Patents

Literature

91results about How to "With automatic centering function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

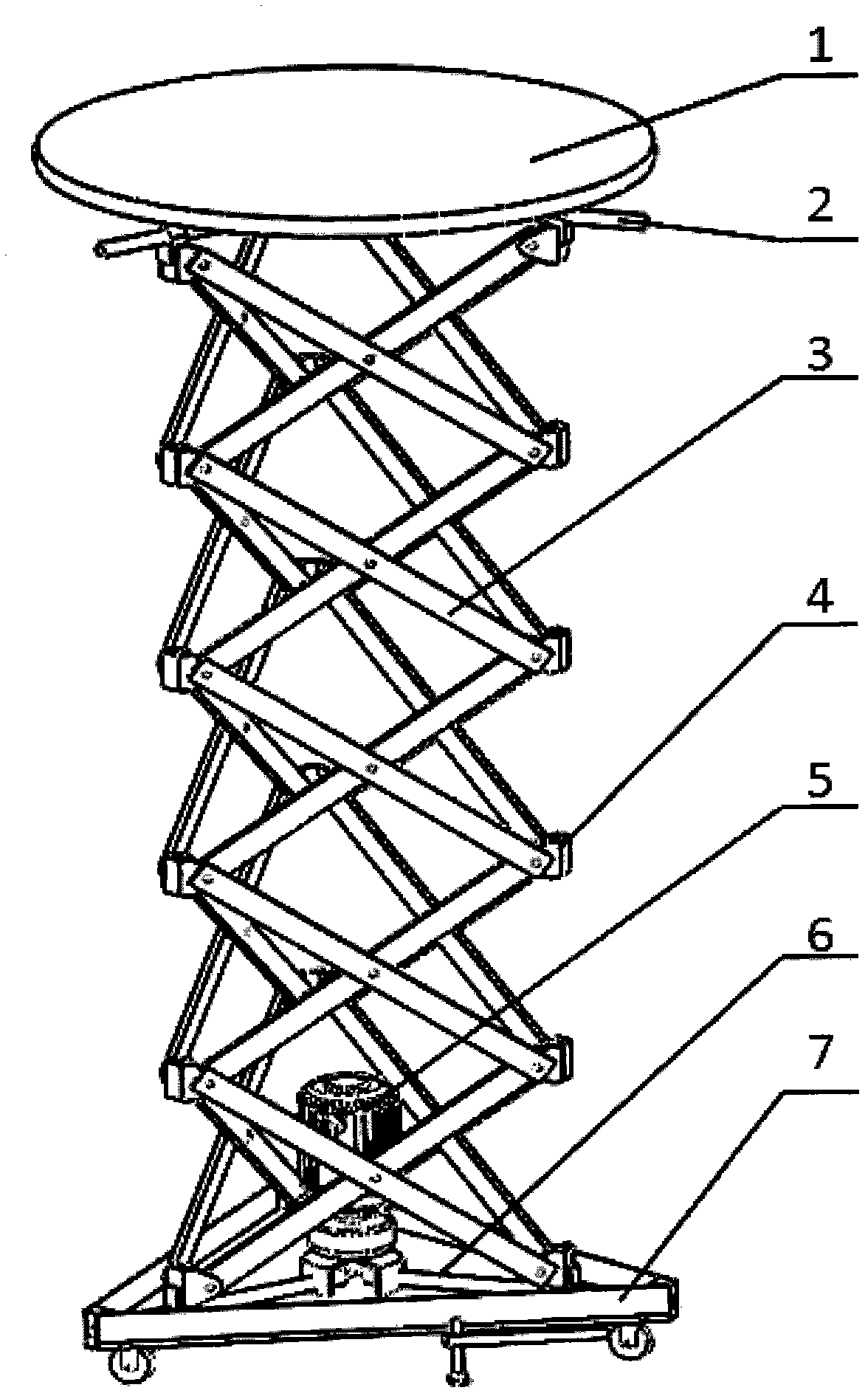

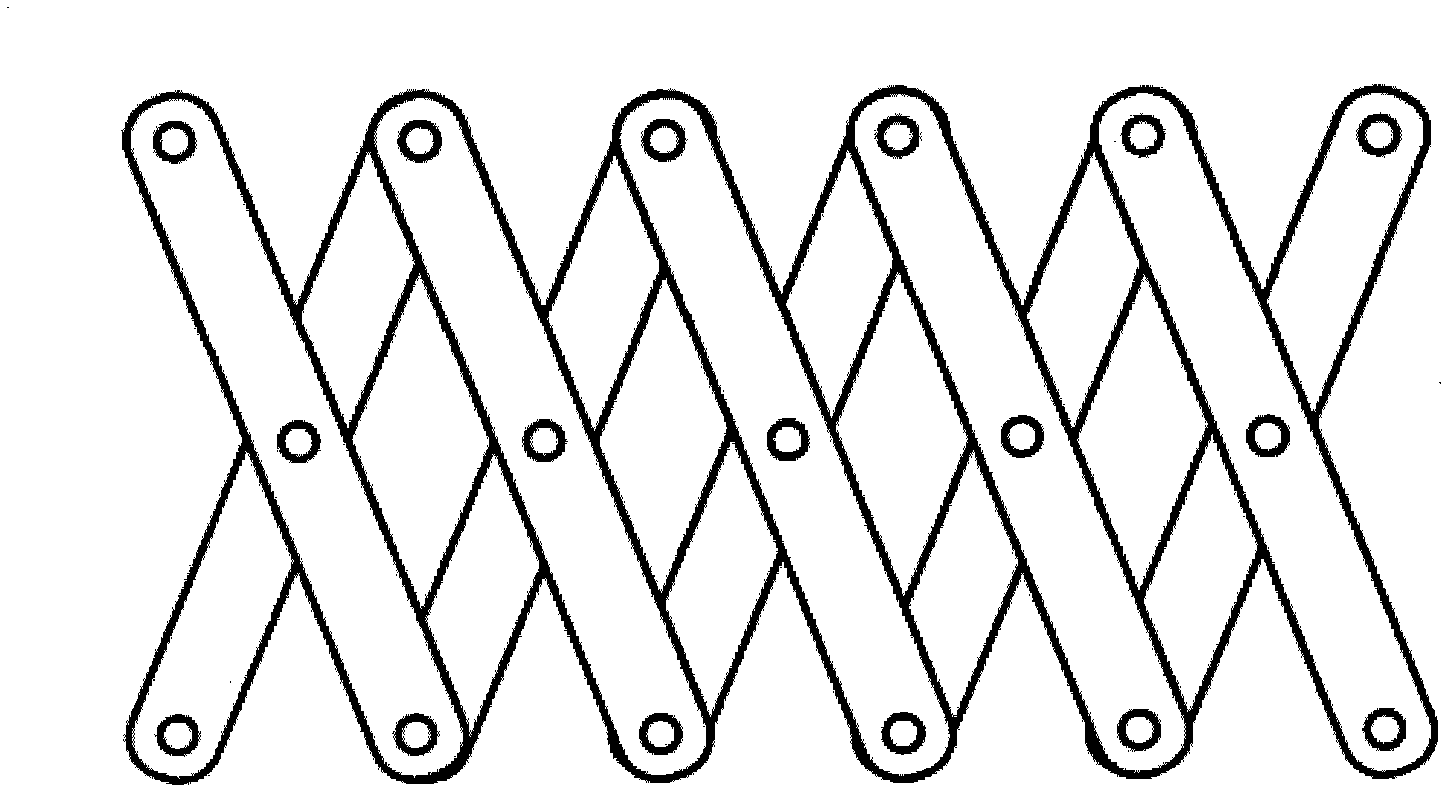

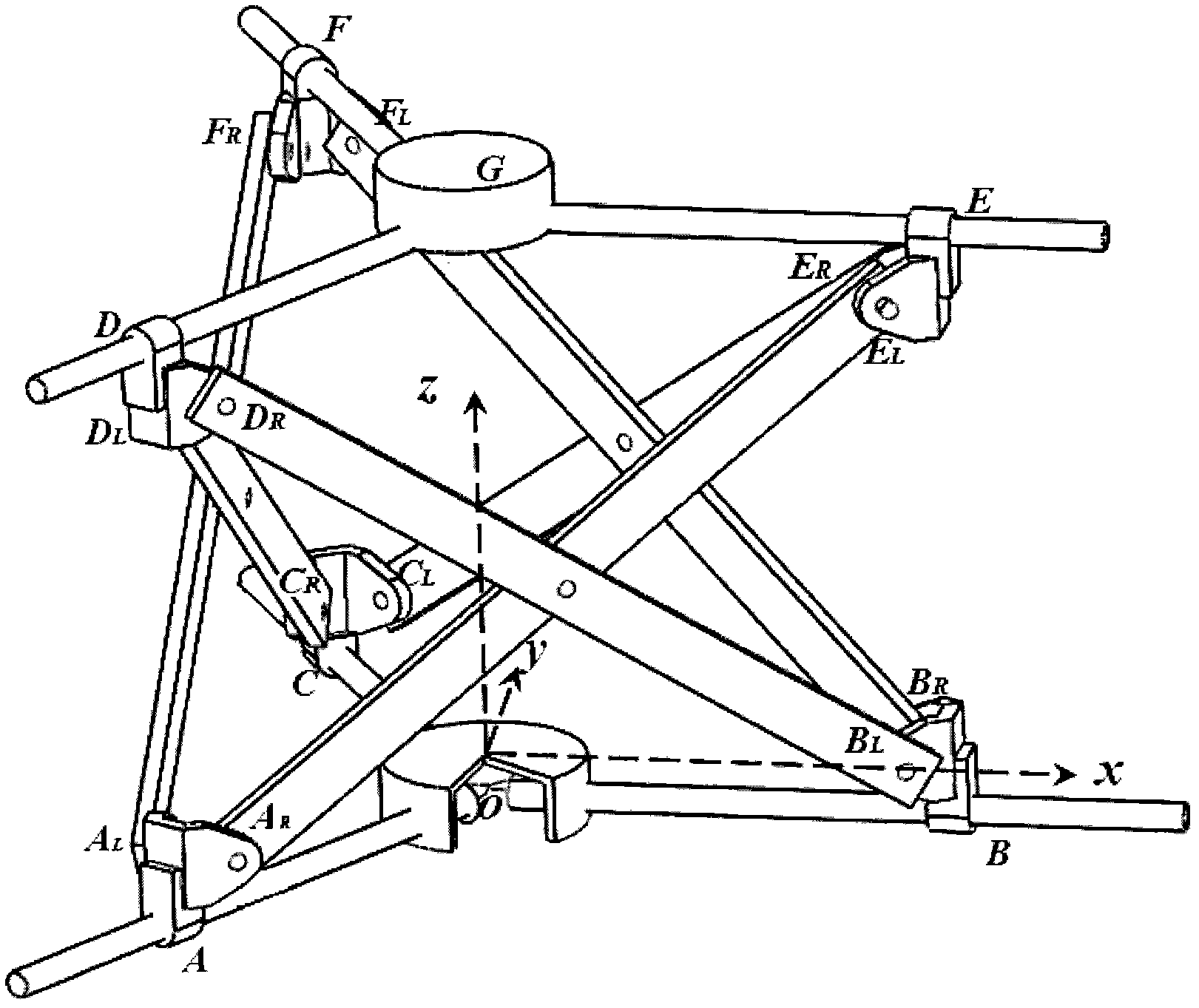

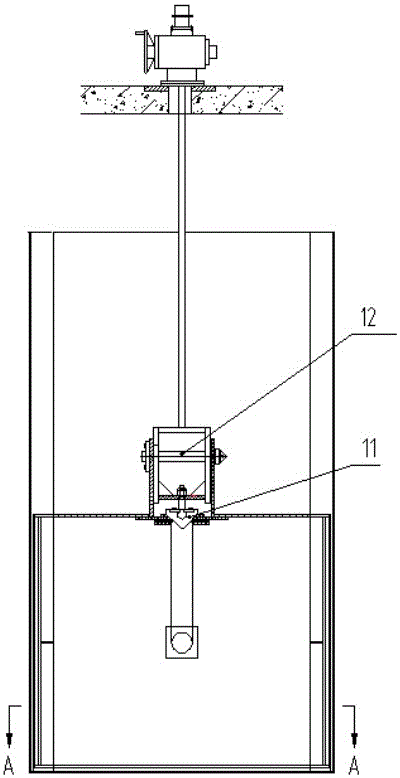

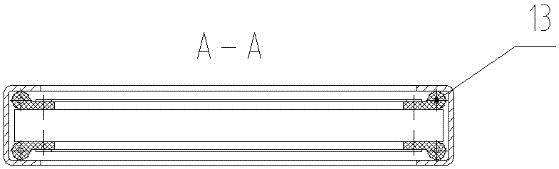

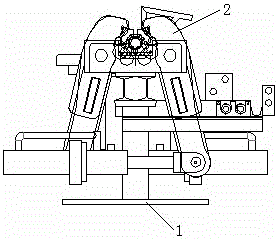

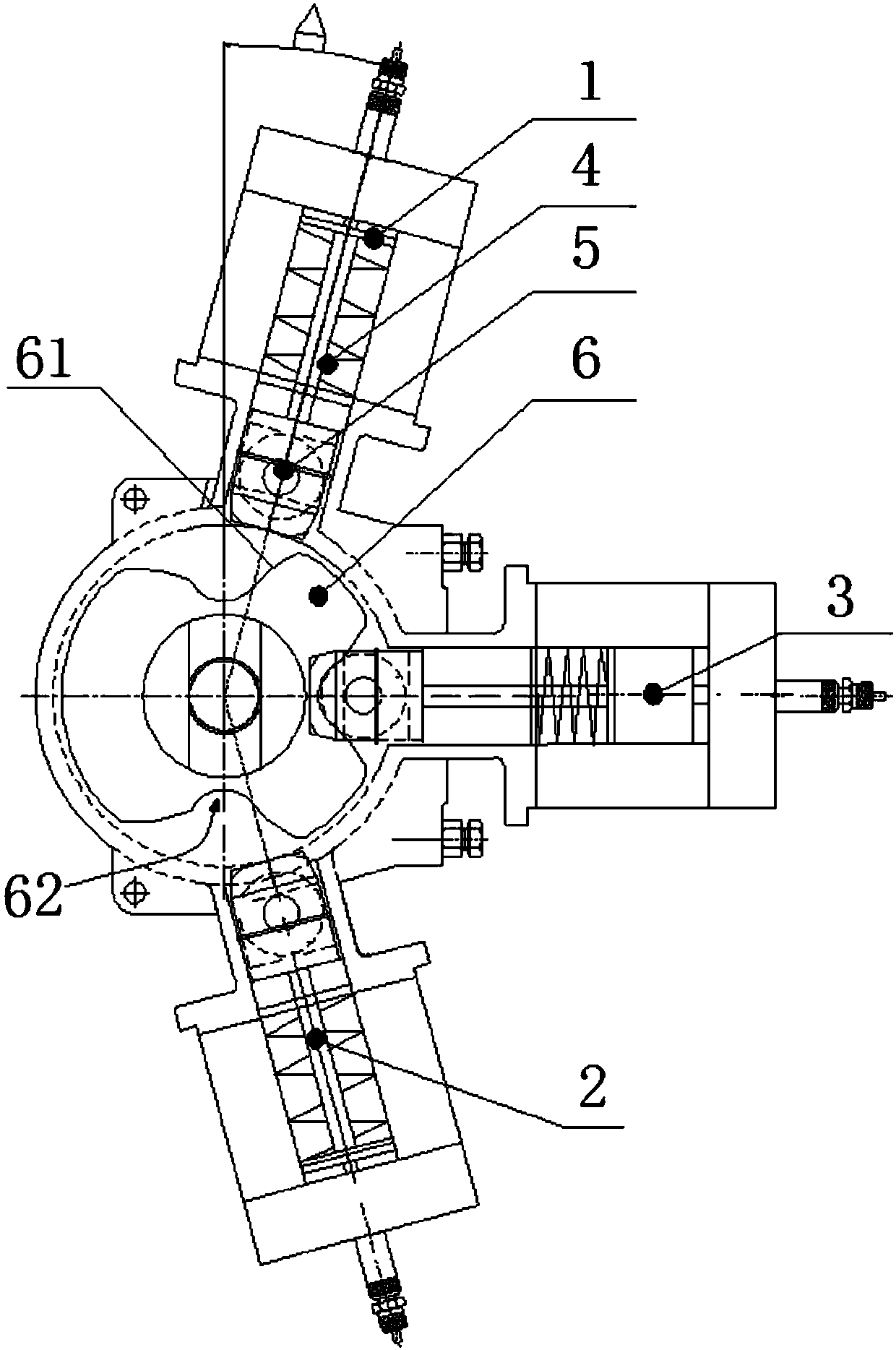

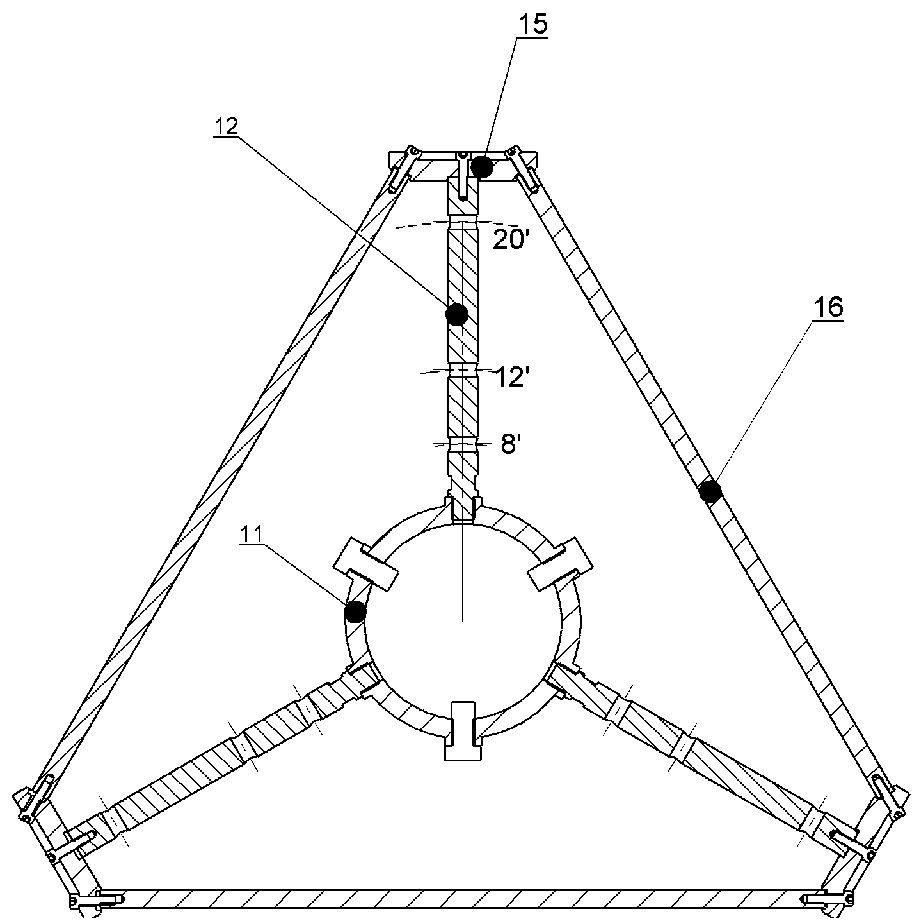

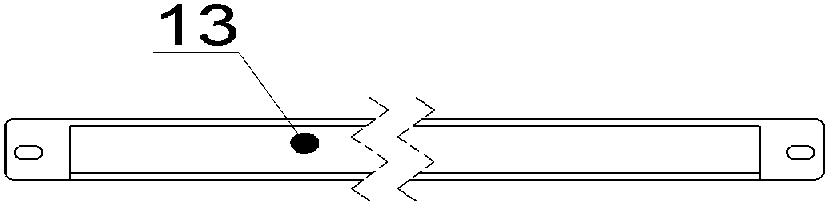

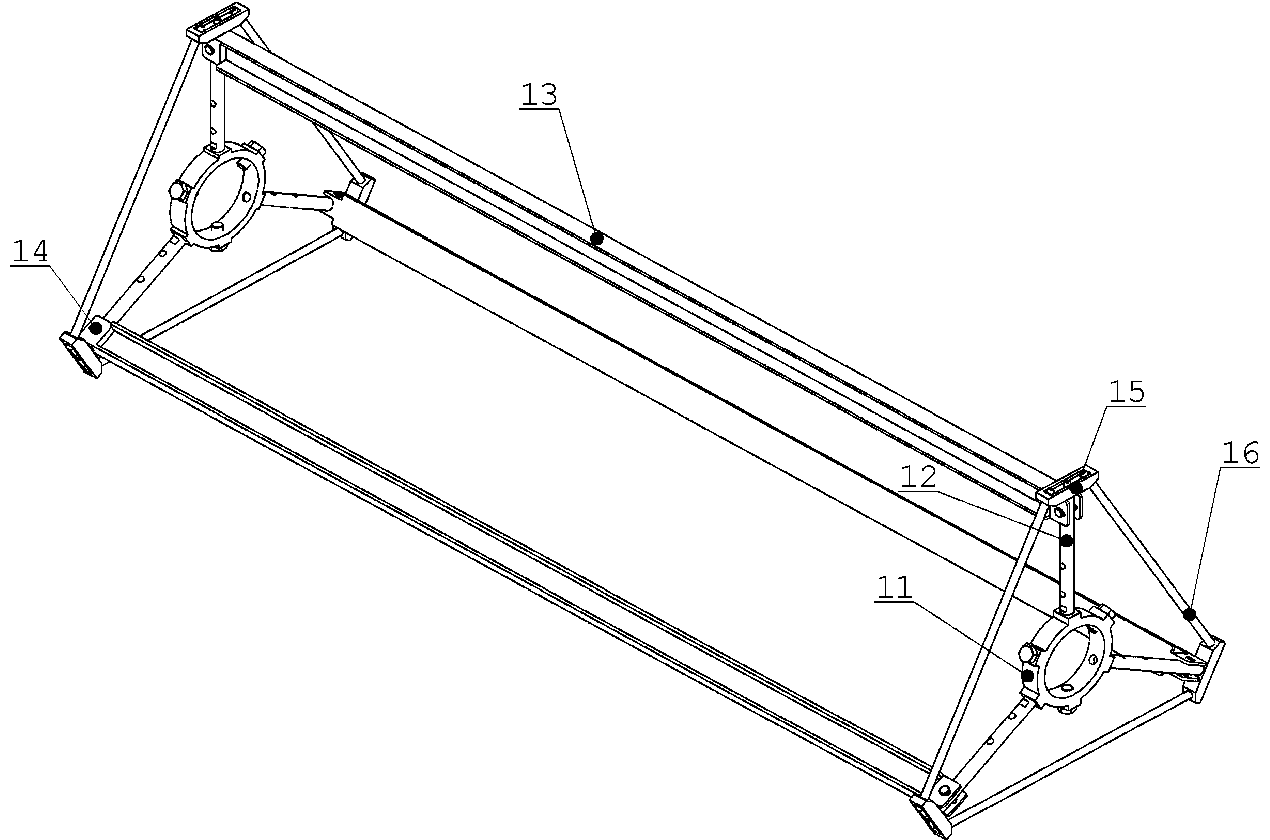

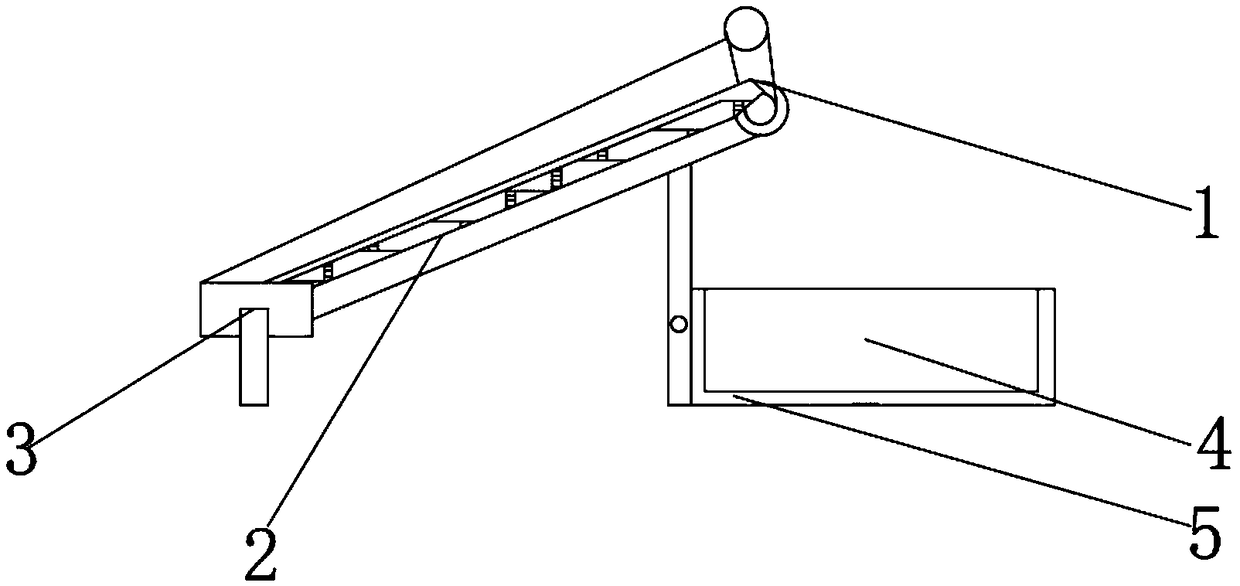

Three-face over-constrained scissor-type lifting mechanism

InactiveCN101913544AWith automatic centering functionIncrease stiffnessLifting framesEngineeringHigh-motion

The invention relates to the field of lifting equipments, particularly to a three-face over-constrained scissor-type lifting mechanism. The mechanism comprises three groups of scissor-type trusses; the plane that each truss is located is vertical to the ground; an included angle between every two trusses is 60 degrees, therefore, the trusses are arranged in a regular triangle; the scissor-type trusses are connected via a plurality of connectors and connected with the connectors via revolute pairs; a lower guide rail is fixedly connected with a base and respectively connected with three connectors at the bottom via prismatic pairs; an upper guide rail is fixedly connected with a bearing platform and connected with three connectors at the top via prismatic pairs; and when the scissor-type trusses are unfolded, the bearing platform is vertically hoisted. The mechanism has the advantages of high strength, large structure rigidity and high motion stability, can be applied to works of overhead installation, maintenance, transportation, and the like, and can bear larger load and satisfy higher work height requirements.

