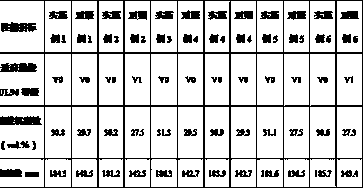

Patents

Literature

317results about How to "Improve thermal protection performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

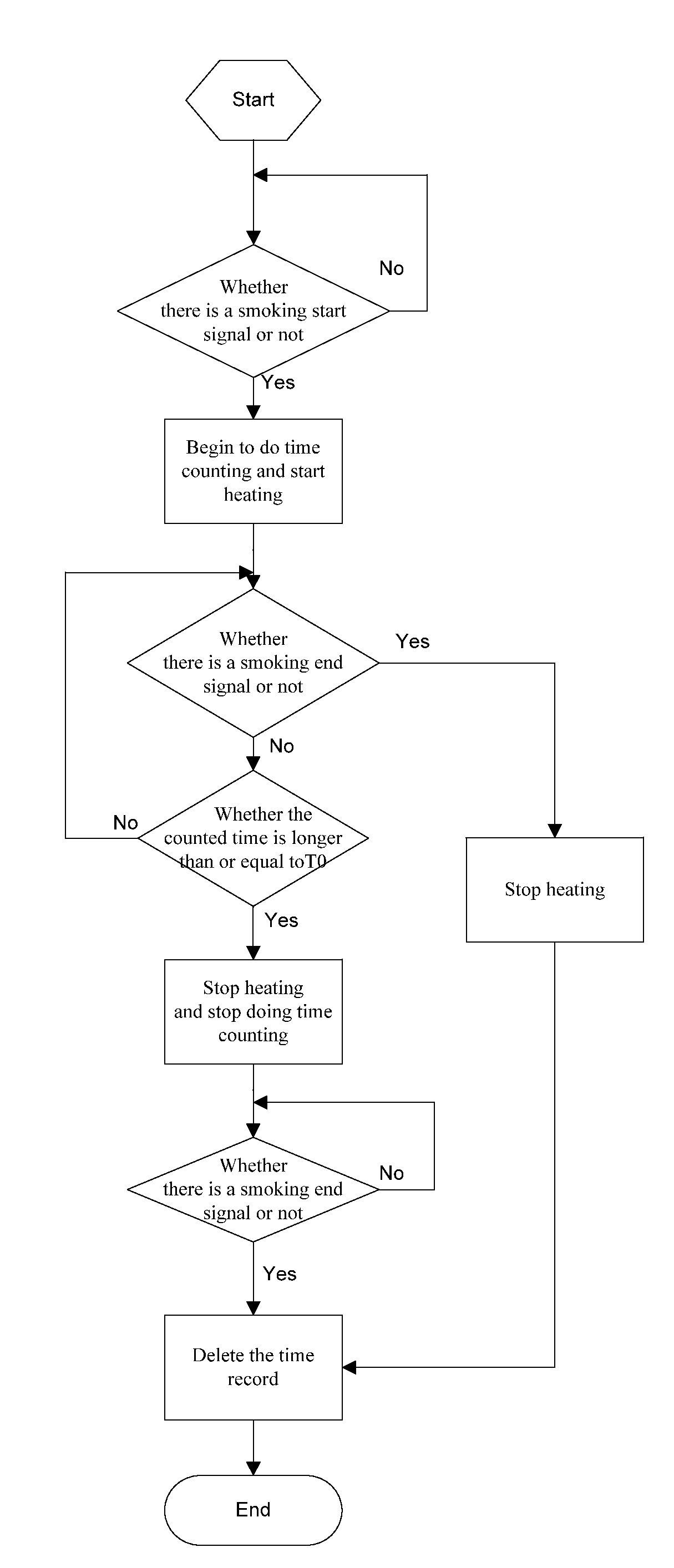

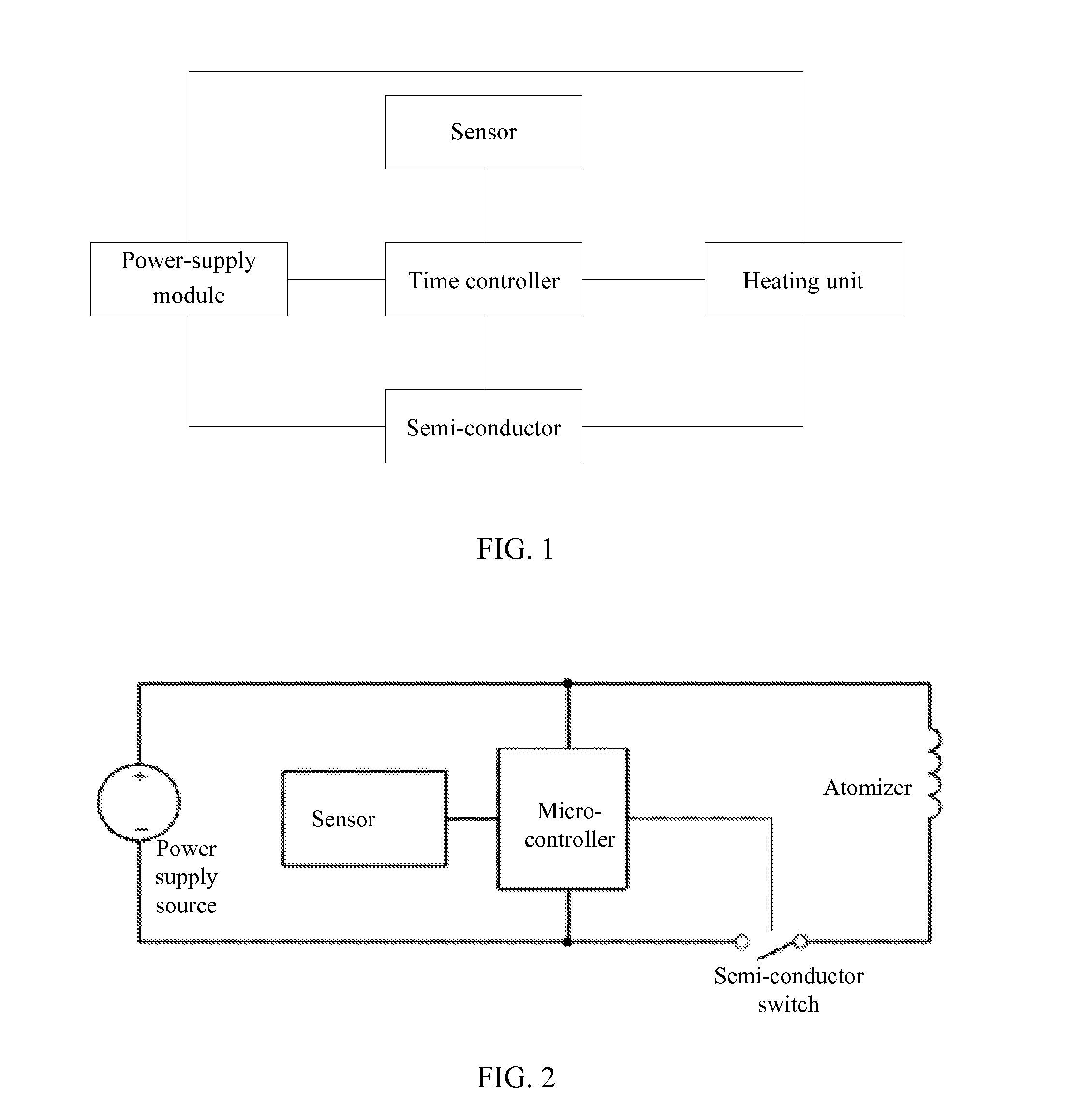

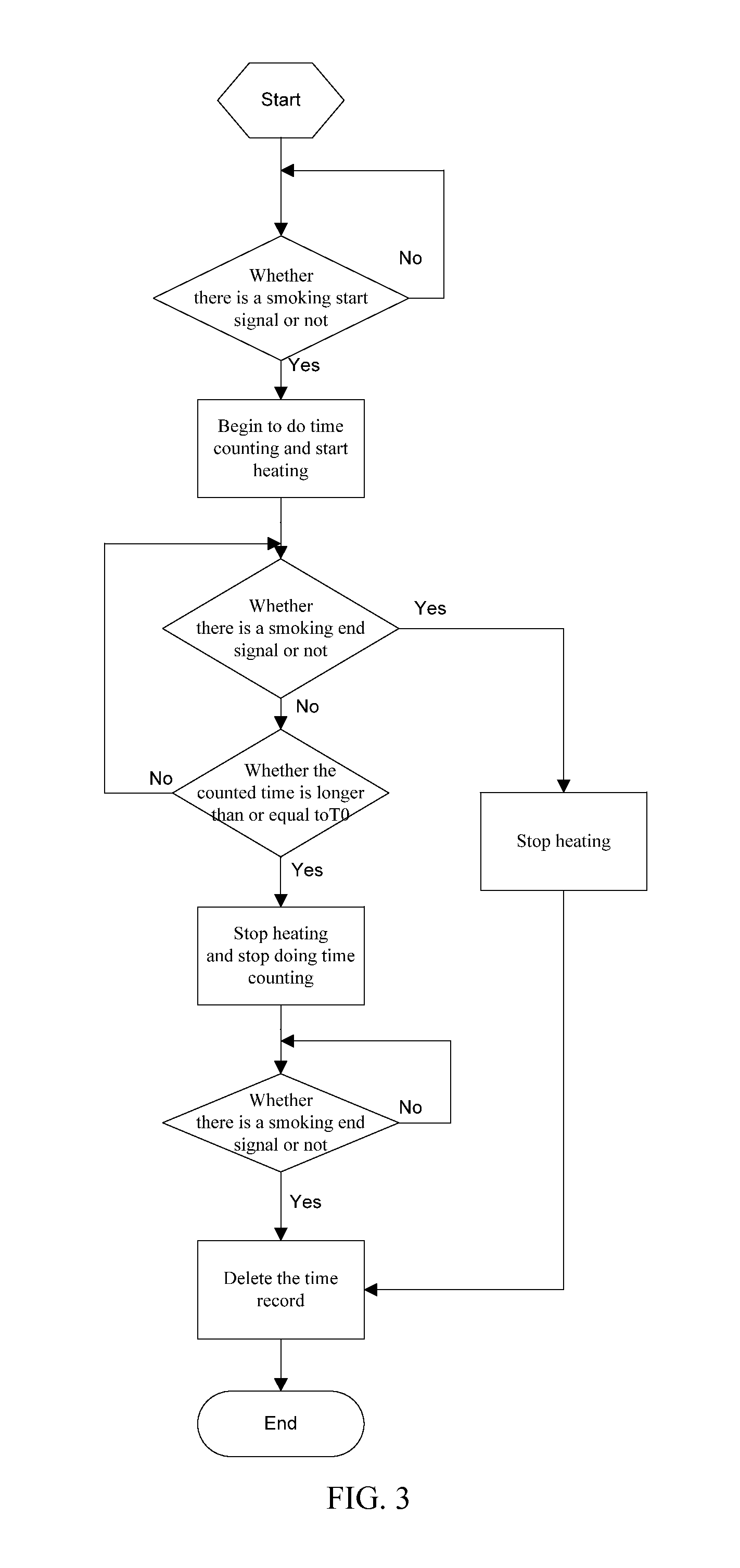

Electronic cigarette with prolonged heating protection and protection method of the same

InactiveUS20140251356A1Stopping heating processImprove heat protectionMechanical power/torque controlLevel controlEngineeringElectronic cigarette

The present invention relates to an electronic cigarette with prolonged heating protection and a protection method of the same. The electronic cigarette can avoid generating peculiar smell due to long time heating processes, and can also avoid scald injuries and fire accidents caused by too high temperatures.

Owner:KIMREE HI TECH

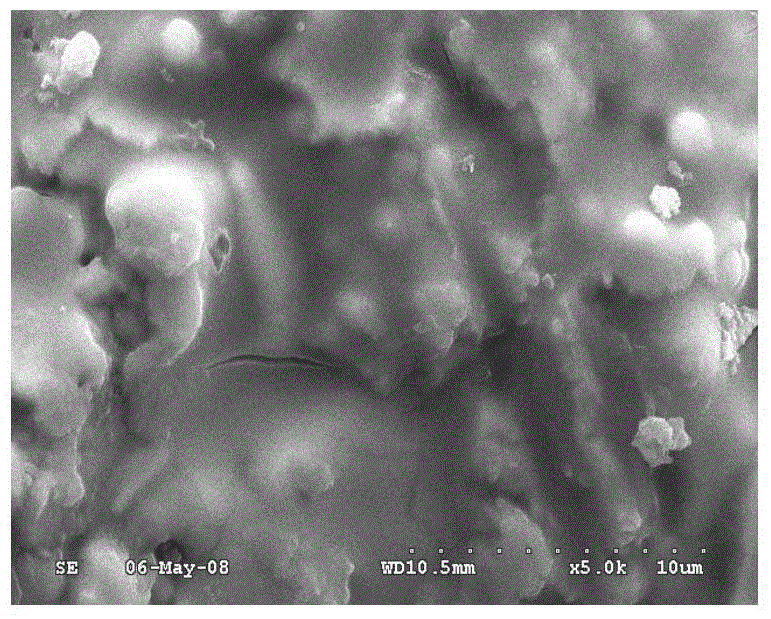

Carbon-based polymer composite material capable of being ceramized and preparation method thereof

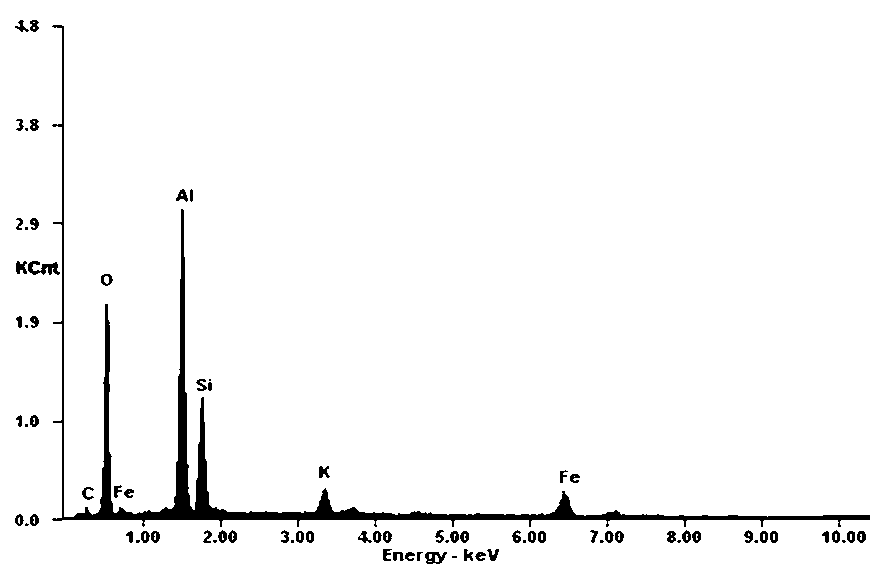

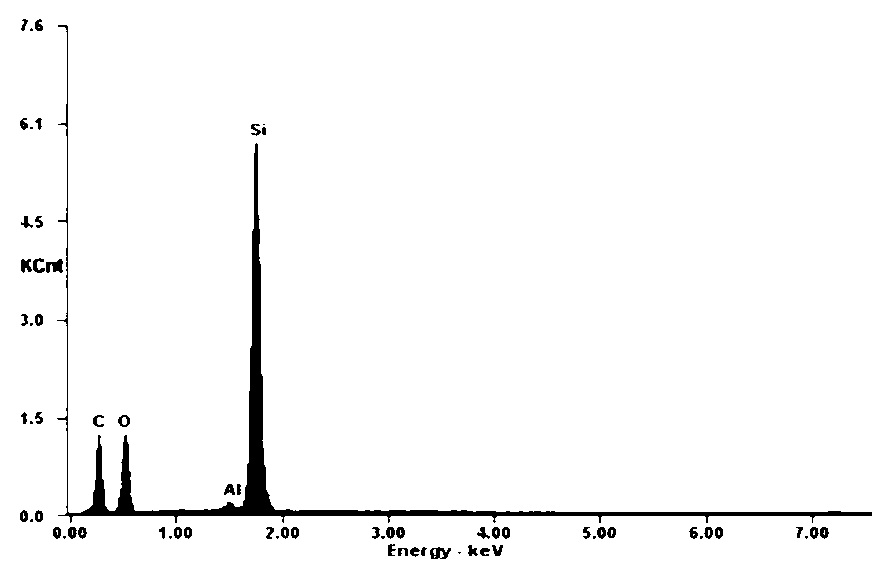

The invention relates to a carbon-based polymer composite material capable of being ceramized and a preparation method thereof. The carbon-based polymer composite material is formed by mixing and pressing carbon-based resin, a fiber-reinforced material, a high temperature-resistant coupling agent, aluminium silicate mineral powder and non-oxide ceramic powder, and the carbon-based polymer composite material specifically comprises the following components in parts by weight: 20-50 parts of the carbon-based resin, 10-40 parts of the fiber-reinforced material, 0.5-2 parts of the high temperature-resistant coupling agent, 10-50 parts of the aluminium silicate mineral powder and 1-10 parts of the non-oxide ceramic powder. Compared with the prior art, the composite material disclosed by the invention has the advantages of good thermal protection performance and anti-scour performance; a forming process of the composite material is simple, and aerobic thermal protection and ceramic formationare integrated; the ceramization temperature is lower and the ceramic conversion rate is higher; and the polymer composite material further has the advantages of capability of being formed by the polymer composite material process, strong designability, good mechanical properties at medium and low temperature, high ceramic conversion rate, low thermal weight loss rate, high retention rate of high-temperature strength and the like.

Owner:WUHAN UNIV OF TECH

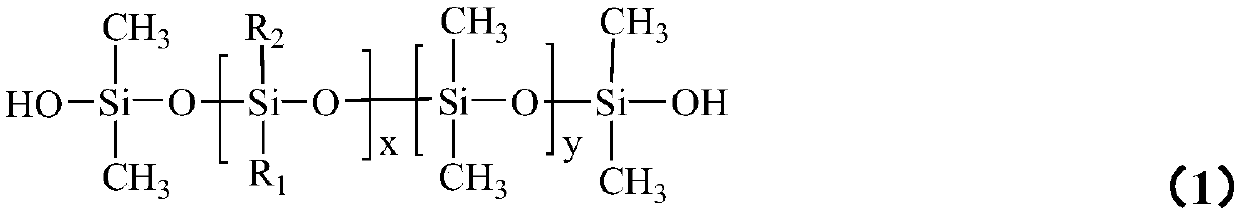

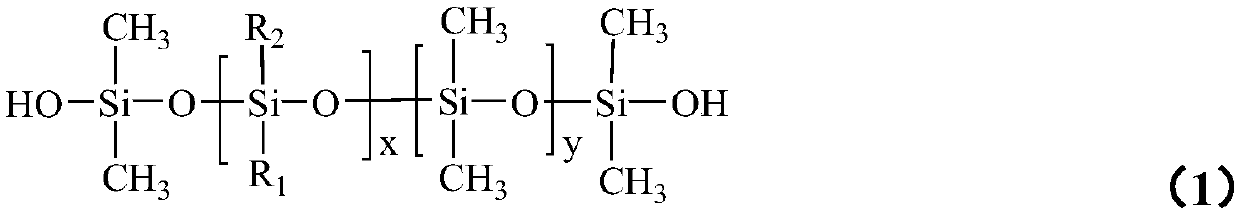

Room-temperature curing high-temperature-resistant organic silicon rubber coating as well as preparations method and application of room-temperature curing high-temperature-resistant organic silicon rubber coating

ActiveCN109593464AImprove mechanical propertiesHigh strengthFireproof paintsCarbon blackPolysilazane

The invention provides a room-temperature curing high-temperature-resistant organic silicon rubber coating as well as a preparations method and application of the room-temperature curing high-temperature-resistant organic silicon rubber coating. The organic silicon rubber coating is prepared from an organic silicon rubber material; and the organic silicon rubber material is characterized in that amatching system of a hydroxy-terminated polysiloxane polymer containing different functional groups, modified white carbon black reinforced filler, high-temperature-resistant and antioxidant filler,high-temperature-resistant and ablation-resistant filler and fibers is designed and used and is matched with a proper polysilazane curing agent based on a mechanism of an interaction among an organicsilicon polymer chain, the reinforced filler, the high-temperature-resistant and antioxidant filler, the high-temperature-resistant and ablation-resistant filler and the fibers in order to meet the harsh requirement for excellent comprehensive performances such as room temperature curing, high temperature resistance and high mechanical properties required in the use of the high-temperature-resistant organic silicon thermal protection coating, so that the formula design of a high-temperature-resistant elastic coating is simplified, and the use of a char forming agent capable of generating hugeinfluences to the mechanical properties is reduced.

Owner:INST OF CHEM CHINESE ACAD OF SCI

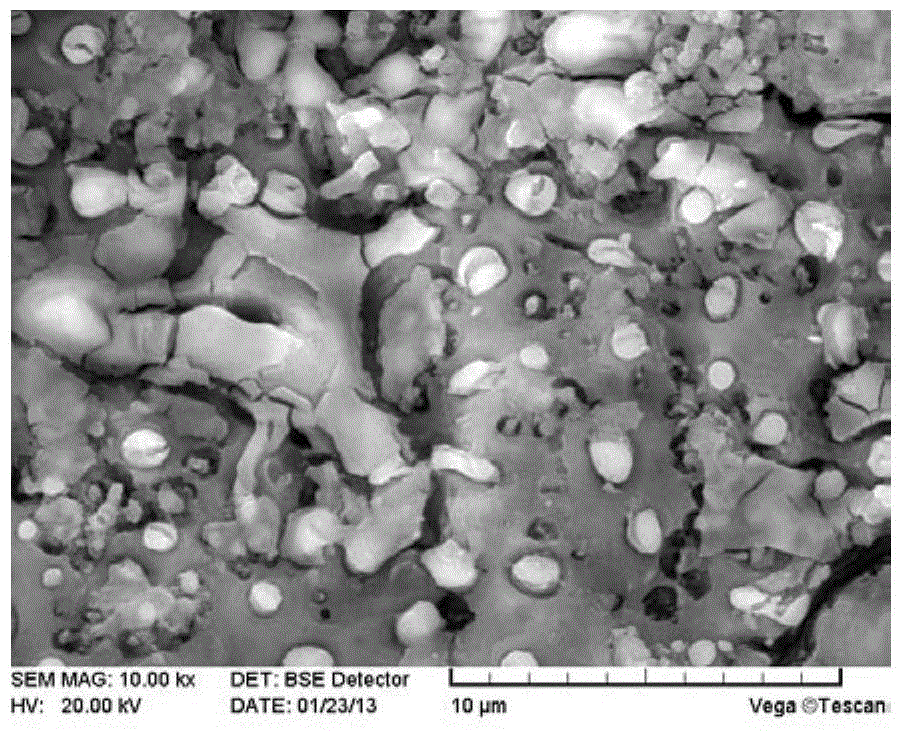

Method for preparing thermal protection ceramic layer on surface of metal or metal composite material

InactiveCN104562128ASimple ingredientsEasy to controlElectrolytic inorganic material coatingElectrolysisHigh energy

The invention discloses a method for preparing a thermal protection ceramic layer on the surface of metal or a metal composite material. The method disclosed by the invention comprises the following steps of: firstly, preparing a nitrate aqueous solution (1), an aqueous solution (2) of nitrate compound metal oxide sol, an aqueous solution (3) of nitrate compound metal oxide nano-particles and an aqueous solution (4) of nitrate compound metal oxide sol and nano-particles (4); and then, putting a sample, on which an insulating barrier layer is pre-prepared, in the solution (1), (2), (3) or (4), or, putting a sample, the surface of which is not processed, in the solution (2), (3) or (4), and applying high-energy pulse voltage on the sample to carry out cathode plasma electrolytic deposition. The method disclosed by the invention has the benefits that by adding the oxide sol and the nano-particles, cathode plasma discharge can be promoted; the fussy process of pre-preparing an insulating barrier film can be avoided; furthermore, the deposition rate of the ceramic layer can be obviously increased; the organization structure of the ceramic layer is improved; and thus, a nano-crystal ceramic layer is formed.

