Patents

Literature

1395 results about "Pile driver" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

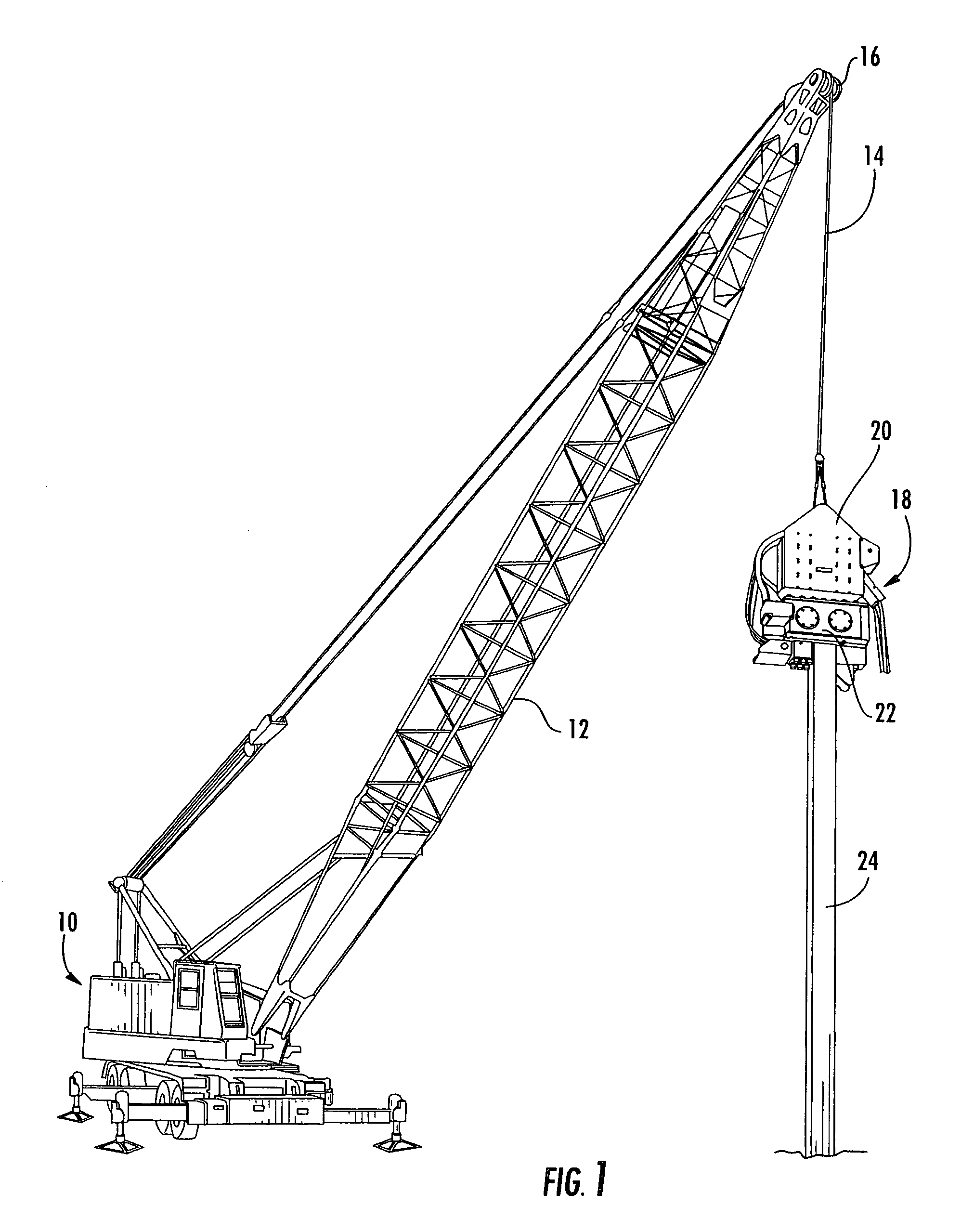

A pile driver is a device used to drive piles into soil to provide foundation support for buildings or other structures. The term is also used in reference to members of the construction crew that work with pile-driving rigs.

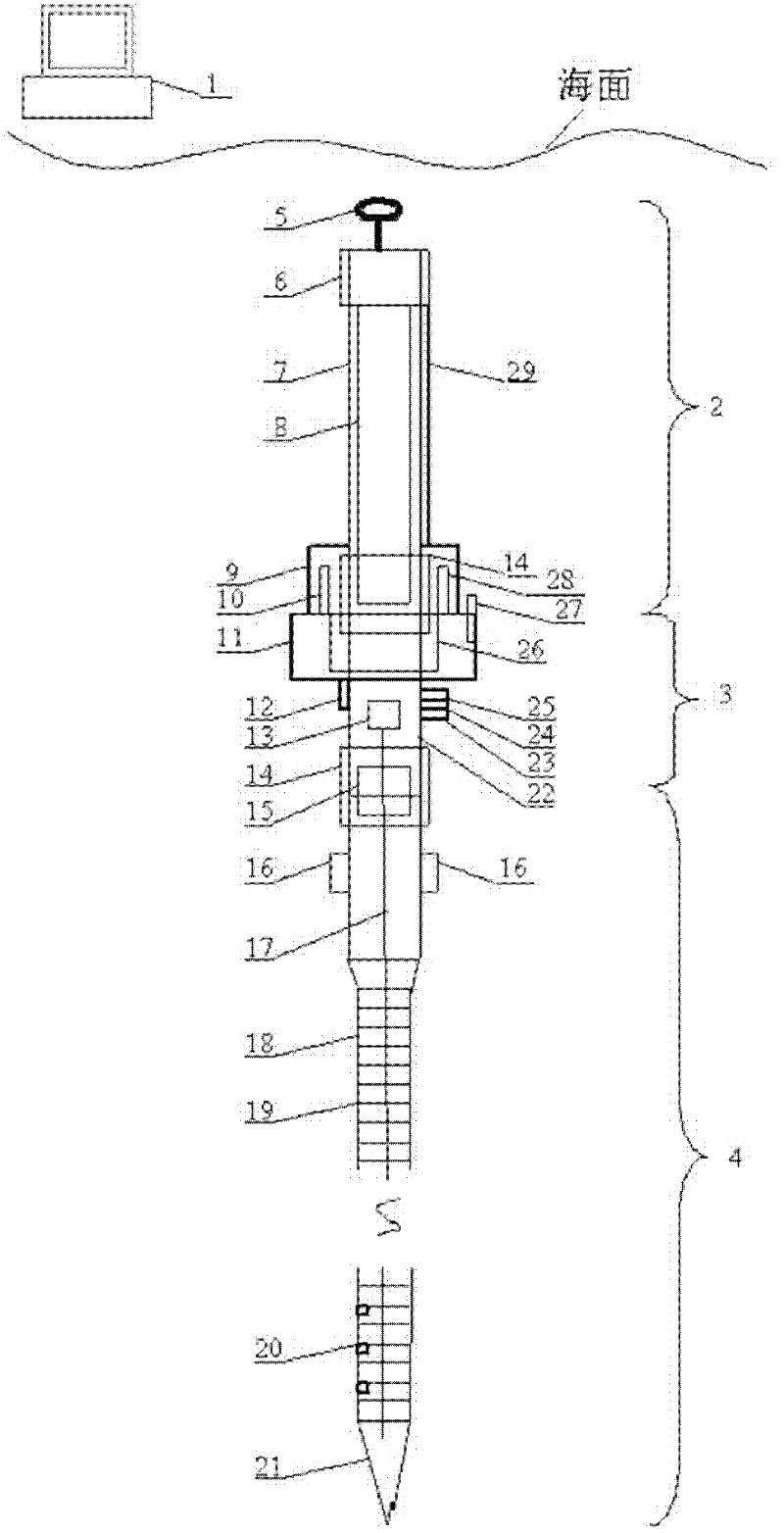

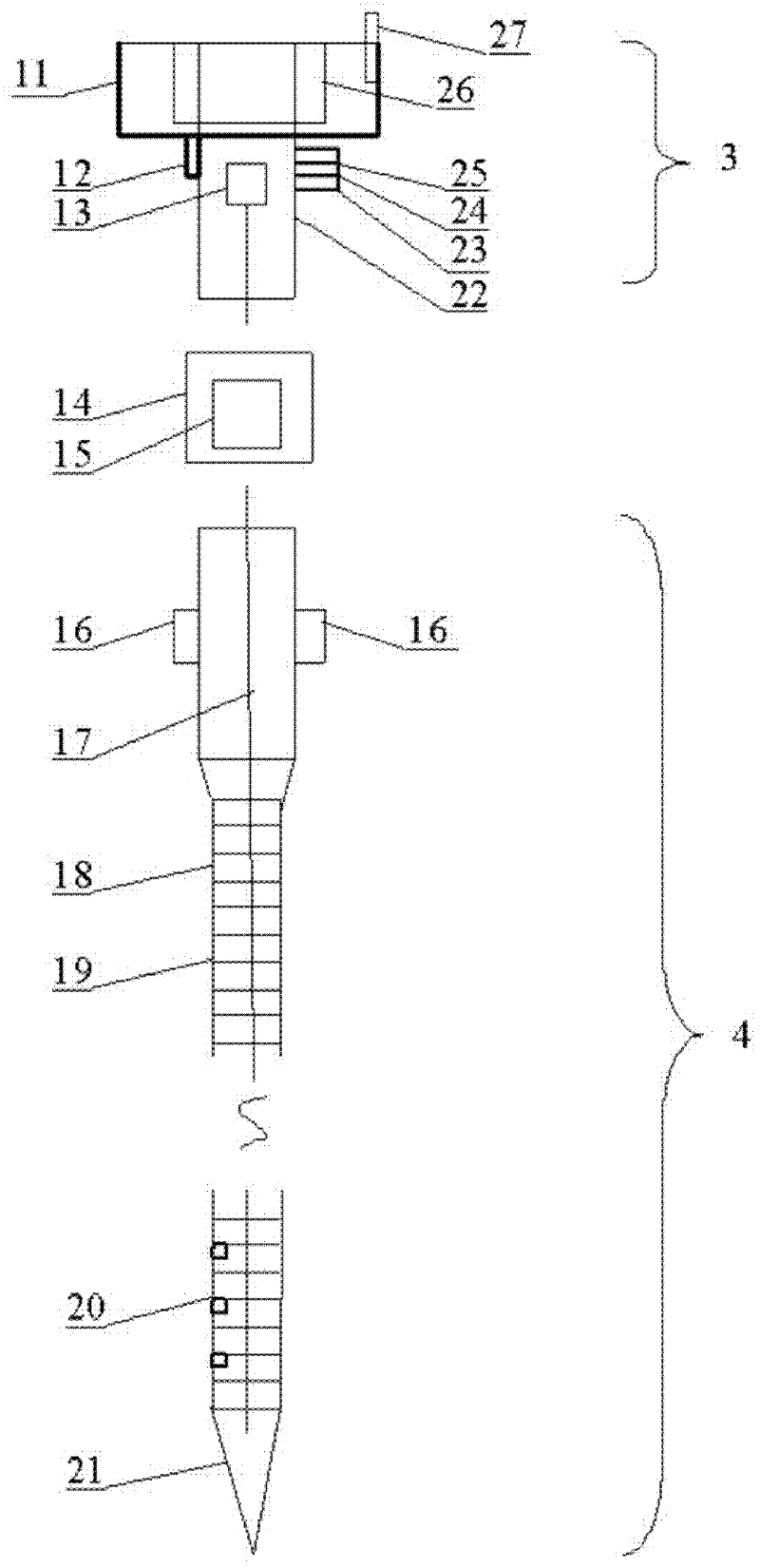

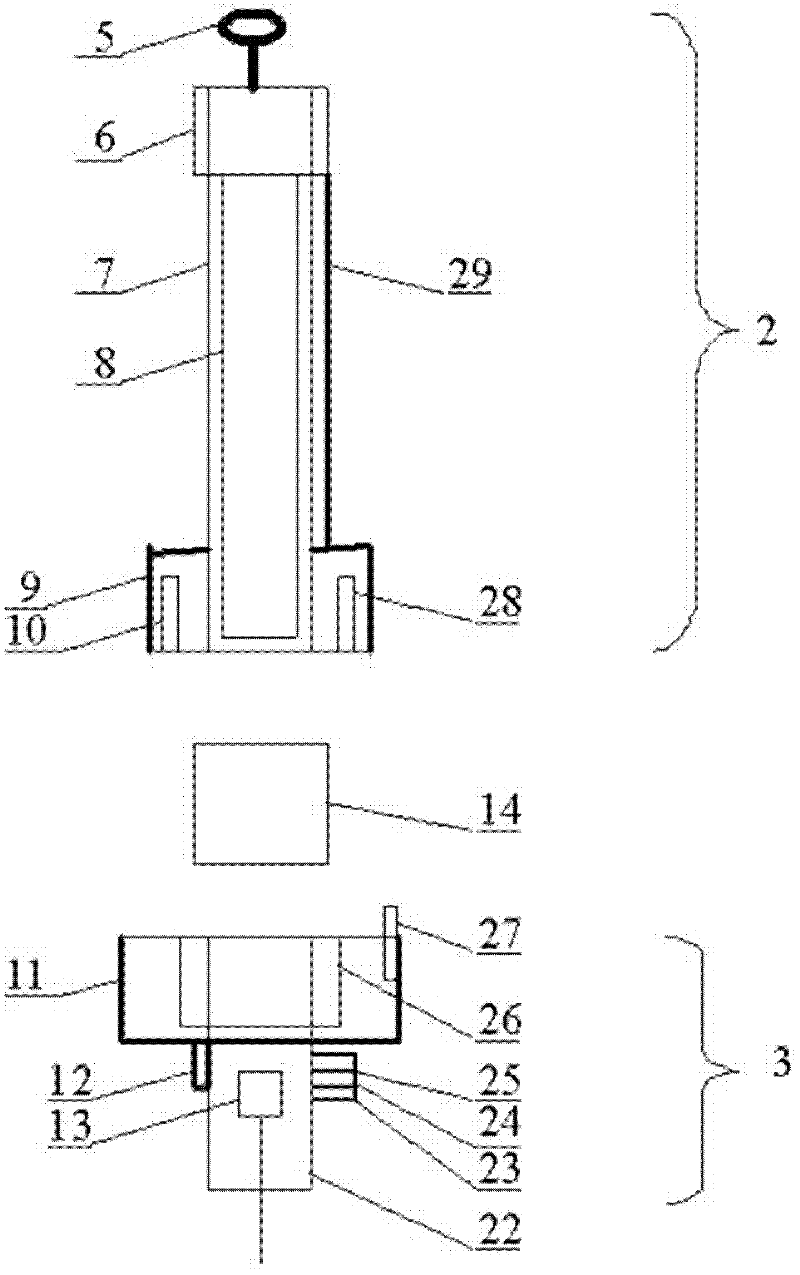

Penetration probe-based deep sea multi-element comprehensive observation system

ActiveCN102331275ARealize synchronous automatic observation recordSimple structureMeasurement devicesTransceiverPore water pressure

The invention discloses a penetration probe-based deep sea multi-element comprehensive observation system, which comprises an upper computer and a data recovery cabin, wherein the upper end and the lower end of the data recovery cabin are connected with a probe rod through a hydraulic separation releaser and a launching device respectively; a small-sized pile driver is arranged in the launching device; the launching device is provided with an underwater search light, an underwater camera and an underwater acoustic communication transceiver; the top of the data recovery cabin is provided with a floating body; a central controller is included in the data recovery cabin; the outer side face of the data recovery cabin is provided with an underwater acoustic transducer; and the outer surface of the probe rod is provided with more than 10 annular electrodes and more than 2 pore water pressure sensors which are connected with the central controller. The system has a simple structure, is reliable in work and accurate in control, can carry various sensors and adapt to a deep sea high pressure environment, and can synchronously and automatically observe and record states and changes of sea water and sediments within a 10m depth range close to a sea water-sediment interface with over 2,000m water depth, including the state of sediments of 6-7m below a sea bottom surface, the condition ofsea water of a bottom layer of 3-4m above the sea bottom surface and the dynamic change in position of the sea bottom surface.

Owner:OCEAN UNIV OF CHINA

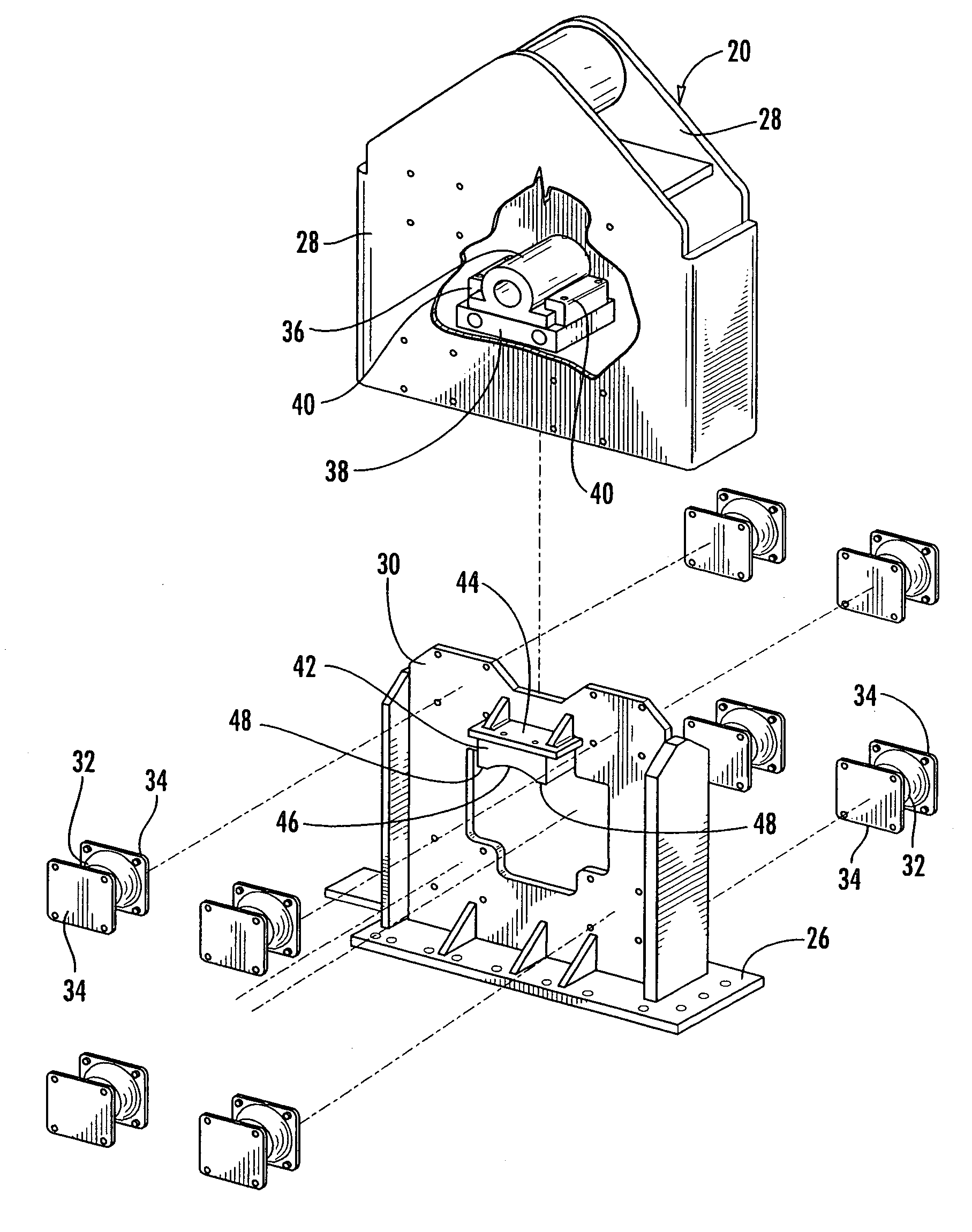

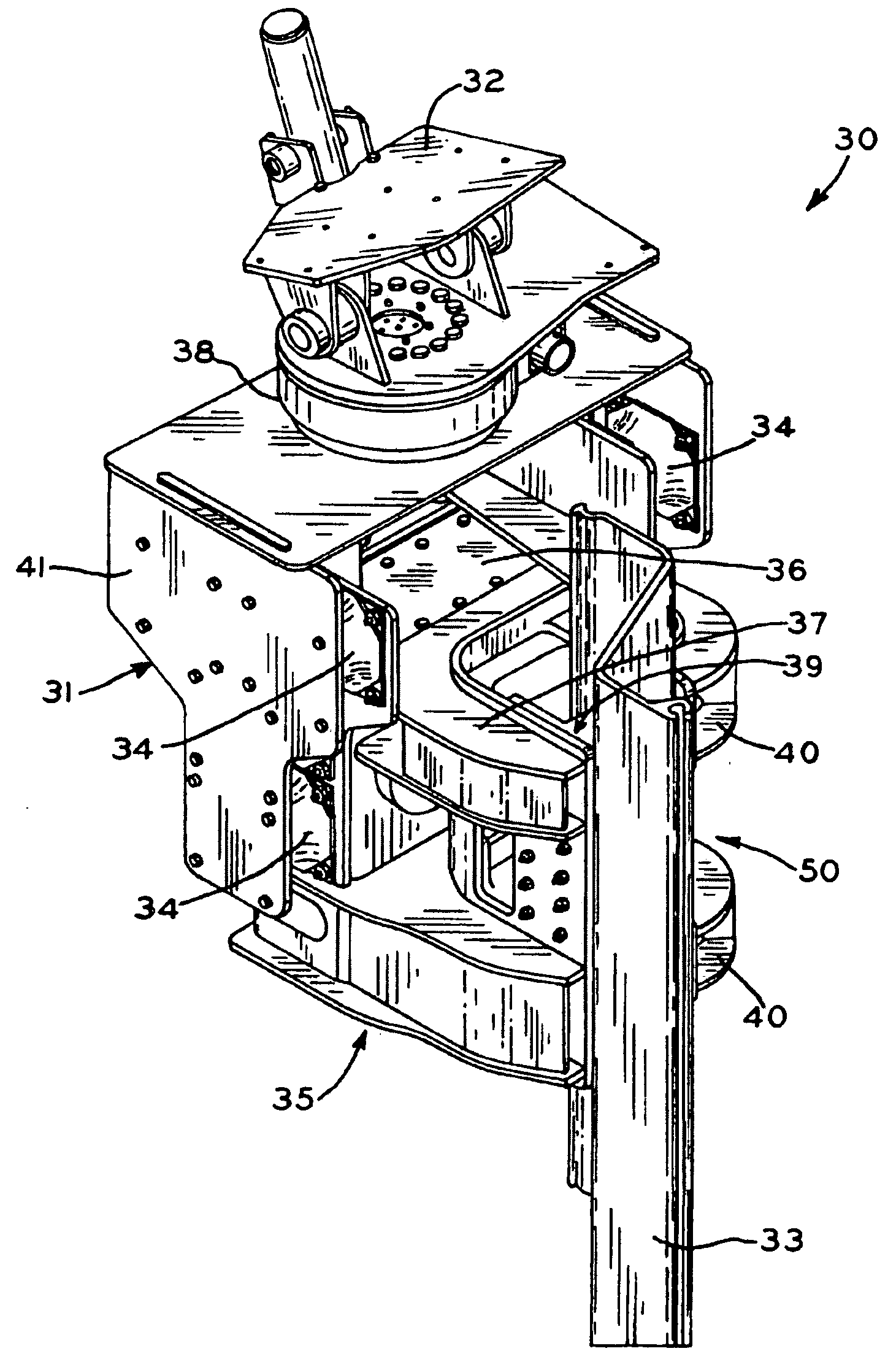

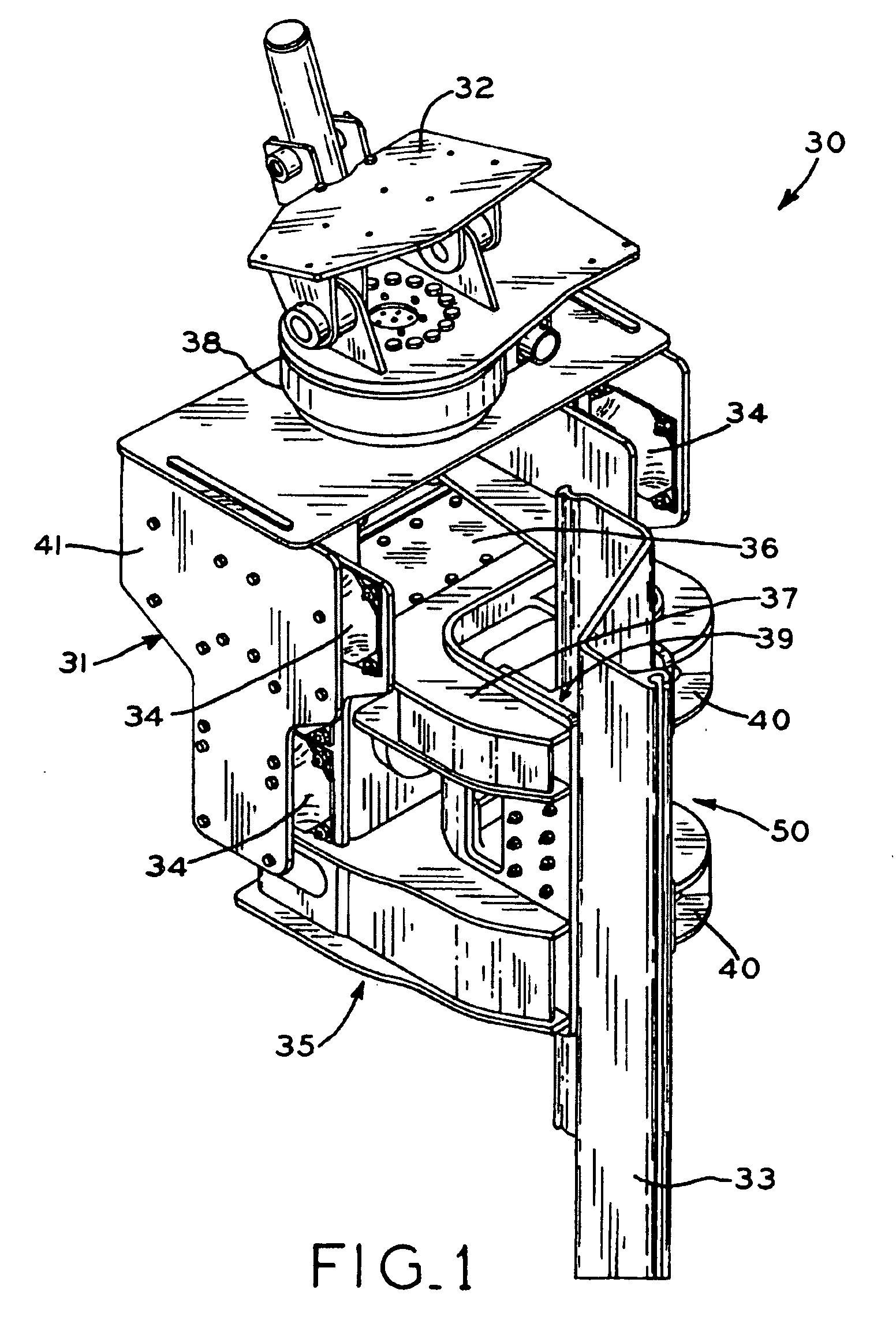

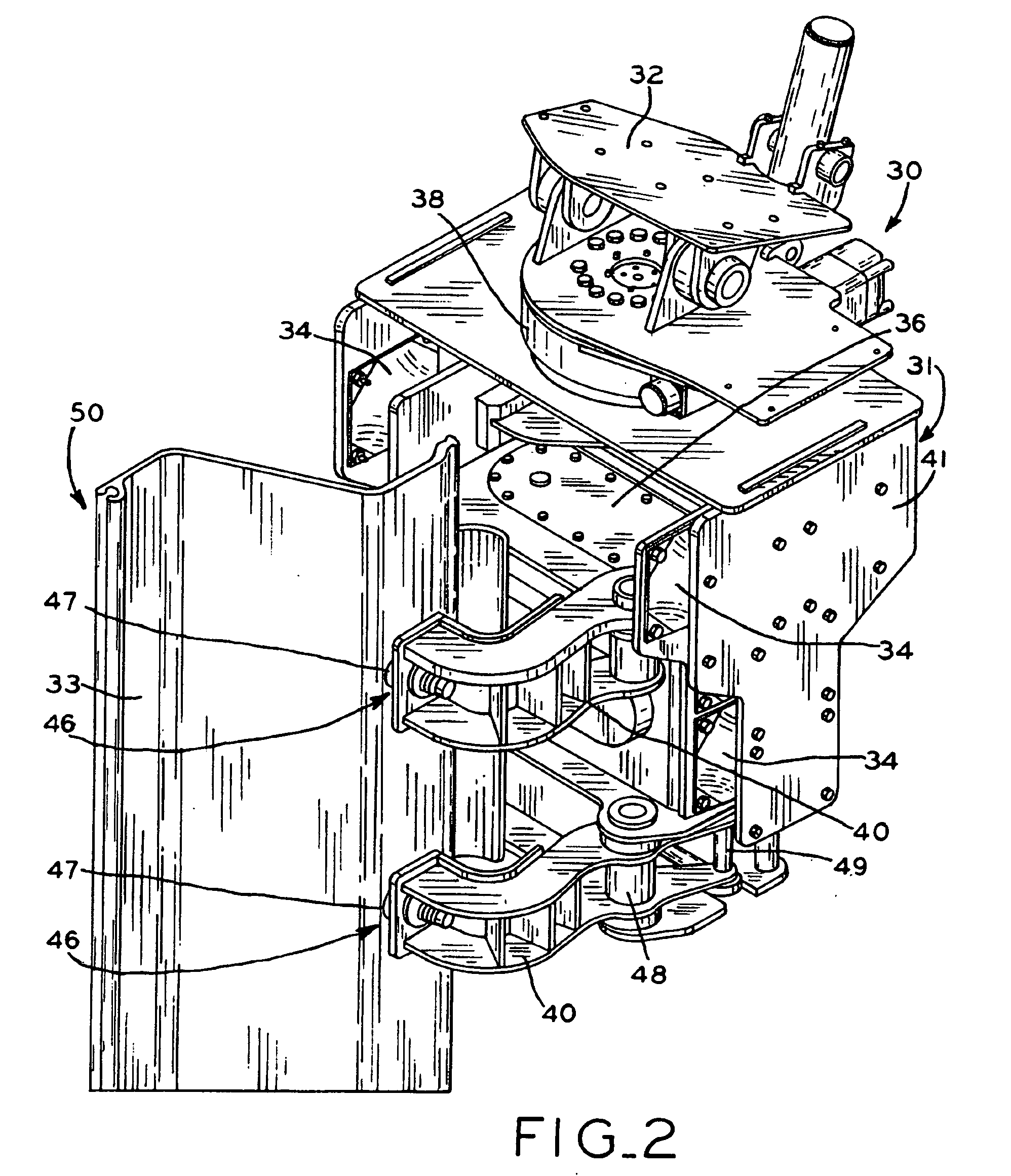

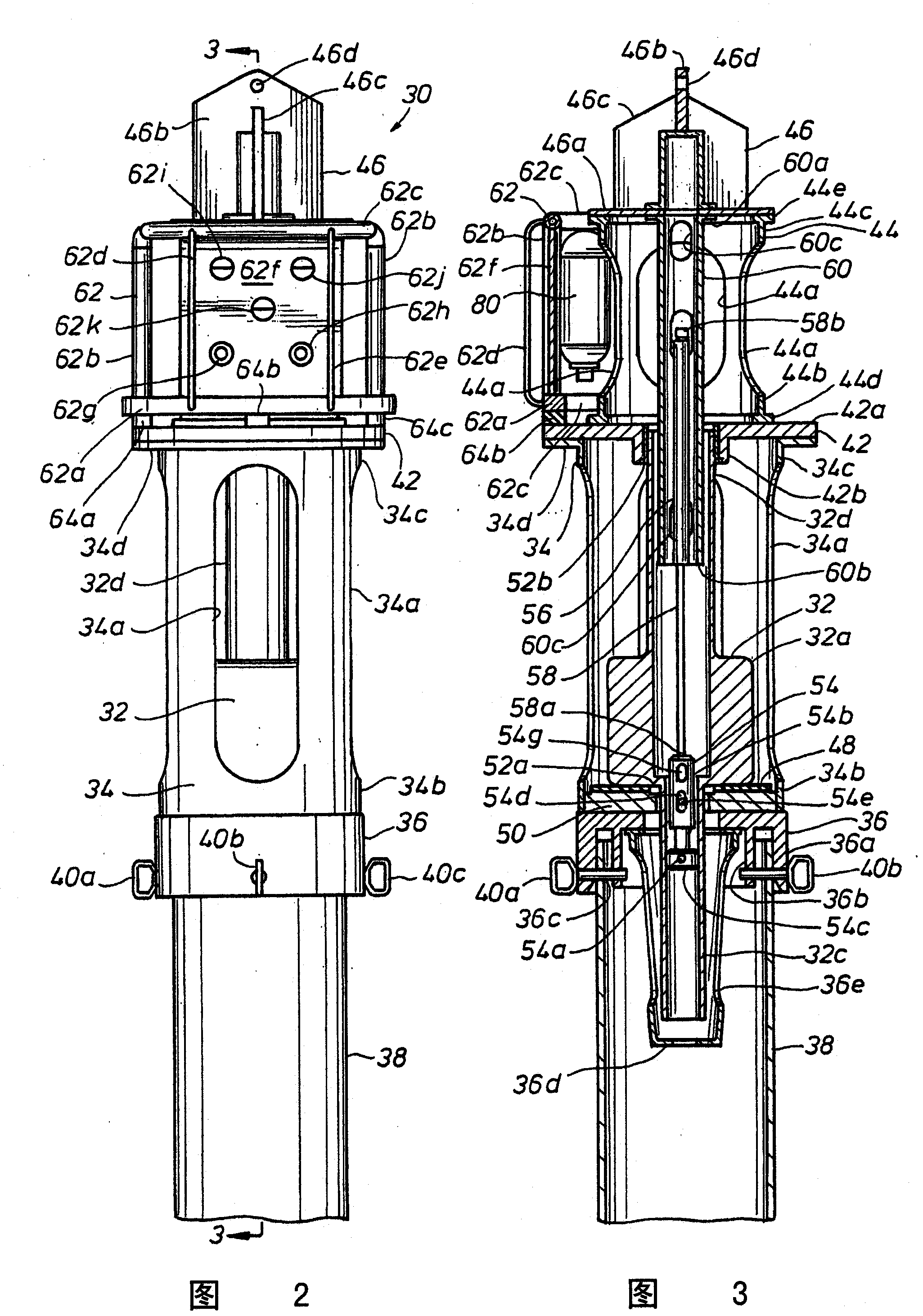

Vibratory pile driver/extractor with two-stage vibration/tension load suppressor

A method and apparatus for driving and extracting piles that includes a vibration / tension load absorber assembly mounted between a housing and the vibratory unit which includes shear-type vibration absorbers connected between the housing and the vibratory unit and operating in combination with at least one compression-type vibration absorber positioned to be compressed between first and second compression plates when the tension load reaches a predetermined level.

