Preparation method of wearable seal coating with titanium fire preventing function

A sealing coating and wear-resistant technology, applied in coating, metal material coating technology, sustainable transportation, etc., can solve problems such as the reduction of compressor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

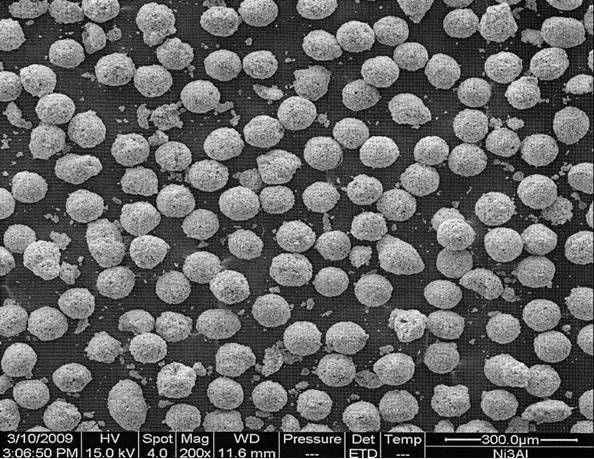

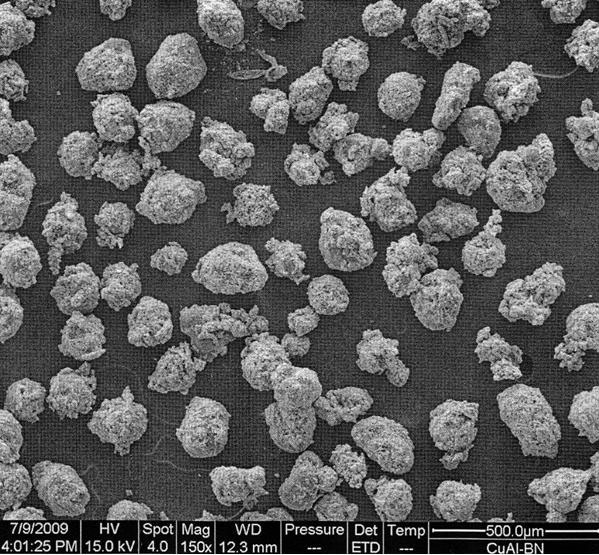

[0021] Ni 3 The particle size of Al powder is -100 mesh to +325 mesh, and the powder is spherical; the particle size of CuAl / BN powder is -80 mesh to +325 mesh, and the powder is spherical; the thickness of the three-layer coating system is Ni 3 Al bottom layer 0.07mm, middle insulation layer Zr0 2 ·Y 2 0 3 Coating 0.15mm, CuAl / BN surface layer 1.0mm.

[0022] Plasma spraying process parameters:

[0023] Ni 3 Al bottom layer process is: current 500A, spraying distance 120mm, spraying power 32kW; Zr0 2 ·Y 2 0 3 Coating process: current 600A, spraying distance 100mm, spraying power 45kW; CuAI / BN coating process: current 400A, spraying distance 110mm, spraying power 20kW.

[0024] The obtained coating has a tensile bonding strength of 6.5 MPa and a surface Rockwell hardness of 45HR15Y.

[0025]

Embodiment 2

[0027] Ni 3 The particle size of Al powder is -100 mesh to +325 mesh, and the powder is spherical; the particle size of CuAl / BN powder is -80 mesh to +325 mesh, and the powder is spherical; the thickness of the three-layer coating system is Ni 3 Al bottom layer 0.10mm, middle insulation layer Zr0 2 ·Y 2 0 3 Coating 0.12mm, CuAl / BN surface layer 1.0mm.

[0028] Plasma spraying process parameters:

[0029] Ni 3 Al bottom layer process is: current 500A, spraying distance 140mm, spraying power 34kW; Zr0 2 ·Y 2 0 3 Coating process: current 600A, spraying distance 100mm, spraying power 45kW; CuAI / BN coating process: current 360A, spraying distance 120mm, spraying power 22kW.

[0030] The obtained coating has a tensile bonding strength of 7 MPa and a surface Rockwell hardness of 50HR15Y.

[0031]

Embodiment 3

[0033] Ni 3 The particle size of Al powder is -100 mesh to +325 mesh, and the powder is spherical; the particle size of CuAl / BN powder is -80 mesh to +325 mesh, and the powder is spherical; the thickness of the three-layer coating system is Ni 3 Al bottom layer 0.10mm, middle insulation layer Zr0 2 ·Y 2 0 3 Coating 0.12mm, CuAl / BN surface layer 1.2mm.

[0034] Plasma spraying process parameters:

[0035] Ni 3 Al bottom layer process is: current 500A, spraying distance 140mm, spraying power 34kW; Zr0 2 ·Y 2 0 3 Coating process: current 600A, spraying distance 100mm, spraying power 45kW; CuAI / BN coating process: current 410A, spraying distance 130mm, spraying power 25kW.

[0036] The obtained coating has a tensile bonding strength of 7.8MPa and a surface Rockwell hardness of 55HR15Y.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com