Patents

Literature

2797results about How to "Shorten working time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

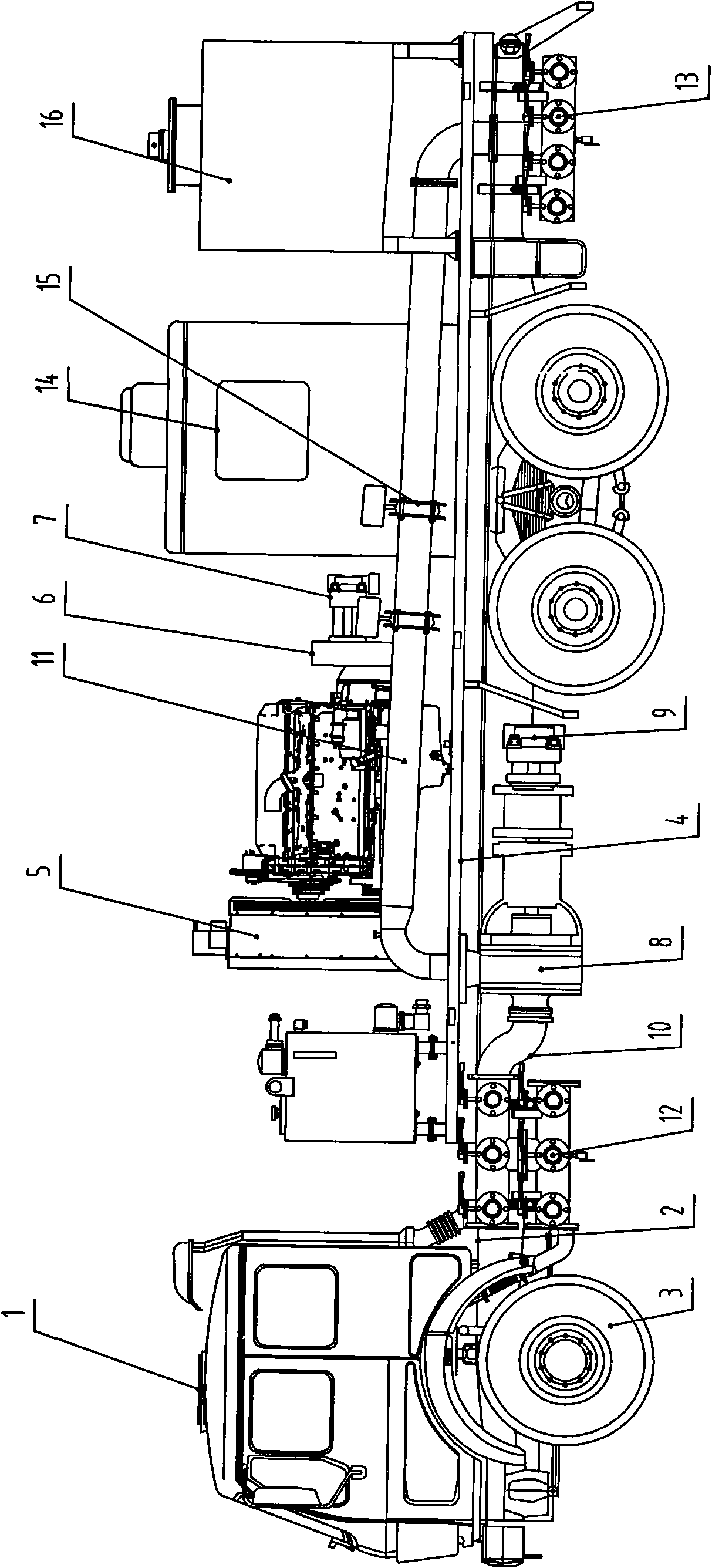

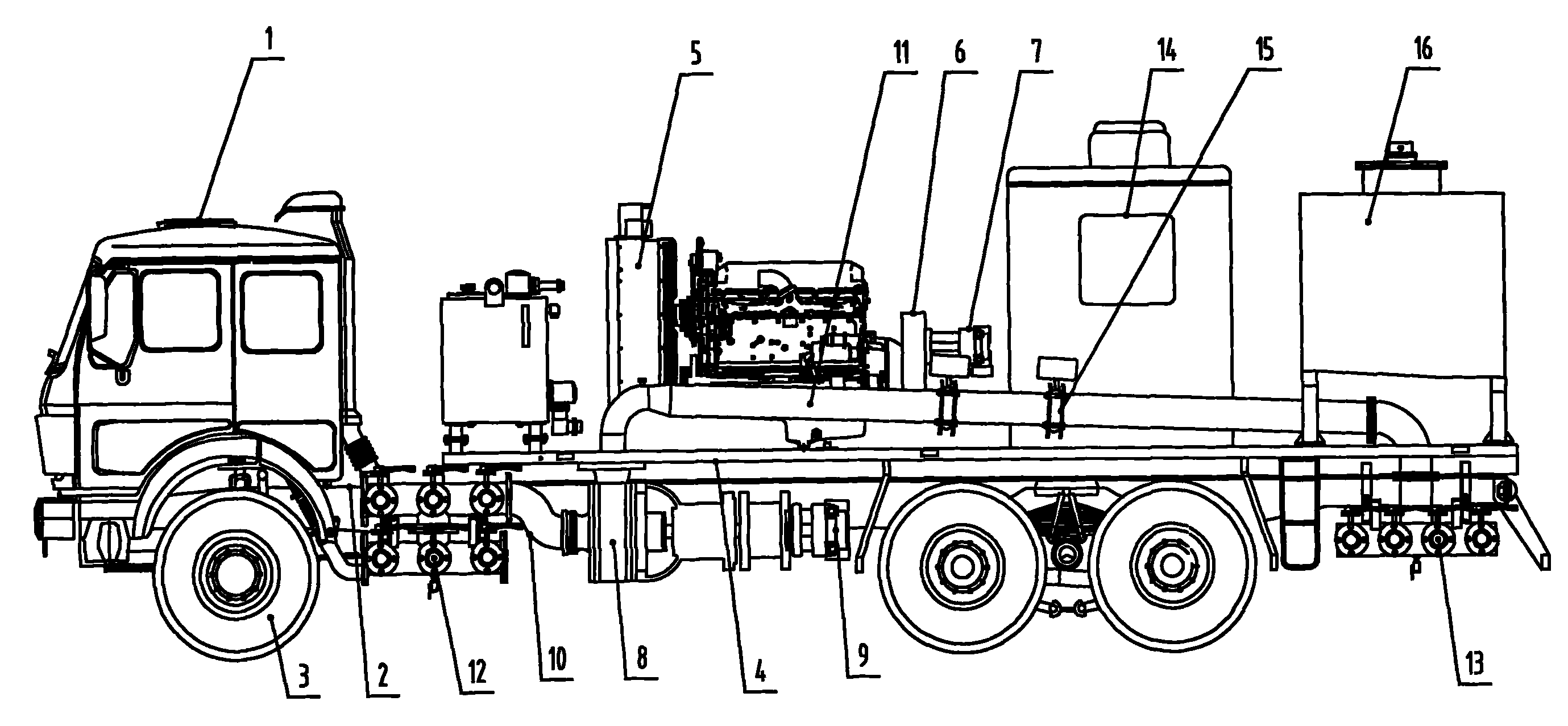

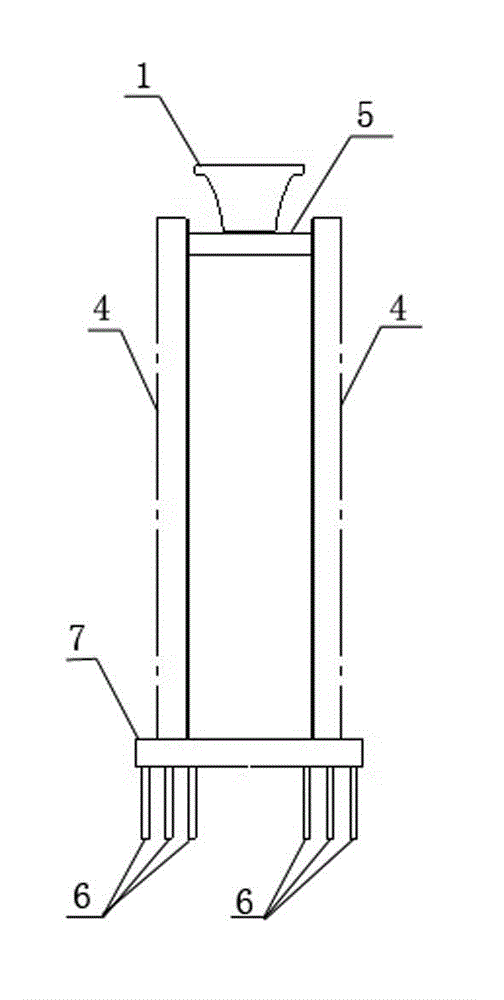

Liquid supply vehicle

ActiveCN101885307ALower suction heightImprove inhalation performanceFluid removalItem transportation vehiclesVehicle frameSewage

The invention discloses a liquid supply vehicle, which comprises a frame with a cab. The lower part of the frame is provided with wheels, the rear upper part of the frame is provided with a bedplate, a power driving device is arranged on the bedplate, a centrifugal pump is arranged below the bedplate, the power driving device is in transmission connection with the centrifugal pump, and an inlet and an outlet of the centrifugal pump are connected with a suction pipe and a discharge pipe respectively. The liquid supply vehicle has the advantages of improving the self-sucking effect of a fracturing truck, improving the operation efficiency of the fracturing truck and shortening the operation time, along with reasonable design, simple structure, easy assembly and manufacture, and also can be used for liquid delivery in other industries of flood drainage, sewage clearing and the like.

Owner:ZYT GASOLINEEUM EQUIP

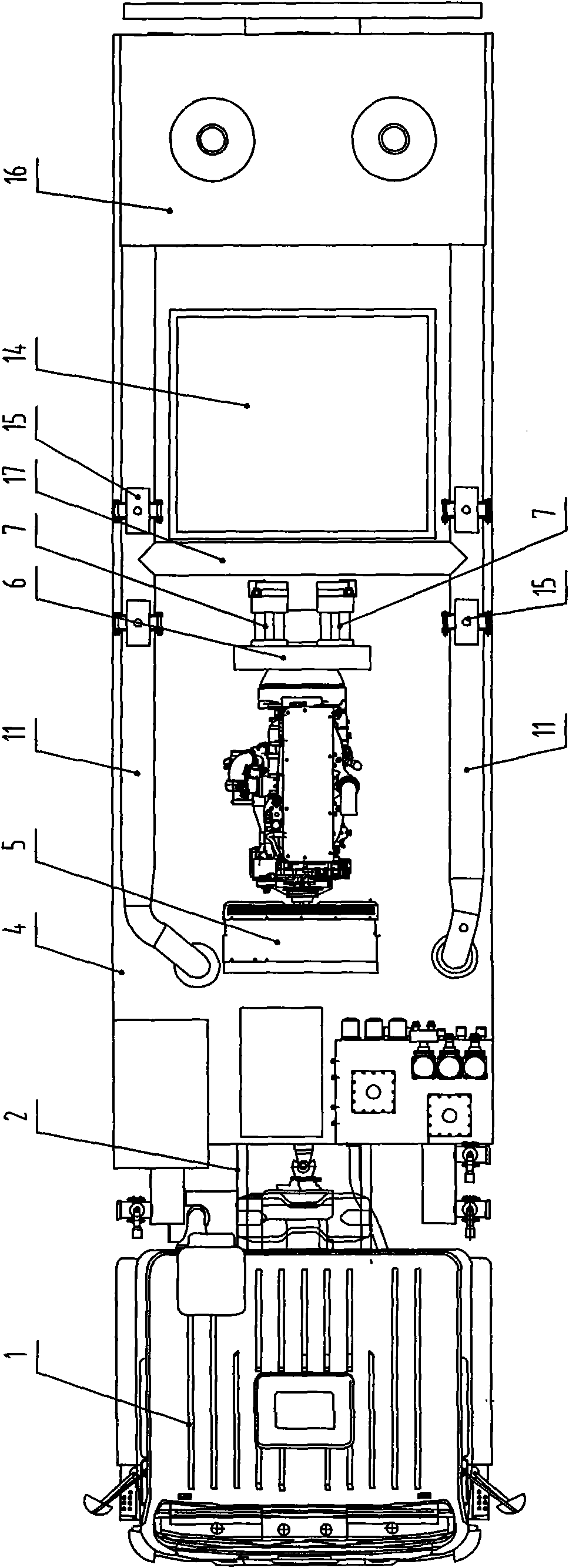

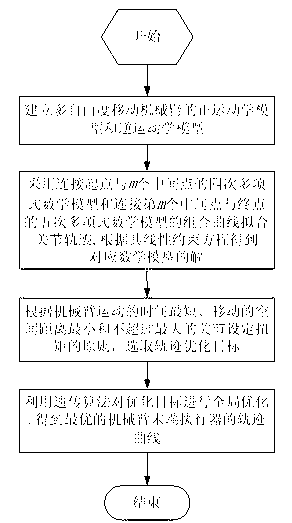

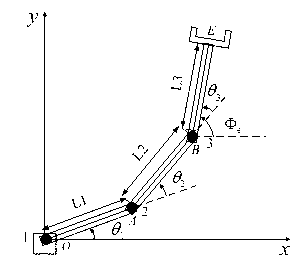

Genetic-algorithm-based trajectory planning optimization method for mobile mechanical arm

The invention relates to a genetic-algorithm-based trajectory planning optimization method for a mobile mechanical arm. According to the technical scheme, the method comprises the following steps of first establishing a forward kinematic model and an inverse kinematic model of a multi-degree-of-freedom mobile mechanical arm; then fitting a joint trajectory by adopting a composite curve of a quartic polynomial mathematical model and a quintic polynomial mathematical model, and calculating solutions of the corresponding mathematical models according to a linear constraint equation; next selecting a trajectory optimization target according to the principles of shortest motion time, minimum spatial motion distance and less than or equal to maximum set joint torque of the mobile mechanical arm; and finally globally optimizing the optimization target by utilizing a genetic algorithm to obtain an optimal trajectory curve of an end actuator of the mechanical arm. According to the method, the trajectory planning efficiency and the tracking accuracy of the mechanical arm are improved, and the problems of real-time trajectory planning of the mobile mechanical arm and trajectory planning optimization and control of the mechanical arm in an uncertain environment are also solved; and the trajectory planning optimization method for the mobile mechanical arm is effective.

Owner:WUHAN UNIV OF SCI & TECH

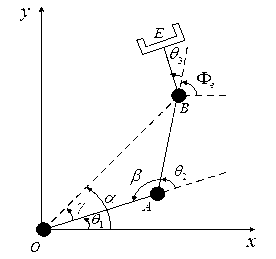

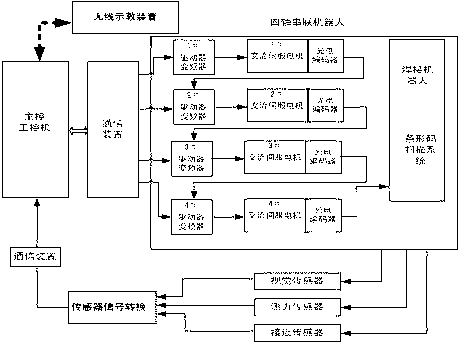

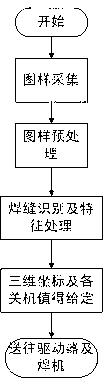

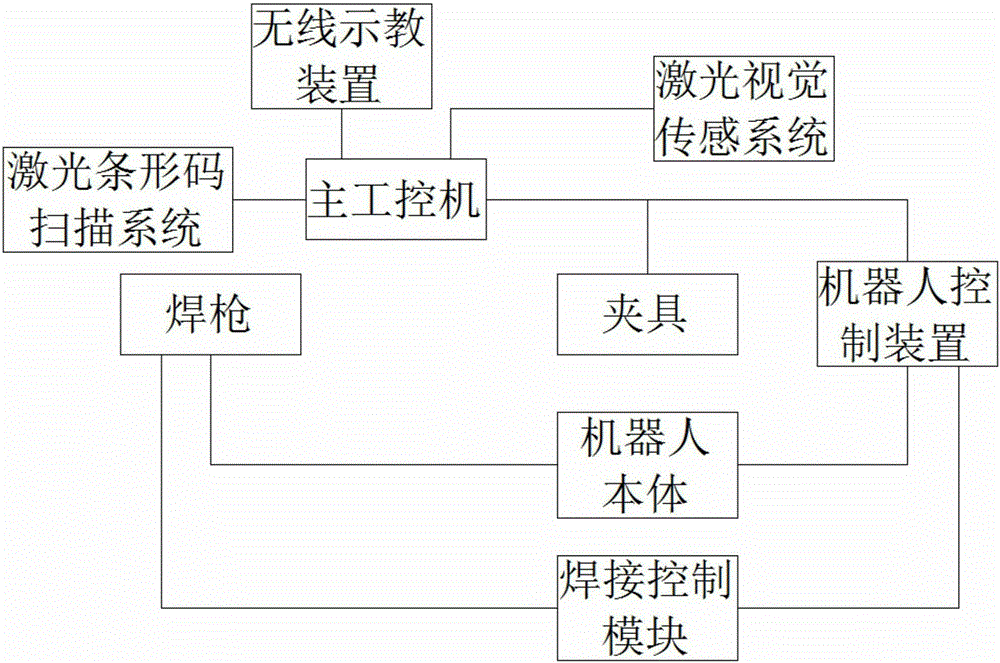

Welding robot control method

InactiveCN103170767AFaster and easier controlFriendly man-machine interfaceWelding/cutting auxillary devicesAuxillary welding devicesLoop controlClosed loop

The invention discloses a welding robot control method, and relates to a welding robot control device. According to the welding robot control method, a laser vision sensing system, a laser barcode scanning system, a main industrial personal computer, a driving device and a wireless demonstration device are utilized. A weldment is scanned through the laser bar code scanning system to form a three-dimensional model, the three-dimensional model is led into the main industrial personal computer, and welding information is directly designated on the three-dimensional model through the wireless demonstration device. The welding information comprises positions and lengths of weld joints, and the swing mode of a welding gun. When welding workpieces needs to be produced in a batch mode, a bar code identification system can be used for reading the welding information of welding bar codes on the welding workpieces, then the welding information is sent to the main industrial personal computer, and the main industrial personal computer converts the information of the bar codes into welding signals. The welding robot control method has the advantages that closed-loop control is realized, demonstration efficiency is improved, control of a welding robot is convenient, the electromagnetic field disturbance resistance ability is high, the demonstration efficiency and the quality of the weld joints of the workpieces are improved, the adaptive ability of a control system is enhanced, and the reliability is high.

Owner:XUZHOU UNIV OF TECH +1

Continuous casting slab high-temperature oxidation resistant coatings and preparation process thereof

InactiveCN101693791AGood anti-oxidation effect at high temperatureRaw materials are easy to getCoatingsOxidation resistantSuspending Agents

The invention relates to a preparation process of continuous casting slab high-temperature oxidation resistant coatings, which is characterized in that less than 120 meshes of powder, reductant containing carbon, inorganic binders, surfactants, suspending agents and the like with the compositions such as 25-55 wt% SiO2, 10-20 wt% Al203, 11-23 wt% MgO and the like are respectively grinded and mixed evenly, then water is used to be mixed and stirred sufficiently evenly, and finally the density of the coatings are adjusted within 1200-1500 kg / m3. The coatings can not only be sprayed onto continuous casting slabs at normal temperature, but also be sprayed onto high-temperature casting slabs, form continuous whole protective coating layers under the action of high temperature, effectively reduce temperature drop of the casting slabs and oxidation burning loss in even heating process of a heating furnace without changing original performance of matrixes, and effectively decrease dilution of alloying elements on the surfaces of the casting slabs. After the casting slabs are out of the heating furnace, natural spalling capability of the coating layers is strong, and oxidation matrixes of the casting slabs are smooth. Raw materials of the oxidation resistant coatings are easy to be obtained, and the coatings have low cost and simple preparation process and are adaptable to oxidation resistance for various steels when being heated at 700-1300 DEG C / 2-8 hours.

Owner:UNIV OF SCI & TECH BEIJING

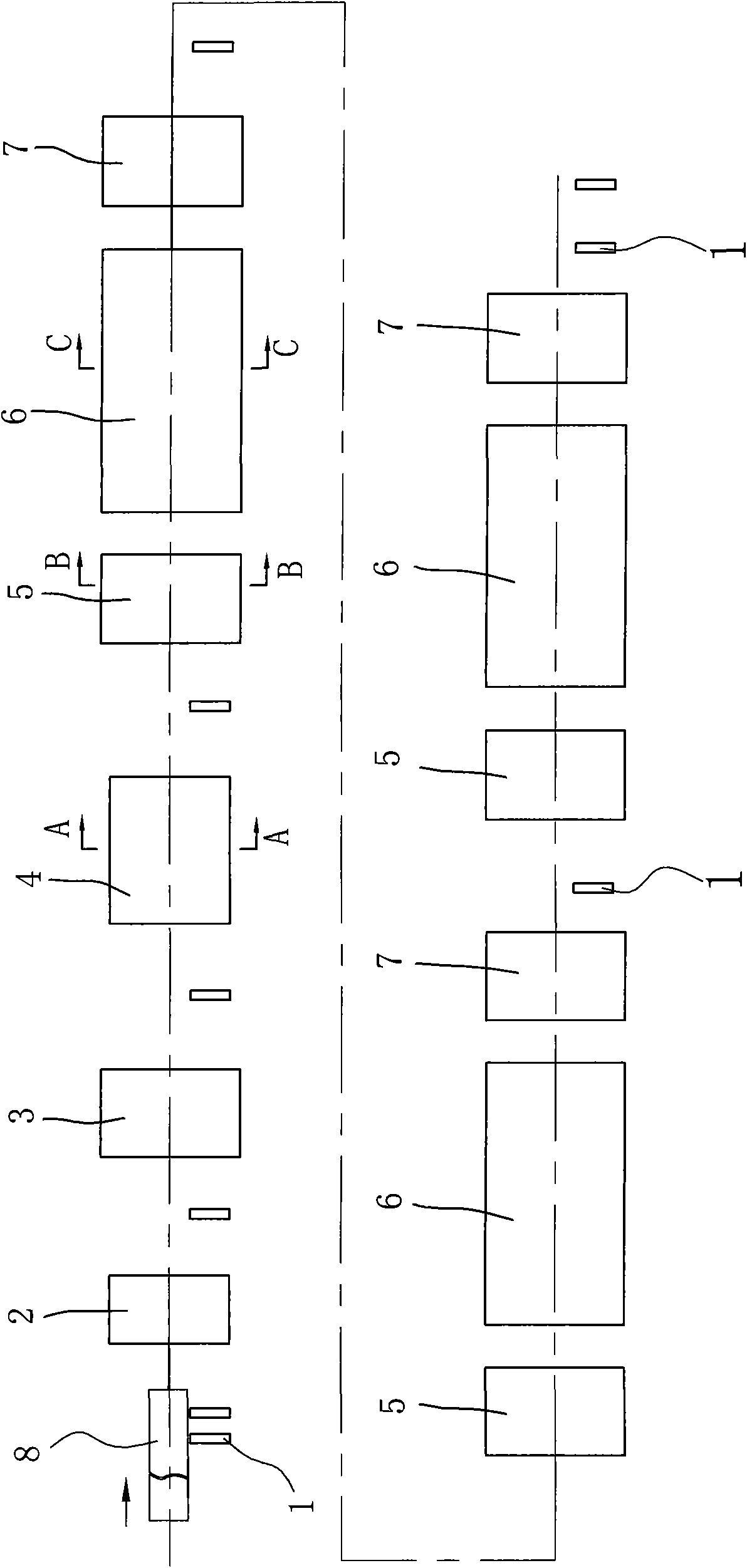

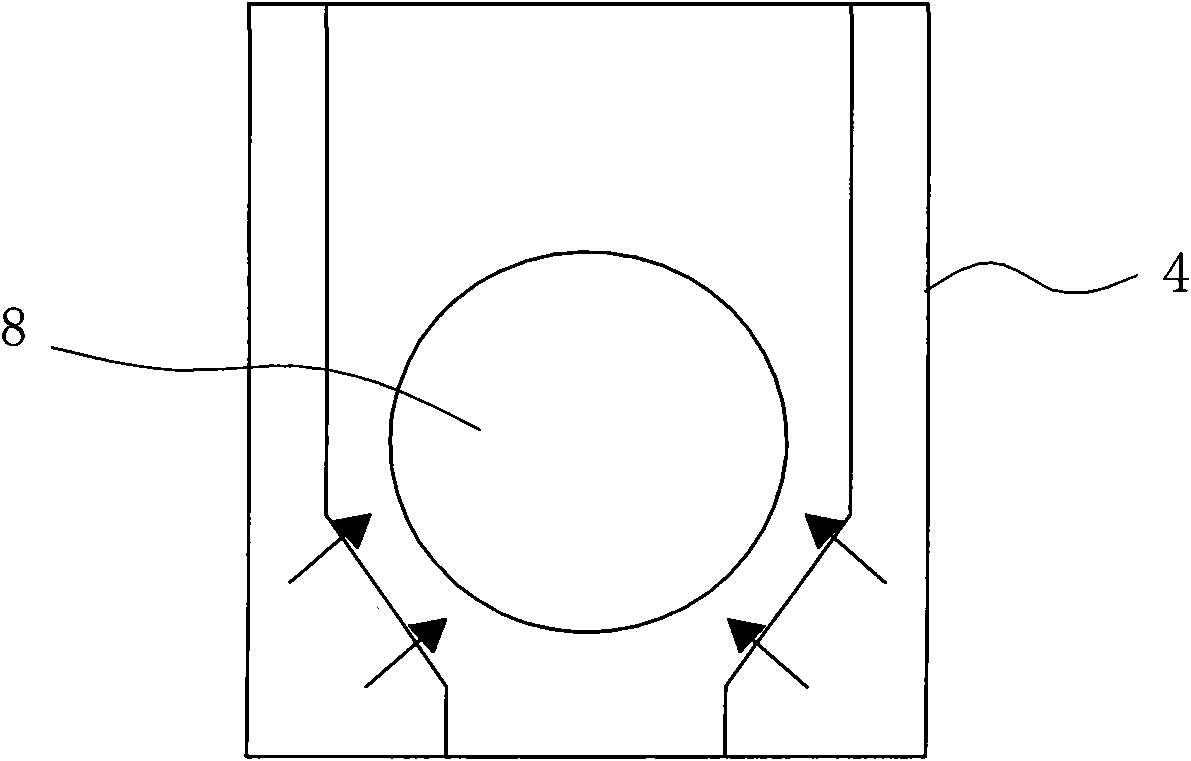

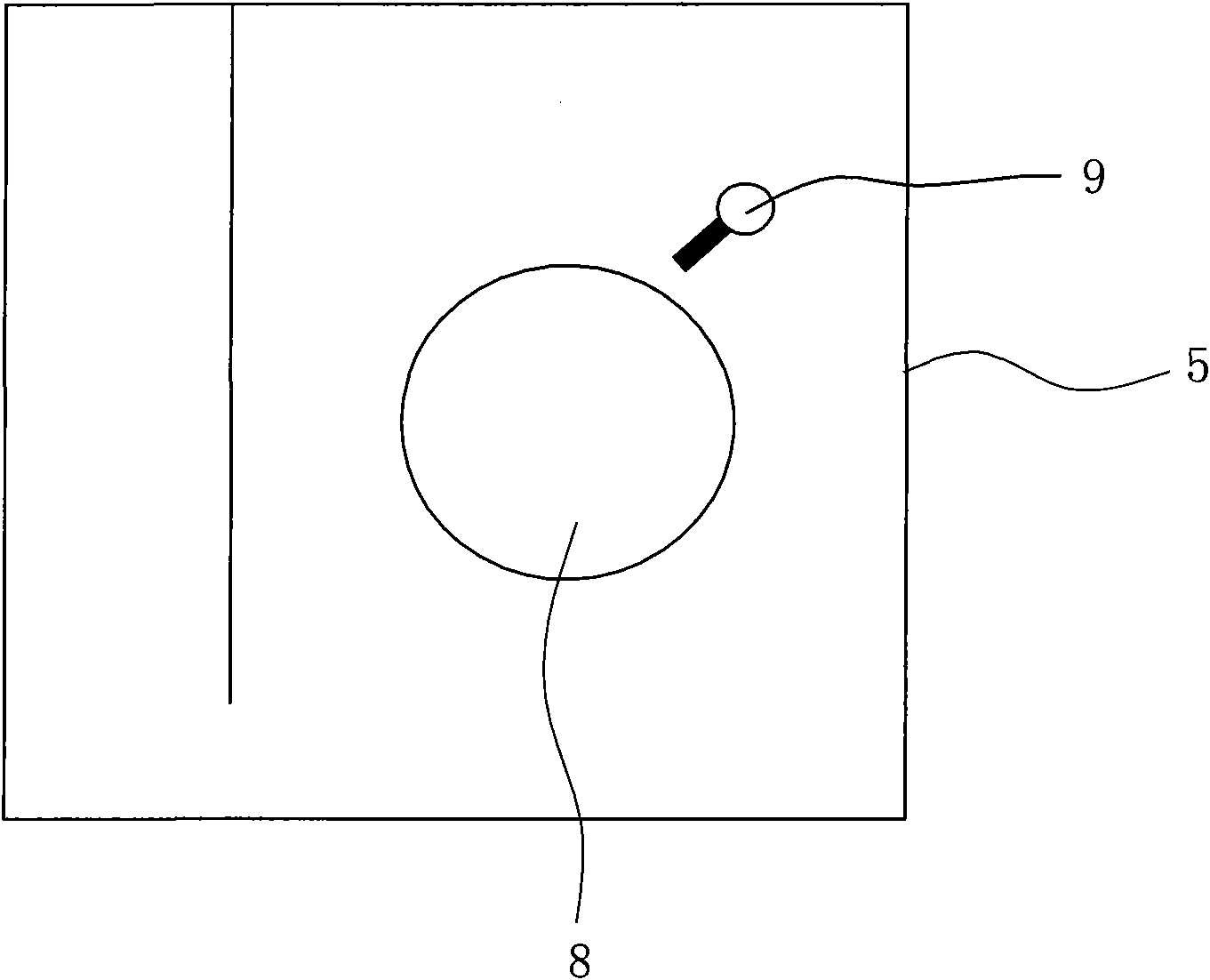

Automatic coating technology of large-scale steel pipe anticorrosion coating and production line thereof

