Patents

Literature

39results about How to "Reduce direct washout" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

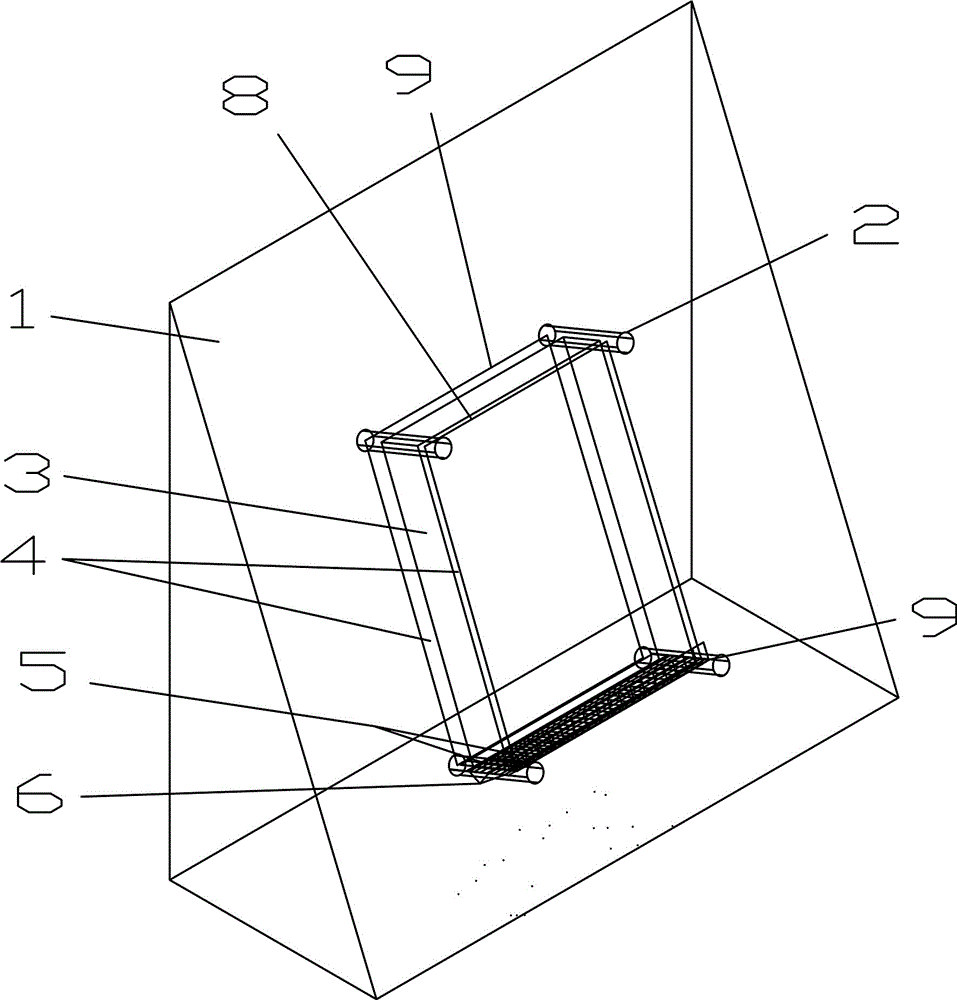

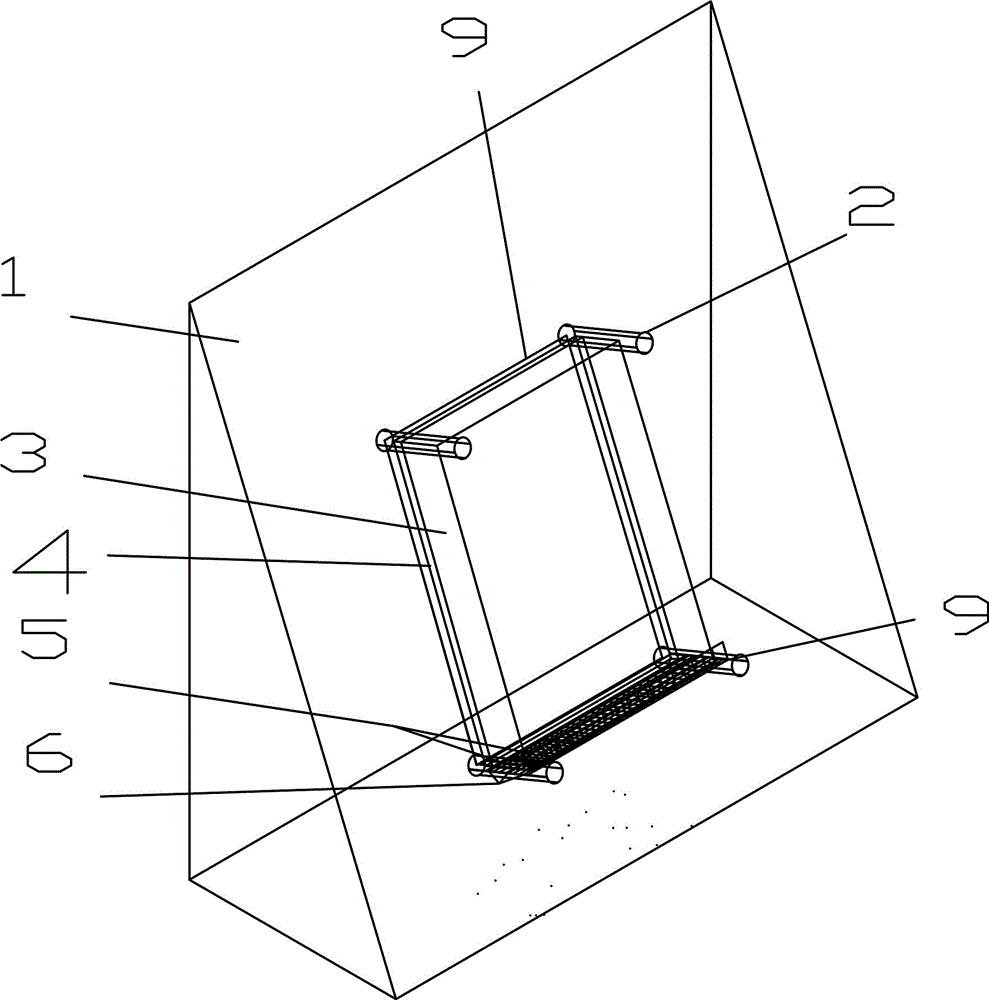

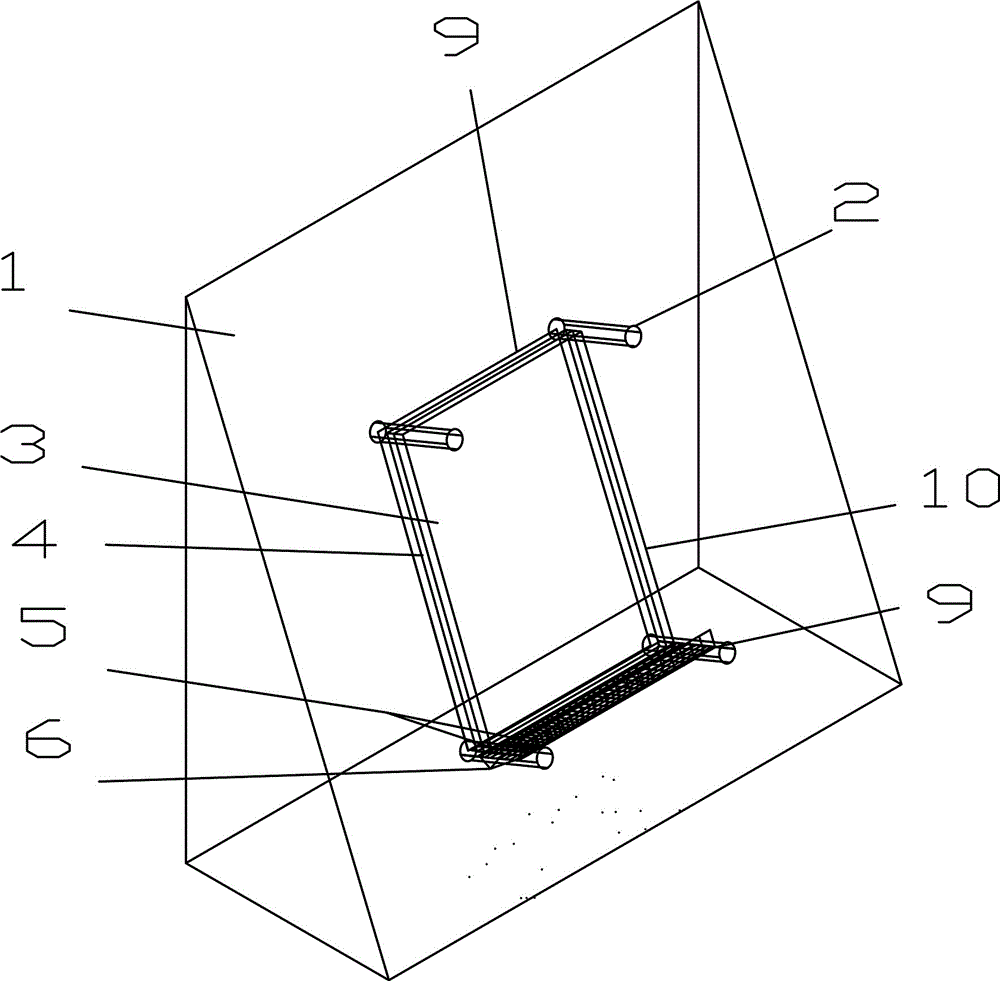

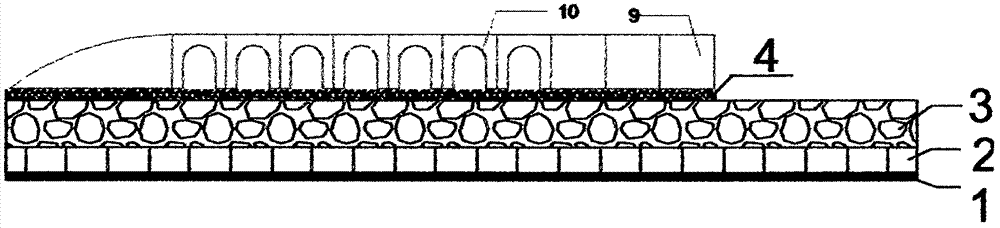

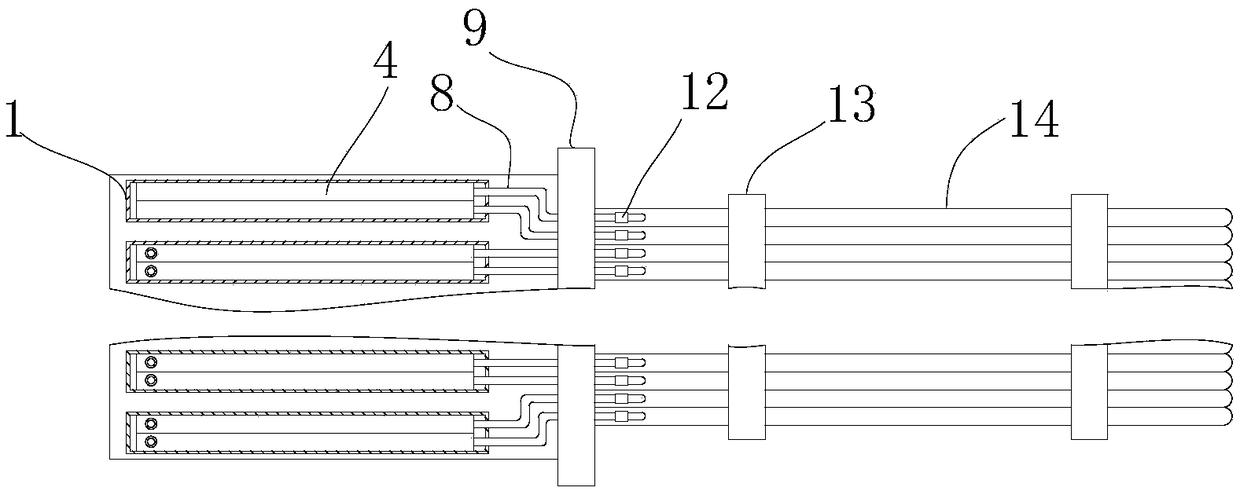

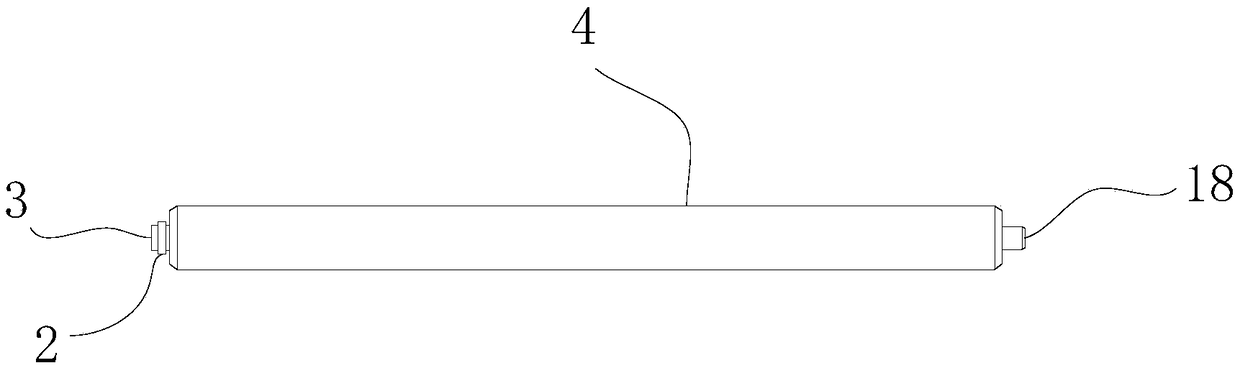

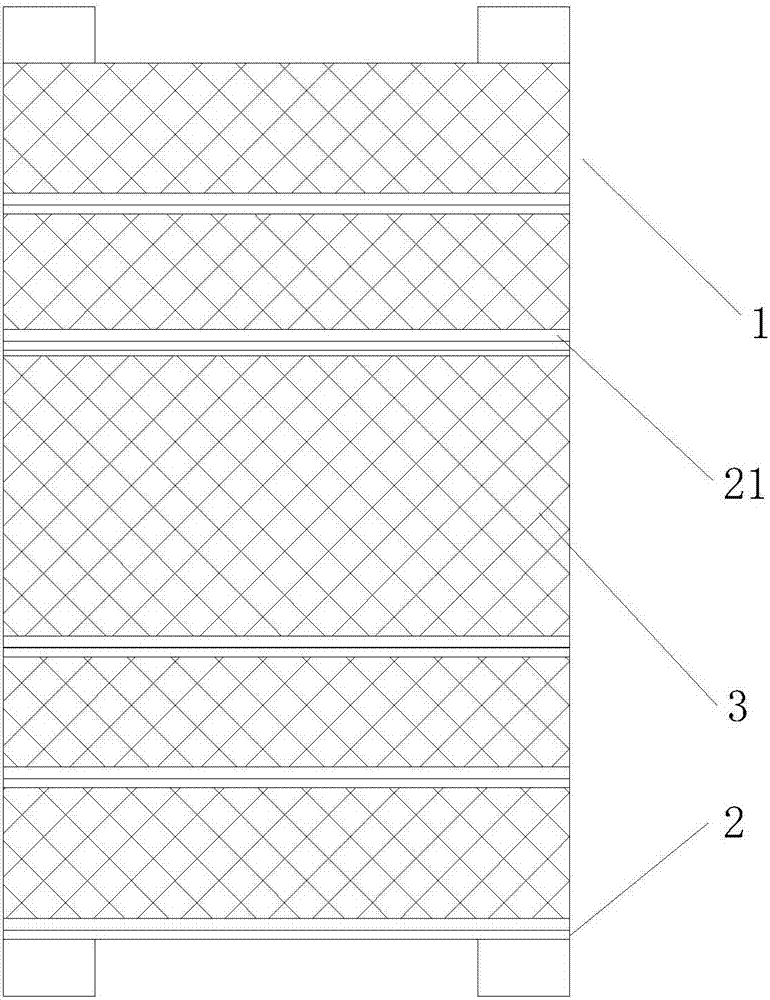

Ecological greening device for side slope with flexible ceramsite plates, and greening method thereof

ActiveCN106638630AImprove survival rateReduce direct washoutExcavationsReceptacle cultivationVegetationGreening

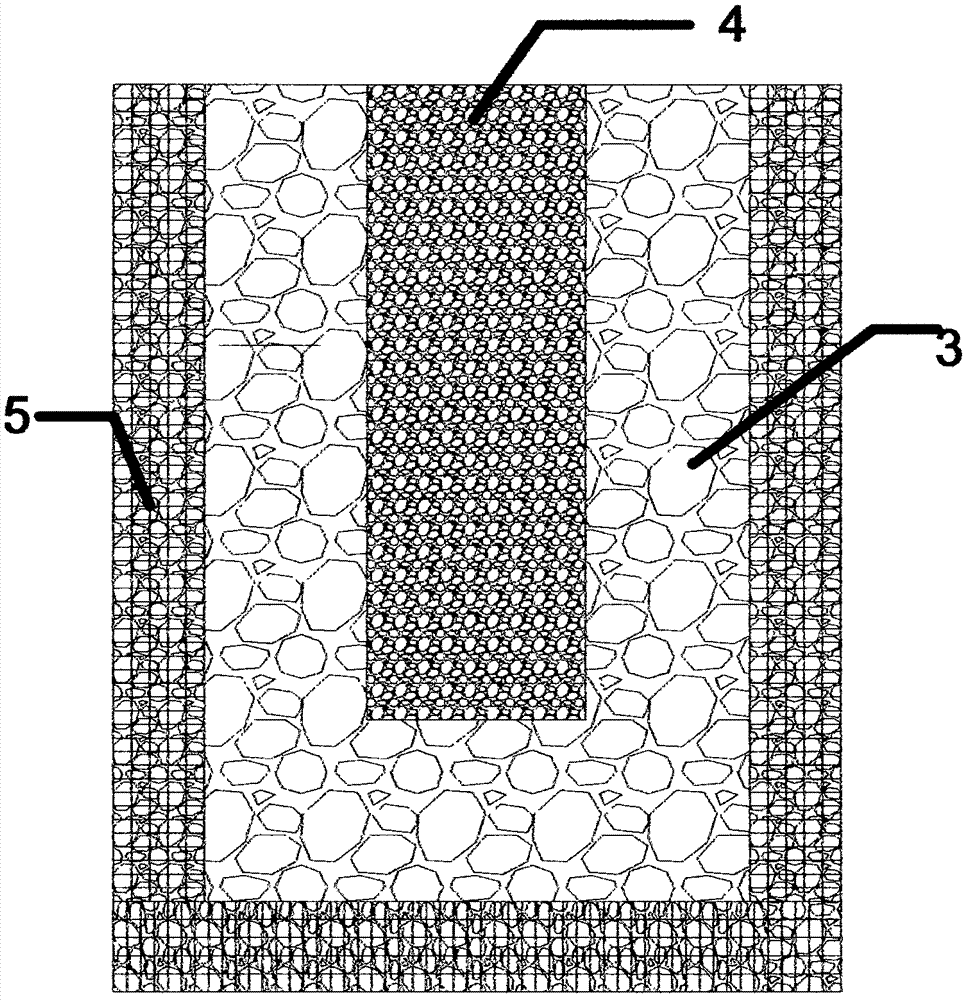

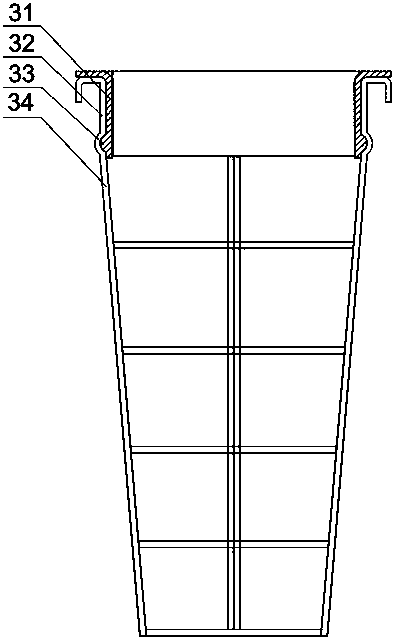

The invention discloses an ecological greening device for a side slope with flexible ceramsite plates. The ecological greening device comprises a plurality of anchor rods embedded in the slope surface of the side slope, wherein each four anchor rods form a square body; the two anchor rods at the lower end of the square body are connected through a plurality of steel wires; iron wire blocks are laid on the plurality of steel wires; a geotextile layer is laid on the slope surface of the side slope among the plurality of anchor rods of the square body and on the iron wire blocks at the lower end of the square body; a nutritive vegetation soil layer is laid on each geotextile layer in the square body; the corresponding flexible ceramsite plate is embedded in each nutritive vegetation soil layer; and planting grass is further laid on each nutritive vegetation soil layer. The ecological greening device for the side slope with the flexible ceramsite plates, and the greening method thereof, which are provided by the invention, are capable of solving the problem that side slope greening cannot be realized or soil is easy to scour of an existing method; and the stability between nutritive vegetation soil and a rock wall can be improved through reducing the direct scouring of rainwater for the nutritive vegetation soil and providing a pressure coating force, thus the survival rate of plants is increased, and a role of large-area greening protection is played.