Owner:TSINGHUA UNIV

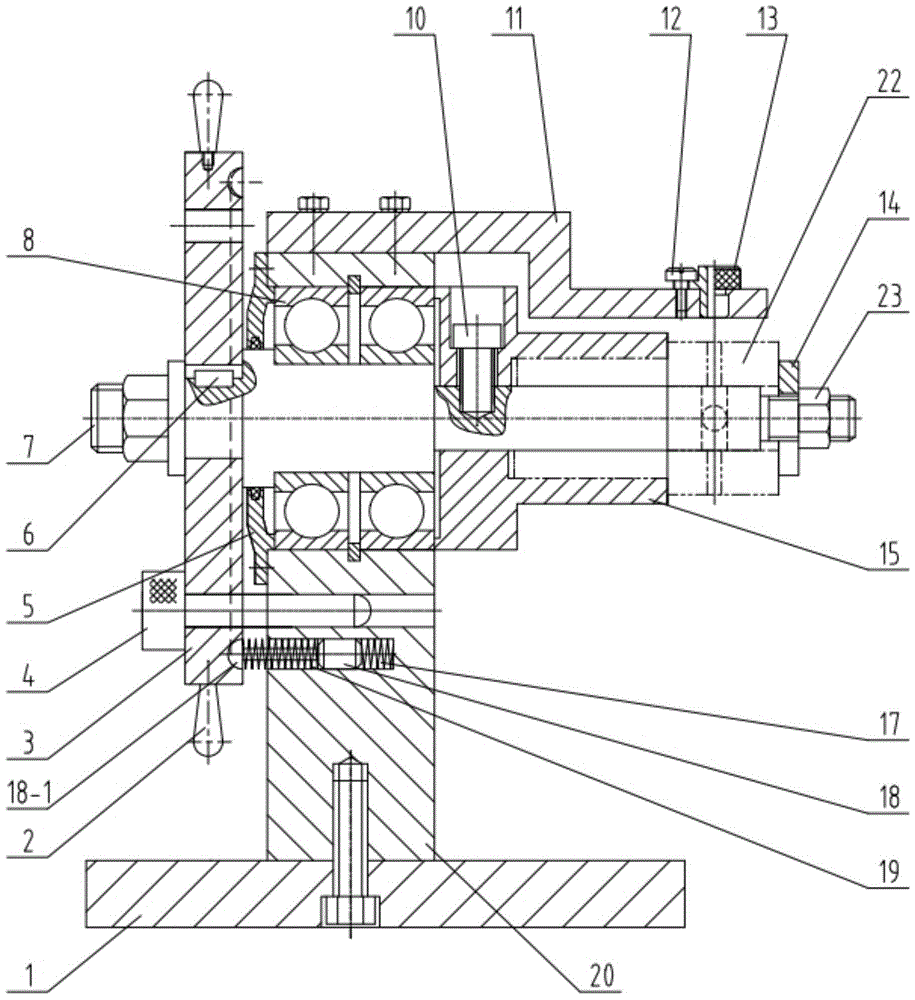

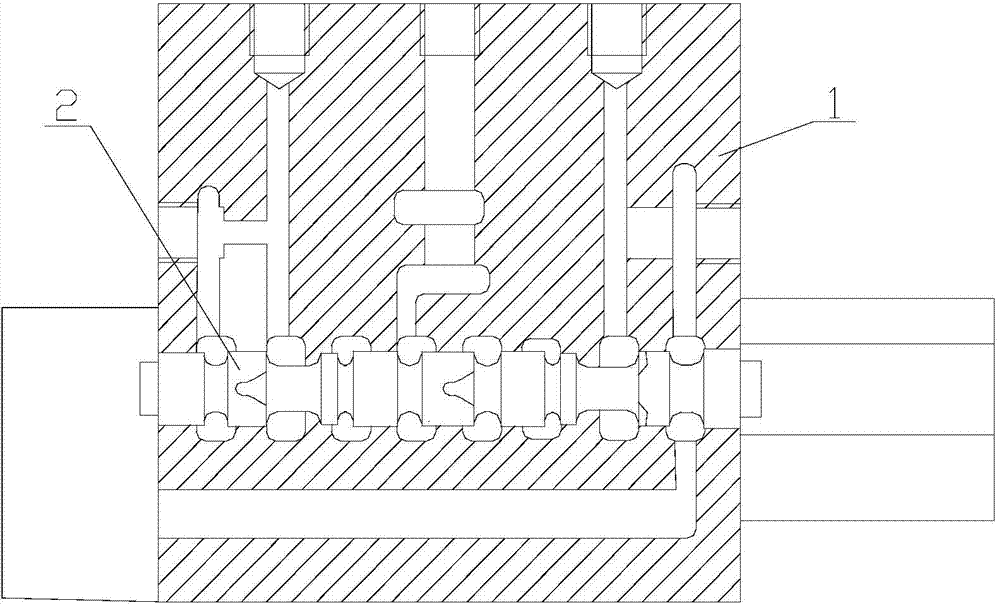

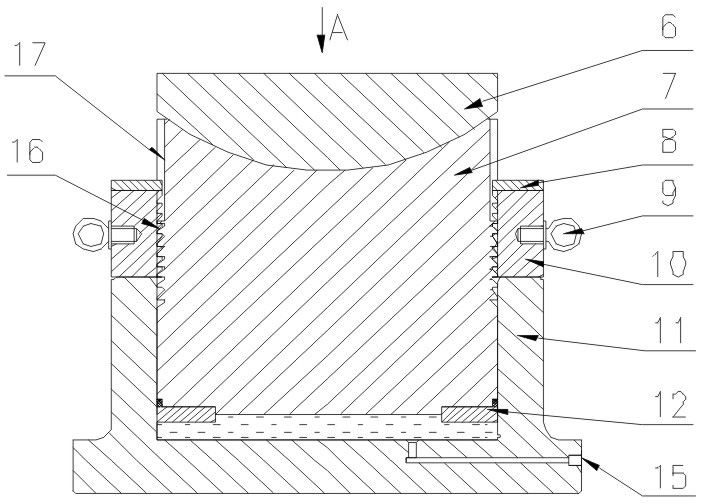

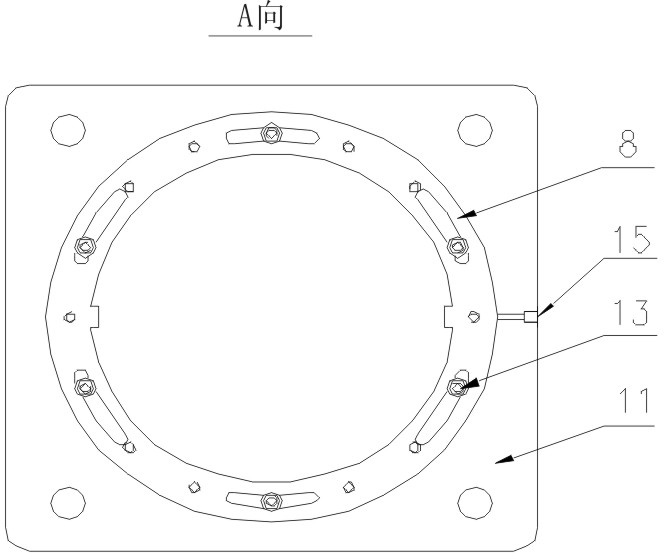

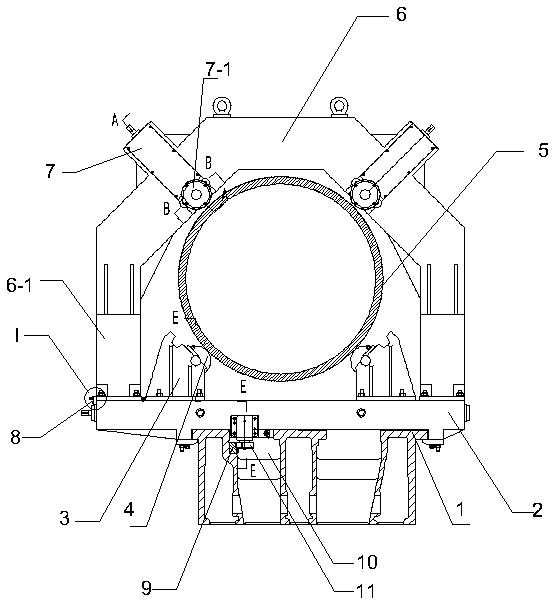

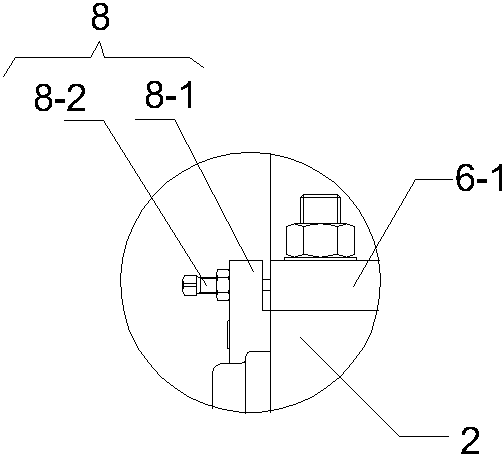

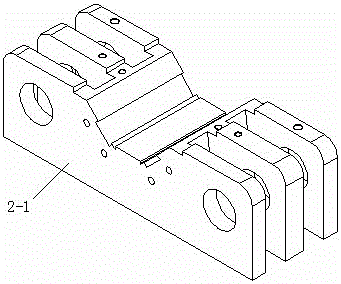

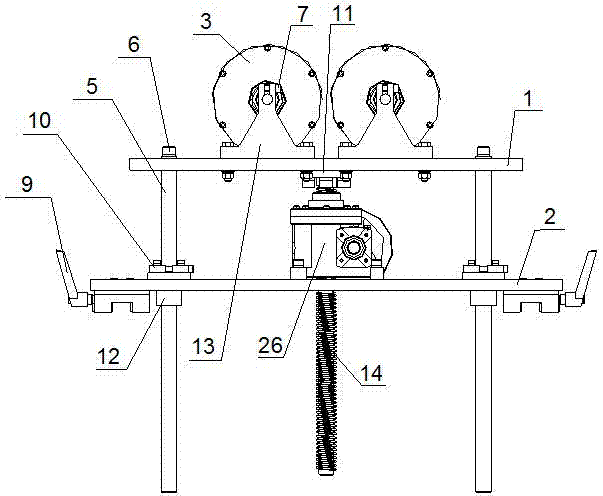

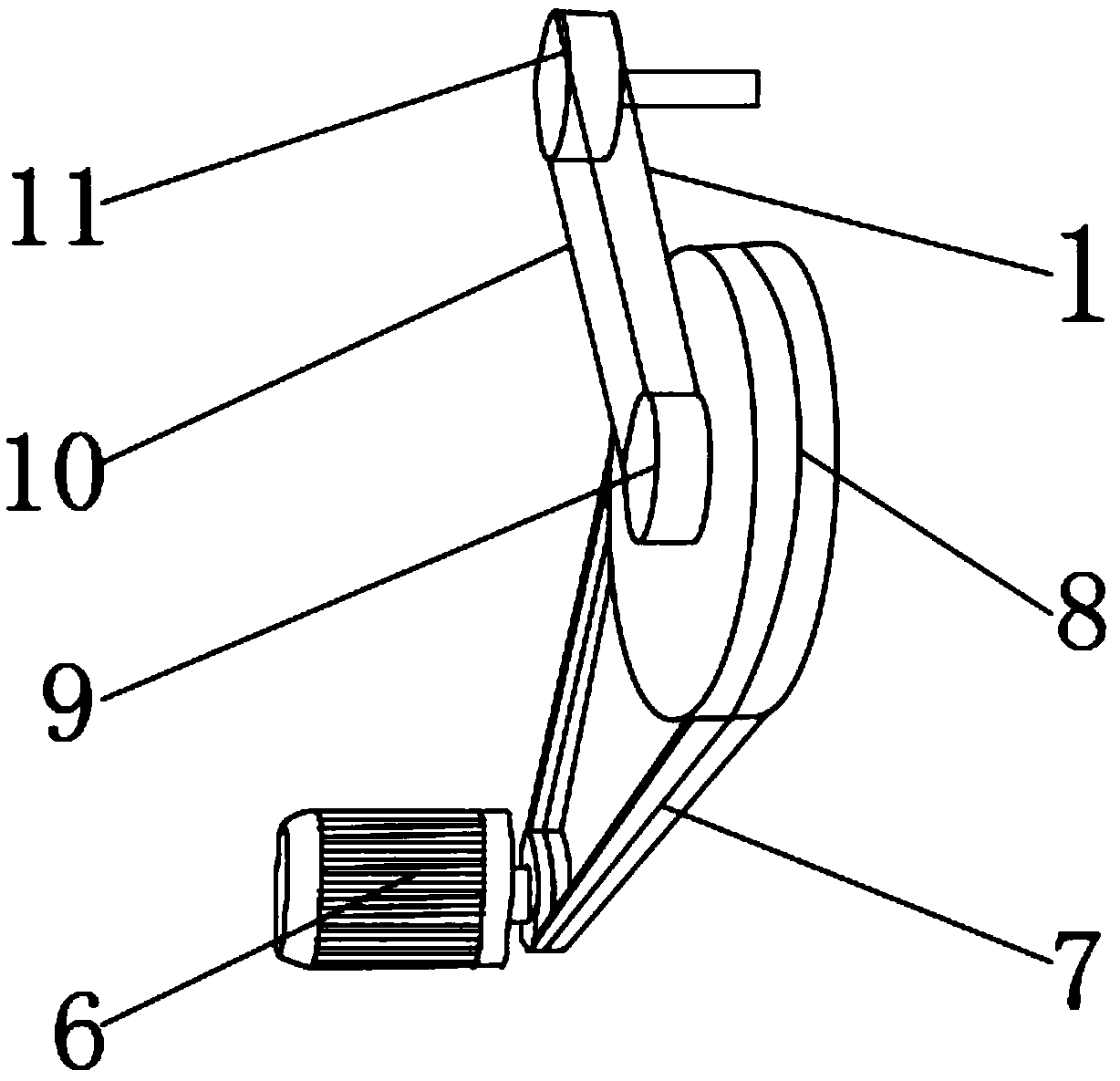

Radial drilling device for shaft sleeve parts

InactiveCN104148693AAvoid the disadvantages of unreliable positioningGood orientationPrecision positioning equipmentPositioning apparatusEngineeringMachining

The invention discloses a radial drilling device for shaft sleeve parts. The radial drilling device comprises a clamp, a drilling jig component, a positioning mandrel, a shaft sleeve part positioning mechanism and an indexing mechanism, the positioning mandrel is supported on the clamp rotatably, the shaft sleeve part positioning mechanism is mounted on the positioning mandrel so as to lock one shaft sleeve part on the positioning mandrel, the drilling rig component is mounted at the top end of the clamp so as to be used for drilling the shaft sleeve part, the indexing mechanism comprises a positioning pin, an indexing plate, an indexing pin and a return spring, the indexing plate sleeves the positioning mandrel, a plurality of indexing grooves and a plurality of positioning holes corresponding to to-be-drilled positions of the shaft sleeve part are formed in the indexing plate, each indexing groove is of an internal arc half-concave sphere structure, the front end of the indexing pin is provided with an arc ball head matched with the indexing grooves, one end of the return spring butts against the clamp, and the other end of the same butts against the indexing pin. By the radial drilling device which is simple and convenient to operate, high positioning accuracy in drilling can be achieved, and radial multi-hole indexing machining is easy to realize.