Owner:INT CONSTR EQUIP

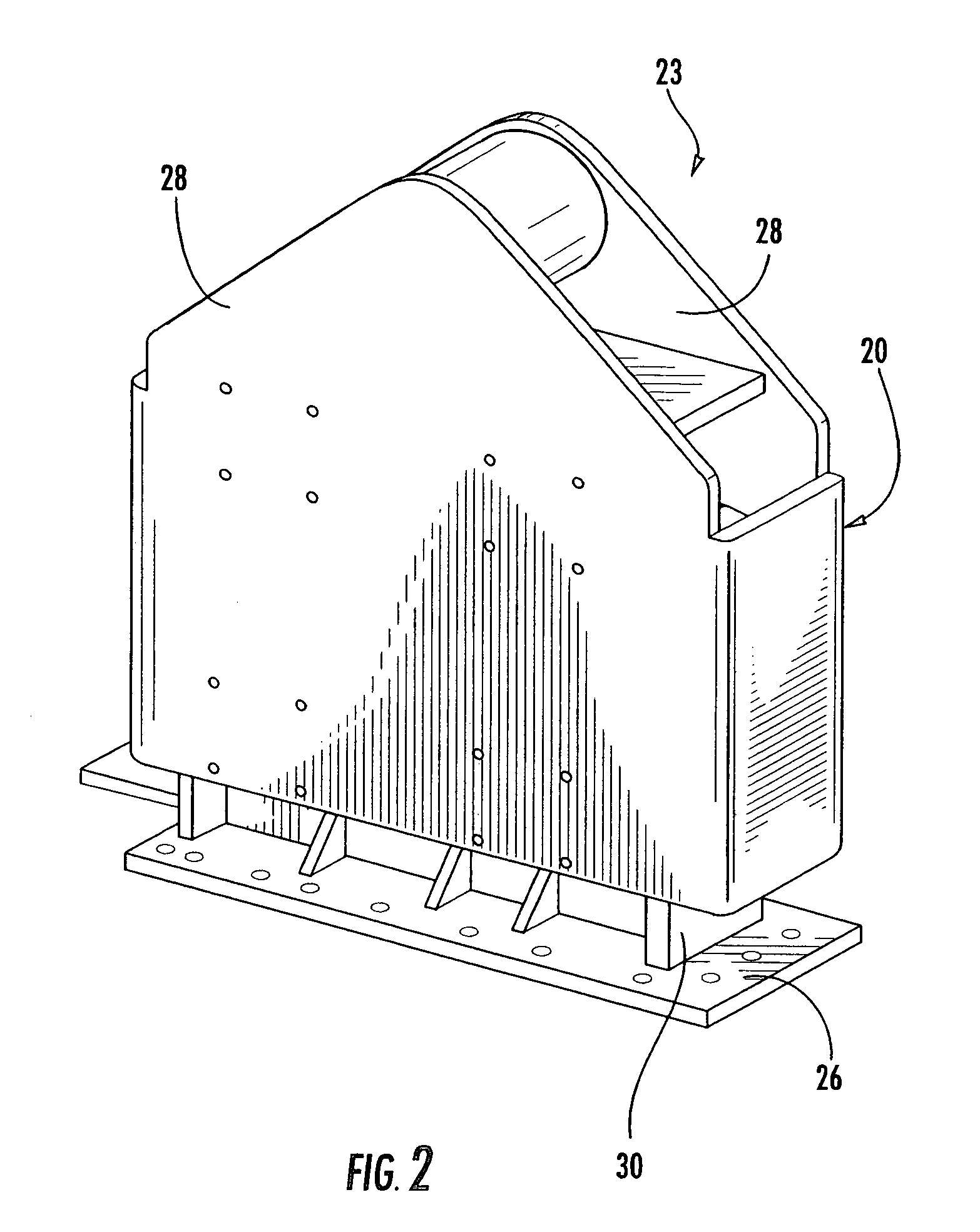

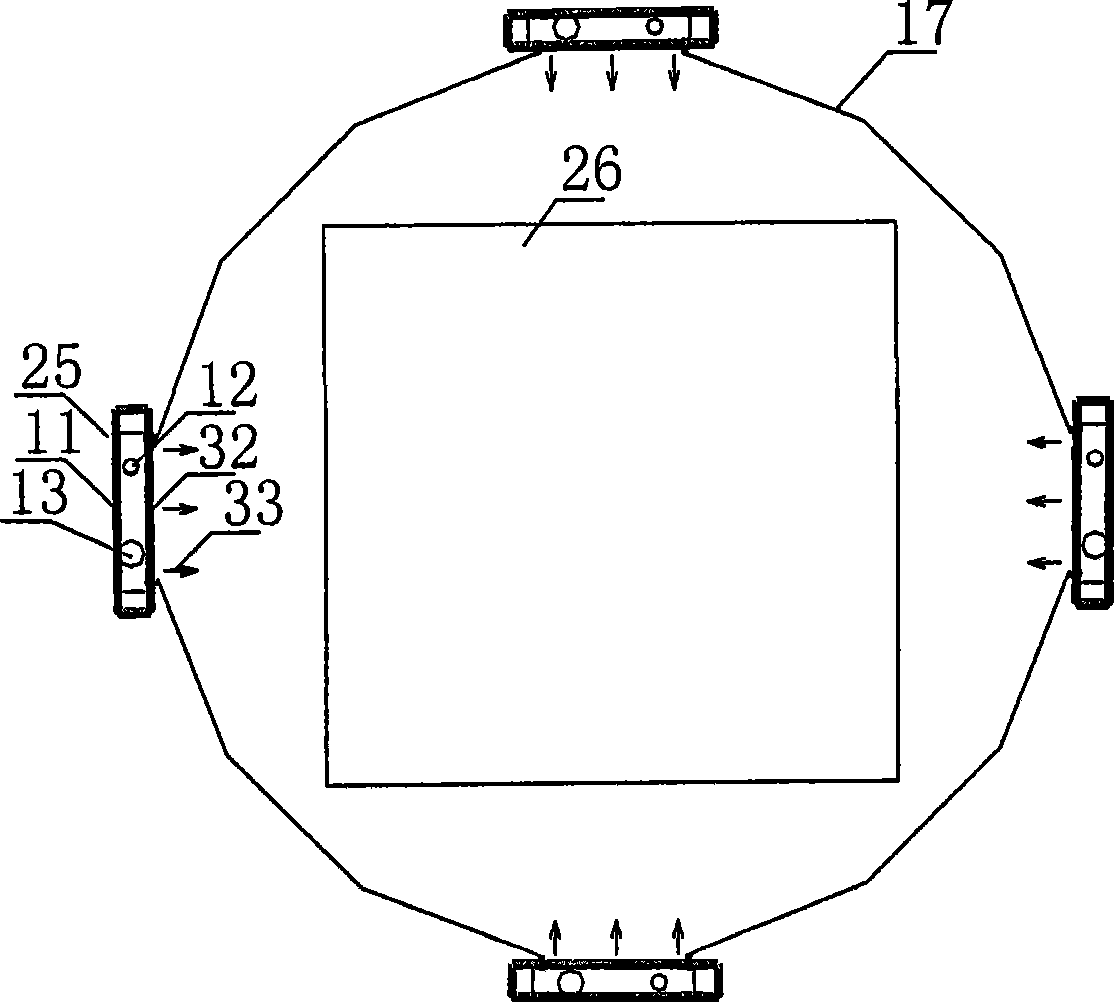

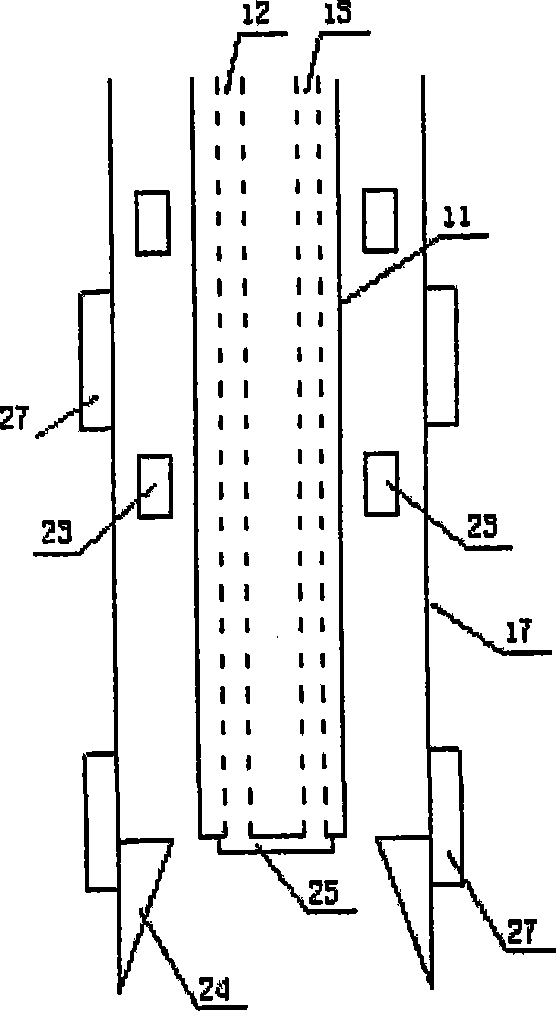

Modular vibratory pile driver system

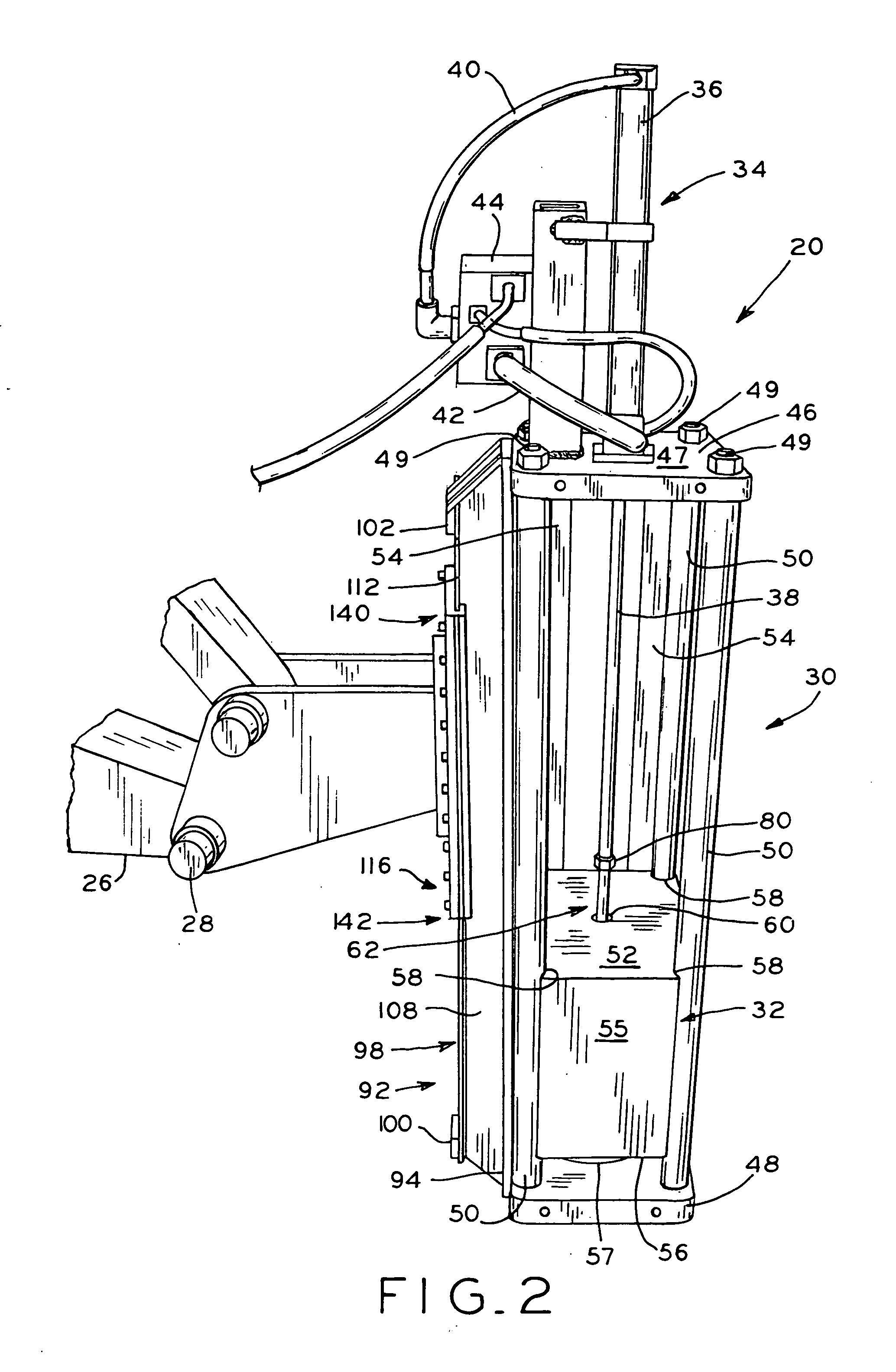

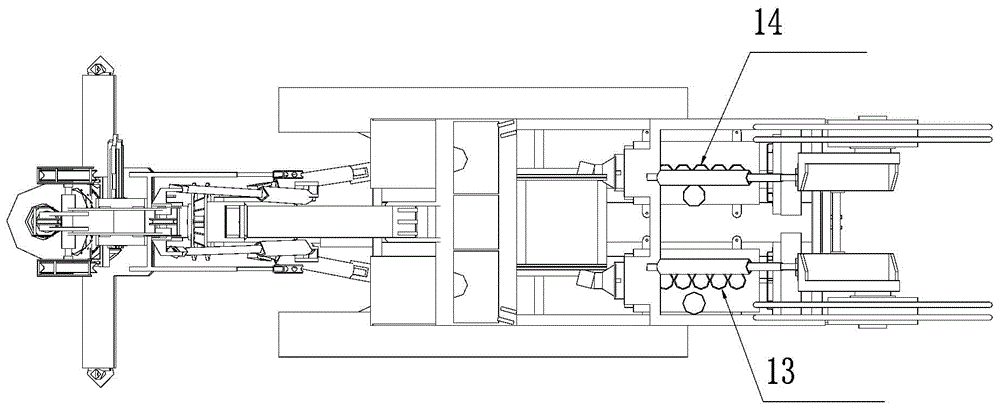

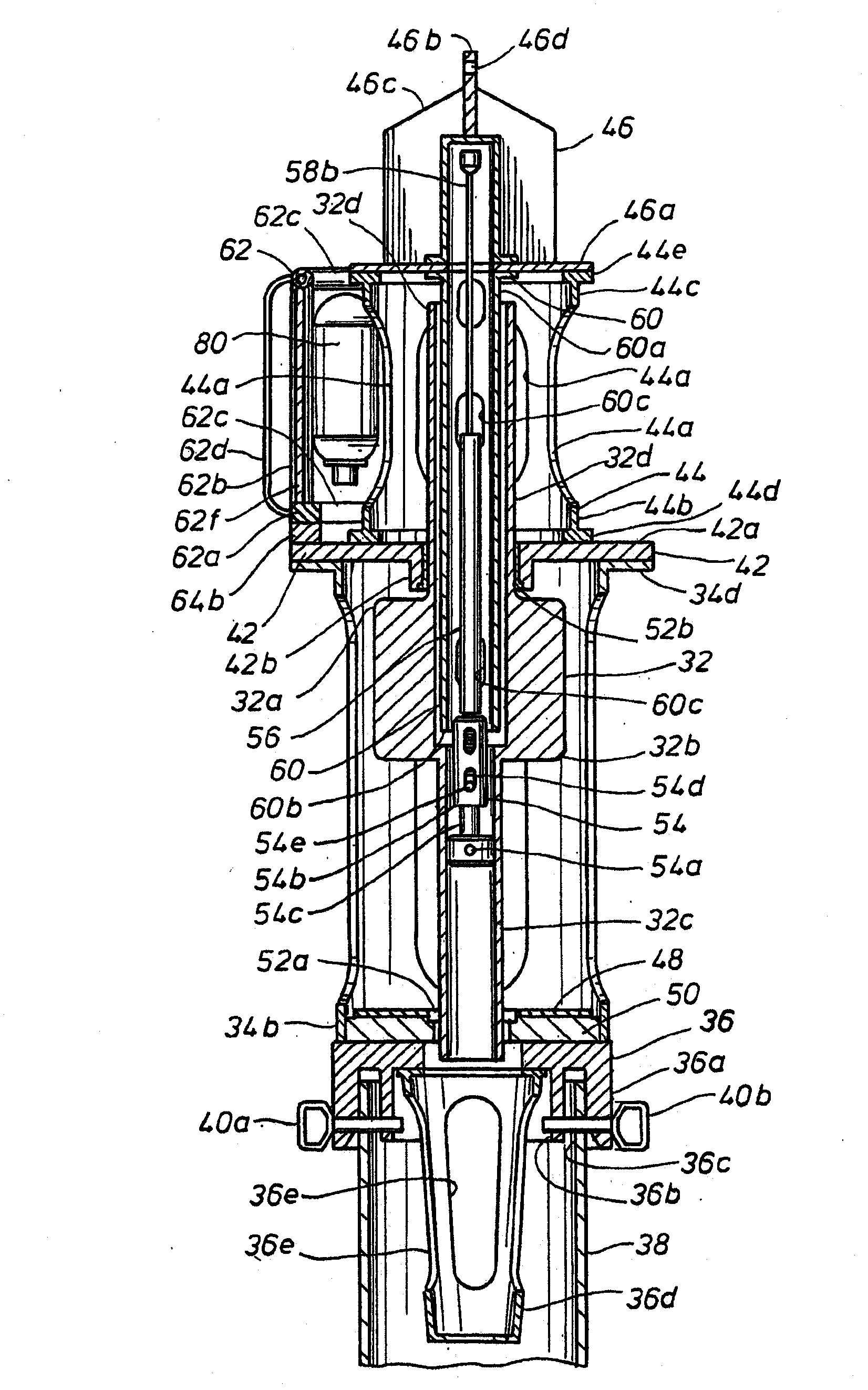

InactiveUS20080310923A1Facilitate centeringImprove energy transfer efficiencyBulkheads/pilesEngineeringMechanical engineering

A modular side grip vibratory pile driver system having a housing, a vibratory gear case and a pair of jaws adapted to grip a variety of pile profiles. The housing is rotatably connected to a construction machine such that the jaws can be moved from a position wherein the jaws are oriented vertically and spaced apart horizontally to a position wherein the jaws are oriented horizontally and spaced apart vertically. A plurality of sets of gripping assemblies having different gripping profiles are interchangeably connected to the jaws.

Owner:UNISTO

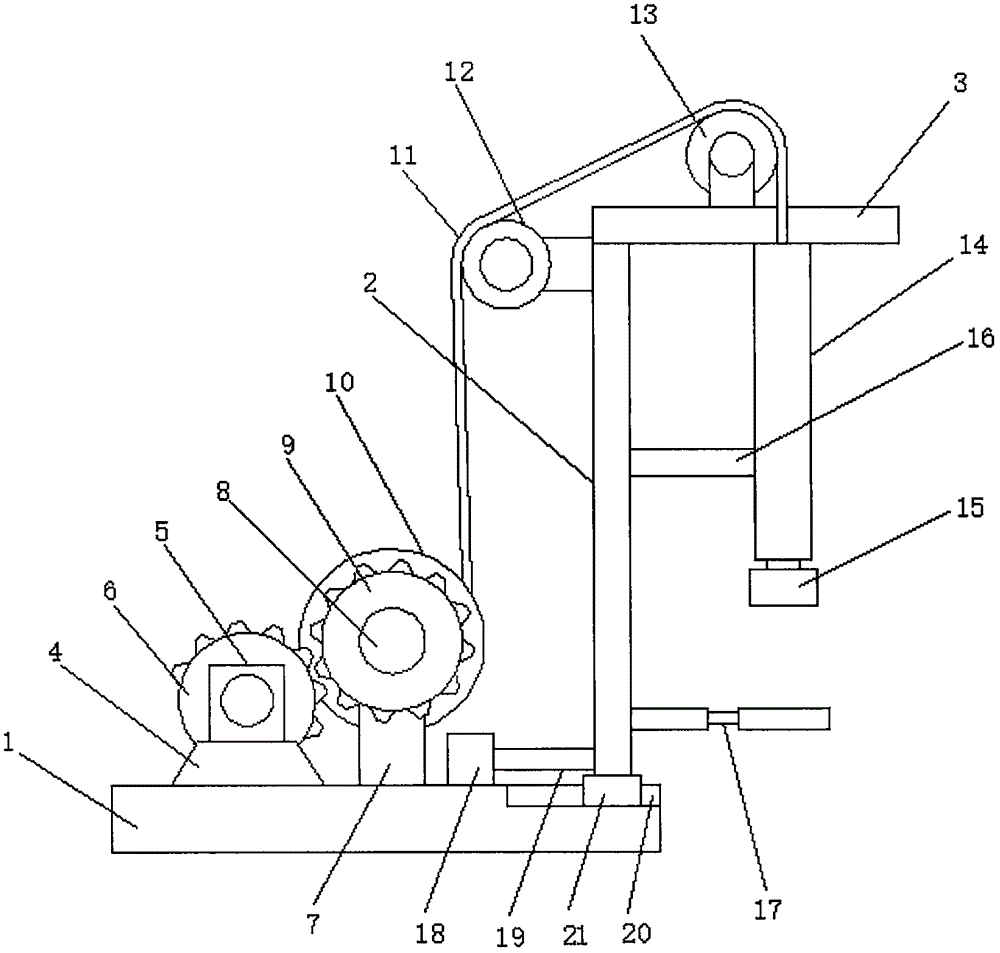

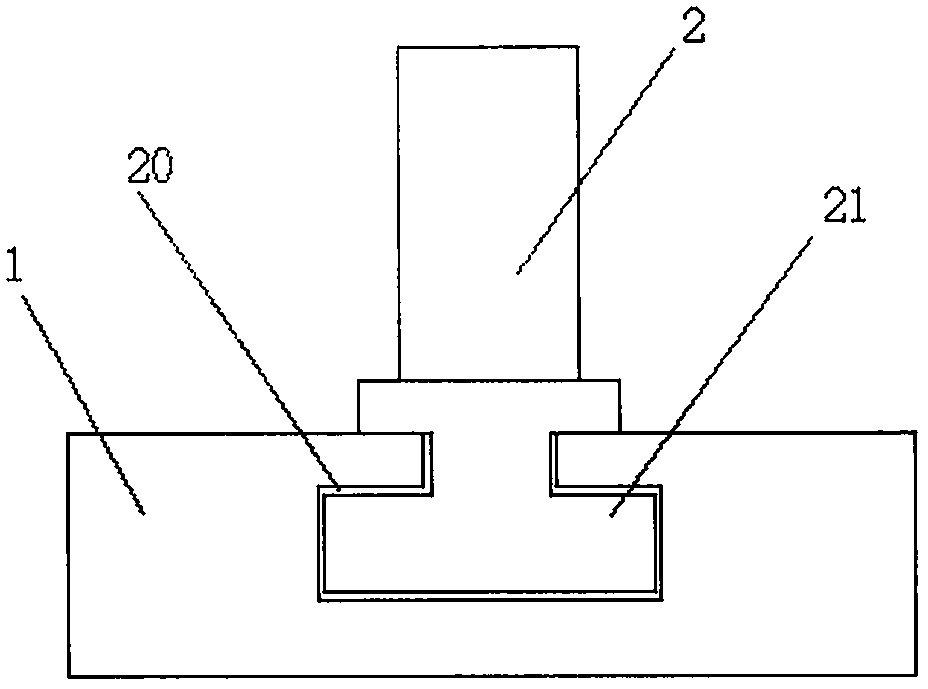

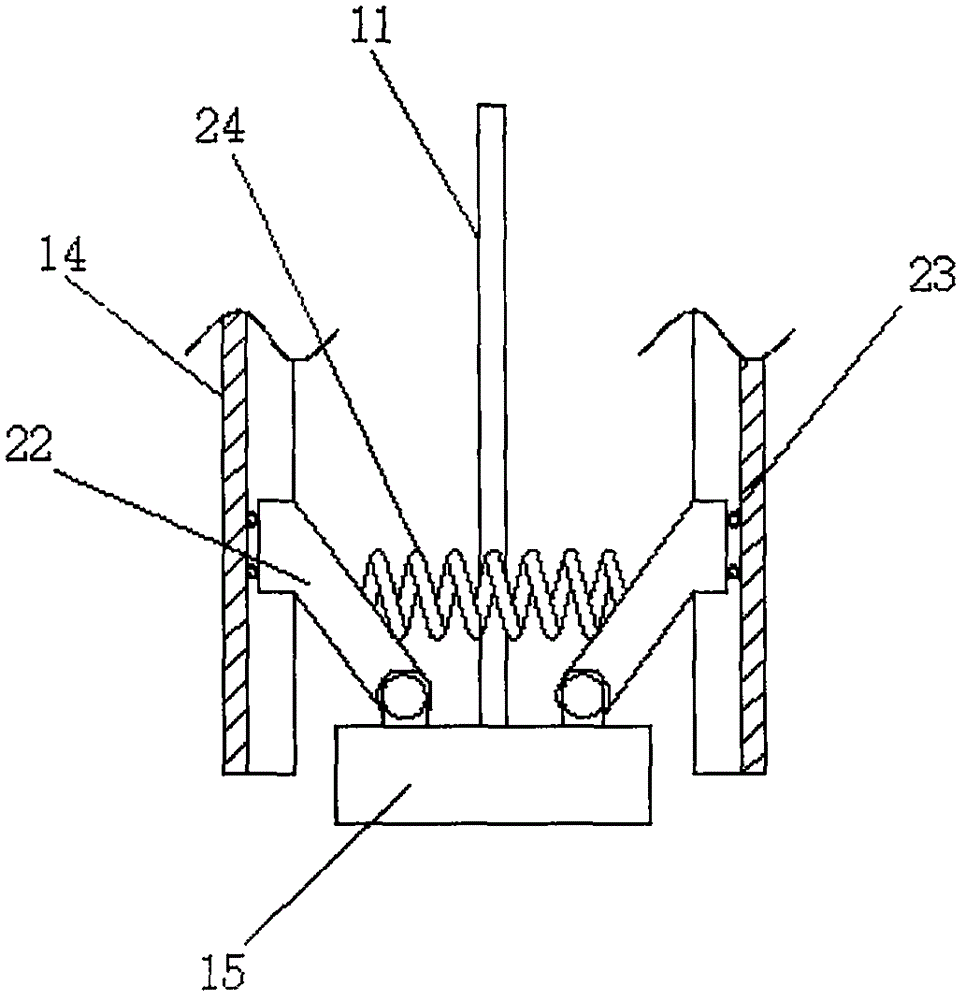

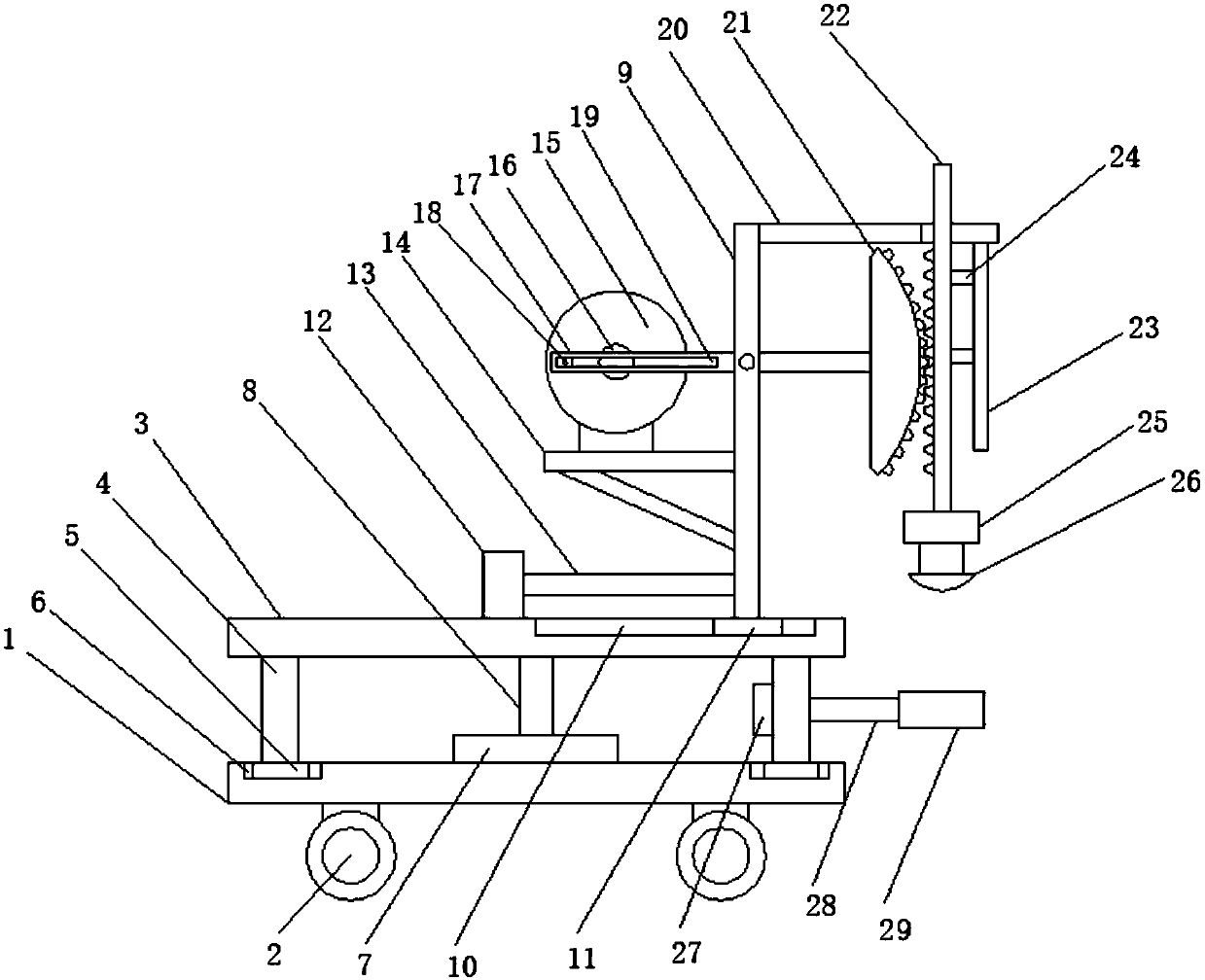

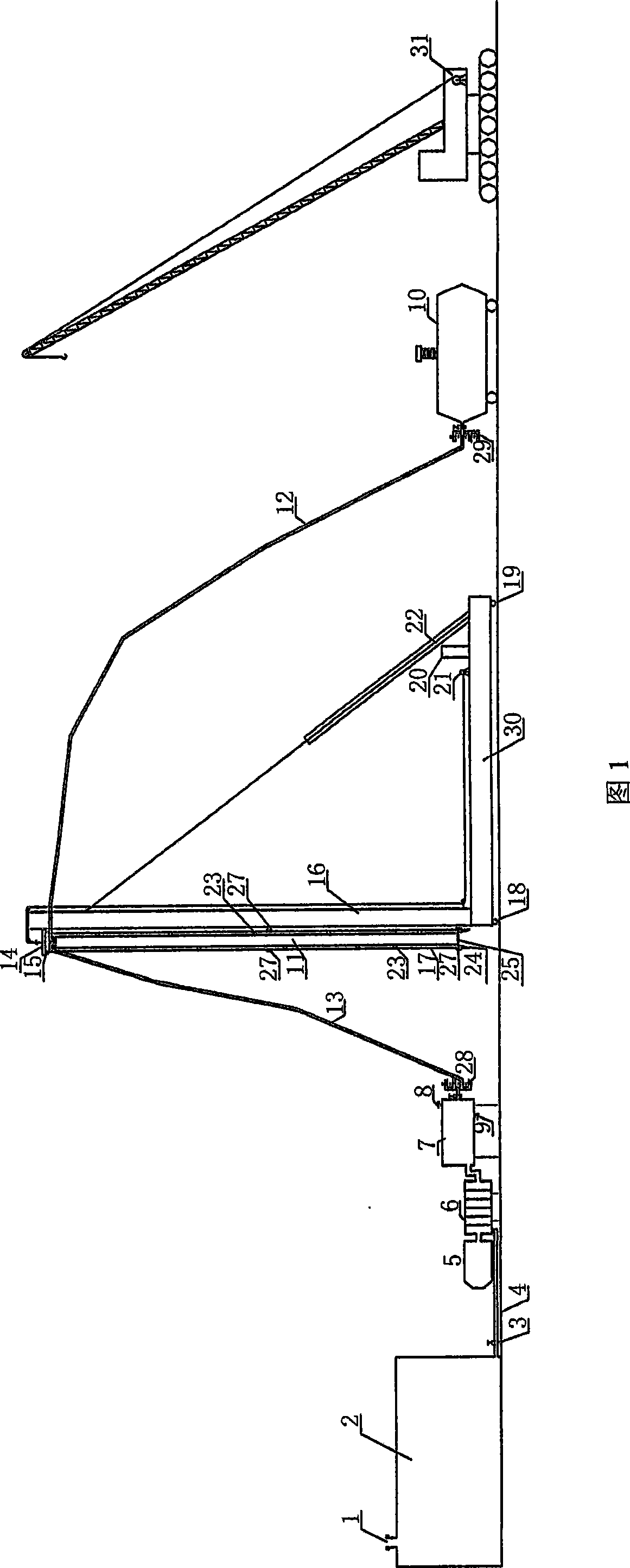

Pile driver for civil engineering

PendingCN107178083AGuaranteed uprightnessIncrease the areaBulkheads/pilesHydraulic cylinderGear wheel