ActiveCN101607247AHigh painting efficiencyShort curing timePretreated surfacesCorrosion preventionSteel tubeSurface finishing

The invention relates to an automatic coating technology of large-scale steel pipe anticorrosion coating and a production line thereof. The coating technology adopts the steps that steel pipes enter into a dehumidification cleaner, an automatic shot blasting machine, a preheating drying chamber, a spray chamber, a paint film solidifying chamber and a cooling chamber under the conveying of a steel pipe conveying mechanism, and after decontamination, dehumidification, surface treatment and preheating, the steel pipes enter into paint spraying, paint film solidifying and cooling processes; the production line comprises a steel pipe conveying mechanism, a dehumidification cleaner, an automatic shot blasting machine and a preheating drying chamber, wherein, the automatic shot blasting machine is arranged between the dehumidification cleaner and the preheating drying chamber; the automatic coating technology and the production line are characterized in that a paint spraying and solidifying unit is also arranged at the rear part of the preheating drying chamber; the paint spraying and solidifying unit comprises a spray chamber, a paint film solidifying chamber and a cooling chamber which are arranged in a line from the front part to the rear part in sequence, wherein, a coating machine for coating anticorrosion coat to the surfaces of the steel pipes is arranged in the spray chamber, and a hot air circulating system is arranged in the paint film solidifying chamber. The invention has the advantages that continuous and automated operation can be performed on a production line, the production efficiency is high, the coating quality is good, and environmental pollution is avoided.

Owner:宁波华恒防腐工程有限公司

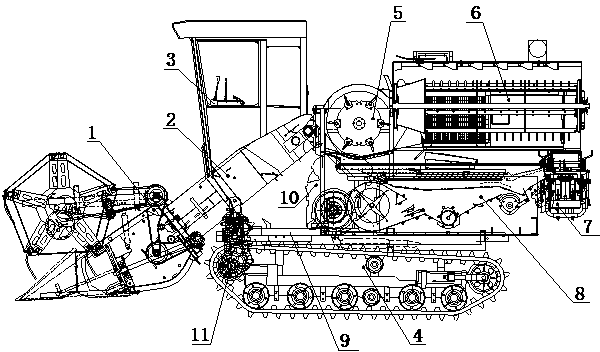

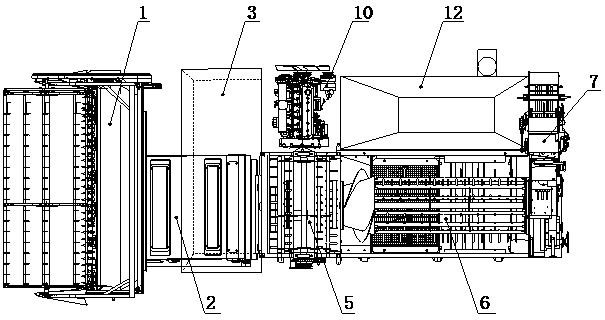

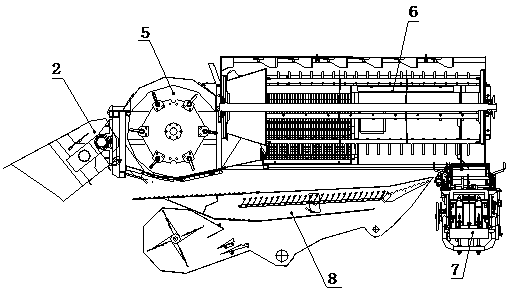

Tangential-longitudinal axial type grain combine harvesting and bundling duplex operation machine

InactiveCN104054449AReduce loss rateImprove work efficiencyMowersBalingAgricultural scienceAgricultural engineering

The invention discloses a tangential-longitudinal axial type grain combine harvesting and bundling duplex operation machine which comprises a grain cutting and conveying system, a seed threshing and separating system, a seed cleaning device, a seed collecting and storing system, a straw compressing and bundling device, a chassis walking system and a driving operation system. When the duplex operation machine harvests grain in the field, firstly, the grain cutting and conveying system cuts stalks of grain and conveys the grain to the seed threshing and separating system, straws where seed threshing and separating are conducted are compressed and bundled through the straw compressing and bundling device, seeds obtained through threshing are cleaned through the seed cleaning device, and seeds obtained through cleaning are conveyed to a grain tank through the seed collecting and storing system. The duplex operation machine can meet the requirements for harvesting seeds of rice and wheat and compressing and bundling threshed straws, and has the advantages of being high in work efficiency, stable in work performance, simple in work procedure and capable of saving time and labor.

Owner:JIANGSU UNIV

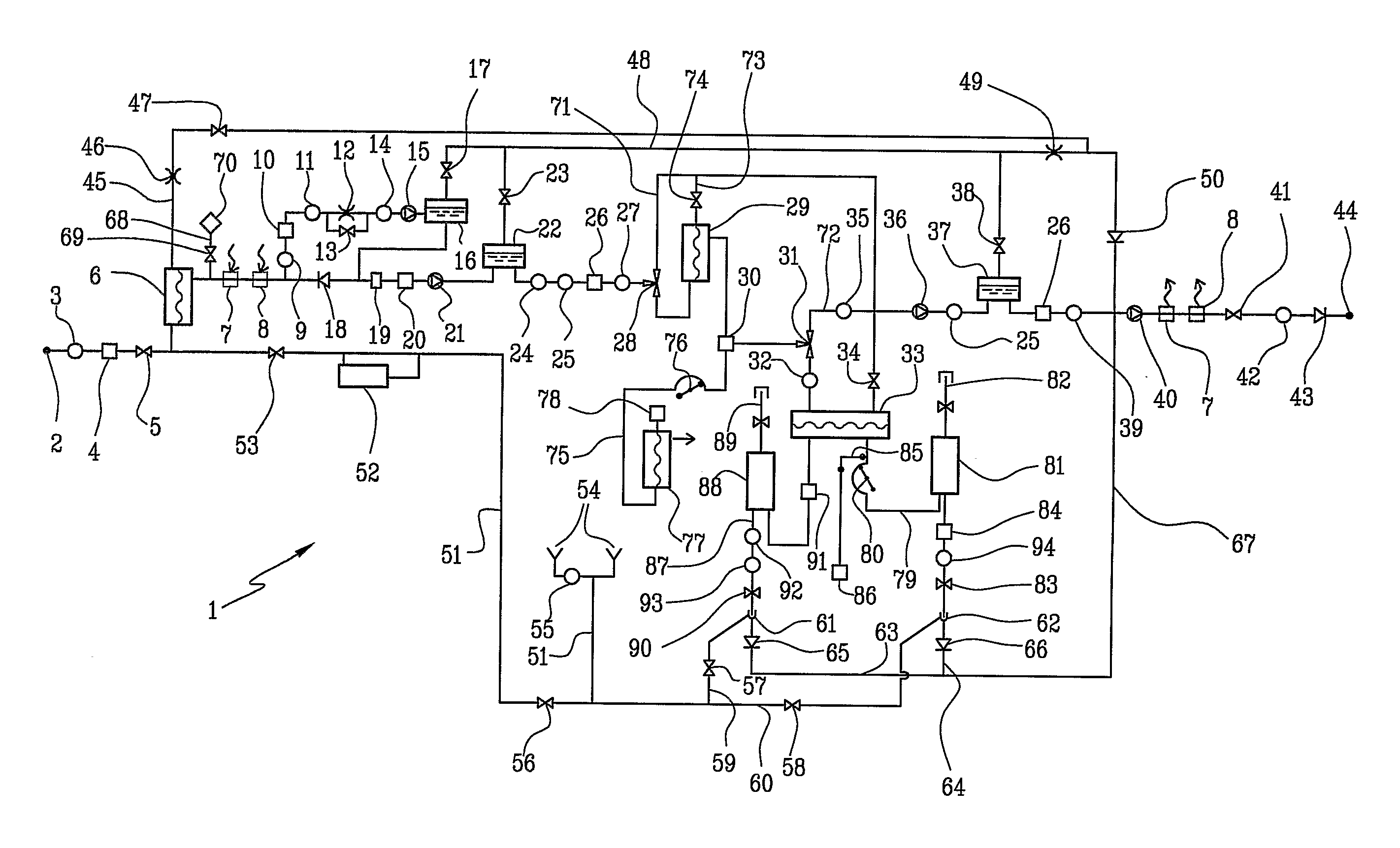

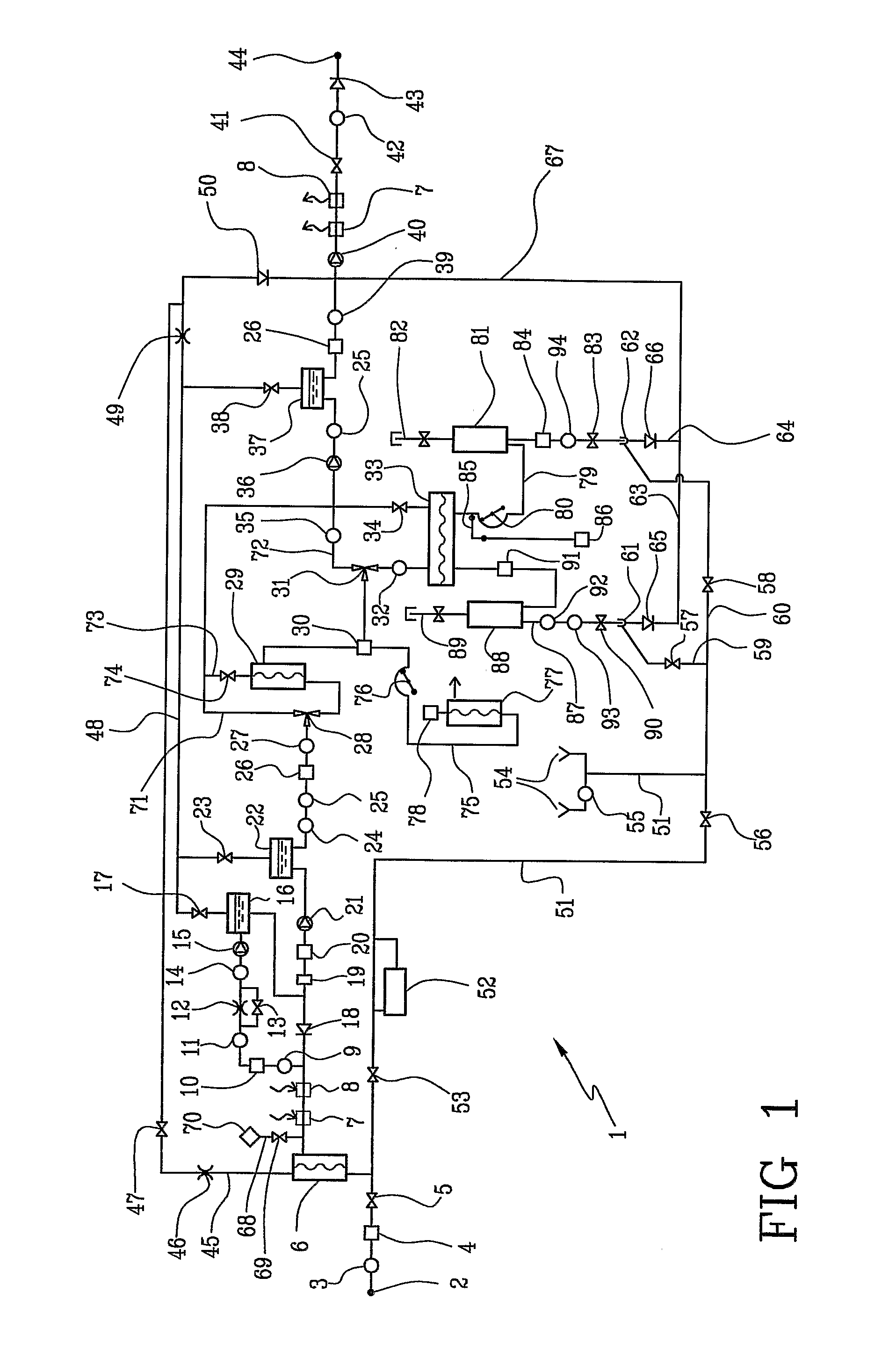

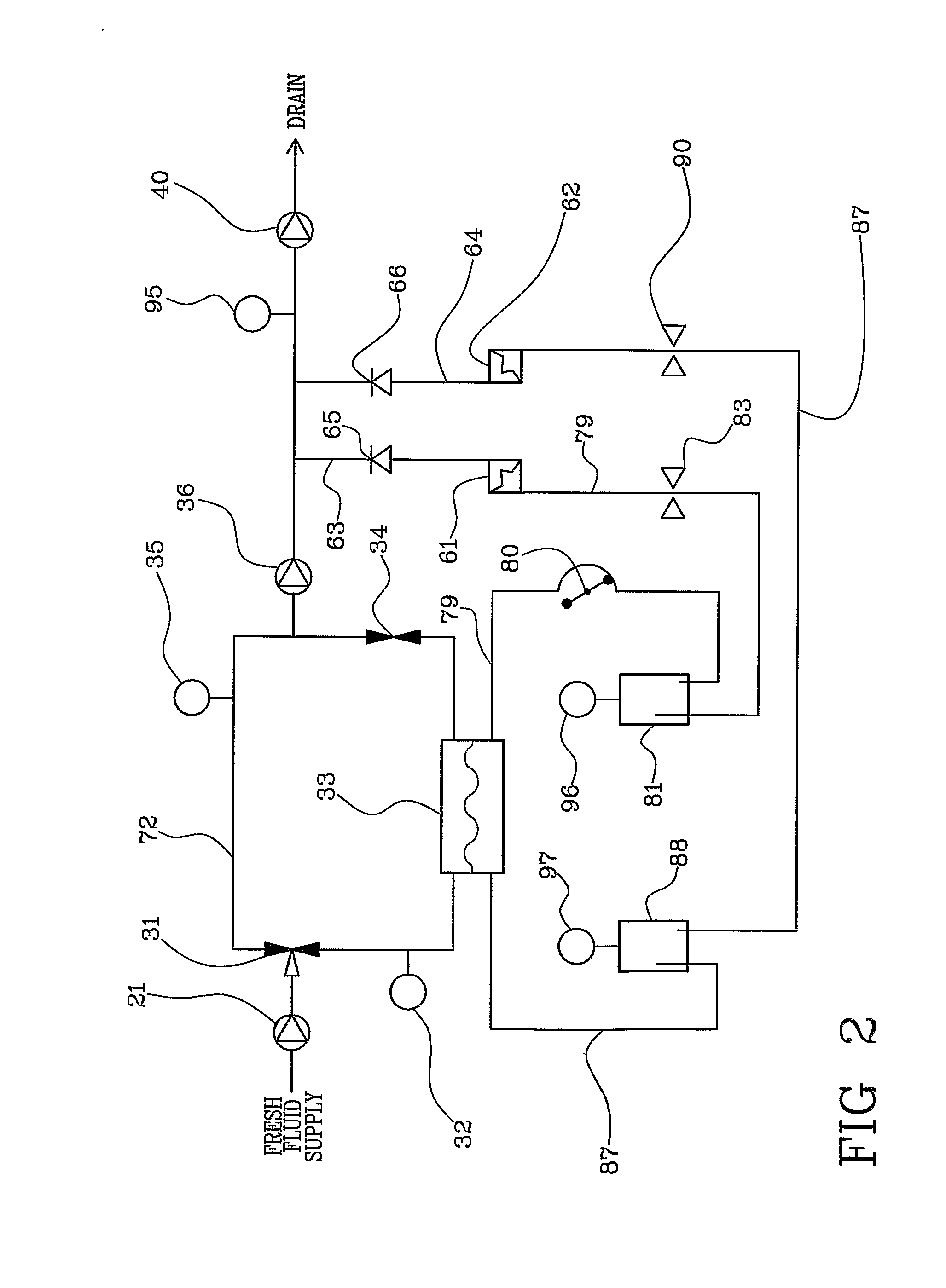

Method and apparatus for priming an extracorporeal blood circuit

ActiveUS20120265117A1Facilitates taskShorten working timeMedical devicesReciprocating systemExtracorporeal circulationVein

A method and apparatus for priming an extracorporeal blood circuit, in which the patient end of an arterial line (79) is connected to a first discharge port (61), and the patient end of a venous line (87) is connected to a second discharge port (62). The two discharge ports are connected to a used dialysate line which connects a dialyser (33) to a drain. The arterial and venous lines are filled with a priming fluid, while the air contained in the arterial and venous lines is evacuated partly through the first discharge port and partly through the second discharge port. Two check valves (65, 66) prevent flow from the used dialysate line towards the two discharge ports. The invention reduces the risk of errors on the part of an operator readying the priming configuration, as well as the risk of contamination of the extracorporeal circuit during the priming phase.

Owner:GAMBRO LUNDIA AB

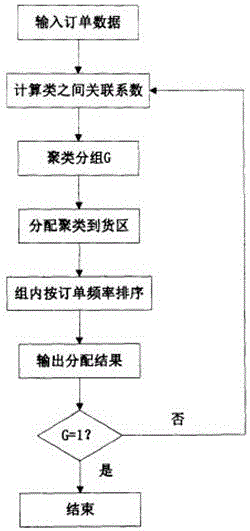

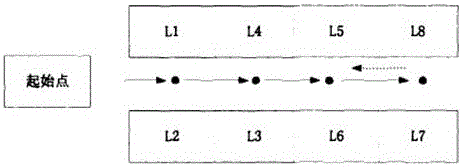

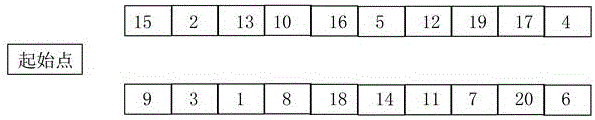

Logistics center storage position allocation method

InactiveCN106709692AImprove work efficiencyShorten working timeLogisticsLogistics managementResearch Object

The invention relates to the technical field of logistics, particularly to a logistics center storage position allocation method. The method comprises the following optimization steps: calculating goods correlation; clustering and analyzing goods; allocating clustered goods to storage areas; allocating goods to specific goods positions and finely adjusting the storage of special goods according to the characteristics of the goods. The method reduces the operating time for a warehouse and improves the operating efficiency of the shelf-type warehouse without increasing equipment investment, by optimizing a logistics center storage position allocation management system, using the shelf-type warehouse center as a research object, optimizing the goods position allocation of the warehouse and beginning with optimization management and dispatching of the warehouse.

Owner:北京远大宏略科技股份有限公司

Automatic tin pick-up machine

InactiveCN105033396AStable workpiece transportReduce noiseSolder feeding devicesSoldering auxillary devicesRosinLinear drive

The invention discloses an automatic tin pick-up machine which comprises a working table. A rosin box and a tin tank which are located on the working table top are sequentially arranged in the X-axis direction of the working table. The automatic tin pick-up machine is characterized in that the working table is provided with a linear driving device and a lifting part-taking device which performs displacement in the X-axis direction of the working table under the driving of the linear driving device. The lifting part-taking device comprises a support, a lifting mechanism lifting in the Y-axis direction of the working table and a part-taking mechanism, wherein the support is connected with the driving device after being arranged in the Z-axis direction of the working table; the lifting mechanism is fixed on the support; and the part-taking mechanism is fixed at the output end of the lifting mechanism. The automatic tin pick-up machine has the advantages of being safe, reliable and good in tin pick-up effect.

Owner:CHANGZHOU ANYI INTELLIGENT TECH

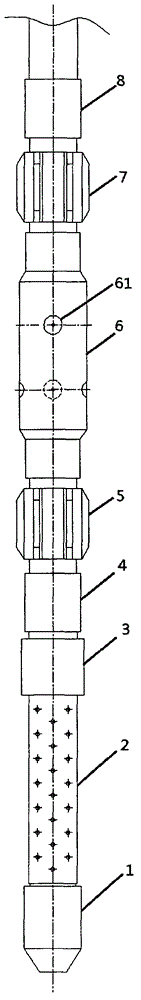

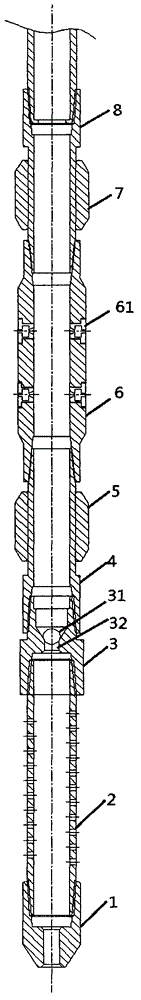

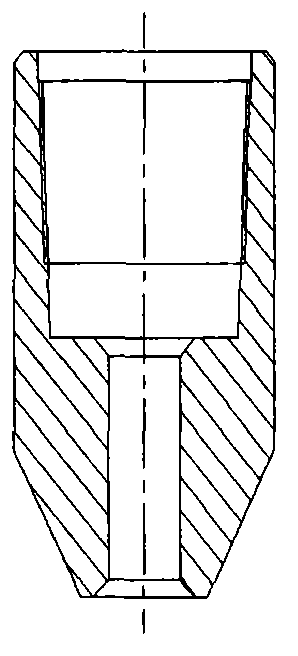

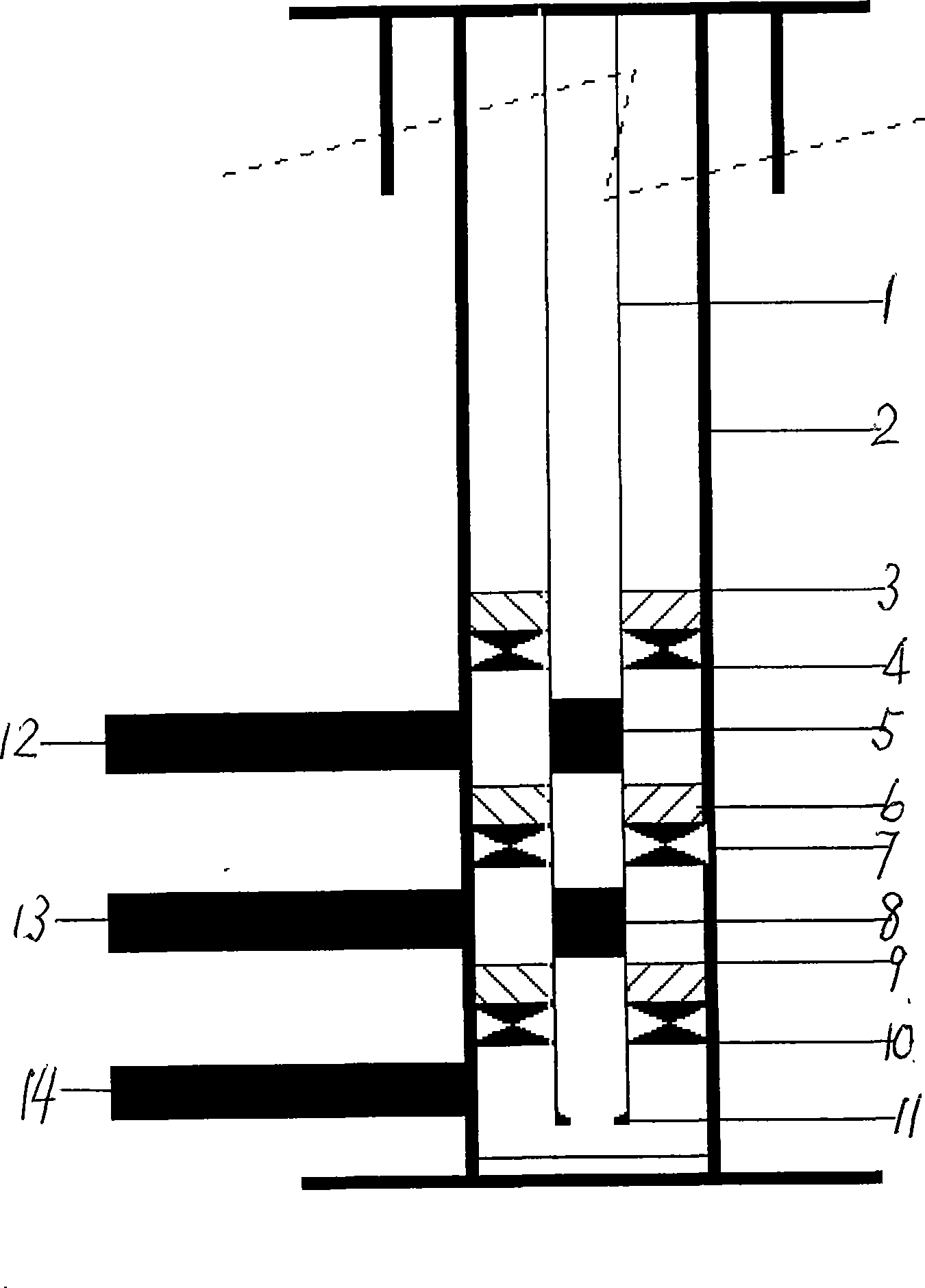

Device and method for immovable-string type packer-free sliding-sleeve hydraulic-jet pulsed acid fracturing

InactiveCN102979497AAvoid the problem of repeated sealing and unsealing, which is easy to failIncrease the lengthDrilling rodsFluid removalAcid fracturingSelf excited oscillation

The invention relates to a device and a method for immovable-string type packer-free sliding-sleeve hydraulic-jet pulsed acid fracturing, belonging to the field of oilfield exploitation and relating to the device and the method for carrying out acid fracturing in a reservoir of an oil / gas well. The device comprises a guide head, a porous tubing nipple, a one-way valve, a first lower nipple, a first centralizer, a first spray gun, a second centralizer and a first upper nipple in sequence from bottom to top, wherein the one-way valve is used for realizing the closing and opening of the device, and the first spray gun is provided with a self excited oscillation nozzle for realizing hydraulic-jet pulsed perforating and acid fracturing. According to the invention, by utilization of a hydraulic entrainment packing effect produced by high-speed pulsed jet to carry out acid fracturing packing, the advantages of simple structure, safety and reliability are achieved; more layers can be subjected to acid fracturing by descending the device for acid fracturing in one step, balls are thrown stepwise to open a sliding sleeve so as to realize the stepwise acid fracturing of multilayer sections of the reservoir by an immovable string, and meanwhile, hydraulic perforating, hydraulic self-packing and pulsed acid fracturing can be realized at the same time; and by means of producing higher fluctuant stagnation pressure on a casing pipe and a well wall, a directional perforated hole can be formed rapidly, and compact belts generated due to explosion of a perforating bullet are prevented for the perforated hole.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Dust fall agent for water mist dust fall

ActiveCN101735771AReduce surface tensionImprove contact effectOther chemical processesDust removalPermeationSURFACTANT BLEND

The invention relates to a dust fall agent for water mist dust fall. 0.06-0.2wt% of wetting agent permeation assistant is added to water, wherein the wetting permeation assistant comprises anionic surfactant, or cationic surfactant, or zwitterionic surfactant, or non-ionic surfactant. Because in the dust fall agent of the invention, 0.06-0.2wt% of wetting agent permeation assistant is added to water, thus the surface tension of the water can be reduced, the contact capacity of the water with dust particles is promoted, and solid materials can be soaked by water more easily through the wetting agent permeation assistant, thereby accelerating the wetting permeation velocity of water to the dust particles, accelerating the fall velocity of the dust particles, and reducing the fall time of the dust particles. Thus, the invention reduces the operation time and the operation cost, protects the health and safety of operation personnel, and can be widely applied to water spray, water sprinkling, dust fall and dust suppression of mines, tunnels or roads.