Owner:CHANGZHOU TEXTILE GARMENT INST

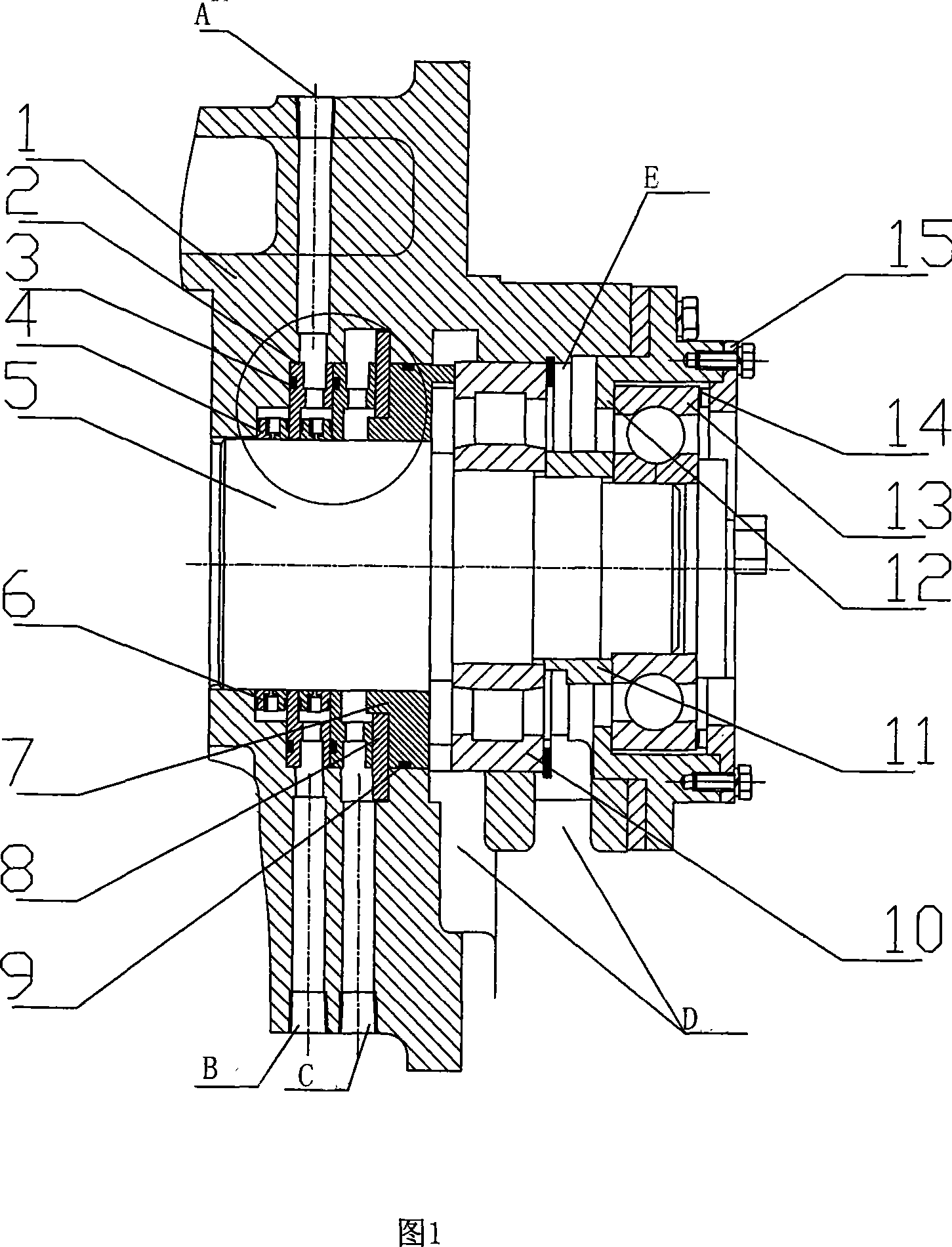

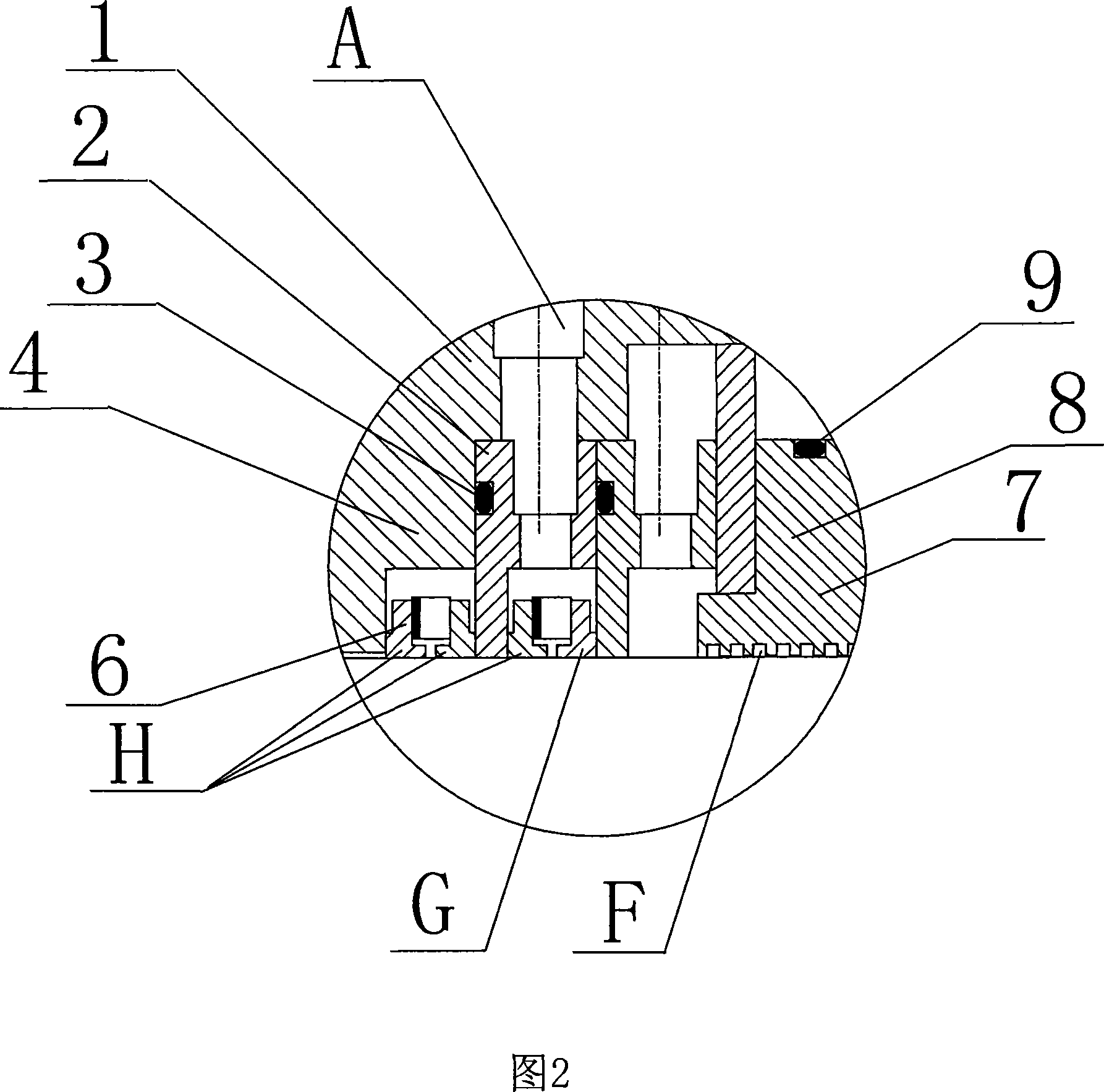

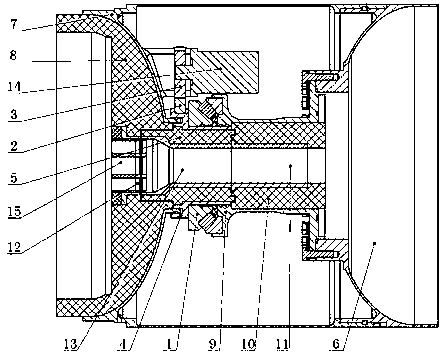

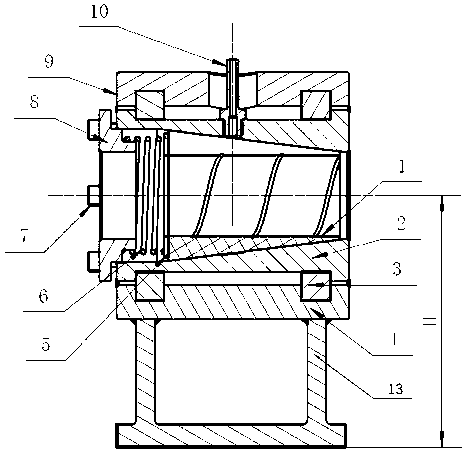

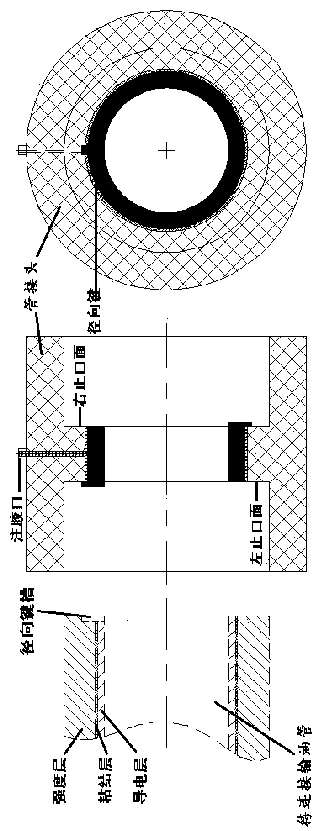

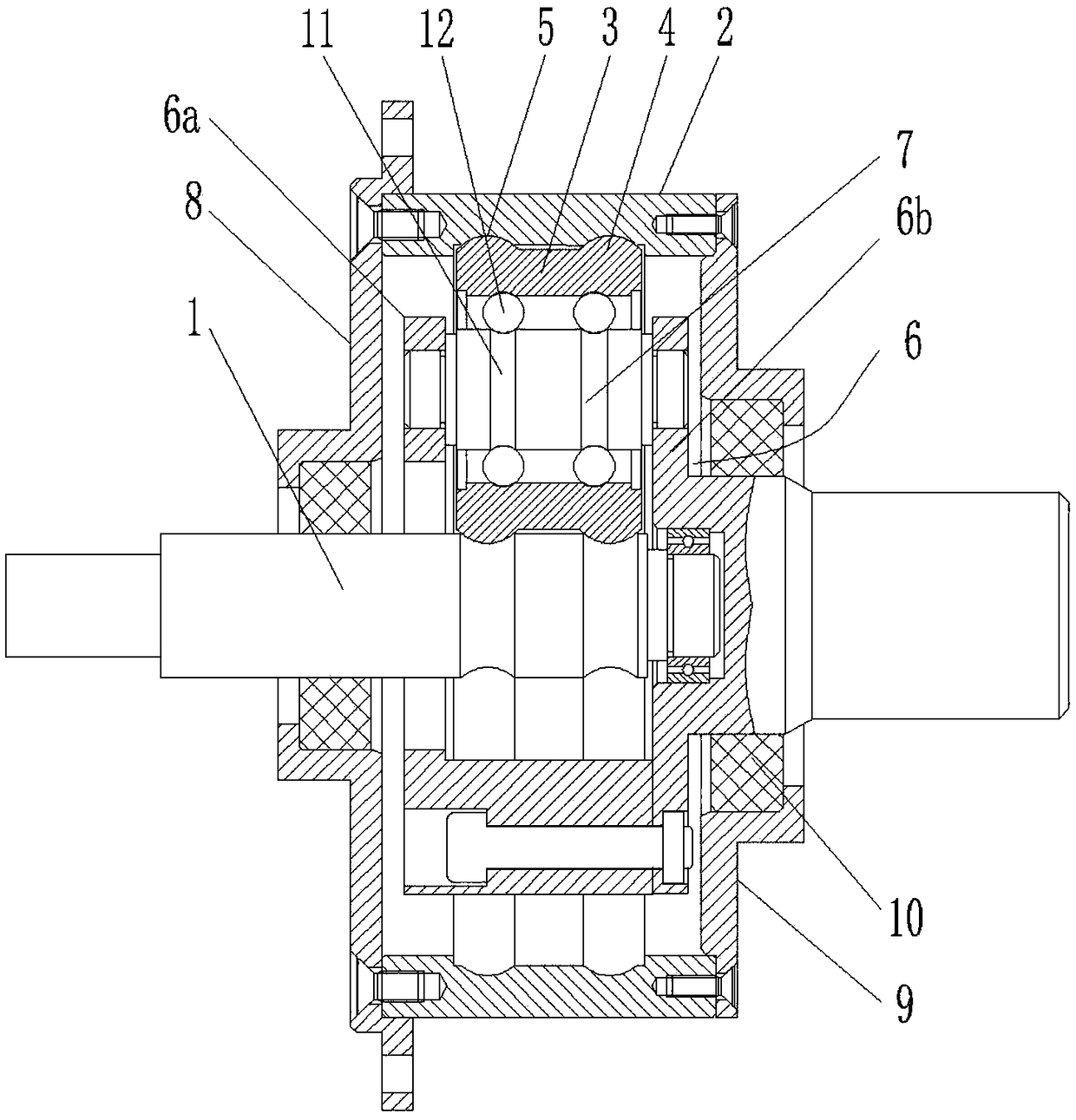

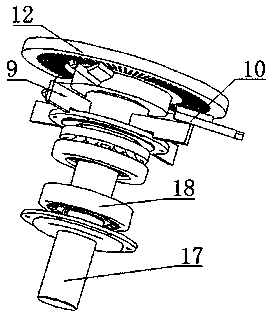

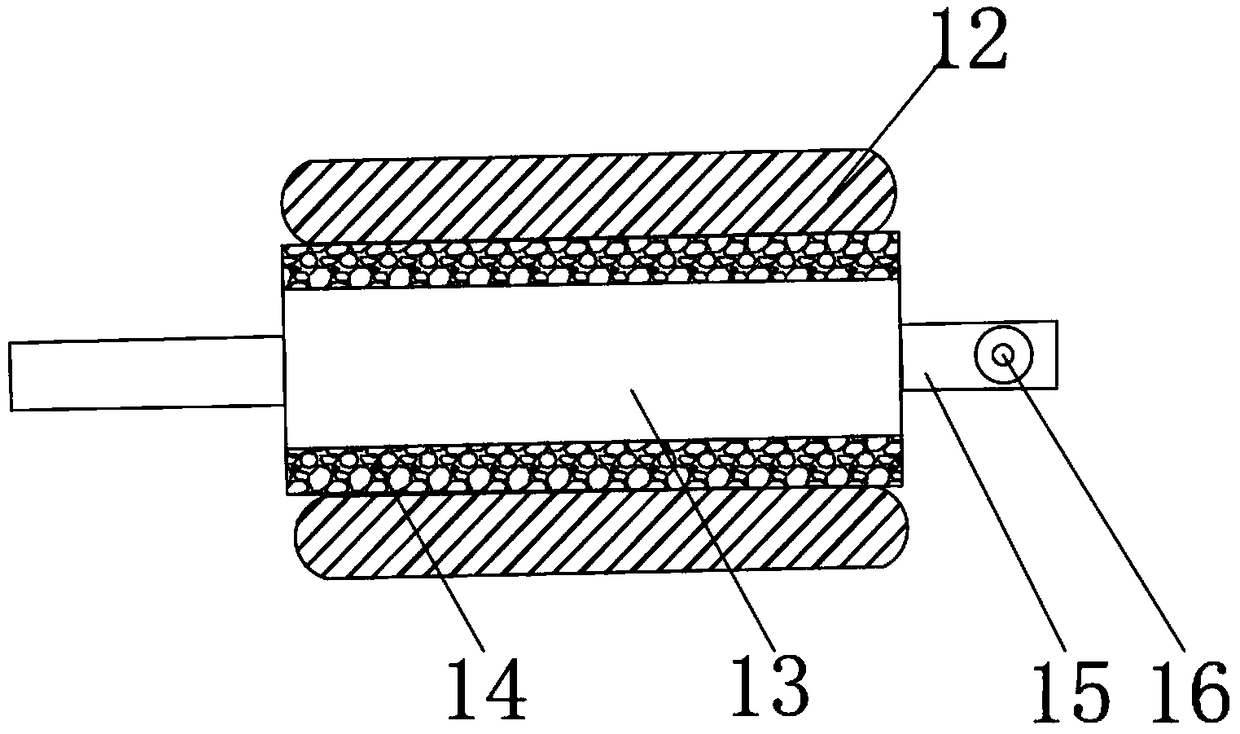

Permanent magnet bearing squeeze oil film damper

ActiveCN103216571AWith automatic centering functionSufficient radial stiffnessRotating vibration suppressionBearingsMagnetic polesShock absorber

The invention discloses a permanent magnet bearing squeeze oil film damper which comprises an oil film shaft neck, a bearing outer ring, a bearing inner ring and a lubricating oil cavity full of lubricating oil, wherein the bearing inner ring is sleeved on a shafting, the bearing outer ring and the oil film shaft neck are both located inside the lubricating oil cavity, and the bearing outer ring is fixedly arranged on the inner side of the oil film shaft neck. The permanent magnet bearing squeeze oil film damper further comprises an elastic squirrel-cage bar, wherein one end of the elastic squirrel-cage bar is located outside the lubricating oil cavity and is fixed, and the other end of the elastic squirrel-cage bar is fixedly connected with the oil film shaft neck. The bearing inner ring and the bearing outer ring are both magnetized in the radial direction, the opposite surface of the magnetized bearing inner ring and the opposite surface of the magnetized outer ring have like magnetic poles, and a gap is formed between the bearing inner ring and the bearing outer ring. The permanent magnet bearing squeeze oil film damper can improve damping ability and radial supporting stiffness.

Owner:JIANGSU UNIV OF TECH

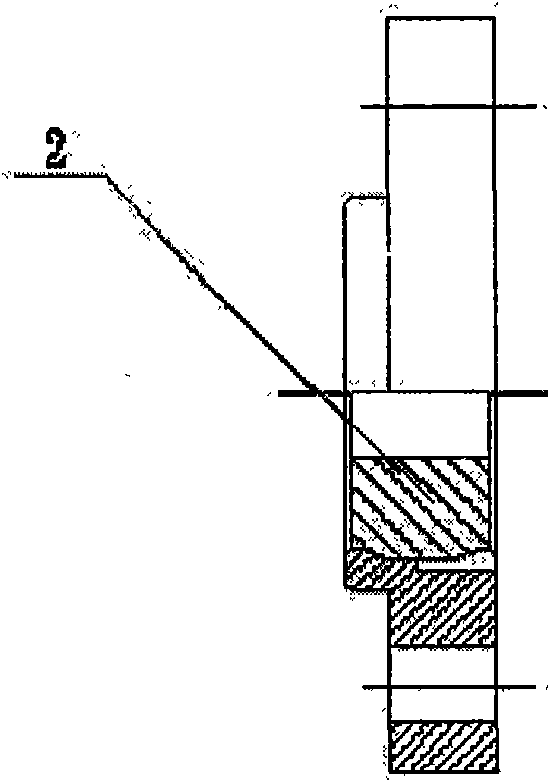

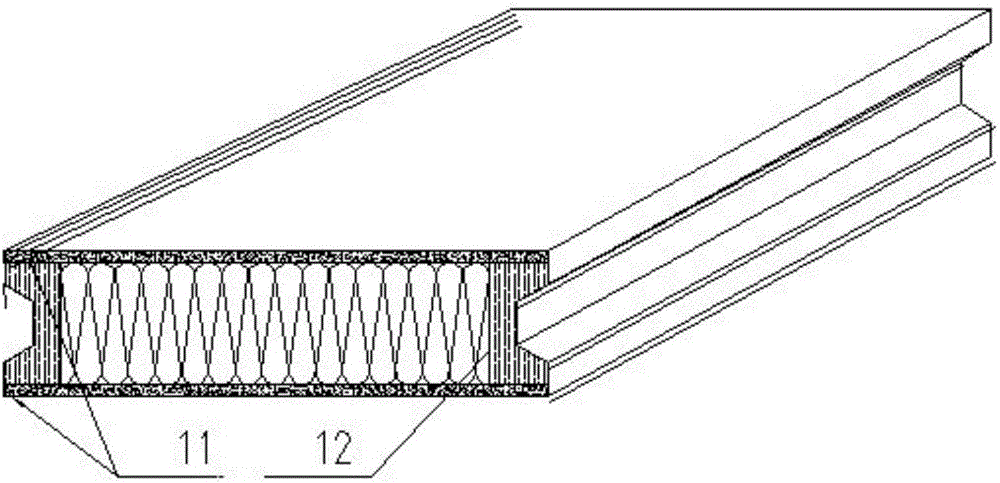

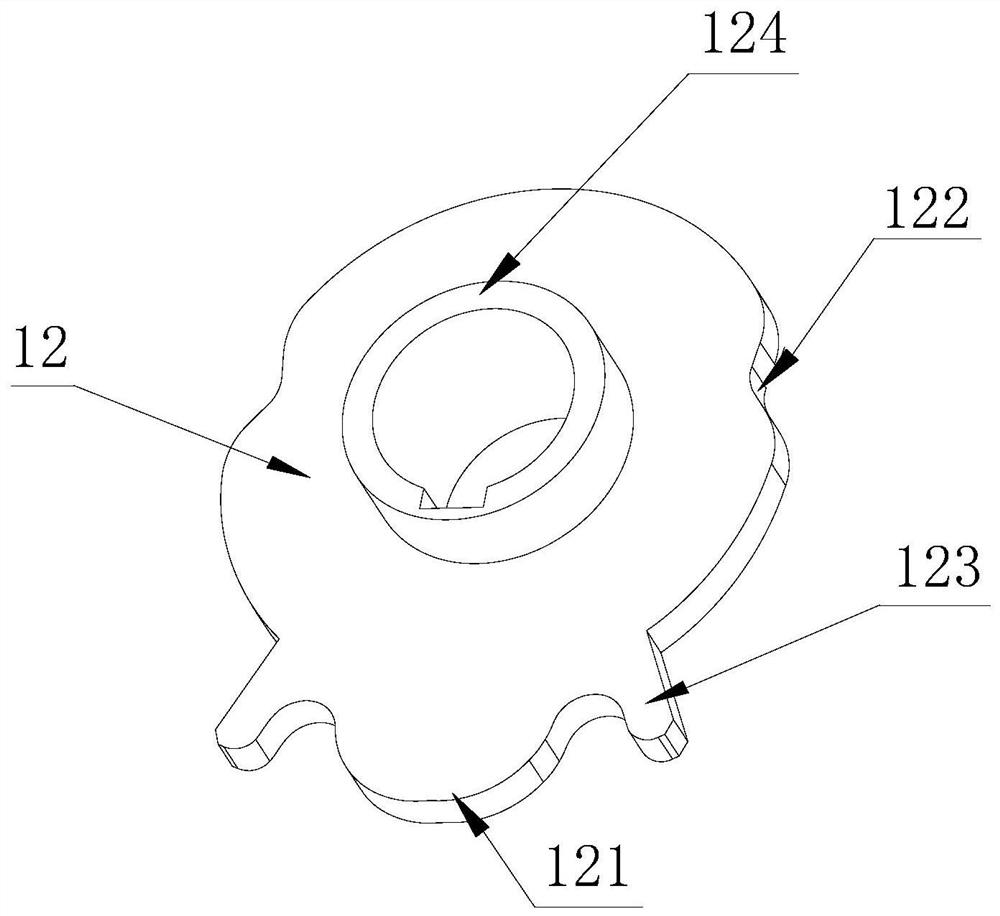

Dry helical lobe compressor host rotor spindle rotor spindle sealing structure

InactiveCN101158355ASimple structureStable sealing performanceSealing arrangement for pumpsMachines/enginesWave shapeRetaining ring

The invention relates to a dry screw compressor host machine rotor shaft sealing structure. The invention is characterized in that an air sealing position is divided into two sealing units by two groups of washers; each sealing unit is provided with two stainless steel sealing rings; a stainless steel wave-shaped spring is arranged between two sealing rings; by virtue of the force of the wave-shaped spring, the end surface of the stainless steel sealing ring can be tightly attached to the washer or shell; meanwhile, when the rotor is rotated, the stainless steel sealing ring is floated on the rotor shaft and an oil retaining ring is sleeved on the rotor shaft. The invention has the advantages of stable sealing performance of the floating ring, reliable operation, long service life, simple manufacture, convenient installation, and low production cost; the floating ring has automatic centering function and the sealing ring is basically not abraded; the invention can effectively block intercommunication of oil and gas, reliably ensures the oil to enter the compression chamber and ensures no oil in the provided pressure gas; the non-contact sealing is adopted, and the sealing can be achieved by the pressure reduction produced in sealed fluid.

Owner:WUXI COMPRESSOR CO LTD

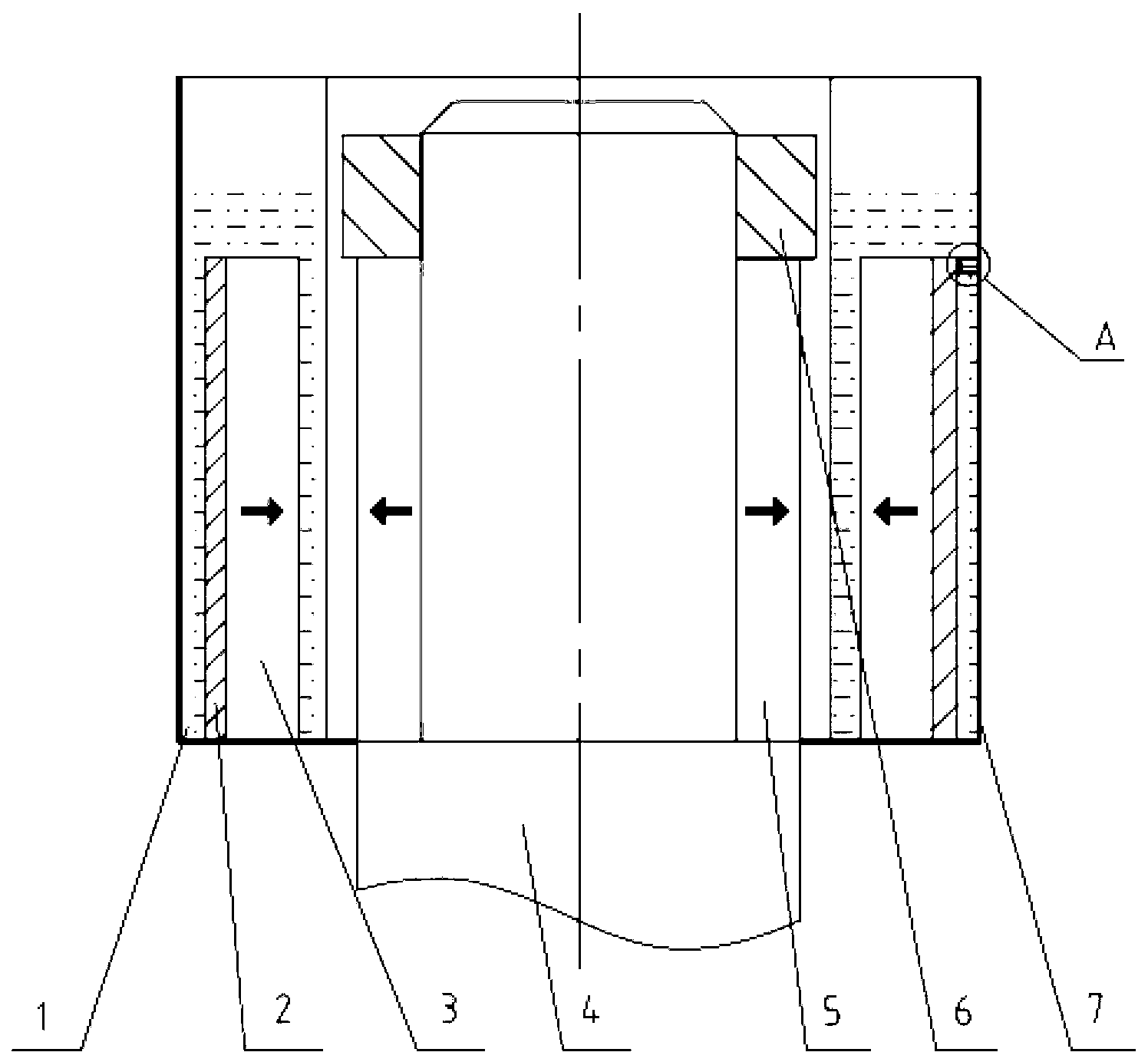

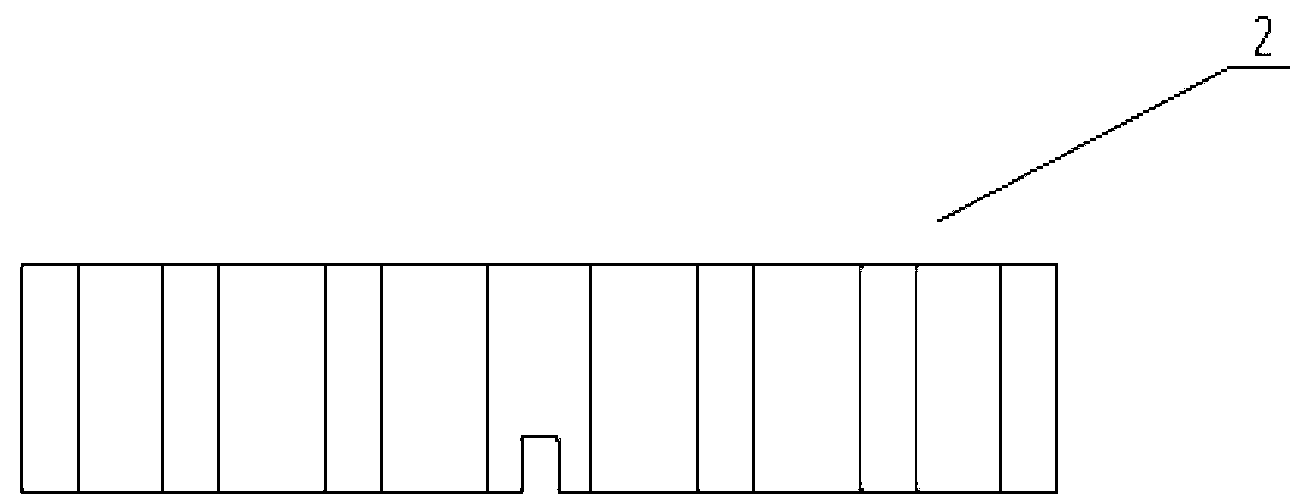

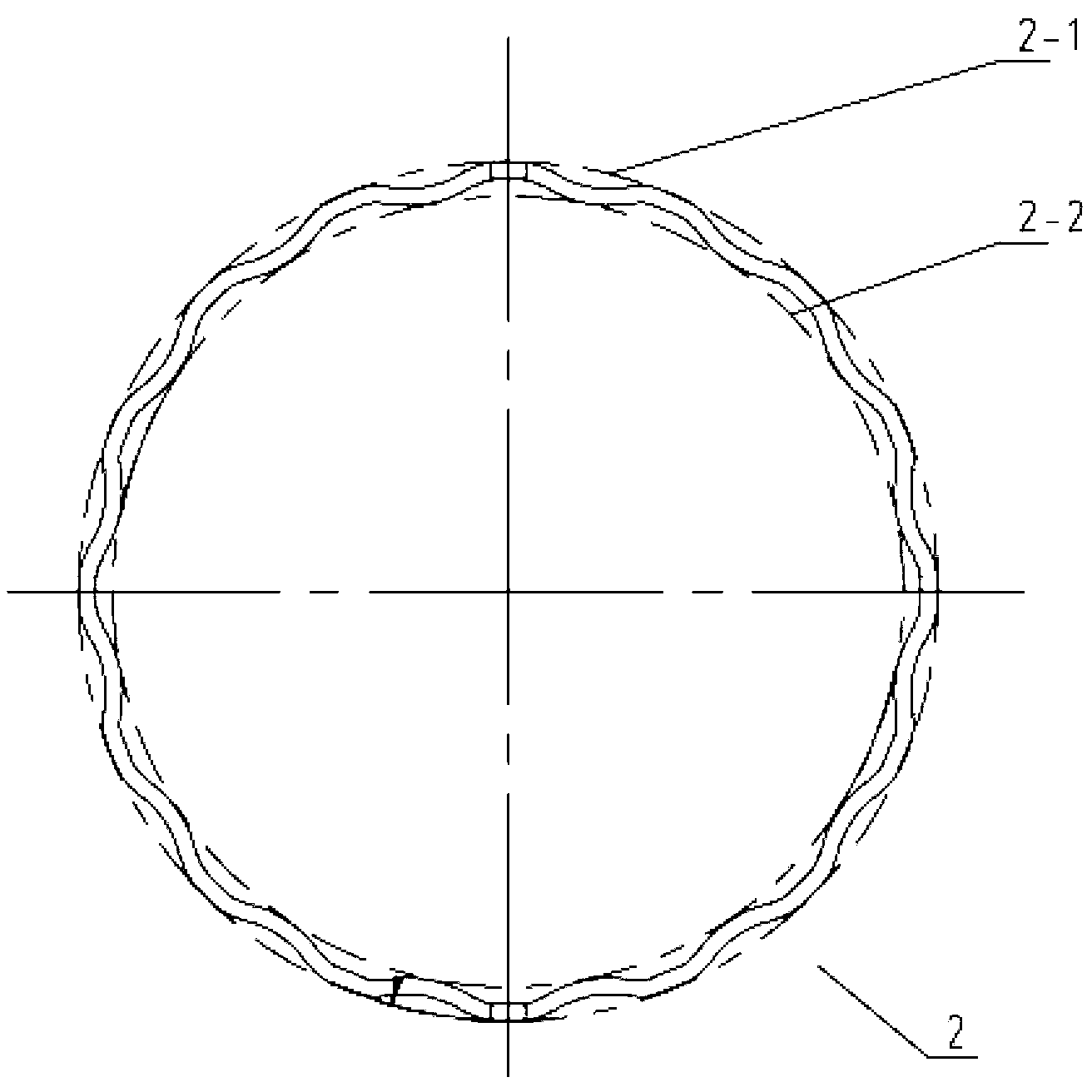

Permanent magnet bearing squeeze film dumper with elastic ring

ActiveCN103225669AReduce hoop tensile stressCompact structureRotating vibration suppressionBearingsMagnetEngineering

The invention discloses a permanent magnet bearing squeeze film dumper with an elastic ring, which comprises a bearing outer ring, a bearing inner ring fixedly sleeved on a shaft system, and a lubricating oil cavity filled with lubricating oil, as well as the elastic ring, wherein the bearing outer ring is mounted in the lubricating oil cavity; the bearing inner ring and the bearing outer ring are radially magnetized, resulting in that the opposite surfaces of the both are like in poles; a gap is reserved between the bearing inner ring and the bearing outer ring; and the inner ring of the elastic ring is propped against the outer ring of the bearing outer ring, while the outer ring of the elastic ring is propped against the lubricating oil cavity. The permanent magnet bearing squeeze film dumper can improve radial bearing rigidity, provides larger damping ability, and is compact in structure.

