Patents

Literature

42results about How to "Continuous force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

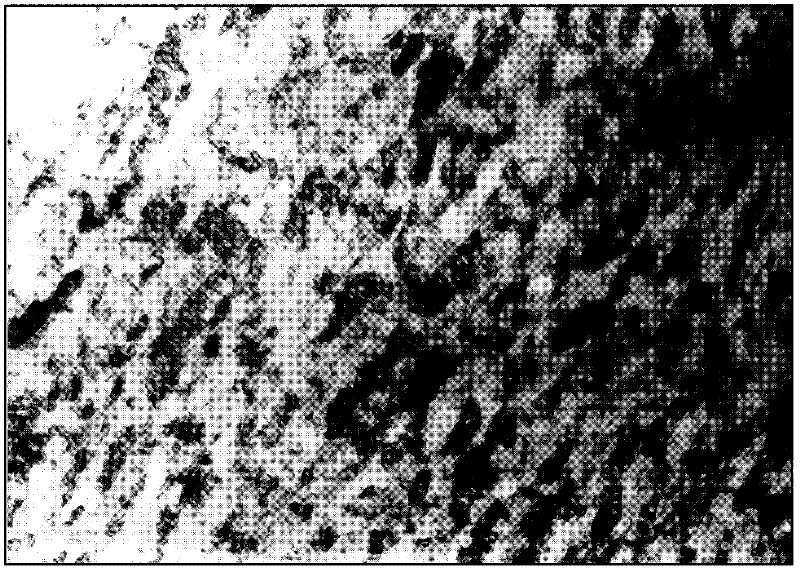

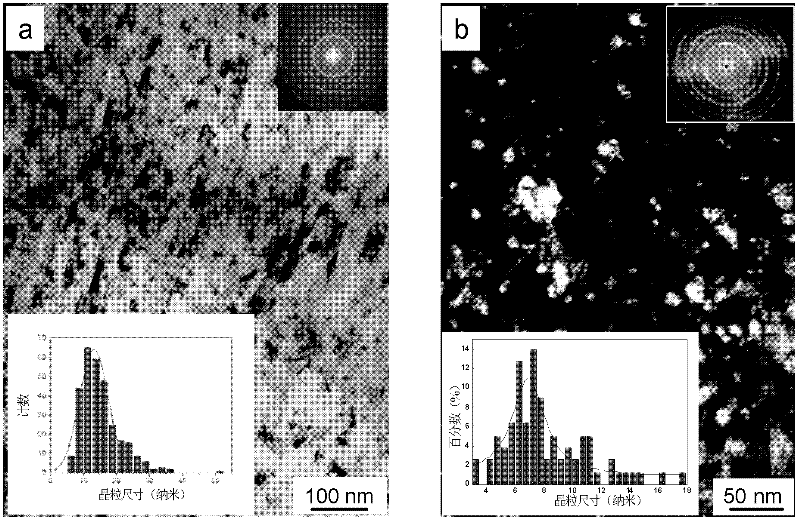

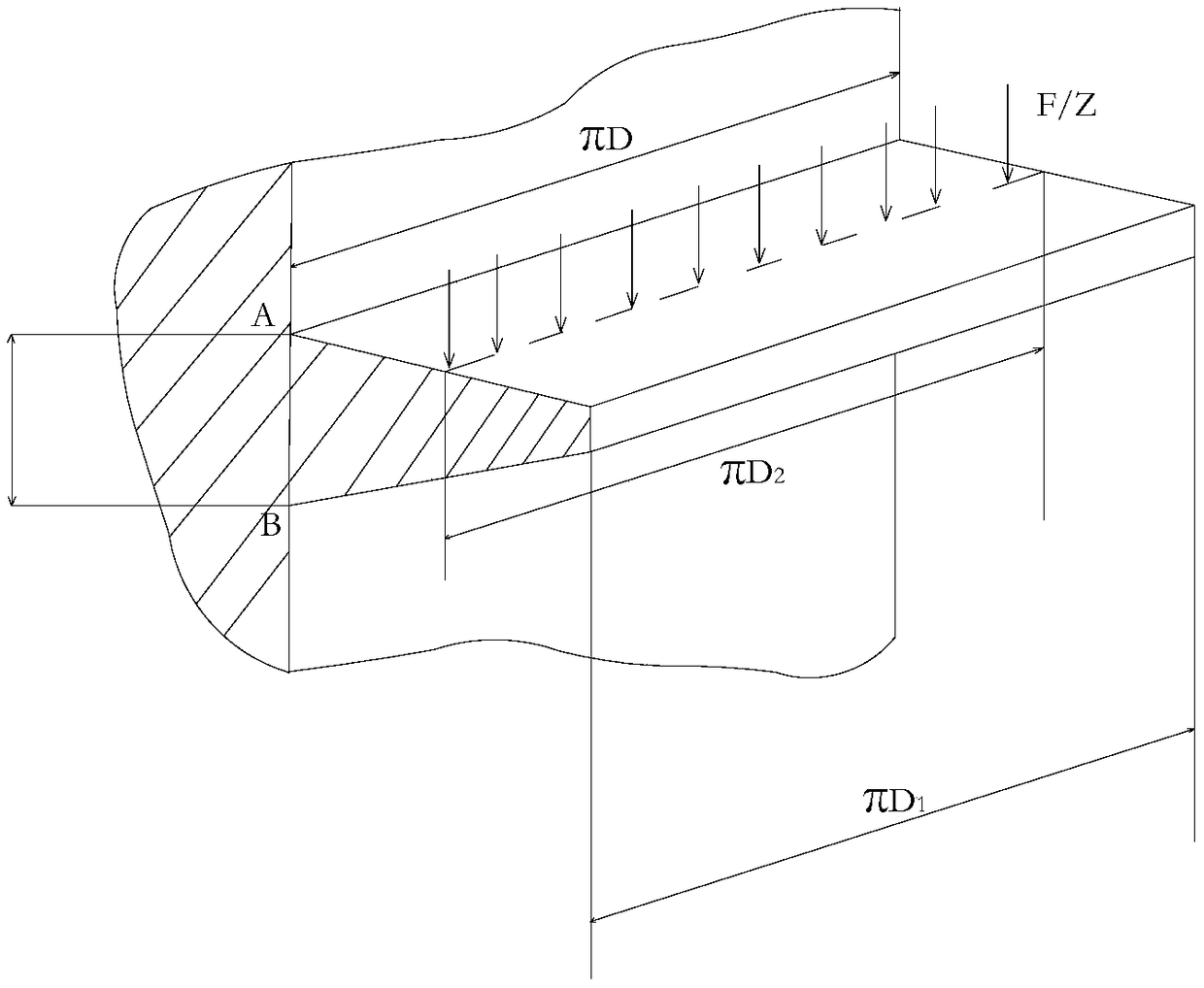

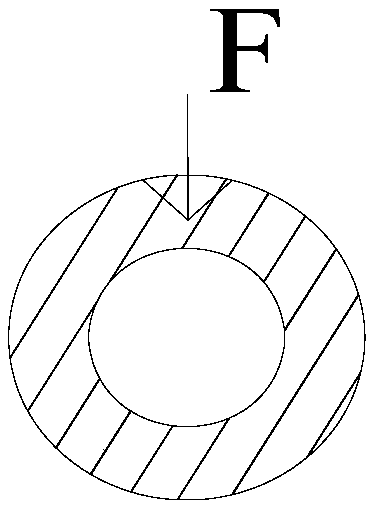

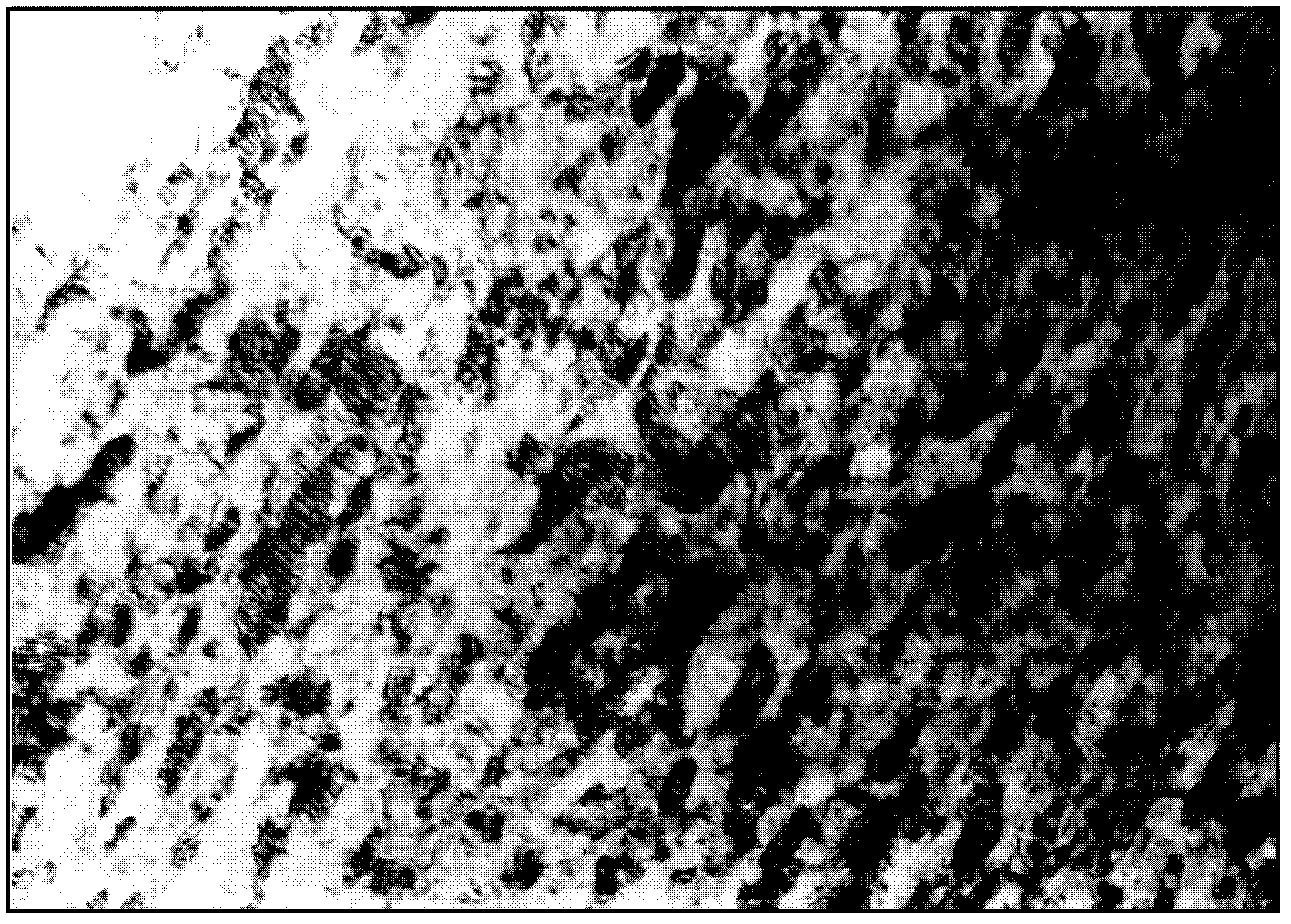

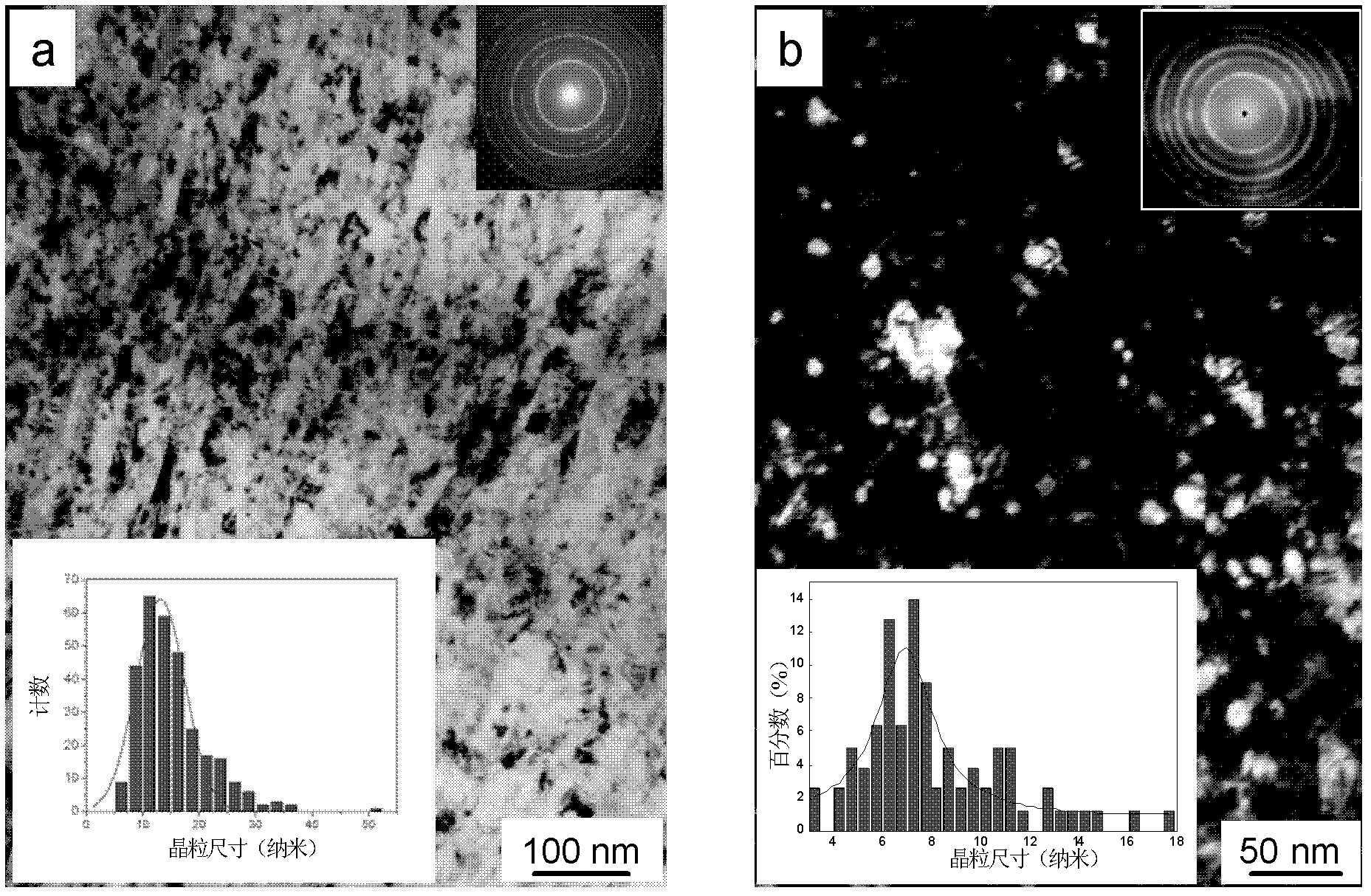

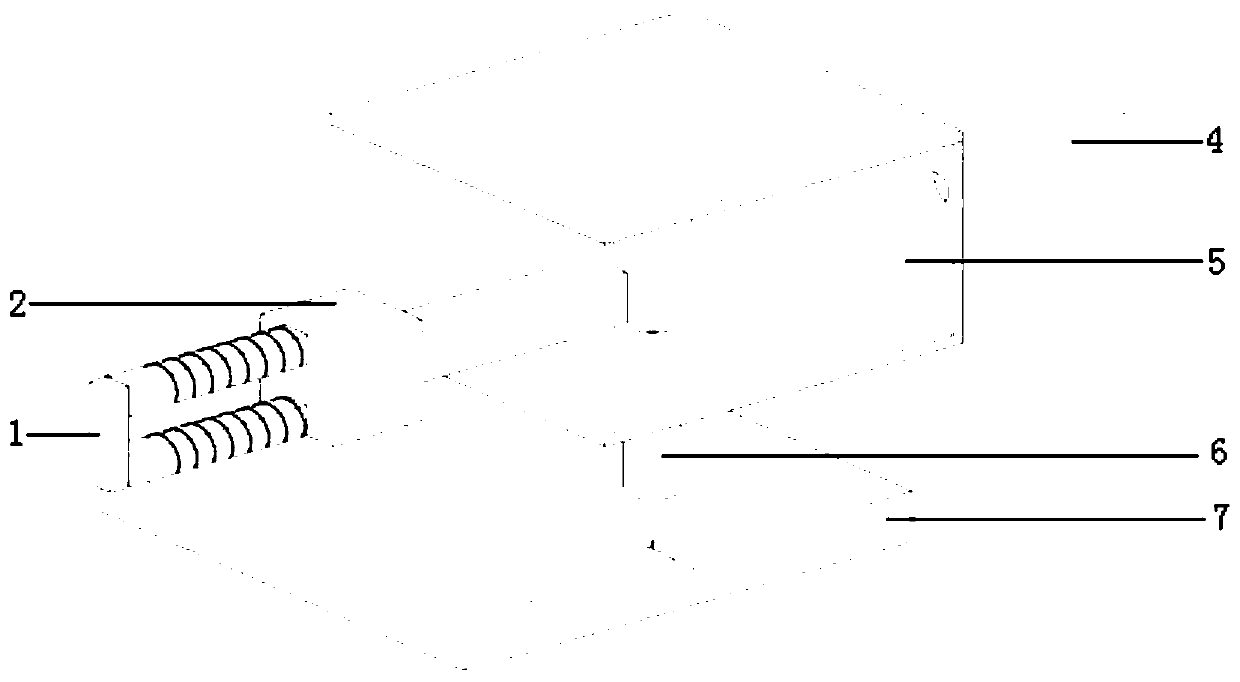

Method for forming nanometer gradient structure on surface layer of shaft metallic material

The invention relates to a surface treatment method for forming a nanometer gradient structure on a surface layer of a shaft metallic material. The invention aims to solve the problems that the surface roughness of the material to be treated is higher, the surface smoothness is not high and a nanometer crystal structure is difficult to form on the surface of a workpiece in the prior art. A spherical treatment tool is adopted to roll on the surface of the rotary shaft metallic material, and meanwhile, the spherical treatment tool moves along the axial direction of the workpiece, and plastic deformation is generated on the surface layer of the material, so that grains on the surface layer of a workpiece material are refined to form the nanometer gradient structure, wherein the depth of the deformation layer of the nanometer gradient structure reaches 100-300 micrometers; and the grains on the surface layer of the workpiece material are nanometer grains, submicron grains, deformation grains and initial grains in sequence in size from the surface to the inside. According to the processing method provided by the invention, the integral mechanical property of the material is improved through improving the microstructure of the surface layer, thereby, the service life of the material is prolonged. The processing method provided by the invention is small in investment and is simple and convenient in operation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

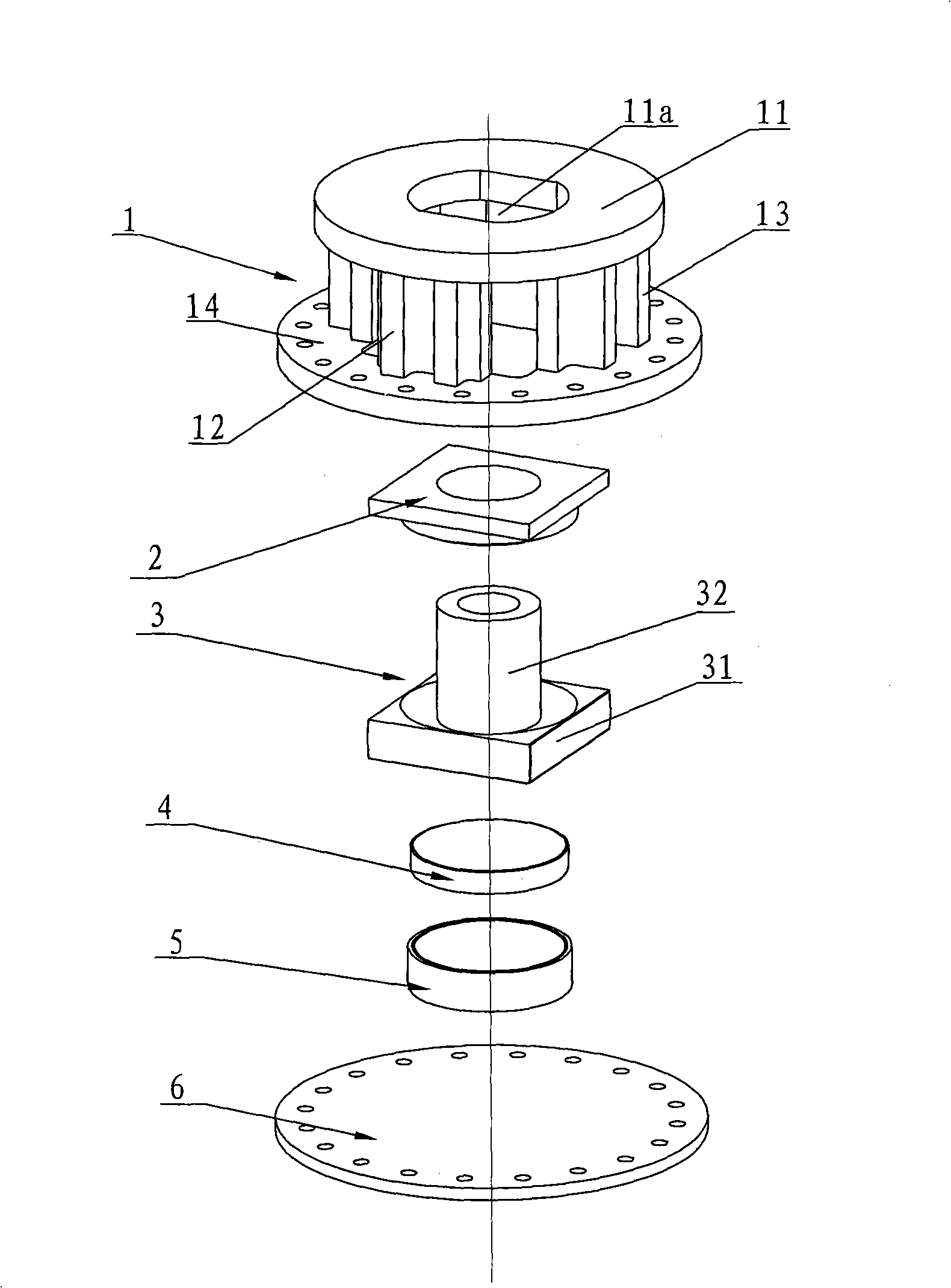

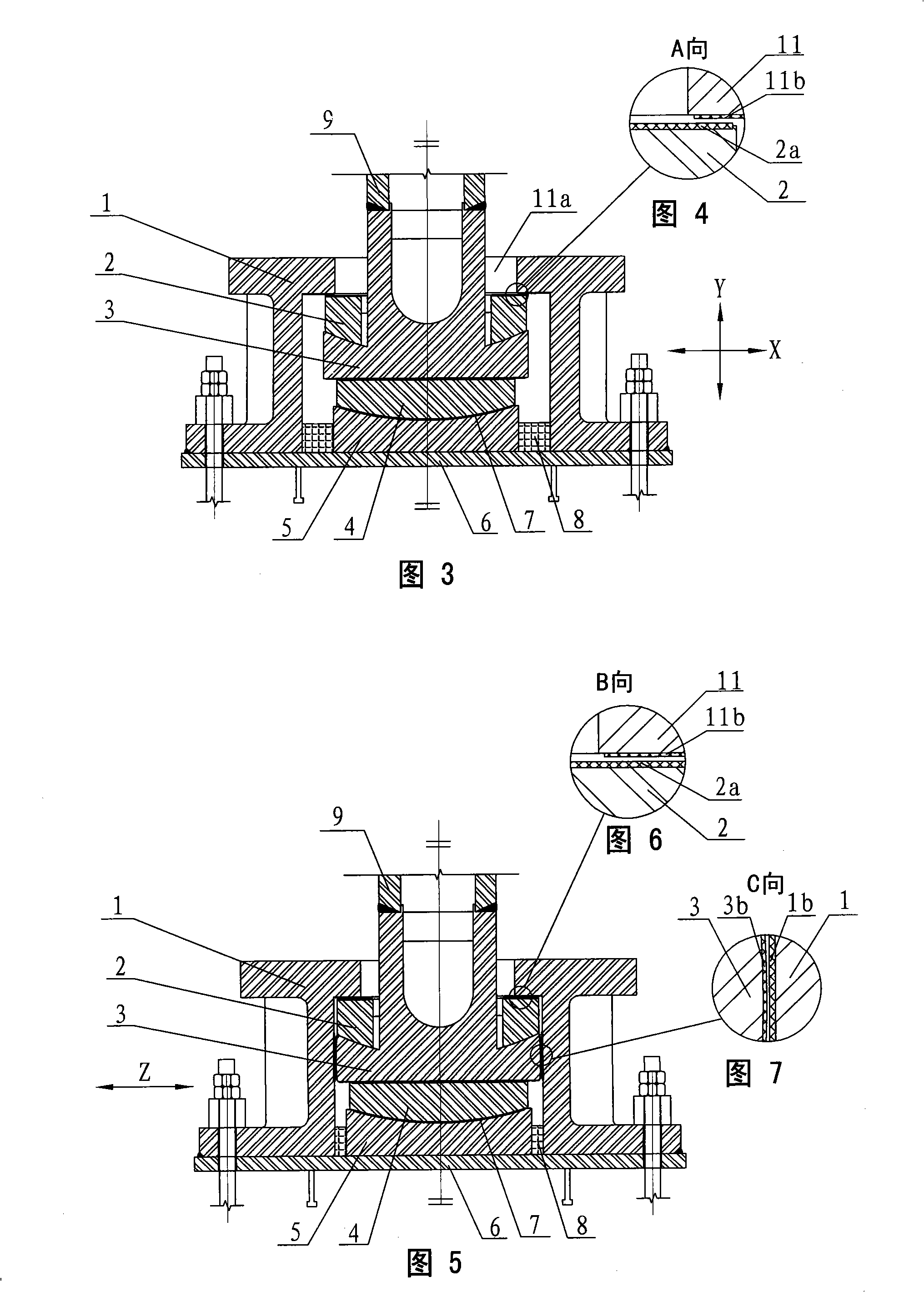

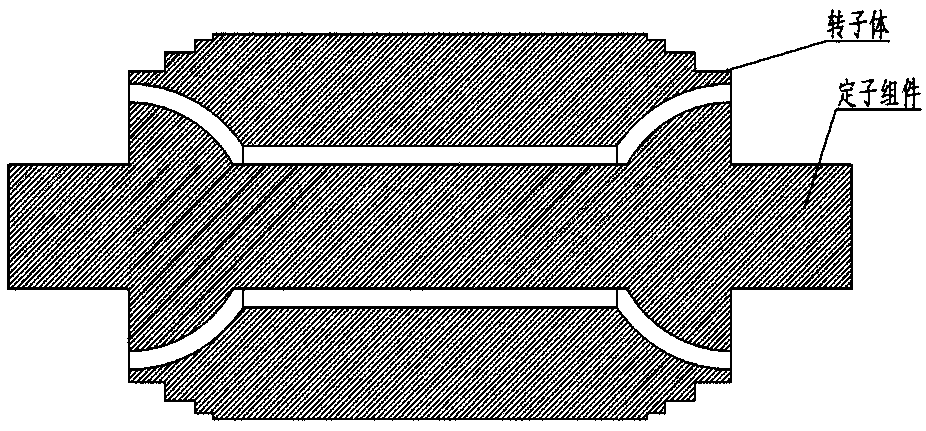

Large pulling resistance slidable ball and socket bearing

ActiveCN101289833AHigh pullout resistanceImprove stress resistanceBridge structural detailsBuilding constructionsPull forceEngineering