Owner:北京首创大气环境科技股份有限公司

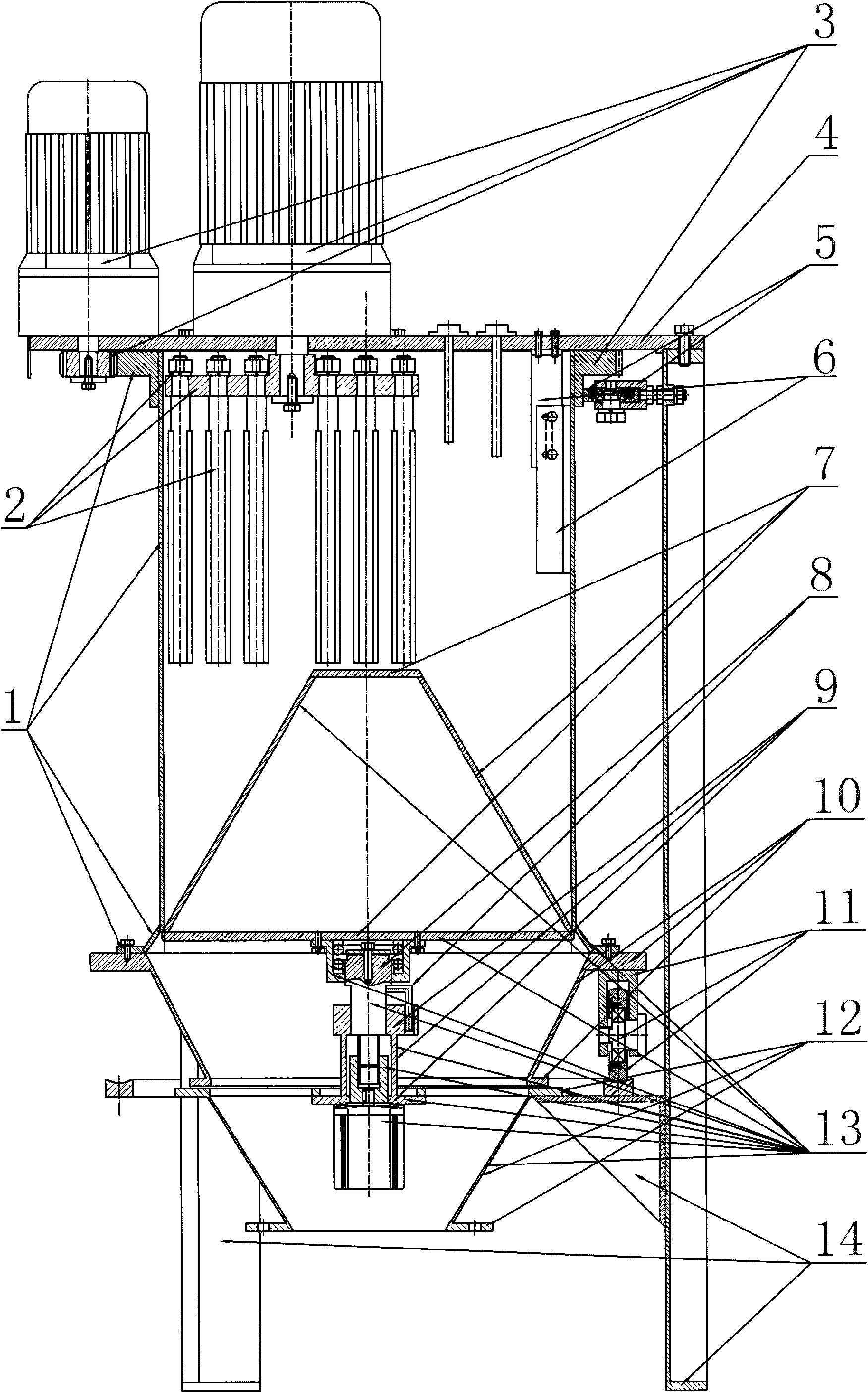

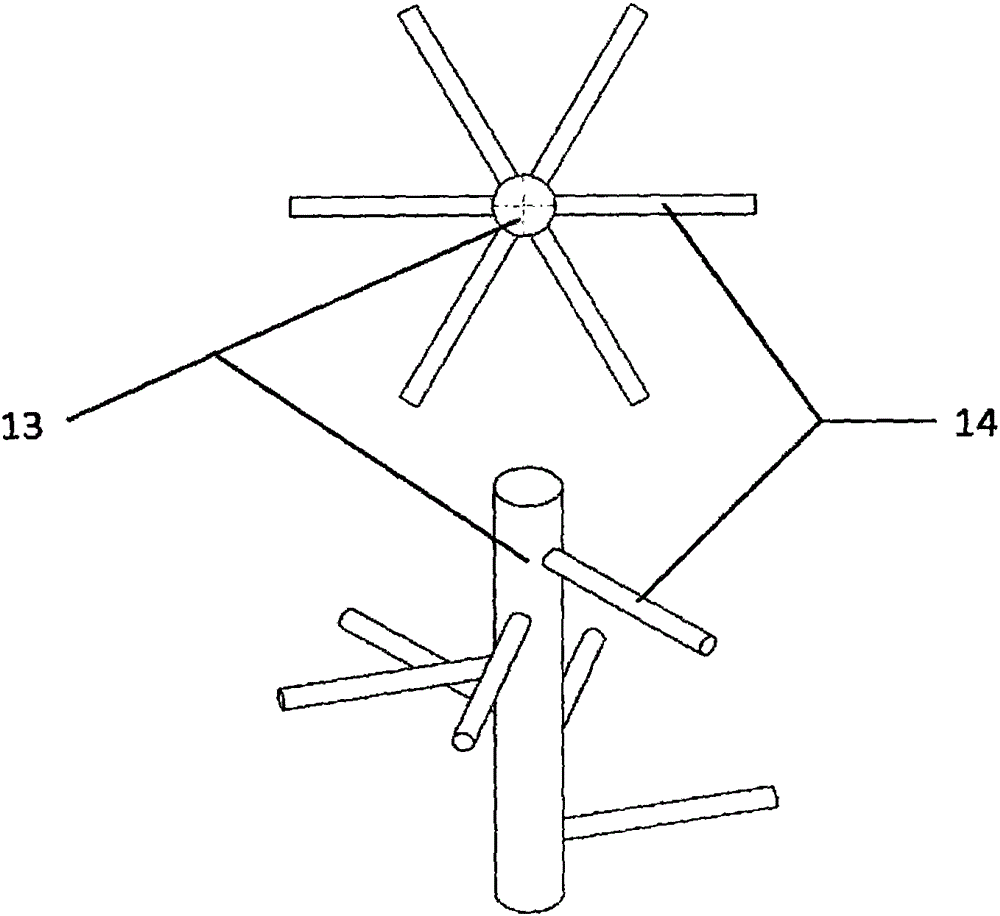

Multifunctional stirring machine

InactiveCN101658771AImprove work efficiencyImprove the quality of workRotating receptacle mixersTransportation and packagingAutomatic controlPulp and paper industry

The invention relates to a multifunctional stirring machine which consists of a rotatable vertical cylindrical container and a stirrer capable of rotating in reverse direction in the container. The structural design that a rotating shaft center of the container and the rotating shaft center of the stirrer are eccentric and a scraper mechanism which is specially arranged can ensure that the multifunctional stirring machine has no stirring dead angles during the work, and an electrical material level automatic control device can ensure the discharge flow of materials by relying on the self-gravity and simultaneously maintain the stable material level in the container. The multifunctional stirring machine can have a plurality of functions of mixing, peeling, clearing, polishing, dampening andthe like by being matched with stirring rods with different structures. When the multifunctional stirring machine is used as a mixing machine, the multifunctional stirring machine has the advantagesof simple structure, low cost, fast mixing speed, high mixing uniformity, small segregation tendency, low energy consumption, simple use and maintenance, long service life and the like. When the multifunctional stirring machine is used as a peeling machine, a clearing machine or a polishing machine, the multifunctional stirring machine has the advantages of high peeling efficiency or good clearingeffect, no production of crushed particles, low energy consumption and the like. When the multifunctional stirring machine is used as a dampening machine, the multifunctional stirring machine has theadvantages of uniform dampening, low energy consumption and the like.

Owner:王洪福

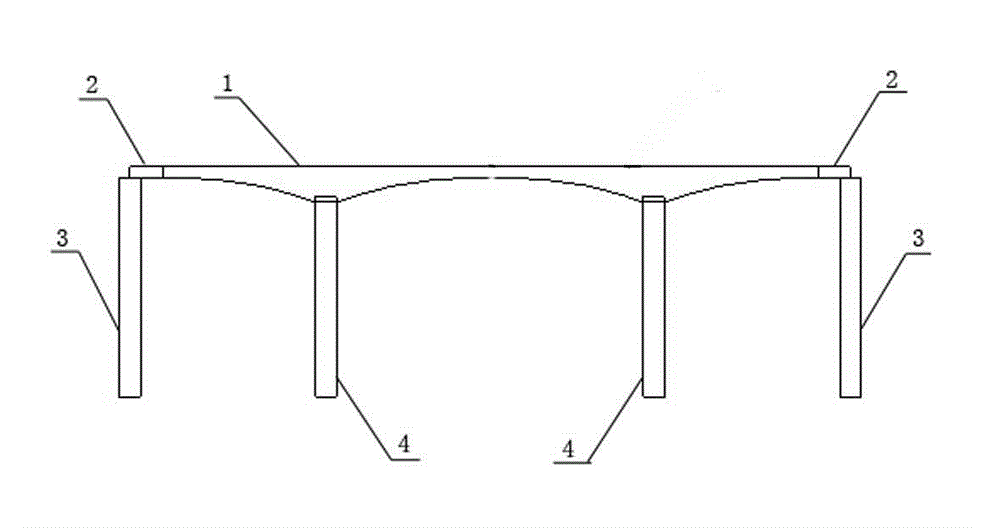

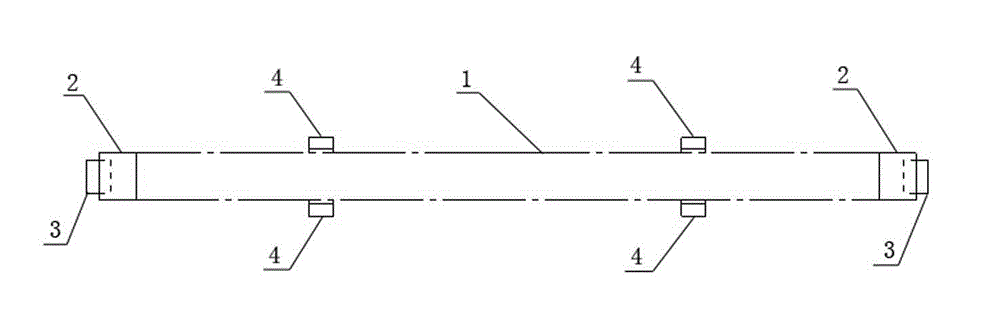

Bridge and construction method thereof

ActiveCN102747677AImprove construction safetyShorten working timeBridge erection/assemblyButt jointArchitectural engineering

The invention relates to the field of construction, in particular to a bridge and a construction method thereof. The bridge and the construction method of the bridge are provided to overcome shortcomings in construction methods of existing bridges, a conventional sequence construction method of performing cast-in-place construction of a beam body after bridge pier construction is finished is changed into a parallel construction operation method of a bridge pier and the beam body. The bridge comprises the bridge pier and the beam body, and the beam body comprises a precast beam body and two side span connecting segments respectively in butt joint with the head end and the tail end of the precast beam body. The bridge pier comprises side piers supported on end sides of the side span connecting segments and main piers symmetrically arranged on two sides of the end of the precast beam body, and a load-bearing beam for supporting the precast beam body is connected between the two main piers positioned on two sides of the end of the precast beam body. The construction method has the advantages of achieving the effects of shortening operating time and reducing cost at once, being high in work efficiency, being not subjected to limitation of a conventional construction process, reducing high-altitude operation difficulty and dangerous sources and improving construction safety for workers.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

Coal bed gas well pulse radial drilling and double-pulsating hydrofracturing method

InactiveCN105464638AIncrease drilling speedShorten working timeFluid removalFracturing fluidCoiled tubing

Disclosed is a coal bed gas well pulse radial drilling and double-pulsating hydrofracturing method and a whole construction scheme. Equipment matched with the method includes a continuous coiled tubing unit, a high pressure pump, a pulsating pump set, a guider, a pulse generator and a porous nozzle. In a coal bed gas well, the pulse generator and the porous nozzle are utilized to generate high-pressure pulse jets to drive a high-pressure hose to quickly drill into a coal bed to form a radial hole of certain length; a ball is cast into a coiled tubing for maintaining pressure, and a pin is cut off to separate the porous nozzle; the high pressure pump and the pulsating pump set are utilized to pump fracturing fluid in at the same time from the coiled tubing and an oil jacket annulus, the pulse generator generates high-frequency low-amplitude pressure fluctuation, the pulsating pump set generates low-frequency high-amplitude pressure fluctuation, double-pulsating fracturing construction with low-frequency hammering and high-frequency oscillating effects is formed to impact and damage the coal bed, size fracturing is realized finally, and the objectives of substantially improving permeability of the coal bed and increasing yield of a single coal bed gas well are achieved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Multi-type welding processing and manufacturing technological method for full-automatic welding robot

InactiveCN105171194ASimple processImprove accuracyArc welding apparatusProduction lineNetwork addressing

The invention discloses a multi-type welding processing and manufacturing technological method for a full-automatic welding robot. According to the method, the welding process can be achieved reliably, conveniently and rapidly, and the method is suitable for welding of welding seams of products of various types. The method comprises the following steps that 1, the welding robot is assembled on a welding station of a welding production line; 2, the welding robot is initialized after being powered on; 3, whether the angles and zero points of all axes of the welding robot are correct or not is determined; 4, a robot control device main network address and a robot slave network address are set, Cartesian coordinates are defined according to actual needs, and the coordinates of a welding gun are determined; 5, a welding piece is scanned into a three-dimensional model through a laser bar code scanning system, the three-dimensional model is guided into a main industrial personal computer, and welding information is directly designated on the three-dimensional model through a wireless teaching device; and 6, program codes are generated according to scanned three-dimensional model information and welding information through the main industrial personal computer, and are sent to a robot control device.