Owner:JIANGSU UNIVERSITY OF TECHNOLOGY

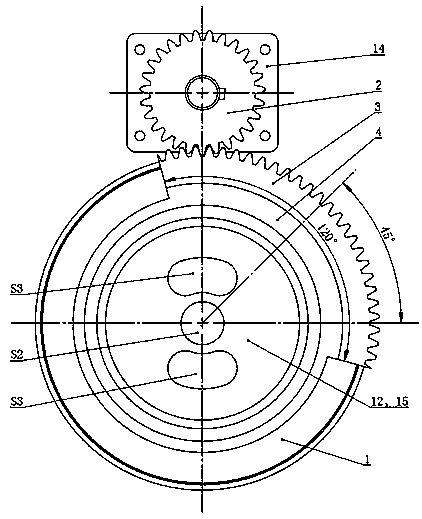

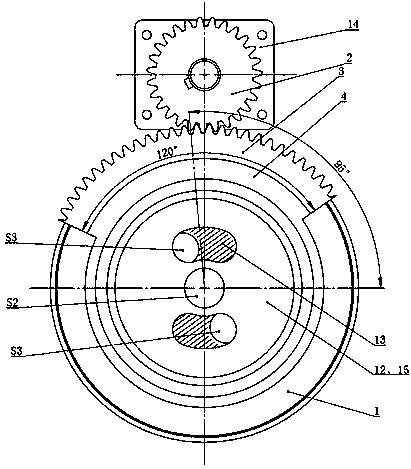

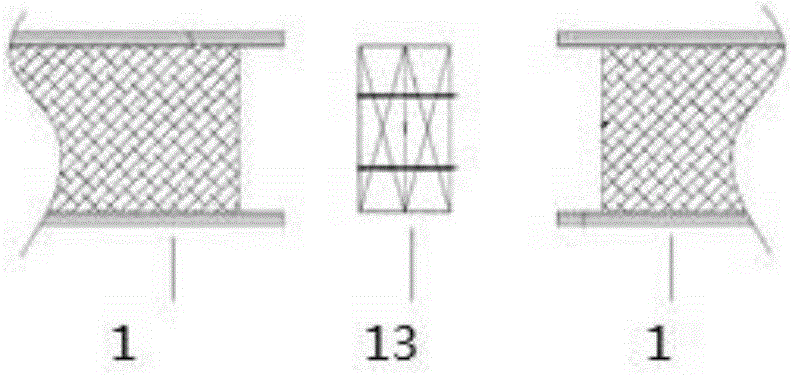

Planetary support structure in simple planetary gear mechanism and its manufacture

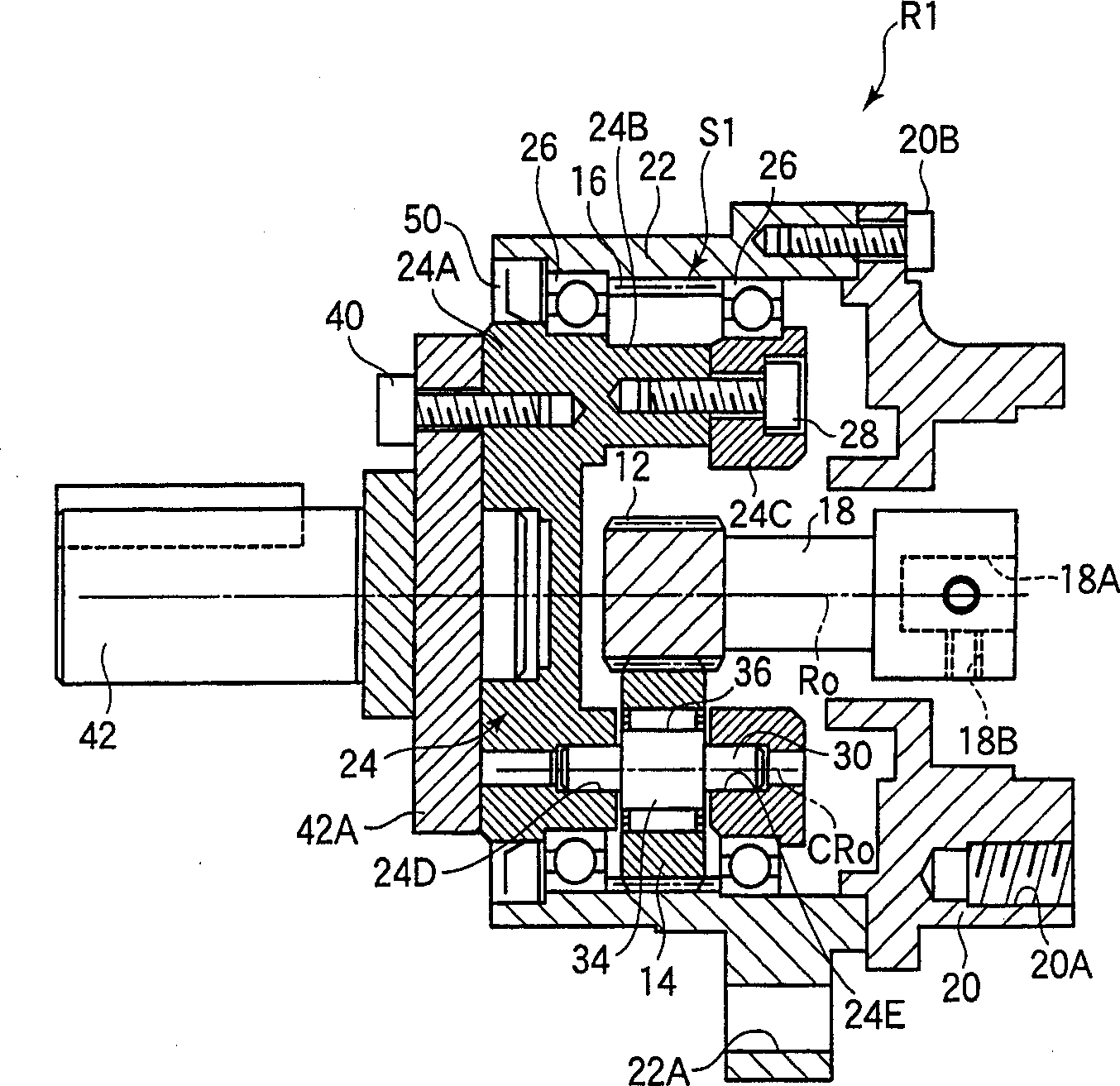

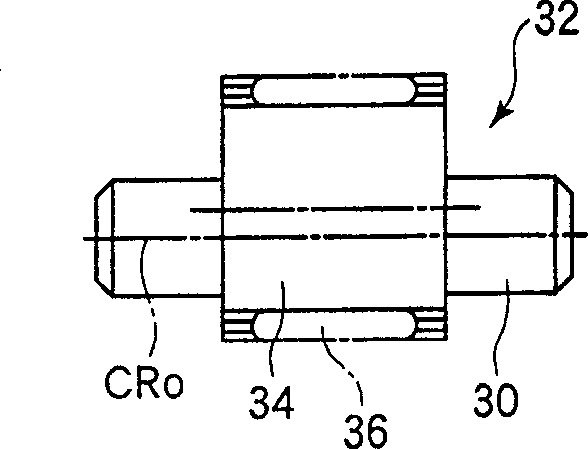

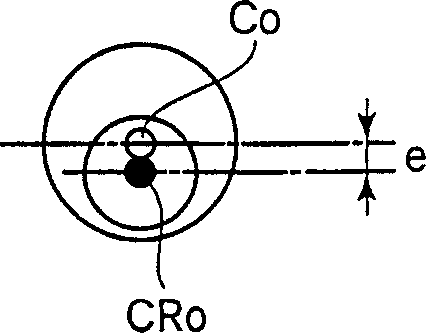

InactiveCN1370937ASmooth and smooth rotation effectSmall backlashToothed gearingsPortable liftingGear wheelEngineering

A simple planetary gear mechanism with an automatic centering function to support the planetary gears, thereby obtaining a reducer with reduced backlash through a simple method. The planetary gears (14) are supported by bracket pins (30) supported by the bracket. The bracket pin (30) includes a crank portion (32) which is eccentric "e" with respect to the axis of the bracket pin and whose eccentric angle α is variable. The planetary gear (14) is rotatably supported around the axis of the crank portion (32). As a result, by making the eccentric angle variable, the shaft centers of the planetary gears are automatically aligned in the radial direction when assembling each gear, so that the backlash can be adjusted to the minimum just by assembling a sun gear of an appropriate size.

Owner:SUMITOMO HEAVY IND LTD

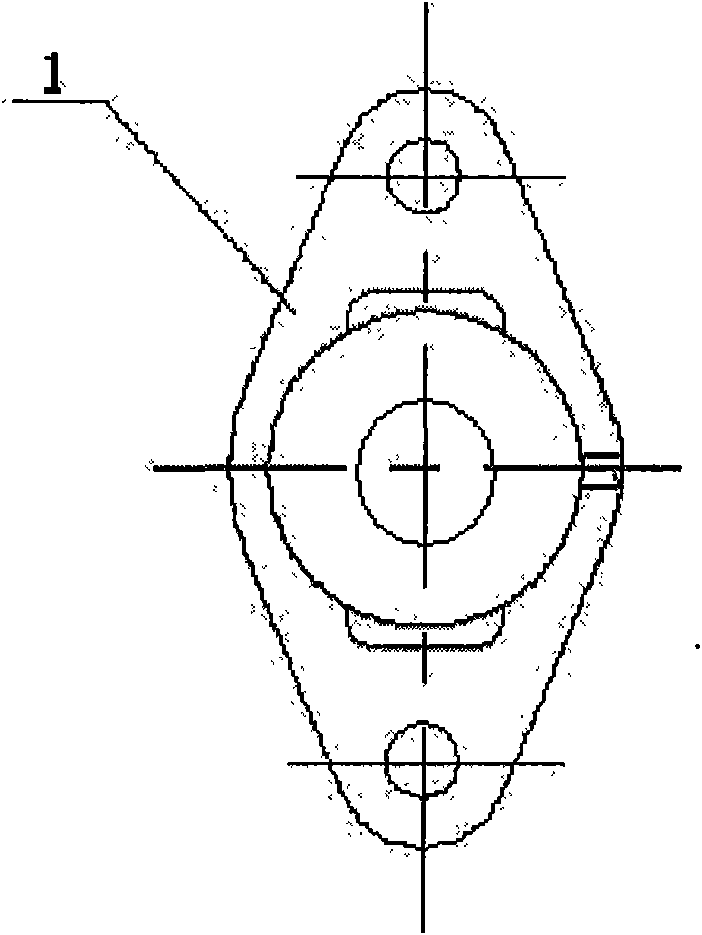

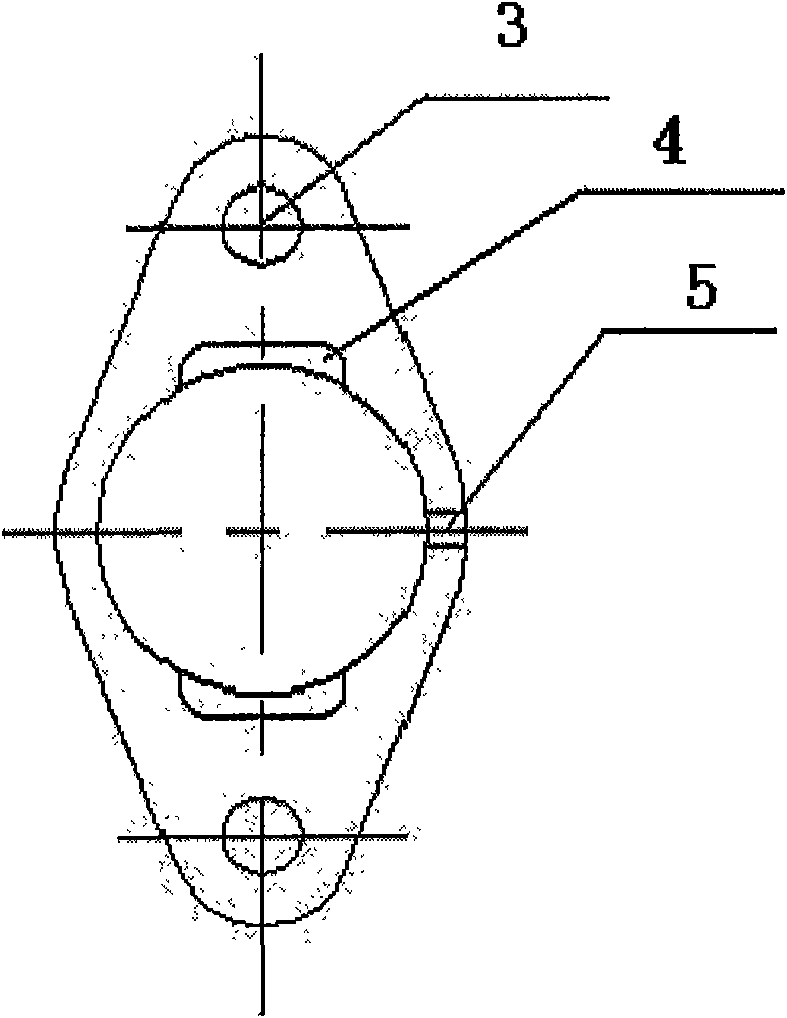

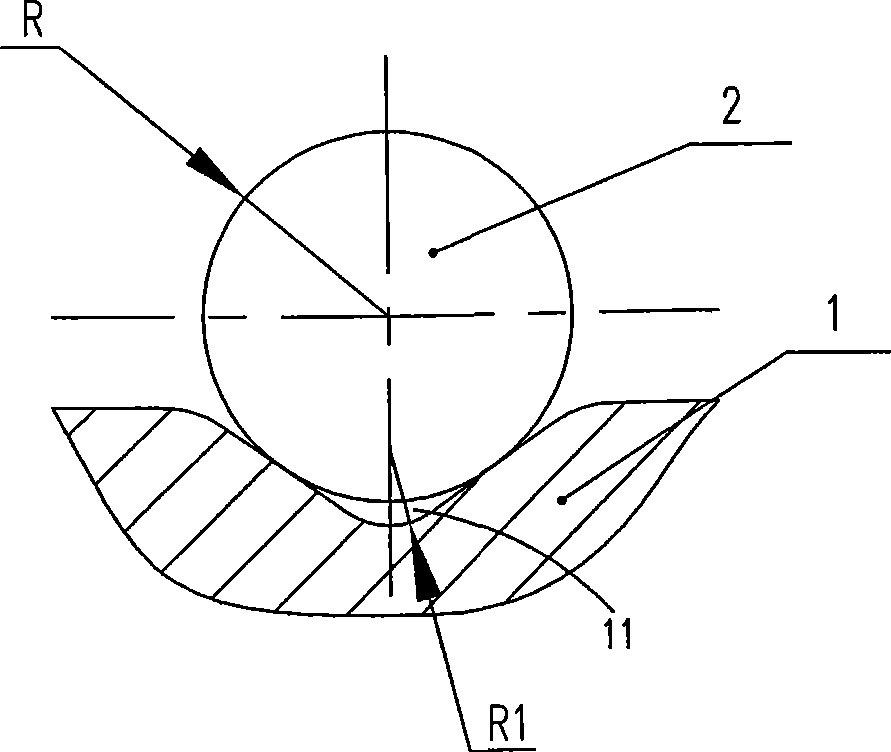

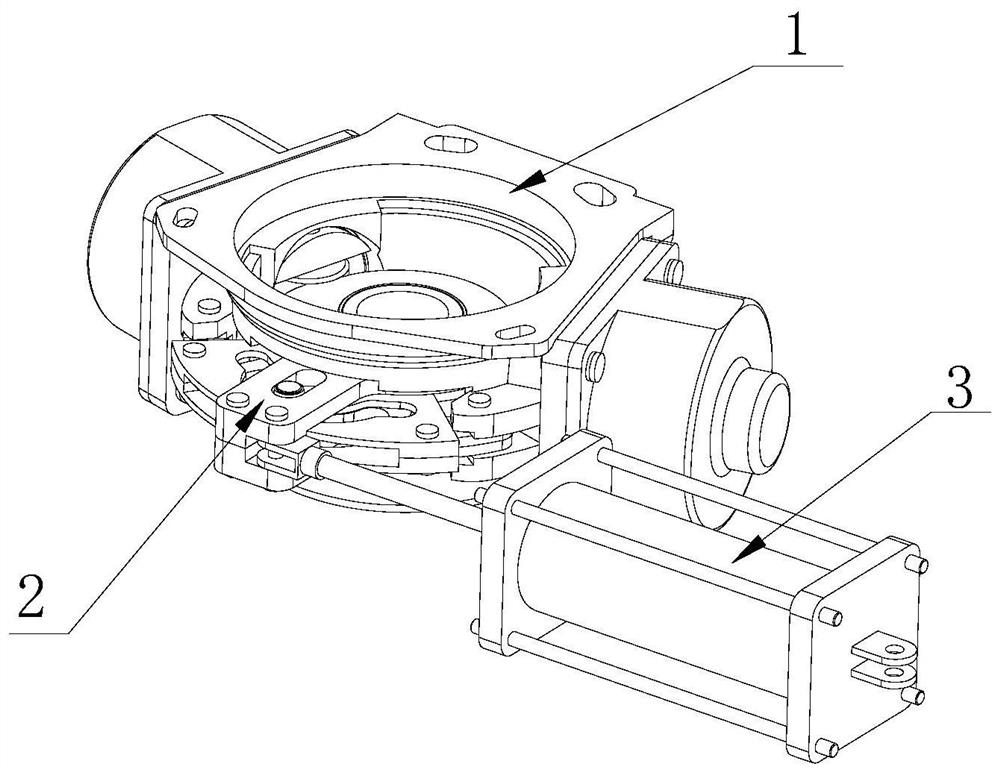

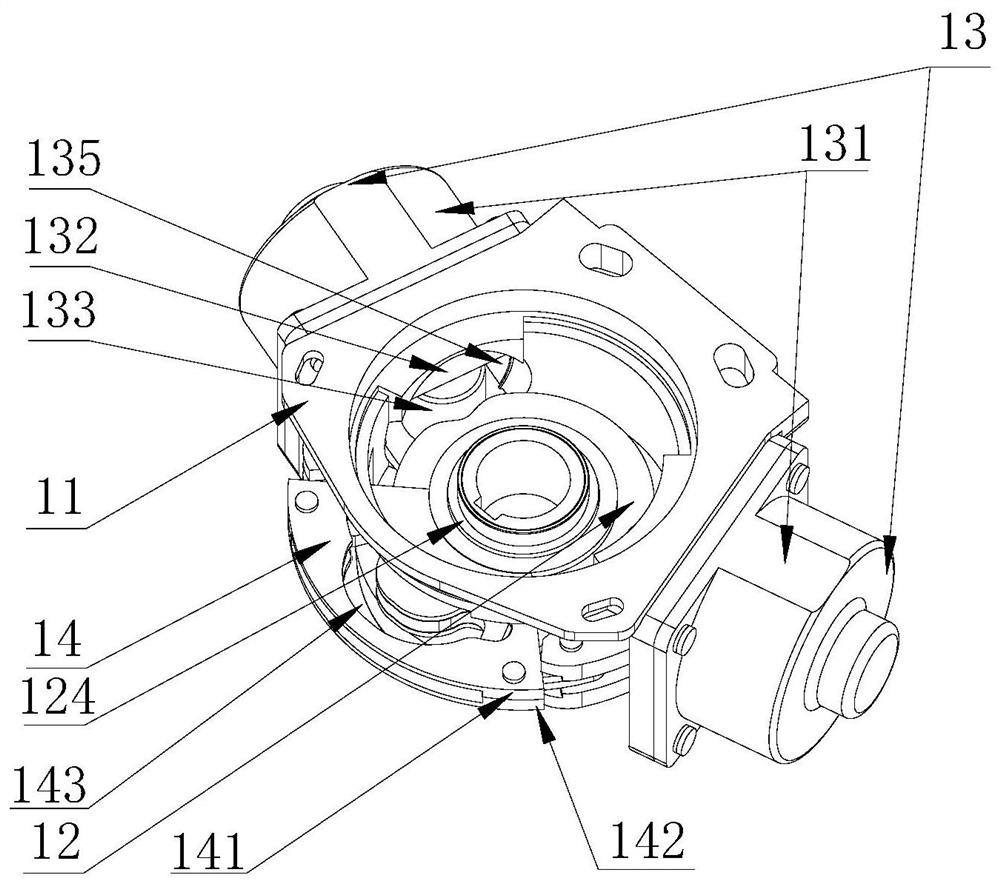

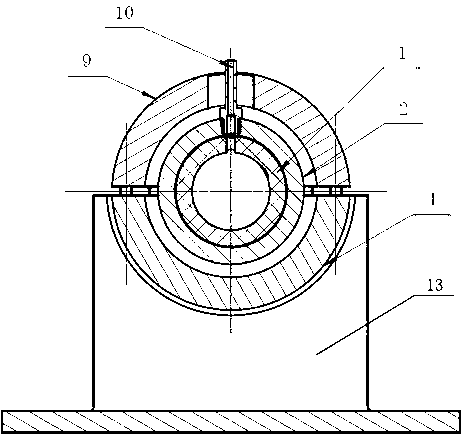

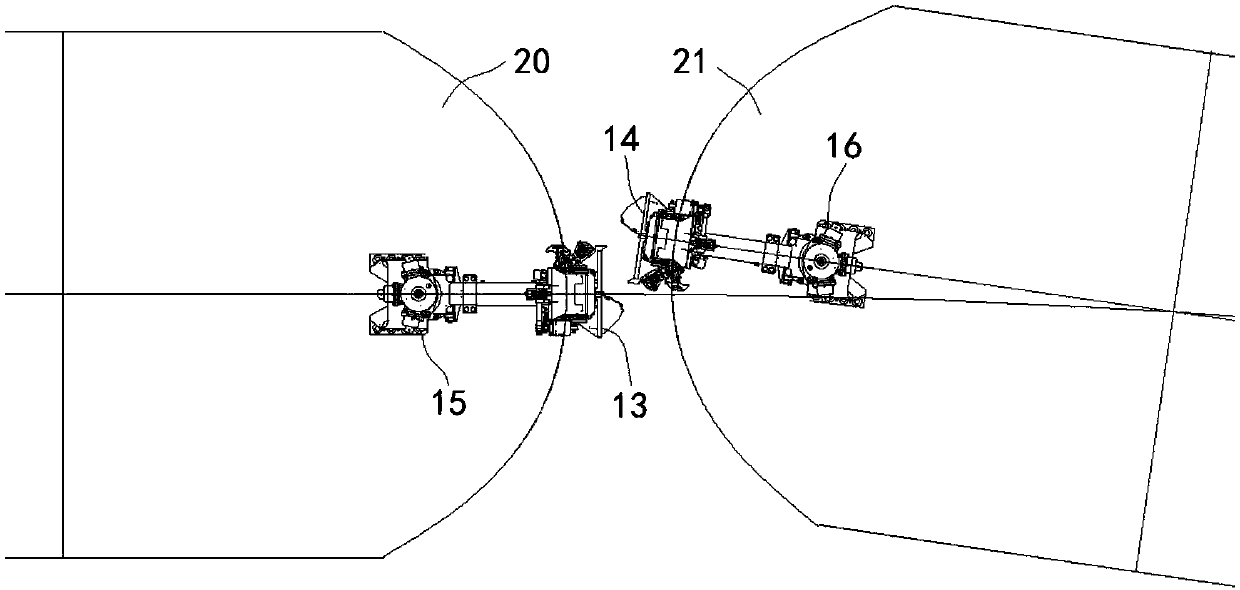

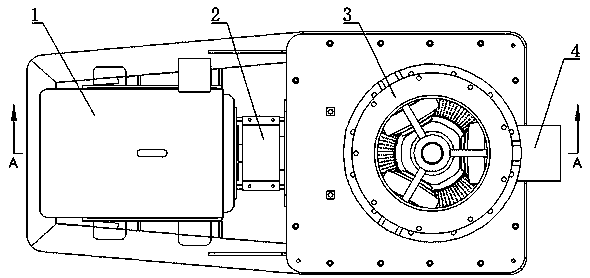

Aligning sliding bearing for efficient air valve of subway

InactiveCN101684842AImprove lubrication conditionsExtended service lifeSliding contact bearingsBearing unit rigid supportAuto regulationMachine parts

The invention belongs to the field of machine parts, and relates to an aligning sliding bearing for an efficient air valve of a subway. The aligning sliding bearing comprises a bearing block body (1),a sliding bearing (2), a bolt hole (3), a demounting hole (4) and an oil hole (5), wherein the bearing block body is fixed with an air valve framework by bolts; the sliding bearing is connected witha blade shaft; the demounting hole is arranged in a square shape along the radial direction of an inner hole of a bearing block; and a position which is in the radial direction of the inner hole of the bearing block and is vertical to the length direction of the bearing block is provided with the oil hole. The spherical contact surface of the sliding bearing is matched with the spherical contact surface on the bearing block, so a sliding ball is difficult to slide off in the bearing block and runs more stably, and the spherical surface assembling mode can automatically adjust the concentricityof two ends of a fan blade shaft so as to effectively solve the problem of unstable running caused by the two non-concentric ends of the fan blade shaft because the fan blade shaft is too long when the air valve is in operation. The design of the oil hole of the sliding bearing block can ensure the spherical surface lubricating condition, reduce the friction, and improve the transmission efficiency and the service life of a material.

