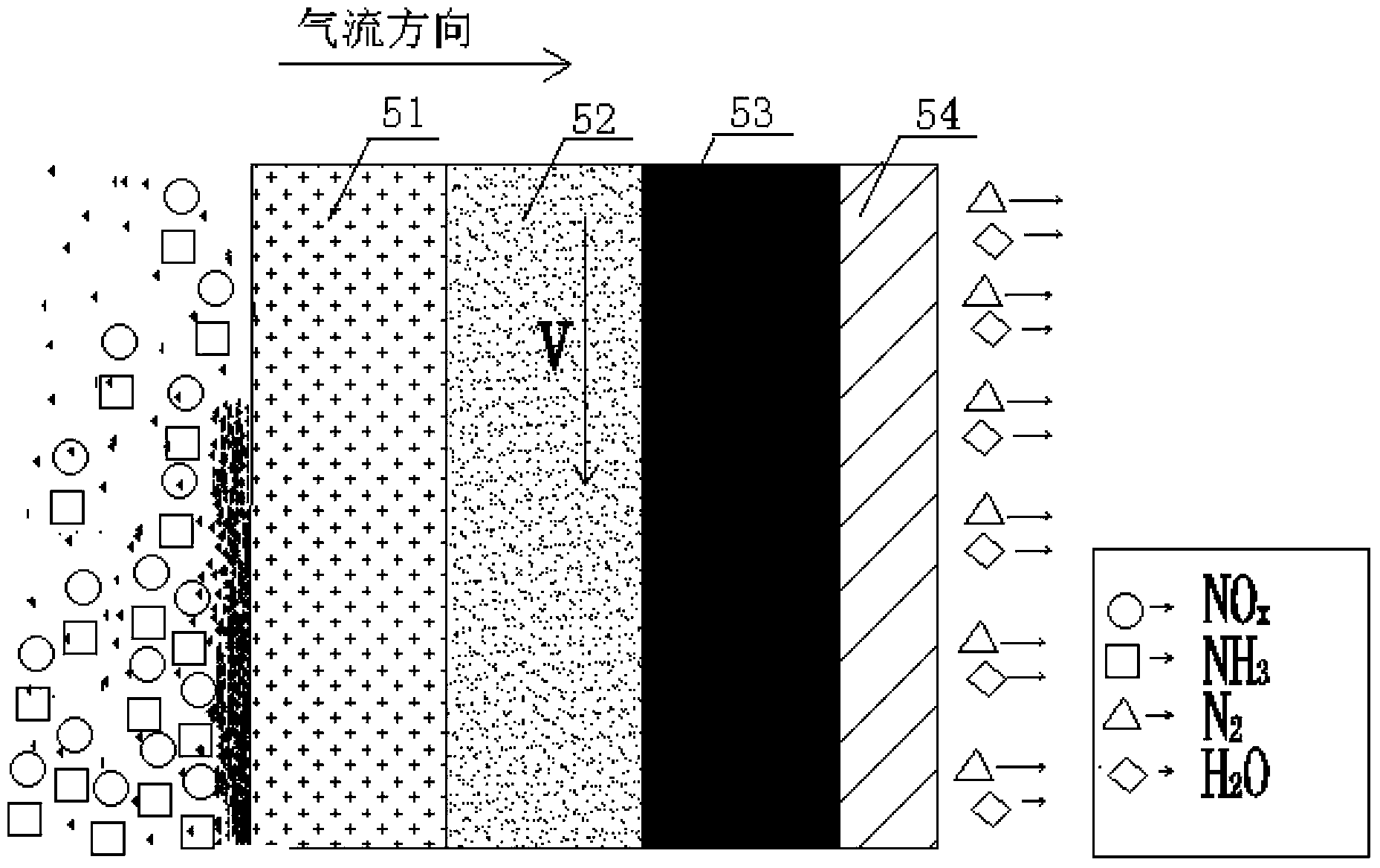

SCR (Selective Catalytic Reduction) denitration device for NOx control of rotary cement kiln

InactiveCN103406006AImprove denitrification efficiencyReduce wearCombination devicesLighting and heating apparatusFlue gasProcess engineering

The invention discloses an SCR (Selective Catalytic Reduction) denitration device for NOx control of a rotary cement kiln, wherein the rotary cement kiln is connected with a heat exchanger; a reducing agent injection system is arranged at the kiln tail part of the rotary cement kiln; the flue gas outlet of the rotary cement kiln is connected with the high-temperature flue gas inlet of the heat exchanger; the low-temperature flue gas outlet of the heat exchanger is connected to the flue gas inlet of a bag type dust collector; the outlet of the bag type dust collector is connected to the low-temperature flue gas inlet of the heat exchanger; the high-temperature flue gas outlet of the heat exchanger is connected to the flue gas inlet of an SCR reactor; the flue gas inlet of a desulfurizing tower is connected with the flue gas outlet of the SCR reactor. The three denitration technologies of SNCR (Selective Non-Catalytic Reduction), integrated dust collection and denitration and SCR are combined so that the flue gas of the rotary cement kiln is denitrated three times; specifically, firstly, NOx in the high-temperature flue gas has a selective non-catalytic reaction with a reducing agent at the tail of the kiln; secondly, the bag type dust collector provided with a denitration-functional catalytic filter bag is used for dust removal and secondary denitration; finally, the third time of denitration is performed in the SCR reactor; as a result, the denitration efficiency is greatly improved.

Owner:ANHUI YUANCHEN ENVIRONMENTAL PROTECTION SCI & TECH

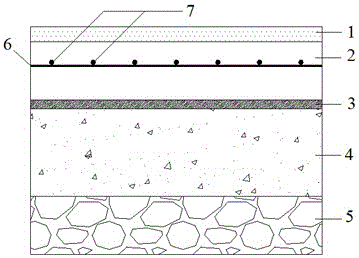

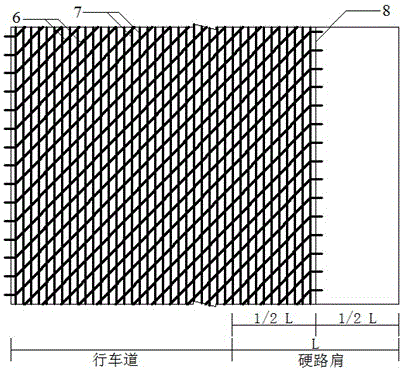

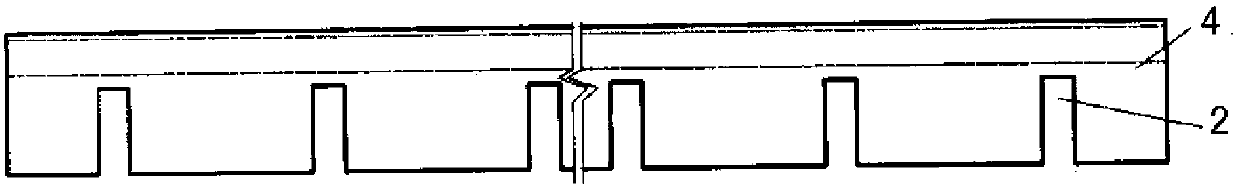

Cement concrete pavement structure provided with continuous steel bars

ActiveCN104988823AReduce maintenance and repair costsGood driving comfortPaving reinforcementsIn situ pavingsRoller-compacted concreteCrushed stone

The invention discloses a cement concrete pavement structure provided with continuous steel bars. The pavement structure comprises a base layer. Roller compacted concrete is adopted in the base layer. A broken stone hardcore is laid below the base layer. Cement concrete surface layers are laid on the base layer. The cement concrete surface layers include the upper surface layer and the lower surface layer. Rubber cement concrete is adopted in the upper surface layer. A transverse induction kerf is arranged on the edge of the upper surface layer on the left side of the driving direction. The continuous transverse steel bars, the continuous longitudinal steel bars and a slidable support are arranged at the portion, within the range of a carriageway and one half of the width (L) of a hardened verge, of the lower surface layer. Plain concrete is formed at the portion, within the other half of the width (L) of the hardened verge, of the lower surface layer. A longitudinal joint is arranged at the portion one half of the width of the hardened verge. A bituminous concrete anti-scouring layer is arranged between the base layer and the surface layers. The pavement structure can solve the problems of existing cement concrete pavements and continuous reinforced concrete pavement structures and can be widely applied to high-grade highways, tunnel pavements and the like on the heavy-duty traffic condition.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

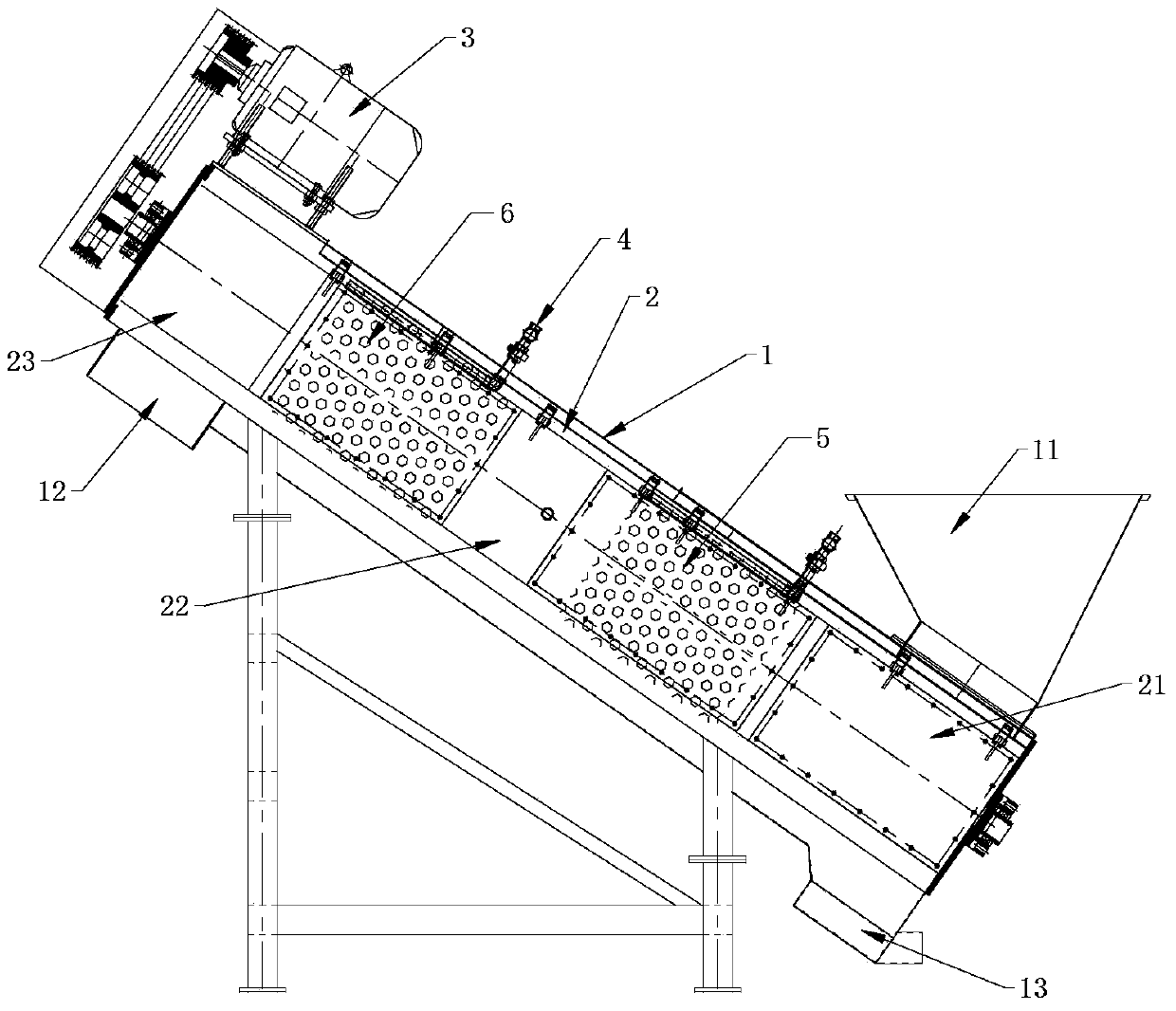

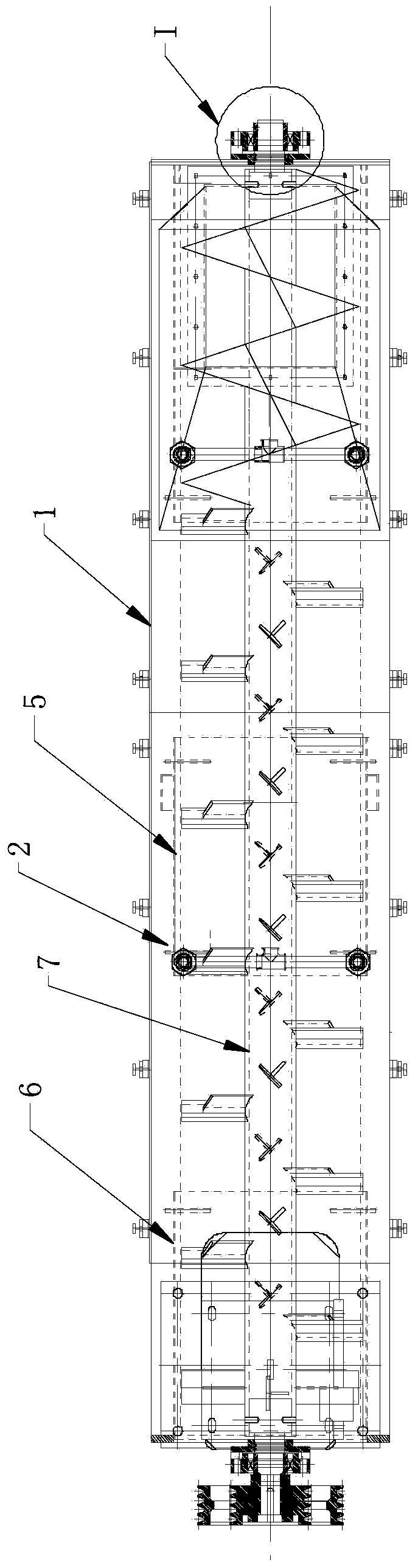

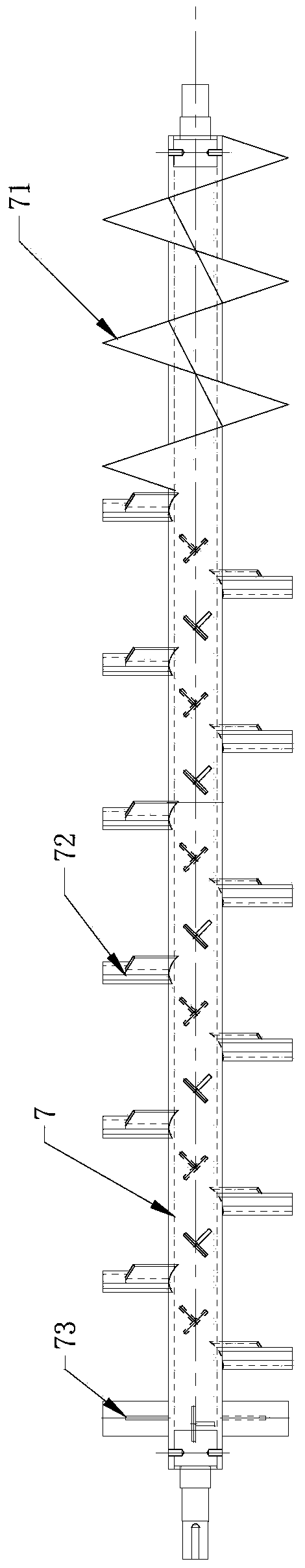

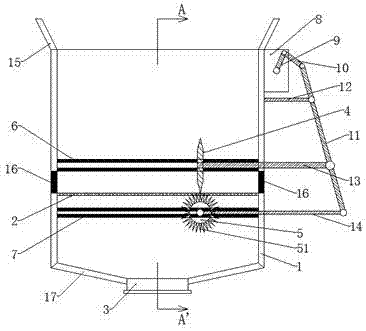

Waste plastic thin film friction washing machine

The invention discloses a waste plastic thin film friction washing machine, which comprises an enclosure, an inner barrel and a main shaft, wherein the inner barrel is axially and fixedly arranged in the enclosure, and comprises a charging friction section, a discharging section and a middle friction section; a first tubular screen is arranged between the charging friction section and the middle friction section, and a second tubular screen is arranged between the discharging section and the middle friction section; the main shaft is arranged in the enclosure in a rotating way, and is driven by a main shaft power device to rotate; a helical pushing blade is arranged within the range of the charging friction section on the main shaft, a plurality of discharging blades are arranged within the range of the discharging section on the main shaft, and friction stirring blades are arranged within a range between the charging friction section and the discharging section on the main shaft; flushing water pipes for flushing the first and second screens and a water supply pipe orifice for supplying water to the inner barrel are arranged on the enclosure. According to the washing machine, the strength of the enclosure of the washing machine can be ensured, and meanwhile, the areas of the screens can be enlarged, so that the sewage discharge efficiency of the washing machine is improved, and a material can be washed long enough in the inner barrel in a friction way.

Owner:ZHANGJIAGANG LIANDA MACHINERY

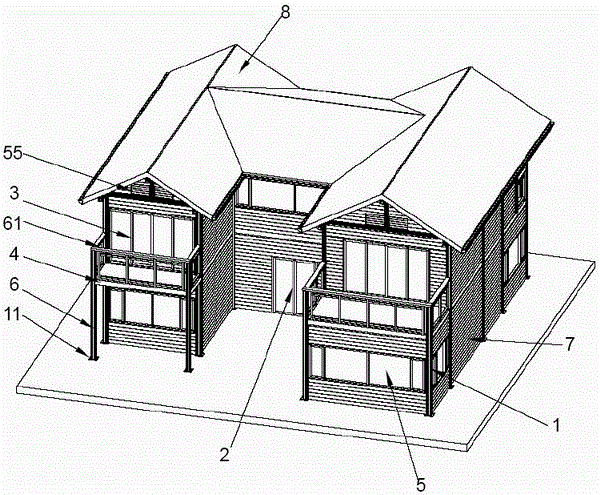

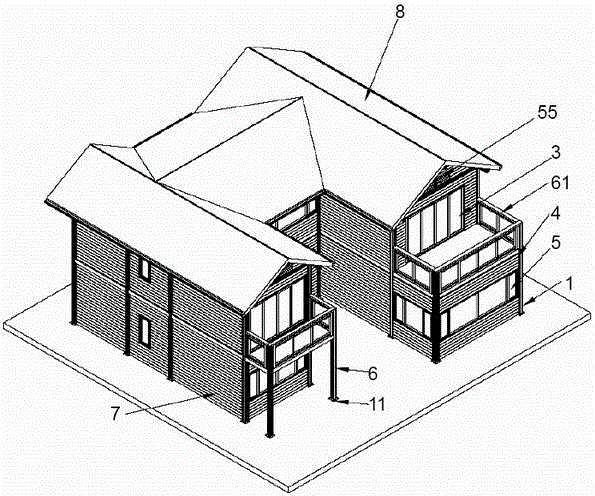

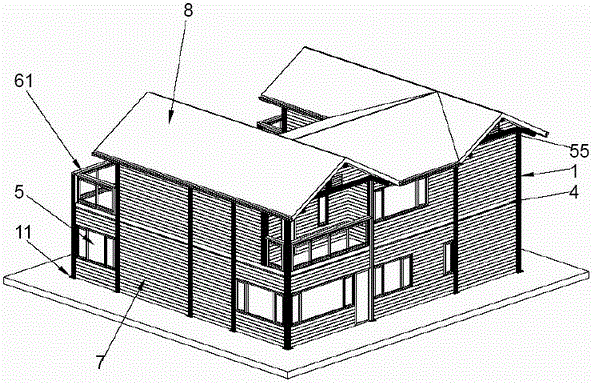

Aluminum alloy house

ActiveCN105040812AFirmly connectedShort design and manufacturing cycleBuilding roofsFloorsSection planeUltimate tensile strength

The invention relates to an aluminum alloy house. Aluminum alloy stand columns are arranged on the periphery and the inner ring of the house at intervals. Aluminum alloy beams are connected to the middle positions, in the height direction, of the aluminum alloy beams on the periphery and the inner ring of the house in a longitudinal and transverse segmented mode to form structures of the bottom layer and the second layer of the aluminum alloy house. Roof supporting columns are arranged on the aluminum alloy beams of the second layer. A roof is arranged on the roof supporting columns and the aluminum alloy stand columns. Three inwards-concave vertical face aluminum alloy combined wall plates are arranged in the middle of the aluminum alloy house in the foresight direction. An aluminum alloy gate is arranged in the middle of the front vertical face aluminum alloy combined wall plate, and therefore an inwards-concave space is formed in the aluminum alloy gate. Reverse Y-shaped sectional structures are arranged on the two sides of the roof. The front portion and the rear portion of the middle part of the roof are each in a slope shape. The two ends of each slope shape are connected with the middle rear portions of the reverse Y shapes on the two sides respectively. The aluminum alloy house is simple and firm in arrangement and connection structure, short in construction period, convenient to install, high in roof bearing strength and excellent in anti-seismic property.