The invention discloses a pile driver for civil engineering. The pile driver for civil engineering comprises a chassis, a stand column and a crane jib. A rotation shaft of a drive motor is provided with an incomplete gear. The support is provided with a cross shaft rotationally connected with the support. The cross shaft is provided with a transmission gear and a rope reel. The stand column is provided with a first pulley. A second pulley is arranged at the top end of the crane jib. The lower end face of the crane jib is provided with two vertically downward guide sliding grooves. A pile hammer is arranged between the two guide sliding grooves. The two sides of the upper end of the pile hammer are both provided with supporting arms which are inclined and upward. A pile clamping mechanism connected with the stand column is arranged under the pile hammer. One end of a connection rod is fixedly connected with the bottom end of the stand column. The lower end of the stand column is connected with the chassis through a sliding mechanism. The chassis is provided with a hydraulic cylinder. The pile driver for civil engineering is simple in structure, good in pile driving upright performance, capable of continuously driving piles, high in pile driving efficiency, easy and convenient to operate and high in practicability.

Owner:ZHENGZHOU UNIV

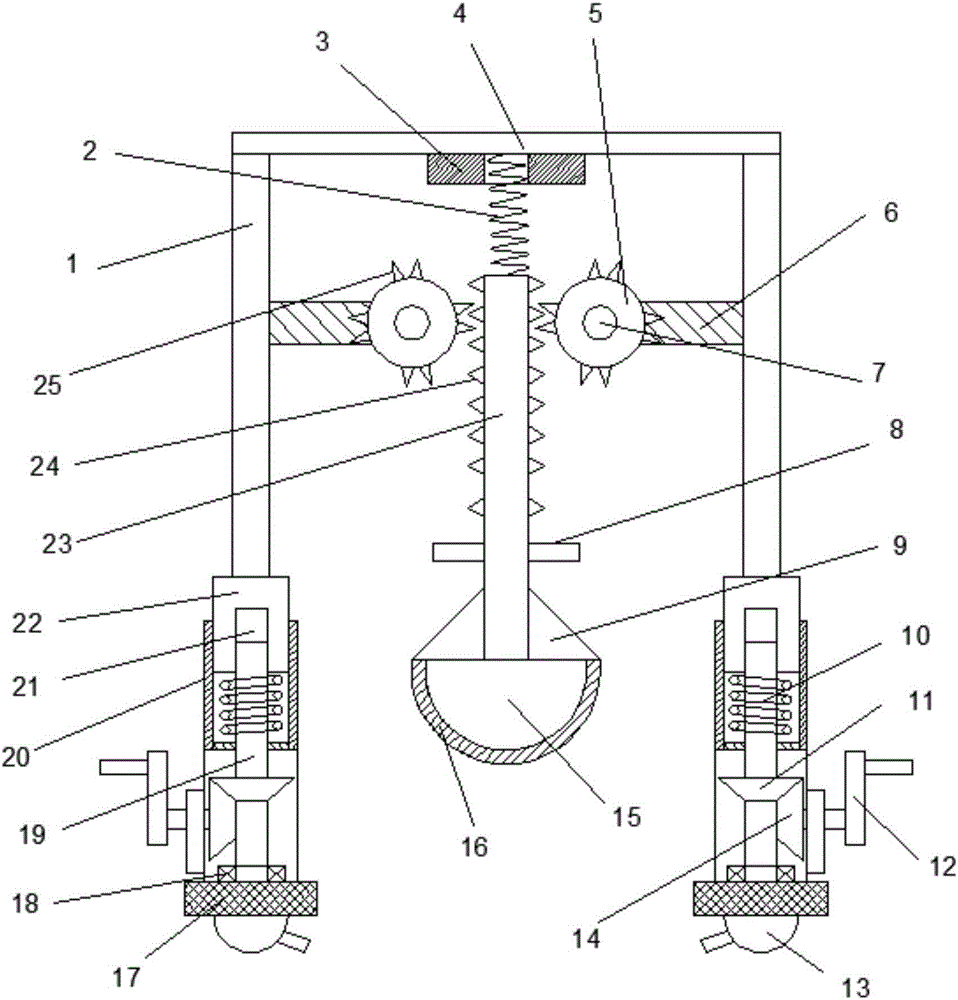

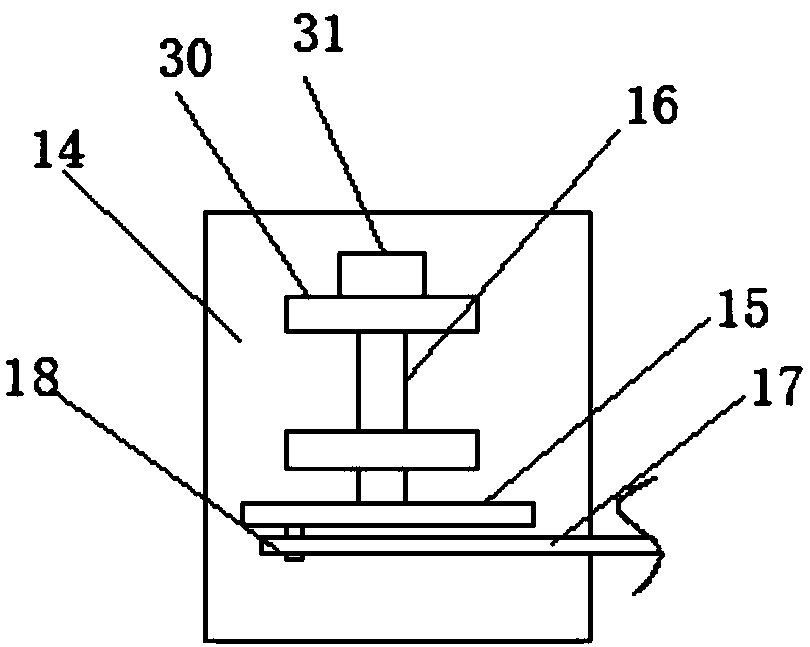

Pure mechanical building pile driver

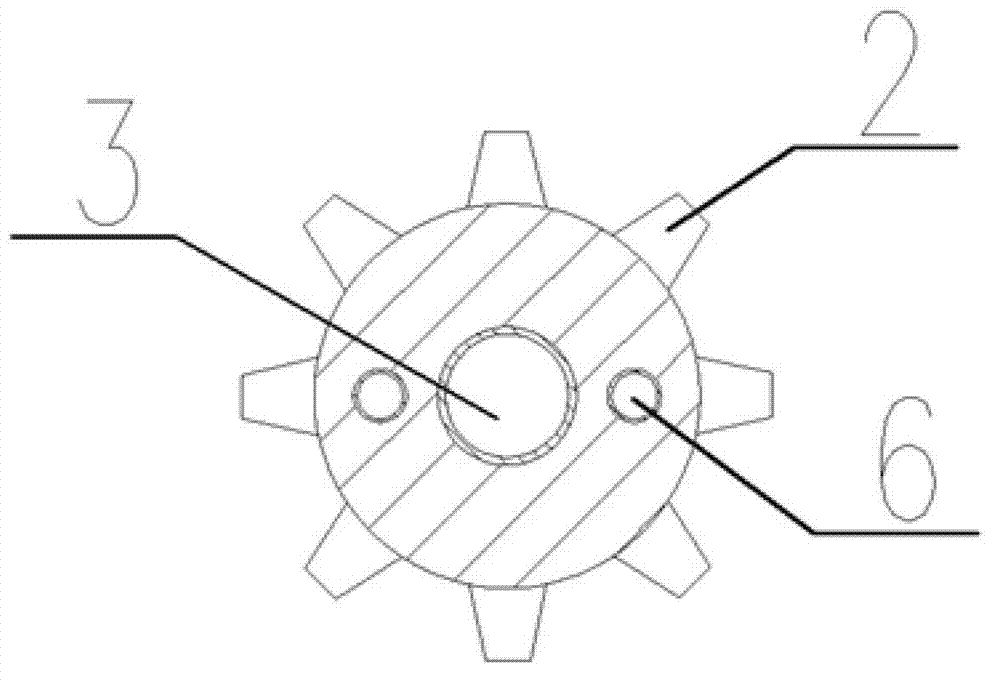

InactiveCN106522223AReasonable structureInnovative designBulkheads/pilesDrive wheelElectric machinery

The invention discloses a pure mechanical building pile driver. The pure mechanical building pile driver comprises bases. The upper ends of the bases are connected with bearings. The upper ends of the bearings are connected with lead screws. Driven wheels are connected to the middle portions of the lead screws. The driven wheels are engaged with drive wheels. Rotation handles are connected to the drive wheels. The upper ends of the lead screws are connected with sliding blocks. The lower ends of the sliding blocks are connected with telescopic springs. The upper ends of the sliding blocks are connected with supporting rods. The middle portions of the supporting rods are connected with fixing rods. Motor shafts are arranged at the middle portions of the fixing rods and connected with rotation wheels. The outer sides of the rotation wheels are connected with gear tooth sets. A beam is connected to the upper ends of the supporting rods. The lower end of the beam is connected with a buffering spring. An annular limiting sleeve is arranged on the outer side of the upper end of the buffering spring. The lower end of the buffering spring is connected with a pile driving rod. The bottom end of the pile driving rod is connected with a pile cone. By means of the pure mechanical building pile driver, constant ascending and descending on a pile hammer are achieved, and therefore the pile body driving function is achieved; usage of a hydraulic system is avoided, and the manufacturing and maintaining cost is greatly reduced; and meanwhile, pollution is small, and energy saving and environment-friendliness are achieved.

Owner:福建泉大建设有限公司 +1

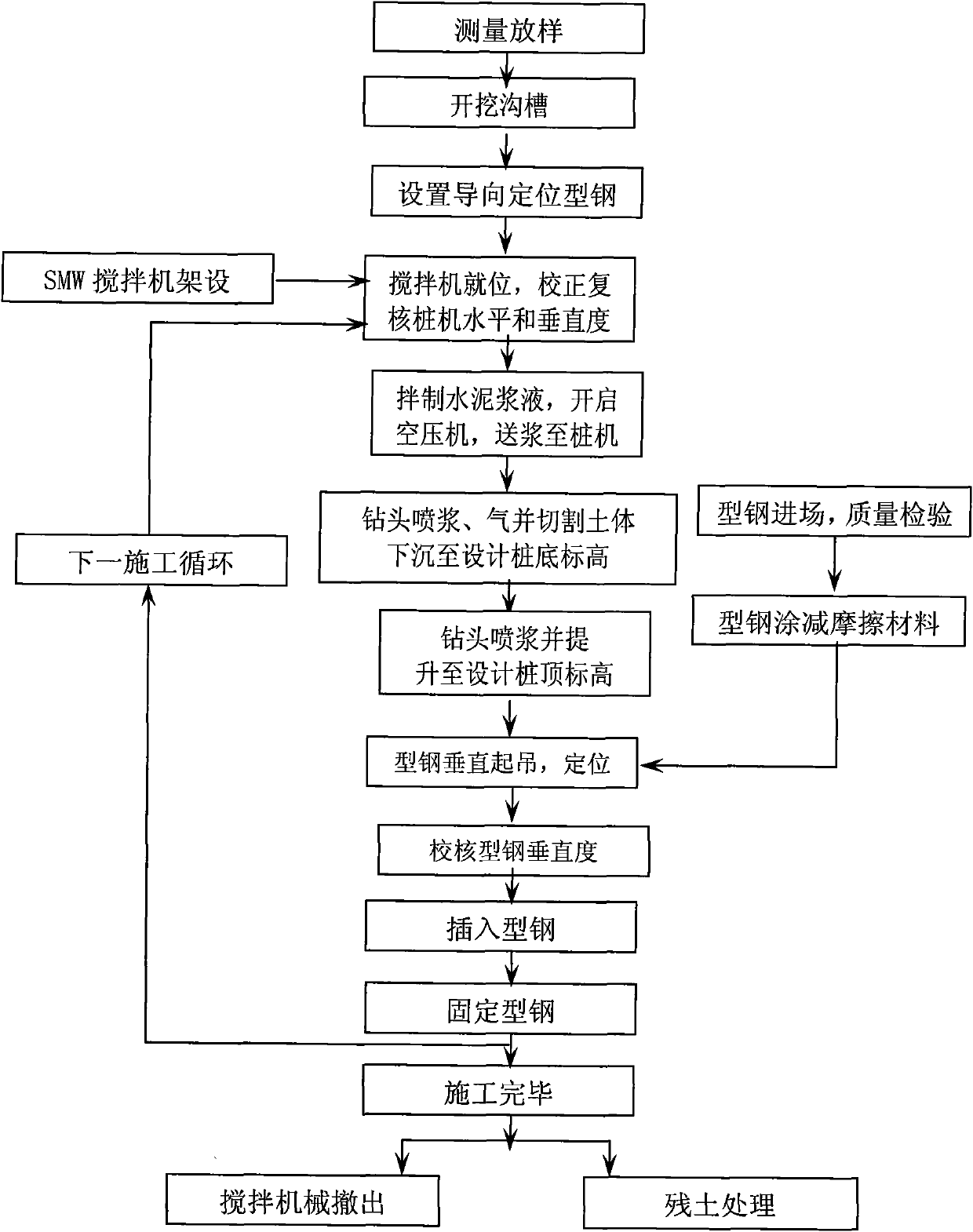

Construction method of section-steel triaxial soil-cement mixing pile

InactiveCN101768961ASolve the difficult problem of pre-stirring and sinkingSolve the problem of too long remixing process timeBulkheads/pilesSlurryEngineering

The invention discloses a construction method of a section-steel triaxial soil-cement mixing pile, comprising the following construction steps: (1) measuring paying-off positioning pile; (2) digging trench; (3) arranging guide positioning section-steel; (4) the mixer taking place, correcting and reviewing levelness and verticality of the pile driver; (5) mixing cement grout, starting an air compressor, and sending the grout to the pile driver; (6) a drill bit spraying grout, gas, cutting soil body and sinking to the elevation of designed pile bottom; (7) the drill bit spraying the grout and elevating to the elevation of designed pile top; (8) vertically lifting the section-steel and positioning the section-steel; (9) correcting and reviewing the verticality of the section-steel; (10) inserting and fixing the section-steel. The pilling process provided by the invention is suitable for cohesive soil with large compression modulus, soft ground layer which is mainly composed of cohesive soil and silty cohesive soil, mucky soil, plain fill and saturation loose sand without flowing underground water; especially for the cohesive soil with large compression modulus, the invention not only can solve the problem that the pre-mixing sinking is difficult, but also can solve the problem that the time of repeatedly-mixing process is too long.