Owner:XIAN TECH UNIV

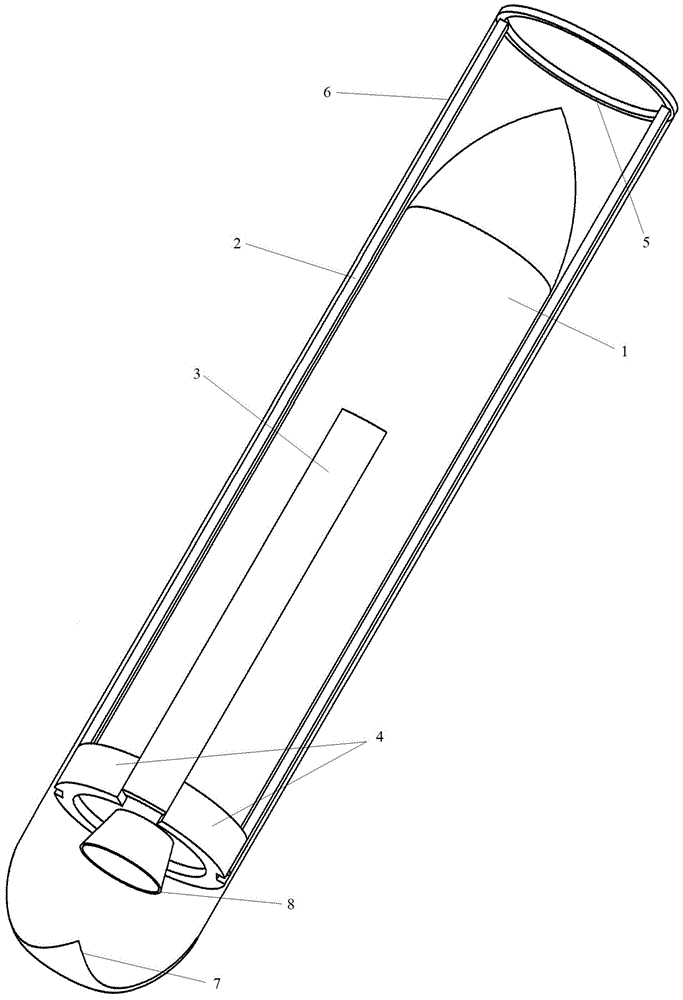

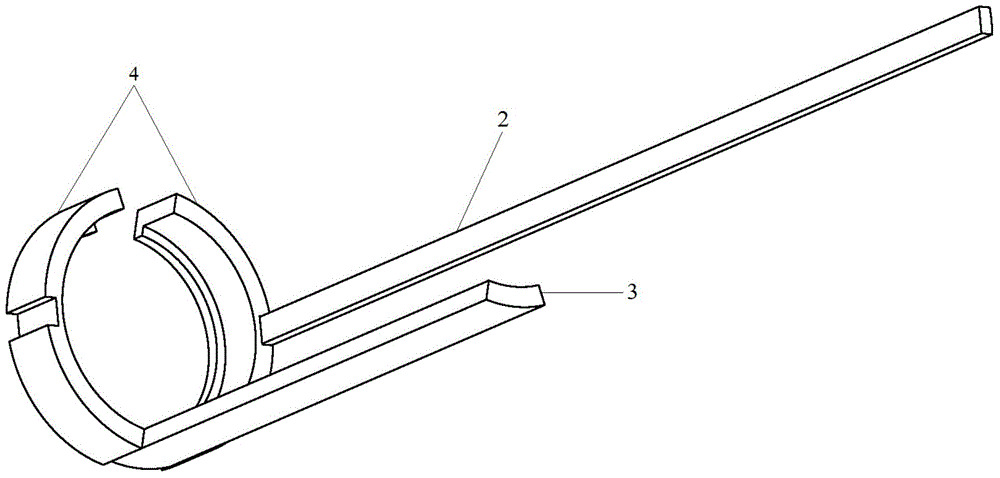

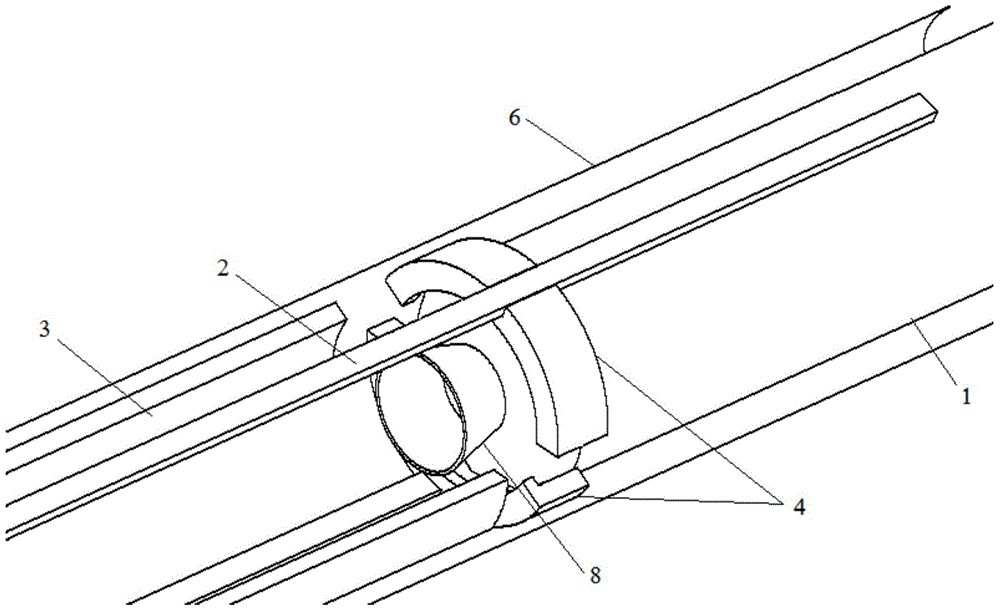

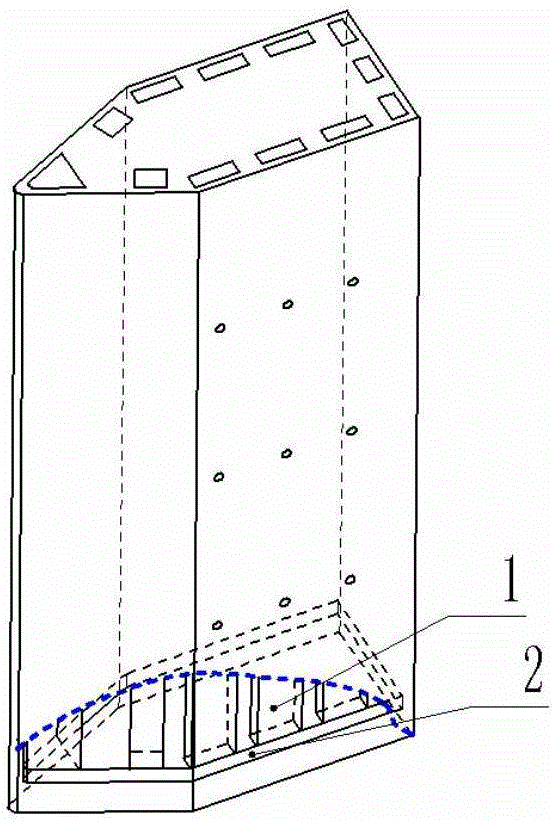

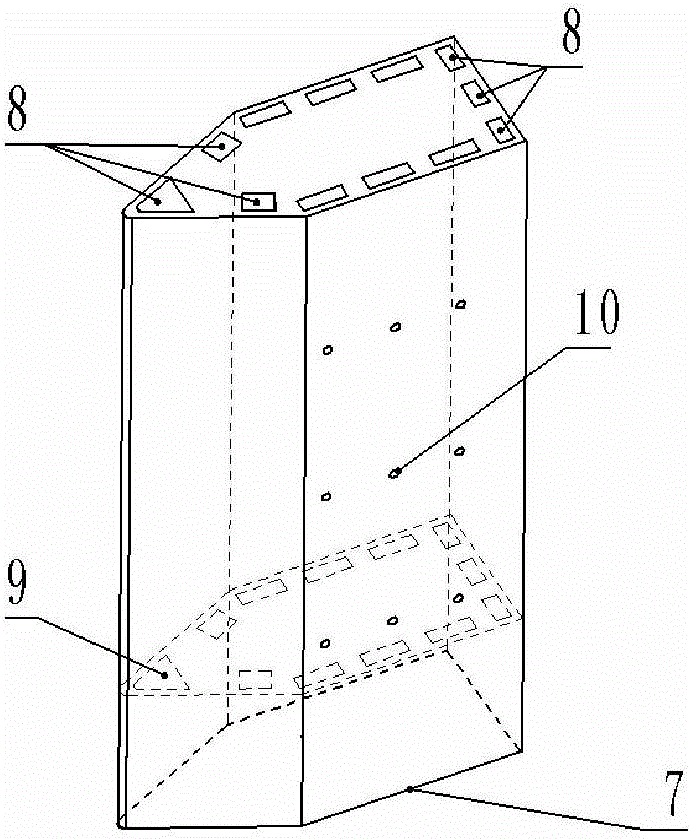

Self-catapulting launching device for guided missile

The invention provides a self-catapulting launching device for a guided missile. The self-catapulting launching device comprises a flow-guiding cone, a limiting mechanism, a buffering device, a long guide rail, a short guide rail and adaptors; the flow-guiding cone is fixedly connected to the bottom end of a launching cylinder, the buffering device is fixedly connected to the outlet of the launching cylinder, the long guide rail and the short guide rail are fixed to the inner wall of the launching cylinder in the axis direction of the launching cylinder and are staggered and evenly distributed in the launching cylinder, grooves of the adaptors are slidingly matched with the long guide rail, gaps between two adjacent adaptors are slidingly matched with the short guide rail, the limiting mechanism is fixedly connected to the inner wall of the launching cylinder, the adaptors are limited to move to the interior of the cylinder in the axis direction of the launching cylinder, and after guided missile is filled, a closed space is defined by the bottoms of the adaptors, the bottom of the guided missile, the end face of the bottom of the long guide rail and the end face of the bottom of the short guide rail in the launching cylinder. The initial launching precision of the guided missile can be improved, and the manufacturing cost and the maintenance cost of the launching device are effectively lowered.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

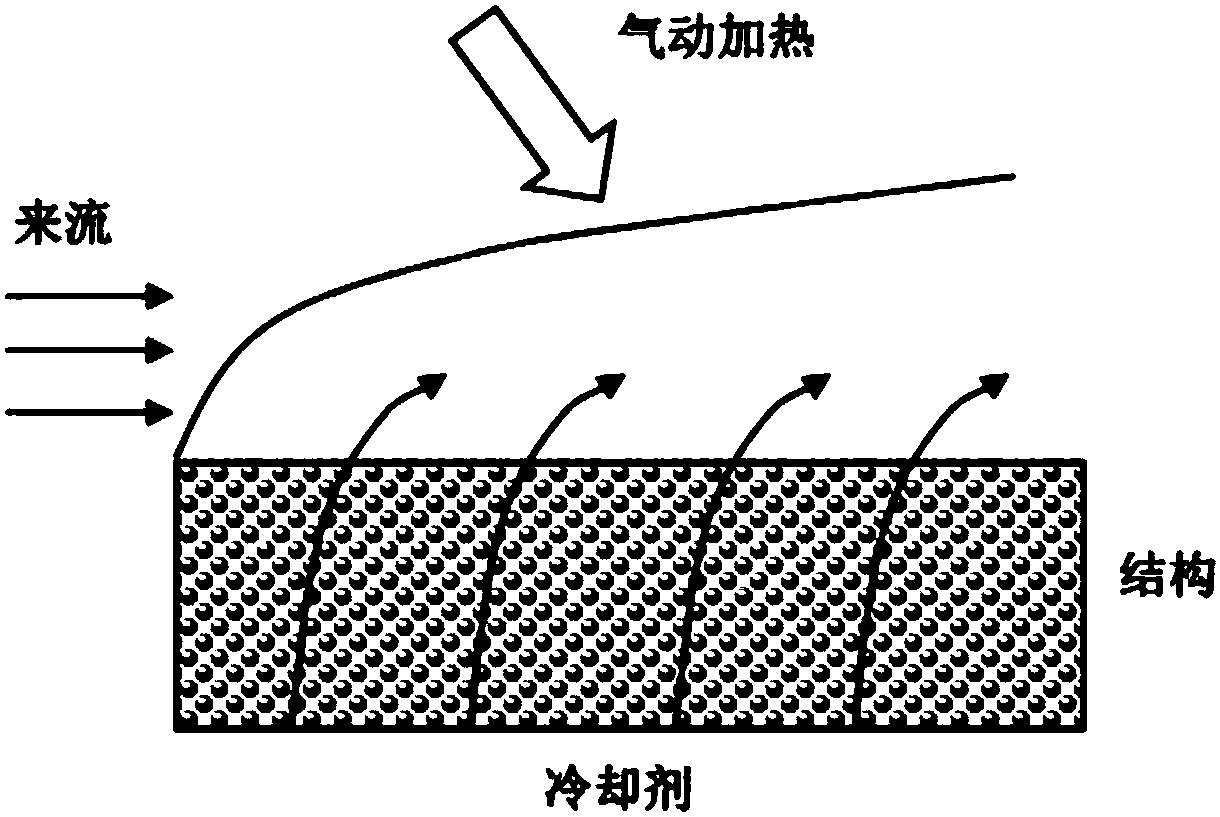

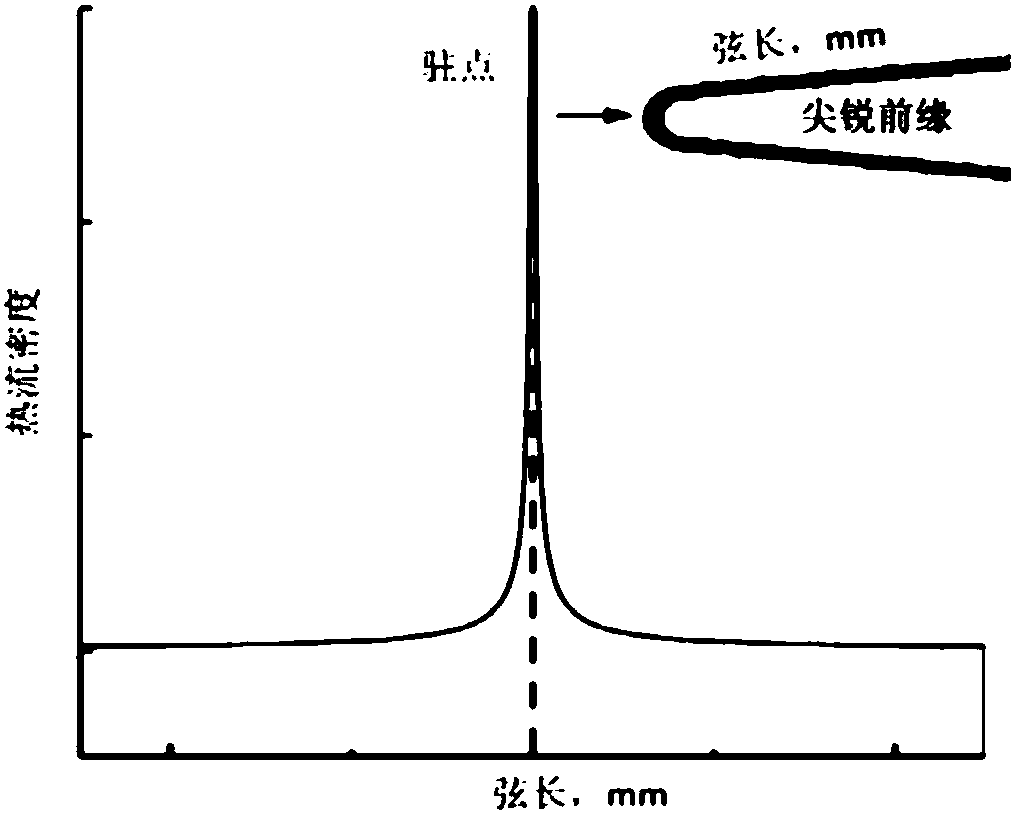

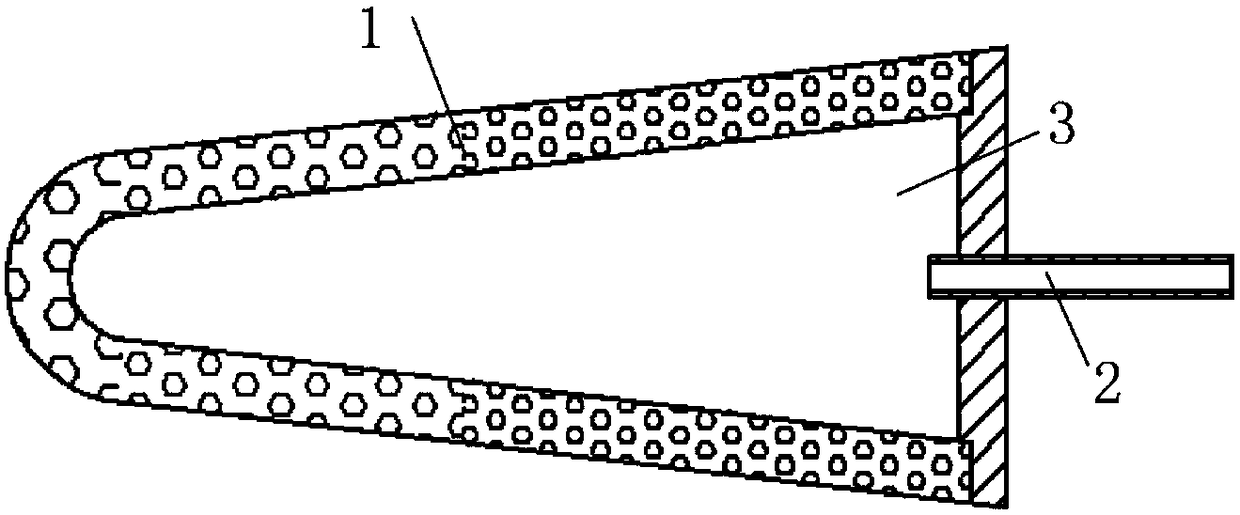

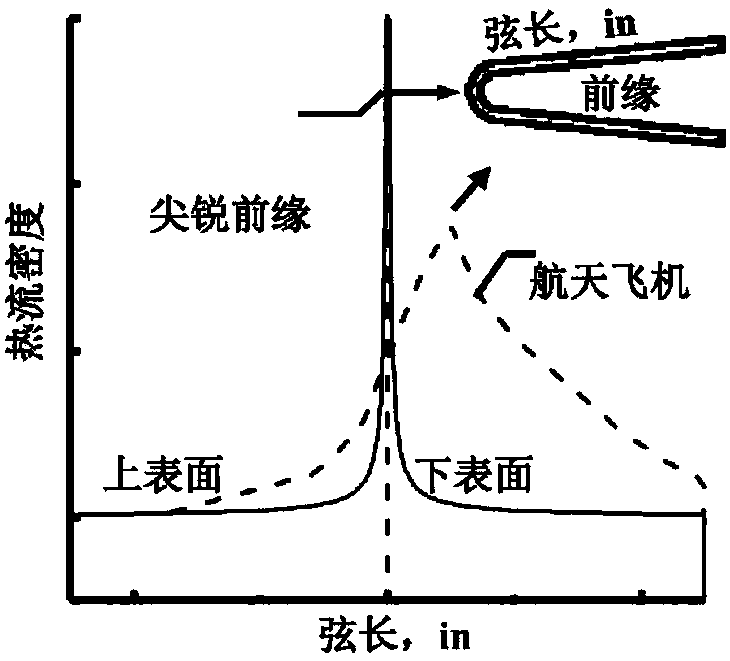

Hypersonic flight vehicle leading edge heat protection method based on gradient porous material

The invention discloses a hypersonic flight vehicle leading edge heat protection method based on a gradient porous material. A porous leading edge with gradient porosity is prepared from a high-temperature-resistant material, the porosity of a stationary point area of the porous leading edge is the maximum, and the porosity decreases backwards; a cooling pipeline is fixedly connected with the backpart of the porous leading edge, a coolant is injected into a cooling cavity through the cooling pipeline and sprayed out of the surface of the leading edge; the coolant is forced to perform heat convection when flowing through the porous leading edge, the temperature of the porous leading edge is decreased, meanwhile, the coolant is injected in a high-temperature mainstream through micropores inthe porous leading edge, and a thicker air film covering layer is formed in the stationary point area of the porous leading edge to isolate the porous leading edge from hot flows. A traditional sweatcooling mode is optimized by use of the gradient porous material, high-accuracy positioning and quantitative injection of the coolant are realized, and the ideal heat protection effect is realized.