Owner:ARCHITECTURAL DESIGN RES INST OF GUANGDONG PROVINCE

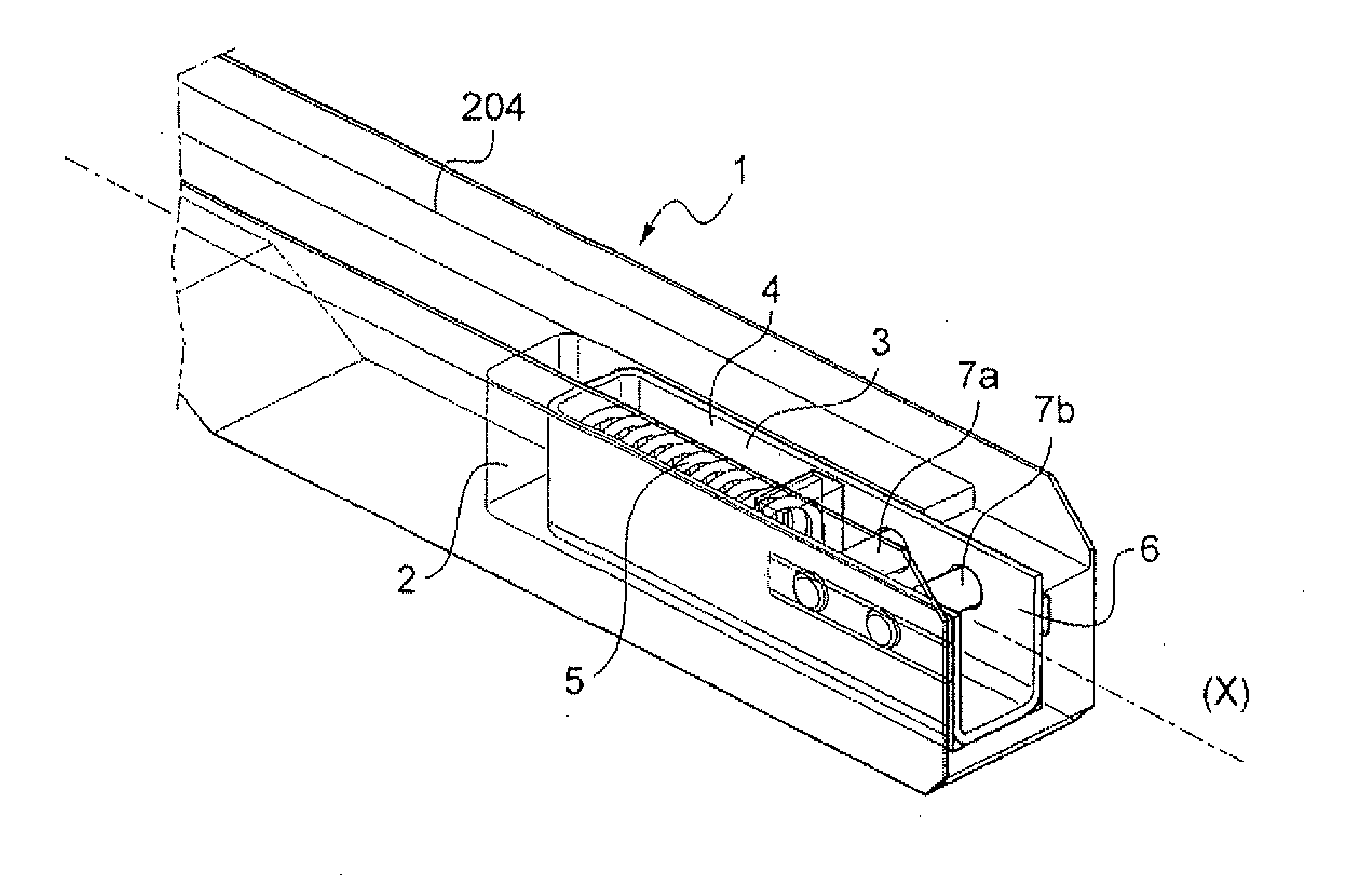

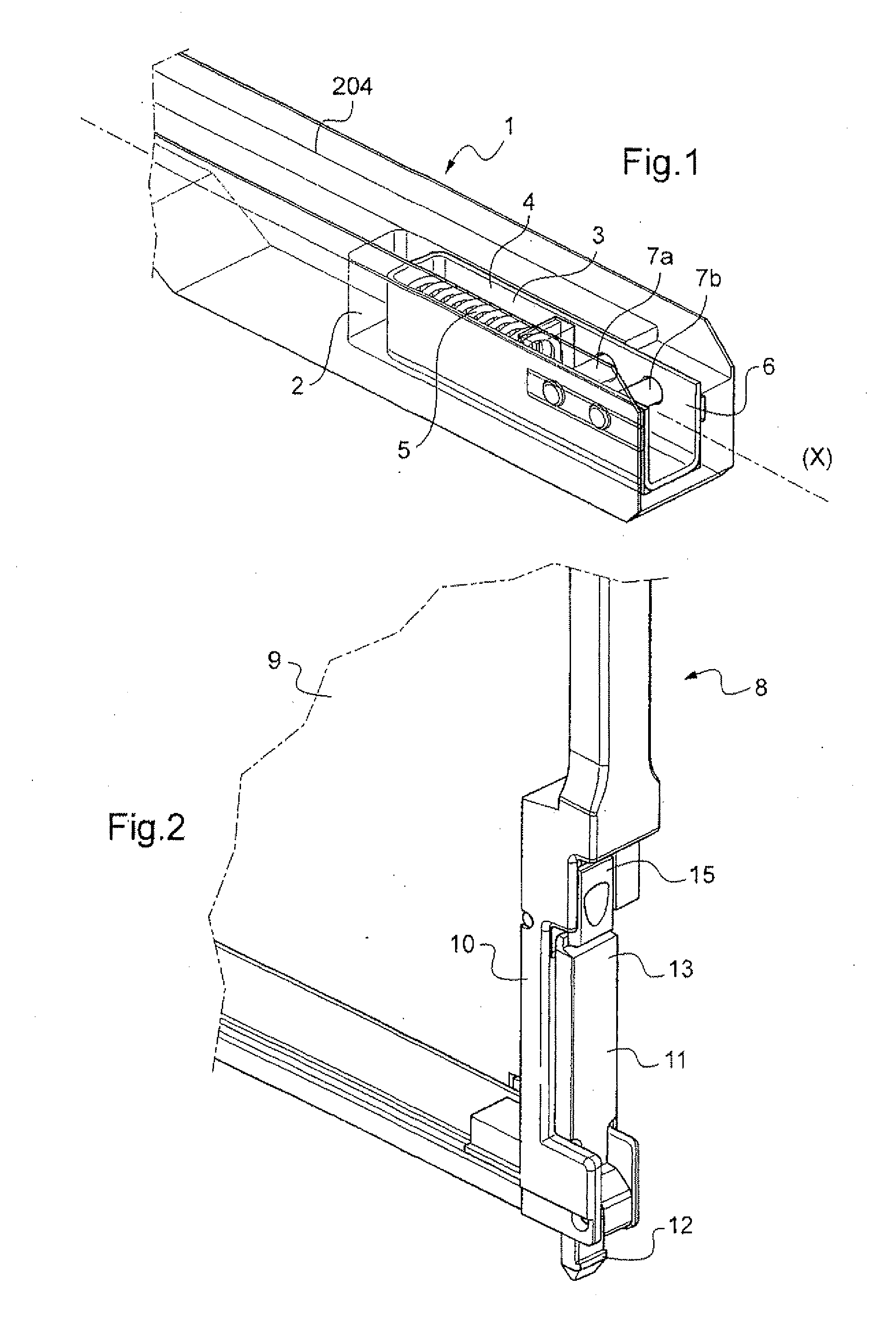

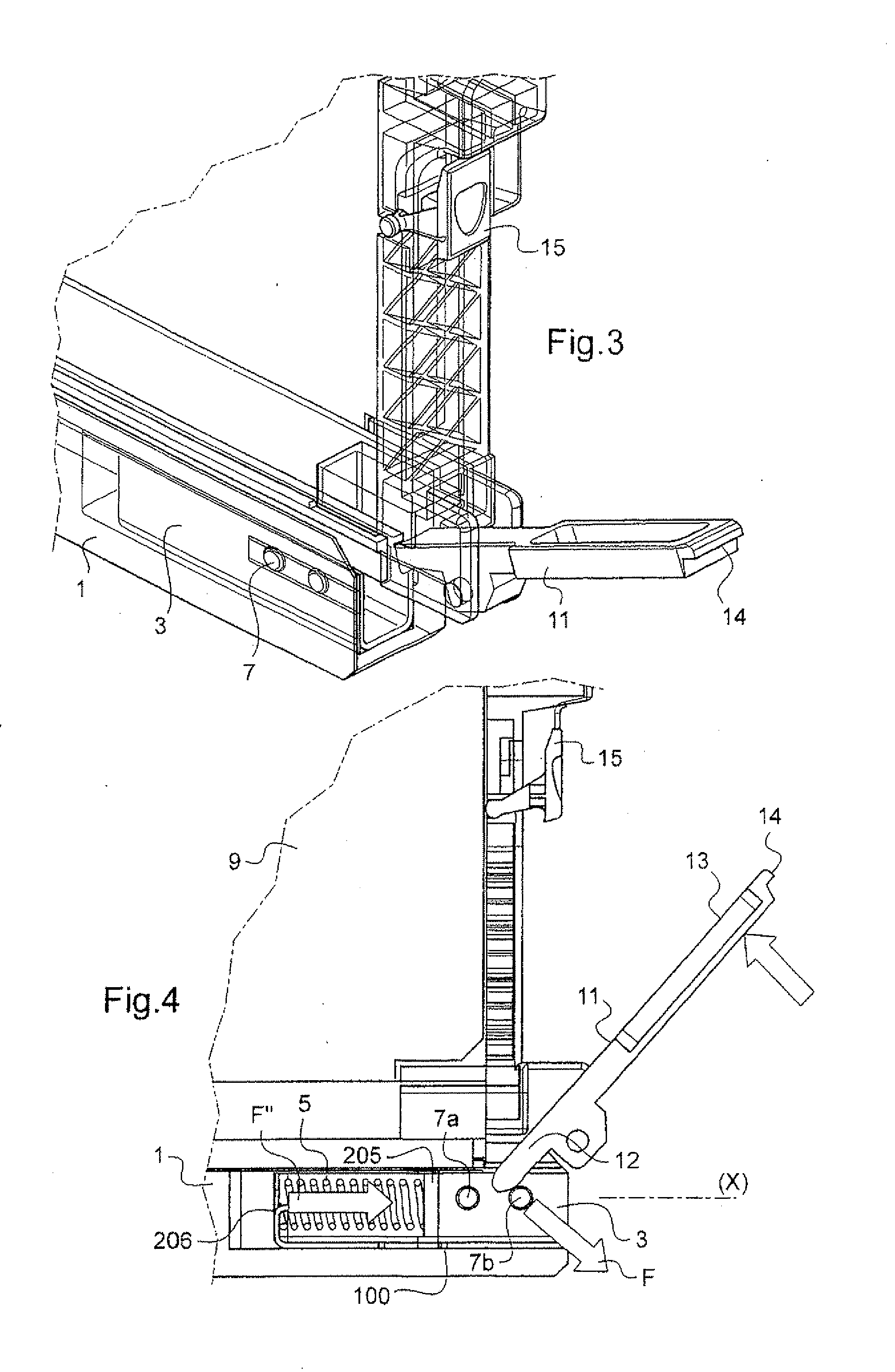

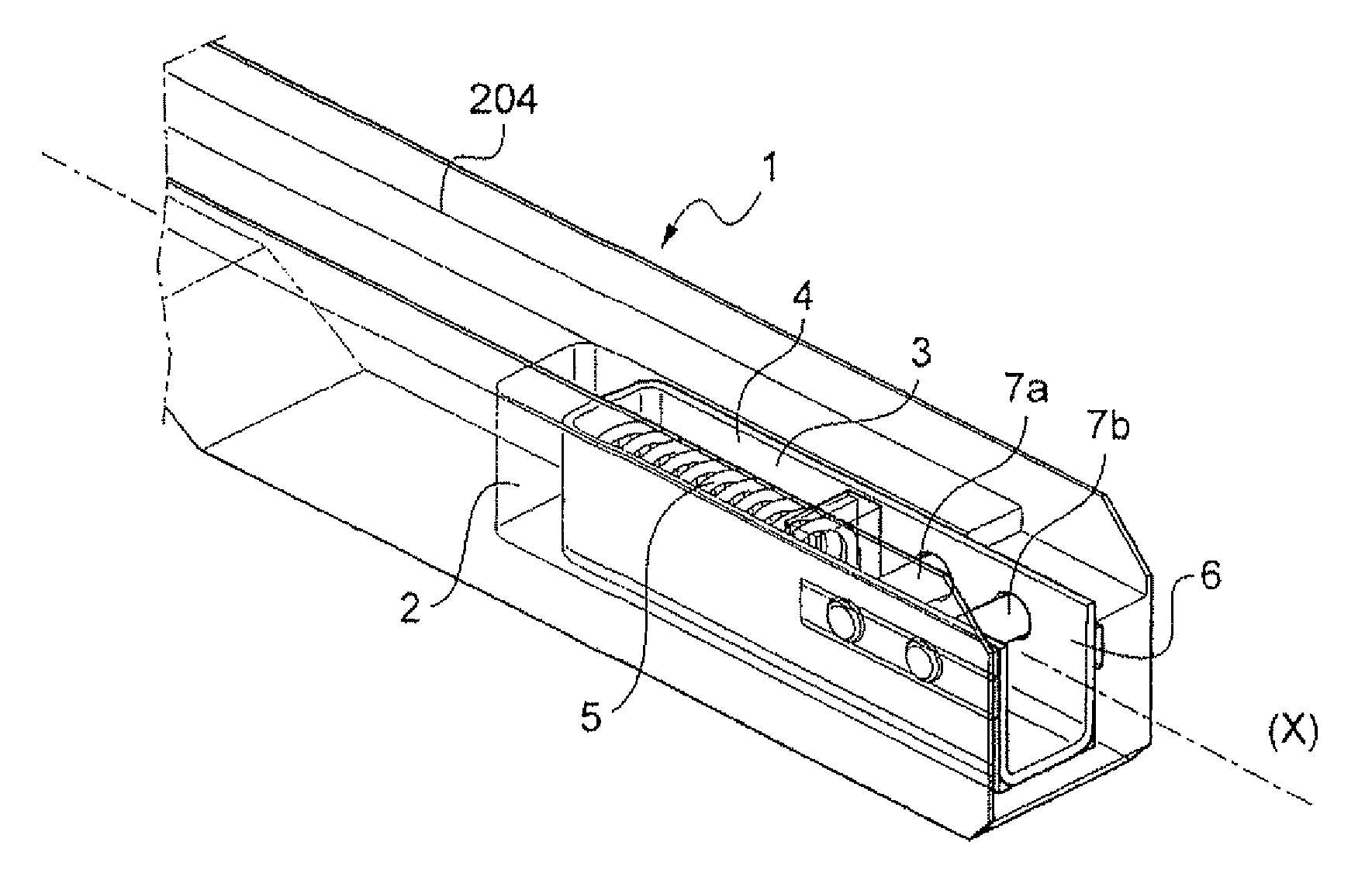

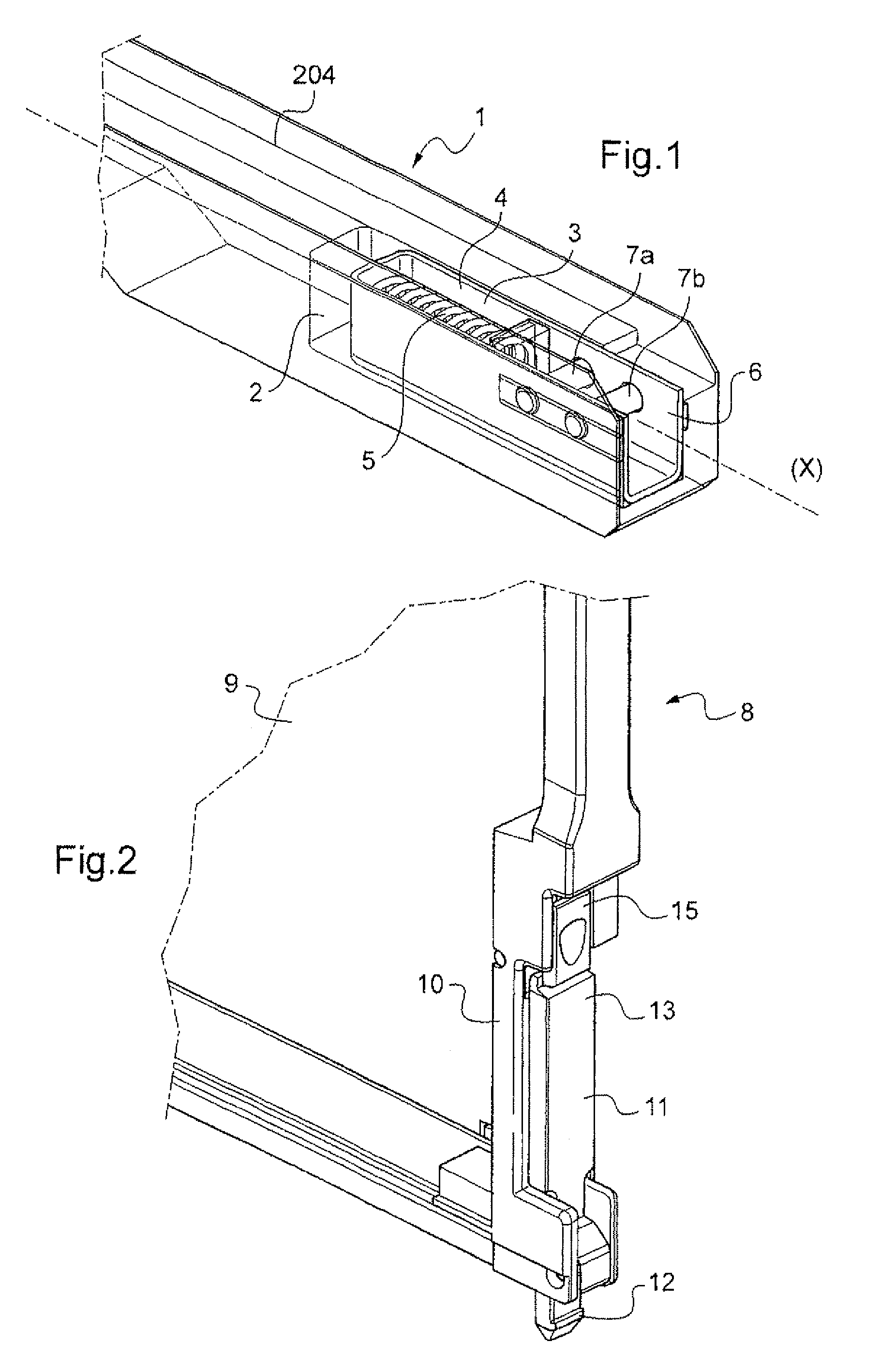

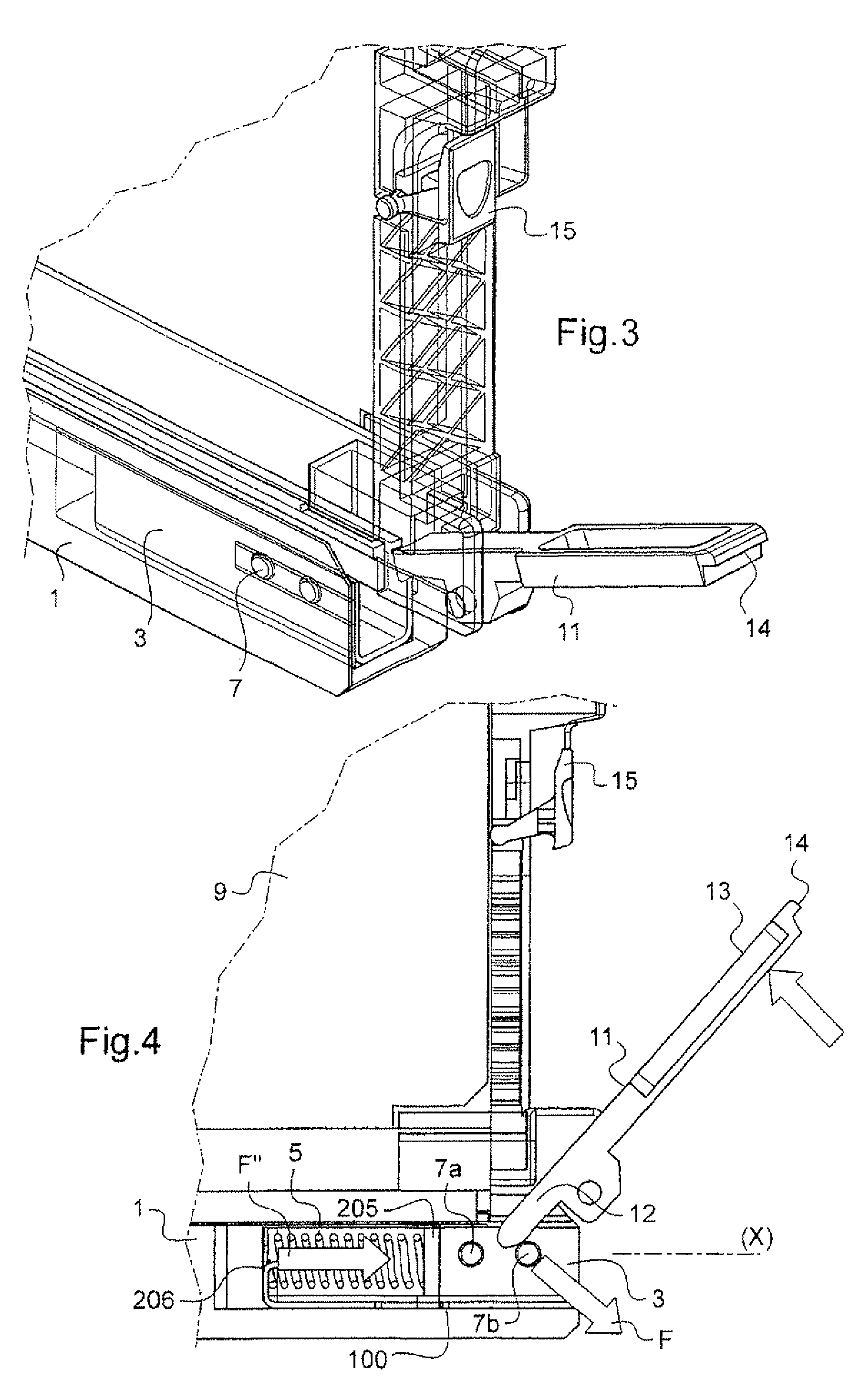

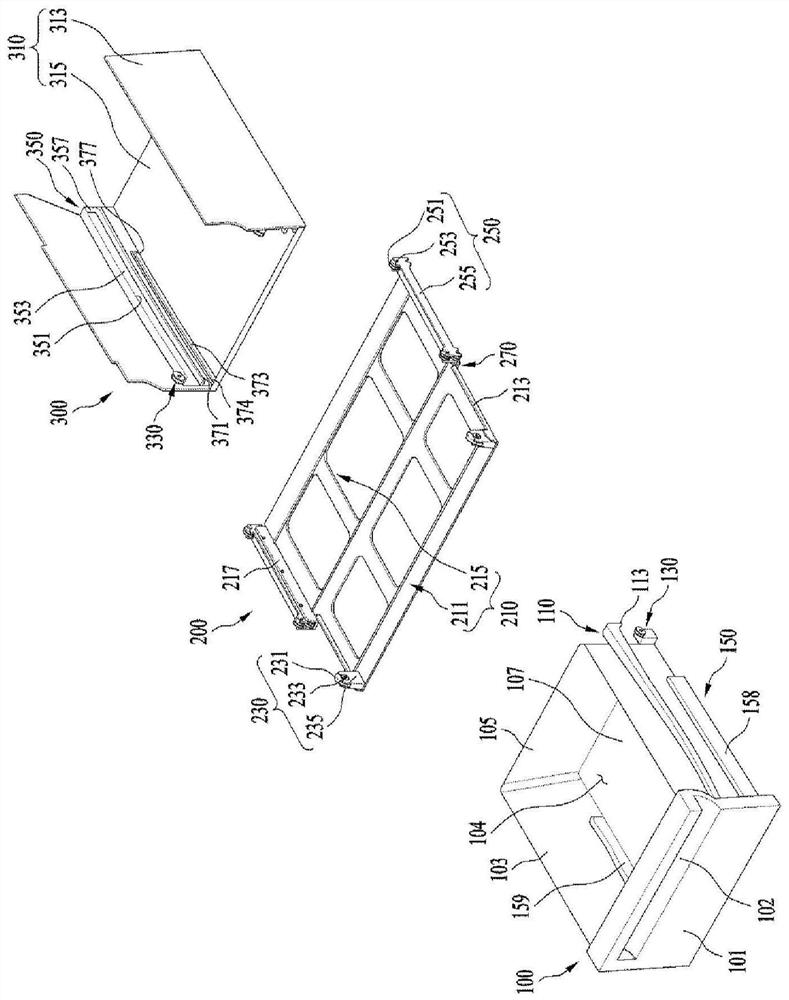

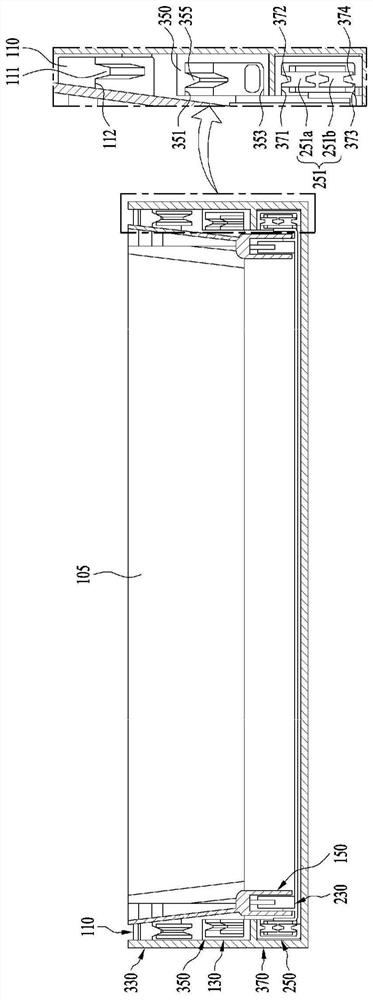

Locking assembly for locking an electronics card to a rack

InactiveUS20100265679A1Accurately positionAvoids useClamping/extracting meansSupport structures on hinges/pivotsElectronicsMechanical engineering

A locking assembly for locking at least one electronics card to a rack, the assembly comprising:at least one electronics card;a rack having a bottom plate with at least one housing; anda locking system for locking the card on the rack;the locking system including at least one resilient prestress element for prestressing the electronics card when it is fastened to the rack.

Owner:RADIALL SA

Locking assembly for locking an electronics card to a rack

InactiveUS8295055B2Continuous forceEasy to installClamping/extracting meansElectrical apparatus casings/cabinets/drawersEngineeringMechanical engineering

A locking assembly for locking at least one electronics card to a rack, the assembly comprising:at least one electronics card;a rack having a bottom plate with at least one housing; anda locking system for locking the card on the rack;the locking system including at least one resilient prestress element for prestressing the electronics card when it is fastened to the rack.

