Patents

Literature

122 results about "Round face" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The facial appearance is more circular than usual as viewed from the front. [pmid:19125436]

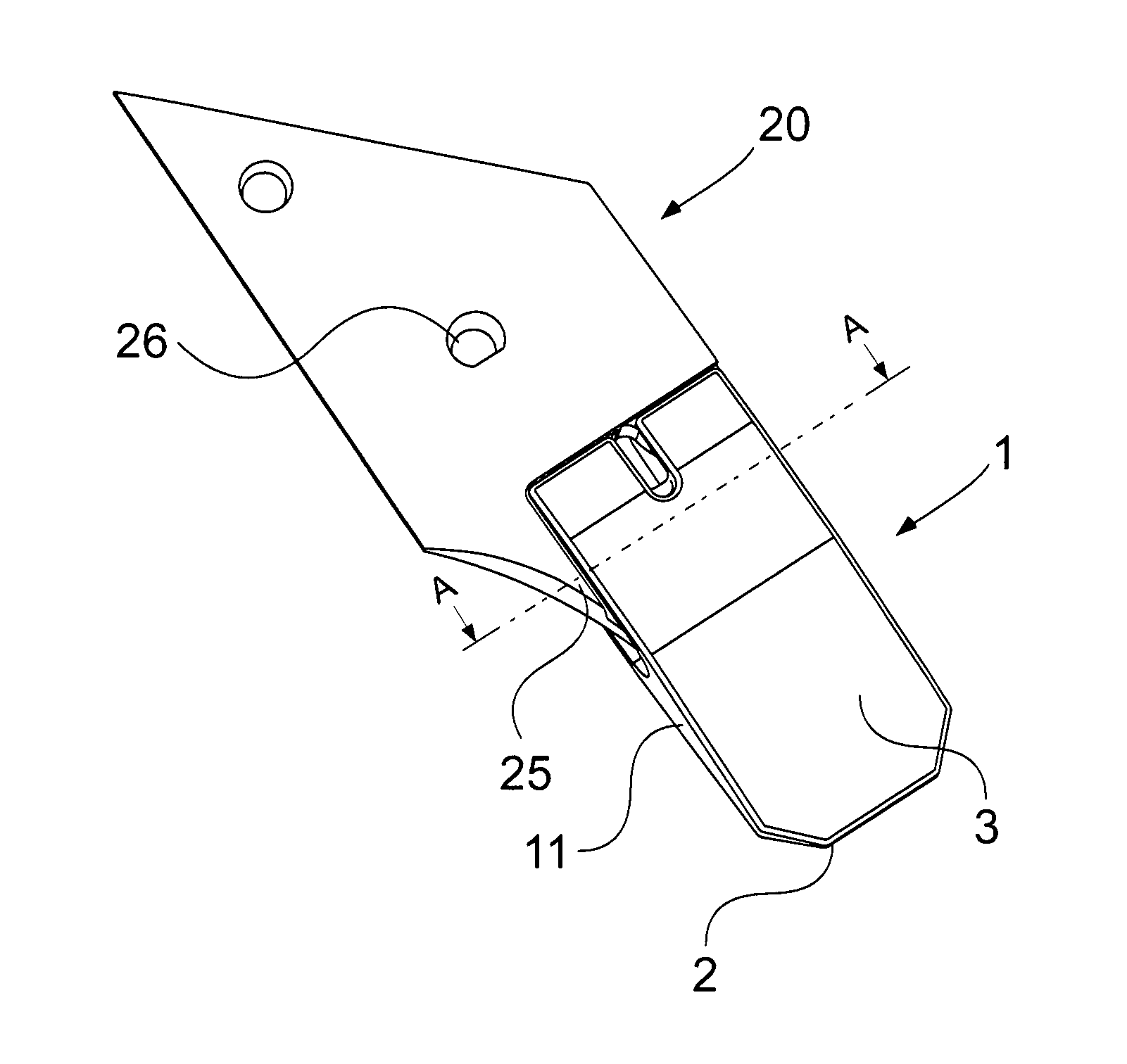

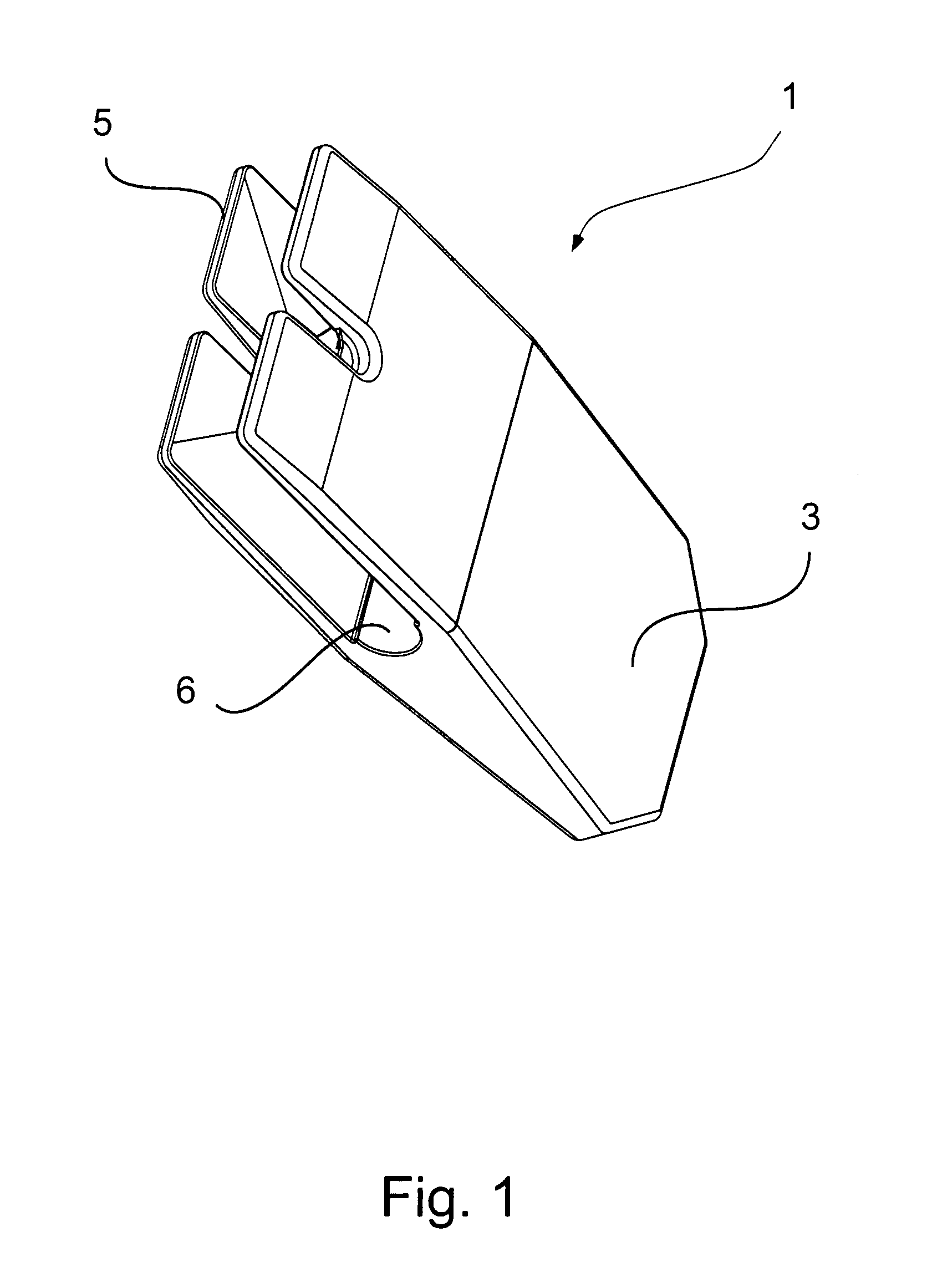

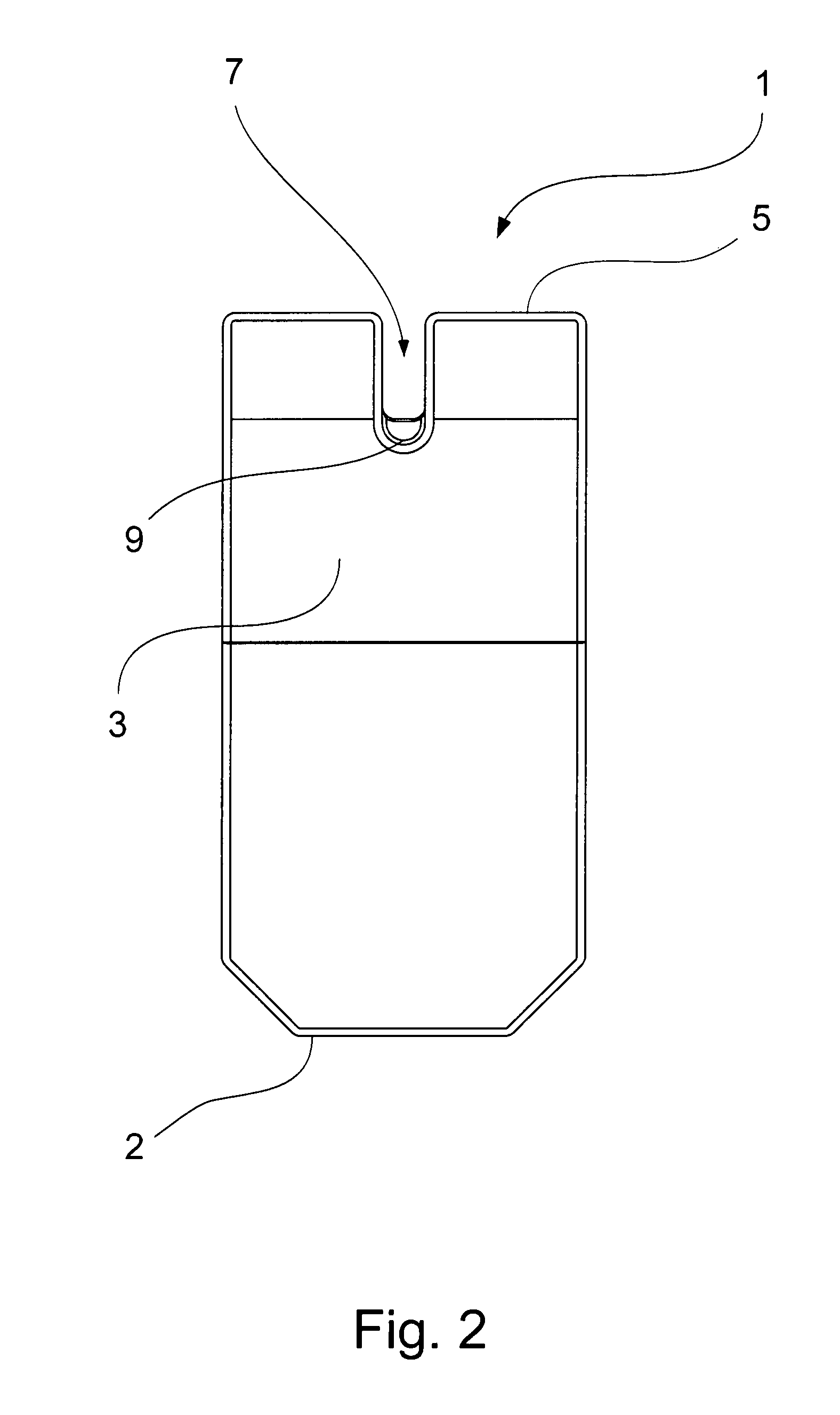

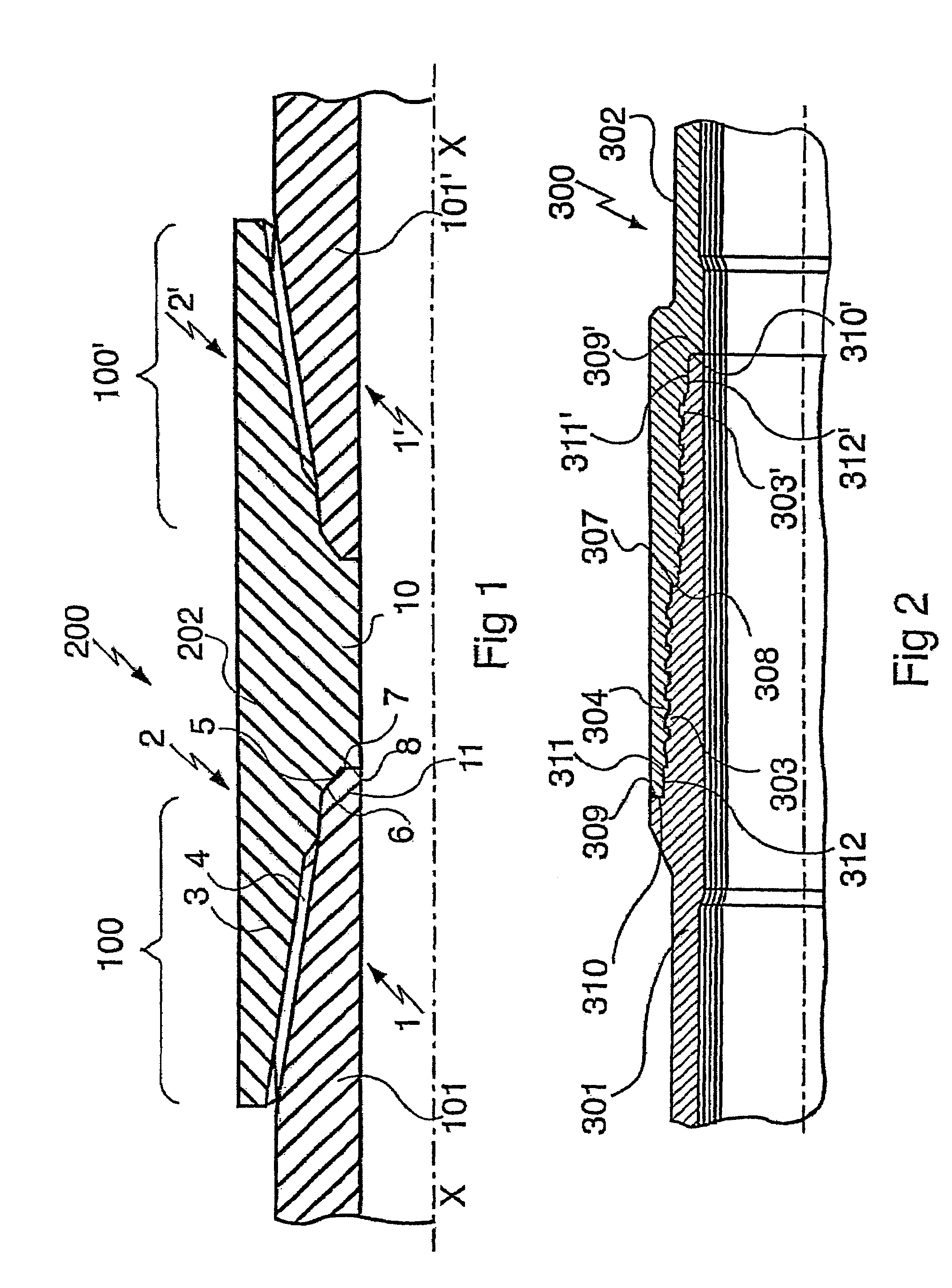

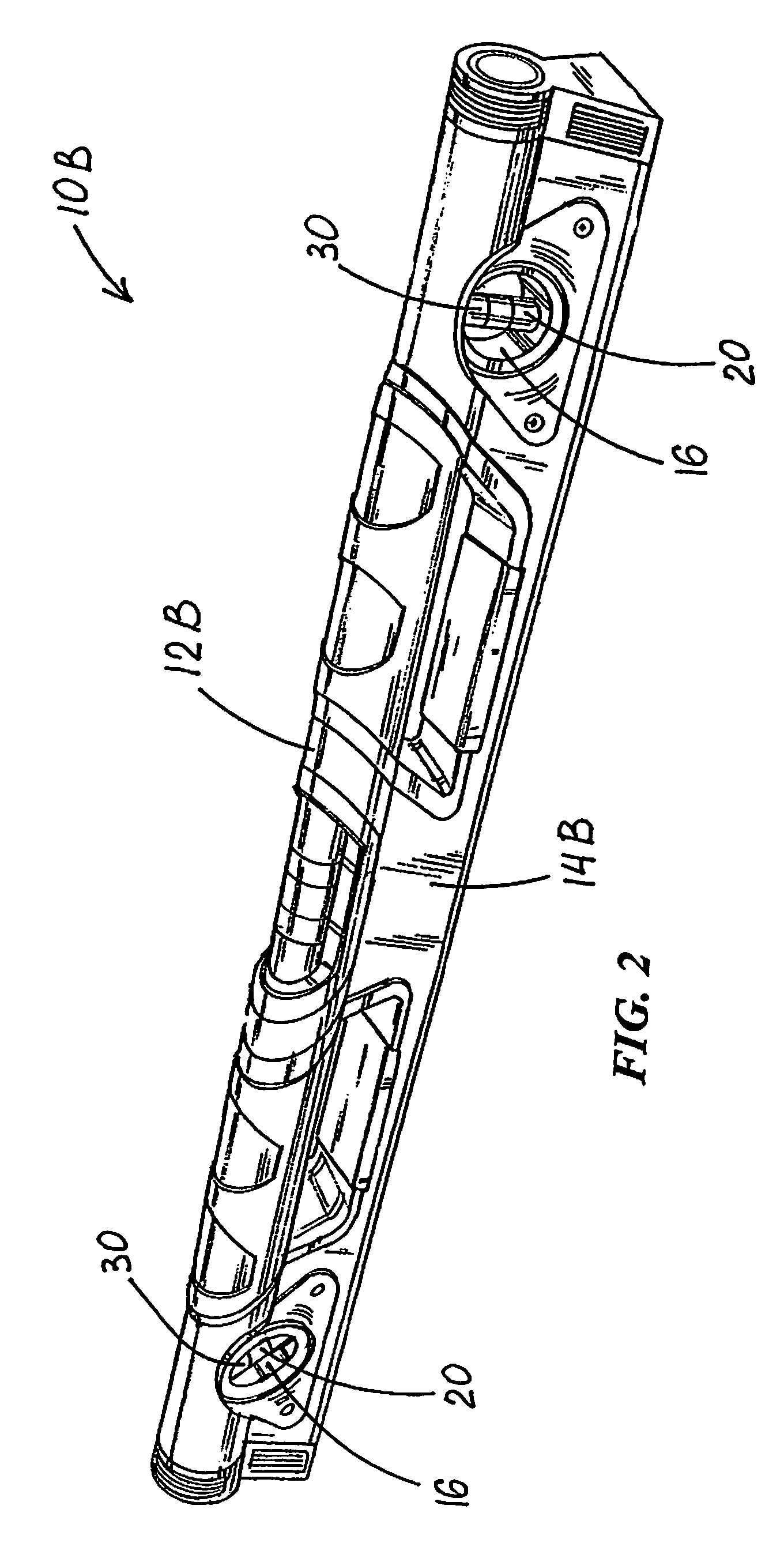

End bit for a soil-working tool

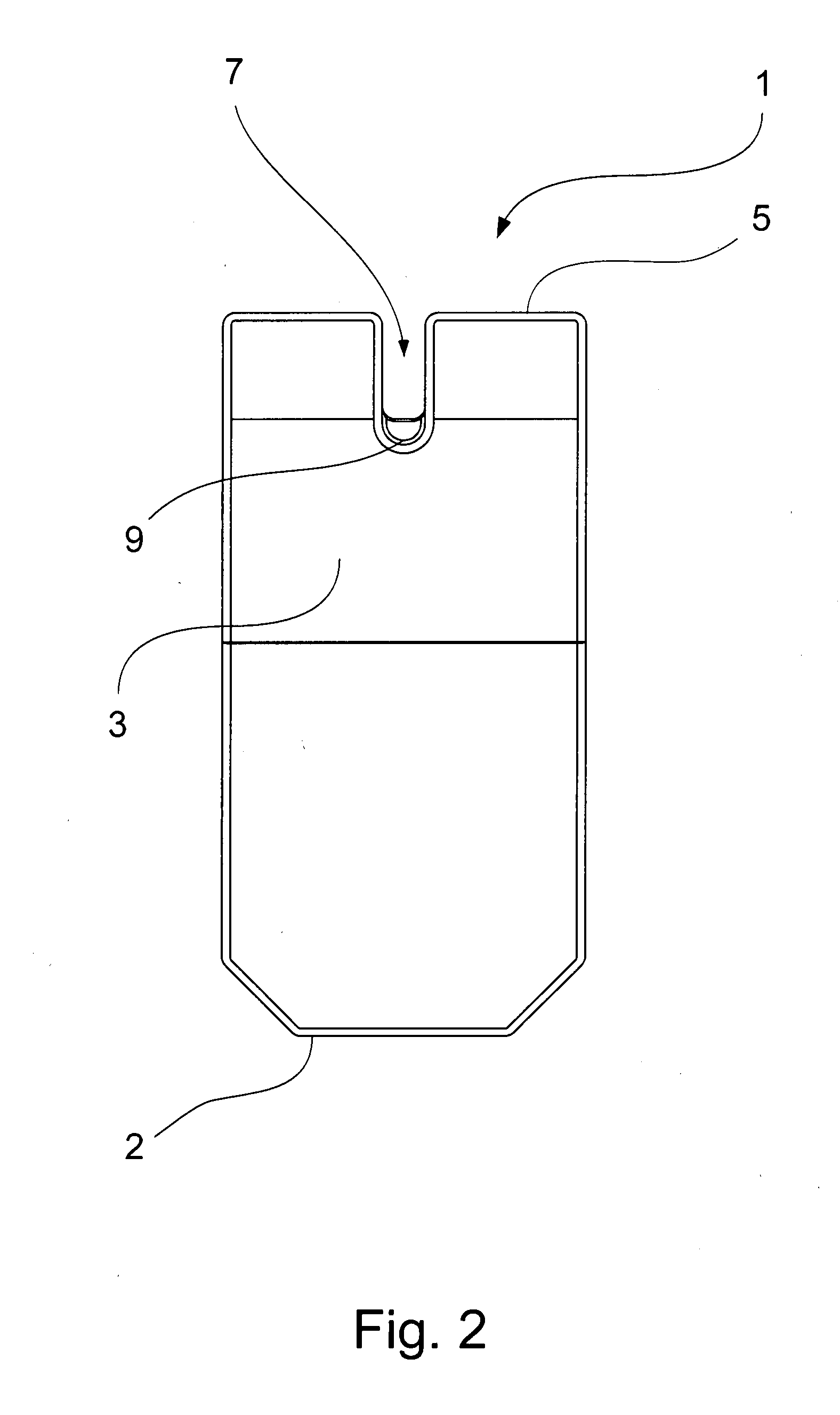

InactiveUS8875424B2Large material thicknessEliminate the effects ofHarrowsSoil-shifting machines/dredgersRound faceTrailing edge

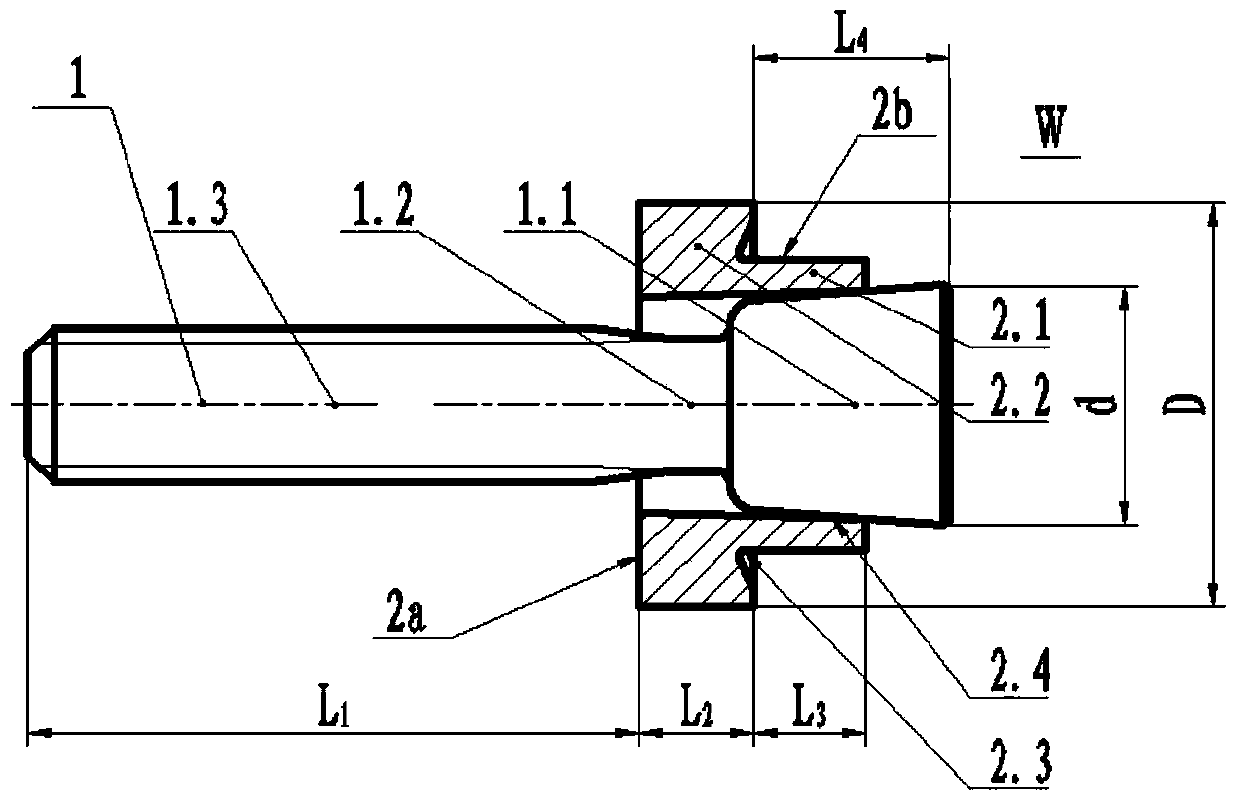

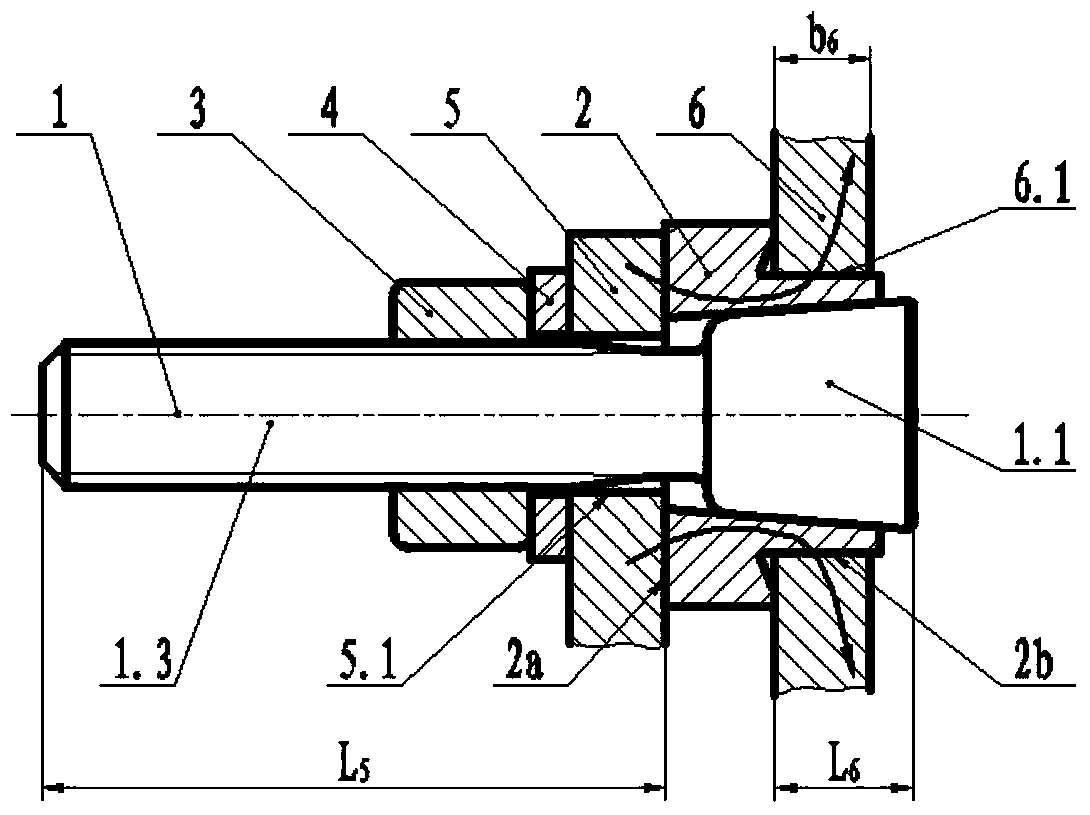

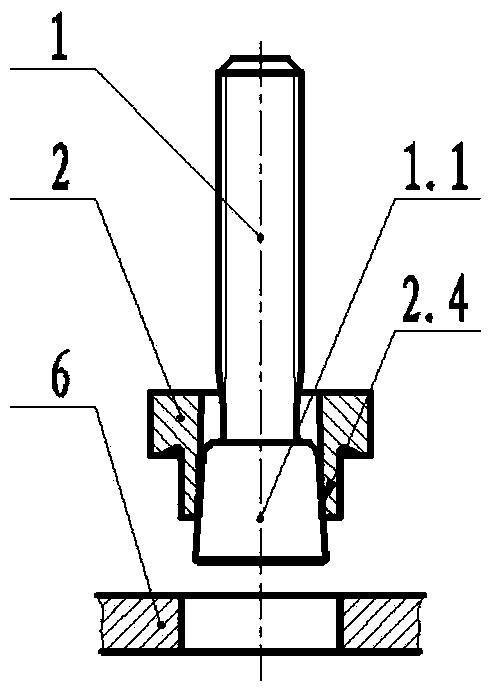

The invention relates to a replaceable end bit for a soil-working tool, which end bit is retained by friction and wherein, at its trailing edge, the end bit is provided with one or more openings that is / are oriented rearwardly relative to the end bit and for receiving couplers from a holder part. The openings may have rounded faces, and the faces may face towards each other. The distance between the rounded faces is increased with the distance from the trailing edge of the end bit. The invention also relates to a holder part for a replaceable end bit for a soil-working tool, which end bit is retained by friction, and wherein the holder part is provided with pairs of protruding couplers, which protruding couplers are provided with a space, where the distance between the two protruding couplers is reduced with the distance from their end faces.