Owner:深圳研控自动化科技股份有限公司

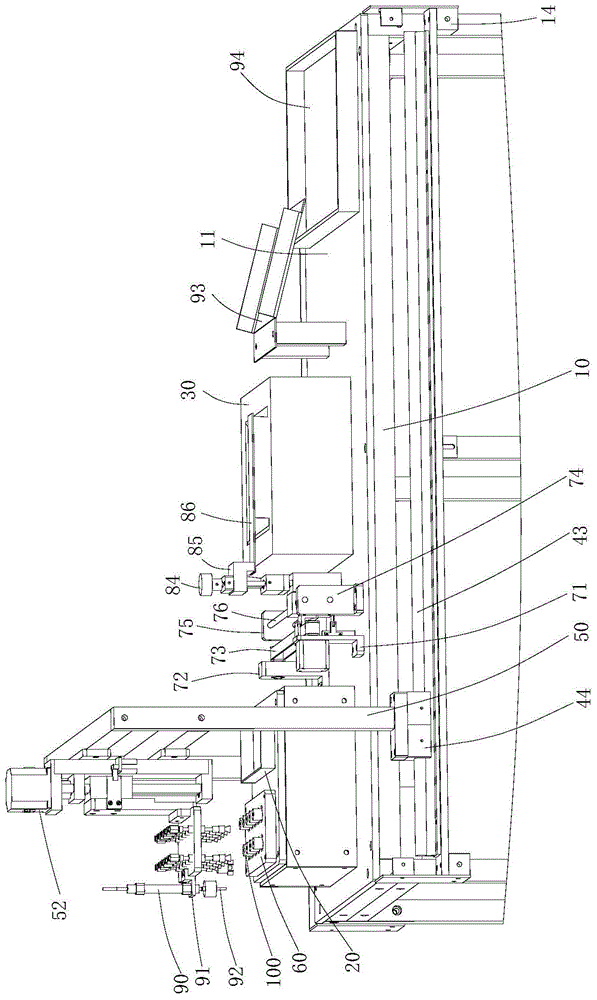

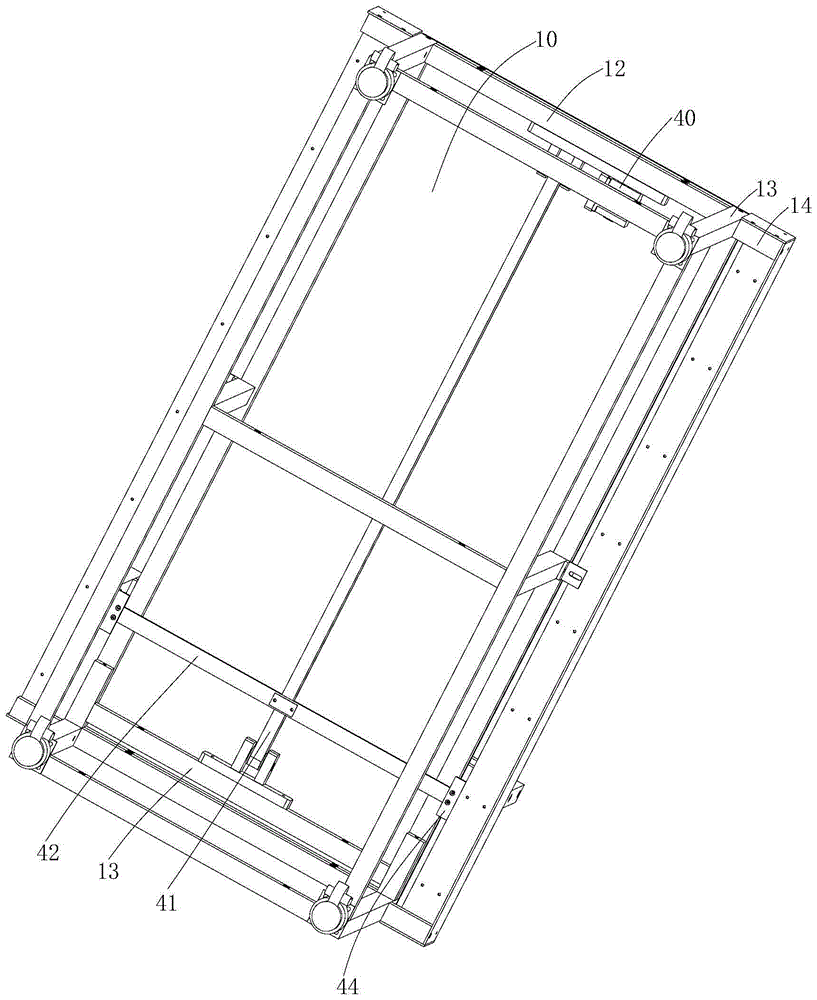

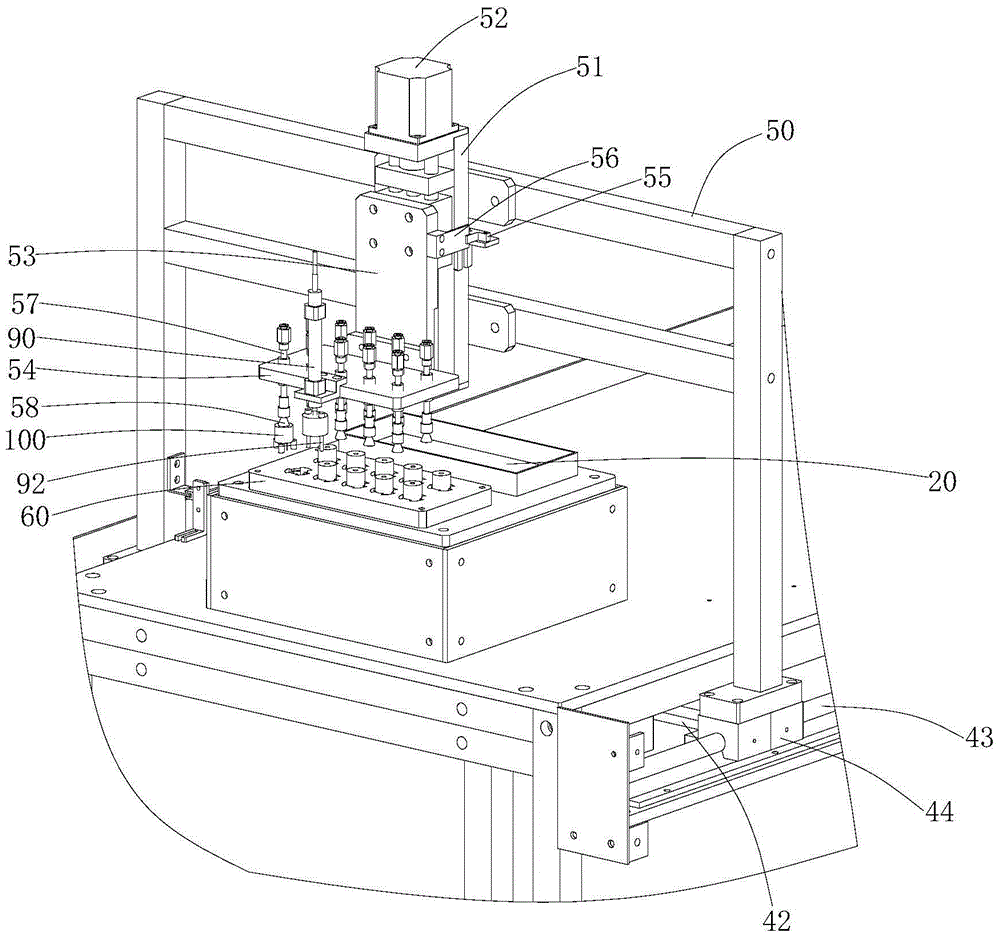

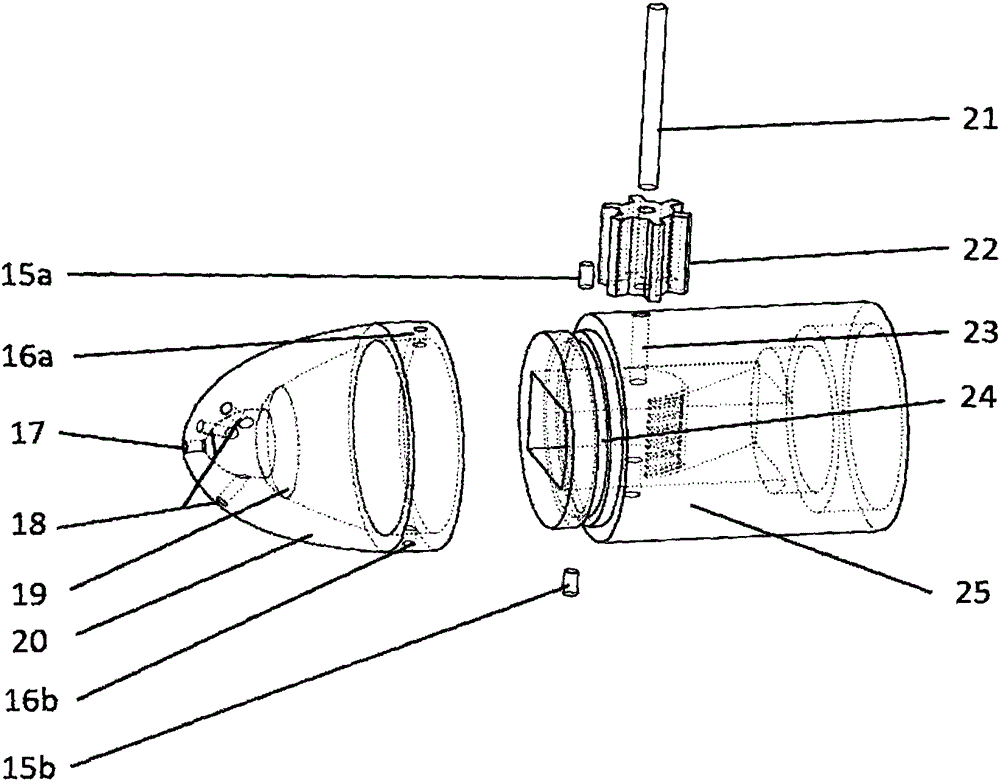

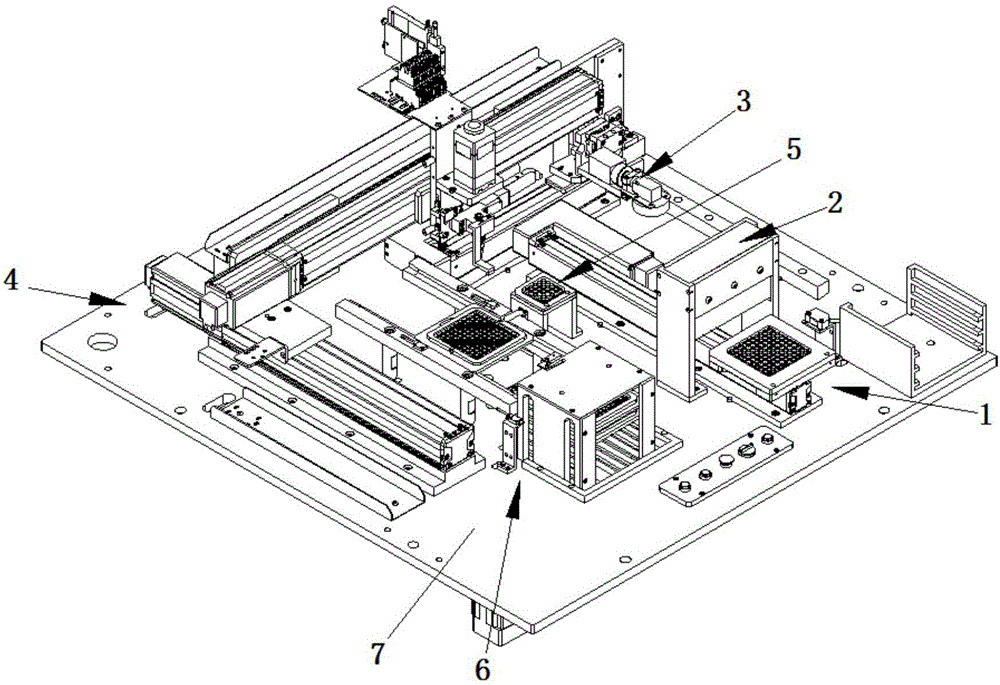

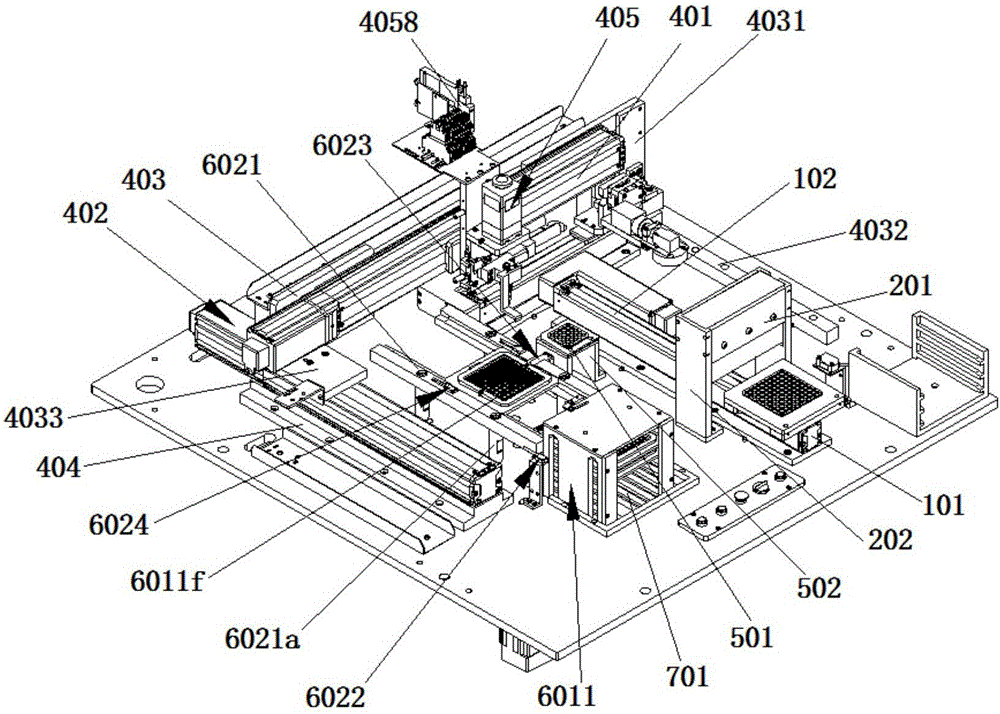

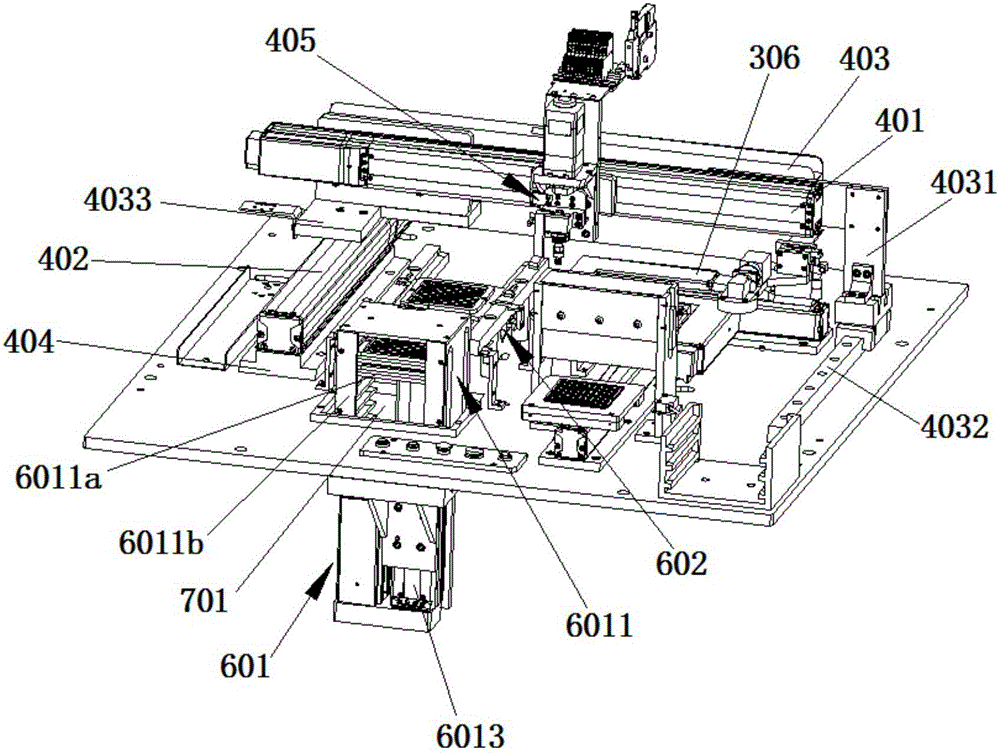

Device for detecting camera modules and method of detecting camera modules through device

ActiveCN106216268ATo achieve synchronous operationCompact structureSortingCamera moduleComputer science

The invention relates to a device for detecting camera modules. The device comprises a camera module conveying unit, a curing unit, a detecting unit, a clamping moving unit, a waste collecting unit and a device installing platform; the device is characterized by further comprising a camera module discharging unit; and the camera module discharging unit is composed of a tray collecting mechanism and a detecting fixing mechanism. The method of detecting the camera modules through the device comprises the following steps that the glue position cured by the curing unit is detected through the detecting unit, and then the qualified and unqualified camera modules are subpackaged into the camera module conveying unit and the waste collecting unit correspondingly. According to the device for detecting the camera modules, the problem that ultraviolet curing of glue is missed can be avoided, the situation that false detection and missing detection caused by fatigue in the process of manual glue inspection can be reduced, the device is 200-300% of manual detection in efficiency, the device accurately classifies the detected qualified and unqualified camera modules through the same mechanism, operation speed is fast, efficiency is high, and cost is low.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

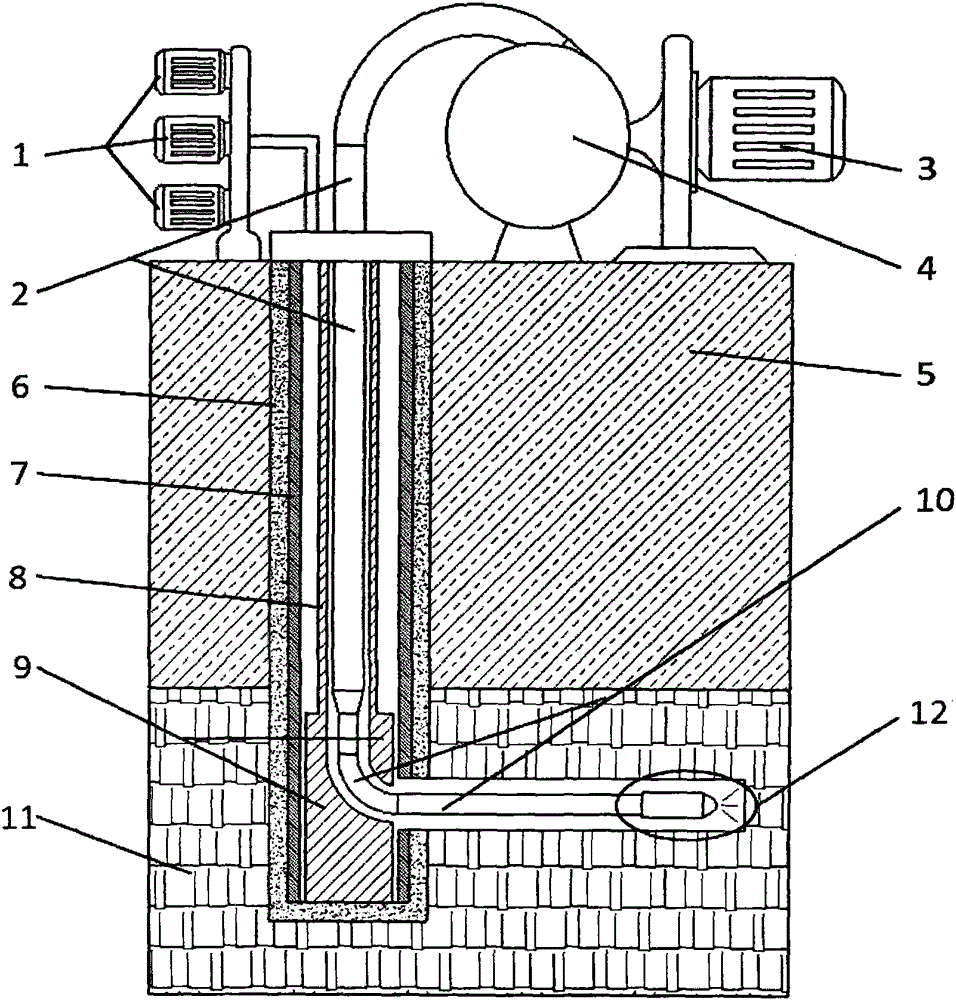

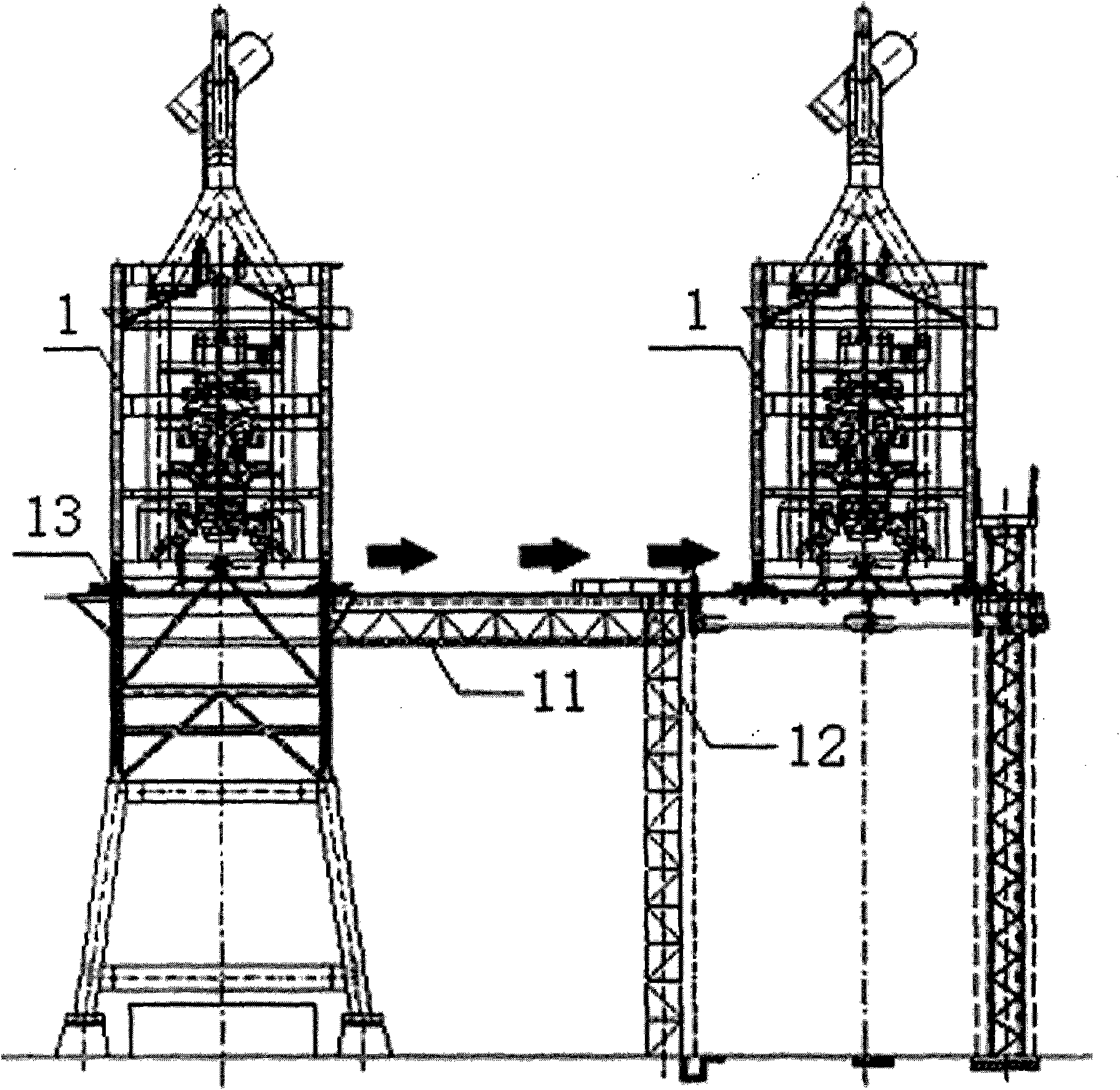

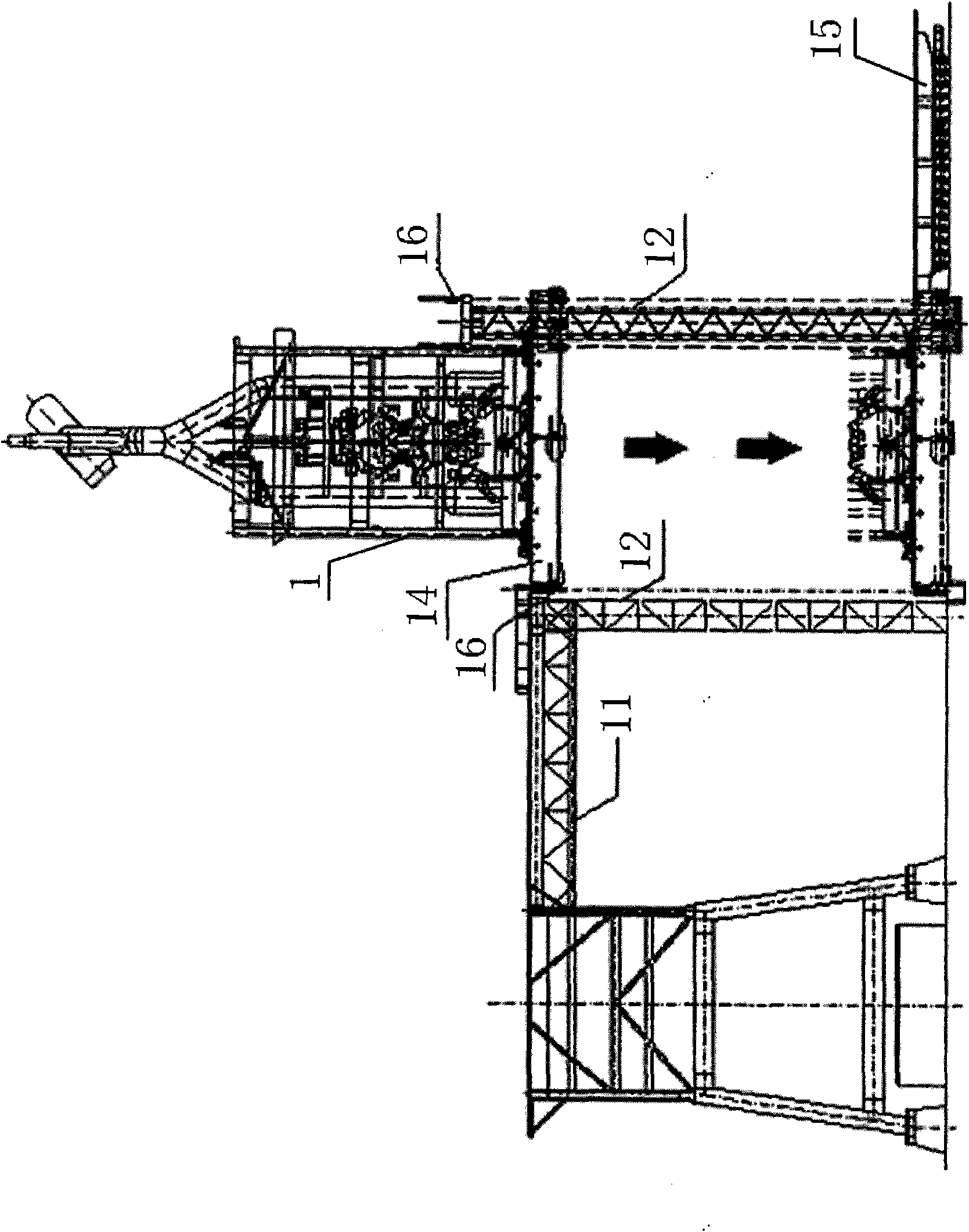

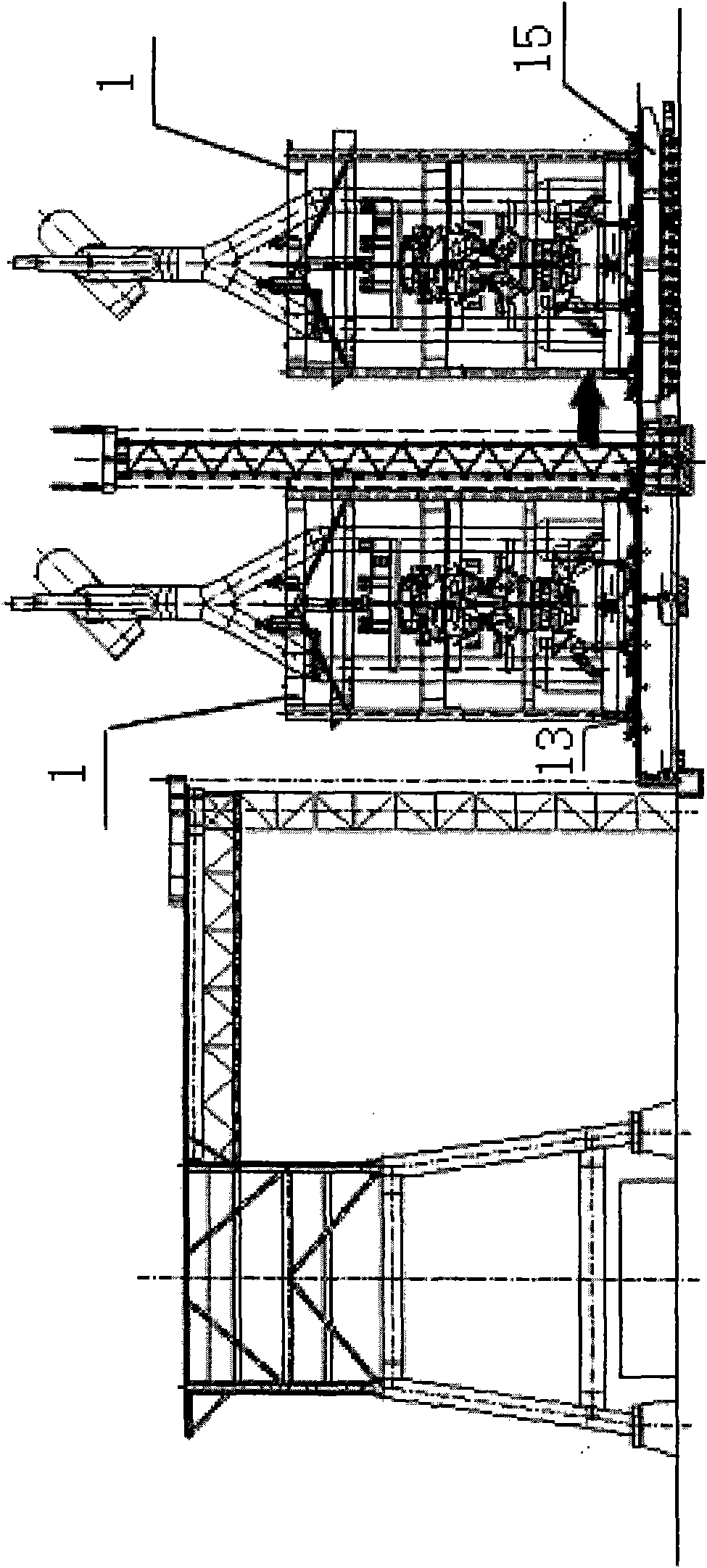

Modularized and integrative disassembling and installing methods for blast furnace

InactiveCN102146488ASatisfy construction safetyMeet construction requirementsBlast furnace componentsBlast furnace detailsCast houseBuilding construction

The invention relates to the installation method field of smelting equipment of iron, in particular relates to modularized and integrative disassembling and installing methods for a blast furnace. The modularized and integrative disassembling method for the blast furnace comprises: disassembling a furnace top system, disassembling a hot wind surrounding pipe, disassembling a layer beam and casting house platform and disassembling a furnace body. The modularized and integrative disassembling method is characterized in that when the furnace top system, the hot wind surrounding pipe, the layer beam and casting house platform and the furnace body are dissembled, the modularized and integrative disassembling method is adopted. The modularized and integrative insulating method for the blast furnace comprises: installing the furnace top system, installing the hot wind surrounding pipe, carrying out furnace body construction, carrying out layer beam and casting house platform construction and carrying out finished product groove construction and is characterized in that when the furnace top system, the hot wind surrounding pipe, the furnace body, the layer beam and casting house platform and the finished product groove are installed, the modularized and integrative installing method is adopted. According to the invention, construction efficiency is high, safety is high, and production cost is reduced.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH

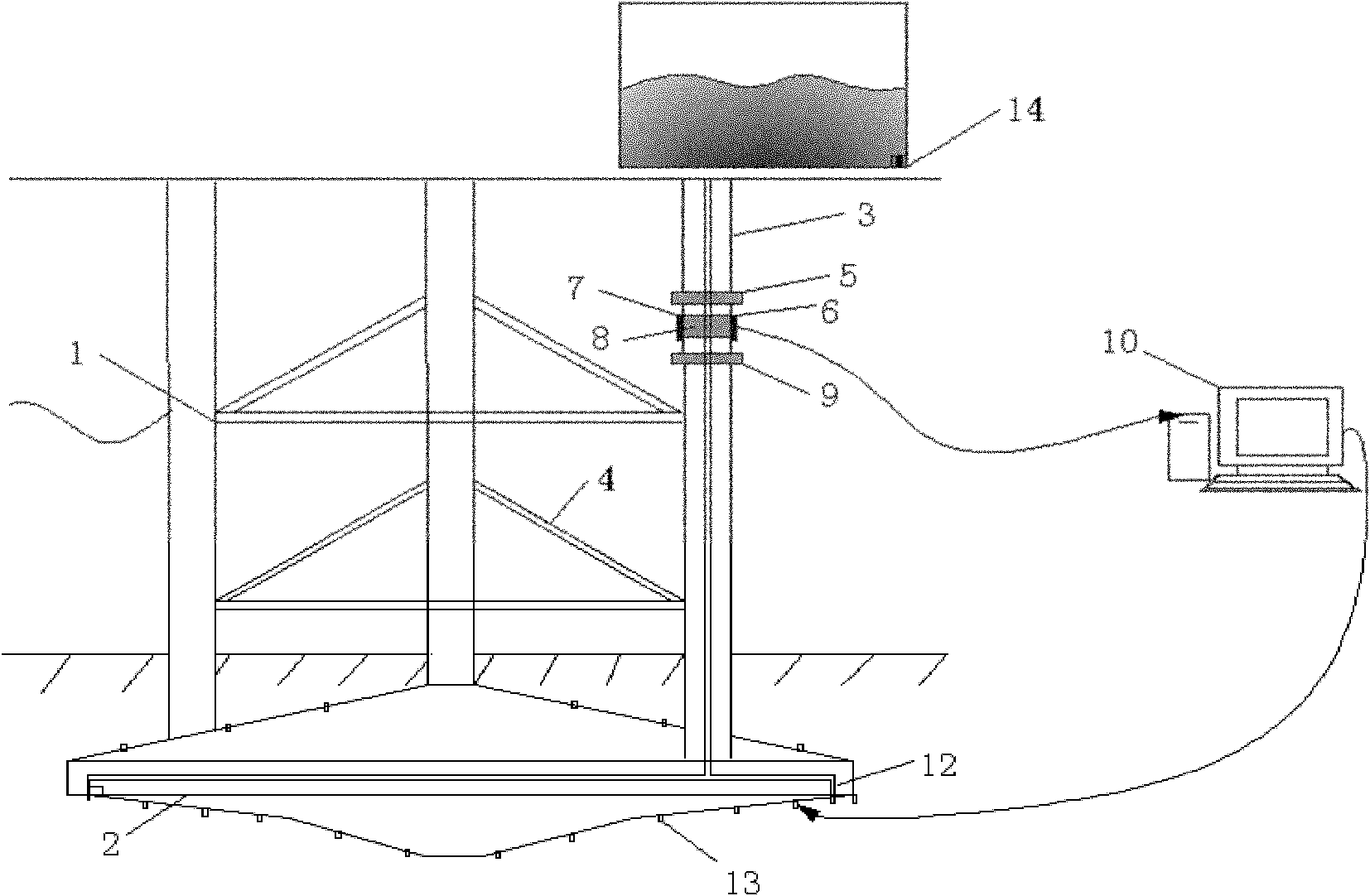

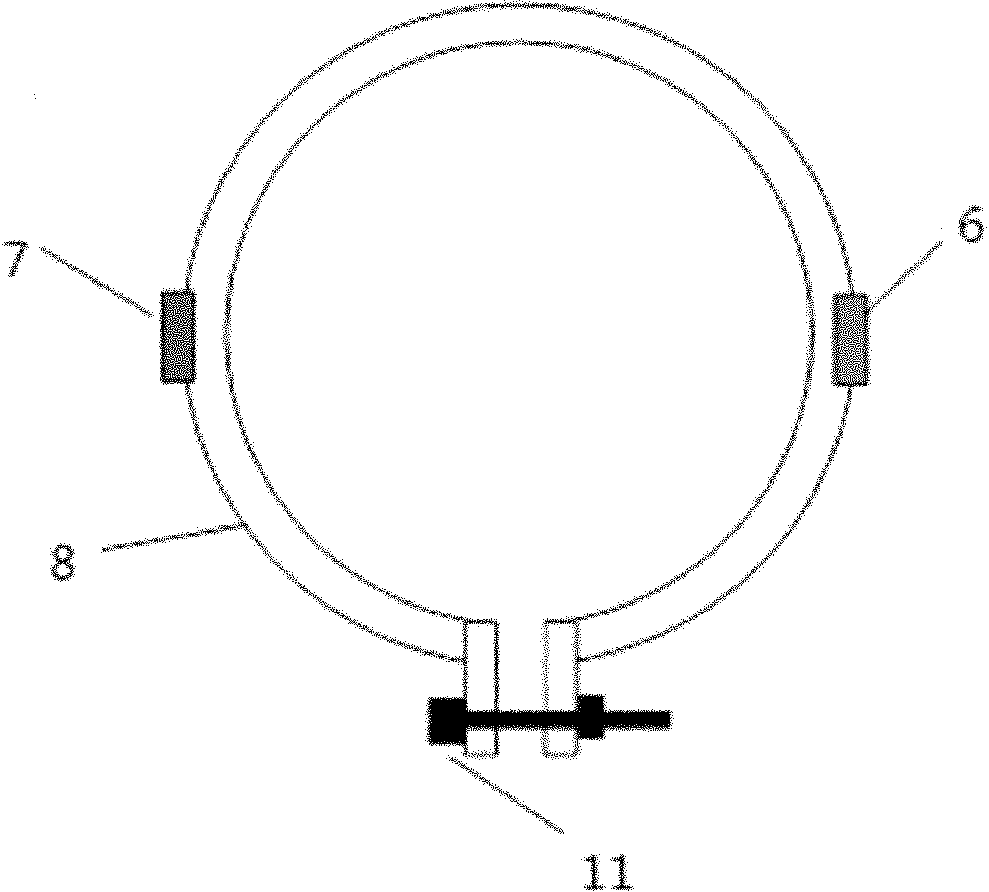

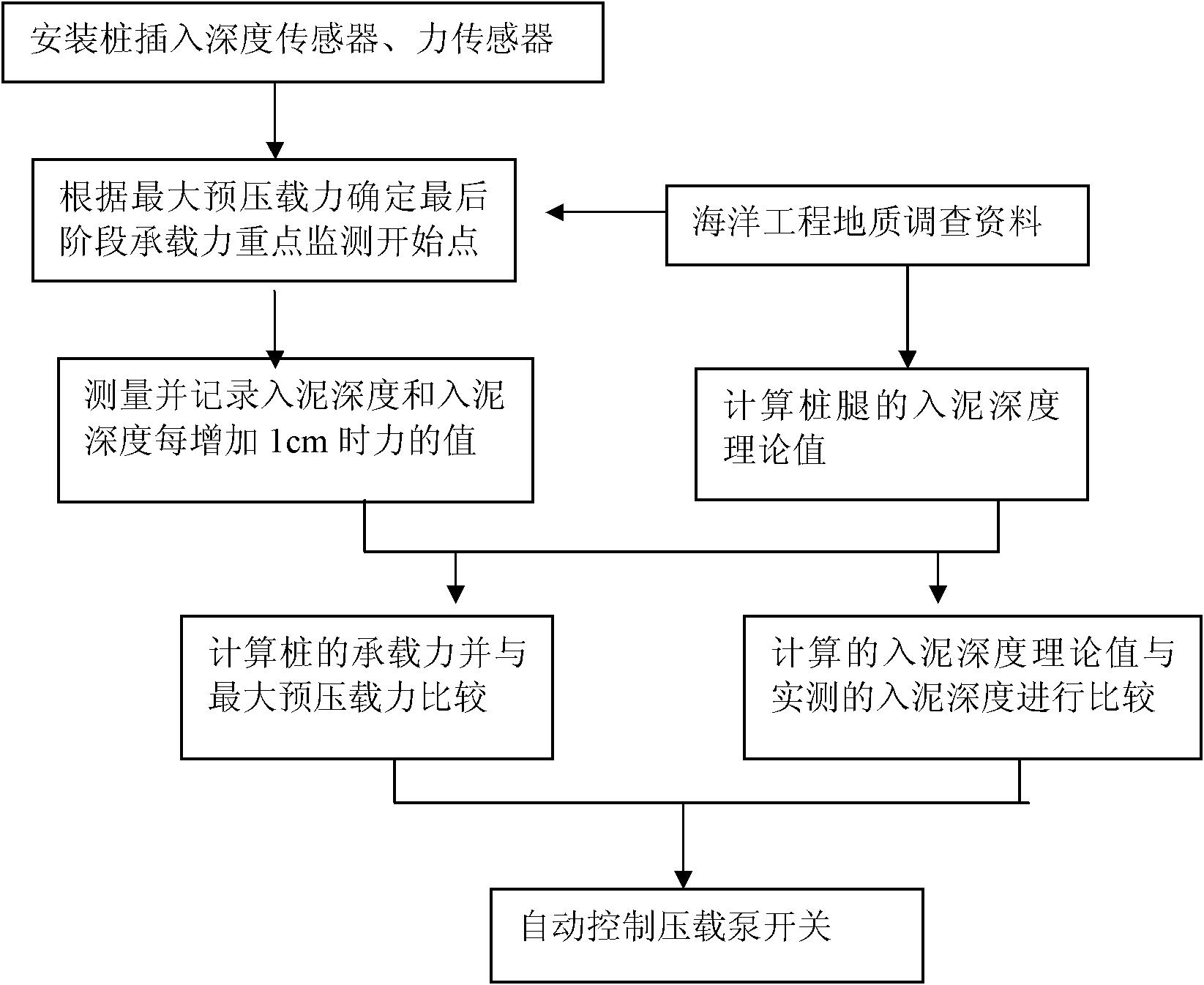

Offshore self-elevating drilling platform pile pitching and pile pulling automatic control device and method

InactiveCN102071690AReal-time monitoring of mud entry depthRealize automatic controlOperating means/releasing devices for valvesPump controlPull forceAutomatic control

The invention relates to an offshore self-elevating drilling platform pile pitching and pile pulling automatic control device and method. The offshore self-elevating drilling platform pile pitching and pile pulling automatic control device comprises a displacement sensor, a force sensor, a computer detection control system, a ballast pump switch and a pile washing valve, wherein the displacement sensor and the force sensor are arranged on a chord member of a pile leg, the ballast pump switch is arranged at a ballast pump control system of a ballast tank, the pile washing valve is arranged on a pile shoe and is connected with a pile washing pipeline. The displacement sensor and the force sensor are respectively used for measuring the driving depth of a pile body, the bearing capacity of the pile leg and a pile pulling force and transmitting the measured data in pile pitching and pile pulling processes into a computer detection control system to be processed, whether the bearing capacity of the pile in the pile pitching process is maximum or not, whether pile washing is required in the pile pulling process and whether the pile is completely pulled out are automatically judged, and the ballast pump switch, the pile washing valve and a pile pulling operation control switch are controlled according to the judging result, thus realizing the offshore self-elevating drilling platform pile pitching and pile pulling automatic control.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

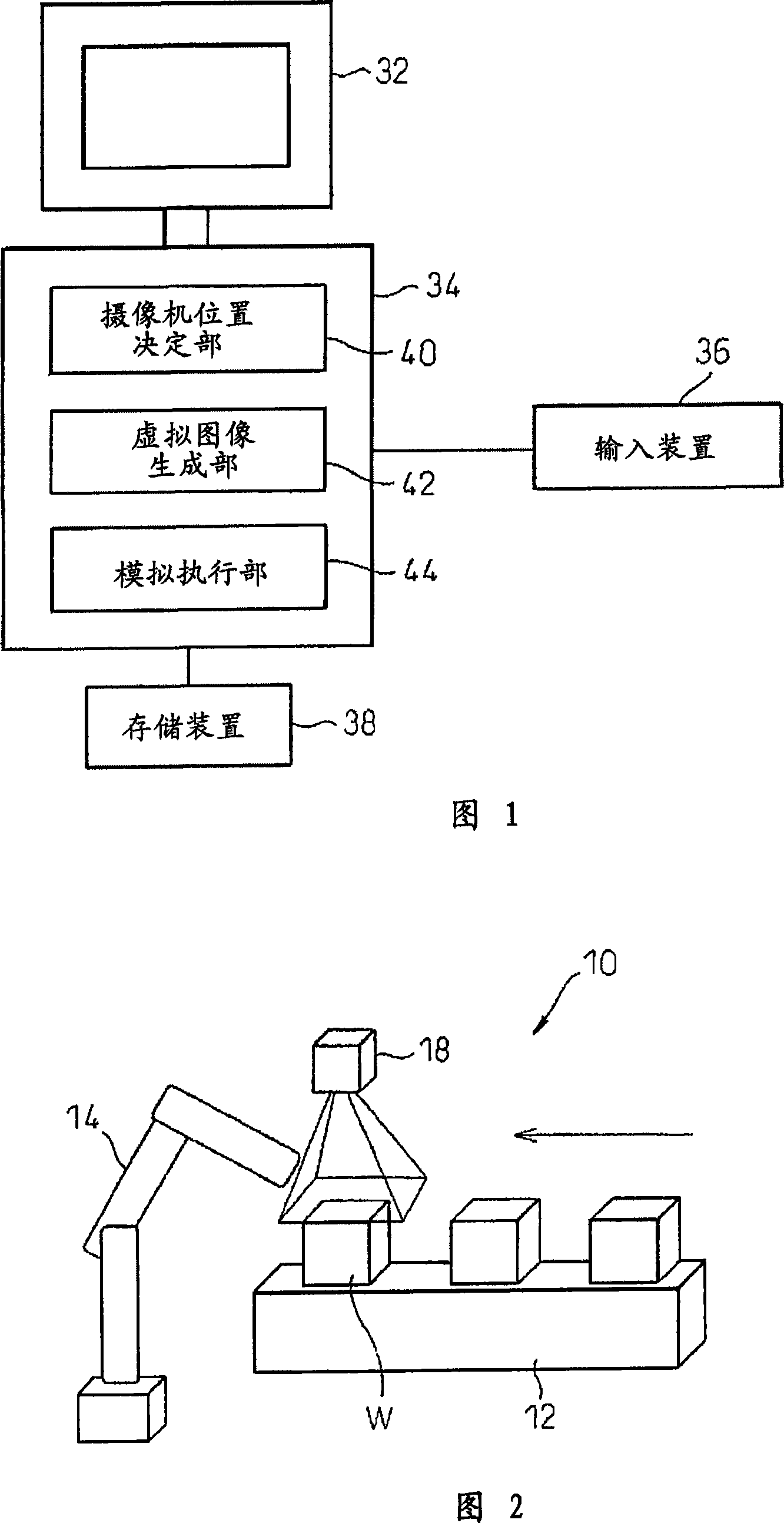

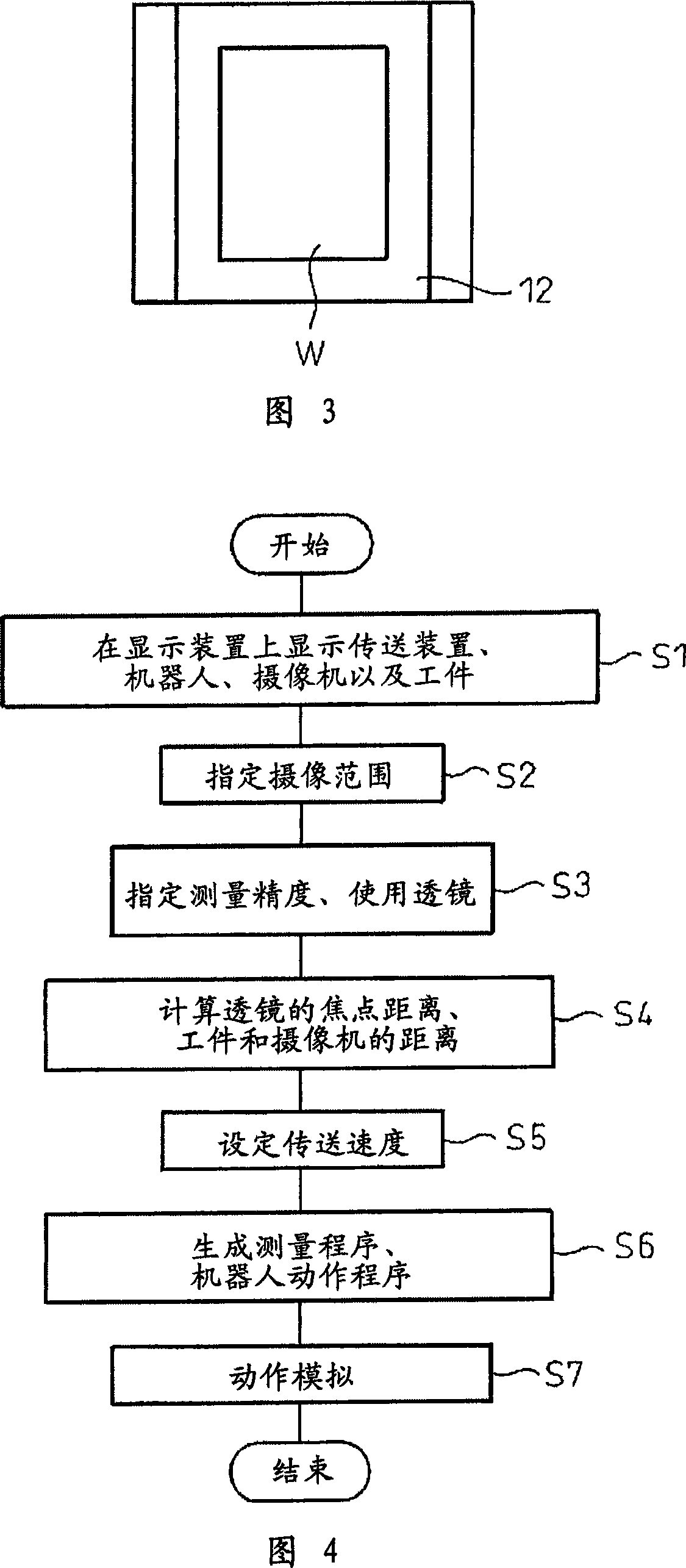

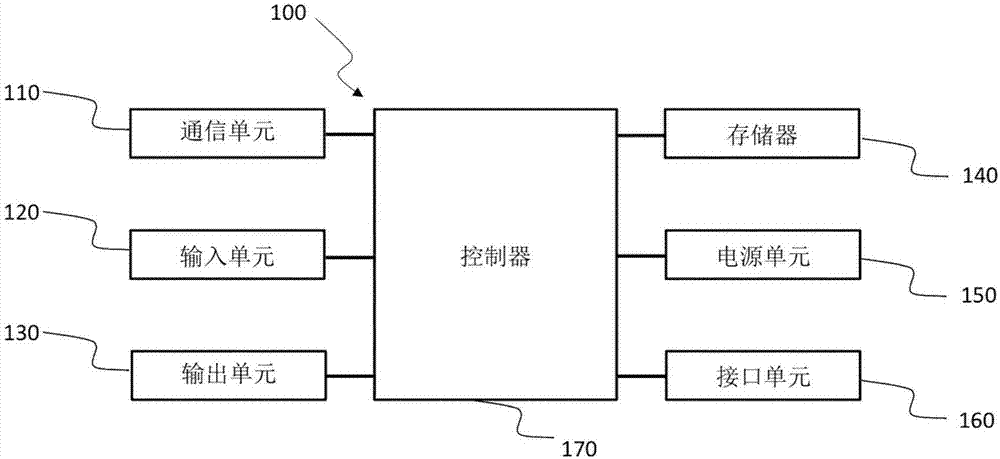

Simulation device of robot system

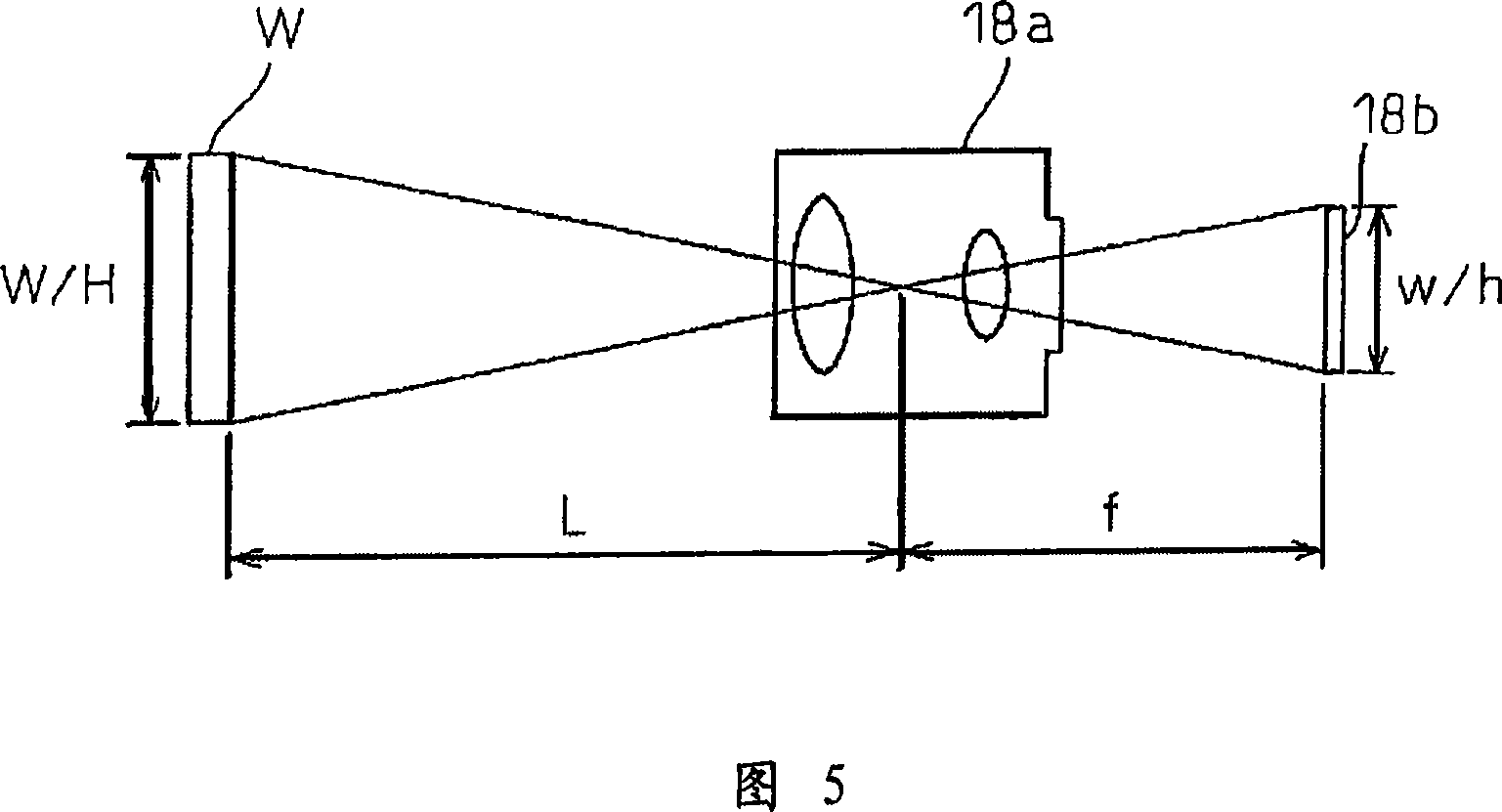

InactiveCN101105715AShorten working timeProgramme controlInput/output for user-computer interactionRobotic systemsVirtual space

A simulation device displays a three-dimensional model of a robot system on a display device and simulates a robot system including a robot and an image pickup camera. The simulation device includes a display device for displaying a three-dimensional virtual space on a screen, a camera position determination unit for determining an installation position of the image pickup camera based on an image pickup range designated by the operator, optical characteristic information of the used image pickup camera, and required measurement precision, and a virtual image generator unit for generating a virtual image to be obtained by the image pickup camera based on the position of the image pickup camera in the three-dimensional virtual space and the optical characteristic information, thereby facilitating the determination of the suitable position of the image pickup camera and adjustment of the detection parameters.

Owner:FANUC LTD

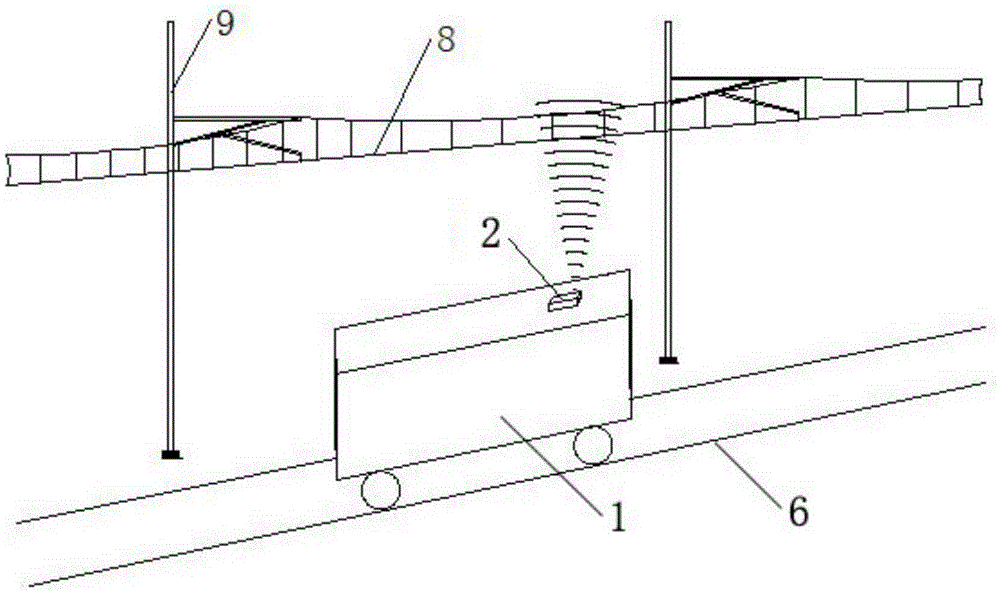

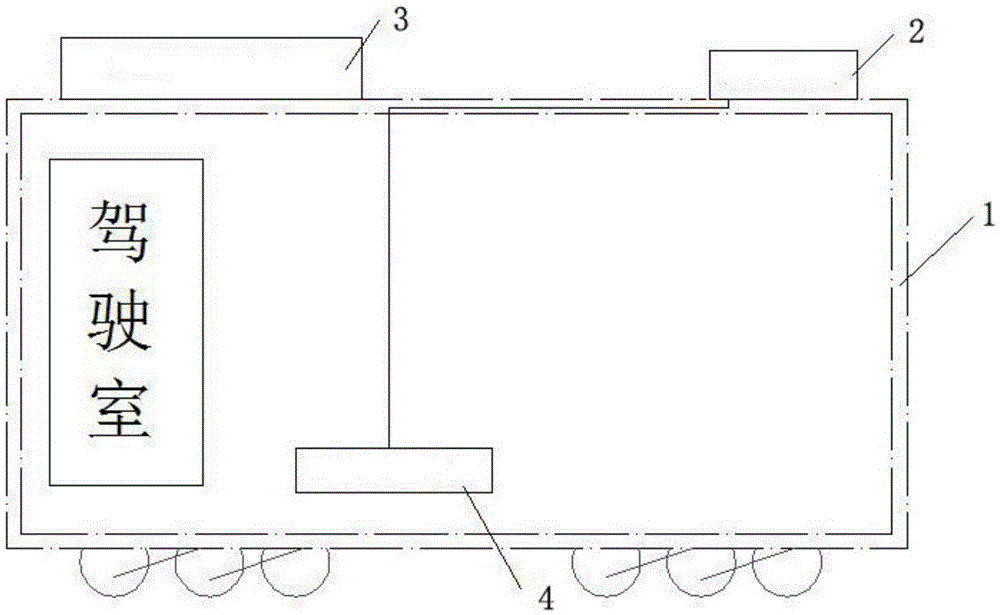

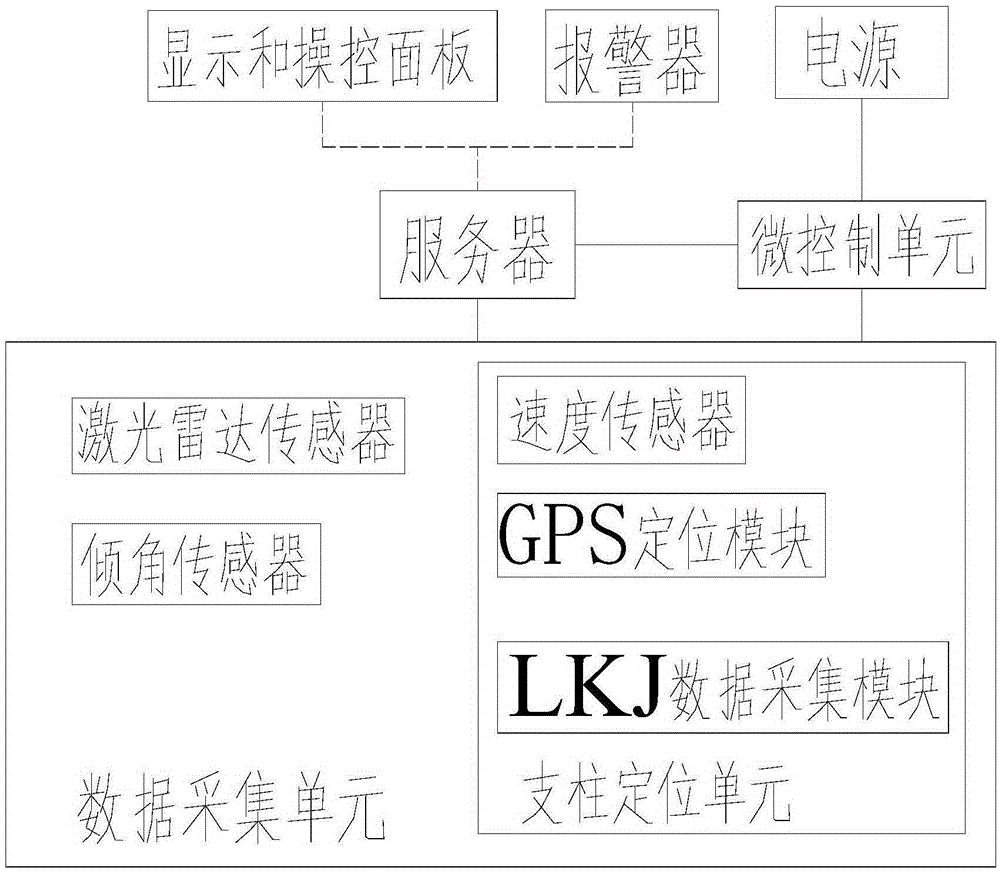

Contact screen detecting and overhauling car and method based on laser radar

The invention relates to a contact screen detecting and overhauling car based on laser radar. The contact screen detecting and overhauling car comprises a detecting car body, a data acquisition unit, a lifting and rotating operation platform and a server used for data analyzing and processing. The data acquisition unit is arranged on the detecting car body. The lifting and rotating operation platform can be rotationally arranged on the back of the top of the detecting car body in a lifted mode and is provided with a display and control panel. The server is connected with the data acquisition unit and the display and control panel. Data collected through the data acquisition unit are analyzed and processed by the server and then transmitted to the display and control panel. According to the contact screen detecting and overhauling car based on the laser radar, the operation effect is improved significantly, the operation time is saved, and the labor intensity is relieved; moreover, after contact screens are maintained, the yield of the contact screens can reach 100%, and artificial misoperations in the maintenance process are avoided effectively.

