Hydraulic pressure adjustable type slipper bearing device for supporting large-sized mill barrel

An adjustable technology for sliding shoe bearings, applied in sliding contact bearings, grain processing, etc., can solve the problems of large production capacity, different contact gaps between bearing bushes and cylinders, manufacturing errors, etc., and achieve the effect of small gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

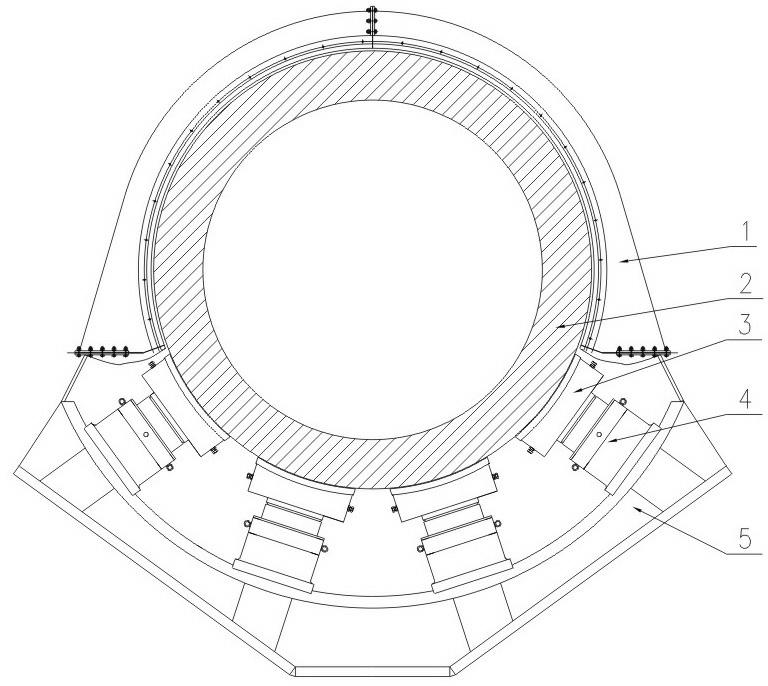

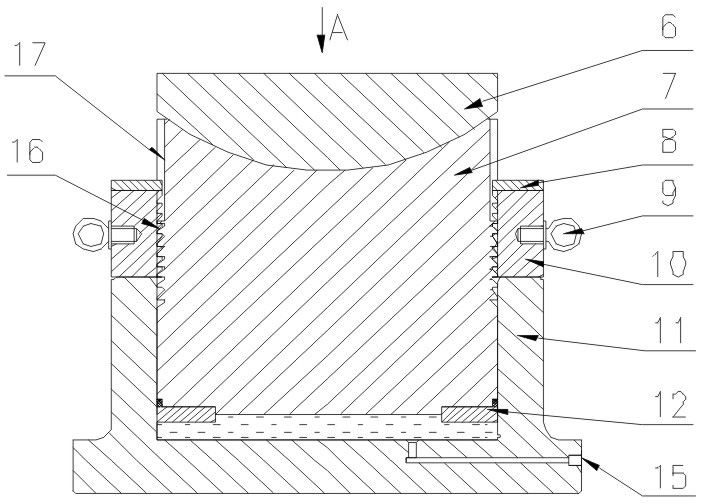

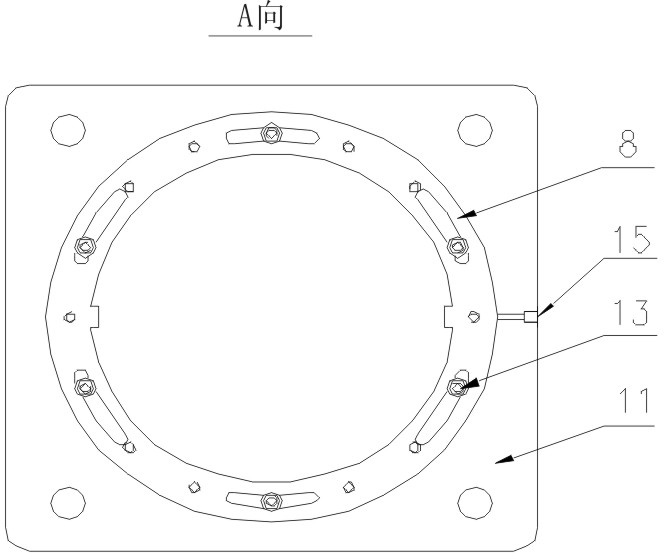

[0021] Such as figure 1 As shown, the hydraulically adjustable sliding shoe bearing device used for the support of the cylinder of a large mill in the present invention includes a protective cover 1, a bearing bush 3, a hydraulic cylinder 4 and a base 5, and the hydraulic cylinders 4 are symmetrically distributed and fixed on the base 5. figure 1 The shown embodiment is configured with four hydraulic cylinders 4, wherein the innermost two hydraulic cylinders 4 are symmetrically distributed and the outermost two hydraulic cylinders 4 are also symmetrically distributed. The jacking force is related to the weight pressure of the mill barrel, which needs to be determined according to the design requirements, and will not be repeated here. The upper end of each hydraulic cylinder 4 is connected to the bearing bush 3, and the bearing bush 3 supports the cylinder body 2. The two ends of the base 5 are connected with a semicircular protective cover 1 that is larger than the outer diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com