Owner:中铁城建集团第三工程有限公司 +1

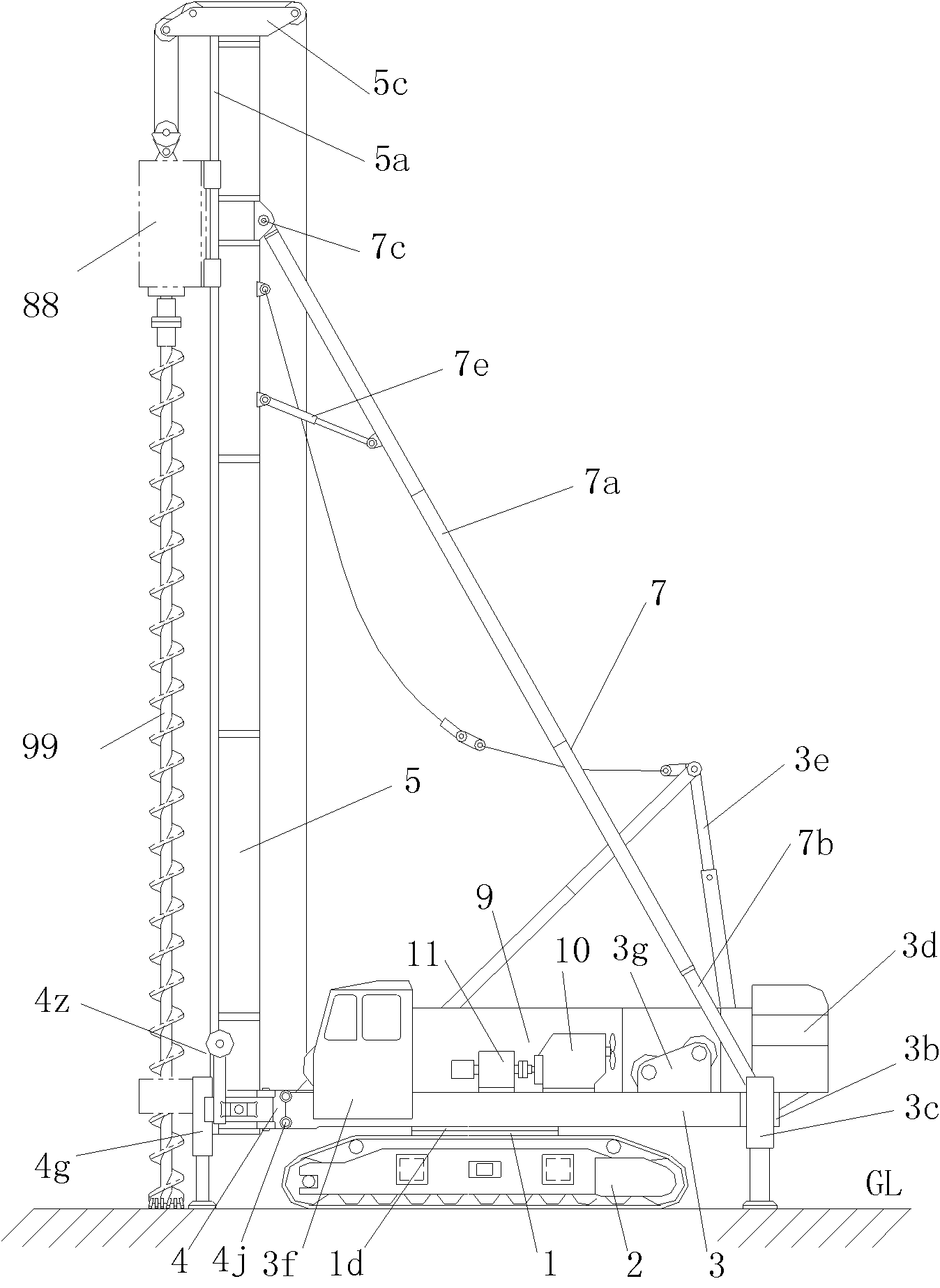

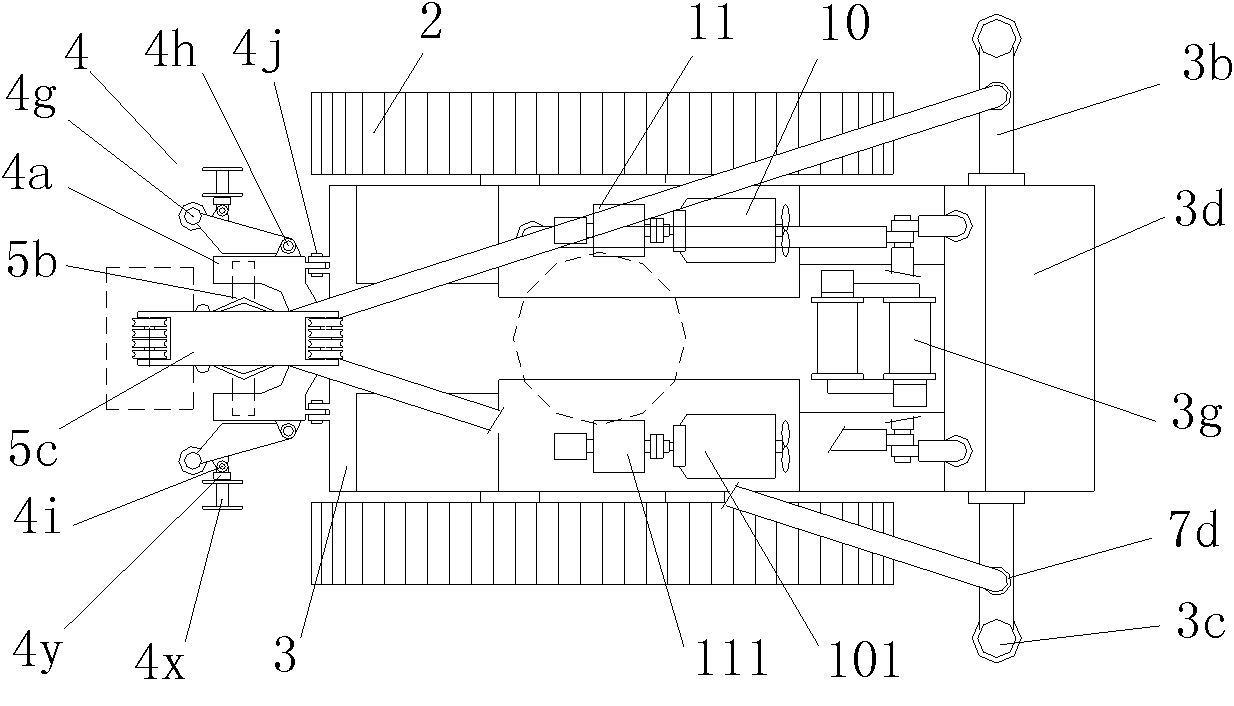

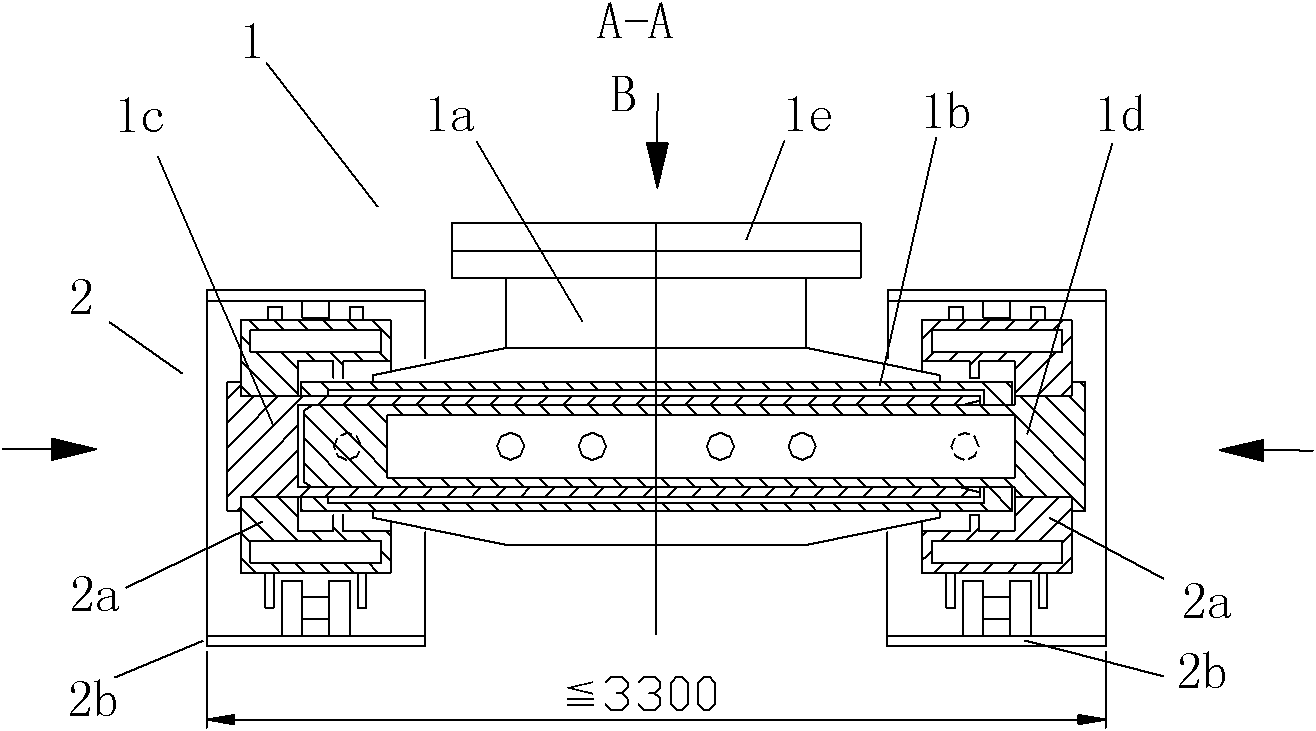

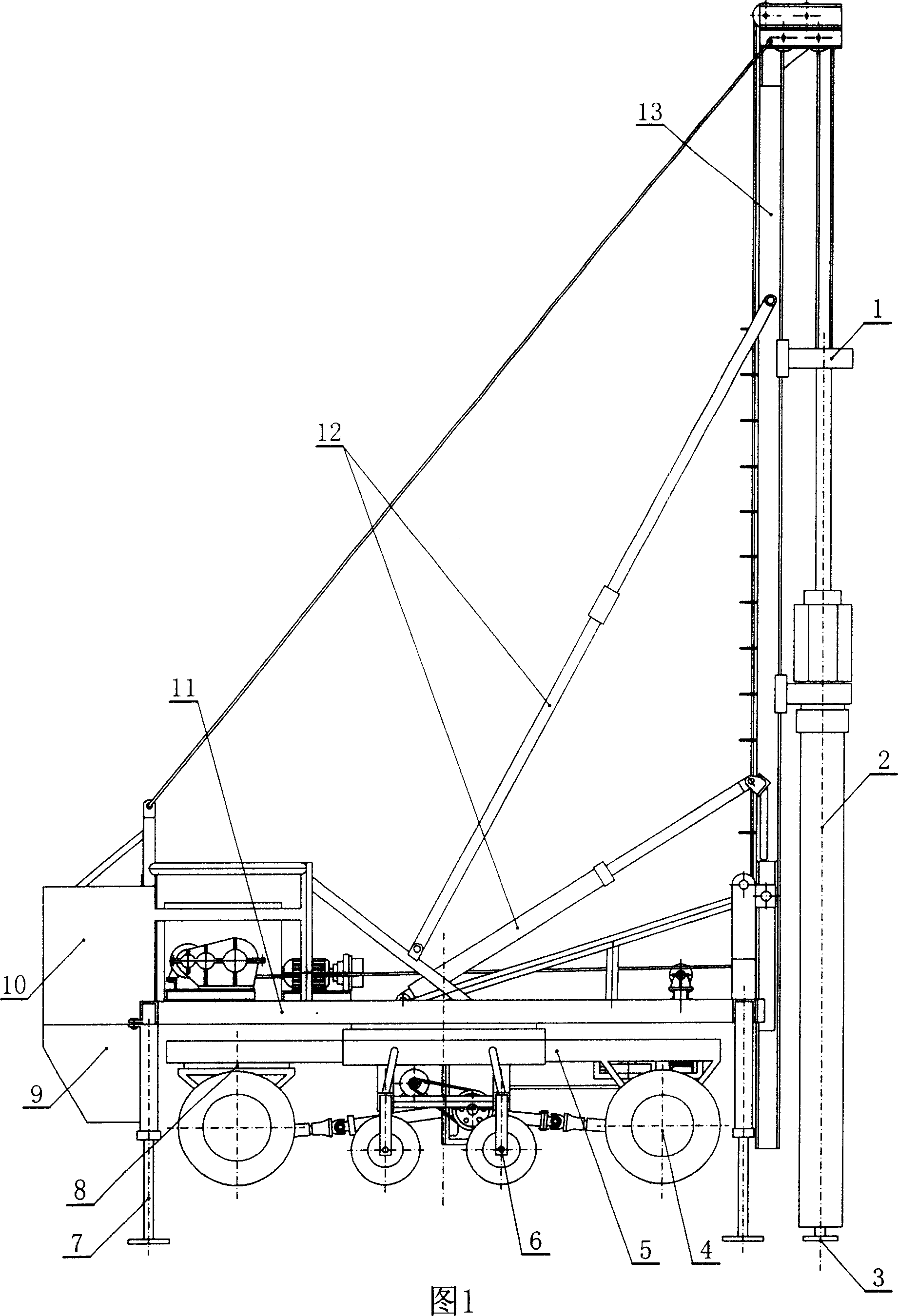

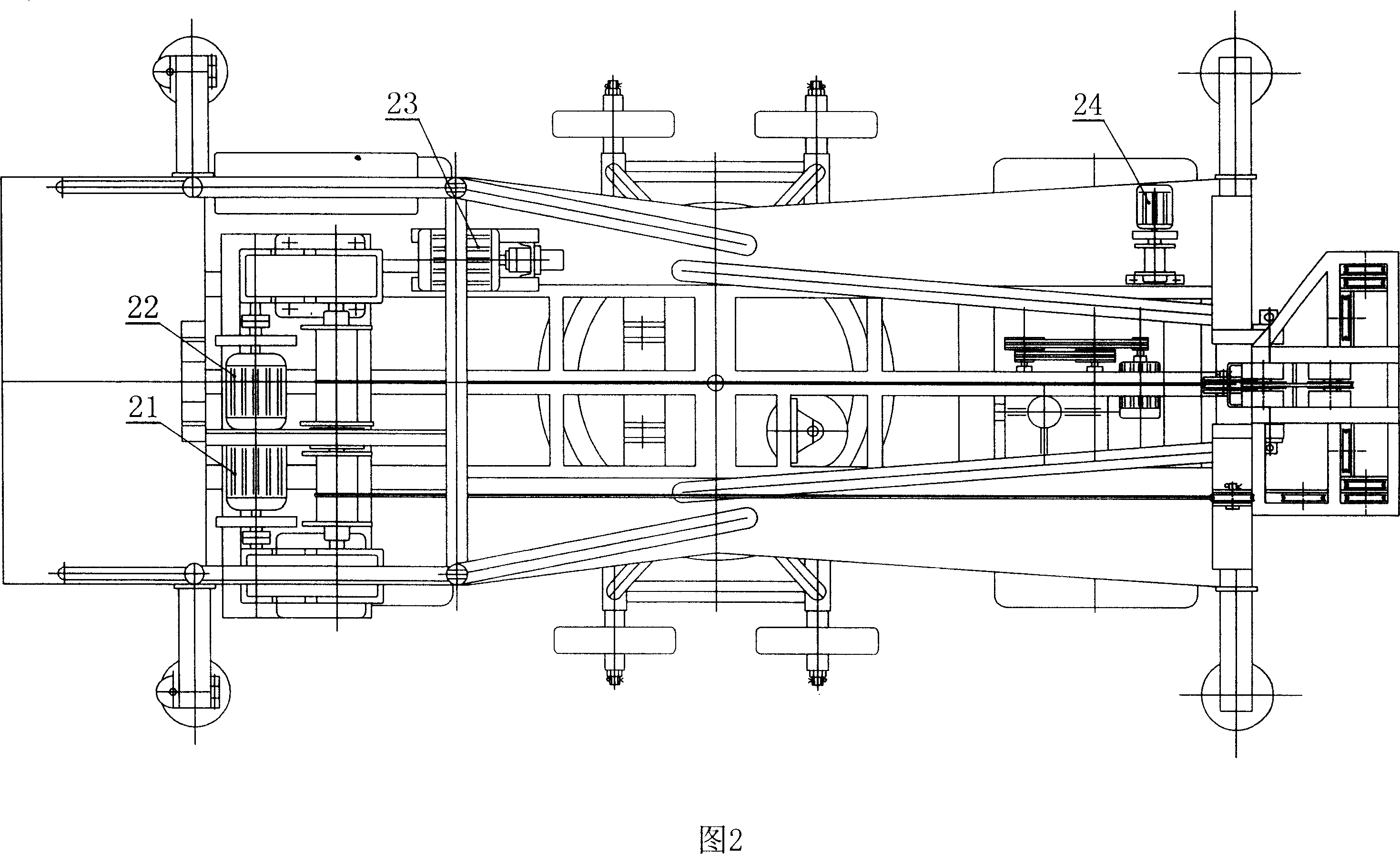

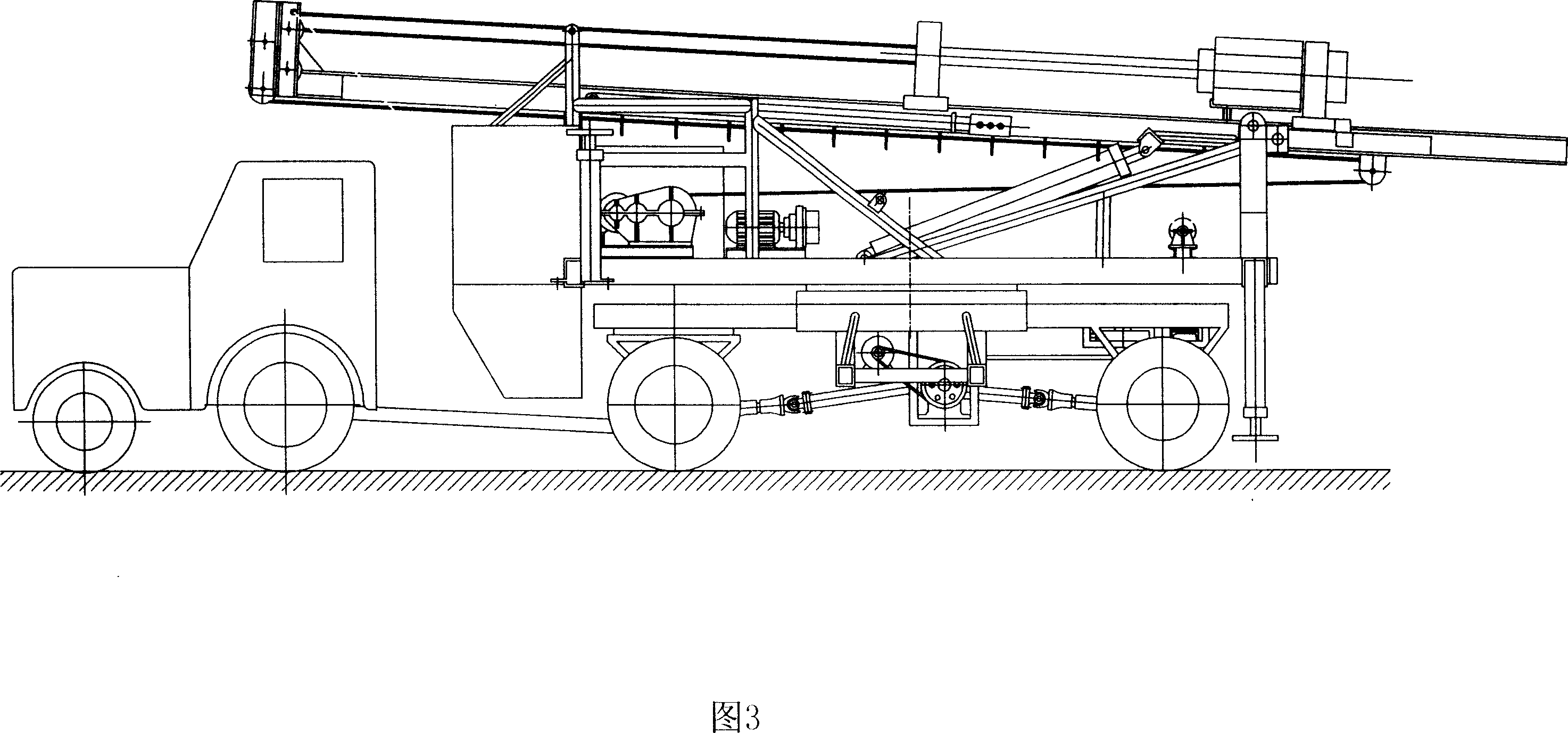

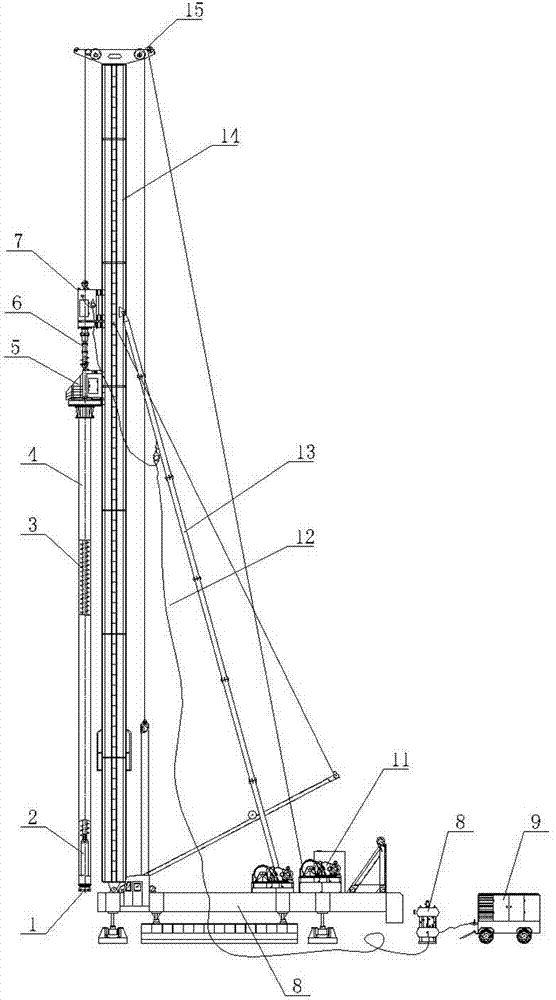

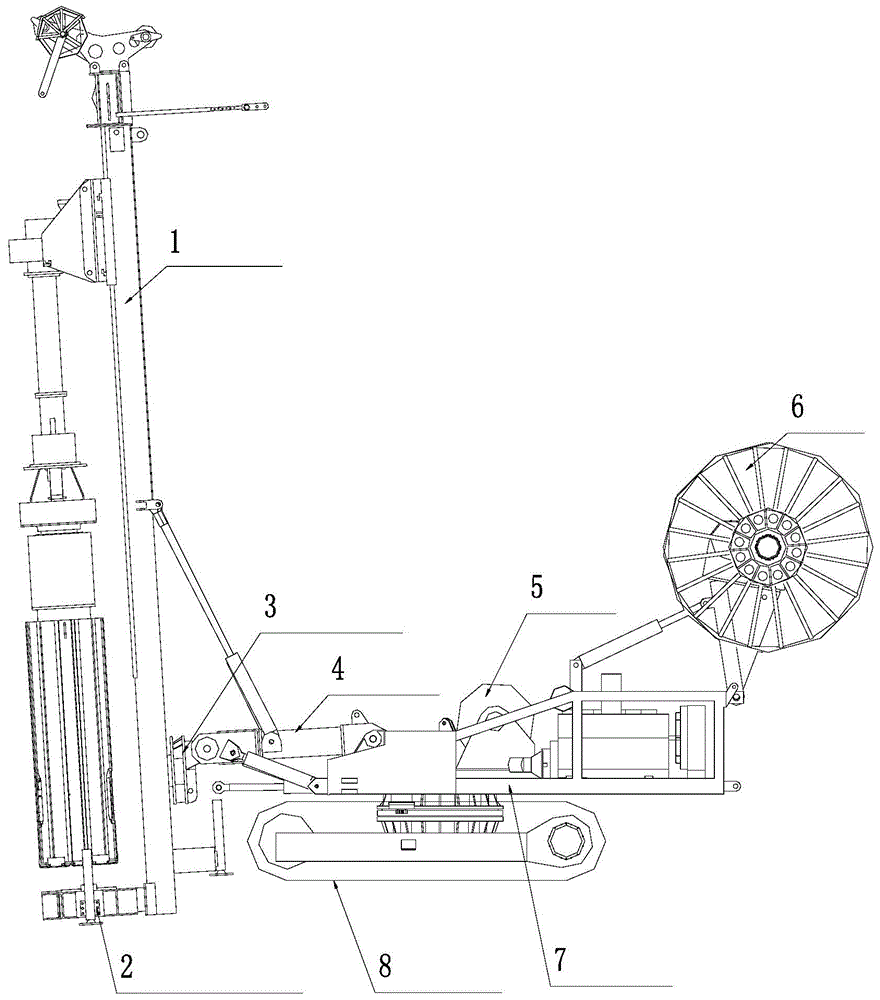

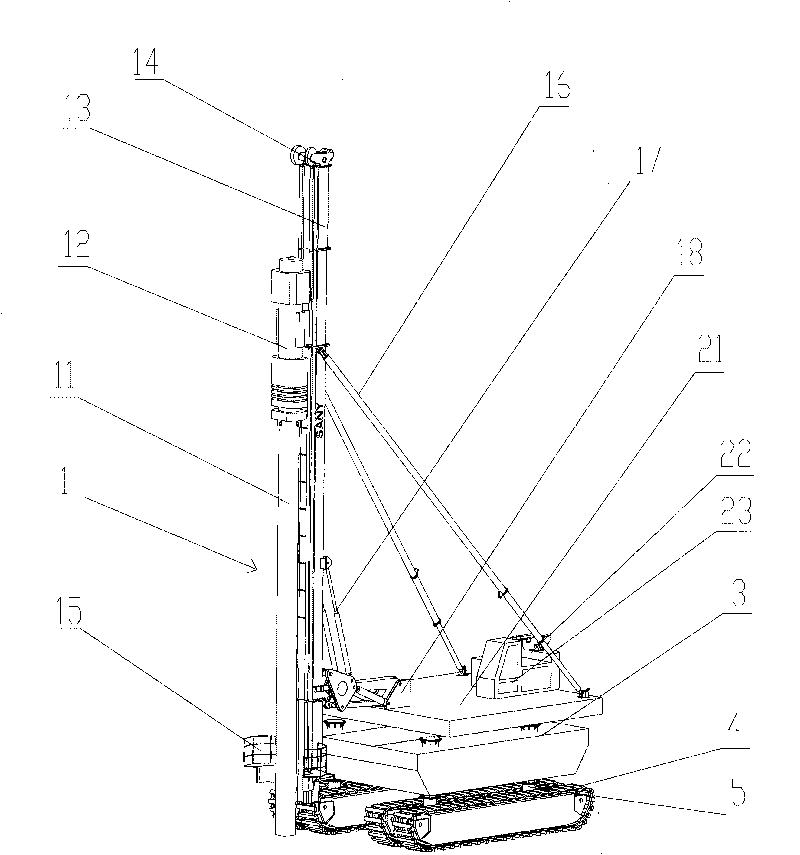

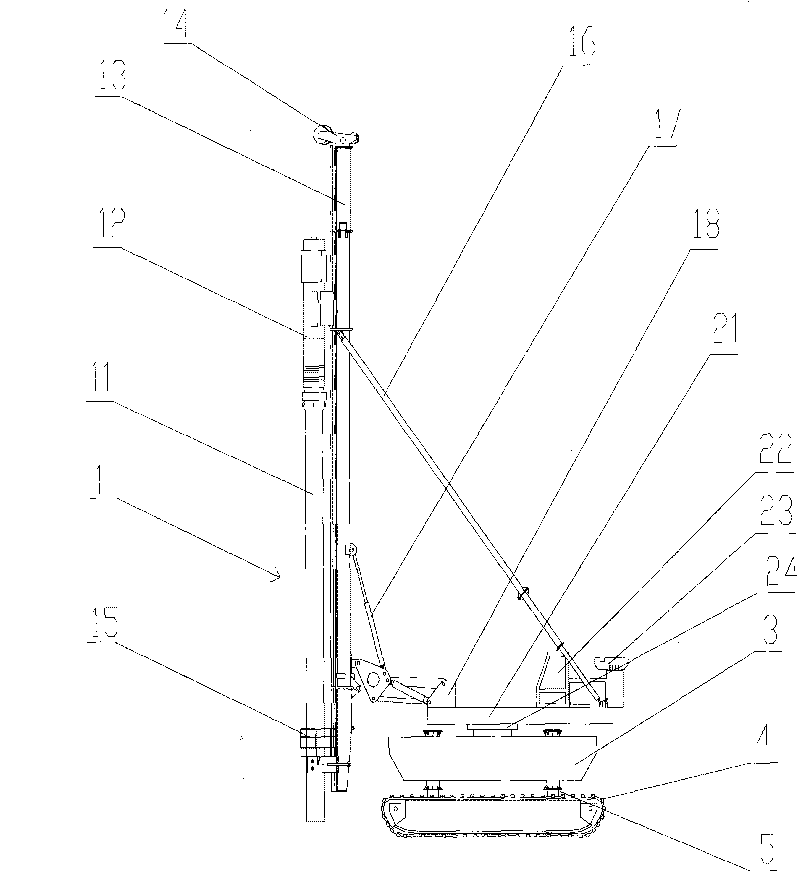

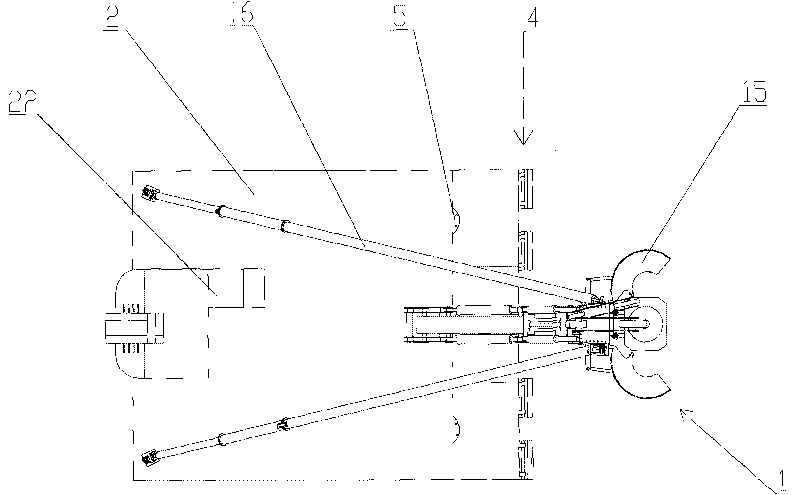

Crawler-type pile frame and method for mounting same

The invention discloses a crawler-type pile frame for suspending and mounting pile drivers, drilling machines and other foundation construction machines and a method for mounting the same. The crawler-type pile frame mainly comprises a chassis provided with a crawler travelling device, a frame body, an upright post, a tilted support and a hydraulic power system, wherein one internal combustion engine for driving one set of hydraulic pump units, and two internal combustion engines of the power system can be used for respectively driving two sets of hydraulic pump units, thus supplying enough power for the power system itself and a carrying device. Accordingly, the power can be supplied in a centralized or separate way, thus ensuring high efficiency and saving the energy; the crawler chassis has a more reasonable structure, thus improving the stability of the entire pile frame in travelling and operating; and the upright post and the tilted support of the pile frame are vertically mounted, so the pile frame is simple, convenient, safe and reliable.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

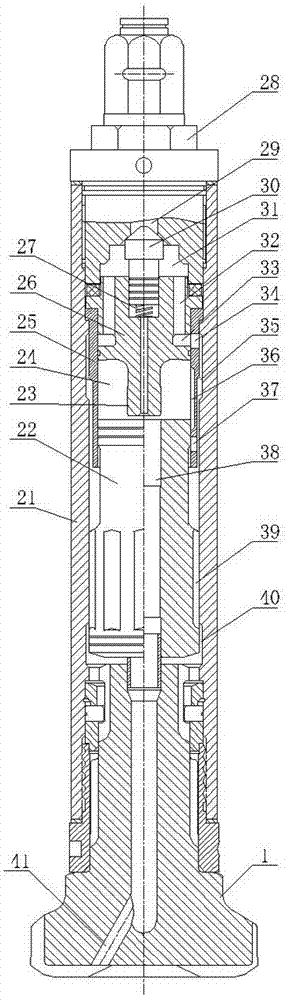

Combined down-hole hammer drilling tool and pile forming construction method thereof

ActiveCN103244051ASimplify the construction processSimple and fast operationDrilling rodsBorehole drivesSlagStructural engineering

The invention relates to a combined down-hole hammer drilling tool and a pile forming construction method thereof. The combined down-hole hammer drilling tool comprises an open type down-hole hammer and a multi-layer toothed threaded drill pipe which are fixed through pins, shafts and sealing gaskets. An impactor of the open type down-hole hammer is a hollow impactor, a movable bottom door capable of being closed is arranged at the bottom of the open type down-hole hammer, reaming blocks are arranged on sides of the open type down-hole hammer, and a pressure air supply hole and a high-pressure exhaust and slag-removing groove are disposed in the open type down-hole hammer. The multi-layer toothed threaded drill pipe is composed of a drill pipe outer tube and a drill pipe inner tube, and the drill pipe outer tube is provided with an air pipe. During pile forming, a pile driver of the combined down-hole hammer drilling tool rotates forward to enter a designed pile bottom elevation, the movable bottom door at the bottom of the down-hole hammer is opened, and concrete is delivered by a high-pressure pump to form a pile through the drill pipe inner tube and the hollow impactor. According to the combined down-hole hammer drilling tool, holes and piles can be formed once, the process of the pile forming construction method is simple, benefits are high, and energy is saved.

