Spring load test system

A technology of load testing and loading, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc. It can solve the problems of complex testing process, low testing accuracy, waste of labor costs, etc., and achieve simple composition, Accurate detection results and saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. However, this embodiment is not intended to limit the present invention, and all similar methods and similar changes of the present invention should be included in the protection scope of the present invention.

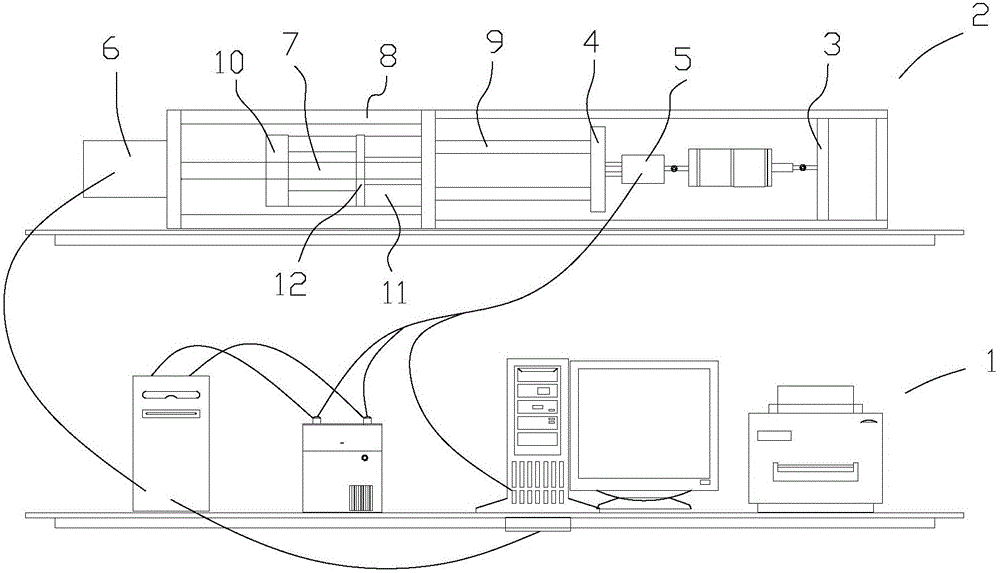

[0016] refer to figure 1 , a spring load testing system described in the present invention is mainly composed of a console 1 and a load installation platform 2 . The load installation platform 2 includes a fixed block 3 and a movable block 4 arranged horizontally opposite each other. The fixed block 3 is fixed in position, and the movable block 4 is driven by a driving device controlled by the console 1 to move horizontally relative to the fixed block 3 . The fixed block 3 is provided with an ear for connecting with one end of the spring load, and the movable block 4 is provided with a force sensor 5 , and the force sensor 5 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com