Owner:ALUHOUSE TECHGD CO LTD

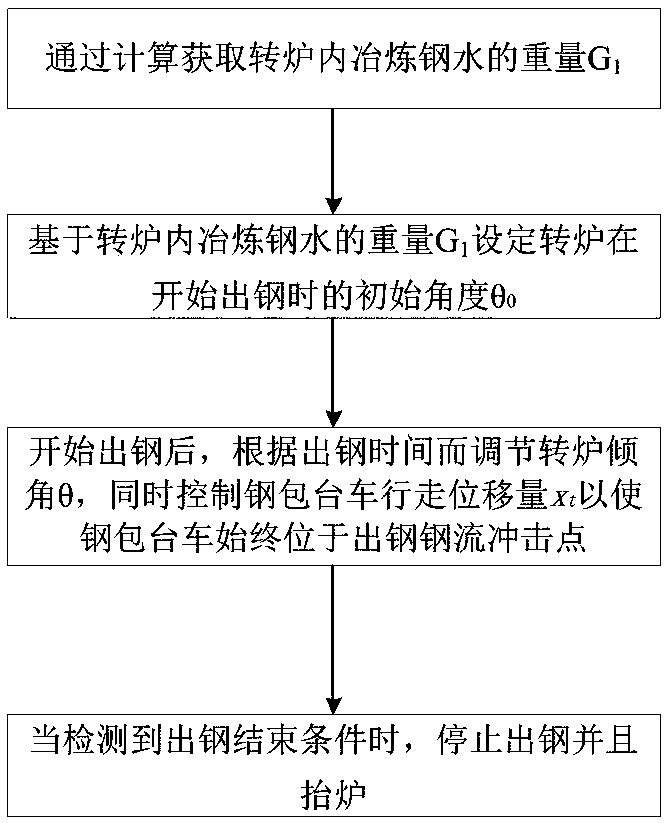

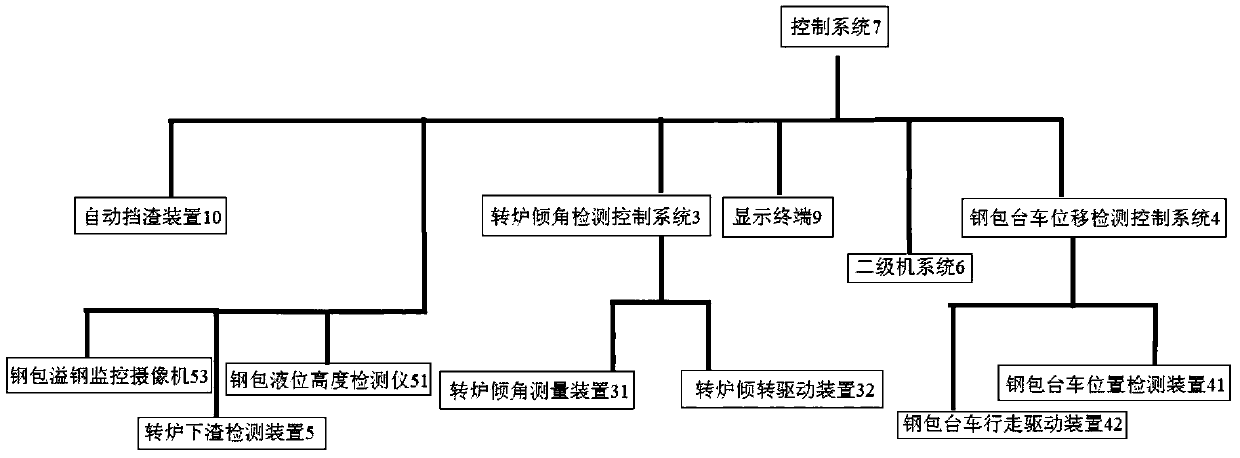

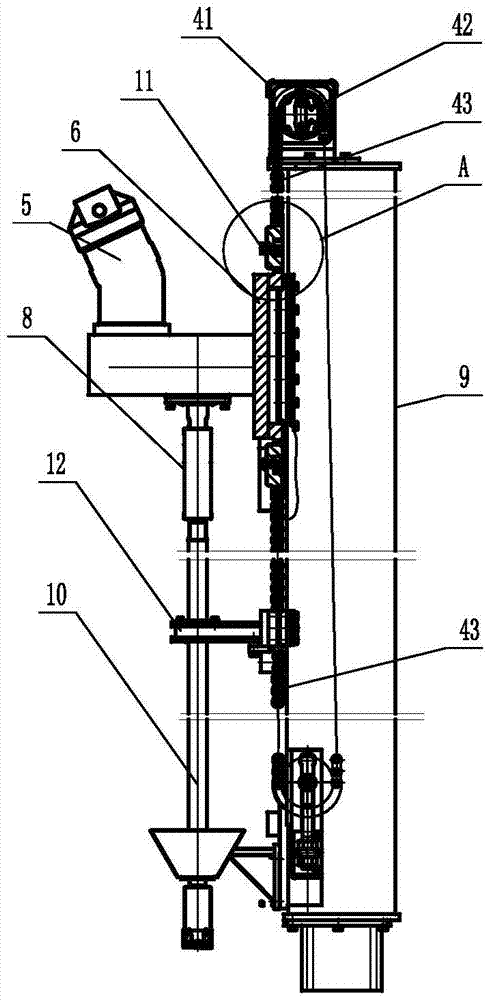

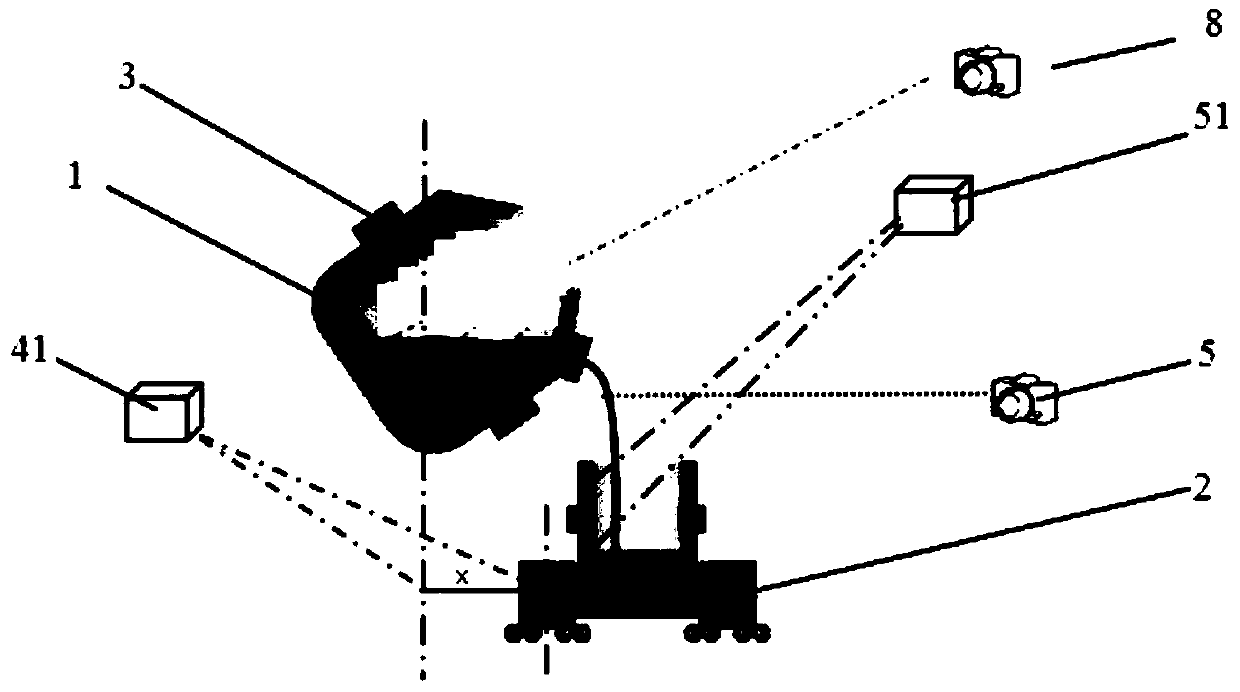

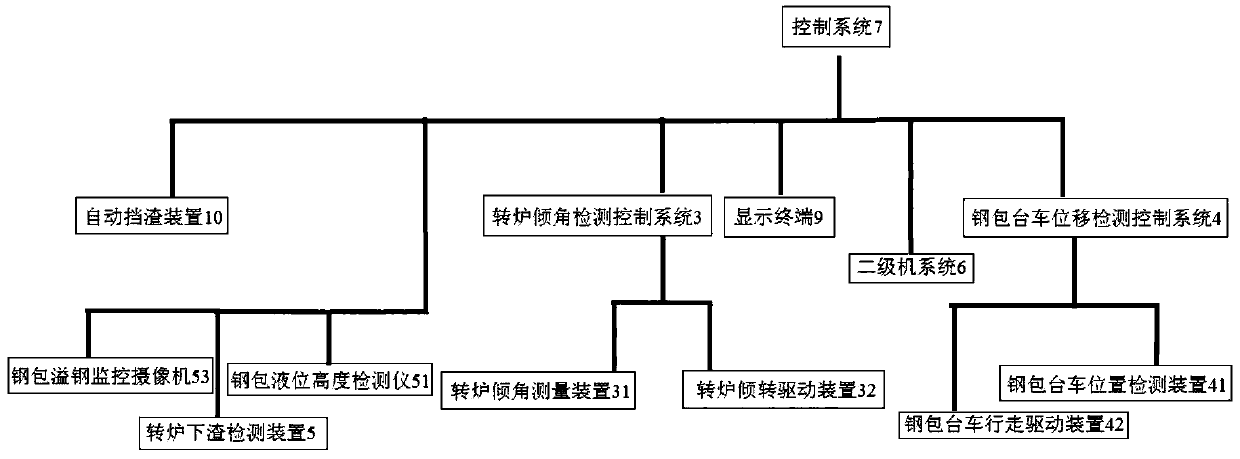

Full-automatic steel tapping method and system of converter

InactiveCN110616288AReduce incidenceLess investmentSteel manufacturing process aspectsManufacturing convertersMeasurement deviceMicrocomputer system

The invention discloses a full-automatic steel tapping method of a converter. The method comprises the steps of (1) obtaining the weight G1 of smelting molten steel in the converter through calculation; (2) based on the weight G1 of the smelting molten steel in the converter, setting the initial angle theta 0 when steel tapping of the converter begins; (3) after steel tapping begins, adjusting theinclination angle theta of the converter according to the steel tapping time, and meanwhile, controlling the walking displacement xt of a steel ladle trolley, so that the steel ladle trolley is located at a steel tapping steel flow impact point all the time; (4) when a steel tapping end condition is detected, stopping steel tapping and lifting up the converter. The invention further discloses a full-automatic steel tapping system of the converter. The system comprises the converter, the steel ladle trolley, a second-level microcomputer system storing steel grade smelting information, a converter inclination angle measurement device for measuring the inclination angle of the converter, a converter tilting driving device connected with the converter, a steel ladle trolley position detectiondevice for detecting the position of the steel ladle trolley in the walking direction, a steel ladle trolley walking driving device connected with the steel ladle trolley, a slag discharging device and a control system.