Owner:北京凯恩特技术有限公司

Gas flow regulation device for rotary spray pipe value of solid rocket-ramjet engine

PendingCN111577484AImprove thermal protection performanceCompact structureRocket engine plantsRam jet enginesRamjetCombustion chamber

The invention discloses a gas flow regulation device for a rotary spray pipe value of a solid rocket-ramjet engine. Each of a first fixed part and a rotating part is provided with one central hole andtwo arc-shaped holes in the axial direction; the front end of a transmission shell and an axial outlet section of a rear sealing head shell of a combustion chamber form a dynamic sealing structure; the tail end of the transmission shell and the head end of a spray pipe shell form a dynamic sealing structure; an outer ring of a thrust self-aligning roller bearing is mounted and fixed to the interior of a shell hole in the head end of the spray pipe shell; and the inner ring of the thrust self-aligning roller bearing is fixed to a shaft neck of the tail end of the transmission shell in a matched manner. A driving motor drives a driven gear to rotate to determine a corresponding angle of a transmission ratio, and finally, drives the rotating part to rotate at a corresponding angle relative to the first fixed part, so that the two arc-shaped holes of the rotating part and the fixed part are staggered and sheltered in the axial direction, thereby changing the effective outlet circulation area of the gas of the combustion chamber and realizing gas flow regulation with determined accuracy. The gas flow regulation device for the rotary spray pipe value of the solid rocket-ramjet engine isbetter in transmission mechanism thermal protection, more compact in structure and has higher work reliability, and can realize higher-precision and larger-range gas flow regulation.

Owner:湖南宏大日晟航天动力技术有限公司

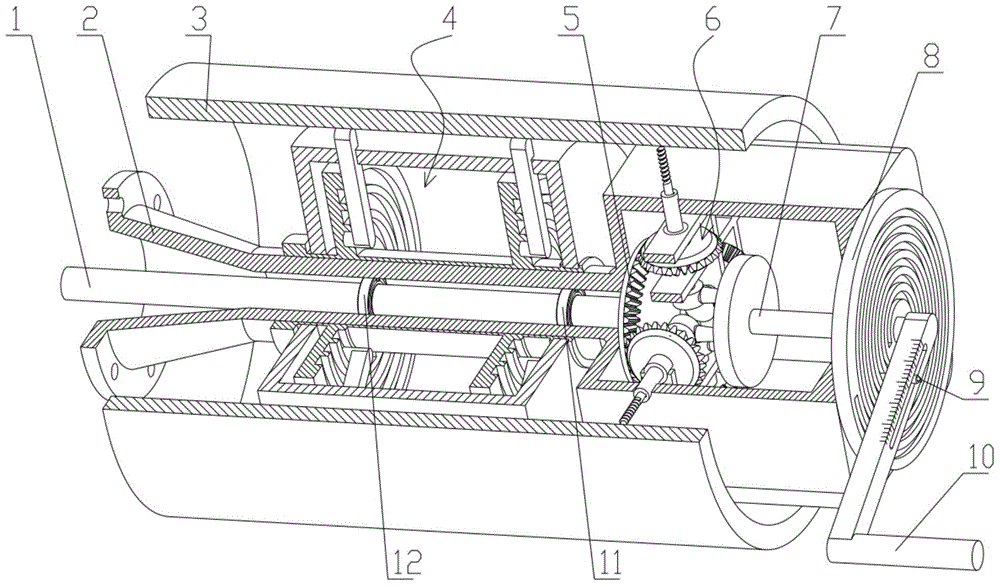

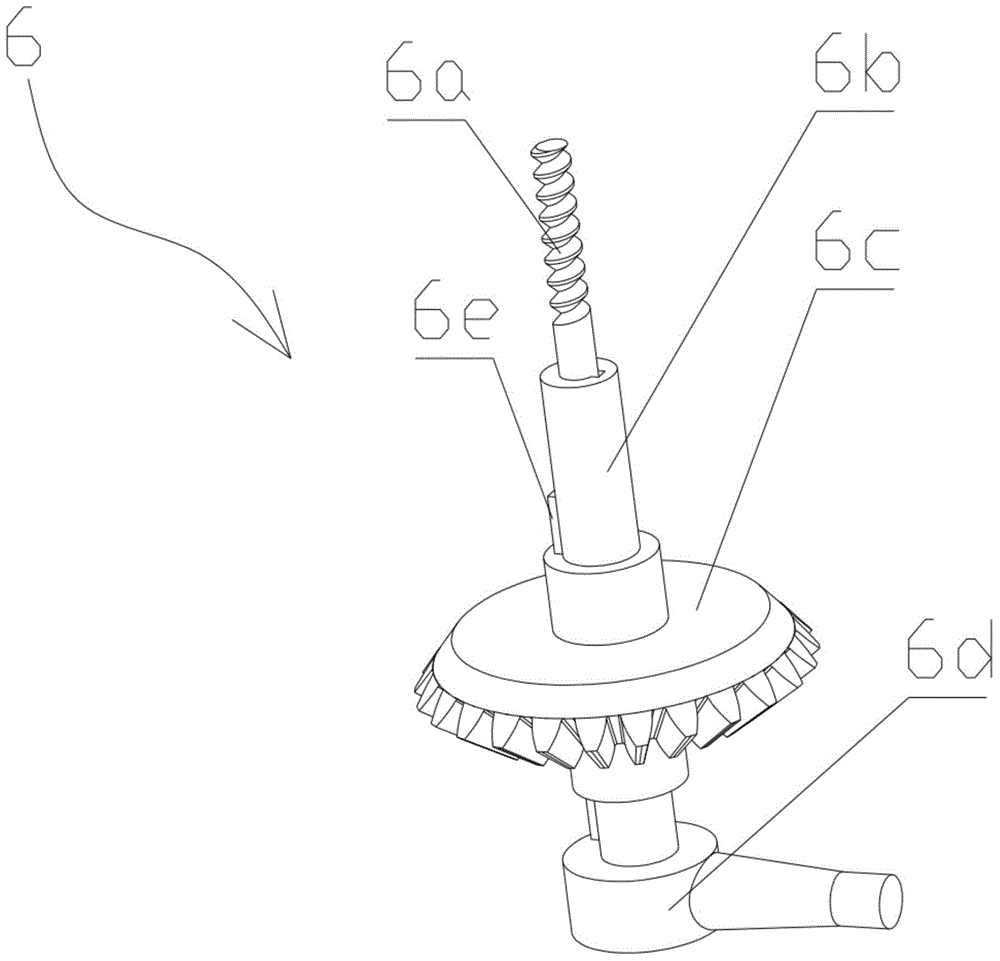

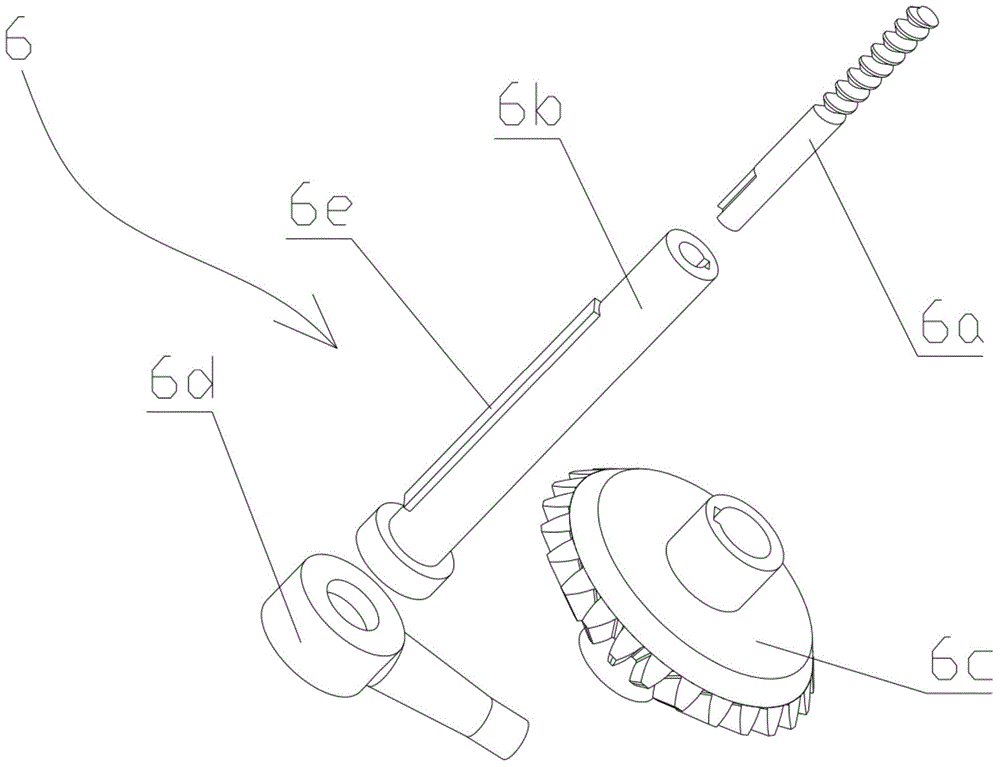

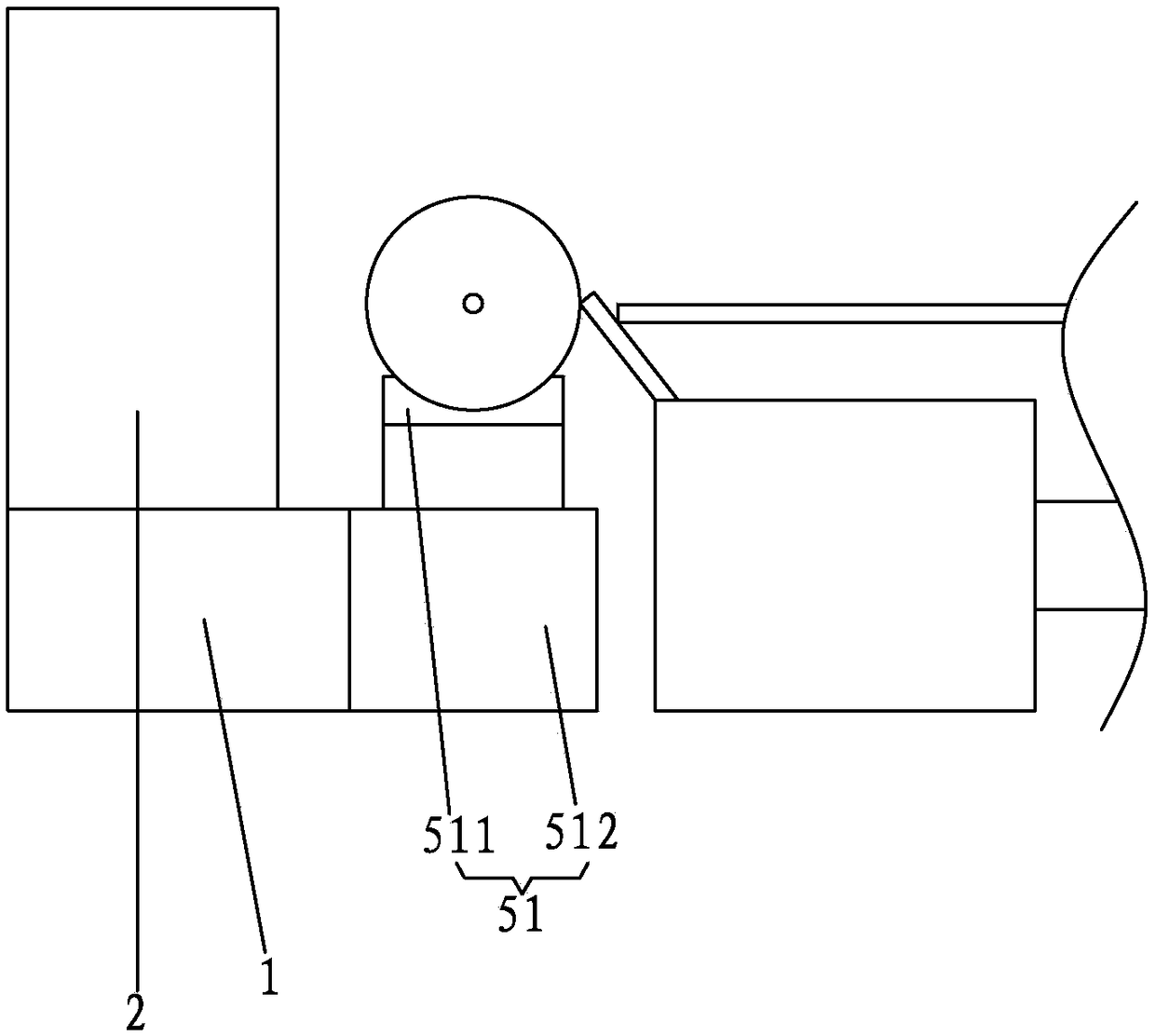

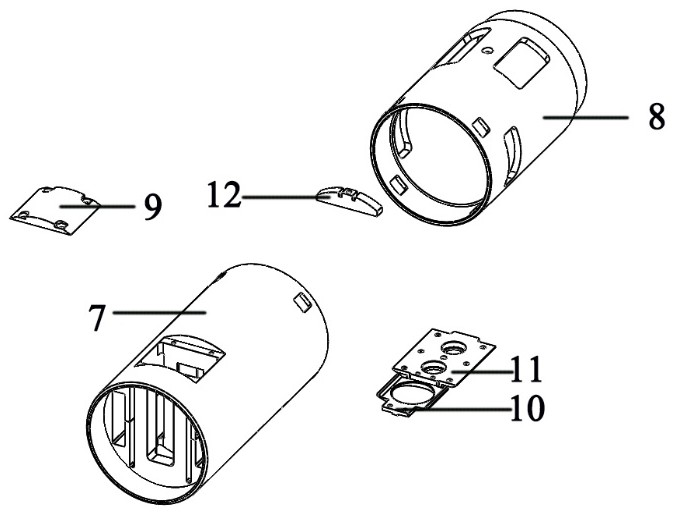

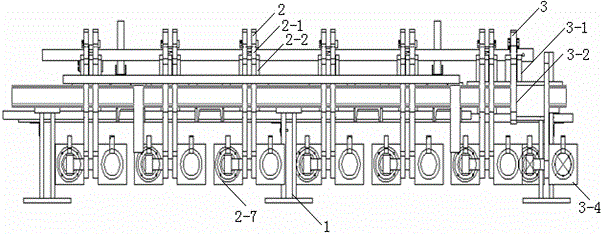

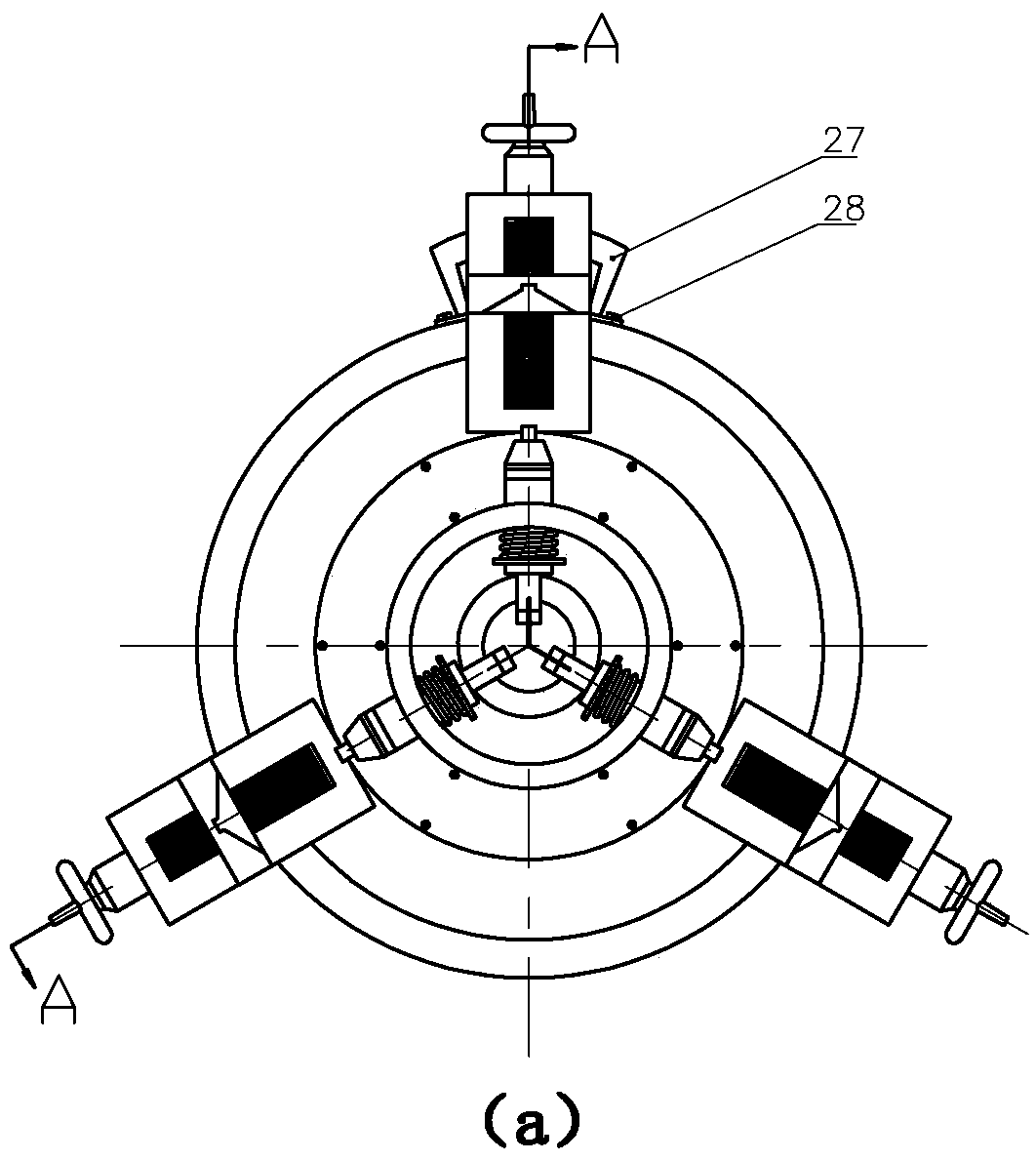

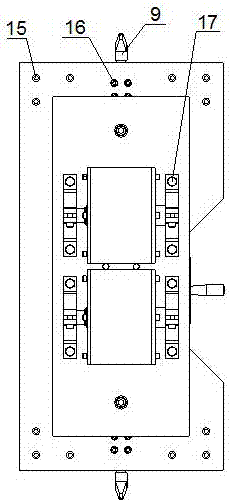

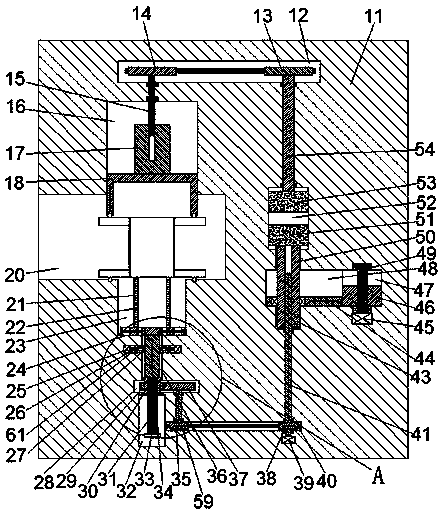

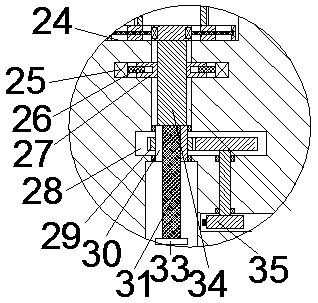

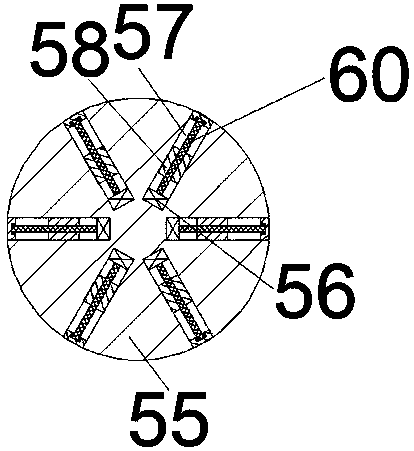

Inner cavity drilled multi-cutter machining device

ActiveCN105057738AImprove processing efficiencyEasy clampingFeeding apparatusDriving apparatusEngineeringBlind hole

The invention discloses an inner cavity drilled multi-cutter machining device. The device comprises a cutter mechanism, a transmission driving mechanism and a feeding mechanism mounted in a box, and a support mechanism connected between the outer wall of the box and a workpiece in a supporting manner, wherein the transmission driving mechanism is connected with the cutter mechanism to drive the cutters to rotate; the feeding mechanism is connected with the cutter mechanism, and controls the radial movement of the cutter mechanism; the cutter mechanism comprises multiple sets of cutter components uniformly distributed in the periphery; and each set of cutter components is mounted in the radial direction, and is arranged towards the inner wall of the workpiece. The device can synchronously machine multiple peripheral blind holes or through holes in the inner cavity of the part, needs no extra fixture in machining to achieve the clamping convenience, and can automatically and quickly center to greatly improve the machining efficiency.

Owner:ZHEJIANG UNIV

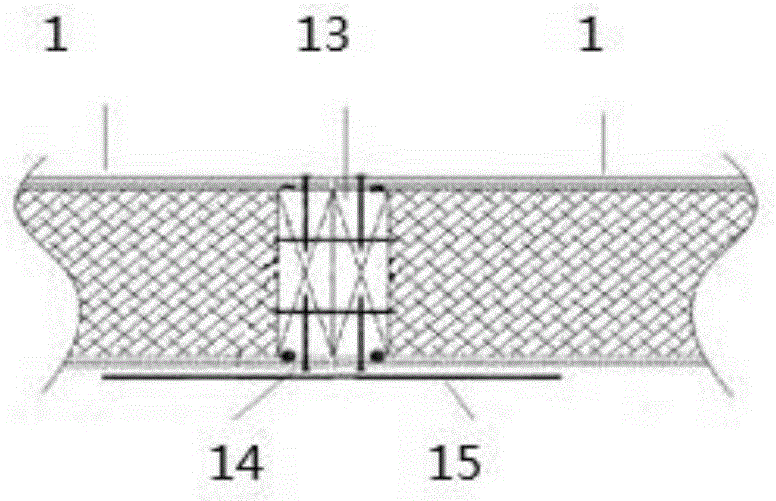

Alignment connector of concave-box wallboard

InactiveCN106320564AWith automatic centering functionImprove pre-registrationWallsAdhesiveEngineering

The invention provides an alignment connector of a concave-box wallboard, using for connecting the wallboard with a concave-box. The alignment connector is a ferrule with cavity in it. The space enclosed by two connected concave-boxes of the wallboard is matched with the shape of the ferrule. The wallboard is capable of automatic centering through the ferrule, meanwhile, a sol space is formed between the concave-box and the ferrule. An adhesive is injected to the openings of the ferrule then the cavity and the sol space are filled. The section of the ferrule is quasi hexagon. The ferrule is matched with the four slopes of the concave box, with the other two sides forming a sol space, or the sides of the ferrule are consecutive or intermittent cambered surface, then the ferrule is matched with the four cambered surfaces of the concave-box, and sol space is formed in the other non-matched sides. The alignment connector achieves a structural connection under the premise of the decorative surface is prevented from the destruction of the wallboard.

