Method for embedding cement purdah into prefabricated reinforced concrete anti-lateral-force pile

A technology for resisting lateral force and mixing soil, applied in excavation, construction, infrastructure engineering, etc., can solve the problems of construction mud pollution, unstable construction quality, slow construction speed, etc., to achieve reliable quality, fast construction speed, The effect of comprehensive cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

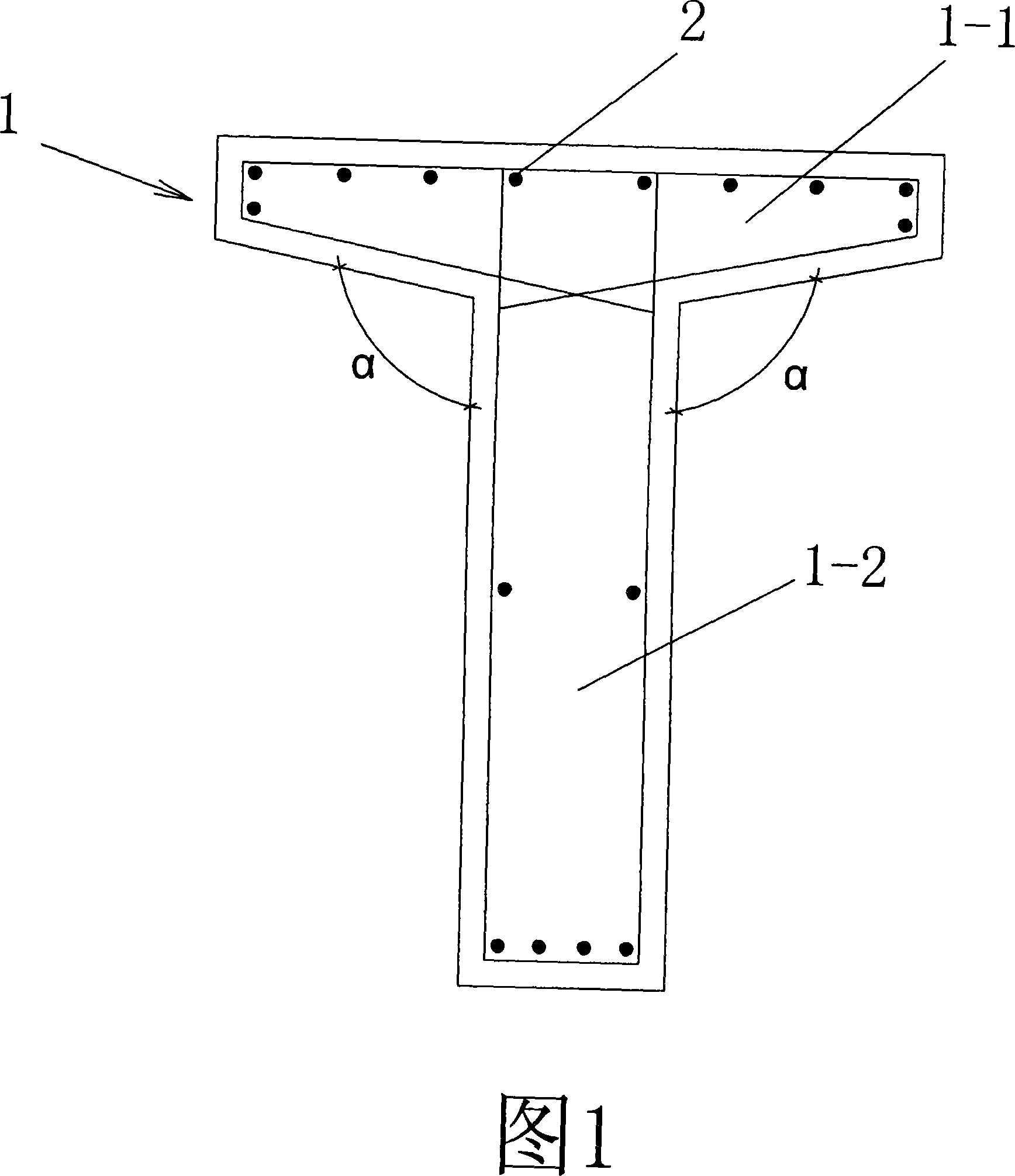

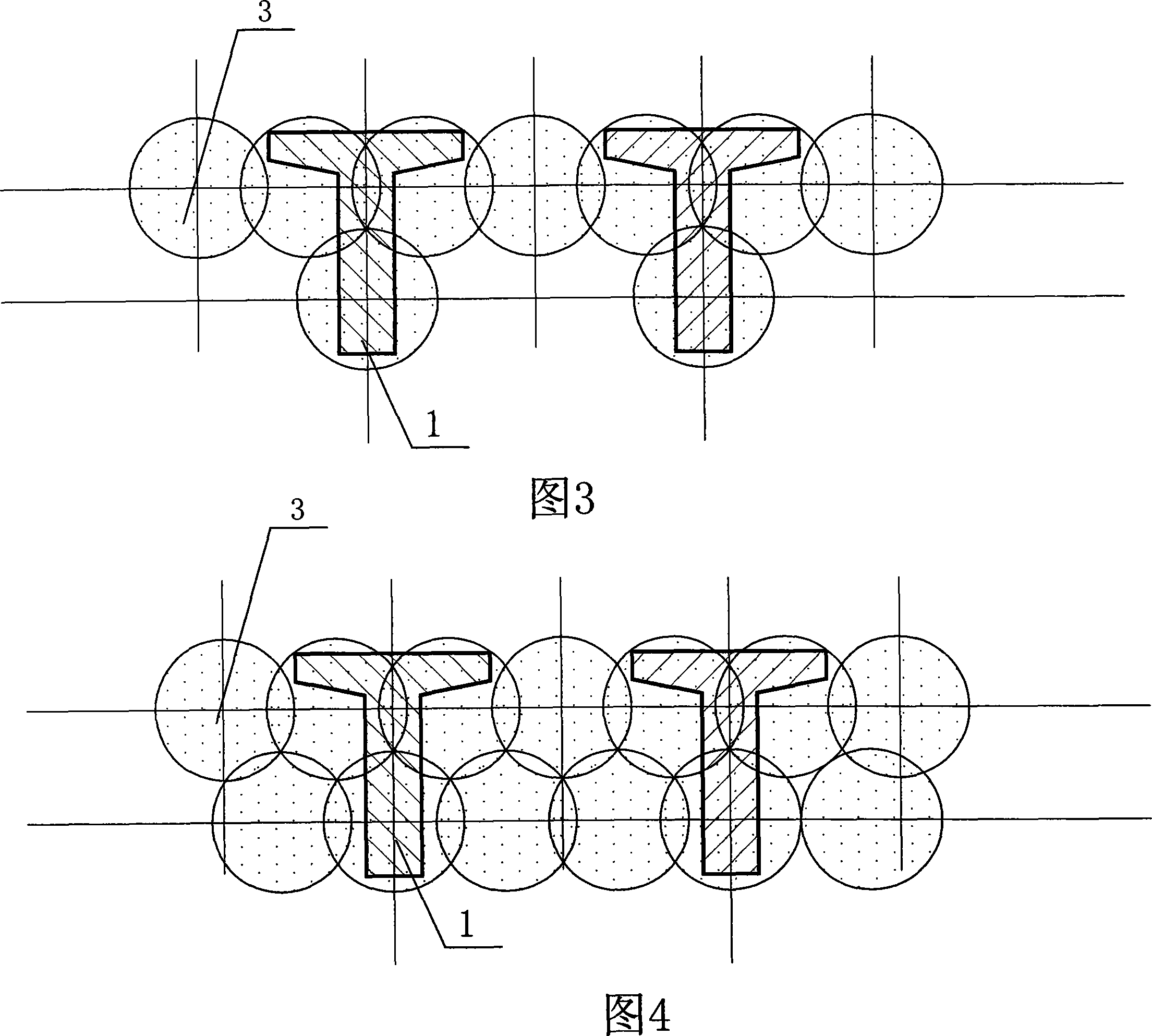

[0026] Embodiment 1: the method for implanting the prefabricated reinforced concrete anti-lateral force T-shaped / I-shaped pile with this cement mixing soil curtain mainly comprises the following steps: at the construction site, earlier use the cement mixer along the implantation depth of the pile body 1, depending on the Soil quality and soil compaction conditions, mixing the soil in the whole process or part of the upper water-stop curtain to form various mixing pile curtains 3, and then using a pile driver to implant the pile body 1 to form the soil-retaining and water-stop required for various enclosure projects enclosure wall. Among them, Figure 3 is a single row of small diameter mixing pile curtain, Figure 4 is a double row of small diameter mixing pile curtain, Figure 5 is a single row of large diameter mixing pile curtain, Figure 6 is an arched mixing pile curtain, Figure 7 is a mixing pile curtain Insert curtains such as moso bamboo 4, wooden stakes, steel pipes, etc....