Owner:BAOSHAN IRON & STEEL CO LTD

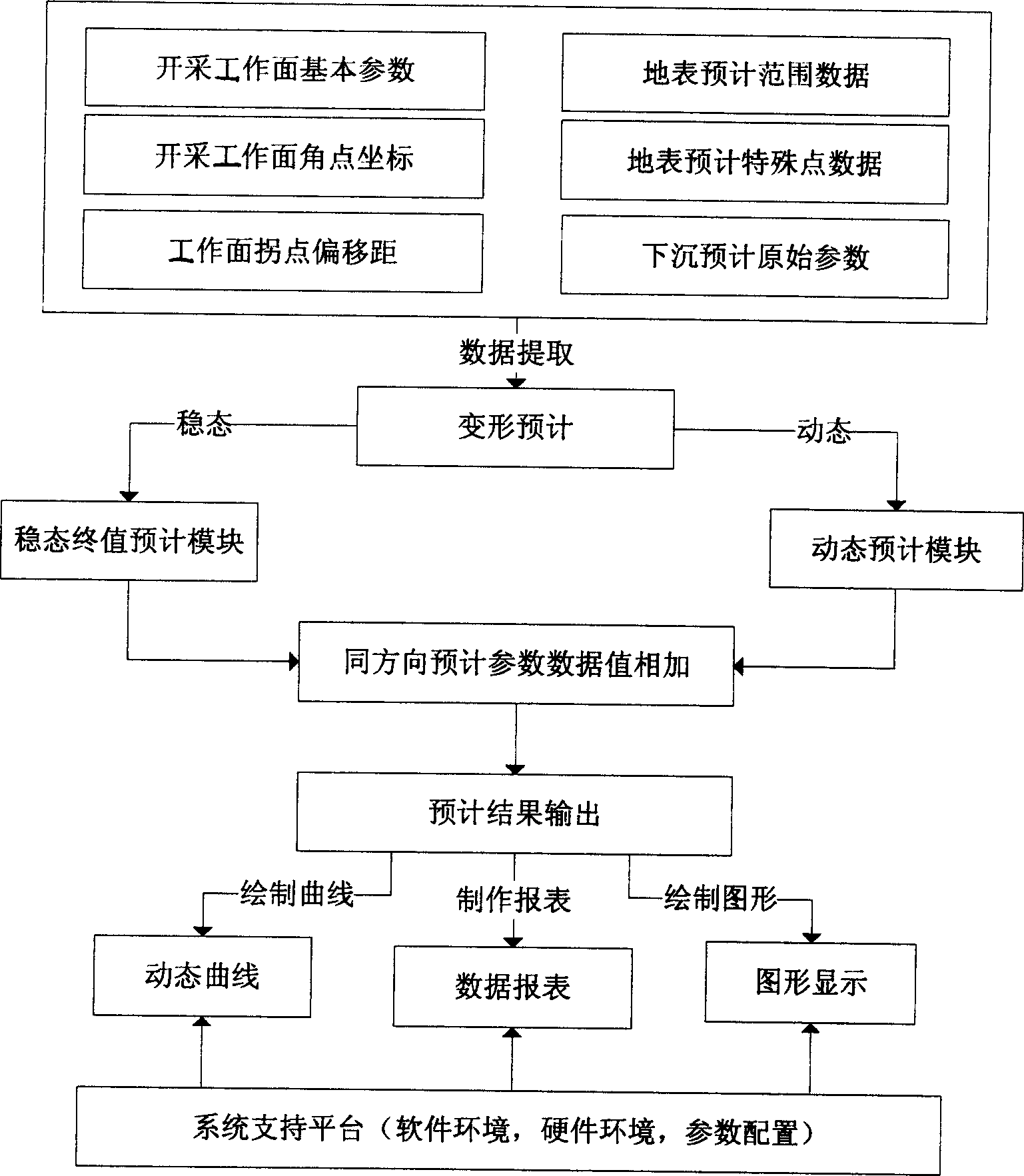

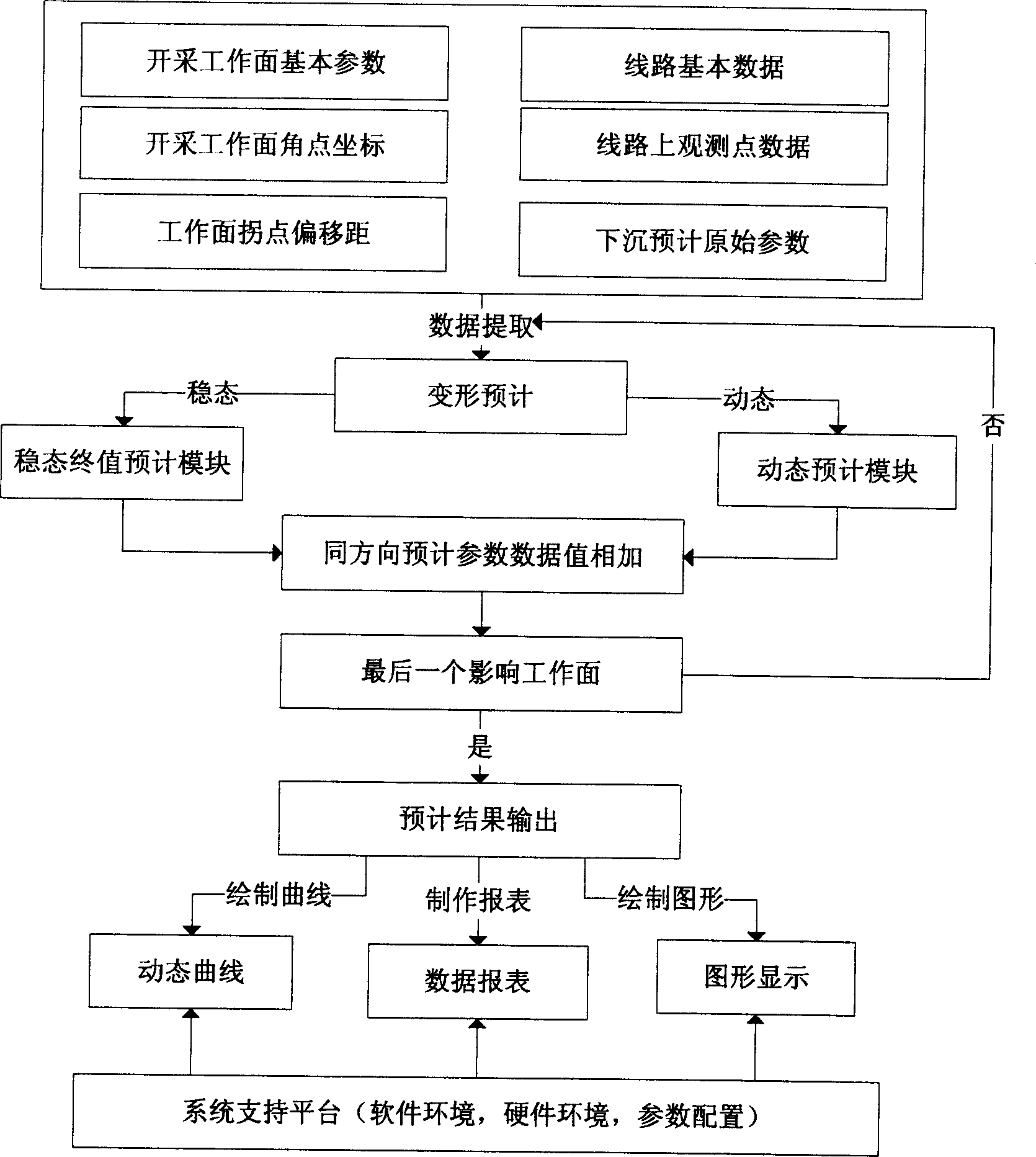

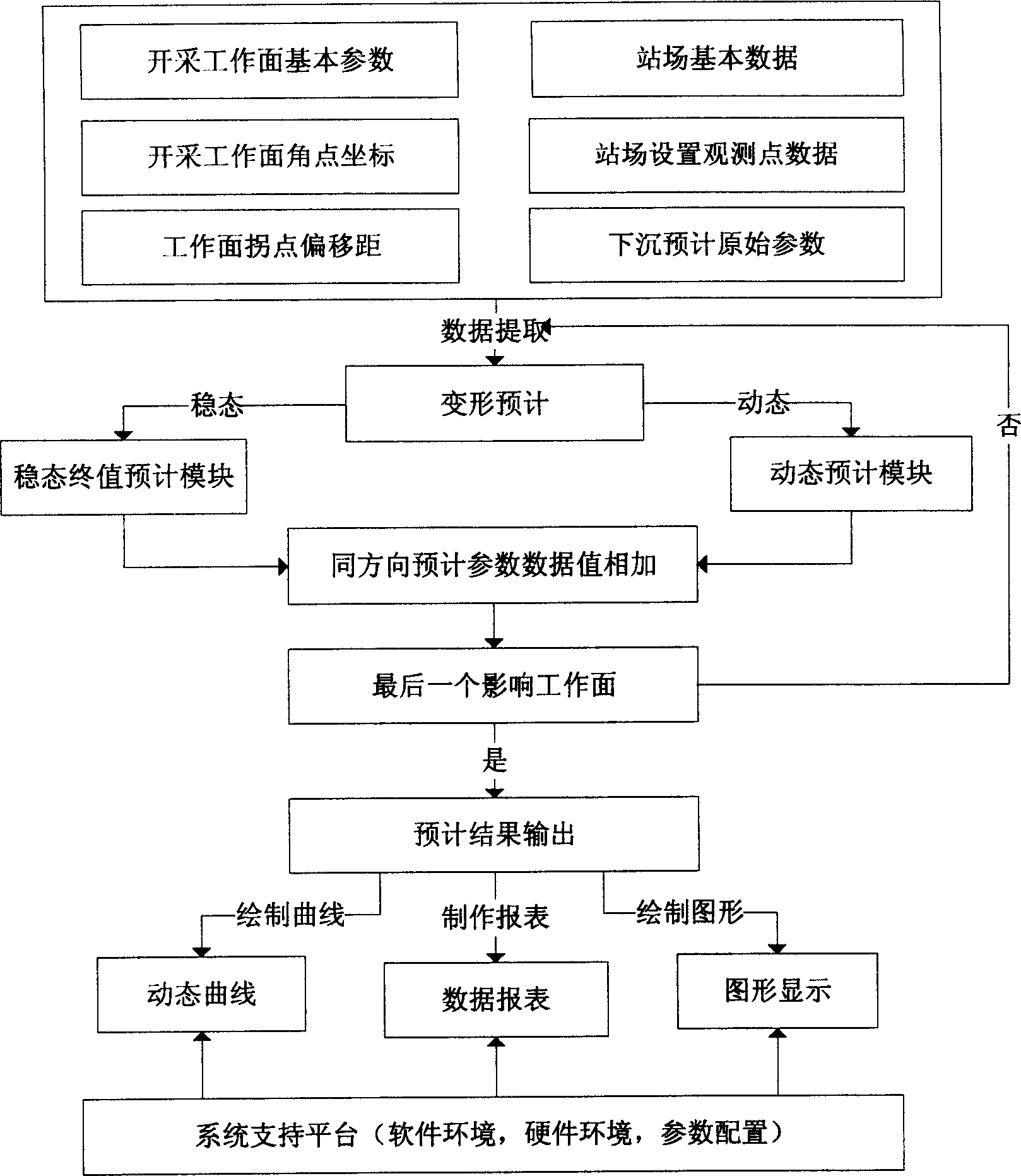

Estimating mining subsidence under turnout cluster of dedicated railroad, and governing expert system

InactiveCN1873674AEasy to operateClear processData processing applicationsDriving safetyRail transportation

The invention discloses an expert system for estimating and controlling mining damage under special railroad switch cluster, comprising a real- time estimating system of ground surface sinkage on underground mining condition, a real-time estimating system of sinkage deformation of special railroads and stations in mine in mining period, an intelligent estimating and control expert system of sinkage deformation of special railroads in mine, and a safety transportation protection technique against sinkage of special railroads and station switch cluster. And the invention establishes an expert system for estimating and controlling the sinkage of special railroads and station switch cluster in mine in the mining period, revealing characters and dynamic variation law of sinkage deformation of the railroads, thus advancing reasonable railroad maintaining measures, especially a control technique of deformation of railroads and station switch cluster. And the invention is simple and convenient to operate, and has a clear flow, and can make dynamic and steady estimation on mining damage under railroad and station switch cluster, and the estimated result has high accuracy. And the invention can raise total social and economic benefits of thick ledge mining under special railroads in mine.

Owner:BEIJING JIAOTONG UNIV

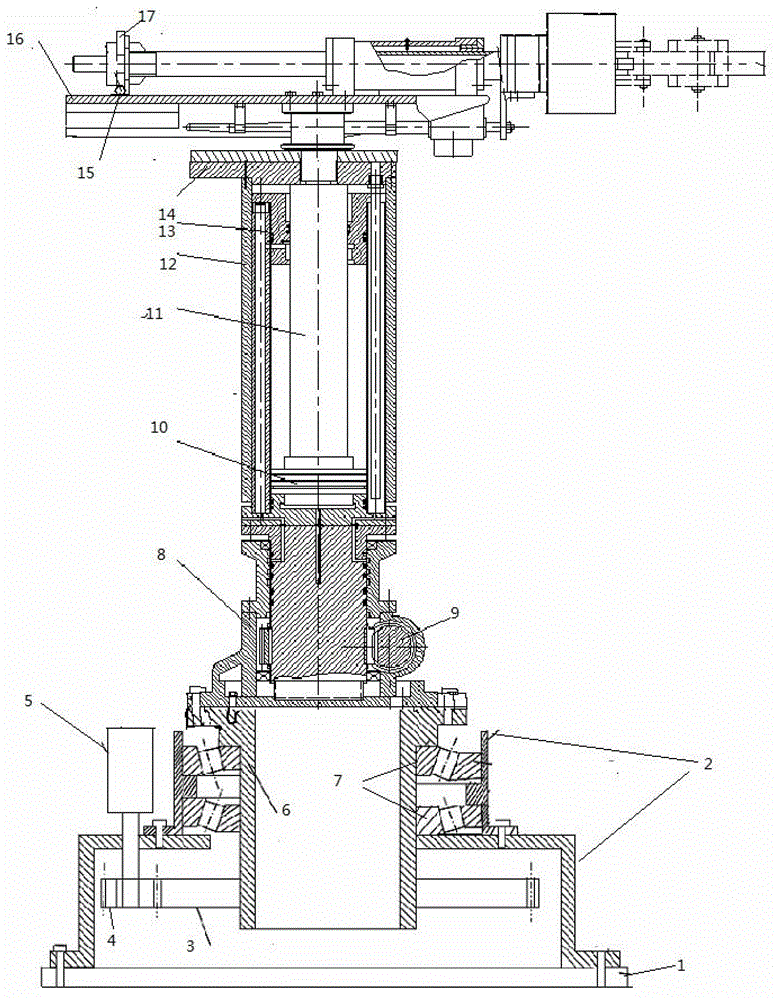

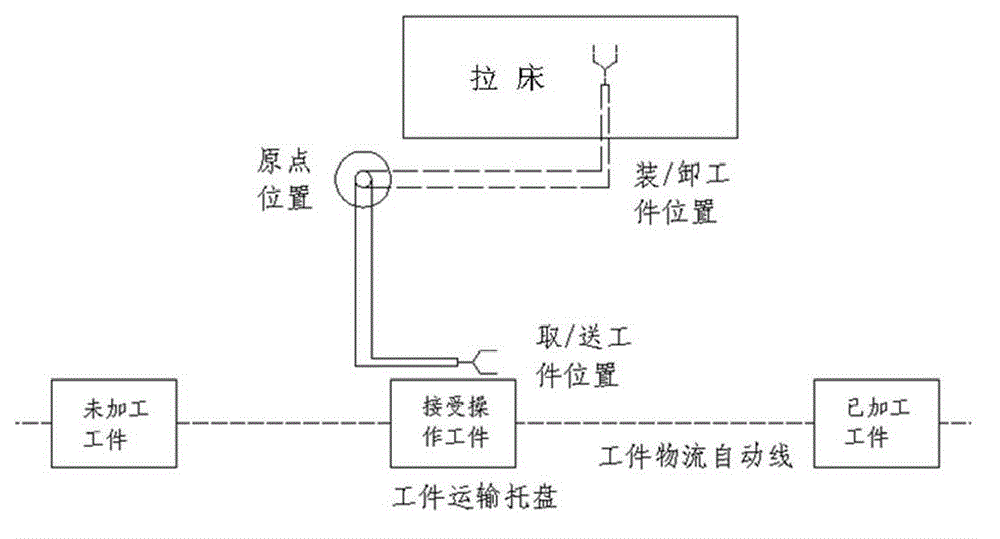

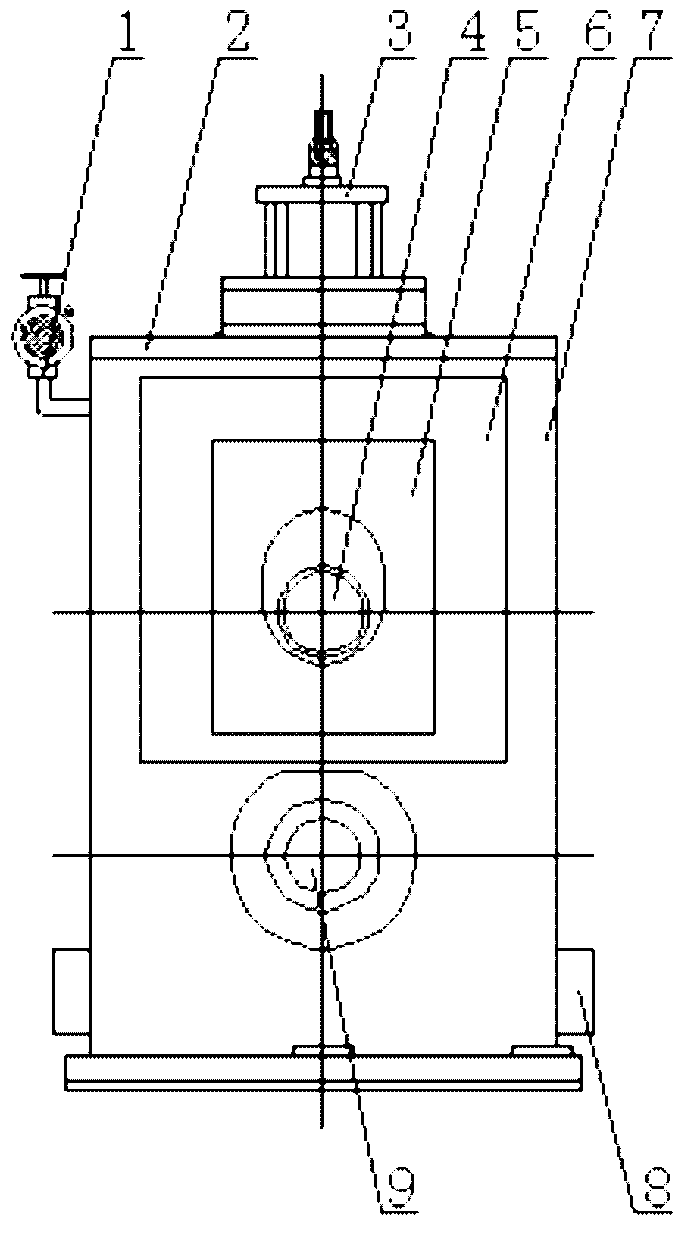

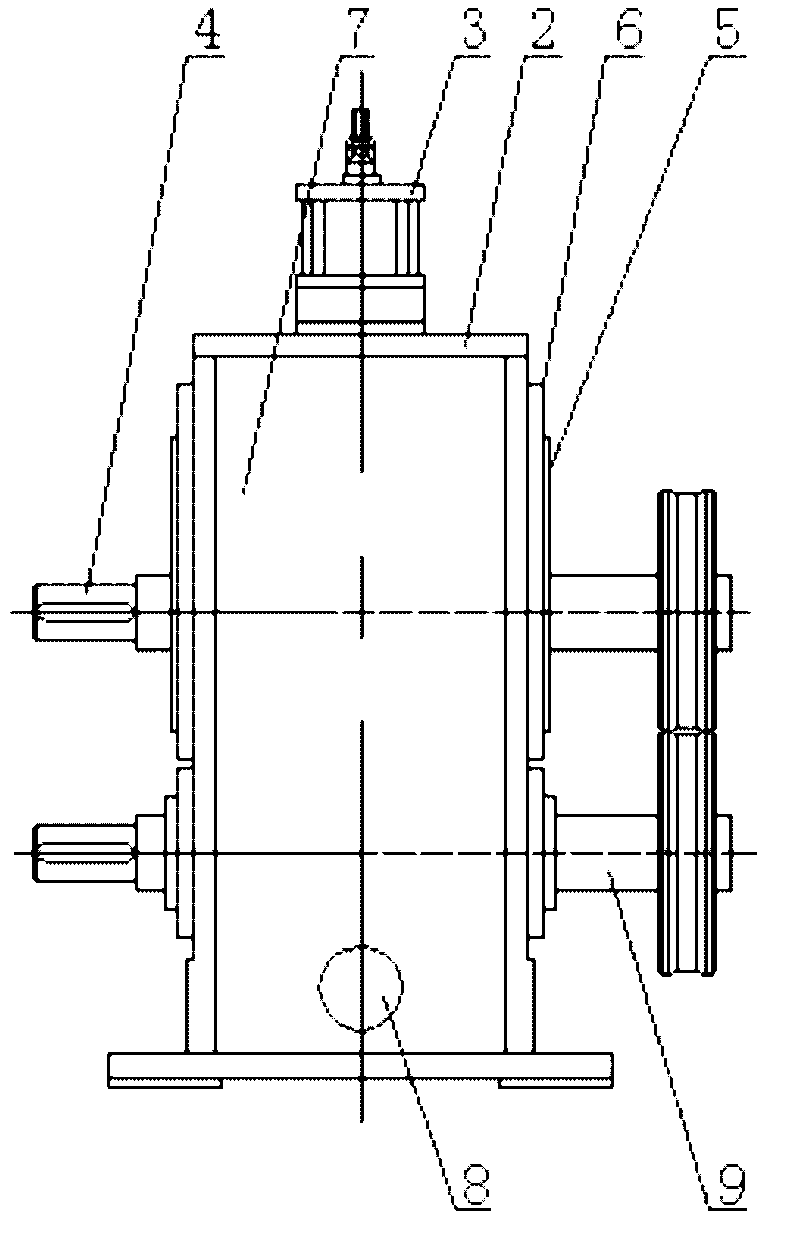

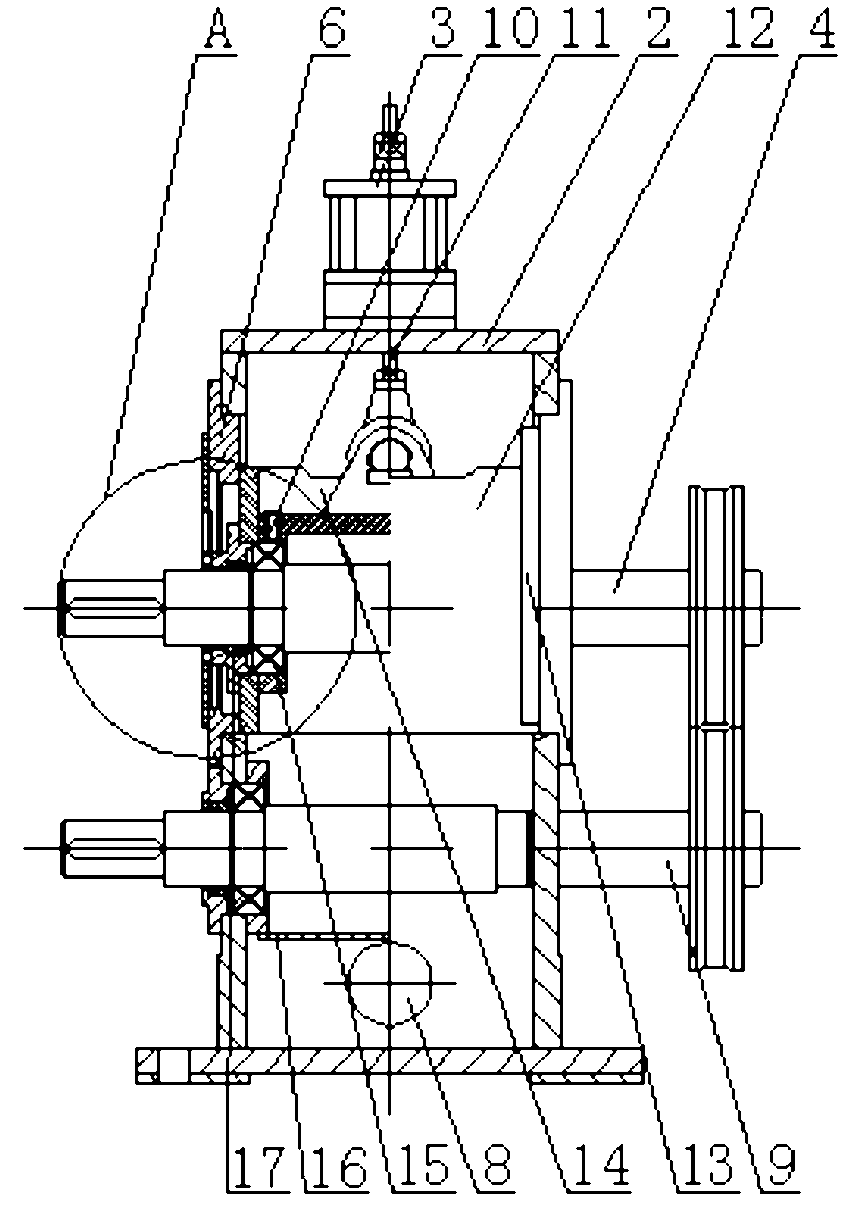

Loading and unloading manipulator system of broaching machine

InactiveCN103331640AGuaranteed servo positioning capabilityCapable of servo positioningProgramme-controlled manipulatorMetal working apparatusHydraulic pumpFuel tank

The invention discloses a loading and unloading manipulator system of a broaching machine, which comprises an executing mechanism, a driving mechanism and a hydraulic control mechanism, wherein the driving mechanism comprises a waist seat, a bull gear, a pinion, a stepping motor, a waist revolving shaft, tapered roller bearings, a fixed upright and a rack cylinder; the executing mechanism comprises a rising oil cylinder, a rising oil cylinder piston, a rising oil cylinder piston rod, a rising guide rod, a sleeve, a lifting platform, a rolling bearing, a support plate, a support frame, a translation oil cylinder, a translation oil cylinder piston rod, a guide rod, a guide bushing, an annular sleeve and a manipulator; the manipulator comprises a paw and a telescopic oil cylinder; and the hydraulic control mechanism comprises a three-phase alternating current asynchronous motor, a hydraulic pump, an oil filter, an oil tank, a two-position two-way solenoid directional valve, a one-way valve, a pilot overflow valve, a three-position four-way solenoid directional valve, a speed regulating valve and a hydraulic cylinder. The system can guarantee the positioning control precision, and reduces impact and vibration to the greatest extent, so that the safety of the system is guaranteed.