Owner:MOLLSOR

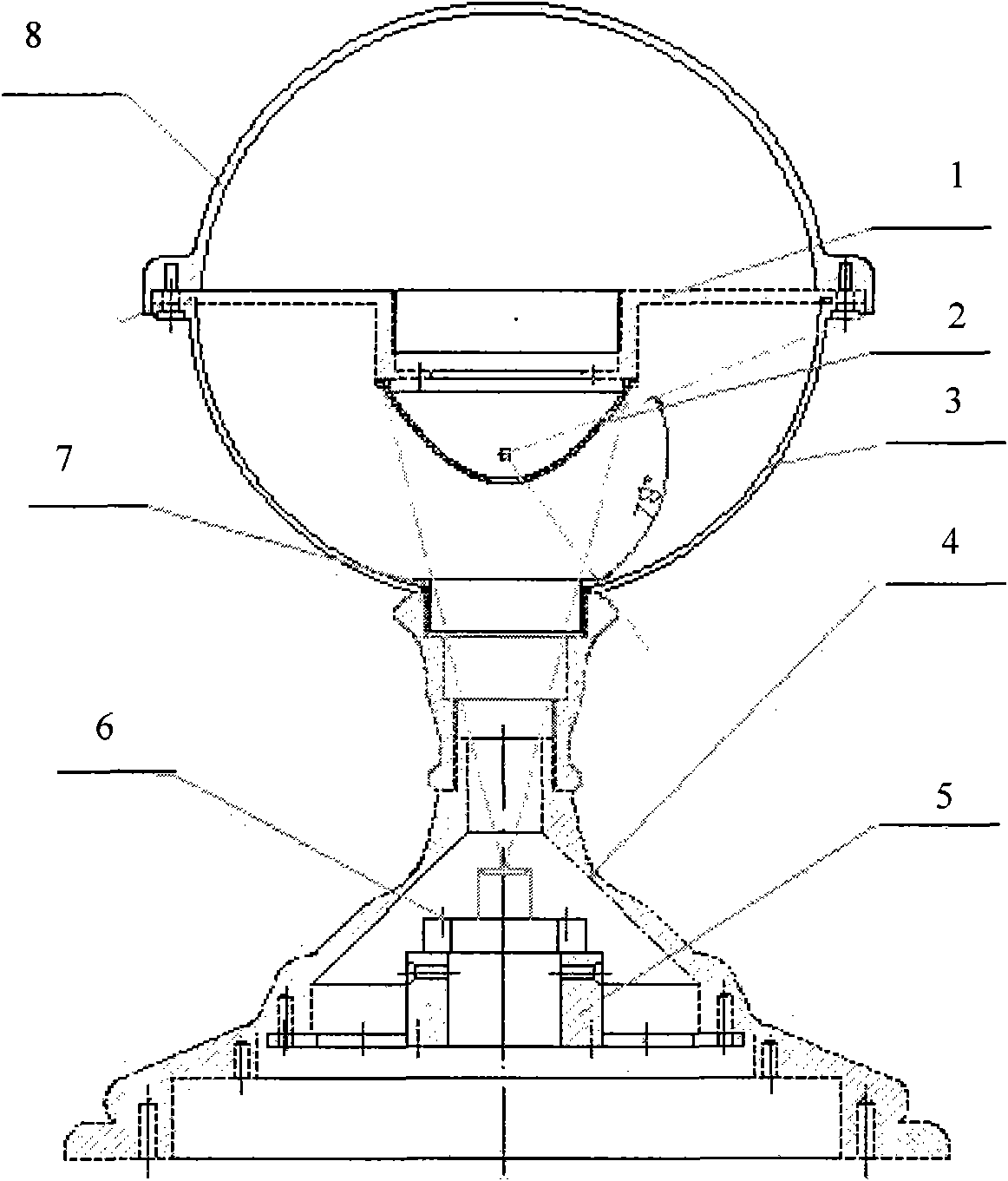

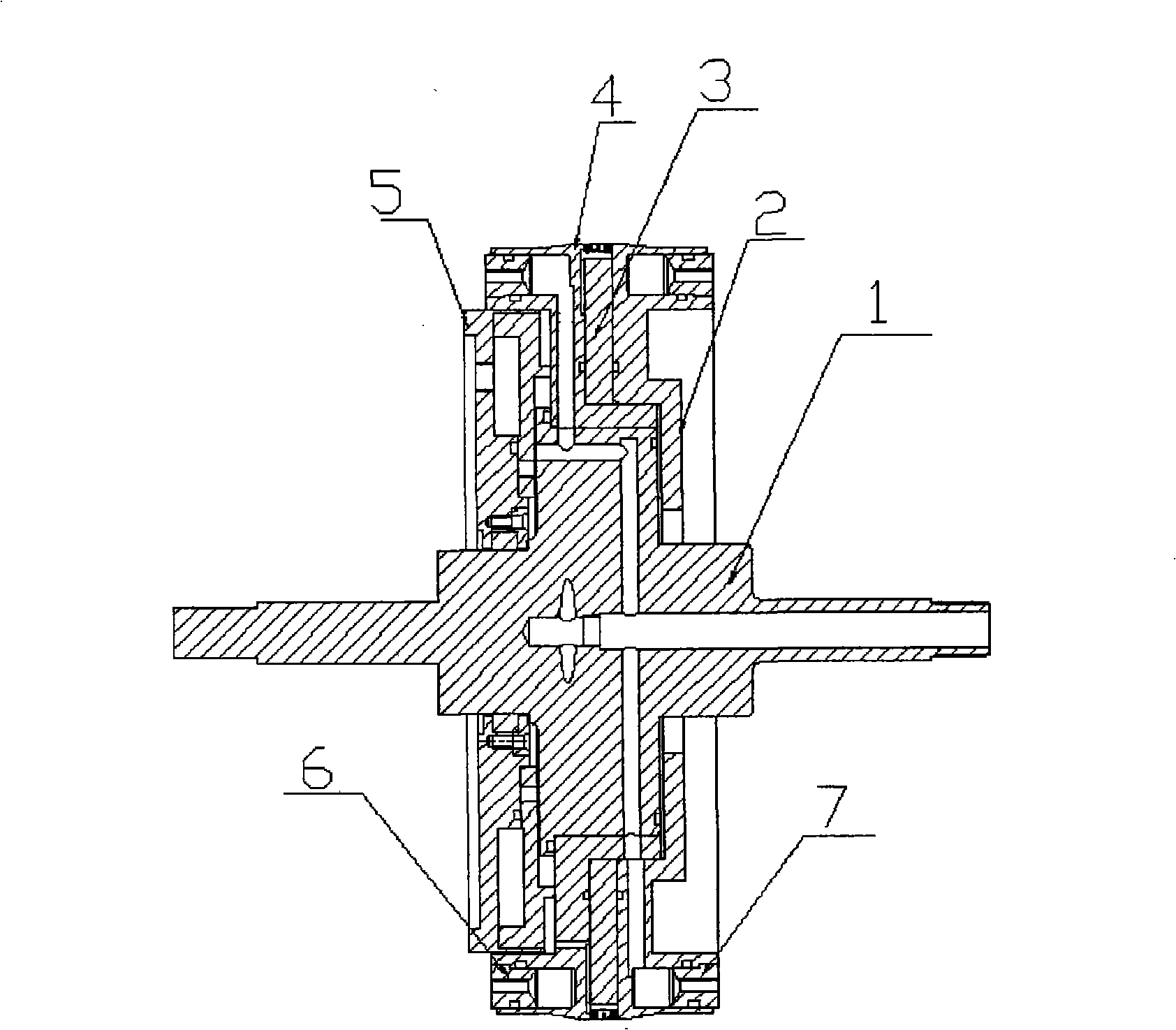

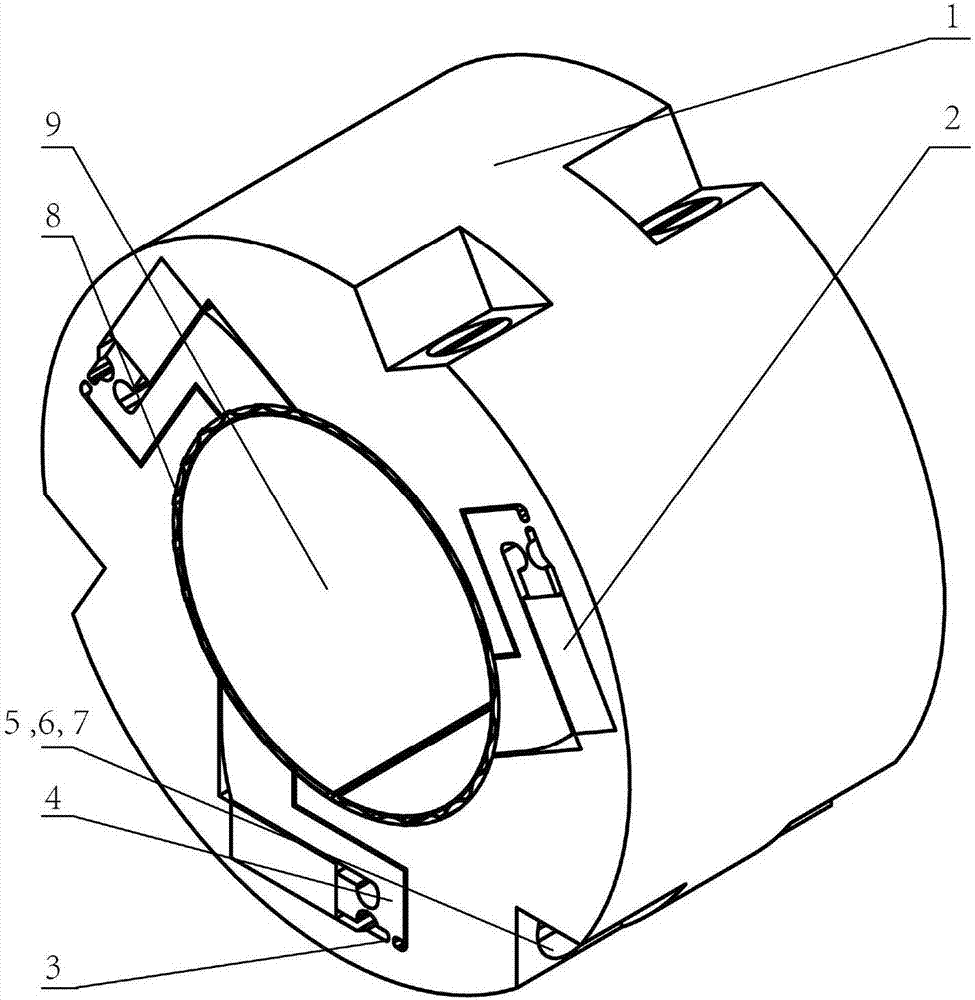

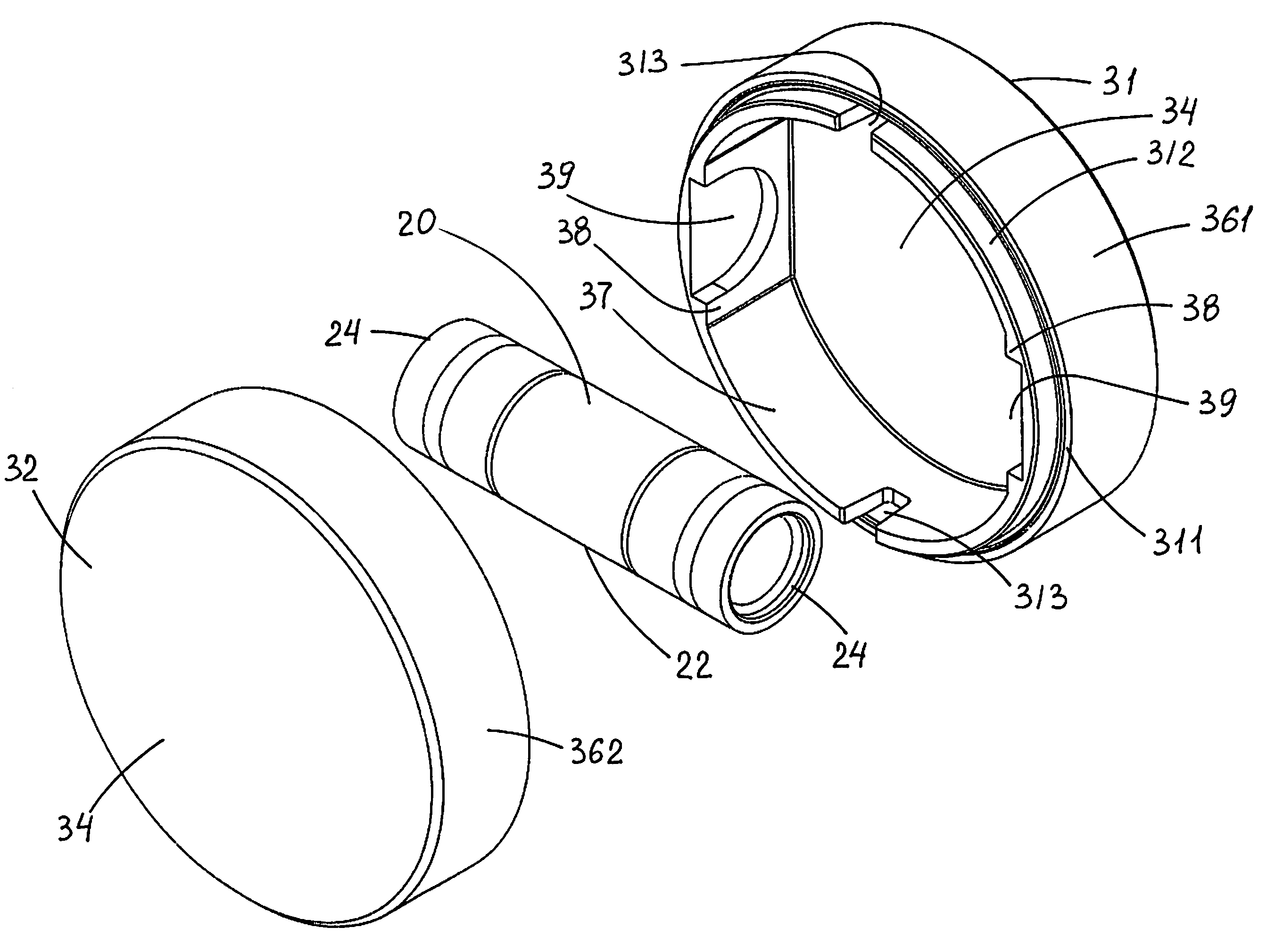

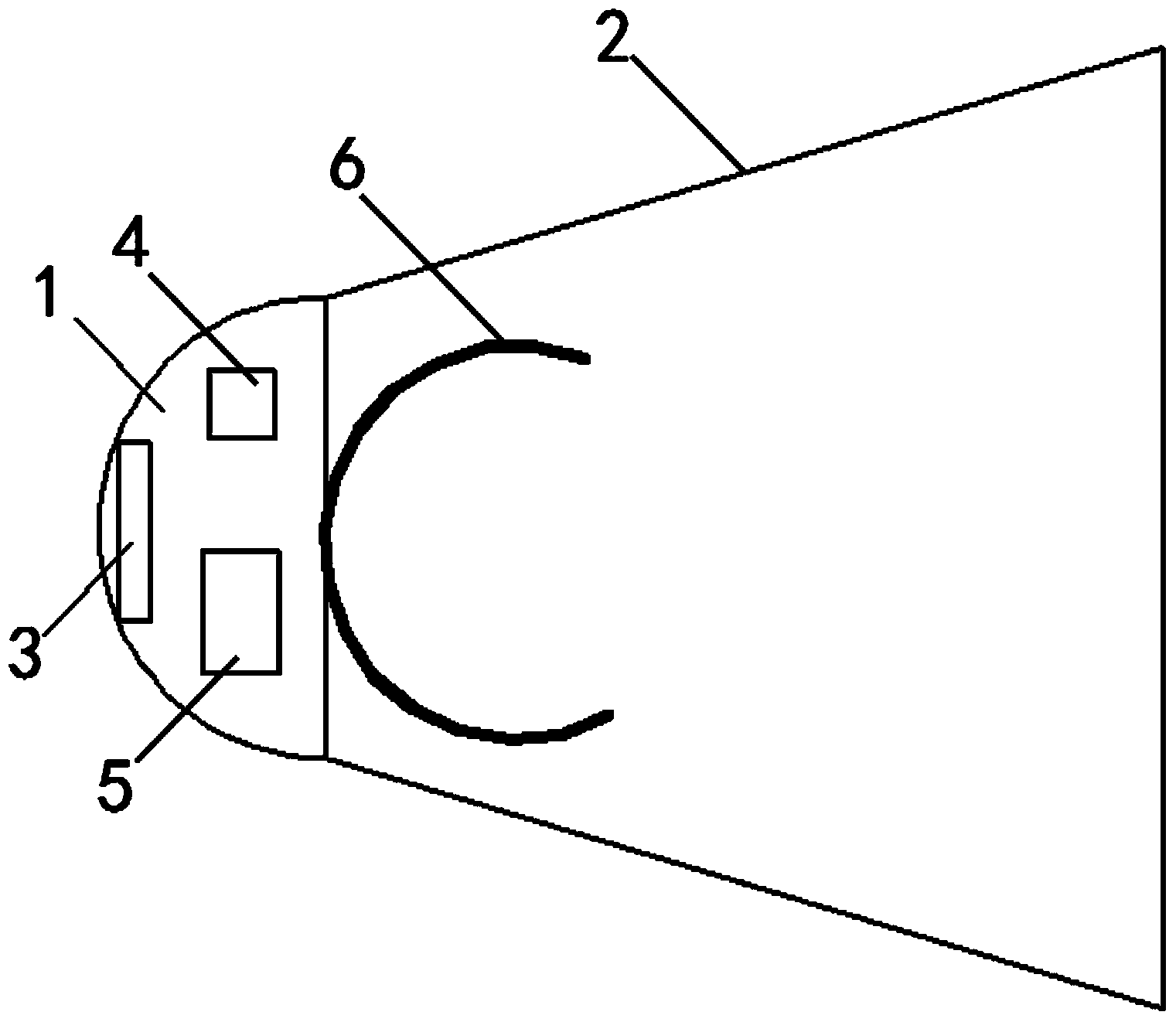

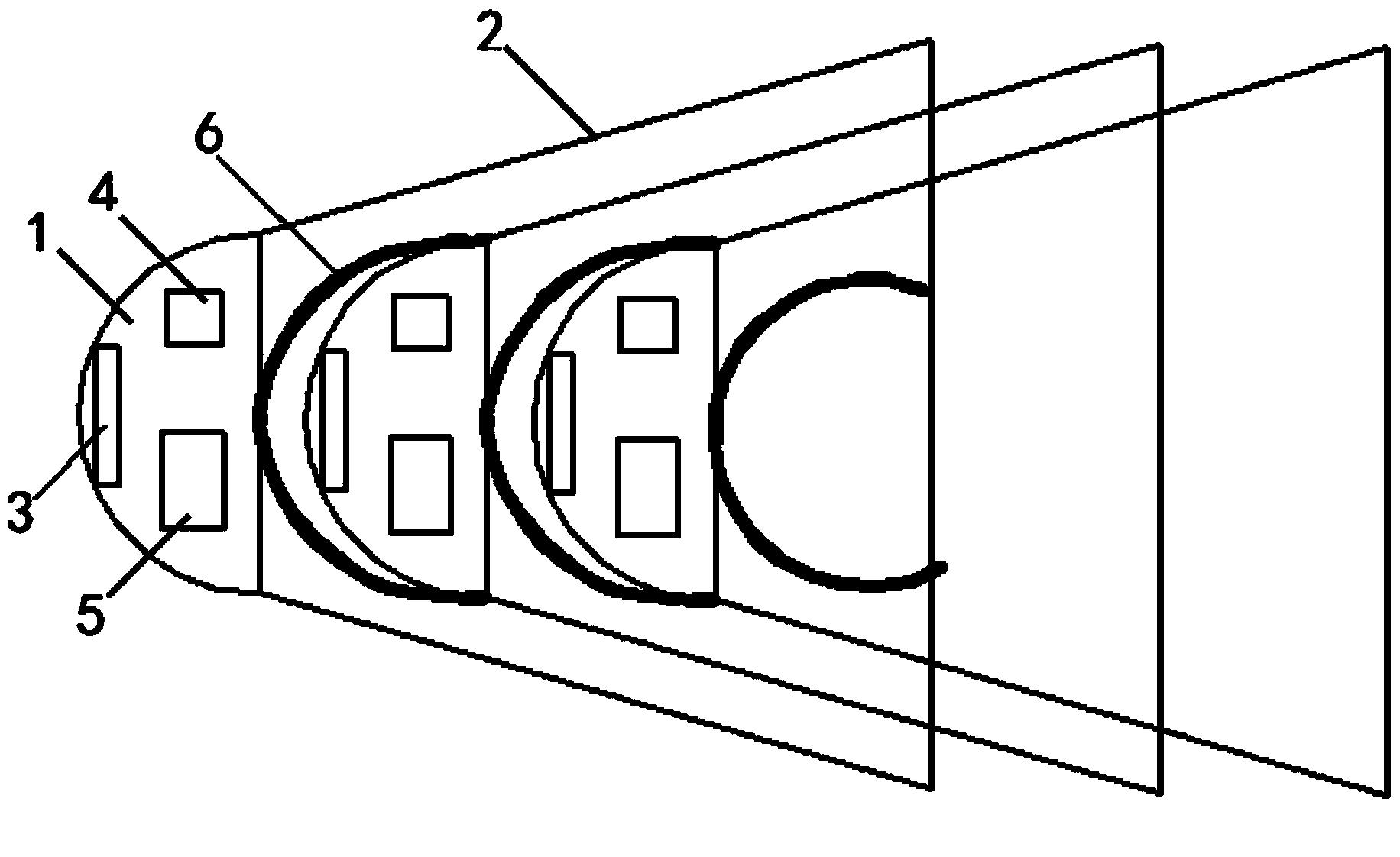

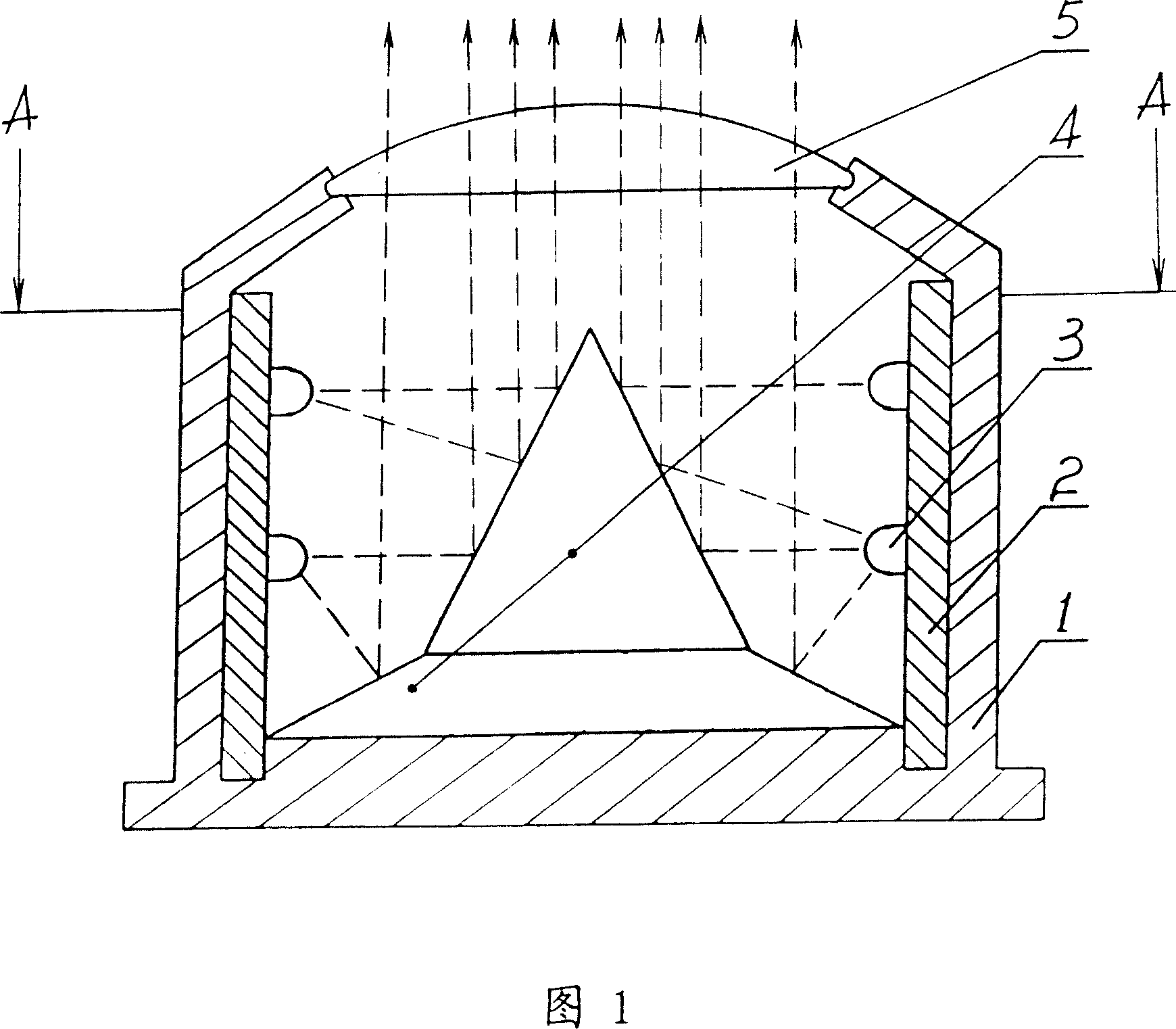

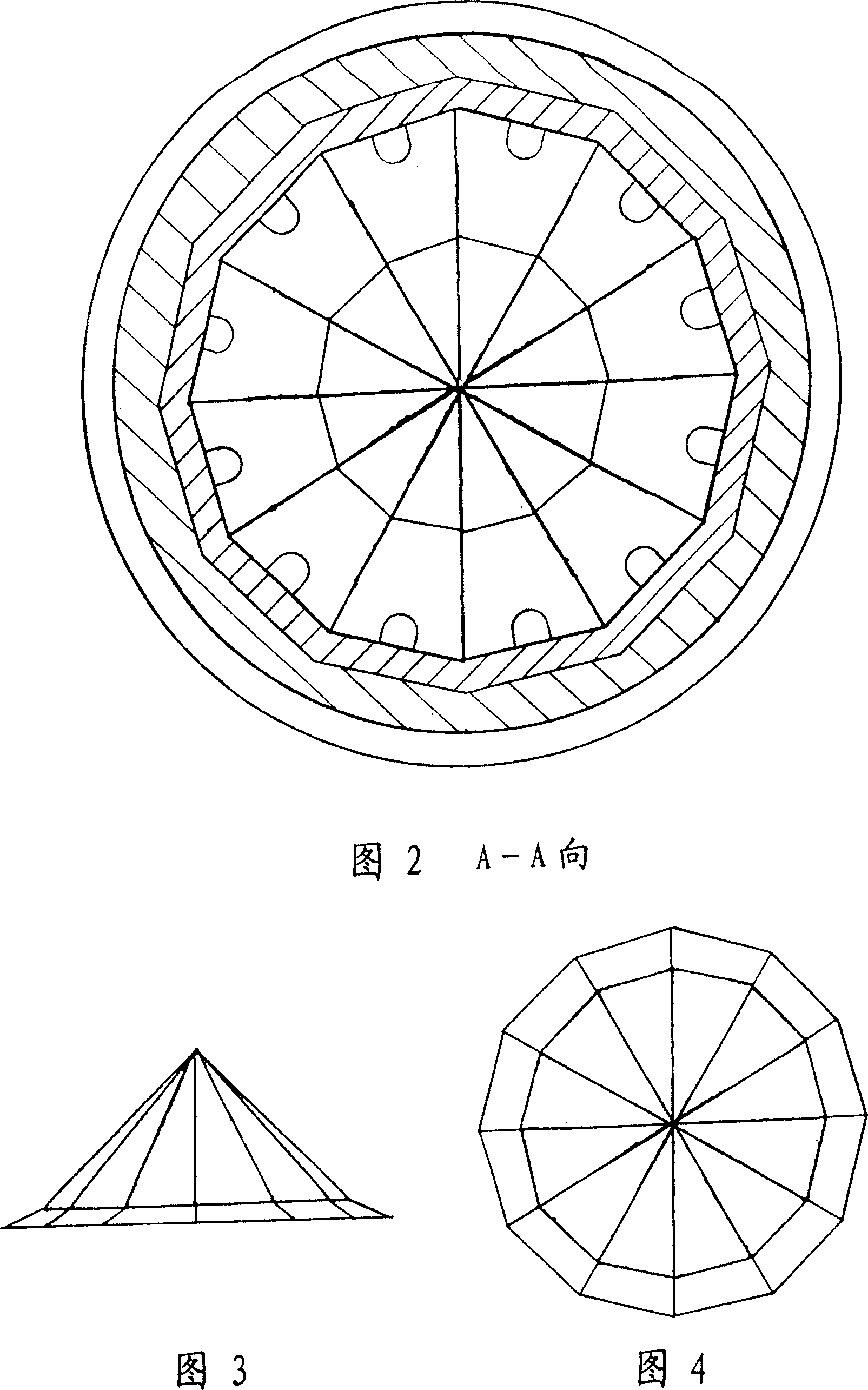

Driving three-dimensional omni-directional vision sensor based on laser diode light source

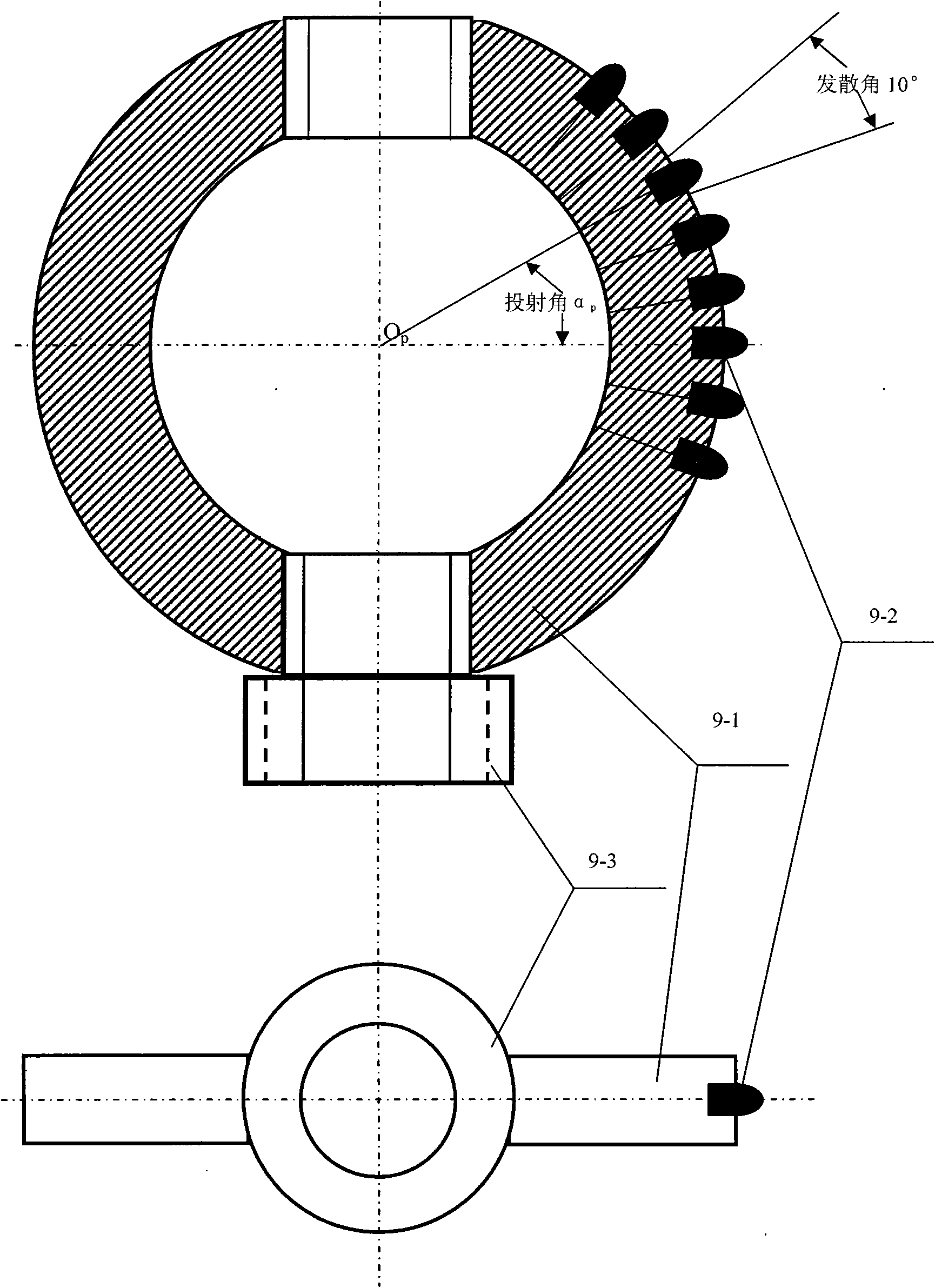

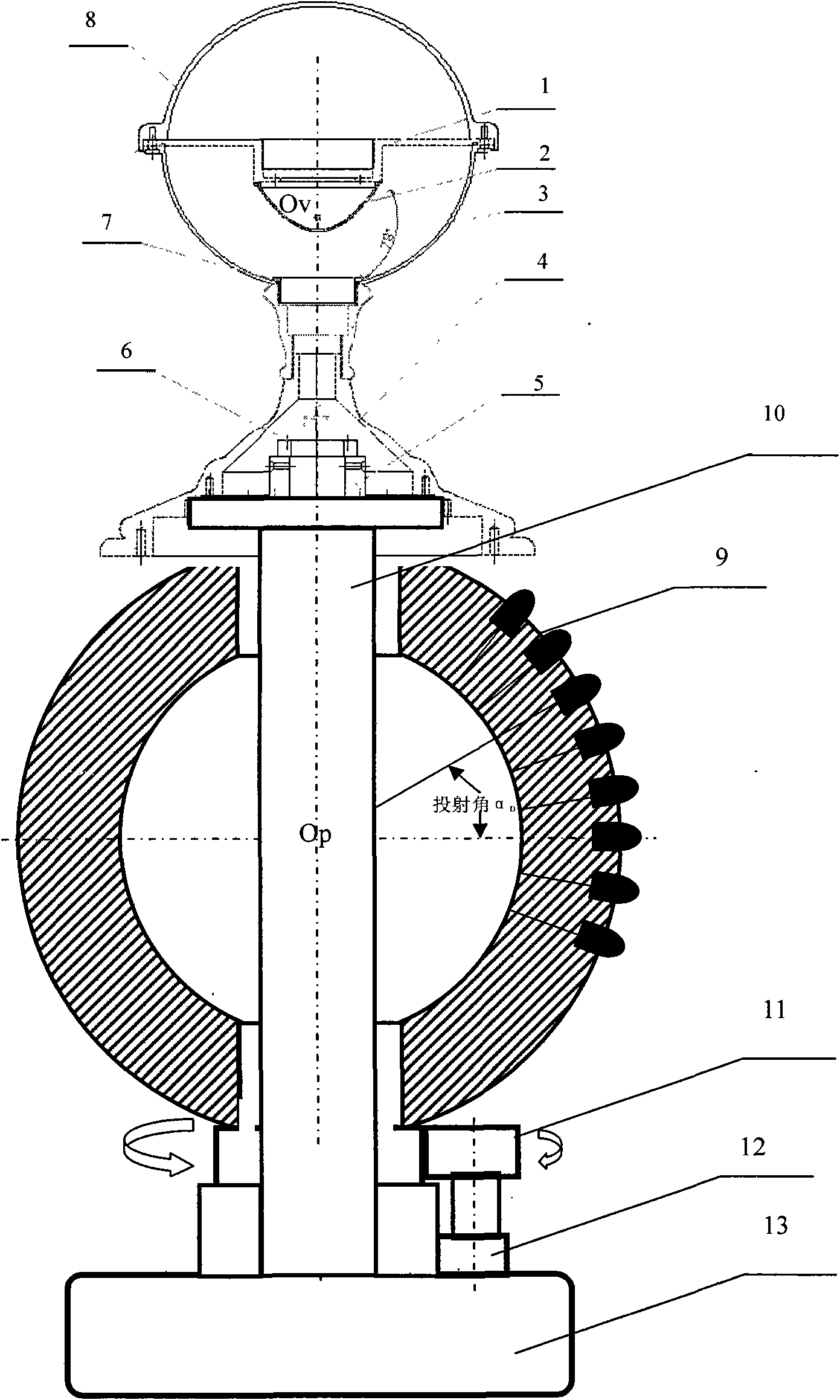

InactiveCN101655347AFast Panoramic Stereo Camera MeasurementHigh resolutionSemiconductor laser arrangementsSemiconductor laser structural detailsViewpointsRound face

The invention relates to a driving three-dimensional omni-directional vision sensor based on a laser diode light source, comprising an omni-directional vision sensor with fixed and single viewpoint, afull-view color body structure optical generator with fixed and single transmitting central point and a microprocessor used for carrying out three-dimensional photographic measurement on the omni-directional images; the viewpoint of the omni-directional vision sensor and the transmitting central point of the full-view color body structure optical generator are configured on a same axis line; theomni-directional vision sensor comprises a photographic unit and a double curved surface catadioptric unit, wherein, the photographic unit is a wide-dynamic CMOS imaging device; the full-view color body structure optical generator comprises a round face body base plate and a group of laser diodes with different luminescence center wavelengths; and the microprocessor comprises an LD light source control unit, a video image reading module, a space information calculating module and a three-dimensional image reconstructing module. The driving three-dimensional omni-directional vision sensor can reduce calculation, fast completes measurement, and has good real time and strong practicability.