Owner:UNIV OF SCI & TECH OF CHINA

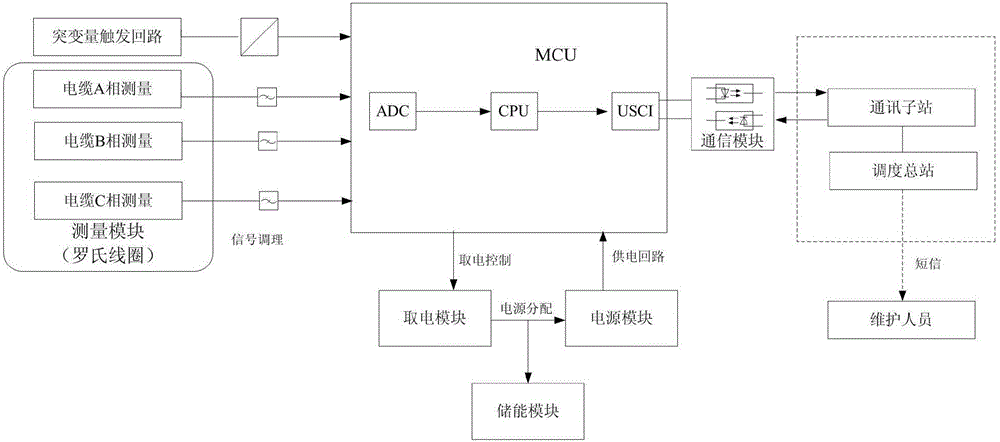

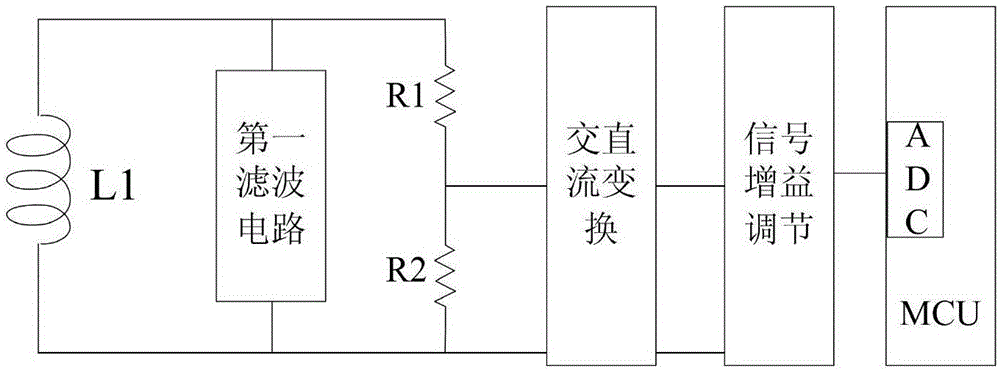

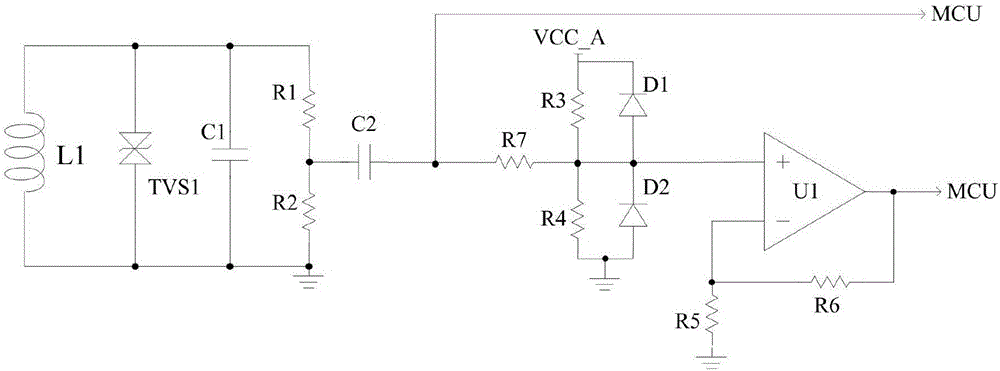

Special fault indicator for high-voltage power transmission network cable line

ActiveCN105116296ANot easy to saturateAcquisition of a wide range of currentFault locationInformation technology support systemFault indicatorHigh pressure

The invention provides a special fault indicator for a high-voltage power transmission network cable line. The special fault indicator comprises a measurement module, a power taking module, a power supply module, an energy storage module, an MCU (microprogrammed control unit) and a communication module, wherein the measurement module is connected with an ADC (analog-to-digital converter) unit in the MCU and is used for transmitting acquired current data of the cable line to a central processing unit in the MCU through the ADC unit and performing cable fault judgment through the central processing unit; the communication module is used for uploading the current data of the monitored cable line and fault signals obtained through judgment to an upper system; the power taking module is used for acquiring electric energy from the cable line through induction, is connected with the energy storage module and charges the energy storage module; the power taking module is connected with the power supply module and supplies power to the MCU; when the cable line has a fault, the energy storage module replaces the power taking module to supply stored power to the MCU. According to the special fault indicator for the high-voltage power transmission network cable line, effective electrical quantity detection can be performed on grounding faults and short-circuit faults of the high-voltage cable, and fast online fault positioning of a fault section is realized.

Owner:STATE GRID CORP OF CHINA +1

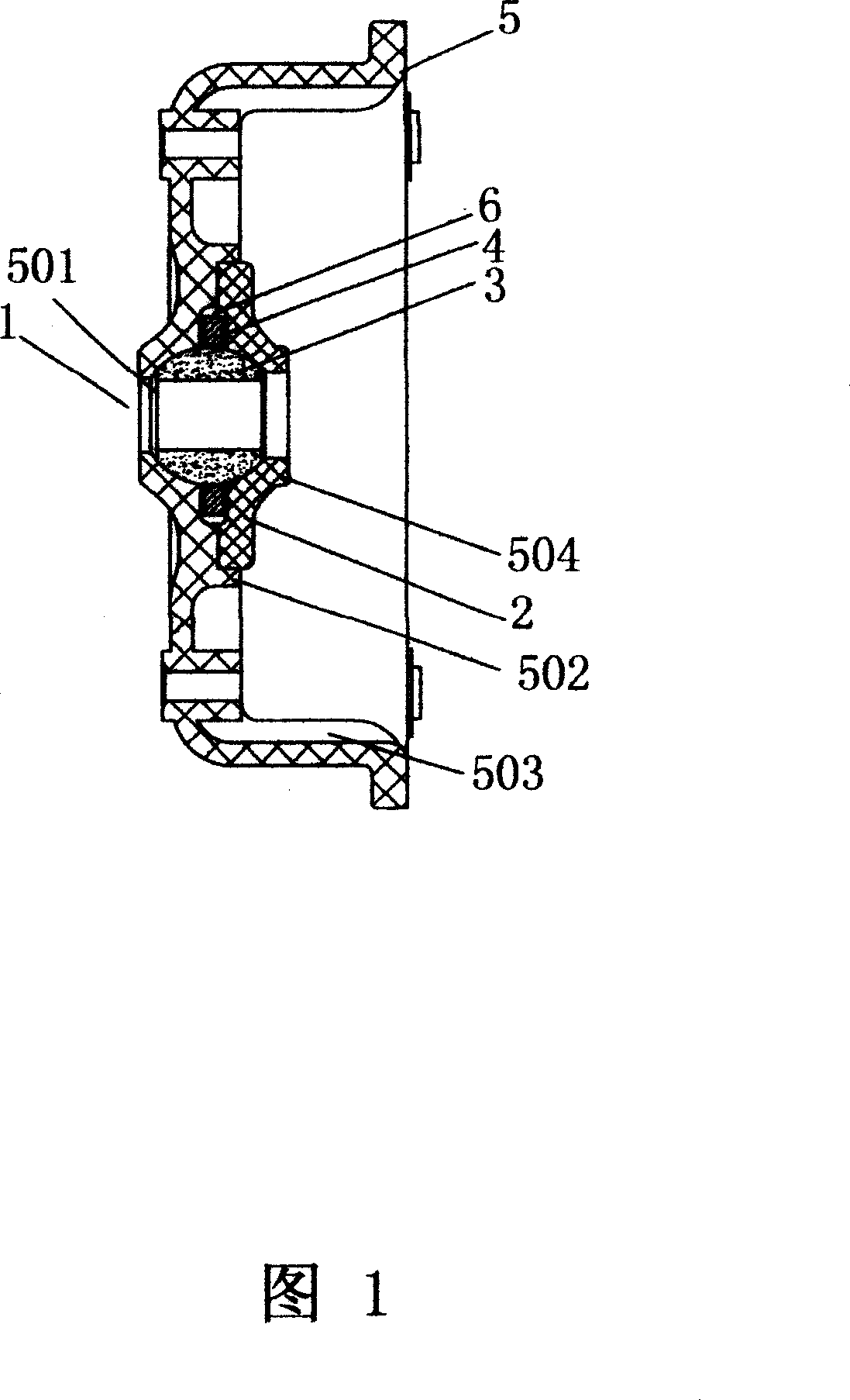

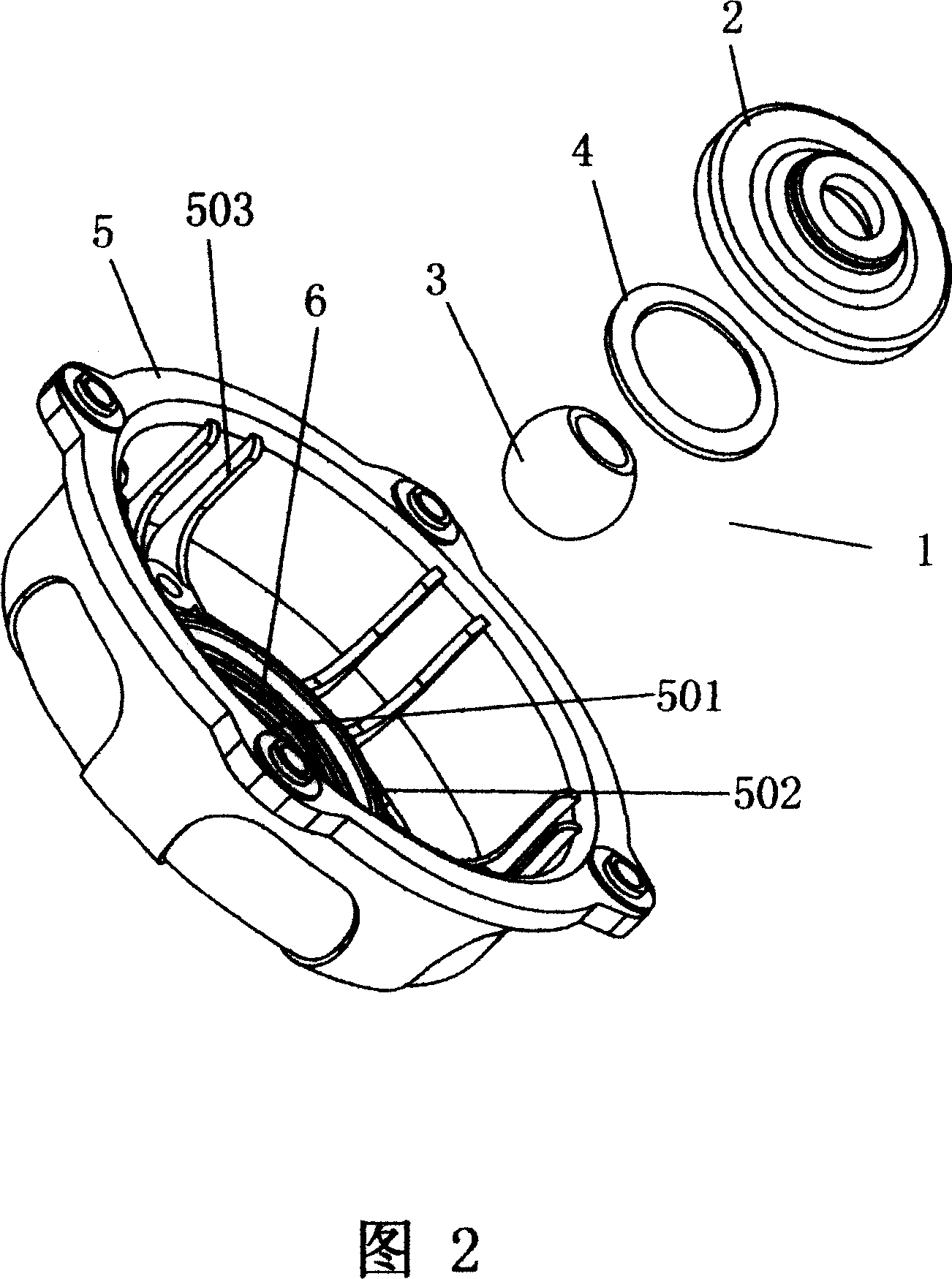

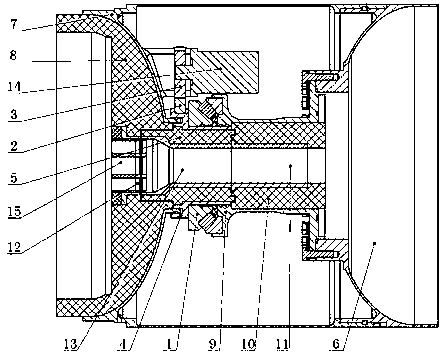

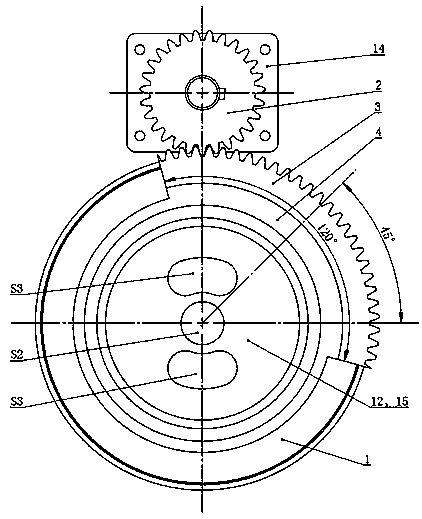

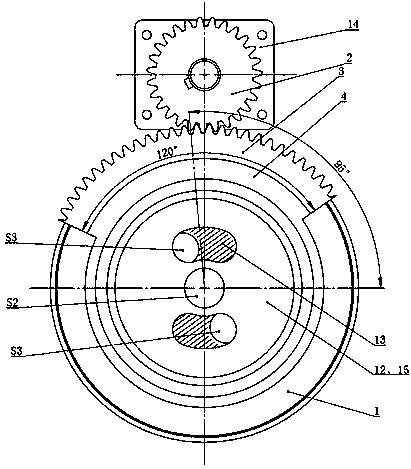

Method for mounting plastic electric machine casing and bearing device

InactiveCN1949632AHigh shaft positioning accuracyExcellent matching adjustment performanceManufacturing dynamo-electric machinesEngineeringInjection moulding

Owner:罗世明

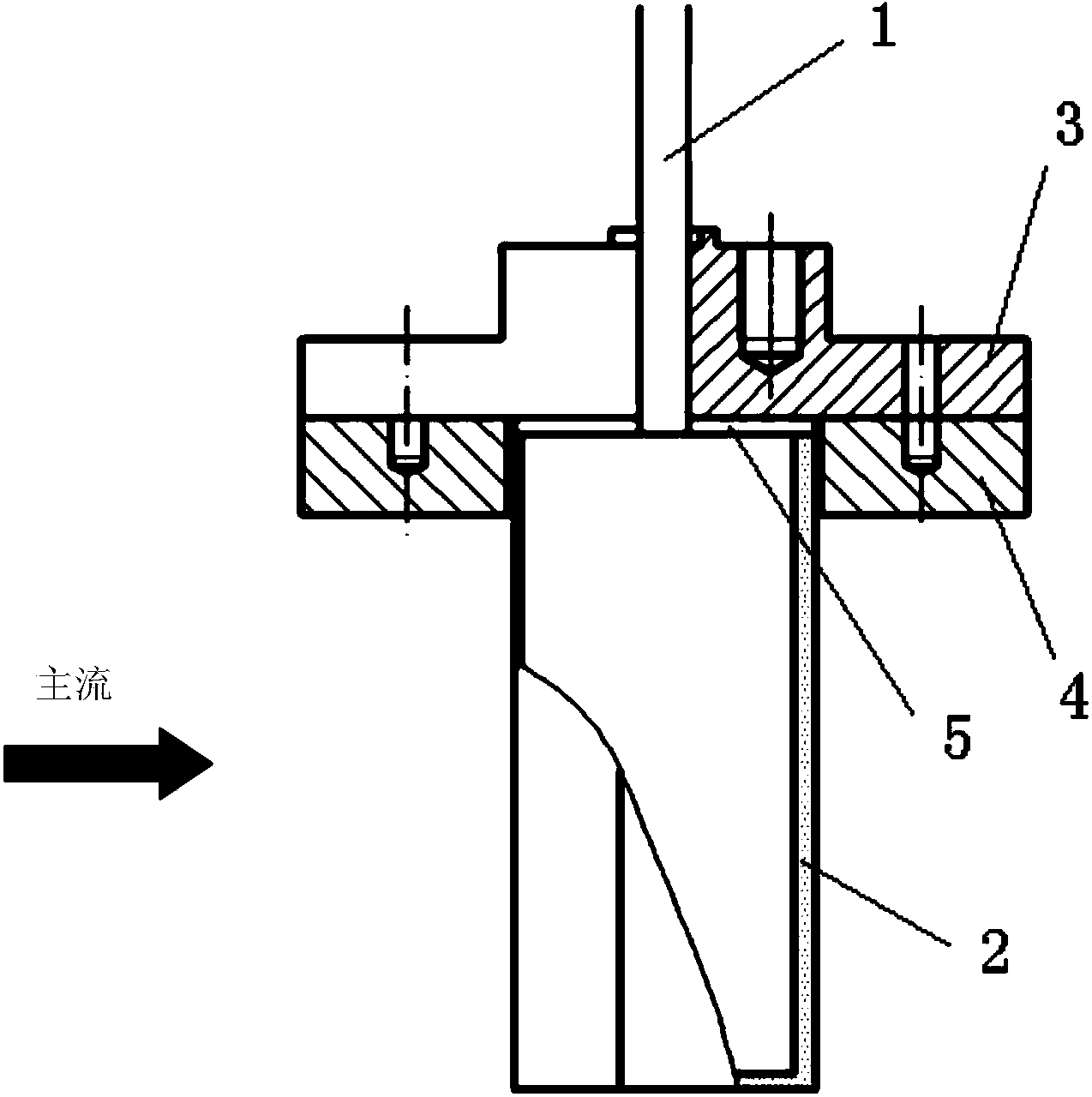

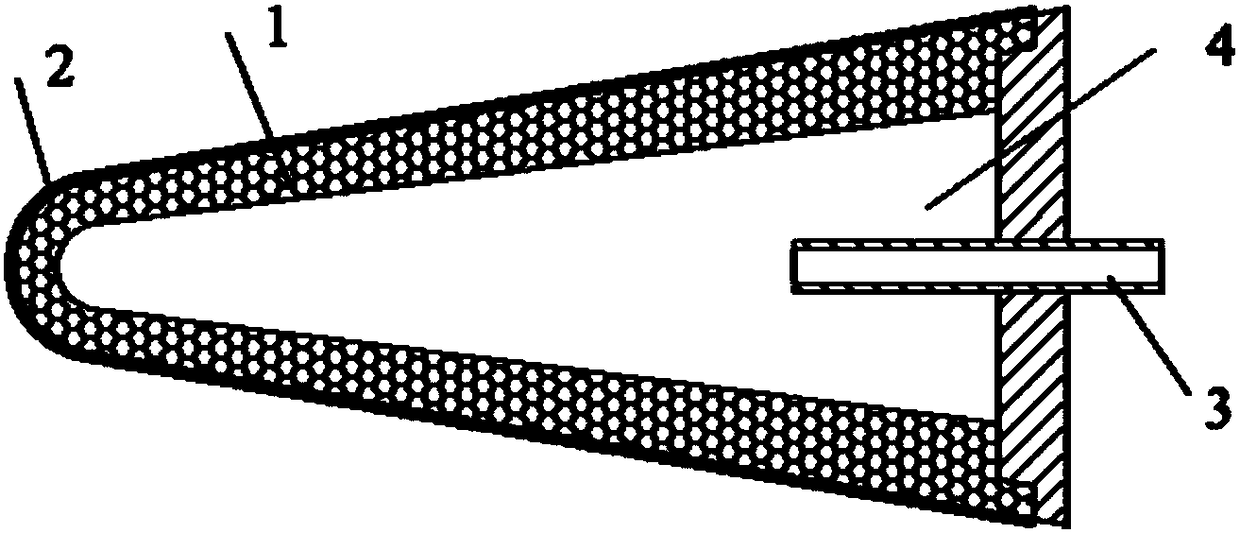

Thermal protection method for scramjet engine fuel injection supporting plate by utilization of transpiration cooling

ActiveCN103672966AReduce the temperatureAvoid ablative damageContinuous combustion chamberRamjetEngineering

The invention relates to a thermal protection method for a scramjet engine fuel injection supporting plate by the utilization of transpiration cooling. The method includes the following steps that (1), high temperature resistant material is used for manufacturing the injection supporting plate of a multi-tiny-hole structure, and a fuel pipe of a scramjet engine is communicated with the injection supporting plate; (2), by the utilization of the process that fuel leaks through holes of the injection supporting plate of the multi-tiny-hole structure, and heat convection is performed forcibly, so that the heat on the surface of the injection supporting plate is taken away; (3), it is utilized that the fuel leaks through the surface of the injection supporting plate to form a thin layer, so that main flows are prevented from performing heat transfer on the injection supporting plate. The multi-tiny-hole structure is manufactured on the injection supporting plate material, the concept of transpiration cooling is used, the fuel serves as a cooling agent, so that strong heat convection happens between the fuel and the injection supporting plate in the process that the fuel flows through the injection supporting plate, meanwhile, the fuel forms the thin layer on the surface of the injection supporting plate, heat transfer between the high temperature main flows and the surface of the injection supporting plate is obstructed, thermal protection on the injection supporting plate and particularly the front edge part of the injection supporting plate is achieved, and the injection supporting plate is prevented from being ablated and damaged. The thermal protection method can be widely applied to thermal protection performed on various ramjet injection supporting plate structures.

Owner:TSINGHUA UNIV

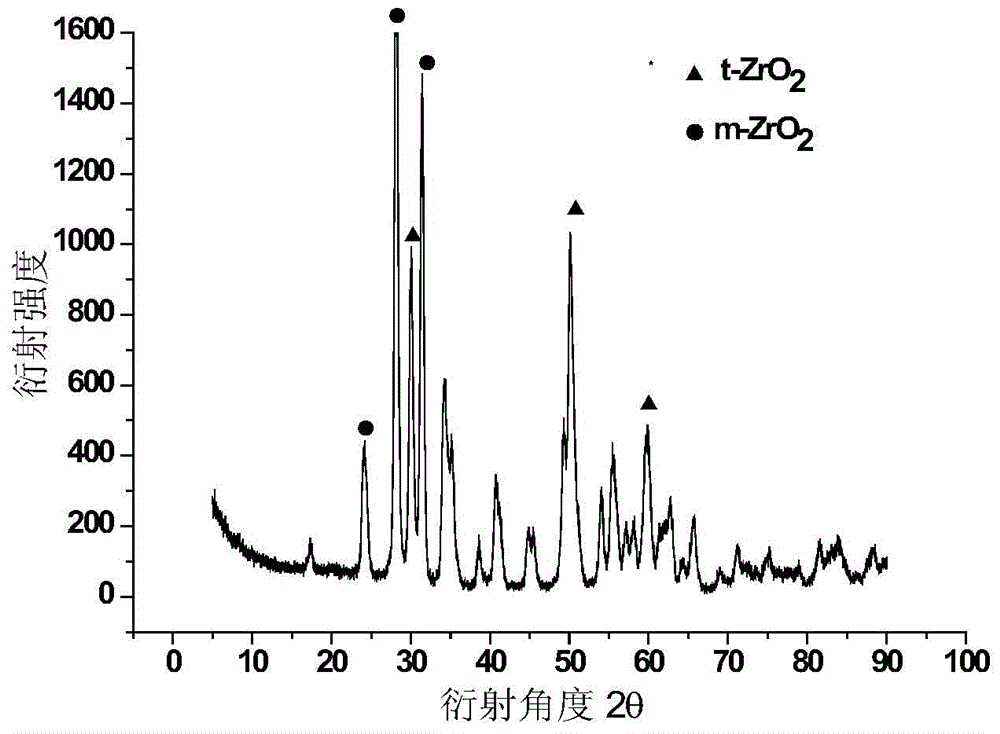

Thermal barrier coating with thermal radiation property as well and preparation method of thermal barrier coating

InactiveCN104451525AHigh densityReduce roughnessMolten spray coatingEfficient propulsion technologiesCoated surfaceSurface layer

The invention discloses a thermal barrier coating with thermal radiation property. The thermal barrier coating is a SiO2 plugging surface layer which is prepared by on the surface of a ZrO2 coating after sol-gel by using a dipping-pull method and is high in finishing degree and low in roughness. On one hand, a function of increasing the thermal radiation rate of the surface of the coating is achieved, on the other hand, a function of filling pores of the thermal resisting coating is achieved, and the pores in the surface of the coating are made up. The composite coating of a novel structure can be used for improving the thermal protection property of the surface of a titanium alloy at high temperature, and has important values on protection of high-speed aircraft shells.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