Owner:ZHEJIANG INT STUDIES UNIV

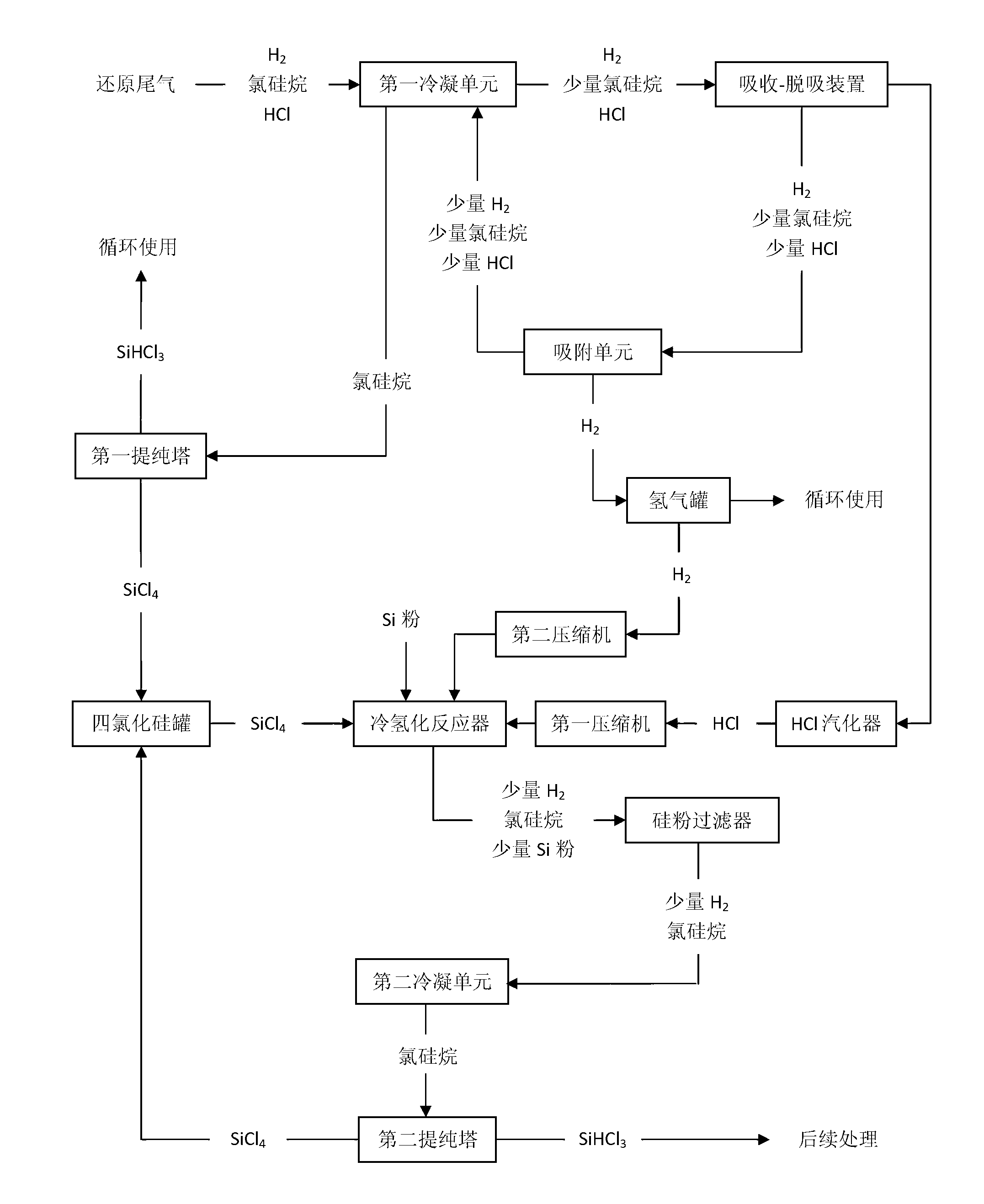

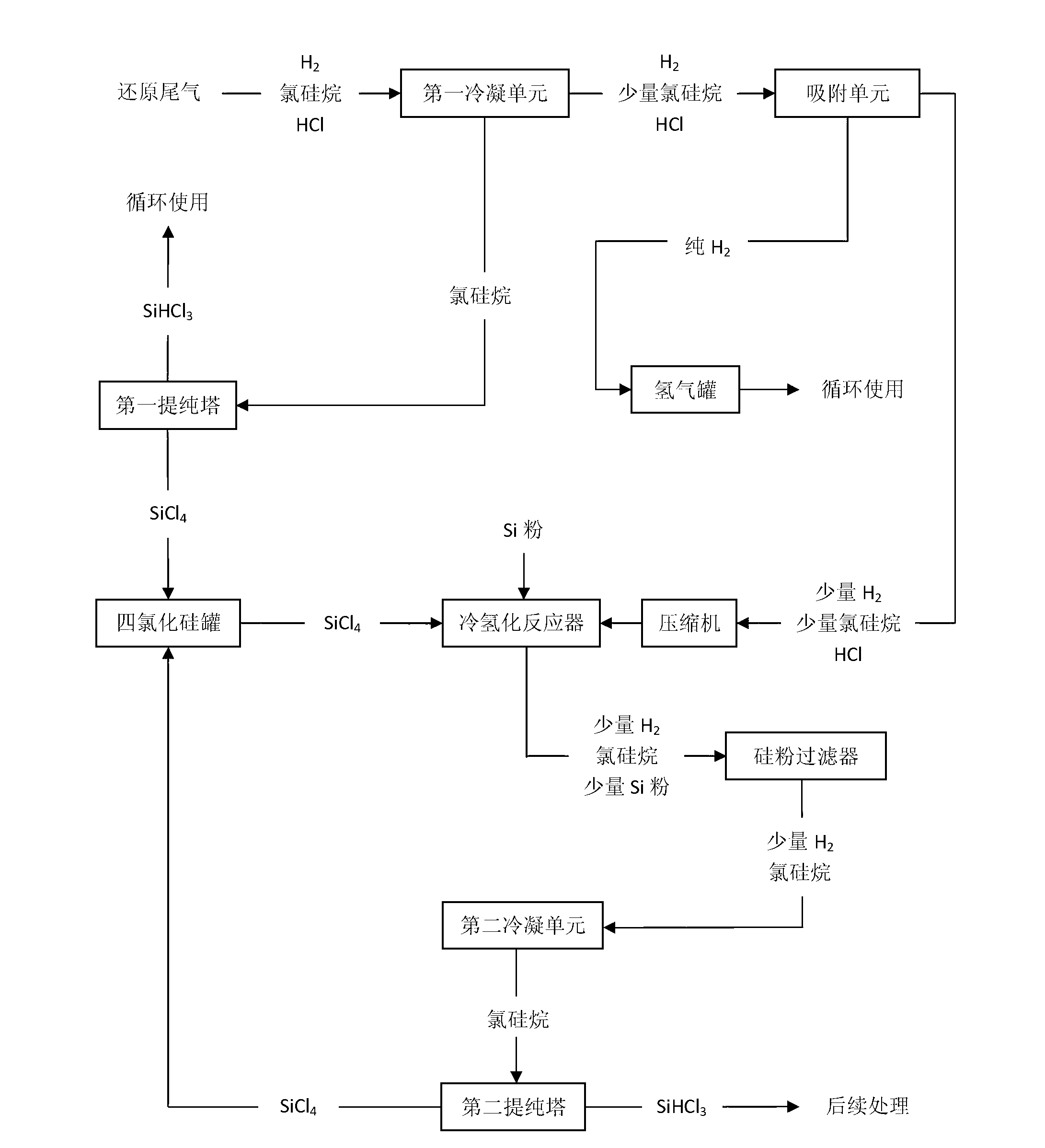

Recovery system and recovery method of by-product in polycrystalline silicon production

ActiveCN103058140ASave heat and coolSave on cooling or heatingChlorine/hydrogen-chloride purificationHydrogen separation using solid contactExhaust gasChemistry

The invention discloses a recovery system and a recovery method of a by-product in polycrystalline silicon production. The system and the method are used for recycling the hydrogen, chlorosilane and chlorine hydride gas in the reducing tail gas produced during the polycrystalline silicon production. The recovery method comprises the following steps: a condensing step for separating most of chlorosilane from the reducing tail gas; an adsorption step for removing all chlorine hydride and the rest chlorosilane from the reducing tail gas by using an absorption unit after the condensing step to obtain the pure hydrogen; a regenerating step for regenerating the absorption unit by using the hydrogen so as to remove the chlorosilane and chlorine hydride absorbed by the absorption unit, and obtaining the regenerative gas containing hydrogen, chlorosilane and chlorine hydride; and a cold hydrogenating step for directly feeding the regenerative gas as the raw material of the cold hydrogenation reaction to a cold hydrogenation reactor. According to the system and method provided by the invention, the HCl can be singly separated from the tail gas without an adsorption-de-adsorption device so as to prevent the HCl from being condensedly separated and gasified, and a great number of heat and cooling capacity is saved.

Owner:巴彦淖尔聚光硅业有限公司

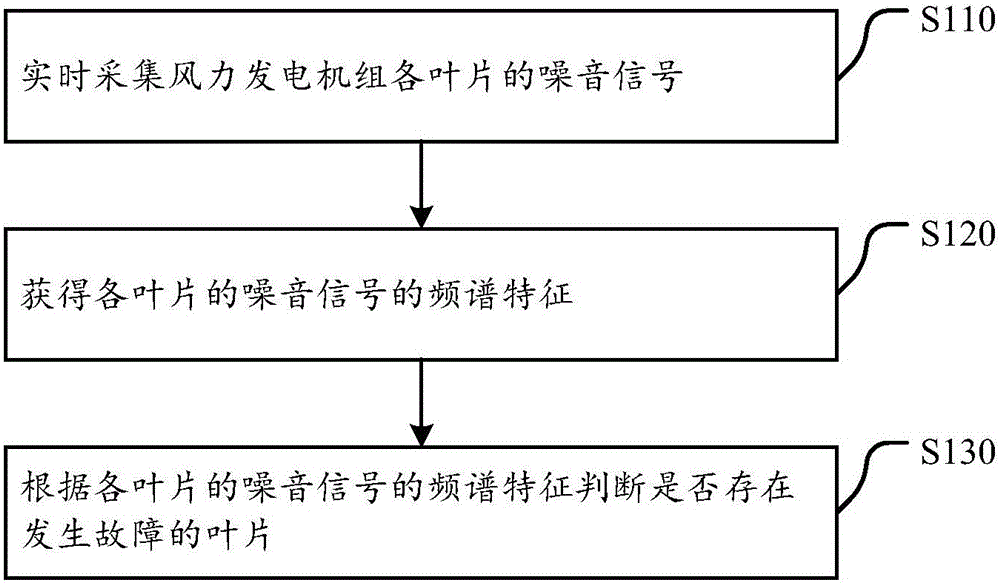

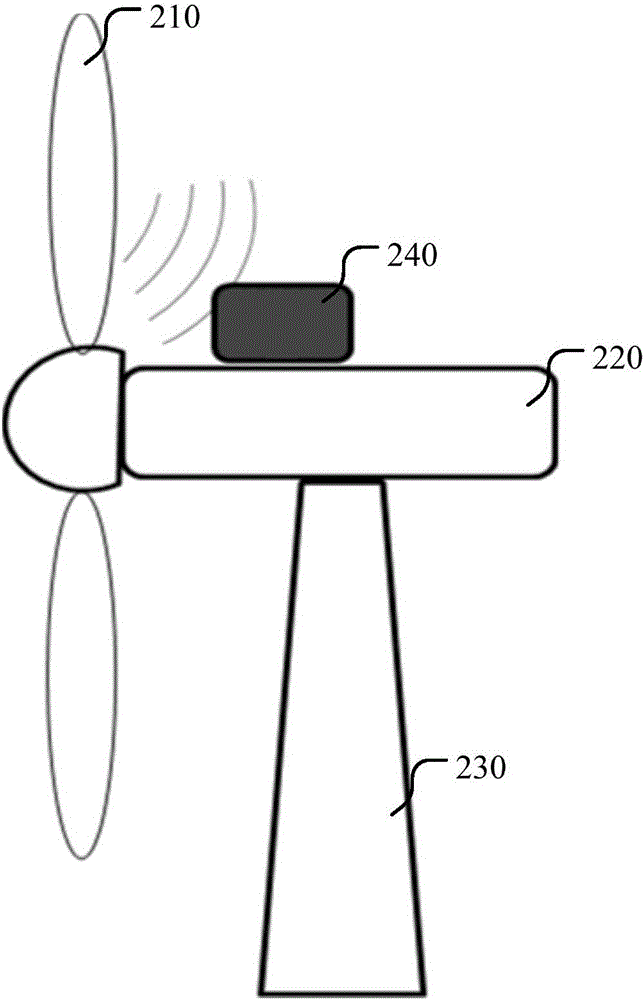

Wind generating set blade fault diagnosis method and device

ActiveCN105136435AImprove reliabilityImprove stabilityMachine part testingFrequency spectrumEngineering

The invention discloses a wind generating set blade fault diagnosis method and device. The method comprises the steps of: collecting noise signals of each blade of a wind generating set; obtaining frequency spectrum characteristics of the noise signals of each blade; and judging whether there is a faulted blade according to the frequency spectrum characteristics of the noise signals of each blade. According to the technical scheme of the invention, on the premise that the normal operation of the wind generating set is not influenced, the blade states are monitored by collecting, processing and analyzing the noise signals of each blade of the wind generating set, various kinds of abnormal states or fault states of the blades can be accurately diagnosed in time, and corresponding solutions can further be made according to the diagnosed faults, so that the unnecessary losses caused by accidents and the power generation loss caused by shutdown maintenance and overhaul are lowered, the maintenance cost of the blades is reduced, and the integral reliability, the stability and the integral benefit of the wind generating set are improved.

Owner:北京汉能华科技股份有限公司

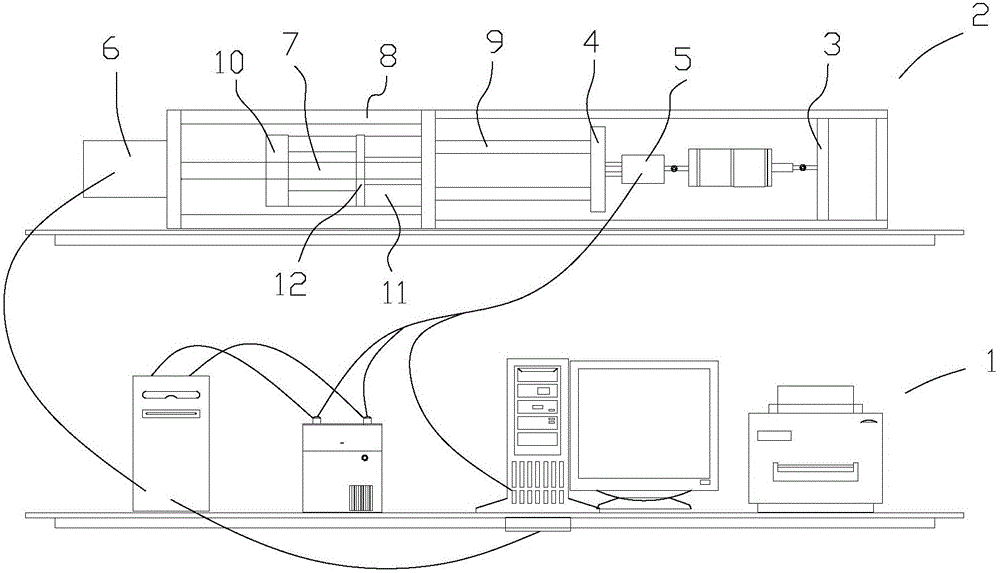

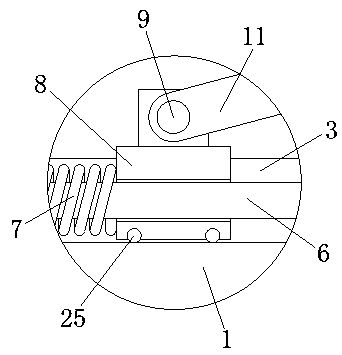

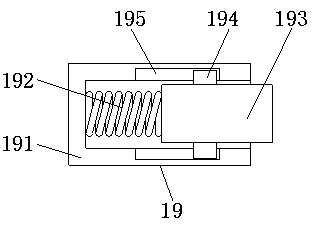

Spring load test system

InactiveCN105136576AReduce labor intensityFunctionalMachine part testingMaterial strength using tensile/compressive forcesEngineeringControl table

The invention discloses a spring load test system, which comprises a control table and a load installing platform, wherein the load installing platform comprises a fixed block and a movable block; the movable block is driven by a driving device controlled by the control table to horizontally move relative to the fixed block; a force sensor is arranged on the movable block; the control table receives an output signal of the force sensor; the control table controls the movable block to displace through controlling the driving device; the spring load is compressed or stretched along; when the compression or stretching displacement change value reaches a preset displacement feature point part, a force test value transmitted by the force sensor is recorded. The system has the advantages that the function is strong; an industrial control computer with higher reliability is used for control; the automation of the detection process is realized. The automation degree is high; the reliability is good; the impact of artificial factors in the original detection process is eliminated, so that a detection result is more accurate; the work intensity of workers is greatly reduced; the operation time is reduced; the production efficiency is improved.

Owner:WUHU CEPREI INFORMATION IND TECH RES INST

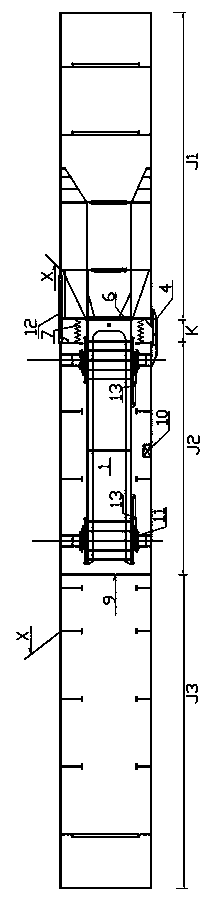

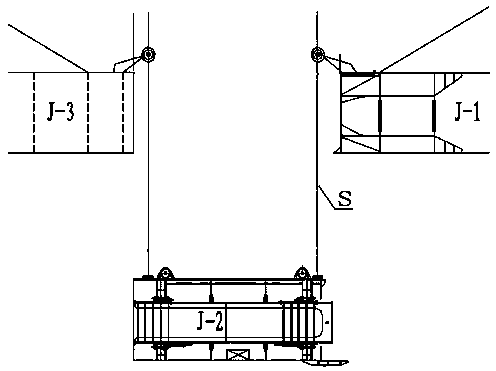

Installation construction method for bridge rigid hinge

InactiveCN103410094ASimple and fast operationReduce construction difficultyBridge erection/assemblyBox girderBuilding construction

The invention discloses an installation method for a bridge rigid hinge and belongs to the technical field of bridge construction. The installation construction method for the bridge rigid hinge includes the steps that firstly, combination and assembling are performed in advance, a running-in test is performed, and accessories are installed; secondly, preparation is performed before hoisting; thirdly, a small box girder is temporarily locked into a J2 kind end beam; fourthly, synchronous hoisting is in place, entering a preset closure gap position is achieved, and adjustment is performed properly; fifthly, a temporary locking device is installed, temporary locking is relieved, the small box girder is moved close to a J1 beam segment fixing end, and a bolt is used for connection; sixthly, a closure seam of a J2 beam segment and a J3 beam segment is forcefully adjusted, temporary fixing accessories are temporarily fixedly combined and installed, construction site connection of the J2 beam segment and the J3 beam segment is finished, and a beam is installed on the J2 beam segment; seventhly, remained facilities are installed, temporary facilities are detached, and rigid hinge supports on the periphery of the small box girder are adjusted. According to the installation method for the bridge rigid hinge, the rigid hinge and parts of the rigid hinge can be accurately and inerrably installed, the rigid hinge and a bridge are stable in structure, and safety and reliability in using the rigid hinge and the bridge are ensured.