Owner:BEIJING TIANGEGAOTONG TECH

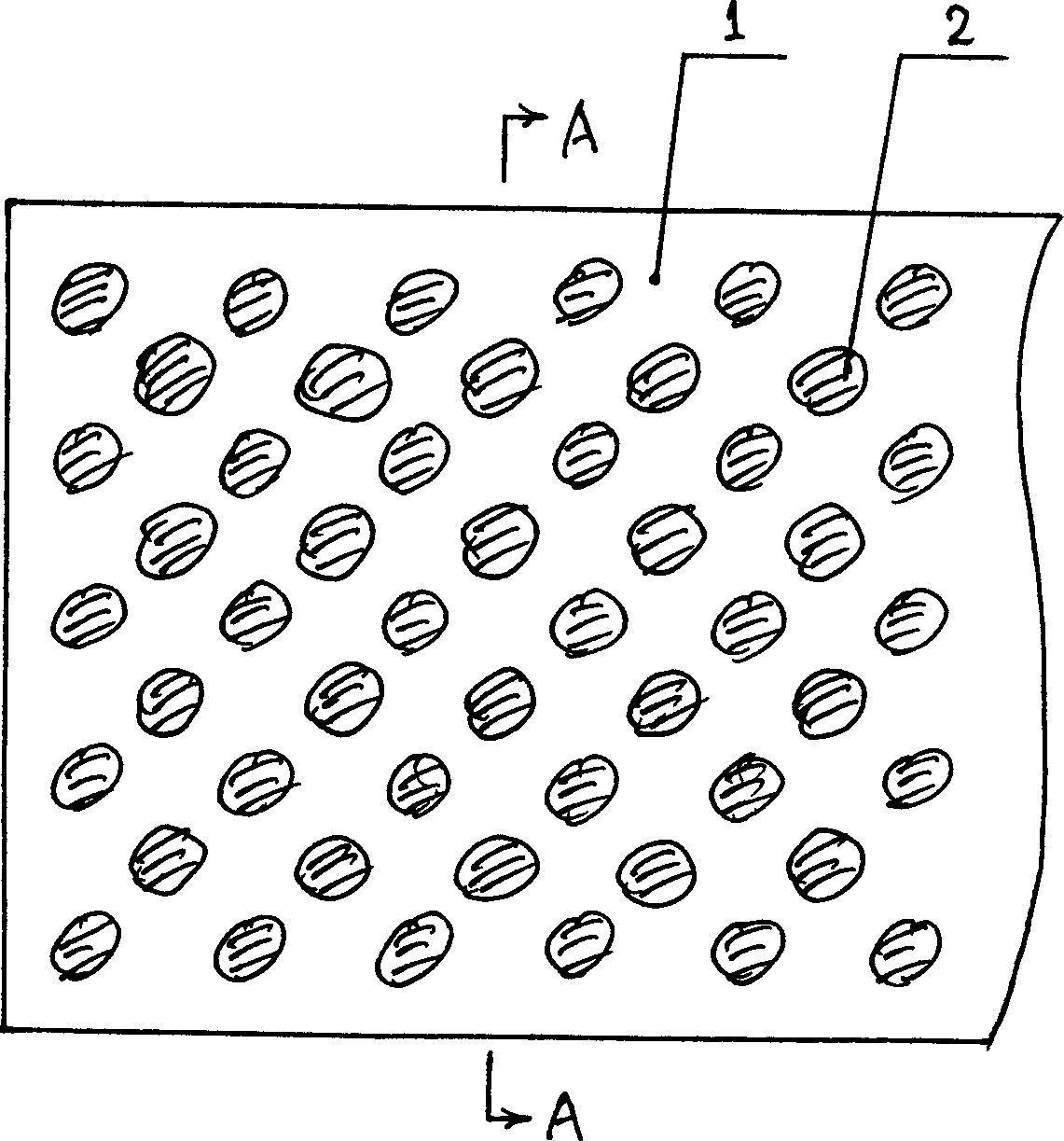

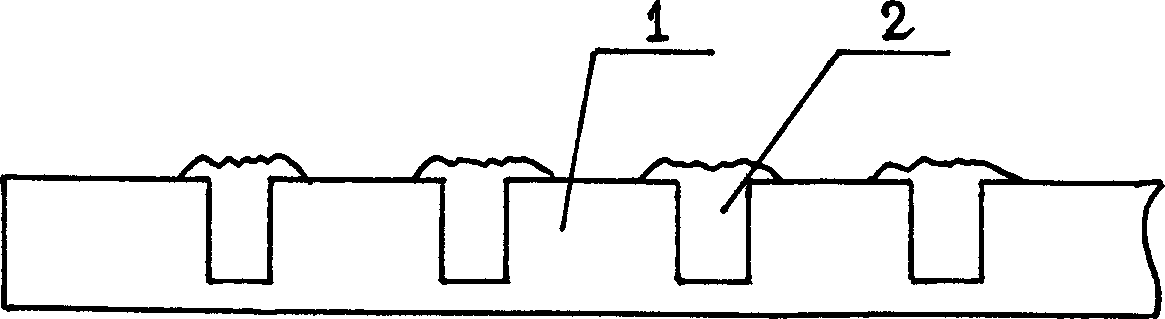

Sticking adiabatic cotton and method of making the same

ActiveCN1654876ASimple processReduce energy consumptionThermal insulationPipe protection by thermal insulationFiberRoom temperature

This invention relates to adhesive heat isolation cotton and its process method, which is applied in forging with constant temperature of alloy with firm shape. The invention is characterized by the following: it comprises the isolation cotton, double adhesive agent, wherein, the isolation cotton is of ceramics fire wearing fiber in sale and its rectangle plate is distributed with parallel and crossed holes with distance between as 50mm and with depth less than the cotton thickness; the double adhesive agent is made by mixture of adhesive agent with room temperature and one with high temperature with their proportion as three to seven. The double adhesive agent in the cotton holes is above the surface of the cotton distributed discontinuously and finally for drying.

Owner:宝武特种冶金有限公司

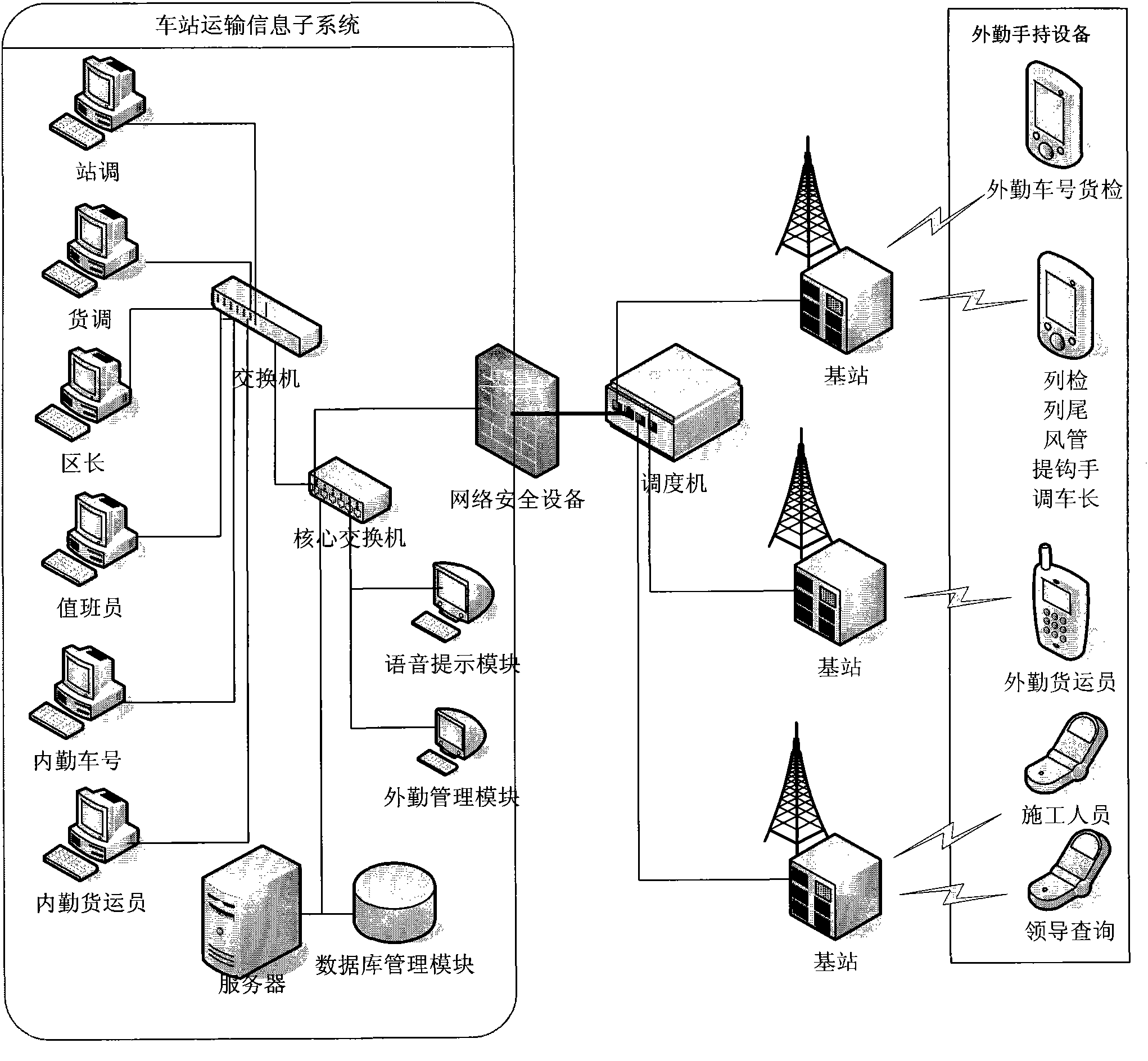

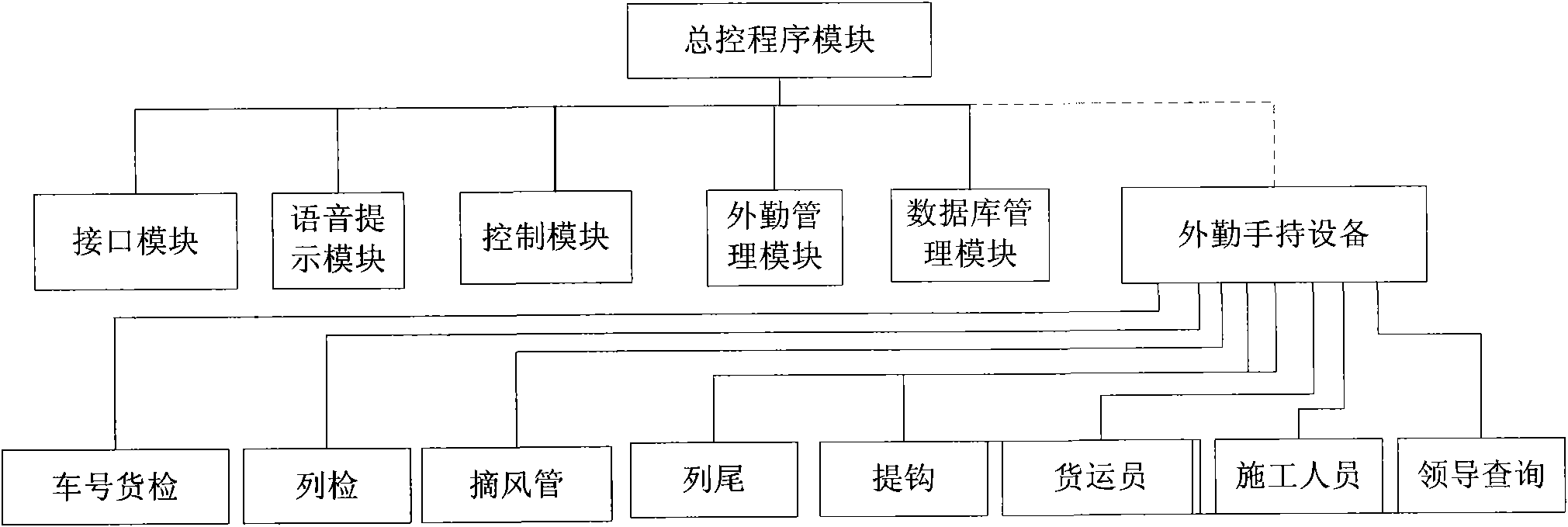

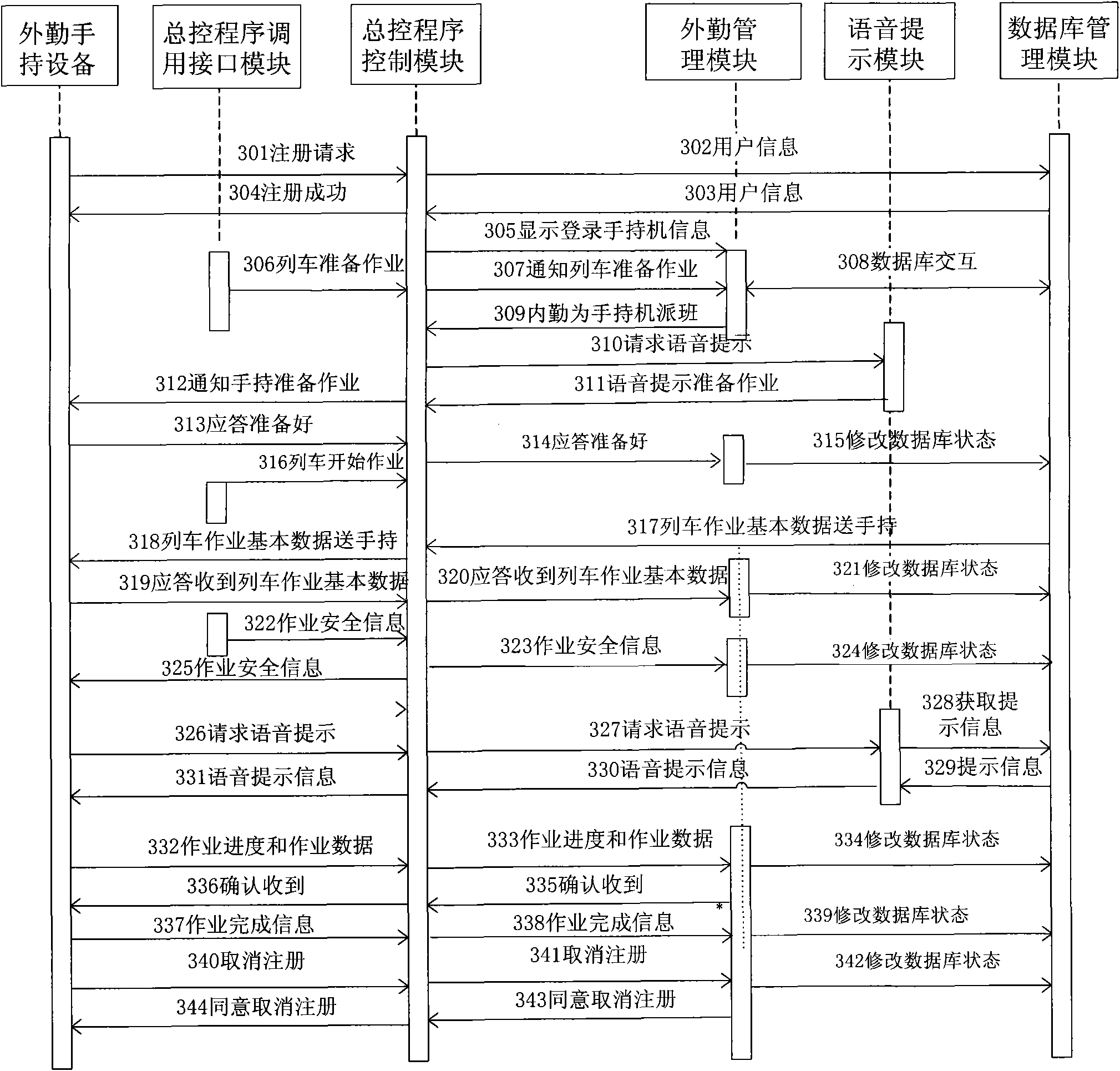

Railway station internal and external work control system

InactiveCN101879909AReal-time control of job progressFaster turnaroundRailway traffic control systemsTransmissionControl systemProgram planning

The invention discloses a railway station internal and external work control system, which comprises a railway station transport information subsystem, a dispatching exchange, a base station and external work handhold devices, wherein the railway station transport information subsystem is connected with the dispatching exchange in a wired mode; the dispatching exchange is connected with the base station in a wired mode; and the base station is connected with the external work handhold devices in a wireless mode. The railway station transport information subsystem makes operation plans for trains, announces the plans in advance, sends the plans to the external work handhold devices, controls the job processing of external workers according to feedback information received from the external work handhold devices and ensures that all external work handhold devices complete train operation according to dispatching regulations; the dispatching exchange and the base station serve as the transfer stations between the railway station transport information subsystem and the external work handhold devices; and the external work handhold devices execute operation according to the operation plans of the trains, and report operation processing information. When the system is used, the operation efficiency and safety can be improved.

Owner:SINORAIL HONGYUAN BEIJING SOFTWARE TECH

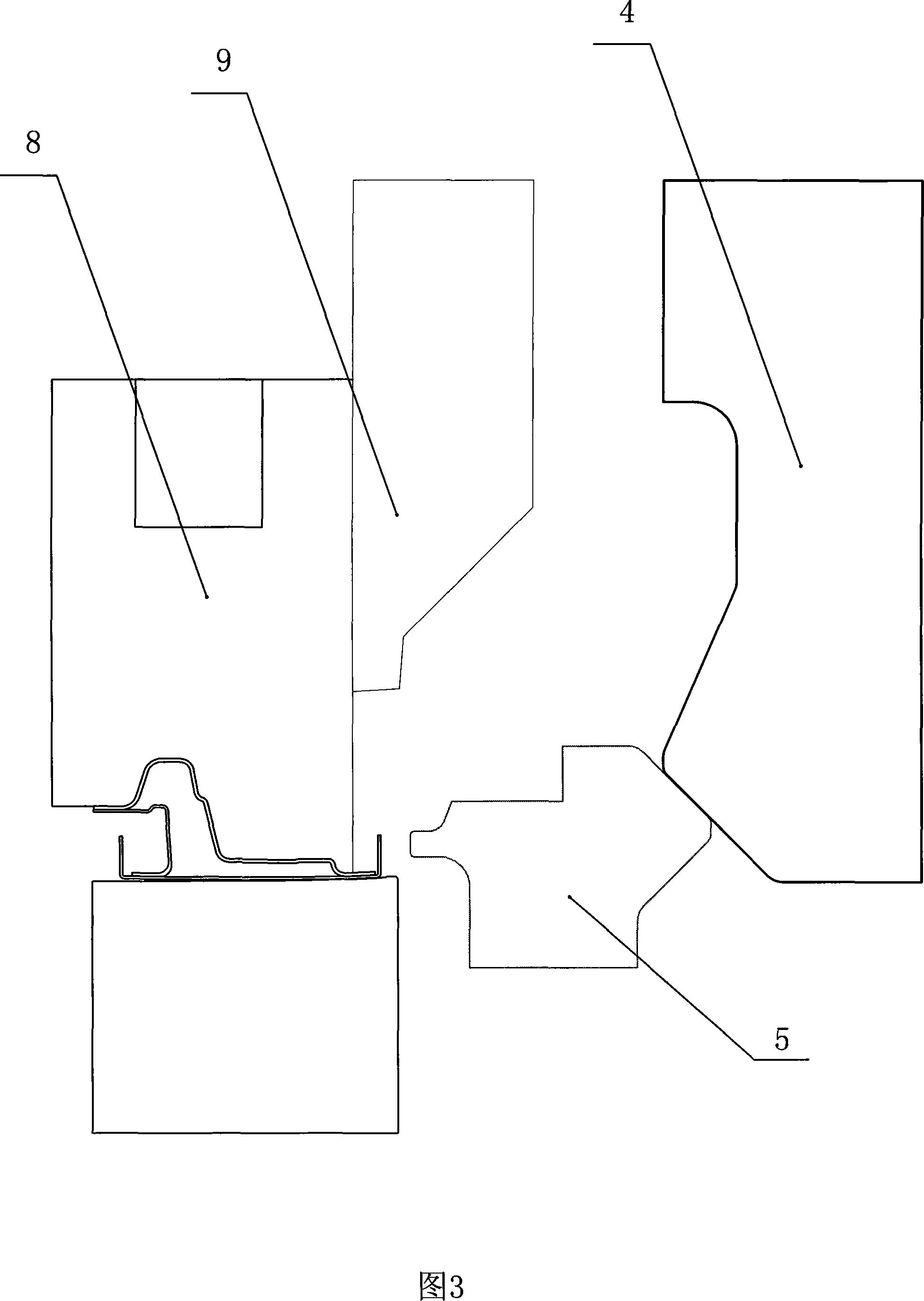

Car door frame edge binding process and mold

The present invention relates to car door production process and apparatus, and is especially technological process and mold for binding edge of car frame edge. The outer door plate is bent and bound by means of the horizontal motion of slide block driven with the edge binding mold. The present invention has no need of replacing mold, short edge binding period, high production efficiency and high product precision.

Owner:WUHAN MINHUI AUTOMOTIVE PARTS

Once tubular column process for combination oil production by multiple fracturing for oil gas well

InactiveCN101418681AReduce operational riskShorten working timeDrilling rodsFluid removalOil productionOil field

The invention relates to a process for fracturing reconstruction and extraction for oil and gas well in oil field. In the process, different fracture technology parameters are determined based on geology materials, then down-hole tools such as a hydraulic anchor, a packer, a sliding sleeve, a ball cup and the like are put into the well in order, the packer is packed and the hydraulic anchor is anchored by once tamping, then deliver balls perform corresponding fracturing reconstruction to the oil gas reservoirs through the switch function of the sliding sleeves, and after the construction works are completed, the merged extraction can be performed. The process determines corresponding fracture pipe string structures based on different reservoirs and different fracture parameters, can realize the selective fracture reconstruction and commingled production mode for the reservior by onetime, has full controllability for each reservior fracture order, has little work risk, can greatly shorten the operation time of fracture construction, and can achieve the purpose of improving the yield of the oil and gas well and the extraction effect.

Owner:CNPC GREATWALL DRILLING ENG

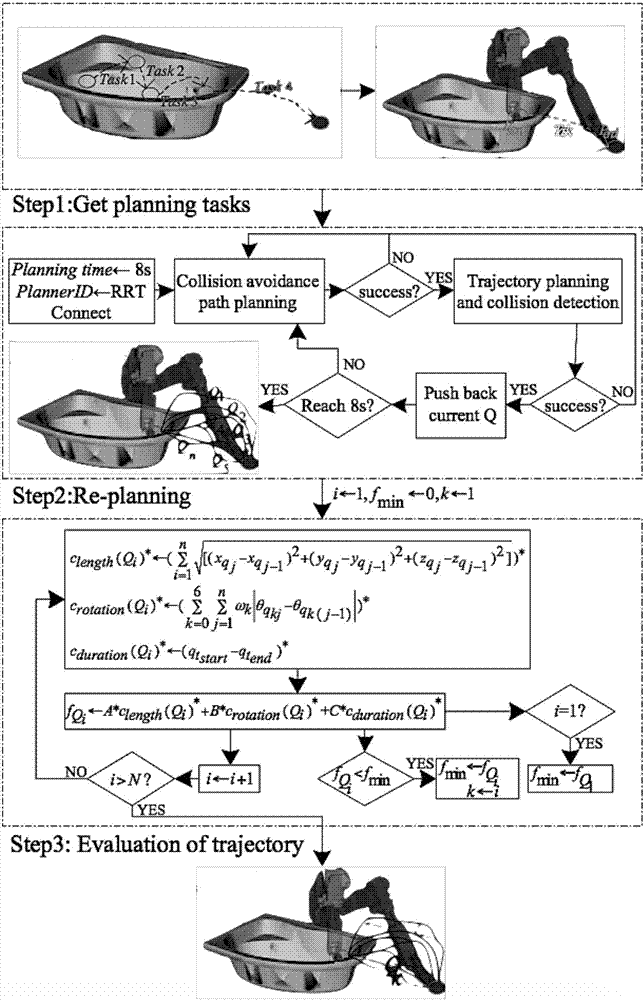

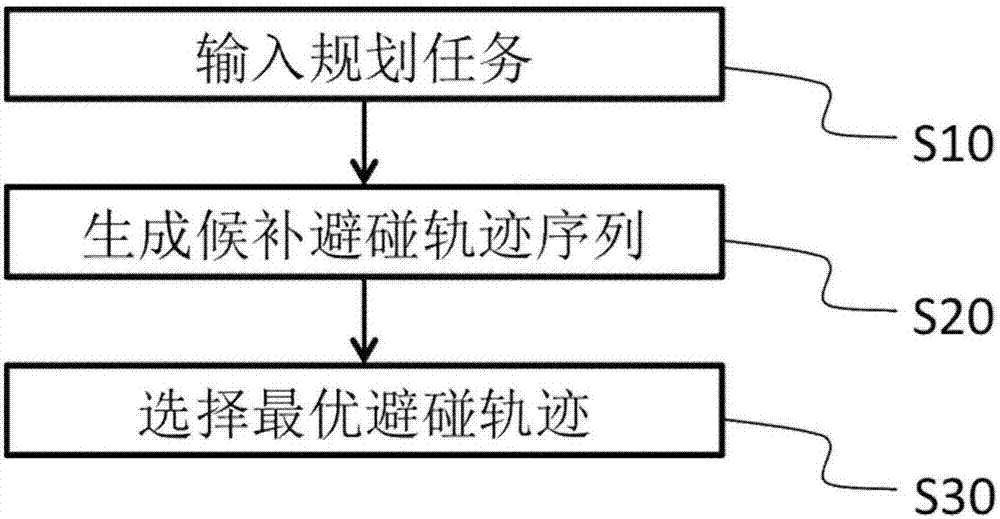

Collision avoidance trajectory planning method and device based on articulated arm robot

ActiveCN107443373AReduce computational complexityReduce computationProgramme controlProgramme-controlled manipulatorPath lengthSimulation

The invention discloses a collision avoidance trajectory planning method and device based on an articulated arm robot. Alternate collision avoidance trajectory sequence is generated in the specified time according to job task requirements, three factors such as the path length, articulation rotating total amount and the used time of operation are considered, the best collision avoidance trajectory is chosen from the trajectory sequence, so that autonomous collision avoidance path planning is achieved, and manual intervention during the operation process is avoided.