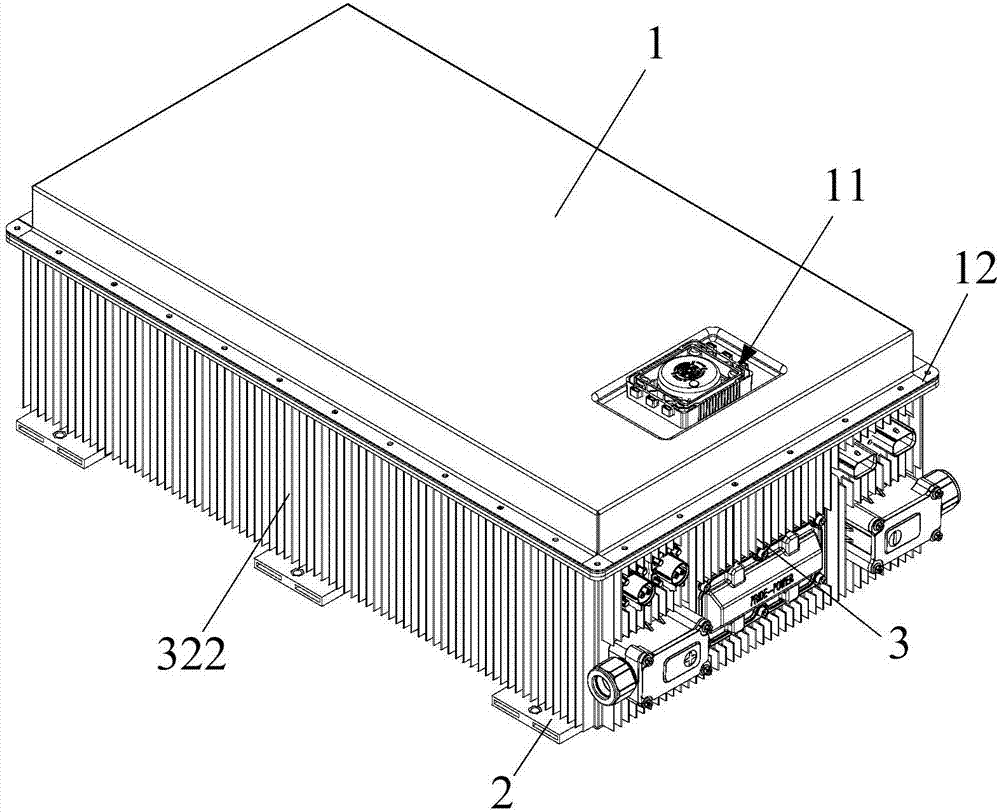

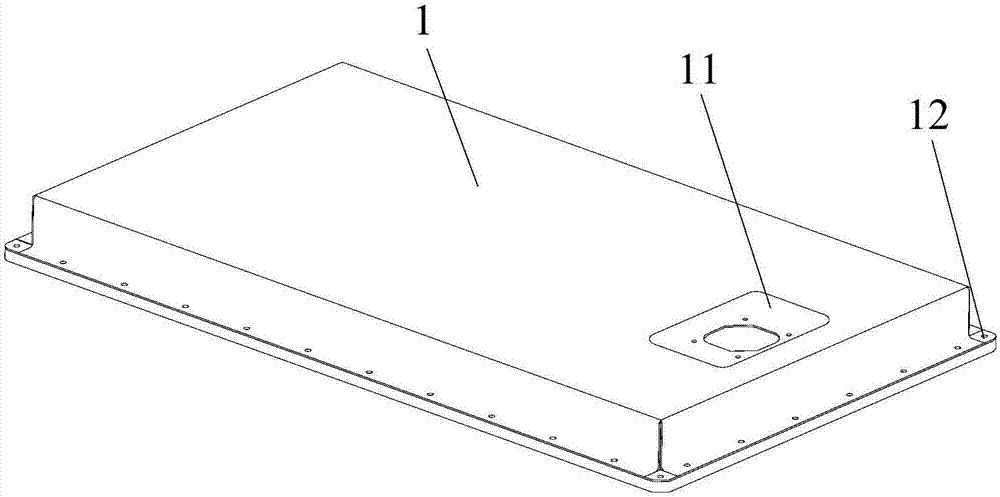

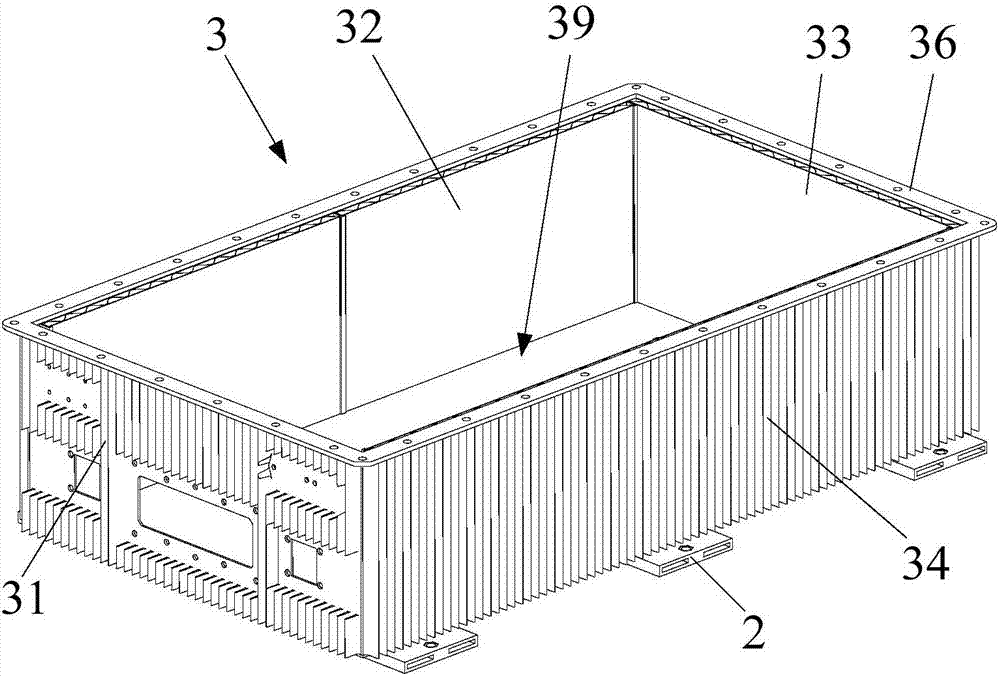

Power battery box for electric vehicle

PendingCN107579181AGuaranteed to workHigh strengthSecondary cellsCell component detailsPower batteryHeat management

The invention relates to the technical field of electric vehicles, in particular to a power battery box for an electric vehicle. The power battery box comprises a box cover and a box body, wherein a lining is connected to the inner wall of the box body and filled with a phase change material; and the box body is formed by extruding molding of an aluminium alloy material. The box body is small in density, lighter in weight, convenient to process and manufacture and low in processing cost; meanwhile, the lining is connected to the inner wall of the box body, and can enhance the integral rigidityand strength of the box body, play the role of vibration and energy absorption and improve the protective capability of the box body; and the lining is filled with the phase change material, and thephase change heat accumulation principle of the phase change material is utilized to assist a heat management system in temperature adjustment of the battery box, so that the temperature in the battery box can meet the requirements on the performance and the service life of a power battery, and the power battery can efficiently work at an appropriate temperature.

Owner:BEIJING PRIDE NEW ENERGY BATTERY

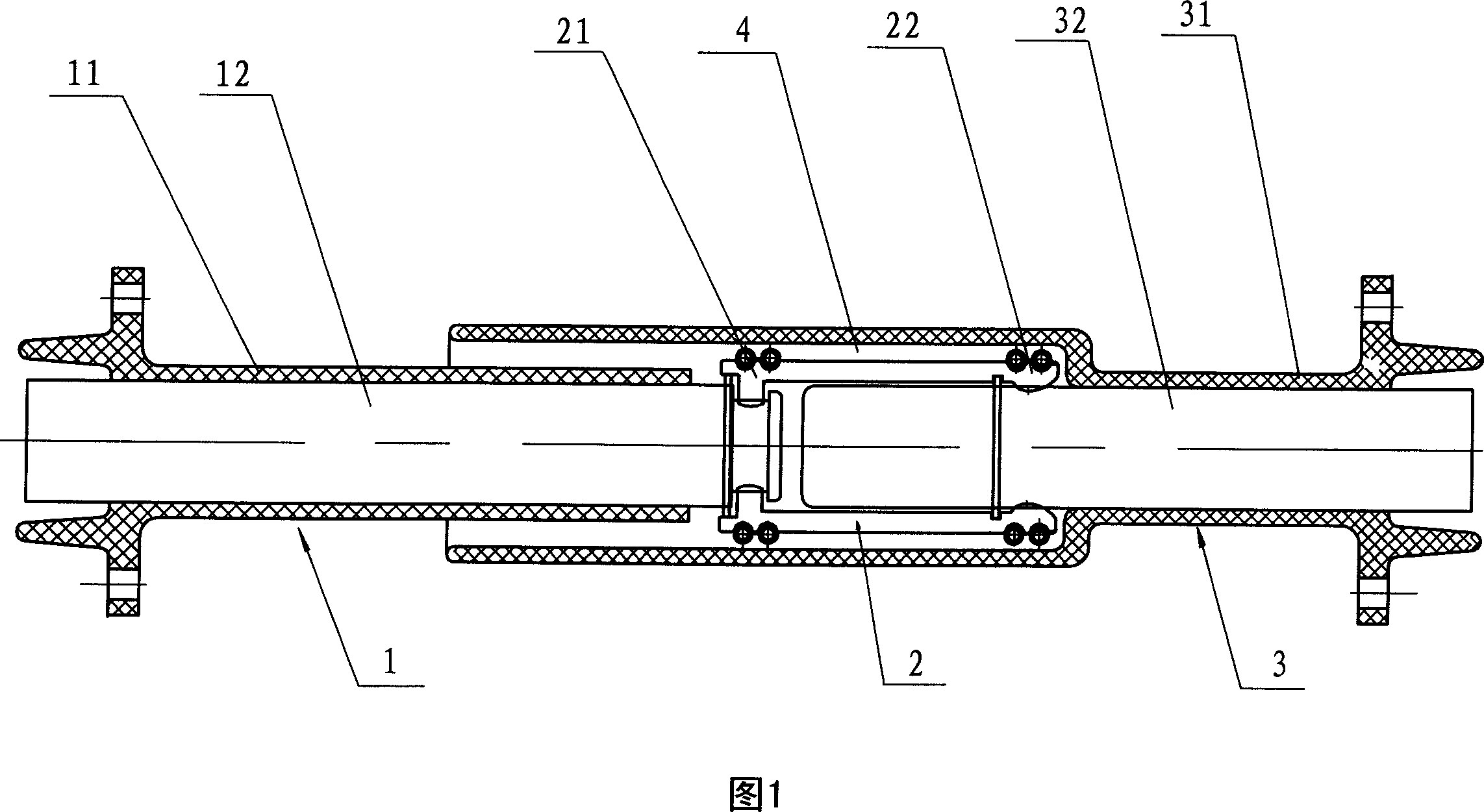

Bus connector

InactiveCN1996680AImprove thermal protection performanceMeet the requirements of high insulation classBus-bar installationCoupling contact membersElectrical conductorHigh pressure

This invention relates to one parent connector for different high voltage connection wire ends in high voltage switch devices, which comprises fix arm, slide arm and plug probe, wherein, the fix arm is composed of one section of insulation cover and one fix conductor imbedded into the fix cover; the fix conductor one end is exposed from one end of insulation cover and connected to the plug probe fix end; the other end of fix conductor is exposed from other end of insulator cover; the said slide arm comprises slide insulation cover and the slide conductor inside the insulation center.