Owner:SHENYANG THRIVE INDALIZED HOUSING

Efficient self-centering rotary cutter

The invention discloses an efficient self-centering rotary cutter. In the rotary-cut process, a first lifting drive device drives a first lifting frame to lift and lower along a first guide frame until the center of a positioning cutting knife is roughly at the same height as the center of a log, a user operates a first operating handle to push a first sleeve body to move along a thread towards the log, the first sleeve body has inward pressure on a first positioning arm through a first top abutting sleeve, the first positioning arm performs clamping through a first top abutting gripper, and top abutting grippers of three positioning arms can perform all-dimensional clamping on the log. A first advance and retreat motor drives a first advance and retreat worm wheel to rotate through a first advance and retreat worm, the first advance and retreat worm wheel drives a first shaft body to slide towards the log through a first advance and retreat screw, a first blade is in contact with thelog in a top abutting mode and the log is rotated to cut a groove corresponding to a first conical head, a first end cover is automatically in contact with the groove formed by rotary cutting in a topabutting mode, and the self-centering effect is realized.

Owner:漳州市炯辉机械有限公司

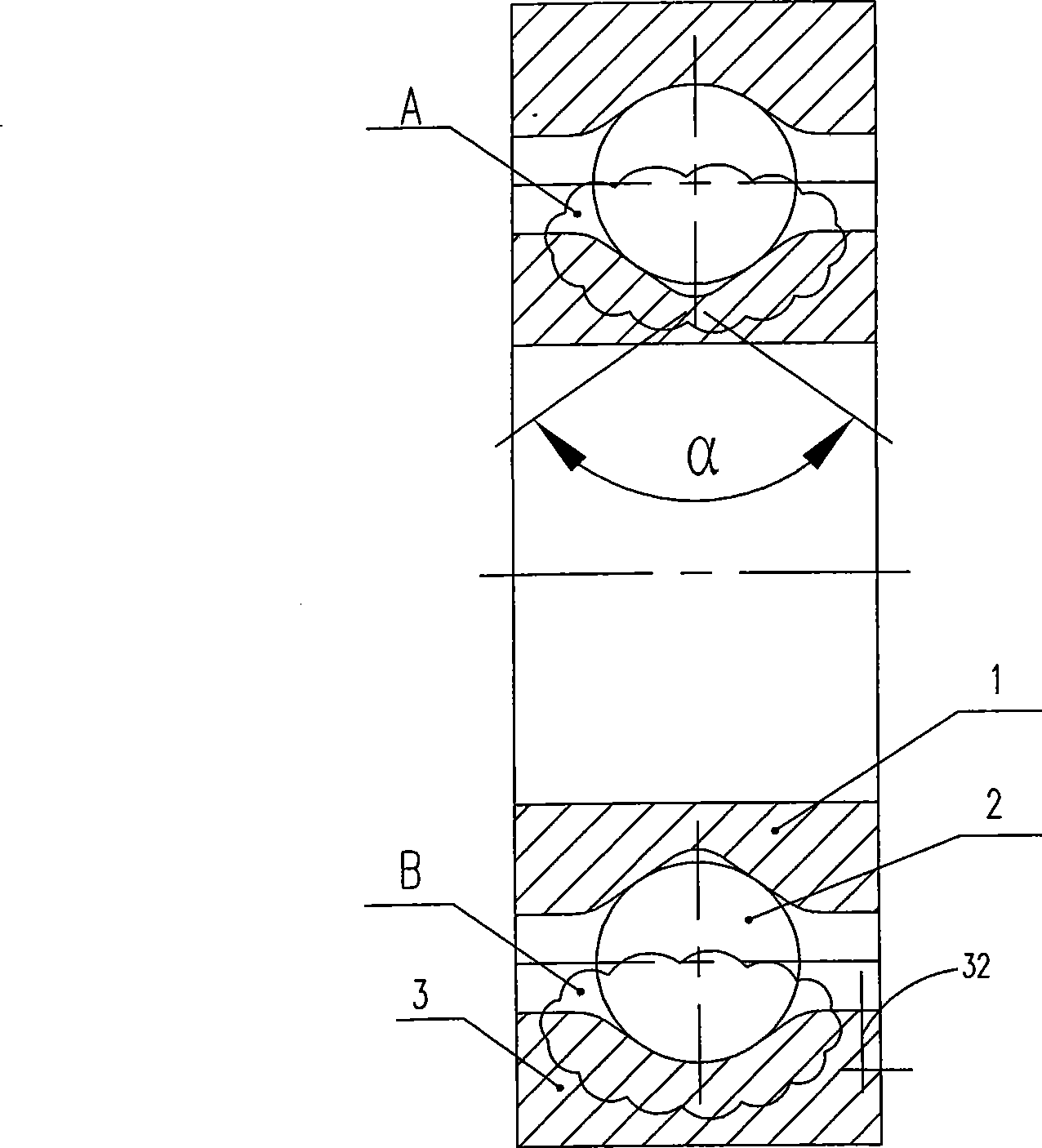

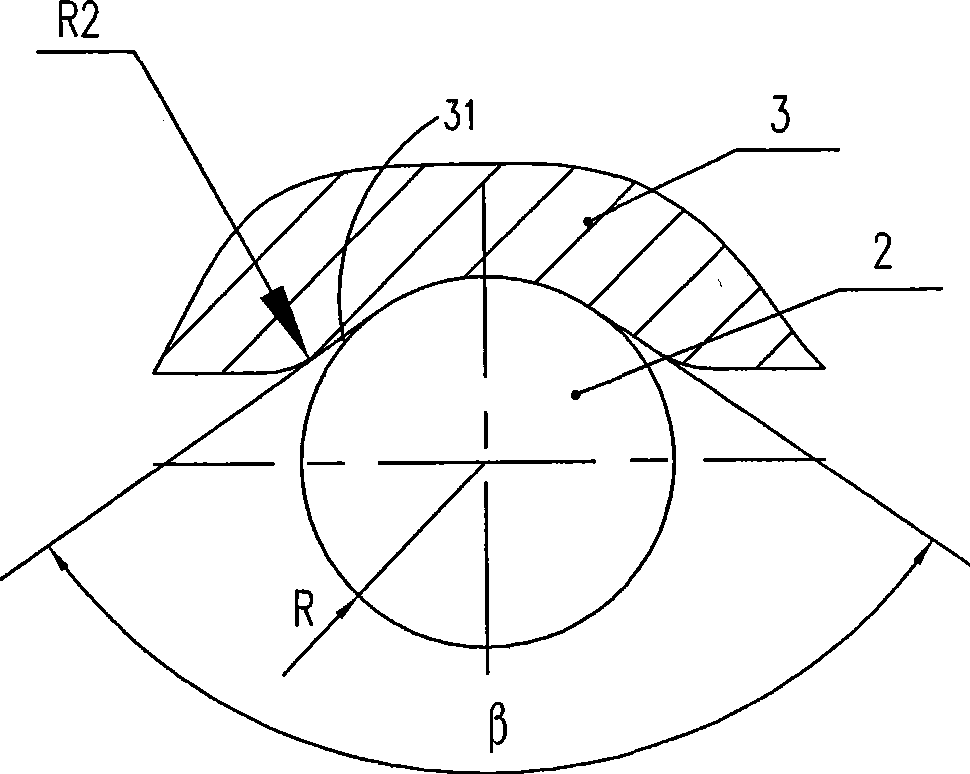

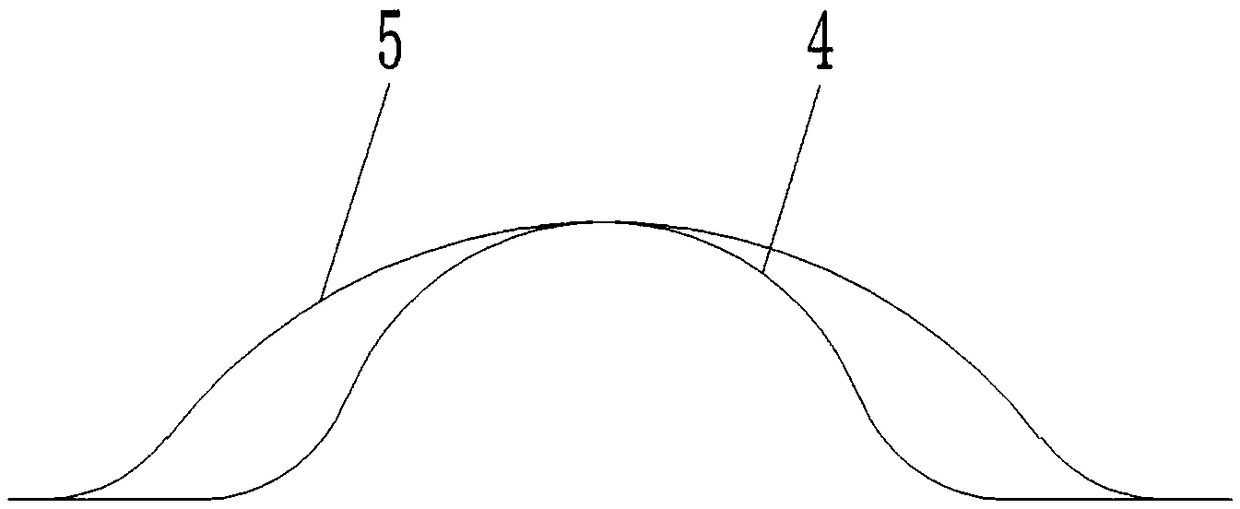

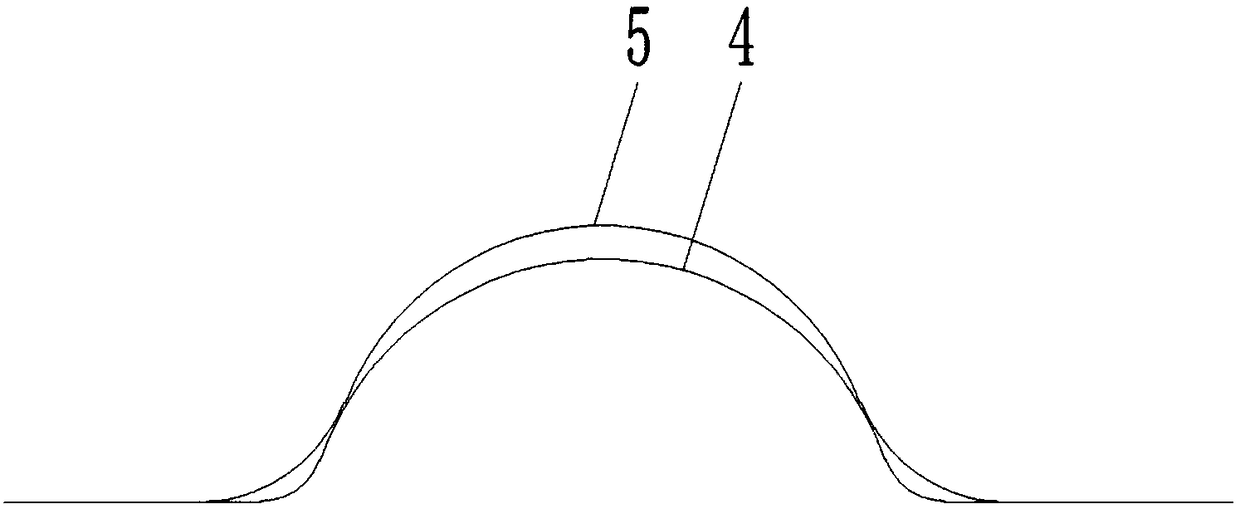

Three-point contact ball bearing

InactiveCN101457785AChange section shapeImprove stress conditionBall bearingsBearing componentsEngineeringMechanical engineering

The invention discloses a three-point contact type ball bearing which comprises a bearing inner ring, a rolling body, and a bearing outer ring; the rolling body is arranged between the bearing inner ring and the bearing outer ring; the invention is characterized in that an annular track the section of which is U-shaped is arranged on the outer side surface of the bearing inner ring; an annular spherical track is arranged on the inner side surface of the bearing outer ring; the included angles between the annular track on the bearing inner ring and the annular spherical track on the bearing outer ring, as well as between the contact point of the rolling body and the central line of the rolling body are between 150 and 270 degrees. The three-point contact type ball bearing is a ball bearing with large size, high rotation speed and adjustable center, and not only can bear a pure radial load, but also can bear a certain radial load; a specially designed lubricating structure greatly improves the lubricating effect and improves the service life of the bearing.

Owner:圣格兰(嘉兴)光机电技术有限公司

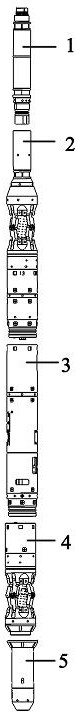

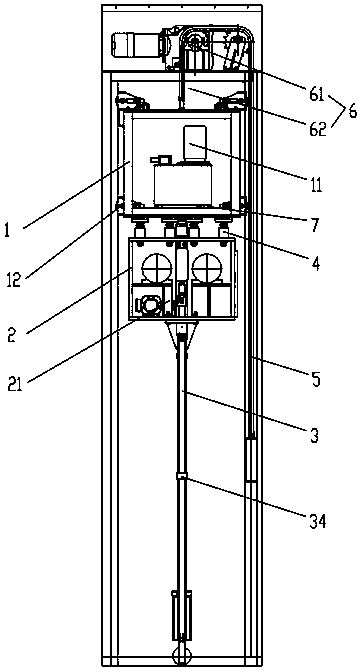

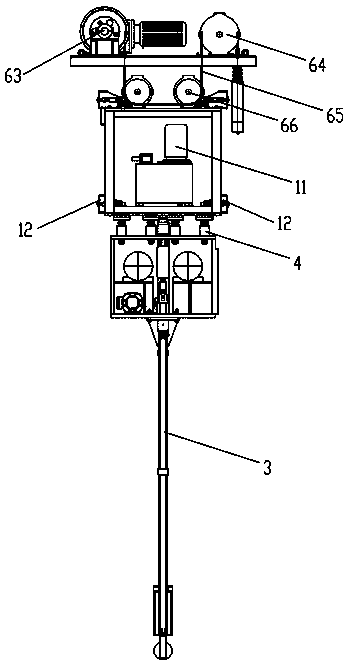

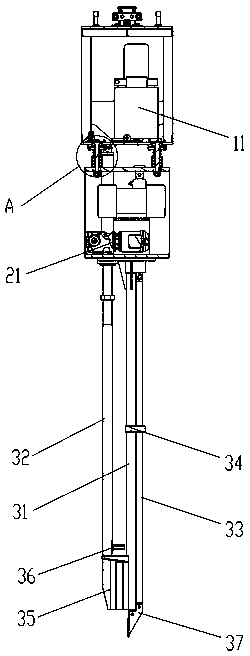

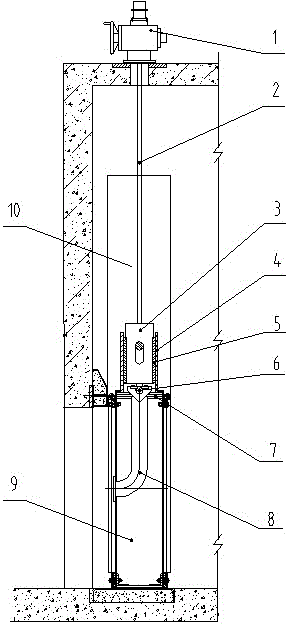

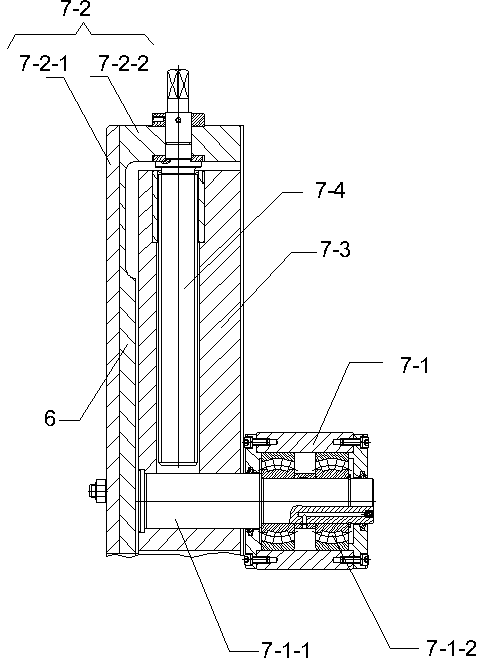

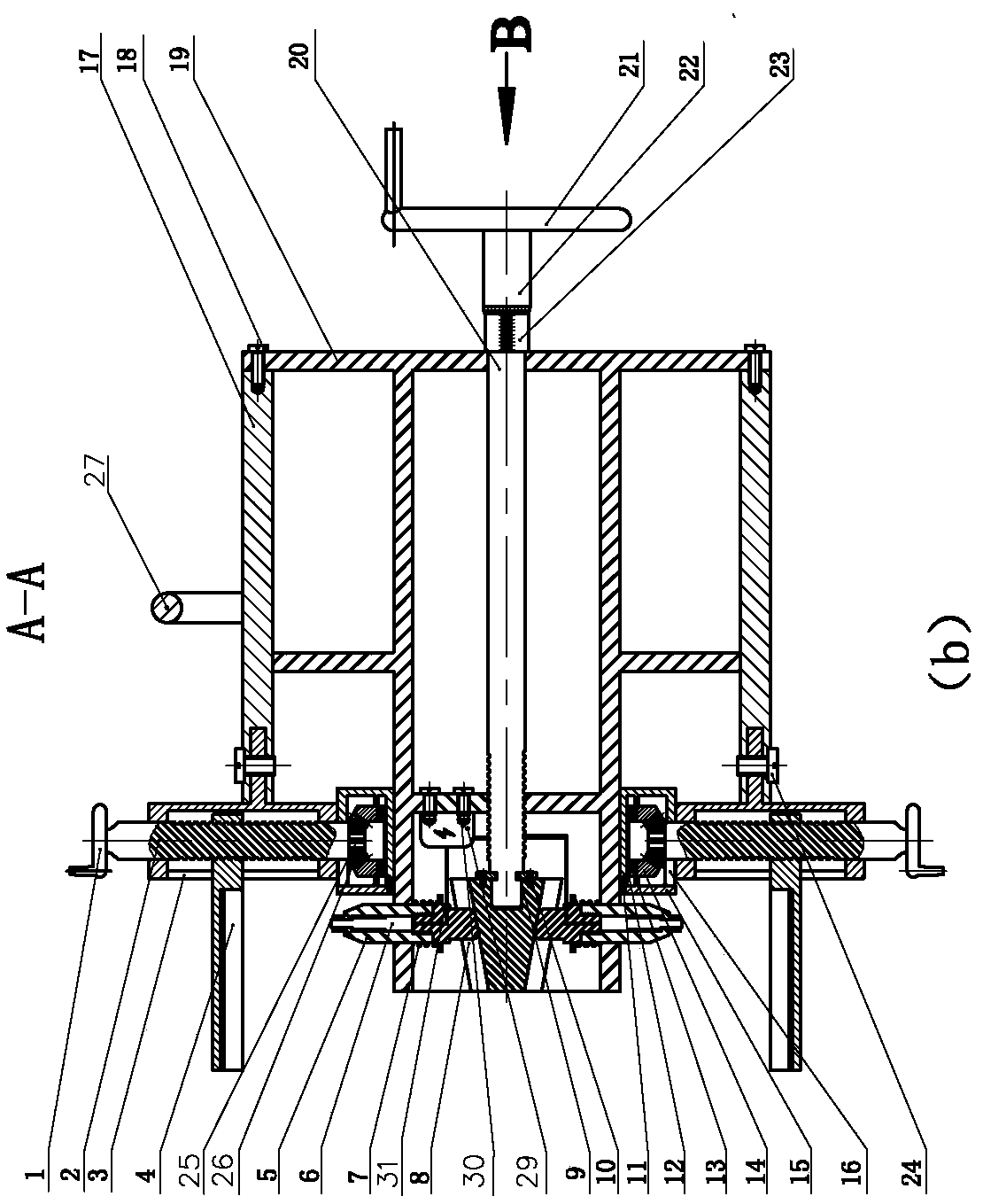

Deep drilling complex environment local wall face stress relieving method testing system

ActiveCN113605886AAvoid risks caused by landslides, etc.Real-time transmissionSurveyConstructionsAutomatic controlSoil mechanics

The invention belongs to the technical field of rock and soil mechanics measurement, and particularly discloses a deep drilling complex environment local wall face stress relieving method testing system. The system comprises an electronic control acquisition subsystem, a pushing and positioning mechanism, a stress relief and strain measurement subsystem and a hydraulic balance subsystem which are connected in sequence, the electronic control acquisition subsystem is connected with a ground controller through communication transmission equipment, the pushing and positioning mechanism is expanded in the radial direction of a center shaft of a drill hole to form a fulcrum and in contact with a well wall, the stress relief and strain measurement subsystem is used for collecting and obtaining strain data of the well wall of a drilling well in the stress relief process, and the hydraulic balance subsystem is used for balancing the internal space of the whole system and the pressure intensity in the drilling well. According to the system, accurately controlling and testing can be carried out on a local wall face with the depth of 3000 meters or above on the ground, automatic control and real-time transmission of test data in a deep drilling complex environment are realized, collapse danger of the drilling well is not easily caused, and the system has the characteristics of simplicity in operation, effectiveness, stability, convenience in maintenance and the like.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI +1

Sampling device

PendingCN107607346ANot mixedGuarantee the precision requirements of procurementWithdrawing sample devicesComputer science

Owner:HUNAN SUNDY SCI & TECH DEV

Gate

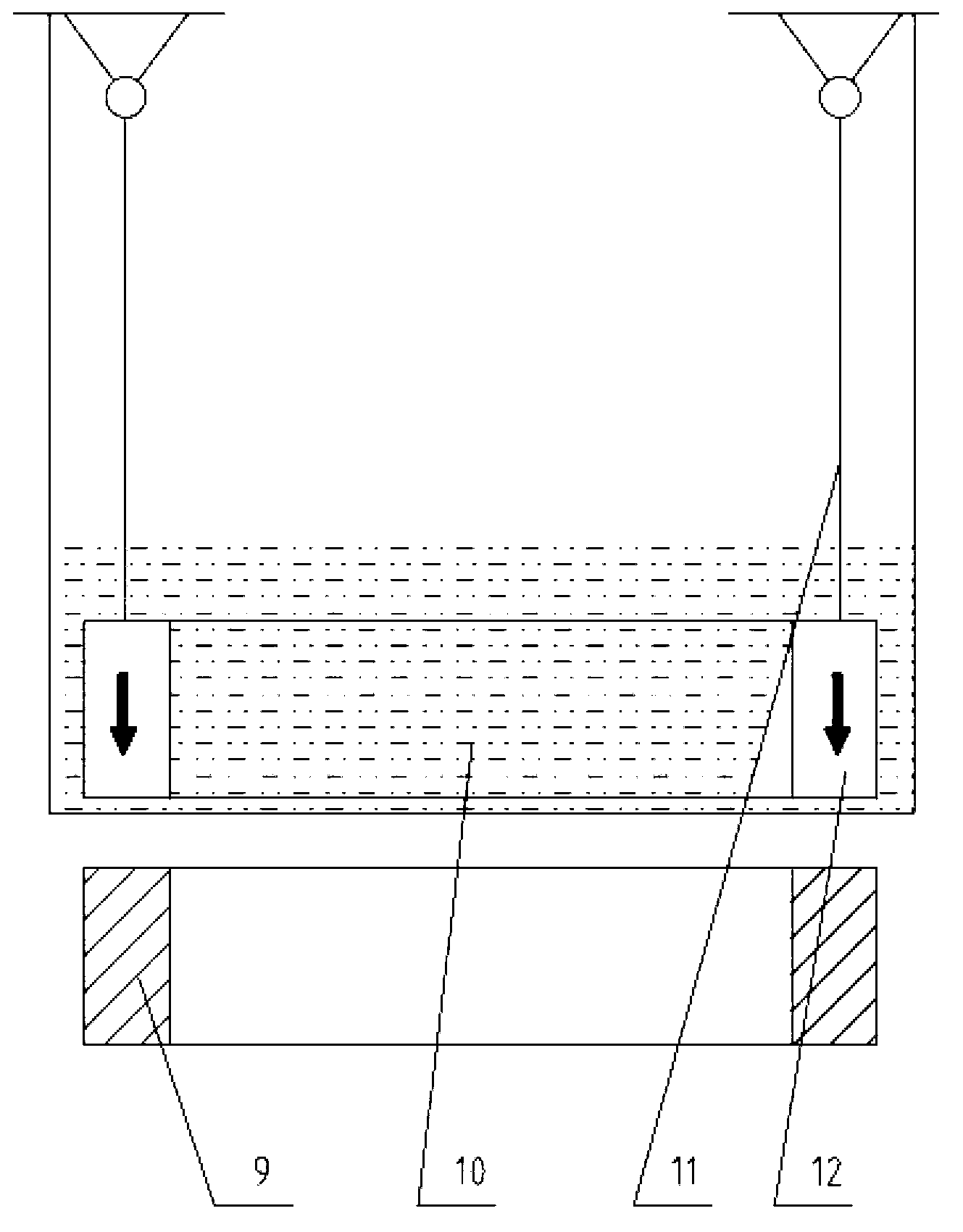

InactiveCN105756021AAvoid excessive frictionSafe and reliable opening and closingBarrages/weirsWater flowEngineering

The invention discloses a gate which comprises a gate body (9) and a gate frame (10). The gate body (9) is mounted in the gate frame (10); the gate body (9) is connected with an on-off device for controlling on-off of the gate body (9); an overflow pipe (8) communicated with both sides of the gate is arranged in the gate body (9); a valve (11) for opening and closing the overflow pipe (8) is arranged on an opening at one side of the overflow pipe (8). Watertight rubber strips are mounted on both surfaces of the steel overhaul gate disclosed by the invention, so that bidirectional compression on the gate can be achieved; by adopting a novel discharge device, the problem of an excessively large friction force when the gate is opened and closed is solved; the gate is safe and reliable to open and close; discharging capacity can be regulated; after overhaul on downstream equipment is completed, impact of water flow to the downstream equipment is effectively reduced.