Owner:GUANGZHOU ZSROBOT INTELLIGENT EQUIP CO LTD +1

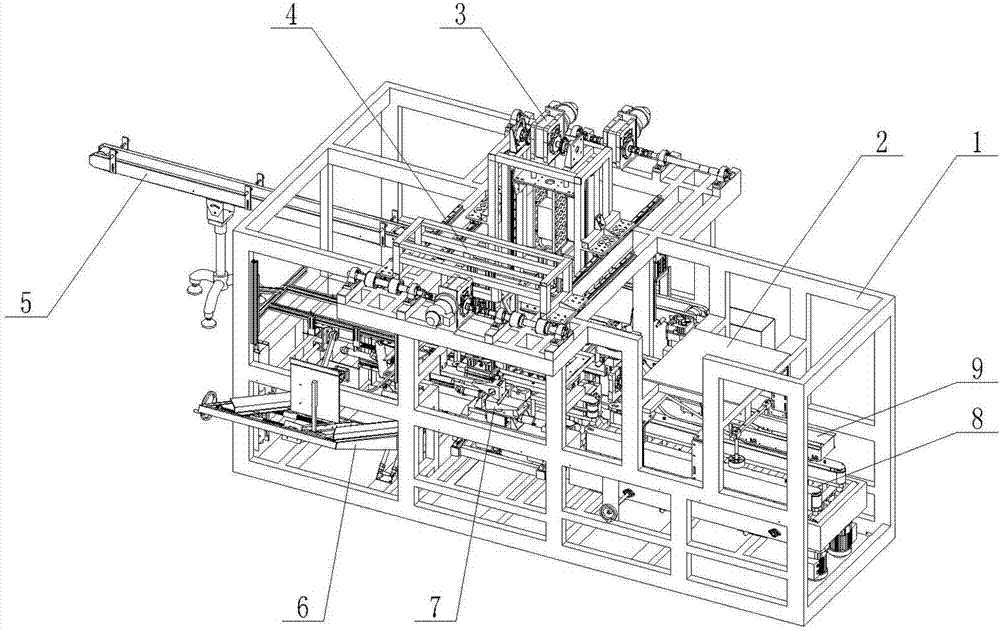

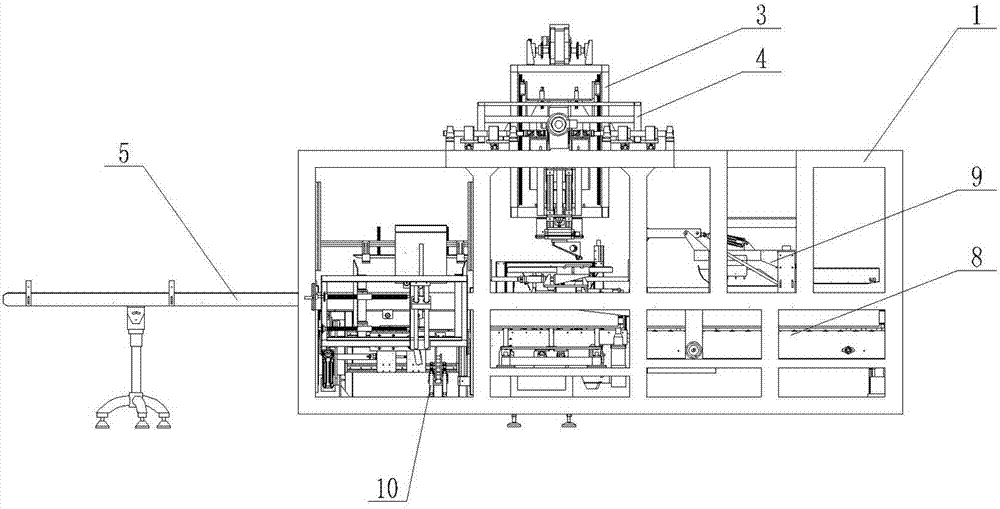

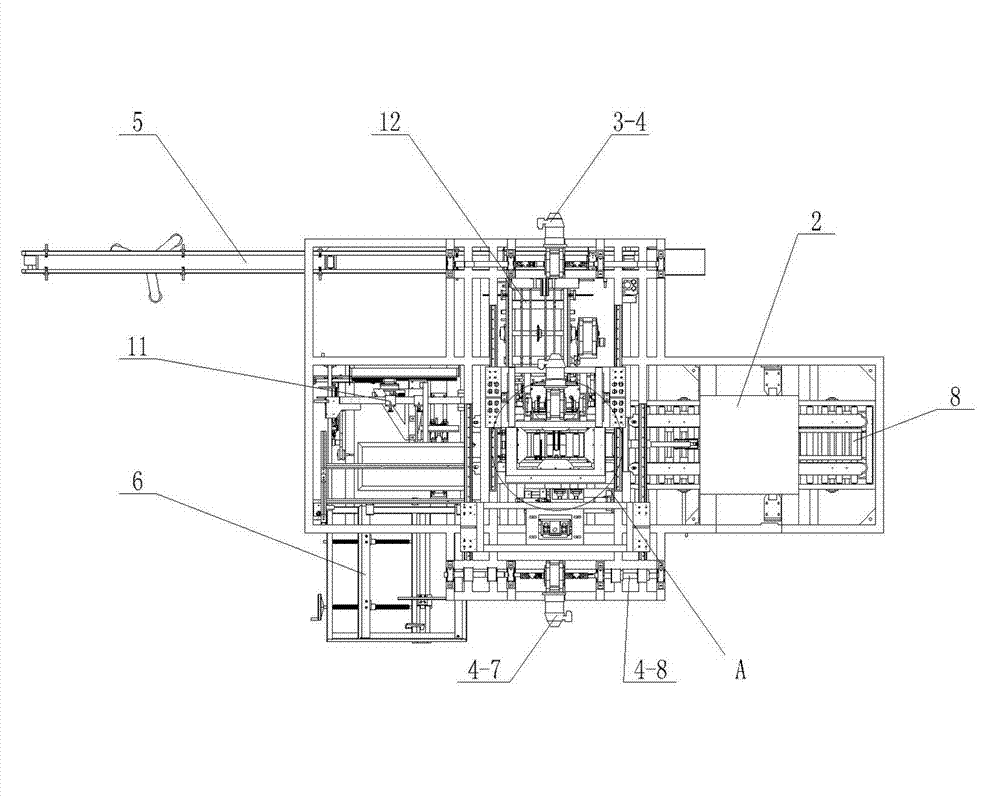

Opening-loading-sealing all-in-one machine for packaging bar products

InactiveCN103662138ALow input costShorten working timeWrapper twisting/gatheringPackaging automatic controlBar productCarton

The invention discloses an opening-loading-sealing all-in-one machine for packaging bar products. A combination box opening machine is arranged on one side of a main frame of the all-in-one machine, a conveying roller way is connected to the box opening machine, a box loading station is arranged on the conveying roller way, and paper boxes are opened and molded through the box opening machine to be conveyed to the box loading station for waiting for box loading; the conveying roller way is respectively connected with a hose sausage body conveying mechanism and a squeezing-out mouth conveying mechanism, a movable hose sausage body box loading mechanism and a squeezing-out mouth box loading mechanism are arranged at the position, above the box loading station, of the conveying roller way, and the box loading mechanisms grab hose sausage bodies and squeezing-out mouths from the conveying mechanisms respectively into the empty paper boxes. The hose sausage body conveying mechanism is provided with a hose sausage body quality testing mechanism and a grouping mechanism, the quality testing mechanism screens out and conveys the qualified hose sausage bodies to the grouping mechanism, and the hose sausage bodies are grouped by the grouping mechanism according to a preset number to be grabbed and carried by the hose sausage body box loading mechanism. The squeezing-out mouth conveying mechanism is also provided with a grouping mechanism, and the squeezing-out mouths are grouped by the grouping mechanism according to a preset number to be grabbed and carried by the squeezing-out mouth box loading mechanism.

Owner:北京阔博包装机械设备有限公司

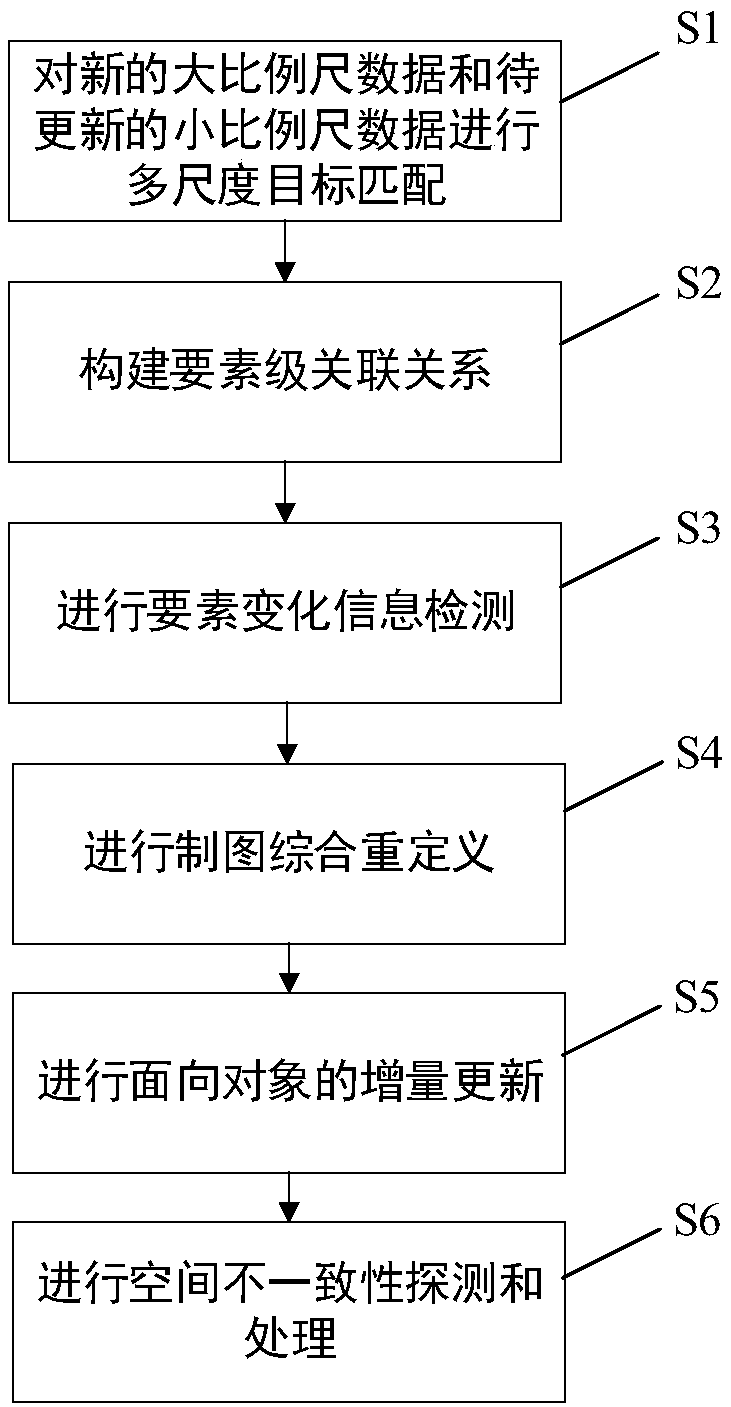

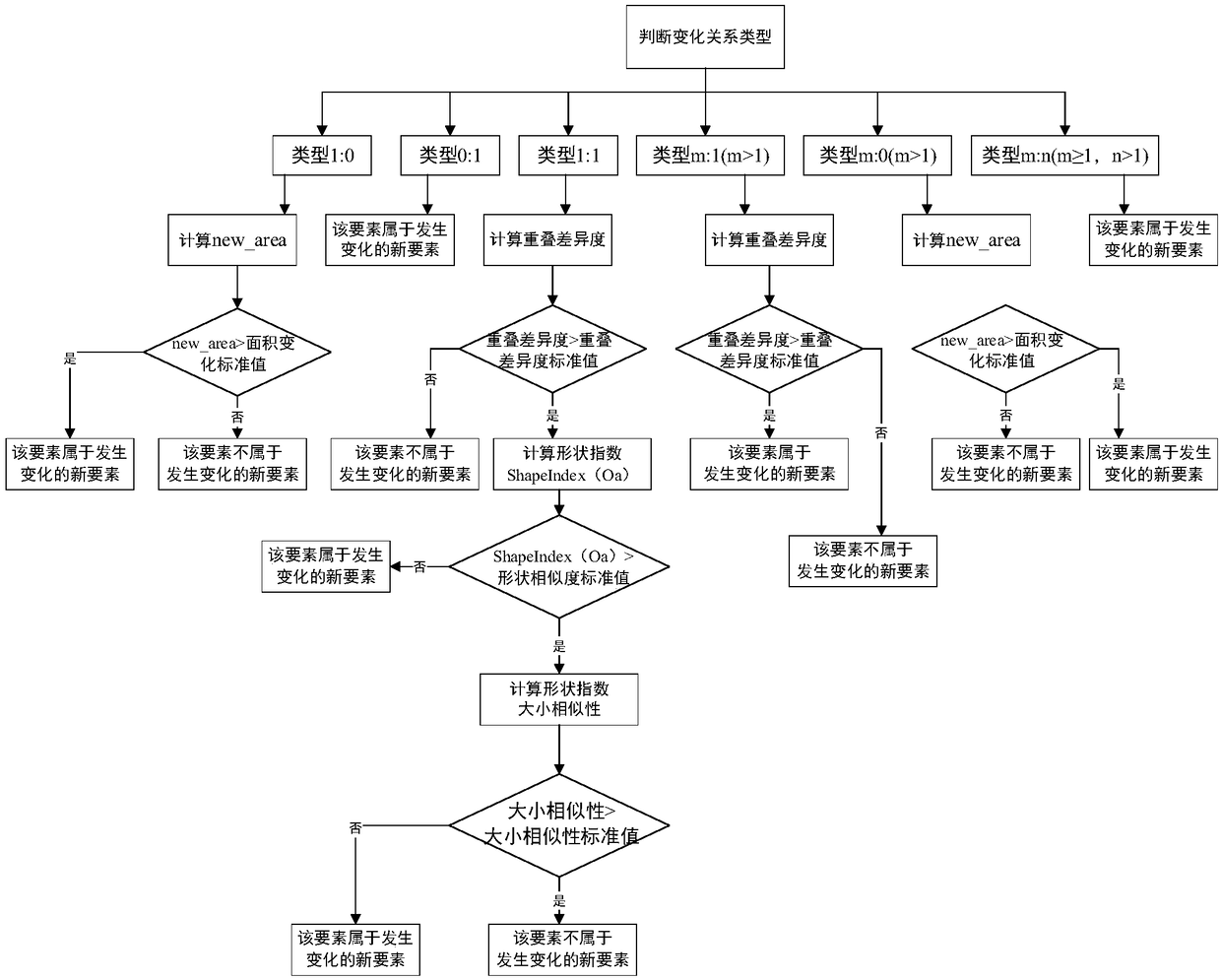

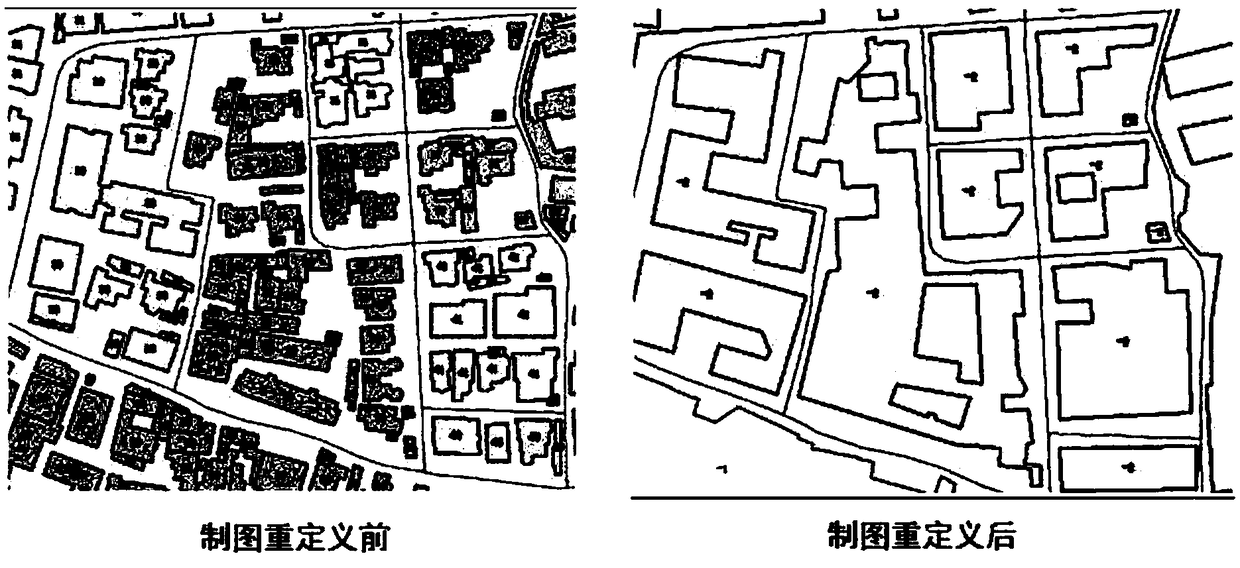

A method for updating multi-scale map data

ActiveCN109145171AImprove matching efficiencyThe matching operation is conciseDatabase updatingSemantic analysisCartographic generalizationLarge scale data

The invention discloses a multi-scale map data updating method, which comprises the following steps: matching the new large-scale data and the small-scale data to be updated with multi-scale targets;constructing element-level relationship; conducting element change information detection; cartographic generalization and redefinition; object-oriented incremental updating; spatial inconsistency detection and processing. The multi-scale map data updating method disclosed by the invention can effectively solve the problems that the prior art is unable to accurately identify the change informationand predict the transmission scale of the change element updating, the matching range of the element is small, and the efficiency of the map element updating is low.