Owner:镇江龙源电力科技有限公司

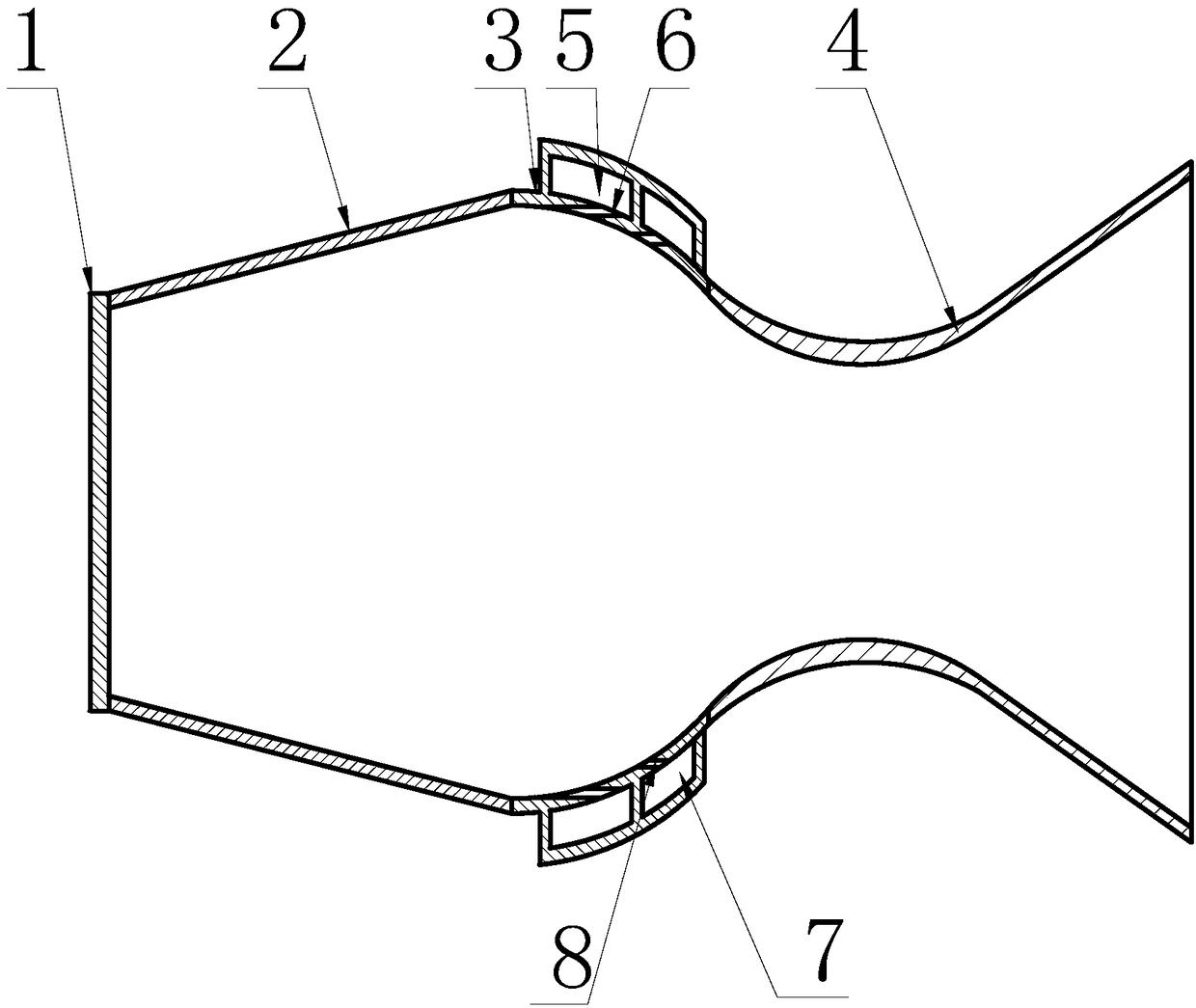

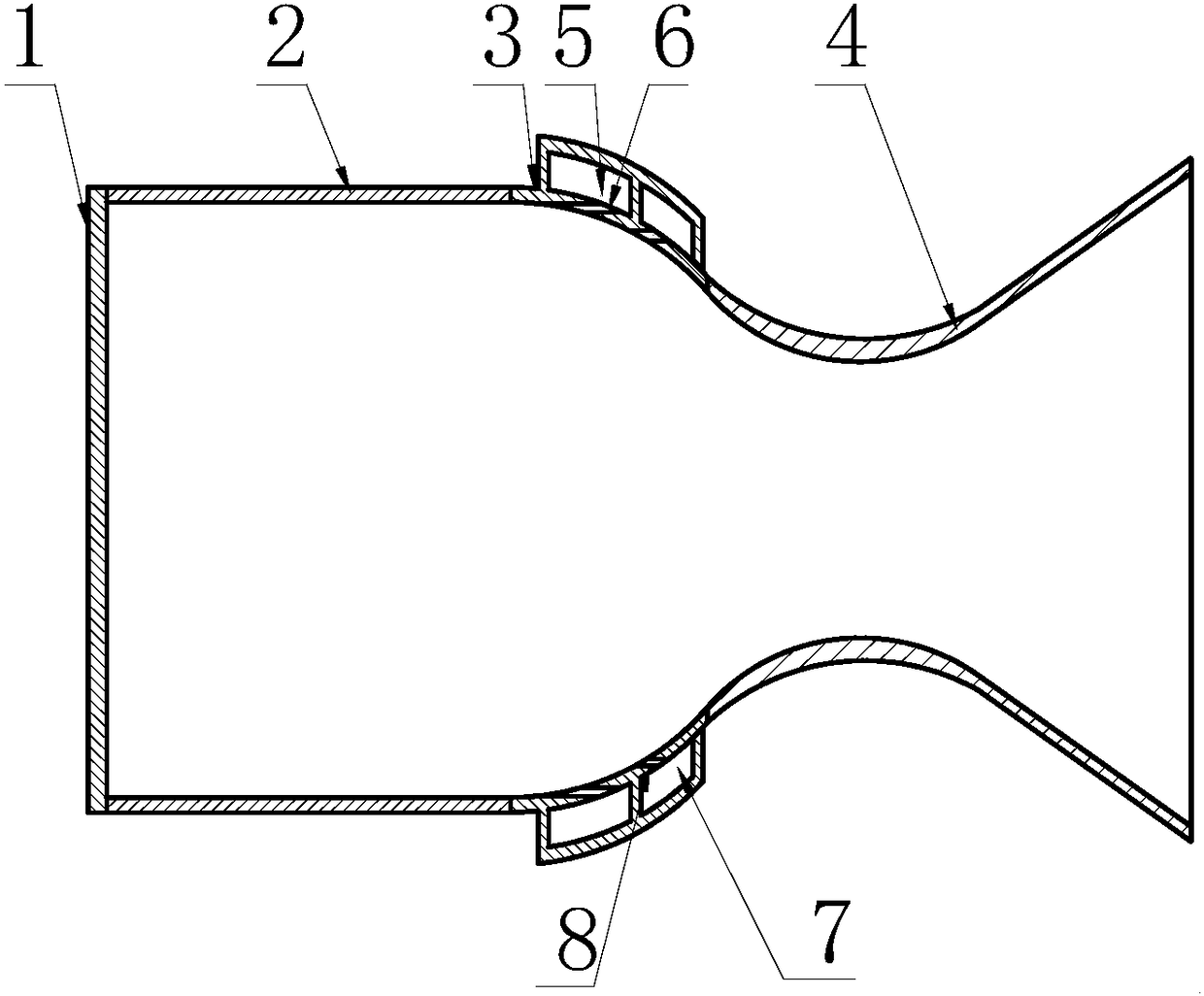

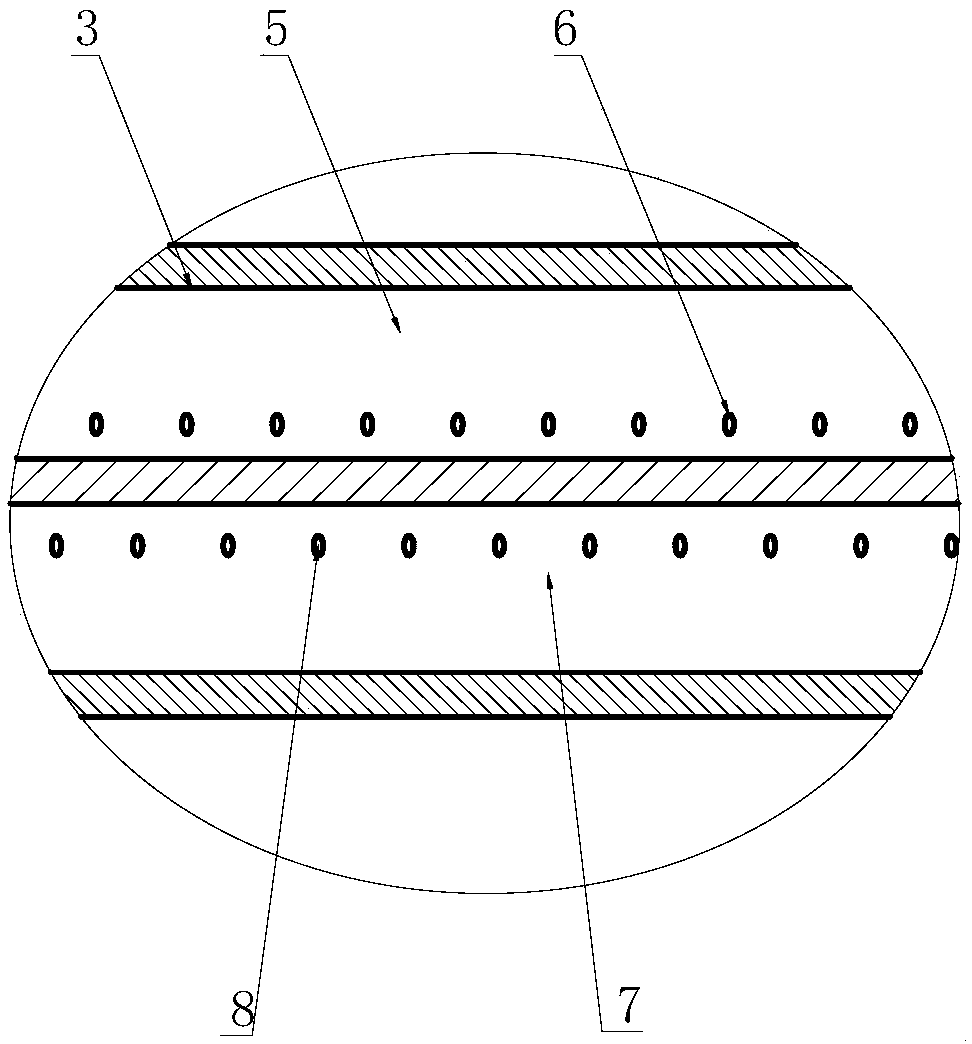

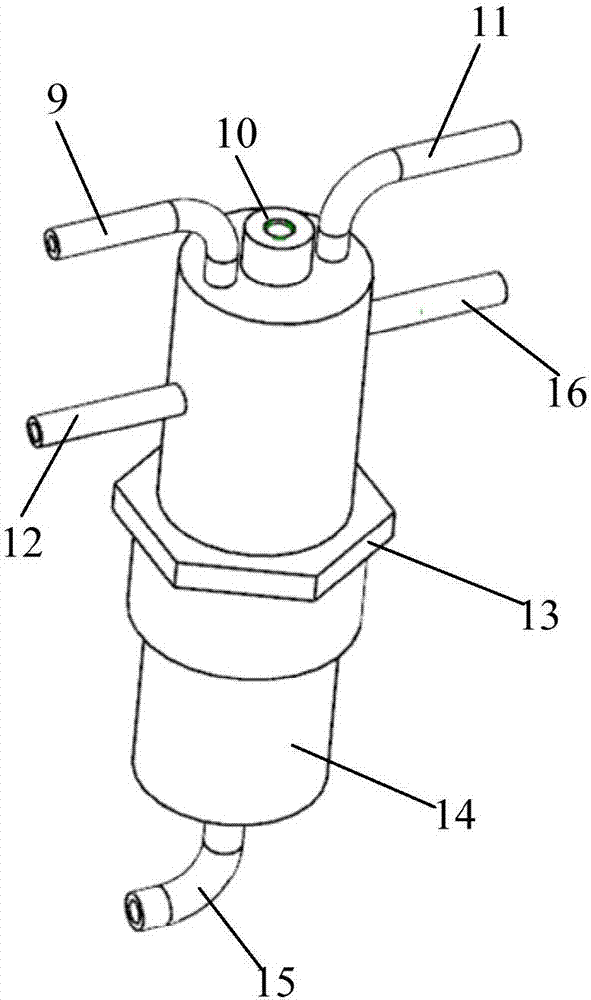

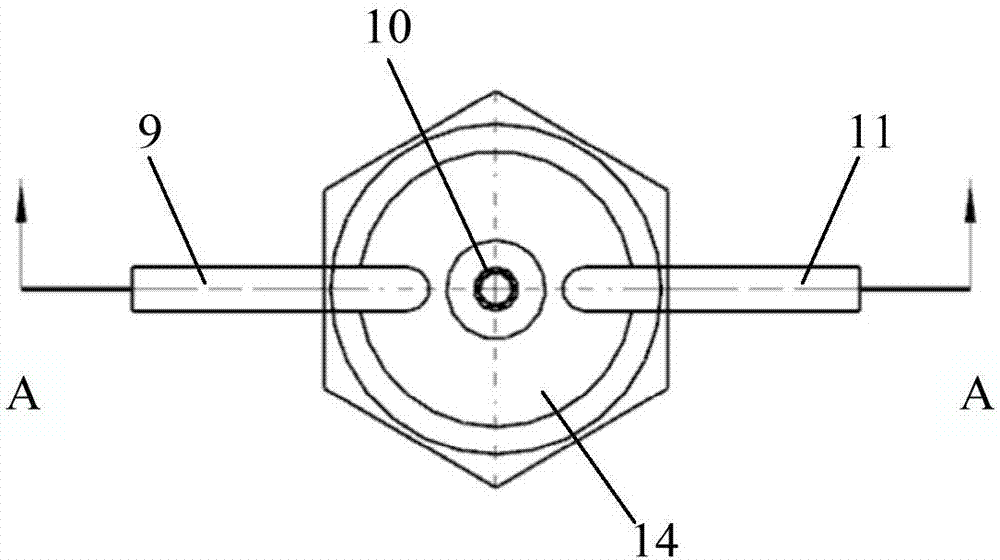

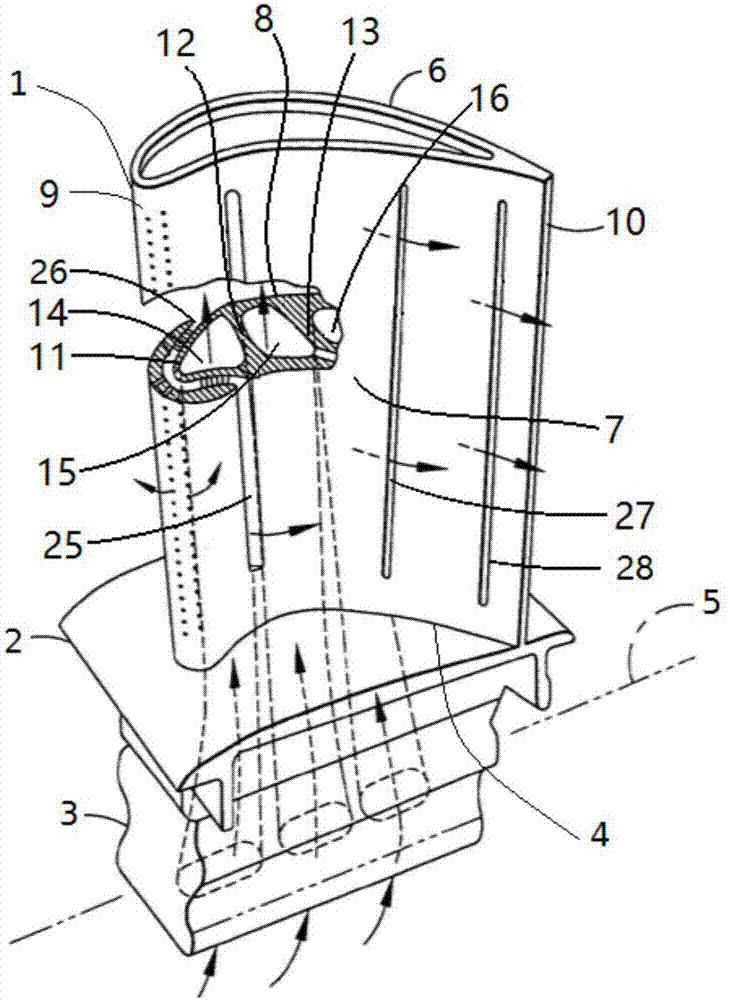

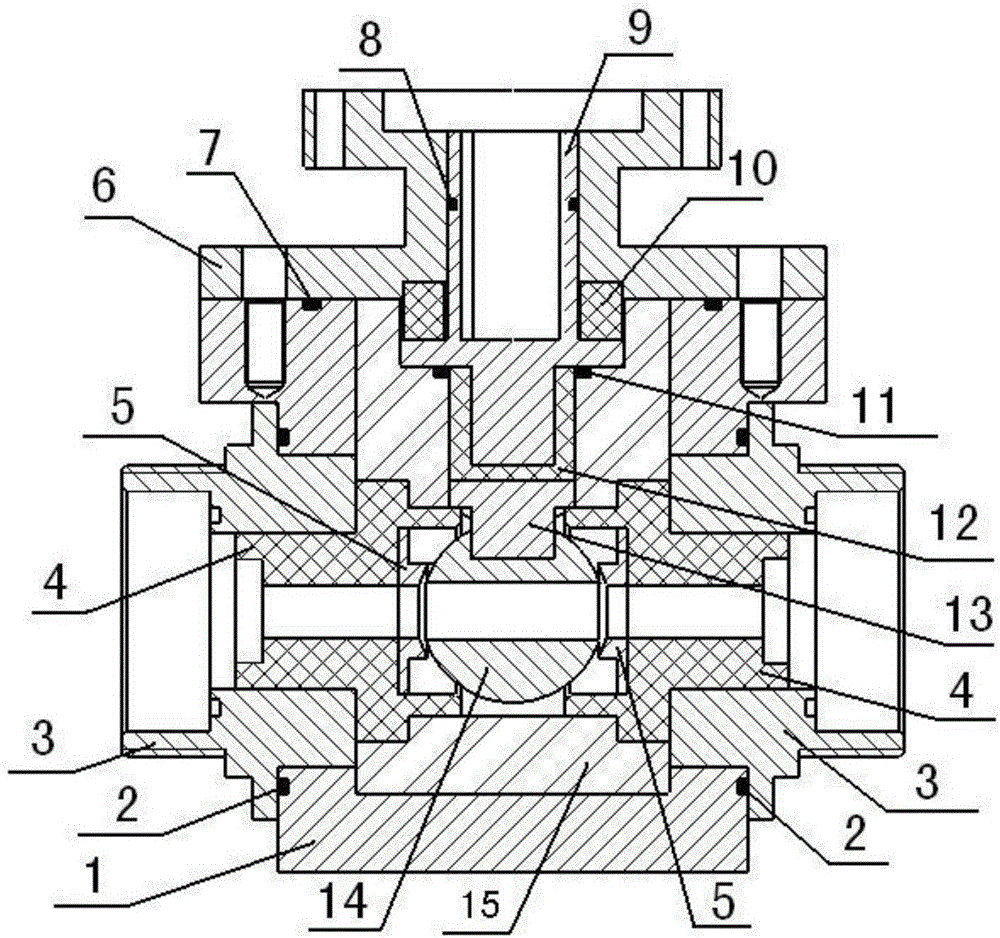

Combustor fuel nozzle and thermal protection structure thereof

ActiveCN106556030AImprove heat transfer performanceImprove thermal protection performanceContinuous combustion chamberAirflowCombustion chamber

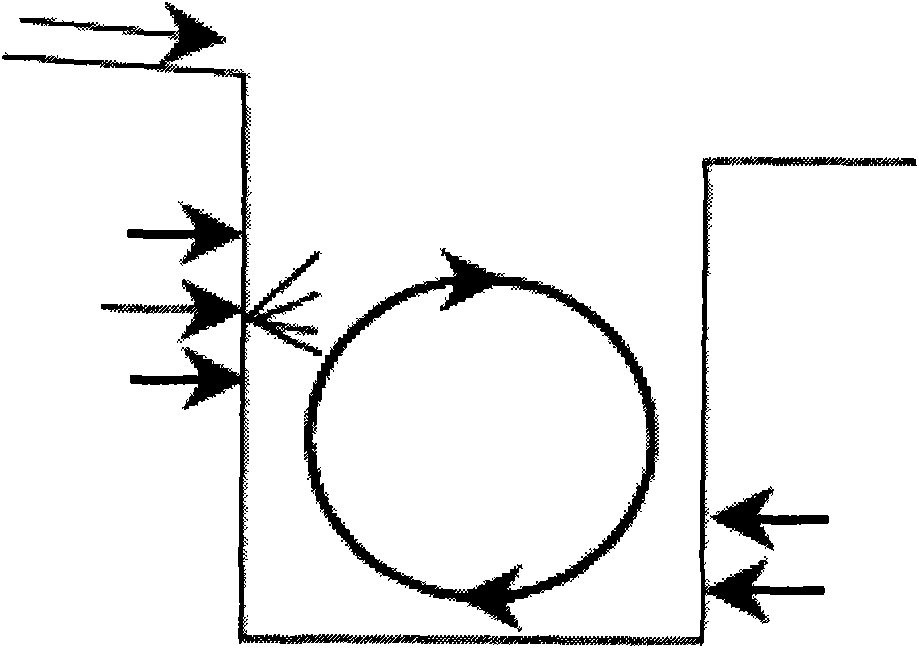

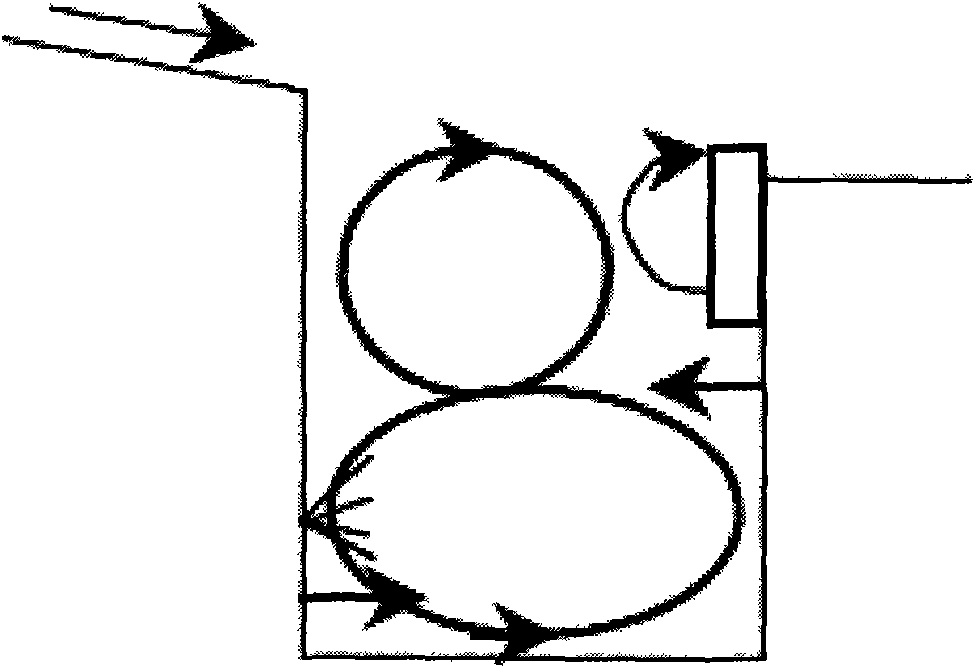

The invention provides a combustor fuel nozzle and a thermal protection structure thereof. The thermal protection structure can reduce possibility that the nozzle is liable to coke fuel during an actual use process. The thermal protection structure comprises a thermal protection pipe and a heat exchange structure, wherein the thermal protection pipe is used for surrounding an oil inlet pipe; the inner wall surface of the thermal protection pipe is used for forming a thermal protection space together with the outer wall surface of the oil inlet pipe; the thermal protection space is divided into an air inlet part and an air outlet part, which are separated and located on two sides of the oil inlet pipe; the air inlet part and the air outlet part are used for forming a cooling air channel together with a pipe-wall inner cavity of an outlet section of the nozzle; the heat exchange structure is arranged in the thermal protection space and comprises a plurality of transverse rib plates and a plurality of longitudinal rib plates; the transverse rib plates are perpendicular to the flowing direction of cooling air; the longitudinal rib plates are radially distributed by taking the oil inlet pipe as a center and intersect the transverse rib plates respectively; and each transverse rib plate is provided with a plurality of airflow holes for allowing the cooling air to flow through.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Direct-current cold-wall type engine combustor

ActiveCN108457768AImprove atomization effectImprove thermal protection performanceRocket engine plantsCombustion chamberCombustor

The invention discloses a direct-current cold-wall type engine combustor. The direct-current cold-wall type engine combustor comprises a combustor upper cover, a combustor linear section, a jet section and a spray pipe convergence and expansion section which are connected in sequence. An oxidizing agent liquid collection cavity, an oxidizing agent jet hole, a fuel liquid collection cavity and a fuel jet hole are formed in the outer wall of the jet section in the circumferential direction. An oxidizing agent enters the oxidizing agent liquid collection cavity via an oxidizing agent regenerativecooling channel and then flows out from the oxidizing agent jet hole to form a jet flow, fuel enters the fuel liquid collection cavity via a fuel regenerative cooling channel and then flows out fromthe fuel jet hole to form a jet flow, the jet flows are close to the inner wall of the combustor linear section but being not in contact with the wall, and the jet flows impact for atomization, mixingand combustion on the combustor upper cover, and are discharged out of the combustor through the spray pipe convergence and expansion section. By means of the combustor, the propellant combustion efficiency and the thermal protection capacity of the combustor can be improved, and the combustor is simple in overall structure and easy to machine and obtain.

Owner:SHANGHAI INST OF SPACE PROPULSION

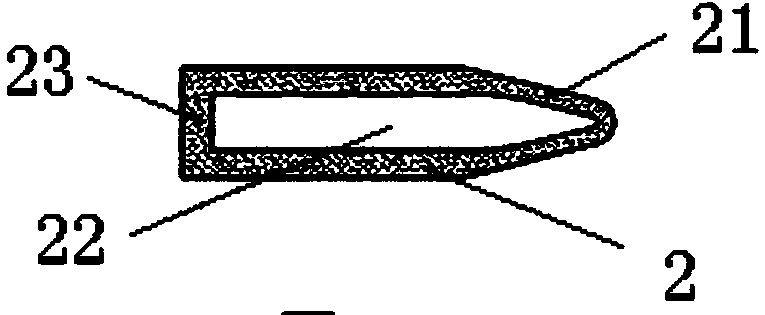

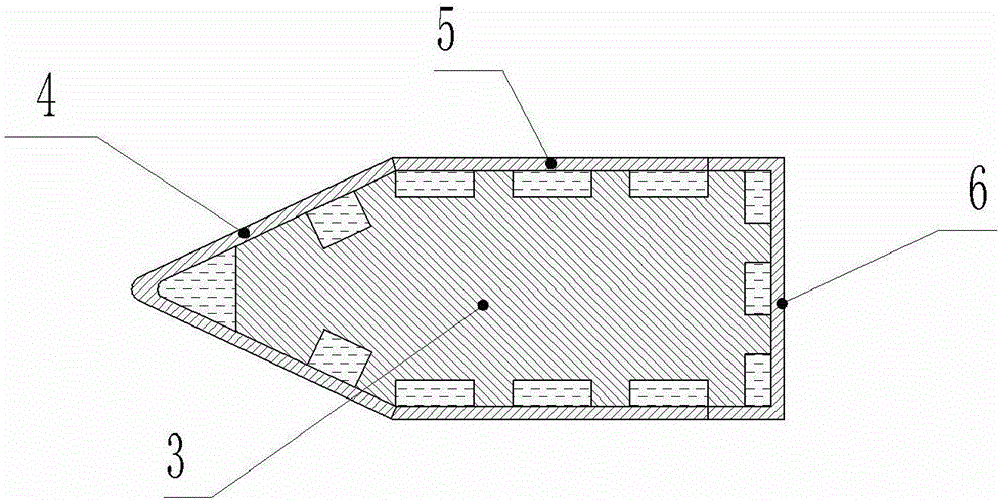

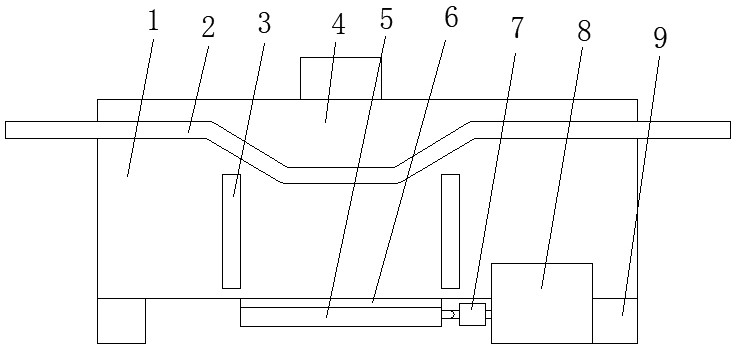

Fuel strut injector

InactiveCN106247407AImprove thermal protection performanceSimple structureContinuous combustion chamberForce convectionEngineering

The invention discloses a fuel strut injector. Fuel of a scramjet engine and a combined circulatory power engine is adopted as a cooling agent, the cooling agent flows in a cooling channel for cooling a strut and is sprayed into a combustion chamber for being subjected to mixing combustion together with fuel gas, and therefore long-time normal work of the strut can be realized. The front edge of the strut is of a rounding wedge-shaped structure, and a flowing channel is located on the inner side of the front edge of the strut; a plurality of channel inlets are formed in each of the inner side of a front part of the strut and the inner side of a rear wall of the strut, a plurality of fuel spraying holes are formed in each of side wall surfaces of the strut, a liquid collection cavity is formed in the bottom of the strut and communicates with the flowing channel and the cooling channel, and the cooling agent enters the channel inlets, flows to the bottom of the strut along the channel, is gathered in the liquid collection cavity and finally is sprayed out of the strut through the fuel spraying holes; and the cooling agent absorbs heat in the channel in a flowing heat exchange mode of forced convection before being sprayed into the combustion chamber, and therefore the temperature of the strut can be lowered, and the fuel can be preheated. The strut injector is simple in structure, the thermal protection effect on the strut is good, and the strut can realize the function of injecting the fuel.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

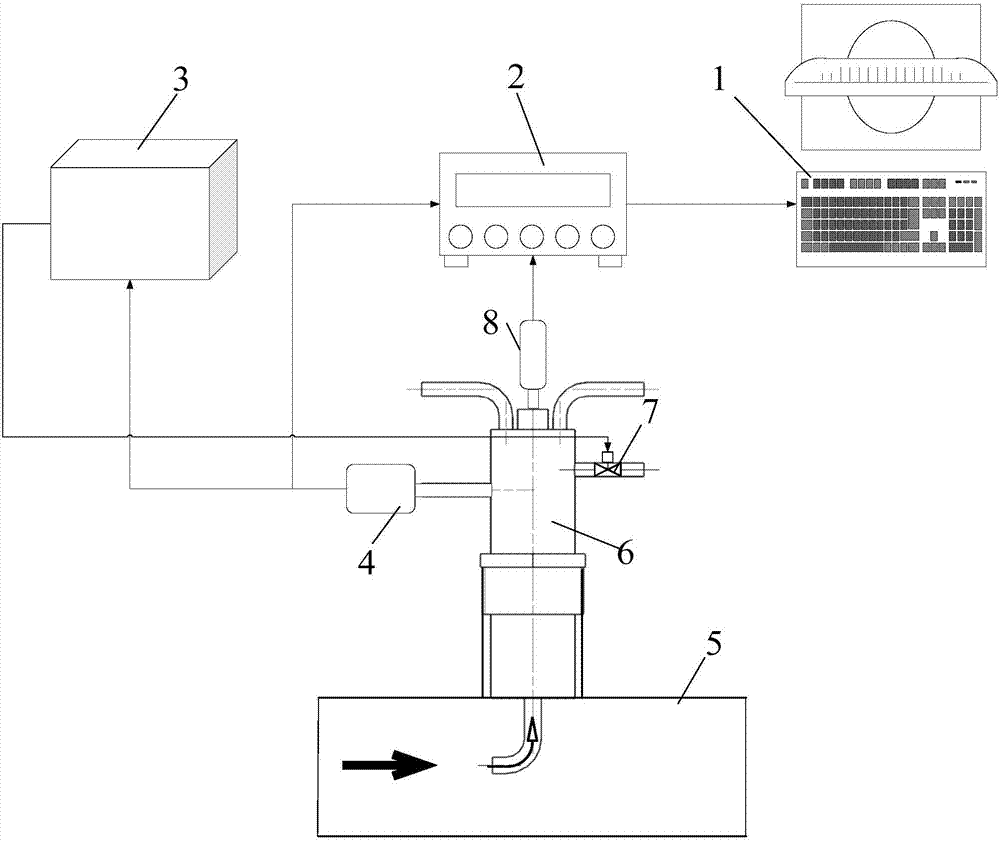

High temperature environmental pressure measuring system

ActiveCN106950009AProtects against thermal shockImprove thermal adaptabilityNuclear energy generationFluid pressure measurementControl cellNitrogen gas

The invention discloses a high temperature environmental pressure measuring system which comprises a computer, a collector, a control unit, a temperature sensor, a test object, a sensor cooling device, a nitrogen shutoff valve and a pressure sensor. The sensor cooling device comprises a cooling heat exchange structure with a hollow cavity. The hollow cavity of the cooling heat exchange structure is divided into inner and outer cavities. The outer cavity is spaced into two parts, wherein the bottom parts of two parts are communicated. A temperature sensor mounting seat which passes through a part of the outer cavity and is communicated with the inner cavity, and a nitrogen supply pipe which passes through the other part of the outer cavity and is communicated with the inner cavity are arranged on the circumference of the cooling heat exchange structure. The output end of the temperature sensor is connected with the input end of the collector and the input end of the control unit. The output end of the control unit is connected with the control end of the nitrogen shutoff valve. The output end of the pressure sensor is connected with the input end of the collector. The output end of the collector is connected with the input end of the computer.