Owner:ZHEJIANG UNIV OF TECH

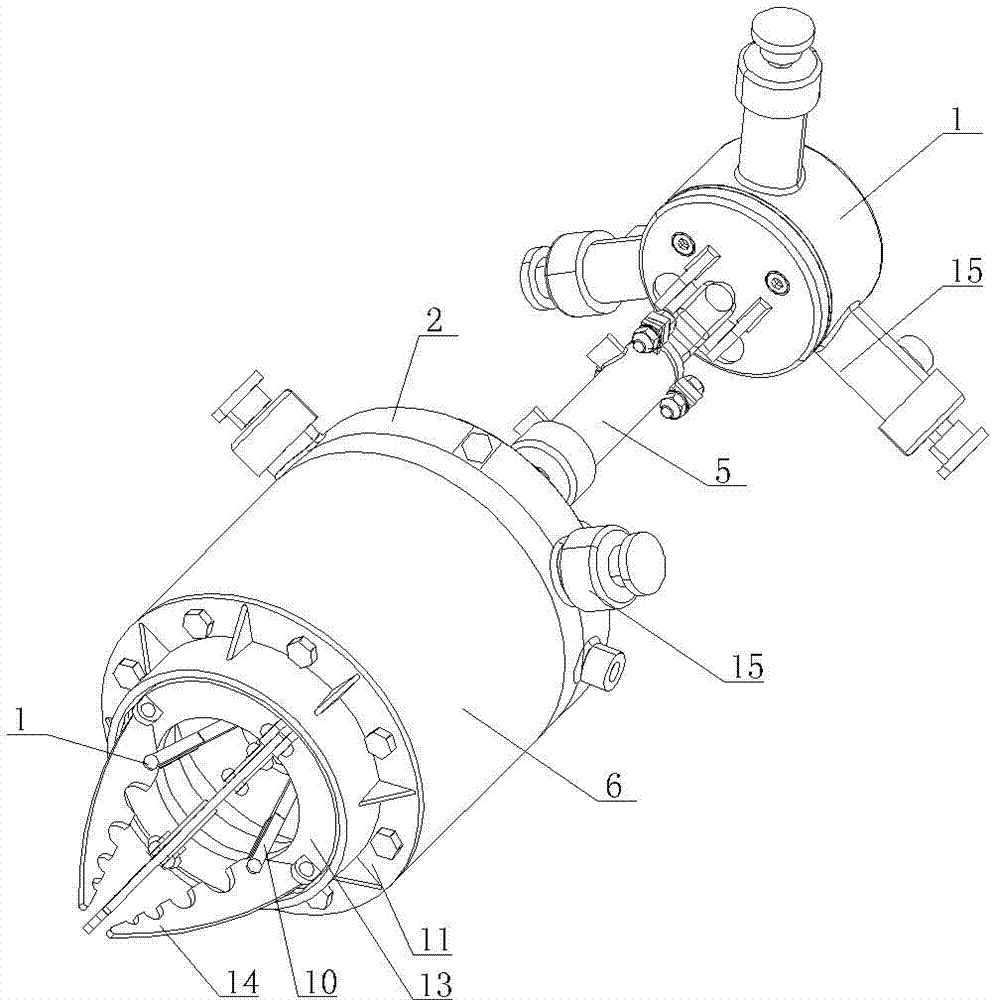

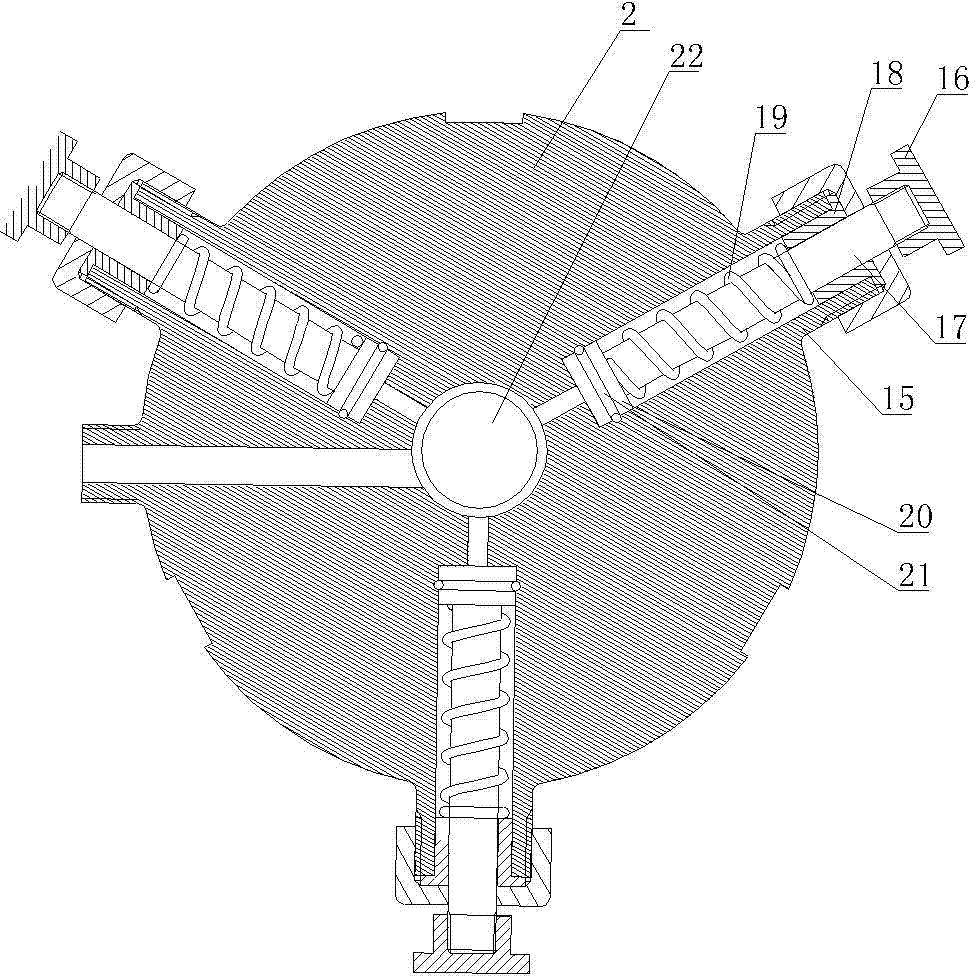

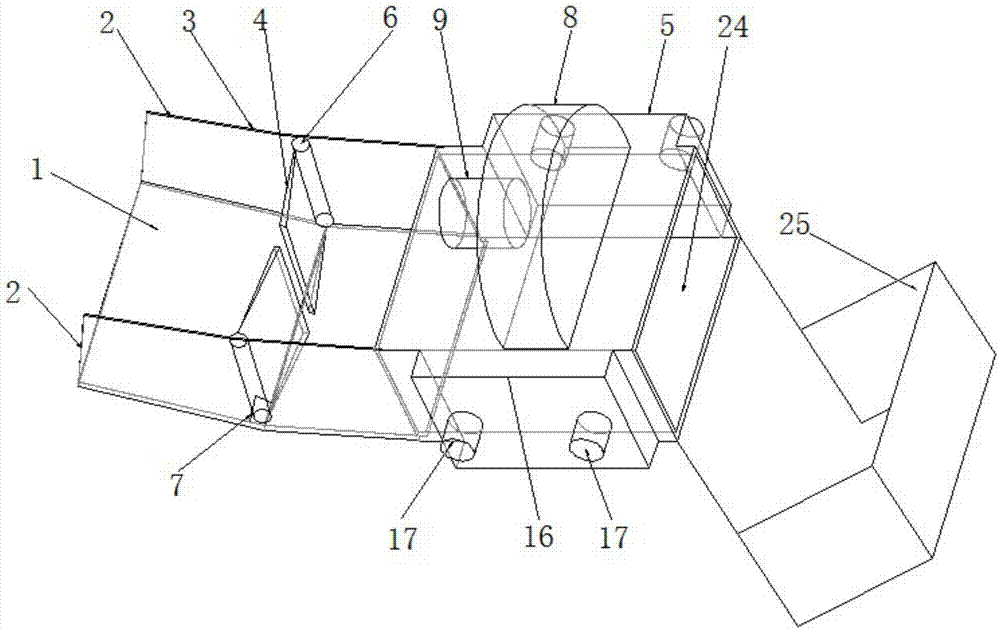

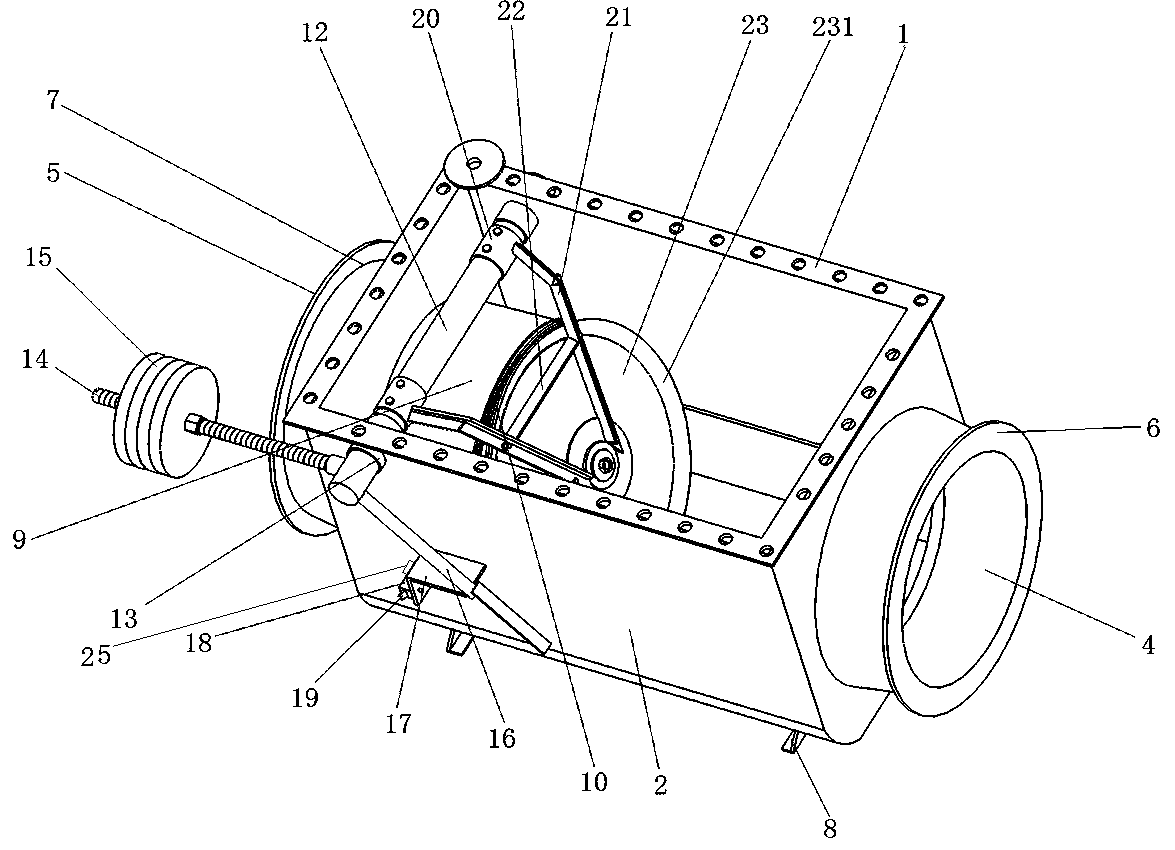

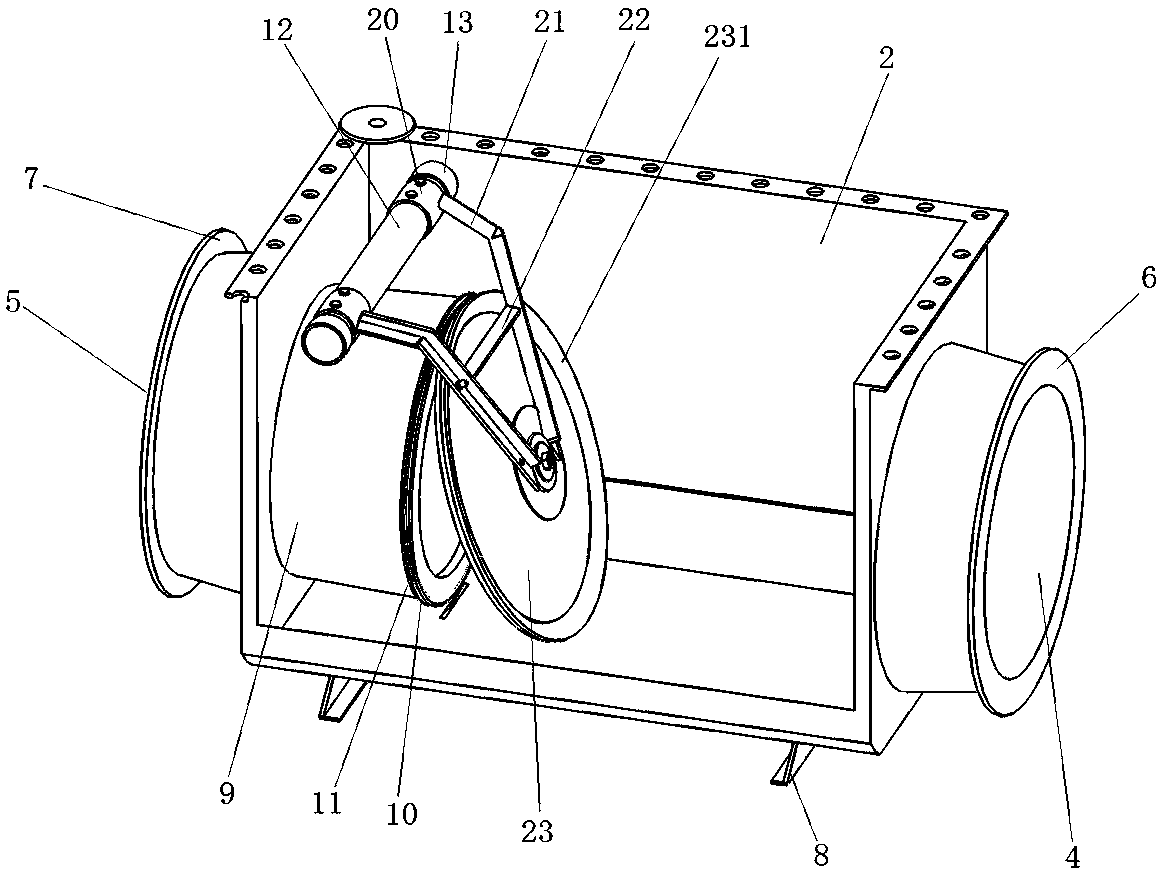

Pipeline dredging device

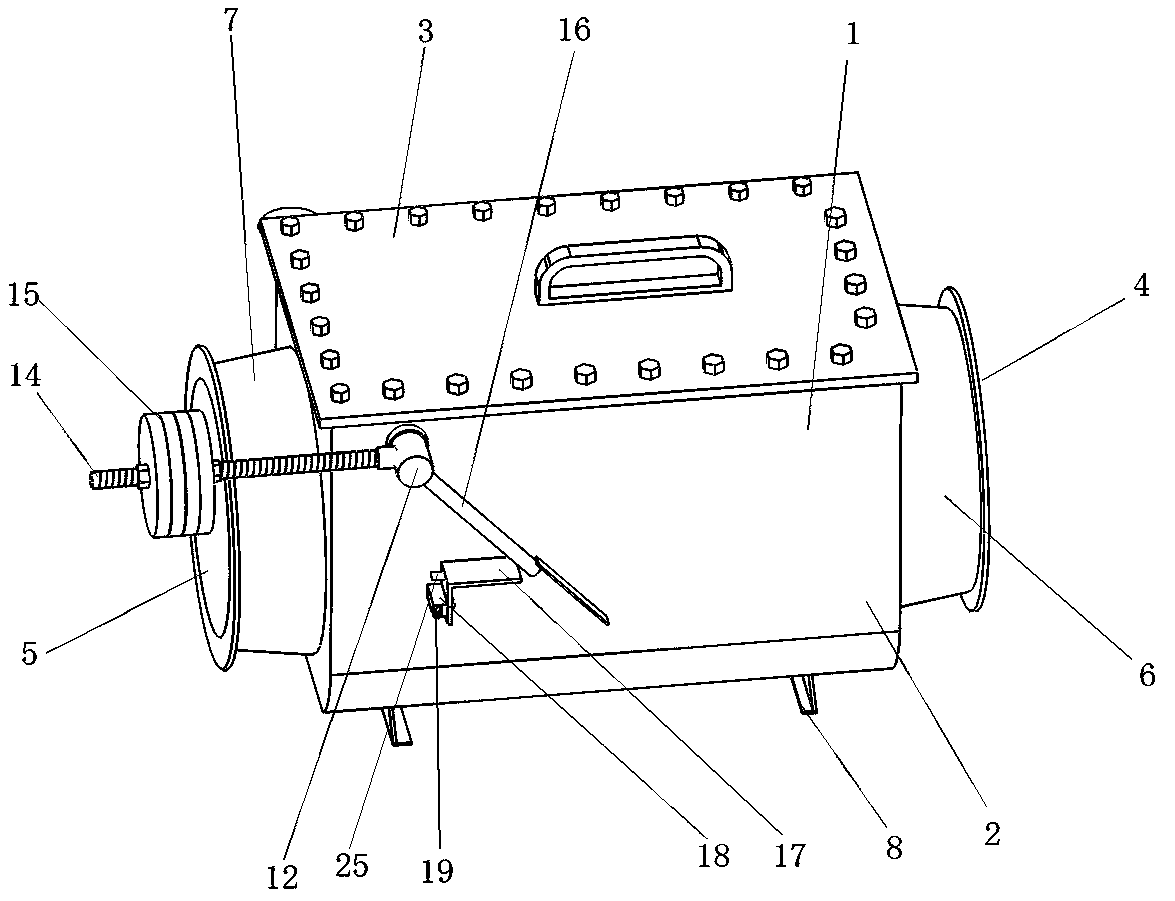

InactiveCN103790227AClean up saves time and effortEasy to cleanSewer cleaningHydraulic cylinderCoupling

The invention provides a pipeline dredging device, and belongs to the structural field of urban sewer line dredging equipment. The pipeline dredging device comprises a tail bearing hydraulic locating seat and a front bearing hydraulic locating seat, a front central protrusion of the tail bearing hydraulic locating seat is connected with a rear central protrusion of the front bearing hydraulic locating seat through a single-acting linear hydraulic cylinder, and the annular face of the front end of the front bearing hydraulic locating seat is connected with the annular face of the rear end of a sealed box in a fastening mode. A single-acting hydraulic cylinder is arranged on a central axis of the sealed box, a base of the single-acting hydraulic cylinder is connected with the sealed box in a fastening mode, the piston end of the single-acting hydraulic cylinder is connected with a base of a servo motor in a fastening mode, the servo motor is arranged in the sealed box, the output end of the servo motor is connected with the rear end of a coupling, and connecting rods are evenly distributed on the outer annular face of the front end of the coupling. The front end of the sealed box is covered with an end cover, an opening is formed in the center of the end cover, a bearing is arranged on the inner ring face of the end cover, the outer ring face of the rear end of a tool rest is born on the inner ring face of the bearing, and cleaning blades are evenly distributed on the outer round face of the front end of the tool rest.

Owner:JIANGNAN UNIV

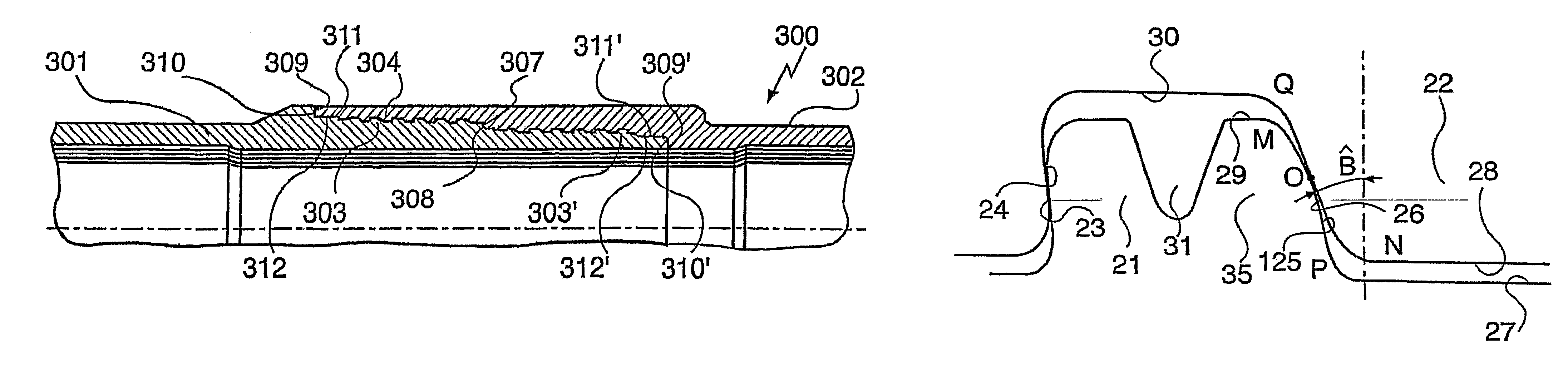

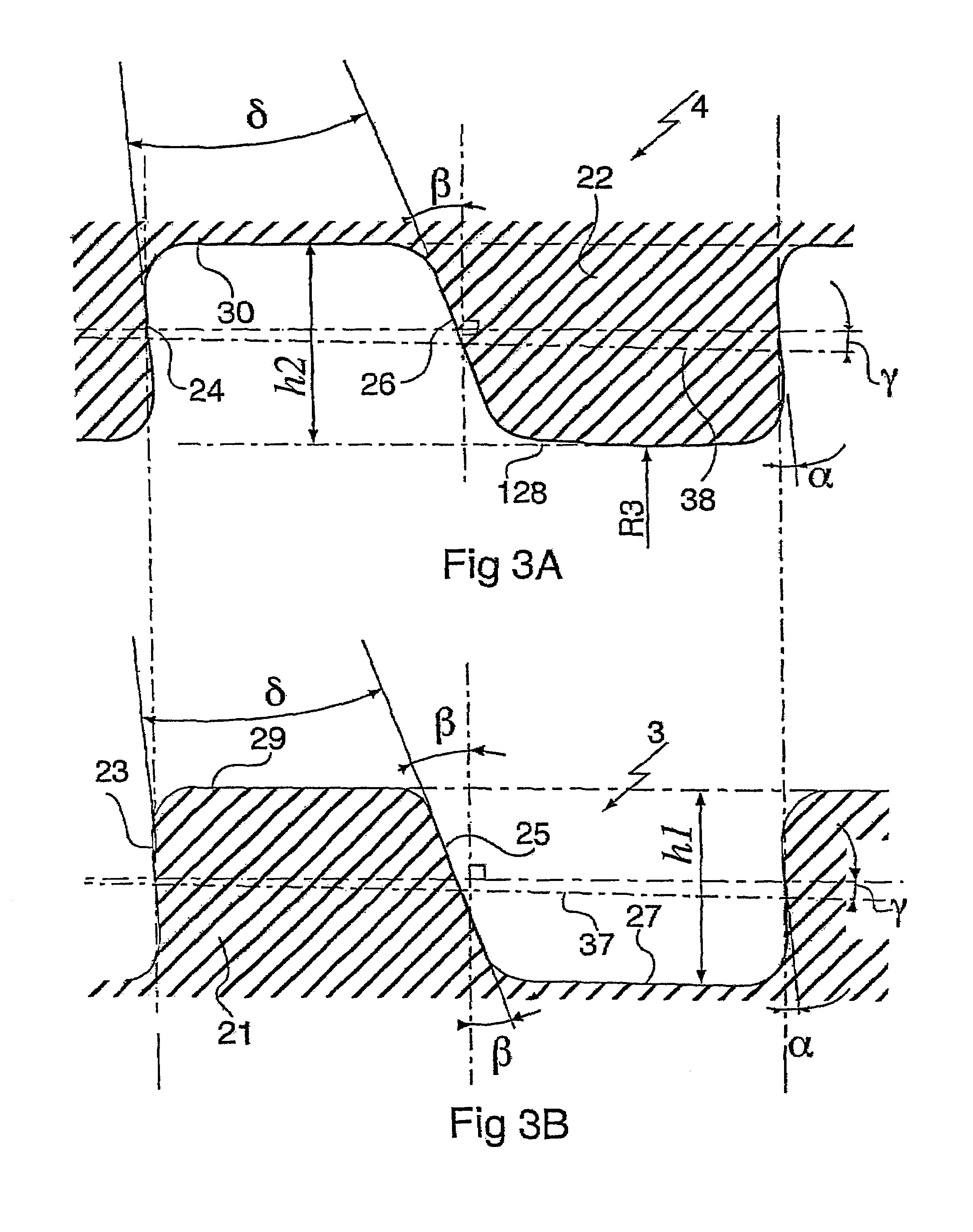

Tubular threaded joint with trapezoid threads having convex bulged thread surface

InactiveUS7331614B2Avoid wear and tearPrevent excessive and deleterious concentration of stressDrilling rodsRod connectionsContact pressureShock resistance

A threaded tubular connection includes two elements, male and female, made up one into the other to a given torque in which, prior to making up, at least one thread face under contact pressure has a convexly rounded shape that is continuous over its width with a radius of curvature in the range 2 to 60 mm and is in point contact with the corresponding face of the mating element. Such a threaded connection has an increased resistance to breakout or to overtorquing. In one embodiment, the convexly rounded face is a male or female thread flank and one of the male or female threads includes a groove opening into the thread crest to render flexible either the convexly rounded flank or the corresponding flank. Such a geometry can accommodate variations in contact between the flanks.

Owner:VALLOUREC OIL & GAS FRANCE SAS +1

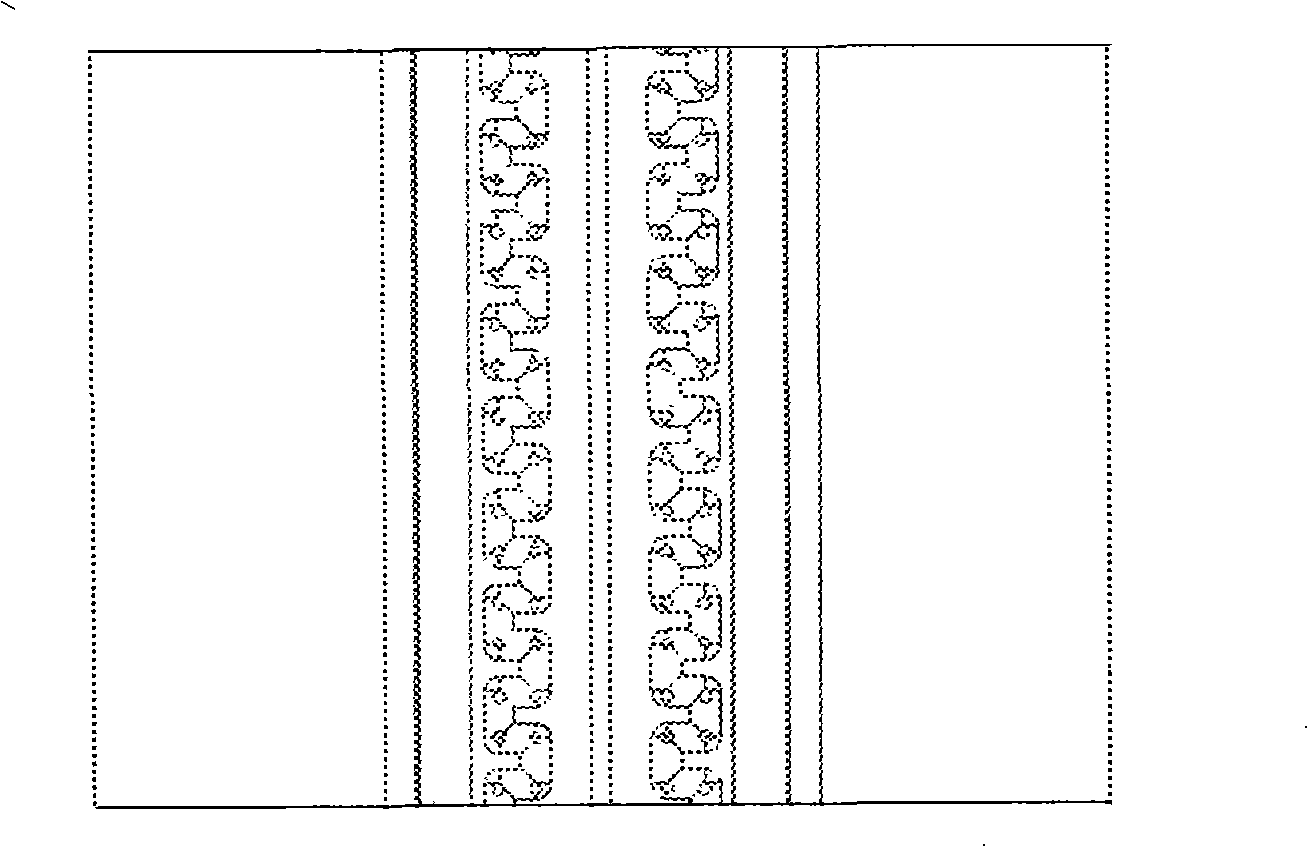

Molding wheel for drip irrigation belt

InactiveCN101352909AReduce flow deviationReduce manufacturing costTubular articlesDrip irrigationEngineering

The invention relates to a labyrinth drip irrigation tape forming wheel, consisting of a shaft, a left cooler pan, a right cooler pan, a forming pan, a water sealing ring and a vacuum pan; wherein, the end face of the forming pan is provided with a small hole which is communicated with an air drain of the left cooler pan, the middle of the outer round face of the forming pan is provided with a ring groove, labyrinth flow passages are symmetrically arranged at two sides of the ring groove, a corner of the labyrinth flow passage is provided with a micropore which is communicated with a small hole on the end face of the forming pan. The labyrinth drip irrigation tape forming wheel is characterized in that: the assembly accuracy of the forming wheel can be increased, the flow deviation of the produced drip irrigation tape can be reduced, the purpose that the drip irrigation tapes with different flow rates are produced by one set of wheels can be realized under the condition that only the forming pan is replaced; furthermore, the processing procedures of the forming pan are reduced, therefore, the cost is lowered.