Owner:LANSHEN GRP CORP LTD

Active corner driving device and rotary car coupler

ActiveCN112977530AReduce loadAvoid the problem of overloadingRailway coupling accessoriesDrive shaftEngineering

The invention provides an active corner driving device and a rotary car coupler. The device comprises a centering mechanism, the centering mechanism comprises a shell assembly, a centering disc and a piston assembly, the centering disc is arranged in the shell assembly in a pivoted mode, the piston assembly abuts against the circumferential wall of the centering disc, a sleeve, a protrusion, a notch and a cam are arranged on the centering disc, and the protrusion and the notch are symmetrically arranged on the two sides of the cam; the guide plate assembly is connected with the shell assembly and the sleeve and provided with an arc-shaped guide groove matched with the cam and the protrusion, and the protrusion is arranged in the arc-shaped guide groove; the driving mechanism is pivotally mounted in the shell assembly and comprises a cam plate assembly provided with a strip-shaped groove and a driving shaft assembly mounted in the strip-shaped groove; and the power assembly is connected with the driving mechanism. The power assembly pushes the cam plate assembly to rotate and extrude the piston assembly, the driving shaft assembly moves along the guide groove, and when the driving shaft assembly moves to make contact with the protrusion, the driving shaft assembly continues to move to push the centering disc to rotate. The centering disc is connected with a mechanical structure, and automatic rotation of the mechanical structure can be achieved.

Owner:CRRC QINGDAO SIFANG ROLLING STOCK RES INST +1

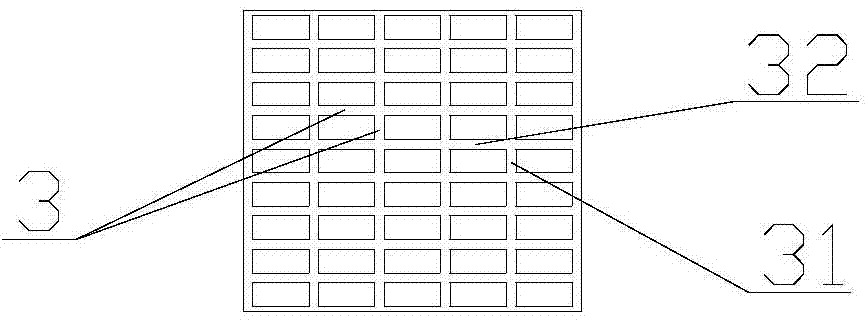

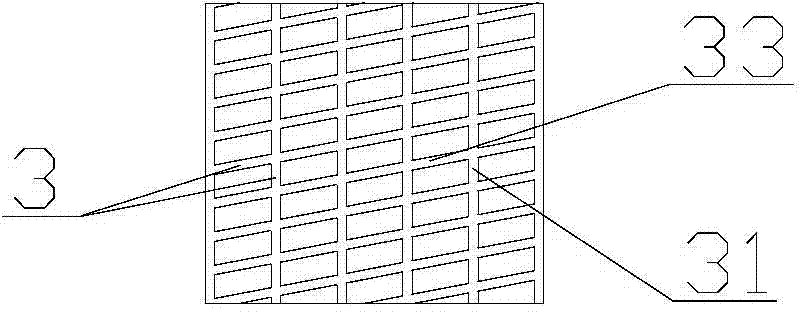

High-pressure multi-way valve based on laser micromachining technology

ActiveCN103925253AReduce leakageIncrease frictionServomotor componentsSlide valveGroove widthHigh pressure

The invention relates to the technical field of hydraulic components, in particular to a high-pressure multi-way valve based on the laser micromachining technology. The multi-way valve is used for solving the problems that in the prior art, because pressure equalizing grooves formed in a valve element cause stress deformation of the valve element, the precision of matching between the valve element and a valve body hole is affected, errors of the coaxiality between the valve element and the valve body hole are enlarged, and consequently the valve element and the valve body hole are tightly clamped together. According to the scheme, the matching circumferential surface of a valve element of the multi-way valve and a valve body of the multi-way valve is provided with netted micro grooves machined through lasers, the groove width of each micro groove ranges from 0.1 mm to 0.3 mm, the groove depth of each micro groove ranges from 0.004 mm to 0.02 mm, the micro grooves include the circumferential grooves arranged in parallel and the axial circumferential grooves arrayed in parallel, the interval between every two adjacent circumferential grooves ranges from 1 mm to 3 mm, and the interval between every two adjacent axial grooves ranges from 1 mm to 3 mm.

Owner:CHANGZHOU XIAOGUO INFORMATION SERVICES +1

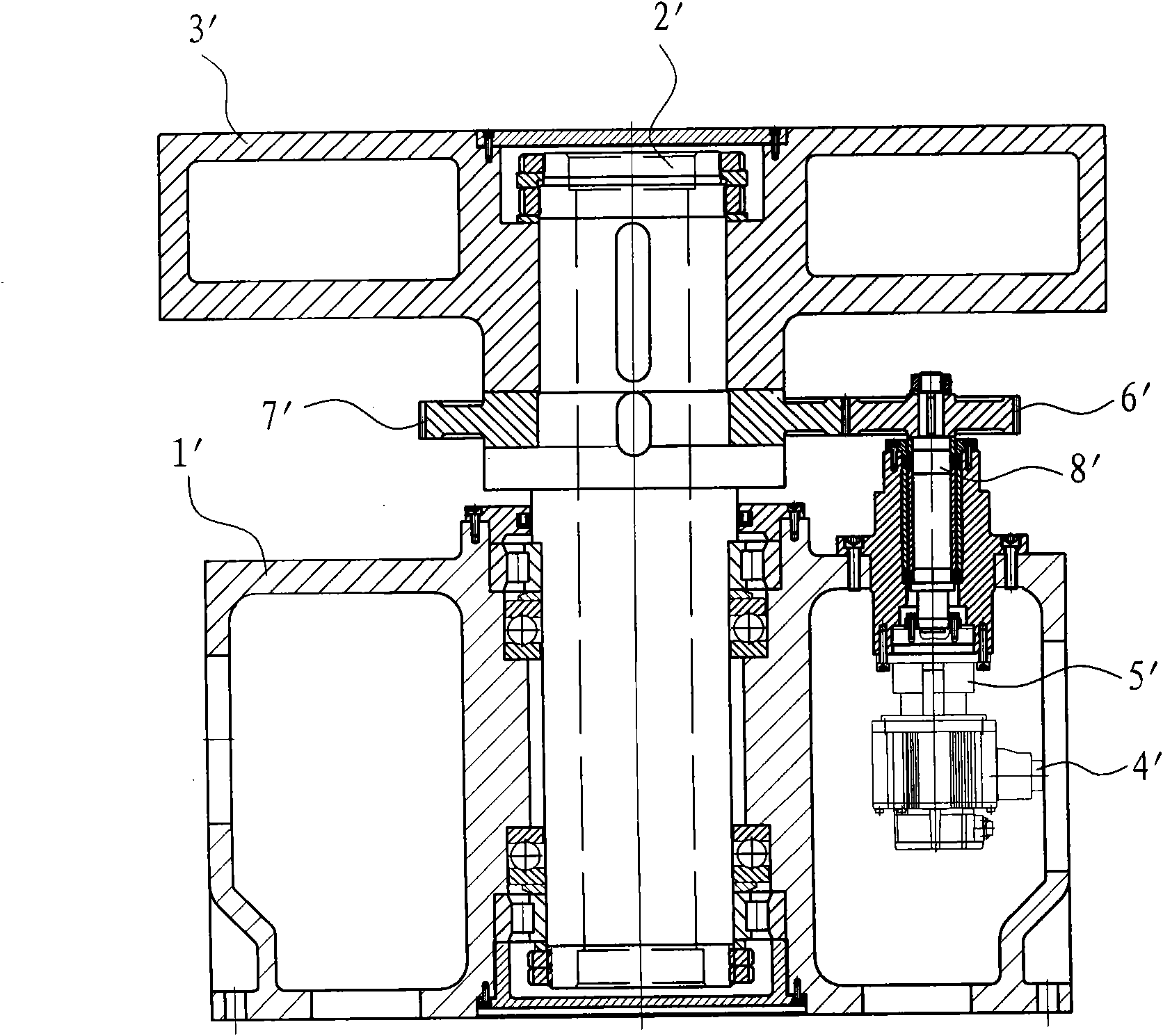

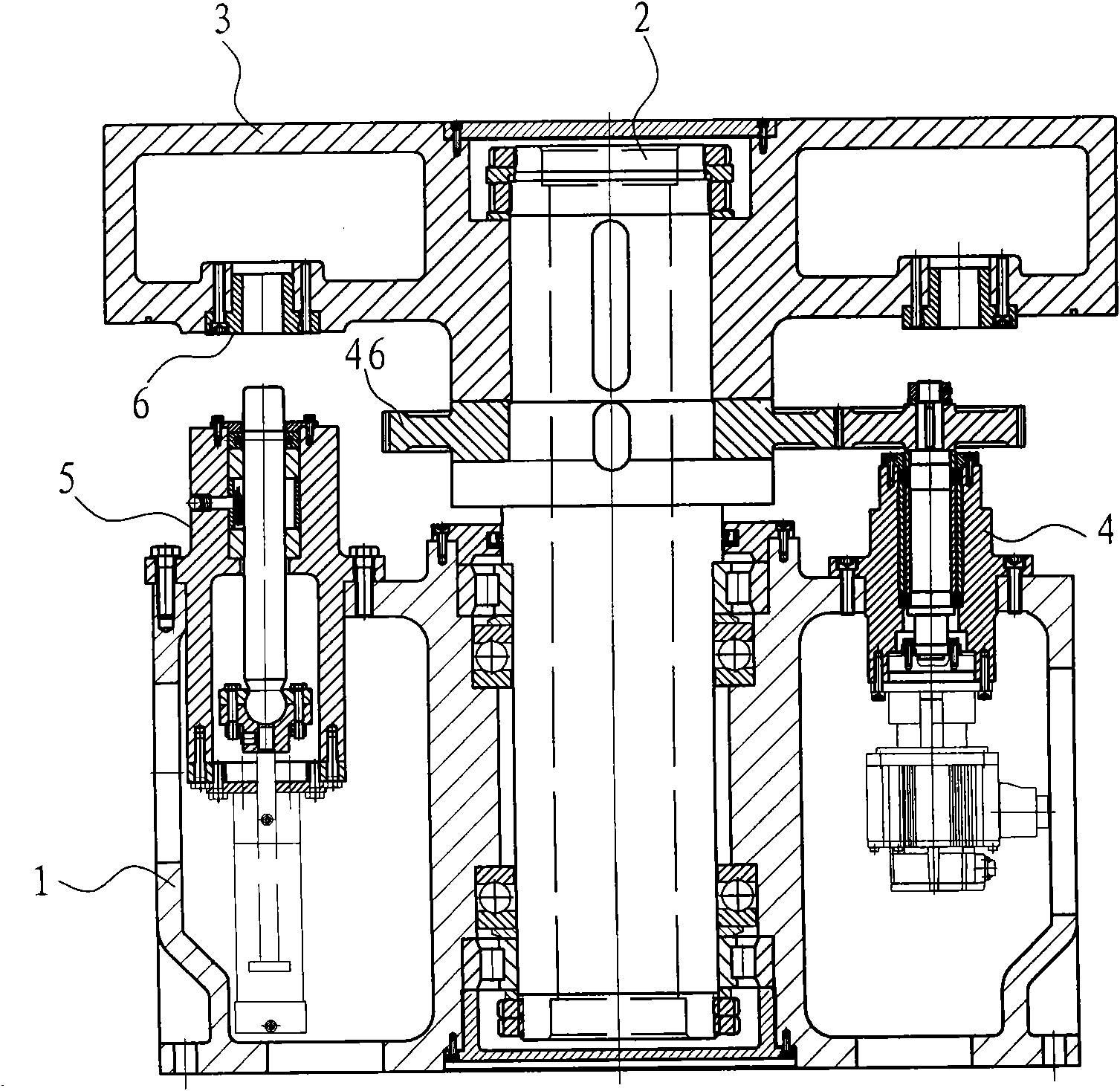

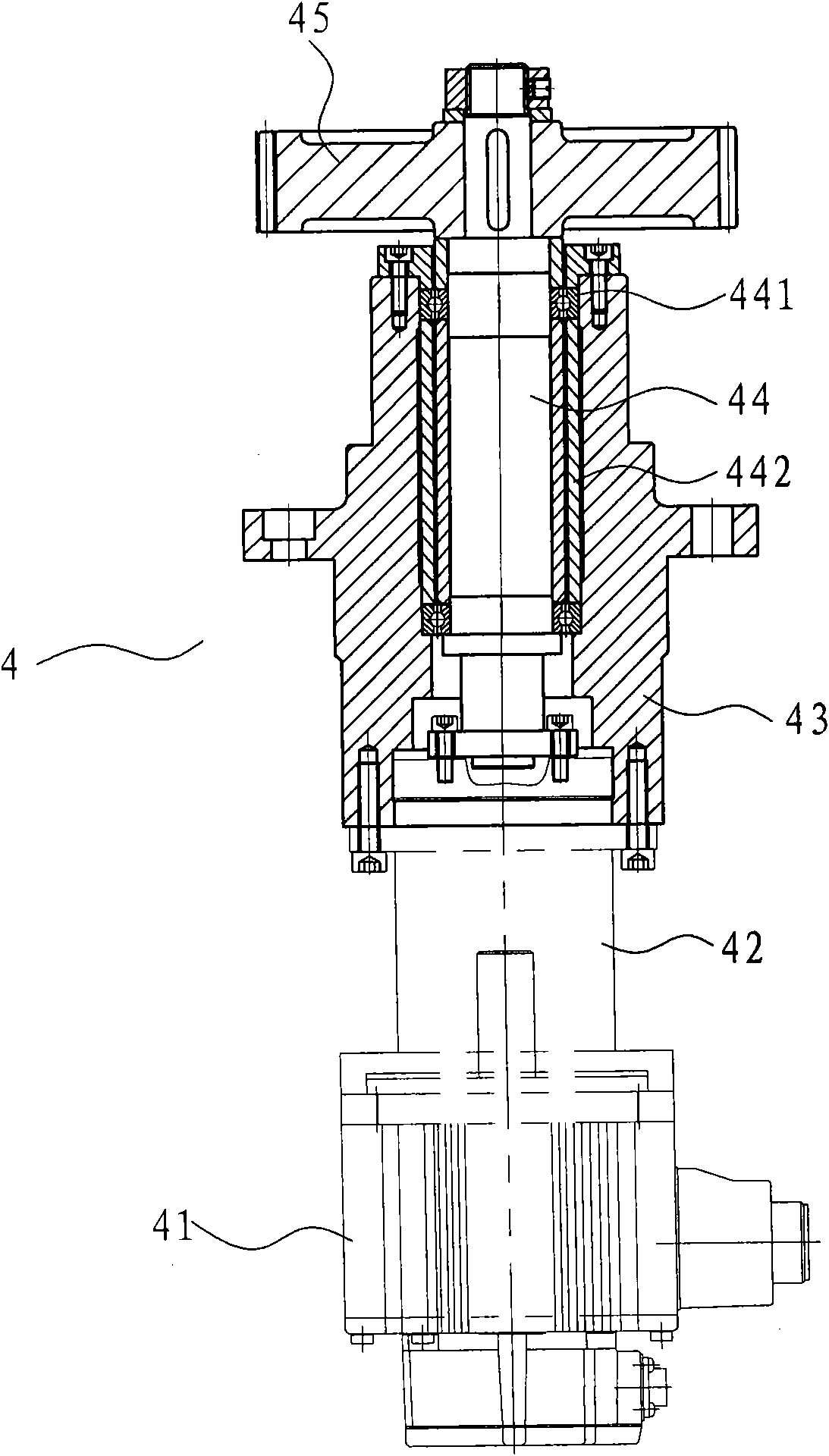

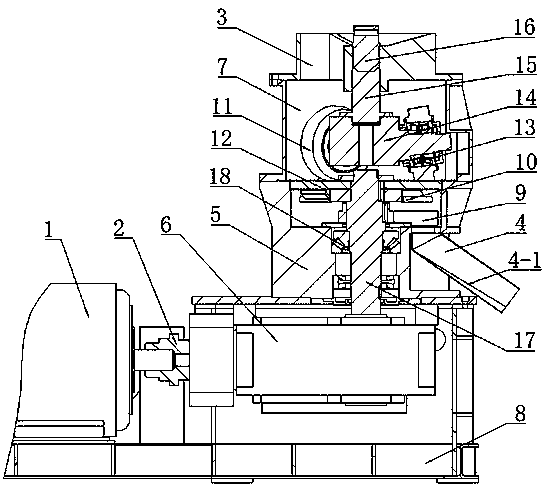

Vertical rotary workbench of numerical control machine tool

InactiveCN102059559AGuaranteed accuracyWith gap adaptive adjustment functionLarge fixed membersEngineeringWorkbench

The invention provides a vertical rotary workbench of a numerical control machine tool with accurate positioning. The vertical rotary workbench comprises a base, a rotating shaft, a workbench and a rotary driving device, wherein the rotating shaft is rotationally arranged on the base; the workbench is fixedly arranged at the top of the rotating shaft; the rotary driving device is arranged betweenthe base and the rotating shaft and used for driving the workbench to rotate; the base is provided with one to four scale division positioning devices; and the lower surface of the workbench is provided with two to eight taper pin sleeves of corresponding scale division angles, and the taper pin sleeves are uniformly distributed along the circumference direction of the workbench.

Owner:泗洪启航精密机械科技有限公司

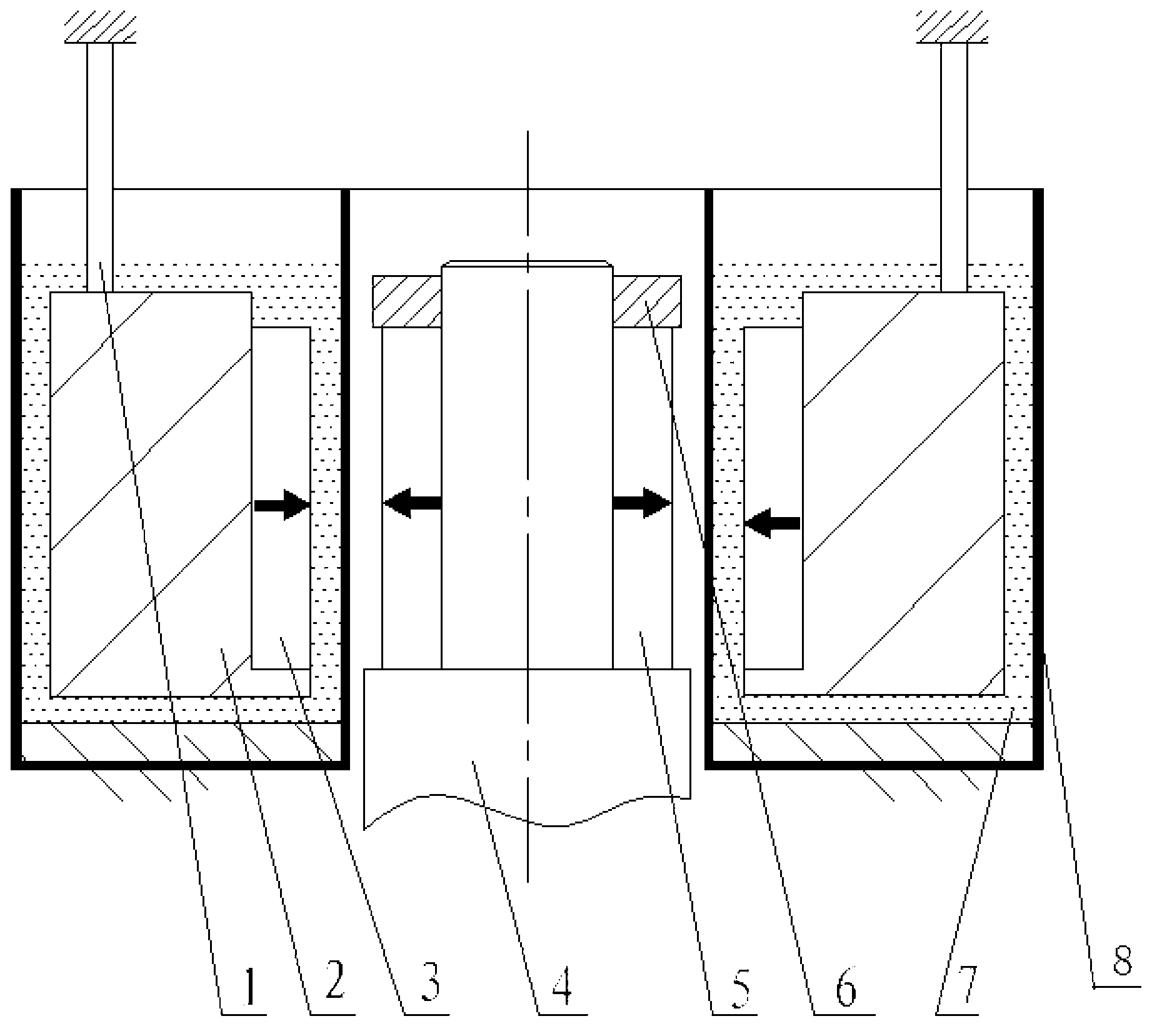

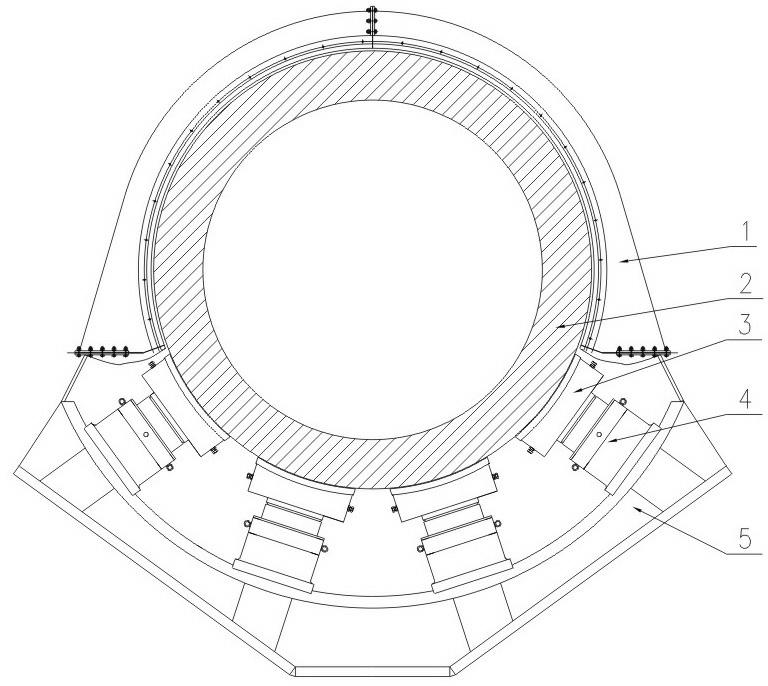

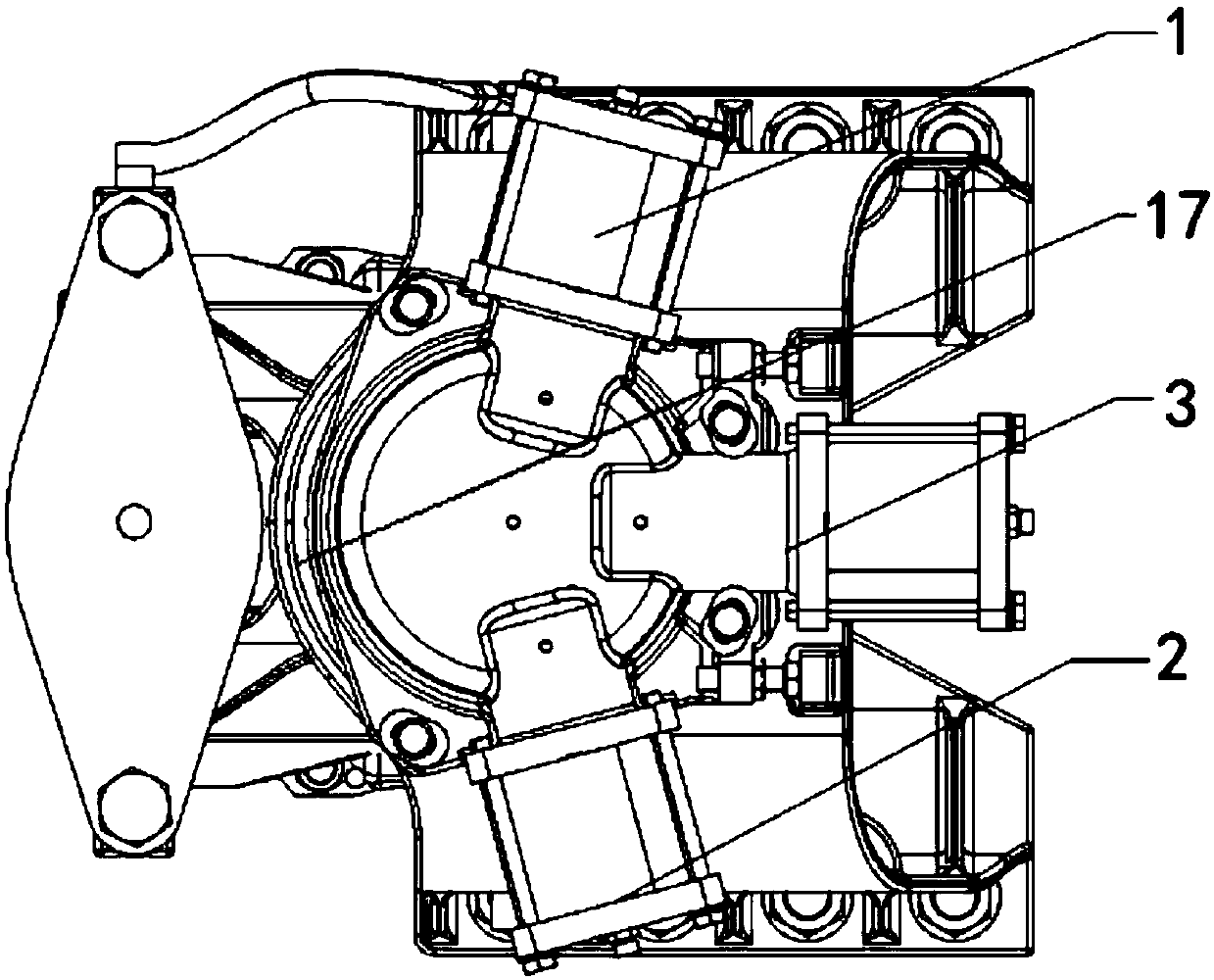

Hydraulic pressure adjustable type slipper bearing device for supporting large-sized mill barrel

