Coal bed gas well pulse radial drilling and double-pulsating hydrofracturing method

A technology for radial drilling and coalbed methane wells, which is applied in earthwork drilling, wellbore/well components, and production fluids, etc. It can solve the problems of reducing seepage resistance in the near-wellbore area, attenuation of pulse energy of fracturing fluid, and inability to segment Fracturing and other problems, to achieve the effect of increasing drilling speed, alleviating serious losses, and saving operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

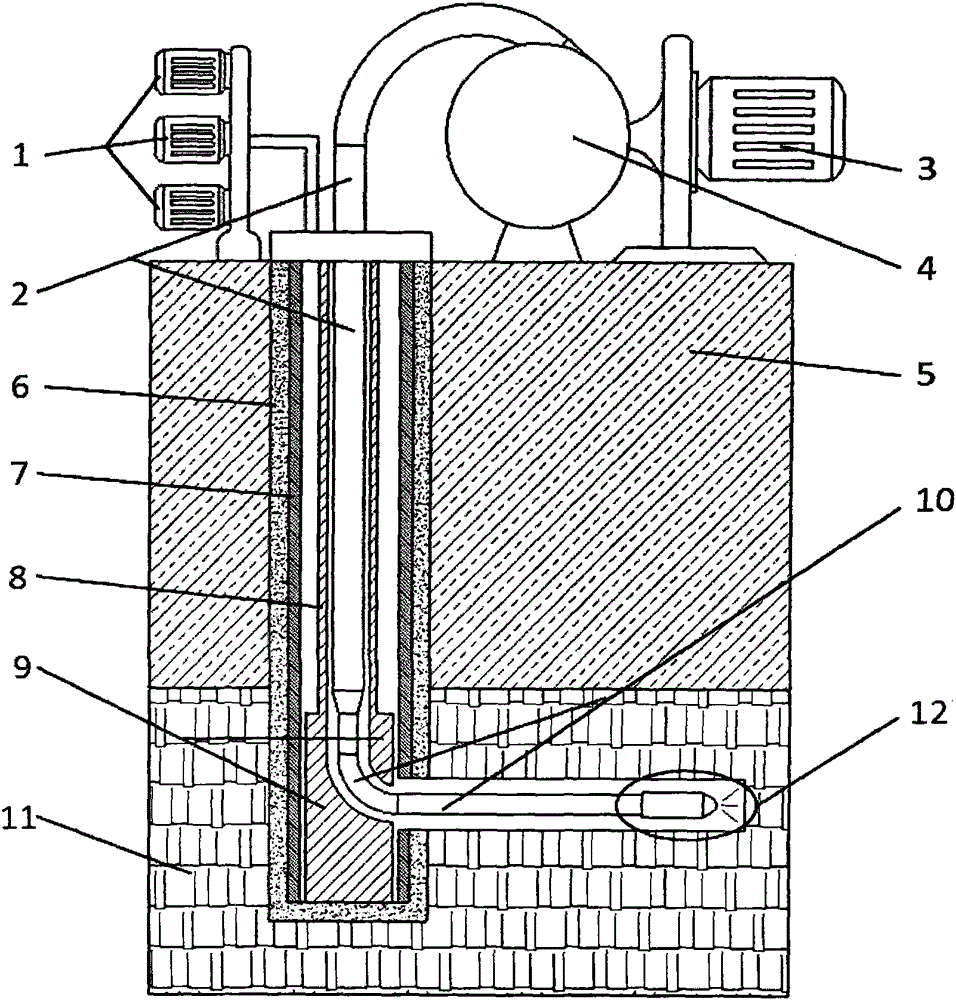

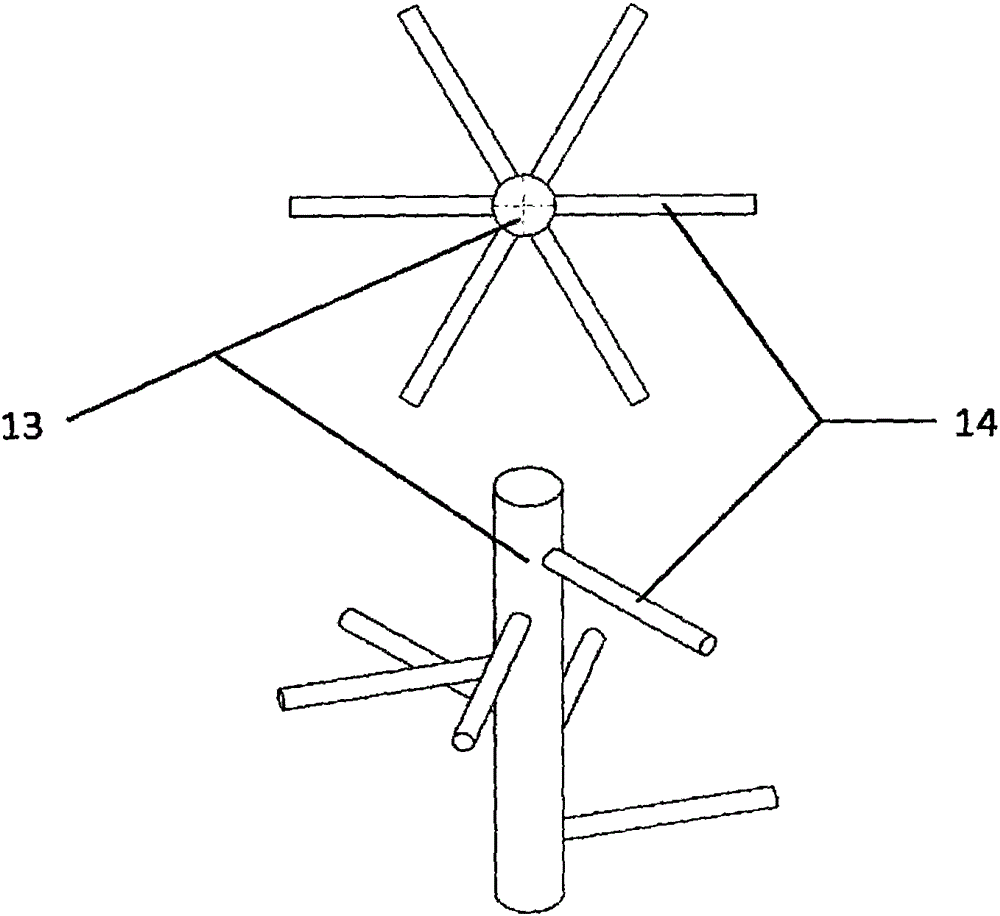

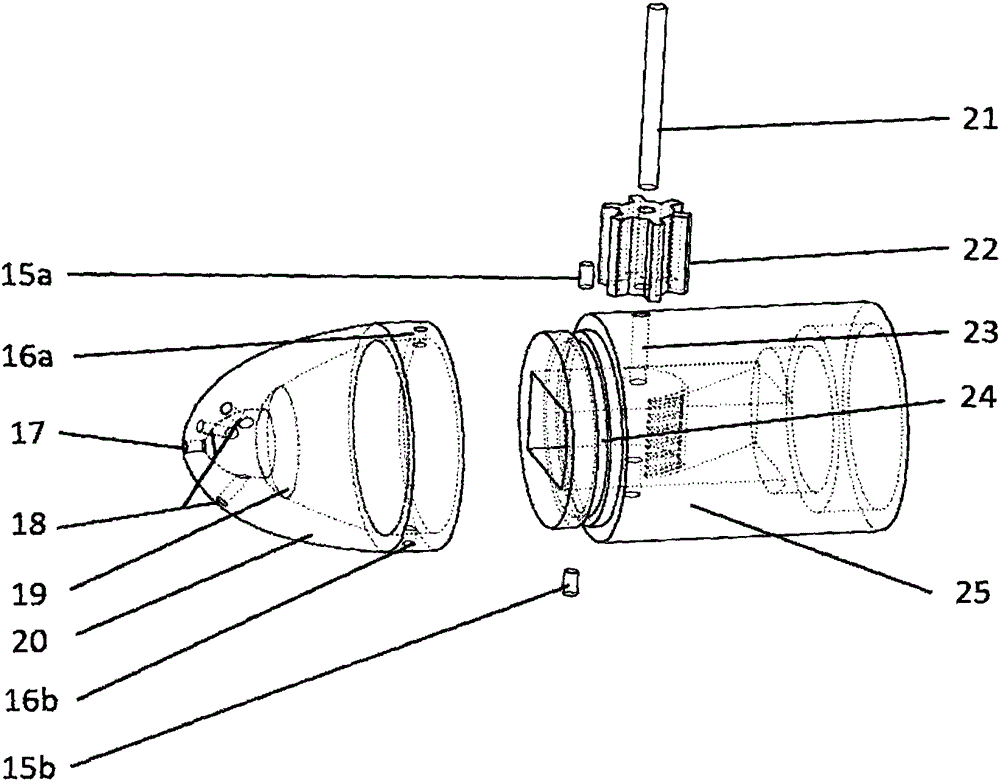

[0022] The present invention proposes a method for pulsed radial drilling and double pulse fracturing of coalbed methane wells. At the same time, it discloses the corresponding downhole tools and a complete set of construction schemes. In order to increase the permeability of coalbeds, increase the productivity of coalbed methane wells, and prolong the period of stable production, Economical and efficient mining of coalbed methane provides a new technical means. Below in conjunction with accompanying drawing, downhole tool of the present invention and construction flow will be further described:

[0023] First, in the main wellbore (13) of the coalbed methane well completed with casing, the casing window opening technology is used to open the casing window at the designated position and orientation; device (9), positioned, orientated and fixed; the coiled tubing (2) is lowered from the ordinary tubing, and the lower end of the coiled tubing is connected with a high-pressure ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com