Owner:CHINA THREE GORGES UNIV

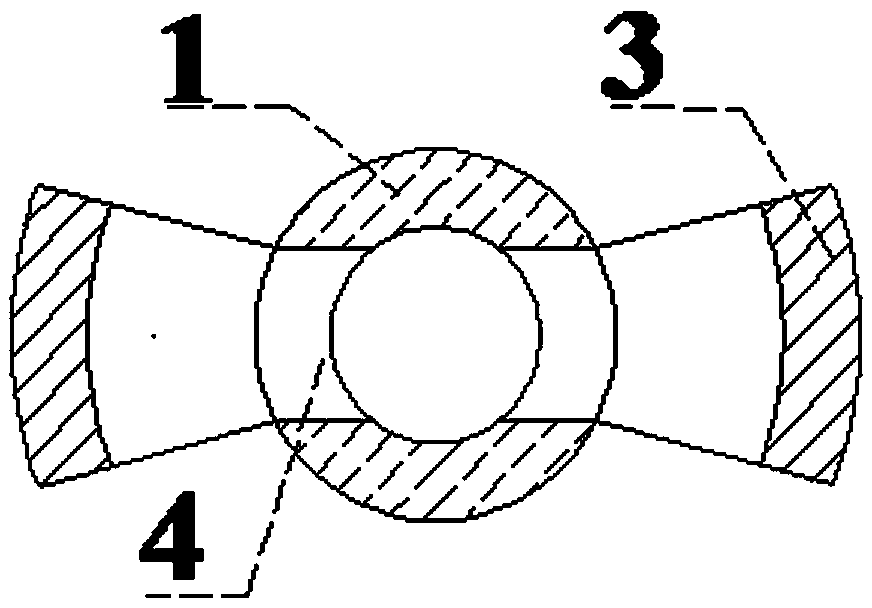

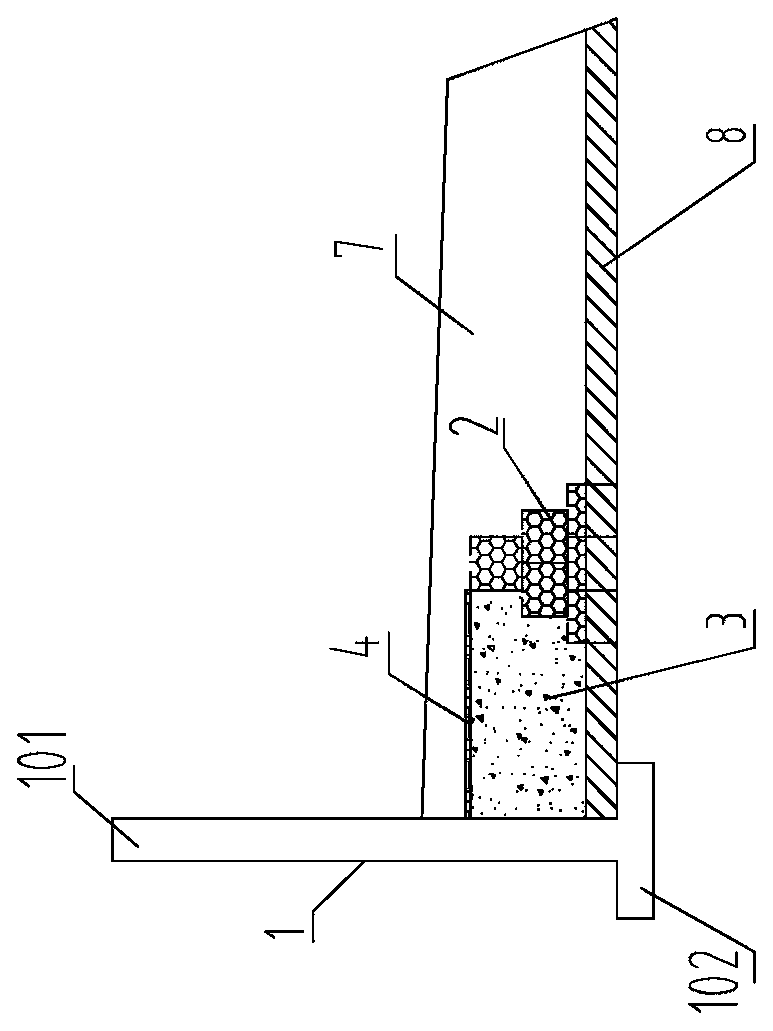

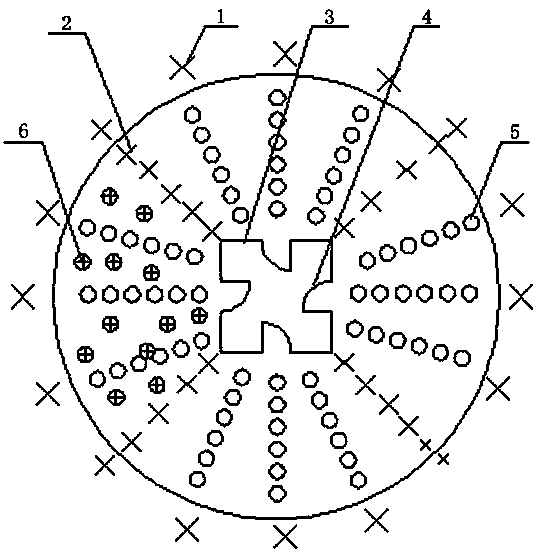

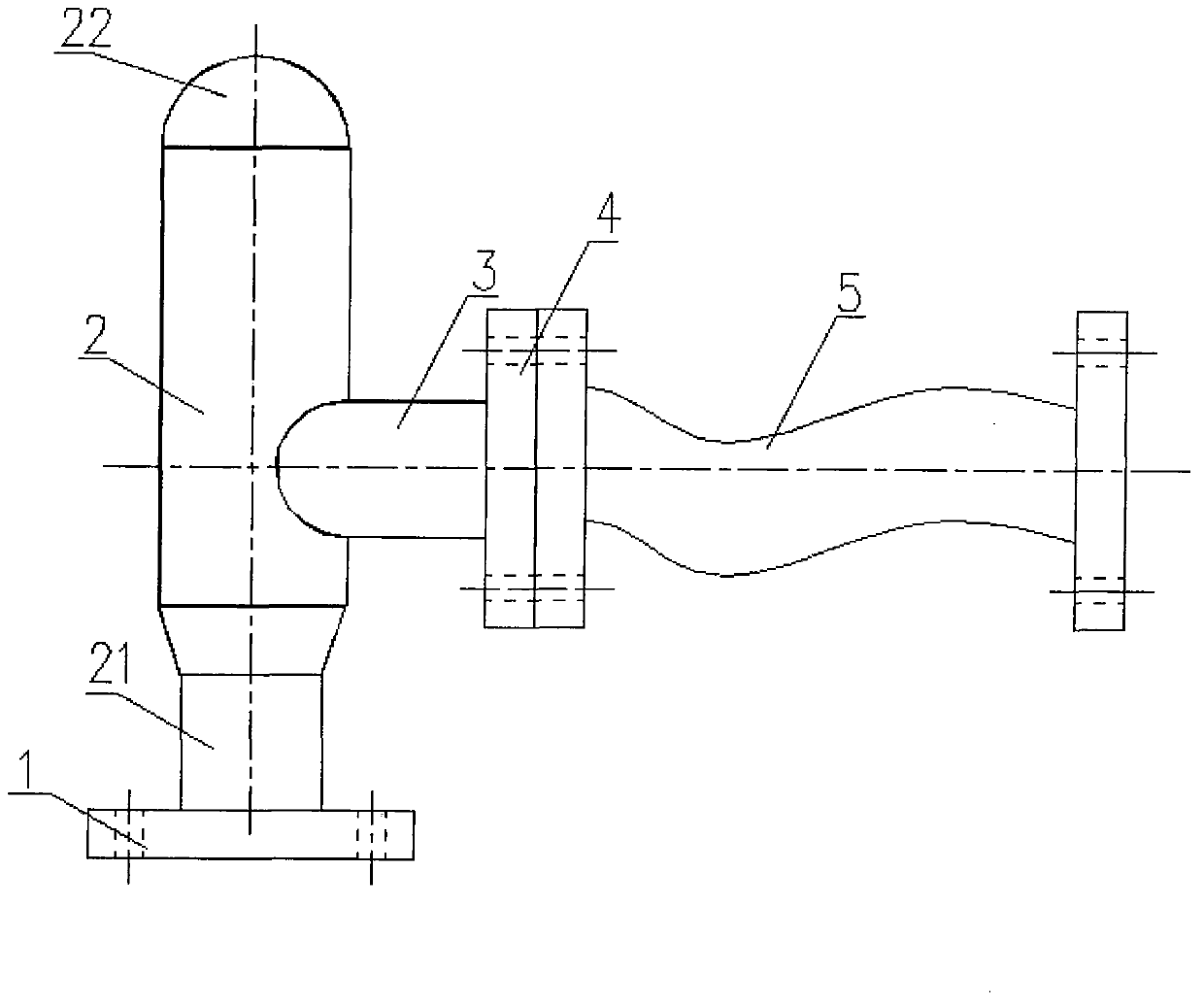

Ecological environmental-protection permeable spur dike structure

PendingCN107119626AReduce shockSmooth and convenient construction conditionsBreakwatersQuaysGeotextileEngineering

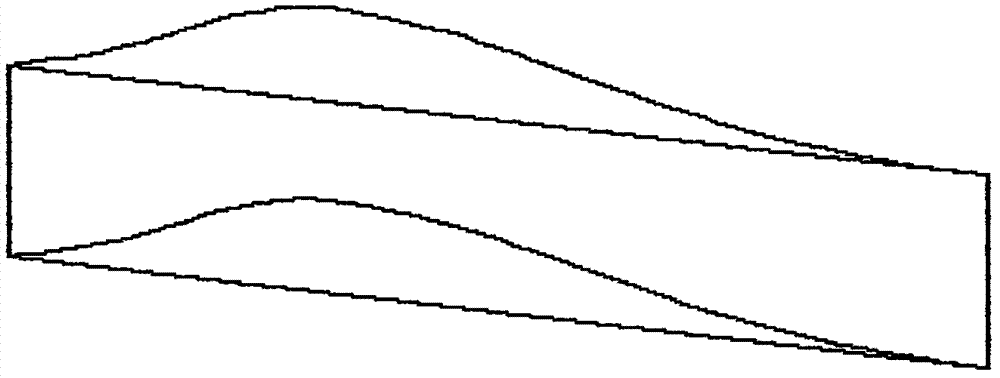

The invention relates to an ecological environmental-protection permeable spur dike structure which consists of a river bottom protection structure and a spur dike structure part; the river bottom protection structure consists of a geotechnical waterproof material layer, a grouted rubble layer, a rubble layer and a crushed stone layer from the bottom up sequentially; the crushed stone layer is simply laid within the range of the spur dike structure part; gabion net cages are arranged at the external edges of the river bottom protection structure, then the river bottom protection structure is leveled, and the spur dike structure part is arranged on the leveled crushed stone layer; the spur dike structure part is formed by splicing a dike root, a dike body and a dike head; the dike root is formed by splicing a plurality of entity components, the bottom of each entity component is a plane, and the upper part of each entity component is a sloping surface structure consisting of a riverside slope and a landside slope; the dike body is formed by splicing a plurality of permeable components; the upper parts of the permeable components are sloping surface structures consisting of riverside slopes and landside slopes; and permeable holes are formed in the middles of the permeable components. The permeable holes of the permeable components are arch-cave-shaped, so that flow turbulent fluctuation at the permeable holes and erosion to the dike body are reduced, and harm to fish in water is reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

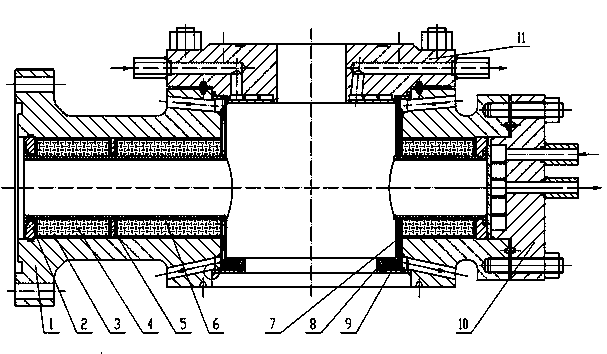

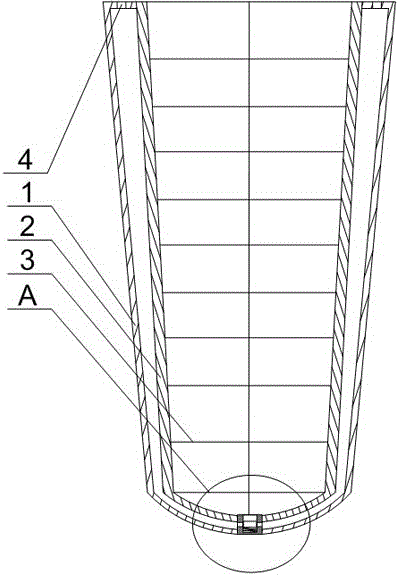

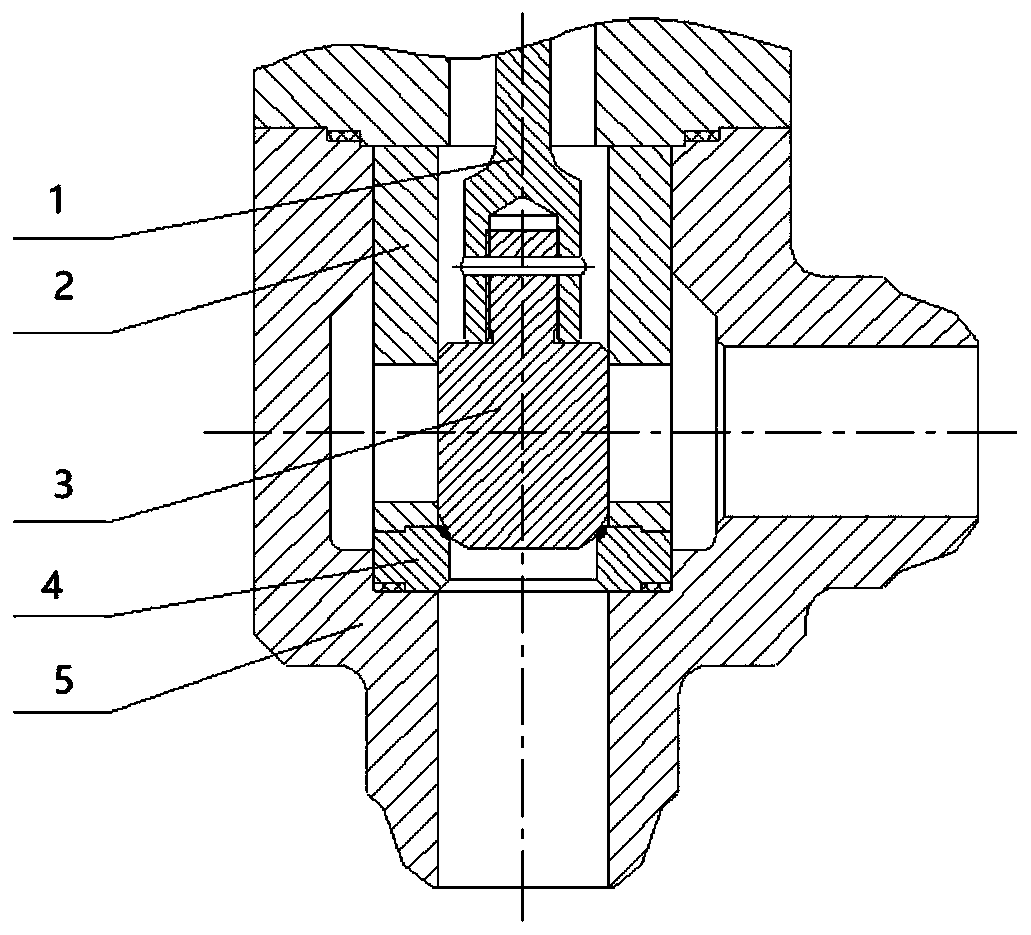

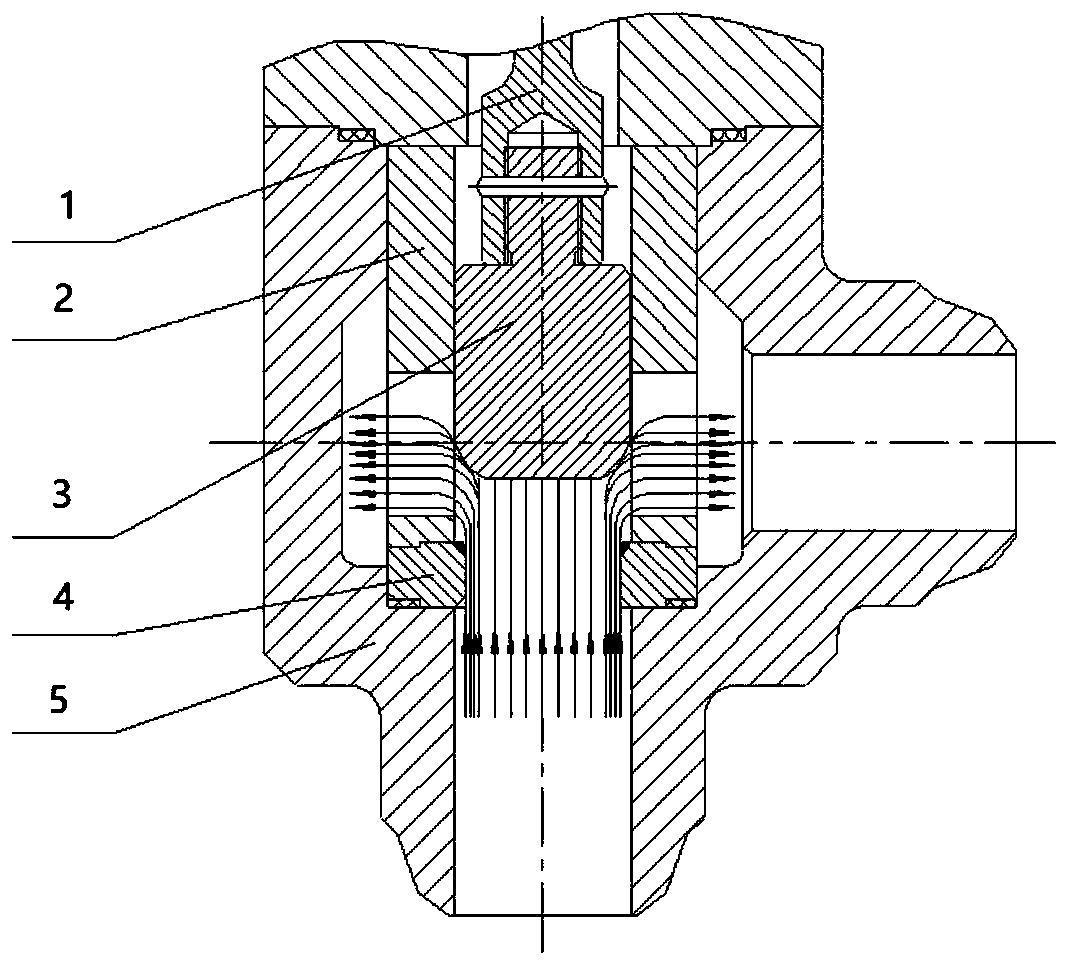

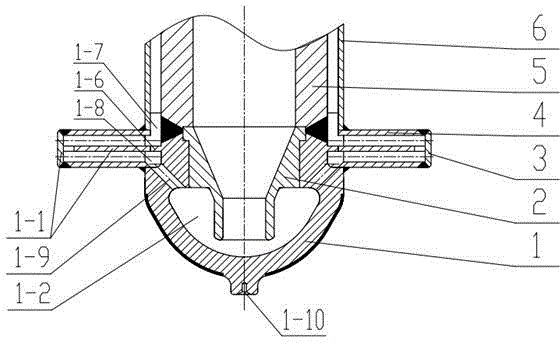

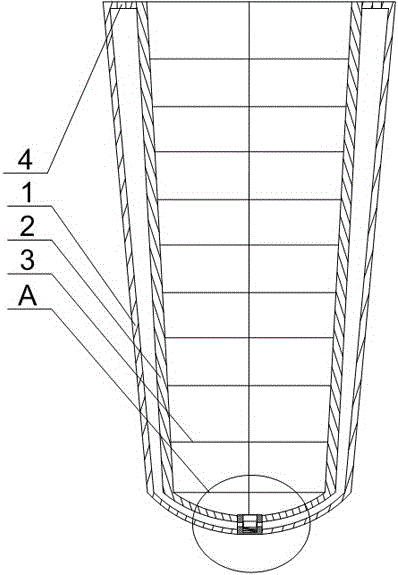

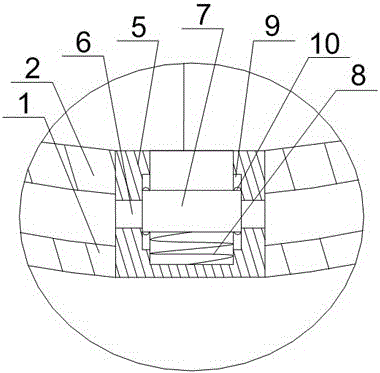

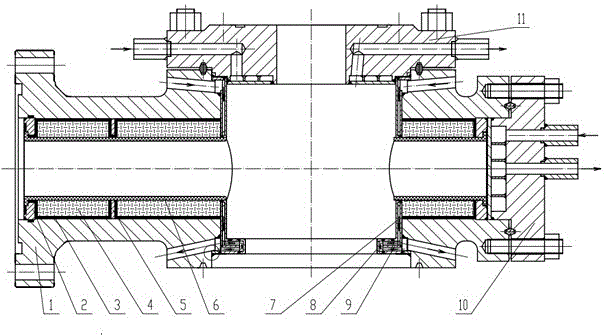

Cooling device of 1500 DEG C ultrahigh-temperature valve body

ActiveCN104455708AReduce direct washoutImprove reliabilityValve members for heating/coolingEngineeringWater cooling

A cooling device of a 1500 DEG C ultrahigh-temperature valve body comprises a medium inlet passage, a valve body middle port position, a valve cover and an end cap. The medium inlet passage and the valve body middle port position are arranged on the valve body and connected with each other, a high-temperature ceramic heat-insulating lining cooling structure is arranged on the medium inlet passage on the valve body, a valve body middle port is provided with a valve body middle port water cooling system, and requirements on safe and reliable running under a working condition of 1500 DEG C and 5.0 MPa are met. Part of heat of a high-temperature medium is absorbed by a midbody water cooling lower portion where pressure drop is formed, and pressure and temperature of the medium are further lowered; due to the structure, direct scouring of a valve seat sealing face by the high-temperature medium can be greatly reduced, service life of the valve is prolonged, and running reliability of the valve is improved.