Owner:CCCC HIGHWAY CONSULTANTS

Novel domestic garbage mixing and scraping filtering and cleaning device

InactiveCN107377345AEasy feedingImprove filtration efficiencySievingScreeningPush pullDomestic waste

The invention provides a novel domestic garbage mixing and scraping filtering and cleaning device which comprises a filter tank; a filter plate is arranged in the filter tank; filter holes are uniformly distributed on the filter plate; a mixing and scraping plate and a roll shaft which are parallel to each other are symmetrically arranged on and under the filter plate respectively; ejector pins are uniformly distributed on the roll shaft; and a pushing device is arranged on the outer wall of the filter tank and comprises a motor, a rotation rod, a transmission rod, a lever, a supporting rod, a first push-pull rod and a second push-pull rod. Compared with the prior art, the novel domestic garbage mixing and scraping filtering and cleaning device has the beneficial effects that garbage feeding is convenient, a large garbage inflow volume can be accepted, and the filter efficiency is improved; and automatic integral garbage filtering and filter screen cleaning work can be realized, the ejector pins of the roll shaft can jack up blockage sundries in the filter holes of the filter plate while the filter plate filters solid garbage in a mixing and scraping manner, and the blockage sundries is taken away by the mixing and scraping plate in the mixing and scraping manner, so that the filtering rate of the filter plate is ensured, the whole filter efficiency of a filter device is improved, and the maintenance and change cost is reduced.

Owner:JIANGSU ZHUODA INFORMATION TECH CO LTD

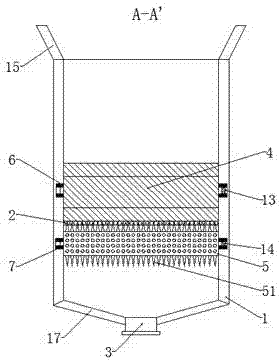

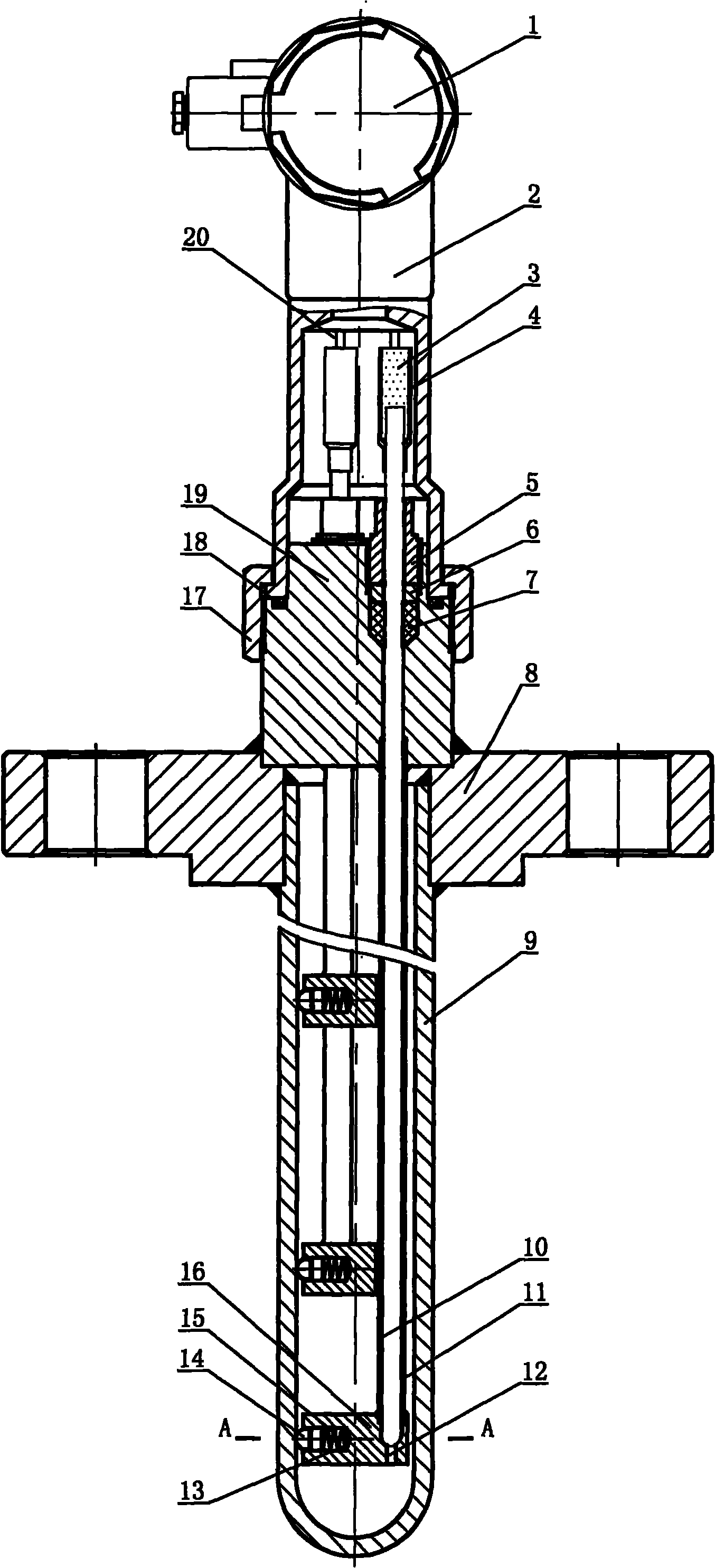

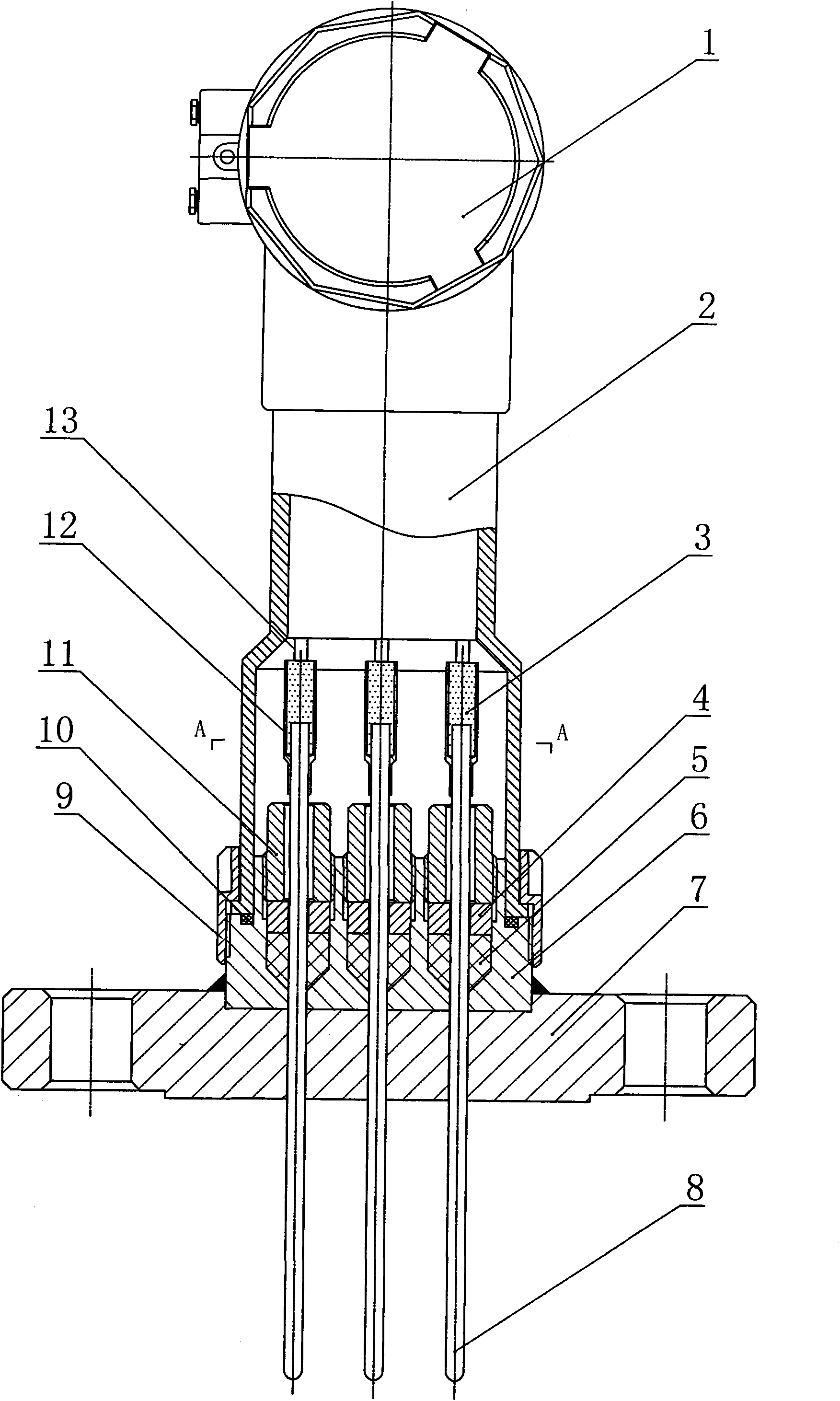

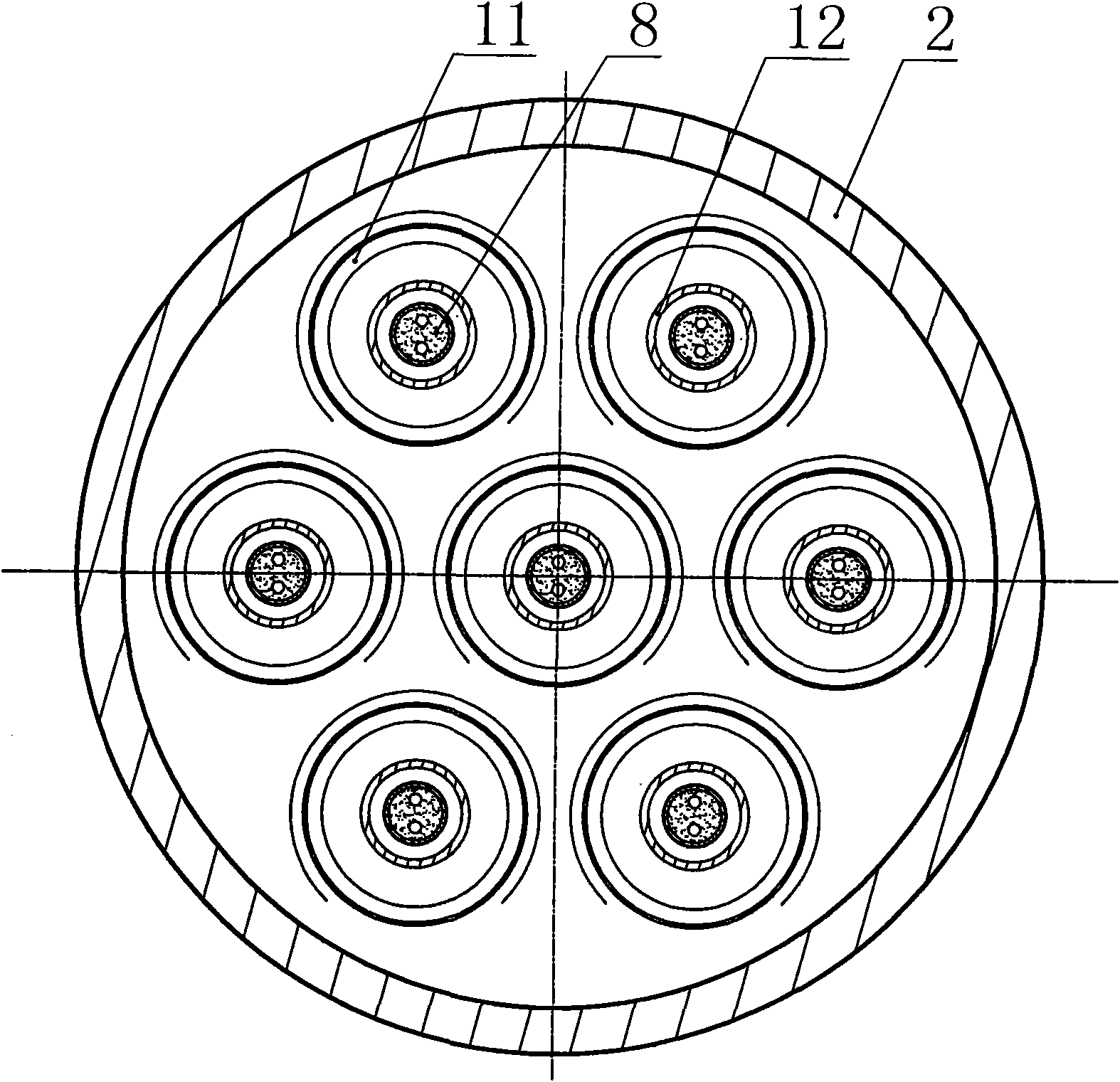

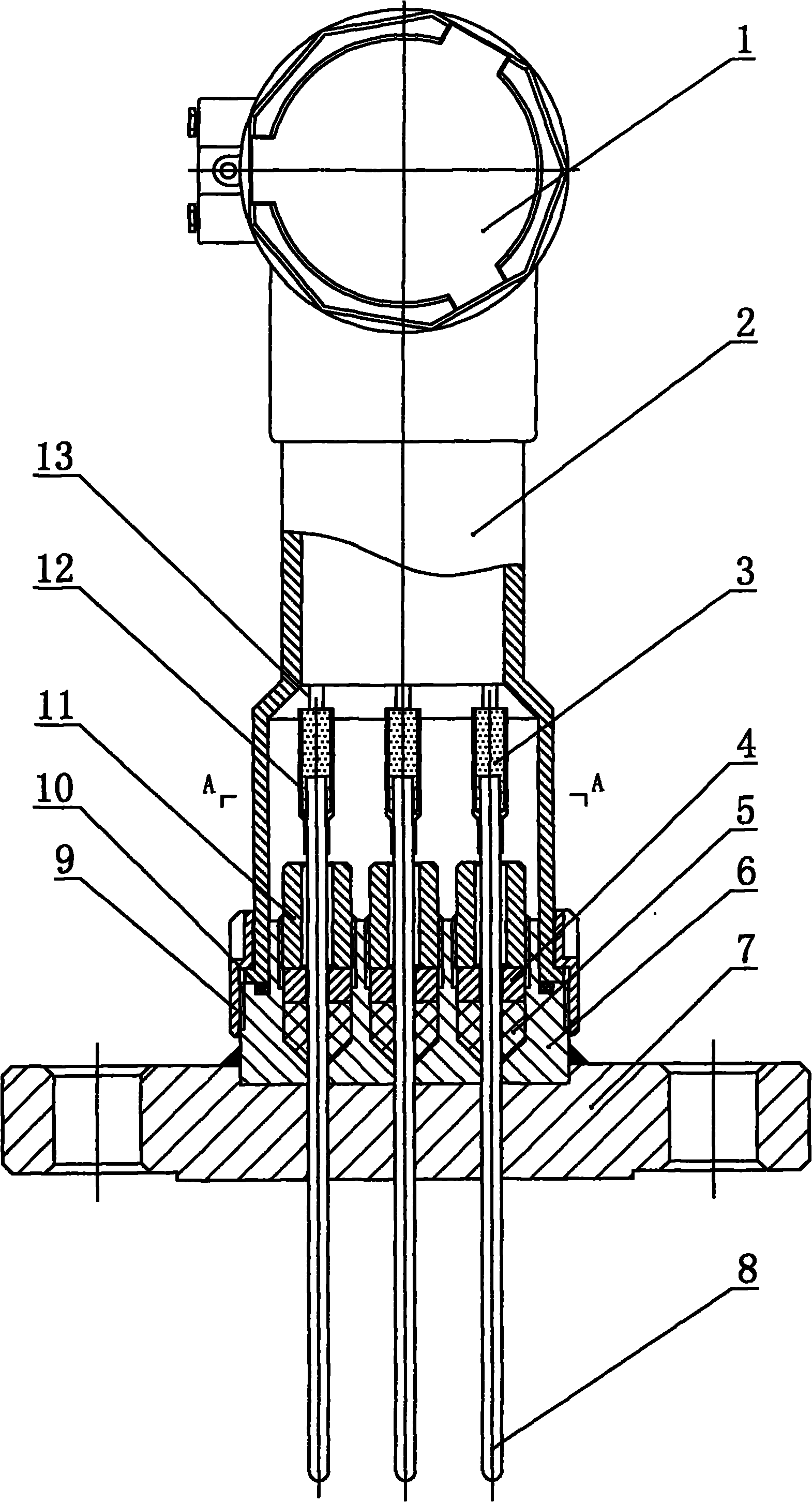

Quick-heat-conduction multi-point armoured thermocouple (thermal resistor)

ActiveCN101806634AQuick measurementShort response timeThermometers using electric/magnetic elementsUsing electrical meansTemperature measurementHAVE QUICK

The invention belongs to a quick-heat-conduction multi-point armoured thermocouple (thermal resistor), which consists of a junction box, a protective casing and temperature measurement elements. The protective casing consists of an upper protective casing and a lower protective casing; the upper end of the upper protective casing is fixedly arranged on the junction box coaxially; the temperature measurement elements are fixedly arranged on the junction box coaxially and are arranged in the protective casing; the temperature measurement element in the lower protective casing is positioned and arranged on a conductive sliding block; and the conductive sliding block slides radially and is arranged on an inner wall of the lower protective casing. The thermocouple (thermal resistor) has quick response to the temperature measurement, relatively high accuracy and safety of the temperature measurement, relatively low maintenance and repair cost and convenient construction, and is quick-heat-conduction multi-point armoured thermocouple (thermal resistor) with relatively strong innovation.