Owner:XINJIANG TIANYE GRP

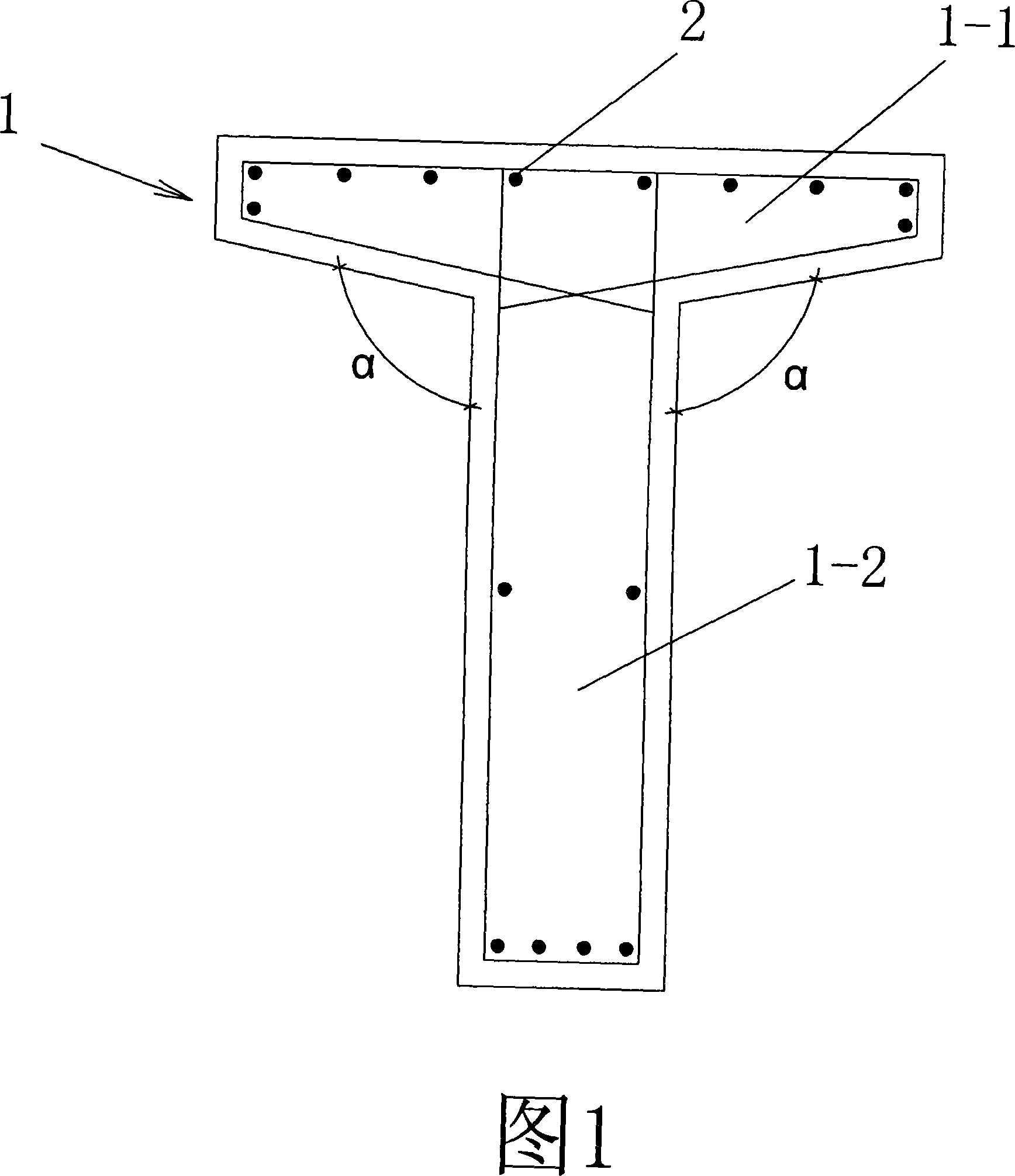

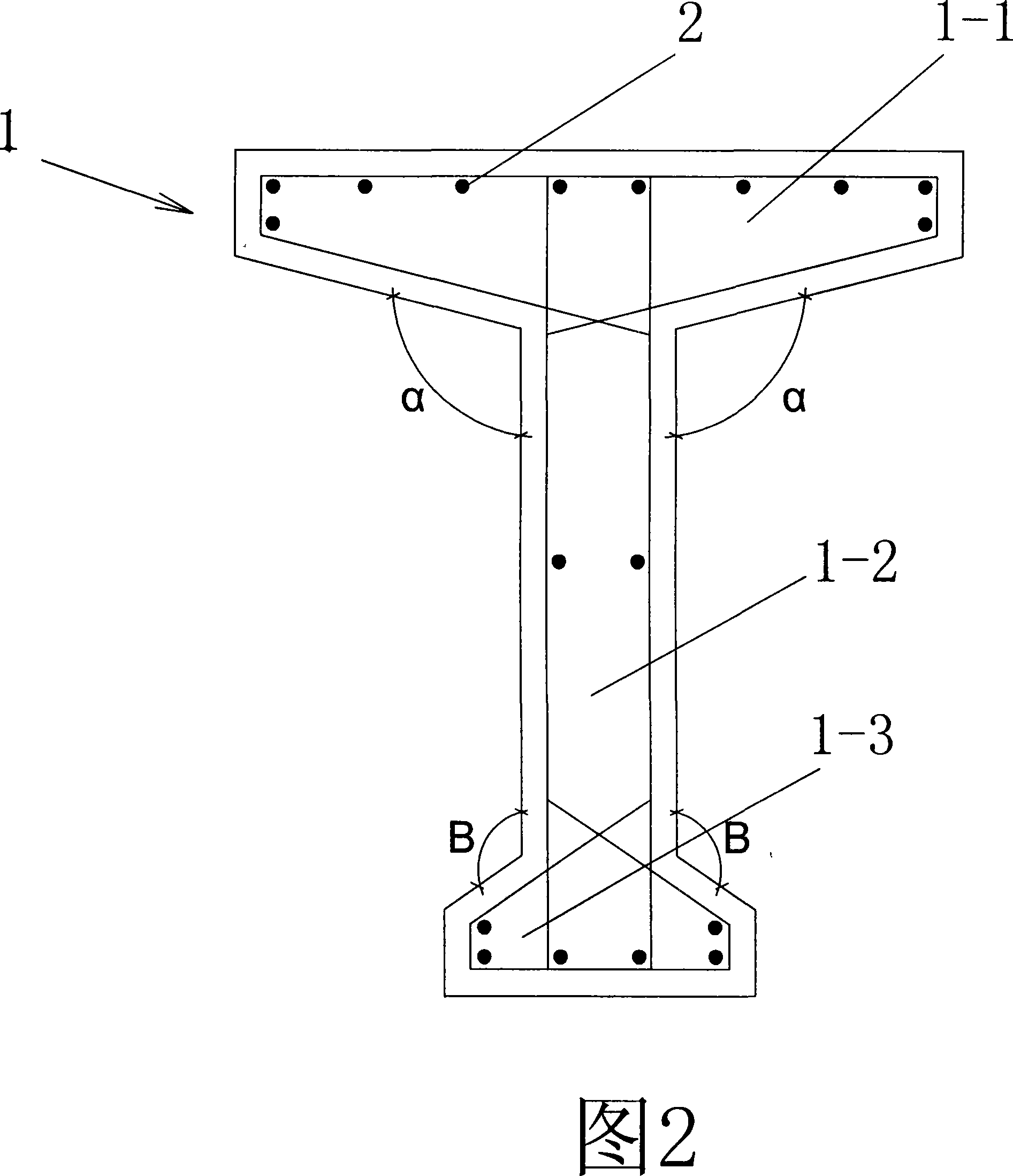

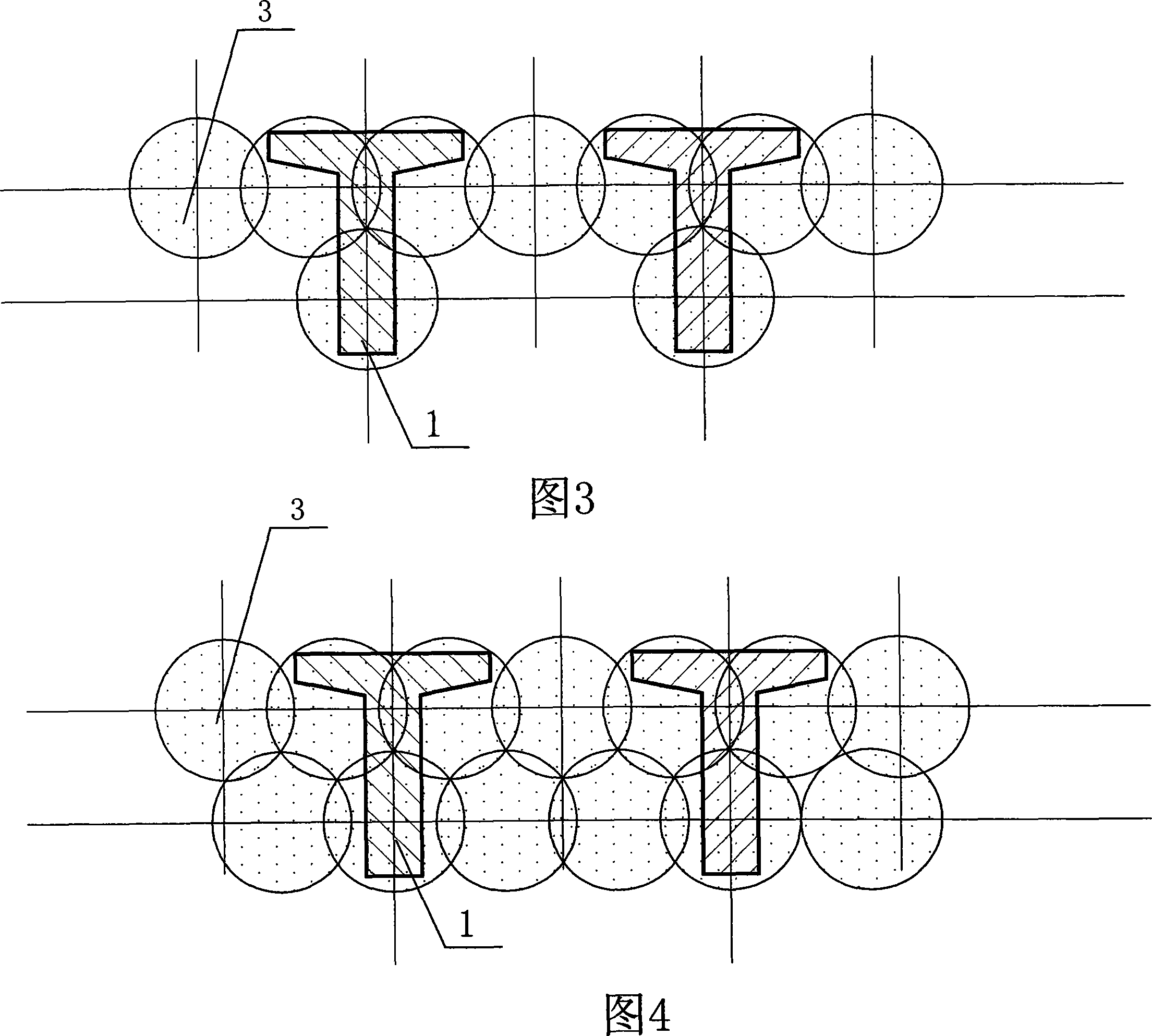

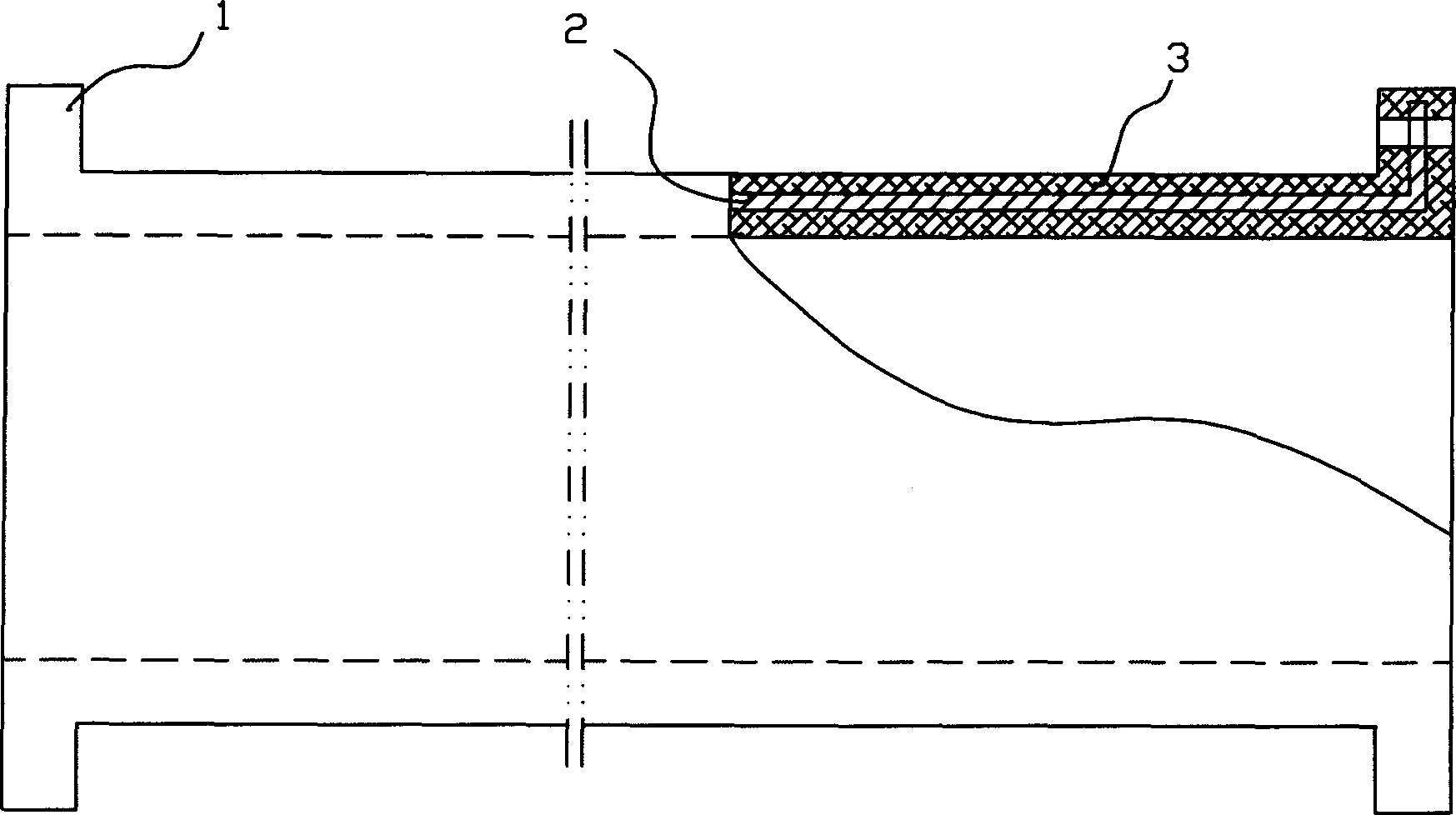

Method for embedding cement purdah into prefabricated reinforced concrete anti-lateral-force pile

InactiveCN101078216AMeet the force requirementsMeet deformation requirementsExcavationsSlurryRound face

The invention relates to a method that cement mixed soil curtain implants lateral force resistance pile of prefabricated reinforced concrete. Main procedures are described as follows. In construction site, cement mixer is used to mix soil in the whole journey or in upper water-stopping curtain part to form curtain along the implanting depth aiming to soil quality and soil extruding status; then it is implanted into pile body by pile driver to form retaining and waterproof enclosure wall. Thereinto pile body adopts prefabricated reinforced concrete T-shape / I-shape pile. Because powerful mixing soil or drilling machine is used to dig hole and inject grout, it is suitable for enclosure project of all kinds of soil qualities in principle. The beneficial effect of invention is that reinforcement ribs of T-shape or I-shape section are located at two ends of section; compared with circular pile with reinforcement ribs distributed along round face, the bending strength can be improved by more than 20% and the section area only is half of corresponding circular pile, namely concrete amount is saved in half. Ant it is provided with rapid construction speed, reliable quality, no noise and no pollution to circumstance by carrying slurry out so on.

Owner:严平 +1

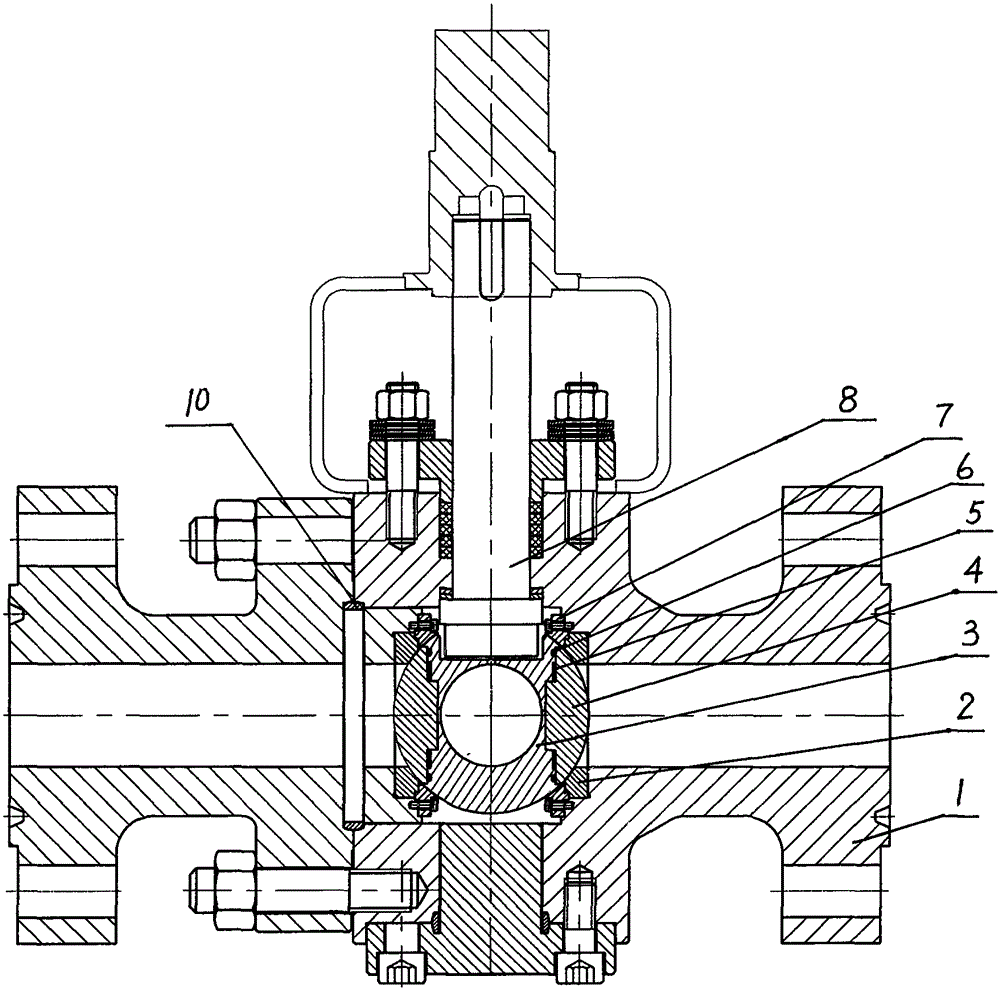

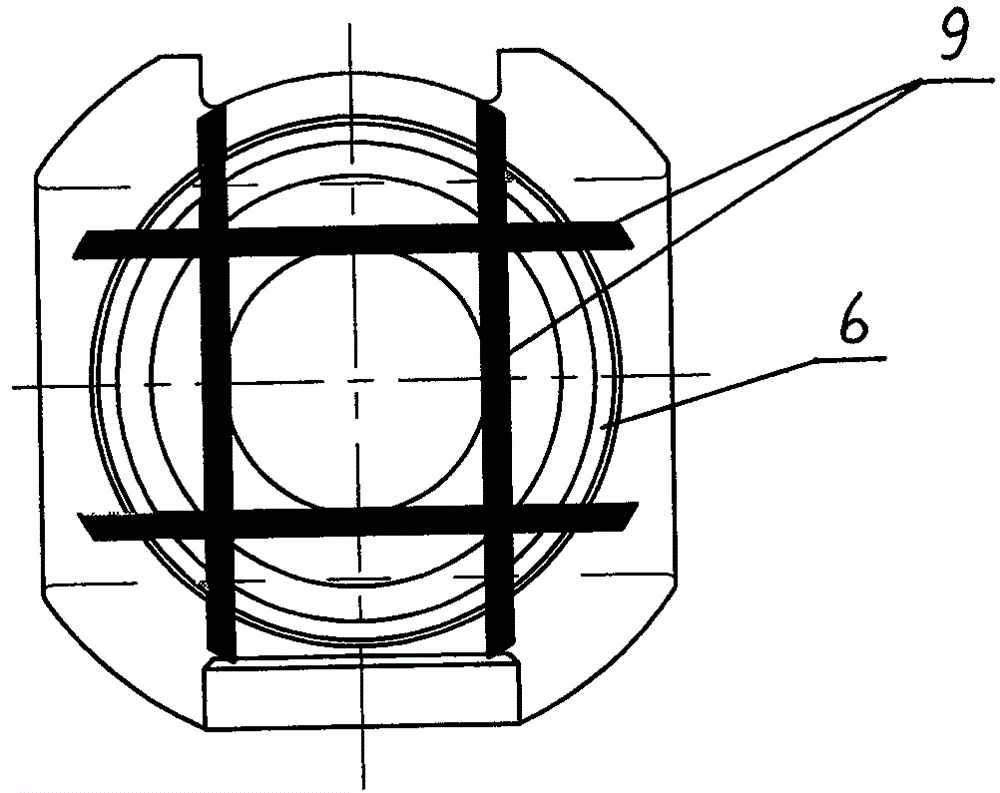

High-temperature and high-pressure metal sealing ball valve

The invention relates to a high-temperature and high-pressure metal sealing ball valve. The high-temperature and high-pressure metal sealing ball valve comprises a valve body, a valve base, a sphere and a valve rod. Mainly, the potions, on the two sides of a center line of a sphere through hole, of the sphere are each provided with a plane; the planes on the two sides of the sphere are each internally provided with a ball clack; the ball clacks are in movable fit connection with round concave holes in the sphere through round convex columns; annular spring cavities and springs in the cavities are manufactured between the ball clack planes on the radial outer sides of the round convex columns and the sphere planes; annular anti-blocking grooves are manufactured in the portions, on the outer sides of the annular spring cavities, of the sphere planes; medium dredging grooves which lead to the outer surface of the sphere and are communicated with the annular anti-blocking grooves are manufactured in the portions, close to the spring cavities in the outer round faces of the round convex column, of the sphere planes; the valve base is fixedly installed in a valve body channel through a positioning ring; and a concave spherical face, matched with the sphere and the spherical faces of the ball clacks, of a positioning ball clack is manufactured on the positioning ring valve cavity side. The ball clacks of the high-temperature and high-pressure metal sealing ball valve are reliable in floatation, good in temperature resistance and suitable for the high-temperature and high-abrasion working condition of particle media.

Owner:应建忠

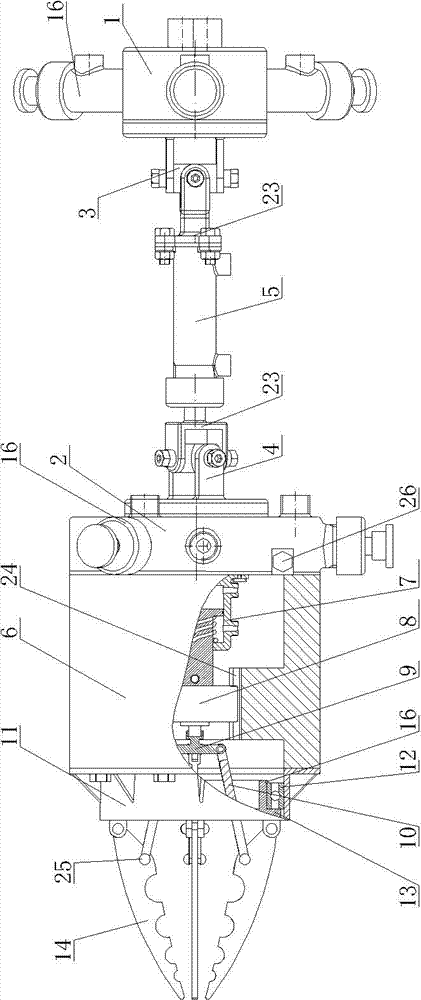

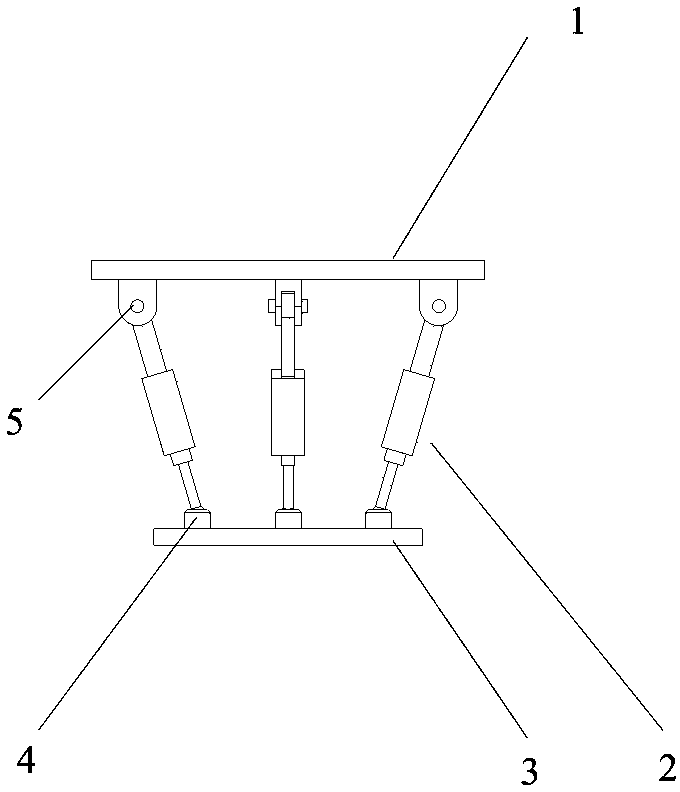

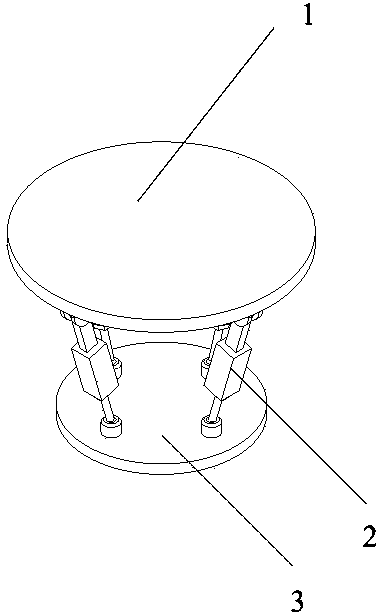

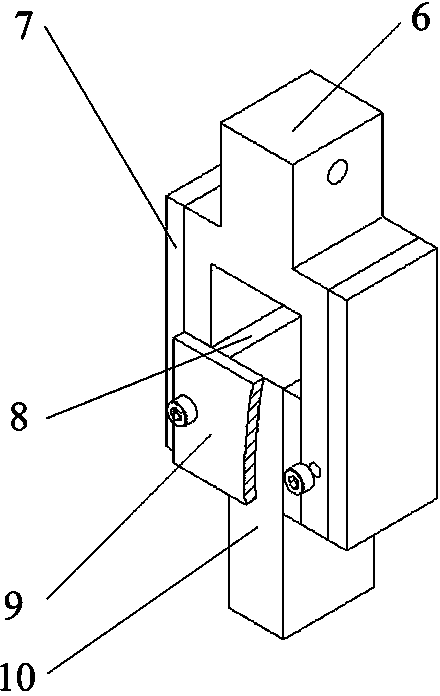

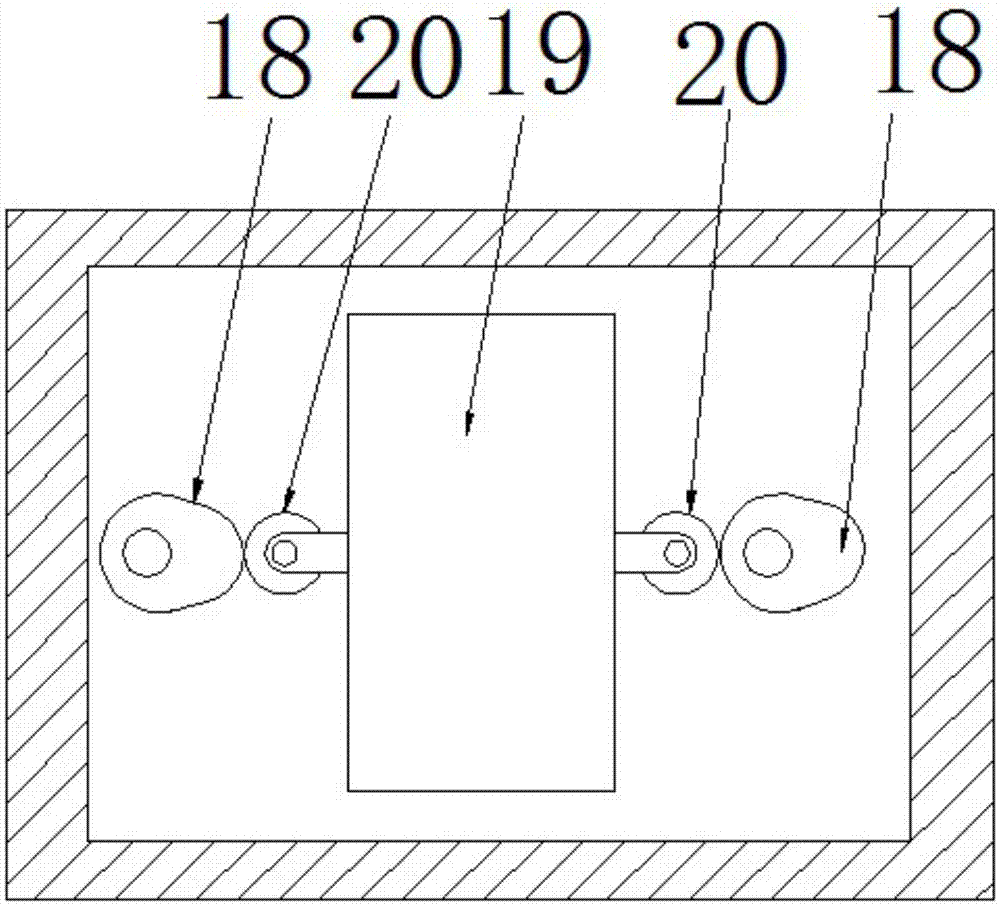

Magnetorheological-elastomer-based parallel power control device

ActiveCN103909468AImprove surface qualityControl magnetic field strengthBurnishing machinesAutomatic grinding controlElastomerRound face

The invention provides a magnetorheological-elastomer-based parallel power control device which can form controllable vector pressure in one direction at the tail end of an industrial robot or a machine tool spindle so as to control polishing pressure applied on the surface of a part more accurately and enable surface quality of the polished part to be improved substantially. The magnetorheological-elastomer-based parallel power control device comprises an upper connecting plate and a lower connecting plate. The magnetorheological-elastomer-based parallel power control device is characterized in that four shearing-type pressure control mechanisms are all arranged in a middle cavity between the upper connecting plate and the lower connecting plate, each shearing-type pressure control mechanism is correspondingly connected with outer-side portions of corresponding round faces of the upper connecting plate and the lower connecting plate and comprises an upper support, a shearing block, a lower support and an electromagnet, each upper support is connected with the upper connecting plate through a rotating hinge, and each lower support is connected with the lower connecting plate through a ball hinge.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

