Dry type pneumatic rock drilling pile-driving machine and working method thereof

A technology of bored piles and construction methods, applied in the direction of drilling equipment and methods, sheet pile walls, drilling equipment, etc., can solve the problems of urban sewer blockage, difficult construction, inclined holes, etc., and achieve a clean and mud-free construction site Pollution, the effect of fast drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

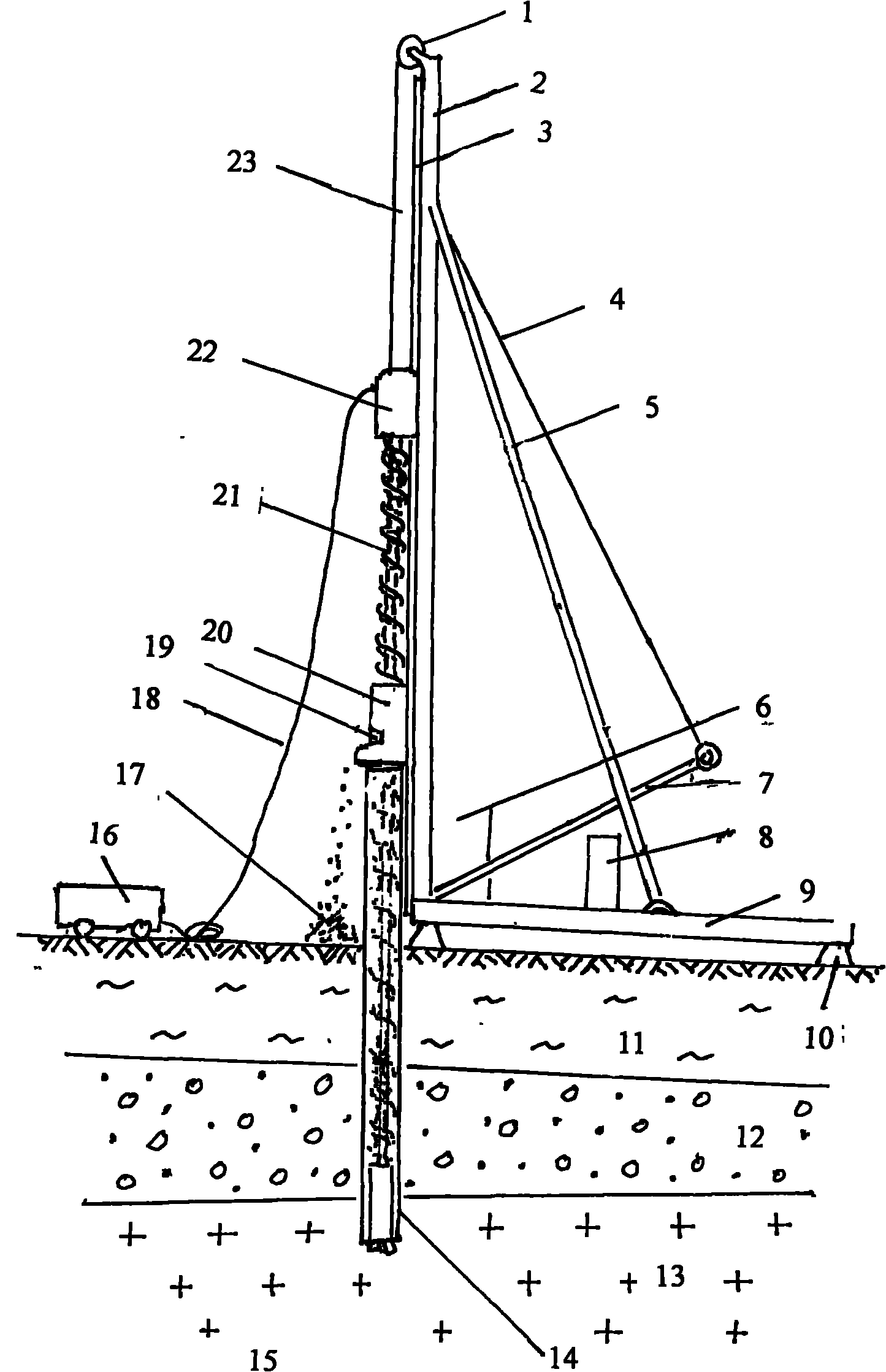

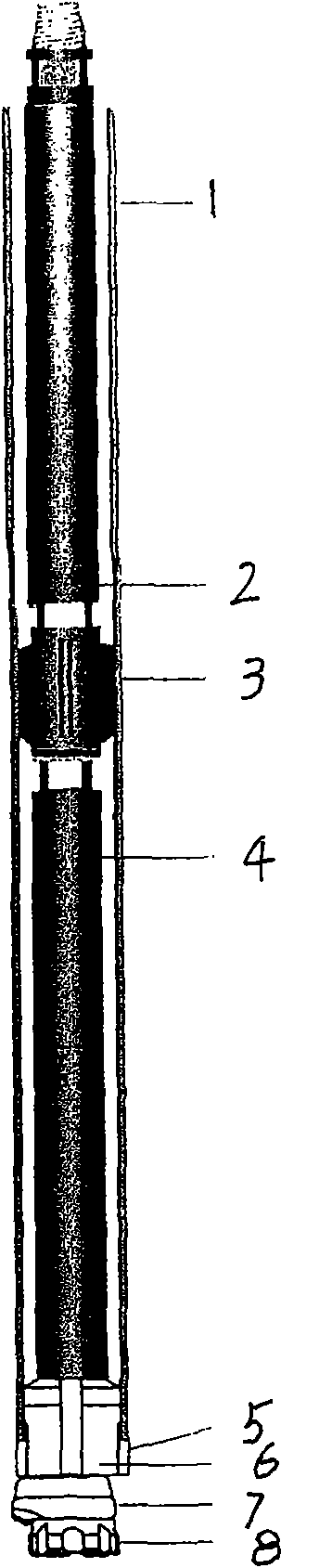

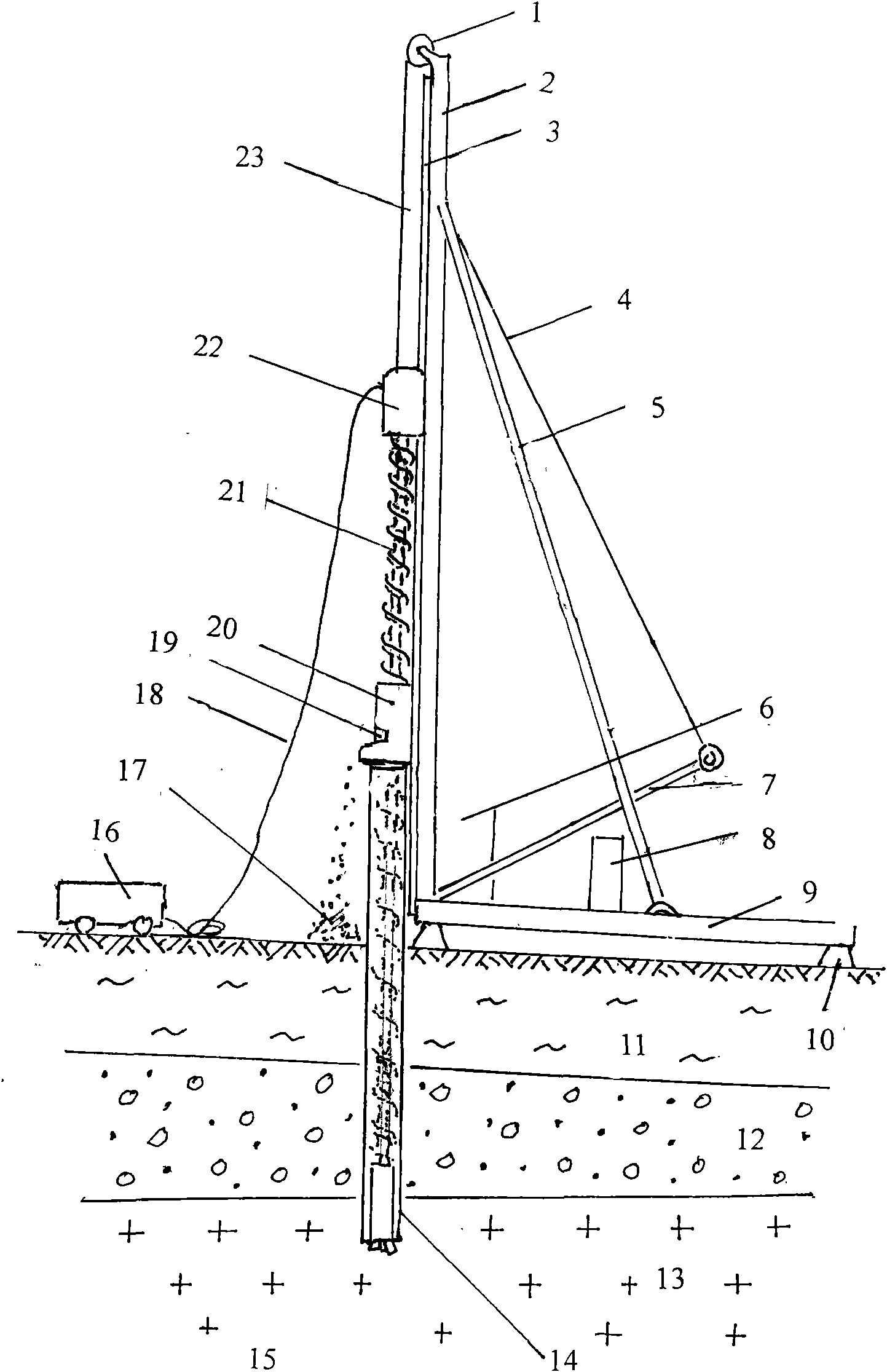

[0011] A typical embodiment of the present invention is figure 1 , earlier the walking support (10), base (9), column (2) diagonal brace (5) are spliced and installed at the construction site. Distribution box (8), operating room (6), undercarriage (7) and undercarriage wire cable (4) are installed on base (9), and pile frame is erected. On the column (2) and the slide bar (3), the upper power head (22) is installed, and the lower power head (20) is positioned on the column (2) by a steel suspension rope (23) on the pulley (1). The lower end of the power head (22) is connected with an auger drill rod (21) and the pneumatic down-the-hole hammer (15), and the steel casing (14) is connected at the lower end of the power head (20). Finally the 50m 3 Air compressor (16) is connected on the upper power head (22) by high-pressure gas delivery pipe (18).

[0012] During construction, the pile driver is first positioned on the pile position, and the operator starts the upper power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com