Owner:LANZHOU HIGH PRESSURE VALVE

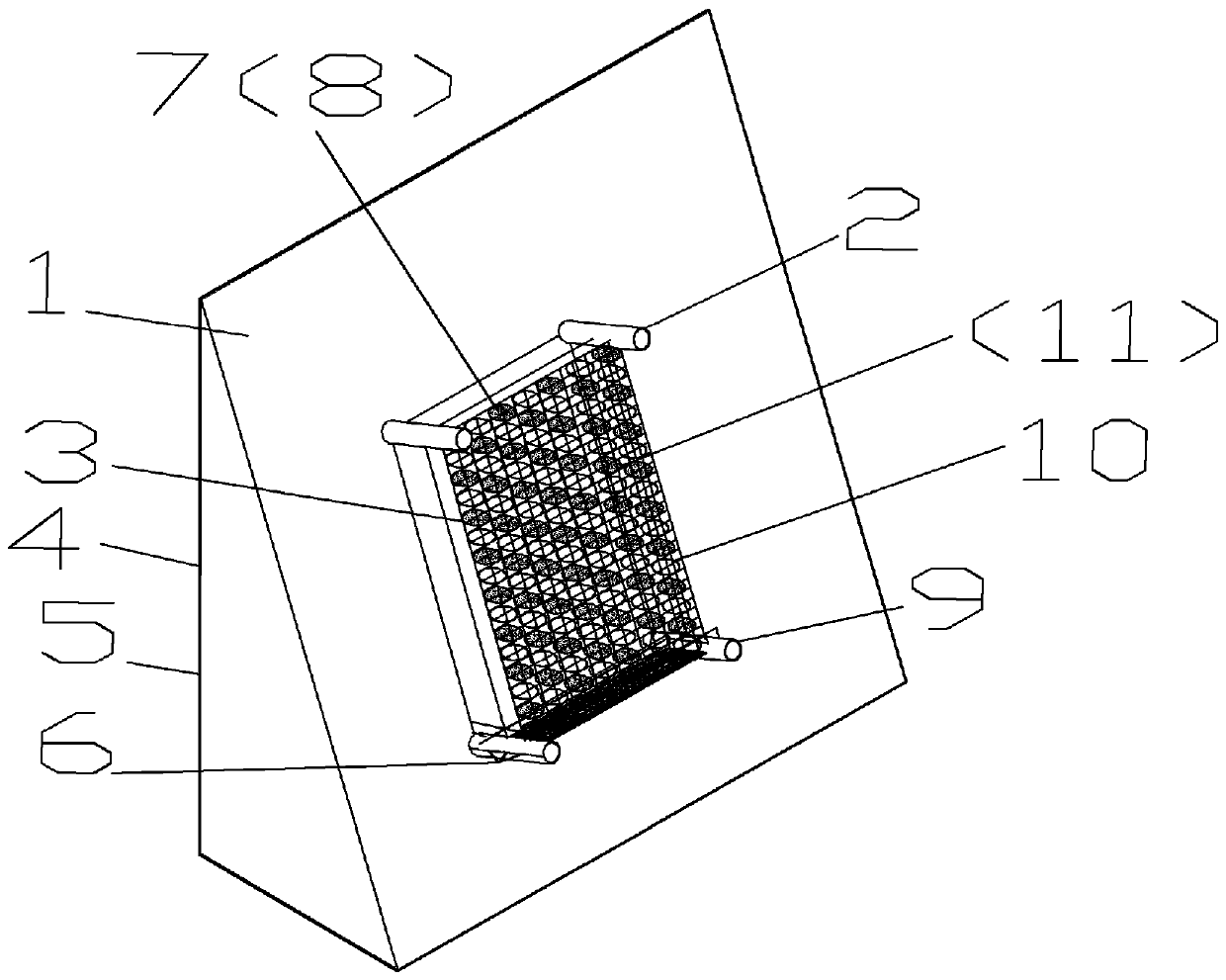

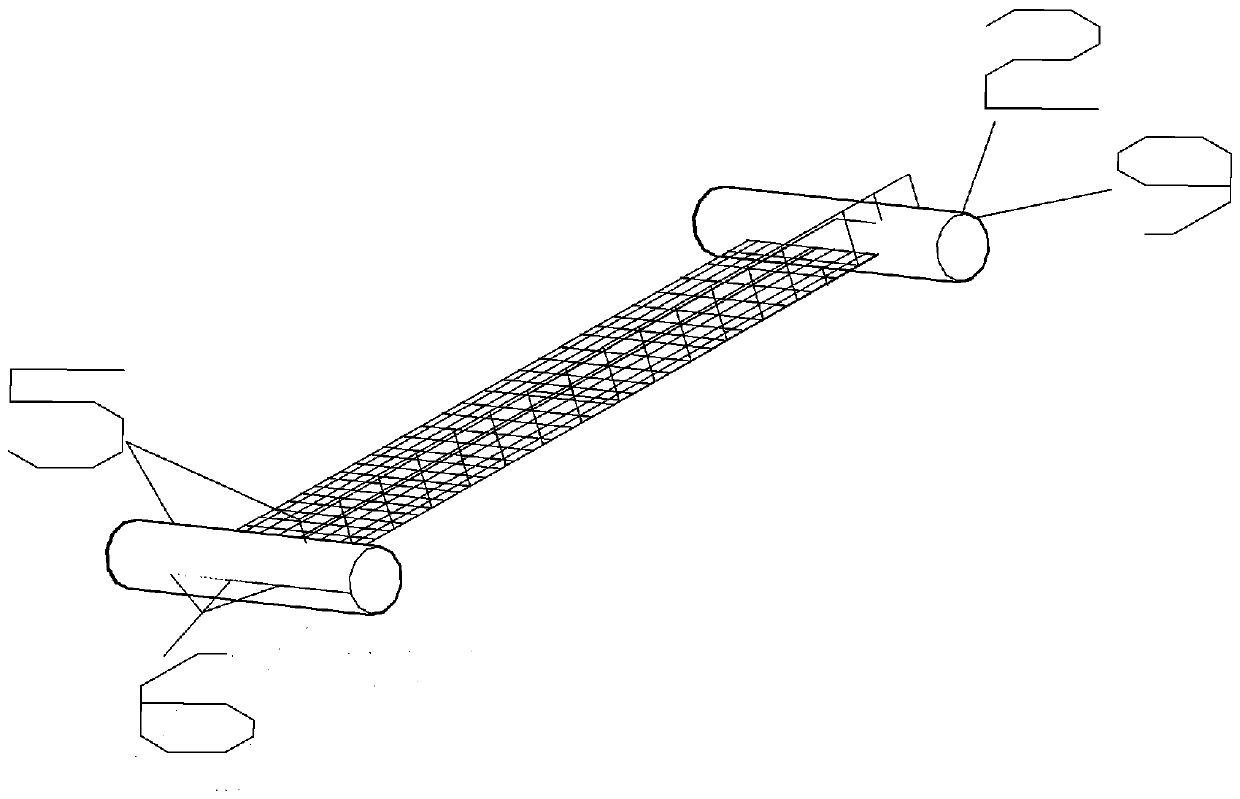

Water conservation slope protector

ActiveCN108914882AIncrease oxygen contentReduce direct washoutCoastlines protectionReceptacle cultivationVegetationEngineering

The invention discloses a water conservation slope protector, comprising one slope protection pipe or more arranged on a slope surface in a sealing manner, wherein the outer wall of each of slope protection pipes is covered with a transparent layer of silica gel, the adjacent slope protection pipes are in contact with each other and sealed, all the slope protection pipes are sealed and spliced into a sealing layer, a planting cavity is formed between the lower end surface of the sealing layer and the slope surface, and vegetation is planted on the slope surface of the planting cavity. According to the water conservancy slope protector, the extrusion force of vehicles passing by can be used to extrude an elastic rubber tube to squeeze air out of the elastic rubber tube, thereby acceleratingrainwater drainage on rainy days, and carrying out gas injection in a riverway at ordinary times; the closed slope protection pipe surface is used to prevent rainwater from scouring slope soil, thereby reducing soil erosion, effectively protecting the planted vegetation and restoring the slope ecology to the greatest extent.