Owner:HUANENG POWER INT INC +1

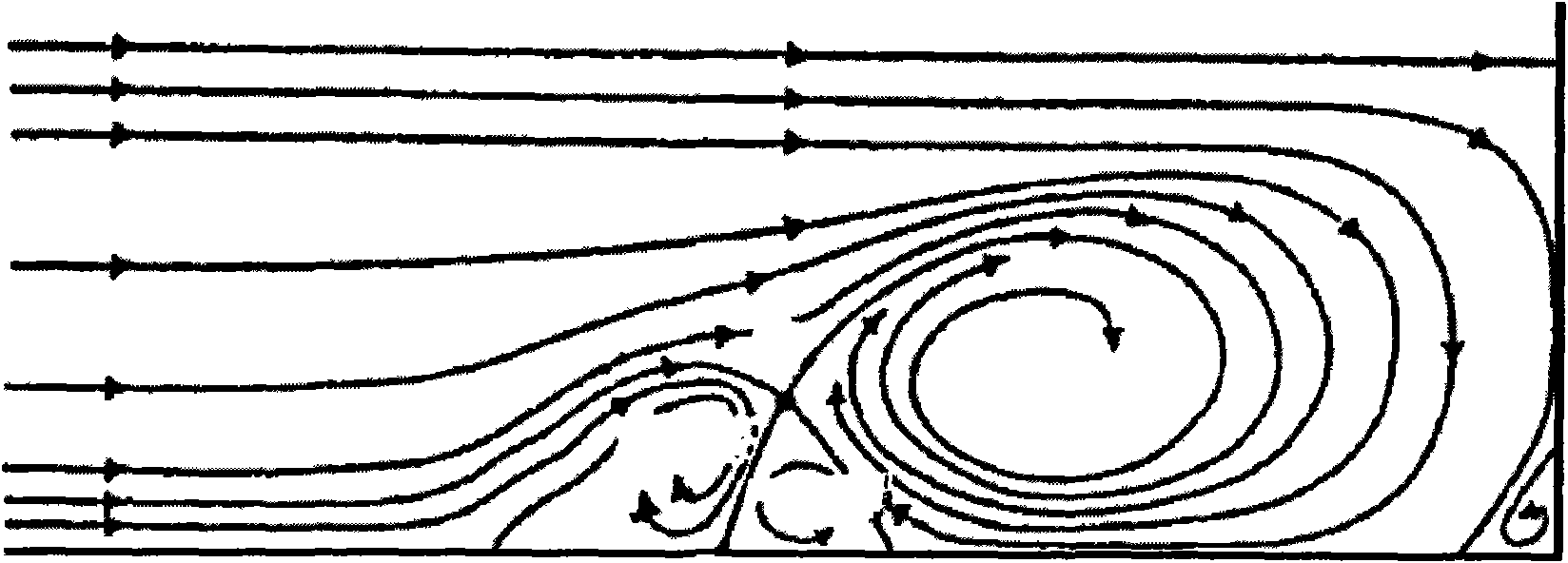

Turbine cooling cascade with vortex structure

InactiveCN101551120AReduce the spatial scaleReduce the impactContinuous combustion chamberCold airLeading edge

A turbine cooling cascade with a vortex structure relates to a turbine cooling cascade. The invention settles the problems of flowing loss, blending loss and easy burning of blade leading edge and end wall surface of blade leading edge caused by the existence of horse shoe vortex structure in the prior blade cascade. According to the blade (2) of the invention, a pressure surface (2-2) next to the blade leading edge (2-1), a suction surface (2-3) of blade (2) next to the blade leading edge (2-1) and the blade leading edge (1-1) of wall (1) are respectively provided with a plurality of elongated slots (3) which are distributed in row. One side wall of each elongated slot (3) is provided with a plurality of cold air injection openings (4). Furthermore the positions of cold air injection opening (4) are next to the base of elongated slot (3). The turbine cooling cascade with vortex structure according to the invention reduces the flowing loss at the inner part of flow passage, reduces the bigger blending loss of air currents with different flowing velocities, provides better thermal protection function for the end wall of blade and the blade surface, effectively protects the end wall adjacent with the blade leading edge and the high-temperature area on the surface of blade, and increases the usage factor of cold air.

Owner:HARBIN INST OF TECH

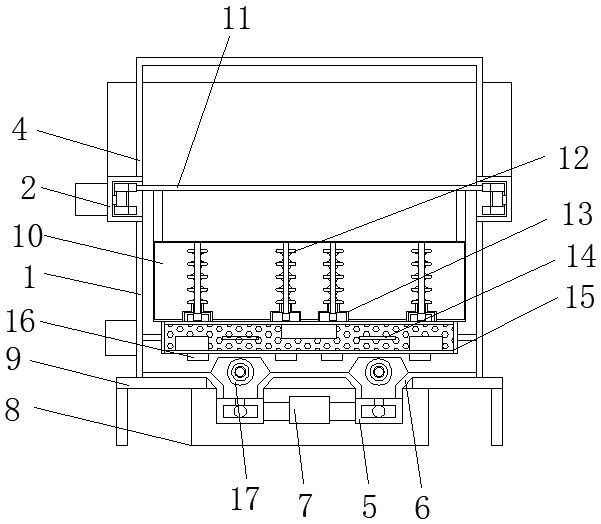

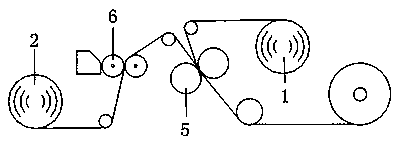

Linen fiber bleaching device for textile production

InactiveCN111826839AImprove bleaching efficiencyReduce lossTextile treatment machine arrangementsTextile treatment carriersFlax fibrePulp and paper industry

The invention discloses a linen fiber bleaching device for textile production and relates to the technical field of textile production. In order to solve the problem that the bleaching time is difficult to control and linen fibers are easy to damage when the linen fibers are soaked in a solution to be stirred, the linen fiber bleaching device specifically comprises a shell, a plurality of supporting frames are fixedly installed at the bottom of the shell, driving mechanisms are fixedly installed on the two sides of the top of the shell, a capping mechanism is fixedly installed between the topends of the two driving mechanisms, and bleaching sections extending downwards are arranged in the middle sections of the driving mechanisms. According to the linen fiber bleaching device for textileproduction, a bleaching solution is in contact with a heating mechanism when being sprayed out; the linen fibers are heated and cooked; the linen fiber bleaching efficiency is improved; the linen fibers are drained; a bleaching solution is recycled; the loss of the solution is reduced; the situation that the working environment is affected due to solution dripping is avoided; raw materials can becontinuously bleached due to the fact that the raw materials enter from one end and exit from the other end, and the linen fiber bleaching processing efficiency is improved.

Owner:宣城红妆美人床上用品有限公司

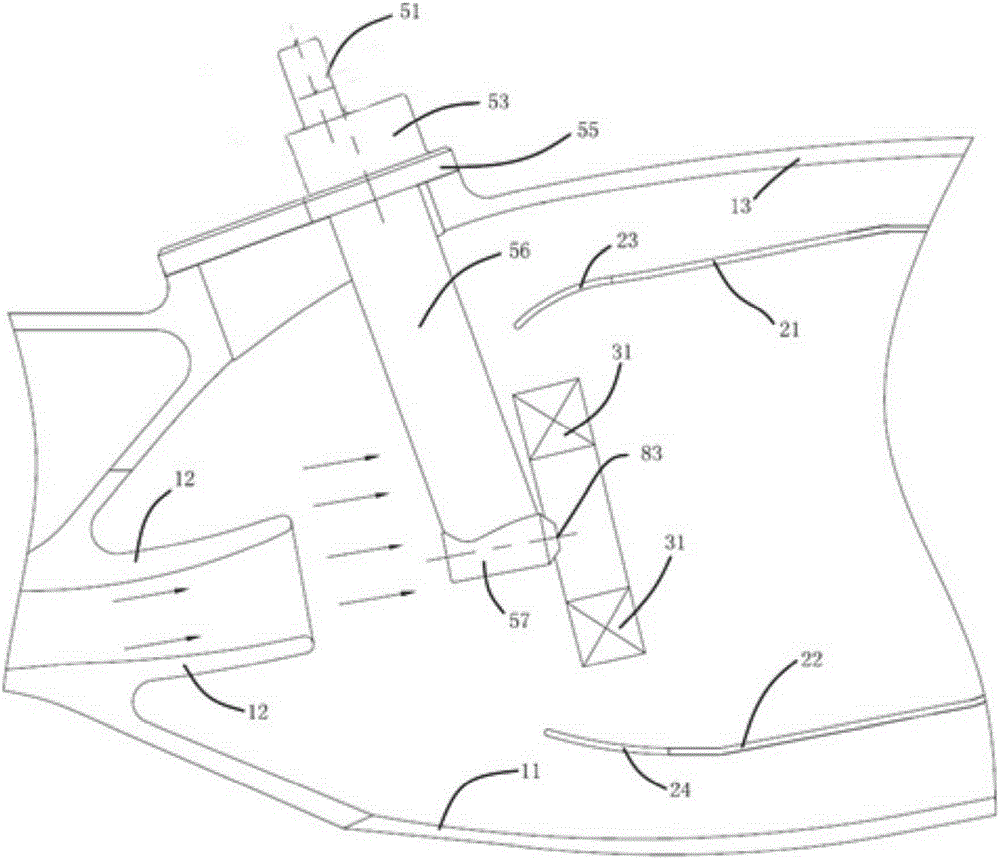

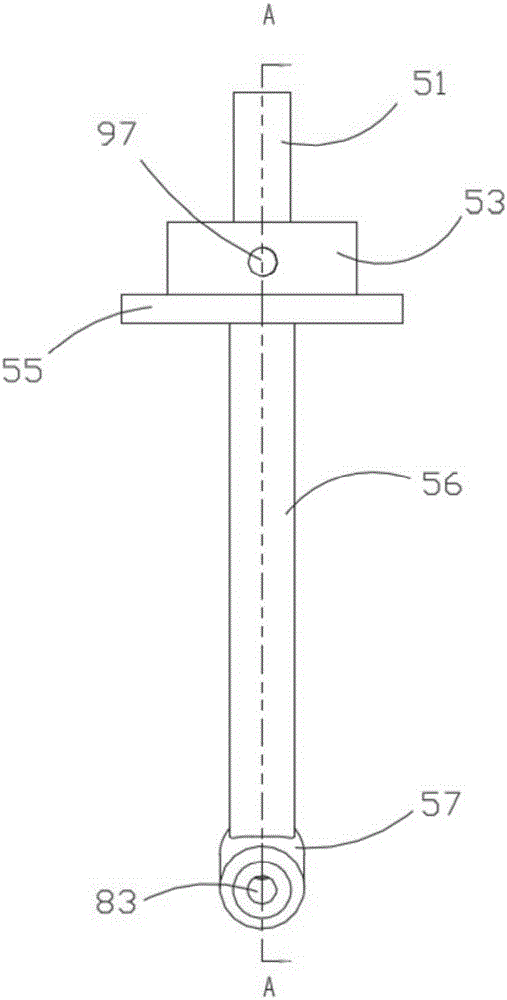

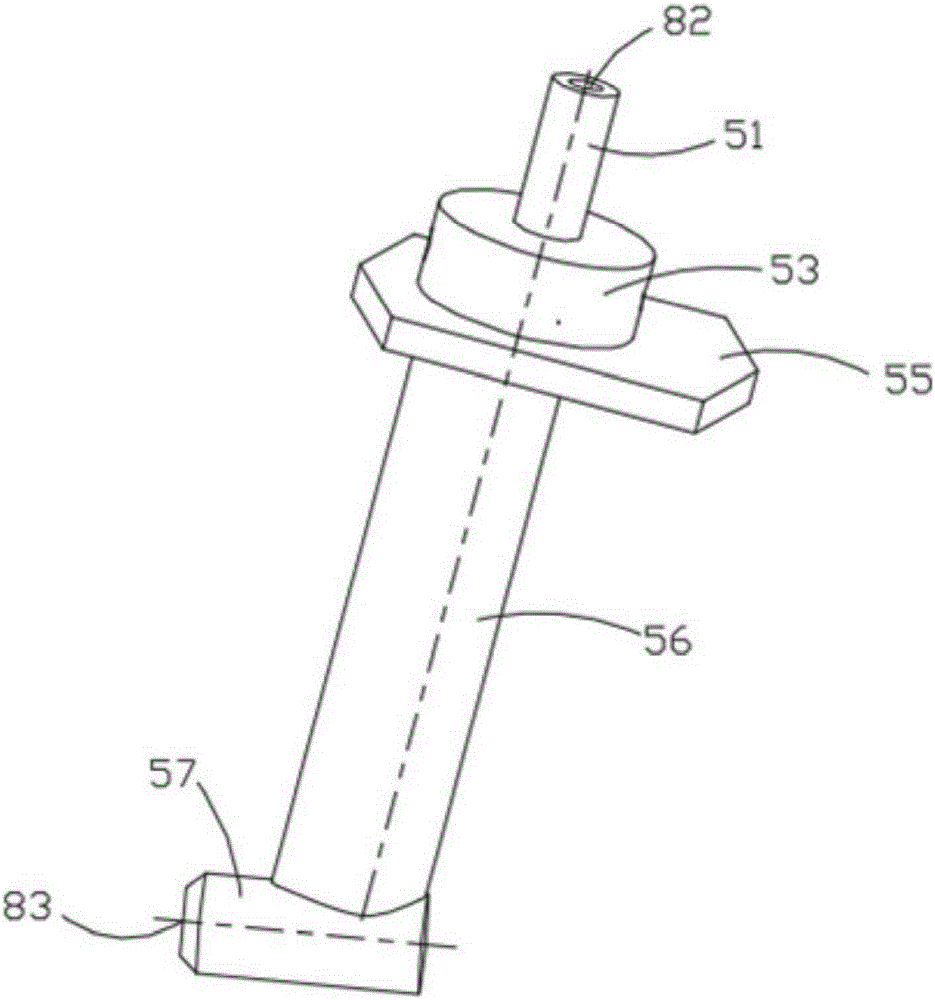

Gas flow regulation device for rotary spray pipe value of solid rocket-ramjet engine

PendingCN111577484AImprove thermal protection performanceCompact structureRocket engine plantsRam jet enginesRamjetCombustion chamber

The invention discloses a gas flow regulation device for a rotary spray pipe value of a solid rocket-ramjet engine. Each of a first fixed part and a rotating part is provided with one central hole andtwo arc-shaped holes in the axial direction; the front end of a transmission shell and an axial outlet section of a rear sealing head shell of a combustion chamber form a dynamic sealing structure; the tail end of the transmission shell and the head end of a spray pipe shell form a dynamic sealing structure; an outer ring of a thrust self-aligning roller bearing is mounted and fixed to the interior of a shell hole in the head end of the spray pipe shell; and the inner ring of the thrust self-aligning roller bearing is fixed to a shaft neck of the tail end of the transmission shell in a matched manner. A driving motor drives a driven gear to rotate to determine a corresponding angle of a transmission ratio, and finally, drives the rotating part to rotate at a corresponding angle relative to the first fixed part, so that the two arc-shaped holes of the rotating part and the fixed part are staggered and sheltered in the axial direction, thereby changing the effective outlet circulation area of the gas of the combustion chamber and realizing gas flow regulation with determined accuracy. The gas flow regulation device for the rotary spray pipe value of the solid rocket-ramjet engine isbetter in transmission mechanism thermal protection, more compact in structure and has higher work reliability, and can realize higher-precision and larger-range gas flow regulation.

Owner:湖南宏大日晟航天动力技术有限公司

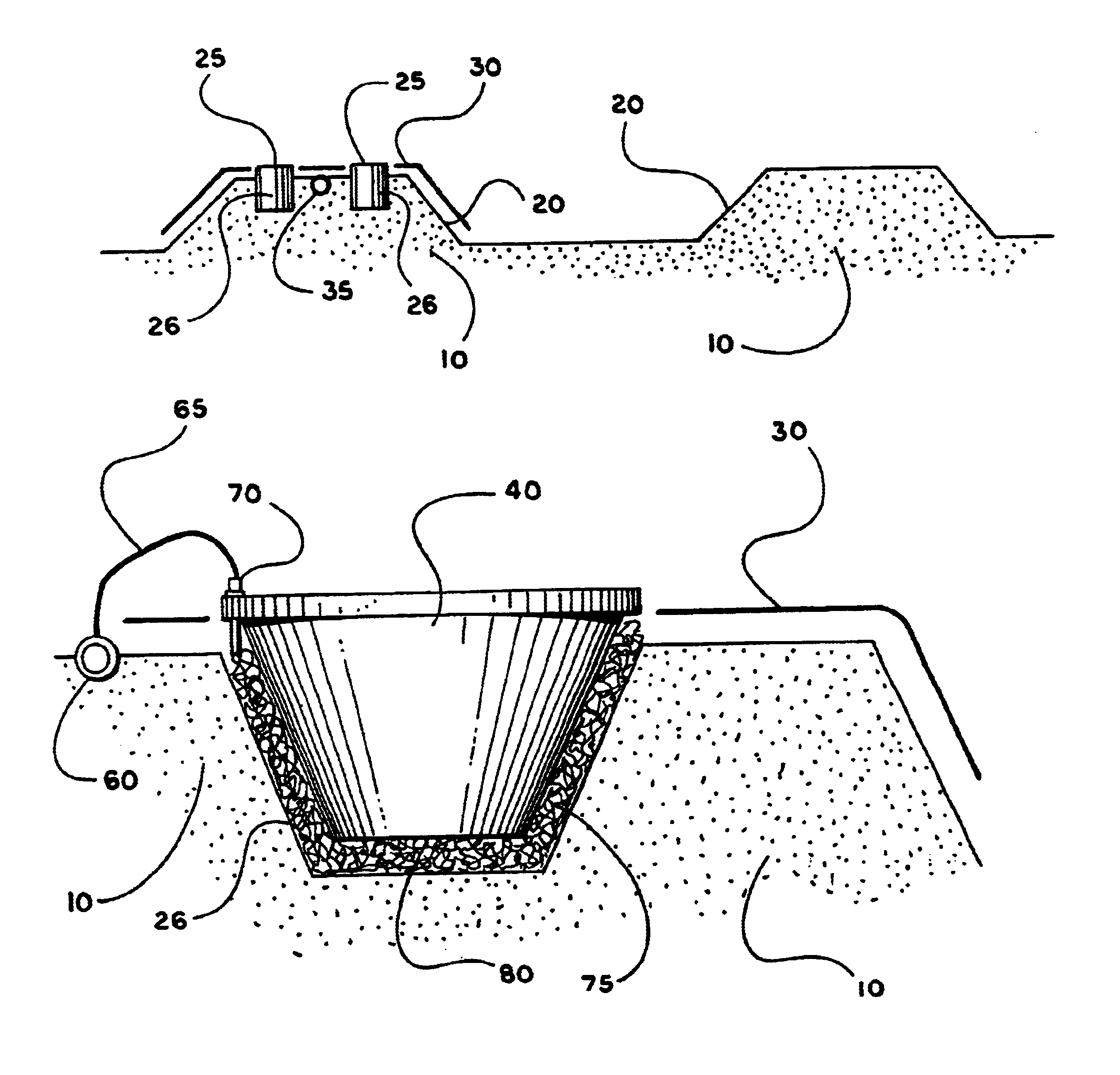

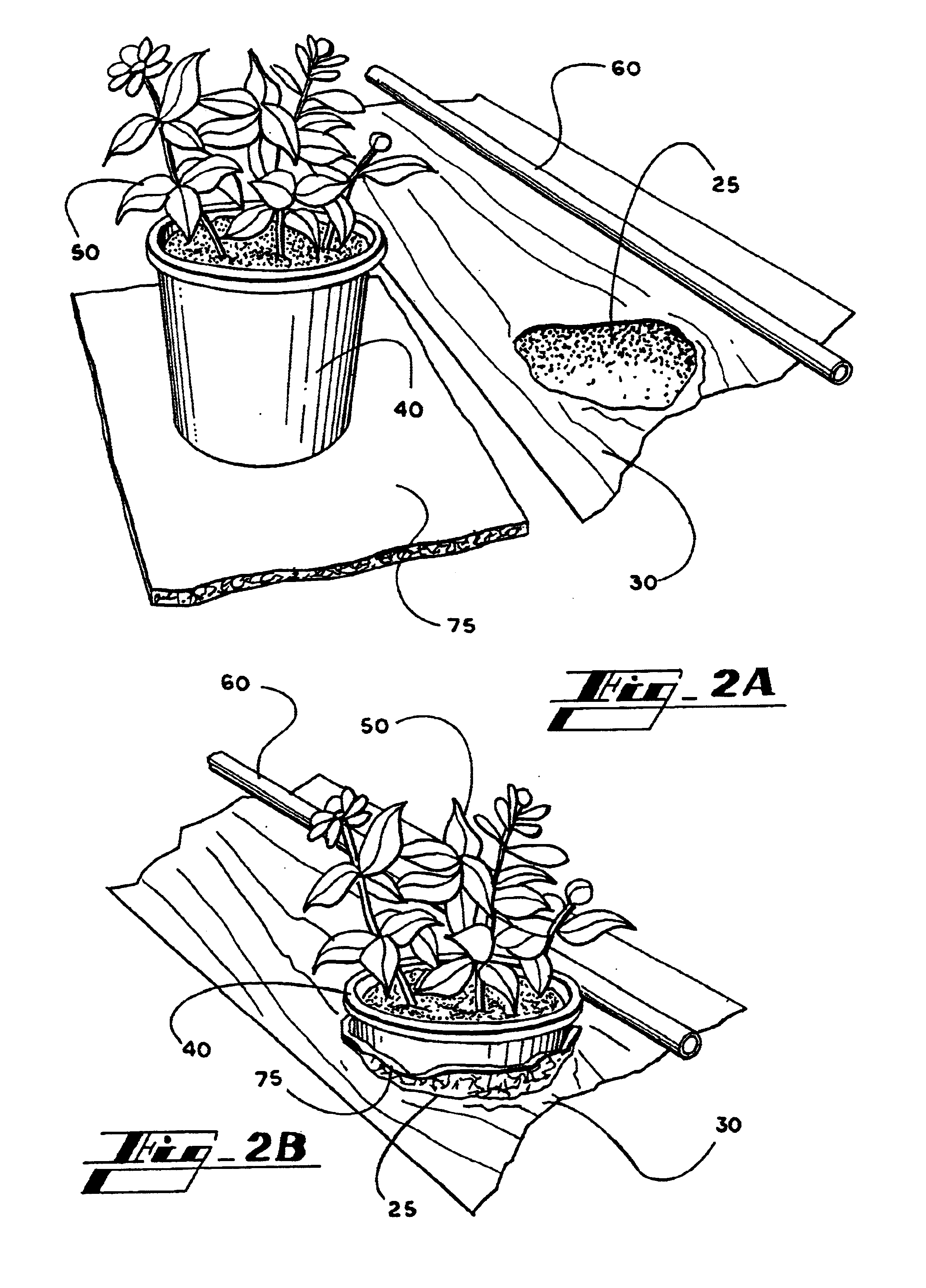

System, method and apparatus for container plant production

InactiveUS6865845B2Efficient growing area climateReduce eliminateSpadesPlanting bedsEngineeringPlant production