Owner:HAINAN ZHUODIAN HIGH TECH DEV

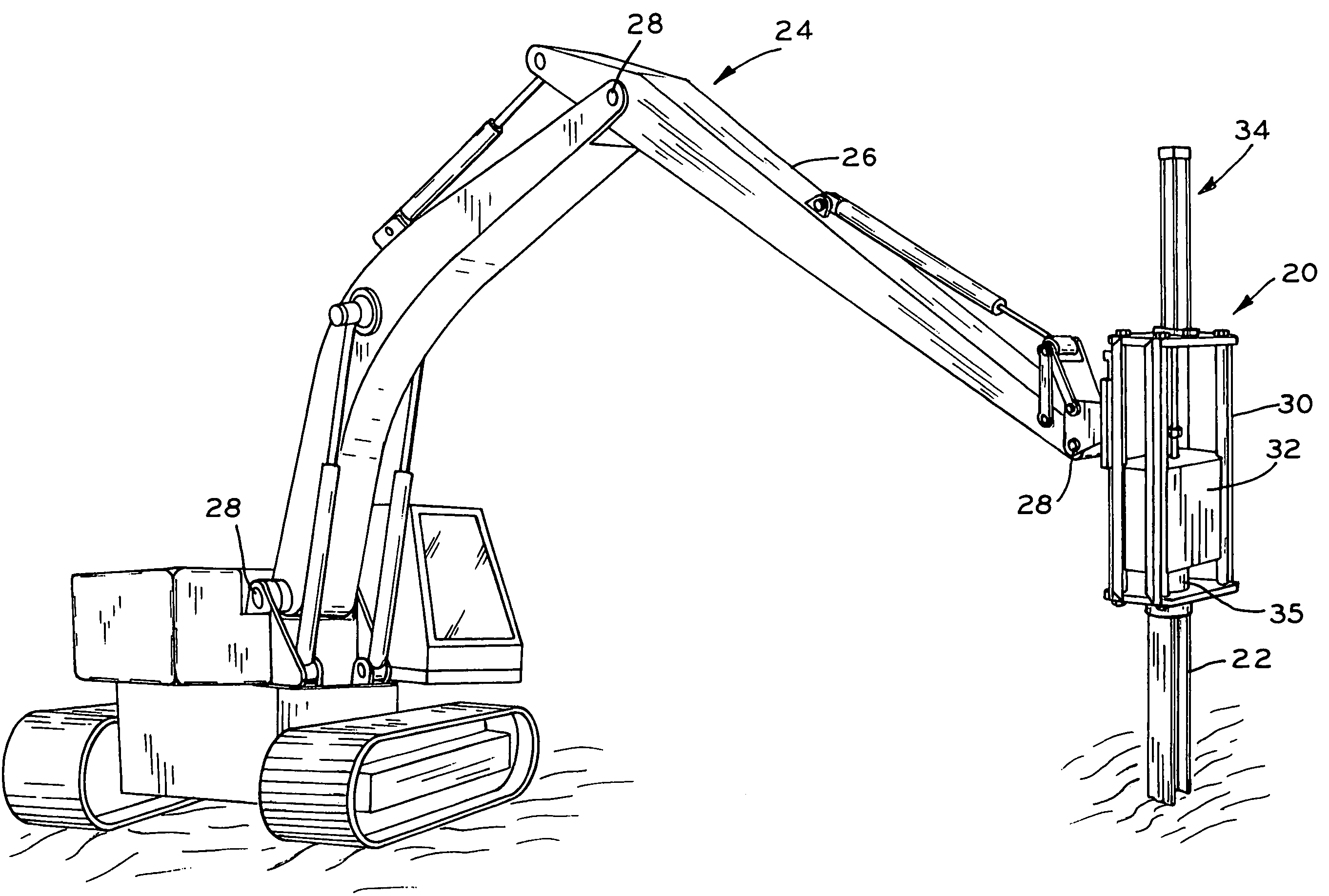

Pile driver

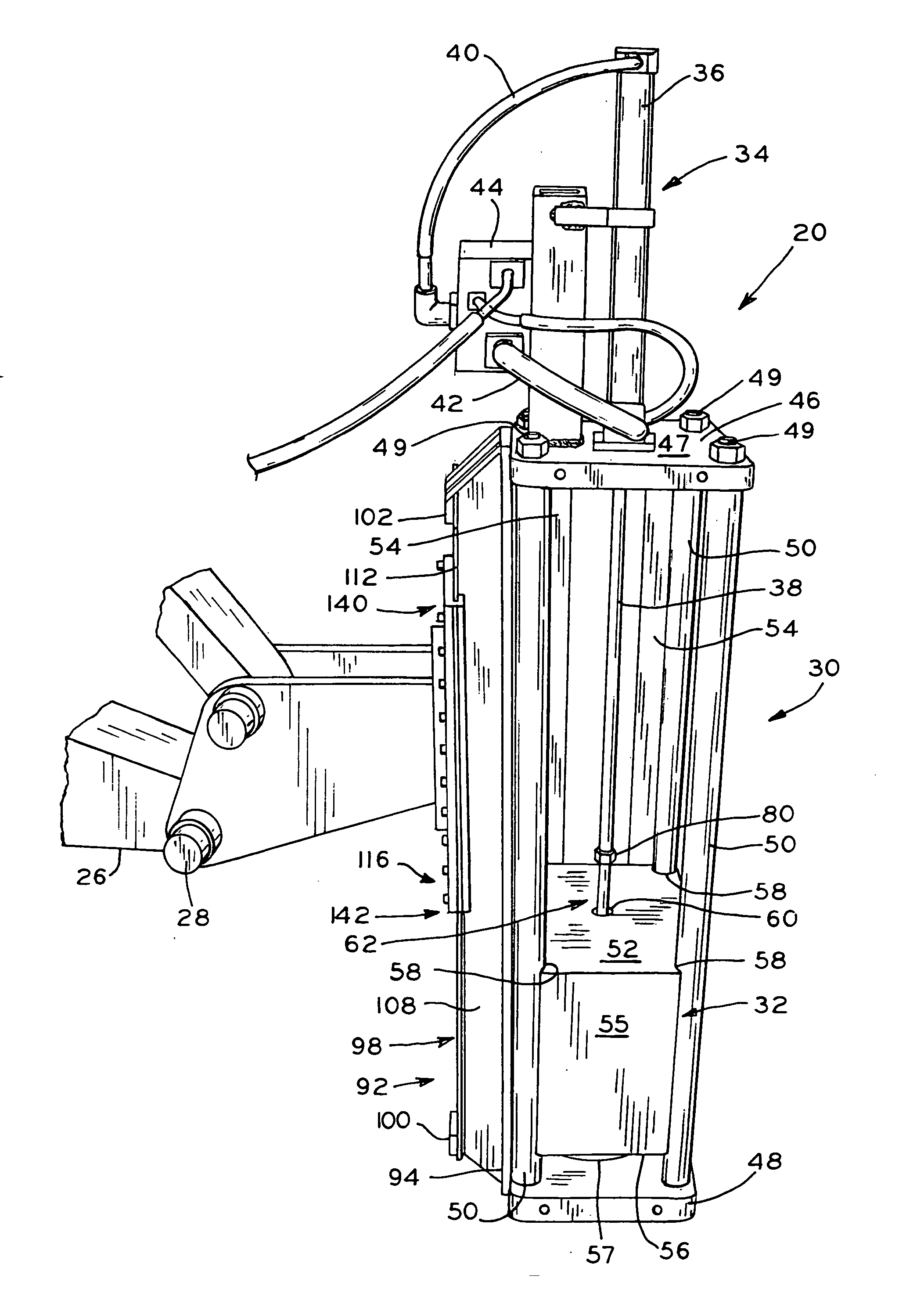

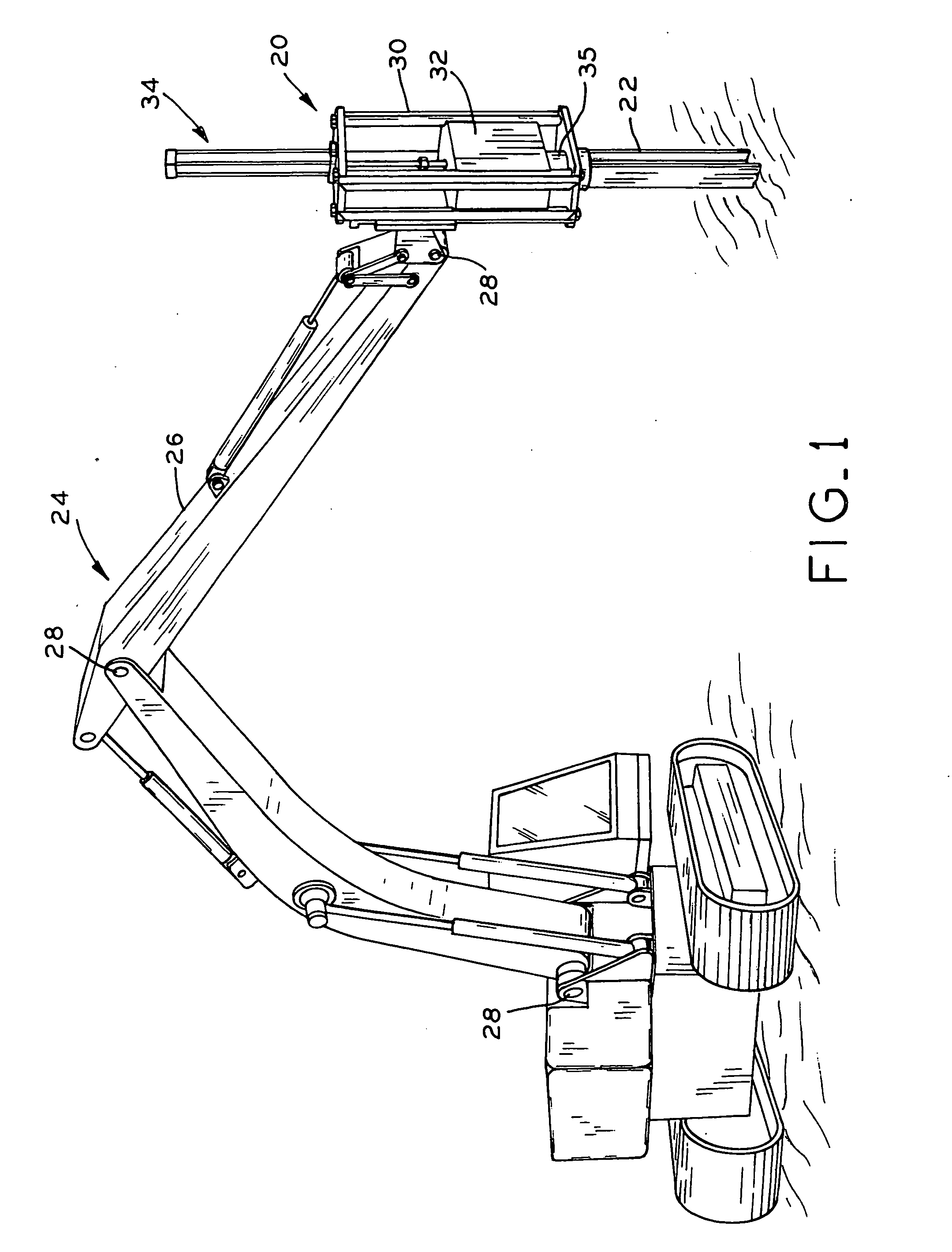

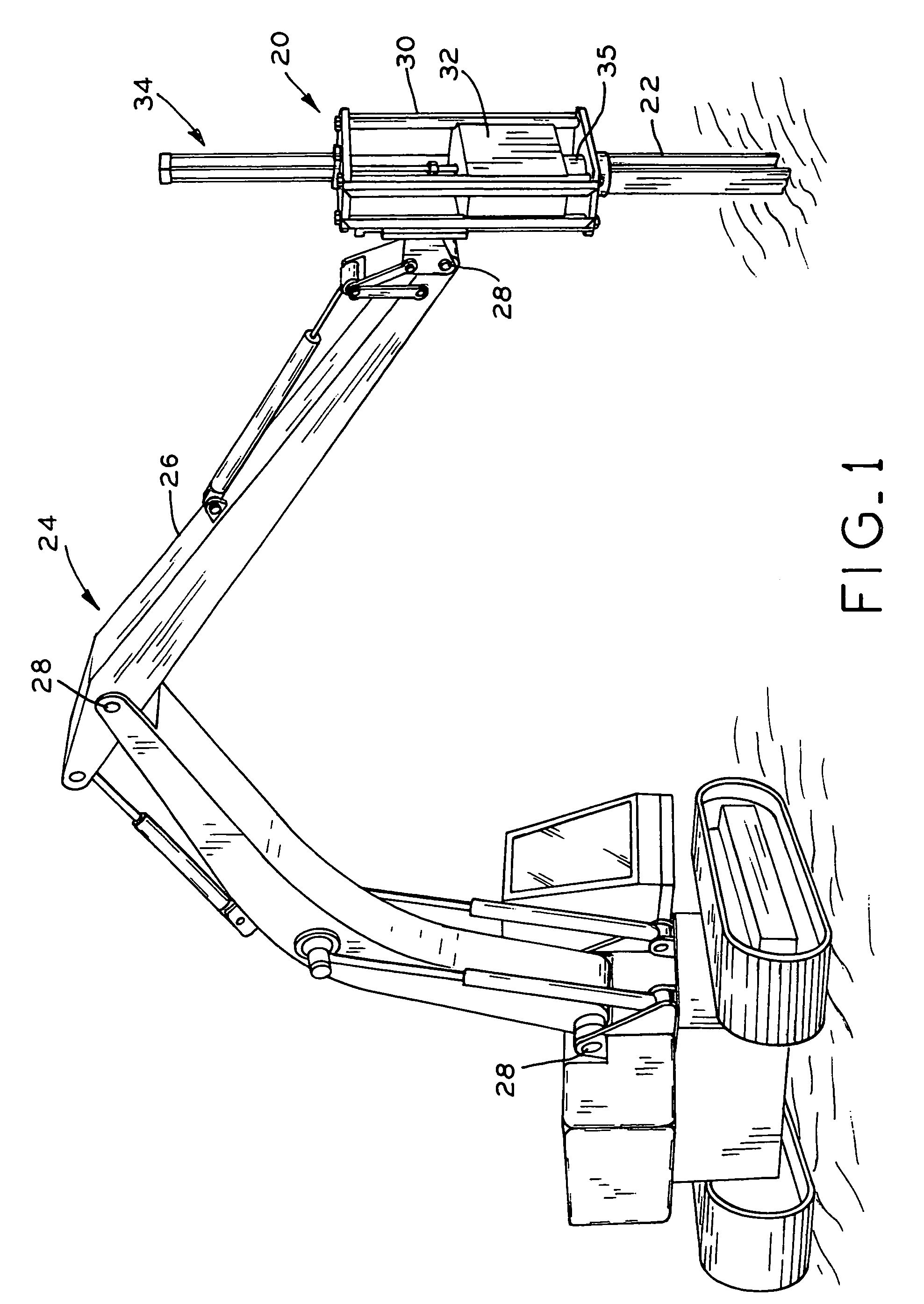

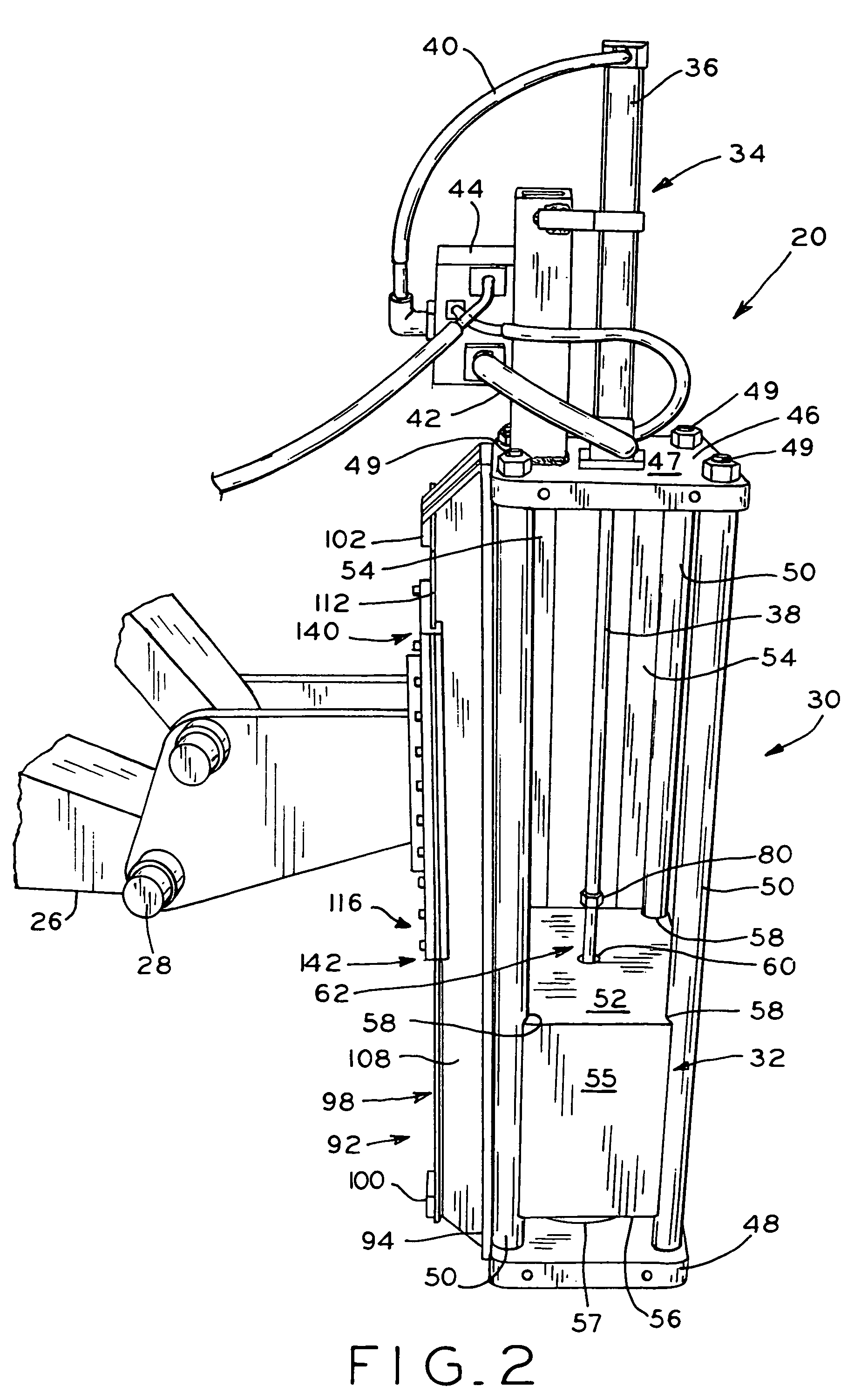

InactiveUS20060213676A1Permit rotationReduce the possibilityReciprocating drilling machinesDerricks/mastsRelative motionExcavator

A pile driver including an apparatus for allowing relative movement between a hammer and a boom of an excavator. The apparatus includes a mounting plate mounted to the boom that interfits with and is slidable with respect to a frame rail mounted to the hammer. In operation, the hammer is placed on top of a pile and, as the pile is driven downwardly, the hammer follows the pile. Owing to the relative movement between the boom of the excavator and the hammer, the hammer follows the pile without requiring continuous downward readjustment of the boom. In one embodiment, the mounting plate assembly does not extend substantially above the hammer frame. In another embodiment, the hammer can rotate with respect to the boom. In one embodiment, the hammer includes a ram, a cylinder for lifting the ram, and rotation-resistant cable connecting the ram and the cylinder.

Owner:HERCULES MACHINERY

Multifunctional pile driver

The present invention relates to a multifunctional pile driver for building construction. It is characterized by that it includes upper pile frame and lower pile frame, said upper pile frame and lower pile frame are oppositely rotatably-connected, the lower pile frame is equipped with a running mechanism, and the upper pile frame is equipped with supporting device, in the rear end of said upper pile frame a counterweight sand box is mounted, in the front end of said upper pile frame a guideway upright post is hinged, on the guideway upright post a pile-sinking device is connected, and said pile-sinking device can be upward and downward slided on the guideway upright post; the front end of said running mechanism is equipped with a front steering apparatus; the middle portion of said lower pile frame is equipped with an auxiliary supporting device; between the upper pile frame and guideway upright post a diagonal bracing device is mounted; the pile-sinking device includes a diesel hammer, said diesel hammer is connected with said guideway upright post and can be upward and downward slided on said guideway upright post, the lower end of said diesel hamper is connected with a pipe pile; said pipe pile is a hollow circular pipe body, its upper end is equipped with an air outlet and its bottom surface is equipped with an air inlet, the lower end of said pipe pile is movable connected with a mud guand.

Owner:邓长峰

Walking dual-swing downhole drill

ActiveCN102828690AFully lubricatedOil Mist StabilizationConstructionsReciprocating drilling machinesEngineeringHigh pressure

The invention discloses a walking dual-swing downhole drill, which comprises a pile frame main body and a drilling main body, wherein the drilling main body comprises an upper power head, a lower power head, an outer sleeve, a spiral drill stem and a downhole hammer; the upper power head is connected with the top end of the spiral drill stem; the bottom end of the spiral drill stem is connected with the downhole hammer; the upper power head drives the spiral drill stem and the downhole hammer to rotate clockwise when working; the lower power head is connected with the outer sleeve and drives the outer sleeve to rotate anticlockwise when working; the downhole hammer comprises an impacter and an impact hammer; the hammer head of the impact hammer is exposed out of the lower opening of the outer sleeve; a high-pressure gas channel is arranged inside the drilling main body, and the high-pressure gas passes through the upper power head, a buffer, the spiral drill stem and the impacter and is finally blown outwards from the bottom part of the impact hammer. The walking dual-swing downhole drill has main characteristics of taking soil to form a hole by a dry method without pollution, and being adapted to various geologies and stratums, such as hard lithosphere, tundra, sand bed with abundant underground water, a rubble layer and boulder, which are difficult to drill by other pile drivers.

Owner:瑞安市八达工程机械有限公司

Pile driver

InactiveUS7387173B2Permit rotationReduce the possibilityReciprocating drilling machinesDerricks/mastsEngineeringRelative motion

A pile driver including an apparatus for allowing relative movement between a hammer and a boom of an excavator. The apparatus includes a mounting plate mounted to the boom that interfits with and is slidable with respect to a frame rail mounted to the hammer. In operation, the hammer is placed on top of a pile and, as the pile is driven downwardly, the hammer follows the pile. Owing to the relative movement between the boom of the excavator and the hammer, the hammer follows the pile without requiring continuous downward readjustment of the boom. In one embodiment, the mounting plate assembly does not extend substantially above the hammer frame. In another embodiment, the hammer can rotate with respect to the boom. In one embodiment, the hammer includes a ram, a cylinder for lifting the ram, and rotation-resistant cable connecting the ram and the cylinder.

Owner:HERCULES MACHINERY

Method for forming variable-cross-section compaction thread pile and compaction drilling tool

The invention provides a method for forming a variable-cross-section compaction thread pile and a compaction drilling tool. The method comprises the following steps: (1) arranging a pile driver in place; (2) forming holes at the upper section of a pile body; (3) axially separating an inner drill stem from an outer drill stem; (4) forming holes at the lower section of the pile body; and (5) lifting and extruding to form the pile. The compaction drilling tool comprises the inner drill stem and the outer drill stem, wherein, the spiral rotary wings of the outer drill stem and the inner drill stem are equipped with reaming heads; the outer drill stem is sheathed outside the inner drill stem; the upper end of the inner drill stem is equipped with an outer spline, the outer drill stem is equipped with an inner spline, the inner spline of the outer drill stem is matched with the outer spline of the inner drill stem, and the circumferential clearance between the outer spline on the upper end of the inner drill stem and the inner spline of the outer drill stem is more than or equal to the width of one spline tooth; and an axial limit block is arranged on the lower end of each tooth of the inner spline of the outer drill stem, and the distance between the axial limit block and an adjacent spline tooth is more than or equal to the width of one spline tooth. The pile body formed by the compaction drilling tool through the method is a variable-cross-section compaction thread pile, and the pile body has the advantage of large bearing capacity.

Owner:武汉谦诚桩工科技股份有限公司

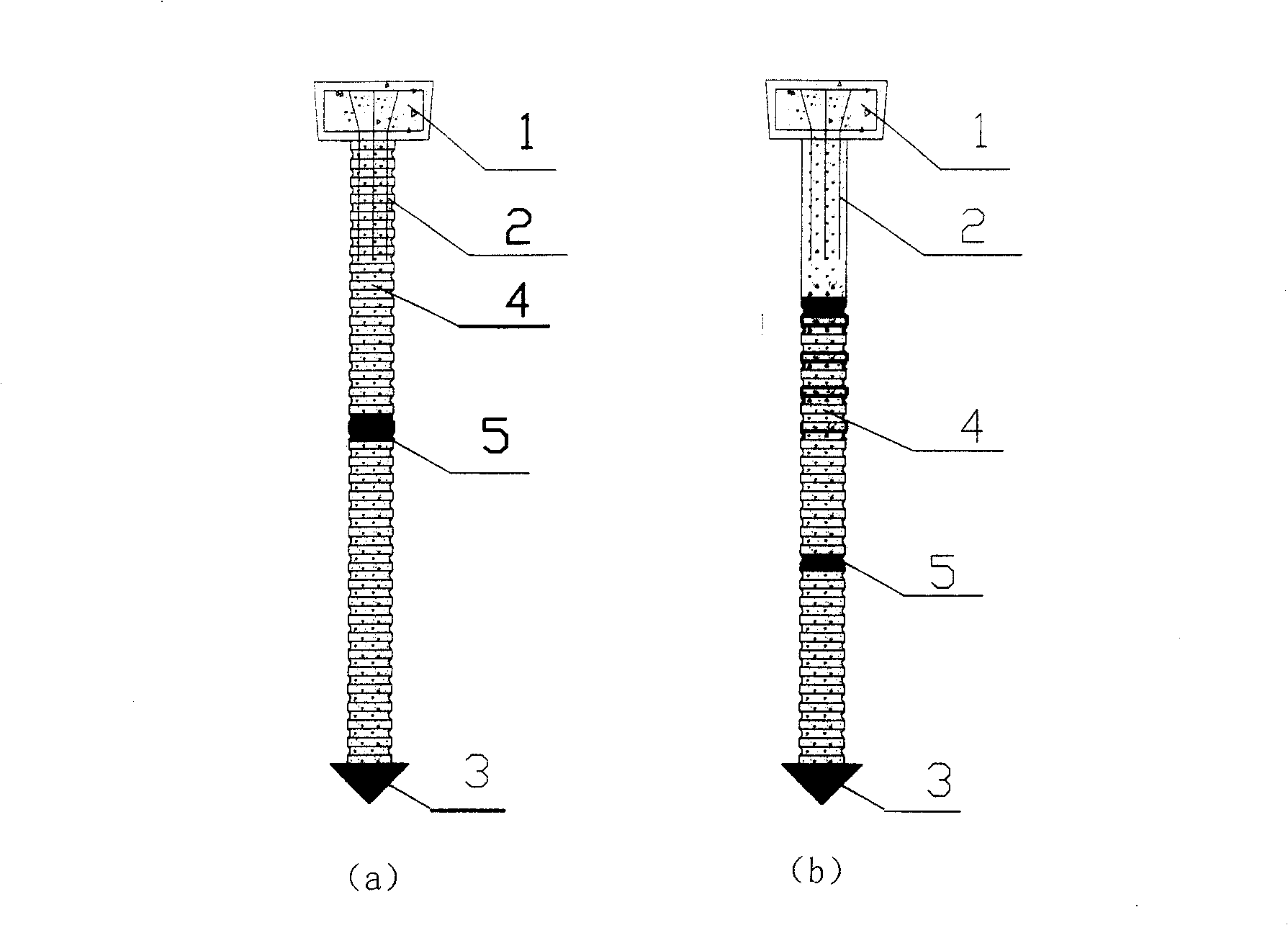

Plastic sleeve concrete pile and method thereof for reinforcing soft soil foundation

The invention relates to a plastic sleeve concrete pile and a construction method thereof. the plastic sleeve concrete pile comprises a cover board, plastic sleeves, pile tips, concrete and sleeve joints, wherein the top of each plastic sleeve is connected with the cover board and the lower part is connected with each pile tip, every two plastic sleeves are connected by the sleeve joint, and the concrete is poured in the plastic sleeves. The construction method comprises the following steps: connecting the prefabricated pile tips with the plastic sleeves, pulling the plastic sleeves together with the pile tips into an immersed tube after lifting the immersed tube at a certain height, starting a plastic sleeve concrete pile driver to drive the plastic sleeves with the pile tips together into the pile length designed depth, lifting the immersed tube after filling water into the plastic sleeves until 1 / 2-2 / 3 of pile length but remaining the plastic sleeves and the pile tips into the foundation, pumping filled water in the plastic sleeves, and pouring a concrete pile body and the cover board into the plastic sleeves to be made into the plastic sleeve concrete pile. The plastic sleeve concrete pile has small soil extrusion action, uneasy broken pile, flexible and rapid construction, easy control of pile body quality, higher bearing capacity of single pile and good cost performance; and the pouring is not influenced by outside.

Owner:HOHAI UNIV

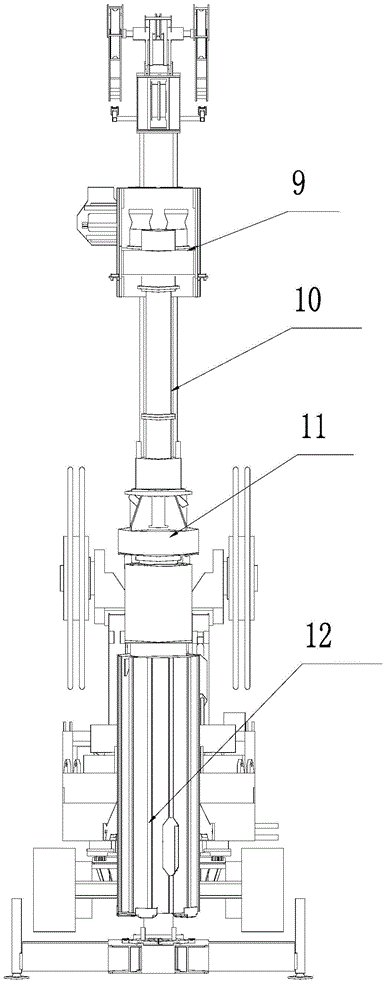

Hydraulic combined impact hammer drilling machine

ActiveCN104594802AChange the problem of difficult constructionImprove construction efficiencyDrilling rodsConstructionsControl engineeringWinch

The invention provides a hydraulic combined impact hammer drilling machine and relates to the field of engineering pile driver devices. The hydraulic combined impact hammer drilling machine comprises a power source, an integrated machine frame, a walking mechanism, a posture mechanism, a liftable reel pipe mechanism, an upper power head, a lower power head, a winch, a drilling rig clamper and a hydraulic combined impact hammer drilling bit. Track walking is adopted by the walking mechanism. The walking mechanism is driven by a hydraulic reducer. The integrated machine frame is installed on a body of the walking mechanism. The power source, the posture mechanism, the power heads, the liftable reel pipe mechanism and the hydraulic combined impact hammer drilling bit are installed on the integrated machine frame. The hydraulic combined impact hammer drilling machine can complete construction operation independently, solves the problems that during traditional construction, a pile foundation is in contact with a rock stratum, and construction is difficult and is high in construction efficiency and low in cost, the practicability and the flexibility of the hydraulic combined impact hammer drilling machine are greatly improved, and the application range of the hydraulic combined impact hammer drilling machine is greatly widened.