Owner:中水生态建设有限公司

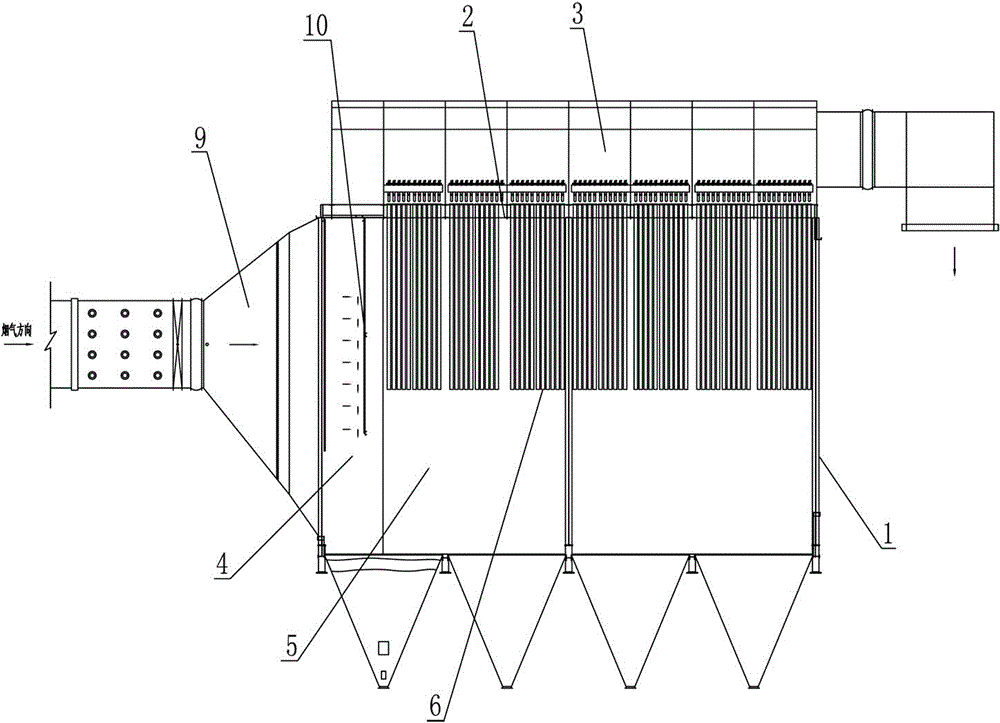

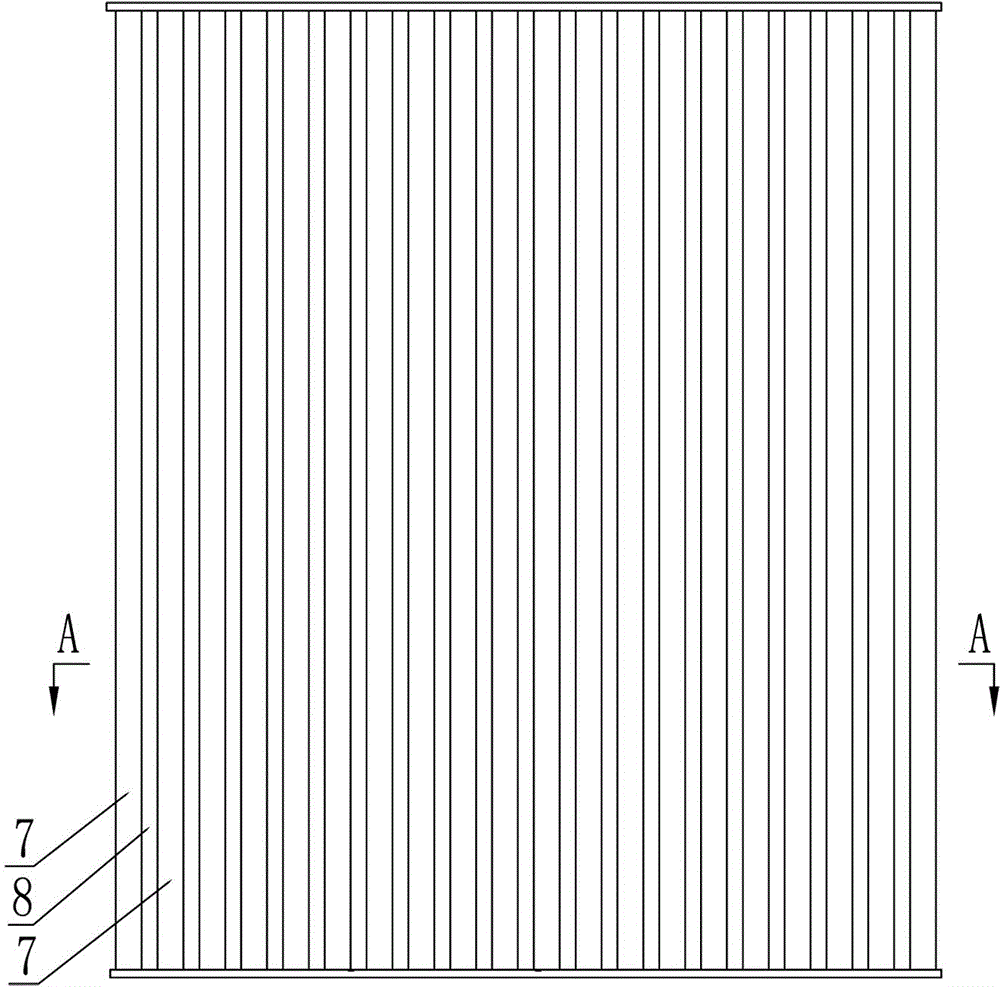

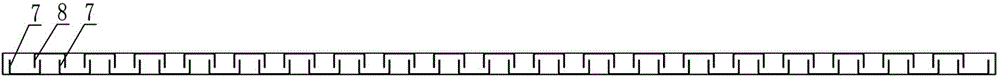

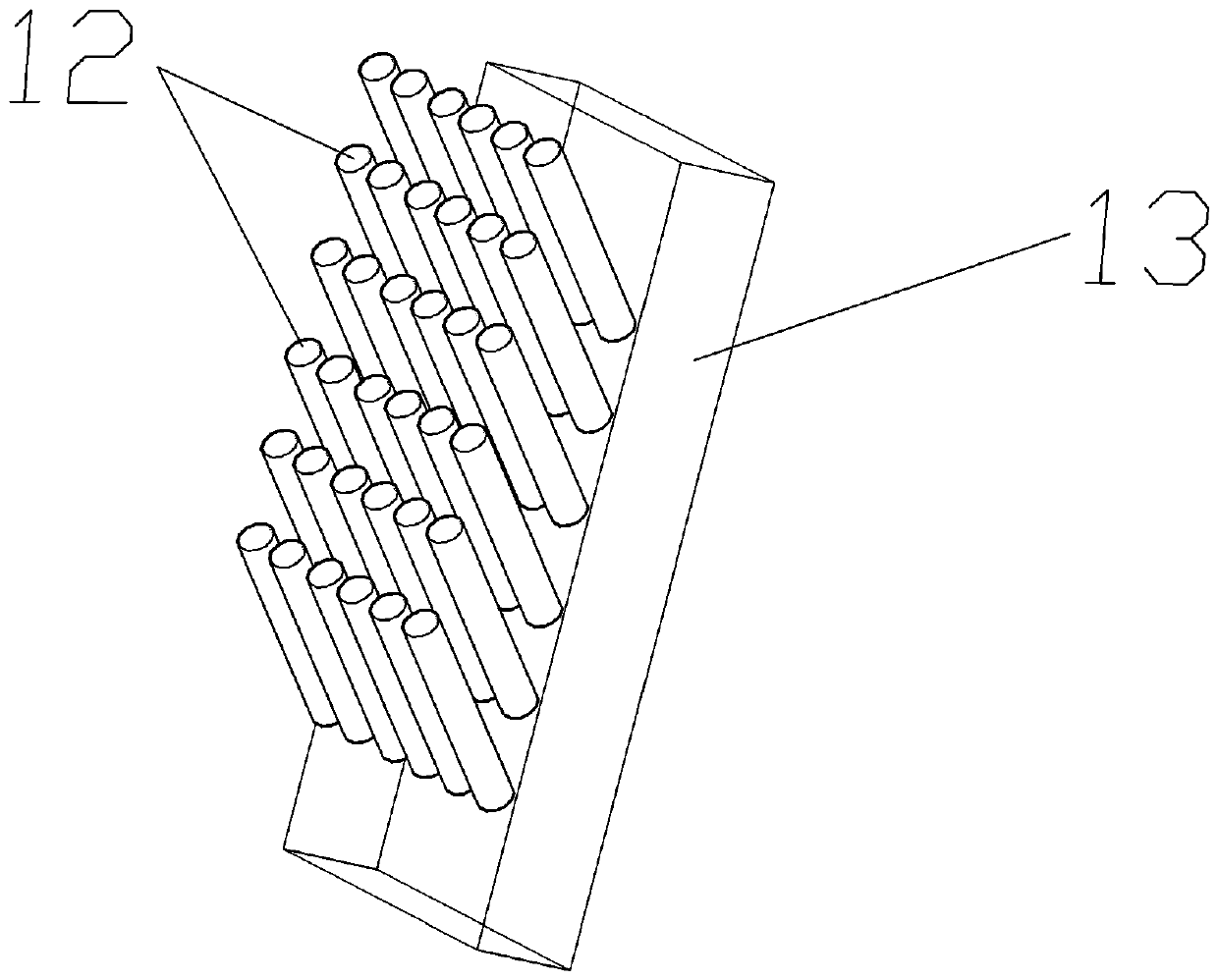

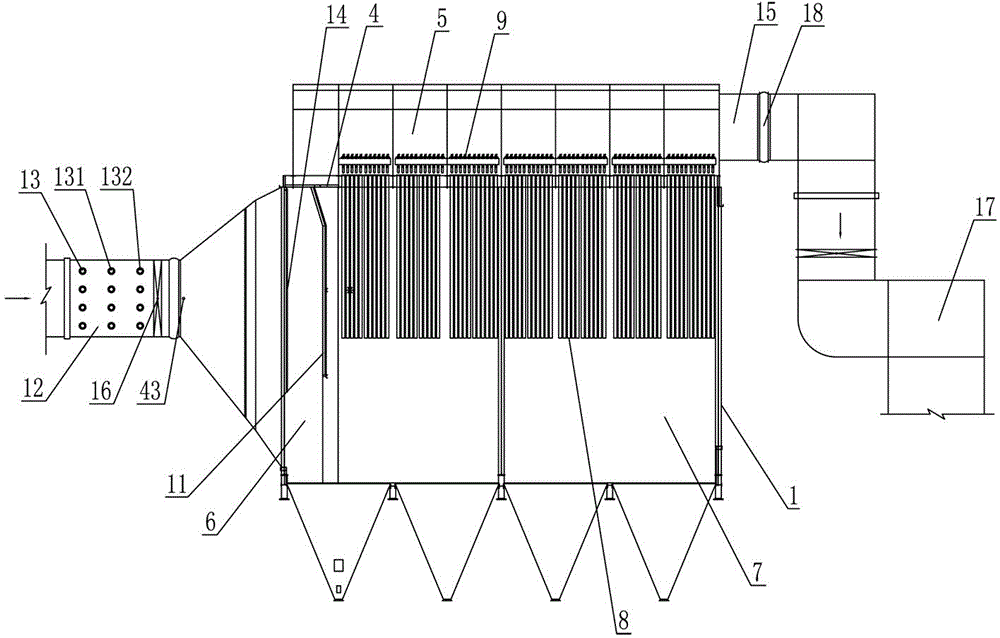

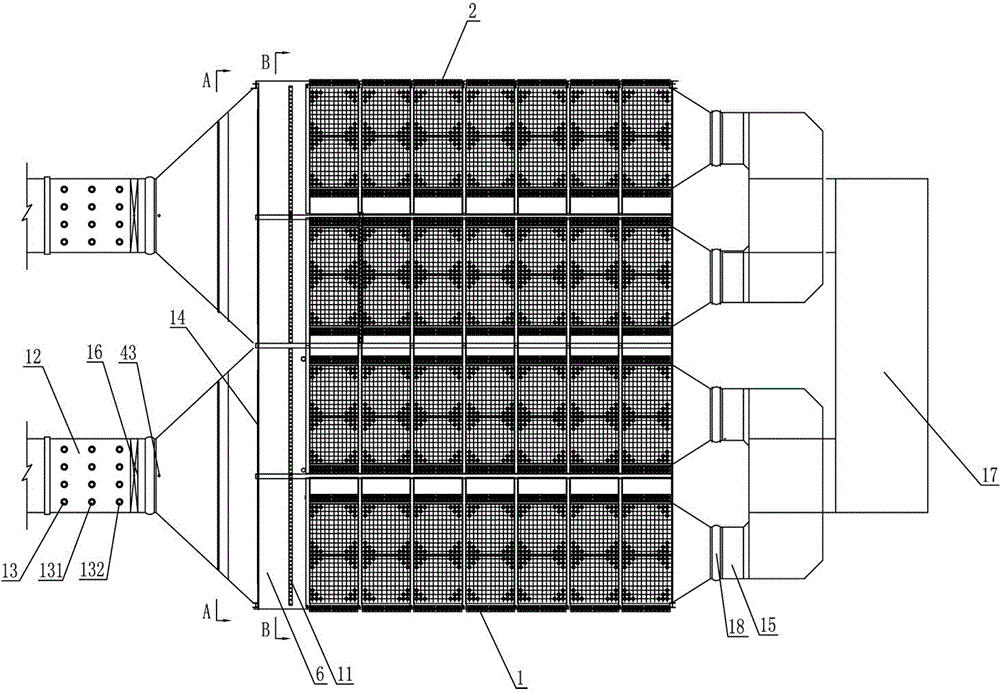

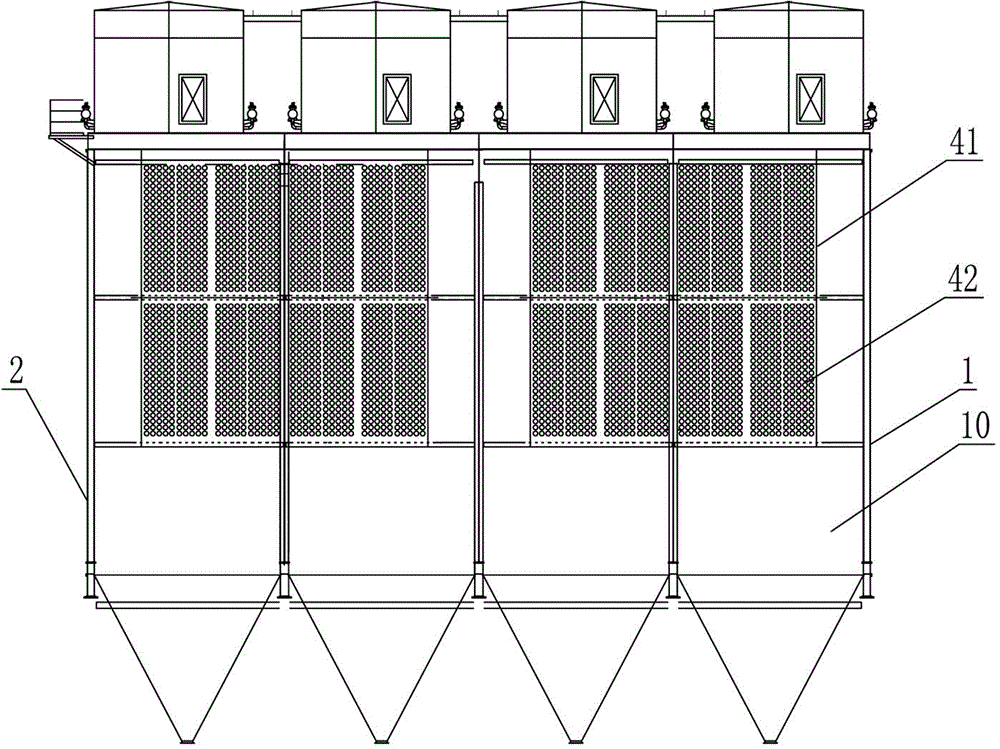

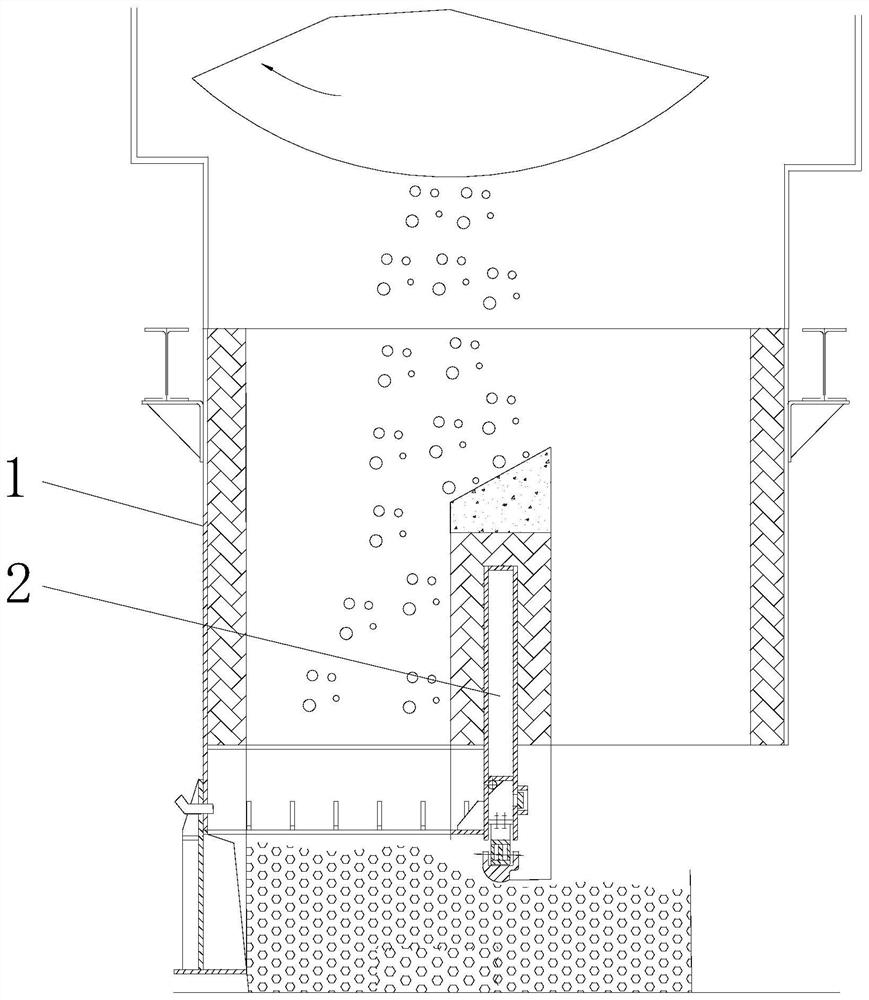

Inertial pre-dedusting flue gas distributor of deduster

The invention discloses an inertial pre-dedusting flue gas distributor of a deduster. The flue gas distributor comprises a dust collector box. The dust collector box is divided by a card into an upper clean gas chamber and a lower flue gas chamber; the lower flue gas chamber comprises a pre-dedusting chamber and a cloth bag dedust chamber, which are communicated; the card in the cloth bag dedust chamber is hanged with a filter bag; the pre-dedusting chamber of the dust collector box is provided with an air inlet, and an air outlet is arranged on the upper clean gas chamber; the pre-dedusting chamber along the flue gas inlet direction is sequentially equipped with a plurality of flue gas pre-dedusting distribution mechanisms; the flue gas pre-dedusting distribution mechanism comprises a plurality of front groove-shaped baffles and rear groove baffles, which are vertically arranged on the pre-dedusting chamber; the notches of all the front groove-shaped baffles are arranged in the flue gas inlet direction; all notches of the rear groove-shaped baffles are arranged all against the flue gas inlet direction; every two adjacent front groove-shaped baffles buckle with one rear groove-shaped baffle; and a gap is left between each rear groove-shaped baffle and the buckled front groove-shaped baffle. The filter bag provided by the invention has the advantage of long service life.

Owner:JIANGSU NEW ENVIRONMENTAL CORP

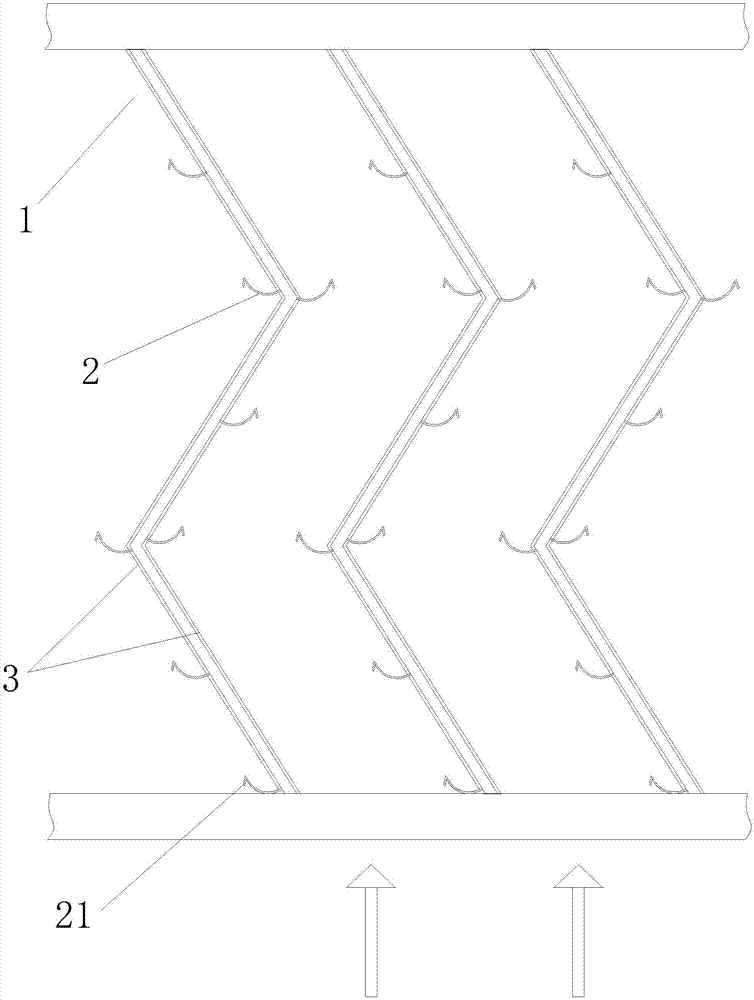

High-efficiency baffling plate type demister

InactiveCN107281819AShort liquid film formation timeReduce secondary waterDispersed particle separationElectrical and Electronics engineeringEngineering

The invention discloses a high-efficiency baffling plate type demister which comprises baffling blades, water collecting tanks, a first supporting assembly and a second supporting assembly, wherein the two ends of the baffling blades are respectively connected with the first supporting assembly and the second supporting assembly, the baffling blades are arranged in parallel, the water collecting tanks are arranged on the baffling blades at intervals, and the water collecting tanks extend in the width direction of the baffling blades; each water collecting tank comprises an arc plate, the arc plate comprises a connecting end and a free end, and the connecting ends of the arc plates are connected with the surfaces of the baffling blades. Therefore, compared with the prior art, the high-efficiency baffling plate type demister disclosed by the invention has the advantages of high demisting efficiency and good demisting effect.

Owner:HEFEI TIANXIANG ENVIROMENT PROJECT

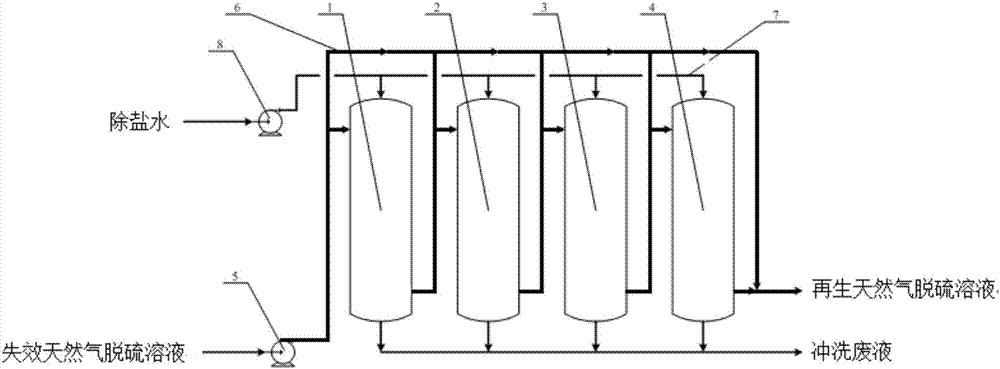

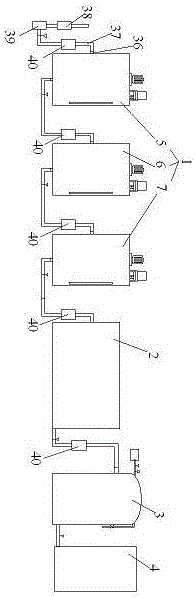

Regenerating device for ineffective natural gas desulfurization solution

PendingCN106975323AImprove regeneration effectSimple equipmentDispersed particle separationGaseous fuelsActivated carbonProcess engineering

The invention discloses a regenerating device for an ineffective natural gas desulfurization solution. The regenerating device comprises an ineffective natural gas delivering pipeline of which the input end is connected to the output end of a solution regenerating pump; the output end of the ineffective natural gas delivering pipeline is connected to a liquid inlet of a solid impurity removing unit, a liquid inlet of a solution decolorizing unit, a liquid inlet of a thermostable salt removing unit and a liquid inlet of an organic impurity removing unit; for liquid outlets of the solid impurity removing unit, the solution decolorizing unit, the thermostable salt removing unit and the organic impurity removing unit, the liquid outlet of the former unit is communicated with the liquid inlet of the latter unit. According to the regenerating device disclosed by the invention, the problems that solid impurity particles cannot be thoroughly removed, decolorized activated carbon is easily broken to form new impurities, organic impurities in the solution cannot be removed and the like in the regenerating process of an existing ineffective natural gas desulfurization solution are solved; meanwhile, four units are connected in parallel by the ineffective natural gas delivering pipeline; corresponding treatment units can be selected according to actual conditions of the desulfurization solution, so that treatment materials are saved and the process progress is accelerated.

Owner:XI'AN PETROLEUM UNIVERSITY

Method for conducting slope support and greening through specific hole-planted shrubs

ActiveCN107604930AAvoid affecting growthImprove survival rateExcavationsCultivating equipmentsSoil textureBiology

The invention discloses a method for conducting slope support and greening through specific hole-planted shrubs. The method comprises the following steps that (1), a material is selected; (2), a slopesurface is selected to be finished and measured; (3), shrub seeds are soaked or shrub seedlings cultivated into seedlings are prepared to manufacture nutritive vegetation soil; (4), a mold is adoptedto manufacture a vegetation concrete module containing the shrub seeds; (5), anchor rods are supported, iron wire bracing and iron wire net erecting are conducted among the anchor rods, and a layer of geotechnical cloth is laid; (6), the thick nutritive vegetation soil is laid, and seeds are planted in the soil; and (7), management after seeding and later-period regular watering and fertilizing protection are conducted. The method for conducting slope support and greening through the specific hole-planted shrubs is suitable for slope surfaces of various rock textures and soil textures and particularly suitable for rock and soil side slope surfaces which are high steep and unsmooth, are provided with multiple small rock gaps and are under bad weather conditions.

Owner:CHINA THREE GORGES UNIV

Dust removing cloth bag for coal charging car

InactiveCN105771452AReduce direct washoutReduce lossDispersed particle filtrationOven incrustations prevention/removalEngineeringCoal

The invention discloses a dust removing cloth bag for a coal charging car. The dust removing cloth bag for the coal charging car comprises an outer bag body, an inner bag body and a skeleton, wherein a secondary air flow passage is formed between the outer bag body and the inner bag body in an annulus manner; the upper end of the outer bag body is provided with an air outlet connected with the secondary air flow passage; a barrel is mounted between the bottom of the inner bag body and the bottom of the outer bag body; an open end of the barrel is communicated with the inside of the inner bag body; two side walls of the barrel are both provided with air holes communicated with the secondary air flow passage; a sliding block is arranged in the barrel in a sliding manner; the bottom of the sliding block is provided with a spring. Acting stress generated during the secondary expansion of the outer bag body is far more than acting stress generated during the primary expansion of the outer bag body, so that mill dust adhered to the outer bag body is completely popped out; in comparison with a dust removing cloth bag with a single-layer structure, the dust removal efficiency of the dust removing cloth bag for the coal charging car is greatly improved; moreover, the expansion of the outer bag body is driven by the expansion of the inner bag body; the direct scour carried out directly on the outer bag body by an air current is decreased; furthermore, the loss of the outer bag is decreased.

Owner:SICHUAN ANCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

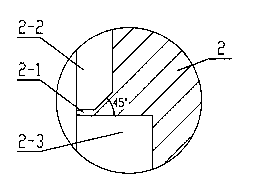

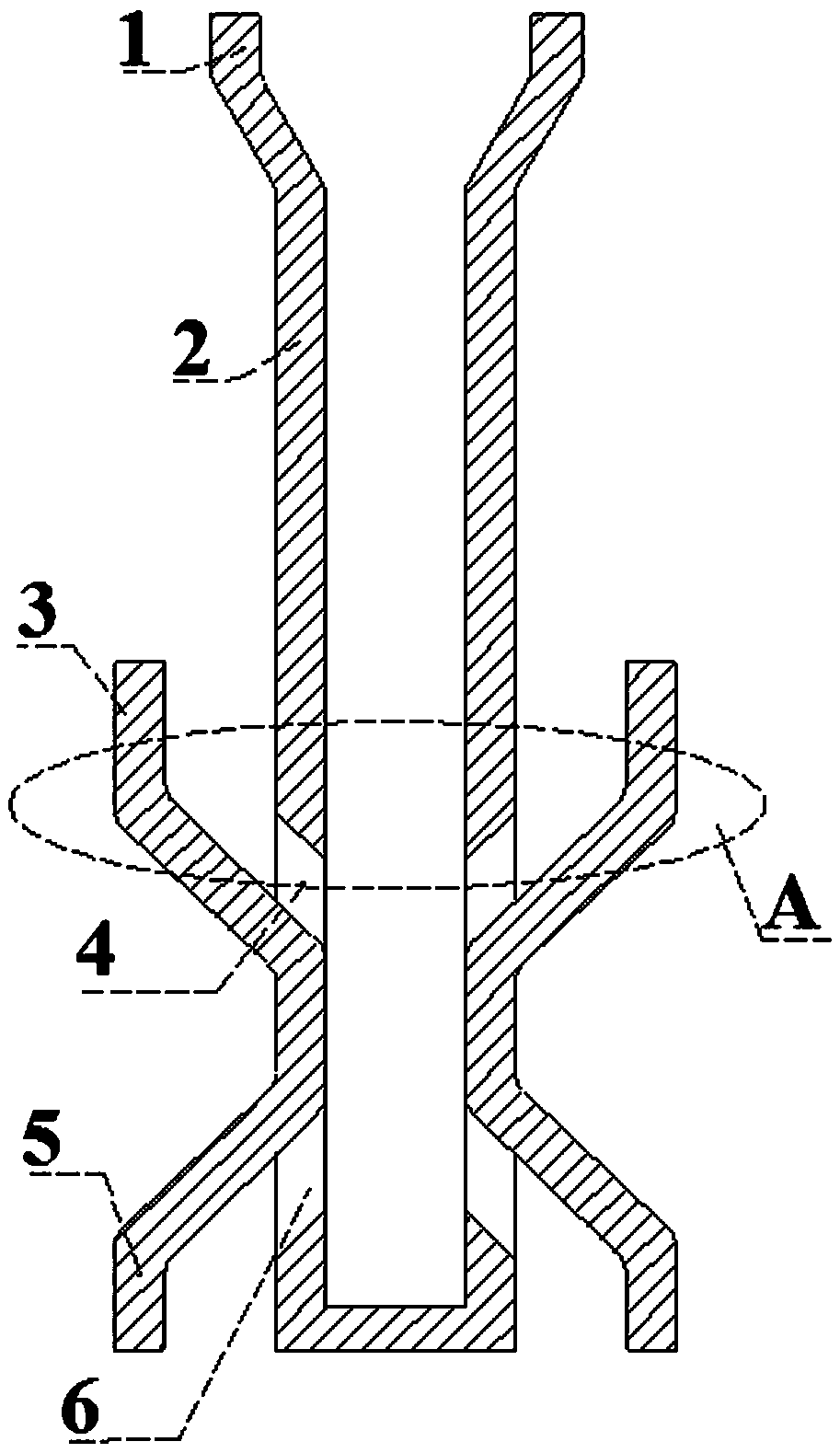

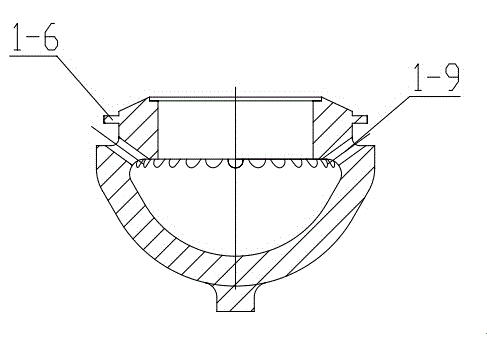

Immersed nozzle of H-shaped leakproof steel

PendingCN110181033AImprove sealingReduce dwell timeMelt-holding vesselsMolten steelMaterials science

The invention discloses an immersed nozzle of H-shaped leakproof steel and belongs to the technical field of steel continuous casting. The immersed nozzle of the H-shaped leakproof steel comprises a nozzle main body, upward blocking dams, upward inclined steel outlets, downward blocking dams and downward inclined steel outlets, the upper part of the nozzle main body is of a bowl opening structure,the lower part of the nozzle main body is of a hollow cylindrical structure with a smooth inner cavity, and the bottom end of the nozzle main body is of a closed structure; the upper part of the bowlopening structure is in a large-aperture hollow cylindrical shape, and the lower end of the bowl opening structure is of a conical structure; the middle lower part of the hollow cylindrical structureof the nozzle main body is symmetrically provided with the pair of upward inclined steel outlets, the lower parts of the upward inclined steel outlets are symmetrically provided with the pair of upward blocking dams, the lower parts of the upward blocking dams are symmetrically provided with the pair of downward blocking dams, and the lower parts of the downward blocking dams are symmetrically provided with the pair of downward inclined steel outlets. Direct flushing of molten steel on a solidified shell can be reduced, occurrence of steel leakage is avoided, the production efficiency is improved, and the production cost is reduced.

Owner:SHANXI TONGCAI IND & TRADE

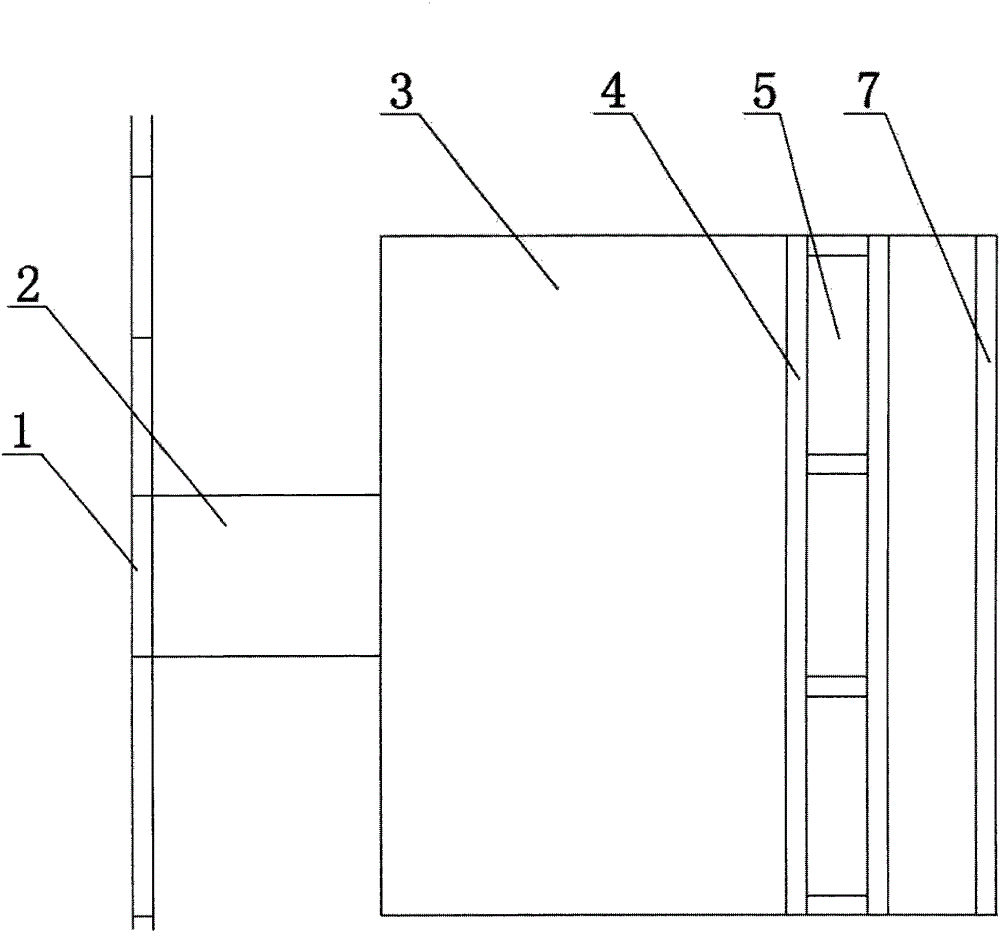

Subgrade scouring preventing and reinforcing structure for gabion wall and groin system combination

PendingCN109487751AReduce risk of water damageSafe and smoothBreakwatersQuaysWater flowSystem combination

The invention relates to a subgrade scouring preventing and reinforcing structure, in particular to a subgrade scouring preventing and reinforcing structure for a gabion wall and groin system combination. The subgrade scouring preventing and reinforcing structure comprises groins, a road shoulder retaining wall and gabion walls, the multiple groins distributed at intervals are distributed on the portions, located on one side of a riverway, of the road shoulder retaining wall, the groin root ends of the groins are fixedly connected with the road shoulder retaining wall, and the groin head endsof the groins obliquely stretch into the riverway. According to the technical scheme, a groin system is arranged on the outer side of the road shoulder retaining wall of a road, the adjacent groins are connected into a whole through the gabion walls, and the gabion walls, the groin system and the road shoulder retaining wall are combined in a built-in mode to form a steady water damage preventionstructure; direct scouring of water flow scouring on the prevention structure and indirect destruction of water flow scouring on road slopes are reduced, the road water damage risk is reduced, and safety and unobstruction of the road are guaranteed; and meanwhile, it can be guaranteed that long-deflecting-flow groins are protected against water damage destruction, and the subgrade scouring preventing and reinforcing structure is mainly suitable for a deflecting-flow groin system with the long groin body and the river reach with the high water flow impact force.