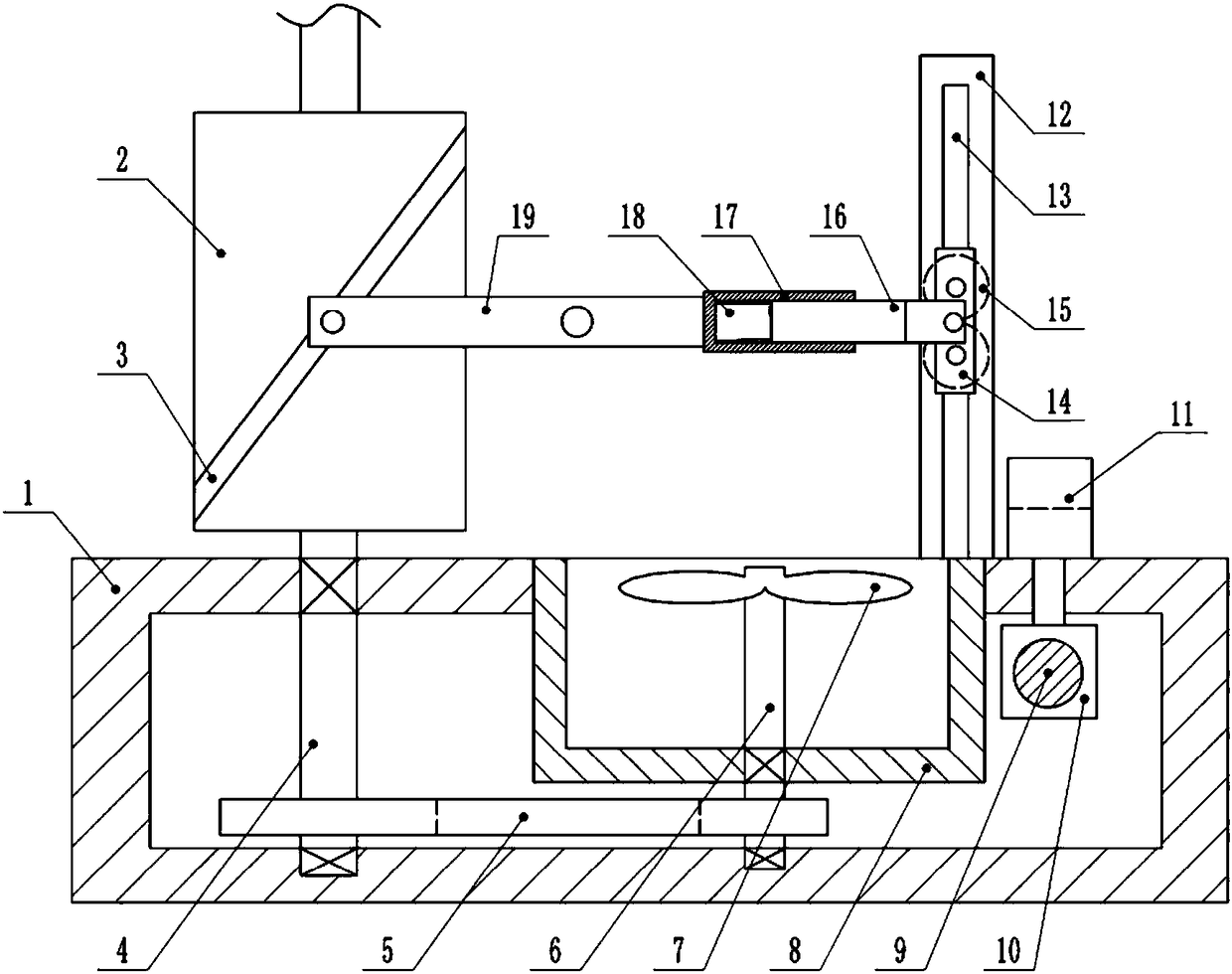

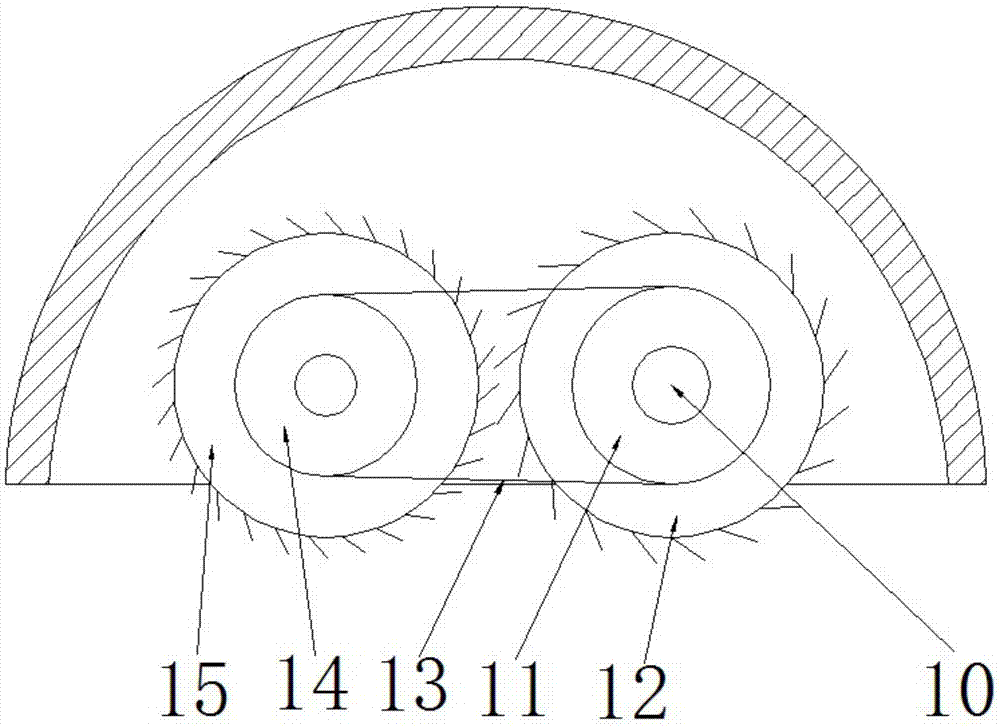

Chipless wood polishing device

PendingCN108544340AImprove grinding efficiencyImprove sanding qualityGrinding carriagesGrinding drivesImpellerRound face

The invention belongs to the technical field of wood processing equipment, and particularly discloses a chipless wood polishing device. The chipless wood polishing device comprises a workbench. A cylinder is rotationally arranged on the workbench. A collection box is arranged on the right side of the cylinder. An impeller is arranged in the collection box and connected with the cylinder through atransmission mechanism. A clamping mechanism for clamping wood is arranged on the workbench. Two supporting plates are arranged on the right side of the collection box. Sliding cavities are formed inthe middles of the two supporting plates correspondingly. Sliding blocks slide in the two sliding cavities correspondingly. A rough polishing roller and a fine polishing roller are rotationally connected between the two sliding blocks. Racks are fixedly connected with the supporting plates. Gears are fixedly connected with the ends of the rough polishing roller and the ends of the fine polishing roller correspondingly. A curved sliding groove is formed in the round face of the cylinder. An oscillating bar is hinged between the cylinder and the supporting plates. The cylinder rotates to drive the oscillating bar to reciprocally swing through the curved sliding groove. Two telescopic rods are fixedly connected with the right end of the oscillating bar. The right ends of the two telescopic rods are hinged to the two sliding blocks correspondingly. According to the scheme, the polishing efficiency is high, and collection treatment on chips is achieved.

Owner:重庆草衣木食文化传播有限公司

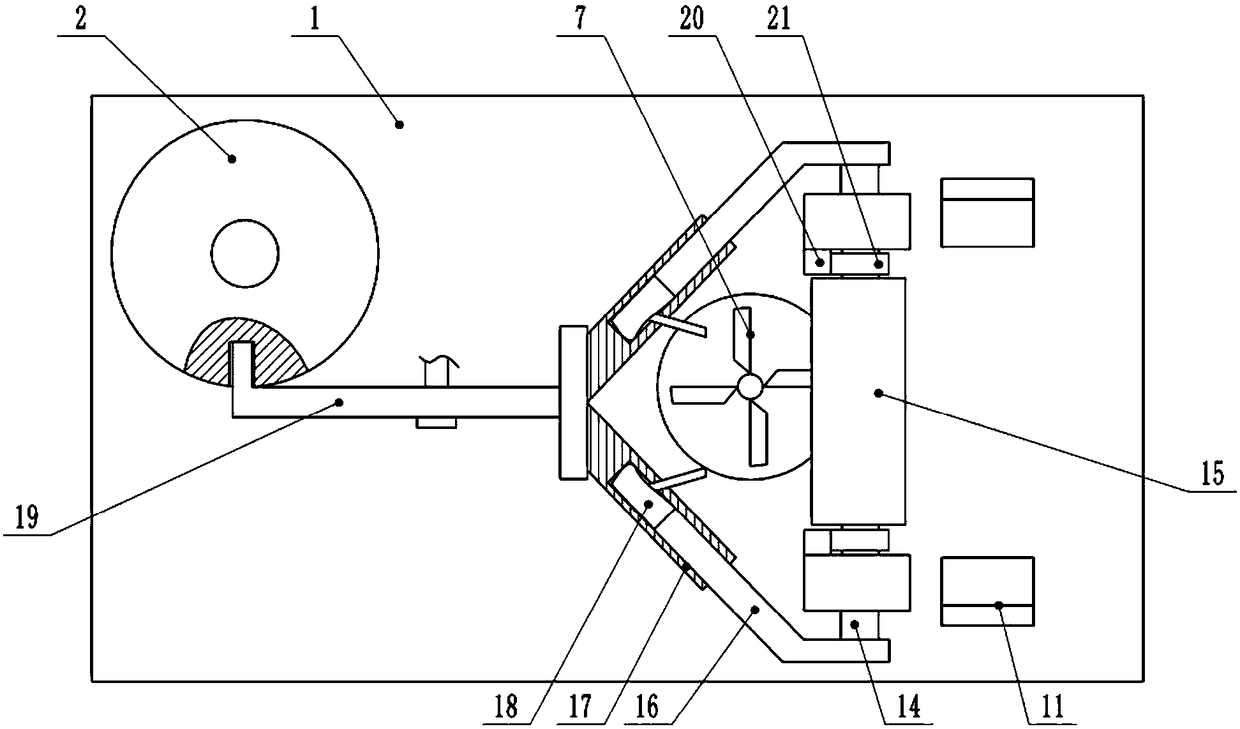

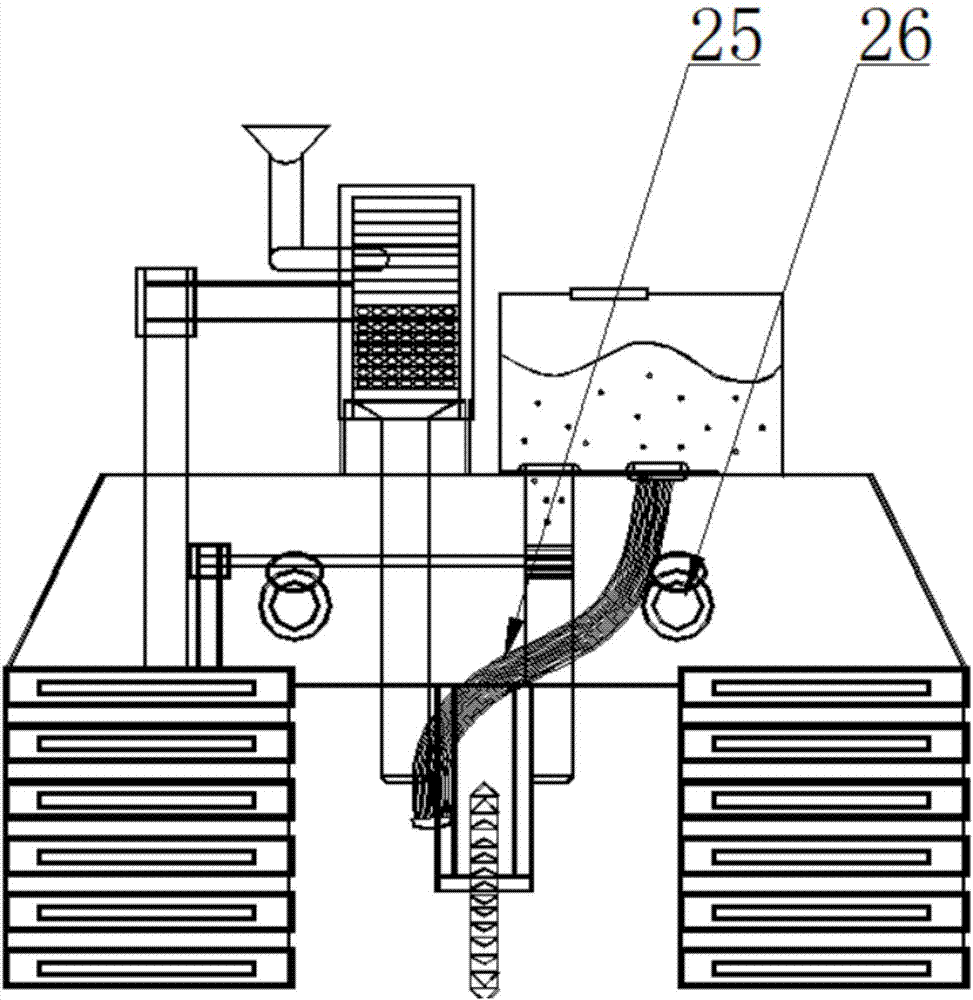

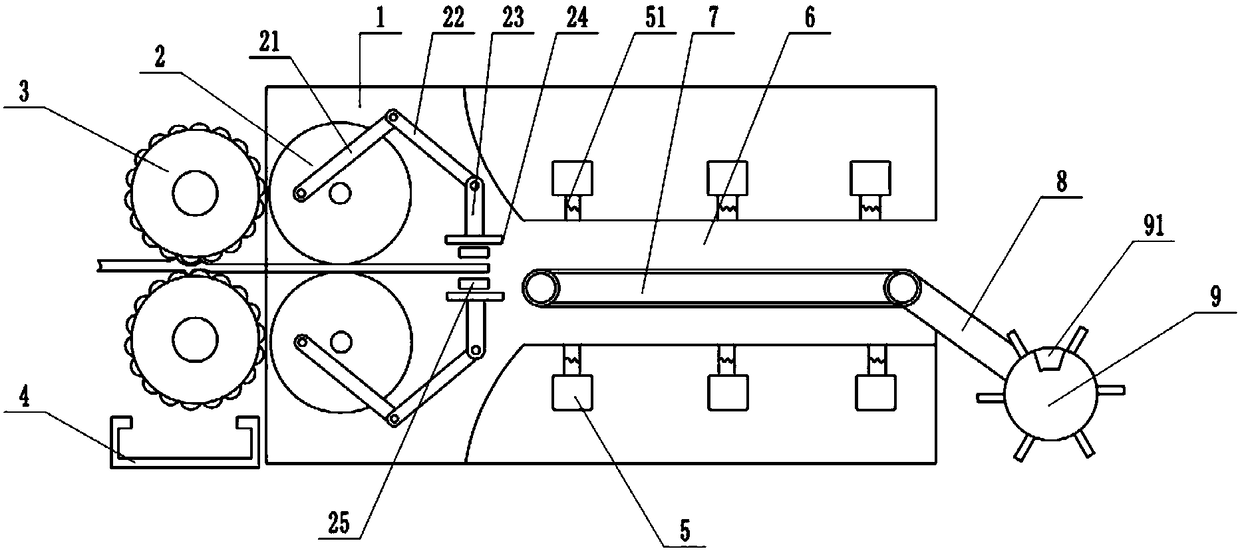

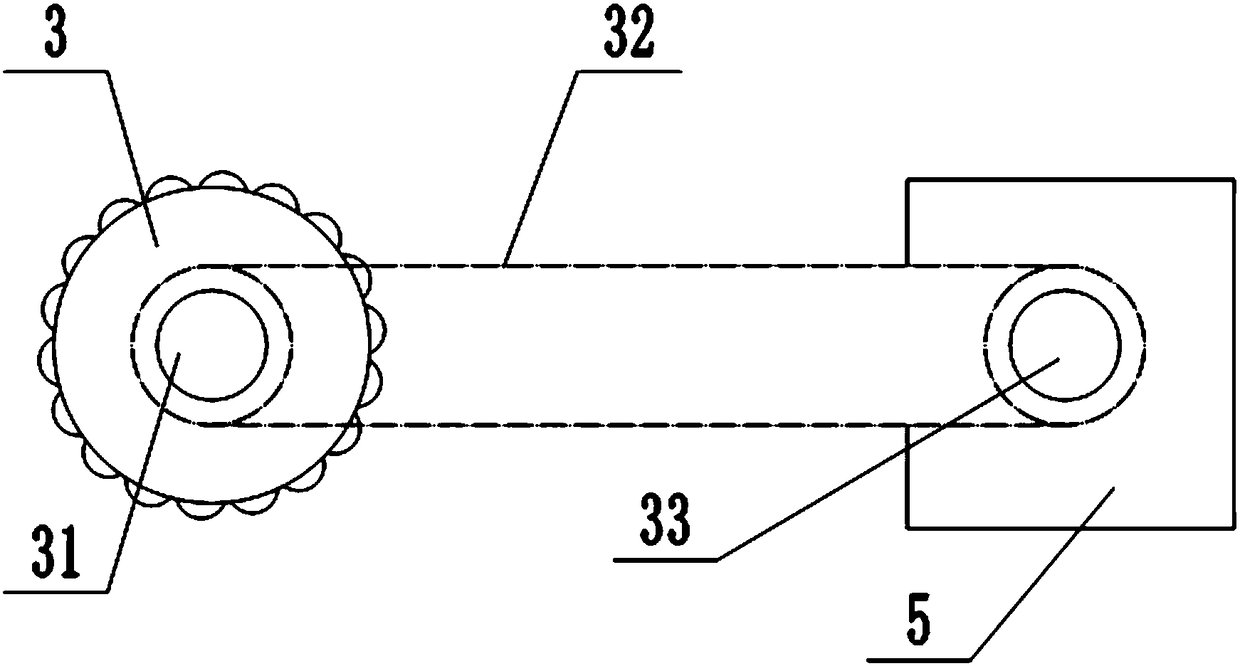

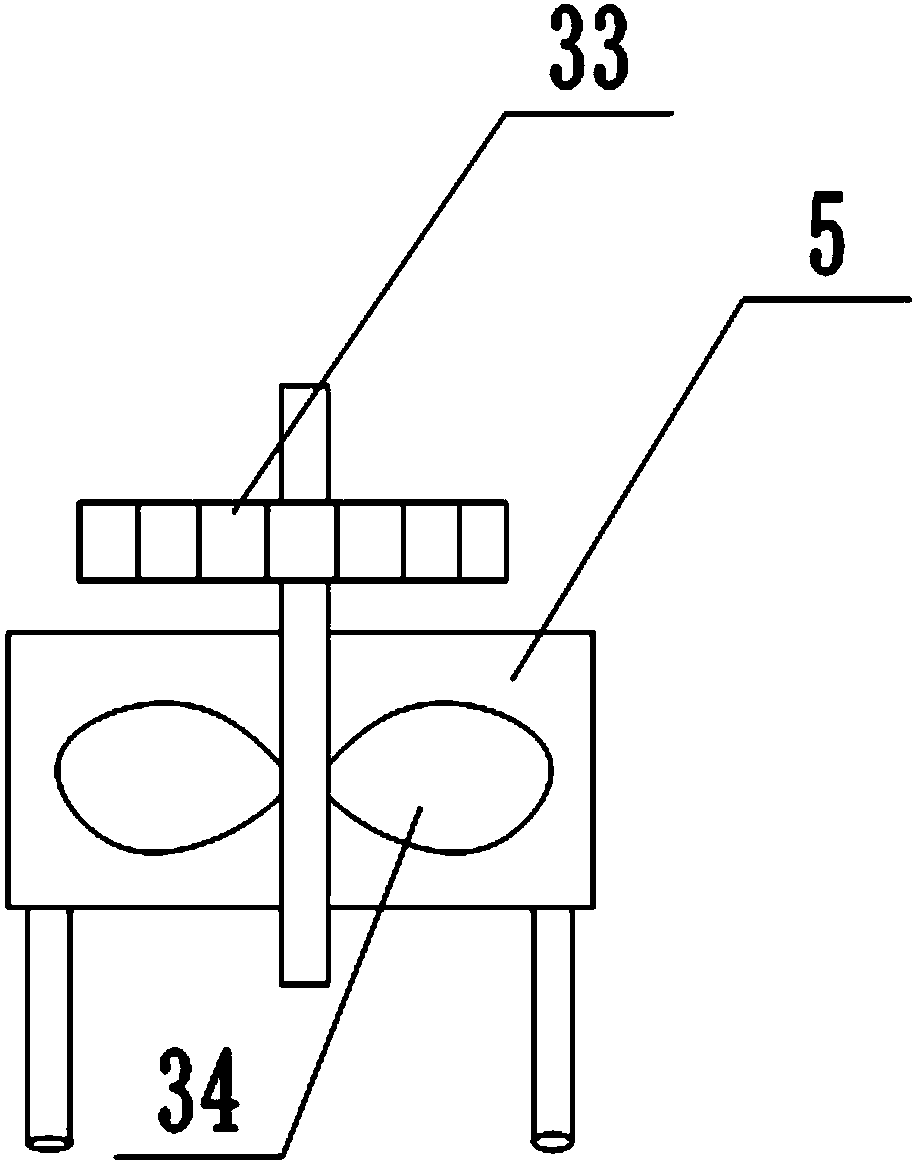

Sport ball washing machine

InactiveCN105435432ARealize push forwardAchieve backward shiftBall sportsMotor driveTransmission belt

The invention provides a sport ball washing machine. The sport ball washing machine comprises a bottom plate and is characterized in that an opening is formed in one side of the bottom plate, side face baffles are arranged on the two sides of the bottom plate, symmetrical one-way doors are arranged on the side face baffles, the bottom plate is connected with a washing cavity, a top washing device is arranged on the upper side of the washing cavity, symmetrical side face washing devices are arranged on the two sides of the washing cavity, and an outlet is formed in the outer side of the washing cavity and connected with a ball collection basket. The top washing motor drives the top brush wheels through a transmission belt so that the tops of balls can be brushed and washed; meanwhile, by means of brushes, balls are in the rotating state in the brushing and washing process, and it is ensured that round faces of balls can be fully brushed and washed. By means of the sport ball washing machine, automatic ball entering and washing can be achieved, and the whole sport ball washing machine is simple in mechanism, high in automation degree, good in washing effect and high in efficiency.

Owner:WEIFANG UNIV OF SCI & TECH

Electrical terminal ground structure and installation method

InactiveCN103996908AFirmly connectedAvoid installation quality impactLine/current collector detailsClamped/spring connectionsAxial compressionRound face

The invention discloses an electrical terminal ground structure and an installation method. The electrical terminal ground structure is characterized in that a bolt is provided with a wedge-shaped head and a threaded section, a shrink-ring is provided with a wedge-shaped face sleeve and a flange, and the wedge-shaped head is sleeved with the sleeve; the external round face of the sleeve is in tight fit with an installation hole of a ground plate in the radial direction; a lock nut and a spacer are installed outside the threaded section; an electrical terminal is axially installed between the flange and the spacer, and an axially screwed nut enables the electrical terminal to make tight contact with the flange of the shrink-ring. The bolt is made of stainless steel, and the shrink-ring is made of aluminum alloy or copper alloy. The installation method comprises the steps that after the surfaces of the bolt and the sleeve are processed, the wedge-shaped head is sleeved with the sleeve, the sleeve is inserted into the installation hole, the bolt is screwed in a riveting device for riveting, and then the bolt is sleeved with the electrical terminal and the nut until axial compression is achieved. The test shows that by the adoption of the structure and size optimization, the properties such as pulling-out force, rotational torque, leakage, a resistance value, impact resistance and vibration resistance can meet the requirements. The existing welding defects are overcome, the connection problem caused when an existing ground plate is made of a composite material is solved, and the electrical terminal ground structure is applied to high-speed trains, railway tracks, buildings and the like and meets the property requirement of ground structures under the complex conditions.

Owner:MEISHAN CRRC FASTENING SYST CO LTD

Explosion arrestment flap valve

PendingCN109027354AExtended service lifeImprove sealingEqualizing valvesSafety valvesRubber ringEngineering

The invention discloses an explosion arrestment flap valve. The explosion arrestment flap valve comprises a valve body. The valve body comprises a valve shell and a valve deck. The bottom end of the valve deck is fixedly provided with support seats. The two ends of the valve deck are provided with a gas inlet and a gas outlet correspondingly. An explosion arrestment mechanism is arranged in the valve body and comprises a blocking pipeline. An explosion arrestment flap is arranged at a pipe opening, located in the valve body, of the blocking pipeline. An overturning mechanism is arranged on theupper side of the blocking pipeline. The pipeline opening, matched with the explosion arrestment flap, of the blocking pipeline is arranged to be of an inclined round face structure. The circumferential face, facing the explosion arrestment flap, of the pipeline opening of the blocking pipeline is provided with an annular seal rubber ring groove and an annular seal rubber ring embedded into the annular seal rubber ring groove. According to the explosion arrestment flap valve, in the manner that the explosion arrestment flap is arranged to be a concave plate, the middle portion of the explosion arrestment flap is not prone to deformation under the action of impact force, and the service life of the explosion arrestment flap is greatly prolonged.