Owner:陶德明

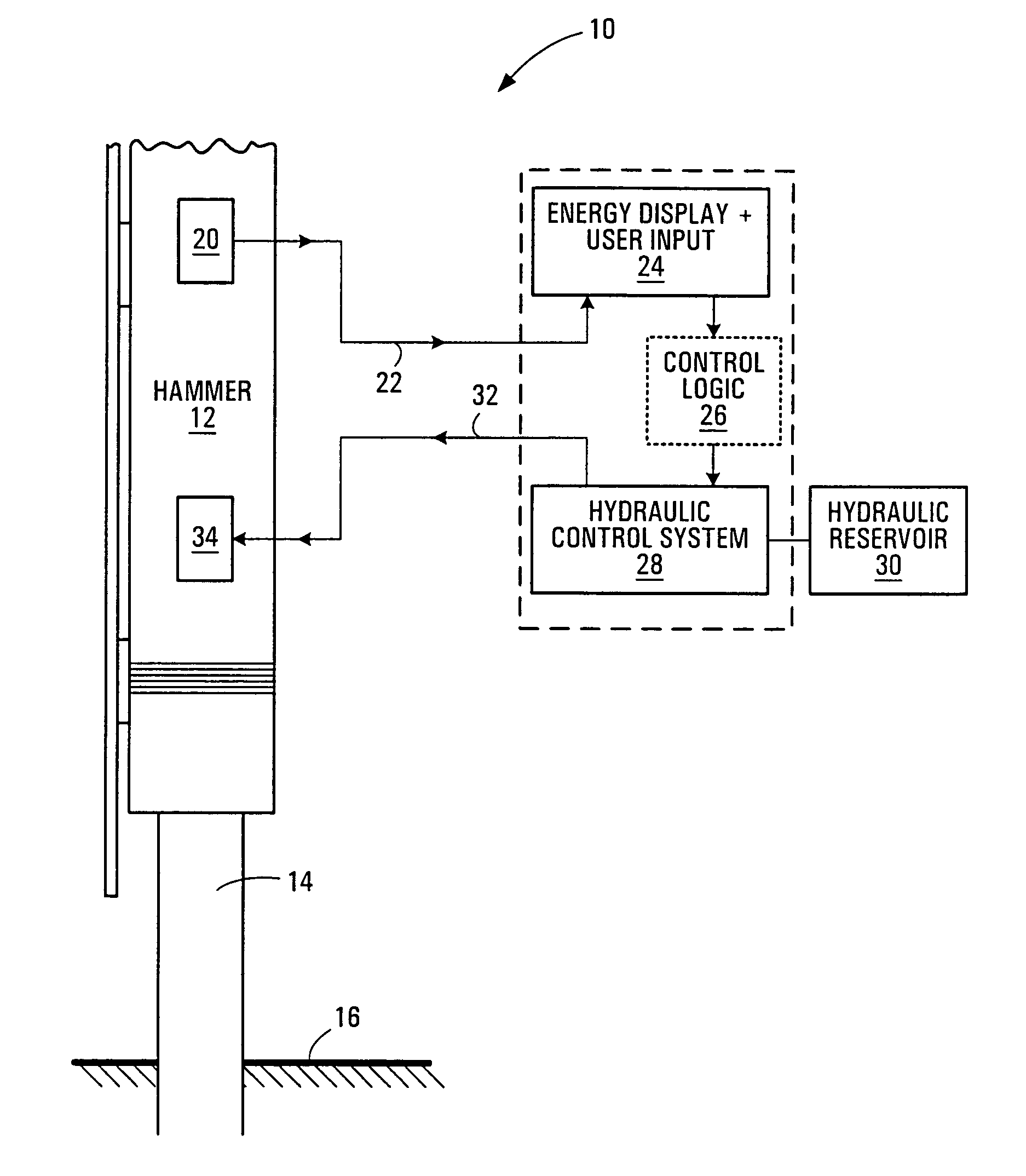

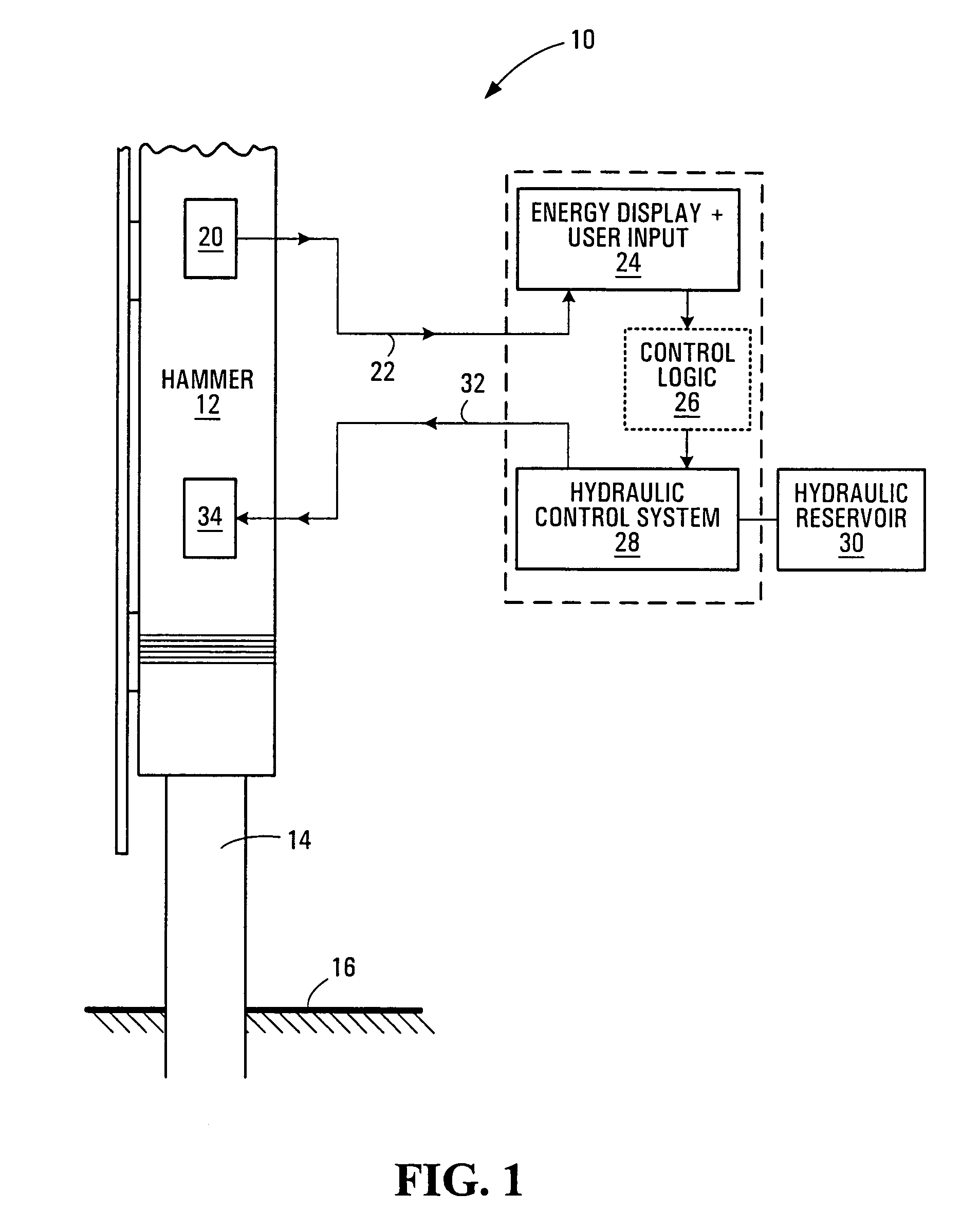

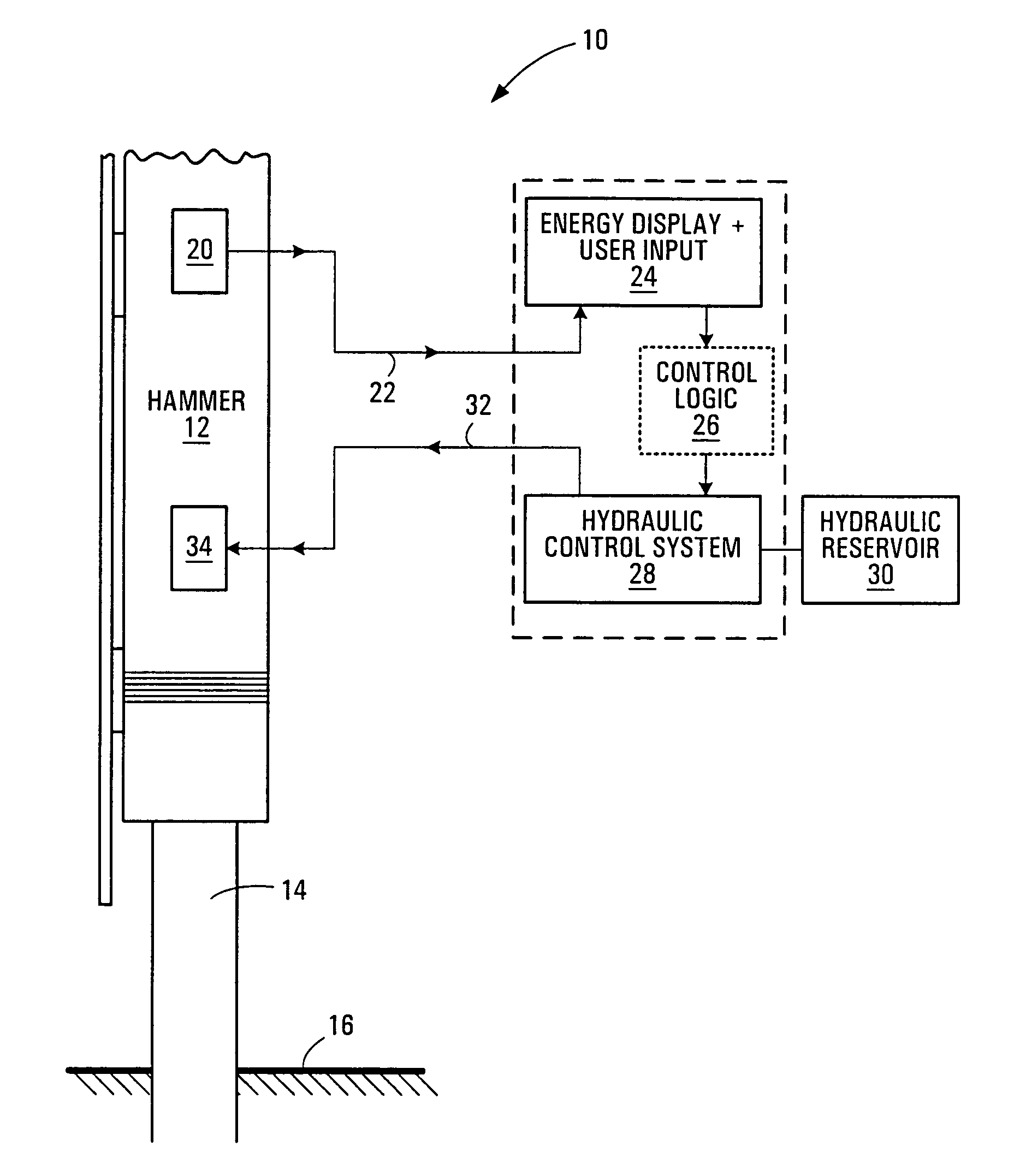

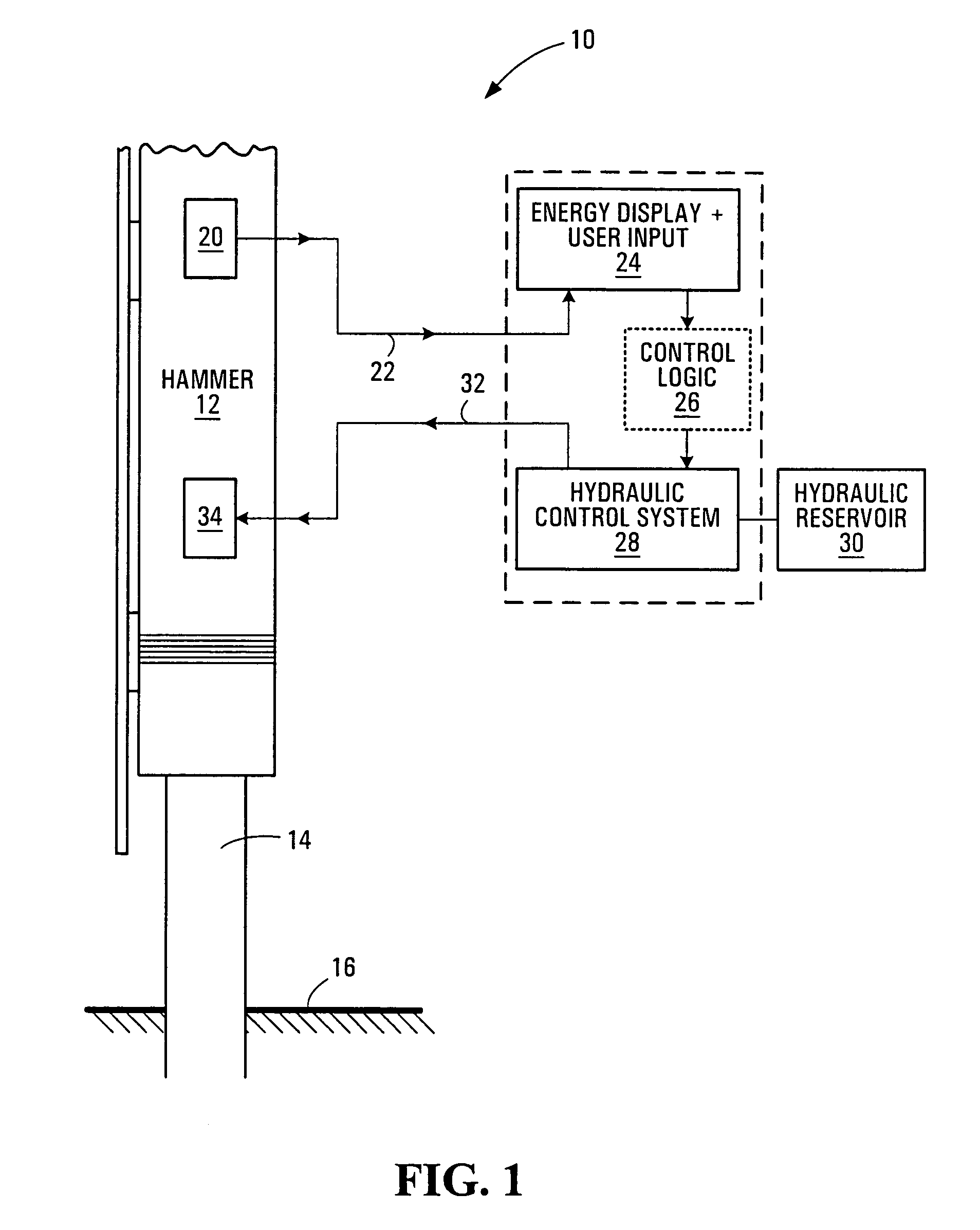

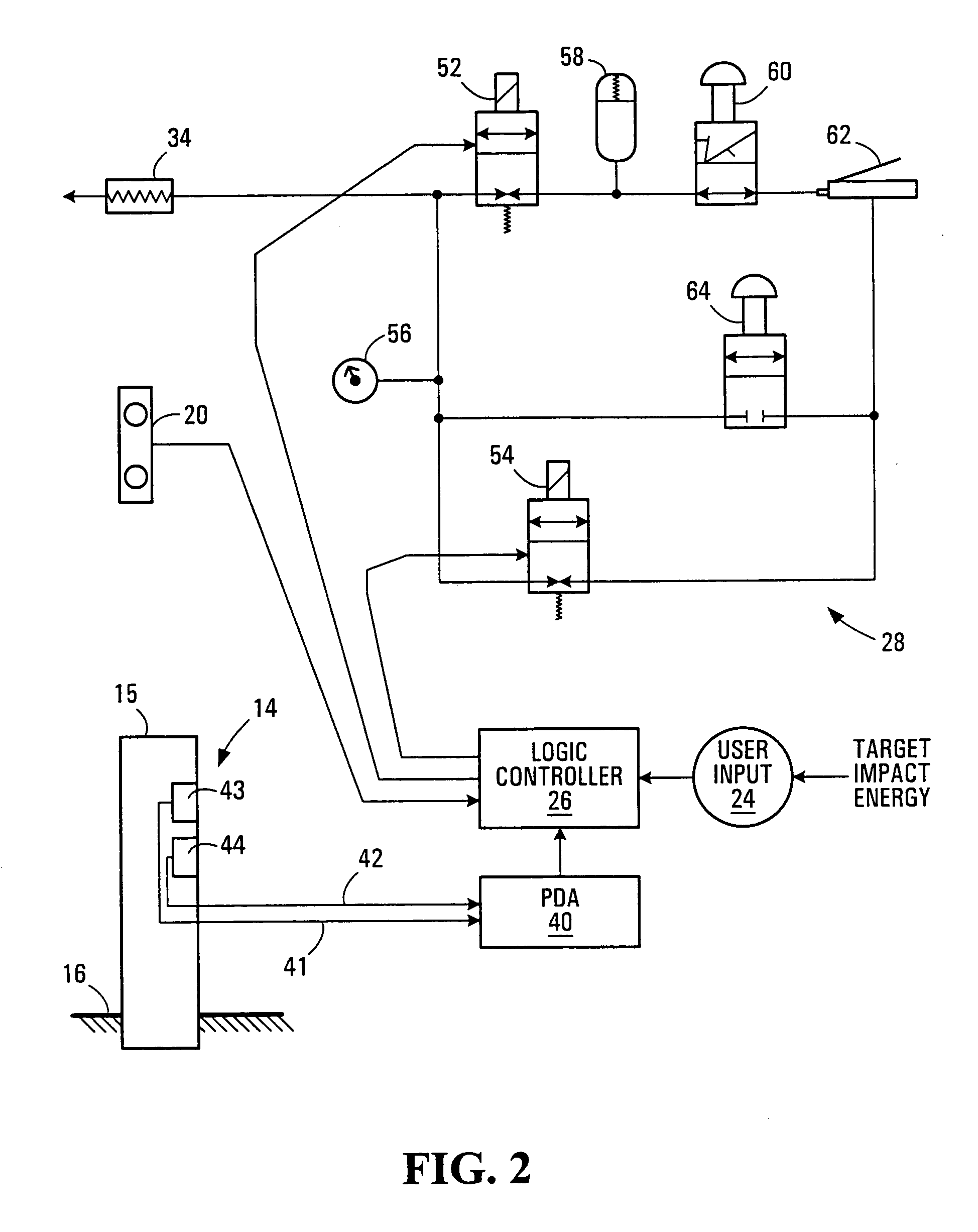

Pile driver with energy monitoring and control circuit

ActiveUS7156188B2Efficient driveIncrease impact energyReciprocating drilling machinesDerricks/mastsAccelerometerControl system

A pile driver comprises a hammer for impacting a pile, a velocity sensor for measuring the velocity at impact, and a control system for adjusting the hammer stroke in accordance with the readings from the velocity sensor so that the optimal impact energy is imparted to the head of the pile. Optionally, the system further comprises a pile driving analyzer (including at least one strain gauge and / or an accelerometer) mounted on the side of the pile itself to determine whether the impact loading on the pile is below the maximum allowable stress. If the pile driving analyzer senses an overload of stress on the pile, the control system will reduce the velocity of the subsequent hammer stroke so that it no longer exceeds the maximum allowable stress.

Owner:BERMINGHAM FOUND SOLUTIONS LTD

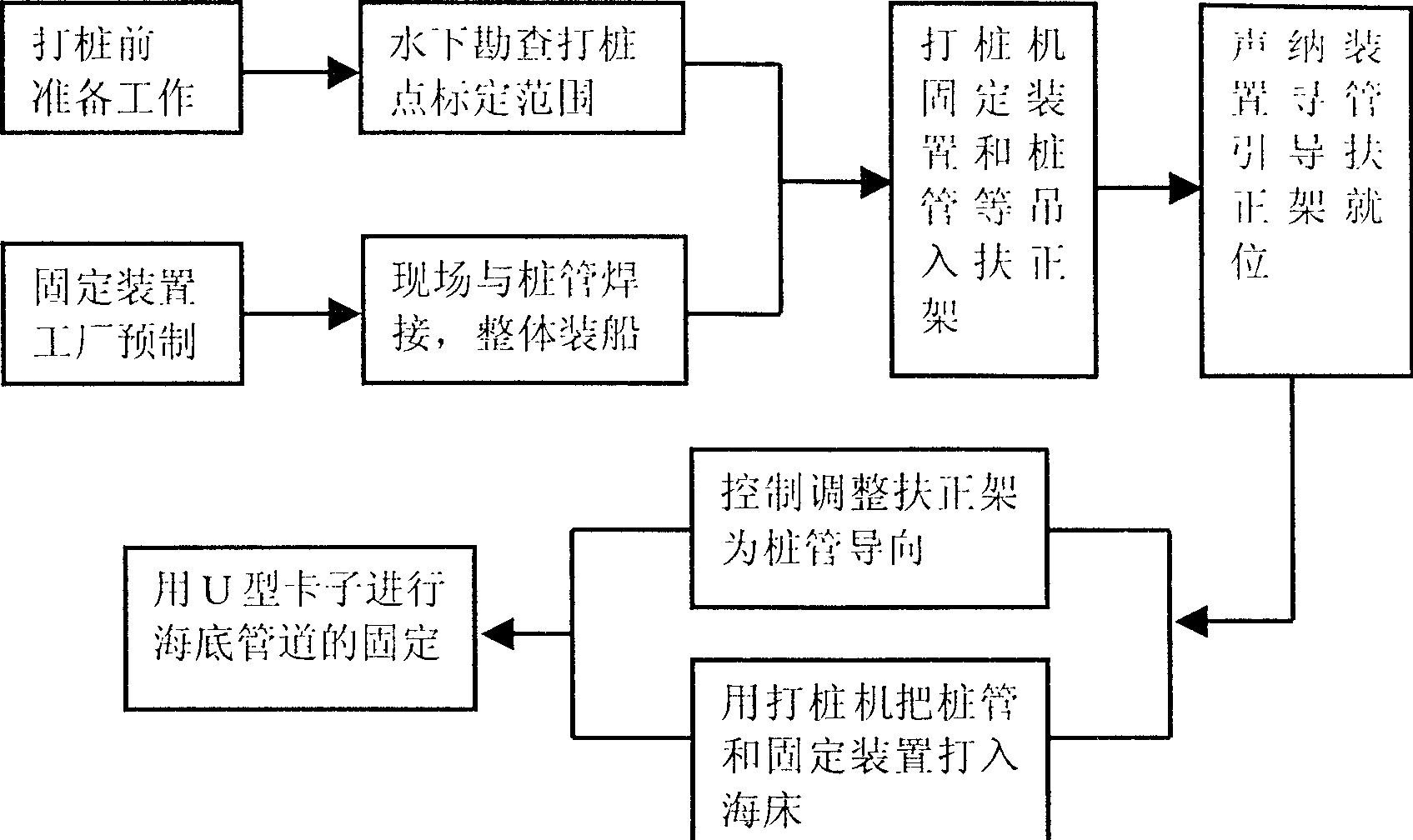

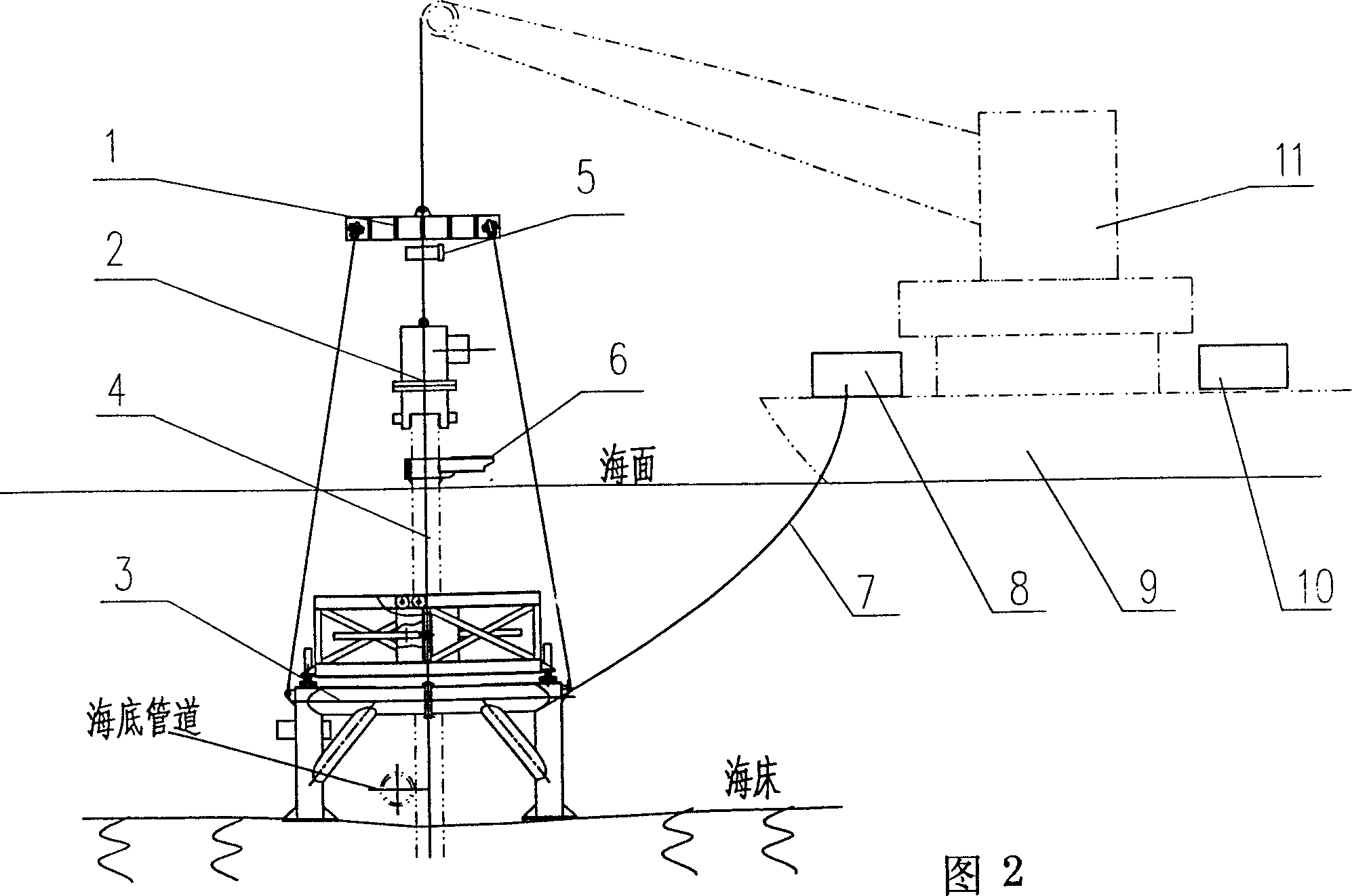

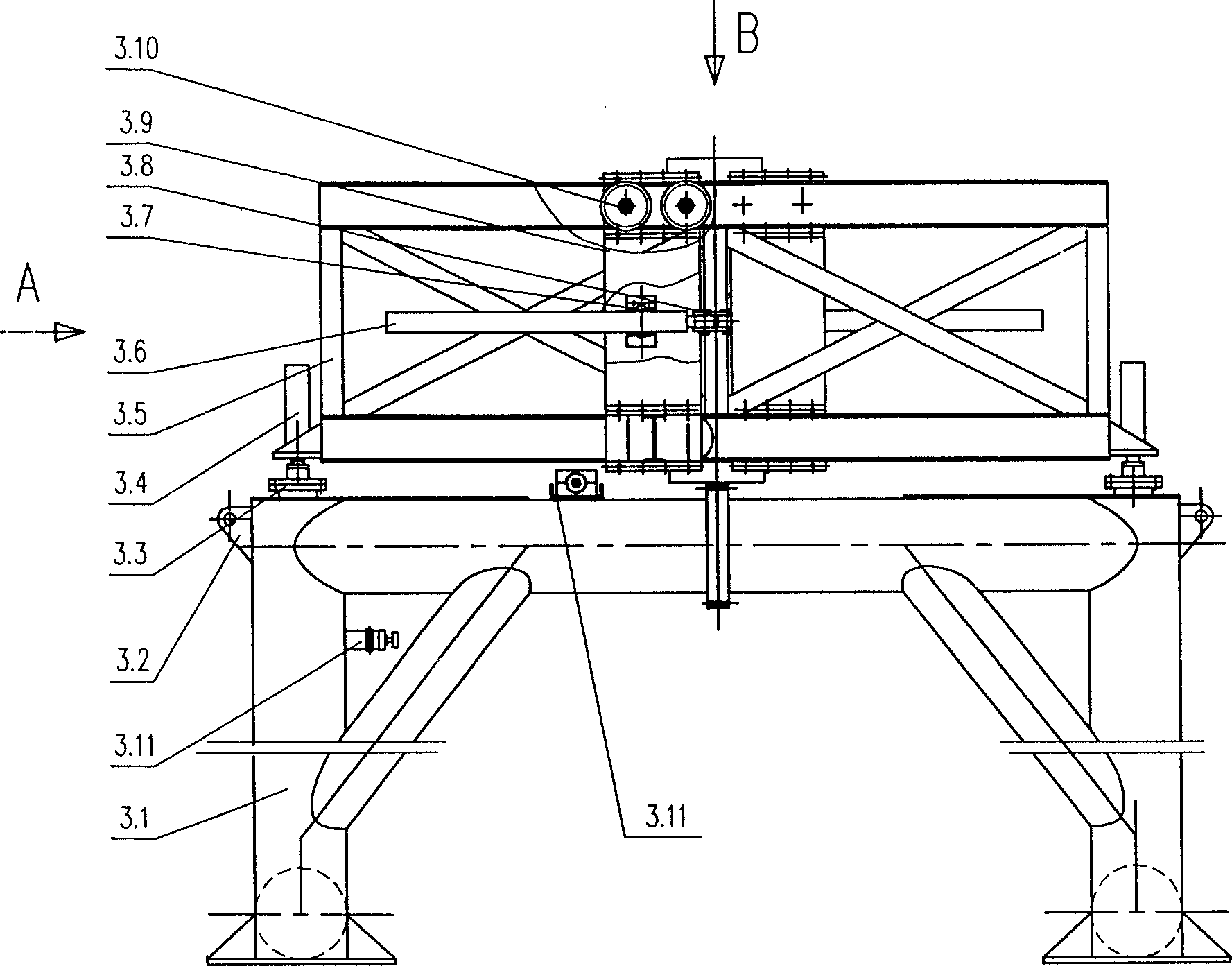

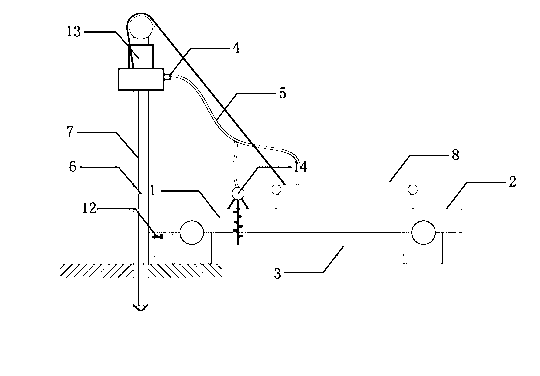

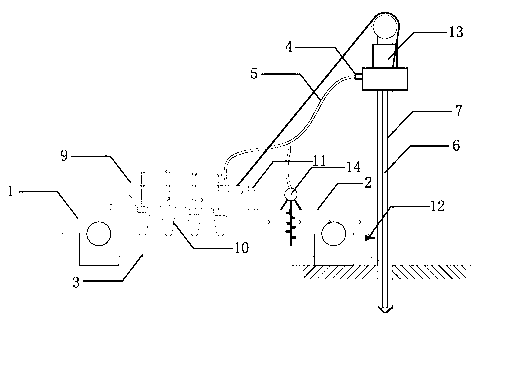

Construction method and device for fixing seabed pipeline

InactiveCN1419068AGuarantee long-term safe operationAvoid swingingPipe laying and repairOcean bottomSea waves

The present invention relates to a submerged pipeline fixing contruction method and its equipment. Said method includes the following steps: firstly, prefabricating fixing equipment in plant, transporting it to seaside field and assembling it and fixing pile pipe into one body, shipping and transferring them to place, using floating crane to lift the piling machine, fixing device and fixing pile pipe together and make the fixing pile pipe come into centering guide, and using asdic method to guide the centering guide accurately be in place, using piling machine to drive fixing pile pipe into sea-bed and make fixing equipment be in place and fixing floating part of the pipeline. Said invented equipment includes hydraulic vibration piling machine, pile pipe centering guide, fixing equipment, fixing pile pipe and others.

Owner:中石化石油工程技术服务有限公司

Amphibious pile driver

InactiveCN101736741ALow turning resistanceImprove passabilityAmphibious vehiclesBulkheads/pilesMarine engineeringPile driver

The invention relates to the technical field of a pile driver and discloses an amphibious pile driver. The amphibious pile driver comprises a base, a working device arranged on the base, an elevated buoyancy tank. The base comprises an internal weight, a powerplant, a gearing device and a control device. The amphibious pile driver also comprises two sets of crawler units respectively arranged on both sides of the base bottom, with each comprising two parallel caterpillar belt mechanisms connected by a binding mechanism; and stretchable outriggers to adjust the height of the elevated buoyancy tank for different working depth. The stretchable outriggers are connected to the binding mechanism and the elevated buoyancy tank and transfer the power to the gearing device to drive the crawler units. This amphibious pile driver of invention can carry out the piling work in the offshore area safe and fast.

Owner:SANY ELECTRIC CO LTD

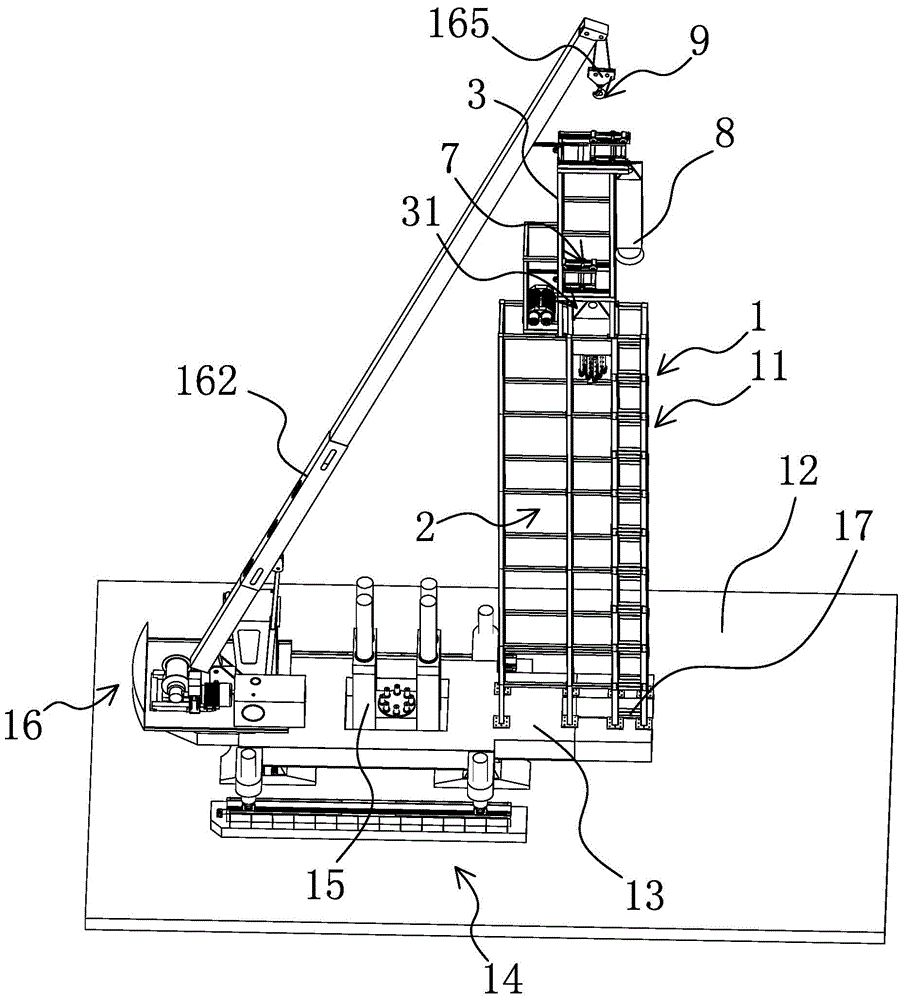

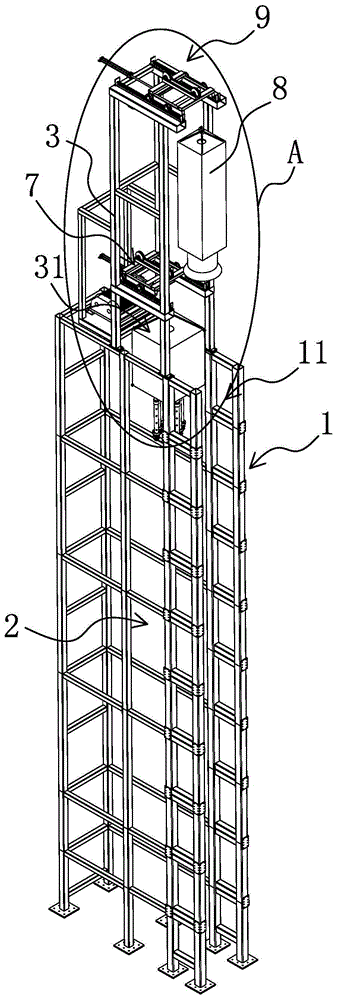

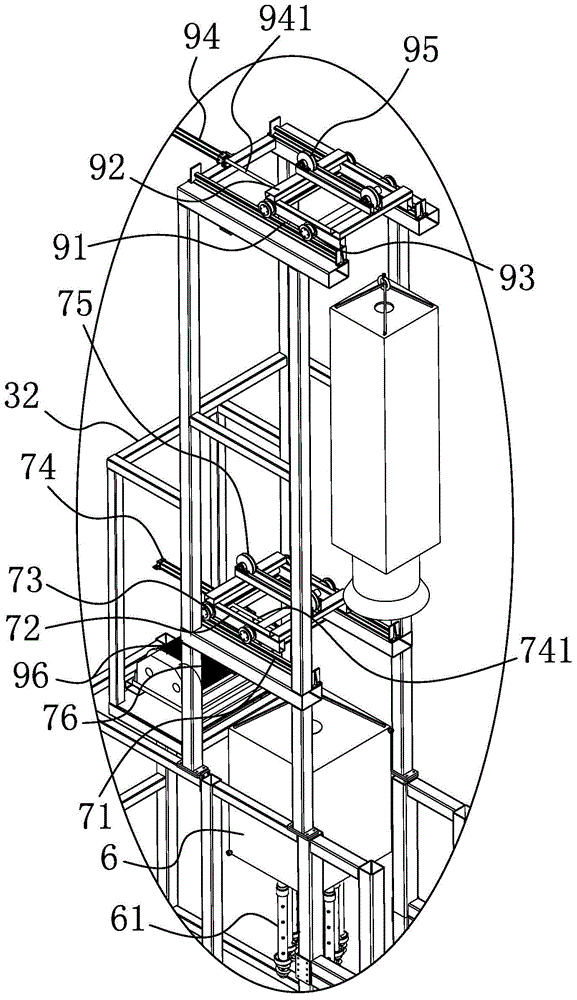

Comprehensive pile driver

ActiveCN105002908AImprove stabilityImprove driving stabilityDerricks/mastsDrilling drivesOperation modePile driver

The invention belongs to the technical field of construction equipment, and particularly relates to a comprehensive pile driver. The comprehensive pile driver solves the problem that an existing pile driver is single in operation mode. The comprehensive pile driver comprises a pile pressing table, a horizontal-movement drive structure, a pile driving bearing platform, a hoisting structure, a support body and a construction passage. A top frame body is arranged at the upper end of the support body. A drill rod containing cavity is formed in the top frame body, and a drill rod base with a plurality of drill rod bodies is arranged in the drill rod containing cavity. The drill rod base is connected with an adjustable drill rod drive structure. A pile hammer body is arranged on one side of the top frame body, and is connected with an adjustable pile hammer drive structure. The comprehensive pile driver has the advantages that a pile driving frame body can move transversely and longitudinally, and the stability of the pile driving frame body is good in the moving process; the weights of all the positions of the pile driver are balanced; the two operation modes of rotational pile driving and impact hammer pile driving are achieved, and the two operation modes do not interfere with each other and can be switched conveniently; the drive stability is good, the protecting effect is good, and the safety is high.

Owner:周兆弟

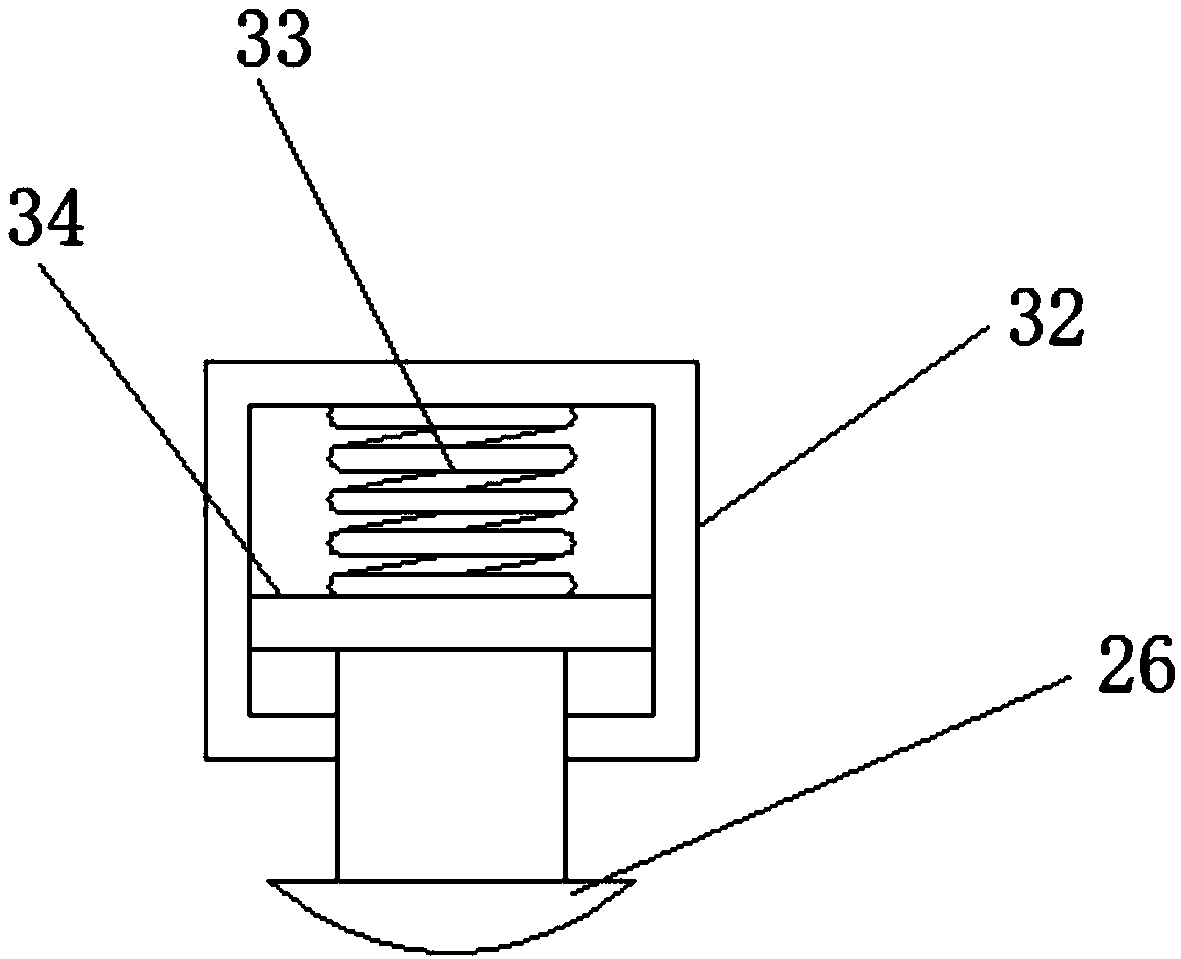

Rotary adjustable construction pile driver

PendingCN107604910AMove down quicklyImprove piling efficiencyBulkheads/pilesPhotovoltaic energy generationCircular discPile driver

The invention discloses a rotary adjustable construction pile driver which comprises a bottom plate. A circular disc parallel to the bottom plate is arranged above the bottom plate. A plurality of supporting posts arranged in a circular ring shape are arranged on the lower end surface of the circular disc. The lower ends of the supporting posts are connected with the bottom plate through a rotarysupporting mechanism. The circular disc is provided with a side plate. A supporting plate is further arranged on the left end surface of the side plate. Supports are arranged on the supporting plate,a transverse shaft is mounted on the supports, a rotating disc is arranged at the other end of the transverse shaft, an oscillating rod is arranged on one side of the end surface of the rotating disc,a driving protruding rod is arranged on the end surface of the rotating disc, a sector gear is arranged at the right end of the oscillating rod, a rack arranged vertically downward is arranged on a top plate and engaged with the sector gear, and a pile hammer is arranged at the lower end of the rack. The rotary adjustable construction pile driver provided by the invention is simple in structure,high in pile driving efficiency, adjustable in pile driving range, wide in applicability, easy and convenient to operate and high in practicability, and piles can be driven rotationally so as to adaptto pile driving of a circular fence.