Owner:RADIALL SA

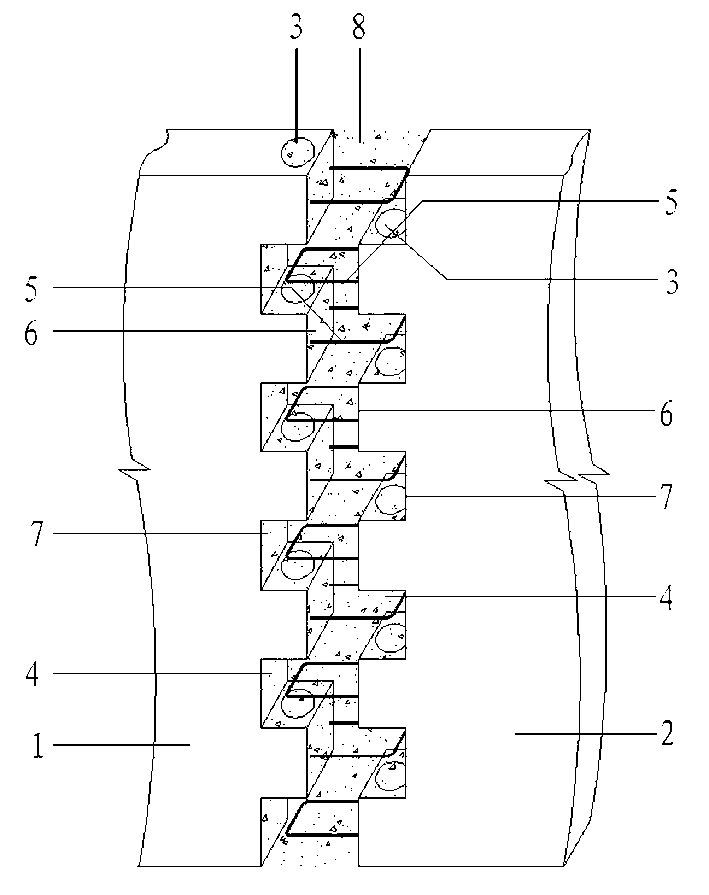

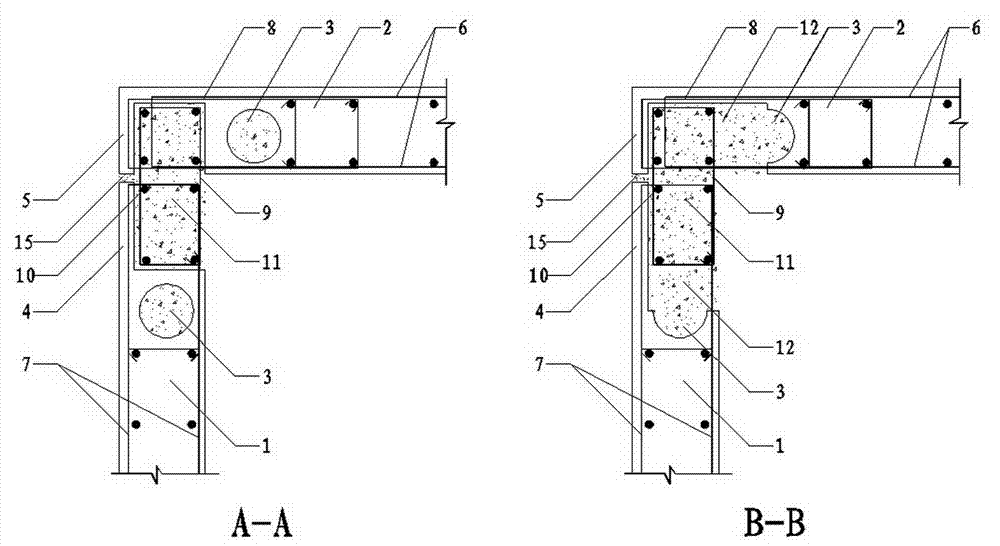

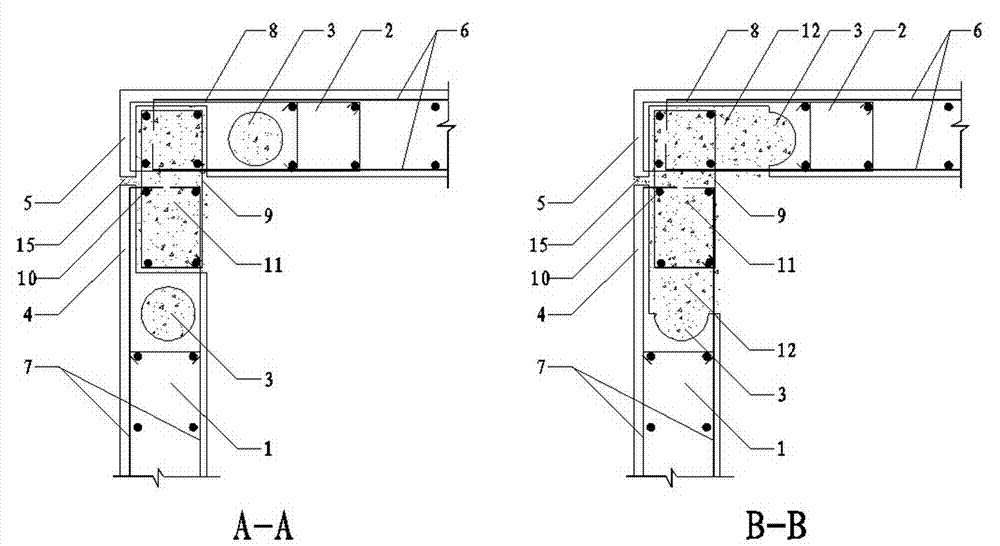

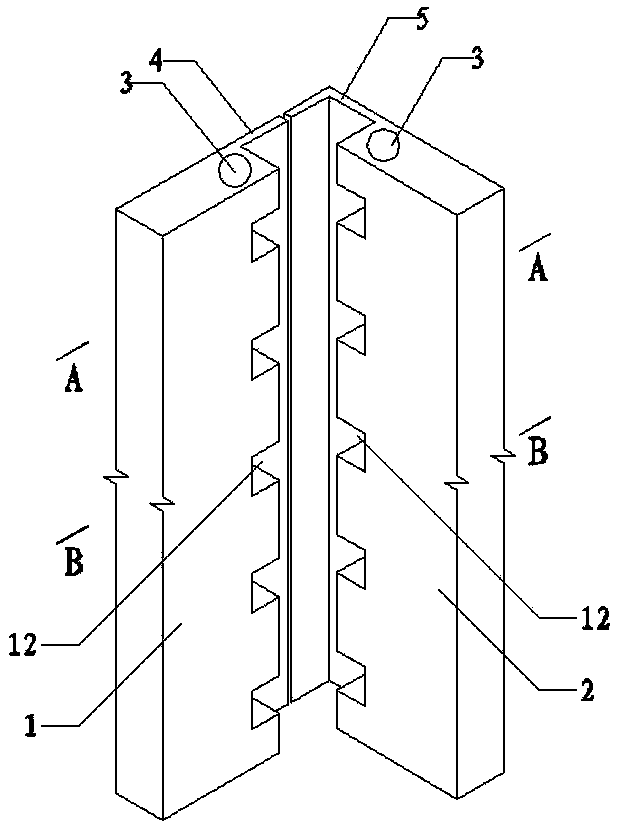

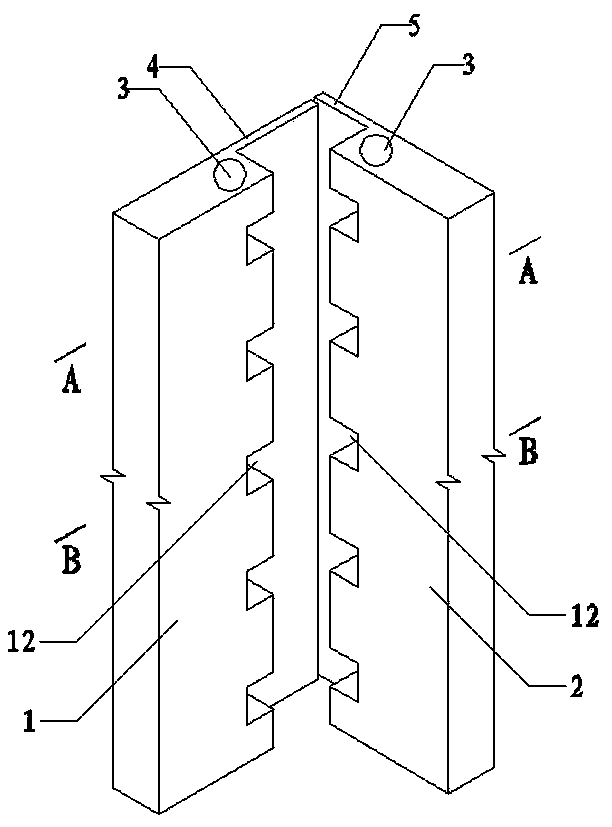

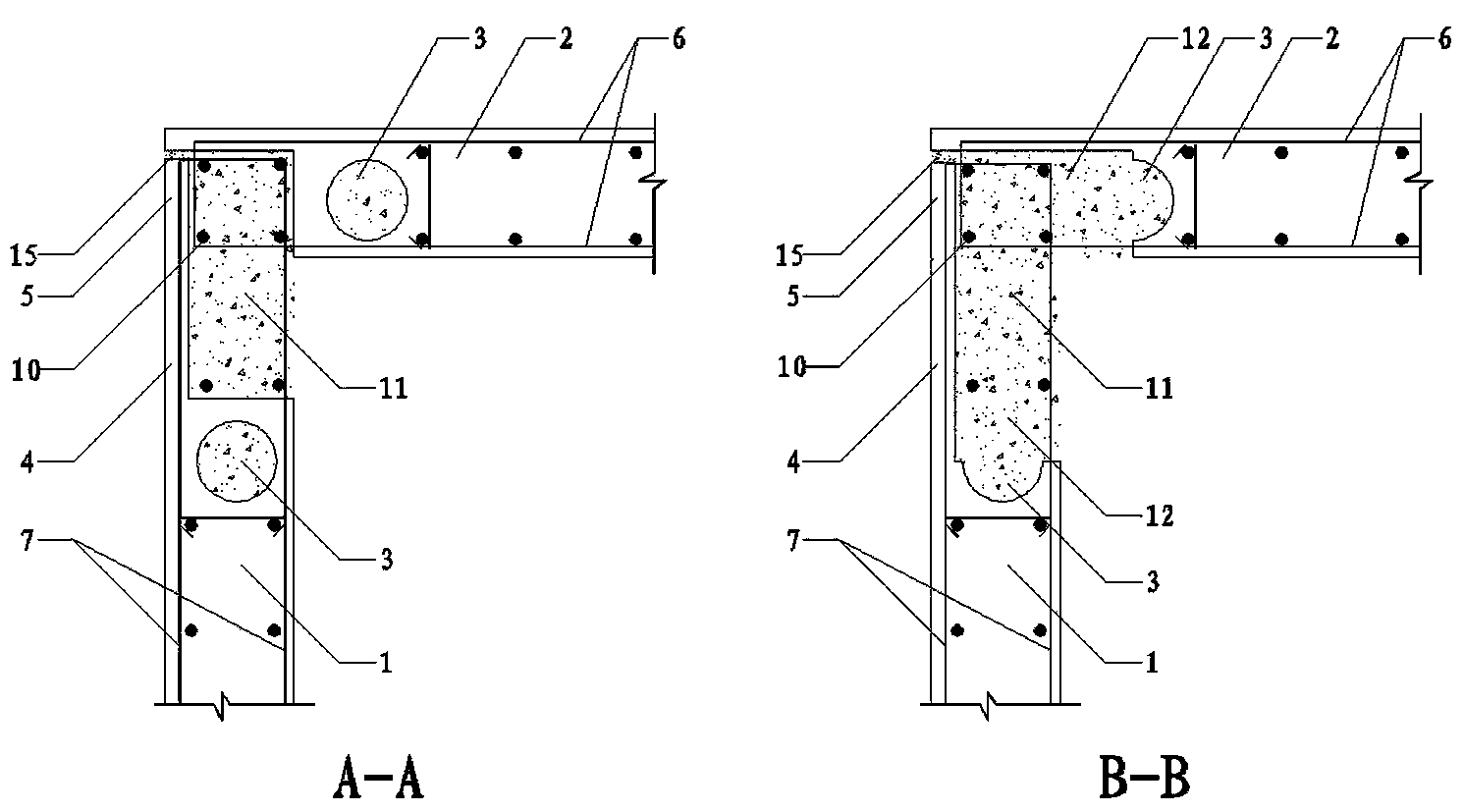

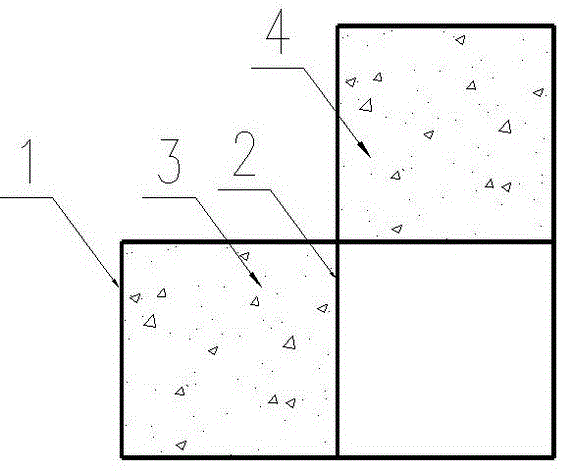

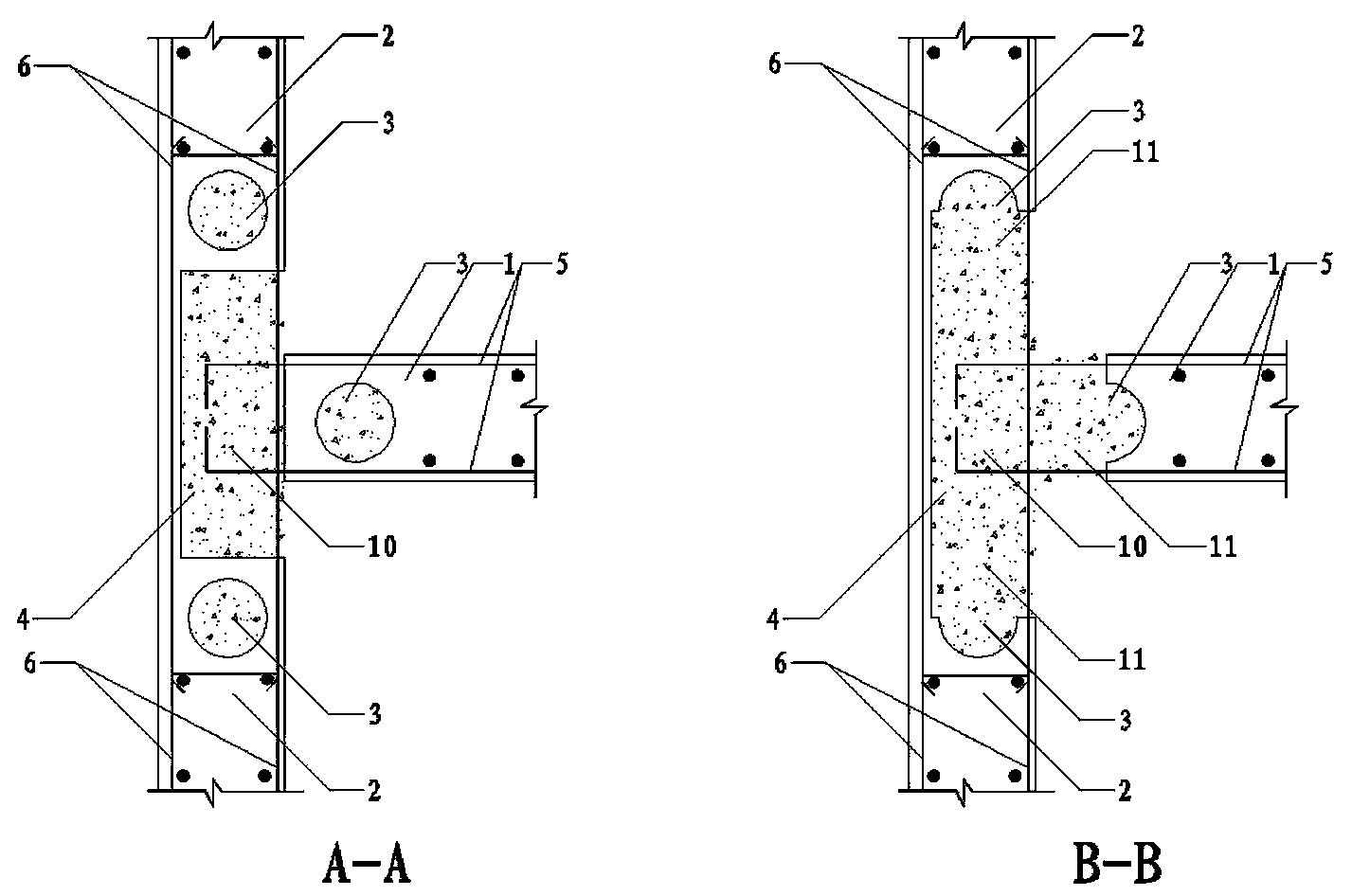

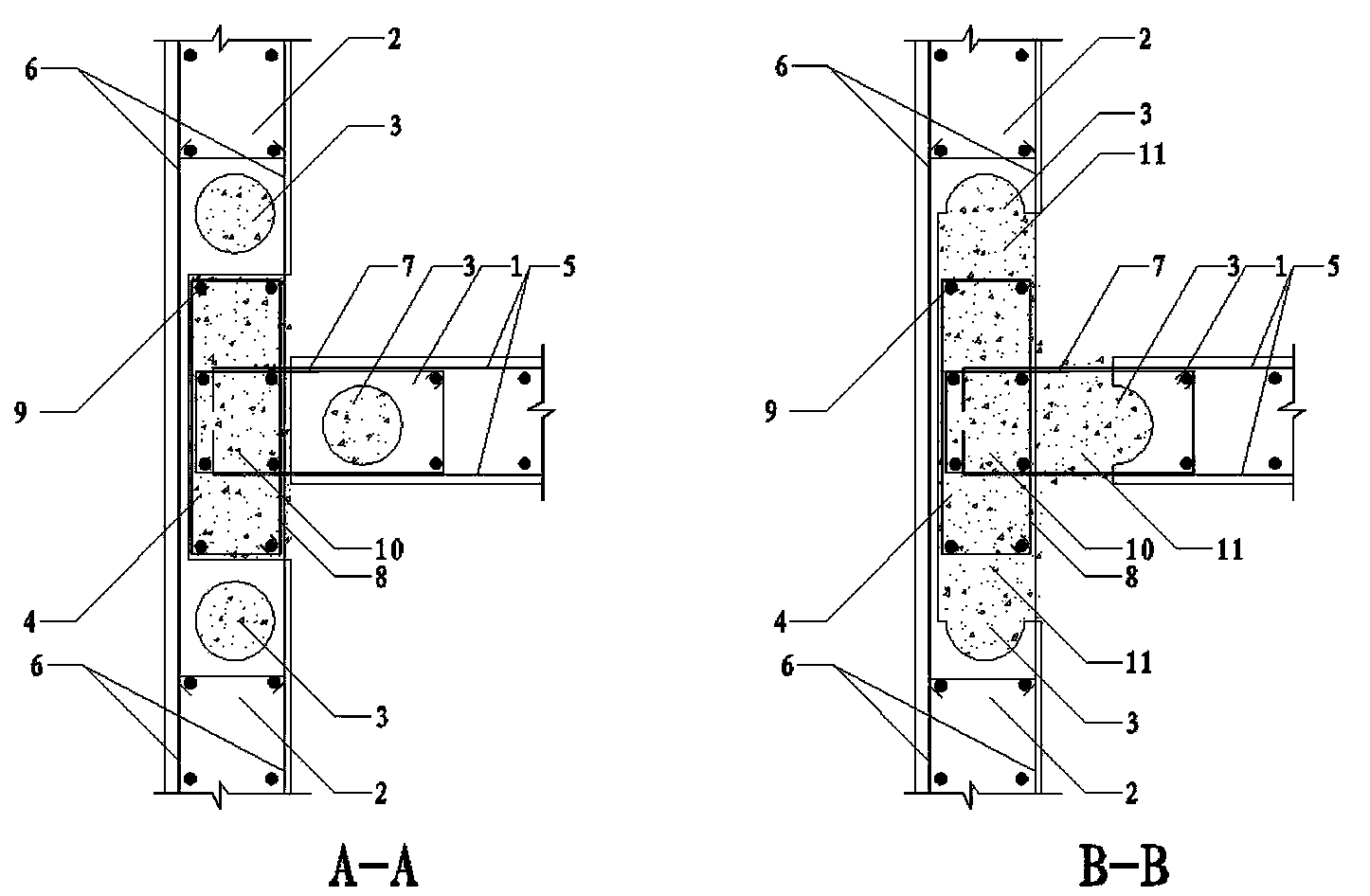

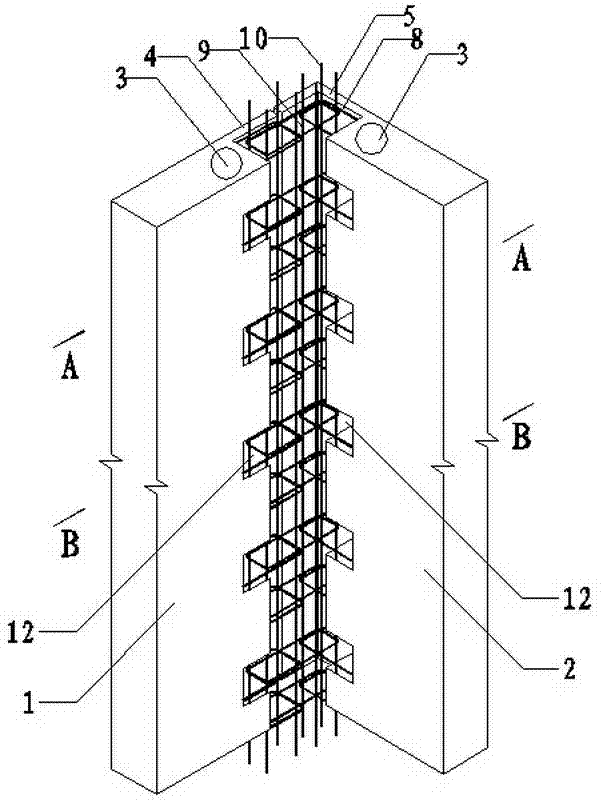

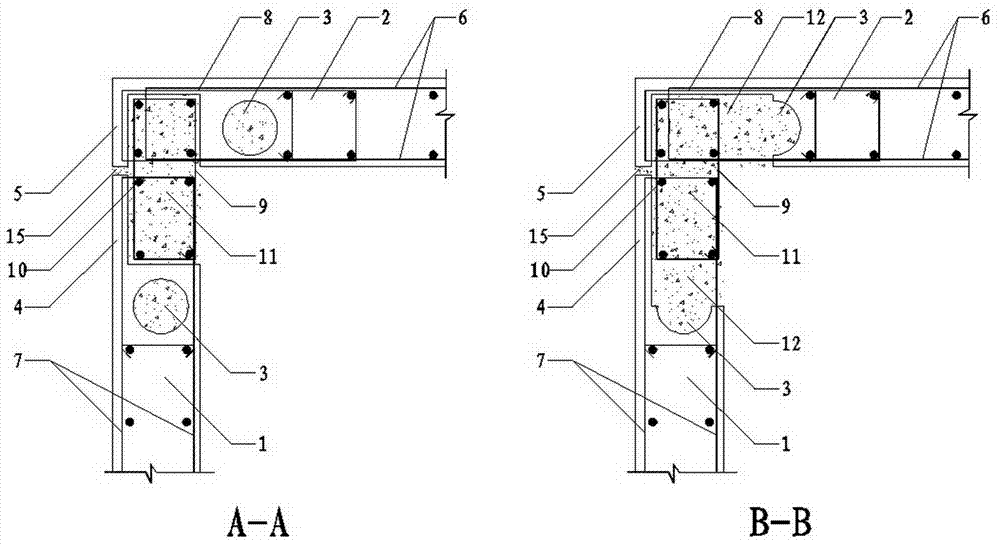

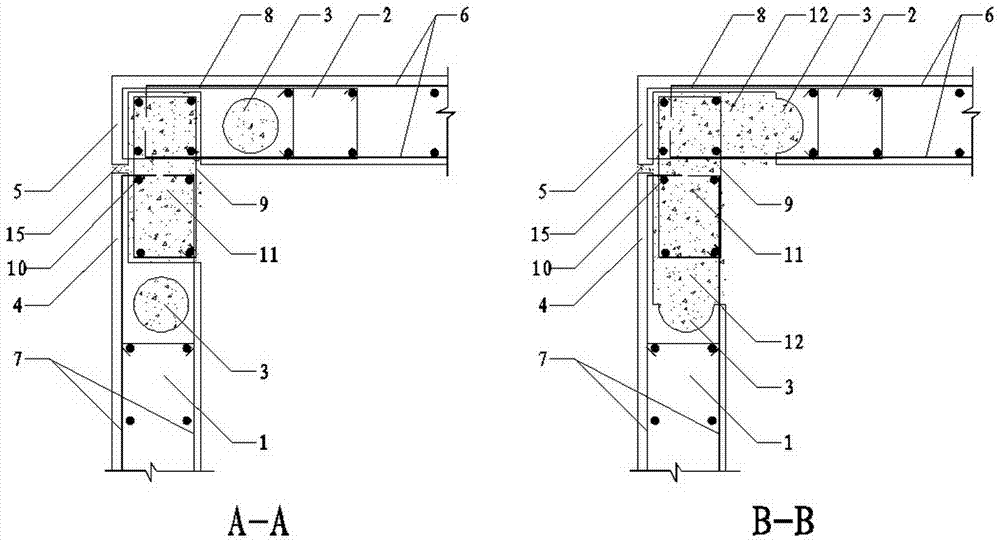

Connecting structure of prefabricated concrete wall body

ActiveCN102797307ASolve the problem of weak seam connectionImprove performanceWallsRebarPrecast concrete

The invention discloses a connecting structure of a prefabricated concrete wall body, and belongs to the technical field of a building structure. The connecting structure of the prefabricated concrete wall body comprises a first prefabricated concrete wall body and a second prefabricated concrete wall body, wherein the positions of the first prefabricated concrete wall body and the second prefabricated concrete wall body, which are close to the end surfaces, are provided with longitudinal communicating holes; the end surfaces are provided with a plurality of horizontal grooves; horizontal grooves of the first prefabricated concrete wall body and the second prefabricated concrete wall body are distributed in a staggering manner; the end surfaces of the first prefabricated concrete wall body and the second prefabricated concrete wall body are provided with U-shaped steel bars which are convex outwards from the inner part of the wall body, and the U-shaped steel bars extend to the positions close to the top surfaces of the horizontal grooves of the second prefabricated concrete wall body and the first prefabricated concrete wall body; and the horizontal grooves, the longitudinal holes and the space between the end surfaces of the prefabricated concrete wall bodies are filled with cast-in-place concrete. The connecting structure disclosed by the invention has the advantages that the integrity of the assembling integration type concrete structure can be improved and the performance of the building structure can be improved.

Owner:初明进

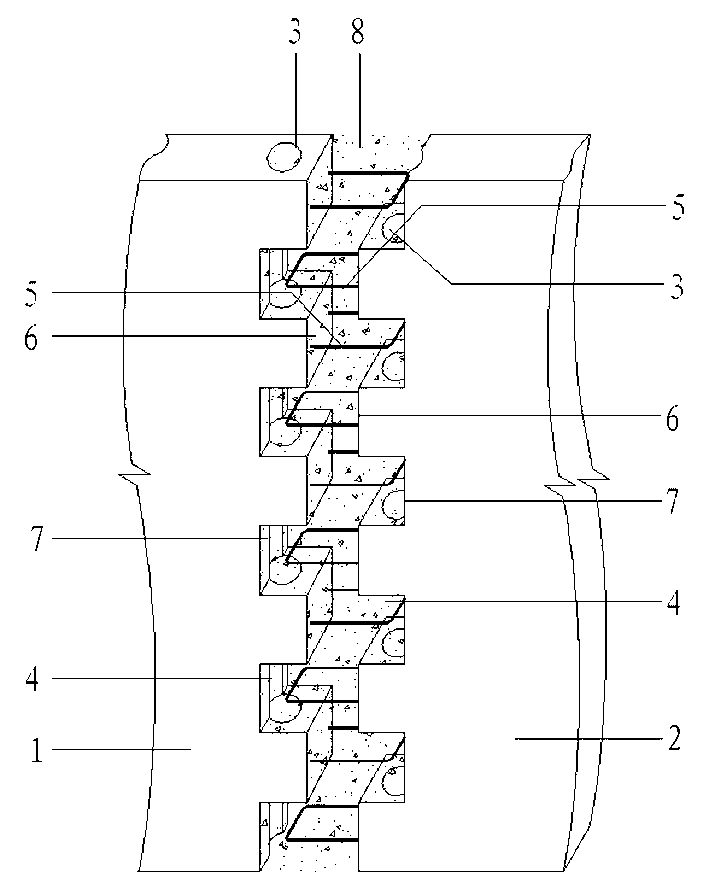

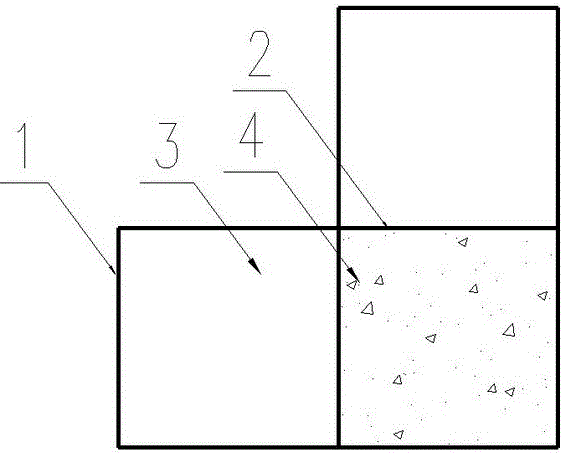

L-shaped precast concrete wall connection

The invention provides an L-shaped precast concrete wall connection, belonging to the technical field of the building structures. The L-shaped precast concrete wall connection comprises a first precast concrete wall and a second precast concrete wall, wherein longitudinal penetrating holes are formed on the precast concrete walls on the connection side in the vicinity of end faces and a plurality of transverse grooves crossing with the longitudinal holes are oppositely formed on the end faces; first and second thin plates extend from the connection-side end faces of the first and second precast concrete walls, respectively; a first horizontal reinforcing steel bar extending to the edge of the first thin plate is arranged in the first precast concrete wall, while a second horizontal reinforcing steel bar and a first embedded column stirrup both extending to the edge of the second thin plate are arranged in the second precast concrete wall; cast-in-place concrete is poured in the space formed by the first and second thin plates, the longitudinal holes and the transverse grooves; and a second embedded column stirrup and a vertical reinforcing steel bar are arranged in the cast-in-place concrete. The L-shaped precast concrete wall connection is capable of improving the integrity of the assembled integrated concrete structure and improving the performance of the building structures.

Owner:初明进

On-load tap changer with an energy storage mechanism

The invention relates to an on-load tap changer having an energy storage mechanism for changing over, without any interruptions, between different winding taps of a tap-changing transformer on load. According to the invention, the energy storage mechanism has one or more compression springs, which are tensioned at the beginning of a changeover operation. In comparison with the tensile springs used to date with such energy storage mechanisms, the compression springs have markedly greater long-term strength.