Owner:河北锐智纳米科技有限公司

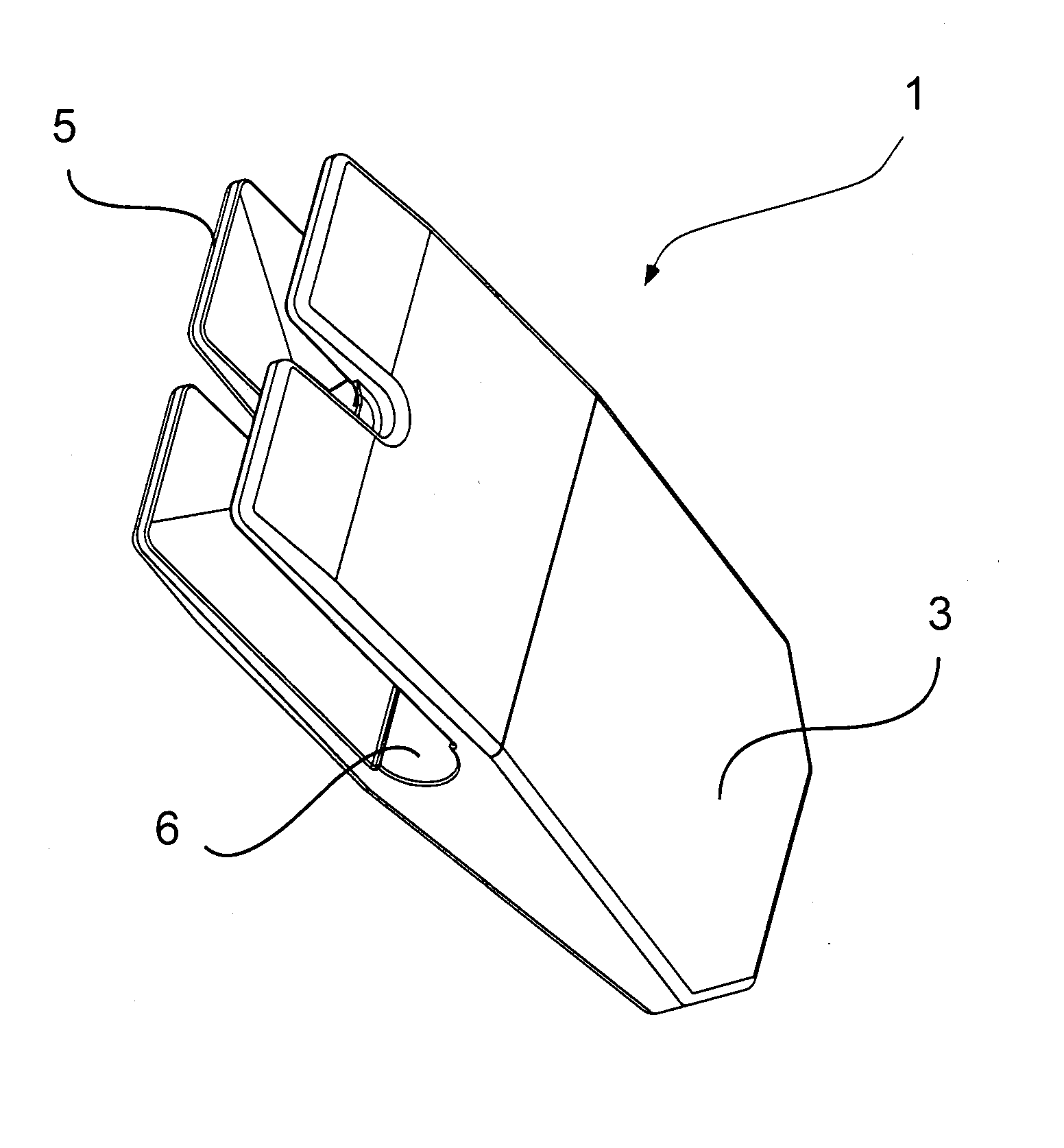

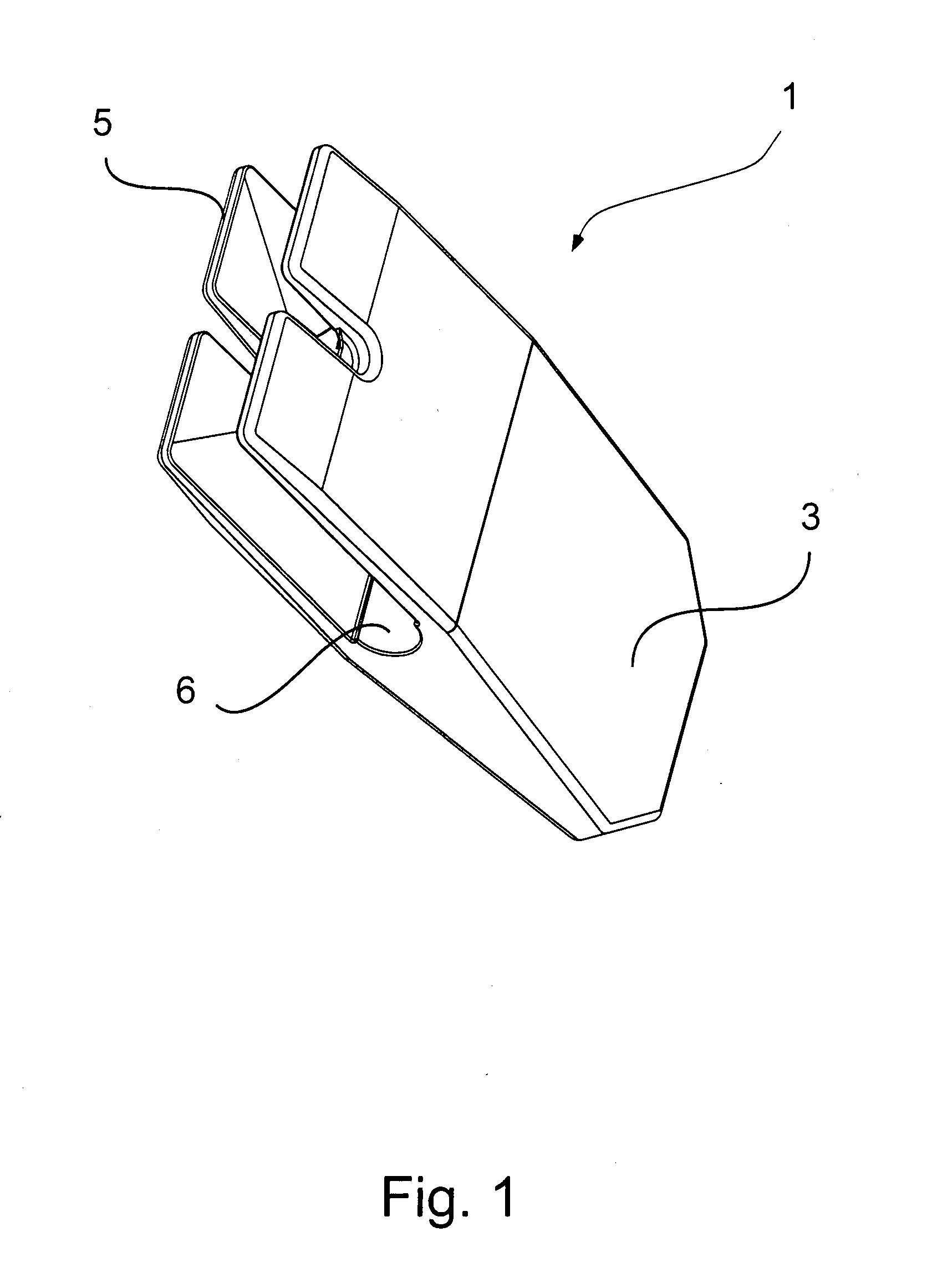

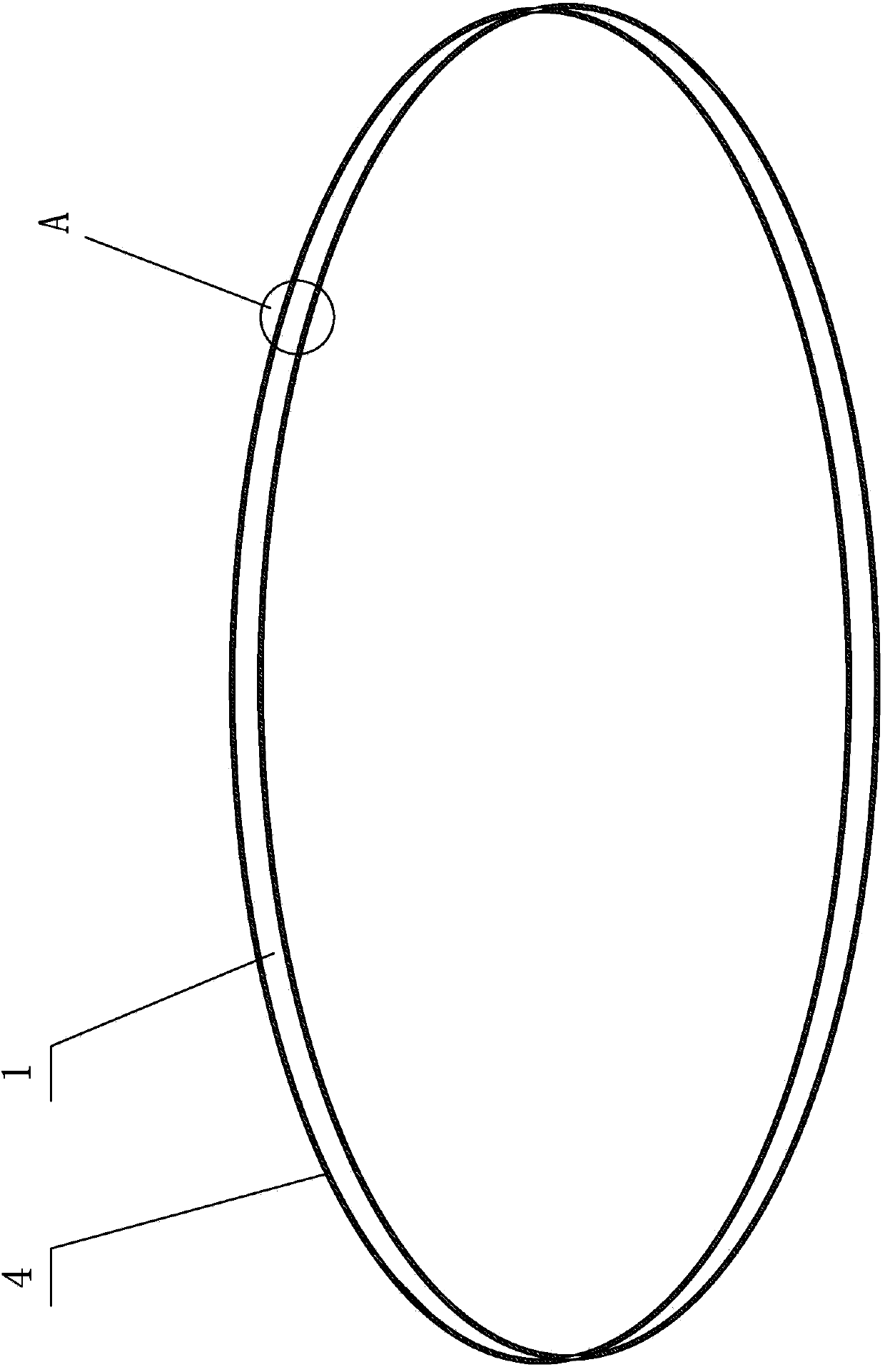

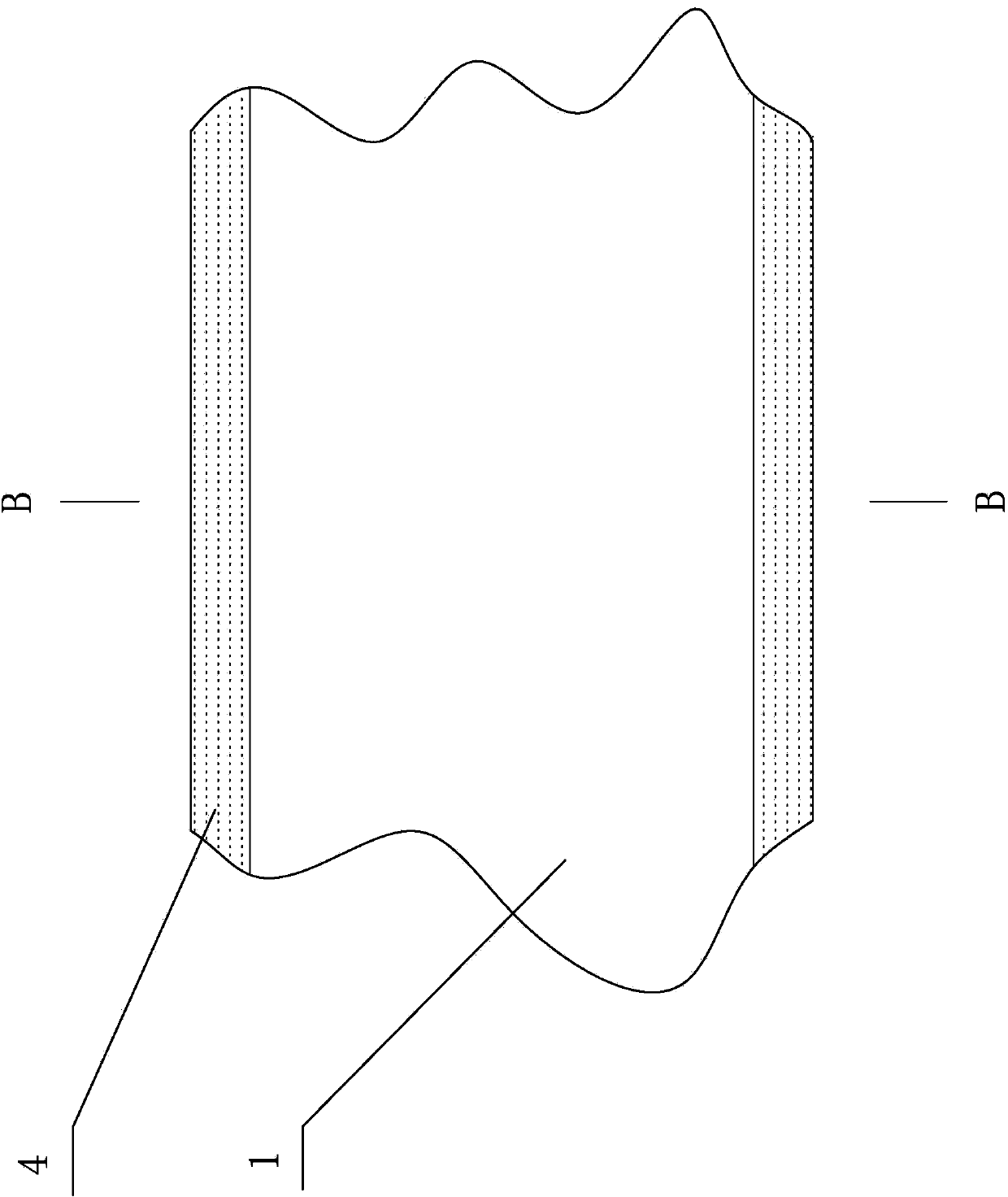

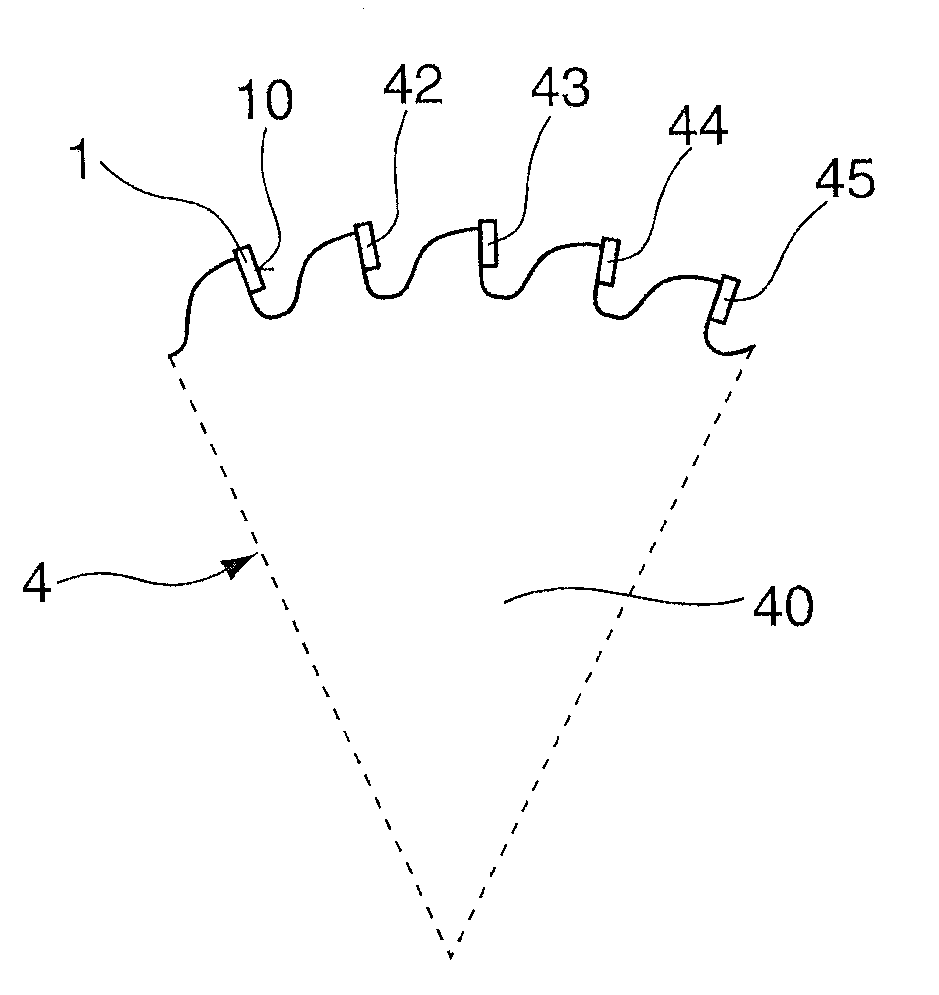

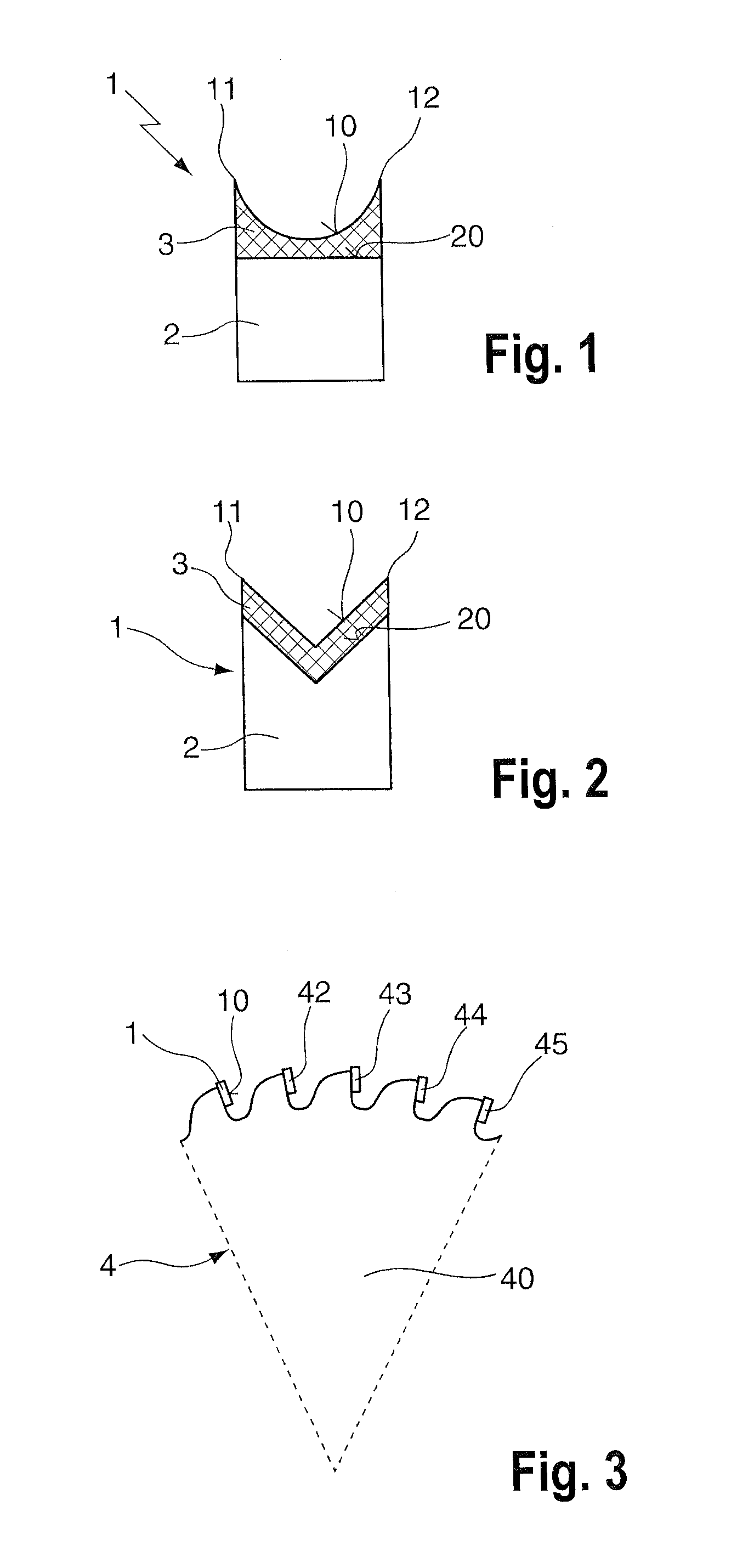

End bit for a soil-working tool

InactiveUS20130091745A1Large material thicknessEliminate the effects ofHarrowsSoil-shifting machines/dredgersRound faceEngineering

The invention relates to a replaceable end bit for a soil-working tool, which end bit is retained by friction and wherein, at its trailing edge, the end bit is provided with one or more openings that is / are oriented rearwardly relative to the end bit and for receiving couplers from a holder part. The openings may have rounded faces, and the faces may face towards each other. The distance between the rounded faces is increased with the distance from the trailing edge of the end bit. The invention also relates to a holder part for a replaceable end bit for a soil-working tool, which end bit is retained by friction, and wherein the holder part is provided with pairs of protruding couplers, which protruding couplers are provided with a space, where the distance between the two protruding couplers is reduced with the distance from their end faces.

Owner:MOLLSOR

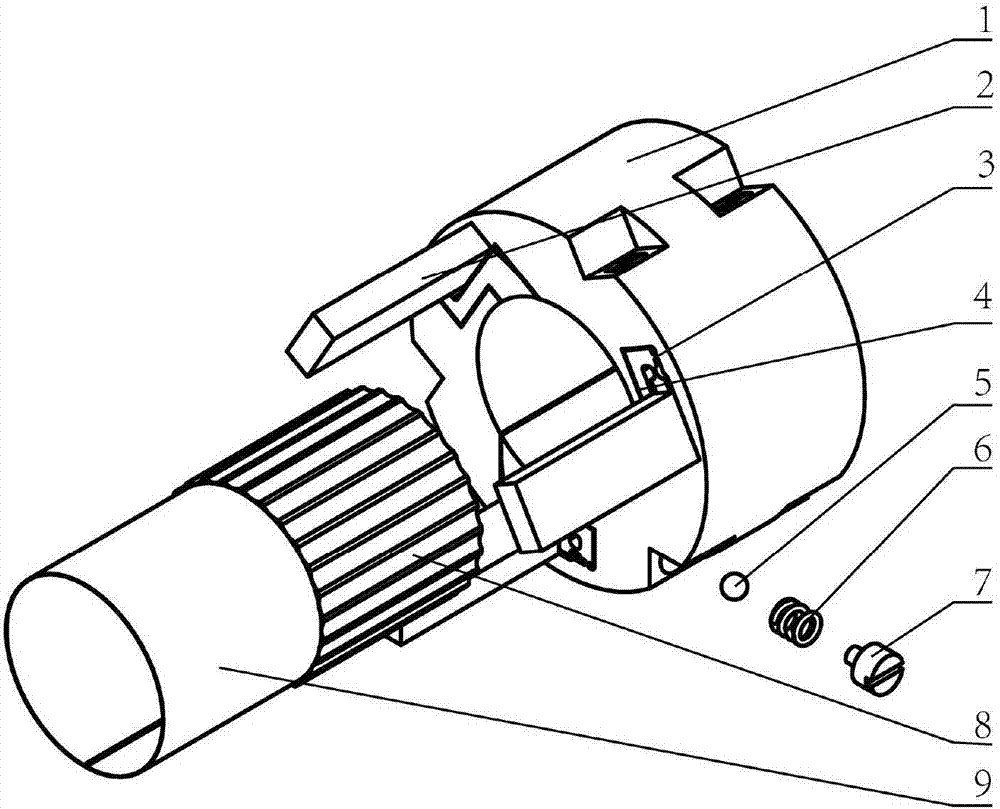

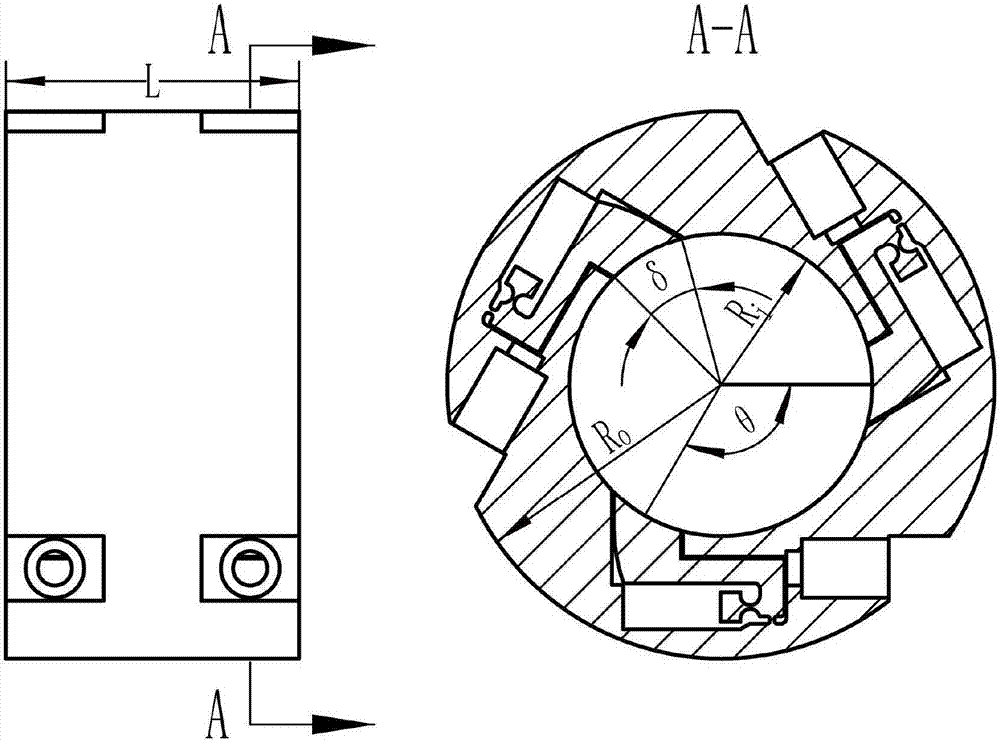

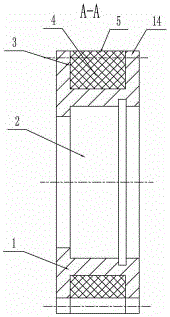

Novel active air foil bearing based on PZTs and flexible hinges

ActiveCN106884870AStable jobImproved stiffness propertiesSliding contact bearingsWire cuttingRound face

The invention discloses a novel active air foil bearing. The bearing comprises a shaft sleeve, the PZTs, the flexible hinges, rigid push rods, precompression exertion devices, wave foil and top foil; the shaft sleeve is machined through wire cutting, three PZT mounting through grooves circumferentially and evenly distributed, the corresponding flexible hinges and the corresponding rigid push rods are obtained, the top ends of the rigid push rods are flush with the inner cylindrical face of the shaft sleeve, the PZTs are mounted in the through grooves, the corresponding precompression exertion devices are designed for the PZTs, the wave foil is formed by pressing of elastic materials, and is arranged on the shaft sleeve and the inner cylindrical faces of the rigid push rods, one end of the wave foil is welded to the inner round face of the shaft sleeve, and the other end of the wave foil is free. The top foil is arranged on the wave foil in a covering manner. Through control over power supply signals of the PZTs, the PZTs mechanically deform, the flexible hinges are enlarged to deform, and are supported through the rigid push rods to be attached to the wave foil on the push rods and the inner wall of the shaft sleeve, a gap between a bearing and a supporting rotor is changed, the wedge space is increased, the crossed coupling effect is weakened, the bearing dynamic pressure effect is enhanced, the rigid characteristic of the bearing is improved, and finally the aims of actively controlling the rigidity characteristics of the bearing and improving the stability of the bearing are achieved.

Owner:HUNAN UNIV

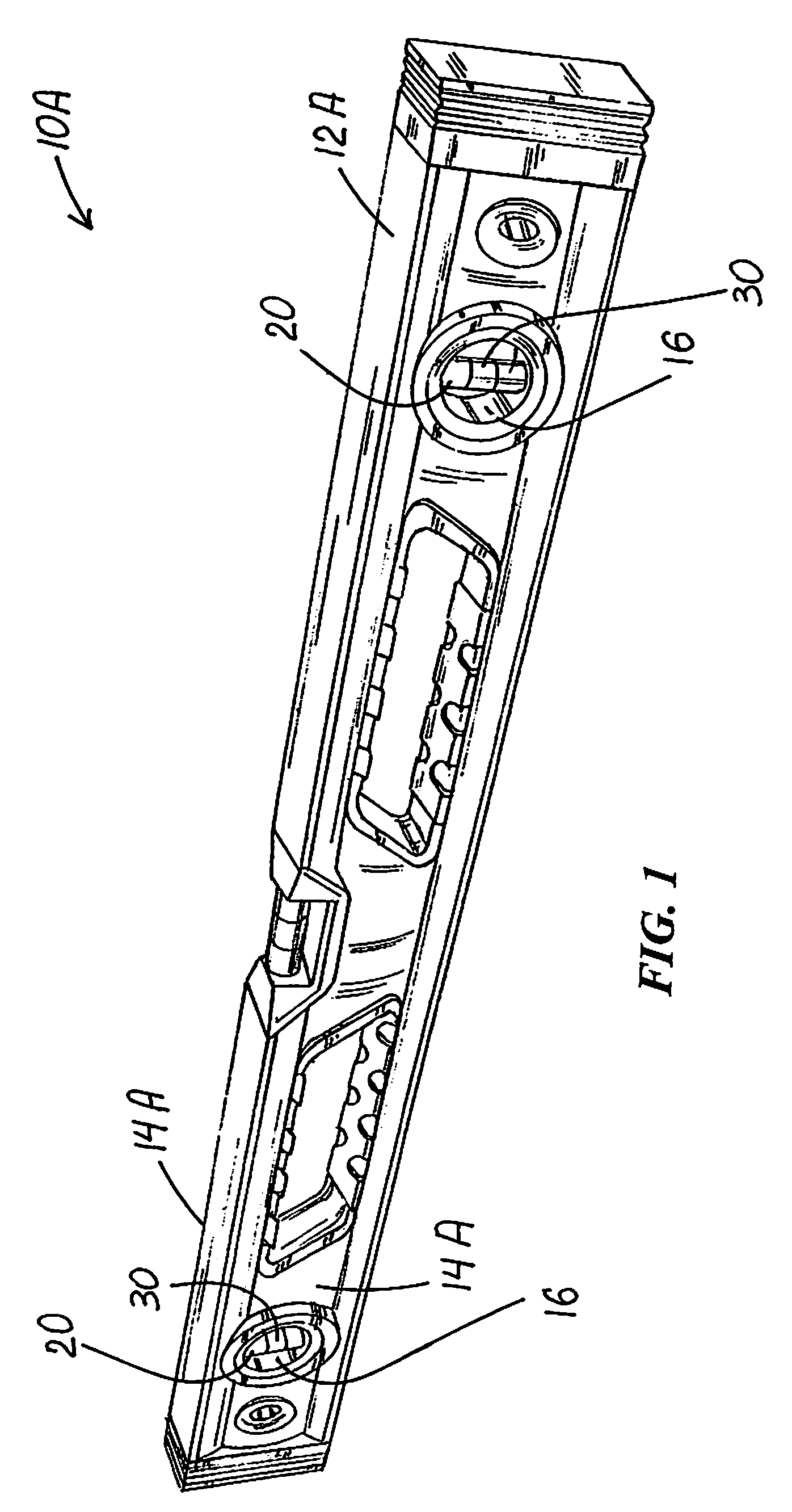

Casing mount for a cylindrical vial

ActiveUS8011109B2Improved casing mountEasy to readStraightedgesIncline measurementHermetic sealRound face

A level of the type having an elongate hollow frame including two sidewalls each defining axially aligned vial openings into the frame. A vial casing is secured with respect to the frame and defines a hermetically sealed single-cavity casing interior entirely enclosing a liquid-and-bubble vial with a substantially cylindrical outer surface extending between two vial ends. The casing is formed of two opposite round face-walls and a surrounding cylindrical wall therebetween. The cylindrical wall has a pair of opposed major wall-portions of first thickness and a pair of opposed intervening wall-portions of second thickness greater than the first thickness. Each intervening wall-portion defines a recess which snugly receives a corresponding one of the vial ends. The inner surface of the surrounding wall is smooth and substantially free of light-ray-interfering structures, whereby the vial appears embedded in the surrounding wall and the face-walls provide uninterrupted full views of and about the cylindrical vial.

Owner:MILWAUKEE ELECTRIC TOOL CORP

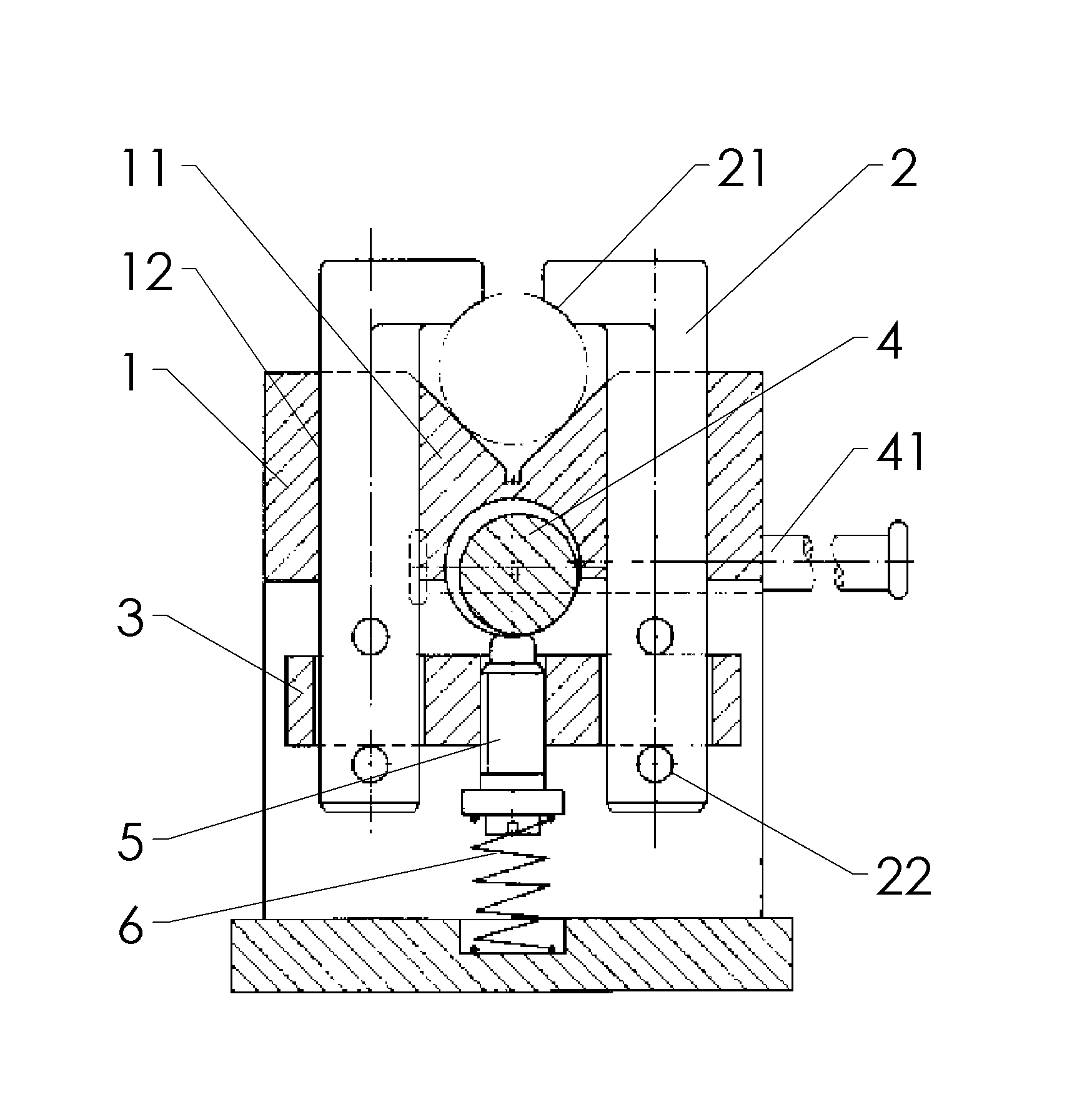

Cam compression clamp

The invention discloses a cam compression clamp and aims to solve the problem that a horizontally arranged columnar workpiece cannot be well fixed in the prior art. According to the scheme disclosed by the invention, the cam compression clamp is characterized by comprising an engine bed and a clamping jaw, wherein the upper surface of the engine bed is a V-shaped supporting surface; the clamping jaw is connected with the engine bed in the manner of vertical shifting, and a left driven end and a right driven end which are used for compressing the top round face of the workpiece are arranged above the V-shaped supporting surface; the engine bed is hinged with the cam; and a driving end arranged on the clamping jaw is abutted with the lower edge of the cam. The technical scheme has the characteristic that the horizontally-arranged columnar workpiece can be well fixed through matching the engine bed with the clamping jaw.