Owner:FRALEIGH NURSERY

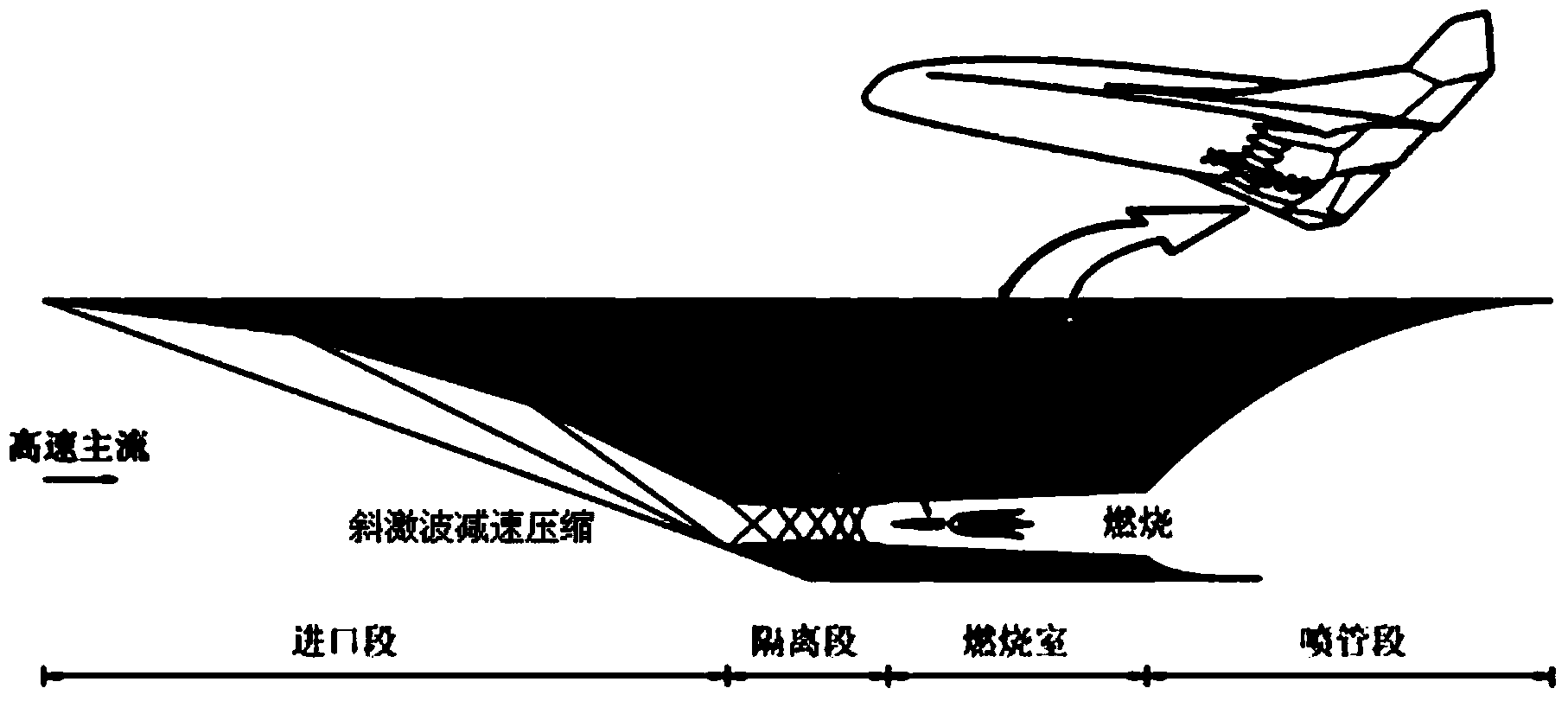

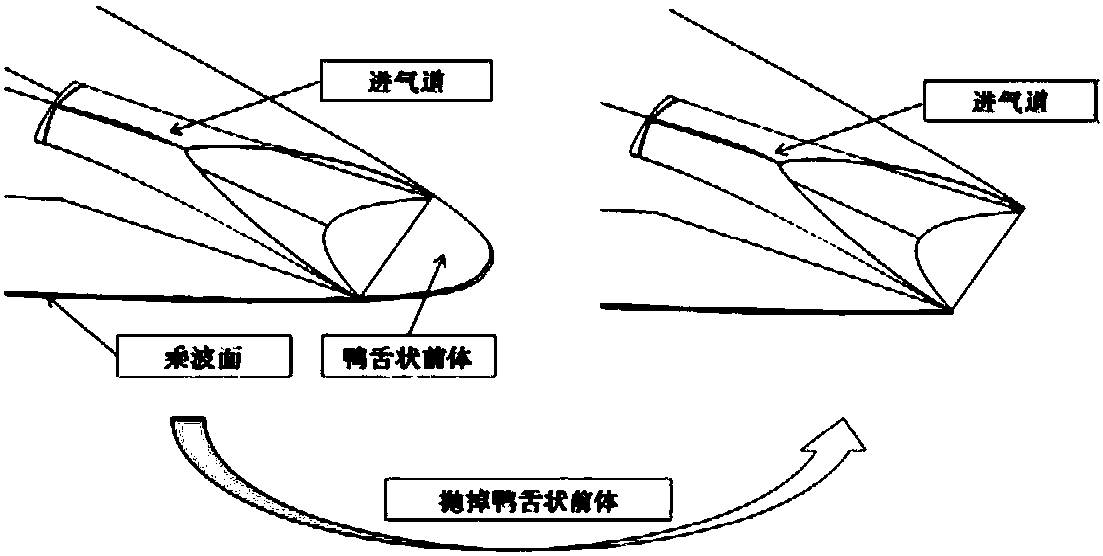

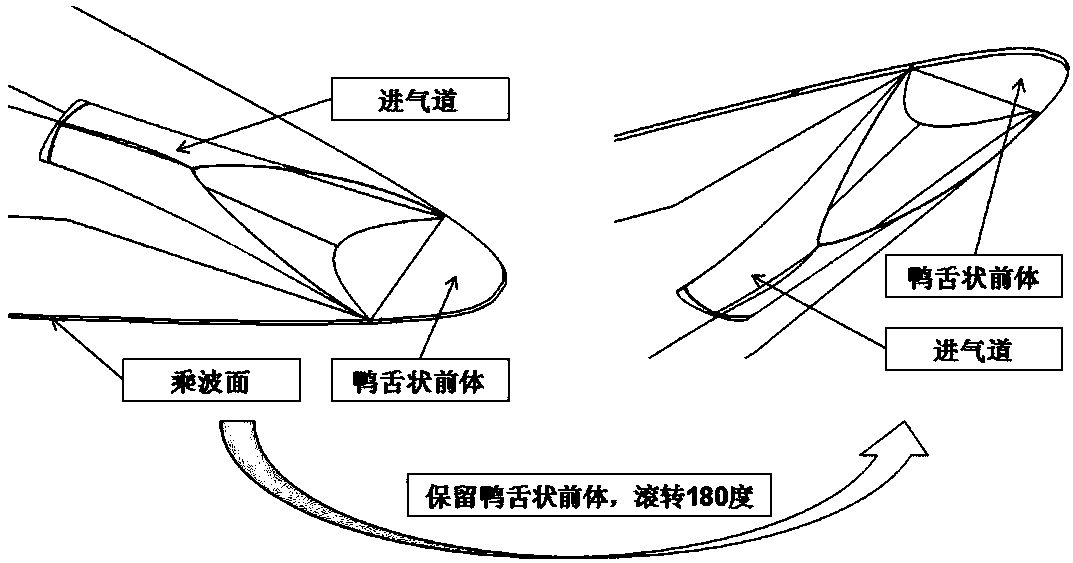

Layout of internal and external flow waverider aircraft

ActiveCN107867387AReduce couplingReduce resistanceFuselagesGround installationsAerospace engineeringRamjet

The invention relates to aerodynamic layout of an internal and external flow waverider aircraft and belongs to the technical field of aerodynamic design of aircrafts. The aircraft is divided into an upper part and a lower part in terms of aerodynamic layout design; the lower part of the aircraft is mainly used for providing high lift-drag ratio for unpowered gliding flight with high Mach number, and a flat waverider layout form is adopted; the upper part of the aircraft is mainly used for arranging an air suction type ramjet. According to the layout form, an engine flow channel and a waveriderplane are mutually independent and non-interfering, so that coupling effect of pneumatics and power is greatly reduced, particularly, resistance produced by an engine during unpowered flight with high Mach number can be obviously reduced, increase of the lift-drag ratio during unpowered flight with high Mach number is facilitated, and furthermore, thermal protection of the engine is facilitated.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

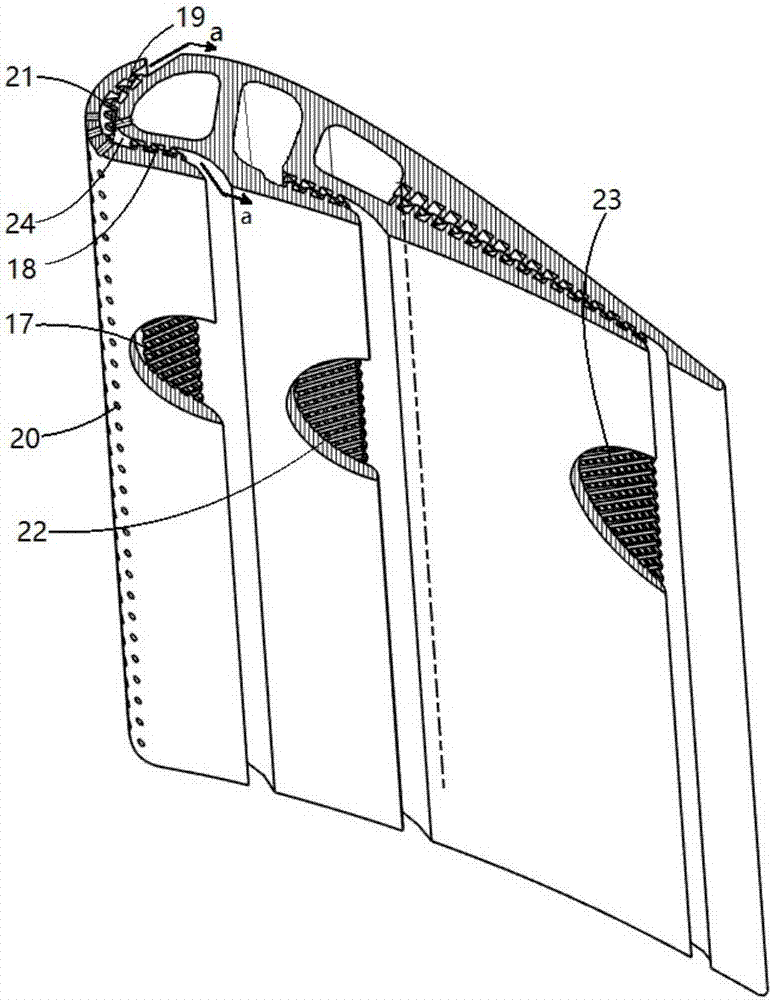

Efficient cooling blade for gas turbine engine

PendingCN107013253AImprove heat transfer effectExcellent adhesionEngine fuctionsBlade accessoriesSuction forceJet flow

The invention discloses an efficient cooling blade for a gas turbine engine. The efficient cooling blade comprises a blade body, an end wall and a tenon head, wherein the blade body is a hollow cylinder, and comprises a pressure surface and a force absorbing surface; first to third bridging beams are sequentially arranged from the front edge of the blade to the tail edge of the blade in the blade body for dividing the inner part of the blade body into a gas cavity, and first to third channels; a first abnormally formed gas film hole which communicates with the gas cavity is formed in the force absorbing surface; a second abnormally formed gas film hole which communicates with the gas cavity, a third abnormally formed gas film hole which communicates with the second channel and a fourth abnormally formed gas film hole which communicates with third channel are formed in the pressure surface; an impact jet hole is formed in the first bridging seam; a spraying hole is formed in the front edge of the blade; and a heat exchange structure is arranged in each of the gas cavity, a connecting channel for the second channel and the third abnormally formed gas film hole, and a connecting channel for the third channel and the fourth abnormally formed gas film hole. While efficient inner cooling is performed on the blade, the disturbance effect, on cooling gas-flow disturbance, of the heat exchange structure is brought into play, and the protective effect of gas film cooling is strengthened.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Highly visible arc protective multilayer composite fabric

PendingCN108943944AImprove visibilityMeet the standard requirementsProtective equipmentSynthetic resin layered productsYarnAdhesive

The invention discloses a highly visible arc protective multilayer composite fabric which at least comprises a surface fabric and an inner fabric, wherein the surface fabric and the inner fabric are adhered by a flame retardant adhesive; the surface fabric is woven from two or more than two of vinyon N, Lenzing flame retardant viscose and flame retardant cotton; the inner fabric is blended from one or two yarns of silicon nitrogen series flame retardant viscose, para-aramid as well as polysulfonamide and polyimide; and the flame retardant adhesive is flame retardant polyurethane or flame retardant EVA (Ethylene-Vinyl Acetate). According to the manner, the fabric disclosed by the invention can achieve long-term and excellent flame retardant and arc protective effects, and the fabric has theeffects of being humidity-absorbing and breathable, comfortable to wear, antibacterial and healthy.

Owner:CHANGSHU BAOFENG SPECIAL FIBER

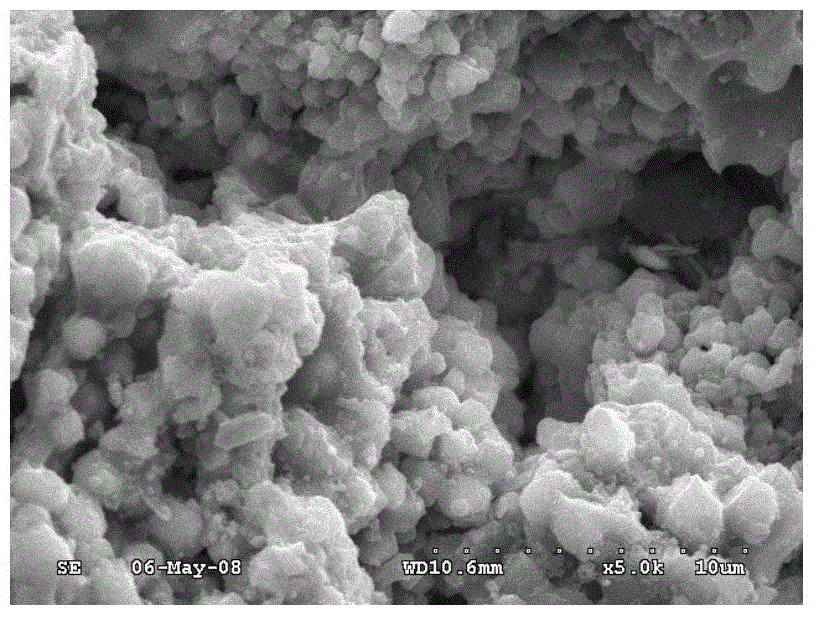

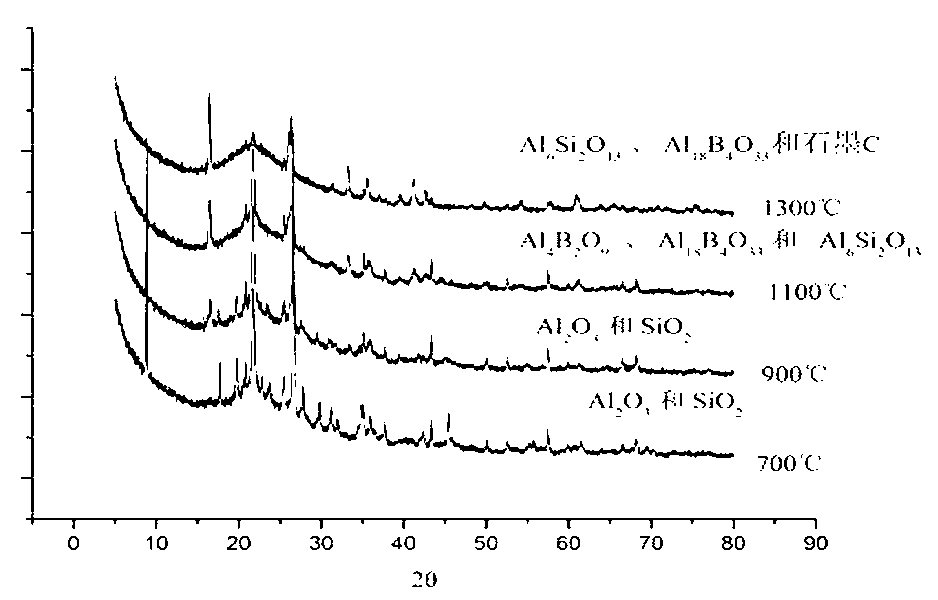

Ceramic high carbon polymer matrix composite and preparation method thereof

ActiveCN103058632ALow porcelain temperatureGood heat protectionClaywaresLamellar structureThermal protection

The invention relates to a ceramic high carbon polymer matrix composite and a preparation method thereof. The composite comprises the following components according to parts by weight: 15-50 parts of high thermoset carbon resin, 5-10 parts of eutecticevaporate mixture, 20-50 parts of clay stratified structure mineral powder, and 0.1-1.5 parts of molding additives. The preparation method comprises the following steps of hot melting and mixing the components according to the proportion, heating and fusing the mixture for vacuum defoamation, casting in a die, and thermocuring for molding at the temperature, so as to obtain the ceramic high carbon polymer matrix composite. The ceramic component of the polymer is characterized in that the ceramic component can be converted into ceramic material containing carbon in high temperature aerobic environment, the temperature for ceramic conversion is controllable, the ceramic conversion rate is high in high temperature aerobic environment, and the ceramic bovine component can be used in the field of antiflaming and fireproofing and thermal protection.

Owner:WUHAN UNIV OF TECH

Special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and preparation method of halogen-free flame-retardant synergistic masterbatch

ActiveCN110591341AEffective protectionImprove thermal protection performanceAcrylonitrilePolytetrafluoroethylene

The invention relates to the technical field of modification and processing of plastics, in particular to special halogen-free flame-retardant synergistic masterbatch for modification of nylon resin and a preparation method of the halogen-free flame-retardant synergistic masterbatch. Multiple-compounded coated aluminum diethylphosphinate is adopted as a phosphorous-based flame retardant of the functional masterbatch, and the functional masterbatch comprises the compositions: in percent by mass, 55.0-65.0% of multiple-compounded coated aluminum diethylphosphinate, 20.0-30.0% of anhydrous zinc borate, 8.0-10.0% of nylon 6 resin, 3.0-5.0% of star-shaped nylon, 0.5-1.0% of styrene-acrylonitrile copolymer-coated polytetrafluoroethylene, 0.5-1.0% of a dispersant and 0.3-0.5% of a lubricant. Whenthe prepared functional masterbatch is compared with traditional flame-retardant functional masterbatch, the heat resistance and thermal stability of aluminum diethylphosphinate are improved significantly, aluminum diethylphosphinate is adaptive to a high processing temperature of nylon resin, so that the flame retardant effect of aluminum diethylphophinate on nylon resin is improved more effectively.

Owner:江苏万纳普新材料科技有限公司

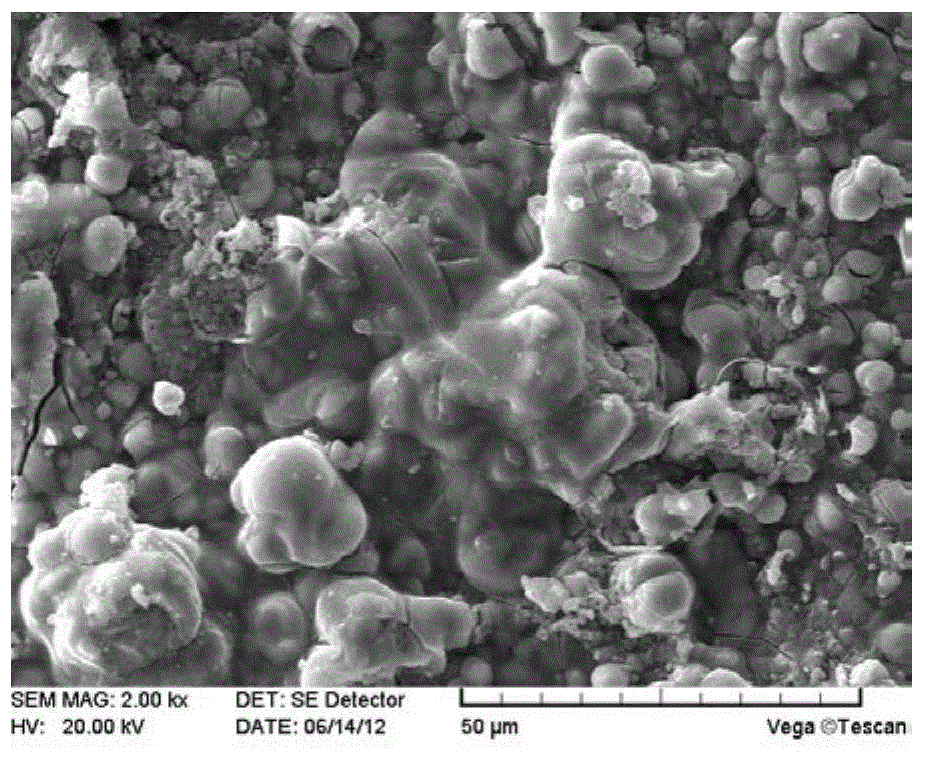

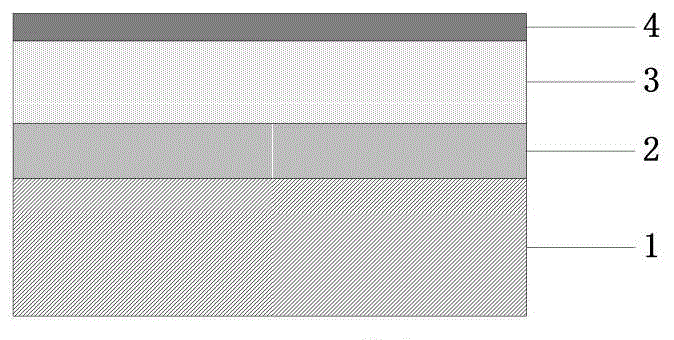

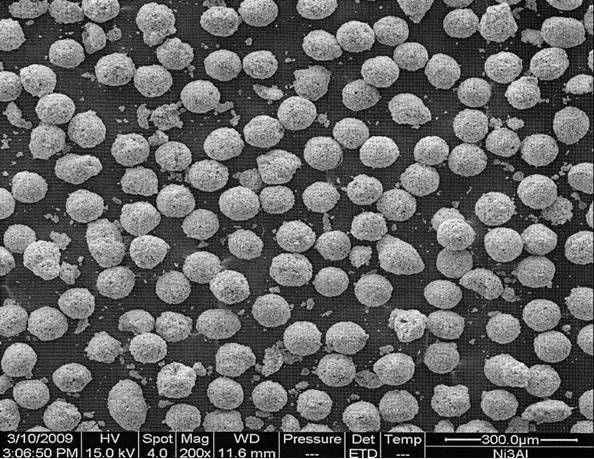

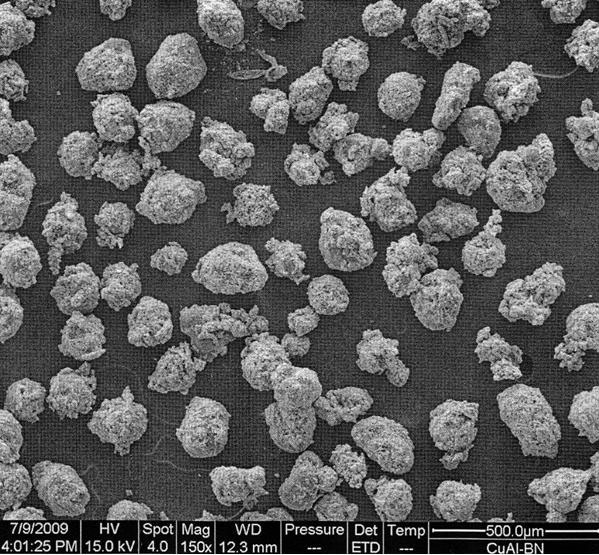

Preparation method of wearable seal coating with titanium fire preventing function

InactiveCN102560322AScour resistantImprove abradabilityMolten spray coatingEfficient propulsion technologiesSurface layerPower flow

The invention aims at providing a preparation method of a wearable seal coating with a titanium fire preventing function. The preparation method is characterized in that the wearable seal coating is a three-layer coating system, wherein a bottom layer is an Ni3Al coating, a middle layer is a ZrO2.Y2O3 heat insulation coating, and a surface layer is a CuAl / BN wearable seal coating. The wearable seal coating is prepared by adopting a plasma spraying method, process parameters are as follows: the bottom layer has a process current of 500-520A and a spraying distance of 120-140mm as well as a spraying power of 30-36kW, the middle layer has a process current of 600-620A and a spraying distance of 80-110mm as well as a spraying power of 42-46kW, and the surface layer has a process current of 360-420A and a spraying distance of 110-130mm as well as a spraying power of 20-25kW. The three-layer coating system has better heat insulation performance, a certain scouring resistance, better wearability and low friction coefficient, and can be used as a titanium fire preventing coating of a titanium alloy casing.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Flame-retardant anti-static two-faced plush cloth

ActiveCN105019119APermanent Flame RetardancyImprove thermal protection performanceWeft knittingYarnModacrylic

The invention discloses flame-retardant anti-static two-faced plush cloth which is formed by blending the following components in parts by weight: 50-60 parts of modacrylic, 30-40 parts of cotton, 5-15 parts of nylon and 1-3 parts of conductive wires. The two-faced plush cloth includes a first surface and a second surface, wherein both the first surface and the second surface are formed by blending and weaving modacrylic fibers and cotton fibers; the first surface and the second surface are connected with each other through polyamide yarns and the conductive wires; the polyamide yarns are arranged parallel to the conductive wires, the distance between adjacent polyamide yarns is 0.08-0.15 cm, and the distance between adjacent conductive wires is 0.8-1.2 cm. The two-faced plush cloth is knitted fabric and has the characteristics that the cloth is resistant to high temperature, non-combustible, free of molten drops, soft, comfortable and good in heat retention property, and does not lose plush.