Embodiment 2

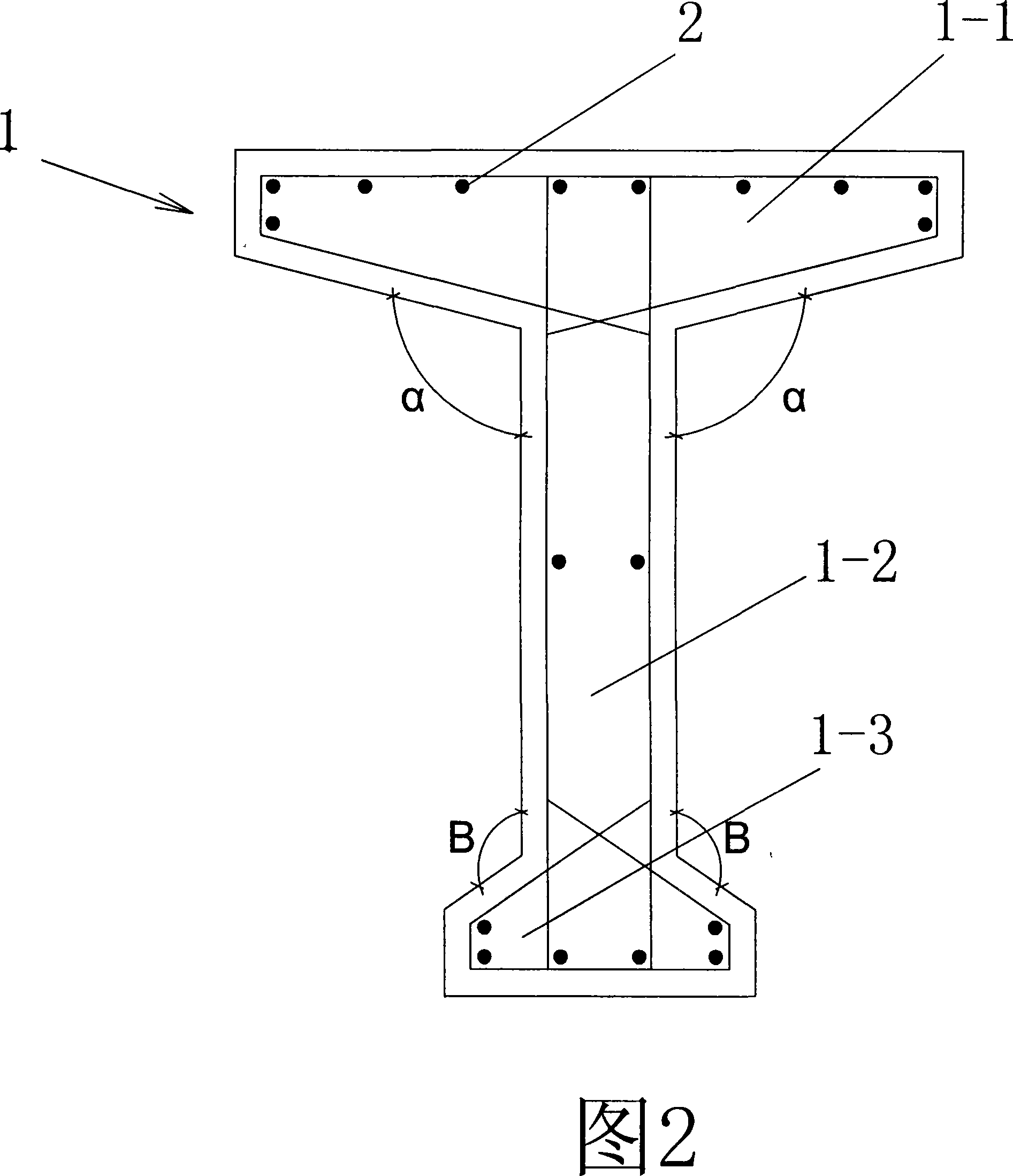

[0029] Embodiment 2: As shown in Figure 2, the difference from Embodiment 1 is that the other end of the web 1-2 is connected with a second wing plate 1-3 and forms an I-shaped shape, and the second wing plate 1-3 The included angle β with both sides of the web 1-2 is greater than 90° and less than 135°.

[0030] As shown in Figure 8.9.10.11.12, the cement mixer is mixed to form a curtain of various mixing piles matching the size of the I-shaped piles, and various required enclosure walls are formed after the I-shaped prefabricated piles are implanted. Among them, Figure 8 is a curtain of single row of small diameter mixing piles, Figure 9 is a curtain of double rows of small diameter mixing piles, Figure 10 is a curtain of single row of large diameter mixing piles, Figure 11 is a curtain of arched mixing piles, Figure 12 is a curtain of mixing piles Moso bamboo, wood piles, steel pipes and other curtains are inserted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com