Owner:重庆市南川区富民科技推广中心

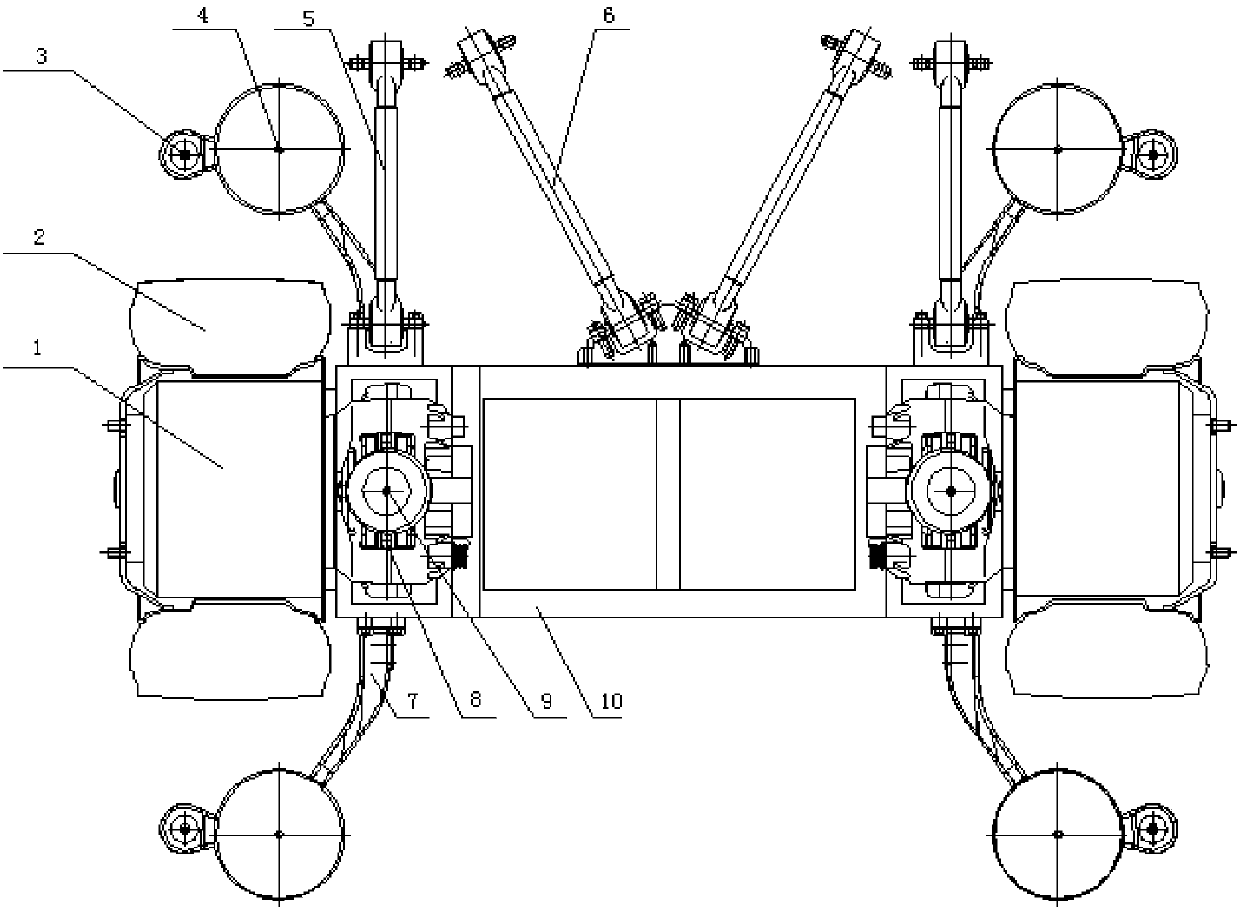

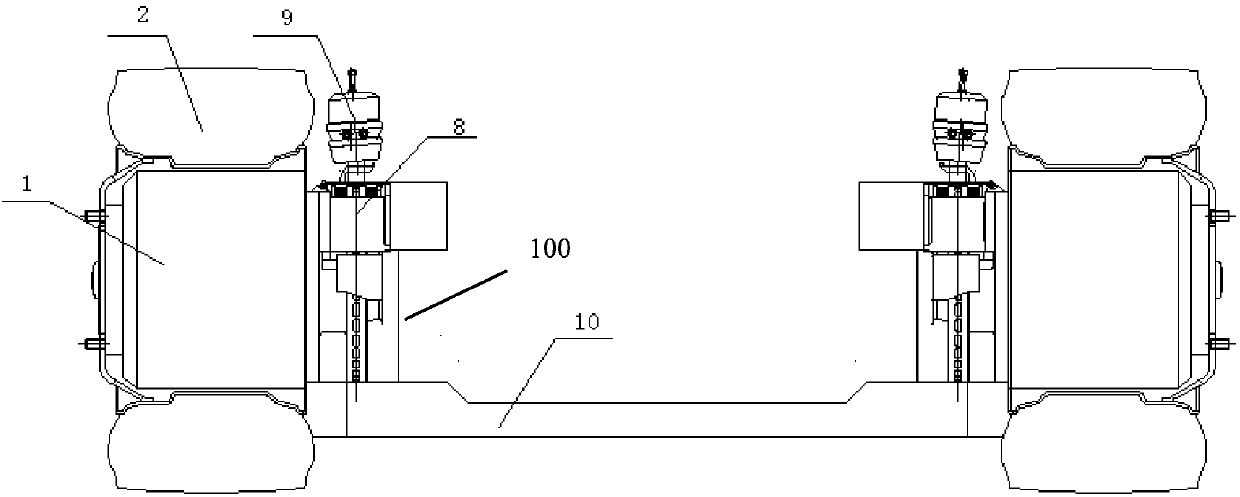

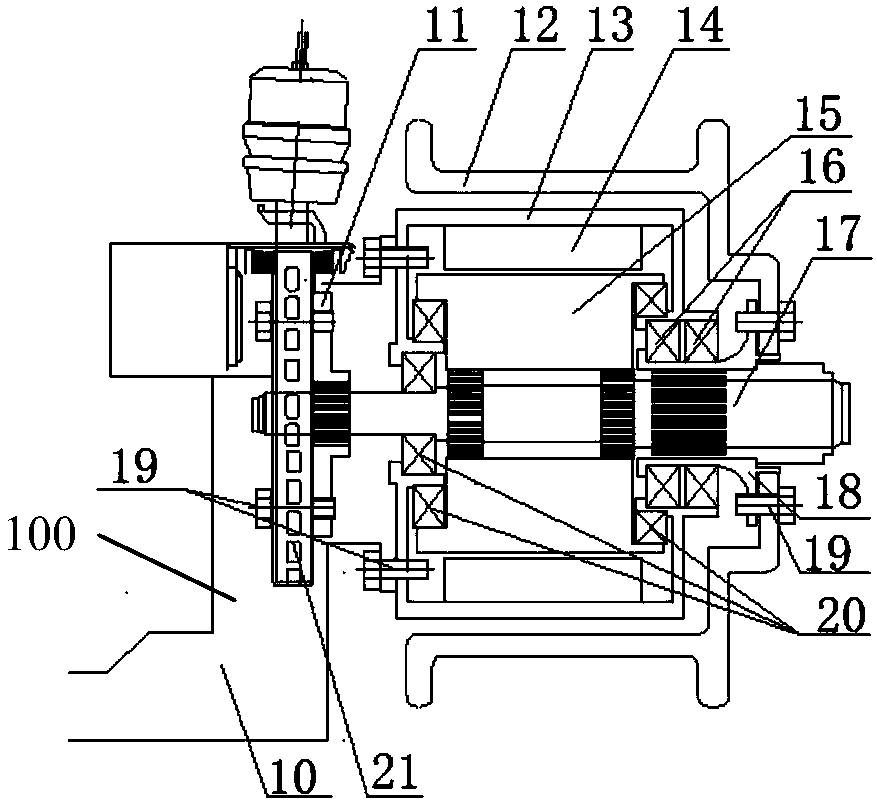

Electric car axle

PendingCN108016288AExtend your lifeImprove reliabilityBraking element arrangementsMotor depositionStator coilElectric machinery

An electric car axle comprises a car axle body, a brake, a motor, a hub and a wide-base and single-tire rim. Stand columns are arranged at the two ends of the car axle body, and a motor mounting station is arranged on the outer side of each stand column. The motor comprises a housing, a stator coil, a rotor coil and a motor spindle, wherein the housing is mounted on the motor mounting stations, the stator coil is fixed to the housing, the motor spindle is rotatably fixed to the housing, and the rotor coil is fixed to the motor spindle. The inner round face of the hub is connected with the outer side end of the motor spindle through a spline, and the outer round face of the hub is supported on the inner edge of the housing of the motor through two tapered roller bearings. The wide-base andsingle-tire rim is fixed with the hub. The motor spindle, the hub and the axis of the hub are in coincidence, and the axis of the motor spindle is parallel to the plane where the plate type structureof the car axle body is placed. The electric car axle can prolong the service life of the motor, improve the reliability of the motor and reduce the height of a car floor.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Machining process for disc spring used for forging press

InactiveCN104439976AExtended service lifeReduce downtime for maintenanceFurnace typesHeat treatment furnacesRepair timeEngineering

The invention relates to a machining process for a disc spring used for a forging press. The machining process is characterized in that round steel is blanked, upsetting operation and drawing-out forging operation are conducted at least four times, after the steel is annealed, the outer round face is turned, holes are drilled, the steel is turned and sliced, the two end faces of each piece are ground and deburred, and cold pressing forming is conducted on each piece on a cold pressing forming die; each piece is quenched, each piece is tempered in a die clamping state and air-cooled to the normal temperature after being tempered, and a product is checked and put in storage after the die is detached. According to the machining process, the process procedure is reasonable, the structural strength and the fatigue resistance of the disc spring are improved, the service life of the disc spring is prolonged, the halt repair time of the forging press is shortened, production efficiency is improved, the workload of workers is reduced, and the labor intensity of the workers is lowered.

Owner:JIANGYIN JIB WD PRECISION

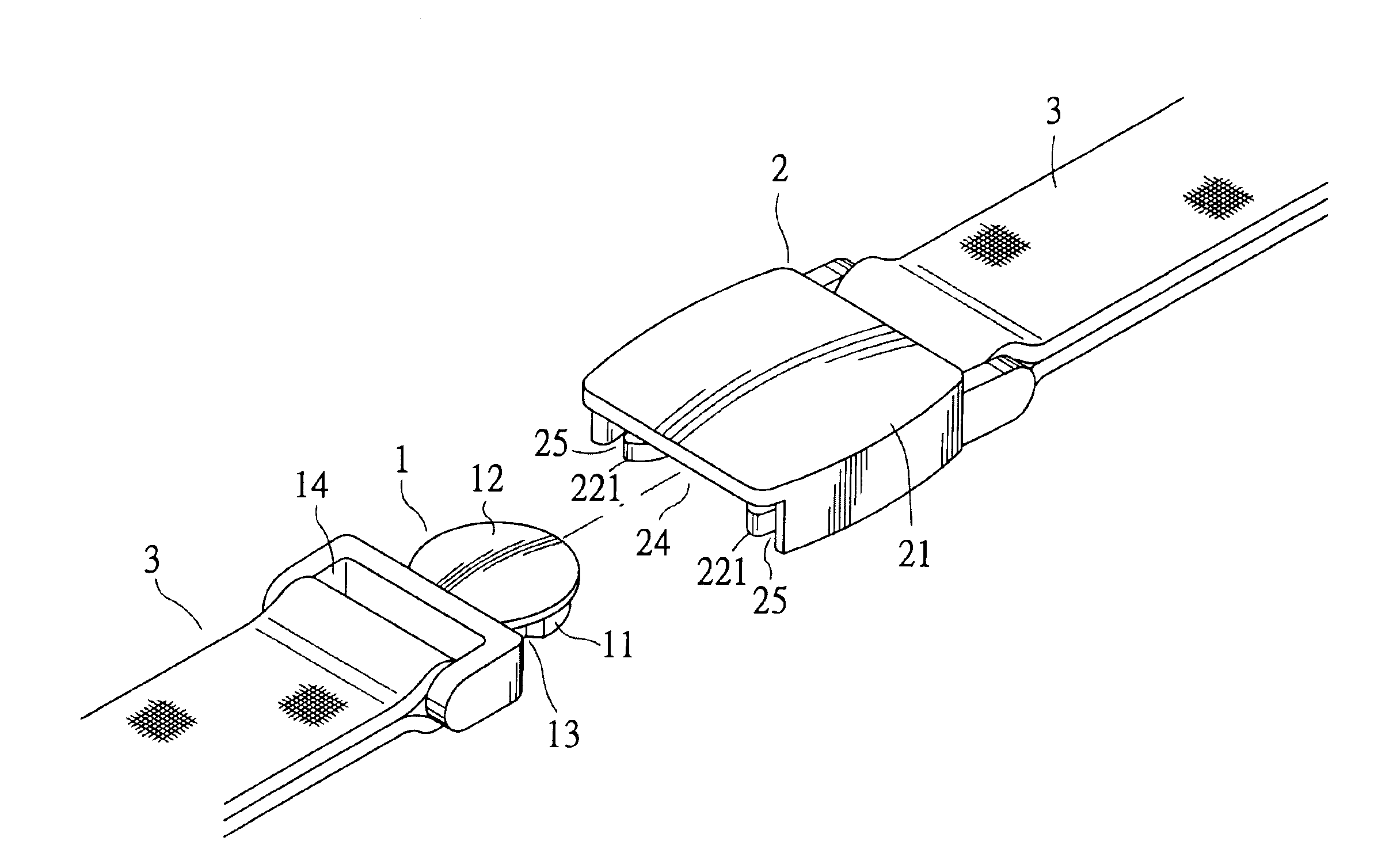

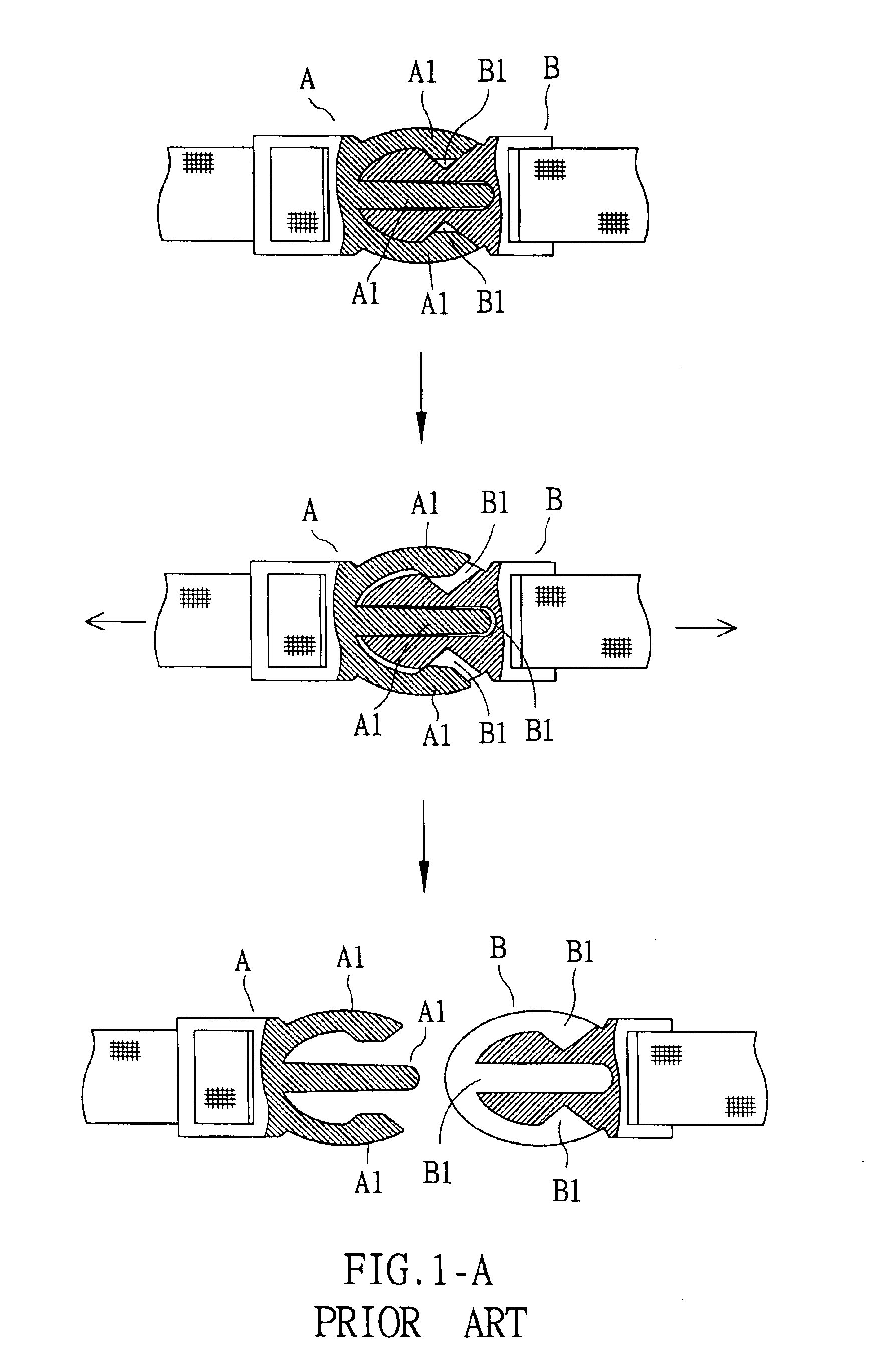

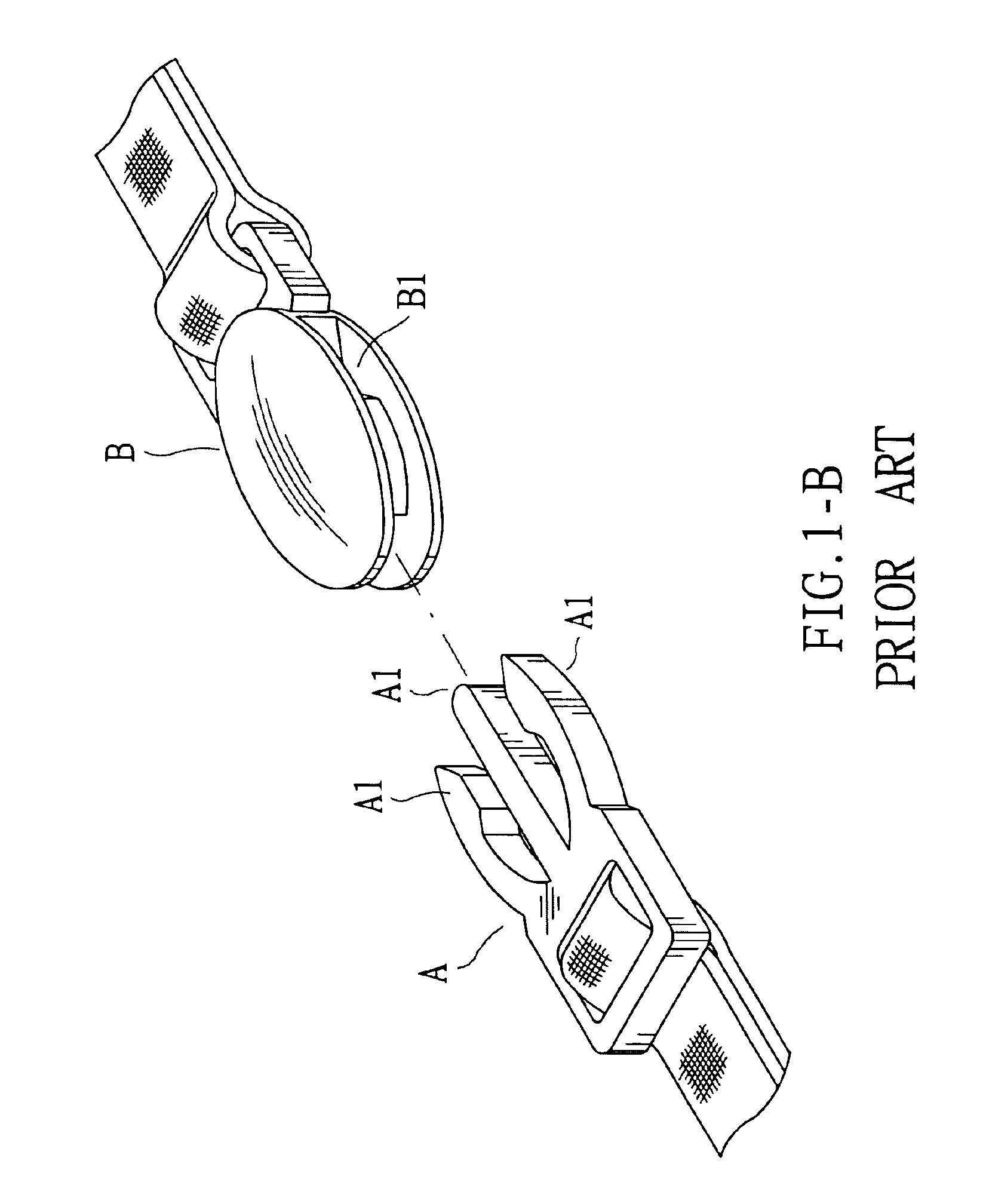

Pet collar buckle structure

Owner:CHEN YING CHIH

Novel badminton ball

The invention discloses a novel badminton ball, and belongs to the field of badminton. The badminton ball comprises a hemispherical ball head and feathers, the hemispherical ball head is made of transparent materials, a piezoelectric power generating piece is arranged on the inner side of the hemispherical ball head, and a light-emitting diode and a capacitor are arranged inside the hemispherical ball head. The positive electrode of the piezoelectric power generating piece is connected to one end of the capacitor and the positive electrode of the light-emitting diode, and the negative electrode of the piezoelectric power generating piece is connected to the other end of the capacitor and the negative electrode of the light-emitting diode. An omega-shaped spring sheet is arranged on the outer side of the round face of the hemispherical ball head. According to the novel badminton ball, when the badminton ball is hit by a badminton racket, the piezoelectric power generating piece generates electric energy due to vibration to light the light-emitting diode, the badminton ball emits light when hit, and people can carry out badminton sport during nights.

Owner:张敬敏

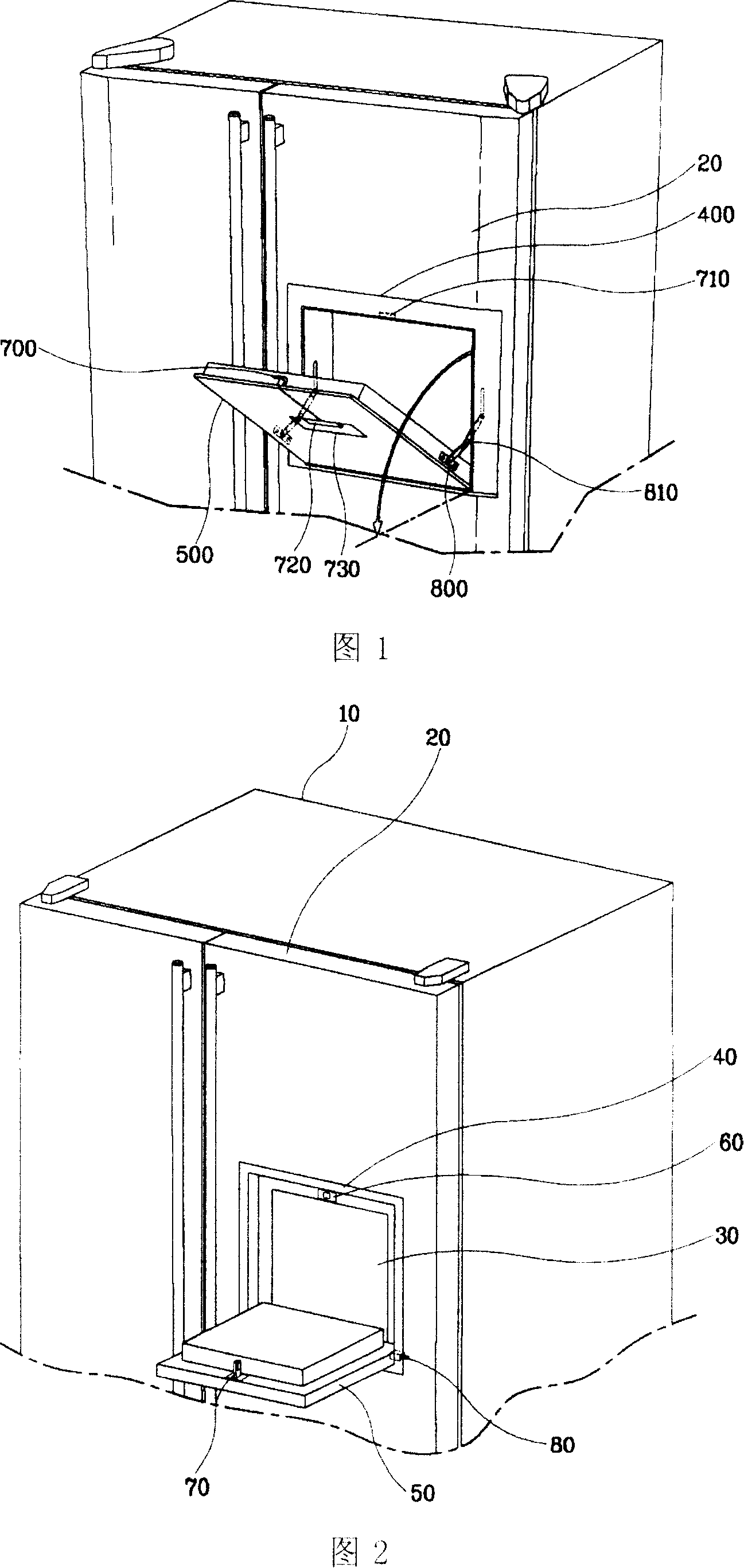

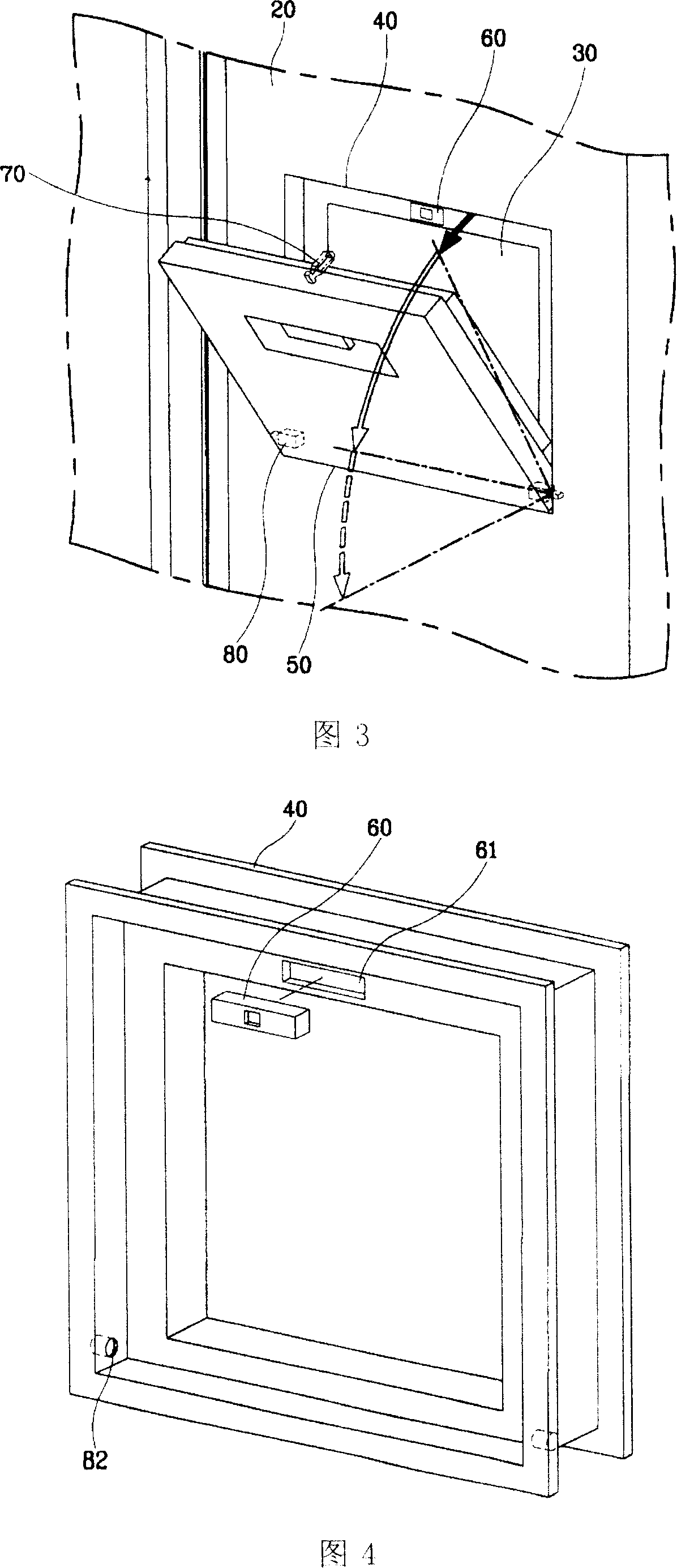

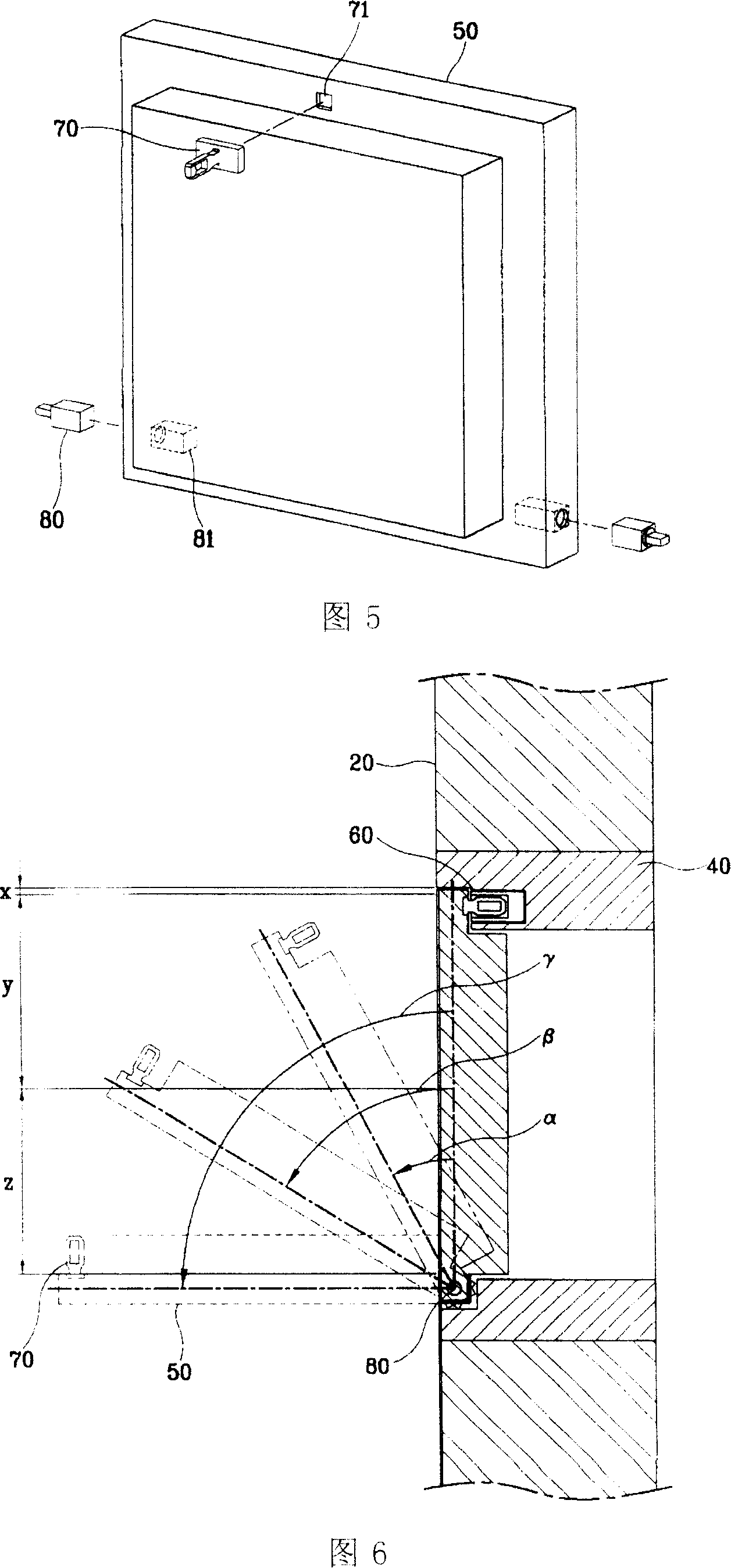

Electric refrigerator with family pub door

InactiveCN101131296ASimplify open/close operationImprove ease of useLighting and heating apparatusDomestic refrigeratorsRound faceRefrigerated temperature

This invention discloses a fridge with domestic bar door. It includes: opening part on the fridge door; domestic bar door frame on the inner round face of opening part; domestic bar door with hinge connecting at inferior end of domestic bar door frame. It is used to open and close the opening part; padlock component on the superior end of domestic bar door inner face; latch unit in the latch trough corresponding to the padlock component on the superior end of domestic bar door frame; a pair of dumping component on two lateral faces of domestic bar door. They protrude outwards and act as rotating shaft. The domestic bar door connects to domestic bar door frame through dumping component. Users can open and close the domestic bar door simply by pressing operation.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

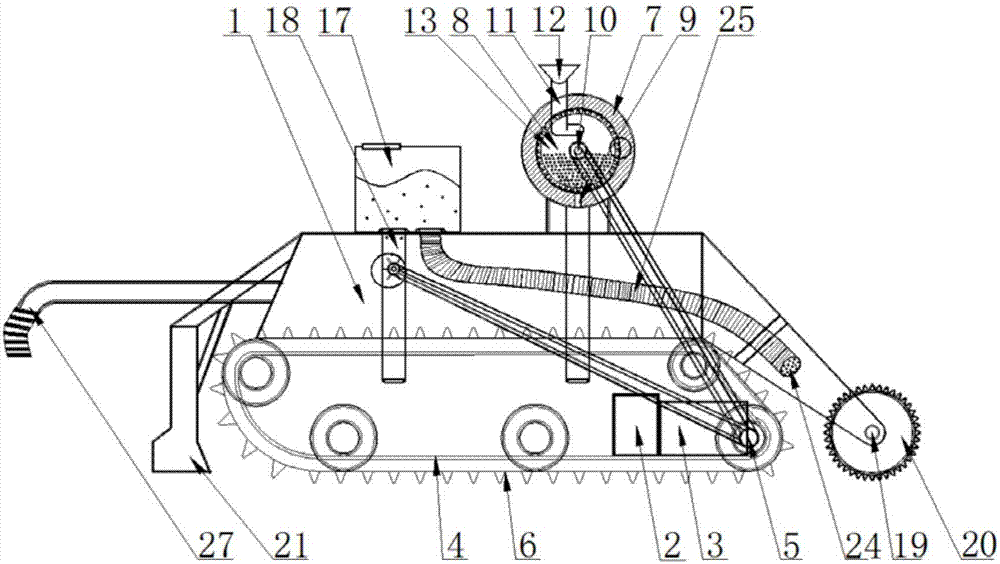

Vegetable planting machine

The invention relates to a vegetable planting machine, comprising a frame, the frame has a power mechanism, a walking mechanism, a seed releasing mechanism, a water supply mechanism and a ditching mechanism, the power mechanism includes a motor and a gearbox, the running mechanism includes a crawler chassis, and the front of the frame The first part is a gearbox for driving the crawler belt. The seed release mechanism includes a first hollow cylinder and a second hollow cylinder. The center of the second hollow cylinder has a first rotating shaft. The hollow cylinder includes a seed storage room and a compartment. There is a water supply mechanism at the rear of the second hollow cylinder. The water supply mechanism includes a water tank and a water pipe. One end of the water pipe is connected to the water tank and the other end is suspended in the air. There are ditch knives. The structure of this design is reasonable. By limiting the water flow mechanism, it can avoid excessive use of water. When using it, you only need to put the seeds into the hopper, and you can realize the work of ditching, planting, watering and closing the ditch by controlling the handrail. It is easy to use .