Owner:ZHENGZHOU UNIV

Pile extractor and construction method for pile extraction

Disclosed is a pile driver which is composed of five parts, including a high pressure pump system, an air compressor system, a sleeve system, a vibratory sink piling system and a hoist system. A four-way joint(28)is arranged on one side of the water storage tank of the high pressure pump system and each tie-in is connected with a flush pipe; the flush pipes are respectively connected to flush pipes at the top parts of the four protecting jackets on the external wall of the sleeve through hollow bolts. A four-way joint is also arranged at one side of the air compressor and four inflation tubes drawn out are respectively connected with the inflation tubes at the top parts of the four protecting jackets. The bottom of each protecting jacket is provided with a water-gas mixture injector and is welded on the external wall of the sleeve. The top parts of the injectors are connected with the flush pipes and the inflation tubes inside the protecting jackets and each injector is provided with three spouts which align with the three tiny holes on the wall of the sleeve. The injectors eject high-pressure water-gas current to incise the soil around the pile to be pulled out, thus reducing the resistance between the pile to be pulled out and the surrounding soil. The pile driver will not break the pile to be drawn out and makes large-scale pile pulling possible.

Owner:江苏华东建设基础工程有限公司

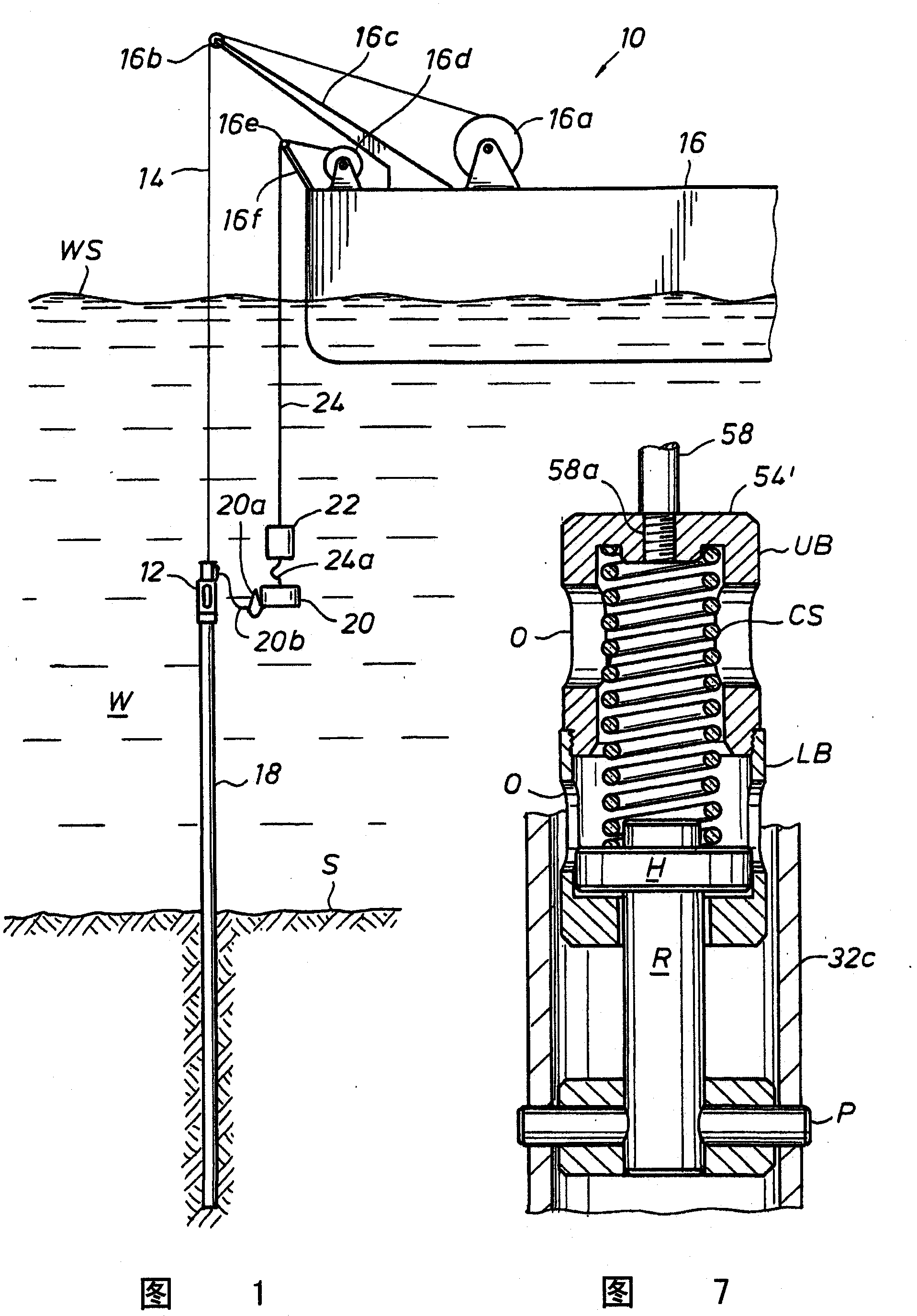

Deep water pile system and method

InactiveCN102159770ACheap manufacturingEasy to modifyBulkheads/pilesDrilling machines and methodsOcean bottomOn board

A pile driver is provided for use in deep water with a remotely operated vehicle (ROV) and a working ship for setting piles, pin piles and well conductors in subsea soil and for soil sampling in deep water and can be used for shallow water and land-based applications. A ram mass or hammer is received in an open frame and hydraulically reciprocated while in contact with water. A piston rod received in a piston cylinder is secured at one end to the hammer through a coupling mechanism, and an external source of hydraulic power is used with an on-board hydraulic circuit. Gas is compressed during an up-stroke to store energy, which is released during a down-stroke to push the hammer downwardly. The coupling mechanism provides a connection between the piston rod and the hammer that can move between an essentially rigid lift connection, an essentially rigid downward-push connection and an essentially non-rigid impact connection for preventing buckling of the piston rod when the hammer strikes at its lowermost point. One embodiment of the coupling mechanism includes a hollow body having opposing longitudinal slots, a rod slidably received in the hollow body that is pinned slideably at oneend in the opposing slots and pinned fixedly at the other end to the hammer, with a spring in the hollow body providing a bias to push the rod toward the hammer.

Owner:詹姆斯·E·阿达姆森

Construction equipment of hole drilling/punching cast-in-place pile with self-provided mud pit and mud separating device

The invention discloses construction equipment of a hole drilling / punching cast-in-place pile with a self-provided mud pit and a mud separating device, which consists of the self-provided mud pit, the mud separating device, normal / reverse circulation drilling / punching drilling machine and a caterpillar pile driver platform, and adopts the construction method that the mud pit is arranged on the caterpillar pile driver platform, the drilling machine simultaneously drills and removes sediments through a sediment removing pipe, and the mud is absorbed into a screen mud conveyor through a mud pipe to be preliminarily separated with the bigger clay particles being separated out; the separated mud flows into a mud separating tank, and the sediments sink into the extrusion mud separator to be removed; the liquid mud flows into the self-provided mud pit of the pile driver through a mud overflow hole and is injected into the pile hole for cyclic utilization through a mud flowrate control valve. The invention has the advantages that the mud pit is not required to be excavated on the construction site, so as to avoid the on-site mud contamination; the mud is filtered layer by layer with the clay particles and sediments being separated out for cyclic utilization; the mud concentration is controllable, the hole is regularly formed, and the hole forming is quick in speed; and the rock embedding performance is high, the bearing capability is high after the pile is driven, and the pile foundation is low in cost.

Owner:徐守田

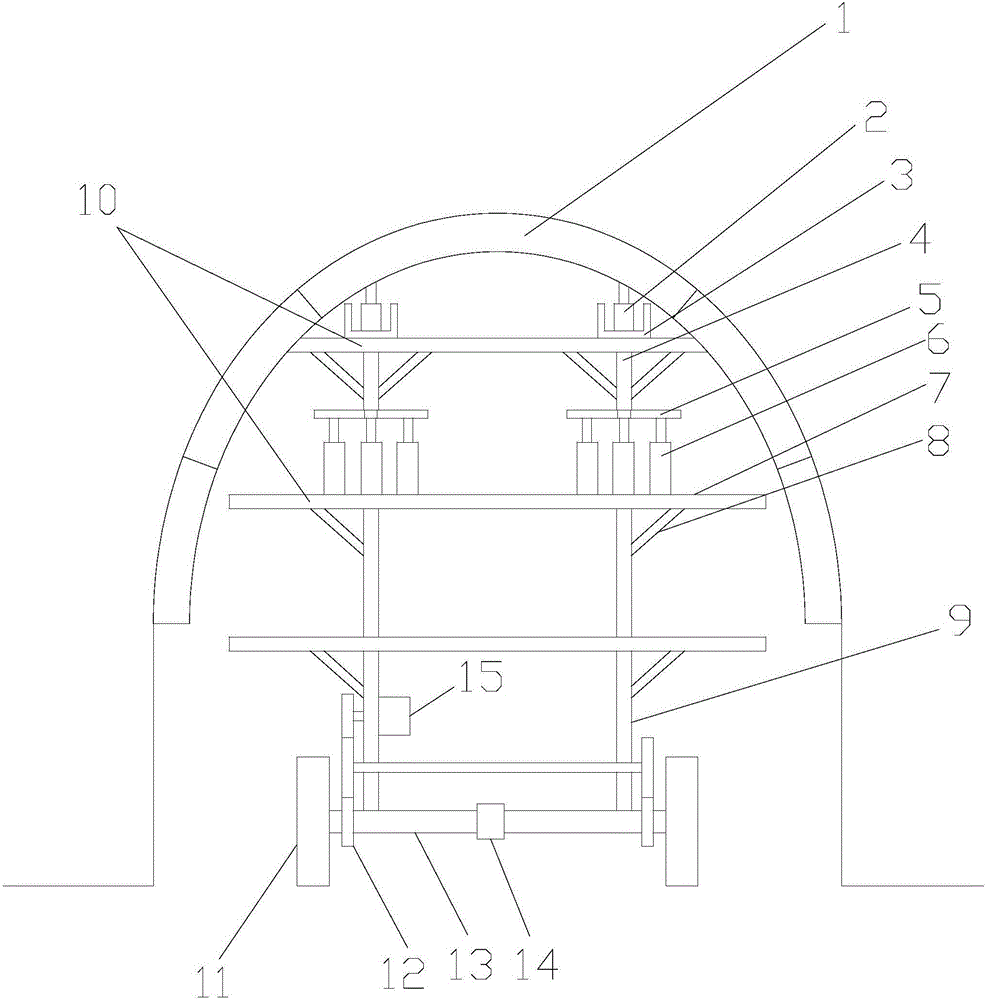

Movable steel arch bracing trolley

ActiveCN105863687AImprove adaptabilityImprove obstacle performanceUnderground chambersWheelsJackscrewRoad surface

The invention discloses a movable steel arch bracing trolley comprising a lower stand, an upper support, a plurality of deformable wheels for supporting the lower stand and driving the lower stand to move, and a steel arch jacking system; the steel arch jacking system comprises a jack unit I which is installed between the lower stand and the upper support for jacking the upper support and a jack unit II which is installed on top of the upper support for jacking a steel arch; both the jack unit I and the jack unit II comprise one or more jacks; the deformable wheels of the trolley are able to deform by driving a certain mechanism, so as to greatly increase the trafficability characteristic of the trolley; while traveling on ordinary roads, the deformable wheels can be kept round, allowing a pile driver traveling steadily at a high speed.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Pile driver with energy monitoring and control circuit

ActiveUS20050023014A1Efficient driveIncrease impact energyReciprocating drilling machinesDerricks/mastsAccelerometerControl system

A pile driver comprises a hammer for impacting a pile, a velocity sensor for measuring the velocity at impact, and a control system for adjusting the hammer stroke in accordance with the readings from the velocity sensor so that the optimal impact energy is imparted to the head of the pile. Optionally, the system further comprises a pile driving analyzer (including at least one strain gauge and / or an accelerometer) mounted on the side of the pile itself to determine whether the impact loading on the pile is below the maximum allowable stress. If the pile driving analyzer senses an overload of stress on the pile, the control system will reduce the velocity of the subsequent hammer stroke so that it no longer exceeds the maximum allowable stress.

Owner:BERMINGHAM FOUND SOLUTIONS LTD

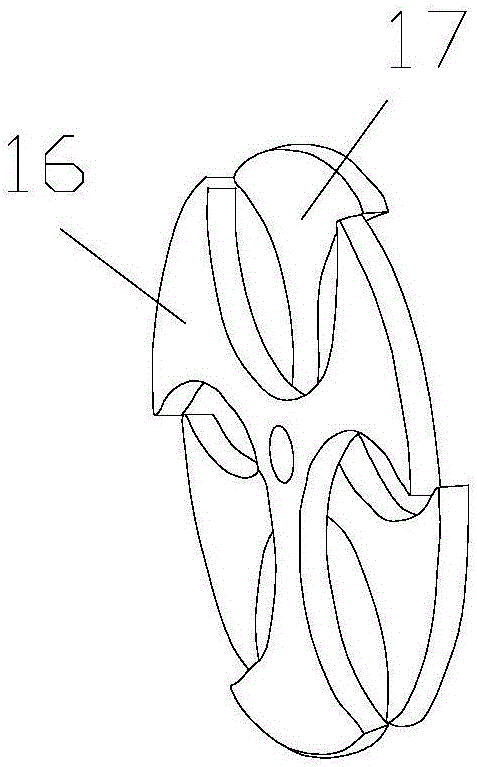

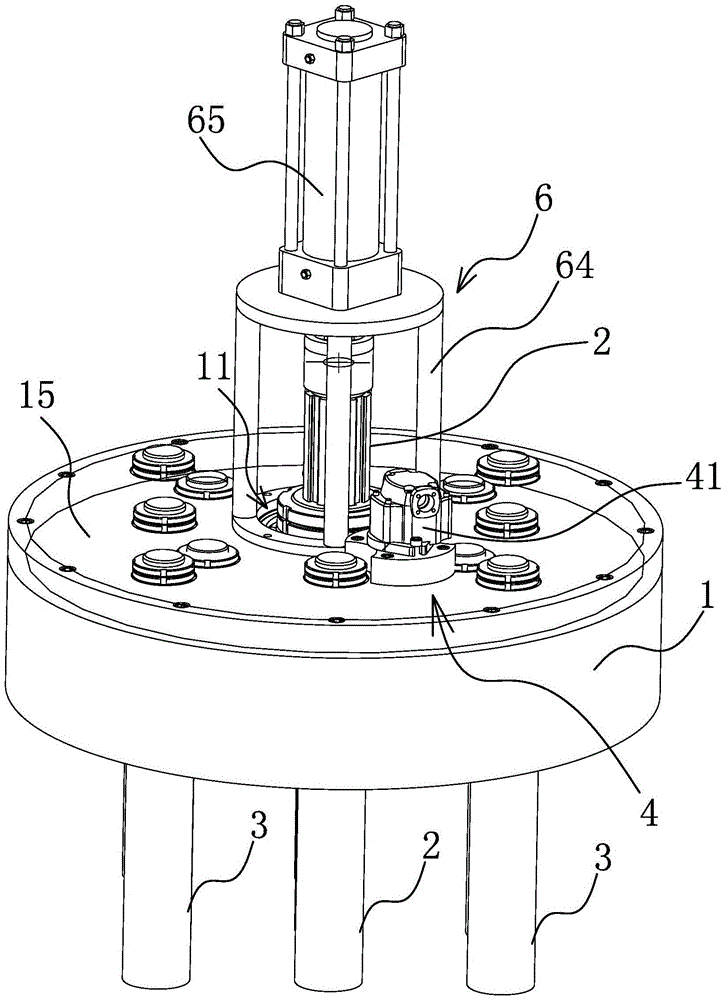

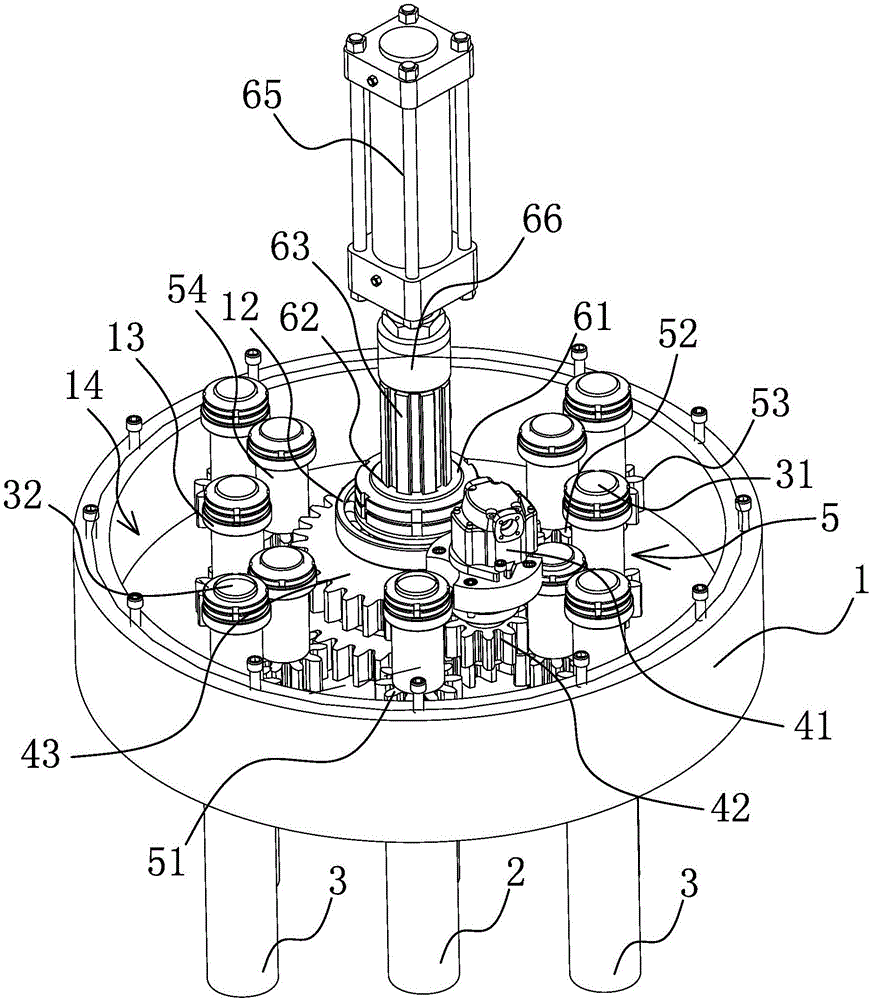

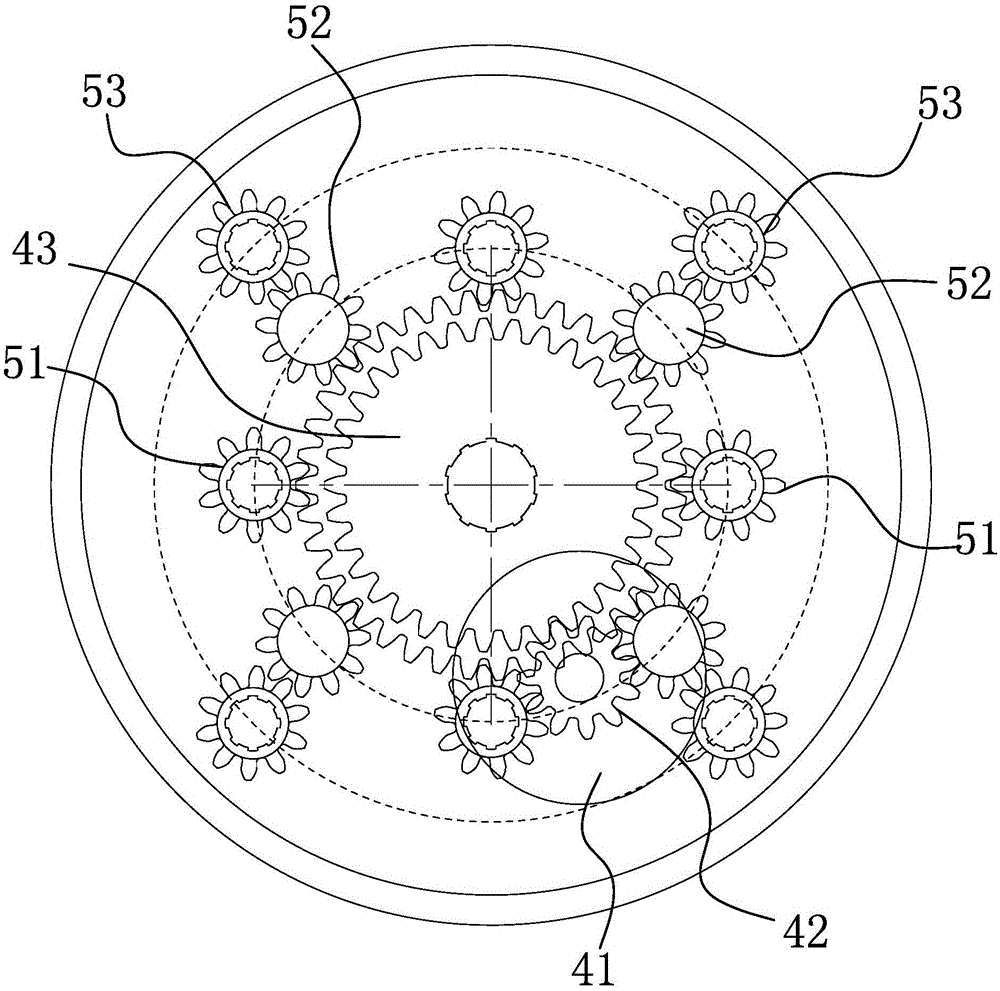

Drill rod rotation driving mechanism of cement soil mixing pile driver

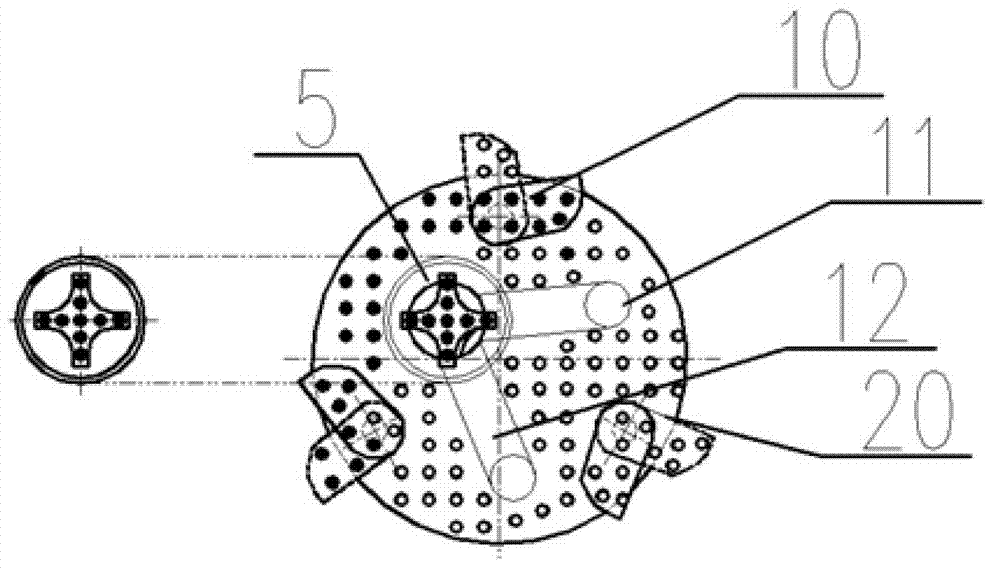

ActiveCN105002898AImprove pullout resistanceIncrease girthBorehole drivesBulkheads/pilesSoil mixingPile driver

The invention belongs to the technical field of construction equipment, and particularly relates to a drill rod rotation driving mechanism of a cement soil mixing pile driver. The drill rod rotation driving mechanism of the cement soil mixing pile driver solves the problem that stirring is uneven when an existing cement soil mixing pile driver is used for drilling. The drill rod rotation driving mechanism of the cement soil mixing pile mixer comprises a drive box with an inner cavity; the drive box is provided with at least one main drill rod arranged in the vertical direction; at least two auxiliary drill rods are arranged on the outer side of the circumference of the main drill rod; the main drill rod is connected with a main drill rod driving structure capable of driving the main drill rod to rotate in the circumferential direction; an auxiliary drill rod transmission structure is arranged between the main drill rod and the auxiliary drill rods. The drill rod rotation driving mechanism of the cement soil mixing pile driver has the advantages that a single driver can achieve homodromous and reverse-direction movement of the main drill rod and the auxiliary drill rods, so that stirring uniformity is improved; drill rod bodies can axially stretch out and draw back and can axially slide while rotating circumferentially, the phenomenon of being unable to drill is not prone to happening, the perimeter of the cross section of a cement soil mixing pile after construction is increased, and the anti-pulling capacity of the cement soil mixing pile is improved.