InactiveCN102128204AReduce gapSafe and reliable workSliding contact bearingsGrain treatmentsPistonHigh pressure

The invention discloses a hydraulic pressure adjustable type slipper bearing device for supporting a large-sized mill barrel, which comprises a protection cover (1), bearing pads (3), hydraulic cylinders (4) and a base (5), wherein the hydraulic cylinders are symmetrically distributed and fixed on the base; the upper end of each hydraulic cylinder is connected with a bearing pad; the bearing pads are used for supporting the barrel (2); the two ends of the base is connected with the protection cover of which the diameter is greater than the external diameter of the barrel and the shape is larger than a semicircle; each hydraulic cylinder consists of a convex sphere seat (6), a piston (7), a regulating nut (10), a cylinder seat (11) and a sealing ring (12); and an anti-loosening device comprises an anti-loosening pressing sleeve (8), a screw (13), a washer (14) and the like. After the height regulation of the piston is determined, the hydraulic cylinders are disassembled, and the high pressure of the barrel acts on the regulating nut; and in order to prevent the loosening of the regulating nut due to vibration generated when the barrel is operated, the anti-loosening pressing sleeve is fixed on the regulating nut through the screw, so that the rotating joint of the regulating nut and the piston cannot be loosened, and the safe and stable operation of the barrel can be ensured.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Workpiece clamping device applied to horizontal lathe

ActiveCN104339191AGuaranteed stabilityImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringPortal frame

The invention aims to provide a workpiece clamping device applied to a horizontal lathe. The workpiece clamping device comprises a supporting baseplate arranged on a lathe surface, wherein two movable brackets are arranged on the supporting baseplate, and support rollers capable of rotating freely are arranged on the brackets. The workpiece clamping device is characterized in that a portal frame is further arranged on the supporting baseplate, vertical plates on two sides of the portal frame are located on the plate surfaces at two ends of the supporting baseplate, adjustable roller devices are arranged on two sides of a top central line of the portal frame respectively, and rollers capable of rotating freely are arranged on the roller devices; and a workpiece is clamped by the two support rollers at the bottom and the two rollers at the top. The clamping device can guarantee the workpiece stability during machining, improves the machining precision, and effectively increases the machining efficiency of the lathe.

Owner:RONGCHENG METAL FORMING MACHINE GROUP

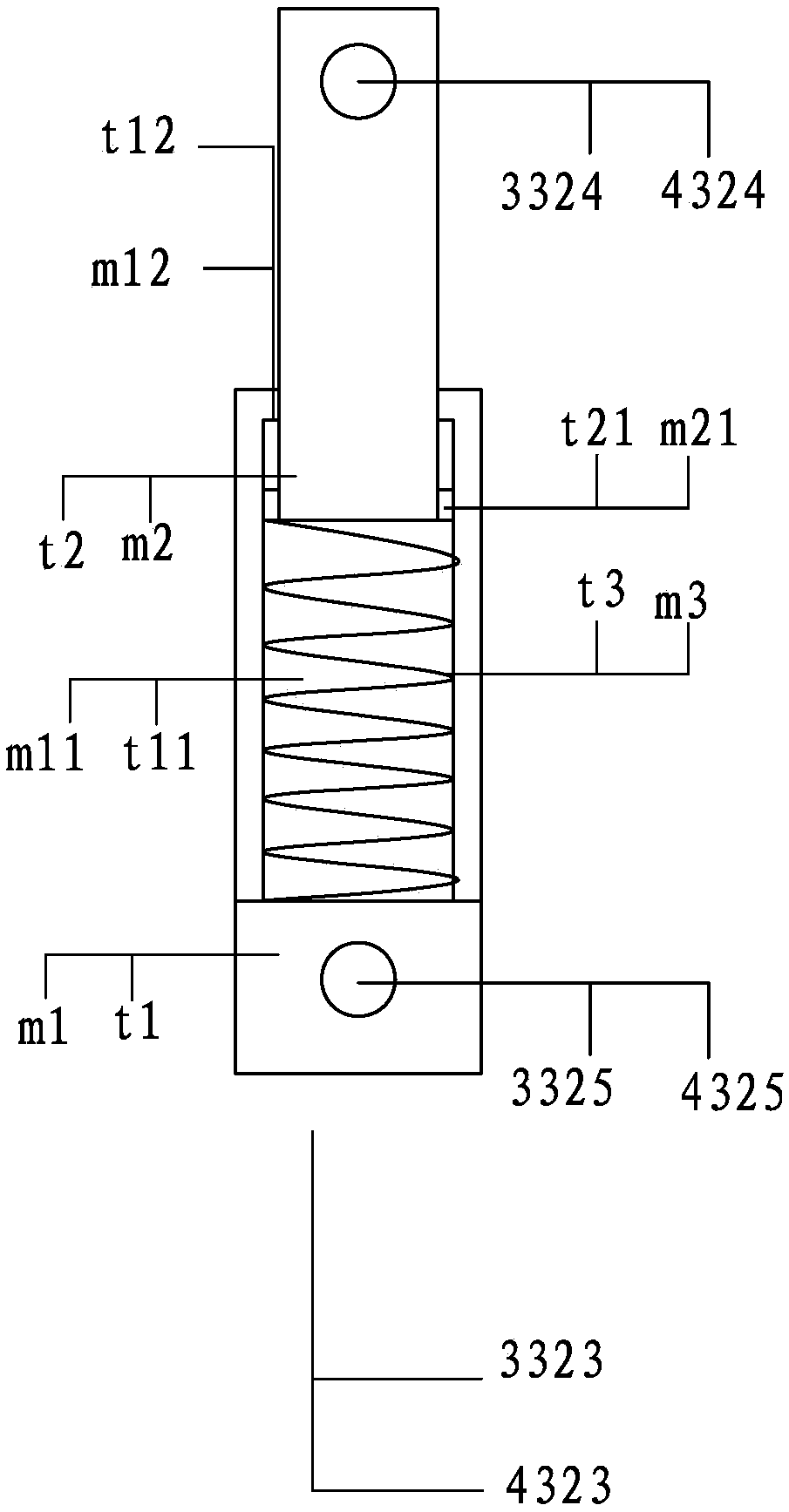

Damping follow rest for turning slender axle

ActiveCN103009075AHigh rotation accuracyGuaranteed processing size and shape toleranceAuxillary equipmentLarge fixed membersCoolantIndustrial engineering

The invention discloses a damping follow rest for turning a slender axle. The damping follow rest comprises a lower support seat and an upper support seat, wherein the upper support seat is matched with the lower support seat, the upper support seat and the lower support seat form a cylindrical hollow cavity structure, the inside of the hollow cavity is sheathed with a fixing sleeve, the inside of the fixing sleeve is provided with a damping sleeve which is provided with an inner hollow structure, the damping sleeve is in taper fit with the fixing sleeve, one larger-diameter end of the damping sleeve is provided with a spring, the spring is fixedly arranged in the fixing sleeve by an end cap, and the spring acts on the large-diameter end surface of the damping sleeve through a gasket. The damping follow rest has the advantages that the vibration is basically eliminated, so the influence caused by the abrasion of the damping sleeve is eliminated; the abrasion speed of an inner hole of the damping sleeve can be reduced by coolant, so a purpose of reducing the abrasion of the damping sleeve is realized; the use specifications of the support seats are reduced, and the material usage amount and the processing amount of the fixing sleeve are reduced, so a purpose of saving energy is realized; the processing size and the shape tolerance of a workpiece are ensured, and the qualified rate is improved; and the processing cost is effectively reduced, and the production efficiency is improved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA +1

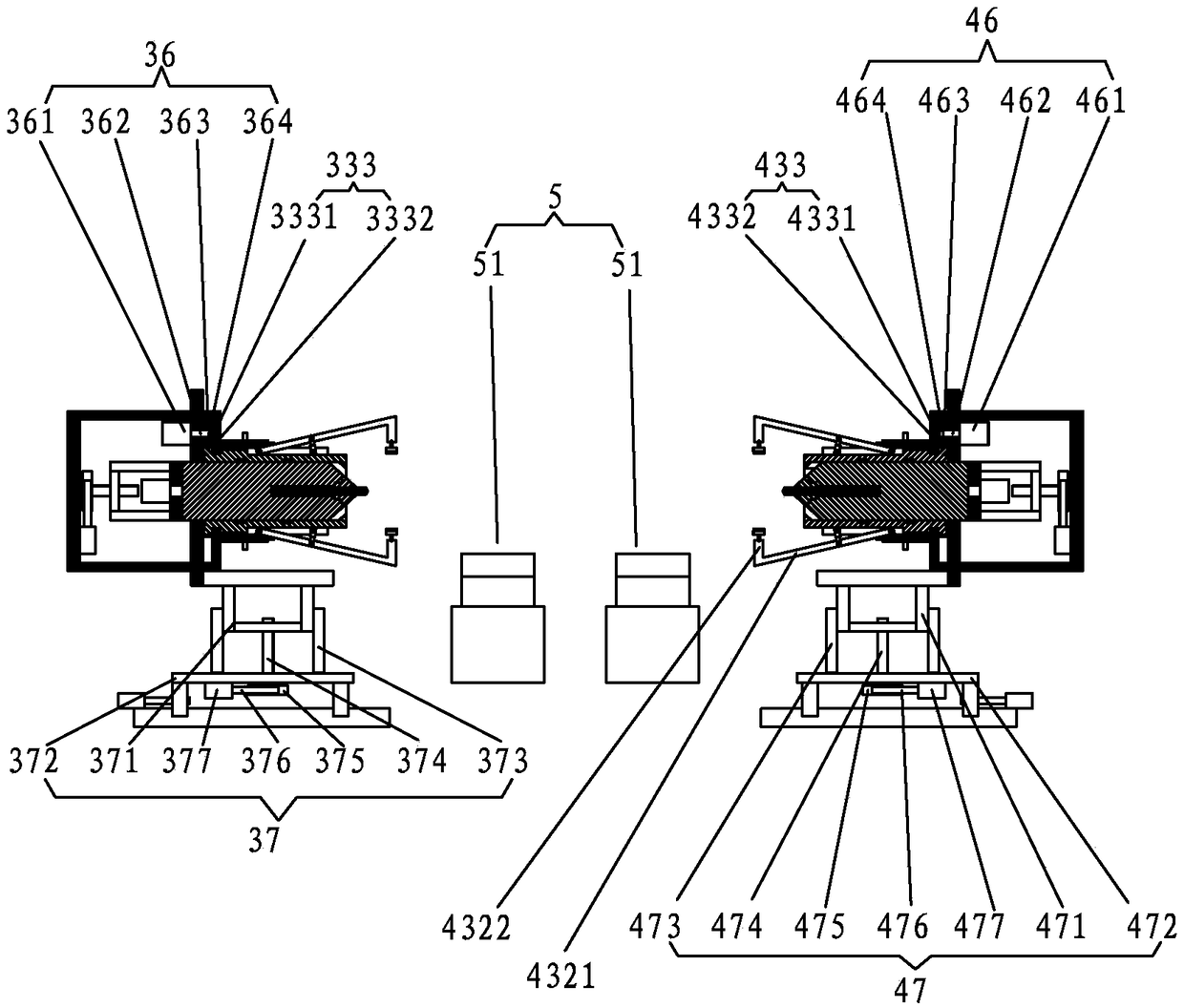

Multi-unit combined cold extrusion press

ActiveCN106583569AFirmly connectedImprove reliabilityMetal-working feeding devicesPositioning devicesMulti unitExtrusion

A multi-unit combined cold extrusion press comprises a base, rod piece joint pressure-welding units and a rod piece connecting sleeve pressure-welding unit, wherein the rod piece joint pressure-welding units and the rod piece connecting sleeve pressure-welding unit are mounted on the base; each rod piece joint pressure-welding unit comprises rod piece pressing arms I and a pressing arm shaft I, and the rod piece pressing arms I form a lever structure by taking the pressing arm shaft I as the fulcrum; the rod piece connecting sleeve pressure-welding unit comprises rod piece pressing arms II and a pressing arm shaft II, and the rod piece pressing arms II form a lever structure by taking the pressing arm shaft II as the fulcrum; and the two or more groups of rod piece joint pressure-welding units are provided, and every two adjacent groups of rod piece joint pressure-welding units are arranged at the intervals required by joints on rod pieces and are fixed in the axial direction of the rod pieces. The multi-unit combined cold extrusion press has the advantages that the connection performance is good, the reliability is high, the operation is convenient and quick, the connection quality is less influenced artificially, energy saving and low consumption are realized, and the multi-unit combined cold extrusion press is green and environment-friendly.

Owner:湖南金峰金属构件有限公司 +1

Electrostatic conductive removal type polyester oil delivery pipe end face radial key groove processing device

ActiveCN108890732AGuaranteed machining accuracyImprove processing efficiencyMetal working apparatusProcessing accuracyPolyester

Provided is an electrostatic conductive removal type polyester oil delivery pipe end face radial key groove processing device. The device comprises a base module, a clamping module and a hot processing module. The electrostatic conductive removal type polyester oil delivery pipe end face radial key groove processing device has the advantages that the function that three linkage clamping claws canbe driven simultaneously and three hot processing cutting heads can be driven simultaneously can be achieved, that is, the device has the function of automatic centering and characteristic of processing same deep key grooves simultaneously, thereby ensuring the processing precision of an electrostatic conductive removal type polyester oil delivery pipe end face radial key groove, the device is simple and reliable, the processing efficiency is high, the adaptation is high, and the site construction performance is good.

Owner:JIANGSU UNIV

Aligning mechanism for vehicle couplers of rail vehicles and vehicle rescue method

ActiveCN107672619AWith automatic centering functionAchieve rescueRailway coupling accessoriesCouplingCam

The invention discloses an aligning mechanism for vehicle couplers of rail vehicles and a vehicle rescue method. The aligning mechanism for the vehicle couplers comprises a cam disc, a first telescopic rod, a second telescopic rod and a third telescopic rod; the cam disc is used for being fixedly connected with a vehicle coupler buffer shell; the first telescopic rod is arranged on one side of thecam disc and used for driving the cam disc to rotate anticlockwise; the second telescopic rod is arranged on the other side of the cam disc and used for driving the cam disc to rotate clockwise; andthe third telescopic rod is arranged between the first telescopic rod and the second telescopic rod and used for keeping the center lines of the vehicle couplers and the center lines of vehicle bodiesbeing aligned; a first notch, a second notch and a third notch are formed in the peripheral surface of the cam disc; when the cam disc rotates anticlockwise, the first notch is engaged with the extending end of the first telescopic rod; when the cam disc rotates clockwise, the second notch is engaged with the extending end of the second telescopic rod; and when the center lines of the vehicle couplers and the center lines of the vehicle bodies are aligned, the third notch is engaged with the extending end of the third telescopic rod. The technical problem of automatic coupling of the vehiclecouplers on a small-radius curve is solved.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO LTD

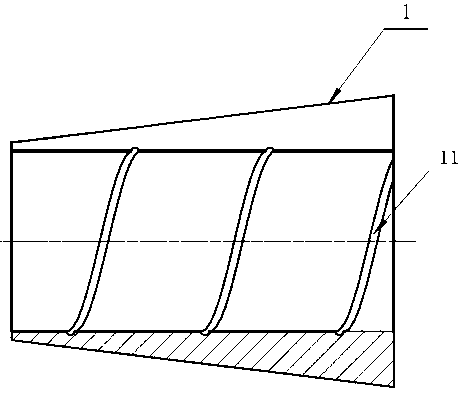

Multi-channel type planet traction transmission bearing type speed reducer

PendingCN109372963AReduced axial positioning structureIncrease contact areaFriction gearingsRelative displacementPlanet

The invention discloses a multi-channel type planet traction transmission bearing type speed reducer. The multi-channel type planet traction transmission bearing type speed reducer comprises a planettraction transmission wheel system formed by a transmission inner shaft, an outer ring, a planet rolling body and a planet carrier jointly. Cooperation pairs are formed between the outer circle of theplanet rolling body and the inner circle of the outer ring and between the outer circle of the planet rolling body and the outer circle of the transmission inner shaft through annular protrusions andannular channels, and the planet rolling body cooperates with the transmission inner shaft and the outer ring in a friction transmission manner. By means of the mutual structural constraint of the annular protrusions and the annular channels, when torque is transmitted between the transmission inner shaft and the planet rolling body, relative displacement of the planet rolling body and the transmission inner shaft in the axial direction and the radial direction of the outer ring can be effectively limited, the functions of a bearing and reduction transmission are achieved, and the speed reducer is high in supporting rigidity, stable in transmission and compact in structure.

Owner:CHONGQING UNIV

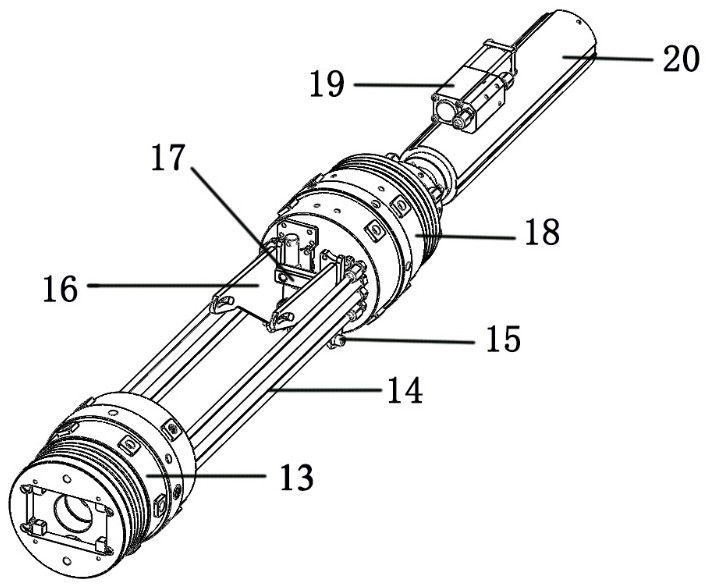

Multipoint interpolation well diameter scale device

ActiveCN103775063AGuaranteed correctnessWith automatic centering functionSurveyMechanical engineeringWellbore

The invention relates to a multipoint interpolation well diameter scale device. The multipoint interpolation well diameter scale device comprises a scale beam, and a scale slide frame which is composed of a centering fixing seat, scale slide rods, slide rod connection rods and slide rod connecting heads. The multipoint interpolation well diameter scale device is characterized in that each scale slide rod is provided with a plurality of pin holes with precise location degrees, the scale beam is connected with the scale slide frame through a tight fit pin, and the scale beam simulates a life-size wellbore. The multipoint interpolation well diameter scale device has a self centering function and improves precision.

Owner:CNPC GREATWALL DRILLING ENG

Press roller type organic fertilizer granulator

The invention discloses a press roller type organic fertilizer granulator which comprises a feeding chamber, a pressing chamber, a forming chamber and a base which are sequentially arranged from top to bottom. A pressing roller assembly is arranged in the pressing chamber; a template is mounted at the lower part of the compression roller assembly in a matched manner; the template is provided witha material forming hole which is through up and down; a cut-off tool connected with the material forming hole is arranged in the forming chamber; a material poking disc is arranged at the lower part of the cut-off tool; and the template and the material poking disc are both sleeved outside the rotating shaft. The granulator can be used for granulation of organic fertilizer cylinders with differentspecifications, and is widely applied to granulation of base fertilizer after fermentation of animal waste and straw.

Owner:山东金格瑞机械有限公司

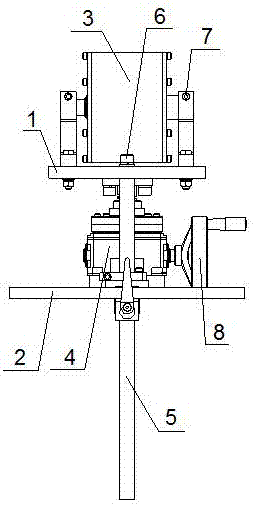

Automatic centering roller central frame device capable of ascending and descending

InactiveCN107511561ARealize the slewing supportWith lifting functionWelding accessoriesInterference fitEngineering

The invention discloses an automatic centering roller central frame device capable of ascending and descending. The upper end of a lifting guide rod is connected with a lifting bottom plate, the middle of the lifting guide rod is fixed to a sliding bottom plate through a linear bearing in an interference fit manner, a guide rod locking device is fixed to the linear bearing, a locking bolt is arranged on the guide rod locking device, a roller bracket assembly is fixed to the lifting bottom plate, and is composed of two roller brackets and used for automatic centering, the locking bolt is arranged on a rotating support of the roller brackets, the rotating support is fixed to the lifting bottom plate, a hand shaking worm gear and worm drive assembly comprises a worm gear and worm speed reducer, a hand shaking wheel, a joint and a screw, and a sliding block is fixedly mounted at the bottom of a sliding bottom plate; the sliding block is arranged on a welding dedicated sliding rail, the sliding bottom plate slides on the welding dedicated sliding rail through the sliding block, and machining of shaft parts with the different lengths can be achieved. A sliding rail clamping device is fixed to the sliding bottom plate, and a locking wrench used for clamping or loosening the welding dedicated sliding rail is arranged on the sliding rail clamping device capable of being wrenched.

Owner:JIANGXI HONGDU AVIATION IND GRP

Cable take-up device and use method thereof

InactiveCN109264498AWith automatic centering functionReduce workloadFilament handlingDrive motorElectric cables

Owner:义乌市建信金属材料有限公司

Vermicelli spreader

InactiveCN108887722AReduce energy consumptionImprove efficiencyFood shapingGlass fiberEconomic benefits

The invention discloses a vermicelli spreader, comprising a conveyer belt, a transmission component, a support frame and a spreading tank. The support frame is fixedly mounted at the lower end of theconveyer belt; the transmission component is fixedly mounted at the upper end of the conveyer belt; the spreading tank is arranged below the transmission component; glass fiber reinforced plastic is fixedly mounted on the inner wall of the spreading tank and includes an outer protective layer, a glass fiber reinforced layer and a base; the glass fiber reinforced plastic is formed by press-fittingthe outer protective layer, the glass fiber reinforced layer and the base sequentially from top to bottom. The vermicelli spreader has the advantages that motor energy consumption can be decreased, economic benefit is effectively improved, motor torque condition can be monitored in real time during spreading to prevent the fact that motor is damaged due to too high torque when jamming occurs during spreading, vermicelli contamination can also be prevented, and cleanliness of vermicelli processing is ensured.

Owner:YINGSHANG TIANHAO FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com