Owner:MASCHFAB REINHAUSEN GEBR SCHEUBECK GMBH & CO KG

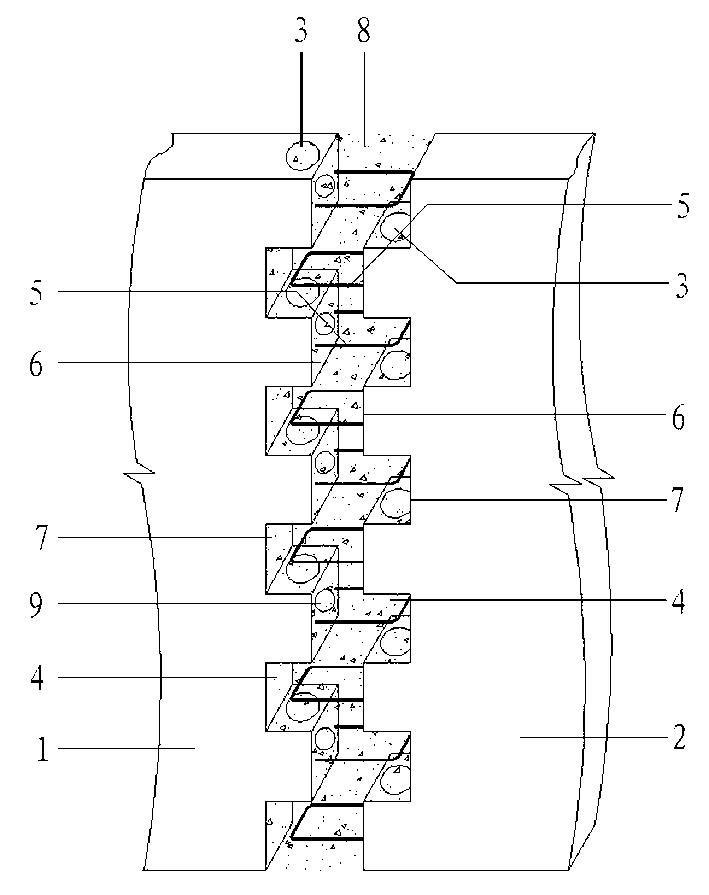

L-shaped prefabricated concrete wall connection joint

The invention provides an L-shaped prefabricated concrete wall connection joint, and belongs to the technical field of construction structures. The L-shaped prefabricated concrete wall connection joint comprises a first prefabricated concrete wall body and a second prefabricated concrete wall body, wherein a longitudinal through hole is formed in the portion, on the joint side and close to the end face, of the first prefabricated concrete wall body, a longitudinal through hole is formed in the portion, on the joint side and close to the end face, of the second prefabricated concrete wall body, a plurality of transverse grooves are formed in the end face on the joint side of the first prefabricated concrete wall body, a plurality of transverse grooves are formed in the end face on the joint side of the second prefabricated concrete wall body, the top portion of each transverse groove extends into the portion, inside the corresponding longitudinal hole, of the corresponding wall body or intersects with the corresponding longitudinal hole, the first prefabricated concrete wall body and the second prefabricated concrete wall body extend on the end faces of the joint sides to form a first sheet and a second sheet respectively, an edge joint is reserved at the joint of the first sheet and the second sheet, and cast-in-place concrete is arranged in the space defined by the first sheet and the second sheet, the longitudinal holes and the transverse grooves. According to the L-shaped prefabricated concrete wall connection joint, the integrality of a prefabricated overall concrete structure can be improved, and performance of the construction structure can be improved.

Owner:初明进

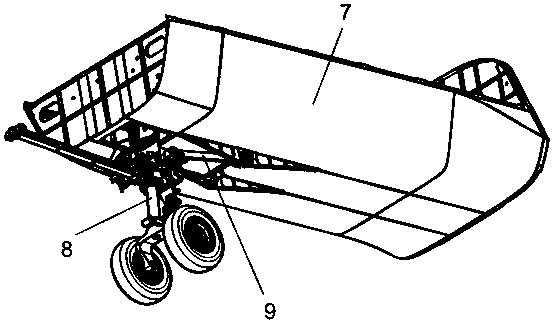

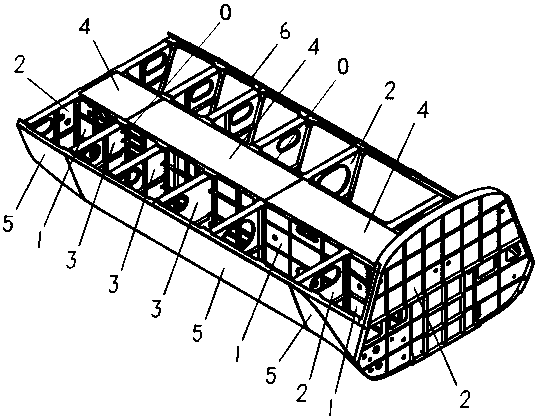

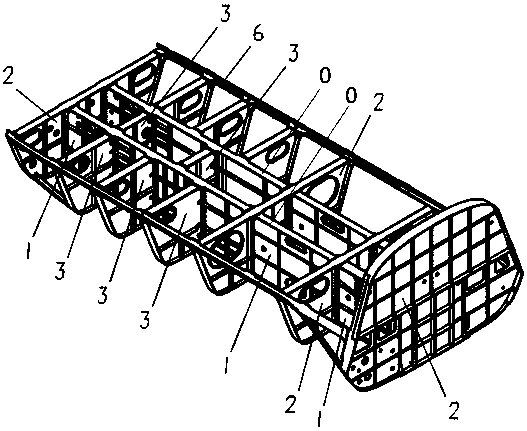

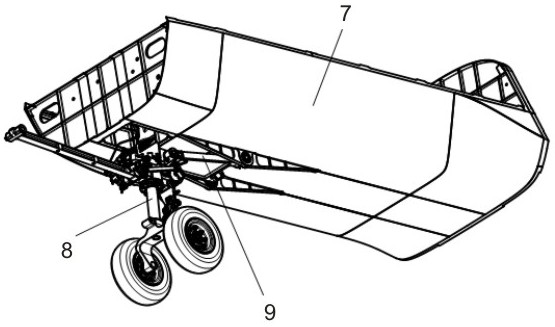

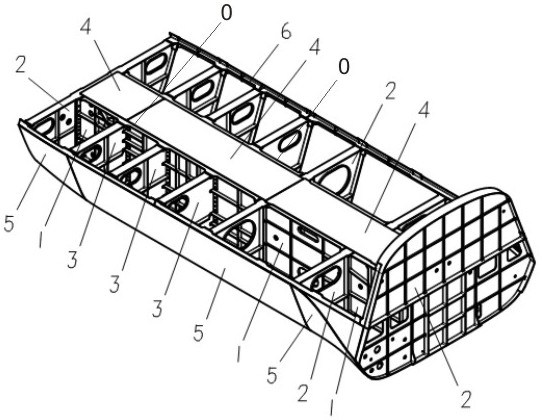

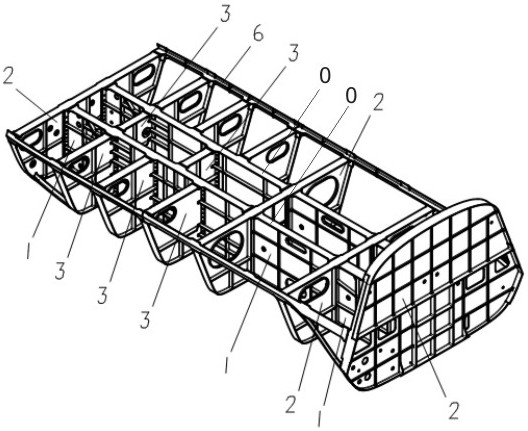

Drone noselanding gear well section based on catapult-assisted take-off

ActiveCN107891965AThe overall structure is light in weightReduce loadFuselage framesFuselage bulkheadsCatapultWall plate

The invention discloses a drone noselanding gear well section based on catapult-assisted take-off. A landing gear well comprises partition frames at the two ends, a girder connected with the partitionframes and a skin; a landing gear fixing compartment is arranged in the middle of the landing gear well, a framework of the landing gear fixing compartment comprises four main girders, the main girders are fixedly connected with the partition frames, and partition plates are arranged at both the two sides of each main girder and the partition frames; the main girders and the partition plates forman integrated wall plate girder, the wall plate girder is hinged to a landing gear main support and a landing gear slant supporting rod, and openings are formed in the skin at the lower portion of the landing gear fixing compartment. The landing gear well is of a box body type structure low in structural weight, the openings are formed among the main girders, the rigidity of other parts of the landing gear well and the rigidity of an overall aircraft cannot be lowered, and additional strength reinforcement setting is also not needed; the wall plate girder penetrating through the whole box body has the advantages of being continuous in stress and short and direct in force transmitting path, and transmitting of instantaneous impact large loading concentrated force and torque inside the structure is benefited.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

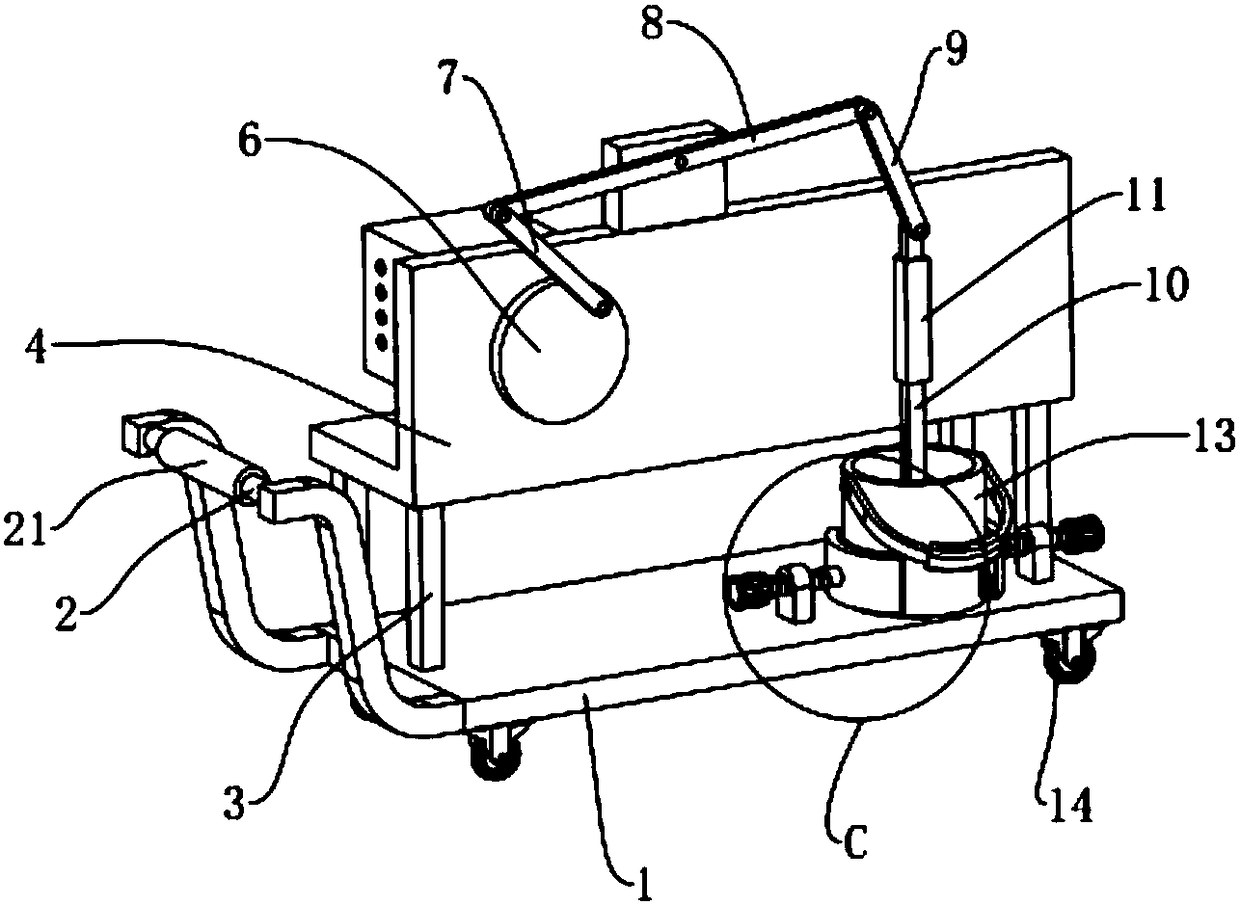

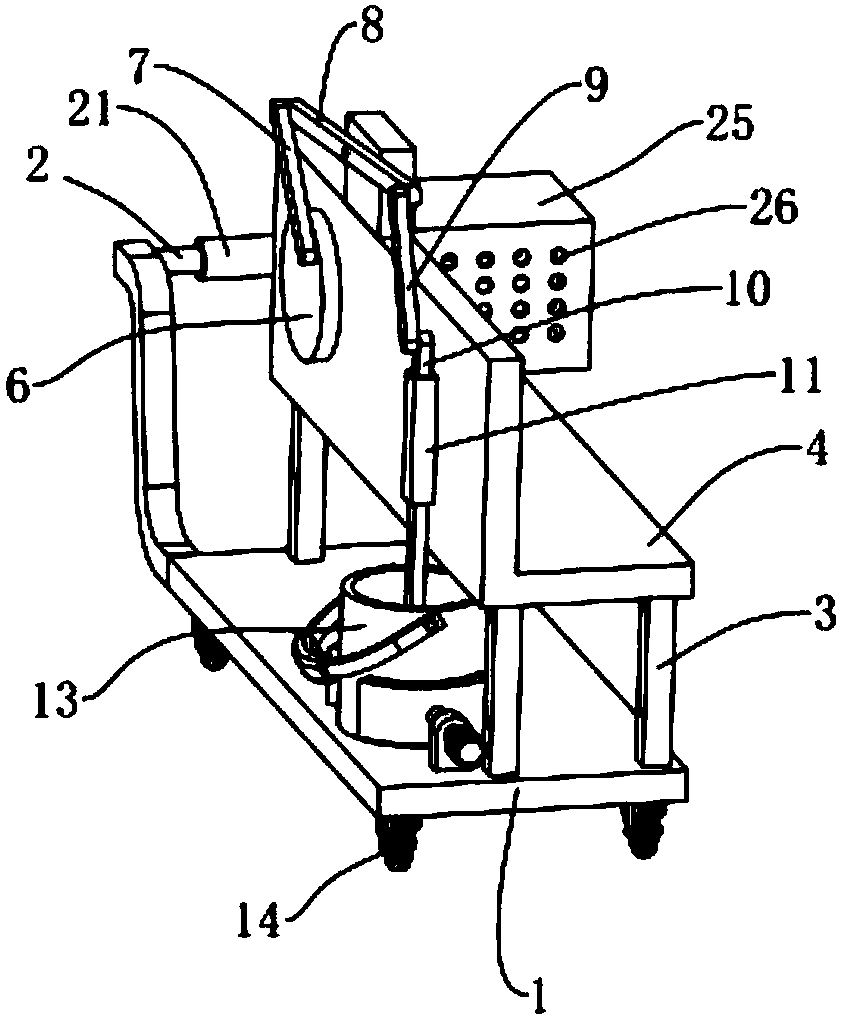

Caked chemical fertilizer mashing machine

InactiveCN108355746AHitting structure is reliableContinuous forceGrain treatmentsElectric machineryMotor shaft

The invention discloses a caked chemical fertilizer mashing machine. The caked chemical fertilizer mashing machine is characterized in that the caked chemical fertilizer mashing machine comprises a supporting plate and a pushing handle fixed to one end of the supporting plate; a bearing plate is fixed to the supporting plate, and a servo motor is fixed to the bearing plate; a rotary disc is fixedto a motor shaft of the servo motor, and a first connecting rod is eccentrically hinged to the rotary disc; a second connecting rod is hinged to the end, away from the rotary disc, of the first connecting rod, and a third connecting rod is hinged to the end, away from the first connecting rod, of the second connecting rod; the middle of the second connecting rod is rotationally connected to the bearing plate, and a fourth connecting rod is hinged to the end, away from the second connecting rod, of the third connecting rod; a sleeve is fixed to the bearing plate, and the fourth connecting rod slides in the sleeve; and a mashing block is fixed to the end, away from the third connecting rod, of the fourth connecting rod. The caked chemical fertilizer mashing machine has the advantages that the striking structure is reliable, striking force exerting is continuous, and the caked chemical fertilizer mashing effect is good.

Owner:XINCHANG COUNTY CHENGGUAN TOWN XINSHENG BEARING FACTORY

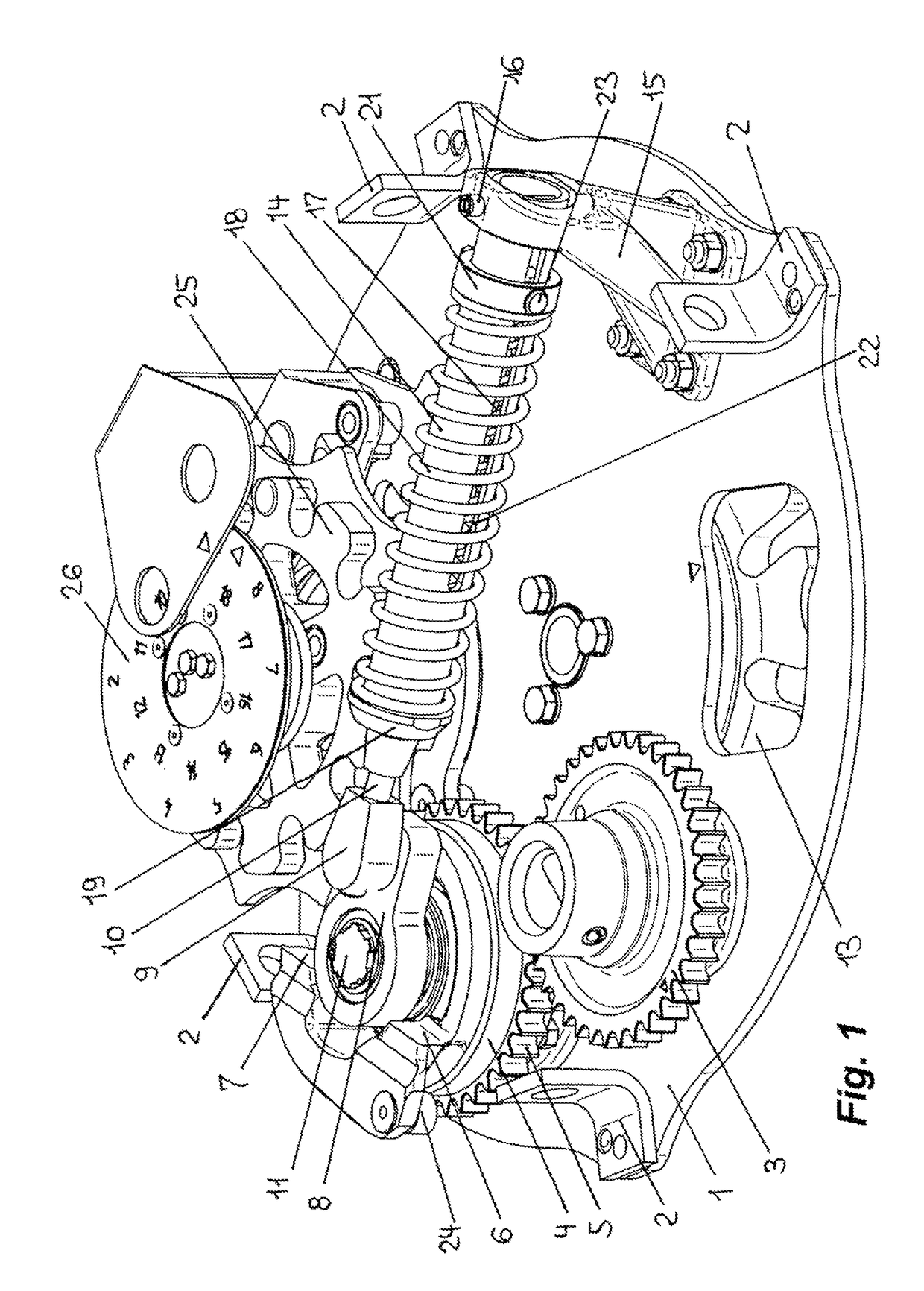

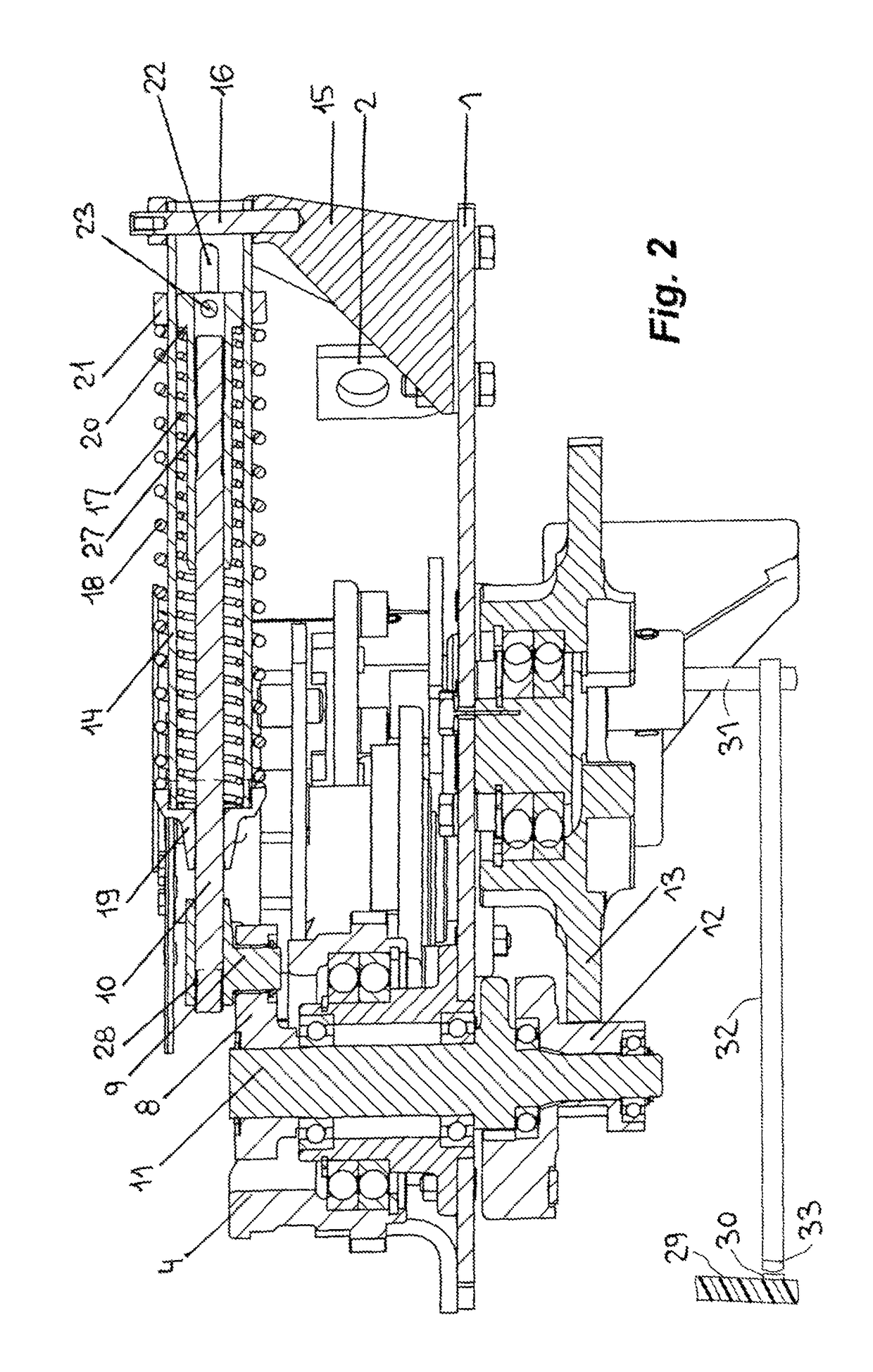

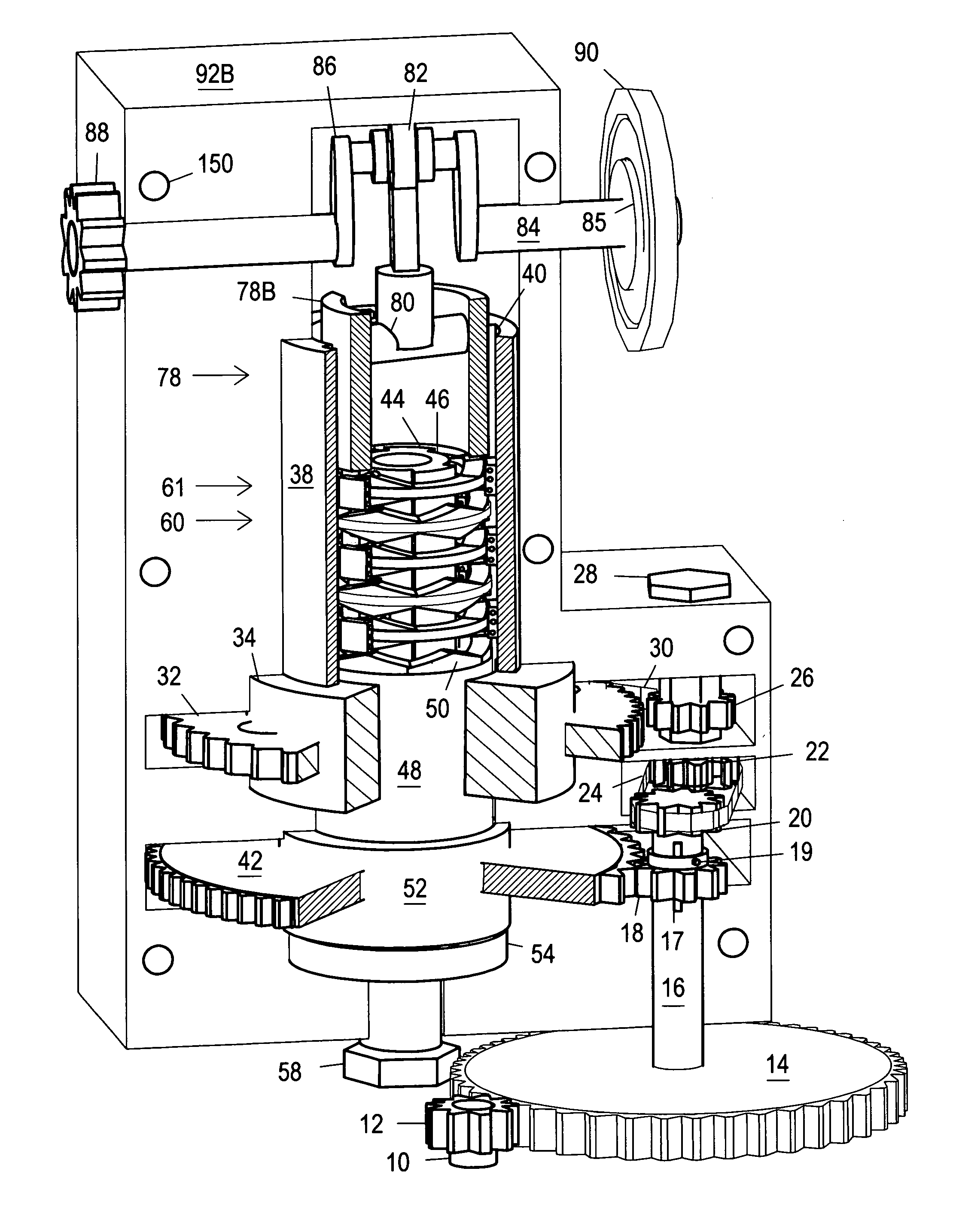

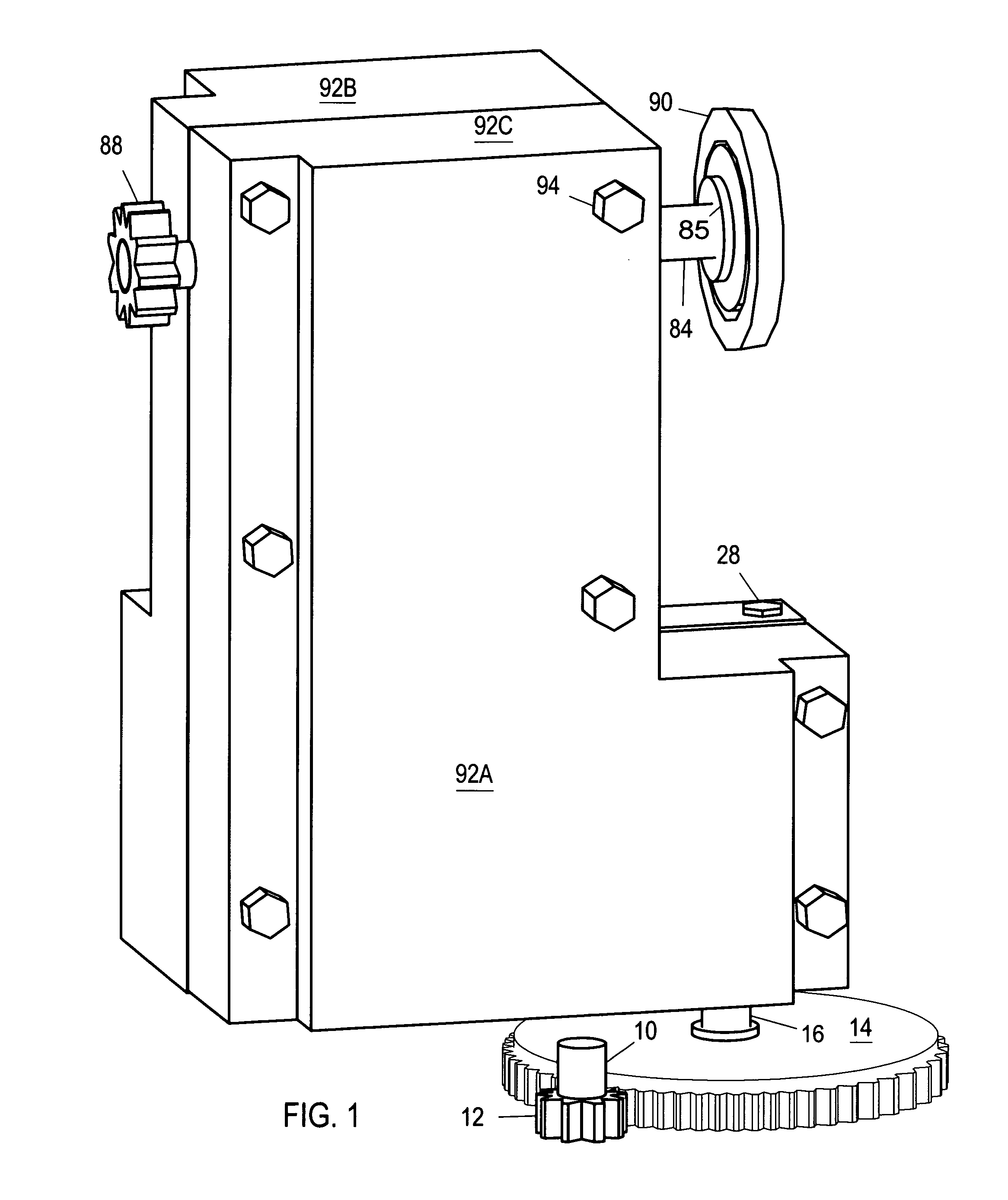

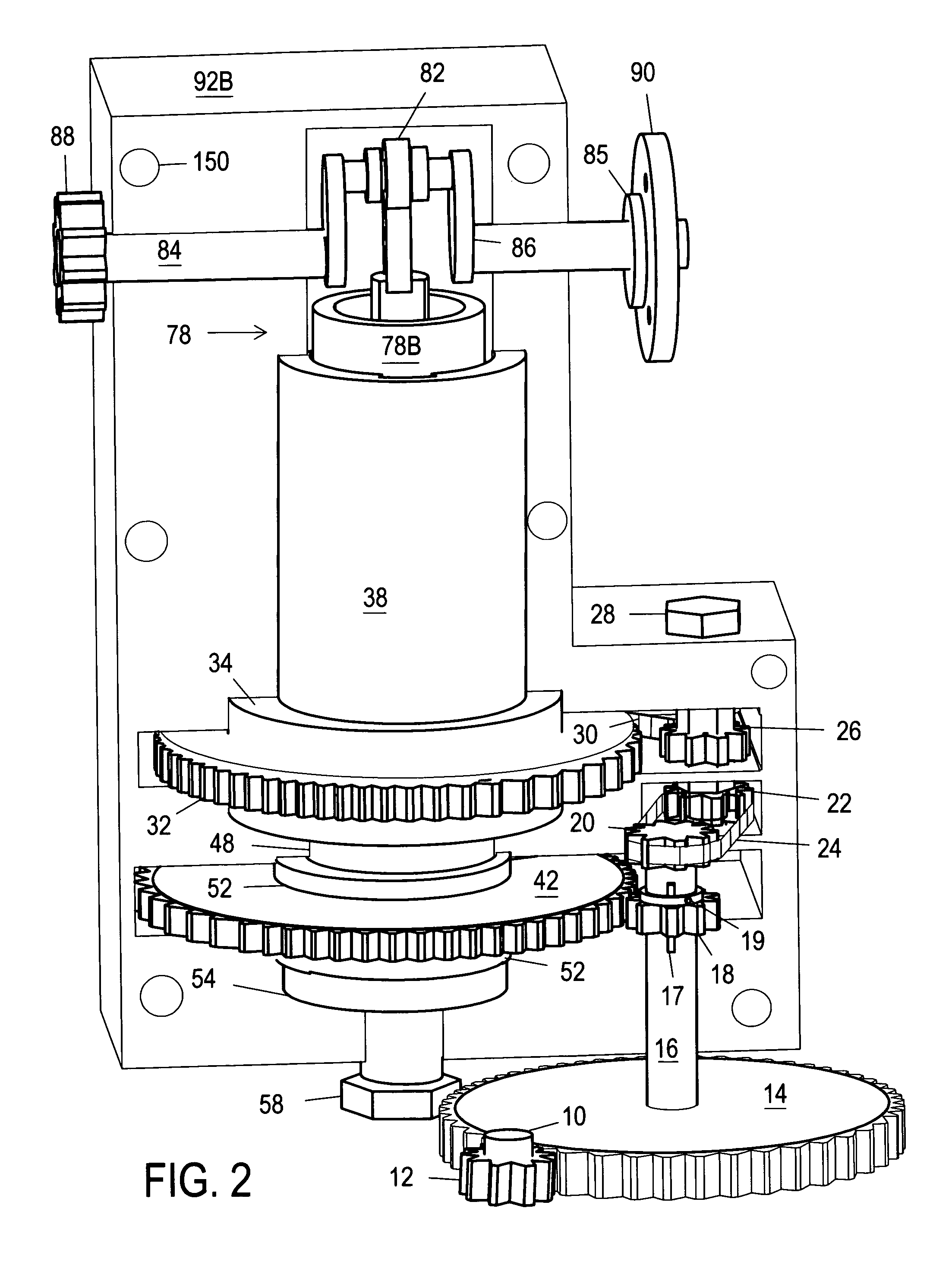

Mechanical module for horsepower amplification

InactiveUS20120222508A1Apply constant forceIncrease energy levelGearingMachines/enginesSupply energyLateral displacement