Owner:新疆维吾尔自治区交通规划勘察设计研究院

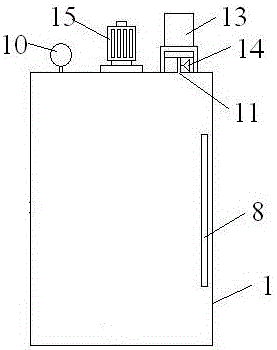

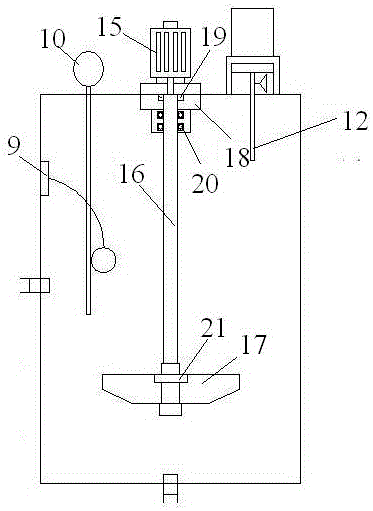

Complete equipment for treating chromium wastewater

ActiveCN106630250AImprove processing efficiencyEasy to handleWater treatment parameter controlWater contaminantsLiquid wasteWater source

The invention provides complete equipment for treating chromium wastewater. The complete equipment comprises a reaction tank, a pressure filter, a mechanical filter and an activated carbon absorber, wherein the reaction tank is provided with a water level meter, a float switch, a pH sensor, a chemical inlet and stirring equipment, the mechanical filter is provided with a high-pressure gas inlet pipe and a gas outlet pipe, and the interior of the mechanical filter is divided into an upper coarse filtering layer and a lower refined filtering layer. The complete equipment has the advantages that the complete equipment is simple in structure, reasonable in design, capable of lowering equipment operation cost, increasing chromium wastewater treatment efficiency and effect and effectively controlling feeding quantity, visual in liquid level, fast in wastewater filtering and high in safety; filtered water is quite clean after being absorbed by activated carbon and can be directly used by other working procedures or used for cleaning, environment pollution is avoided, water resource utilization rate is increased, and waste is avoided.

Owner:JIANGSU HUAXING ELECTRICAL TECH

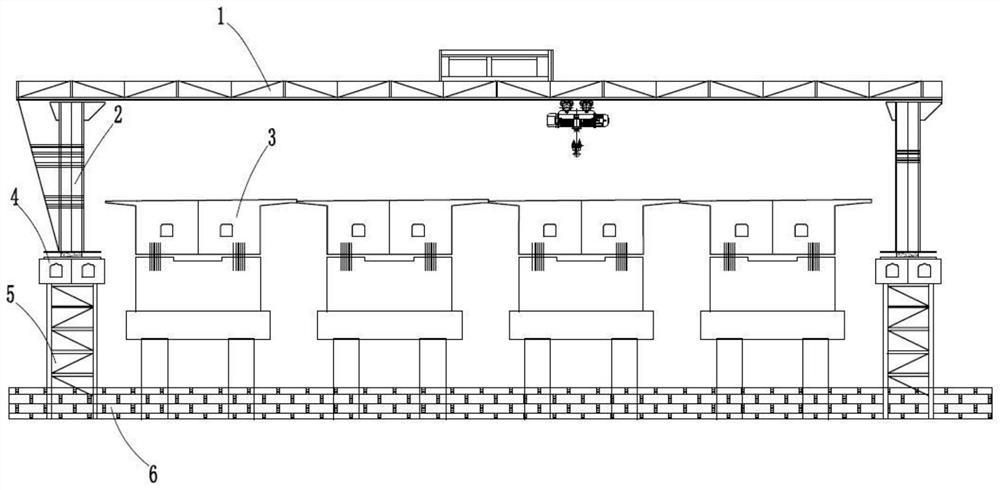

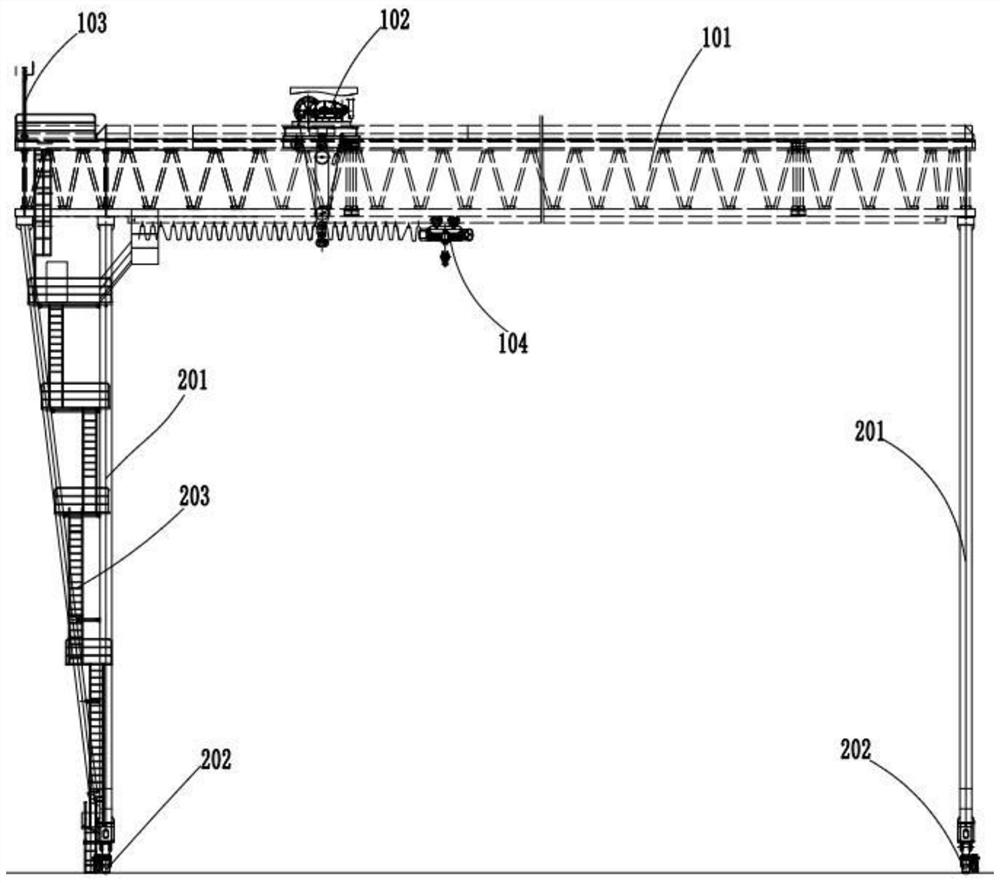

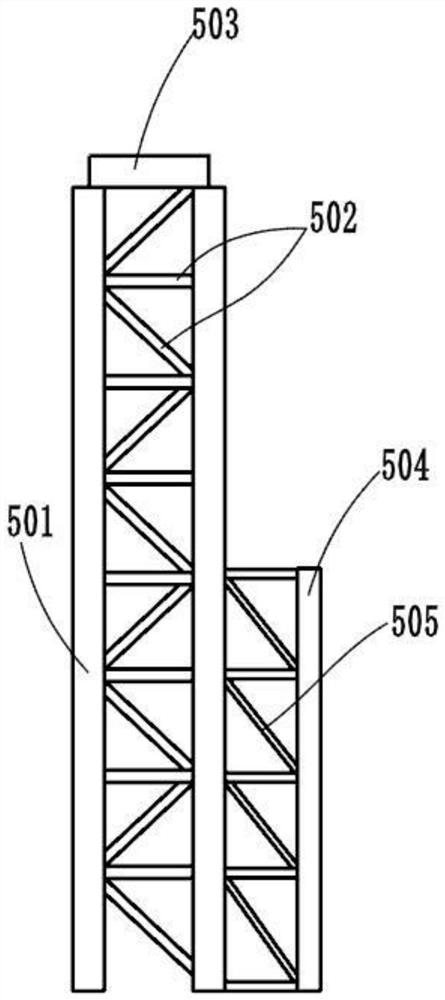

Large-span bridging gantry crane and construction method thereof

PendingCN112523097AGuaranteed stabilityReduce direct washoutBridge erection/assemblyTrackwayArchitectural engineering

The invention discloses a road and bridge construction technology. A large-span bridge gantry crane comprises temporary track bridges arranged on the two sides of an existing river-crossing bridge, sliding tracks are arranged on the temporary track bridges, the large-span bridge gantry crane further comprises a gantry crane portal frame arranged above the existing river-crossing bridge, supportinglegs are connected to the lower portion of the gantry crane portal frame, and sliding groove bases corresponding to the sliding tracks are arranged at the lower ends of the supporting legs. The large-span bridge gantry crane ingeniously starts from the construction angle, gantry crane equipment is arranged above an existing river-crossing bridge, hoisting operation is easily achieved, precise hoisting equipment is provided for widening or dismantling or maintaining construction of the existing river-crossing bridge, and the wading construction precision of the equipment is guaranteed.

Owner:SICHUAN FIRST CONSTR ENG

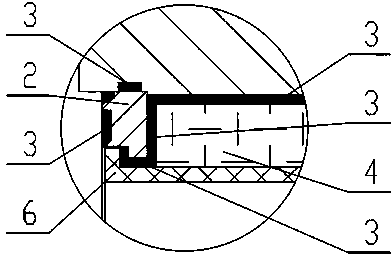

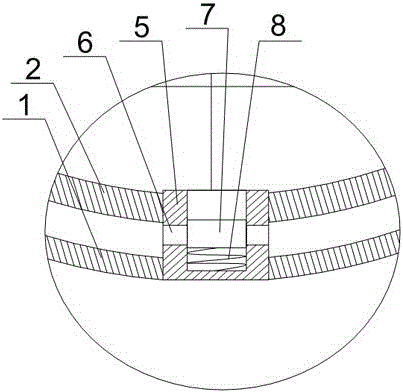

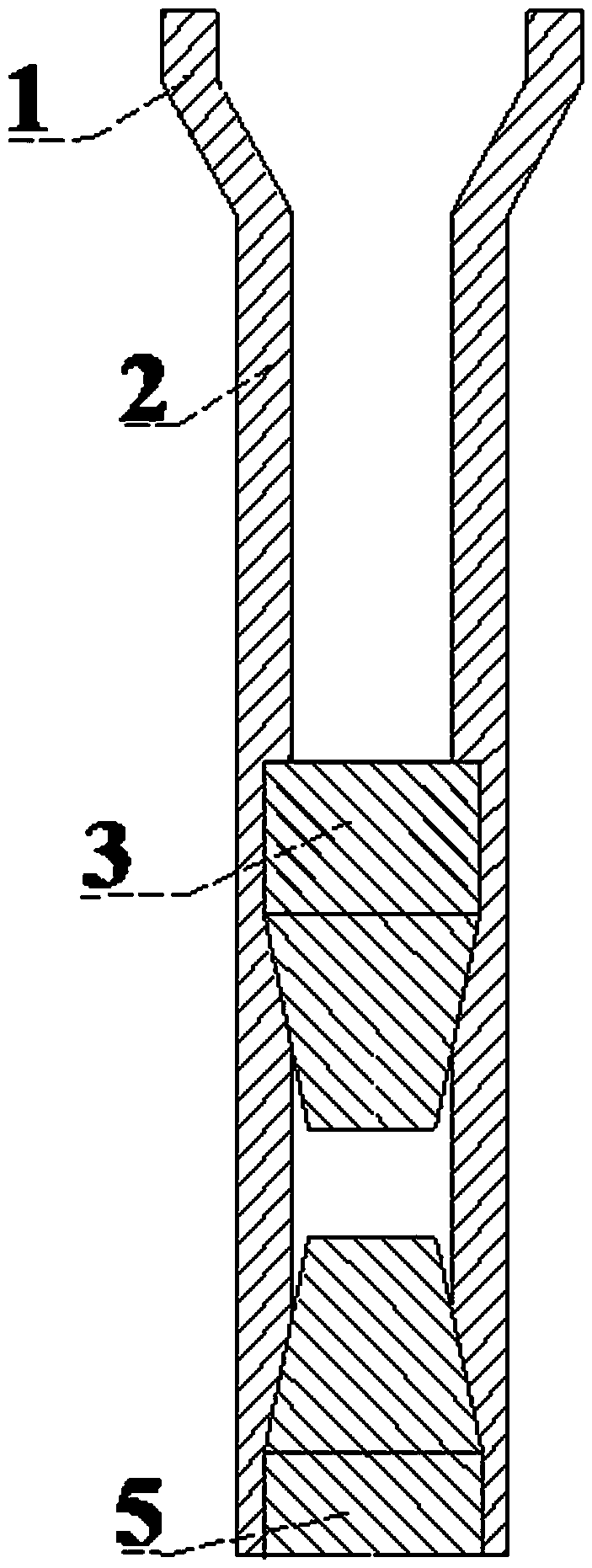

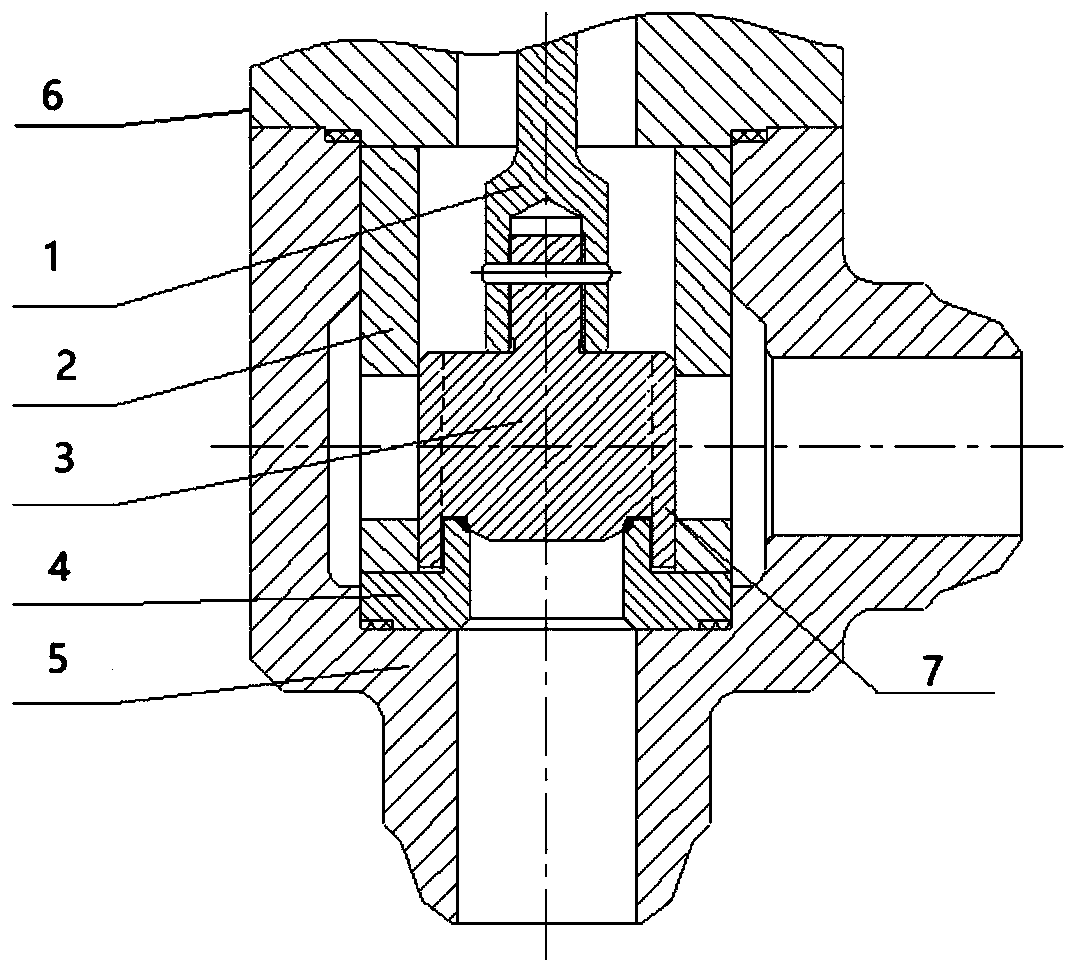

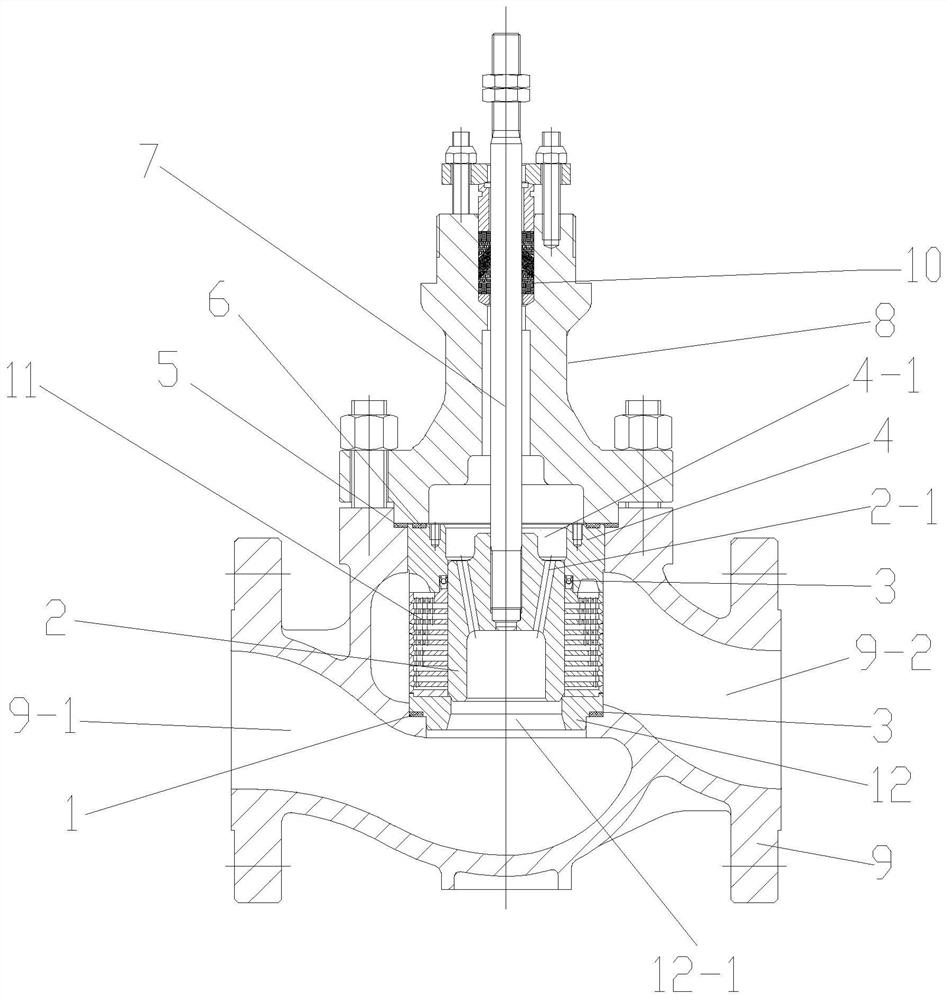

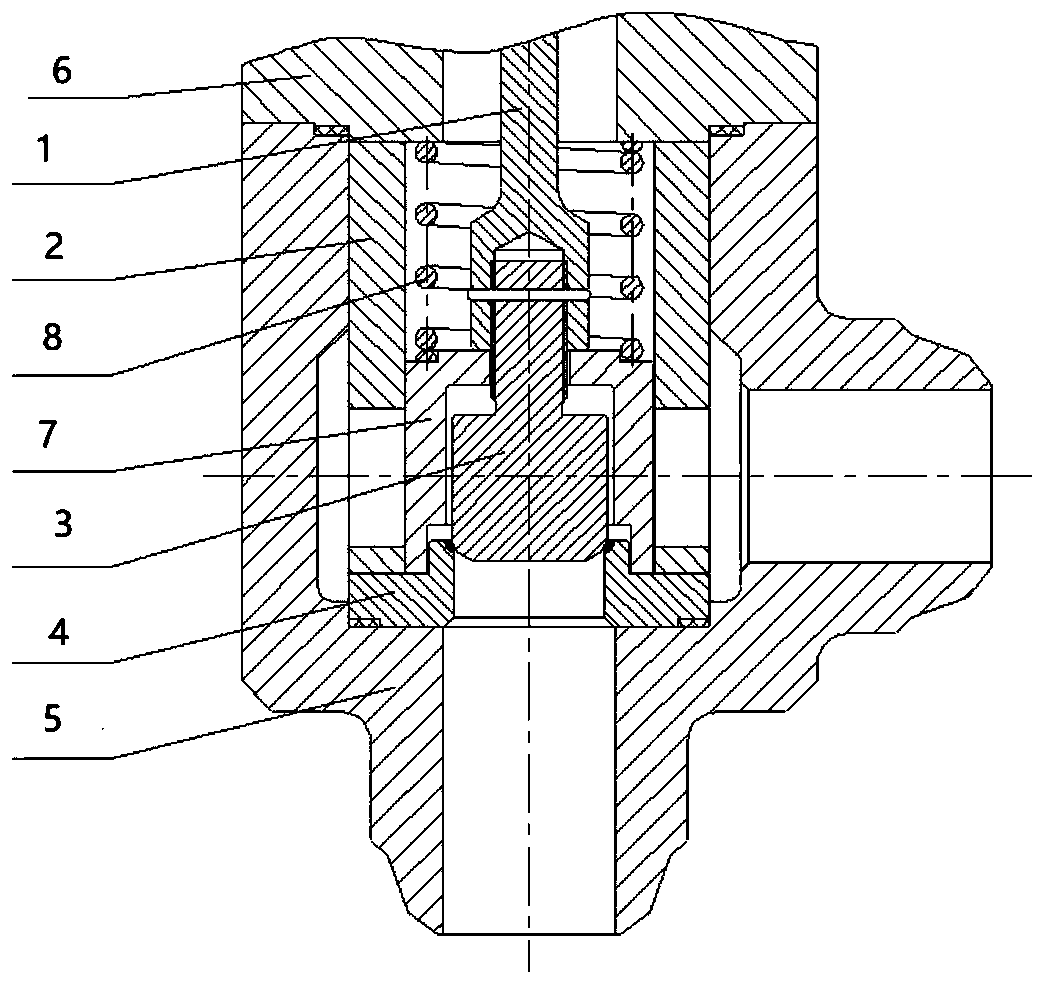

Regulating valve integral self-protection sealing surface structure

PendingCN110805697AEasy to replaceLower cavity heightValve members for absorbing fluid energyLift valveSleeve valveEngineering

The invention discloses a regulating valve integral self-protection sealing surface structure. The regulating valve integral self-protection sealing surface structure is characterized by comprising avalve rod, a sleeve, a valve element, a valve seat, a valve deck and a valve body, wherein the lowermost end of the interior of the valve body is provided with the valve seat; the valve element is arranged in the valve body and on the upper portion of the valve seat; the lower end of the valve rod penetrates through the valve deck to extend into the valve body to be connected with the valve element; the outer side of the valve element is fixedly connected with a valve element protection device; and the outer side of the valve element protection device is provided with the sleeve. Through the regulating valve integral self-protection sealing surface structure, the direct scouring action of a medium on a valve element sealing surface is reduced, and erosion and abrasion of the medium to thesealing surface are effectively reduced; and accordingly, the repair or replacement frequency of the valve element sealing surface is reduced, the service cycle is prolonged, and the maintenance costis reduced economically.