Owner:周兆弟

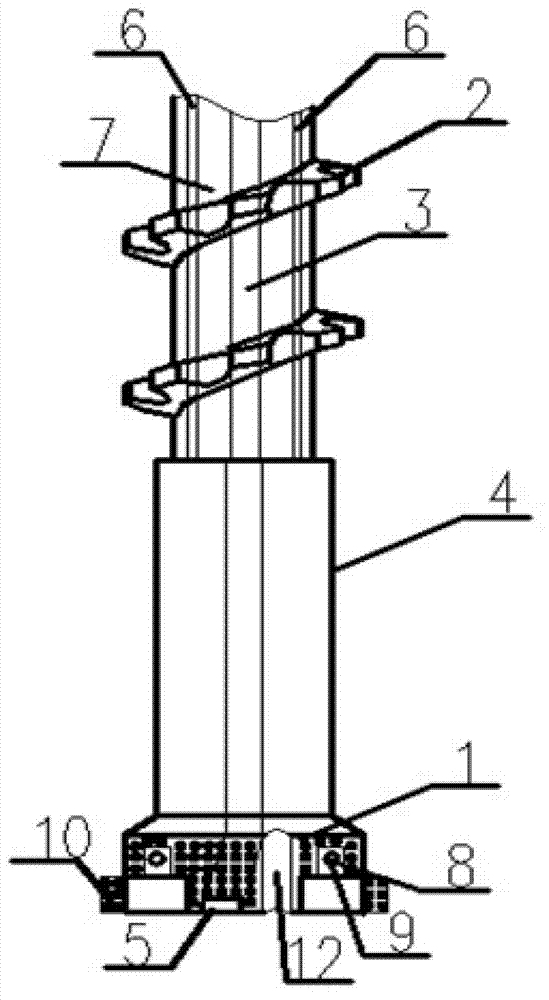

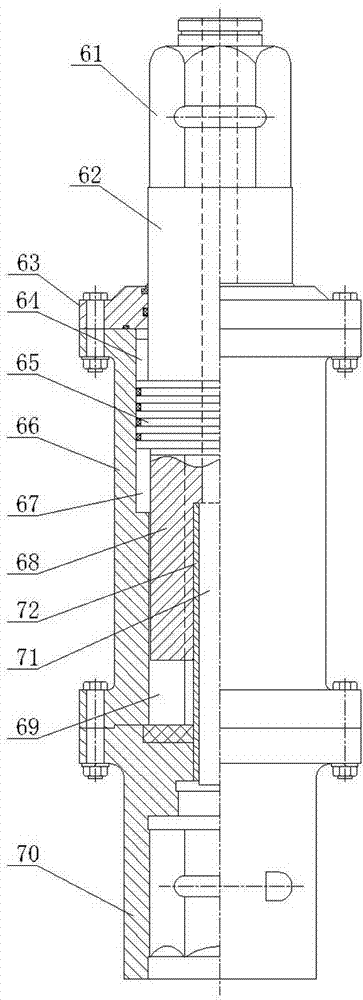

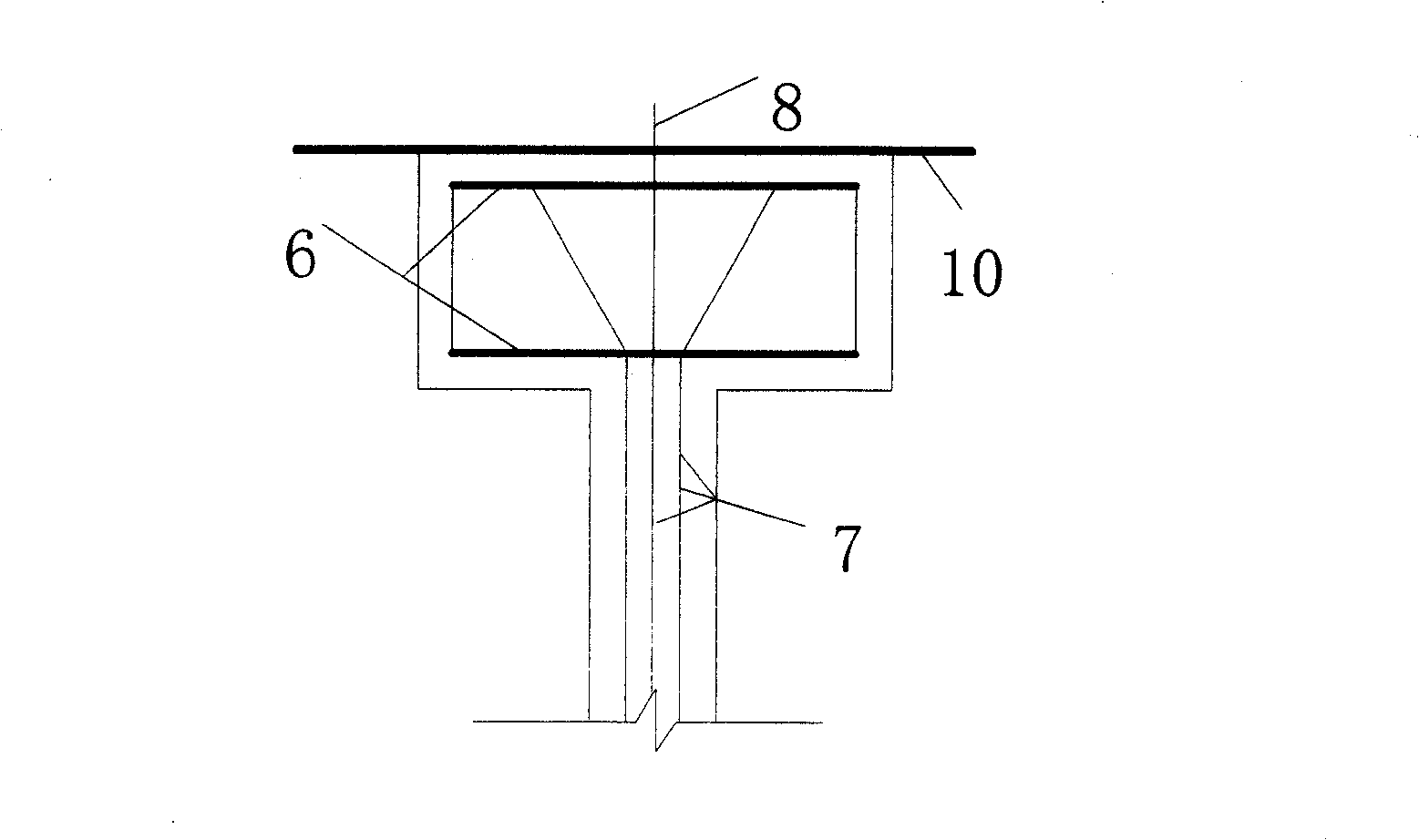

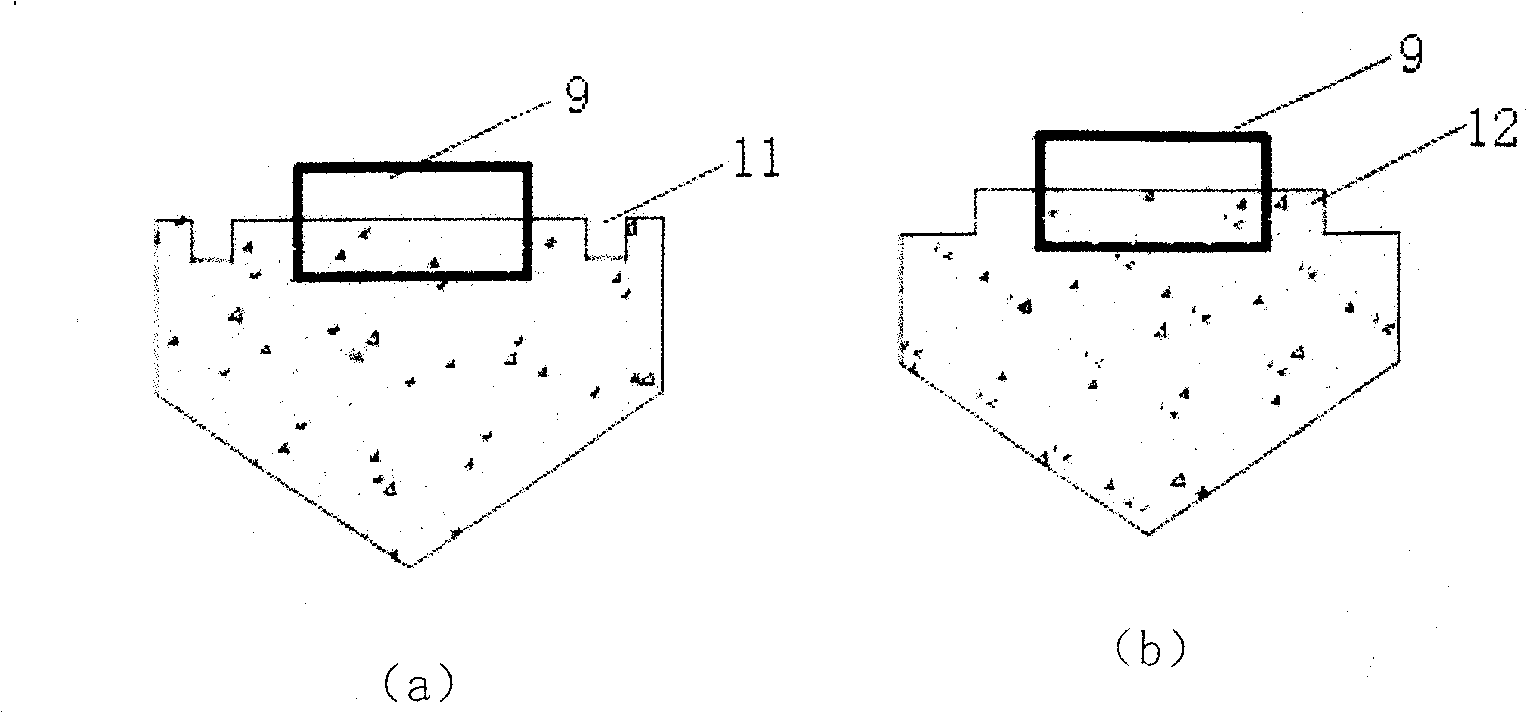

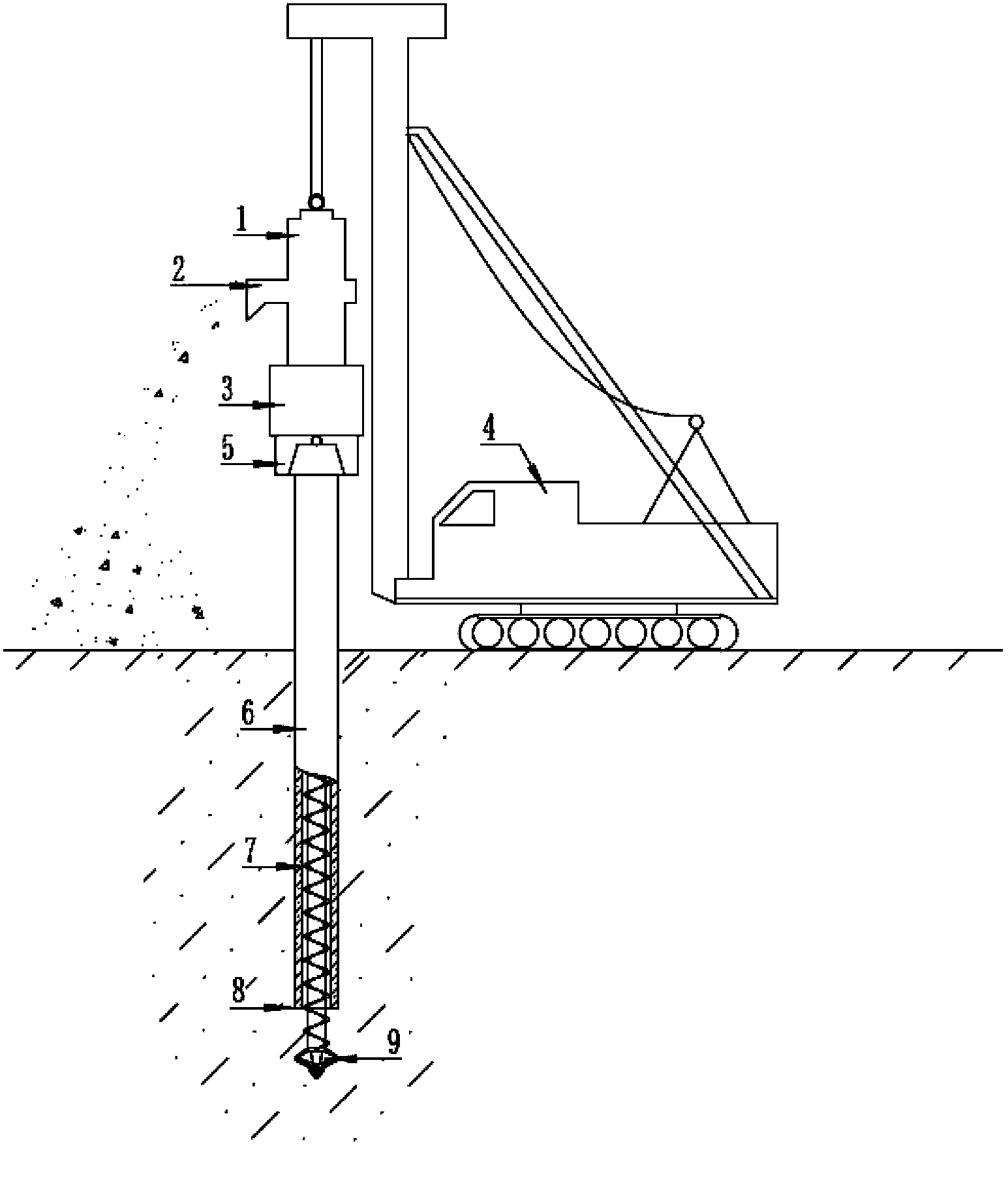

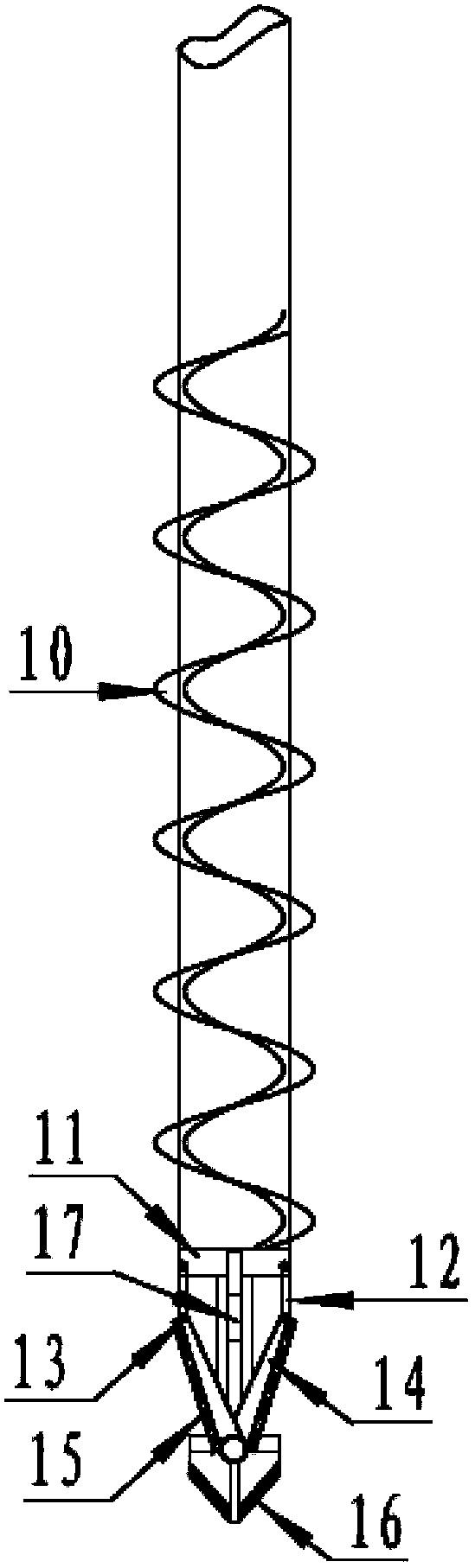

Construction method and device for guide displacement pressure precast pile

InactiveCN103628480AEasy extractionSpeed up construction progressDrill bitsBorehole drivesHardnessDisplacement pressure

The invention discloses a construction method and device for a guide displacement pressure precast pile. The construction device comprises a spiral drill power head (1), a soil outlet (2), a multi-functional pile hammer (3), a pile driver (4), a chuck (5), a long spiral drilling tool (7), a precast pile bottom (8), a drill bit (9) and a spiral piece (10), wherein the drill bit (9) is a diameter-expanded drill bit. In the construction process, the drill bit (9) can expand outwards to spirally cut off the soil on the lower portion of the precast pile; after the construction, the drill bit (9) contracts so as to draw back smoothly. Because the construction method and device are adopted for construction, construction programs are simple, and the construction can be smoothly carried out on a hard stratum with great hardness.

Owner:SHANGHAI ZHONGJI PILE IND

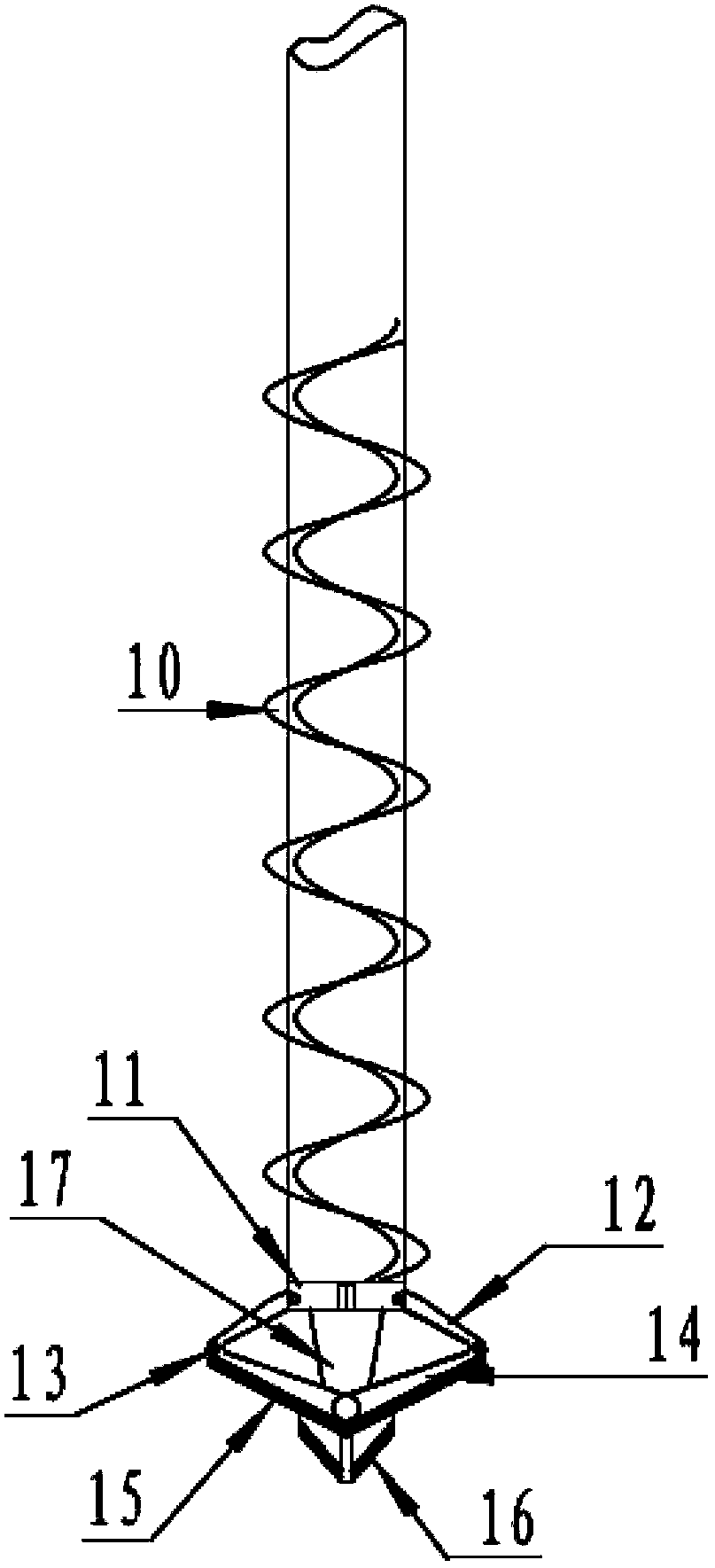

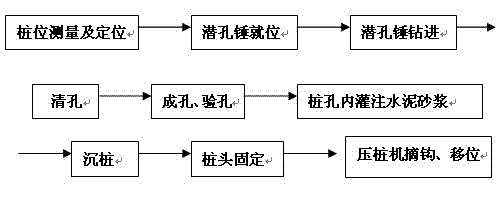

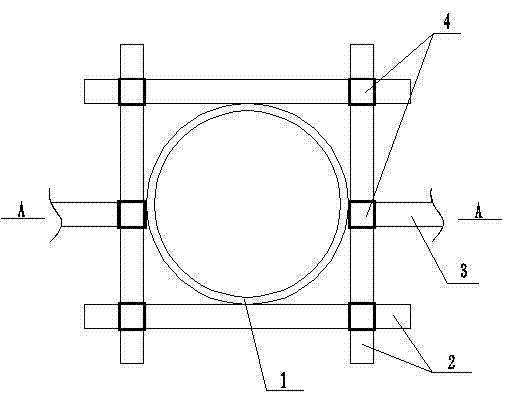

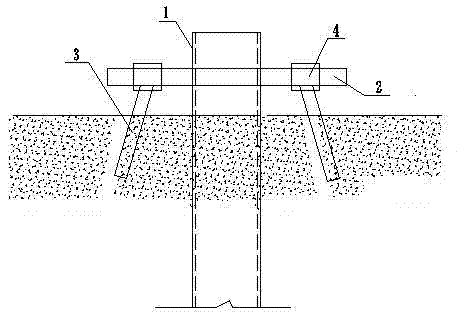

Prestressed pipe pile construction method under boulder group geological conditions

InactiveCN103290840AHigh selectivityPrevent buried drilling phenomenonBulkheads/pilesPre stressArchitectural engineering

The invention relates to a pipe pile construction method, in particular to a prestressed pipe pile construction method under boulder group geological conditions. According to the method, a down-the-hole hammer drilling process is adopted for guide hole construction; during pile sinking construction, first cement mortar is poured in a pile hole, and then a static pile driver is utilized to press a pipe pile into the pile hole; during pile head fixing construction, a #-shaped fixing frame formed by connecting fasteners is utilized to fix a pile head through a steel pipe at the position of an orifice of the pile hole, a splayed steel pipe is adopted to support two ends of the #-shaped fixing frame, the lower end of the steel pipe is embedded in a soil layer; and after the cement mortar is hardened and is integrated with surrounding rock stratums and the pipe pile, prestressed pipe pile construction is finished. According to the prestressed pipe pile construction method, a hole forming speed is quick, a construction period is short, and construction cost can be reduced by over 10%; by adopting a mode of pouring the cement mortar in the guide hole, pipe pile side pressure, end bearing capacity and the position of the pile side can be guaranteed, and side-direction stress safety of the pipe pile can be guaranteed; a pile head fixing head is simple, construction is convenient, verticality of the pipe pile is guaranteed, and bearing capacity of the prestressed pipe pile is also effectively improved.

Owner:二十二冶集团天津建设有限公司

High-intensity prestressed concrete tubular pile lead hole hammering construction method for soft soil layer

ActiveCN102011401ASolve the carrying capacityAddress mechanical propertiesFoundation testingBulkheads/pilesMaterials processingEarth surface

The invention discloses a high-intensity prestressed concrete tubular pile lead hole hammering construction method for a soft soil layer. The method comprises the following construction steps of: measuring and positioning; performing lead hole construction by using a long twist drill; and constructing by using a guide-rod diesel hammer pile driver. The construction method solves the problems of low earth surface bearing capacity, inconvenient construction machinery, material processing and transportation, serious influence of weather and the like existing on a construction site. A pile foundation is manufactured without cast-in-place concrete, so that the defect of reaching design required intensity of a concrete pile foundation by waiting for about a month is overcome; and gas shielded welding is performed between pile sections, so that the shearing resistance of a weld position is enhanced. After all, the construction method fulfills the aims of shortening construction period, saving money and ensuring engineering quality and is particularly suitable for construction of soft soil layers with poor bearing force and prestressed tubular piles with earthquake-proof intensity of lower than grade 7. Of course, the construction method is widely applicable to construction of other floor civil buildings.

Owner:PINGMEI SHENMA CONSTR ENG GROUP

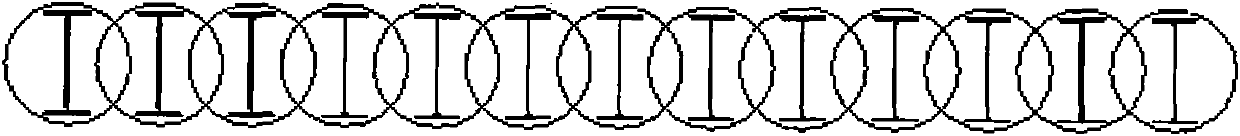

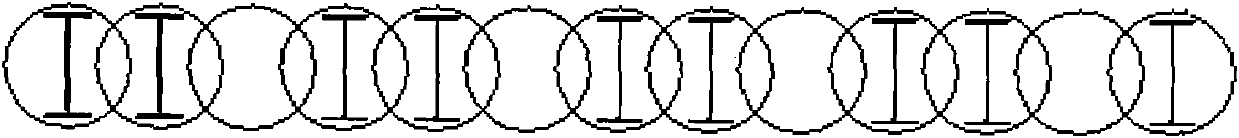

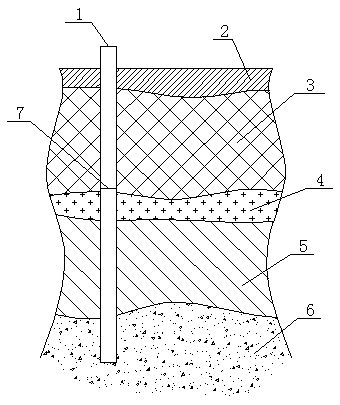

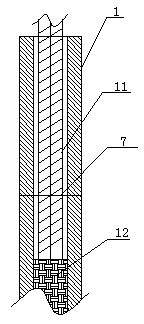

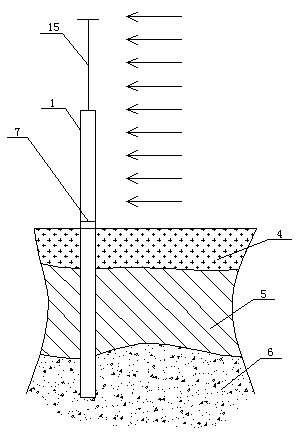

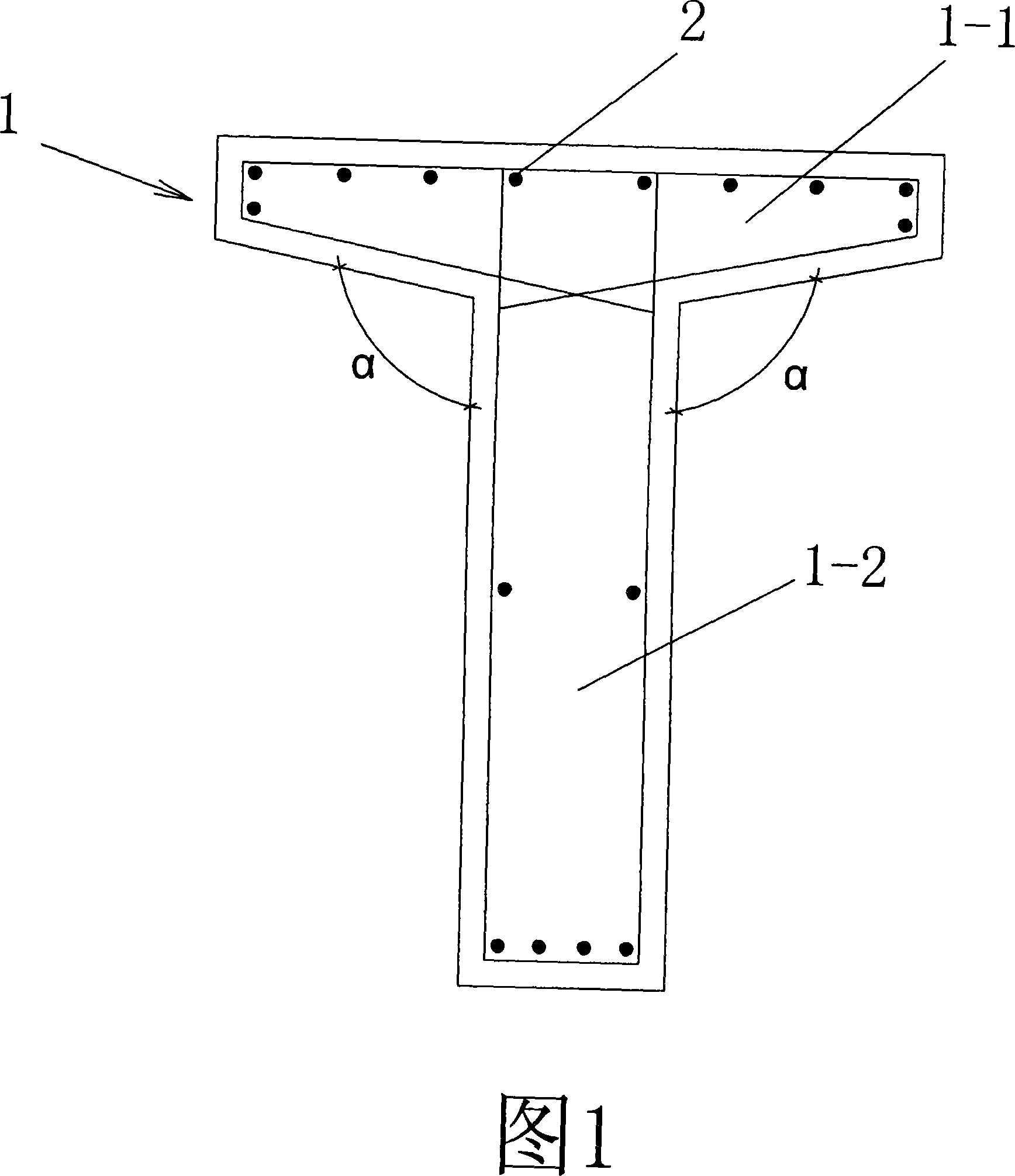

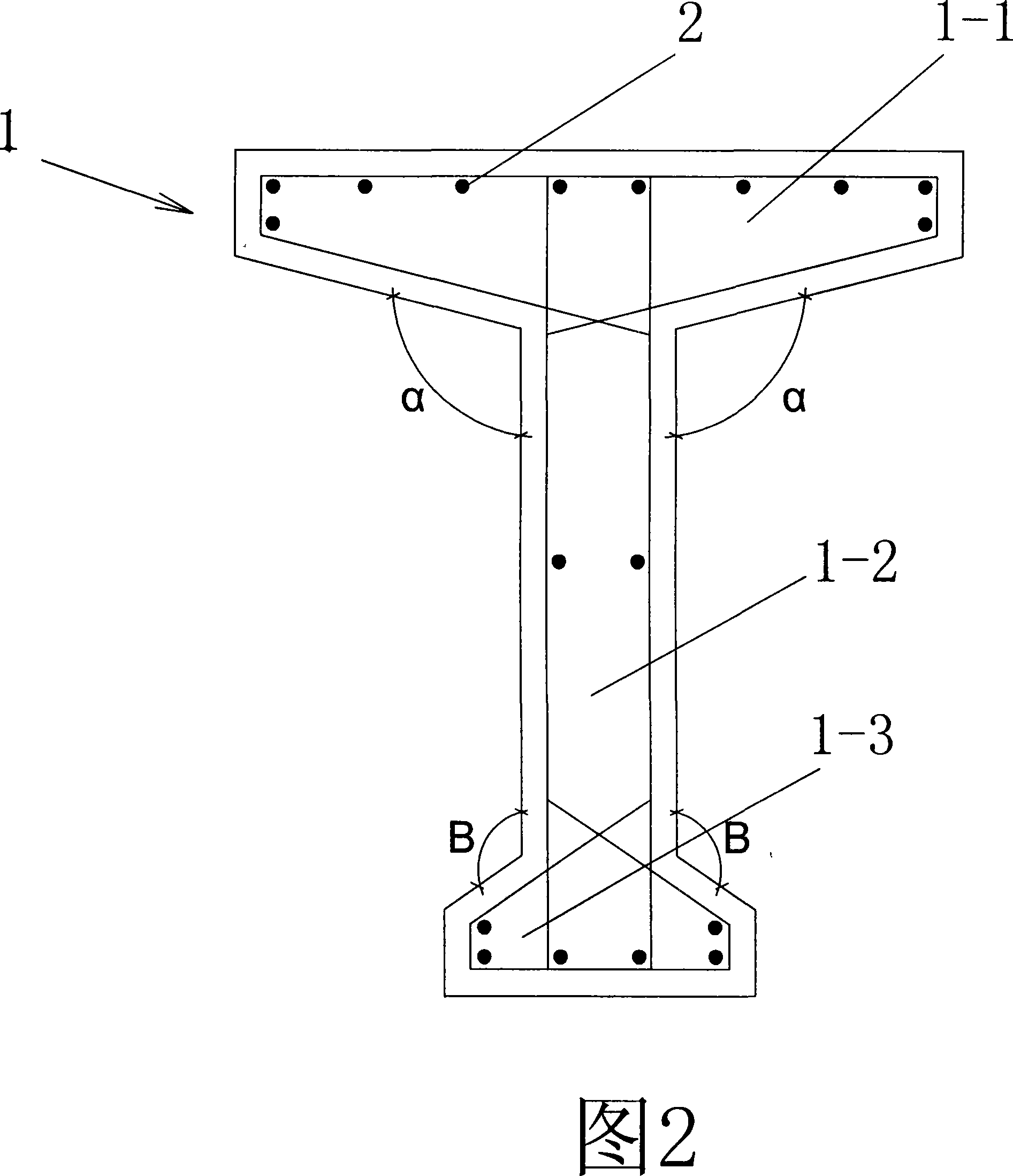

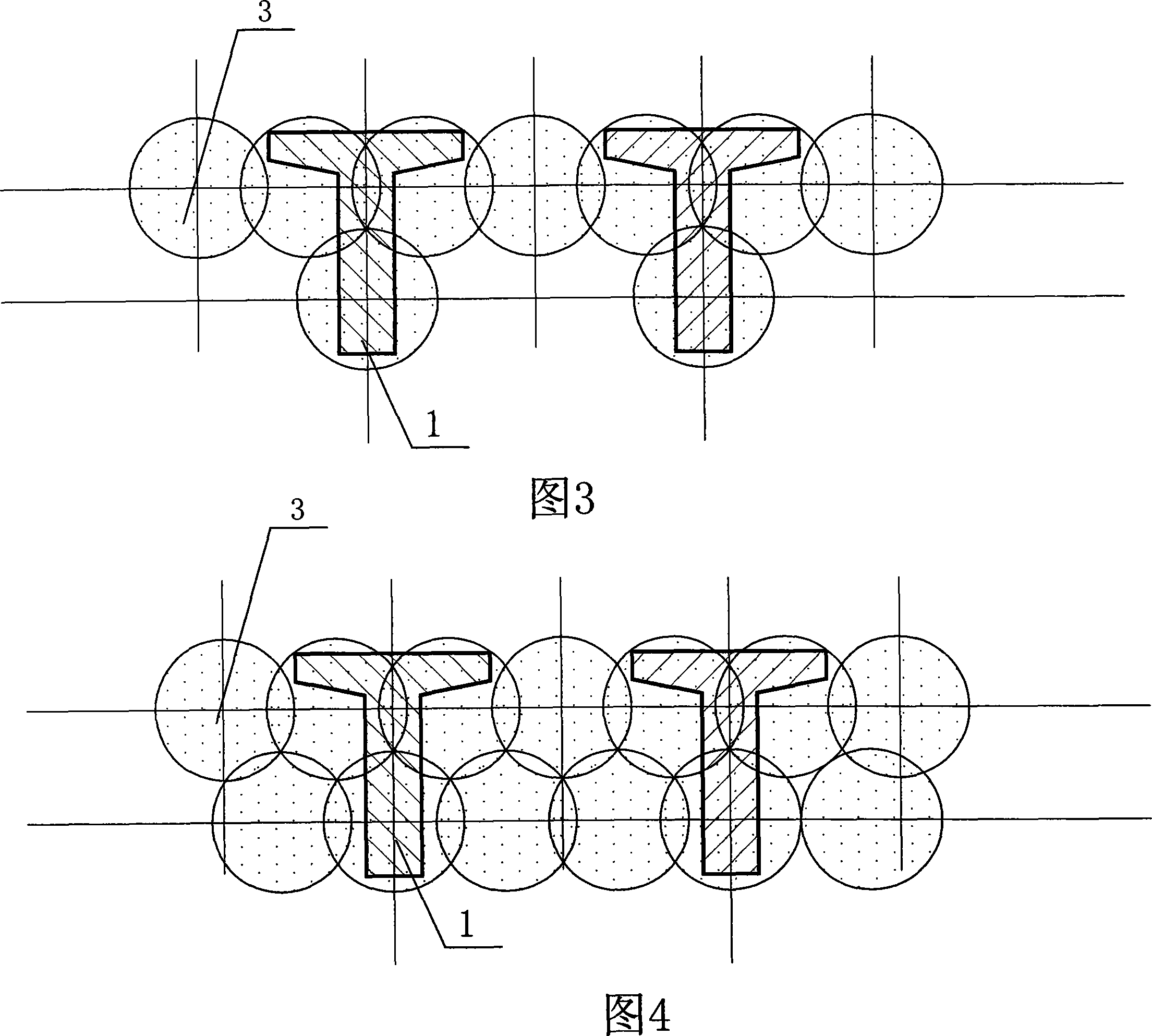

Method for embedding cement purdah into prefabricated reinforced concrete anti-lateral-force pile

InactiveCN101078216AMeet the force requirementsMeet deformation requirementsExcavationsSlurryRound face

The invention relates to a method that cement mixed soil curtain implants lateral force resistance pile of prefabricated reinforced concrete. Main procedures are described as follows. In construction site, cement mixer is used to mix soil in the whole journey or in upper water-stopping curtain part to form curtain along the implanting depth aiming to soil quality and soil extruding status; then it is implanted into pile body by pile driver to form retaining and waterproof enclosure wall. Thereinto pile body adopts prefabricated reinforced concrete T-shape / I-shape pile. Because powerful mixing soil or drilling machine is used to dig hole and inject grout, it is suitable for enclosure project of all kinds of soil qualities in principle. The beneficial effect of invention is that reinforcement ribs of T-shape or I-shape section are located at two ends of section; compared with circular pile with reinforcement ribs distributed along round face, the bending strength can be improved by more than 20% and the section area only is half of corresponding circular pile, namely concrete amount is saved in half. Ant it is provided with rapid construction speed, reliable quality, no noise and no pollution to circumstance by carrying slurry out so on.

Owner:严平 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com