One embodiment of the horsepower amplifier module (FIG. 2) proofs the usefulness of a new approach to mechanical interventions. Mechanical advantage principles and the laws of leverage are fully exploited to increase energy efficiency while operating any horsepower producing means. Newly designed pressure ring (60), and pressure ring (61), are mounted respectably on rotary assemblies (FIG. 2B) and (FIG. 2C). Rotational energy applied to assemblies prompts the lateral displacement of components (60) and (61). A more powerful force is created and is directed to collector (78). Multiple modules supplying energy to same shaft (as shown in FIG. 3) offer a variety of options for effective operation of adopted application. A second embodiment (FIG. 4) is described as a possible arrangement available to enhance the overall capabilities of the horsepower multiplier module.

Owner:ZAMBRANA LUIS ANTONIO

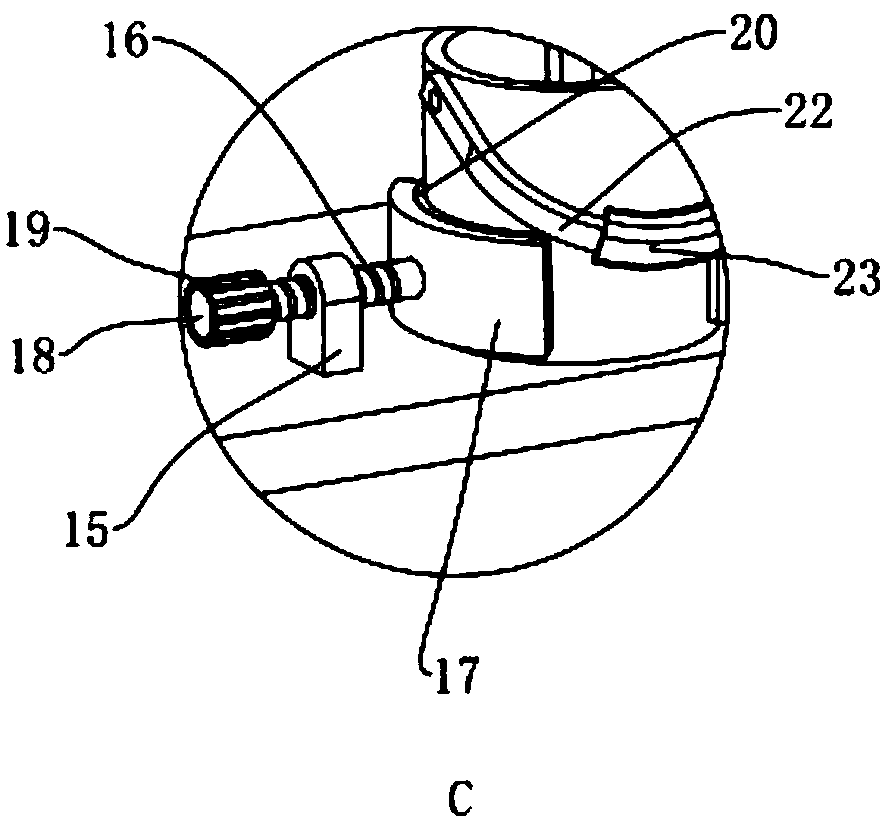

Probe bracket for ultrasonic artificial detection of steel plate

InactiveCN103884779AContinuous forceStable distanceAnalysing solids using sonic/ultrasonic/infrasonic wavesSheet steelEngineering

The invention relates to a probe bracket for the ultrasonic artificial detection of a steel plate. The probe bracket comprises a shell, a stress application part and a displacement part, wherein the shell comprises a base and an upper support seat connected with the base by screw thread; the base and the upper support seat are respectively provided with a center hole used for arranging a probe; the upper end of the probe is connected with an ultrasonic detector by a lead; the stress application part is a spring arranged between the upper support seat and the probe; the displacement part comprises a pull rod connected with the upper support seat. The probe bracket for the ultrasonic artificial detection of the steel plate mainly comprises the upper support seat, the base, the spring and the pull rod, so that the manufacturing cost is low and maintenance is not needed; the upper support seat, the base and the spring are assembled, so that the stress applied to the probe is uniform, stable and continuous under the action of the elastic force of the spring; the distance between the lower end surface of the probe and the steel plate is stable, so that the coupling effect is improved, the detection sensitivity and the reflection echo are in accordance with the standard requirements, and defect misjudgement or missing detection can be avoided.

Owner:JIGANG GRP

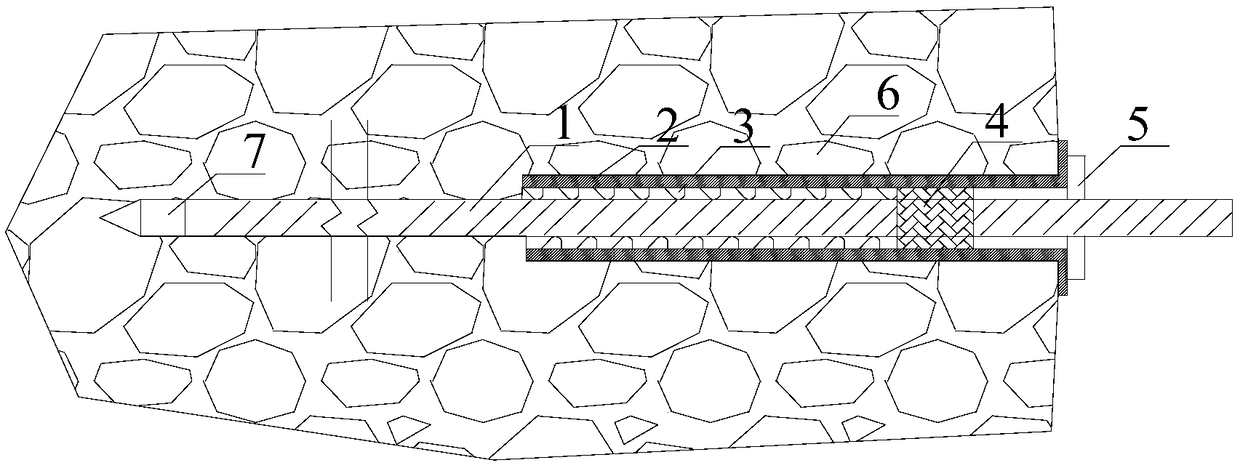

Threaded metal yielding anchor rod device

InactiveCN109505640AContinuous forceContinuous yielding effectAnchoring boltsContinuous/uninterruptedScrew thread

The invention provides a threaded metal yielding anchor rod device including a fixed anchor head, an anchor rod body, a metal head, a metal protection sleeve and a thread yielding ring. The thread yielding ring is disposed in the metal protection sleeve in the form of an internal thread, and the diameter of the metal head is greater than the minor diameter of the thread yielding ring and smaller than the internal diameter of the metal protection sleeve. During the use, the fixed anchor head is mounted in a drilled hole of a surrounding rock, and the metal protection sleeve is mounted in a drilled hole port of the surrounding rock; one end of the anchor rod body passes through the thread yielding ring and is connected with the fixed anchor head, the other end is connected with the metal head, and the metal head is placed in the metal protection sleeve. The thread yielding ring is disposed in the metal protection sleeve in the form of the internal thread, since the thread is continuous and uninterrupted and there is no gap between two yielding rings, when the metal head causes axial deformation of the thread yielding ring, an acting force is continuous, a stable and continuous yielding effect is generated, and the yielding effect is improved.

Owner:SHAANXI COAL & CHEM TECH INST

Method for forming nanometer gradient structure on surface layer of shaft metallic material

The invention relates to a surface treatment method for forming a nanometer gradient structure on a surface layer of a shaft metallic material. The invention aims to solve the problems that the surface roughness of the material to be treated is higher, the surface smoothness is not high and a nanometer crystal structure is difficult to form on the surface of a workpiece in the prior art. A spherical treatment tool is adopted to roll on the surface of the rotary shaft metallic material, and meanwhile, the spherical treatment tool moves along the axial direction of the workpiece, and plastic deformation is generated on the surface layer of the material, so that grains on the surface layer of a workpiece material are refined to form the nanometer gradient structure, wherein the depth of the deformation layer of the nanometer gradient structure reaches 100-300 micrometers; and the grains on the surface layer of the workpiece material are nanometer grains, submicron grains, deformation grains and initial grains in sequence in size from the surface to the inside. According to the processing method provided by the invention, the integral mechanical property of the material is improved through improving the microstructure of the surface layer, thereby, the service life of the material is prolonged. The processing method provided by the invention is small in investment and is simple and convenient in operation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

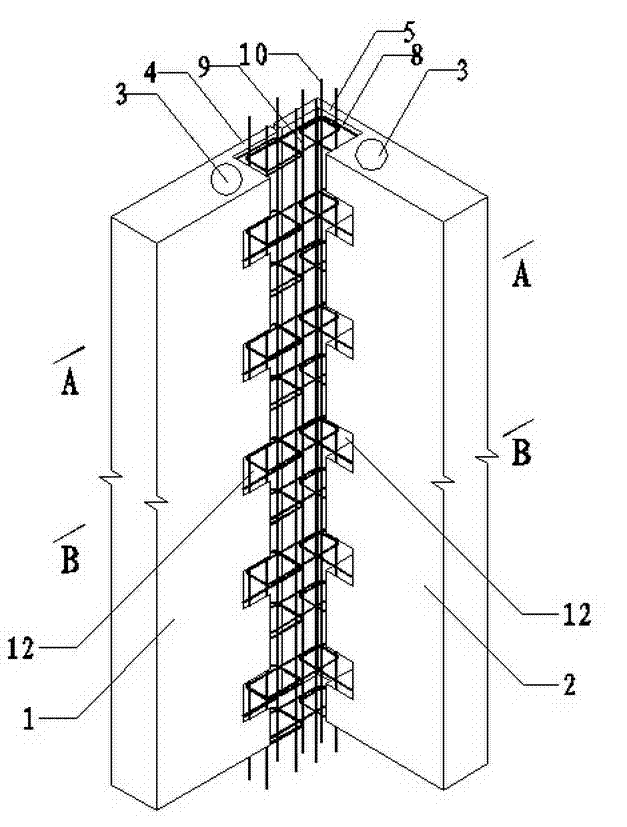

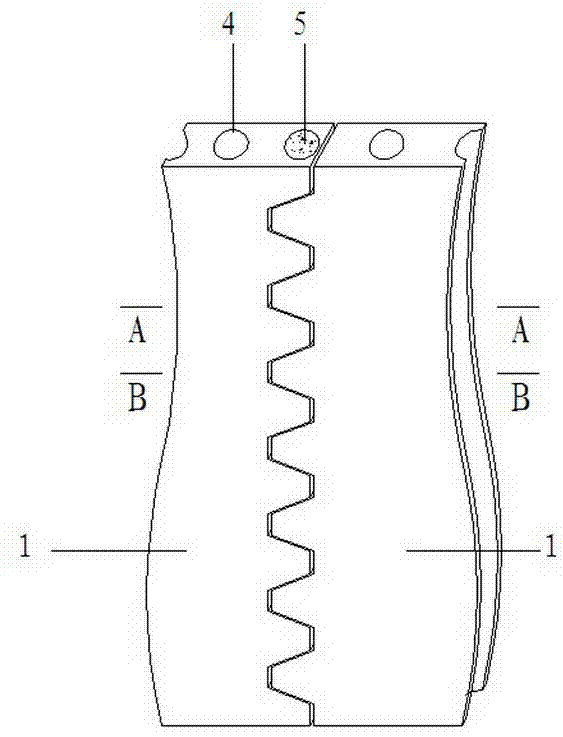

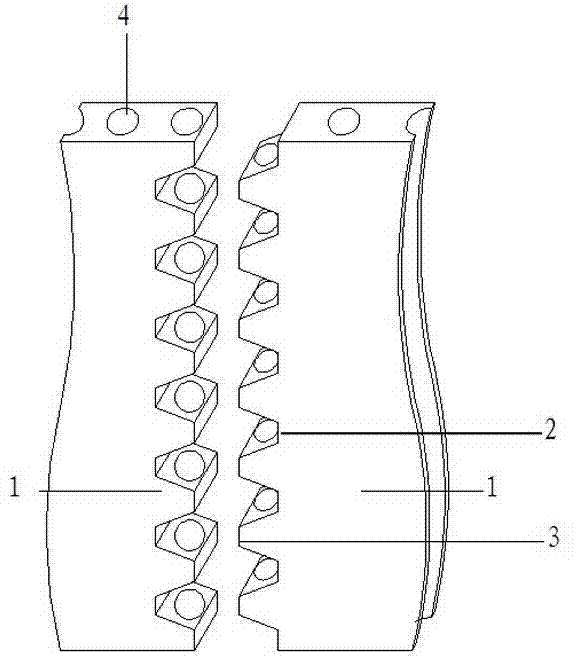

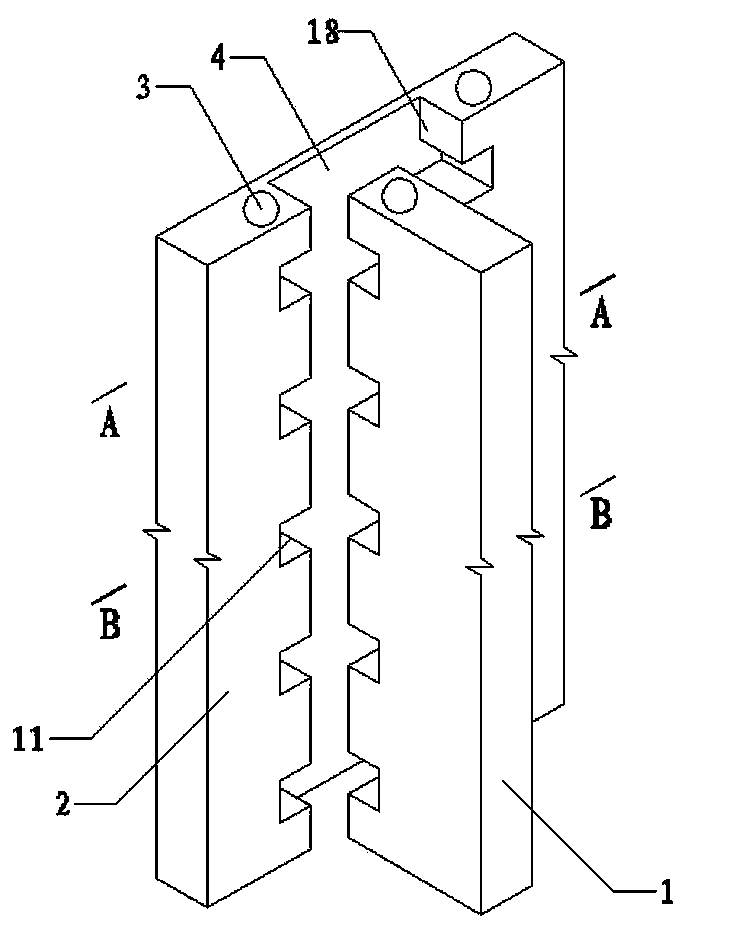

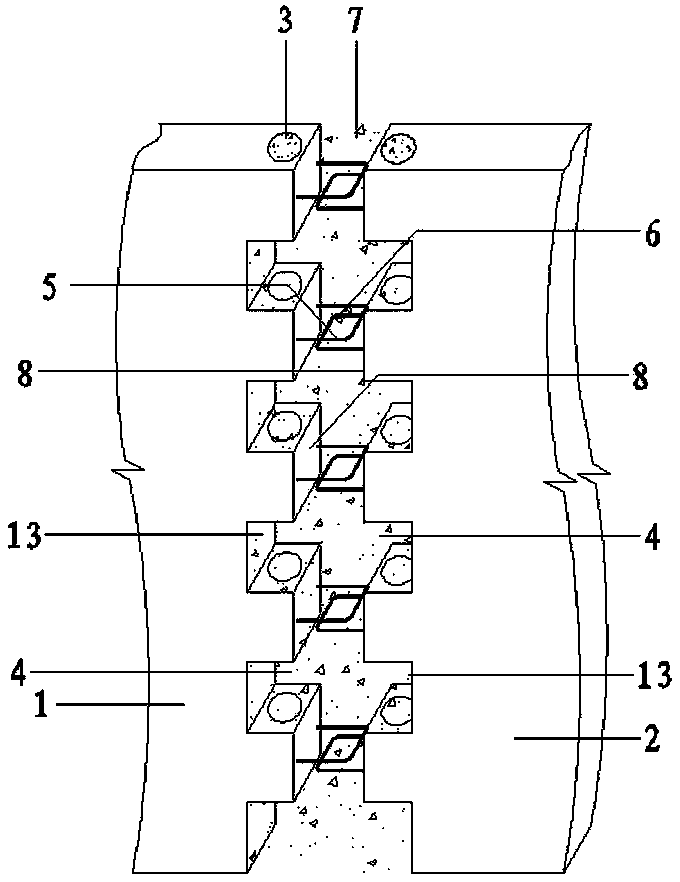

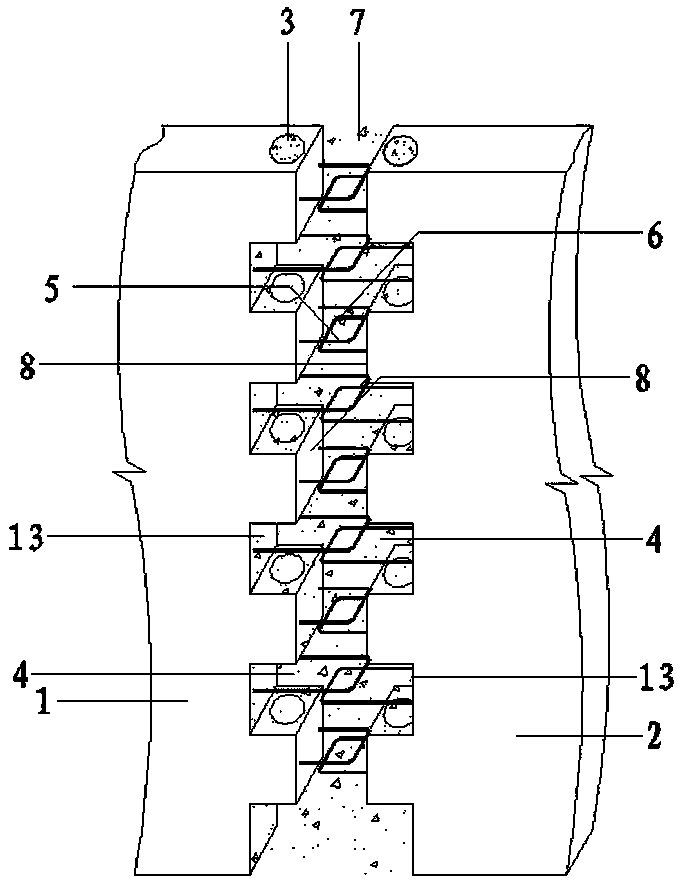

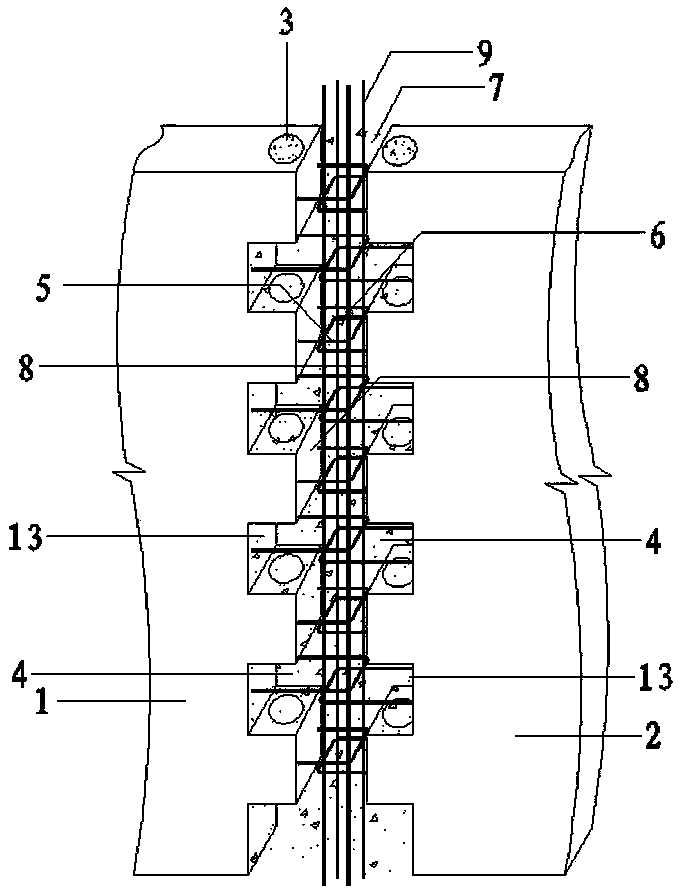

Notch-key type prefabricated member connection node and connection method

ActiveCN103572840BContinuous forceSimple structureBuilding constructionsVertical edgePrecast concrete

The invention relates to a notch-key type prefabricated member connection node and a connection method thereof, which belong to the technical field of architectural structures. The node comprises prefabricated concrete members and cast-in-place concrete, each prefabricated member is provided with a plurality of vertical through holes parallel with the surface along the length direction, and the vertical edge of the prefabricated member is provided with spaced horizontal notches which intersect outer vertical holes, so that the notches and projections of the edge of the prefabricated member are alternately distributed; the projections of one prefabricated member of the node are inserted into the notches of the other prefabricated member of the node, at least one part or all of the vertical holes of the two prefabricated members are superposed, concrete is poured into the superposed vertical holes, and thereby the notch-key type node is formed. The fabrication method includes the following steps: the prefabricated concrete members are transported to a site and assembled, the notches and projections of the neighboring prefabricated members are engaged with each other, part or all of the vertical holes of the edges of the two members are superposed, concrete is poured into the superposed vertical holes of the two prefabricated members of the node and the node area, and thereby the notch-key type prefabricated member connection node is formed. The notch-key type prefabricated member connection node is used for connecting a prefabricated concrete vertical member with a horizontal member, and can enhance the integrity and structural properties of assembled integrated concrete structures and promote the development of building industrialization.