Owner:SHANGHAI POWER EQUIP RES INST

Gravity inertial bag type composite dust remover

The invention discloses a gravity inertial bag type composite dust remover, comprising at least a dust collector box. Each dust collector box is divided into at least two columns of independent filter chamber, each column of filter chamber comprises a gravity inertia pre-dedusting chamber with an air inlet and a filter bag filter chamber; each column of the filter chamber is divided by board hanging with a filter bag into an upper clean gas chamber, and a lower flue gas chamber communicated with the gravity inertial pre-dedusting chamber; the upper clean gas chamber is provided with a low pressure pulse blowing mechanism; the gravity inertial dedust chamber is provided with a flue gas pre-dedusting allocation mechanism; all gravity inertial pre-dedusting chambers are communicated with a smoke inlet pipe provided with an inlet baffle door; the smoke inlet pipe is provided inside with a flue gas cooling mechanism; the smoke inlet pipe at the inlet of the gravity inertial pre-dedusting chamber is equipped with a three-dimensional smoke distribution mechanism; each upper clean gas chamber is respectively communicated with a smoke outlet branch pipe provided with outlet baffle door; and all smoke outlet branch pipes are communicated with all the smoke outlet header pipe. The filter bag provided by invention has the advantage of long service life.

Owner:江苏新任环保科技有限公司

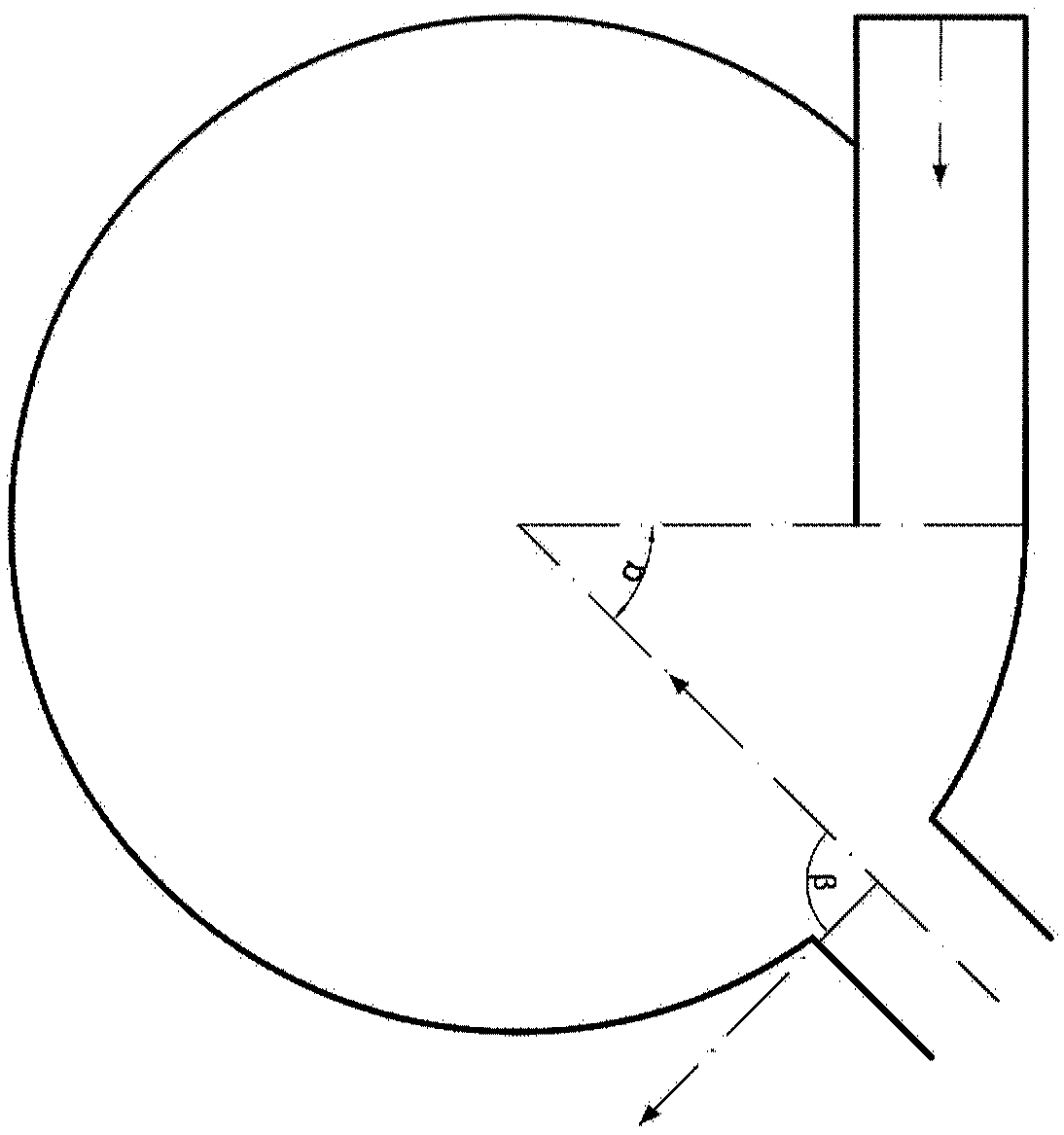

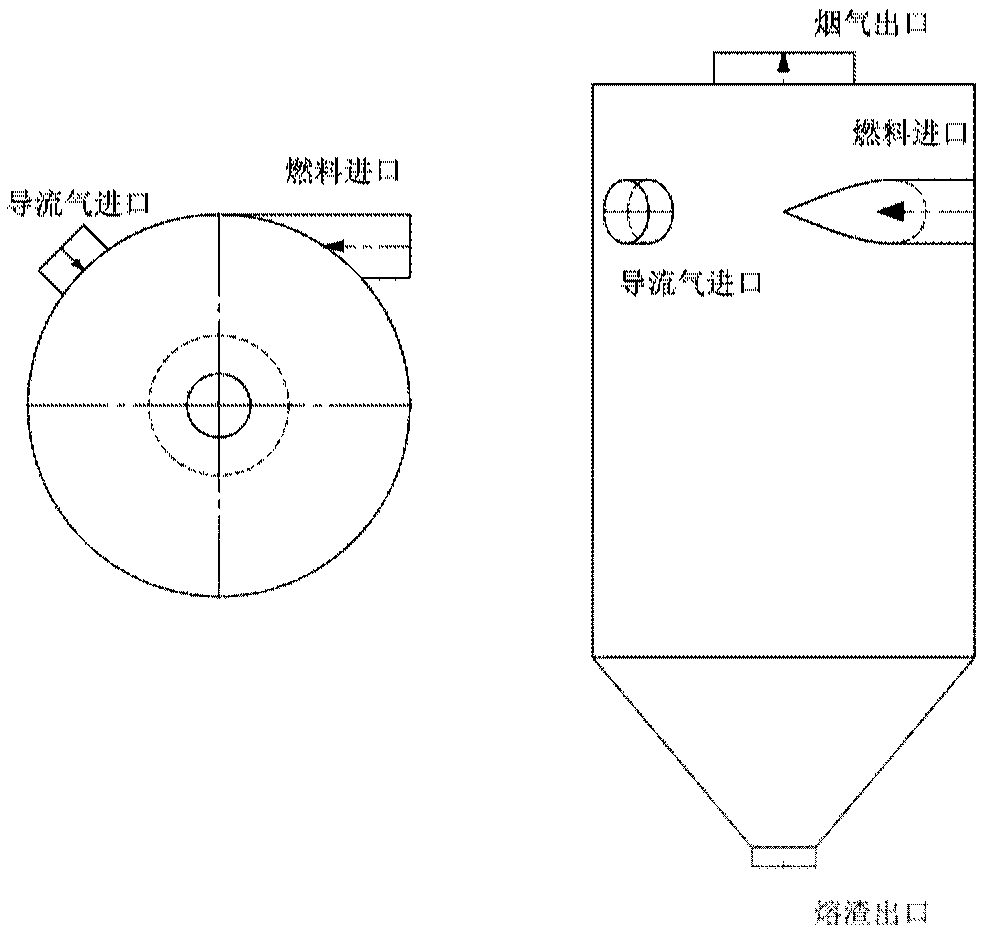

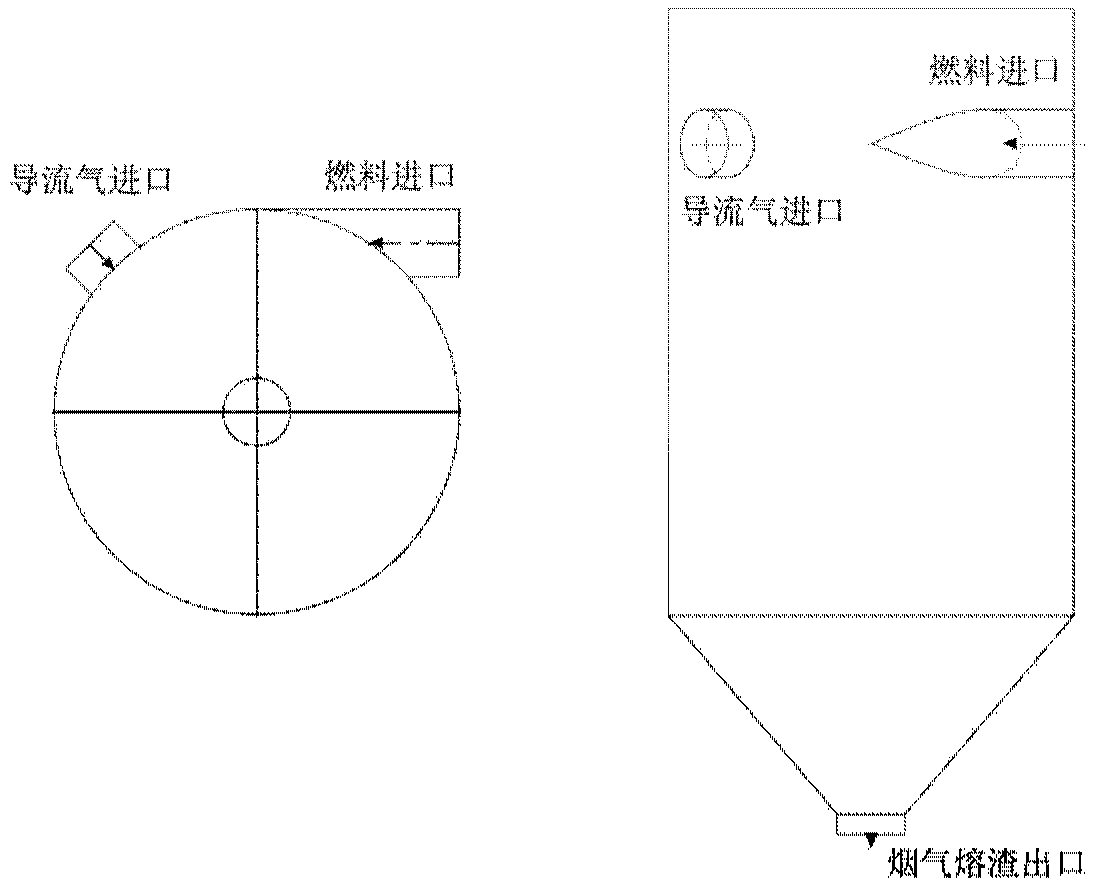

Cyclone melting furnace and using method thereof

InactiveCN110397935AReduce direct washoutIncrease reaction strengthIndirect carbon-dioxide mitigationAir/fuel supply for combustionCycloneMelting furnace

The invention provides a cyclone melting furnace which comprises a furnace body and a fuel inlet, wherein the fuel inlet is tangentially arranged in the furnace body and is configured to introduce reaction fuel; and the furnace body is also provided with a guide gas inlet, and the guide gas inlet is arranged on a target area part, directly impacted by the reaction fuel, in the furnace body. According to the cyclone melting furnace, the reaction strength of the oxygen-enriched air and coke particles in high-temperature solid-containing gas is enhanced through arrangement of the guide gas inlet.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

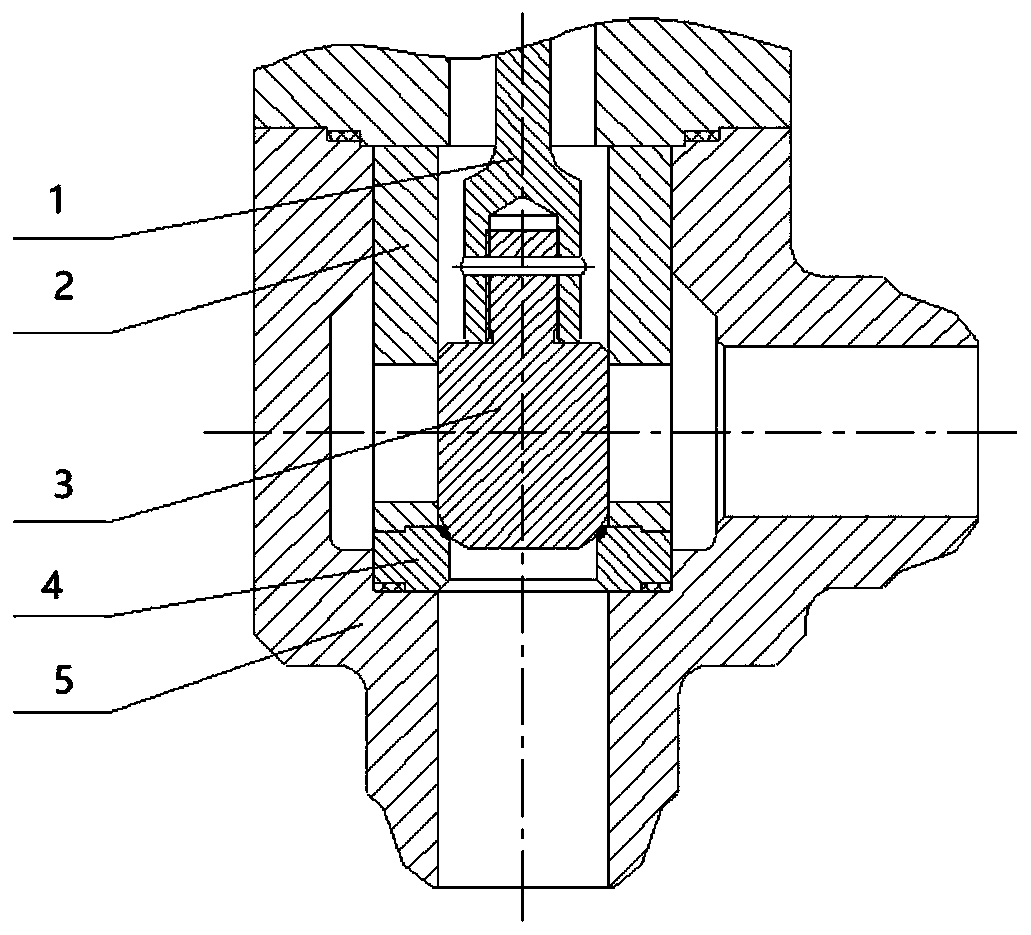

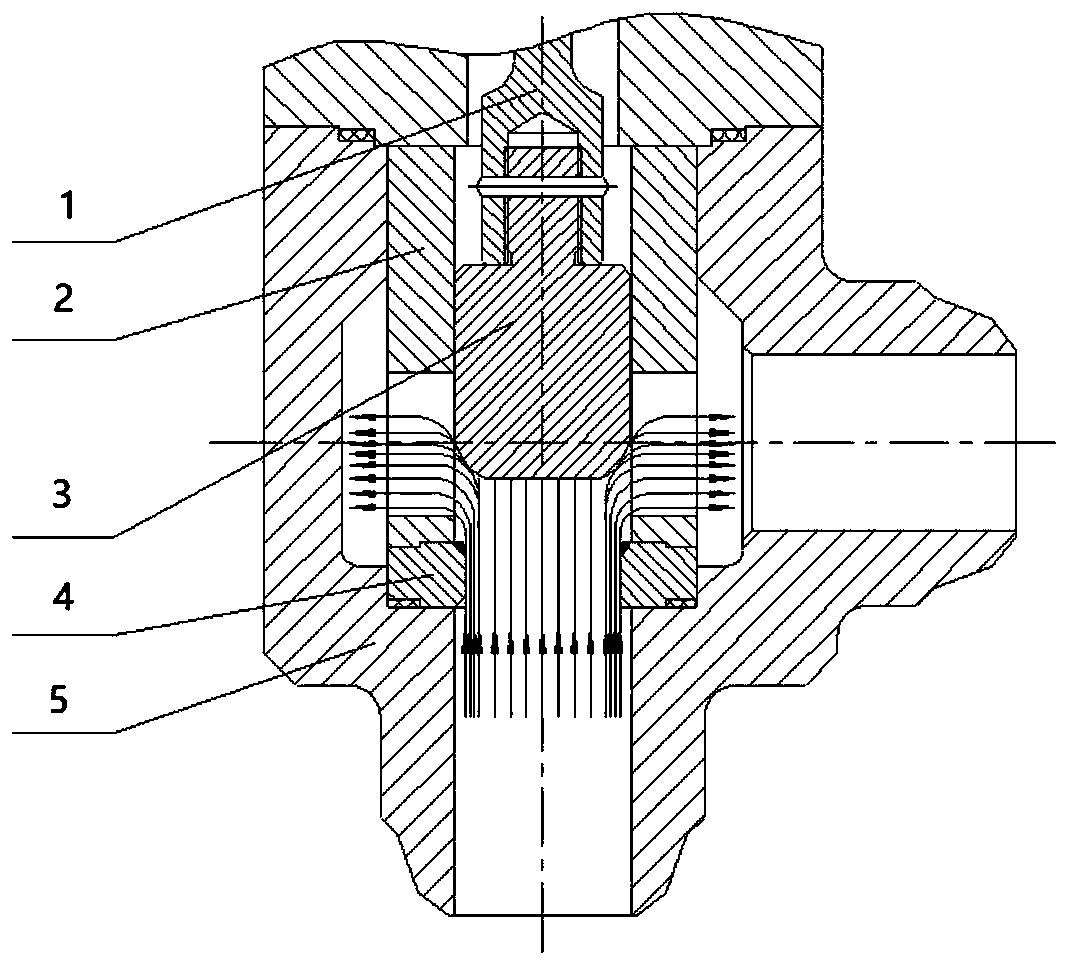

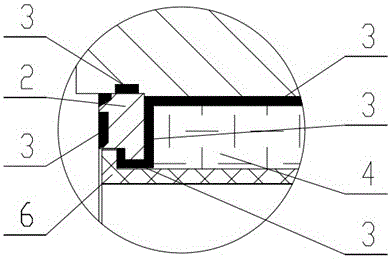

Water cooling valve clack structure of 1500 DEG C ultrahigh-temperature valve

ActiveCN104455707AGuaranteed uptimeReduce direct washoutValve members for heating/coolingEngineeringVALVE PORT

A water cooling valve clack structure of a 1500 DEG C ultrahigh-temperature valve comprises a valve rod and a valve clack body. The upper end of the valve clack body is connected with a convex lug through a flange, a runner inlet end in the convex lug is communicated with a concave pit in the valve clack body while a runner outlet end in the same is connected with a recycling end of an externally-connected cooling system, the concave pit is communicated with an inlet end of the externally-connected cooling system through a water cooling nozzle, the convex lug comprises an inner ring portion and an outer ring portion which are hermetically assembled into a whole, grooves are uniformly distributed in the outer circumferential face of the inner ring portion, holes in up-down arrangement are processed in the grooves, and upper-layer holes and lower-layer holes are formed in the whole periphery and all communicated with the inner surface of the inner ring portion. Due to the structure, direct scouring of a valve seat sealing face by a high-temperature medium is greatly reduced, and service life of the valve is prolonged, and running reliability of the valve is improved; heat transfer and thermodynamic calculation shows that a valve clack can run safely and reliably under a working condition of 1500 DEG C.

