Deep water pile system and method

A hammer block and component technology, which is applied in the field of tamping equipment, can solve the problem of the limit of the usable depth of the pile hammer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention provides a ramming or beating device that can be used in extremely deep water and methods and systems for using the same. The equipment can be used to drive piles, drive pipes used as deep water well-leaders, and can be used to drive soil sampling devices into subsea soil. Ramping or beating equipment can be used in shallow water and on land, however it is believed to be especially useful in deep water applications.

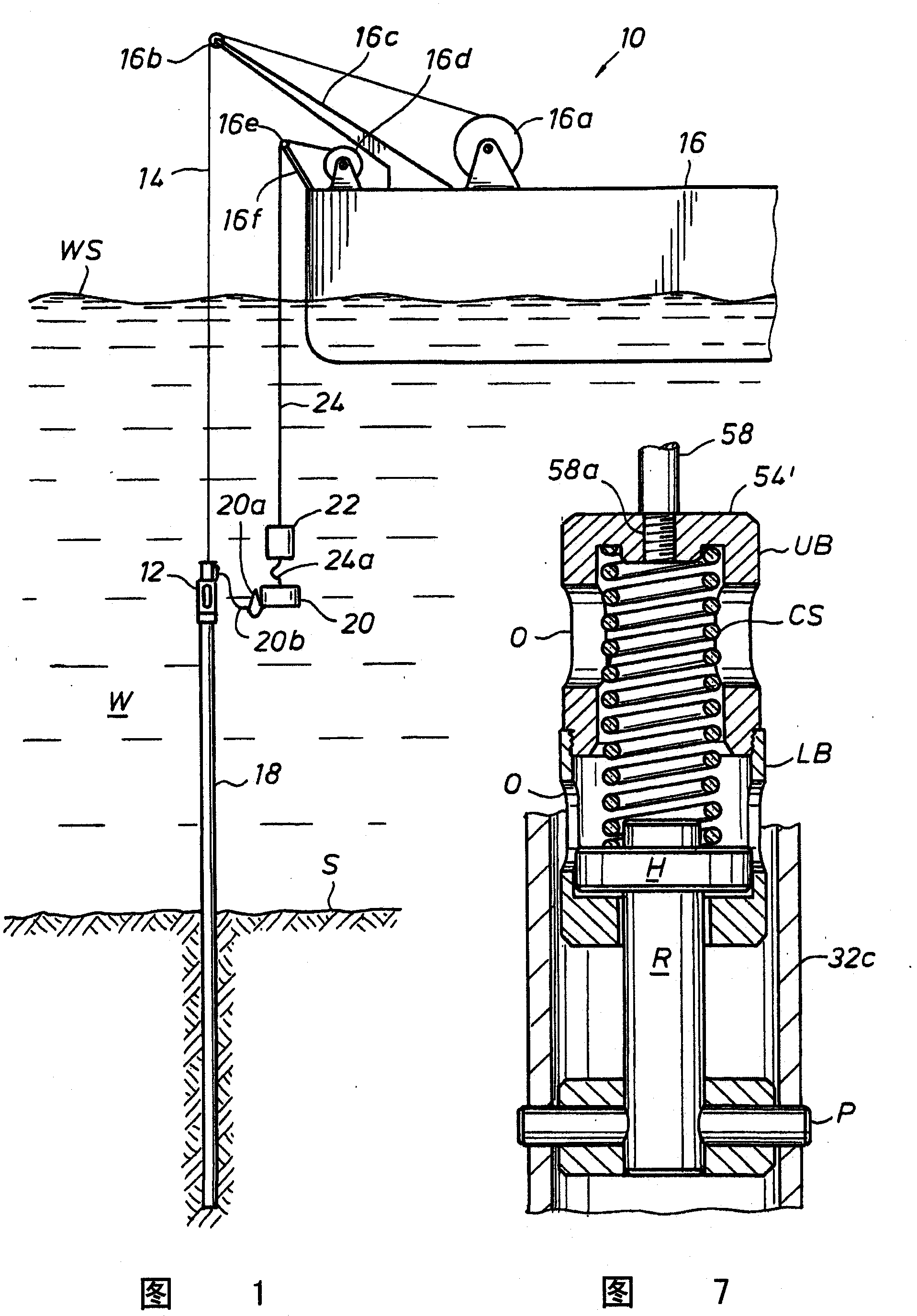

[0023] Go to attached image and refer to figure 1 , shows a side view of the ramming or beating system 10 of the present invention. The ramming or beating device 12 is connected by a lift line 14 to a water supply vessel 16 such as a boat or barge via a hoist 16a which can be used to lower and raise the ramming device 12 . The lift line 14 passes through a pulley 16b attached to the crane arm 16c. The hammering device 12 is shown in this embodiment as driving a stake 18 into subsea soil S, which may be located several thousand feet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com