Owner:初明进

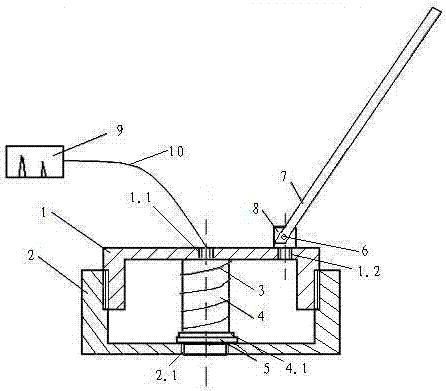

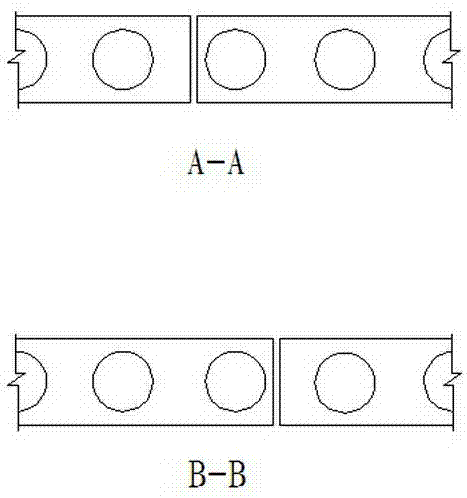

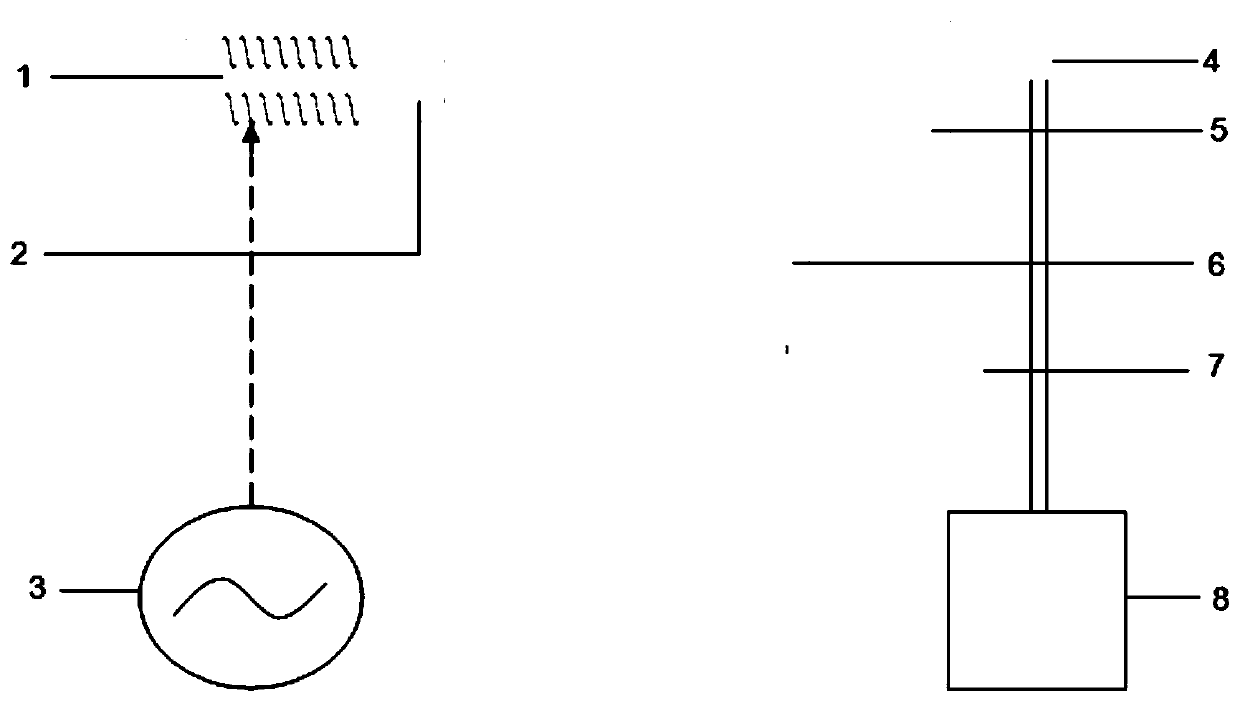

Ultrasonic liquid knife impacting metal material surface nanocrystallization method and special device thereof

The invention relates to the field of metal material surface nanocrystallization, in particular to an ultrasonic liquid knife impacting metal material surface nanocrystallization method and a specialdevice thereof. According to the method, a high-pressure liquid is adopted to carry high-energy ultrasonic waves, and the surface of a metal material is impacted through a liquid knife nozzle. The method comprises the following steps: 1, matrix pretreatment, specifically, carrying out conventional surface polishing and cleaning by using acetone and alcohol; and 2, surface nanocrystallization, specifically, adopting the high-pressure liquid to carry the ultrasonic energy waves and move at a high speed to impact the surface of the metal material. The device comprises a liquid knife device and anultrasonic generating device, wherein the ultrasonic generating device comprises an ultrasonic generator, an ultrasonic horn and an ultrasonic transducer; and the liquid knife device comprises a liquid knife liquid inlet pipe, an impact liquid tank, a liquid knife nozzle and a liquid knife pressurizing tank. According to the method and the device, through the processing method for generating plastic deformation on the surface layer of the material, the grain size of the surface layer of the material is formed into a structure sequentially comprising nano-sized grains, submicron-sized grains,deformed grains and initial grains from the surface to the inside.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

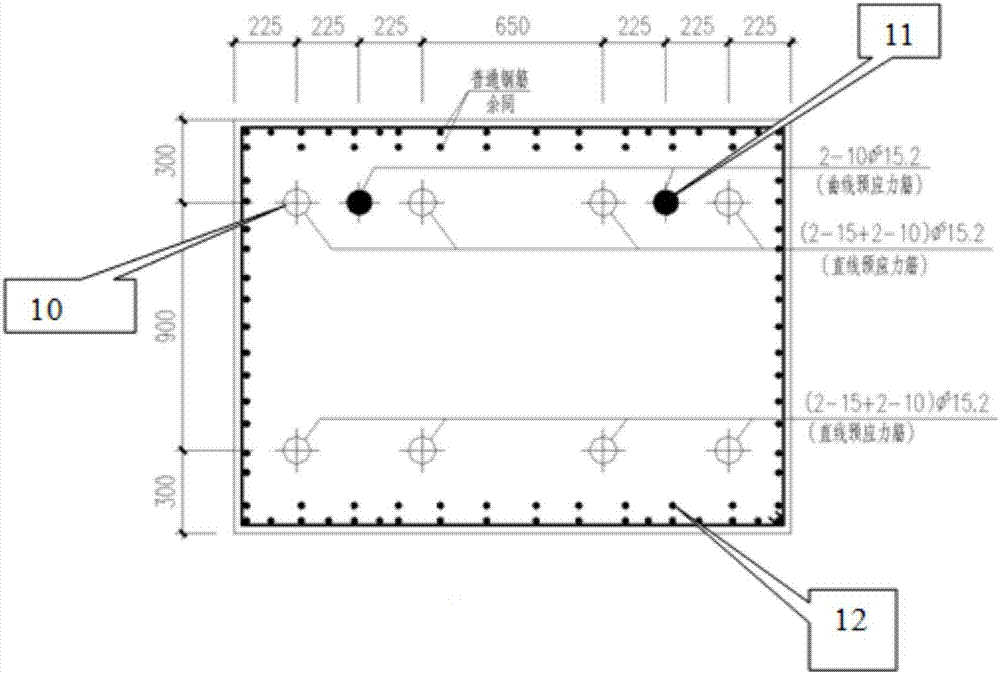

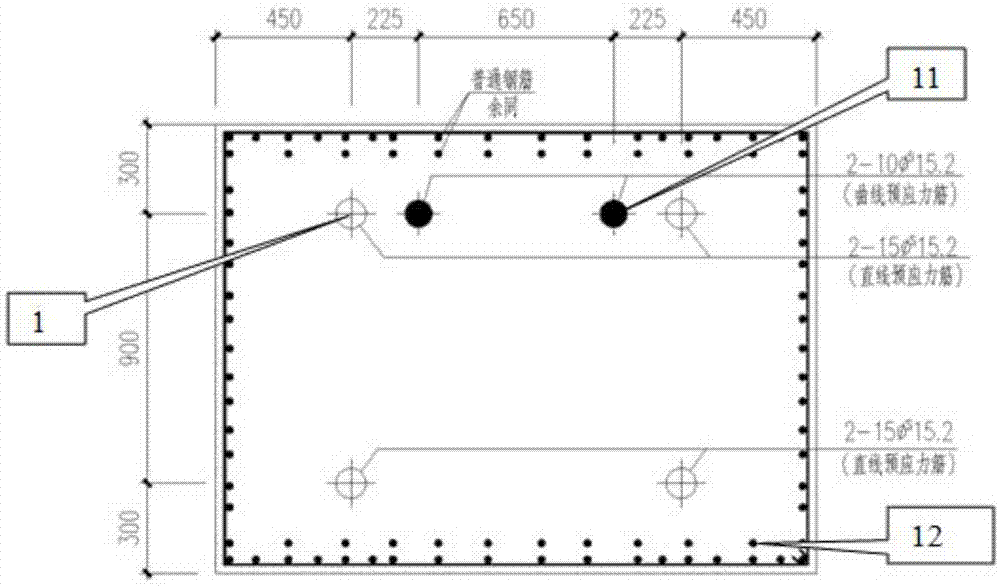

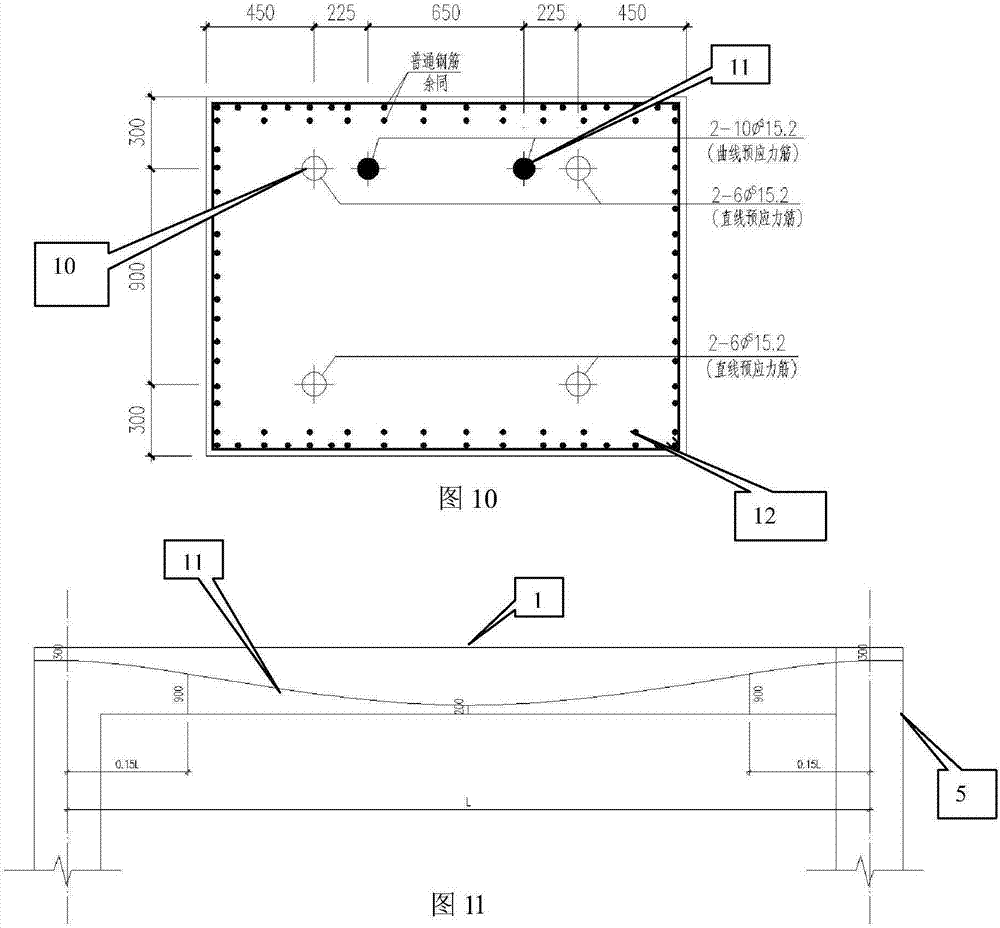

Saddle-shaped spatial pre-stressed ring beam

ActiveCN107419849AIncrease stiffnessPrevent buckling damageGirdersJoistsPrestressed concrete beamPre stress

The invention relates to a saddle-shaped spatial pre-stressed ring beam. The saddle-shaped spatial pre-stressed ring beam consists of an inner ring beam, an outer ring beam and radial beams, wherein the inner ring beam is connected with the outer ring beam through the radial beams; the inner ring beam is a multi-span uniform-section continuous variable-elevation pre-stressed concrete beam; the outer ring beam is a multi-span uniform-section continuous variable-elevation reinforced concrete beam; the radial beams are single-span uniform-section horizontal reinforced concrete beams; curve pre-stressed tendons, straight-line pre-stressed tendons and regular reinforcements are arranged in the inner ring beam in a ring-shaped manner; the pre-stressed tendons and the regular reinforcements of the inner ring beam are arranged in the way that after arrangement of the regular reinforcements, the straight-line pre-stressed tendons are uniformly arranged along the periphery of the beam section at first within the range of a reinforcement cage formed by the regular reinforcements, and then the curve pre-stressed tendons are arranged between the straight-line pre-stressed tendons at the top layer; the inner ring beam and the outer ring beam are connected with a lower concrete structure through cast-in-place reinforced concrete beam-column joints; a cable-membrane structure and a spatial saddle-shaped ring beam are connected through a sliding hinged support; and the sliding hinged support realizes radial horizontal constraint release and circumferential horizontal constraint preservation.

Owner:ARCHITECTURAL DESIGN & RES INST OF TSINGHUA UNIV

L-section steel and concrete combined structural member

InactiveCN105839848AImprove the level of industrializationReduce the amount of pouringStrutsPillarsSteel platesLoad carrying

The invention relates to an L-section steel and concrete combined structural member and belongs to the technical field of steel and concrete structures. This structural member comprises a steel member with L-shaped contour and concrete, the steel member is formed by connecting steel plates or section steel and forms a plurality of cavities, concrete is poured into part of the cavities, and other cavities receive no concrete. Load-carrying capacity and industrial level of a structure will be improved.

Owner:初明进

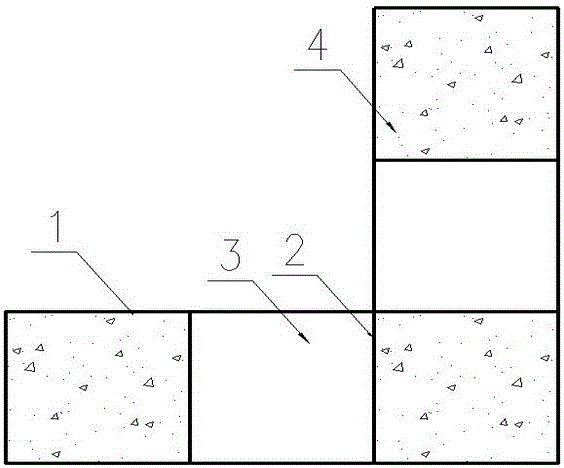

T-shaped prefabricated concrete wall connection joint

InactiveCN103835390ASolve the problem of weak seam connectionImprove performanceWallsTransverse groovePrecast concrete

The invention provides a T-shaped prefabricated concrete wall connection joint, and belongs to the technical field of construction structures. The T-shaped prefabricated concrete wall connection joint comprises a first prefabricated concrete wall body and a second prefabricated concrete wall body, wherein the first prefabricated concrete wall body and the second prefabricated concrete wall body intersect to form the T-shaped connection joint, a longitudinal through hole is formed in the portion, on the joint side and close to the end face, of the first prefabricated concrete wall body, a plurality of transverse grooves are formed in the end face of the joint side of the first prefabricated concrete wall body, the thickness of the second prefabricated concrete wall body decreases in the joint area to form a plate face groove, longitudinal through holes are formed in the portions, close to the end faces and on the two sides of the plate face groove, of the second prefabricated concrete wall body, a plurality of transverse grooves are formed in the end faces of the portions, on the two sides of the plate face groove, of the second prefabricated concrete wall body, the top portion of each transverse groove extends into the portion, inside the corresponding longitudinal hole, of the corresponding wall body or intersects with the corresponding longitudinal hole, and cast-in-place concrete is arranged in the longitudinal holes, the transverse grooves and the plate face groove of the second prefabricated concrete wall body. According to the T-shaped prefabricated concrete wall connection joint, the integrality of a prefabricated overall concrete structure can be improved, and performance of the construction structure can be improved.

Owner:初明进

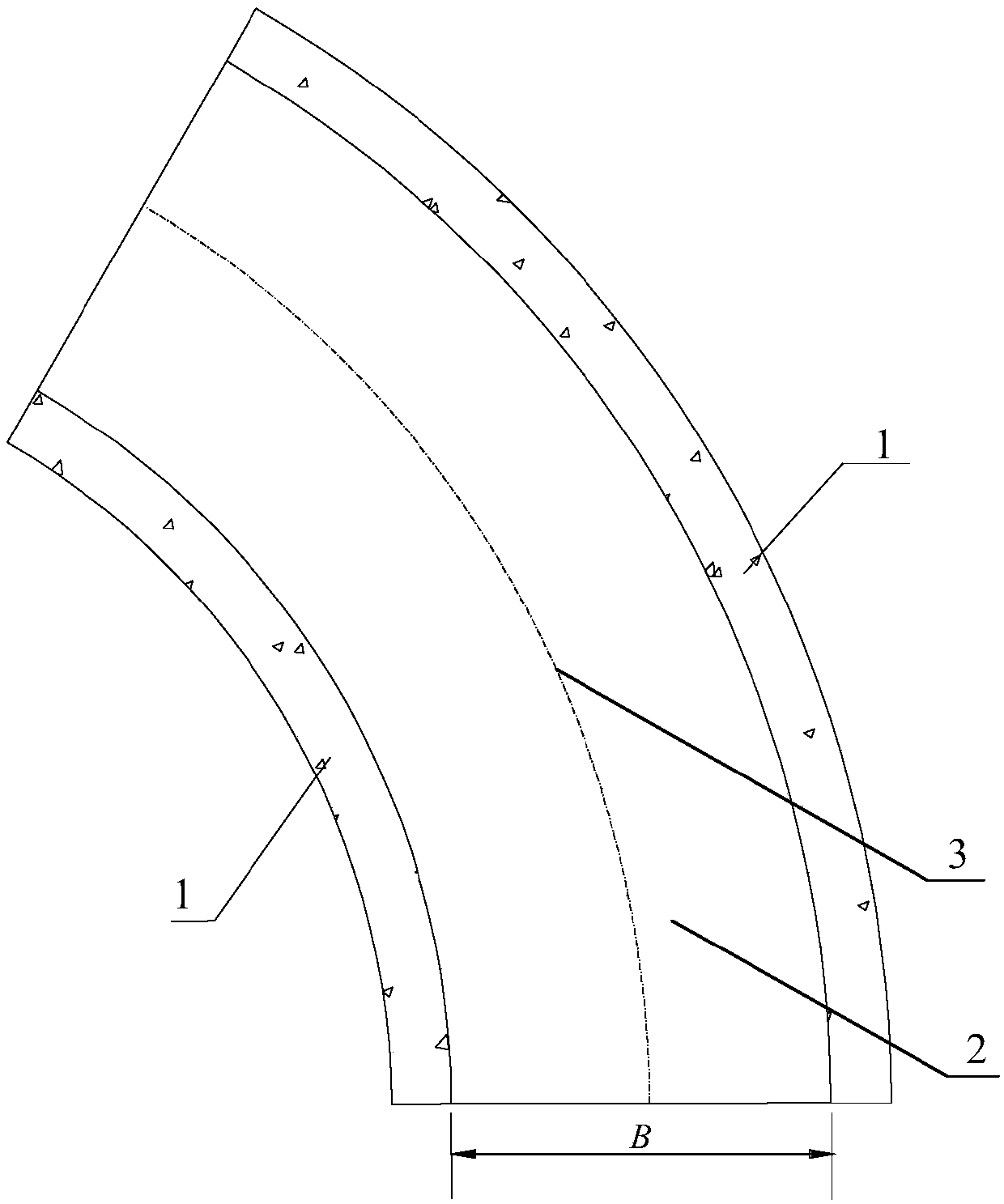

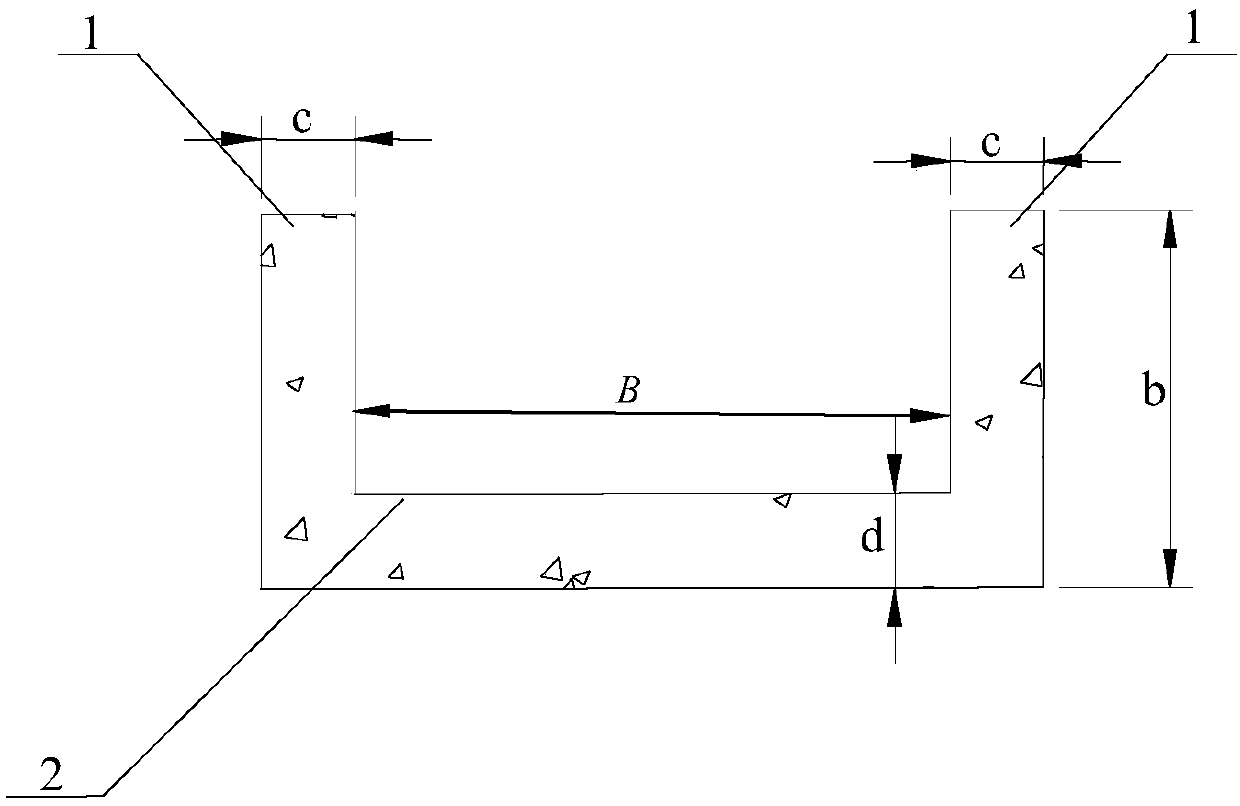

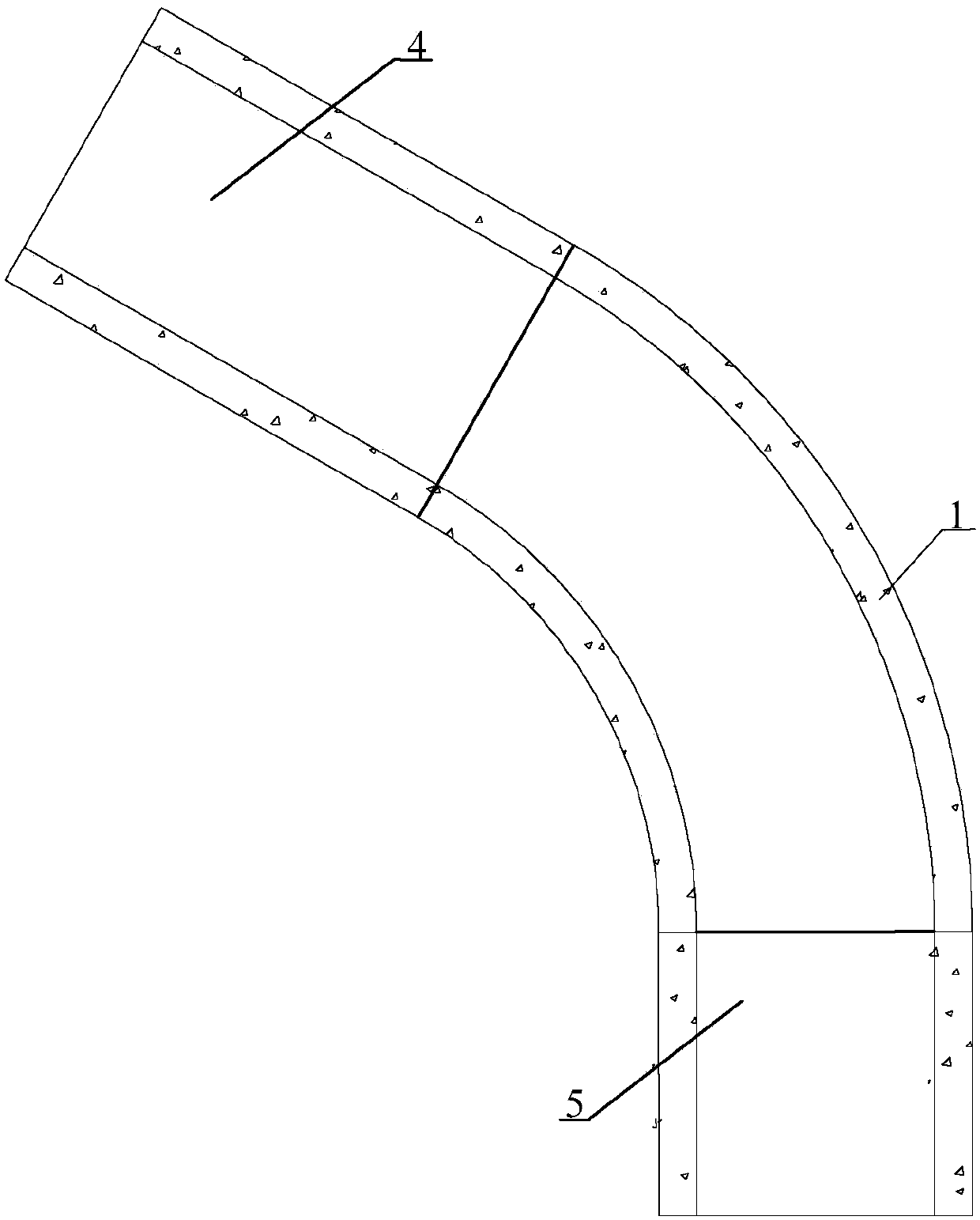

Variable-curvature open channel bend

InactiveCN108560480ASmooth connectionContinuous forceBarrages/weirsHydraulic modelsWater flowEngineering

The invention discloses a variable-curvature open channel bend. The variable-curvature open channel bend is composed of a base plate and side walls, wherein the base plate is bent in the water flow direction, and the side walls are arranged along the two sides of the base plate. A connection line between the midpoint of a bend inlet fracture surface base plate and the midpoint of a bend outlet fracture surface base plate serves as the x axis, the midpoint of the connection line serves as a coordinate origin, and a straight line which passes through the coordinate origin and is perpendicular tothe x axis serves as the y axis, so that a rectangular plane coordinate system is established. In the coordinate system, the convex bank edge curvilinear equation of the base plate can be found in the specification; and the concave bank edge curvilinear equation of the base plate can be found in the specification. By means of the variable-curvature open channel bend, the problems that bend waterflow is disorderly in flow state, the water surface superelevation is large, and pressure intensity is distributed nonuniformly can be solved; meanwhile, the discharging capacity of the bend is not affected; and the cavitation and cavitation erosion possibilities are lowered.

Owner:SICHUAN UNIV

L-shaped precast concrete wall connection

The invention provides an L-shaped precast concrete wall connection, belonging to the technical field of the building structures. The L-shaped precast concrete wall connection comprises a first precast concrete wall and a second precast concrete wall, wherein longitudinal penetrating holes are formed on the precast concrete walls on the connection side in the vicinity of end faces and a plurality of transverse grooves crossing with the longitudinal holes are oppositely formed on the end faces; first and second thin plates extend from the connection-side end faces of the first and second precast concrete walls, respectively; a first horizontal reinforcing steel bar extending to the edge of the first thin plate is arranged in the first precast concrete wall, while a second horizontal reinforcing steel bar and a first embedded column stirrup both extending to the edge of the second thin plate are arranged in the second precast concrete wall; cast-in-place concrete is poured in the space formed by the first and second thin plates, the longitudinal holes and the transverse grooves; and a second embedded column stirrup and a vertical reinforcing steel bar are arranged in the cast-in-place concrete. The L-shaped precast concrete wall connection is capable of improving the integrity of the assembled integrated concrete structure and improving the performance of the building structures.

Owner:初明进

Suction cup spoon basket

InactiveCN105534223AEfficient collectionEasy to useKitchen equipmentTablewaresEngineeringWater collection

The invention discloses a suction cup spoon basket, and aims to provide a suction cup spoon basket which is stable in structure and long in service life. According to the technical scheme, the suction cup spoon basket is characterized by comprising a spoon basket body and a suction cup base connected with the spoon basket body; the suction cup base comprises a support detachably connected with the spoon basket body and a suction cup assembly hinged to the support; a limiting groove is formed in one side of the spoon basket body, and a water collection drawer is arranged at the bottom of the spoon basket body; a protrusion abutting against the suction cup assembly is arranged at the end, hinged to the suction cup assembly, of the support, a supporting strip abutting against the outer surface of the suction cup assembly is arranged on one side of the support, and a fixing block used for fixing the support is arranged at the bottom of the support, namely, the support and the suction cup assembly are stably connected through cooperation of the protrusion on the support, the hinging end of the support and the supporting strip on the support. The suction cup spoon basket is reasonable in structure, convenient to use and good in effect, and the spoon basket body can be well fixed.