Owner:LANZHOU HIGH PRESSURE VALVE

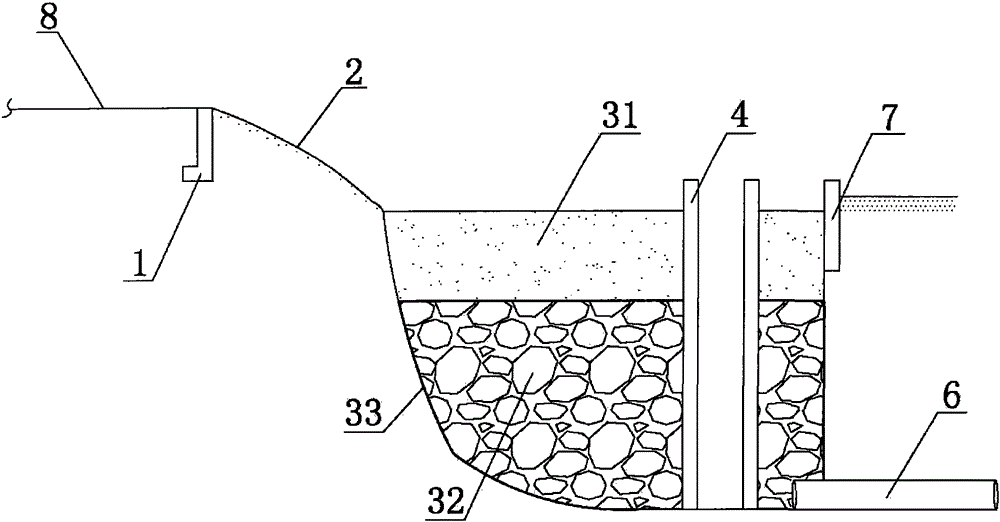

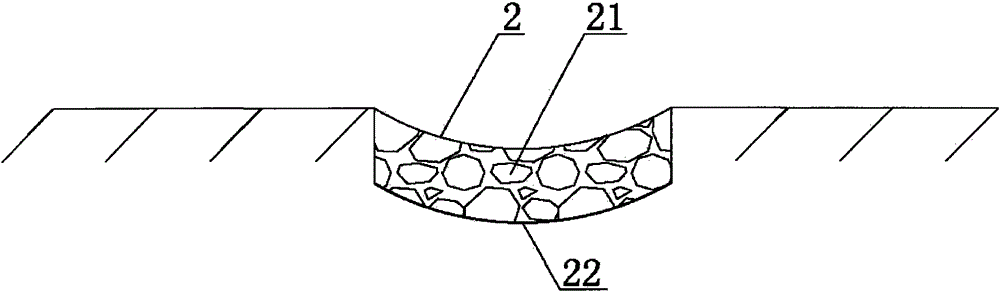

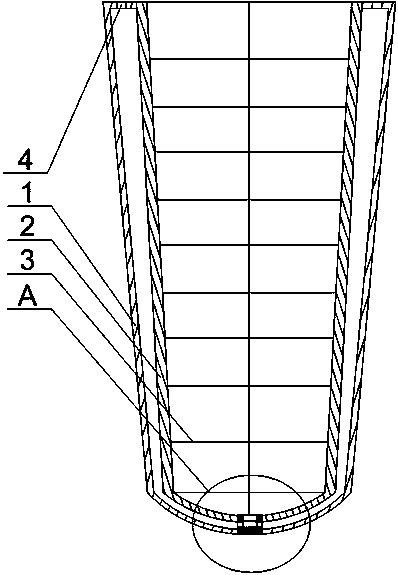

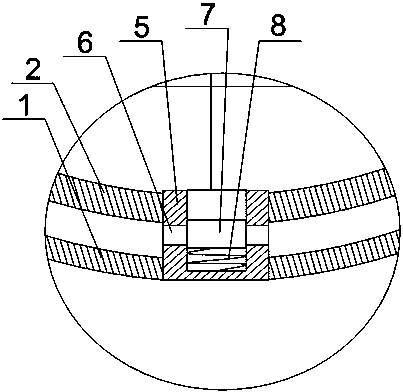

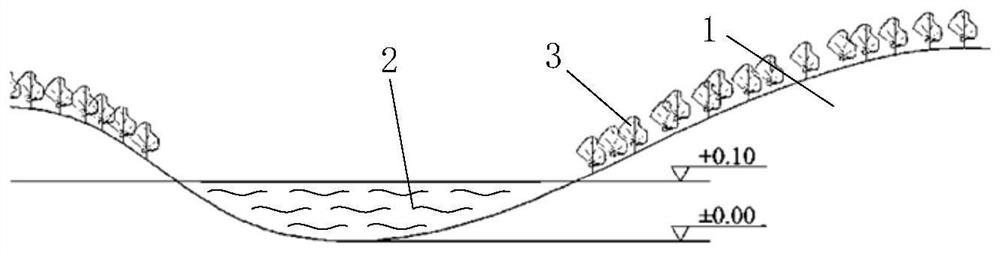

A rainwater bioretention pond for phosphorus removal beside a highway

InactiveCN103758204BPrevent eutrophicationReduce direct washoutSewerage structuresPaving gutters/kerbsEngineeringStreamflow

The invention relates to a rainwater bioretention pond for phosphorus removal beside an expressway. The rainwater bioretention pond comprises a low kerb, a water-passing channel, a bioretention pond body, a pervious concrete box body, a phosphorus removal box and a drainage pipe. One end of the water-passing channel is connected with the low kerb, and the other end of the water-passing channel is connected with the bioretention pond body. The pervious concrete box body is arranged in the bioretention pond body, and the bioretention pond body is divided into a left portion and a right portion. The phosphorus removal box is arranged in the pervious concrete box body. The drainage pipe is arranged on the bottom of the bioretention pond body. The rainwater bioretention pond for phosphorus removal beside the expressway removes phosphorus carried in the runoff to some extent in a reinforced mode, and the ability to remove the phosphorus is higher than 80 percent. Meanwhile, the rainwater bioretention pond for phosphorus removal stores, permeates and purifies the rainwater runoff, reduces the downstream rainwater flow and the rainstorm peak flow, reduces direct scouring on a watercourse and the like from rainwater, reduces the erosion phenomenon of the watercourse, and reduces pollution to the water environment from the road.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

A kind of three-dimensional breeding method in rocky desert mountains

InactiveCN104160847BReduce direct washoutReduce churnWatering devicesCultivating equipmentsLand resourcesBroiler

The invention discloses a three-dimensional planting and cultivating method for a rock desert mountain land and belongs to the technical field of three-dimensional agriculture. The three-dimensional planting and cultivating method comprises the steps of filling soil, adding fertilizers, planting drought-enduring plants, planting fruit trees, conducting underwood chicken cultivation and arranging a water storage and irrigation system. According to the technical scheme, planting and cultivating are combined in a three-dimensional mode, and underwood broiler cultivation is conducted while economic crops are planted, so that the advantage that boilers and the economic crops enhance growth of each other is achieved. By arranging the water storage and irrigation system in a master and branch combination mode, part of rain is retained, part of the rain is drained, direct flush of the rain to a mountain is reduced, and water and soil loss is reduced to a certain extent. Land resources are made full use of while stony desertification is effectively treated, and high economic benefits and social benefits are created.

Owner:普定县远山林下养鸡场

Filter bag for flue gas treatment of coke furnace charging car

The invention discloses a filter bag for flue gas treatment of a coke oven coal-charging vehicle, which includes an outer bag body, an inner bag body and a skeleton. There is an air outlet connected to the secondary air channel, and a cylinder is installed between the bottom of the inner bag and the bottom of the outer bag. The open end of the cylinder communicates with the inside of the inner bag, and openings There is an air hole communicating with the secondary air flow channel, the slider is slidably arranged in the barrel, and a spring is installed at the bottom of the slider. The stress generated by the second expansion of the outer bag is much greater than the stress generated by the first expansion, that is, the dust attached to the outer bag is completely ejected. Compared with the single-layer dust bag, the dust removal efficiency is greatly improved. , and the expansion of the outer bag is driven by the expansion of the inner bag, which reduces the direct erosion of the outer bag by the air flow, thereby reducing the loss of the outer bag.

Owner:付建军

Dry dust removal filter bag for coke oven

InactiveCN105771457AReduce direct washoutReduce lossDispersed particle filtrationCoke ovenEngineering

The invention discloses a dry dust removal filter bag for a coke oven. The dry dust removal filter bag, which comprises an outer bag body, an inner bag body and a skeleton, wherein a secondary air flow path is annularly arranged between the outer bag body and the inner bag body, and an air outlet connected with the secondary air flow path is formed in the upper end of the outer bag body; a barrel is arranged between the bottom of the inner bag body and the bottom of the outer bag body, and the open end of the barrel is communicated with the inside of the inner bag body; pores communicated with the secondary air flow path are formed in the two side walls of the barrel, and a sliding block is arranged in the barrel in a sliding way; a spring is arranged at the bottom of the sliding block. The acting stress generated by secondary expansion of the outer bag body is much larger than the acting stress generated by primary expansion thereof, i.e., dust attached to the outer bag body is completely ejected; compared with a dust removal cloth bag with a single-layer structure, the dust removal efficiency is greatly improved, and the expansion of the outer bag body is driven by the expansion of the inner bag body, so that the direct sweeping of air flow on the outer bag body is reduced, and thus the loss of the outer bag body is reduced.

Owner:SICHUAN ANCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

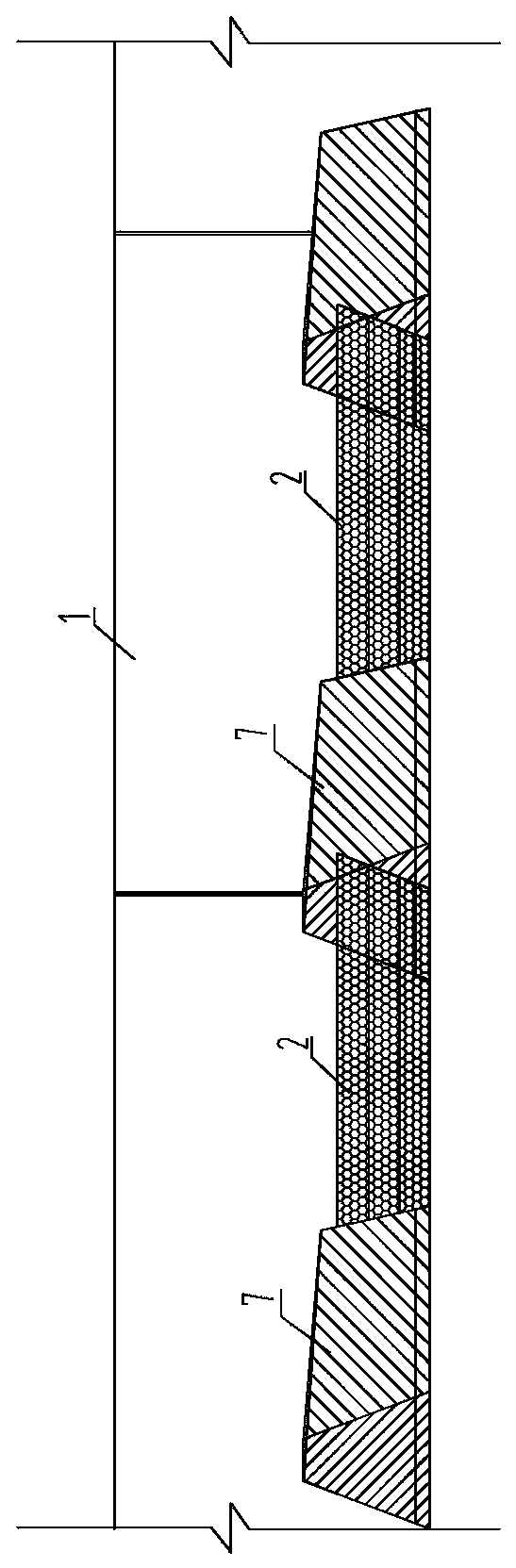

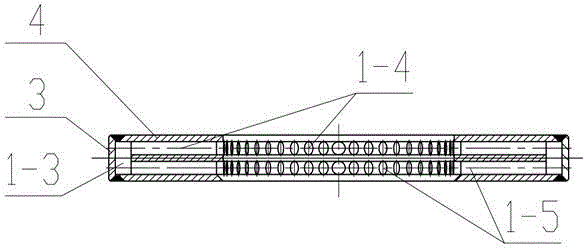

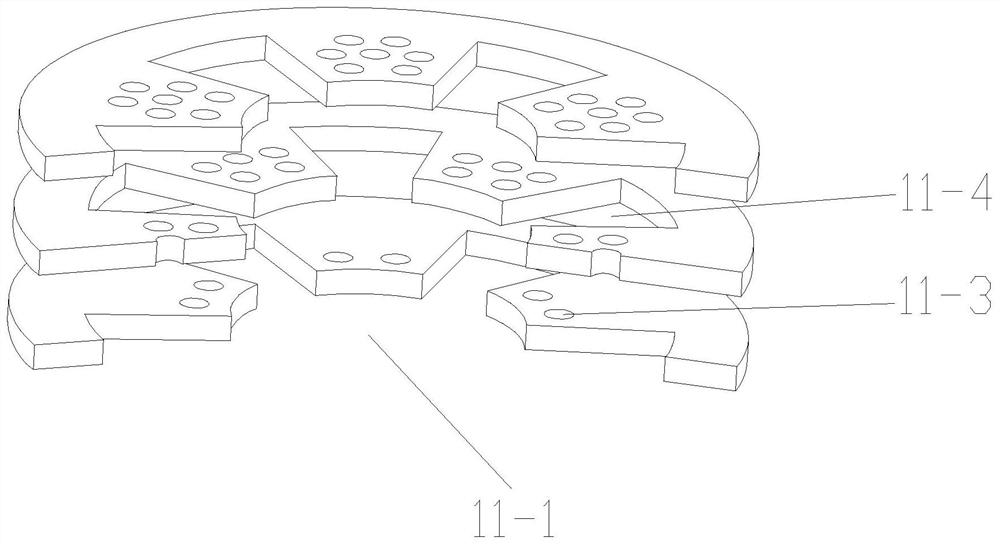

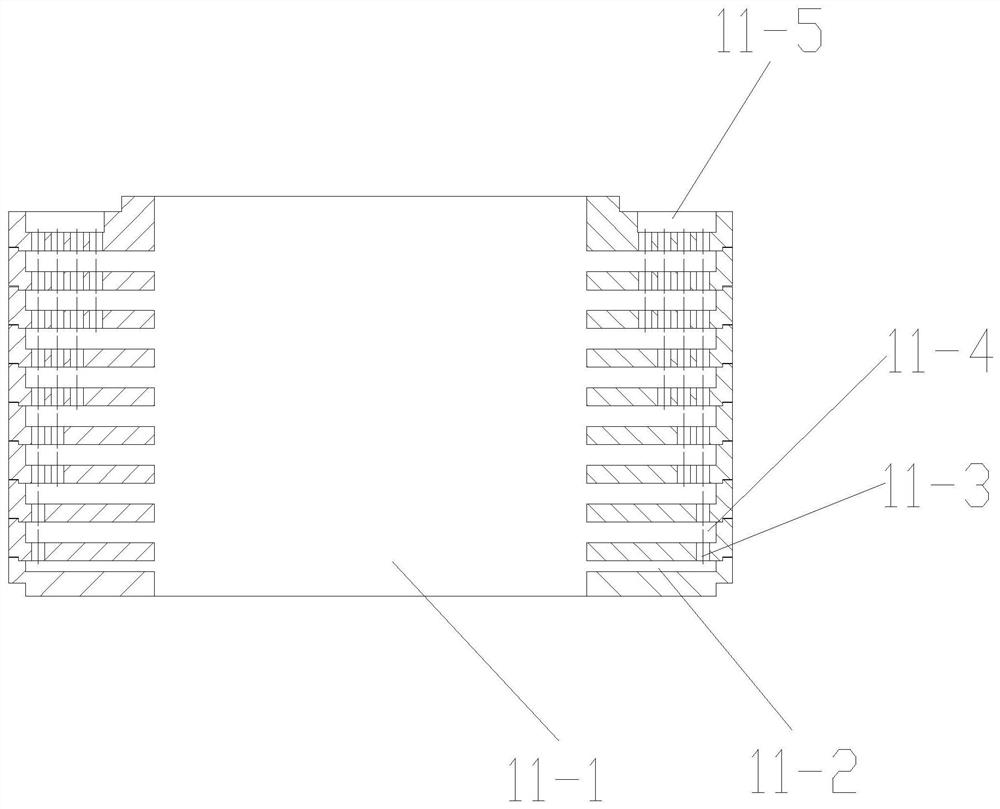

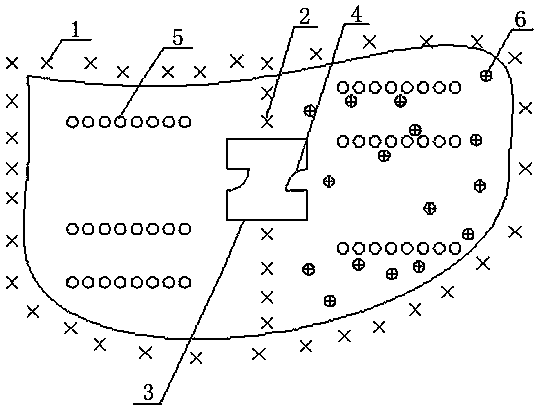

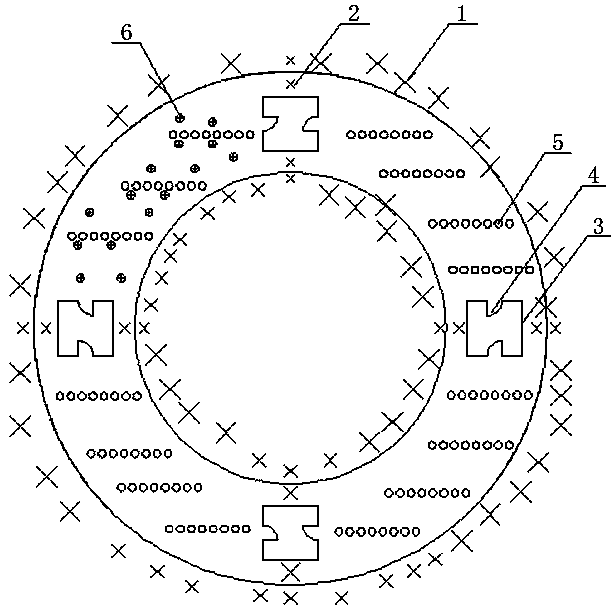

Axial-flow type pressure reduction assembly and axial-flow type gradual change pressure reduction valve internal part structure

PendingCN112780831AEasy to assemble and disassembleEasy maintenanceValve members for absorbing fluid energyValve housingsEngineeringPressure reduction

The invention relates to an axial-flow type pressure reduction assembly and an axial-flow type gradual change pressure reduction valve internal part structure. A valve element hole is formed in the middle of the assembly, a drainage groove is formed in the lower portion of the center of the assembly and communicated with the valve element hole, pressure reduction holes and pressure reduction grooves are sequentially formed in the upper portion of the drainage groove at intervals, and a liquid outlet is formed in the upper portion of the assembly and communicated with the pressure reduction hole or the pressure reduction groove in the uppermost layer. The axial-flow type pressure reduction assembly and the axial-flow type gradual change pressure reduction valve internal part structure have the advantages of effectively reducing pressure, preventing cavitation corrosion, reducing valve noise, reducing vibration, being convenient, reliable, easy to maintain, long in service life and the like, and are suitable for a special high-pressure-difference process control process. The axial-flow type pressure reduction assembly and the axial-flow type gradual change pressure reduction valve internal part structure are convenient to disassemble, assemble and maintain, a special disassembly tool does not need to be designed, a special pneumatic or hydraulic auxiliary tool does not need to be provided for disassembly and assembly of the axial-flow type pressure reduction assembly, meanwhile, compared with complex labyrinth flow channel machining, the pressure reduction holes distributed in the axial direction can be achieved only through simple turning and drilling, a machining center is not needed, the machining cost is low, the equipment utilization rate is high, and the harsh delivery cycle can be met.

Owner:WUXI SMART AUTO CONTROL ENG CO LTD

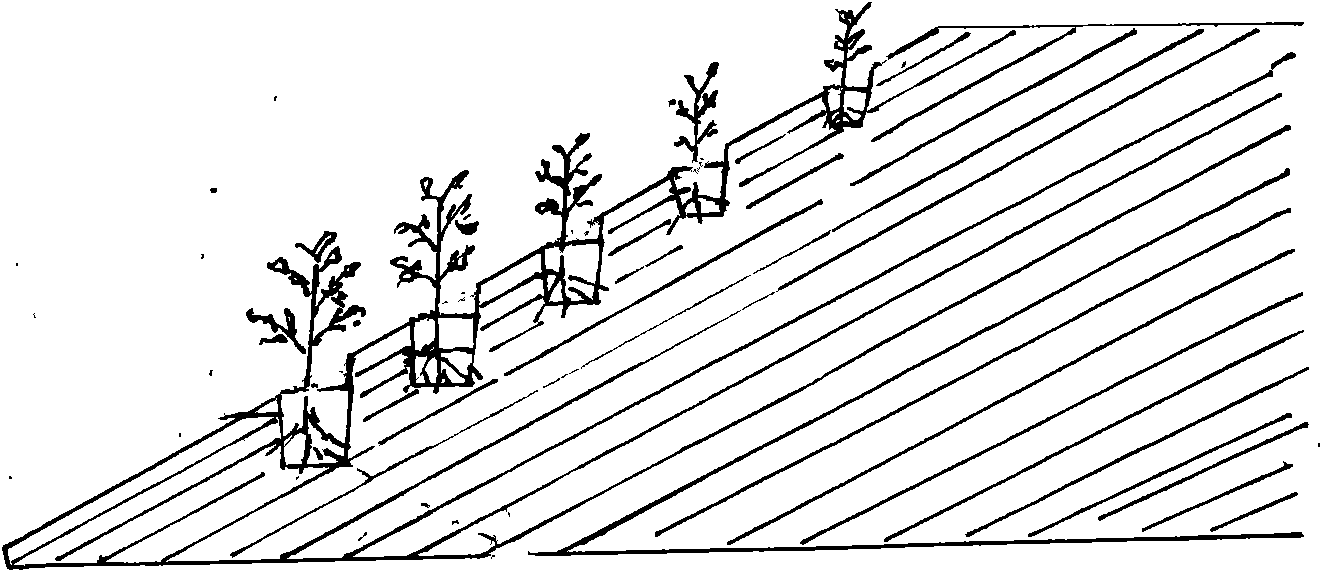

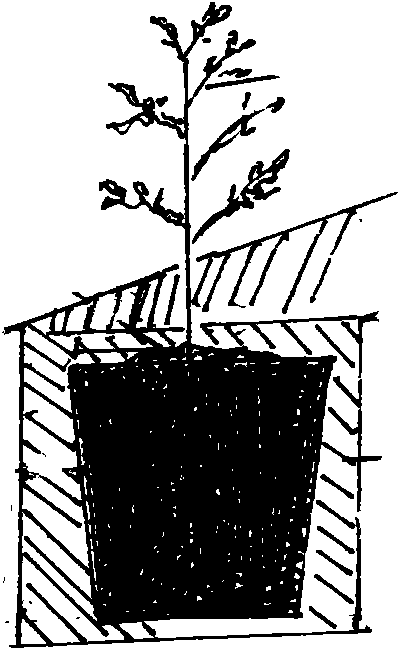

Slope forest planting method

InactiveCN101715708BImprove toughnessLarge bearing capacityForestryReceptacle cultivationEcological environmentSurvival ratio

The invention discloses a slope forest planting method which is mainly used for reclaimation tree-planting on the slope of a waste disposal site of an open pit in arid regions. The method mainly comprises the following steps of: selecting surface soil peeled from the open pit and nutritional soil prepared from sheep and cow dung, putting the nutritional soil in a planting basket weaved by plant wickers, planting seedlings in and putting in a seedling cultivating ditch, then irrigating, transplanting into a slope planting cave together with the planting basket after various seedlings are watered and irrigated for 3 to 18 months, filling by surface soil, well trimming the seedlings, and preserving a water hole at the periphery, wherein the seedling survival ratio after three-year watering can reach more than 88 percent. The planting basket is weaved by plant wickers, which can become fertilizer after rotting and has no pollution to environment. The root system of a tree after growing upcan stabilize the soil, protect the slope and prevent soil erosion and water loss; branches and leaves at the crown can reduce the wind speed and runoff amount, prevent rain water from directly scouring the slope and protect the slope, therefore, the ecological environment of a plurality of tree and grass vegetation is formed.