Owner:连云港梦宇家庭农场有限公司

LED beam-condensing unit

InactiveCN1963294ASimple and convenient workHigh refractive indexPoint-like light sourceElectric circuit arrangementsElectricityElectric light

This LED light gathering device belongs to electric light source field. It comprises a base, a circuit board, a LED, a cone and a convex mirror, with the base fastened to the circuit board, glued to the cone and hooked with the latch of the convex mirror, and the circuit board and LED connected through light. The cone is a round face or multi face cone. The base takes on the shape of a barrel or the barrel with multi faces. The circuit is in the shape of a barrel or with the walls in multi faces. The multi face cone has 3-18 sides. And the inner wall of the barrel takes on the shape with 3-18 walls. So does that of the circuit board. The electric link of the circuit board and the LED is separated into 1-10 lines of electric linkage with 3-180 LEDs. The cone is made of high refraction material. It can be used for lighting or all kinds of electric apparatus. It is energy saving, high adjustable luminance, free from cooling or driving and any other material in making, large range of color development, quick ignition and extinguishing, with extensive use and long life.

Owner:黄耀生

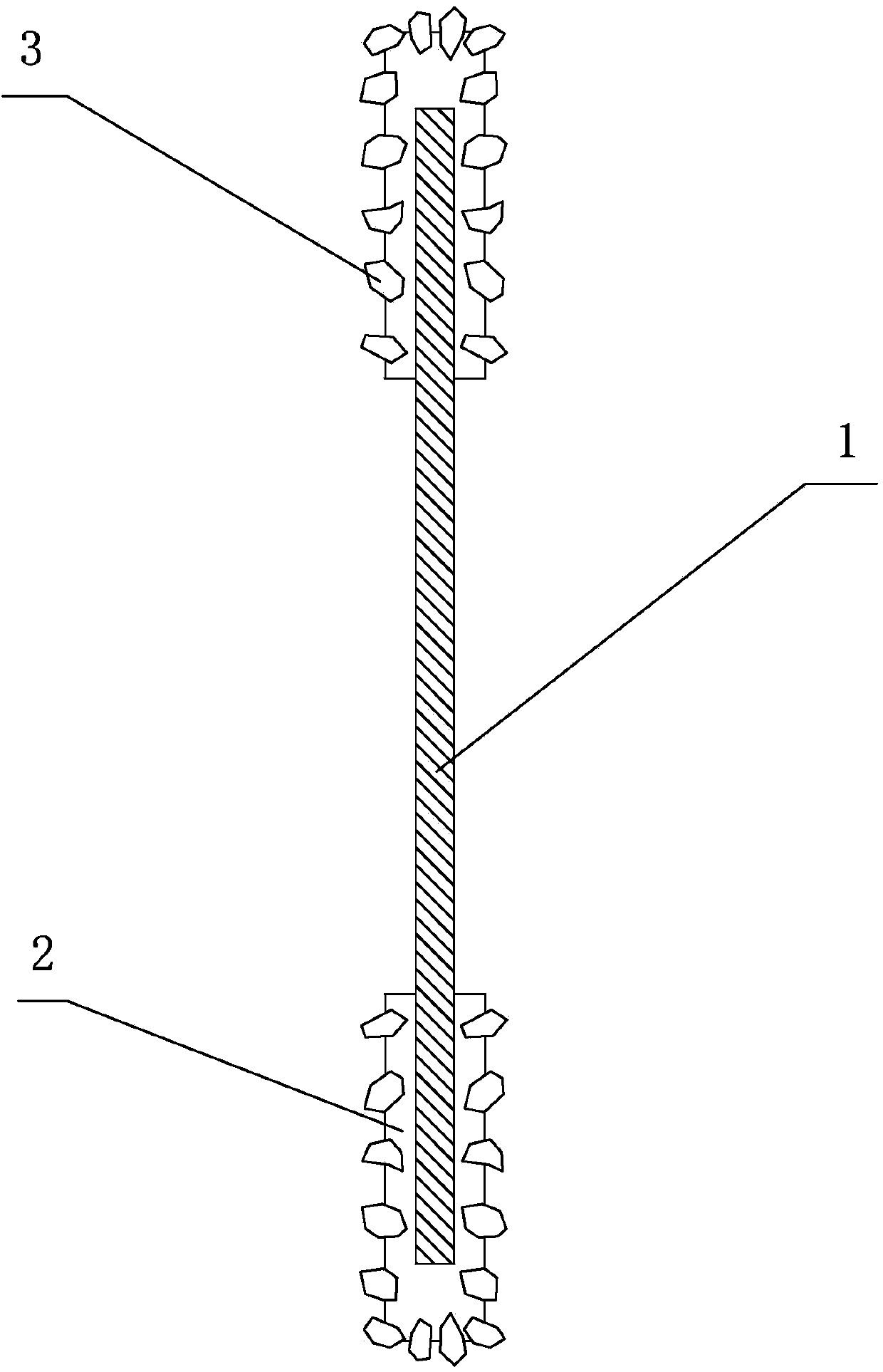

Annular diamond double-blade band saw and manufacturing method thereof

ActiveCN104210038AAvoid mixingAvoid granulationElectrolytic coatingsMetal sawing tool makingRound faceSteel belt

The invention discloses an annular diamond double-blade band saw and a manufacturing method thereof. Diamond particles are uniformly solidified on an electroplated layer by electroplating electrodeposited metal layers coating the two side edges of a stainless steel belt, and a diamond composite coating constructed by the electrodeposited metal layers and the diamond particles is applied to chip machining. The band saw disclosed by the invention can be made into different widths and different lengths, and diamond particles of different particle sizes can be used as required; the band saw can be arranged on different types of equipment, and is mainly applied to high-speed one-way band saw machining and linear cutting; the two edges of the stainless steel belt are provided with the diamond composite coatings, so that the service life of a diamond tool is prolonged, and the utilization ratio is increased; the band saw can be used for cutting hard and crisp materials into slices, and a certain round face can be machined according to the width of the band saw; meanwhile, the band saw has trimming and edge grinding capability, and has a very wide application prospect.

Owner:中国有色桂林矿产地质研究院有限公司

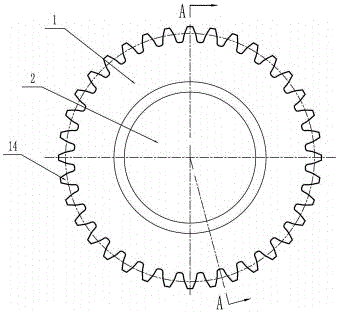

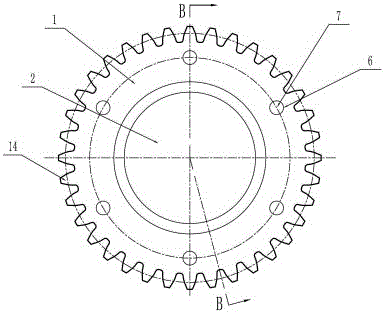

Low-noise gear

InactiveCN105822748AHigh strengthReduce noisePortable liftingGearing elementsLow noiseHigh intensity

The invention relates to a low-noise gear. It is characterized in that: the outer peripheral wall of the base body is provided with a circle of first annular groove, and the first annular insert made of nylon material is poured into the first annular groove, and the outer circular surface of the base body is processed with multiple a plurality of first teeth, and a plurality of second teeth are simultaneously processed on the outer surface of the first annular insert, and the plurality of first teeth and the plurality of second teeth form a complete set of teeth in one-to-one correspondence. The two ends of each complete tooth of the present invention are made of steel, and the middle is made of nylon. The teeth of steel have the advantage of high strength, and the teeth of nylon have the advantage of low noise. Therefore, the gear of the present invention simultaneously It has the advantages of high strength and low noise during operation.

Owner:XINCHANG YUYANG MACHINERY CO LTD

Large diameter steel-plastic pipe

InactiveCN1710311AImprove corrosion resistanceImprove rust performanceRigid pipesGlass fiberHigh density

The invention discloses a kind of steel-plastic tube of large caliber, which includes tube body. The tube body is composed of steel tube and the plastic layer wrapped onto the internal and external round face; the material of plastic layer is made by polyethylene of high density, Fiberglass, butyl or propyl cellulose acetate which are mixed by the proportion: polyethylene of high density: 25-60parts; Fiberglas 10-30parts; cellulose acetate 0.5-2.5parts. The advantages of the invention are as follows: increase by large scale causticity resisting, decrease by large cost and the weight. At the same time, it offers a broad way to reuse the deposing plastic, and it also makes the active social effect to depose the pollution of deposing plastic.

Owner:张思忠

Dyed fabric drying and winding device

ActiveCN108507278ASolve the problem that the strength is not well controlledDrying gas arrangementsDrying machines with progressive movementsRound faceEngineering

The invention relates to a dyeing and drying device, in particular to a dyed fabric drying and winding device. The device comprises a box body and a rack, and transmission rollers are connected to therack; a feeding opening and a discharging opening are formed in the box body, the transmission rollers are arranged at the position, close to the feeding opening, of the outer side of the box body, the round faces of the transmission rollers are coaxially connected with a linkage mechanism, the tail end of the linkage mechanism is connected with air outlet devices, press rollers are arranged on the inner side of the box body, a connecting rod mechanism is arranged on the press rollers, small magnets are in sliding connection into the box body, a ventilation pipe is arranged in the box body, aconveying belt is arranged in the ventilation pipe, the air outlet devices are arranged on the upper side and the lower side of the ventilation pipe, a winding plate is arranged at the tail end of the conveying belt, and a tightening rotating wheel is arranged on one side of the winding plate. Through mutual attraction of the small magnets, the cloth end face can be clamped, the air outlet devices on the two sides of the ventilation pipe blow the cloth for drying, the wind can blow the cloth for transportation, the wind can drive the tightening rotating wheel to rotate so as to enable the cloth to be tightened on the tightening rotating wheel, and the problem that in the prior art, cloth needs to be put into the device manually can be solved.

Owner:宁波隆锐机械制造有限公司

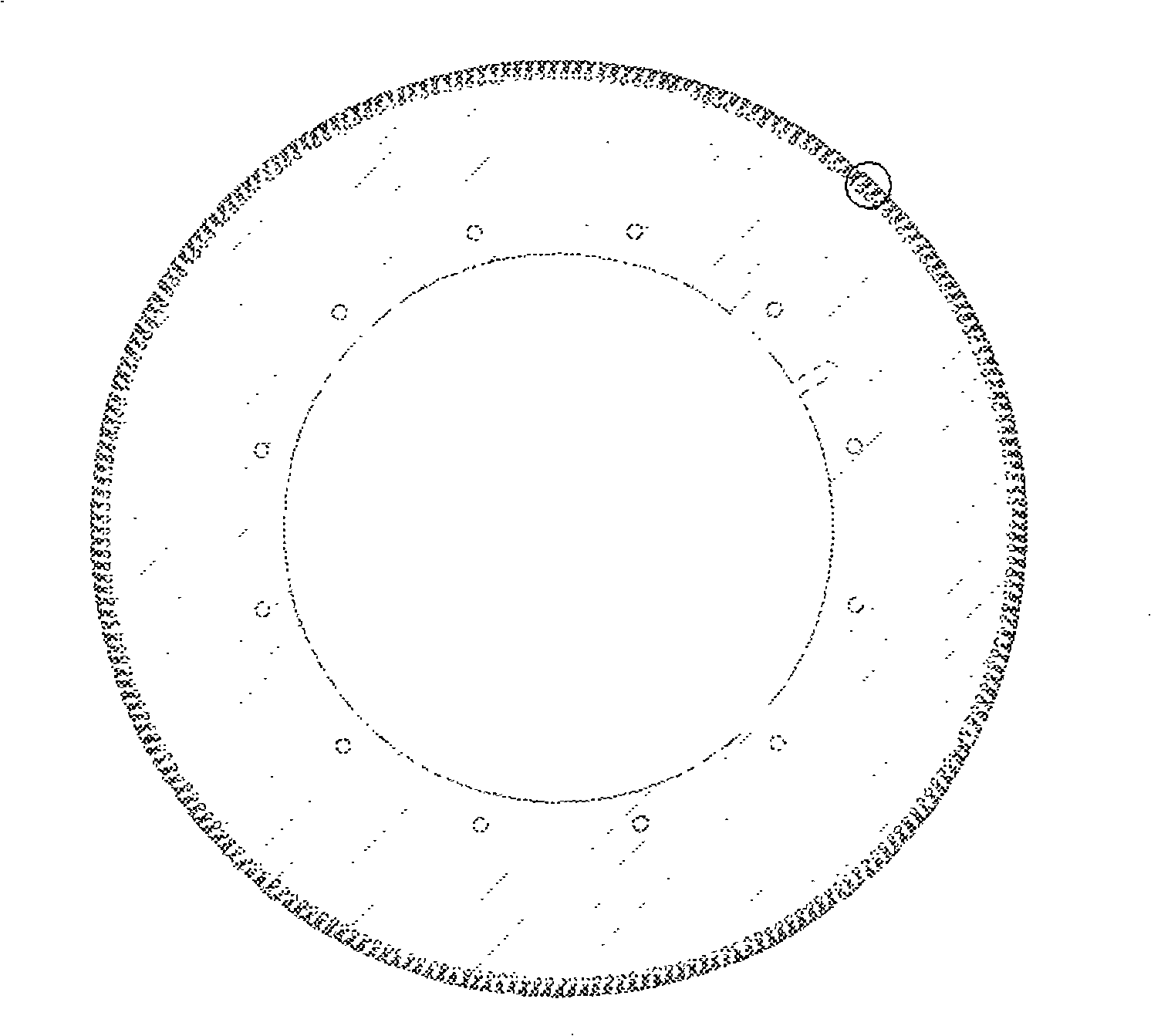

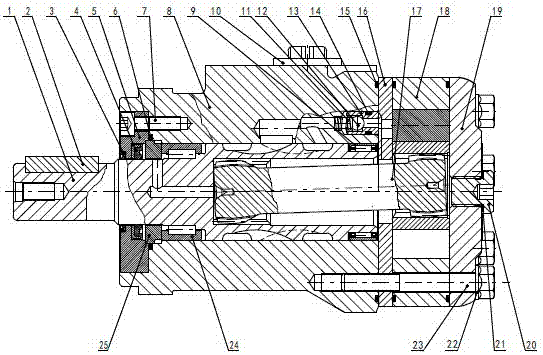

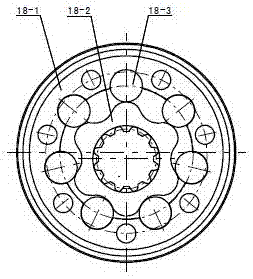

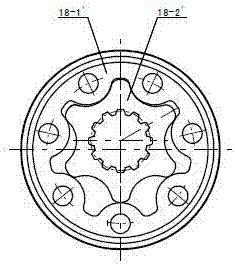

Large-radial-force supporting shaft flow distribution cycloid hydraulic motor

The invention relates to a large-radial-force supporting shaft flow distribution cycloid hydraulic motor, and belongs to the technical field of hydraulic transmission. The front end of a motor output shaft is provided with a front prop which refers to a full complement cylindrical roller bearing. The outer circle of the front prop and the outer circle of a rear prop are mounted onto the through hole round face of a body shell. A step of the output shaft abuts against a cylindrical roller of the front bearing prop and further conducts axial limitation. A gap is kept between a supporting frame of the front bearing prop and the axial direction of the output shaft. The supporting frame of the cylindrical roller bearing abuts against a check ring, and the other end of the check ring abuts against a front cover. By the adoption of the large-radial-force supporting shaft flow distribution cycloid hydraulic motor, the structure of the motor is made simpler and more reliable, radial and axial force bearing capacity of motor shaft extension is higher, the fabrication property is good, and the problems of rigidity, reliability and the like of a main force-carrying bearing are well solved.

Owner:ZHENJIANG DALI HYDRAULIC MOTOR

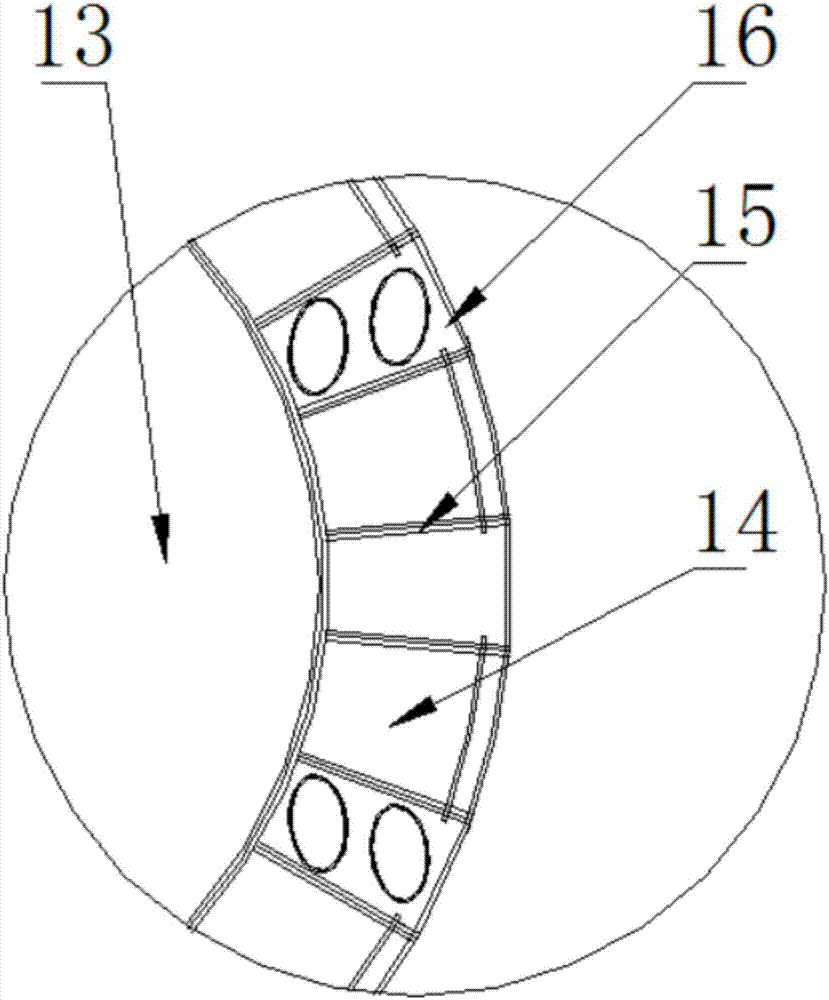

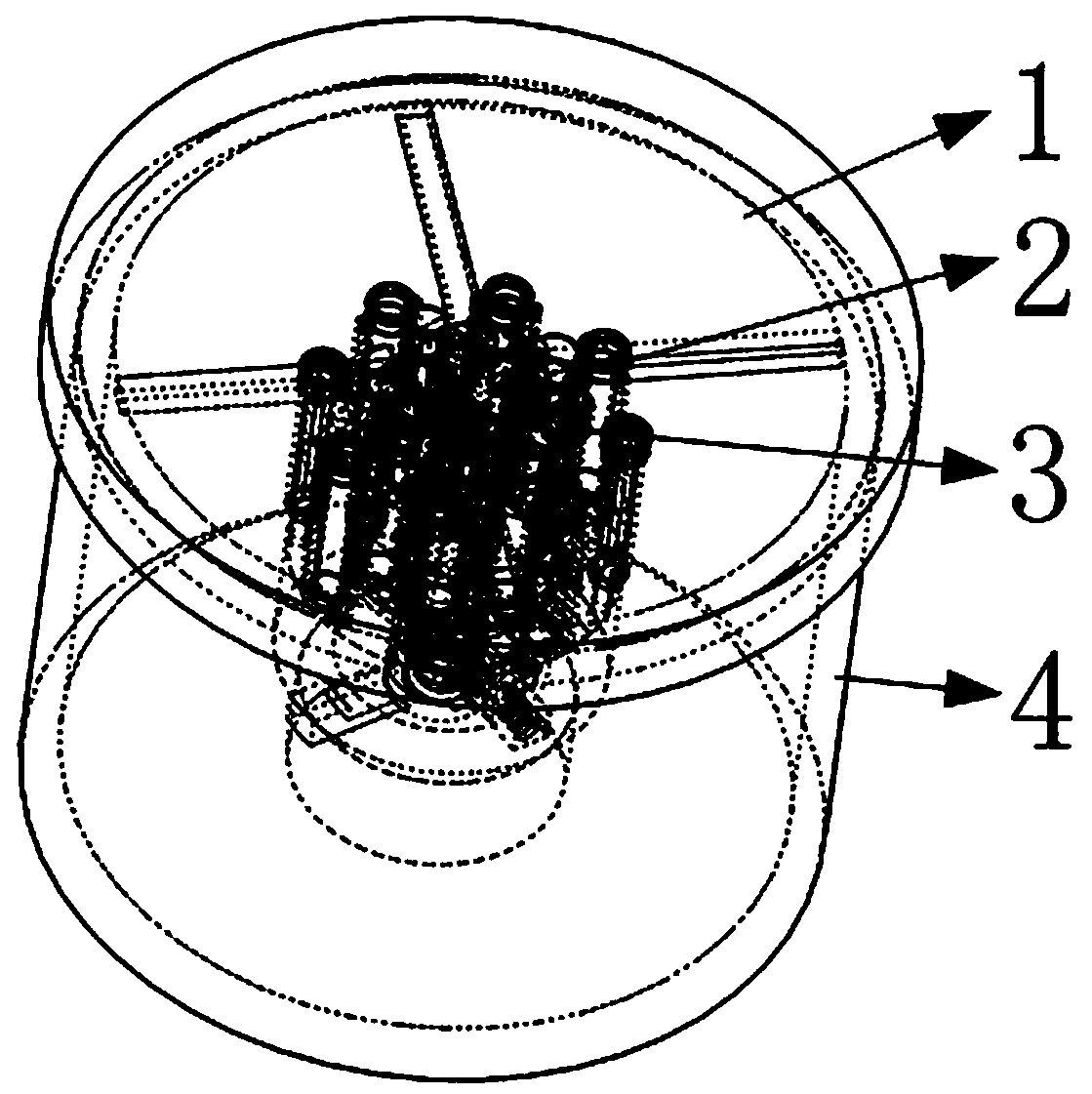

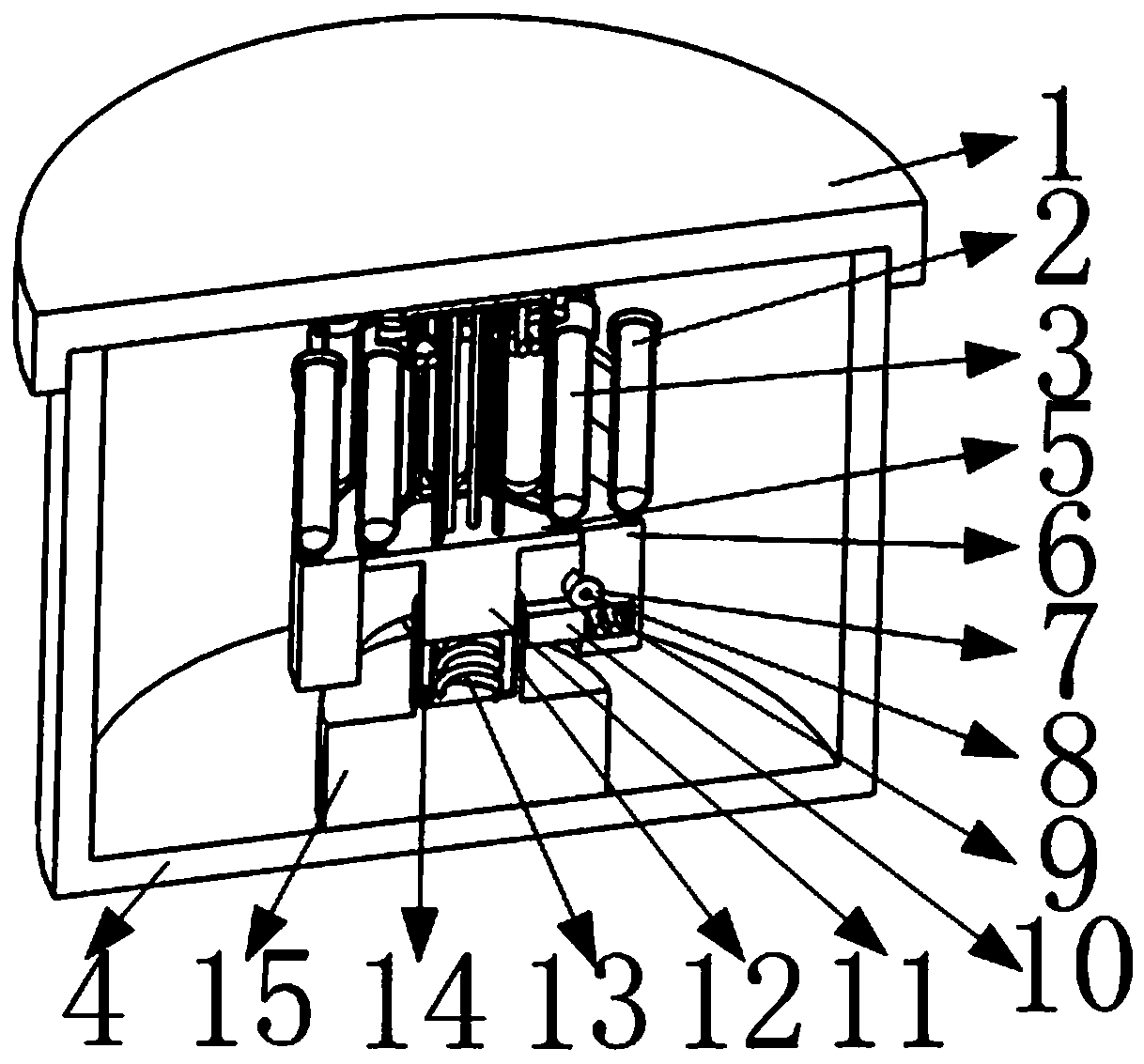

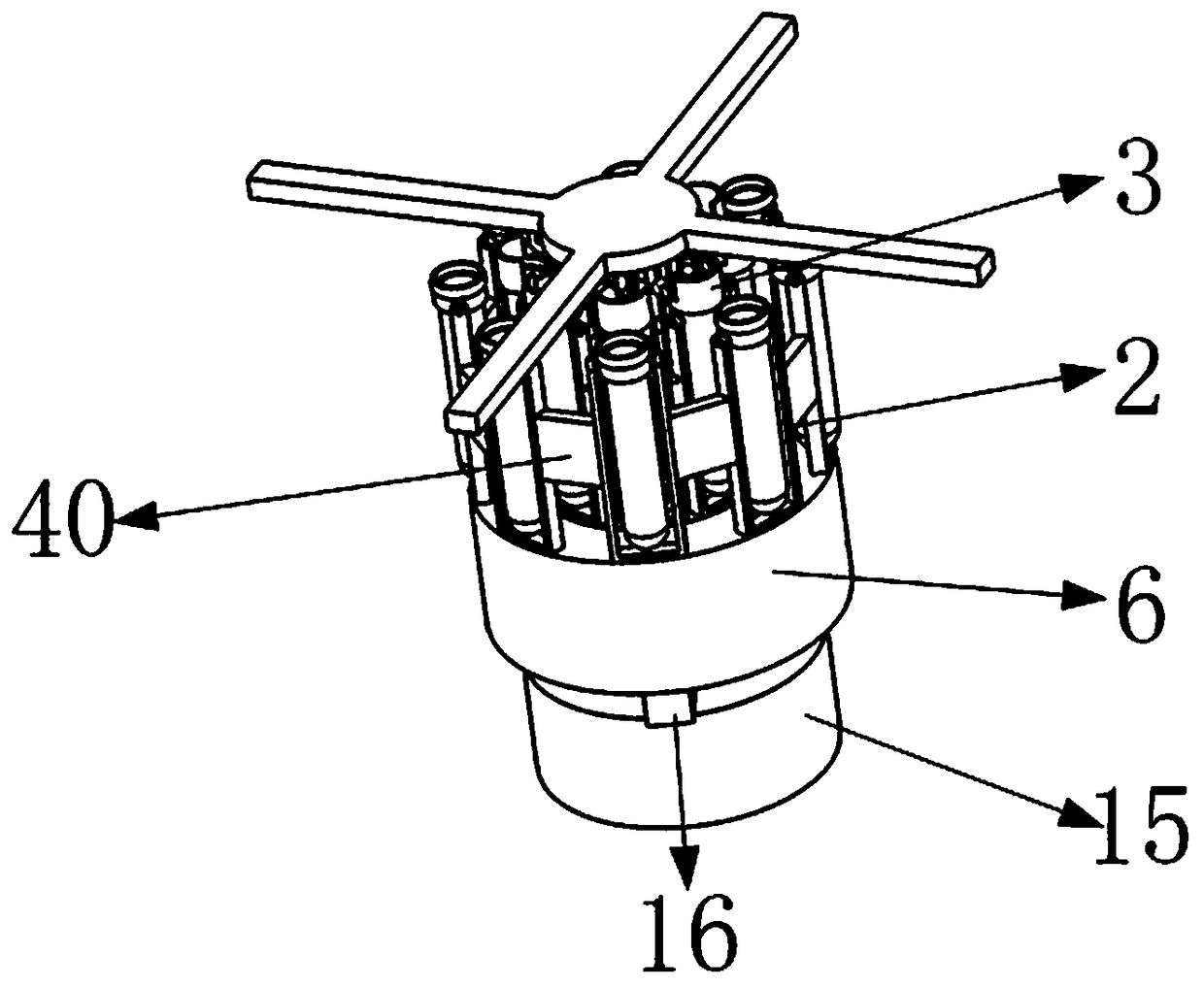

Dual-row-test-tube automatic adjusting centrifugal machine based on gear transmission

ActiveCN108187919AEasy to installThe function of installing on the inner end face of the fixed shell is to facilitate drivingCentrifugesGear wheelRound face

The invention belongs to the technical field of test tube centrifugal machines, and particularly relates to a dual-row-test-tube automatic adjusting centrifugal machine based on gear transmission. Thedual-row-test-tube automatic adjusting centrifugal machine based on gear transmission comprises a cover plate, a first centrifugal mechanism, a second centrifugal mechanism, a fixed shell, a second fixed ring, a first connecting block, a second connecting block, a drive ring, a drive gear and the like; the end face of an electric motor is arranged on the inner end face of the fixed shell, a second round hole is formed in the end face of a motor shaft, two guide grooves are symmetrically formed in the inner round face of the second round hole, and one ends of two L-shaped drive blocks are symmetrically arranged on the outer circular face of the motor shaft. The end face of the electric motor is arranged on the inner end face of the fixed shell, and the first centrifugal mechanism and the second centrifugal mechanism are conveniently driven to move; dual rows of test tubes are arranged in the centrifugal machine. Compared with a traditional centrifugal machine, the centrifugal machine is higher in work efficiency.

Owner:常州默里克仪器装备制造有限公司

Saw tooth with hard layer

InactiveUS20070266840A1Improve cut qualityImprove quality lifeMetal sawing devicesTool workpiece connectionHard metalRound face

Owner:AKE KNEBEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com