Owner:徐州美欣生物材料有限公司

Suction disc towel rack

Owner:枣庄瑞衡建筑工程有限公司

Suction Cup Spoon Basket

InactiveCN105534223BEfficient collectionEasy to useKitchen equipmentTablewaresEngineeringWater collection

Owner:徐州美欣生物材料有限公司

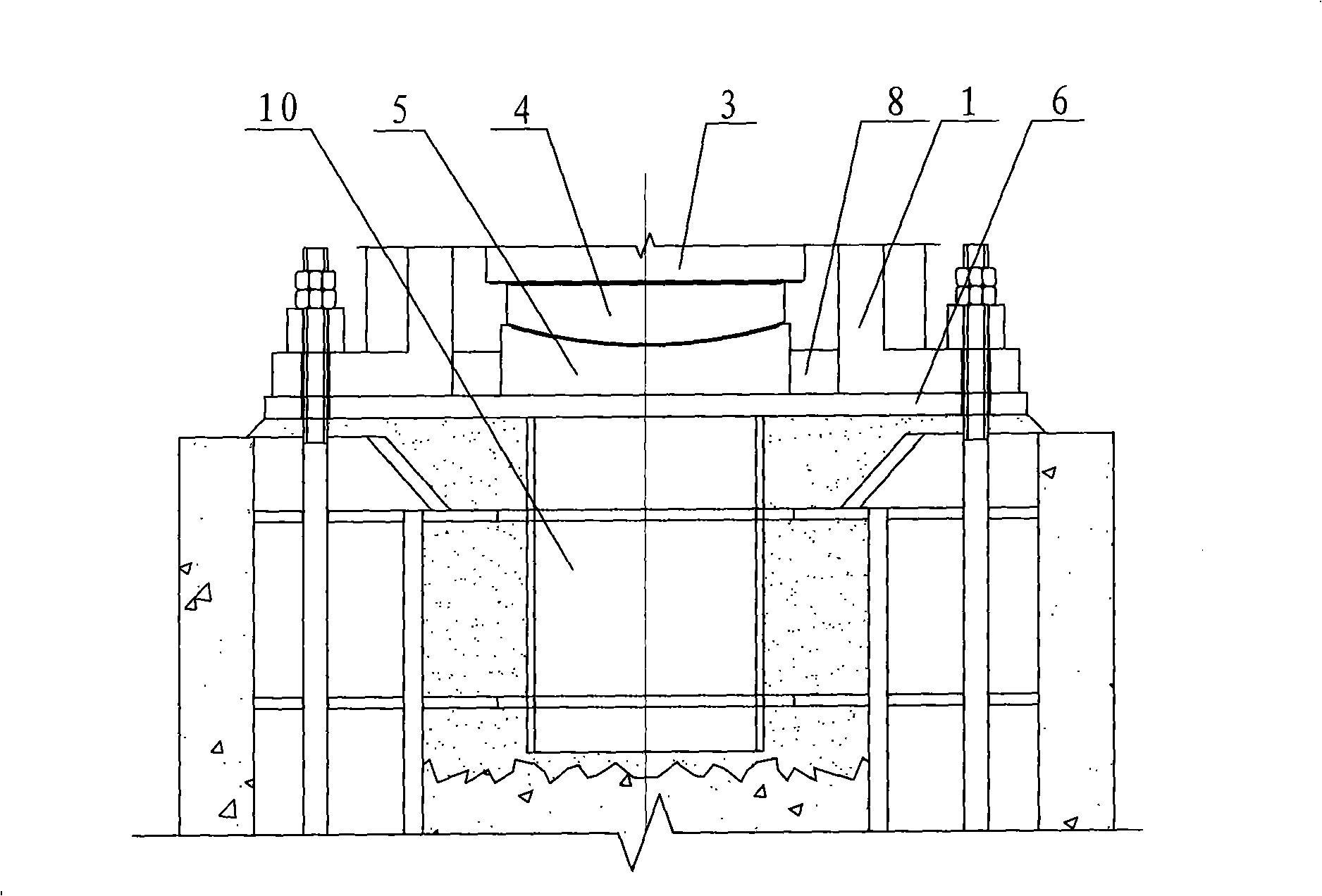

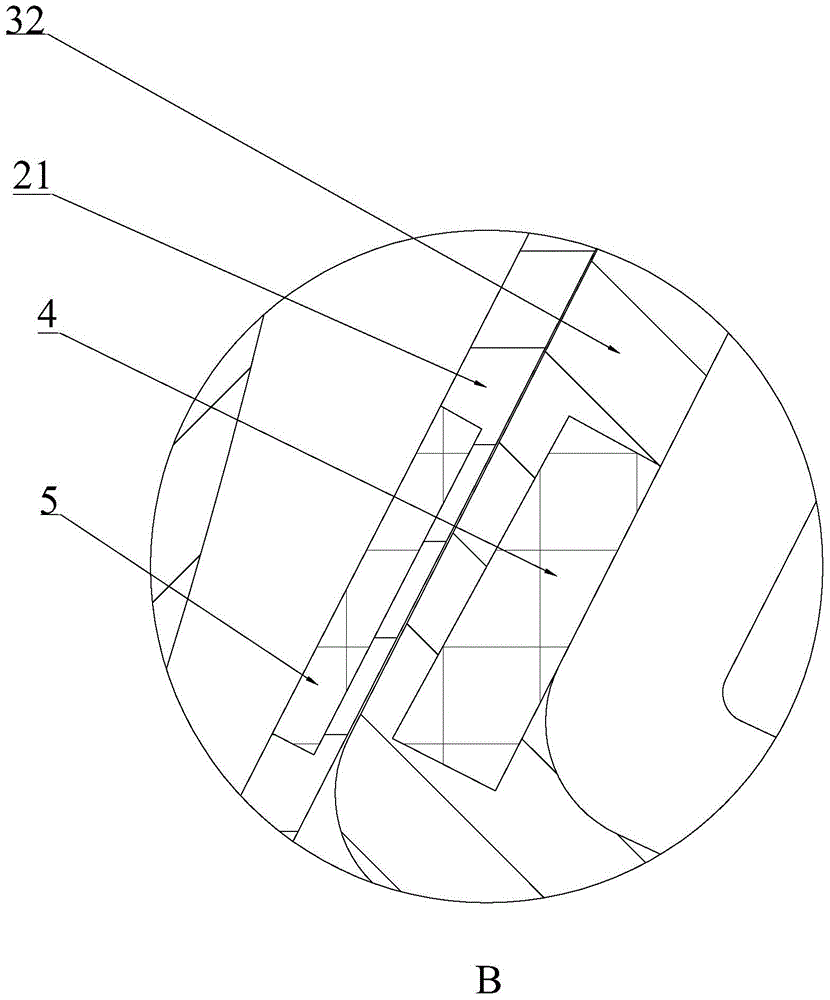

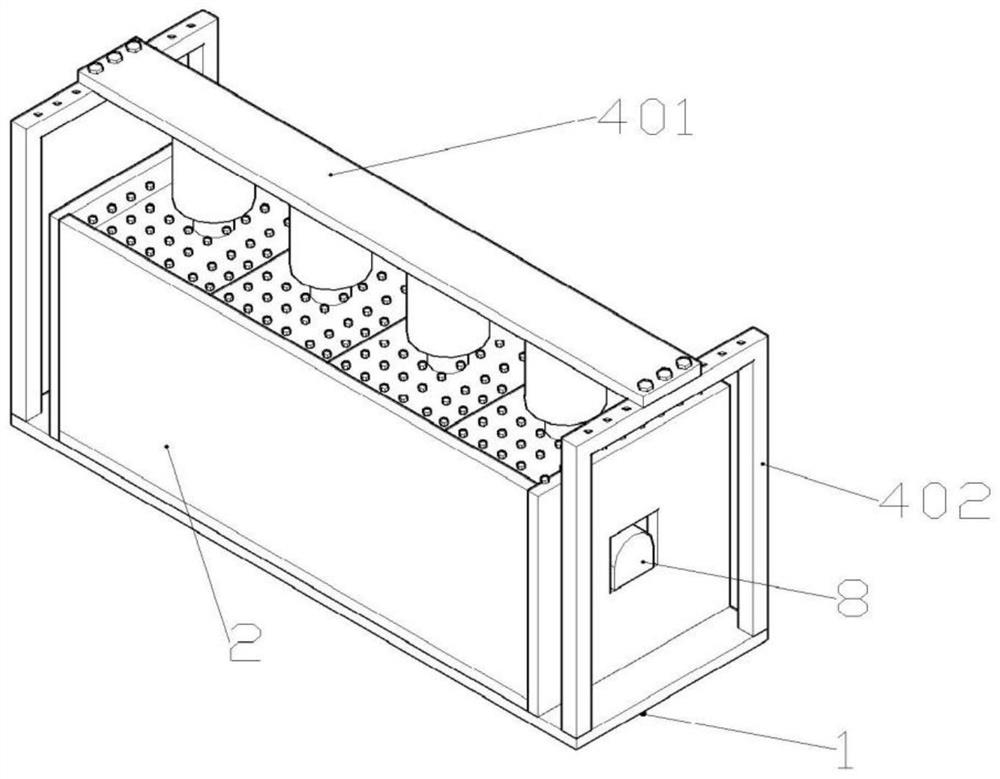

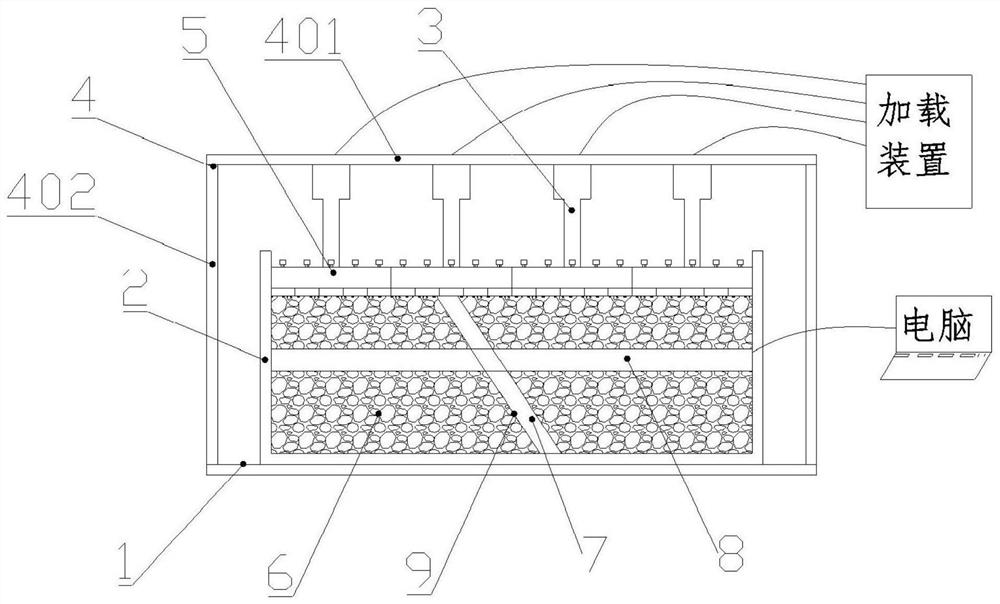

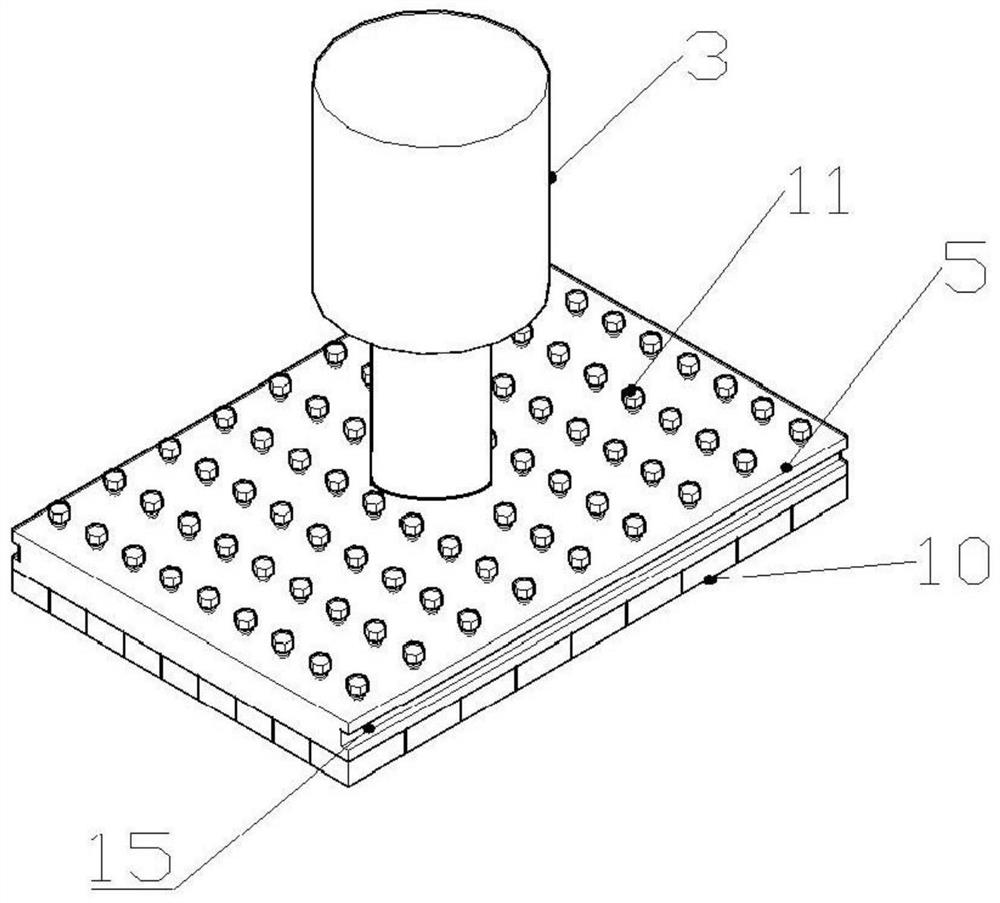

An experimental device for simulating the excavation of tunnels crossing faults

ActiveCN112067789BAdjust local pressureDoes not affect cleaningEarth material testingStructural engineeringPressure cell

The invention discloses an experimental device for simulating the excavation of a tunnel crossing a fault, comprising a test box body, a loading structure, a support structure, a force-transmitting steel plate, surrounding rock simulation materials, fault simulation materials, and a tunnel lining model; the experiment box body is without a cover Box-shaped structure; surrounding rock simulation materials, fault simulation materials, and tunnel lining models are all located in the experimental box; the tunnel lining model is equipped with differential digital display displacement gauges and strain-type earth pressure cells on the outside of the primary lining; one end of the loading structure is connected to the The support structure is connected, and the other end is connected to the force-transmitting steel plate; the force-transmitting steel plate is facing the opening surface of the experimental box, and is used to squeeze the surrounding rock simulation material in the experimental box. In the present invention, a plurality of pressure transmission blocks are movably connected to the bottom surface of the force transmission steel plate, and the pressure transmission block is driven by the driving member to move axially along the force transmission steel plate, and squeezes the surrounding rock simulation material in the experimental box, thereby adjusting the surrounding rock simulation material The local pressure improves the flexibility of experiment parameter adjustment.

Owner:SOUTHWEST PETROLEUM UNIV

A UAV front landing gear compartment based on catapult take-off

ActiveCN107891965BThe overall structure is light in weightDoes not weaken stiffnessFuselage framesFuselage bulkheadsMechanical engineeringAirplane

The invention discloses a drone noselanding gear well section based on catapult-assisted take-off. A landing gear well comprises partition frames at the two ends, a girder connected with the partitionframes and a skin; a landing gear fixing compartment is arranged in the middle of the landing gear well, a framework of the landing gear fixing compartment comprises four main girders, the main girders are fixedly connected with the partition frames, and partition plates are arranged at both the two sides of each main girder and the partition frames; the main girders and the partition plates forman integrated wall plate girder, the wall plate girder is hinged to a landing gear main support and a landing gear slant supporting rod, and openings are formed in the skin at the lower portion of the landing gear fixing compartment. The landing gear well is of a box body type structure low in structural weight, the openings are formed among the main girders, the rigidity of other parts of the landing gear well and the rigidity of an overall aircraft cannot be lowered, and additional strength reinforcement setting is also not needed; the wall plate girder penetrating through the whole box body has the advantages of being continuous in stress and short and direct in force transmitting path, and transmitting of instantaneous impact large loading concentrated force and torque inside the structure is benefited.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