Owner:上海俊首安防科技有限公司 +1

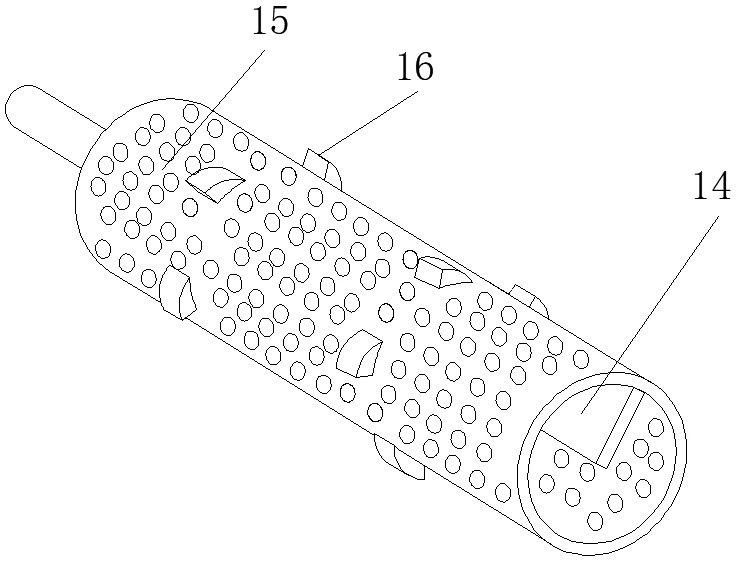

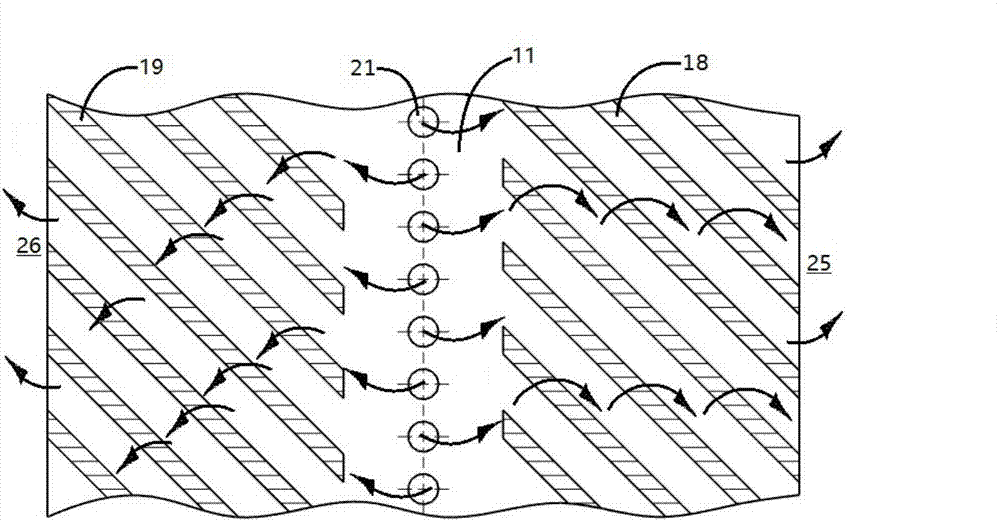

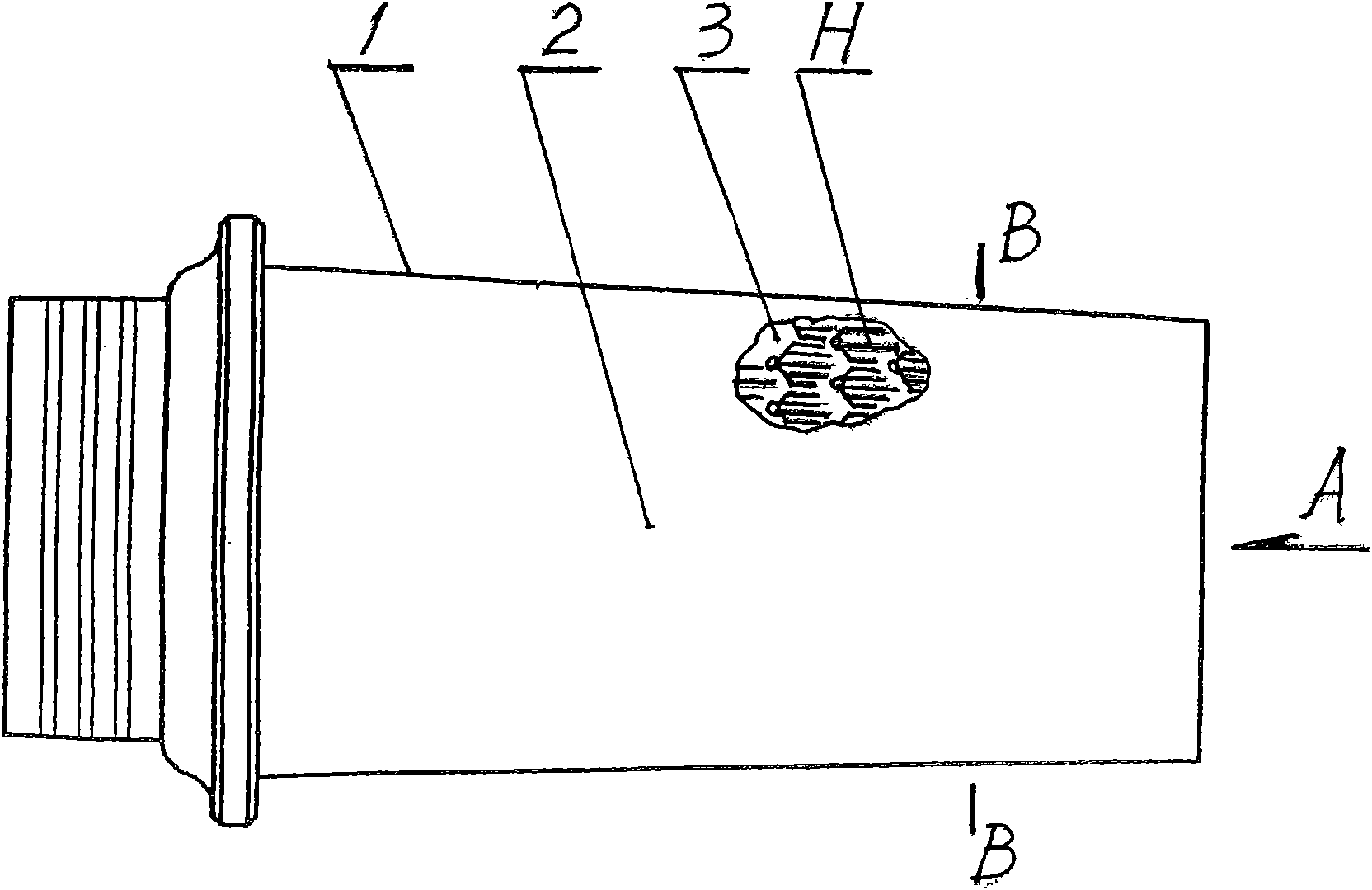

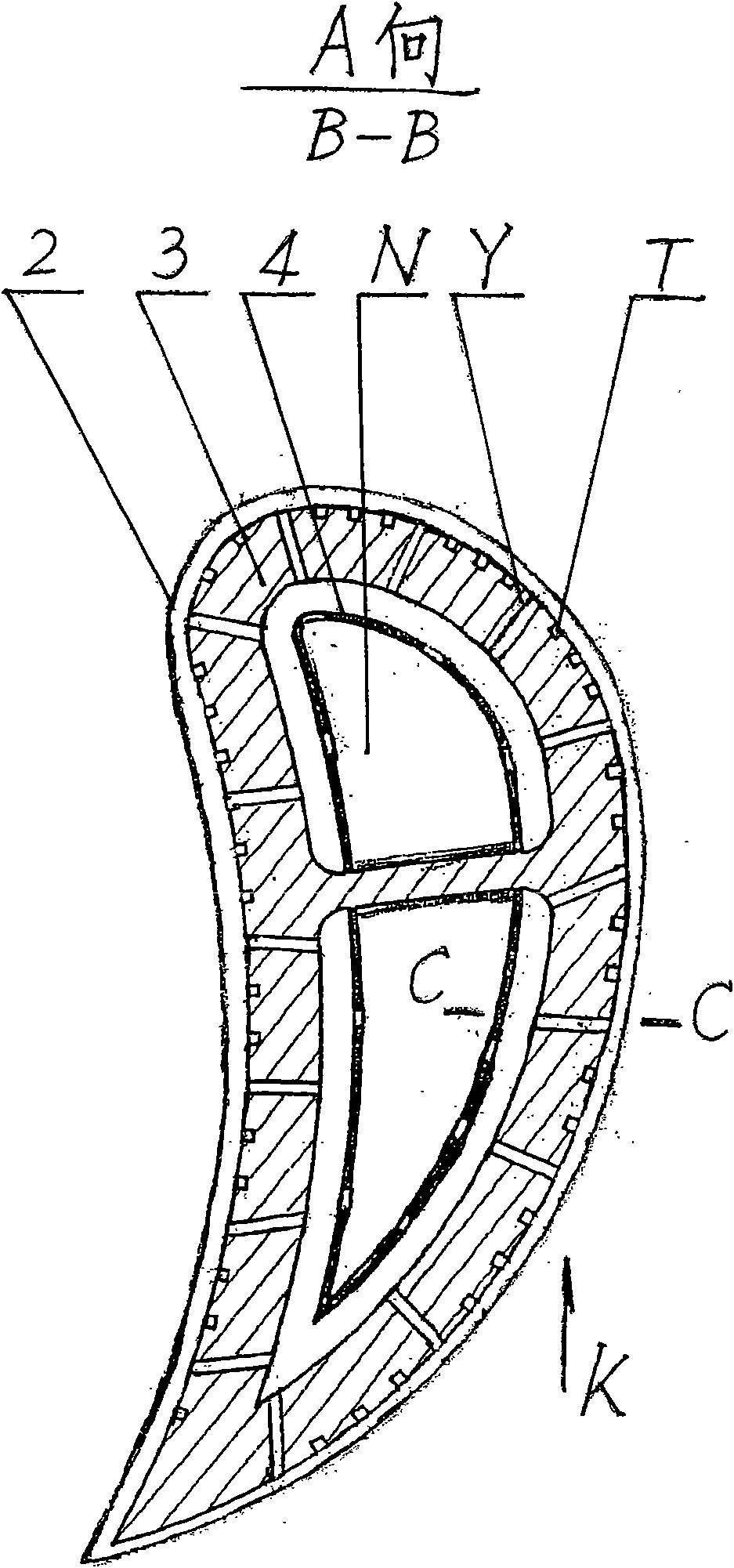

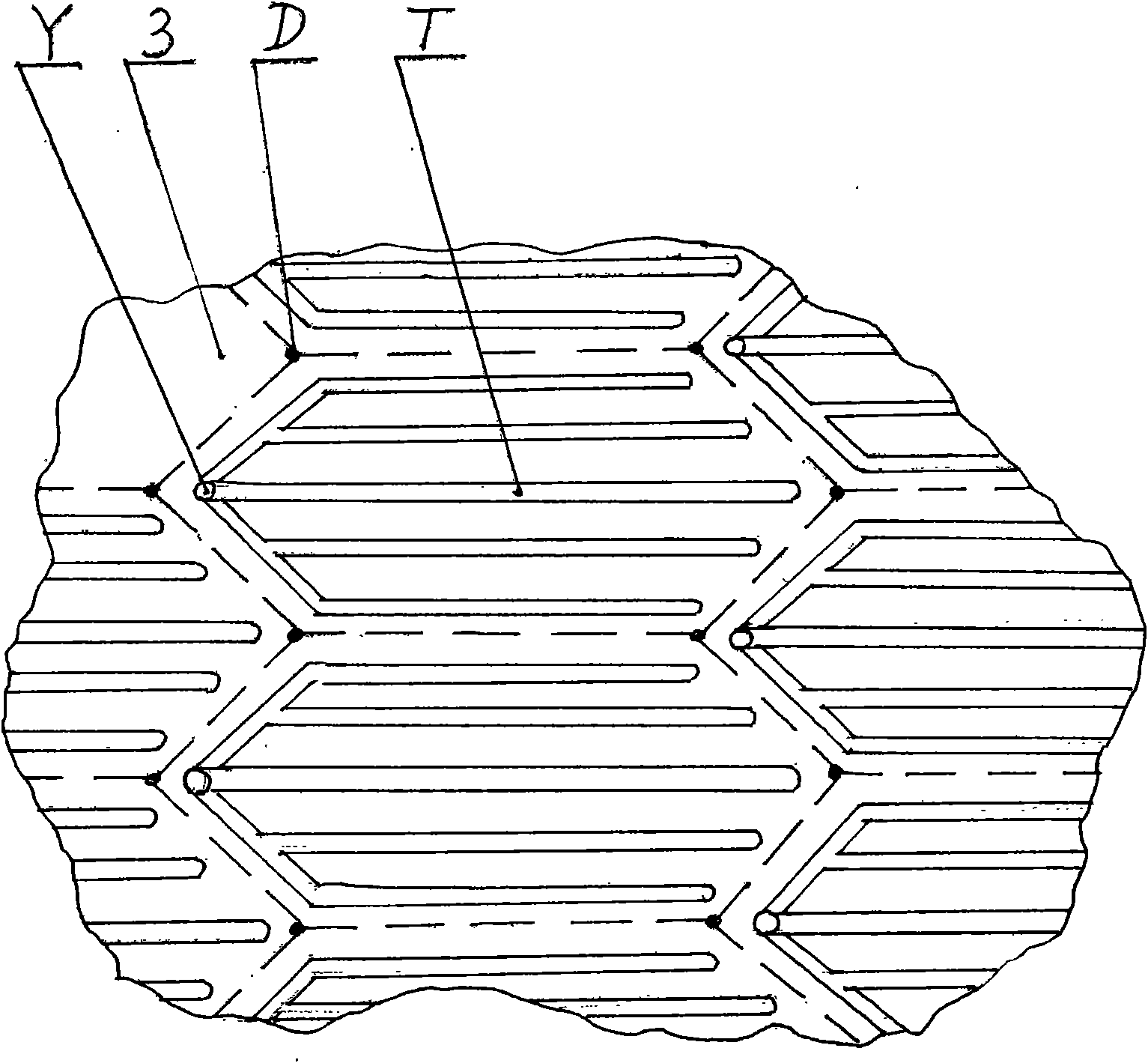

Clustered shunt type thermal protection for turbine rotor blade of aeroengine

InactiveCN101586475AImprove performanceIncrease profitBlade accessoriesMachines/enginesAviationTurbine blade

The invention discloses clustered shunt type thermal protection for a turbine rotor blade of an aeroengine. A load bearing frame (3) of the turbine rotor blade (1) is provided with a plurality of air bleeding holes (Y) which are communicated with an inner cavity (N) of the blade, each air bleeding hole (Y) is communicated with a plurality of gas channels (T) to form a cooling unit (H), and the load bearing frame (3) is densely distributed with a plurality of the cooling units (H). Cooling air in the inner cavity (N) of the blade flows toward the gas channels (T) through the air bleeding holes (Y), and is sprayed outward through a micro-air film hole (W) and a dust exhaust air film hole (P) on a blade wall surface (2) to form an air film (M), and strengthened heat exchange cooling is performed on a hot end of the turbine rotor blade (1), and separation is performed on heat transfer. The thermal protection can enlarge the area of cooling and heat exchange, prolong cooling time, improve the utilization rate of the cooling air, strengthen thermal protection property, and improve the temperature of fuel gas in front of turbines of the aeroengines.

Owner:张金山

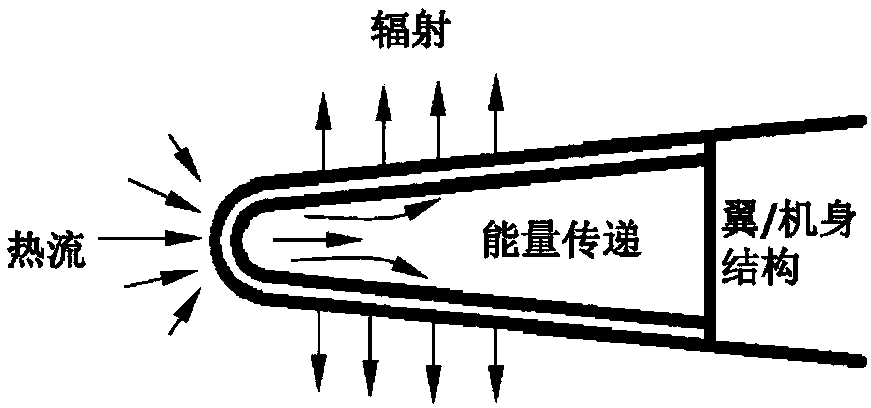

Adaptive local activation transpiration cooled hypersonic speed leading edge thermal-protection method

InactiveCN108438205AImprove thermal protection performanceHeat reducing structuresFuselagesCooling chamberEngineering

The invention discloses an adaptive local activation transpiration cooled hypersonic speed leading edge thermal-protection method. A high temperature-resistant material is used for preparing a leadingedge body having a microporous structure, the surface of the leading edge body is covered with a layer of sublimation-type impervious ablation coating, a coolant supply channel is fixedly connected with a rear part of the leading edge body, and a cooling chamber enclosed by the leading edge body is sealed with a coolant in advance; the surface temperature of the ablation coating is lower than thesublimation temperature of the material of the ablation coating, an aperture at the surface is enclosed, and at this time, a transpiration cooled system cannot be activated; under effect of externalchange hot fluid, the ablation coating of a high hot-fluid area positioned at a leading edge body arrest point gives priority to sublimation, an active transpiration cooled mechanism is partially activated, the coolant is leaked from the aperture, a layer of a protection gas film is used for covering, and local thermal protection of the area can be enhanced. The method can increase the thermal-protection effect of a high hot-fluid area of a leading edge arrest point, and the optimized utilization of the coolant amount is realized.

Owner:UNIV OF SCI & TECH OF CHINA

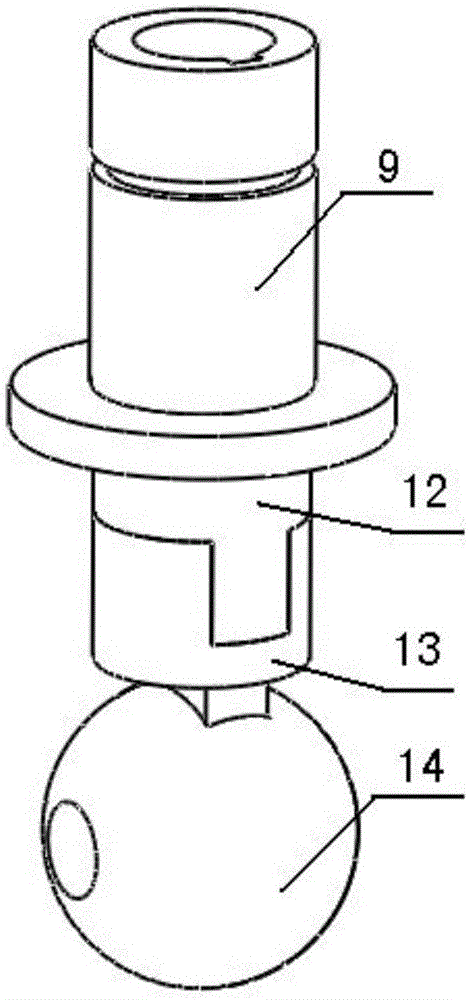

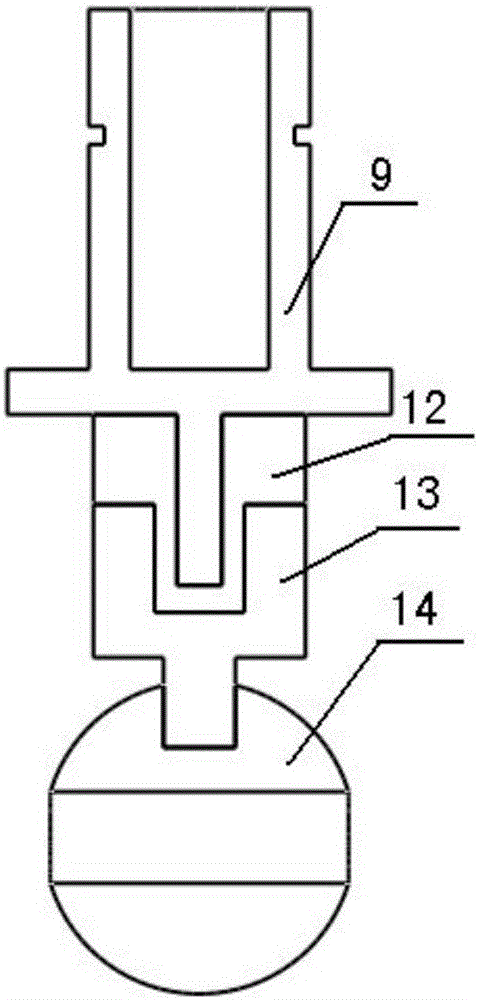

High-temperature fuel gas adjusting valve used for rocket engine

InactiveCN105889548ASimple structureEasy to operatePlug valvesOperating means/releasing devices for valvesRamjetSolid fuel

The invention discloses a high-temperature fuel gas adjusting valve used for a rocket engine. The high-temperature fuel gas adjusting valve used for the rocket engine is composed of a valve body, an upper end cover, connection end covers, a motor shaft sleeve, a rotating shaft, a valve element and a valve element bracket. The motor is fixedly connected with the upper end cover; an output shaft of the motor is fixedly connected with the motor shaft sleeve which is connected with the rotating shaft and the valve element in a cooperative manner, and positioning and transmission are achieved; and the valve element is connected with the valve element bracket. Gas conveying pipe heat insulating pieces are installed at the two ends of the valve element bracket and fixedly connected with the connection end covers; the valve body is in threaded connection with the connection end covers and is fixedly connected with the upper end cover through bolts; and the connection end covers are connected with a fuel gas pipeline. The high-temperature fuel gas adjusting valve changes the circulating area by changing the rotating angle of the valve, and therefore thrust adjustment of a solid propellant engine, flow adjustment of a solid fuel gas generator or fuel gas flow adjustment of a primary fuel gas generator of the solid rocket ramjet engine can be achieved; and the high-temperature fuel gas adjusting valve is safe and reliable. The high-temperature fuel gas adjusting valve is simple in structure, convenient to install and operate and good in heat protection effect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com