Owner:TIANJINSHI ZHONGHUAN TEMPERATURE METERS

Transporting device of geothermal energy equipment

ActiveCN109160058ASolve the problem of not having shock absorption effectGuaranteed service lifePackaging vehiclesContainers for machinesEngineeringPressure groove

The invention discloses a transporting device of geothermal energy equipment, the device includes a bottom plate, the bottom of the bottom plate is fixedly provided with moving wheels, the top of thebottom plate is symmetrically provided with side pressure grooves, a spring support pad is fixedly connected at the top of the bottom plate and at a position between the two side pressure grooves, thetop of the spring support pad is provided with a placing plate, the left side of the inner wall of the side pressure groove is fixedly connected with a first limit lever, the right end of the first limit lever is fixedly connected with the right side of the inner wall of the side pressure groove, and the inner wall of the side pressure groove, away from the spring support pad, of the side pressure groove is fixedly connected with a first shock absorbing spring on. The transporting device of the geothermal energy equipment can clamp and fix the equipment of different sizes and protect the equipment from shock from the bottom and both sides, thereby effectively preventing the internal components of the equipment from being damaged due to the bumps in the transportation and transfer process,ensuring the service life of the geothermal energy equipment, reducing the maintenance cost and facilitating the use.

Owner:YUHUAN JIANGLIN PLUMBING HOSE & PARTS

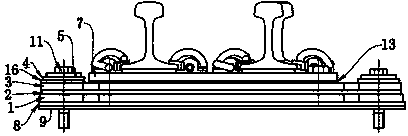

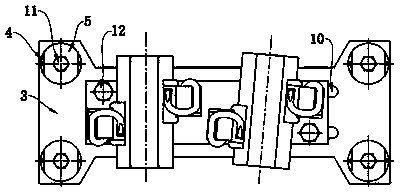

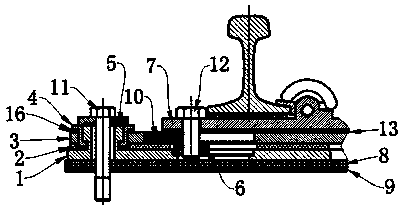

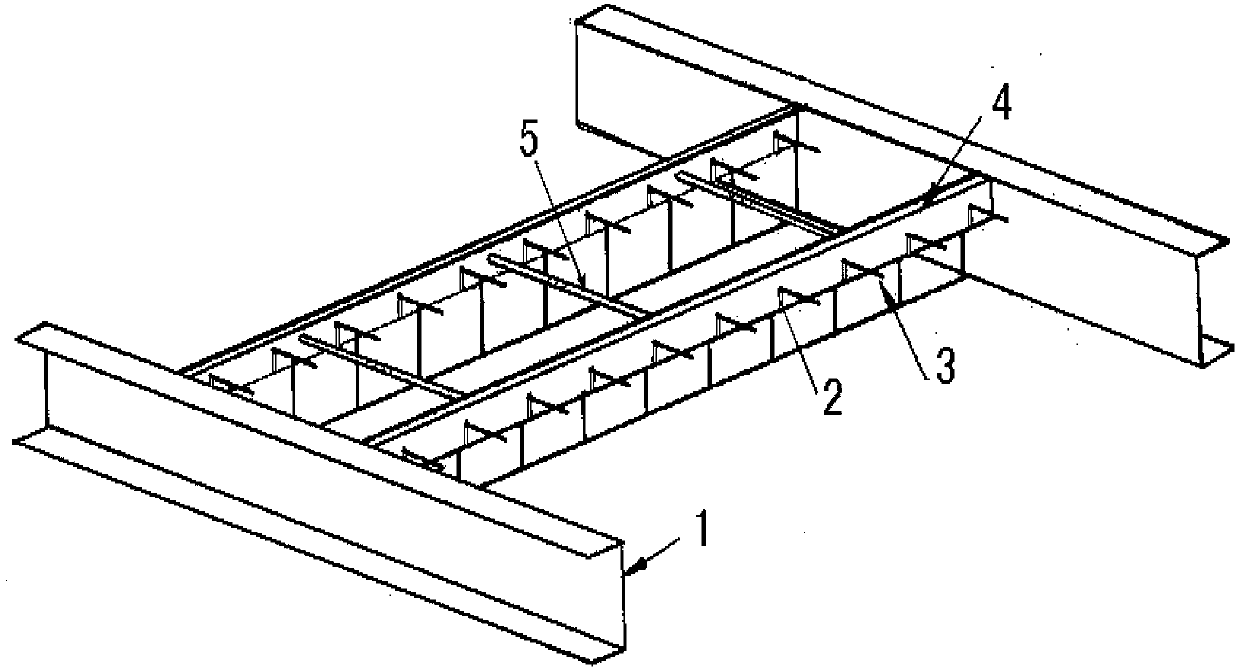

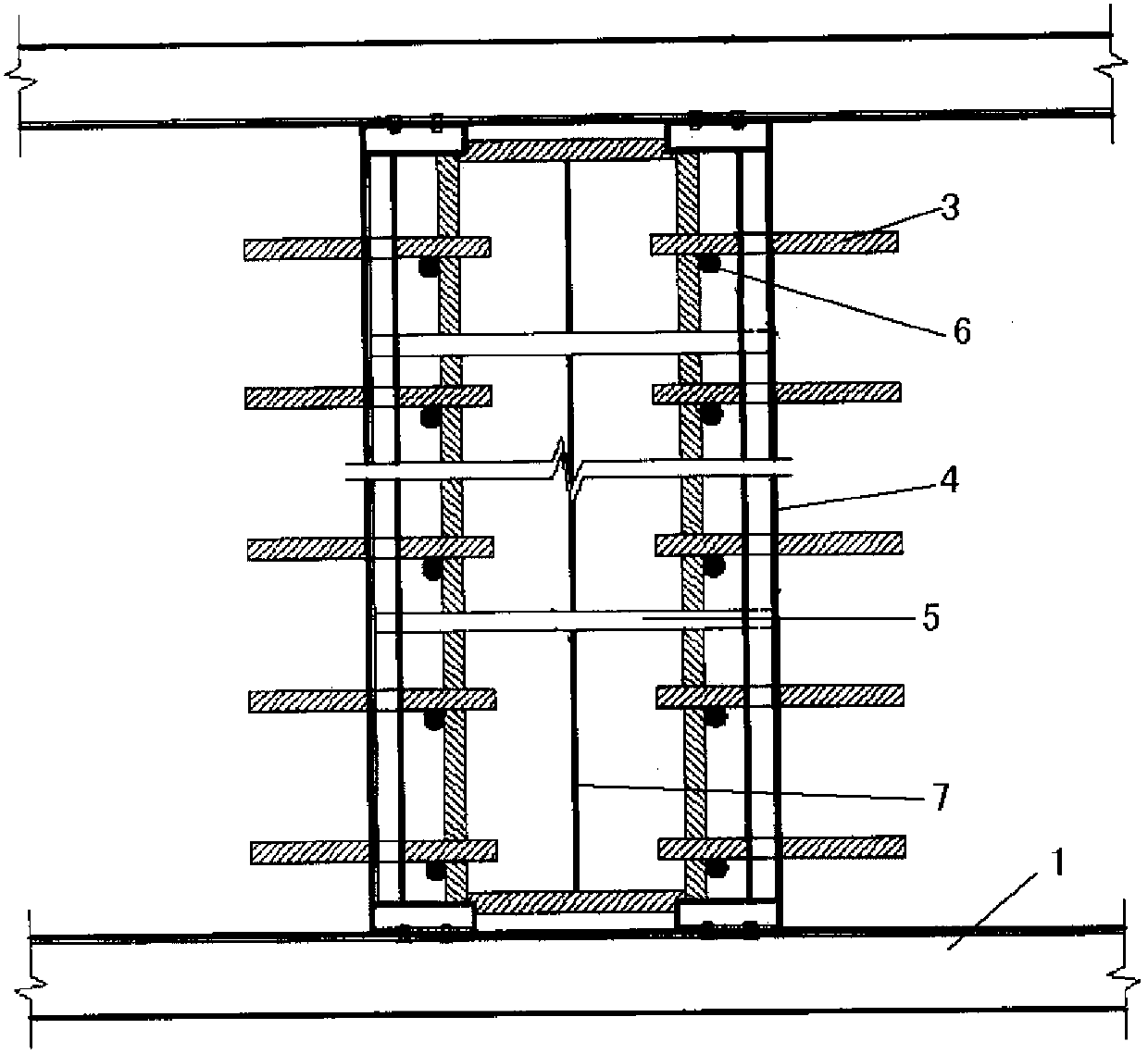

Vibration reduction turnout pedestal system and assembly method

ActiveCN104179080AReduce processing difficultyReduce maintenance and repair costsRail switchesRailway track constructionEngineeringRail traffic

The invention belongs to the field of rail traffic, and provides a vibration reduction turnout pedestal system and an assembly method. The vibration reduction turnout pedestal system comprises a lower bottom plate (1), a middle elastic insulating pad (2), an upper bottom plate (3), a turnout fastener base (7), a distance adjusting connecting positioning assembly and the like. The upper bottom plate (3) and the turnout fastener base (7) are connected together through the distance adjusting connecting positioning assembly, and the relative position of the turnout fastener base (7) and the upper bottom plate (3) can be adjusted through the distance adjusting connecting positioning assembly. The lower bottom plate (1), the middle elastic insulating pad (2) and the upper bottom plate (3) are locked and connected together. The vibration reduction turnout pedestal system has the advantages of being easy to machine and manufacture, low in cost, detachable, low in maintenance and replacement cost, convenient to install on the scene and the like.

Owner:洛阳双瑞橡塑科技有限公司

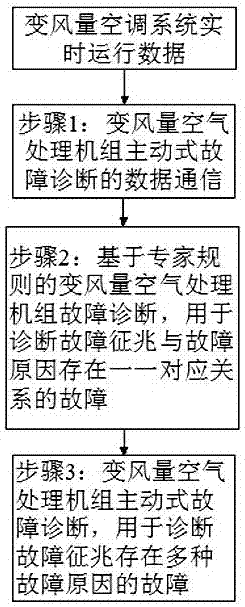

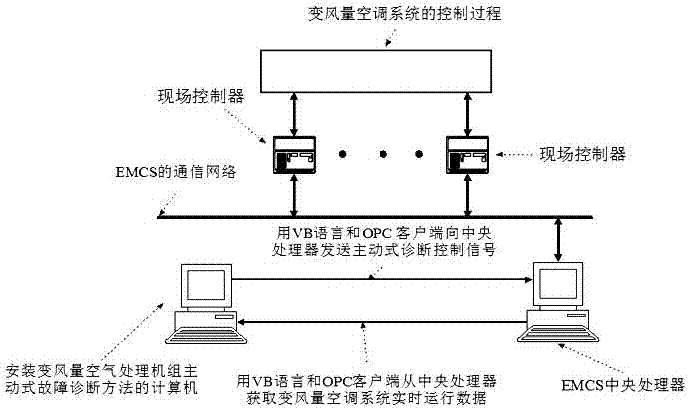

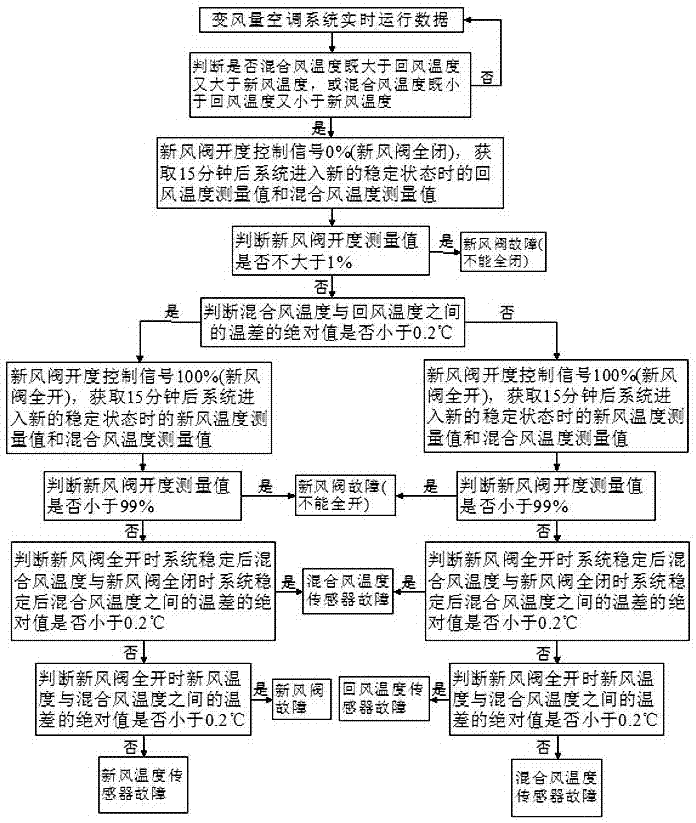

Active fault diagnosis method for variable air volume air handling unit

ActiveCN106871389ASolve the key problems of fault diagnosisReduce energy consumptionMechanical apparatusSpace heating and ventilation safety systemsSurface coolingActive fault

The invention discloses an active fault diagnosis method for a variable air volume air handling unit. The method comprises the steps of data communication, fault diagnosis based on expert rules and active fault diagnosis. In the step of data communication, real-time operation data of the variable air volume air handling unit is obtained from a central processing unit of an EMCS system through VB language and an OPC client side. In the step of fault diagnosis based on expert rules, if the temperature difference between the measurement value of air supply temperature and the set value of air supply temperature is larger than 1.5 DEG C, the measurement value of the opening of a water valve of a surface cooler is smaller than 95%, and the keeping time is longer than 30 min, it is judged that a surface cooler water valve fault exists on a variable air volume air conditioner system. In the step of active fault diagnosis, the faults with various fault reasons in fault symptoms are detected through expert rules, the variable air volume air handling unit enters the preset the active fault diagnosis step, potential fault reasons are eliminated successively, and the faults of the variable air volume air handling unit are separated and diagnosed.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

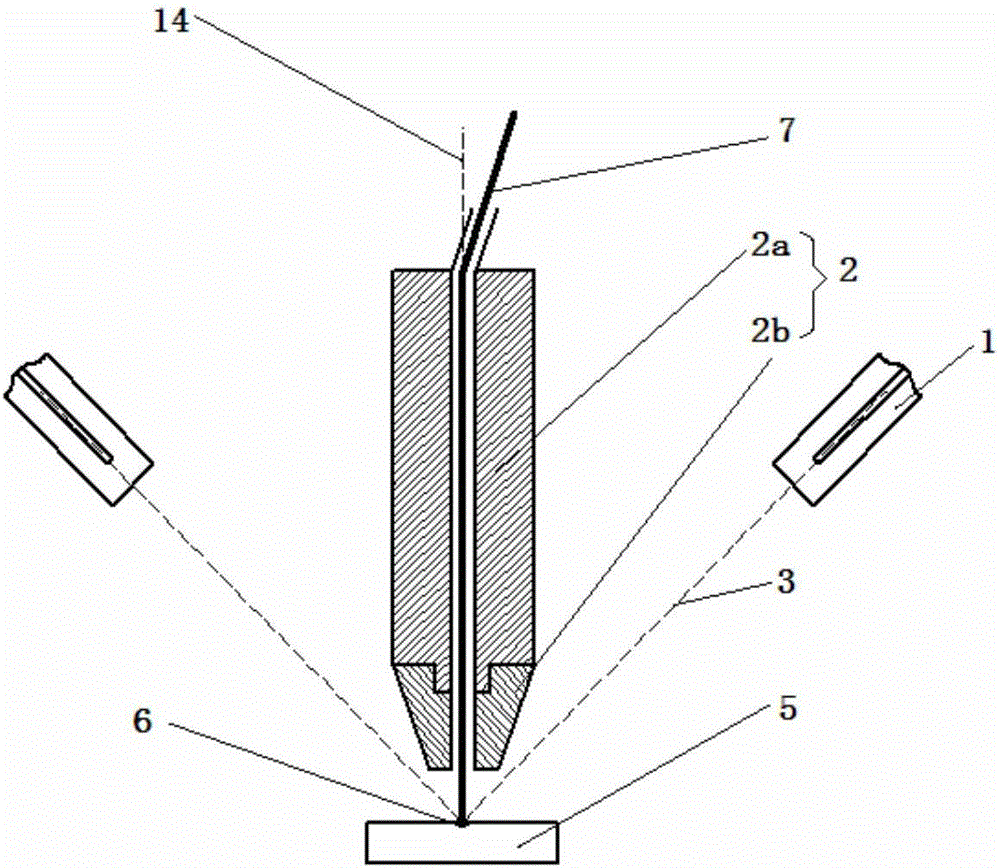

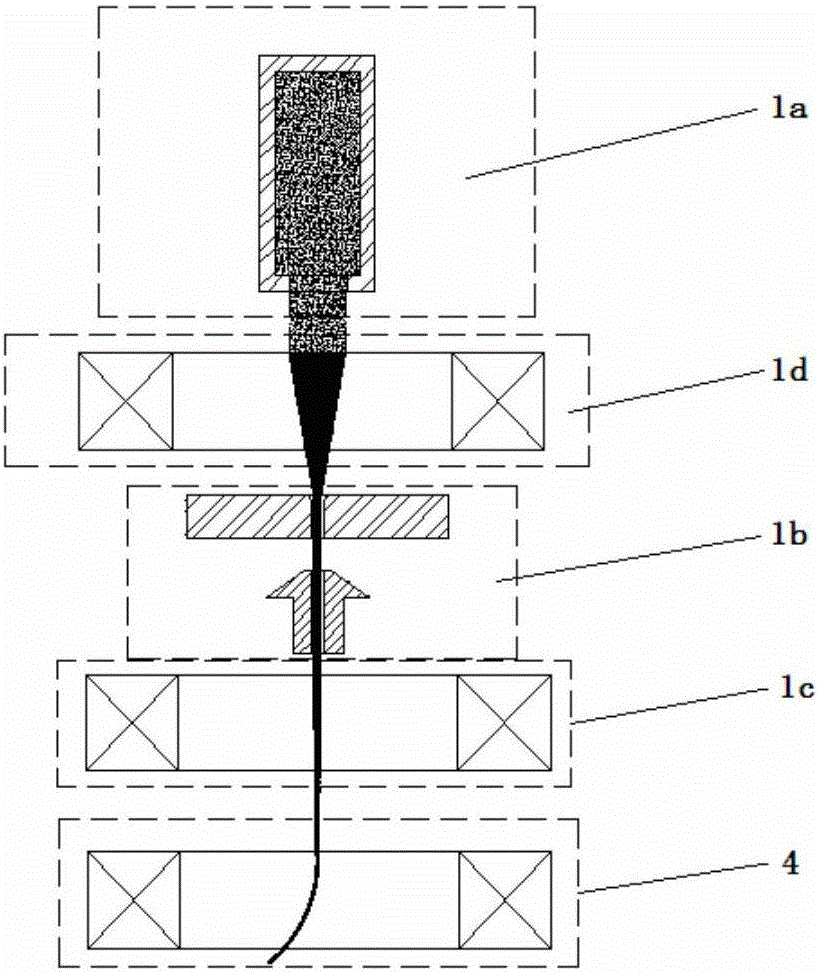

Electron beam processing system and processing method of multi-electron beam central wire feeding

ActiveCN106392290AGood uniformity of energy distributionSimple structureElectron beam welding apparatusElectron beam machiningAtomic physics

The invention discloses an electron beam processing system and processing method of multi-electron beam central wire feeding. The electron beam processing system comprises a plurality of electron beam guns and a wire feeding system, wherein the electron beam guns comprise electron beam generation systems, electron beam acceleration systems, electron beam accumulation systems and electron beam deflection systems; the wire feeding system comprises a wire feeding pipe and a wire feeding nozzle; the wire feeding nozzle is connected at the lower part of the wire feeding pipe; the wire feeding pipe and the wire feeding nozzle are arranged on a central axis of the structure; and the plurality of electron beam guns are in uniform lattice distribution along the circumference of the central axis. According to the electron beam processing system, the isotropy of electron beams on the surface of a workpiece can be guaranteed, the quality uniformity of the processed workpiece is improved, the processing process is continuous and unintermittent, the electron beam gun structures and a central wire feeding structure do not interfere with each other, and the processing system is applicable to electron beam processing fields of electron beam welding, electron beam cladding, electron beam metal 3D printing, and the like.