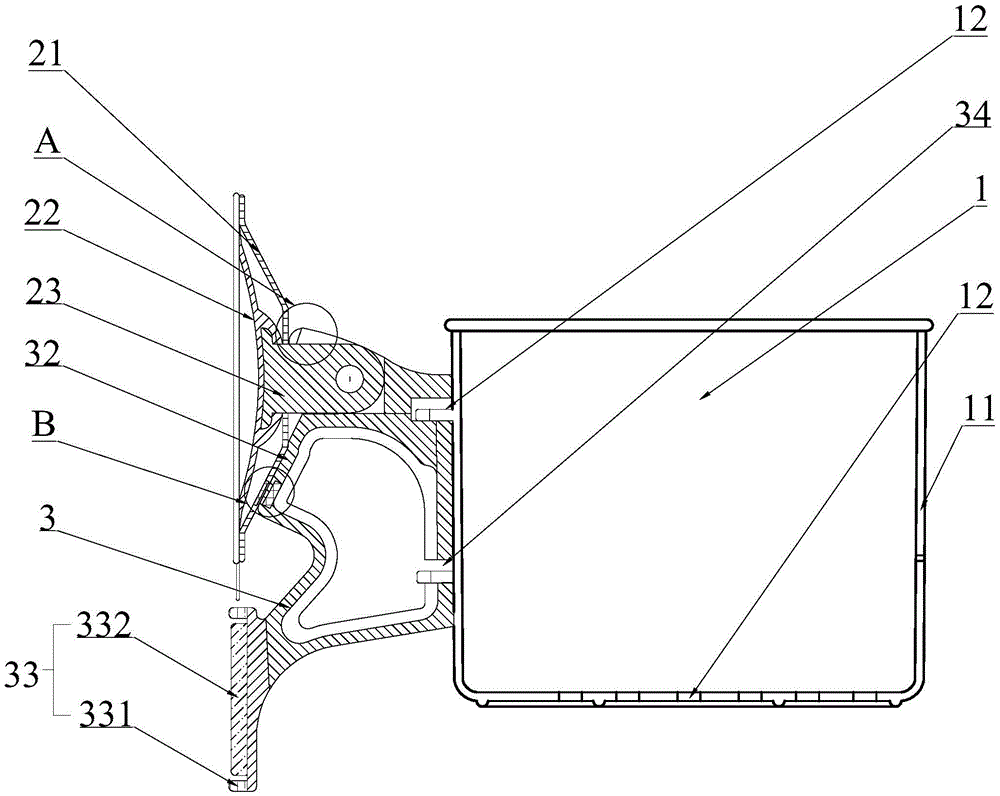

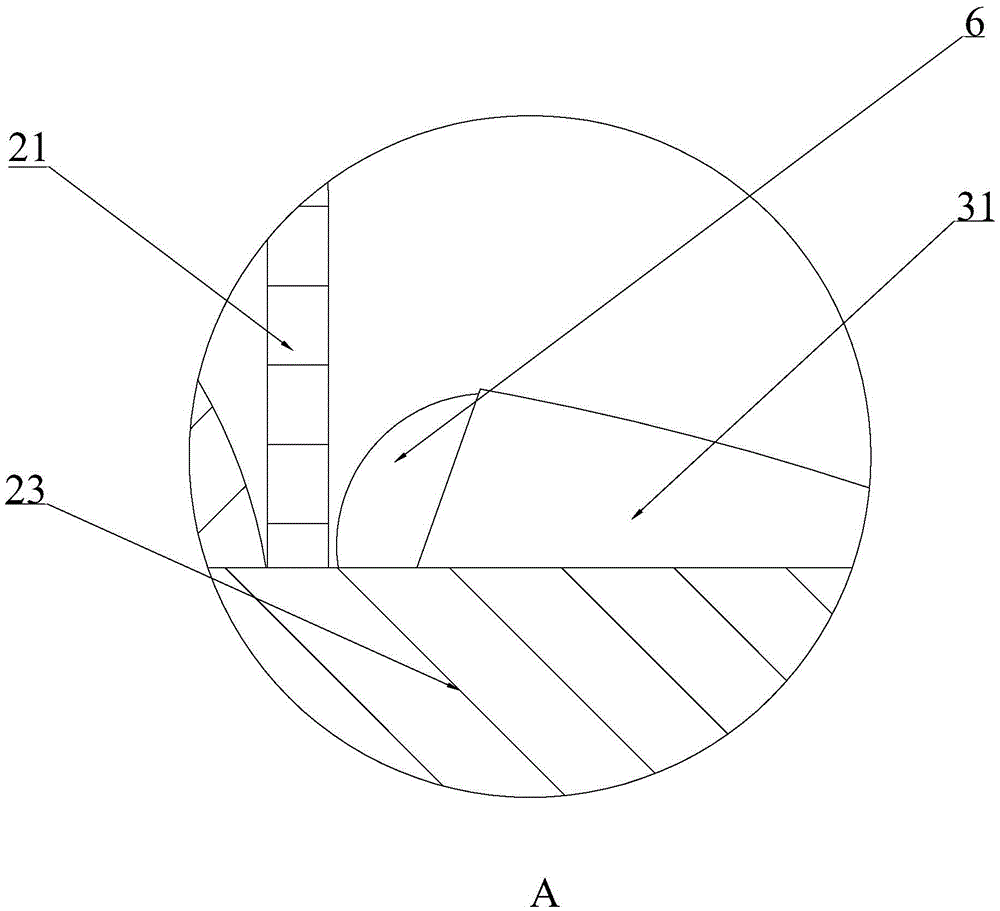

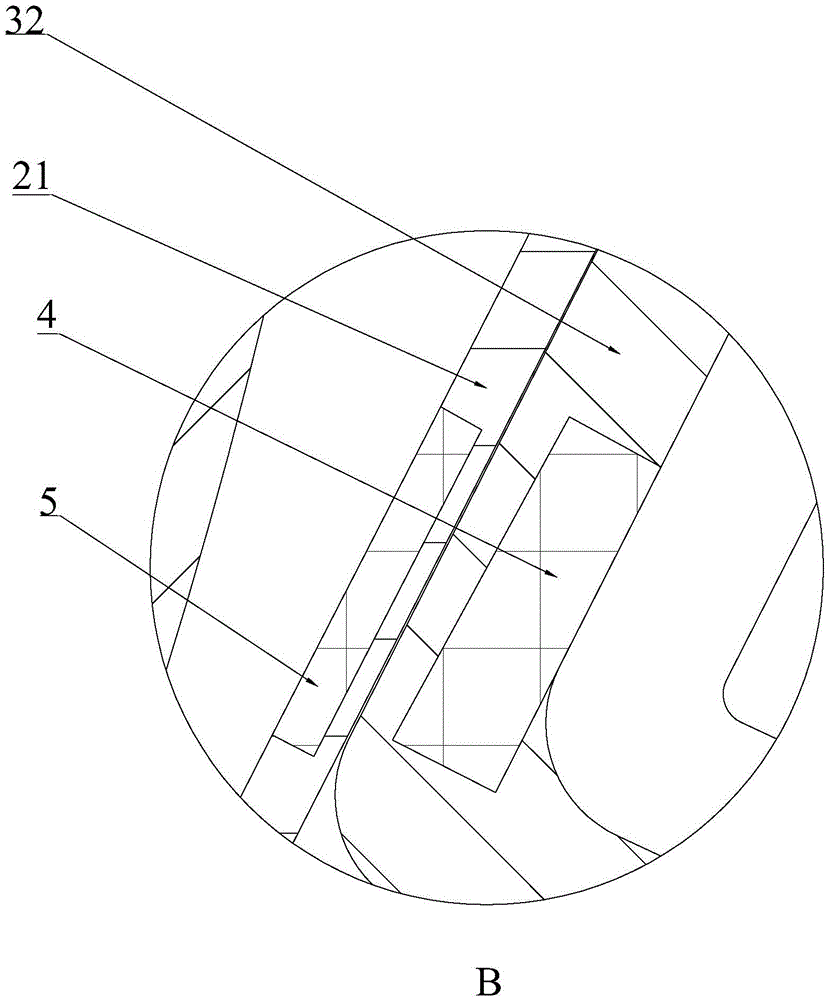

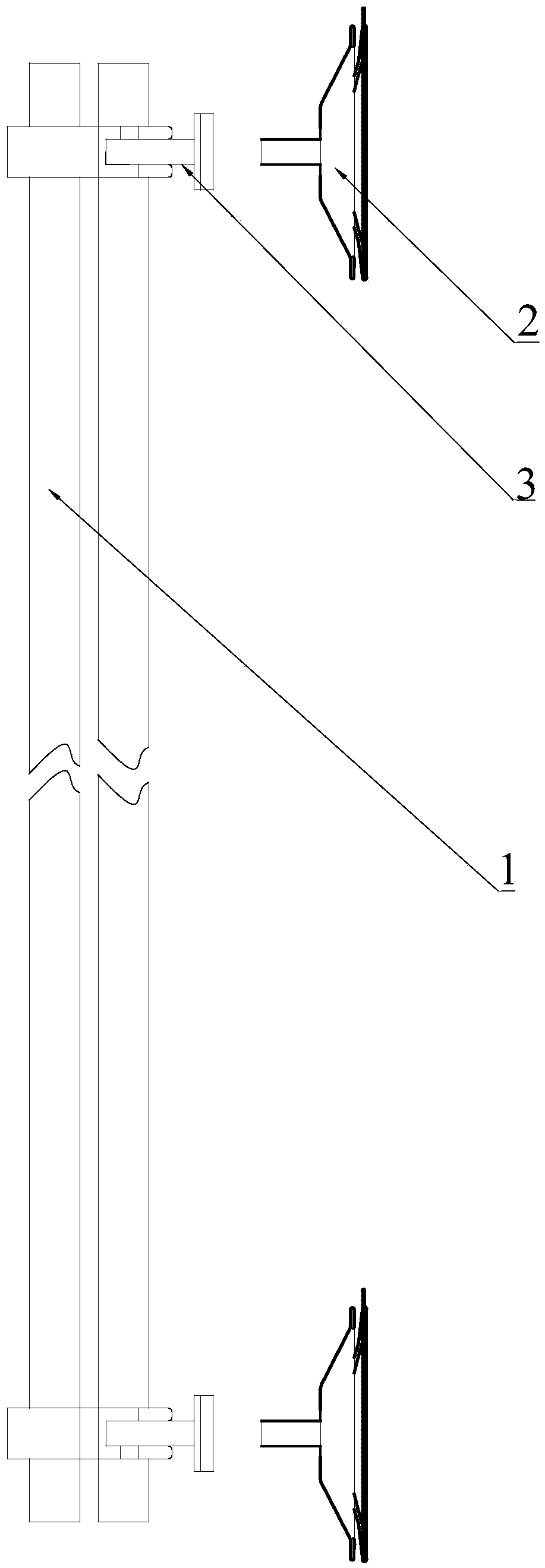

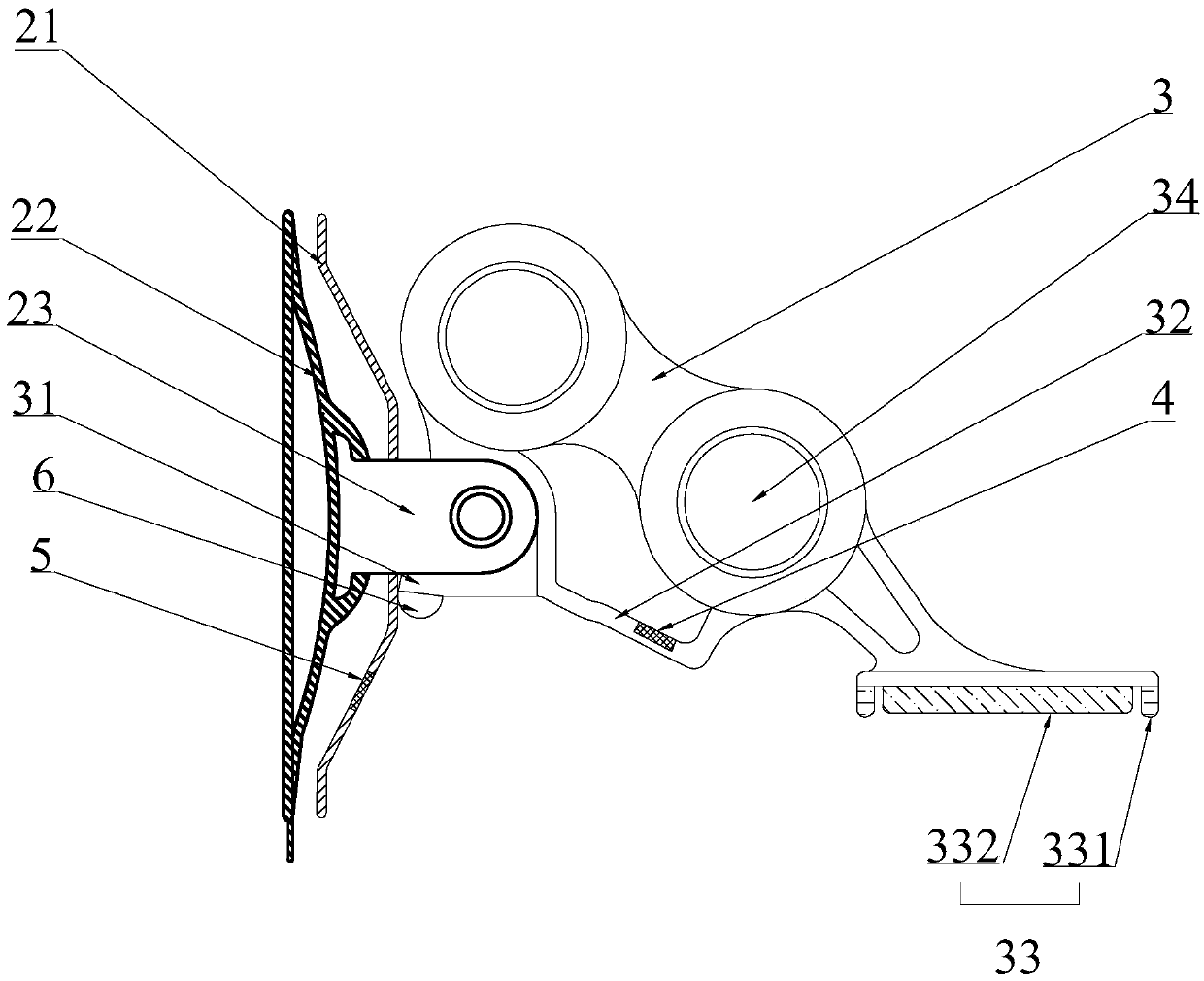

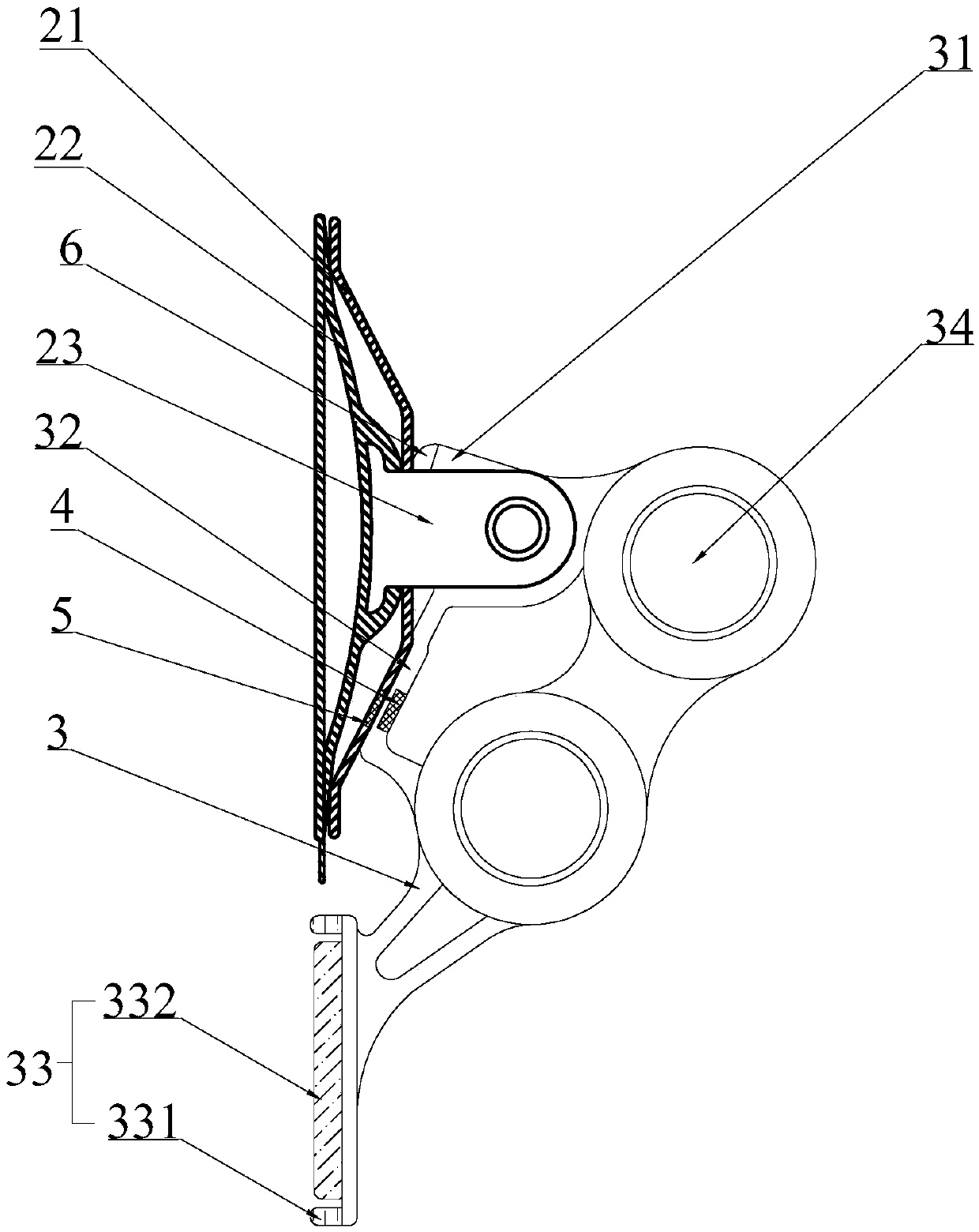

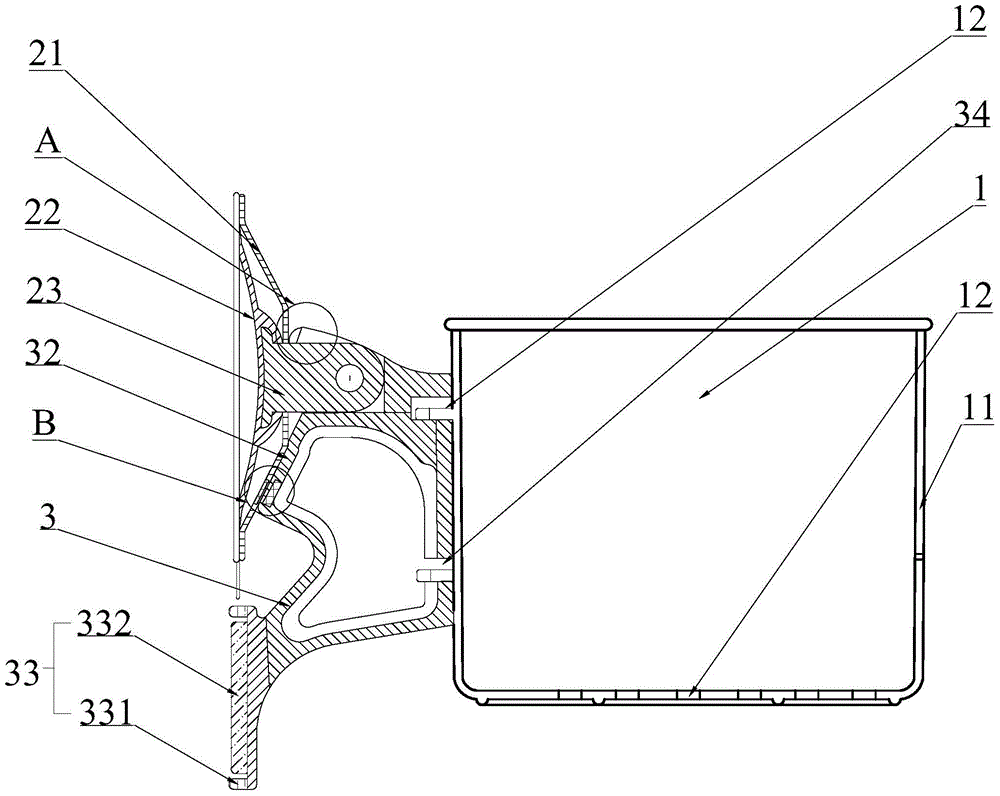

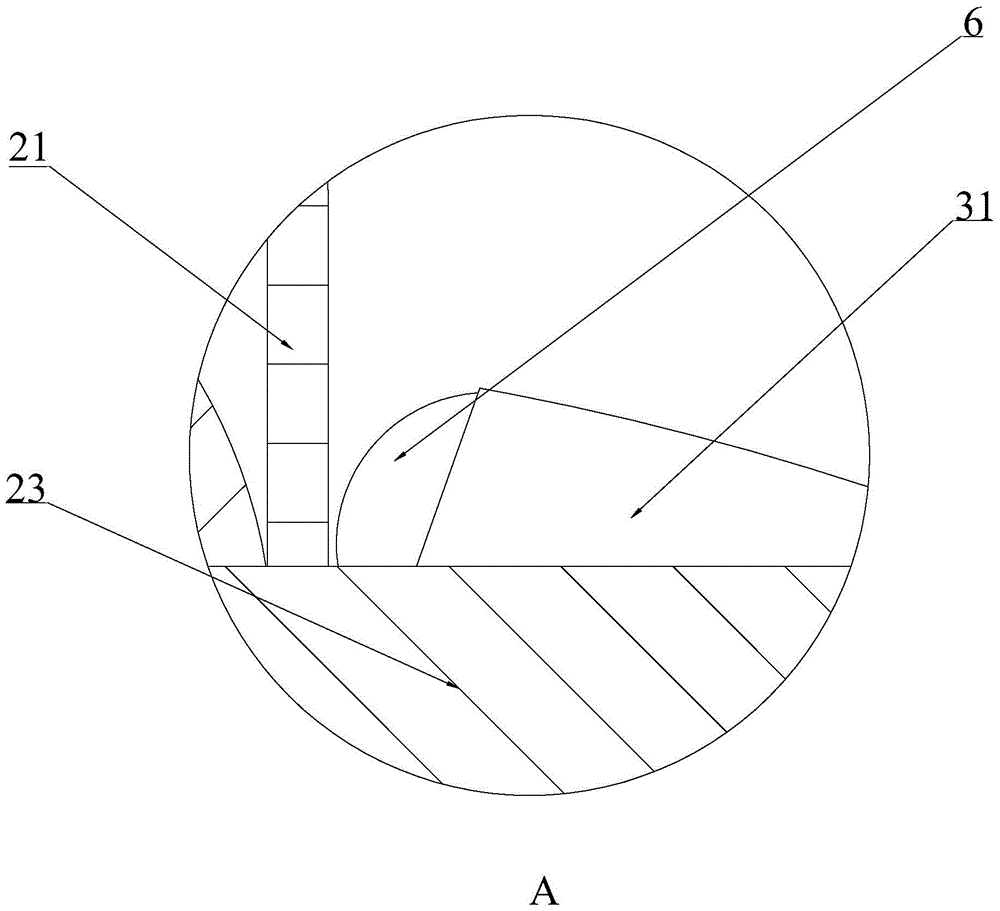

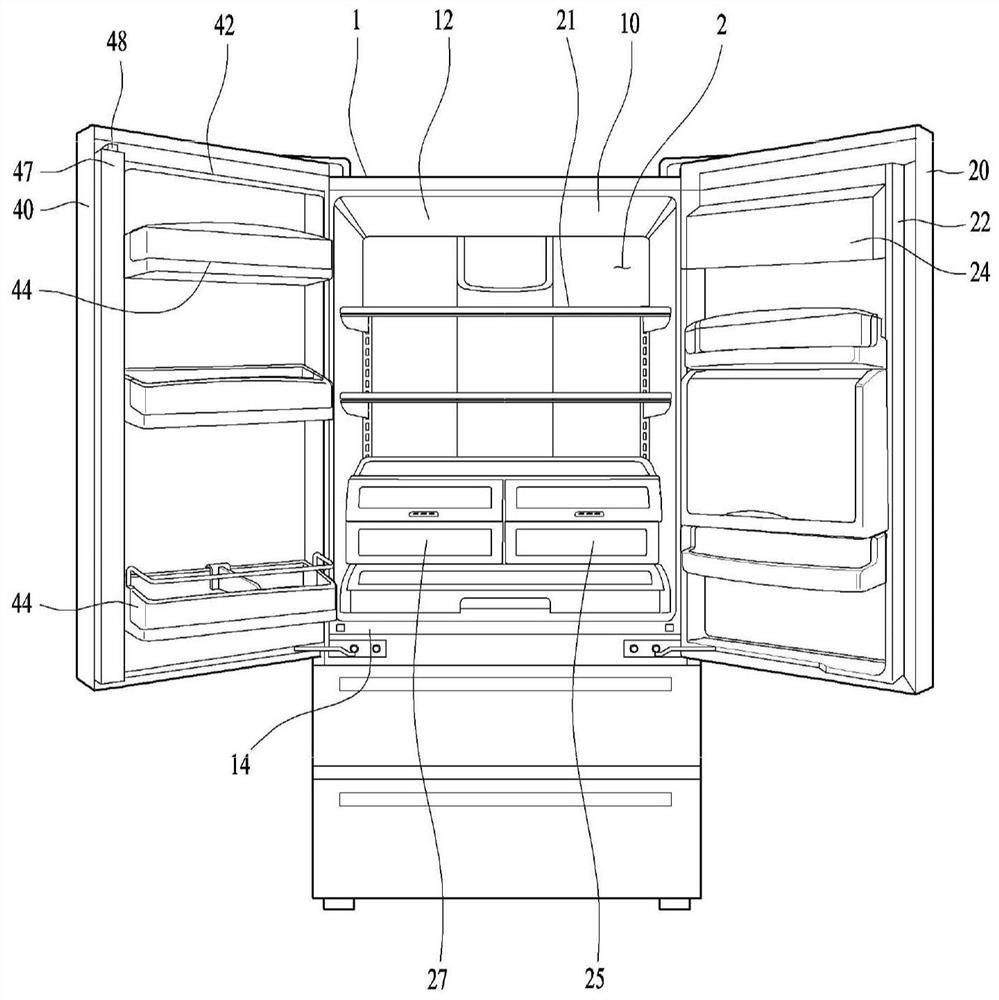

refrigerator

ActiveCN109387023BContinuous forceGuaranteed capacityLighting and heating apparatusDrawersIceboxMechanical engineering

The present invention provides a refrigerator. The refrigerator of the present invention comprises: a cabinet provided with a storage room with an open front; a drawer disposed in the storage room in a removable manner, including a first roller portion and a guide rib extending toward the taking-out direction ; the second roller part is arranged at the front end of the storage chamber to support the underside of the guide rib in a movable manner; the first roller guide is arranged on both sides of the storage chamber to provide the first The moving path of the roller; and the movable support part, which is arranged in the storage room, can be taken out in a manner linked with the drawer, and is arranged at the lower part of the drawer to support the load of the drawer; the guide rib It includes a first inclined portion inclined backward from the front end of the drawer, the first roller portion is provided at the rear end of the drawer, and the rear end of the first roller guide is aligned with the second roller guide. An angle of inclination of the inclined portion is inclined downward in the rearward direction in a corresponding manner.

Owner:LG ELECTRONICS INC

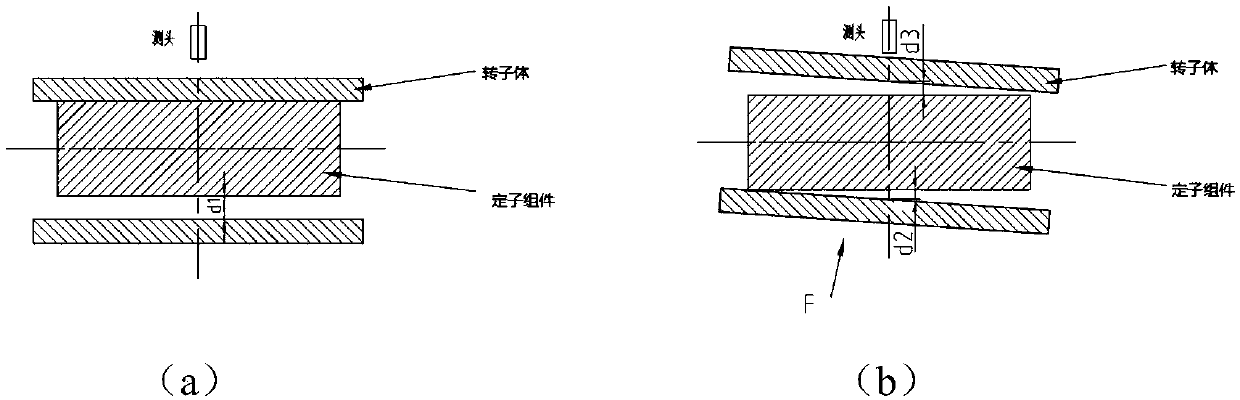

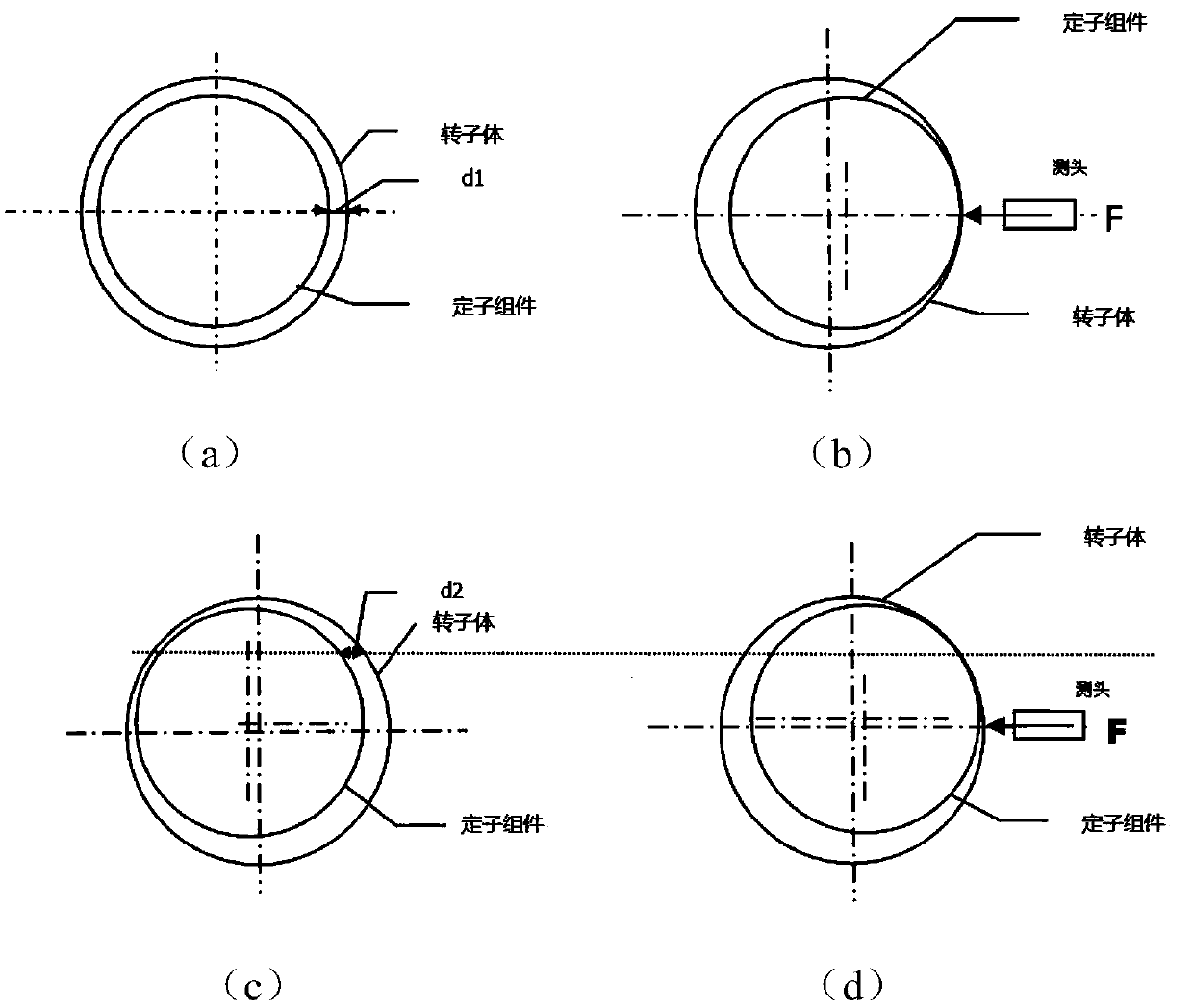

Automatic force application device and method for gap measurement of air-floating rotor gyroscope dynamic pressure motor

ActiveCN107144251BWith automatic centering functionWith closed loop controlMeasurement devicesMechanical pressure/force controlGyroscopeRectangular coordinates

The invention proposes an automatic force exerting device and a method for an air floatation rotor gyroscope dynamic pressure motor gap measurement, which belong to the spaceflight inertial device precision technology field. The automatic force exerting device comprises three-axis precise displacement platforms, a control loop circuit, a force sensor installation plate, a dynamic pressure motor, a left side fixing plate, a right side fixing plate, a horizontal plate and a middle clamping device. The three-axis precise displacement platforms are mounted on the horizontal plate. The three precise displacement platforms are vertical to each other in the moving direction to form a Descartes rectangular coordinate system. The fixing devices at two sides are used to have the middle clamping device fixed, and the middle clamping device realizes the tight clamping of the dynamic pressure motor via the closed finger clamping body. The automatic force exerting device of the invention is applied to the method for measuring the air floatation rotor gyroscope dynamic pressure motor gap, and comprises two fixed ends and a tightly clamped middle to realize automatic circle adjustment and automatic force exertion. With the invention, it is possible to realize the continuous controlling and loading of force and to realize the automatic circle adjustment to a tested component based on the device of the invention.

Owner:DALIAN UNIV OF TECH

Connecting structure of prefabricated concrete wall body

The invention provides a connecting structure of a prefabricated concrete wall body and belongs to the technical field of building structures. The connecting structure of the prefabricated concrete wall body comprises a first prefabricated concrete wall body and a second prefabricated concrete wall body, wherein longitudinal through holes are arranged at the positions close to the end faces of the first prefabricated concrete wall body and the second prefabricated concrete wall body, and the end faces of the first prefabricated concrete wall body and the second prefabricated concrete wall body are correspondingly provided with a plurality of transverse grooves. The end face of the first prefabricated concrete wall body is provided with a first U-shaped steel bar protruding outward from the inside of the wall body, the end face of the second prefabricated concrete wall body is correspondingly provided with a second U-shaped steel bar protruding outward from the inside of the wall body, the intersected portions of the first U-shaped steel bar and the second U-shaped steel bar form a rectangular steel bar ring, and cast-in-place concrete is arranged in spaces among the transverse grooves, the longitudinal through holes and the prefabricated concrete wall bodies. The connecting structure can improve integrity of an assembled monolithic concrete structure and the performance of a building structure.

Owner:初明进

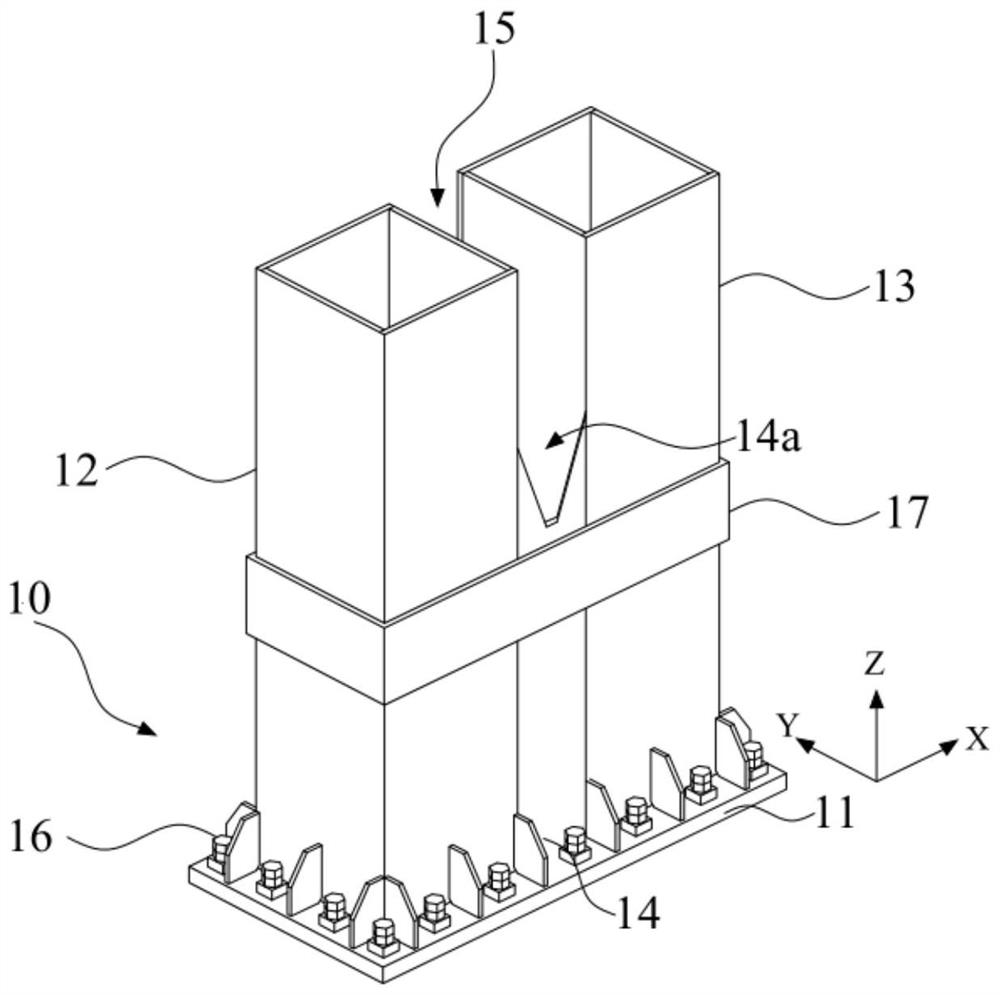

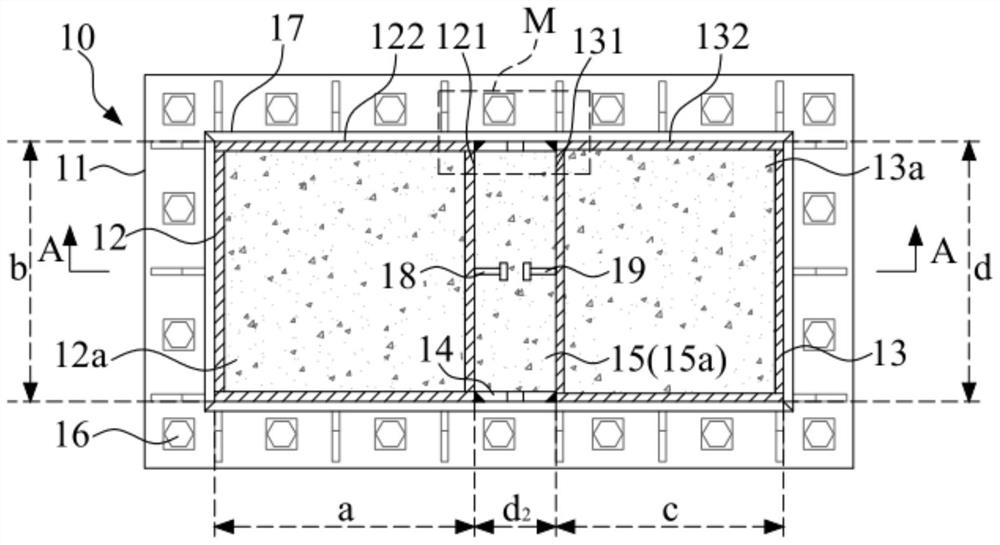

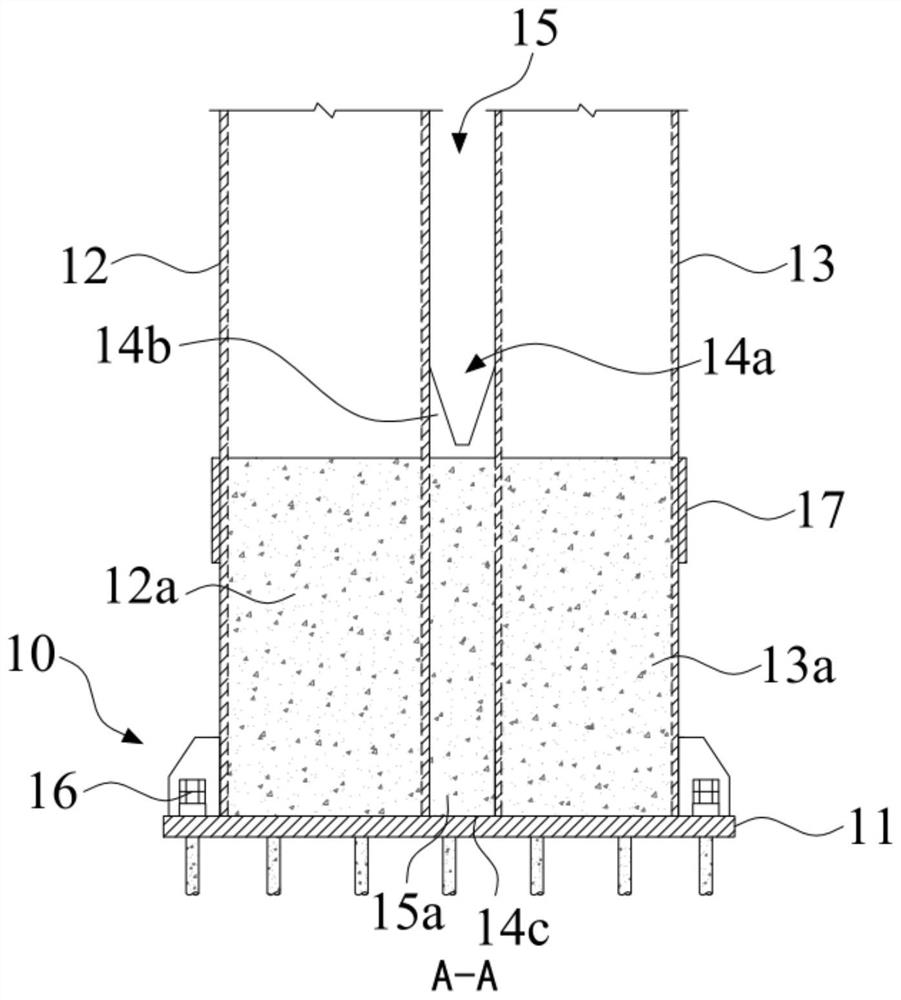

Double-steel-column combined column foot structure and construction method thereof

PendingCN113389275AEnsure safetyReduce stressBuilding constructionsStress concentrationSteel columns

The invention discloses a double-steel-column combined column foot structure and a construction method thereof. The double-steel-column combined column foot structure comprises a bottom plate, a first steel column, a second steel column and a connecting plate, wherein the first steel column and the second steel column are arranged on the bottom plate in a spaced mode, an expansion joint is formed between the first steel column and the second steel column, the connecting plate is connected to the ends, close to the bottom plate, of the first steel column and the second steel column, and the connecting plate is positioned in the expansion joint. By adopting the scheme, when the first steel column and the second steel column are subjected to bending moment or the shearing force action in the same direction, the stress of the column foot bottom plate and a column foot anchor bolt can be reduced by utilizing the rigidity superposition effect of the first steel column and the second steel column, so that the situation that the column foot bottom plate and the column foot anchor bolt are possibly broken due to stress concentration can be avoided; and when the first steel column and the second steel column are subjected to bending moment or the shearing force action in opposite directions, the connecting plate can reduce force borne by the first steel column and the second steel column, and the safety of the first steel column and the second steel column is guaranteed.

Owner:SHENZHEN GENERAL INST OF ARCHITECTURAL DESIGN & RES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com