Owner:GUANGZHOU URBAN PLANNING & DESIGN SURVEY RES INST

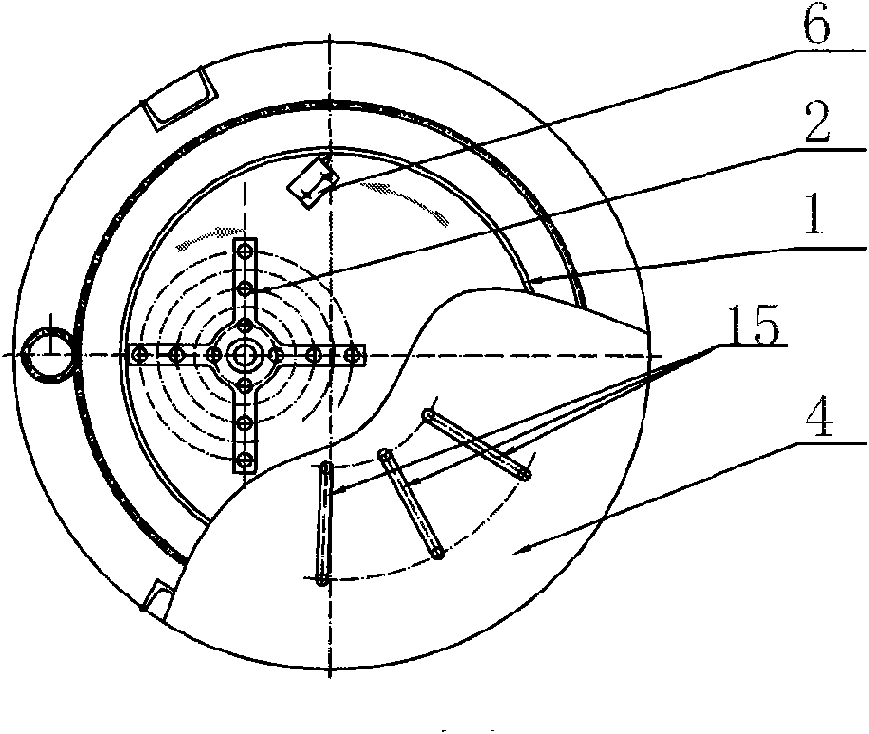

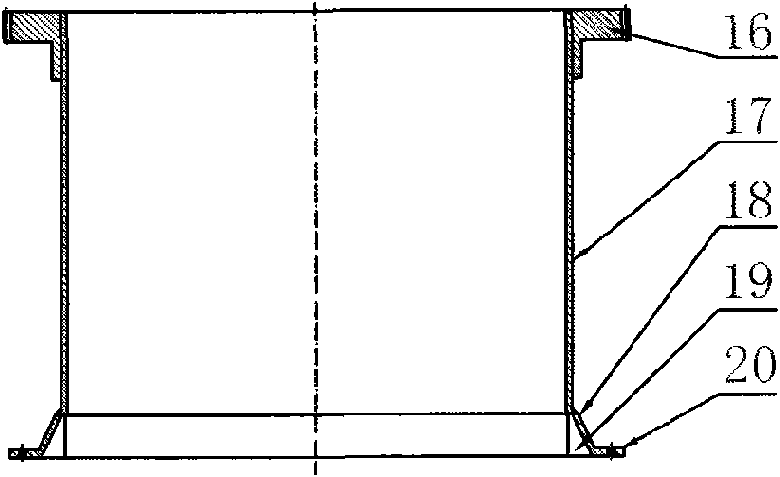

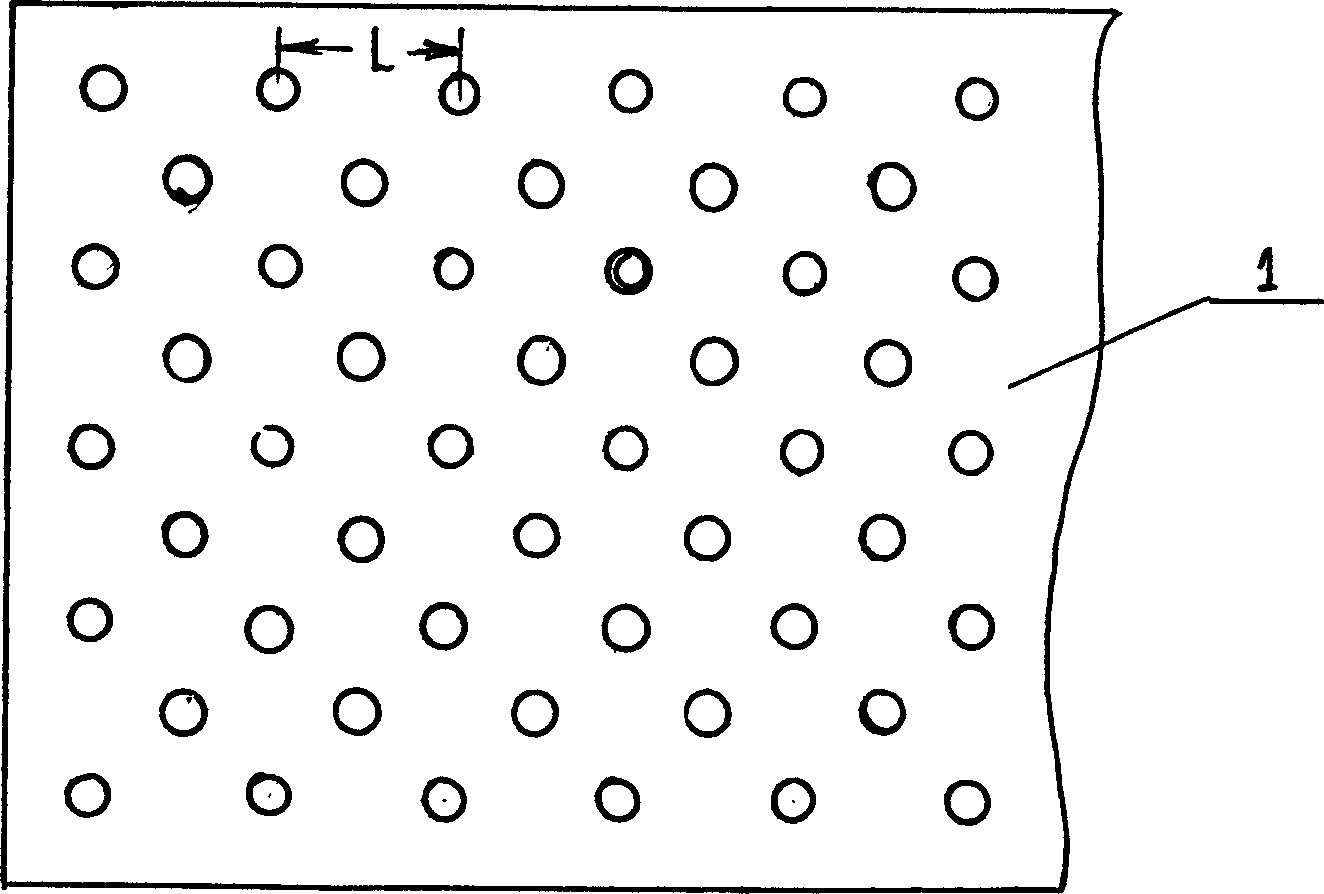

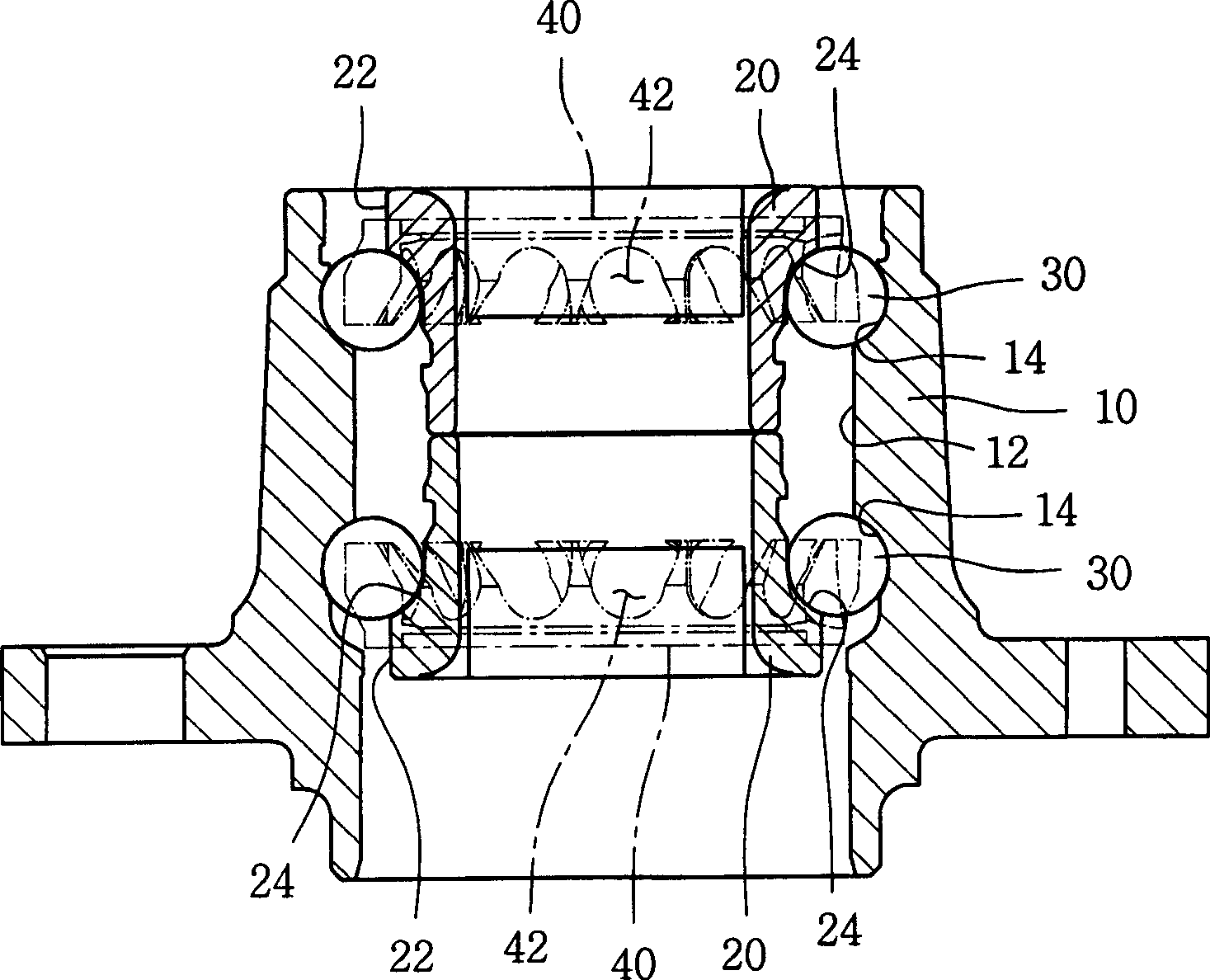

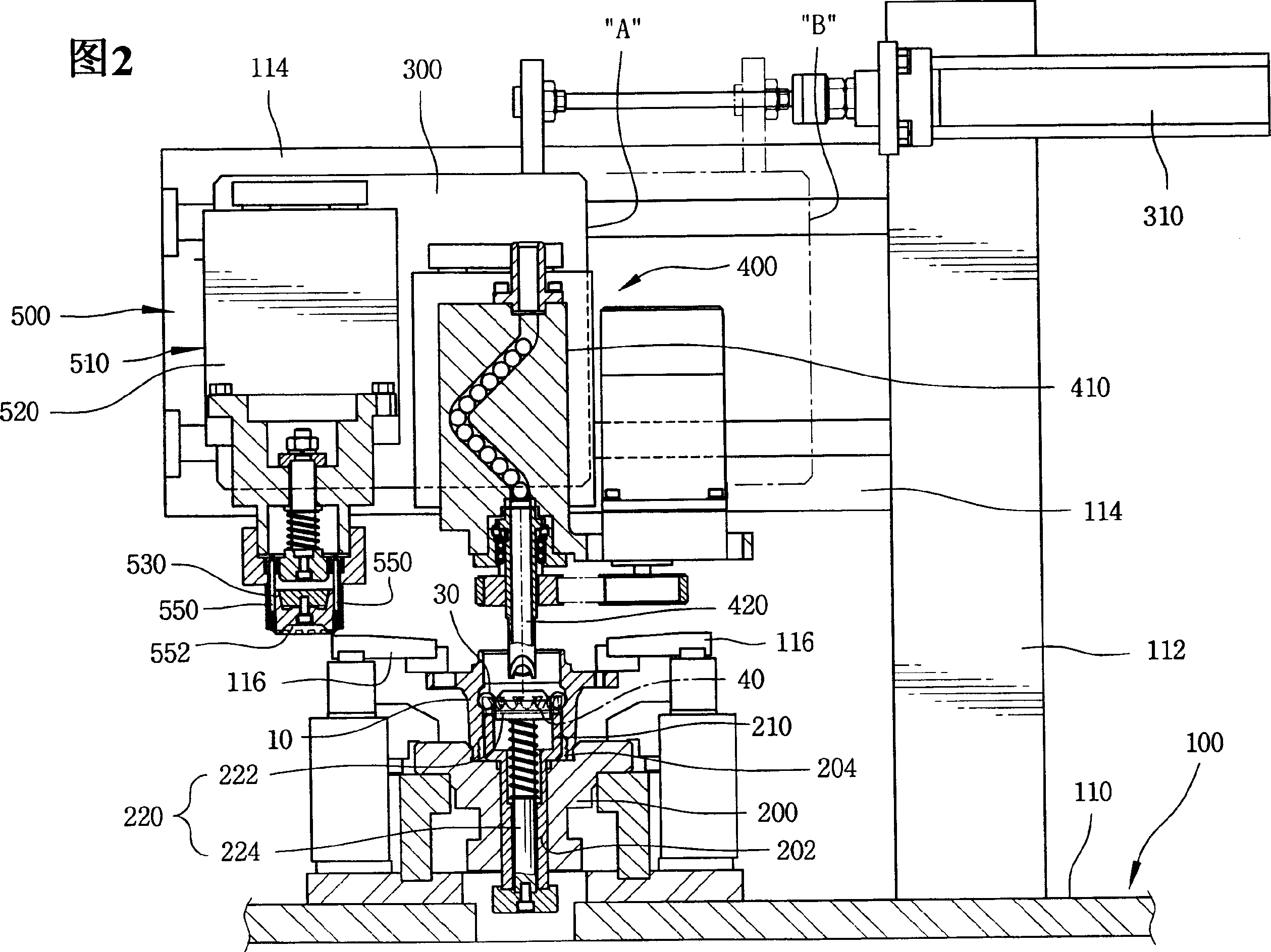

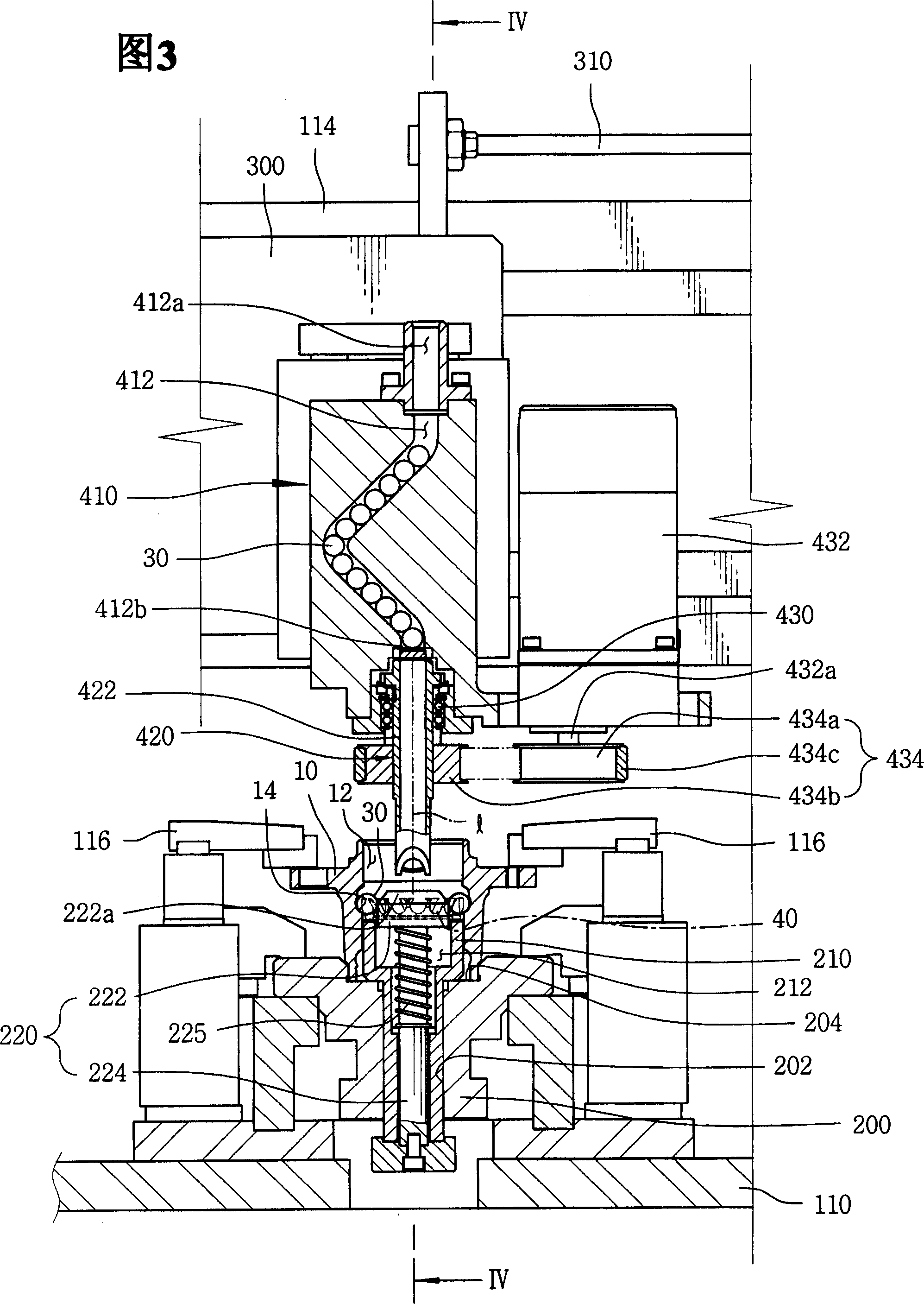

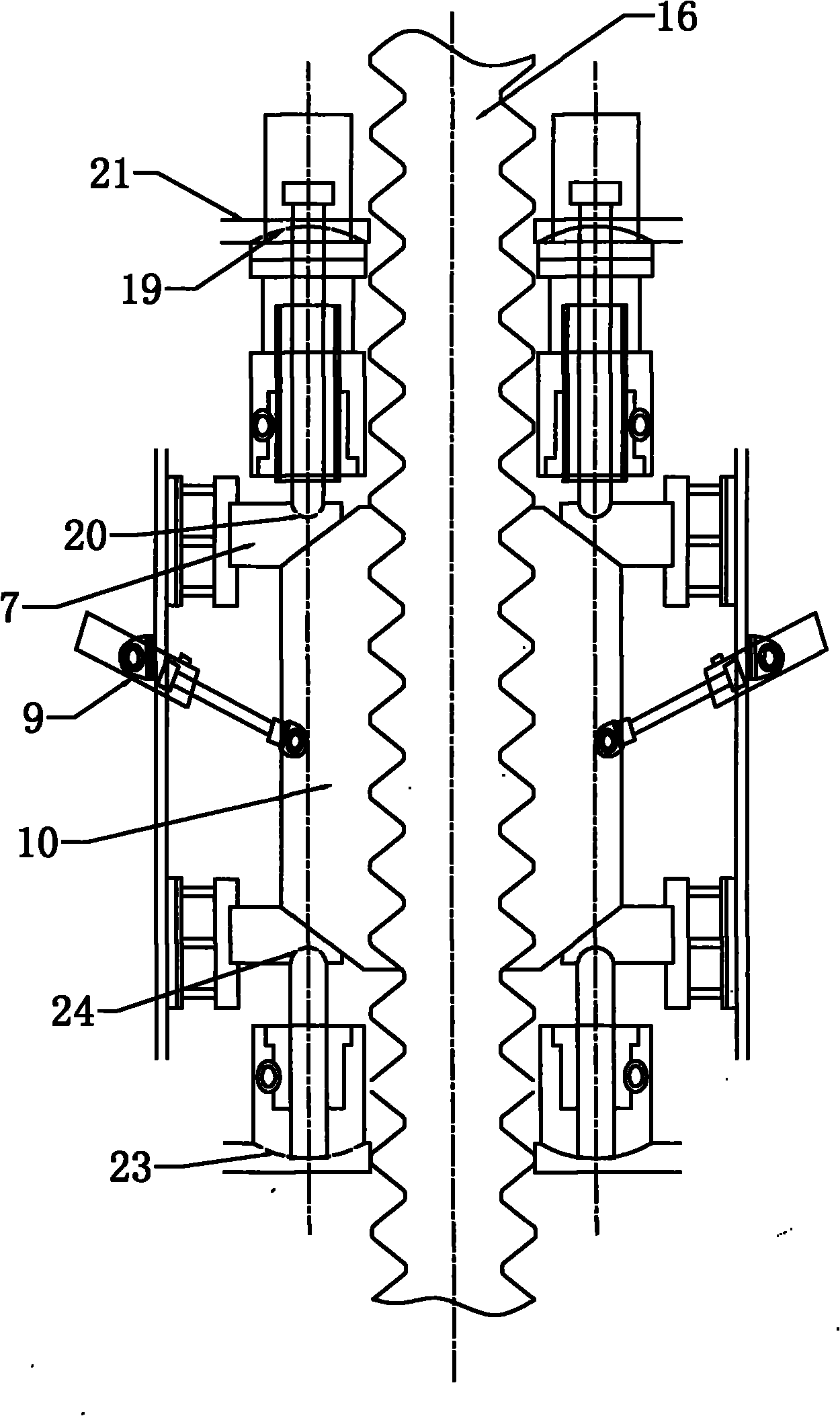

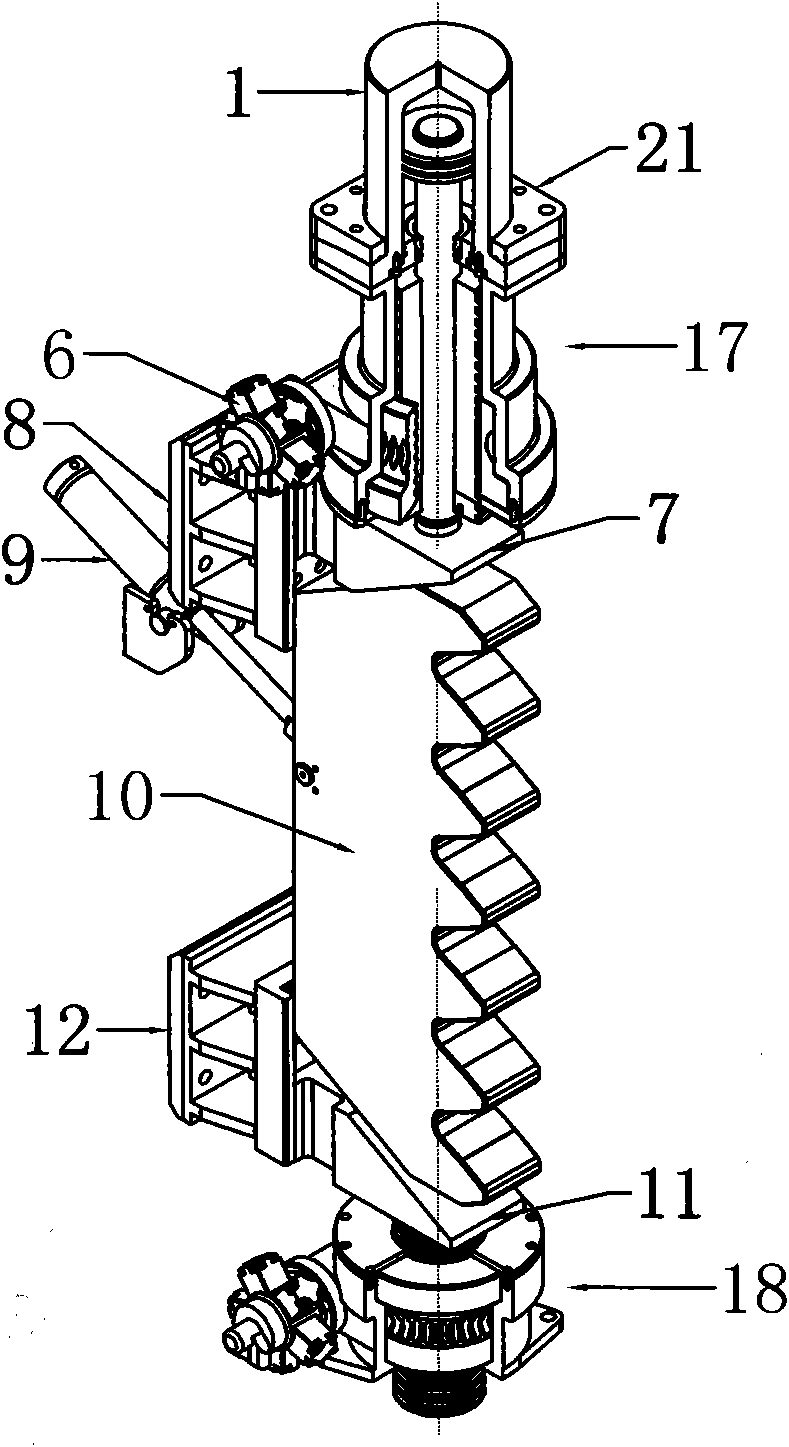

Ball supply and ball quantity checking device for bearing

InactiveCN1637308AEasy to manufactureEasy to checkMachine bearings testingBearing componentsProduction rateEngineering

Provided is a ball supply and ball quantity inspection device for a bearing, which supplies balls to a rolling surface formed on the inner periphery of a bearing outer ring and checks the quantity of the supplied balls. The ball supply and ball quantity inspection device of the present invention comprises: a frame (100), a base (200), a ball supply tool (410), a ball guide (220), a ball quantity inspection device (510), a carriage ( 300) and motion devices. According to the present invention, balls are automatically supplied and distributed to the inside of the outer ring, and at the same time, whether the correct number of balls are supplied is automatically checked, thereby making it very easy to manufacture and inspect the bearing. In particular, there is an effect of improving productivity by reducing working time and labor.

Owner:DOOSAN INFRACORE CO LTD

Locking device with double spherical hinge bearing structure for pile legs of self-elevating drilling platform

ActiveCN101871208AEliminate bad effectsEliminate binding forceArtificial islandsUnderwater structuresEngineeringMechanical engineering

The invention provides a locking device with hinge with a double spherical hinge bearing structure for pile legs of a self-elevating drilling platform, which comprises a top locking assembly, a bottom locking assembly and a locking block, wherein the locking block is tabled on a pile leg rack through a cog, and the top locking assembly and the bottom locking assembly are respectively assembled on bearing platforms at the upper side and the lower side of the locking block and are respectively contacted with the locking block through a top wedge block and a bottom wedge block; and a top upper spherical hinge, a top lower spherical hinge, a bottom upper spherical hinge and a bottom lower spherical hinge are respectively arranged at the contact places of the top locking assembly and the bottom locking assembly as well as the bearing platform, the top wedge block and the bottom wedge block. With the scheme, the invention not only ensures the effective locking of the platform, but also solves the problem that the locking device is difficult to unlock; and each locking device is uniformly loaded after locking, and the load smoothly transfer between a lifting device and the locking device, thereby greatly saving the operating time of the staff.

Owner:KEEN OFFSHORE ENG CO LTD +1

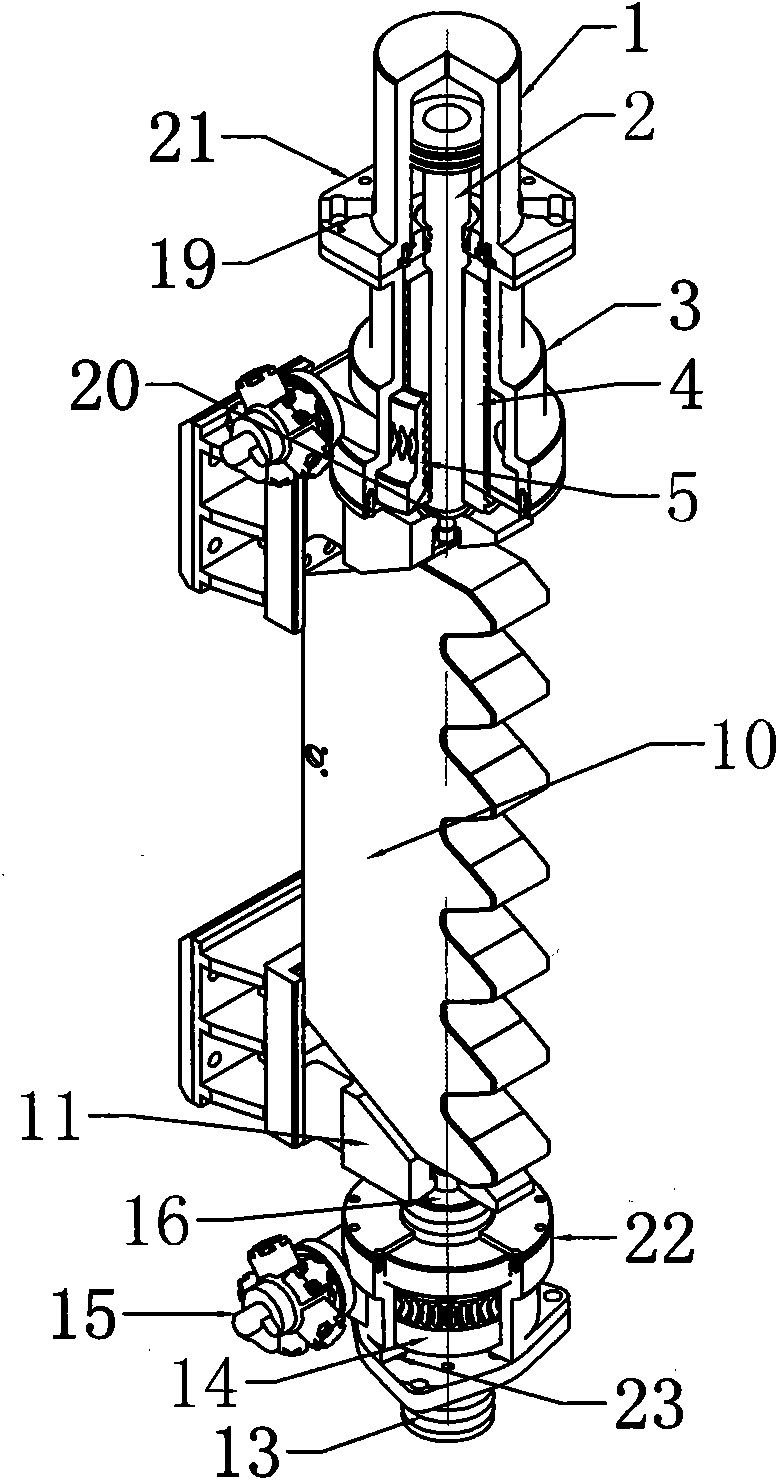

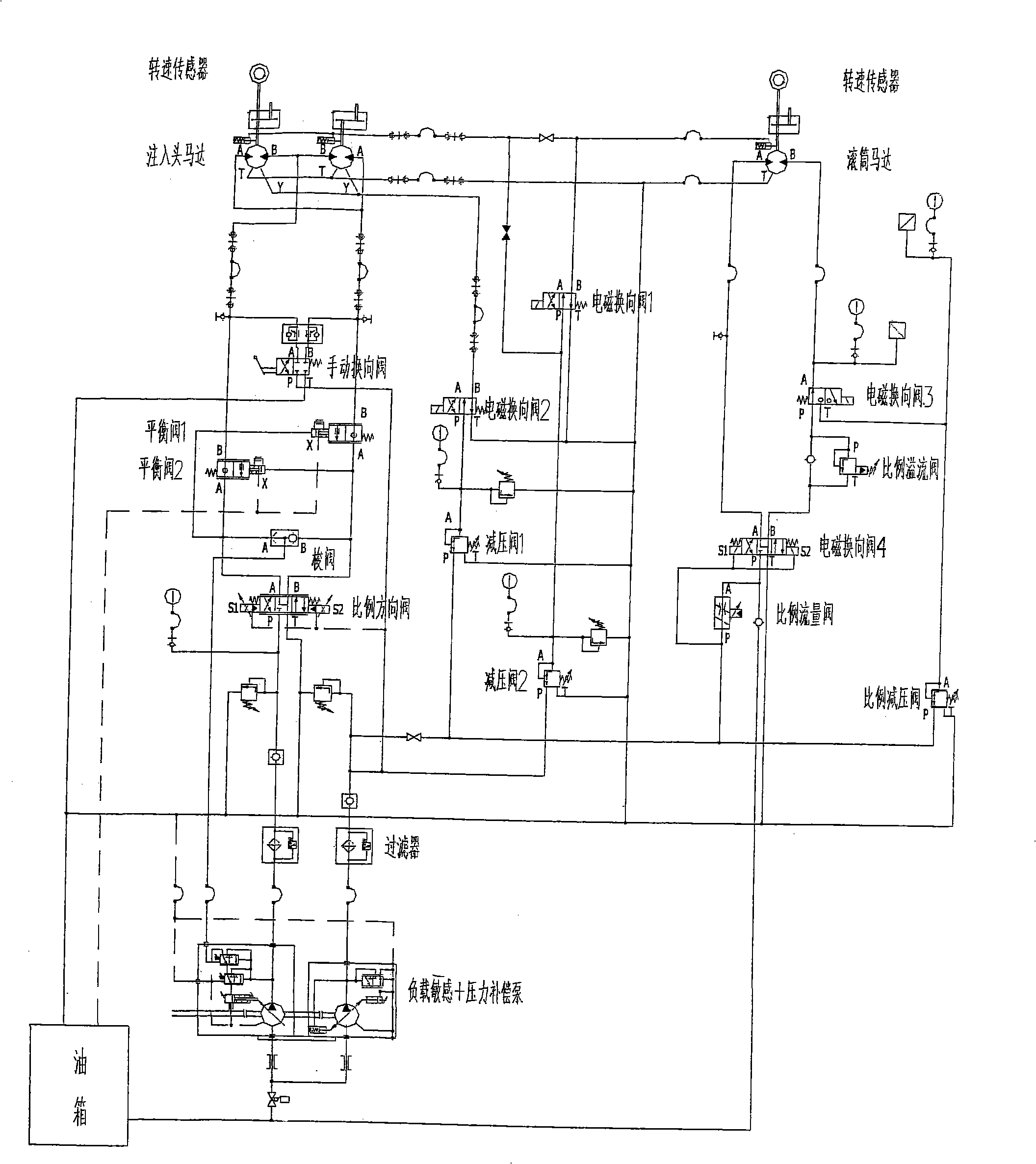

Speed matching control device between continuous tube apparatus infusion head and drum

The invention provides a control device for matching the speed between an injection head of a continuous pipe assembly and a roller. The invention is applied to the continuous pipe construction in the petroleum industry and is characterized in that the device consists of a load sensing pressure compensation pump, a proportional direction valve, a shuttle valve, two equilibrium valves, a manual reversing valve, two injection head motors, a roller motor, two reducing valves, two rotating speed sensors, four electromagnetic reversing valves, a proportional overflow valve and an oil box, each component is connected and assembled according to the invention. The control device has the advantages that the cooperation control of the two subsystems of the injection head and the roller is realized, the roller injection or lifting speed is the same as the speed for loosening or winding the injection head continuous pipe, the 'back drawing force' of the continuous pipe on the roller is constant basically, thereby reducing the harm on the continuous pipe and the continuous pipe assembly, prolonging the service life, shortening the operation time, saving the operation cost and avoiding unnecessary loss caused by misoperations.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com