Owner:孙明文

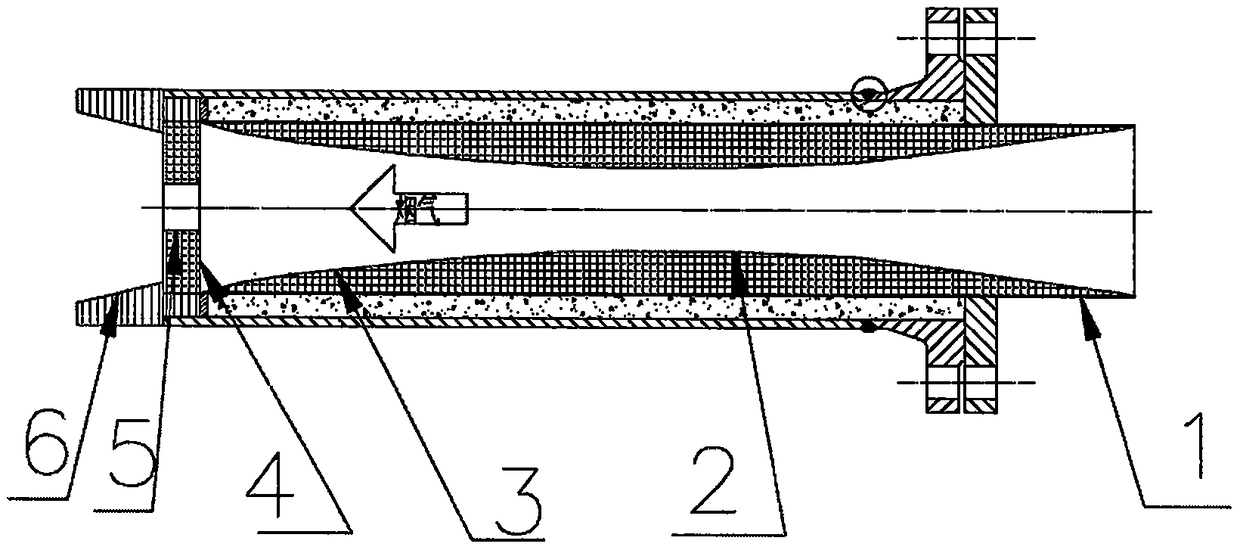

Wear Mitigation Technology of Double Venturi Structure Nozzle for Regenerated Flue Gas

ActiveCN105195348BSmall pressure dropReduce direct washoutCatalytic crackingSpray nozzlesFlue gasEngineering

The invention relates to an abrasion retarding process of a regeneration flue gas double-Venturi-structure spray nozzle, and provides the composition of the regeneration flue gas double-Venturi-structure spray nozzle. Smoke gas and catalysts enter a contraction section of a first Venturi structure and enters a throat passage of the first Venturi structure; the smoke gas and the catalysts are compressed through caliber reduction, and the pressure drop is generated; the smoke gas and the catalysts are accelerated and then enter a diffusion section of the first Venturi structure; the speed is decelerated; the pressure drop generated by the throat passage enables the pressure drop of the diffusion section and a hole plate throat passage of a second Venturi structure to be reduced; the smoke gas and the catalysts in the hole plate throat passage are fast diffused through caliber increase of the diffusion section of the second Venturi structure; the generation of the eddy current intensity in the diffusion section is reduced; the backflow due to eddy current is also prevented; the eddy current abrasion and the direct flushing on the hole plate body and the hole plate throat passage outlet are reduced; the double Venturi structures are used; through the pressure drop added in front of the hole plate by the first structure and the direct flushing of the eddy current at an interference outlet of the second structure on the hole plate body and the spray nozzle throat diameter, the service life is prolonged.

Owner:LUOYANG SENDE PETROCHEM ENG

Split type self-protection sealing surface structure of regulating valve

PendingCN110805713AEasy to disassemblePlay a buffer roleValve members for absorbing fluid energySlide valveSleeve valveEngineering

The invention discloses a split type self-protection sealing surface structure of a regulating valve. The structure comprises a valve rod, a sleeve, a valve core, a valve seat, a valve cover and a valve body, wherein the valve core is arranged in the valve body, the lower end of the valve rod penetrate through the valve cover so as to extend into the valve body and be connected with the valve core, a valve core protection device is arranged on the outer side of the valve core, and the sleeve is arranged on the outer side of the valve core protection device. The structure is characterized in that the upper end of the valve core protection device is connected with the valve cover through a spring, and the inner space height of the valve core protection device is larger than the height of thevalve core. According to the split type self-protection sealing surface structure of the regulating valve, the direct flushing effect of an medium on the sealing surface of the valve core is reduced,erosion and abrasion of the medium to the sealing surface are effectively reduced, the repairing or replacement frequency for the sealing surface of the valve core is reduced, the service period is prolonged, and the maintenance cost is also reduced economically.

Owner:SHANGHAI POWER EQUIP RES INST

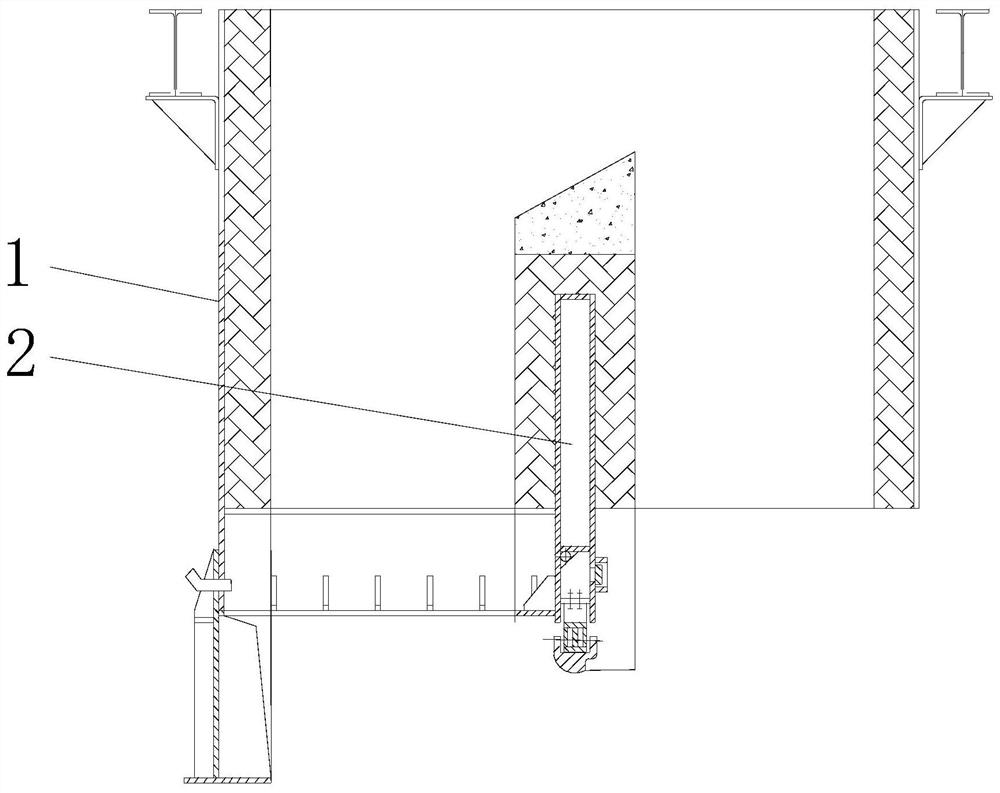

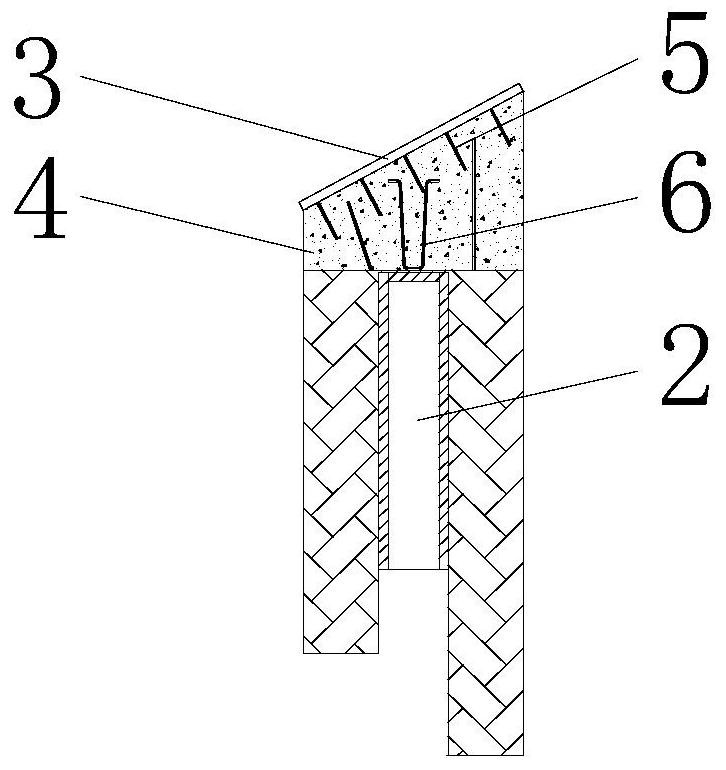

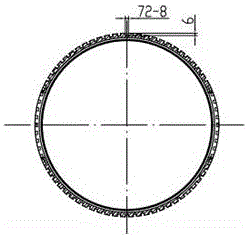

Refractory masonry structure of ring cold machine feed hopper

ActiveCN111678346AGuaranteed not to slipReduce washoutCharge manipulationHandling discharged materialRefractoryEngineering

The invention discloses a refractory masonry structure of a ring cold machine feed hopper. The refractory masonry structure comprises a feed hopper, the bottom of an inner cavity of the feed hopper isfixedly connected with an air cooling wall, the top of the air cooling wall is fixedly connected with a second anchoring nail through a steel plate, the surface of the second anchoring nail is sleeved with a steel fiber corundum castable, and a heat-resistant and wear-resistant stainless steel plate is arranged at the top of the steel fiber corundum castable. The second anchoring nail is welded to the upper portion of the air cooling wall of the inner cavity of the feed hopper, firmness is guaranteed through continuous welding, the first anchoring nails are welded to the bottom of the heat-resisting and wear-resisting stainless steel plate, and the firmness is guaranteed through continuous welding; the formwork is erected before construction, and the formwork guarantees that castable is inclined by at least 30 degrees; the heat-resisting and wear-resisting stainless steel plate is buckled on the steel fiber corundum castable in a pressing mode, the heat-resisting and wear-resisting stainless steel plate and the steel fiber corundum castable form a combined structure, materials fall onto the heat-resisting and wear-resisting stainless steel plate which is obliquely arranged, scouring of the materials is weakened, and the wear-resisting performance is improved.

Owner:XINXING ENERGY EQUIP

Cooling device for 1500°C ultra-high temperature valve body

ActiveCN104455708BReduce direct washoutImprove reliabilityValve members for heating/coolingEngineeringWater cooling

A cooling device of a 1500 DEG C ultrahigh-temperature valve body comprises a medium inlet passage, a valve body middle port position, a valve cover and an end cap. The medium inlet passage and the valve body middle port position are arranged on the valve body and connected with each other, a high-temperature ceramic heat-insulating lining cooling structure is arranged on the medium inlet passage on the valve body, a valve body middle port is provided with a valve body middle port water cooling system, and requirements on safe and reliable running under a working condition of 1500 DEG C and 5.0 MPa are met. Part of heat of a high-temperature medium is absorbed by a midbody water cooling lower portion where pressure drop is formed, and pressure and temperature of the medium are further lowered; due to the structure, direct scouring of a valve seat sealing face by the high-temperature medium can be greatly reduced, service life of the valve is prolonged, and running reliability of the valve is improved.

Owner:LANZHOU HIGH PRESSURE VALVE

Method and system for improving high-altitude soil through biomass charcoal assisted chicken breeding

InactiveCN109451909AGood immediacyContinuous and Effective Nutrient SupplySoil lifting machinesBird housingsMicroorganismBiomass

The invention discloses a method and system for improving high-altitude soil through biomass charcoal assisted chicken breeding. The method for improving the high-altitude soil through biomass charcoal assisted chicken breeding includes the steps of site dividing, planting and stocking. According to the method, alternate stocking is carried out, mixed feed to which biomass charcoal is added is supplied, the mixed feed to which the biomass charcoal is attached is digested by chicken flocks and then discharged to land, leaching of rainfall to chicken manure is restrained through the chicken manure rich in biomass charcoal, proliferation of soil microorganisms is facilitated through the biomass charcoal rich in chicken manure, and the soil is instantly improved. The system comprises an edge fence, an isolation fence and an exchange chicken house. By means of the system, through the edge fence and the isolation fence, stocking communities of different styles are divided, by means of the stocking chicken house arranged between the two stocking communities, on one hand, the effect of rest of the chicken flocks is achieved, and on the other hand, the chicken flocks can be guided to enterthe different stocking communities; by means of plant planting regions, the effect of direct washing of the rainfall to the soil is achieved.

Owner:云南农业职业技术学院 +2

Elbow connecting pipe

The invention relates to an elbow connecting pipe which comprises a straight pipe (5). The elbow connecting pipe is characterized in that one end of the straight pipe (5) is provided with a first flange (1), the other end of the straight pipe (5) is an arc sealing end (22), a bent pipe (3) which is arranged perpendicular to the straight pipe and is communicated with the straight pipe is arranged on the pipe wall in the middle of the straight pipe (5), a second flange (4) is arranged on the end portion of the bent pipe (3), and a rubber connecting pipe (5) is connected on the second flange of the end portion of the bent pipe (3). The elbow connecting pipe has the advantages that the diameter of the straight pipe is larger than that of the straight pipe flange, so that flow speed of water thick liquid is slowed, the top portion of a buffer pipe is in an arc shape, erosion resistance is strong, direct erosion on a pipeline elbow by water thick liquid materials is lowered, the service life of the pipeline elbow is prolonged, the rubber connecting pipe and the flanges are added, and maintaining and replacing of the elbow are convenient.

Owner:吴军红

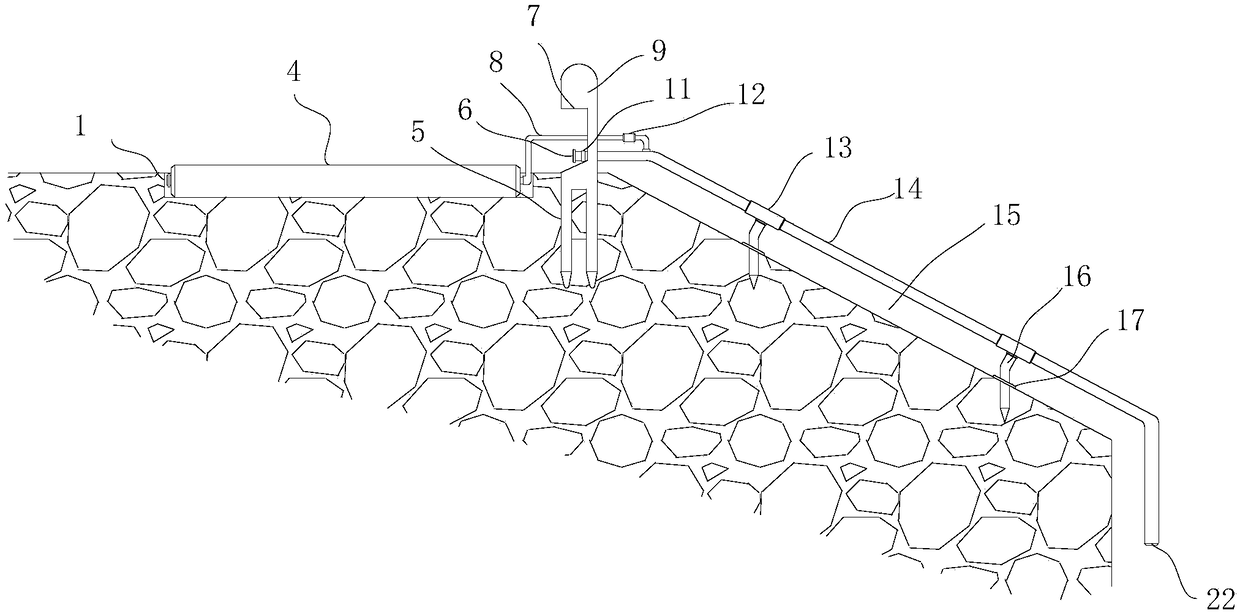

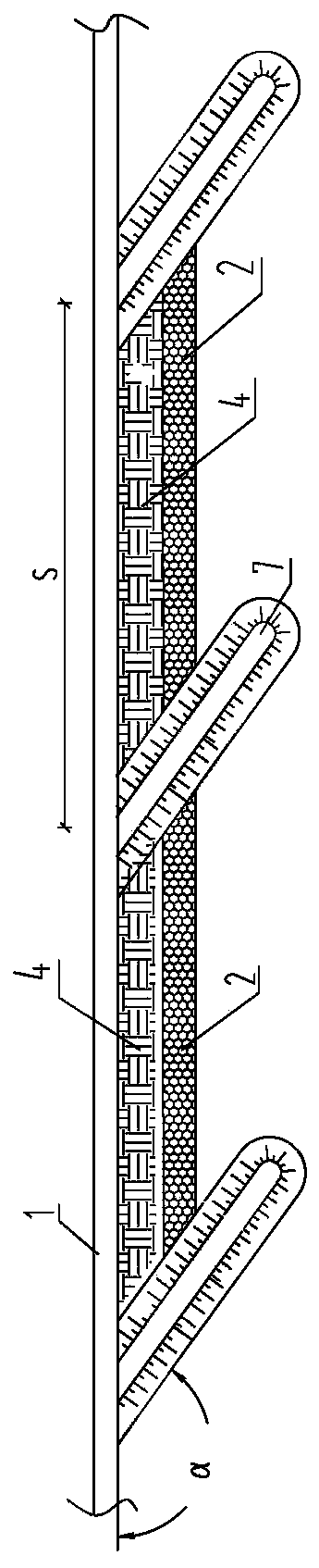

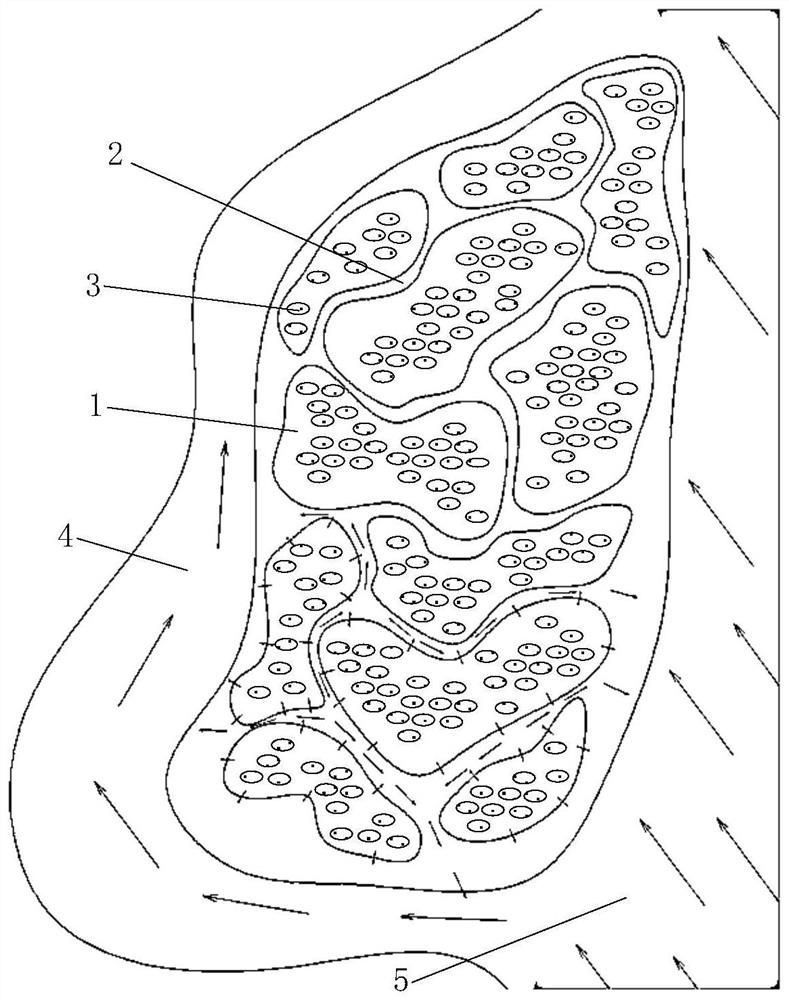

Aggregated mangrove forest artificial planting system and method thereof

PendingCN114793740AReduce direct washoutAvoid erosionIrrigation ditchesStream regulationTidal flatMangrove

The invention provides a gathering mangrove forest artificial planting system and method, the gathering mangrove forest artificial planting system comprises a plurality of planting ridges located on a beach land, the planting ridges are used for planting mangrove forest plants, and the mangrove forest plants on the planting ridges are gathered in a cluster shape; every two adjacent planting ridges are separated by a tidal creek, the tidal creeks are connected to form a regular or irregular gridding structure, the planting ridges are higher than the tidal creeks, and the planting ridges are partially or completely submerged in the direction from the circumferential direction to the center along with rising of the water level of the tidal creeks when the tidal land rises; the planting ridges are gradually exposed out of the sea surface from the center to the periphery along with decline of the water level of the tidal creek during tidal falling of the beach. According to the planting system, a plurality of planting ridges are divided through the tidal creek of a grid structure, the planting ridges are characterized in a cluster-shaped planting mode, the tidal creek provides nutrition for mangrove forest plants in a planting area in the fluctuation and ebb tide period, direct scouring of water flow to a tidal flat is relieved, natural drainage after the ebb tide is facilitated, and tidal flat erosion is avoided.

Owner:EAST CHINA NORMAL UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com