Owner:辽宁新锋精密光电科技有限公司

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367BMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time,hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improvethe medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

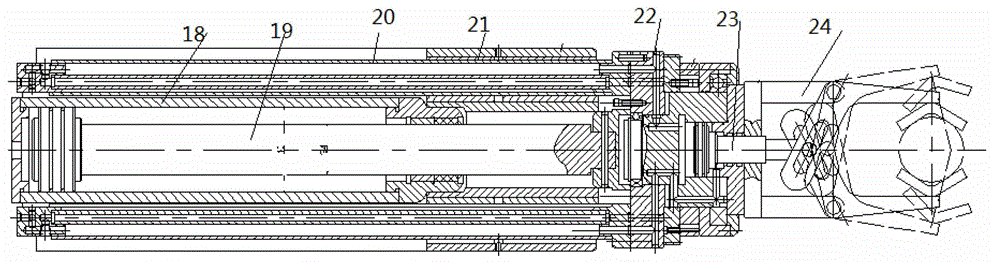

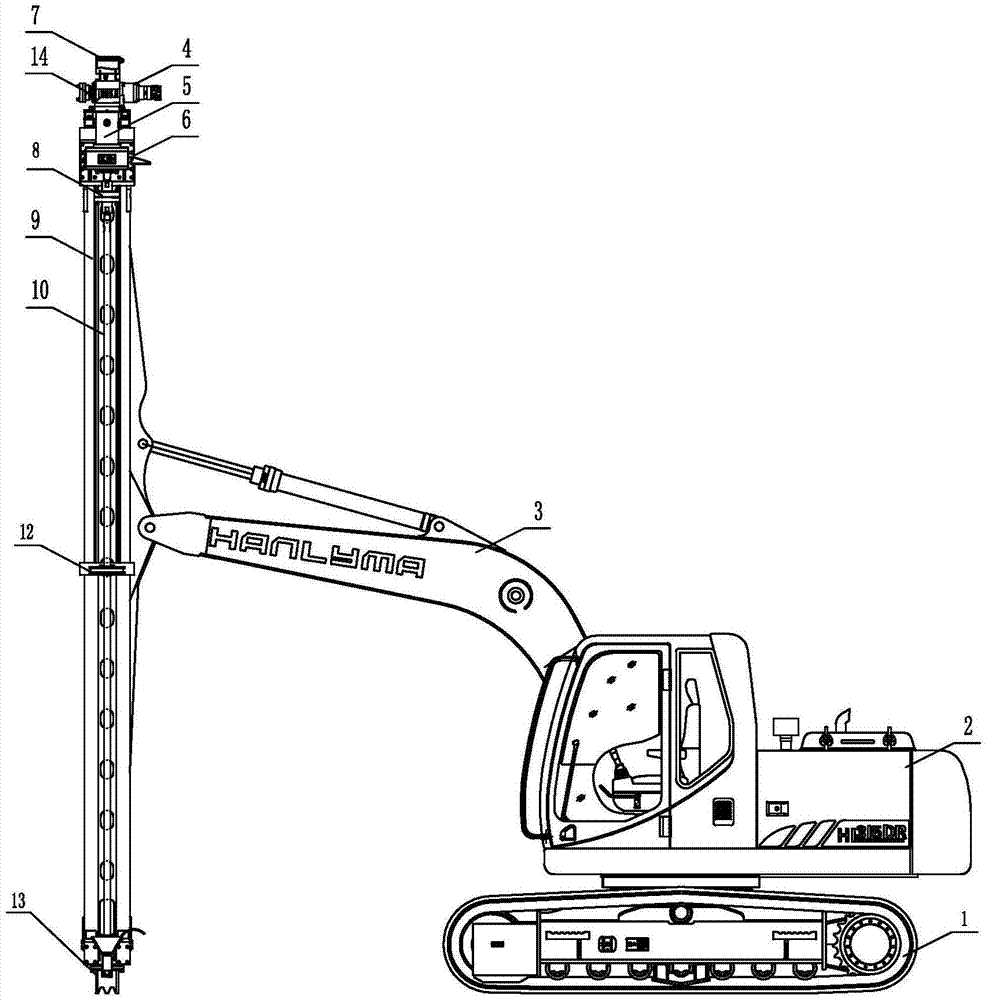

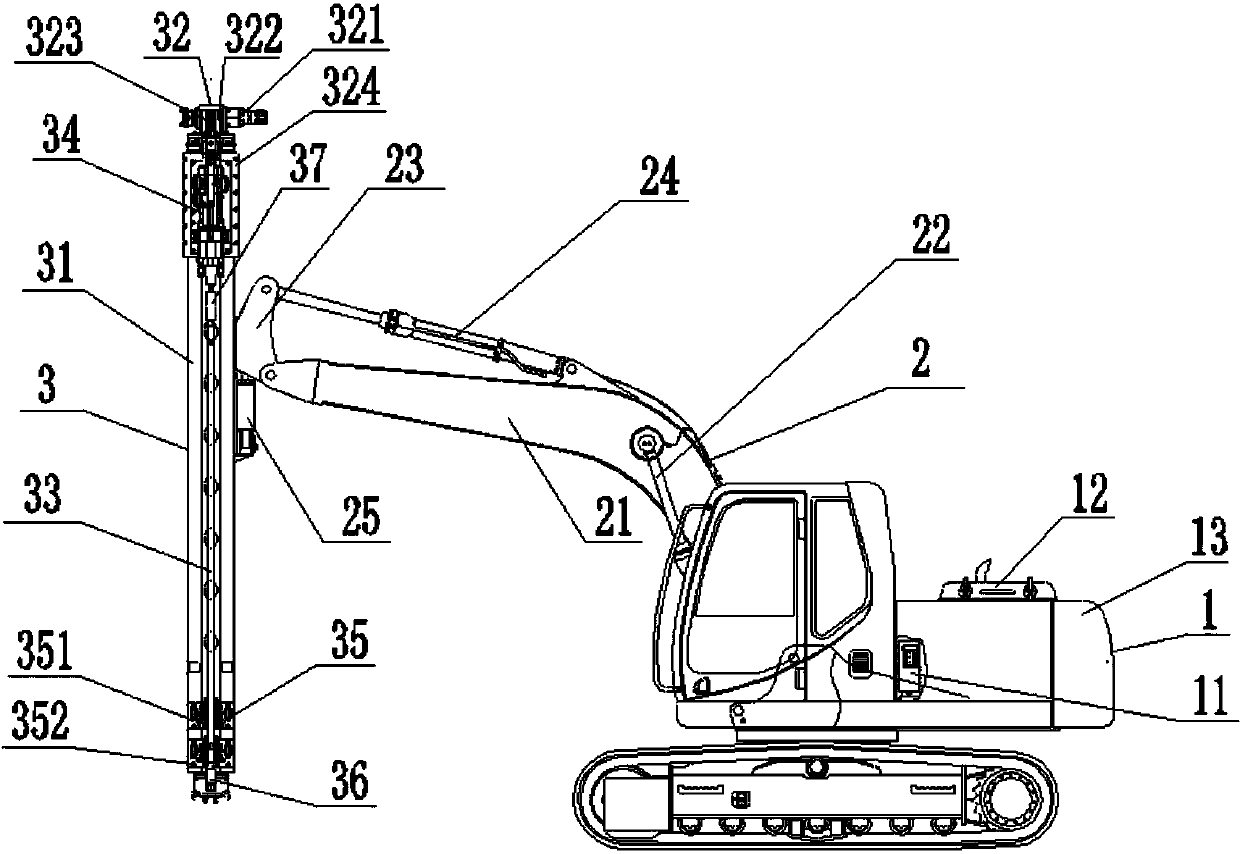

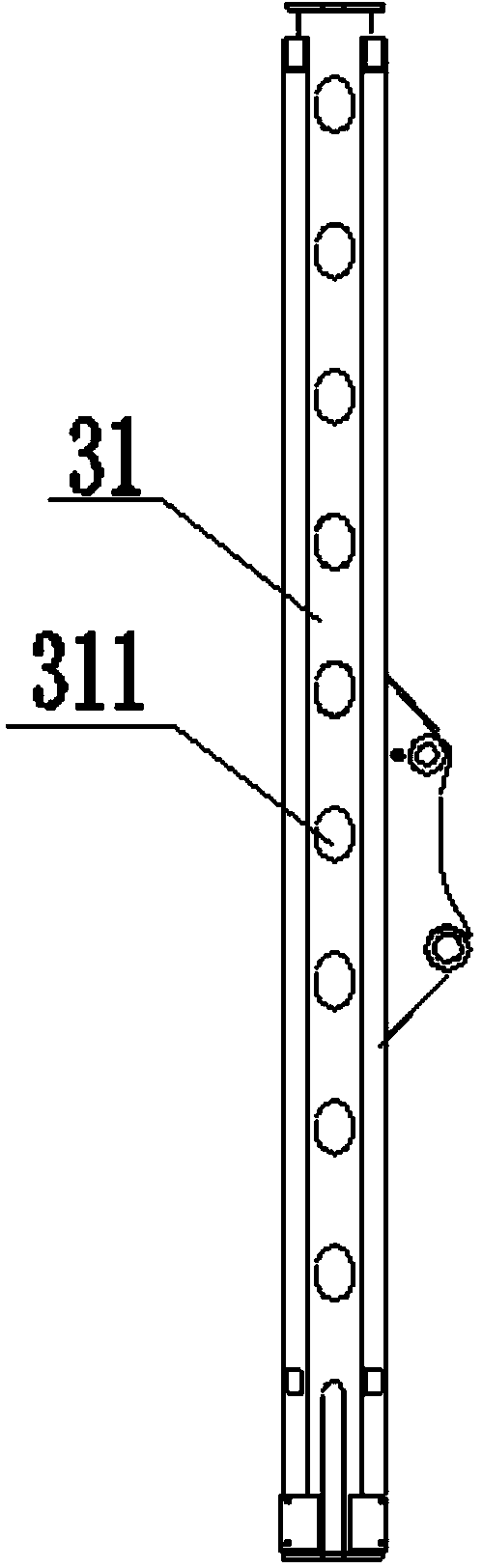

Double-speed double-torque crawler type hydraulic cutting drilling machine

InactiveCN103670272AReduce labor intensitySave energyRotary/oscillating piston combinations for elastic fluidsDrilling rodsAir volumeReduction drive

Provided is a double-speed double-torque crawler type hydraulic cutting drilling machine. A double-speed double-torque control device and a drill rod rotation control device are arranged in a power head, a chain, a chain wheel and a feed motor with a speed reducer are adopted in a pushing mechanism, an air compressor is a large-air-volume rotary screw air compressor and is provided with a dedicated air storage device and a motor protection device, and an intelligent lubrication system is arranged at the top of a drill arm. The cutting drilling machine can adapt to rock strata of different rigidities, and is high in hole drilling efficiency, drill rod rotation control is easy and convenient, and labor intensity is low. In the hole drilling process, applied pressure is large, rod lifting speed is high, the maintenance of the chain is good, the service life is long, and the maintenance cost is low. The air compressor is simple and compact in transmission structure, large in exhaust air rate, stable in air pressure, smooth in slug discharge and high in efficiency. The motor is stopped smoothly, impact vibration is small, the drill arm and the drill rod are high in strength and good in torque resistance and impact resistance, the drill rod is connected with a power head shaft through a coupling with a buffering function, and the power head shaft, a bearing and a transmission gear can be prevented from being damaged.

Owner:GUILIN HUALI HEAVY INDS

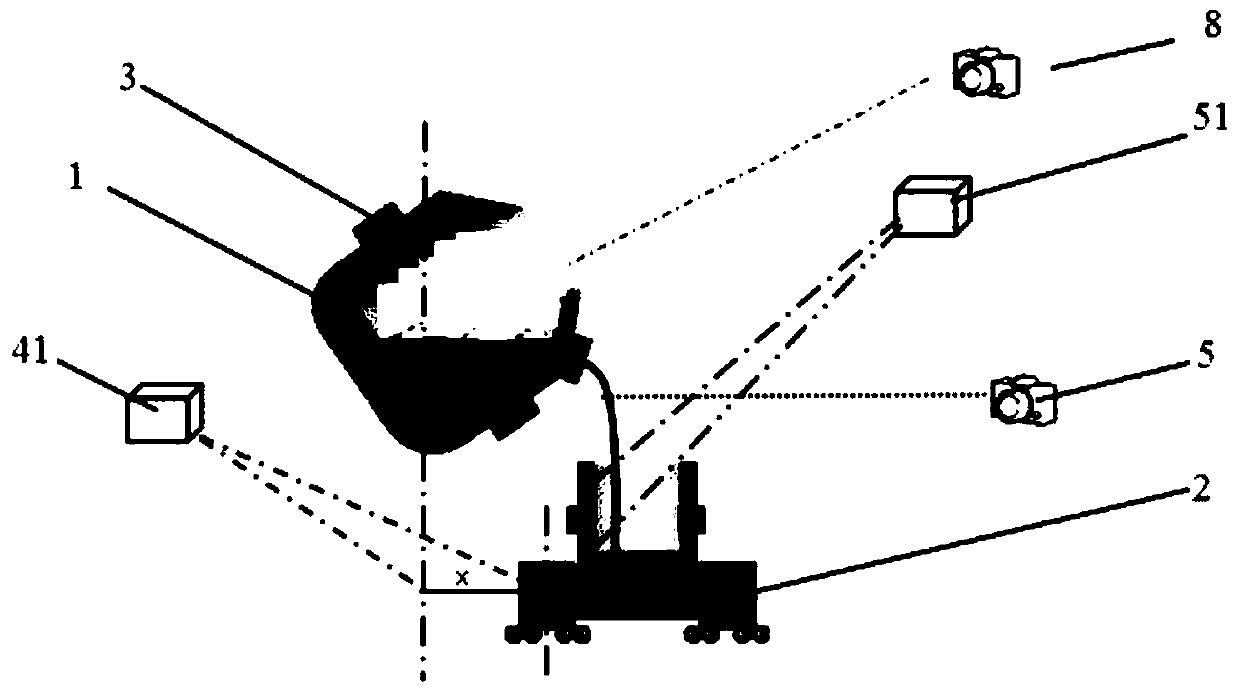

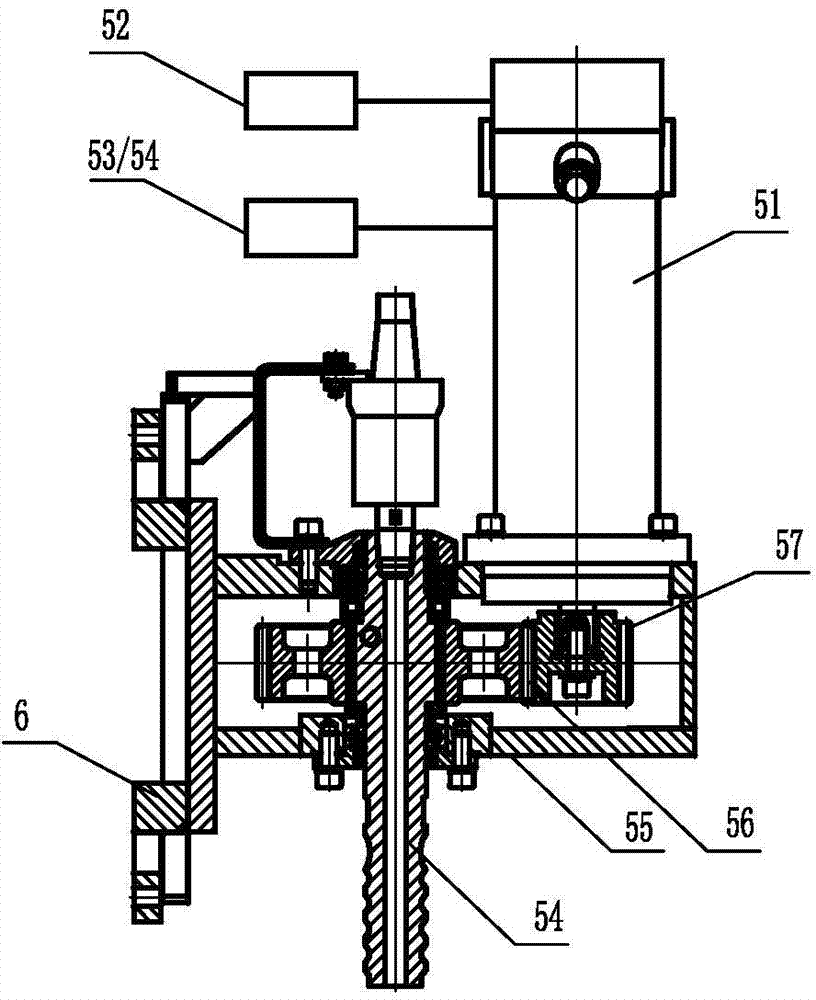

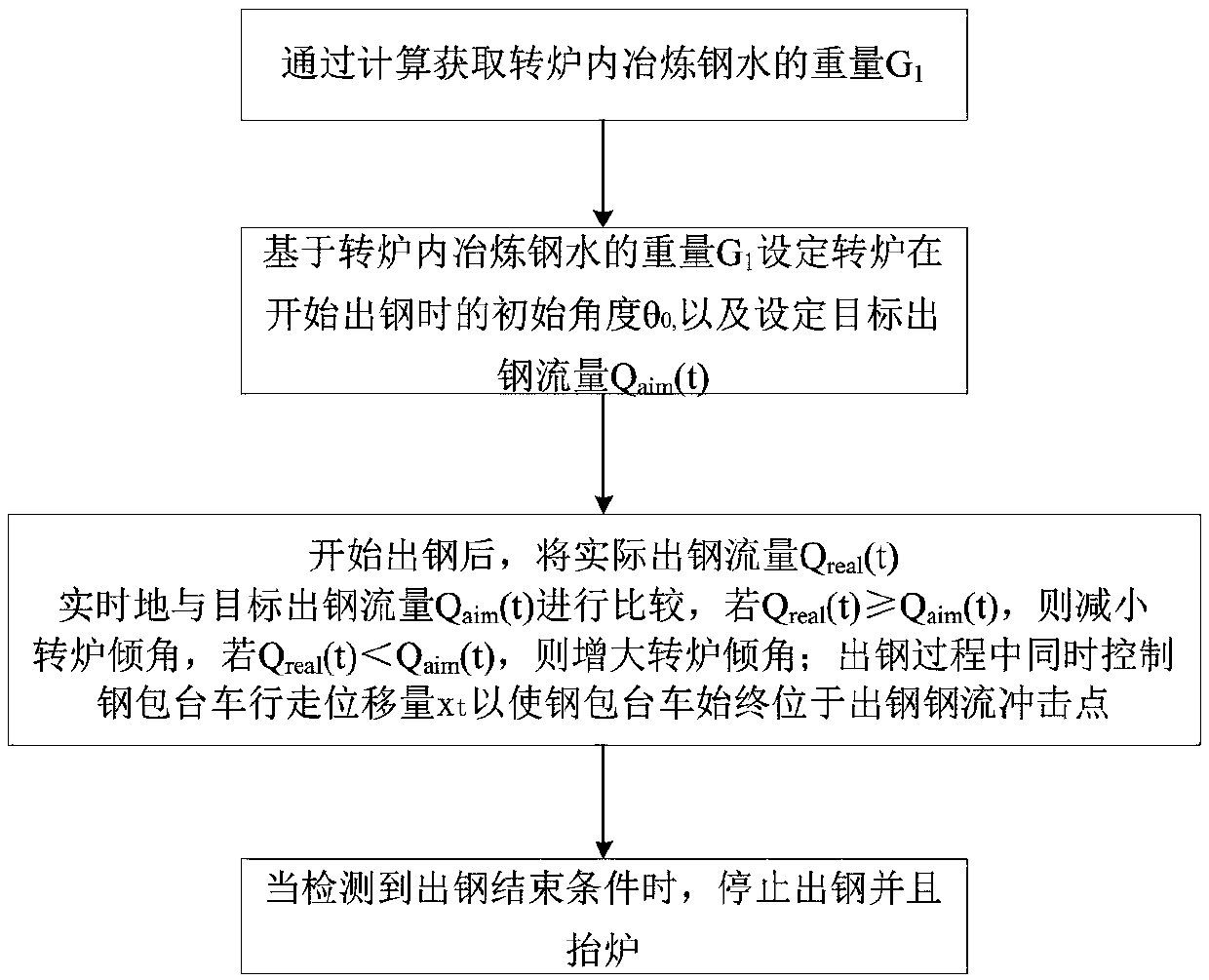

Tapping flow control method and system for full-automatic converter tapping

InactiveCN110616289ALess investmentReduce maintenance and repair costsManufacturing convertersSpecial data processing applicationsControl systemMolten steel

The invention discloses a tapping flow control method for full-automatic converter tapping. The method comprises the following steps that (1) the weight G 1 of molten steel in a converter is obtainedthrough calculation; (2) the initial angle Theta 0 of the converter when tapping starts is set based on the weight of the molten steel in the converter, and target tapping flow Q<aim> (t) is set; (3)when the tapping starts, actual tapping flow Q<real> (t) is compared with the target tapping flow the Q<aim> (t) in real time, if the Q<real> (t) is larger than or equal to the Q<aim> (t), the inclination of the converter is reduced, and if the Q<real> (t) is smaller than the Q<aim> (t), the inclination angle of the converter is increased; and in the tapping process, the walking displacement amount xt of a ladle trolley is controlled at the same time, so that the ladle trolley is always located at an impact point of tapping steel flow; and (4) when the condition that the tapping is finished isdetected, the is stopped and the converter is lifted. In addition, the invention further discloses a tapping flow control system for full-automatic converter tapping.

