Multifunctional pile driver

A piling machine, multi-functional technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of narrow application range, low efficiency, labor and time-consuming method of excavating foundation groove cast-in-place piles, etc., and achieves a wide range of applications. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

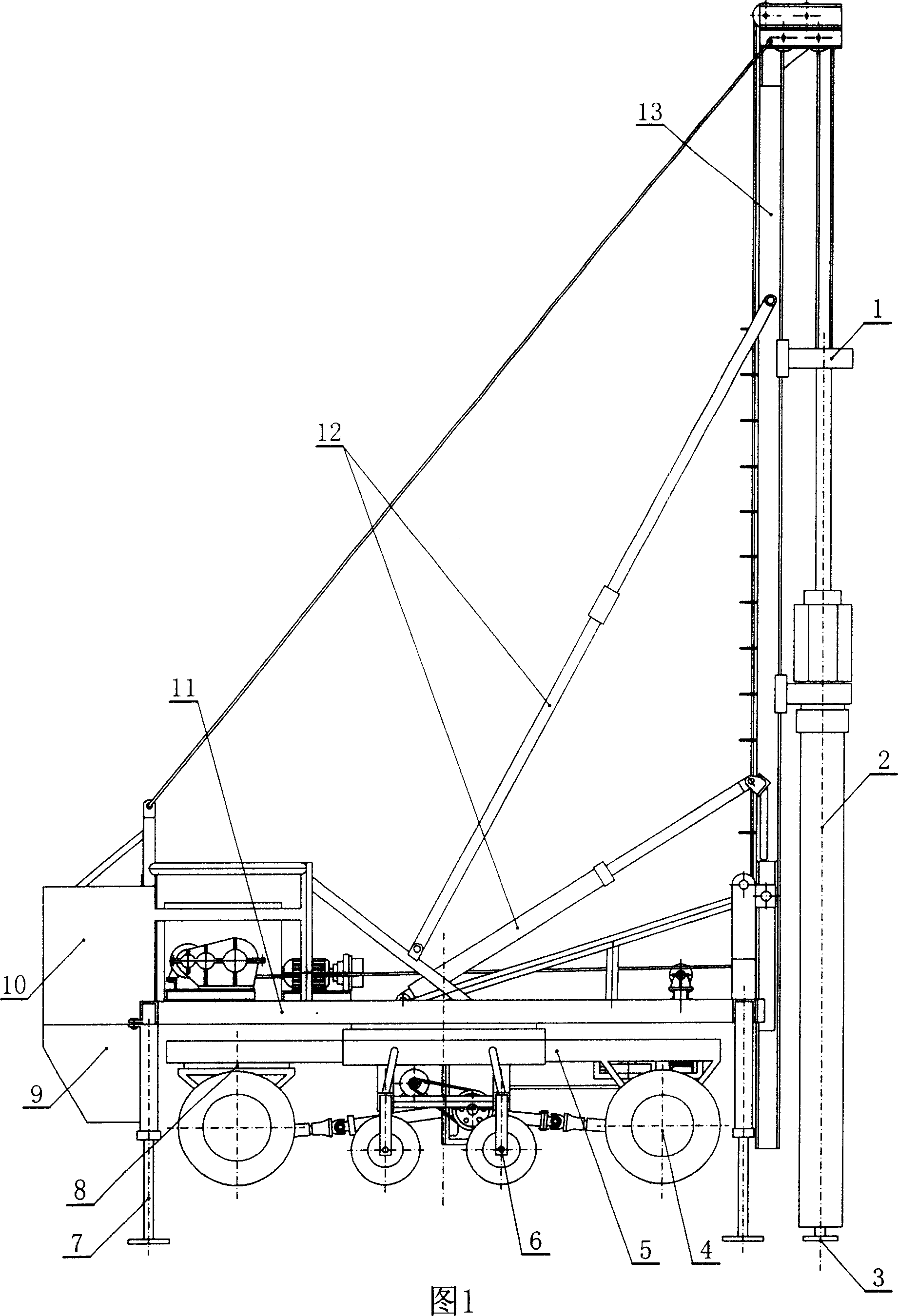

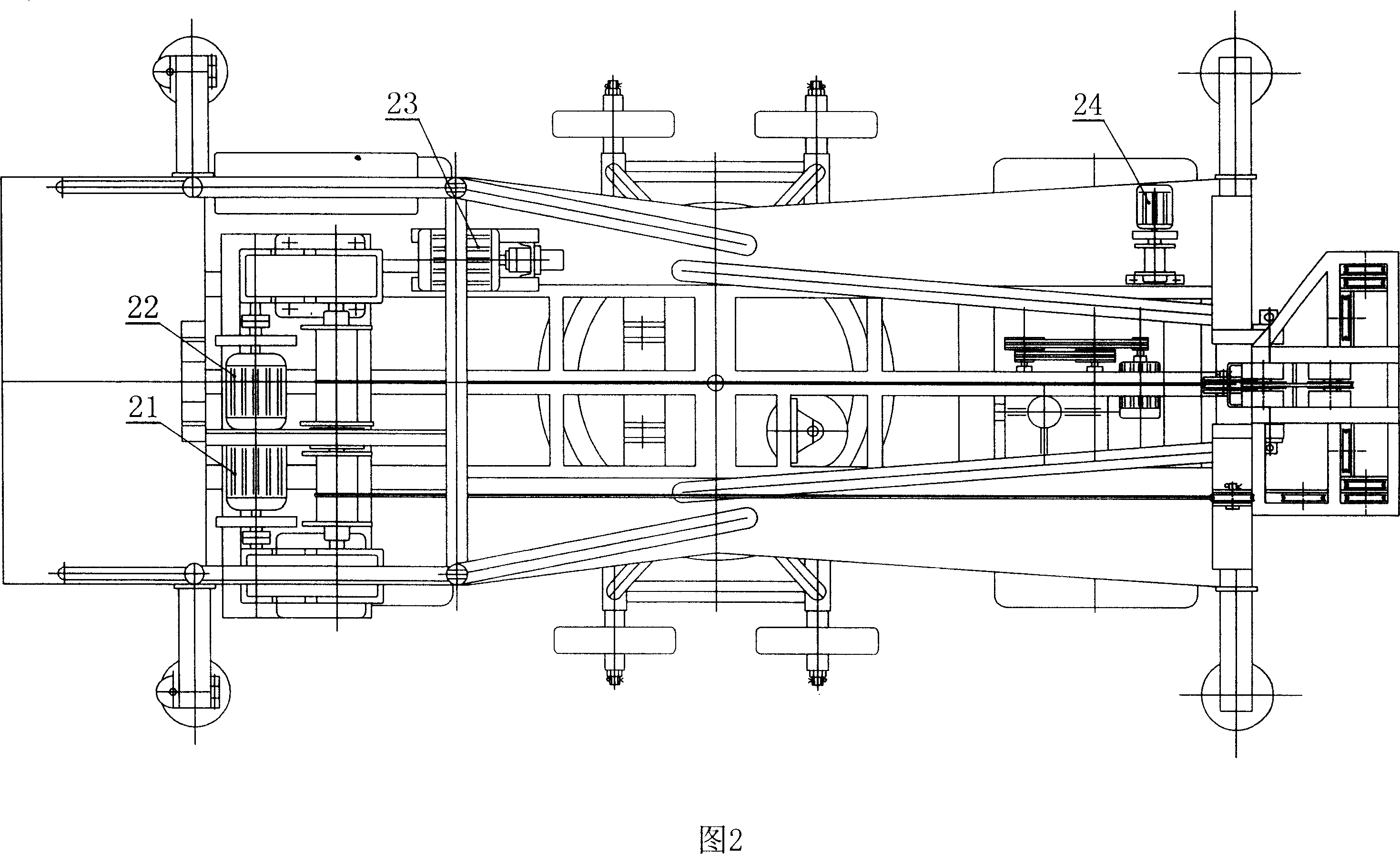

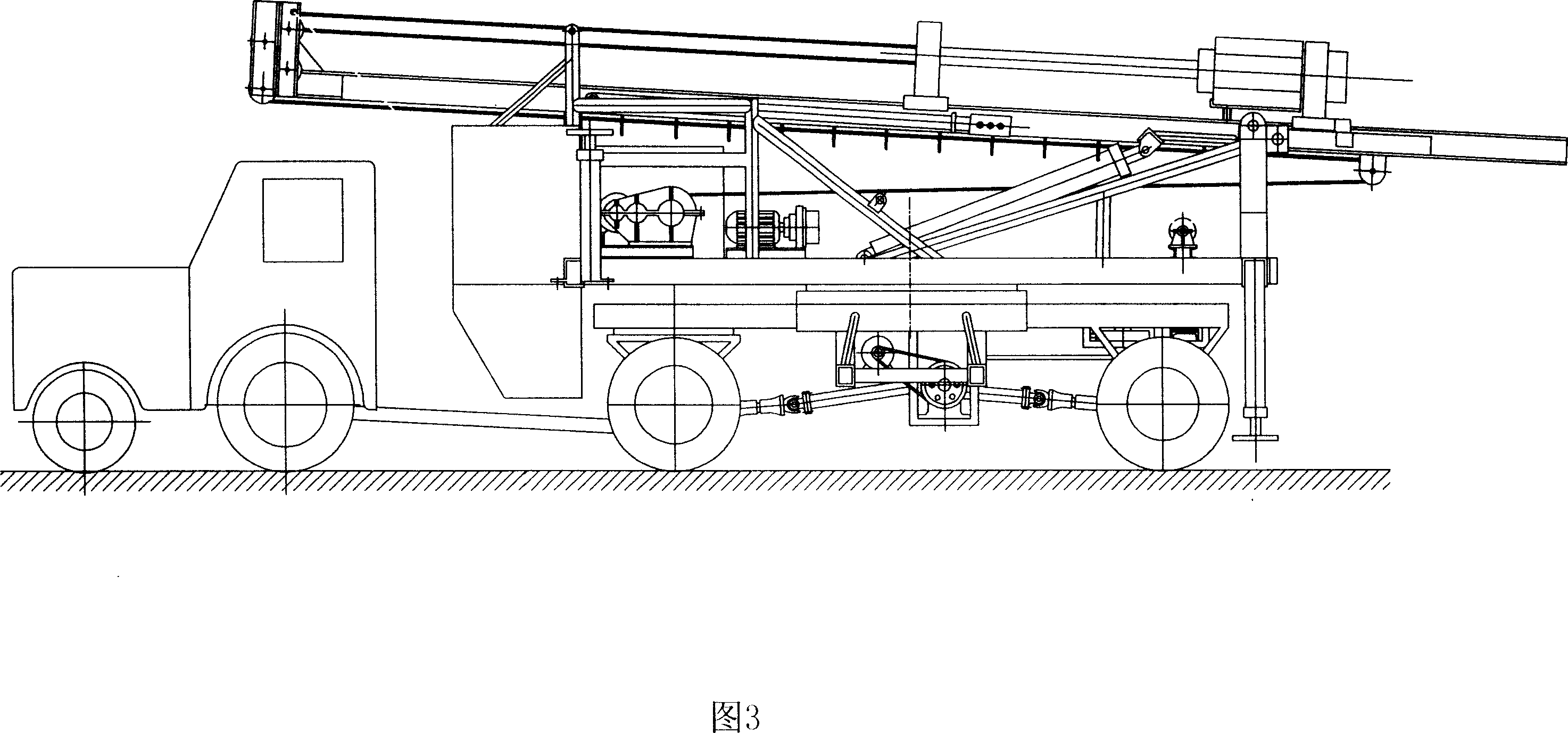

[0056] A multifunctional pile driver, as shown in Figures 1 to 28, Figure 31, and Figure 32, includes an upper pile frame 11 and a lower pile frame 5, the upper pile frame 11 and the lower pile frame 5 are connected in relative rotation, and the lower pile frame Frame 5 is equipped with walking device 4, and pile frame 11 is equipped with supporting device 7, and counterweight sand box 9 is installed at the rear end of pile frame 11, and the front end of pile frame 11 is hinged with guide rail column 13, and guide rail column 13 slides up and down and is connected with Pile sinking device; the front end of the walking device 4 has a front steering device 8; the middle part of the lower pile frame 5 has an auxiliary support device 6; a diagonal brace device 12 is installed between the upper pile frame 11 and the guide rail column 13; in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com