Owner:BAOSHAN IRON & STEEL CO LTD

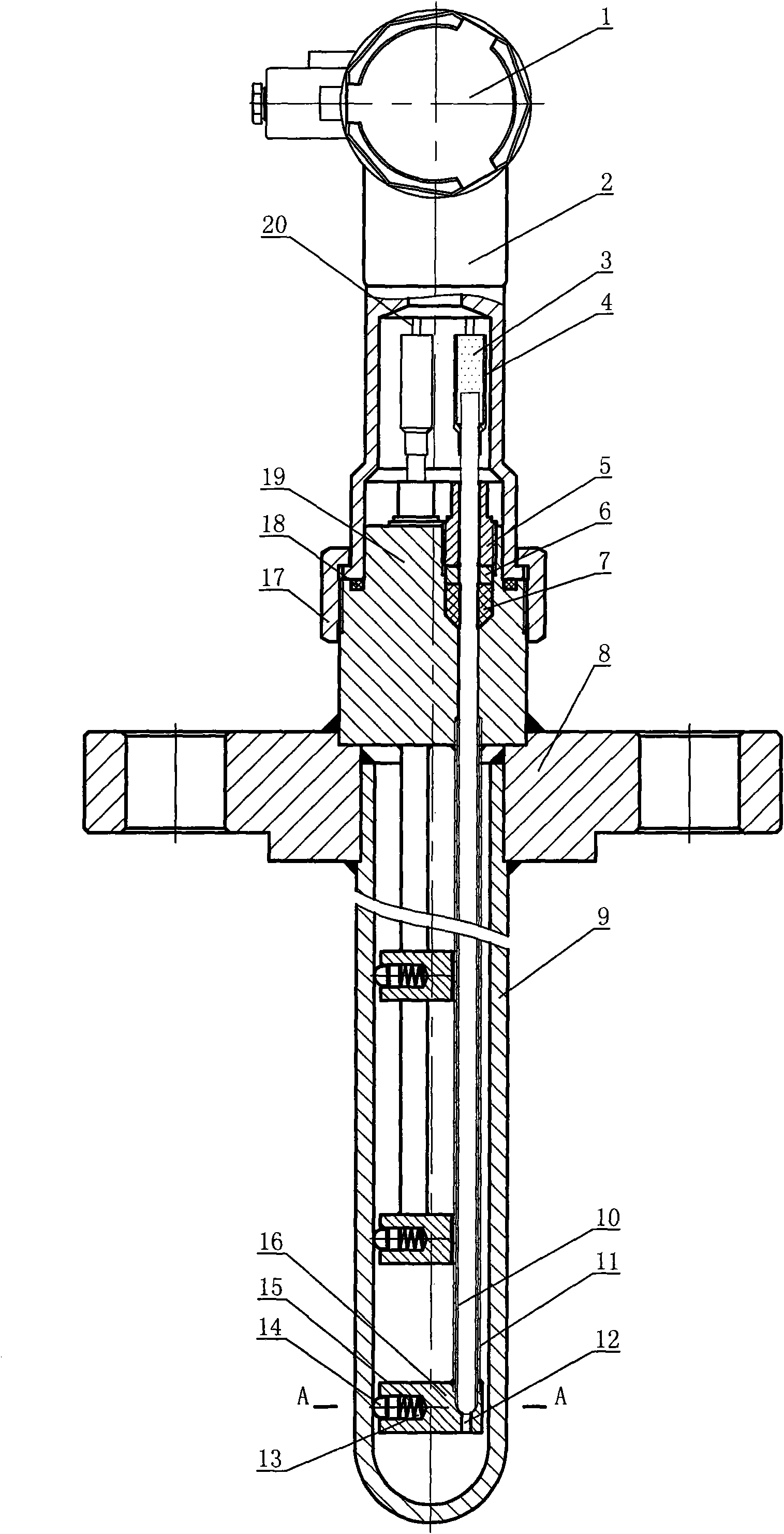

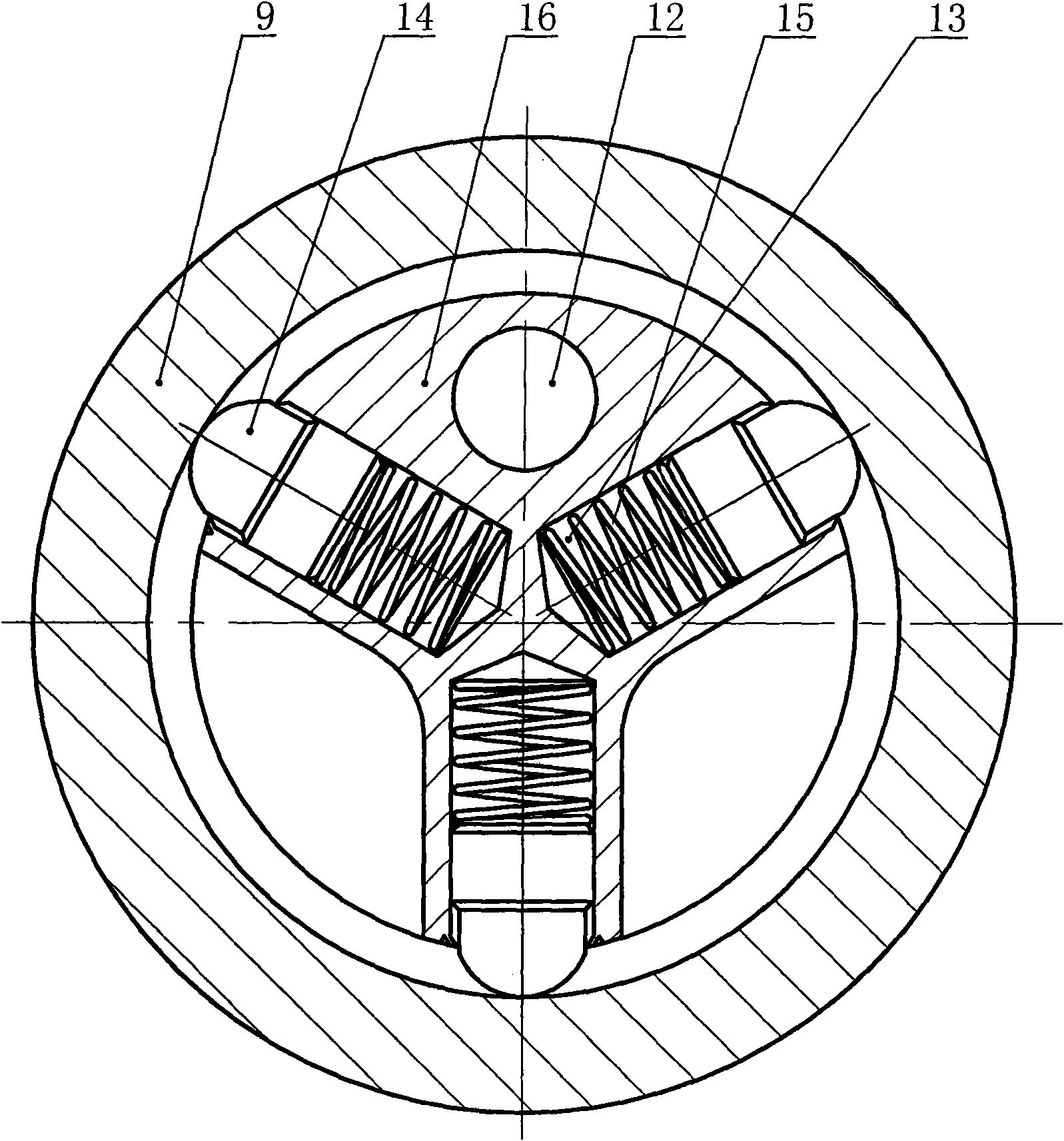

Adjustable armored thermocouple (resistor) with multipoint leakage resistance

InactiveCN101806637AEffectively adjust the direction of the outletQuick installationThermometers using electric/magnetic elementsUsing electrical meansThermocoupleMeasurement precision

The invention belongs to an adjustable armored thermocouple (resistor) with multipoint leakage resistance, comprising a junction box, a protection sleeve and a temperature measuring element; wherein the upper end of the protection sleeve is fixedly arranged on the junction box; the temperature measuring element is coaxially arranged in the protection sleeve, a soft wire of the temperature measuring element is fixedly arranged on the junction box, and the lower end of the temperature measuring element is positioned and arranged through a leakage-resisting seal seat, wherein the lower end of the protection sleeve and the leakage-resisting seal seat are coaxially arranged through an adjustable lock nut, and a compressed leakage-resisting device of the temperature measuring element is arranged on the leakage-resisting seal seat. The invention realizes that the measuring position of the temperature measuring element in the protection sleeve is adjusted at will, is convenient to replace the temperature measuring element and has higher measurement precision and security, better vibration resistance and longer service life.

Owner:TIANJINSHI ZHONGHUAN TEMPERATURE METERS

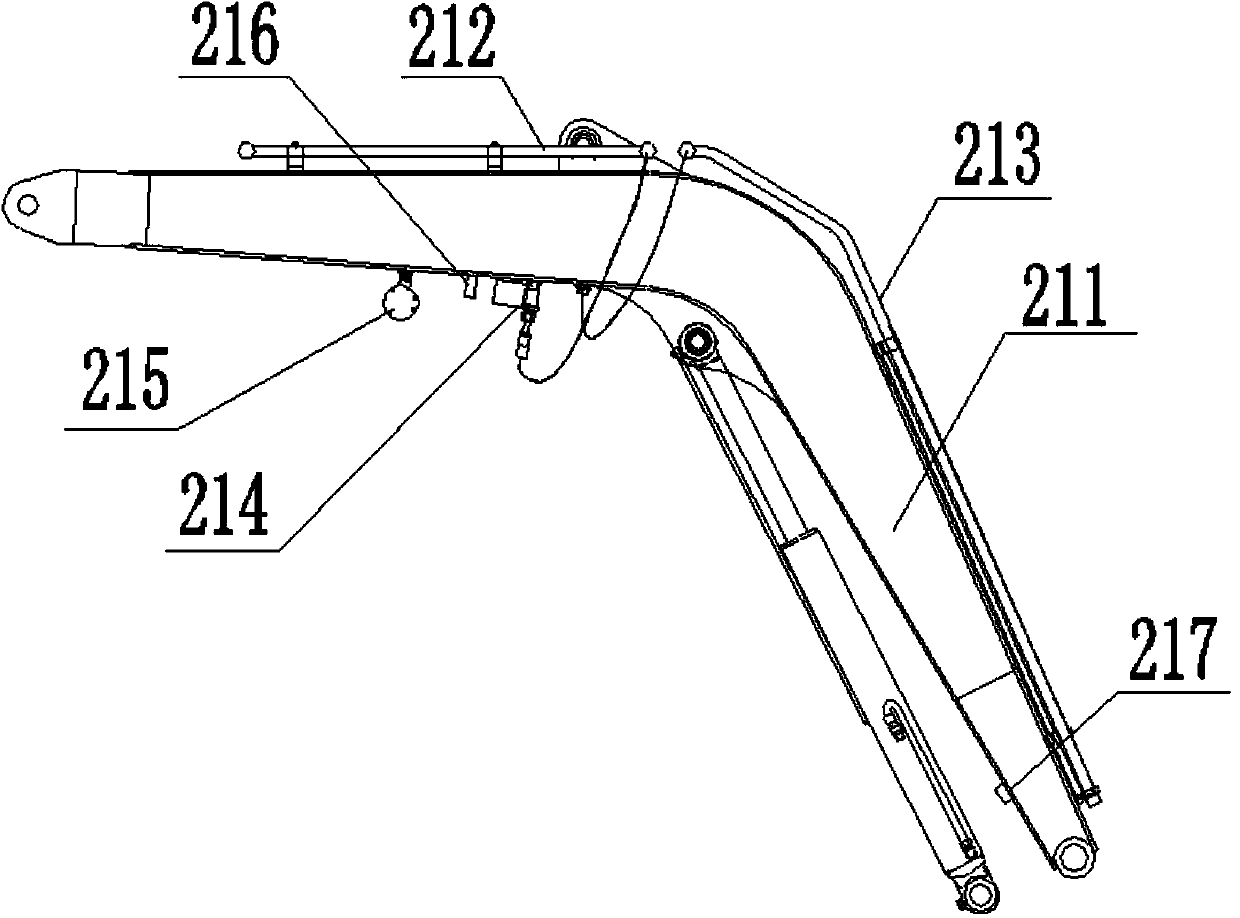

Deflection-swinging type semi-automatic rod replacing hydraulic rock drilling machine

InactiveCN104196445AReduce security risksExpand the scope of workDrilling rodsConstructionsSemi automaticEngineering

The invention relates to a deflection-swinging type semi-automatic rod replacing hydraulic rock drilling machine. The machine comprises a carrier machine, a movable arm and a drilling machine body. One end of the movable arm is arranged at the upper end of the carrier machine, and the other end of the movable arm is connected with the middle of the drilling machine body. The movable arm drives the drilling machine body to swing in a deflected mode. Compared with the prior art, drill rod replacing is convenient, potential safety hazards are reduced, the directions for deflection swinging of the drilling machine are increased, and drilling precision is improved.

Owner:GUILIN HUALI HEAVY INDS

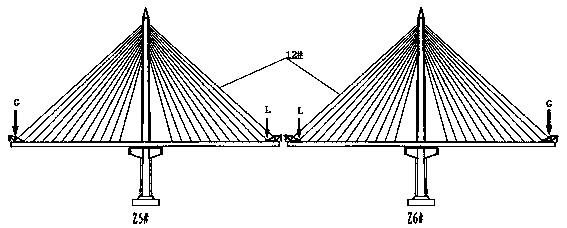

Variable cross-section box girder bridge closure segment construction method

InactiveCN105040594AReduce maintenance and repair costsReduce the cost of trainingBridge erection/assemblyBridge engineeringSocial benefits

The invention belongs to the field of bridge engineering construction and particularly provides a variable cross-section box girder bridge closure segment construction method. The method comprises the following steps of side span closure segment formwork mounting, side span stiff skeleton welding, side span reinforcing steel bar machining and mounting, transverse and vertical side span prestressed tendon mounting, side span closure segment concrete pouring, side span closure segment prestressing tendon tensioning and pipeline grouting, midspan closure hanging basket moving and balance weight arranging, midspan closure segment pushing, midspan closure segment concrete pouring, midspan closure segment prestressing tendon tensioning and midspan closure segment formwork and support dismantling. According to the method, jacks are adopted for jacking beam ends, stiff skeletons are additionally arranged in beams, the tensioning procedures are reasonably designed, the bearing capacity of a closure segment is effectively guaranteed, the number of engineering accidents is reduced, the adverse social influence produced after the accidents is eliminated, and good social benefits are achieved.

Owner:NANNING MUNICIPAL ENG GRP

Clamping and conveying device for conveying steel bars

InactiveCN102319822ASave shipping timeImprove transportation efficiencyMetal-working feeding devicesPositioning devicesEngineeringRebar

The invention relates to a clamping and conveying device for conveying steel bars. The device comprises a main box, a secondary box, an upper roller, a lower roller and a cylinder, wherein the secondary box is glidingly arranged in the main box at the upper part of the lower roller; the secondary box is driven by the cylinder fixedly arranged at the top of the main box; the main box at two ends of the upper roller is provided with symmetrical end covers respectively; each end cover is provided with an upper roller sliding hole and an oil return baffle plate; the lower part of the oil return baffle plate is provided with an oil return oil; an oil baffle cover plate is fixedly arranged at the outer side of the end cover; the oil baffle cover plate is provided with a cover plate through holecorresponding to the upper roller sliding hole; and a dustproof oil baffle cover is fixedly arranged on the upper roller bearing end cover between the oil baffle cover plate and the oil return baffleplate. The device has compact structure, scientific and reasonable design, low manufacturing cost, small volume and high clamping accuracy, and can adapt to the steel bars of different specifications; the lubricating mode is circulating oil reinforced lubrication; and the device is reliable in sealing and high in transport velocity, improves the production efficiency of the steel bars, prolongs the service life of the steel bars, and is safe and reliable.

Owner:王丽燕

No-cutting-seam cement concrete pavement structure and construction method thereof

ActiveCN103276651AWith force transmission effectNo reduction in structural durabilityPaving detailsRoad surfaceRebar

The invention discloses a no-cutting-seam cement concrete pavement structure and a construction method thereof, belonging to the technical field of traffic road construction. The no-cutting-seam cement concrete pavement structure is characterized in that an aluminium plate is fixed on a foundation at a cutting seam of a traditional concrete pavement, an induced joint is reserved in the aluminium plate, and high-ductility fiber reinforced cement-based composite material is poured on the aluminium plate, so that an induced joint structure is formed between two concrete pavements; the construction method comprises the following steps of: fixing the aluminium plate on the foundation, wherein the induced joint is reserved in the aluminium plate; arranging two anchor steel bar brackets on the two sides of the aluminium plate along the center line of the joint; fixing a mould onto a side formwork, wherein a rabbet is reserved in the mould; and firstly pouring common concrete according to a traditional pavement construction technology, and then pouring and plastering the high-ductility fiber reinforced cement-based composite material in a preformed groove after the mould is disassembled. The no-cutting-seam cement concrete pavement structure guarantees the integrity of pavement, improves the road driving comfort, effectively reduces the engineering cost, reduces the maintenance cost and reduces the traffic jam caused by maintenance.

Owner:TSINGHUA UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com